Patents

Literature

235results about How to "Solve the force problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

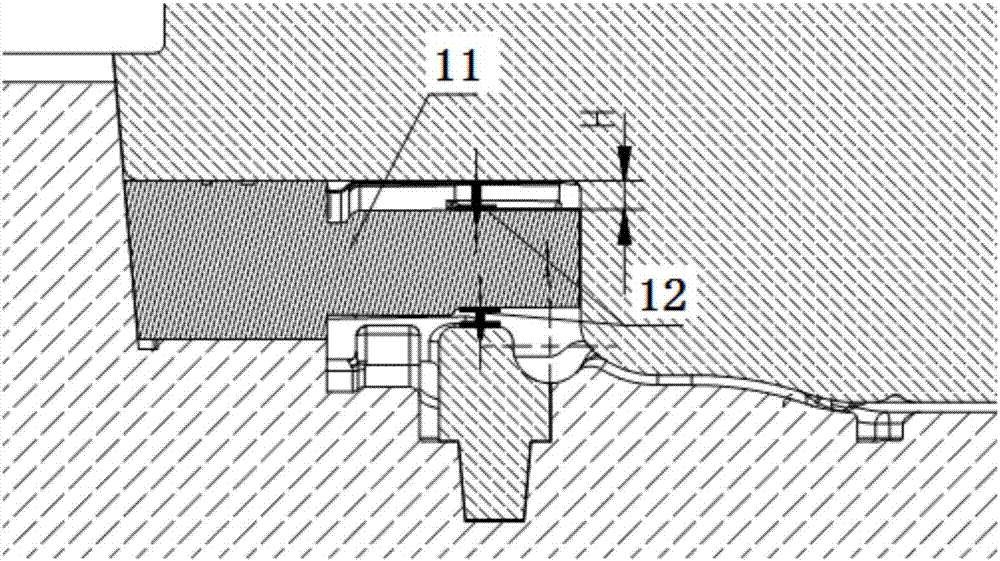

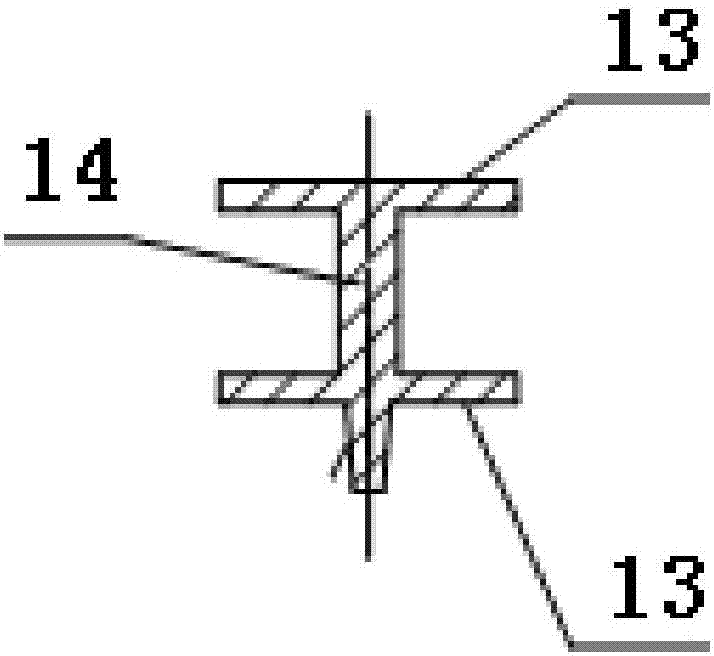

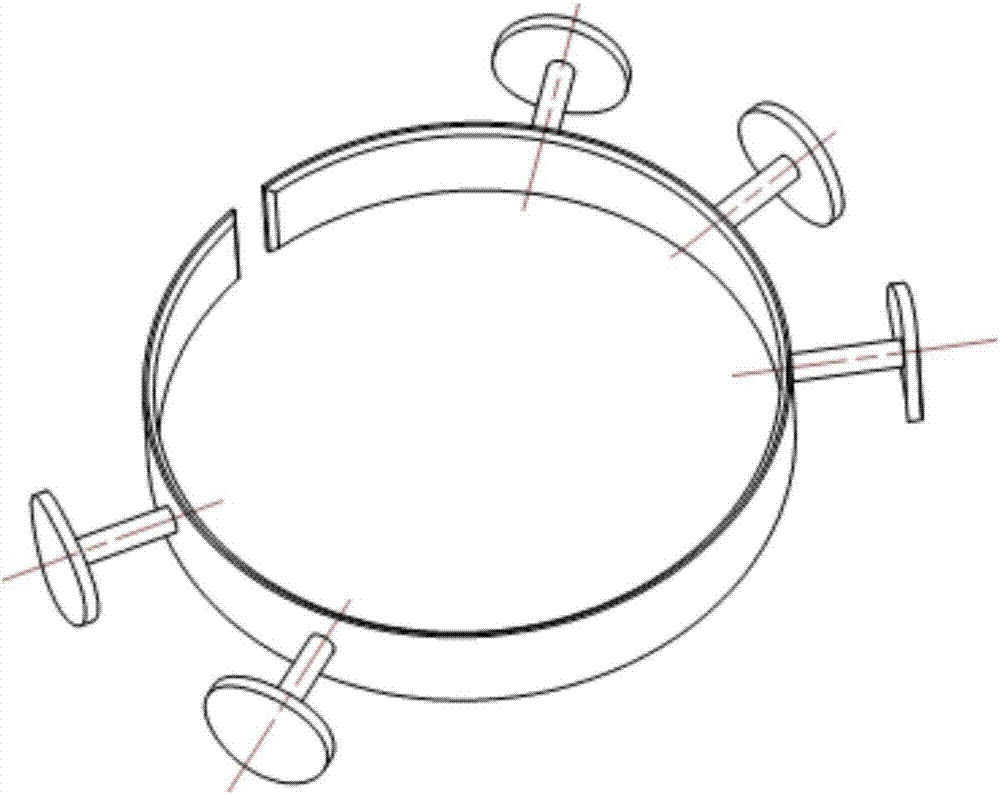

Integral lifting reconstruction method for high-span overweight continuous box girder

InactiveCN101892636ASolve the problem of setting up a reliable jacking systemAddress the risk of collapseBridge structural detailsBridge erection/assemblyReconstruction methodHydraulic equipment

The invention discloses an integral lifting reconstruction method for a high-span overweight continuous box girder. The method comprises the following steps of: cutting the top of a pier; reinforcing an upper box girder; welding a limiting device on the outer side of an upright post hoop, and integrating the limiting structure and a concrete pier into a whole to limit the lifting of the girder; debugging a lifting jack and a follow-up jack; lifting formally until the girder is lifted to a position which is 1cm higher than a designed elevation, screwing up a self-threaded device of the lifting jack, disassembling the follow-up jack, arranging a support and a permanent cushion block; loosening the self-threaded device on the lifting jack and allowing the jack to drop for 1 cm to the designed elevation; and disassembling the lifting device, the hoop and the limiting device and joining the lifted pier. The method can adapt to the high-span continuous box girder with limited height at the support, heavy weight, high requirements on a lifting hydraulic device and small width at the ribbed part of the box girder and can realize safe integral lifting of the continuous box girder with an accurate position.

Owner:SHANGHAI XIANWEI CIVIL ENG

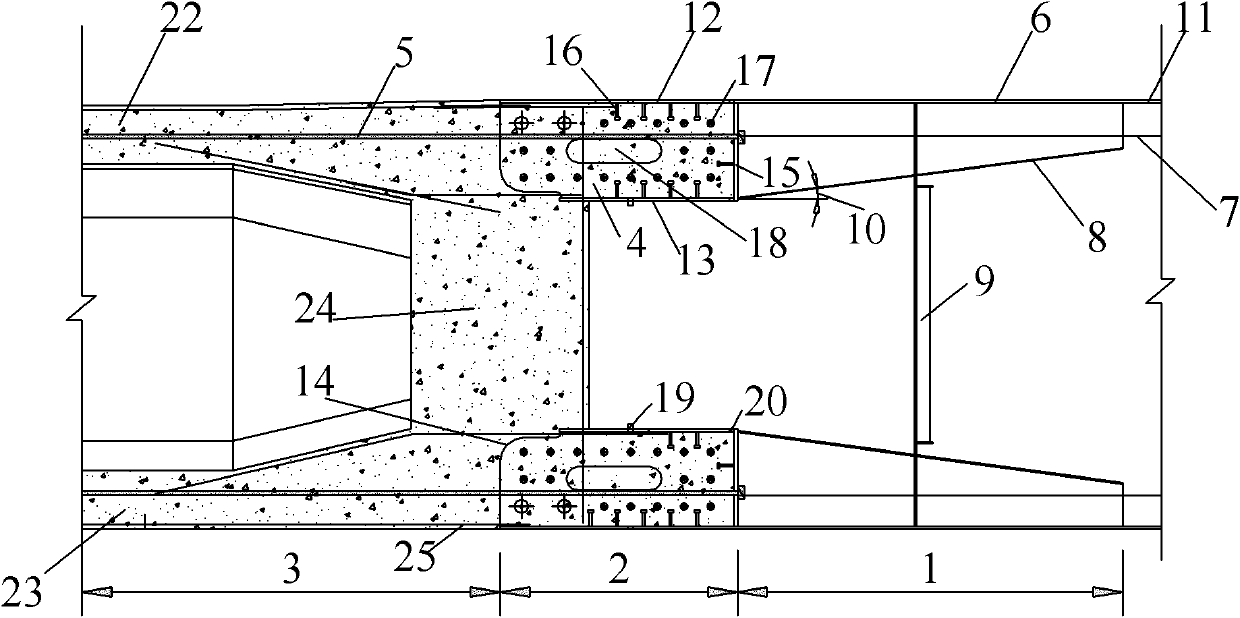

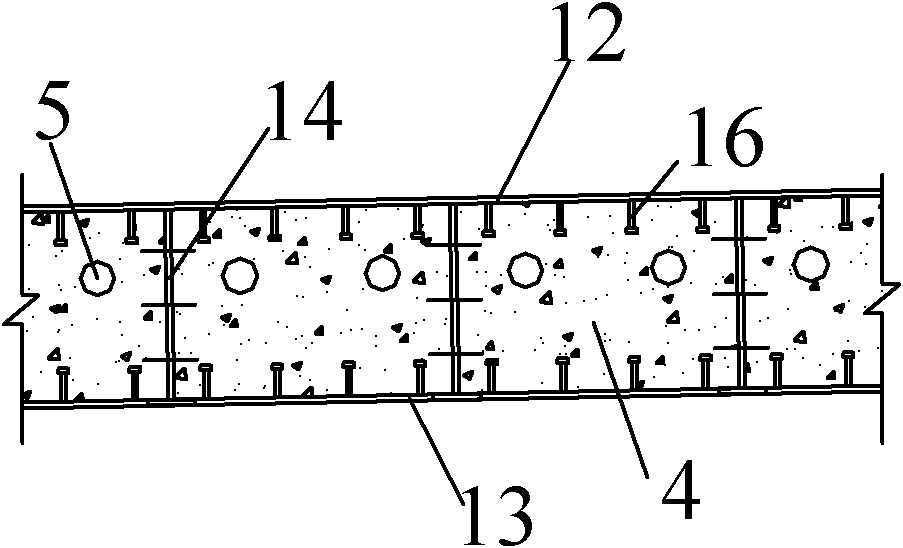

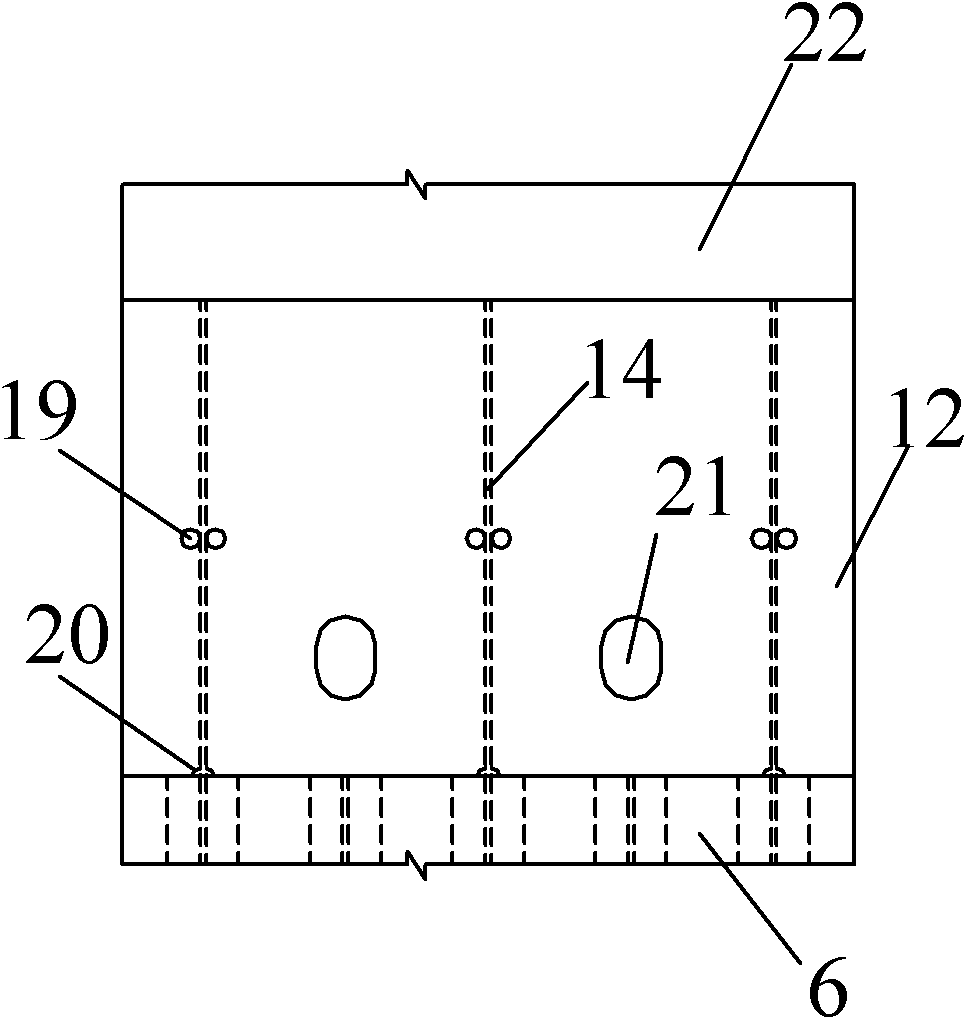

Celled hybrid beam junction with composite connectors

InactiveCN102561172AImprove clearanceImprove applicable spanCable-stayed bridgeBridge structural detailsBridge engineeringConcrete beams

The invention discloses a celled hybrid beam junction with composite connectors, which relates to the technique of bridge engineering and used for a main beam of a large-span hybrid beam cable-stayed bridge. Concrete-filled steel cell structures are disposed at the ends of a steel box girder, welding nail connectors are disposed on a top plate, a bottom plate and a bearing plate of each steel cell while the top plate, the bottom plate and the bearing plate are attached with concrete, and perforated plate connectors (PBL (perfobond leiste) connectors) are disposed on partition plates of each steel cell and integrally concreted with a concrete beam. When the celled hybrid beam junction is used, the main beam has the single-cell single-box, multi-cell and single box or single-cell and double-box cross section, and longitudinal prestress is applied to the interior of each steel cell. By means of the celled hybrid beam junction, the problem of stress of the main beam of the large-span hybrid beam cable-stayed bridge is solved effectively, structural safety is improved, welding of a great quantity of welding nail connectors in each steel cell is avoided, and the applicable span of the hybrid beam cable-stayed bridge is enlarged greatly.

Owner:CCCC HIGHWAY CONSULTANTS

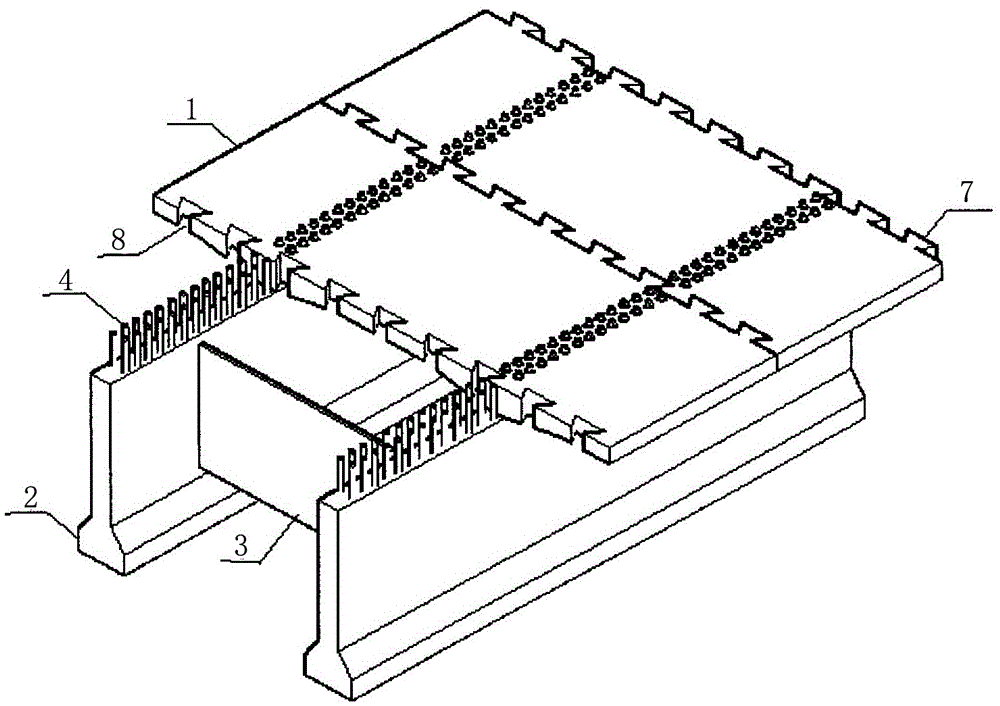

Prefabricated T beam and construction method

The invention discloses a prefabricated T beam and a construction method. The prefabricated T beam comprises bridge panels, a longitudinal beam and a steel transverse partition plate. The bridge panels and the longitudinal beam are prefabricated parts. The adjacent bridge panels are connected in an embedded mode. The portions, at the upper end of the longitudinal beam, of the bridge panels are evenly provided with preformed holes. Pre-buried deformed steel bars are arranged inside a bridge beam of the longitudinal beam. A pre-buried steel plate is arranged on the side face of the longitudinal beam. The pre-buried deformed steel bars need to stretch out of the upper edges of the spliced bridge panels on the basis of the length. The steel transverse partition plate is fixedly connected with the pre-buried steel plate on the longitudinal beam. The construction method comprises the steps of prefabricating the bridge panels and the longitudinal beam; connecting the steel transverse partition plate with the longitudinal beam after the longitudinal beam is suspended to a bridge pier and abutment; placing the bridge panels on the longitudinal beam, and connecting the adjacent bridge panels in the embedded mode; pouring epoxy mortar concrete into the preformed holes. The bridge panels and the longitudinal beam of the T beam are partially prefabricated separately, and therefore the wet joint problem existing in concrete T beam splicing is effectively solved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

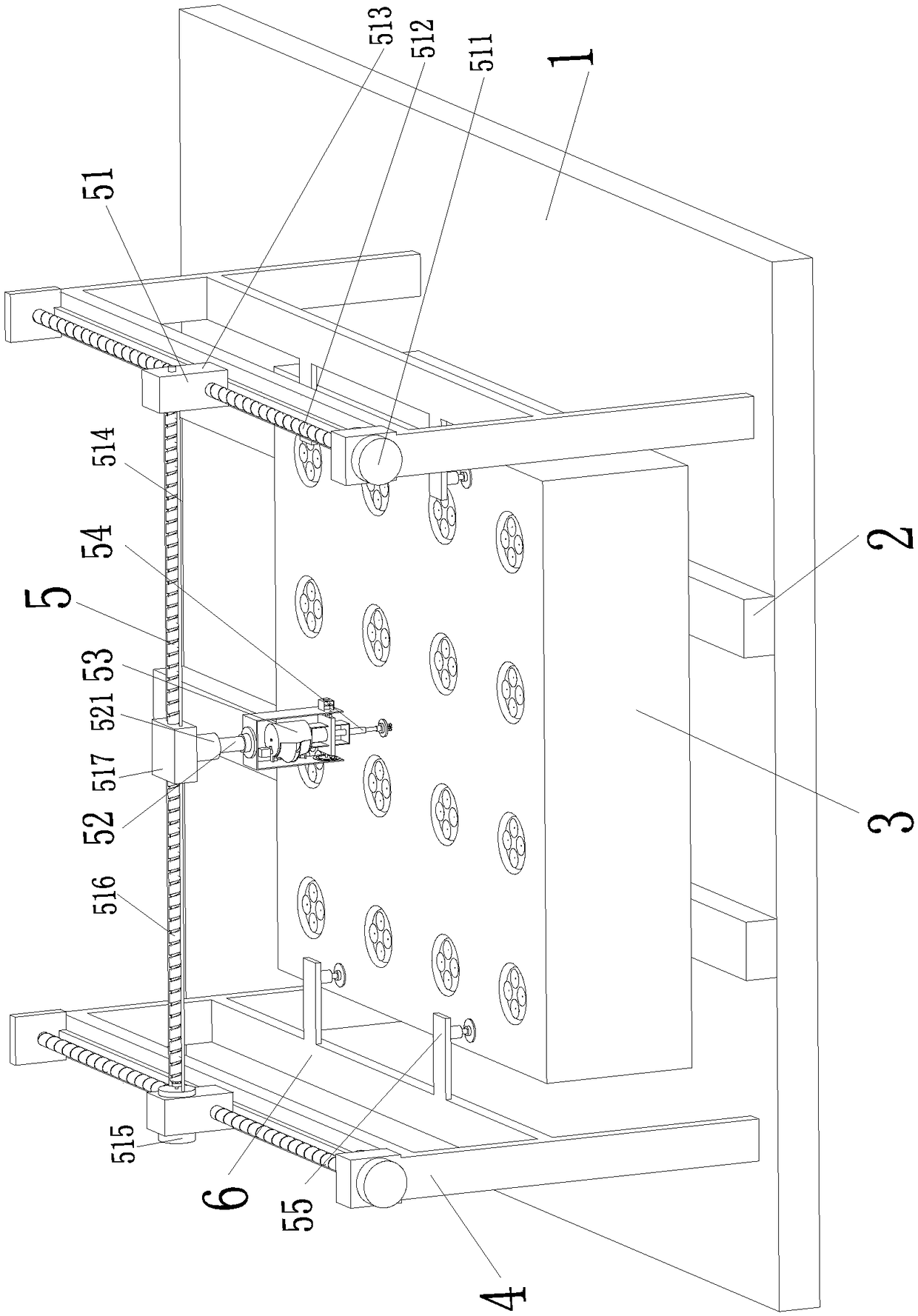

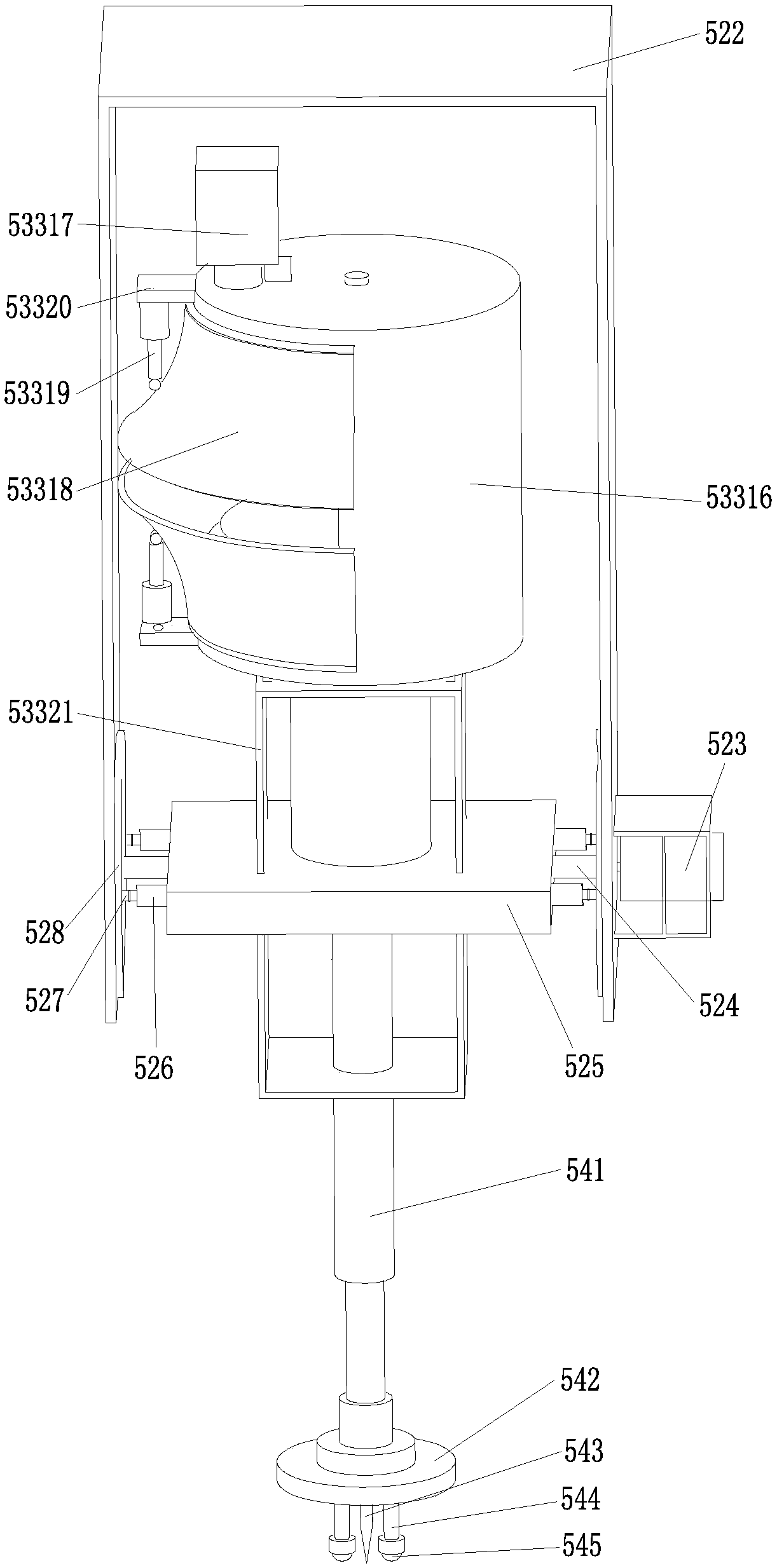

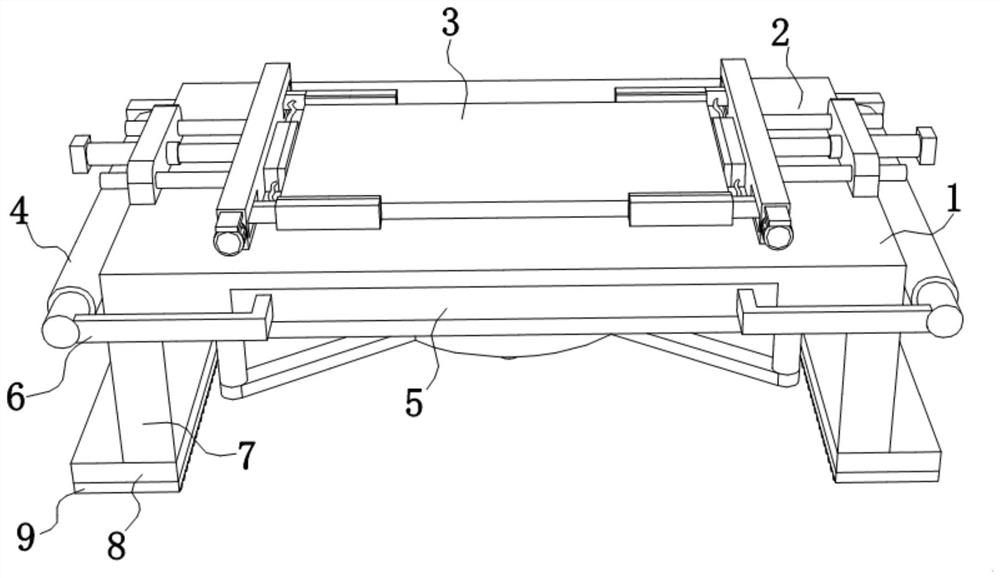

Intelligent cutting and polishing production line for deep processing of glass and deep processing method of glass

ActiveCN108840556APrevent slippingSlip off withoutEdge grinding machinesGlass severing apparatusEngineeringDeep processing

The invention relates to an intelligent cutting and polishing production line for deep processing of glass and a deep processing method of glass. The production line comprises a bottom plate, an electric support slider, a support device, feeding support frames, an execution device and a support frame transverse plate, wherein the electric support slider is mounted in the middle of the bottom plate, the support device is mounted on the electric support slider, the feeding support frames are symmetrically mounted at left and right ends of the bottom plate and adopt an inverted U-shaped structure, the support frame transverse plate is arranged between inner walls of middles of the feeding support frames, and the execution device is mounted between the two feeding support frames. During working, the glass is conveyed onto the support device, the support device fixes the glass, then, the execution device cuts and edges the glass, manual operation is not required during processing, glass breakage caused by operation errors is avoided, the labor intensity of workers is reduced, the working efficiency is improved, and a cutting and edging procedure integrated continuous processing functionduring deep processing of the glass can be realized.

Owner:ALL GLASS SUQIAN

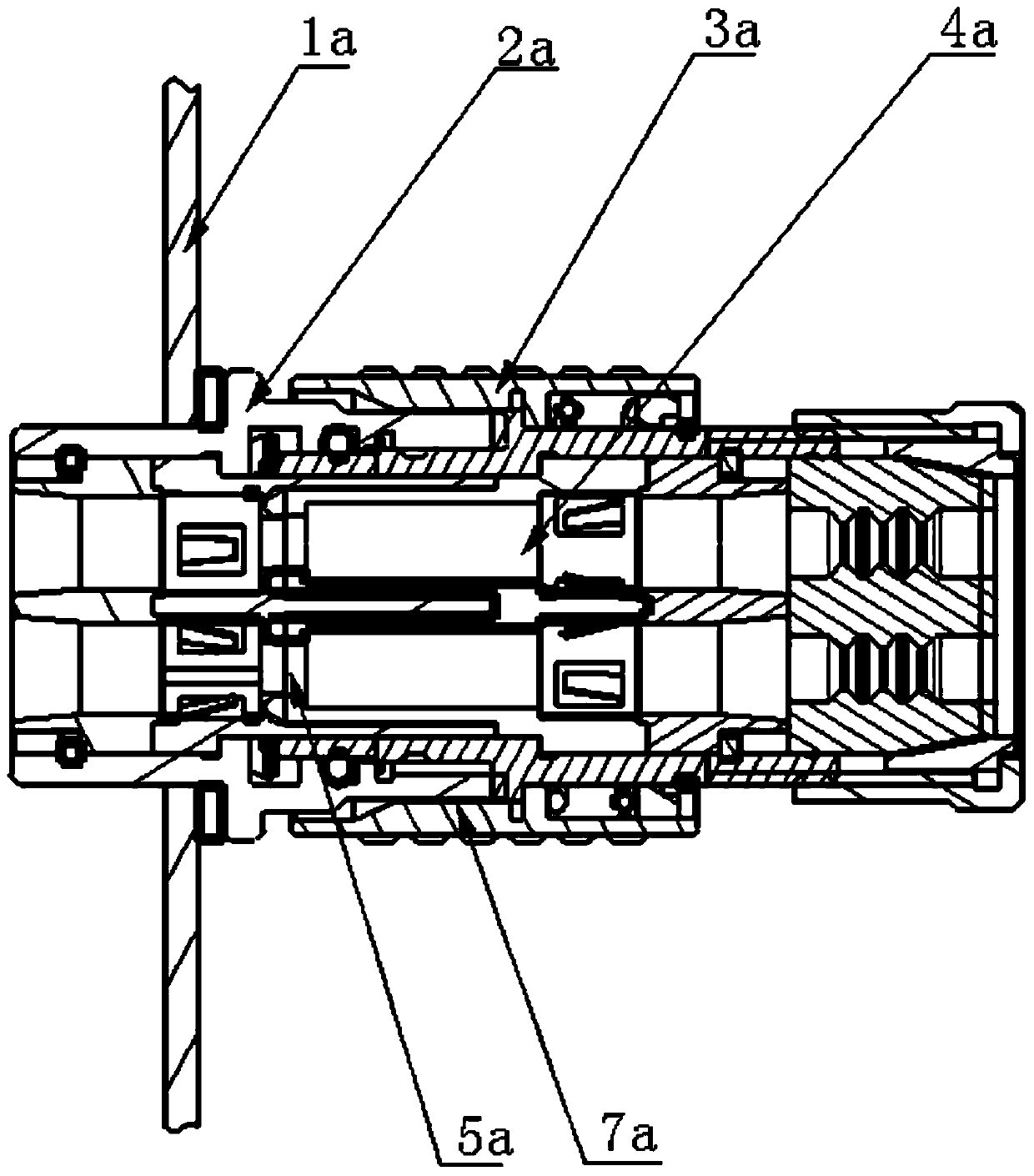

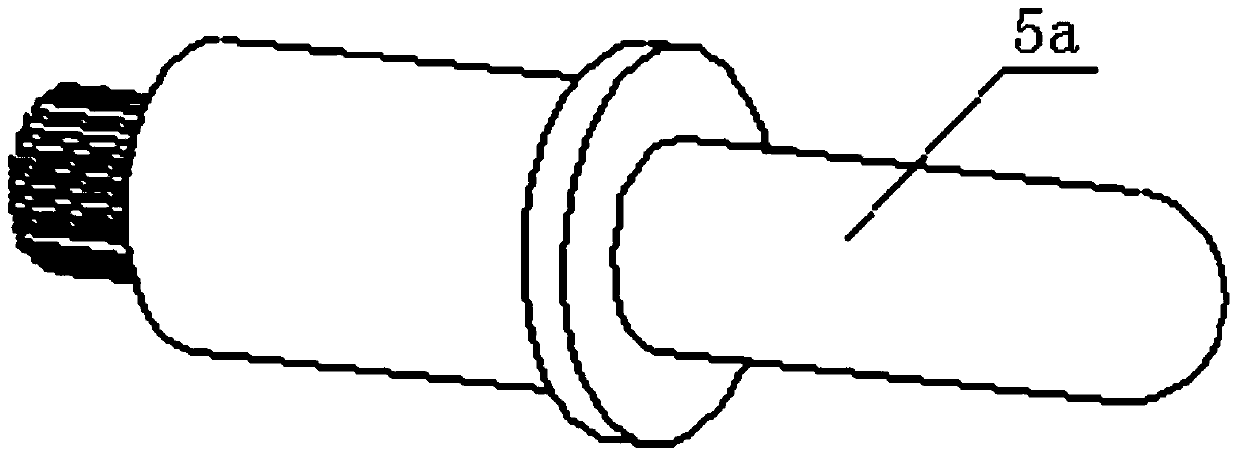

Cable connector

ActiveCN103441358AEasy to fixOptimize layoutSecuring/insulating coupling contact membersCoupling contact membersInterference fitCantilever

The invention discloses a cable connector. A containing space is formed in a shell of the cable connector. A through hole communicated with the containing space is formed in a side of the shell. A penetrating hole is formed in a cylindrical main body contained in a cable protection sleeve and the outer wall of the cylindrical main body is in interference fit with the inner wall of the through hole. The insulating protection sleeve comprises a first connection part and a second connection part, wherein the first connection part and the second connection part are arranged in the containing space. The second connection part penetrates through a lower shell body of the shell and is connected with a first fixation nut. A contact pin terminal comprises a long-bar-shaped body, a limiting round disc and a cable connector, wherein the long-bar-shaped body, the limiting round disc and the cable connection head are integrally formed. A second wiring hole is formed in a jack terminal. A cable penetrates through the penetrating hole and is electrically connected with the second wiring hole. The free end of the cable connector penetrates through the second wiring hole and is connected with a second fixation nut. A second end of the long-bar-shaped body penetrates through the first connection part and the second connection part and is electrically connected with an electric device. The cable connector solves the problem of stress on a cantilever beam and has universality and interchangeability.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

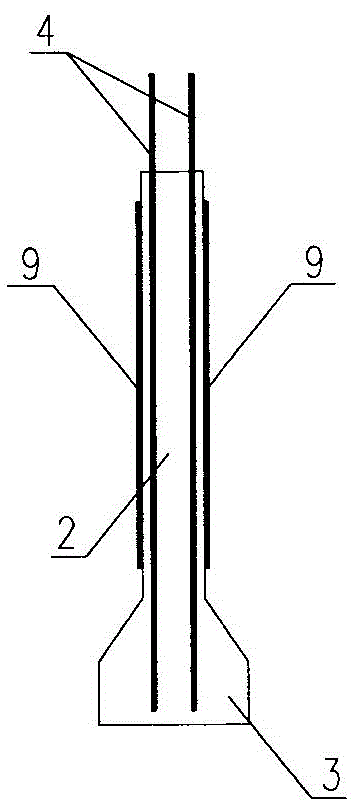

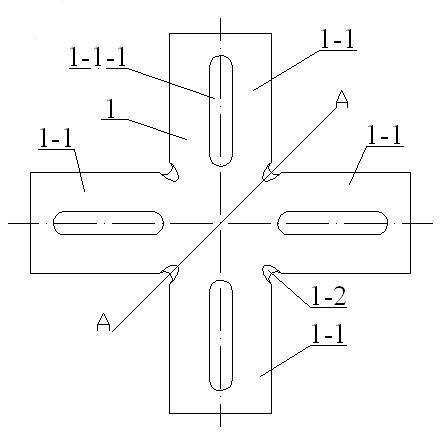

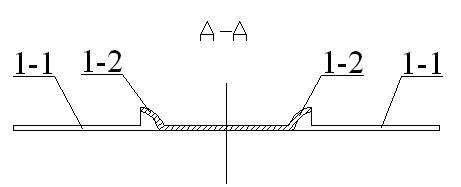

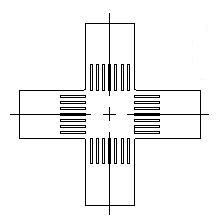

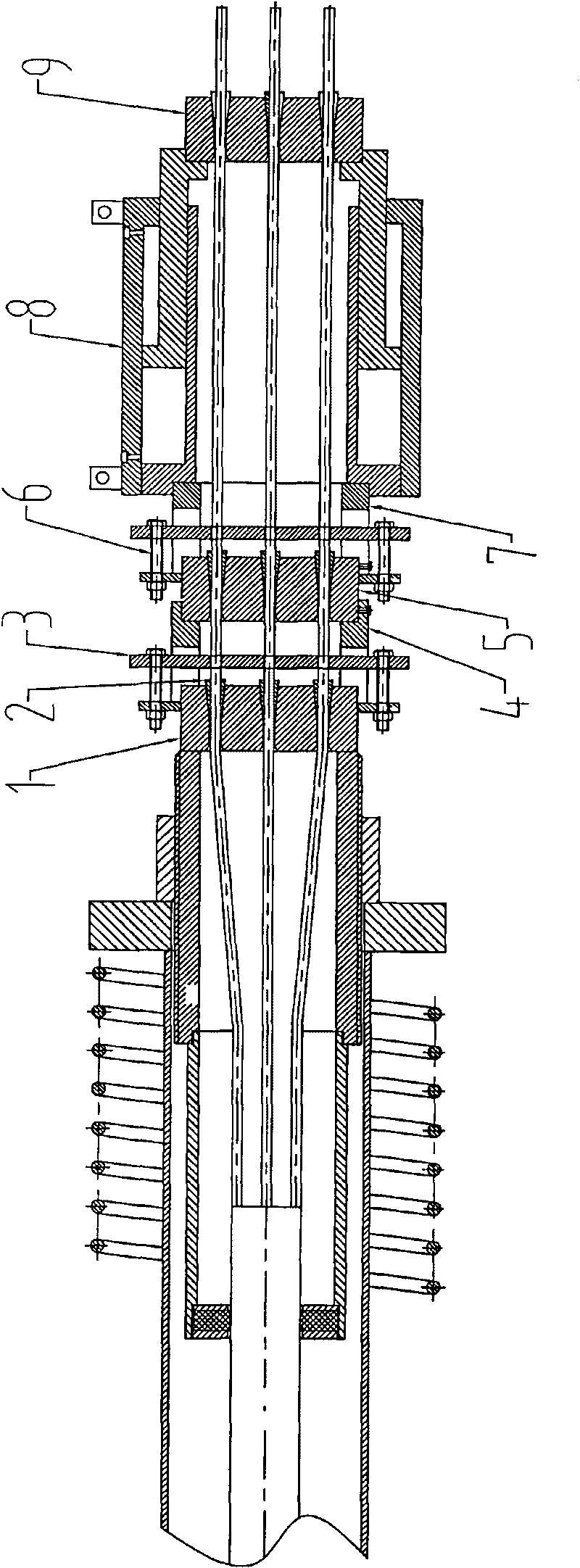

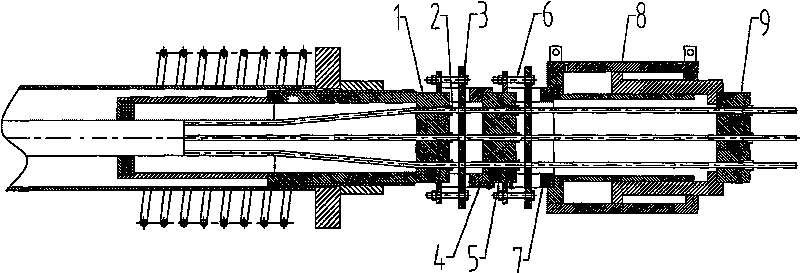

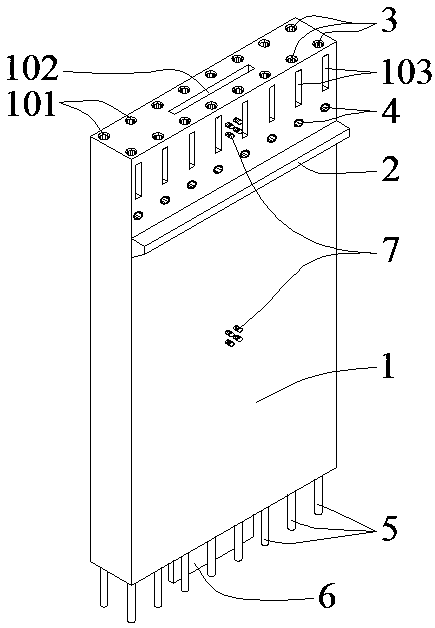

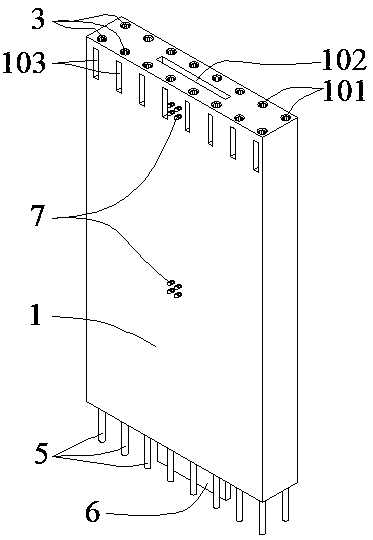

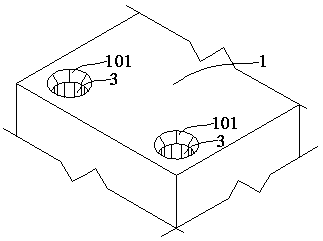

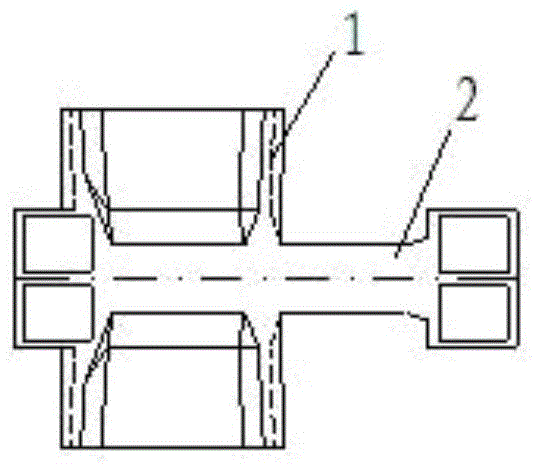

Three-dimensional cross-shaped biaxial tension test piece

InactiveCN101893532AReduce the impactSolve the force problemStrength propertiesEngineeringLarge deformation

The invention provides a three-dimensional cross-shaped biaxial tension test piece. The invention relates to a biaxial tension test piece. The invention solves the problems that stress at the center of the existing cross-shaped test piece is nonuniform and large deformation can not be achieved. The invention is composed of one cross-shaped tension piece (1), the end face at the junction of each two adjacent arms of the four arms (1-1) on the cross-shaped tension piece (1) is provided with a pit (1-2), and the four pits (1-2) are arranged on the same side of the cross-shaped tension piece (1). The invention is used for providing a biaxial tension test piece, so as to test the biaxial tension property of plate and obtain accurate material model.

Owner:HARBIN INST OF TECH

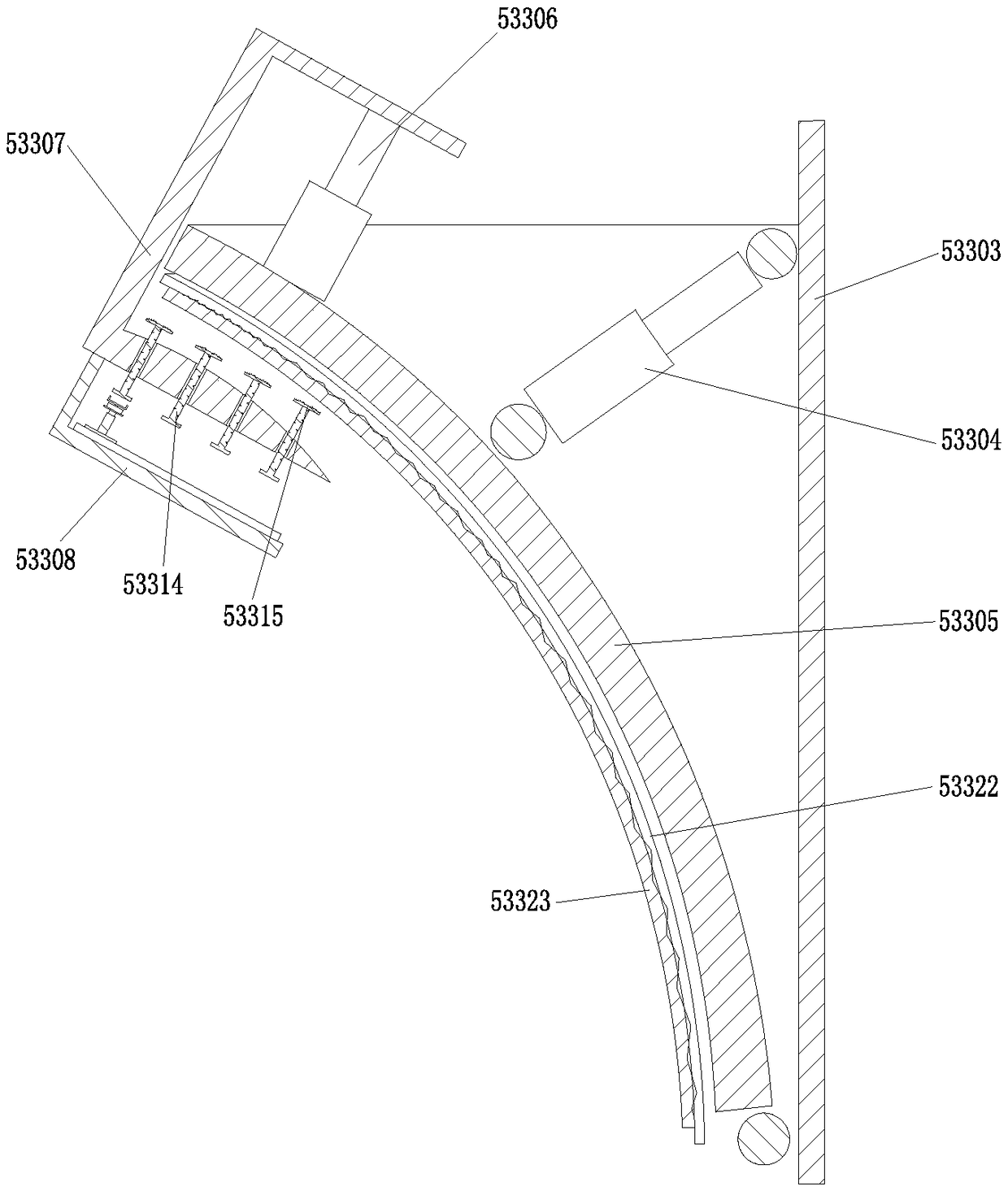

Two arm-brace stretching method of arc bridge tie bar cable

The invention discloses a two arm-brace stretching method of an arc bridge tie bar cable, comprising the following steps of: sequentially installing a working anchor, a working anchor arm brace, a rear tool anchor, a tool anchor arm brace, a hydraulic jack and a front tool anchor, enabling the working anchor and the rear tool anchor in a loosening state, clamping a prestressing steel strand by using the front tool anchor and stretching an oil cylinder by using the hydraulic jack to feed oil and pushing the front working anchor for stretching the prestressing steel strand; stopping the stretching of the oil cylinder by using the hydraulic jack to feed oil when the hydraulic jack reaches the maximum stroke, clamping the prestressing steel strand by using the rear tool anchor to enable the front tool anchor to be in a loosening state and stretching the oil cylinder by using the hydraulic jack; carrying out next round of stretching operation after stretching the oil cylinder by using the hydraulic jack to return oil in place; and clamping the prestressing steel strand by using the working anchor when the prestressing steel strand reaches the requirement. In the stretching process, a working clamping piece of the working anchor is not forced, thus the invention solves the problems that the work clamping piece of the working anchor is repeatedly forced and teeth are blocked in the stretching process of a long steel strand cable in the prior art and prolongs the service life of the working anchor.

Owner:中铁大桥(郑州)缆索有限公司

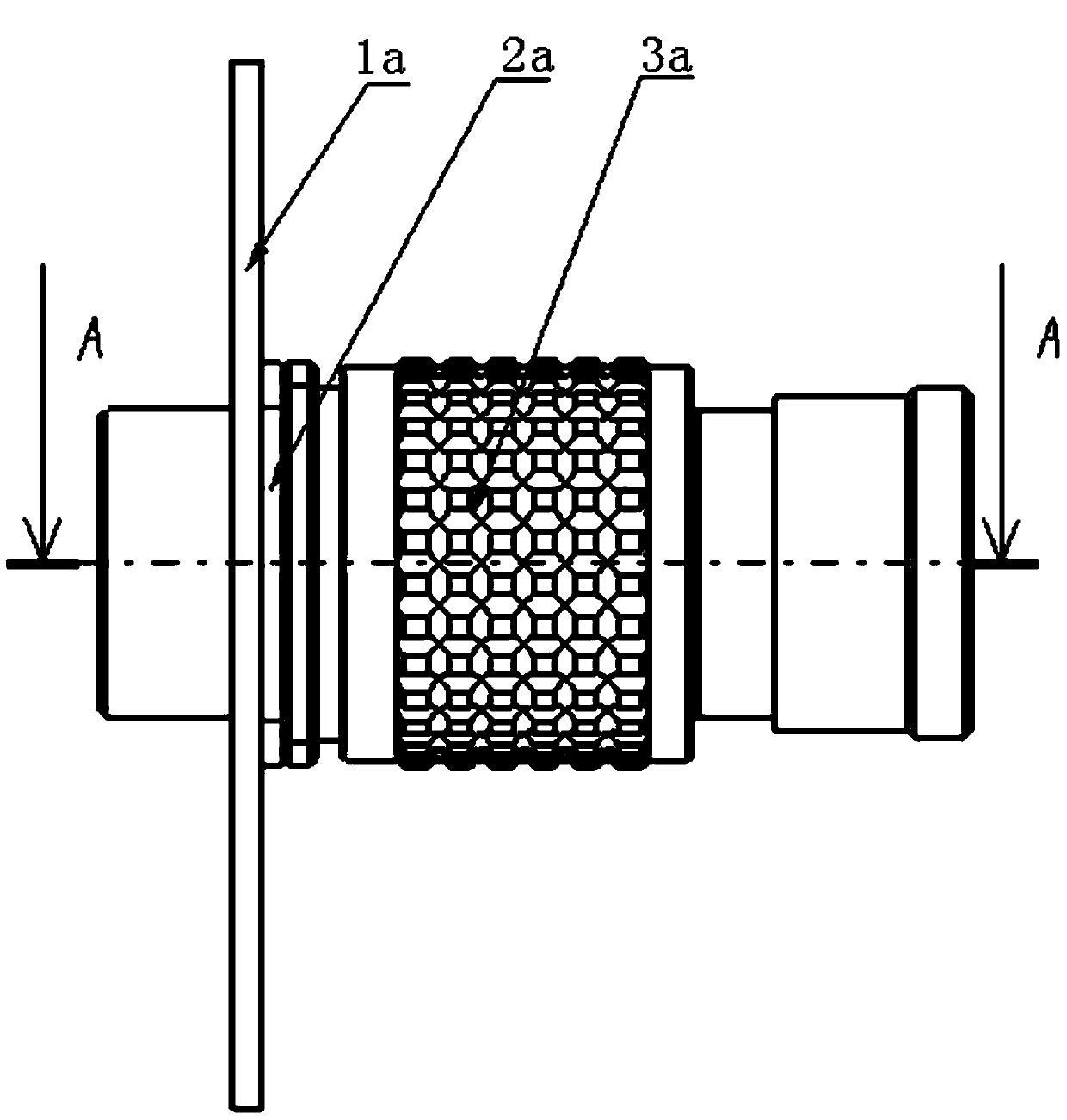

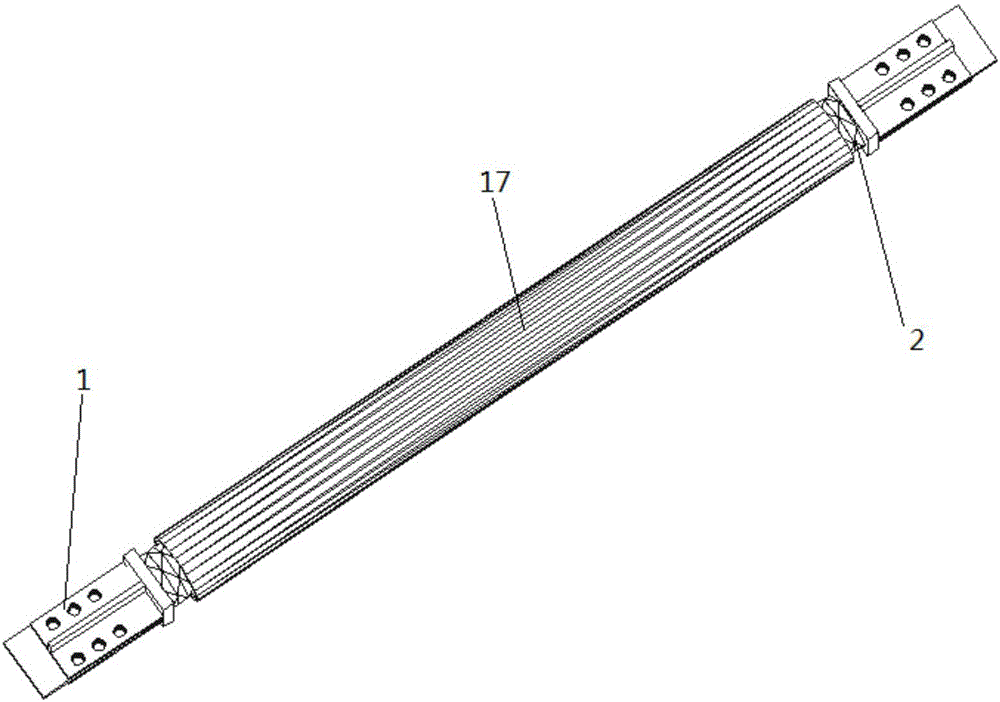

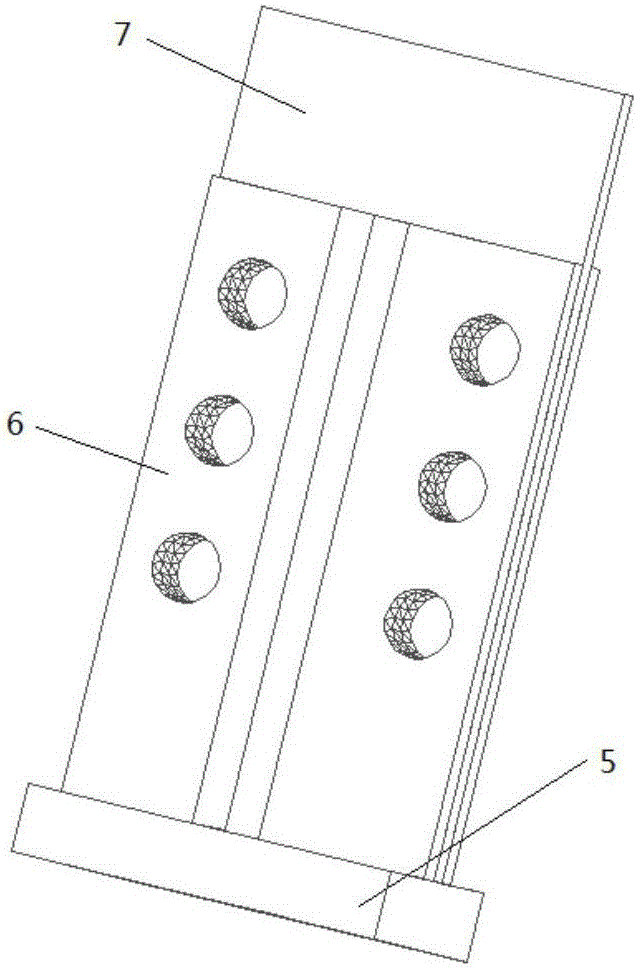

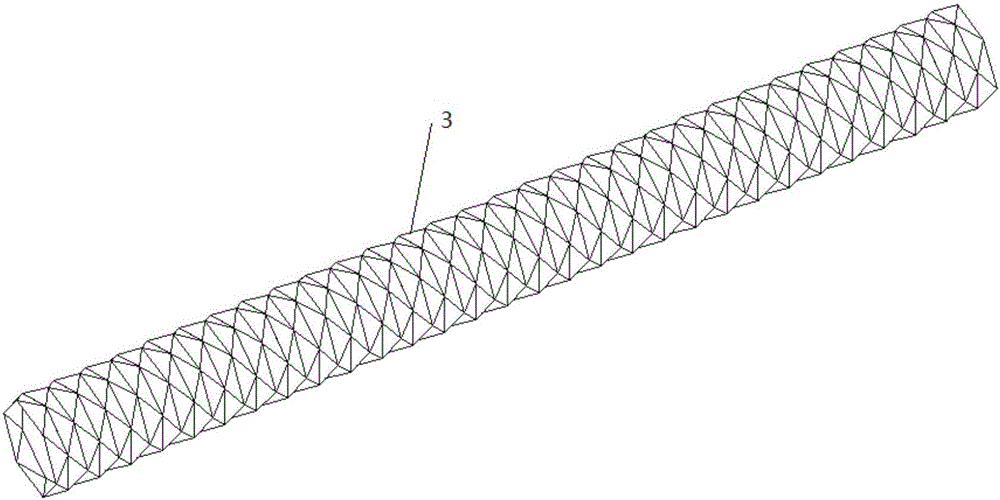

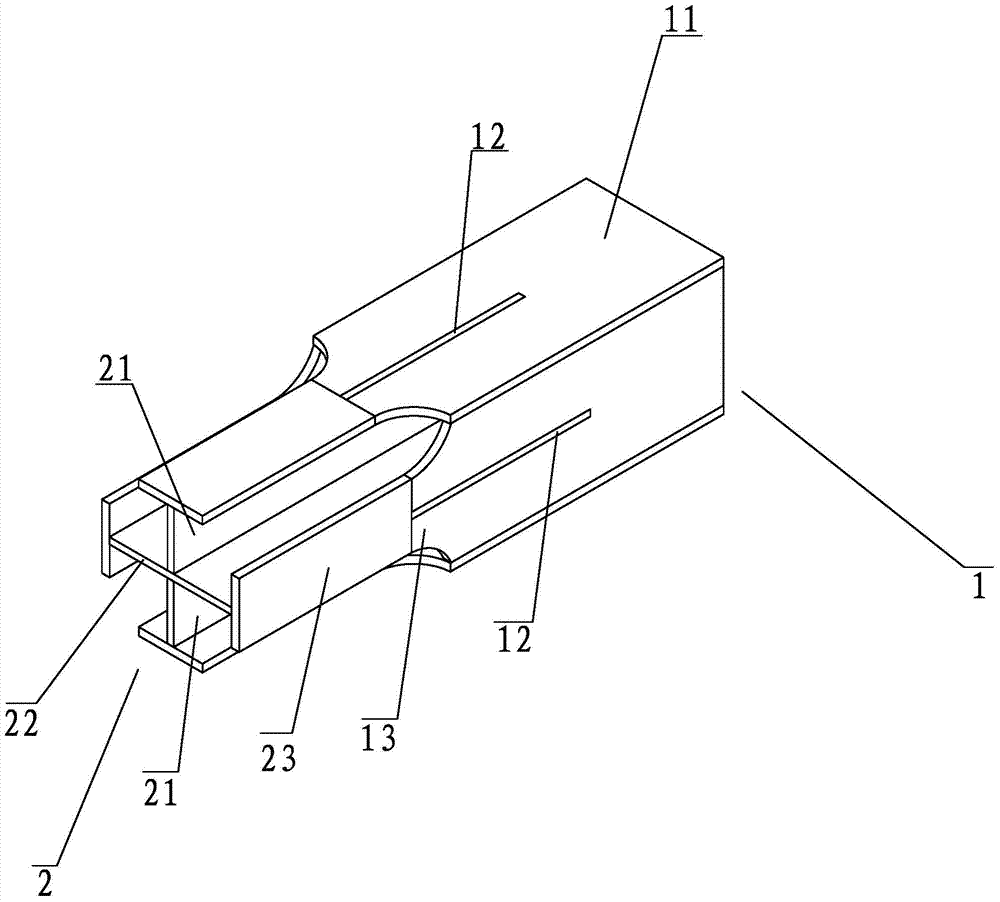

Bush constraint buckling-preventing support with diamond-shaped energy dissipation unit

ActiveCN105971355AFlexible layoutImprove protectionProtective buildings/sheltersShock proofingBuckling-restrained braceSnubber

The invention discloses a bush constraint buckling-preventing support with a diamond-shaped energy dissipation unit. The bush constraint buckling-preventing support is characterized in that the bush constraint buckling-preventing support comprises an end constraint segment, an energy dissipation segment and a bush; and the two ends are connected with beams or column components or nodes to form a whole through bolts so as to achieve the purpose of improving of the resistant-lateral rigidity of components. The bush constraint buckling-preventing support with the diamond-shaped energy dissipation unit is adopted, and thus under the action of a small earthquake, the bush constraint buckling-preventing support keeps elasticity; and under the action of a medium earthquake or a severe earthquake, the energy dissipation segment enters a yield stage, and the effect of a damper can further be achieved through the good hysteretic energy dissipation performance of the energy dissipation segment. The bush constraint buckling-preventing support with the diamond-shaped energy dissipation unit can be prefabricated and formed in a factory, the quality of the components is ensured, the workload of site operation is reduced, and energy conservation and environment protection are achieved.

Owner:SOUTHEAST UNIV

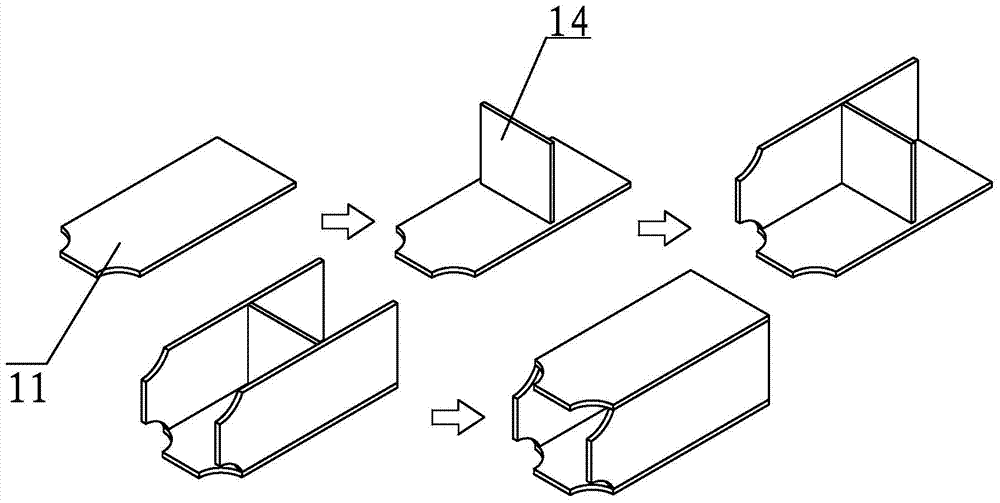

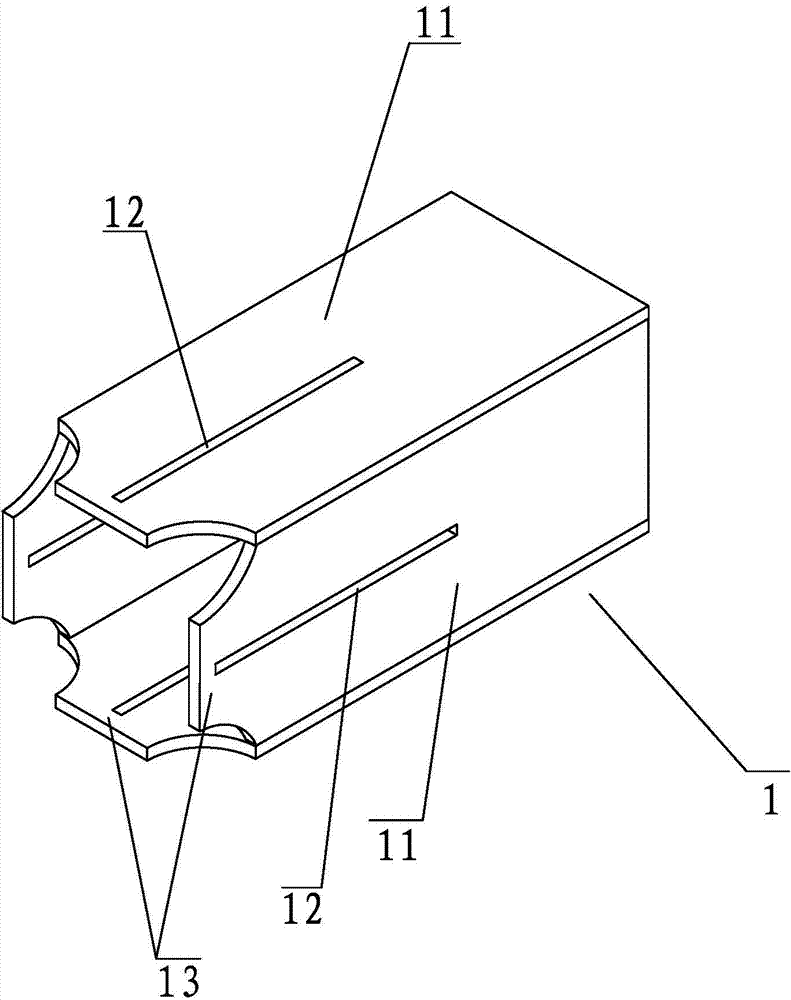

Cross box transfer structure and processing method thereof

ActiveCN104278751ASolve space problemsSolve environmental problemsBuilding constructionsSurface plateSteel structures

The invention belongs to the technical field of building steel structures, and in particular relates to a cross box transfer structure and a processing method thereof. The cross box transfer structure comprises a box post and a cross post, wherein the box post is defined by four blocks of box panels; the cross post is arranged in the box post, and is formed by welding of two small cross post webs and a large cross post web; one part of the cross post is exposed out of the box post; a cutting groove is formed in each box panel; each side of the cross post is correspondingly inserted and welded into the corresponding cutting groove; each side of the cross post is welded with a cross post wing plate; the cross post wing plates and the box panels are connected with each other and are arranged on the same horizontal plane. The processing method comprises the following steps: assembling the box post; forming the cutting grooves; cutting the large cross post web; assembling the cross post; integrally assembling and welding. The problems of complicated stress situations and difficulty in designing a member bar connection joint are solved, and the cross box transfer structure has the advantages of simple and reasonable structural design and the like.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

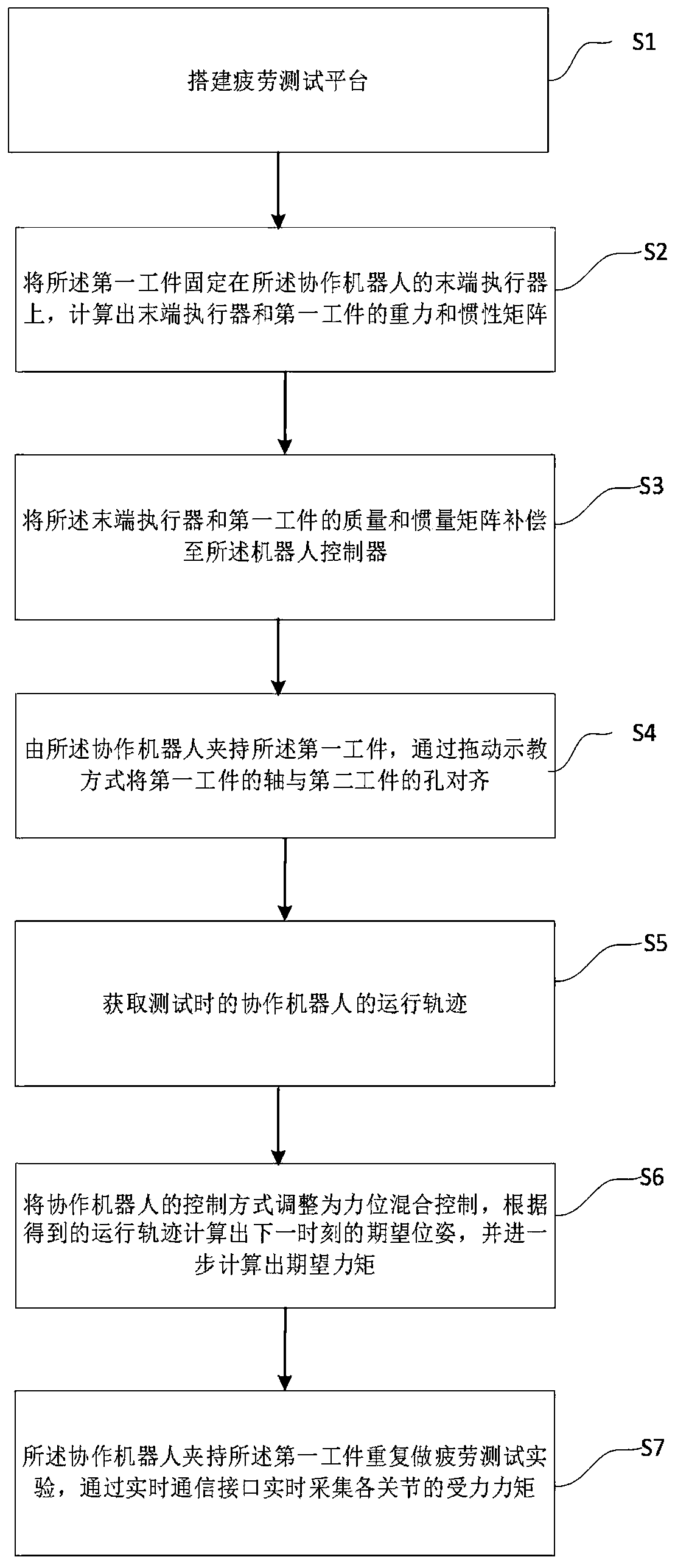

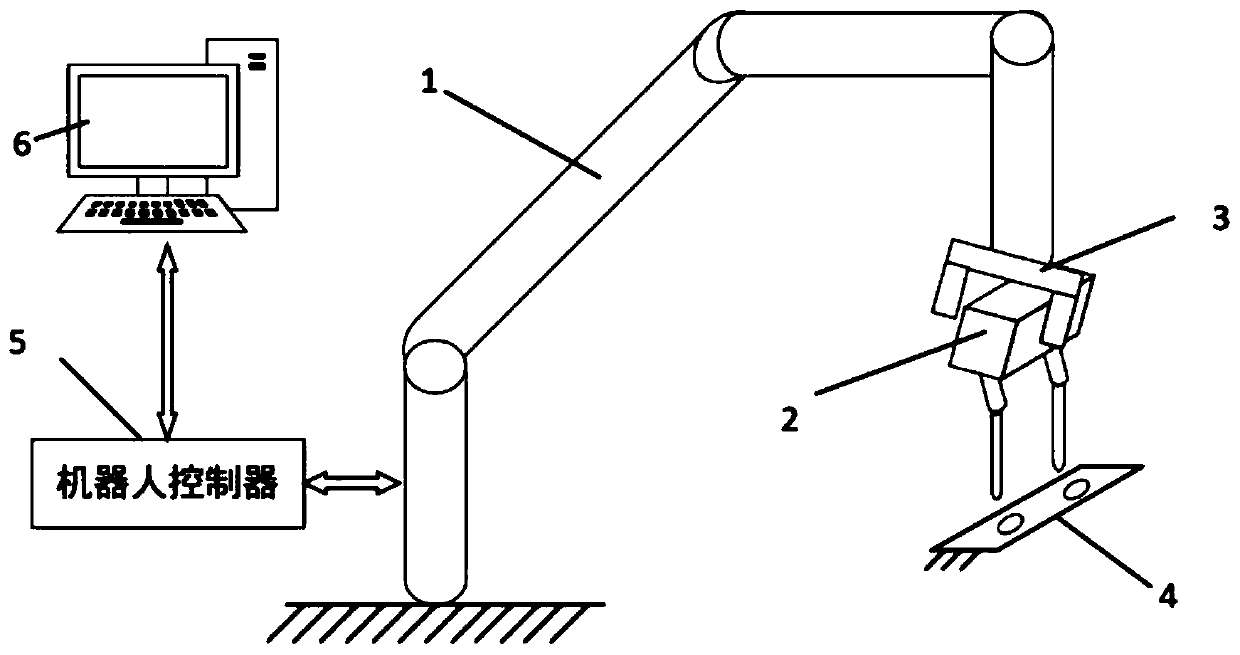

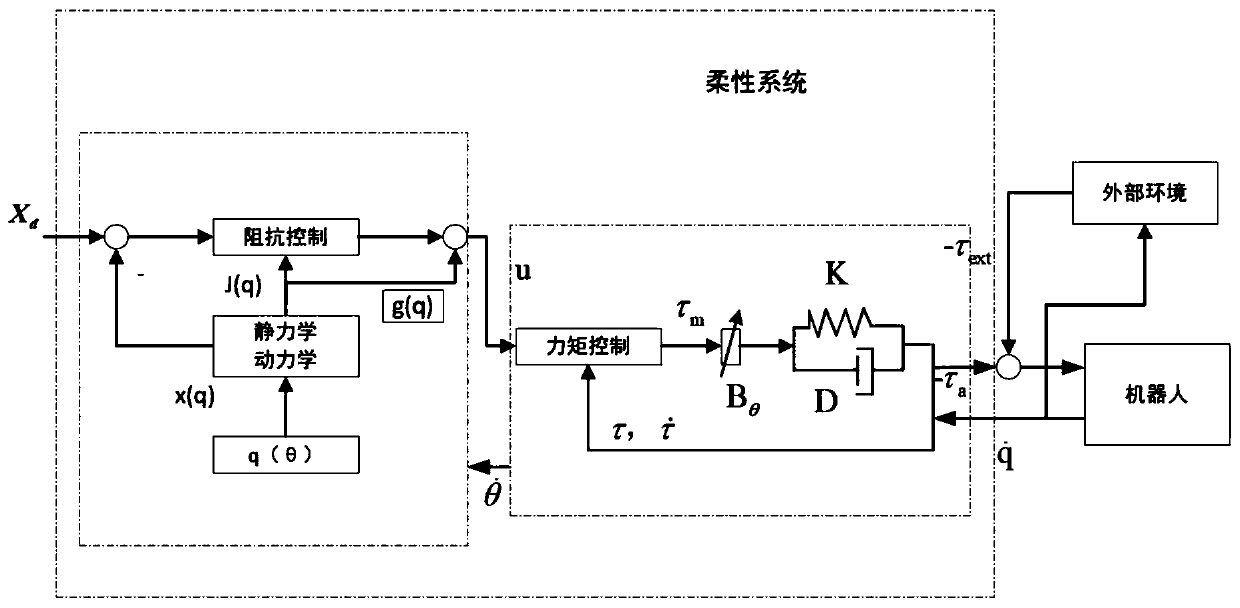

Workpiece fatigue testing method based on cooperation robot

ActiveCN110450143AAvoid Rig Structural DesignVersatilityProgramme-controlled manipulatorEngineeringActuator

The invention provides a workpiece fatigue testing method based on a cooperative robot. The workpiece fatigue testing method comprises the steps that a fatigue testing platform is built; a first workpiece is fixed on an end effector of the cooperative robot, and the gravity and the inertia matrix of the end effector and the first workpiece are calculated; the mass and inertia matrix of the end effector and the first workpiece are compensated to a robot controller; the first workpiece is clamped by using the cooperation robot, and an axis of the first workpiece and a hole of a second workpiececan be aligned through dragging a teaching mode; the running track of the cooperative robot is acquired during testing; a control mode of the cooperative robot is adjusted to be a force position mixing control, an expected pose of the next moment is calculated according to the obtained running track, and the expected moment is further calculated; the first workpiece is clamped by the cooperative robot to perform a repeated fatigue test experiment, and the stress moment of each joint in real time is acquired through a real-time communication interface. According to the workpiece fatigue testingmethod based on the cooperation robot, active flexibility is realized from a control angle, complicated special machine structure design is avoided, and universality is achieved.

Owner:珞石(武汉)机器人有限公司

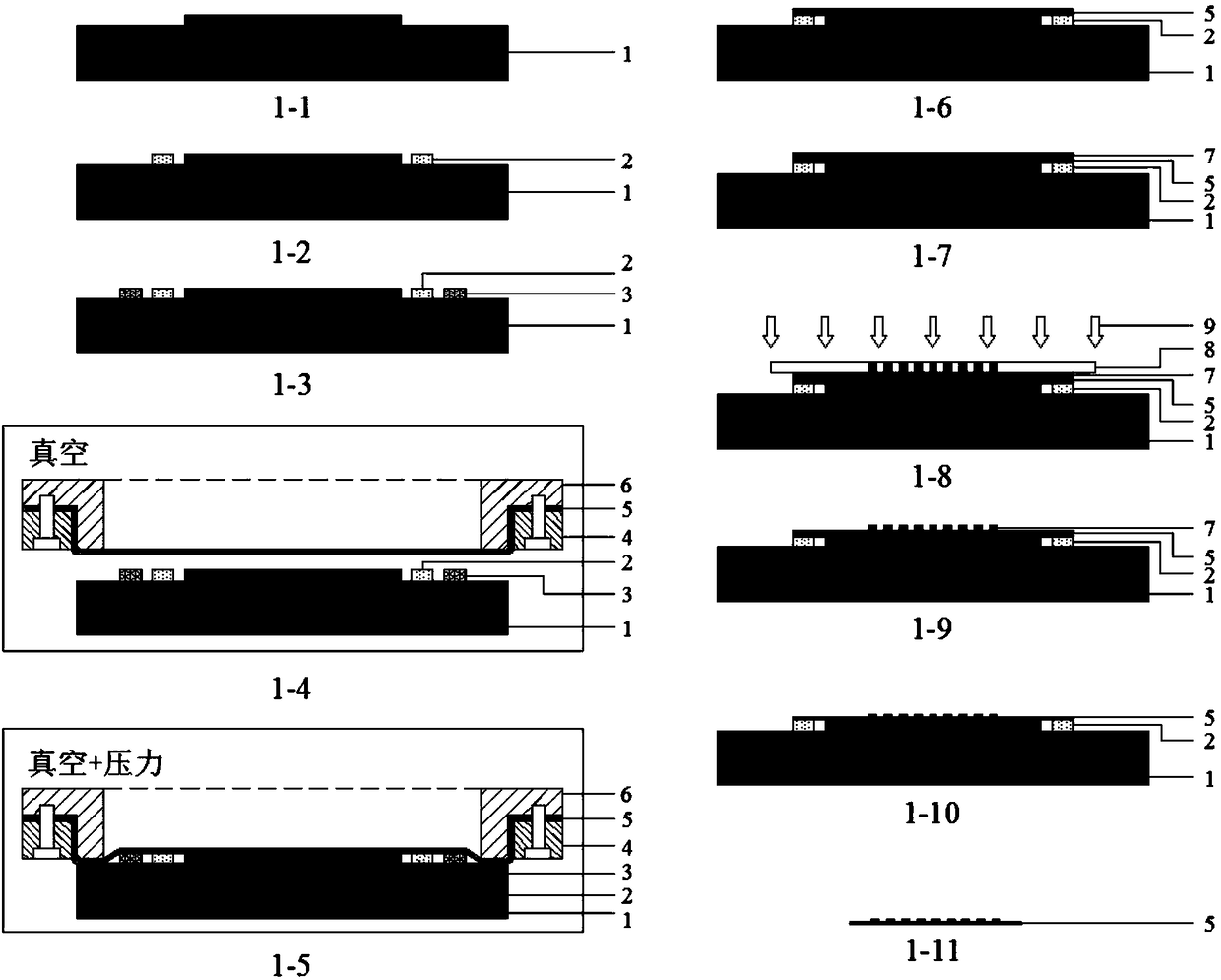

High-precise preparation method of micro-nano structure on flexible film substrate

ActiveCN108467008ARealize the purpose of "hardening"Solve operational problemsPrecision positioning equipmentDecorative surface effectsMicro nanoPressure difference

The invention discloses a high-precise preparation method of a micro-nano structure on flexible a film substrate. The preparation method comprises the following steps: firstly closely laminating a tightened flexible film on a hard material substrate surface with high flatness in a gapless way to realize an aim of hardening the flexible film, wherein the stressed flexible film is not prone to produce deformation due to the pressure differential between the upper surface and the lower surface of the film and the friction force existent between the film and the substrate; and then preparing the micro-nano structure on the hardened flexible film by using the micro-nano processing technology; and finally taking down the flexible film with the high-precision micro-nano structure on the surface from a hard substrate. Compared with the existing processing method, the problem that the stressed flexible film is easy to deform and cannot be closely laminated on a mask in the micro-nano processingprocedure is solved, the line width precision and the location precision of the micro-nano structure are greatly improved, and the high-precision preparation of the micro-nano structure on the flexible film substrate is realized.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

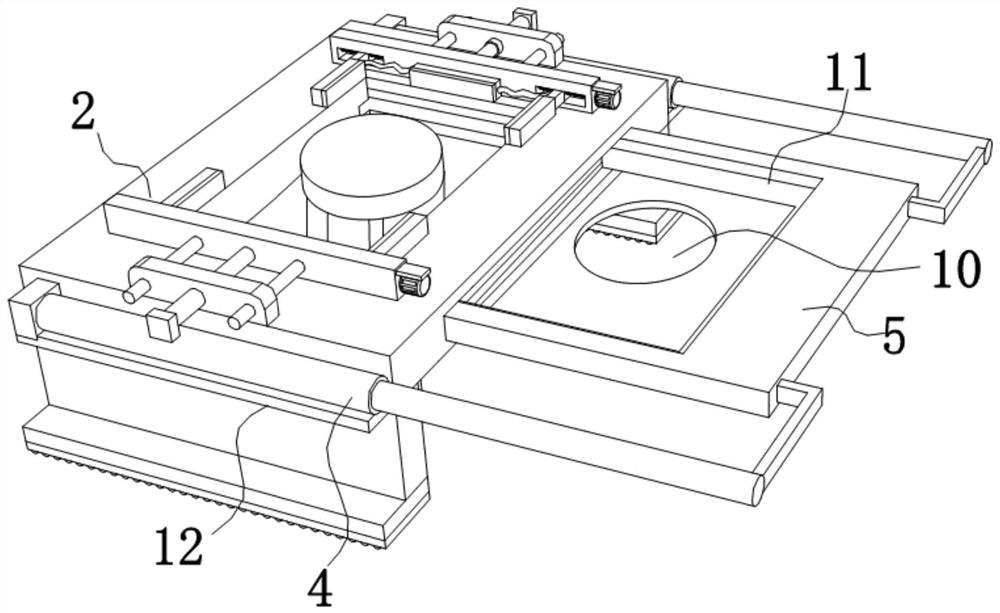

Rapid fixing clamp for aluminum alloy machining

InactiveCN112846874ASolve the problem of centering clampingQuick fixPositioning apparatusMetal working apparatusHydraulic cylinderElectric machinery

The invention belongs to the technical field of aluminum alloy machining auxiliary devices, and discloses a rapid fixing clamp for aluminum alloy machining. The rapid fixing clamp comprises a fixing table and an aluminum alloy plate, the fixing table is symmetrically provided with two clamping assemblies, each clamping assembly comprises a fixing plate, a hydraulic cylinder is arranged in the interior of each fixing plate in a penetrating mode, a movable plate is arranged at the output end of each hydraulic cylinder, a first sliding groove is formed in the interior of each movable plate, a lead screw is rotationally connected to the interior of each first sliding groove through a bearing, a supporting plate is arranged on one side of each movable plate, a motor is arranged on one side of each supporting plate, an output shaft of each motor penetrates through each movable plate to be fixedly connected with each lead screw, and two receding grooves are formed in one side of each movable plate. According to the rapid fixing clamp for aluminum alloy machining, through the arrangement of a feeding frame, the two clamping assemblies and a lifting plate, the aluminum alloy plate can be quickly centered and fixed, the conditions of clamping deformation and cutting stress deformation of the aluminum alloy plate in the machining process are avoided, the good shock absorption effect is achieved, and the clamping effect and the working efficiency of the device are improved.

Owner:陈云

Production of high-strength polyester abrasive cloth

ActiveCN101028704AImprove water resistanceWith dry and wet grinding performanceGrinding devicesPolyesterPolymer science

A process for preparing high-strength polyester-type abrasive cloth features that its substrate cloth is pretreated by high-tension stretching and hot shape-fixating and finishing. Its apparatus has additionally two high-tension stretching unit, a group of 10 high-temp ironing drums and a baking room at 190-210 deg.C.

Owner:新沂市张氏磨具发展有限公司

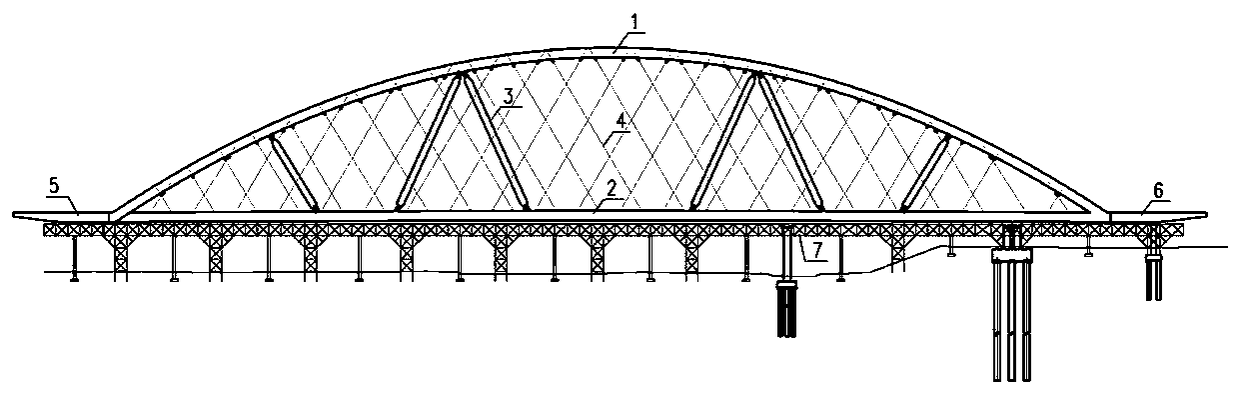

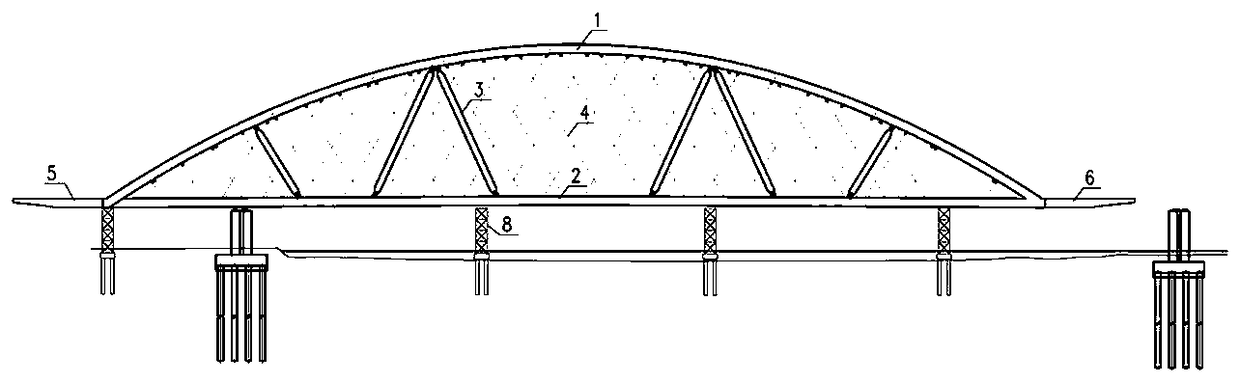

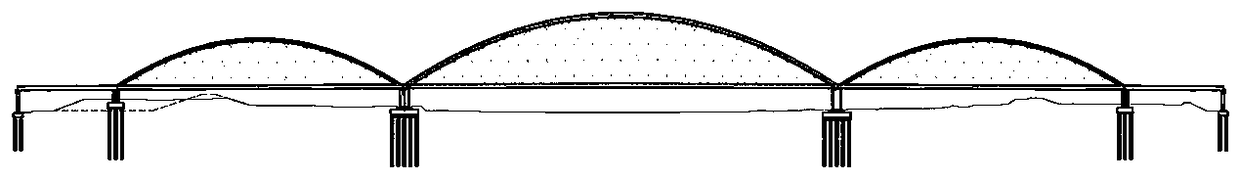

Pushing construction method for a large-span composite arch bridge with adjustable construction state

PendingCN109252454AGuarantee joint forceReduce in quantityBridge erection/assemblyArch-type bridgeEngineeringStressed state

The invention relates to a pushing construction method for a large-span composite arch bridge with adjustable construction state, which is characterized in that a steel arch, a steel beam, a hanger and a connecting steel arch, a temporary strut of a steel beam are assembled into a beam-arch composite system on the shore in advance, and the suspension rods are pretensioned. In the process of pushing the composite arch bridge with suspension rods and temporary struts as a whole, the construction state is adjusted by optimizing the tension of suspension rods based on the structural function of component stress limits. The construction method adjusts the stress state of the composite arch bridge in real time by adjusting the tension of the suspension bar, to some extent, it ensures the cooperation of arch and beam, improves the mechanical performance of the structure, reduces the number of temporary piers and arch beam temporary struts in water, reduces the complexity of the structure construction, and has high popularization value in applicability, economy, construction quality, construction period and other aspects, which is of pioneering significance for similar projects in the future.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

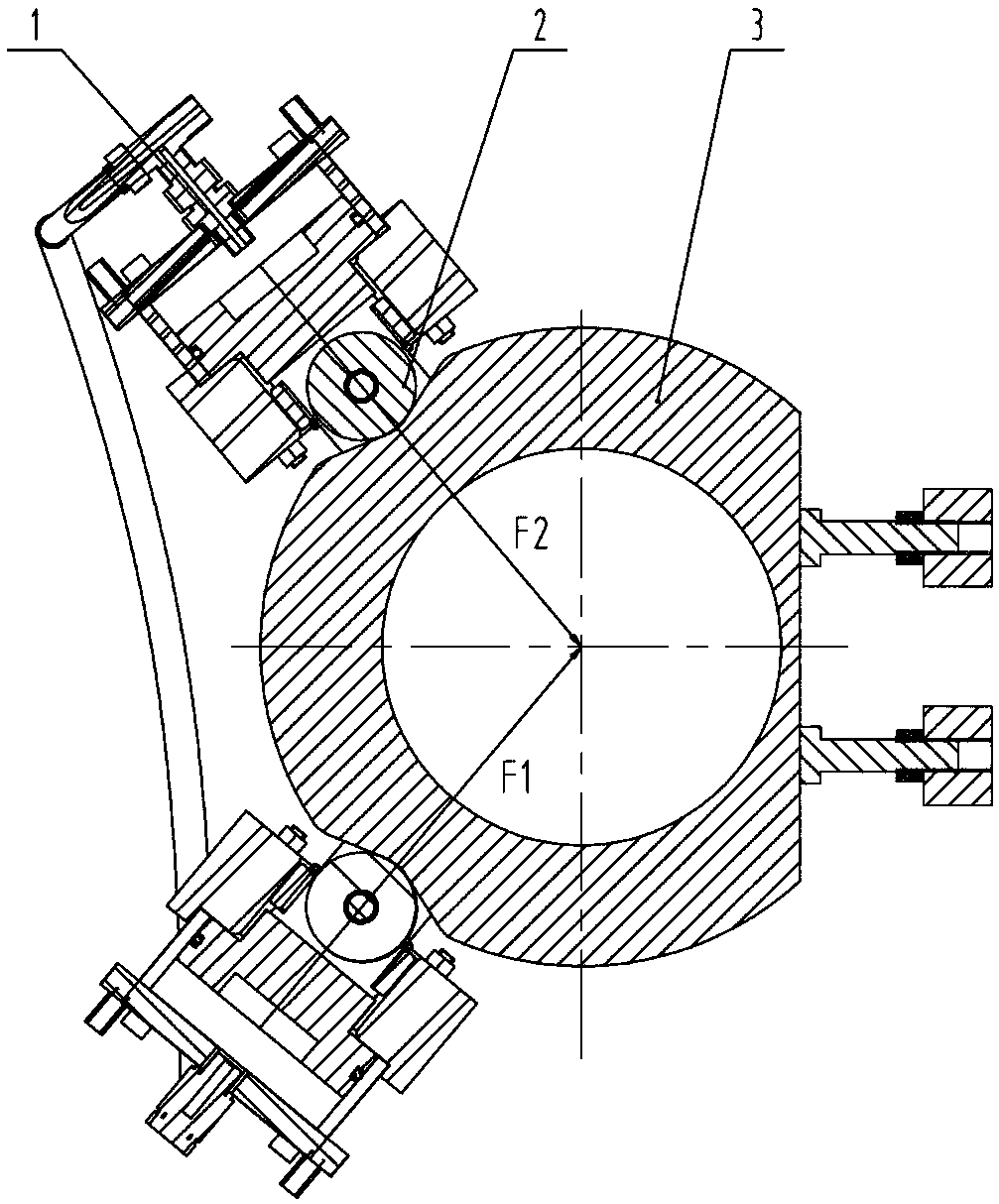

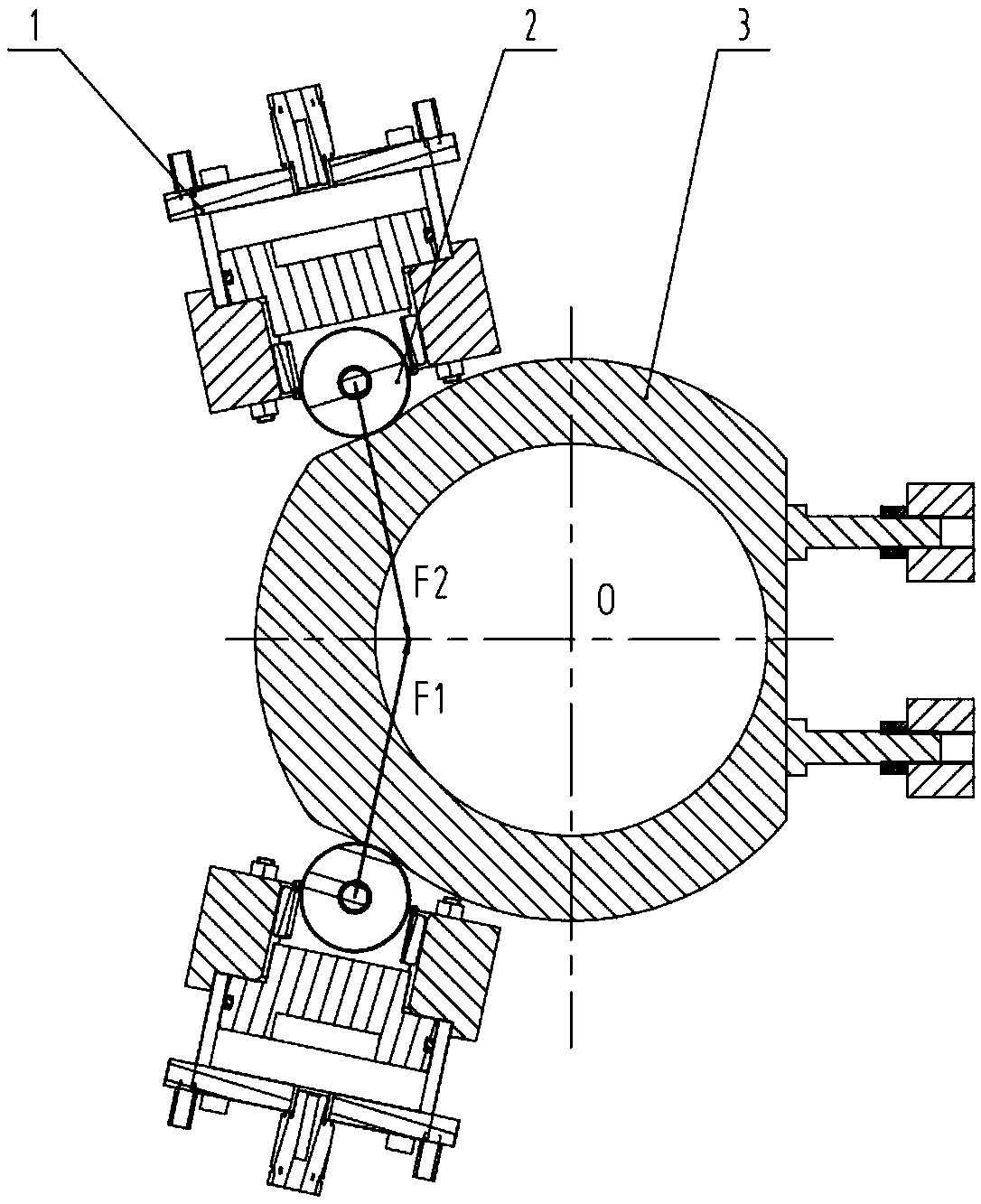

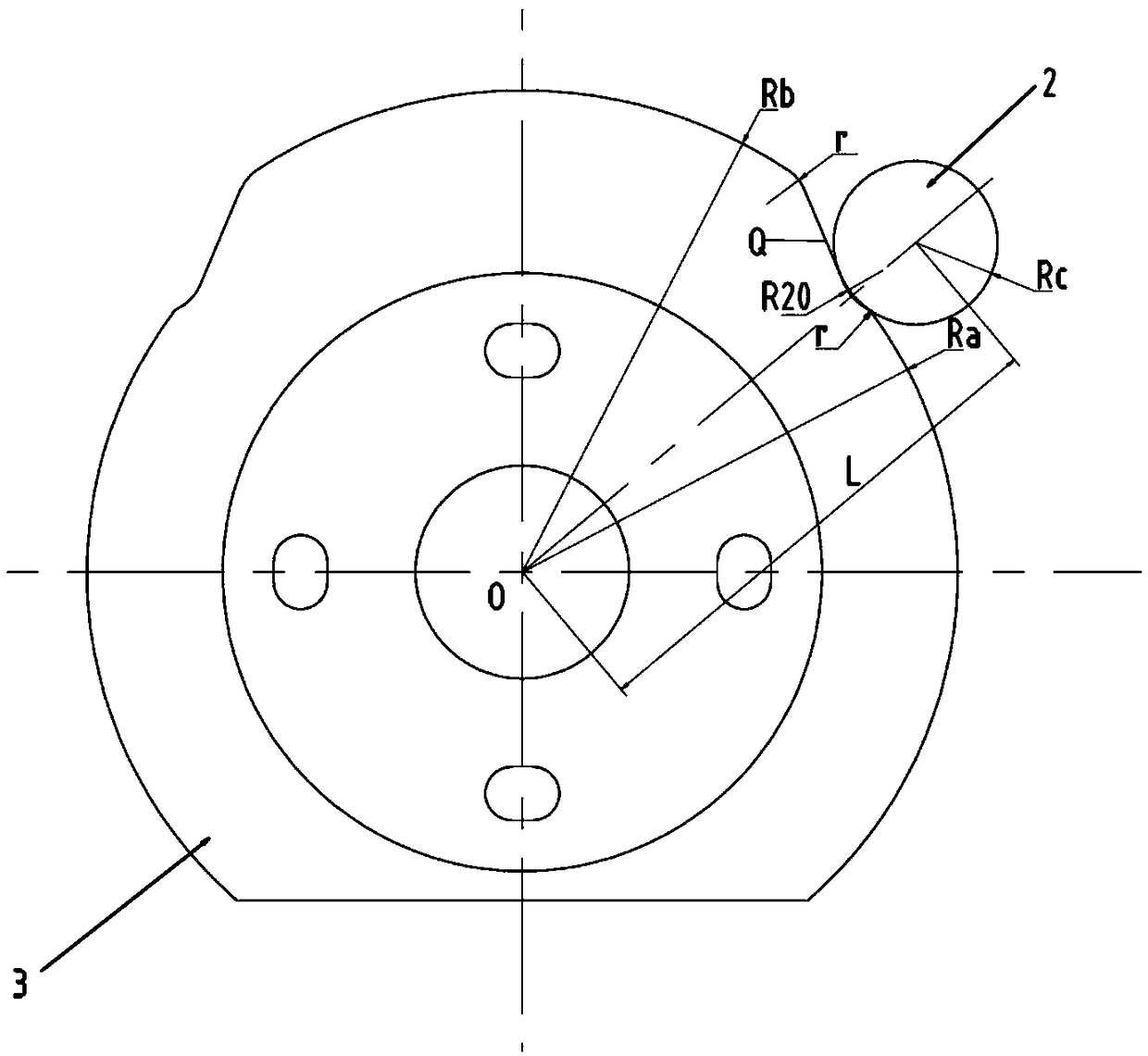

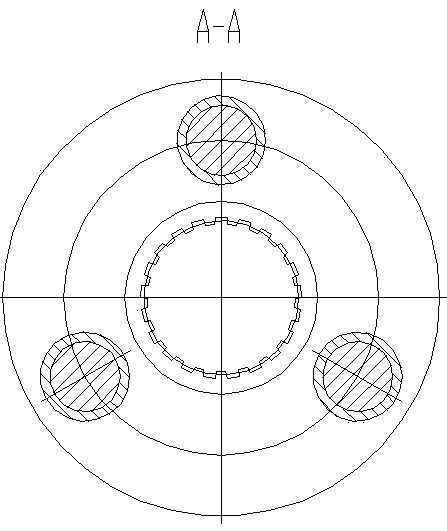

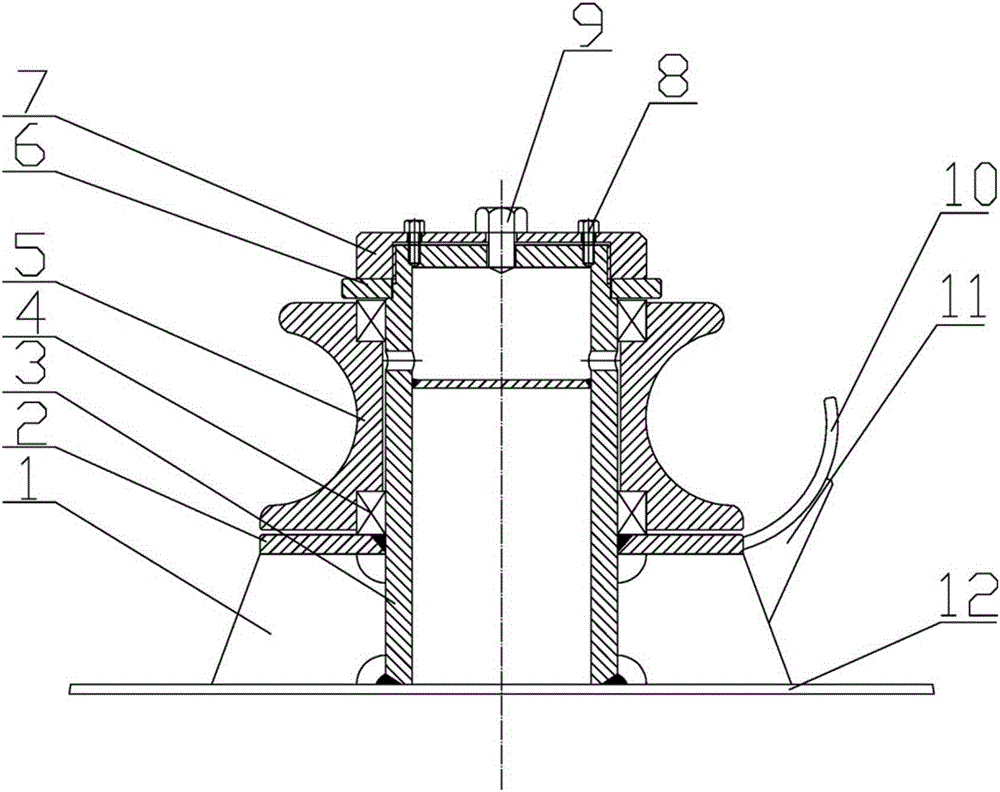

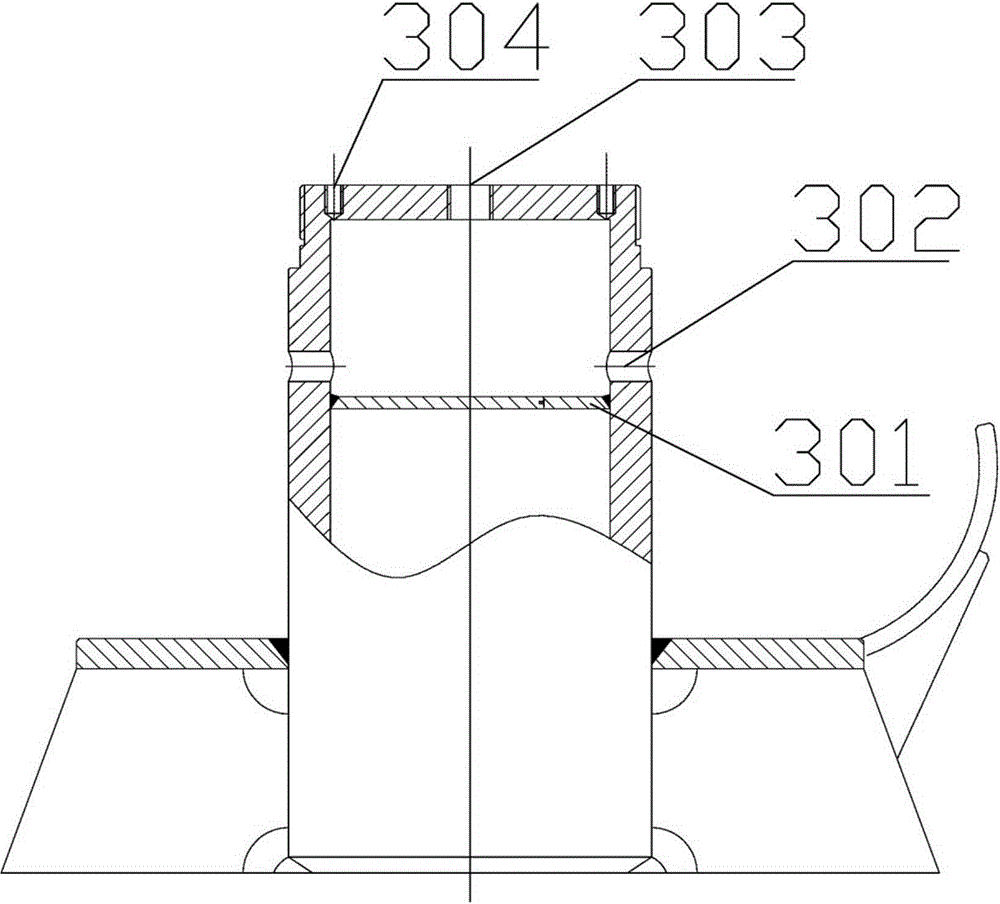

Centering supporting mechanism, car coupler buffering device adopting centering supporting mechanism and centering method

PendingCN109278787ASolve the force problemSolve the problem of force dislocationRailway coupling accessoriesMobile vehicleCoupling

The invention relates to a centering supporting mechanism, a car coupler buffering device adopting the centering supporting mechanism and a centering method, and belongs to the technical field of moving vehicles. The centering supporting mechanism comprises a centering disc forming the car coupler swing center, and pressuring devices located on two sides of the extending direction of a car coupler. The pressuring devices form cam pairs with centering grooves of the centering disc by idler wheels. The centering grooves are close to the small diameter section of the centering disc, and are connected with the large diameter section of the centering disc by a diameter-increasing curve. The pressuring directions of the pressuring devices departure the swinging center of the centering disc towards the large diameter section by idler wheel centers falling into the centering grooves. The problems of automatic coupling of vehicles on a curved track and roller force dislocation are cleverly solved by simple and reasonable design for the centering disc profile combined with pressure bias.

Owner:QINGDAO SRI TECH CO LTD

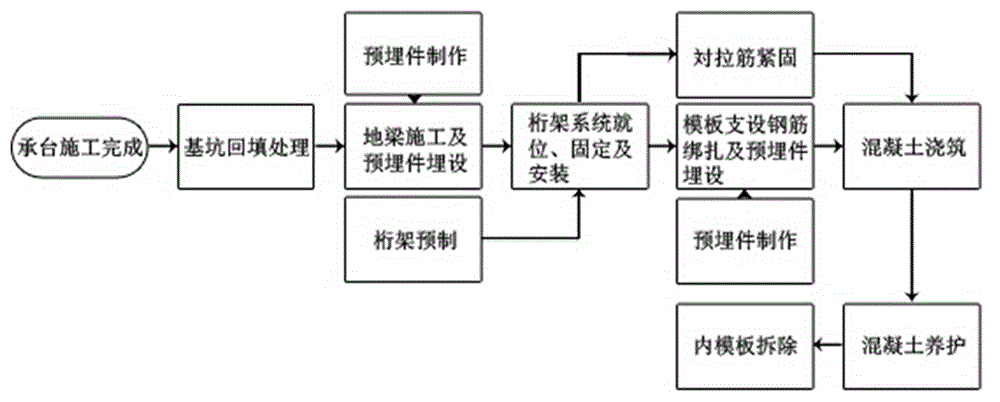

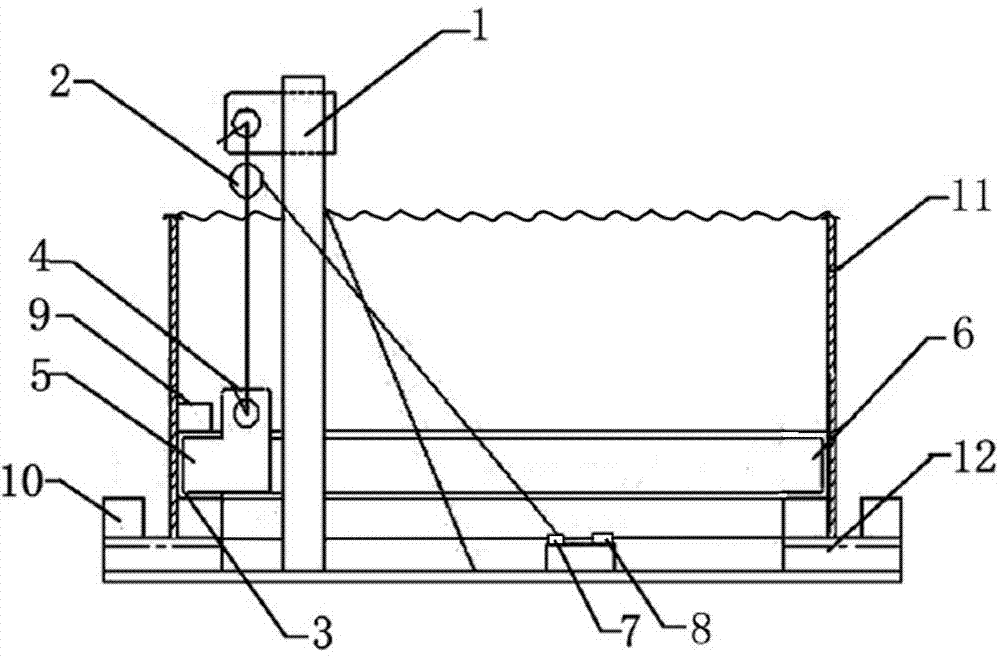

V-shaped pier outer support construction method

ActiveCN104929047ASolve the force problemEnsure safetyBridge erection/assemblyArchitectural engineeringRebar

A V-shaped pier outer support construction method comprises preparation work before construction, foundation pit refilling and processing, ground beam truss foundation construction, right-angle truss installation, pier rebar and formwork installation, fine rolling and rough twisted steel installation, V-shaped pier concrete pouring, V-shaped pier formwork and right-angle truss dismounting and other procedures. By means of the comprehensive application of two construction technologies of opposite pulling of a right-angle truss and fine rolling twisted steel, the single item construction technology is simple, and operation is easy. Compared with a traditional construction method, it is guaranteed that the integrity of a V-shaped pier is kept, no large circulation component penetrates through an inclined leg, additional bending moment cannot be produced at the bottom, and cracks cannot be produced either; the input of circulation materials is little. Meanwhile, the construction safety is guaranteed, the construction process is improved, and the construction cost is reduced.

Owner:SHENYANG MUNICIPAL GROUP

Tank body assembling electric lifting system by flip chip method and hoisting method thereof

InactiveCN102815609AGood strength and toughnessAvoid wear and scratchesLoad-engaging elementsLift systemExpansion joint

The invention provides a tank body assembling electric lifting system by a flip chip method, wherein the tank body assembling electric lifting system by the flip chip method comprises a plurality of electric lifting devices distributed uniformly in the inner side of a cylinder body and an expansion ring fixed on the inner wall of the cylinder body; the expansion ring is an enclosed circular ring with a concave clamping groove; each electric lifting device comprises a rack and an electric inverted chain hanged on the rack; and the electric inverted chain is connected with an expansion ring hanging fixture which is provided with a clamping body adaptive to the concave clamping groove on the expansion ring. The invention provides the lifting system and the hoisting method, and also discloses a lifting method of the tank body assembling by the flip chip method. The lifting system and the hoisting method provided by the invention not only overcomes the defect that the cylinder body rotates automatically during the lifting process and leads to inaccurate positioning, but also electric control is adopted for the full-distance lifting, the lifting system and the hoisting method are simple and feasible, not only relieves the labor intensity, but also lowers the assembling cost, improves the working efficiency, and increases the operation convenience and quickness and safety.

Owner:河北二十冶建设有限公司

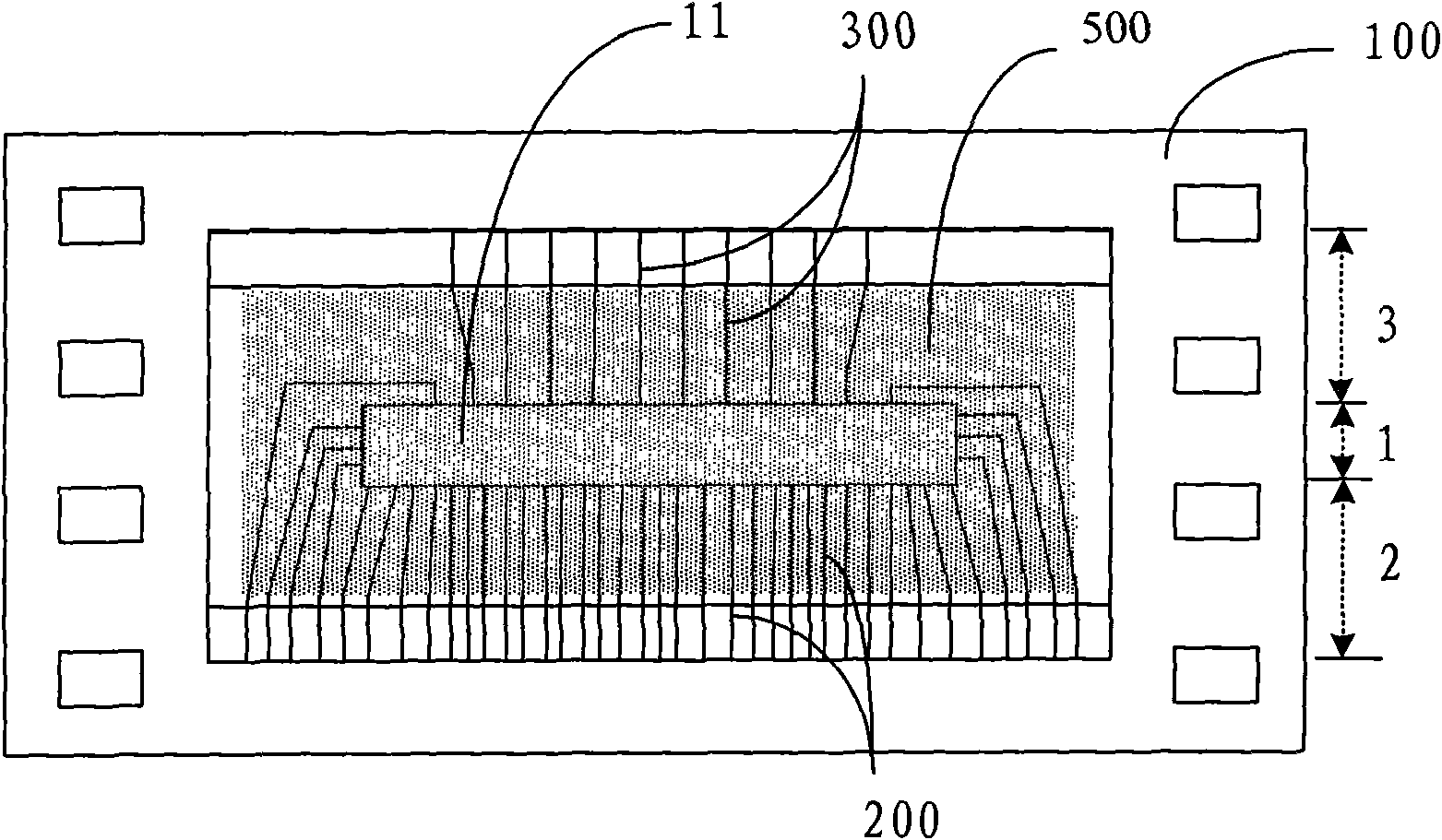

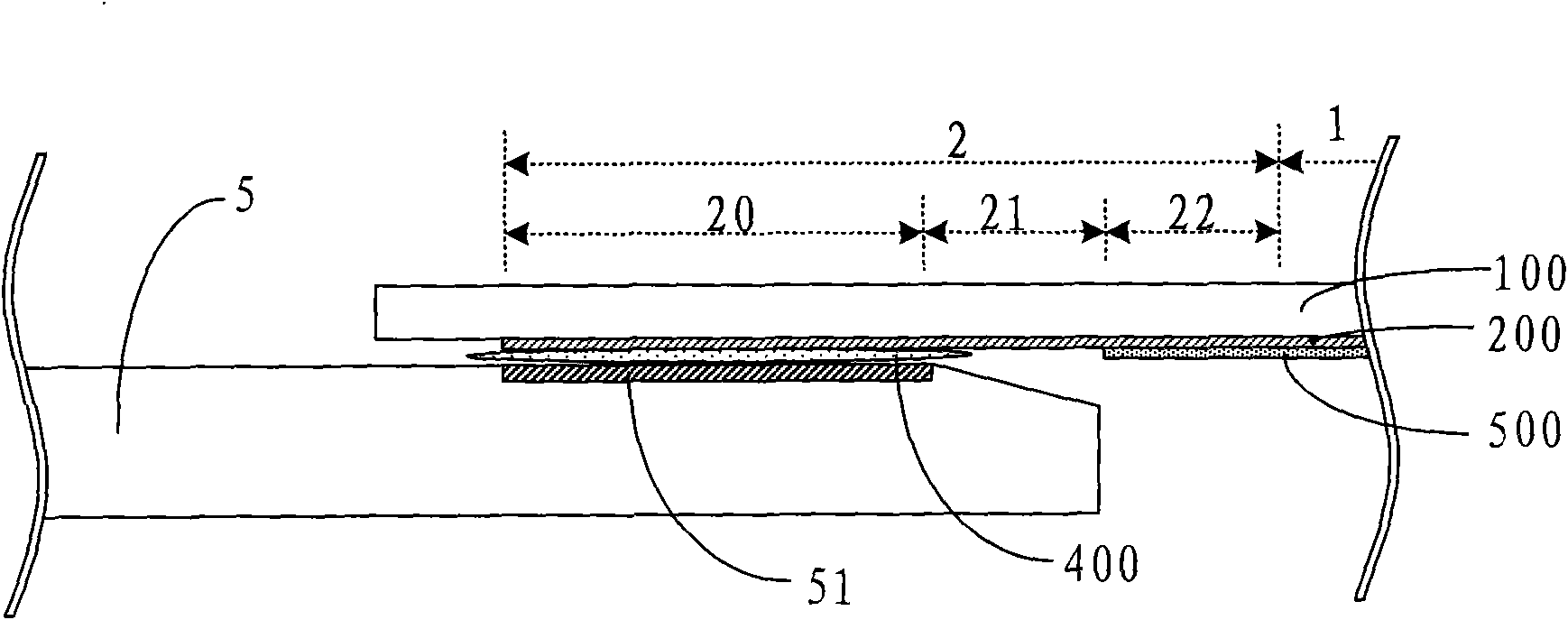

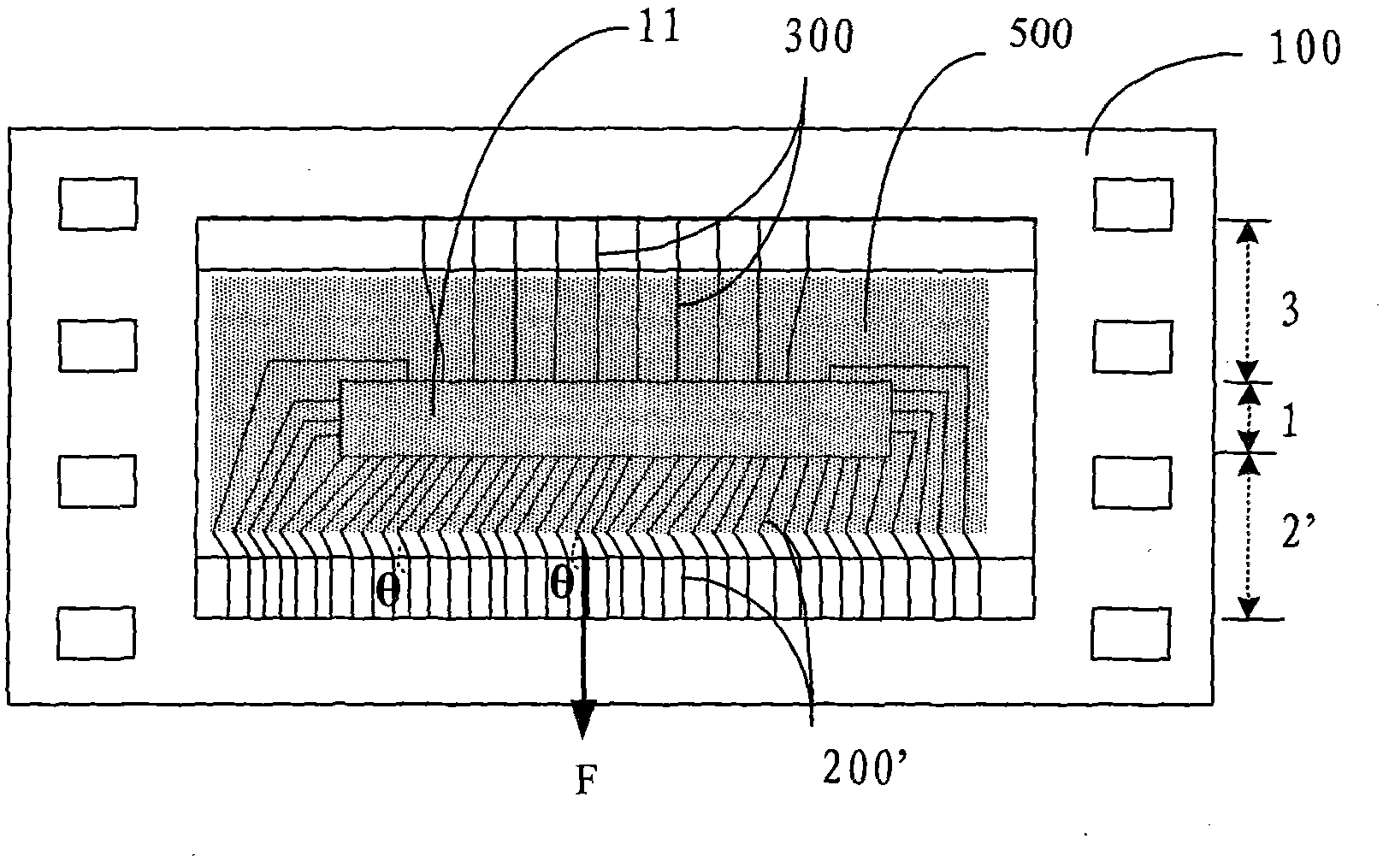

Flexible printed circuit board of flat panel display device

ActiveCN101820722AReduce stressSolve the force problemPrinted circuit detailsStatic indicating devicesEngineeringFlat panel display

The invention discloses a flexible printed circuit board of a flat panel display device, comprising a chip region, an array substrate side lead region and a driving circuit board side lead region, wherein the array substrate side lead region has a crimping region, an S / R covering region and an exposing region; and leads in the exposing region and the crimping region have an included angle which is not zero or 180 degrees; and the included angle can be a obtuse angle capable of tapering from the middle to the two sides. The invention effectively solves the problem of lead cracking or fracturing due to stress by forming slant leads in the exposed region of the flexible printed circuit board so as to decrease the stress of the leads.

Owner:BOE TECH GRP CO LTD +1

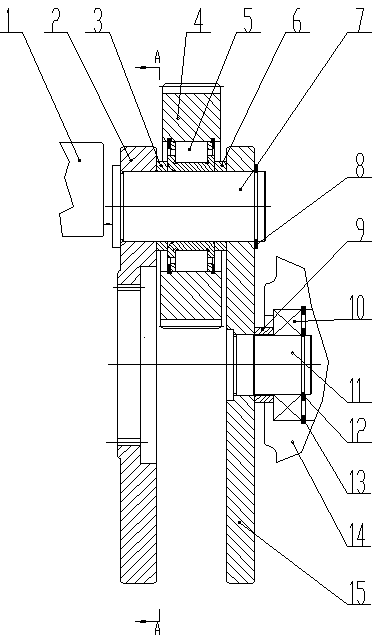

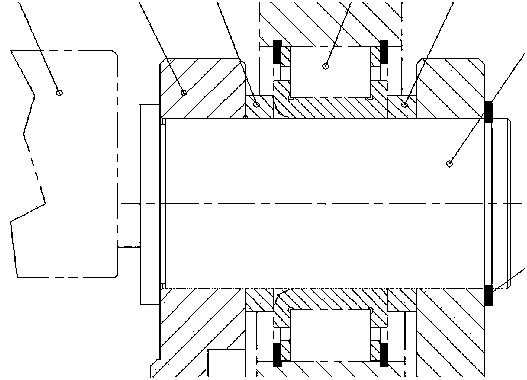

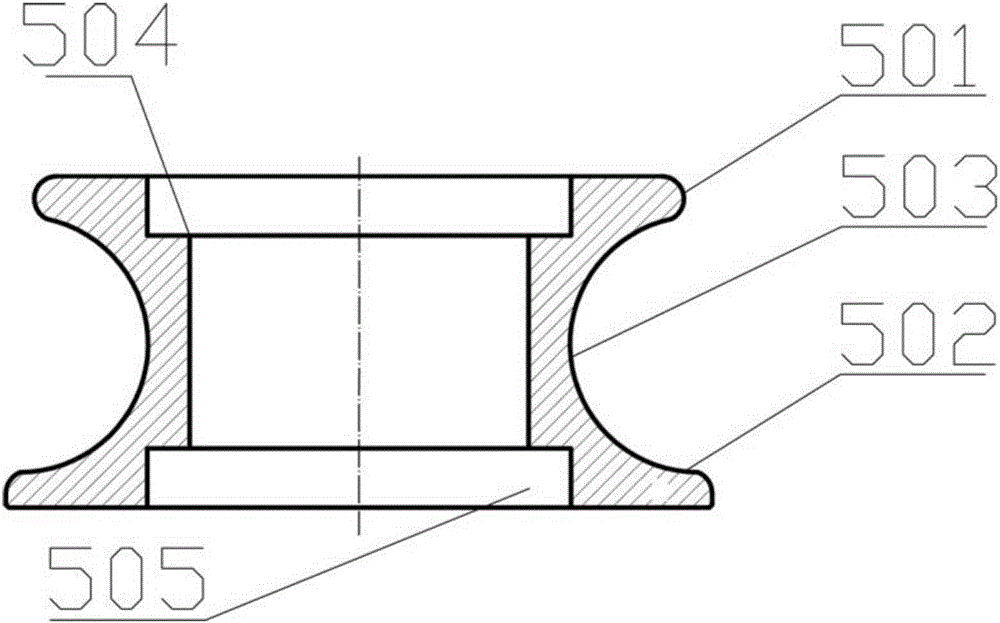

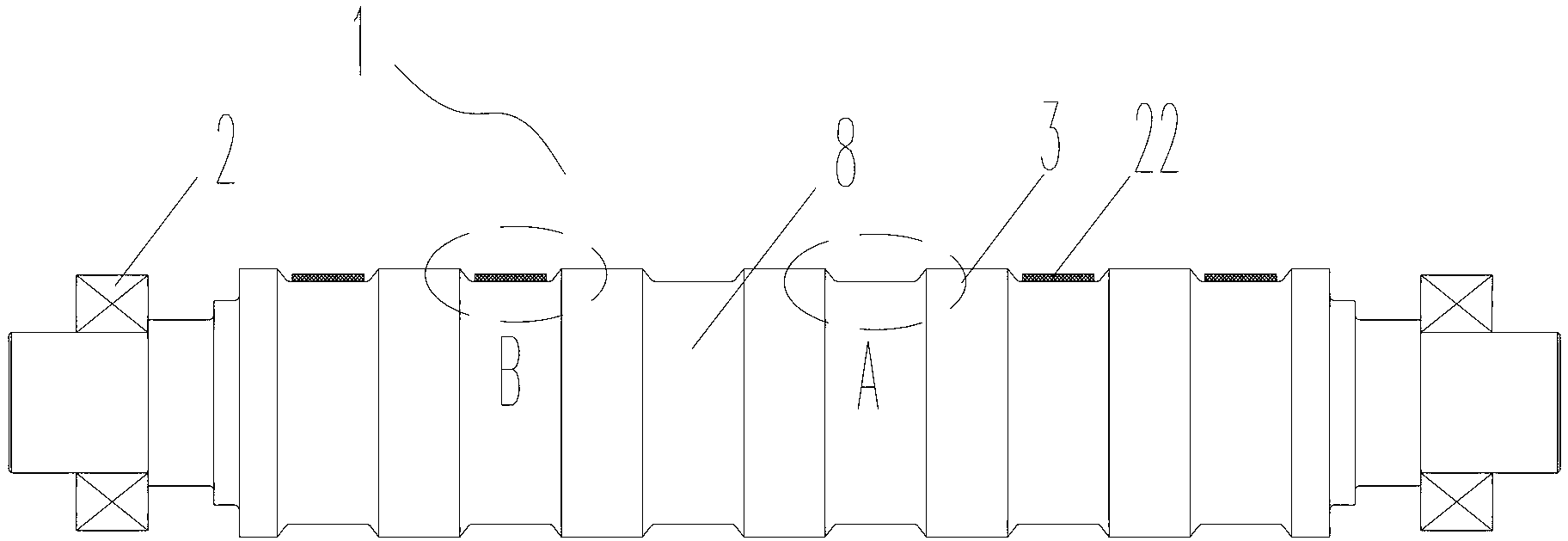

Axially-adjusted combined planet carrier

The invention discloses an axially-adjusted combined planet carrier for multi-stage planetary gear transmission, and belongs to the technical field of planetary gear transmission reducers. The axially-adjusted combined planet carrier comprises a planet carrier body A and a planet carrier body B, and the planet carrier body A and the planet carrier body B are oppositely arranged in parallel. The planet carrier body A and the planet carrier body B are connected through a plurality of planet gear shafts, and the planet gear shafts are evenly distributed around the center of the planet carrier body A. A mounting hole is formed in the center of the planet carrier body A. An adjusting shaft is mounted at the center of the planet carrier body B, and the adjusting shaft is mounted on a rear cover. The adjusting shaft is provided with an adjusting sleeve. Adjusting sleeves and adjusting shafts of different axial lengths are produced and assembled according to an adjusting assembling method, so that an adjusting gap delta is guaranteed. The axially-adjusted combined planet carrier integrates the advantages of the planet carrier body A and the advantages of the planet carrier body B, a blank of the axially-adjusted combined planet carrier is easy to form and convenient to machine and assemble, and the overall force bearing status of the axially-adjusted combined planet carrier is superior to that of a third planet carrier; in addition, the axially-adjusted combined planet carrier can be axially adjusted and shows excellent performance in the reality.

Owner:XUZHOU KEYUAN HYDRAULIC

Prefabricated reinforced concrete shear wall and construction method

The invention relates to a prefabricated reinforced concrete shear wall and a construction method. The shear wall comprises a wall board, a bracket, sleeves, casing pipes, joint bars, a steel plate and anchor bolts and is characterized in that the bracket is located on the lateral side of the wall board, the sleeves are pre-embedded into the upper portion of the wall board, the casing pipes are pre-embedded into the lateral side of the wall board, the joint bars and the steel plate extend out from the bottom surface of the wall board, and the anchor bolts are pre-embedded into two lateral sides of the wall board; each sleeve comprises an outer tube, a pressing piece and bolts, the upper portion of each sleeve is in squeezing connection with one joint bar, and the lower portion of each sleeve is connected with one joint bar in a threaded and sleeved manner. During construction, downward pressure is applied through supports to allow two walls to contact tightly, and bolts on the sleevesare screwed to clamp the joint bars to achieve squeezing connection. The prefabricated reinforced concrete shear wall has the advantages that the stress and construction problems of the prefabricatedreinforced concrete shear wall can be solved, node areas are good in stress performance and seismic performance, firm vertical reinforcing bar connection is achieved, and the shear wall is easy to construct.

Owner:SHANDONG UNIV OF SCI & TECH

Heavy-duty rolling wheel cable guider

InactiveCN106476989AImprove docking safetySolve the force problemWaterborne vesselsEngineeringHeavy duty

A heavy-duty rolling wheel cable guider is provided. A main shaft is fixed on a deck of a ship body via a welding way; a plurality of reinforcing rib plates are evenly arranged on the periphery of the bottom section of the main shaft and the main shaft and the reinforcing rib plates are welded; a base plate is fixed on the reinforcing rib plates via a welding way; a rolling wheel sleeve covers the main shaft to form a clearance fit; two thrusting ball bearings are arranged in an upper bearing seat and a lower bearing seat of a rolling wheel; a thrusting ball bearing inner ring is in interference fit with the main shaft; a press plate is mounted on shaft shoulder parts of the main shaft; a round nut is in a threaded fixed connection with an external thread of the top end of the main shaft; an arc-shaped plate is connected with the base plate; and rib plates are arranged on the external arc-shaped surface of the arc-shaped plate. By the use of the heavy-duty rolling wheel cable guider, problems of great changes of parking steel cable stress direction and size due to large water level difference of mountainous rivers and artificial reservoirs can be solved, so ship parking safety can be improved and safety of people on the ship and other articles can be guaranteed.

Owner:YICHANG DONGJIANG SHIPBUILDING CO LTD

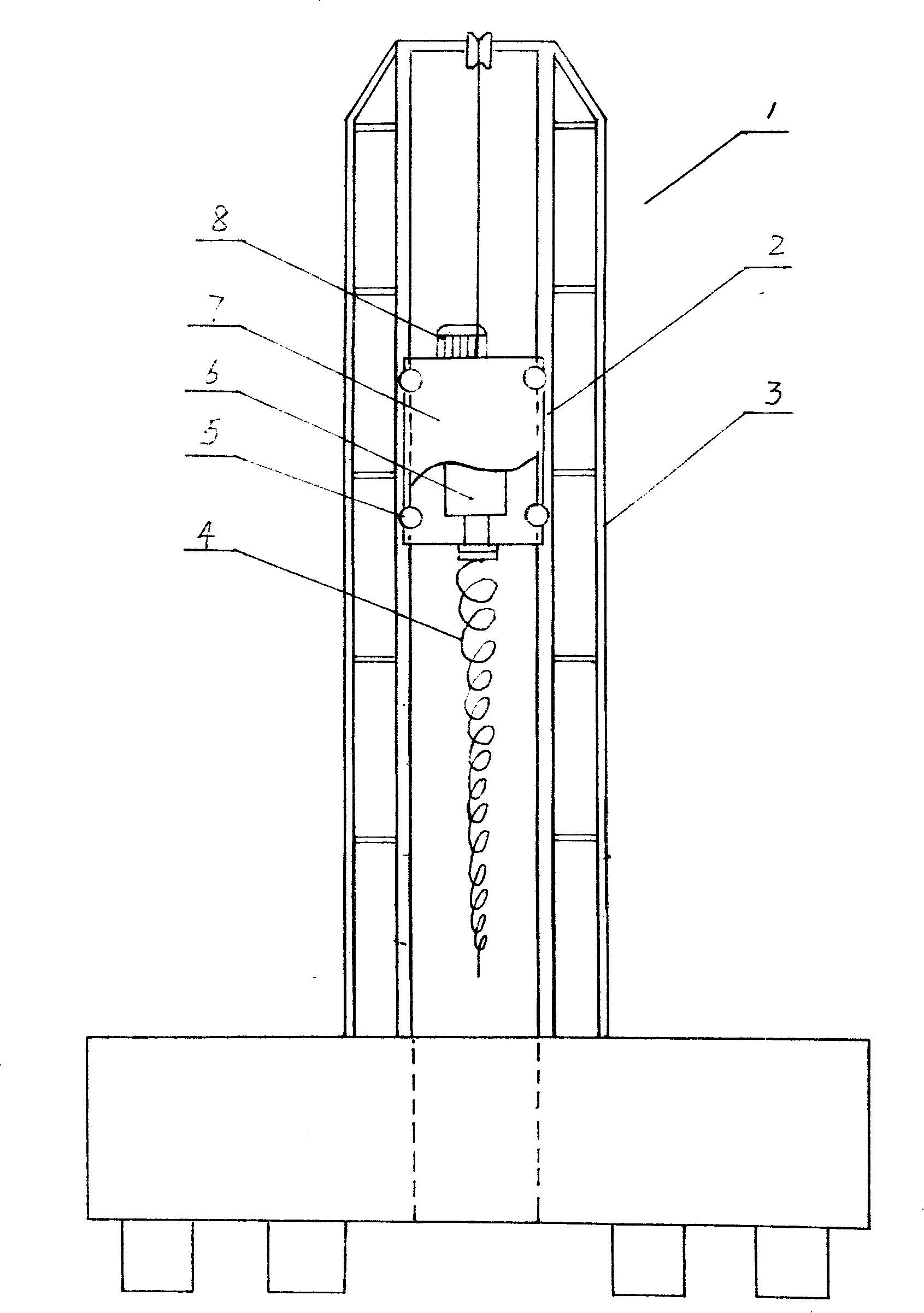

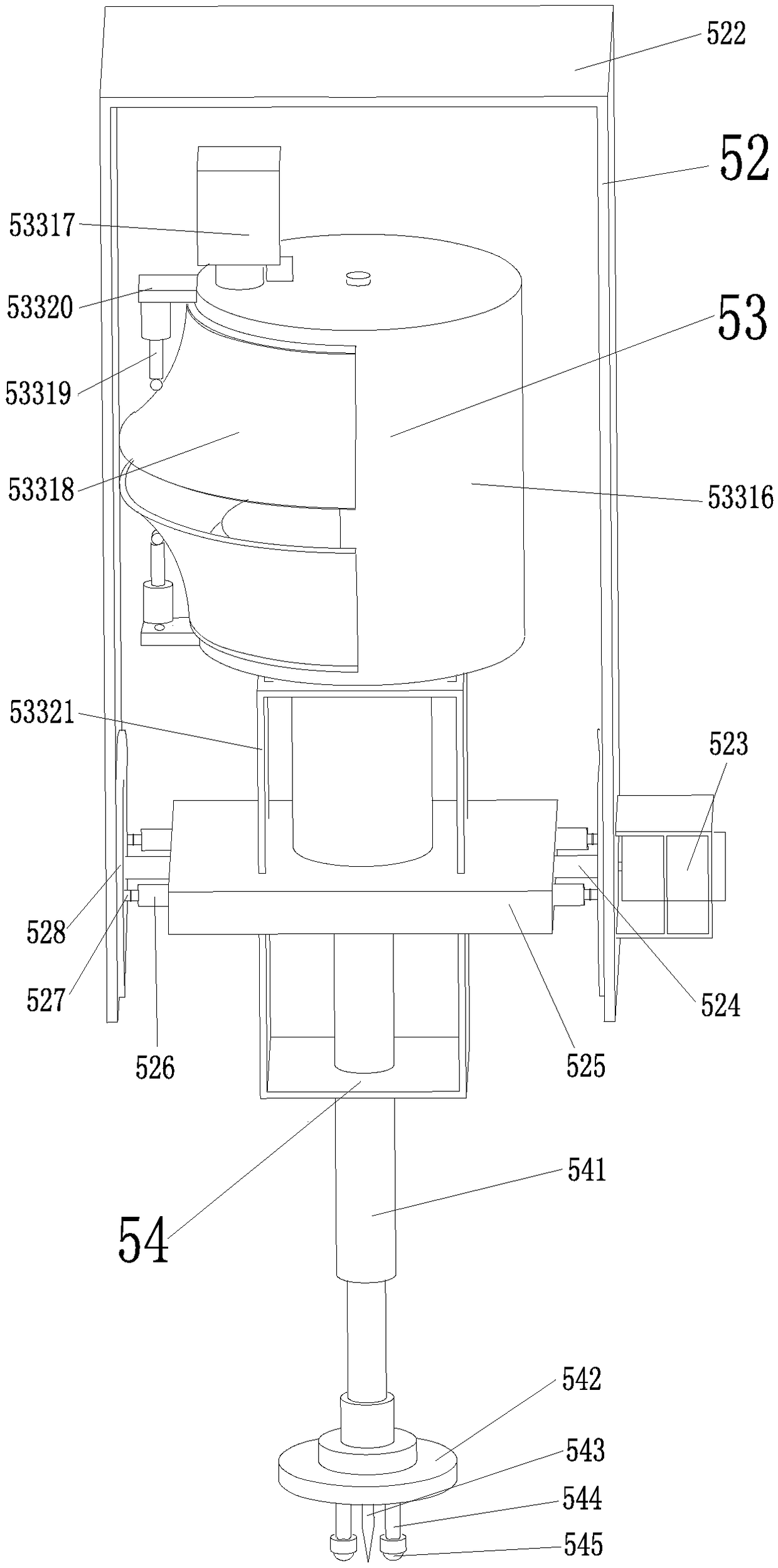

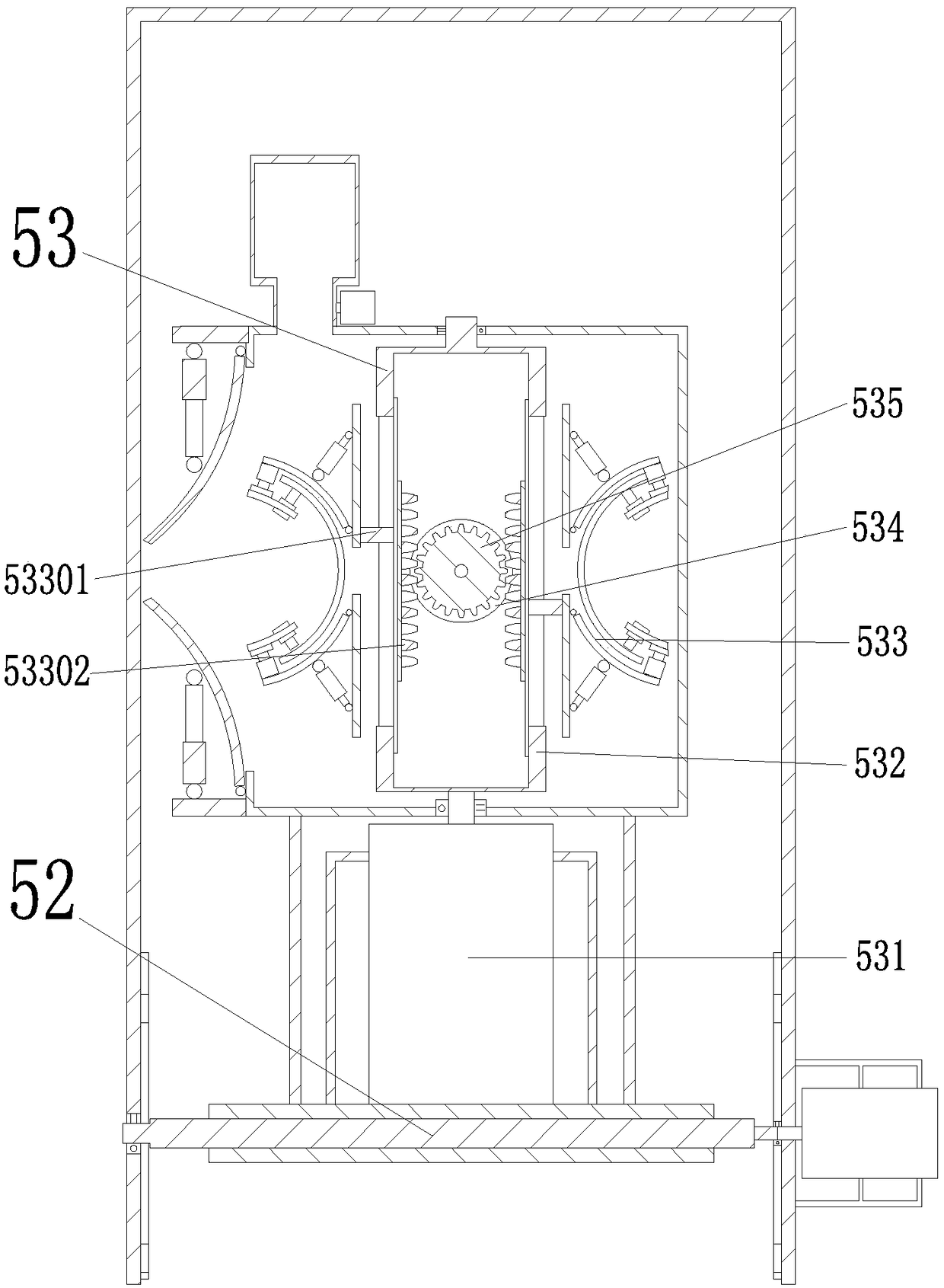

Pile machine having drilling function and drilling static pressure method

ActiveCN101230574ASolve the force problemAvoid damageDrilling rodsDerricks/mastsStructural engineeringEngineering

The invention relates to a device and a method which make use of a static pile press machine for drilling and piling, and the device comprises the static pile press machine and a drilling system that is positioned among upright standers in the static pile press machine and is connected with a draughting mechanism on the top of the stander of the static pile press machine by a pulling rope; the drilling system moves up and down along the upright standers under the traction of the draughting mechanism. The invention has the advantages of initiating the precedent that a static tube pile machine is provided with the drilling system, leading the static tube pile machine not only to have the function of static tube pile, but also to have the function of drilling, and solving the phenomenon of press bursting caused by excessive stress of a tube pile by enforcing to static press the tube pile ever since a long time ago. What is more, the damage of destructive crack, etc. occurring in the surrounding building caused by the pressed tube pile is solved.

Owner:浙江兆弟技术有限公司

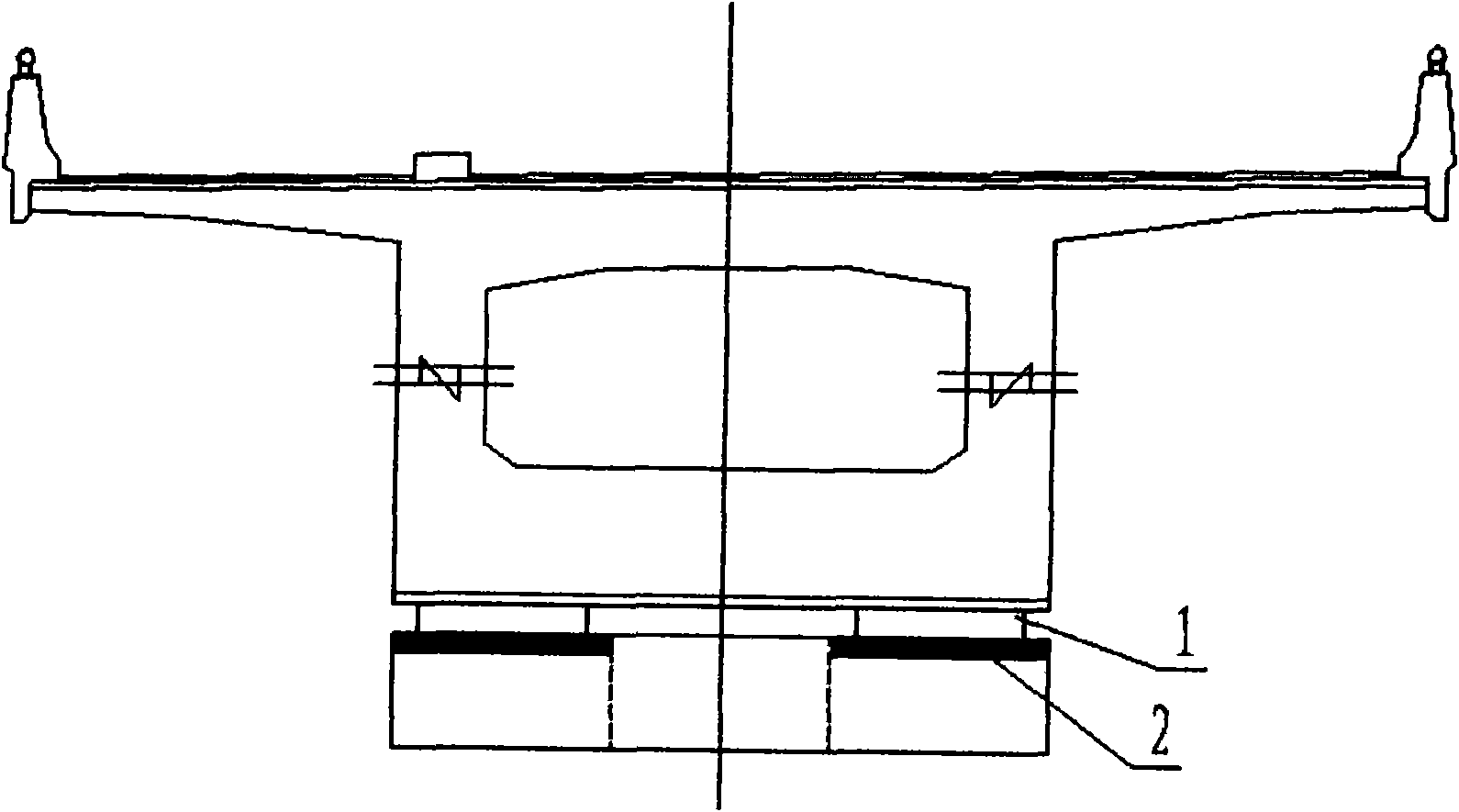

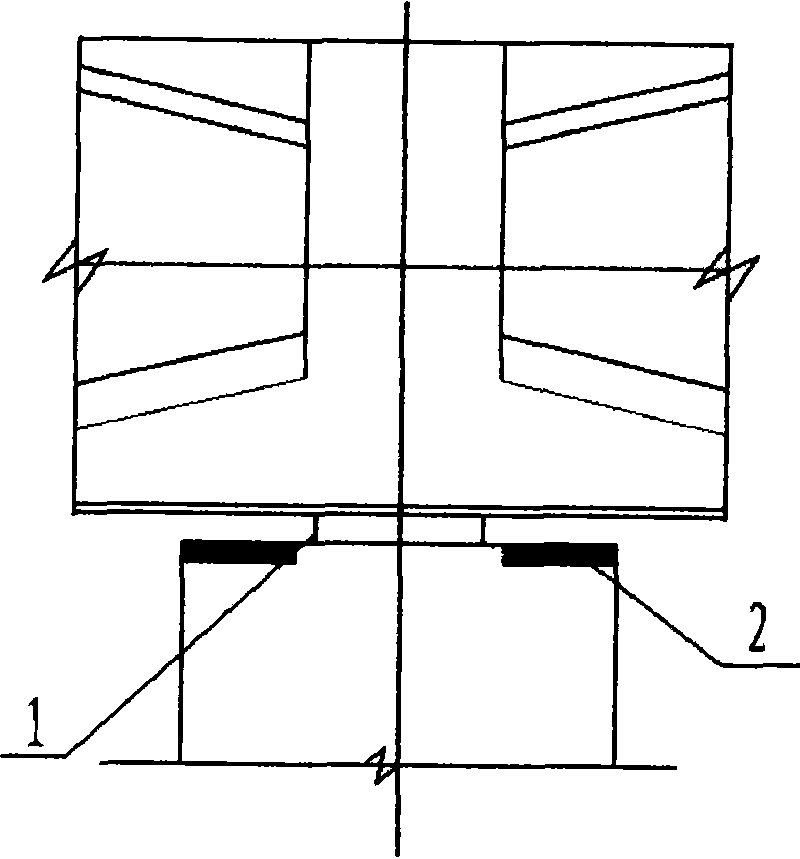

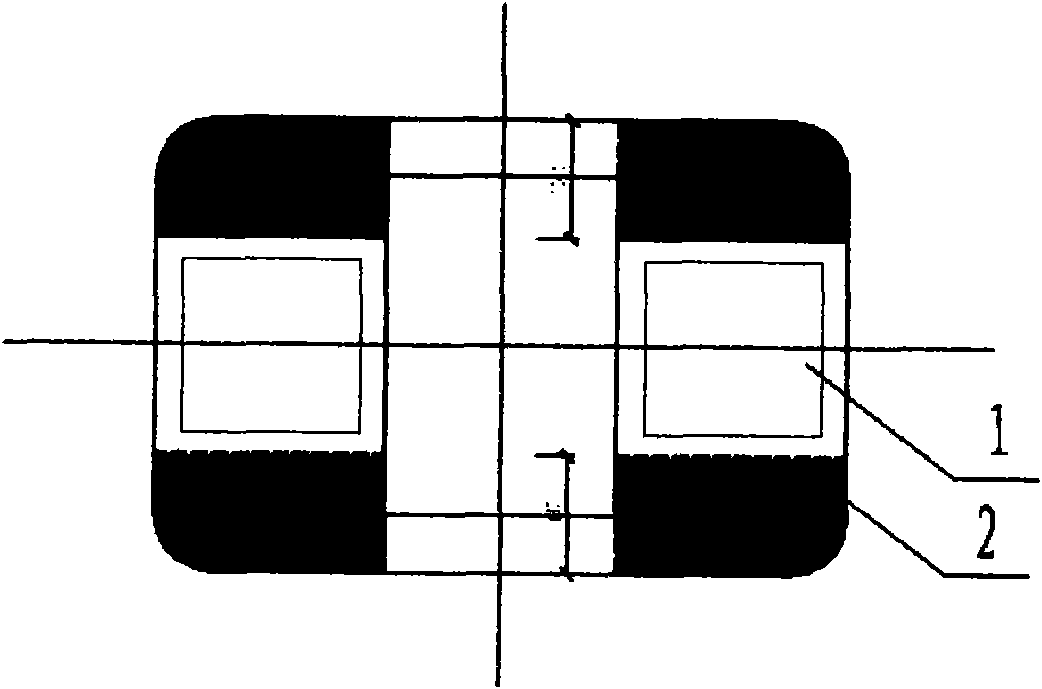

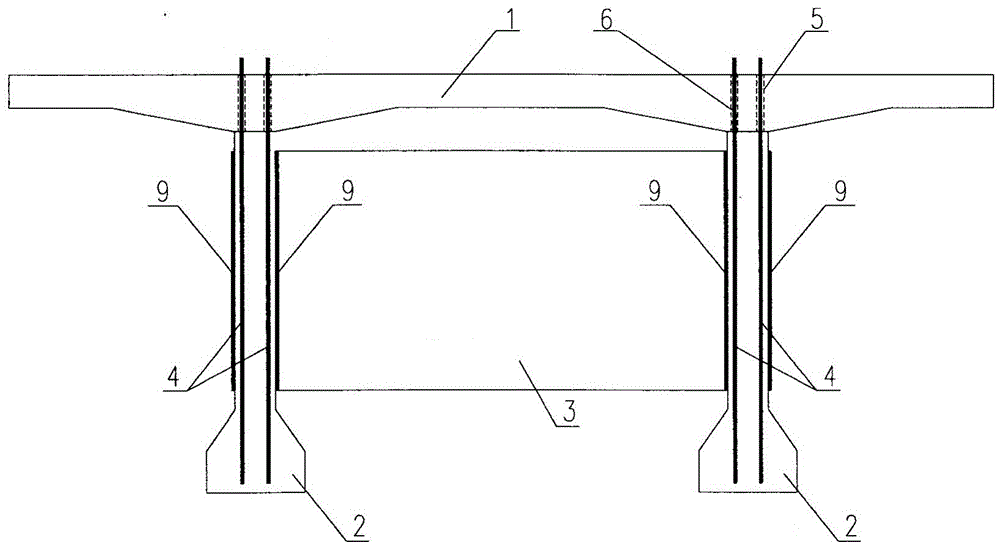

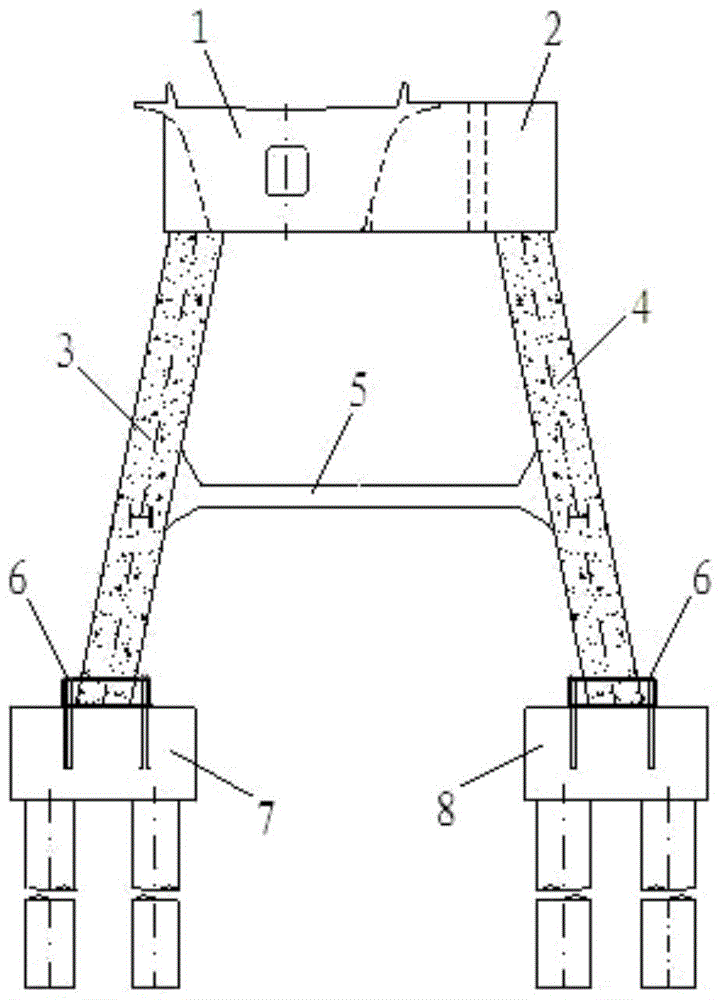

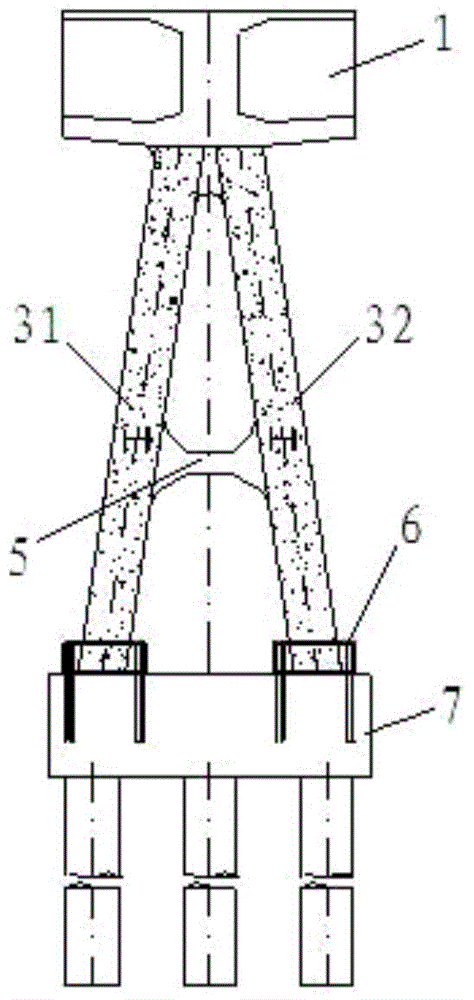

Double-row four-slanting-leg steel-structure gate-type pier

The invention belongs to the technical field of bridge pier columns, and particularly relates to a double-row four-slanting-leg steel-structure gate-type pier. The double-row four-slanting-leg steel-structure gate-type pier comprises a NO. 0 block and a steel bent cap; the two ends of the bottom of the steel bent cap are respectively connected with a left-row pier column and a right-row pier column; a left bearing platform and a right bearing platform are respectively arranged at the bottoms of the left-row pier column and the right-row pier column; the left-row pier column comprises a first left pier column and a second left pier column, the tops of the first left pier column and the second left pier column intersect at one end of the bottom of the steel bent cap, and the bottoms of the first left pier column and the second left pier column are respectively connected with the two ends of the left bearing platform; the right-row pier column comprises a first right pier column and a second right pier column; the tops of the first right pier column and the second right pier column intersect at the other end of the bottom of the steel bent cap, and the bottoms of the first right pier column and the second right pier column are respectively connected with the two ends of the right bearing platform. By the adoption of the double-row four-slanting-leg steel-structure gate-type pier, a large-span bridge structure can be eliminated, so that the investment is reduced, the construction schedule is accelerated, and interference to existing roads is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

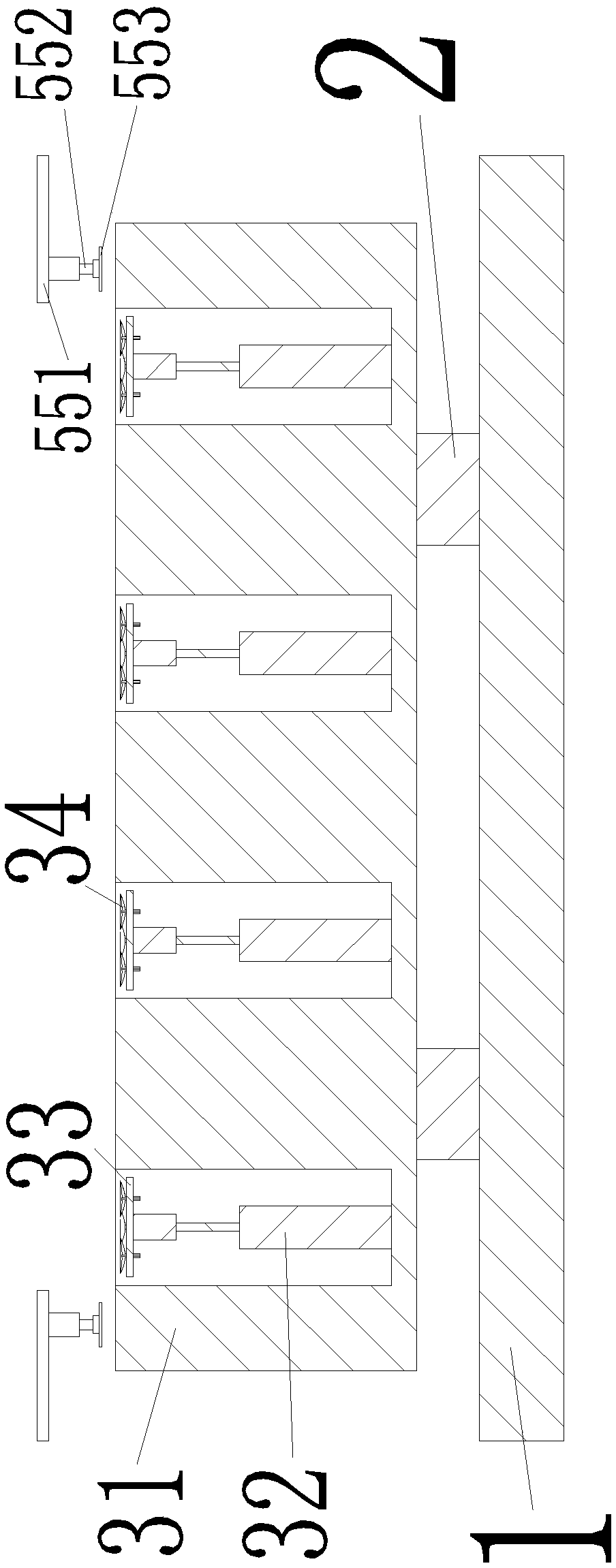

Tempered glass machining system and tempered glass machining method thereof

ActiveCN109049348AReduce labor intensityDecrease productivityEdge grinding machinesGrinding wheel securing apparatusEngineeringMachining system

The invention relates to a tempered glass machining system and a tempered glass machining method thereof. The tempered glass machining system comprises a supporting executing mechanism, a grinding executing mechanism and a cutting executing mechanism, the grinding executing mechanism is installed on the upper side of the bottom end of the supporting executing mechanism, the cutting executing mechanism is installed on the lower side of the bottom end of the supporting executing mechanism, the supporting executing mechanism drives the grinding executing mechanism and the cutting executing mechanism to move to a designated position, edge grinding machining is performed on tempered glass by the grinding executing mechanism, and cutting machining is performed on the tempered glass by the cutting executing mechanism. Manual operation is not needed in the machining process, so that breakage of the tempered glass caused by misoperation is avoided, the labor intensity of workers is reduced, theworking efficiency is improved, and the function of performing cutting and edge grinding machining continuously at the same station in the deep machining process of the tempered glass can be realized.

Owner:SHANDONG FANGDING SAFETY GLASS TECH CO LTD

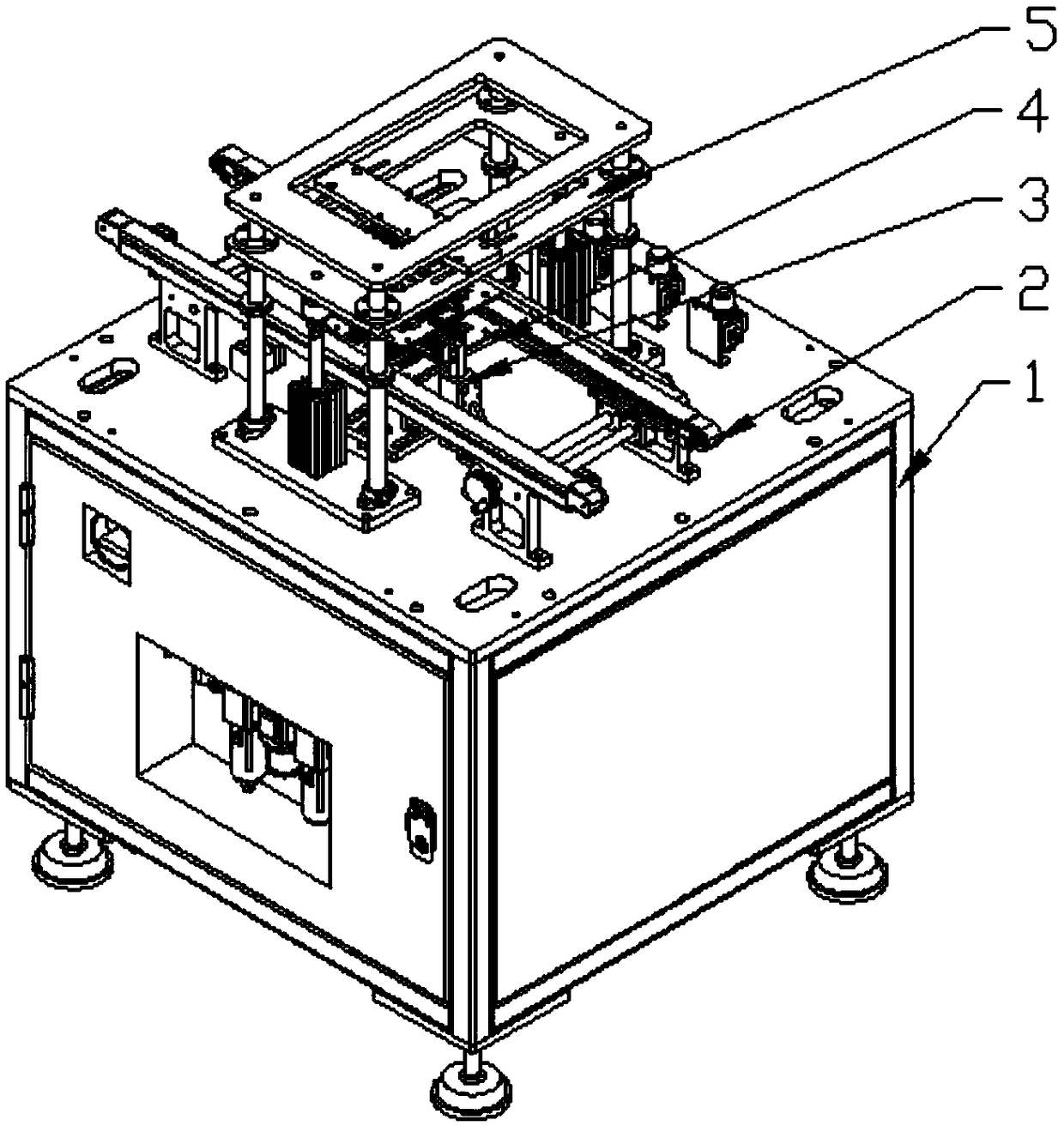

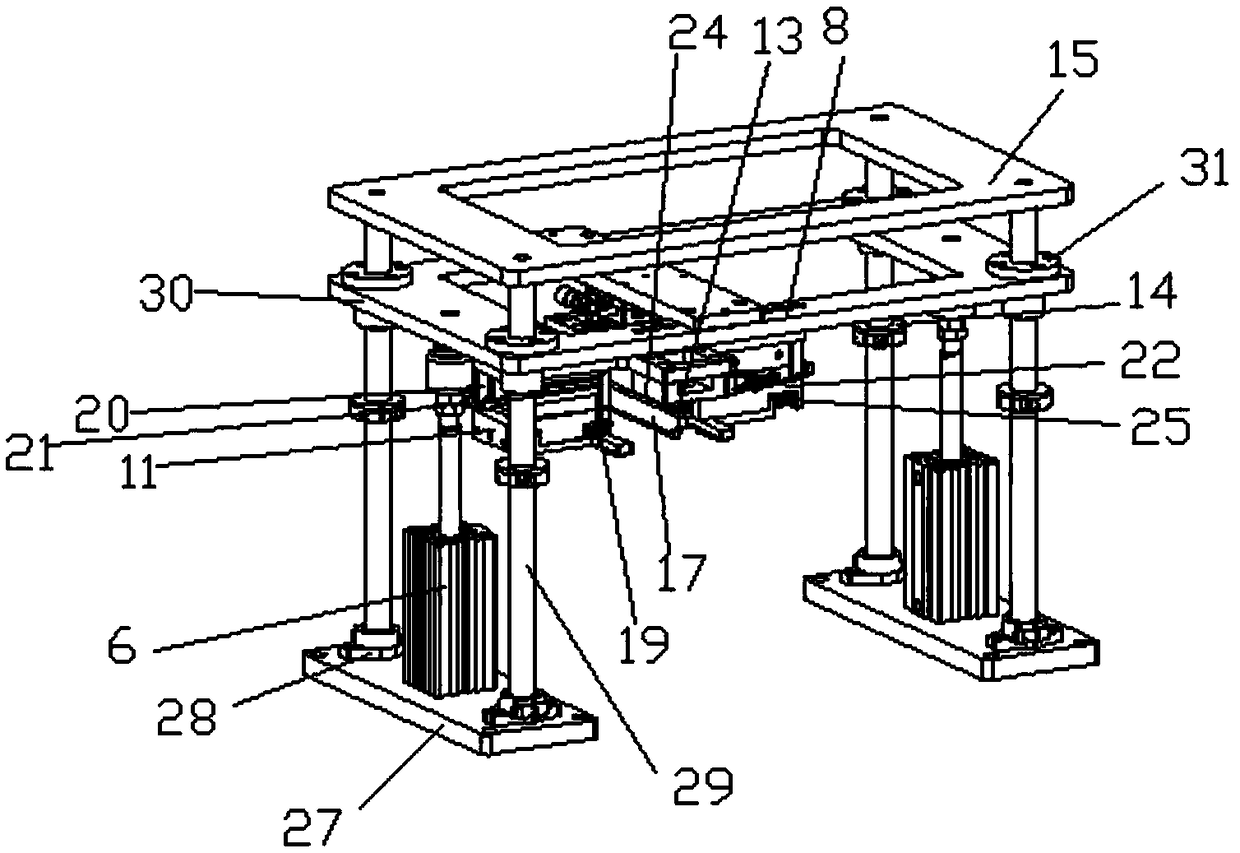

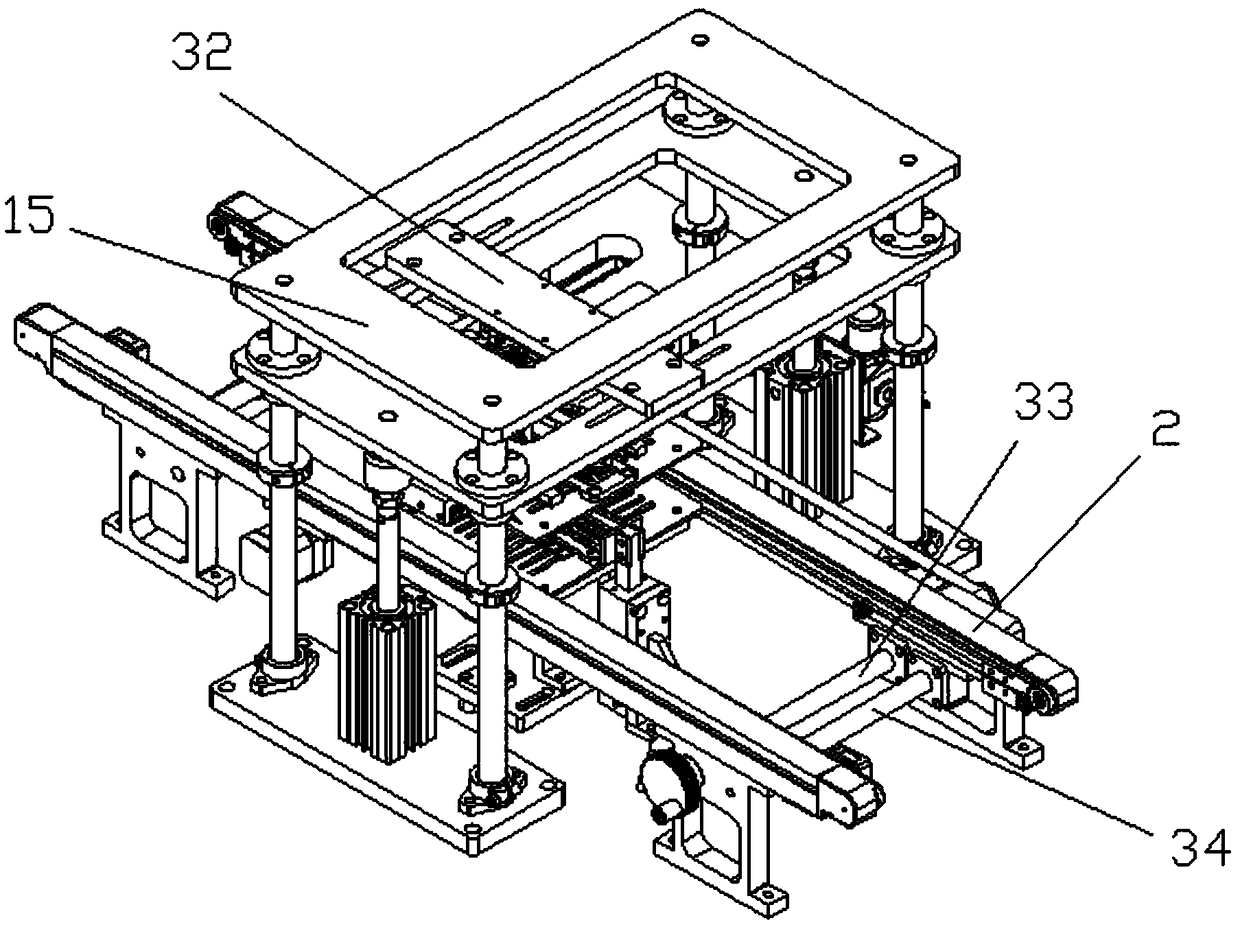

Assembly machine with plug-in mechanism

PendingCN108927645ASolve the force problemSolve factors such as excessive pressing forceMetal working apparatusAssembly machine

The invention provides an assembly machine with a plug-in mechanism. The assembly machine comprises the plug-in mechanism, a jacking mechanism, a conveyor, a positioning device and a support mechanism, wherein the plug-in mechanism comprises a lower pressing block, a lower pressing air cylinder, a left plug-in, a right plug-in and a sliding base; the lower pressing block is positioned between theleft plug-in and the right plug-in and is connected with the lower pressing air cylinder; the left plug-in and the right plug-in are connected with a transverse pushing air cylinder separately and arepositioned on the sliding base; a spring is arranged in the sliding base; the jacking mechanism is connected with the plug-in mechanism and is arranged on the conveyor; the positioning device is connected with the jacking mechanism; and the plug-in mechanism is hung above the support mechanism. The assembly machine can solve the factors that the plug-in is stressed nonuniformly or the pressing force is excessively large, ensures the product quality and reliability, reduces the production cost and improves the production efficiency which is 3-5 times of that of manual operation.

Owner:SUZHOU VS ELECTRONICS

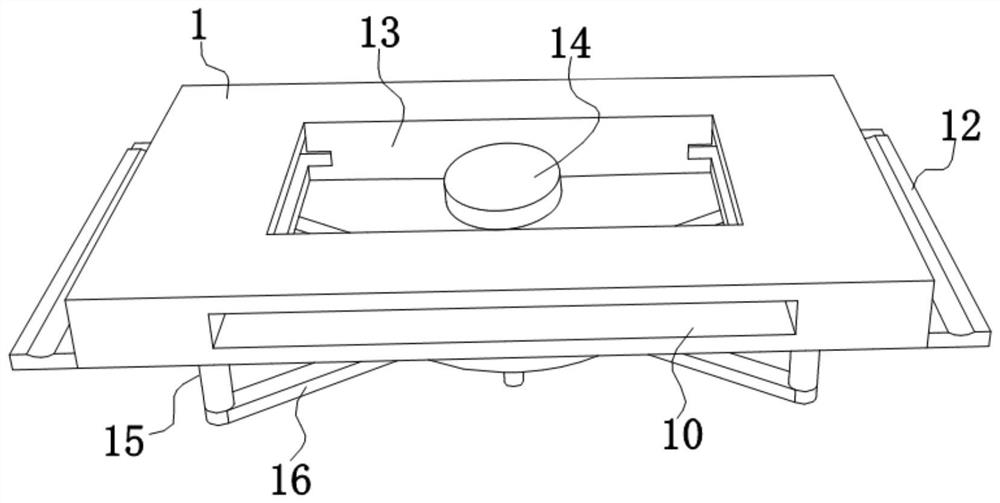

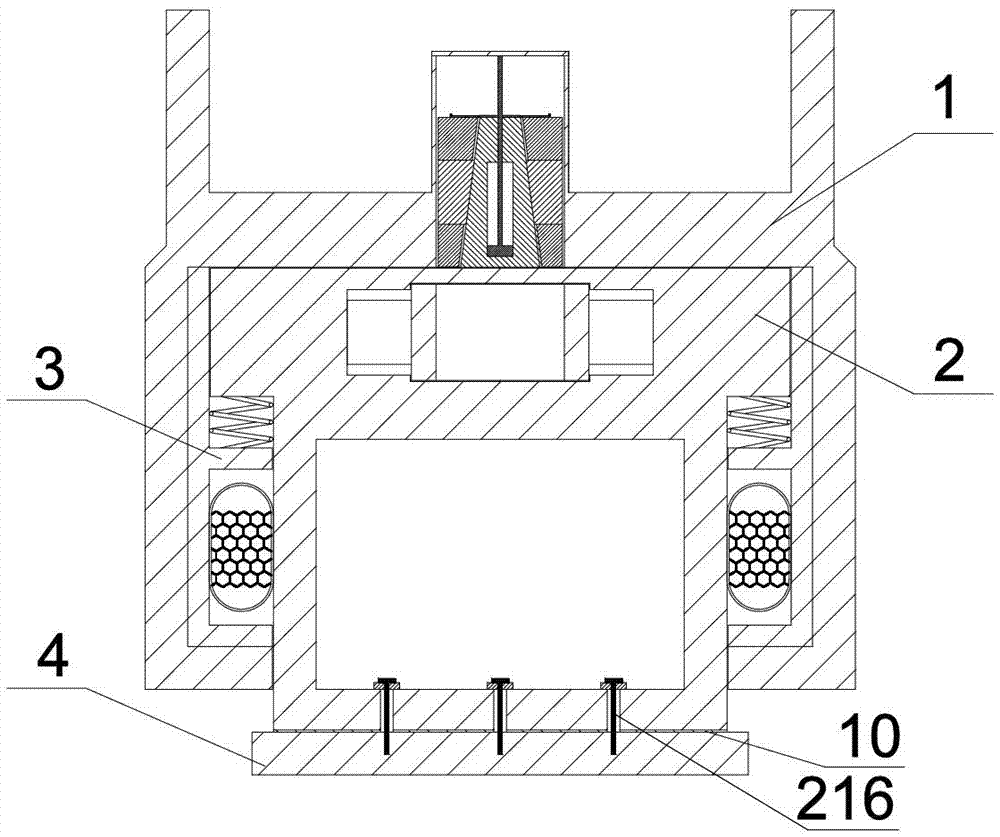

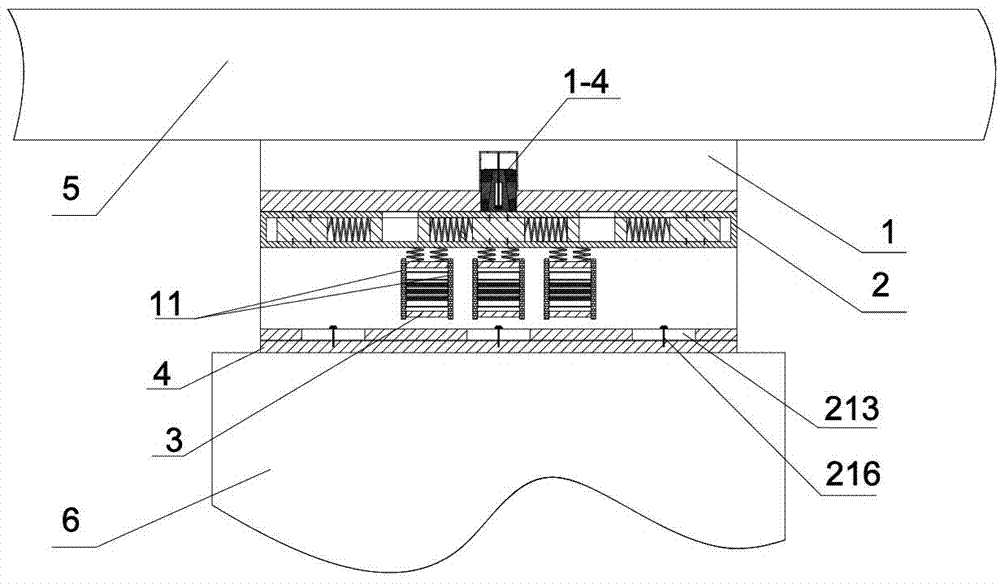

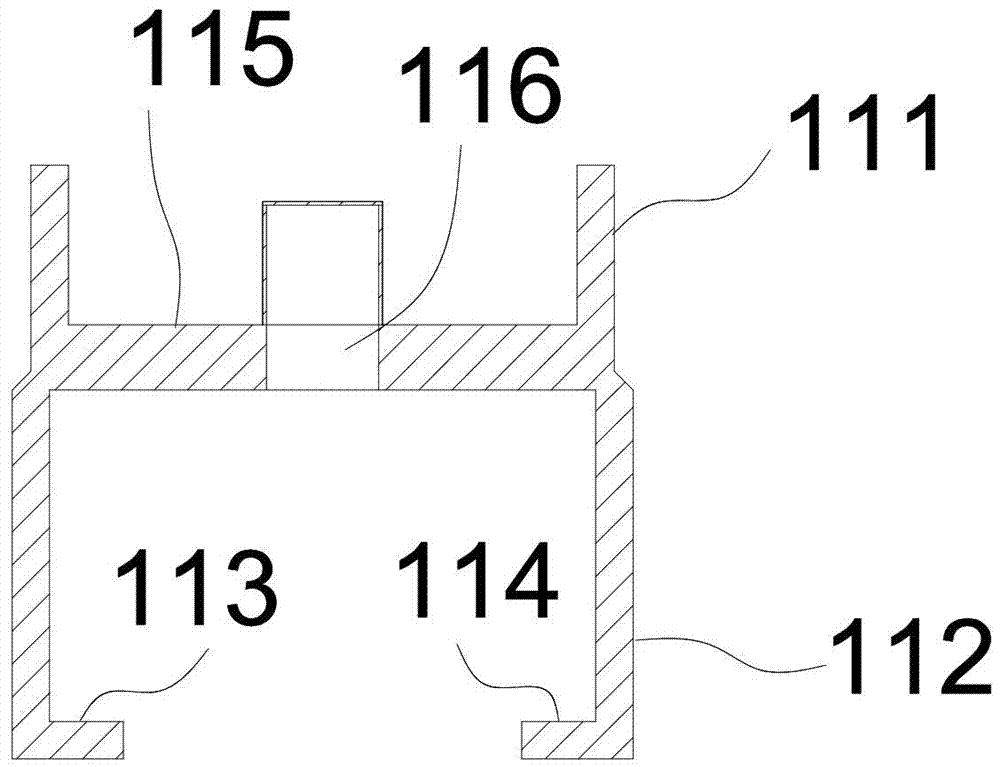

Continuous beam bridge hierarchical control and bidirectional shock-resistant connecting damping device

ActiveCN107022951AAvoid the adverse effects of a sharp increase in seismic responseControlling Joint StiffnessBridge structural detailsBridge erection/assemblyContinuous beamStructural engineering

The invention relates to a continuous beam bridge hierarchical control and bidirectional shock-resistant connecting damping device. The continuous beam bridge hierarchical control and bidirectional shock-resistant connecting damping device comprises an upper sliding block, a lower sliding block, two or more inversed F-shaped components and a bottom plate; the top end of the upper sliding block is fixedly arranged at the bottom end of a beam body; the lower sliding block is positioned in the lower part of the upper sliding block; the bottom end of the lower sliding block is fixed with the top end of the bottom plate; a friction layer is arranged between the bottom end of the lower sliding block and the top end of the bottom plate. The continuous beam bridge hierarchical control and bidirectional shock-resistant connecting damping device is a novel large-tonnage continuous beam bridge damping device which is simple in structure, economic and durable, and convenient to check and maintain; the continuous beam bridge hierarchical control and bidirectional shock-resistant connecting damping device can provide new design concept and technical thinking for design of a new bridge and strengthening of an old bridge, and is suitable for newly building of the bridge and aseismic strengthening of the old bridge.

Owner:SHIJIAZHUANG TIEDAO UNIV

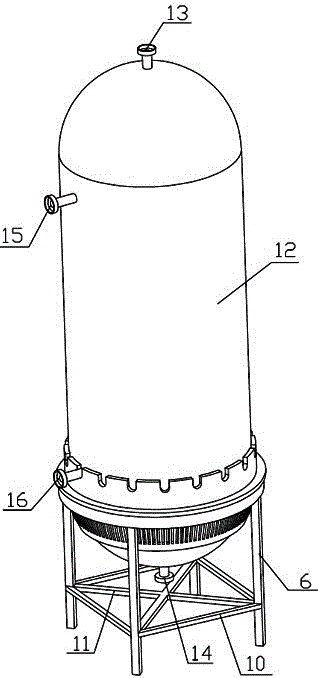

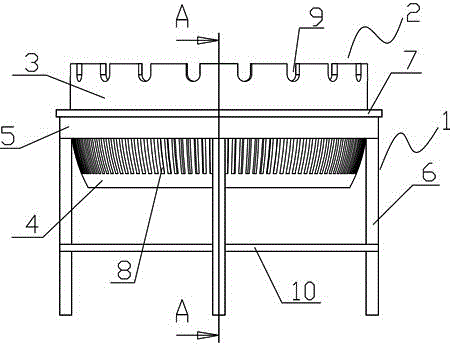

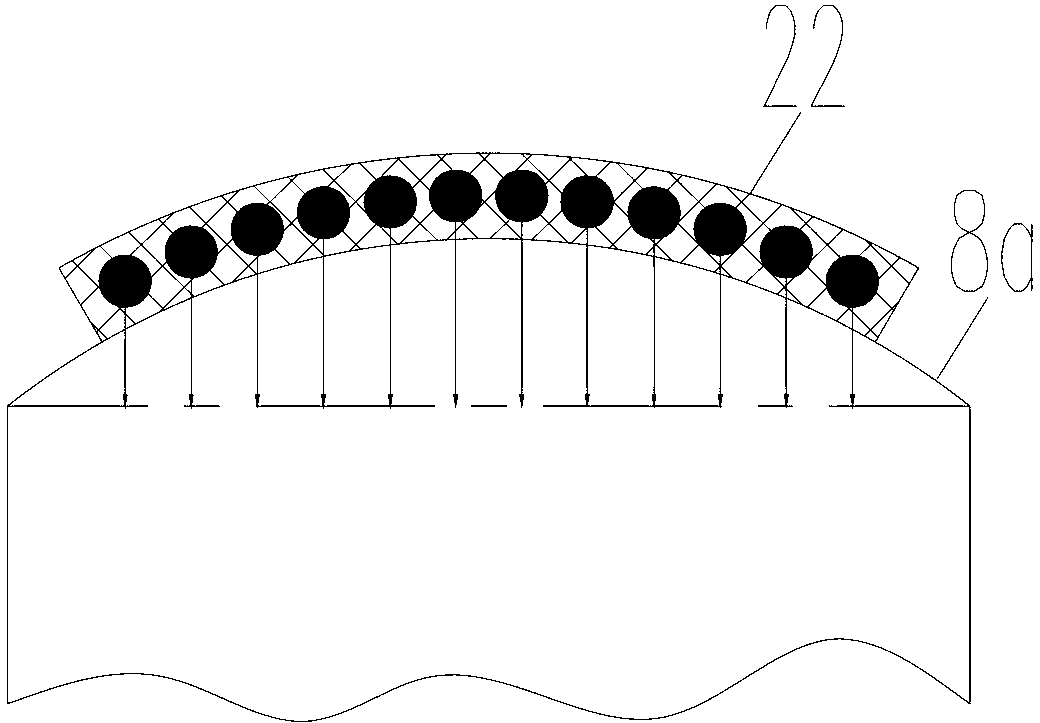

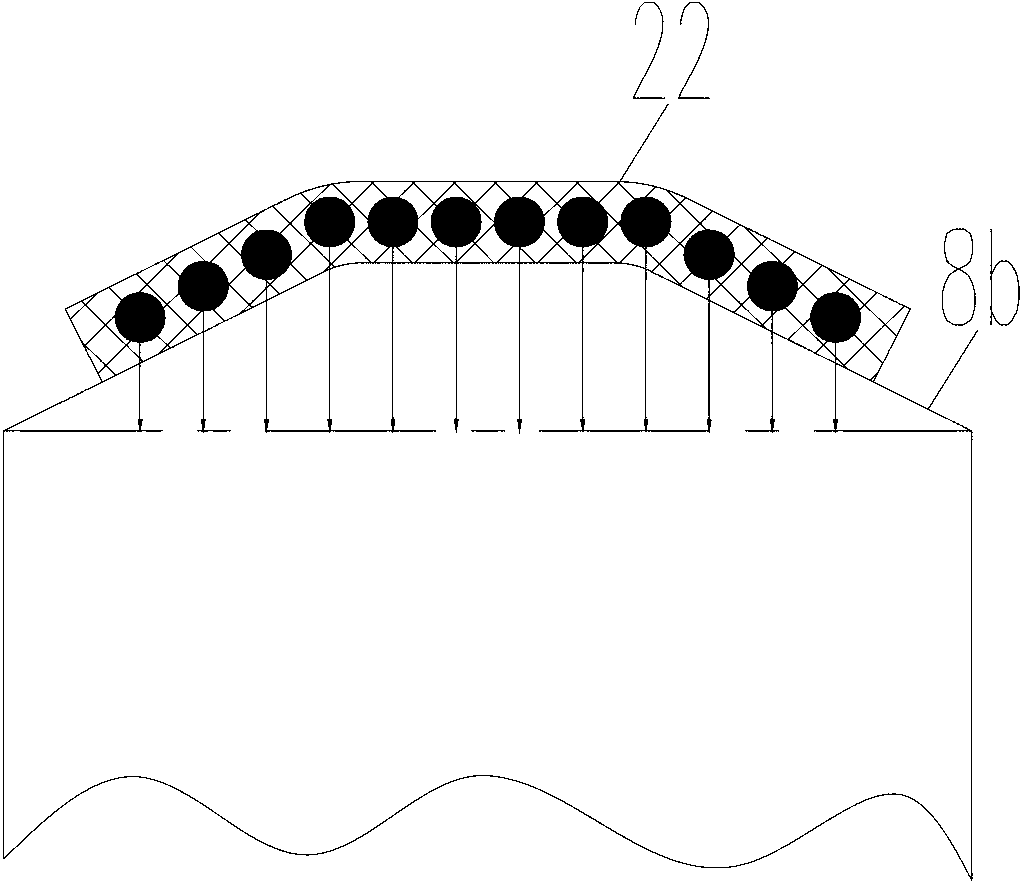

Flue gas purification device

InactiveCN106621635AEfficient removalImprove purification effectGas treatmentUsing liquid separation agentFlue gasEngineering

The invention discloses a flue gas purification device, comprising a purifying barrel, a support frame and a mounting rack installed on the support frame in a detachable way, wherein the upper end and the lower end of the purifying barrel are in circular arc shapes, a flue gas outlet is formed in the top of the purifying barrel, and a spray water outlet is formed in the bottom of the purifying barrel; a spray water inlet is formed in the barrel wall at the upper part of the purifying barrel, and a flue gas inlet is formed in the barrel wall at the lower part of the purifying barrel; the purifying barrel is internally provided with a spray device communicated with the spray water inlet; the mounting rack comprises a circular barrel arranged at the upper part, and an arc-shaped barrel, matched with the bottom of the purifying barrel, arranged at the lower part; the inner diameter of the arc-shaped barrel is equal to the outer diameter of the bottom of the purifying barrel; the support frame comprises a ring-shaped mounting seat and a plurality of support rods arranged at the bottom of the mounting seat; the inner surface of the mounting seat is matched with the outer surface of the arc-shaped barrel. The flue gas purification device has the beneficial effects that the existing point contact manner between the purifying barrel and a bracket is changed into a surface contact manner, so that the contact area between the purifying barrel and the bracket is enlarged, and the technical defect that the purifying barrel is damaged due to larger local stress is overcome.

Owner:MORAL ELECTRICAL APPLIANCE KUNSHAN

Plate-type composite steel belt leading sheave

The invention discloses a plate-type composite steel belt leading sheave. The plate-type composite steel belt leading sheave comprises a guide groove. The plate-type composite steel belt leading sheave is characterized in that the guide groove is a flat-bottomed groove. The plate-type composite steel belt leading sheave not only can achieve automatic centering of a composite steel belt, guarantee smooth running of the composite steel belt in the guide groove, and completely avoid the phenomenon of passline deflection of the composite steel belt, but also can further improve a stress state of the composite steel belt, prolong the service life of the plate-type composite steel belt leading sheave, and meanwhile reduce vibration and noise. The plate-type composite steel belt leading sheave can be used for a dragging and running wheel on an elevator, a guide pulley, a car roof wheel, a car bottom wheel, a counterweight wheel and the like, really be suitable for a long-time running of the elevator, simplify installation technology of the elevator, and meanwhile guarantee the service life of the composite steel belt.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

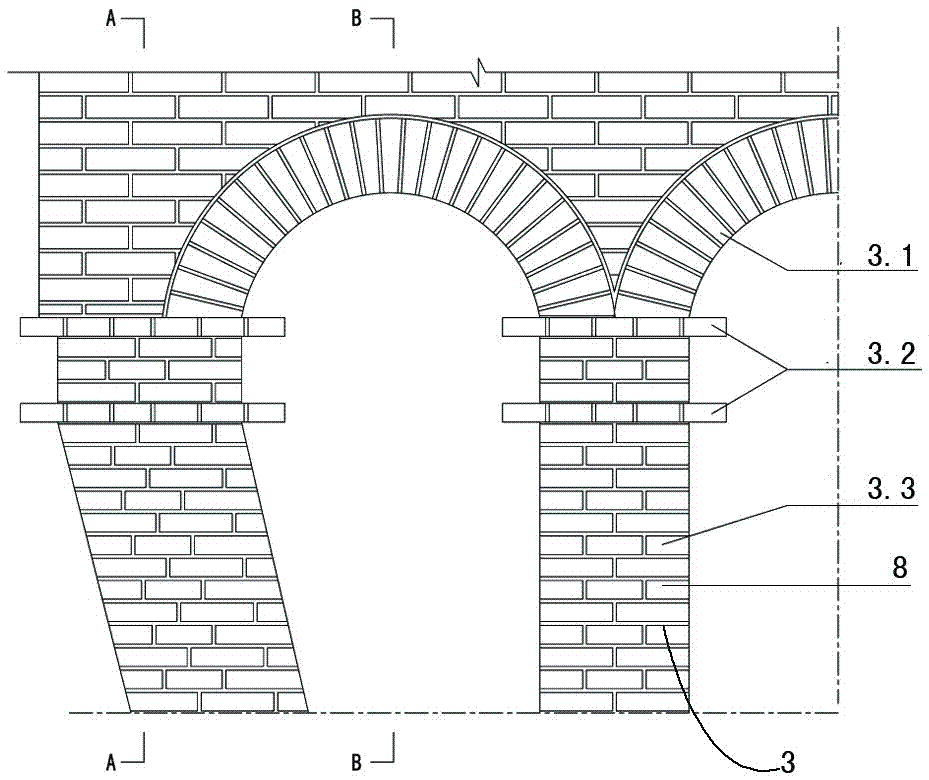

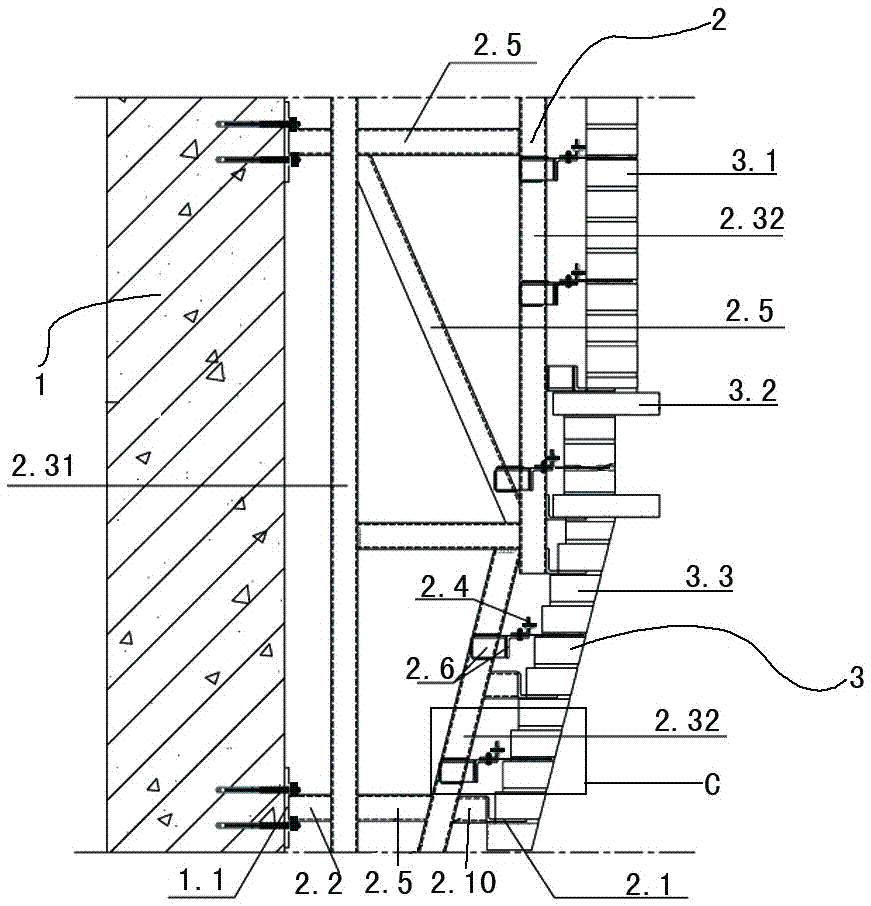

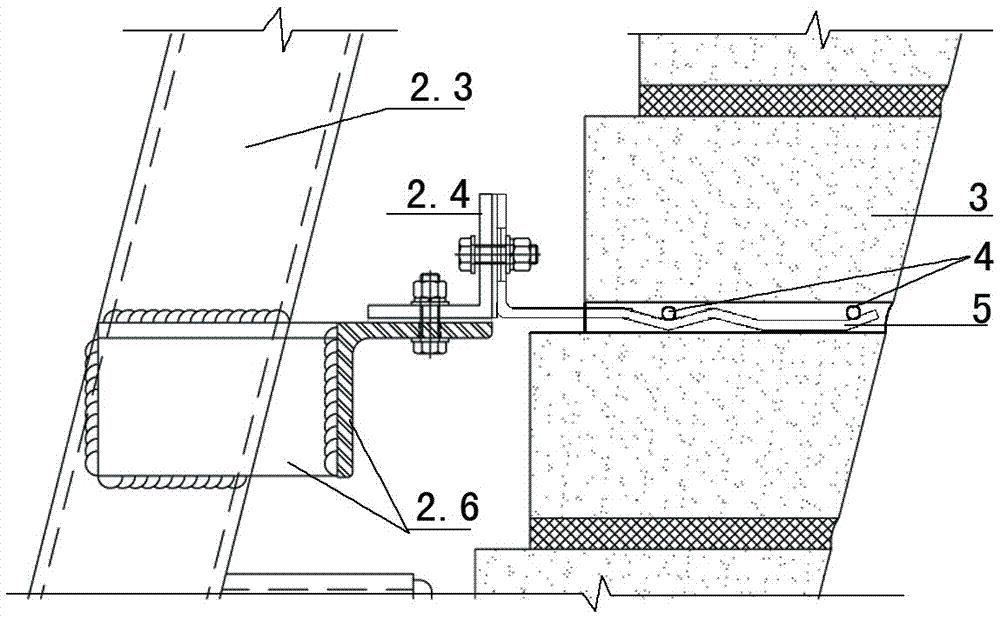

Inverted-cone-shaped cantilever brick multi-arch curtain wall system and construction method thereof

ActiveCN107227812AFix the angle problemSolve the problem of center of gravity deviationWallsClimate change adaptationBrickKeel

The invention provides an inverted-cone-shaped cantilever brick multi-arch curtain wall system and a construction method thereof. The problems of barycenter deviation and anti-falling potential hazards of an inverted-cone-shaped cantilever brick wall and multiple arches are solved, and brick wall shaping and designing effect is realized while structural safety is guaranteed. A horizontal supporting steel angle is added for four bricks, so that horizontal bracing effect is realized while the problem of barycenter deviation is solved; cantilever size of all bricks is smaller than half bricks, so that hidden trouble in barycenter deviation is reduced from the aspect of scale division; stainless steel pins and stainless steel hanging rings are used for the arches to shoulder horizontal thrust of the arches and vertical load of dead weight. A steel structure keel is adopted as a load-bearing system and comprises a structural keel, a supporting keel and a hanging connection component, the structural keel comprises a main secondary keel, an additional keel, an arch full-length transverse keel and an arch oblique keel, the problems of building angle and barycenter deviation of single bricks in the brick wall are solved, structural safety and surface flatness of an oblique cantilever brick wall multi-arch curtain wall structure system are improved, and European classical exterior wall effect of the system is reduced.

Owner:BEIJING LIUJIAN CONSTR GRP

Main oil way cast chaplet of large diesel engine

InactiveCN107225222AImprove reliabilityGuaranteed StrengthMoulding flasksDiesel engineSupport surface

The invention discloses a main oil way cast chaplet of a large diesel engine. The main oil way cast chaplet comprises an outer supporting surface, an inner supporting surface and a supporting shaft, wherein the outer supporting surface is a circular arc surface; the inner supporting surface is a circular arc surface matched with a to-be-supported main oil way sand core surface, and is concentric with the outer supporting surface; the inner side of the outer supporting surface and the inner and outer sides of the inner supporting surface are chamfered; the supporting shaft is of a circular ring structure, and is separately connected with the outer supporting surface and the inner supporting surface through inner and outer circular arc edges; the main oil way cast chaplet is of an I-shaped sector structure; and a plurality of through holes are uniformly formed in the middle of the supporting shaft in the circumferential direction. According to the main oil way cast chaplet of the large diesel engine, the I-shaped sector structure is adopted, so that strength of the chaplet is guaranteed, the chaplet is conveniently arranged on a sand core, and a placing problem of the chaplet is solved; and through the shape design of the supporting surfaces and the supporting shaft of the main oil way cast chaplet, the strength requirement of the chaplet is met, molten iron and the chaplet are fused conveniently, and strength and fusion problems of the chaplet are solved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com