Patents

Literature

127results about How to "Settling time is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

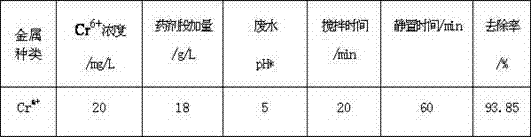

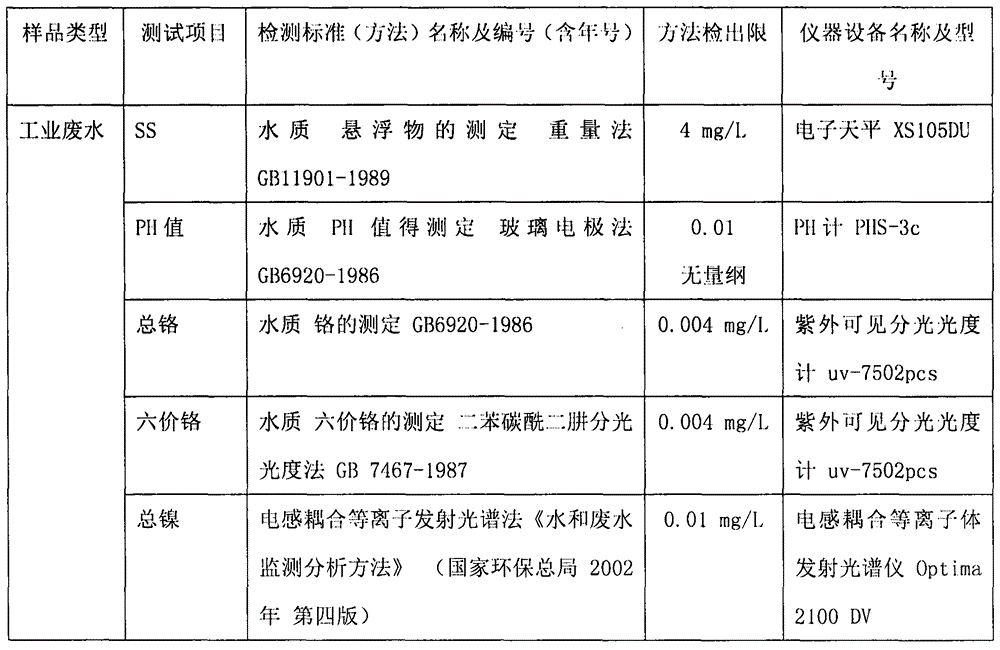

Hexavalent chromium-containing waste water treatment method

InactiveCN102070261AEasy to handleLess residueWater contaminantsMultistage water/sewage treatmentSolid phasesChemistry

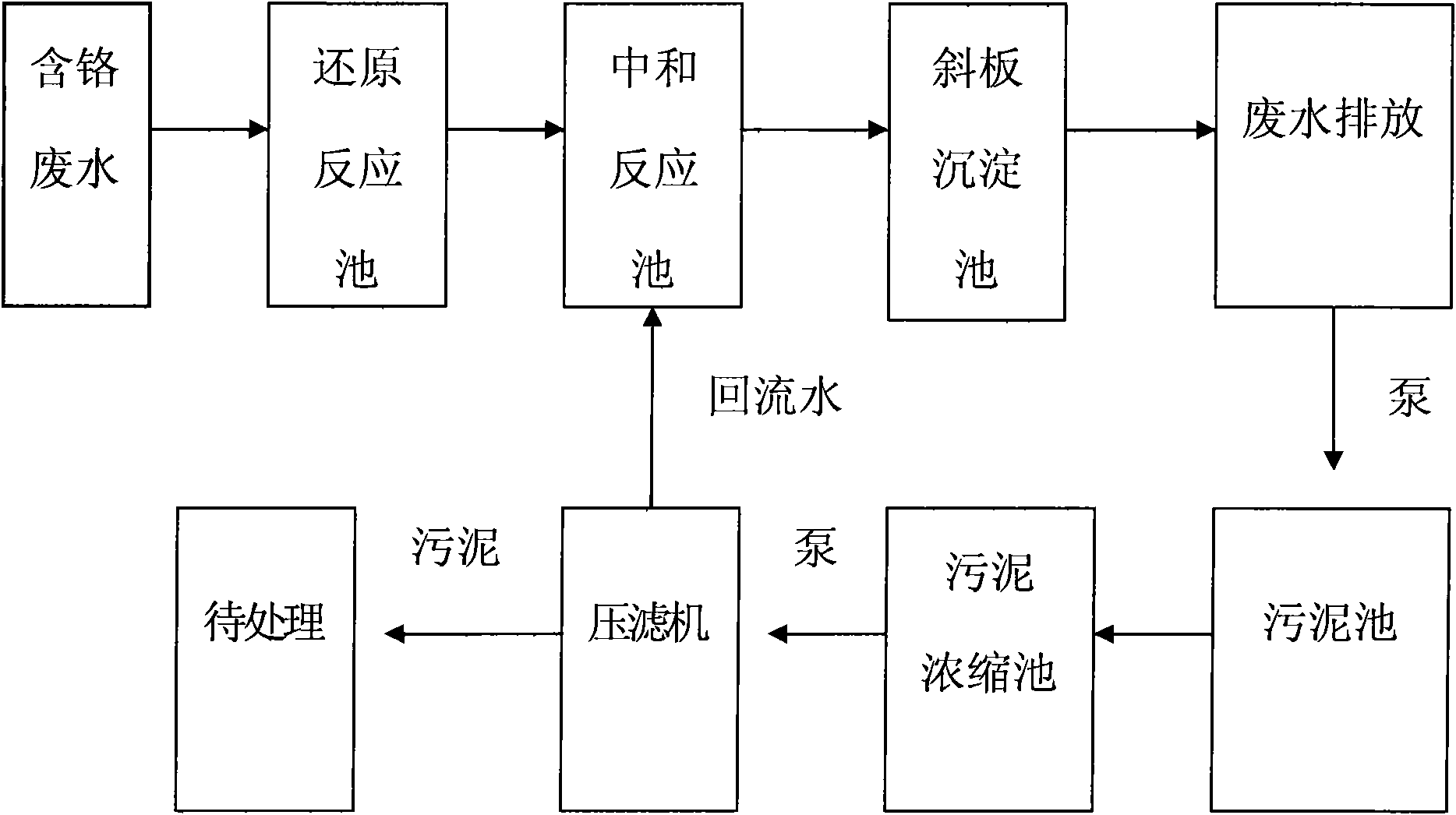

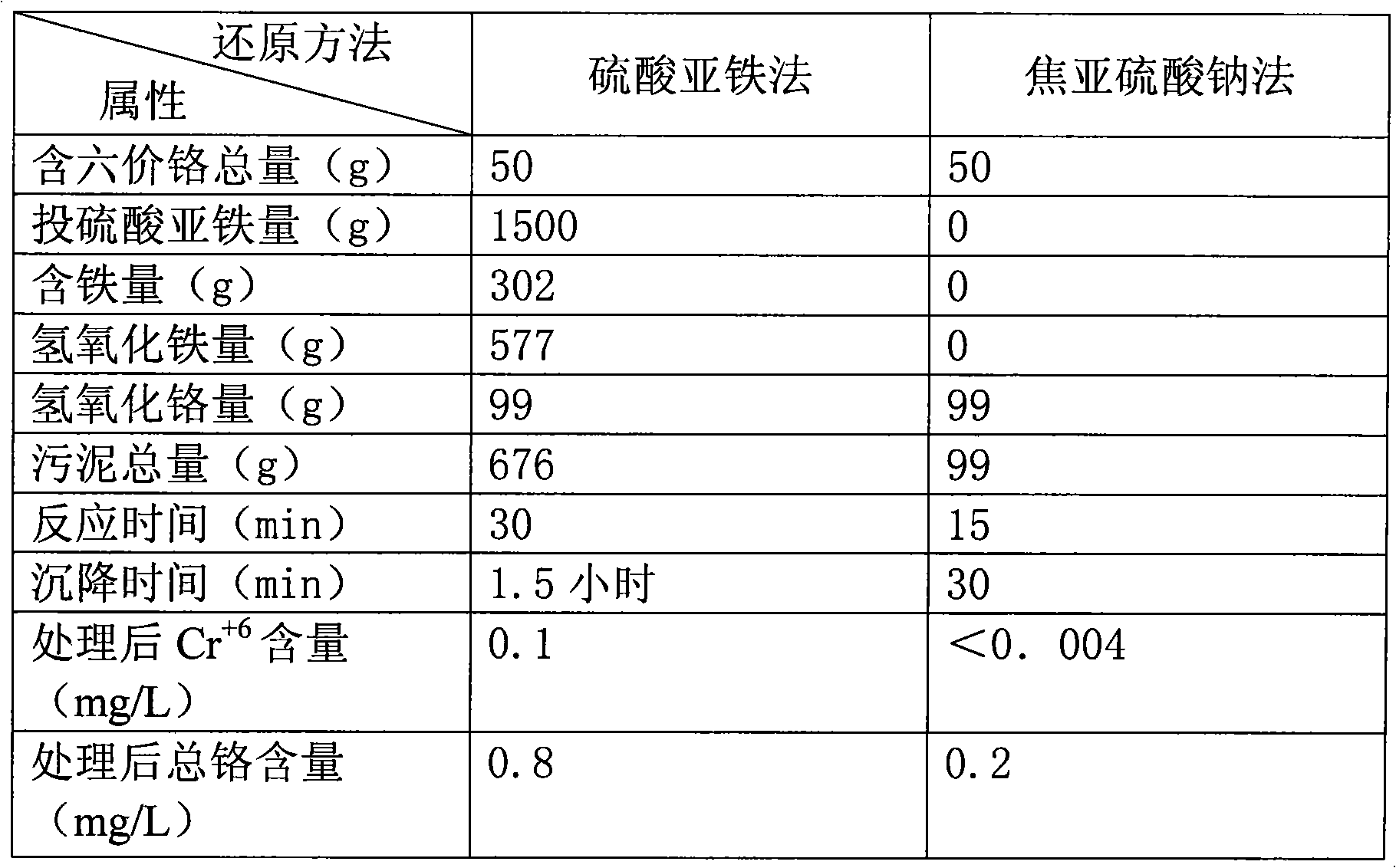

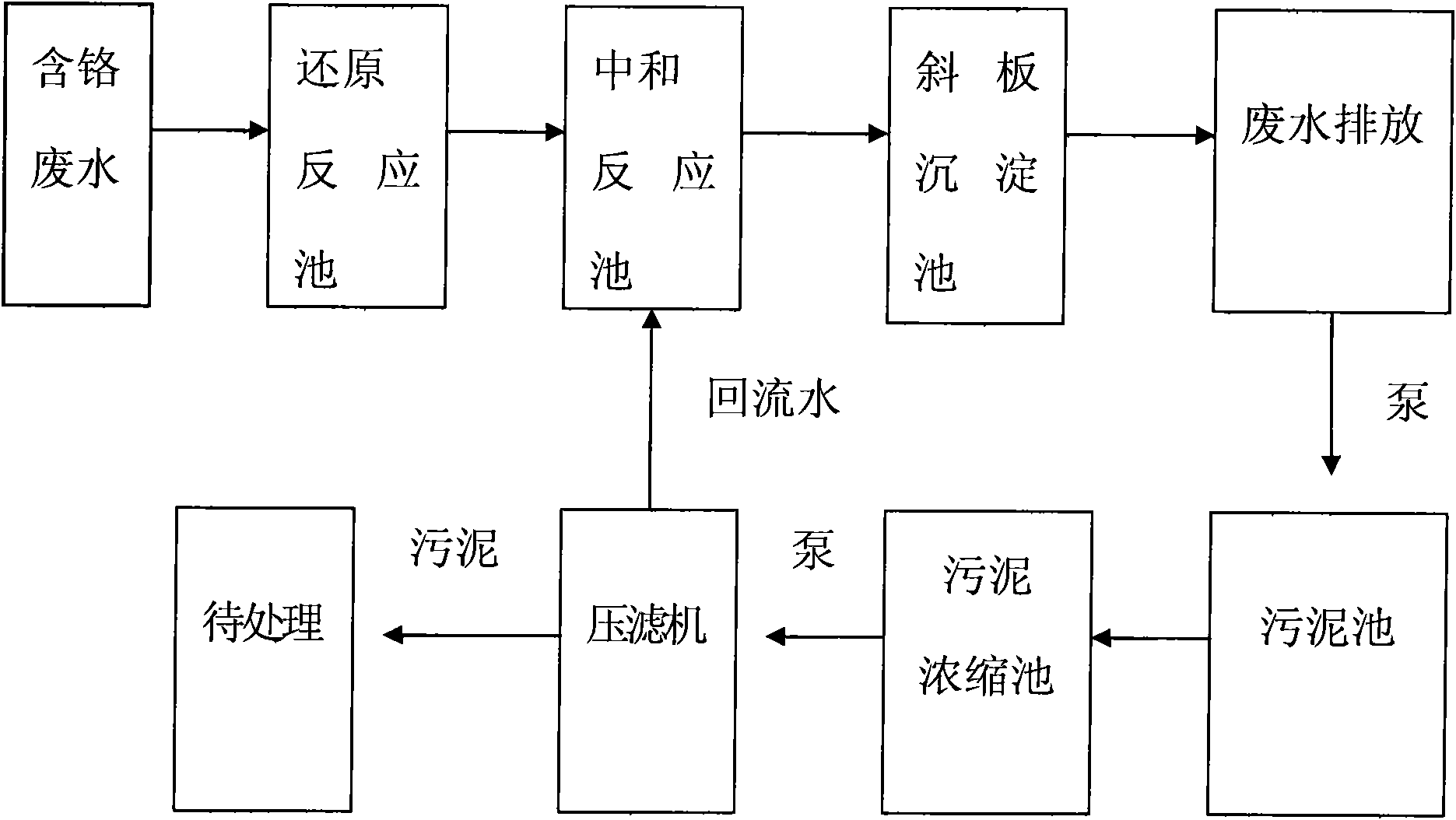

The invention discloses a hexavalent chromium-containing waste water treatment method, which uses sodium hydrogensulfite generated by hydrolysis of sodium pyrosulfite as a reducer and adopts an intermittent process technique for treatment. The concrete treatment process comprises: 1, adding sulfuric acid into waste water, and regulating the pH value of the waste water to 2.0 to 3.0; 2, adding sodium pyrosulfite to reduce hexavalent chromium in the waste water into trivalent chromium, wherein the adding ratio of the sodium pyrosulfite is calculated according to the weight ratio of sodium pyrosulfite to hexavalent chromium of 3.5-5:1; 3, adding sodium hydroxide into a neutralization tank to regulate the pH value of the waste water to 8 to 9 to precipitate the trivalent chromium completely in form of chromium hydroxide; and 4, separating a solid phase from a liquid phase by using the flocculation force of a polyacrylamide polymeric flocculant and the action of a tube sedimentation tank, discharging waste water, piling mud in a centralized manner after press-filtering the mud by a press filter, and processing the mud uniformly according to regulations.

Owner:AVIC STANDARD PARTS MFG

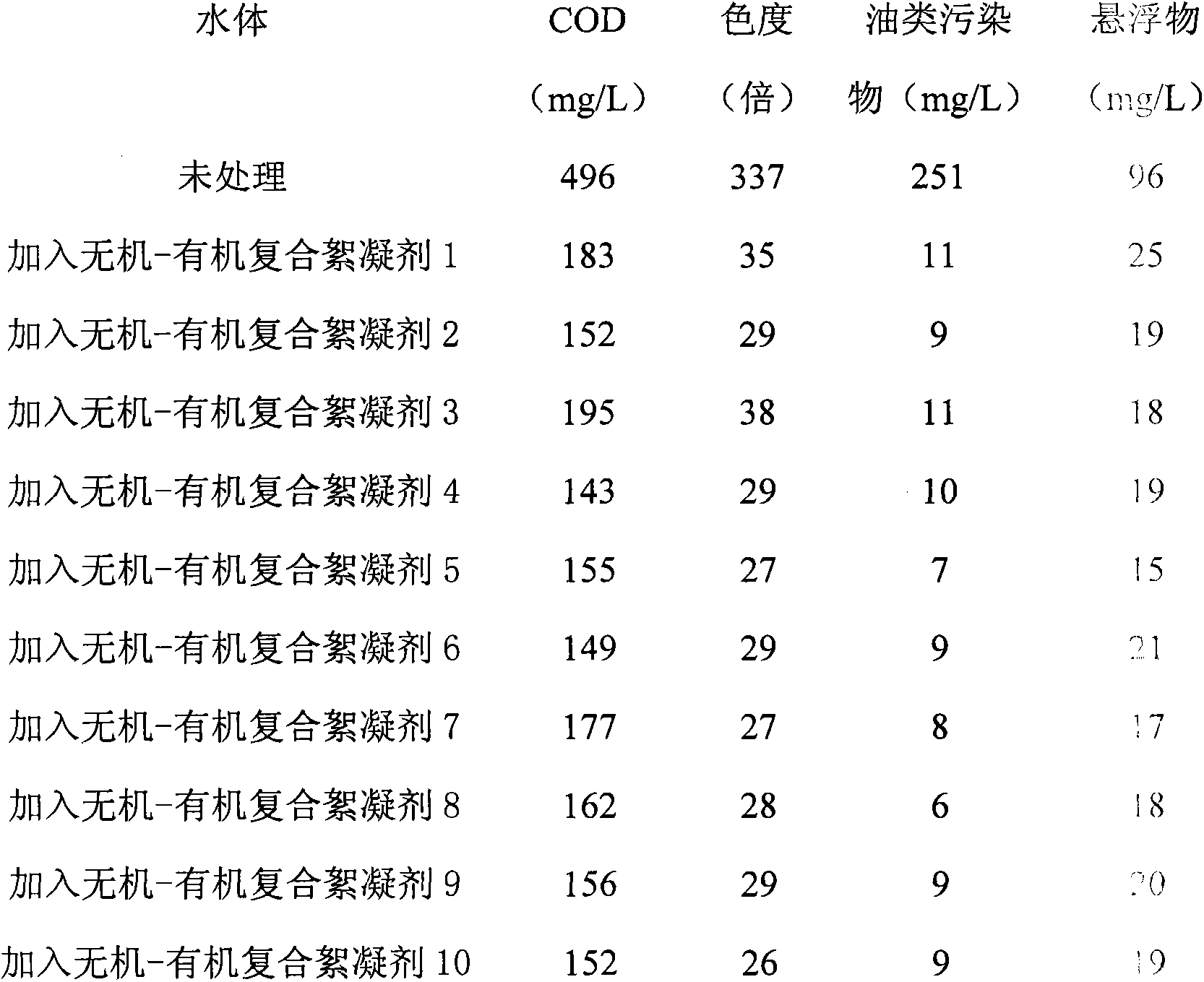

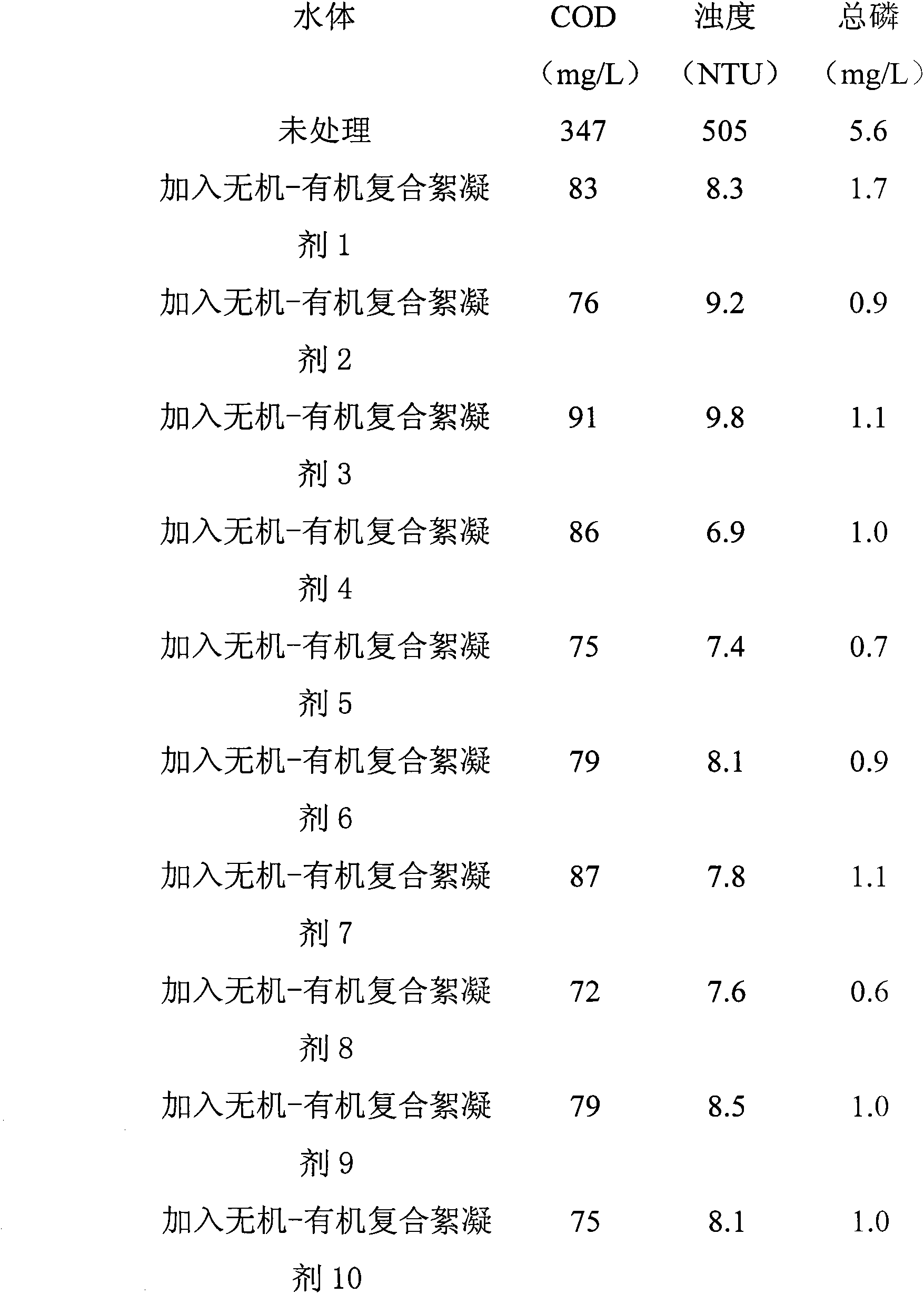

Dephosphorization flocculating agent and preparation method thereof

ActiveCN104261530AGood flocculation effectGood dephosphorization effectWater/sewage treatment by flocculation/precipitationAluminateWater quality

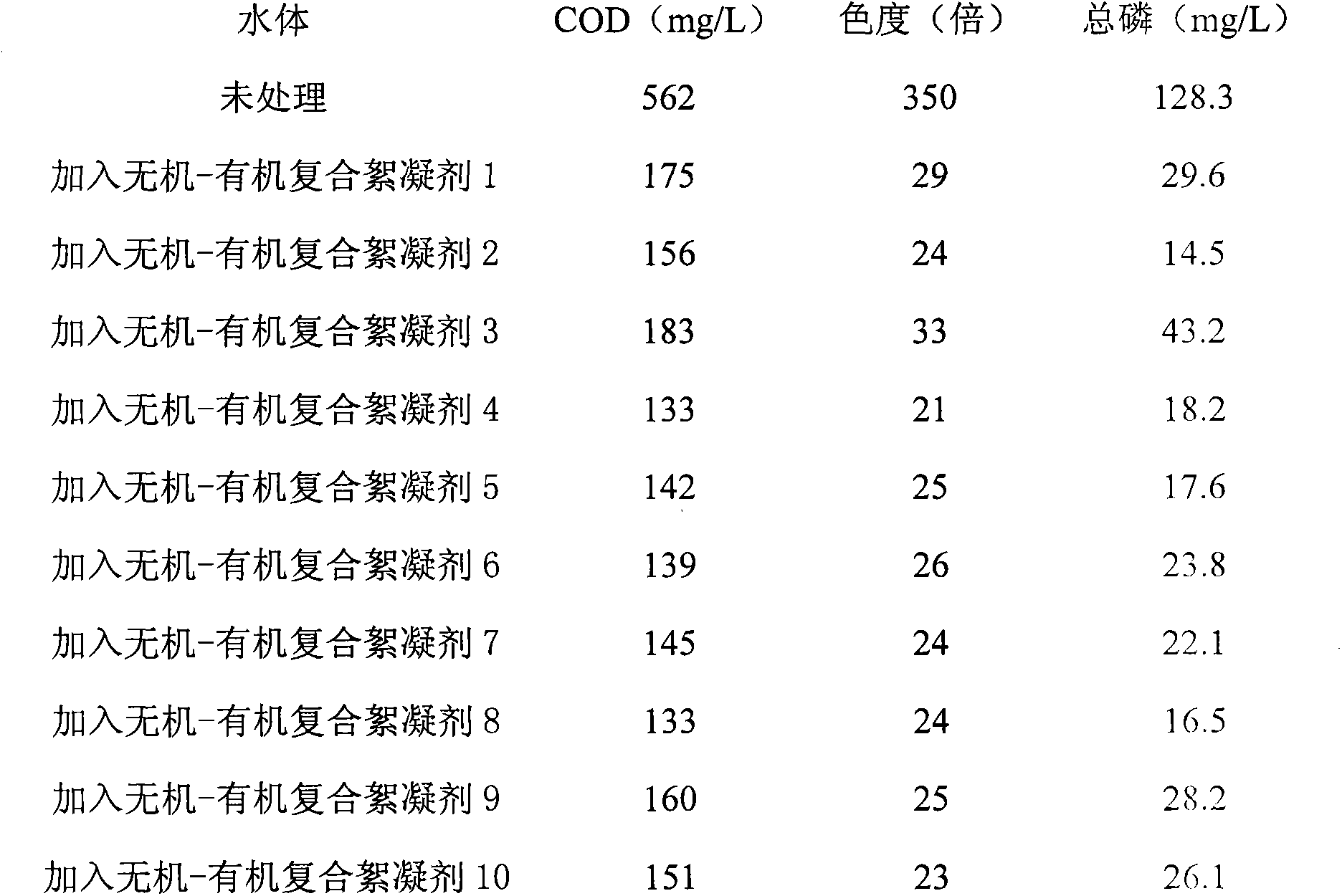

The invention discloses a dephosphorization flocculating agent and a preparation method thereof. The dephosphorization flocculating agent is formed by compounding an inorganic flocculating agent and an organic flocculating agent. The raw materials of the inorganic flocculating agent comprise sodium ferrate, borax, ferrous sulfate, silicate or aluminate; the raw materials of the organic flocculating agent comprise modified chitosan or modified polyacrylamide. The preparation process comprises the following steps: firstly adding a non-oxidizing acid into the silicate or aluminate to obtain a polysilicate colloid or an aluminum hydroxide colloid, then adding a borax solution and a sodium ferrate solution sequentially while stirring, further dropping a ferrous sulfate solution, mixing to form the inorganic flocculating agent, standing, then adding the modified polyacrylamide or modified chitosan into the inorganic flocculating agent, curing and adding the acid till the pH value is less than 7 to obtain the finished dephosphorization flocculating agent. The flocculating agent is suitable for a wide range of water quality, is little affected by co-existing salts, the pH value of sewage and temperature and is particularly effective for dye wastewater, oilfield sewage and the like.

Owner:内蒙古昕晟科贸有限责任公司

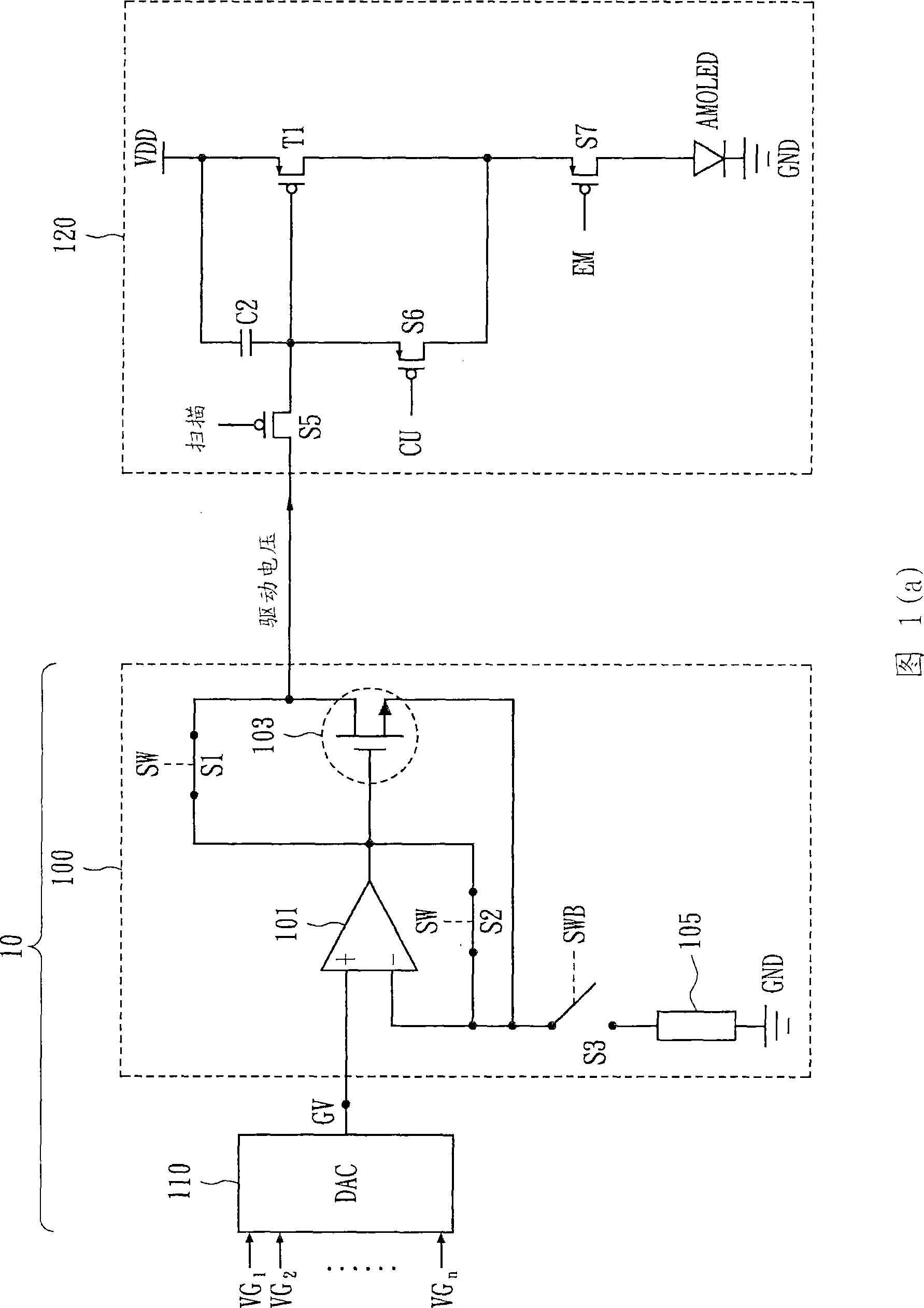

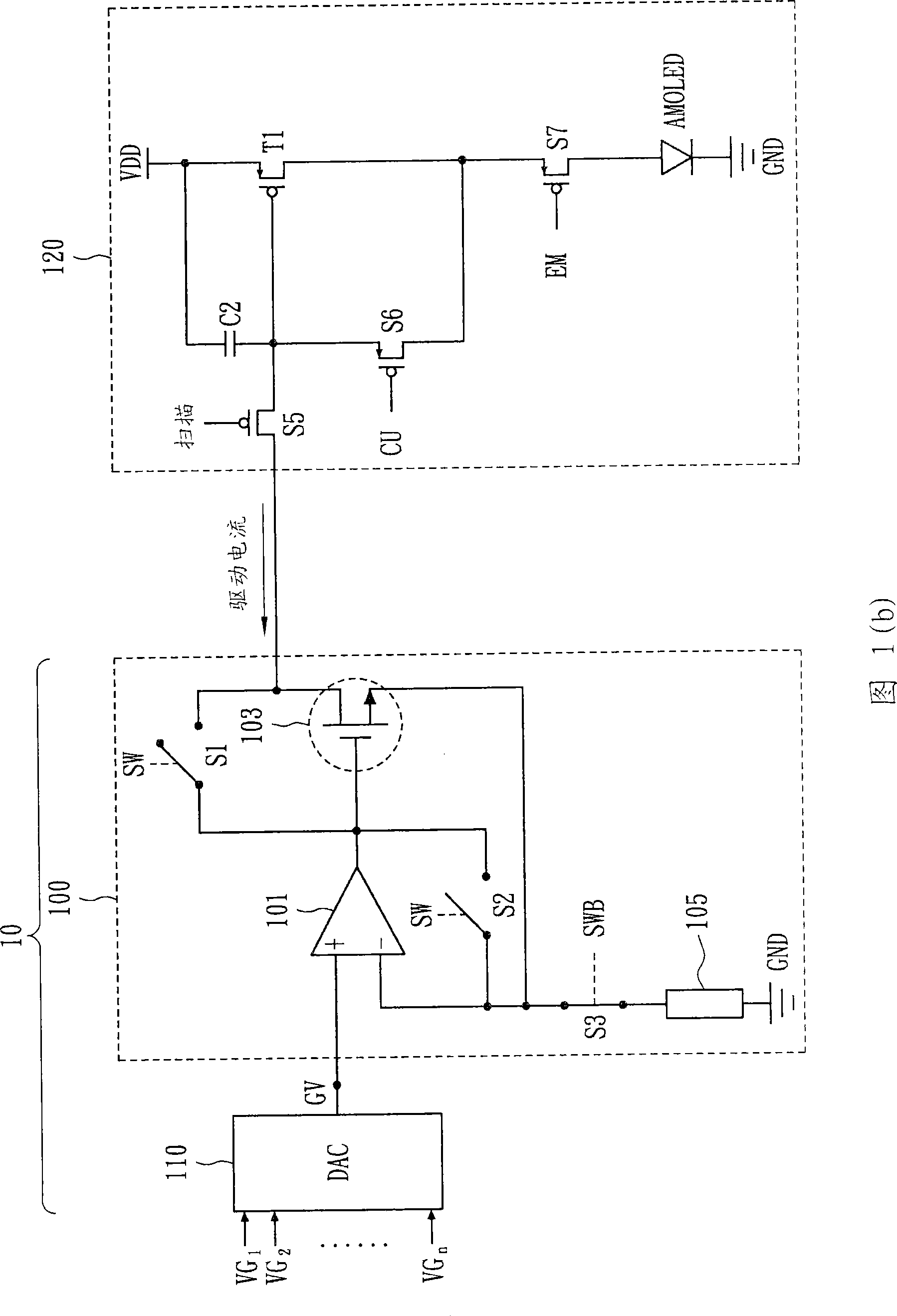

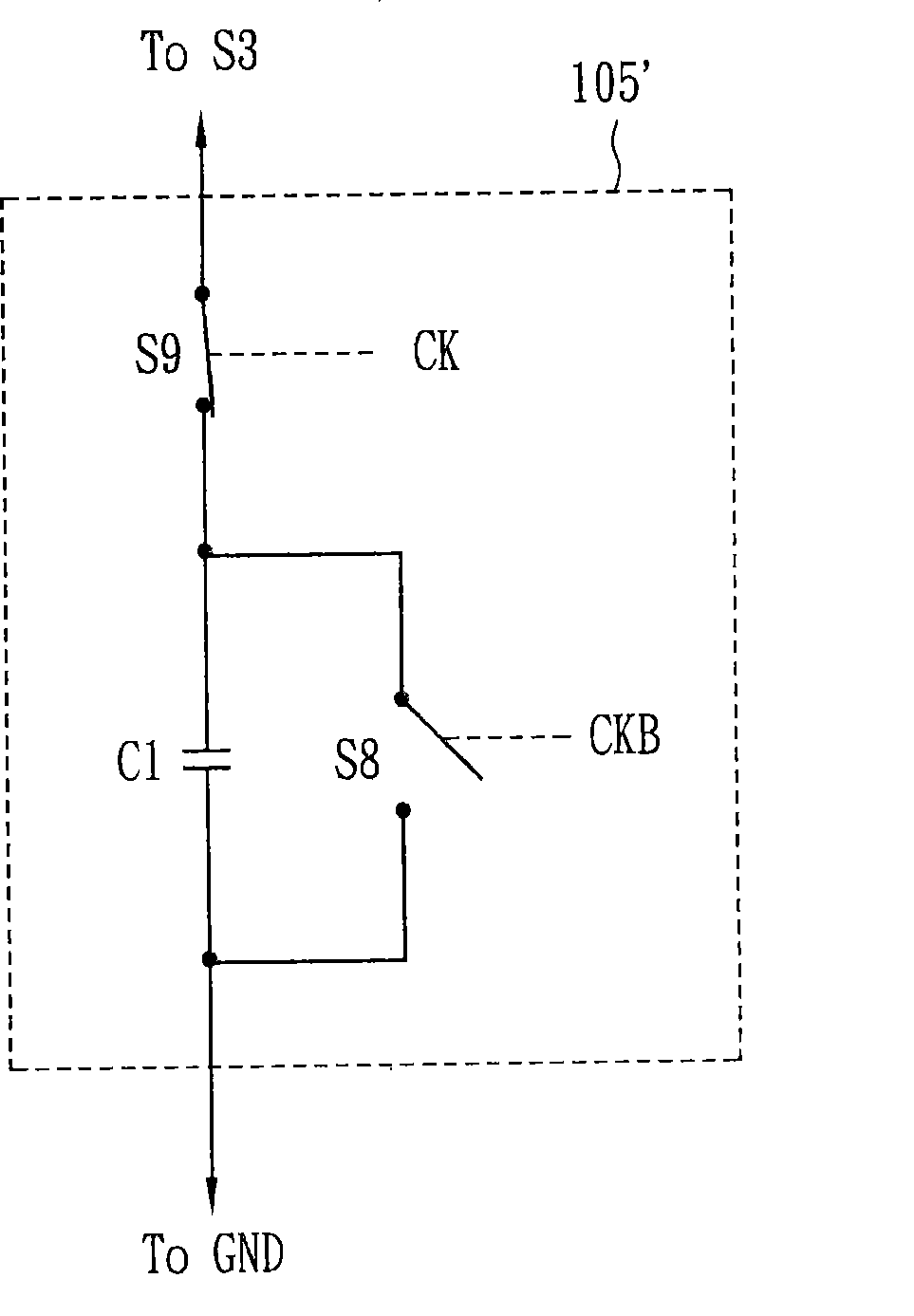

Driver and driver circuit for pixel circuit

The invention provides a driver used for pixel circuit and a driver circuit. The driver has a digital-to-analog converter receiving a pixel value and outputting a gamma voltage corresponding to the pixel value and an output stage which provides a driving voltage and a driving current corresponding to the gamma voltage output from the converter, where the driving voltage and current are provided during the first and second stages of a programming period, respectively.

Owner:HIMAX TECH LTD

Environmental functional material applied to electroplating wastewater treatment

InactiveCN101648735ALarge floc particlesDense flocWater contaminantsWaste water treatment from metallurgical processSodium BentoniteTherapeutic effect

The invention discloses an environmental functional material applied to electroplating wastewater treatment; all components are as follows by mass percentage; kieselguhr, modified purified diatomite,bentonite, modified purified bentonite, attapulgite, modified purified attapulgite, kaoline and / or 20-80 percent of modified purified kaoline, 10-40 percent of humic acid and 10-40 percent of chitosan. The material has convenient usage, good treatment effect, and large and dense formed floccules, shortens settling time, and is easy to lead heavy metal ions, COD, ammonia-N, phosphorus, chromaticity and other indexes in wastewater to synchronously achieve discharge standard regulated nationally, the produced residue can recycle heavy metal, and secondary pollution is not easy to generate. Thematerial is suitable for treating wastewater in industries such as circuit boards, electro-plating, metal finishing, photographic film manufacturing, coal plants, municipal or industry waste incineration, battery production and the like.

Owner:NANJING NORMAL UNIVERSITY

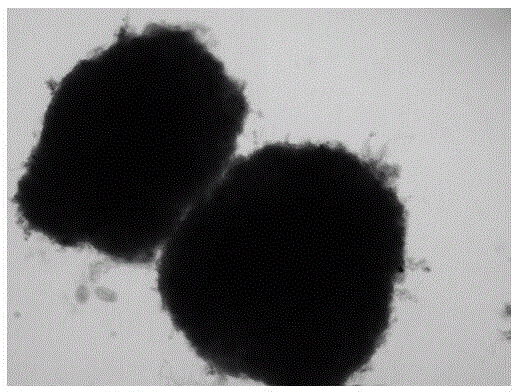

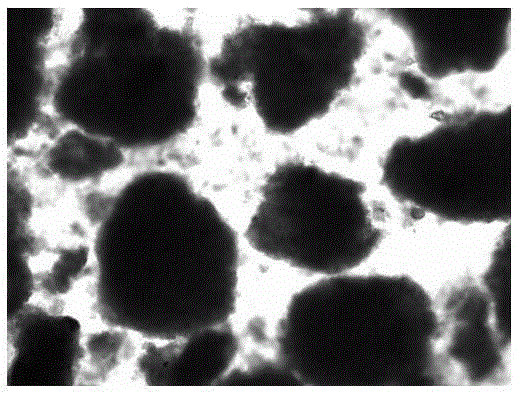

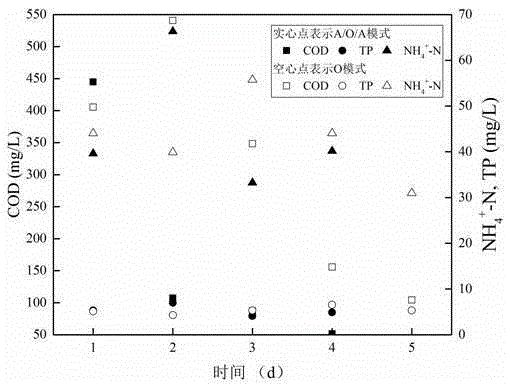

Method for rapidly culturing aerobic granular sludge

ActiveCN105254012AReduce incubation timeSettling time is shortTreatment using aerobic processesTreatment with aerobic and anaerobic processesSequencing batch reactorWater source

The invention discloses a method for rapidly culturing aerobic granular sludge, belonging to the technical field of environment protection. According to the method, a hydraulic shearing force is enhanced by virtue of a cylindrical sequencing batch reactor (SBR), sludge is inoculated at the room temperature, manual simulation wastewater is taken as a water inlet source, and therefore, aerobic granular sludge is rapidly obtained; granular sludge can be obtained in the fourth day by virtue of the SBR working in an anaerobic / aerobic / anoxic (A / O / A) manner when high water inlet load, strong aeration condition and short settling time are maintained, and aerobic granular sludge is obtained in the fifth day by virtue of the SBR working in a one-segment pure aeration (O) manner. According to the method, the starting period of the aerobic granular sludge is greatly shortened, and the problem that the starting periods of current aerobic granular sludge reactors are generally long is solved.

Owner:WUHAN UNIV

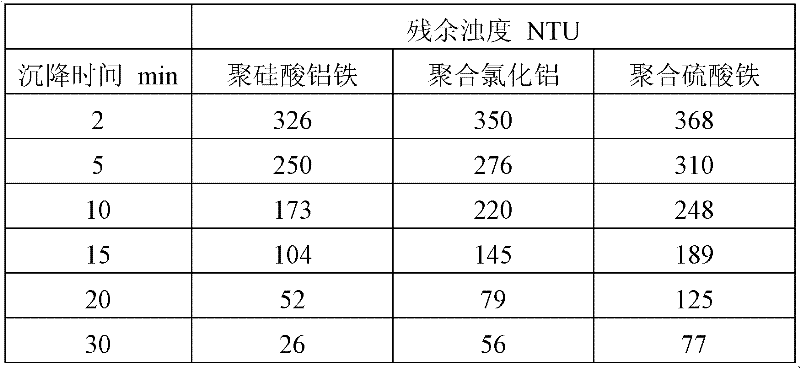

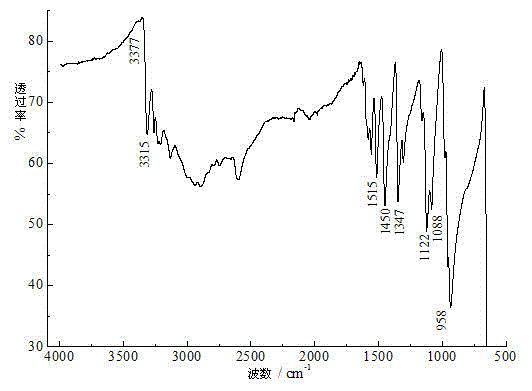

Method for preparing polysilicate ferro-aluminum sulfate composite flocculant from red mud waste

InactiveCN108083345AHigh molecular weightGood flocculation effectIron sulfatesWater/sewage treatment by flocculation/precipitationRed mudSilicon oxide

The invention discloses a method for preparing a polysilicate ferro-aluminum sulfate composite flocculant from red mud waste. The method comprises the following steps: (1) putting red mud waste and anactivating agent into a muffle furnace to be roasted and grinding the red mud waste to obtain activated red mud powder; (2) putting an oxidizing agent and the activated red mud powder into a sulfuricacid solution to react; (3) adding adjusting salt to adjust a molar ratio of Fe to Al to Si in the solution as 1 to 1 to (0.2 to 0.7), utilizing a pH conditioning agent to adjust a pH of the solutionto 1 to 6; (4) adding a stabilizer to react and filtering to obtain the polysilicate ferro-aluminum sulfate composite flocculant. By means of the method disclosed by the invention, ferric oxide, aluminum oxide and silicon oxide in the red mud waste are effectively utilized to prepare the polysilicate ferro-aluminum sulfate composite flocculant; not only are the problems that the waste red mud occupies a lot of land and pollutes underground water are solved, but also the waste red mud can be resourcefully utilized, production cost is low, added value of products is high, and a novel way for comprehensively utilizing the red mud waste is provided.

Owner:SUN YAT SEN UNIV

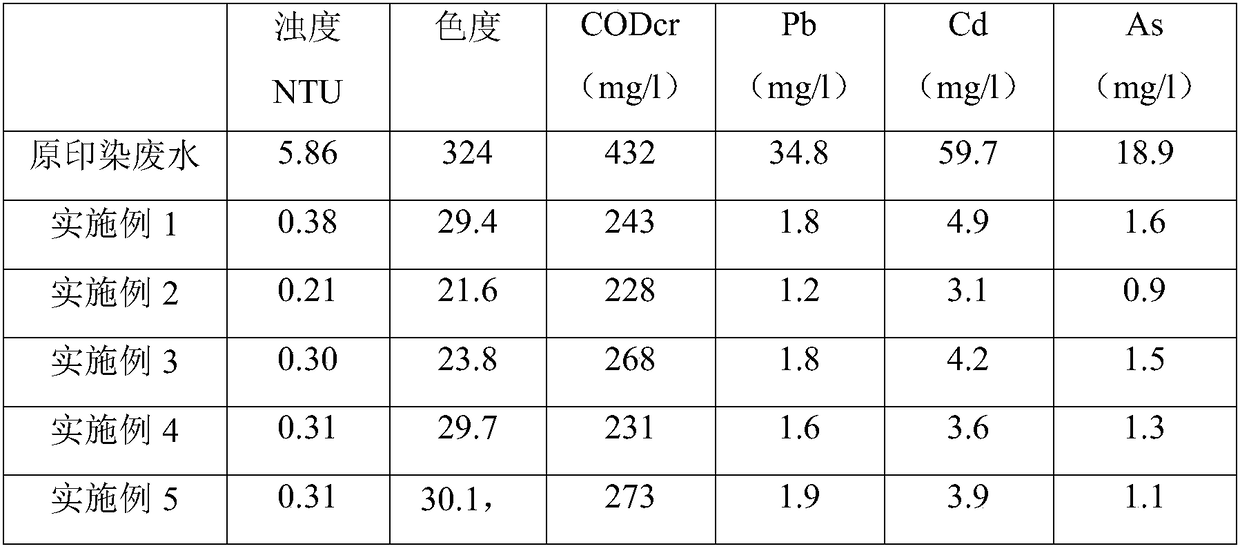

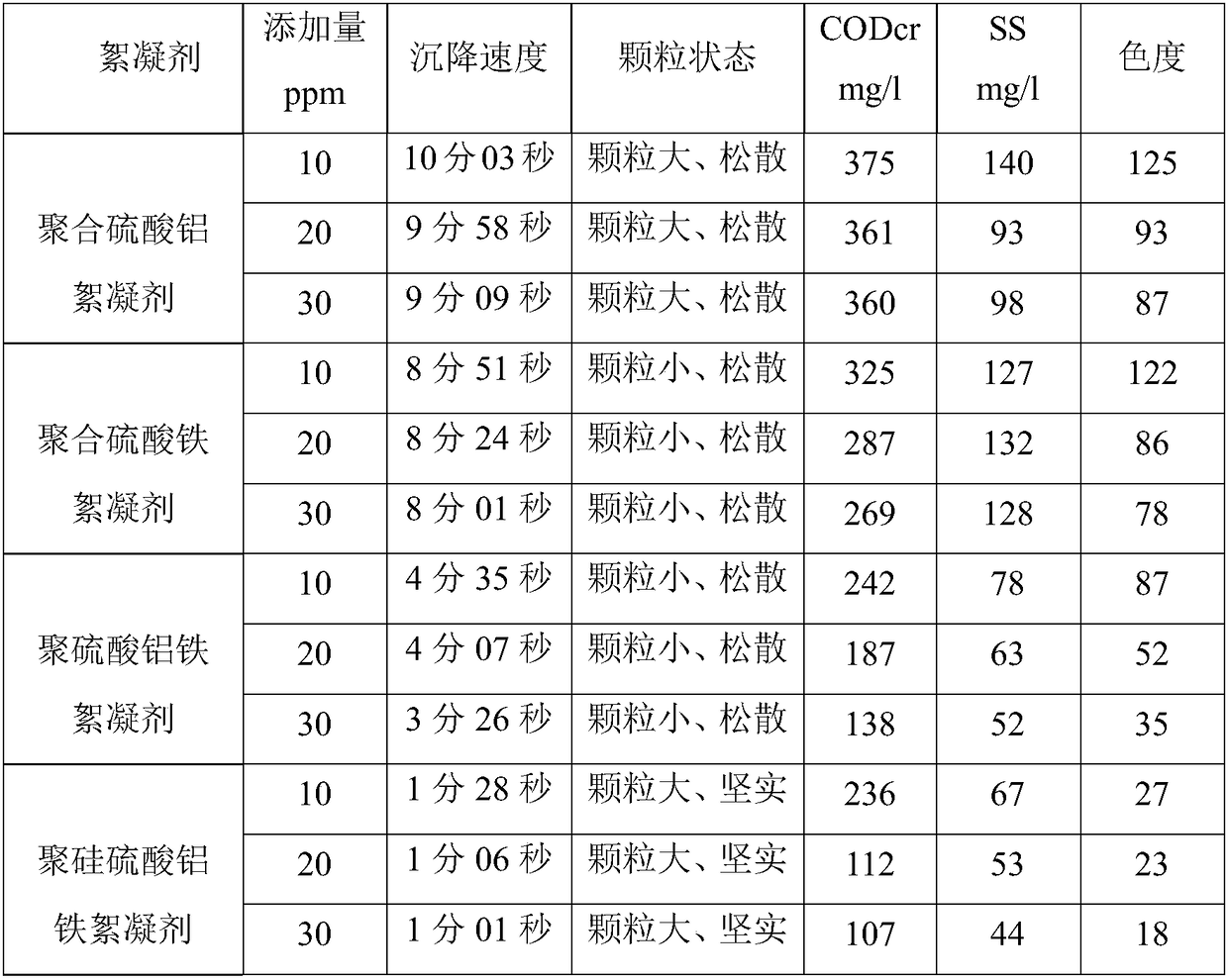

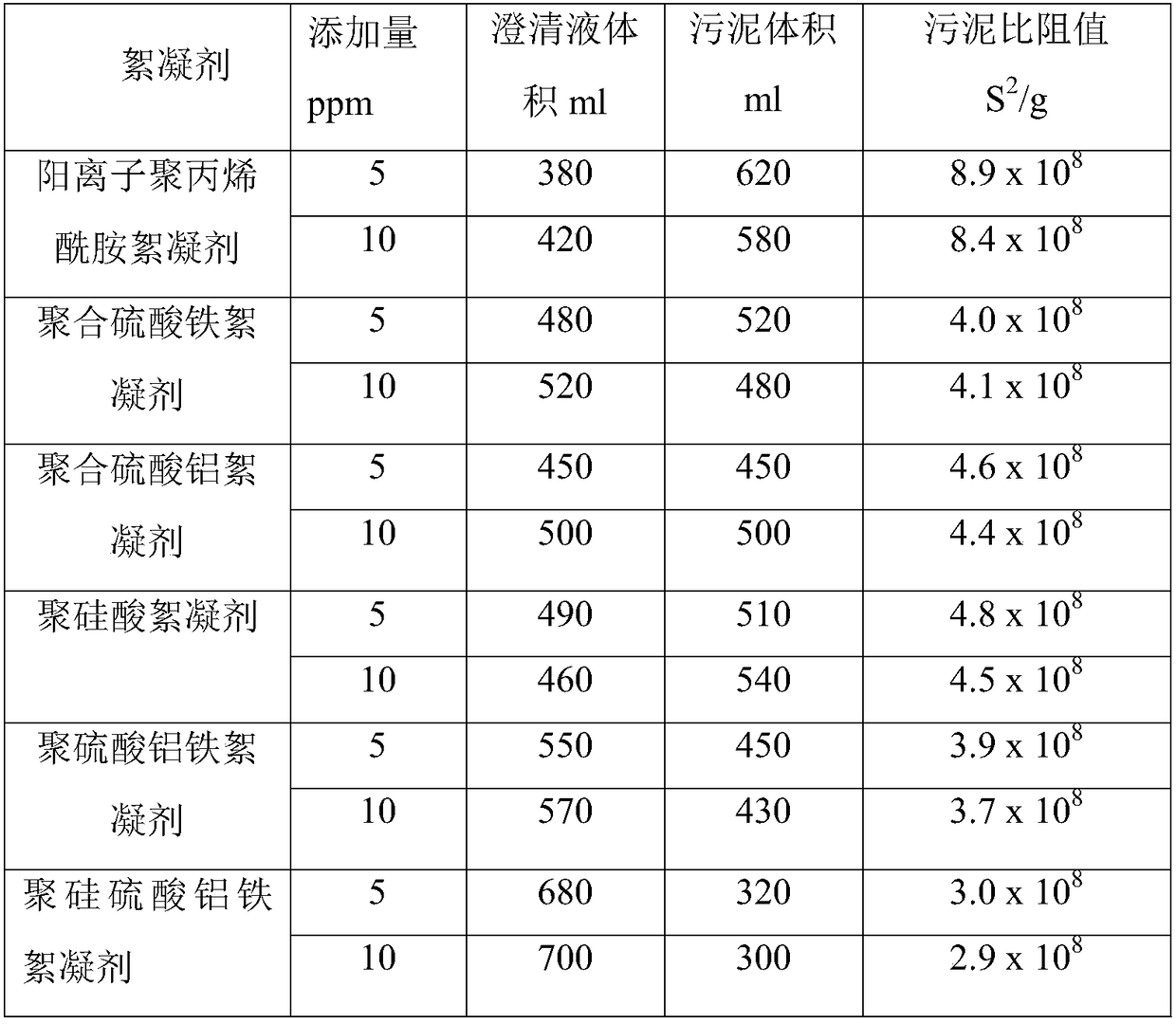

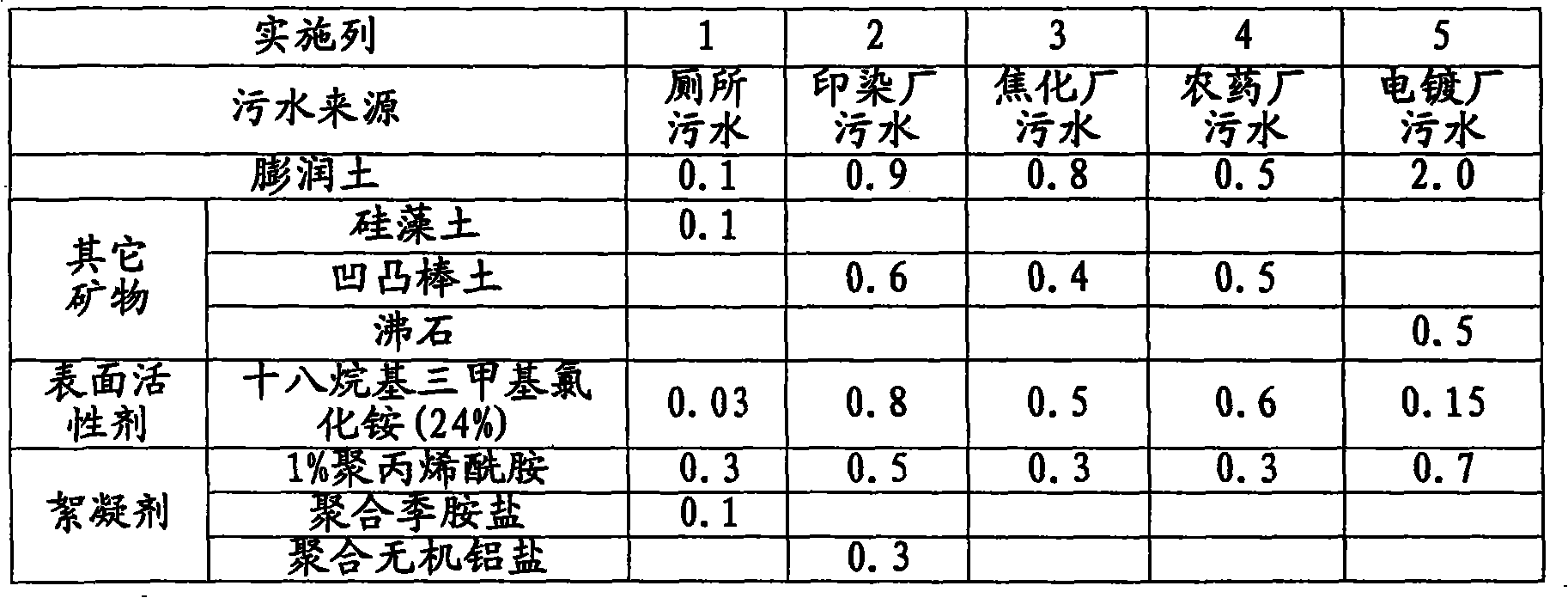

Mineral complex sewage treating method

ActiveCN101254994ALow costImprove adsorption capacityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSodium BentoniteSludge

The invention relates to a mineral composite sewage treatment method. calcium based, sodium based or acidic bentonite is crushed into 101 to 600 mesh, other minerals are crushed into 60 to 600 mesh, the bentonite and other kinds of minerals form a mineral composite, the mineral composite is poured into sewage to be treated, and is blended, then 24% octadecyl trimethyl ammonium chloride is poured into the sewage and stirred, then a flocculating agent is poured into the sewage and stirred for subsiding, and then soil and water separation and micro-organism treatment are performed , and satisfying drainage standard can be reached; the weight ratio of the sewage and the added mineral composite is (1000:0.2)-(1000:2.5), the ratio of the dosage of the bentonite and the dosage of any another mineral is (1:1)-( 4:1), the dosage ratio of the mineral composite and the octadecyl trimethyl ammonium chloride is (2:1)-(17:1), and the dosage ratio of the mineral composite and the flocculating agent is (0.5:1)-(4:1). The method can be used for the treatment of toilets, printing and dyeing, coking, agricultural chemicals and galvanization sewage, and has the advantages of low treatment cost, wide application range and smaller sludge deposit, and has no influence on the subsequent microorganism treatment.

Owner:浙江华特新材料有限公司

Method for preparing thalli/ bentonite organic and inorganic composite adsorbent

The invention discloses a method for preparing a thalli / bentonite organic and inorganic composite adsorbent, and relates to a method for preparing a water treatment agent. The method comprises the following steps of: 1) preparing raw materials: drying and crushing fungal thalli, sieving with a sieve of 200 meshes, crushing natural bentonite, and sieving with a sieve of 200 meshes; and 2) preparing the water treatment agent: mixing the thalli powder and the bentonite in a mass ratio of 1: (10-40) (g / g), adding 3 to 5 percent by mass of industrial hydrochloric acid or 3 to 7 percent by mass of sulfuric acid in a mass / volume ratio of 1: (1.2-1.7) (g / mL), stirring and mixing for 10 to 15 minutes, standing and activating for 15 to 25 minutes, modifying with microwave of 400 to 480W, drying, crushing, and thus obtaining the thalli / bentonite organic and inorganic composite adsorbent product. The adsorbent has a good adsorption and decolorization effect and high removal rate on active dyes, acid dyes, alkali dyes, disperse dyes and heavy metals.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

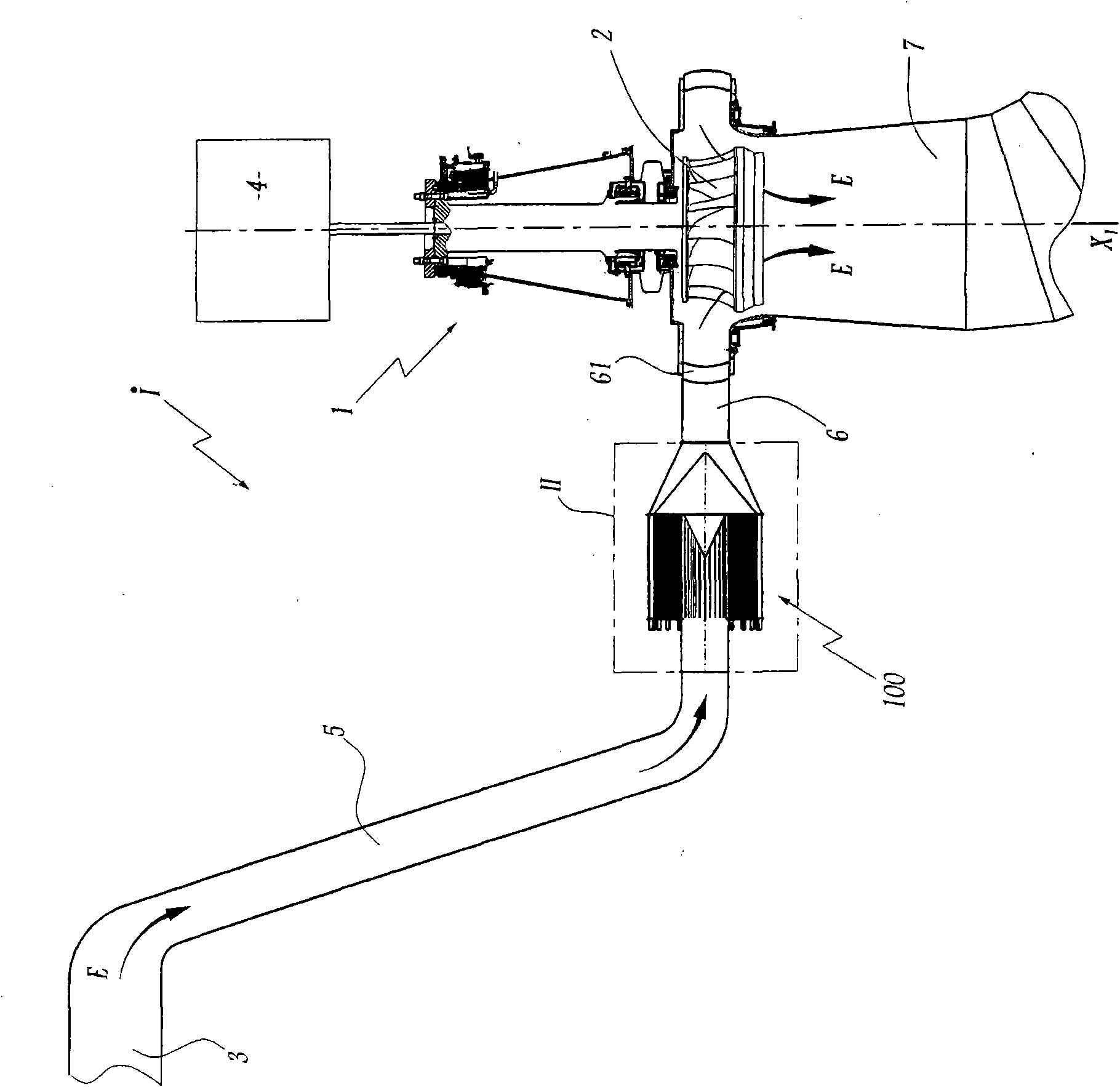

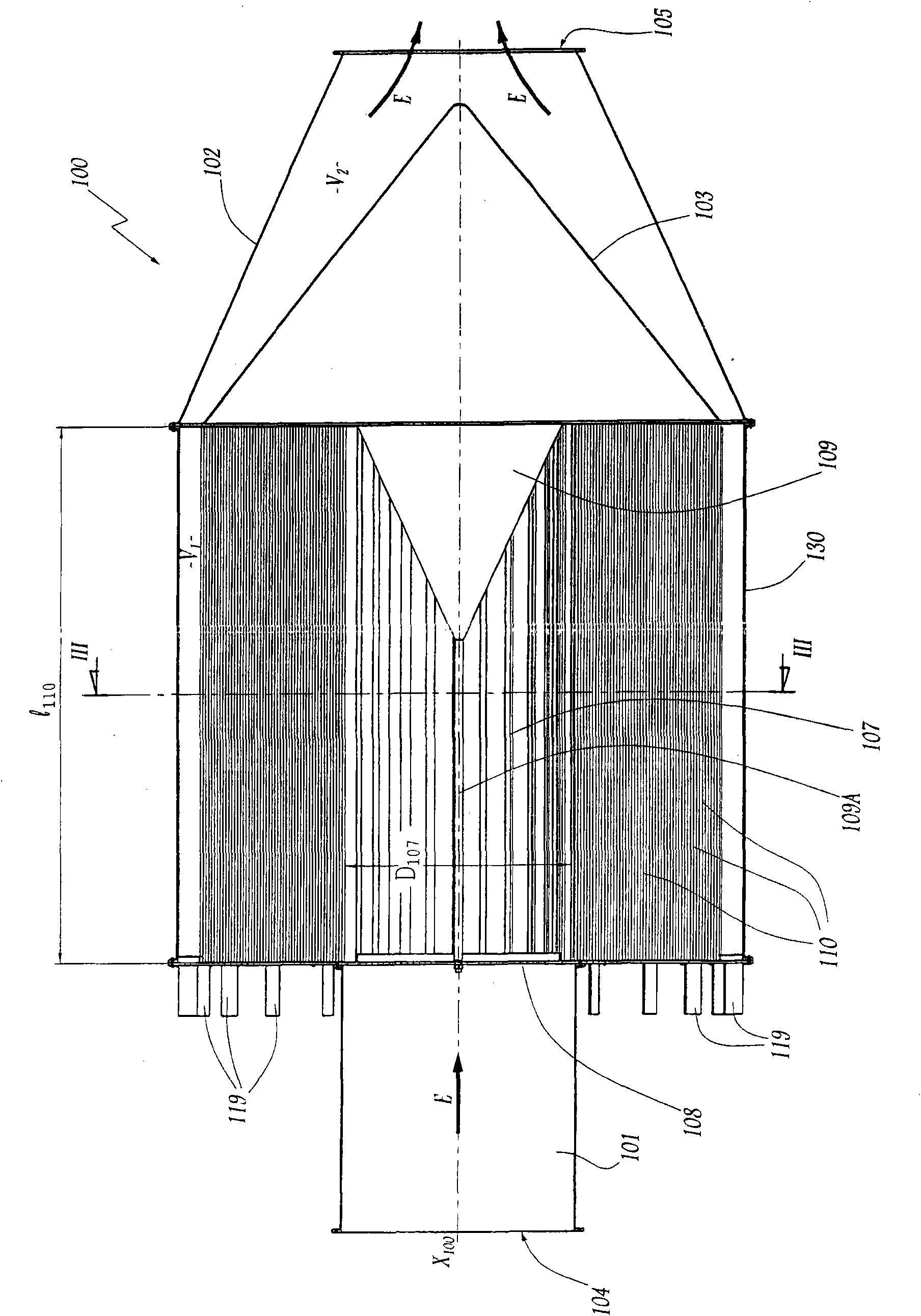

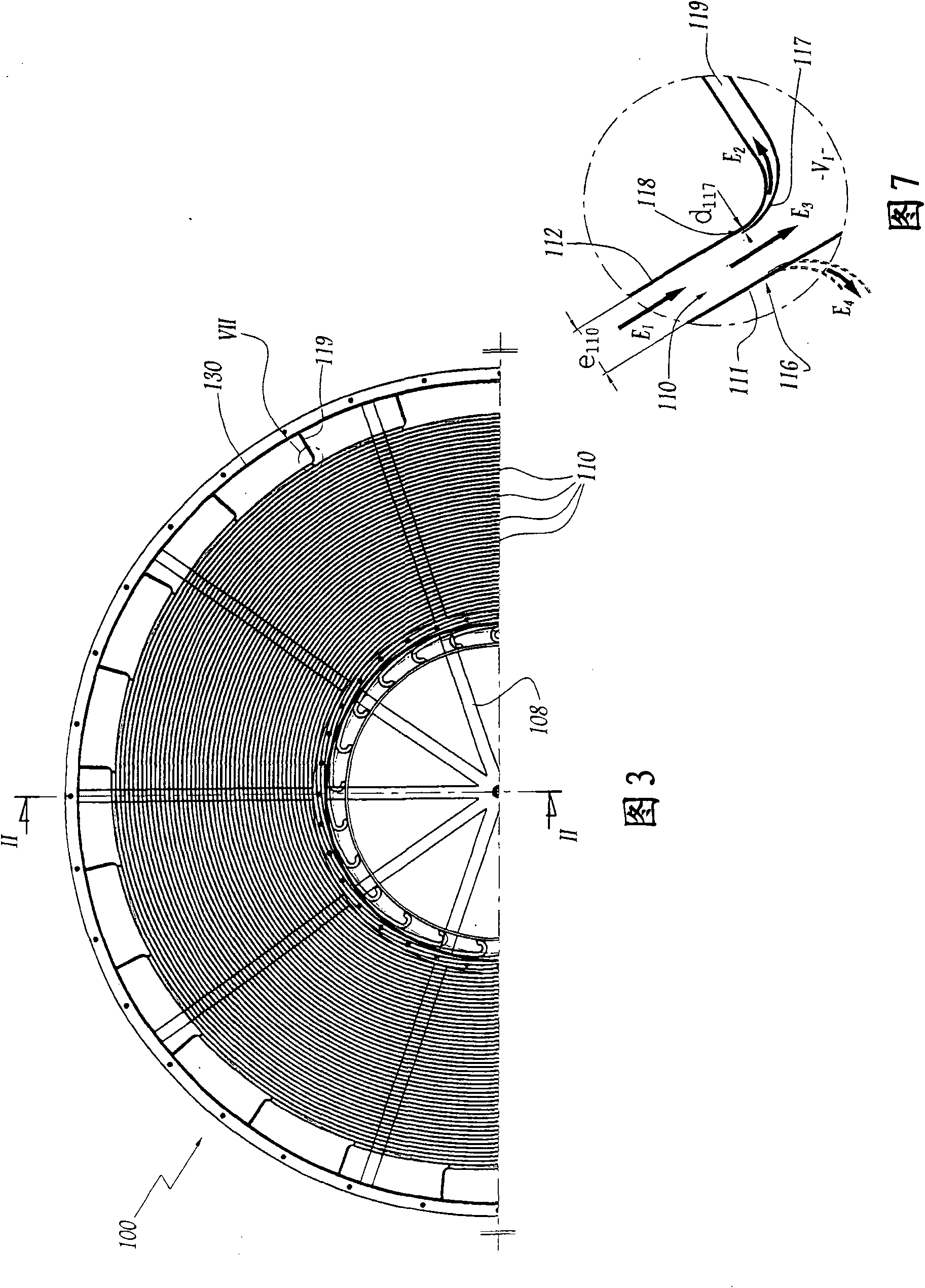

Apparatus for the separation of solid particles from water and haudraulic installation containing such separation apparatus

InactiveCN101628187AReduce workloadLow costBarrages/weirsCentrifugal force sediment separationSection planeWater flow

The device (100) serves to separate solid particles from the water of a flow (E) feeding a hydraulic machine of the turbine, pump, or turbine-pump type. The device has flow inlet and outlet zones (104, 105) for the flow that are spaced apart along an advance axis (X100) of flow advance-through the device (100). The device (100) comprises a plurality of ducts (110) placed in parallel, each having a mouth and a downstream end between the inlet zone (104) and the outlet zone (105). In section perpendicular to the advance axis (X100), each duct presents a section in the form of a spiral with a radius of curvature that increases from the mouth towards the downstream end or from the downstream end towards the mouth, with each duct (110) presenting a thickness measured in a generally radial direction relative to the advance axis that is less than 10% of the width (l110) of said duct, measured parallel to said axis (X100).

Owner:ALSTOM RENEWABLE TECH

Method for preparing polysilicate aluminum ferric chloride by using aluminum foil acid and ferrous acid

ActiveCN102689906ASolve the emission problemIncrease production capacitySilicon compoundsWater/sewage treatment by flocculation/precipitationChemical oxygen demandSlag

The invention relates to a method for preparing polysilicate aluminum ferric chloride by using aluminum foil acid and ferrous acid, in particular to a method for preparing the polysilicate aluminum ferric chloride by copolymerization of aluminum foil acid, iron and steel picking solution, aluminum slag and other industrial wastes as main raw materials as well as pentahydrate sodium silicate, and belongs to the technical field of recycling of aluminum foil acid and aluminum slag resources in the electronic aluminum foil industry. The object of the invention is to provide a method for preparing the polysilicate aluminum ferric chloride with high flocculability and stability by using the aluminum foil acid and other wastes. The polysilicate aluminum ferric chloride is finally prepared by ferrite oxidization, silicic acid activation, basification and polymerization and other processes; and a coagulant prepared by the method can be widely used for treatment such as dyeing wastewater, domestic sewage, industrial wastewater treatment, and has strong COD (Chemical Oxygen Demand) removal, decoloring and turbidity removal capabilities, the formed floc is large and dense, and the settlement time of the floc is short.

Owner:GUANGDONG HUAFENG NEW ENERGY TECH CO LTD +1

Method for preparing poly aluminum ferric silicate composite flocculating agent by using red mud and ferrous sulfate

InactiveCN102557208AHigh degree of molecular polymerizationImprove stabilityWater/sewage treatment by flocculation/precipitationSocial benefitsResource utilization

The invention relates to a method for preparing a poly aluminum ferric silicate composite flocculating agent by using red mud and ferrous sulfate. The method comprises the following steps: fully mixing the red mud and the ferrous sulfate as well as alkali according to the weight ratio of 1:06-1.3:0.4-0.9, roasting and cooling a mixture at a temperature of 700-1000 DEG C; acid-pickling a cooled product and hydrochloric acid with a volume ratio of 1:1 according to the weight ratio of 1:4-25 at a temperature of 40-95 DEG C; and centrifugally separating an acid-pickled product and aging a filtrate to obtain the poly aluminum ferric silicate composite flocculating agent. The method has the benefits that the process flow is simple, the investment is less, and the operating expense is low; a synthesized product integrates the advantages of an aluminum flocculating agent and a ferric flocculating agent, and the stability and the water purification effect are good; and meanwhile, the invention provides a new approach for the utilization of the red mud as well as by-product ferrous sulfate for producing titanium dioxide, so that the resource utilization rate is improved, and the economic benefit, the environmental benefit and the social benefit are excellent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Sewage treatment agent as well as preparation method and application thereof

ActiveCN104355356AThorough treatmentTreatment agent for sewage treatment thoroughlyWater contaminantsWater/sewage treatment by flocculation/precipitationSludgeHazardous substance

The invention relates to a sewage treatment agent as well as a preparation method and application thereof. The sewage treatment agent is composed of magnesium oxide, zeolite, sulfate, an alkalizer and a high polymer coagulant. The sewage treatment agent disclosed by the invention, when used for treating sewage, can physically adsorb pollutants in water, in particular ultra-micro molecules, other components can perform differentiated treatment on other pollutants in the water and especially acid pollutants can be decomposed and converted completely, and by processing suspended materials through flocculation of sulfate and the like, harmful substances are cladded and such heavy metals as chromium are agglutinated under attractive and repulsive force between ultra-micro particles, so that the harmful substances are prevented from being dissolved; moreover, the sewage processing agent is large in flocculant granules, short in settling time and relatively low in sludge, and therefore thorough sewage treatment is realized; treatment rate can reach more than 95%; regenerated water source after treatment is free from harm, and the processed water not only can reach discharge standard but also bring about benefit for recycling; and the sewage processing agent is suitable for popularization and application in the fields related to domestic and industrial wastewater comprehensive treatment.

Owner:东莞市台腾环保材料科技有限公司

Industrial wastewater flocculating agent and preparation method thereof

InactiveCN105198057AShort flocculation and sedimentation timeSettling time is shortWater/sewage treatment by flocculation/precipitationHigh concentrationHazardous substance

The invention discloses an industrial wastewater flocculating agent and a preparation method thereof, belonging to the field of water treatment agents. The industrial wastewater flocculating agent comprises the following raw materials in parts by weight: 15-30 parts of polyacrylamide, 10-25 parts of polyacrylate, 3-9 parts of aluminum potassium sulfate, 5-10 parts of polysilicate, 3-9 parts of poly-aluminum calcium chloride, 5-10 parts of ferric chloride, 5-10 parts of gypsum, 10-25 parts of silica, 8-18 parts of zeolite, 3-9 parts of ferric citrate, 5-15 parts of polyphosphate ferric chloride, 1-5 parts of polymeric ferric sulfate and 50-90 parts of water. The industrial wastewater flocculating agent is short in flocculent precipitation time, good in effect and low in cost, is capable of improving the the emulsifying ability of water molecules and degrading harmful substances in water, particularly can be used for effectively treating high-concentration and high-turbidity wastewater and non-biochemical wastewater and can be widely applied to the treatment of municipal wastewater and various types of industrial wastewater as well as the water quality treatment of polluted rivers and lakes, and treated water can be circularly used.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

Method for treating waste water containing sericin protein

InactiveCN101182062ALower protein contentLow costWater contaminantsWater/sewage treatment by flocculation/precipitationSocial benefitsChemical oxygen demand

The invention discloses a treatment method for wastewater containing sericin, which utilizes sericin itself to undergo a coordination reaction with metals to synthesize a sericin metal complex, and uses the complex as a flocculant to agglomerate and precipitate silk factory wastewater sericin, so as to effectively treat the wastewater, and finally recover the sericin protein at low cost by dilute acid washing. The method not only solves the environmental pollution problem caused by the high chemical oxygen demand of the waste water, but also effectively protects the water quality; at the same time, it realizes low-cost and effective recovery of the sericin in the waste water, turning waste into treasure. The development and implementation of this new process will bring not only good social benefits but also considerable economic benefits to silk enterprises in terms of wastewater treatment, so it has broad industrial application prospects.

Owner:重庆工学院

High-dryness conditioning and dehydrating method for sludge

ActiveCN103771682AImproved magnetizabilitySimple structureSludge treatment by de-watering/drying/thickeningPolymeric surfaceBound water

The invention discloses a high-dryness conditioning and dehydrating method for sludge. A compound conditioning agent is adopted, the strong oxidizing property of an oxidant, the flocculating function and magnetic field force function of magnetic powder and the electrical neutralization of an inorganic flocculating agent are organically combined with the adsorptive bridging function and the macromolecular sweeping and trapping effects of a compression double-electron layer and an organic flocculating agent, and the advantage of each conditioning agent is brought into play in a synergetic manner, so that the sludge structure and property are improved effectively, water in sludge cells and bound water on the surface of an extracelluar polymer are released, the dehydration performance of the sludge is improved remarkably, and high-dryness dehydration is realized. The method has the advantages of high sludge dehydration degree, good flocculating effect, short flocculating and settling time, high volume reduction rate and low dehydration cost.

Owner:广州福之源环保科技有限公司

Industrial wastewater treating agent

InactiveCN103663579AImprove adsorption capacityImprove flocculation abilityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSodium BentoniteSludge

The invention relates to an industrial wastewater treating agent, and belongs to the field of sewage treatment. The industrial wastewater treating agent comprises raw materials of flue ash, bentonite, corn starch, citric acid, sodium chloride, saccharide and activated carbon. According to the industrial wastewater treating agent, the flue ash and the bentonite are taken as main raw materials for sewage treatment, so that the sewage treatment cost is reduced; the absorption and flocculation capacity of the bentonite is high, the sedimentation time is shorter, and less sludge exists, so that the effect and the efficiency of sewage treatment are further improved; and corn starch, saccharide and activated carbon are added, so that the absorption and flocculation capacity is further improved, and no chemical agent is left in treated water.

Owner:栾晓健

Novel industrial wastewater flocculant and preparation method thereof

InactiveCN105084500AShort flocculation and sedimentation timeSettling time is shortWater/sewage treatment by flocculation/precipitationHigh concentrationHazardous substance

The invention discloses a novel industrial wastewater flocculant and a preparation method thereof, and belongs to the field of water treatment agents. The novel industrial wastewater flocculant comprises the following raw materials in parts by weight: 1 to 9 parts of polyethyleneimine, 3 to 9 parts of sodium carboxymethyl cellulose, 5 to 10 parts of aluminium polychlorid, 3 to 9 parts of potassium permanganate, 1 to 5 parts of magnesium sulfate, 5 to 10 parts of sodium polyacrylate, 3 to 9 parts of polyoxyethylene, 1 to 9 parts of polysilicate, 4 to 8 parts of alginic acid, 4 to 16 parts of barium carbonate, 1 to 5 parts of fly ash, and 70 to 90 parts of water. The novel industrial wastewater flocculant has the advantages that the flocculating and settlement time is short, the effect is good, the cost is low, the activity and emulsion capability of water molecules are improved, the harmful matters and heavy metal in water are degraded, the high-concentration and high-turbidity wastewater and the wastewater which cannot be chemically treated are effectively treated, and the treated water can be recycled.

Owner:邓忆凯

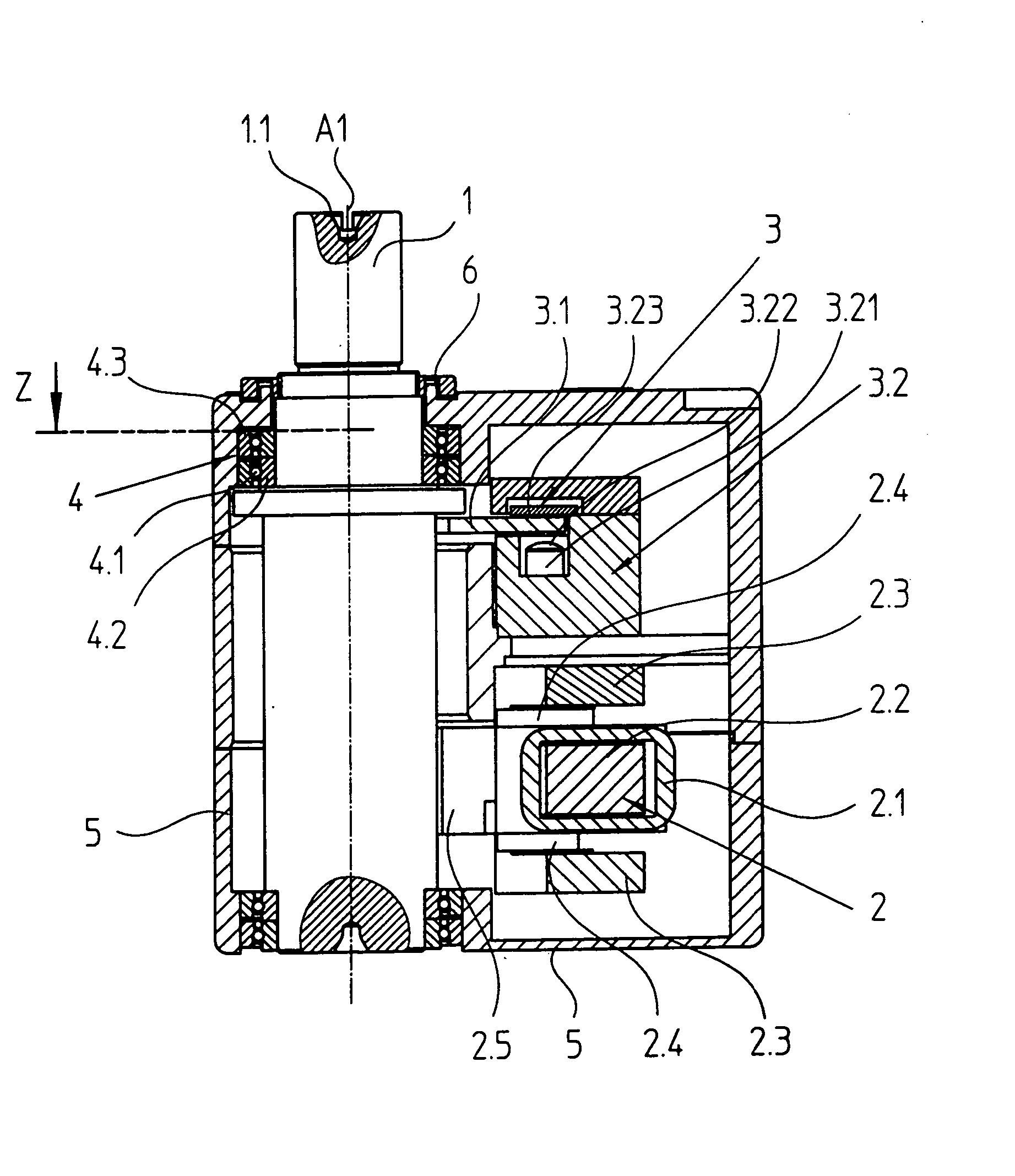

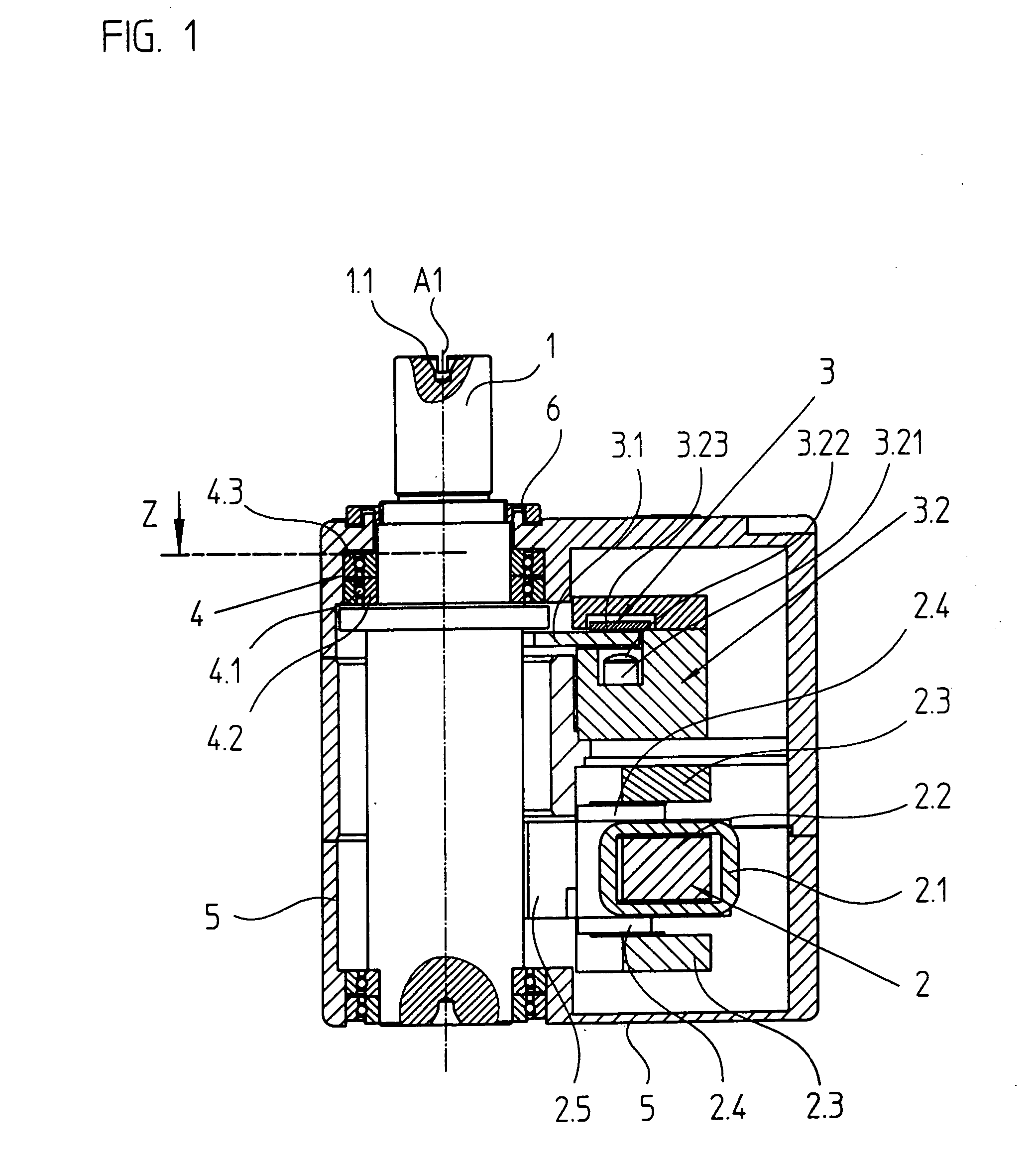

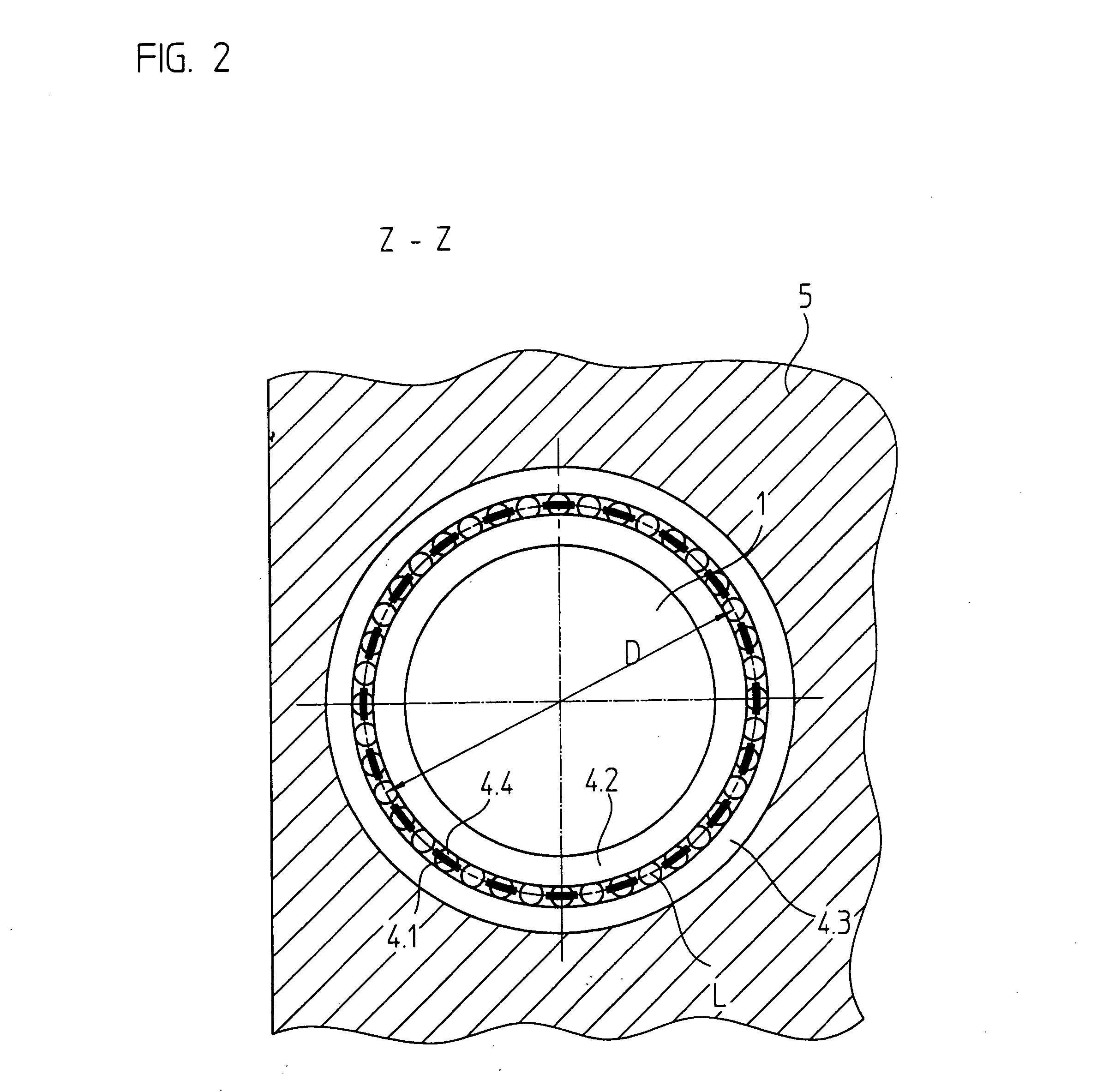

Positioning device

InactiveUS20050134993A1Easy to operatePrecise positioningDriving/moving recording headsRecord information storageEngineeringMechanical engineering

A positioning device includes a swiveling shaft, at one end of which an element to be positioned may be attached, a swivel drive, made up of a rotor, which is movable relative to a stator, a position measuring device, made up of two parts movable relative to each other, and a roller bearing, which includes several rolling elements. The rotor of the swivel drive and a first part of the position measuring device are connected to the shaft in a rotatably fixed manner. The rolling elements are made of a ceramic material.

Owner:DR JOHANNES HEIDENHAIN GMBH

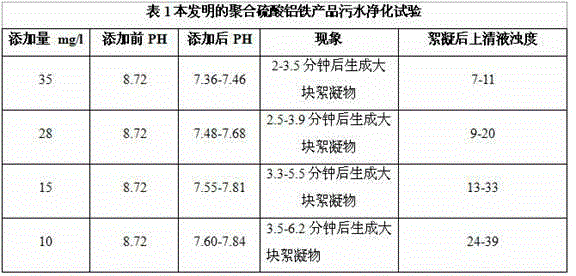

Method for producing polymeric aluminium ferric sulfate solution from industrial waste sulfuric acid generated during purification of acetylene gas and red mud

ActiveCN104445441ARealize comprehensive utilizationSave processing powerIron sulfatesWater/sewage treatment by flocculation/precipitationPhosphateRed mud

The invention discloses a method for producing a polymeric aluminium ferric sulfate solution from industrial waste sulfuric acid generated during purification of acetylene gas and red mud. The method comprises the following steps: adding water to the red mud to pulp the red mud, mixing the pulped red mud with waste sulfuric acid in a weight ratio of (2-5) to 1, stirring and mixing the materials to react for 1-4 hours to obtain a reaction mixture, standing to leach the mixture for 6-12 hours to obtain leachate, filtering the leachate to obtain filtrate, extracting rare metal impurities in the filtrate with di(isooctyl) phosphate, extracting organic matter impurities in a solution with an extracting agent and alkalifying and polymerizing raffinate to obtain the polymeric aluminium ferric sulfate solution with polymeric aluminium ferric sulfate mass content not less than 8% (in terms of aluminium ferric oxide). The method has the positive beneficial effects that the existing and potential environmental problems caused by discharge of the waste sulfuric acid after neutralizing treatment or direct discharge of the waste sulfuric acid and stacking and storage of the red mud on the land are solved; the polymeric aluminium ferric sulfate product capable of purifying sewage is produced from the waste sulfuric acid and the red mud, thus reducing environmental pollution caused by the waste sulfuric acid and the red mud; the process is simple and is easy to operate, so that the waste treatment cost is reduced; when serving as a flocculating agent, the prepared polymeric aluminium ferric sulfate product has the advantages of high settling time, large flocs, few metal residues and good sewage purifying effects.

Owner:河南开祥精细化工有限公司

Preparation method of sulfide heavy metal trapping agent C2H4N2S4

InactiveCN102942512AReduce dosageReduce manufacturing costOrganic chemistryWater/sewage treatmentTrappingSulfide

The invention discloses a preparation method of sulfide heavy metal trapping agent C2H4N2S4. Cyclohexanol and acetone are prepared according to a certain volume ratio and used as a mixed solvent, carbon disulfide is dissolved in the mixed solvent to obtain a carbon disulfide mixed solution, the carbon disulfide mixed solution is slowly added in hydrazine hydrate in dropwise mode under stirring state according to a certain molar ratio, reaction is performed at a certain temperature, suction filtration is performed on reaction products, a filter cake is washed through absolute ethyl alcohol, and C2H4N2S4 can be obtained. The method selects cyclohexanol to replace ethylene glycol, can greatly reduce dosage of cyclohexanol in the mixed solvent, simultaneously improves product yield, and reduces production cost of C2H4N2S4.

Owner:NANJING NORMAL UNIVERSITY

Heavy metal wastewater treatment agent and preparation method of heavy metal wastewater treatment agent

InactiveCN105540812AShort settling timeGood effectWater contaminantsWater/sewage treatmentChemistryAluminium

The invention discloses a heavy metal wastewater treatment agent and a preparation method of the heavy metal wastewater treatment agent. The heavy metal wastewater treatment agent is prepared from the following raw materials in parts by weight: 3 to 8 parts of polyacrylamide, 15 to 22 parts of phosphorus ferric polychloride, 12 to 18 parts of gypsum, 20 to 28 parts of zeolite, 10 to 15 parts of sodium lignin sulfonate, 6 to 10 parts of polymerized ferric phosphate, 50 to 58 parts of water, 3 to 8 parts of calcium oxide, 12 to 18 parts of aluminum hydroxide, 3 to 8 parts of calcium chloride, 5 to 10 parts of active carbon, 12 to 15 parts of aluminum potassium sulfate and 5 to 8 parts of diatomite. The heavy metal wastewater treatment agent is prepared by treating the polyacrylamide, the phosphorus ferric polychloride, the polymerized ferric phosphate, the calcium chlorid, the sodium lignin sulfonate and the zeolite by high-pressure water steam to prepare a mixture A, mixing the gypsum, the calcium oxide, the aluminum hydroxide, the active carbon, the aluminum potassium sulfate, the diatomite and the water, and carrying out ultrasonic treatment to obtain a mixture B, and putting the mixture A into the mixture B and treating. The heavy metal wastewater treatment agent disclosed by the invention has a chelating effect on heavy metal, has the advantages of short precipitation time, good effect, low cost and complete treatment, and can be widely applied to the field of heavy metal wastewater treatment.

Owner:范洲卫

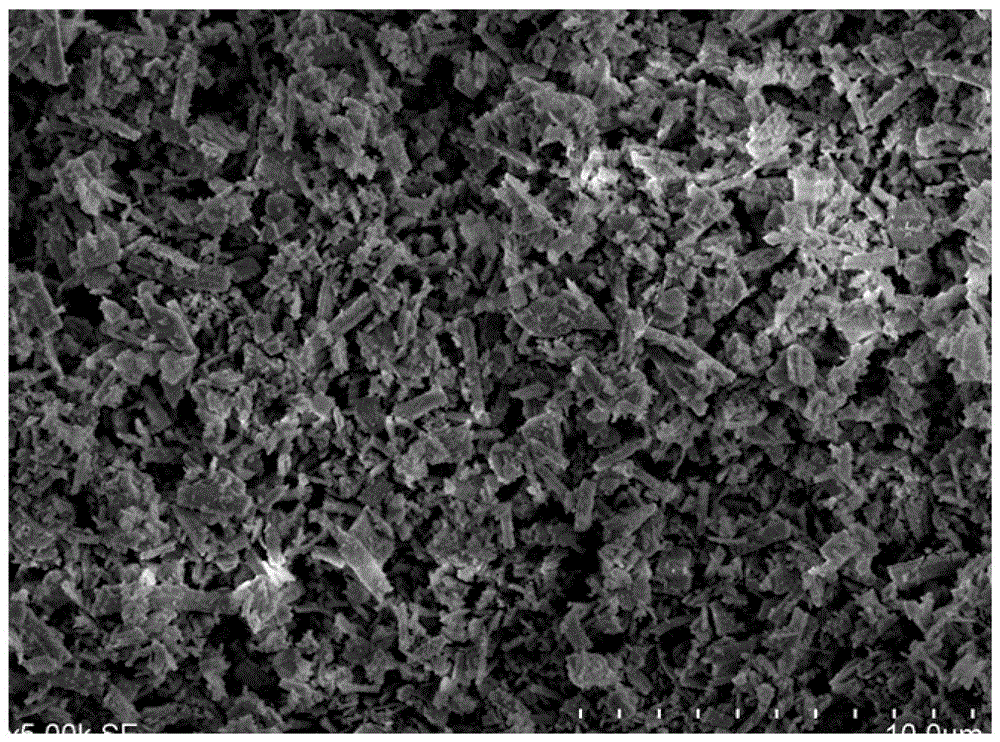

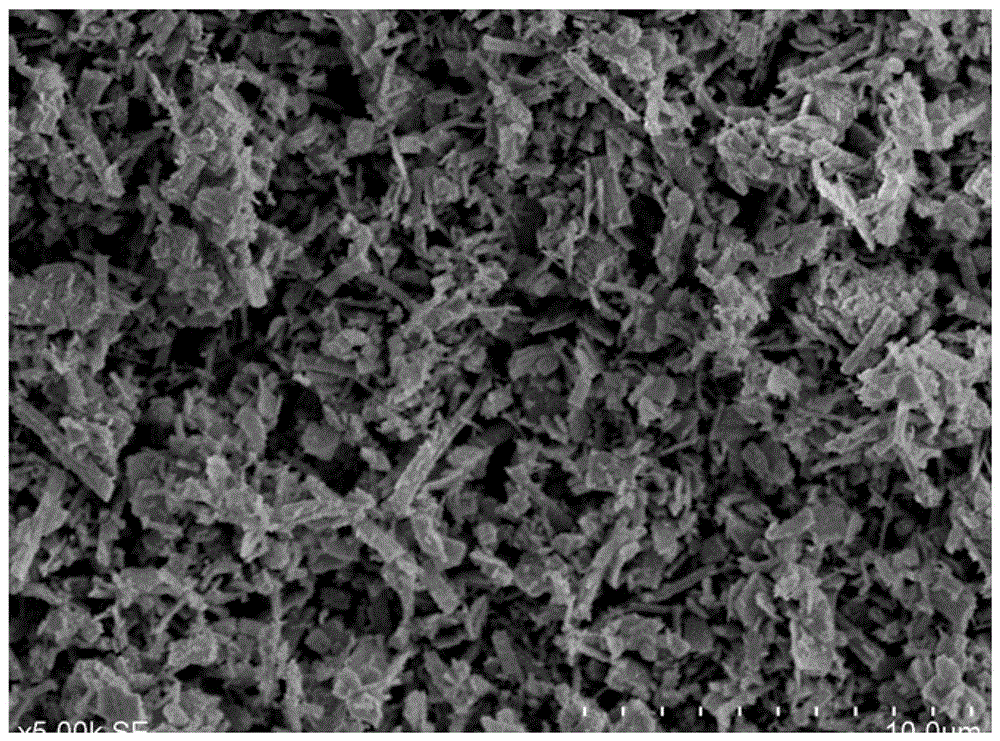

Preparation method of 1-2-micron samarium oxide

ActiveCN106044834AUniform particlesEasy to operateRare earth metal oxides/hydroxidesOxalatePolyethylene glycol

The invention discloses a preparation method of 1-2-micron samarium oxide. The preparation method comprises the following steps: step 1, the concentration of oxalic acid is 0.8-1.5 mol / L, pH is regulated to 3-5 with an ammonia water solution with the mass fraction of 28%, and a dispersing agent polyethylene glycol accounting for 5%-10% by mass of samarium oxide is added; the concentration of a samarium chloride solution is 0.8-2.0 mol / L, and pH is regulated to 2 with the ammonia water solution with the mass fraction of 28%; step 2, oxalic acid and the samarium chloride solution are proportioned in the mole ratio being 1.8:1, under the condition of constant temperature of 40-60 DEG C, the samarium chloride solution after pH value regulation in the step 1 is added to the oxalic acid solution after pH value regulation in the step 1, and precipitation is performed for 3-20 min; step 3, after a reaction, filtering and washing are performed; burning is performed at 900-1,000 DEG C and heat preservation is performed for 2 h; an ultrafine samarium oxide product with the particle size of 1-2 microns, uniform particle and rod-shaped morphology is obtained.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Flocculating agent for industrial wastewater treatment and manufacturing method thereof

InactiveCN105217756AShort flocculation and sedimentation timeSettling time is shortWater/sewage treatment by flocculation/precipitationPhosphateHazardous substance

The invention discloses a flocculating agent for industrial wastewater treatment and a manufacturing method thereof, and belongs to the field of water treatment agents. The flocculating agent is manufactured from, by weight, 8-18 parts of polyacrylamide, 5-15 parts of ferrous sulfate, 3-9 parts of aluminum potassium sulphate, 4-12 parts of polysilicate, 4-12 parts of aluminium polychlorid, 8-12 parts of polyoxyethylene, 5-10 parts of barium carbonate, 10-25 parts of tripoli, 8-18 parts of zinc chloride, 3-9 parts of aluminium chloride, 5-15 parts of polymeric phosphate-ferric chloride, 1-5 parts of polymeric ferric phosphate and 50-70 parts of water. The flocculating agent for industrial wastewater treatment is short in flocculent precipitate time, good in effect and low in cost, the active emulsifying ability of hydrones is improved, hazardous substances and heavy metal of water are degraded, high-concentration and high-turbidity wastewater and non-degradable wastewater can be effectively treated particularly, the flocculating agent can be widely used for municipal wastewater and various industrial wastewater treatment and polluted river and lake water treatment, and the treated water can be recycled.

Owner:GUILIN CHUNXIAO ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method for attapulgite clay nanorod crystal composite microsphere adsorbent

ActiveCN104069801AGuaranteed adsorption effectLarge specific surface areaOther chemical processesAlkali metal oxides/hydroxidesActivated attapulgiteSorbent

The invention relates to a preparation method for an attapulgite clay nanorod crystal composite microsphere adsorbent. According to the method, hydrochloric acid activated attapulgite clay nanorod crystals, concentrated ammonia liquor, ethyl orthosilicate, water and a solvent--absolute ethyl alcohol are reacted at a certain temperature, and through hydrolytic condensation and bonding of ethyl orthosilicate, a loose microsphere is formed by the attapulgite clay nanorod crystals. A loose microsphere composite material is formed by bonding each single attapulgite clay nanorod crystal with silica produced after hydrolytic condensation of ethyl orthosilicate, so the preparation method is simple; and the prepared microsphere composite material has good adsorption performance and has good application prospects in the field of sewage treatment.

Owner:LANZHOU UNIVERSITY

Sewage treating agent

InactiveCN107055724AThorough treatmentEasy to recycleBiocideDead animal preservationWater sourceHazardous substance

The invention discloses a sewage treating agent, and relates to the technical field of sewage treatment. The sewage treating agent is prepared from, by weight, 12 parts of active carbon, 15 parts of sepiolite powder, 35 parts of corn starch, 0.3 part of sodium hydroxide caustic soda flake, 4 parts of polyaspartic acid, 0.3 part of amino trimethylene phosphonic acid, 35 parts of polyaluminium chloride, 28 parts of chitosan, 5 parts of diatomite, 15 parts of polyaspartic acid, 4 parts of graphene nanolayer composite, 18 parts of crosslinking rectorite, 20 parts of zeolite, 18 parts of sulfate, 12 parts of polyacrylamide, and 35 parts of deionized water. The active carbon and zeolite are applied to physically absorb pollutants in the water, in particular to ultramicron molecule; other pollutants in the water are differentiated through other components; suspended solids are treated by sulfate and other flocculants; harmful substances are coated while chrome and other heavy metals are agglutinated by means of attraction and rejection among ultramicron particles; thus the harmful substances are not dissolved, and the fundamental sewage treatment is realized, and the harmless recycled water source is guaranteed.

Owner:冯志容

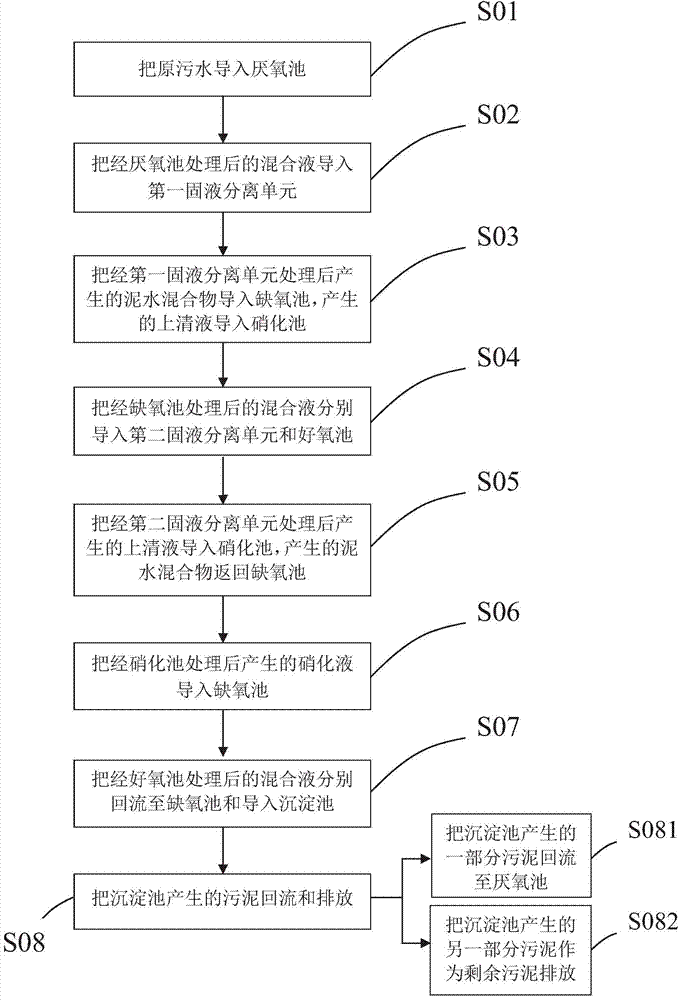

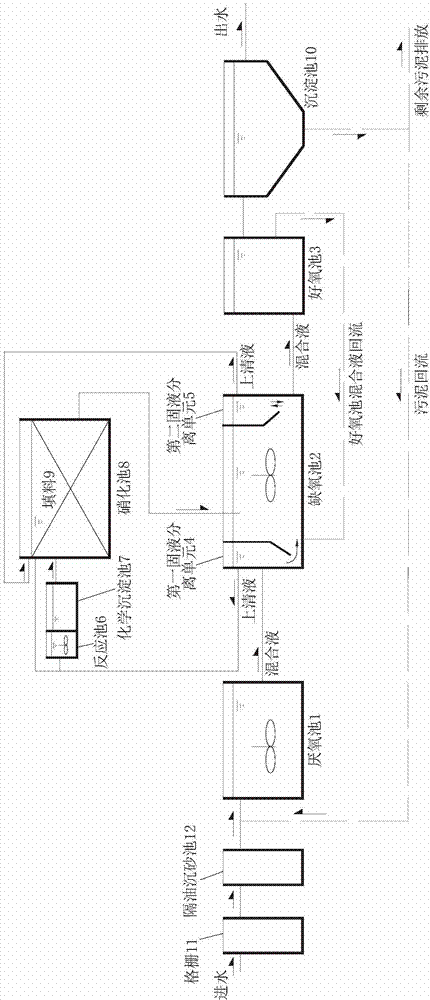

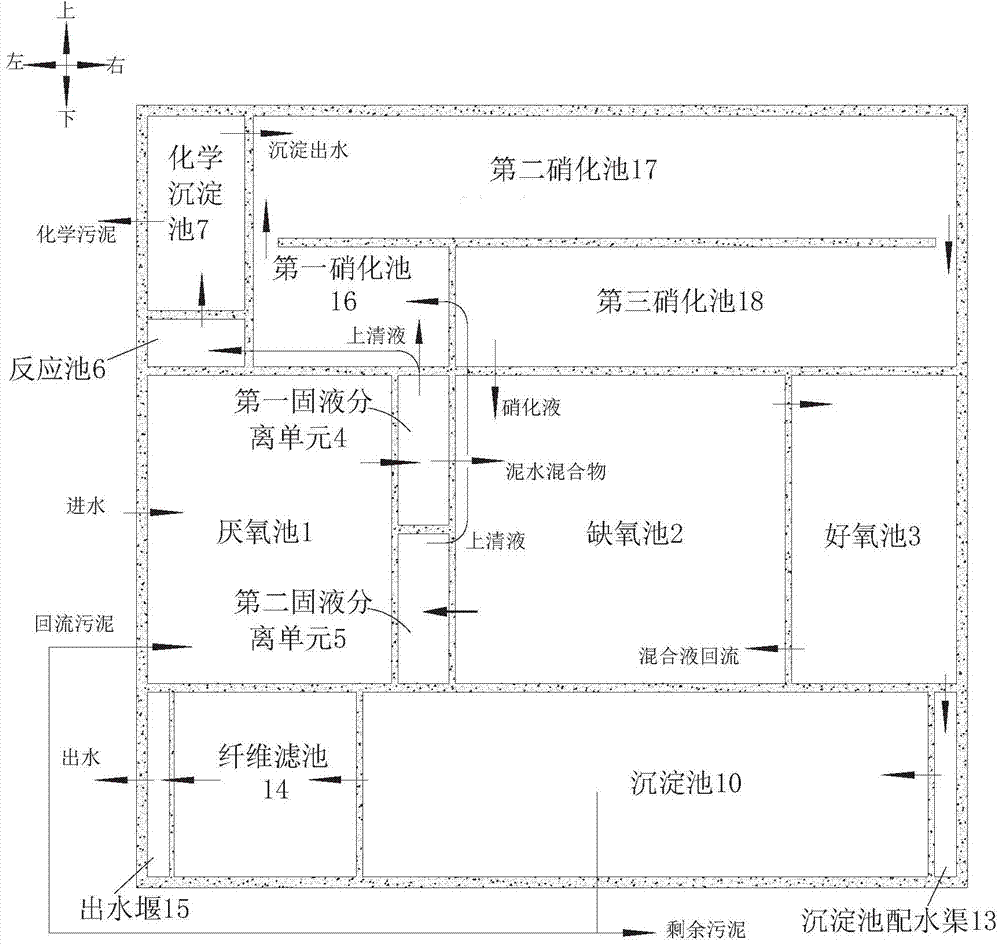

Method and device for advanced sewage nitrogen and phosphorus removal

ActiveCN103482829AOvercoming the Sludge Age (SRT) ParadoxSolve problemsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentNitrogen removalAfter treatment

The invention discloses a method and device for advanced sewage nitrogen and phosphorus removal. The method comprises the steps of (I) guiding raw sewage into an anaerobic tank; (II) guiding the mixed liquid after treatment in the anaerobic tank into a first solid-liquid separation unit, guiding the supernate into a nitrifying tank, and guiding the produced mud-water mixture into an anoxic tank; (III) guiding the mixture after treatment in the anoxic tank into a second solid-liquid separation unit and an aerobic tank respectively; (IV) guiding the supernate produced after treatment by the second solid-liquid separation unit into the nitrifying tank, and returning the mud-water mixture into the anoxic tank; (V) guiding the nitrified liquid after treatment in the nitrifying tank into the anoxic tank; (VI) enabling the mixed liquid after treatment in the aerobic tank to flow back to the anoxic tank, and guiding into a sedimentation tank; (VII) performing backflow and discharge on the sludge produced by the sedimentation tank. By adopting the method and device disclosed by the invention, the competition conflict for a carbon source between phosphorus removal and nitrogen removal of the sewage treatment system is solved, advanced sewage phosphorus and nitrogen removal can be realized, and the standing time of the solid-liquid separation unit is short. The method and the device are suitable for building a new sewage plant, and the transformation of an existing sewage plant is easily realized by separating tanks of the A2 / O technology.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

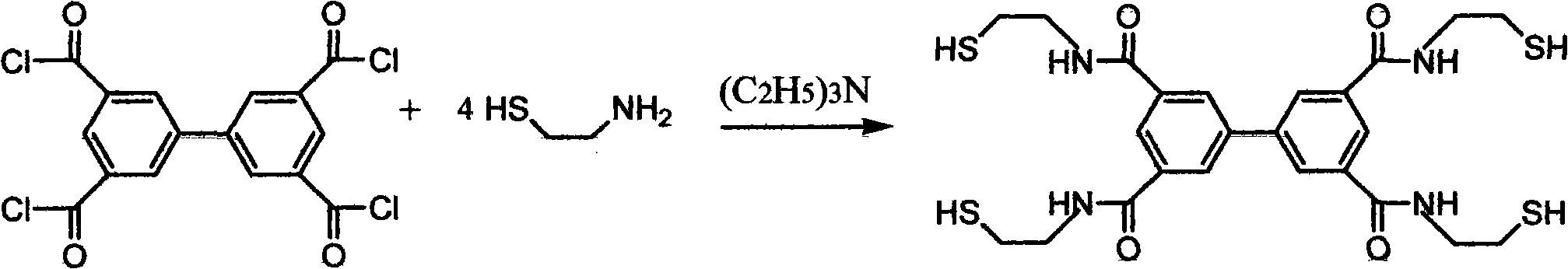

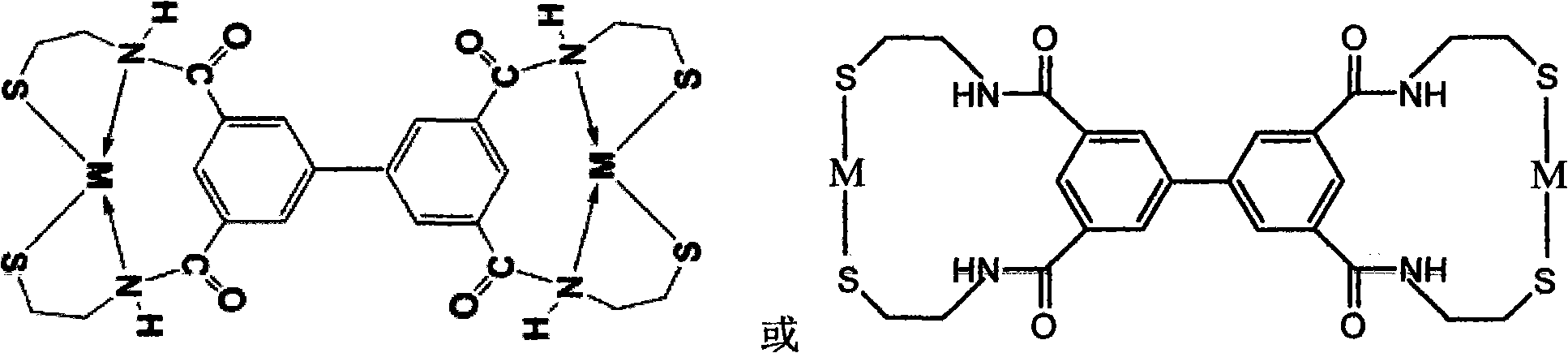

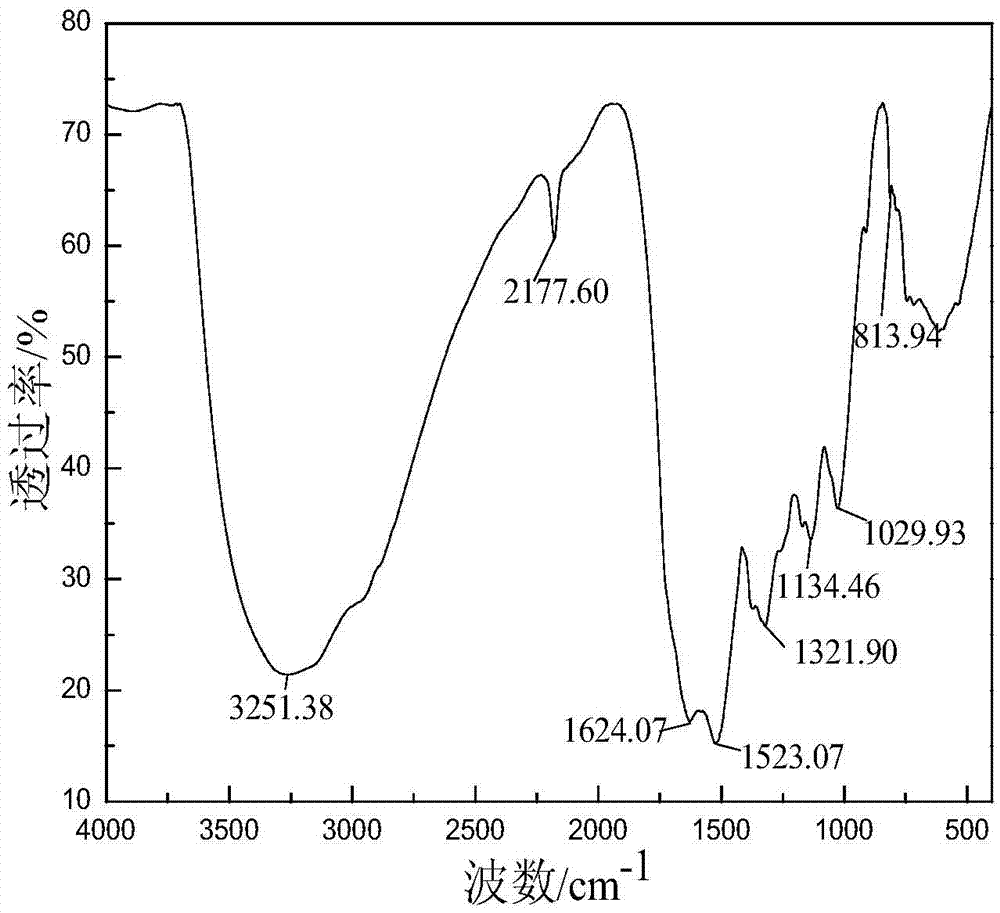

Sulfide heavy metal chelating trapping agent and preparation method thereof

InactiveCN101898824ADense flocSettling time is shortThiol preparationWater/sewage treatmentRotary evaporatorTrapping

The invention discloses a sulfide heavy metal chelating trapping agent. The trapping agent is prepared by a method of: dissolving 550g of mercaptoethylamine hydrochloric acid into 3L of chloroform; adding 900g of triethylamine as an acid binding agent; adding 400g of 3,3',5,5'-biphenyl 4-formyl chloride into 2L of chloroform; stirring and mixing the two kinds of solution, wherein the stirring velocity is between 30 and 100 r.min<-1>; performing a condensation reaction in an ice bath for 3 to 8 hours under protection of nitrogen; filtering the mixture, and extracting with water and the chloroform respectively; and distilling out redundant solvent with a rotary evaporator to obtain a white precipitate, namely a target product. The trapping agent fast reacts with various heavy metal ions in waste water at the normal temperature and generates a water-insoluble sulfide precipitate. The sulfide heavy metal chelating trapping agent has the advantages of simple preparation process and convenient use. The particle size of the produced sulfide precipitate is large, the floc is compact, the precipitation time is reduced, the concentration of heavy metal ions in the waste water below the national discharging standard, generated residue can be used for recycling heavy metal, and no secondary pollution is generated, The trapping agent can also be used for recycling precious metal in aqueous solution.

Owner:南京正隆环保工程有限公司

Sewage treatment agent

InactiveCN105016438ALow costImprove adsorption capacityWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationDisinfectantTherapeutic effect

The present invention relates to the field of water treatment equipment, particularly to a sewage treatment agent, which comprises: 15-20 parts of an inorganic flocculant, 2-5 parts of a disinfectant, 15-25 parts of sodium chloride, 5-8 parts of sodium silicate, 0.5-1 part of calcium carbonate, and 30-35 parts of an adsorbent, wherein the main component of the inorganic flocculant is the hydroxyl and oxy polymer of Fe(III) Si(IV), and the main component of the adsorbent is bentonite. According to the present invention, the bentonite is adopted as the main raw material for the sewage treatment, such that the sewage treatment cost is reduced; and the calcium carbonate has characteristics of strong absorption and strong flocculation, such that the sedimentation time is short, and the sludge is less so as to further improve the sewage treatment effect and the sewage treatment efficiency.

Owner:天津市绿通环保工程设备开发有限公司

Water purifying agent

InactiveCN1406878AReduce potential harmSimple processWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateWater quality

A water cleaning agent is prepared from aluminium polyalumiante, iron polyaluminate, polyacrylamide and fluorescent whitening agent through mixing. Its advantages are high effect, low dosage, short period and no secondary pollution.

Owner:林品蓁

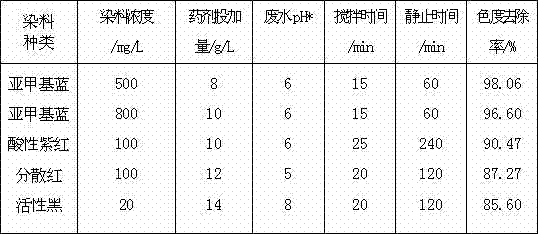

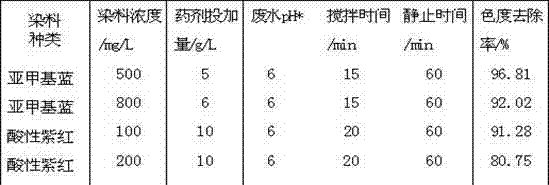

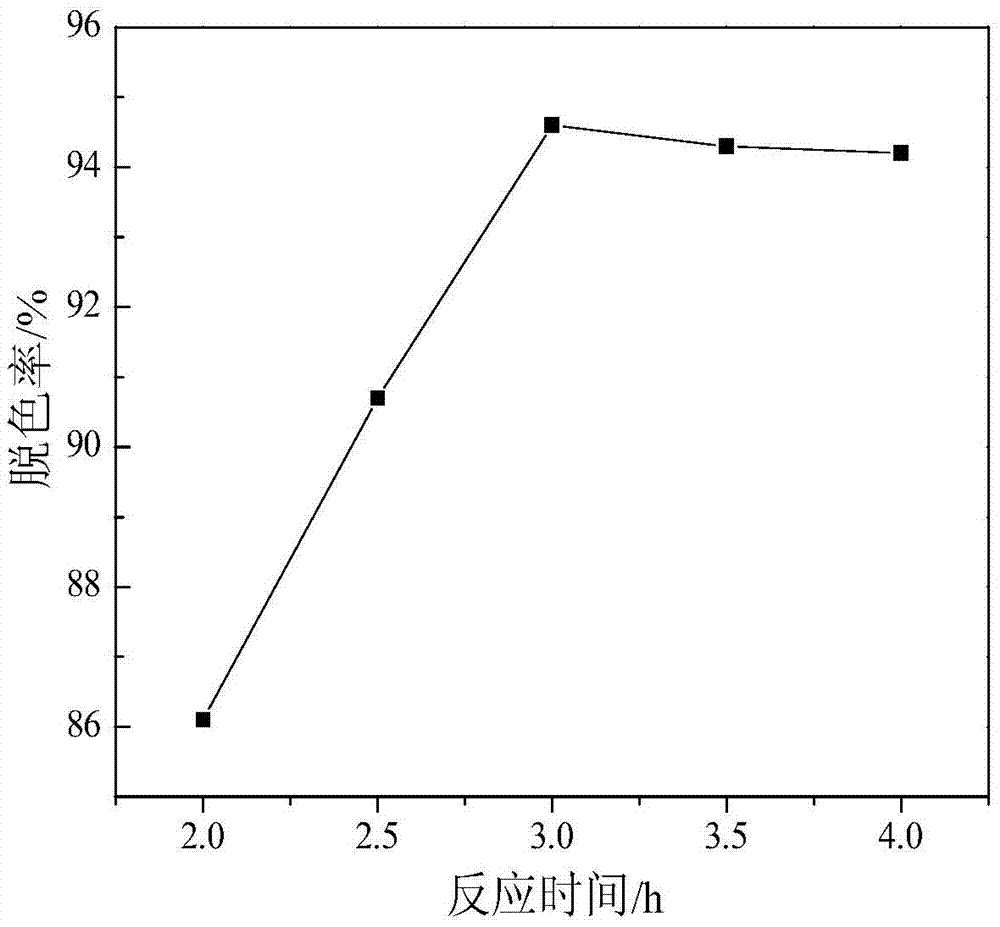

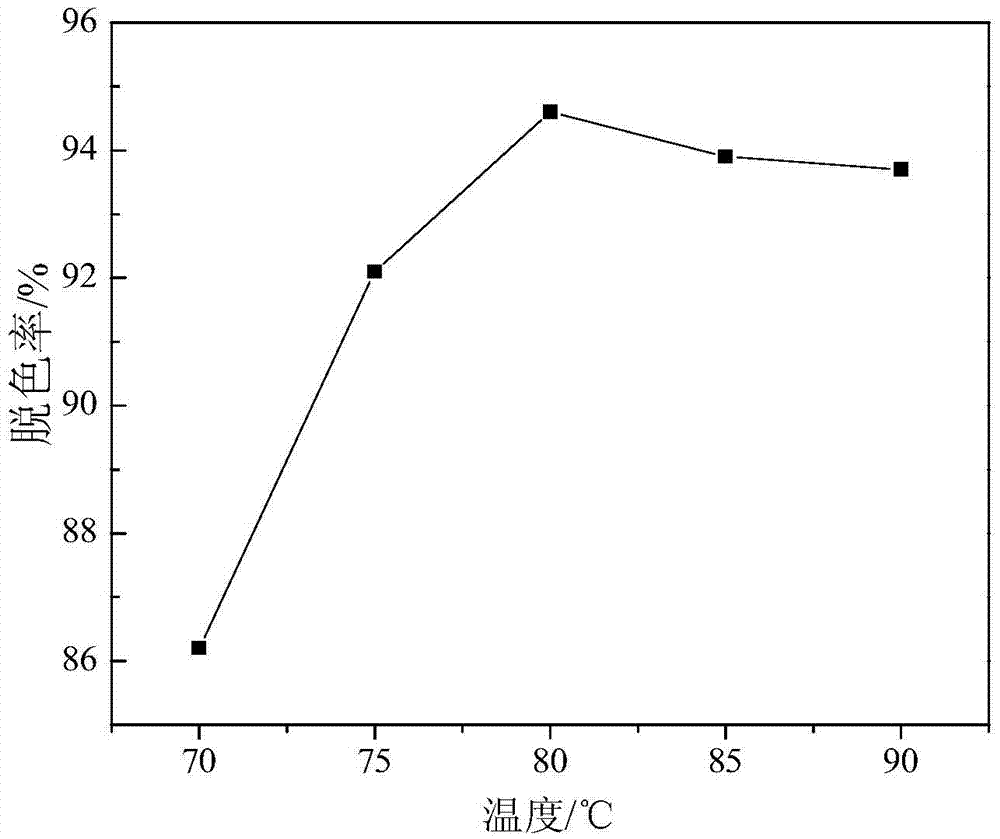

Composite decolorizing agent for printing and dyeing wastewater treatment

InactiveCN105439267AThe synthesis process is simpleHigh molecular weightWater treatment compoundsSpecific water treatment objectivesProcess engineeringDyeing wastewater

The invention provides a composite decolorizing agent for printing and dyeing wastewater treatment. The composite decolorizing agent is prepared from an organic flocculation decolorizing agent and an inorganic flocculation decolorizing agent. The composite decolorizing agent is mainly used for decolorizing the printing and dyeing wastewater, the organic flocculation decolorizing agent and an inorganic flocculation decolorizing agent are used in cooperation, decolorizing performance is improved, the use amount of the organic decolorizing agent can be reduced, and treatment cost can be reduced.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com