Patents

Literature

336results about How to "Efficient dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

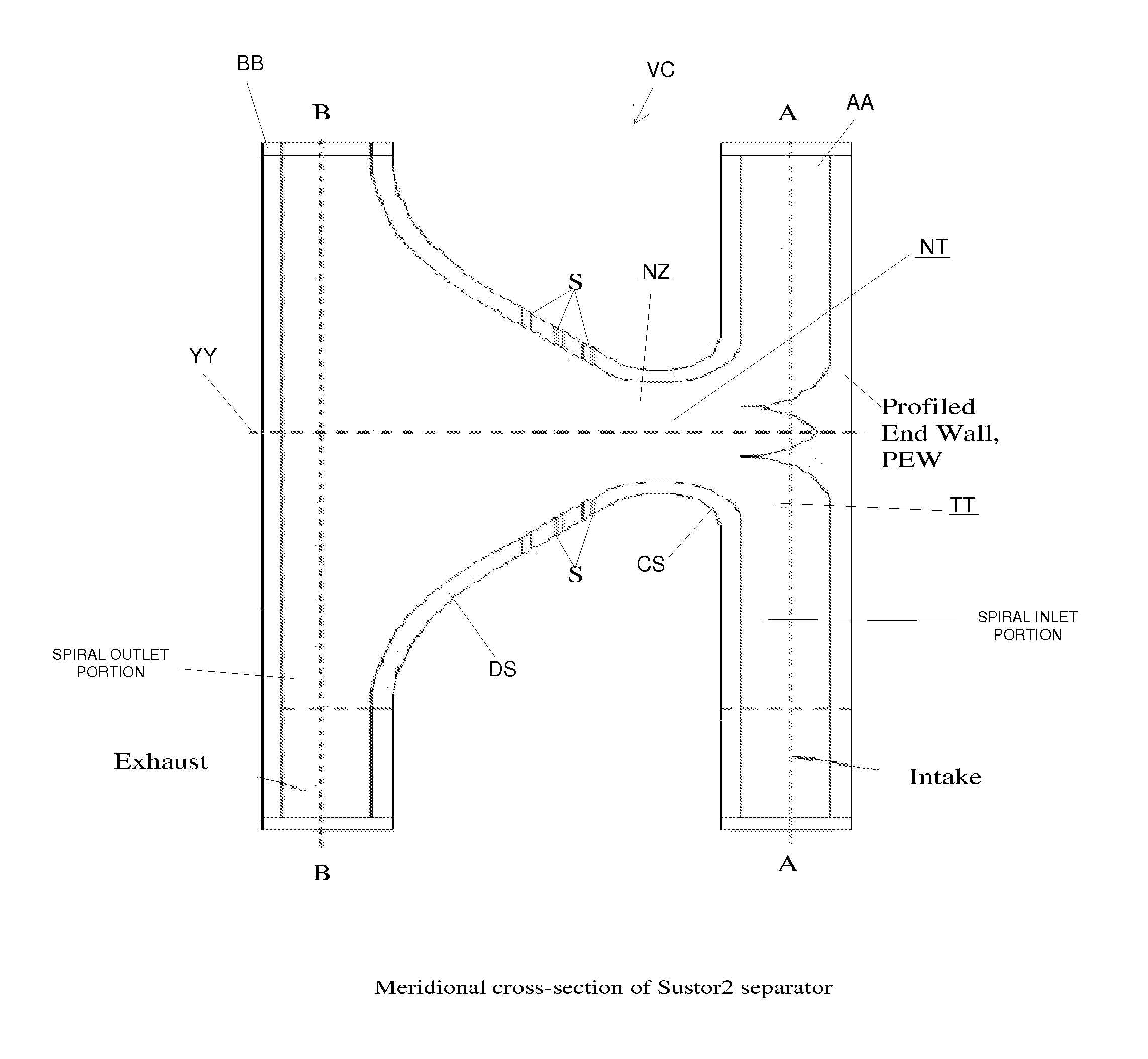

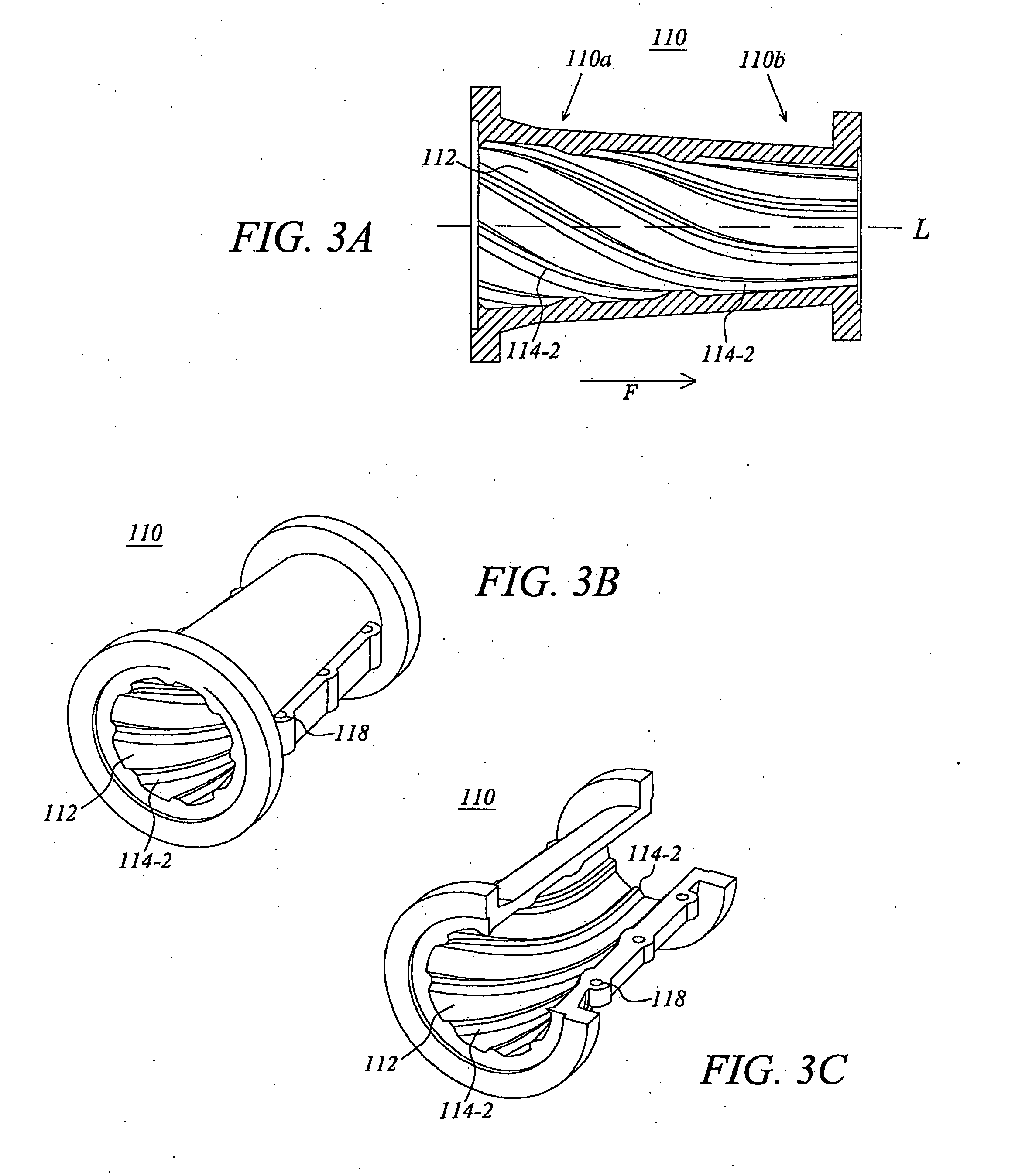

Supersonic swirling separator 2 (Sustor2)

Sustor2 provides deep cooling of a gas flow, practically total condensation of a vapor, and fast and effective removal of the condensed liquid with a significantly reduced pressure losses compared with the prior art. Sustor2 performs the said operations by developing a strong swirling flow starting from its entrance, followed by spiral flow convergence in the inlet disc-like part, and then in a converging-diverging nozzle, by centrifugal removal of droplets, and removal of the liquid film through slits, then by spiral flow divergence and leaving the vortex chamber through tangential outlet.A gas enters from a pipeline (see the arrow in the A-A cross-section shown in FIG. 7) connected to Sustor2 by a flange and the inlet transition pipe ITP in FIG. 7, spirally converged in the disc-like part, marked by A-A in FIG. 6, enters the converging-diverging nozzle (FIG. 6). The flow is high-speed and swirling even at the near-entrance region of the vortex chamber. This swirl results in the centrifugal force that presses the through-flow to the sidewall. The flow accelerates near the nozzle throat up to a supersonic velocity with subsonic axial and supersonic swirl velocity components. This acceleration results in the gas temperature drop down to 200K and even less values. The reduced temperature causes rapid condensation of vapor into droplets. The centrifugal force pushes the droplets to the sidewall where they are removed through slits. Next the dried gas spirally diverges and leaves the vortex chamber through the tangential outlet. This results in the pressure recovery and transformation of the swirl kinetic energy into the longitudinal kinetic energy of the gas. Both the effects decrease pressure losses which is the Sustor2 advantage compared with the prior art.

Owner:BORISSOV ANATOLI +2

Absorbent structures comprising fluid storage members with improved ability to dewater acquisition/distribution members

InactiveUS6551295B1Effectively and efficiently dewateredImprove distributionOther chemical processesBaby linensAbsorption capacityDesorption

The present invention is an absorbent structure to be used in absorbent articles, having at least a first region for acquisition / distribution of fluid and a second region for storage of fluid. The first region can contain materials which have a relatively high capillary desorption pressure, as the materials in the second region exhibit a sufficiently high capillary absorption pressure so as to still efficiently drain the first region.The first region material has a Capillary Sorption Desorption Height (CSDH 90) of more than 40 cm and the second region material satisfies at least one of following requirements:(a) an absorption capacity of at least 15 g / g at 35 cm in the capsorption test;(b) an absorption capacity of at least 15 g / g at 0 cm in the capsorption test and an absorption efficiency of at least 55% at 40 cm;(c) a Capillary Sorption Absorption height at 50% of its capacity at 0 cm absorption height (CSAH 50) of at least 35 cm in the capsorption test.

Owner:THE PROCTER & GAMBLE COMPANY

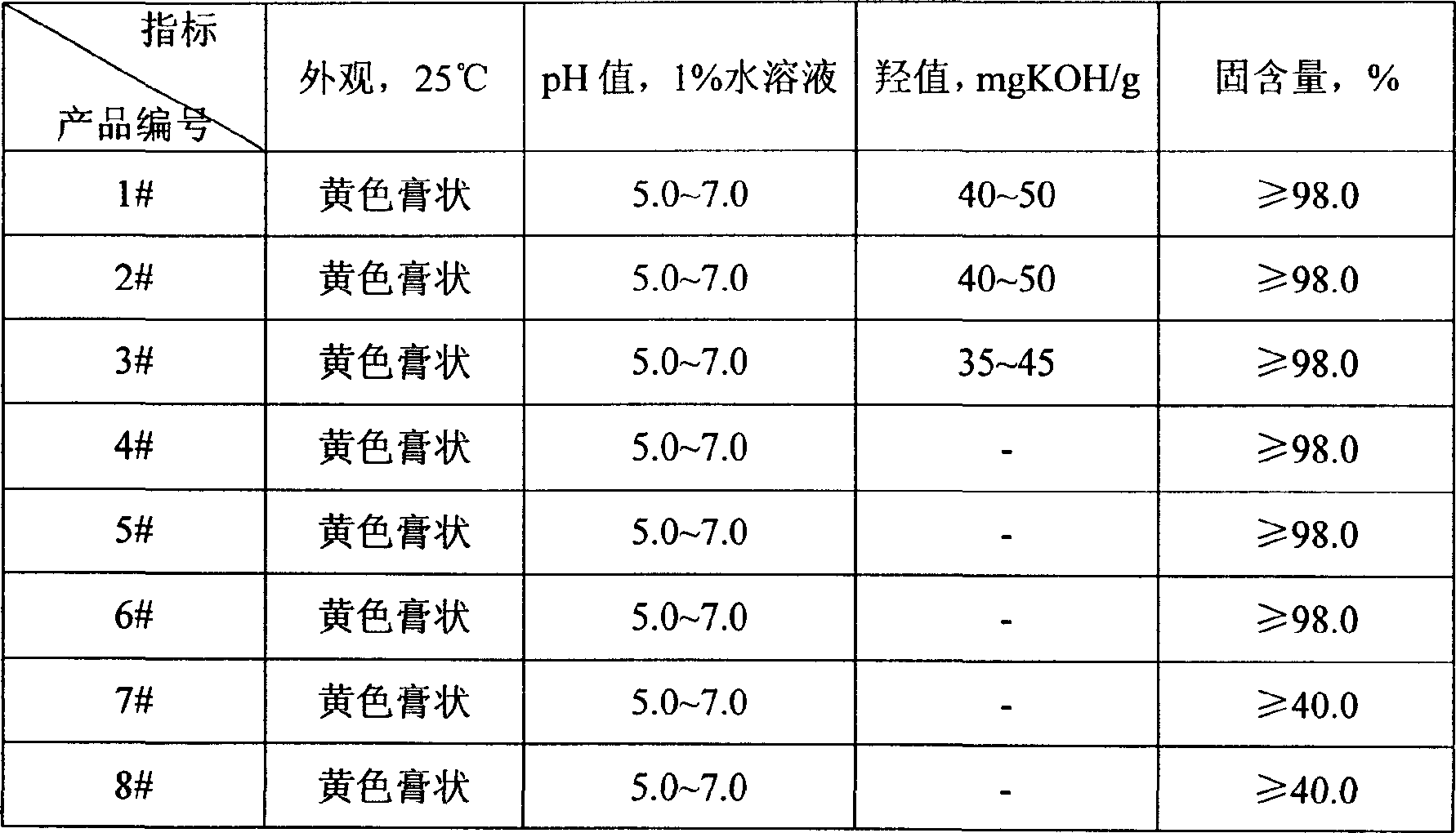

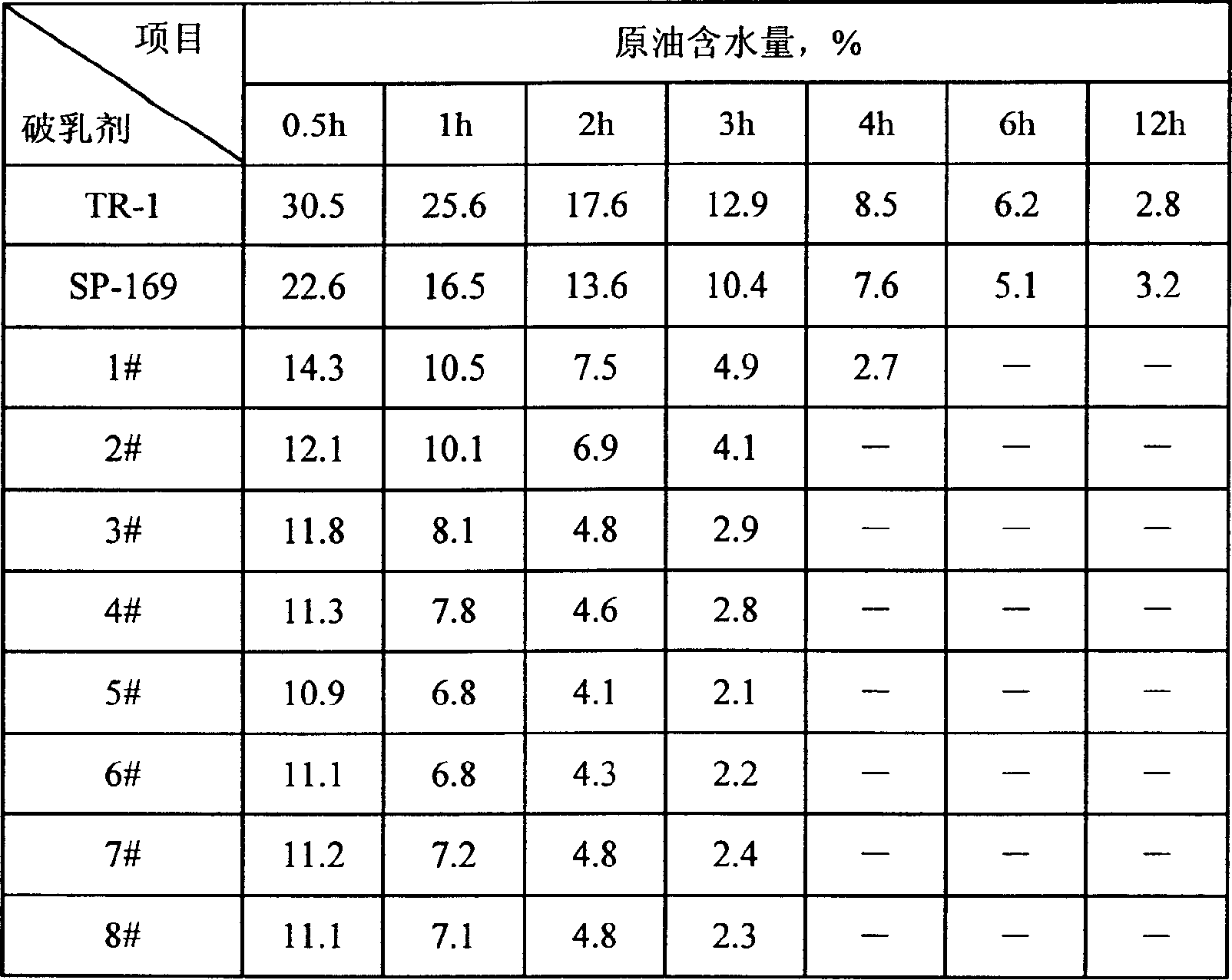

Thick oil demulsifier and its prepn

ActiveCN1810933ALow densityIncrease viscosityHydrocarbon oil dewatering/demulsificationEpoxyDemulsifier

The present invention is one kind of thick oil demulsifier and its preparation process, and belongs to the field of petrochemical technology. The present invention features that phenol-amine resin as the initial material is block polymerized with epoxy propane ad epoxy ethane under the action of catalyst to obtain stereo netted macromolecular polyether as the thick oil demulsifier. The polyether as the thick oil demulsifier may be further chain expanded for even high demulsifying effect. The thick oil demulsifier can reach the oil-water interface fast to lower the elasticity and viscosity of the interface film, speed the aggregation of liquid drops and demulsify effectively. The thick oil demulsifier has simple preparation process, is suitable for industrial production, and may be used in the efficient dewatering of oil field produced liquid with different water contents.

Owner:LIAONING OXIRANCHEM INC

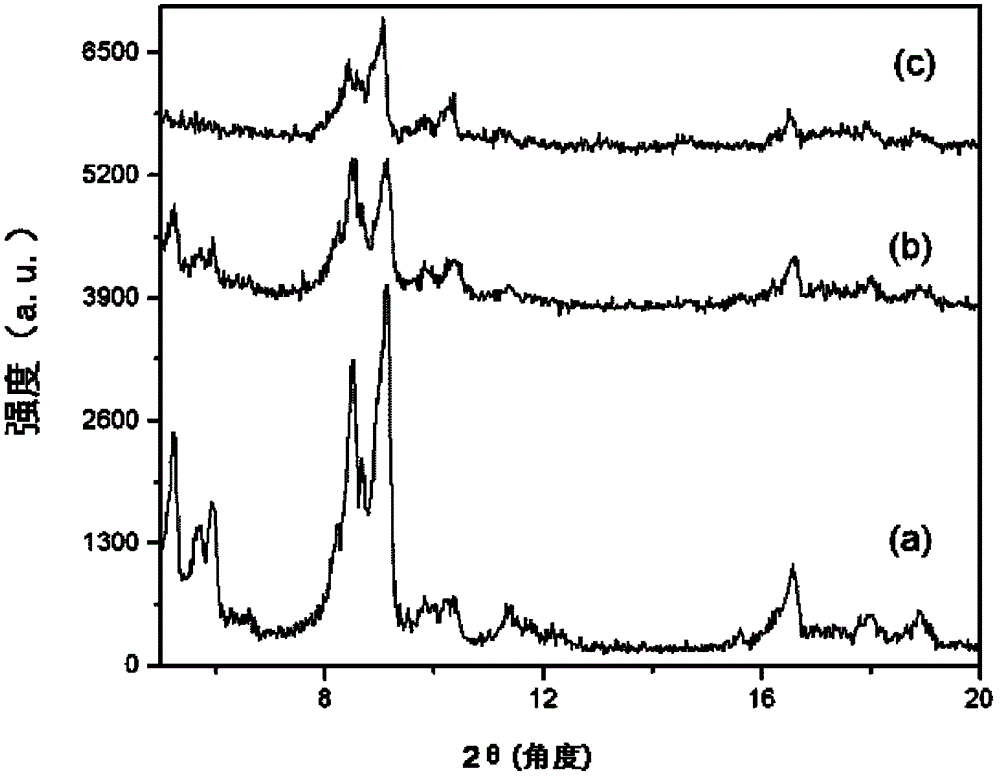

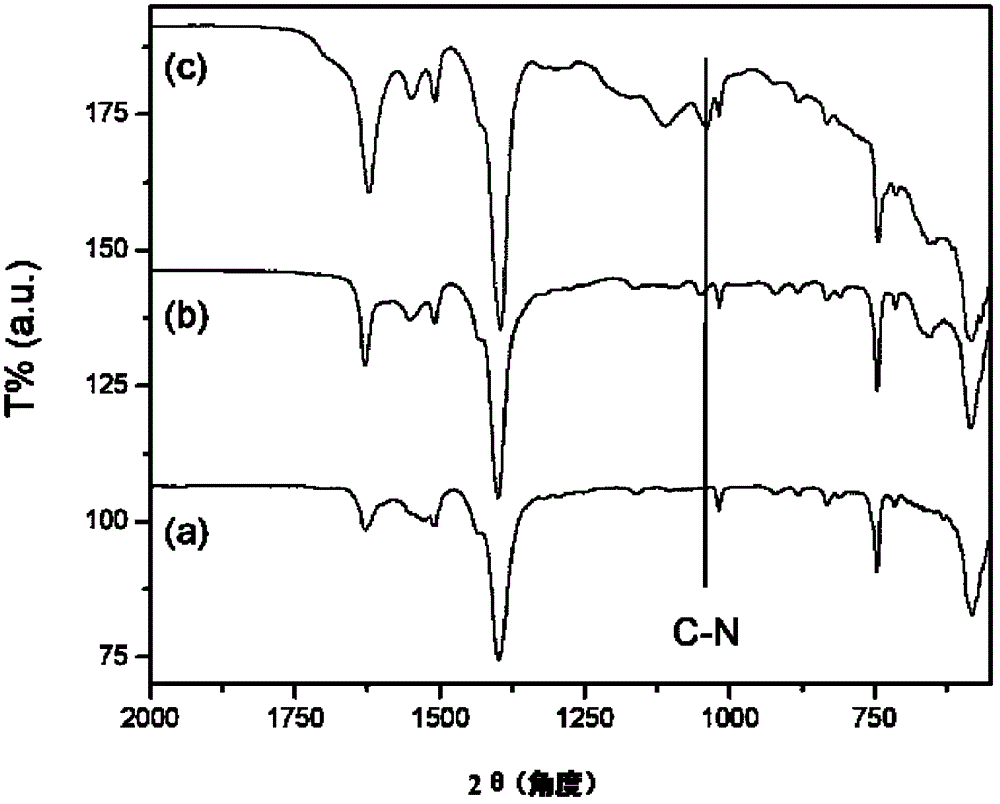

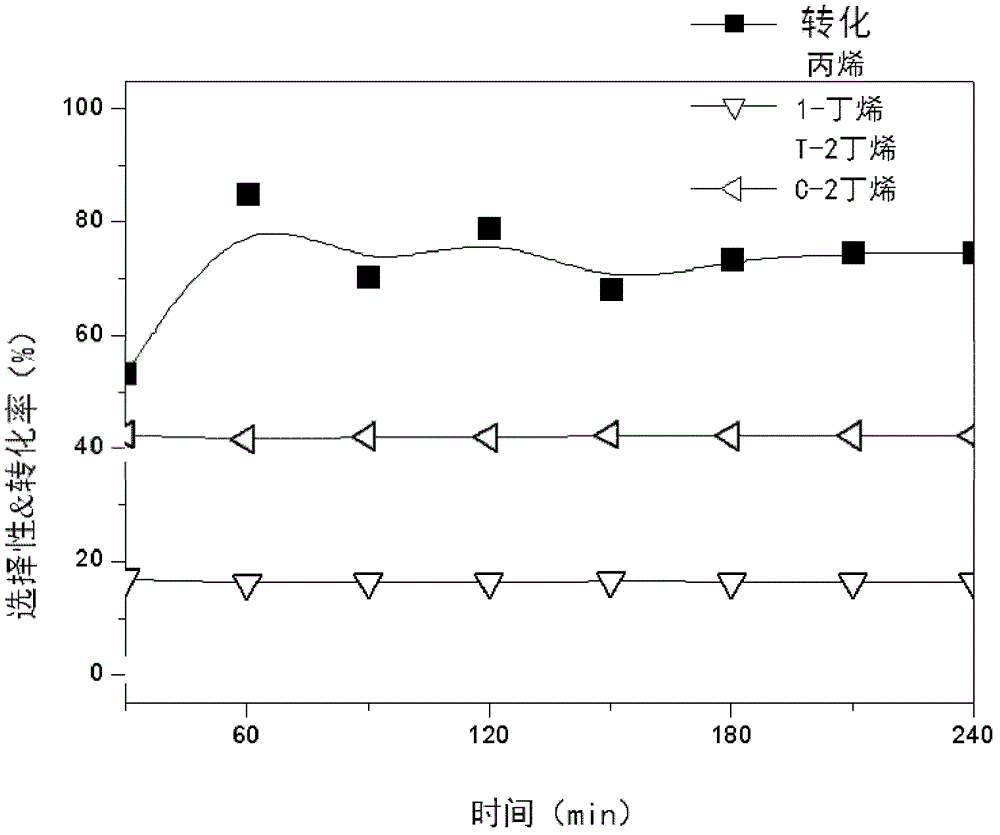

Method for functionalizing porous metal-organic framework materials, solid acid catalyst using same, and method for evaporating alcohol using the solid acid catalyst

InactiveCN102744105AThe functional method is simpleThe functional approach worksOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlcoholSorbent

The present invention relates to a method for functionalizing porous metal-organic framework materials which have a large surface area and molecular- or nano-scale pores, and which can thus be used for an absorbent, gas storage, a sensor, a membrane, a functional thin film, a catalyst, a catalyst carrier, and the like, to a method for preparing a solid acid catalyst using same, and to a method for evaporating alcohol using the catalyst.

Owner:KOREA RES INST OF CHEM TECH

Irrigation solution and methods for use

InactiveUS7238342B2Lower toxicitySuperior propertyBiocideCosmetic preparationsSmear layerBone surface

Methods and solutions are provided for removal of the smear layer on prepared tooth and bone surfaces, especially in endodontic environments.

Owner:DENTSPLY SIRONA INC

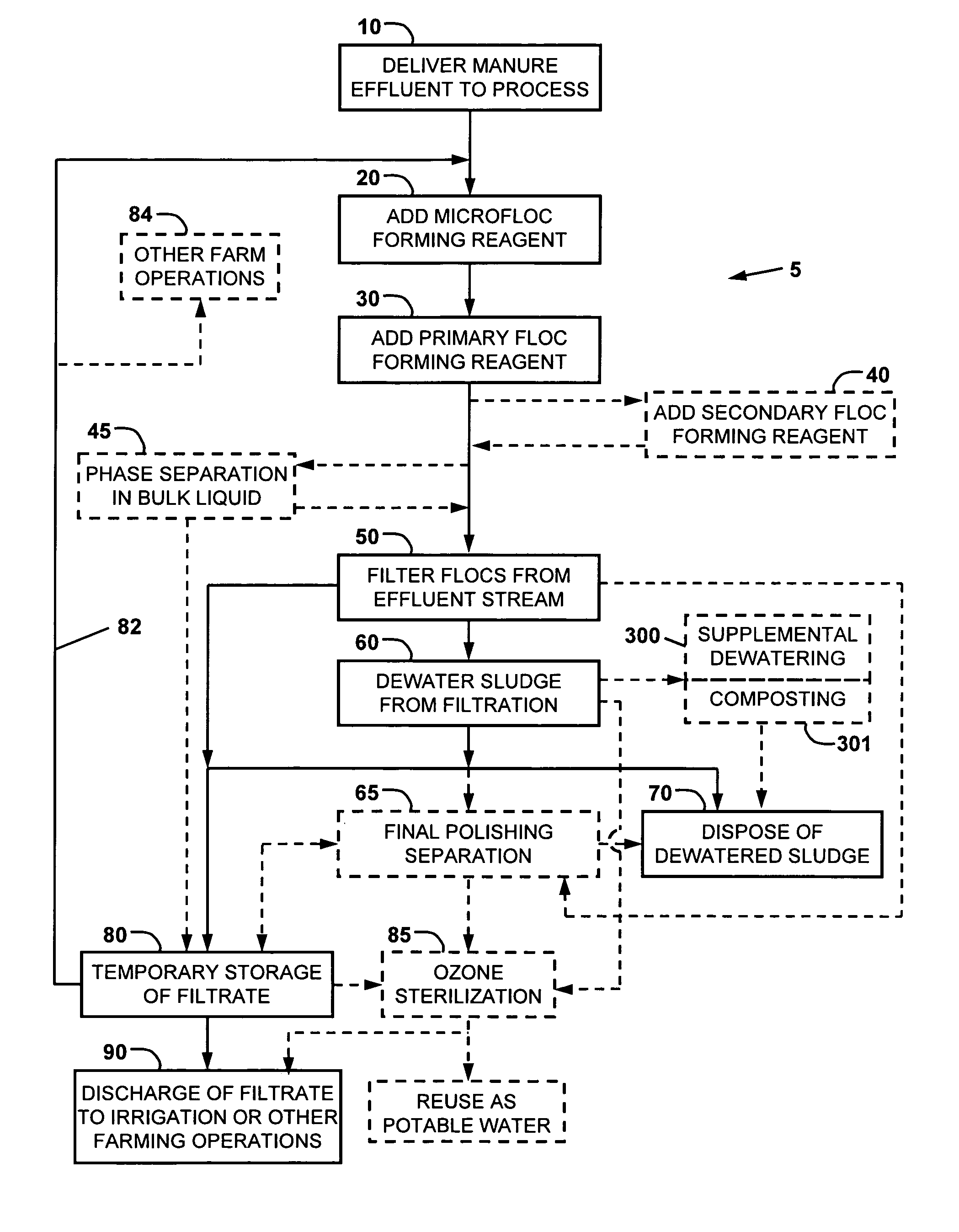

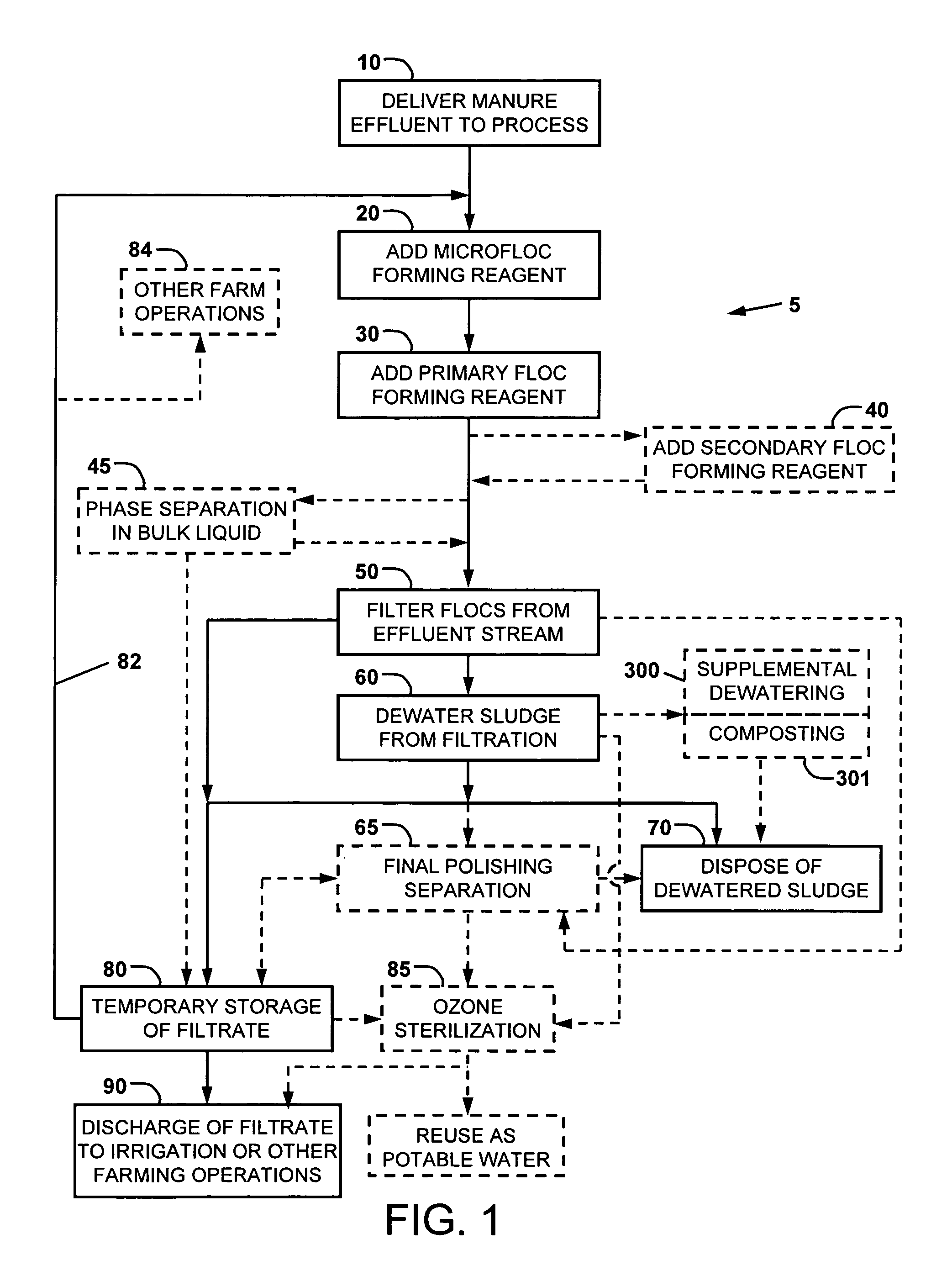

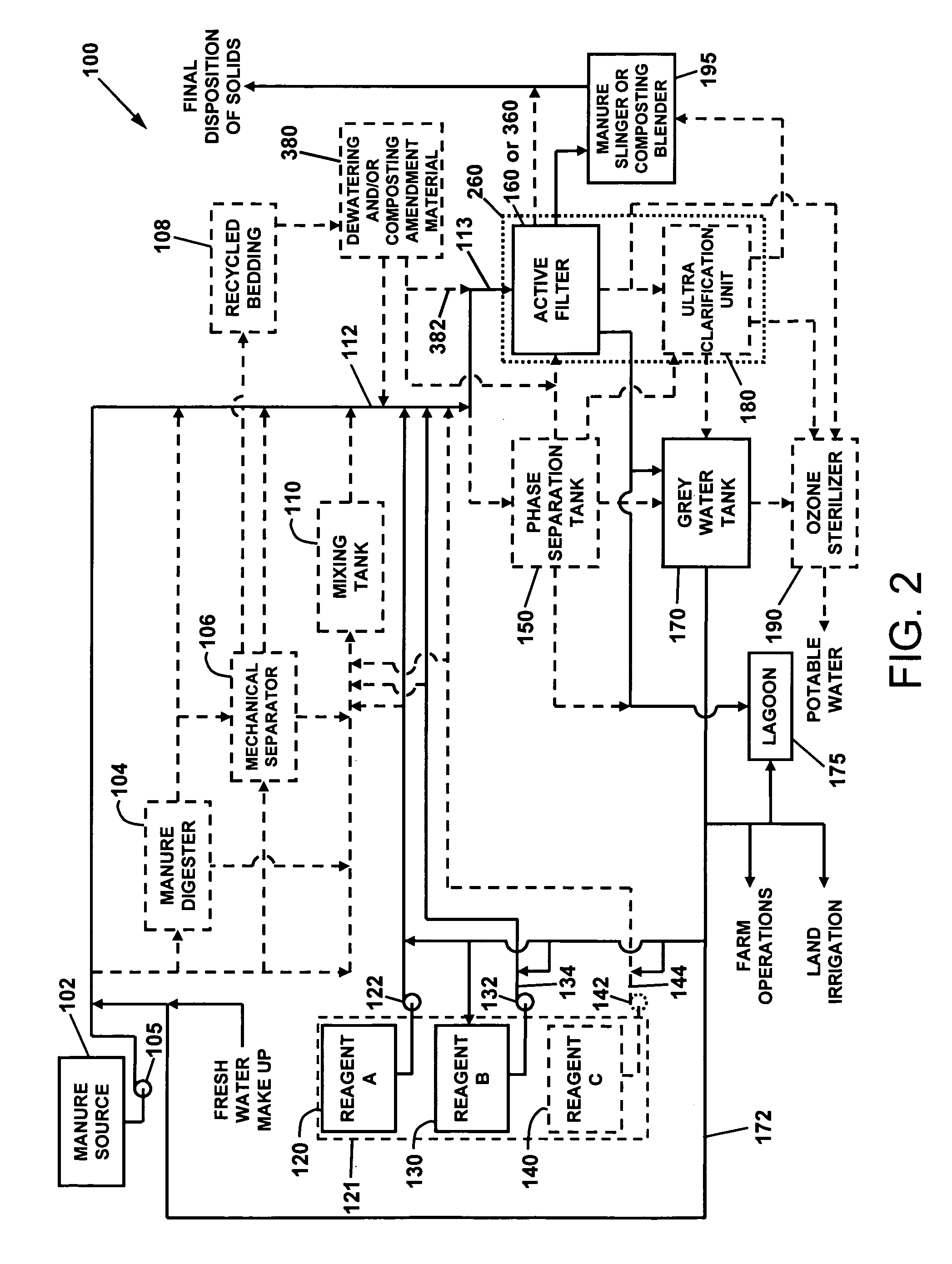

Method for treatment of agricultural waste

InactiveUS7972517B1Improved filtrate clarityReduce shipping costsSludge treatment by de-watering/drying/thickeningExcrement fertilisersLiquid wasteFeces

A method for treating a portion of liquid waste manure comprising adding a first reagent to the portion in a first vessel to cause the formation of waste manure flocs of a first size; adding a second reagent to liquid portion to cause growth of the waste manure flocs of the first size into separable waste manure flocs; adding optionally a third reagent to the portion of liquid containing waste manure flocs to cause further growth of the separable waste manure flocs; separating the liquid volume containing separable waste manure flocs into a waste manure sludge and a first filtrate; and dewatering the waste manure sludge in a filtration system comprising a first filter including a first housing, a first displaceable filter medium, and a first displacement actuator disposed between the first housing and the first displaceable filter medium.

Owner:INNOVATIVE ENVIRONMENTAL PRODS

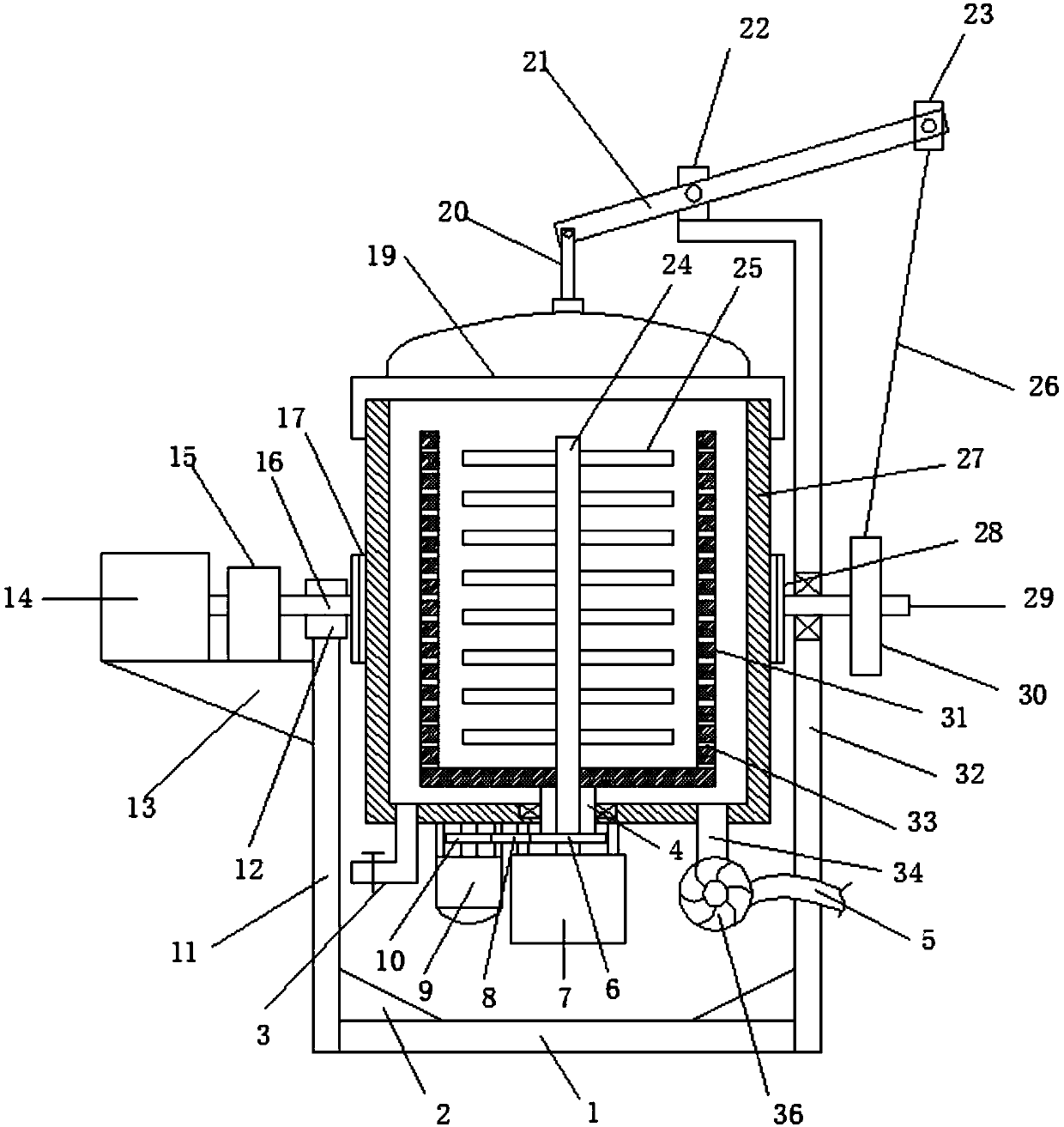

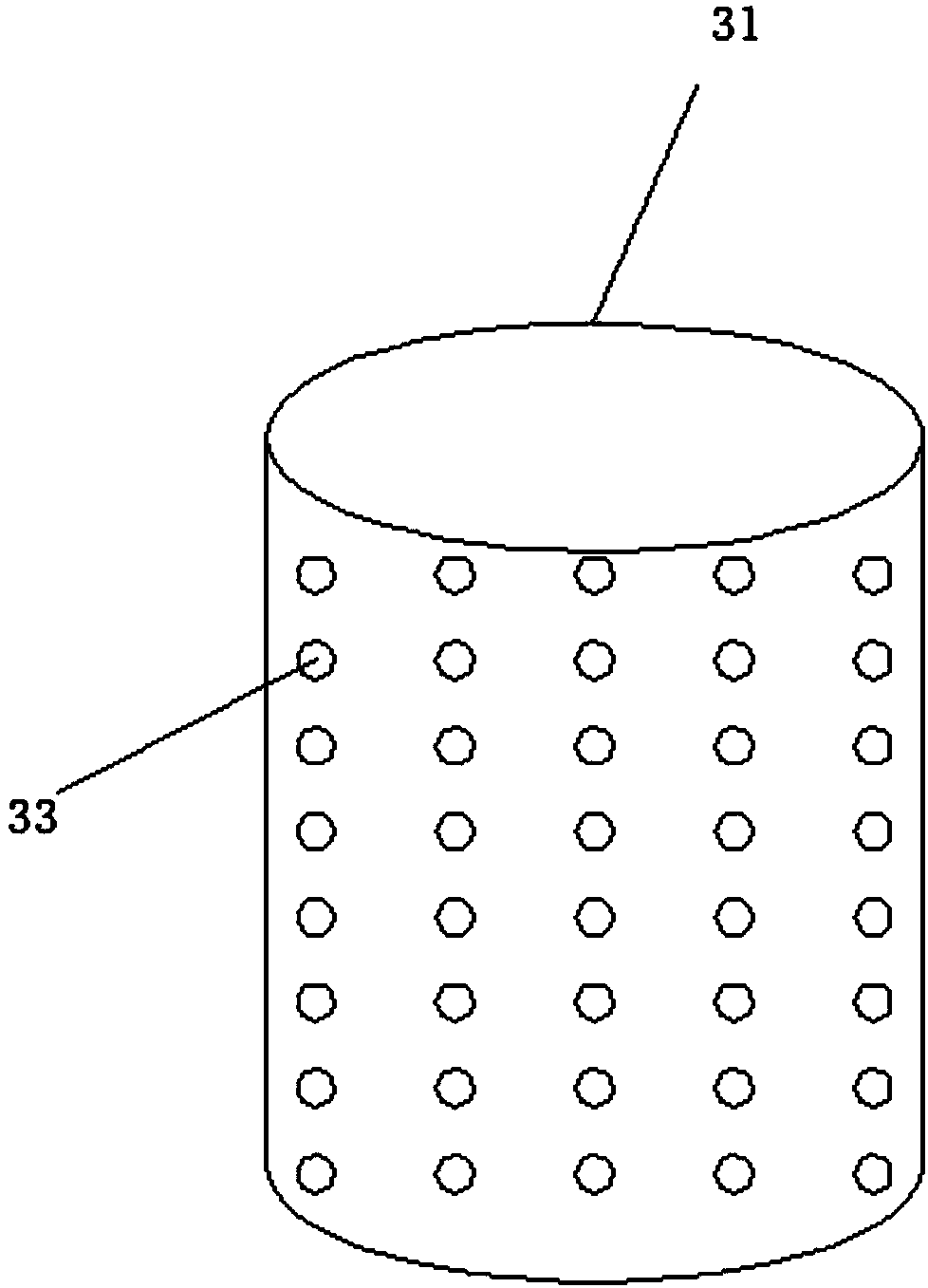

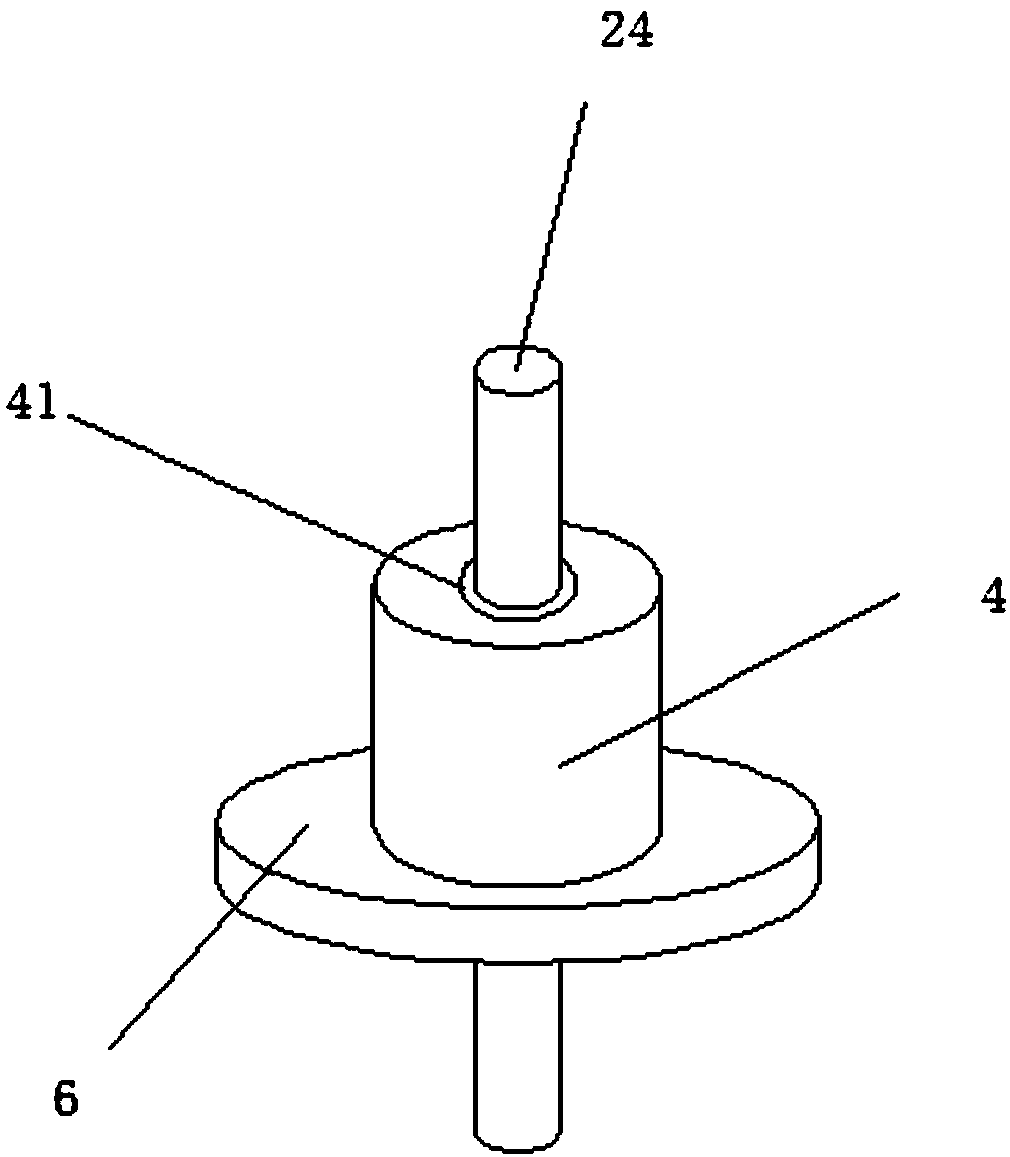

Roller centrifugal type environment-friendly treatment device for sludge dewatering

InactiveCN108033664AReasonable structureInnovative designSludge treatment by de-watering/drying/thickeningRotary centrifugesDrive shaftEngineering

The invention discloses a roller centrifugal type environment-friendly treatment device for sludge dewatering. The device comprises a fixing base plate; a first supporting frame is arranged on the left side of the upper end of the fixing base plate; a guide base is arranged at the upper end of the first supporting frame; a driving shaft is arranged in the middle of the guide base; a first rotatingdisc is arranged at the right end of the driving shaft; a second supporting frame is arranged on the right side of the upper end of the fixing base plate; a driven shaft is arranged in the middle ofthe second supporting frame through a bearing; a second rotating disc is arranged at the left end of the driven shaft; an outer cylinder is arranged between the first rotating disc and the second rotating disc; a first motor is arranged on the left side of the lower end of the outer cylinder; a driving belt wheel is arranged at the upper end of the first motor; a driven belt wheel is connected tothe right end of the driving belt wheel through a belt; a main shaft is arranged at the upper end of the driven belt wheel; an inner cylinder is arranged at the upper end of the main shaft; and a counter shaft is arranged in the main shaft. According to the device, sludge can be efficiently dewatered by utilizing the centrifugal force, the dewatering efficiency of the sludge can be improved, and meanwhile, the dewatered sludge can be quickly poured out.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

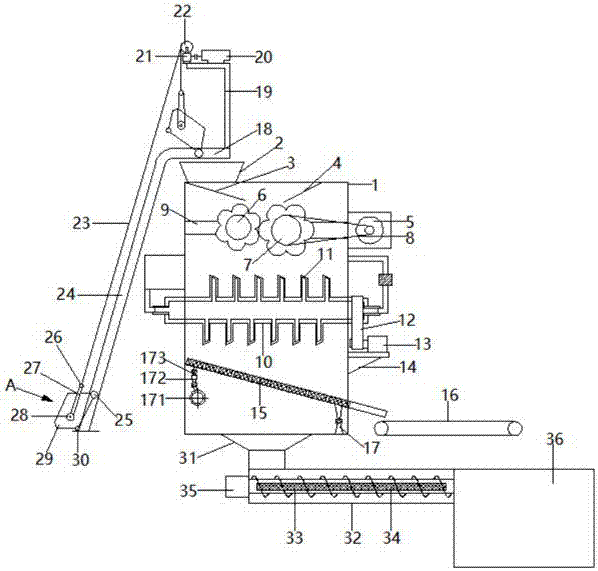

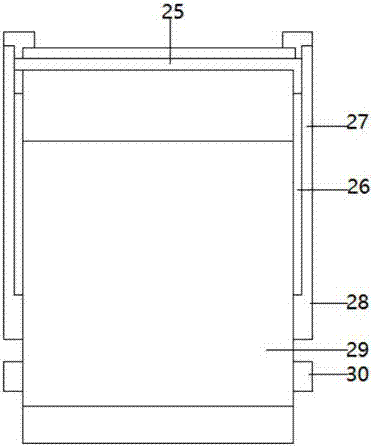

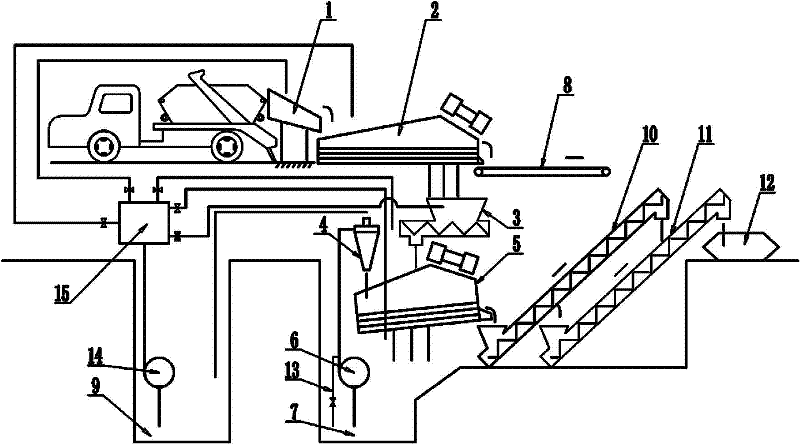

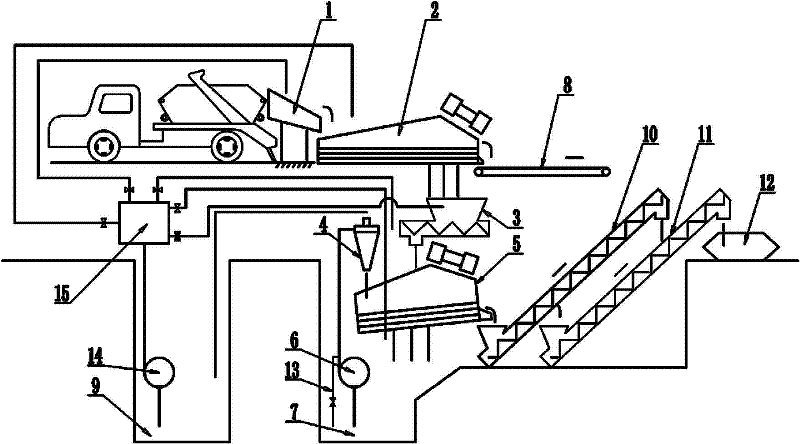

Garbage crushing and sorting treatment device for environmental protection engineering

InactiveCN107115920ARealize automatic feedingImprove work efficiencyGrain treatmentsGround contactEnvironmental resistance

The invention discloses a rubbish crushing and sorting device for environmental protection engineering, which comprises a machine body, a feed inlet is arranged at the left end of the upper side of the The rail is connected with the inclined rail contacting the ground, the upper part of the support is fixedly equipped with a feeding motor, and the upper side of the body is provided with a garbage coarse crushing device. It can fully crush and cut the garbage, and can also screen the crushed garbage, and realize the classified collection and treatment of garbage, which greatly improves the efficiency of garbage treatment. Cooling and cooling effectively prolong the service life of the entire device and ensure long-term stable work. In addition, the garbage feeding is completed by the feeding and lifting mechanism. The entire working process does not require manual operation and has a high degree of automation.

Owner:杨水红

Method for efficiently dewatering of sludge

InactiveCN102826733AEfficient dehydrationShorten the concentration timeSludge treatment by de-watering/drying/thickeningDiaphragm pumpDry weight

The invention relates to a method for efficiently dewatering of sludge. The method comprises the following steps of: adding an organic flocculant and a physical conditioner to a gravity thickening tank, wherein the amount of the added organic flocculant is 0.2 per mill to 5.0 per mill of the dry weight of the thickened sludge, and the amount of added physical conditioner is 1% to 10% of the dry weight of the thickened sludge; tempering: adding a calcium coagulant aid to the sludge slurry based on the amount of 1% to 5% of the dry weight of the thickened sludge; and then adding a ferrum flocculant after 1 to 10 minutes based on the amount of 0.5% to 5% of the dry weight of thickened sludge; reacting for 1 to 20 minutes; dewatering: introducing the tempered sludge into a plate-and-frame filter press through a pneumatic diaphragm pump, and charging for 20 to 30 minutes, and dewatering at 0.5 to 2.5Mpa; and discharging: discharging the dewatered sludge from the plate-and-frame filter press. According to the method, the chemical and physical combination mode is adopted to condition for boosting coagulation in the sludge thickening stage; the inorganic flocculant and the coagulant aid are added for further preprocessing in the sludge tempering stage; mechanical equipment with relatively high pressure is adopted to dewater, so that the effect of dewatering can be further improved, and efficient dewatering of the sludge in the urban wastewater treatment plant can be achieved.

Owner:NANJING FORESTRY UNIV

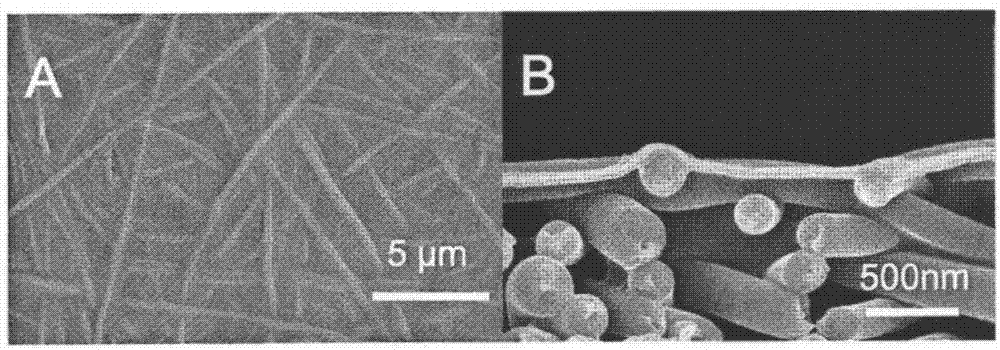

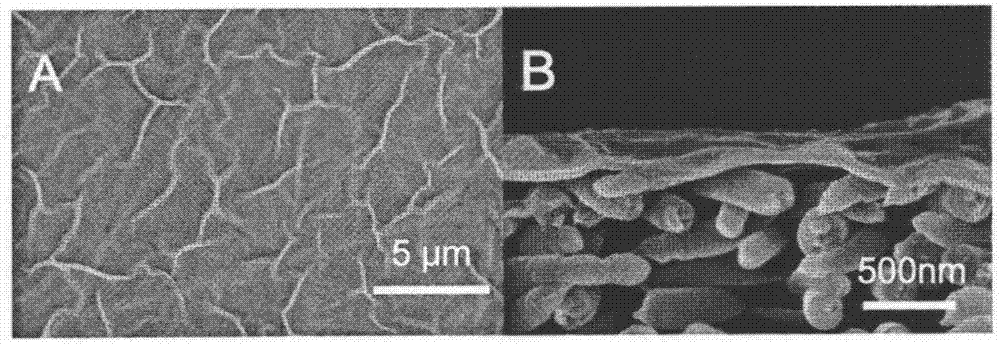

Nano-fiber-based composite pervaporation membrane and preparation method thereof

ActiveCN106964262AEfficient and stable separation performanceEfficient dehydrationMembranesDistillationFiberSurface layer

The invention provides a nano-fiber-based composite pervaporation membrane and a preparation method thereof. The nano-fiber-based composite pervaporation membrane is characterized by including a basic layer, a middle transitional layer and a surface layer, wherein the basic layer is a nano-fiber porous support layer, the middle transitional layer is a modified oxidized graphene layer, and the surface layer is a separation layer having interfacial polymerization activity. The simple, modified, thickness-controllable, flexible and ultrathin oxidized graphene skin layer serves as the middle transitional layer, the thickness and uniformity of a function barrier layer on the surface of the composite membrane and the interface acting force of a compact separation layer and the middle transitional layer can be rapidly and accurately adjusted and controlled by controlling interfacial polymerization and optimization, and accordingly the pervaporation performance of the composite membrane is enhanced.

Owner:DONGHUA UNIV

Dewatering of calcium carbonate

InactiveUS6123855AImprove productivityReduced dispersant demandCalcium/strontium/barium carbonatesCoatings with pigmentsPrecipitated calcium carbonateSlurry

The present invention relates to dewatering of an aqueous slurry of calcium carbonate. More particularly, the present invention relates to the use of non-ionic surfactants in dewatering aqueous slurries of an aragonitic precipitated calcium carbonate. Calcium carbonate slurries dewatered using the non-ionic surfactants of the present invention have higher weight percent solids, decreased dispersant demand, and result in higher productivity.

Owner:MINERALS TECH

Formula for deep dehydration of sludge and operation method of formula

InactiveCN105330123AEfficient dehydrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningCeramic materials productionSludgeSewage

The invention relates to deep dehydration of sludge, in particular to a formula for deep degradation of sludge and an operation method of the formula. The formula comprises steps as follows: preparation of auxiliary materials, primary treatment of the sludge, thermal refining of the sewage, mechanical filter pressing and backflow of filtrate. According to the formula for deep dehydration of the sludge and the operation method of the formula, continuous treatment can be performed, the treatment efficiency is improved, energy is saved, consumption is reduced, the controllability is high, and recycling is realized.

Owner:ZHEJIANG JIEFENG ENVIRONMENTAL PROTECTION TECH ENG COMPANY

Air dehydration membrane

ActiveUS20050252377A1Low selectivityNot affect selectivityMembranesSemi-permeable membranesCoated membraneWater vapor

An air dehydration membrane is made of a hydrophilic polymer having a permeability for water vapor which is greater than its permeability for air, and having low selectivity between oxygen and nitrogen. The membrane has a hydrophilic coating, which itself may be a polymer. The coating does not affect the selectivity of the coated membrane with respect to oxygen and nitrogen, but does increase selectivity of the membrane with respect to water vapor. A preferred material for the membrane is polysulfone. Preferred materials for the coating are poly vinyl alcohol and Triton X-100. The membrane is selected such that the dominant mechanism for gas flow through the membrane is Knudsen flow. The membranes are made at low cost, and can outperform existing commercial membranes in either volumetric productivity or product recovery.

Owner:GENERON IGS

Sludge treatment method and device for urban drainage pipe network

ActiveCN102225834AReduce shipping costsPromote resource utilizationSludge treatment by de-watering/drying/thickeningDraining tubeSludge

A sludge treatment method for an urban drainage pipe network comprises the following steps of: 1) multi-stage screening; 2) conveying the separated slag into a garbage bucket by a conveying device; 3) conveying the separated sewage to a sewage-collecting pool; 4) arranging a first submersible sewage pump outlet on the sewage-collecting pool, wherein the pump is connected to a cyclone desander andis used to separate mud and sand with micro particle sizes, discharging the separated mud and sand through a sand-settling nozzle for the screening step, allowing the separated sewage to enter the underground drainage pipe network through an overflow pipe of the cyclone desander; 5) setting a reclaiming pool, pumping reclaimed water to a flushing distributor by a second submersible sewage pump, and conveying the reclaimed water to each screening device and each conveying device by the flushing distributor according to working conditions; slag with a water content of below 40%, and clear waterwhich is allowed to directly enter the underground drainage pipe network for circulation can be obtained through above steps. The invention can perform rapid dehydration treatment of sludge in a sewer well; the treated water is allowed to directly enter the drainage pipe network for circulation, while the slag can be transported by common vehicles. The purposes of high efficiency, environmental protection, and safe dredging are achieved.

Owner:SAFECLEEN TECH

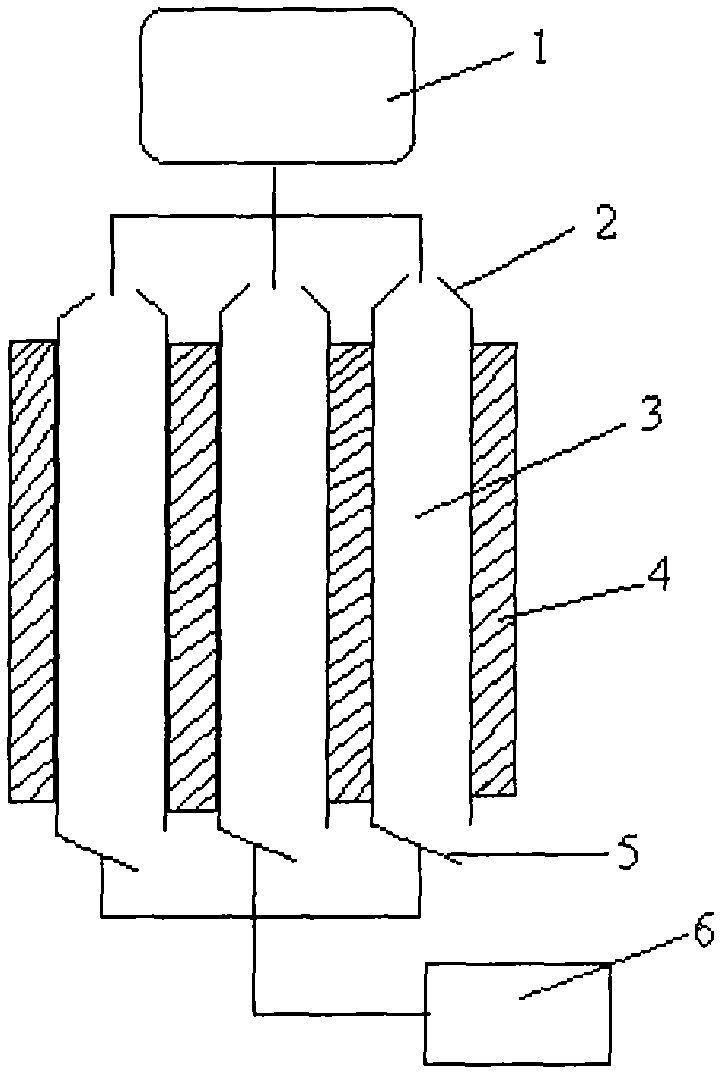

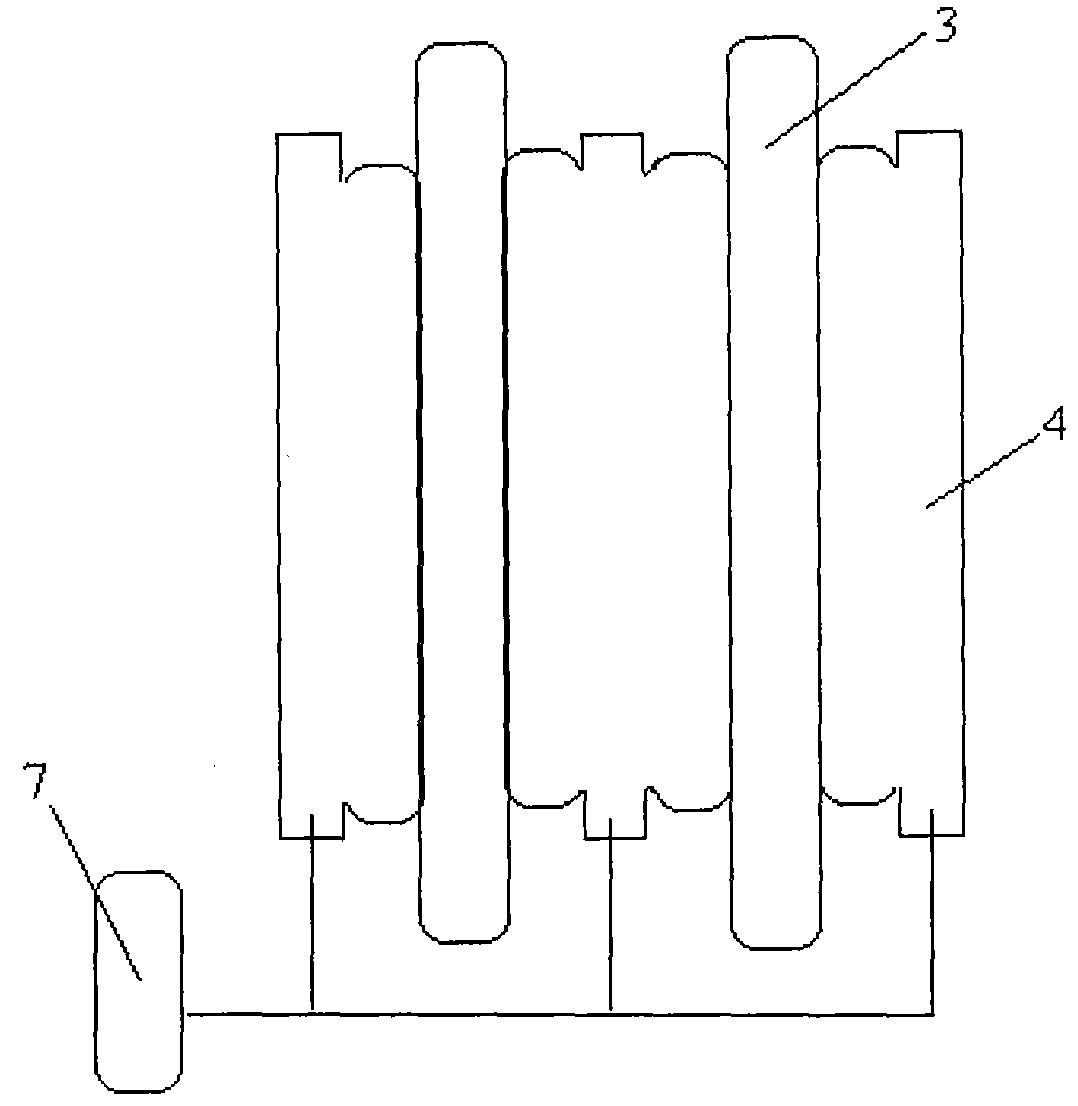

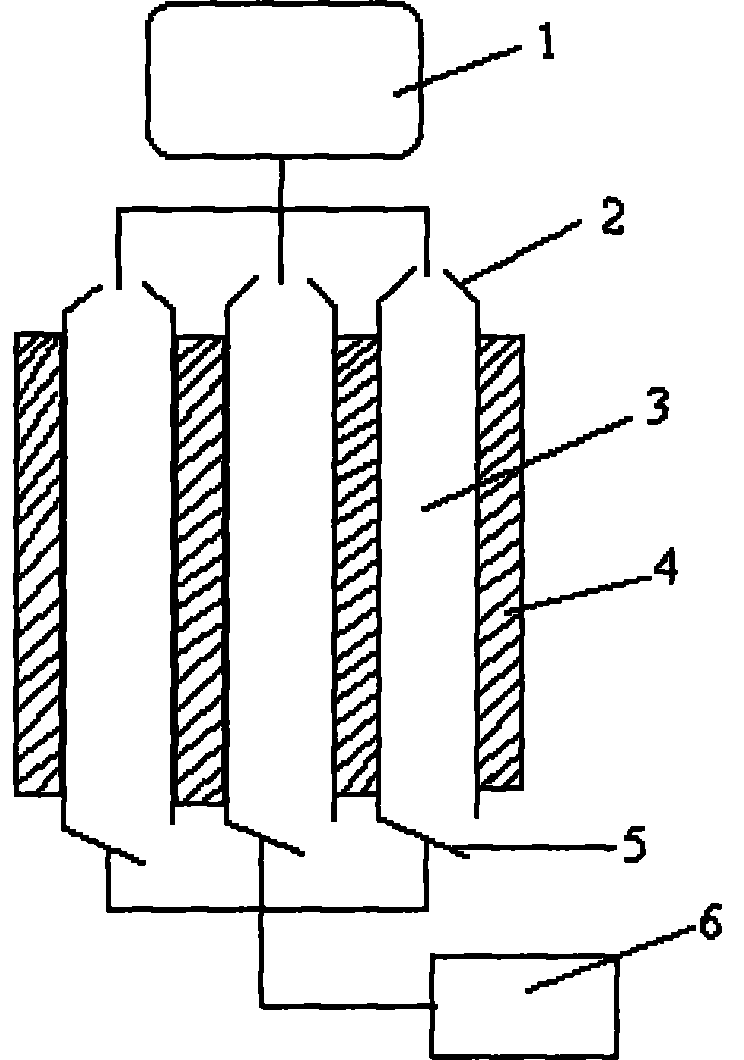

Water-contained material pressing and dehydrating method and device

The invention relates to a water-contained material pressing and dehydrating method and a device. Water-contained materials are simultaneously conveyed to all the filter bags of a pressing device through a feeding device, an air bag or a water bag is utilized to press the filter bags for pressing and dehydrating the materials, and the dehydrated materials are simultaneously discharged from the lower ports of the filter bags under the action of gravity. The device presses and dehydrates the materials which have high solid contents, and has high feeding and discharging speeds, and has the characteristics of high efficiency, simplicity in operation and the like.

Owner:YIXING NENGDA ENVIRONMENTAL PROTECTION TECHCO

System and method for dewatering coal combustion residuals

ActiveUS20180030362A1Accelerates the removal of moistureLower the volumeDrying solid materials without heatSolid fuelsBottom ashCombustion

The installation of prefabricated drains in a horizontal, generally co-planar pattern below the surface of the CCR with suction or a vacuum to withdraw water from the CCR material to lower the water level down to the level of the prefabricated drains below the CCR surface. Dewatering may be coupled with imparting vibrations to the material to further promote both additional dewatering and compaction of the CCR material in the pond. A suitably graded bottom ash, fly ash, sand or large-diameter-solid particle layer may be added on top of the horizontal drains to enhance dewatering of finer CCR material.

Owner:AECOM TECHNICAL SERVICES INC

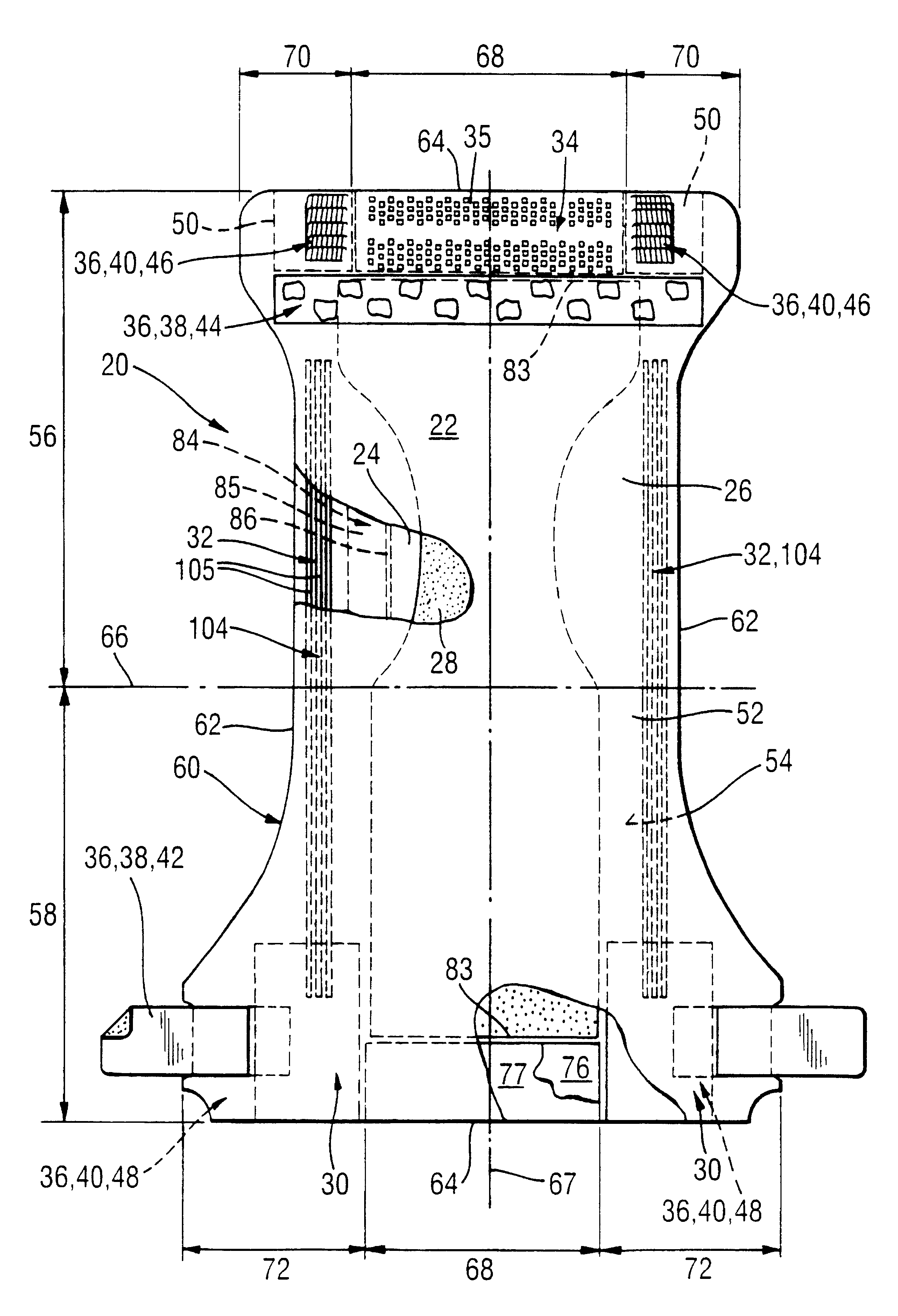

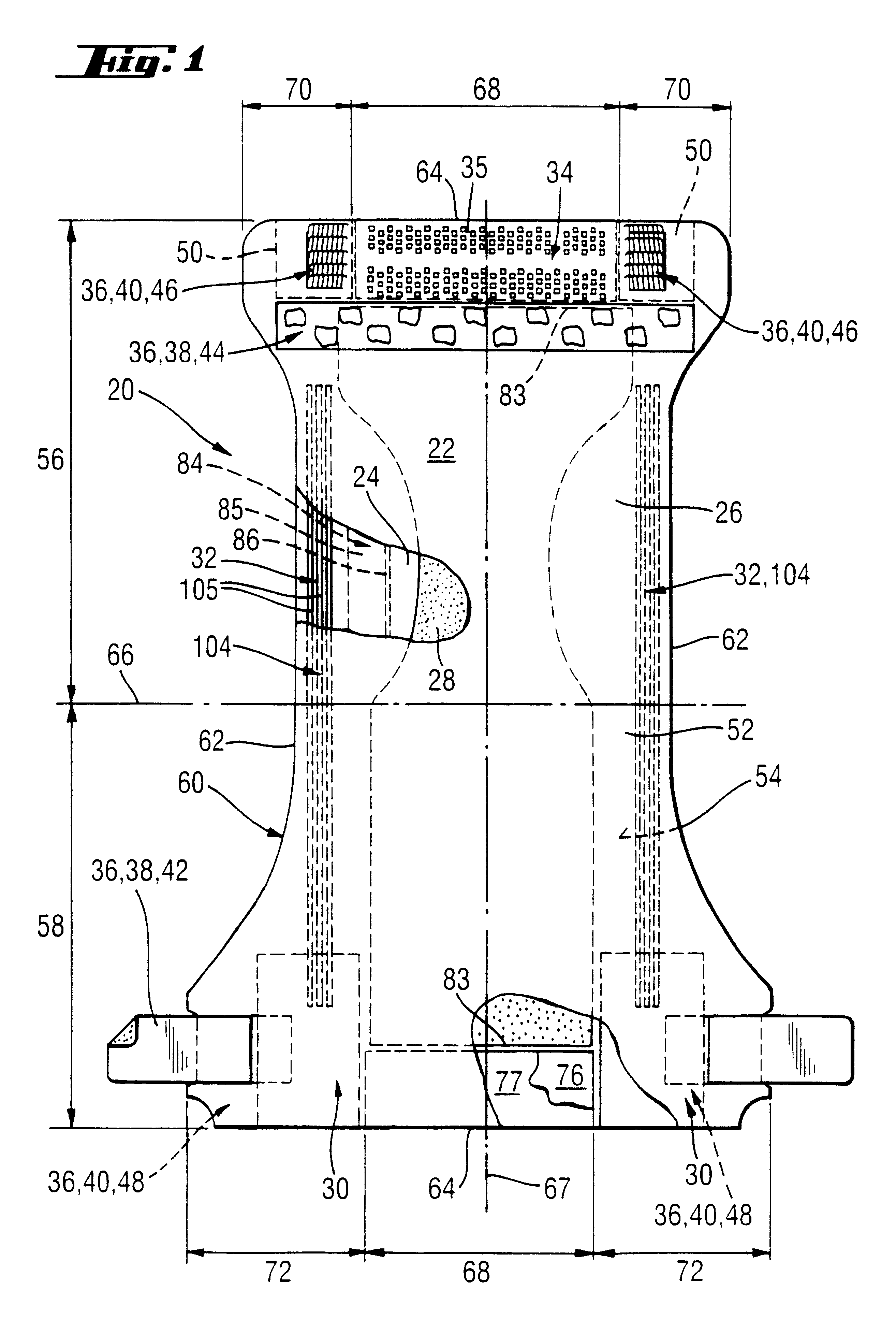

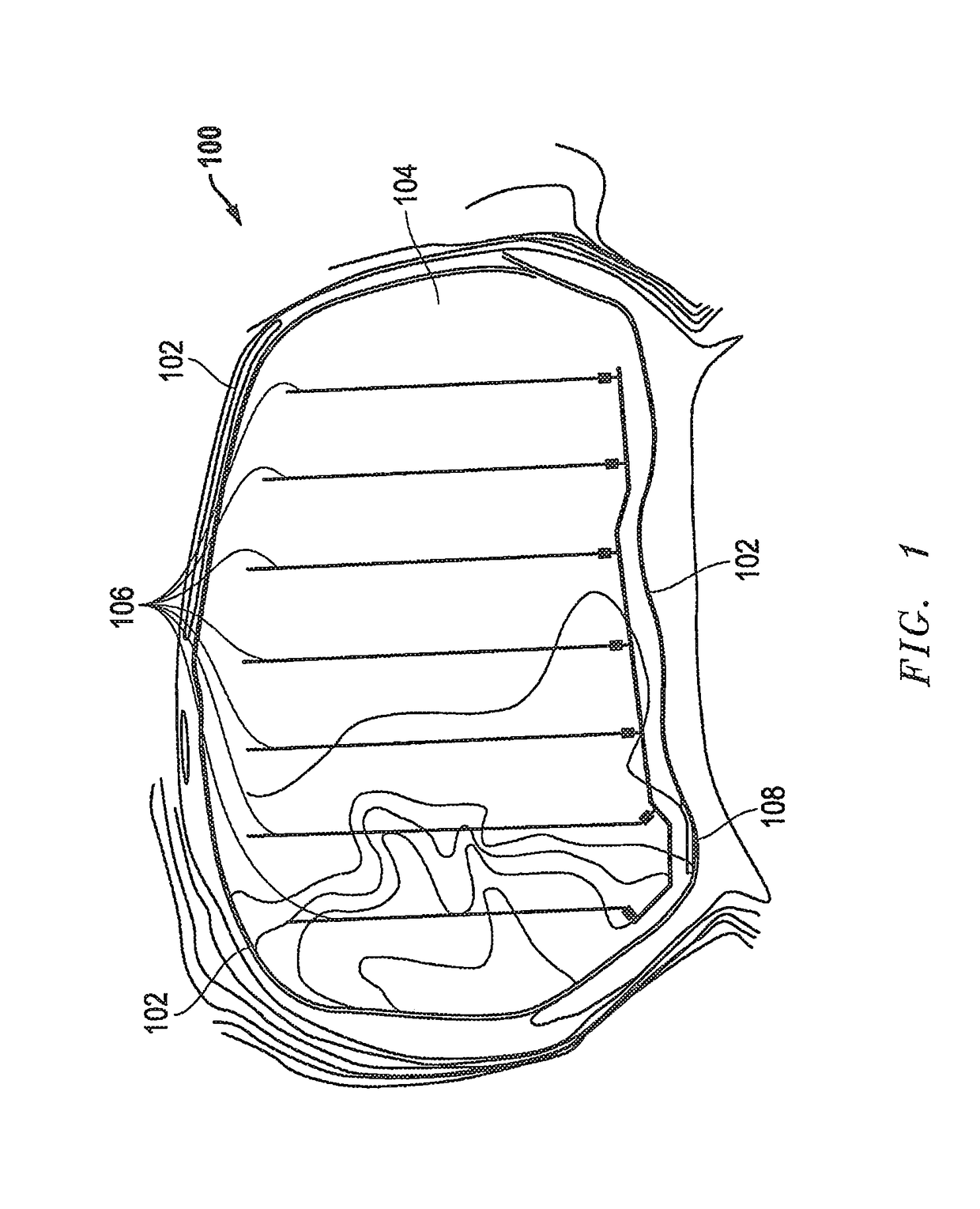

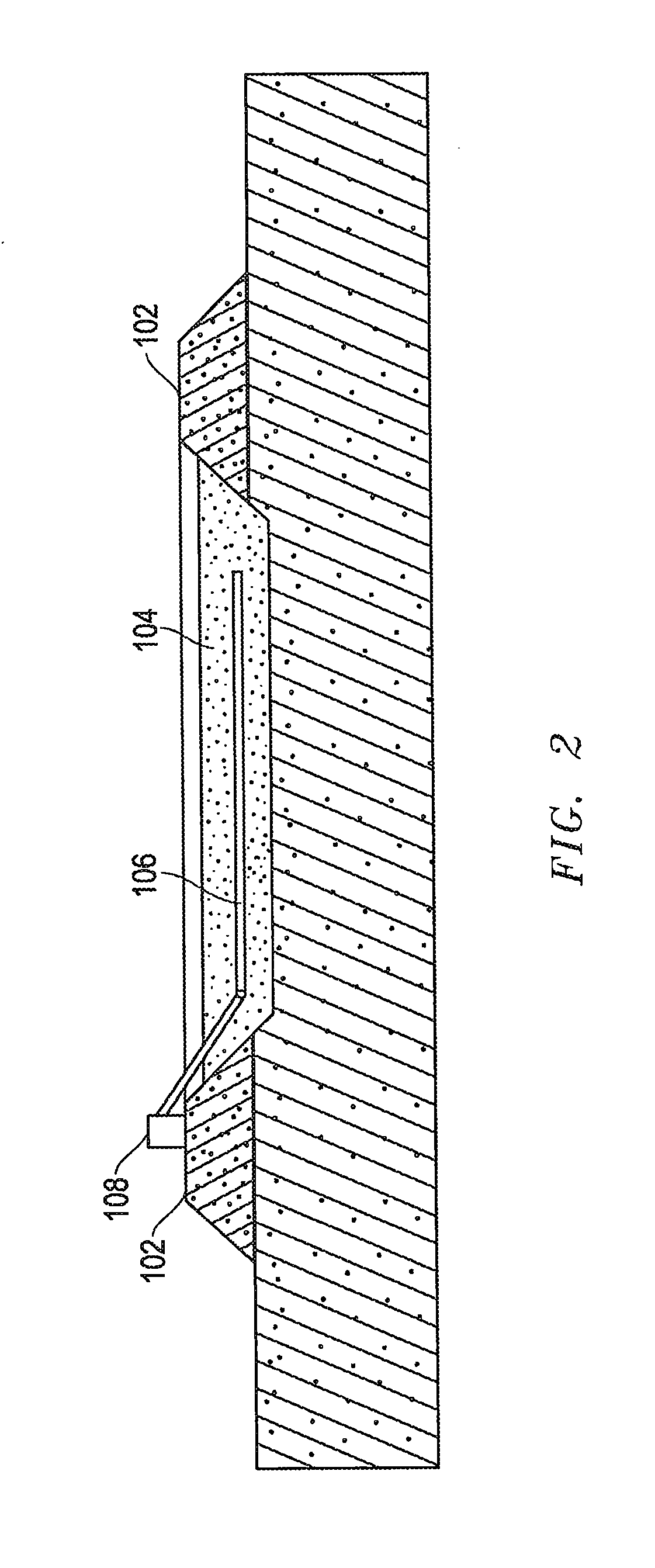

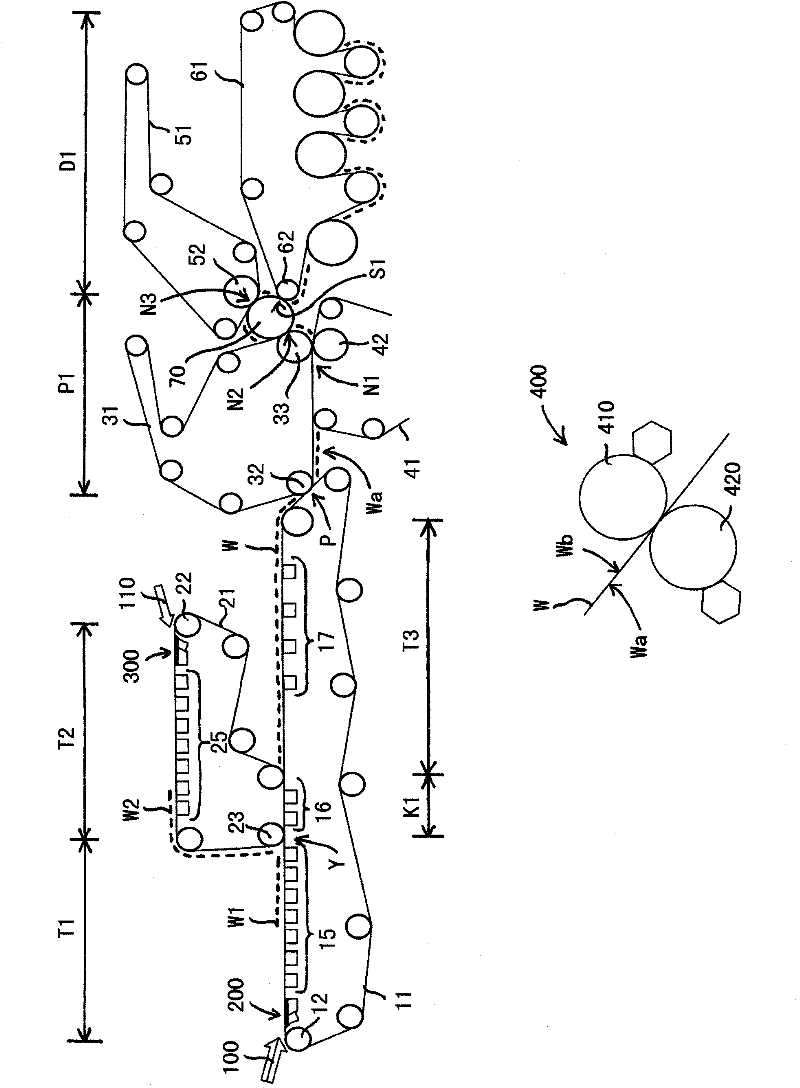

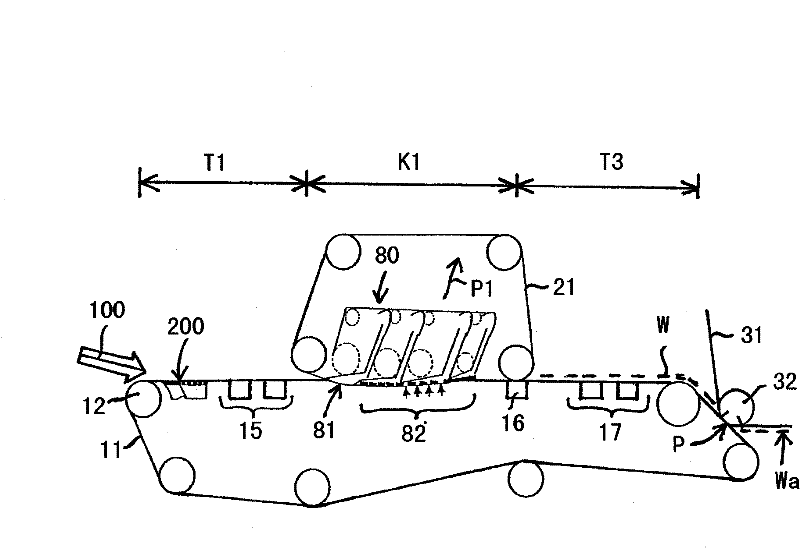

Board machine

InactiveCN102131981ADoes not affect layered purityAvoid deformationMachine wet endEngineeringCoating

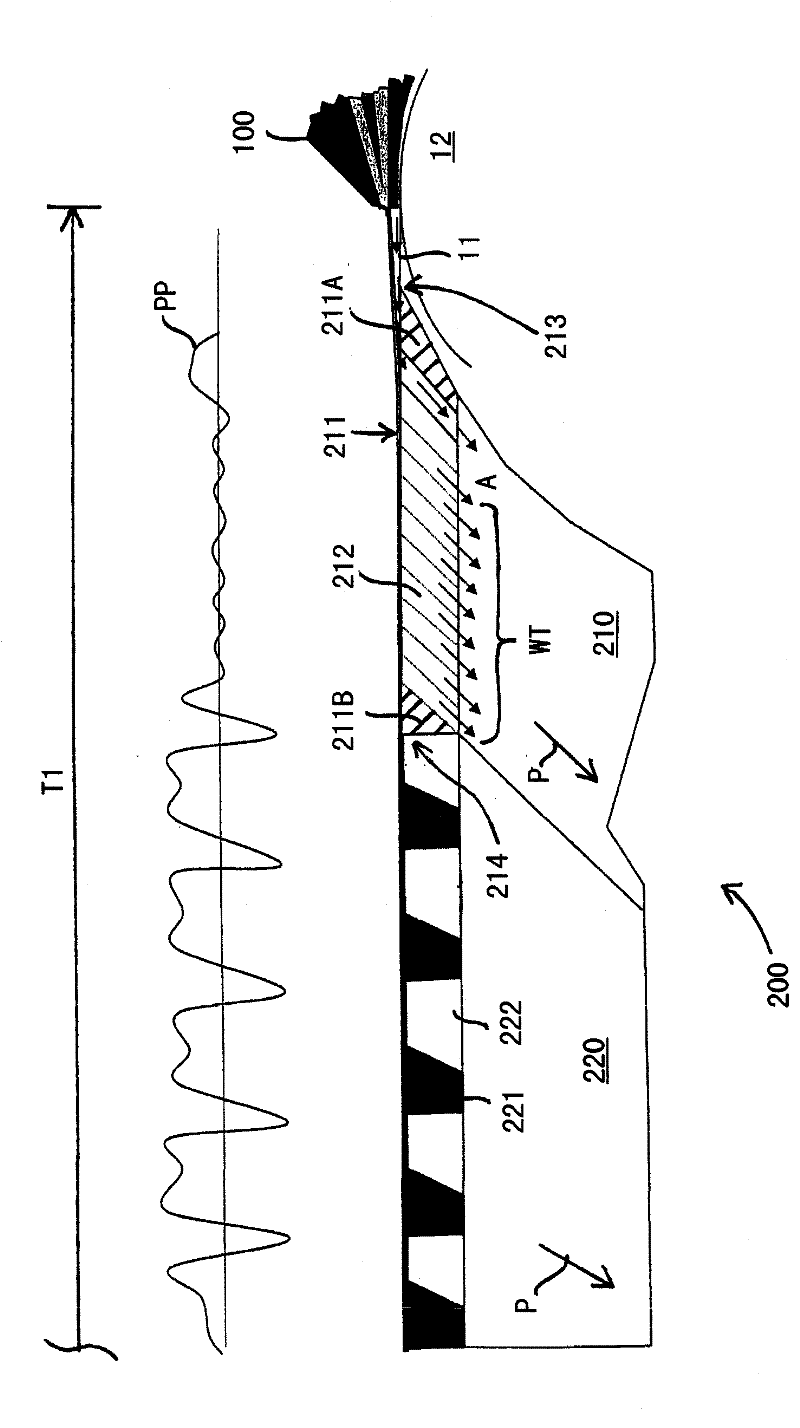

A board machine comprises a forming section where a lower wire loop (11) forms a fourdrinier-wire section (Tl) at the beginning of which is located a forming board (200) which consists of at least one stationary, non-pulsating forming shoe (210). In the forming shoe (210), there is a cover (211) provided with thorough holes (212), setting against the inner surface of the lower wire loop (11). A first headbox (100), which is a multi-layer headbox, feeds a pulp suspension jet onto the forming shoe (210). The board machine further comprises a press section (Pl) where a surface (Wa) of the web (W) having been against the lower wire loop (11) is pressed against a smooth surface, a dryer section (Dl) where the web (W) is dried with at least one cylinder-dryer group and a coating section (400) where at least the surface (Wa) of the web (W) having been against the lower wire (11) is coated.

Owner:METSO PAPER INC

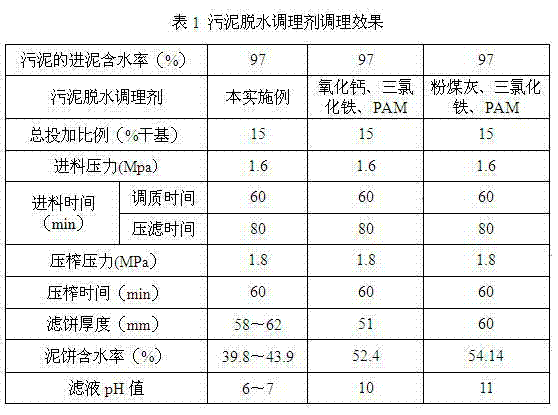

Compound type sludge dewatering conditioner and application method thereof

ActiveCN103113013AChange surface chargeEfficient dehydrationSludge treatment by de-watering/drying/thickeningChemical industryActive agent

The invention provides a compound type sludge dewatering conditioner which comprises the following components in parts by weight: 3-6 parts of ferric trichloride, 3-6 parts of calcium oxide, 1-2 parts of magnesium oxide, 1-4 parts of surfactant and 1-2 parts of sulfuric acid. The compound type sludge dewatering conditioner provided by the invention can realize efficient dewatering of sludge, the conditioning technology is simple and quick, the dosage of the conditioner is small, the moisture content of the dewatered sludge is reduced to below 45%, the pH value is 6-7, foul smell and the problem of capacity increase are avoided, and sludge reduction can be realized; and the compound type sludge dewatering conditioner has good environmental benefits, is favorable for subsequent sludge resource utilization, can be widely applied to the sewage and sludge treatment of the industries such as chemical industry, municipal affairs and the like, and is particularly suitable for treating the domestic sludge of urban sewage plant.

Owner:SHENZHEN WATER GRP CO LTD

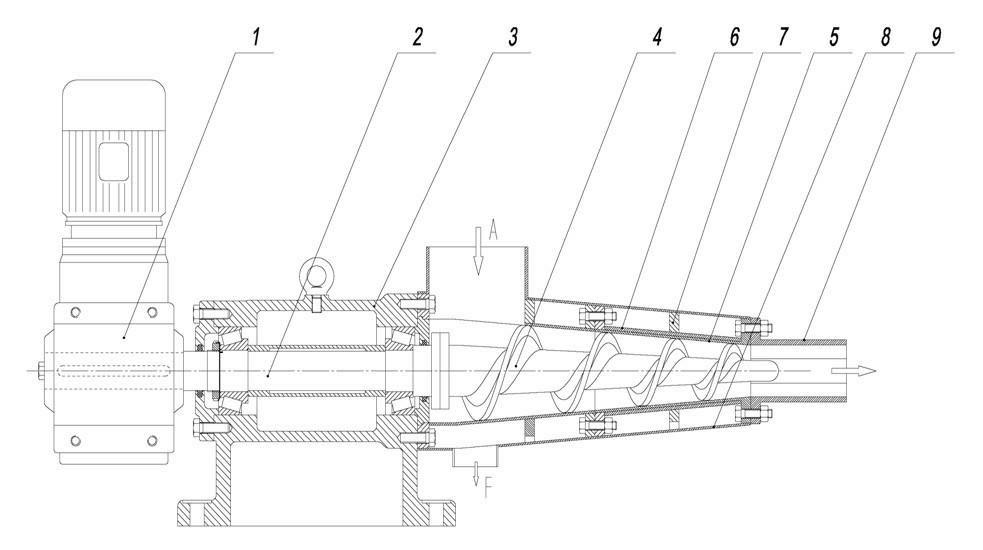

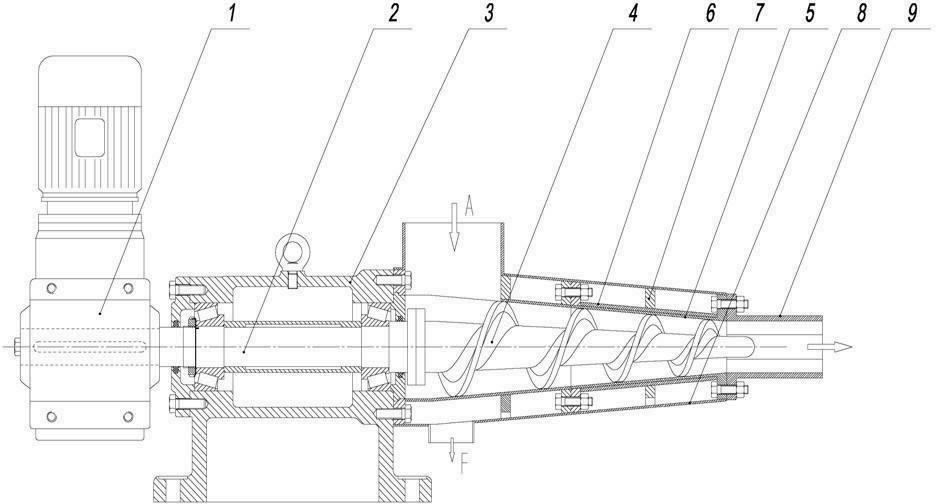

Plug screw feeder for feeding cellulose pulp/chips

ActiveUS20100186609A1Dewatering property increaseDecrease inclinationRollsMetal rolling arrangementsEngineeringMechanical engineering

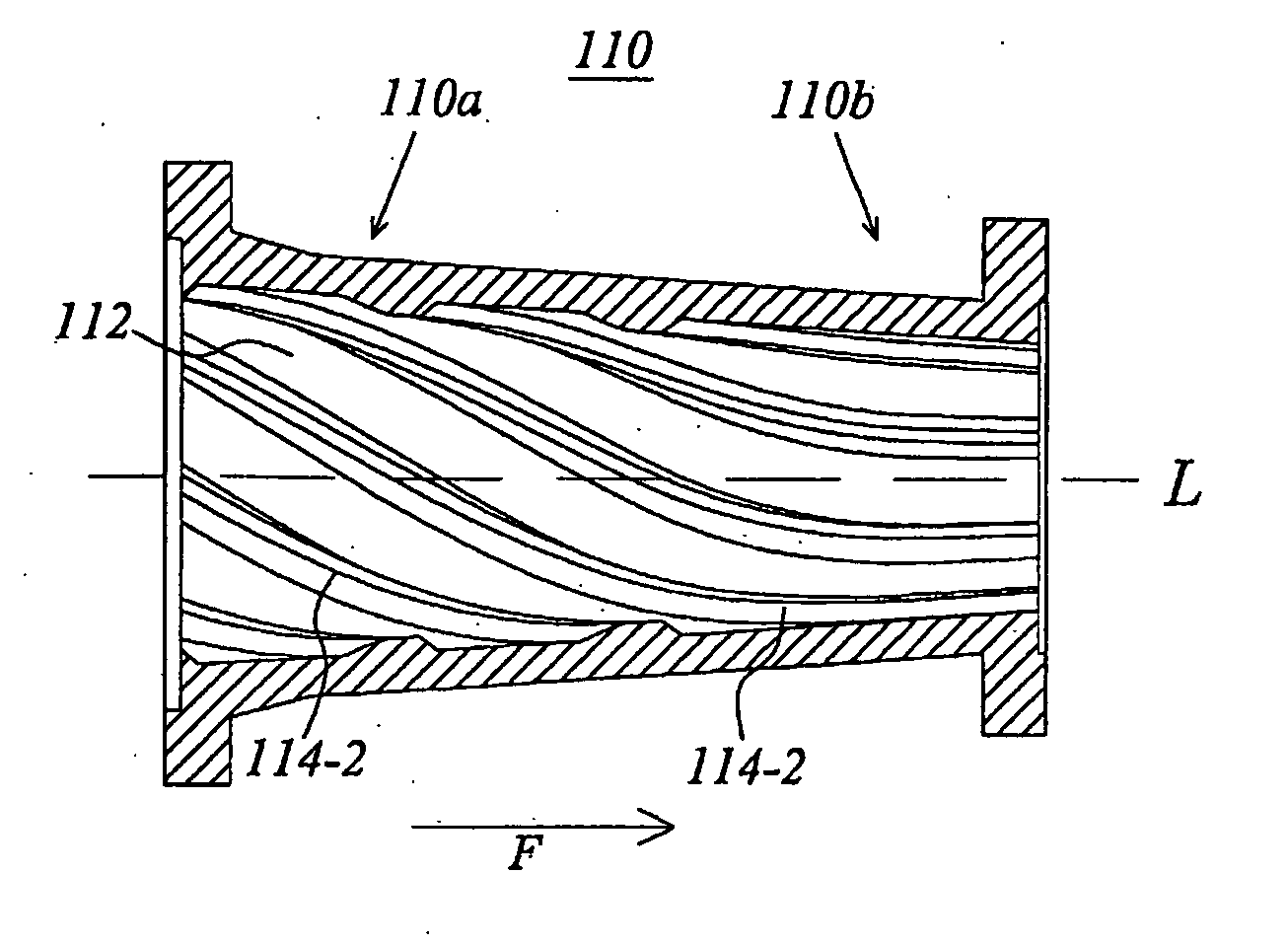

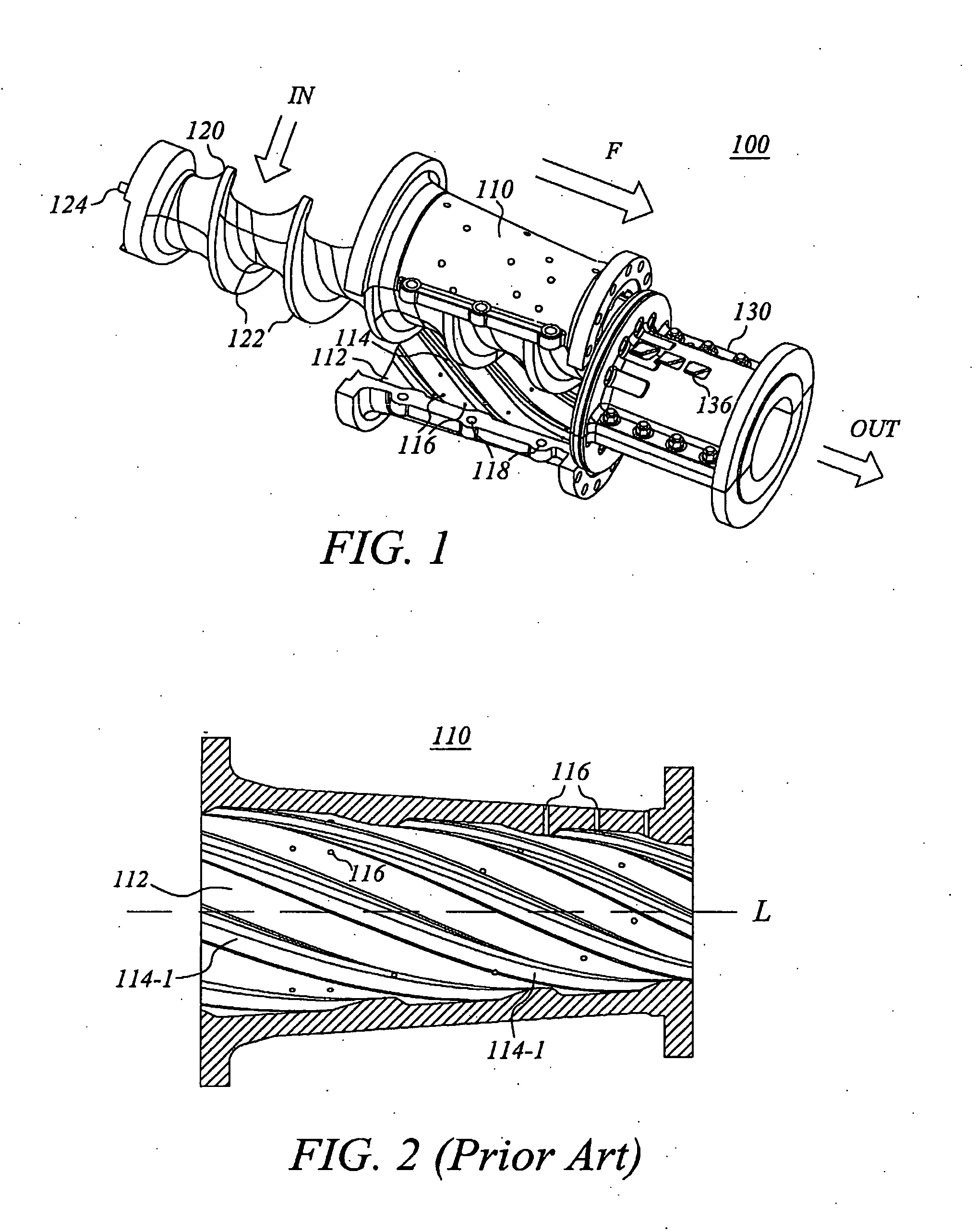

A screw pipe unit intended to cooperate with and at least partly enclose a screw in a plug screw feeder for cellulose chips / pulp is provided. The screw pipe unit comprises a plurality of openings for filtrate dewatered from the chips / pulp in the screw pipe when the plug screw feeder is in operation. The screw pipe is, on at least a portion of its inner surface, provided with bars inclined with respect to the longitudinal axis of the screw pipe. The angle of inclination of the bars decreases in the longitudinal direction, from a first portion of the screw pipe unit with maximum inclination to a second portion of the screw pipe unit with bars substantially parallel to the axis, the second portion being further away from the inlet end of the screw pipe unit than the first portion.

Owner:VALMET TECHNOLOGIES INC

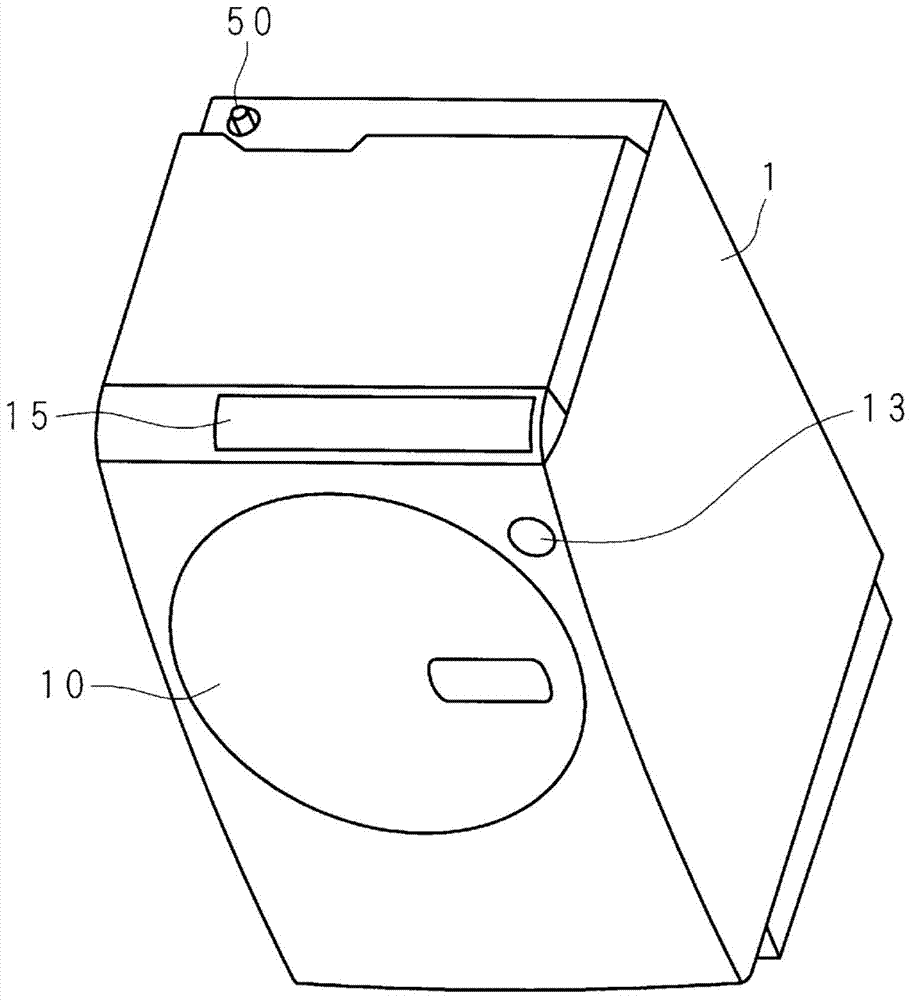

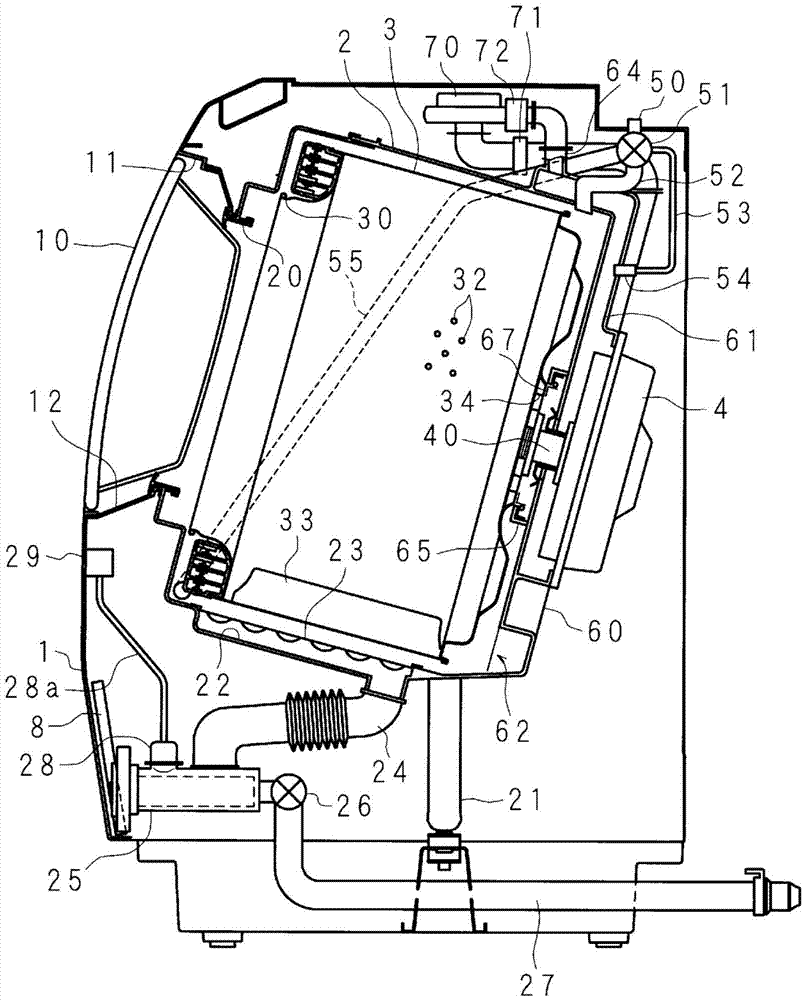

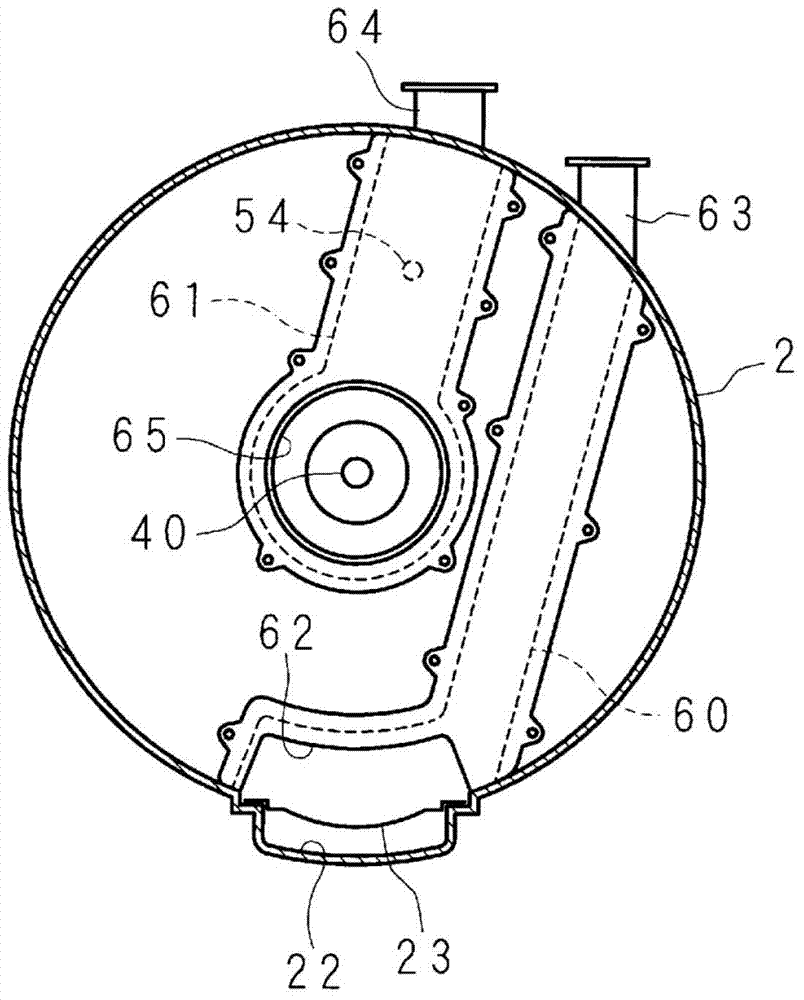

Washer-dryer

ActiveCN103842573AEfficient dehydrationEliminates sticking to the drumOther washing machinesControl devices for washing apparatusEngineeringLaundry

A washer-dryer is provided with: a washing tank (2); a rotating drum (3) which rotates inside the washing tank (2); a dry air passage which circulates dry air inside the washing tank (2) and the rotating drum (3); and a fan (70) which is provided in the dry air passage and which blows the dry air. The washer-dryer implements, in order: a washing step in which laundry which is inside the rotating drum (3) is washed; a water removing step in which water is removed from the laundry, this step being repeated multiple times; and a drying step in which the laundry is brought into contact with the dry air, and dried.; The washer-dryer is provided with a fan control means which, during the multiple repetitions of the water removing step, stops the operation of the fan (70) until the final repetition of the water removing step is initiated, and which initiates the operation of the fan (70) during the final repetition of the water removing step.

Owner:SHARP KK

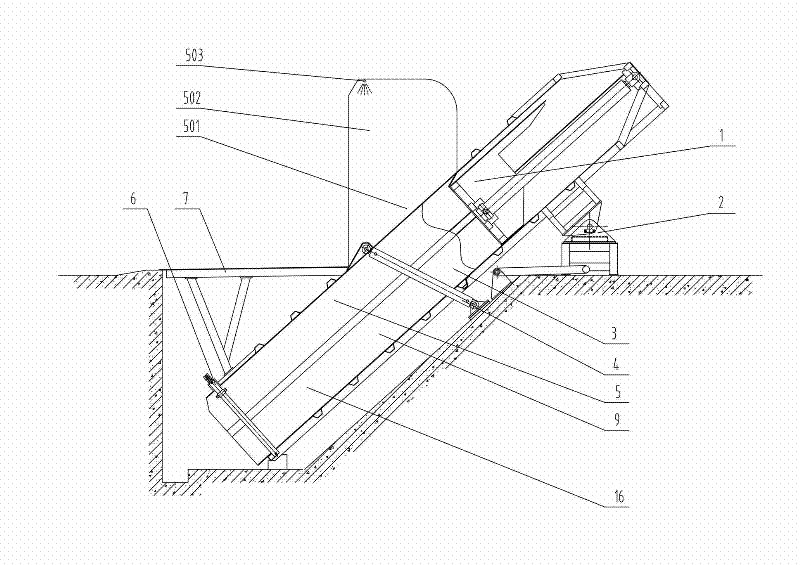

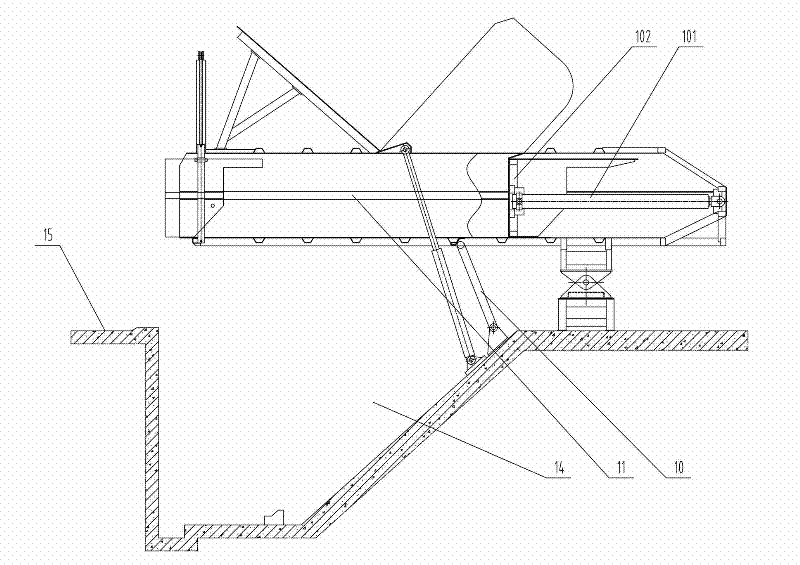

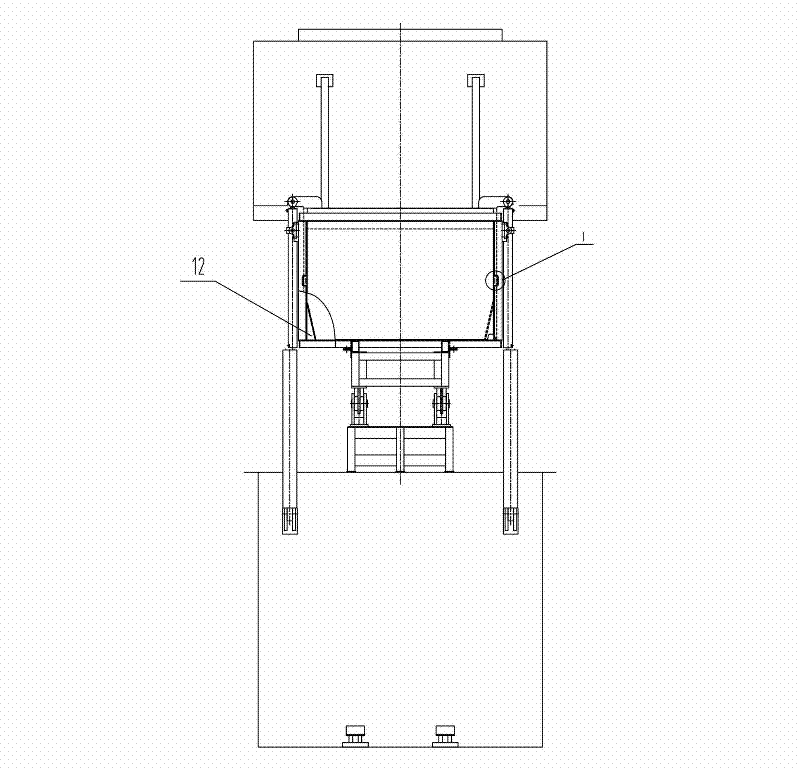

Refuse compressor

ActiveCN102173331AImprove pressing efficiencyImprove liquidityRefuse receptaclesRefuse transferringEngineering

The invention discloses a refuse compressor, which comprises a box body, a compression pusher component and a gate component, wherein the compression pusher component and the gate component are arranged in the box body; a box body cavity between the compression pusher component and the gate component forms a compression cavity; one end, adjacent to the gate component, of the box body extends intoa working pit which is positioned under the ground; and the other end of the box body is connected to or pressed against the ground. The refuse compressor has the advantages of high compression efficiency, good compression effect and the like.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Biomass waste residue squeezer

InactiveCN102493250ASolve the problem of easy slipping in extrusionSmall shapePulp de-wateringLitterSludge

The invention discloses a biomass waste residue squeezer which is provided with a power box, a transmission shaft, a bearing seat, a conical screw shaft, a filtering net barrel, a lining net barrel, a reinforcing rib frame, a shell and an anti-skidding cylinder, and is characterized in that: the filtering net barrel, the lining net barrel, the reinforcing rib frame and the shell form a multi-layer combined type conical shell; a feed port is arranged at a big end of the conical shell, and a discharge port is arranged at a small end; the anti-skidding cylinder is arranged at the discharge port at the small end of the conical shell; and the section of the cylinder opening is a regular hexagon. The biomass waste residue squeezer disclosed by the invention is developed and designed based on the biomass raw materials such as papermaking waste residue, and has unique structure, high squeezing efficiency and large dehydration dryness; and the biomass waste residue squeezer not only can be used for dehydrating and drying the papermaking waste residue, but also can realize powerful efficient dehydration of other biomass garbage such as sawdust, waste slurry, sludge and the like, thereby having a wide application range.

Owner:湖南骏泰新材料科技有限责任公司

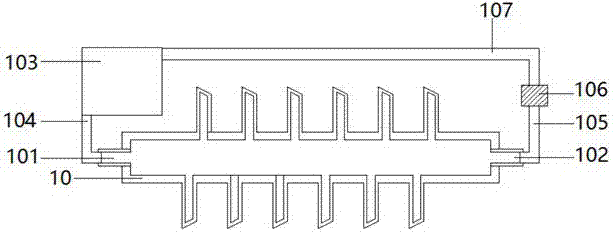

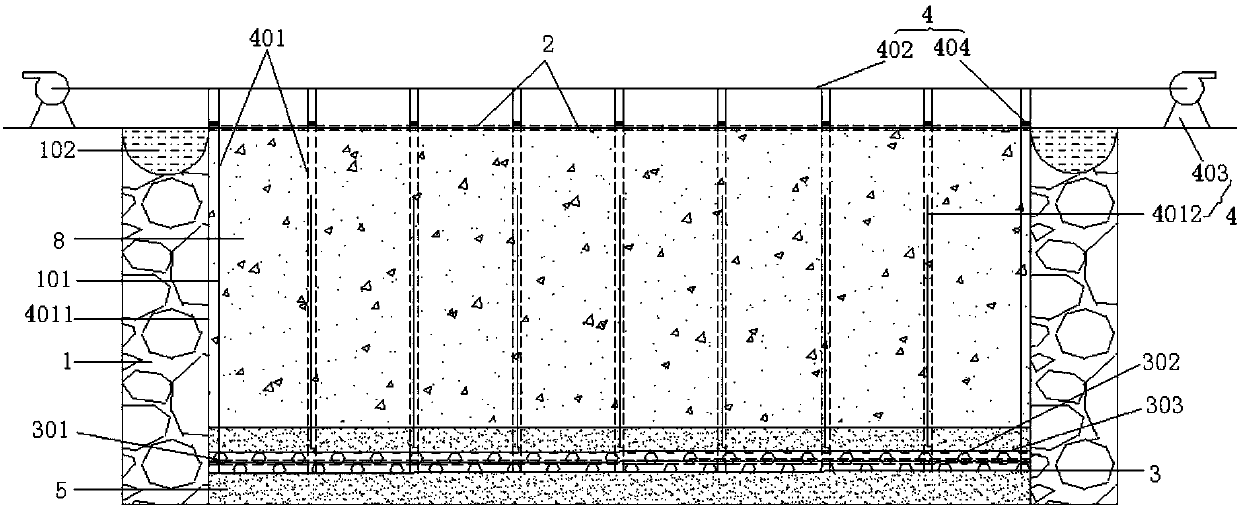

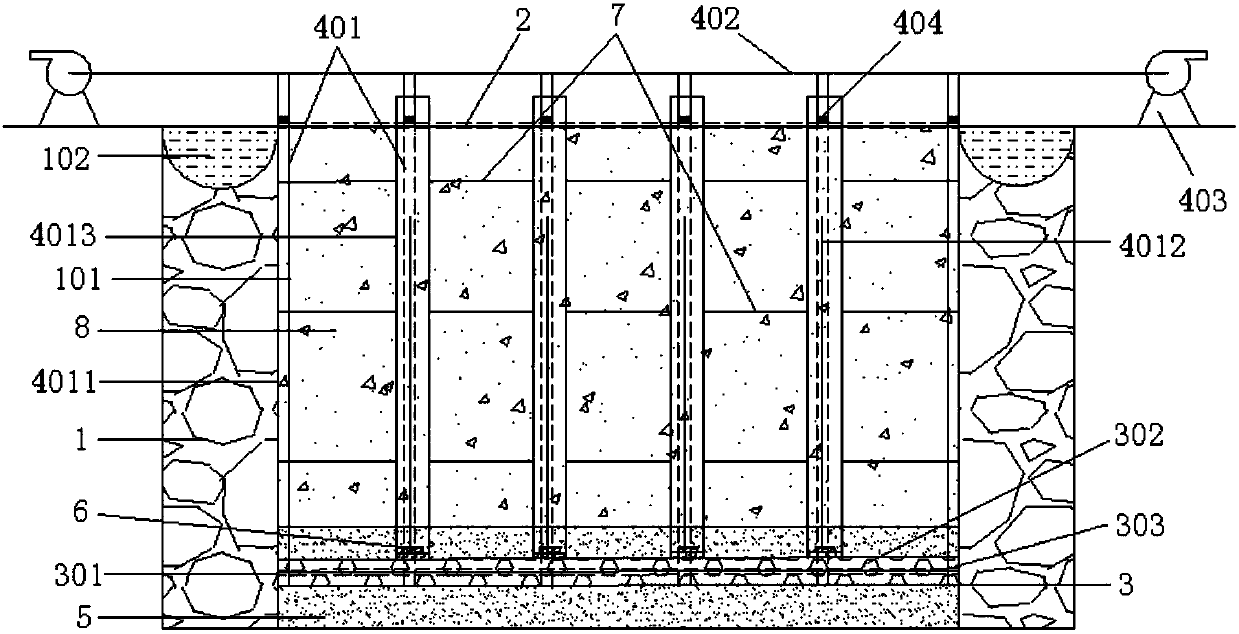

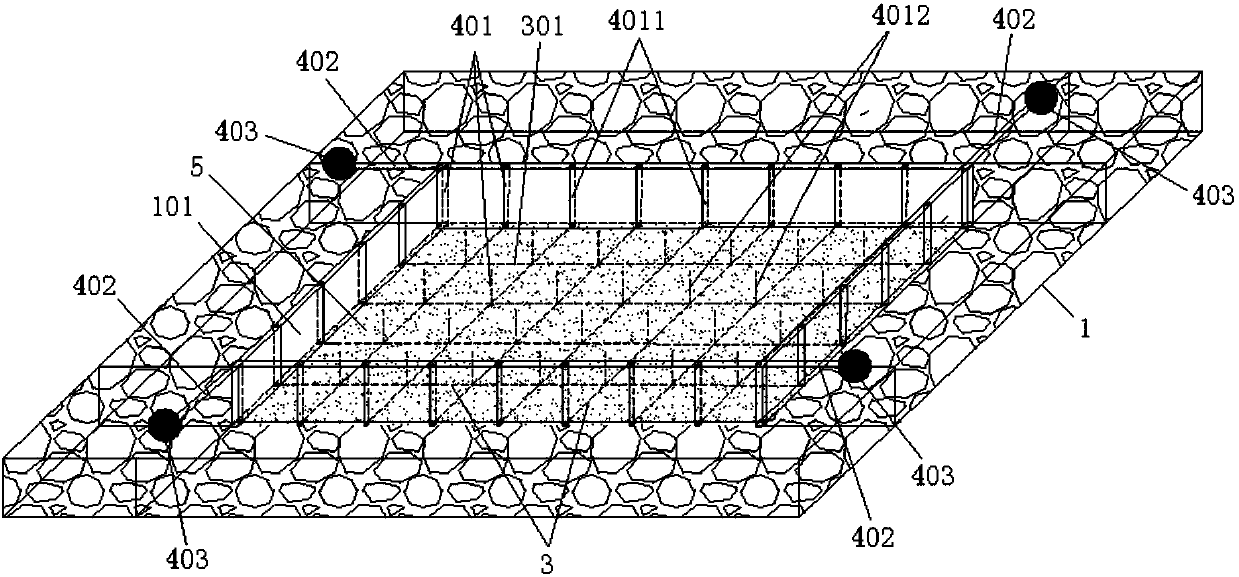

Drainage-type muck pond and multi-dimensional seepage and dehydration method of earth-pressure-balance shield muck

ActiveCN107587578AReduce moisture contentRealize harmless treatmentSewage drainingSoil preservationEarth pressure balanceEngineering

The invention discloses a drainage-type muck pond and a multi-dimensional seepage and dehydration method of earth-pressure-balance shield muck. The drainage-type muck pond comprises a pond base used for being loaded with the muck, a sealing structure is arranged in an opening of the upper portion of the pond base and used for sealing the pond base fully loaded with the muck and making an pond baseinner cavity loaded with the muck be sealed, a bottom pipe network used for collecting water seeping downward from the muck from the lower portion is arranged on the bottom of the pond base inner cavity, and a suction and drainage device is connected onto the bottom pipe network, wherein the suction and drainage device is used for sucking outward the water collected in the bottom pipe network andmaking the balanced negative pressure be formed in the sealed cavity so that water in the muck can be forced to seep outward fast. Through the action of the vacuum negative pressure, drainage of themuck to the surrounding and the bottom is forced, and moisture which enters a channel of the suction and drainage device is sucked by the suction and drainage device for being drained outward, so thatthe water content of the muck in the sealed space is lowered, harmless treatment is achieved, and a foundation is laid for resource utilization; the method is suitable for dehydration treatment of all shield construction muck and muck with high water content.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Sewage treatment environmental-friendly sludge dehydration device

InactiveCN107698128AEasy to dehydrateReduce gapSludge treatment by de-watering/drying/thickeningWater/sewage treatment apparatusToxic gasProblem of time

The invention provides a sewage treatment environmental-friendly sludge dehydration device and relates to the field of sewage treatment. The sewage treatment device comprises a device body, wherein asupport plate is arranged at the bottom of the device body; an operation panel is arranged on one side of the support plate; a mounting support block is arranged at the other end of the support plate;a material feeding and discharge conveyer belt is arranged on one side of the operation panel; a driving motor is arranged inside the material feeding and discharge conveyer belt; a sewage treatmentcylinder is arranged at the top of the support plate; the sewage treatment cylinder comprises an outer cylinder and an inner cylinder. At present, for most sludge dehydration devices in the market, moisture inside sludge is evaporated by using a heating method; since the sludge contains a great amount of toxic gases and impurities, material feeding and discharge conveyer belt such as internal fireor even explosion can be easily caused inside the devices when heating is implemented, and meanwhile the problem that sludge treatment is not qualified can be caused since the sludge is treated in asingle treatment mode generally; the problem of time and labor consumption is solved as materials are fed and discharged in a mechanical mode.

Owner:NINGBO YINZHOU DORCOO AUTODOOR

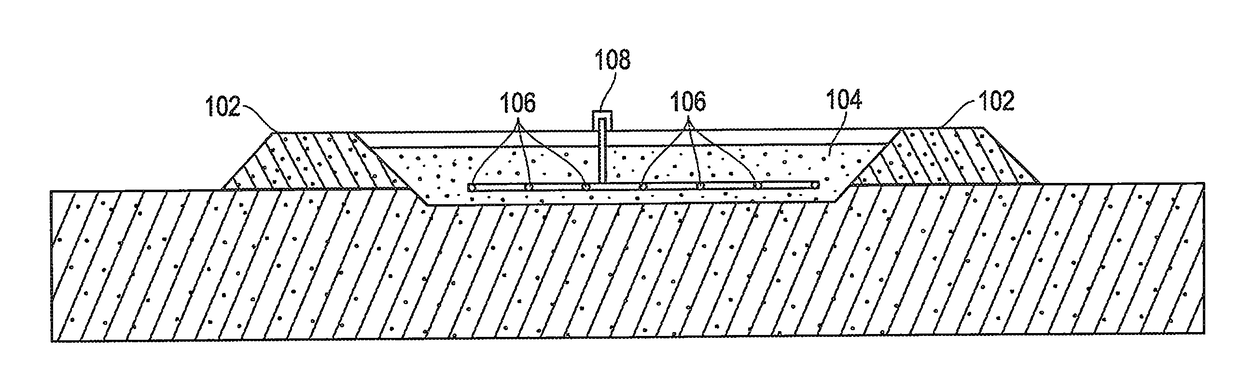

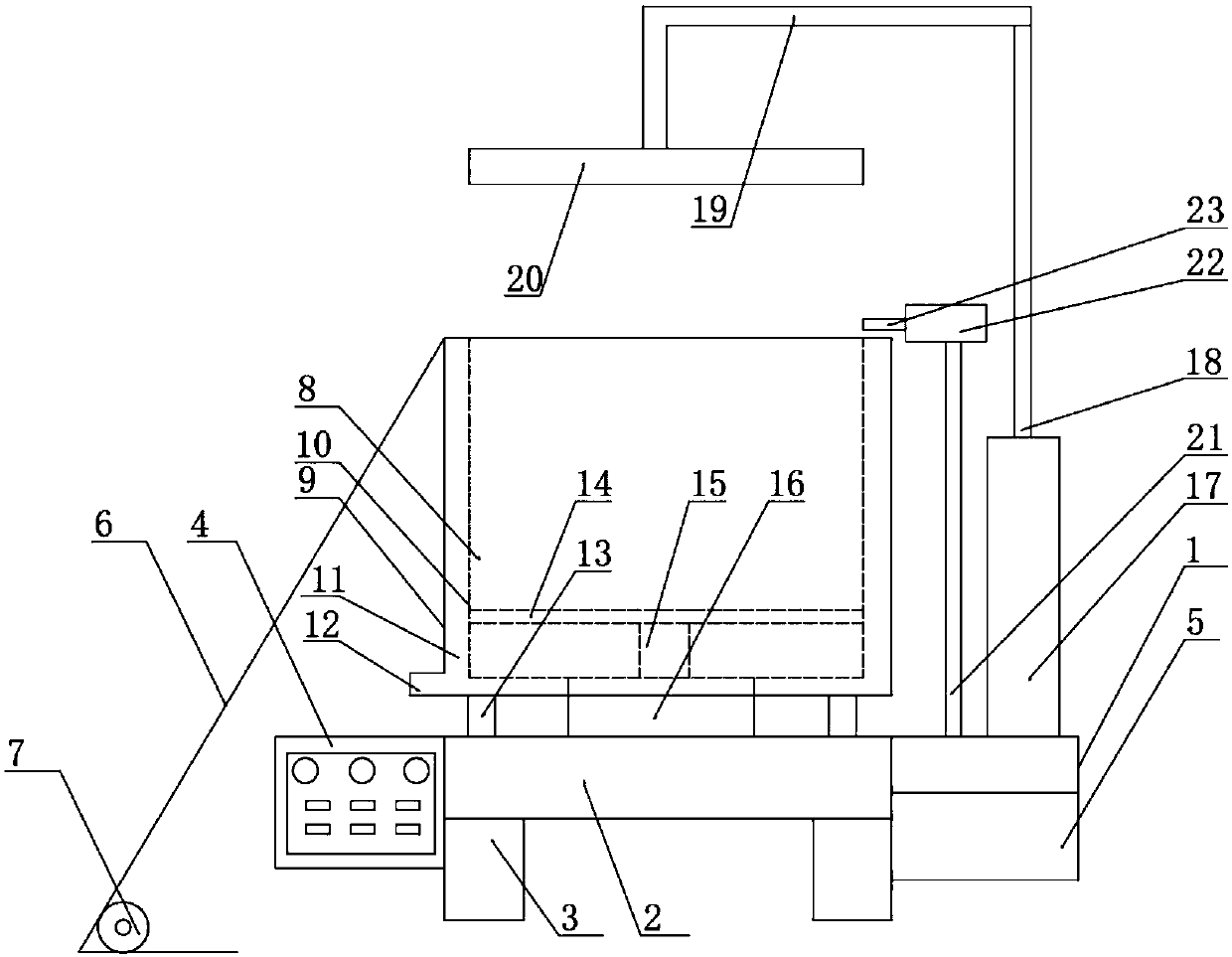

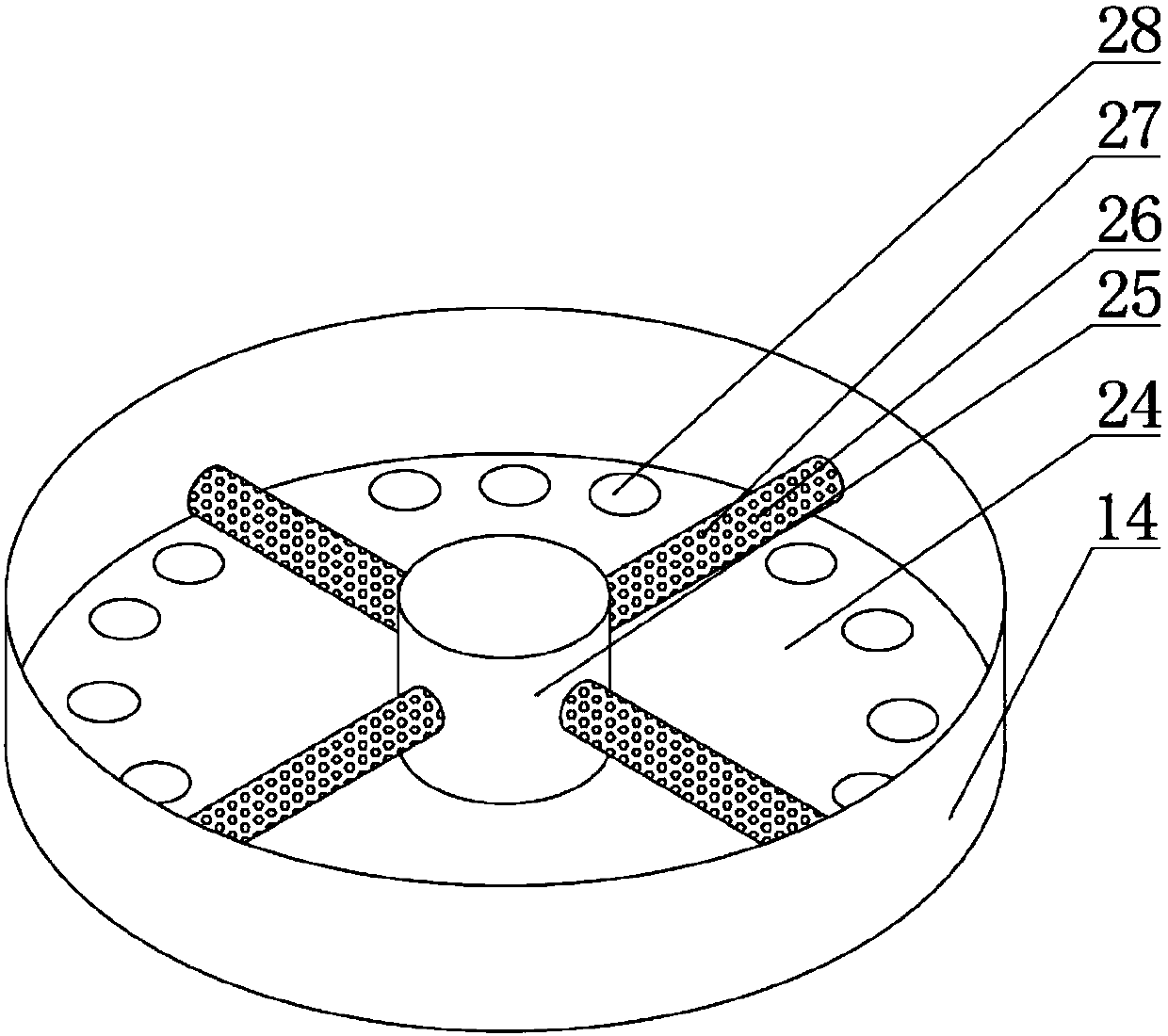

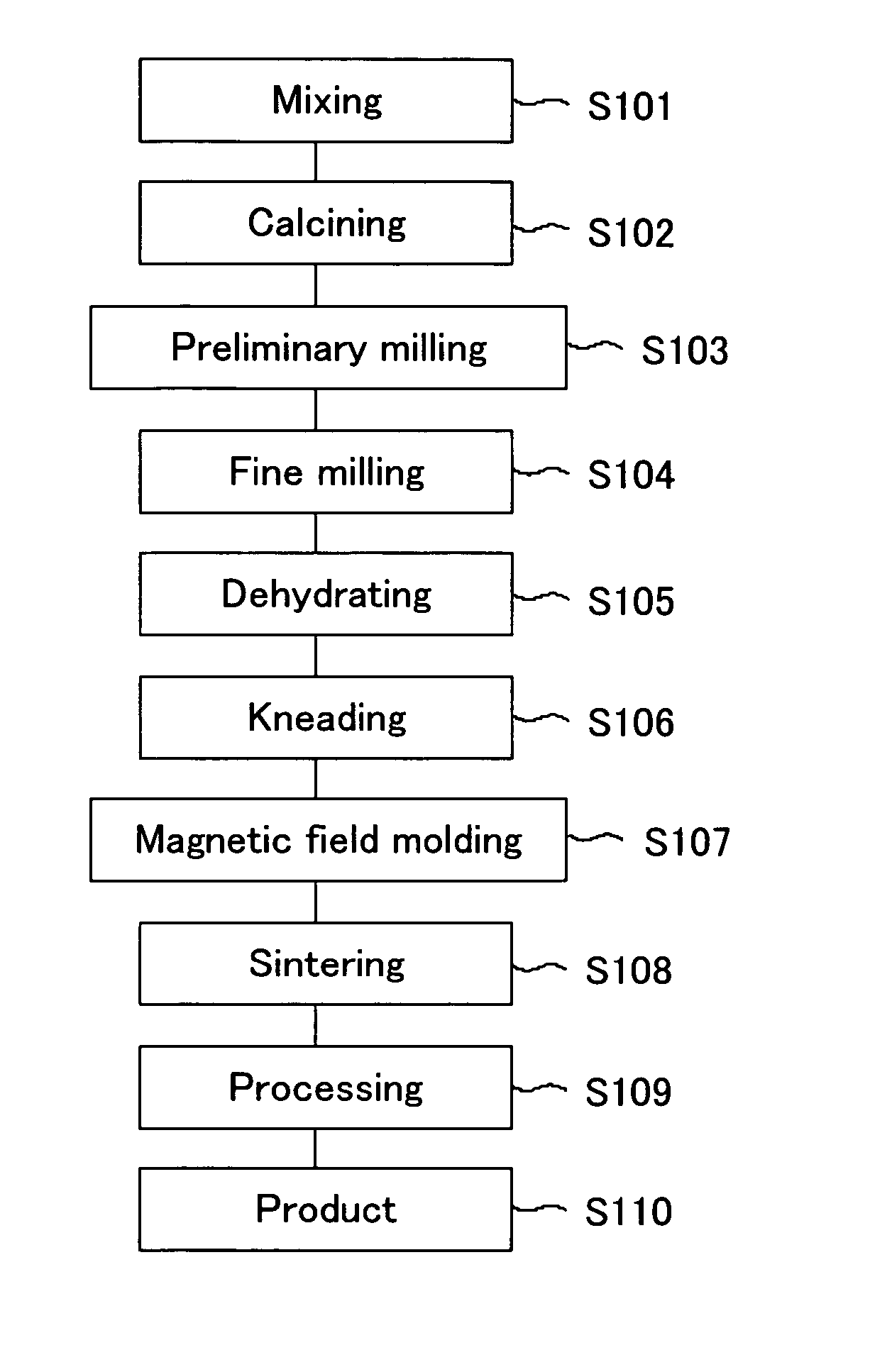

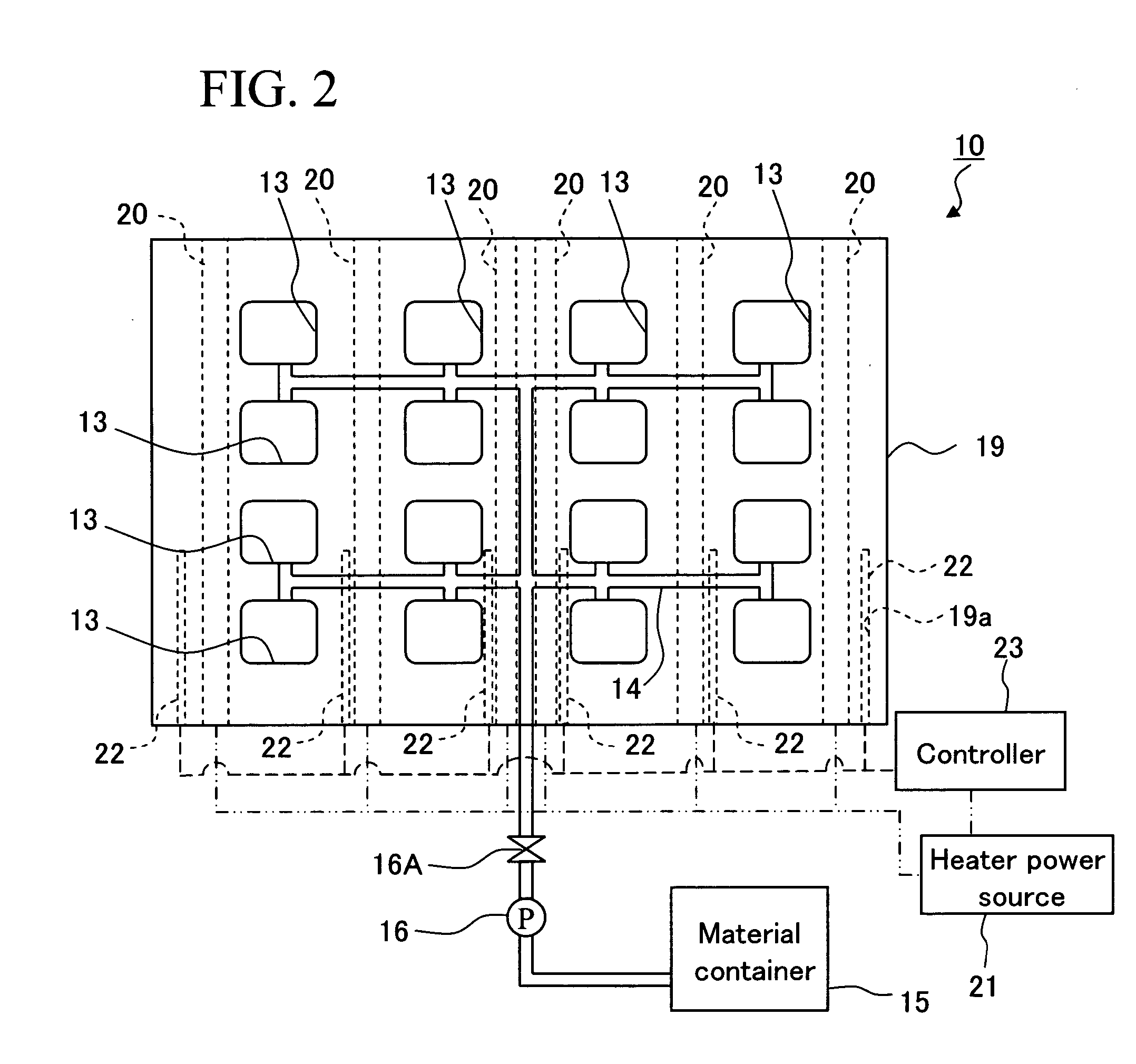

Magnetic field forming device, ferrite magnet producing method, and mold

InactiveUS20060219323A1Efficiently dehydrateImproved yieldMelt-holding vesselsInorganic material magnetismMagnetMetallurgy

The objects of the present invention are to provide a magnetic field molding device, and method for producing a ferrite magnet, or the like, capable of improving yield in a production line and stabilizing product quality, and method for producing a ferrite magnet. In molding in a magnetic field, the mortar-shaped die 19 provided with a plurality of the cavities 13 is heated by the heater member 20 at a given temperature level, under the control of the controller 23. The temperature level is preferably controlled by the controller 23 at 40° C. or higher as mortar-shaped die 19 temperature T1, sensed by the sensor 22. A molding slurry can be kept at a high temperature level in the cavities 13 by heating the mortar-shaped die 19, and can have high dehydration properties and improve product yield.

Owner:TDK CORPARATION

Air dehydration membrane

ActiveUS7294174B2Low selectivityNot affect selectivityMembranesSemi-permeable membranesCoated membranePolyvinyl alcohol

Owner:GENERON IGS

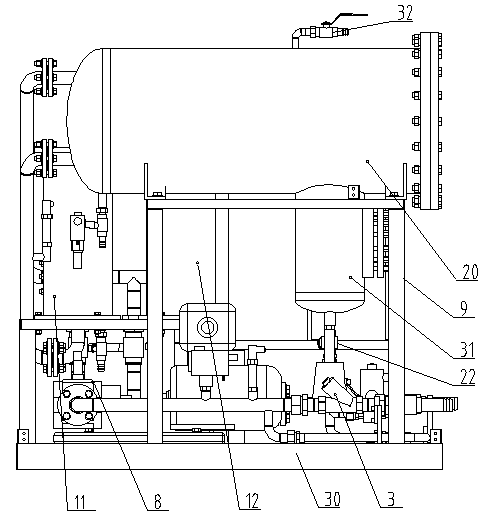

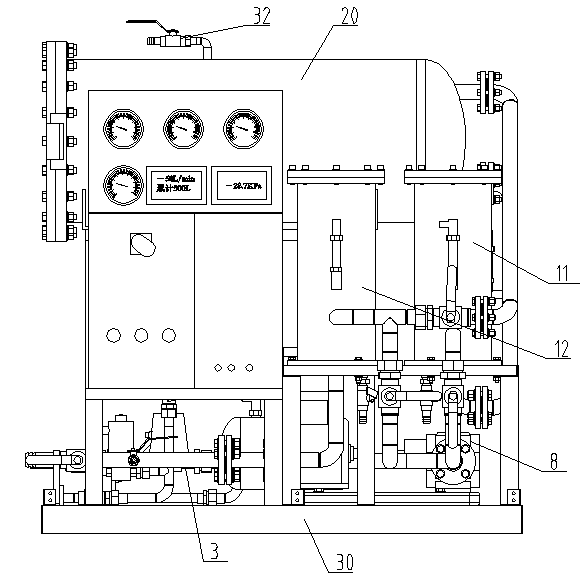

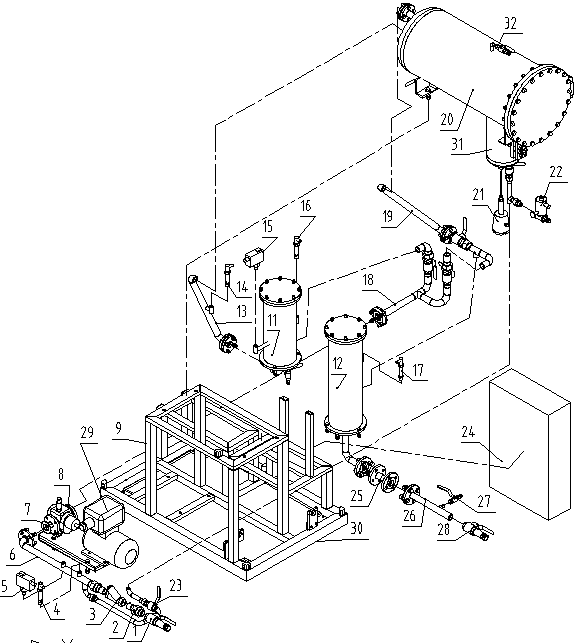

Oil purifier for oil used in anti-explosion boat

ActiveCN102979651AProtect safe operationGuaranteed uptimeMachines/enginesLubricant mounting/connectionEnergy consumptionDehydration

The invention discloses an oil purifier for oil used in an anti-explosion boat. The oil purifier for the oil used in the anti-explosion boat is characterized by comprising a bottom plate and an oil inlet portion, a filtering portion, an oil outlet portion and a control portion, wherein the an oil inlet portion, the filtering portion, the oil outlet portion and the control portion are arranged on the bottom plate. The oil inlet portion is provided with an oil pump which is used as oil power, and an oil inlet end of the oil pump is provided with an oil suction filter for primary filtering; and then the filter portion is sequentially provided with a protection filter, a coalescing separator and a fine filter so as to achieve multiple-layer filtering. By adopting the coalescing separator and combining the principle of comprehensive multiple-layer filtering, the oil purifier for the oil used in the anti-explosion boat is capable of achieving high-efficiency dehydration and meeting demands of fine separation and real-time separation, and has the advantages of being small in size, low in energy consumption, little in vibration, long in service life, easy and convenient to operate and maintain, low in operation cost, good in anti-explosion performance, safe and reliable and high in automatic degree.

Owner:中船重工重庆长平机械有限责任公司

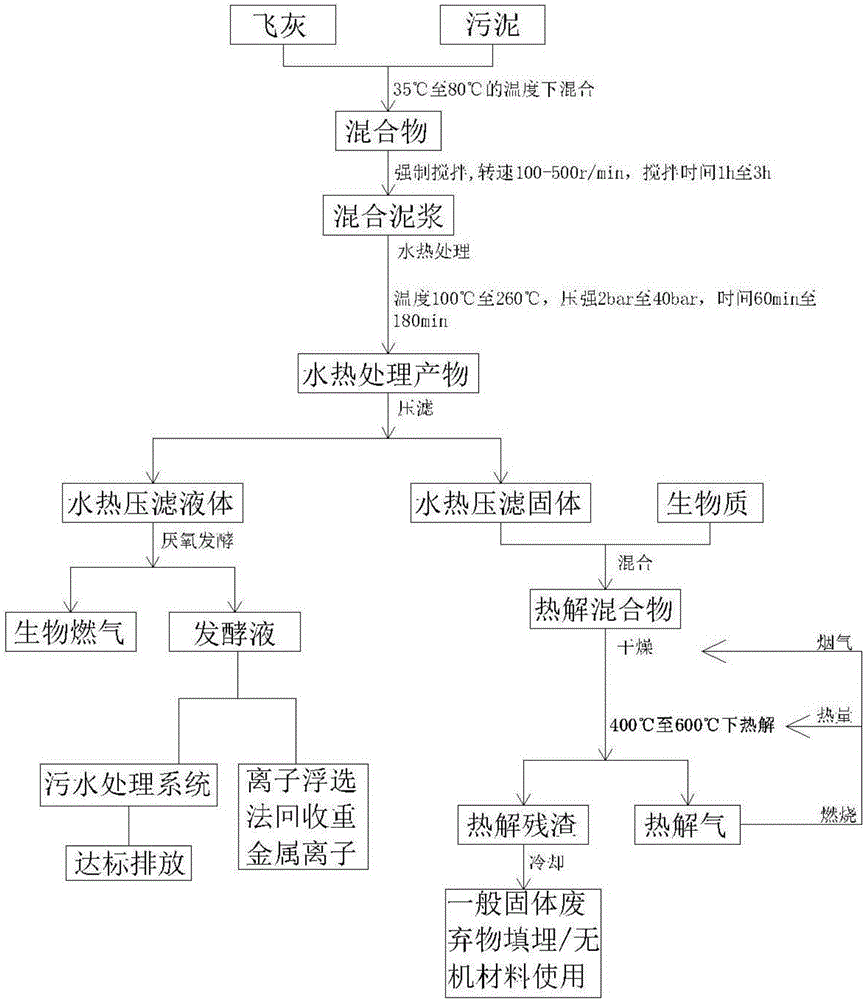

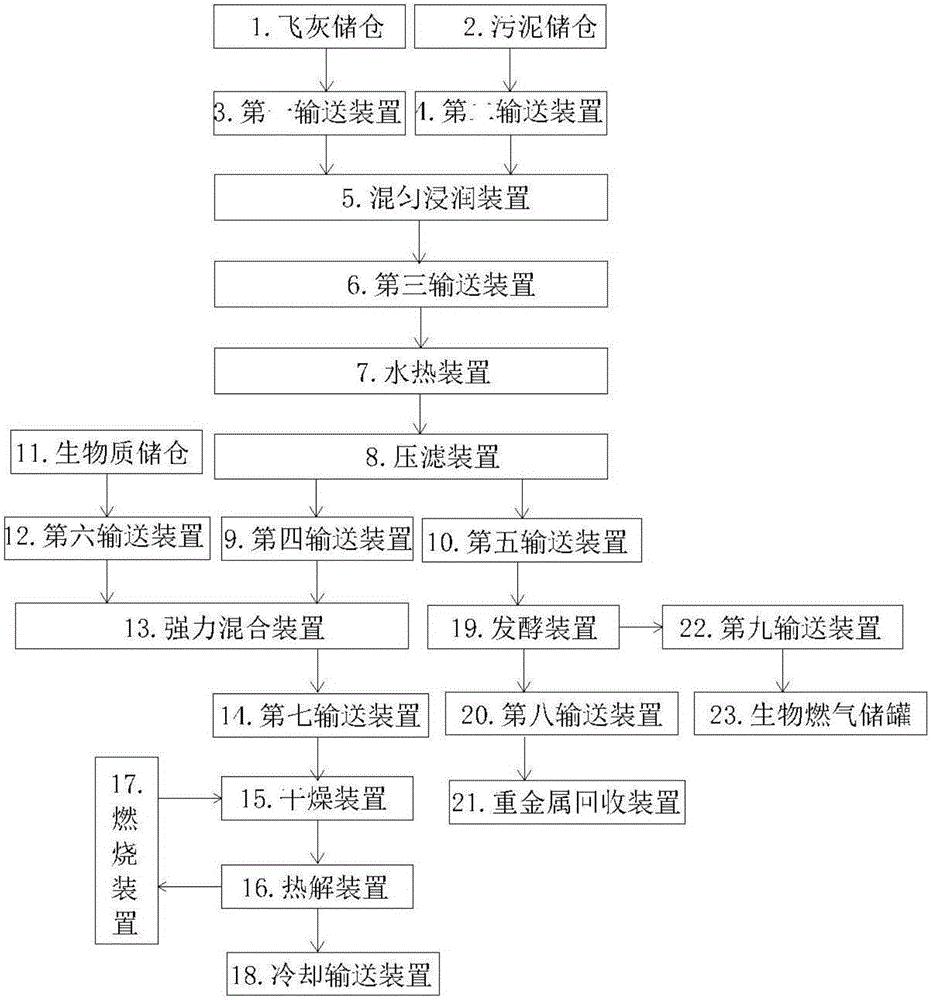

Method for treating fly sh by sludge

ActiveCN106424077AImprove dehydration efficiencyEfficient hydrolysis detoxificationSludge treatment by de-watering/drying/thickeningSolid waste disposalSludgeTreated water

The invention discloses a method and equipment for treating fly sh by sludge. The method comprises the following steps: a mixture of the fly ash and the sludge is forcedly stirred to obtain mixed mud; the mixed mud is hydrothermally treated to obtain a hydrothermal treatment product; the hydrothermal treatment product performs solid-liquid separation through a pressing filter mode to obtain hydrothermal pressing filter liquid and a hydrothermal pressing filter solid; a biomass is added in the hydrothermal pressing filter solid to form a pyrolysis mixture; the pyrolysis mixture is pyrolyzed to obtain pyrolysis residues; the pyrolysis residues serve as general solid wastes for backfilling or serve as inorganic materials for use; the hydrothermal pressing filter liquid performs anaerobic fermentation to generate gas and fermentation liquid; the fermentation liquid generated by fermentation is purified; and the treated water is qualified for emission. The invention further provides equipment for realizing the method. The method uses the sludge for realizing detoxification of the fly ash and stabilization, thoroughly eliminates dioxin substances in the fly ash to prevent secondary pollution, and realizes harmless treatment of the fly ash.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Dehydrating agent for sludge, and preparation and application thereof

InactiveCN106608709AAccelerate and increase removal efficiencyWell mixedSludge treatment by de-watering/drying/thickeningOil phaseMixing effect

The invention specifically relates to a dehydrating agent for sludge, and preparation and application thereof, belonging to the field of stabilization and reduction of sludge. The dehydrating agent for sludge comprises, by weight, 28 to 48 parts of an inorganic oxide component and 52 to 72 parts of an organic polymer component. When the dehydrating agent for sludge is used for treating oily sludge, high dehydration efficiency is obtained, and the water content of the oily sludge is reduced to 30 to 50% or below from original 98% or above; for oily sludge with water content of 95% or above, a water phase, a sludge phase and an oil phase of the oily sludge can be separated via homogenization and uniform mixing effect of the dehydrating agent; and a breakthrough is made to most conventional oil-removing and dehydration manners for oily sludge, and a complementary mode is employed in the invention to conduct key operation in reduction of oily sludge, i.e., separation of a water phase, a sludge phase and an oil phase.

Owner:LYUCHENG INVESTMENT SHANGHAI CO LTD

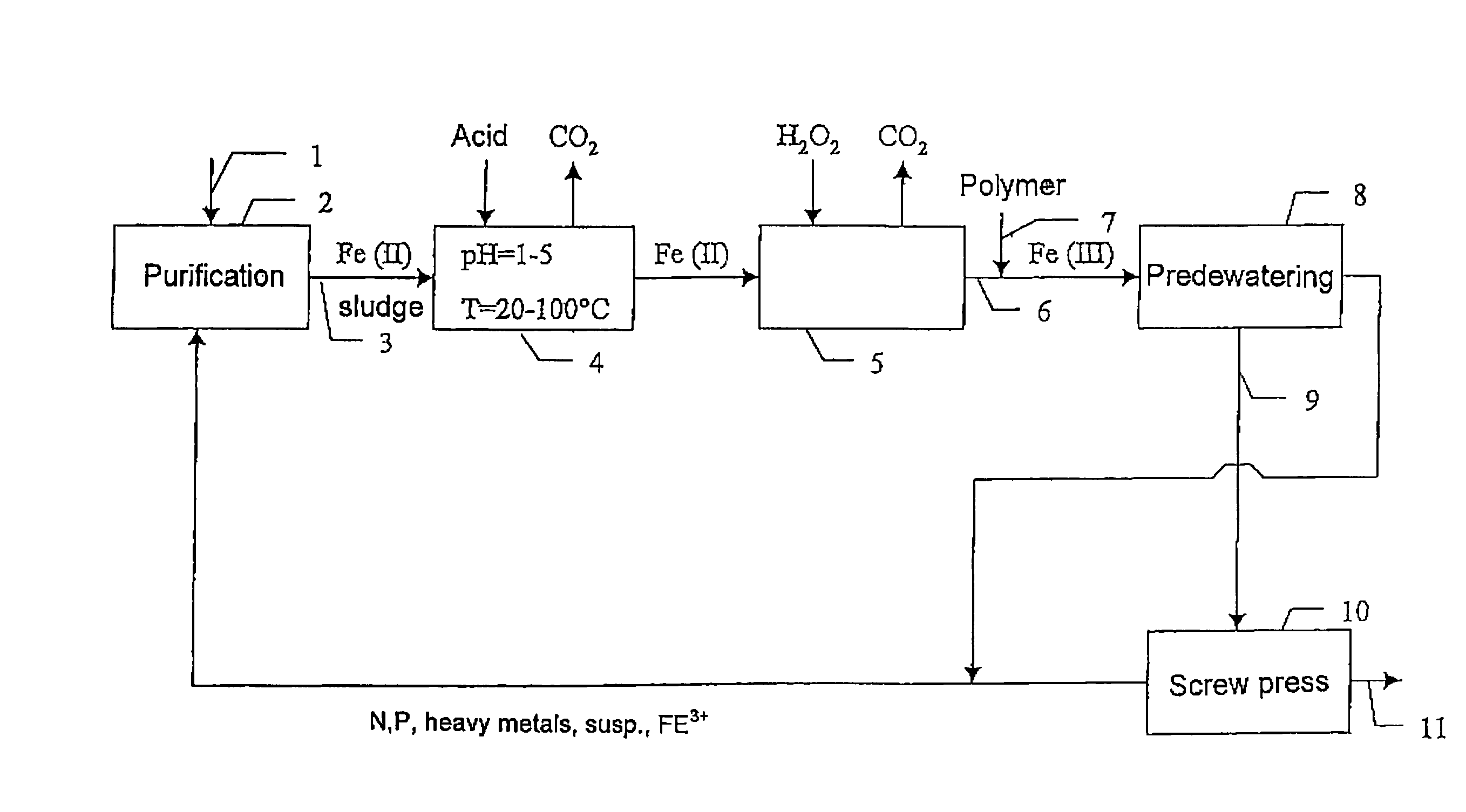

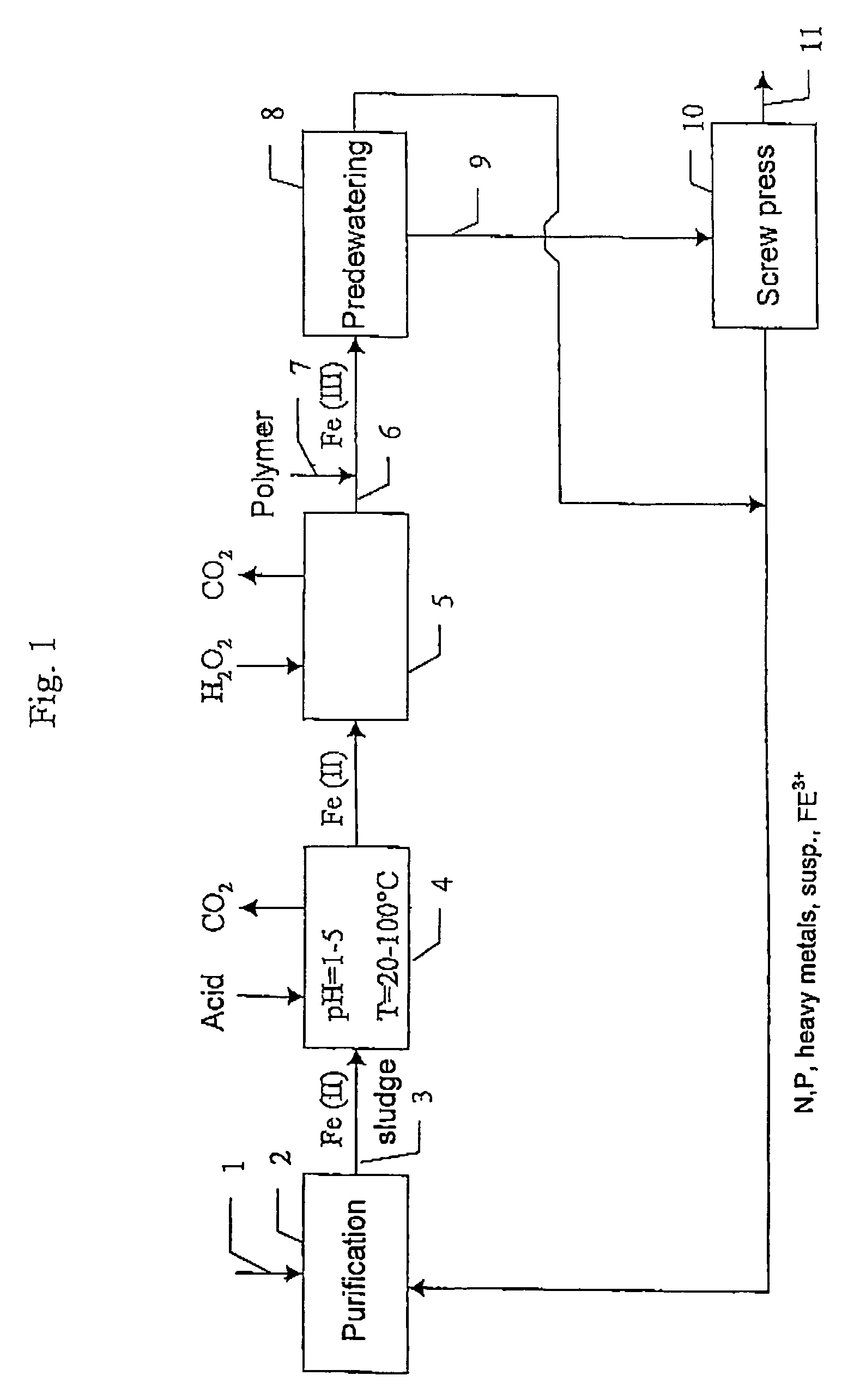

Method of treating digested sludge

InactiveUS7166227B2Improve filtering effectKeep drySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeDissolved iron

A method of treating, in wastewater purification, sludge containing organic matter, divalent iron and phosphorus, in whichthe sludge that is treated is made to contain dissolved iron and phosphorus at a molar ratio Fe:P of above 1:1,the sludge is treated at 0–100° C. with an acid at a pH of 1–5 for dissolution of divalent iron and phosphorus from the sludge,the sludge is supplied with an oxidizer selected from hydrogen peroxide and percompounds, wherein divalent iron is oxidized by Fenton's reaction to trivalent iron, and(i) trivalent iron is precipitated as trivalent iron phosphate(ii) free radicals with a deodorization and sanitation effect are formed by Fenton's reaction,the sludge is then dewatered at a pH of at most 7, andthe aqueous solution obtained in dewatering is recirculated to the wastewater purification.

Owner:KEMIRA KEMI AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com