Patents

Literature

53results about How to "High degree of dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

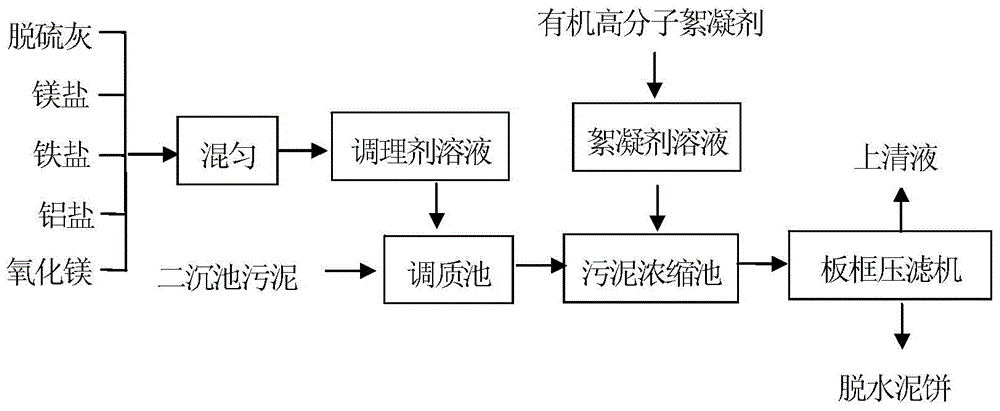

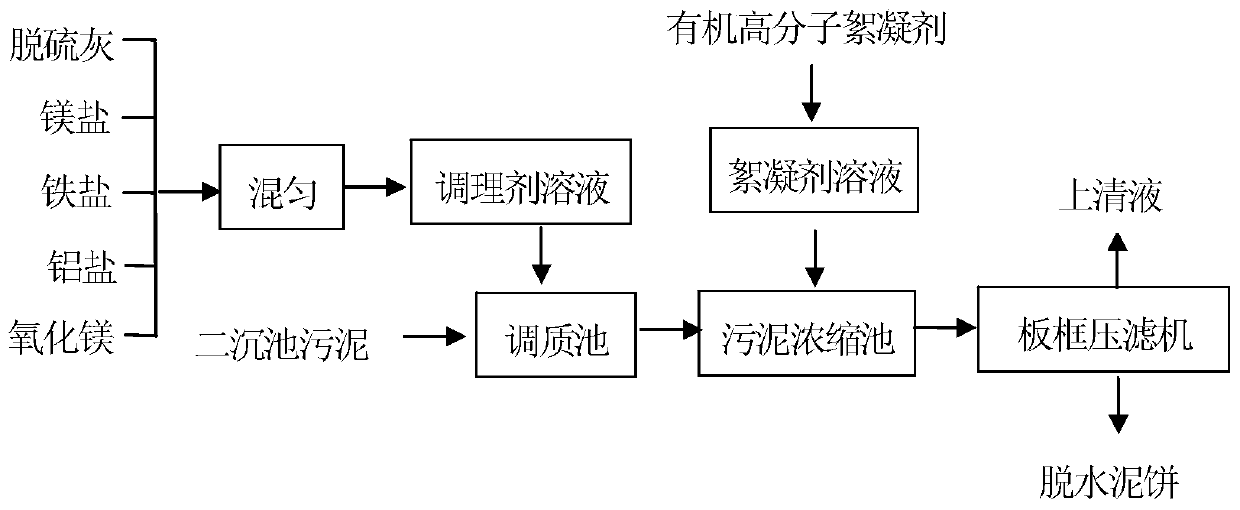

Sludge dewatering conditioning agent and dewatering method thereof

ActiveCN105314815AThe conditioning process is simpleReduce dosageSludge treatment by de-watering/drying/thickeningChemistryIron salts

The present invention discloses a sludge dewatering conditioning agent, which comprises, by weight, 30-70% of desulfurization ash, 5-15% of a magnesium salt, 5-30% of an iron salt, 2-20% of an aluminum salt, and 0.1-15% of magnesium oxide. The invention further provides a dewatering method of the conditioning agent, wherein the dewatering method comprises conditioning agent solution preparing, sludge conditioning, flocculant solution preparing, sludge dewatering and other steps. According to the present invention, the characteristics of wide used raw material source, and low raw material price, low preparation cost and good dewatering effect are provided, the method can be performed through the existing sludge dewatering facility, the implementation process is simple, the stability and the reliability of the sludge dewatering process can be effectively improved, and the sludge dewatering conditioning agent and the dewatering method can be widely used for treatments of various wastewater, sewage and sludge.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Conditioner for sludge dehydration and conditioning method

ActiveCN102001814ALow costEasy accessSludge treatment by de-watering/drying/thickeningCoal gangueIron salts

The invention discloses a conditioner for sludge dehydration. Based on the dry weight of the sludge to be treated, the formula of the conditioner contains 10 to 20 percent of iron salt, 10 to 20 percent of burnt lime, 10 to 20 percent of coal gangue and 0.01 to 0.05 percent of potassium permanganate bactericide. The invention also discloses a conditioning method for the conditioner for the sludge dehydration, which comprises the following steps of: adding the potassium permanganate bactericide into the sludge to be treated at normal temperature under normal pressure, treating the sludge for at least 2 minutes with stirring, and then adding the iron salt to react for at least 2 minutes; and then adding the burnt lime to adjust the pH value to be neutral, reacting the mixture for at least 2 minutes, adding the coal gangue to react for at least 2 minutes, and finally performing pressure filtration. The invention has the advantages of low cost, wide raw material source, no toxicity, environmental friendliness, short treatment time, high sludge dehydration degree and the like.

Owner:湖南多普生环境能源有限公司

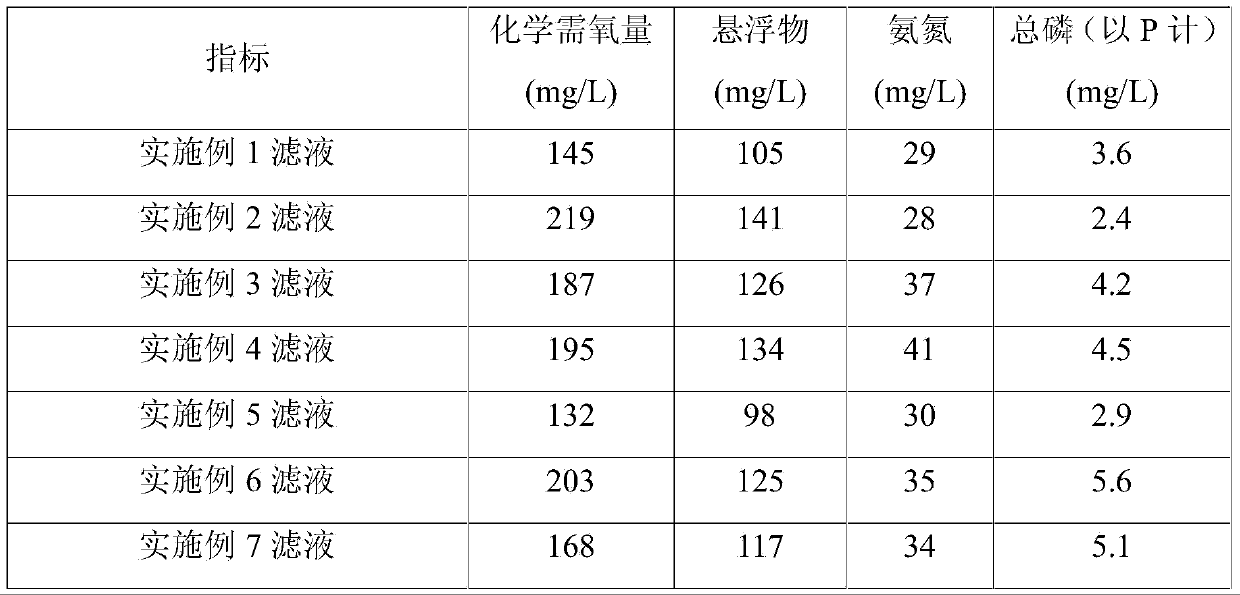

Deep dehydration recycling method for livestock and poultry feces

ActiveCN103723906AWide range of processingHigh degree of dehydrationSludge treatment by de-watering/drying/thickeningAnimal fecesFilter press

The invention relates to the field of livestock and poultry feces treatment methods, and in particular relates to a deep dehydration recycling method for livestock and poultry feces. The method specifically comprises the following steps: adjusting the pH value of the livestock and poultry feces to be 2-4, adding ferrite or ferric salt into the livestock and poultry feces with the adjusted pH value, uniformly stirring, subsequently adding hydrogen peroxide into the livestock and poultry feces, stirring for 50-180 minutes, adding a phosphorus curing agent into the treated livestock and poultry feces, adjusting the pH value to be 8.5-10.5, uniformly stirring, and performing filter pressing on the treated livestock and poultry feces by a filer press for dehydration. The method is high in speed, short in period, high in solid recycling rate, high in dehydration degree, low in energy consumption and low in cost.

Owner:HUNAN UNIV

Combined chemical conditioning method for deep drying of dehydrated sludge

ActiveCN105645732AHigh degree of dehydrationMeet the requirements for effective useSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationBound waterFiltration

The invention discloses a combined chemical conditioning method for deep drying of dehydrated sludge. The method comprises steps as follows: to-be-treated dehydrated sludge is diluted with water, so that the moisture content of the dehydrated sludge is 90%-93%, strong acid is added to adjust the pH value to range from 4 to 5 after dilution, then potassium ferrate with the adding amount accounting for 0.1%-0.5% of that of absolutely dried sludge amount is added in the form of a solution with the mass percent concentration of 0.5%-2% and the pH value of 9-11, and oxidation treatment is finished after stirring for full reaction; then poly-aluminum chloride salt with the adding amount accounting for 4%-10% of that of absolutely dried sludge amount is added for coagulation treatment; then calcium hydroxide with the adding amount accounting for 0.3%-1% of that of absolutely dried sludge amount is added to adjust the pH value to range from 6 to 7, finally, poly-quaternary ammonium salt with the adding amount accounting for 0.1%-0.3% of that of absolutely dried sludge amount is added for filtration aiding, and chemical conditioning is finished. Through optimized combination of dilution, acidification, oxidation, coagulation, flocculation, filtration aiding and the like, the effect of bound water on sludge can be reduced, indexes including specific resistance of sludge, compressibility, hydraulic characteristic and the like can be improved, the proportion of releasable free water can be effectively increased, and the sludge dehydrating effect can be improved.

Owner:BENGBU QIRUN ENVIRONMENTAL ENG TECH CO LTD

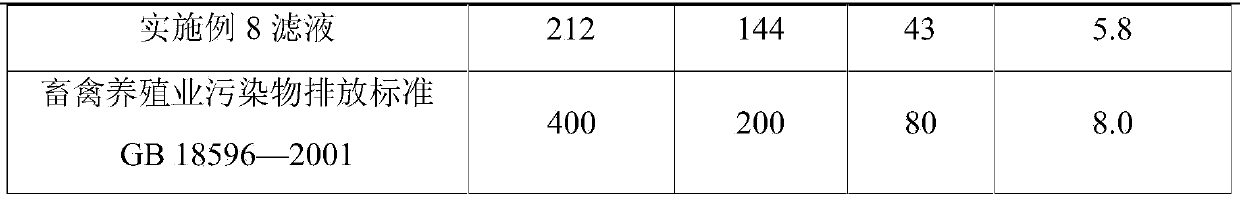

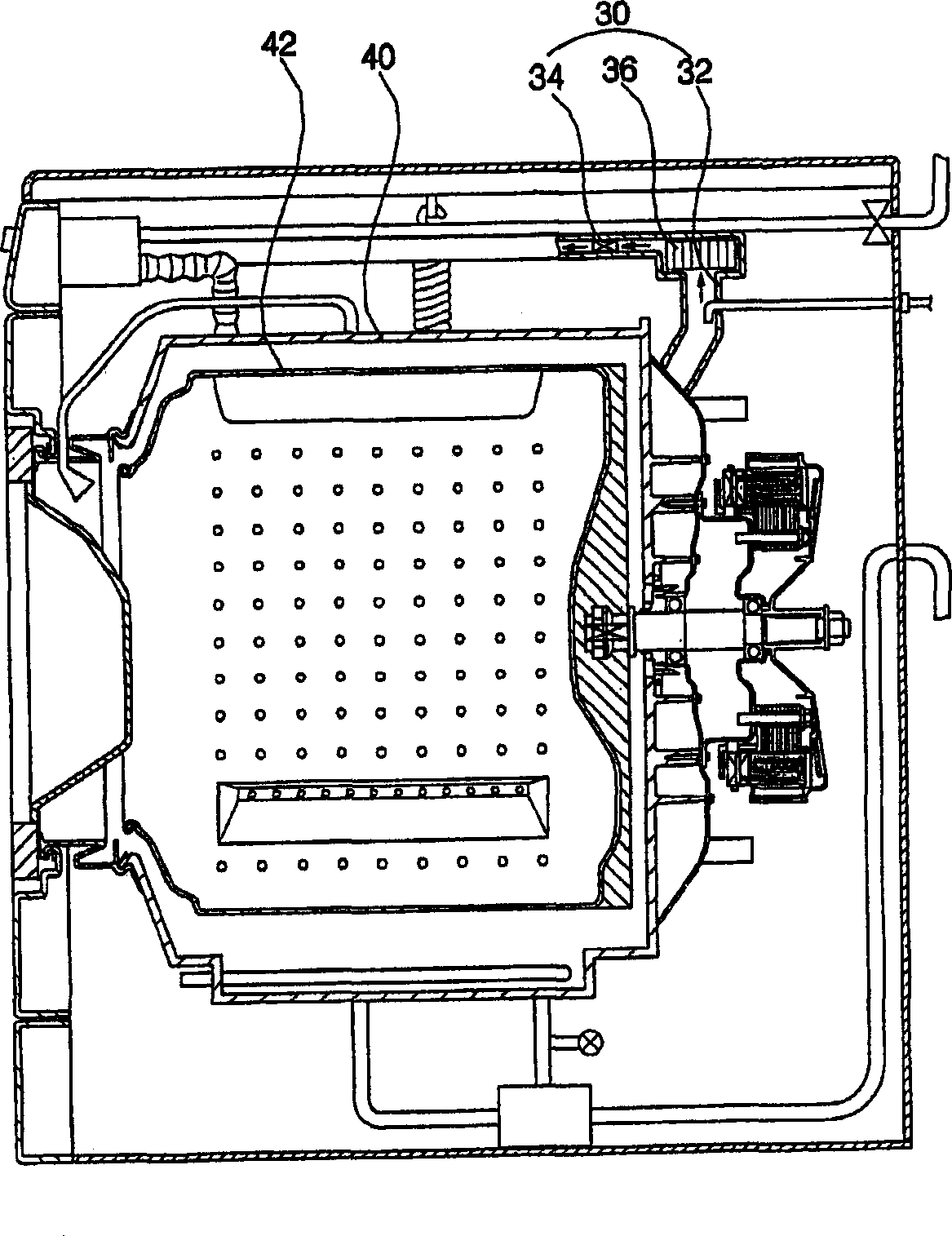

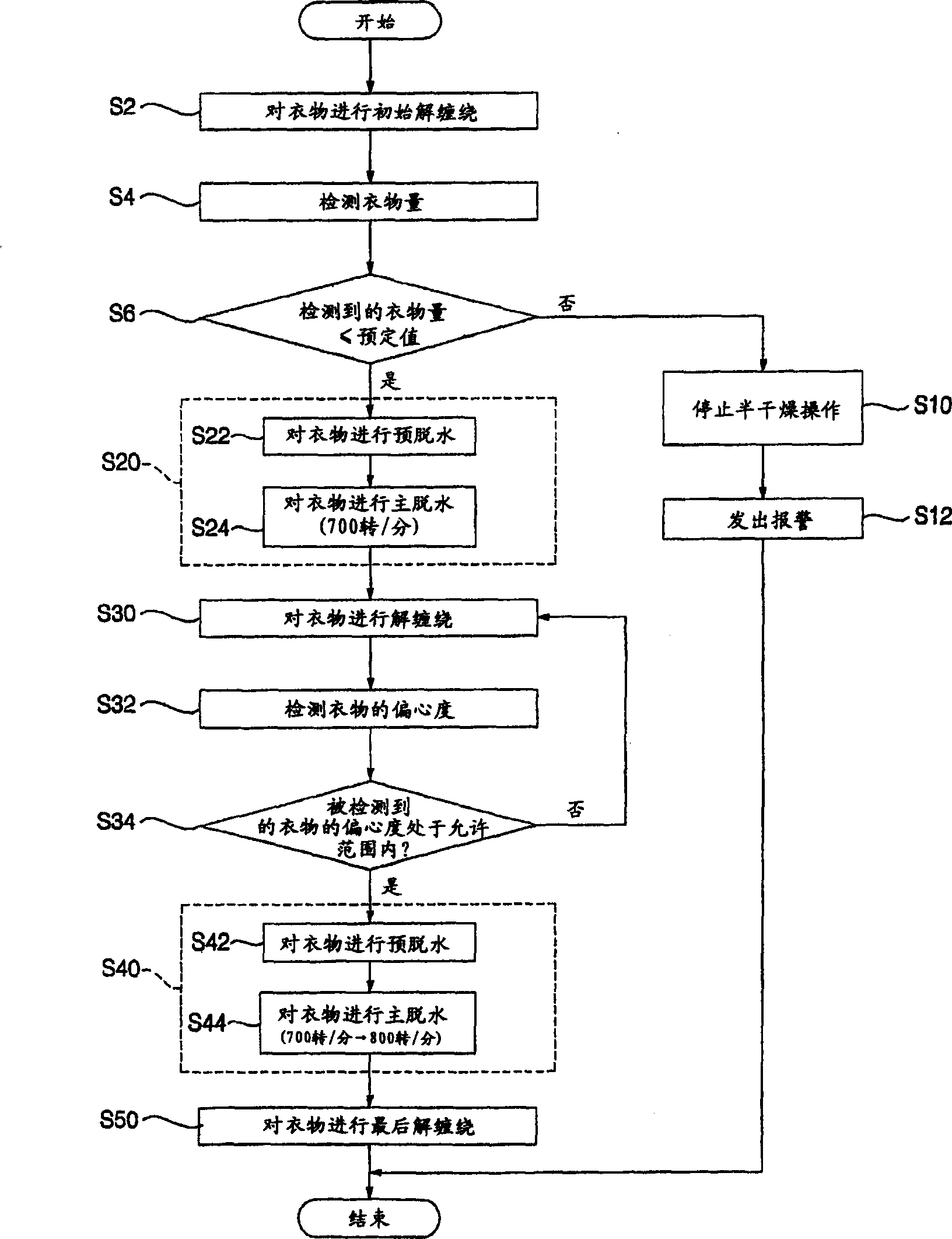

Semi-dry method of washing machine and the ventilating structure, control apparatus for the same

InactiveCN1856613AAvoid damageAvoid wrinklesControl devices for washing apparatusTextiles and paperProcess engineeringDehydration

A semi-drying method of a washing machine, and a ventilating structure and a control apparatus for the same. In the semi-drying method, the dehydration and disentanglement of cloth are repeated plural times, and a washing tub is rotated at a designated dehydration speed for a time longer than that of the conventional dehydrating operation so as to minimize the jamming of the cloth into water pores of the washing tub, thereby increasing the dehydration degree of the cloth compared to the conventional dehydrating operation, removing offensive odors from the cloth, preventing damage to the cloth, allowing a user to select the duration of a semi-drying operation and to see the state of the semi-drying operation, and ventilating the washing tub during the semi-drying operation to improve the dehydration degree of the cloth.

Owner:LG ELECTRONICS INC

Efficient inorganic environment-friendly conditioner for deep dewatering of sludge

ActiveCN103011549AReduce dosageEfficient curingSludge treatment by de-watering/drying/thickeningAdditive ingredientSludge

The invention discloses an efficient inorganic environment-friendly conditioner for deep dewatering of sludge. The efficient inorganic environment-friendly conditioner comprises the following ingredients by weight percent: 5-40% of MgO, 35-65% of Ca(OH)2, 5-50% of coal ash, 1-10% of magnetite ore tail, 1-10% of Al2O3, and 1-10% of KH2PO4. The environment-friendly conditioner is added to squeeze and dewater under the condition that the organic matter content of the municipal sludge is smaller than or equal to 45%, and the dewatering effect is obvious. The efficient inorganic environment-friendly conditioner disclosed by the invention is abundant in agent raw material source, low in price, economic and environment-friendly, and less in additive amount; the general additive amount is 10-30% of weight of dry sludge matter; the change range of the pH value of the sludge is small; the original property of the sludge is not changed; the sludge can be handled according to the property of the sludge after being dewatered; a part of active heavy metal in the sludge is cured, and the sludge disposal risk in land utilization can be reduced.

Owner:HANGZHOU WANDESI ENVIRONMENTAL PROTECTION TECH

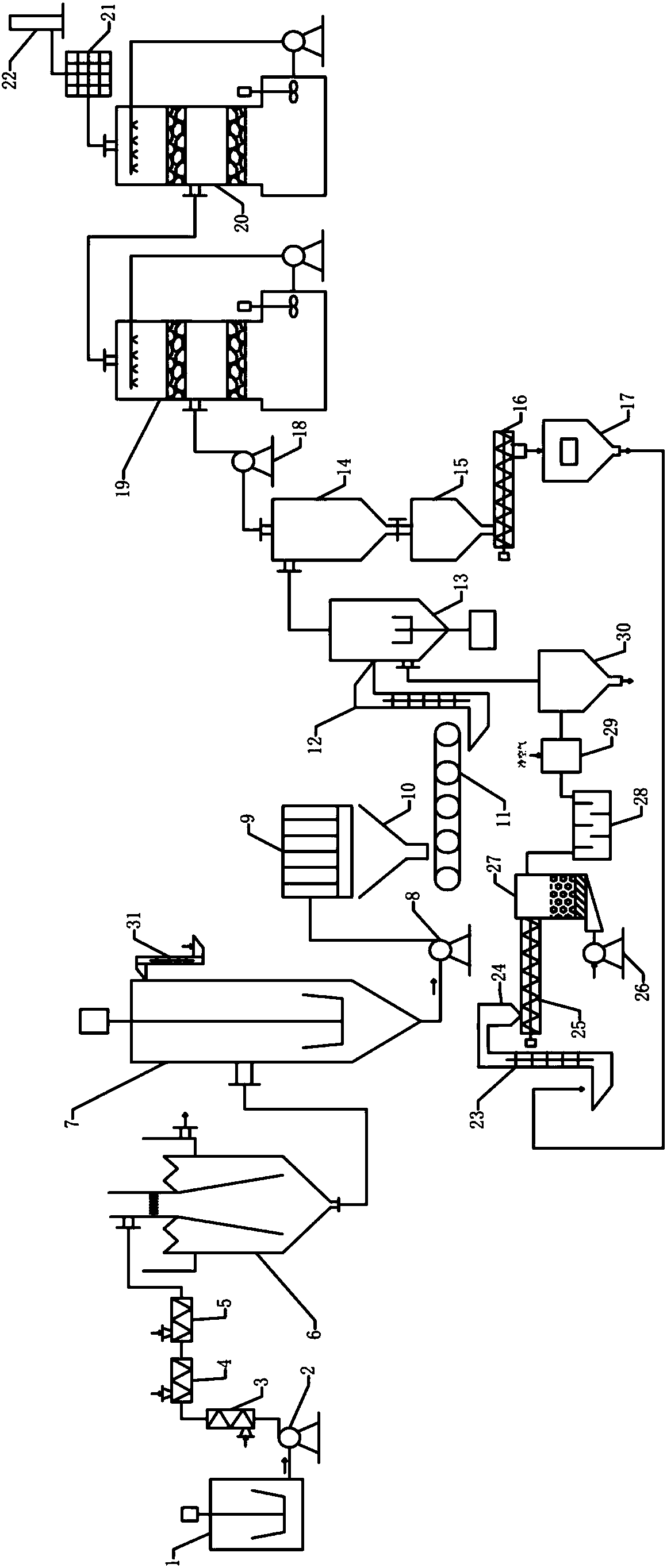

Self-heat-supply type sludge dewatering and drying method and system

PendingCN107867790AImprove the coagulation effectReduce dosageSludge treatment by de-watering/drying/thickeningGas treatmentFlocculationCombustion

The invention relates to a self-heat-supply type sludge dewatering and drying method and system. The dewatering and drying method comprises the following steps: firstly, adding a flocculation chemicalto to-be-treated sludge, and performing concentration and dewatering to obtain concentrated sludge; adding a sludge conditioner to the concentrated sludge, and stirring the sludge uniformly to obtainconditioned sludge; performing press filtration dewatering on the conditioned sludge to obtain a sludge filter cake; crushing and drying the sludge filter cake in high-temperature flue gas to obtaina dust and sludge mixture; conveying the dust and sludge mixture to a gas-solid separation device, and separating the sludge from the flue gas to obtain powdery sludge with water content being 15wt.%-20wt.%; feeding the sludge into a combustion heat supply mechanism after granulation, performing combustion to obtain high-temperature flue gas, cooling the high-temperature flue gas and conveying thehigh-temperature flue gas to a crushing and drying device. The method and the system are high in continuity and dewatering degree, the sludge treatment process is short, the operation cost is low, anexternally added heat source is not needed, so that energy cost is reduced greatly, and the sludge mass is further reduced by combustion.

Owner:HUNAN BAILIN BIOLOGICAL TECH

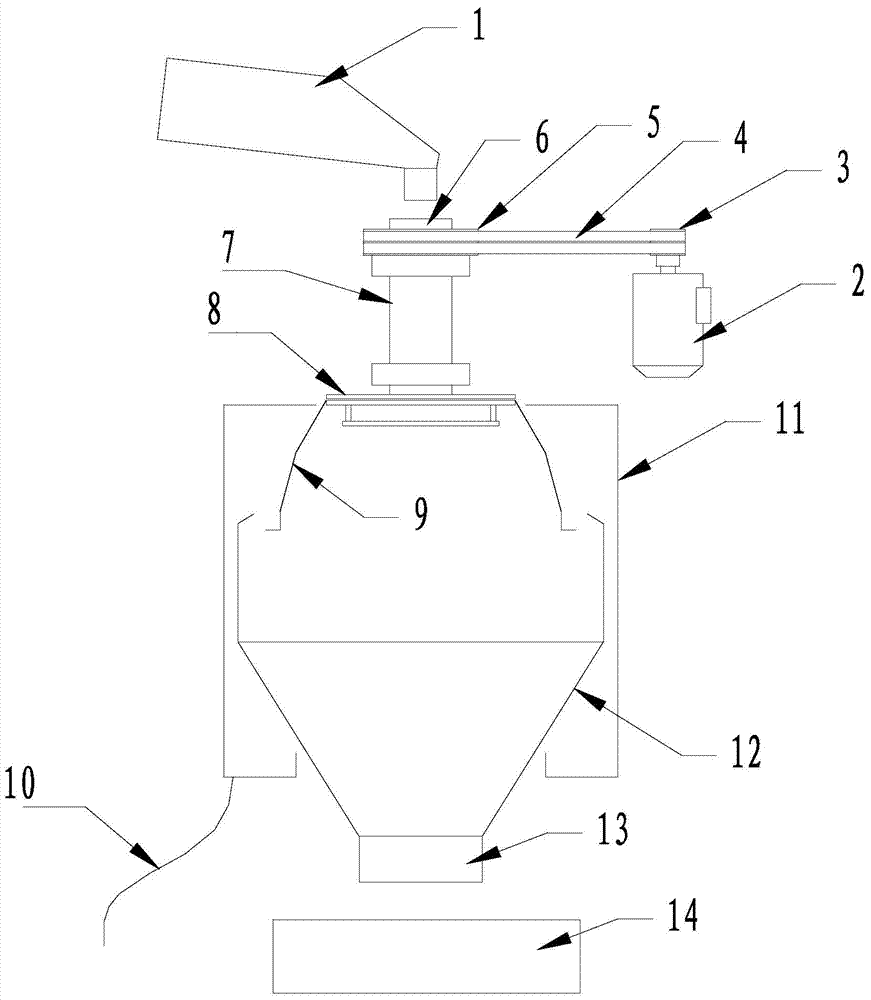

High-dryness conditioning and dehydrating method for sludge

ActiveCN103771682AImproved magnetizabilitySimple structureSludge treatment by de-watering/drying/thickeningPolymeric surfaceBound water

The invention discloses a high-dryness conditioning and dehydrating method for sludge. A compound conditioning agent is adopted, the strong oxidizing property of an oxidant, the flocculating function and magnetic field force function of magnetic powder and the electrical neutralization of an inorganic flocculating agent are organically combined with the adsorptive bridging function and the macromolecular sweeping and trapping effects of a compression double-electron layer and an organic flocculating agent, and the advantage of each conditioning agent is brought into play in a synergetic manner, so that the sludge structure and property are improved effectively, water in sludge cells and bound water on the surface of an extracelluar polymer are released, the dehydration performance of the sludge is improved remarkably, and high-dryness dehydration is realized. The method has the advantages of high sludge dehydration degree, good flocculating effect, short flocculating and settling time, high volume reduction rate and low dehydration cost.

Owner:广州福之源环保科技有限公司

Sludge dewatering method

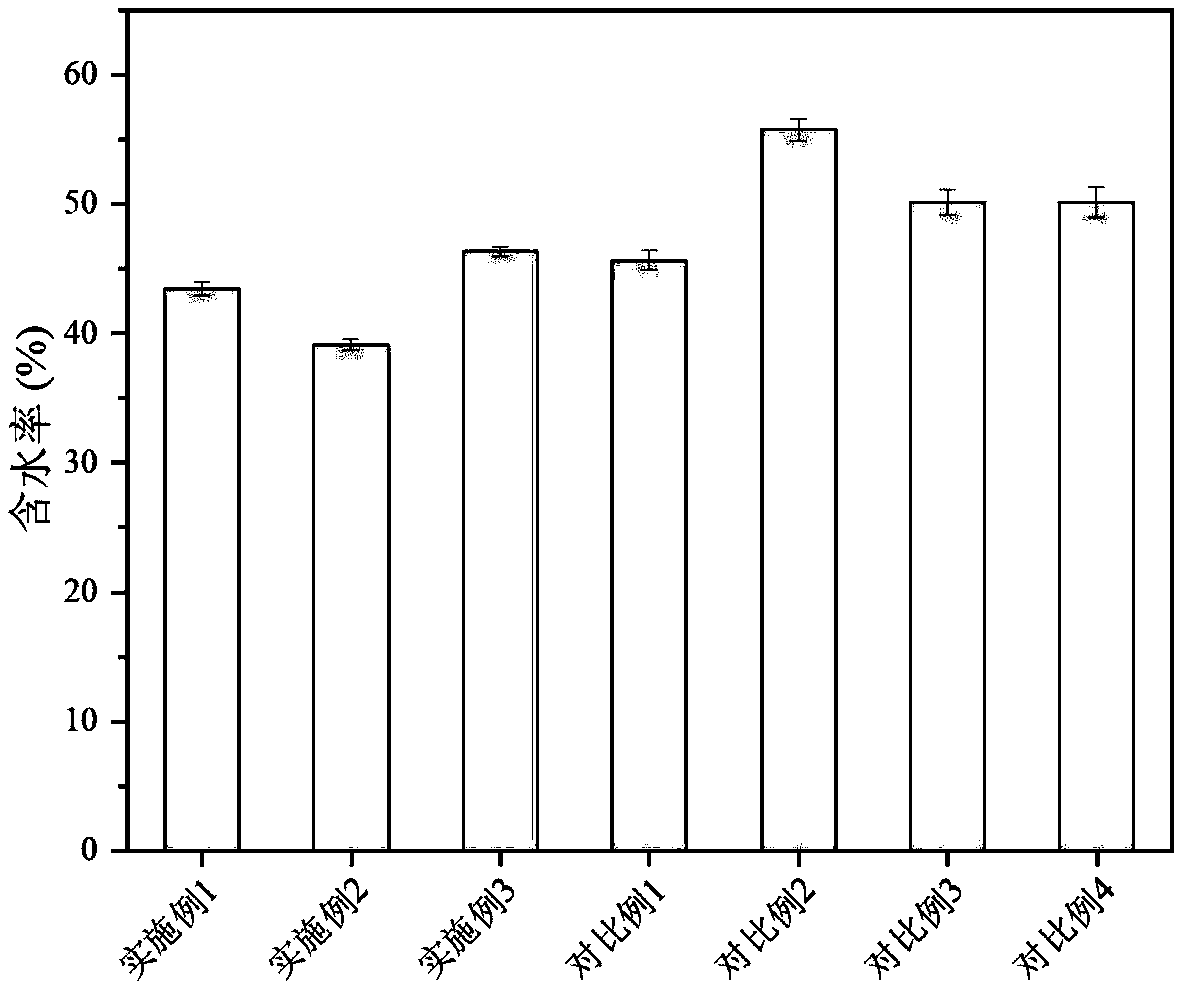

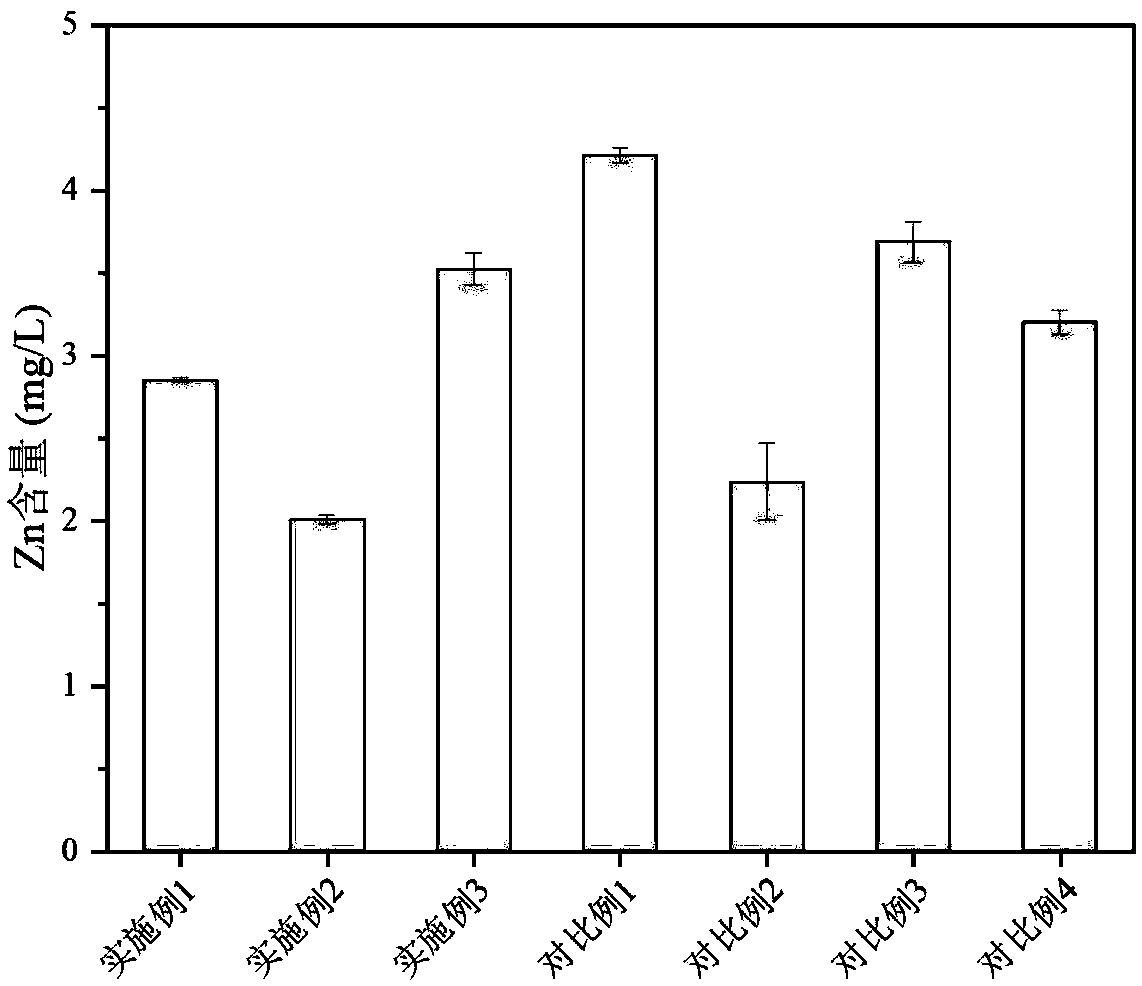

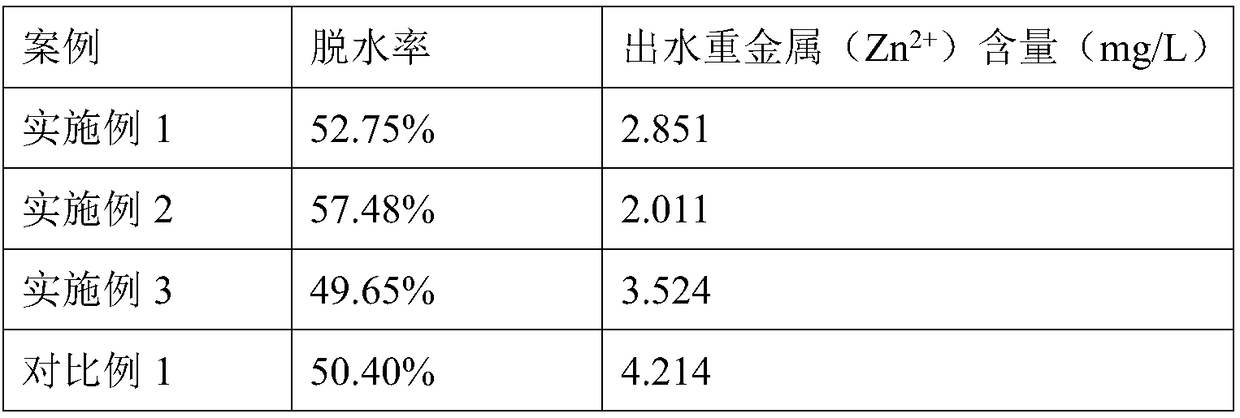

ActiveCN109368985AHigh degree of dehydrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningReaction systemToxic industrial waste

The invention belongs to the technical field of sludge treatment, and particularly discloses a sludge dewatering method. The method comprises the following steps: performing pre-reaction on sludge anda conditioner M; adding a flocculating agent to the pre-reaction system, and performing hydrothermal reaction under the sealed condition; finally, performing solid-liquid separation to recover waterin the pre-reaction system to obtain dry sludge. The conditioner M comprises industrial waste residues and an activator. According to the method, the content of heavy metals in water removed from thesludge is lower, and harmless treatment and reduction of the sludge are achieved.

Owner:肇庆市珈旺环境技术研究院

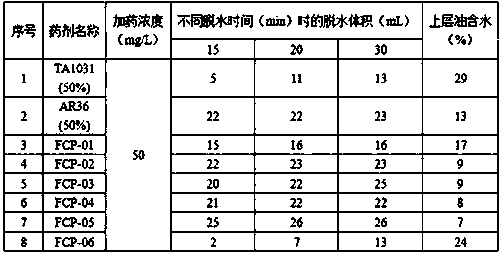

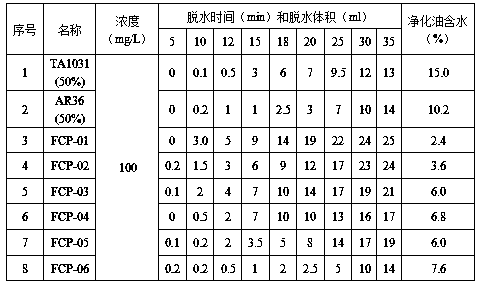

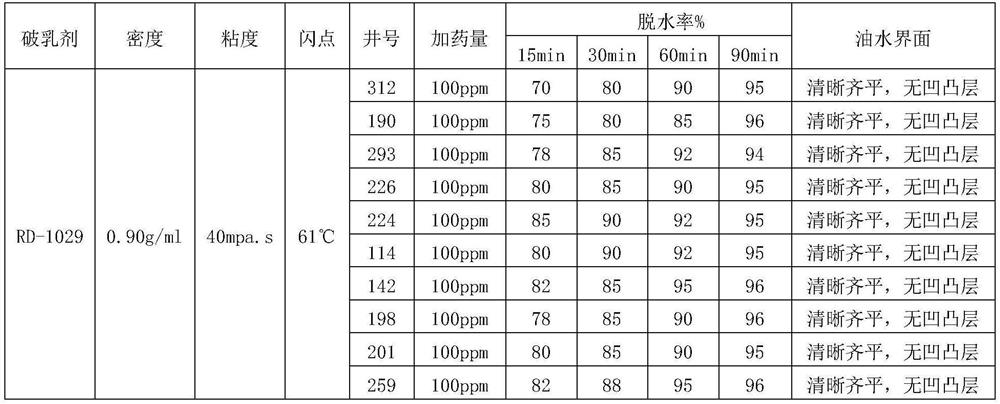

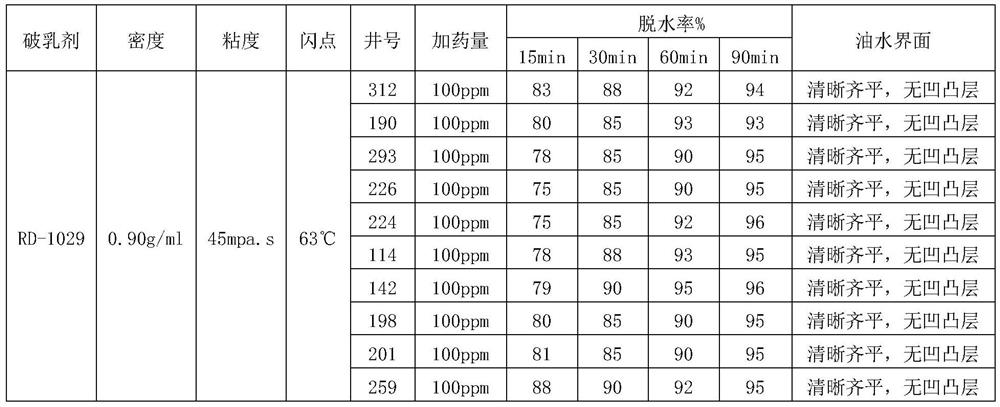

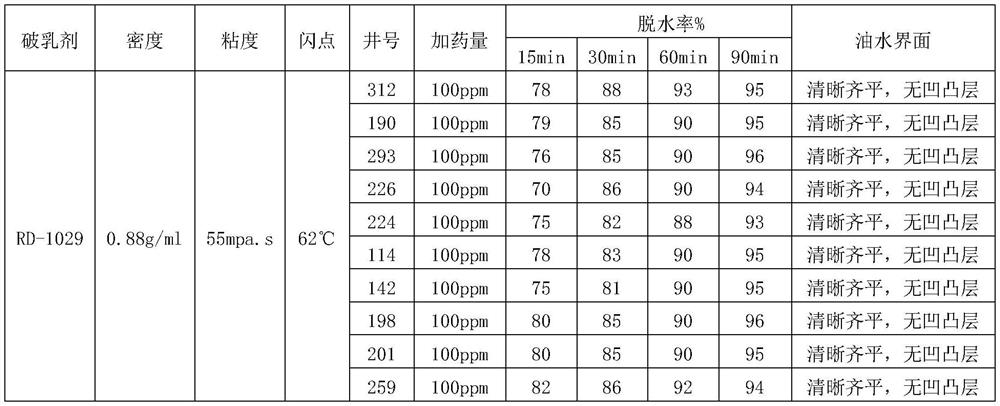

Fluoride-contained crosslinked polyether demulsifier and preparation method thereof

ActiveCN107641523AReduce usageFast dehydration rateDewatering/demulsification with chemical meansDemulsifierPotassium hydroxide

The invention discloses a fluoride-contained crosslinked polyether demulsifier and a preparation method thereof. The fluoride-contained crosslinked polyether demulsifier is prepared by adding an initiator and potassium hydroxide to a high-temperature and high-pressure reaction vessel, heating and dehydrating in vacuum, charging propylene epoxide and ethylene oxide, performing anion block polymerizing to obtain fluoride-contained polyether, and then reacting the fluoride-contained polyether and unsaturated acid in an alkylbenzene solvent under the effects of an esterifying catalyst and the initiator. The fluoride-contained crosslinked polyether demulsifier has the characteristics of a plurality of aromatic nucleuses, a plurality of branches, and high molecular weight, is capable of effectively reducing the oil-water interface strength and achieving the purpose of completely separating oil and water, and can also be independently used as or compounded with other demulsifiers to be used as the demulsifier for dehydrating liquid produced by an oilfield and dehydrating and desalting of an oil refinery.

Owner:CHINA NAT OFFSHORE OIL CORP +2

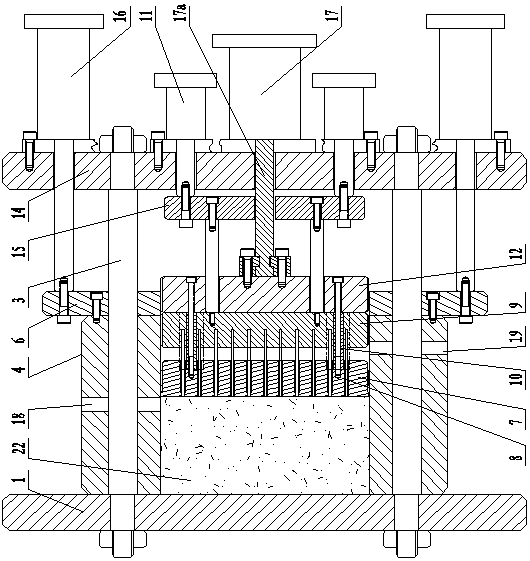

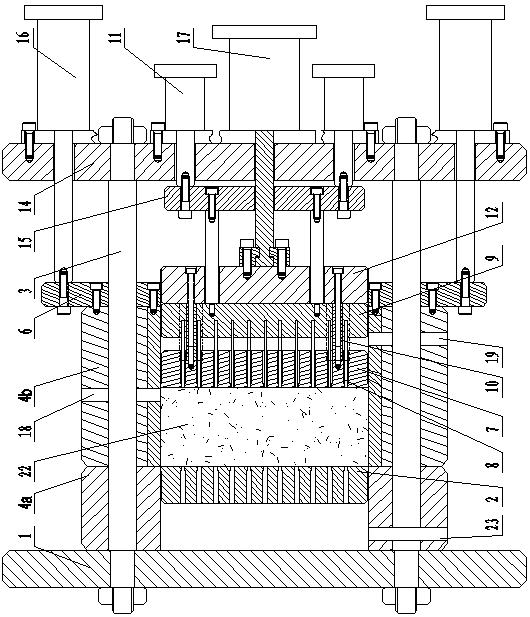

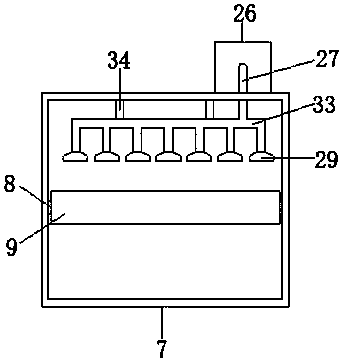

Sludge dewatering device

ActiveCN102701566ADehydration fastPrevent outflowSludge treatment by de-watering/drying/thickeningReciprocating motionFilter press

The invention discloses a sludge dewatering device which comprises a cavity body, a movable plunger and a movable plunger driver, wherein the movable plunger is capable of sliding in the cavity body to and fro; a group of dewatering holes are arranged on the movable plunger; a sludge pushing component which is used for preventing the dewatering holes from being blocked is arranged at the rear end of the movable plunger and the rear end is far away from the sludge; the sludge component comprises a group of ejector pins, ejector pin fixing plates and ejector pin drivers; each ejector pin is located in a corresponding dewatering hole; and the ejector pin fixing plates are used for fixing the ejector pins and driving the ejector pins to reciprocate in the dewatering holes under the driving of the ejector pin drivers. The efficient sludge dewatering device disclosed by the invention combines the advantages of plate frame type and belt type filter presses, has the advantages of rapid sludge dewatering efficiency and high dewatering degree, and is capable of finishing the circular dewatering of sludge within 2 minutes.

Owner:徐凌

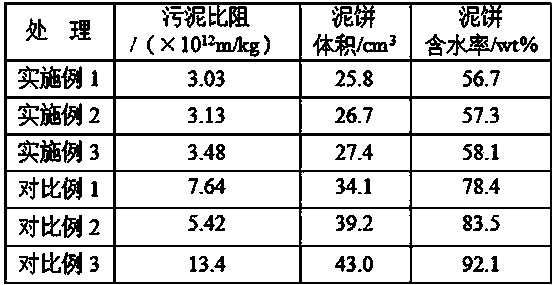

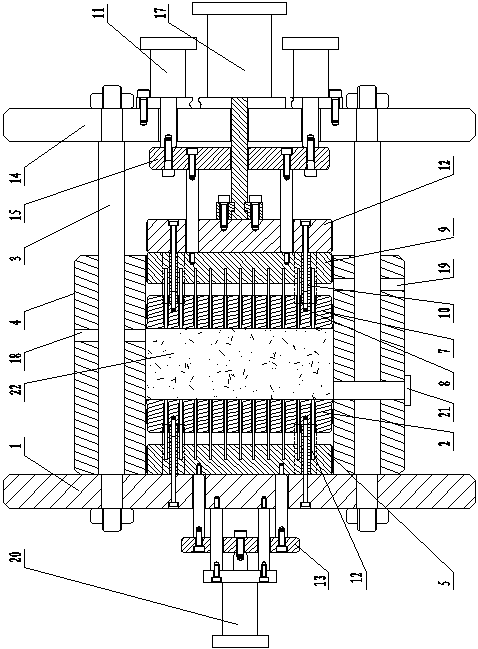

Chemical conditioning method for improving dehydration property of surplus sludge

InactiveCN103058472AChange surface charge propertiesChange moisture distributionBiological sludge treatmentSequencing batch reactorBüchner funnel

The invention relates to a chemical conditioning method for improving dehydration property of surplus sludge, which is characterized by comprising the following steps: putting surplus sludge in an SBR (sequencing batch reactor), stirring with an electric stirrer, carrying out hydrolytic acidification at room temperature in an two-stage control mode (alkali (pH=10.0) after acid (pH=3.0)) (8 days for each stage), and regulating the pH value with 30% HCl and 20% NaOH solution; taking a sample every two days, and storing the sample in a 4 DEG C environment; measuring sludge resistivity by a Buchner funnel method; measuring the solid content in the filter cake with a halogen quick moisture meter; and analyzing the dehydration property of the sludge regulated by acid and alkali according to the measured resistivity and the solid content of the filter cake. The method provided by the invention can improve the dehydration property of the sludge, and promote the release of abundant organic matters in the sludge; and after the sludge is recycled, the problem of insufficient carbon sources for the sewage plant can be solved, thereby lowering the routine operation cost of the sewage plant.

Owner:TIANJIN CHENGJIAN UNIV

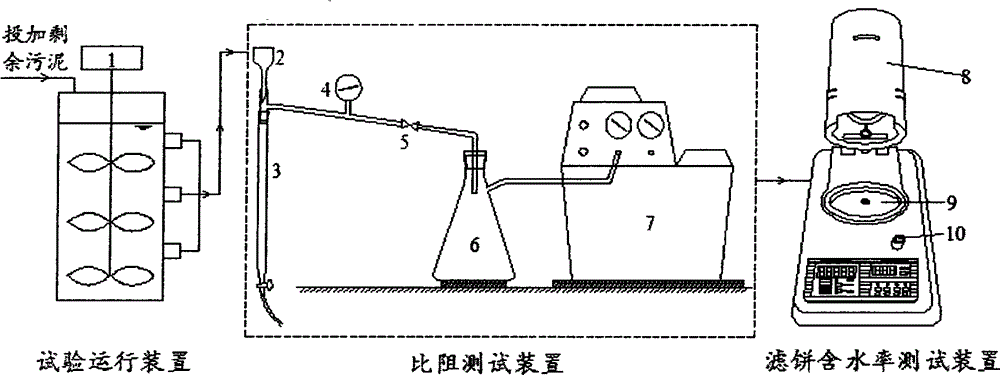

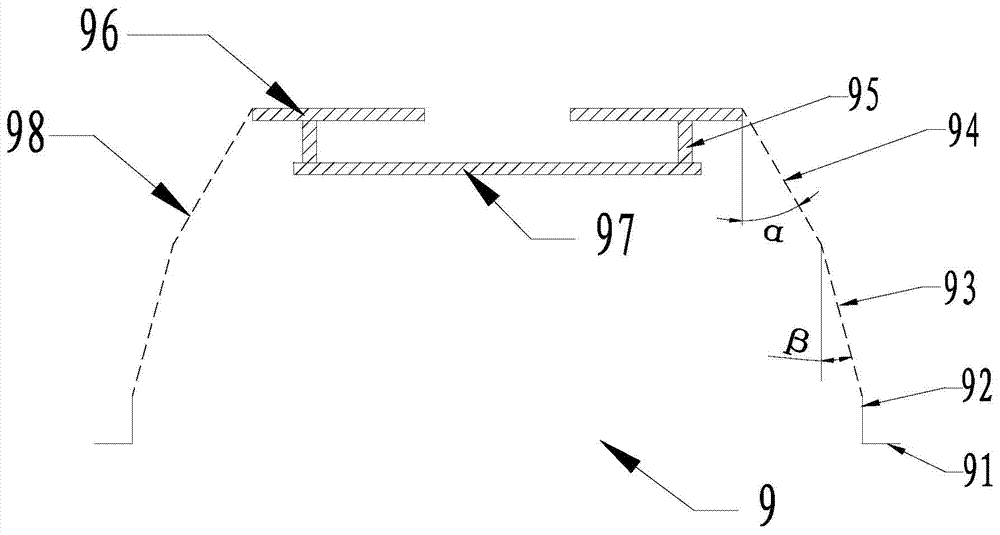

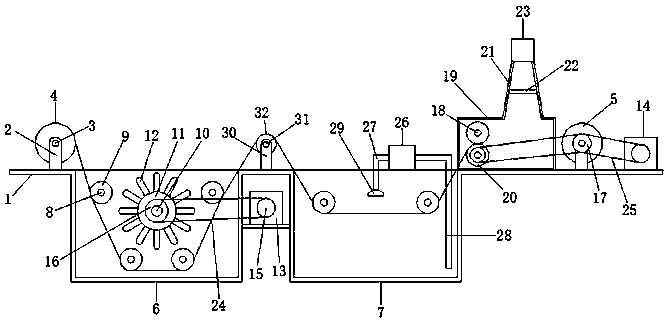

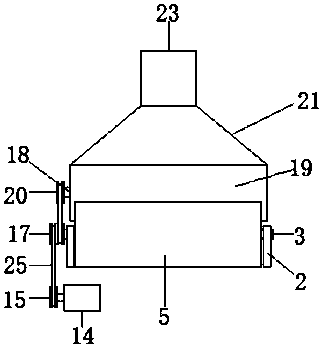

Hot pickled mustard tuber continuous dehydration centrifugal separator with bottom upwards

ActiveCN104741248AEasy to produceHigh degree of dehydrationRotary centrifugesDraining tubeEngineering

The invention discloses a hot pickled mustard tuber continuous dehydration centrifugal separator with the bottom upwards. The centrifugal separator comprises a vibration hopper used for conveying hot pickled mustard tubers, and a hollow shaft used for collecting materials, and a motor transmits rotating power to the hollow shaft through a power transmitting device; the lower end of the hollow shaft is provided with a hollow rotary table, a rotary drum is installed at the lower end of the hollow table with the bottom upwards, and the rotary drum rotates along with the hollow shaft and the hollow rotary table through rotary power provided by the motor; an inner barrel is outside the lower end of the rotary drum and used for receiving the hot pickled mustard tuber materials thrown out of the rotary drum, and the materials fall into a finished product groove through a material falling port in the bottom of the inner barrel; an outer barrel is further arranged outside the rotary drum and the inner barrel and used for collecting water thrown out of the rotary drum, and the water is drained out through a drainage pipe. The hot pickled mustard tuber continuous dehydration centrifugal separator has the advantages of being convenient to use, efficient, capable of achieving continuous production and low in cost. The hot pickled mustard tuber continuous dehydration centrifugal separator is stronger in dehydration effect and higher in dehydration degree, and meanwhile, the materials can continuously go out without barriers, and cleaning is facilitated.

Owner:湖南省香味园食品股份有限公司

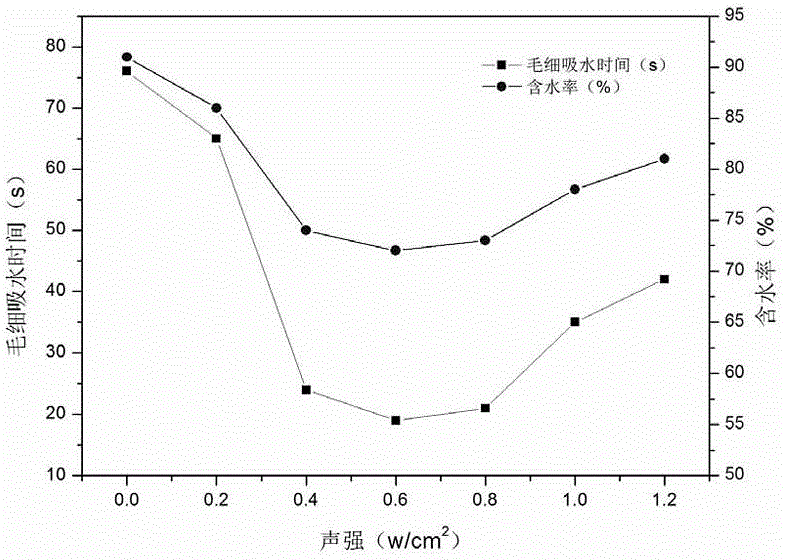

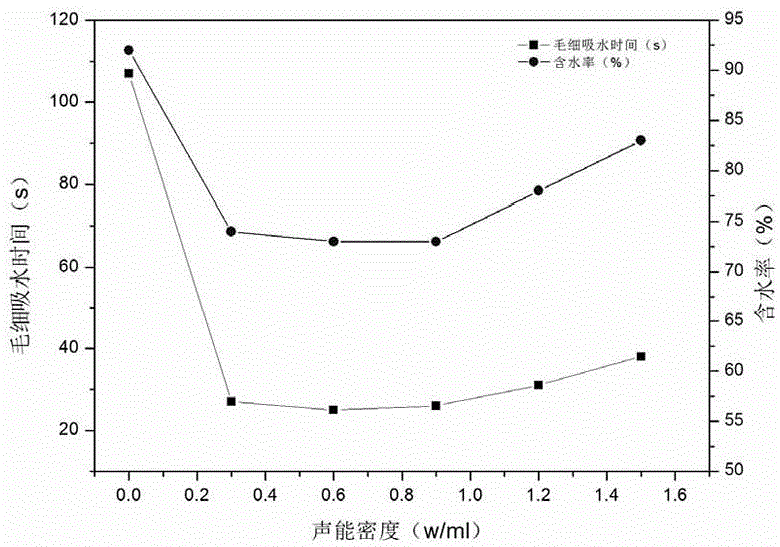

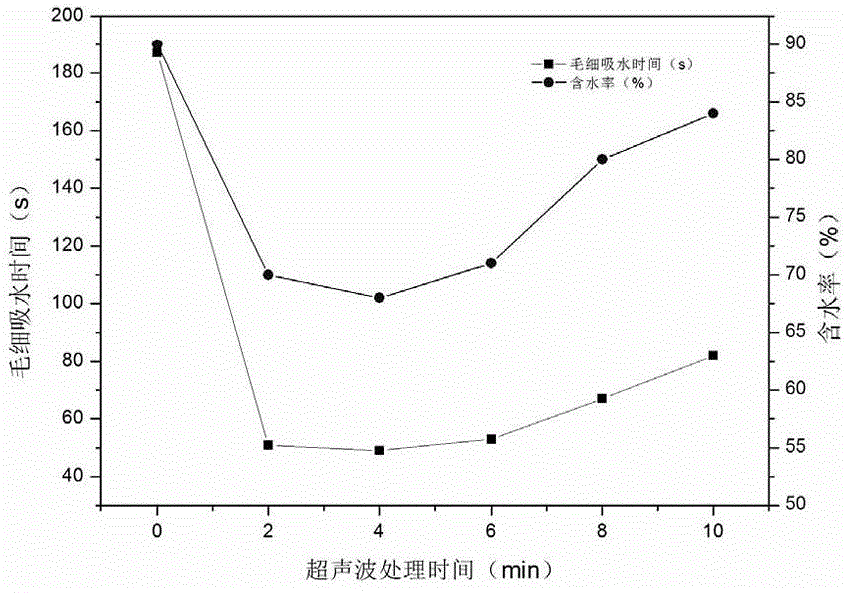

Spirulina dehydration method

InactiveCN104370431BHigh degree of dehydrationReduce weightSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPhylum CyanobacteriaCyanobacteria

The invention discloses a blue algae dehydrating method. The method comprises the steps of performing ultrasonic processing, adding a flocculant and filter-pressing to dehydrate, wherein the specific steps are as follows: ultrasonically processing the blue algae for 2-6min; adding the flocculant in the blue algae after the ultrasonic processing, and uniformly stirring; filter-pressing the blue algae after adding the flocculant to dehydrate. Through the adoption of the method disclosed by the invention, the volume of the blue algae is greatly reduced, the heat value is not changed, and the dehydrating degree is high; the processing speed is high, the operation is simple, the large-scale production is facilitated, and the method has wide application prospect.

Owner:HUNAN UNIV

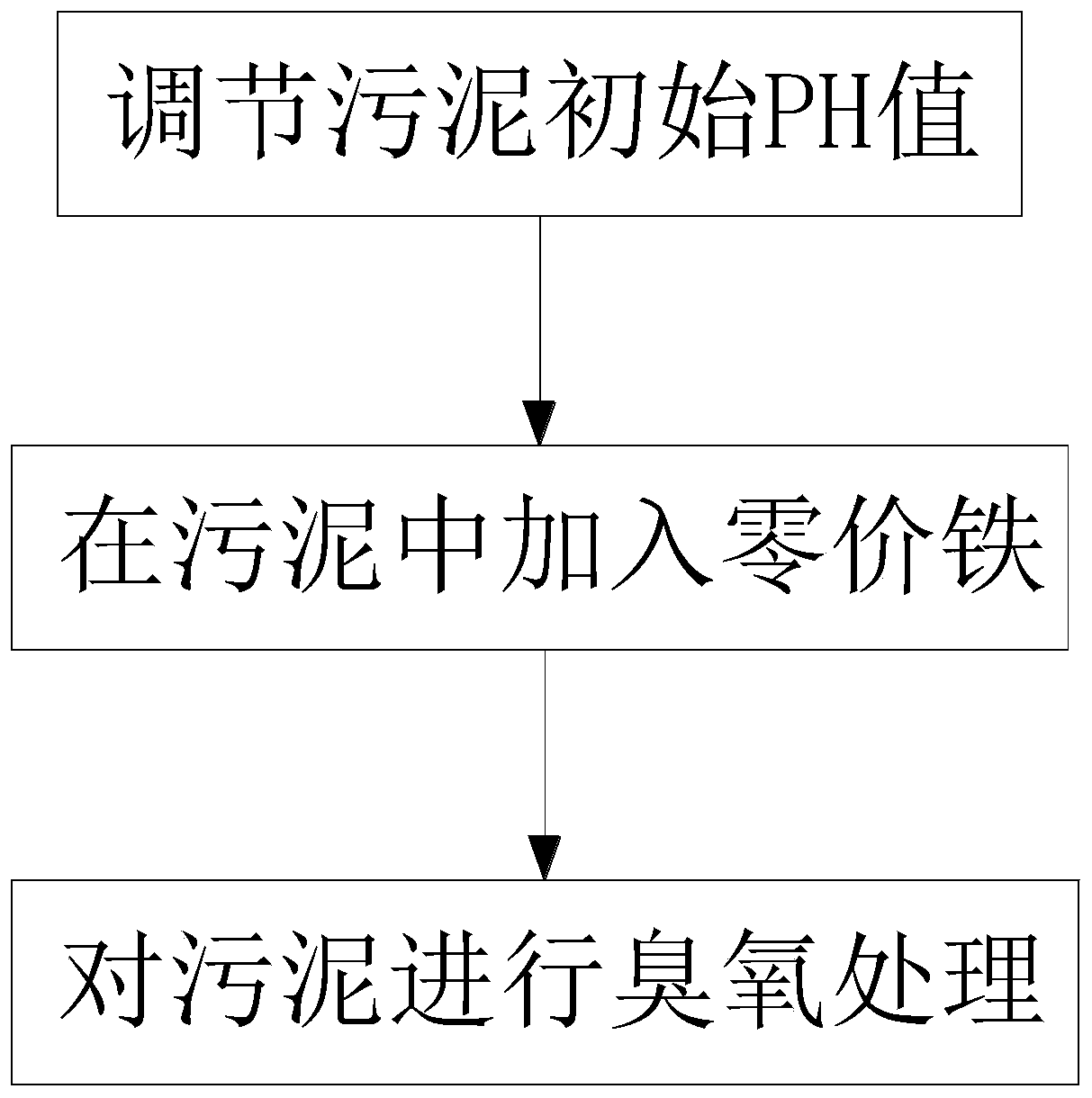

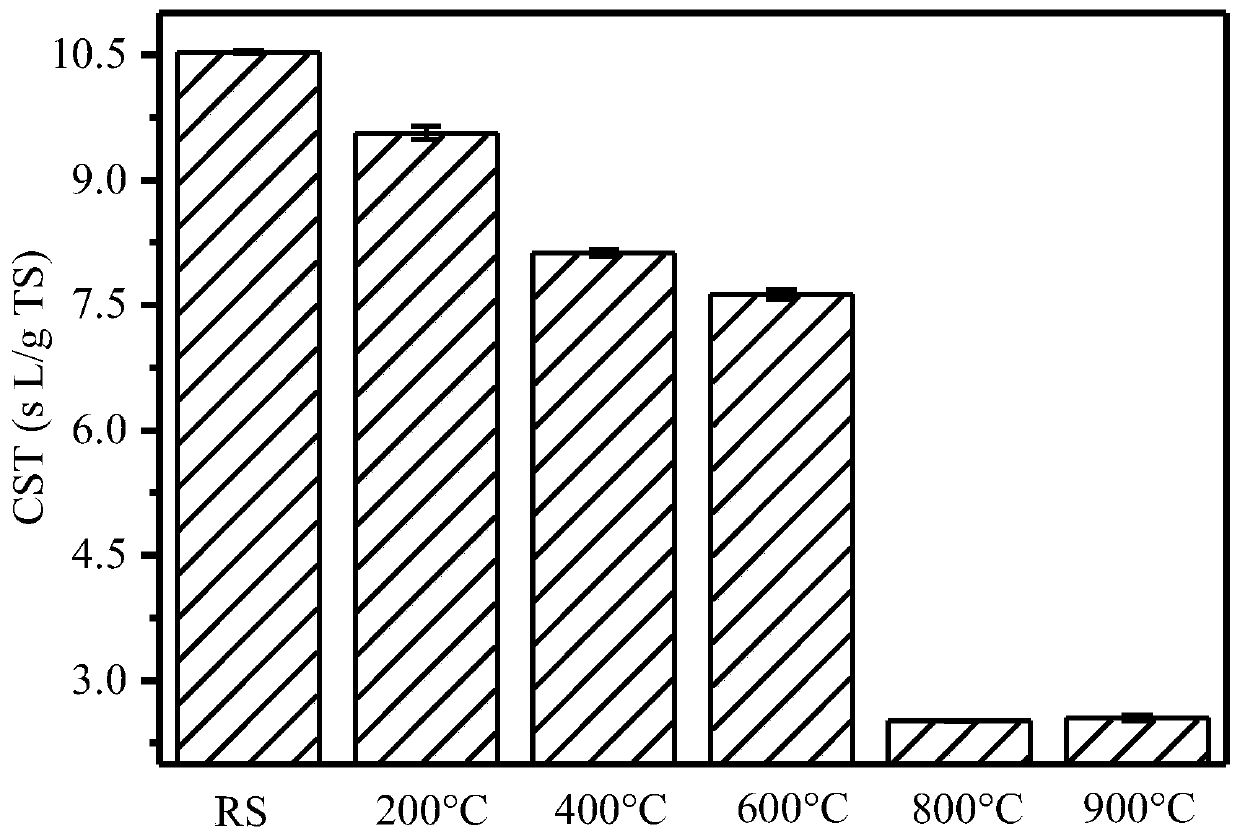

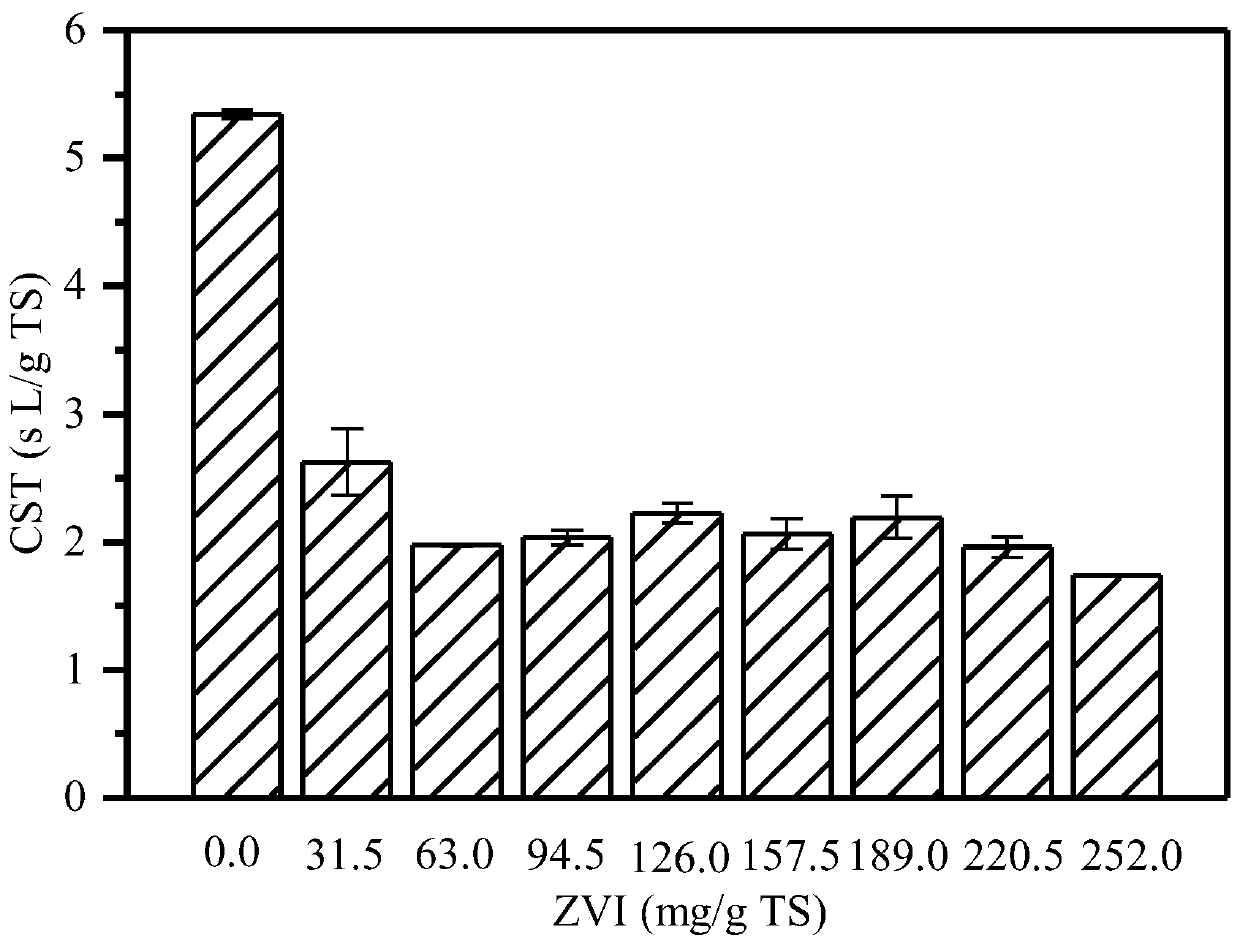

Novel multifunctional sludge treatment method with sterilization and dewatering functions

InactiveCN110590117AImprove dehydration effectConducive to subsequent resource utilizationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesBound waterReduction treatment

The invention discloses a novel multifunctional sludge treatment method with sterilization and dewatering functions. The novel multifunctional sludge treatment method sequentially comprises the following steps: firstly, acidizing sludge; secondly, adding 32-252 g / g of TS zero-valent iron at room temperature, and stirring and mixing the sludge; then, performing ozonation on the mixture; and finally, carrying out filter-press dewatering treatment. The novel multifunctional sludge treatment method treats the sludge with acid-zero-valent iron-ozone, so that bound water in sludge cells becomes freewater to be removed, and the sludge dewatering performance is improved; besides, microorganisms in the sludge can be killed, and following resource utilization of the sludge is facilitated; in addition, the method is simple in process condition, short in process and treatment time, stable in reaction, good in universality, beneficial to automatic treatment of a large amount of sludge, good in conditioning effect and high in sludge dewatering degree; and the method has high reduction treatment universality for excess sludge and has wide application prospects.

Owner:安徽国祯环卫科技有限公司 +1

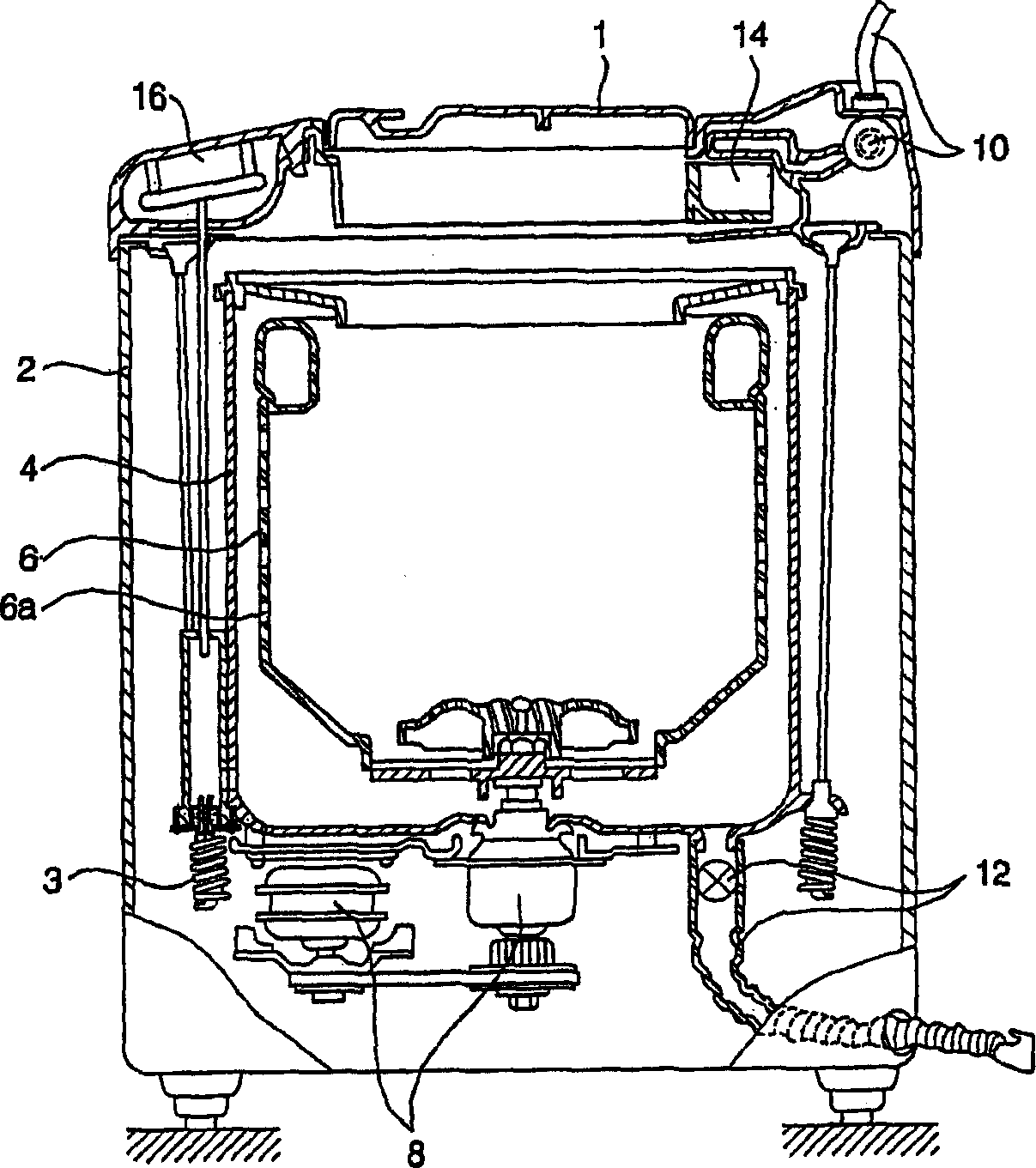

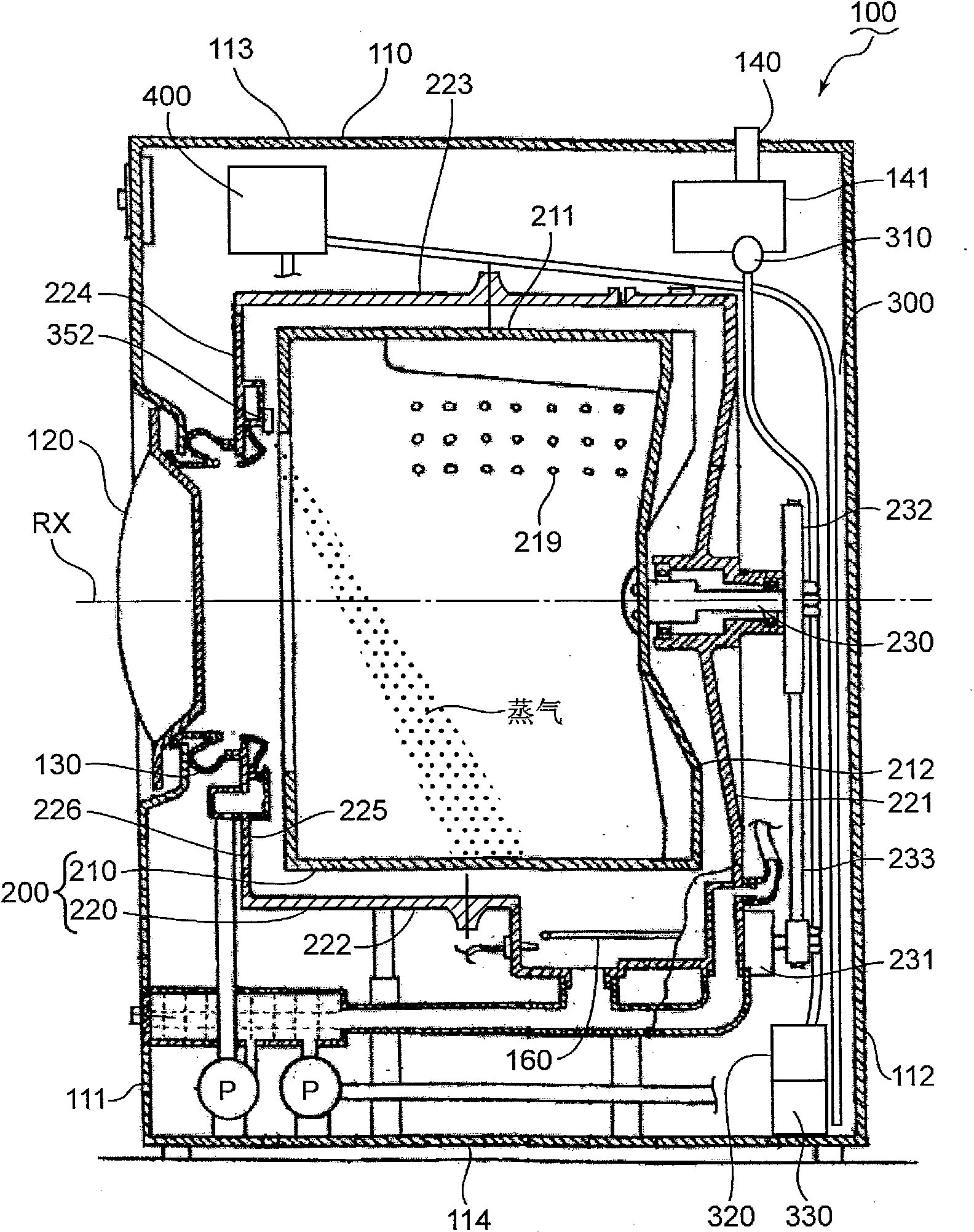

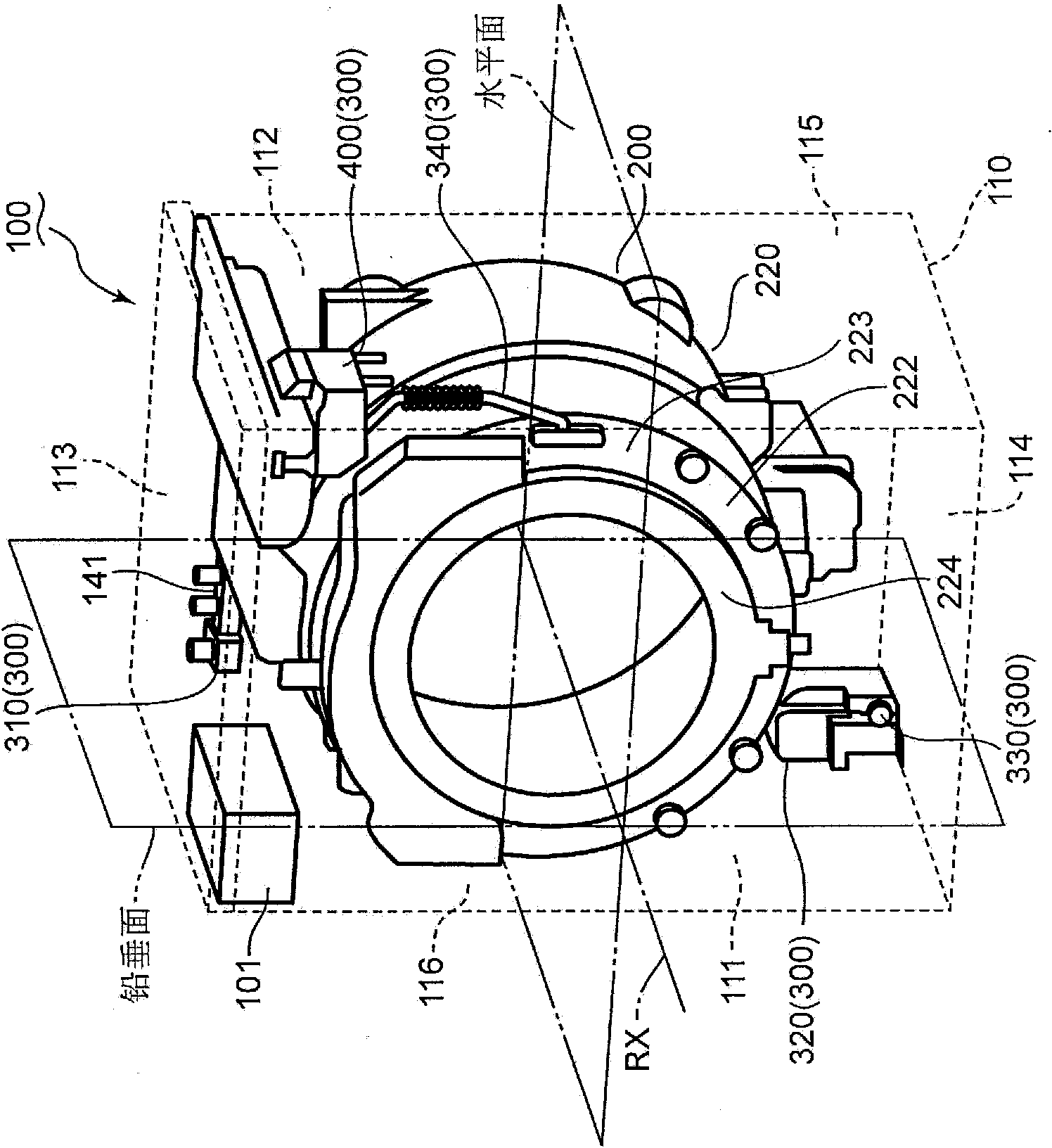

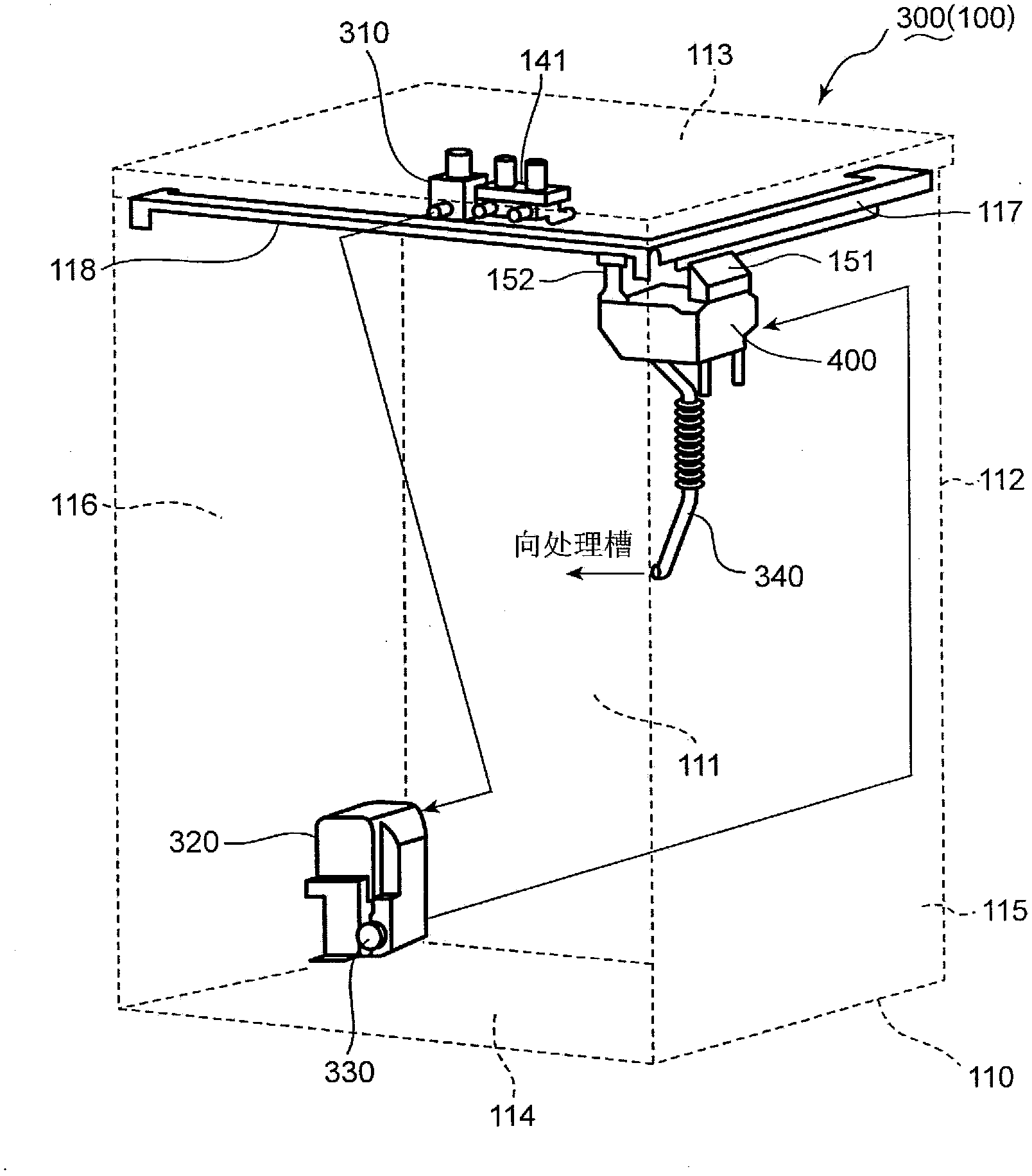

Clothes treatment device

ActiveCN103459697AHigh degree of dehydrationOther washing machinesWashing machine with receptaclesEngineeringCentrifugal force

This application discloses a clothes treatment device comprising: a rotating drum (210) which receives clothes and which has holes; a receiving tank (200) which houses the rotating drum; and a vapor supply mechanism (300) which supplies vapor into the rotating drum. In a dewatering step in which the clothes are dewatered by being pressed against the rotating drum by centrifugal force generated by the rotation of the rotating drum, the vapor supply mechanism supplies the vapor into the rotating drum.

Owner:PANASONIC CORP

Automatic silk yarn cleaning device

InactiveCN108950929AEfficient washingSimple structureLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnEngineering

The invention discloses an automatic silk yarn cleaning device. The device comprises a base plate, four first mounting plates are fixedly connected to the top wall of the base plate, a silk yarn axleis rotationally connected between the side walls of the two first mounting plates located on the same side, a first silk yarn wheel is installed on the side wall of each silk yarn axle, second silk yarn wheels are installed on the side walls of the two silk axles, and second motors are arranged on the out sides, away from one sides of the first silk yarn wheels, of the second silk yarn wheels. Accordingly, the structure is simple and easy to implement, by means of cooperation of all devices in a washing box, silk yarn can be effectively washed, the washing effect is thorough, the washing speedis high, the washed silk yarn can be washed out, the phenomenon that a cleaning solution remains on the silk yarn is avoided, odor is removed, dehydration and drying can be conducted on the silk yarnin time, the problem that the silk yarn is affected by residual water, and then the silk yarn fades and even mildews is avoided, and the device has the advantages of being high in dehydration degreeand thorough in drying effect.

Owner:姚娟娟 +4

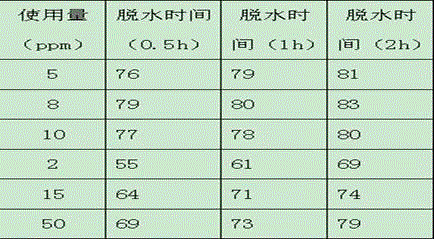

Application method of crude oil composite demulsifier

InactiveCN105907420AReduce usageImprove dehydration effectDewatering/demulsification with chemical meansDemulsifierBetaine

The invention discloses an application method of a crude oil composite demulsifier. The problems that an existing demulsifier is large in use quantity and cannot achieve an ideal demulsifying effect are solved. The method comprises the steps that 1, the crude oil composite demulsifier is prepared, wherein the crude oil composite demulsifier contains 48-52 wt% of polyoxyethylene polyoxypropylene block polyether, 0.8-1.2 wt% of sodium hexadecyl sulfonate, 2-5 wt% of lauramidopropyl betaine, 10-15 wt% of C2-C6 carboxylic acid and the balance water; 2, the crude oil composite demulsifier is added into crude oil according to the adding quantity of 5-10 ppm. The application method has the advantages that the dewatering effect can be effectively improved while the use quantity is reduced.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

Industrial sludge deep dehydration conditioning agent and preparation method thereof

InactiveCN108863018ALow cost of dehydrationImprove adsorption capacitySludge treatment by de-watering/drying/thickeningBound waterFiltration

The invention provides an industrial sludge deep dehydration conditioning agent and a preparation method thereof, and relates to the technical field of sludge dehydration. The industrial sludge deep dehydration conditioning agent is prepared from the following raw materials: calcium oxide, silica, a coagulant, anionic polyacrylamide, citric acid and additives. The industrial sludge deep dehydration conditioning agent provided by the invention can be used for performing surface chemical modification on sludge particles, so that the water on the surfaces of the sludge particles and the bound water in capillary channels are enabled to become free water, the water can be further separated out by means of mechanical pressure filtration, and the purpose of dewatering the sludge is accordingly achieved; the conditioning agent also has a stronger absorption function, and can disperse sludge flocs and destroy the floc structure, thus improving the dehydration degree of the sludge; furthermore,the industrial sludge deep dehydration conditioner has the advantages of being non-toxic and harmless, and not causing secondary pollution to the environment.

Owner:ANQING FENGYUAN CHEM

Conditioner and conditioning method for dewatering of domestic sludge

ActiveCN101985386BEnvironmental protection dehydration treatmentAdd lessSludge treatment by de-watering/drying/thickeningAluminum sulphatePulp and paper industry

The invention discloses a conditioner for dewatering of a domestic sludge, a formula of the conditioner includes a polyacrylamide being 0.3%-0.9% of the sludge to be processed, a bamboo charcoal being 5%-20% of dry weight of the sludge to be processed, a quaternary ammonium salt being 2%-1% of dry weight of the sludge to be processed, a quick lime being 2%-5% of dry weight of the sludge to be processed, and a polymeric aluminum sulfate being 5%-20% of dry weight of the sludge to be processed; and the method comprises the following steps of: at normal temperature and normal pressure, orderly adding the polymeric aluminum sulfate, the quick lime and the bamboo charcoal into the sludge to be processed, stirring the sludge for reaction for at least 5 minutes, further orderly adding the polyacrylamide and the quaternary ammonium salt, stirring the sludge for at least 3 minutes, finally, performing a filter pressing step. The conditioner and the conditioning method for dewatering of the domestic sludge have the advantages of being short in conditioning reaction time, fast in sludge depositing speed, good in dewatering effect and protective for environment without pollution.

Owner:湖南多普生环境能源有限公司

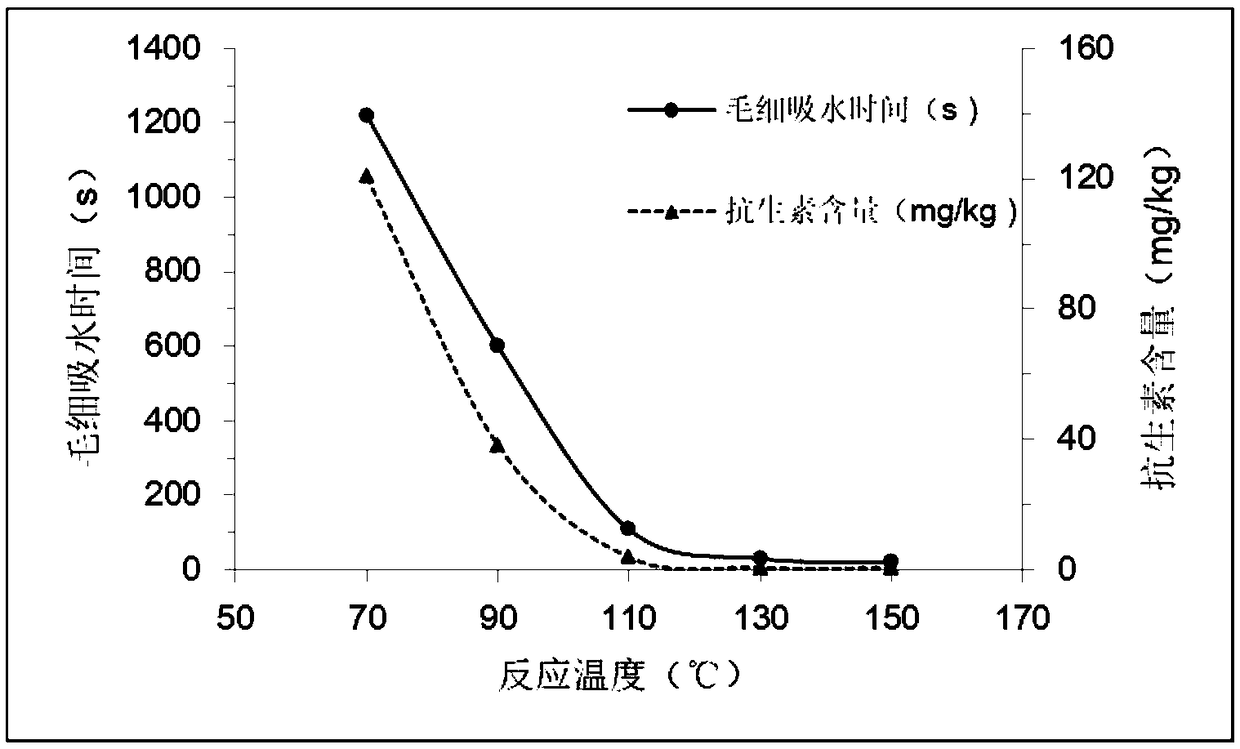

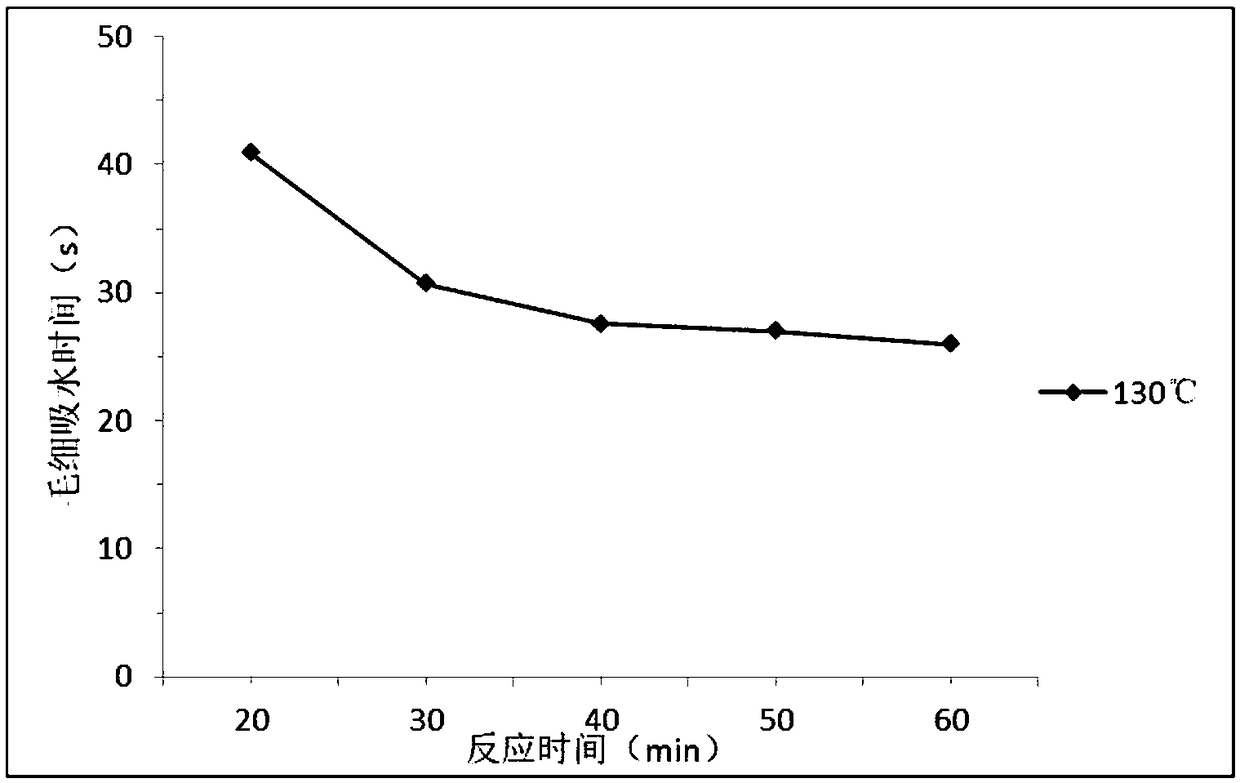

Poultry excrement hydrothermal treatment dewatering method

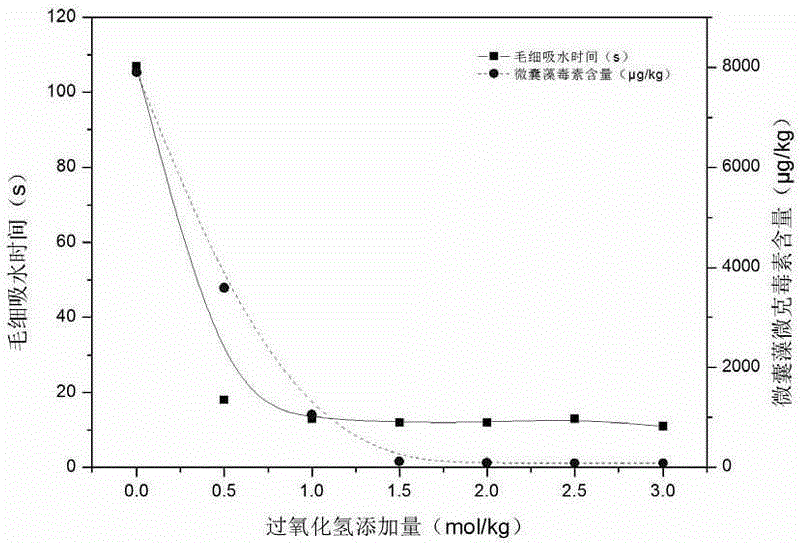

InactiveCN109320039AReduce capillary water absorption timeHigh degree of dehydrationSludge treatment by oxidationWater contaminantsFecesThermal treatment

The invention provides a poultry excrement hydrothermal treatment dewatering method which comprises the following steps: adding an oxidizing agent into fresh poultry excrement, mixing and performing hydrothermal reaction treatment; mixing the treated poultry excrement with a proper amount of water, then dewatering to finish the treatment on the poultry excrement. The poultry excrement hydrothermaltreatment dewatering method can perform dewatering treatment on the poultry excrement and has the advantages that equipment is simple and easy to operate, a treating speed is quick, a period is short, a dewatering degree is high, a solid recovery rate is high, energy consumption is low, cost is low, and a wide application prospect is achieved.

Owner:HUNAN AGRICULTURAL UNIV

Using method of sour crude oil emulsion breaker

InactiveCN105907419AReduce usageImprove dehydration effectDewatering/demulsification with chemical meansDemulsifierCarboxylic acid

The invention discloses a using method of a sour crude oil emulsion breaker. The problem that the ideal emulsion breaking effect cannot be achieved even when an existing emulsion breaker using amount is large is solved. The method comprises the steps that 1, a crude oil composite emulsion breaker is prepared, wherein the crude oil composite emulsion breaker is prepared from 48-52 wt% of polyoxyethylene polypropylene oxide block polyether, 0.8-1.2 wt% of sodium hexadecyl sulfonate, 5-8 wt% of d-Limonene, 10-15 wt% of C2-C6 carboxylic acid, and the balance water; 2, the crude oil composite emulsion breaker is added into crude oil according to the addition amount of 5-10 ppm. The method has the advantages of lowering the consumption amount and effectively improving the dehydration effect.

Owner:CHENGDU GAOPU PETROLEUM ENG TECH

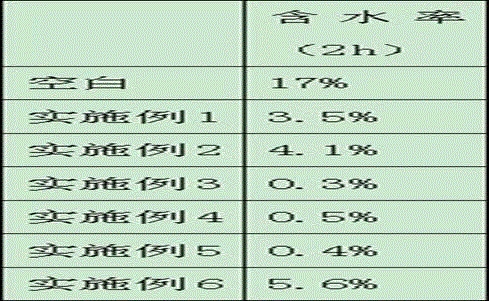

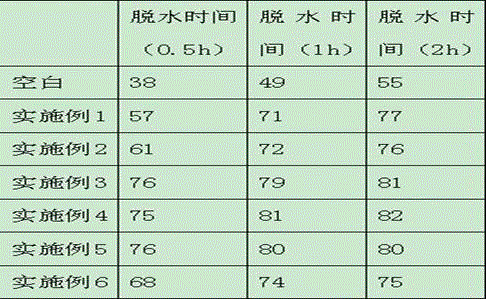

A kind of sludge dehydration conditioner and dehydration method thereof

ActiveCN105314815BSolve the use problemSolve the slow expansion defectSludge treatment by de-watering/drying/thickeningIron saltsMagnesium salt

The invention discloses a sludge dehydration conditioner, which comprises the following components in weight percentage: 30-70% desulfurization ash, 5-15% magnesium salt, 5-30% iron salt, 2-20% aluminum salt, 0.1 ~15% Magnesium Oxide. At the same time, it also provides a dehydration method of the conditioner, including the steps of preparation of conditioner solution, conditioning of sludge, preparation of flocculant solution, sludge dehydration and the like. The raw materials used in the present invention have wide sources, low price, low preparation cost, convenient use, good dehydration effect, can rely on existing sludge dewatering facilities, simple implementation process, and can effectively improve the stability and reliability of the sludge dewatering process It can be widely used in the treatment of various waste water, sewage and sludge.

Owner:BAOSHAN IRON & STEEL CO LTD +1

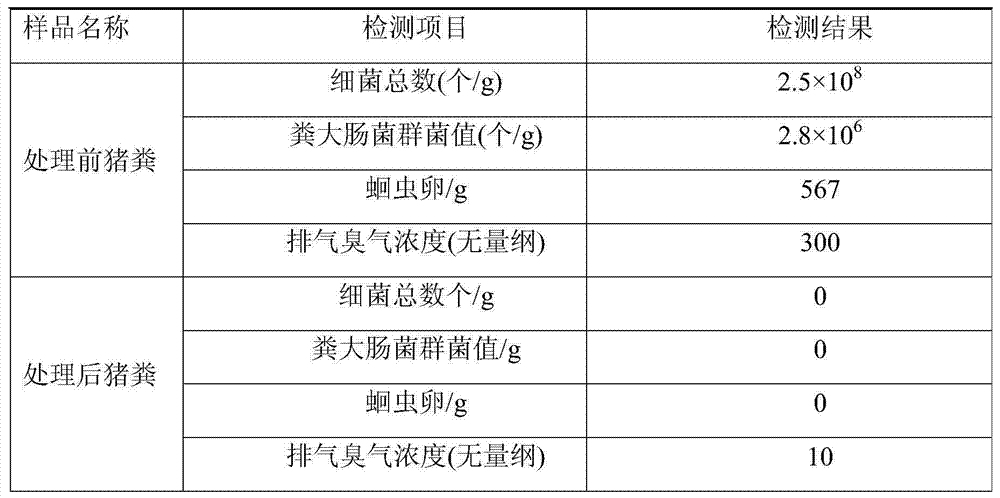

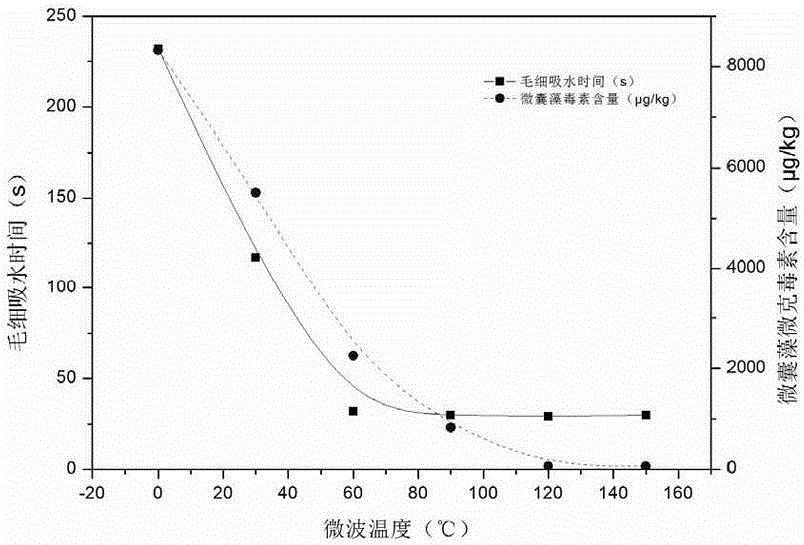

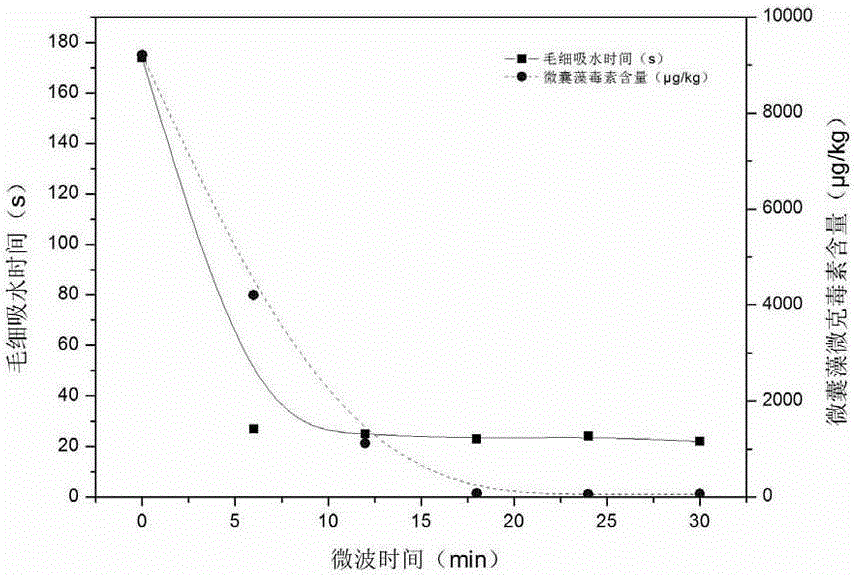

Sterilization, deodorization and deep-dehydration method for livestock excrements

ActiveCN103708689BWide range of processingHigh degree of dehydrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFecesMicrowave

The invention relates to the field of treatment of livestock excrements, and in particular relates to a sterilization, deodorization and deep-dehydration method for livestock excrements. The method comprises the steps of acidification, namely adjusting the pH of the livestock excrements to be 3 to 6 by using acid; oxidization, namely adding an oxidizing agent into the acidified livestock excrements at the ratio that 0.5 to 1.2 moles of oxidizing agent is added into every kilogram of dry livestock excrements, and performing uniform stirring; microwave heating treatment, namely heating the oxidized livestock excrements to 95 to 120 DEG C by using microwaves, and continuing performing microwave treatment while stirring for 5 to 12 minutes at the temperature; pressure filtration dehydration, namely performing pressure filtration dehydration on the microwave-treated livestock excrements by using a pressure filter. The method is low in using cost, easy to operate and high in treatment speed, and the treated livestock excrements are high in solid recovery rate, low in heat value reduction and high in dehydration degree.

Owner:HUNAN UNIV

Sludge heat treatment recycling process

PendingCN111533412APromote hydrolysisImprove acidificationWater treatment parameter controlSludge treatment by thermal conditioningMicroorganismCompression molding

The invention belongs to the technical field of sludge treatment, and particularly relates to a sludge heat treatment recycling process which comprises the following steps: S1, preheating sludge, S2,carrying out heat treatment, S3, cooling, S4, dehydrating, and S5, carrying out compression molding. According to the sludge heat treatment recycling process, the sludge is deeply dewatered, the effects of disintegrating the sludge and improving organic matter dissolution can be achieved, and therefore the phosphorus release capacity of the sludge is improved, the pH value of a sludge system aftertreatment is 7, a treatment container is not corroded, and the salinity in the system cannot be improved. The process can be used for effectively sterilizing, killing germs in sludge and inhibiting fermentation microorganisms from generating a large amount of acidic biogas, so that pipeline equipment is corroded and damaged, and the burst risk caused by more biogas is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A method for simultaneously detoxifying and dehydrating cyanobacteria

InactiveCN104399315BEfficient dehydrationReduce capillary water absorption timeFiltration separationEnergy based chemical/physical/physico-chemical processesMicrobiologyCyanobacteria

The invention discloses a method for simultaneously detoxifying and dehydrating blue-green algae, which specifically comprises the following steps: adjusting the pH of blue-green algae to be acidic; adding an oxidant to the acidic blue-green algae, and then performing microwave radiation treatment; Carry out pressure filtration and dehydration to complete the treatment of cyanobacteria. The invention can carry out detoxification and rapid dehydration treatment on large quantities of salvaged cyanobacteria, with simple equipment, low use cost, convenient operation and maintenance, high degree of dehydration, greatly reduced volume of cyanobacteria, thorough detoxification, no secondary pollution, and broad application potential. Application prospects.

Owner:HUNAN UNIV

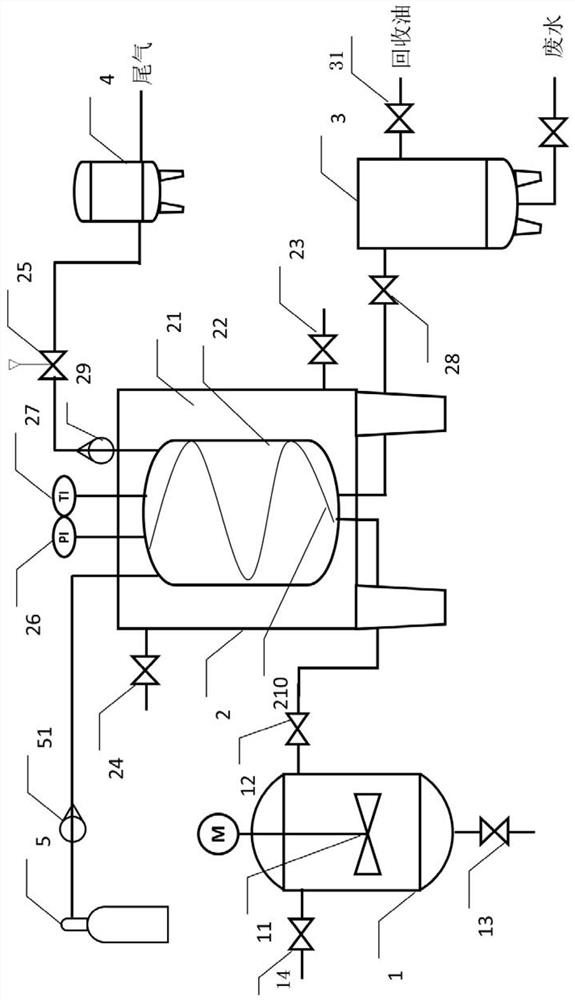

Oil-sludge-water heat treatment separation and recovery system and method

ActiveCN111908743AAchieve separationCompact structureSludge treatmentLiquid hydrocarbon mixture productionOil sludgeOil water

The invention provides an oil sludge water heat treatment separation and recovery system and method. The system comprises a hydrothermal reactor, a flash condensation tank and an oil-water separator,wherein the hydrothermal reactor is provided with a material inlet, a discharge port and a gas outlet, the discharge port of the hydrothermal reactor is located at the lower part of the hydrothermal reactor, and the gas outlet of the hydrothermal reactor is located at the upper part of the hydrothermal reactor; the flash condensation tank is provided with a material inlet, a liquid outlet and a gas outlet; a liquid outlet of the flash condensation tank is positioned at the lower part of the flash condensation tank; a gas outlet of the flash condensation tank is positioned at the upper part ofthe flash condensation tank; the oil-water separator is provided with a material inlet, a water phase outlet and an oil phase outlet; a gas outlet of the hydrothermal reactor is connected with a material inlet of the flash evaporation condensation tank, and a liquid outlet of the flash evaporation condensation tank is connected with a material inlet of the oil-water separator. The system is suitable for heat treatment separation and recovery of oily sludge water, and can effectively realize separation of water, oil and solid-phase residues in oily sludge.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Modified polyether, composite crude oil demulsifier, and preparation method and application of composite crude oil demulsifier

PendingCN111848943ALow costWide variety of sourcesDewatering/demulsification with chemical meansDemulsifierPhenol

The invention relates to modified polyether, a composite crude oil demulsifier, and a preparation method and application of the composite crude oil demulsifier. The preparation method of the modifiedpolyether comprises the following steps: sealing and preheating phenols and vinylamine at 50-70 DEG C under normal pressure for 30-50 minutes, heating to 110-130 DEG C within 30-60 minutes in an N2 orinert atmosphere at a stirring speed, dropwise adding a formaldehyde aqueous solution, heating to 0.2-0.6 MPa, reacting for 2-5 hours at a constant temperature of 110-130 DEG C, adding alkali into the first intermediate product under the condition of keeping the previous stirring rotation speed, dropwise adding an epoxy alkyl compound aqueous solution under the conditions of 0.2-0.6 MPa and 110-130 DEG C, carrying out constant-temperature and constant-pressure stirring reaction for 5-7 hours, cooling to 70-90 DEG C, reducing the pressure to normal pressure, cooling to room temperature, and neutralizing and purifying to obtain the modified polyether. According to the composite crude oil demulsifier provided by the invention, the used raw materials are wide in source and low in cost, and subsequent oil refining equipment is not corroded, so that the cost can be saved, and the utilization rate of the equipment is improved.

Owner:ANTON OILFIELD SERVICES (GRP) LTD +1

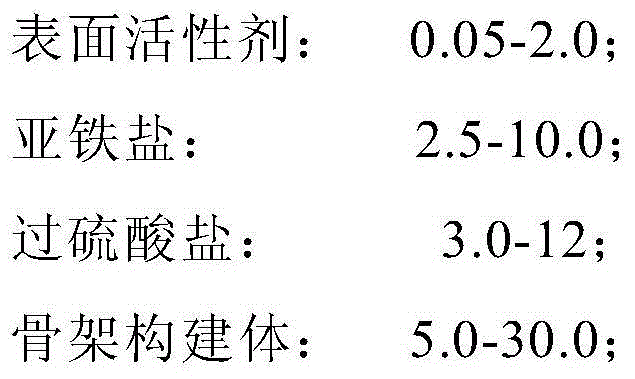

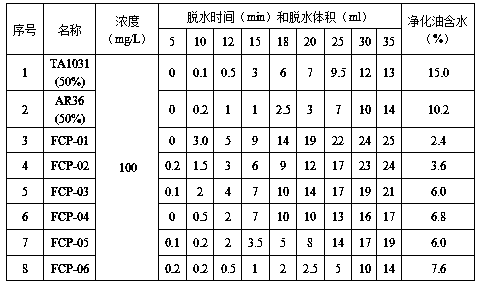

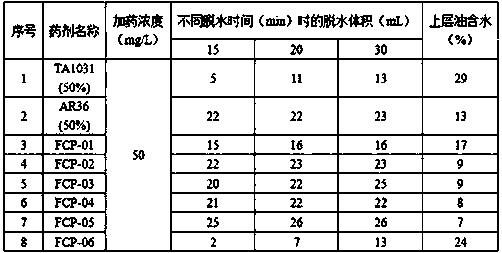

A kind of sludge deep dehydration composite conditioner and its application

ActiveCN103819072BHigh degree of dehydrationGood compressibilitySludge treatment by de-watering/drying/thickeningDry weightFerrous salts

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of fluorine-containing cross-linked polyether demulsifier and its preparation method

ActiveCN107641523BReduce usageFast dehydration rateDewatering/demulsification with chemical meansDemulsifierPotassium hydroxide

The invention discloses a fluoride-contained crosslinked polyether demulsifier and a preparation method thereof. The fluoride-contained crosslinked polyether demulsifier is prepared by adding an initiator and potassium hydroxide to a high-temperature and high-pressure reaction vessel, heating and dehydrating in vacuum, charging propylene epoxide and ethylene oxide, performing anion block polymerizing to obtain fluoride-contained polyether, and then reacting the fluoride-contained polyether and unsaturated acid in an alkylbenzene solvent under the effects of an esterifying catalyst and the initiator. The fluoride-contained crosslinked polyether demulsifier has the characteristics of a plurality of aromatic nucleuses, a plurality of branches, and high molecular weight, is capable of effectively reducing the oil-water interface strength and achieving the purpose of completely separating oil and water, and can also be independently used as or compounded with other demulsifiers to be used as the demulsifier for dehydrating liquid produced by an oilfield and dehydrating and desalting of an oil refinery.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com