A method for simultaneously detoxifying and dehydrating cyanobacteria

A technology for cyanobacteria and filter press dehydration, which is applied in the field of cyanobacteria pollution control, can solve the problems of high moisture content in algae-rich water, unfavorable transportation and final disposal, and increased volume of cyanobacteria, so as to facilitate large-scale industrial production and reduce weight and volume , high dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for simultaneously detoxifying and dehydrating cyanobacteria, specifically comprising the following steps:

[0038] (1) Add concentrated nitric acid to the salvaged cyanobacteria (initial water content 98%) and stir evenly to adjust the pH of the cyanobacteria to 3.

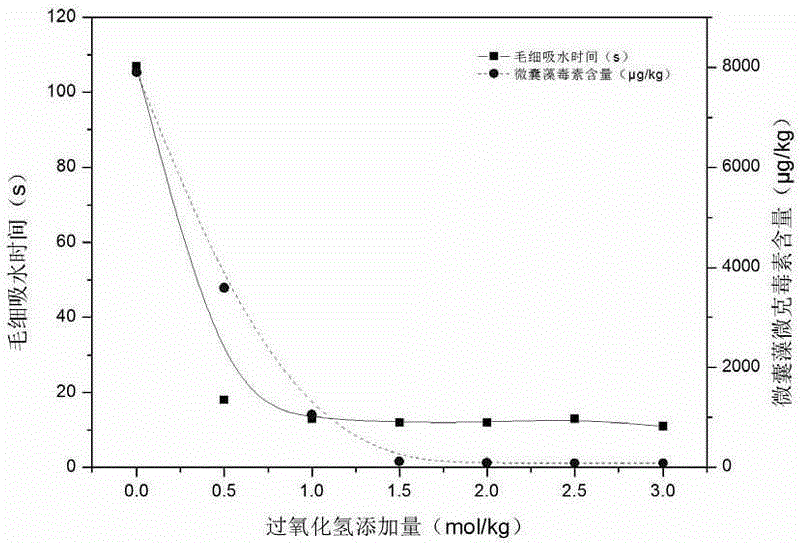

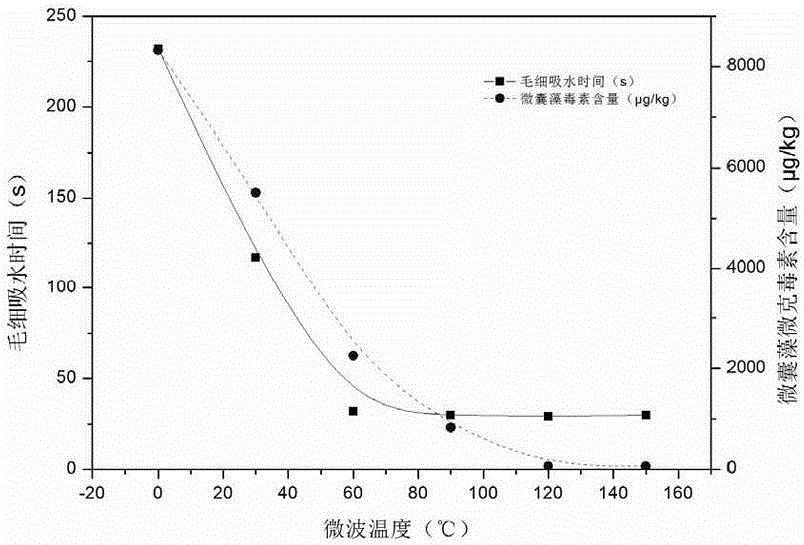

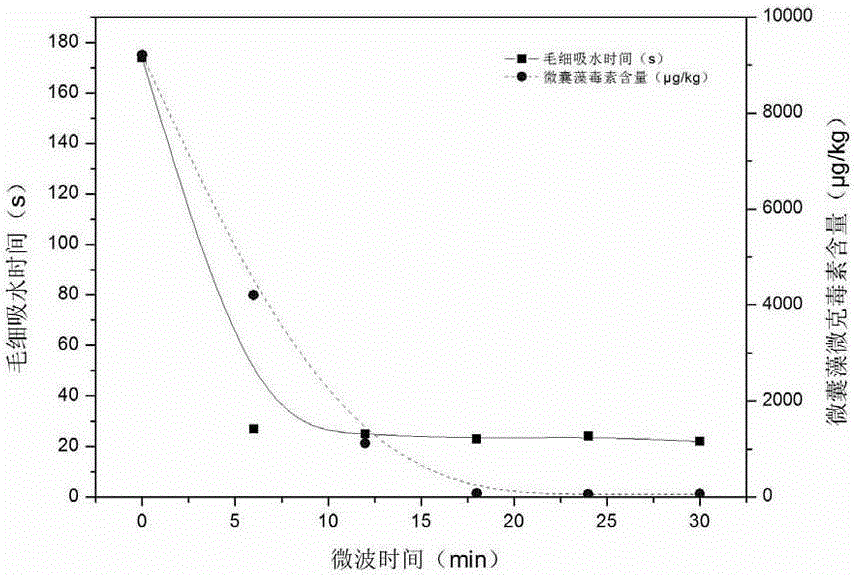

[0039] (2) Add 1.8 mol / kg hydrogen peroxide solution of dry weight of cyanobacteria to the cyanobacteria with pH 3 in step (1), stir evenly, and then treat with microwave radiation at 120°C for 25min. Stir the cyanobacteria rapidly at a stirring speed of 80 r / min while microwave treatment.

[0040] (3) The cyanobacteria obtained after step (2) are dehydrated through a plate and frame filter press. The pore diameter of the filter cloth of the plate and frame filter press is 15 μm.

[0041] The capillary water absorption time of the untreated cyanobacteria in this example is greater than 89s, the calorific value on a dry basis is 19.89MJ / kg, and the microcystin content on a dry basis is 9237 μg / kg...

Embodiment 2

[0043] A method for simultaneously detoxifying and dehydrating cyanobacteria, specifically comprising the following steps:

[0044](1) Add concentrated sulfuric acid to the salvaged blue-green algae (initial water content of 95%) and stir evenly to adjust the pH of the blue-green algae to 2.

[0045] (2) Add 2.5 mol / kg dry weight of cyanobacteria peracetic acid solution to the cyanobacteria with a pH of 2 in step (1), stir evenly, and then treat with microwave radiation at 130° C. for 20 minutes. Stir the blue-green algae rapidly at a stirring speed of 100 r / min while microwave treatment.

[0046] (3) The cyanobacteria obtained after the step (2) are dehydrated through a chamber filter press. The pore diameter of the filter cloth of the chamber filter press is 30 μm.

[0047] The capillary water absorption time of the untreated cyanobacteria in this example is 365s, the calorific value on a dry basis is 20.48MJ / kg, and the microcystin content on a dry basis is 11245 μg / kg. ...

Embodiment 3

[0049] A method for simultaneously detoxifying and dehydrating cyanobacteria, specifically comprising the following steps:

[0050] (1) Add concentrated hydrochloric acid to the salvaged cyanobacteria (initial water content 99%) and stir evenly to adjust the pH of the cyanobacteria to 5.

[0051] (2) Add 1.3 mol / kg dry weight of blue-green algae peracetic acid solution to the blue-green algae with a pH of 5 in step (1), stir evenly, and then treat it with microwave radiation at 110° C. for 15 min. Stir the cyanobacteria rapidly at a stirring speed of 40 r / min while microwave treatment.

[0052] (3) The cyanobacteria obtained after step (2) are dehydrated through a membrane filter press. The pore diameter of the filter cloth of the membrane filter press is 10 μm.

[0053] The capillary water absorption time of the untreated cyanobacteria in this example was 76s, the calorific value on a dry basis was 19.45 MJ / kg, and the microcystin content on a dry basis was 6579 μg / kg. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com