Method for recycling fine and superfine cassiterites from oxidized lode tin mud tailings

An oxidizing, fine-grained technology, used in solid separation, flotation and other directions, can solve the problems of not realizing the effective recovery of fine-grained and fine-grained cassiterite, fine-grained cassiterite embedded particle size, and complex symbiotic relationship. The effect of restoration of ecological environment, improvement of recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the specific steps of fine-grained and fine-grained cassiterite in the reclaiming oxidized vein tin ore slime tailings of the present embodiment comprise as follows:

[0026] (1) Add water to the oxidized vein tin ore slime tailings with a tin content of 0.20wt% until the slurry concentration is 25wt%;

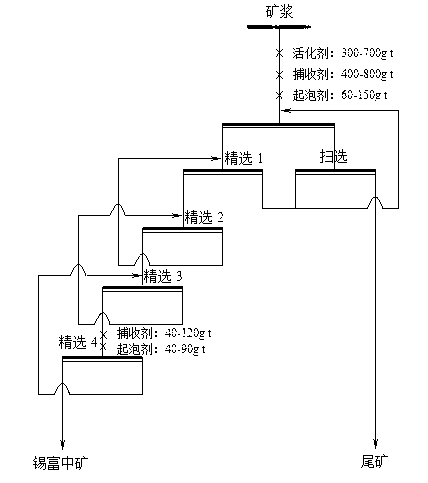

[0027] (2) Roughly select the slurry obtained in step (1), and add 300g of activator and 500g of collector in turn for each ton of oxidized vein tin ore tailings according to the mass of oxidized vein tin ore tailings 1. The foaming agent of 60g, the foam product obtained through roughing is the roughing concentrate, and the product in the tank obtained is the roughing ore;

[0028] (3) Under the condition of not adding any chemical agent, the rough beneficiation obtained in step (2) is scavenged, the foam product obtained after scavenging is the scavenging ore, and the product in the tank is the final tailings. Return to the rough selection operation and...

Embodiment 2

[0031]Embodiment 2: the specific steps of fine-grained and fine-grained cassiterite in the reclaiming oxidized vein tin ore slime tailings of the present embodiment comprise as follows:

[0032] (1) Add water to the oxidized vein tin ore tailings with a tin content of 0.12wt% to adjust the slurry concentration to 28wt%;

[0033] (2) Roughly select the slurry obtained in step (1), and add 500g / t of activator, 400g / t collector, 100g / t foaming agent, the foam product obtained through roughing is roughing concentrate, and the product in the tank obtained is roughing ore;

[0034] (3) Under the condition of not adding any chemical agent, the rough ore obtained in step (2) is scavenged once, the obtained foam product is the scavenging ore, the product in the tank is the final tailings, and the scavenging is returned to the rough Choose a job and choose again;

[0035] (4) The rougher concentrate obtained in step (2) has been selected four times, and the products in the tank obtain...

Embodiment 3

[0037] Embodiment 3: the specific steps of fine-grained and fine-grained cassiterite in the reclaiming oxidized vein tin ore slime tailings of the present embodiment comprise as follows:

[0038] (1) Add water to the oxidized vein tin ore slime tailings with a tin content of 0.10wt% until the slurry concentration is 30wt%;

[0039] (2) Roughly select the slurry obtained in step (1), and add 700g / t of activator, 800g / t collector, 150g / t foaming agent, the foam product obtained through roughing is roughing concentrate, and the product in the tank obtained is roughing ore;

[0040] (3) Under the condition of not adding any chemical agent, the rough beneficiation obtained in step (2) is scavenged, the foam product obtained after scavenging is the scavenging ore, and the product in the tank is the final tailings. Return to the rough selection operation and choose again;

[0041] (4) The rougher concentrate obtained in step (2) has been selected four times, and the products in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com