Patents

Literature

1768results about "Printing pre-treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative Working, Heat-Sensitive, Lithographic Printing Plate Precursor

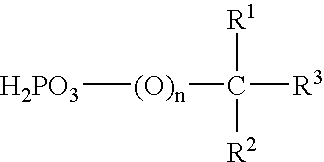

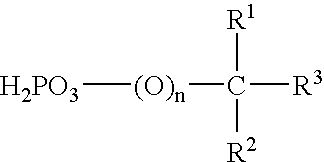

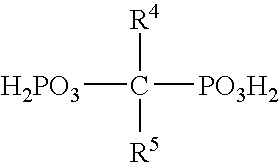

ActiveUS20080213696A1Number of defectSize of defectPhotosensitive materialsDuplicating/marking methodsSimple Organic CompoundsPhosphoric acid

A heat-sensitive negative-working lithographic printing plate precursor includes on a grained and anodized aluminum support a coating including hydrophobic thermoplastic polymer particles, a hydrophilic binder, and an organic compound, wherein the organic compound includes at least one phosphonic acid group or at least one phosphoric acid group or a salt thereof.

Owner:AGFA OFFSET BV

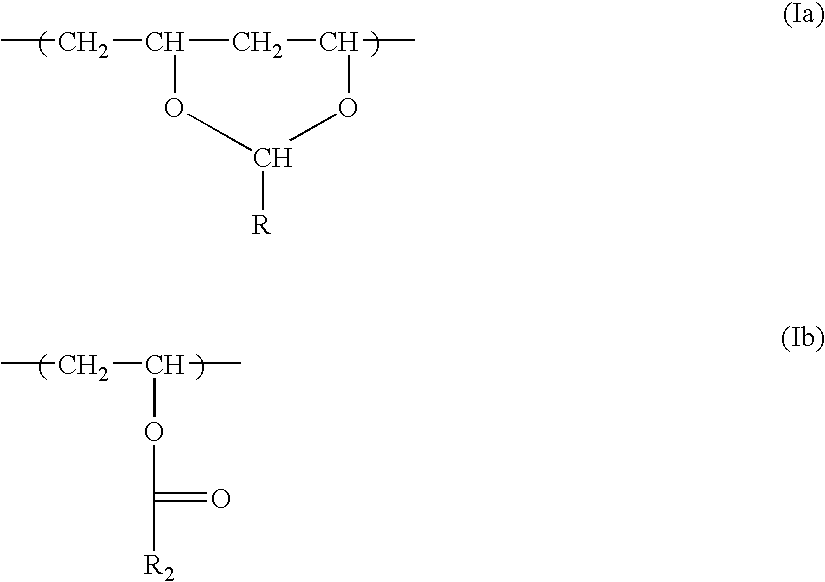

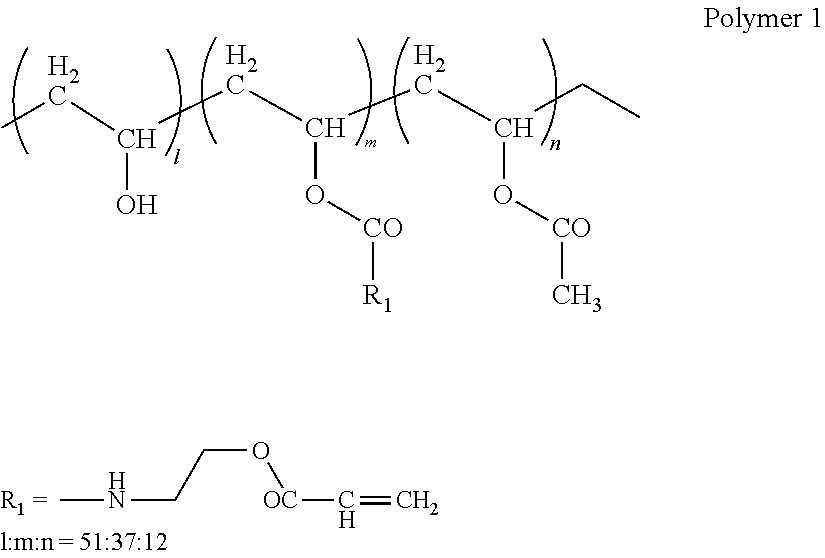

High speed negative-working thermal printing plates

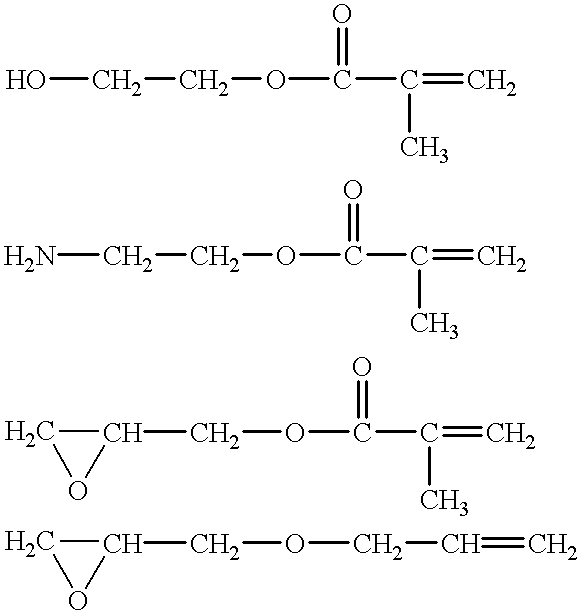

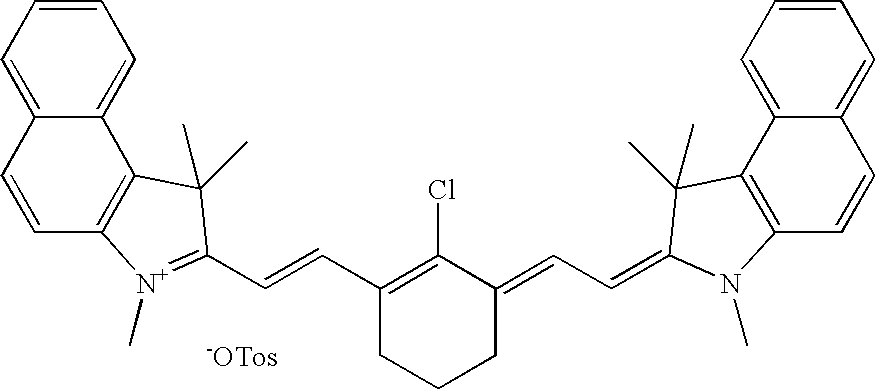

Negative working thermally imageable elements useful as lithographic printing plate precursors and methods for their use are disclosed. The elements have a substrate, a layer of imageable composition over the substrate, and, optionally, an overcoat layer over the layer of imageable composition. The imageable composition has an allyl-functional polymeric binder. Optimum resolution and on-press performance can be attained without a post-exposure bake. The elements do not require a post-exposure bake and can be used in on-press development applications.

Owner:KODAK POLYCHROME GRAPHICS

Method of making a photopolymer printing plate

ActiveUS20050266349A1High degree of polymerizationImage deteriorationPhotosensitive materialsDuplicating/marking methodsPhotopolymerEngineering

A method of making a lithographic printing plate comprising the steps of: a) providing a lithographic printing plate precursor comprising (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a photopolymerizable coating on said support, b) image-wise exposing said coating in a plate setter, c) developing the precursor, thereby removing the non-exposed areas of the coating from the support, whereby the developing step is carried out off-press in a gumming unit by treating the coating of the precursor with a gum solution.

Owner:AGFA OFFSET BV

Negative-acting no-process printing plates

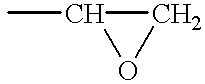

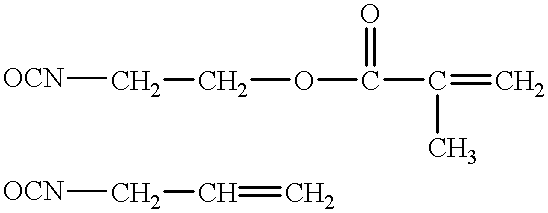

InactiveUS6171735B1Platen pressesSemiconductor/solid-state device manufacturingFunctional monomerOligomer

Owner:3M INNOVATIVE PROPERTIES CO

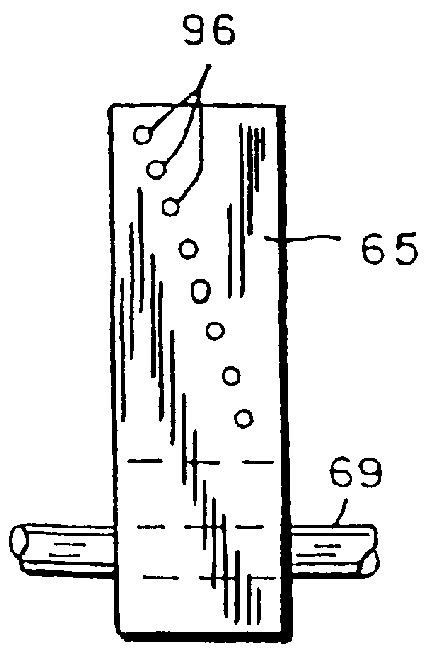

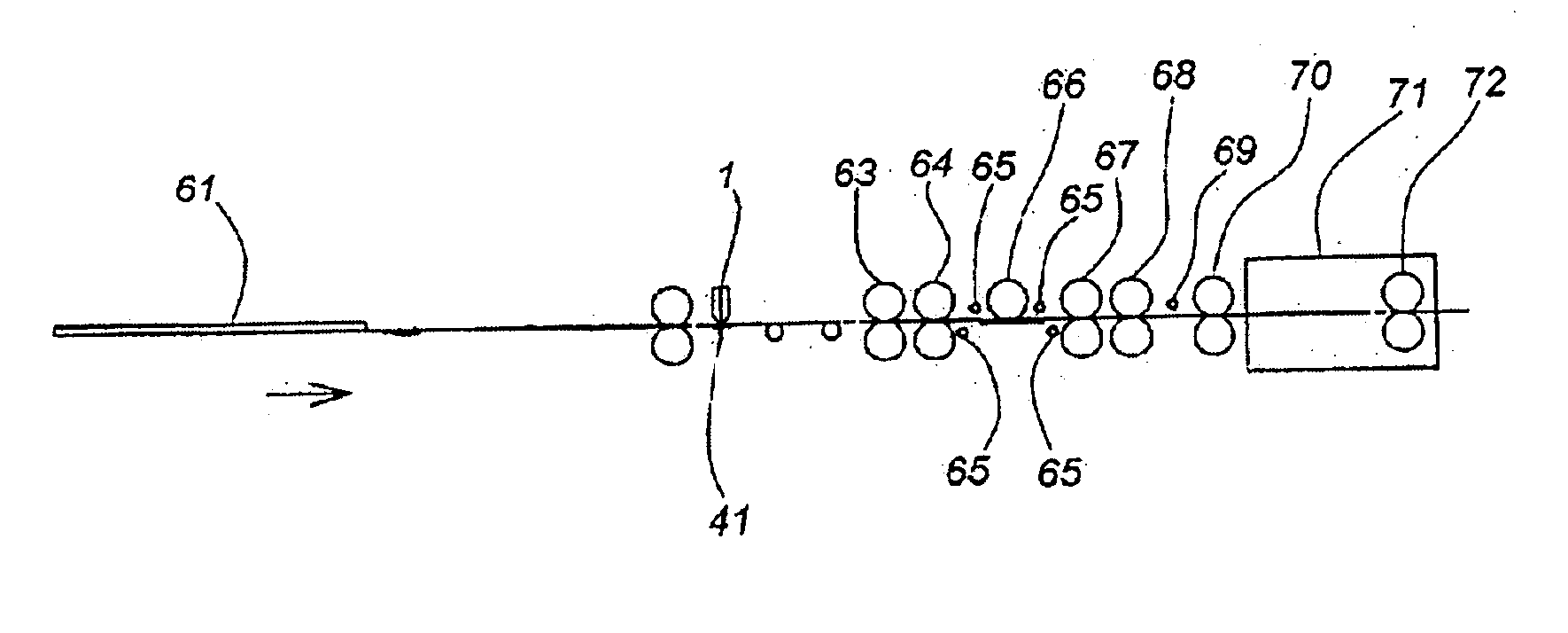

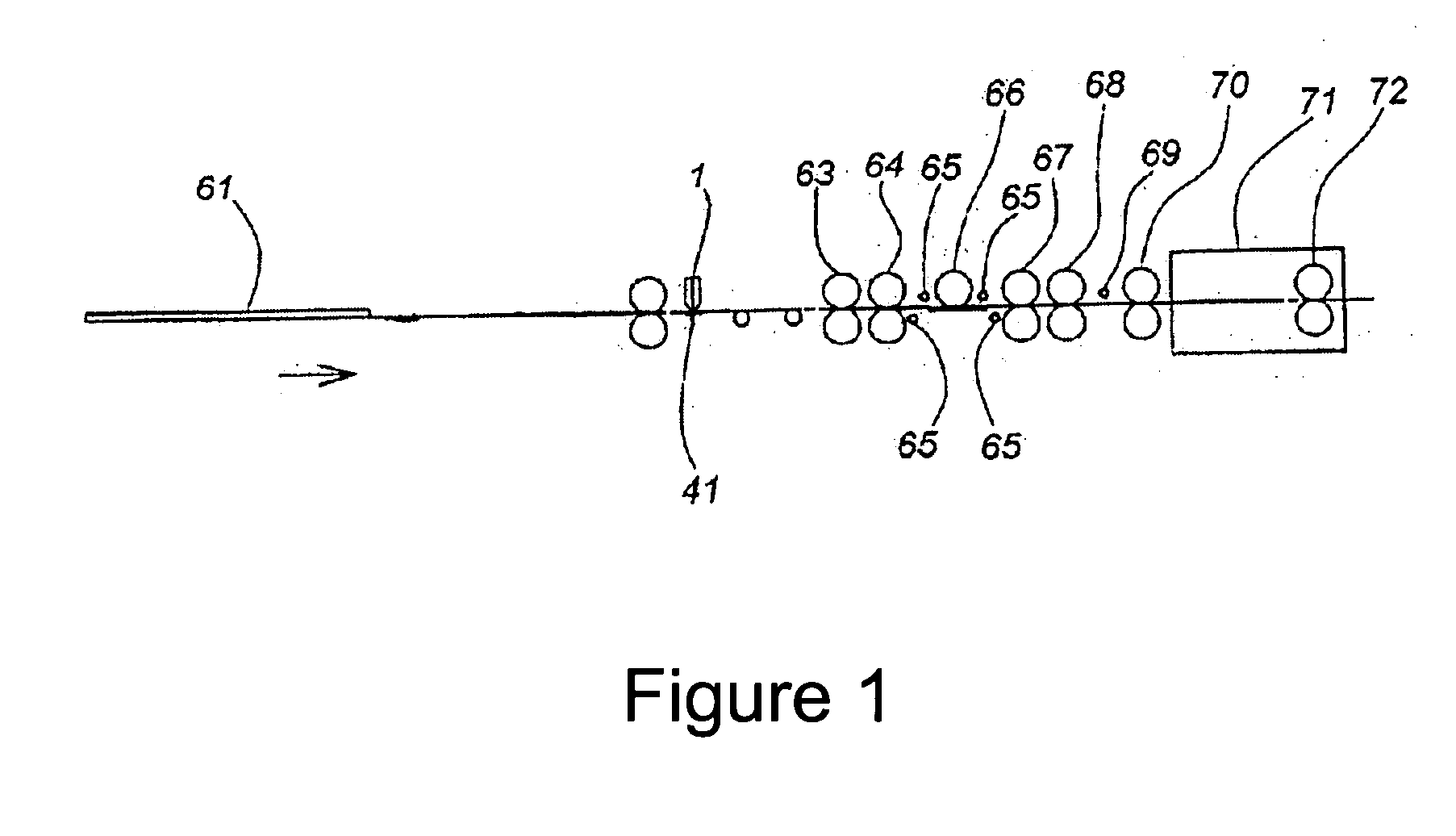

Method of making a lithographic printing plate

ActiveUS8232043B2High degree of polymerizationQuality improvementPlaten pressesPhotosensitive materialsInter layerEngineering

A method of making a lithographic printing plate includes the steps of a) providing a lithographic printing plate precursor including (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a coating on the support including a photopolymerizable layer, and, optionally, an intermediate layer between the photopolymerizable layer and the support, b) image-wise exposing the coating in a plate setter, c) optionally, heating the precursor in a preheating unit, and d) developing the precursor off-press in a gumming unit by treating the coating of the precursor with a gum solution, thereby removing the non-exposed areas of the coating from the support, wherein the coating further includes a compound capable of interacting with the support, the compound being present in the photopolymerizable layer and / or in the intermediate layer.

Owner:AGFA OFFSET BV

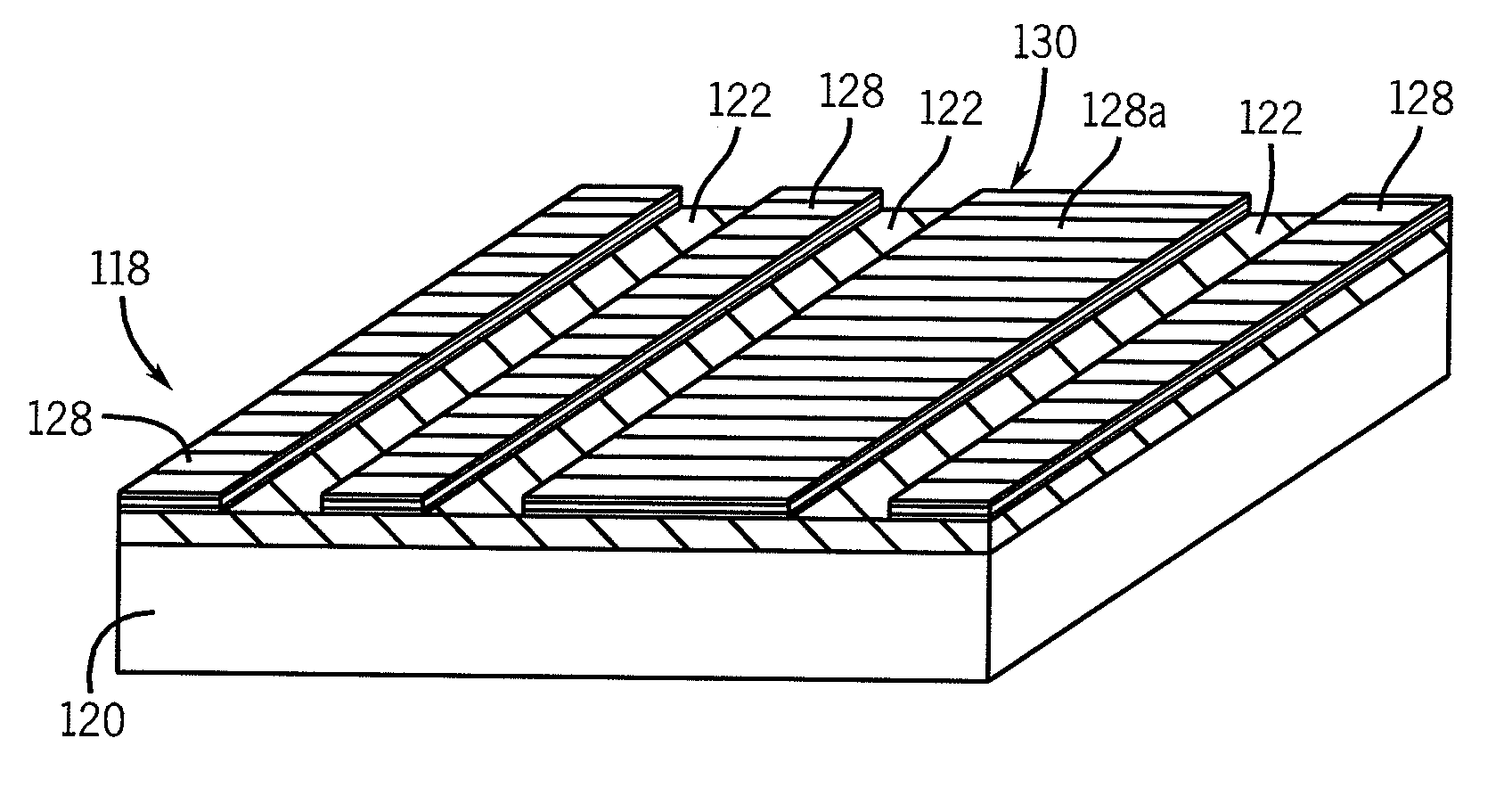

Method to Produce Nanometer-Sized Features with Directed Assembly of Block Copolymers

Owner:MICRON TECH INC

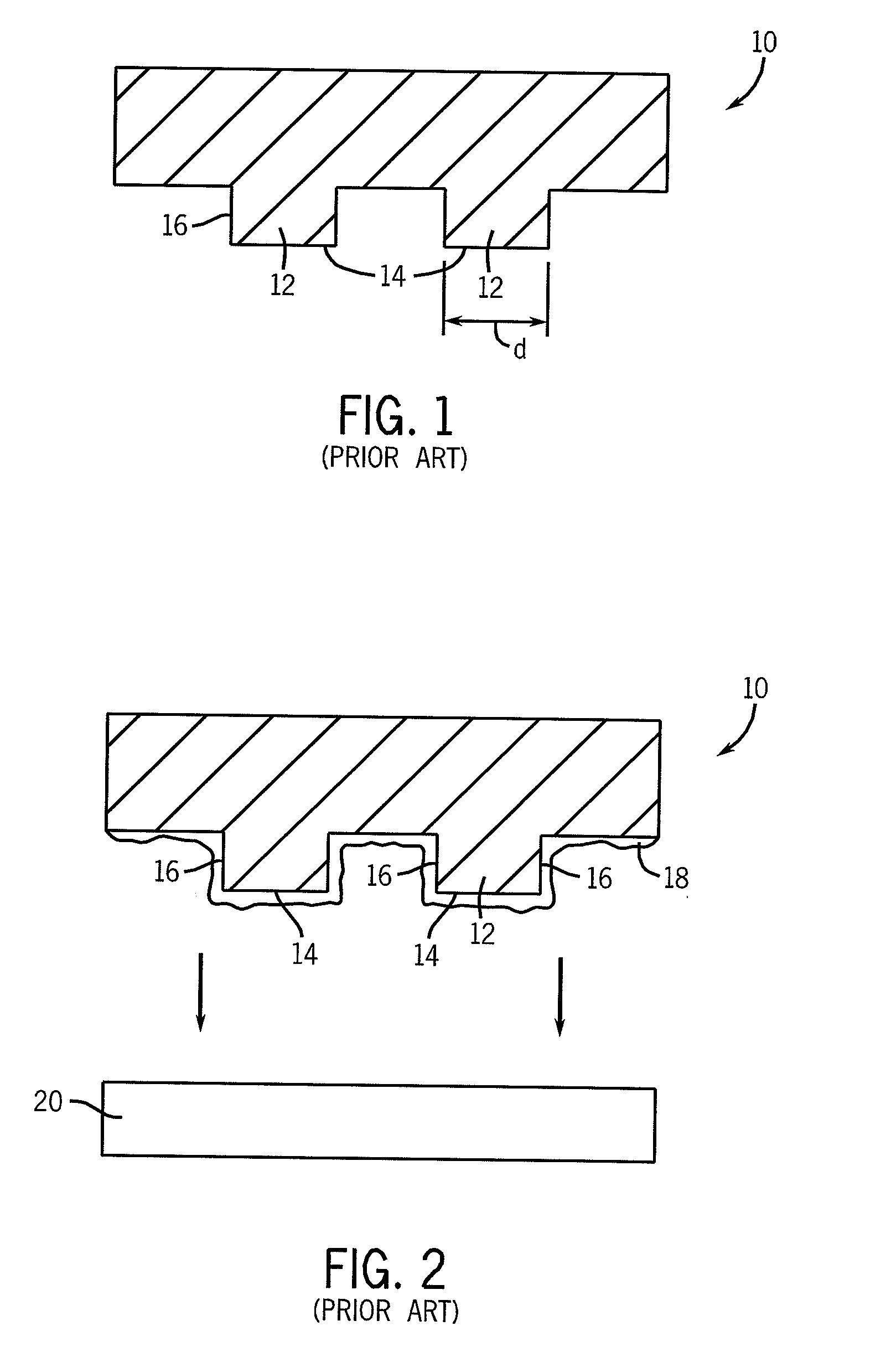

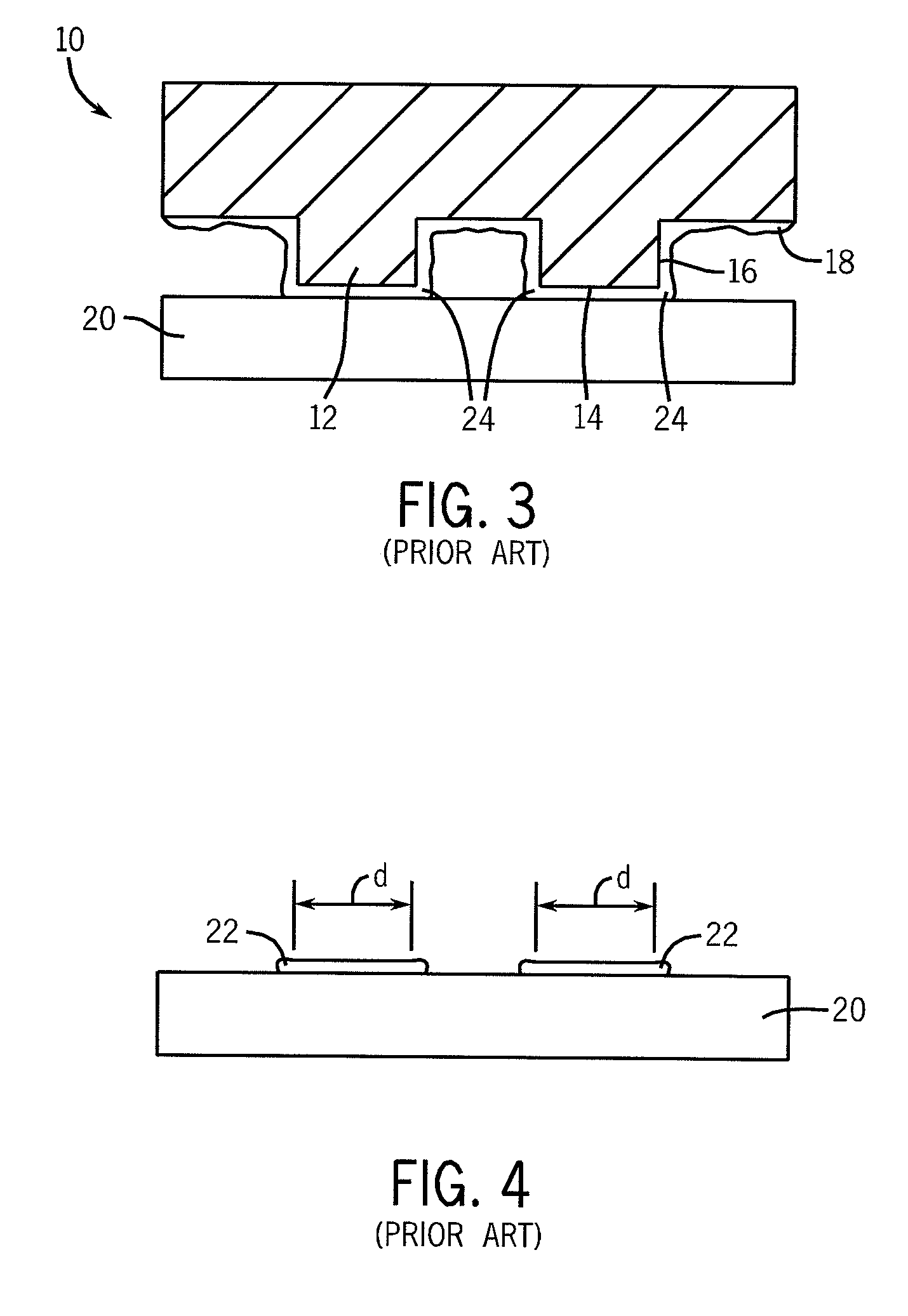

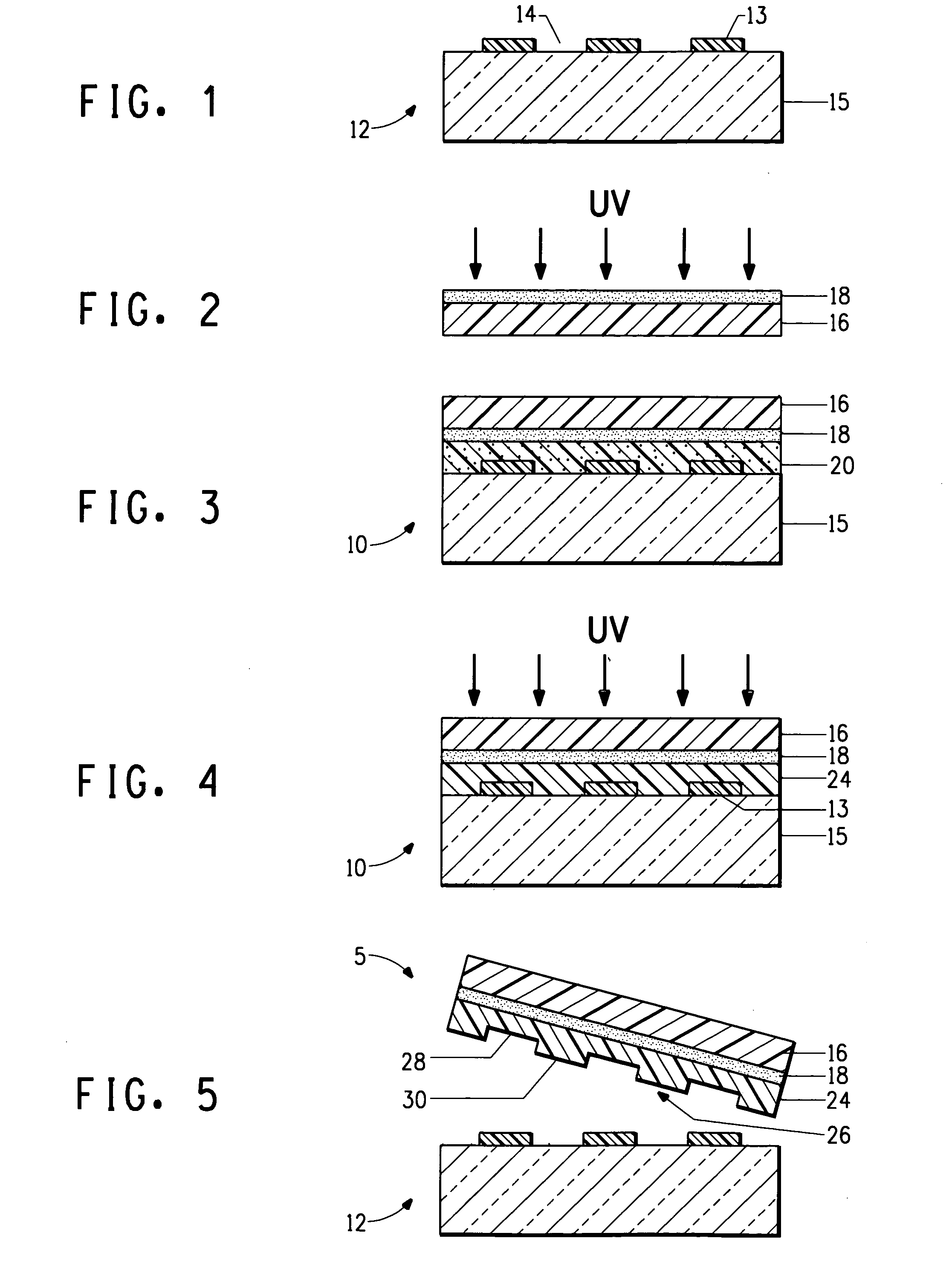

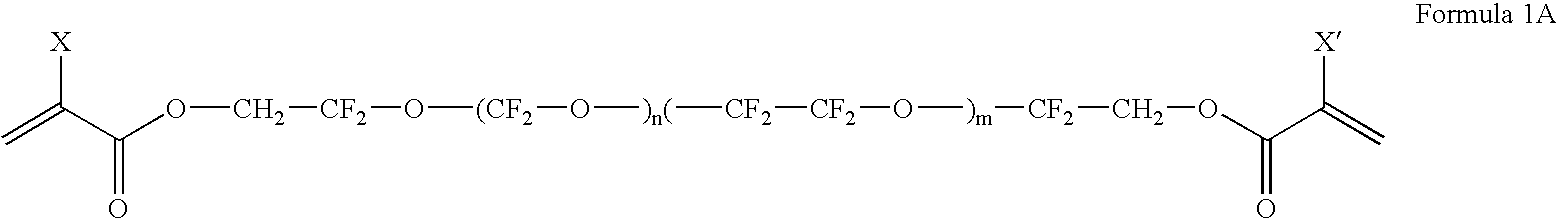

Printing form precursor and process for preparing a stamp from the precursor

The invention pertains to a printing form precursor and a method for preparing a stamp from the precursor for use in soft lithographic applications. The printing form precursor includes a composition layer of a fluorinated compound capable of polymerization upon exposure to actinic radiation and a flexible support transparent to the actinic radiation adjacent the composition layer.

Owner:EI DU PONT DE NEMOURS & CO

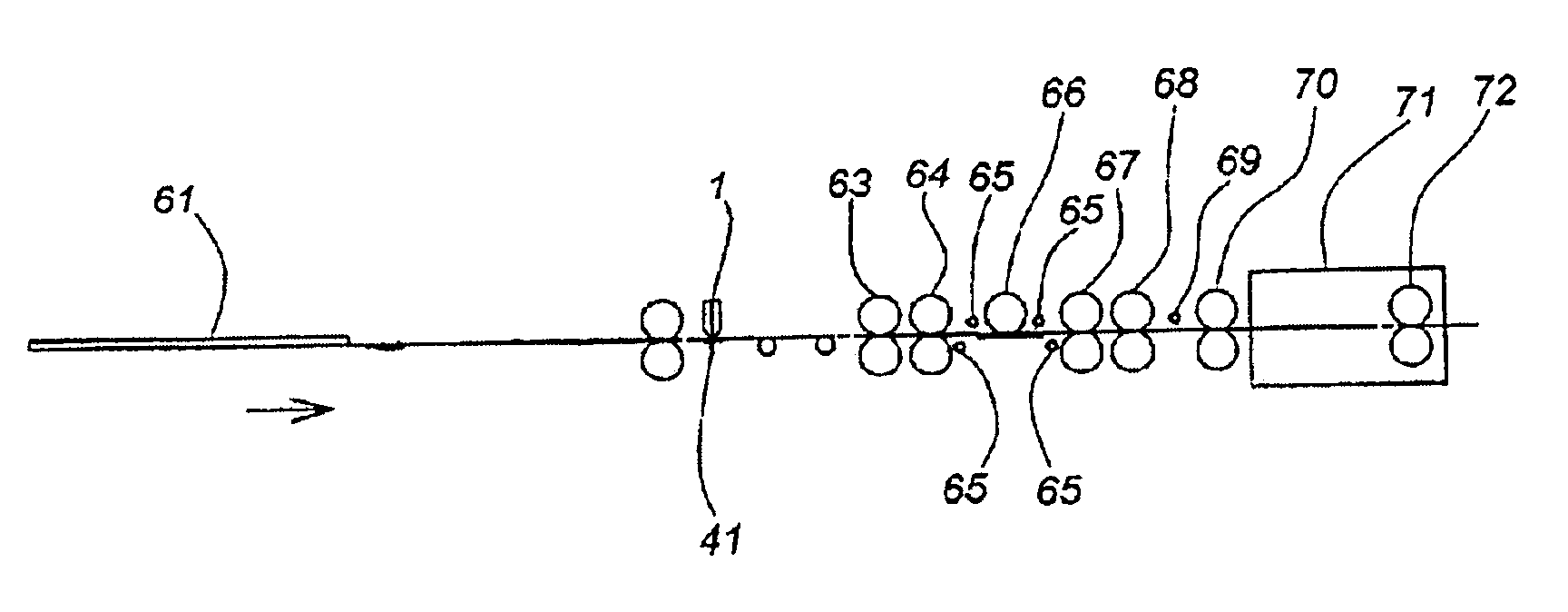

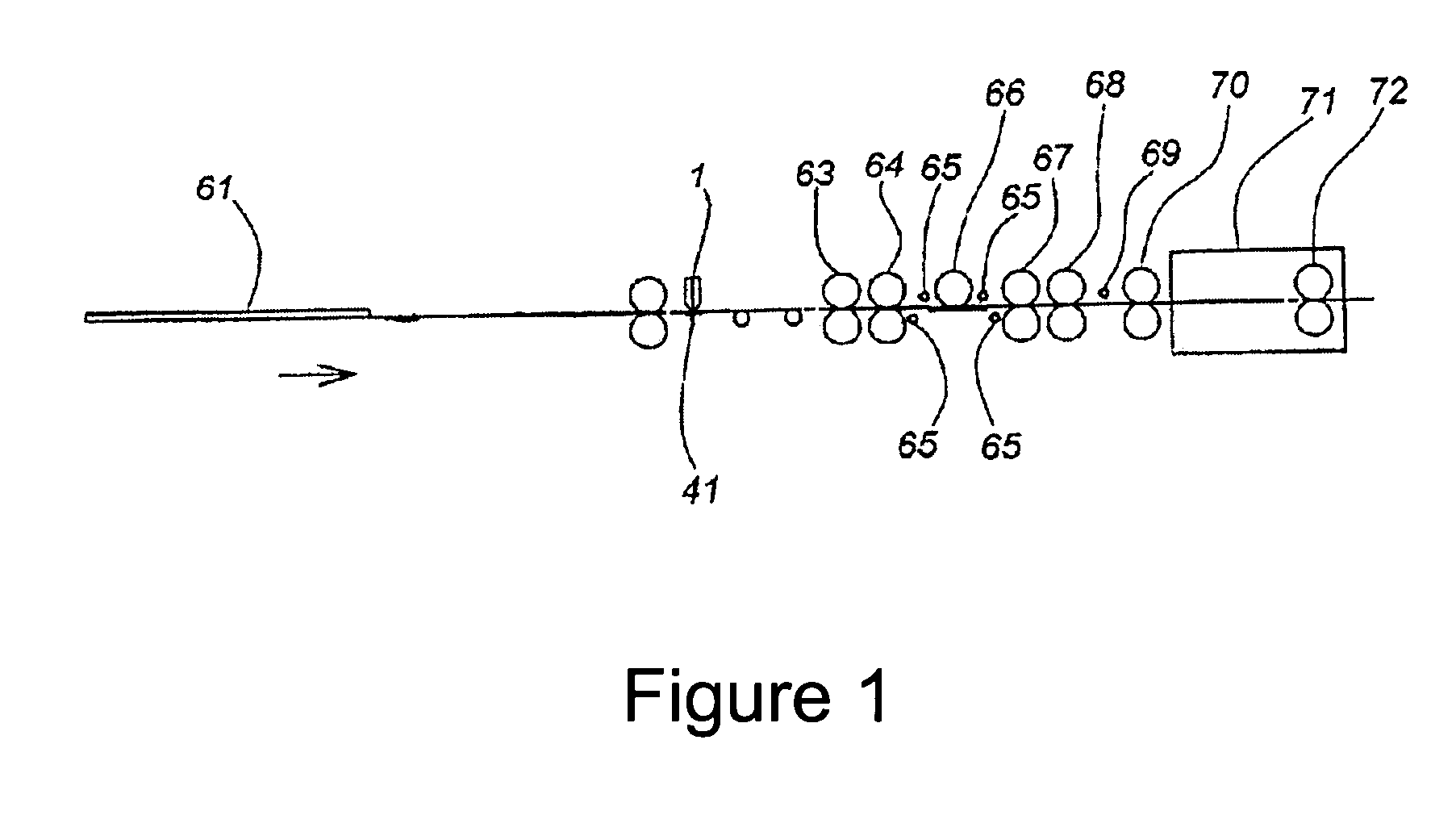

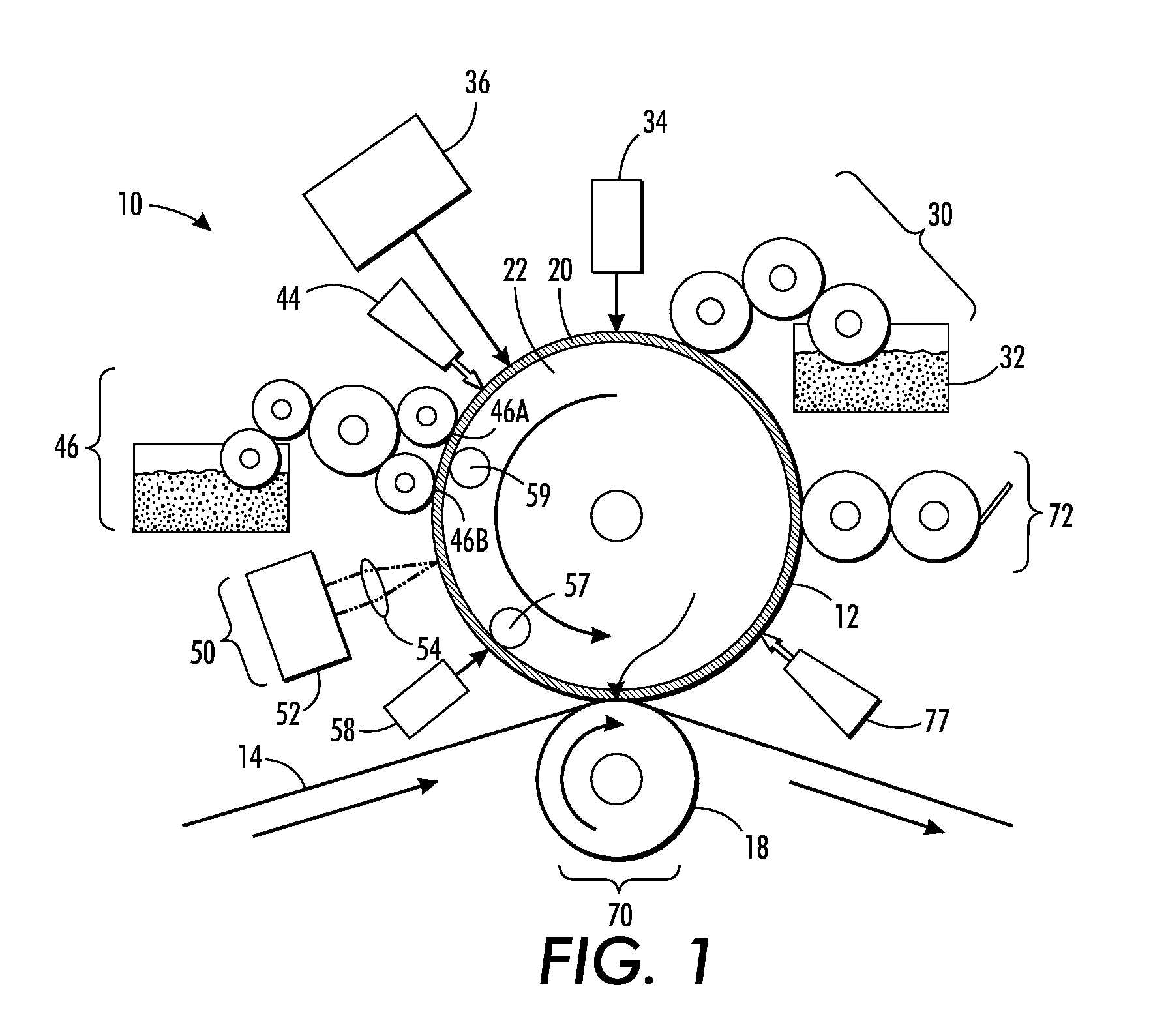

Method for making a lithographic printing plate involving on press development

InactiveUS6030750AImprove printing effectSemiconductor/solid-state device manufacturingPlate printingEngineeringPrinting press

The present invention provides a method for making a lithographic printing plate comprising the steps of: (1) image-wise exposing to light an imaging element comprising (i) on a hydrophilic surface of a lithographic base an image forming layer comprising hydrophobic thermoplastic polymer particles capable of coalescing under the influence of heat and dispersed in a hydrophilic binder and (ii) a compound capable of converting light to heat, said compound being comprised in said image forming layer or a layer adjacent thereto; (2) and developing a thus obtained image-wise exposed imaging element by mounting it on a print cylinder of a printing press and supplying an aqueous dampening liquid and / or ink to said image forming layer while rotating said print cylinder.

Owner:EASTMAN KODAK CO

Method for developing multilayer imageable elements

InactiveUS20050162505A1Recording apparatusSemiconductor/solid-state device manufacturingEngineeringStochastic screening

A method for forming an image by imaging and developing a multi-layer imageable element, in which the developer is fresh developer and the developer is not reused, is disclosed. Much smaller variation in dot percentage is obtained when each imaged imageable element is developed in fresh developer than when the developer is reused to develop additional imaged imageable elements. The method is especially suited to the formation of images using stochastic screening. Either a solvent based developer or a high pH developer may be used.

Owner:KODAK POLYCHROME GRAPHICS

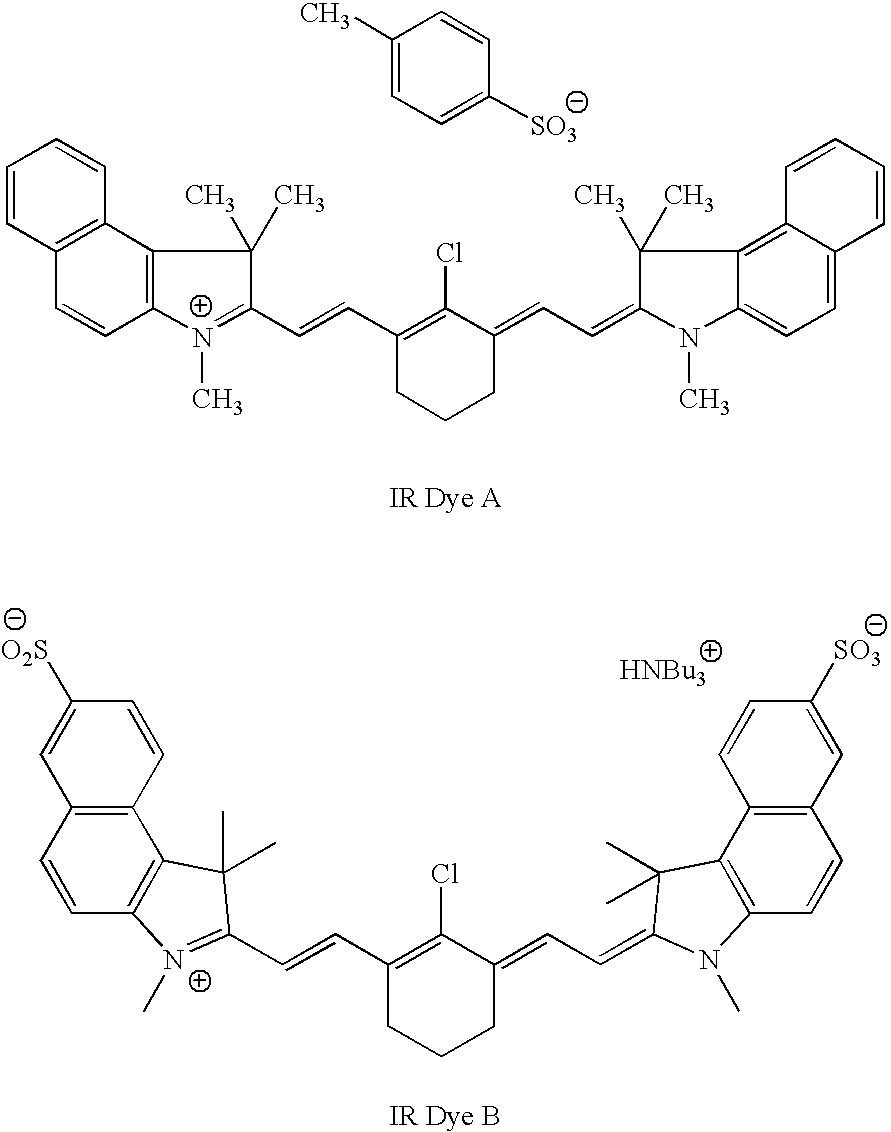

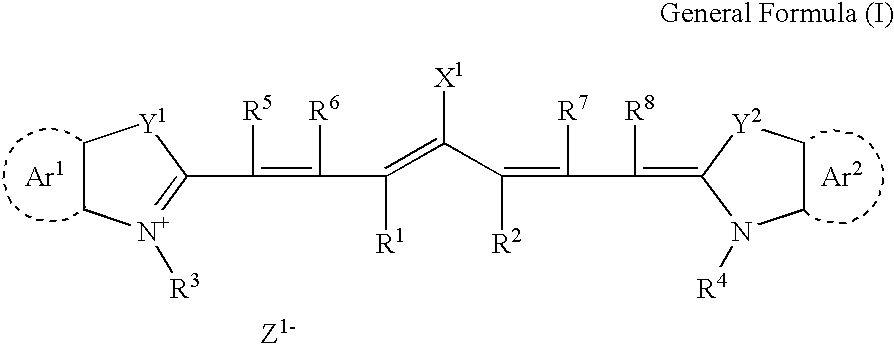

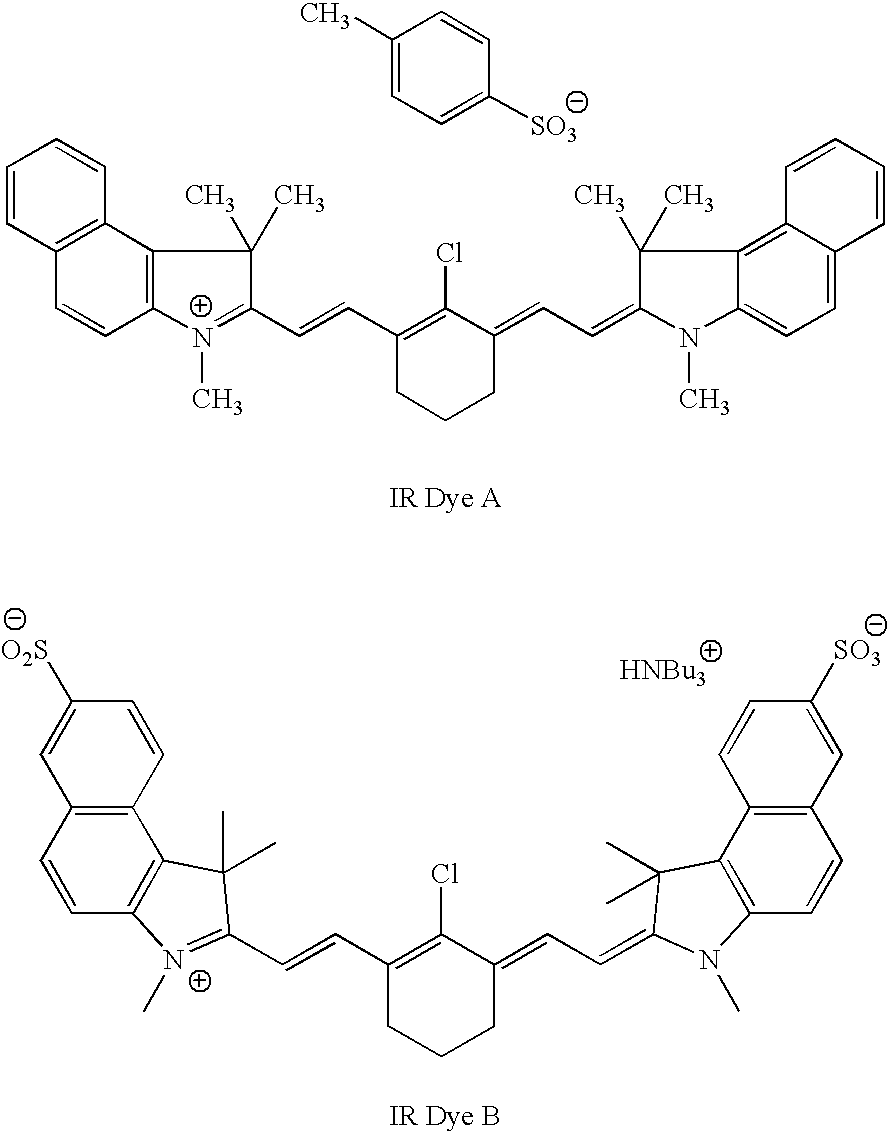

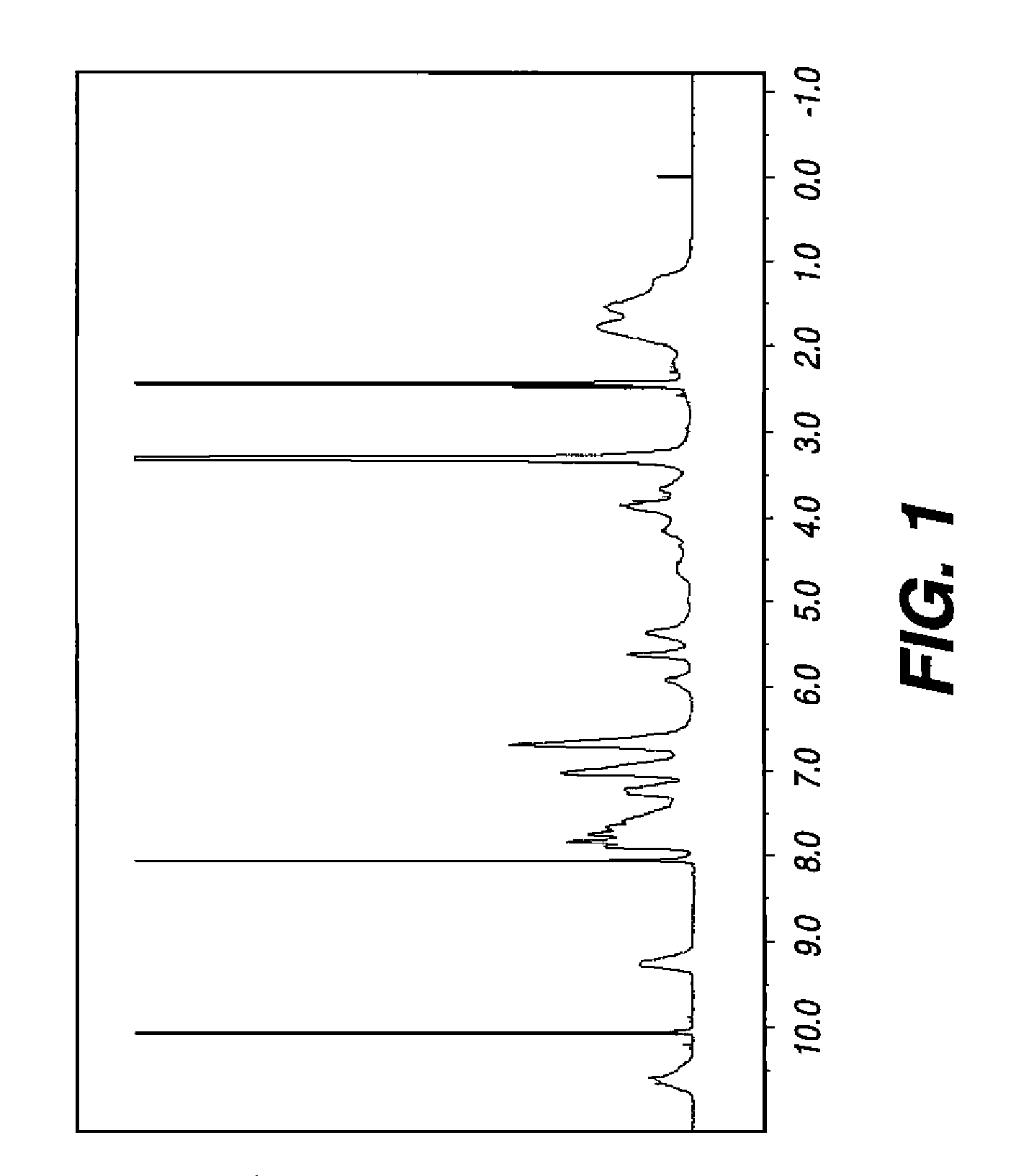

Thermosensitive lithographic printing plate

InactiveUS7108956B2Favorable image formationHigh sensitivityPhotosensitive materialsSemiconductor/solid-state device manufacturingPolymer scienceWater insoluble

A thermosensitive lithographic printing plate comprising: a hydrophilic support; a lower layer comprising a water-insoluble and alkali-soluble resin; and an upper thermosensitive layer comprising a water-insoluble and alkali-soluble resin and an infrared absorbing dye, whose dissolution in an alkaline aqueous solution increases upon exposure, wherein a surface of the upper thermosensitive layer has protrusions caused by ununiformity of thickness of the upper thermosensitive layer in a proportion of 0.1 or more and not more than 7 per μm2 or the upper thermosensitive layer comprises at least two alkali-soluble resins having a different dissolution speed in an alkaline aqueous solution from each other, and the at least two alkali-soluble resin cause phase separation from each other.

Owner:FUJIFILM HLDG CORP +1

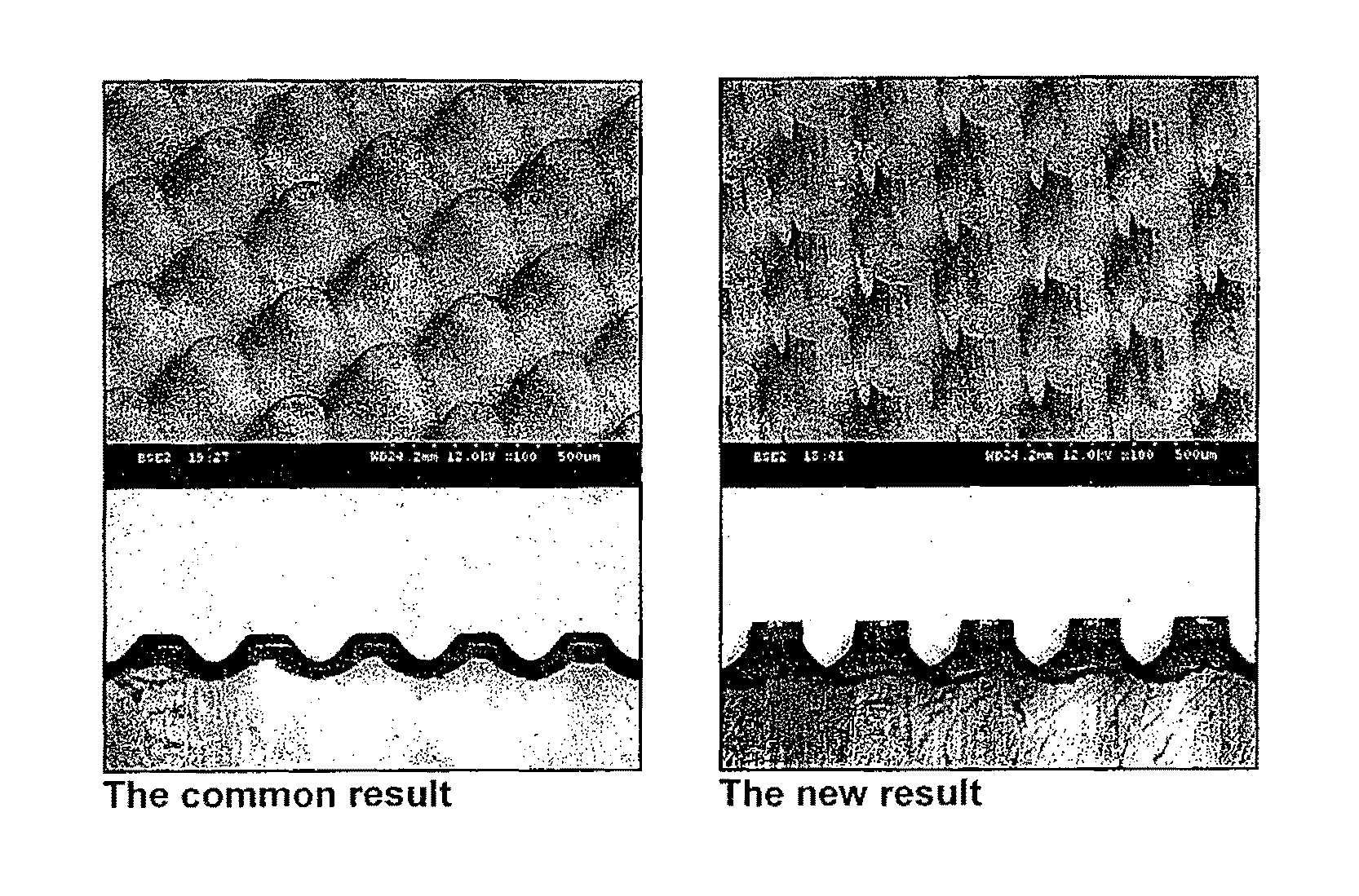

Method of improving print performance in flexographic printing plates

ActiveUS8158331B2Promote resultsReduces print flutingPhotosensitive materialsDuplicating/marking methodsCross-linkEngineering

Owner:MACDERMID PRINTING SOLUTIONS

Planographic printing plate

InactiveUS6017677AHigh sensitivitySemiconductor/solid-state device manufacturingPhotosensitive material processingSide chainPhotoacid generator

The present invention provide a planographic printing plate comprising a substrate having thereon a recording layer which comprises at least one of a polymer compound carrying on a side chain a functional group which generates sulfonic acid under influence of an acid, base or heating; and a photo acid-generating agent or acid-generating agent; thermal base-generating agent; or an infrared ray absorbing agent, and by this structure, a high sensitive positive type planographic printing plate which can be developed with water or requires no developing is provided.

Owner:FUJIFILM CORP

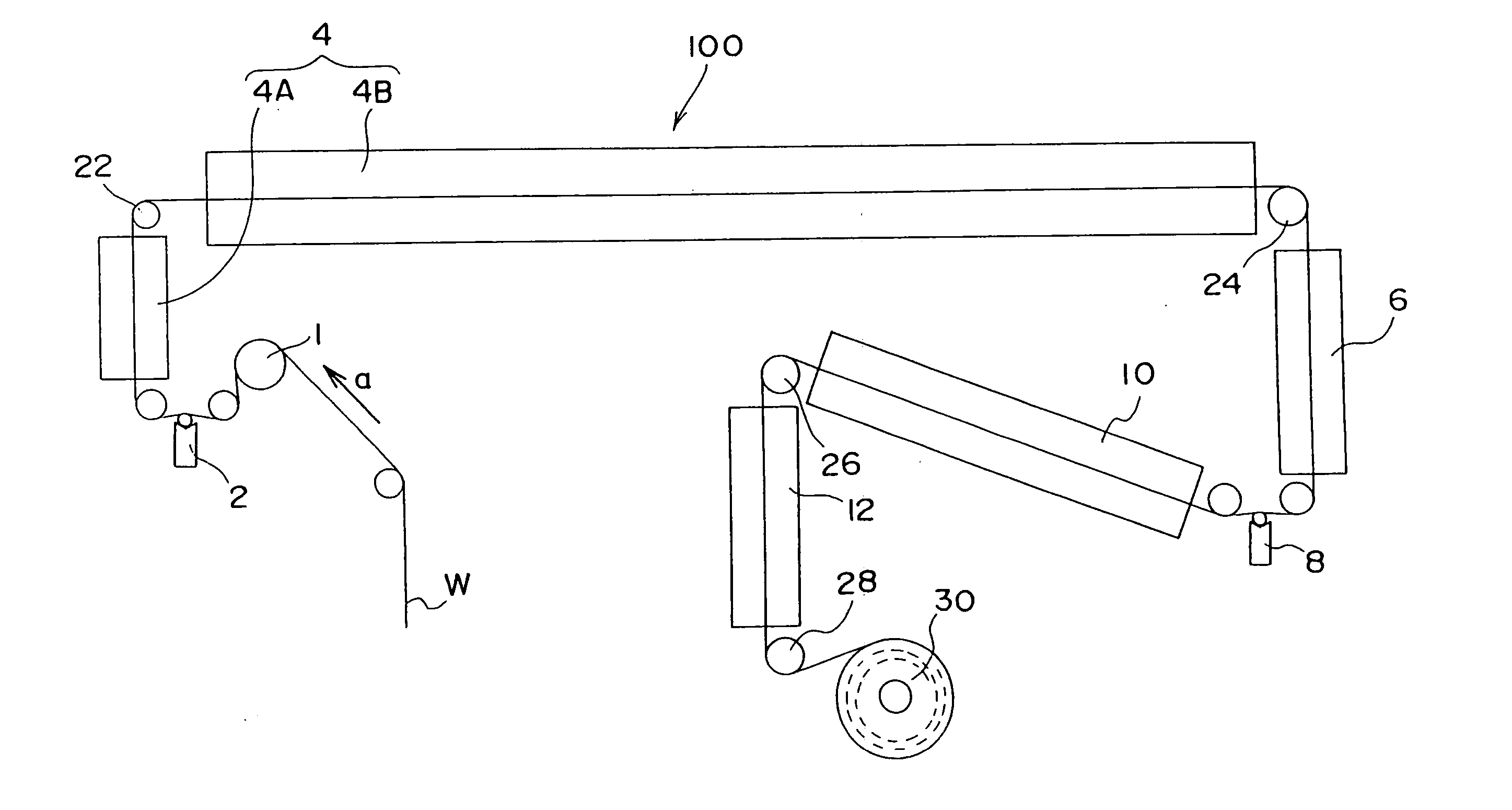

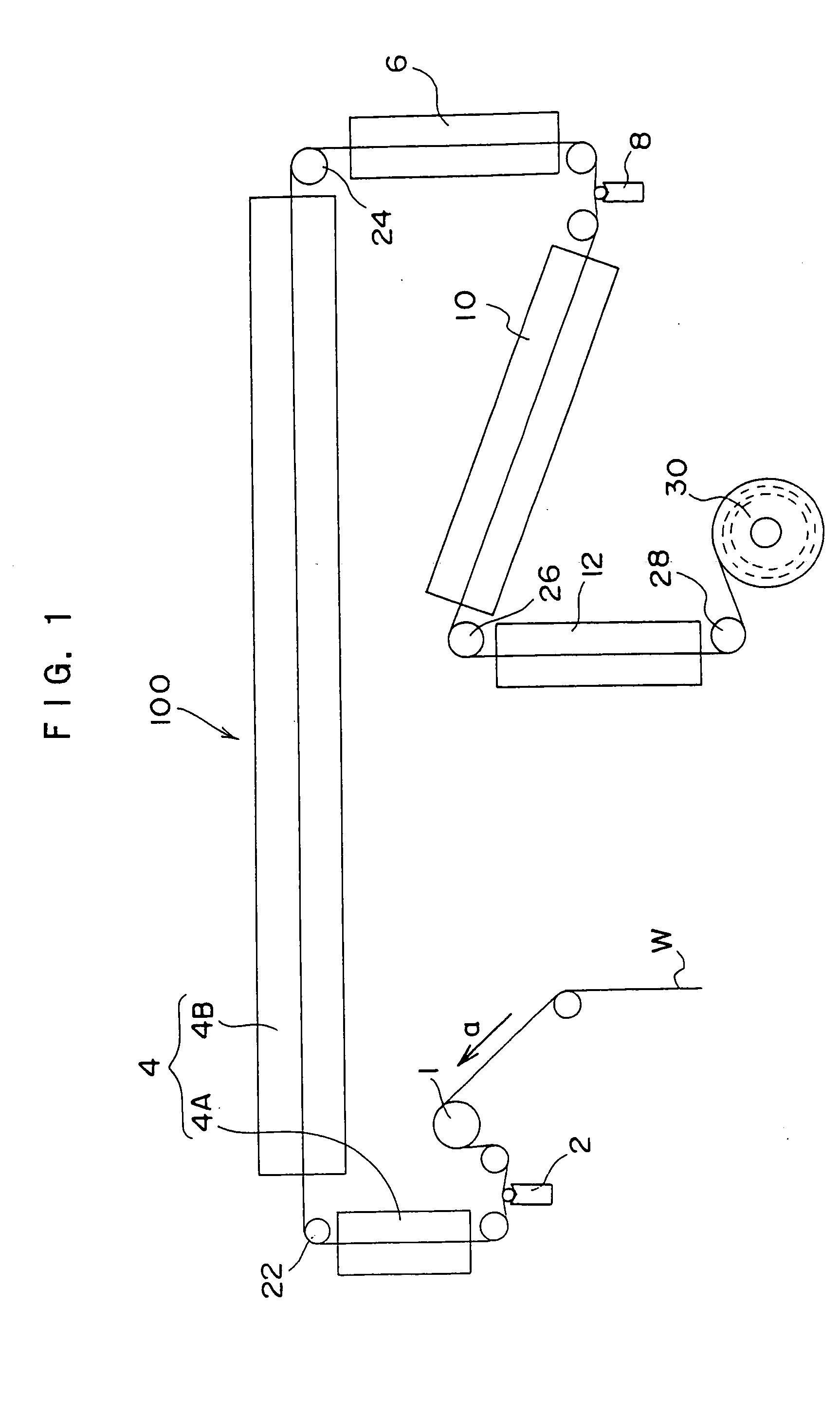

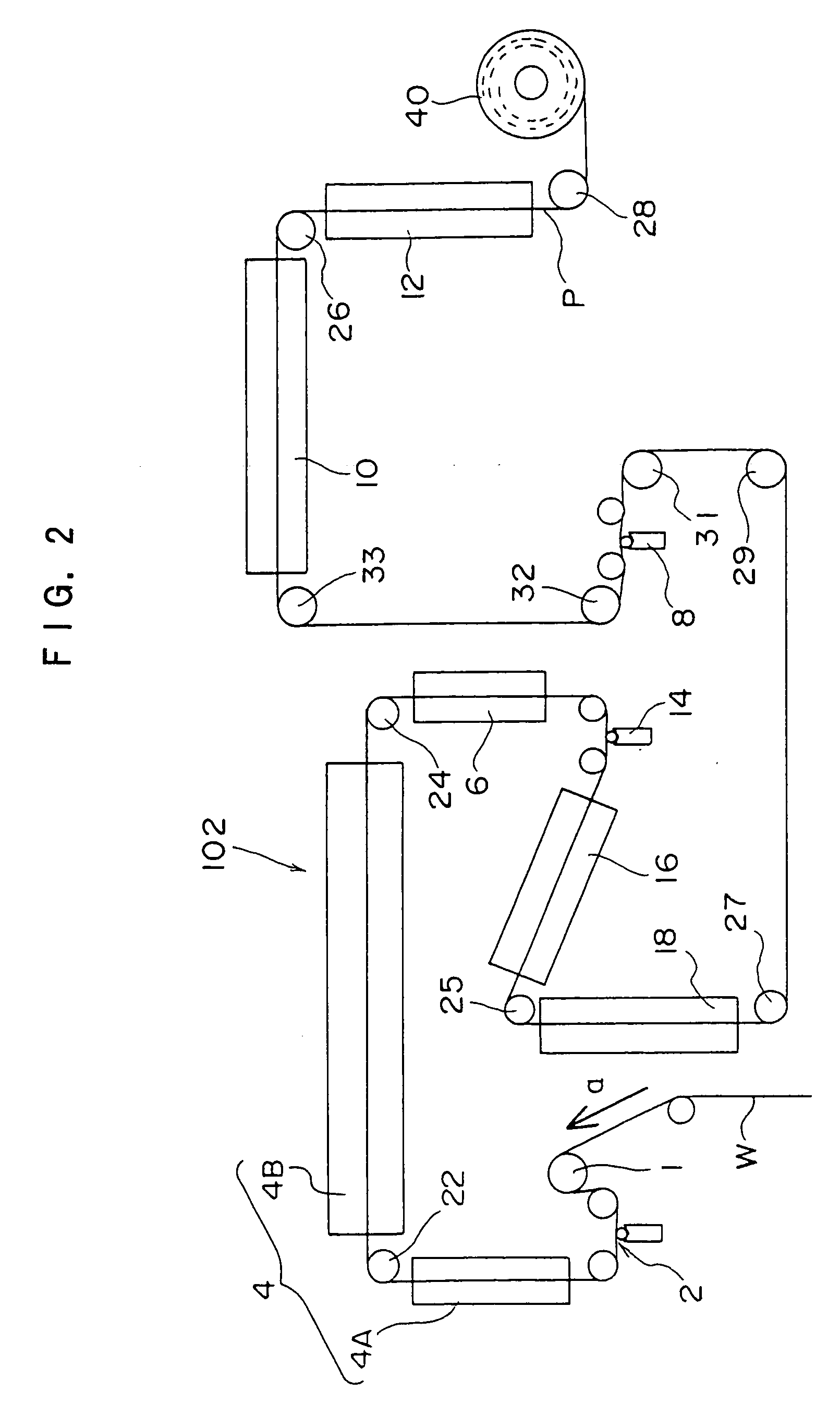

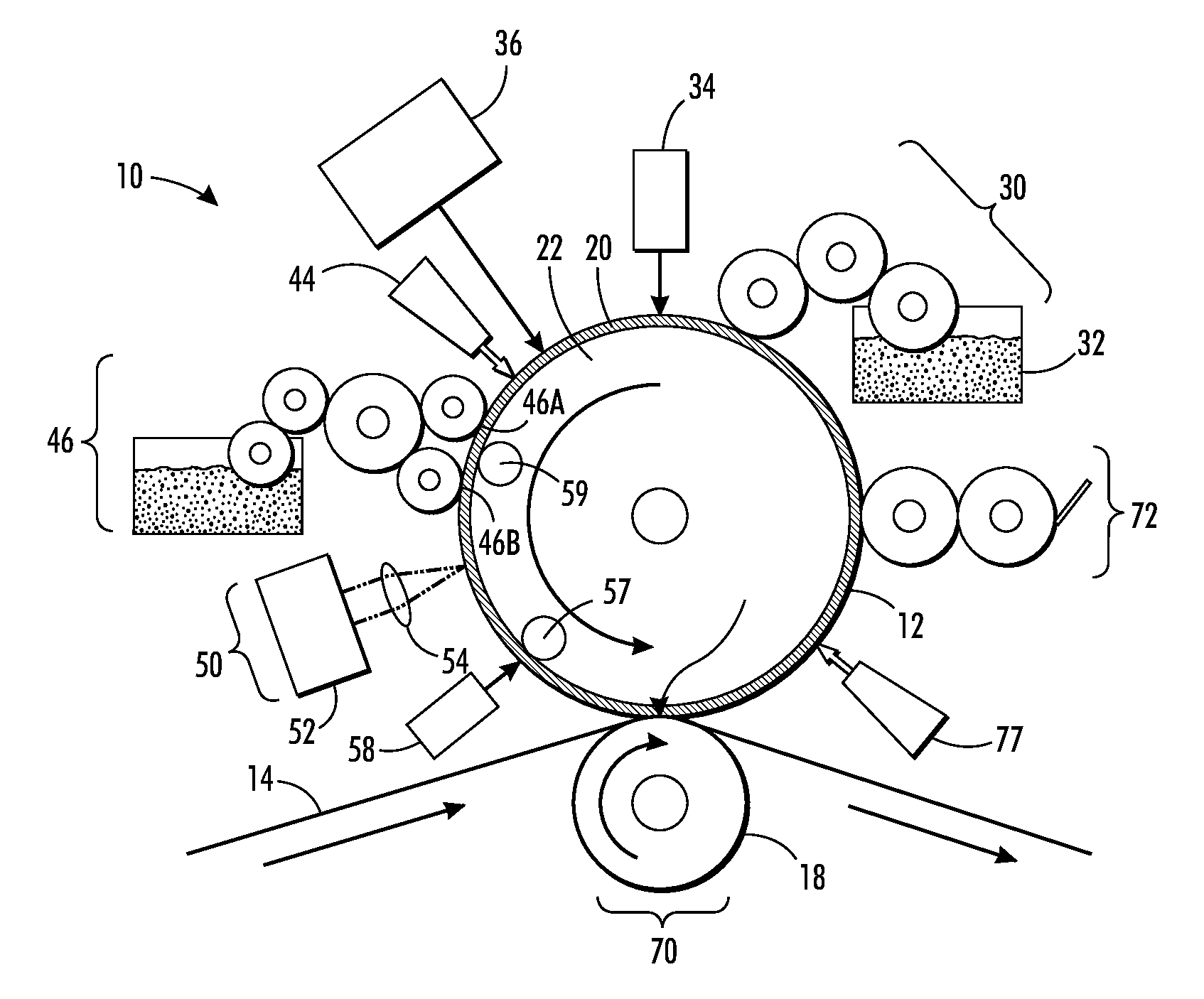

Coating method and planographic printing plate

InactiveUS20050005794A1Low costImprove uniformityPretreated surfacesPhotomechanical coating apparatusPlanographic printingMaterials science

The present invention provides a method of coating a coating solution comprising: providing a web; providing a coating solution; coating the coating solution on at least one surface of the web; and drying the coating solution to form a coated layer, wherein a temperature of the web is maintained at 35° C. or more during coating. According to the coating method, a multi-layered planographic printing plate can be manufactured at low energy cost and running cost.

Owner:FUJIFILM HLDG CORP +1

Planographic printing plate precursor and planographic printing method

ActiveUS7005234B2Excellent plate-wear resistanceAvoid small quantitiesPhotosensitive materialsRadiation applicationsPlanographic printingPhotochemistry

The present invention provides a planographic printing plate precursor comprising a photosensitive layer on a support, the photosensitive layer including an infrared absorbent, a radical polymerization initiator and a radical polymerizing compound, the photosensitive layer being recordable with irradiation with an infrared ray, and being at least one of soluble and dispersible in water.

Owner:FUJIFILM CORP

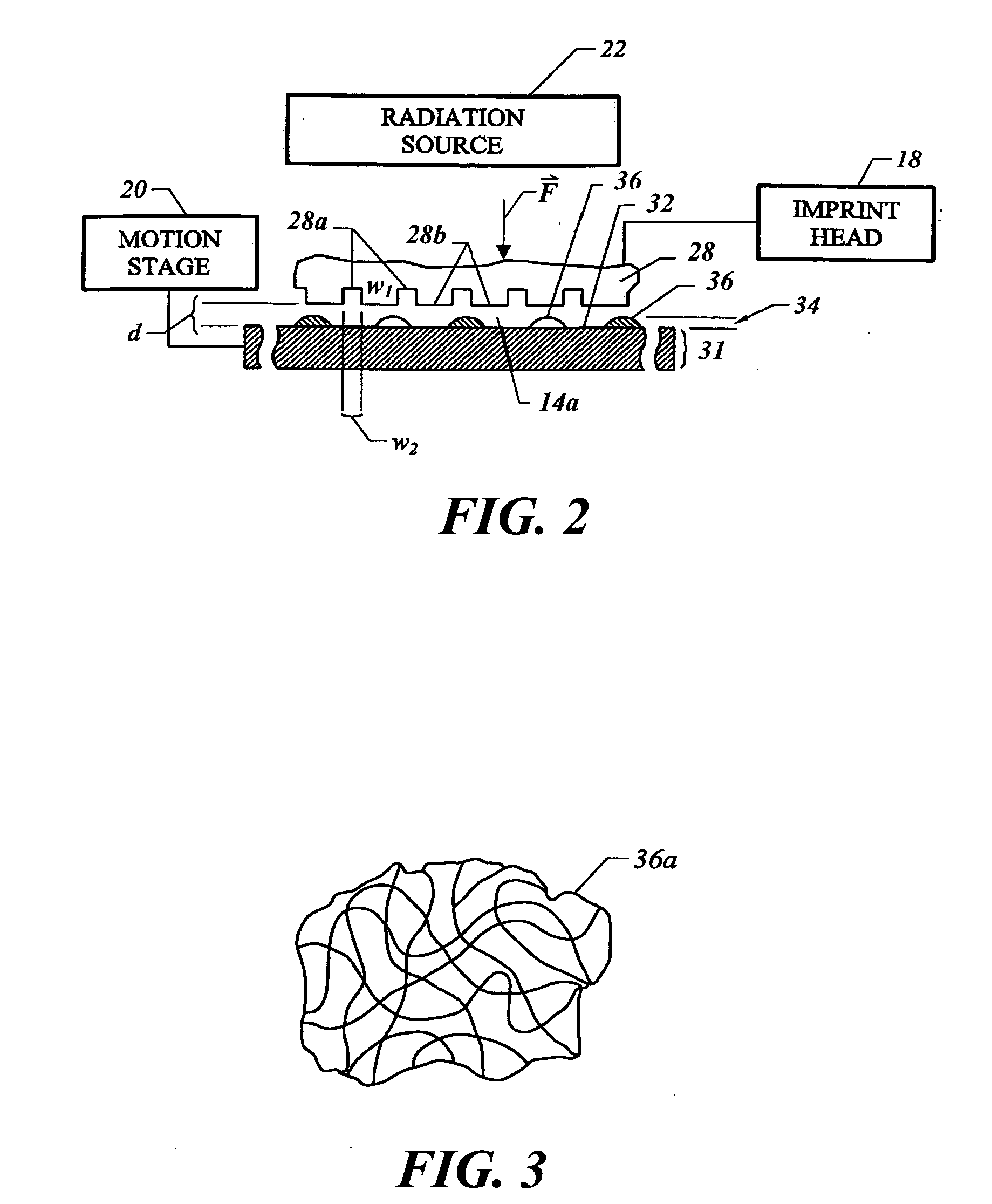

Materials and methods for imprint lithography

One embodiment of the present invention relates to an imprinting material for imprint lithography that includes the surfactant 3M™ Novec™ Fluorosurfactant FC-4432, and another embodiment of the present invention relates to a method for imprint lithography that uses the imprinting material.

Owner:MOLECULAR IMPRINTS

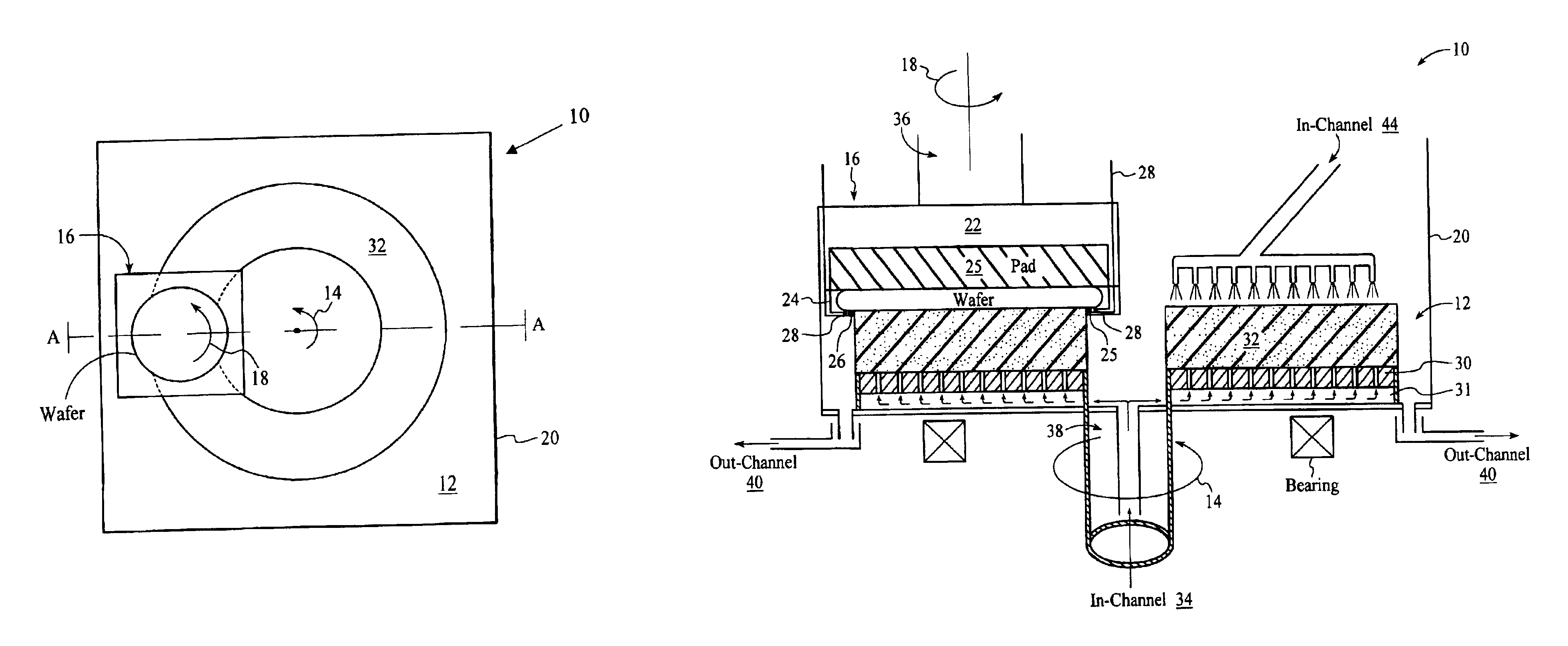

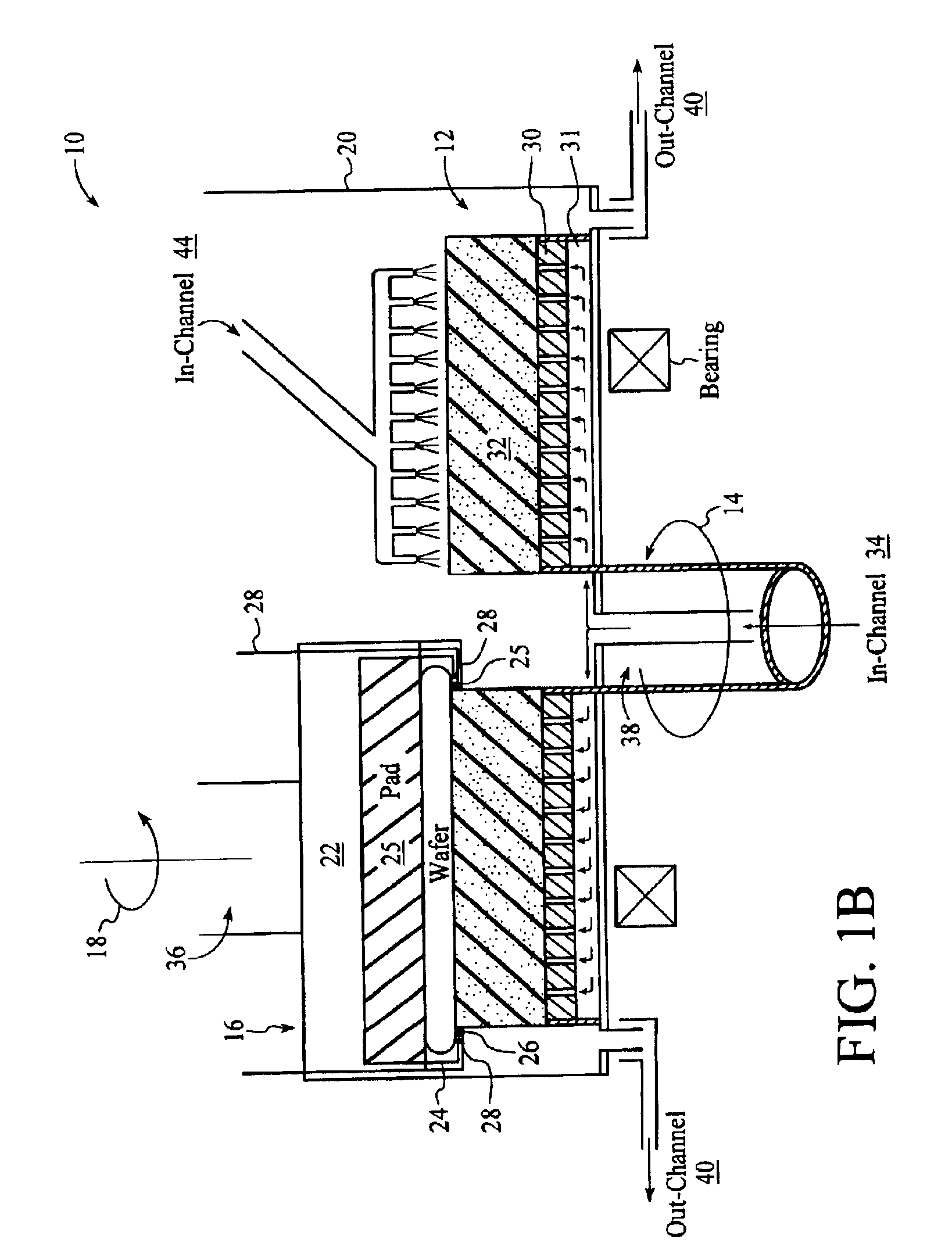

Method and apparatus for electro-chemical mechanical deposition

InactiveUS6902659B2Avoid accumulationReduce exposureElectrolysis componentsSemiconductor/solid-state device manufacturingEngineeringConductive materials

The present invention deposits a conductive material from an electrolyte solution to a predetermined area of a wafer. The steps that are used when making this application include applying the conductive material to the predetermined area of the wafer using an electrolyte solution disposed on a surface of the wafer, when the wafer is disposed between a cathode and an anode, and preventing accumulation of the conductive material to areas other than the predetermine area by mechanically polishing the other areas while the conductive material is being applied.

Owner:NOVELLUS SYSTEMS

Method for developing multilayer imageable elements

InactiveUS6992688B2Recording apparatusSemiconductor/solid-state device manufacturingSolvent basedEngineering

A method for forming an image by imaging and developing a multi-layer imageable element, in which the developer is fresh developer and the developer is not reused, is disclosed. Much smaller variation in dot percentage is obtained when each imaged imageable element is developed in fresh developer than when the developer is reused to develop additional imaged imageable elements. The method is especially suited to the formation of images using stochastic screening. Either a solvent based developer or a high pH developer may be used.

Owner:KODAK POLYCHROME GRAPHICS

Positive-working radiation-sensitive imageable elements

InactiveUS20110059399A1High sensitivityHigh image resolutionPlaten pressesPhotosensitive materialsImideAryl

Positive-working imageable elements having improved sensitivity, high resolution, and solvent resistance are prepared using a water-insoluble polymeric binder comprising vinyl acetal recurring units that have pendant hydroxyaryl groups, and recurring units comprising carboxylic acid aryl ester groups that are substituted with a cyclic imide group. These imageable elements can be imaged and developed to provide various types of elements including lithographic printing plates.

Owner:EASTMAN KODAK CO

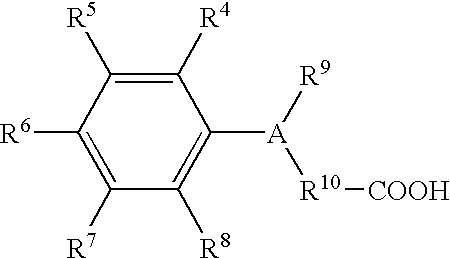

Aluminum substrates and lithographic printing plate precursors

ActiveUS20130052582A1Enhance layeringImprove adhesionPhotosensitive materialsLayered productsSide chainCarboxylic acid

An aluminum-containing substrate can be provided for use in lithographic printing plate precursors. Before radiation-sensitive layers are applied, a grained and sulfuric acid anodized aluminum-containing support is treated with an alkaline or acidic pore-widening solution to provide its outer surface with columnar pores. The diameter of the columnar pores at their outermost surface is at least 90% of the average diameter of the columnar pores. Directly on this treated surface, a hydrophilic layer is applied, which hydrophilic layer contains a non-crosslinked hydrophilic polymer having carboxylic acid side chains.

Owner:EASTMAN KODAK CO

Curable jettable liquid for flexography

InactiveUS20060054040A1Fast and simple and environmentalThe way is simple and fastDuplicating/marking methodsInksOligomerPlasticizer

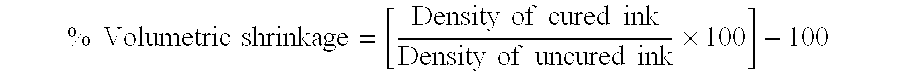

A curable jettable liquid for manufacturing a flexographic printing plate comprising at least one photo-initiator, at least one monofunctional monomer, at least 5 wt % of a polyfunctional monomer or oligomer and at least 5 wt % of a plasticizer both based on the total weight of the curable jettable liquid capable of realizing a layer after curing having an elongation at break of at least 5%, a storage modulus E′ smaller than 200 MPa at 30 Hz and a volumetric shrinkage smaller than 10%.

Owner:AGFA NV

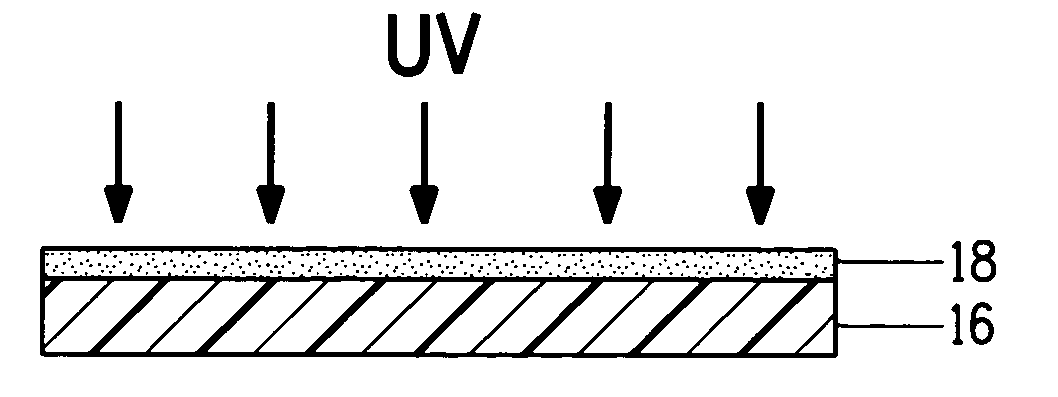

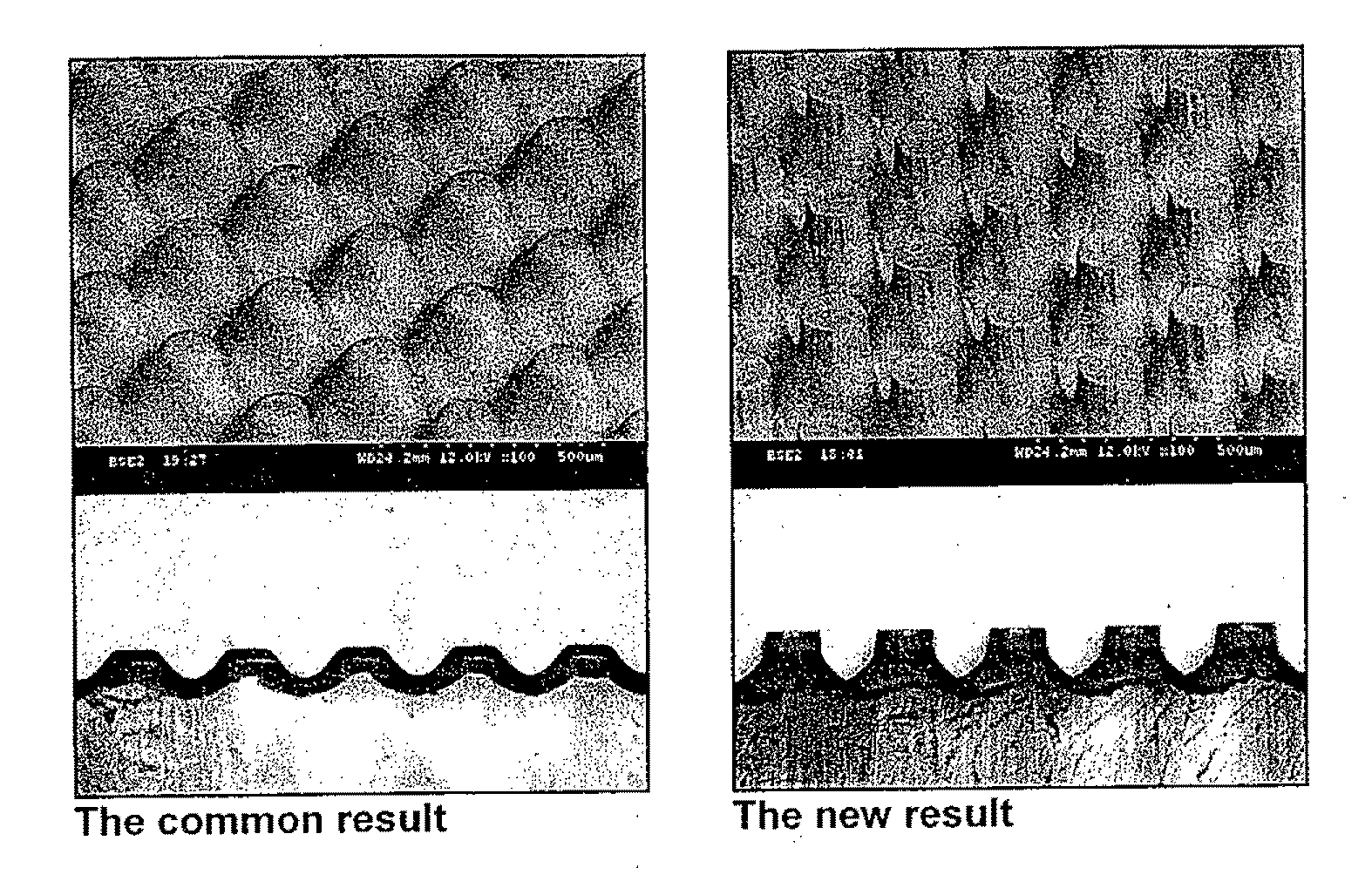

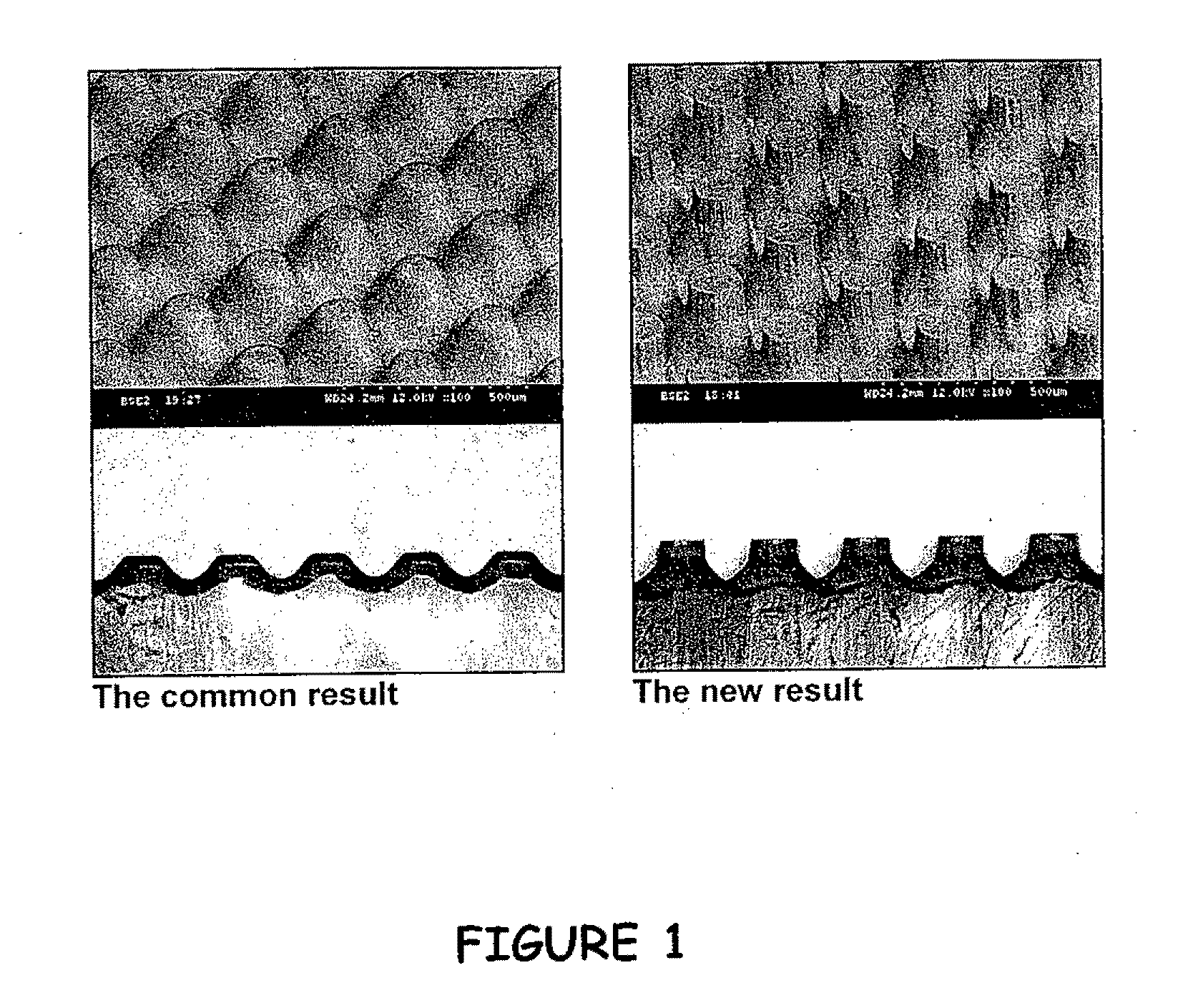

Method of Improving Print Performance in Flexographic Printing Plates

ActiveUS20110081614A1Promote resultsReduces print flutingPhotosensitive materialsDuplicating/marking methodsCross-linkEngineering

A method of making a relief image printing element from a photosensitive printing blank is provided. A photosensitive printing blank with a laser ablatable layer disposed on at least one photocurable layer is ablated with a laser to create an in situ mask. The printing blank is then exposed to at least one source of actinic radiation through the in situ mask to selectively cross link and cure portions of the photocurable layer. Diffusion of air into the at least one photocurable layer is limited during the exposing step and preferably at least one of the type, power and incident angle of illumination of the at least one source of actinic radiation is altered during the exposure step. The resulting relief image comprises a plurality of dots and a dot shape of the plurality of dots is produced that is highly resistant to print fluting for printing on corrugated board.

Owner:MACDERMID PRINTING SOLUTIONS

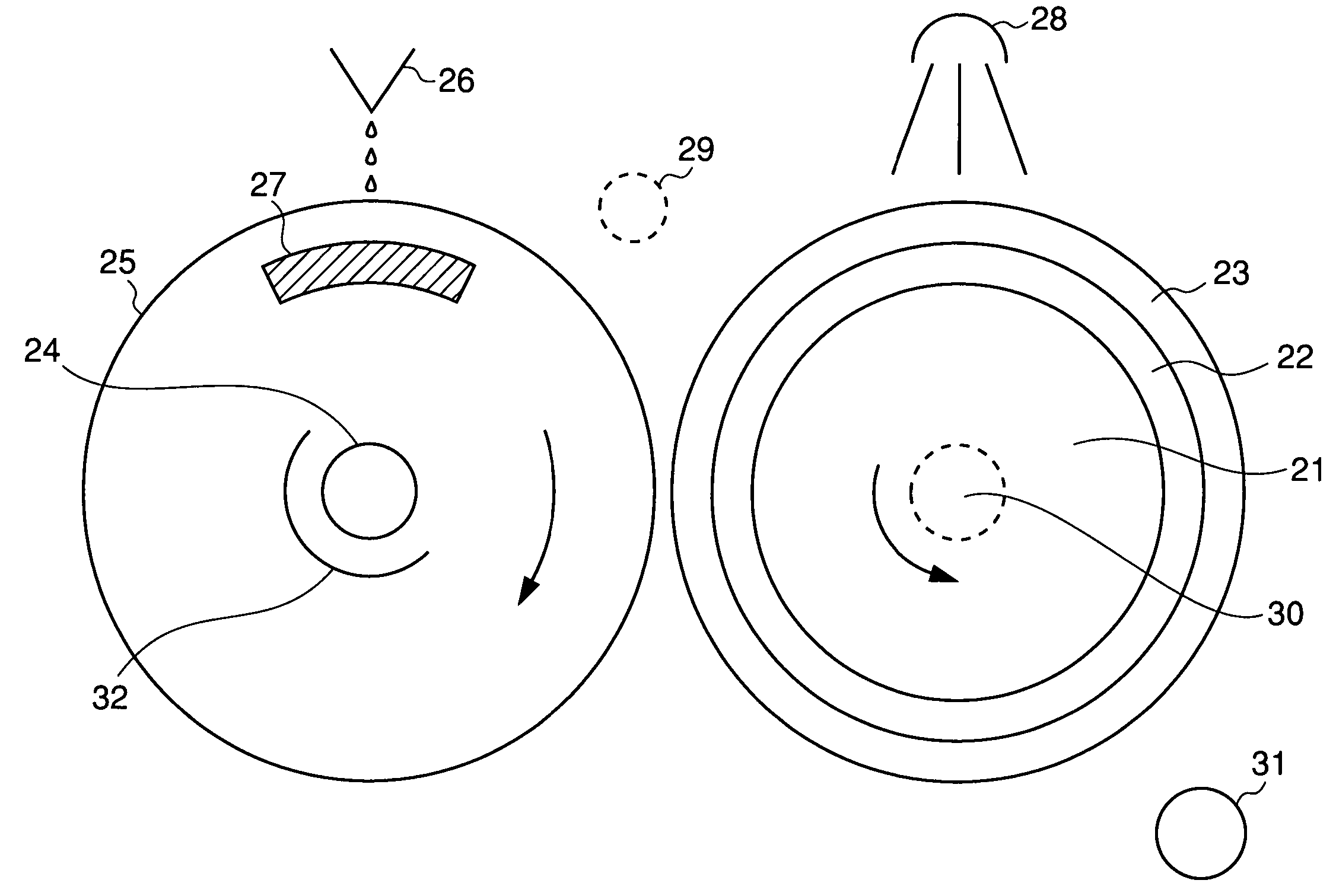

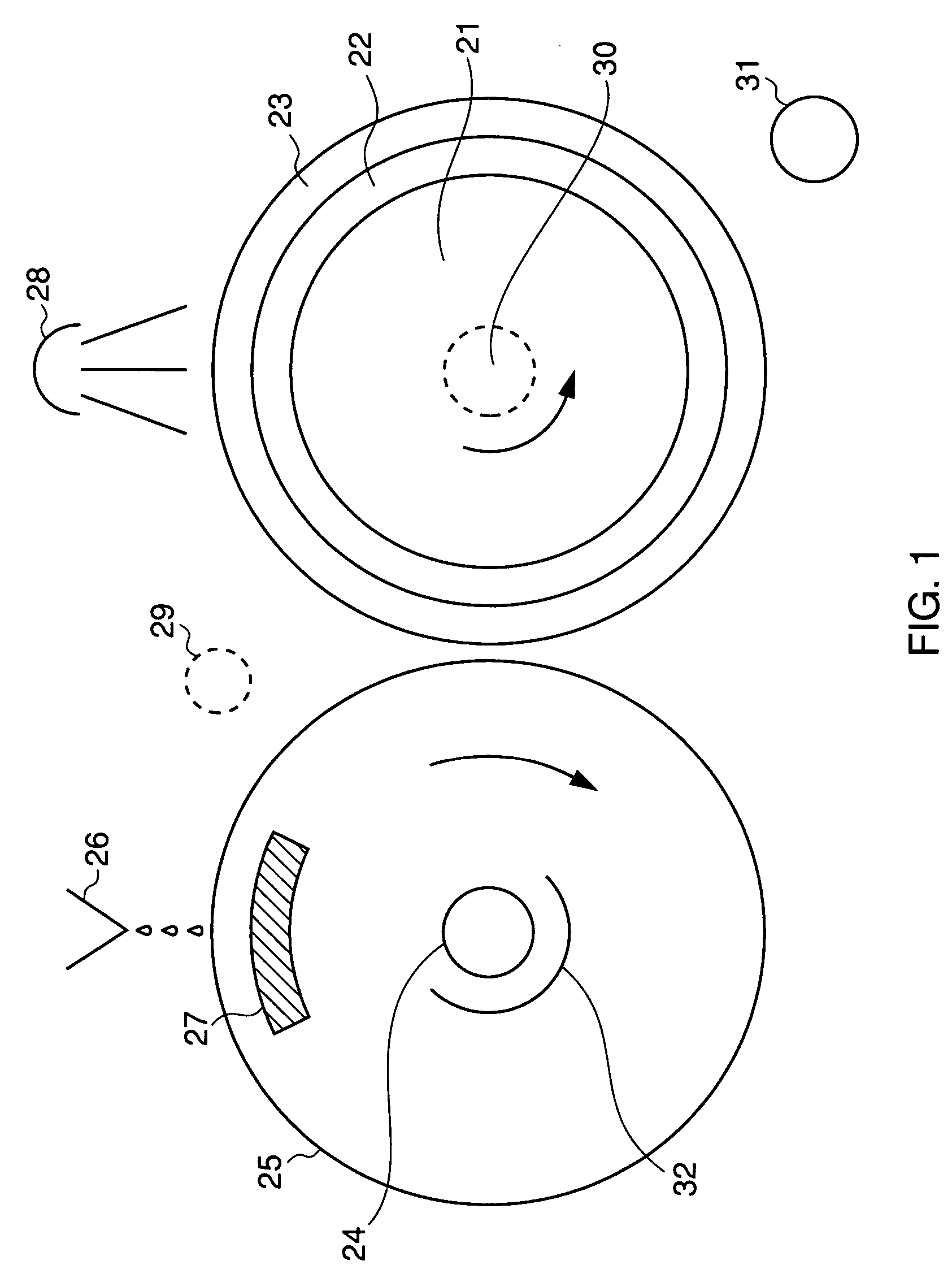

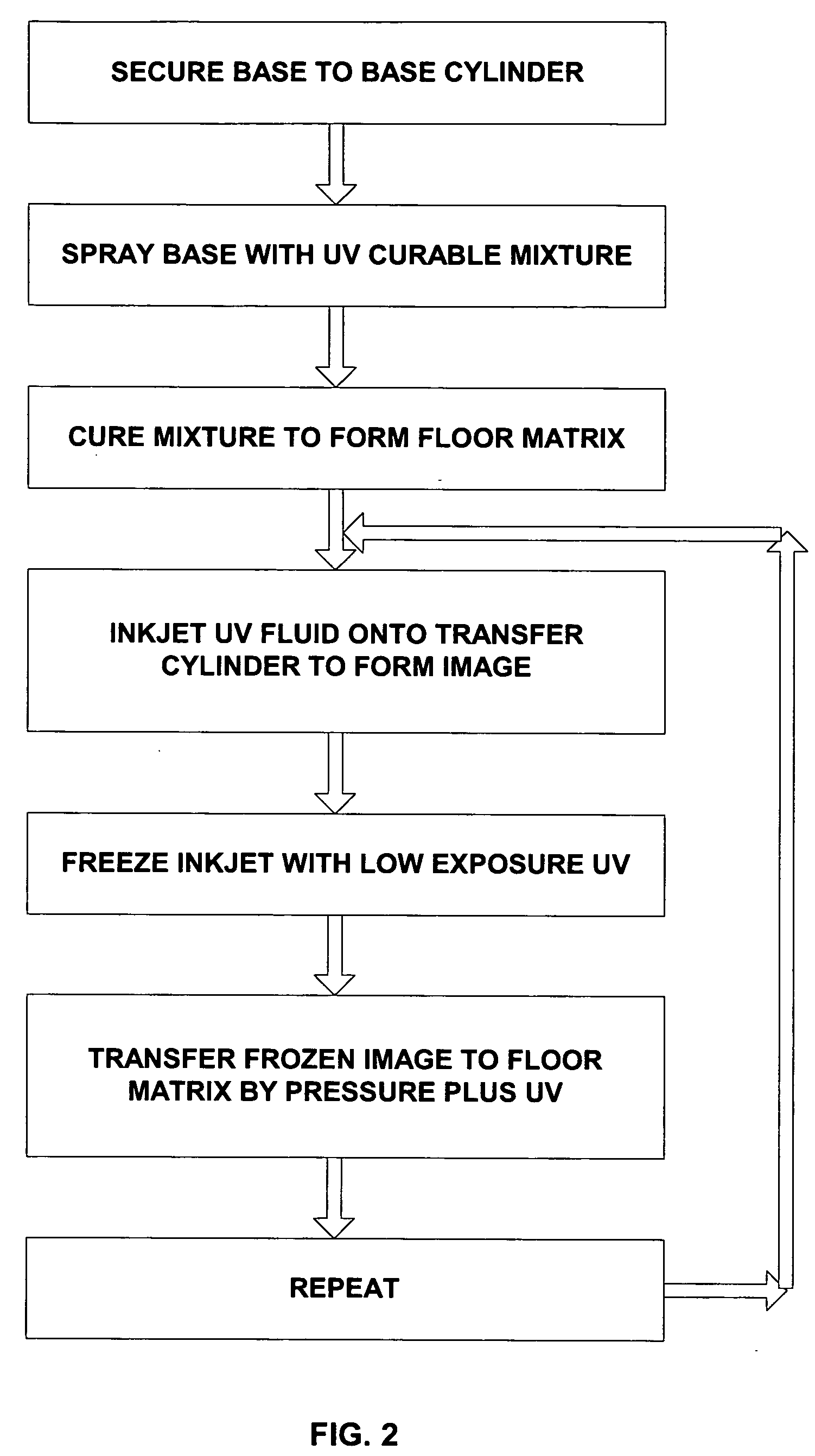

Method for producing a flexographic printing plate formed by inkjetted fluid

InactiveUS20040129158A1Rapid and inexpensive mannerDuplicating/marking methodsMounting boardsEngineeringElectrical and Electronics engineering

Owner:KODAK IL

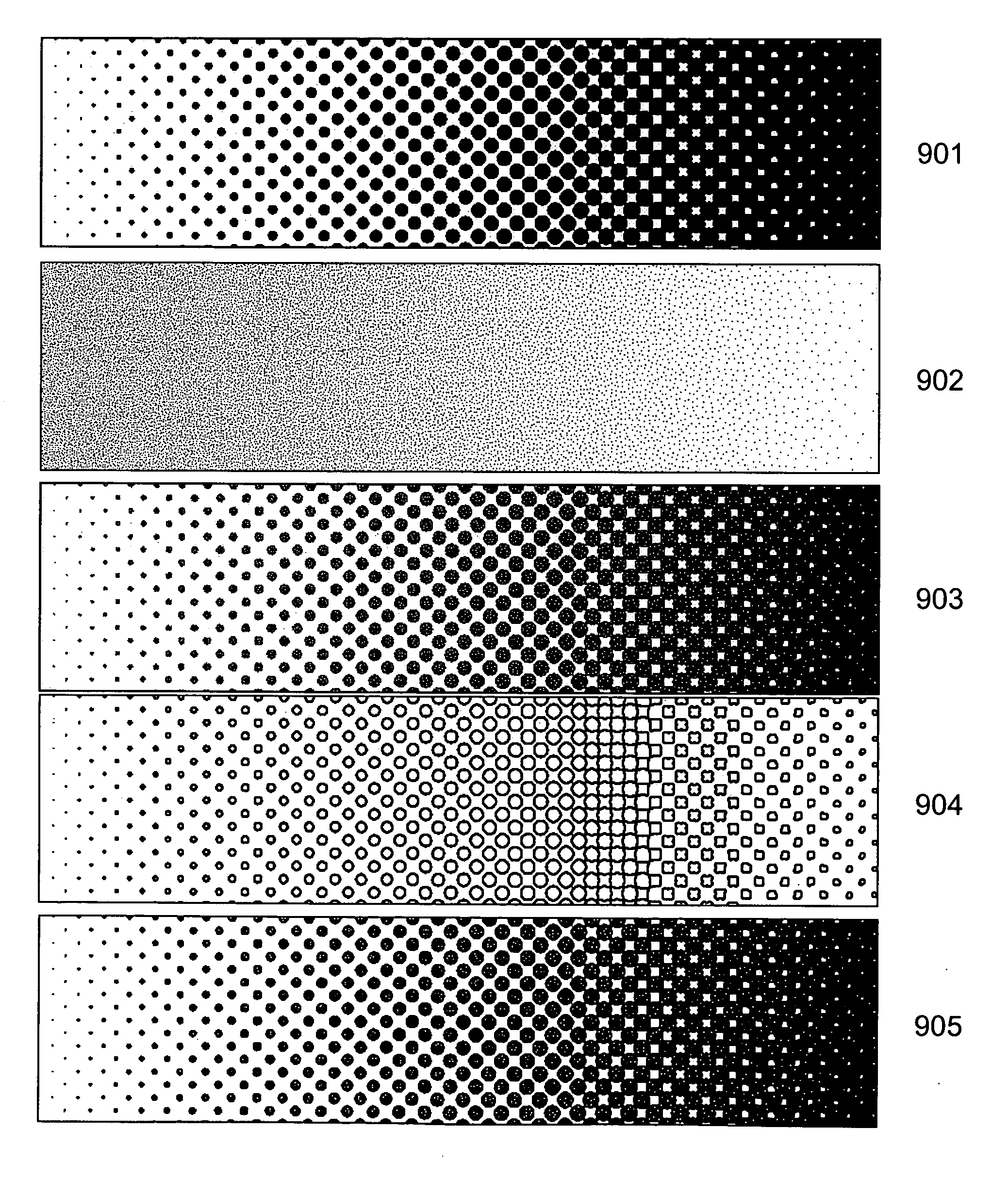

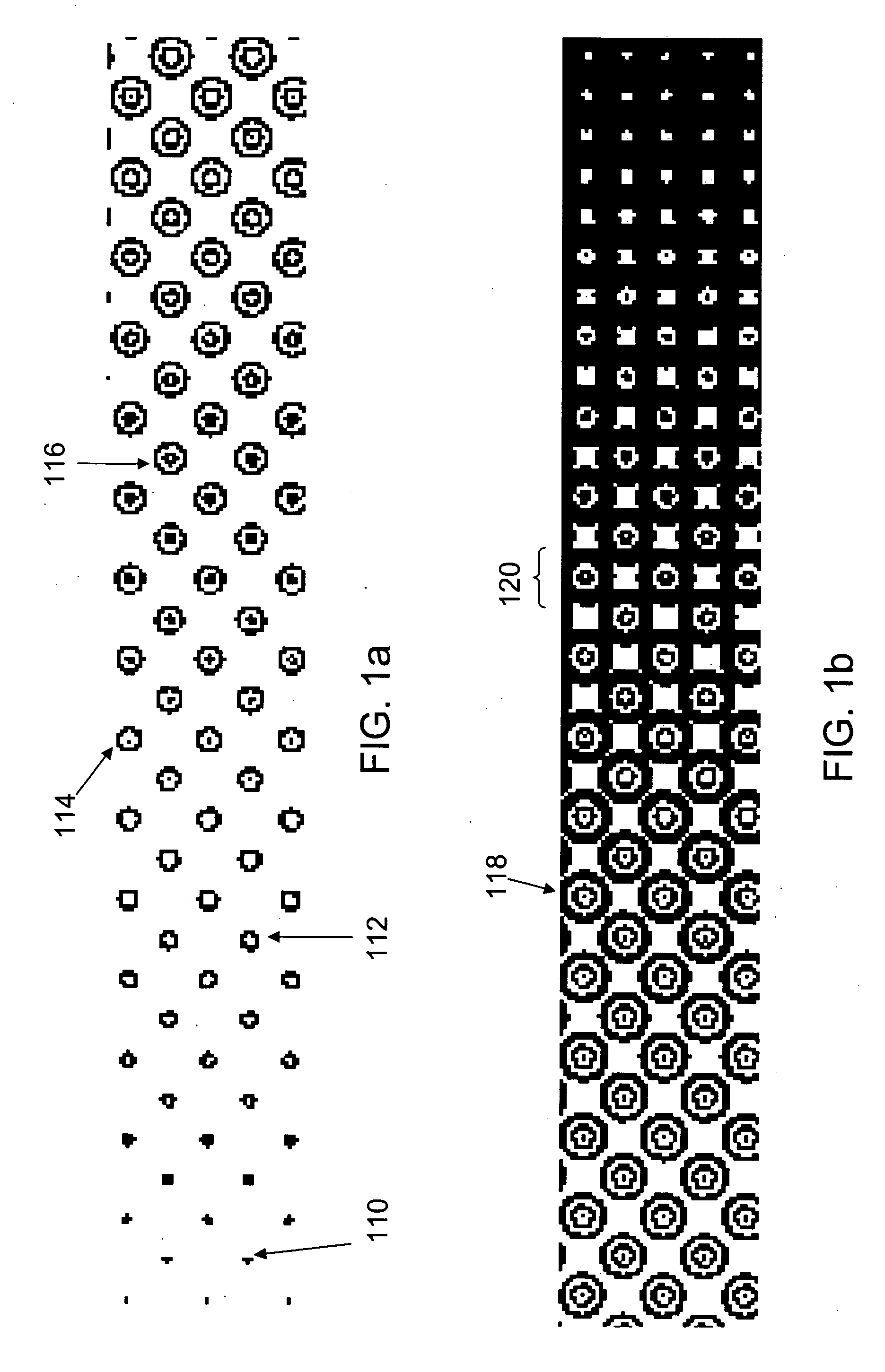

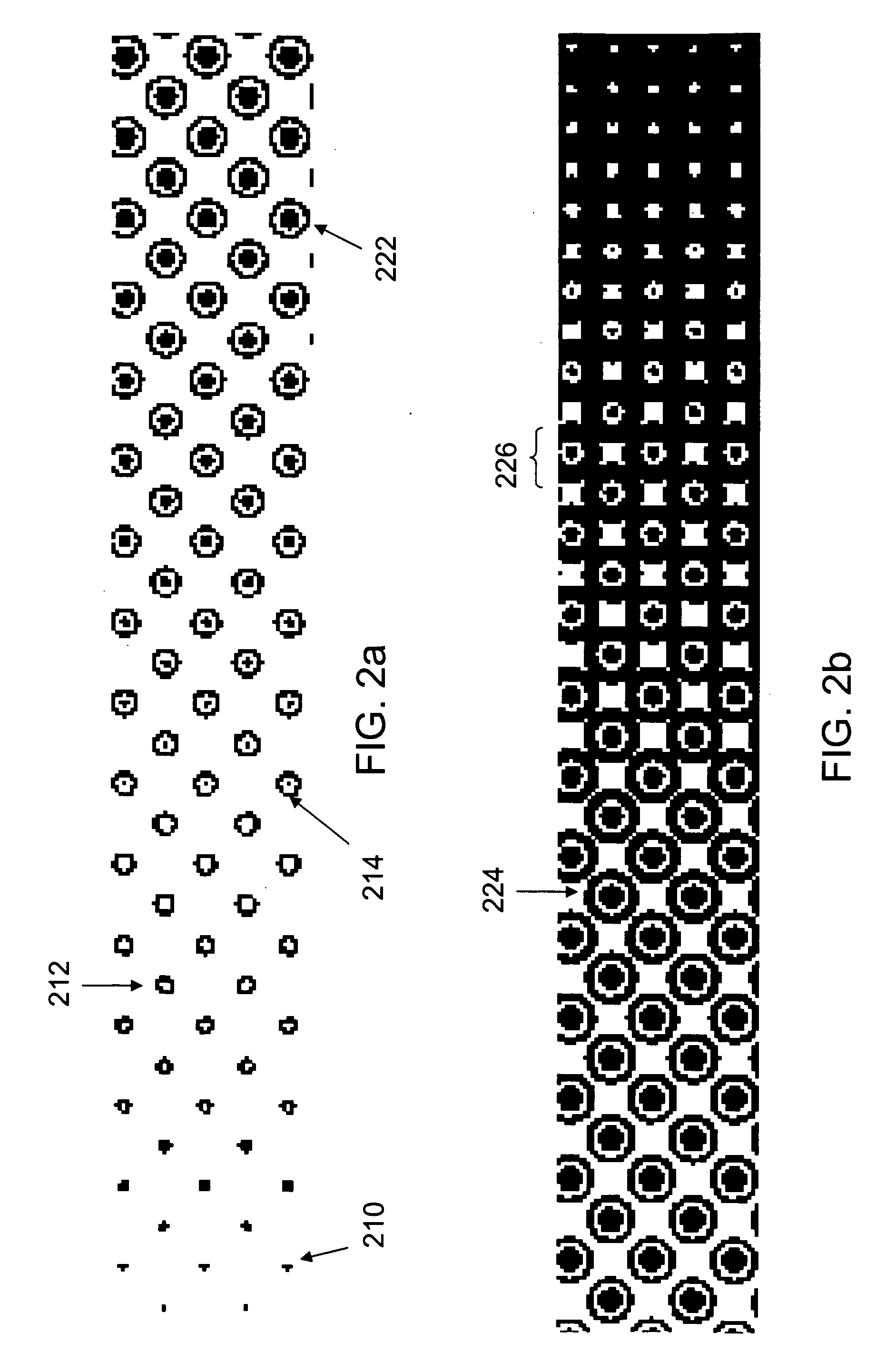

Method of controlling ink film thickness on a printing plate

A method of generating a digital AM halftone image output includes the steps of: (a) receiving a grey scale image from an image source; (b) generating an image component from the grey scale image; and (c) producing the digital AM halftone image output. The digital AM image output includes a plurality of halftone dots, each of which comprises at least one ink-receptive portion and at least one non-receptive portion. Patterns of halftone dots prepared in this manner may be sent as a digital output to an platesetter for producing a printing plate.

Owner:ESKO SOFTWARE BV

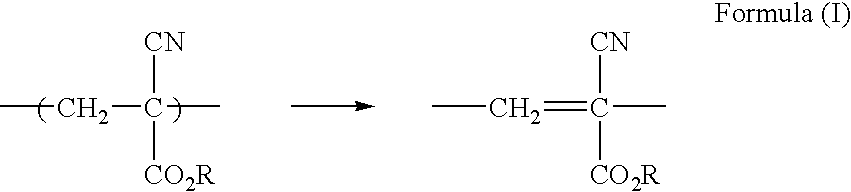

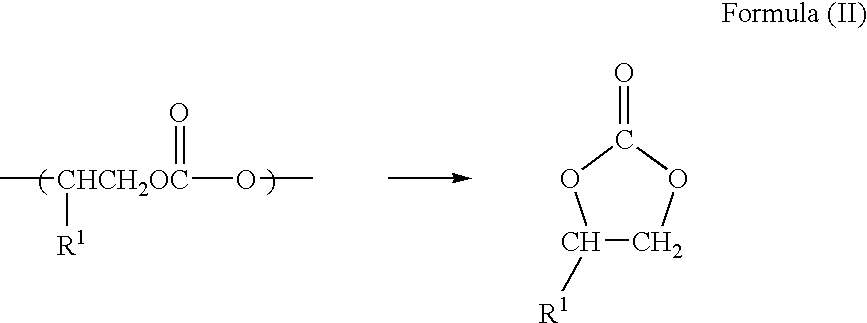

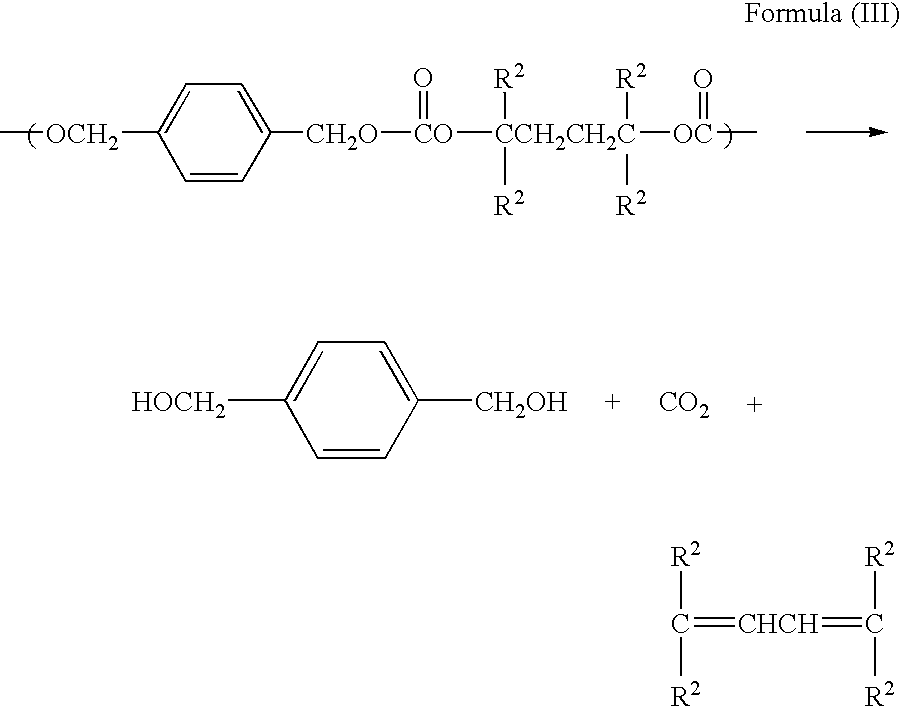

Ablatable elements for making flexographic printing plates

InactiveUS20080258344A1Reduce the environmentReduce health hazardsRadiation applicationsSynthetic resin layered productsPolymerLaser ablation

Flexographic printing plates and other relief images can be formed from a laser-ablatable element having a laser-ablatable layer that is at least 20 μm in thickness. The laser-ablatable layer includes a film-forming material that is a laser-laser-ablatable material or the film-forming material has dispersed therein a laser-ablatable material. The laser-ablatable material is a polymeric material that when heated to 300° C. at a rate of 10° C. / minute, loses at least 60% of its mass to form at least one predominant low molecular weight product. The element can be imaged by ablation at an energy of at least 1 J / cm2 to provide a relief image.

Owner:EASTMAN KODAK CO

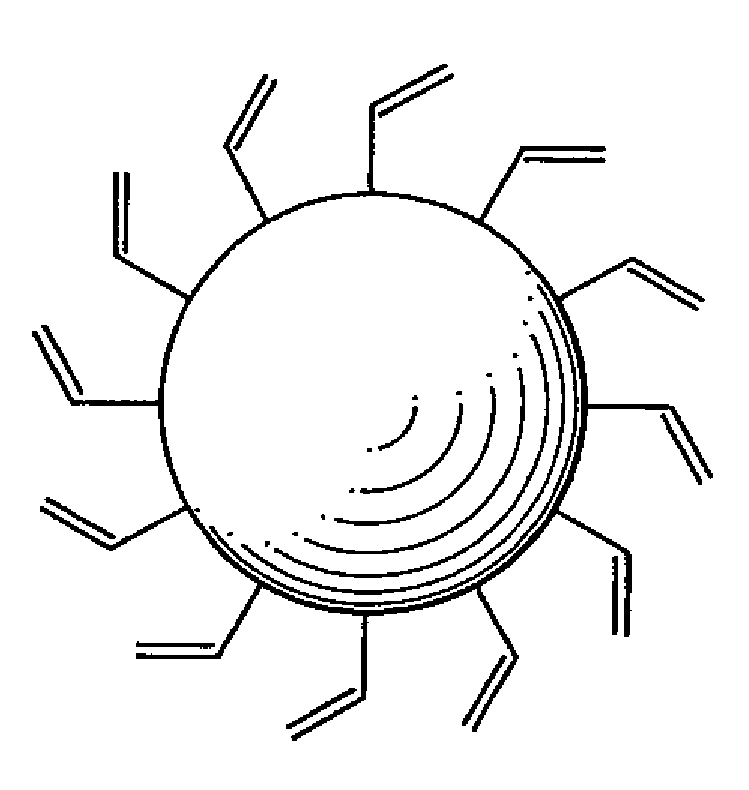

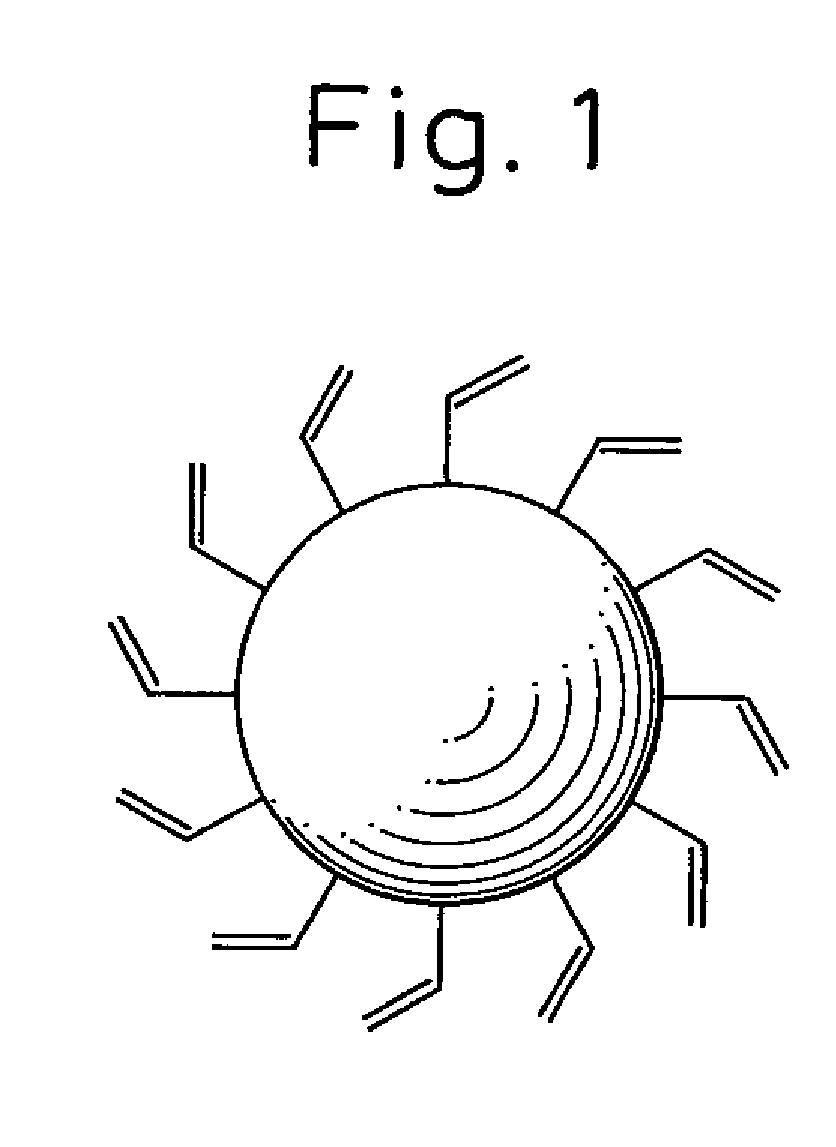

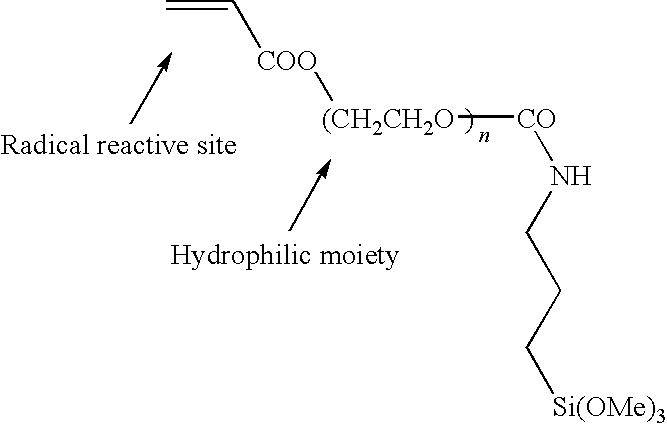

Modified silica particles, and photosensitive composition and photosensitive lithographic printing plate each containing the particles

InactiveUS20090092923A1Increase run lengthMaintain adhesionPigmenting treatmentSilicaSilica particleSimple Organic Compounds

An object of the present invention is to satisfactorily maintain adhesion between a photosensitive layer and a substrate after the exposure of the photosensitive lithographic printing plate.Modified silica particles, the surface of which is modified by an organic compound having at least one ethylenically unsaturated group, at least one hydrophilic moiety and at least one silyloxy group, are incorporated into a photosensitive layer of the photosensitive lithographic printing plate.

Owner:EASTMAN KODAK CO

Alcohol-free fountain solution with high viscosity and low surface tension

InactiveCN103935150AHigh effective contentReduce pollutionPrinting pre-treatmentAlcohol freeAqueous alcohol

The invention discloses alcohol-free fountain solution with high viscosity and low surface tension. The alcohol free fountain solution with high viscosity and low surface tension comprises the following components by weight, 30-55 parts of alcohol solvents, 2-6 parts of buffer agents, 3-8 parts of wetting agents, 1-4 parts of surface active agents, 0.3-2.2 parts of antifoaming agents, 0.5-3 parts of thickening agents, 0.5-1.2 parts of anticorrosion and bactericidal agents, 1-3 parts of penetrating agents, 0-2 parts of electrolyte and 20-45 parts of viscosity modifier water. The fountain solution is free of volatile solvents containing alcohol and isopropyl alcohol and pollution to the environment, the surface tension ranges from 4*10-2N / m to 7*10-2N / m, pH ranges from 4.8 to 5.5, the heat conduction rate ranges from 800mus / cm to 1200mus / cm, and therefore, quality requirements of the fountain solution can be met better.

Owner:苏州禾川化学技术服务有限公司

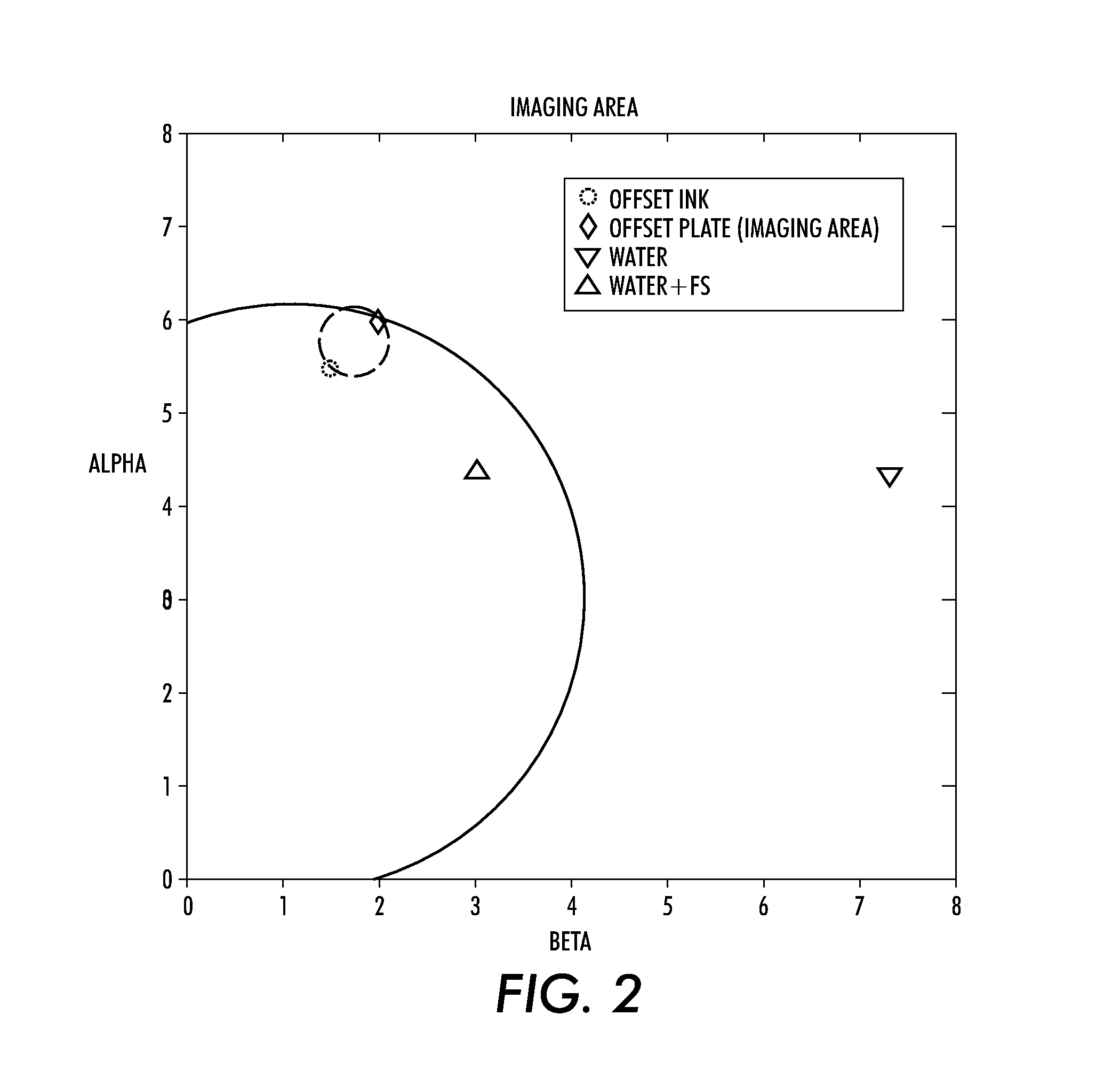

Dampening fluid for digital lithographic printing

ActiveUS20130104756A1Less residueSilicon organic compoundsPlaten pressesElectrical polarityVaporization

Different solvents for a dampening fluid are disclosed. The solvent is a volatile hydrofluoroether liquid or a volatile silicone liquid. Such liquids have a lower heat of vaporization, a lower surface tension, and better kinematic viscosity compared to water, which is the conventional solvent used in dampening fluids. The dampening fluids, which are relatively nonpolar, can be used in a combination with polar inks to form a new type of digital lithographic printing system.

Owner:XEROX CORP

Processing of positive-working lithographic printing plate precursor

InactiveUS20100047723A1Simplify image processingDevelopment and “ gummingDuplicating/marking methodsSemiconductor/solid-state device manufacturingBoiling pointChemical compound

Positive-working imageable elements can be imaged and processed using a processing solution that comprises at least 0.03 N of an organic amine or a mixture thereof, whose conjugated acids have a pKa greater than 9 and a boiling point greater than 150° C. The imageable element is a single-layer, infrared radiation-sensitive positive-working imageable element comprising a substrate and an infrared radiation absorbing compound. It also has an imageable layer that comprises a developability-enhancing compound and a poly(vinyl acetal) in which at least 25 mol % of its recurring units comprise pendant phenol, naphthol, or anthracenol groups that are substituted with one or more electron-withdrawing groups.

Owner:EASTMAN KODAK CO

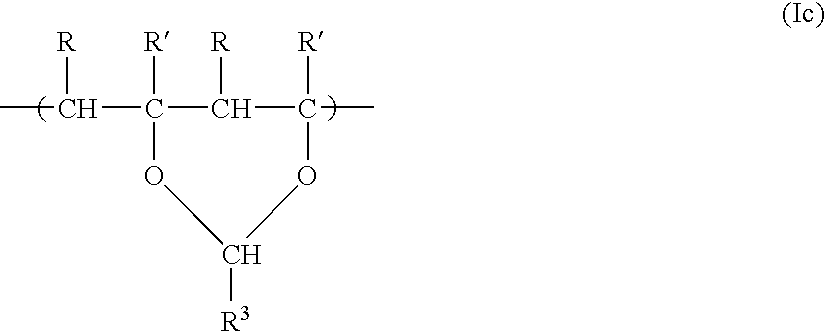

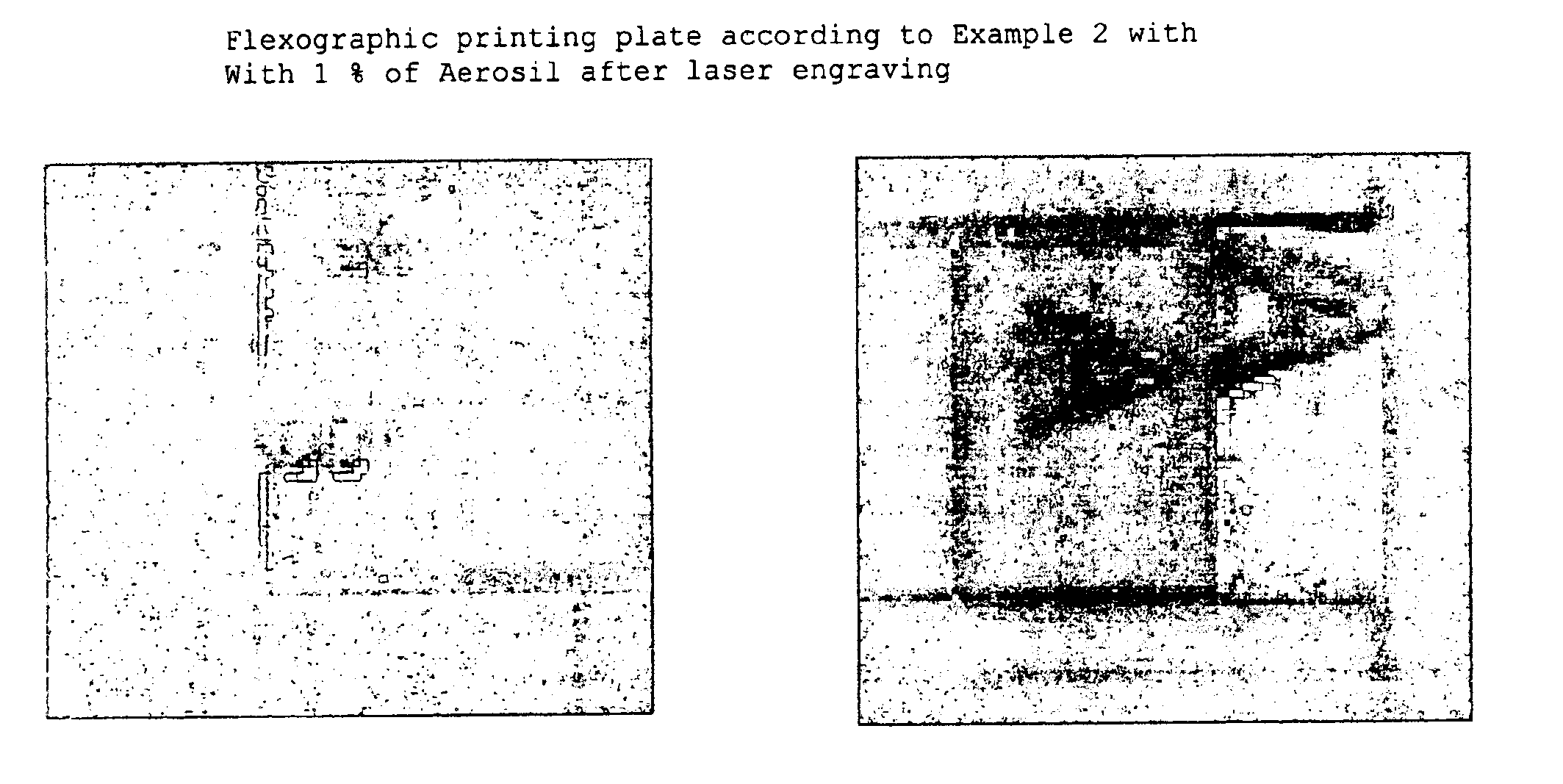

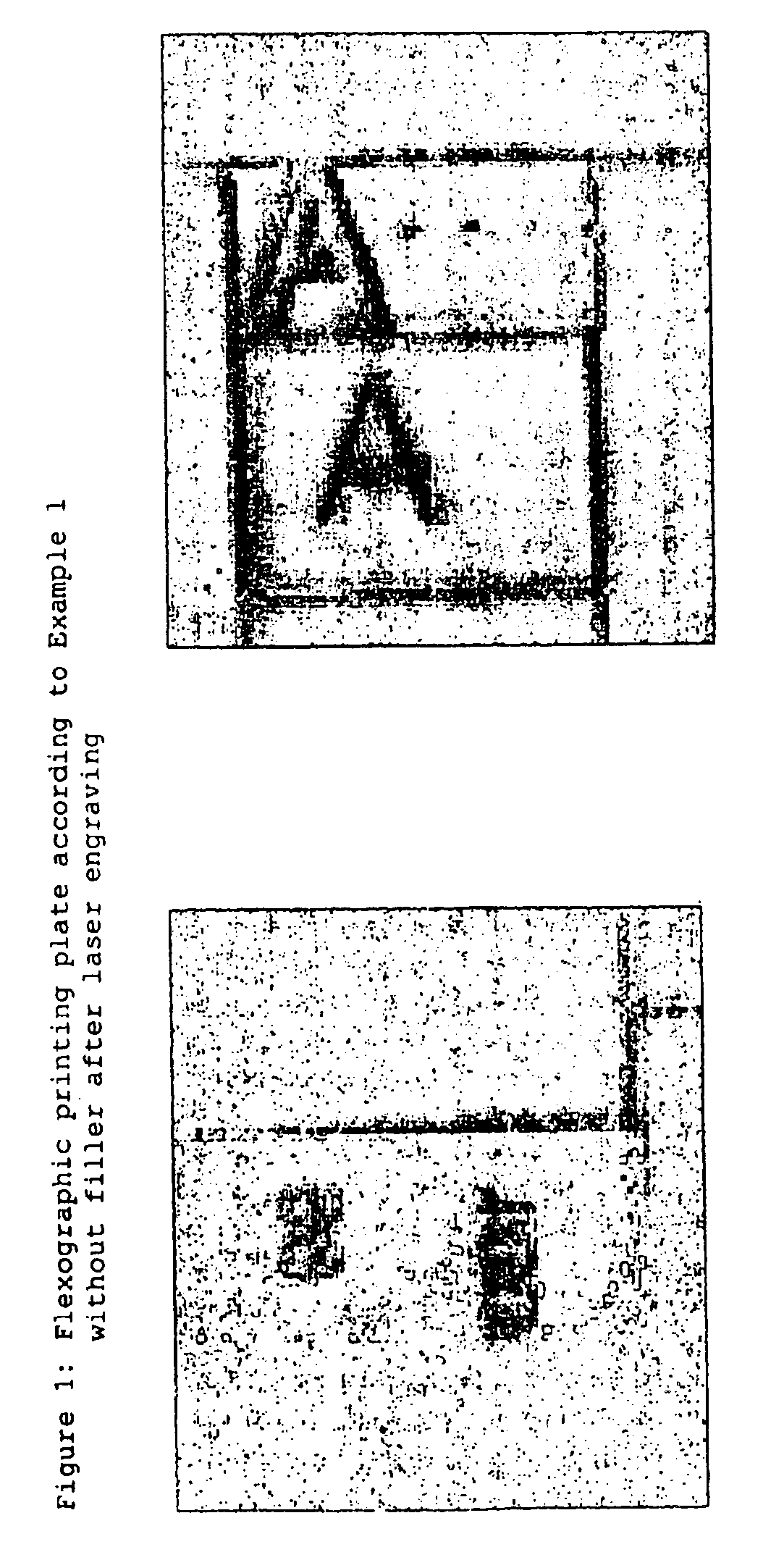

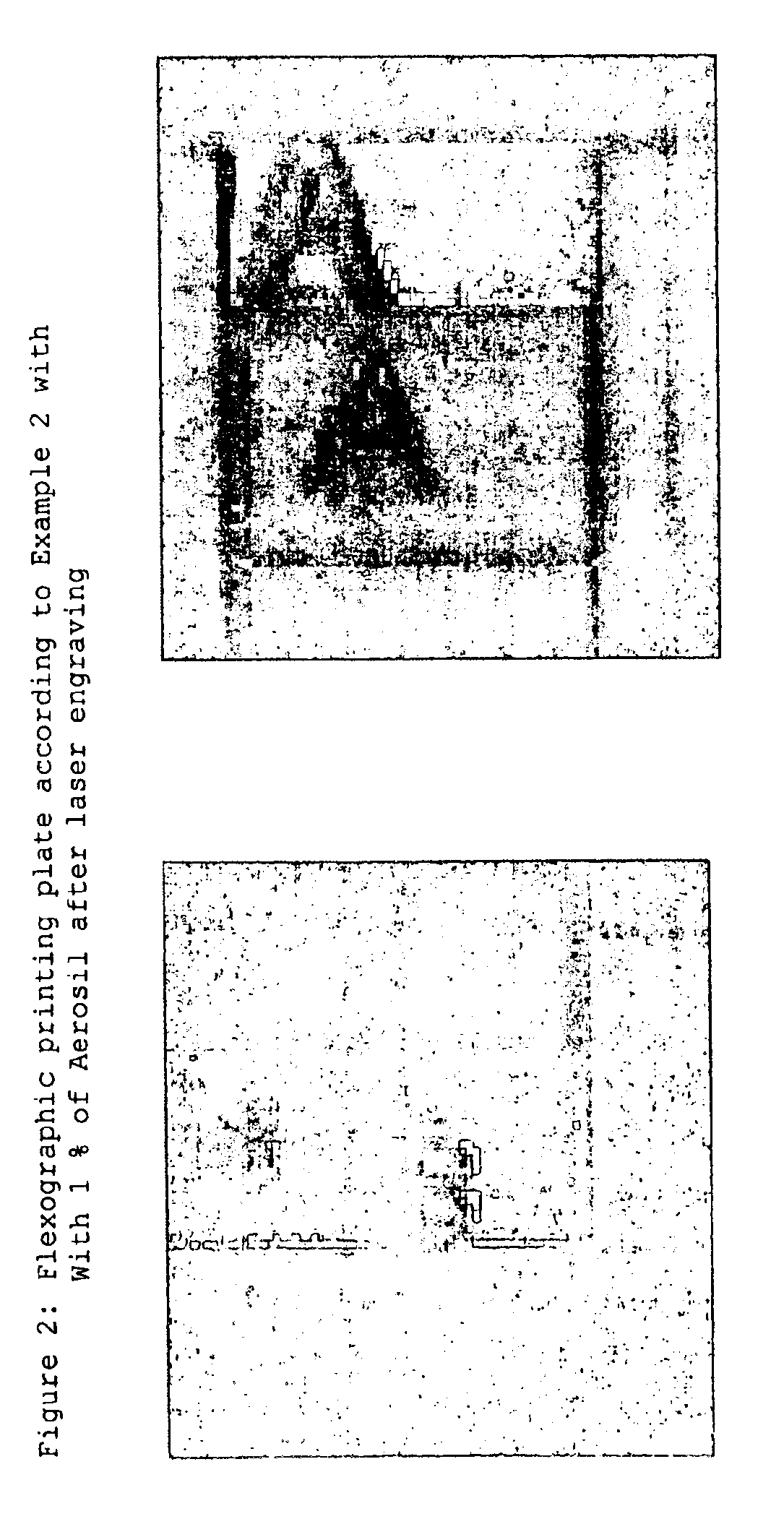

Method for producing flexographic printing plates by means of laser engraving

InactiveUS6935236B2High resolutionAvoid it happening againDuplicating/marking methodsSemiconductor/solid-state device manufacturingCross-linkLaser engraving

The invention relates to a method for producing flexographic printing forms by engraving a printing relief on a flexographic printing element that can be laser engraved, said element having a photochemically cross-linked relief layer. The relief layer is transparent and comprises oxidic, siliceous or zeolitic solid matter with a particle size between 1 and 400 nm in a quantity of between 0.1 and 8 wt. % in relation to the quantity of all components in the relief layer.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

Photosensitive element having reinforcing particles and method for preparing a printing form from the element

InactiveUS20090075199A1Photosensitive materialsDuplicating/marking methodsCarbon nanotubeTransmittance

The invention provides a photosensitive element and a method for preparing a printing form from the element. The photosensitive element includes a layer of a photosensitive composition containing a binder, a monomer, and a Norrish type II photoinitiator, wherein the photosensitive layer has a transmittance to actinic radiation of less than 20% and contains reinforcing particles of graphene and / or carbon nanotubes.

Owner:DUPONT ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com