Large mining height triangular hydraulic support

A hydraulic support and triangle technology, applied in mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of support handling, difficult installation and maintenance, high investment in support equipment, reduce the roof control area, and improve the resource recovery rate. , The effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

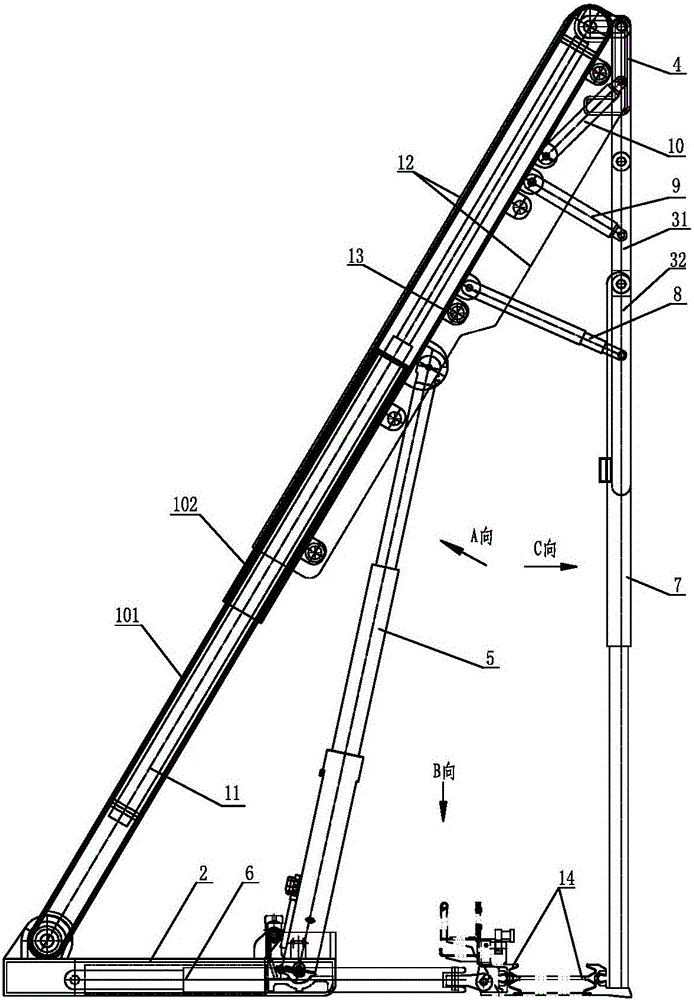

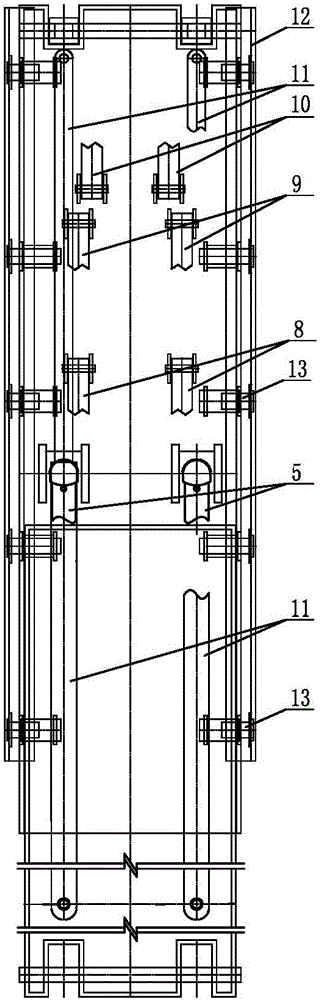

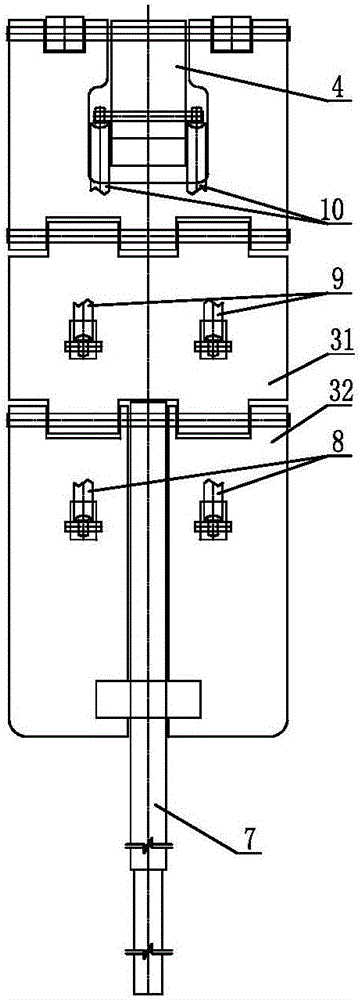

[0030] like Figure 1 to Figure 5 As shown, the present embodiment provides a large mining height triangular hydraulic support, the first box-shaped plate 101 is slidingly connected with the second box-shaped plate 102, the first box-shaped plate 101 is an inner sleeve structure, and the second box-shaped plate 102 It is an outer sleeve structure that can be nested on the outer surface of the inner sleeve structure. The telescopic jack 11 is located inside the first box-shaped plate 101 of the inner sleeve structure and the second box-shaped plate 102 of the outer sleeve structure. The telescopic jack 11 The two ends of the first box-shaped plate 101 and the second box-shaped plate 102 are respectively connected, and the telescopic jack 11 drives the first box-shaped plate 101 to extend and retract from the second box-shaped plate 102, and the telescopic jack 11 and the column 5 Coordinated actions can flexibly adjust the support height, which is suitable for mining support in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com