Patents

Literature

3830results about How to "Easy injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

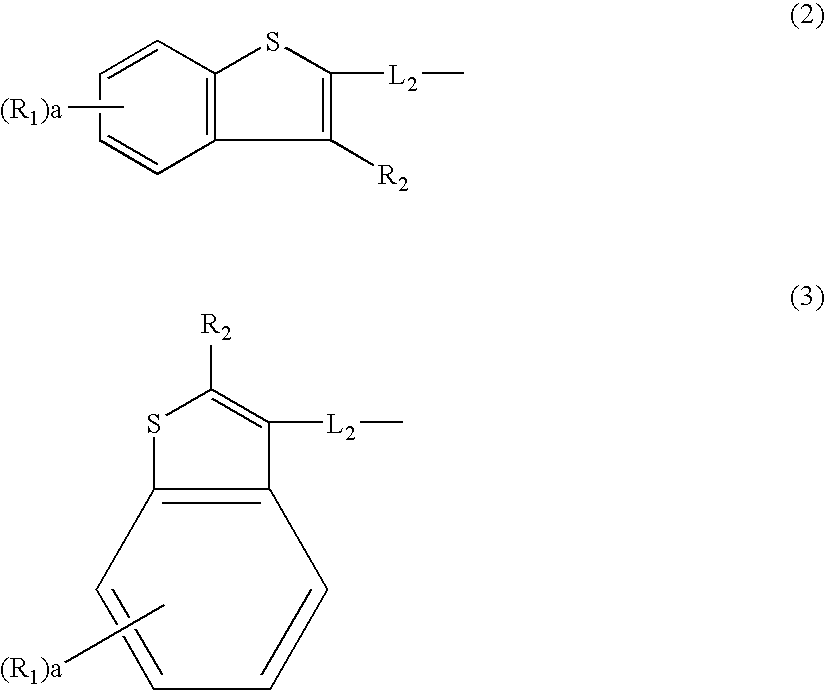

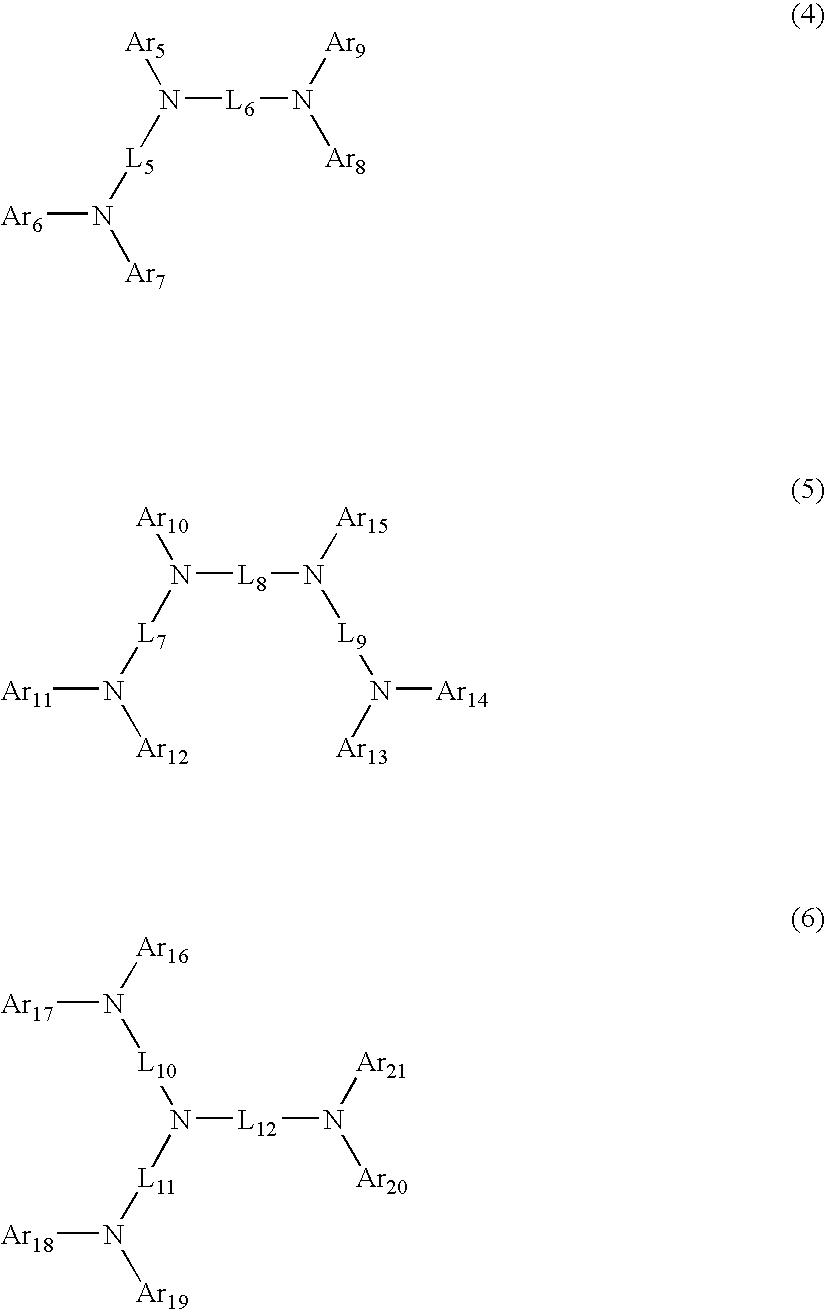

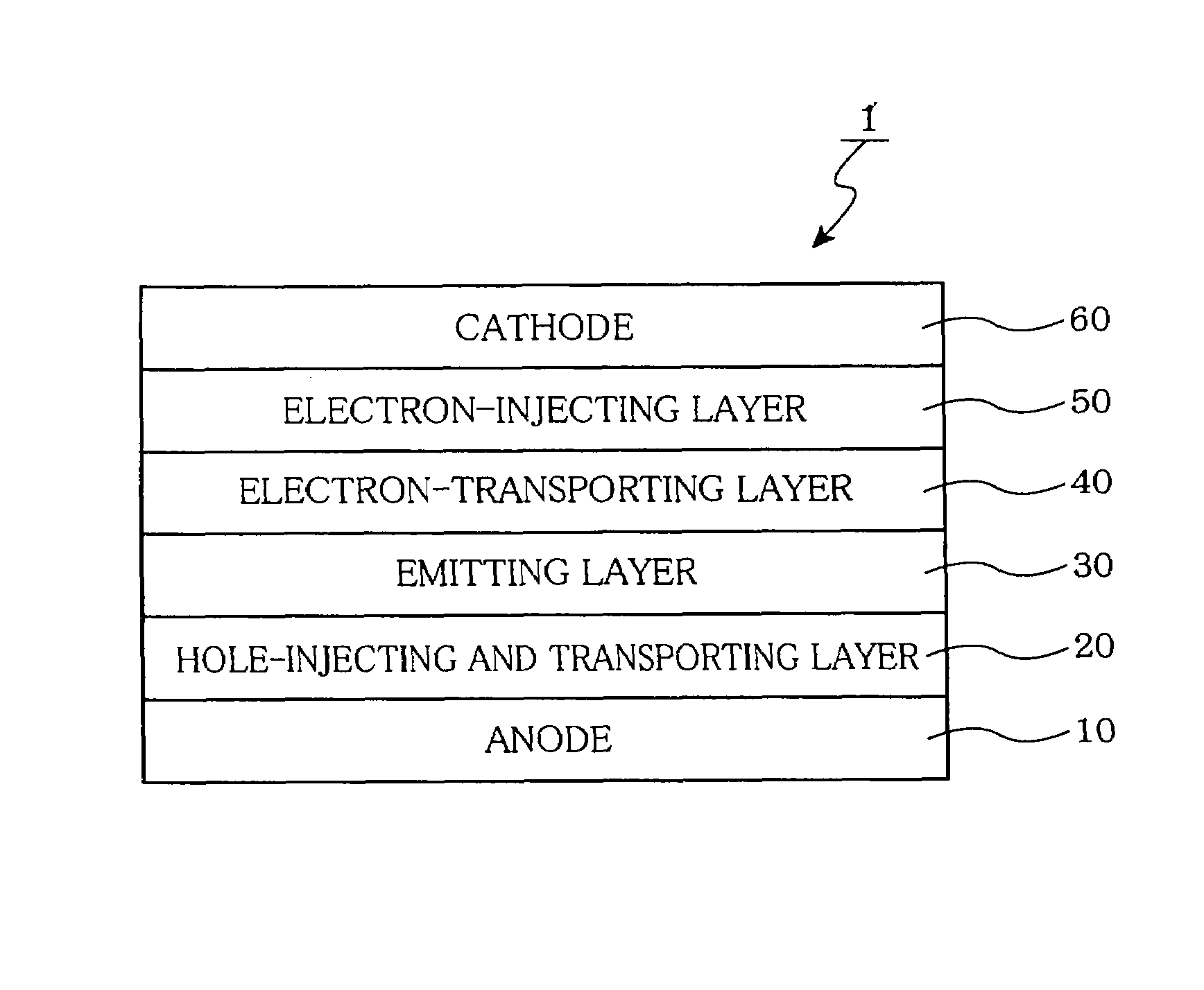

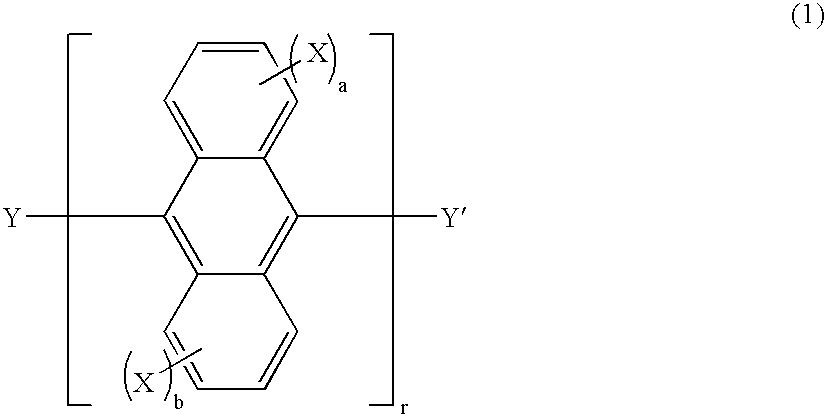

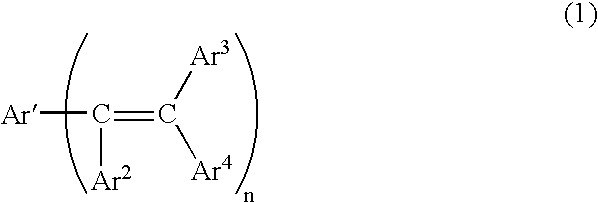

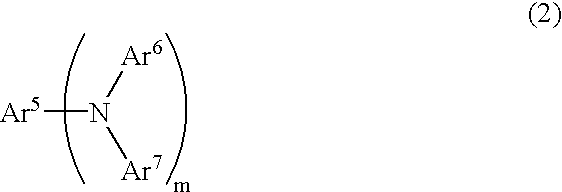

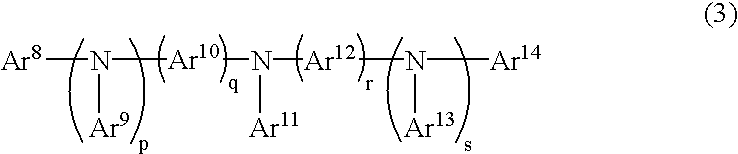

Aromatic amine derivatives and organic electroluminescent device using same

InactiveUS20080106190A1Less liableImproved in yield in producingOrganic chemistryDischarge tube luminescnet screensHole transport layerOrganic electroluminescence

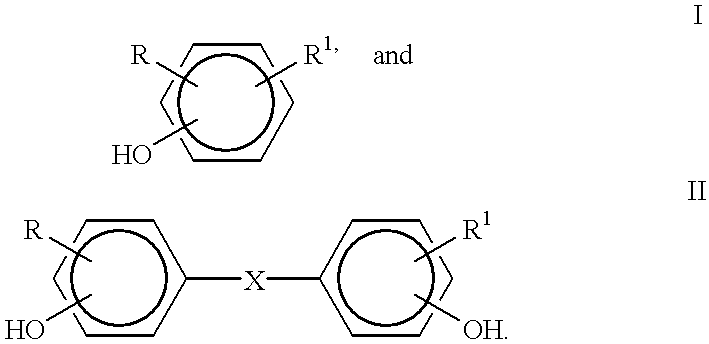

The present invention provides a novel aromatic amine derivative having a specific structure and an organic electroluminescence device in which an organic thin film layer comprising a single layer or plural layers including at least a light emitting layer is interposed between a cathode and an anode, wherein at least one layer in the above organic thin film layer, particularly a hole transporting layer contains the aromatic amine derivative described above in the form of a single component or a mixed component. Use of the aromatic amine derivative described above materialize an organic electroluminescence device which reduces a driving voltage and makes molecules less liable to be crystallized and which enhances a yield in producing the organic EL device and has a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

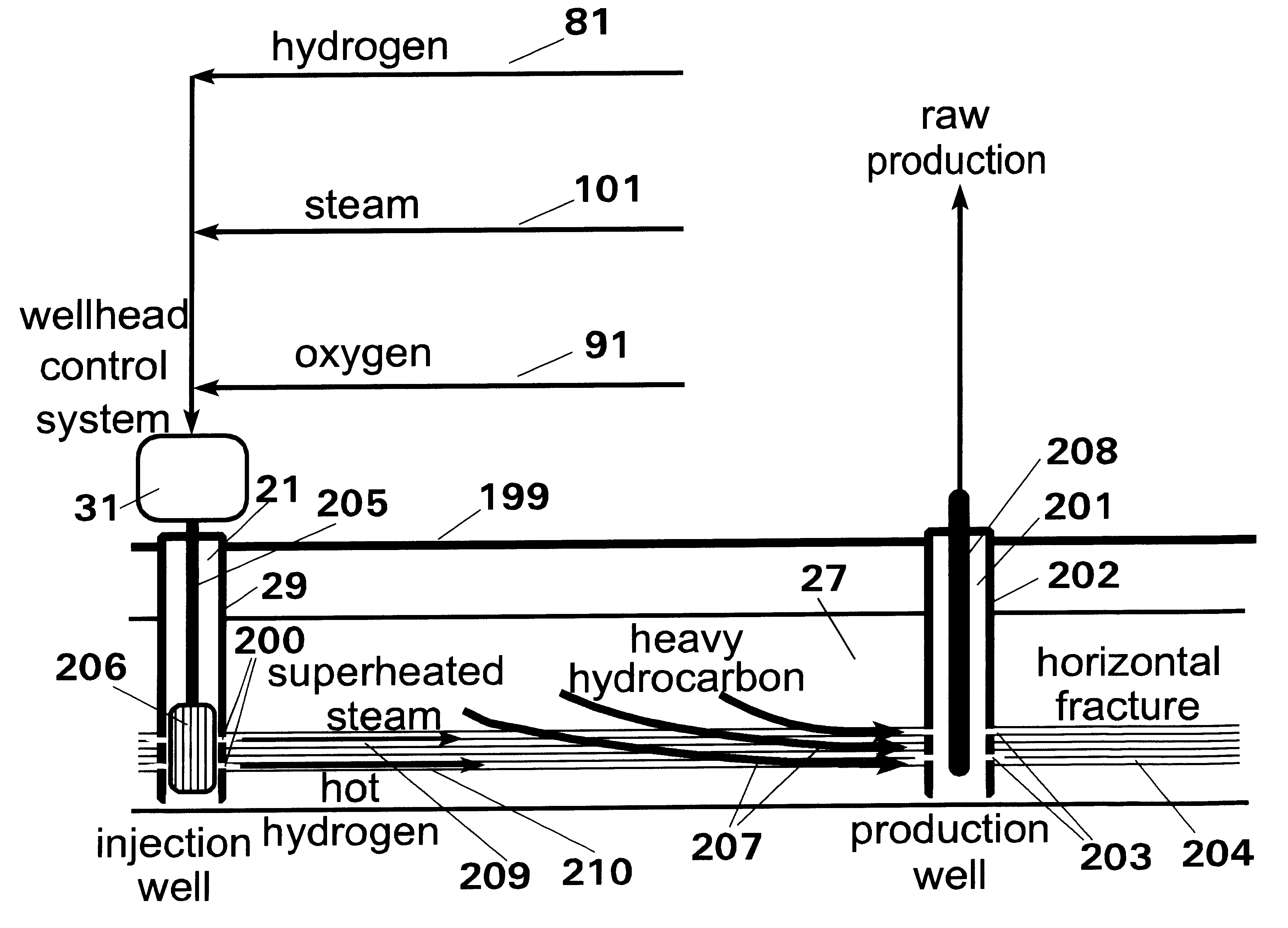

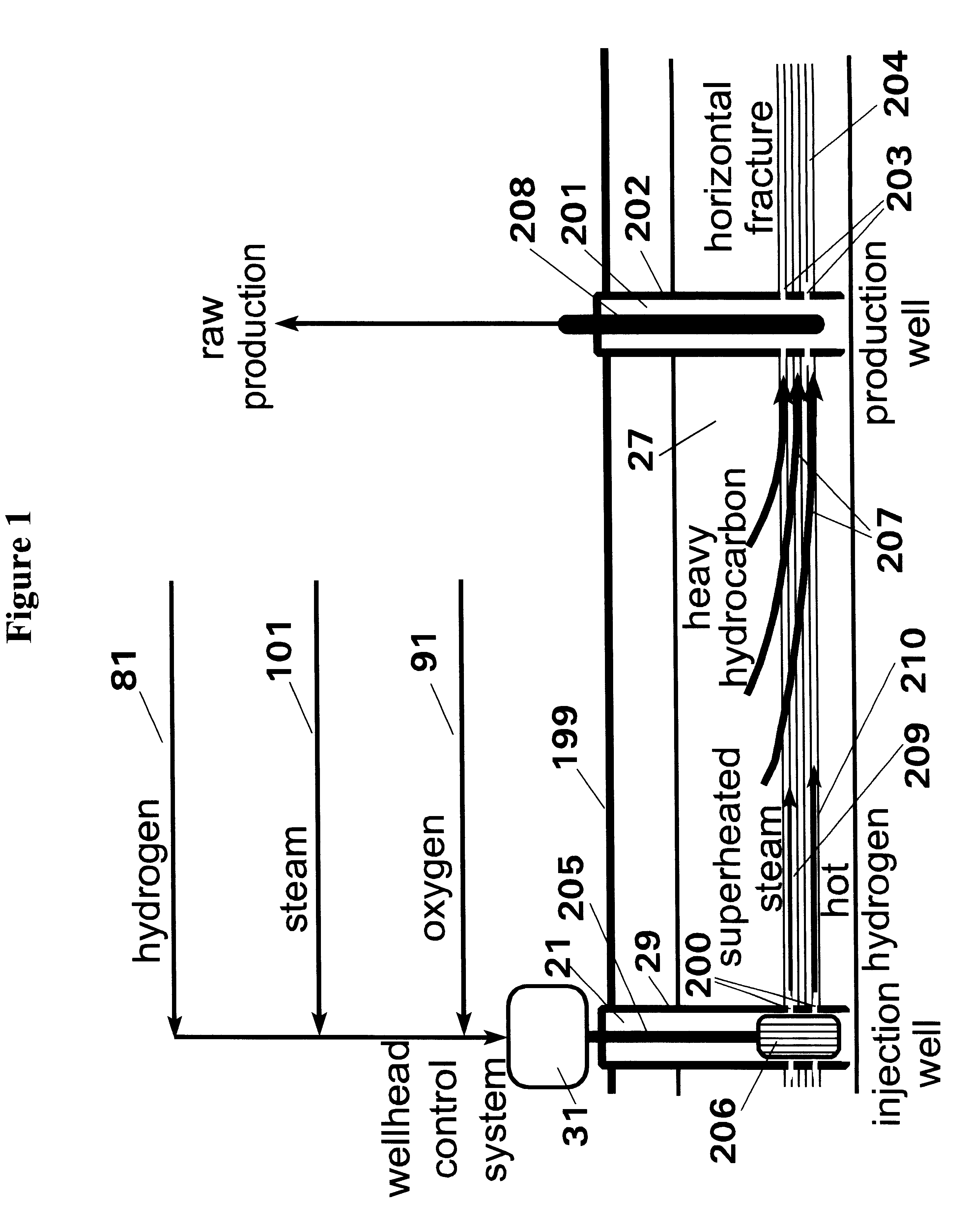

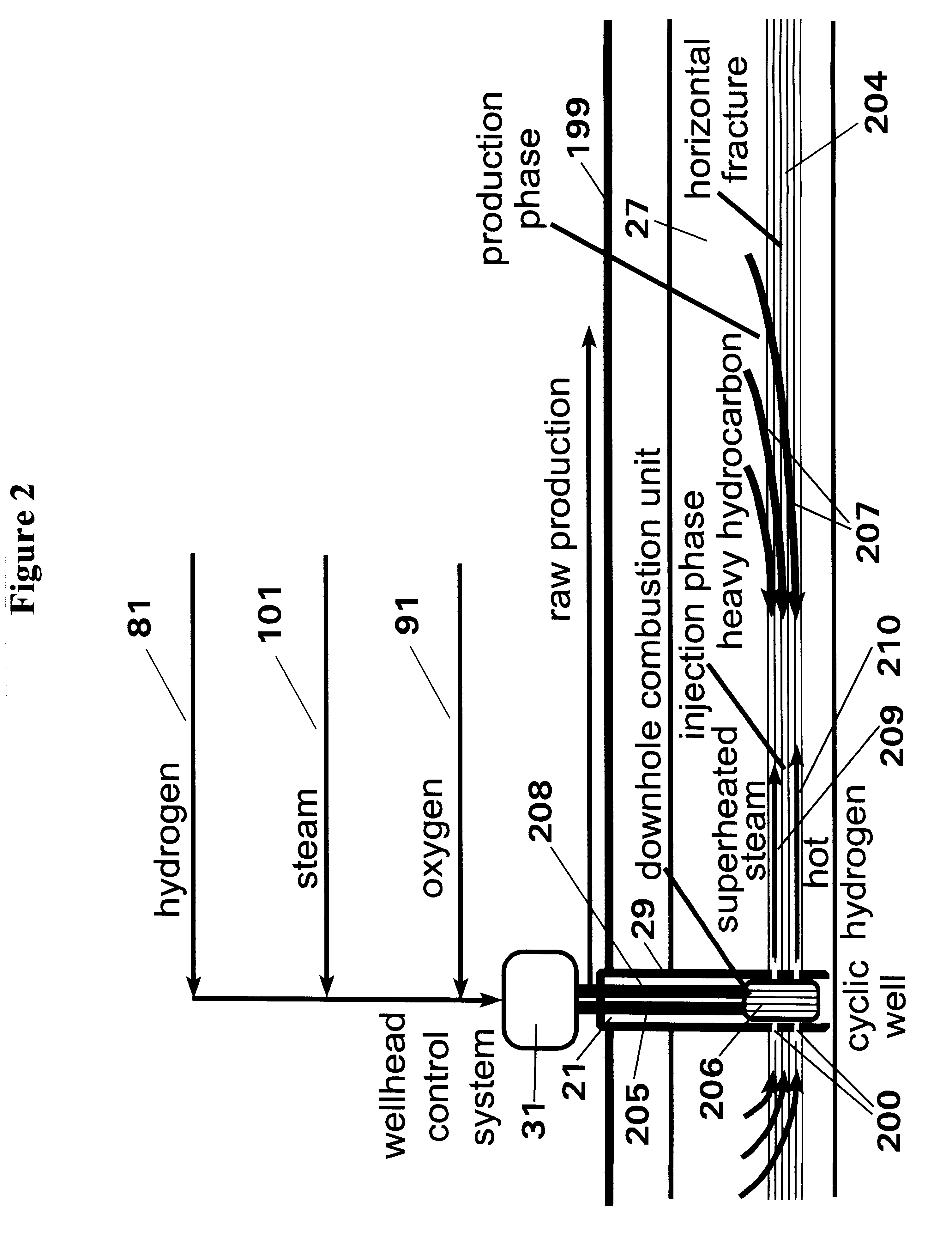

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

Infusion pump with an electronically loadable drug library and label reader

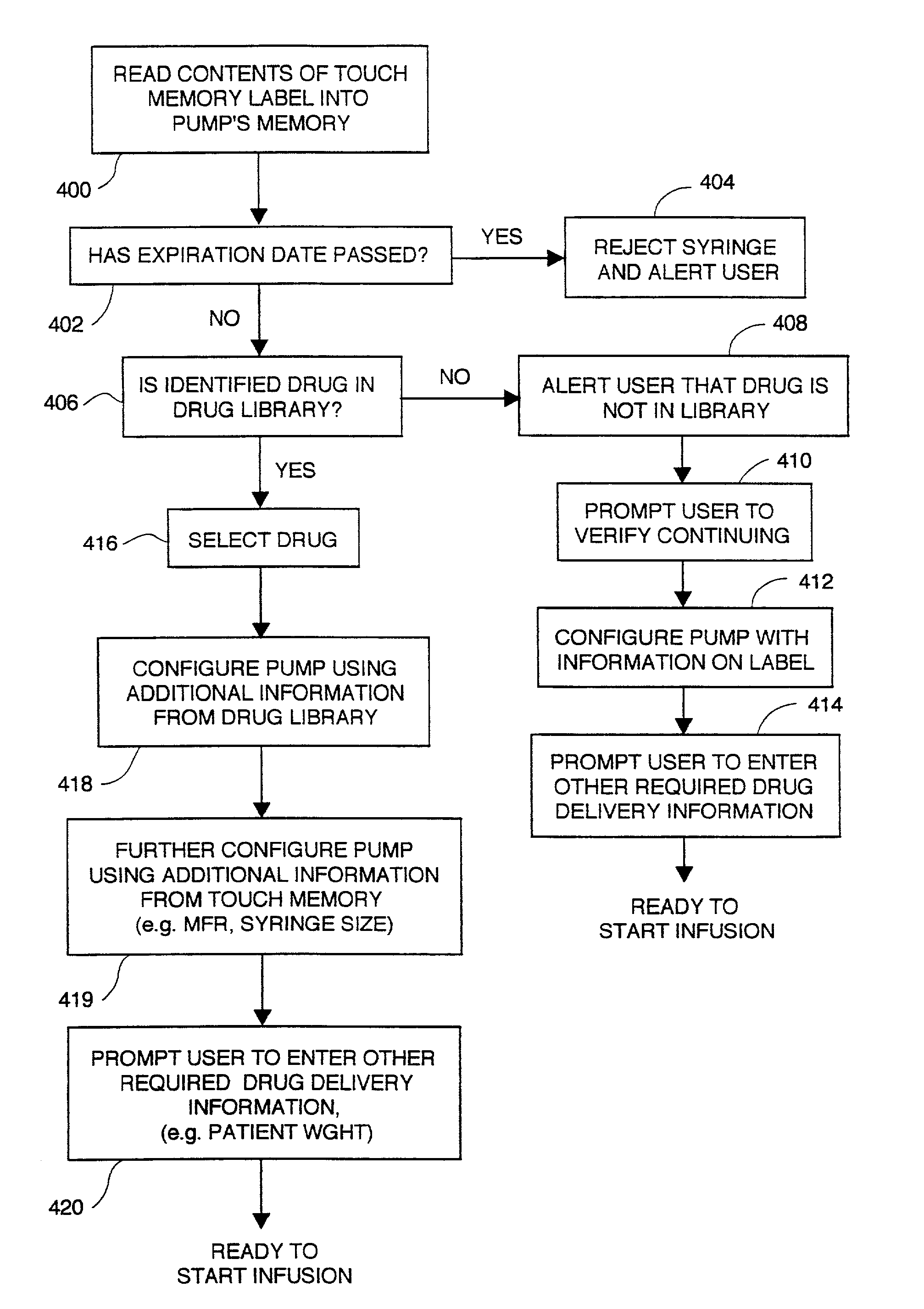

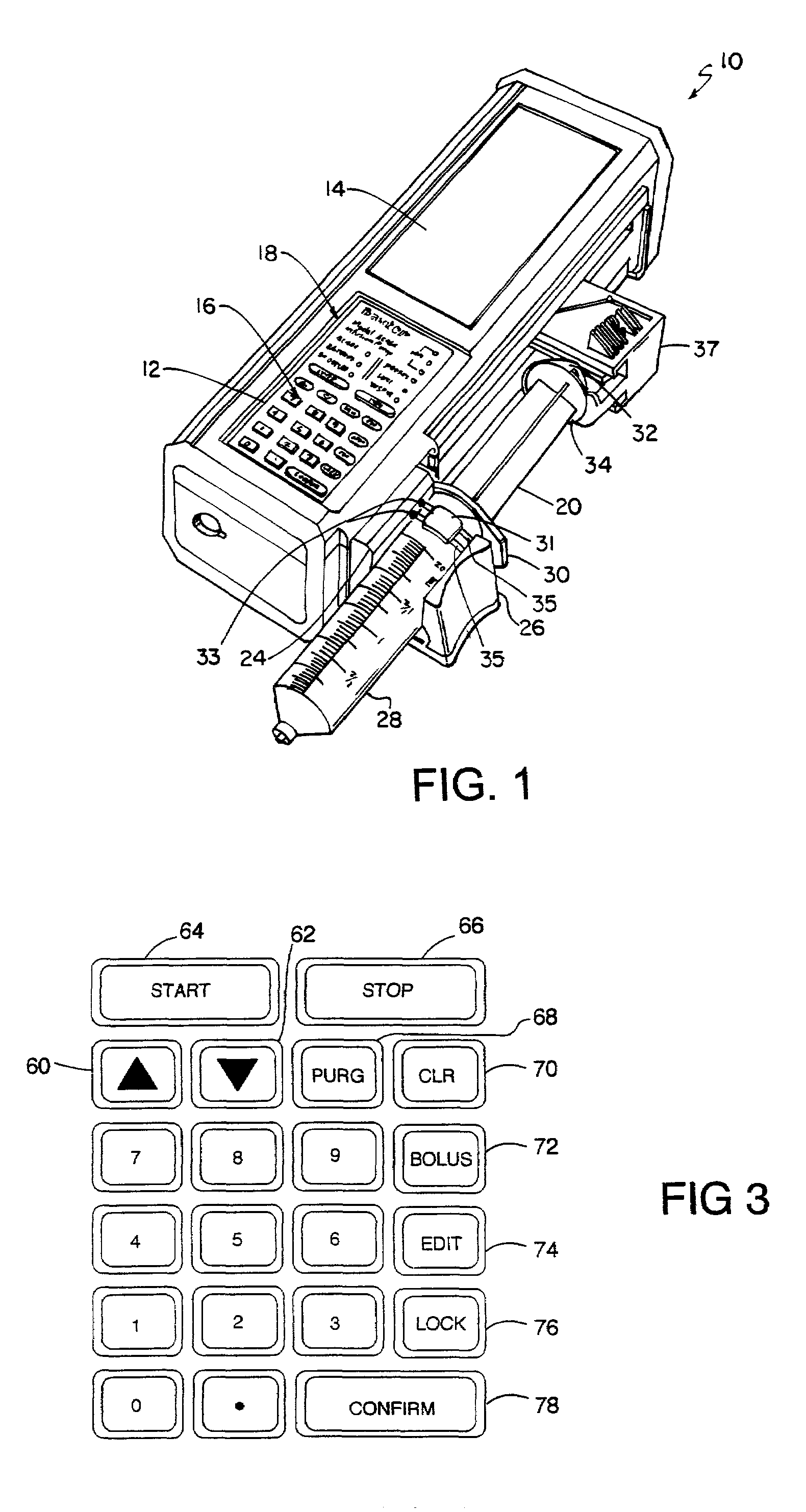

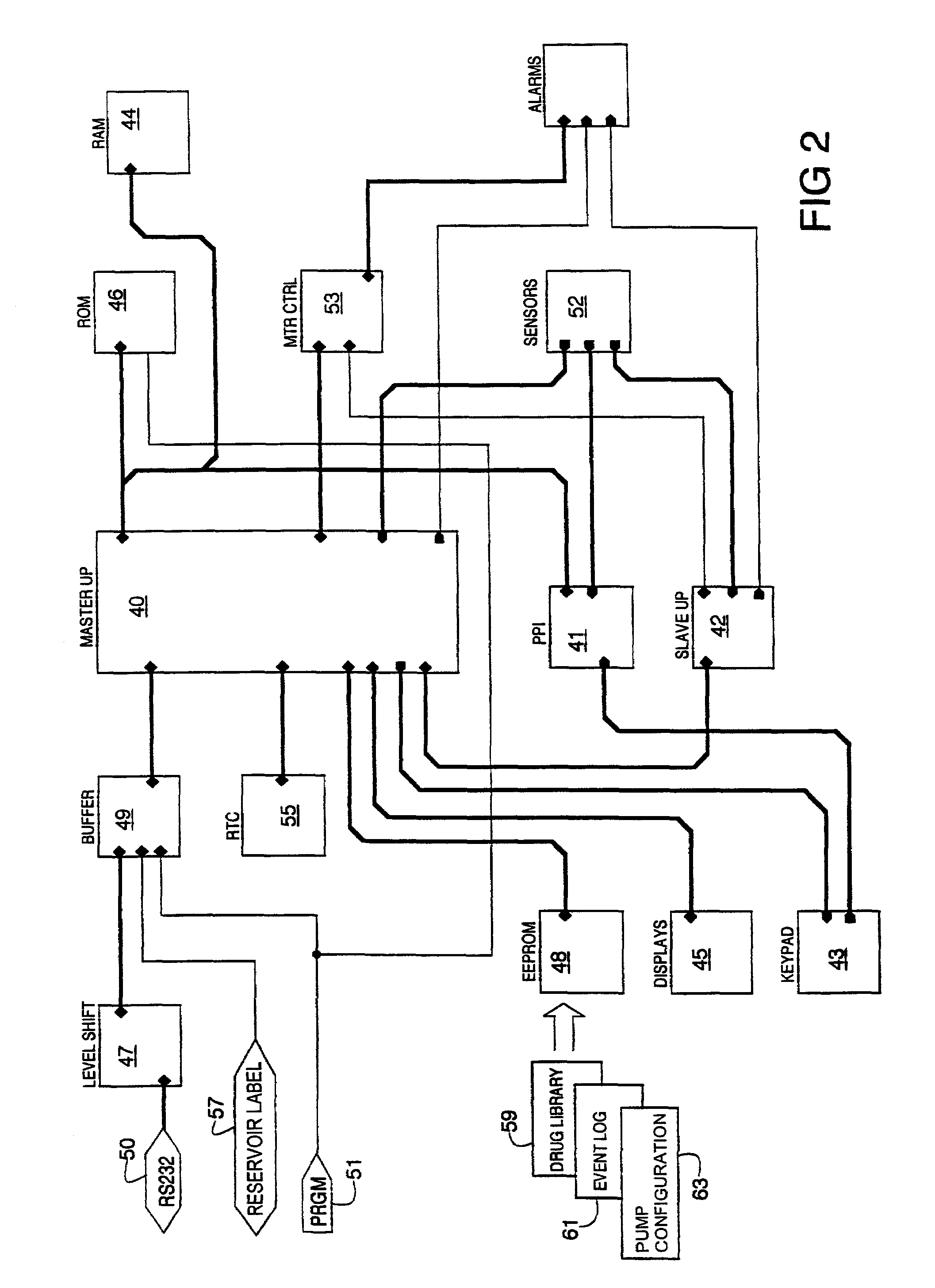

InactiveUS7471994B2Easy to customizeEasy injectionDrug and medicationsMedical devicesMedicineDrug product

A system for creating a customized drug library for an electronically loadable drug infusion pump, the system including a drug library containing a plurality of drug entries, there being associated with each drug entry a set of associated drug delivery parameters and / or drug delivery protocols for configuring the drug infusion pump; a tool for selecting a set of drug entries from among the plurality of drug entries in said drug library; a tool for adding the selected drug entries along with the sets of drug delivery information associated therewith to a customized library; and a loading tool for causing the system to electronically load the customized library into the drug infusion pump.

Owner:THE GENERAL HOSPITAL CORP +1

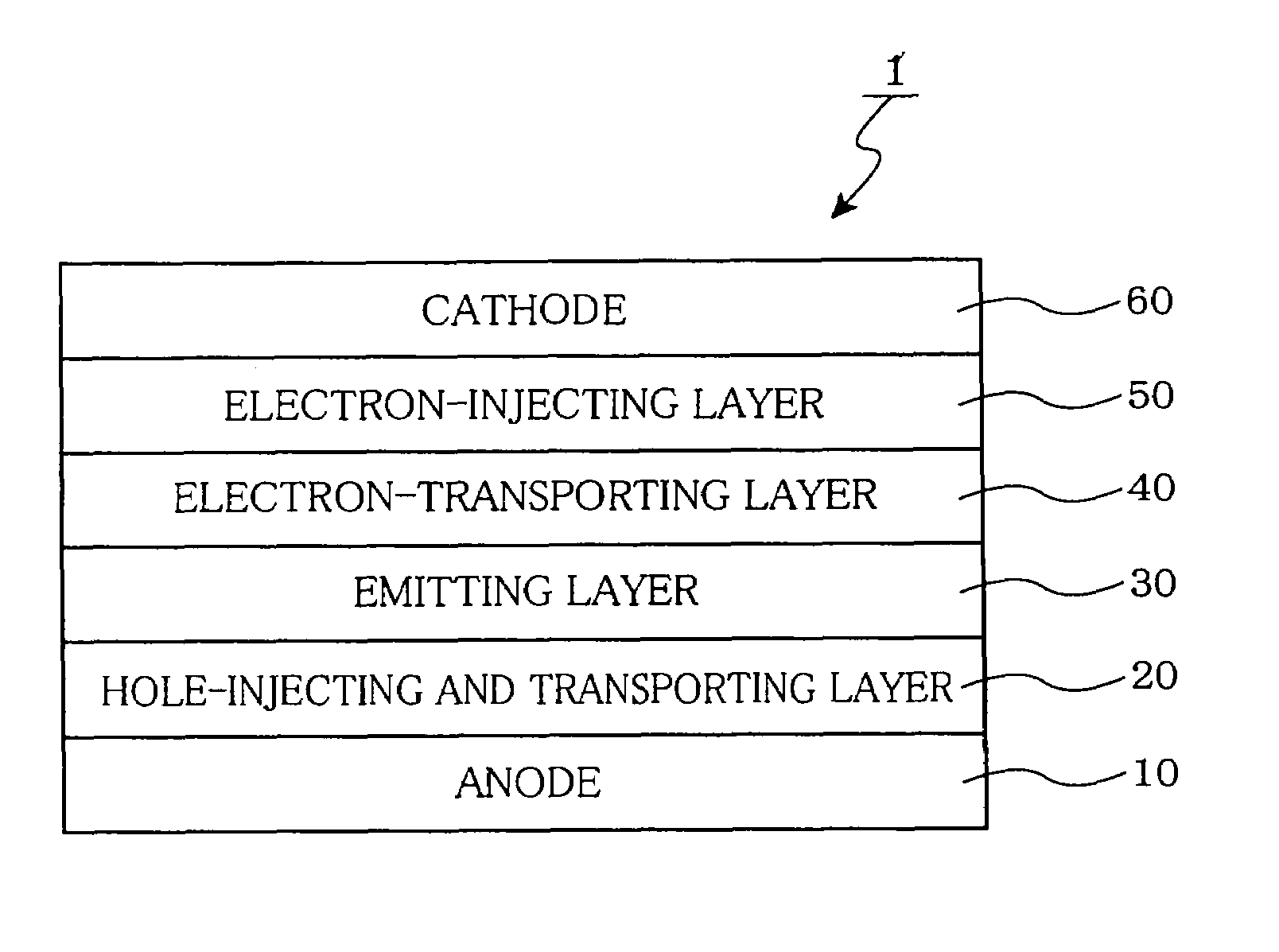

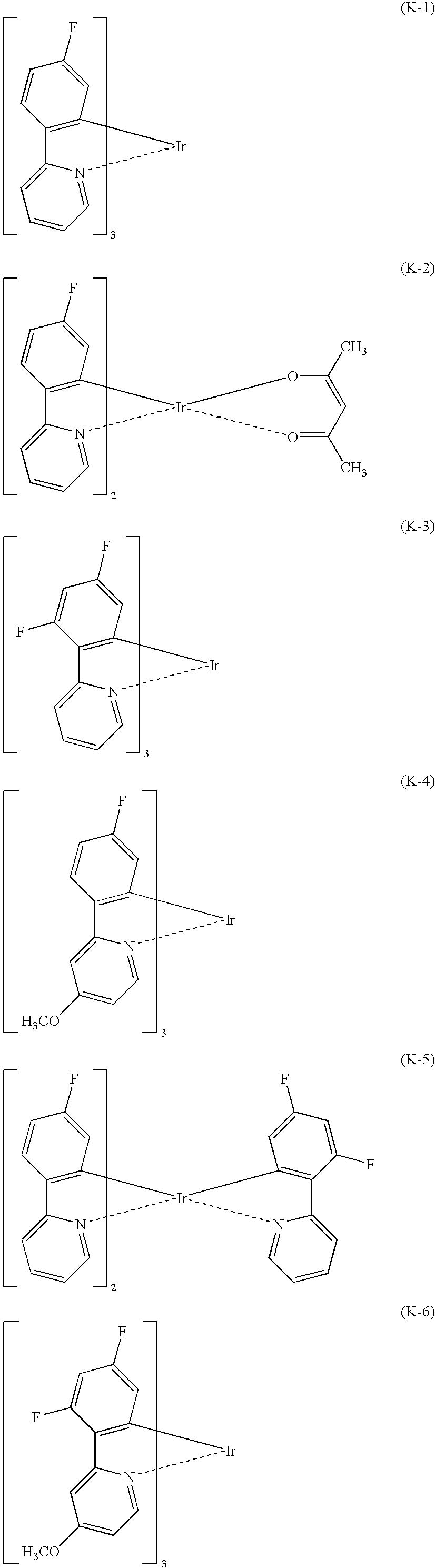

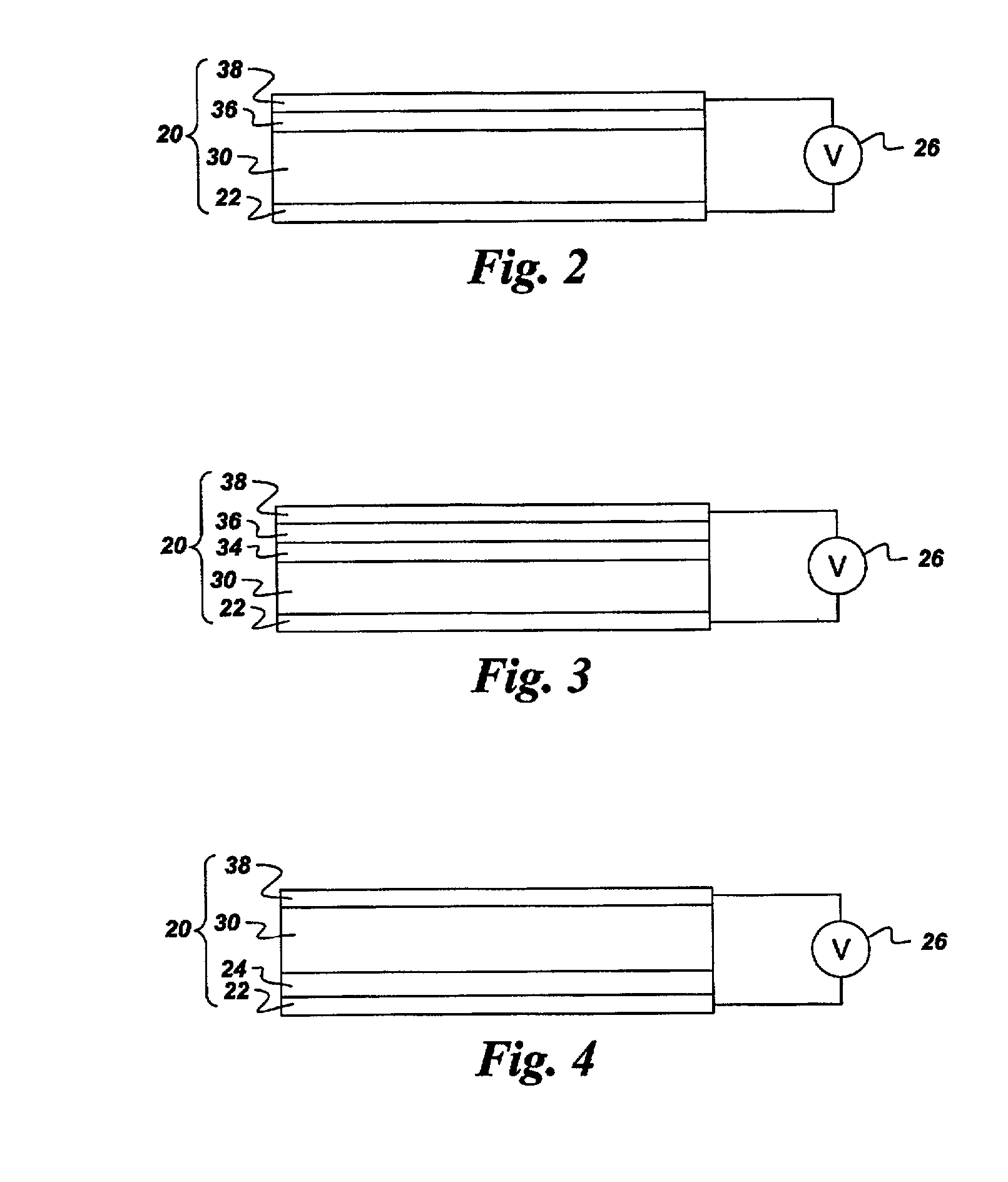

Organic electroluminescent device

InactiveUS20080193796A1High efficiencyLong lifeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceQuantum yield

An organic electroluminescent device including: an anode, a cathode, and at least an emitting layer, an electron-transporting layer and an electron-injecting layer interposed between the anode and the cathode; the emitting layer containing a host material which is a pyrene derivative, a chrysene derivative, a fluorene derivative or an anthracene derivative; the electron-transporting layer containing an electron-transporting material which is a pyrene derivative, a chrysene derivative, a fluorene derivative or an anthracene derivative, the anthracene derivative containing no heterocyclic ring, and has a heterocyclic ring and having a fluorescence quantum yield which is smaller than that of the host material contained in the emitting layer; and the electron-injecting layer containing a non-complex compound having a nitrogen-containing five-membered heterocyclic structure.

Owner:IDEMITSU KOSAN CO LTD

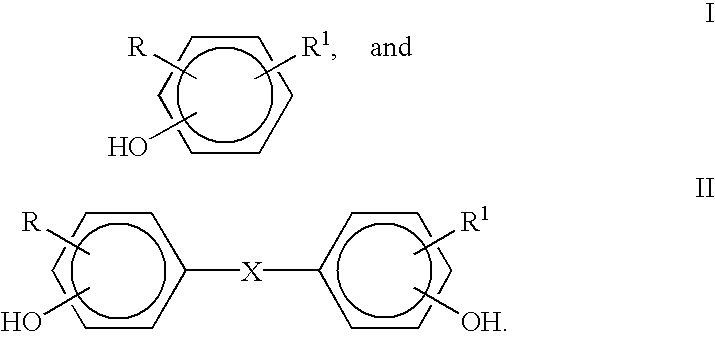

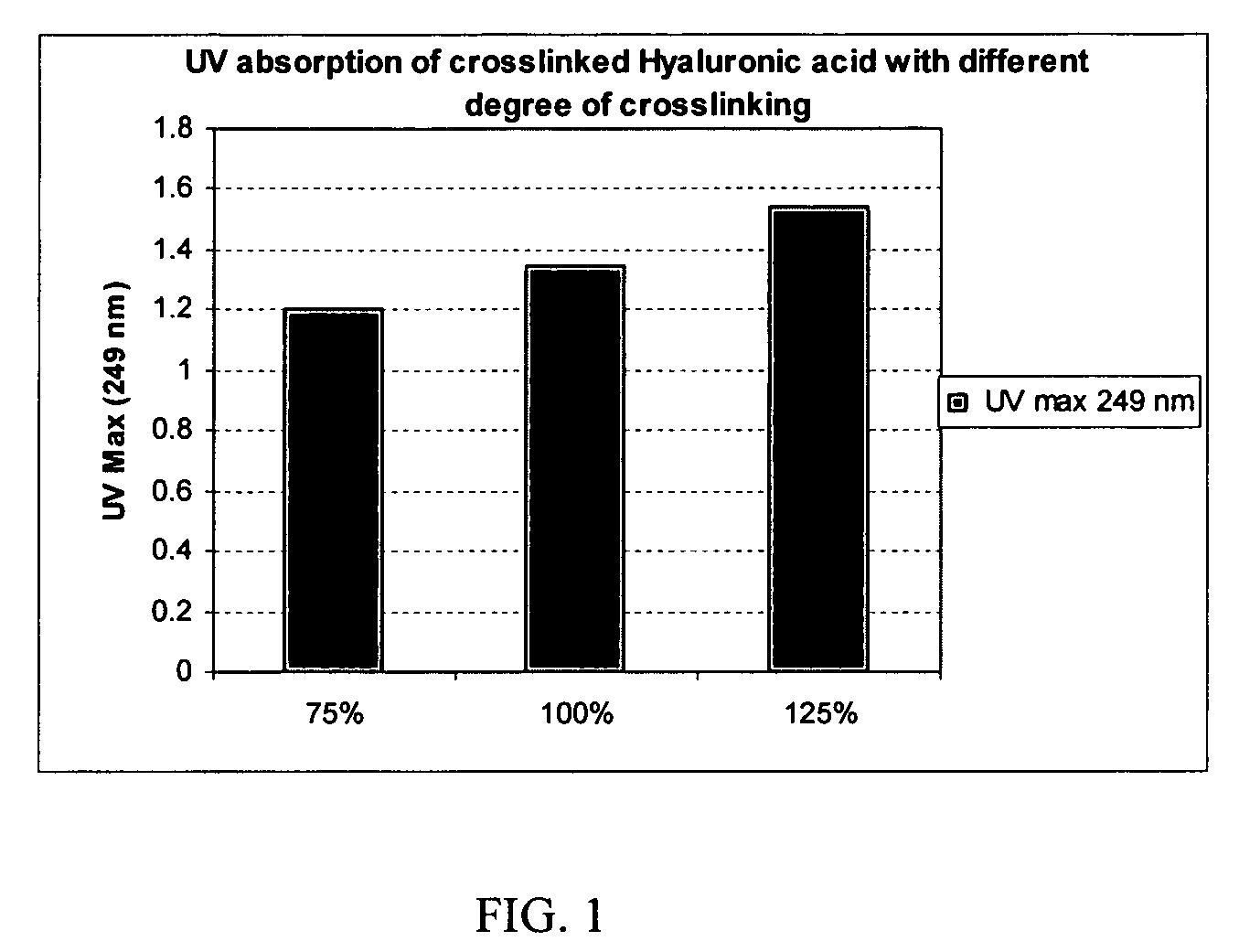

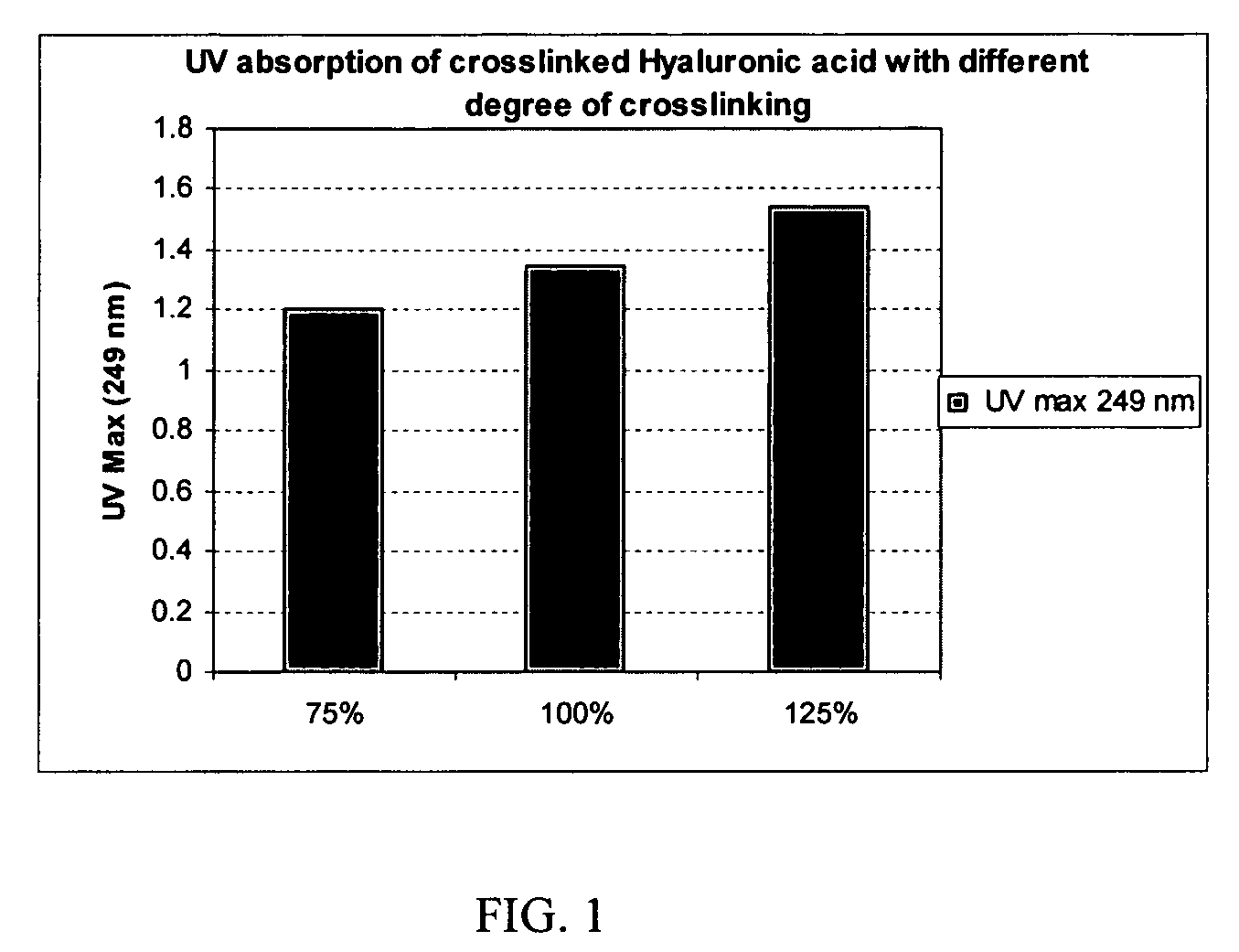

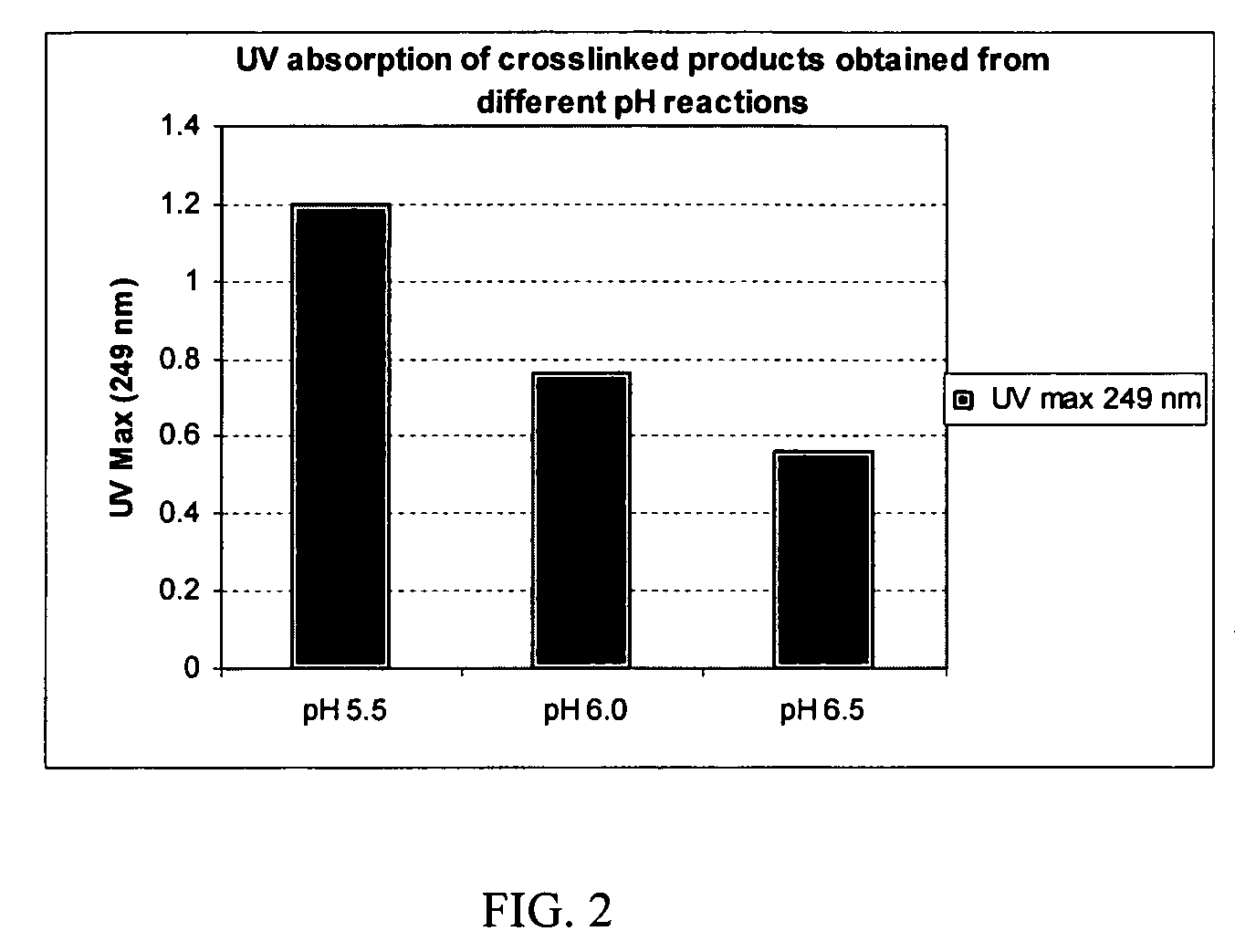

Crosslinked hyaluronic acid compositions for tissue augmentation

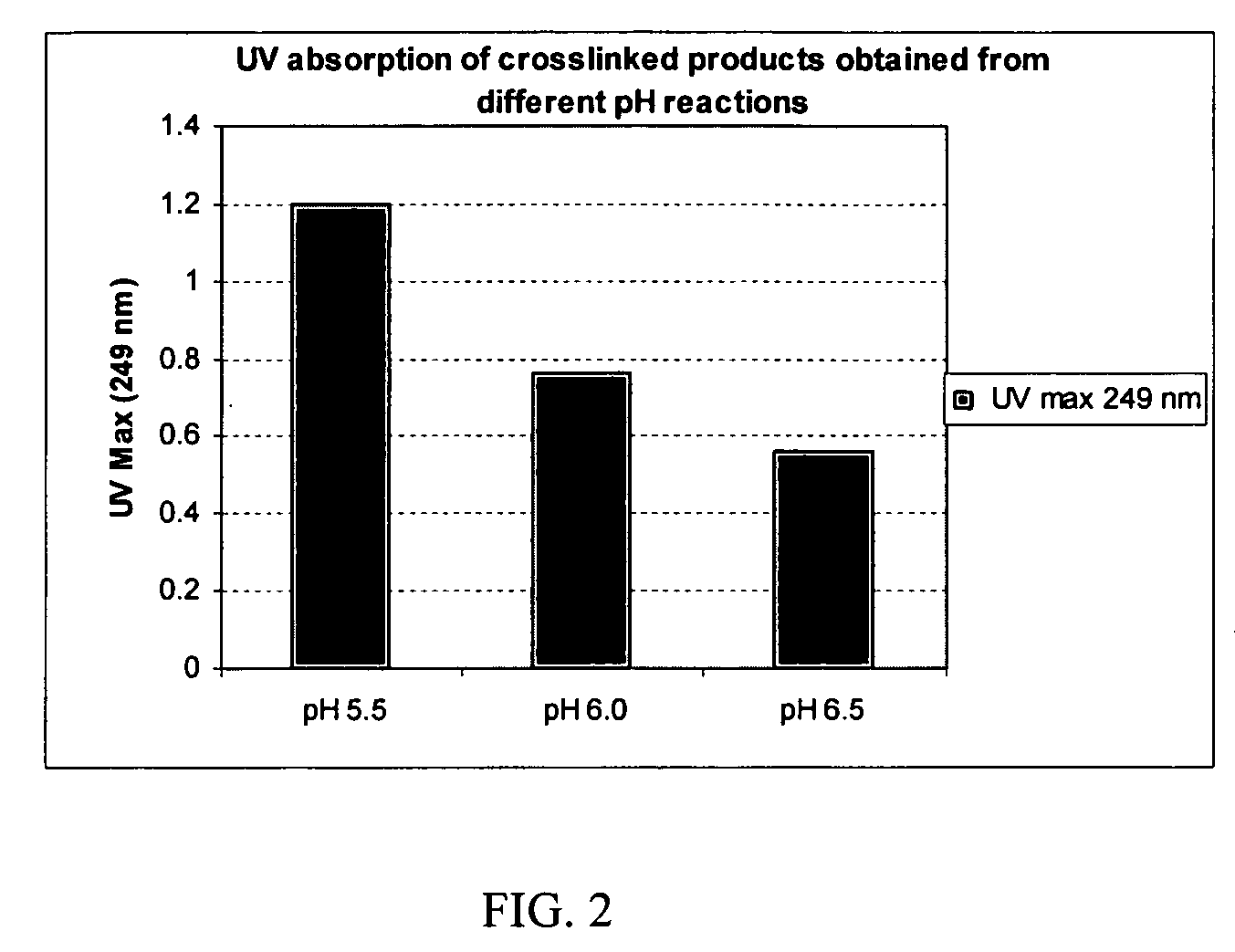

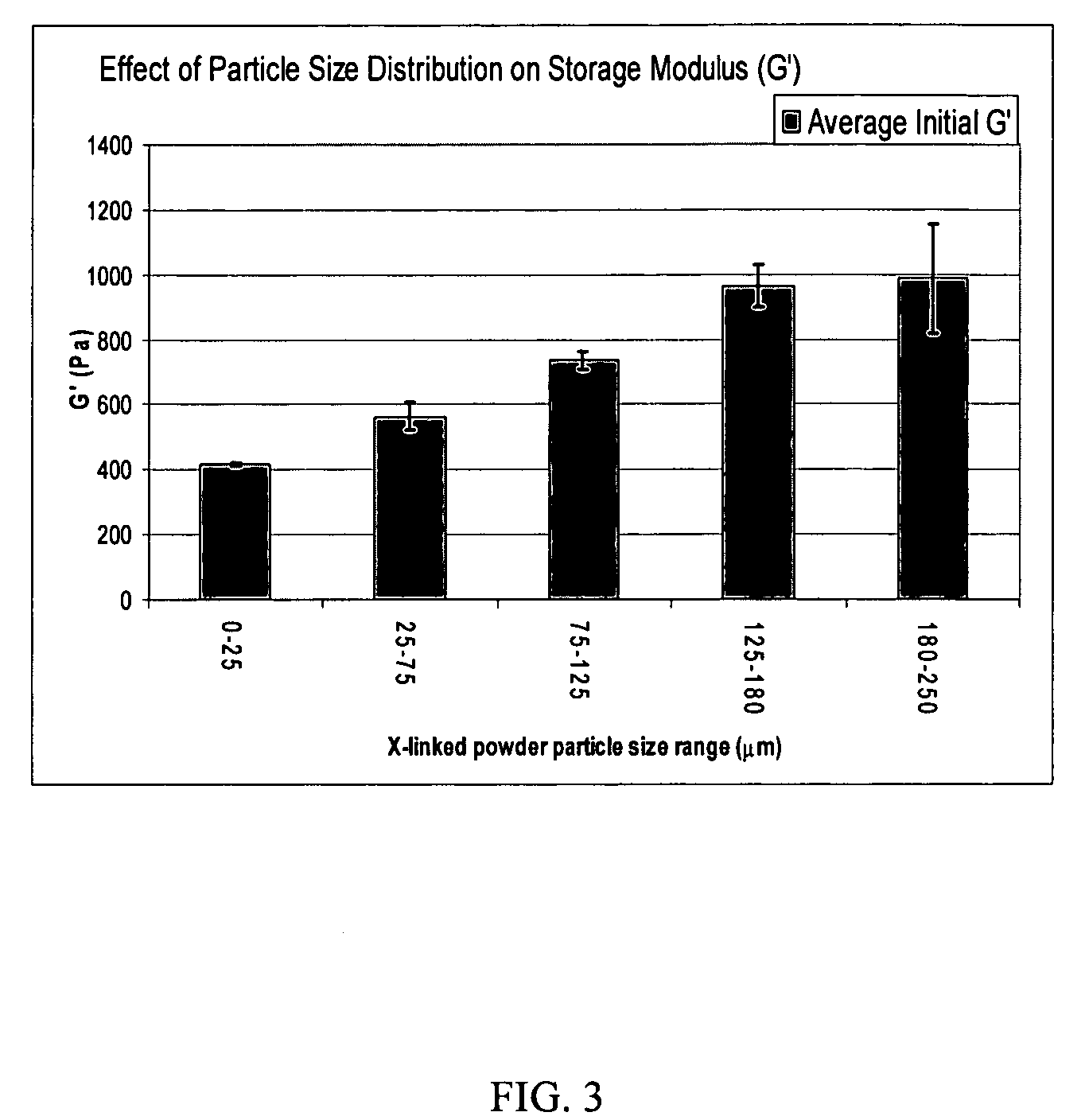

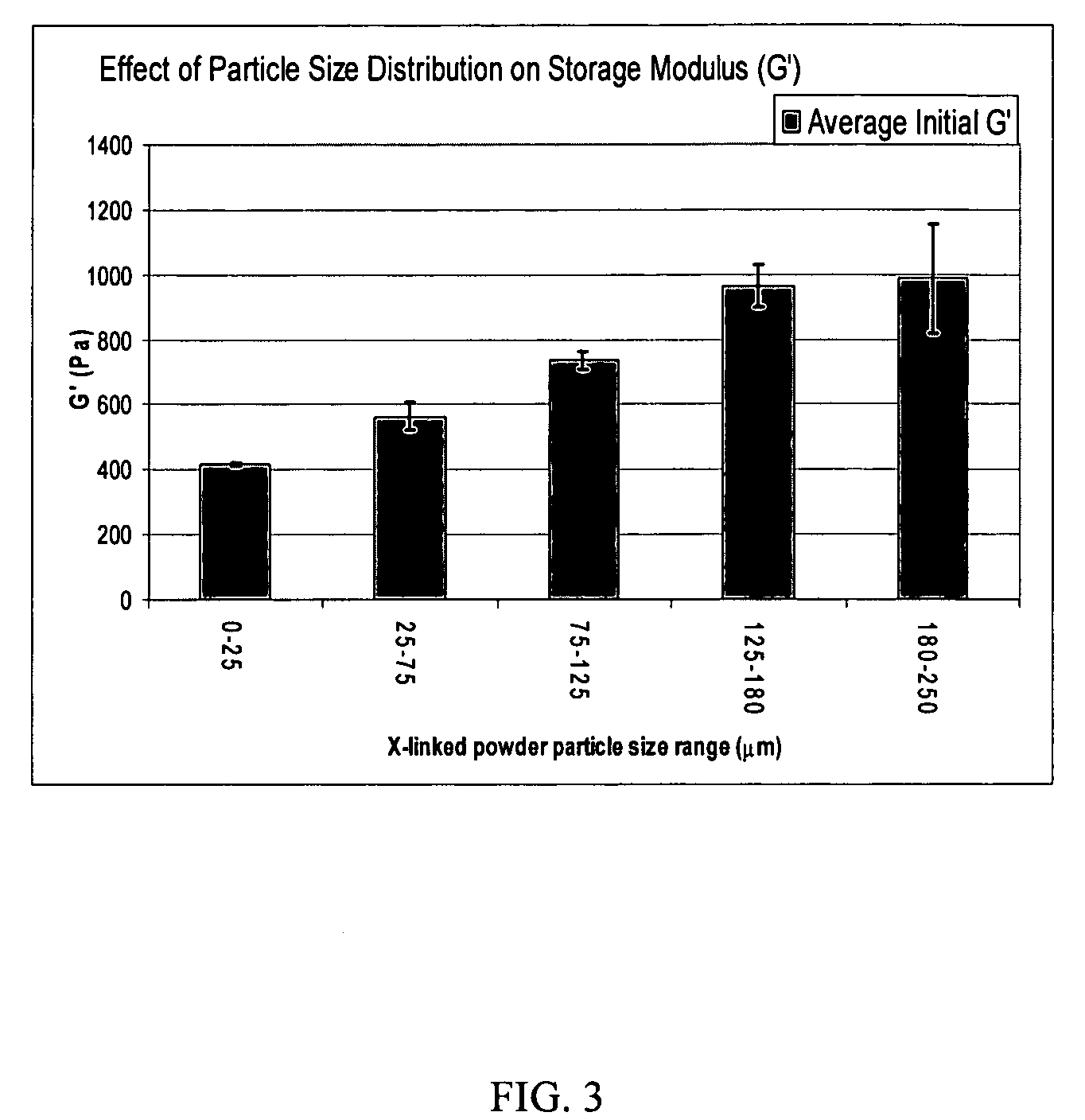

ActiveUS20050136122A1Improve drug deliveryReduce frequencyAntibacterial agentsBiocideAqueous solutionAverage diameter

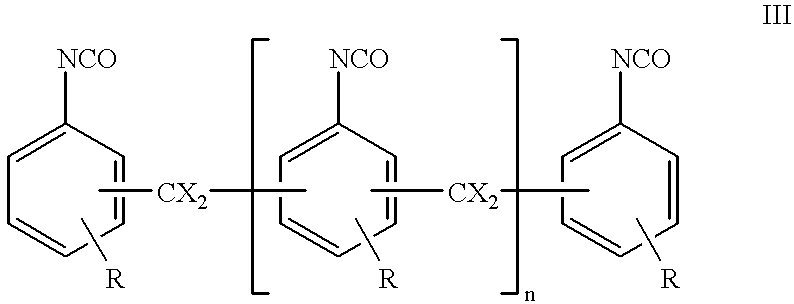

A hyaluronic acid (HA) composition includes crosslinked, water-insoluble, hydrated HA gel particles. The HA includes crosslinks represented by the following structural formula: HA—U—R2—U—HA The variables are defined herein. A method of augmenting tissue in a subject includes inserting a needle into a subject at a location in the subject that is in need of tissue augmentation, wherein the needle is coupled to a syringe loaded with the HA composition, and applying force to the syringe, to deliver the HA composition into the subject. A method of preparing the HA composition, includes forming water-insoluble, dehydrated crosslinked HA particles, separating the water-insoluble, dehydrated particles by average diameter, selecting a subset of particles by average diameter, and hydrating the subset of dehydrated particles with a physiologically compatible aqueous solution. Another method of preparing the crosslinked HA composition includes crosslinking a precursor of the crosslinked HA with a biscarbodiimide in the presence of a pH buffer and dehydrating the crosslinked HA. Also included is a method of augmenting tissue in a subject that is in need of tissue augmentation. A method of stabilizing crosslinked HA includes hydrating water-insoluble, dehydrated crosslinked HA with a physiologically compatible aqueous solution that includes a local anesthetic, wherein the value of storage modulus G′ for the stabilized composition is at least about 110% of the value of G′ for a non-stabilized composition,. Also included is the stabilized HA composition.

Owner:ANIKA THERAPEUTICS INC

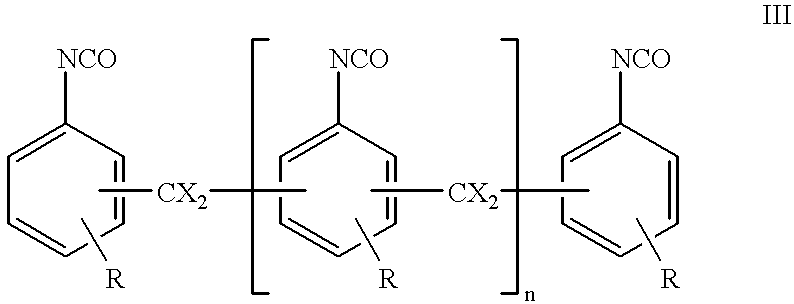

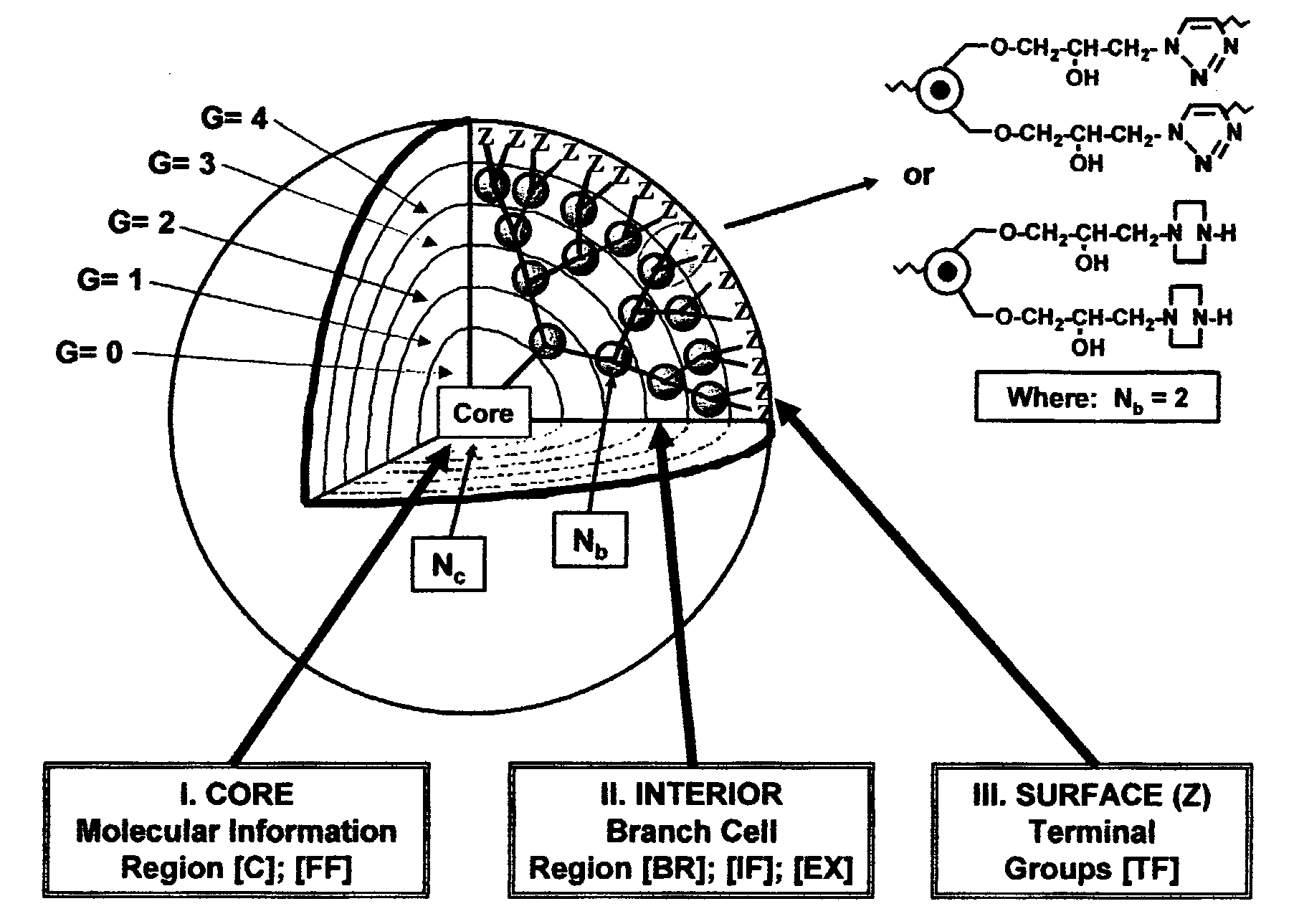

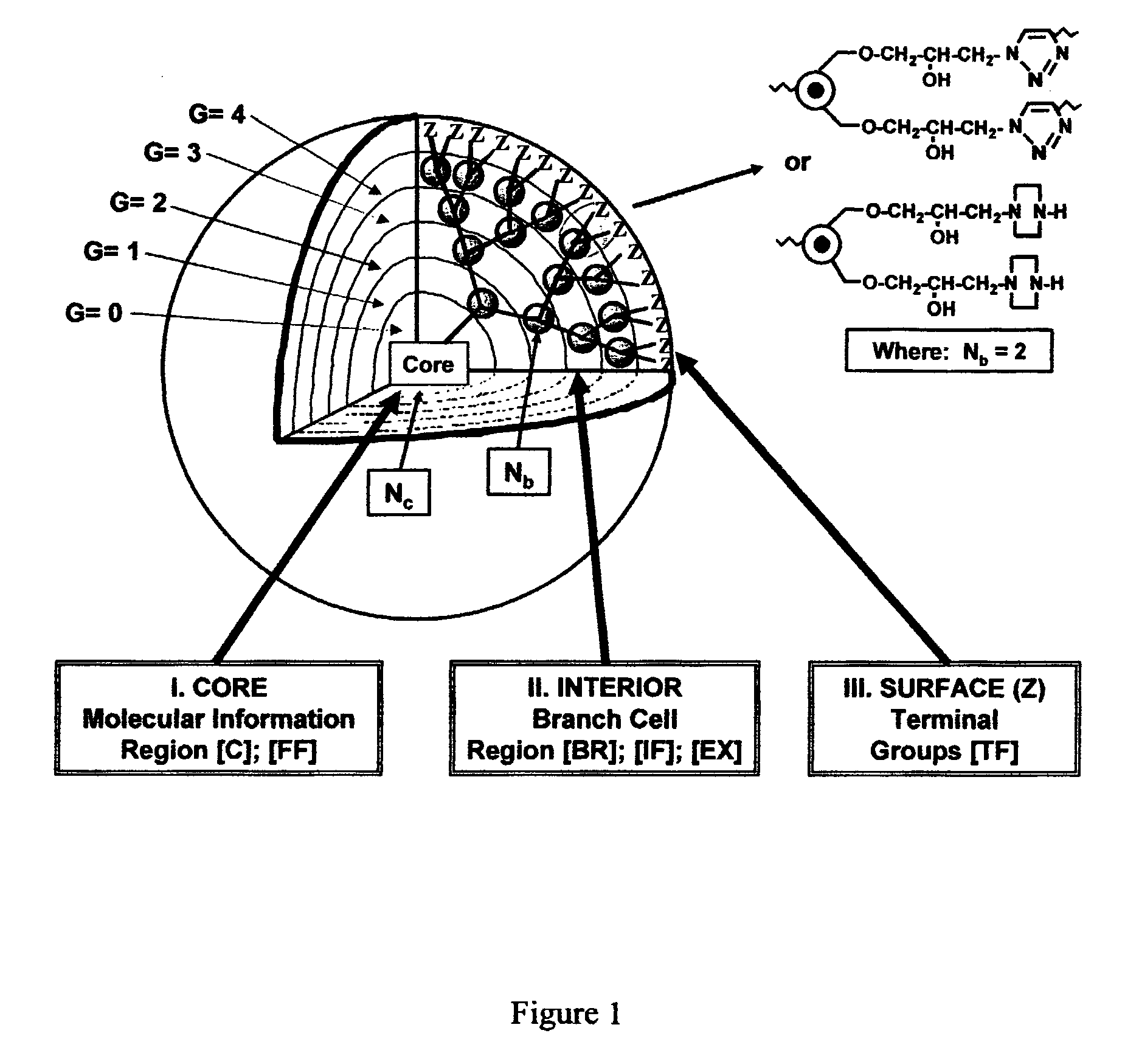

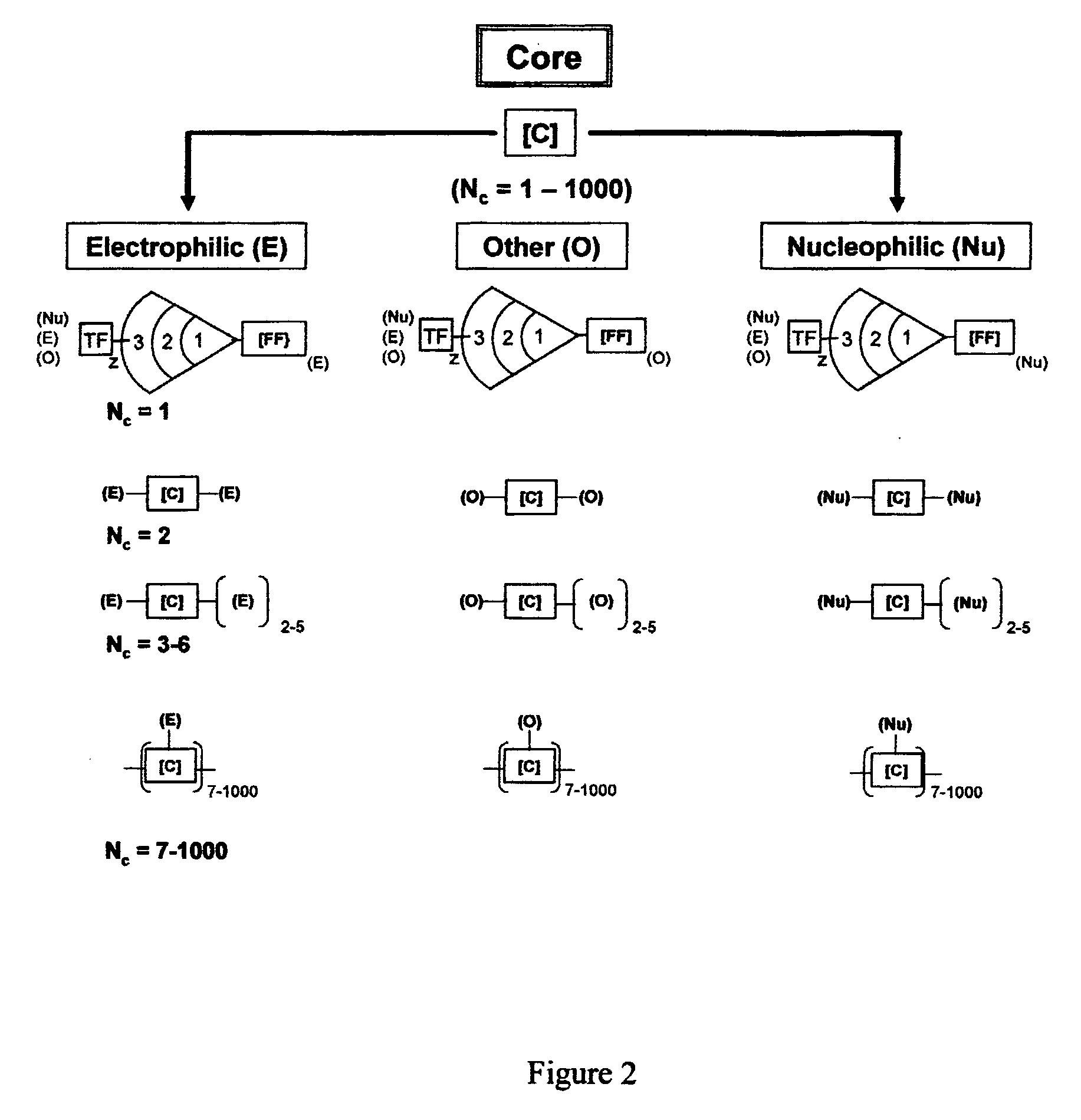

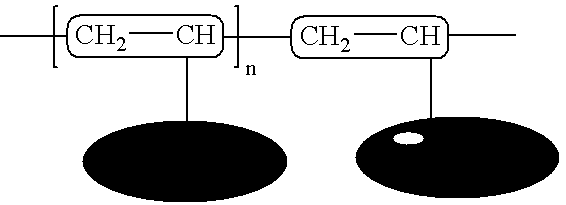

Dendritic Polymers With Enhanced Amplification and Interior Functionality

ActiveUS20070298006A1Reduced responseSizePowder deliveryOrganic active ingredientsCross-linkScavenger

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

Tissue engineering composite

InactiveUS6991652B2Facilitate formationNon-invasive methodBiocideCosmetic implantsTissue engineeringDamages tissue

The invention provides a biocompatible composite for use in a living subject for purposes of repairing damaged tissues and reconstructing a new tissue. The composite includes a biodegradable or absorbable three-dimensional support construct, a liquid or viscous fluid forming a gel matrix or viscous fluid when delivered to an area of interest in a living subject. The biodegradable construct provides an ideal surface for cell or cell extract attachment, while the gel matrix or viscous fluid acts as both a carrier material and a separator for maintaining the space between the constructs as well as the structural integrity of the developing issue.

Owner:CLEMSON UNIV RES FOUND +1

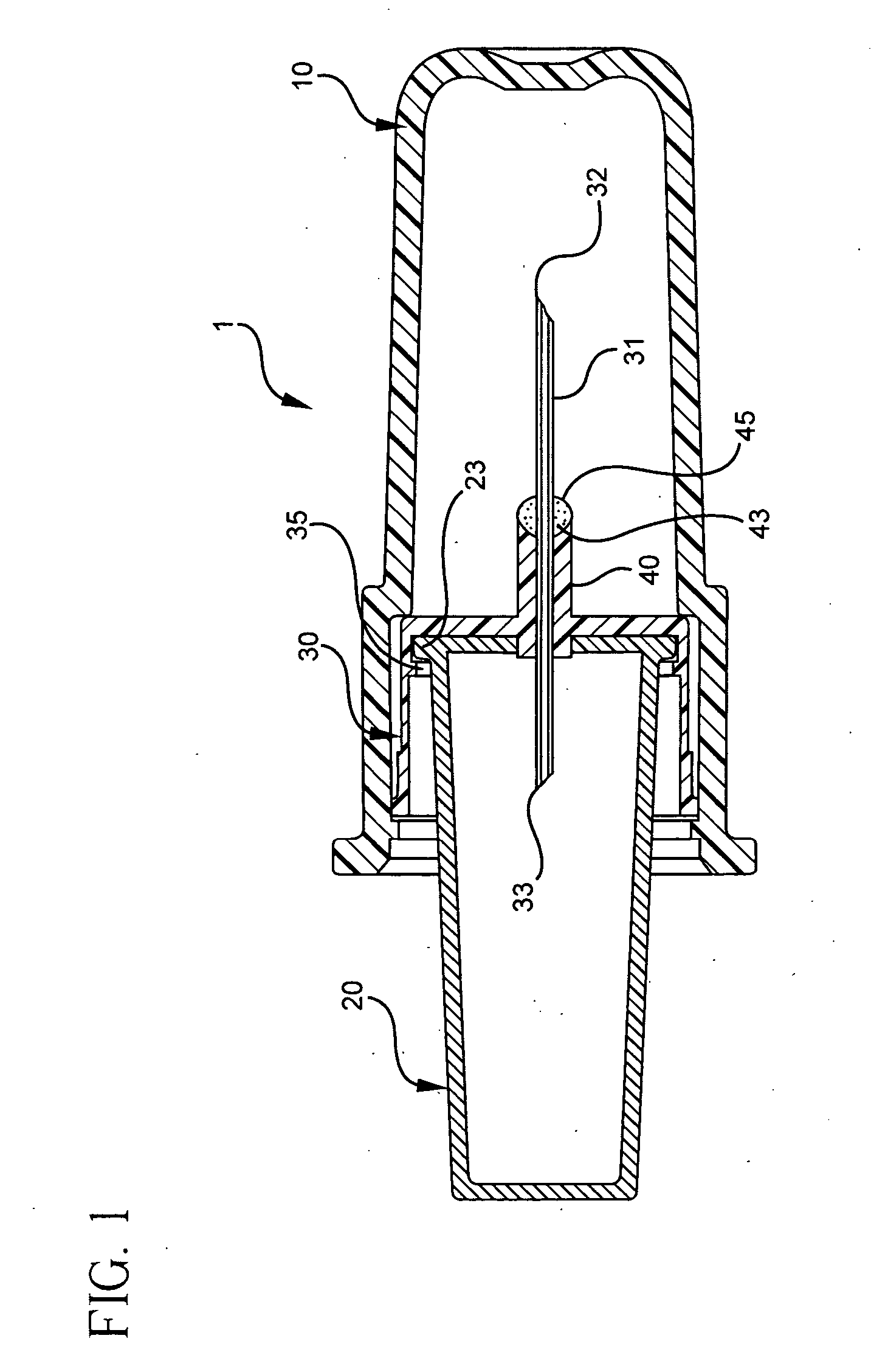

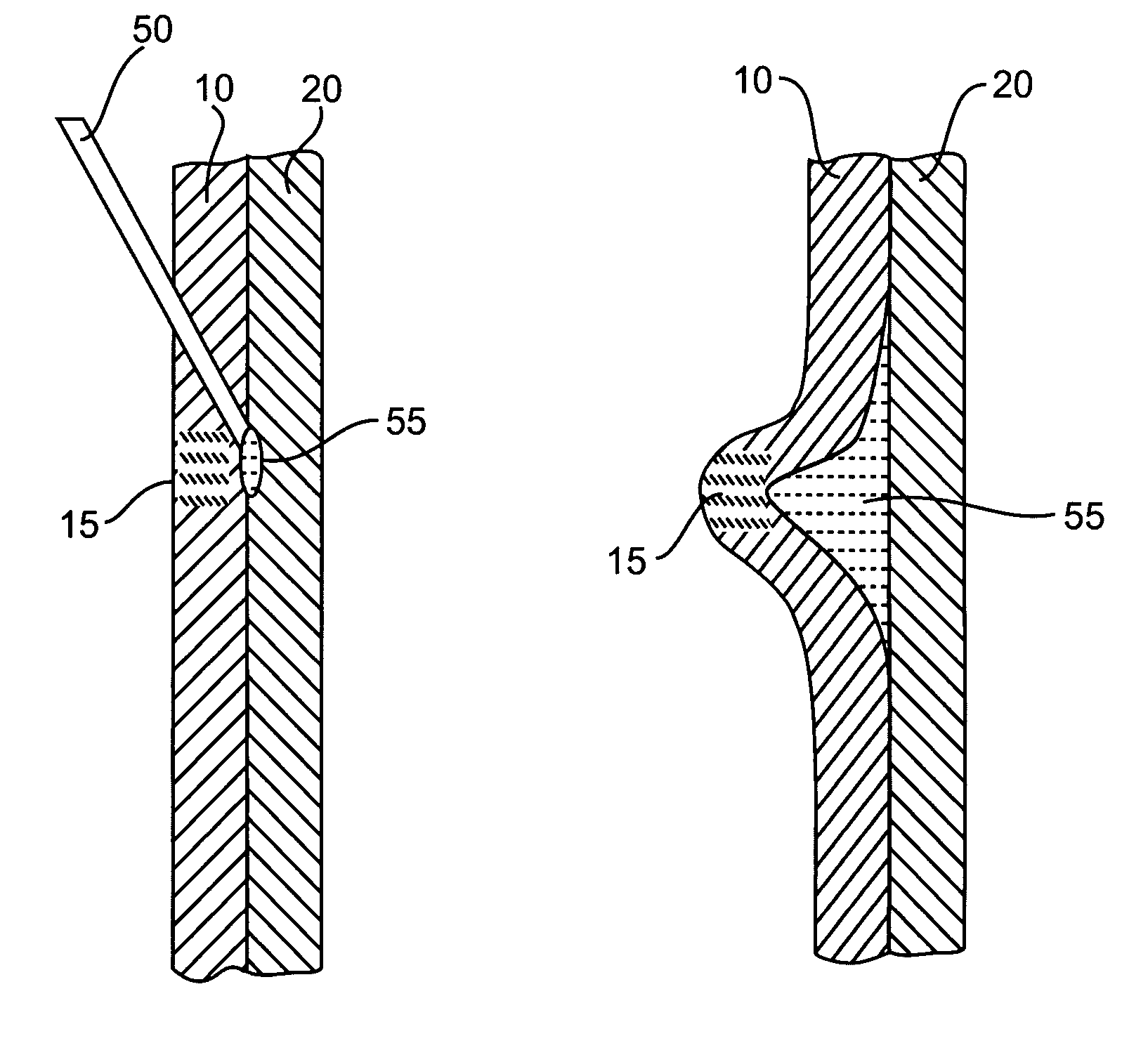

Disposable needle and hub assembly

ActiveUS20070149924A1Easy injectionFacilitates stress concentration relocationMedical devicesInfusion needlesDisposable NeedleTissue skin

A needle assembly including a cover, an inner shield, a needle and a hub assembly is provided. After use, the cover is placed over the distal (patient) end of the needle and the inner shield can be used to cover the proximal (non-patient) end of the needle. The inner shield comprises flexible extensions above its open end to secure the inner shield over the proximal end of a needle in the needle assembly. A needle hub is also provided that eliminates adhesive bumps at the base of the needle and further distributes needle angular bending along an irregular surface, which facilitates proper insertion technique and effective needle length. The hub further includes stanchions or castellations on its edge such that when the patient uses proper injection techniques, the edges of the hub leave a distinctive impression in the skin of a user for a short period of time.

Owner:EMBECTA CORP

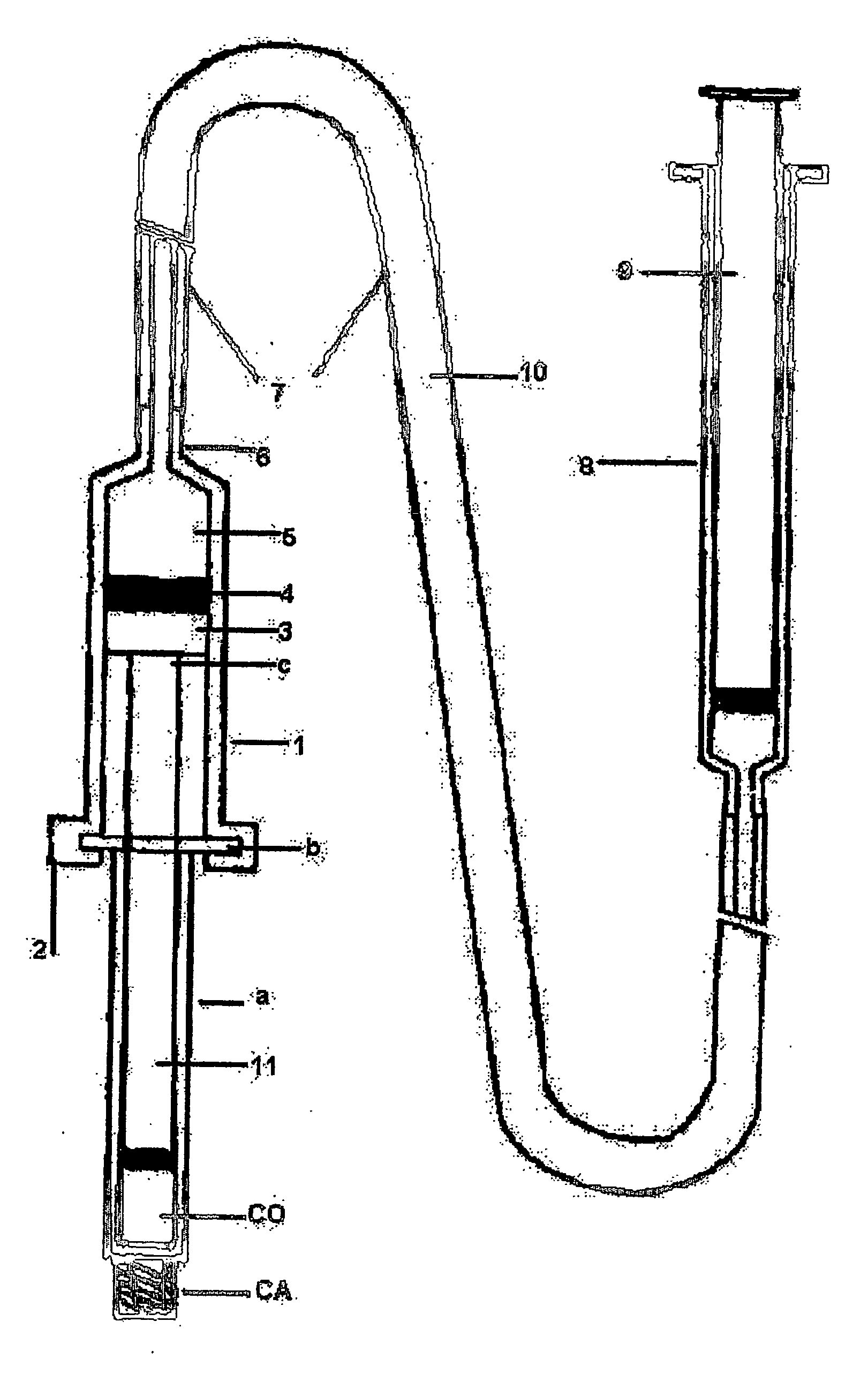

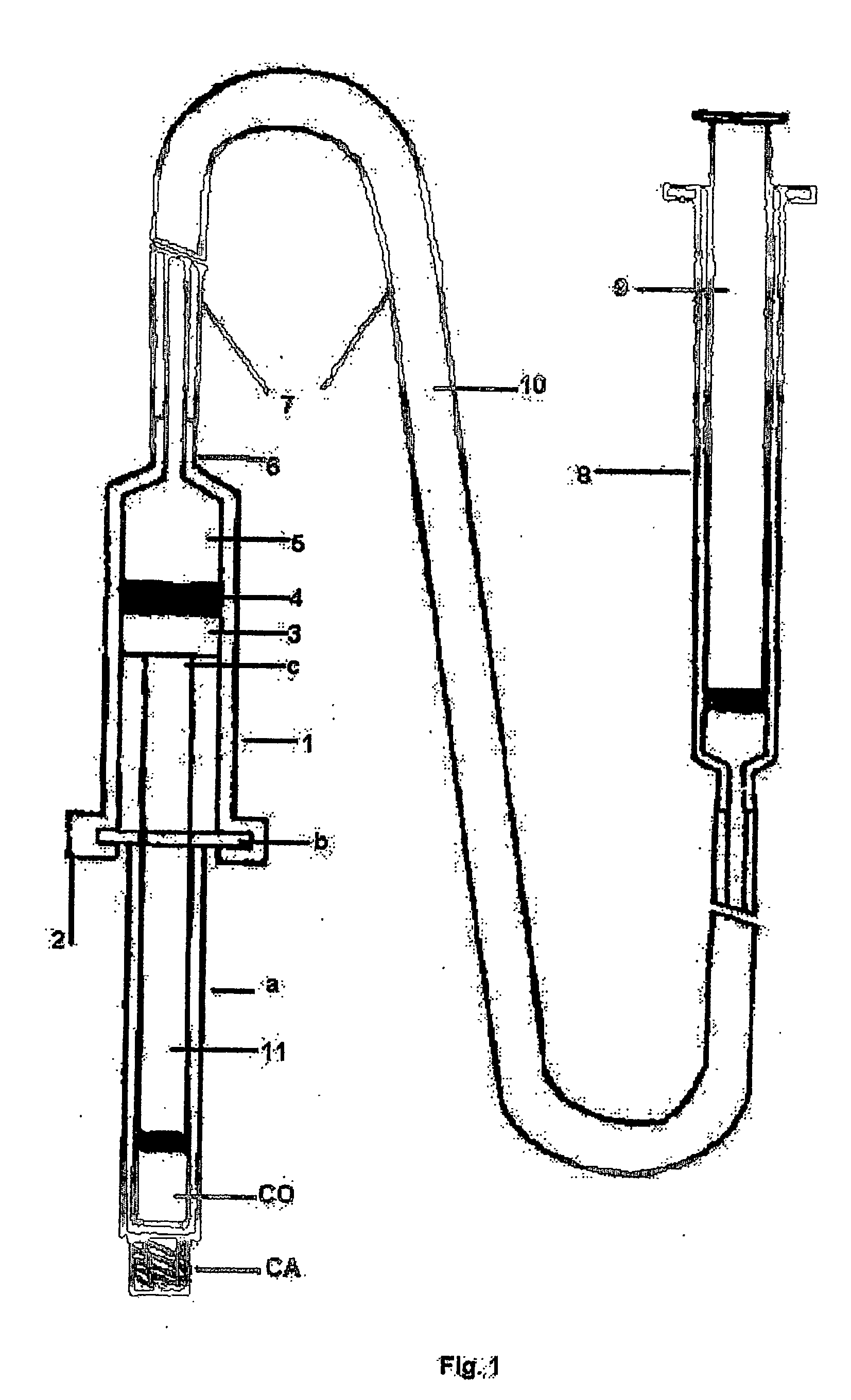

Hydraulic device for the injection of bone cement in percutaneous vertebroplasty

InactiveUS20060264967A1Reduce radiationReduce overexposureJoint implantsIntravenous devicesFluid controlPressure transmission

The present invention relates to the medical field, in particular relates to the practice of percutaneous vertebroplasty where a pair of syringes in the distal extreme of a lengthened hydraulic device, are united by a camera of intermediate connection of larger diameter (pressure exerting body) or modified inverted syringe tube with a bolster, a hydraulic connecting tube of flexible material that transmits the pressure of the smaller diameter manual or impulsion syringe in the proximal extreme of the device toward the intermediate cylindrical larger diameter camera (pressure exerting body), this camera is in an inverted position with regard to the first syringe (fluid control), this intermediate camera has a moving piston longitudinal to the axis of the cylinder that is controlled with the first syringe (manual) and in cooperation with the atmospheric pressure. The injecting syringe loaded with bone cement is coupled with the bolster of the body of pressure, and to the needle that drives the cement toward the interior of the bone. The intermediate camera (pressure exerting body) together with the hydraulic tube and the manual syringe form a hydraulic press system (F / A=f / a) that allows to increase in a potential way the pressure exerted in the first syringe and to make the injection of polymethylmethacrylate (PMMA) at an approximate distance of 1.0 m to 1.5 m.

Owner:DEPUY SYNTHES PROD INC

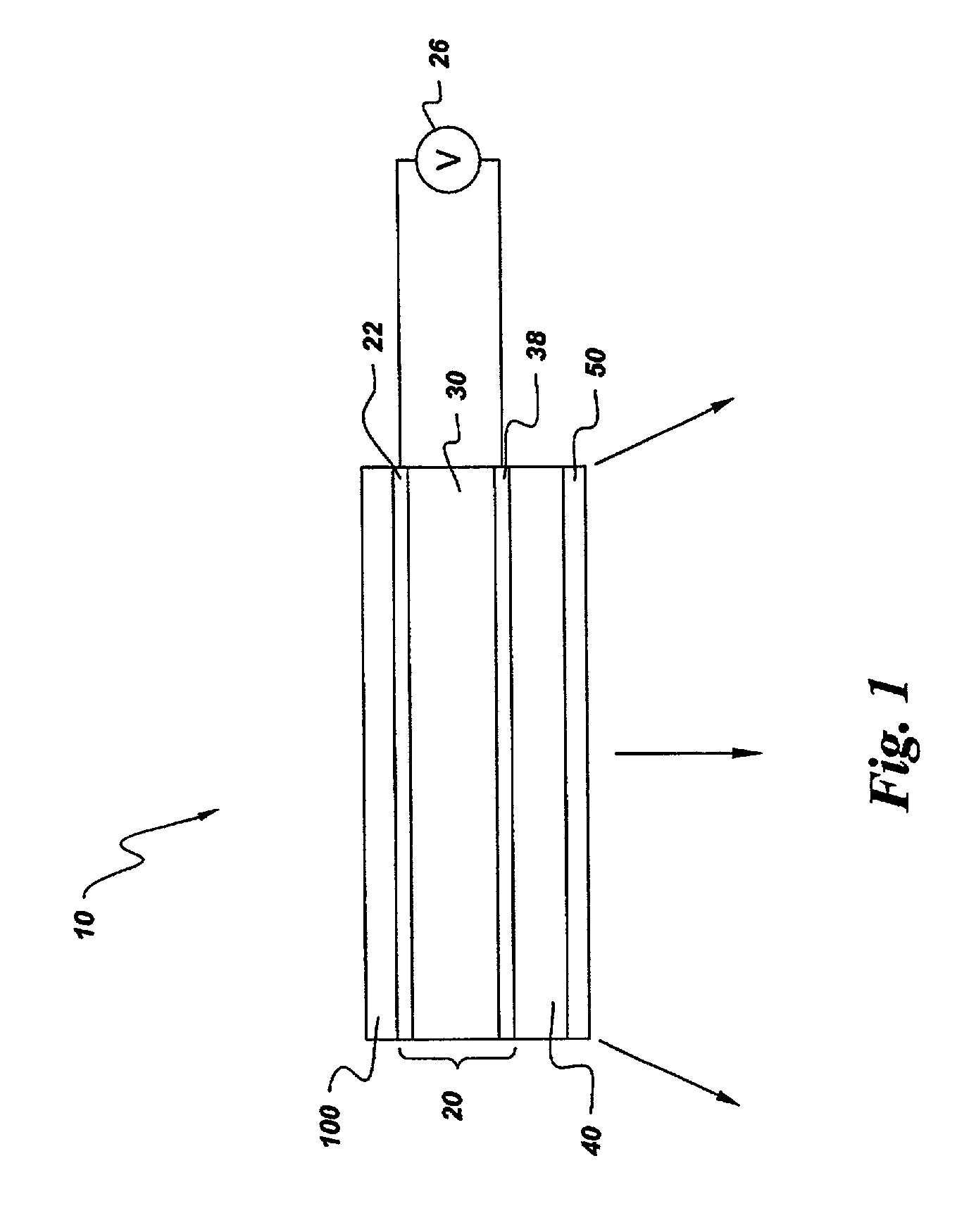

Organic electroluminescent device and method of manufacture thereof

InactiveUS6416888B1Increased durabilityReduce the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesInorganic compoundThin layer

An organic EL device having a low driving voltage and exhibiting high luminous brightness and superior durability, and a method of manufacturing the same. The organic EL device has an anode layer, an organic light-emitting layer, and a cathode layer. An inorganic thin layer, comprising an inorganic compound of Ge, Sn, Zn, Cd, etc. and an inorganic compound of an element of Group 5A to Group 8 in the periodic table in combination, is provided between the anode layer and the organic light-emitting layer and between the cathode layer and the organic light-emitting layer, or the anode layer or the cathode layer comprises a chalcogenide of Si, Ge, Sn, Pb, Ga, In, Zn, Cd, Mg, etc. and an inorganic compound of an element of Group 5A to Group 8 in the periodic table in combination.

Owner:IDEMITSU KOSAN CO LTD

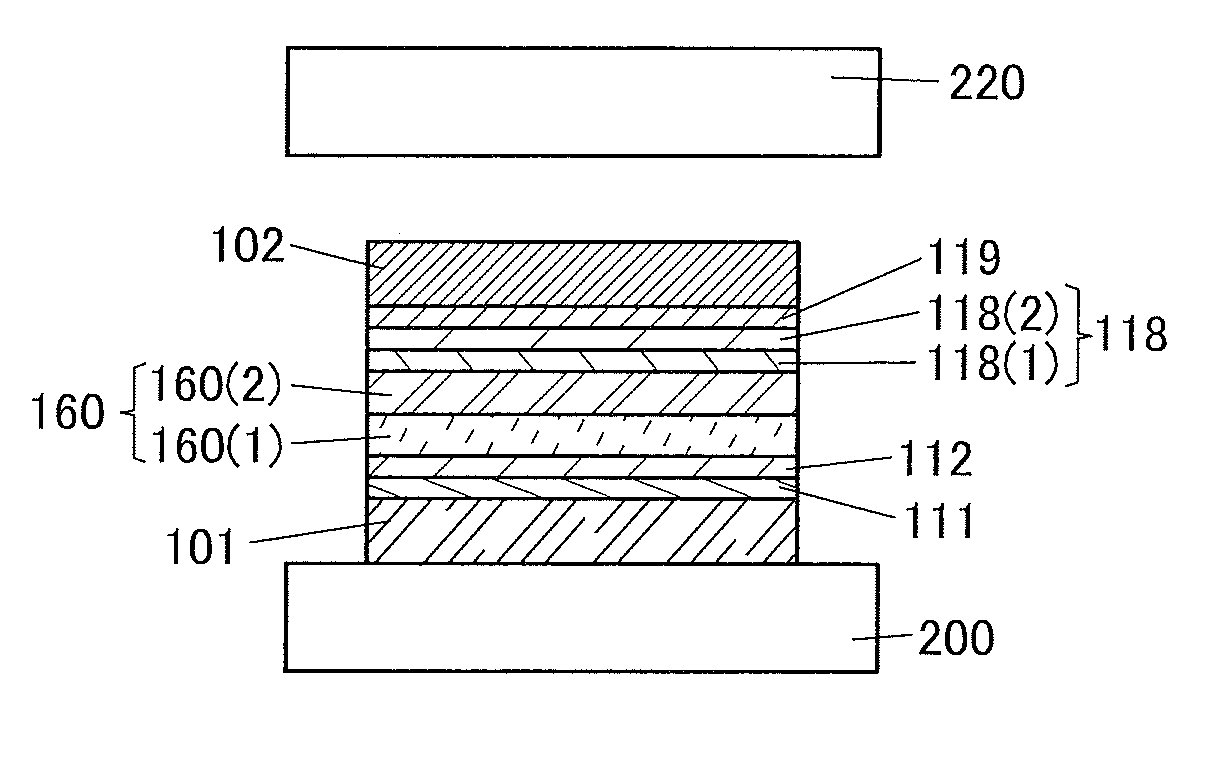

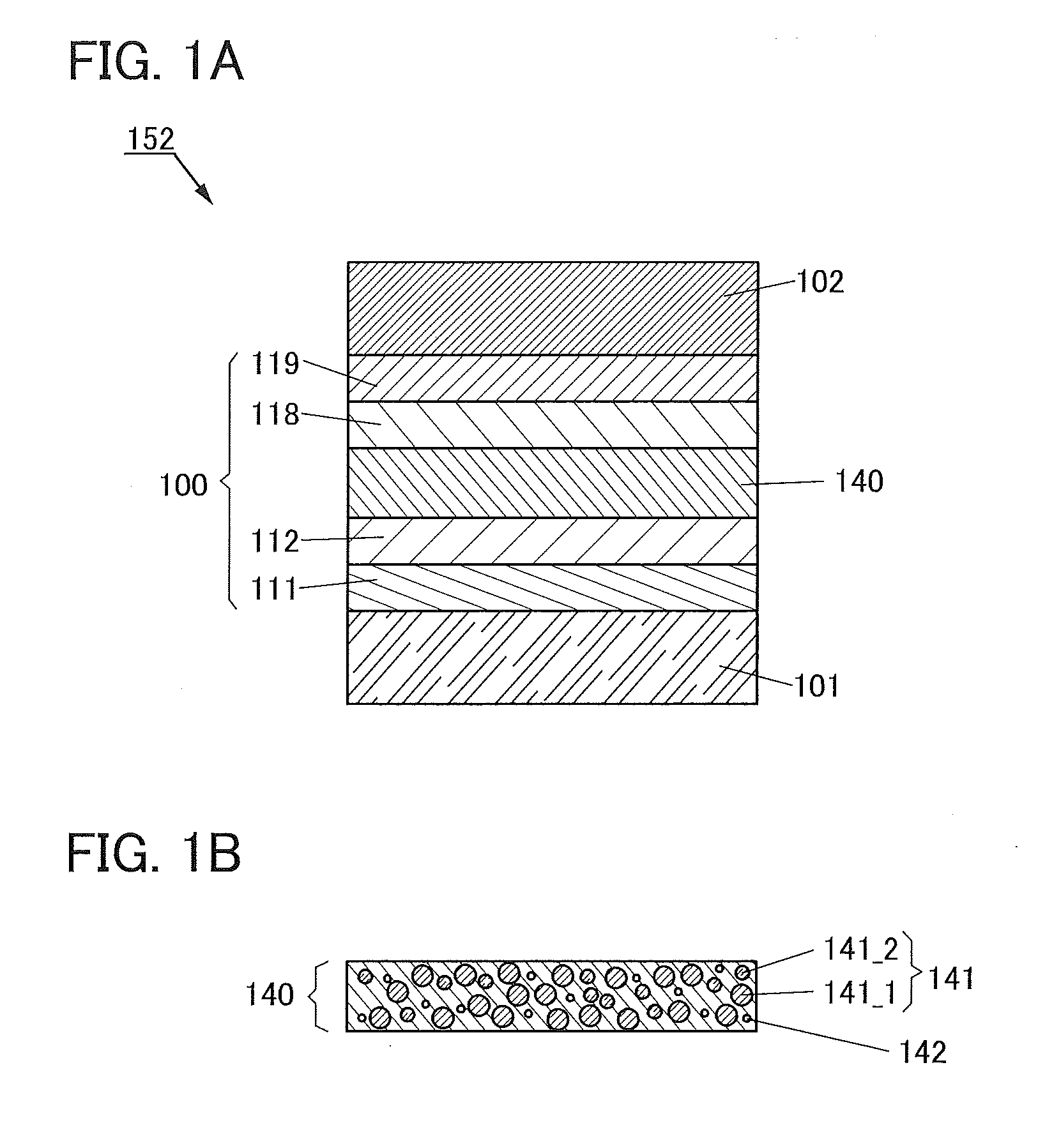

Light-Emitting Element, Display Device, Electronic Device, and Lighting Device

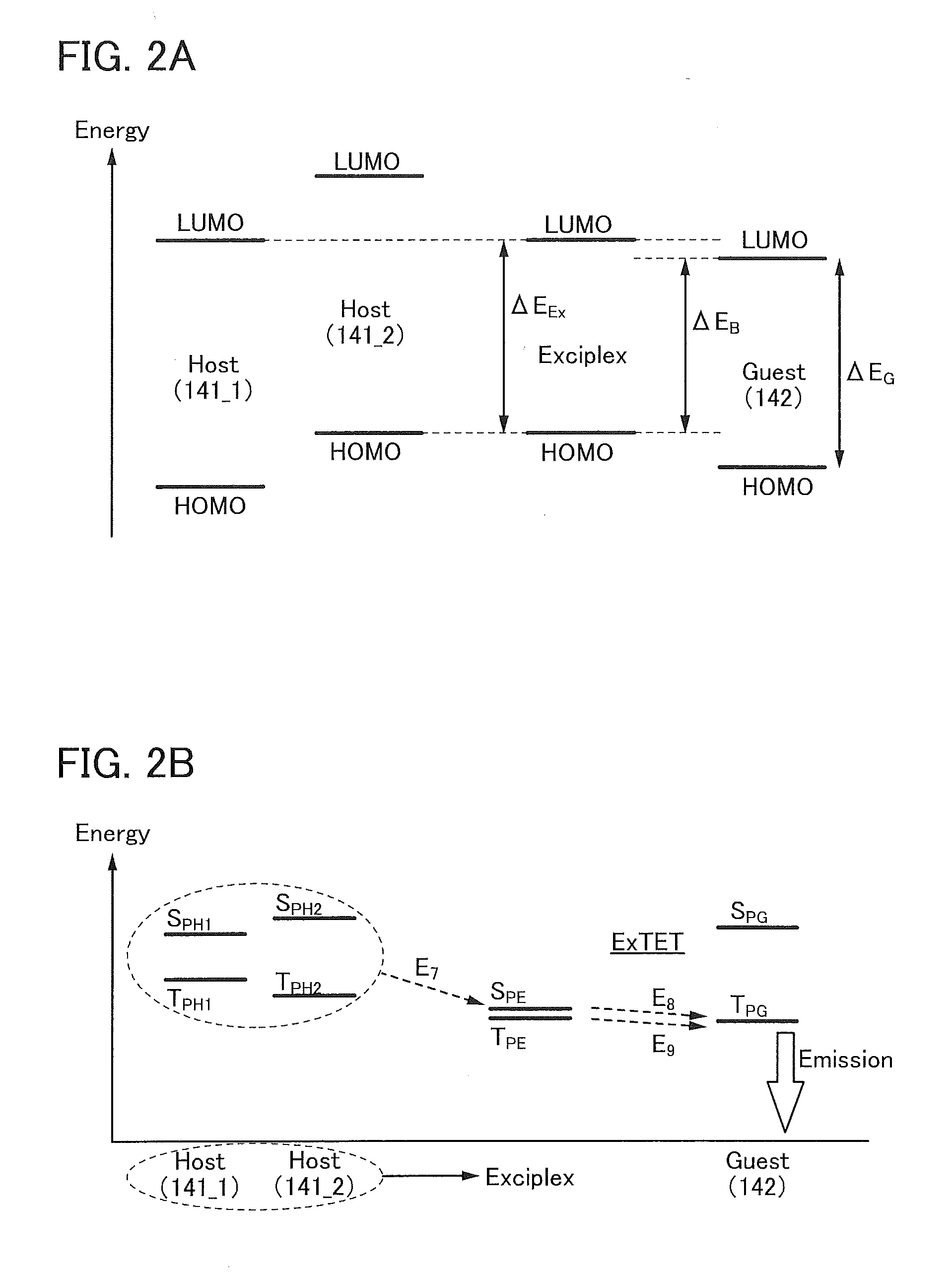

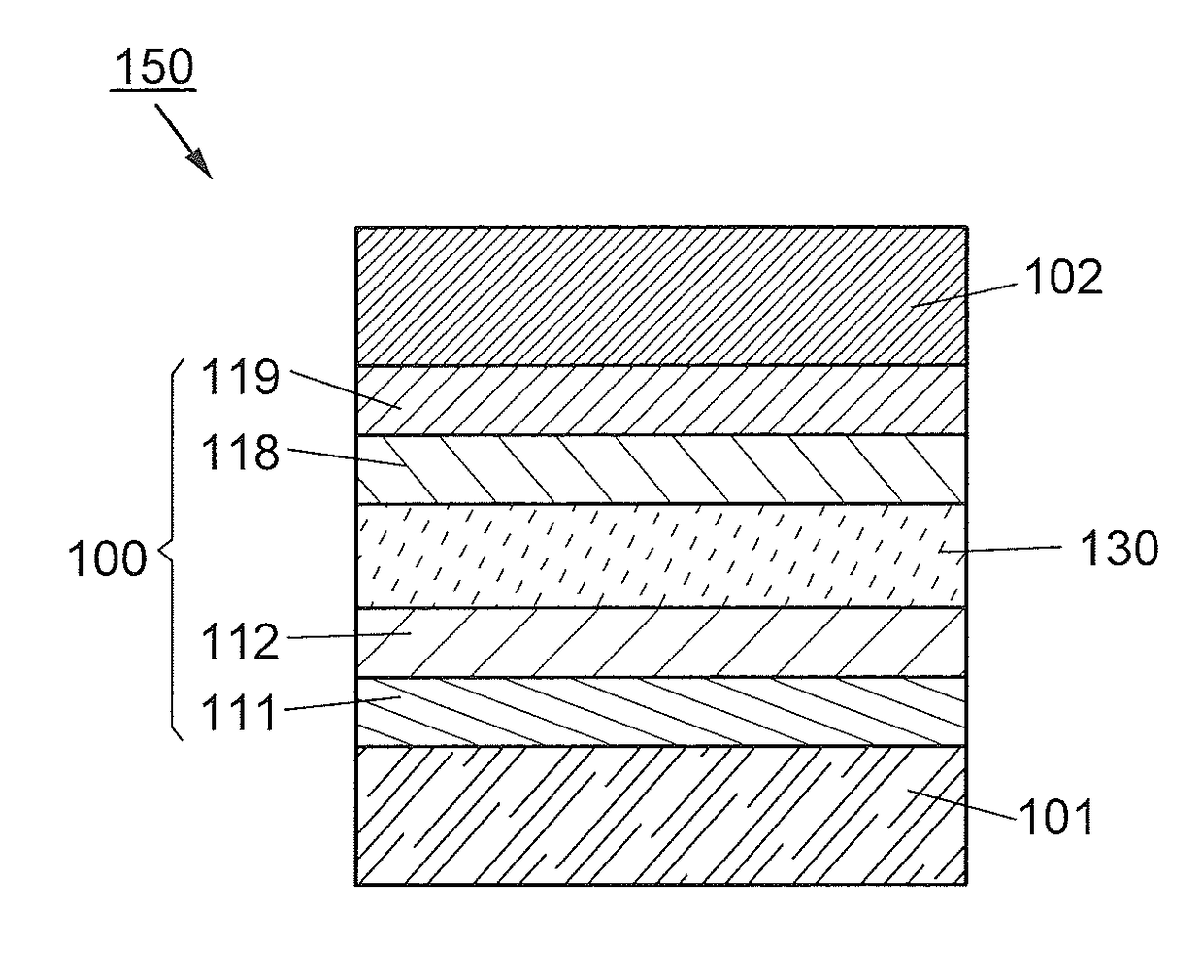

ActiveUS20170025615A1Improve efficiencyHigh light emission energyIndium organic compoundsElectroluminescent light sourcesDisplay deviceOrganic compound

Provided is a light-emitting element including a first organic compound, a second organic compound, and a guest material. The LUMO level of the first organic compound is lower than that of the second organic compound. The HOMO level of the first organic compound is lower than that of the second organic compound. The LUMO level of the guest material is higher than that of the first organic compound. The HOMO level of the guest material is higher than that of the second organic compound. An energy difference between the LUMO level and the HOMO level of the guest material is larger than an energy difference between the LUMO level of the first organic compound and the HOMO level of the second organic compound. The guest material can convert triplet excitation energy into light emission. The combination of first organic compound and the second organic compound can form an exciplex.

Owner:SEMICON ENERGY LAB CO LTD

Light-Emitting Element, Display Device, Electronic Device, and Lighting Device

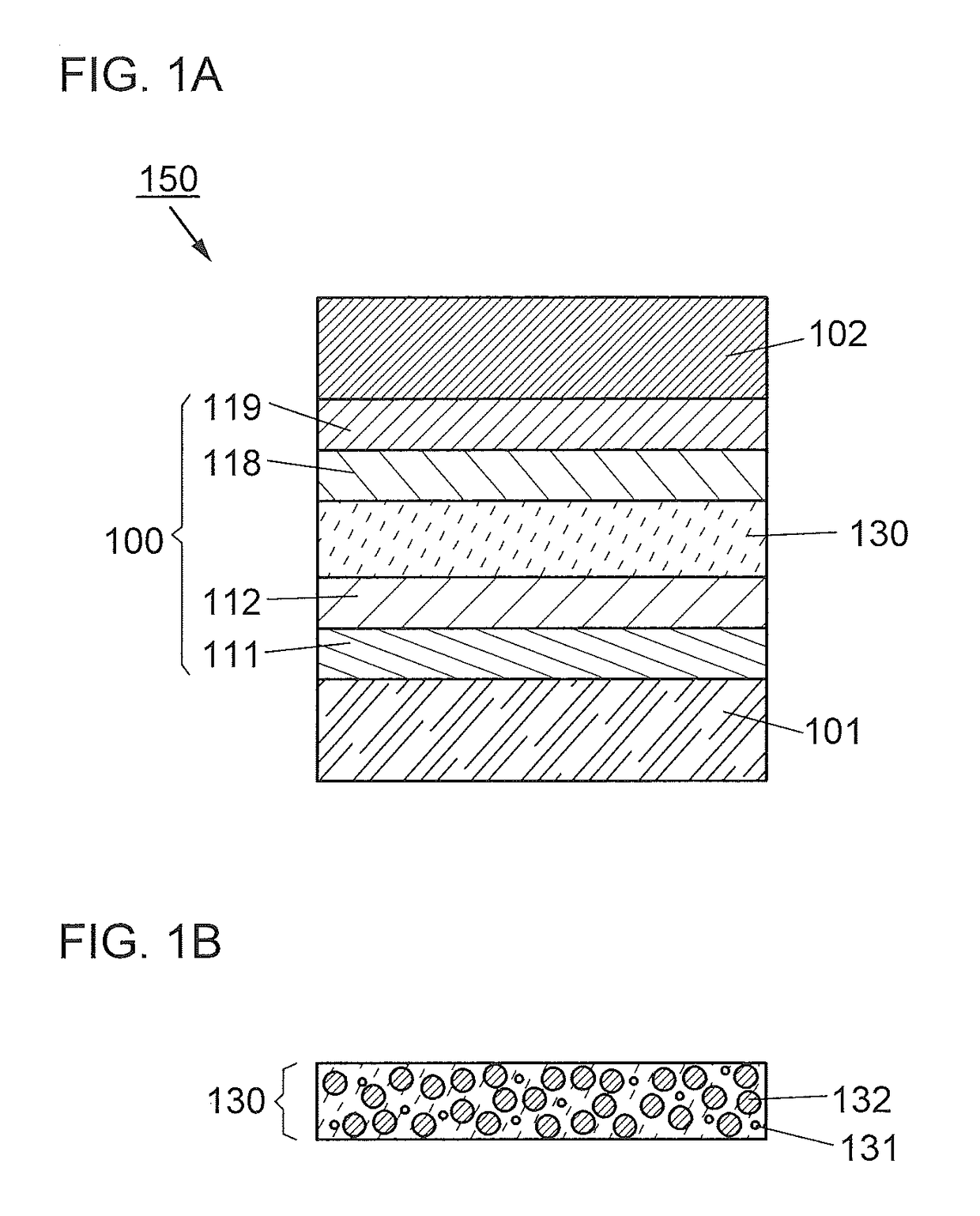

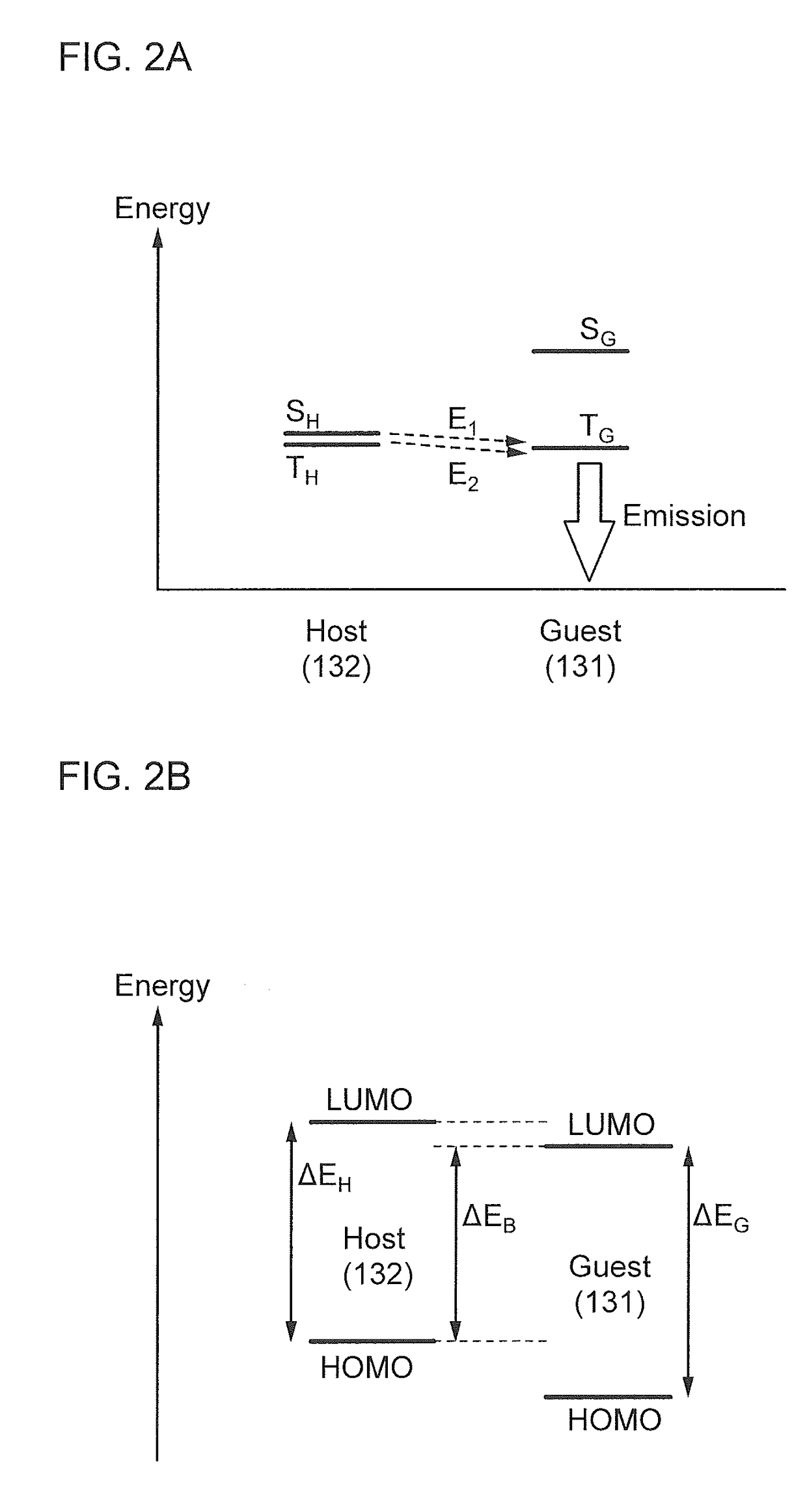

InactiveUS20170092889A1Improve emission efficiencyReduce power consumptionOrganic chemistrySolid-state devicesDisplay deviceHost material

To provide a light-emitting element with high emission efficiency and low driving voltage. The light-emitting element includes a guest material and a host material. A LUMO level of the guest material is lower than a LUMO level of the host material. An energy difference between the LUMO level and a HOMO level of the guest material is larger than an energy difference between the LUMO level and a HOMO level of the host material. The guest material has a function of converting triplet excitation energy into light emission. An energy difference between the LUMO level of the guest material and the HOMO level of the host material is larger than or equal to energy of light emission of the guest material.

Owner:SEMICON ENERGY LAB CO LTD

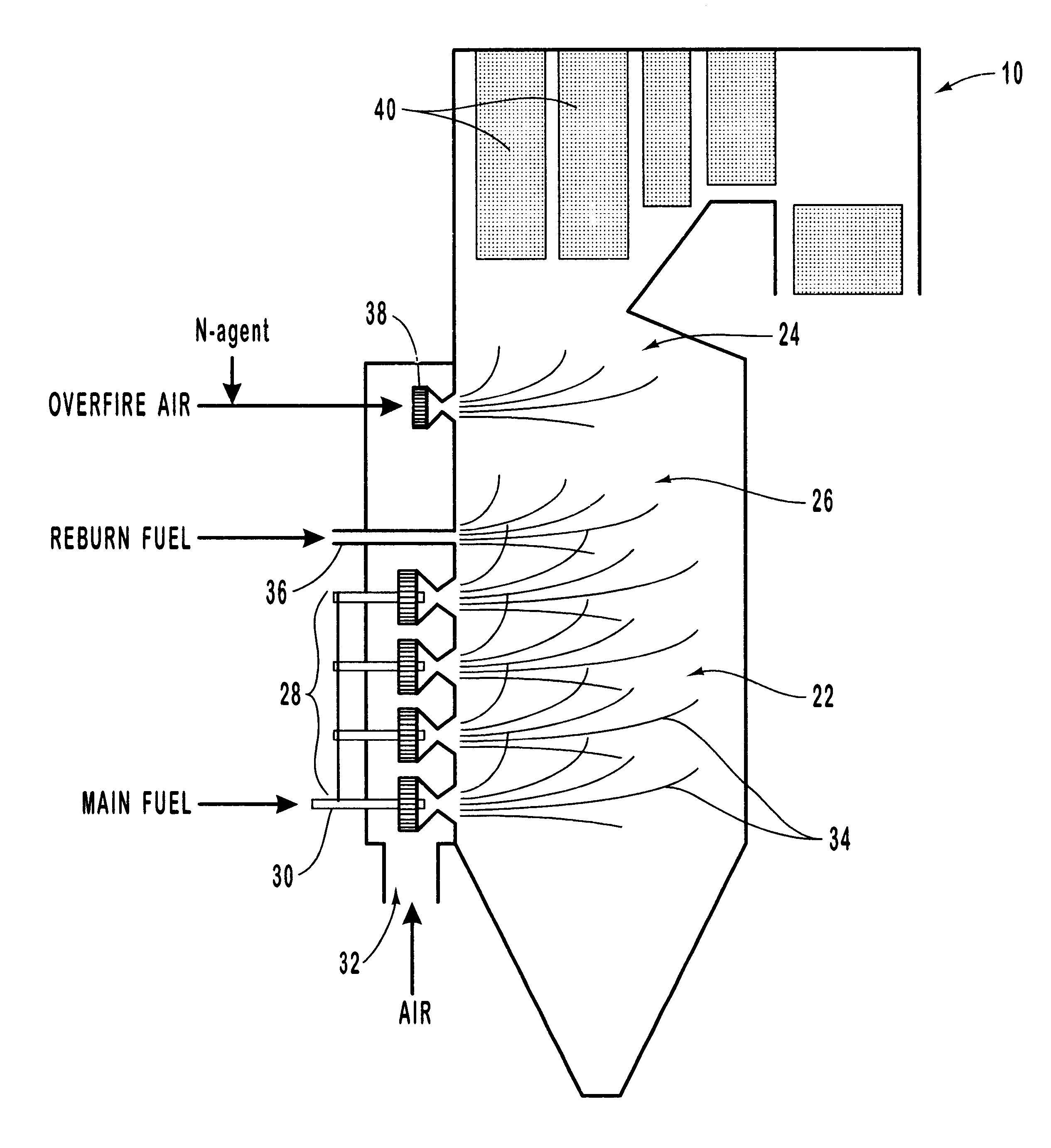

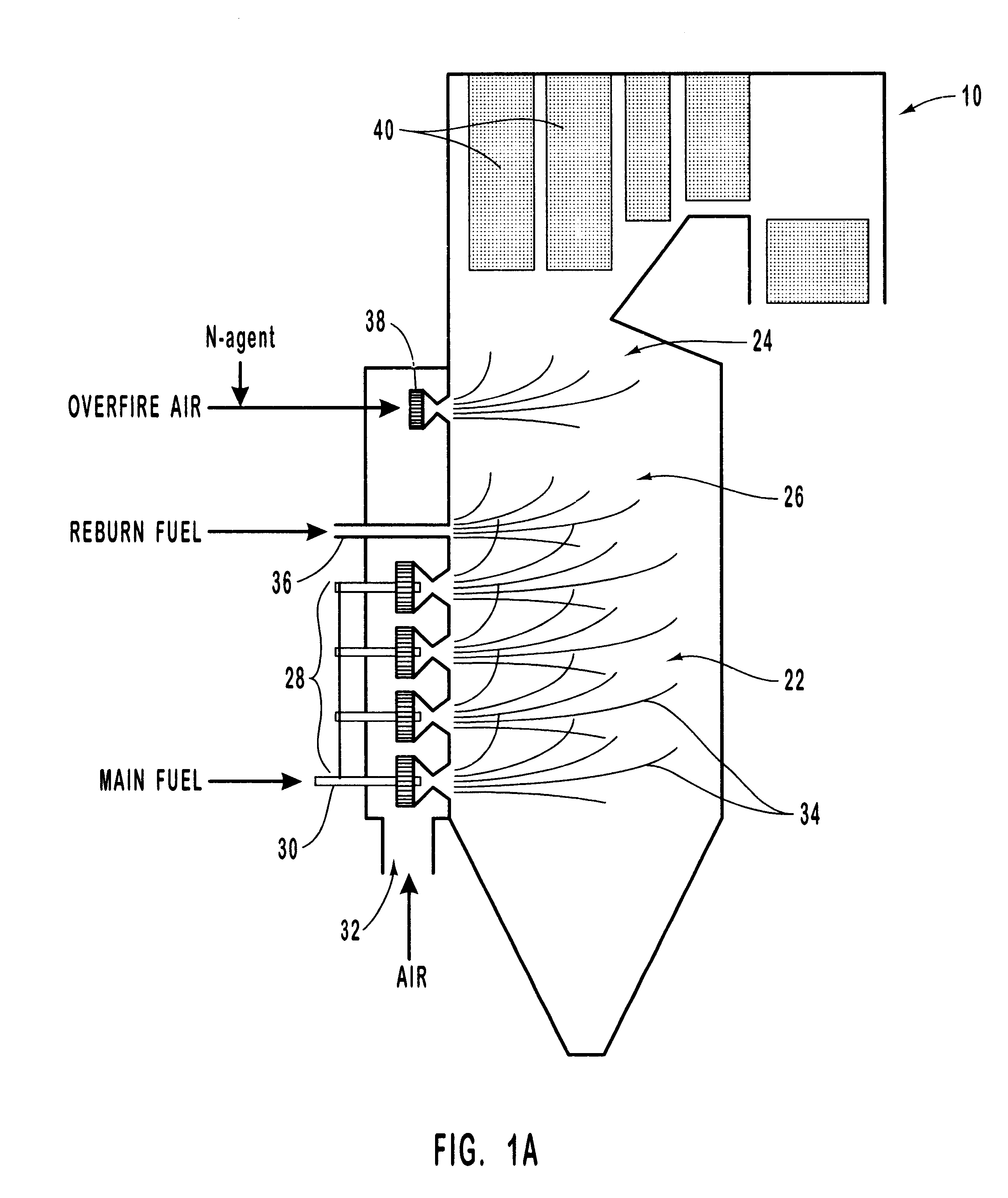

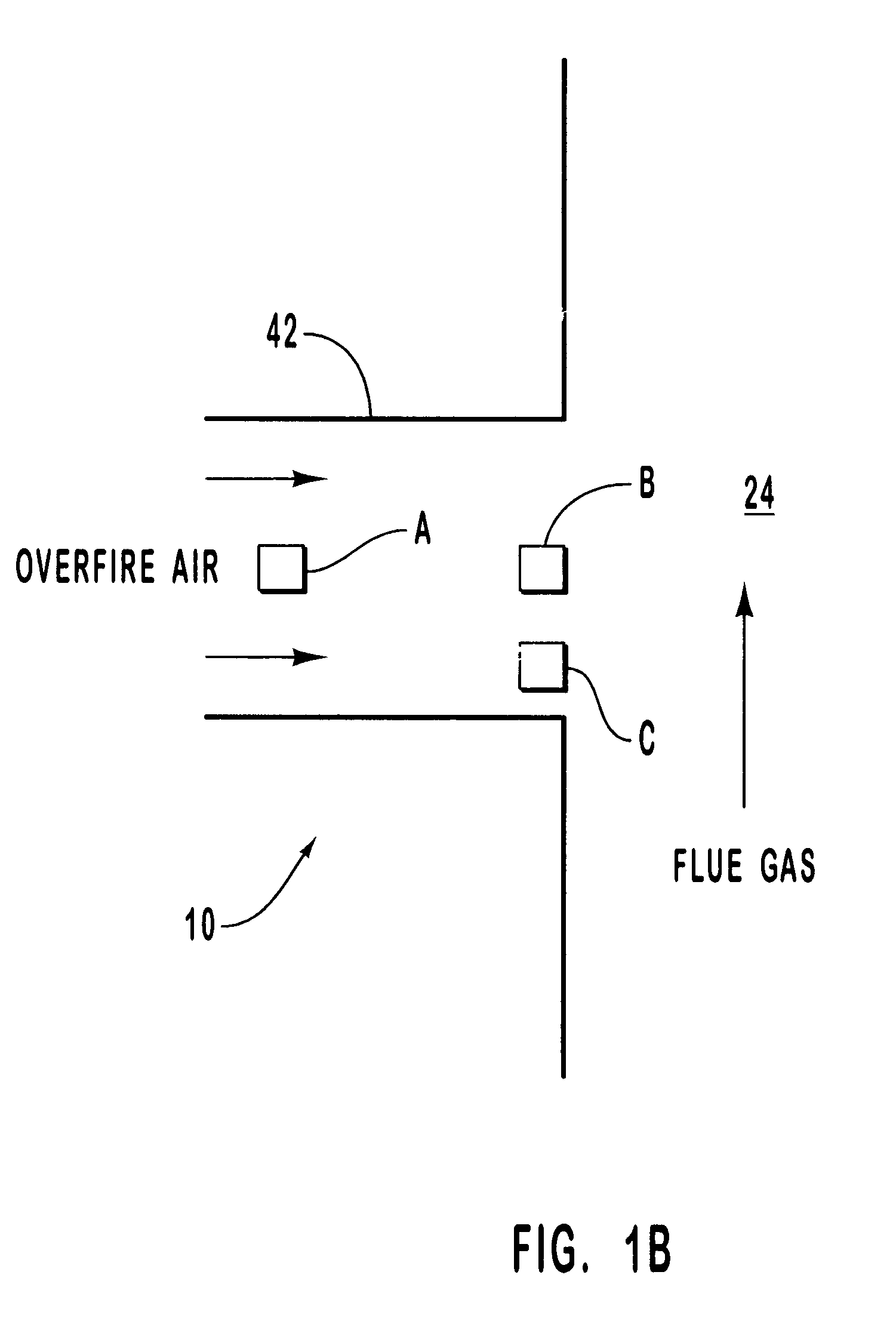

Method of reducing NOx in a combustion flue gas

InactiveUS6280695B1Improve efficiencyReduce impactNitrogen compoundsEmission preventionFlueChemistry

Methods are provided for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion emissions. The methods are carried out by forming a combustion flue gas in a combustion zone, the combustion flue gas including nitrogen oxides, injecting overfire air and droplets of a solution or a powder of a selective reducing agent into a burnout zone, and contacting the combustion flue gas with the overfire air and the selective reducing agent in the burnout zone to thereby decrease the concentration of nitrogen oxides therein. The selective reducing agent is provided in an aqueous solution or powder which is injected into the overfire air in optimized droplet or particle form prior to or concurrently with injection of the overfire air into the burnout zone.

Owner:GE ENERGY & ENVIRONMENTAL RES

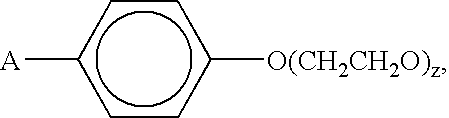

Method of improving the permeability of an underground petroleum-containing formation

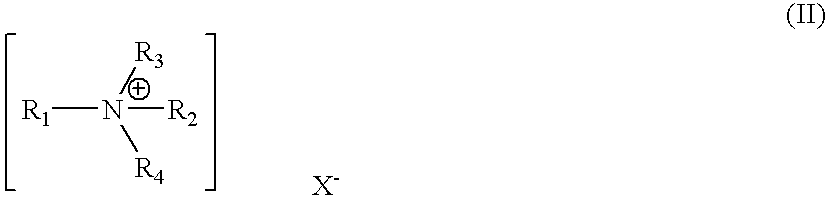

InactiveUS6972274B1Restore permeabilityEasy injectionOther chemical processesJoints with sealing surfacesAmmonium compoundsAlcohol

The present invention generally relates to a method and a composition useful in restoring the permeability of a porous underground petroleum containing formation. Restoring permeability to the formation enhances the injectivity thereby accelerating petroleum recovery. The method of the invention comprises treating said formation with a composition which comprises a combination of at least one nonionic compound, preferably an alkoxylated alcohol, with at least one cationic compound, preferably a quaternary ammonium compound, in an amount effective to improve the permeability of the formation. The composition may also optionally contain an alkyl glycoside.

Owner:AKZO NOBEL CHEM INT BV

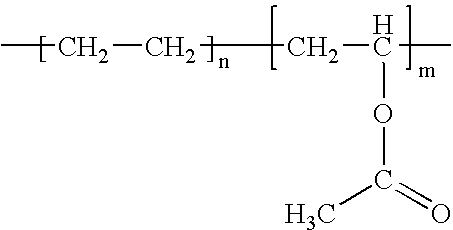

Compositions comprising carbon nanotubes and articles formed therefrom

InactiveUS20050186378A1Easy injectionImprove the immunityMaterial nanotechnologyCell electrodesFiberPolymer science

Improved compositions comprise a polymer and carbon fibers, such as nanotubes. In some embodiments, the carbon fibers, e.g., nanotubes, can be mechanically blended or incorporated into the polymer, while in some embodiments carbon nanotubes also may be covalently bonded to the polymer to form corresponding covalent materials. In particular, the polymer can be covalently bonded to the side walls of the carbon nanotubes to form a composite with particularly desirable mechanical properties. Specifically, the bonding of the polymer to the nanotube sidewall can provide desirable mechanical properties of the composite due to the orientation relative to other types of association between the nanotubes and the polymer. The processing of the nanotubes can be facilitated by the dispersion of the nanotubes in an aqueous solution comprising a hydrophylic polymer, such as ethyl vinyl acetate. A dispersion of nanotubes can be combined with a polymer in an extrusion process to blend the materials under high shear, such as in an extruder. In general, various articles can be formed that take advantage of the properties of the composite materials incorporating a polymer and carbon fibers, such as carbon nanotubes.

Owner:ENTEGRIS INC

Coupling agents for orthopedic biomaterials

ActiveUS7270813B2Improve lubrication and flow propertyEasy injectionBiocideTissue regenerationPolymer compositesBiocompatible polymers

The invention provides a method for the preparation of bone-polymer composites wherein the mineral portion of the bone is treated with a coupling agent before being incorporated into a biocompatible polymeric matrix. The resulting composites may be used as such or be further processed to form an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

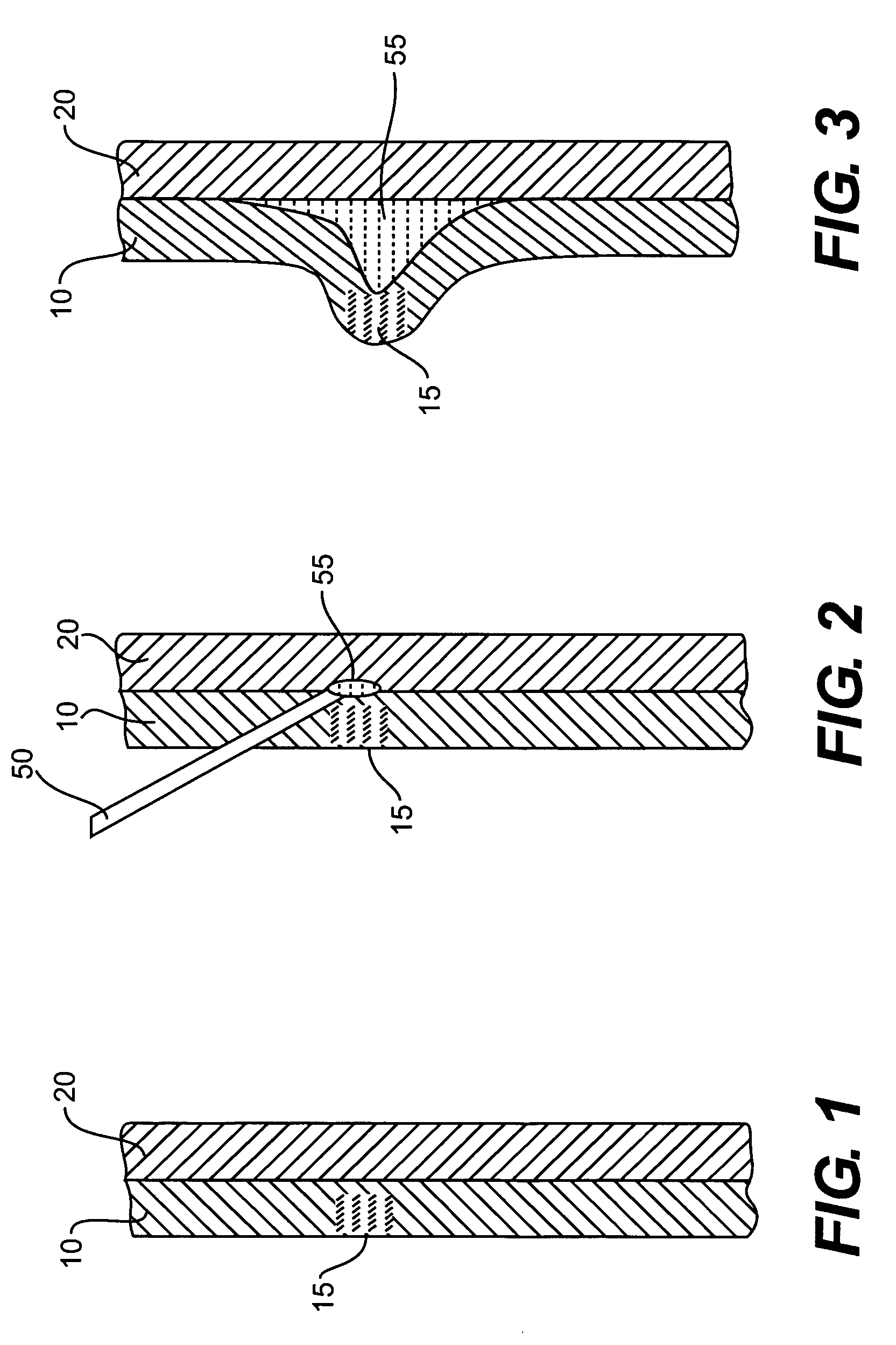

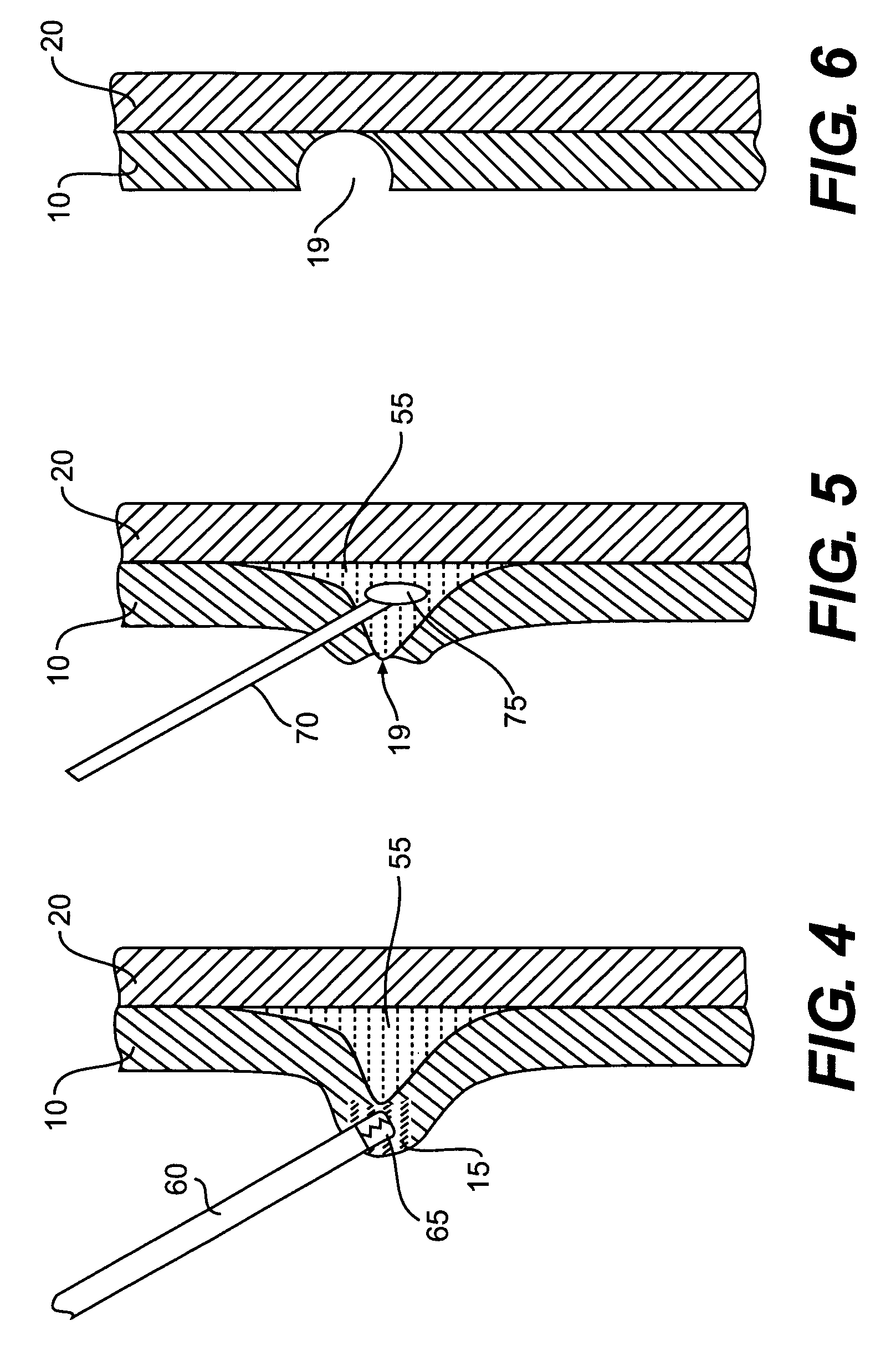

Devices and methods for agent-assisted medical procedures

ActiveUS7909809B2Easy injectionEasy to disassembleSurgical needlesMedical devicesMedical deviceBiomedical engineering

Various embodiments of bulking or cushioning agents or material and related medical devices and methods are disclosed. For example, a method of performing a medical procedure in a tract of a body may include injecting a material in a liquid phase proximate a target site between a first tissue layer and a second tissue layer, allowing the material to transition from the liquid phase to the gel phase in response to a raise in temperature of the material to approximately at or above the predetermined temperature, and performing a surgical procedure on the target site. The material may have the liquid phase at temperatures below a predetermined temperature and a gel phase at temperatures approximately at or above the predetermined temperature.

Owner:BOSTON SCI SCIMED INC

Crosslinked hyaluronic acid compositions for tissue augmentation

ActiveUS8124120B2Improve drug deliveryReduce frequencyAntibacterial agentsOrganic active ingredientsMedicineWater insoluble

Disclosed are hyaluronic acid (HA) compositions including crosslinked, water-insoluble, hydrated HA gel particles. Also disclosed are methods of making the HA compositions, and methods of using the HA composition to augment tissue in a subject.

Owner:ANIKA THERAPEUTICS INC

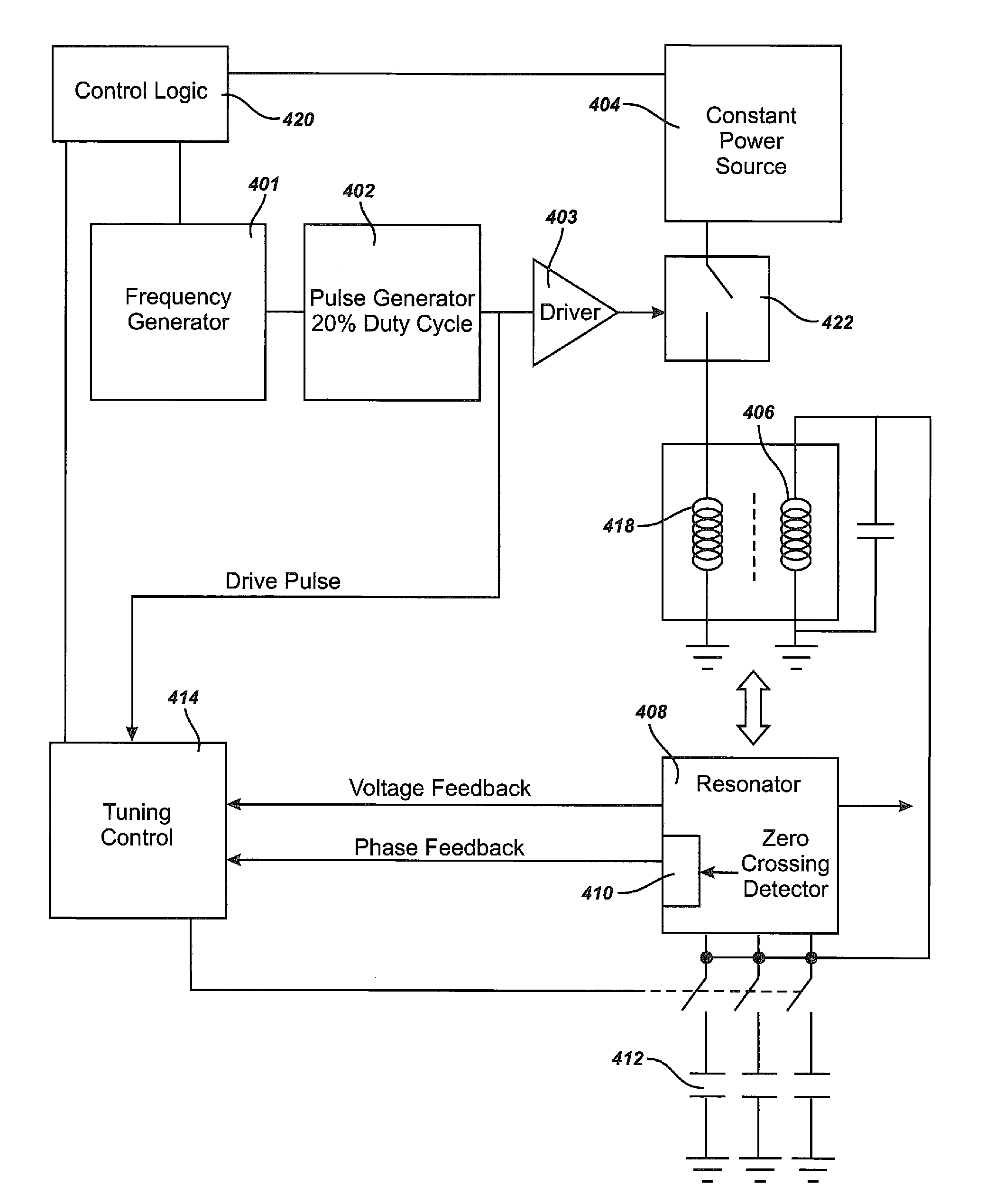

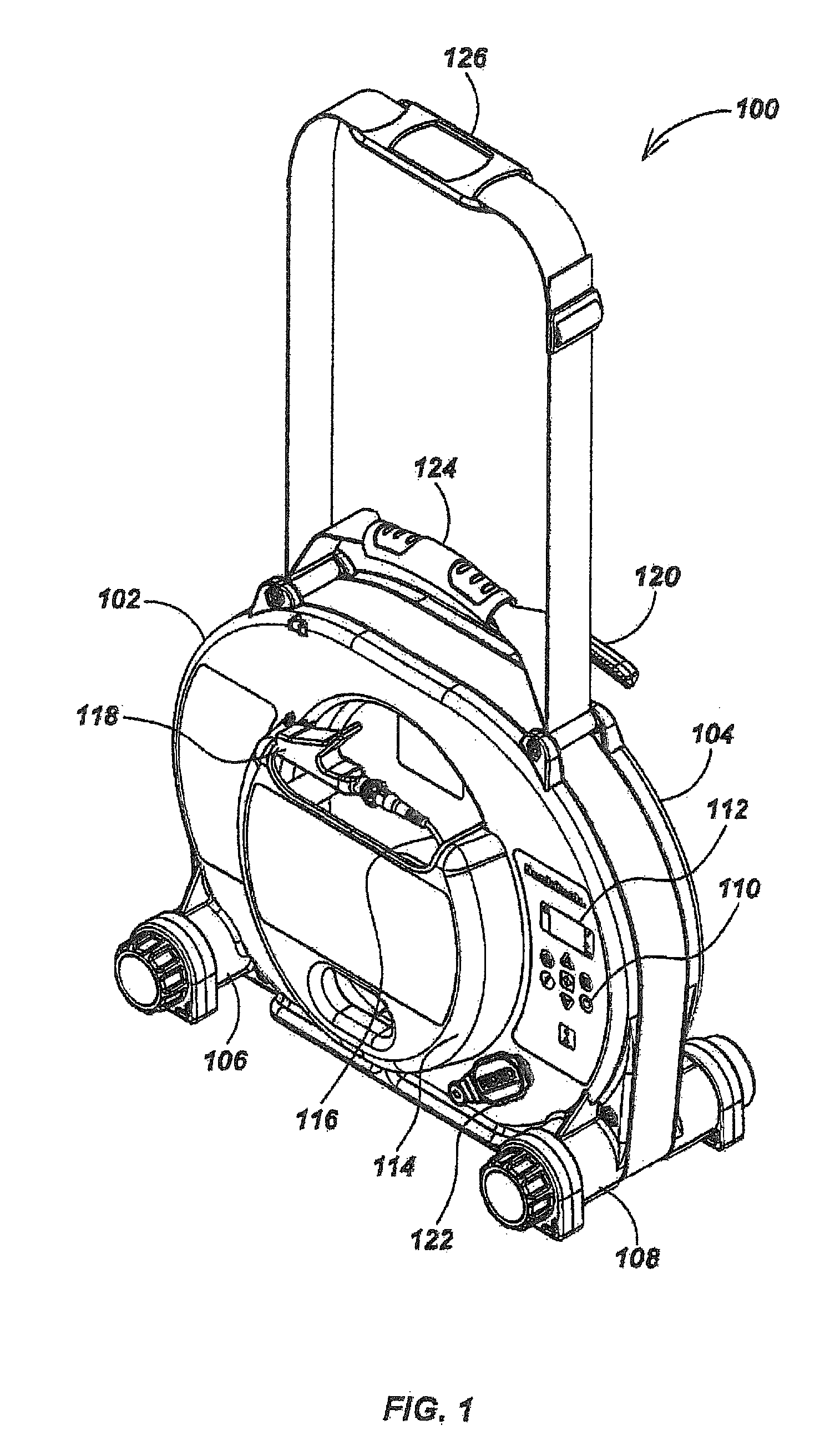

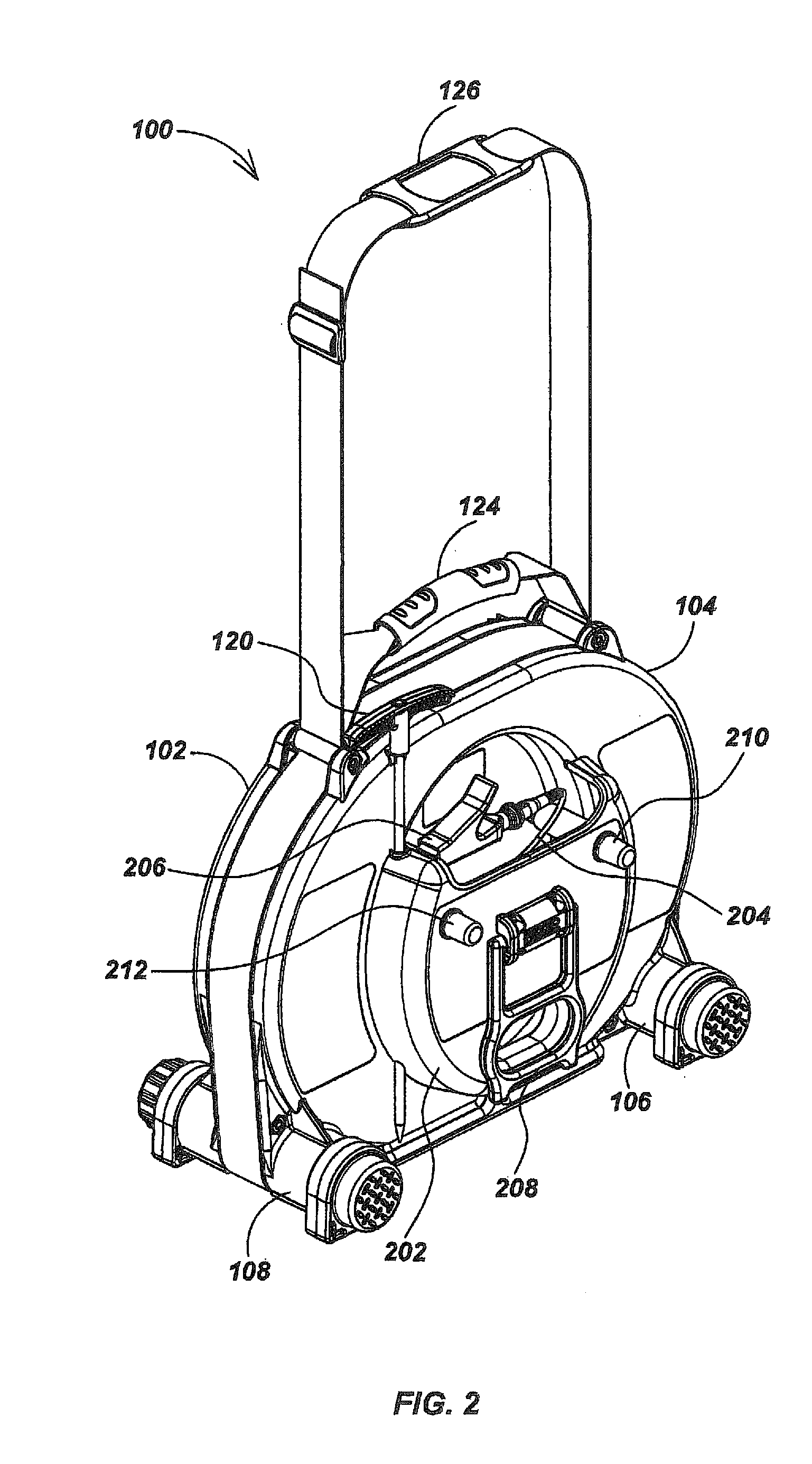

High-Q self tuning locating transmitter

ActiveUS8013610B1Reduce AC-lossOptimize quality ( “ Q ” ) factorMagnetic property measurementsHaberdasherySelf-tuningElectrical conductor

A high-Q human-portable, battery-powered self-correcting tunable resonator in a transmitter apparatus for inducing alternating currents of high quality in buried conductors to facilitate their location. The transmitter apparatus employs an FET-driven capacitive tuning circuit and a coil design that achieves high precision, high-quality transmission signals, and which is equipped with a high-voltage booster for facilitating fault-localization applications.

Owner:SEEKTECH

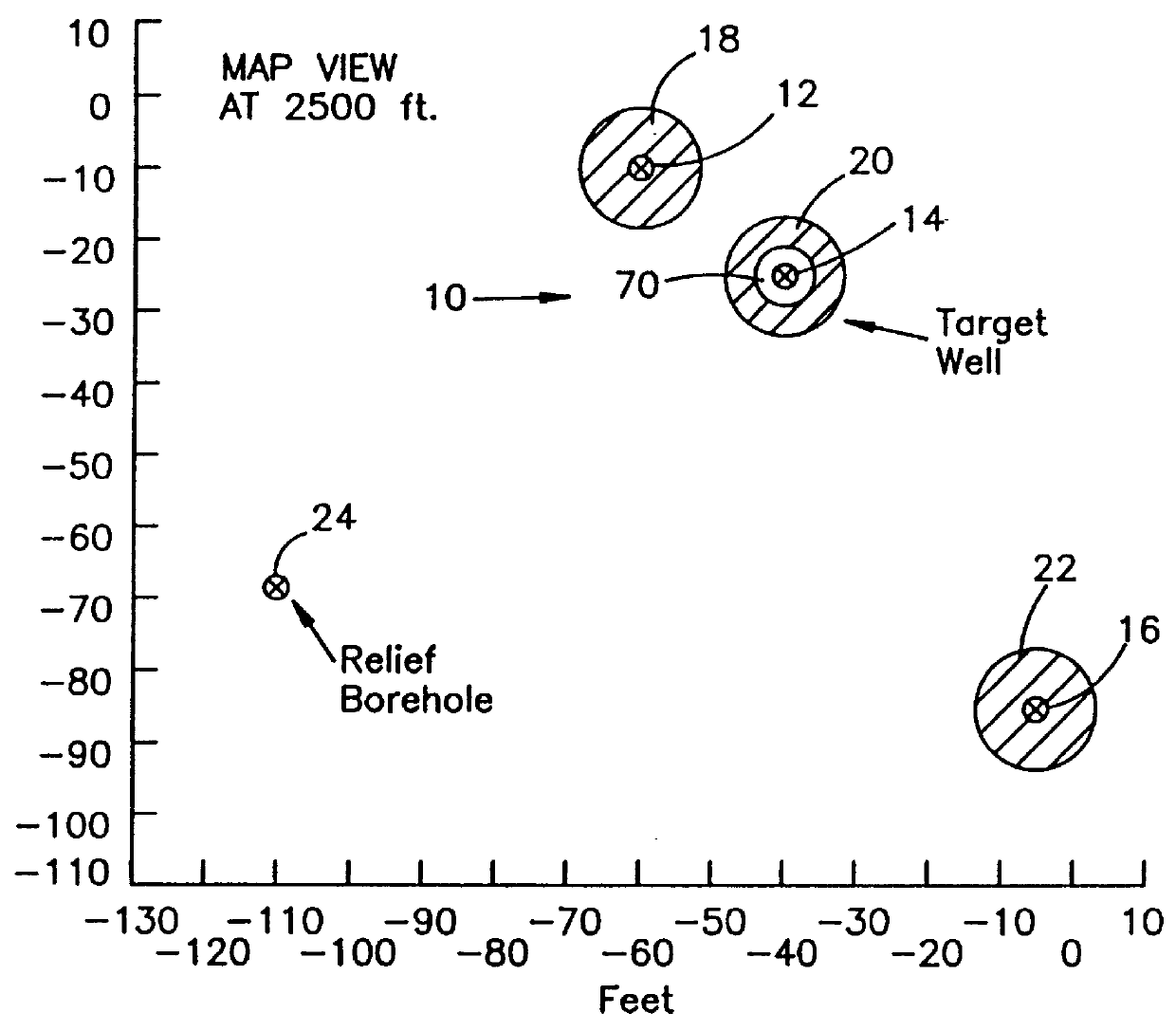

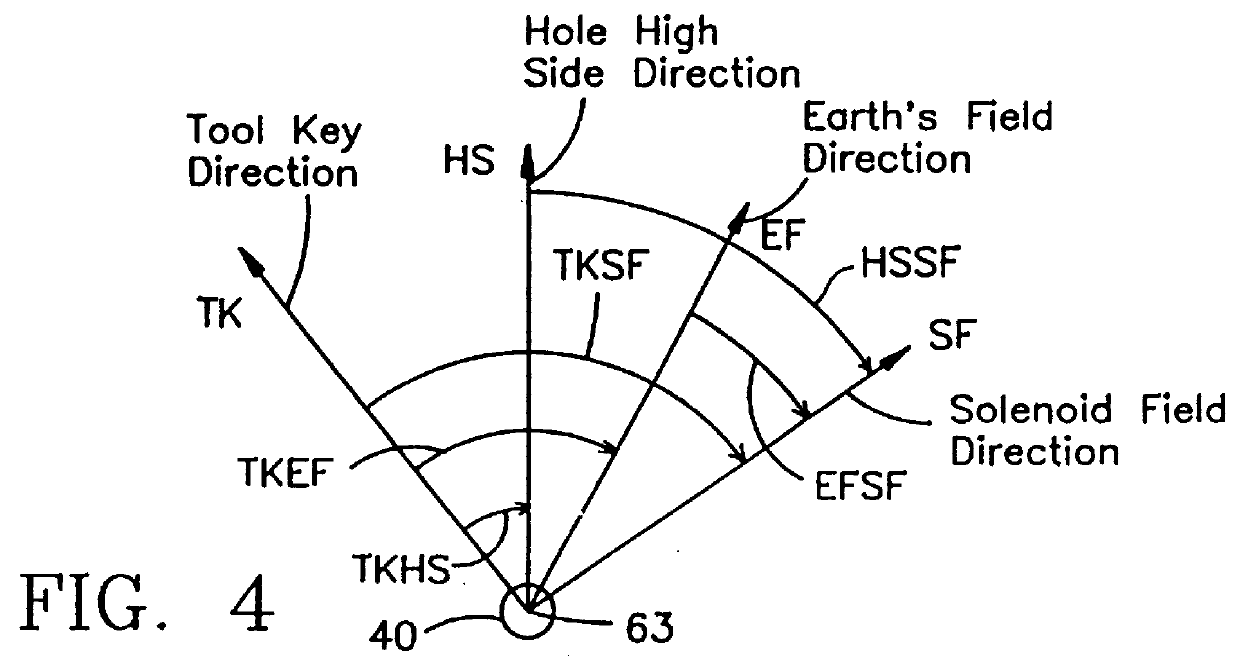

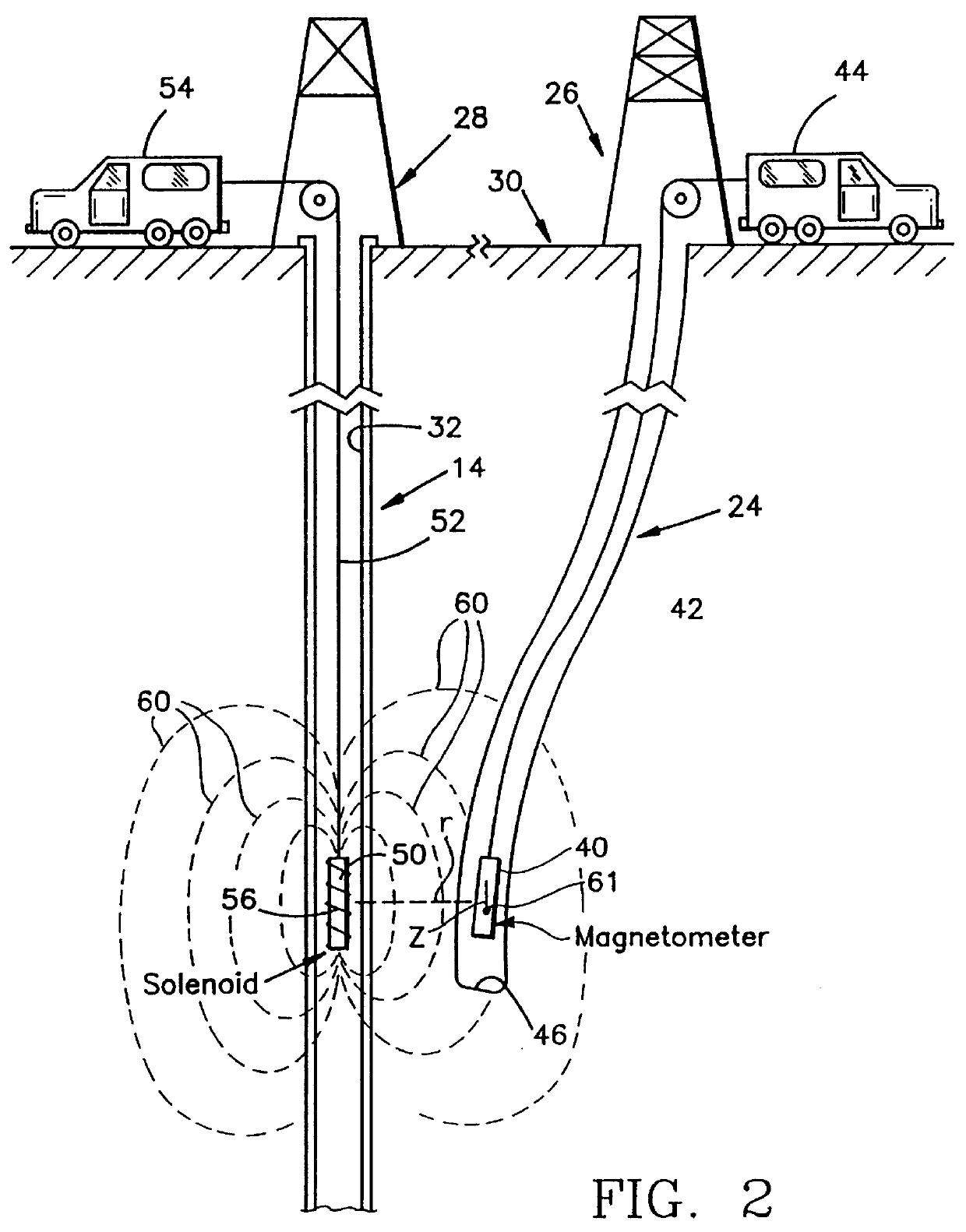

Method and apparatus for measuring distance and direction by movable magnetic field source

InactiveUSRE36569E1Measure directlyIntroduce inaccuracyElectric/magnetic detection for well-loggingSurveyAcousticsSolenoidal magnetic field

Methods for determining the distance from a borehole to a nearby, substantially parallel target well for use in guiding the drilling of the borehole, including positioning a magnetic field sensor in the borehole at a known depth and providing a magnetic field source in the target well. The wells may be vertical or horizontal, and the source preferably is a solenoid movable in the target to a location at approximately the same depth as that of the sensor. The distance between the borehole and the solenoid is determined, in one embodiment, by moving the solenoid to depths above and below the depth of the sensor, and detecting maximum field vectors. The distance the solenoid moves between the maxima is the distance between the wells. In another embodiment, the ratio of solenoid magnetic field vectors is used to determine the ratio of the difference in depth z between the solenoid and the sensor to the lateral distance R between the wells. This ratio z / r is then used to determine the separation of the wells.

Owner:HALLIBURTON ENERGY SERVICES INC

Organic electroluminescent device

InactiveUS20060257684A1Improve efficiencyLow efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesTriplet stateElectron

An organic electroluminescence device comprising a cathode, an anode and at least one layer comprising a phosphorescent light emitting material and a host material which is sandwiched between the cathode and the anode and further comprising an electron injecting layer which is adhered to the light emitting layer and is capable of transporting electrons, wherein an ionization potential of the host material is 5.9 eV or smaller, and wherein an energy gap of the electron transporting material in the electron injecting layer is smaller than that of the host material in the light emitting layer or wherein a triplet energy of the electron transporting material in the electron injecting layer is smaller than that of the host material in the light emitting layer. It emits phosphorescent light with enhanced efficiency because it comprises a light emitting layer and an electron injecting layer both satisfying specified condition and employs a light emitting layer capable of electron transporting.

Owner:IDEMITSU KOSAN CO LTD

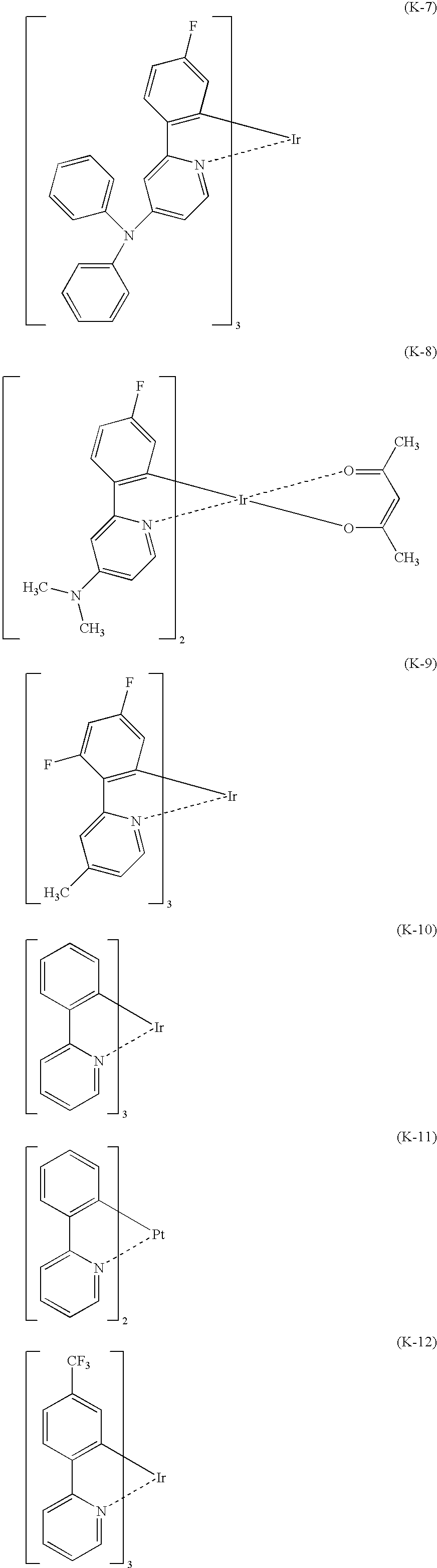

Method of crystalline lens replacement

InactiveUS6413262B2Easy injectionSuitable refractive powerEye surgerySurgical instrument detailsLens crystallineLens substance

A method of crystalline lens replacement for eyes comprises the steps of forming a small hole that penetrates through the lens capsule, removing a part of the crystalline lens substance through the hole, refilling the lens capsule by injecting a composition comprising a hydrophilic polymer directly into the lens capsule, and closing the hole. The method of crystalline lens replacement may be performed on animals or humans. Furthermore, the method of crystalline lens replacement may be performed on a patient suffering from cataract, where the opaque crystalline lens substance in the lens capsule is removed.

Owner:SAISHIN MOTOTSUGU +3

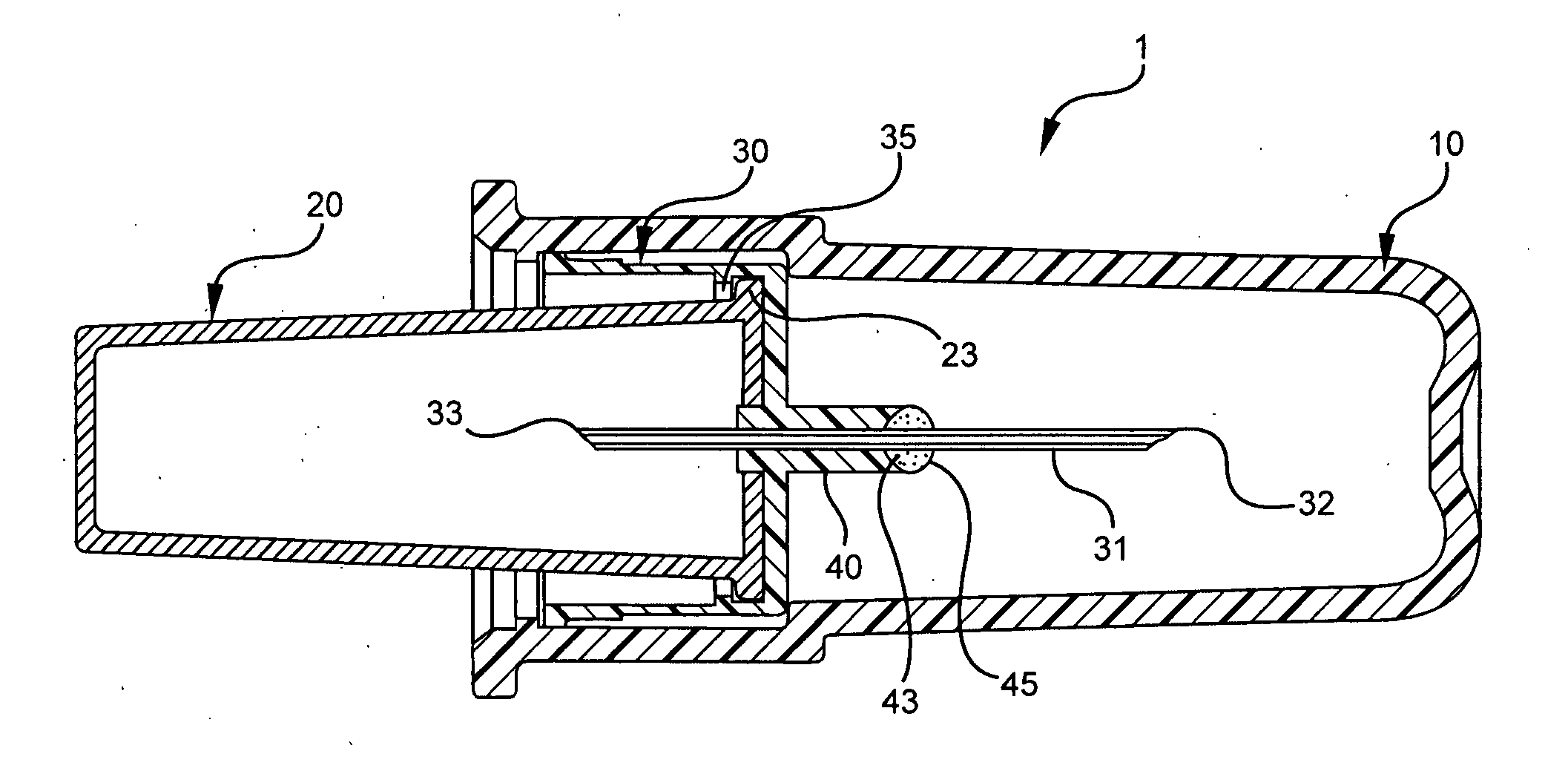

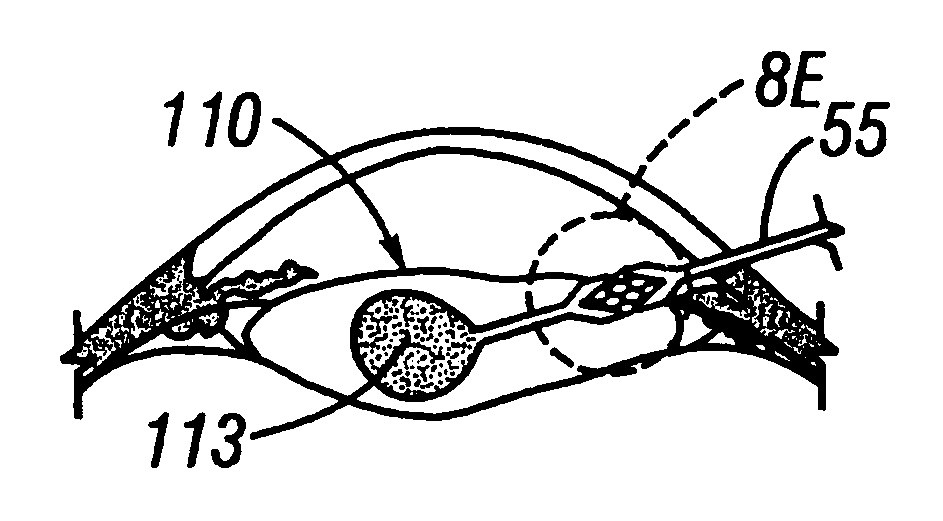

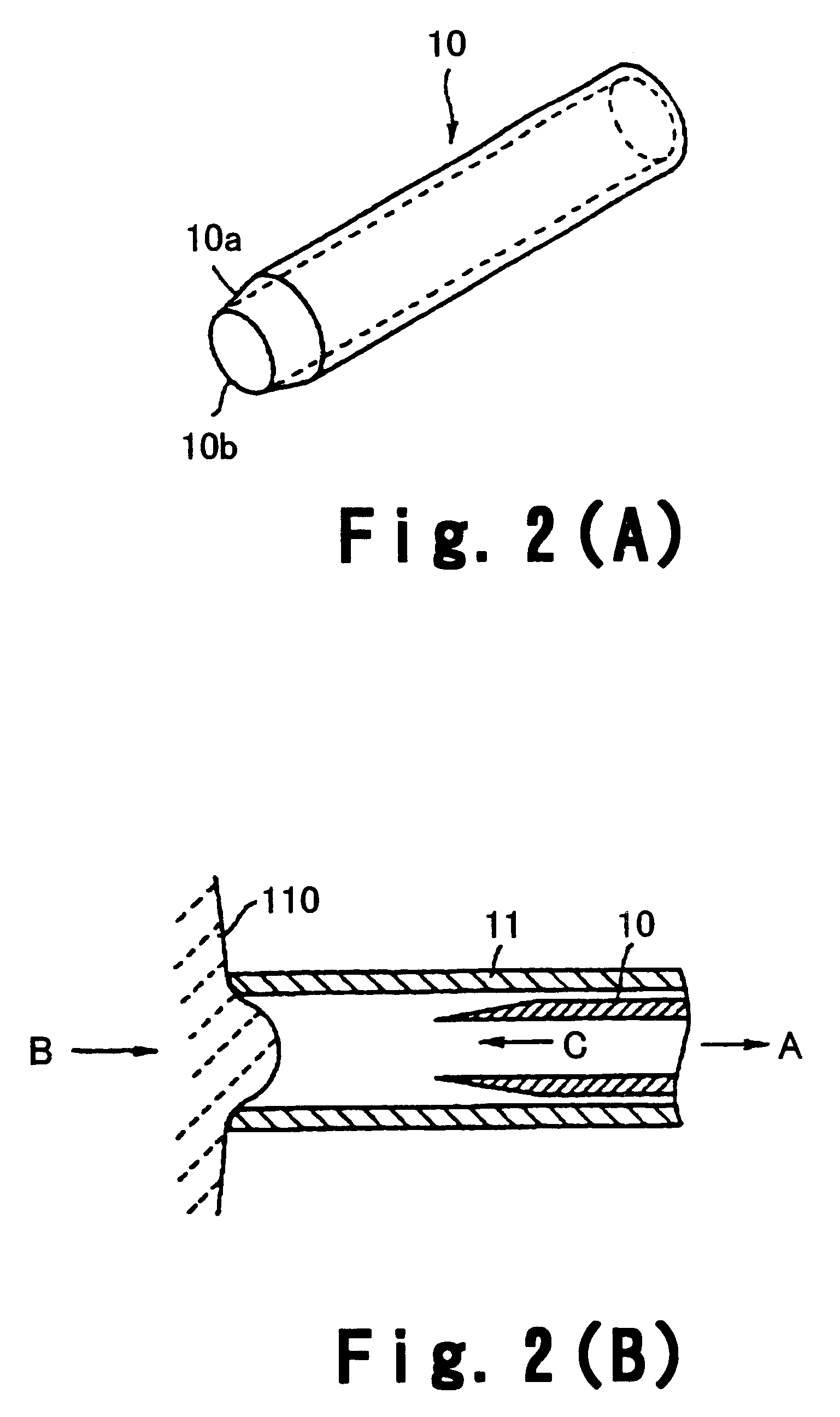

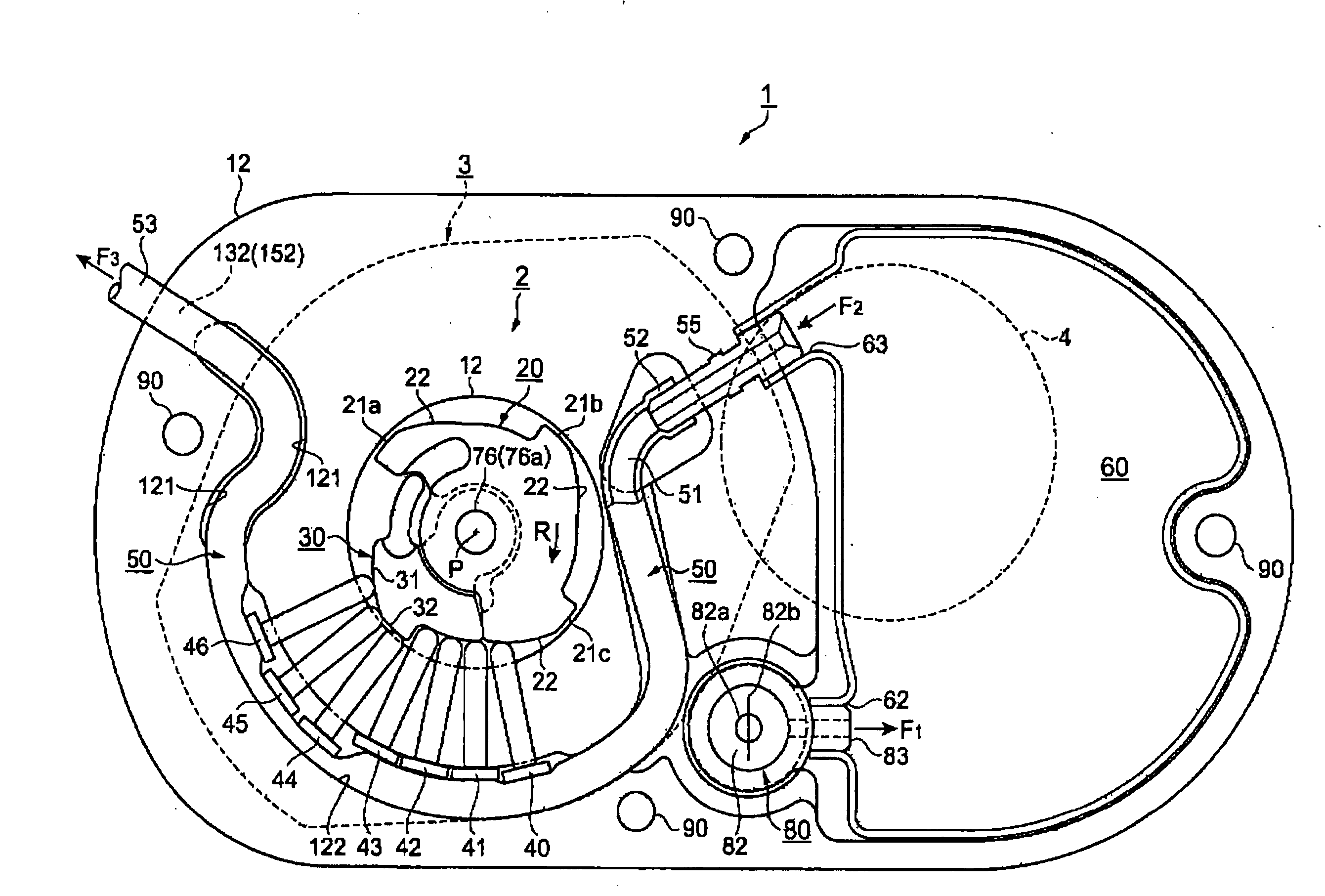

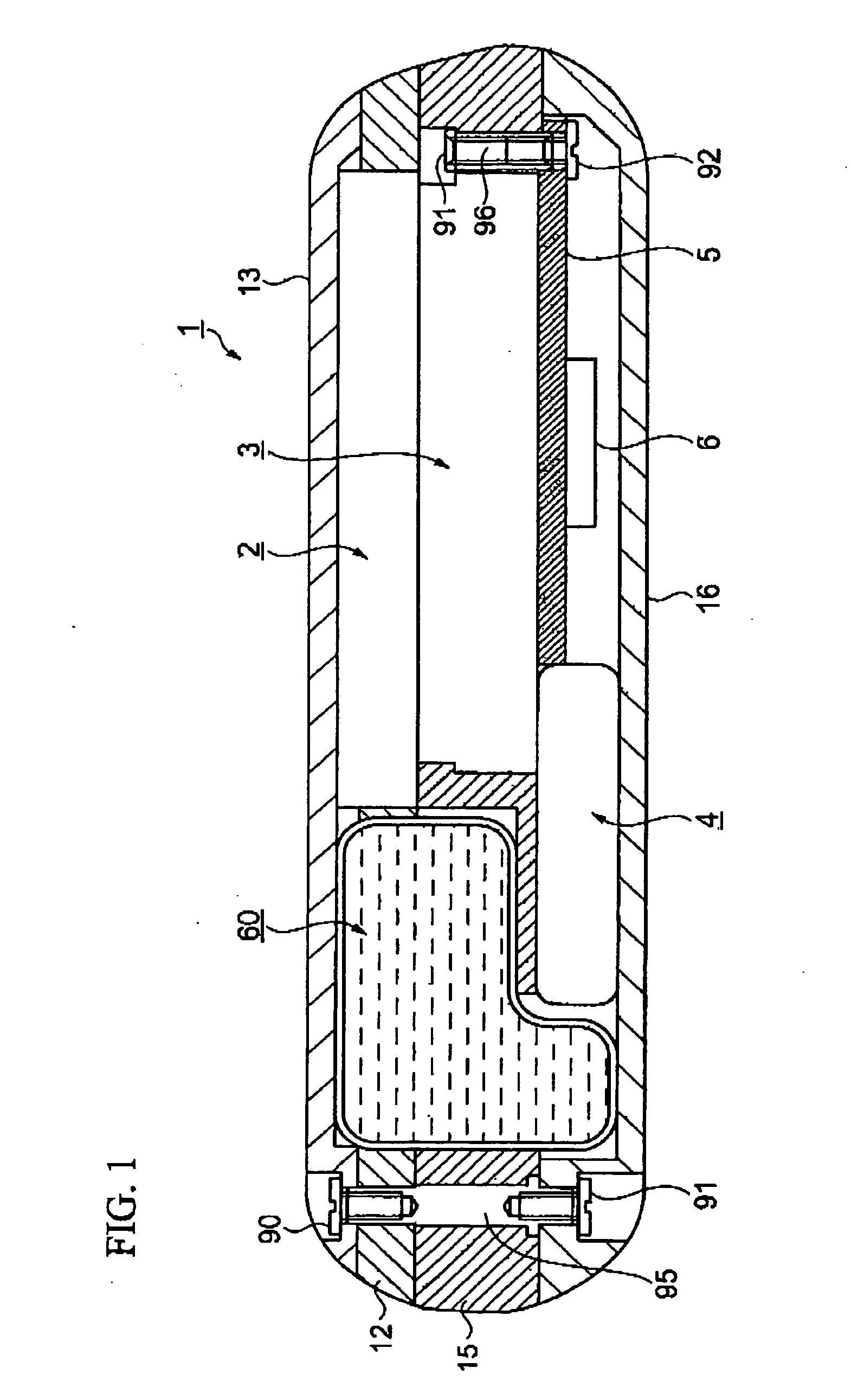

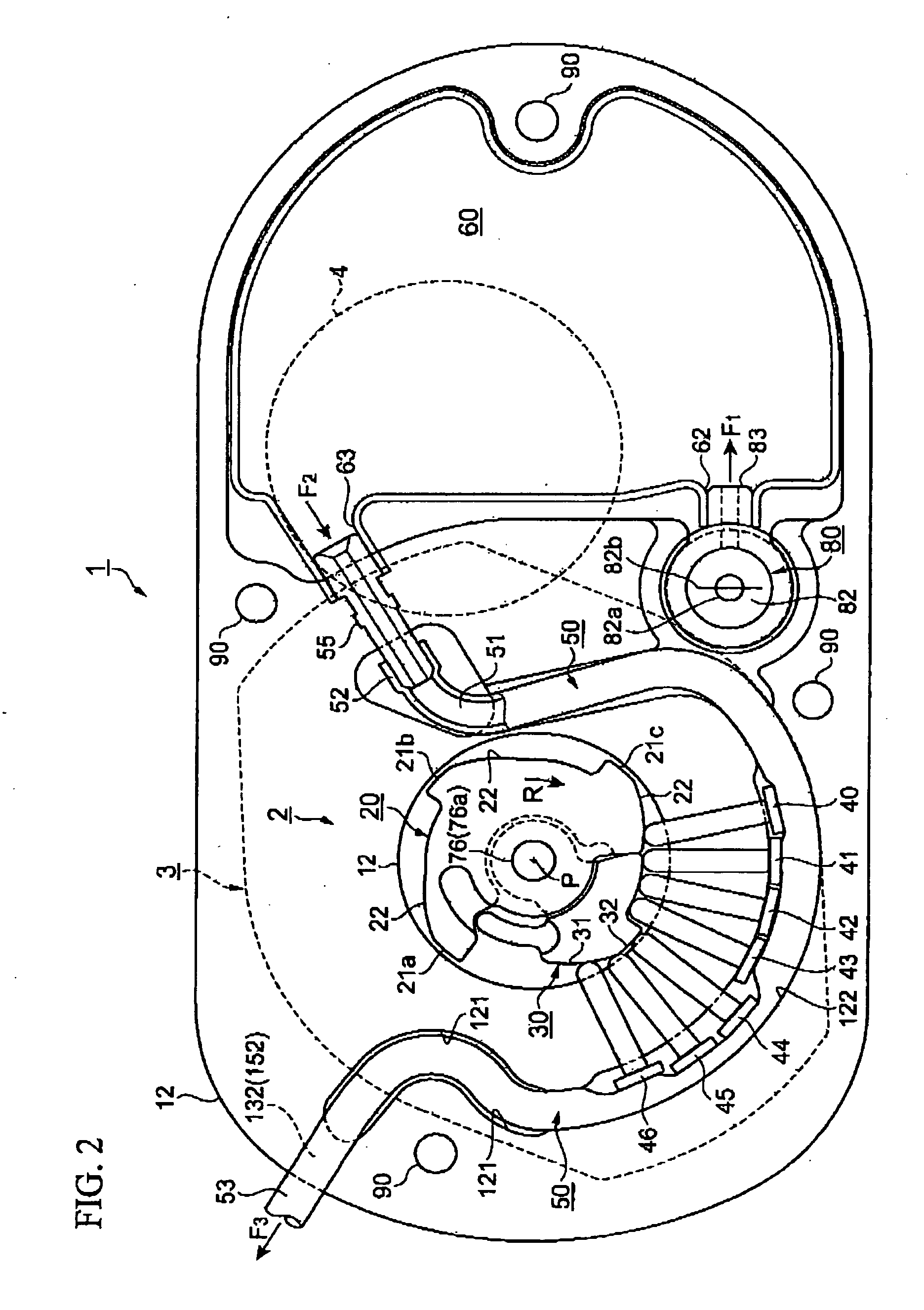

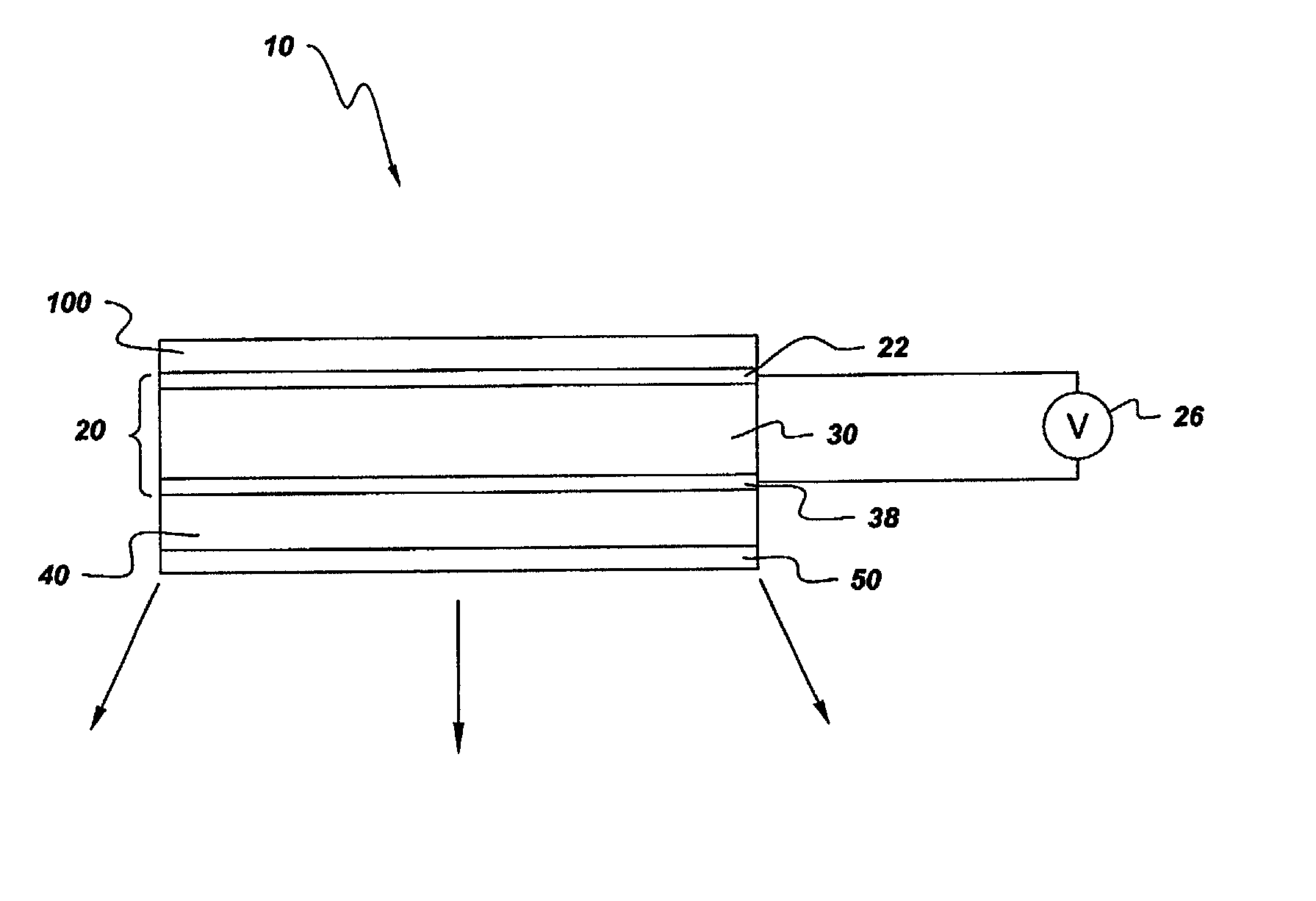

Fluid transportation device

InactiveUS20070154336A1Compatibility to skinReduce the burden onFlexible member pumpsPressure infusionFluid transportEngineering

A fluid transportation device includes: an outer case having a sealed space; a tube having elasticity; a fluid transport mechanism having fingers that occlude the tube and a cam that successively presses the plurality of fingers; a driving force transmission mechanism disposed so as to be overlapped with the fluid transport mechanism, and transmitting a driving force to the fluid transport mechanism; a reservoir disposed at a position so as not to overlap the fluid transport mechanism and the driving force transmission mechanism; a port through which the fluid is injected into the reservoir; and an electric power supply supplying electric power to the driving force transmission mechanism. In this fluid transportation device, at least the fluid transport mechanism, the driving force transmission mechanism, and the electric power supply are housed in the sealed space of the outer case.

Owner:SEIKO EPSON CORP +1

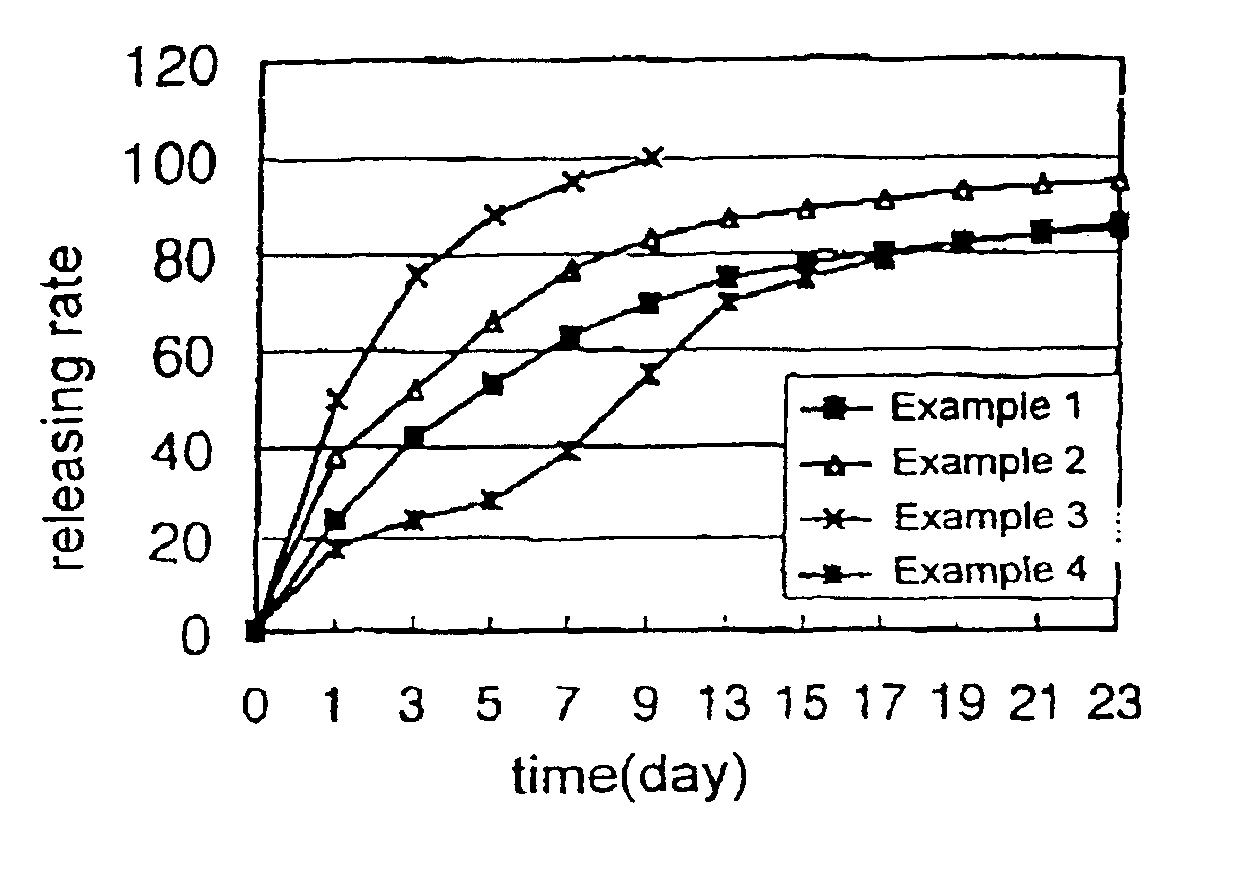

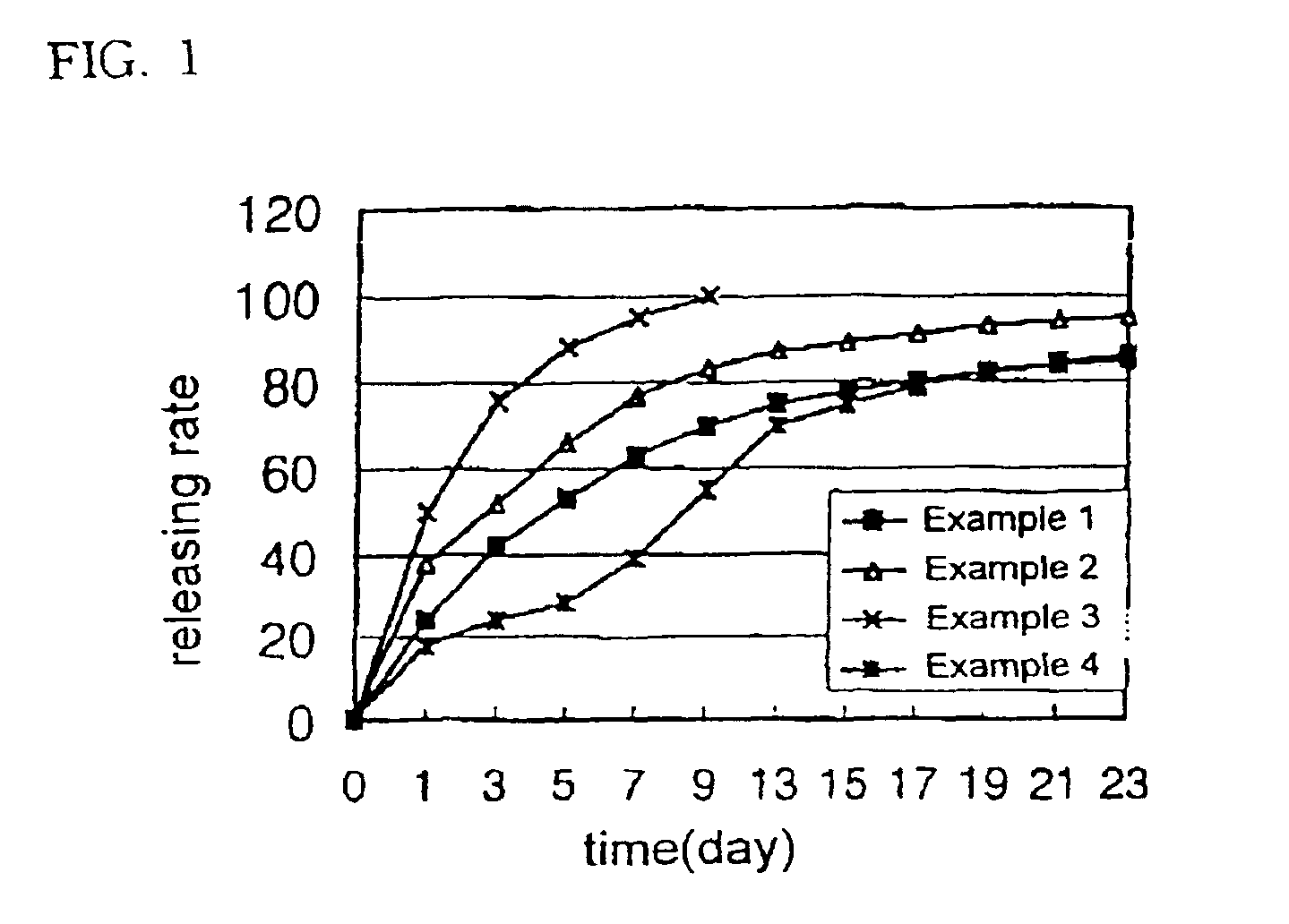

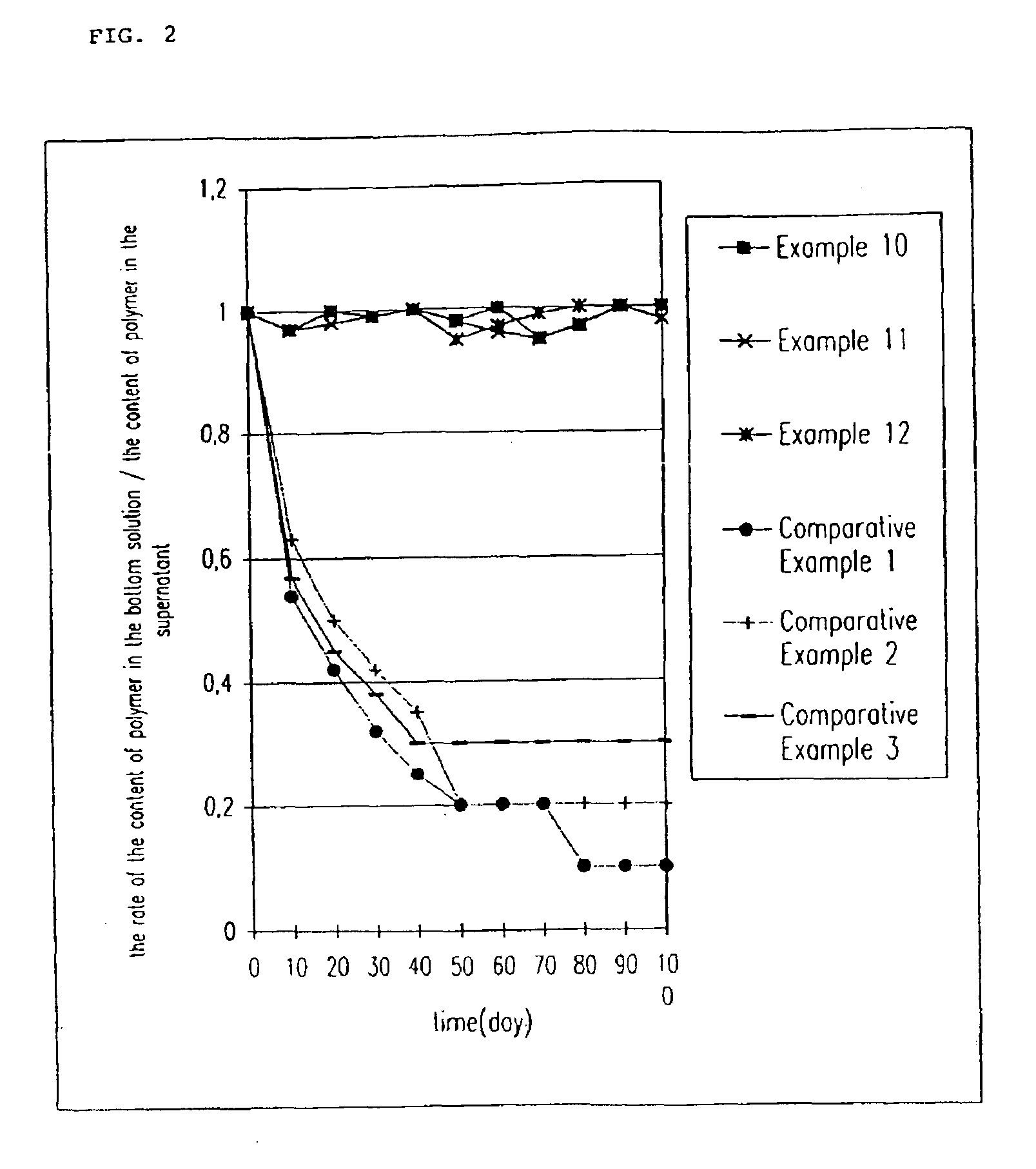

Liquid composition of biodegradable block copolymer for drug delivery system and process for the preparation thereof

InactiveUS6916788B2Rule out the possibilityAvoid hydrolysisAntibacterial agentsOrganic active ingredientsPolyethylene glycolWater soluble

The present invention relates to a liquid polymeric composition capable of forming a physiologically active substance-containing implant when it is injected into a living body and a method of preparation thereof. The composition comprises a water-soluble biocompatible liquid polyethylene glycol derivative, a biodegradable block copolymer which is insoluble in water but soluble in the water-soluble biocompatible liquid polyethylene glycol derivative and a physiologically active substance.

Owner:SAMYANG BIOPHARMLS CORP

Light-emitting device with organic electroluminescent material and photoluminescent materials

InactiveUS20030111955A1Easy to controlEasy to adjustDischarge tube luminescnet screensElectroluminescent light sourcesPhotoluminescenceOrganic electroluminescence

Owner:BOE TECH GRP CO LTD

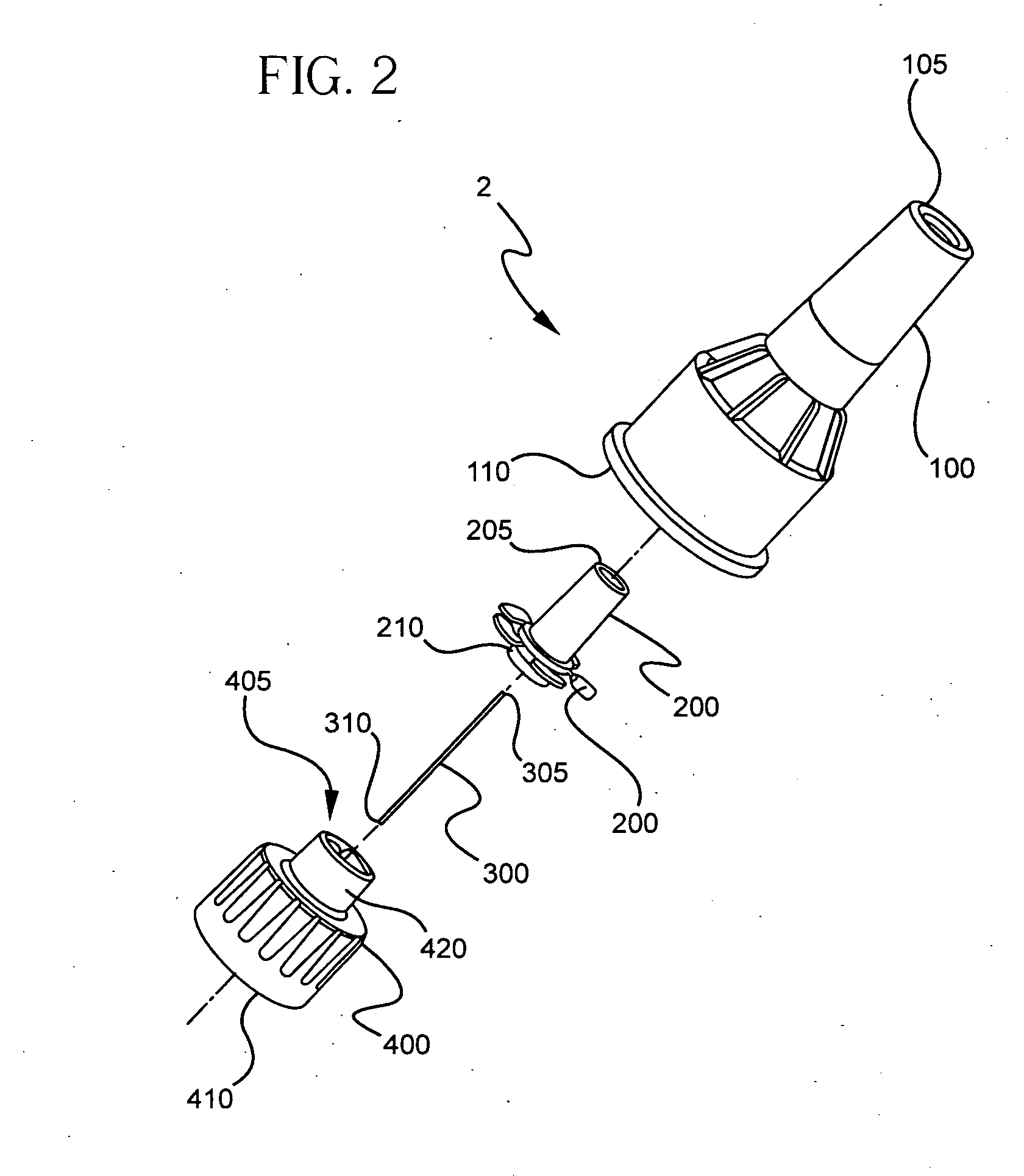

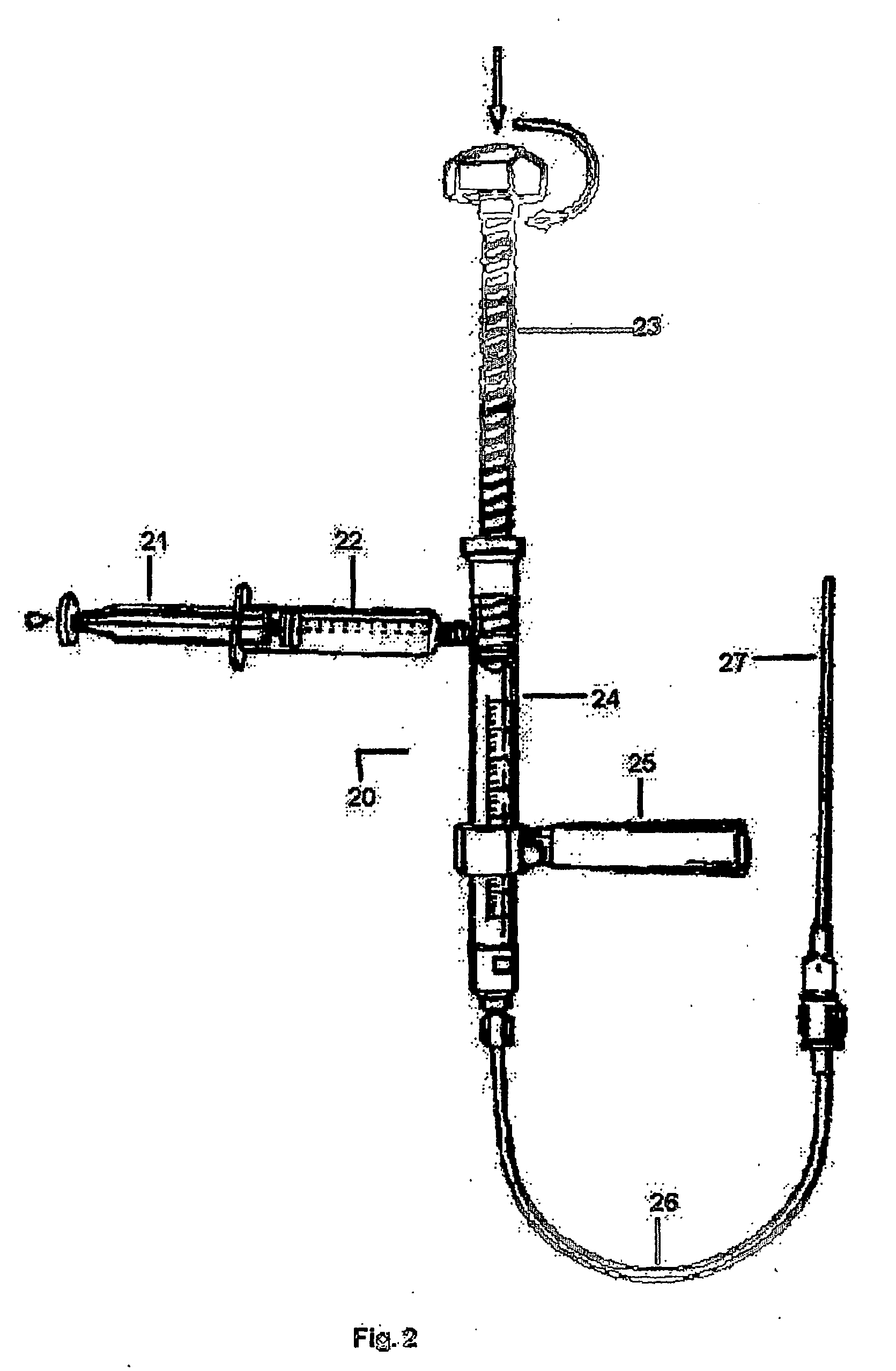

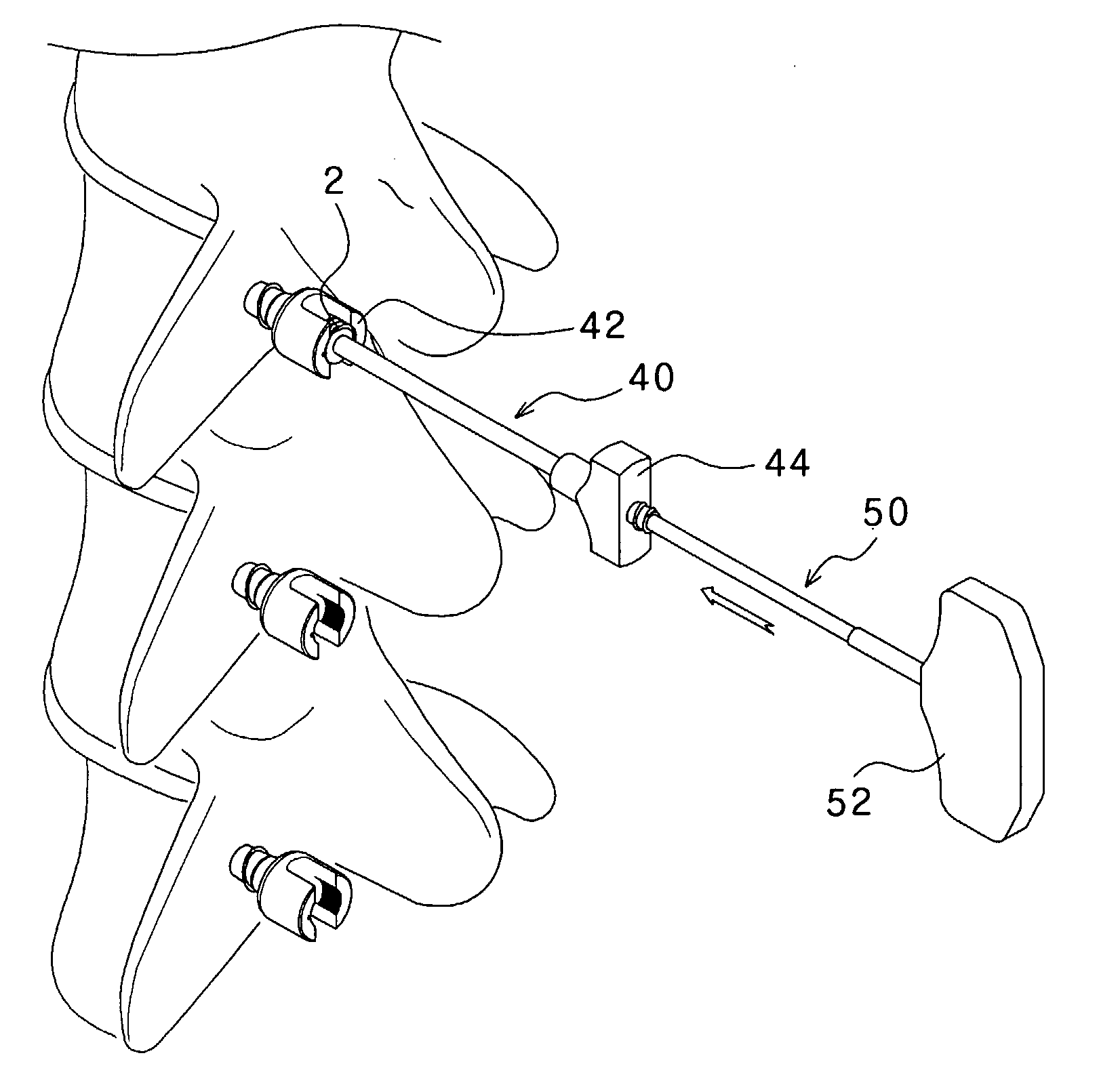

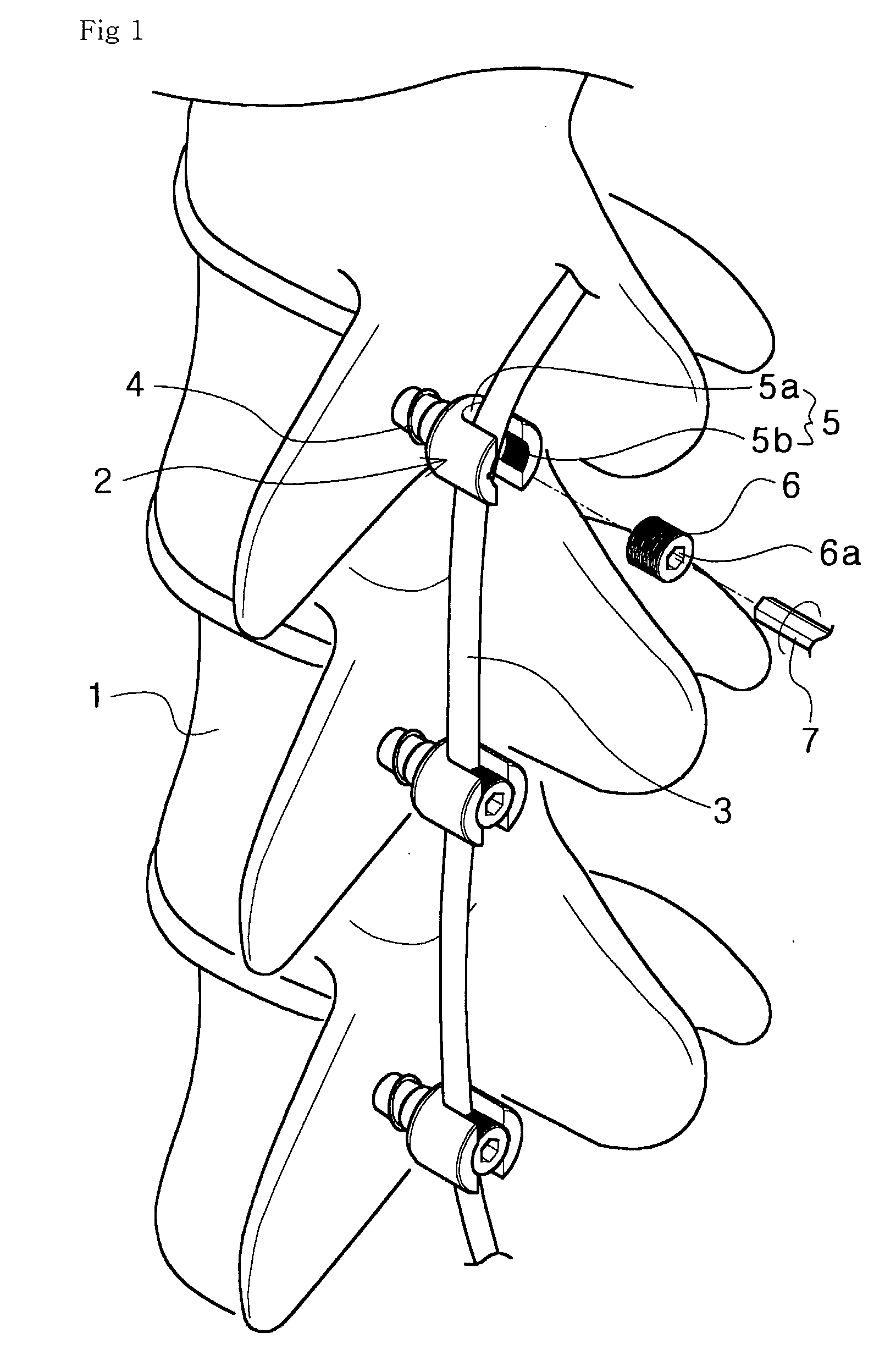

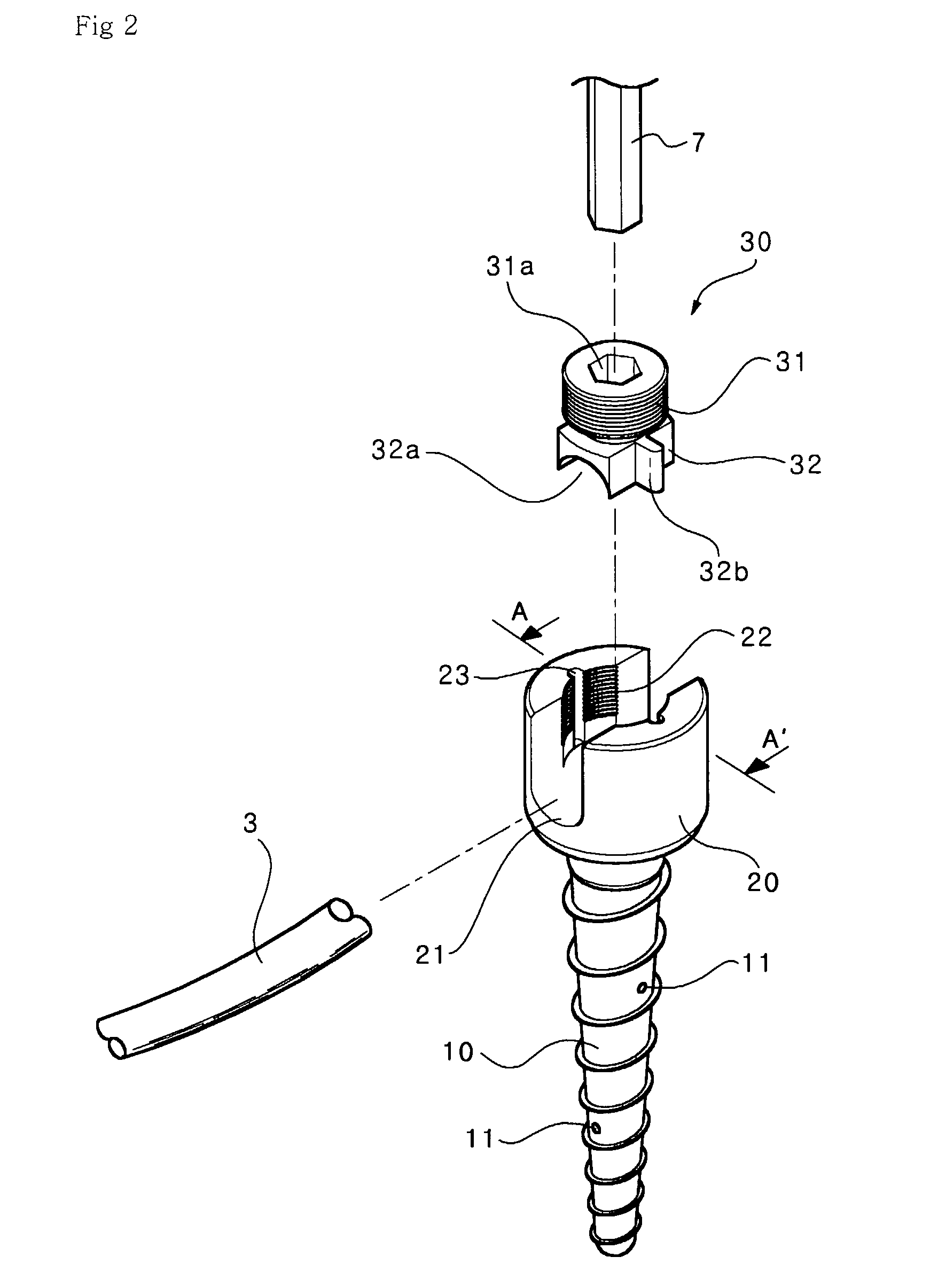

Pedicle Screw and Device for Injecting Bone Cement into Bone

InactiveUS20070299450A1Easily and stably implanted into boneEasy to fixInternal osteosythesisJoint implantsBone mineralBone cement

Disclosed is a pedicle screw used in spinal fusion surgery and a device for injecting bone cement into a spine having low bone mineral density by using the pedicle screw so as to enhance strength of the spine. The pedicle screw includes a screw rod fixedly inserted into a bone, a head section provided at an upper portion of the screw rod and formed at an inner portion thereof with a U-shaped recess and a screw part, and a coupling section coupled with the screw part of the head section. The coupling section is coupled with a rod support section including a bolt having a screw structure provided at an upper portion of the rod support section, a reverse U-shaped recess formed at a lower portion of the rod support section, and a pair of protrusions provided at lateral portions of the rod support section. The screw part of the head section is formed with a pair of guide slots. The screw rod is formed at an inner portion thereof with a hollow section, injection holes communicated with the hollow section are formed in the screw rod, and a feeding hole is formed in the U-shaped recess for feeding bone cement. The bone cement injection device has a cannula including an elongated body, a pedicle screw coupling member provided at one end of the elongated body so as to be fixed to the pedicle screw, and a handle provided at the other end of the elongated body and having an injector coupling member which is coupled to an inlet of an injector, and an impactor including an elongated cylindrical pressing rod inserted into the elongated body of the cannula and having a length longer than a length of the elongated body of the cannula, and a handle attached to one end of the elongated cylindrical pressing rod.

Owner:HER JI HOON +1

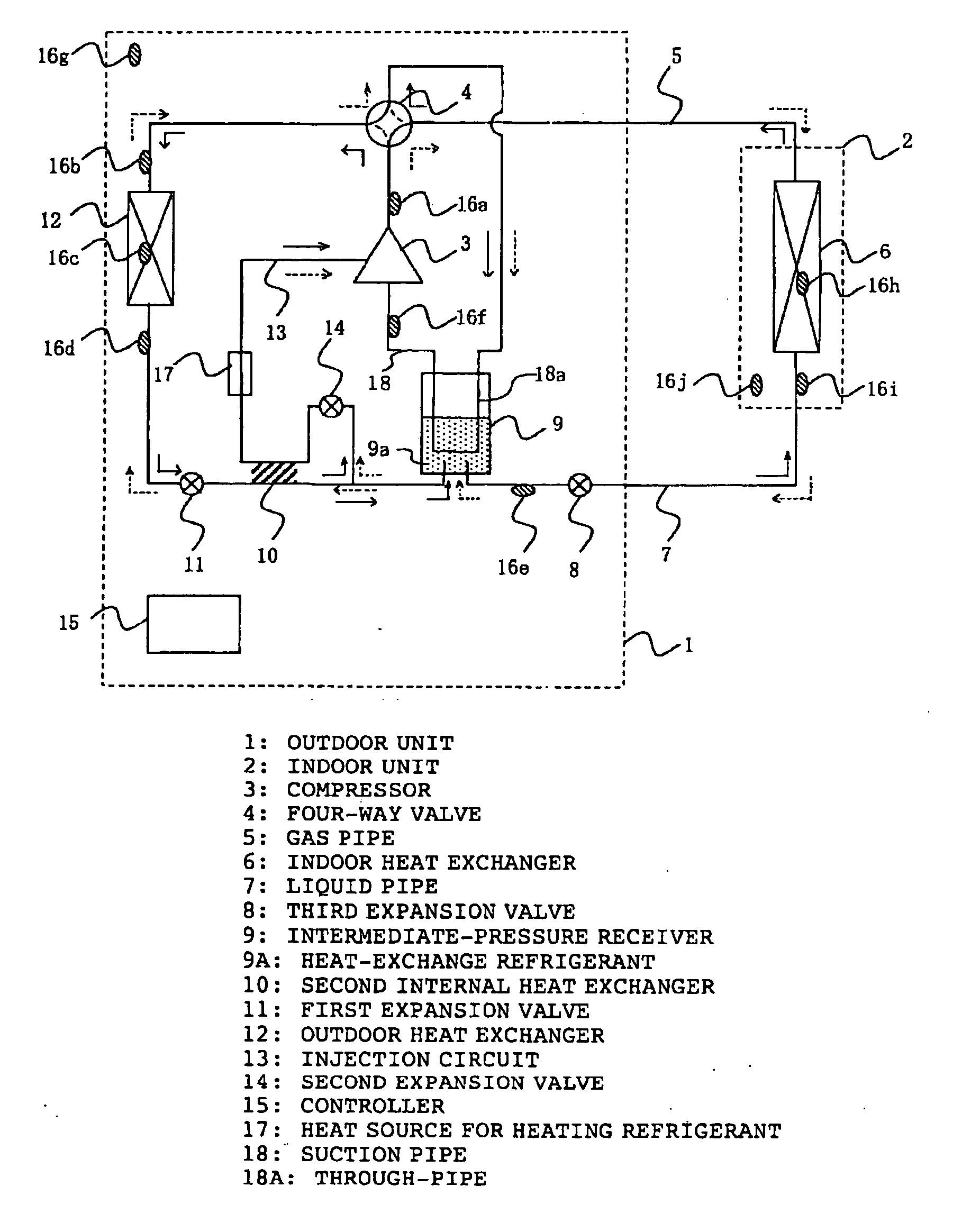

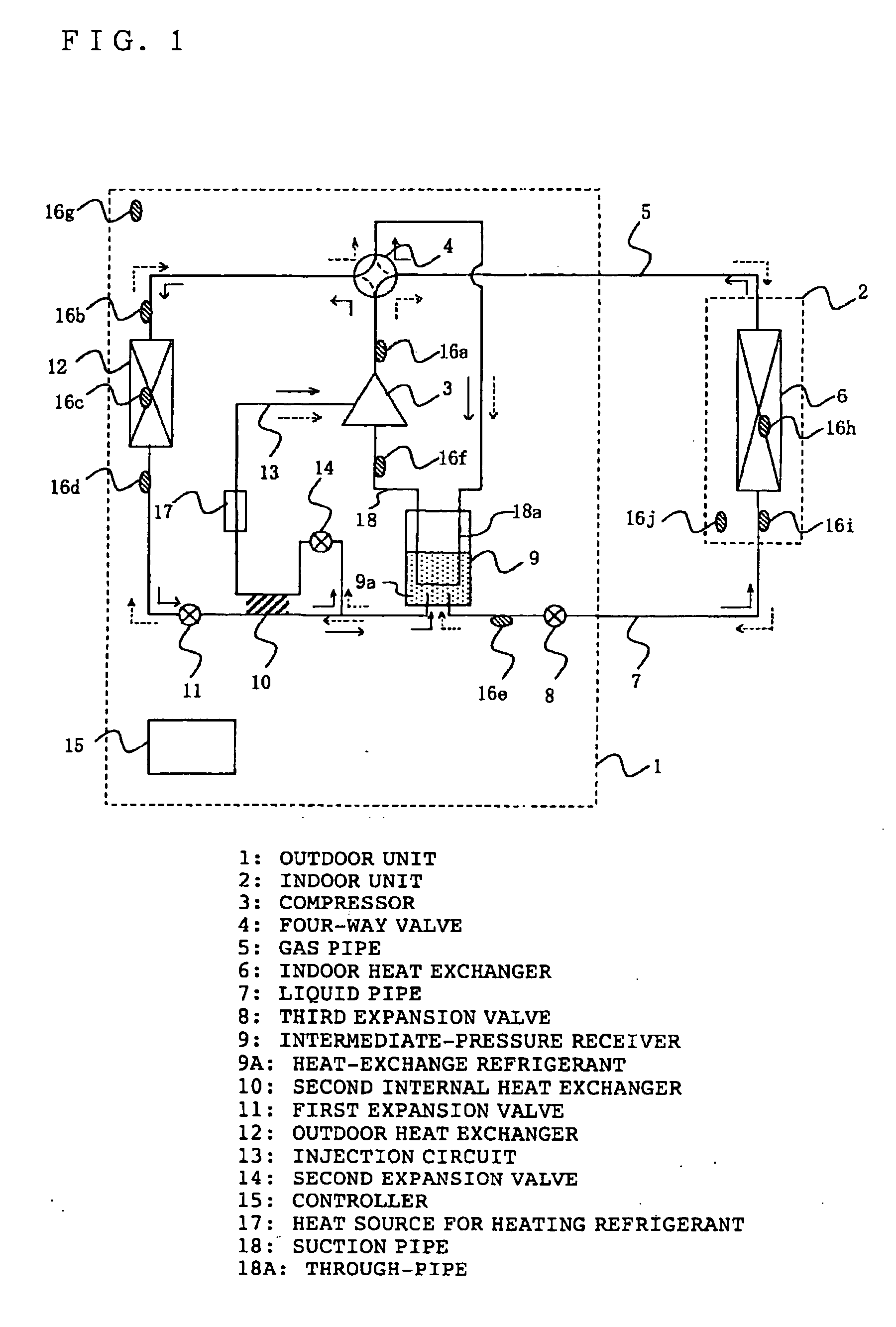

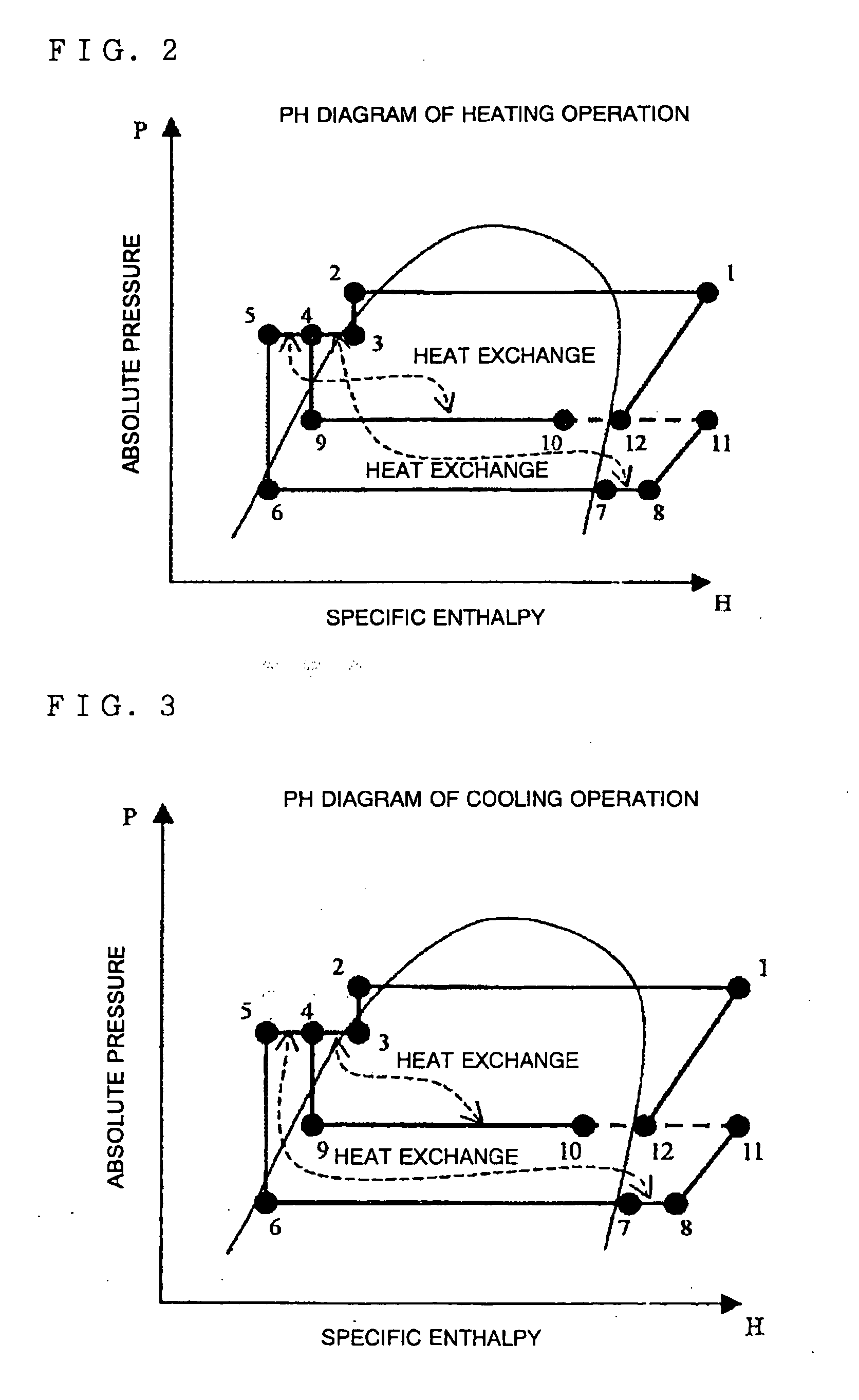

Refrigeration/air conditioning equipment

ActiveUS20060080989A1Increase heating capacitySolve insufficient capacityMechanical apparatusCompression machines with non-reversible cycleEngineeringAir conditioning

Refrigeration / air conditioning equipment includes a first internal heat exchanger for exchanging heat between a refrigerant to be sucked in a compressor and a high-pressure liquid refrigerant, an injection circuit for evaporating a bypassed high-pressure liquid at intermediate pressure and injecting the vaporized refrigerant into the compressor, a second internal heat exchanger for exchanging heat between the high-pressure liquid refrigerant and the refrigerant to be injected, and a heat source for heating the refrigerant to be injected.

Owner:MITSUBISHI ELECTRIC CORP

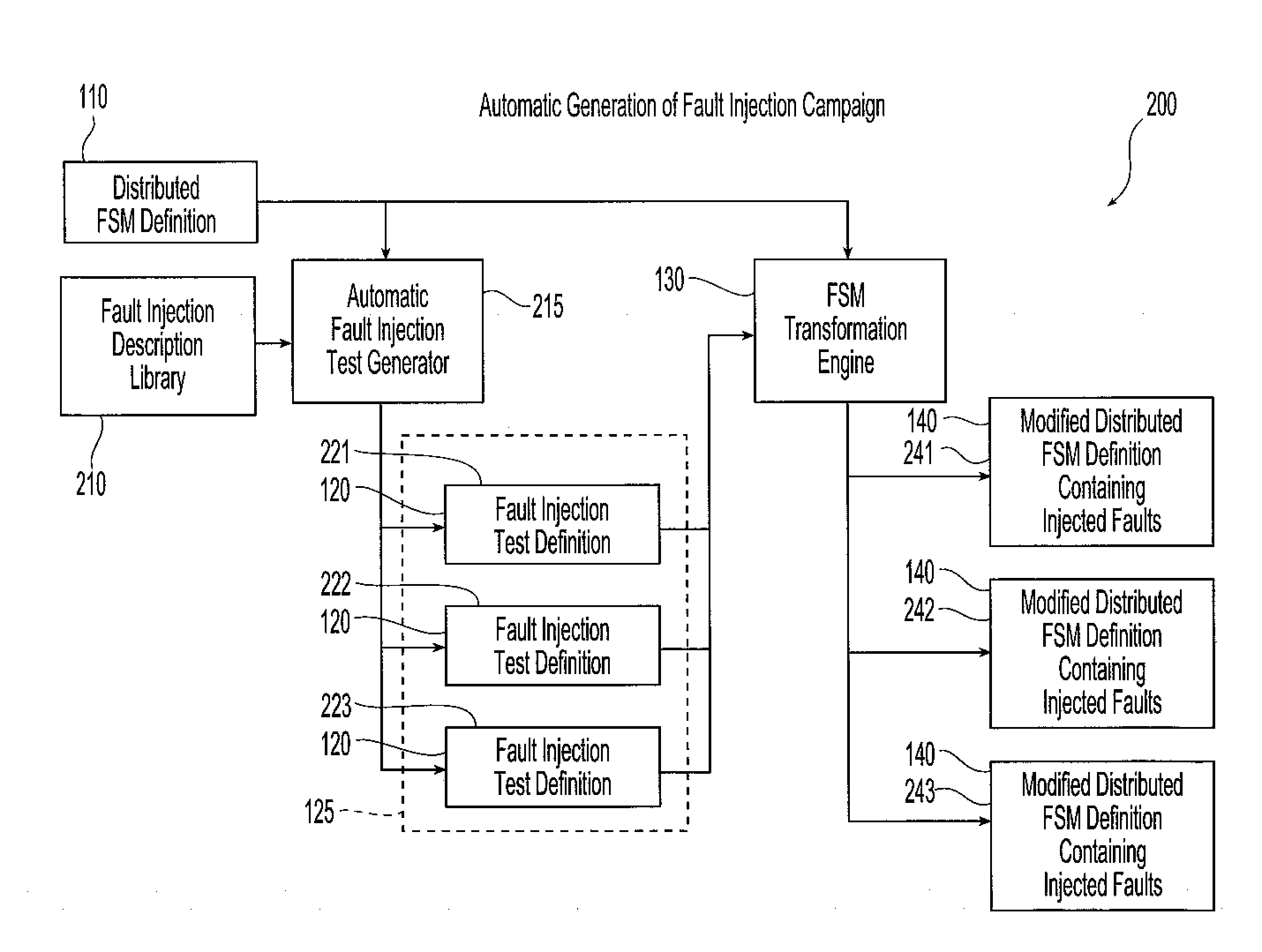

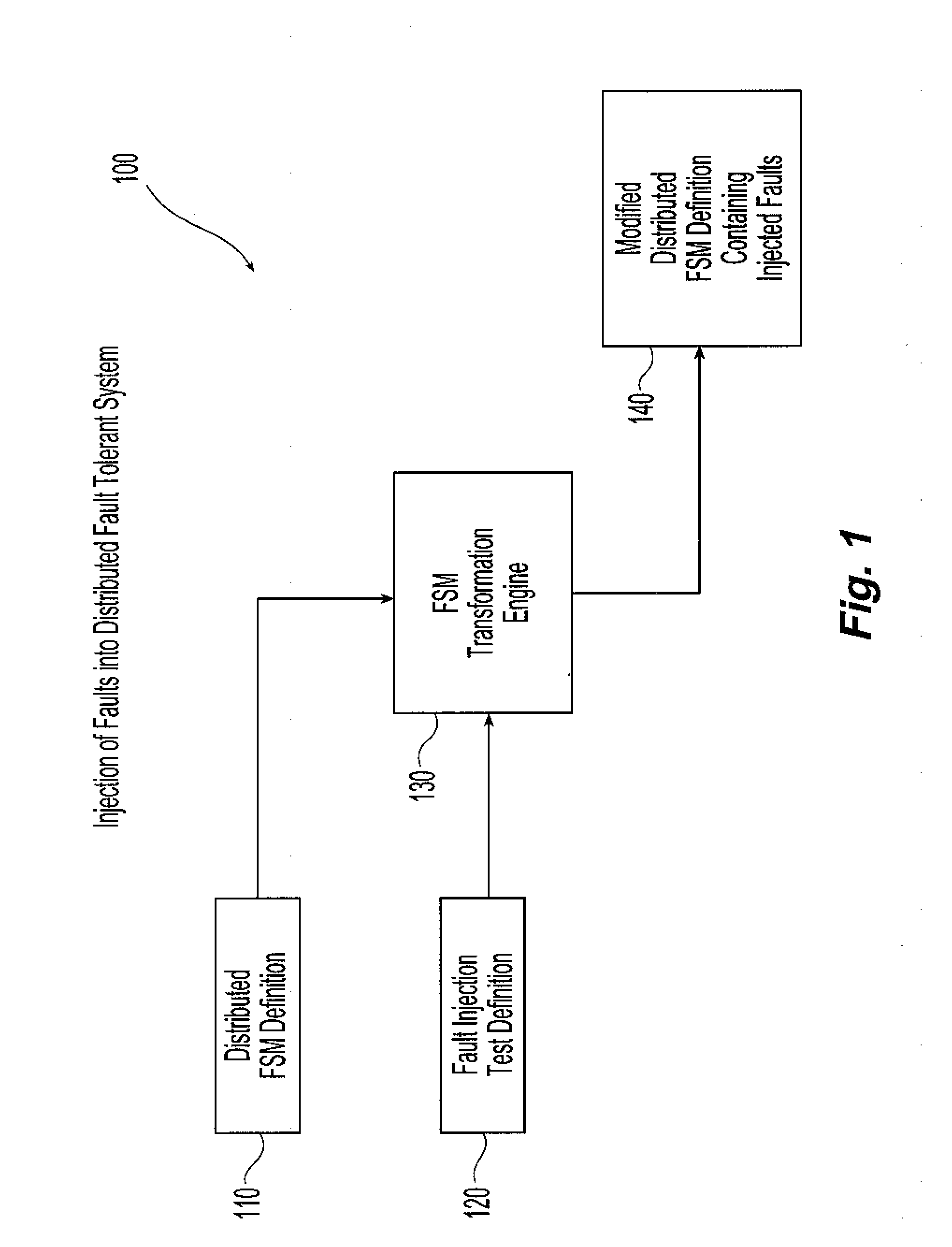

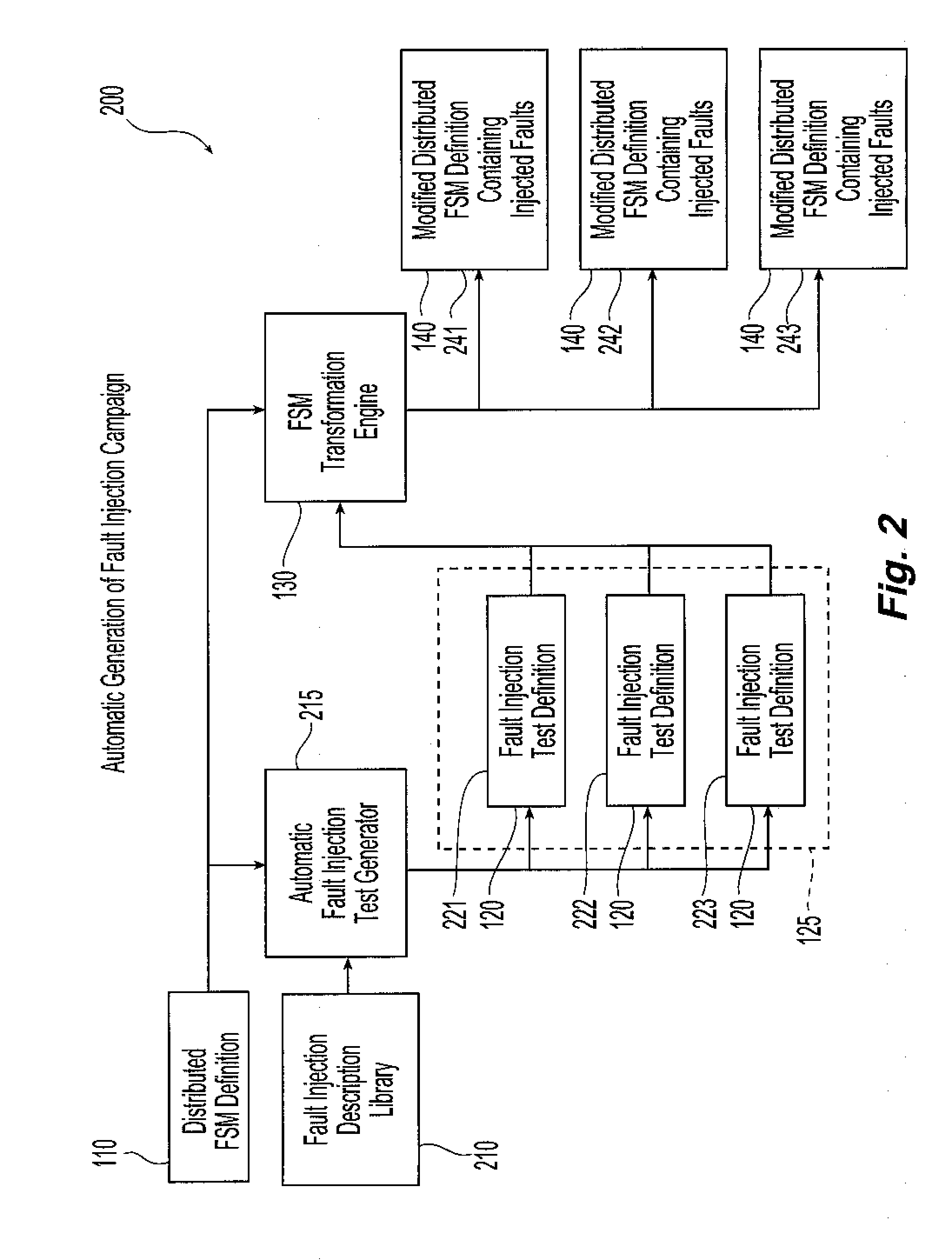

Distributed fault injection mechanism

InactiveUS20080215925A1Validating the robustness of a distributed computing systemEasy injectionError detection/correctionGraphicsGraphical user interface

Methods and systems are provided for testing distributed computer applications using finite state machines. A finite state machine definition for use in a distributed computer system is combined with the fault injections definitions contained within a fault injection campaign that is created for testing the computer application employing that finite state machine. The definition and combination of the finite state machine definition and the fault injection campaign is carried out automatically or manually, for example using a graphical user interface. This combination creates at least one modified finite state machine definition containing the desired injected faults. The modified finite state machine definition is separate from the originally identified finite state machine definition, and the originally identified finite state machine remains intact without injected faults. Trigger points within the finite state machine definition are identified for each fault injection test definition, and the modified finite state machine definition containing the fault injection test definition associated with a given trigger point are used in place of the original finite state machine definition upon detection of that trigger point during runtime of the finite state machine definition.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com