Celled hybrid beam junction with composite connectors

A composite connection and hybrid beam technology, applied in bridges, bridge parts, bridge forms, etc., to achieve the effect of increasing the force transmission ratio, increasing the safety reserve, and improving the applicable span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

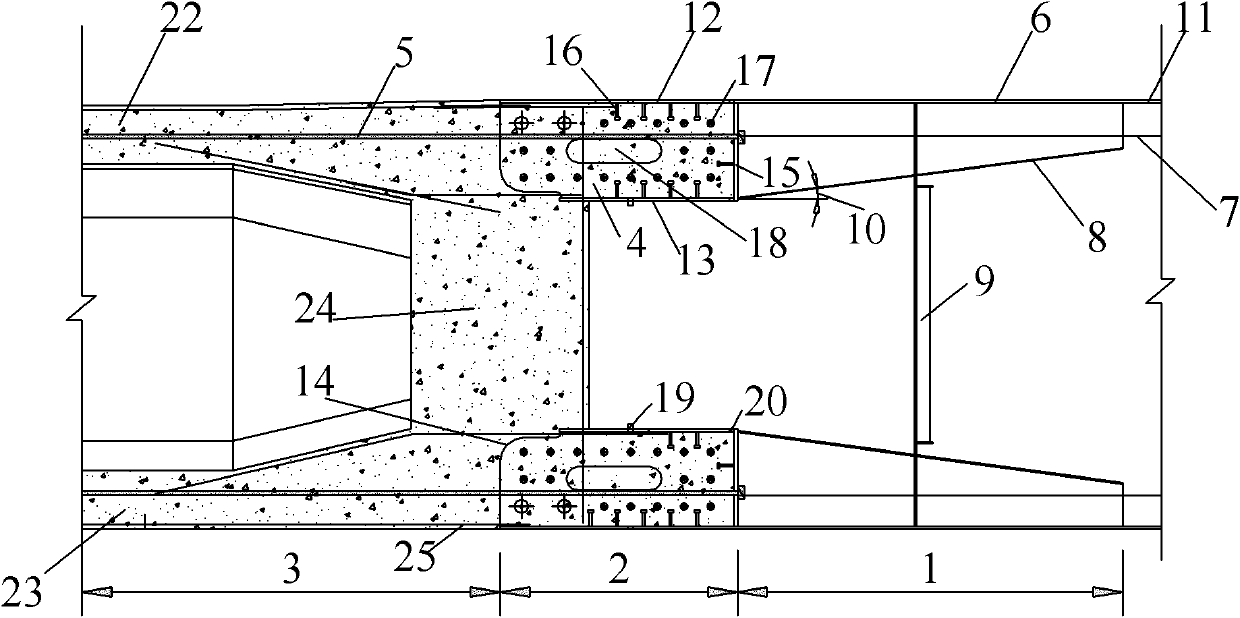

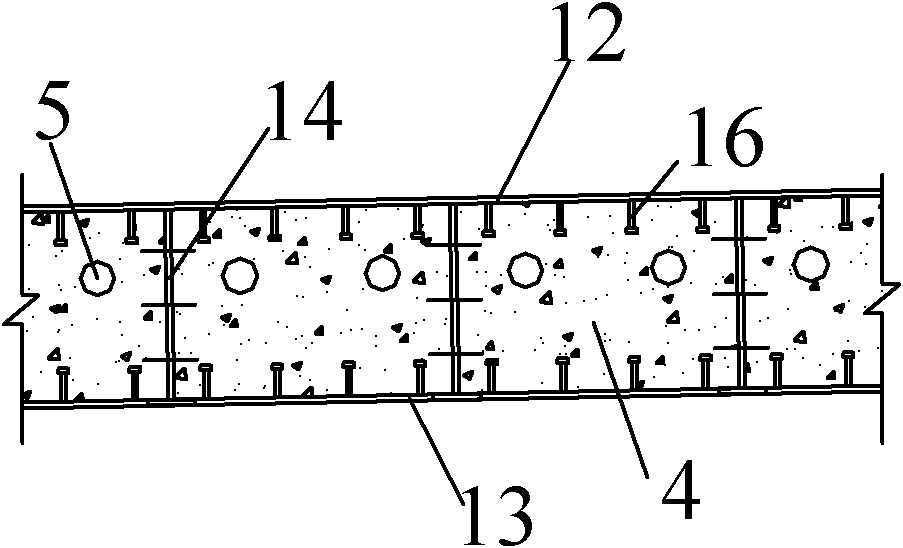

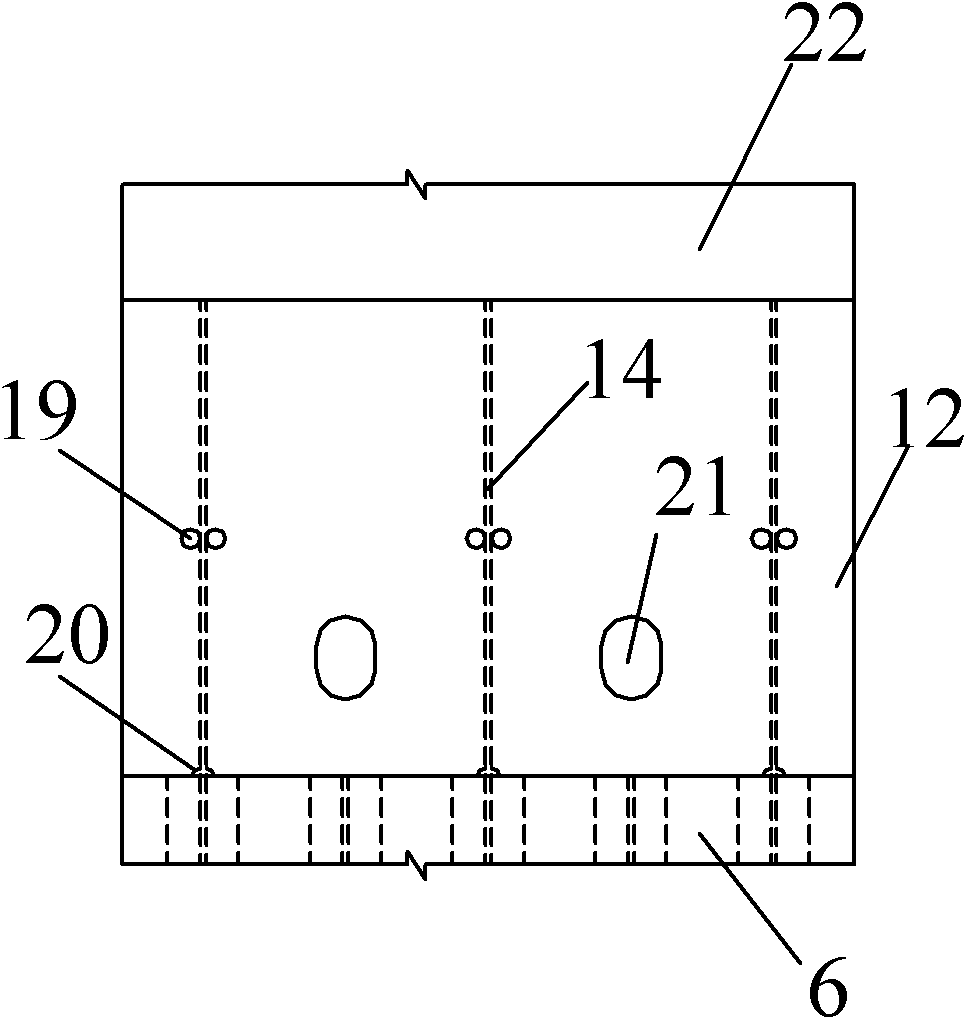

[0033] See figure 1 As shown in ~4, it is a hybrid beam joint with cells provided with composite connectors according to the present invention. It is composed of a steel beam transition section 1, a steel grid room 2 and a concrete beam transition section 3. The steel grid room 2 is filled with concrete 4 and is located between the steel beam transition section 1 and the concrete beam transition section 3. The longitudinal prestressed steel beams 5 pass through The steel cell 2 is placed on the pressure-bearing steel plate 15 . The steel beam transition section 1 is composed of a steel roof 6 , a U-shaped stiffener 7 , a variable-height stiffener 8 and a diaphragm 9 . The steel grid room 2 is connected to the steel main beam 11 through the steel beam transition section 1 . The steel roof 6 is at the same level as the steel girder 11, and is integrated by the horizontal extension of the steel girder 11, and extends horizontally to the top of the steel cell 2 to form the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com