Patents

Literature

452 results about "Conical shell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cone shell. noun. any of numerous, chiefly tropical, marine gastropods of the genus Conus, having a smooth, brightly colored, conical shell with a short, flattened spire.

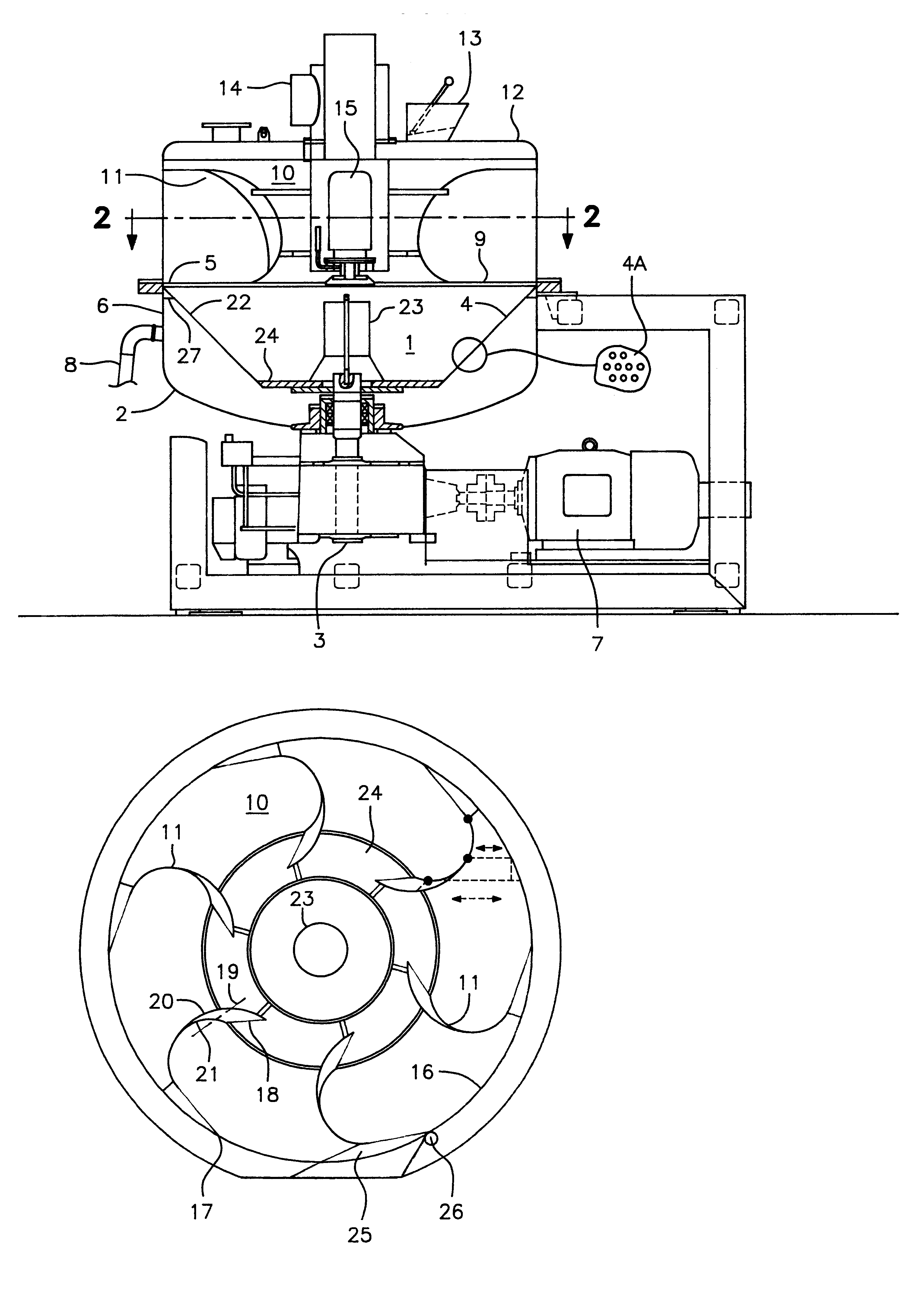

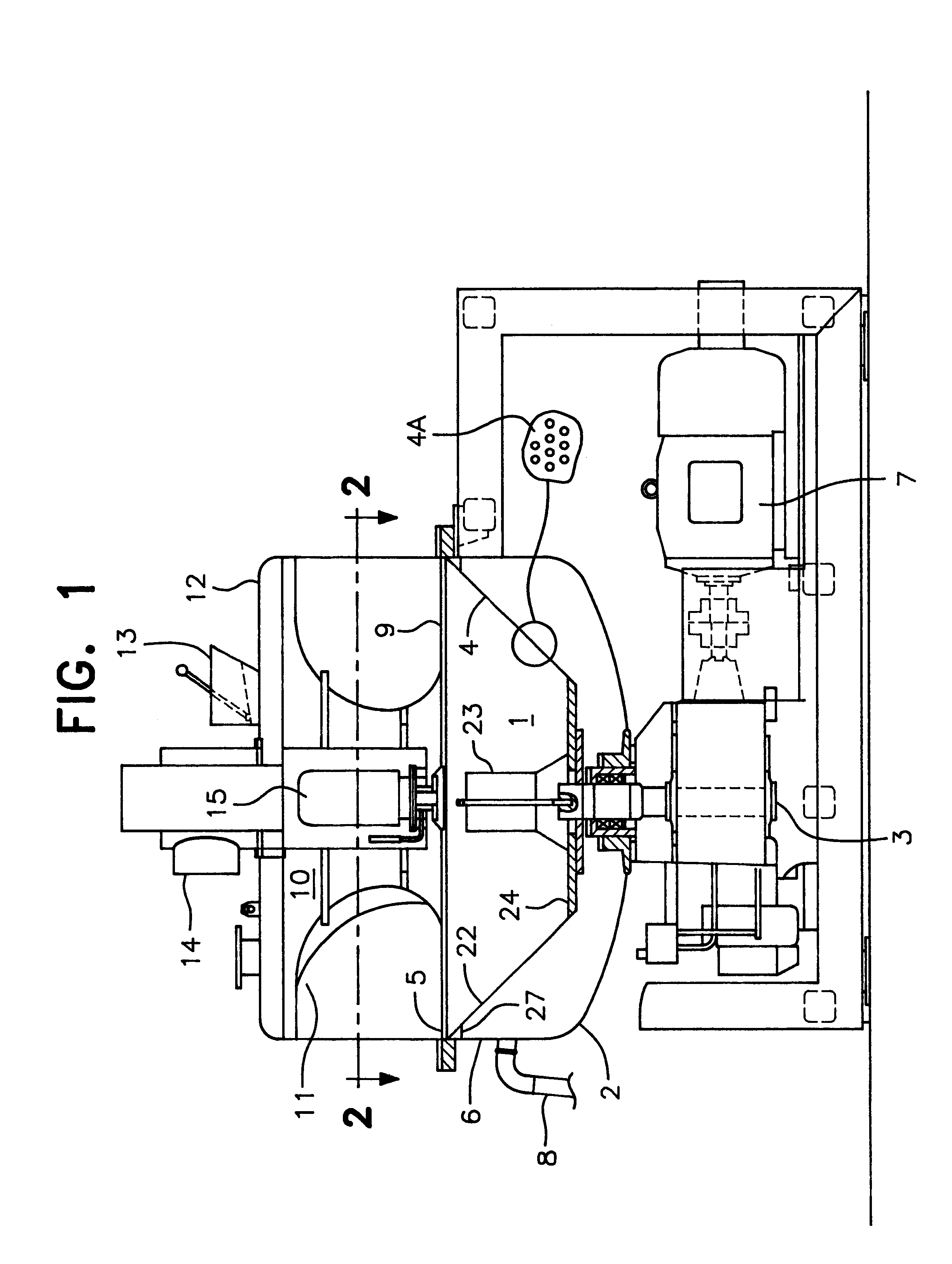

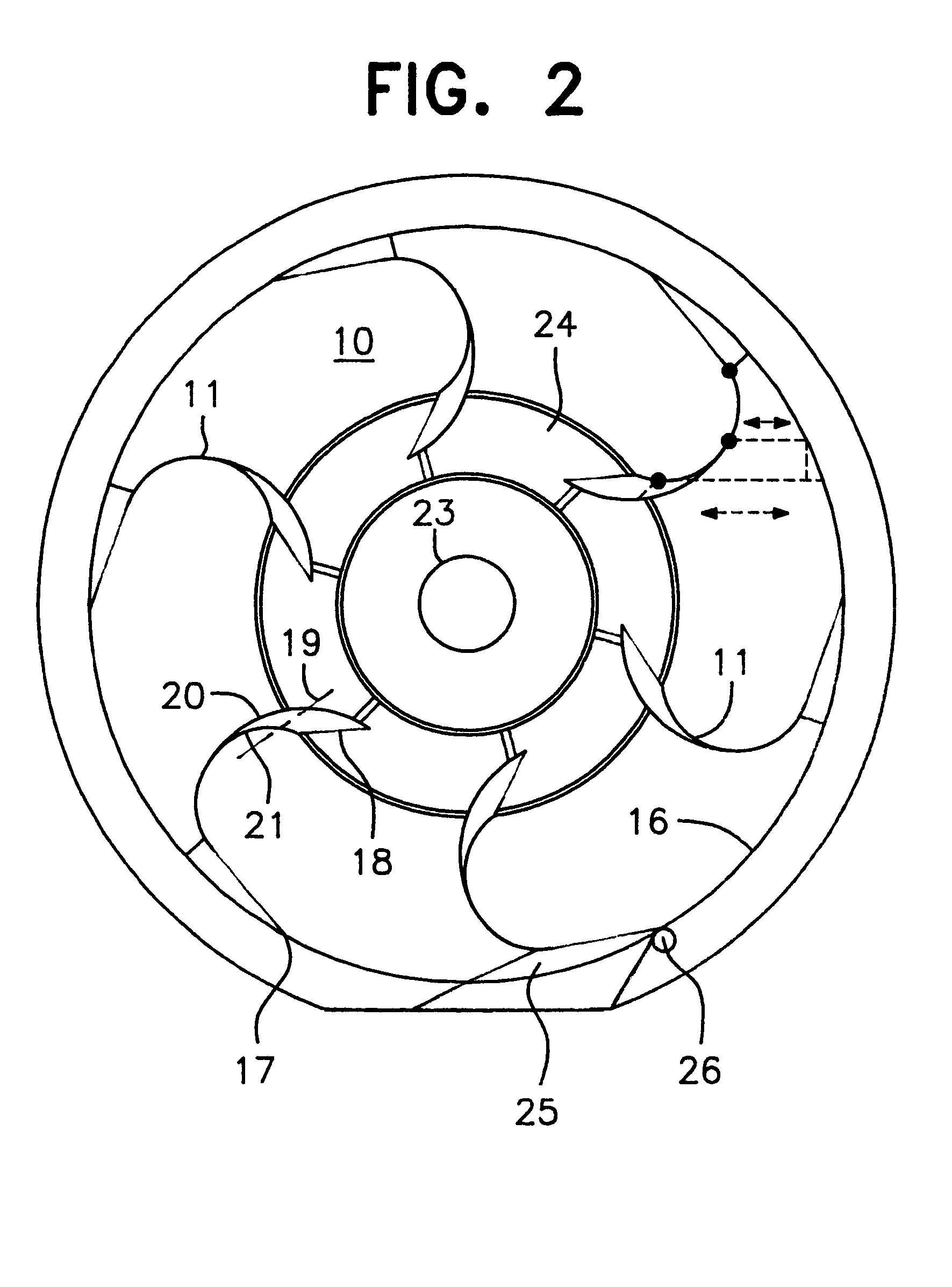

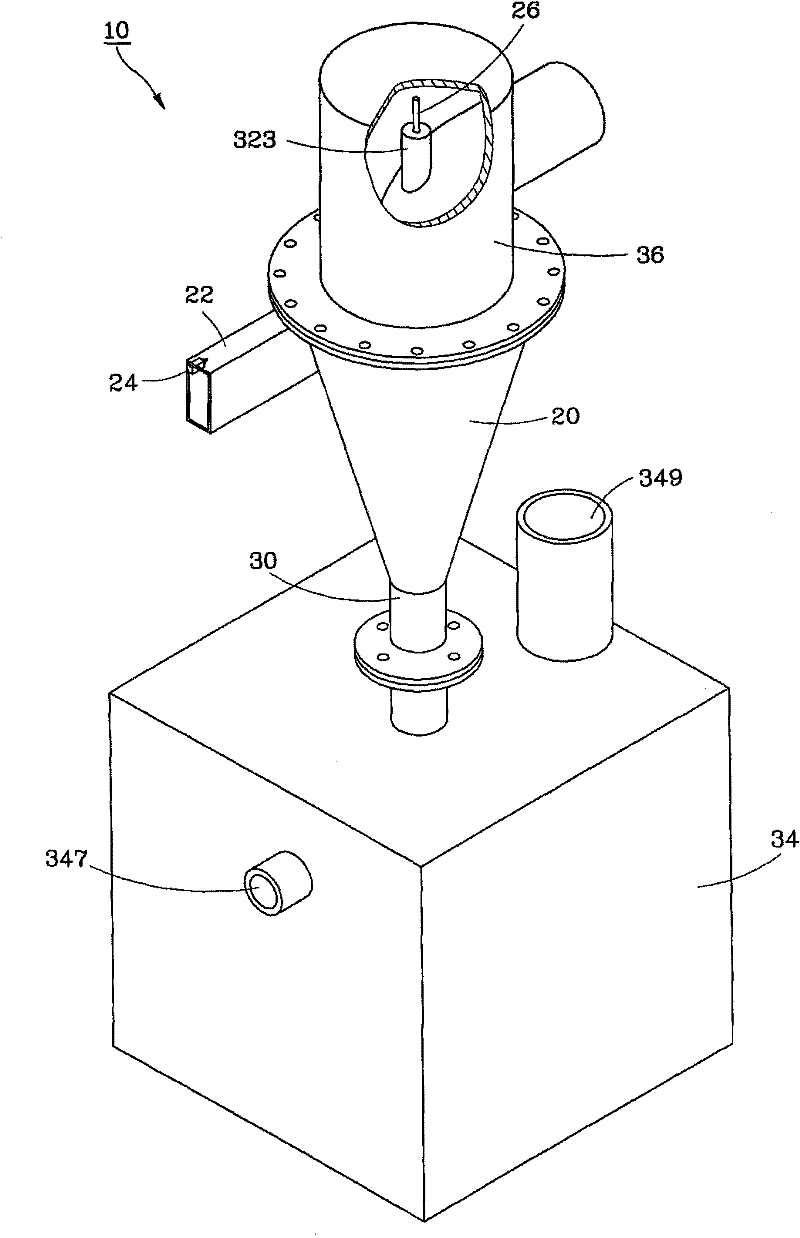

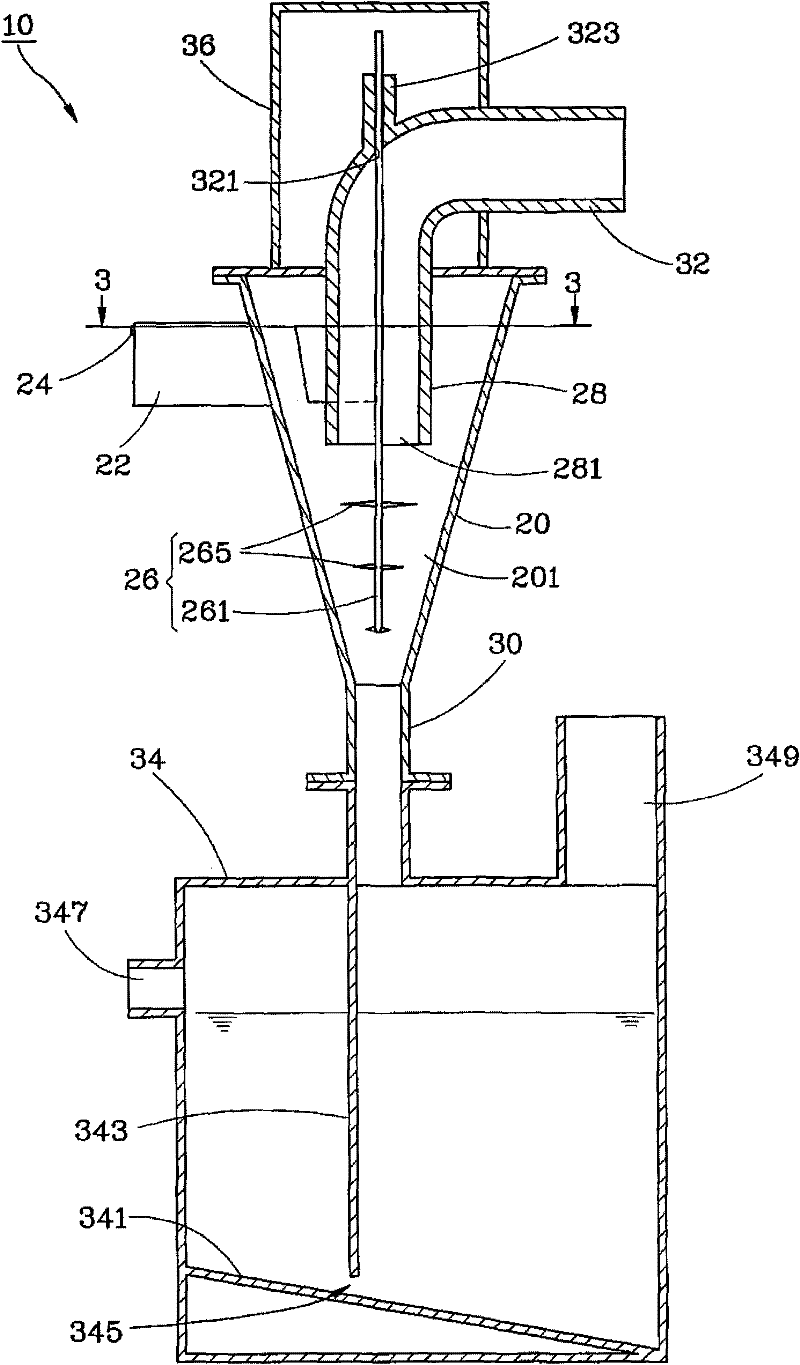

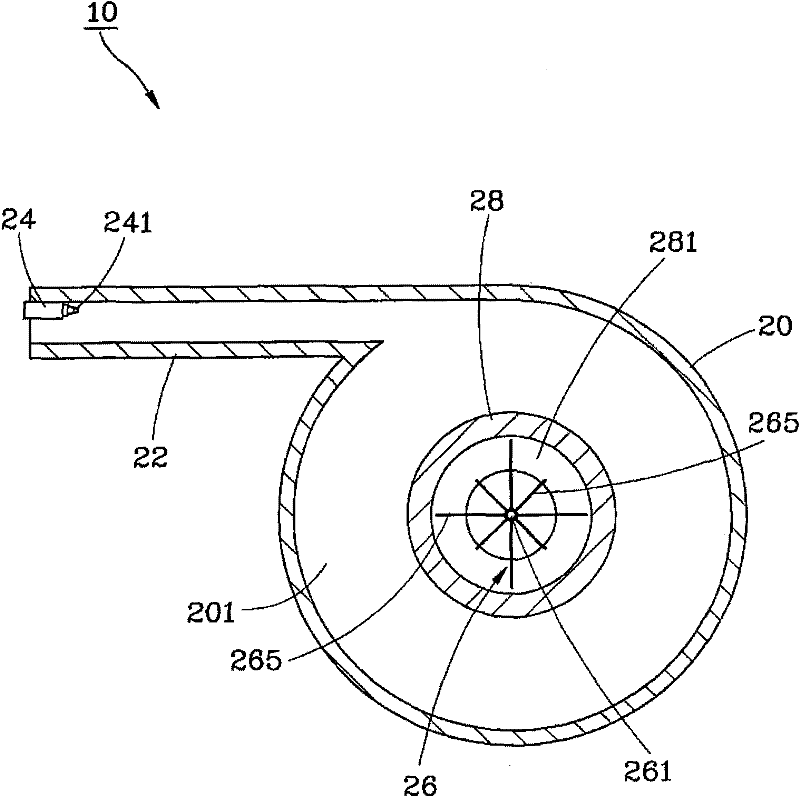

Device for producing a pourable product with a guide vane therein

InactiveUS6354728B1Avoid loadRotating receptacle mixersLiquid surface applicatorsEngineeringMechanical engineering

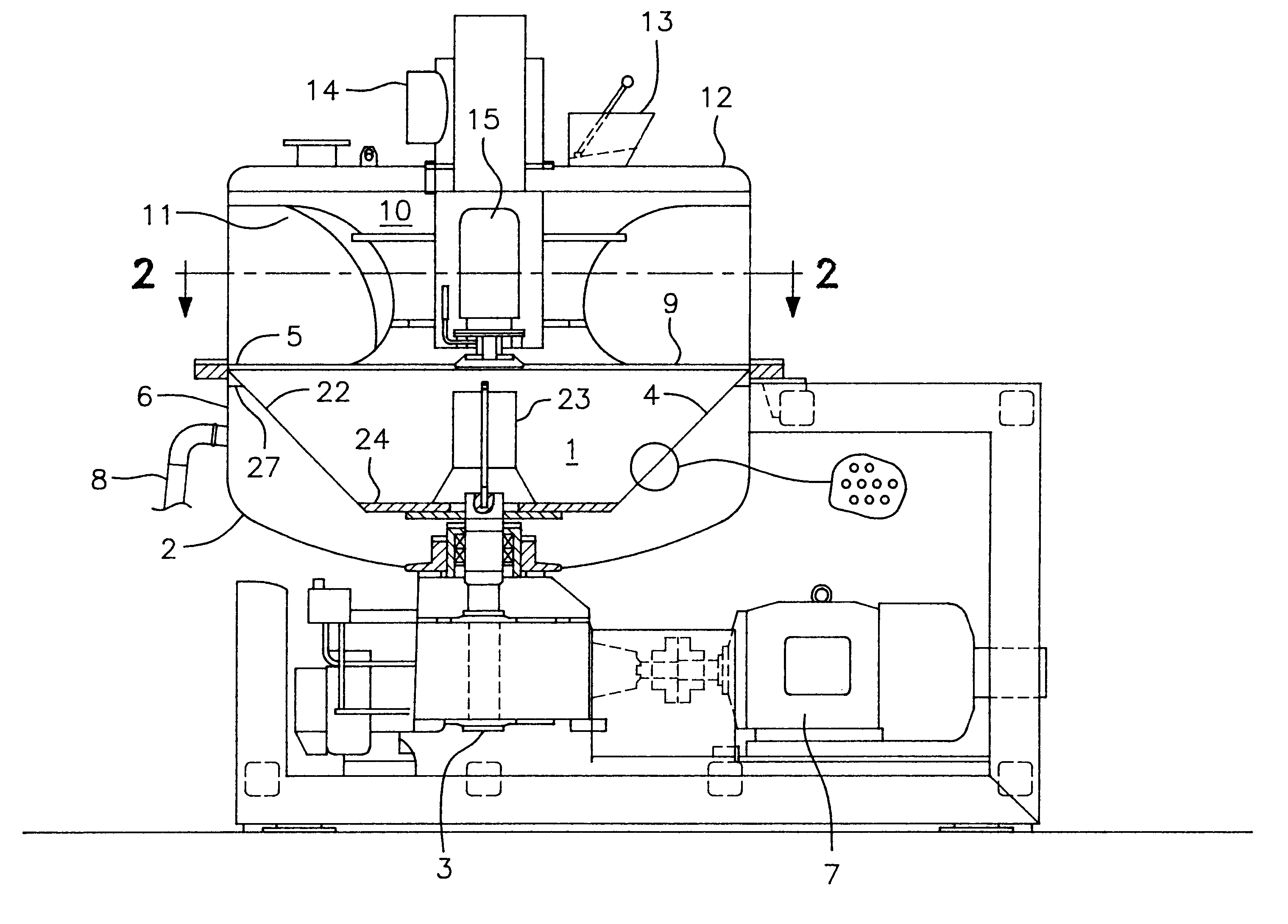

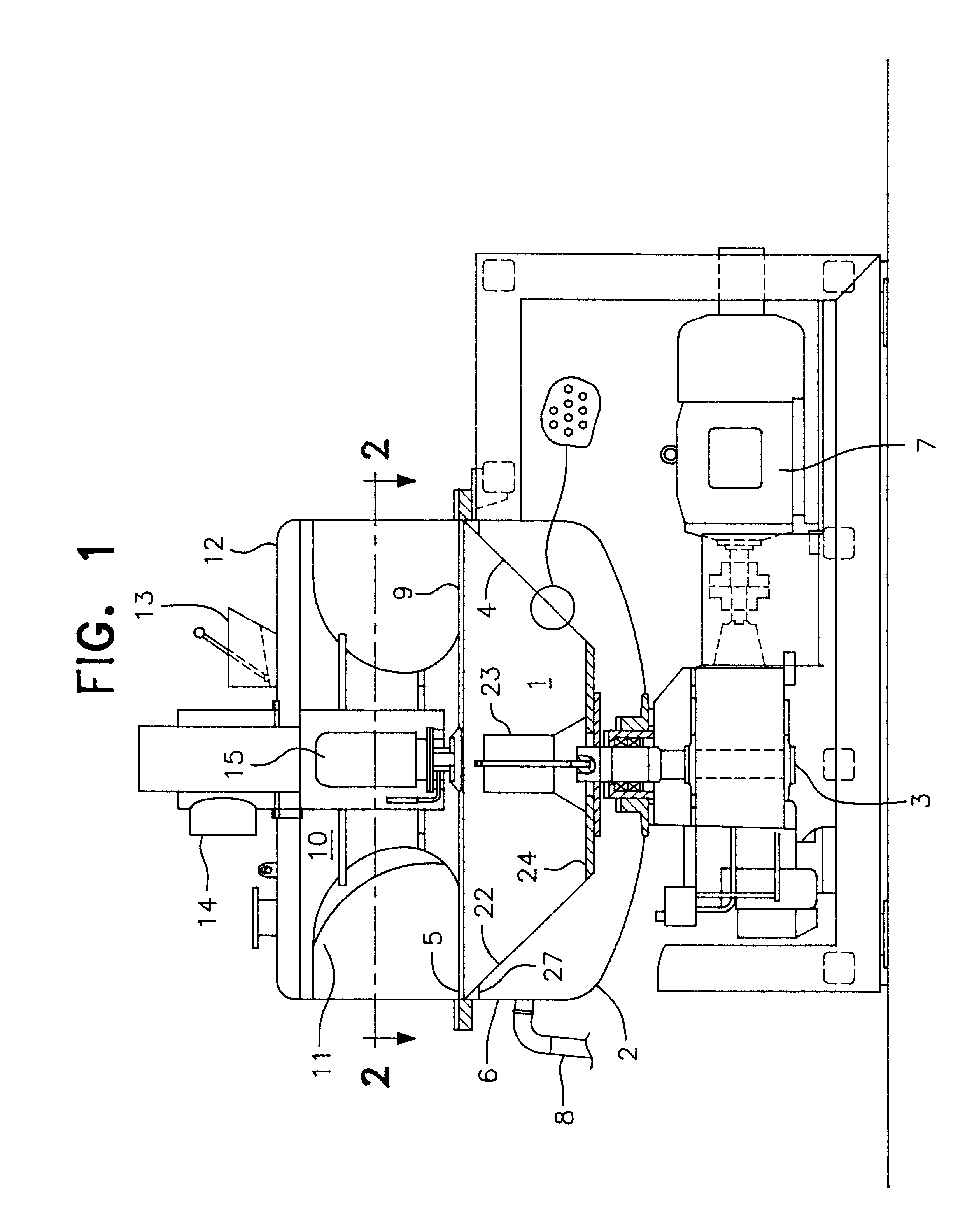

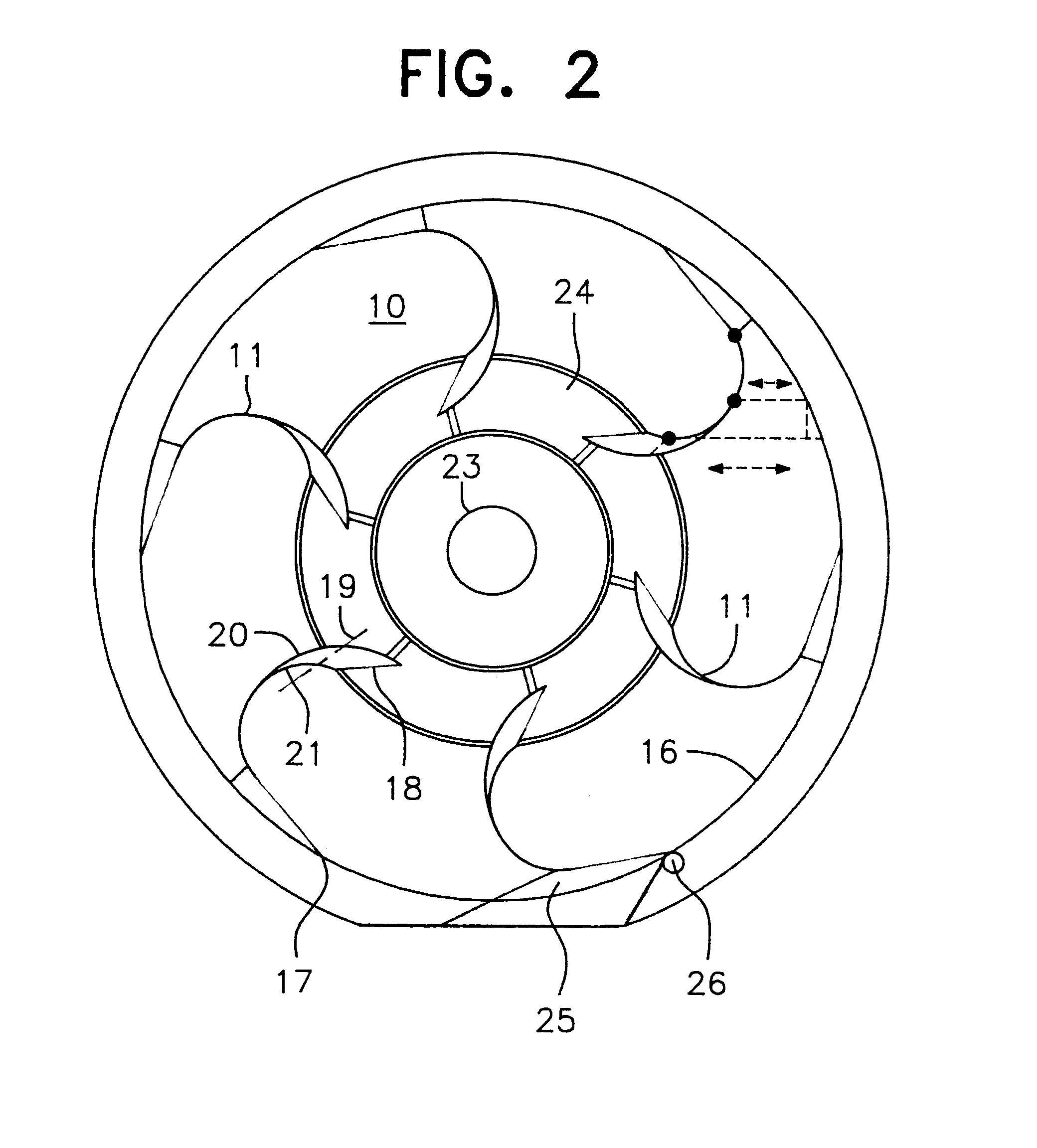

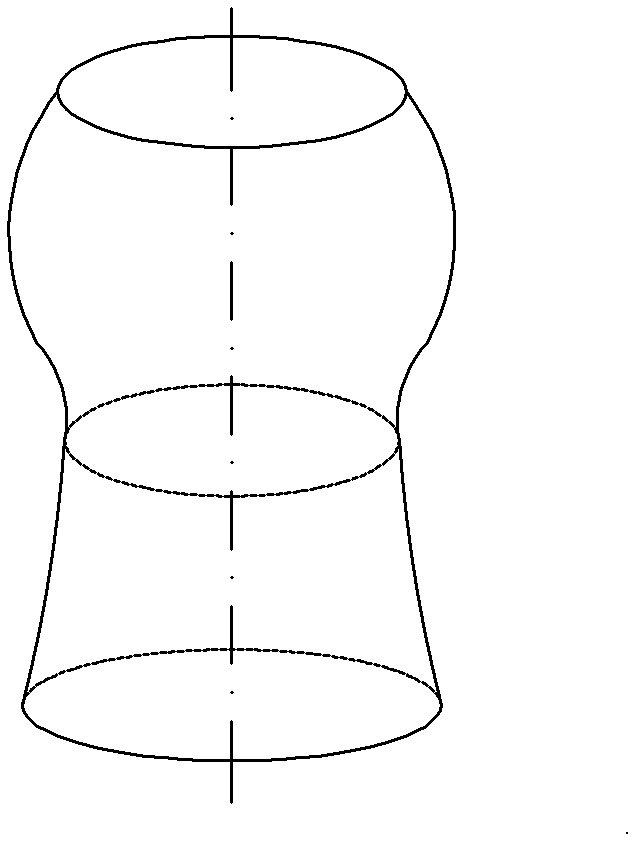

Device for producing a pourable product with a guide vane therein and method for using the device. The device includes a rotor chamber in which a rotor is arranged with a vertical rotor axis. The rotor has, at least in its radially outer third, the shape of a conical shell. Guide vanes for circulating starting materials or the product are arranged statically on an inner wall of the rotor chamber above the plane of the upper edge of the rotor. The guide vanes have, in cross section to the rotor axis, essentially the shape of a segment of a circle or spiral. The inner ends of the guide vanes lie approximately in the middle part of the rotor radius. The conical shell may have at least partially sheet-like gas passages in the form of perforations or screens. The device is used for producing pourable products.

Owner:REINER NOWAK +2

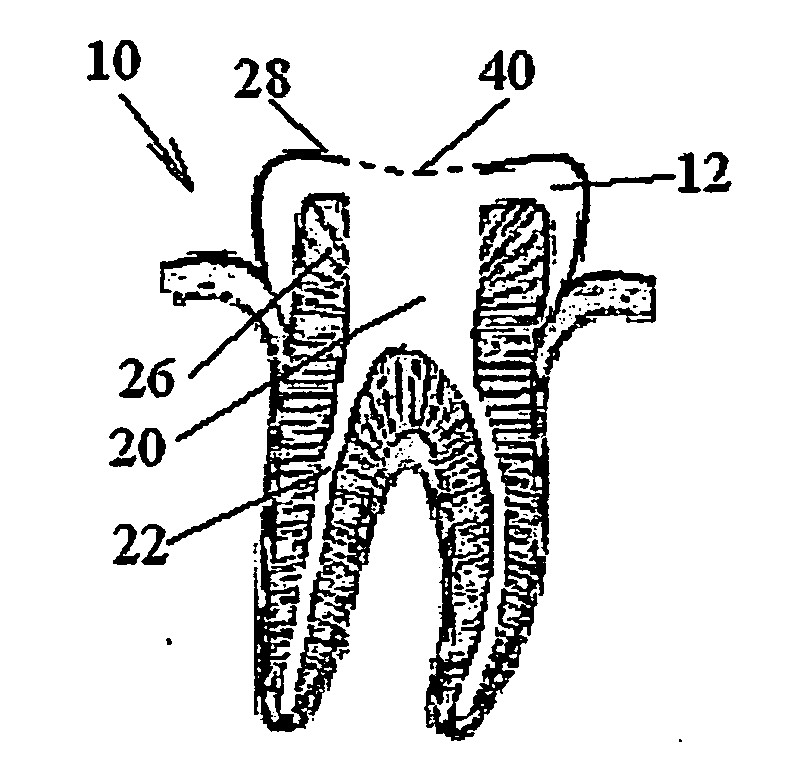

Photo-sterilization

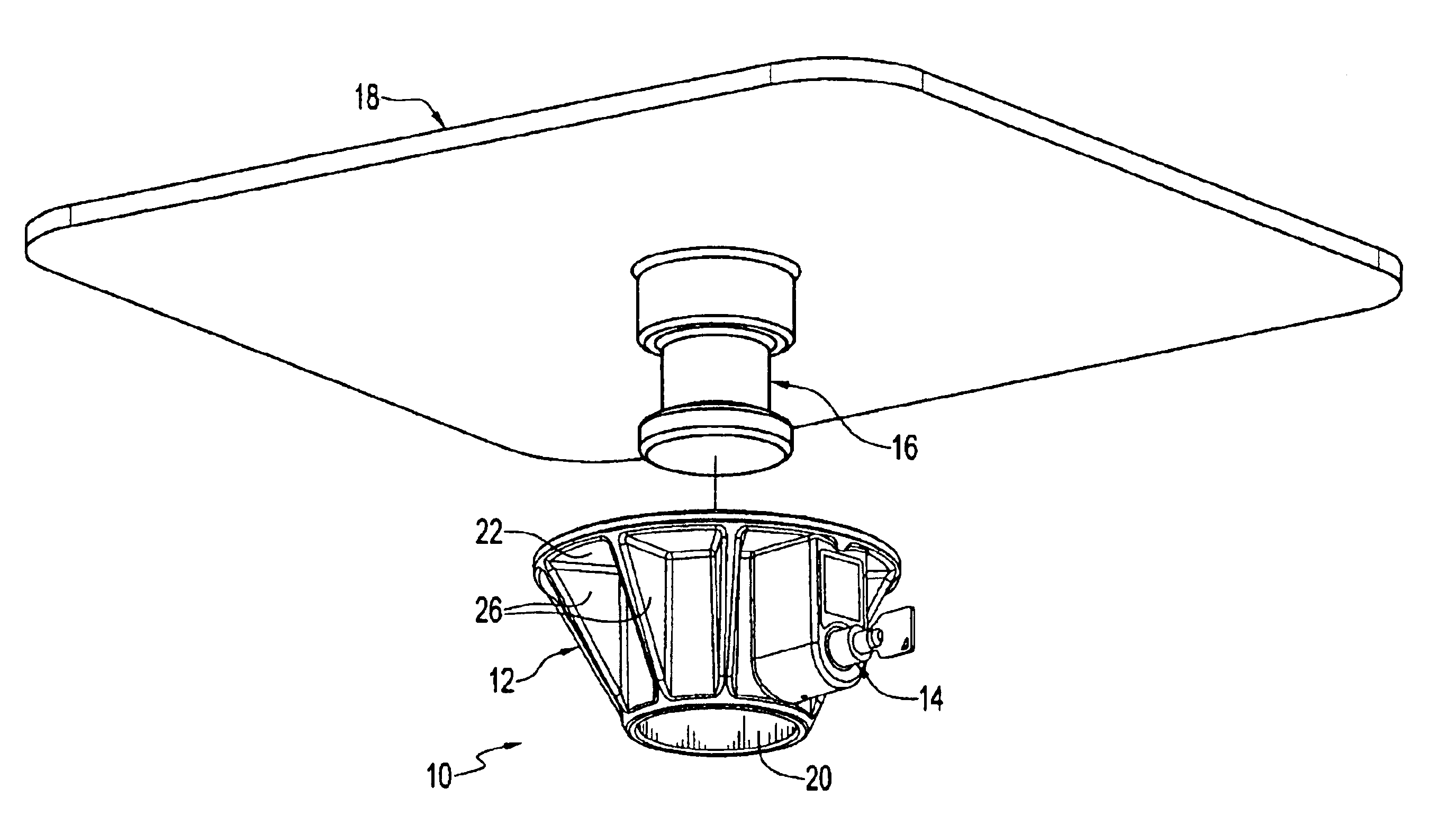

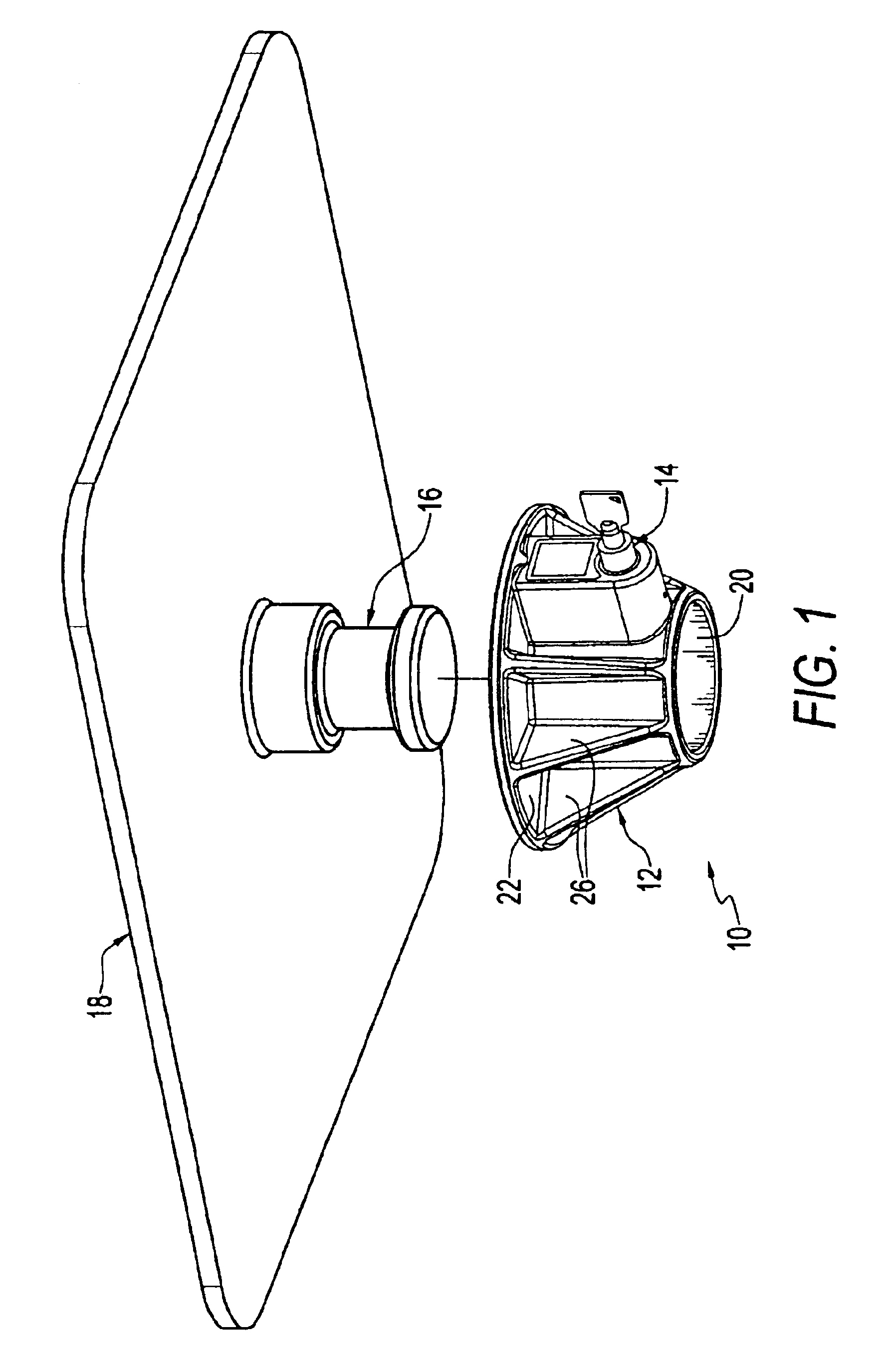

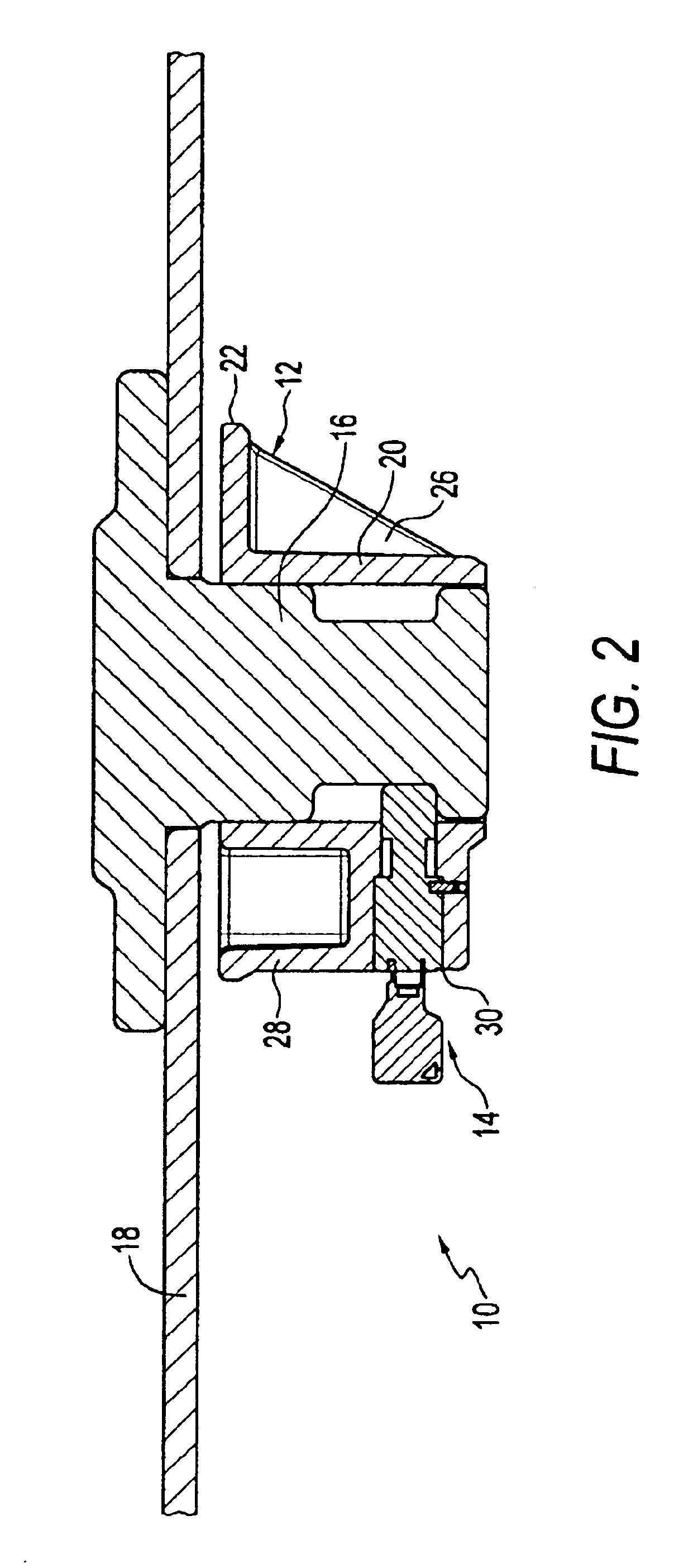

InactiveUS20070072153A1Excellent light diffusionHigh light transmittanceDisinfectionLight therapyEndodontic therapyMedicine

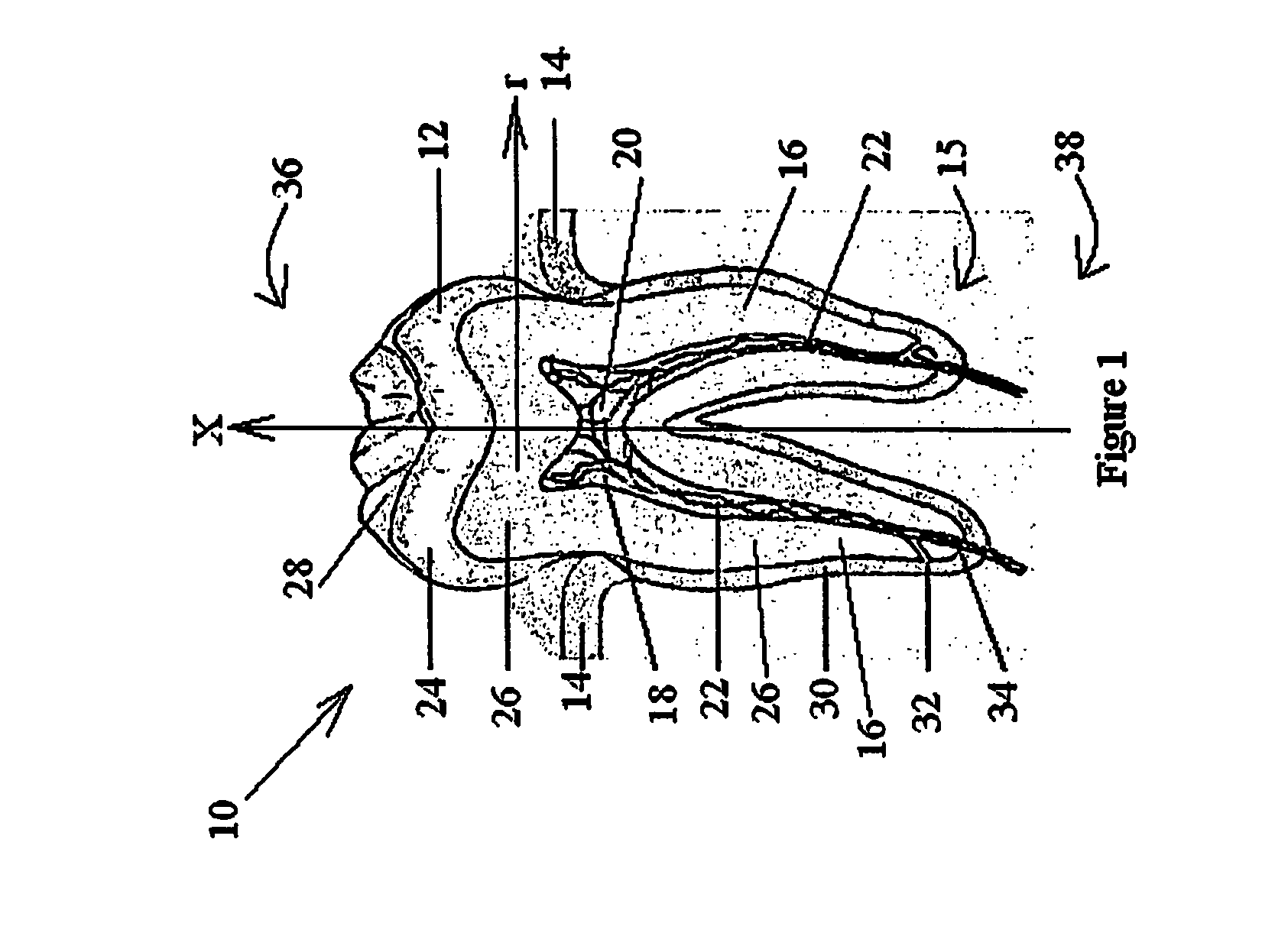

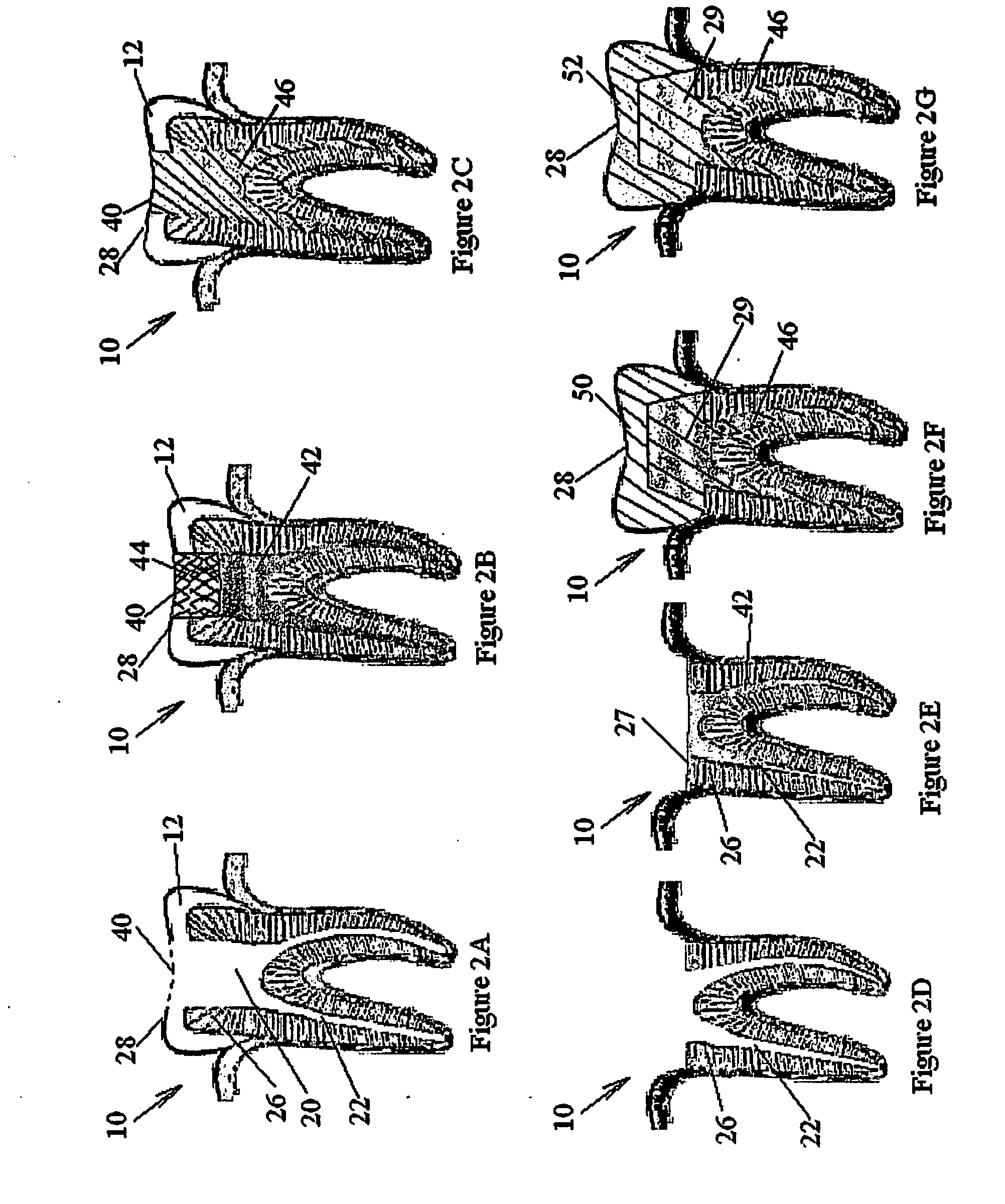

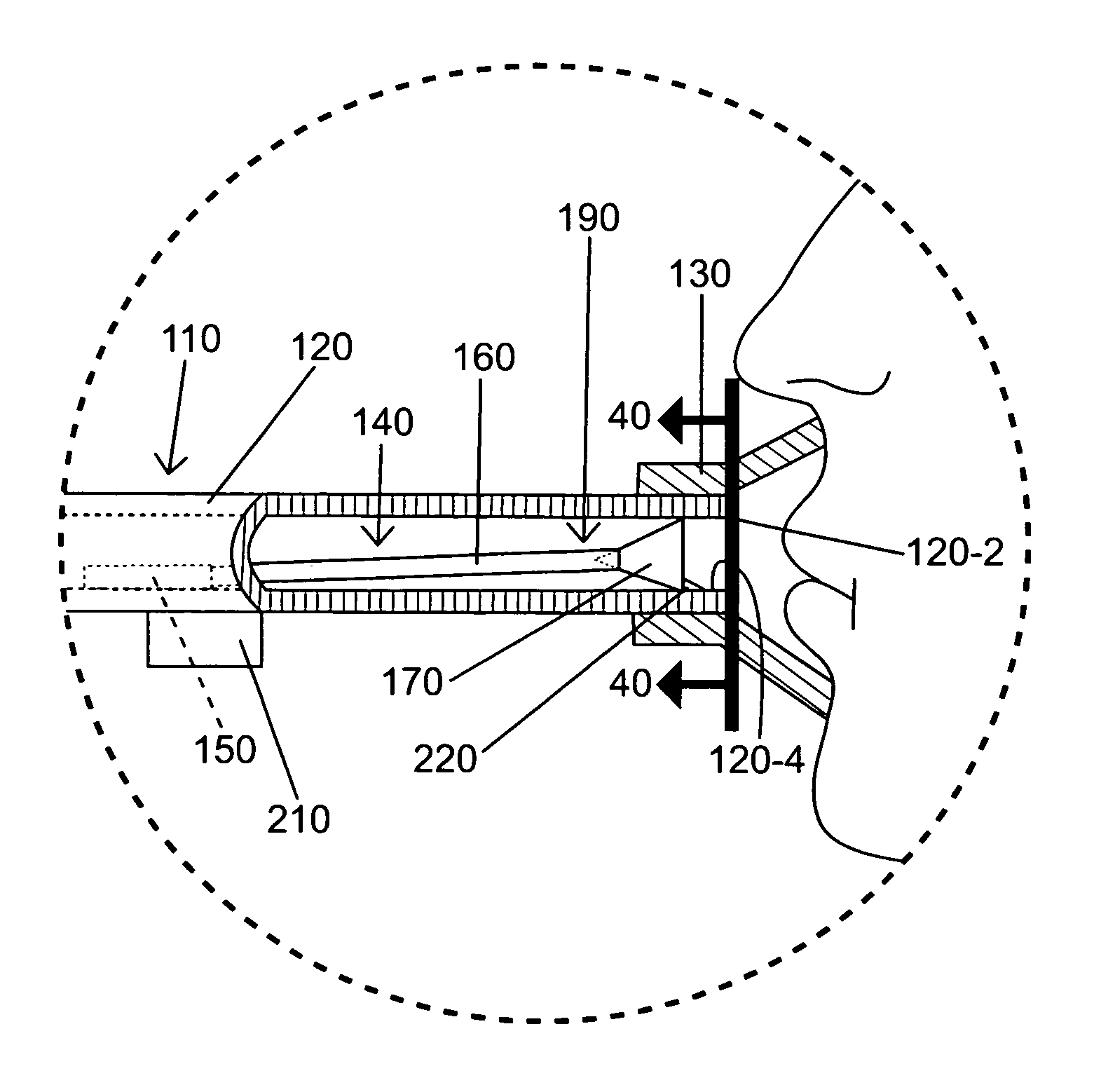

The present invention provides substances, devices, methods, and kits for photo-sterilization of a root canal, prior to and when performing endodontics, as well as periodically as post-endodontic prophylactic measures. The root-canal filling includes a light-transmitting element, operative as a diffuser, and methods are provided for communicating light to the diffuser, for disinfecting the walls of the root canals, by photo sterilization. The diffuser may be formed of silicone polymers, synthetic fused silica, quartz or the like, and may be surrounded by a light-transmitting sealer. The diffuser may be incorporated with an endodontic post, or a specially designed post, which may be transparent and (or) hollow. In a preferred embodiment, the diffuser is formed of a light transmitting conical shell of Cyclic Olefin Copolymers (COC), filled with a fluid such as air, distilled water, or silicone oil.

Owner:INTERLIGHT

Device and method for drying pourable products

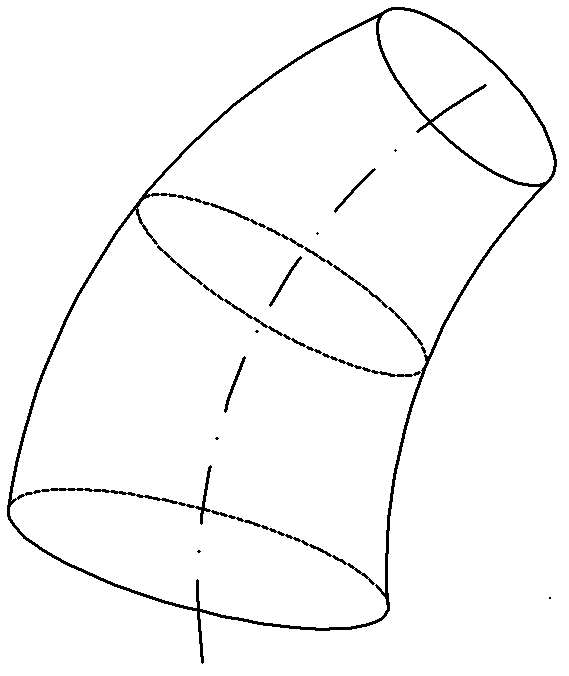

Device and method for drying a pourable products. The device includes a rotor chamber in which a rotor is arranged with a vertical rotor axis. The rotor has a central horizontal surface and, at least in its radially outer third, a conical shell which is inclined to the axis of rotation by 20° to 70°, in such a way that the end face of the conical shell has the largest diameter and is located at the top. The conical shell has, at least partially, sheet-like gas passages in the form of perforations or screens. The method for drying pourable products provides for dry gas to be fed in a sheet like manner to the products to be dried during the radially peripheral circulation of the products without the products being swirled up and being exposed to unacceptable compressive, concussive and / or frictional loads.

Owner:GLATT SYSTTECHN +2

Heated engine nose cone using spiral channels

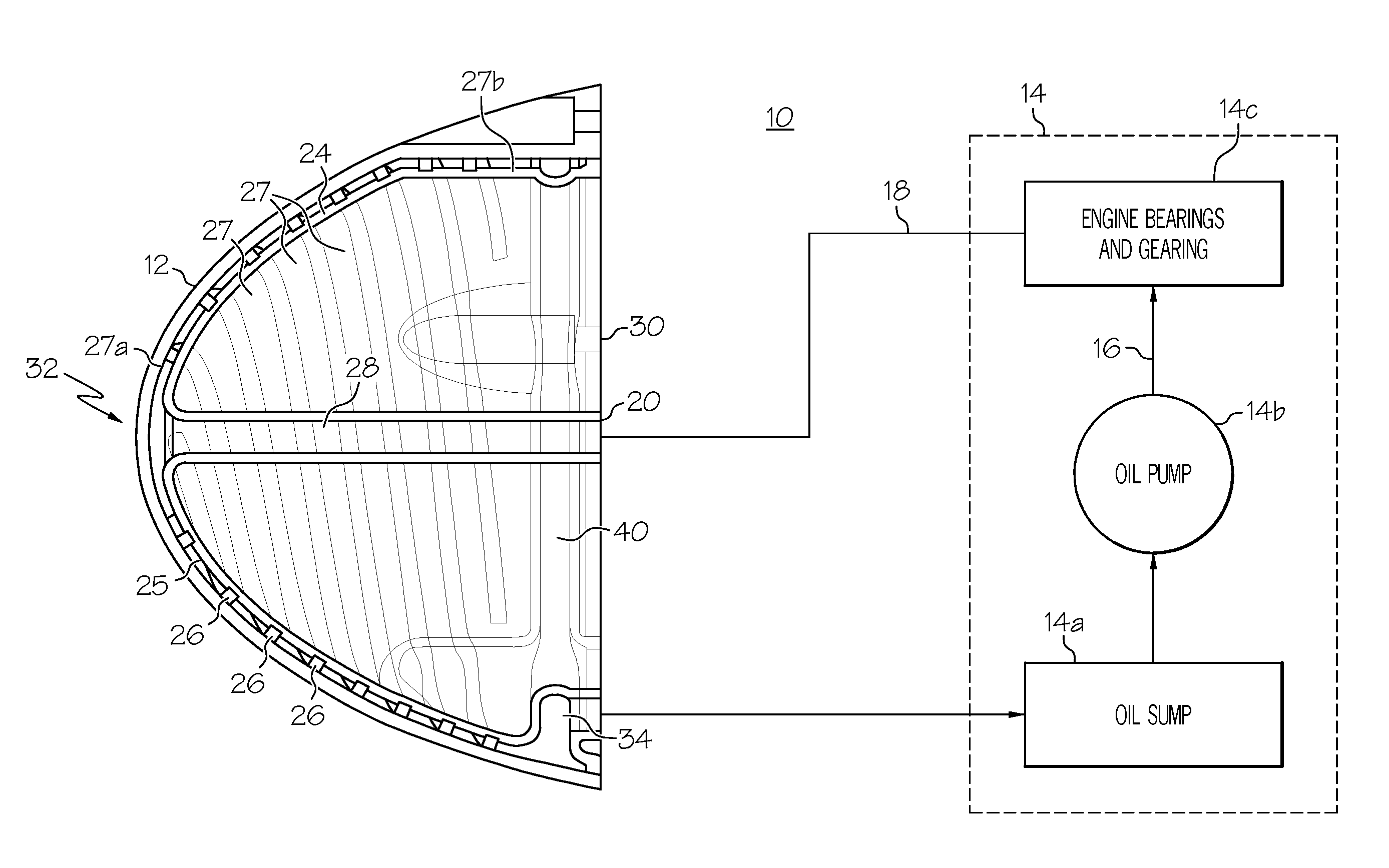

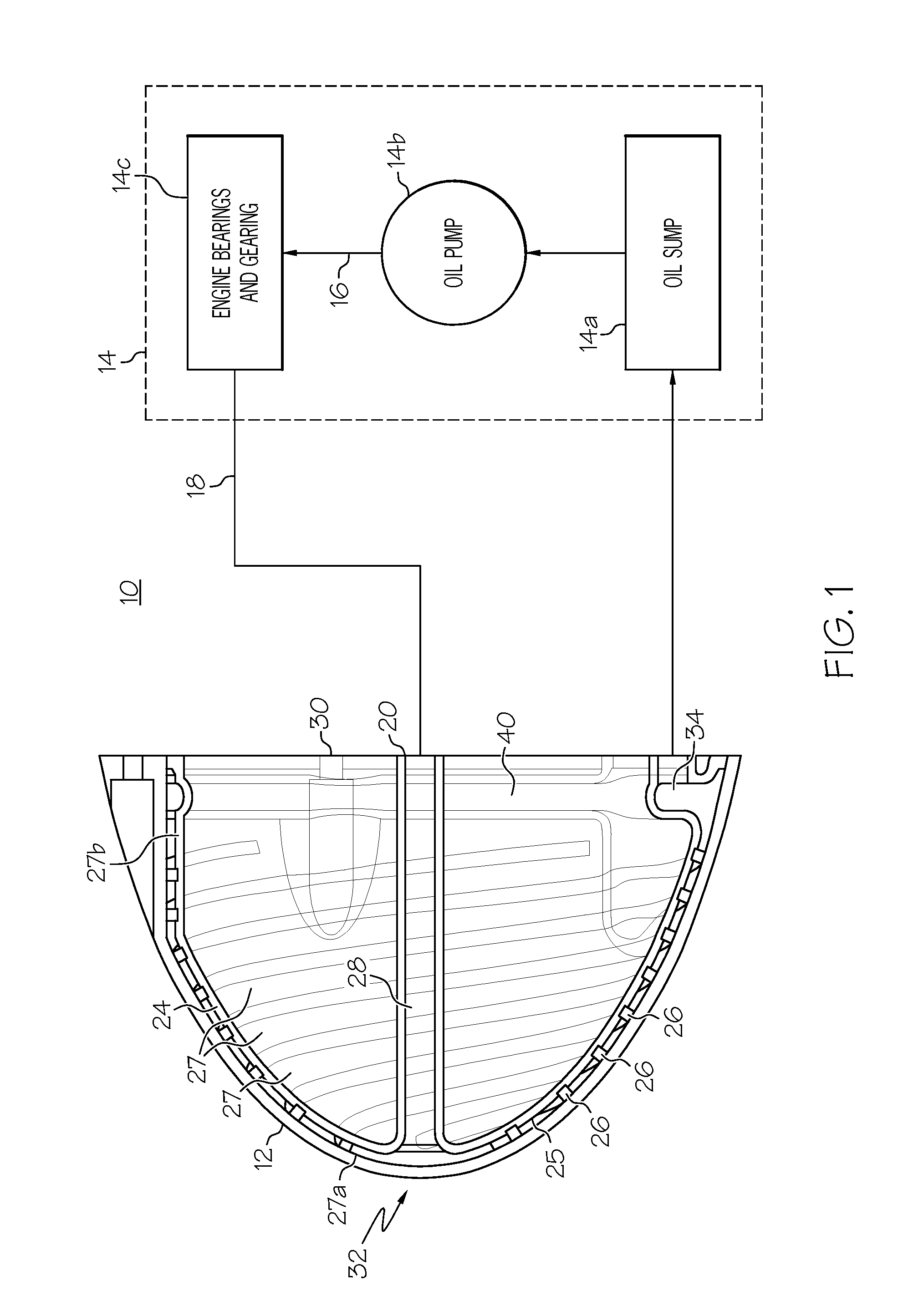

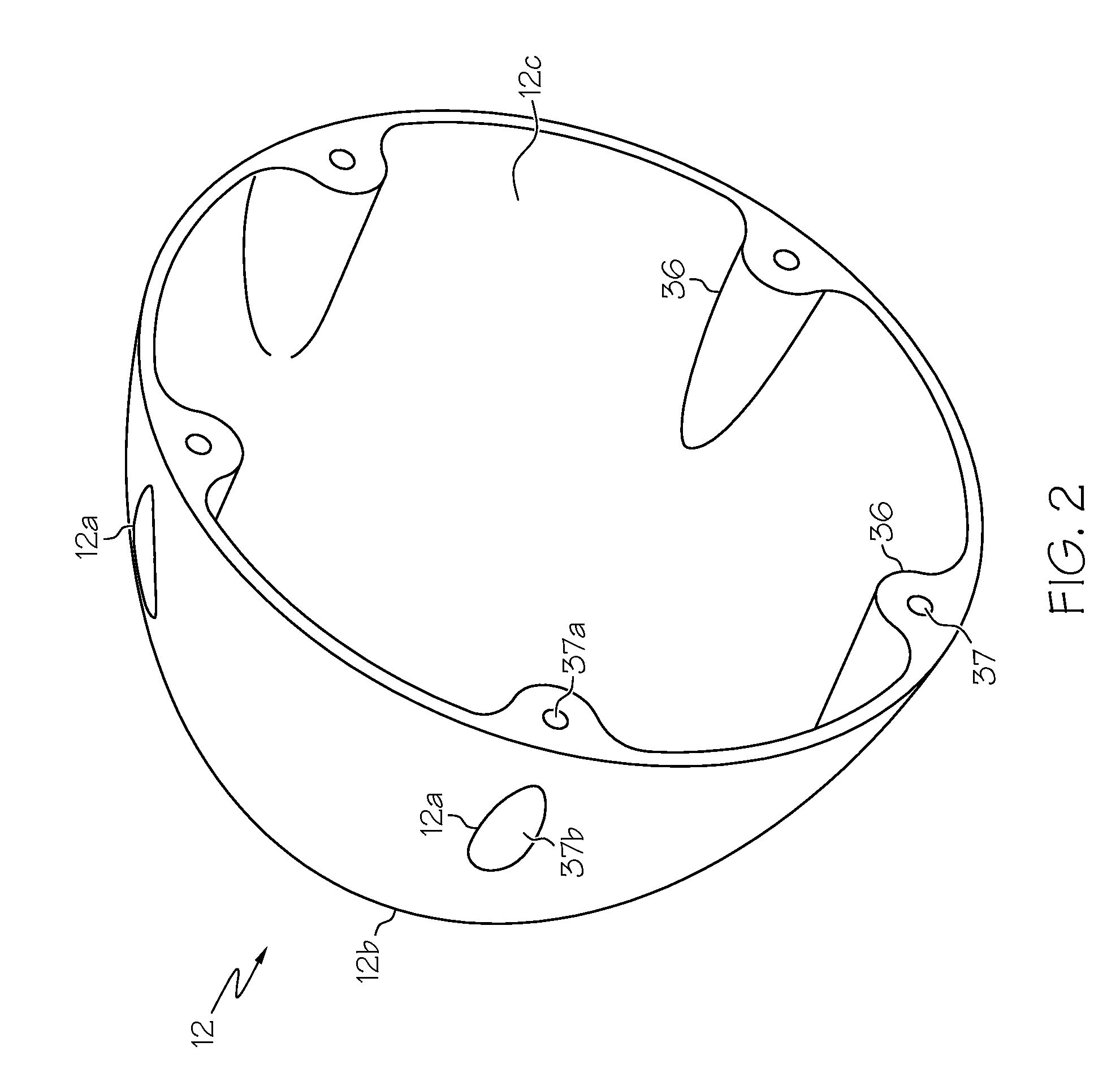

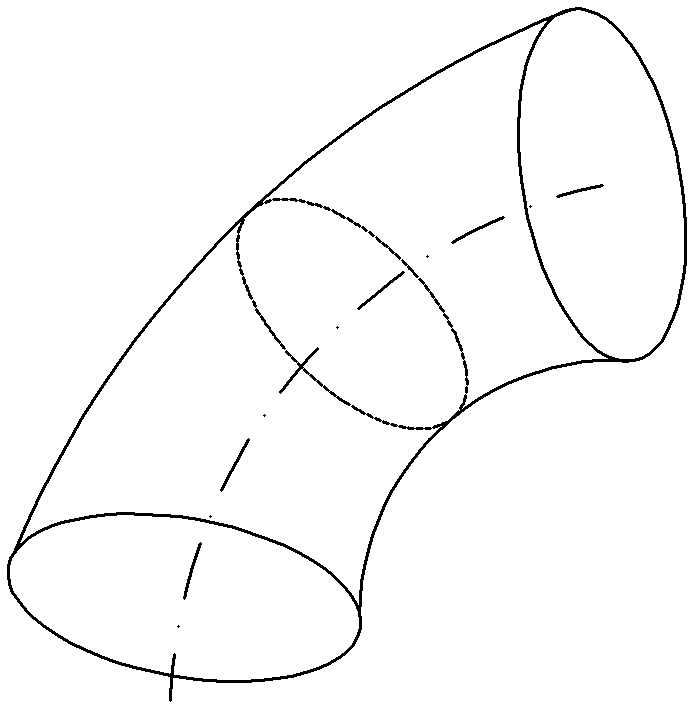

A nose cone of a turbomachine, such as an aircraft engine, is heated to prevent ice formation. The nose cone is configured as a conical shell positioned concentrically over an inner shell with a space therebetween. Spiral spacers in the space provide distributed passages through which heated lubricating oil flows. A system for separating entrained air from the lubricating oil as part of this mechanism is disclosed.

Owner:HONEYWELL INT INC

Kingpin lock

A kingpin lock includes a vertically-oriented tube with a conical shell formed by a plurality of gussets projecting radially from the tube. The gussets are triangular in shape, so that the conical shape tapers from the upper end to the lower end of the tube. A plunger type lock is mounted on the tube and is operable to move a securement pin into a notch on the kingpin to secure the kingpin within the tube, and to withdraw the pin from the notch to permit removal of the kingpin from the tube.

Owner:SECURUS ENTERPRISES

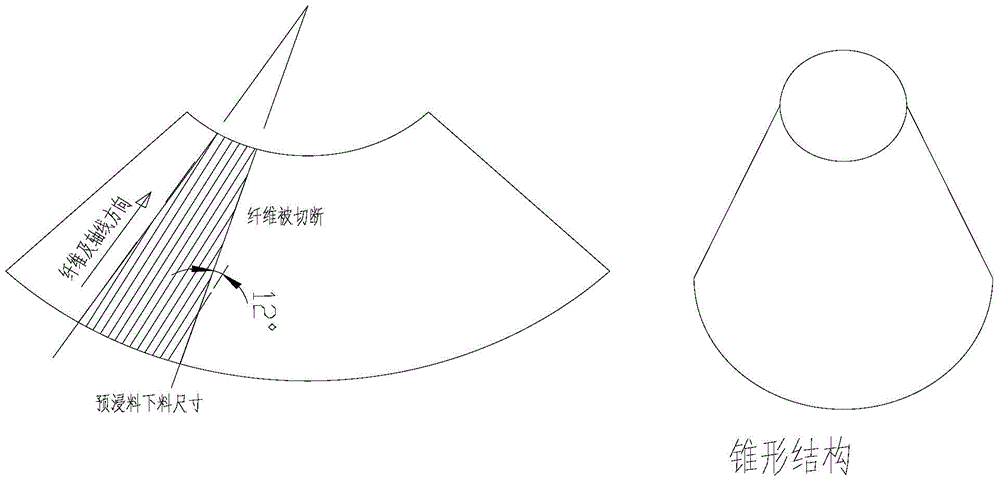

Automatic fiber laying variable-angle path planning method for non-developable curved surface part

The invention discloses an automatic fiber laying variable-angle path planning method for a non-developable curved surface part, which relates to a fiber laying path plan making method for a non-developable curved surface part and is used for solving the problem that in the complexity of a fiber laying process, the appearance accuracy and various properties of a composite material are influenced by inevitable shearing and re-conveying phenomena occurring in the automatic fiber laying process of the non-developable curved surface part. In a scheme I, the method comprises the following steps of: acquiring data information from a non-developable revolving barrel part; calculating the laying reference angle of a presoaked tow on each intersection line; determining points on an initial path; determining points on other paths; and making a path line. A scheme II is different from the scheme I in that data information is acquired from a non-developable curved surface variable-section conical shell part; and a scheme III is different from the scheme I and the scheme II in that data information is acquired from a non-developable curved surface variable-section joint part. The method is used for planning an automatic fiber laying variable-angle path on the outer surface of the non-developable curved surface part.

Owner:HARBIN INST OF TECH

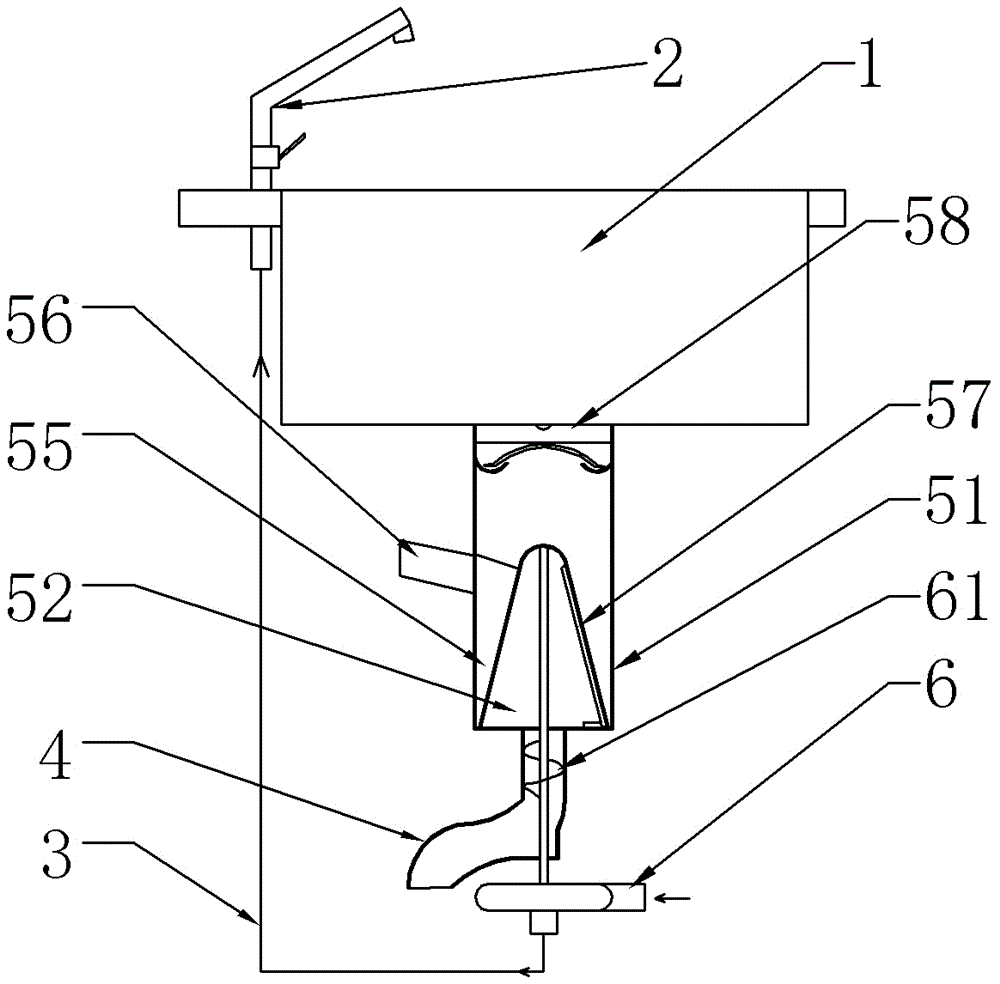

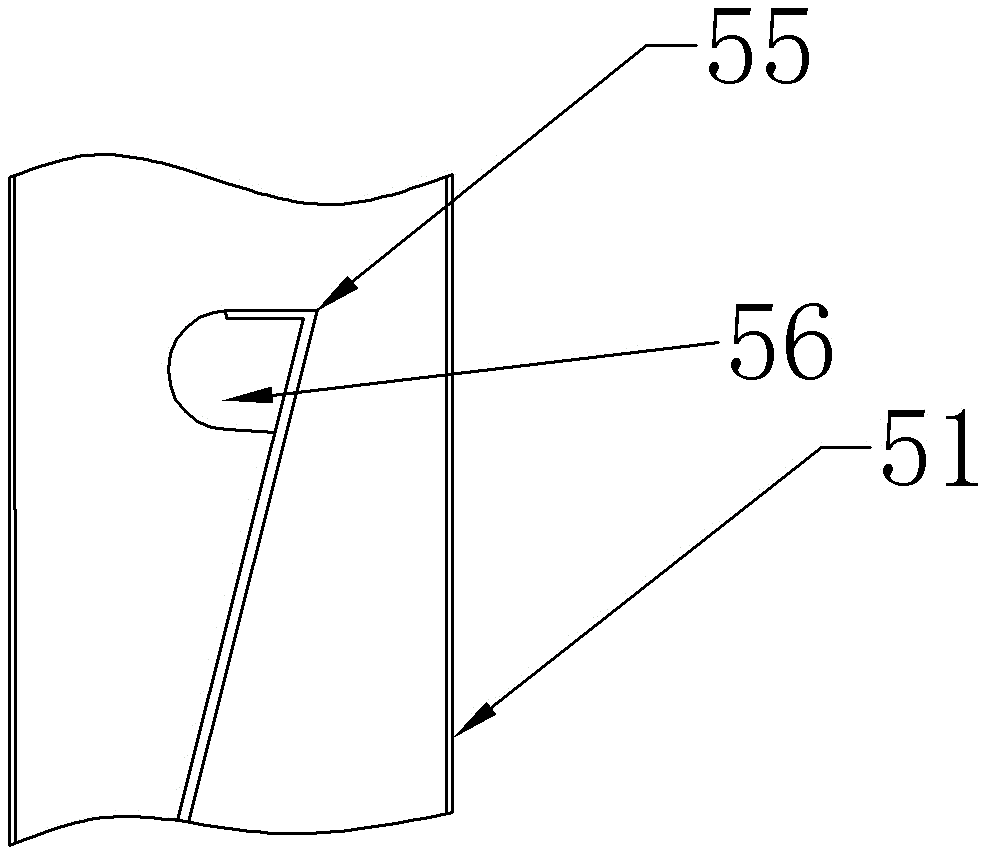

Self-cleaning type water-saving anti-blocking sink

ActiveCN106592714AAchieve separationGood filter functionDomestic plumbingWater savingWater discharge

The invention relates to a kitchen sink, in particular to a self-cleaning type water-saving anti-blocking sink. The sink comprises a sink body and a water discharging pipe; a water distributor is serially connected between the sink body and the water discharging pipe; the water distributor comprises a cylindrical shell, a water seal mounted at the upper part of the cylindrical shell, a conical filter net mounted in the center of the lower part of the conical shell, and a power apparatus for driving the conical filter net to rotate; the water discharging pipe is arranged in the bottom center of the cylindrical shell; a scraping plate in contact with the outer wall of the conical filter net is arranged on the inner wall of the cylindrical shell; a residue discharging hole is formed in the upper end part of the scraping plate; the power apparatus comprises a centrifugal pump; a rotary shaft of the centrifugal pump penetrates through the water discharging pipe and is fixed with a rotary shaft of the conical filter net; a tangential hole of the centrifugal pump serves as a water inlet; an axial hole of the centrifugal pump serves as a water outlet and is connected with a tap; a hairbrush in contact with the conical filter net is arranged on the inner side of the conical filter net; and the hairbrush is fixed at the bottom of the cylindrical shell. The sink adopting the technical scheme is good in anti-blocking effect, can be automatically cleaned, and has a water-saving effect.

Owner:CHONGQING JIZHI CHUANGXIANG IND DESIGN CO LTD

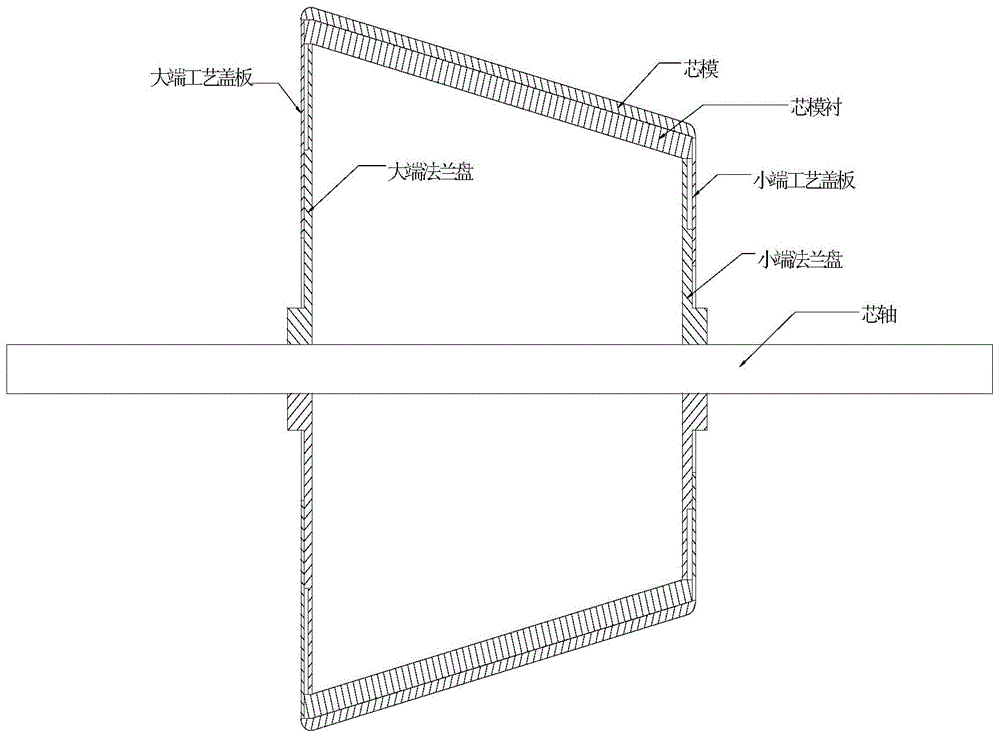

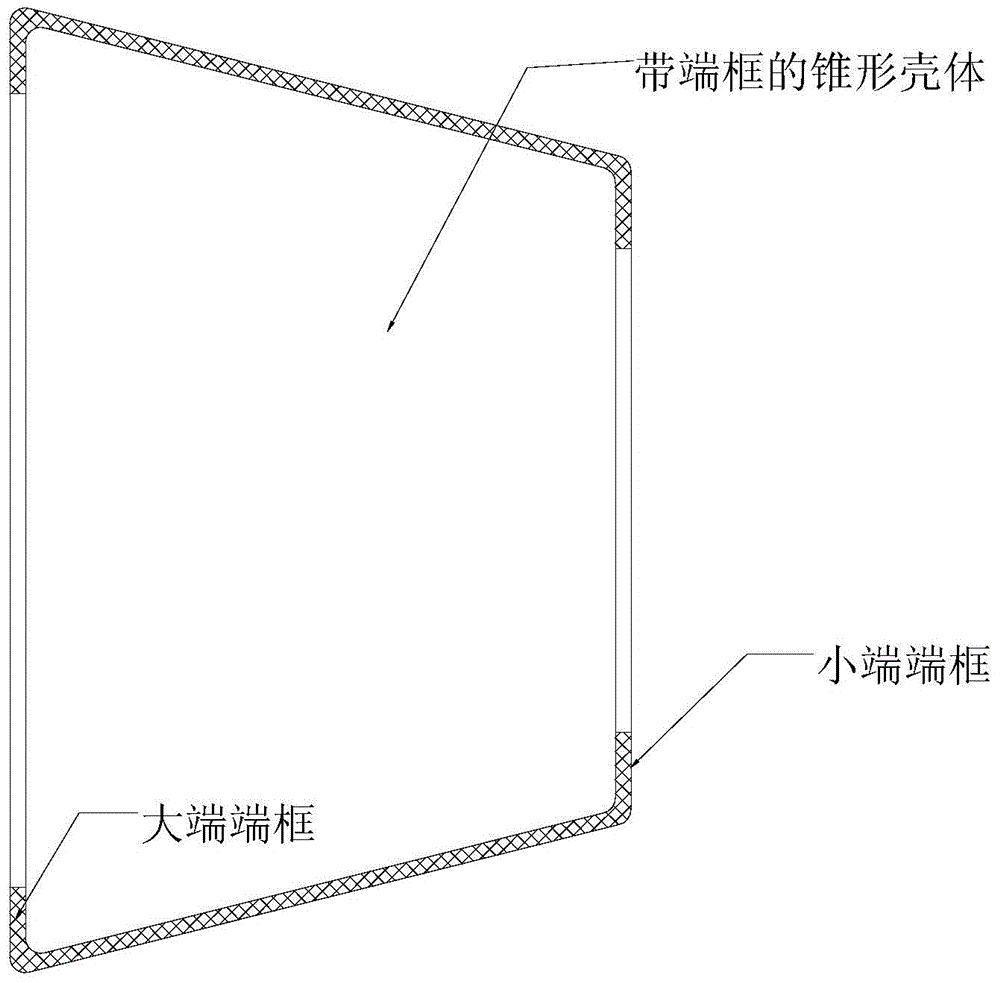

Method for forming composite conical shell with end frame

ActiveCN103978698AConducive to take advantage of the designImprove bearing efficiencyMaterials scienceConical shell

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

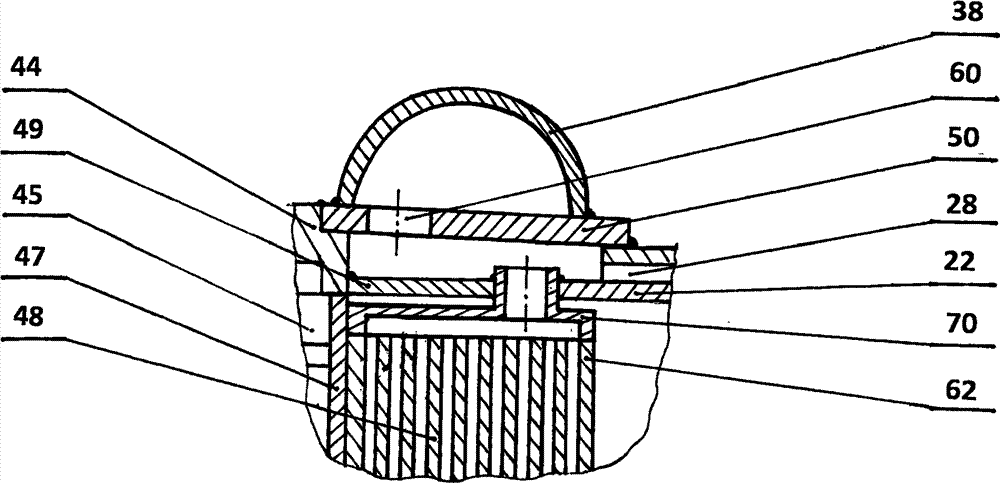

Wet static cyclone dust collector

ActiveCN102527515AImprove removal efficiencyExternal electric electrostatic seperatorElectrode constructionsCycloneCorona discharge

The invention relates to a wet static cyclone dust collector. The dust collector comprises a conical shell, an air inlet pipe, a water supply part, a discharge electrode pipe, a drain pipe connected with the shell and an exhaust pipe connected with the shell, wherein the interior of the conical shell is hollow and provided with a cavity, and the shell is made of a conductive material; the air inlet pipe is connected with the shell and extends along the tangential direction of the shell; the water supply part is arranged inside the air inlet pipe or inside the shell; and the discharge electrode pipe is accommodated in the cavity of the shell and provided with an axle tube part, a plurality of through holes and a plurality of extension parts, each through hole passes through the inside and outside of the axle tube part, and each extension part is arranged on the outer wall of the axle tube part. Therefore, an electric field can be formed between the shell and the discharge electrode pipe, when waste gas to be treated passes through the air inlet pipe and enters the inner cavity of the shell, particles in the waste gas are electrified by virtue of a corona discharge mechanism of the discharge electrode pipe and move toward the inner wall surface of the shell under the action of the electric field and centrifugal force, at the moment, washing water sprayed from the water supply part flows along the inner wall surface of the shell in a helical shape, thus the particles are washed and removed.

Owner:JG ENVIRONMENTAL TECH +2

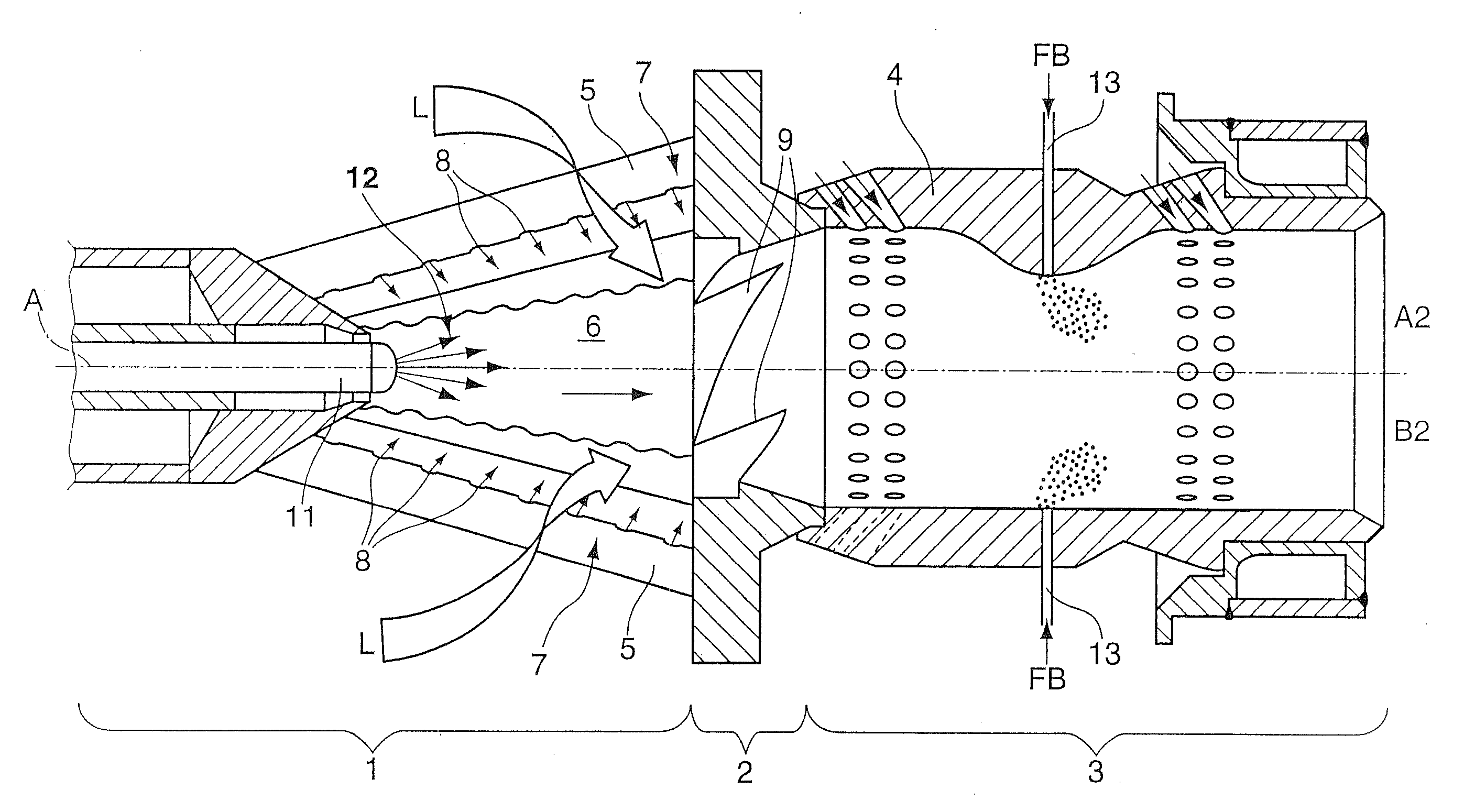

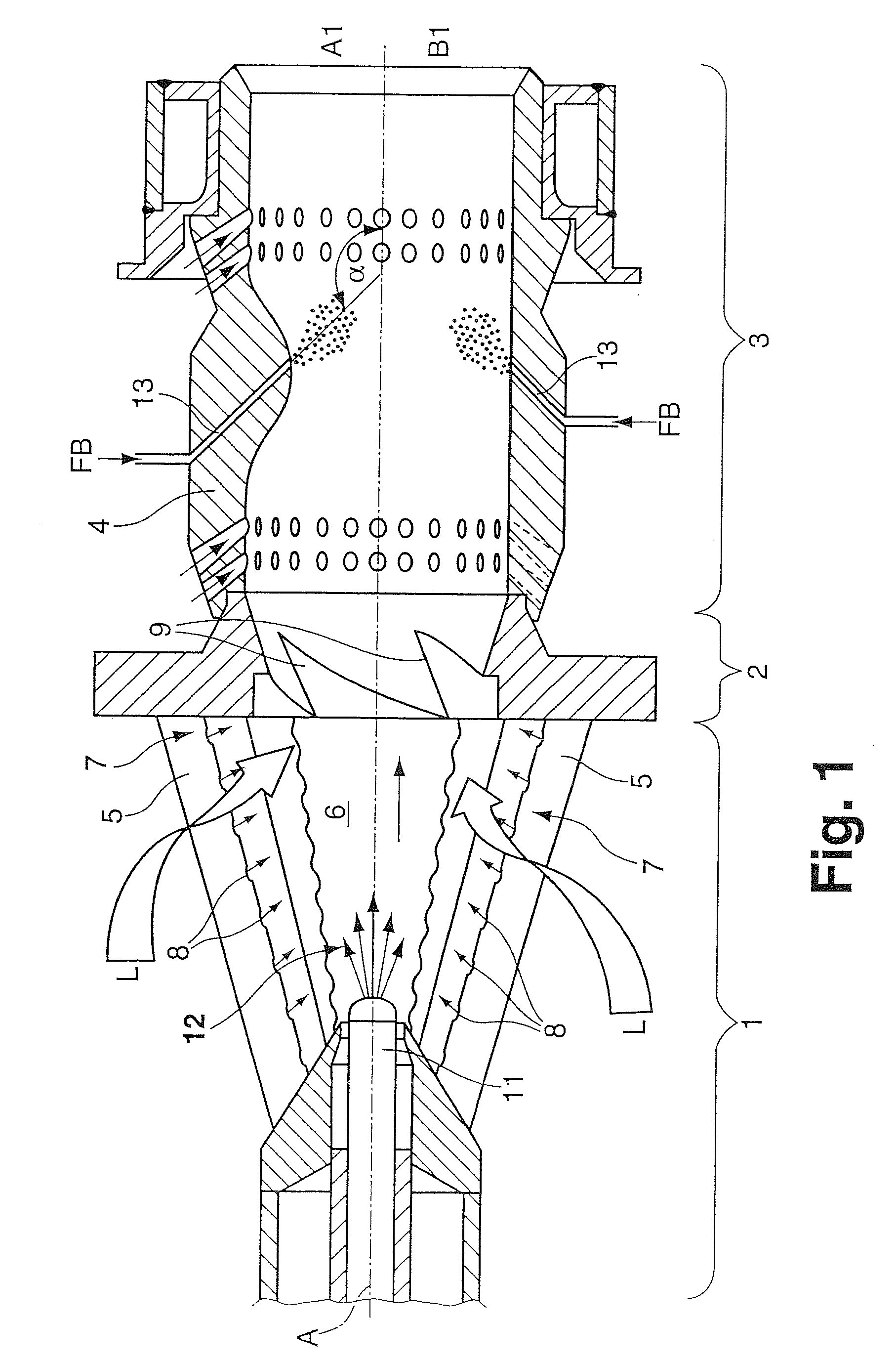

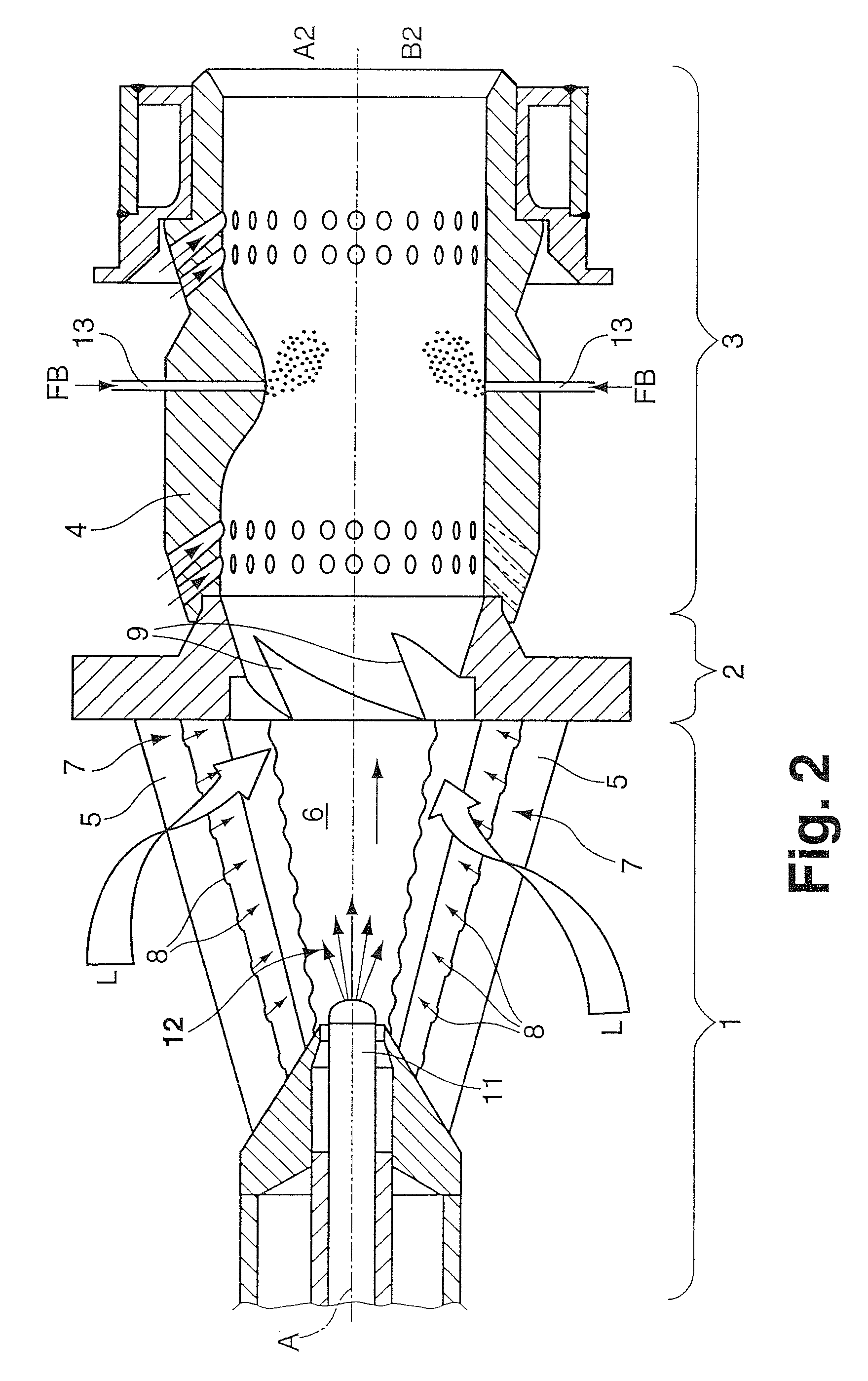

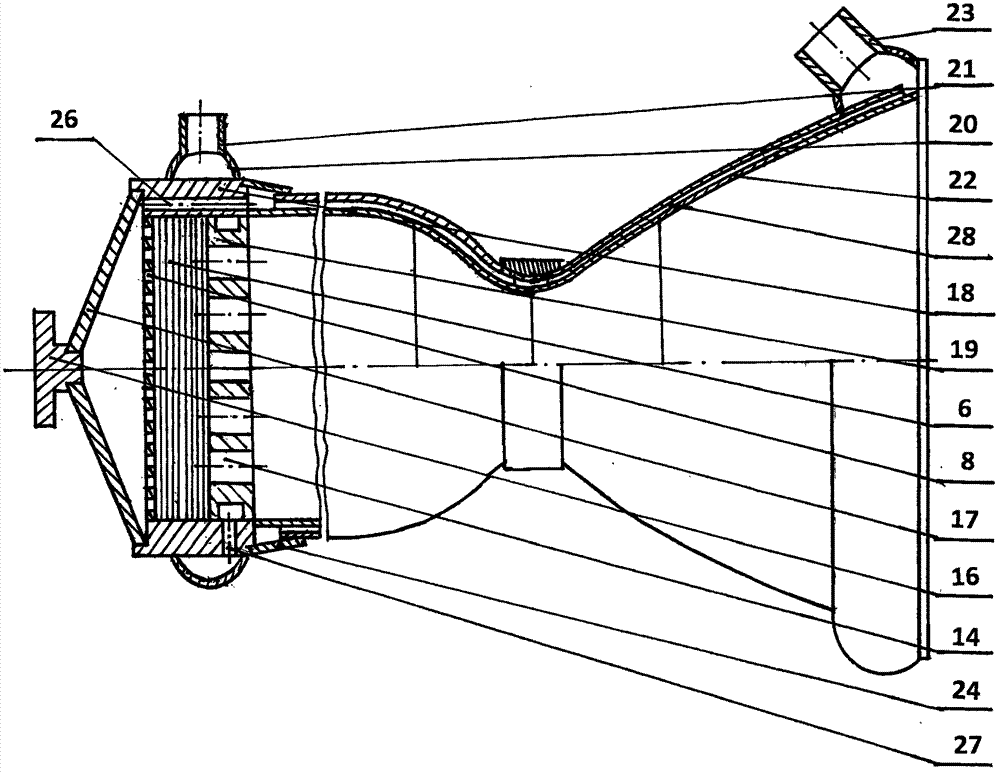

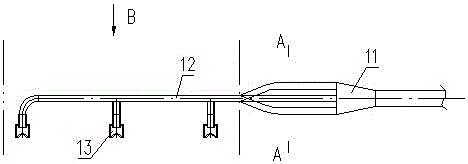

Premix burner with mixing section

InactiveUS8057224B2Minimize and completely eliminate increasing riskOutput maximizationCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorEngineering

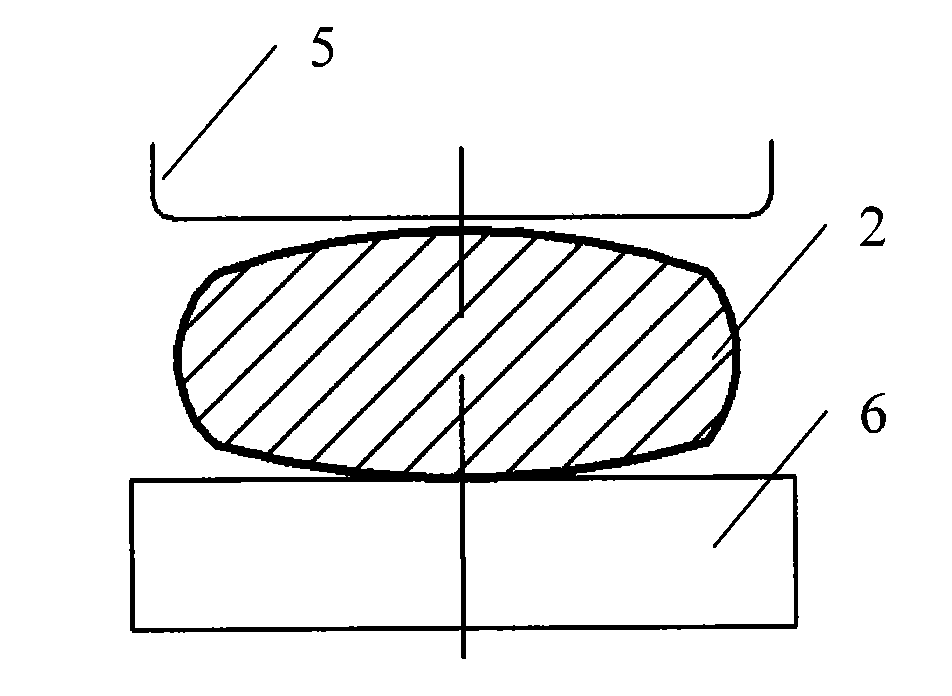

A premix burner has a mixing section (3) for a heat generator, sectional conical shells (5) which complement one another to form a swirl body, enclose a conically widening swirl space (6), and mutually define tangential air-inlet slots (7), along which feeds (8) for gaseous fuel are provided in a distributed manner, having at least one fuel feed (11) for liquid fuel, this fuel feed (11) being arranged along a burner axis (A) passing centrally through the swirl space (6), and having a mixing tube (4) adjoining the swirl body downstream via a transition piece (2). At least one additional fuel feed (13) for liquid fuel is provided in the region of the swirl body, the transition piece (2), and / or the mixing tube (4).

Owner:ANSALDO ENERGIA SWITZERLAND AG

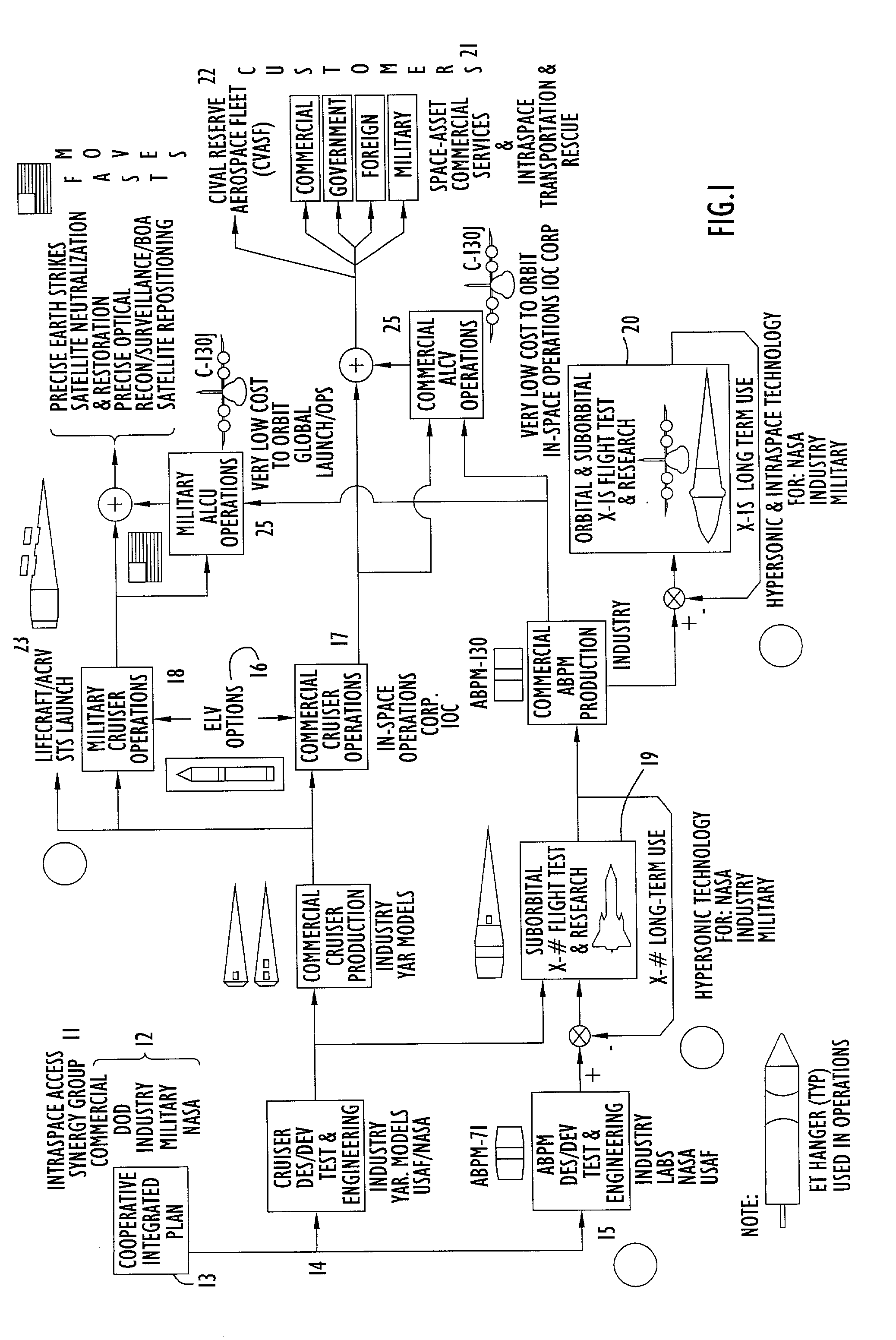

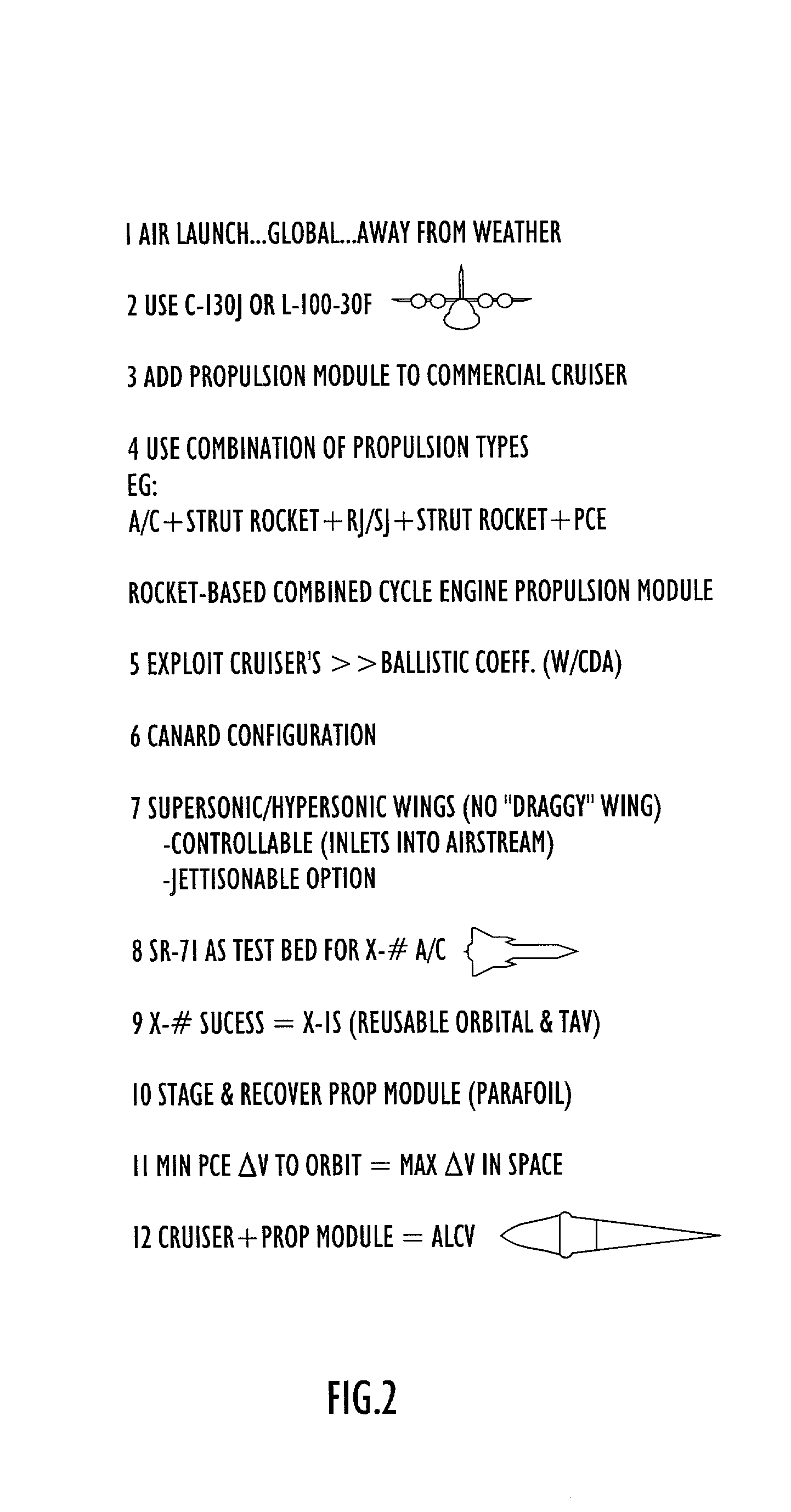

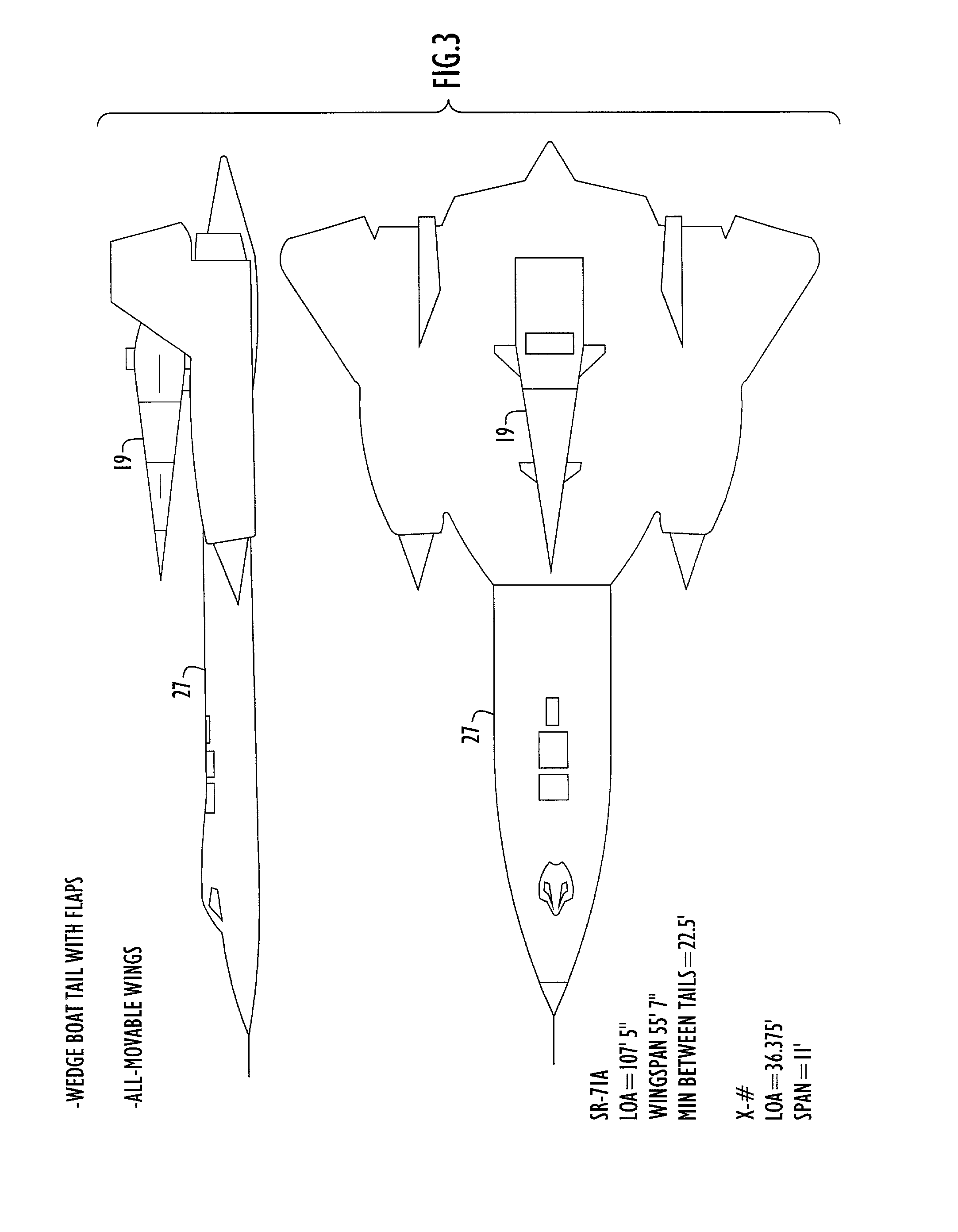

Hypersonic and orbital vehicles system

A method for developing and utilizing a Space Cruiser vehicle efficiently combines resources from relevant end users in industry and the military. The preferred vehicle has an elongated conical shell with an elliptical transverse cross section. The cabin of the vehicle preferably has a circular transverse cross section, leaving space between the cabin and the shell to store vehicle fuel. The cabin is insulated and capable of supporting occupants in a shirt-sleeve, air-breathing environment whether in the Earth's atmosphere or in outerspace. The vehicle is capable of being launched from conventional aircraft, and also being stored in and launched from a space shuttle or orbiting space station.

Owner:REDDING JR FRED WHITNEY +1

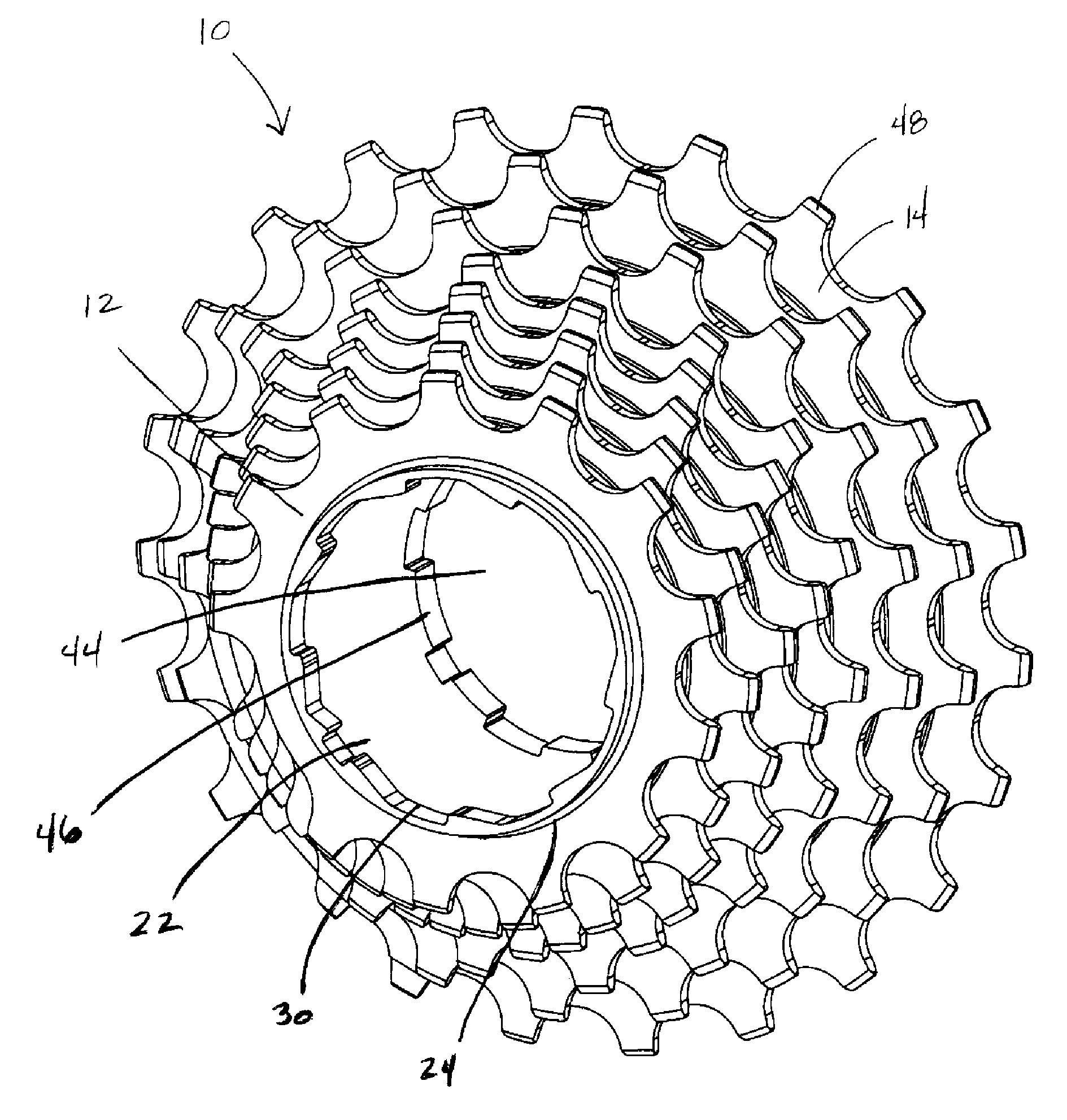

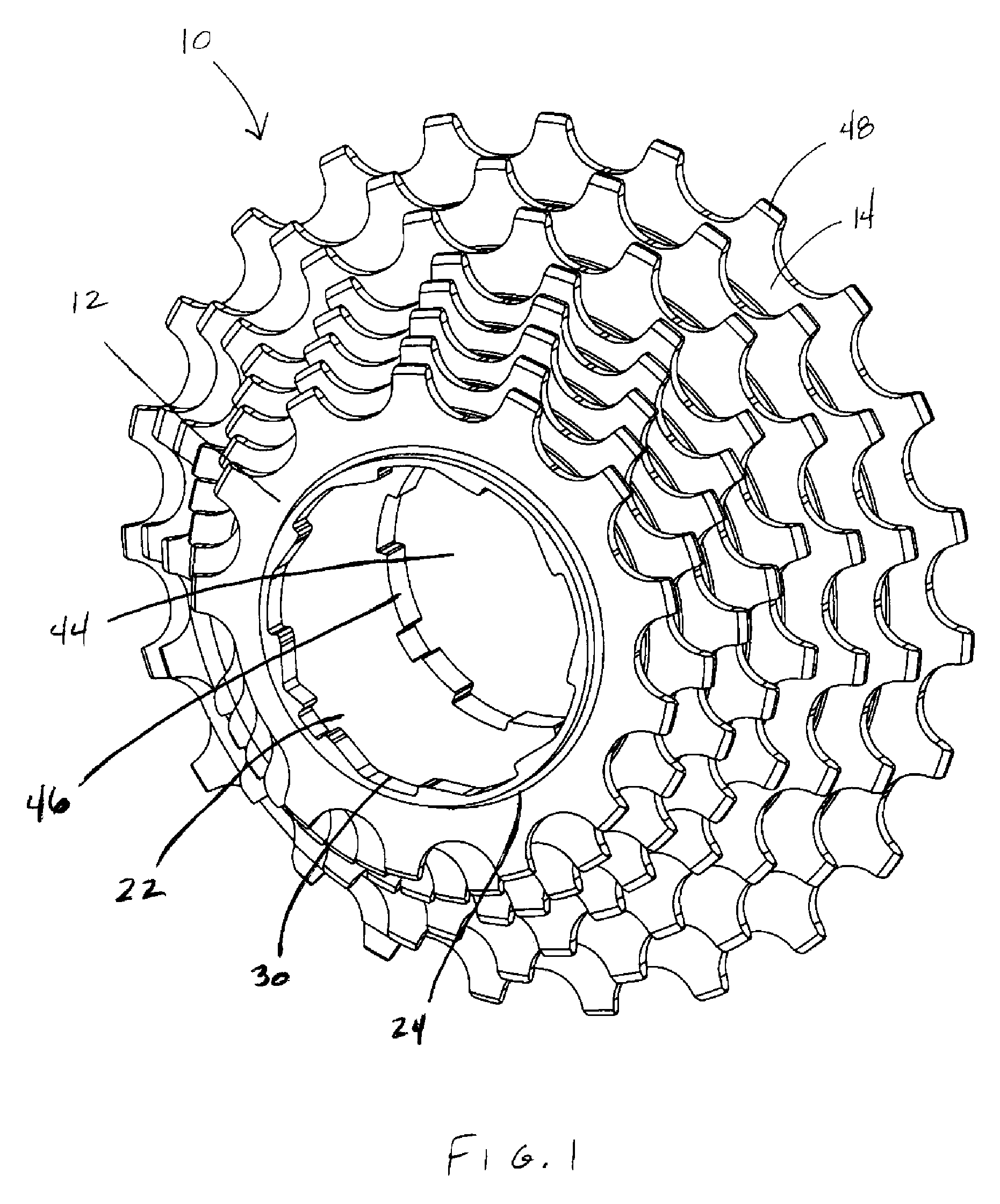

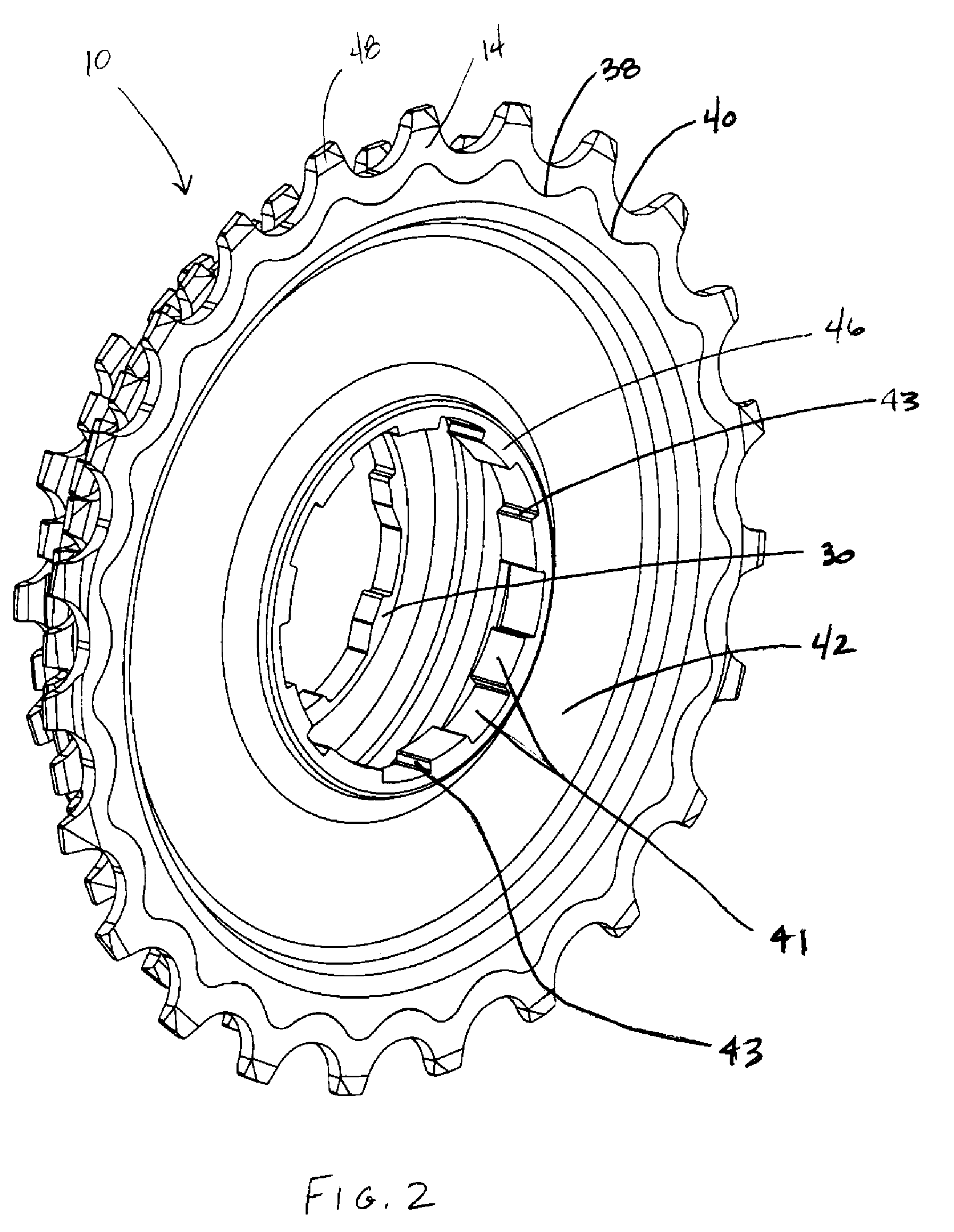

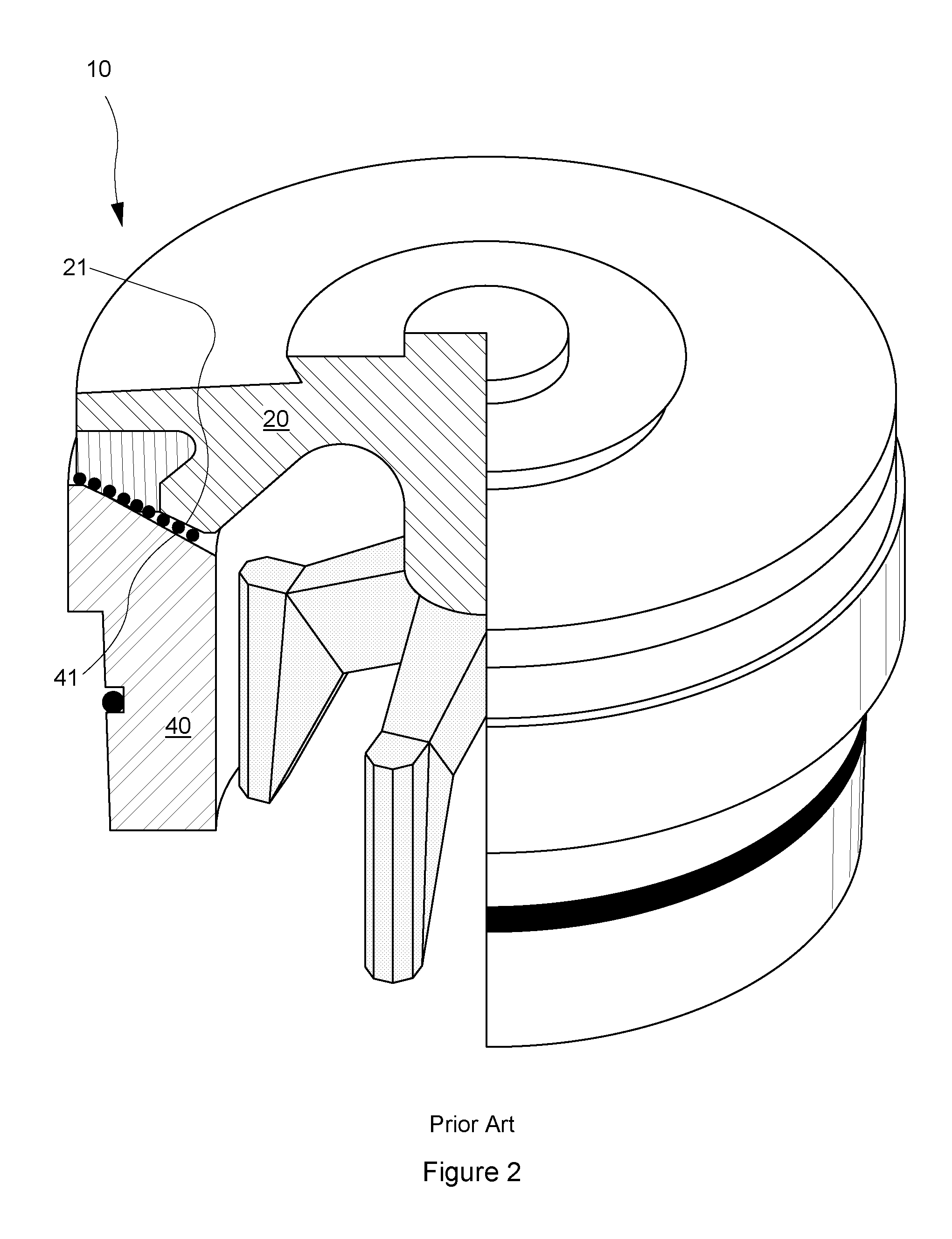

Bicycle Multi-Gear Cassette

A bicycle multi-gear cassette mountable to a wheel hub driver mechanism that includes truncated conical shell having a first opening proximate a small shell base and a second opening proximate a large shell base. The openings are coaxial with an axis of the shell. A plurality of toothed sprockets having different numbers of teeth are disposed on the shell and extend radially of the central axis. A torque load transmitting profile is configured on the shell proximate one of the small and large shell bases. A radial load transmitting profile is configured on the shell proximate one of the small and large shell bases. The shell, sprockets, and the load transmitting profiles embody a single piece. The torque load transmitting profile forms a featureless contact surface for frictional engagement with the hub driver mechanism.

Owner:SRAM CORPORATION

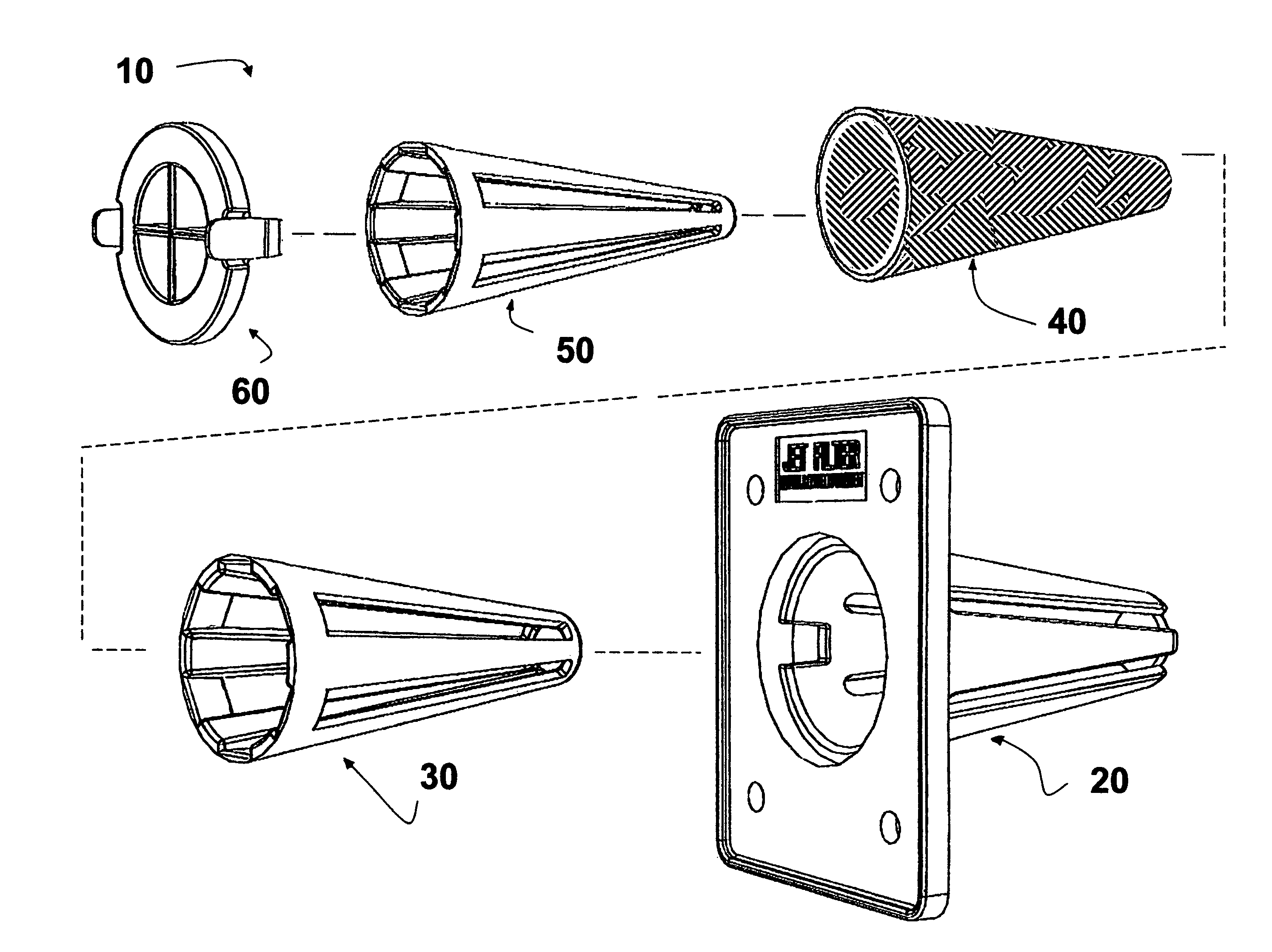

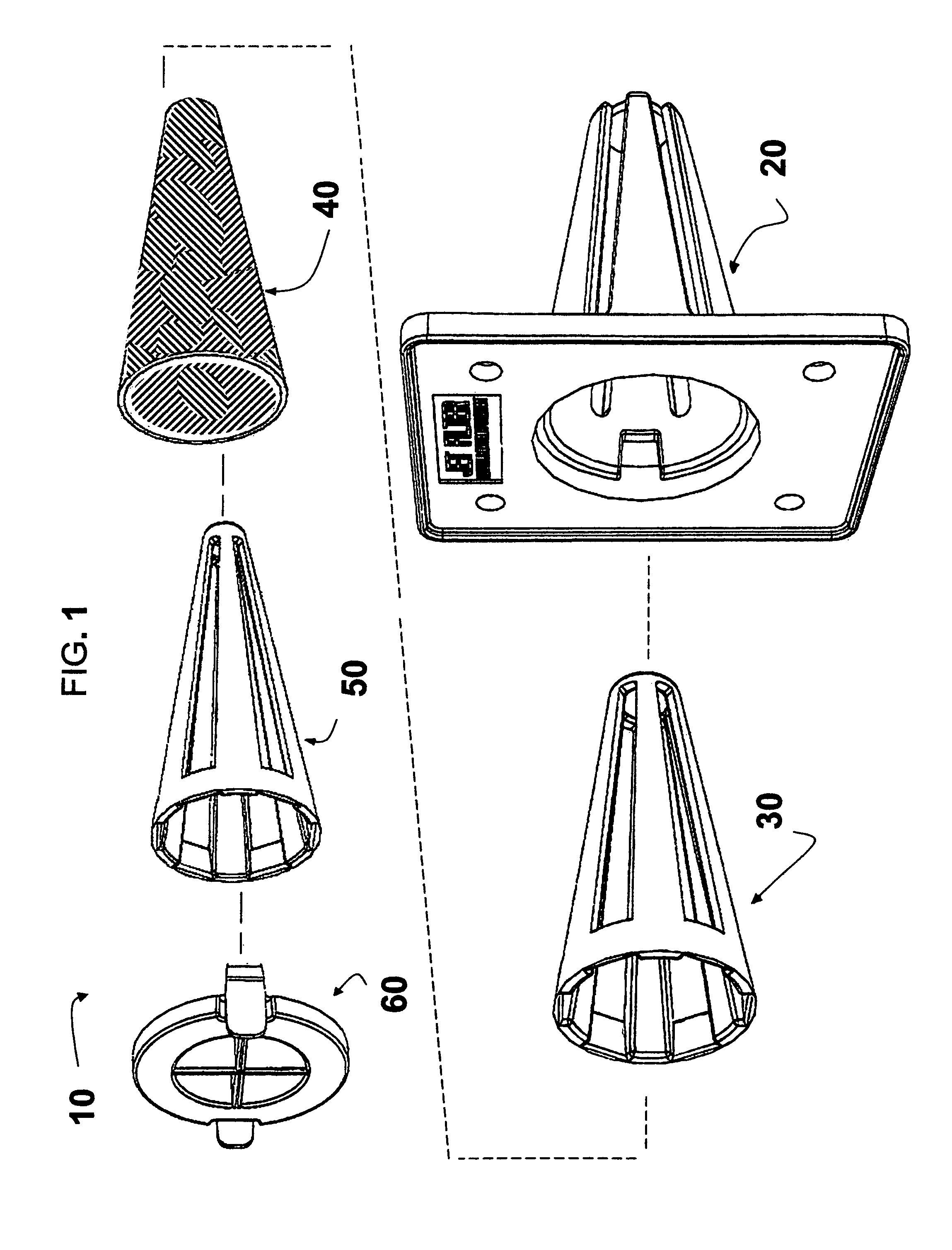

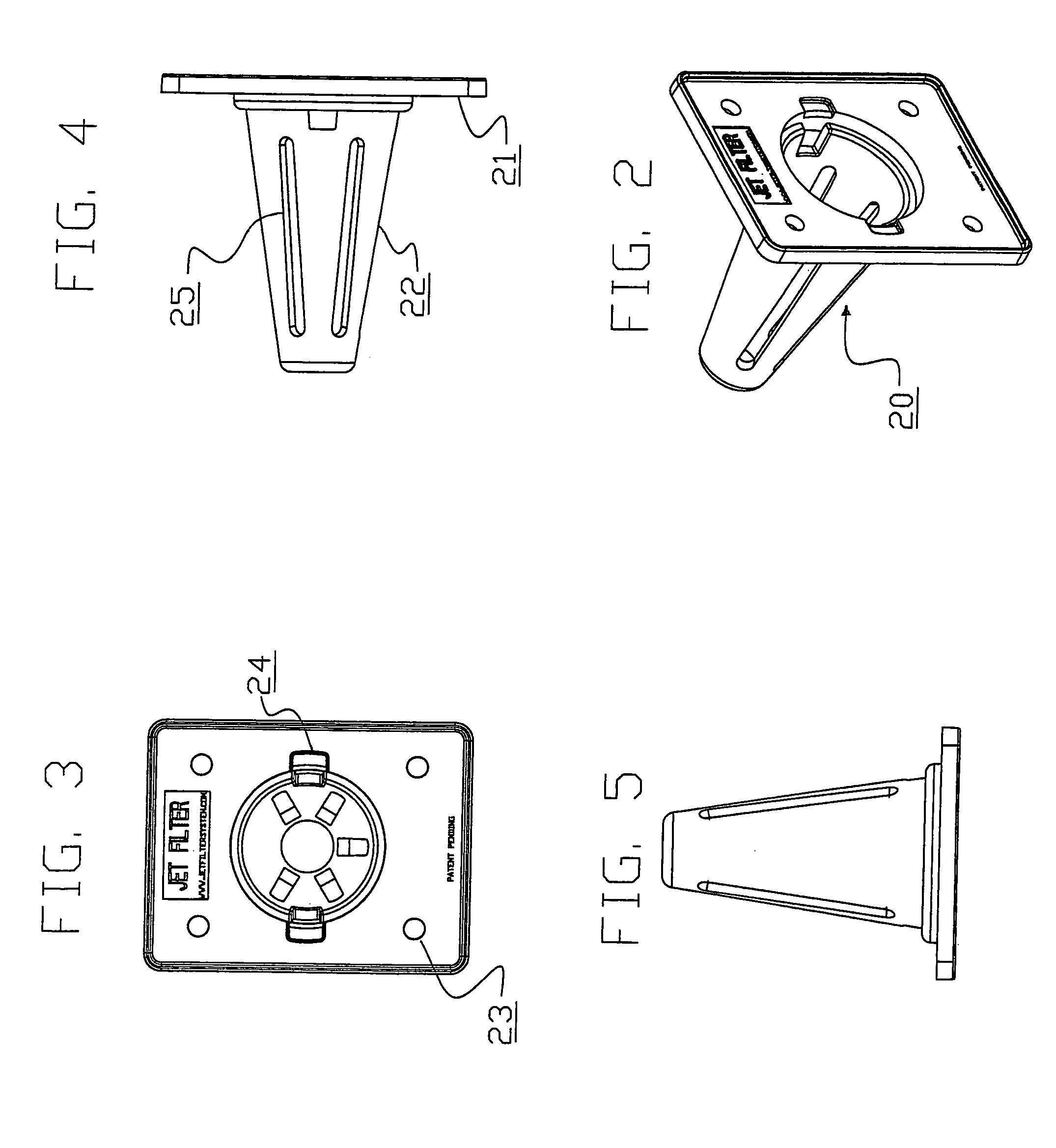

Seawall filter

ActiveUS7615148B1Easy to installGreat surface area of filtrationLoose filtering material filtersCartridge filtersWater flowGroundwater

A filter assembly for a seawall filters the flow of groundwater through a hole in the wall. The filter assembly includes: (a) a housing containing a flat flange and a perforated conical shell, the shell adapted to extend into the hole with its apex extending toward the landward side, the flange having a seaward side adapted to fit flushly against the seawall, the flange having a landward side connected to the shell, the flange having an opening that defines an open base for the shell; (b) a perforated conical cage having an open base that fits within the shell of the housing; (c) a conical filter element having an open base that fits within the cage; (d) a perforated conical sleeve having an open base that fits within the filter element; and (e) a perforated cap that is removably and flushly fastened to the opening in the flange to secure the cage, filter element, and sleeve within the shell of the housing.

Owner:JET FILTER SYST

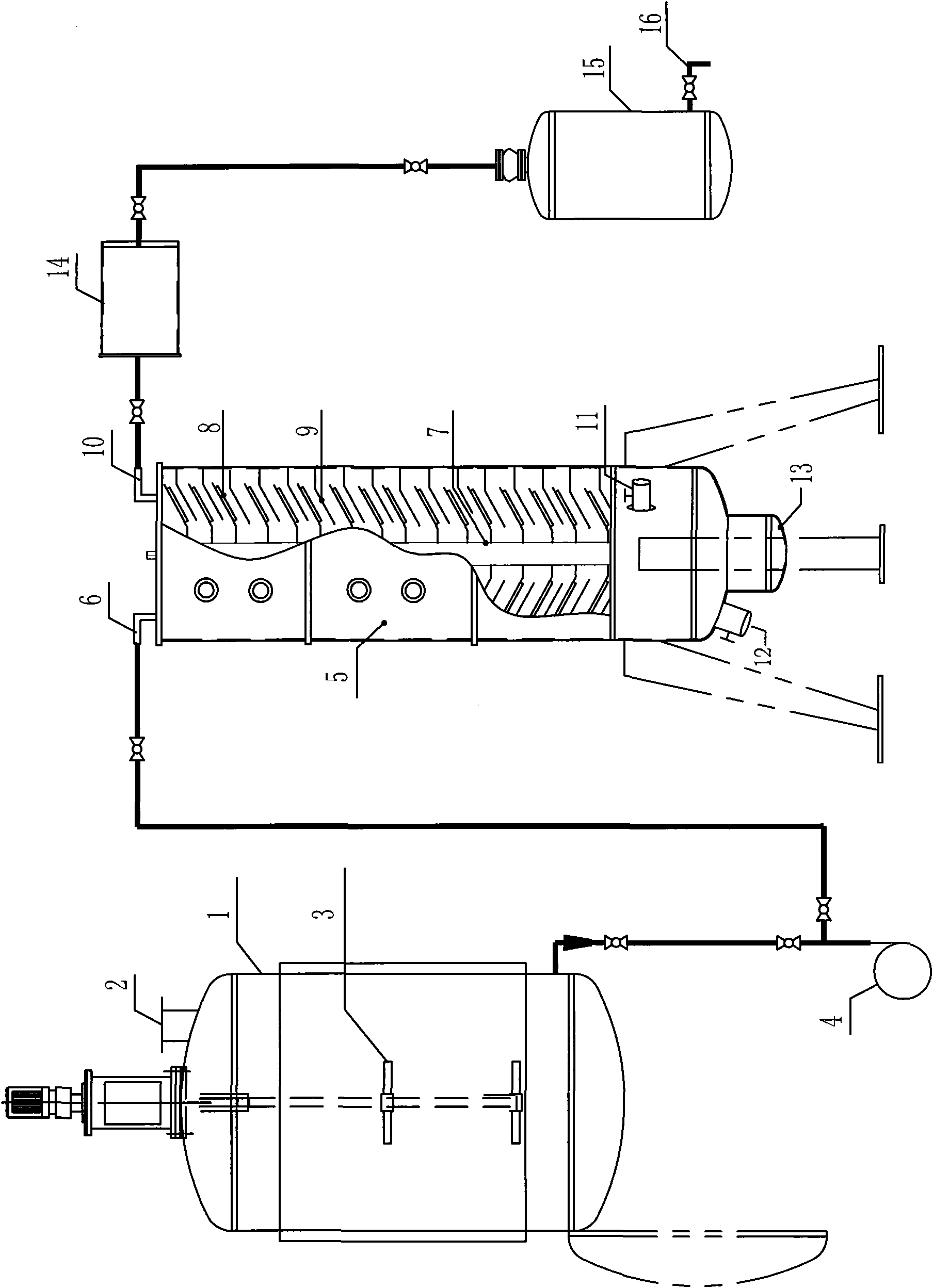

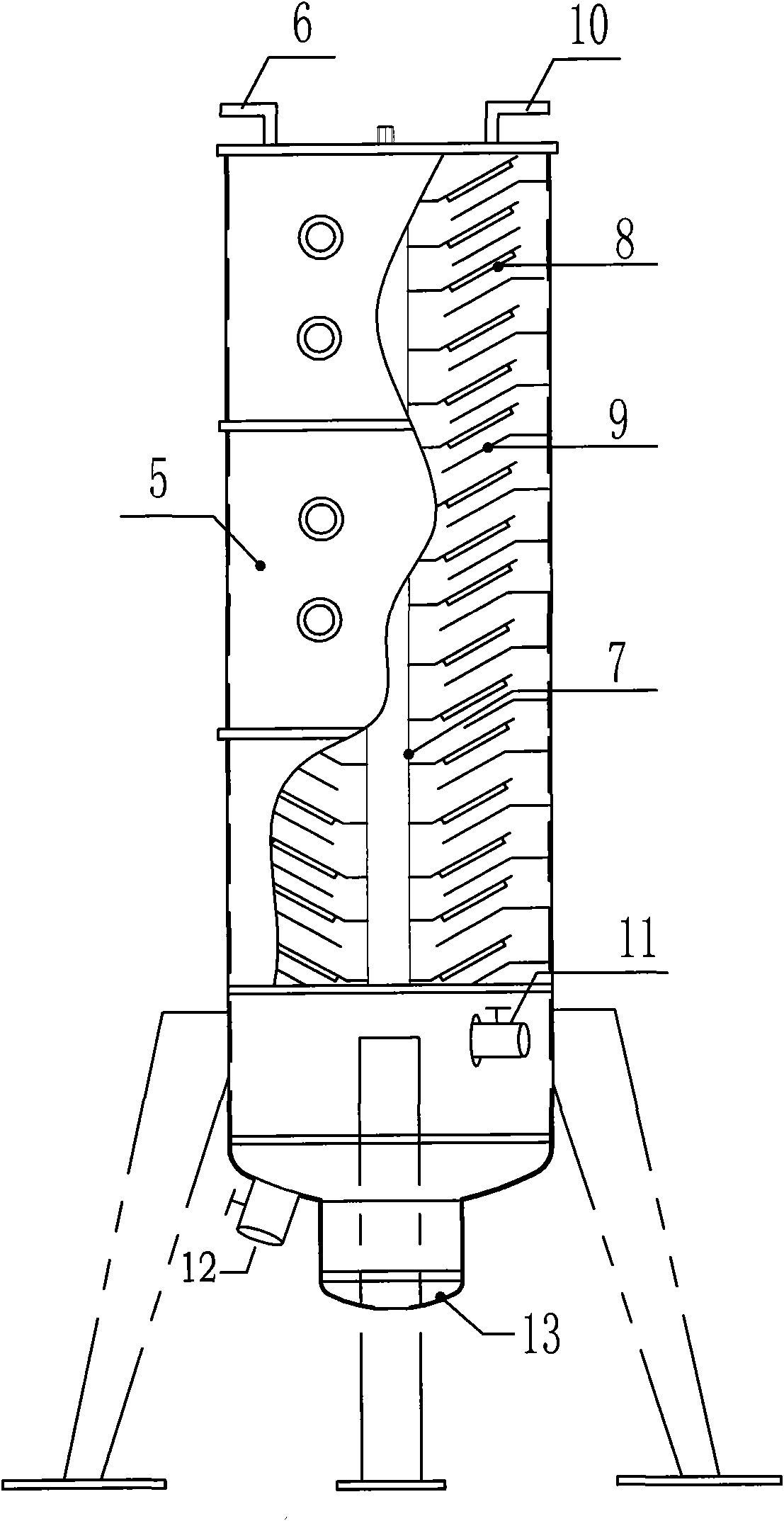

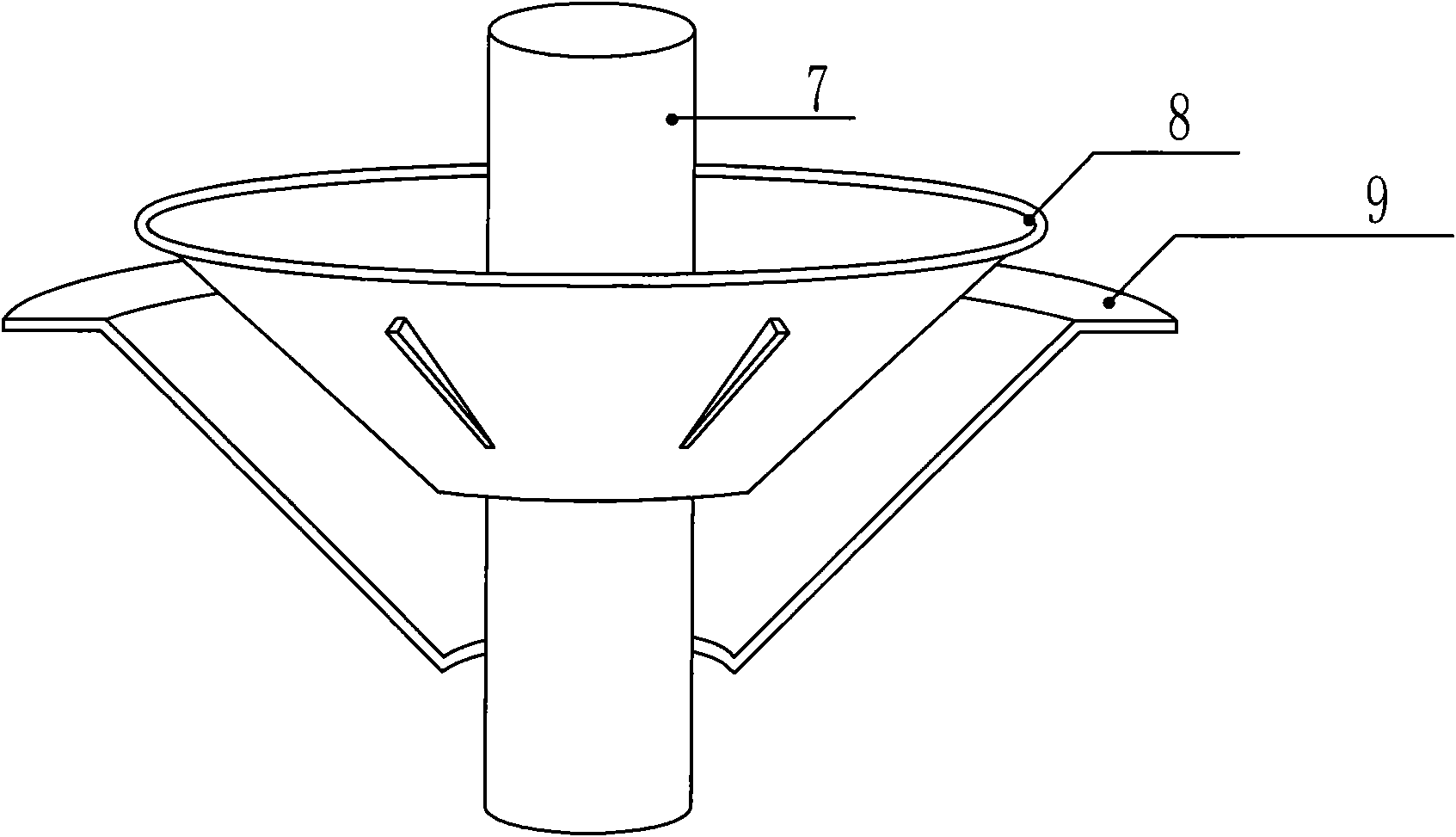

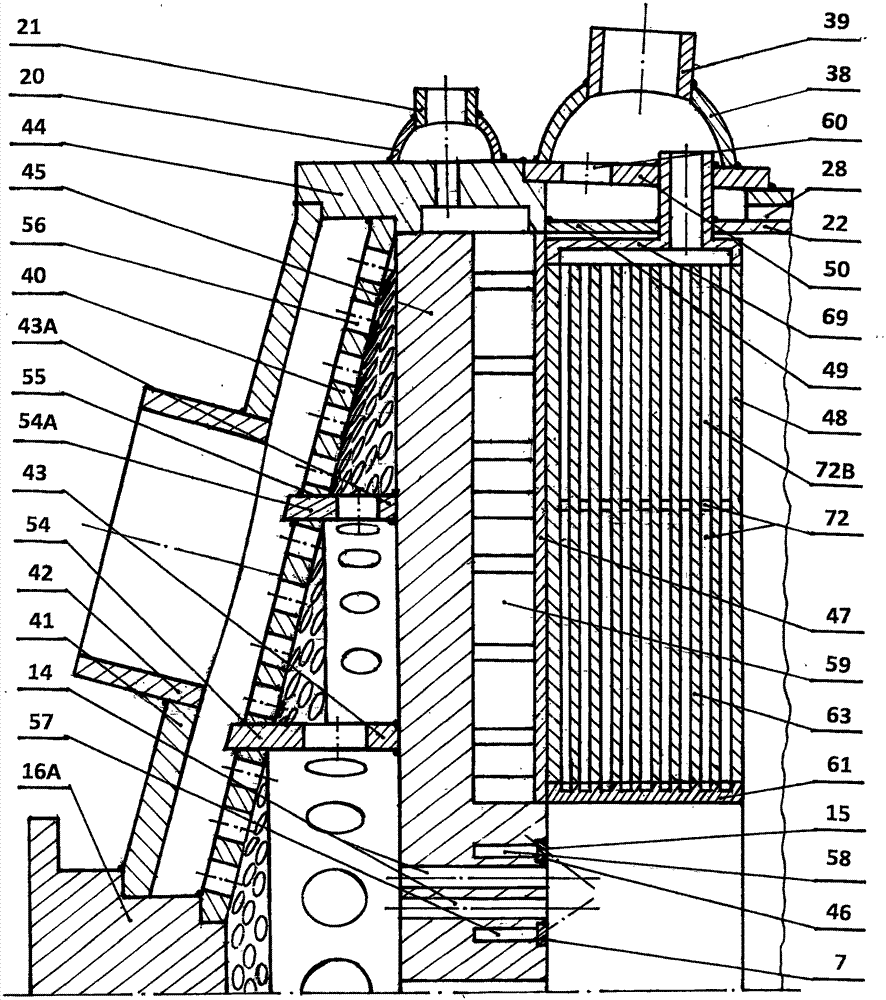

Rotary steam distillation equipment

InactiveCN101612486AAchieve continuous supplyIncrease productivitySteam distillationWater vaporSteam distillation

The invention discloses rotary steam distillation equipment and belongs to the technical field of steam distillation equipment. The rotary steam distillation equipment is a vertical cylinder body, wherein the center of the shell is provided with a vertical rotary plunger; the rotary plunger is provided with a plurality of layers of funnel-form conical shells; and funnel-form conical shells connected with the shell are inserted between the funnel-form conical shells. The number of the layers of the funnel-form conical shells is 7 to 35. The rotating speed of a motor is 0 to 10,000 r / min. The included angle between the funnel-form conical shells and the rotary plunger is 30 to 75 degrees. The plurality of funnel-form conical shells are parallel. The funnel-form conical shells connected with the rotary plunger are parallel to the funnel-form conical shells connected with the shell. The rotary steam distillation equipment has the advantages that: the continuous feed of raw materials is realized, so the production efficiency is improved; the efficiency is high; the natural flavor of the materials is retained, so high-quality of fragrance is obtained; the loss of the components of the fragrance is less; and the selection range of the fragrant materials is wide.

Owner:HUBEI CHINA TOBACCO IND

Powdered metal inlay

InactiveUS7540470B1Trend downEasy to carryOperating means/releasing devices for valvesPositive displacement pump componentsCemented carbideLeak testing

Hot-isostatic-pressure (HIP) is used to make substantially nonporous cemented carbide inlays on metal substrates. A radiused shell preform typically comprising at least one metal carbide and at least one nonvolatile cement is shaped as a rigid frusto-conical shell having a substantially uniform thickness and a predetermined radius on every edge. HIP pressure is applied via a conforming adjustable sliding element to compress the preform against a conforming substrate. Surfaces of the conforming adjustable sliding element and conforming substrate, and / or the radiused shell preform, may in certain embodiments be coated substantially uniformly with at least one nonvolatile cement. Space around a radiused shell preform is evacuated without the need to totally enclose the radiused shell preform and its substrate in a can. Certain embodiments provide for leak testing of welded seals prior to application of HIP, and other embodiments make the use of welded seals unnecessary.

Owner:NOVATECH HLDG CORP

Forging method of large scale conical shell

InactiveCN101199979AEasy to makeImprove performanceMetal-working apparatusMaterials scienceConical shell

The utility model discloses a forging method of large conical cylinder, comprising the following steps: the first step is upsetting, process the billet material from the original columnar shape into a cake-like shape; a circular hole is pinched out at the center of the cake-shape billet material; after that, put a rotating shaft through the circular hole of the billet material; the rotating shaft drives the billet material to rotate, meanwhile, external pressing force is given on the outer side face of the billet material, making the billet material into a cylinder shape; the rotating shaft drives the billet material to rotate, meanwhile, external pressing force is given on different segment of the outer side face of the billet material, making the outer side of the billet material into a step shape; then the rotating shaft drives the billet material to rotate, and meanwhile, external pressing force is given on the highest step of the step shape billet material, making the step shape billet material into a rudiment shape of a big conical cylinder; finally, trim the rudiment shape of the large conical cylinder, and a large conical cylinder is obtained. The forging method of large conical cylinder provided by the invention has the advantages that the manufacturing steps are simple, and a large conical cylinder with good performance can be made conveniently and rapidly.

Owner:SHANGHAI HEAVY MACHINERY PLANT +1

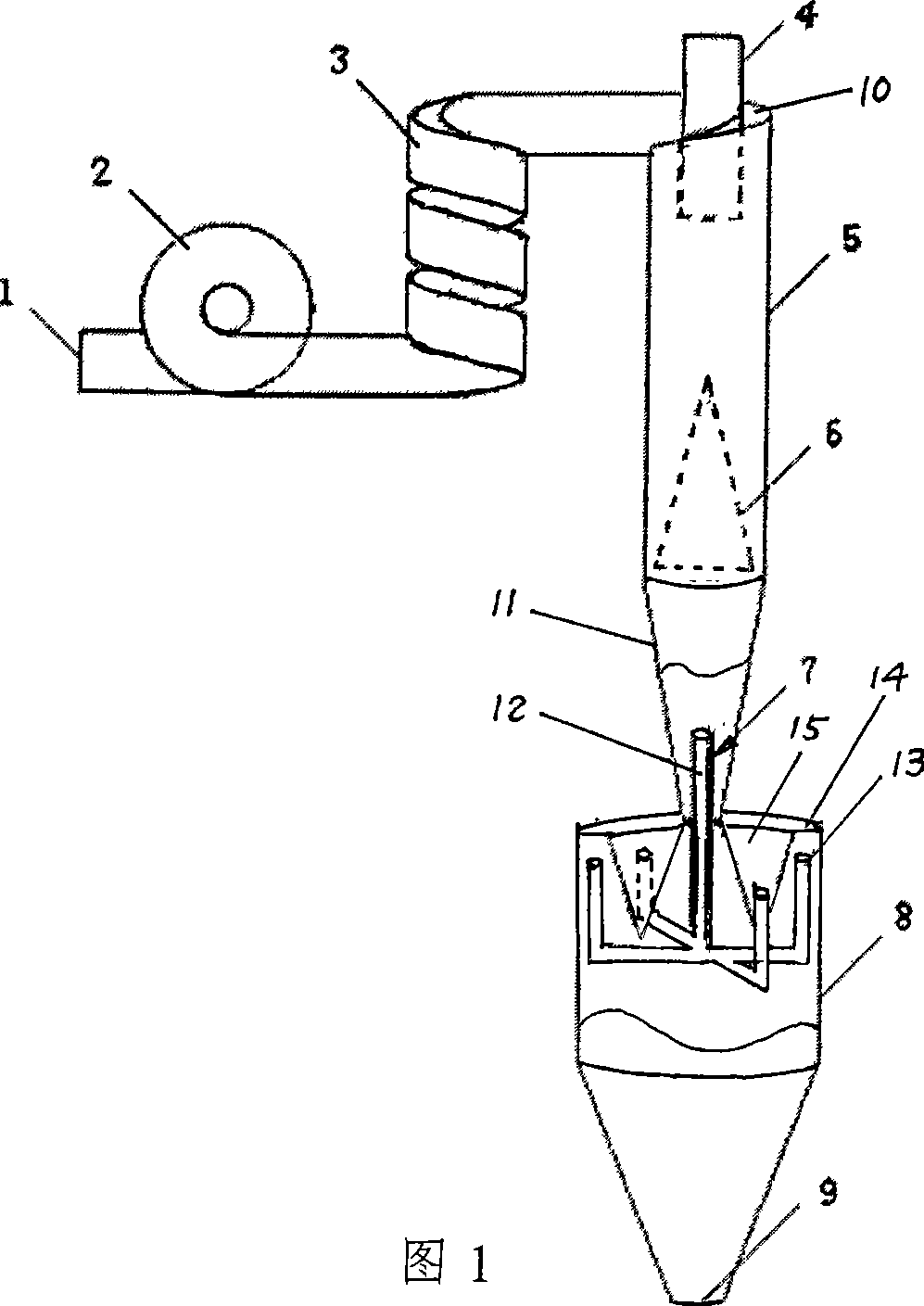

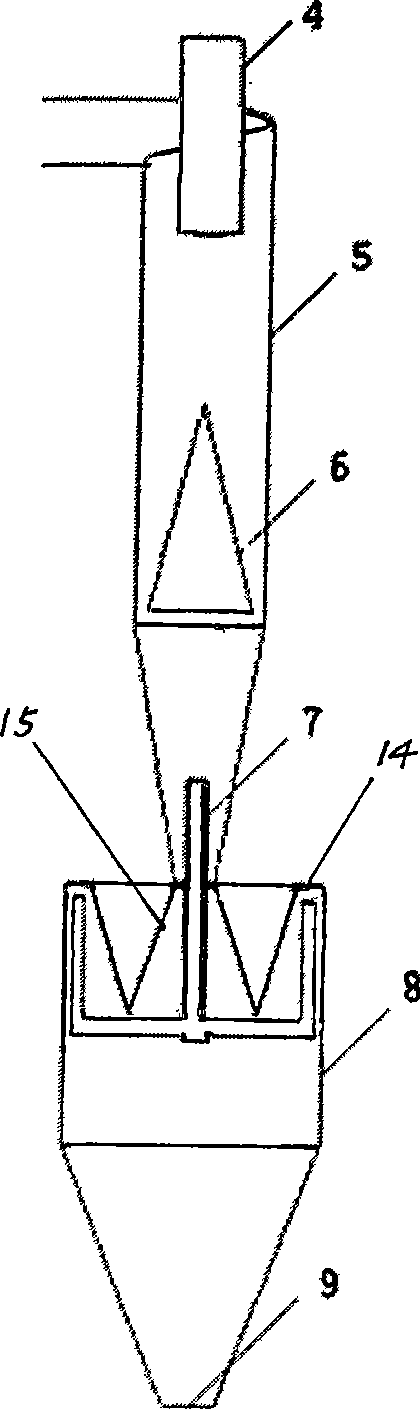

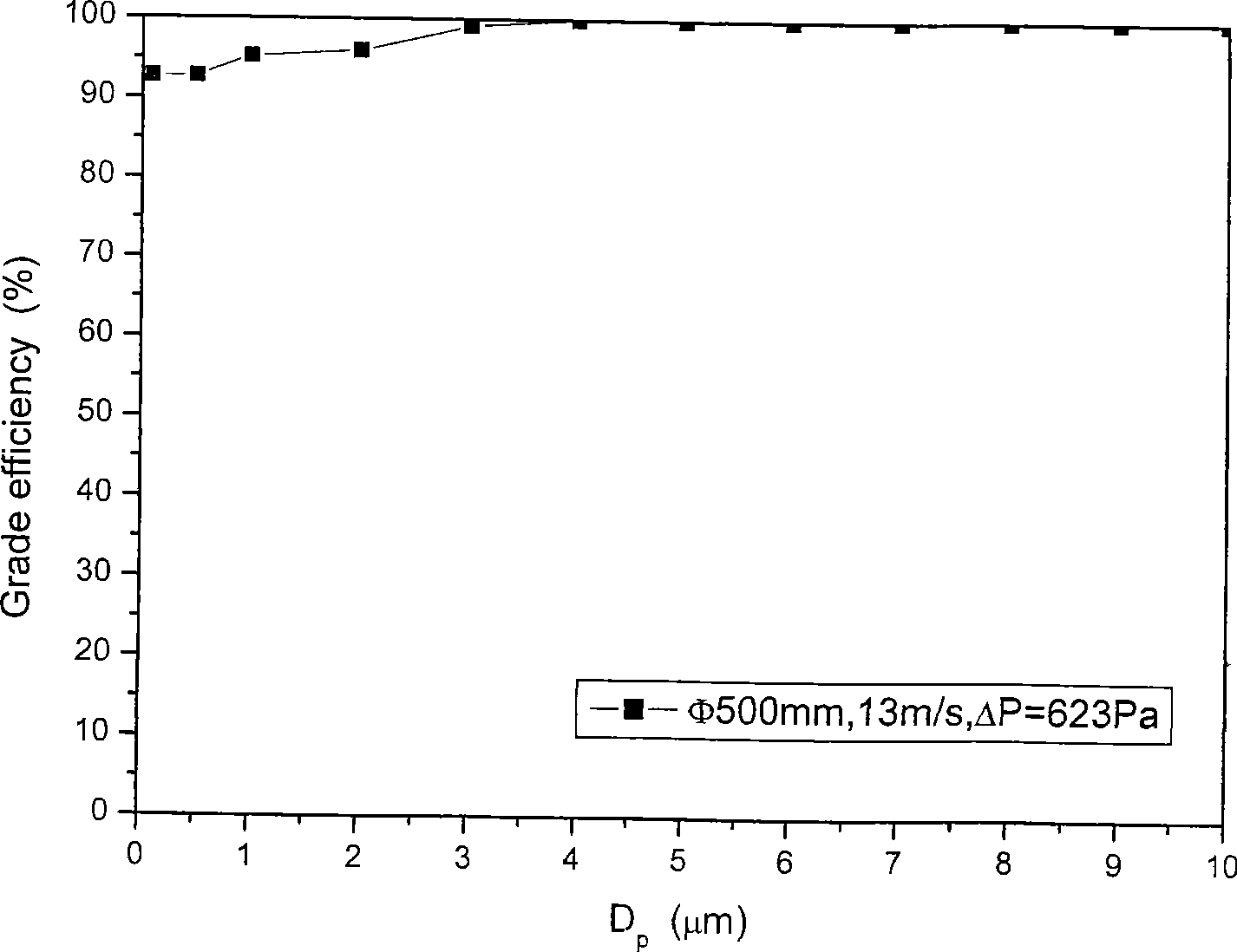

Multiple-effect cyclone separating device

InactiveCN101391239AReduce gas velocityStable flow patternReversed direction vortexCycloneEngineering

Disclosed is a multi-effect cyclone separator. A shell of a main body of the separator comprises an upper cylinder, a spiral top cover plate and a lower reverse conical cylinder. An air exhaust pipe extends into the cylinder. An ash bin is fixed at the lower end of the reverse conical shell. An air inlet is tangentially arranged at the upper end of the cylinder through a vertical Alpha-shaped first grade pre-separating spiral tube and a second grade pre-separating spiral tube sequentially connected with each other. The cross sections of the air inlet as well as the first grade pre-separating spiral tube and the second grade pre-separating spiral tube are all rectangles. The rotation angles of the first grade pre-separating spiral tube and the second grade pre-separating spiral tube are 360 degrees and 1080 degrees respectively. A throttling steady flow wimble cone is fixed at the lower part of the cylinder. A gas suction pipe is disposed at the upper part of the ash bin, and a V-shaped ring groove is arranged in the middle of a top cover plate of the ash bin. The cyclone separator has advantages of small pressure drop, high separation efficiency to submicron particles and small scaling effect. The dust concentration during air exhaust meets the environmental protection requirements. The cyclone separator effectively eliminates the secondary flow in a flow field, and has advantages of stable flow pattern, low gas velocity, low equipment abrasion and long service life. The cyclone separator can replace cloth bags and electrostatic dust collectors to undertake the tail end dust removal of dust-laden gas.

Owner:QINGDAO UNIV OF SCI & TECH

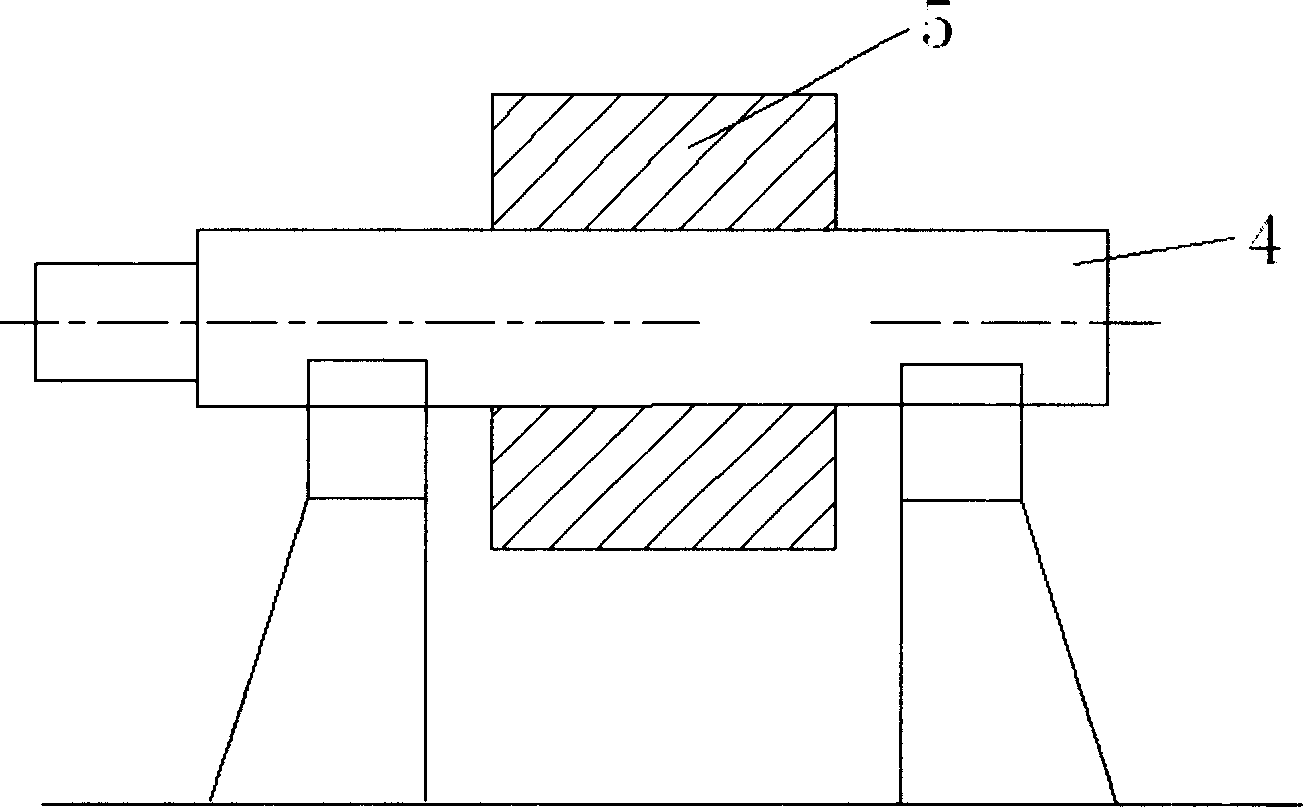

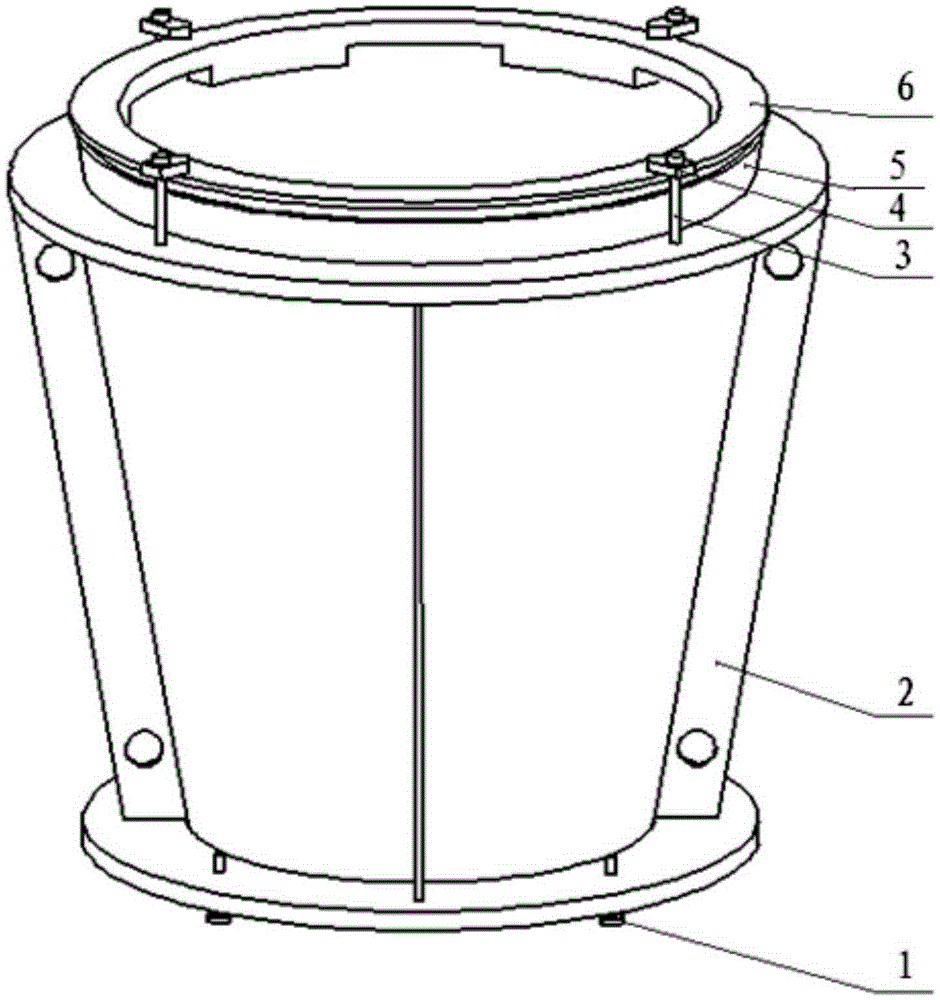

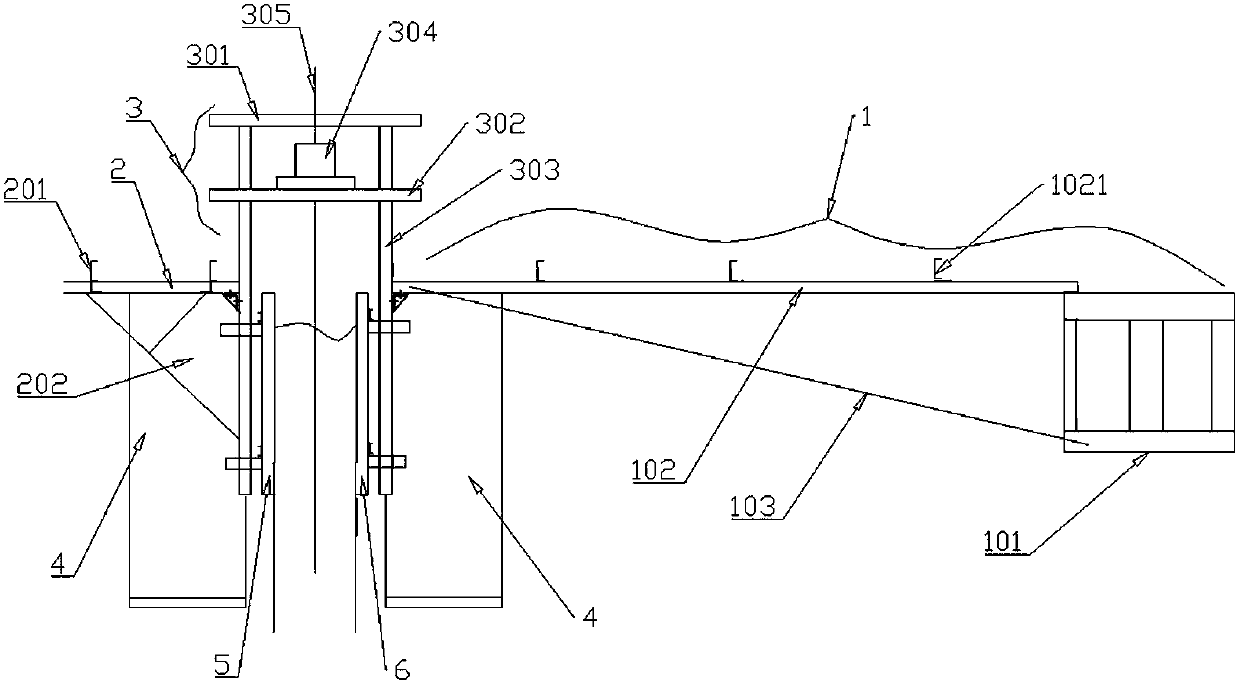

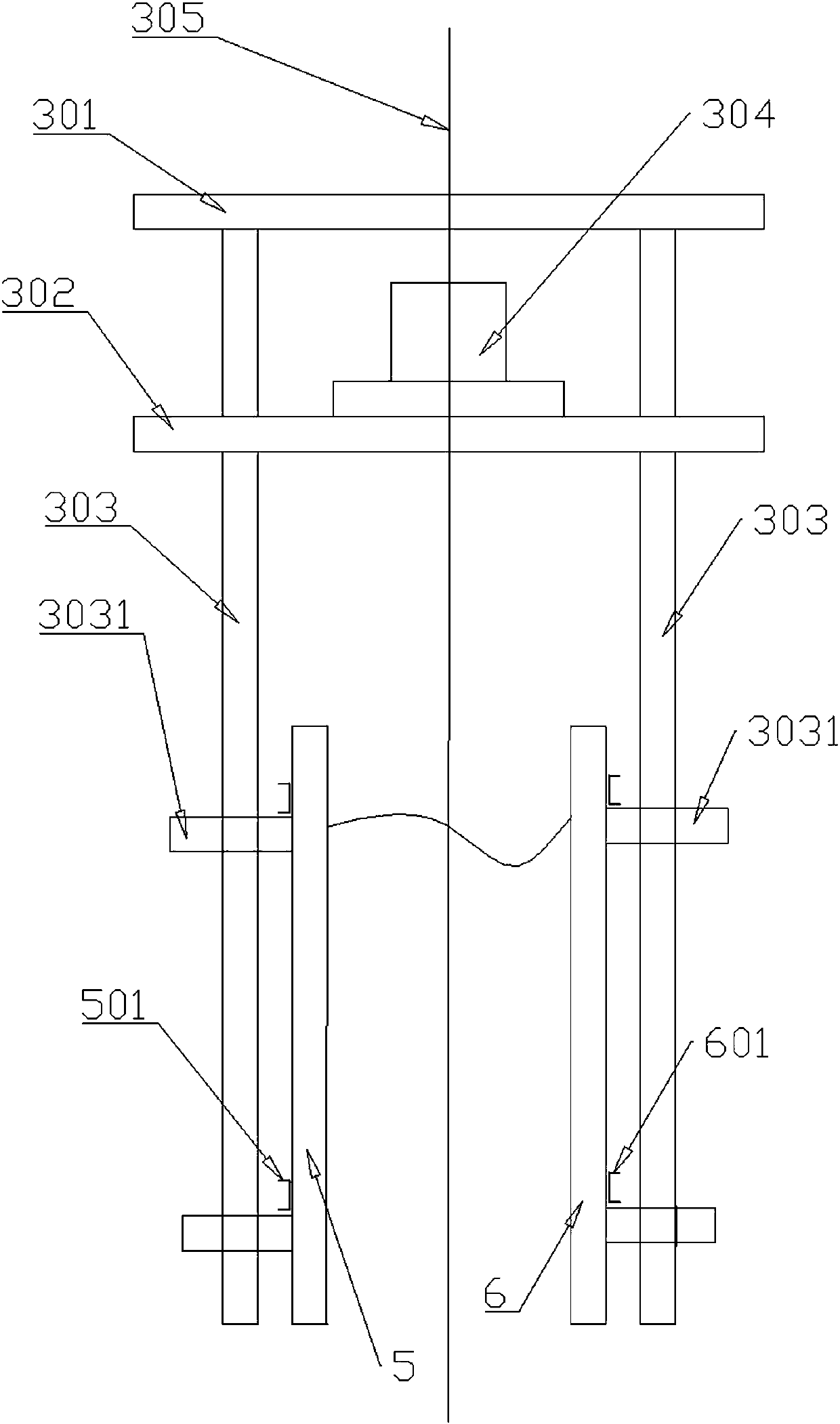

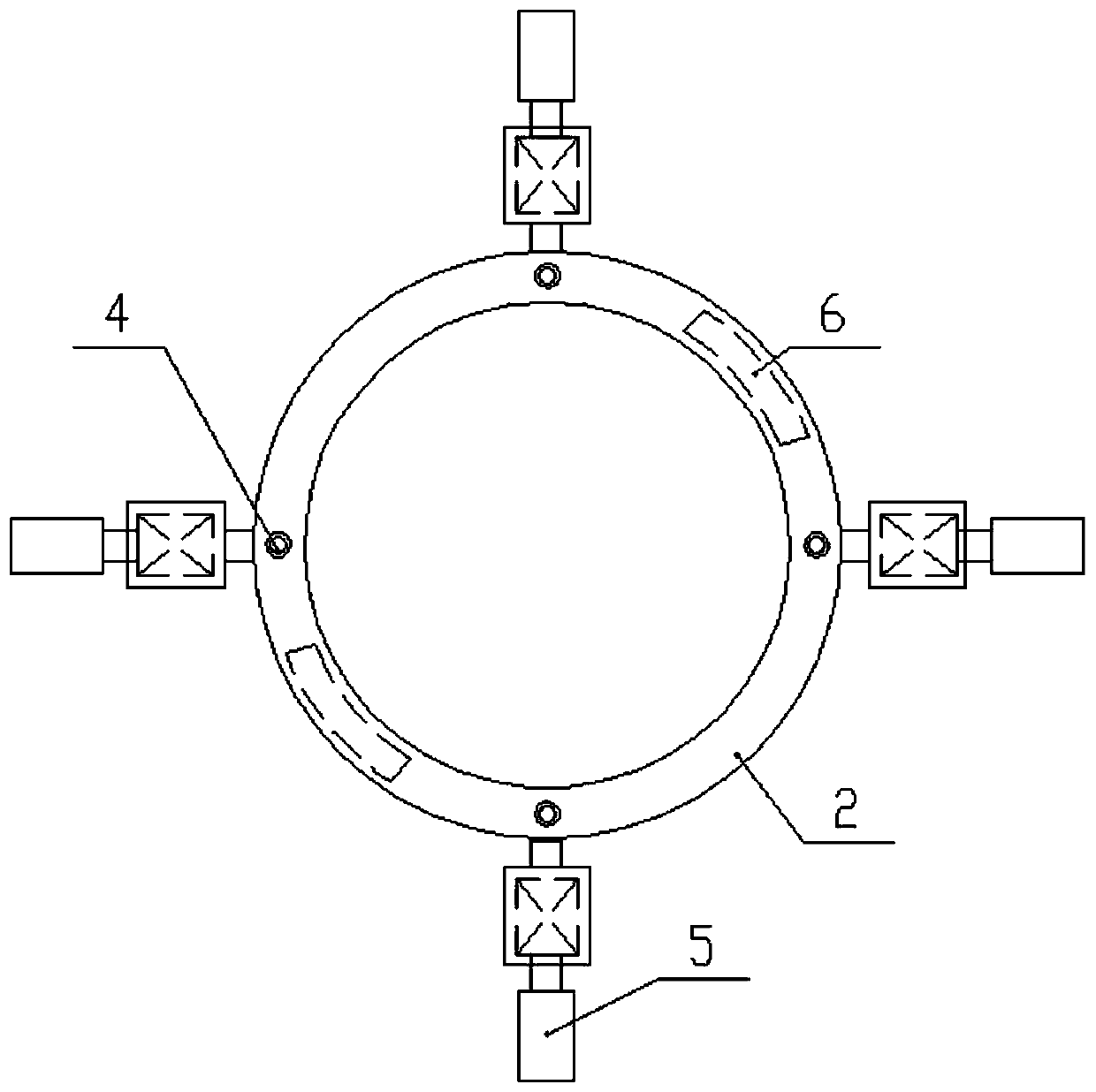

Numerical control machining clamping and positioning device for large thin-wall conical shell part

ActiveCN105345515ANo deformationAvoid giving up the knifePositioning apparatusMetal-working holdersNumerical controlReference alignment

The invention provides a numerical control machining clamping and positioning device for a large thin-wall conical shell part and belongs to the technical field of numerical control machining. The numerical control machining clamping and positioning device aims at solving the problems that when machining is conducted without an external clamping and fixing tool, the final size is difficult to guarantee, the part scrapping phenomenon is likely to happen, and the amount of feed is usually reduced in order to avoid the situation, so that machining efficiency is low, time is wasted, and the period is long. A conical barrel is supported on a workbench through supporting bolts of the clamping and positioning device, and the large-diameter end of the conical barrel is placed upwards; the machined workpiece is placed in the conical barrel, and the machined workpiece and the conical barrel are coaxially arranged; and a large-end conical ring liner plate is pressed on a large-end conical stop opening of the machined workpiece, and the machined workpiece is axially fixed through pressing plate bolts and pressing plates. It is guaranteed that the machined thin-wall conical shell part is not deformed in the machining process; angular reference alignment is convenient, and axial positioning is accurate; the structure is simple, and clamping and fixing are reliable; and the manufacturing period is short, and cost is low.

Owner:航天科工哈尔滨风华有限公司

Construction method of major diameter reinforced concrete silo and device for conical shell construction

ActiveCN108019076AReduce support loadGuaranteed accuracyClimate change adaptationForms/shuttering/falseworksReinforced concreteEconomic benefits

The invention relates to a construction method of major diameter reinforced concrete silo and a device for conical shell construction. The construction method of major diameter reinforced concrete silo comprises that the rigid platform used in silo wall construction is used in the supporting platform of the cone shell construction on the top of silo, steps of removing the rigid platform and reconstructing the supporting platform are avoided, the construction period is shorten, the cost is saved, and the good economic benefit is achieved; unloading wireropes are connected between the rigid platform and conical shell moulds, and the supporting load of the rigid platform can be reduced to a certain extent; auxiliary wireropes can support carriers for center supporting frames to play a role ofstabilizing the center supporting frames; in the construction of the silo wall, a slip form is subjected to taper adjustment by installing an enclosure, when the taper of an inner formwork is 0.3%, the inner formwork is tilted to the outside of the silo, when the taper of an external framework is 0.2%, the external framework is tilted towards the interior of the silo, the inner framework and theexternal framework are corrected, and the accuracy of the template is ensured, at the same time, sliding and demoulding of the slip from are convenient.

Owner:河南宏程工程建设有限责任公司

Novel series of hydrogen peroxide thrust chambers used for rockets and airships

InactiveCN107152353AEasy to useHigh working reliabilityRocket engine plantsSemi openAttitude control

The invention relates to novel series of hydrogen peroxide thrust chambers used for rockets and airships. The novel series of hydrogen peroxide thrust chambers comprise micro attitude control types, small-sized orbit control types, middle-sized acoustic cavity types, large-sized partition types and ultra-large types; industrial 79.1%-84.9% hydrogen peroxide is used as an oxidizing agent and a regenerative coolant; a non-toxic homogeneous miscible fuel (NHMF), kerosene or liquid hydrogen is taken as a fuel; non-toxic storable components account for 95%-100% of a propellant, so that the use is convenient; the decomposition rate of a catalyst bed is controlled within 75%-95%, the development and service life prolonging of the catalyst bed are facilitated; and novel structures such as a high strength head, a regenerative cooling nineteen-zone partition, a semi-opening acoustic cavity, a gas-liquid impinging injector, a multihole conical shell are adopted. According to the novel series of hydrogen peroxide thrust chambers used for rockets and airships, the combustion temperature, decomposition temperature and regenerative cooling temperature rise are low, so that the working conditions are improved at lot; besides, the density-specific impulse is higher, the propulsive performance is better, and therefore the thrust chambers are applicable to boosters, first-stage and second-stage engines as well as first-stage core engines, which are capable of being used for over 25 times, of novel manned Moon and Mars landing rockets and airships.

Owner:葛明龙 +1

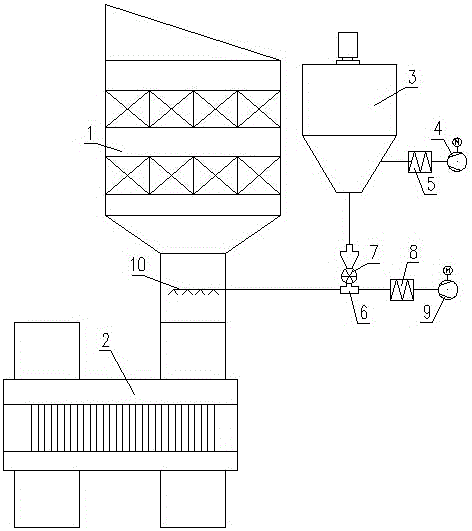

Device and method for removing sulfur trioxide in boiler flue gas

PendingCN106621785AReduce consumptionReduce resistanceGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a device for removing the sulfur trioxide in boiler flue gas. The device comprises an absorbent storage bunker; a conical shell is arranged at the lower part of the absorbent storage bunker; a fluidization fan is connected with an inner cavity of the conical shell by a fluidized air heater; the bottom of the conical shell is connected with a feeding hole of a feeder; an air inlet pipe of the feeder is connected with a conveying fan by a delivery air heater, and an air outlet pipe of the feeder is connected with a spray master pipe; the spray master pipe is connected with two or more spray branch pipes, and each spray branch pipe is connected with one or more nozzles; the nozzles are arranged in a flue in front of a flue gas inlet pipe of a boiler air pre-heater. The invention also discloses a method for removing the sulfur trioxide in the boiler flue gas. The device and the method not only solve the problems of corrosion and blockage of the air pre-heater, and the like, but can also reduce the consumption of an absorbent, improve the removal efficiency and reduce the flue resistance increment.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Pipeline dredging and guiding device for water conservancy construction

The invention discloses a pipeline dredging and guiding device for water conservancy construction. The pipeline dredging and guiding device comprises a rotating head, an outer cylinder, an inner cylinder, a core assembly and a rear end cover, wherein the rotating head comprises a conical shell-shaped main body, cutter teeth are arranged on the inner side wall of the main body, blades are arrangedon the outer side wall of the main body, and the blades are gradually shortened from the large end to the small end of the main body; an outlet of a water outlet pipeline is arranged by facing a cutting face of the rotating head; jet holes for ejecting water flow are formed nearby the bottoms of water injection cavities of the inner cylinder, and the water flow ejected from the jet holes just impacts the blades to drive the rotating head to perform rotary cutting; a mandrel is connected with a bullet structure through a connecting rod fixed on the inner wall of a core tube to be fixed in the core tube in a suspended manner, the rear end of a rotating shaft is mounted on the rear end cover, and a hollow cavity of the rear end cover is communicated with the water injection cavities of the inner cylinder; a discharge port penetrating through the inner cylinder and the outer cylinder is formed in the lower side wall, close to the rear end cover, of the core tube. The device is high in dredging capacity and quite high in dredging efficiency.

Owner:李建岗 +3

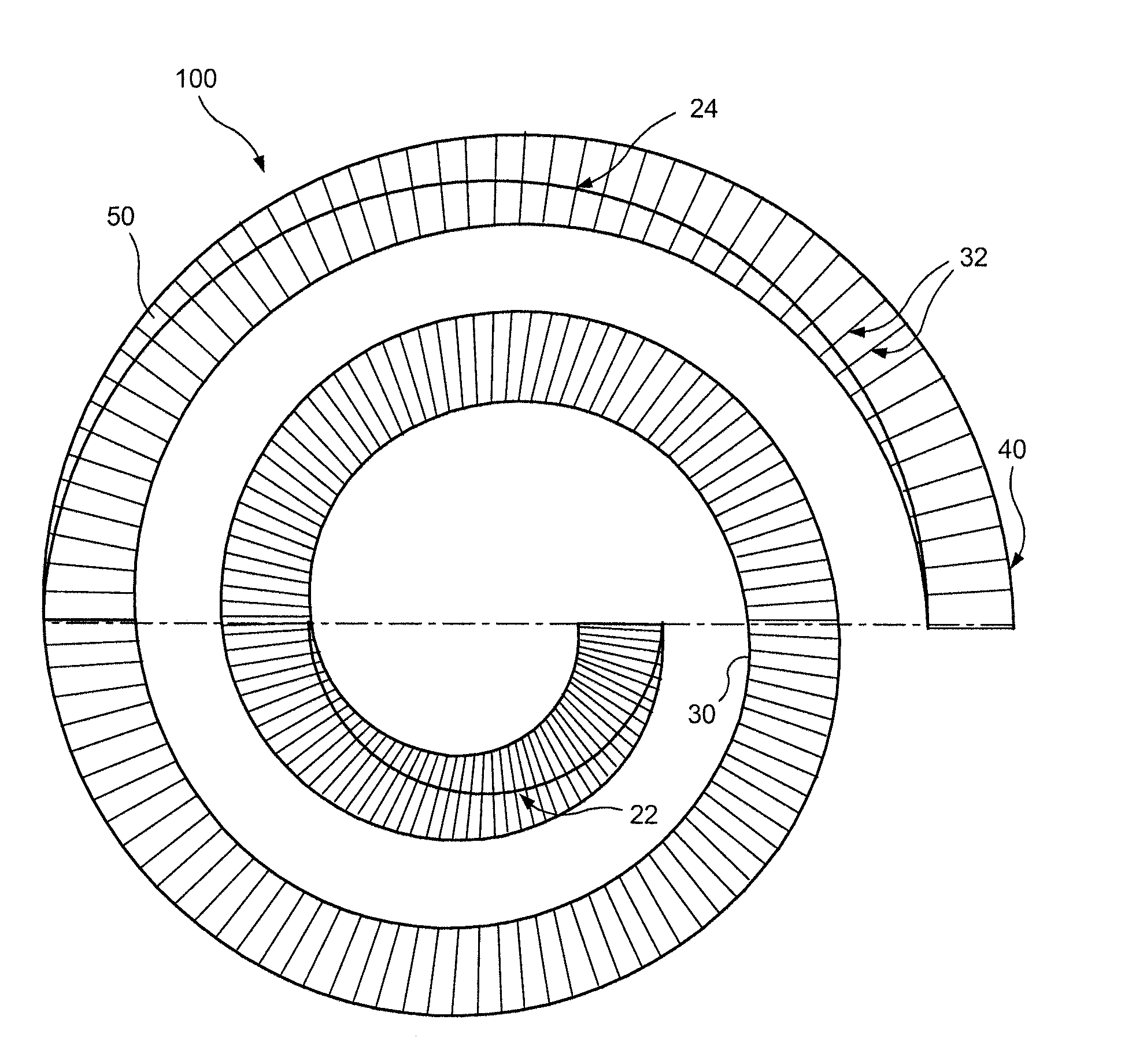

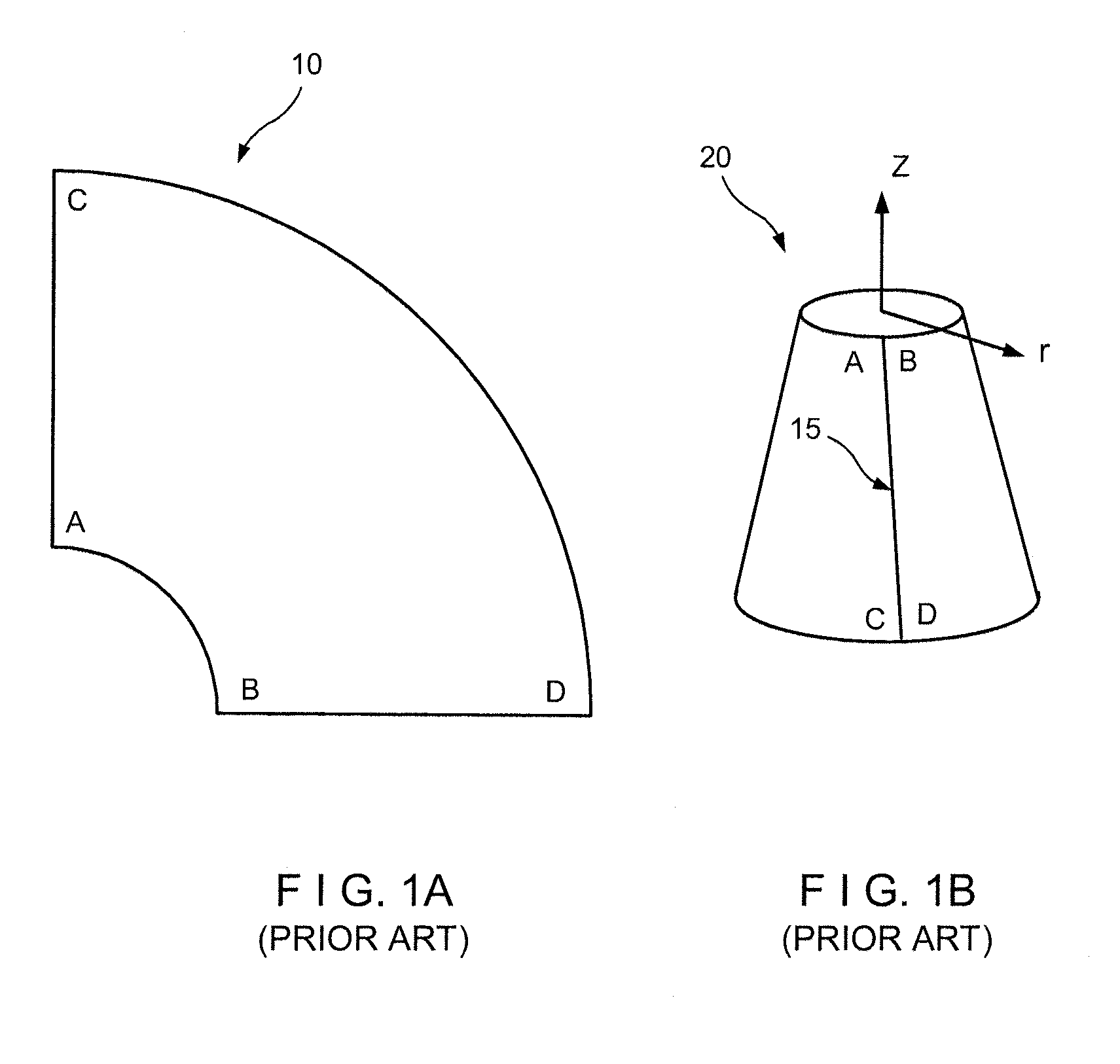

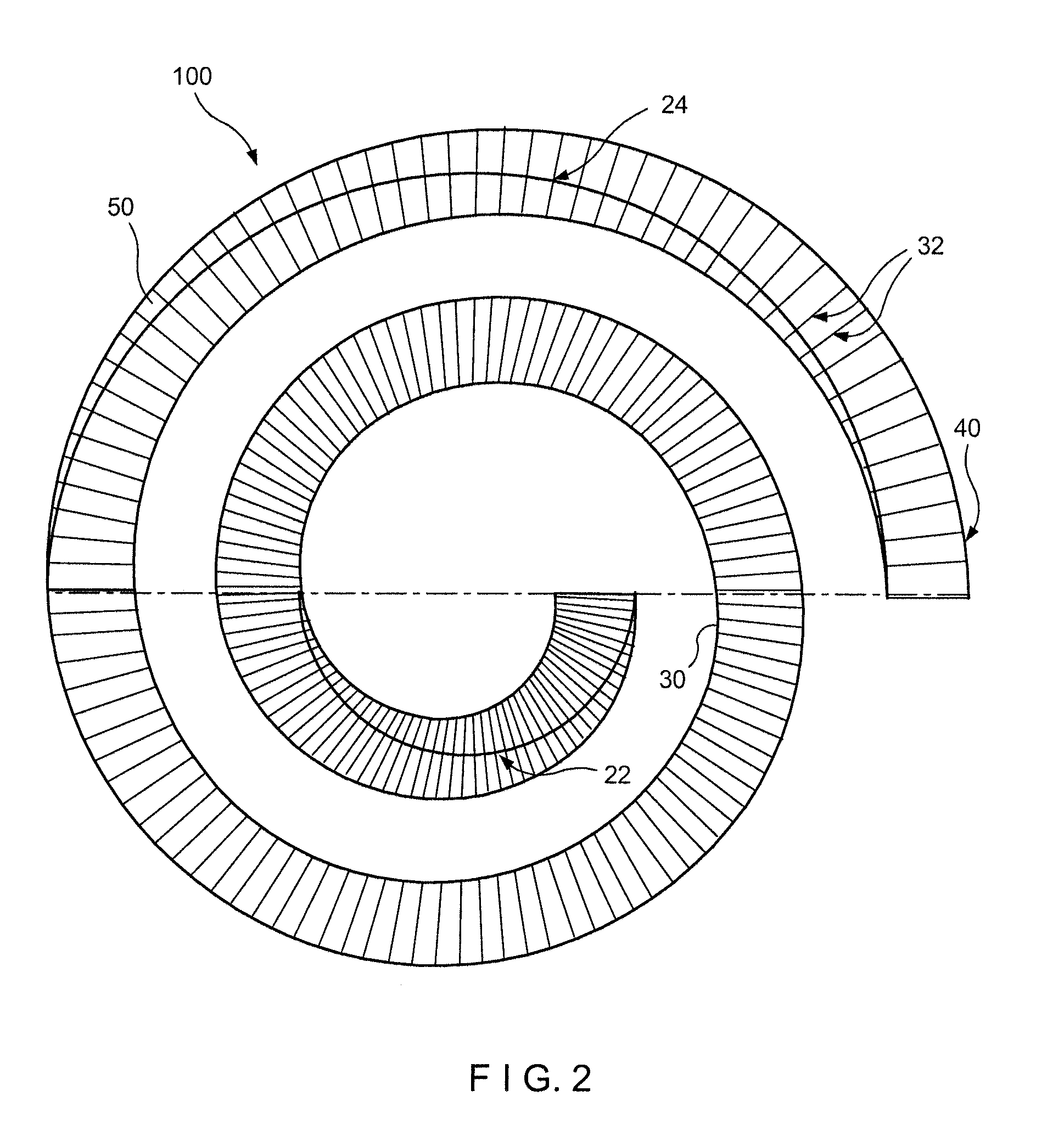

Fiber preform, fiber reinforced composite, and method of making thereof

ActiveUS20110097526A1Least amount of wastageMinimize the numberLayered productsLoomsEngineeringFiber-reinforced composite

A woven fiber preform, a fiber reinforced composite incorporating the preform, and methods of making thereof are disclosed. The woven preform includes a plurality of warp and weft yarns or fibers interwoven to form a continuous spiral fabric. The spiral fabric may take the shape of an Archimedes spiral. The weft yarns in the preform may have a uniform or variable pick spacing, or a uniform or variable angular separation. The spiral fabric of the Archimedes spiral may be assembled or wrapped to form a conical shell structure, which could be a portion of a spinner or an exit cone. The spiral fabric may be woven on a loom equipped with a differential take-up mechanism.

Owner:ALBANY ENGINEERED COMPOSITES

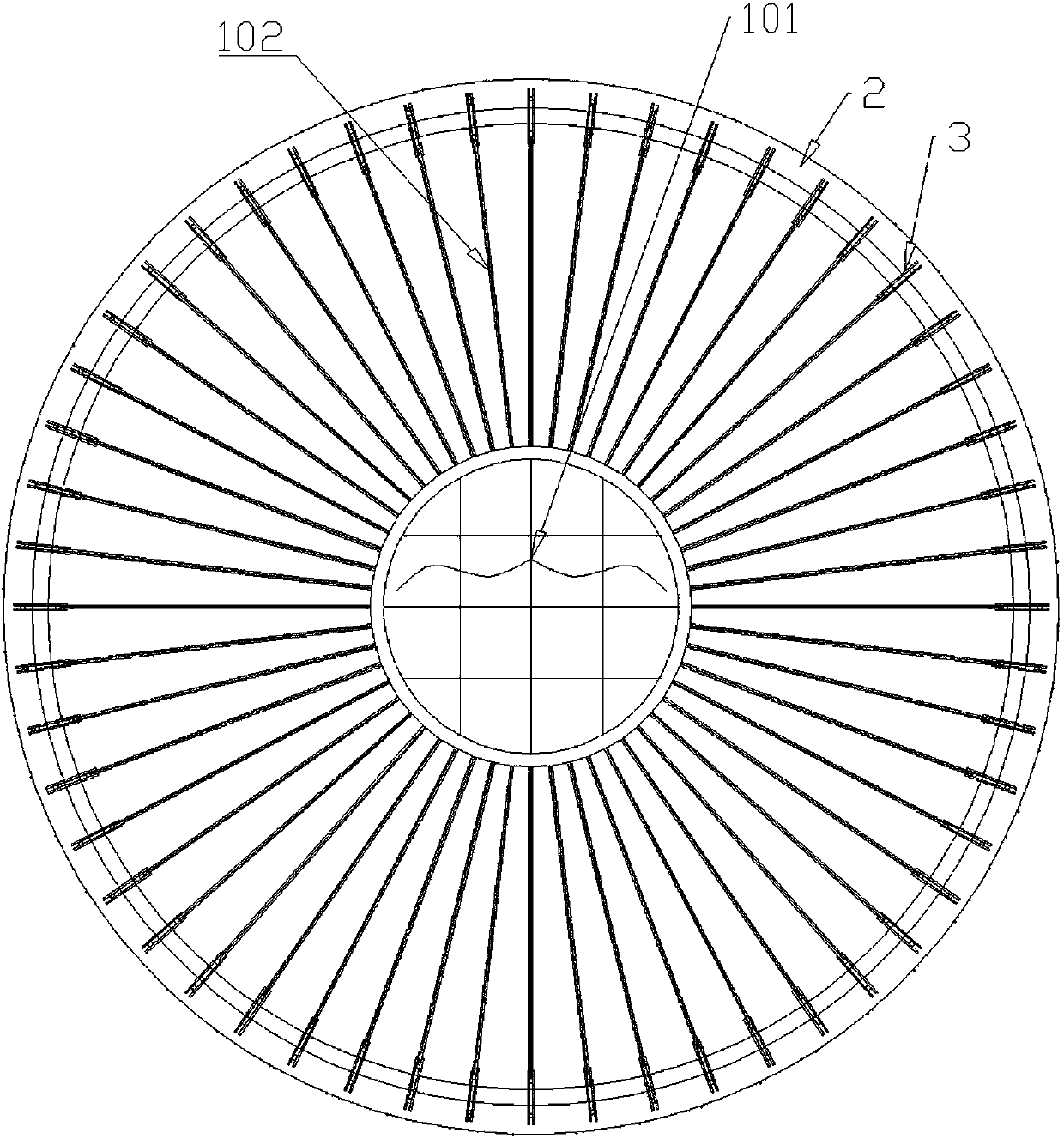

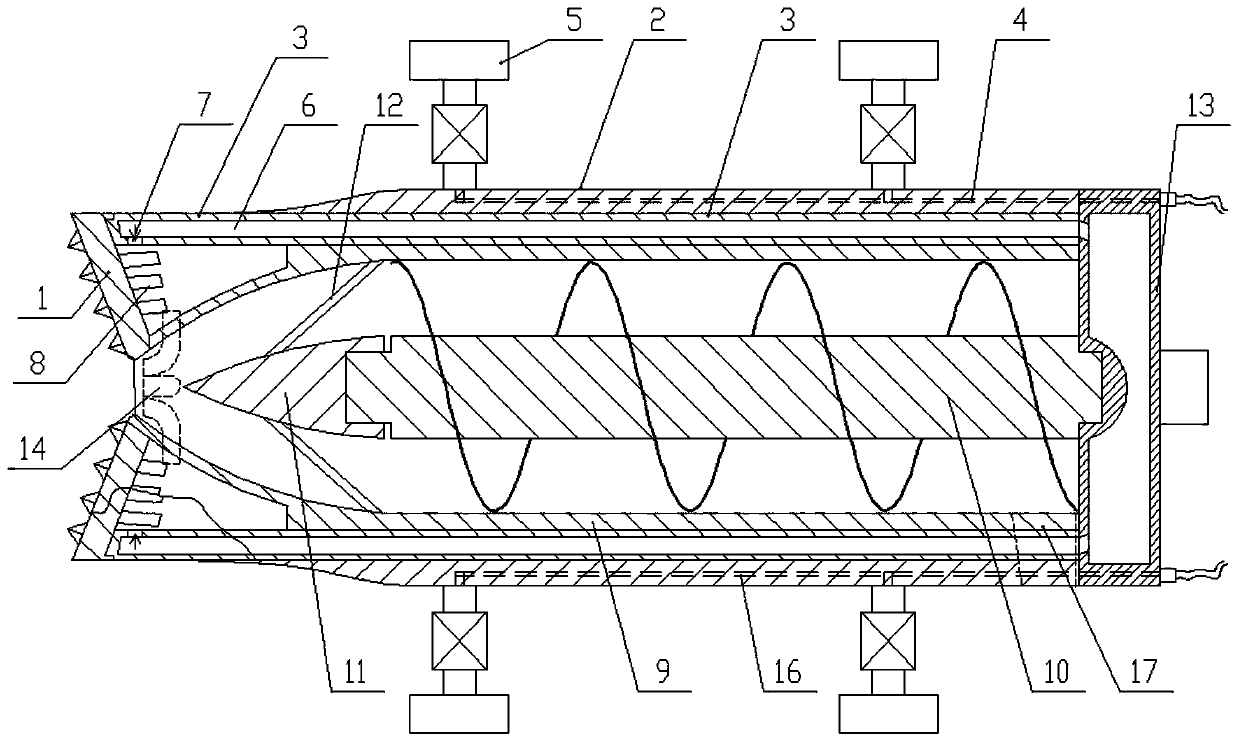

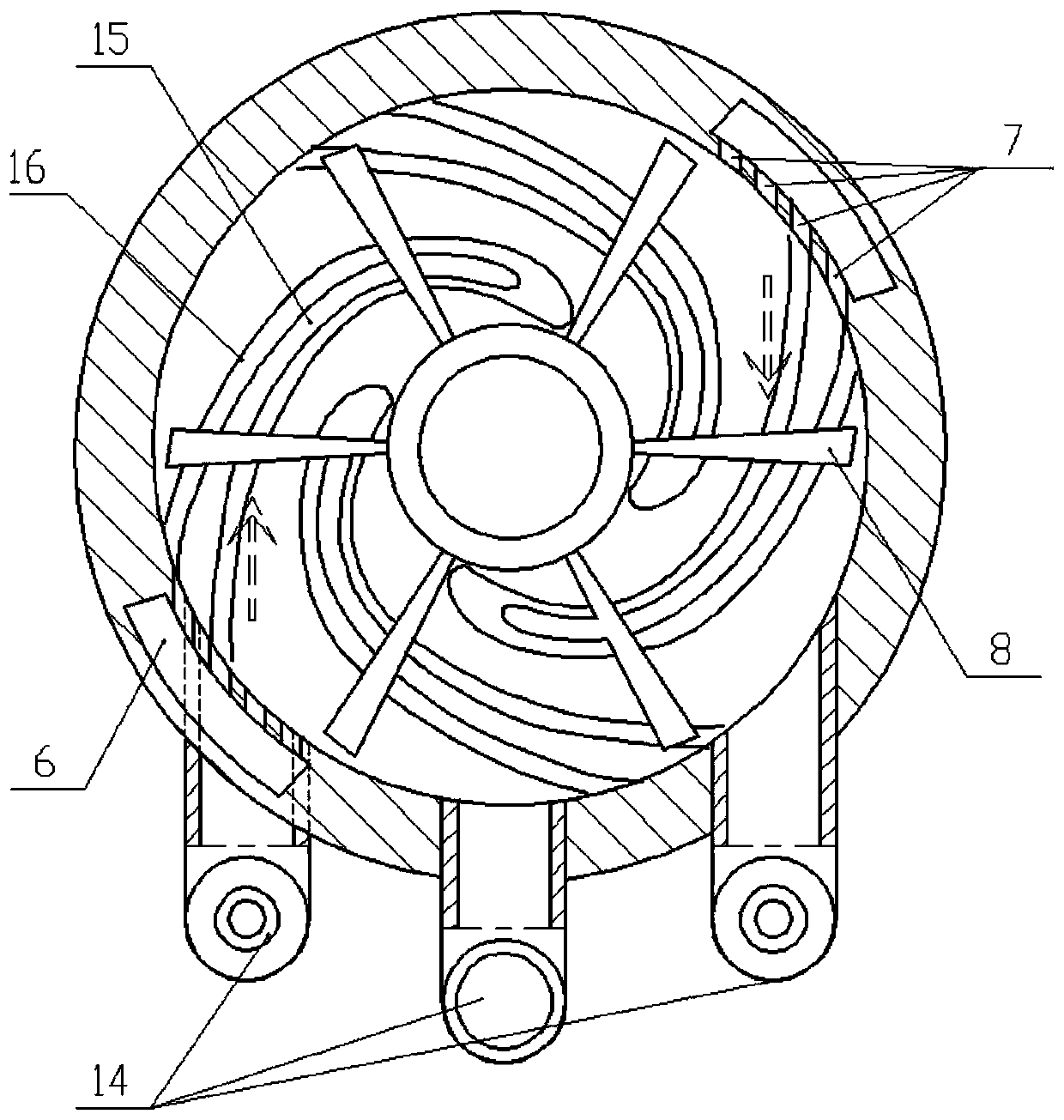

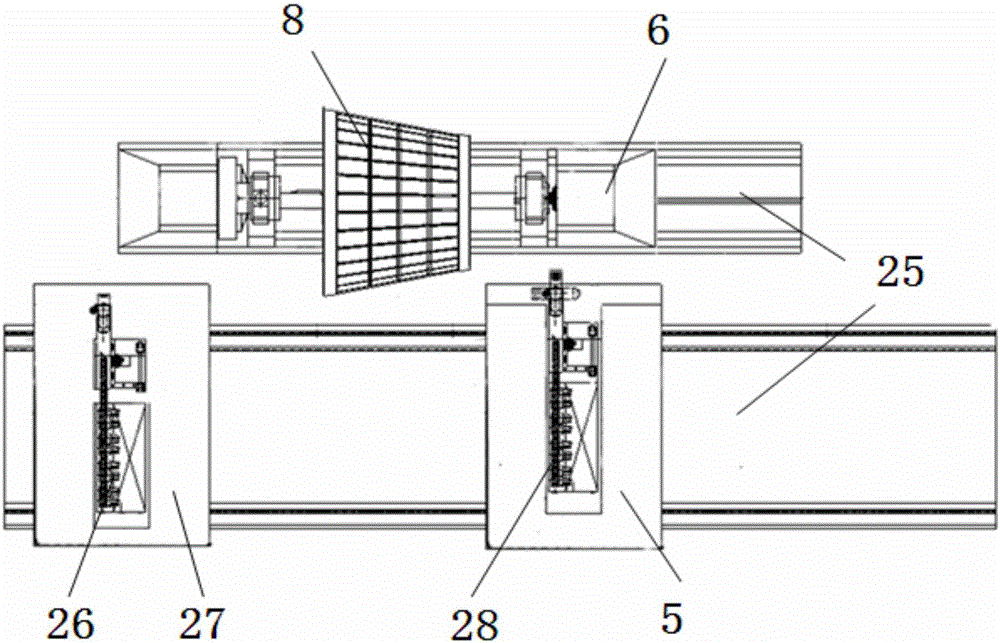

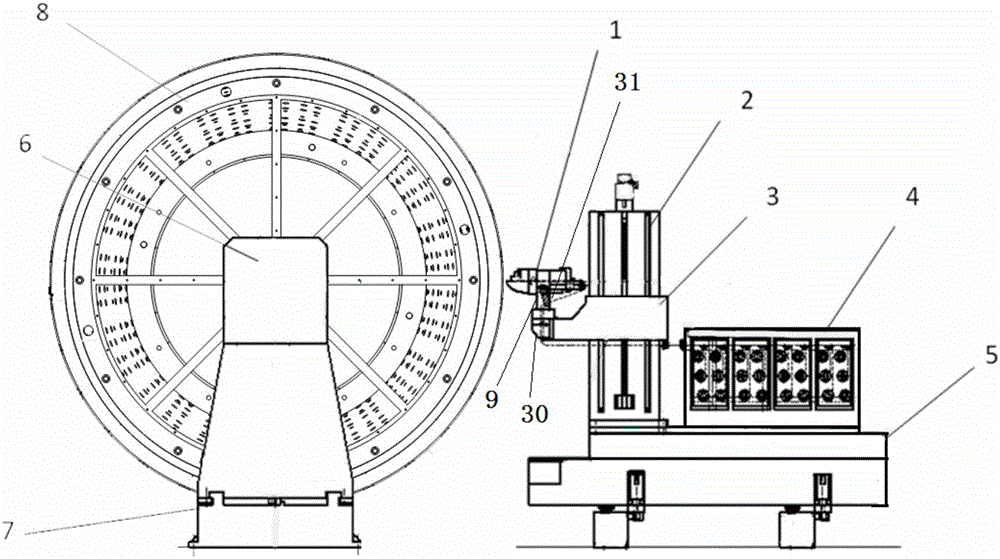

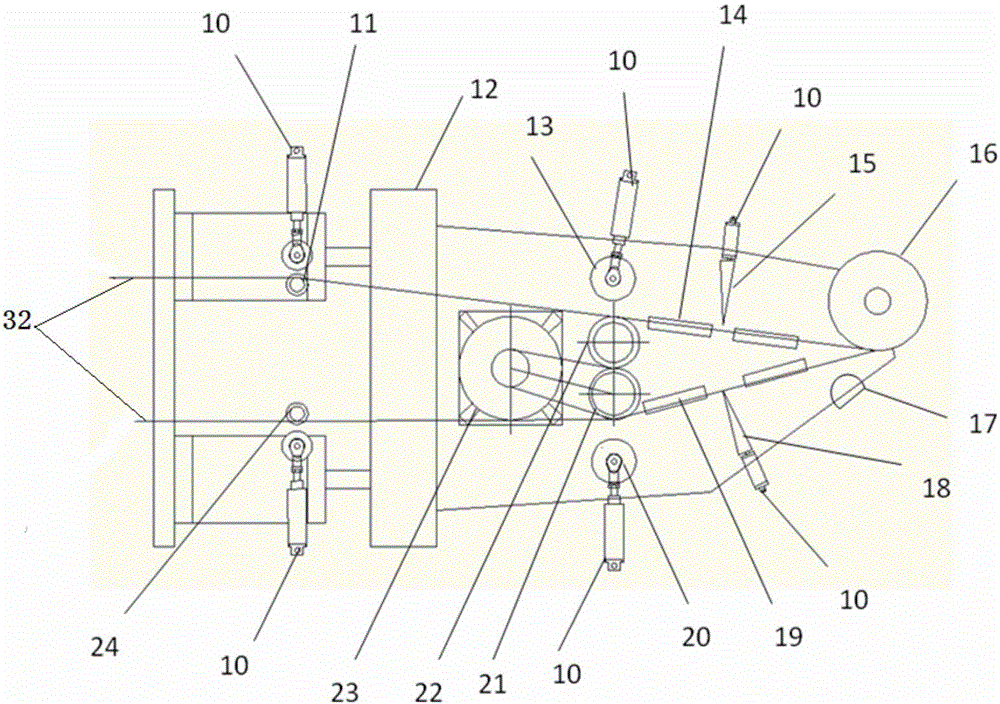

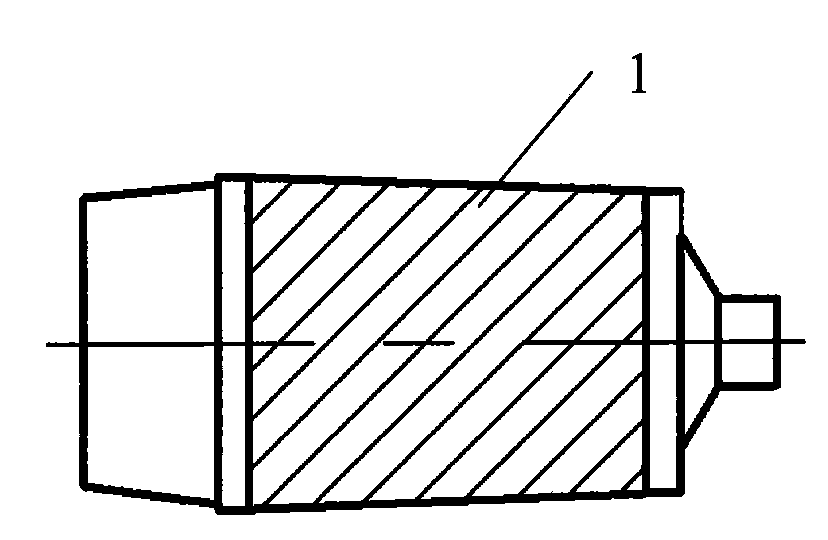

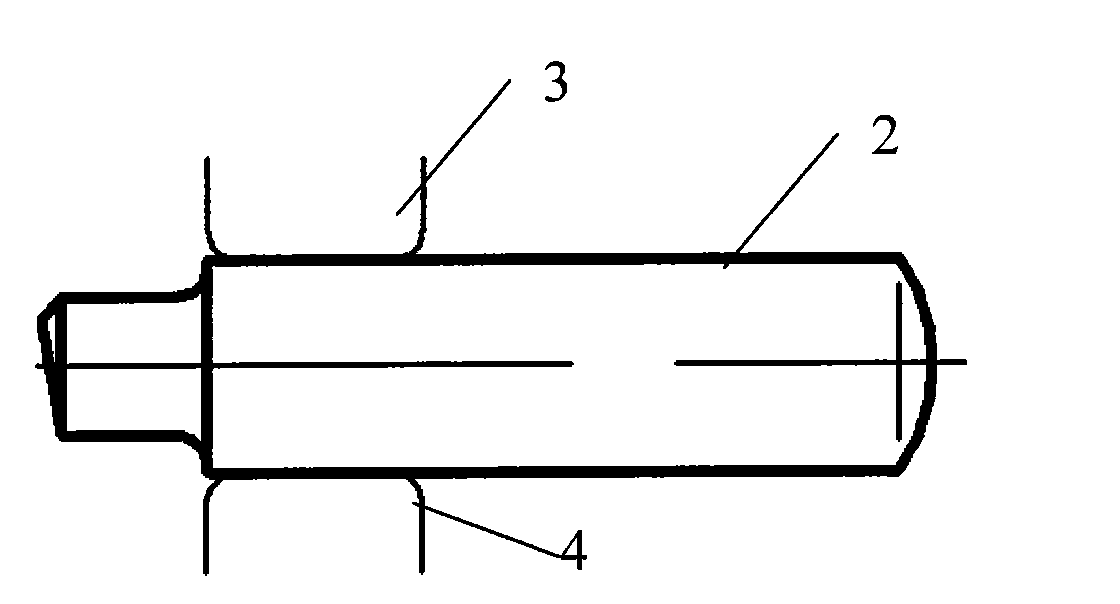

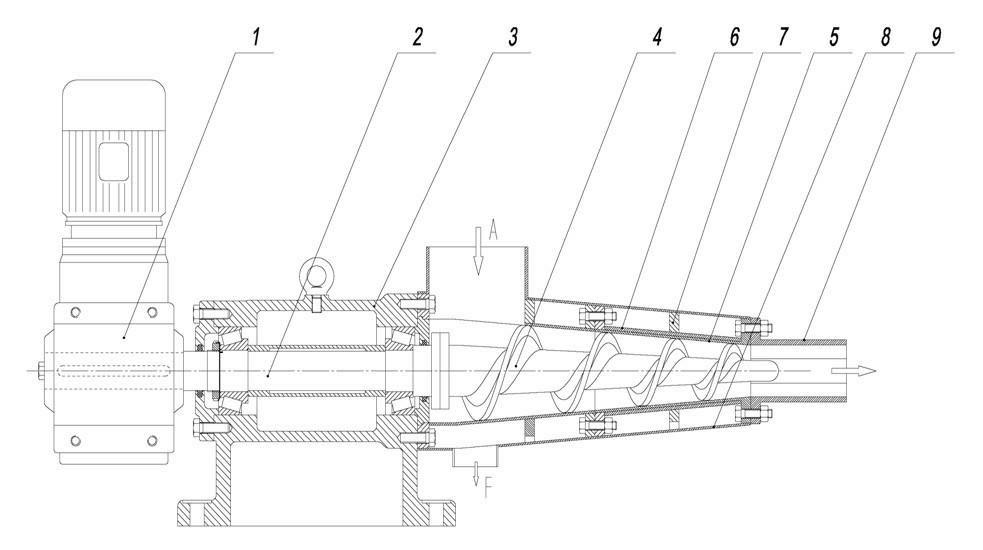

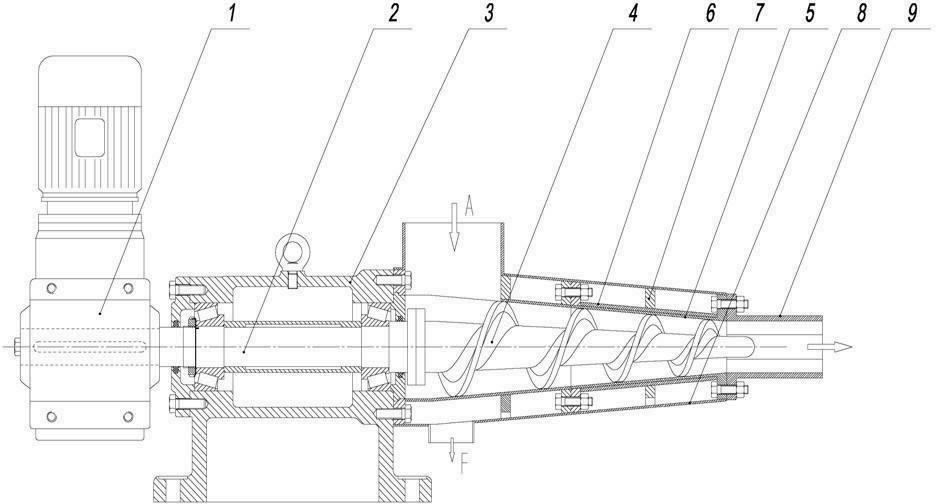

Composite material grid conical shell fiber placing and winding integrated molding device

ActiveCN105799187AImprove molding qualityImprove product qualityTemperature controlMaterials preparation

The invention discloses a composite material grid conical shell fiber placing and winding integrated molding device, and relates to the technical field of composite material preparation. The device comprises a grid conical shell component mold, a winding device, a winding trolley, a fiber placing device and a fiber placing trolley. The integrated molding device not only can be used for finishing the winding of grid ribs, but also can be used for finishing the fiber placement molding of stressed-skin constructions, and has a tow resin temperature control ability to realize control over the prepreg tow viscosity in the transmission process; a heating system is configured in a placing head to enable prepreg tows to be heated, so that the prepreg tows have a certain viscosity and then the process requirements are satisfied. The device disclosed in the invention can be applied to composite material grid conical shell components, and is good in molding quality, high in placing precision, good in product quality and high in manufacture efficiency; an automatic fiber placing system and a grid rib winding system are integrated in a set of equipment, so that the high-efficiency and high-quality composite integrated molding of the composite material grid conical shell components is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

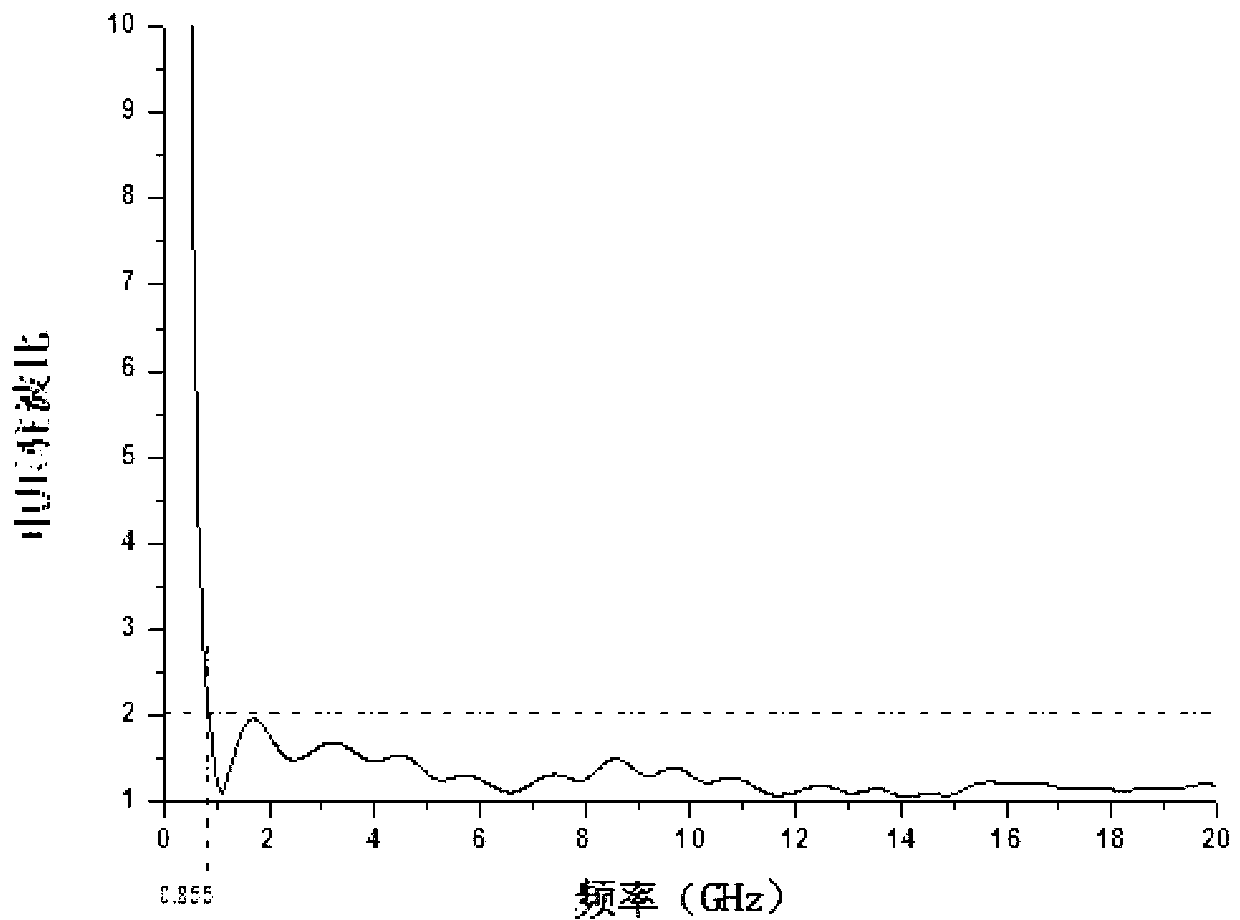

Small ultra-wideband omnidirectional antenna

ActiveCN103296388AWith ultra-wideband characteristicsReduce the numberWaveguide hornsRadiating elements structural formsElectricityUltra-wideband

A small ultra-wideband omnidirectional antenna comprises one radiation floor, one insulating medium, one feed body shaped in a conical shell, one radiating body shaped in the conical shell, at lease one short circuit body and one feed joint. The insulating medium is installed on the radiation floor. The feed body is installed on the insulating medium. The radiating body extends upwards at the upper end of the feed body to be formed, and a taper angle of the radiating body is larger than that of the feed body. Two ends of each short circuit body are respectively connected with the radiating body and the radiation floor. The feed joint is provided with an inner metal core connected with the feed body. The small ultra-wideband omnidirectional antenna is smaller in size and has an ultra-wideband feature.

Owner:上海航空机械有限公司

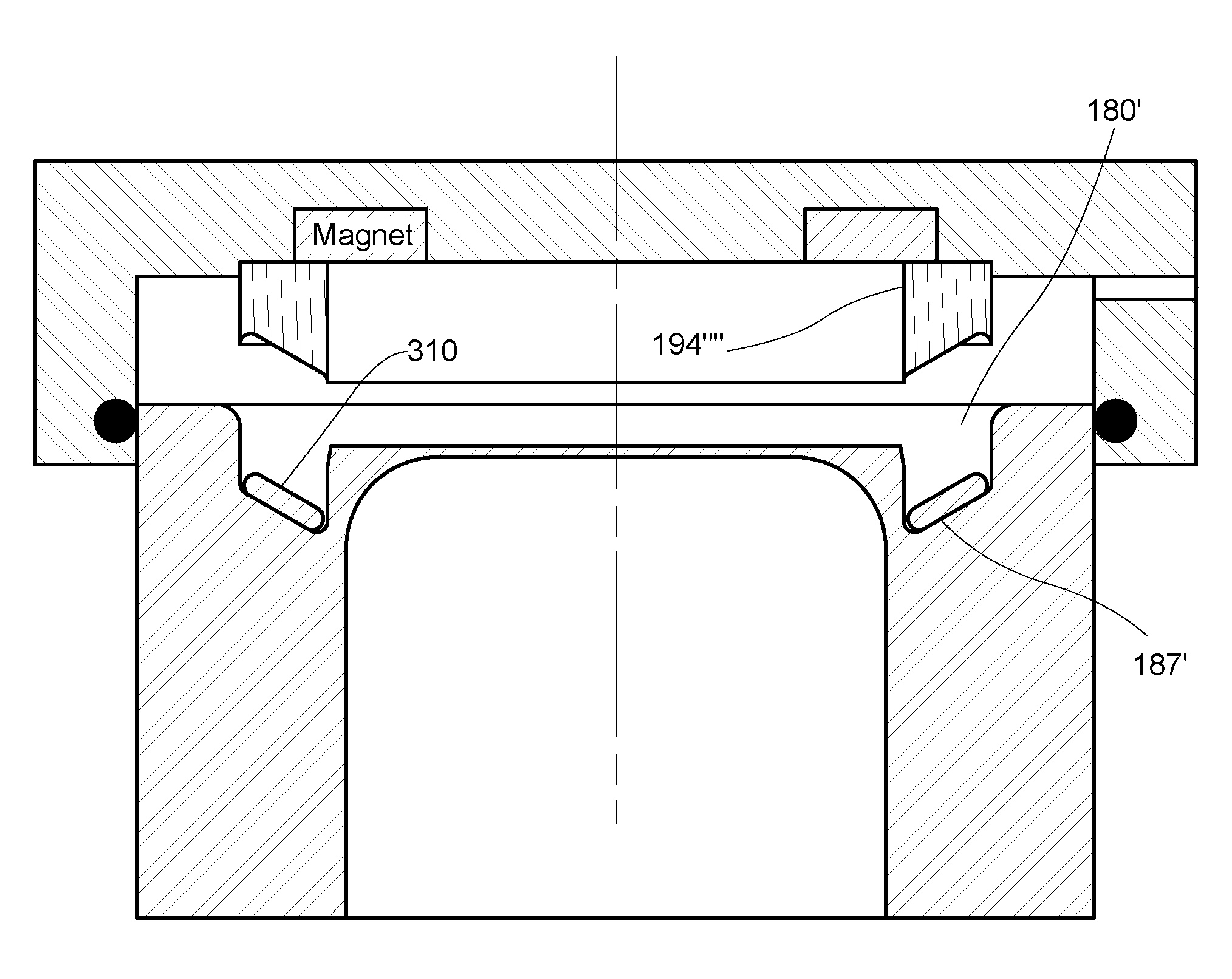

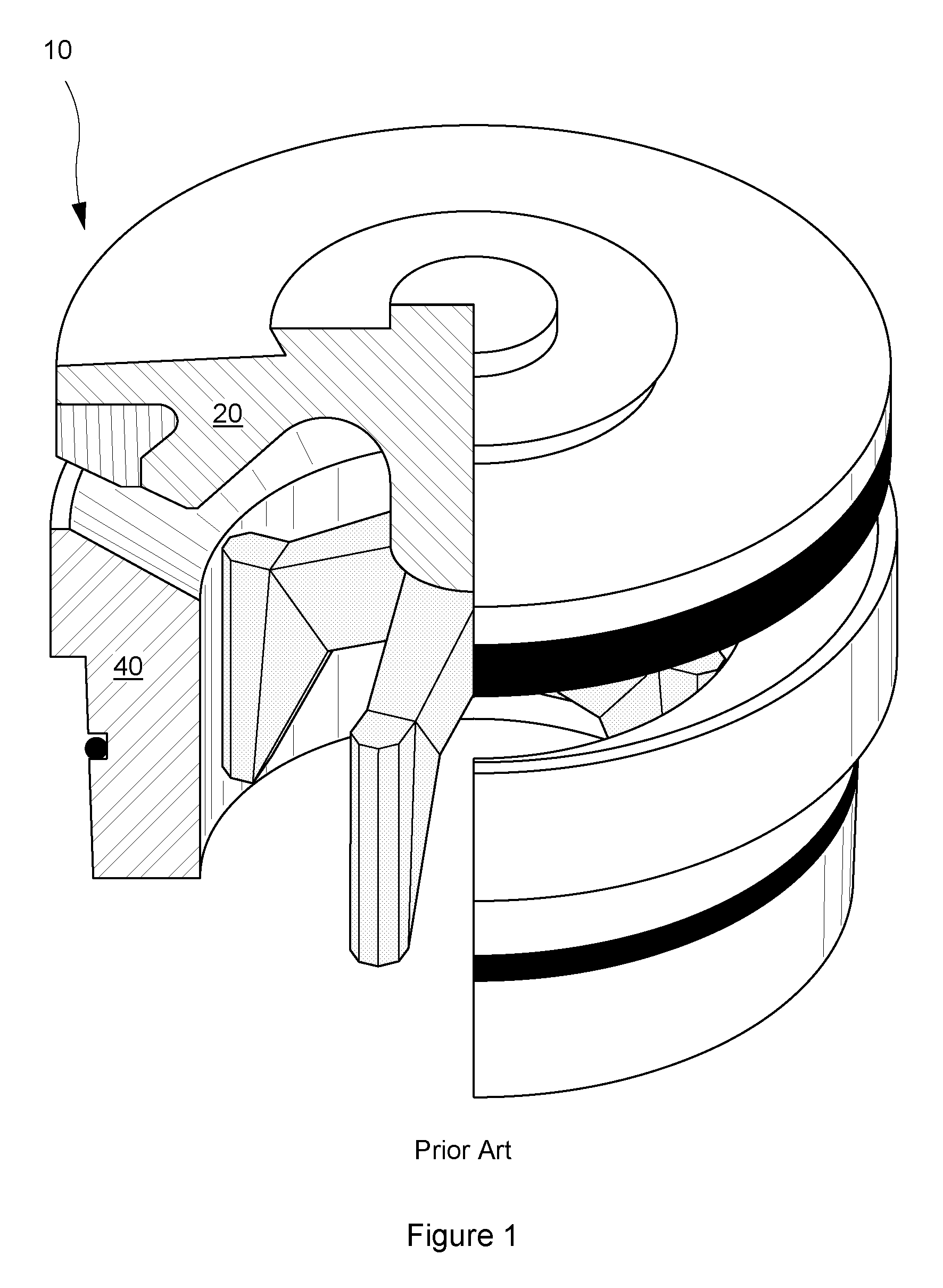

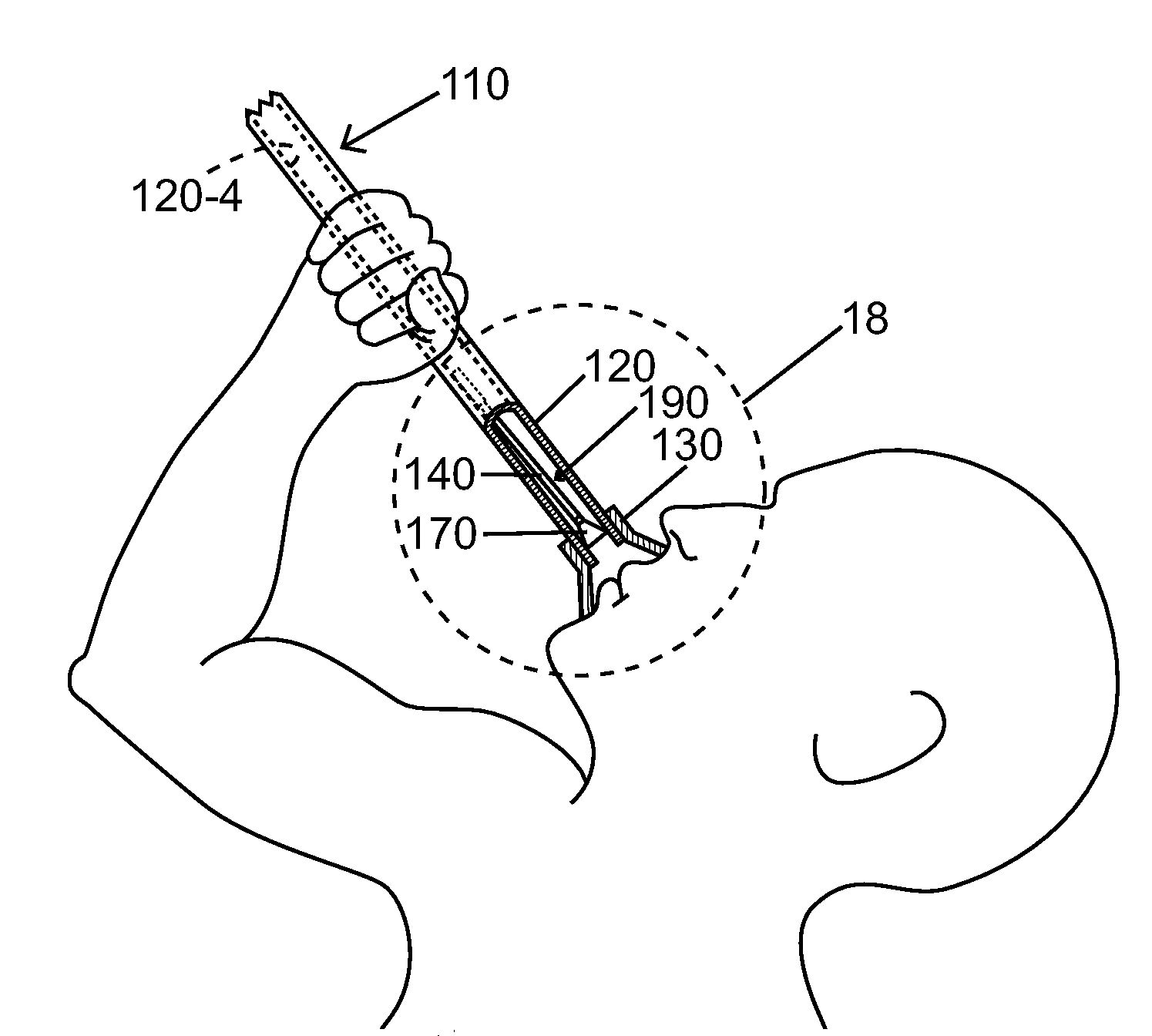

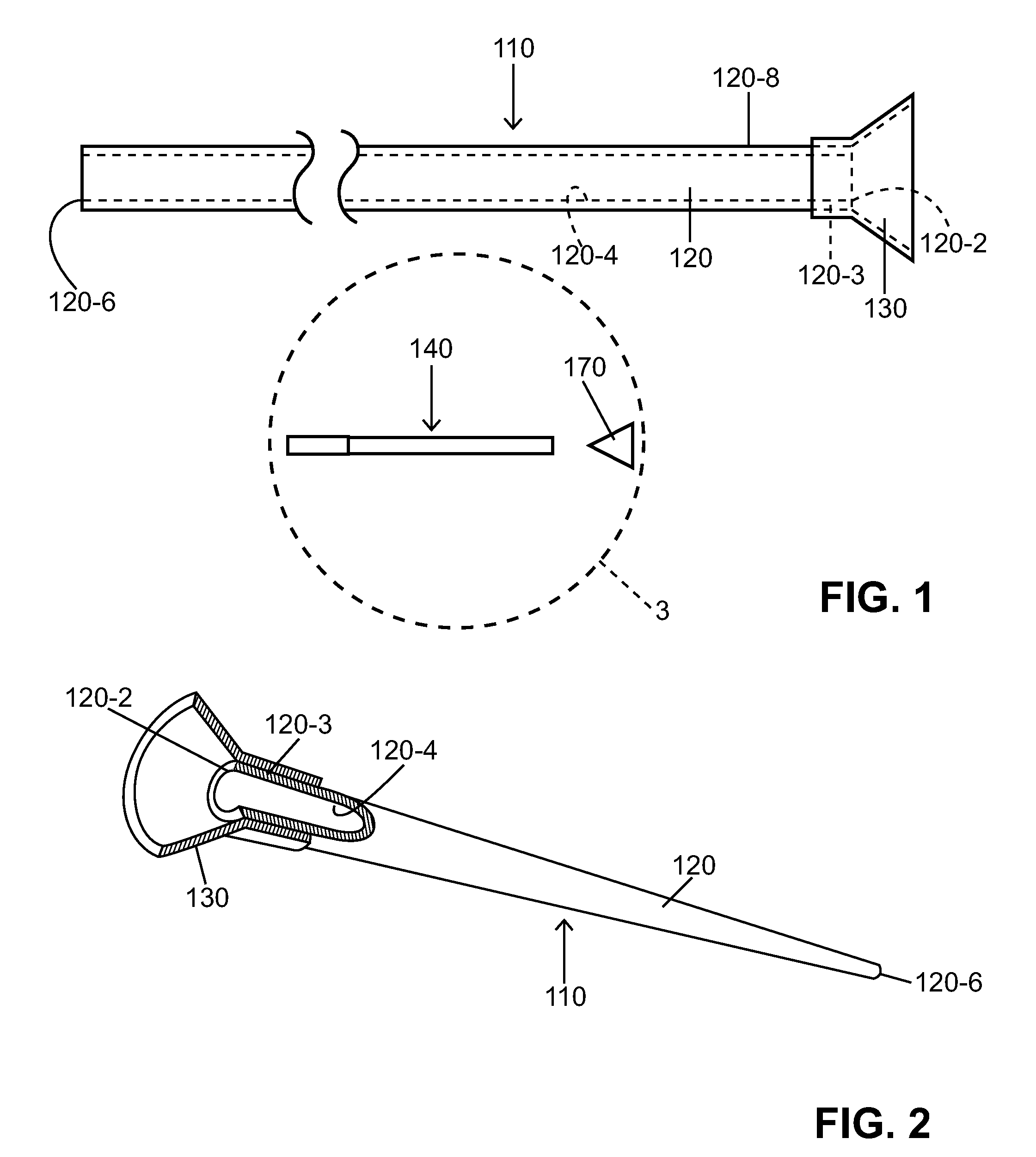

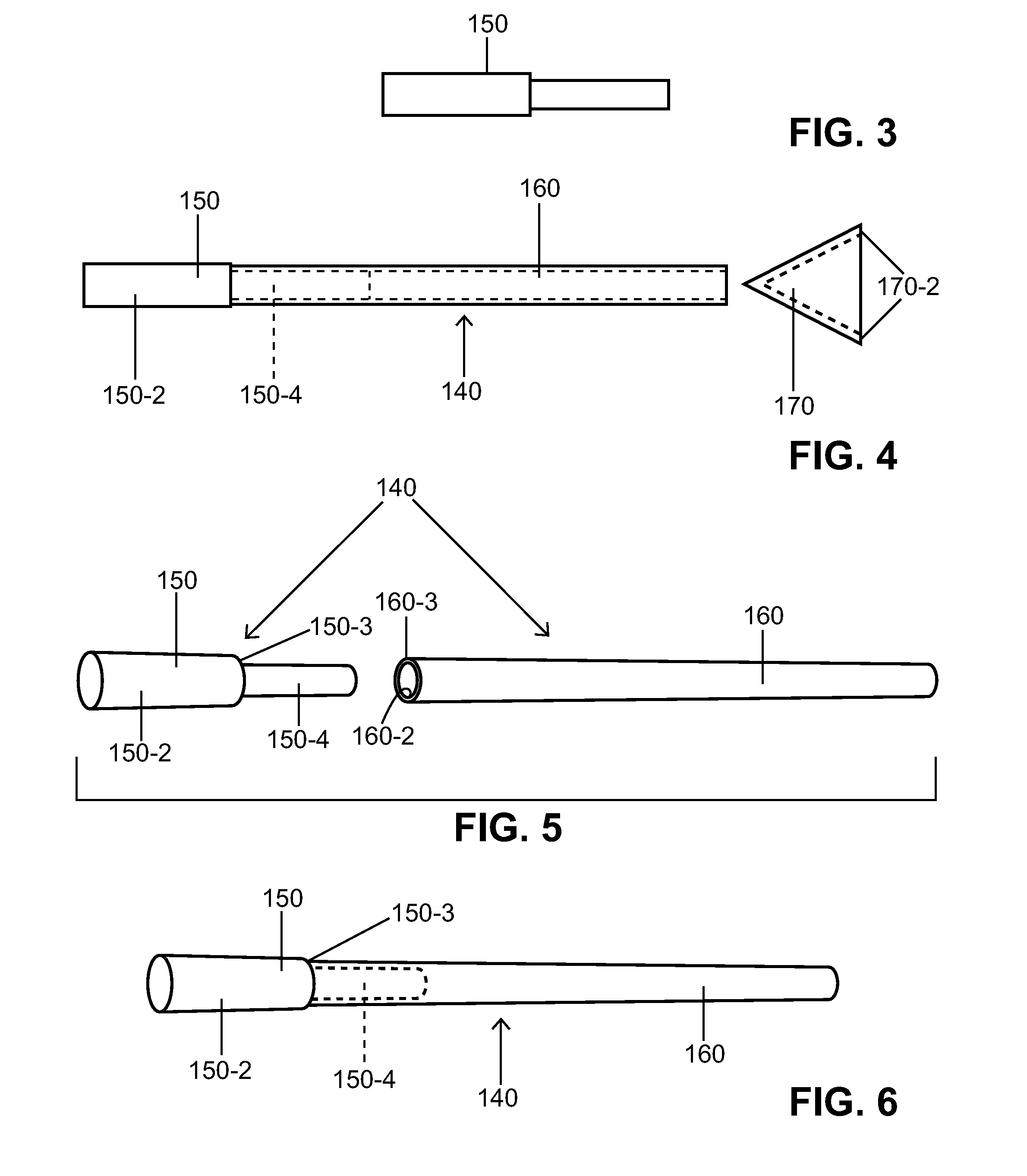

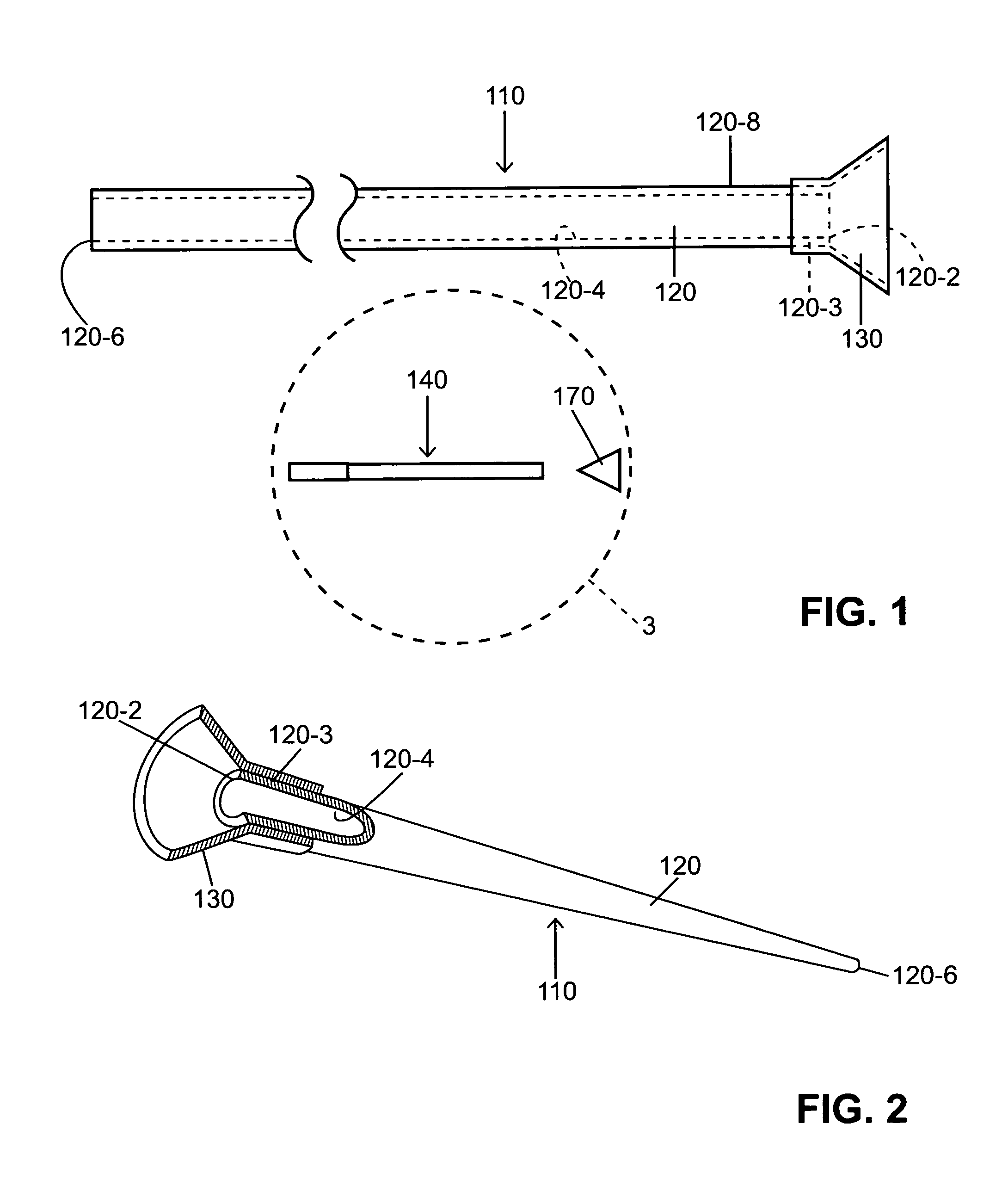

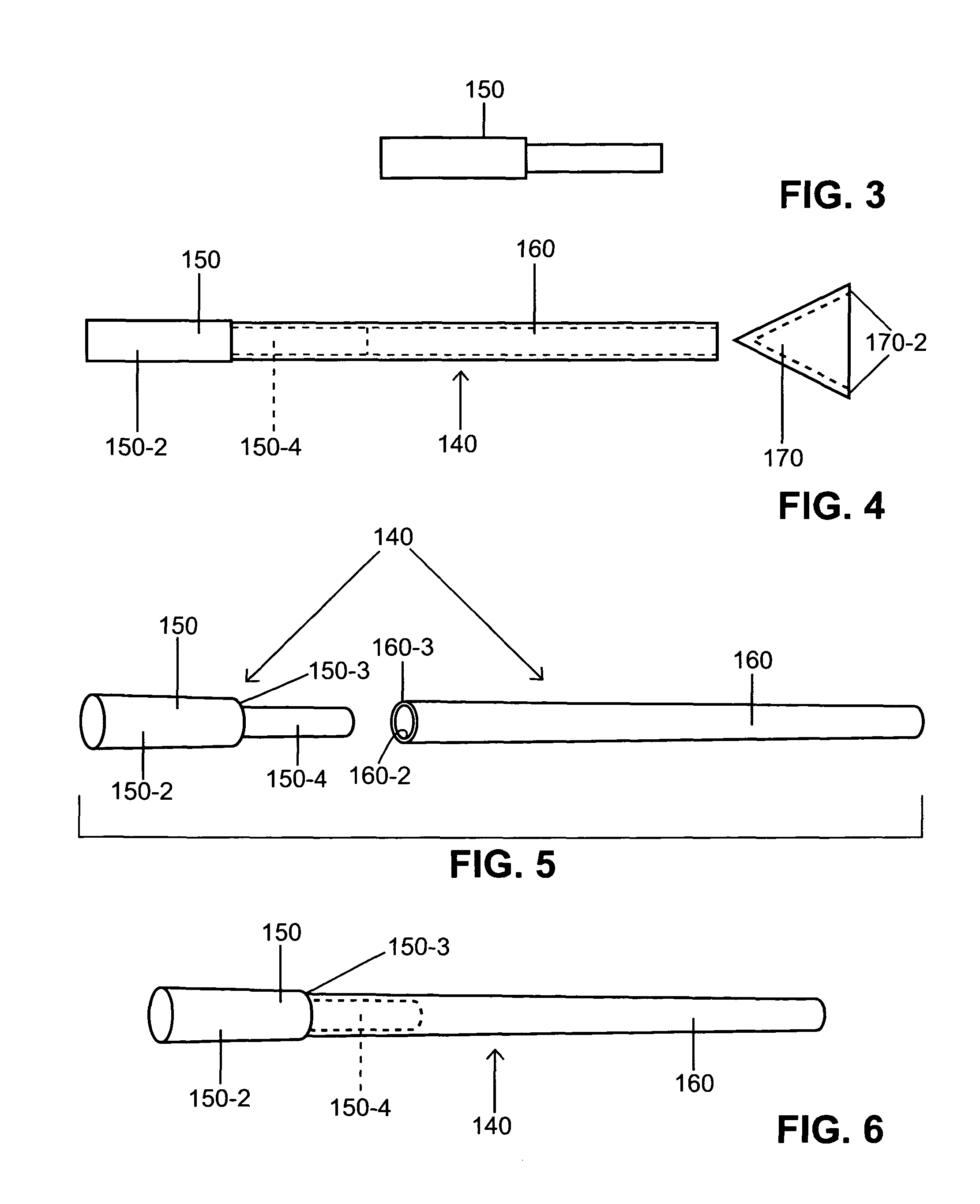

Apparatus for launching subcaliber projectiles at propellant operating pressures including the range of operating pressures that may be supplied by human breath

A blowgun for efficiently and accurately launching subcaliber projectiles comprises:an elongate barrel;a detent comprising a magnet affixed near the proximal end of the barrel and a protrusion partially obstructing the bore breech;an associated conical shell discarding sabot; andan associated subcaliber projectile having a magnetically attractable foreshaft and a lightweight elongate shaft.The magnet and the protrusion cooperate antagonistically to hold the projectile abuttingly seated against the sabot in loaded disposition pending launch. The projectile shaft serves in-flight as an aerodynamic stabilizer. Alternatively a subcaliber steel BB-shot is launched with a foam sabot. Another alternative embodiment operates without a detent. An additional alternative embodiment utilizes a blowgun comprising a barrel having a longitudinal straight-line groove in the inner surface of the bore. During launch, the groove guides a cooperating portion of an optional projectile, selectively subcaliber or full-caliber.

Owner:KENWORTHY BILL WHISTLER

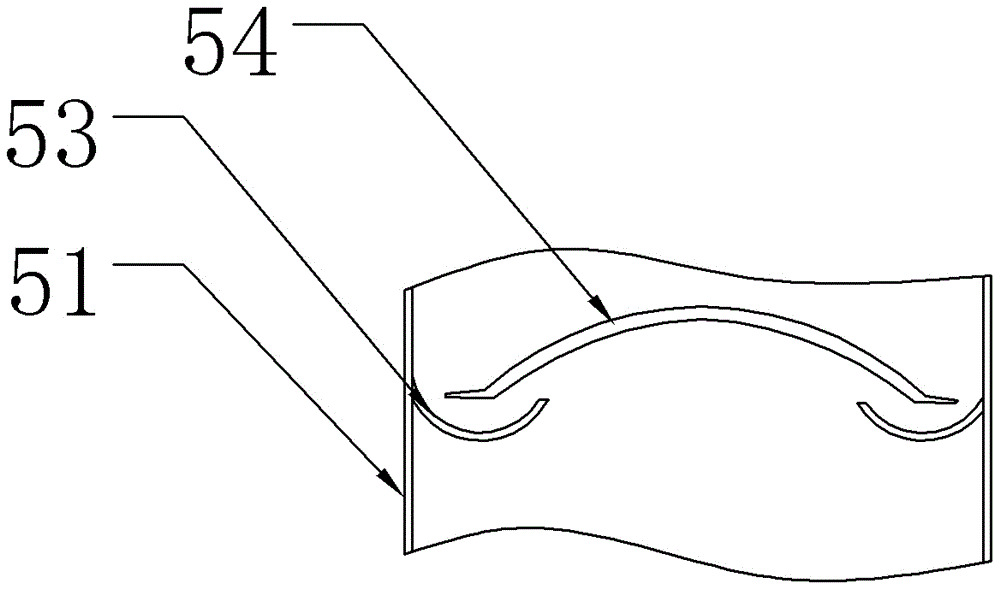

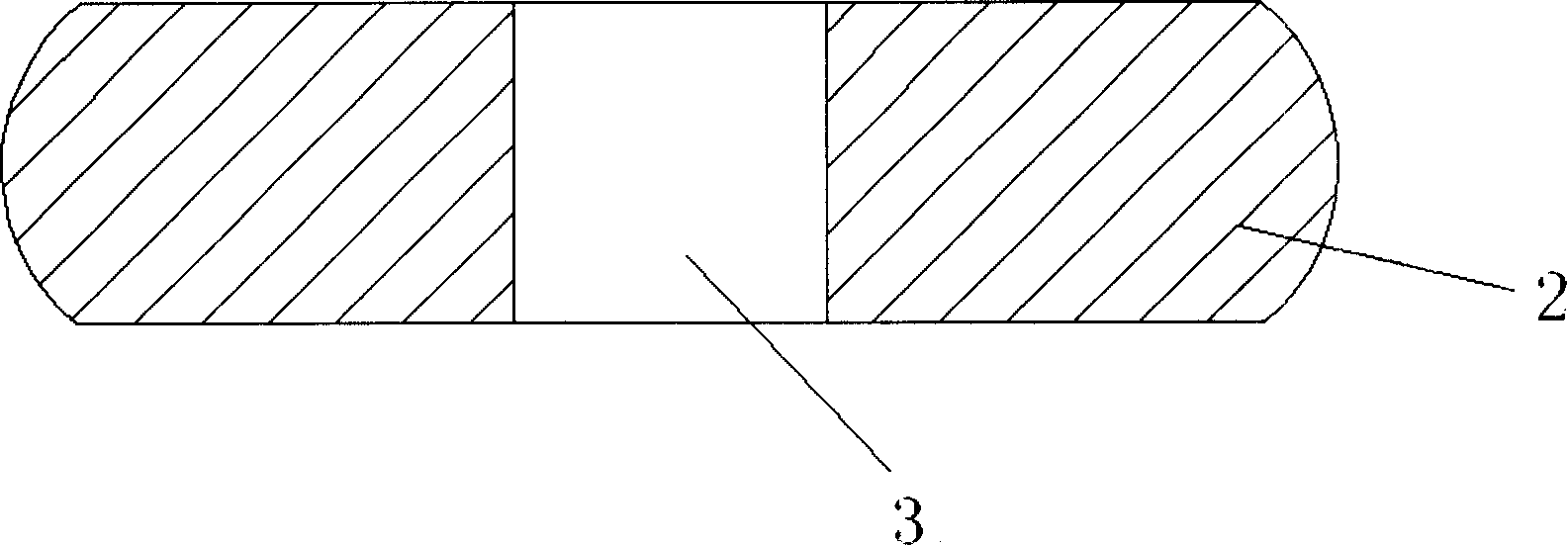

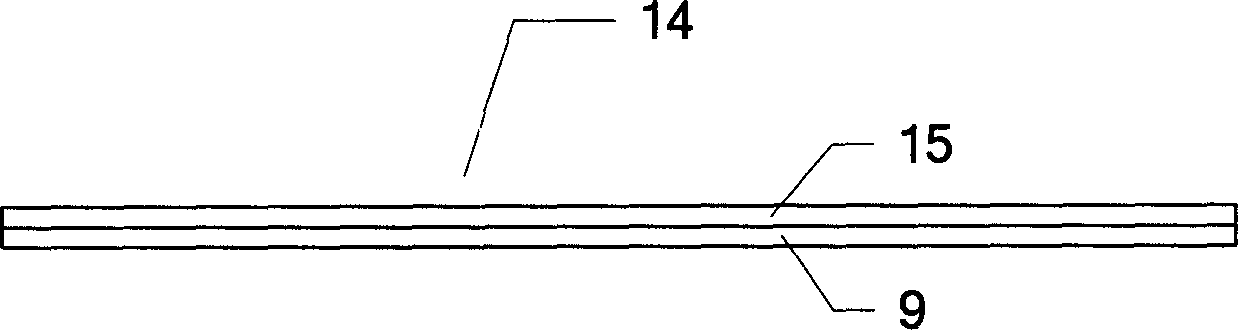

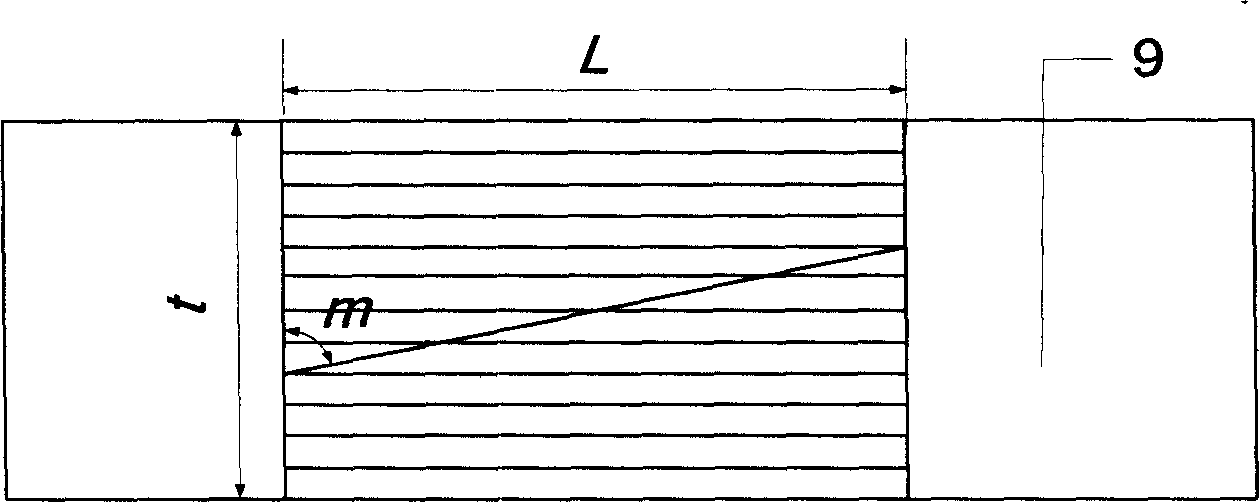

Method and device for forming composite conical shell zero-degree layer

InactiveCN1827341AMeet various needs in the manufacturing fieldImprove molding efficiencyDomestic articlesCoatingsEngineeringMechanical engineering

The invention provides a method for molding the composite taper case 0-degree layer and relative device. First, slicing the constant breadth prepreg belt into two right-angle trapezia prepreg plates according to preset slicing length and angle, wherein, one is transcribed to one liner film after peeling off and first arranging it on the surface of taper case; turning core mould a certain angle, then arranging another one on its side edge to form a isosceles trapezia prepreg plates, while several this one can form the 0-degree layer of taper case. The inventive device adds a additive on the head of general layer, which comprises a air-powered instruction device, a additive flexible compression roller and a transcribed roller, while the air-powered instruction device and the transcribed roller transcribed the right angle trapezia prepreg belt, and the additive flexible compression roller is used to lay the transcribed prepreg belt on the surface of taper case. The invention can improve the molding efficiency, reduce the waste rate and reduce the producing cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

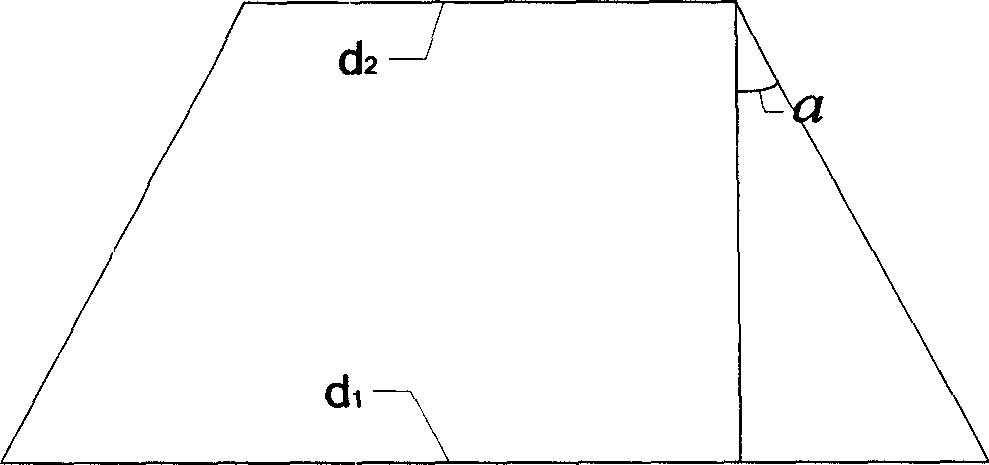

Design method of middle blank and prefabricating blank during conical shell forgeable piece forming process

ActiveCN101537468ASmall machining allowanceControl taperMetal-working apparatusSpecial data processing applicationsNuclear powerHydrogenation reaction

The invention relates to a design method of a middle blank and a prefabricating blank during a nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming process, which belongs to the filed of forging and is suitable for the production engineering and a manufacturing process of nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming. The invention adopts a method of combining an analysis method and finite element modeling to develop a dimension relational expression of the prefabricating blank, the middle blank and a final forgeable piece during the nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming process and provides the design method of the middle blank and the prefabricating blank. The design method and a design formula of the middle blank and the prefabricating blank during the nuclear power and hydrogenation reaction chamber conical shell forgeable piece forming process are suitable for producing significant parts, such as megawatt nuclear power conical shells, large-sized hydrogenation reaction chamber conical shells, and the like; when the middle blank and the prefabricating blank designed by the design method are adopted to produce conical shell forgeable pieces, the middle blank and the prefabricating blank designed by the design method can nicely control the conicity of the conical shell forgeable pieces, thereby solving the problem of the difficult forming and the unreliable machining dimension precision of traditional conical shell forgeable pieces.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Biomass waste residue squeezer

InactiveCN102493250ASolve the problem of easy slipping in extrusionSmall shapePulp de-wateringLitterSludge

The invention discloses a biomass waste residue squeezer which is provided with a power box, a transmission shaft, a bearing seat, a conical screw shaft, a filtering net barrel, a lining net barrel, a reinforcing rib frame, a shell and an anti-skidding cylinder, and is characterized in that: the filtering net barrel, the lining net barrel, the reinforcing rib frame and the shell form a multi-layer combined type conical shell; a feed port is arranged at a big end of the conical shell, and a discharge port is arranged at a small end; the anti-skidding cylinder is arranged at the discharge port at the small end of the conical shell; and the section of the cylinder opening is a regular hexagon. The biomass waste residue squeezer disclosed by the invention is developed and designed based on the biomass raw materials such as papermaking waste residue, and has unique structure, high squeezing efficiency and large dehydration dryness; and the biomass waste residue squeezer not only can be used for dehydrating and drying the papermaking waste residue, but also can realize powerful efficient dehydration of other biomass garbage such as sawdust, waste slurry, sludge and the like, thereby having a wide application range.

Owner:湖南骏泰新材料科技有限责任公司

Apparatus for launching subcaliber projectiles at propellant operating pressures including the range of operating pressures that may be supplied by human breath

A blowgun for efficiently and accurately launching subcaliber projectiles comprises:an elongate barrel;a detent comprising a magnet affixed near the proximal end of the barrel and a protrusion partially obstructing the bore breech;an associated conical shell discarding sabot; andan associated subcaliber projectile having a magnetically attractable foreshaft and a lightweight elongate shaft.The magnet and the protrusion cooperate antagonistically to hold the projectile abuttingly seated against the sabot in loaded disposition pending launch. The projectile shaft serves in-flight as an aerodynamic stabilizer. Alternatively a subcaliber steel BB-shot is launched with a foam sabot. Another alternative embodiment operates without a detent. An additional alternative embodiment utilizes a blowgun comprising a barrel having a longitudinal straight-line groove in the inner surface of the bore. During launch, the groove guides a cooperating portion of an optional projectile, selectively subcaliber or full-caliber.

Owner:KENWORTHY BILL WHISTLER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com