Heavy-duty rolling wheel cable guider

A technology of fairleads and rollers, which is applied to ships and other directions, can solve the problems of large changes in the force direction and size of berthing steel cables, and achieve the effect of improving docking safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

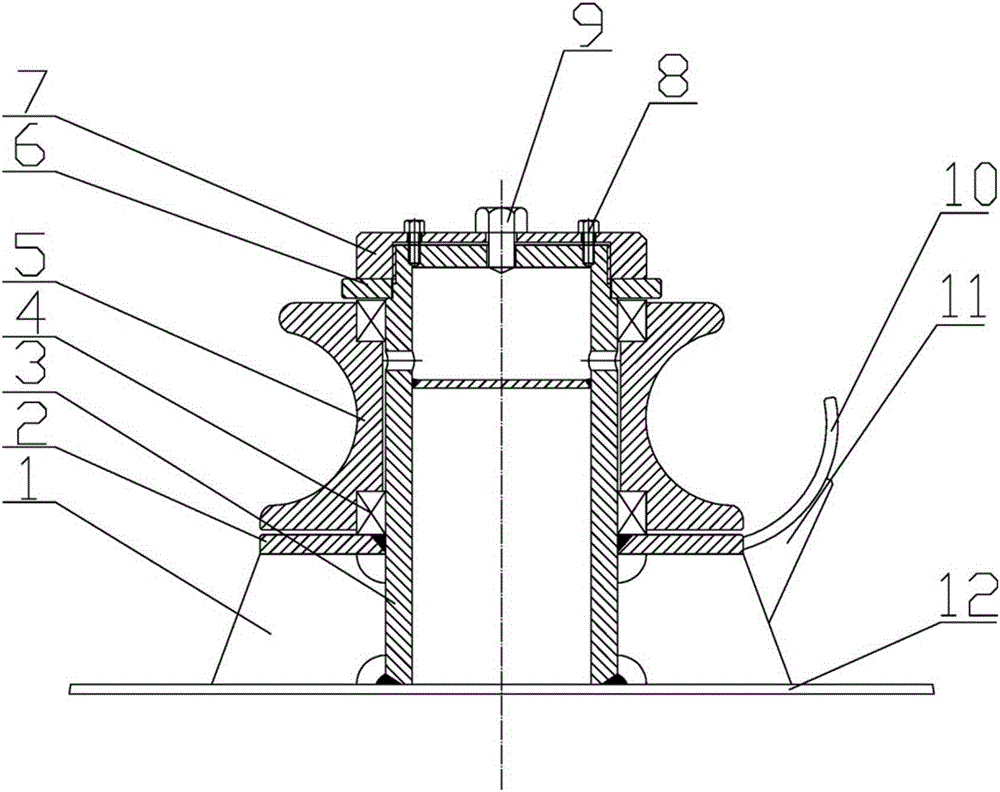

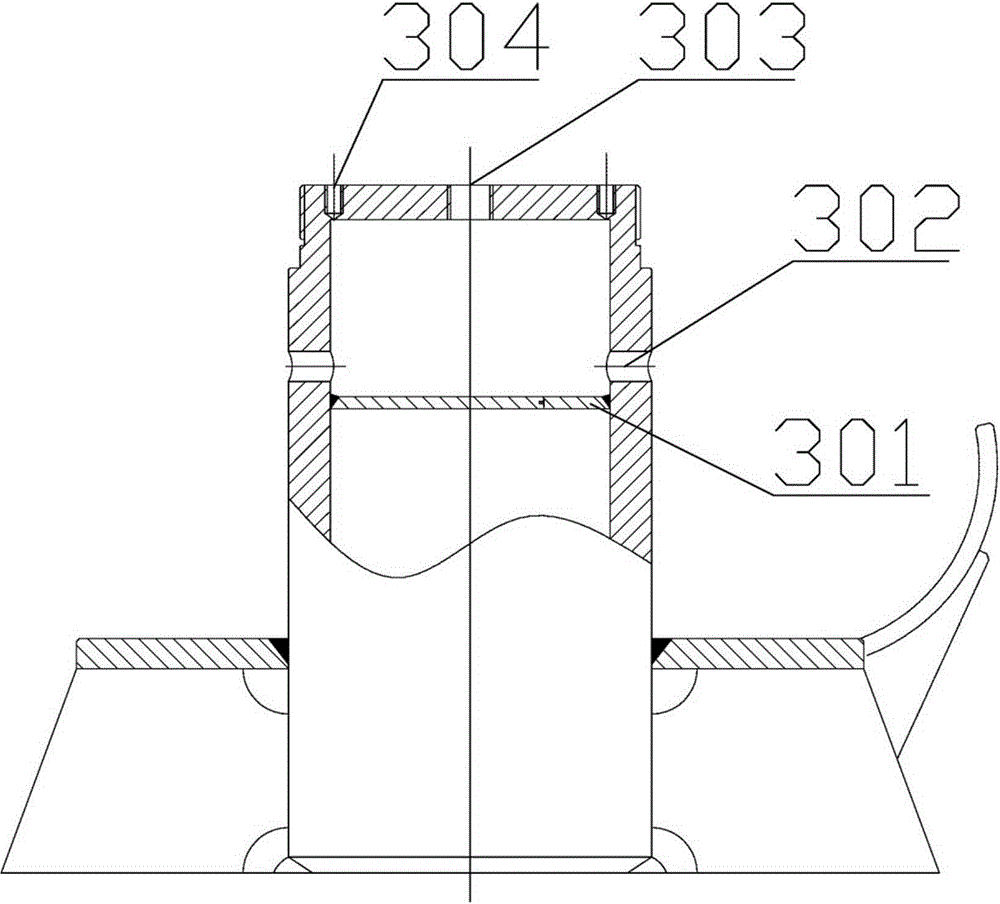

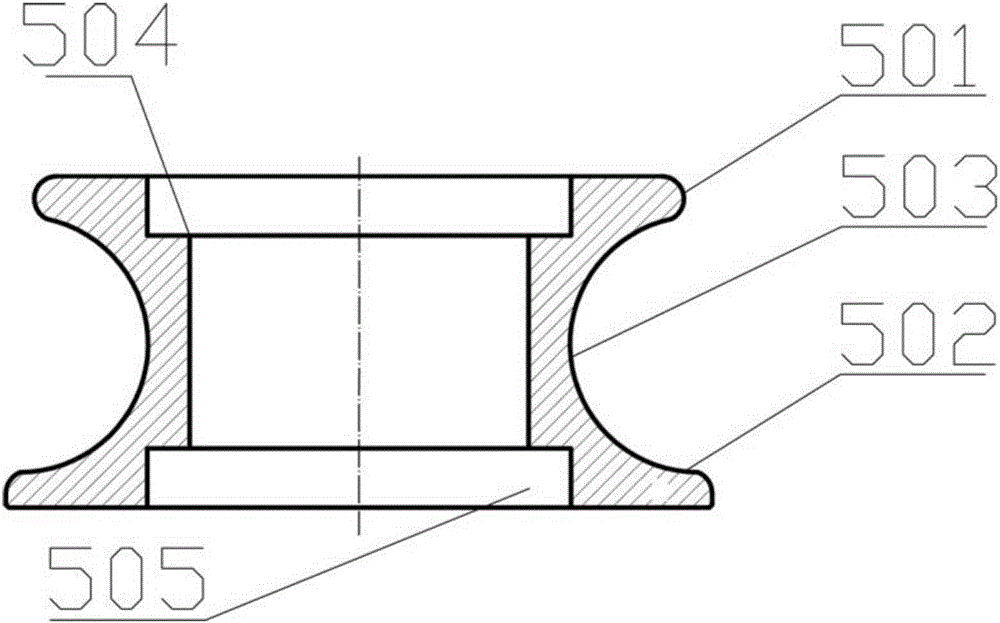

[0019] see Figure 1-4 , heavy-duty roller fairlead, the main shaft 3 is fixed on the deck 12 of the hull by welding, a plurality of reinforcing ribs 1 are evenly arranged on the outer periphery of the bottom section of the main shaft 3 and are welded with the main shaft 3 and the reinforcing ribs 1 at the same time, the bottom plate 2 is fixed on the rib plate 1 by welding, the roller 5 is set on the main shaft 3 and forms a clearance fit, and the two thrust ball bearings 4 are arranged in the upper bearing seat 504 and the lower bearing seat 505 of the roller 5, the thrust ball bearing 4. The inner ring forms an interference fit with the main shaft 3. The pressure plate 6 is arranged at the shoulder of the main shaft 3. The round nut 7 forms a threaded connection with the external thread at the top of the main shaft 3. There is a threaded hole 701 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com