High-dryness conditioning and dehydrating method for sludge

A high-dryness, sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of limited magnetization, unstable dewatering effect, and difficulty in magnetization, and achieve uniform distribution, low cost of dewatering agents, and dewatering. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

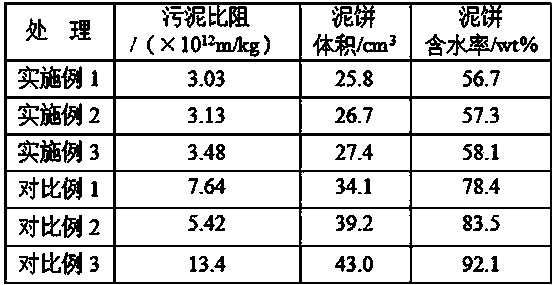

Examples

Embodiment 1

[0028] (1) Take 100mL of concentrated activated sludge (water content 97.5%), acidify it with industrial sulfuric acid to pH=5, stir the acidified sludge at a speed of 150rpm, add ferrous sulfate according to 6% of the dry weight of the sludge, and then press Add hydrogen peroxide 800mg / L to the sludge volume meter, and continue to stir and react for 15 minutes;

[0029] (2) Stir the sludge at a speed of 250rpm, add 100mg / L of magnetic powder, continue to stir for 10min, then add 150mg / L of polyferric sulfate, continue to stir for 10min, so that the coagulant and sludge particles are fully mixed;

[0030] (3) Stir the sludge at a speed of 60rpm, add a cationic polyacrylamide (CPAM) aqueous solution with a volume of 1.5v / v% of the sludge (pre-prepared cationic polyacrylamide into a 0.1wt% aqueous solution, and dissolve it for more than 1 hour) , stirred and reacted for 10 minutes, and the conditioning was completed;

[0031] (4) Pour the conditioned sludge evenly into the Buch...

Embodiment 2

[0033] (1) Take 100mL of concentrated activated sludge (water content 96.2%), acidify it with industrial sulfuric acid to pH=5, stir the acidified sludge at a speed of 150rpm, add ferrous sulfate according to 4% of the dry weight of the sludge, and then press Add hydrogen peroxide 600mg / L to the sludge volume meter, and continue to stir and react for 10 minutes;

[0034] (2) Increase the stirring speed to 250rpm, add 50mg / L magnetic powder, continue stirring for 10 minutes, then add 200 mg / L polyferric chloride, continue stirring for 10 minutes, so that the coagulant, magnetic powder and sludge particles are fully mixed;

[0035] (3) Reduce the stirring speed to 60rpm, add a cationic polyacrylamide (CPAM) aqueous solution with a volume of 1v / v% of the sludge (pre-prepared cationic polyacrylamide into a 0.1wt% aqueous solution, and dissolve it for more than 1 hour), and stir the reaction 5min, complete conditioning;

[0036] (4) Pour the conditioned sludge evenly into the Buch...

Embodiment 3

[0038] (1) Take 100mL of concentrated activated sludge (water content 97.3%), acidify it with industrial sulfuric acid to pH=5, stir the acidified sludge at a speed of 150rpm, add ferrous sulfate according to 4% of the dry weight of the sludge, and then press Add 600mg / L of hydrogen peroxide to the sludge volume meter, and continue to stir and react for 20 minutes;

[0039] (2) Increase the stirring speed to 250rpm, add 50mg / L magnetic powder, continue stirring for 10 minutes, then add 200 mg / L polyferric chloride, continue stirring for 10 minutes, so that the coagulant, magnetic powder and sludge particles are fully mixed;

[0040] (3) Reduce the stirring speed to 60rpm, add a cationic polyacrylamide (CPAM) aqueous solution with a volume of 2v / v% of the sludge (pre-prepared cationic polyacrylamide into a 0.1wt% aqueous solution, and dissolve it for more than 1 hour), and stir the reaction 5min, complete conditioning;

[0041] (4) Pour the conditioned sludge evenly into the B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com