Construction method of major diameter reinforced concrete silo and device for conical shell construction

A reinforced concrete and construction device technology, applied in the field of building construction, can solve the problems of consuming a lot of man-hours and manpower, and being difficult to demould, and achieve the effects of saving costs, shortening the construction period, and reducing the supporting load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

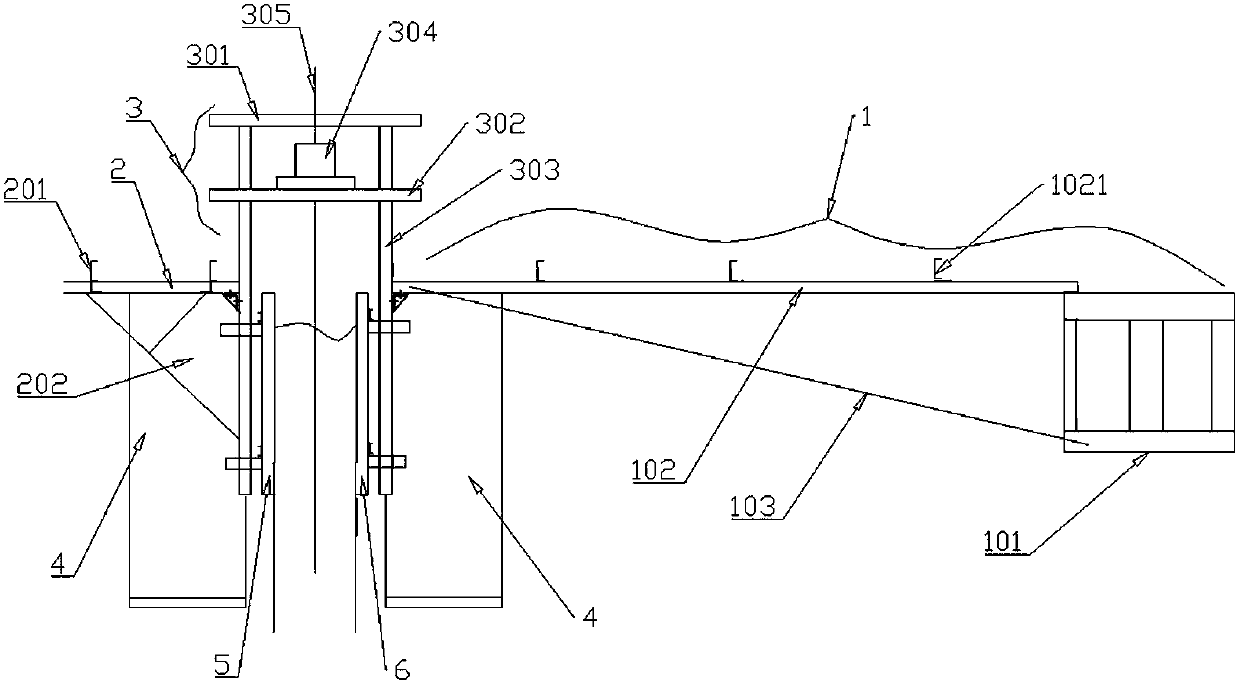

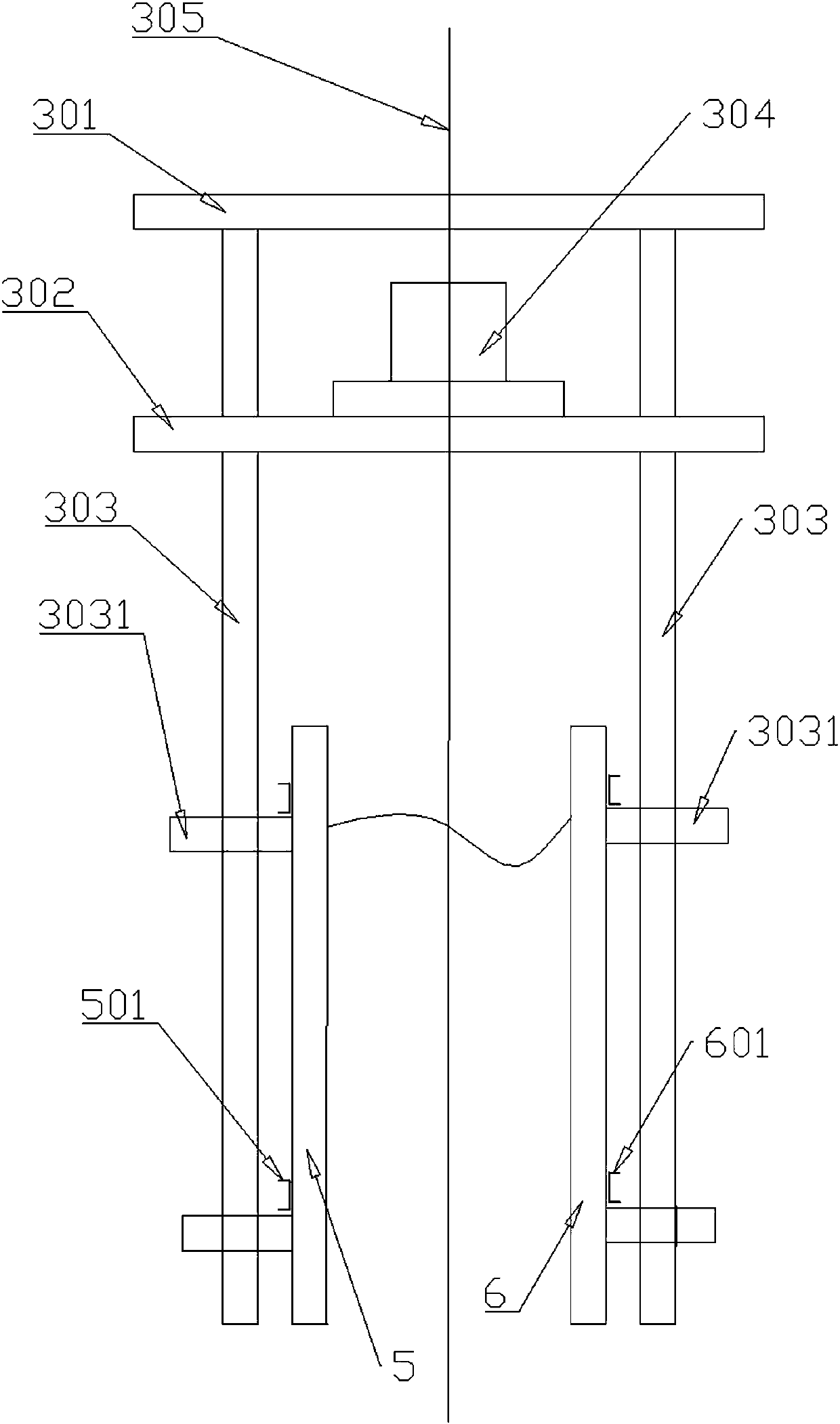

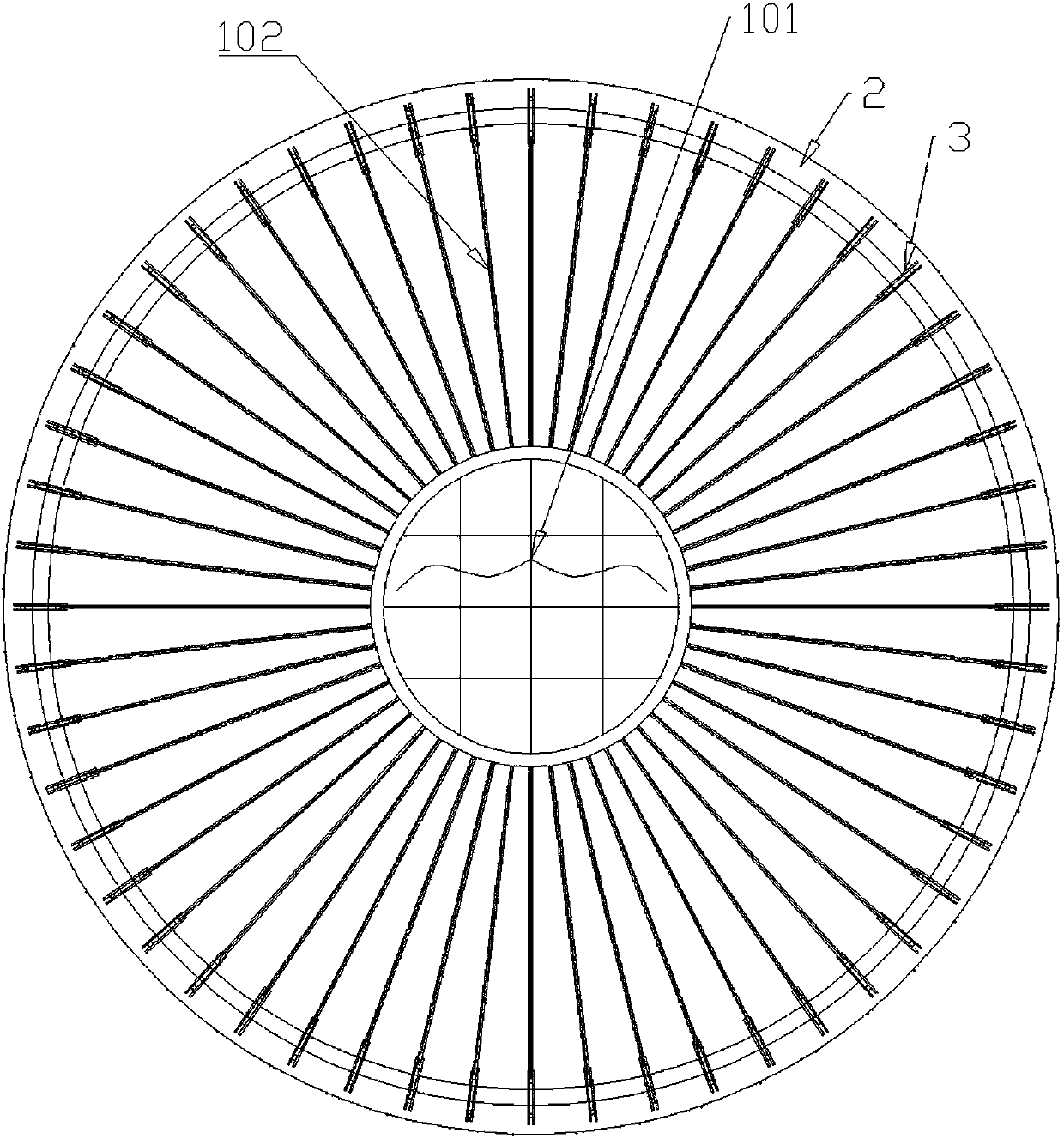

[0050] The specific embodiment of the present invention sees Figure 1-6 :

[0051] The present invention mainly discloses a construction method for a large-diameter reinforced concrete silo and a construction device for a conical shell. The diagrams compared below mainly express the structural representations related to the characteristics of the present invention, and do not and do not need to be completely drawn according to the actual size , explained first.

[0052] A large-diameter reinforced concrete silo construction method, such as Figure 1-6 , including the following steps:

[0053] a. Using a slipform platform to pour the silo wall 7

[0054] (1) Install the sliding form platform

[0055] (a) Install the opening lifting frame 3 and the sliding form

[0056] According to the silo structure and design plan, lift the lifting frame 3 into place, fix and support the frame to ensure the verticality of the vertical support 303 and the levelness of the upper beam 301 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com