Patents

Literature

567results about How to "Less residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

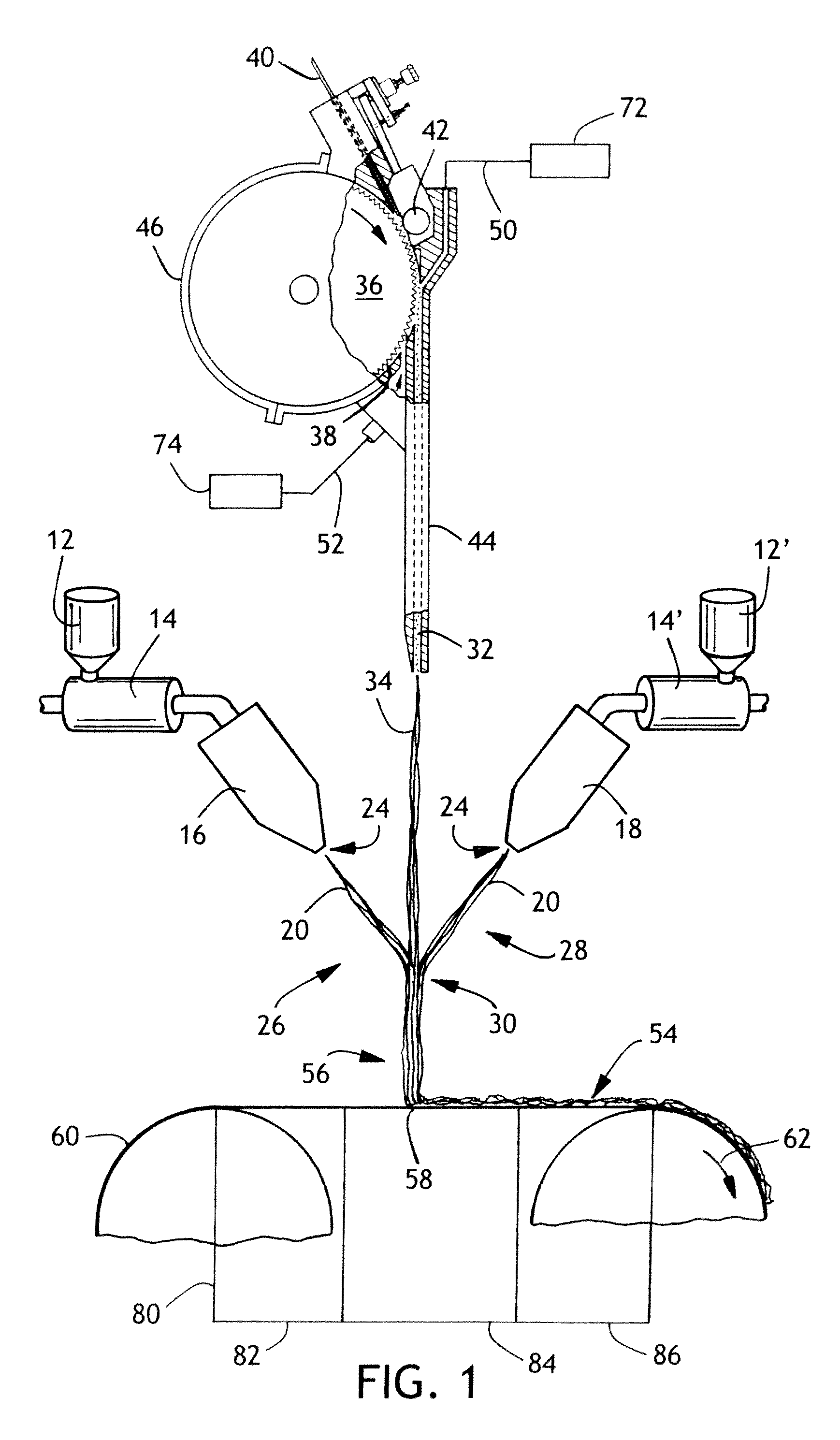

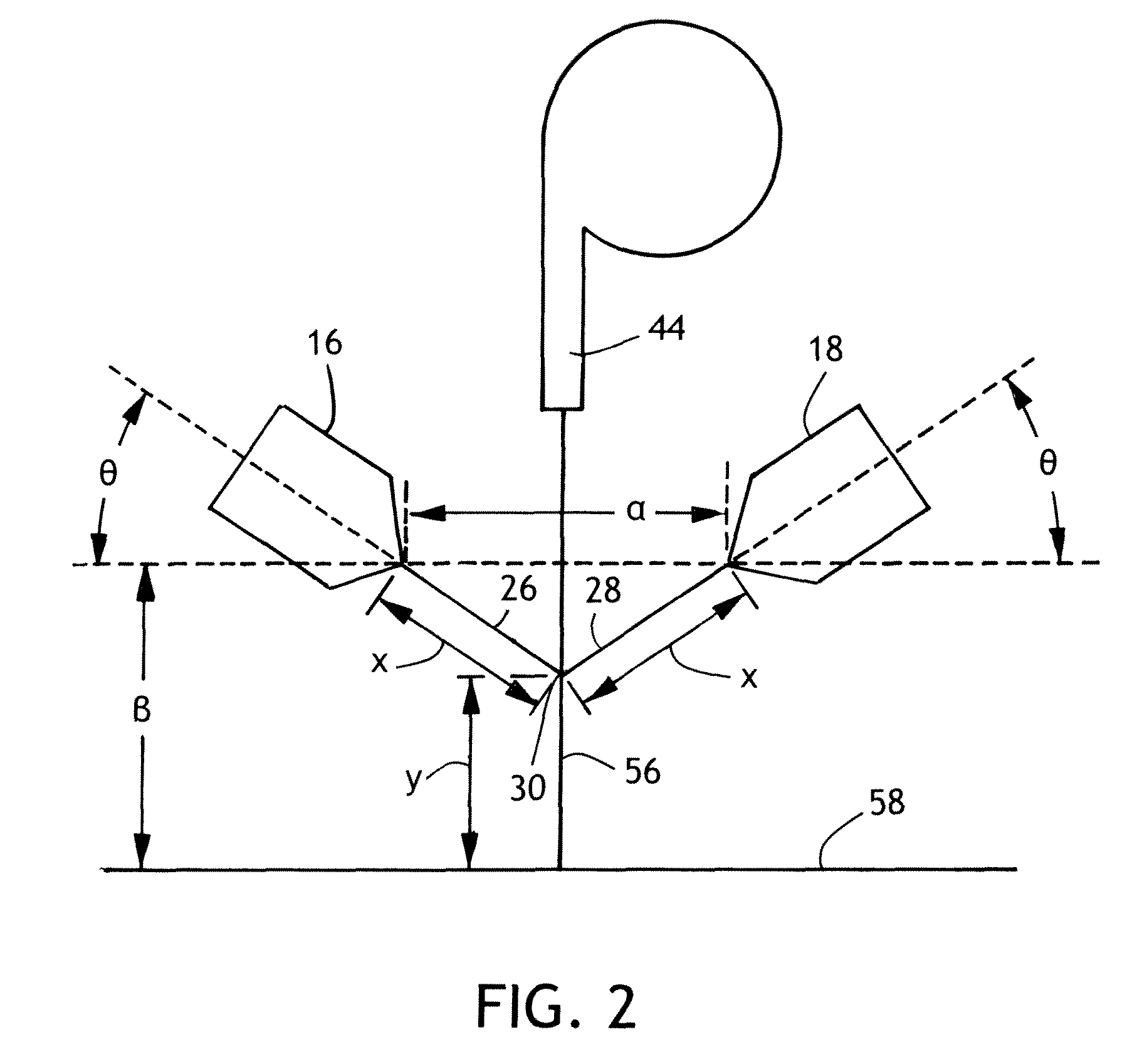

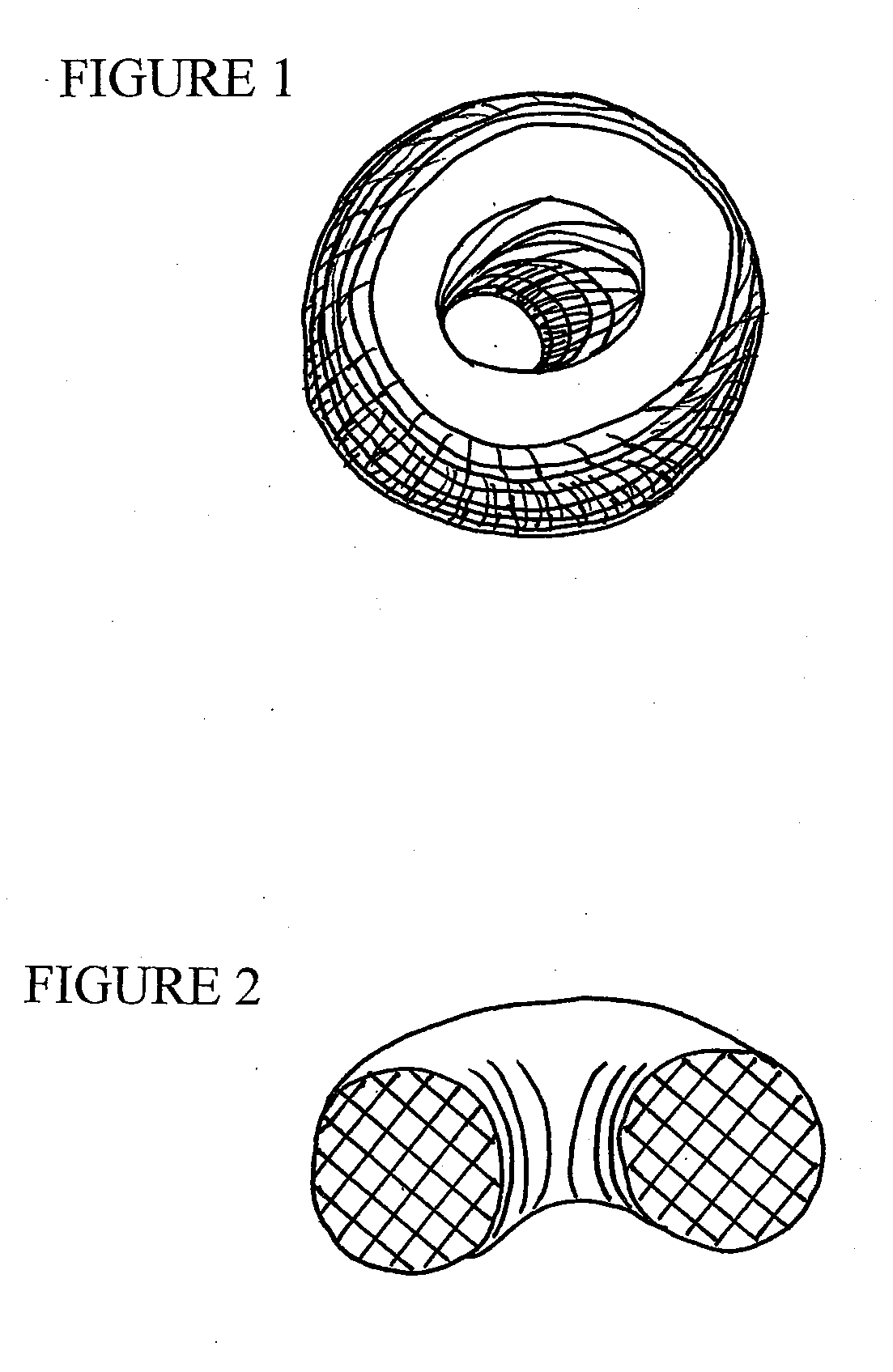

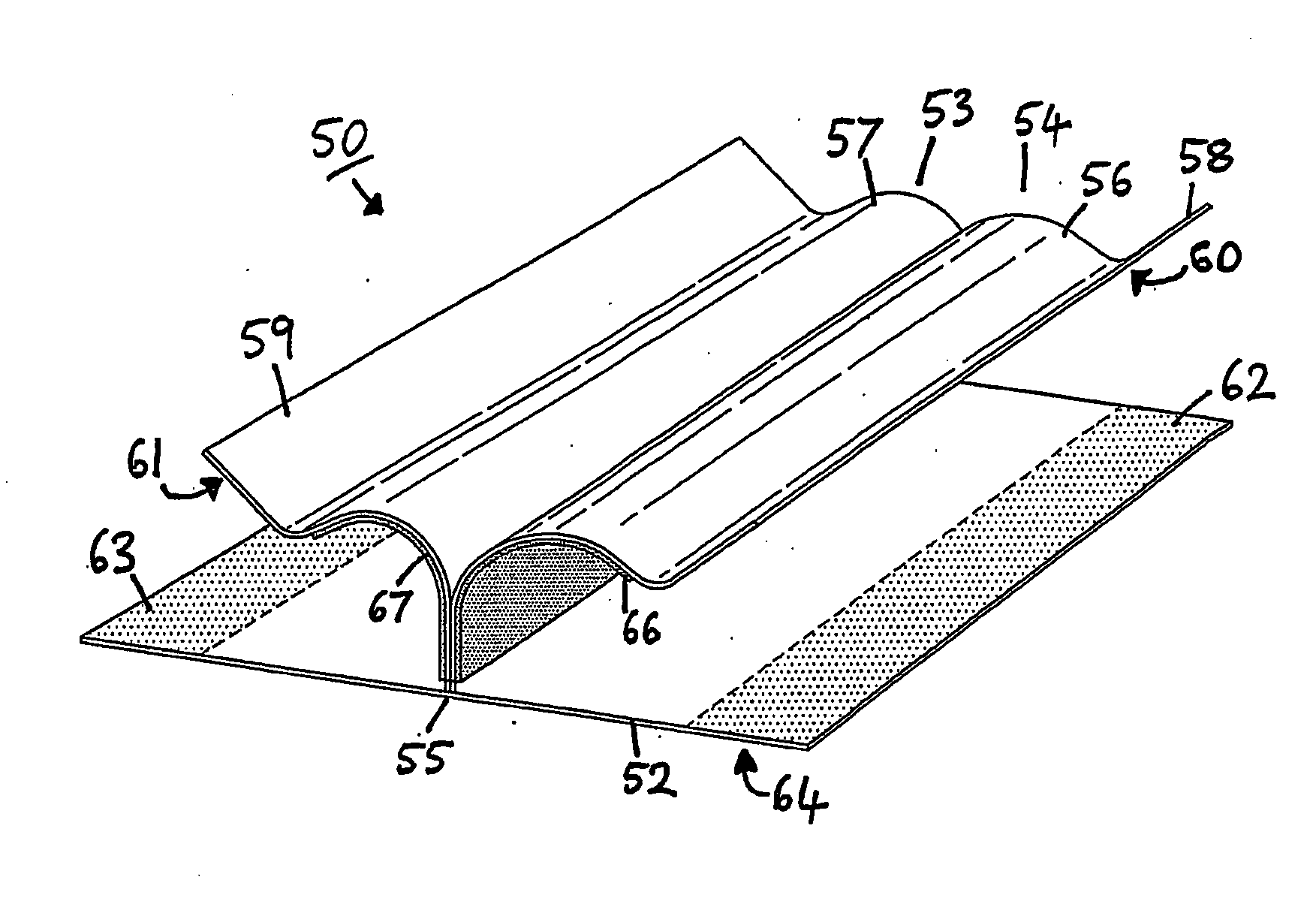

Fibrous nonwoven structure having improved physical characteristics and method of preparing

ActiveUS8017534B2Better sheet squarenessSoft touchLayered productsAbsorbent padsFiberMaterials science

Disclosed is a fibrous nonwoven structure comprising meltblown fibrous materials and at least one secondary fibrous material and method of preparing. In one aspect, the fibrous nonwoven structure has a formation index of between 70 and 135. In another aspect, the fibrous nonwoven structure has an opacity that is greater than 72 percent at a basis weight of between about 35 and 55 grams per square meter. The fibrous nonwoven substrate may be utilized as a moist wipe.

Owner:KIMBERLY CLARK GLOBAL SALES LLC

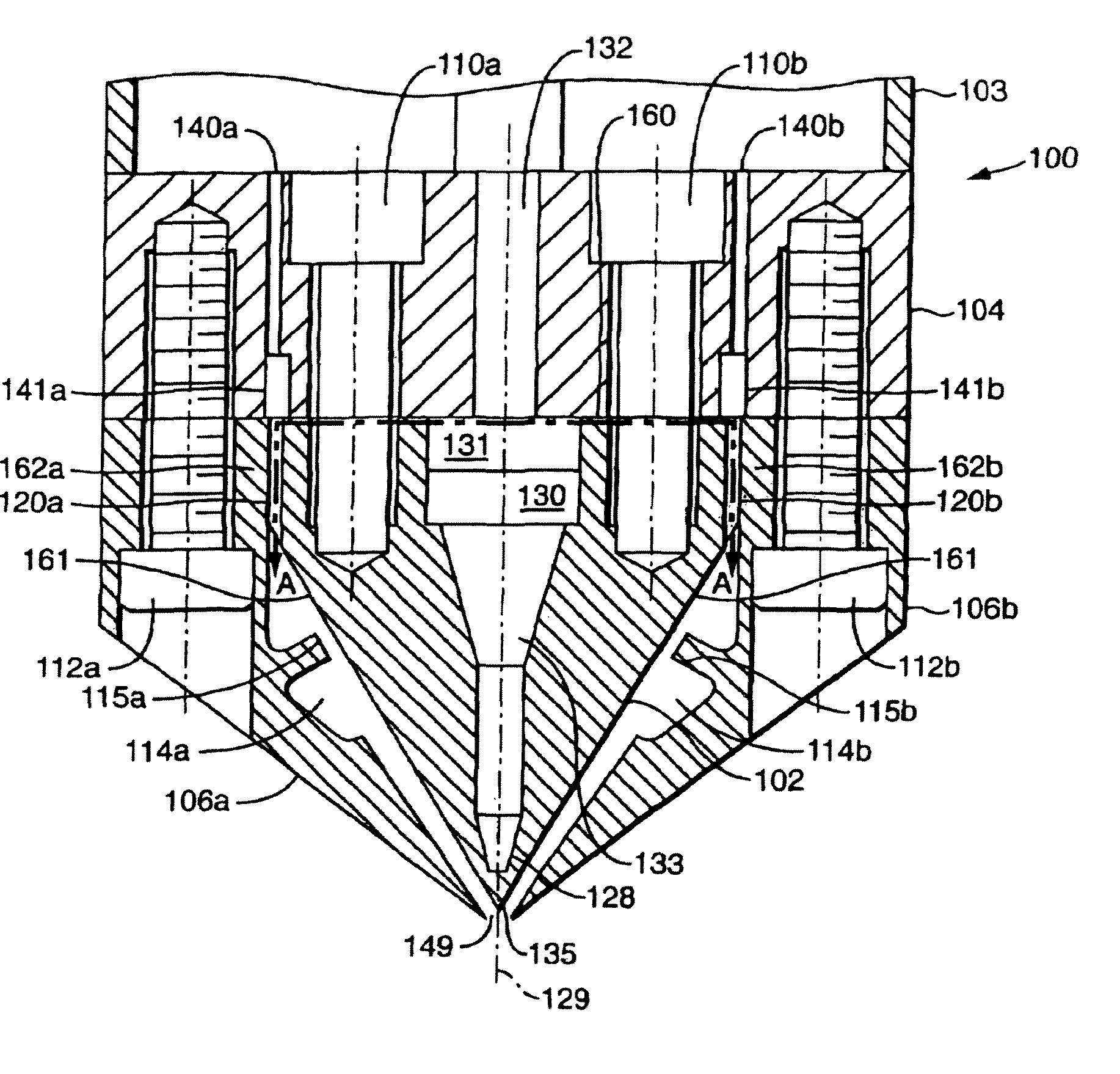

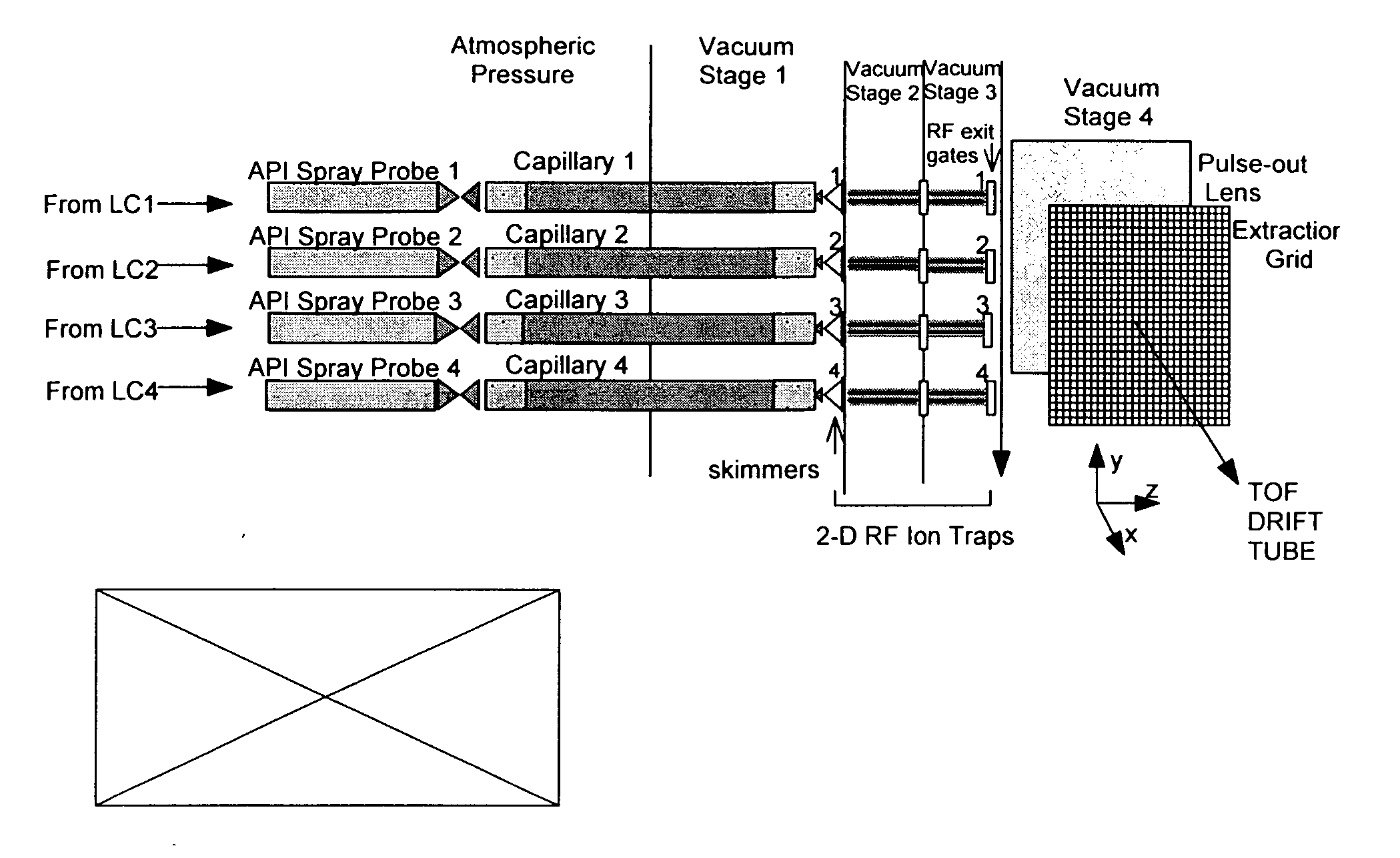

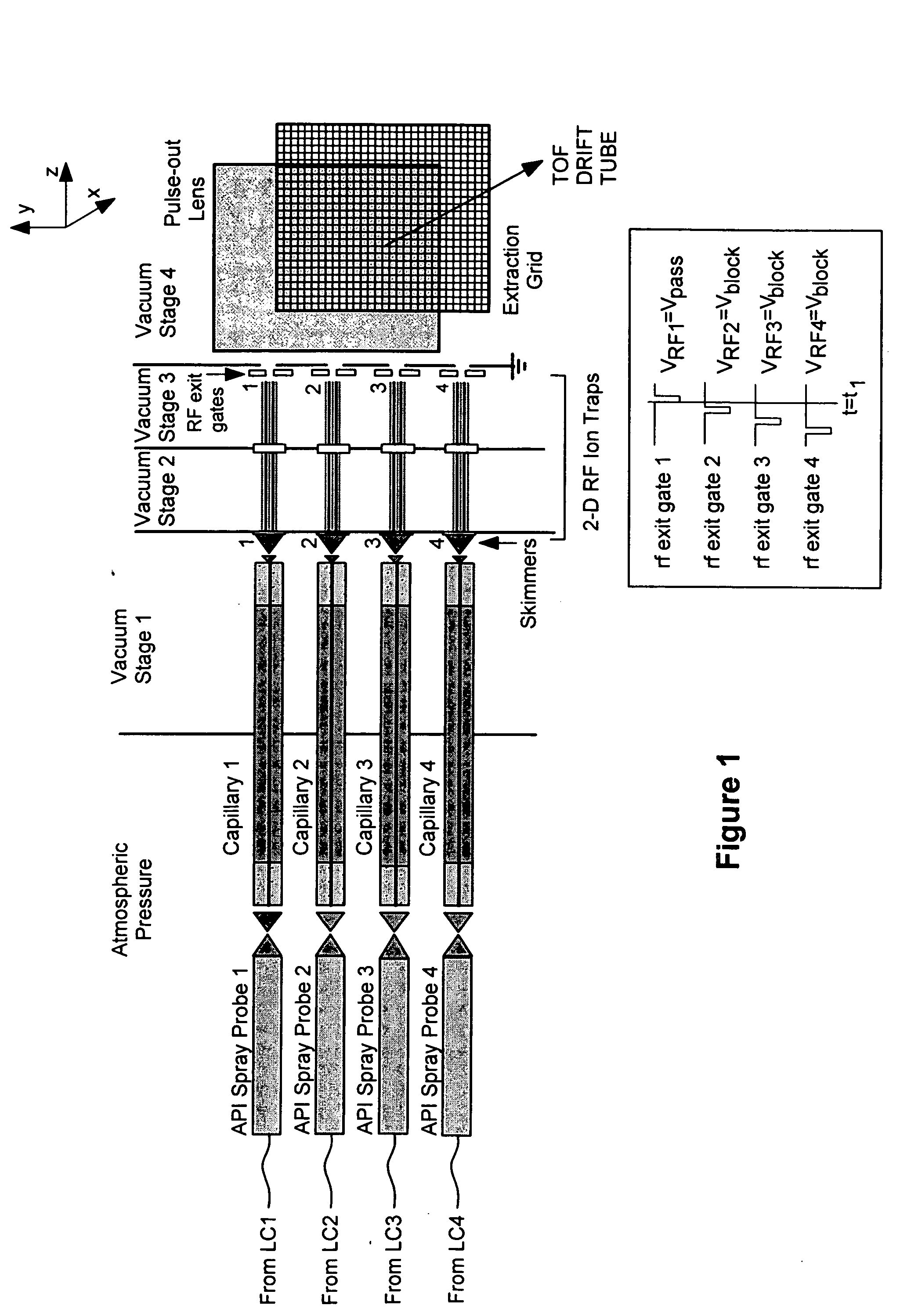

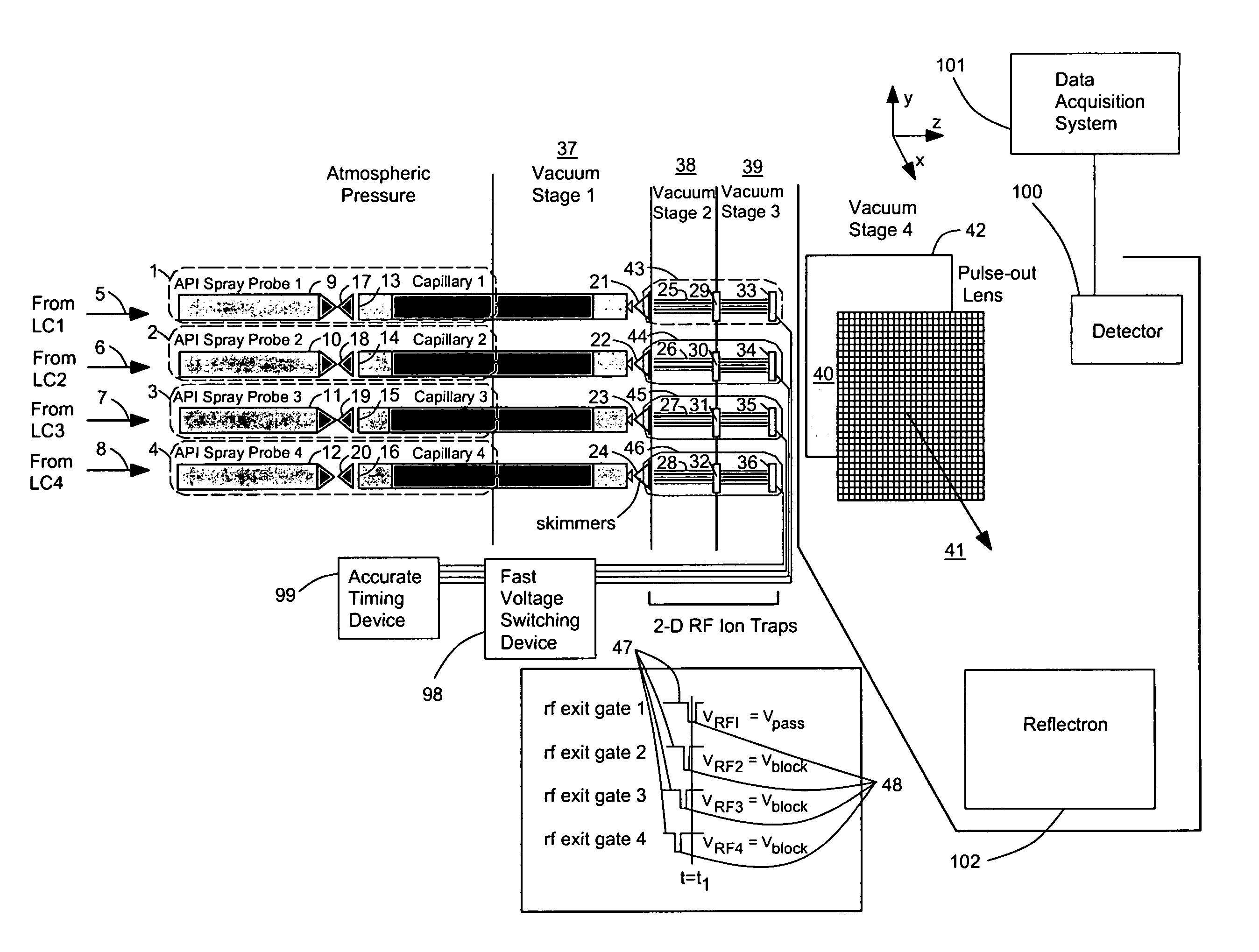

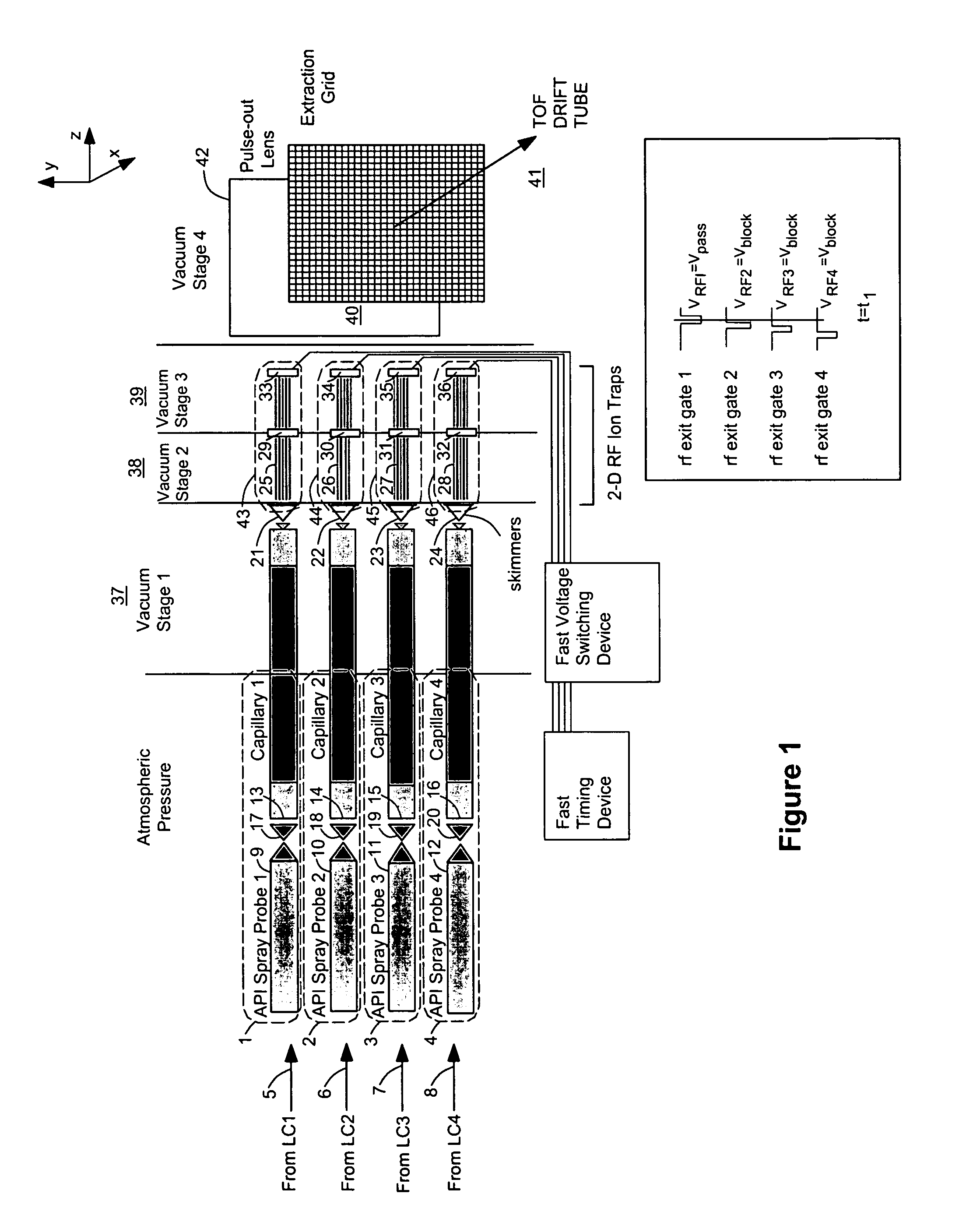

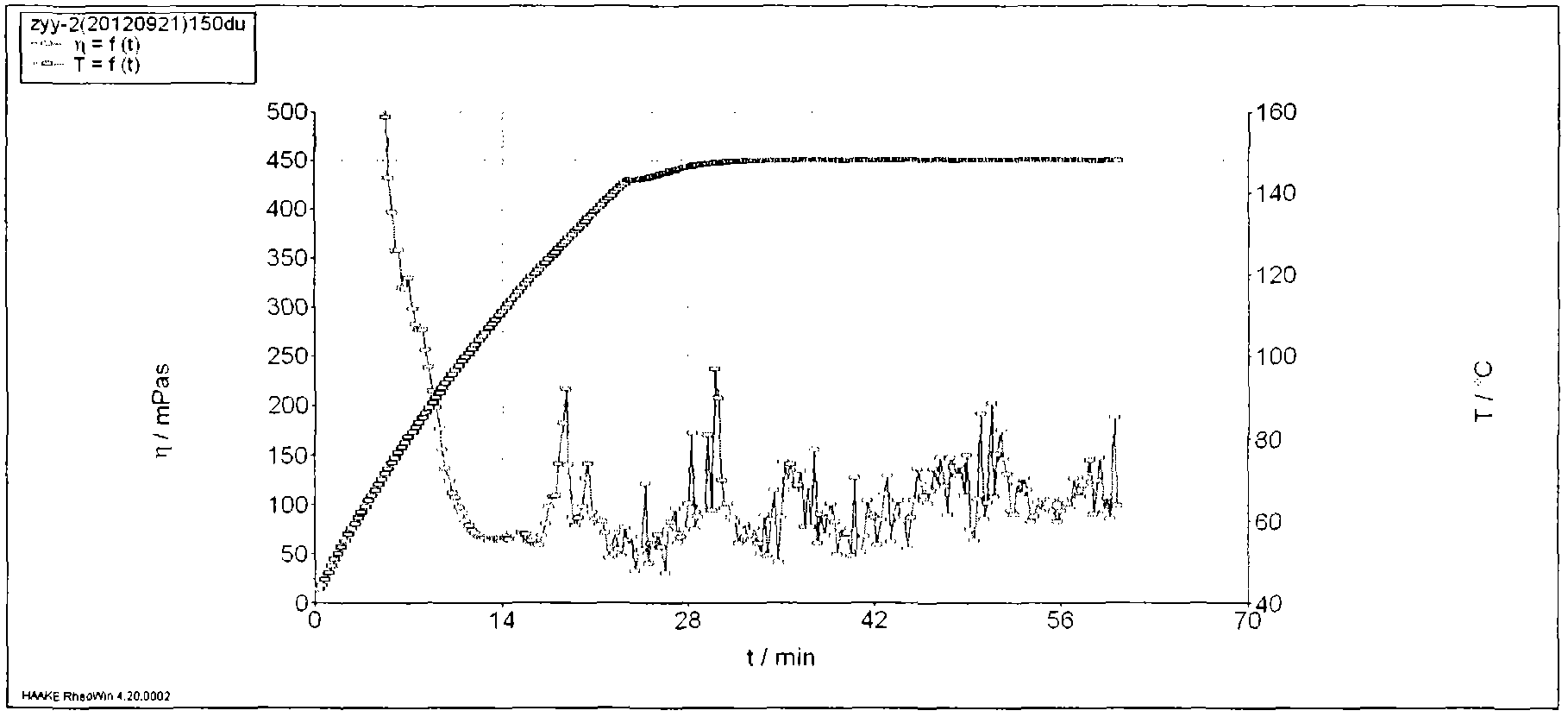

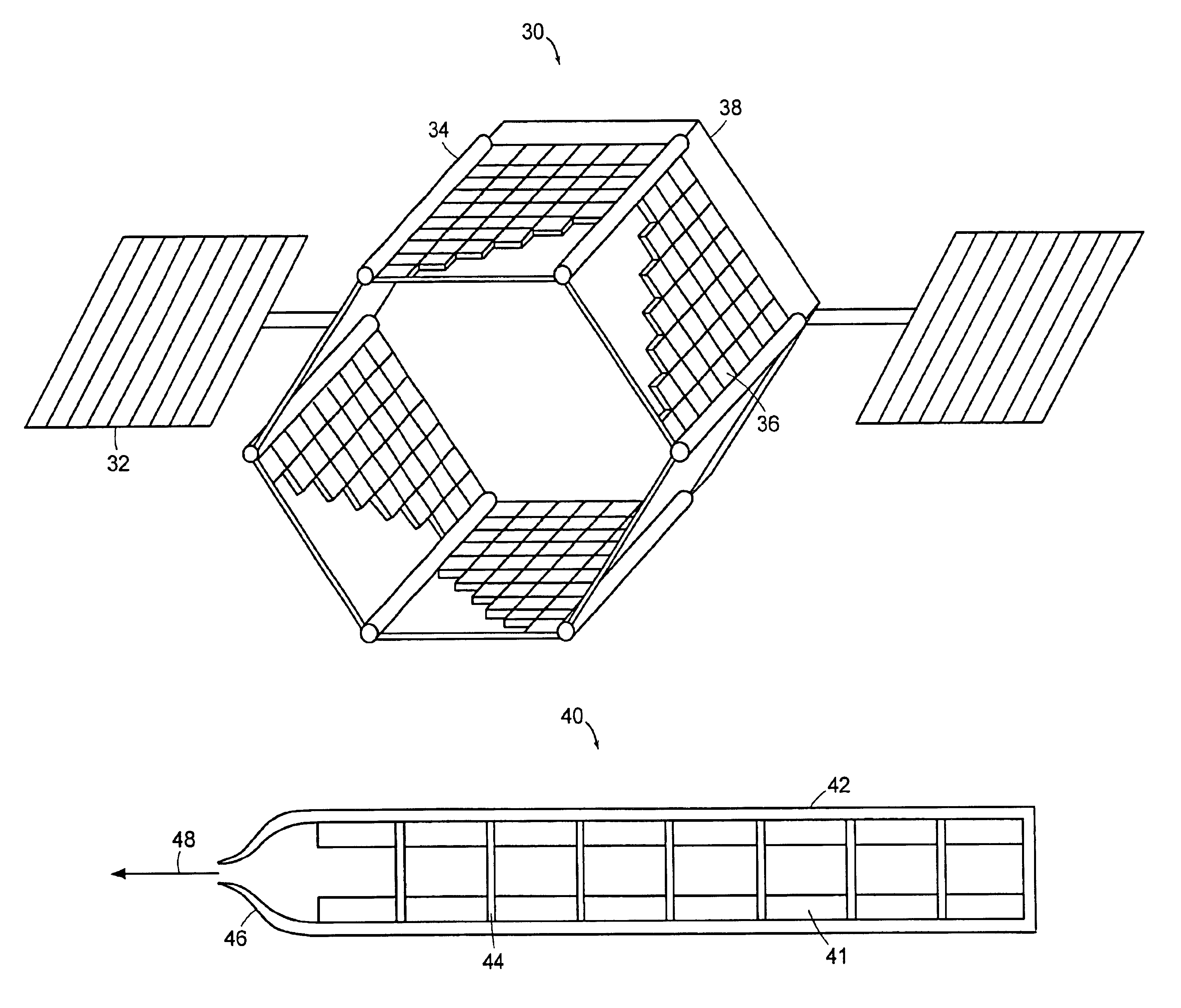

Method and apparatus for multiplexing plural ion beams to a mass spectrometer

ActiveUS20060091308A1Quick checkImprove throughputTime-of-flight spectrometersIsotope separationIon trap mass spectrometryIon beam

A method / apparatus for multiplexing plural ion beams to a mass spectrometer. At least two ion sources are provided with means of transporting the ions from the ion sources to separate two-dimensional ion traps. Each ion trap is used for storage and transmission of the ions and operates between the ion sources and the mass analyzer. Each ion trap has a set of equally spaced, parallel multipole rods, as well as entrance and exit sections into which and from which ions enter and exit the trap, respectively. For each ion trap, the entrance section is placed in a region where background gas pressure is at viscous flow. The pressure at the exit section drops to molecular flow pressure regimes without a break in the structure of the ion trap. Each trap alternately stores and transmits ions by way of a fast voltage switch applied to the ion trap exit lens.

Owner:PERKINELMER HEALTH SCIENCES INC

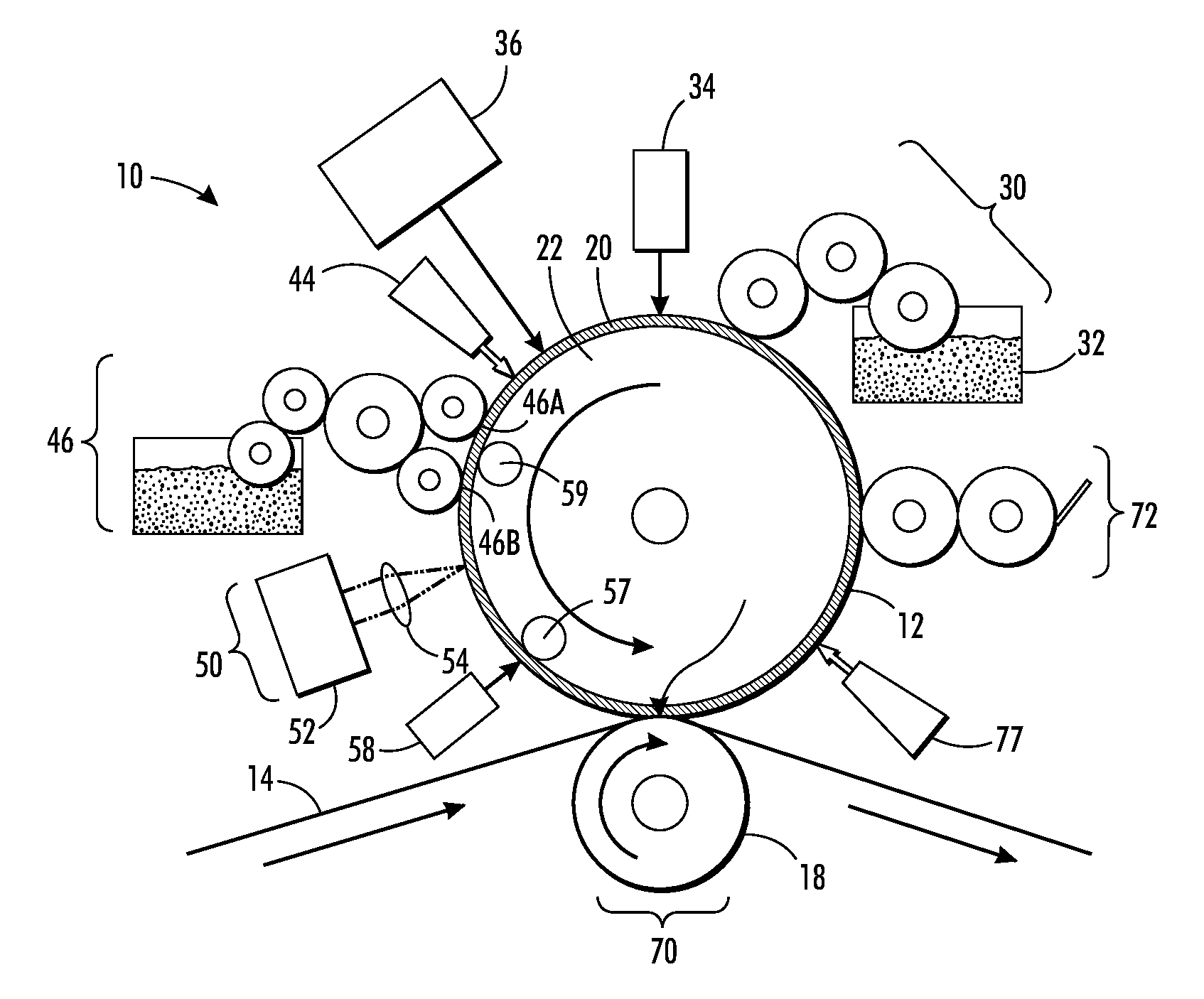

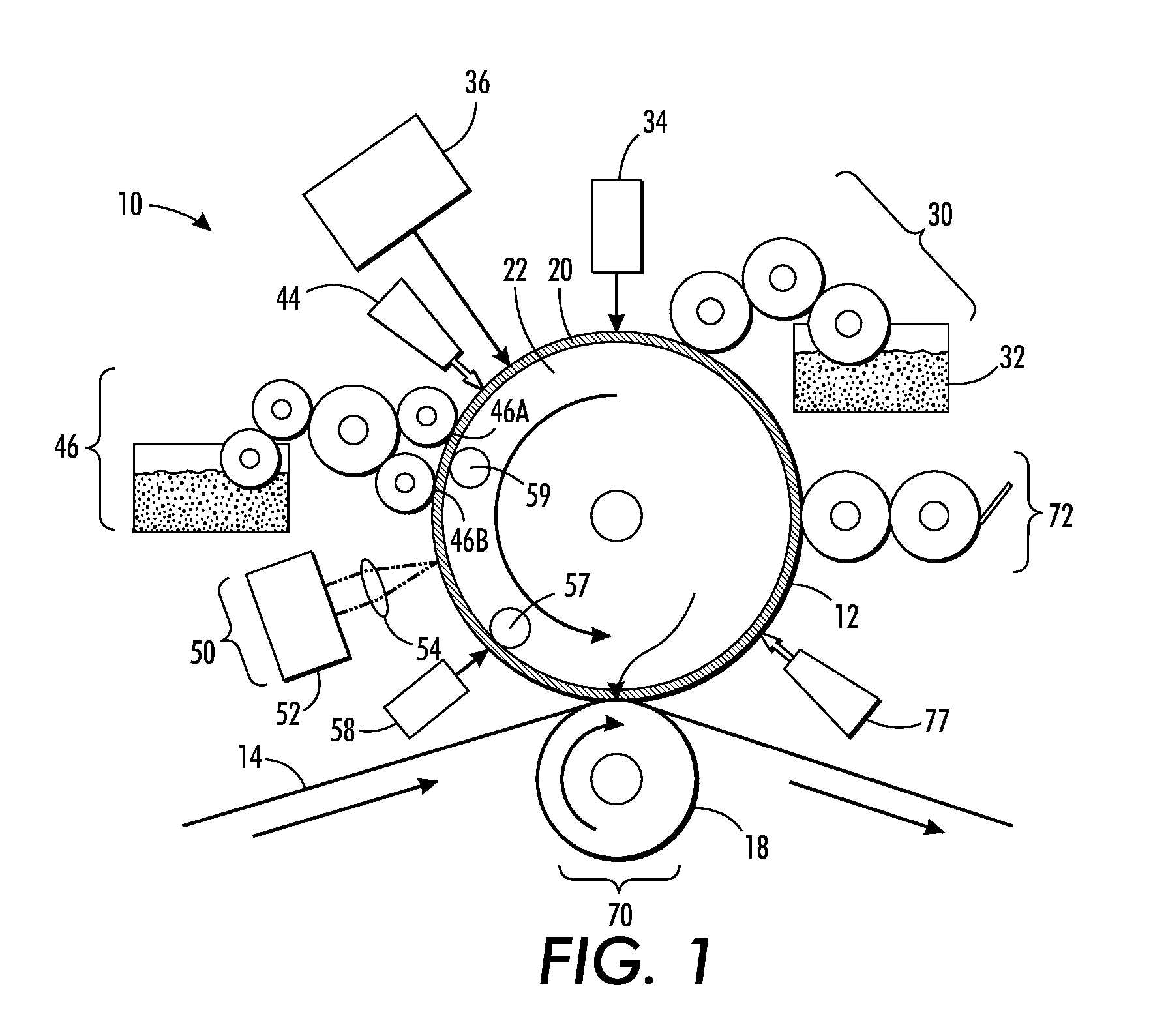

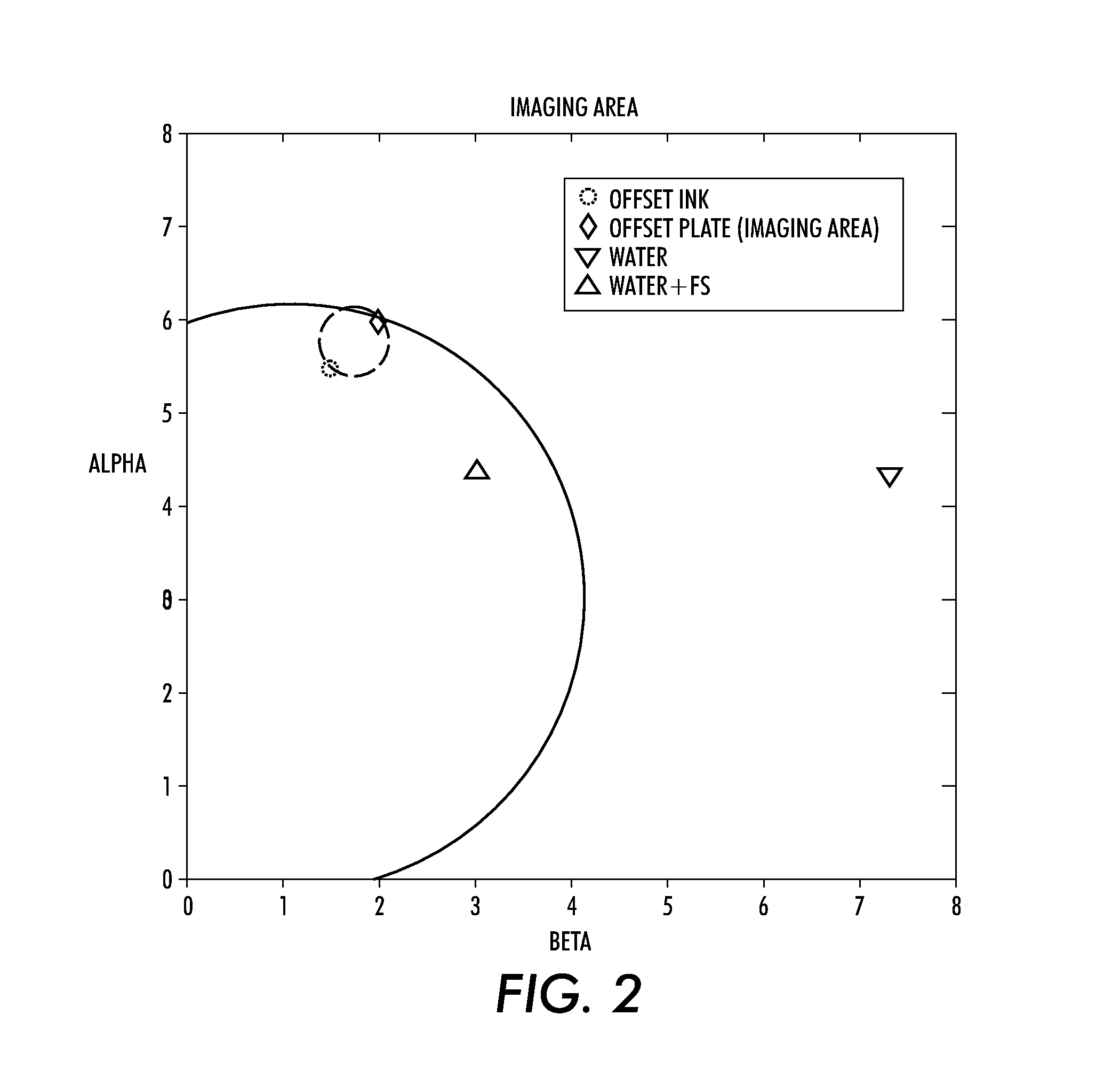

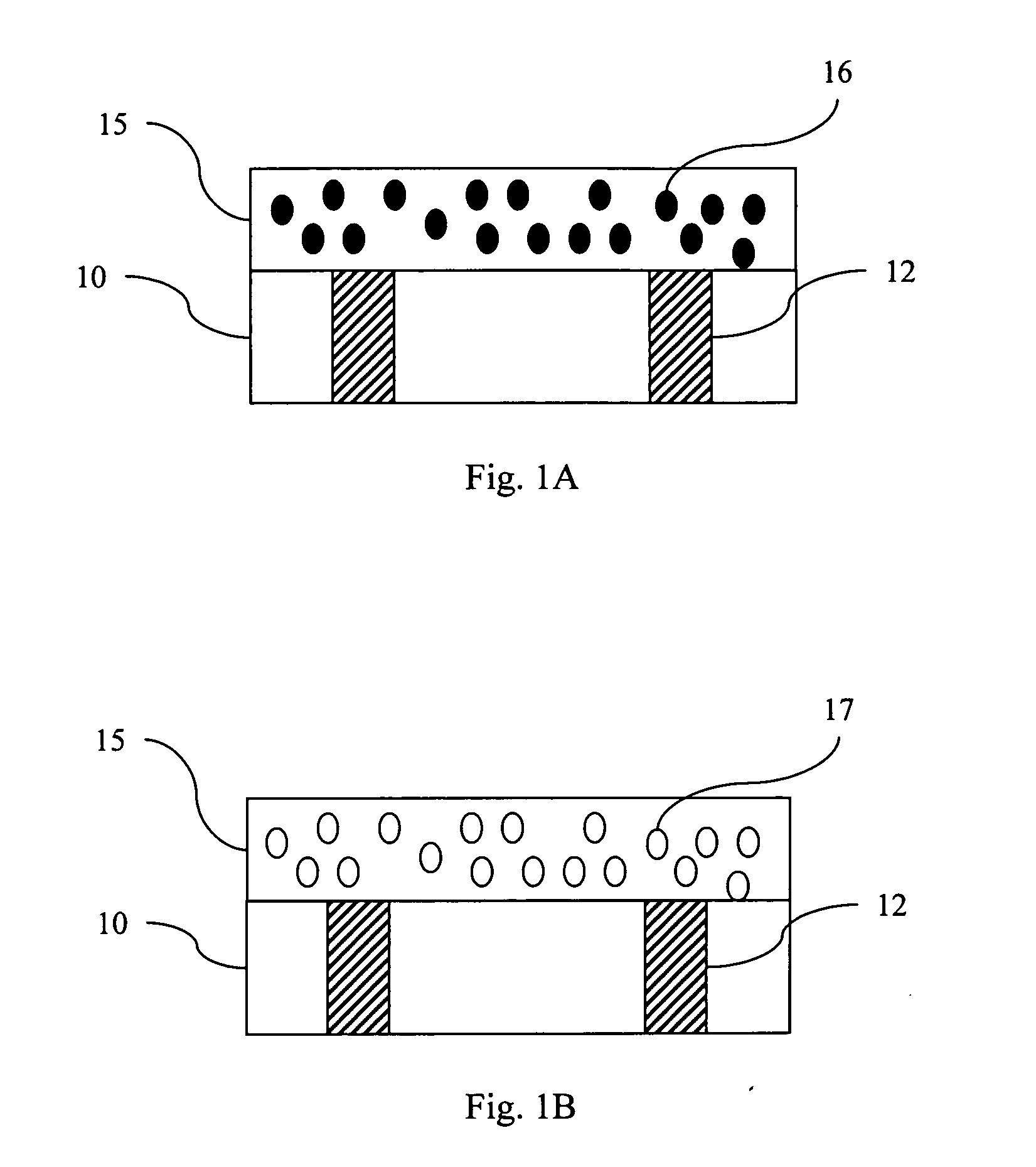

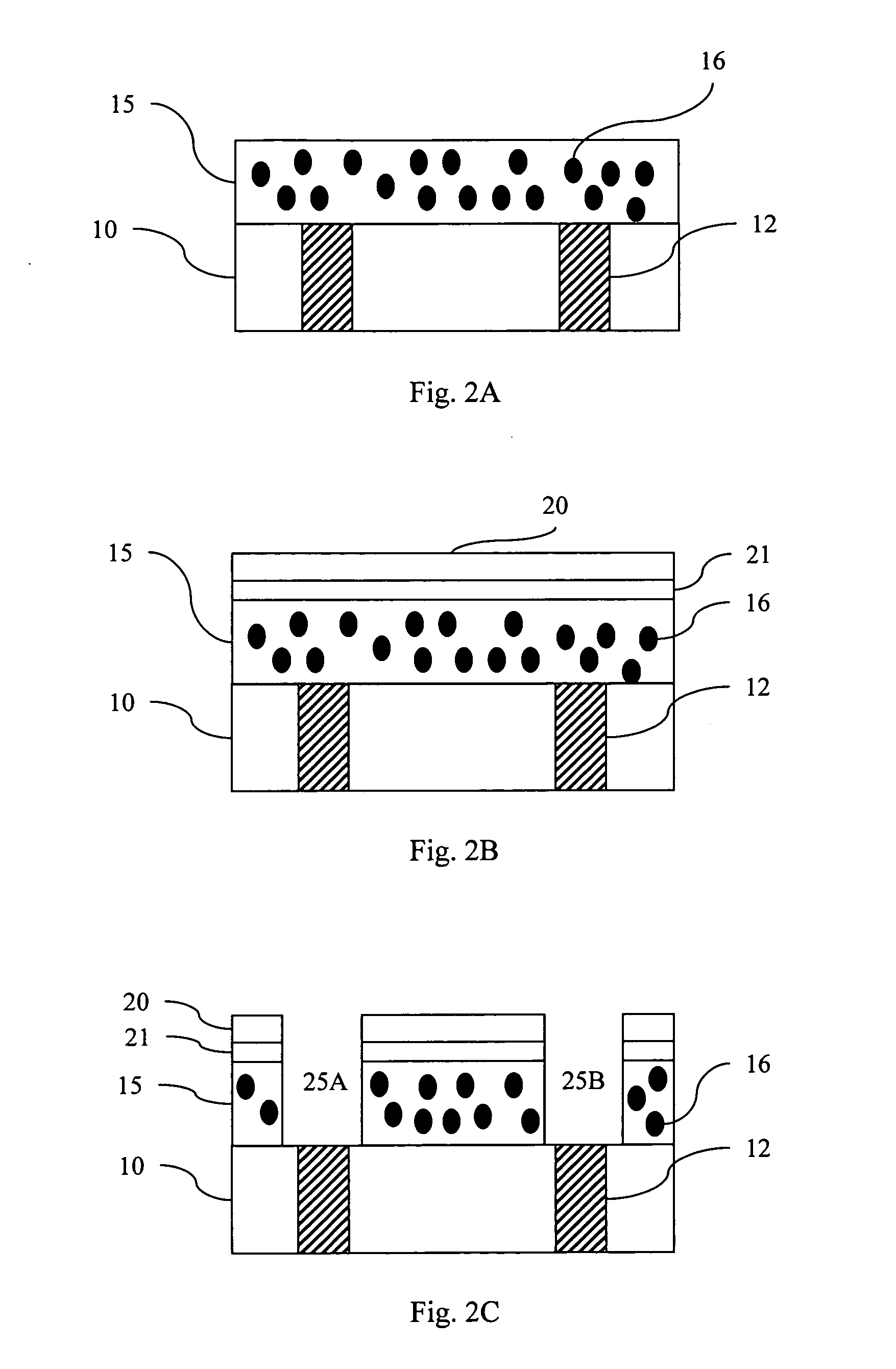

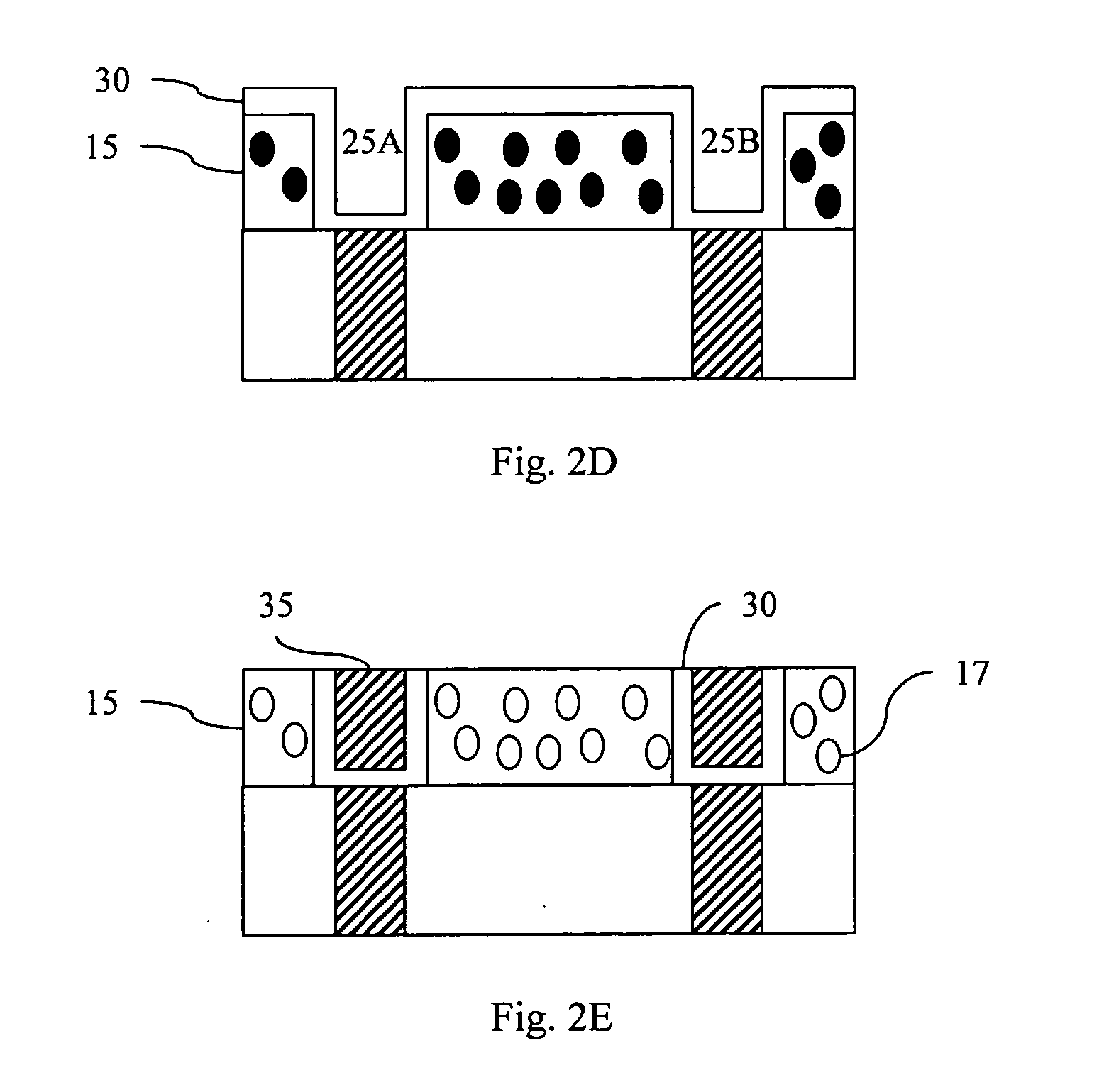

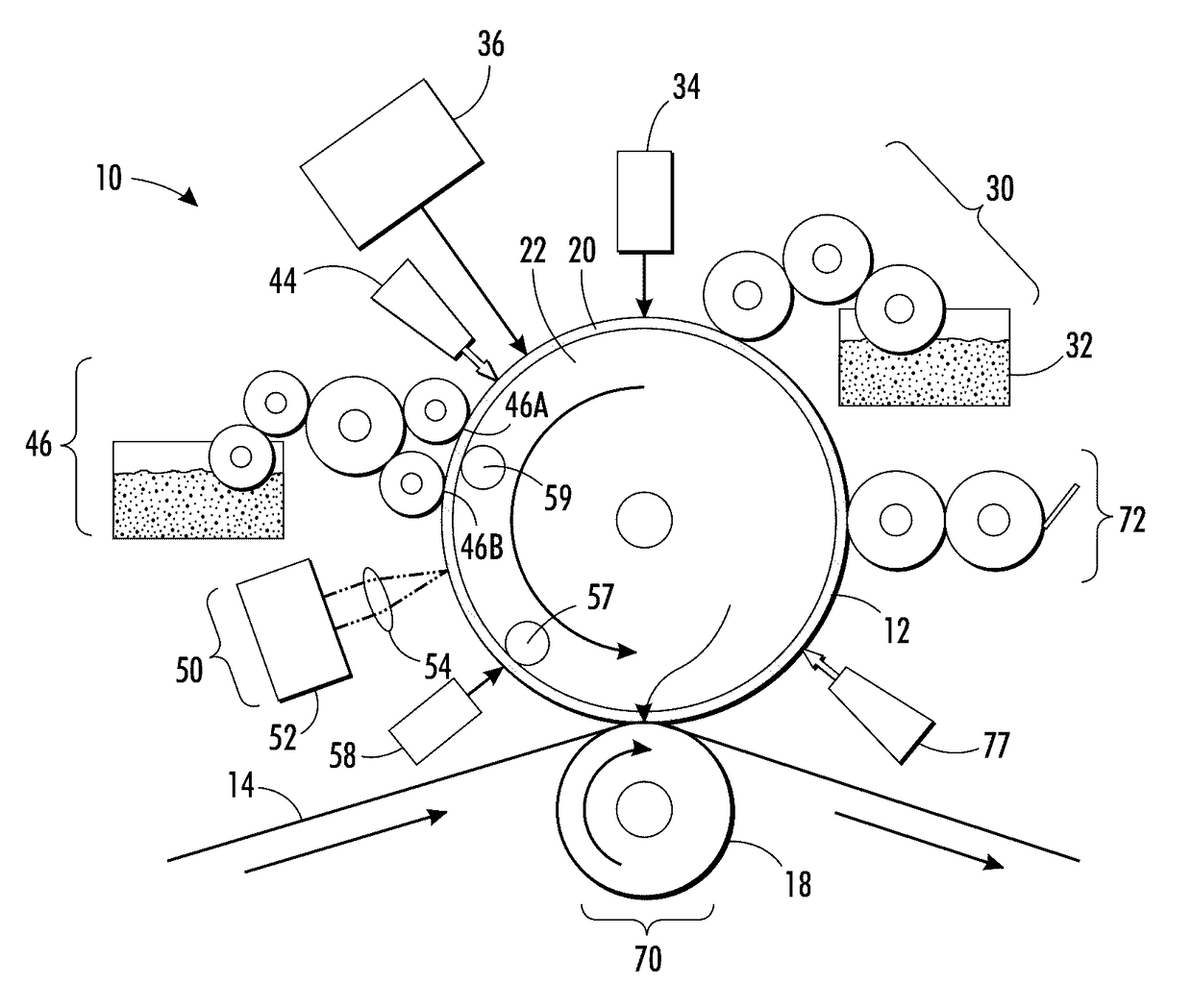

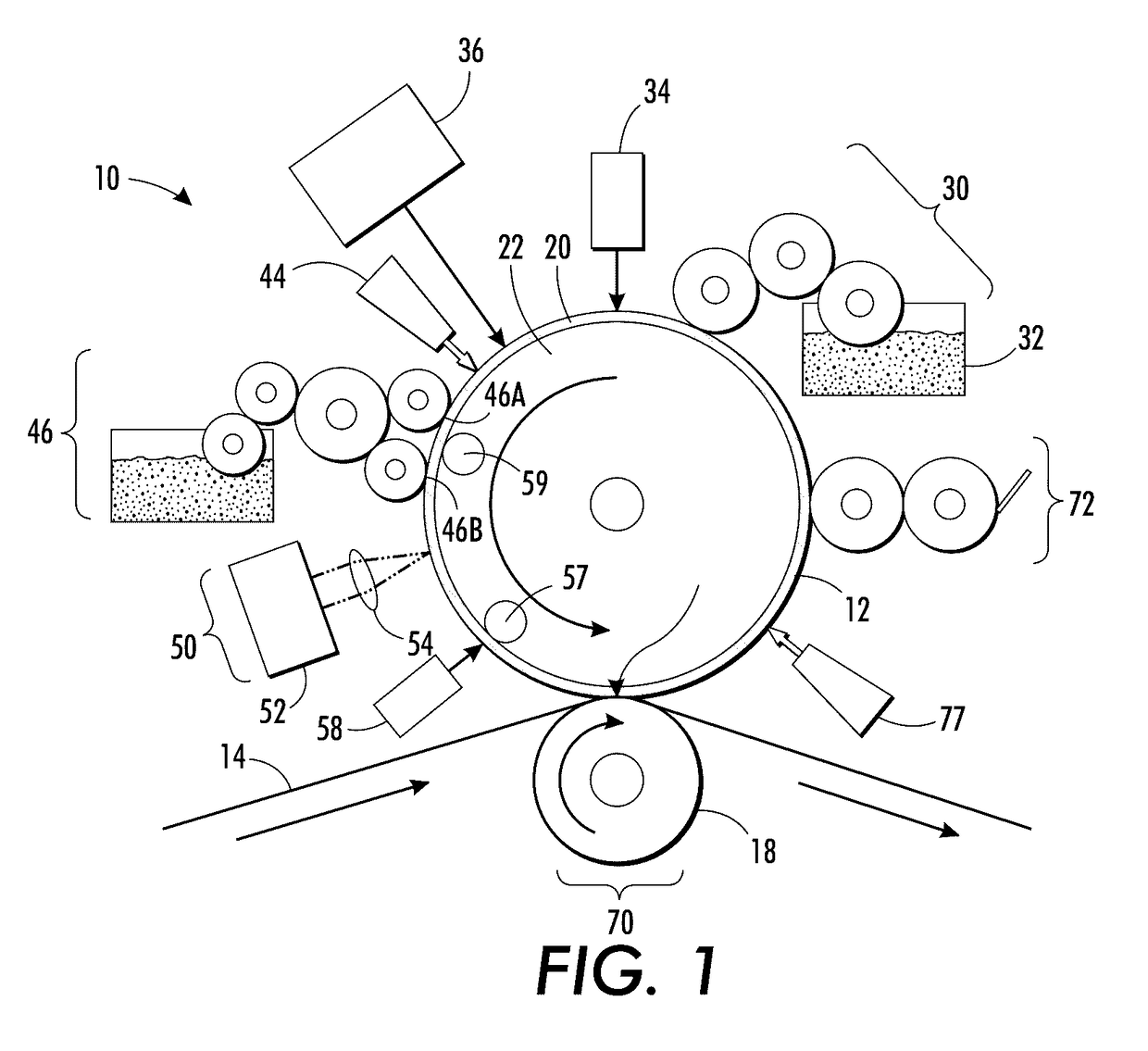

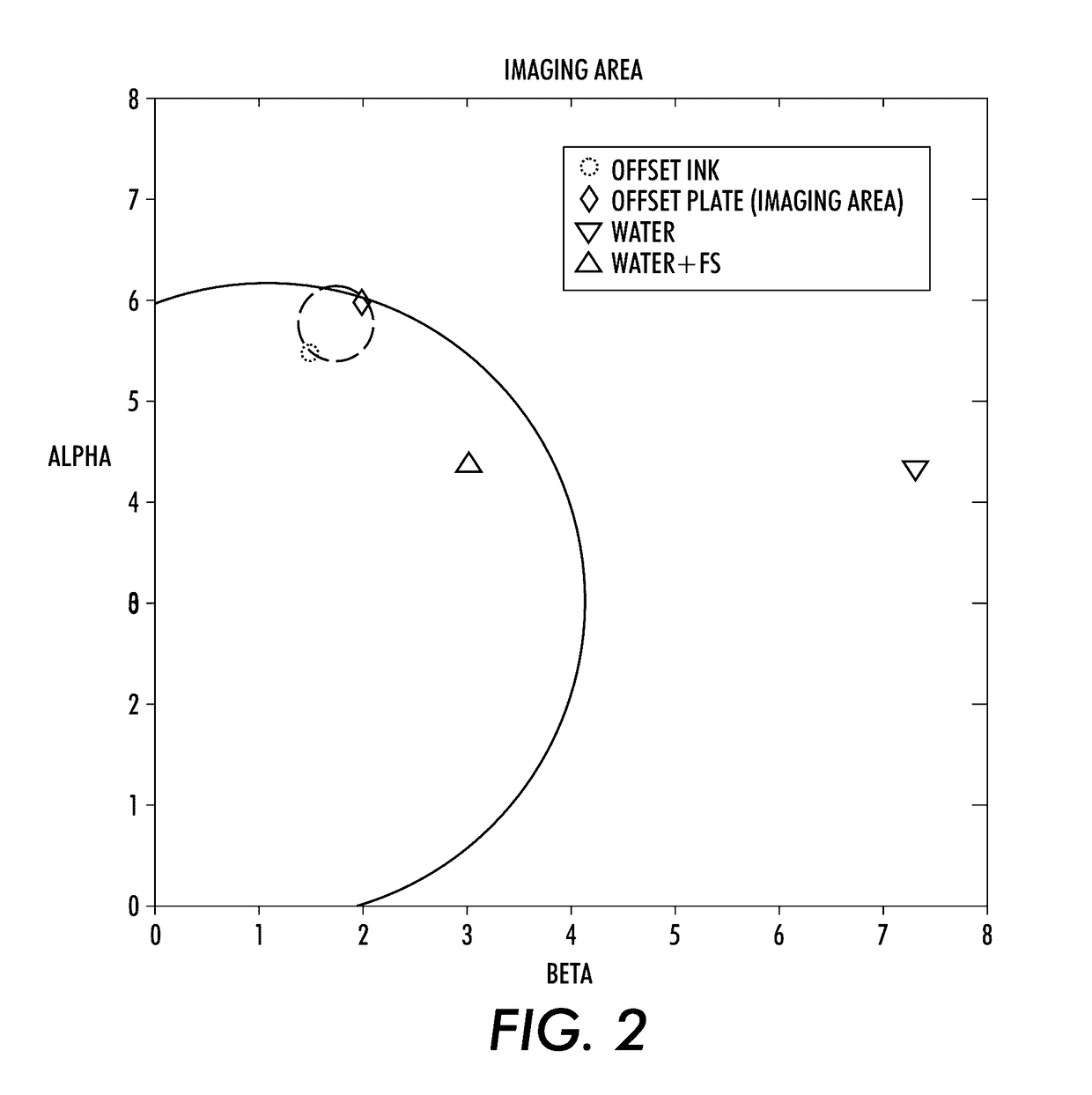

Dampening fluid for digital lithographic printing

ActiveUS20130104756A1Less residueSilicon organic compoundsPlaten pressesElectrical polarityVaporization

Different solvents for a dampening fluid are disclosed. The solvent is a volatile hydrofluoroether liquid or a volatile silicone liquid. Such liquids have a lower heat of vaporization, a lower surface tension, and better kinematic viscosity compared to water, which is the conventional solvent used in dampening fluids. The dampening fluids, which are relatively nonpolar, can be used in a combination with polar inks to form a new type of digital lithographic printing system.

Owner:XEROX CORP

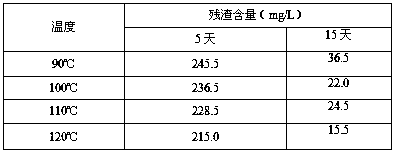

Composition and method

InactiveUS20060069171A1Less residueSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuitChemistry

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

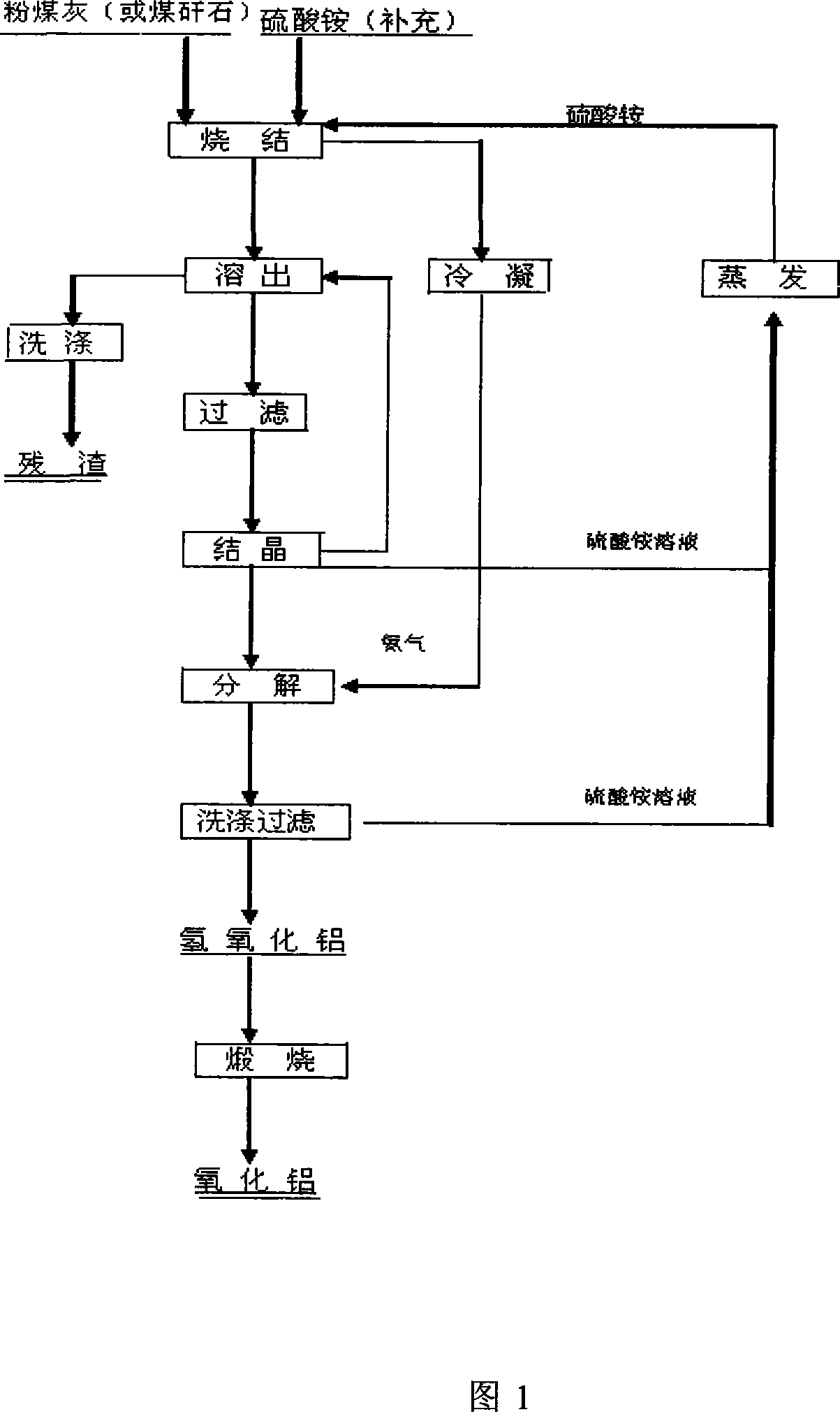

Method for extracting aluminium oxide from coal ash

ActiveCN101117228AEfficient use ofLess corrosiveAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium hydroxideAmmonium aluminium sulfate

The invention provides a method to extract aluminum oxide from a fly ash, and relates to a technological method which is to extract aluminum oxide from the fly ash and comprehensively utilize the residue after extracting aluminum oxide. The invention is characterized in the method which is as follows: ammonium sulfate is mixed into the fly ash to sintering, and the solid is dissolved to obtain the solution containing aluminum-ammonium sulfate; the solution is crystallized to form solid aluminium-ammonium sulfate; solid aluminium-ammonium sulfate reacts with ammonia gas to obtain aluminium hydroxide and ammonium sulfate, and aluminium hydroxide and ammonium sulfate are washed and filtrated to obtain solid aluminium hydroxide; solid aluminium hydroxide is calcined to obtain aluminum oxide; ammonium sulfate can be circularly used after being evaporated in the liquid phase. The ammonium sulfate which is used by the method of the invention is weak acidic, the corrosiveness on the equipment is small, and the ammonium sulfate can be used circularly. The whole process is easy to industrial application. The requirement of the corrosion resistance on the equipment is low. The amount of the residue is small which is beneficial to the comprehensive utilization of the residue after extracting the aluminum oxide.

Owner:河南华慧有色工程设计有限公司 +1

Method and apparatus for multiplexing plural ion beams to a mass spectrometer

ActiveUS7217919B2High sample throughputCompromise sensitivityTime-of-flight spectrometersIsotope separationIon trap mass spectrometryIon beam

A method / apparatus for multiplexing plural ion beams to a mass spectrometer. At least two ion sources are provided with means of transporting the ions from the ion sources to separate two-dimensional ion traps. Each ion trap is used for storage and transmission of the ions and operates between the ion sources and the mass analyzer. Each ion trap has a set of equally spaced, parallel multipole rods, as well as entrance and exit sections into which and from which ions enter and exit the trap, respectively. For each ion trap, the entrance section is placed in a region where background gas pressure is at viscous flow. The pressure at the exit section drops to molecular flow pressure regimes without a break in the structure of the ion trap. Each trap alternately stores and transmits ions by way of a fast voltage switch applied to the ion trap exit lens.

Owner:PERKINELMER HEALTH SCIENCES INC

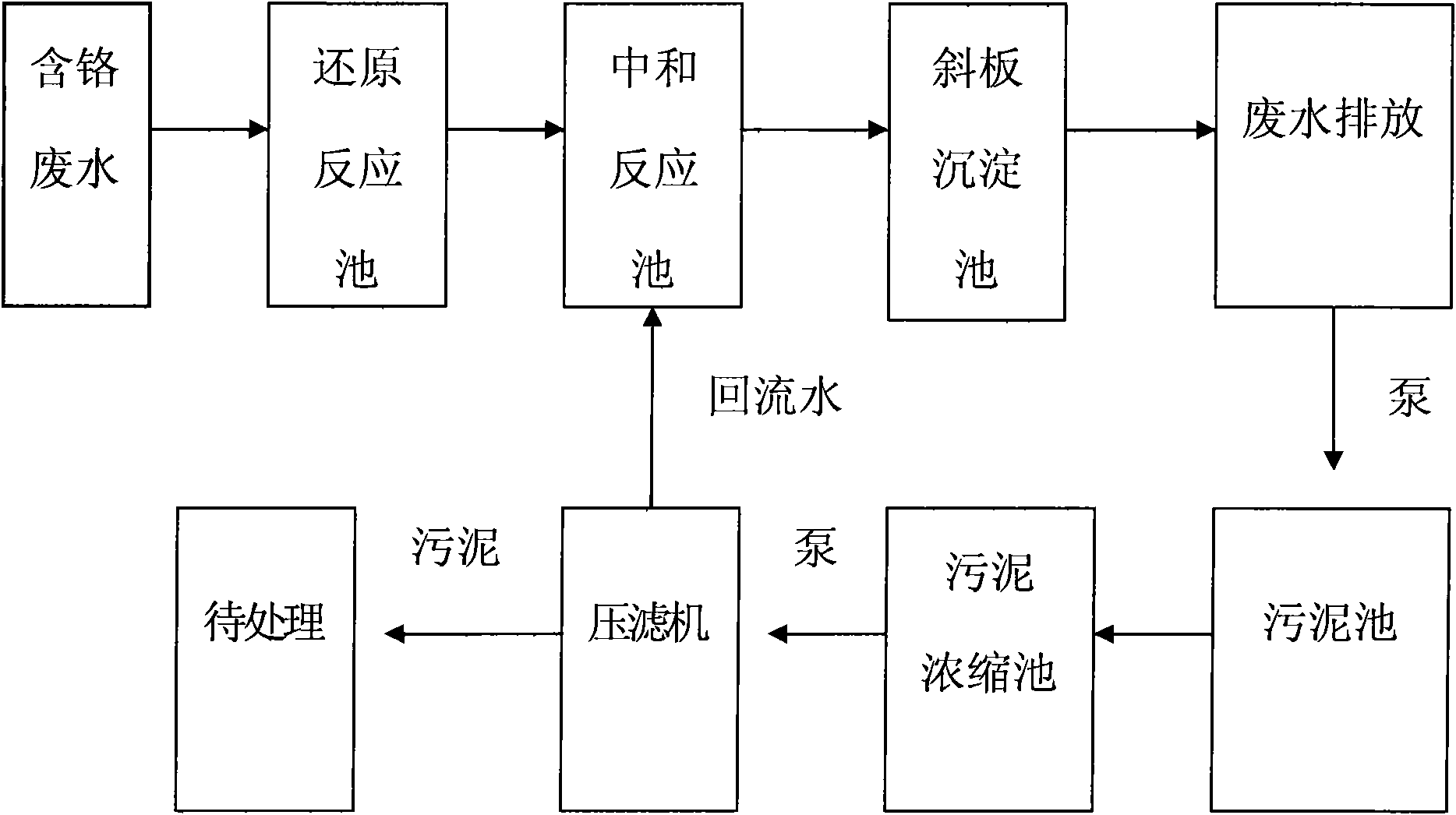

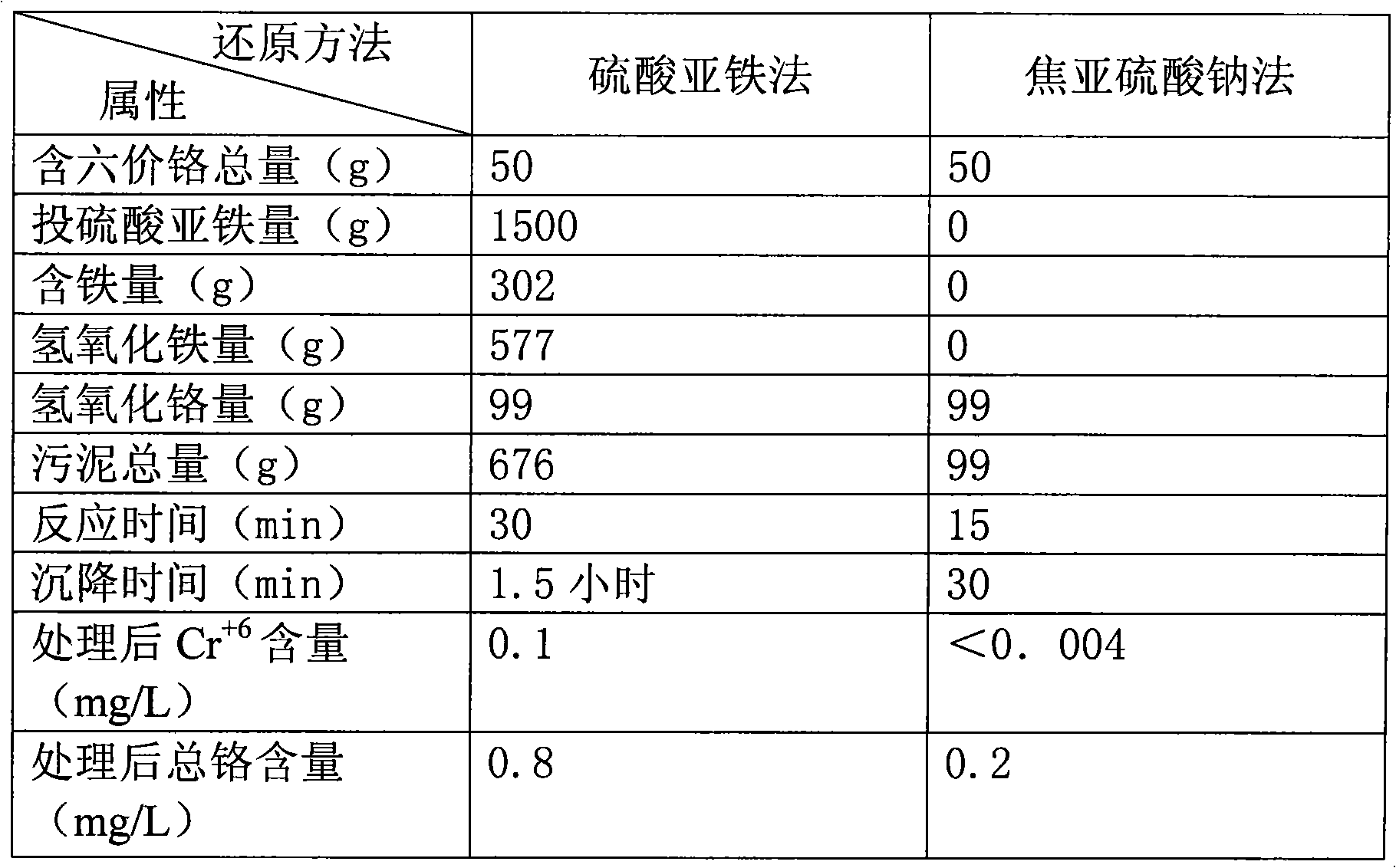

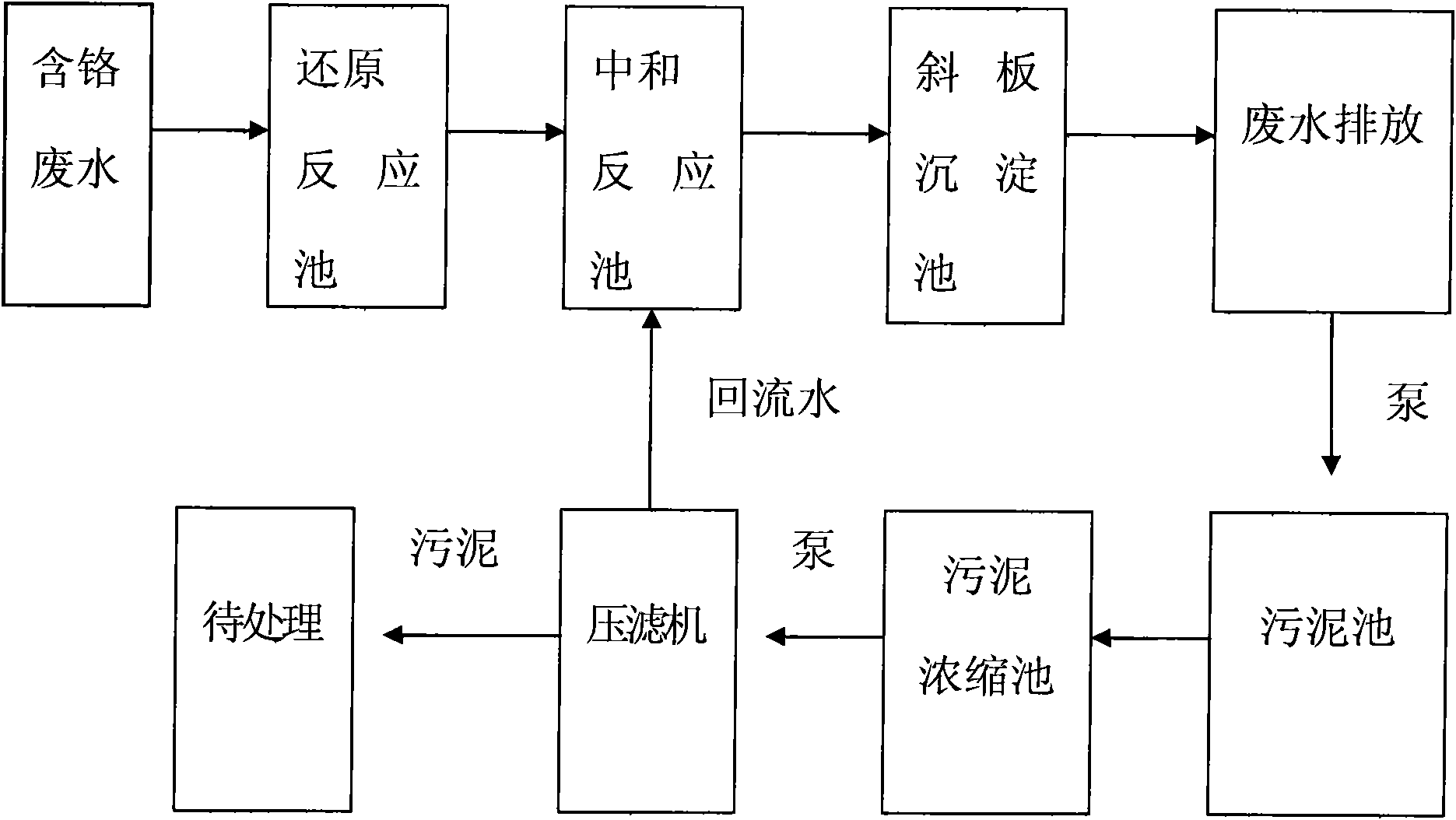

Hexavalent chromium-containing waste water treatment method

InactiveCN102070261AEasy to handleLess residueWater contaminantsMultistage water/sewage treatmentSolid phasesChemistry

The invention discloses a hexavalent chromium-containing waste water treatment method, which uses sodium hydrogensulfite generated by hydrolysis of sodium pyrosulfite as a reducer and adopts an intermittent process technique for treatment. The concrete treatment process comprises: 1, adding sulfuric acid into waste water, and regulating the pH value of the waste water to 2.0 to 3.0; 2, adding sodium pyrosulfite to reduce hexavalent chromium in the waste water into trivalent chromium, wherein the adding ratio of the sodium pyrosulfite is calculated according to the weight ratio of sodium pyrosulfite to hexavalent chromium of 3.5-5:1; 3, adding sodium hydroxide into a neutralization tank to regulate the pH value of the waste water to 8 to 9 to precipitate the trivalent chromium completely in form of chromium hydroxide; and 4, separating a solid phase from a liquid phase by using the flocculation force of a polyacrylamide polymeric flocculant and the action of a tube sedimentation tank, discharging waste water, piling mud in a centralized manner after press-filtering the mud by a press filter, and processing the mud uniformly according to regulations.

Owner:AVIC STANDARD PARTS MFG

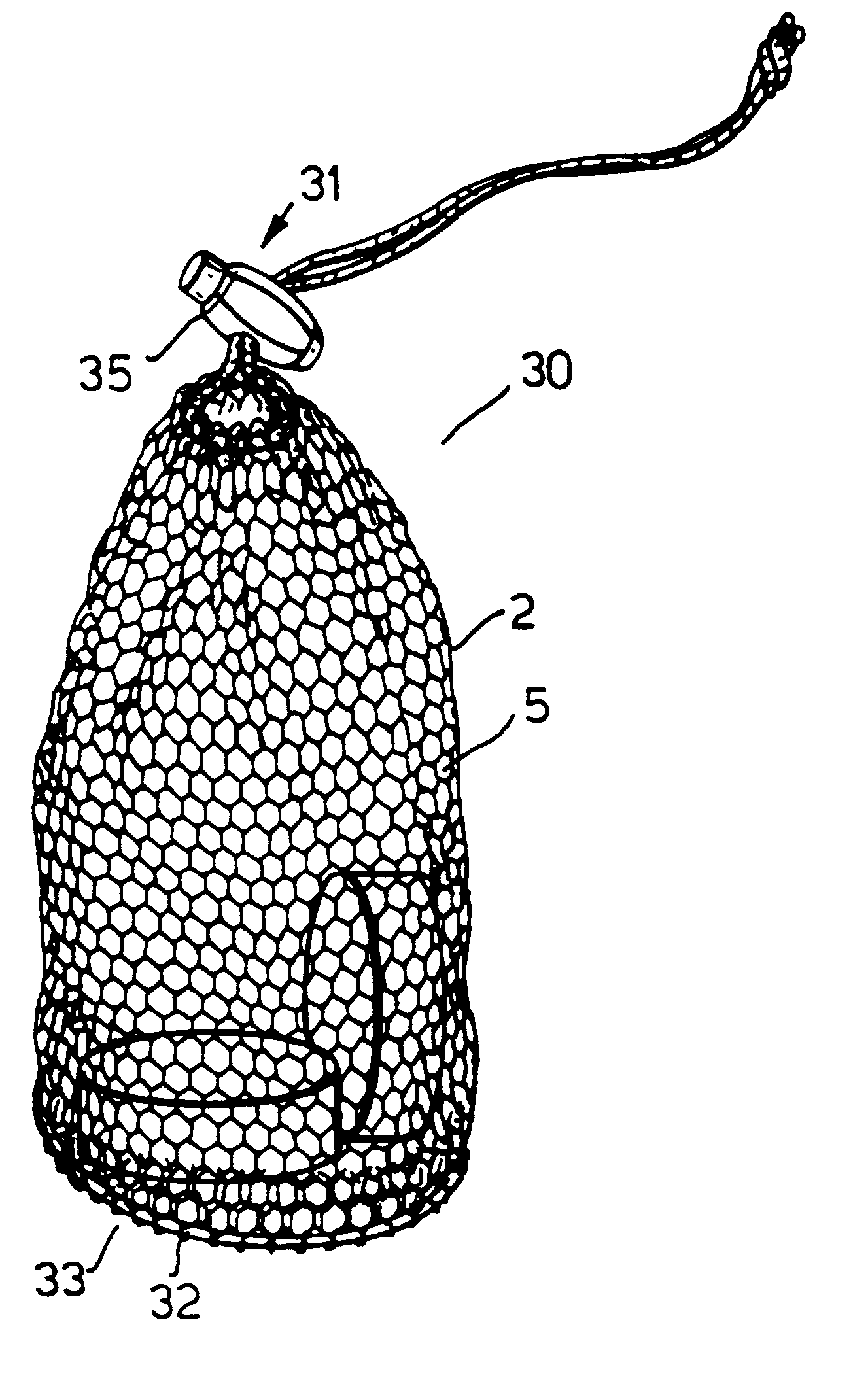

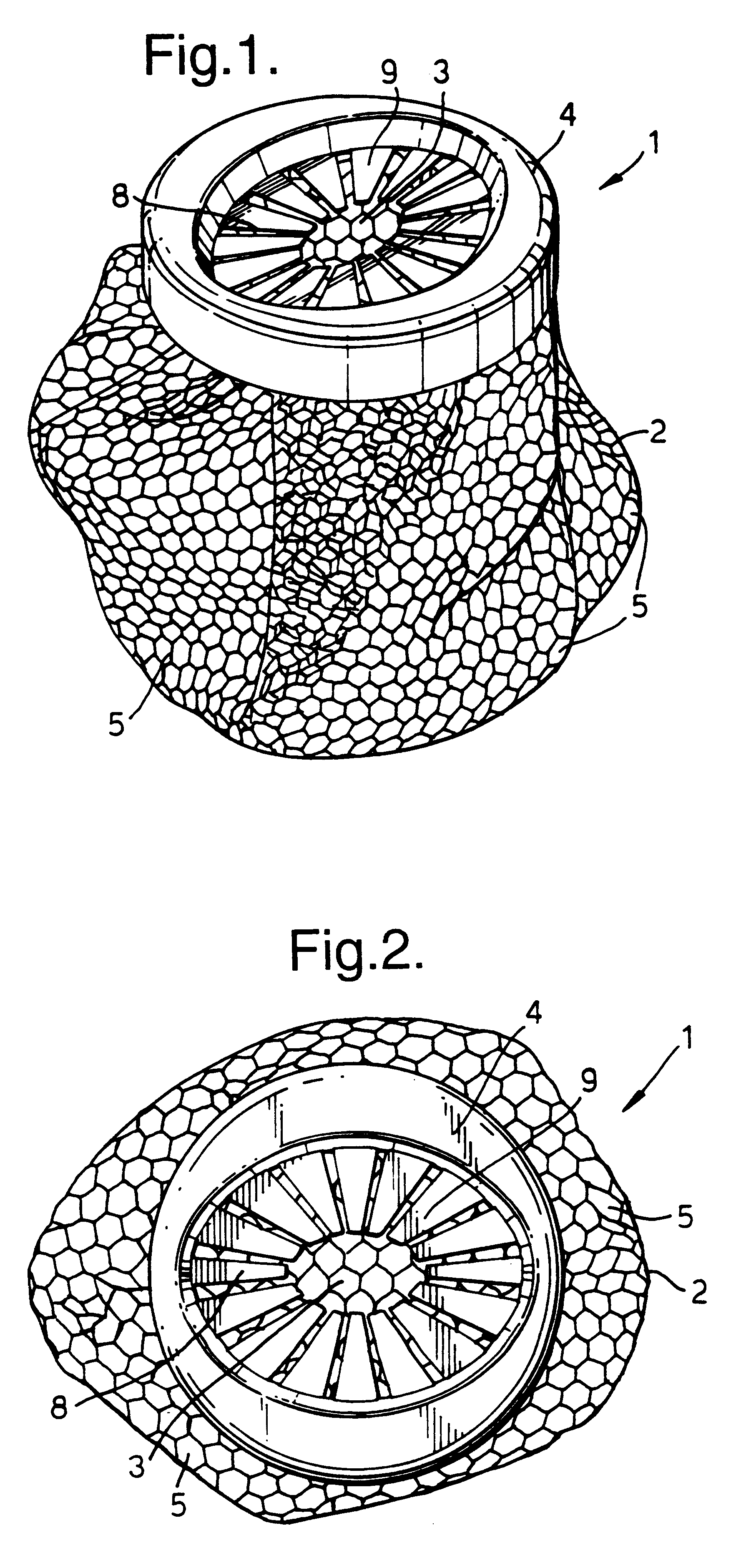

Process and dispensing device for washing laundry in a washing machine

InactiveUS6174848B1Less residueEffect of direct contact between the tablet and the clothes, decreasesBagsOther washing machinesProcess engineeringLaundry

A process for washing laundry in a washing machine employs a receptacle for dispensing detergent tablets. The receptacle comprises a loosely fitting net bag having apertures with an average mesh size of between 1 and 10 mm. One or more tablets are placed in the dispensing receptacle before being placed into a washing machine along with laundry to be washed and a washing operation is carried. After the washing operation, the device is removed from the machine and stored for subsequent use.Moreover, the invention relates to a dispensing device for carrying out this process and a use of the device in laundry washing.

Owner:HENKEL IP & HOLDING GMBH

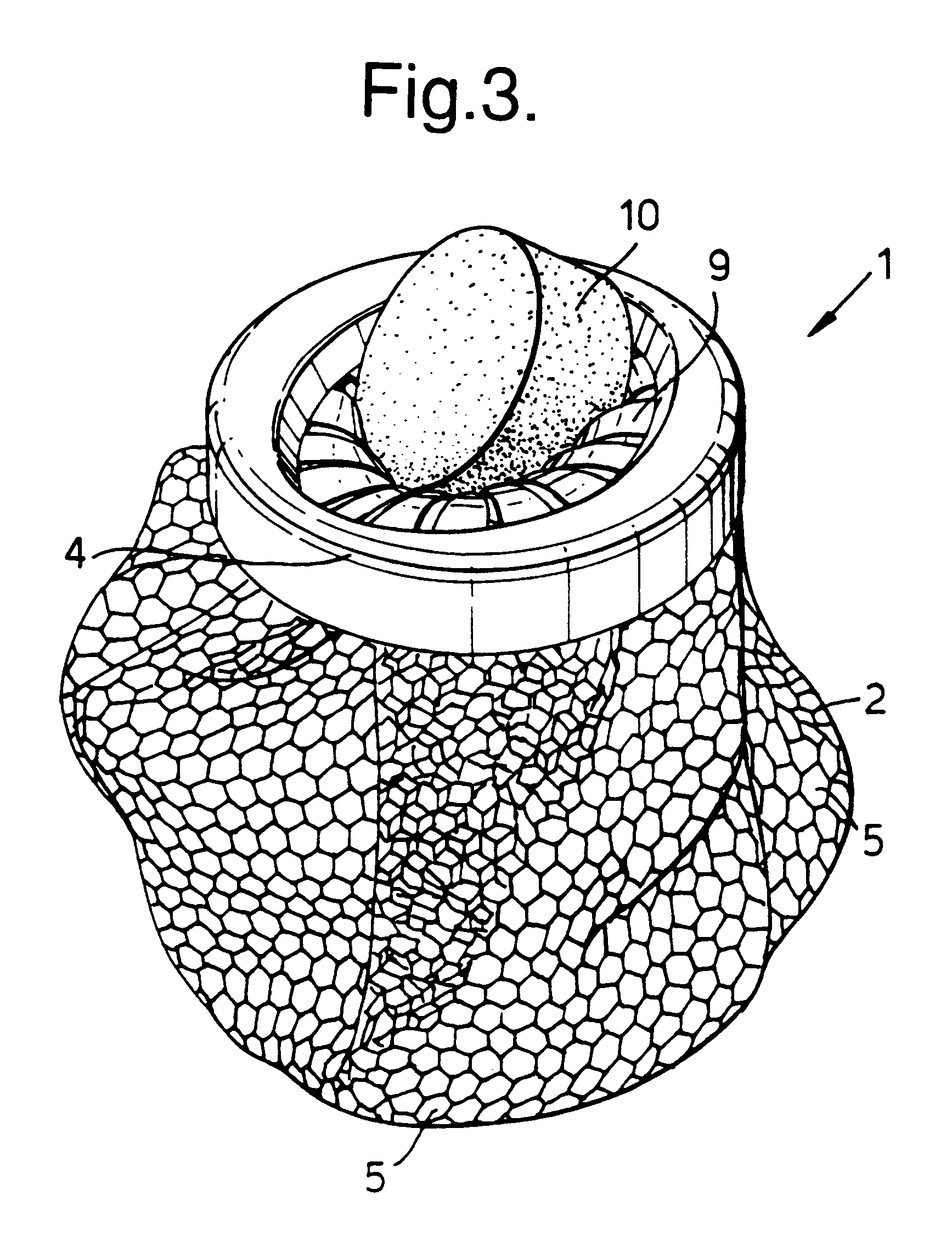

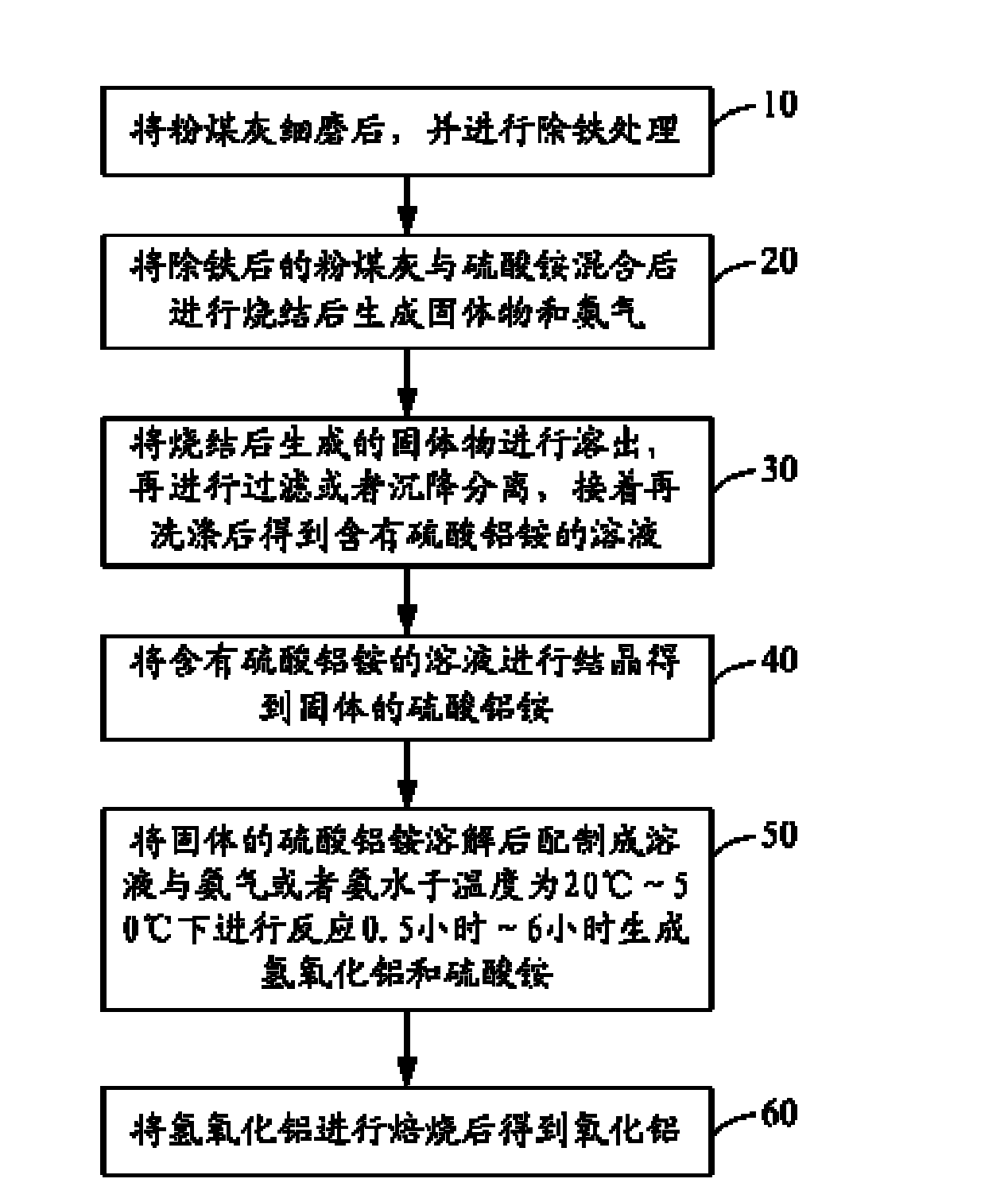

Method for extracting aluminum oxide from pulverized flue ash

ActiveCN102120593ALess corrosiveLess residueAluminium oxides/hydroxidesAluminium hydroxideAluminum ammonium sulfate

The invention relates to a method for extracting aluminum oxide from pulverized flue ash. The method comprises the following steps of: finely grinding the pulverized flue ash, and deironing; mixing the deironed pulverized flue ash and ammonium sulfate and then sintering to generate solid and ammonia gas; dissolving out the solid generated through sintering, then filtering or settling out, washing to obtain a solution containing aluminum ammonium sulfate; crystallizing the solution containing the aluminum ammonium sulfate to obtain solid aluminum ammonium sulfate; dissolving the solid aluminum ammonium sulfate, then preparing into a solution which reacts with the ammonia gas or ammonia water for 0.5-6h at a temperature of 20-50 DEG C to generate aluminum hydroxide and ammonium sulfate; roasting the aluminum hydroxide to obtain the aluminum oxide. The method for extracting the aluminum oxide from the pulverized flue ash is simple, ensures that less byproduct is produced and is easy to realize industrial application.

Owner:北京世纪地和控股有限公司

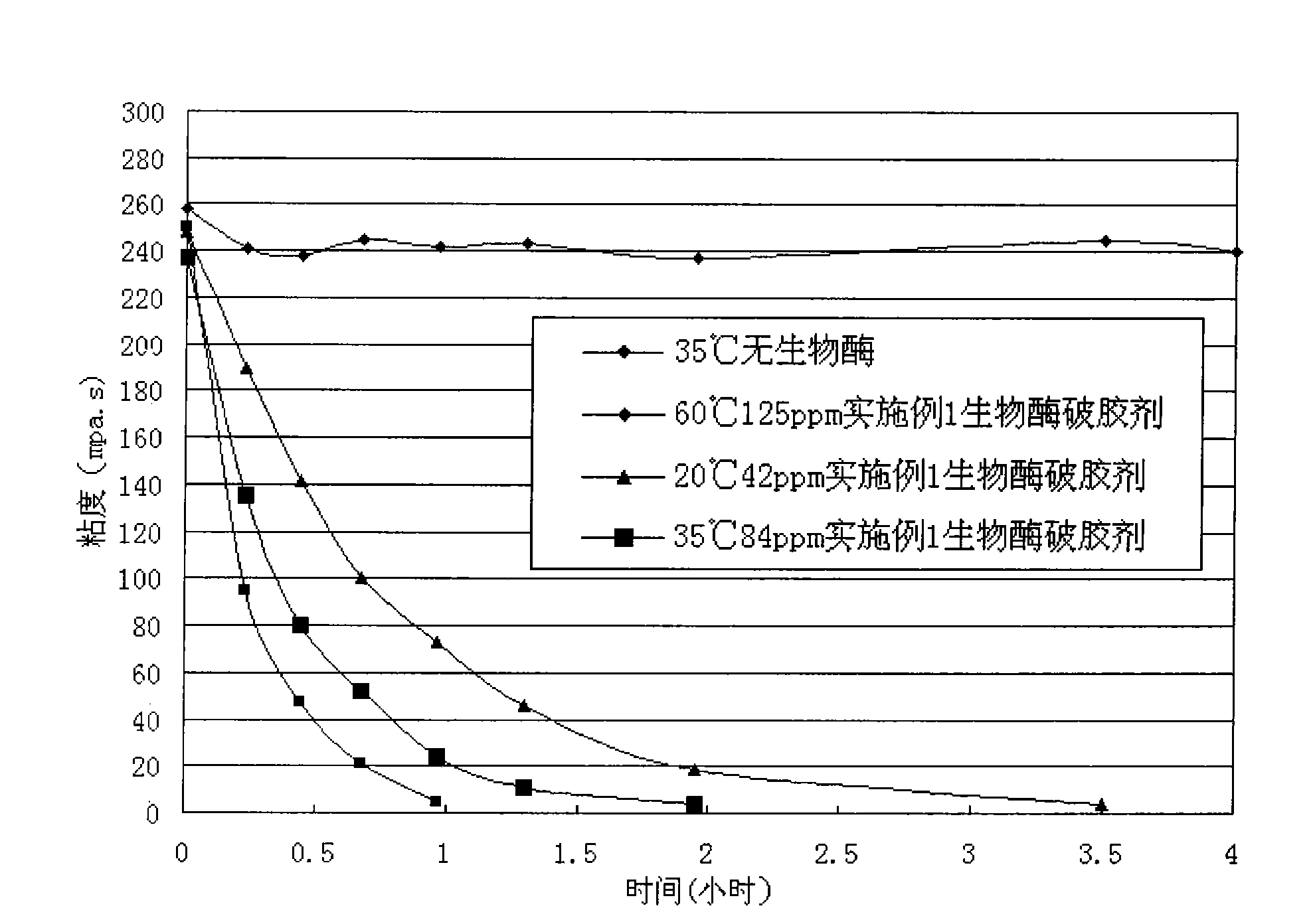

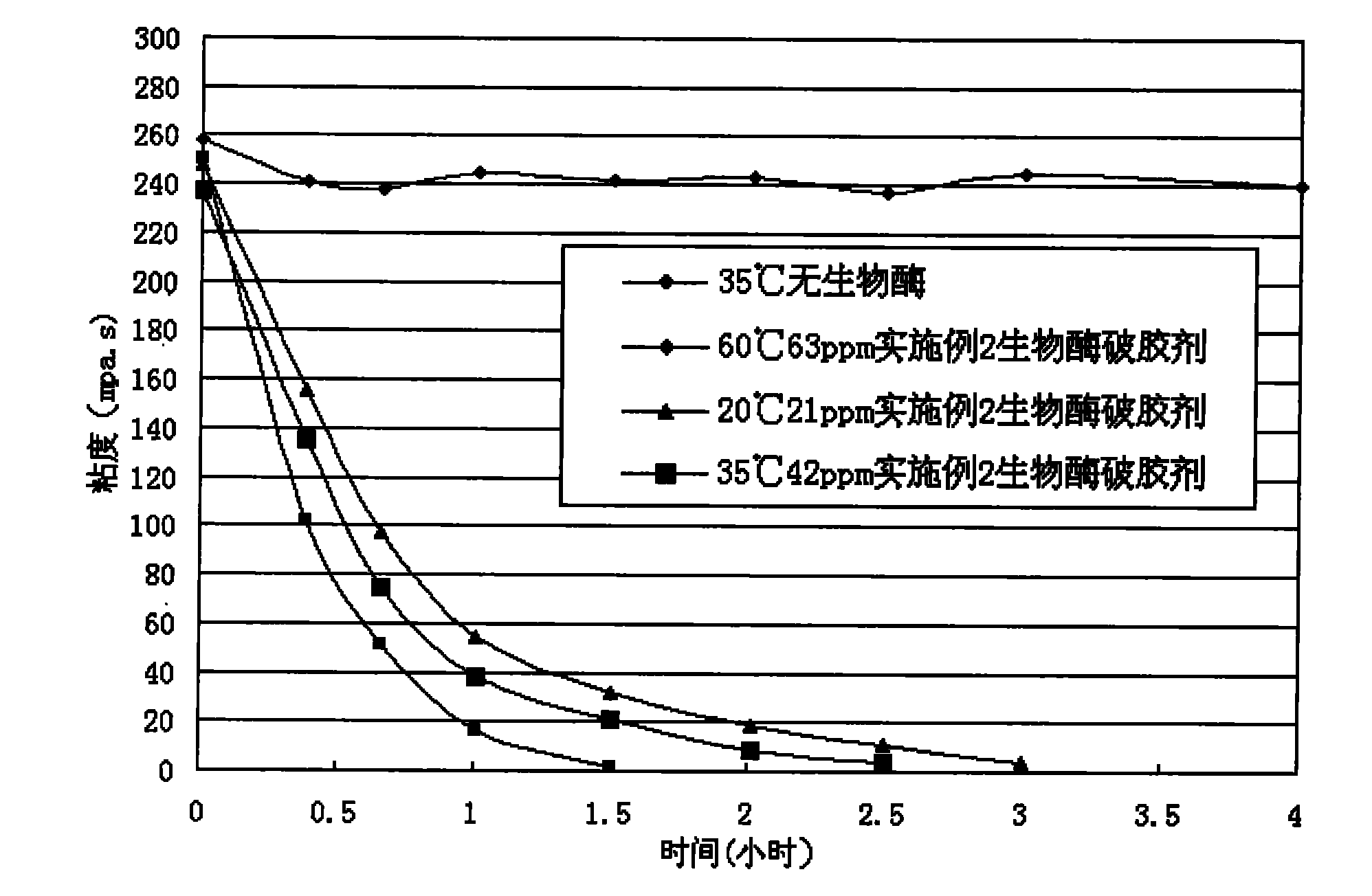

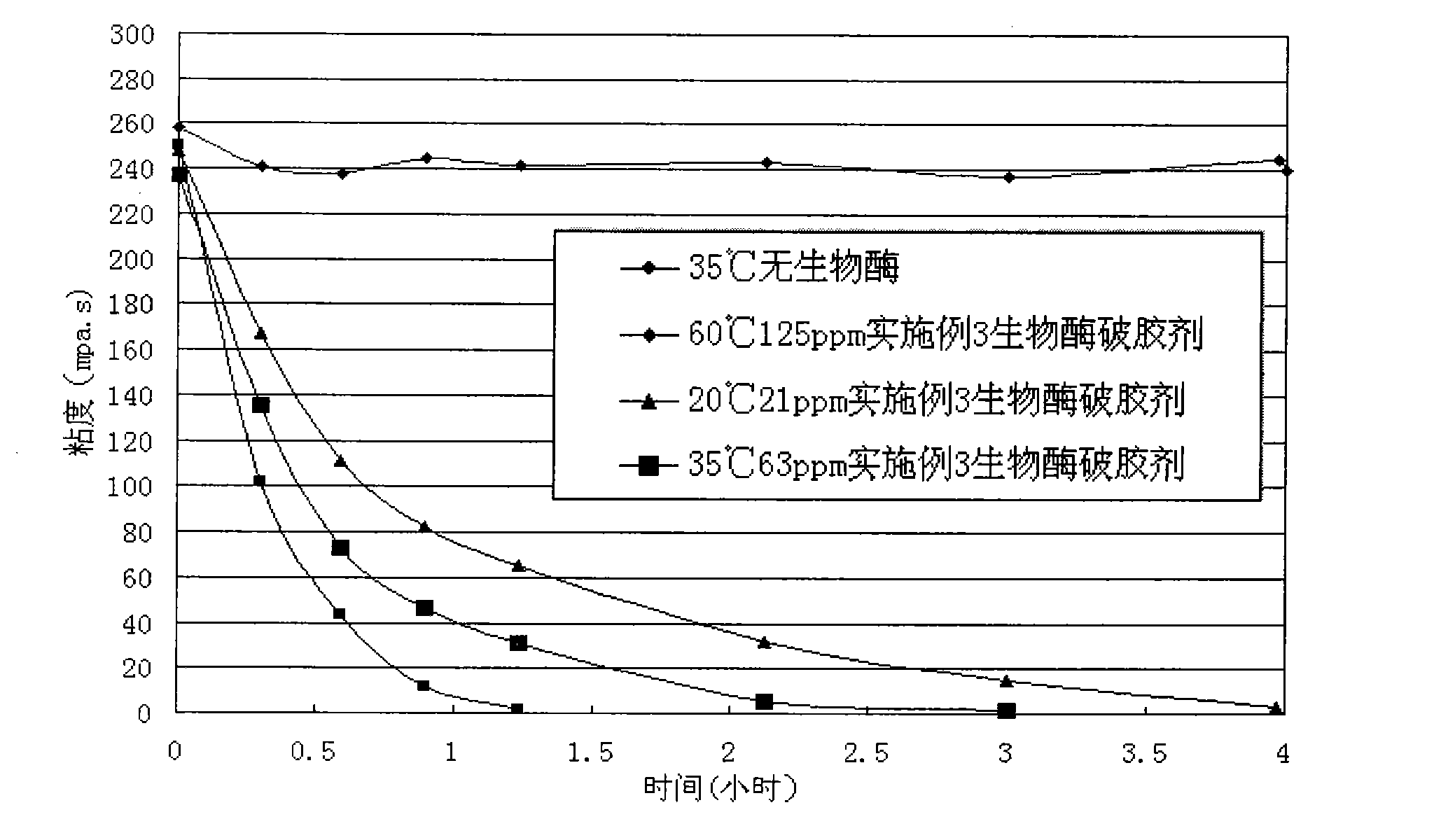

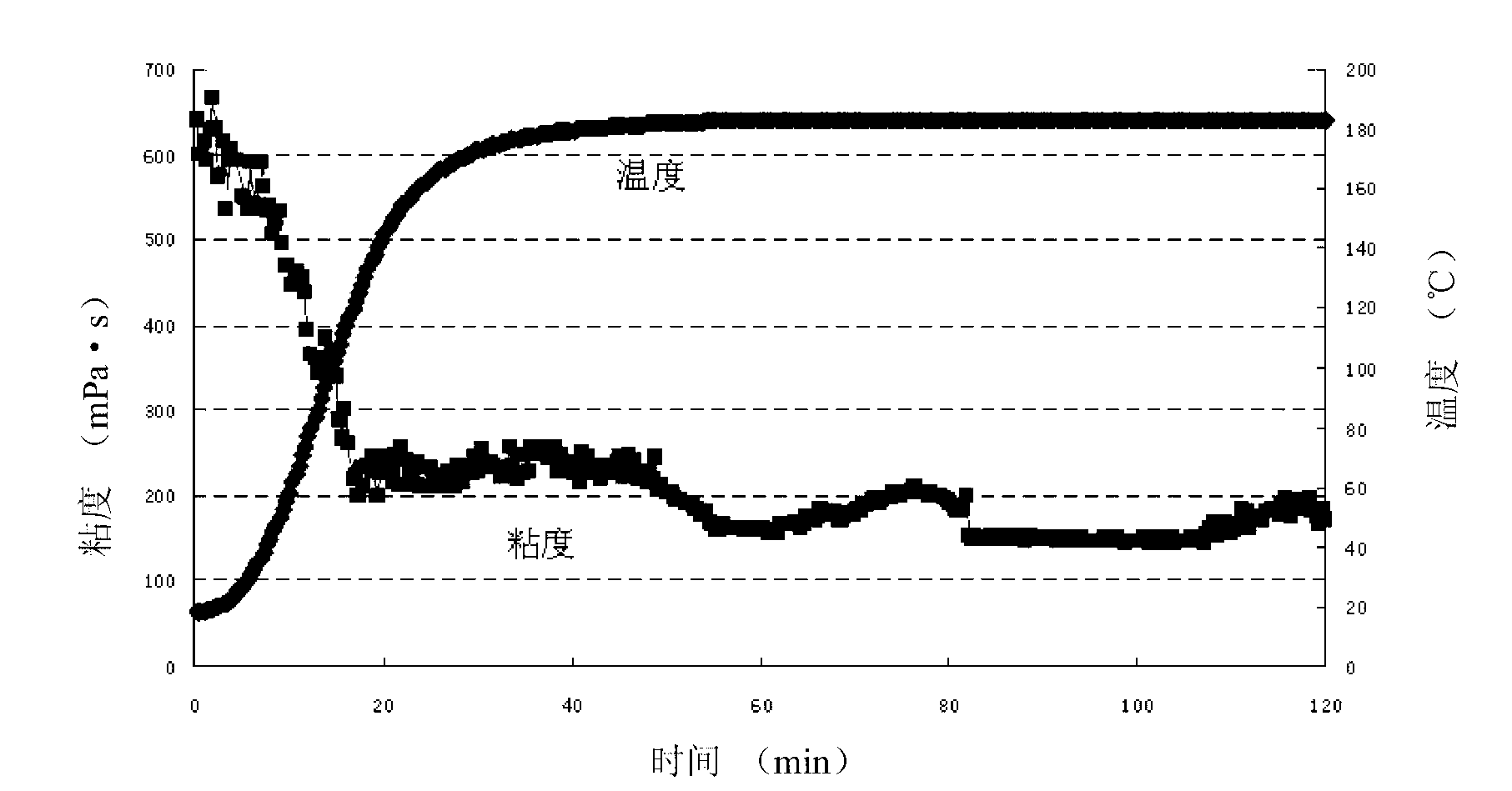

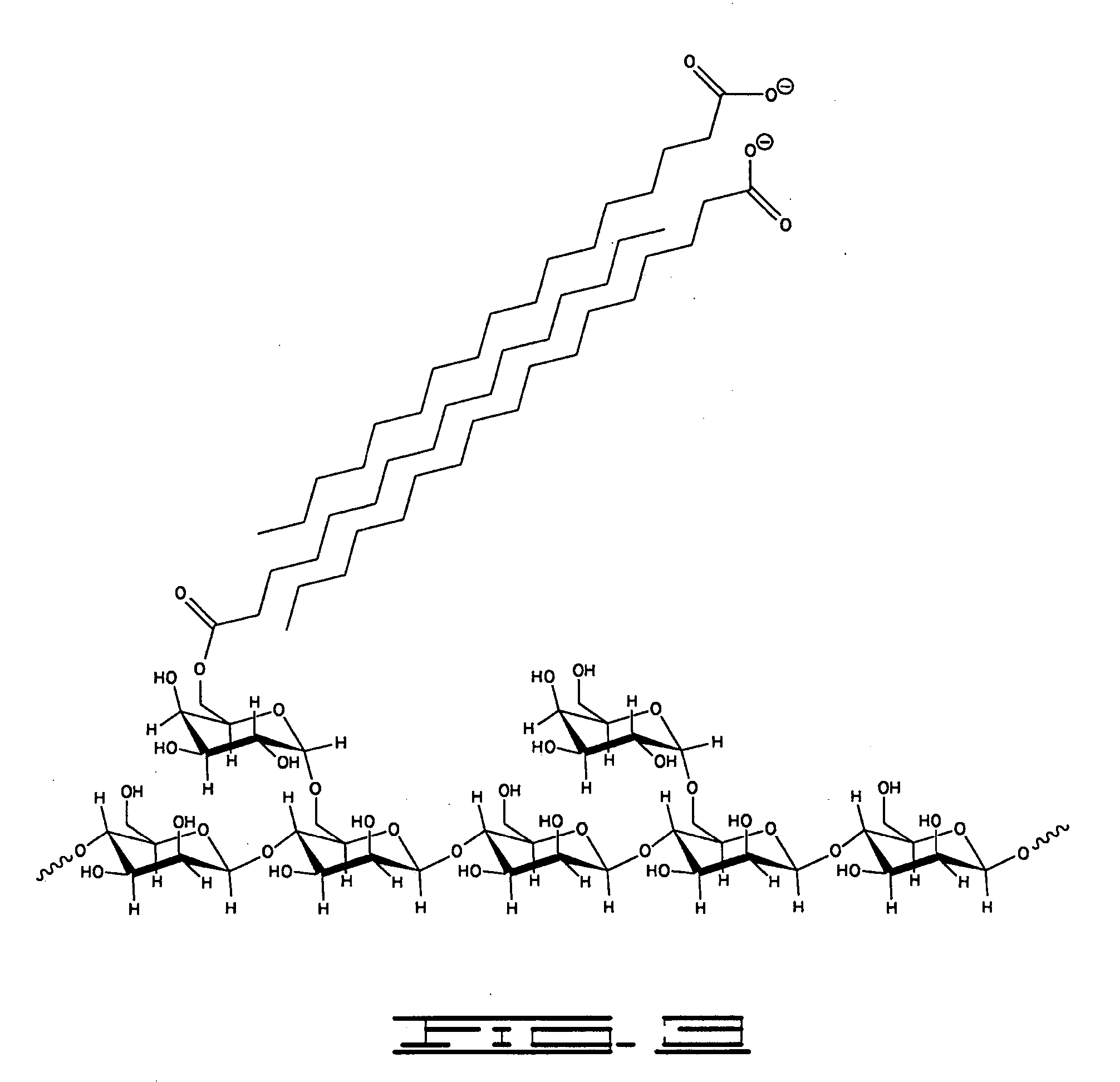

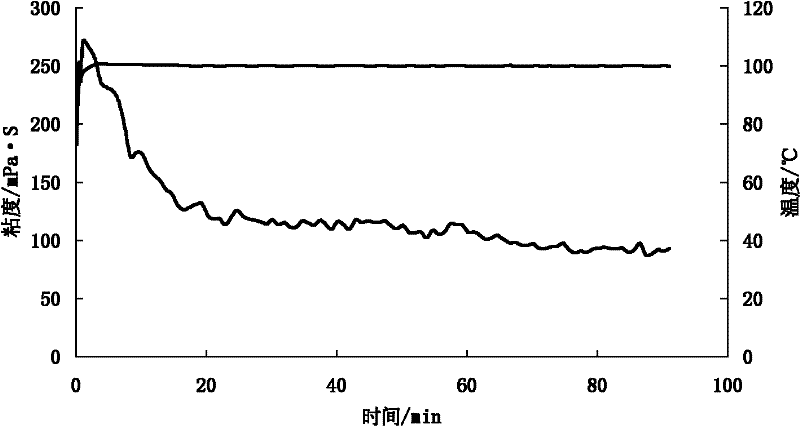

Bio-enzyme gel breaker and technique for water-based guargum fracturing gel breaking with the same

InactiveCN101781552AImprove performanceEasy to storeFluid removalDrilling compositionWater basedPectinase

The invention relates to bio-enzyme gel breaker, in particular to formula and technique for gel breaking of water-based guargum fracturing fluid by using the bio-enzyme gel breaker. The bio-enzyme gel breaker contains the following components in percentage by weight: 10-50% of beta- mannose, 0-20% of cellulose, 0-10% of pectinase, 0-15% of glucanase, 0-10% of xanthase, 3-10% of (NH4)2SO4, 2-5% of NaCl, 1.5-5% of ZnCL2 and 0-60% of persulfate. The fracturing fluid gel breaking technique comprises the following steps: dissolving the bio-enzyme gel breaker in borax crosslinked fluid; mixing and blending the crosslinked fluid and the guargum base fluid, crosslinking, forming jelly, and then mixing with proppant, pressing the mixture into the oil-water well until the mixture enters the fractured crack. In this way, the fracturing process is finished. The bio-enzyme gel breaker degrades the macromolecular guargum in the stratum fracturing fluid into small micromolecular sugar, and when the jelly breaks up, the proppant is left underground, the fracturing gel breaking fluid flows back, and in this way, the construction can be completed. The bio-enzyme gel breaker has good gel breaking performance, the construction process is reasonable, the viscosity of the fracturing fluid can not decrease too early, the gel of the fracturing fluid can be broken evenly and thoroughly with little residue and small harm to the stratum, and the operation is simple and convenient.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

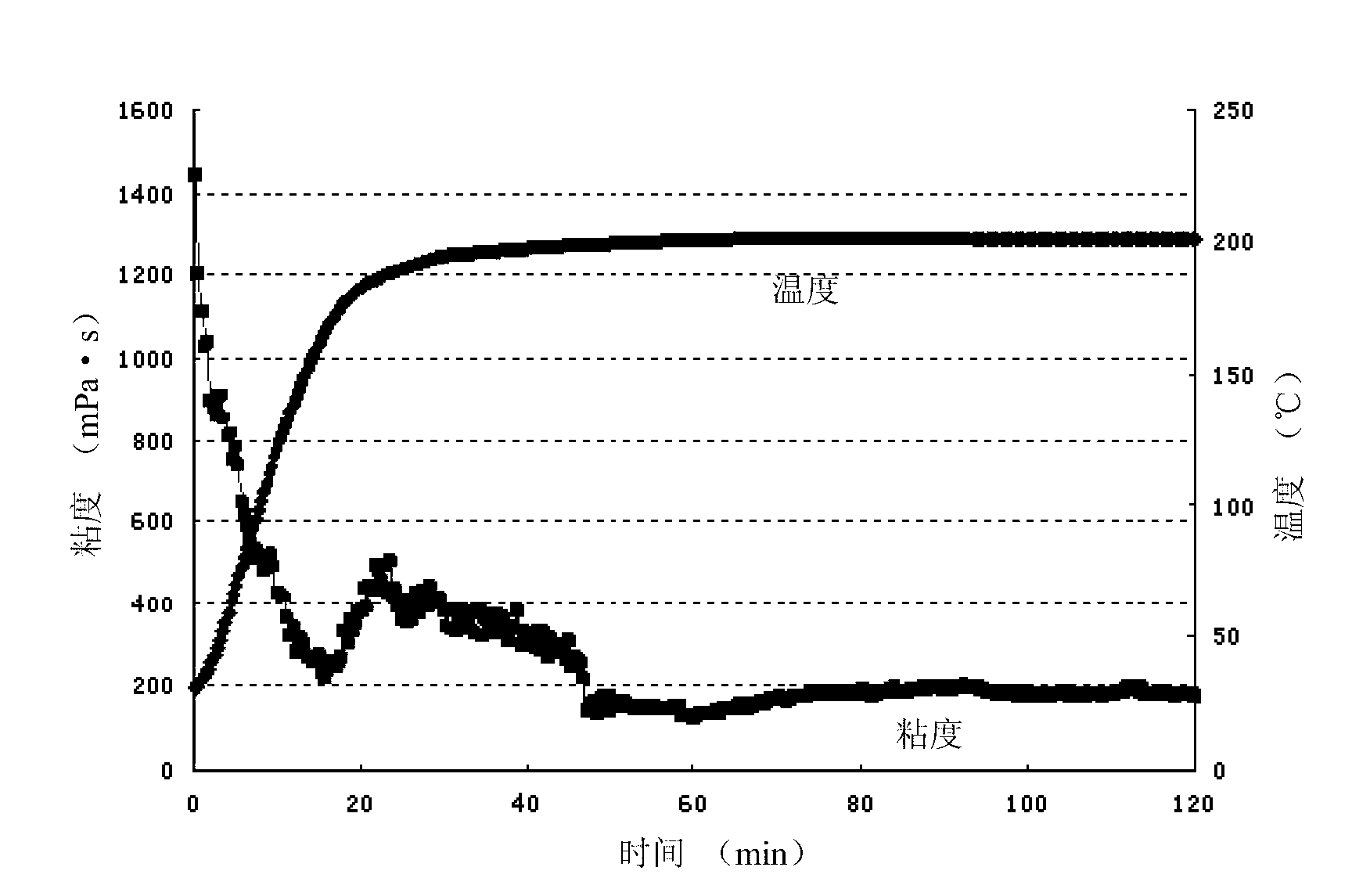

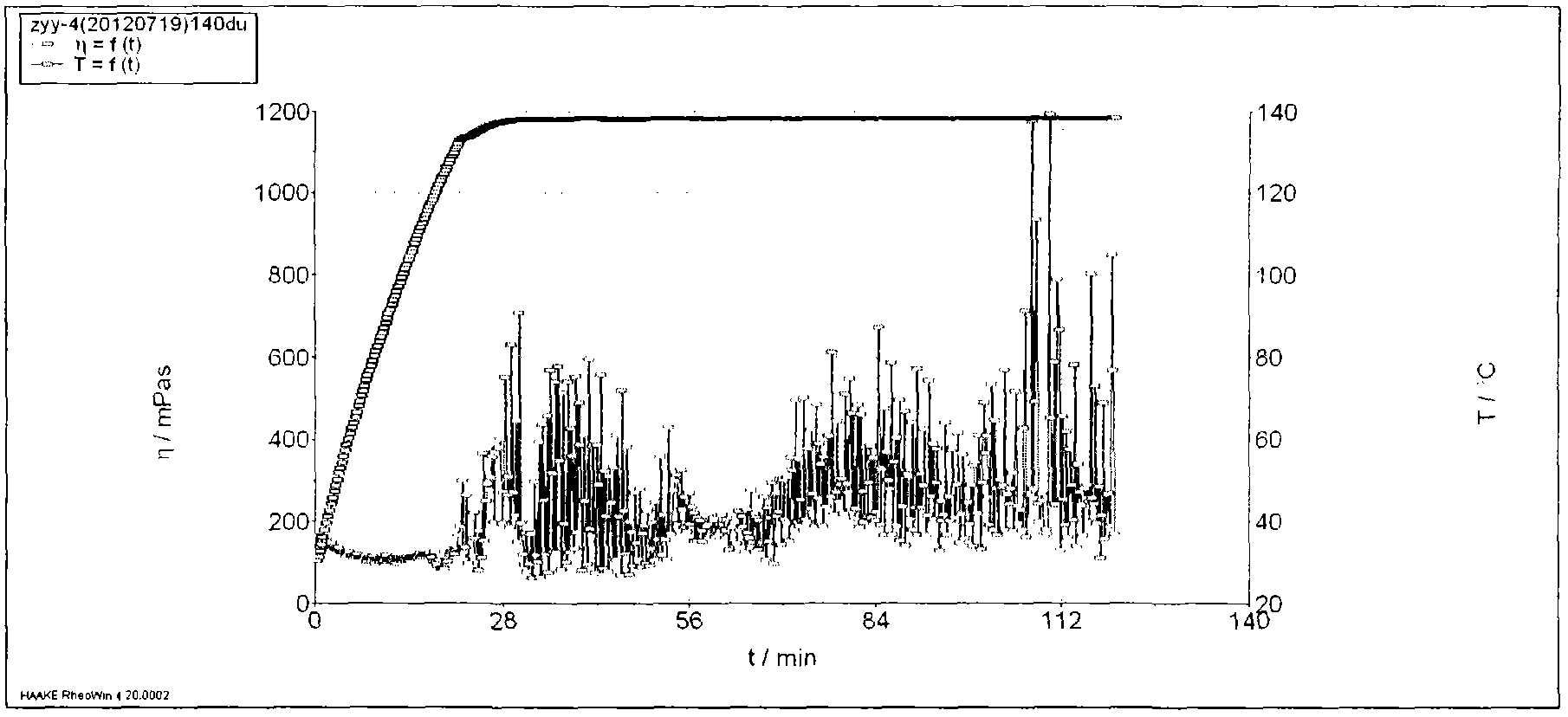

Ultra-temperature organic zirconium crosslinker suitable for polymer crosslinking and prepared fracturing solutions of ultra-temperature organic zirconium crosslinker

ActiveCN102838781AImprove high temperature resistanceAdd lessDrilling compositionOrganic acidAlcohol

The invention relates to an ultra-temperature organic zirconium crosslinker suitable for polymer crosslinking and prepared fracturing solutions of the ultra-temperature organic zirconium crosslinker. The organic zirconium crosslinker comprises the following raw materials in part by mass: 200 to 350 parts of water, 170 to 280 parts of organic alcohol, 40 to 100 parts of zirconium compounds, 20 to 50 parts of organic acid and 300 to 350 parts of alkanolamine. The preparation method of the organic zirconium crosslinker comprises the steps as follows: adding the organic alcohol into the water; heating the solution to 50 to 60 DEG C after uniformly mixing the organic alcohol and the water; adding the zirconium compounds into the solution for reacting for 3 to 4 hours; then adding the organic acid and the alkanolamine; and stirring at the temperature of 50 to 60 DEG C for 2 to 3 hours so as to prepare the organic zirconium crosslinker. The invention further relates to polymer fracturing solutions and a preparation method thereof, and the organic zirconium crosslinker and PAM aqueous solutions are adopted to prepare the ultra-temperature resistant fracturing solutions which can resist the temperature over 200 DEG C; and the fracturing solutions further have the characteristics of acid gluing, low damage, no residue and the like.

Owner:PETROCHINA CO LTD

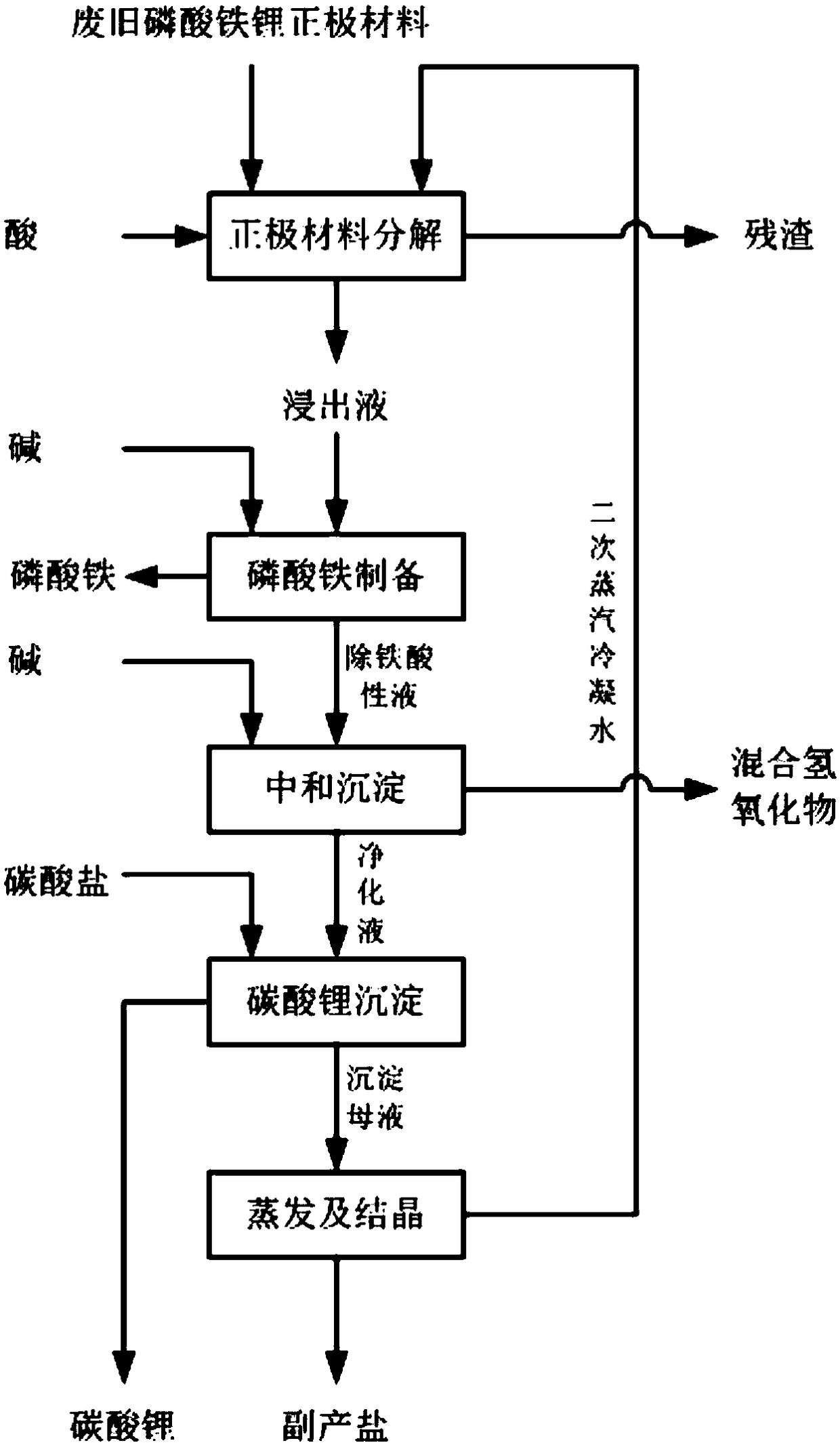

Integral recycling method of lithium iron phosphate positive electrode material

ActiveCN108075202AApplicable recyclingAchieve recyclingWaste accumulators reclaimingProcess efficiency improvementElectrical batteryPhosphate

The invention provides an integral recycling method of a lithium iron phosphate positive electrode material. The integral recycling method comprises the steps of (1) preparing paste from the lithium iron phosphate positive electrode material, mixing the paste and an acid for leaching reaction, and performing liquid-solid separation to obtain a leaching liquid and residue; (2) adjusting a pH valueof the leaching liquid to 1.5-3, and performing solid-liquid separation to obtain iron phosphate and a deironing acid liquid; (3) adjusting a pH value of the deironing acid liquid to 5-8, and performing solid-liquid separation to obtain a precipitant of aluminum and iron and a lithium-containing purification liquid; and (4) and performing post-treatment on the purification liquid to obtain a lithium product and a precipitation mother liquid. By the method, the recycling rates of lithium, iron and phosphate all are larger than 95wt%, the purity of the obtained lithium carbonate product is larger than 98.5wt%, the impurity content conforms to the requirement of GB / T11075-2013, the iron phosphate product conforms to the quality requirement (HG / T 4701-2014) of battery-level iron phosphate, theresidue discharging quantity is reduced by 85wt%, the flow is simple, and the process is clean.

Owner:北京中科百特科技有限公司

Dampening fluid for digital lithographic printing

Owner:XEROX CORP

Cleaning-free lead-free solder soldering fluid not containing halide

ActiveCN101367160AReduce surface tensionEnhance wetting powerWelding/cutting media/materialsSoldering mediaSolventCorrosion

The invention discloses halogen-free cleaning-free soldering flux for lead-free solder, which comprises the compositions in percentage by weight: 1.5 to 4.5 percent of organic acid activator, 0.5 to 8.5 percent of high-quality abietic resin, 0.3 to 1.5 percent of activated reinforcer, 0.2 to 0.8 percent of surfactant, 3.0 to 15.0 percent of wet strengthening agent, and the balance being solvent isopropanol, absolute ethyl alcohol or deionized water. The soldering flux fully meets various regulation requirements for limiting halogen. The soldering flux developed by using a novel material which does not contain the halogen can scientifically reduce the surface tension of the lead-free solder, strengthen the wetting power of the lead-free solder, improve the solderability, can be compatible with a plurality of welding materials, and has no corrosion effect on lead-free solder alloy; composing materials are volatilized by stages during the welding process, so after the welding, the surface of a PCB board has less residue, even spread, less ion residue, and reliable electrical insulating property, and does not need to be washed; and the soldering flux is a novel environment-friendly halogen-free cleaning-free soldering flux for the lead-free solder.

Owner:深圳市唯特偶新材料股份有限公司

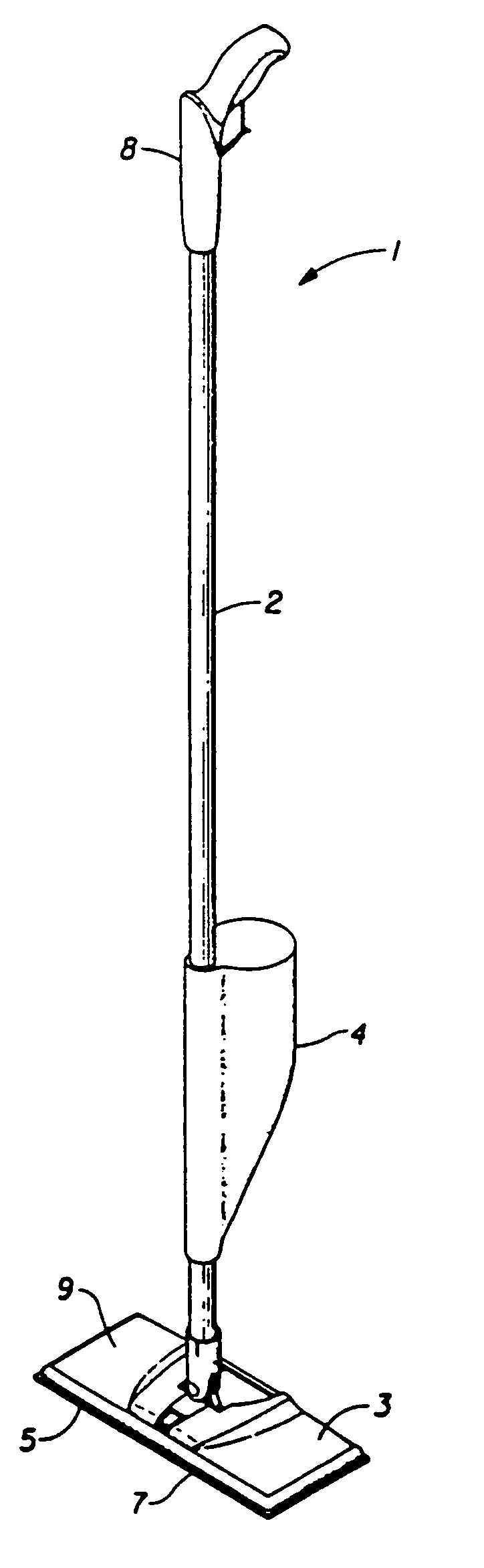

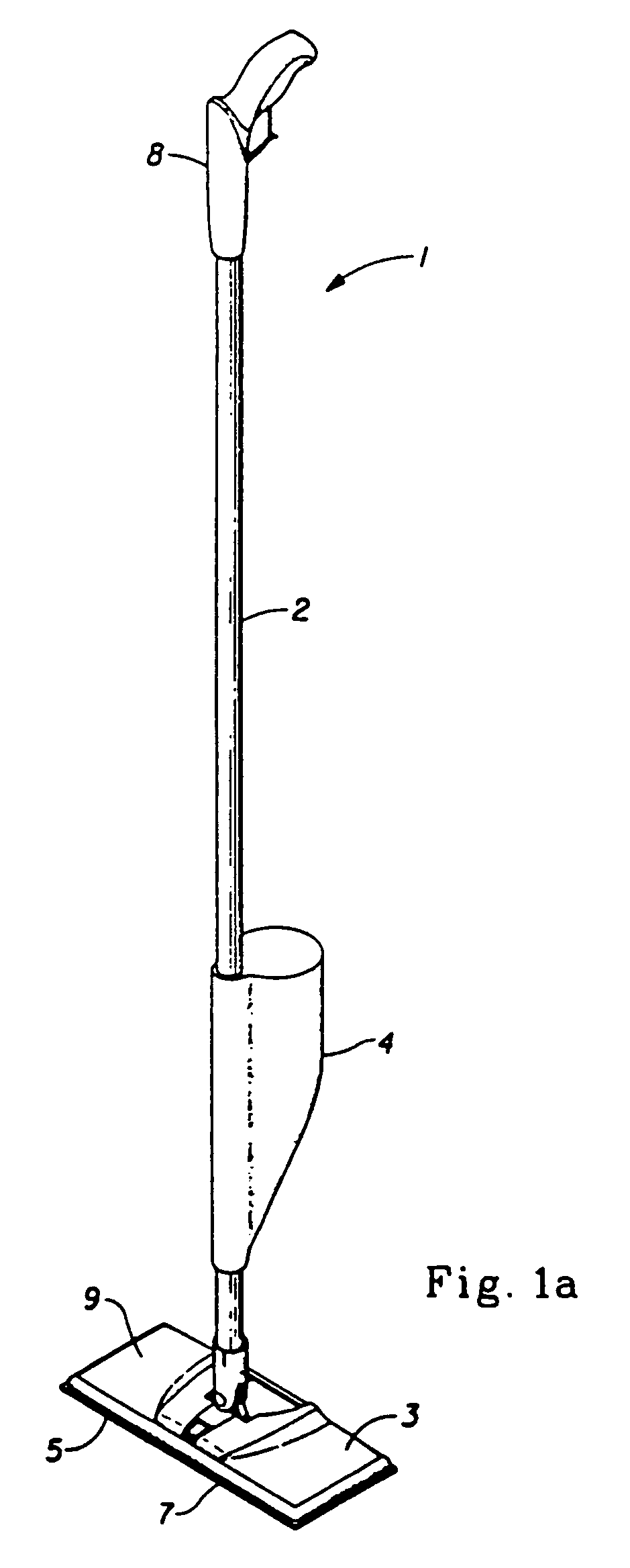

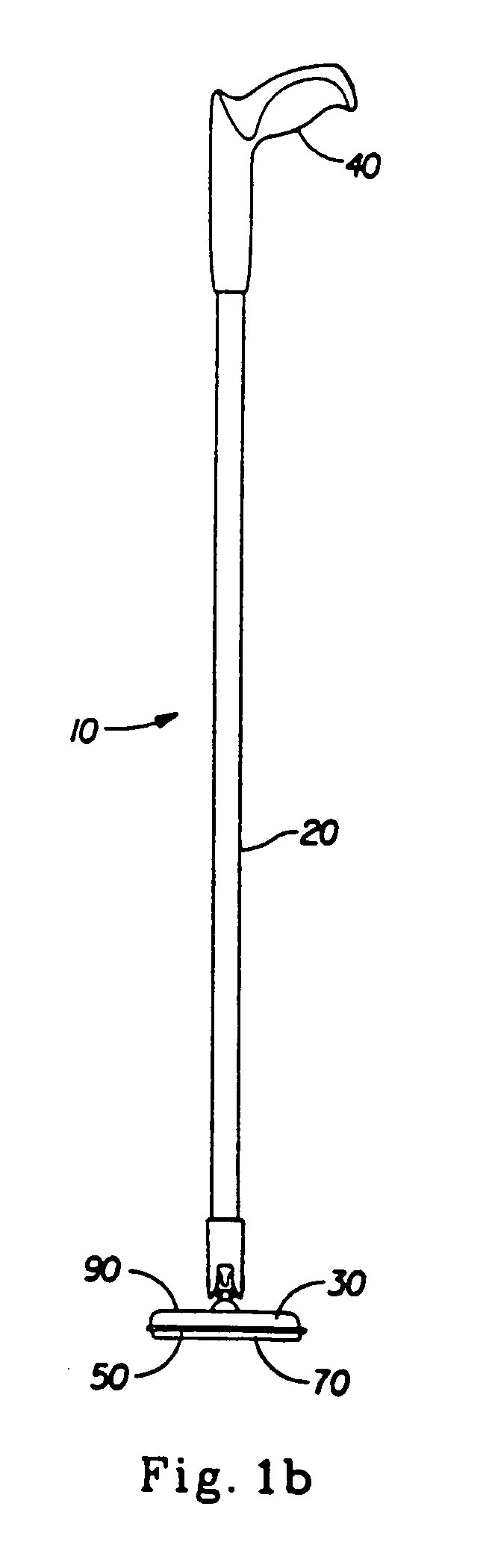

Detergent composition for hard surfaces comprising hydrophilic shear-thinning polymer at very low level

InactiveUS6979371B1Avoid absorptionAvoid streaking/filming problemOrganic detergent compounding agentsCarpet cleanersSolventSURFACTANT BLEND

A detergent composition and / or solution for floors comprising a hydrophilic shear-thinning polymer at very low level for improved cleaning end result. The solution can be used with conventional implements known in the art, including sponges, cloths and / or sponge, string, and / or strip mops and floor cloths such as those sold at retail and speciality stores. In a most preferred embodiment, the solution is used with a cleaning pad comprising an effective amount of a superabsorbent material, said pad preferably being part of cleaning implement comprising a handle and said cleaning pad preferably being removable. The detergent composition preferably contains a limited amount of a detergent surfactant, preferably linear in structure and relatively hydrophilic, the level of solvent in the formula preferably being kept below about 5.0%, and the pH preferably being maintained above about 9. The process of using the detergent solution with cleaning implements, including those of the most preferred embodiment, cleaning pad, and the provision of a kit containing both detergent composition and cleaning pad are disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

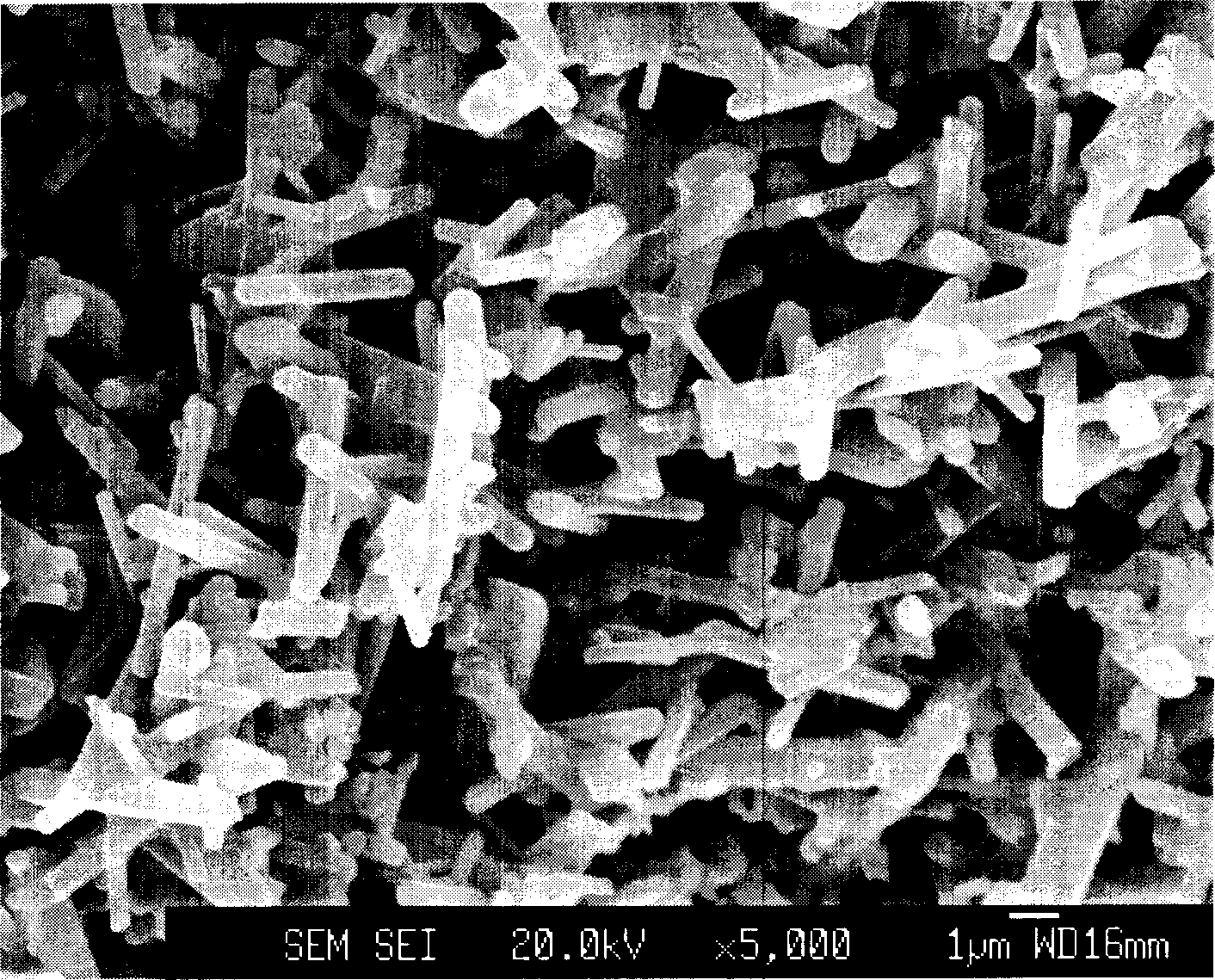

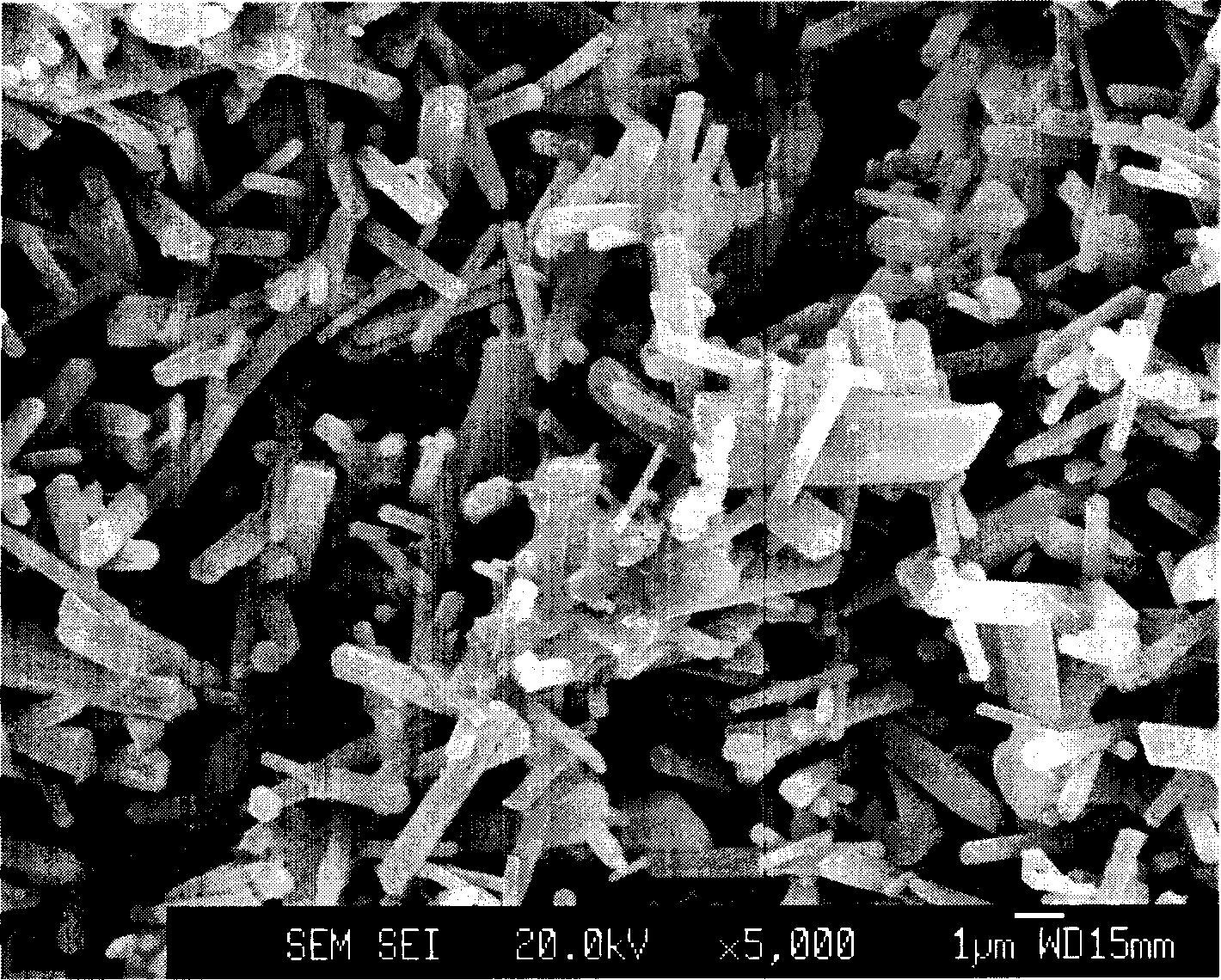

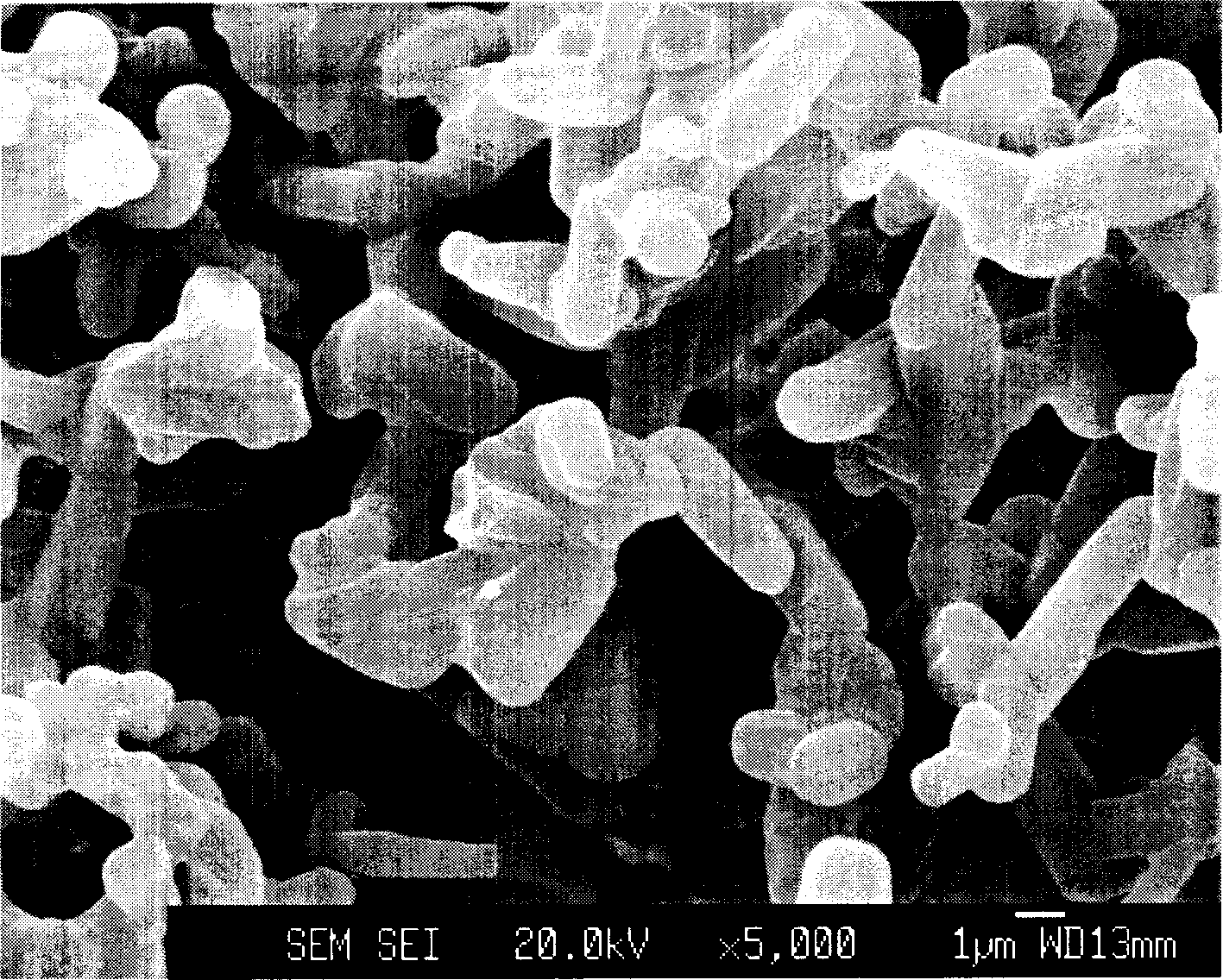

Silicon nitride porous ceramics and its preparing method

The porous silicon nitride ceramic is prepared with C and CO2 in 75-95 wt%, silicon nitride 1-10 wt%, and sintering assistant 2-20 wt%. The C / CO2 weight ratio is 0.4-0.6; and the sintering assistant is at least one the metal oxides Y2O3, Al2O3 and MgO. The preparation process includes the following steps: ball milling the materials, drying and sieving to obtain mixture powder; pressure forming in mold; and sintering in a nitrogen atmosphere furnace through raising temperature at the rate of 600deg.c / hr to 1500deg.c, further raising temperature at the rate of 180deg.c / hr to 1700-1800deg.c, and maintaining at nitrogen pressure of 6-10 atm for 2-8 hr to obtain the sintered body. The porous silicon nitride ceramic may be used as base filter material for separating gas in high temperature and corrosive atmosphere, heat resisting material and reinforcing material in gas turbine, engine, space shuttle, etc.

Owner:XI AN JIAOTONG UNIV

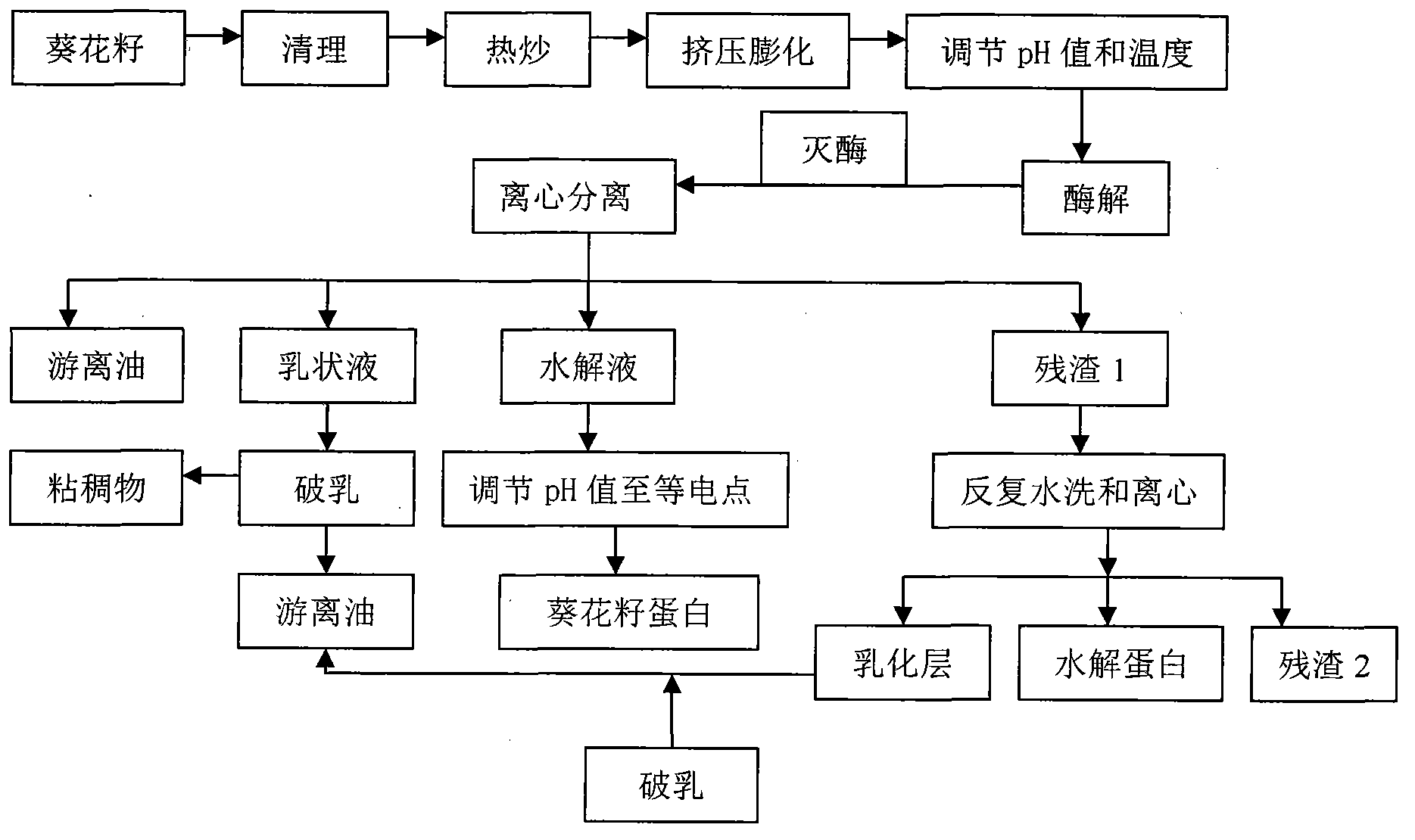

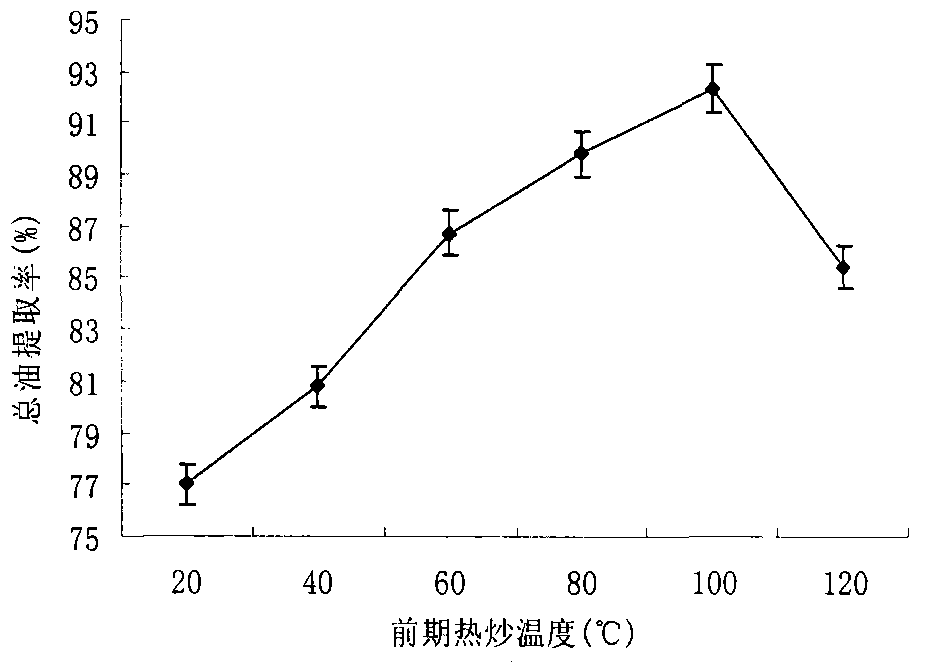

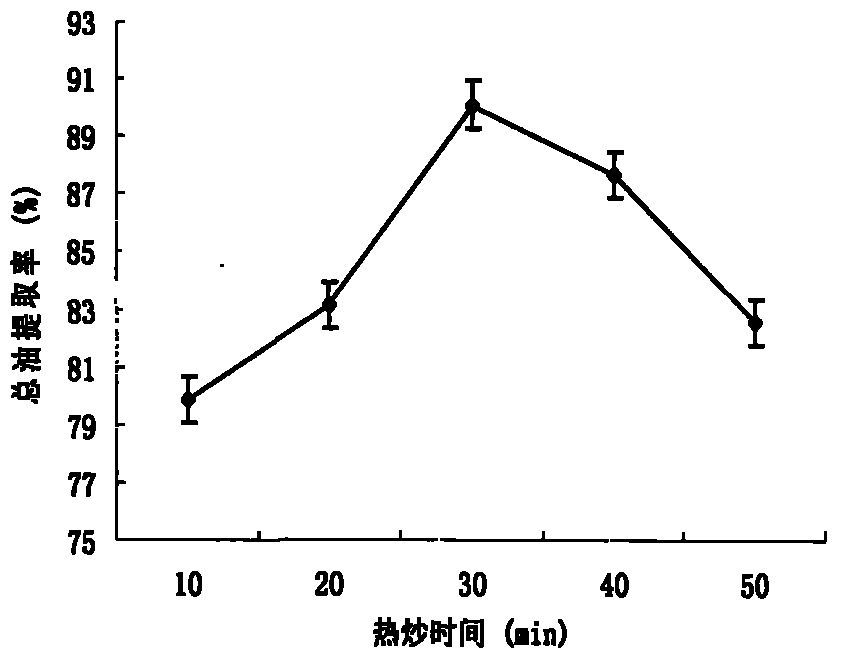

Method for extracting fragrant sunflower seed oil

InactiveCN102703206ALess residueLess investmentFatty-oils/fats refiningFatty-oils/fats productionCelluloseHydrolysate

The invention discloses a method for extracting a fragrant sunflower seed oil and belongs to the extraction processing technique of plant fat. The method comprises the following steps: (1) frying cleaned sunflower seeds; (2) carrying out extrusion puffing pre-treatment to the fried sunflower seeds to obtain pressed fragrant sunflower oil and a puffed product; (3) mixing the puffed product obtained in the step (2) with water to obtain mixed solution, adding compound cellulose to the mixed solution to enzymatically hydrolyze and obtain an enzymatic hydrolysate; (4) enzyme-inactivating the enzymatic hydrolysate and centrifugally separating to obtain the free fragrant sunflower seed oil. According to the method of extracting the fragrant sunflower seed oil, the sunflower seed oil is separated in a method of combining frying, extrusion puffing pretreatment and bio-enzyme; after the emulsified oil subjected to separation is demulsified, the oil of high quality can be obtained without refining and has high nutritional value; the total oil extraction rate is up to 96.98 percent; the action conditions are mild and degradation products in the system are not reacted with the extract, so that the qualities of various components can be protected effectively.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Cleaning and disinfectant compositions

ActiveUS20060100122A1Improve stabilityLess residueNon-surface-active detergent compositionsDetergent compounding agentsAdjuvantWater dispersible

Cleaning and disinfectant compositions are provided particularly for use with hard surfaces. The compositions include hydrogen peroxide and an acid or salt thereof which is resistant to oxidation other than phosphorous based acids. Replacement of phosphorous based acids with acids of the invention results in improved hydrogen peroxide stability while maintaining or increasing the efficacy of cleaning and antimicrobial activity of the compositions. Typically, acids of the invention include substituted or unsubstituted carboxylic acids such as R4—C (R2) (R3) —R1—COOH. Inventive compositions may further include surfactants, a chelating agent or sequestrant, a water soluble or water dispersible solvent, corrosion inhibitors and other adjuvants well known to those skilled in the art. There are further provided methods of use and methods of preparing inventive compositions.

Owner:JOHNSONDIVERSEY INC

Water-Soluble, Quick-Dissolve Flavor Tablets

InactiveUS20080187628A1Easily consumeReadily dissolveMilk preparationButtermilkChemistryWater soluble

The invention is directed to quick-dissolve flavor tablets for use by consumers in flavoring beverages, such as water, and methods for flavoring such beverages. The tablet comprises a flavor component and a quick-dissolve carrier component which disintegrates rapidly upon placement into the beverage container with minimal residue.

Owner:CHAMPION MELINDA L

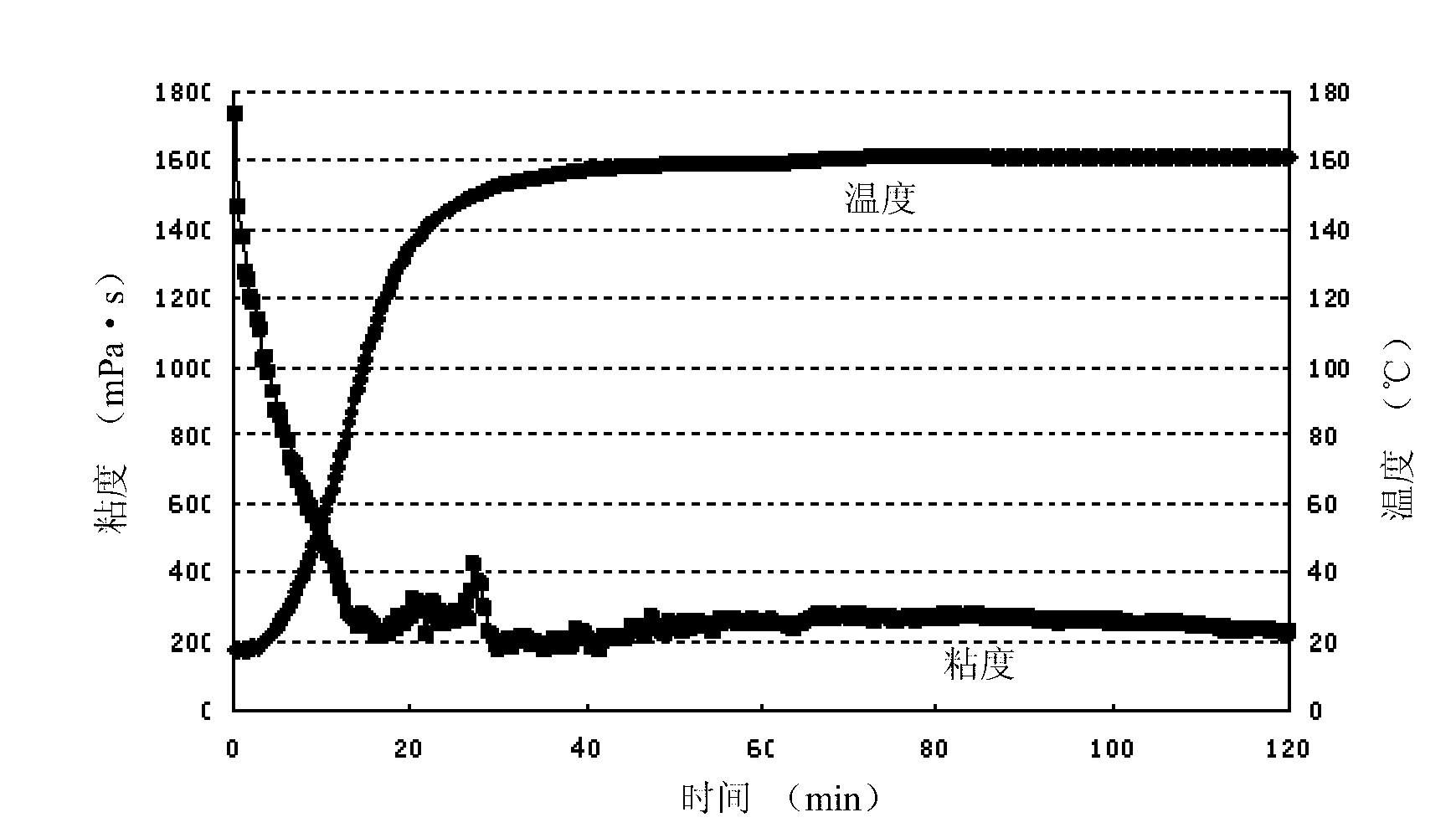

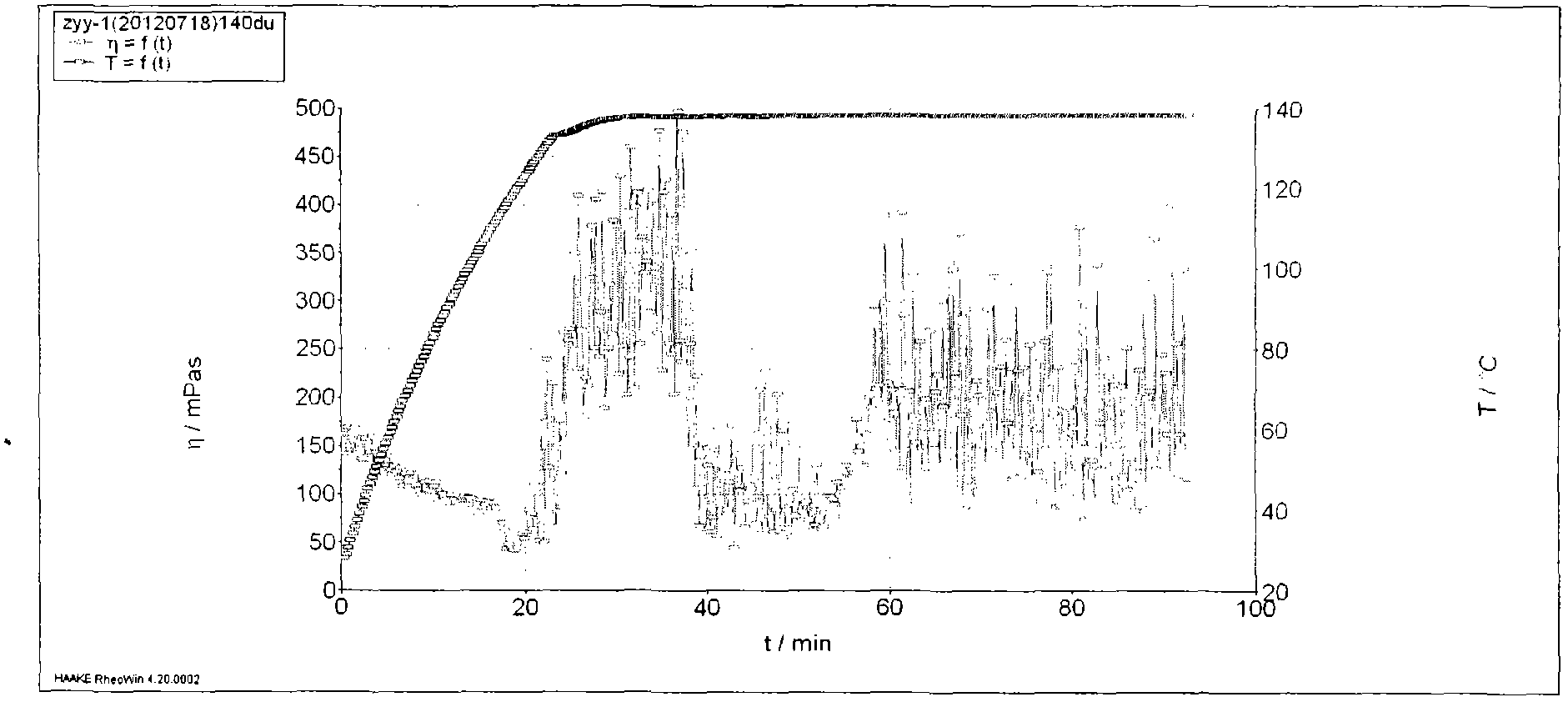

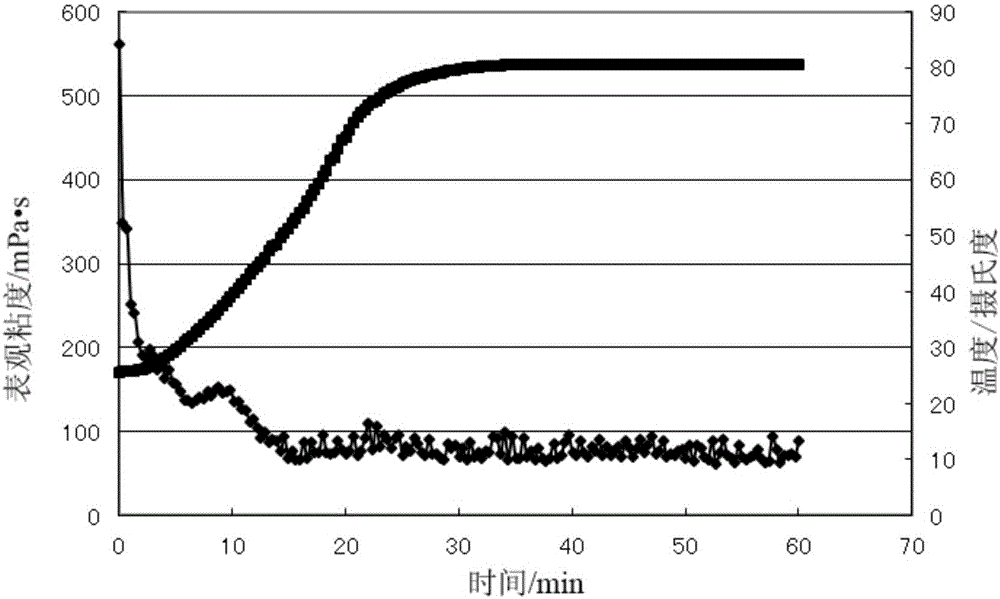

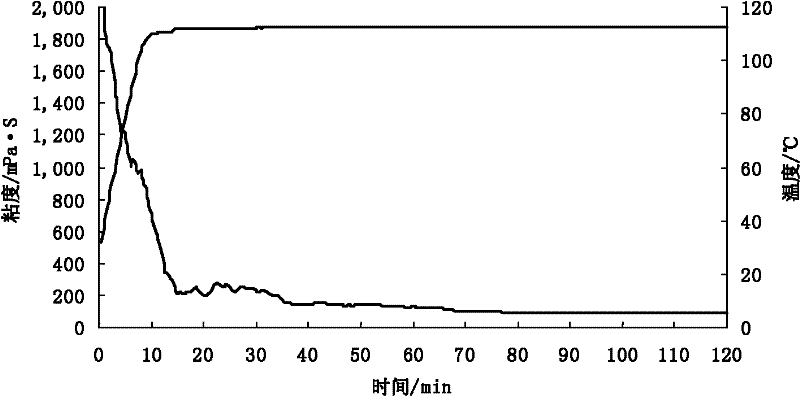

Preparation method of polyacrylamide nano composite fracturing fluid

ActiveCN104109525AHigh temperature resistantSalt resistantDrilling compositionIn situ polymerizationFracturing fluid

The invention adopts polyacrylamide and a nano inorganic phase to prepare a polyacrylamide nano composite material through an in-situ polymerization method and then forms a fracturing fluid thickening agent. The nano inorganic phase is prepared by mixing the products of intercalation reactions between an organic long-chain intercalator and layered silicate with magnesium nitrate and aluminum nitrate. The nano inorganic phase, acrylamide monomer, a coupling agent, a complexing agent, an initiator, an oxidant, a reductant, a cosolvent, an auxiliary agent, and deionized water form a suspension fluid reaction system, and the polyacrylamide nano composite material is formed after the polymerization-intercalation composite reactions. The polyacrylamide nano composite material with a mass percentage of 0.25% is taken as the thickening agent, and then is mixed with a crosslinking agent with a mass percentage of 0.20%, a gel breaker with a mass percentage of 0.20%, and other auxiliary agents to form a fracturing fluid system. The system is sheared for 70 minutes under a shearing speed of 170 s<-1> at a temperature of 150 DEG C so as to form a fracturing fluid with a viscosity larger than 50 mPa.s, and the fracturing fluid has the characteristics of high temperature resistance, shearing resistance, low frictional resistance, complete glue breaking effect, and good compatibility with the formation fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

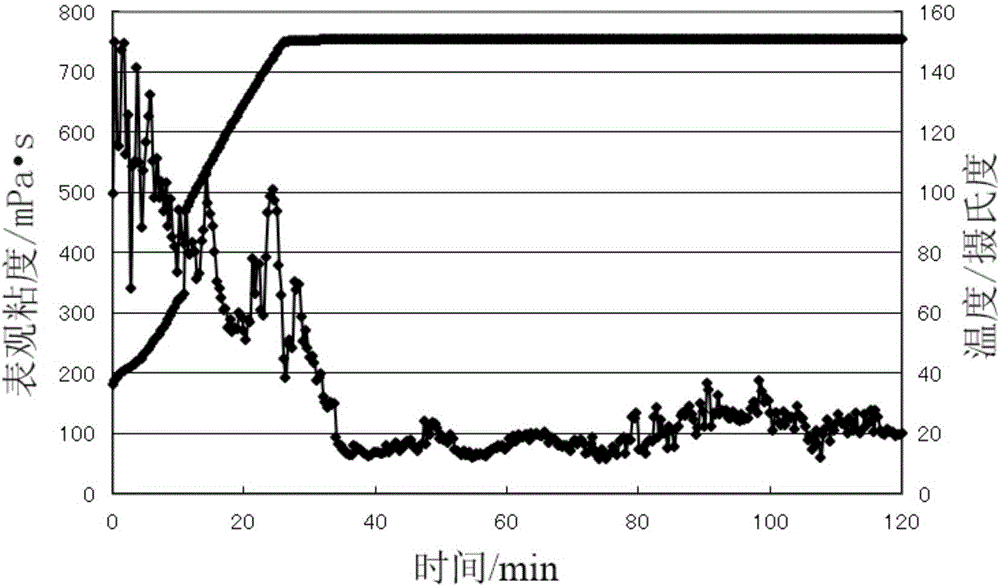

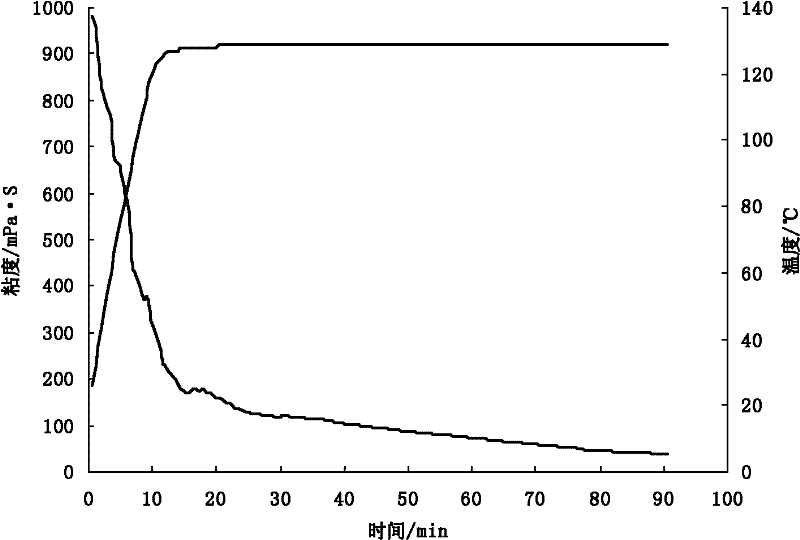

High-temperature resistant CO2 foam cleaning and associated fracturing fluid and preparation method and application thereof

ActiveCN106675546AFast water solubilityEasy to prepareFluid removalDrilling compositionCross-linkPolymer science

The invention provides high-temperature resistant CO2 foam cleaning and associated fracturing fluid and a preparation method and application thereof. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid comprises a fracturing fluid base solution, a cross-linking agent, a gel breaker and liquid CO2, wherein the cross-linking agent and the gel breaker account for 0.3%-0.8% and 0-0.05% of the fracturing fluid base solution in parts by weight separately; and the liquid CO2 accounts for 30%-70% of total volume of the CO2 foam cleaning and associated fracturing fluid. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid provided by the invention has the characteristics of being few in additive types, simple in preparation, controllable in crosslinking, low in residue, low in damage, low in friction, high in foaming efficiency, high in flowback rate and resistant to high temperature.

Owner:PETROCHINA CO LTD

Organic powder nutritional formula containing select carbohydrate combinations

InactiveUS20070281054A1Reduce dispersionNice appearanceMilk preparationFood preparationLipid formationCORN SYRUP SOLIDS

Disclosed are organic powder nutritional formulas, including infant formulas, comprising organic lipid, organic protein, and organic carbohydrate, wherein the organic carbohydrate is a blend containing at least one carbohydrate selected from organic maltodextrin, organic corn syrup solids, and organic corn syrup, and at least one carbohydrate selected from organic sucrose and organic lactose. The organic powder nutritional formulas provide improved physical appearance due to less granular residue and improved dispersibility.

Owner:ABBOTT LAB INC

Polyoxymethylene as structural support member and propellant

InactiveUS6904749B2Improve featuresChange pressureCosmonautic vehiclesCosmonautic propulsion system apparatusCombustionSatellite

A vehicle includes at least one polyoxymethylene structural support member. The polyoxymethylene structural support member includes a polyoxymethylene component that is a propellant that provides thrust to the vehicle upon pyrolysis or combustion of the polyoxymethylene component of the product of pyrolysis of the polyoxymethylene component. The vehicle can be a satellite or other type of spacecraft.

Owner:PHYSICAL SCI

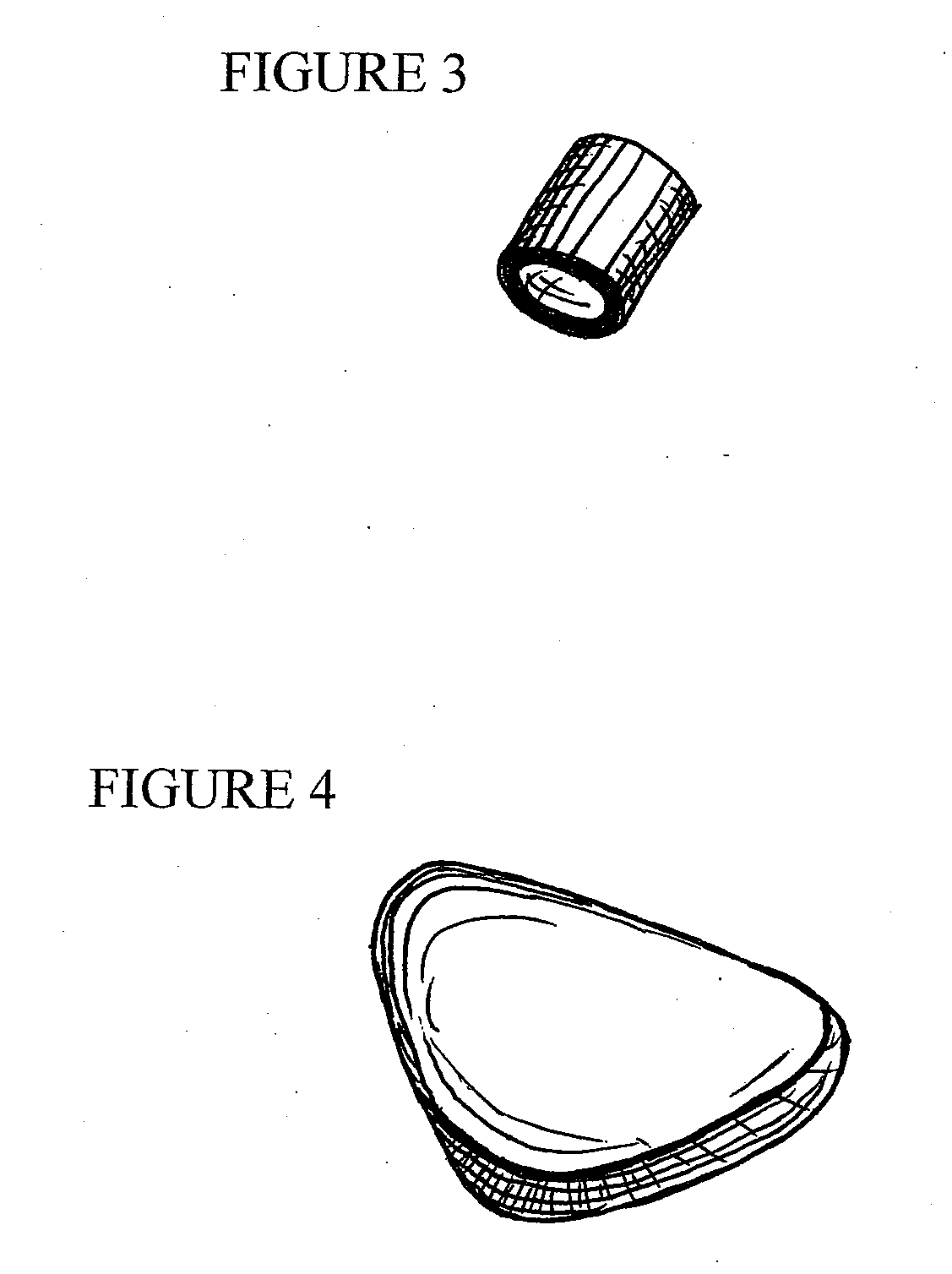

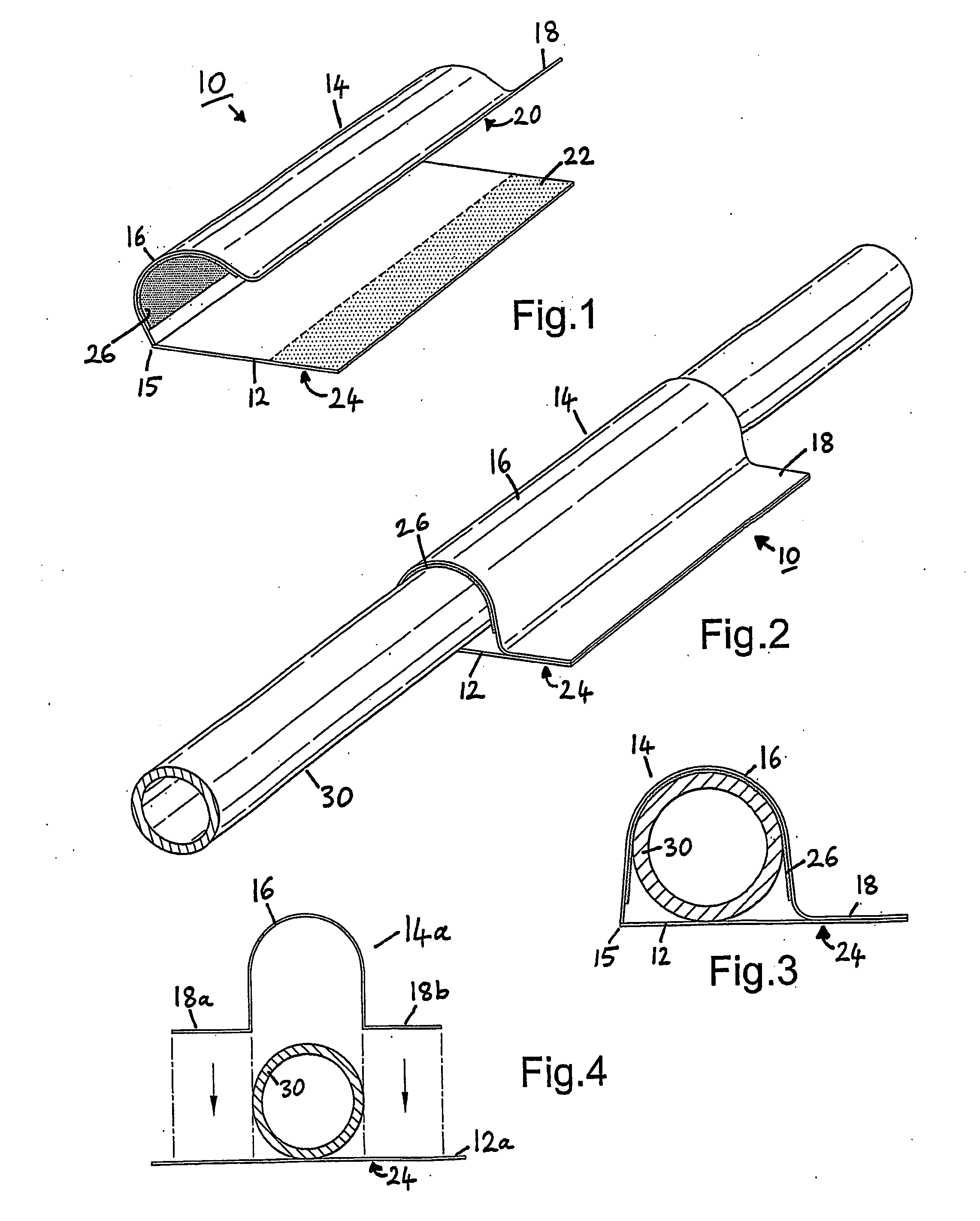

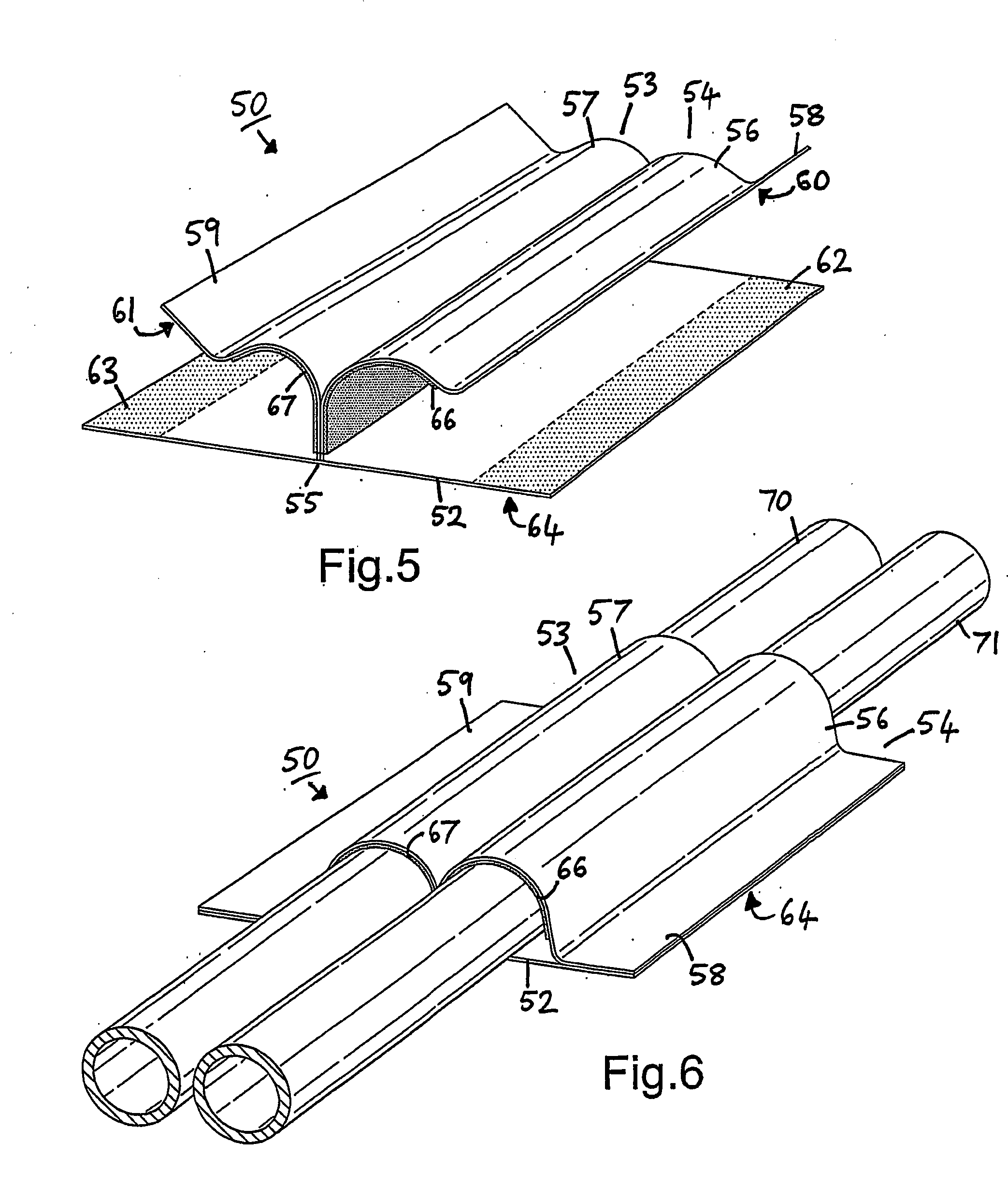

Support devices for catheters

InactiveUS20090299294A1Improve gripBroaden applicationCatheterInfusion needlesCatheter deviceIntermediate region

A device for securing a catheter tube against a patient's body, said device comprising a base member for attaching to the patient's body in use, and a gripping member, the gripping member comprising: a first region that is attached to, or attachable, to, or integral with, the base member; an attachment region that is attachable to the base member; and an intermediate region between the first region and the attachment region, the intermediate region being adapted to wrap over a catheter tube; the device being arranged such that, in use, the first region of the gripping member is attached to the base member, the intermediate region is wrapped over a catheter tube, and the attachment region is attached to the base member, thereby securing the catheter tube between the base member and the gripping member. Also provided is a device for securing two catheter tubes against a patient's body, said device comprising a base member for attaching to the patient's body in use, and two gripping members, each gripping member comprising: a first region that is attached to, or attachable to, or integral with, the base member; an attachment region that is attachable to the base member; and an intermediate region between the first region and the attachment region, the intermediate region being adapted to wrap over a catheter tube; the device being arranged such that, in use, the first region of each gripping member is attached to the base member, the intermediate region of each gripping member is wrapped over a respective catheter tube, and the attachment region of each gripping member is attached to the base member, thereby securing the two catheter tubes between the base member and the respective gripping members. This device is particularly suited for use with single or dual-lumen catheters, for example as used in haemodialysis.

Owner:EAST & NORTH HERTFORDSHIRE NHS TRUST

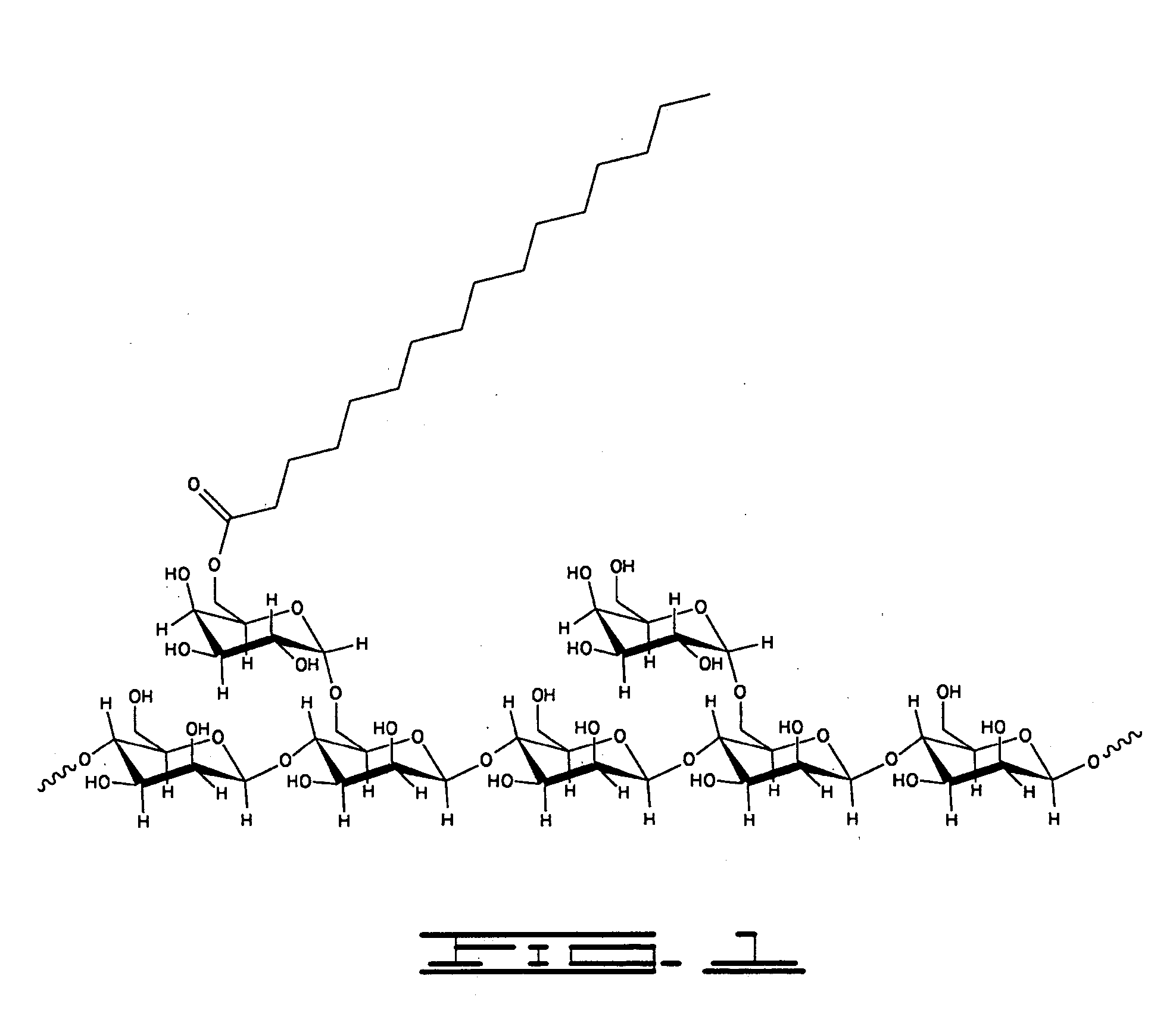

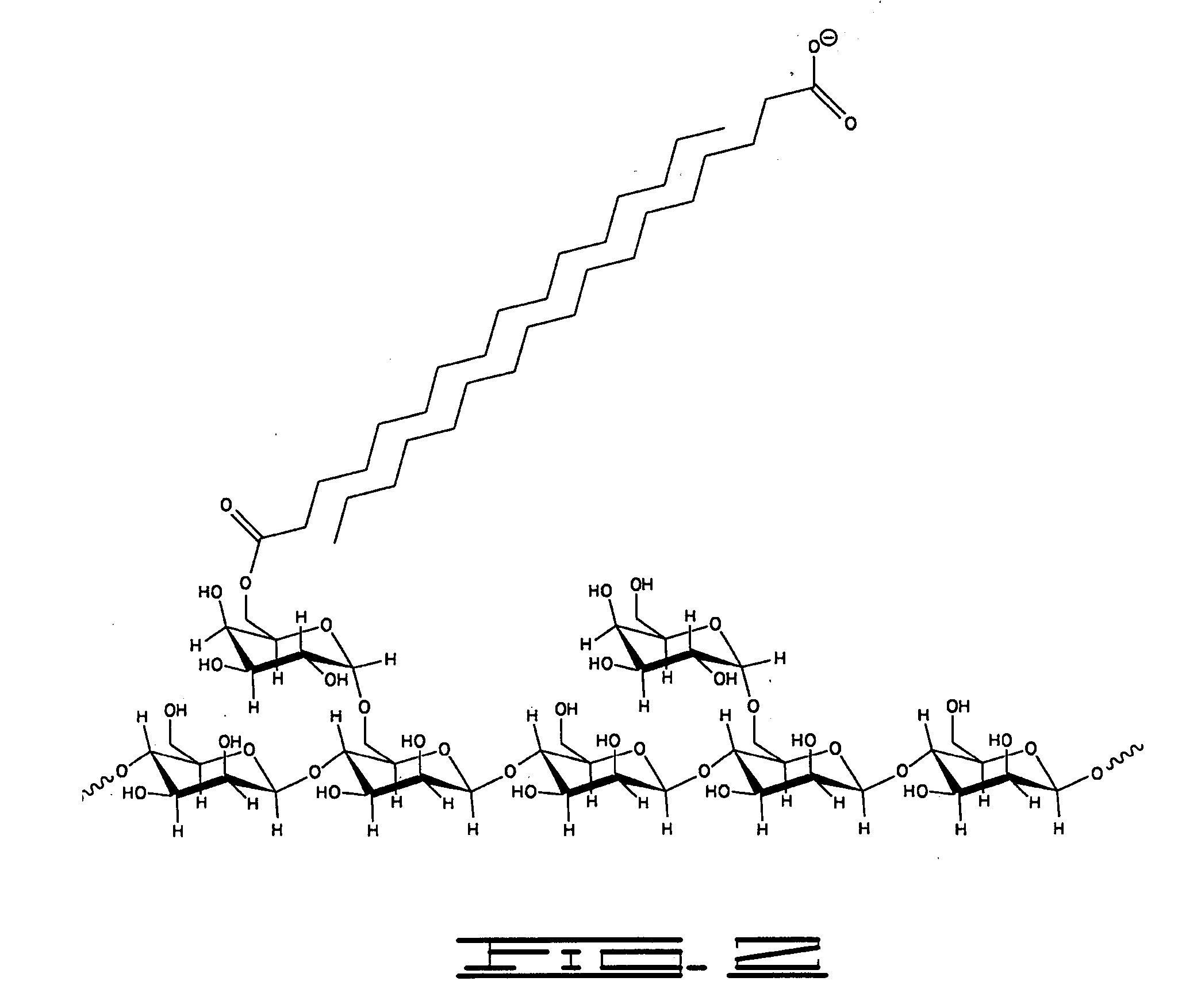

Methods and compositions for treating subterranean formations

InactiveUS20050065038A1Less residueIncreased gelling agent polymer molecule radius of gyrationFluid removalFlushingFluid compositionWater soluble

Methods for treating subterranean formations and aqueous treating fluid compositions are provided. The aqueous treating fluid compositions comprise water, a water soluble hydrophobically modified gelling agent polymer produced by grafting a low concentration of hydrophobic monomers thereon, and a low concentration of an ionic surfactant the hydrophobic chain portion of which is associated with the hydrophobic monomers grafted onto the gelling agent polymer resulting in gelling agent polymer molecules having increased radiuses of gyration.

Owner:HALLIBURTON ENERGY SERVICES INC

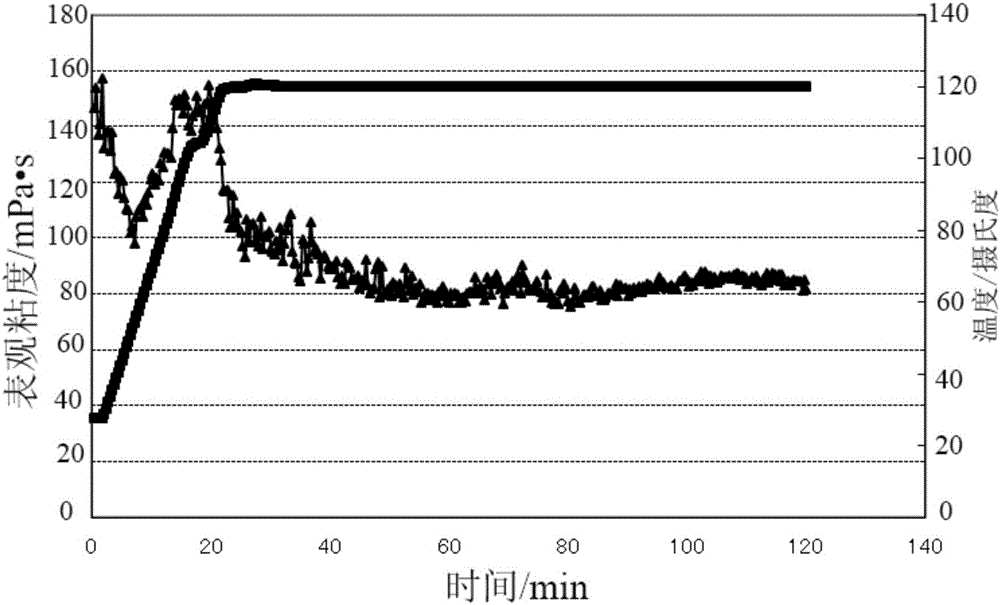

Acidic water repellent associated matter fracturing fluid

ActiveCN102206484ALess residueGood anti-expansion effectDrilling compositionDemulsifierSalt resistance

The invention relates to acidic water repellent associated matter fracturing fluid. The fracturing fluid consists of crosslinked fluid and original fluid, wherein the crosslinked fluid comprise the following components in percentage by weight: 0.2 to 0.5 percent of acidic crosslinked agent, 0.01 to 0.035 percent of crosslinked regulator A, 0.02 to 0.3 percent of crosslinked regulator B, 0.02 to 0.2 percent of gelbreaker and the balance of water; and the original fluid comprises the following components in percentage by weight: 0.3 to 0.7 percent of FS-927 polymer, 1 to 4 percent of potassium chloride, 0.5 to 1.5 percent of MJ-1 high-temperature discharge aiding agent, 0 to 2.5 percent of JTY-100 fluid loss agent, 1 percent of PR-1 demulsifier, 0 to 0.02 percent of temperature stabilizer and the balance of water. The fracturing fluid has the advantages of high crosslinking delaying performance, temperature resistance, salt resistance and shearing resistance, high sand carrying capacity, small damages to stratum, low friction resistance, low residue amount and good expansion preventing effect, can easily break gel and flow back, and breaks through the traditional concept that retarded crosslinking polymer fracturing fluid has temperature resistance and sheering resistance which can be realized at the temperature of not more than 100 DEG C.

Owner:PETROCHINA CO LTD

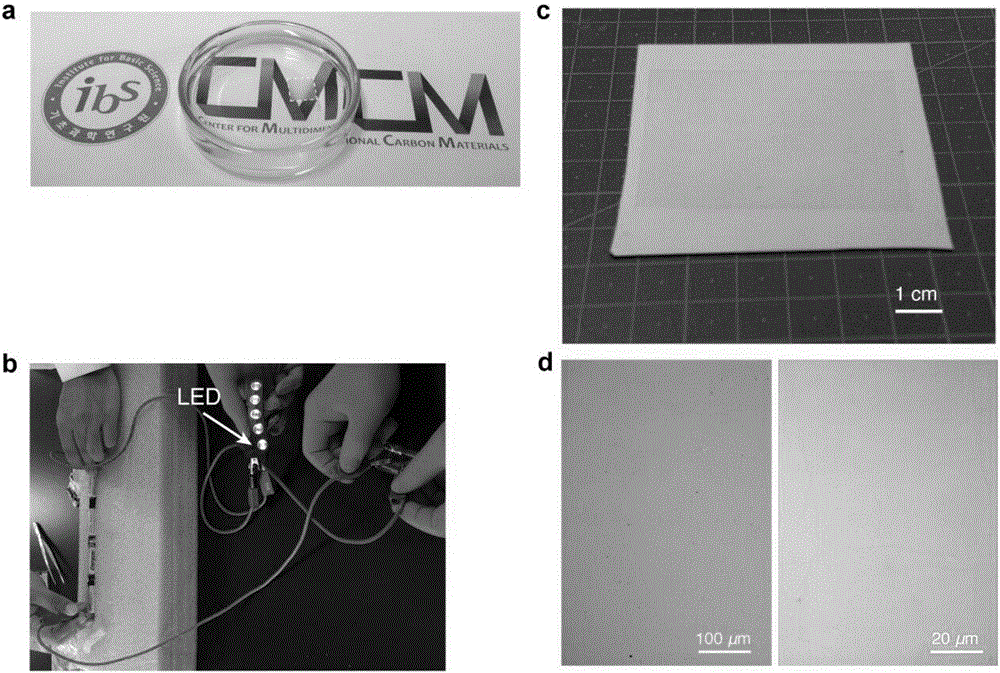

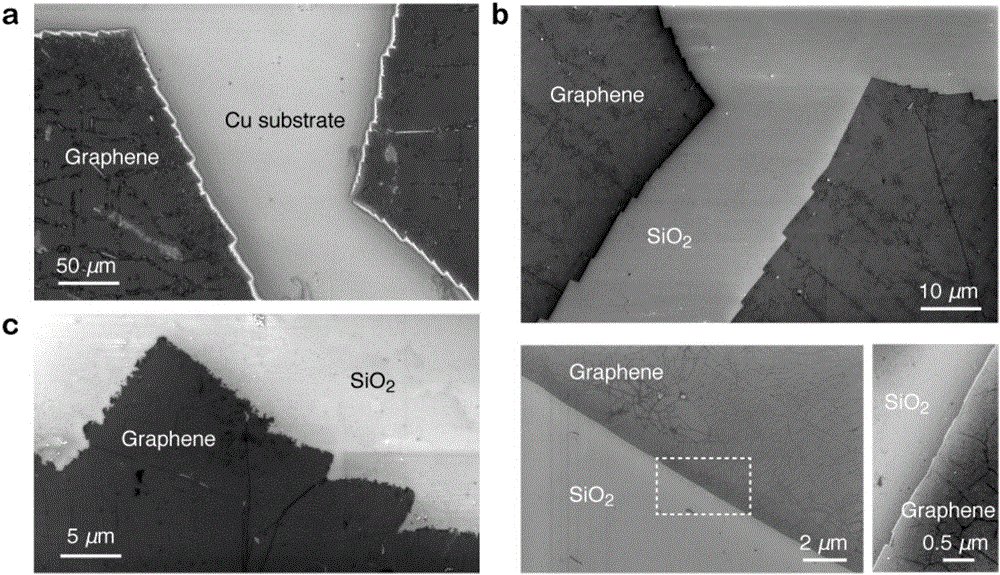

Method for transferring graphene by using micro-molecule paraffin

The invention relates to a method for transferring graphene by using micro-molecule paraffin. The method comprises the following steps: preparing a graphene film growing on a copper foil by using a CVD (chemical vapor deposition) method, and then etching the graphene film away from one surface of the copper foil by using oxygen plasmas to ensure that the graphene film is remained on a single surface of the copper foil; spin-coating molten and heated paraffin to the graphene film at a certain rotating speed; after the graphene film is cooled to room temperature, corroding off the copper foil by using corrosive liquid; infiltrating the paraffin / graphene film by using clear water for multiple times, and then transferring the film to a target base; and drying the film for a plurality of hours until graphene and the base are adhered tightly, annealing by using an annealing furnace to remove the paraffin, thereby obtaining the graphene film transferred to the target base. The obtained graphene film, compared with a graphene film transferred by using macromolecules, has a cleaner surface, namely a support film is removed more thoroughly, and the continuity and good electrical conductivity of the graphene film are kept. By use of the method, graphene can be cleanly transferred to any base on a large scale.

Owner:TIANJIN UNIV

Pourable frying composition

InactiveUS20020142088A1Good spattering behaviourImprove liquidityEdible oils/fats with fatty acid estersFinished edible oils/fats preservationBiopolymerPolymer

Water continuous, pourable compositions comprising more than 50 to 80 wt % fat, an emulsifier having a hydrophilic / lipophilic balance value of at least 7, an antispattering composition and optionally a biopolymer in an amount of at most at most 0.3 wt % on total composition weight are suitable frying compositions.

Owner:THOMAS J LIPTON DIV OF CONOPCO

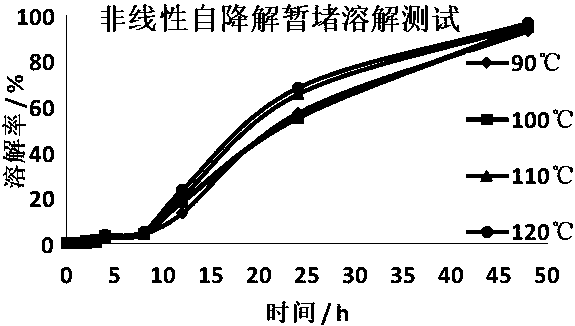

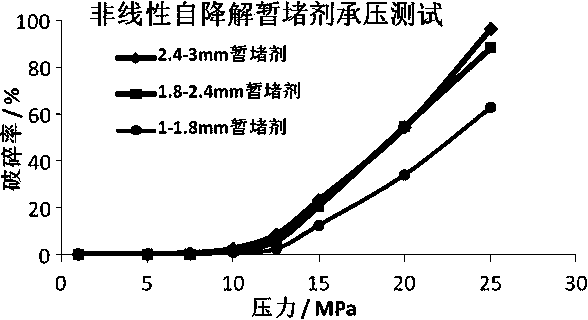

In-section multi-cluster fracturing transformation nonlinear self degradation temporary plugging agent and preparation method thereof

InactiveCN109233773AEasy to pumpMeet the technical requirements of multi-cluster fracturing constructionDrilling compositionMulti clusterPolyvinyl alcohol

The invention provides an in-section multi-cluster fracturing transformation nonlinear self degradation temporary plugging agent and a preparation method thereof. The in-section multi-cluster fracturing transformation nonlinear self degradation temporary plugging agent is prepared from the following substances in percentage by weight: 80 to 90 percent of body, 2 to 5 percent of initiators, 2 to 5percent of lubricating agents, 5 to 10 percent of shaping agents, 0.2 to 0.8 percent of enhancing agents and 1 to 3 percent of degradation accelerating agents, wherein the body is a mixture formed bypolyglycolide, polylactide-glycolide and polyvinyl alcohol; bonding cannot occur after the water meeting at the normal temperature; pumping injection is facilitated; the degradation in a limited timeis slow; the dissolution speed at the reservoir temperature and the time show the nonlinear relationship; the technical requirements of multi-cluster fracturing construction in the horizonal well section can be met; the micro expansion capability is realized; the intensity at the later plugging stage in a crack is improved; the slow degradation can also be realized under the condition of the medium environment change; the harm to the reservoir is small. Through the combination of an intermittent stirring reactor and a double-screw extruding machine, the influence of the temperature change of the production process on the temporary plugging agent product is improved; the product physical and chemical property index is more stable.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

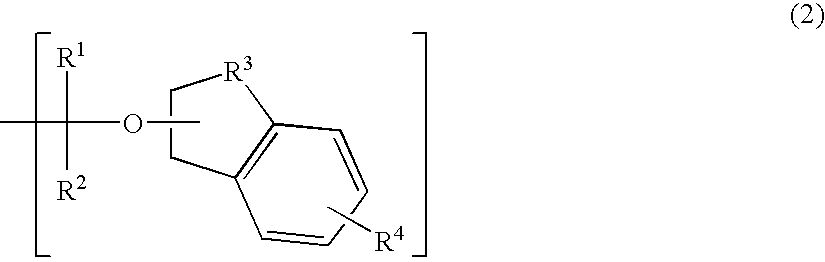

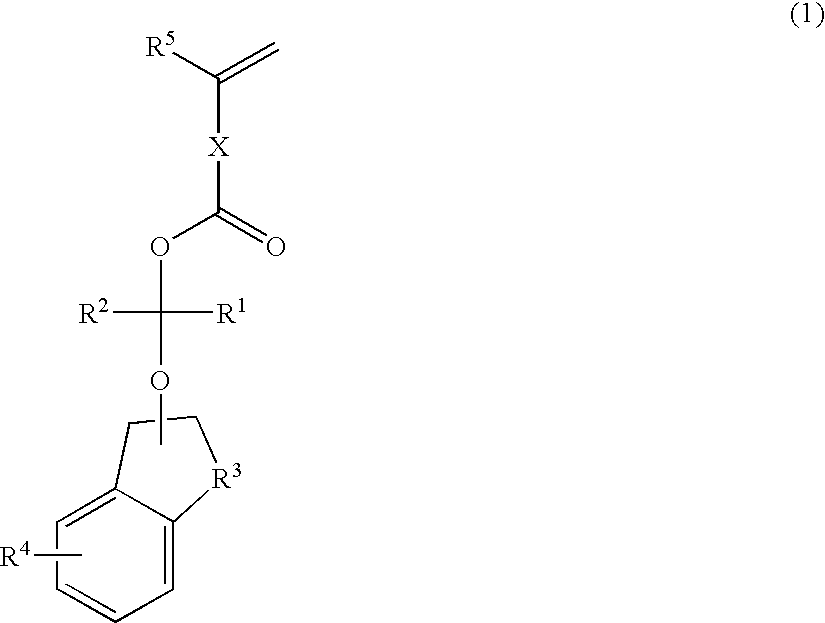

Polymerizable compound, polymer, positive resist composition, and patterning process using the same

ActiveUS20090297979A1High sensitivity and resolutionPattern configurationOrganic chemistryOrganic compound preparationResistSize difference

The present invention provides; a polymer suitable as a base resin for a positive resist composition, in particular a chemically amplified positive resist composition, having a higher resolution, a larger exposure allowance, a smaller sparse-dense size difference, a better process applicability, a better pattern configuration after exposure, and in addition, a further excellent etching resistance, than a conventional positive resist; a positive resist composition using the same; a patterning process; and a novel polymerizable compound to obtain a polymer like this.The present invention was accomplished by a polymer whose hydrogen atom of at least a carboxyl group is substituted by an acid labile group represented by the following general formula (2), a positive resist composition using the same, a patterning process, and a novel polymerizable compound to obtain a polymer like this.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com