Plate-type composite steel belt leading sheave

A guide pulley and composite steel technology, which is applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of high friction coefficient between the composite steel belt and the wheel groove, the failure of the composite steel belt to slip, and the inability to achieve slippage, etc. To achieve the effect of solving the problem of deviation and uneven force, avoiding the phenomenon of deviation, and preventing deviation or prolapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

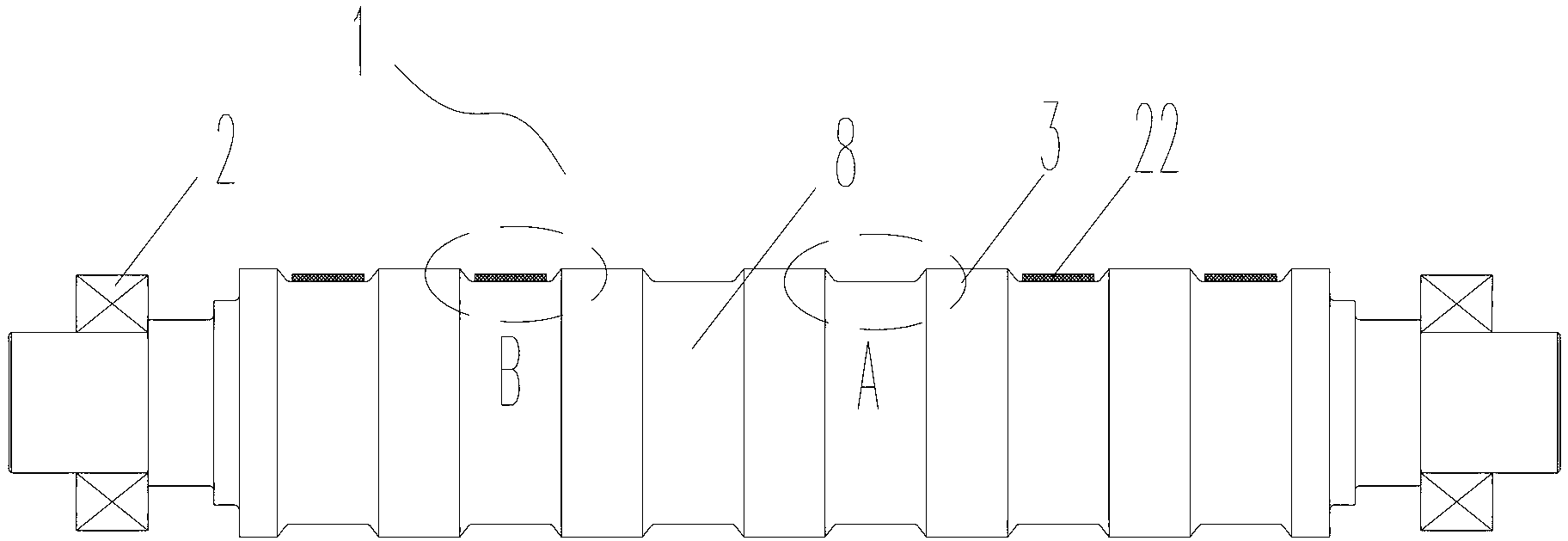

[0023] A flat composite steel belt guide pulley of the present invention can be used as the traction wheel, guide wheel, car top wheel, car bottom wheel or counterweight wheel of an elevator, and each traction wheel, guide wheel, car top wheel, The same groove shape can be set on the car bottom wheel and the counter wheel. The present invention will be further described in detail below in conjunction with the accompanying drawings and the elevator car top wheel as specific examples, but the present invention is not limited to this specific example.

[0024] Such as image 3 As shown, the guide pulley of this example is the car roof pulley 1. Both ends of the car top wheel 1 are provided with bearings 2 for installing the car top wheel 1 on the car top beam. The car top wheel 1 is provided with a plurality of guide grooves 8 .

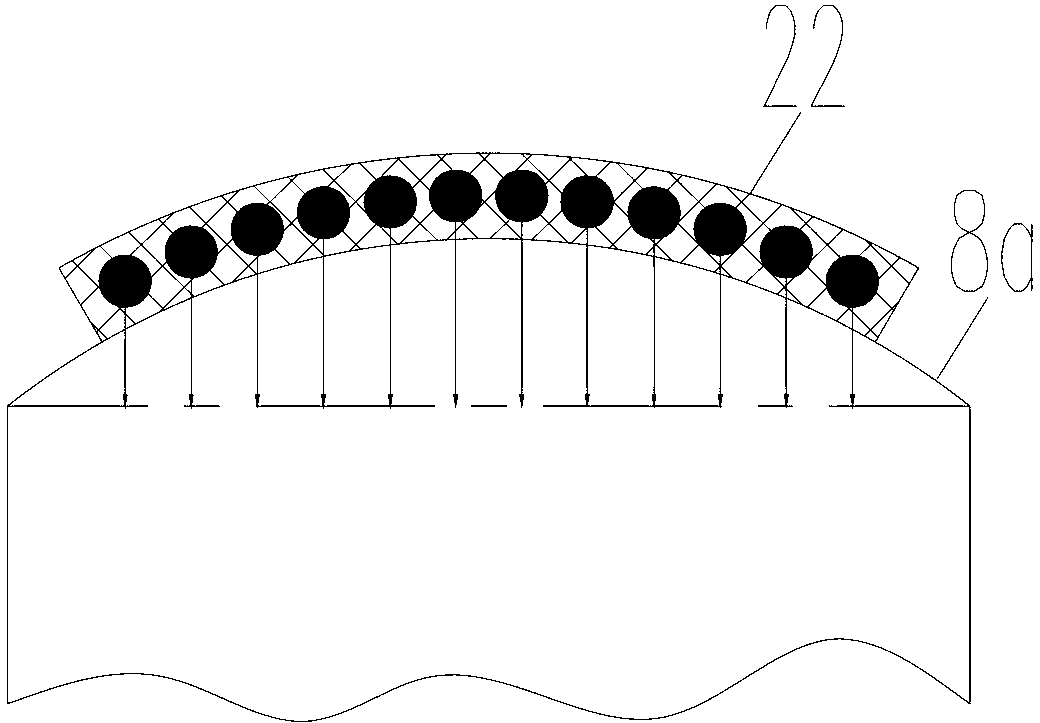

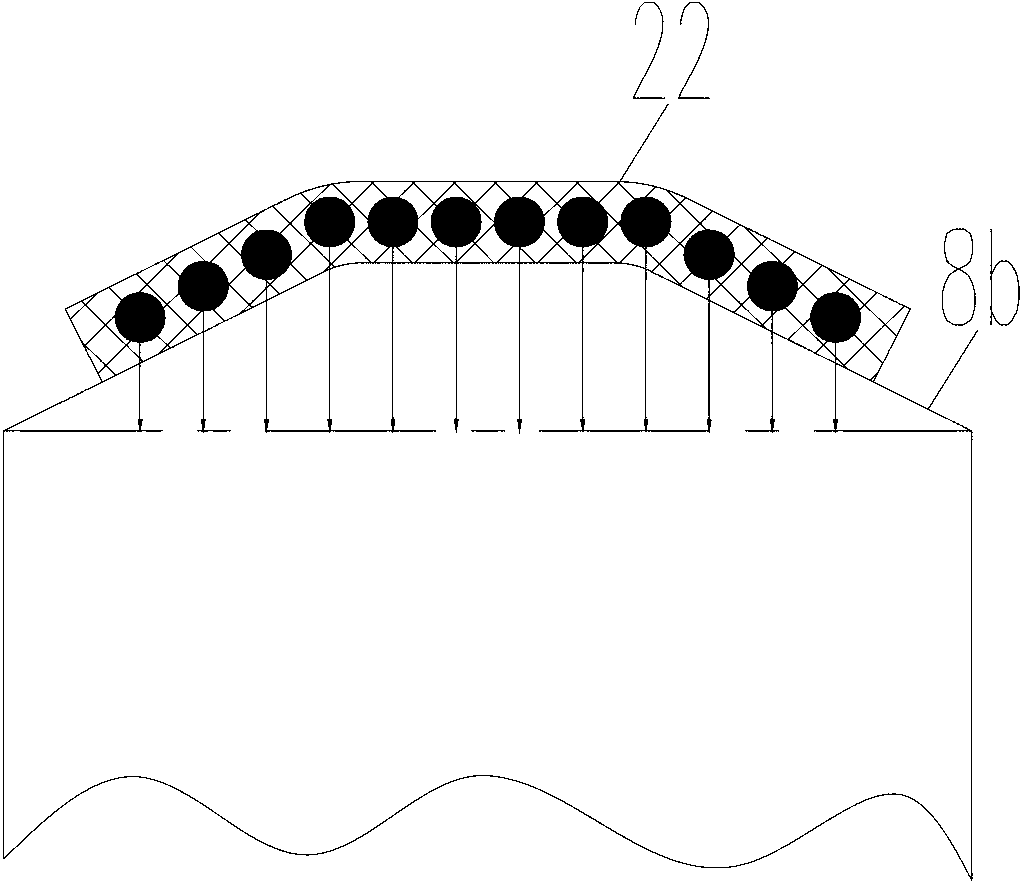

[0025] Such as Figure 4 , 5 As shown, the guide groove 8 is a flat-bottomed groove, which not only enables the composite steel strip 22 to be aut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com