Patents

Literature

100results about How to "Reduce AC loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

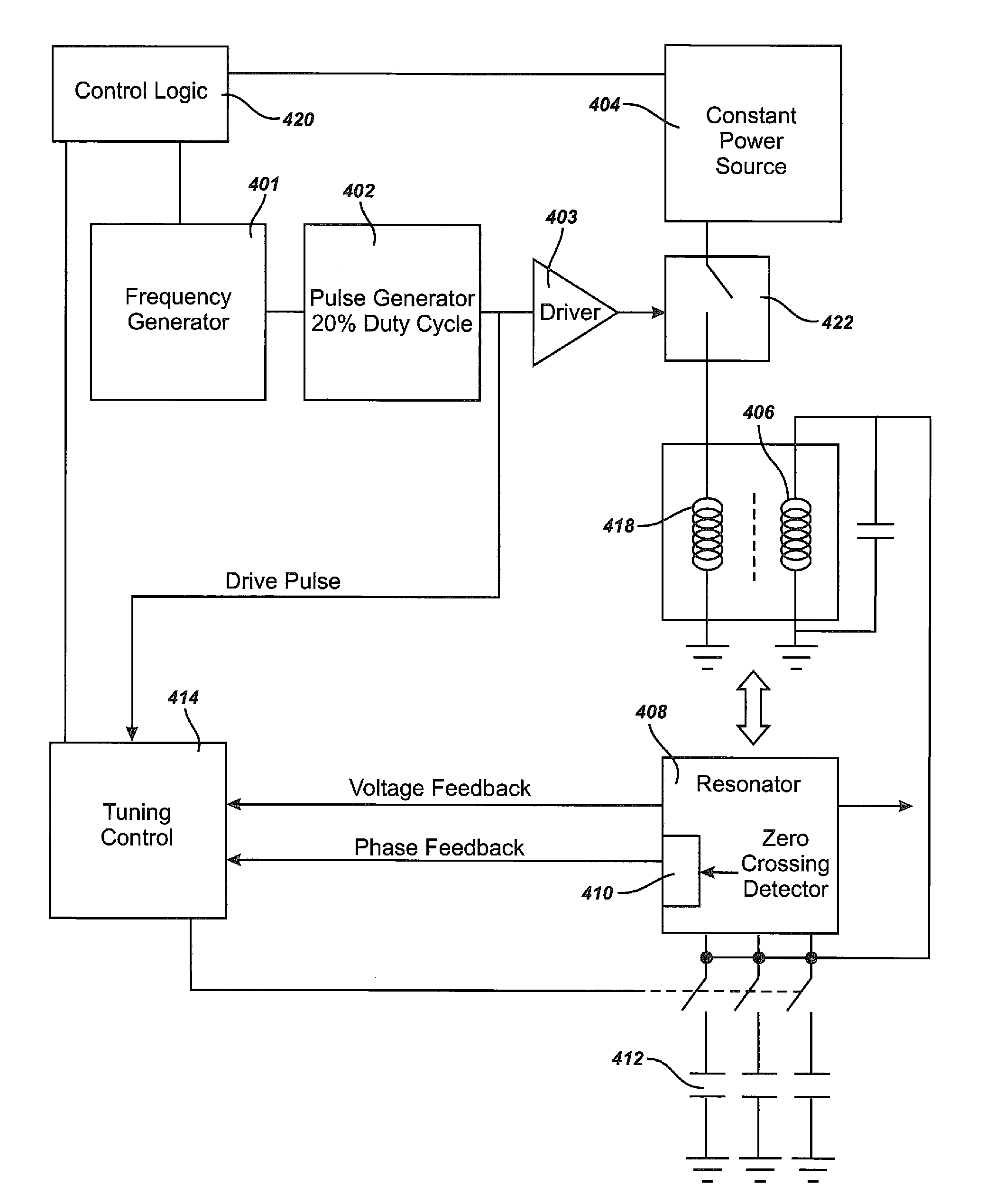

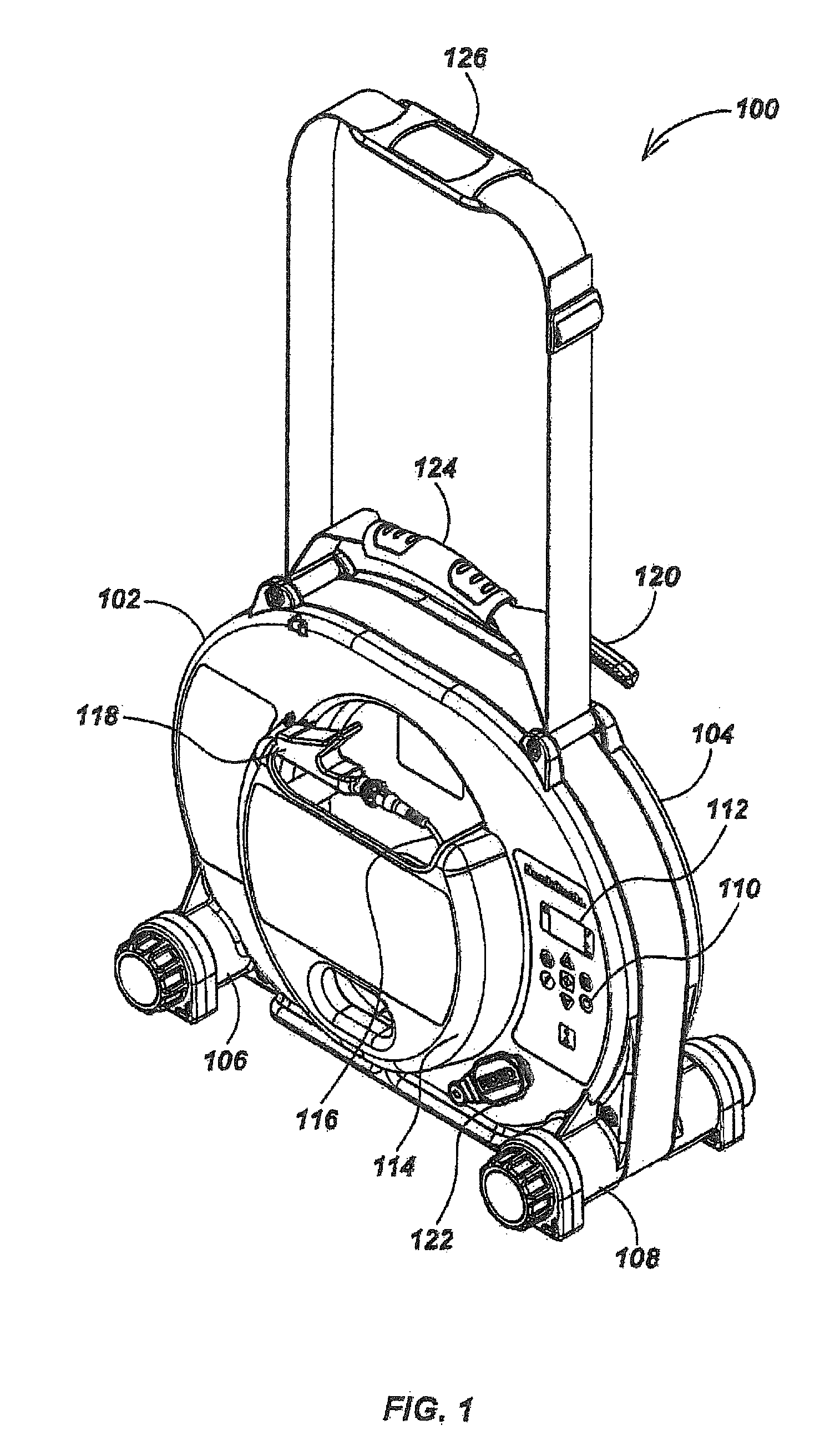

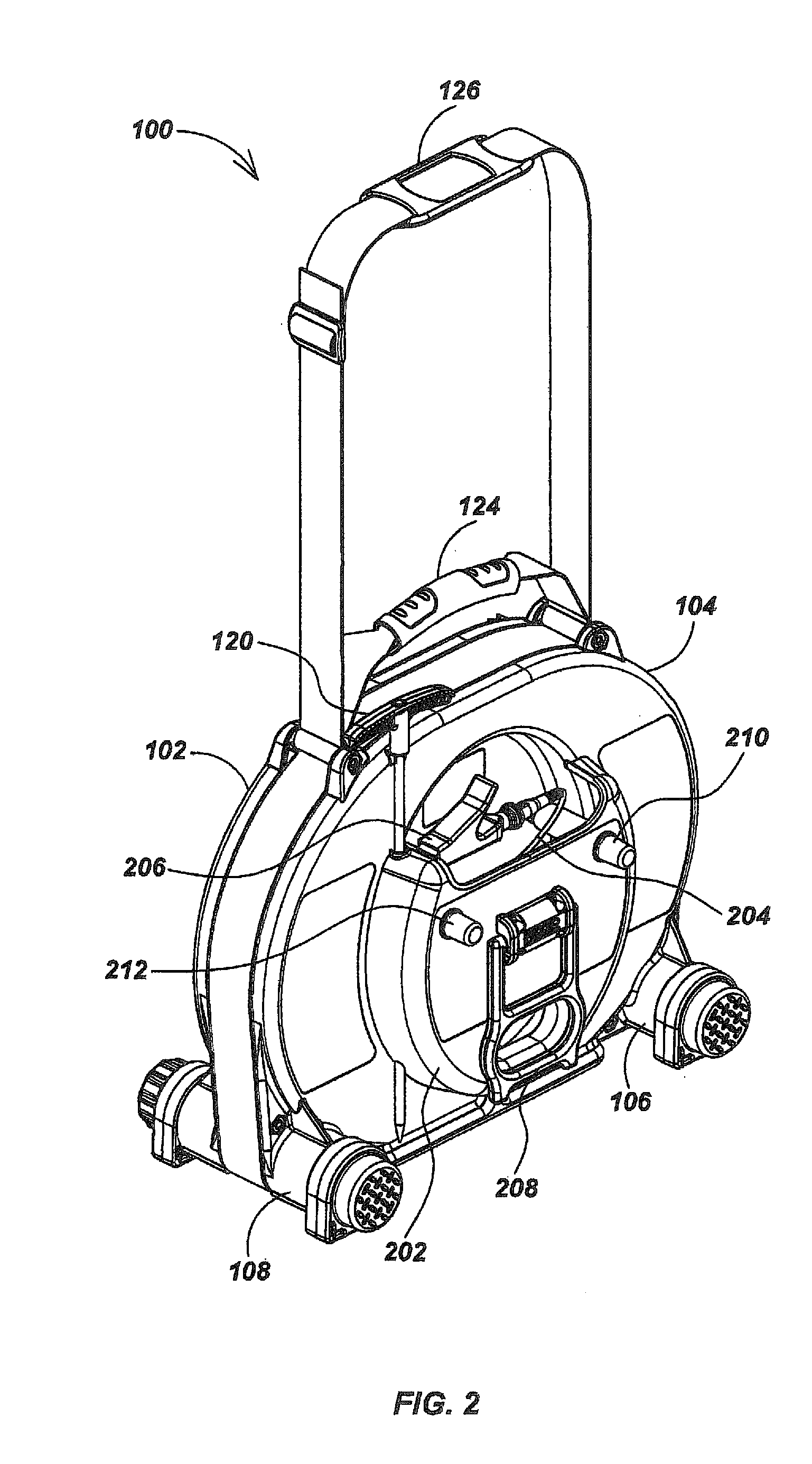

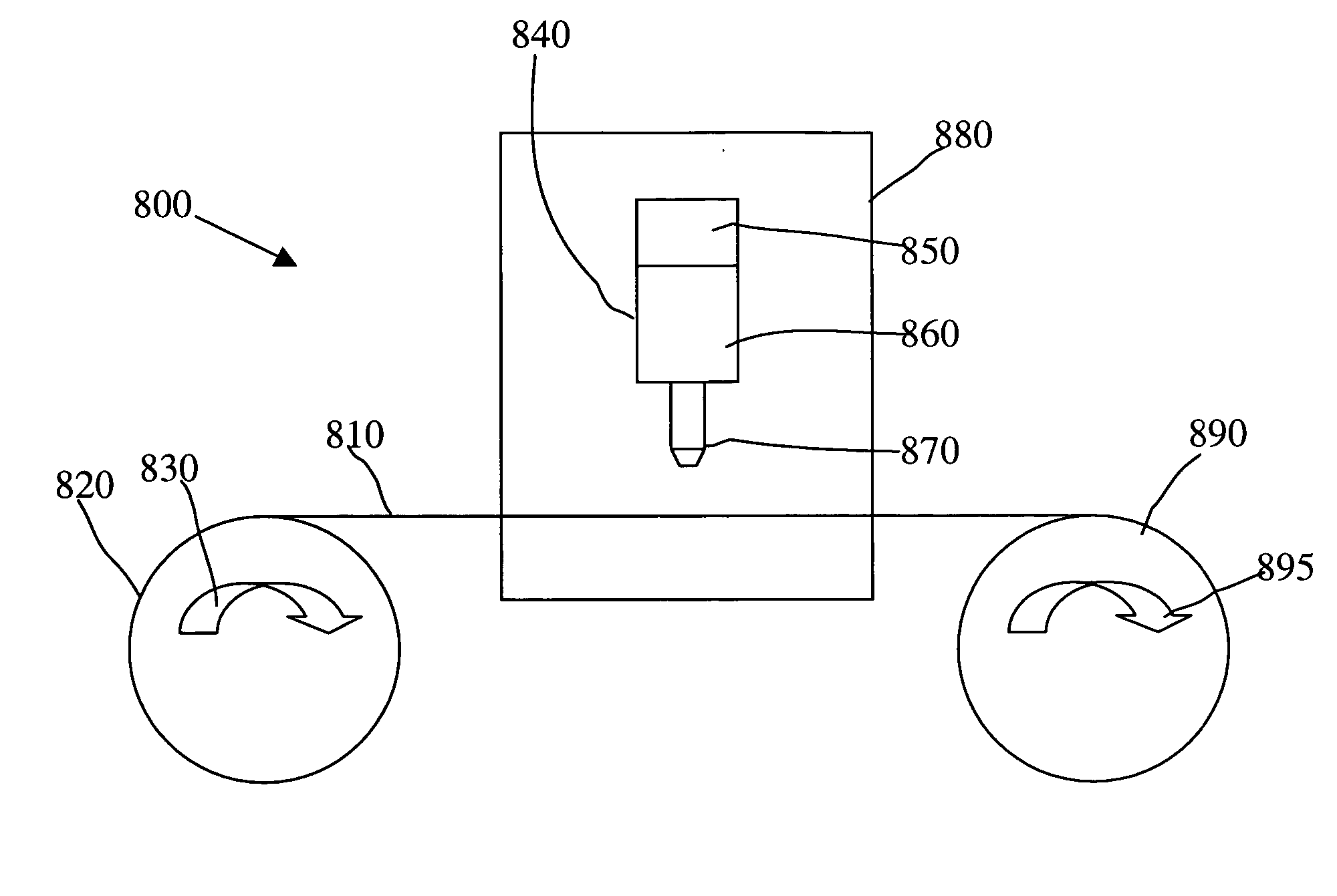

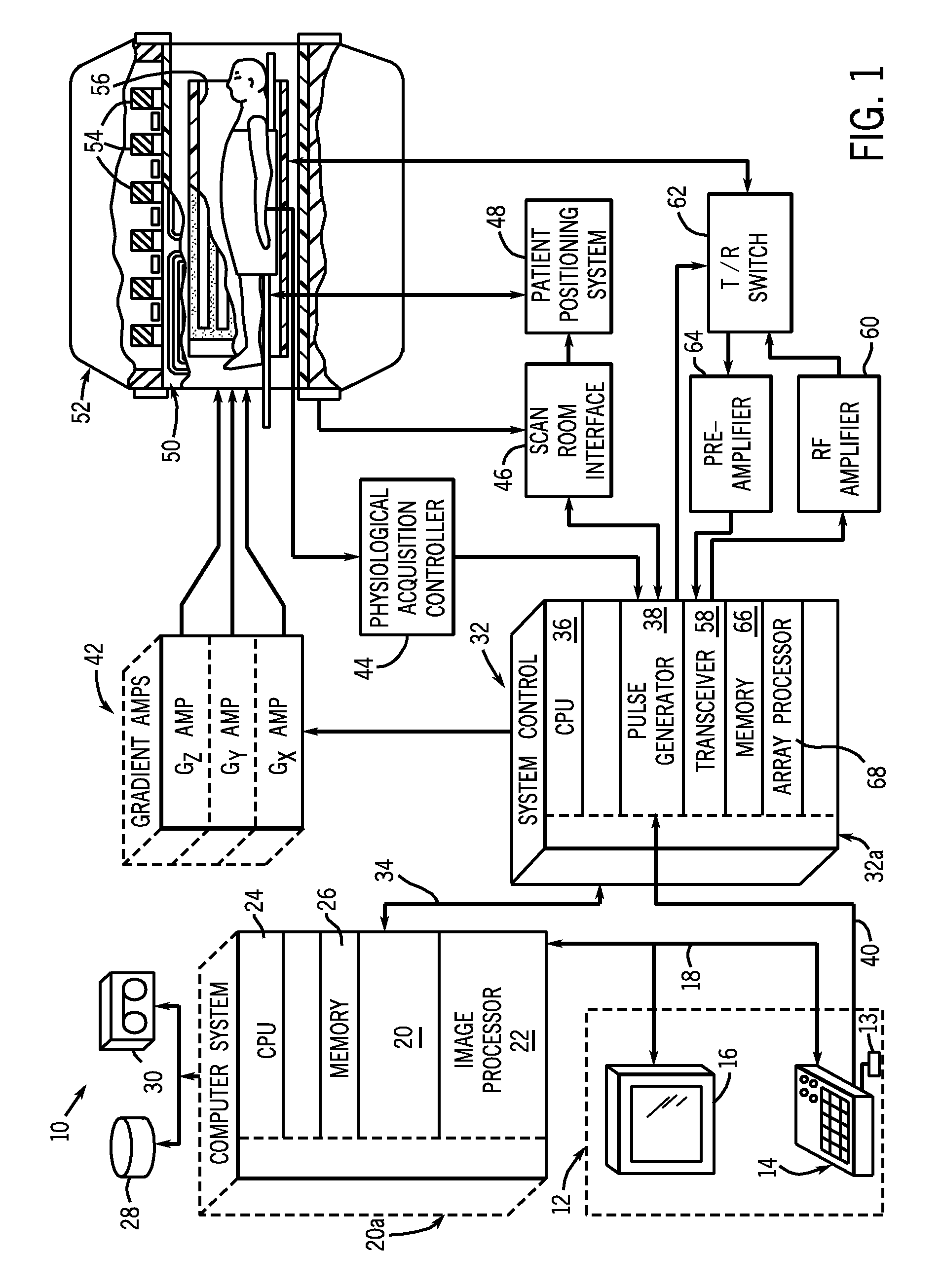

High-Q self tuning locating transmitter

ActiveUS8013610B1Reduce AC-lossOptimize quality ( “ Q ” ) factorMagnetic property measurementsHaberdasherySelf-tuningElectrical conductor

A high-Q human-portable, battery-powered self-correcting tunable resonator in a transmitter apparatus for inducing alternating currents of high quality in buried conductors to facilitate their location. The transmitter apparatus employs an FET-driven capacitive tuning circuit and a coil design that achieves high precision, high-quality transmission signals, and which is equipped with a high-voltage booster for facilitating fault-localization applications.

Owner:SEEKTECH

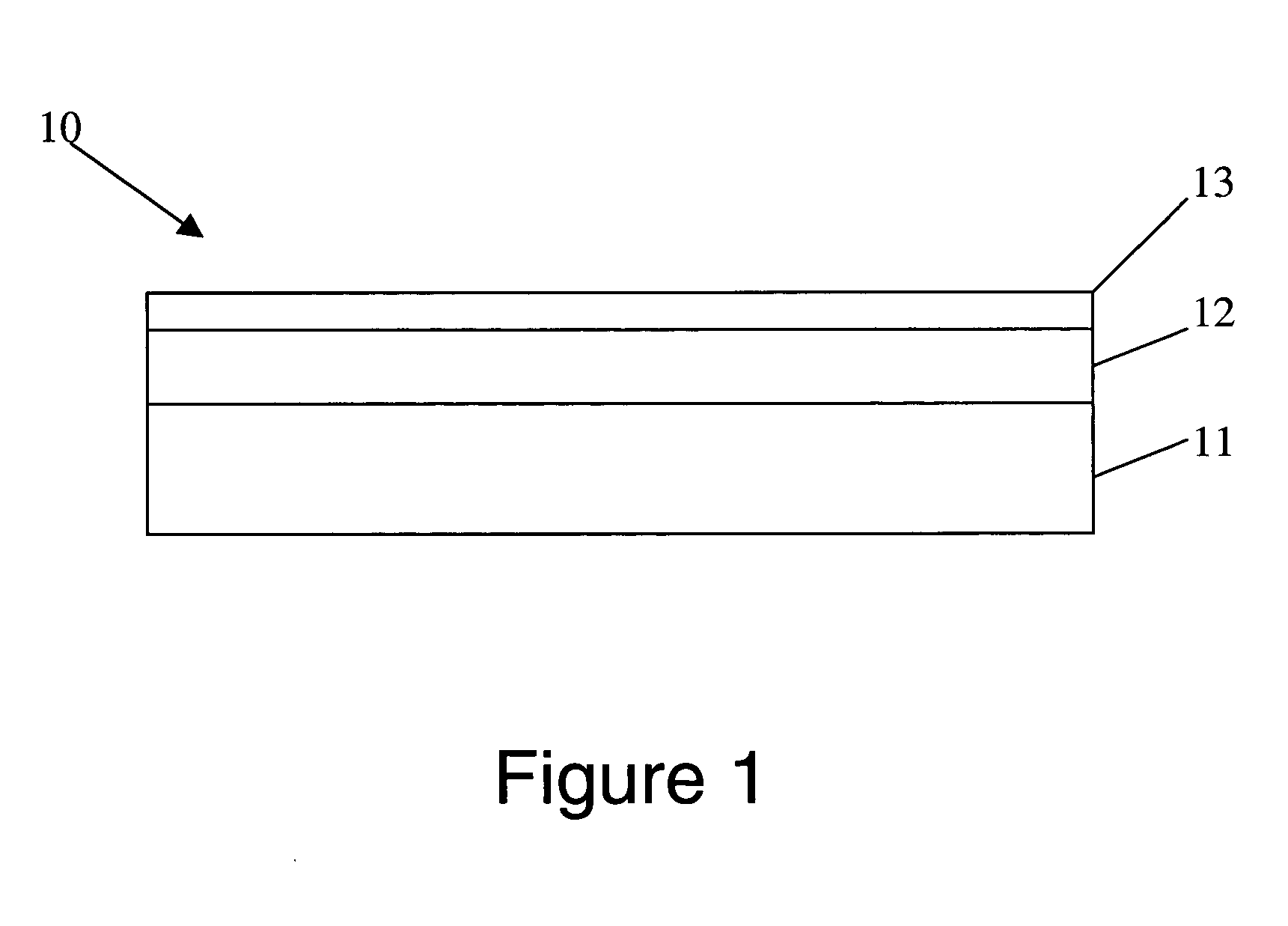

Dropwise deposition of a patterned oxide superconductor

InactiveUS20060040829A1Reduce AC-lossReduced ac lossesSuperconductors/hyperconductorsVacuum evaporation coatingElectrical conductorReaction zone

An oxide superconductor article having an oxide superconductor layer of a predetermined pattern is prepared by continuously advancing a wire having a textured surface into a deposition zone, dispensing droplets of a precursor solution to an oxide superconductor from a reservoir and the depositing droplets onto the textured surface of the wire that is introduced into the deposition zone, heating the wire or tape in the reaction zone under conditions to convert the precursor solution into an oxide superconductor; and collecting the wire after heating.

Owner:AMERICAN SUPERCONDUCTOR

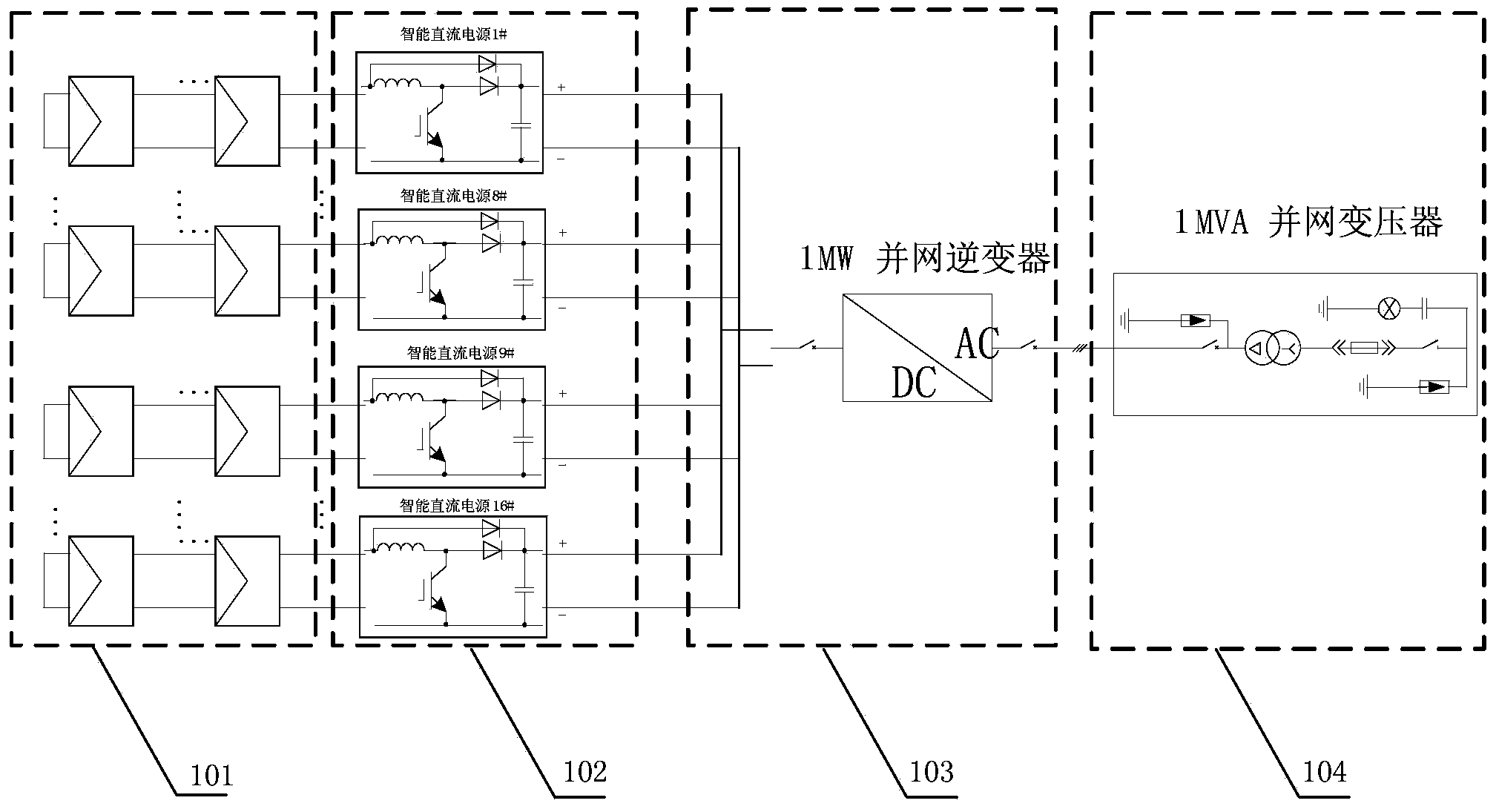

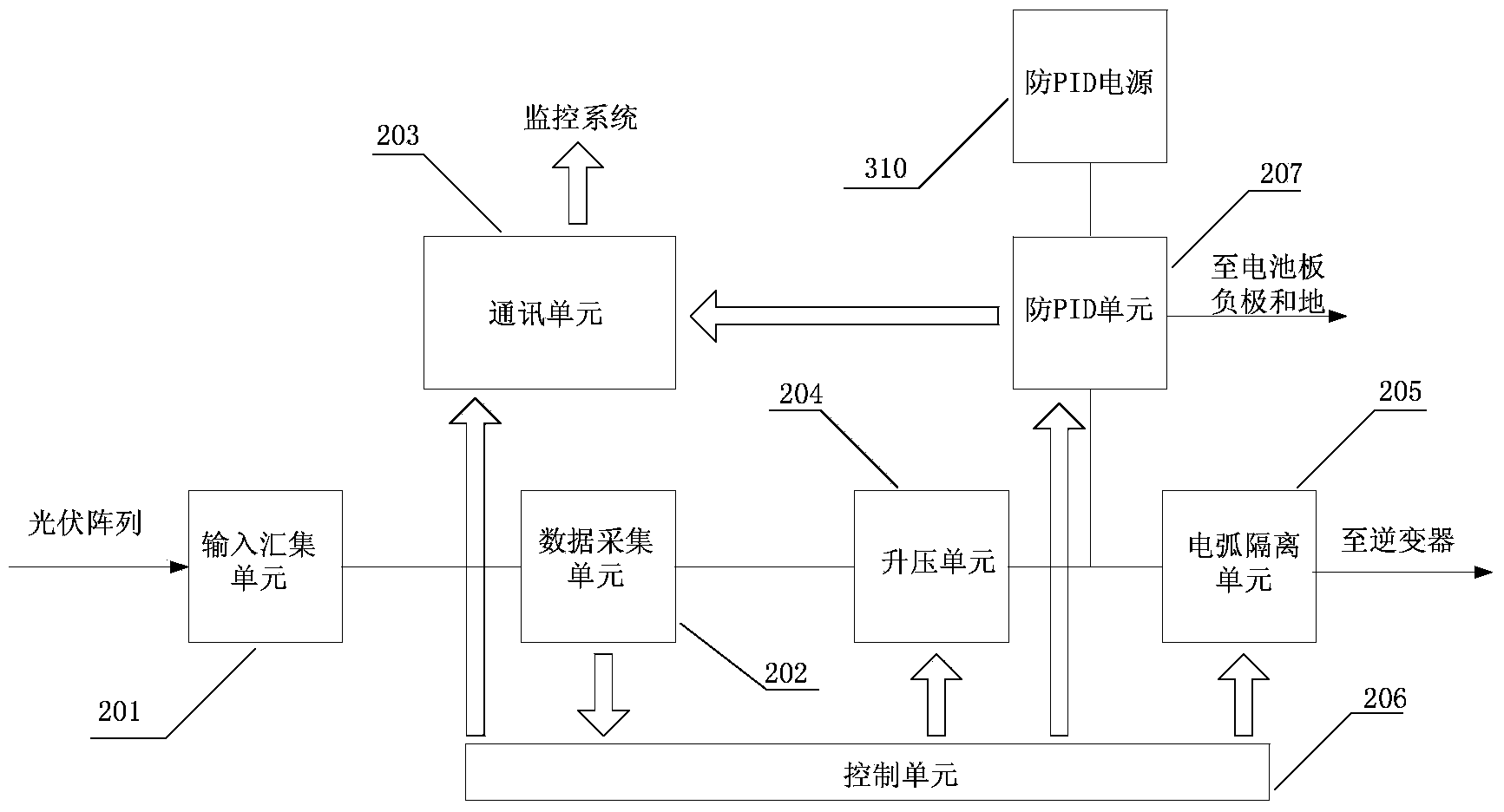

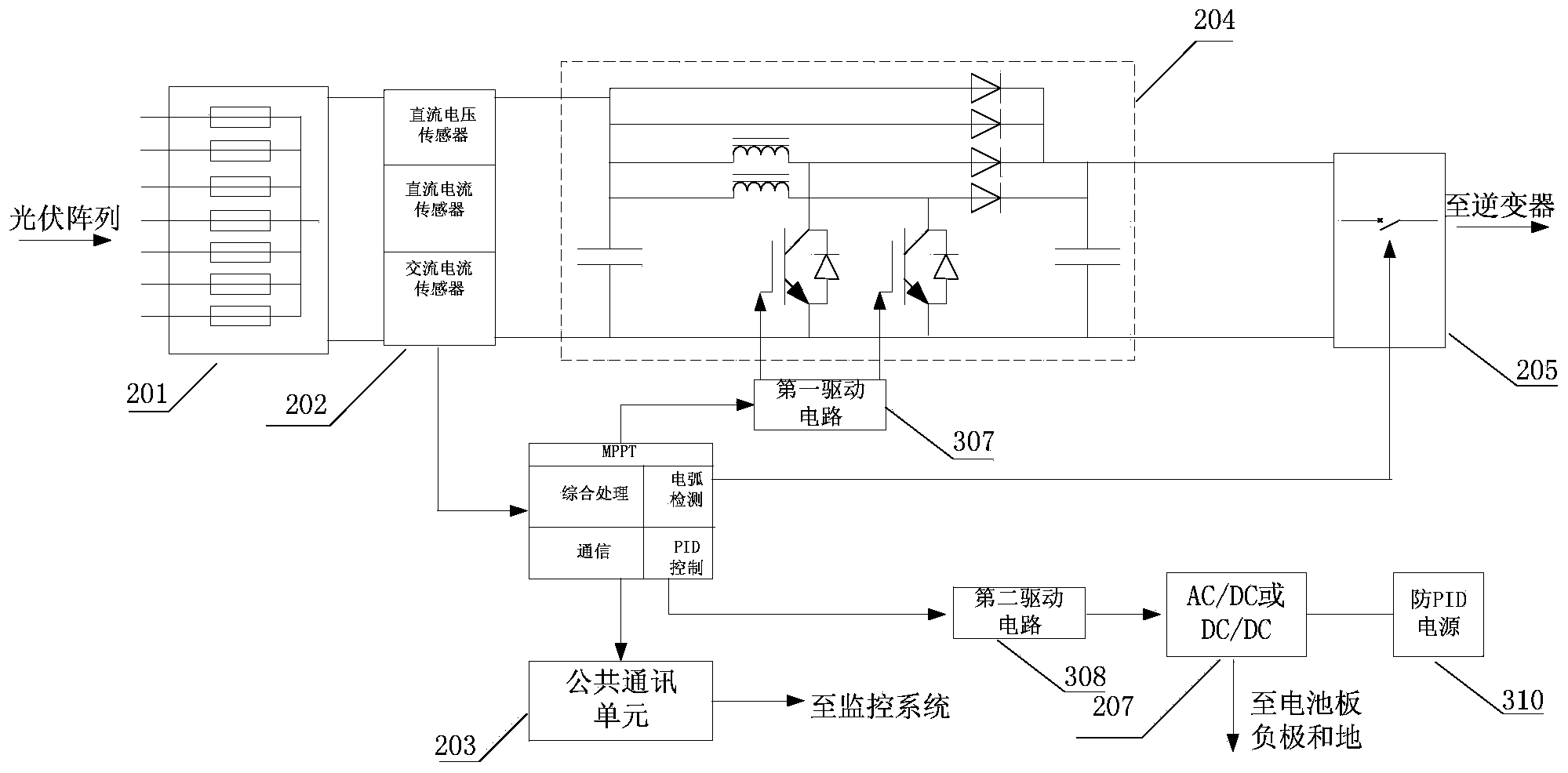

DC bus distributed MPPT photovoltaic power generation system

ActiveCN104377732AIncrease the DC voltage levelSolve reactive power balanceSingle network parallel feeding arrangementsPhotovoltaic energy generationGrid connected inverterElectrical battery

The invention discloses a DC bus distributed MPPT photovoltaic power generation system. The system comprises a photovoltaic cell array, a DC conflux boosting unit, a grid-connected inverter unit and an AC boosting unit, wherein the photovoltaic cell array, the DC conflux boosting unit, the grid-connected inverter unit and the AC boosting unit are connected in sequence; the photovoltaic cell array is composed of one or more cell arrays; the DC conflux boosting unit is composed of one or more DC power sources, and the intelligent DC power sources are used for boosting variable photovoltaic cell voltages sent by the photovoltaic cell array into stable high voltages; the grid-connected inverter unit comprises an inverter and is used for stabilizing output voltages of the DC conflux boosting unit and being responsible for start and stop of the working logic of the whole system; the AC boosting unit comprises a transformer. The DC bus distributed MPPT photovoltaic power generation system has the advantages of being simple in structure, low in cost, capable of improving the overall efficiency and the like.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

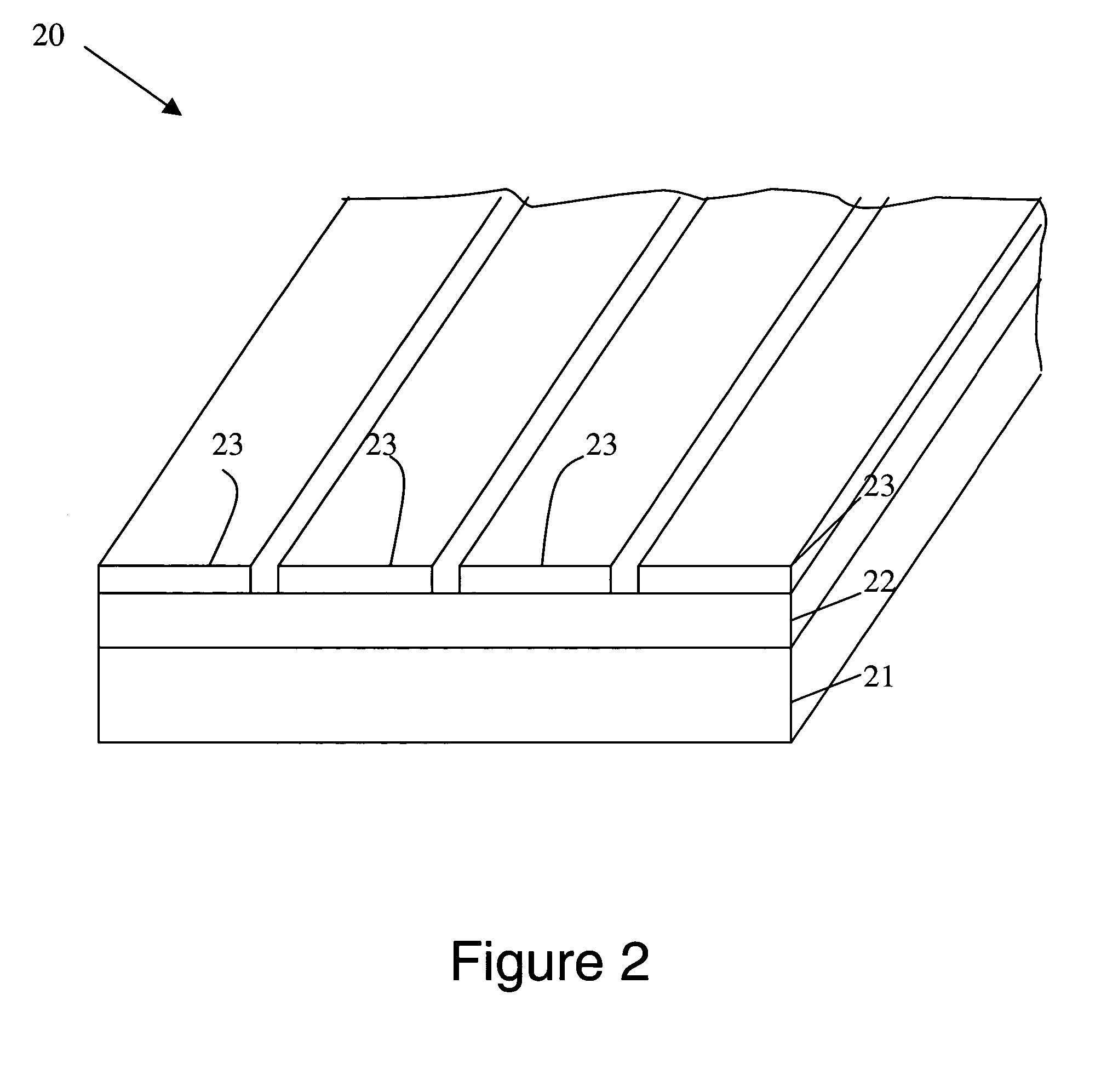

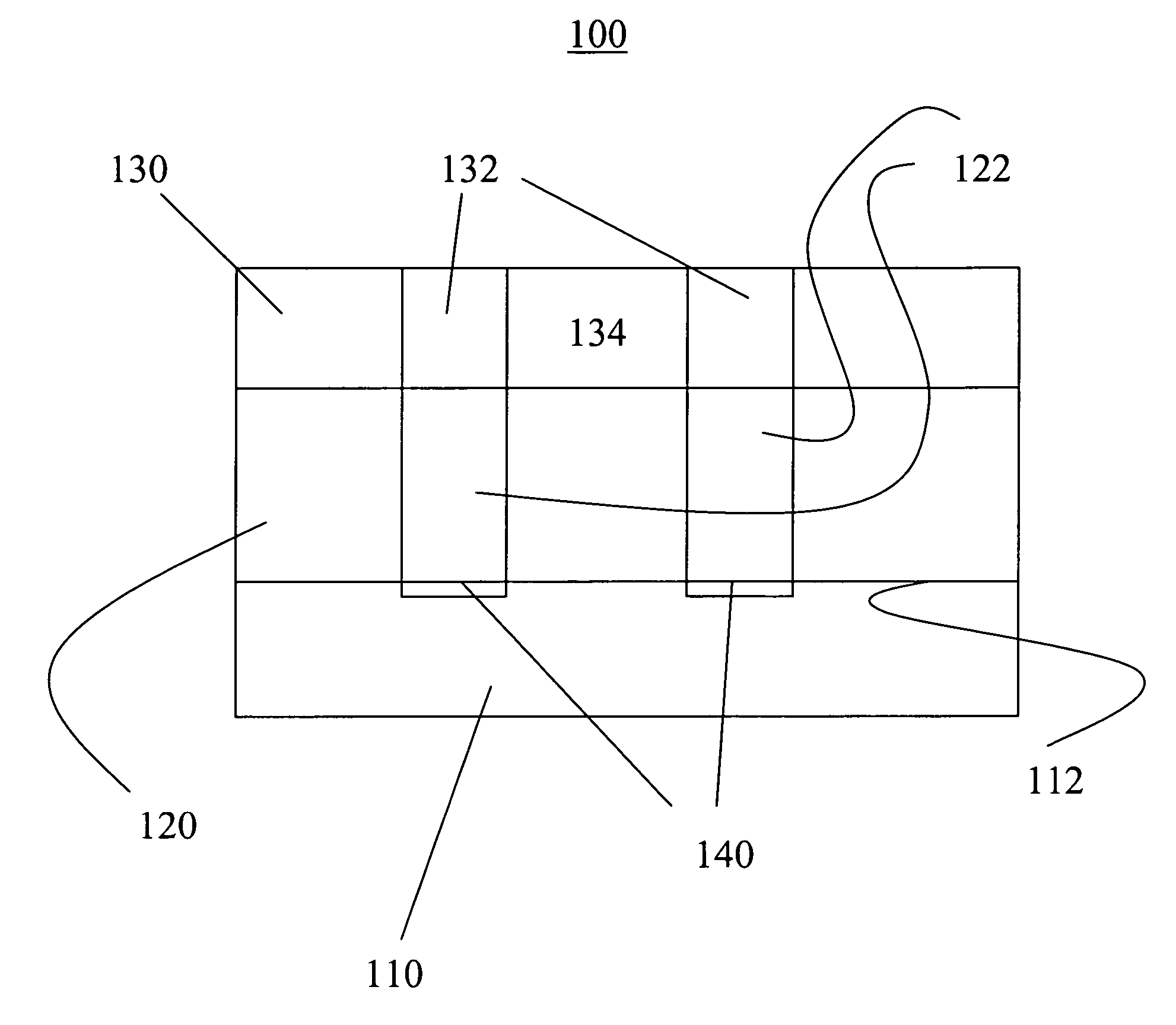

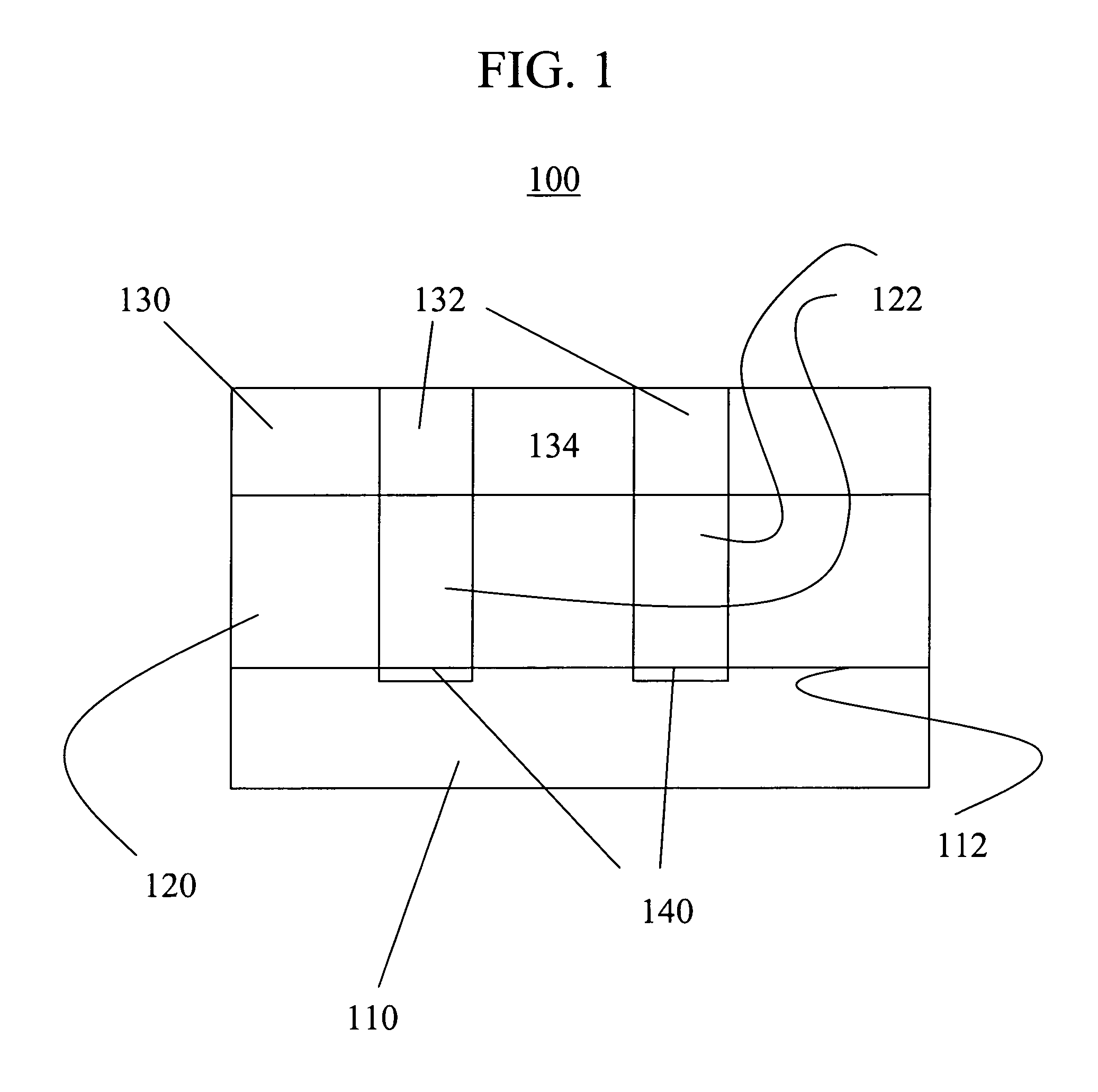

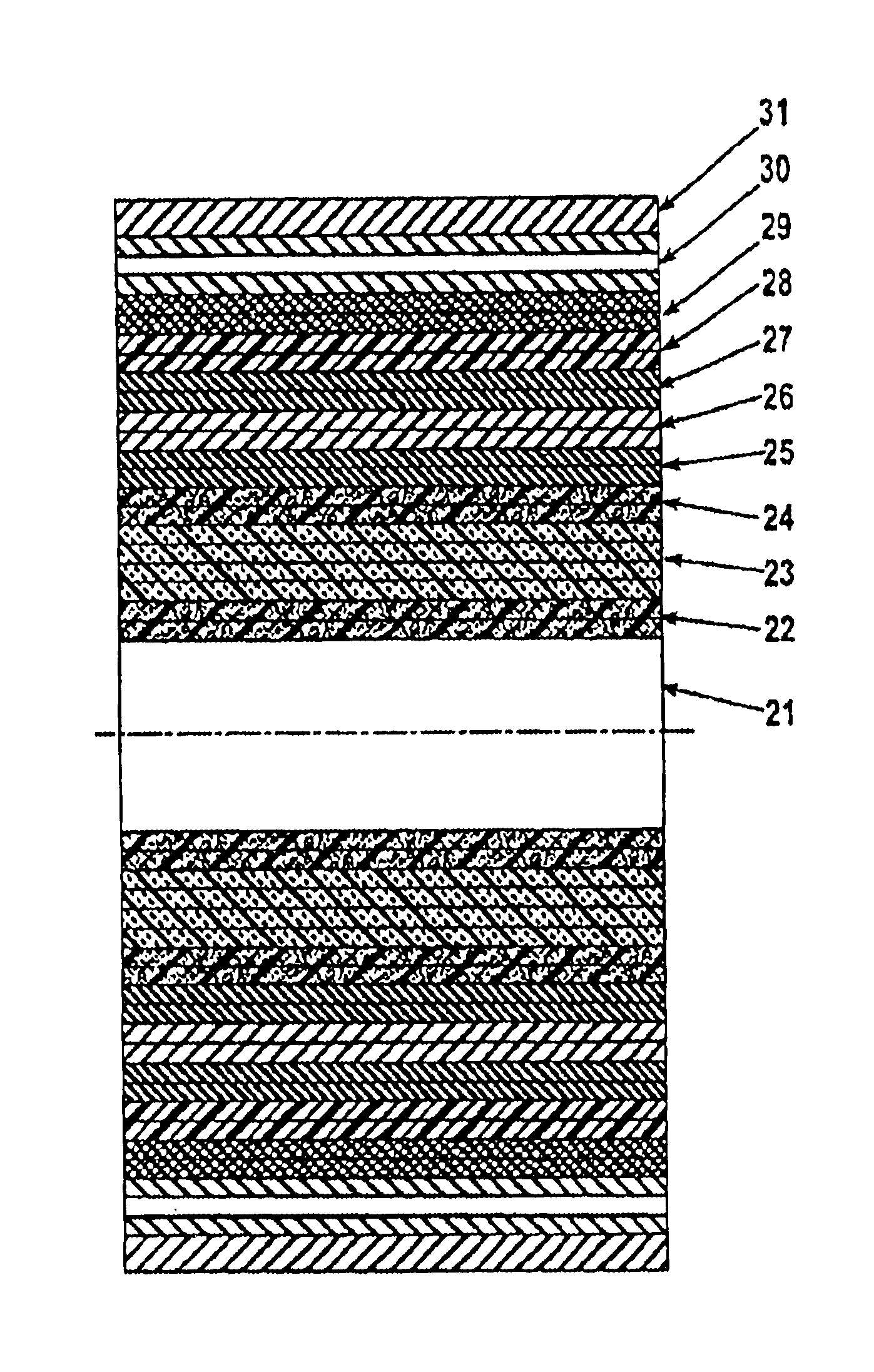

Segmented superconducting tape having reduced AC losses and method of making

ActiveUS20070191202A1Reduce AC-lossReducing AC losses in such tapesSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorHigh-temperature superconductivity

A superconducting tape having reduced AC losses. The tape has a high temperature superconductor layer that is segmented. Disruptive strips, formed in one of the tape substrate, a buffer layer, and the superconducting layer create parallel discontinuities in the superconducting layer that separate the current-carrying elements of the superconducting layer into strips or filament-like structures. Segmentation of the current-carrying elements has the effect of reducing AC current losses. Methods of making such a superconducting tape and reducing AC losses in such tapes are also disclosed.

Owner:TRIAD NAT SECURITY LLC

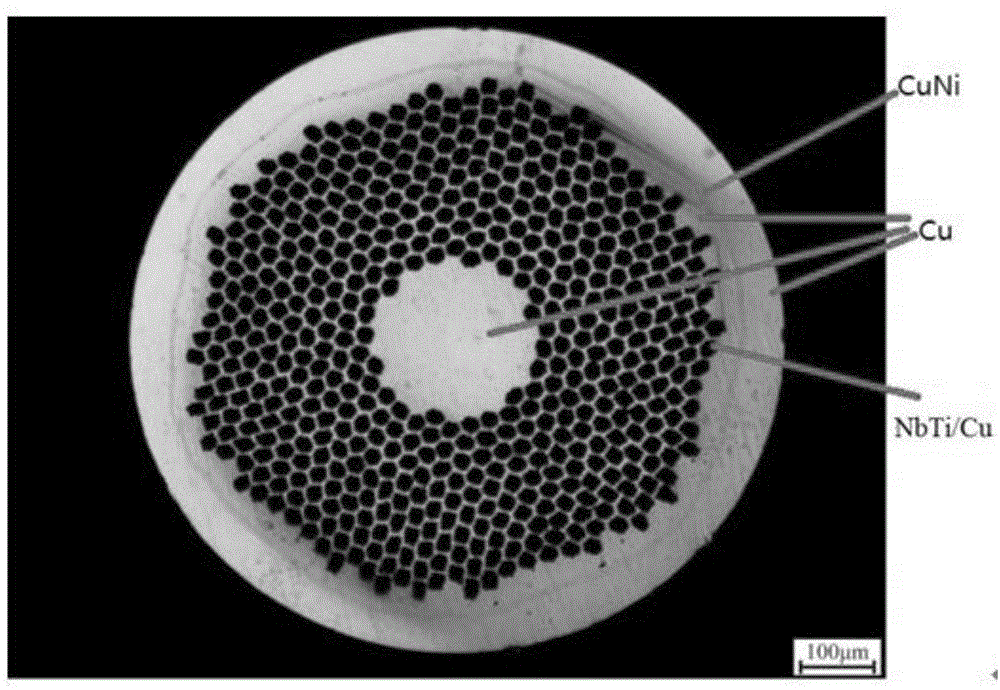

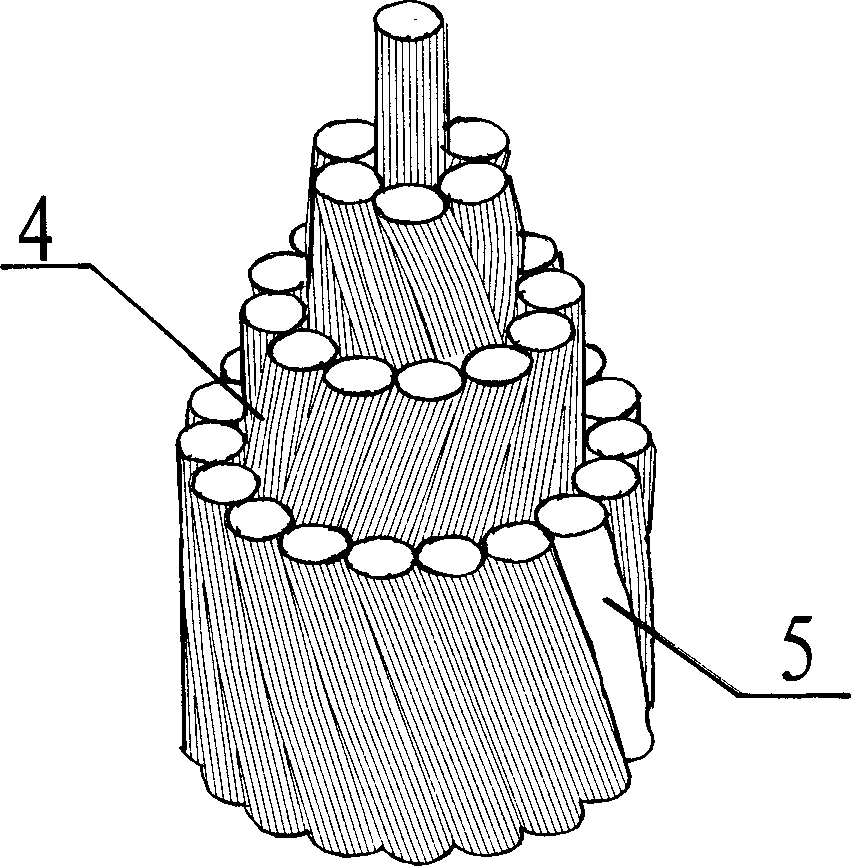

Method for manufacturing NbTi-CuNi-Cu superconductive composite wire rod

ActiveCN103956219AReduce manufacturing costFacilitate hot extrusion and cold drawing processingSuperconductors/hyperconductorsSuperconductor devicesExtension methodMaterials science

The invention discloses a method for manufacturing an NbTi-CuNi-Cu superconductive composite wire rod. The method comprises the following steps of putting an NbTi alloy rod into a Cu tube, and obtaining an NbTi-Cu single-core composite rod blank through a hot extrusion or sleeve extension method; extending the NbTi-Cu single-core composite rod blank to a hexagonal rod to obtain an NbTi-Cu single-core composite rod, putting the NbTi-Cu single-core composite rod into a copper tube to manufacture an NbTi-Cu multi-core composite rod; putting the NbTi-Cu single-core composite rod or the NbTi-Cu multi-core composite rod into a copper tube, sleeving a CuNi tube with the copper tube, sleeving another copper tube with the CuNi tube, and sealing two ends of the copper tube; reducing space in the copper tube through a hot isostatic pressure method and performing hot extrusion to obtain an NbTi-CuNi-Cu composite rod; performing multiple cold extension and aging treatment on the NbTi-CuNi-Cu composite rod to obtain the superconductive composite wire rod with the required dimension and shape. By means of the method, alternating current loss of the NbTi superconductive composite wire rod is reduced, production processes are simplified, and production cost is reduced.

Owner:西部超导材料科技股份有限公司

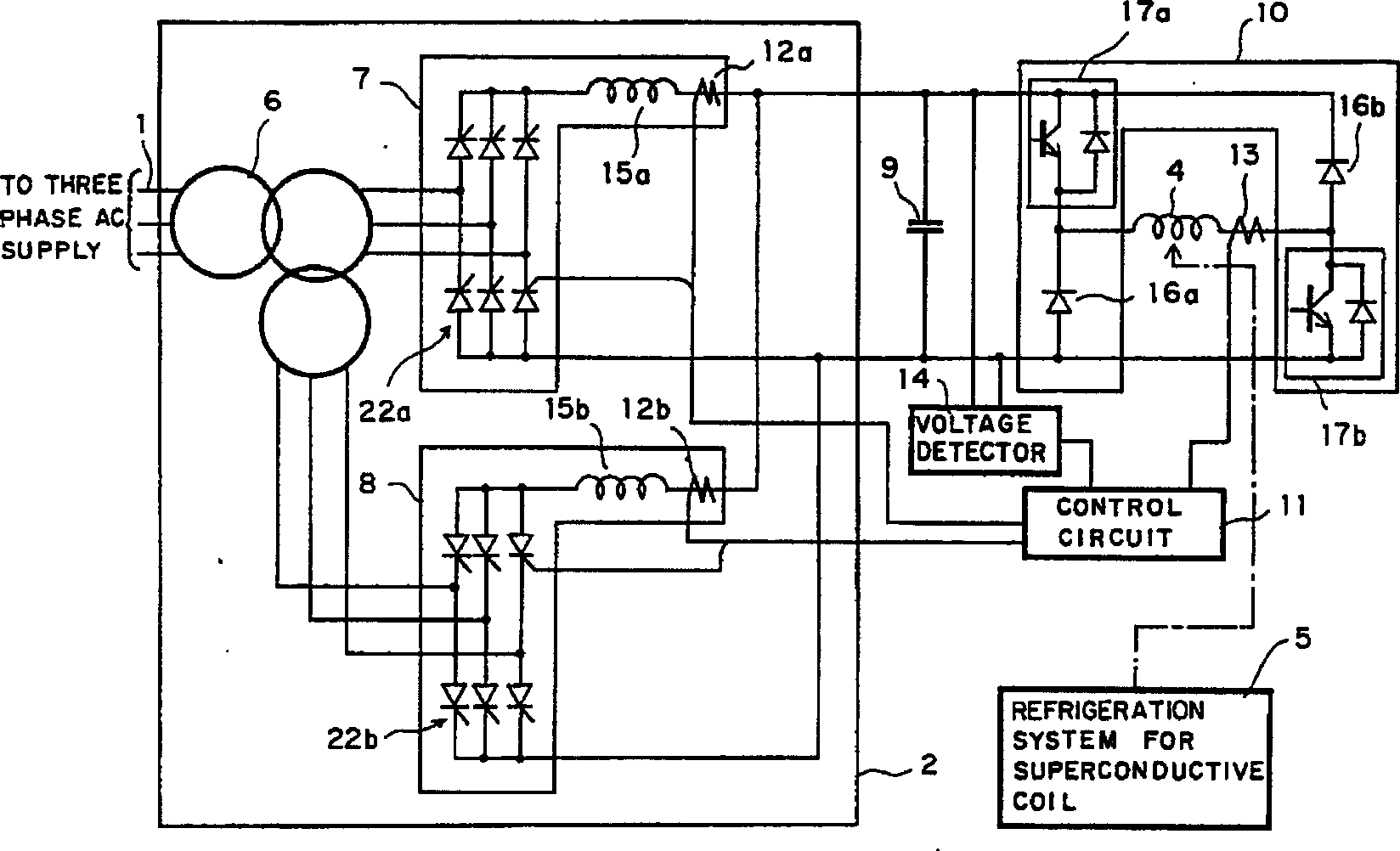

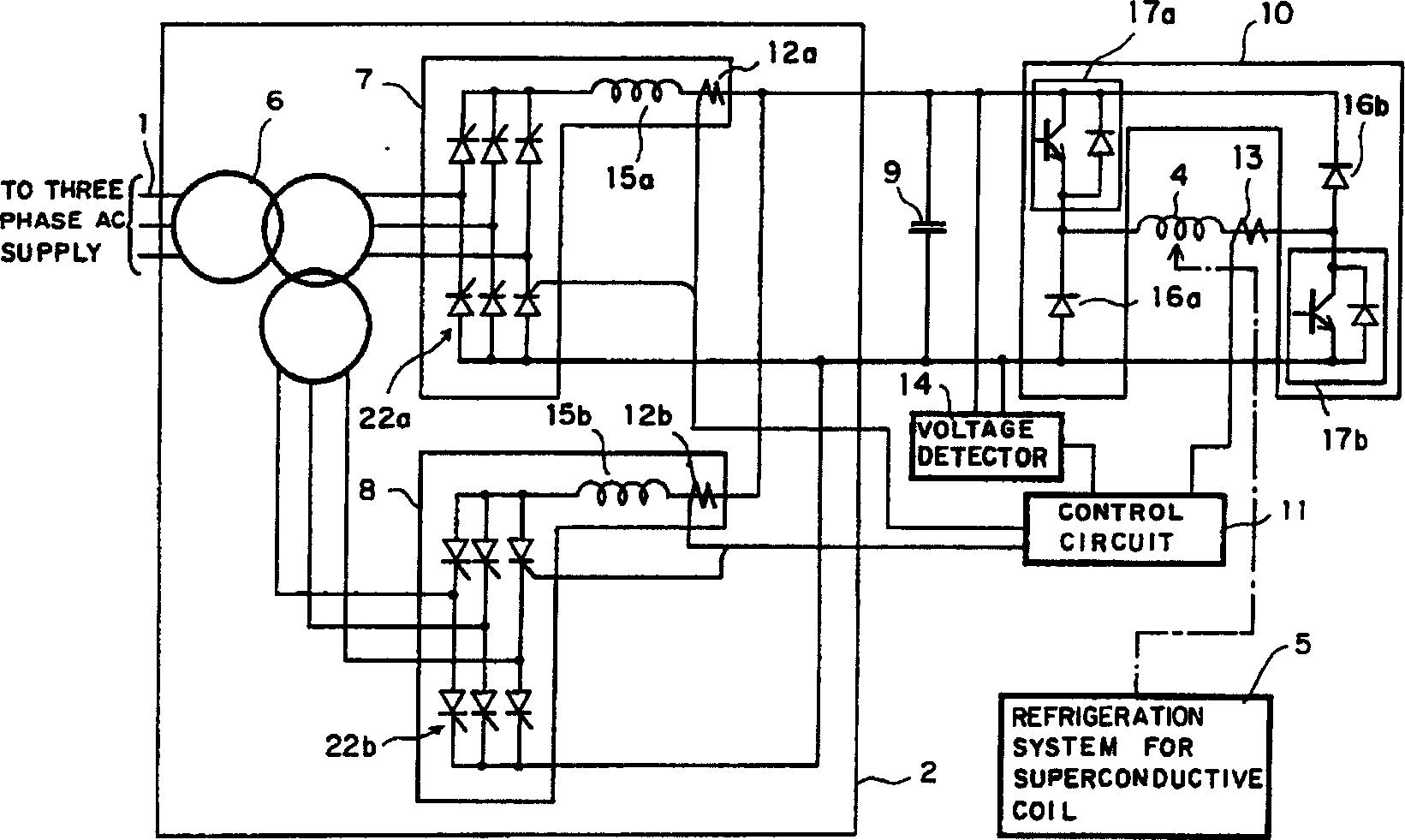

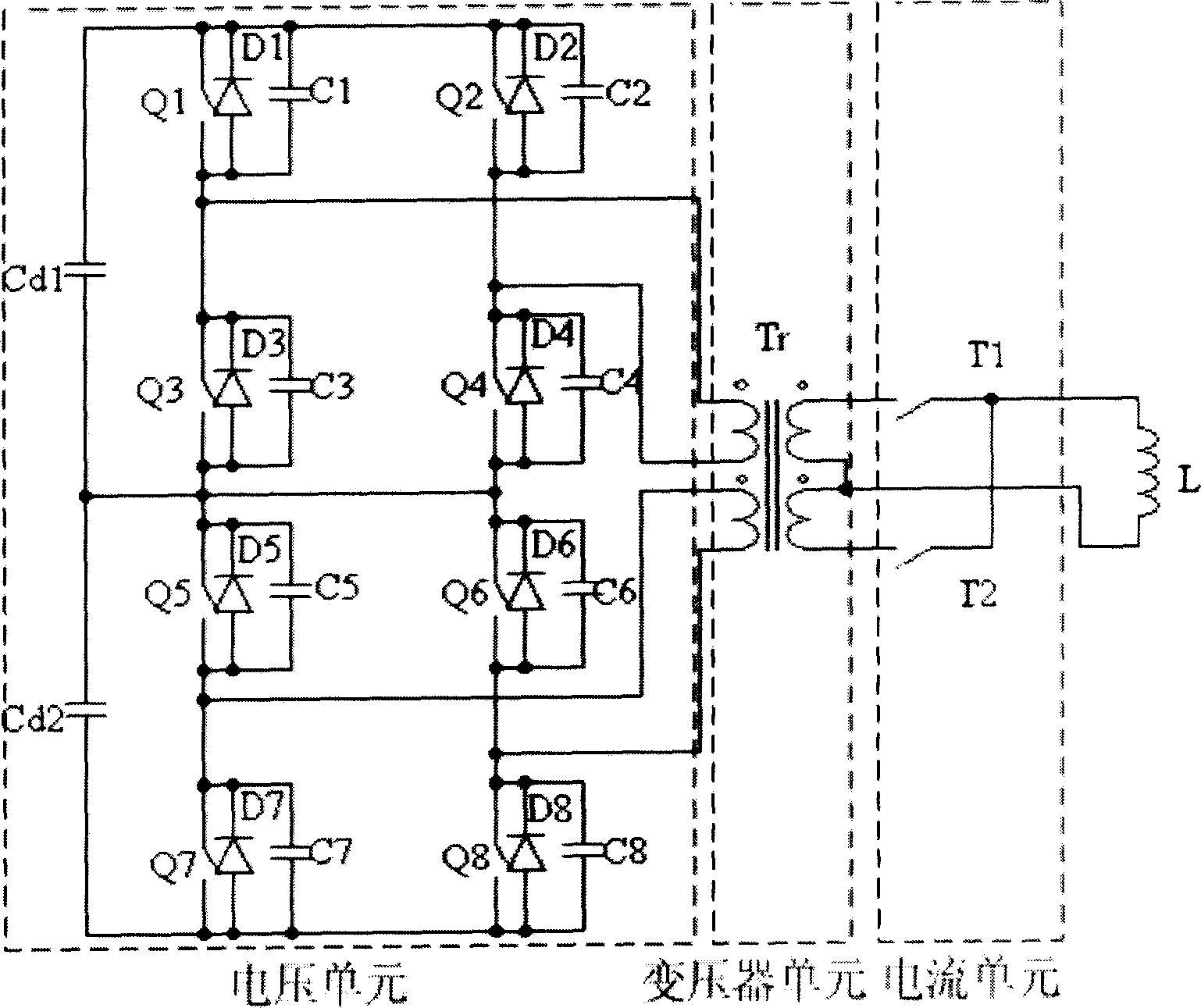

Bidirectional three-level soft switch DC/DC for superconducting energy storage and its voltage side pulse width controlling method

InactiveCN1845433AReduce AC lossSolve the problem of point voltage imbalanceEfficient power electronics conversionApparatus with intermediate ac conversionThree levelTransformer

The dual-way tri-level soft switch DC / DC for superconductance energy-storage comprises a voltage unit composed by two tri-level semi-bridges with midpoint clamping diode, a transformer unit, and a current unit with structure decided by the last unit, total-bridge / total-wave current source inverter for common transformer / transformer with middle tap. Wherein, paralleling capacitors on top and bottom switch tubes of the semi-bridge, but not on two tubes on middle; or paralleling capacitors on all tubes; connecting midpoints of semi-bridge and clamping diode to midpoint of connecting line of two voltage-dividing capacitors. This invention can overcome the unbalance problem of midpoint voltage.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

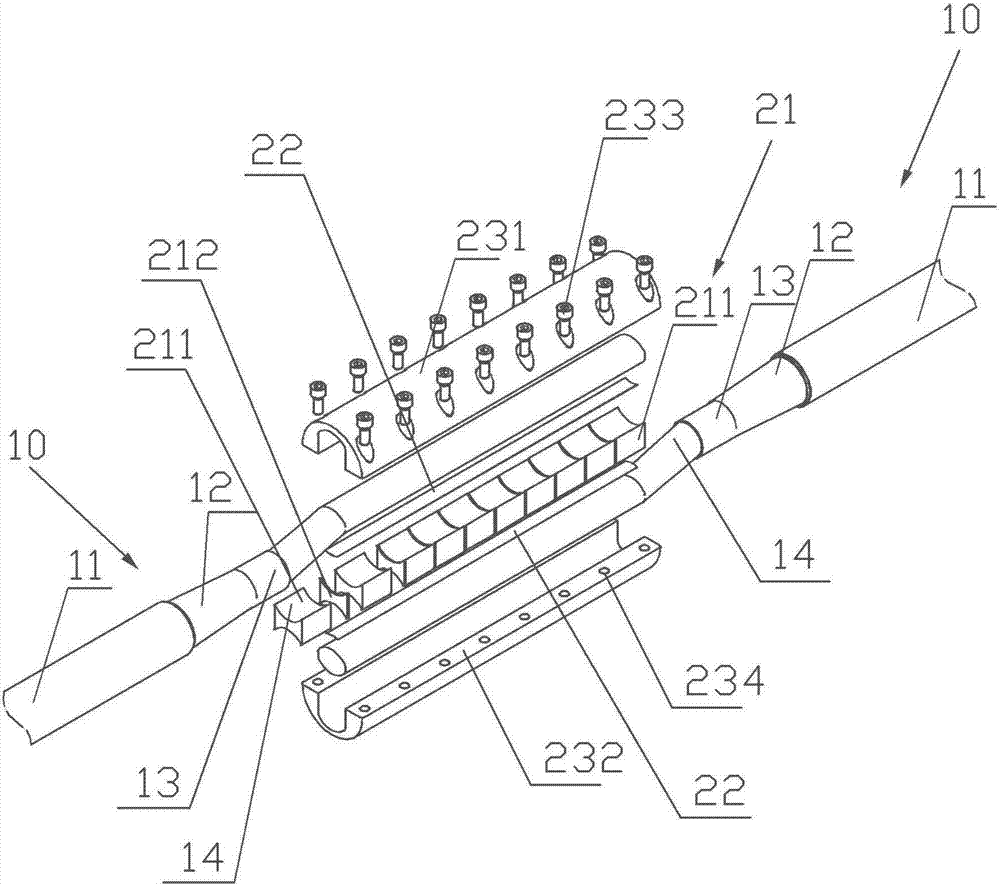

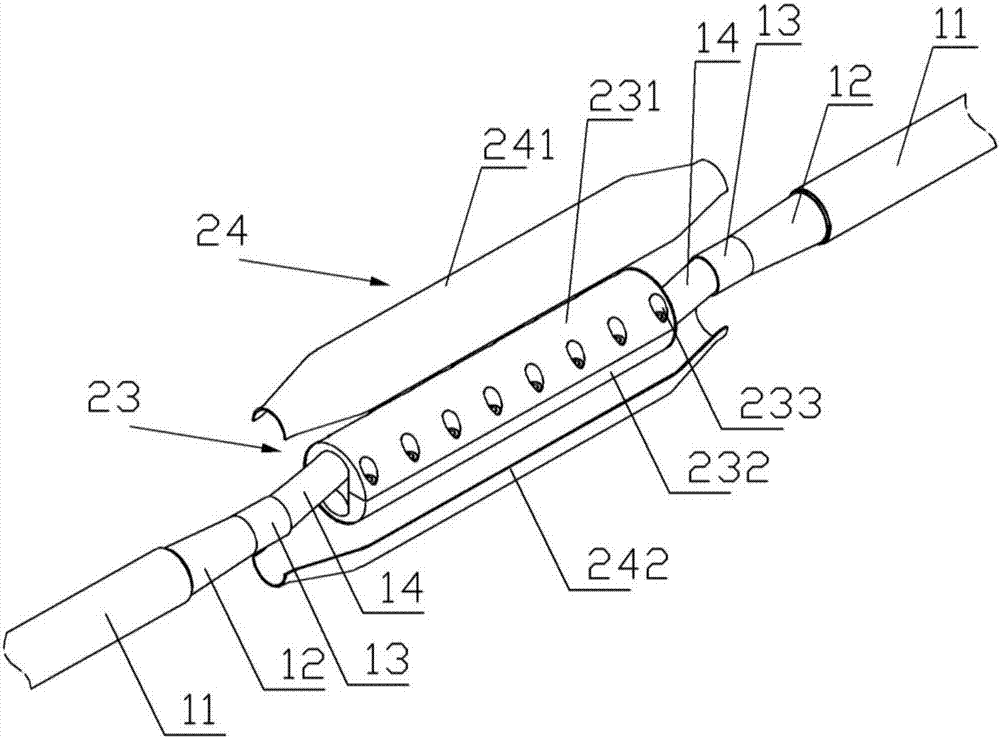

Connector assembly of two low-temperature superconduction cable terminals and fabrication method of connector assembly

ActiveCN107104293ACompact structureReduce AC lossLine/current collector detailsNuclear energy generationSolderingCopper

The invention discloses a connector assembly of two low-temperature superconduction cable terminals and a fabrication method of the connector assembly. A connector for welding two low-temperature superconduction cable terminals is provided with a copper cushion layer, two soldering layers and a fixture mechanism, wherein two sides of the copper cushion layer are arranged at the two low-temperature superconduction cable terminals in parallel, the two soldering layers are sandwiched between the two low-temperature superconduction cable terminals and the copper cushion layer, the fixture mechanism wraps outer surfaces of the low-temperature superconduction cable terminals, and the copper cushion layer, the soldering layers and the low-temperature superconduction cable terminals are tightly clamped in the fixture mechanism from inside to outside. The invention provides the connector assembly of the two low-temperature superconduction cable terminals, the connector assembly is compact in structure, the welding of the low-temperature superconduction cable terminals is achieved by employing the fixture mechanism to extrude a saddle-shaped copper cushion block, the conduction of a helium flow cooling loop is achieved by hermetical welding of an inner-layer shell, and the high-voltage insulation fabrication of the low-temperature superconduction cable terminals is achieved by hermetical welding of an outer-layer shell.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

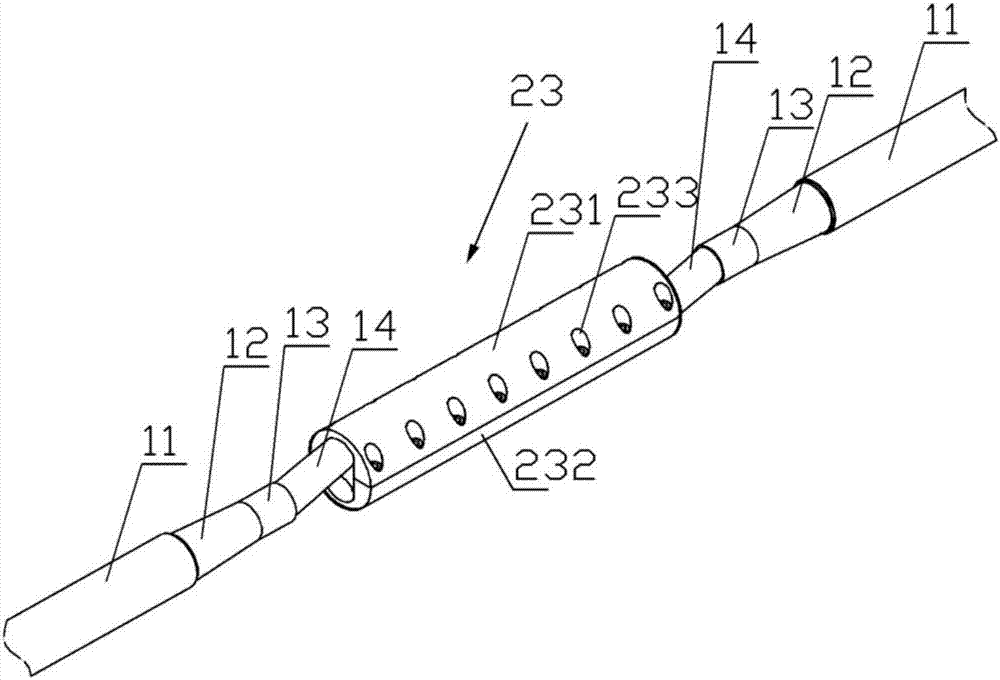

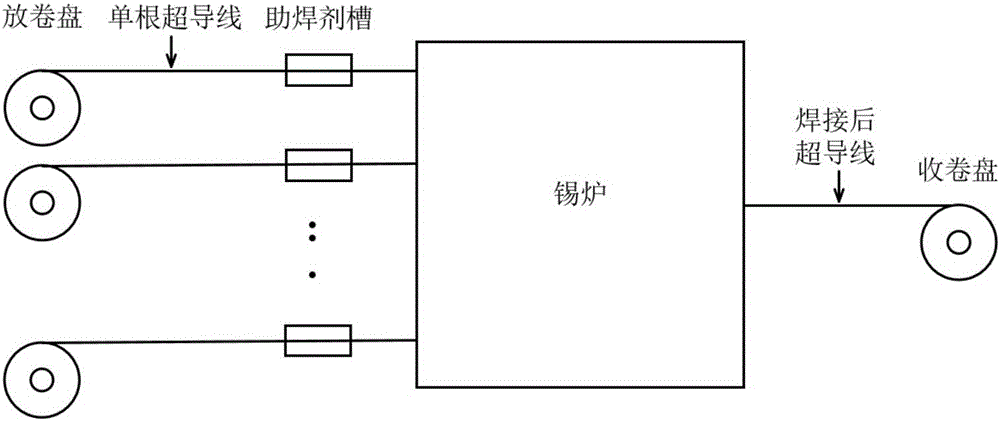

Preparation method of high-temperature superconducting line

ActiveCN105869782AClosely arrangedImprove physical strengthSuperconductors/hyperconductorsManufacturing wire harnessesUltrasound attenuationHigh-temperature superconductivity

The invention discloses a preparation method of a high-temperature superconducting line. A plurality of strips are stacked together and welded into the high-temperature superconducting line in a hot dip coating manner. The preparation method particularly comprises the following steps: fixing each strip on a pay-off device and positioning center lines of the strips; conveying each strip into a solder furnace by a method of loading unreeled strips in unreeling spools; and positioning all strips in the solder furnace through idler wheels, welding and merging the strips into a line and drawing a charge to obtain the high-temperature superconducting line. The prepared high-temperature superconducting line is round or square, is high in critical current and suitable for bending and twisting, has relatively high physical strength and is not easily damaged; an external magnetic field sensed by a superconductor can be reduced; the critical current attenuation and the AC loss can be reduced; and the prepared high-temperature superconducting line has obvious advantages when applied to large superconducting power equipment.

Owner:SHANGHAI JIAO TONG UNIV

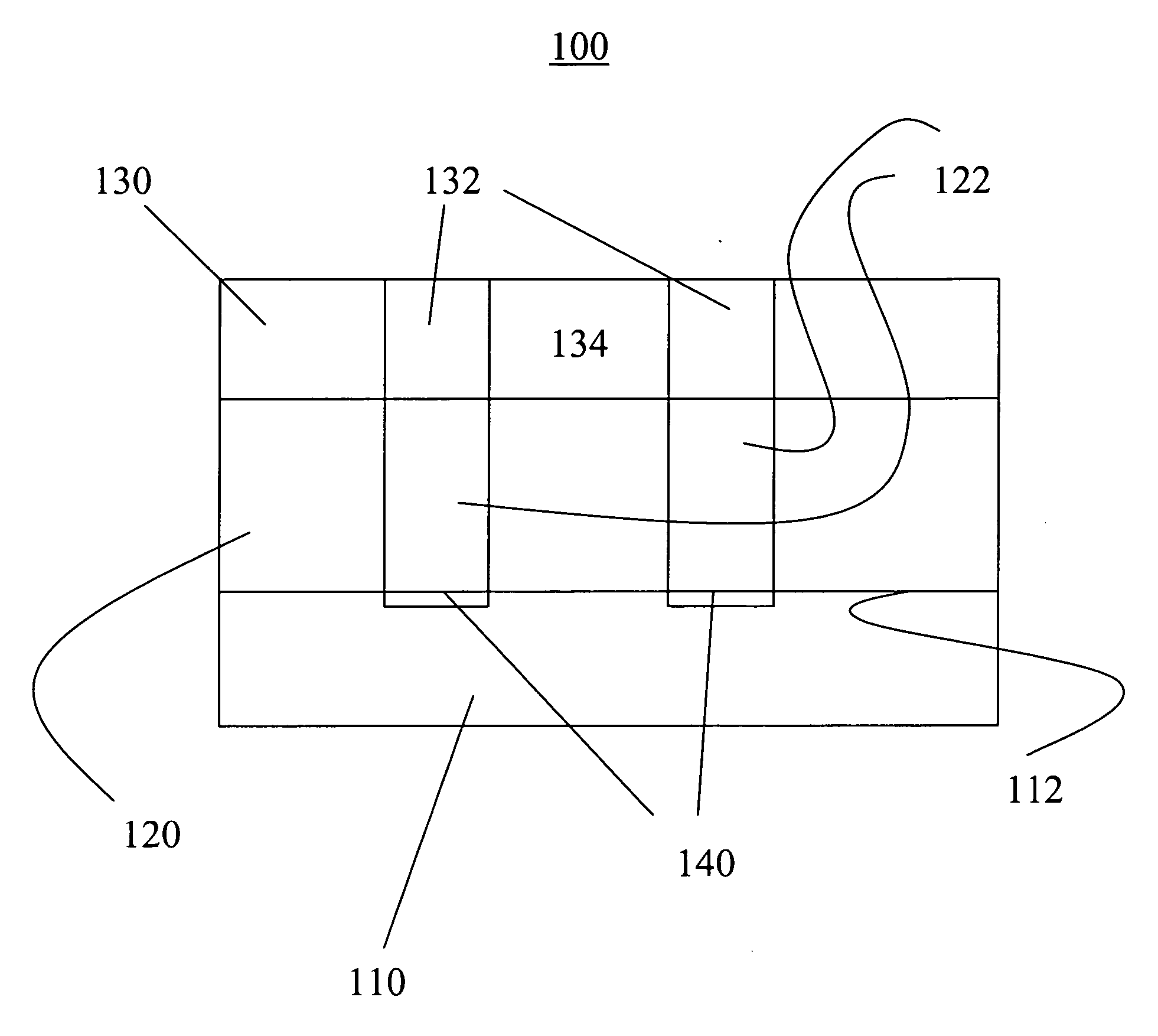

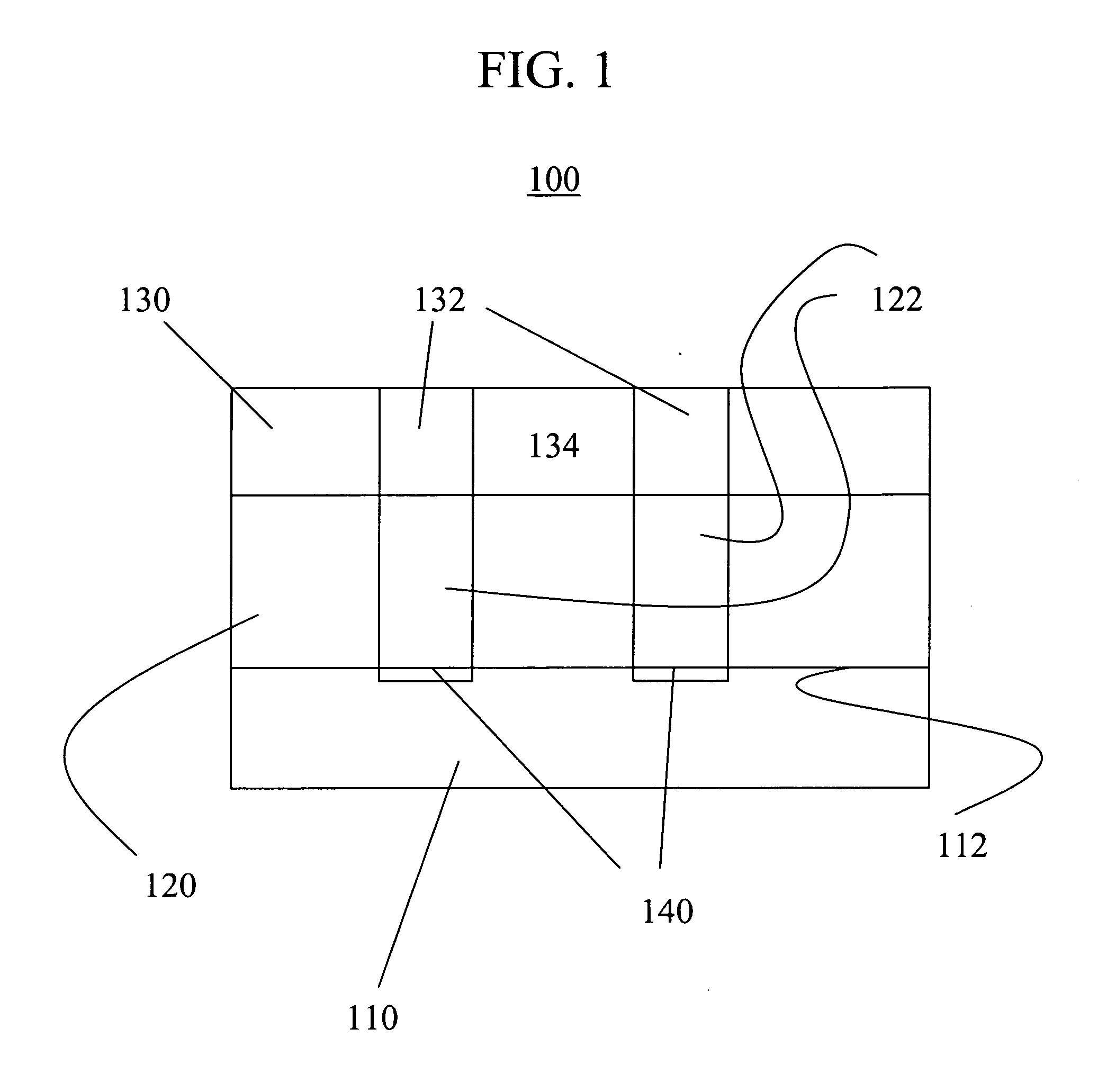

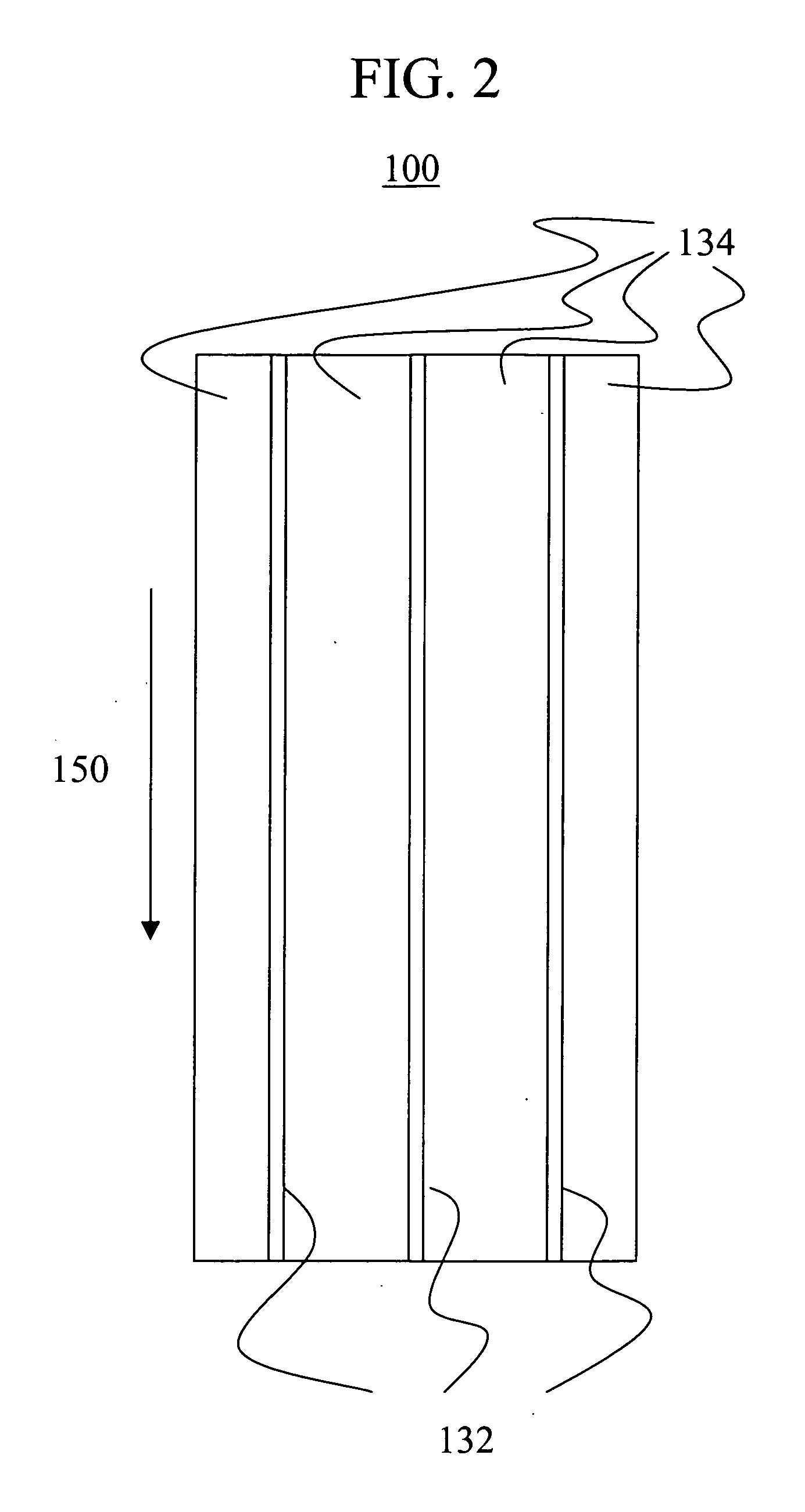

Segmented superconducting tape having reduced AC losses and method of making

ActiveUS7593758B2Reduce AC-lossReducing AC losses in such tapesSuperconductors/hyperconductorsSuperconductor detailsHigh temperature superconductingAc current

A superconducting tape having reduced AC losses. The tape has a high temperature superconductor layer that is segmented. Disruptive strips, formed in one of the tape substrate, a buffer layer, and the superconducting layer create parallel discontinuities in the superconducting layer that separate the current-carrying elements of the superconducting layer into strips or filament-like structures. Segmentation of the current-carrying elements has the effect of reducing AC current losses. Methods of making such a superconducting tape and reducing AC losses in such tapes are also disclosed.

Owner:TRIAD NAT SECURITY LLC

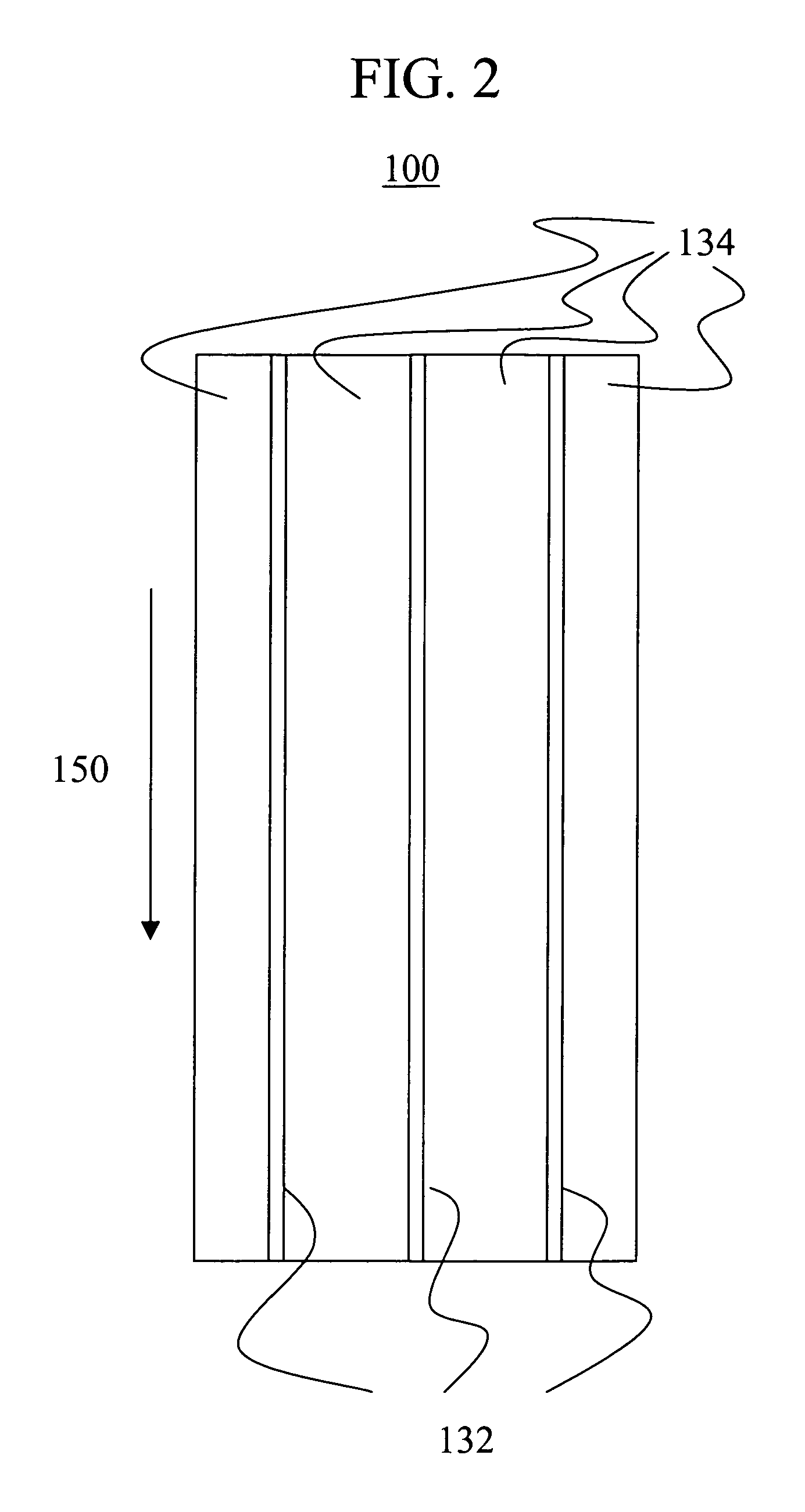

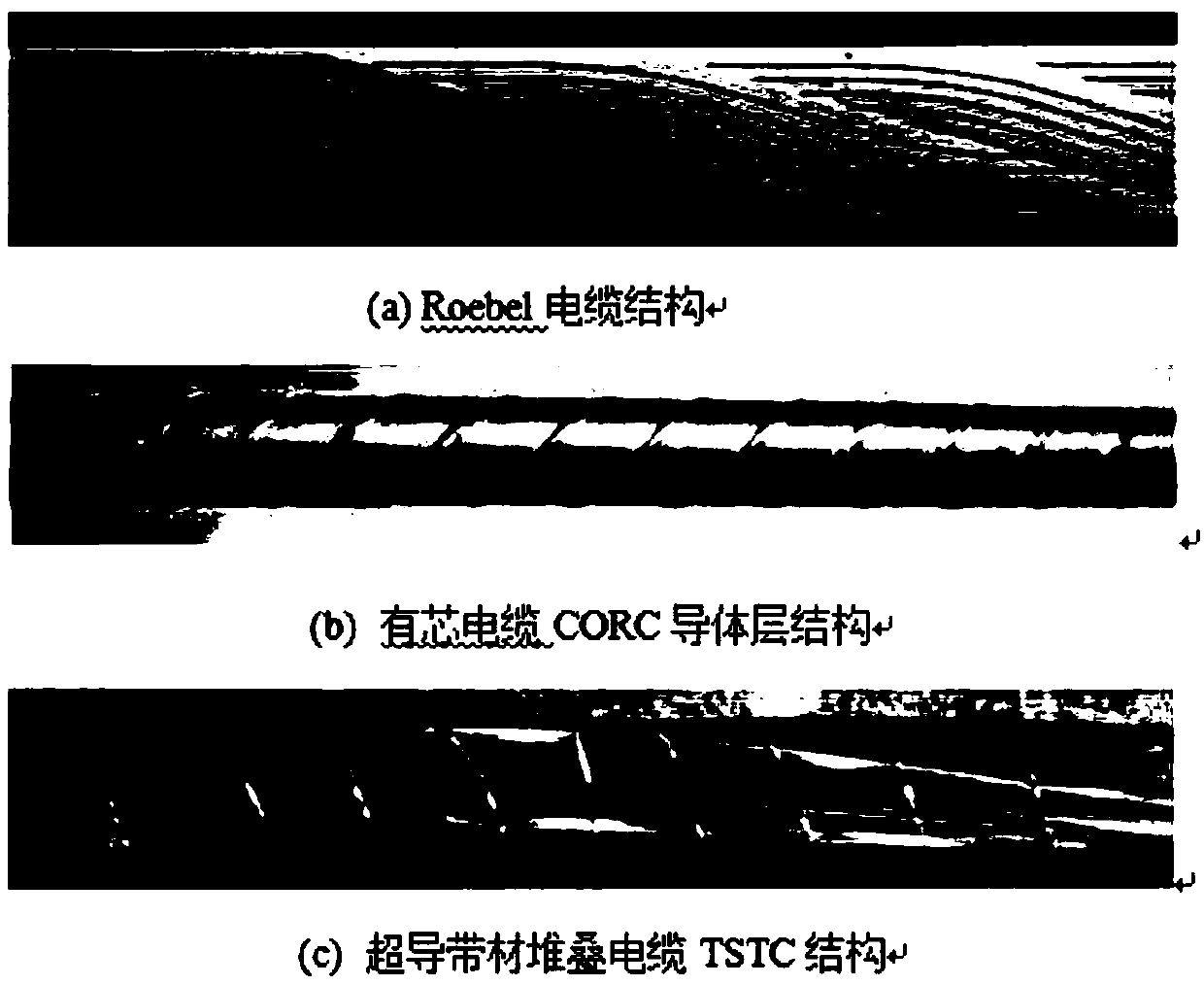

High-temperature superconducting twisted wire winding method

InactiveCN105489314AWith characteristicsHave made significant progressCable/conductor manufactureHigh-temperature superconductivitySuperconducting Coils

The invention discloses a high-temperature superconducting twisted wire winding method. The winding method is characterized by comprising a step of strip cutting, wherein a high-temperature superconducting strip is cut into wire-shaped superconducting thin belts in a length direction; and a step of strip weaving, wherein the superconducting thin belts are weaved to form a new superconducting wire. According to the high-temperature superconducting twisted wire winding method, the macroscopic geometric structure of the superconducting strip is changed; the critical current of a superconducting magnet is improved in the application of the superconducting magnet; the alternating current loss is lowered, and the performance of the superconducting magnet is dramatically improved; and under the same condition, the cost for a user is equivalently reduced.

Owner:SHANGHAI JIAO TONG UNIV

High-temperature superconducting cable with composite electromagnetic shielding layer

ActiveCN108039248AReduce anisotropyImprove current carrying capacitySuperconductors/hyperconductorsInsulated cablesHigh-temperature superconductivityEngineering

The invention discloses a high-temperature superconducting cable with a composite electromagnetic shielding layer and belongs to the superconducting technological field. The structure of the high-temperature superconducting cable is composed of an internal cavity, a metal frame, a superconducting layer, an insulating layer, a ferromagnetic layer, and a metal armoring layer which are distributed from inside to outside sequentially. The cable of the present invention is characterized in that the inner layer superconductor and the outer ferromagnetic layer are matched with each other to form a magnetic silencing structure, and therefore, the cable can greatly increase current carrying capacity compared to a single wire; and the cable can substantially decrease alternating current loss and reduce the anisotropy of strips. The cable has the advantages of low anisotropy, low alternating current loss and high current carrying capacity.

Owner:BEIJING EASTFORCE SUPERCONDUCTING TECH

High performance Fe/Cu wrapping structure magnesium diboride multiple core superconductive wire preparation method

InactiveCN101150004AGuaranteed thermal stabilityHigh critical current density valueSuperconductors/hyperconductorsSuperconductor devicesMagnesium diborideNon doped

This invention relates to a preparation method for MgB2 multi-core super-conductive wires with Fe / Cu jacket structure including the following steps: putting Mg and B powder in the mol ratio of 1 : 2 and Mg, B powder and doped material in the mol ratio of 1 : 2 : 0.5 into a Fe / Cu composite pipe to be pressed and sealed to get a single-core lead with Fe / Cu composite jacket after swaging, pass rolling and drawing, then a processed hardened layer of the single-core structure is eliminated and aligned to assemble the doped and non-doped single-core wires tightly in a seamless Cu pipe to be swaged and drawn to a MgB2 wire of multi-core Fe / Cu jacket structure to be processed for 0.5-5h under 650-950deg.C to become a MgB2 multi-core superconductive wire in the high performance Fe / Cu jacket.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

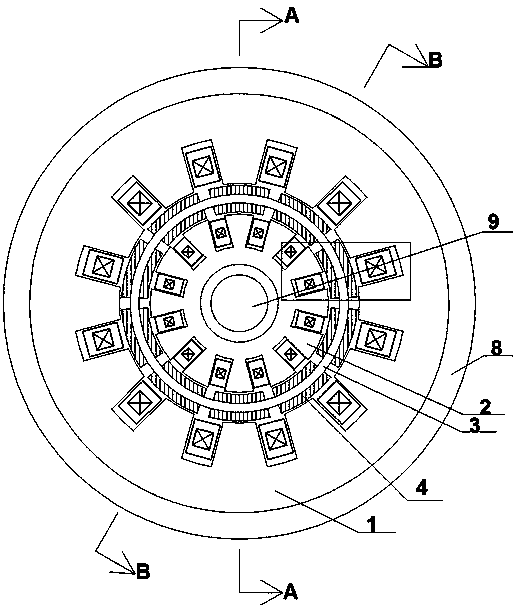

Dual-stator structure type high temperature superconducting permanent magnet wind driven generator

InactiveCN103780036ANo rotary seal issuesImprove reliabilityMagnetic circuit rotating partsCooling/ventillation arrangementLow speedHigh temperature superconducting

The invention discloses a dual-stator structure type high temperature superconducting permanent magnet wind driven generator. In the housing, the rotor is a hollow cup-shaped rotor, the bottom portion of the rotor is fixedly connected with a spindle, permanent magnets are attached and distributed uniformly and separately on inner and outer walls of the rotor in the circumferential direction; inner and outer stators are arranged inside and outside the rotor in the circumferential direction separately, an air gap exists between the inner and the outer stators and the permanent magnets on the inner and outer walls of the rotor; outer stator grooves are distributed uniformly and separately on the inner side of the outer stator in the circumferential direction, a first superconducting armature winding is wound on two adjacent outer stator grooves; inner stator grooves are distributed uniformly and separately on the outer side of the inner stator in the circumferential direction, a second superconducting armature winding is wound on two adjacent inner stator grooves, and the first and second superconducting armature windings are sealed through first and second cooling devices separately. The wind driven generator of the invention adopts the dual-stator structure, so the rotary sealing problem with cooling liquid does not exist, advantages of simple and reliable structure, less loss and high power density can be realized, and the wind driven generator is suitable for direct drive type low-speed wind turbine generator systems.

Owner:ZHEJIANG UNIV

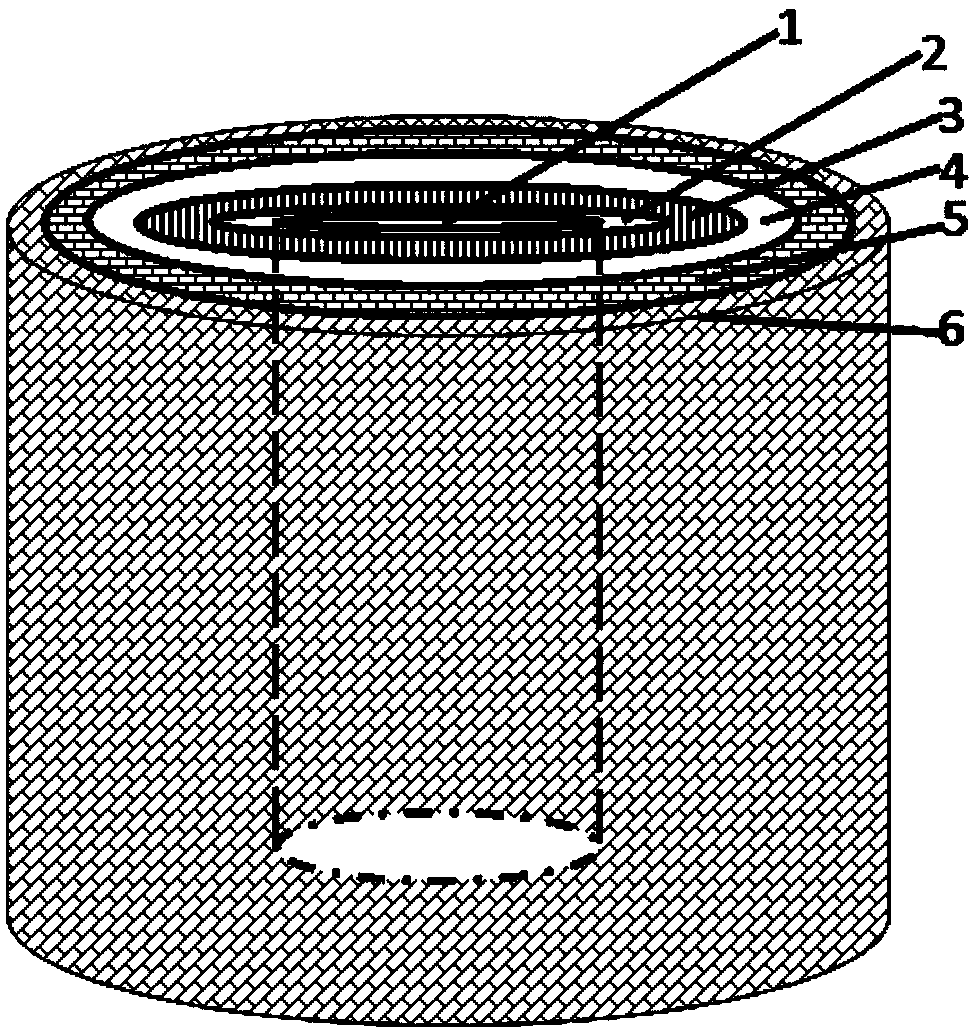

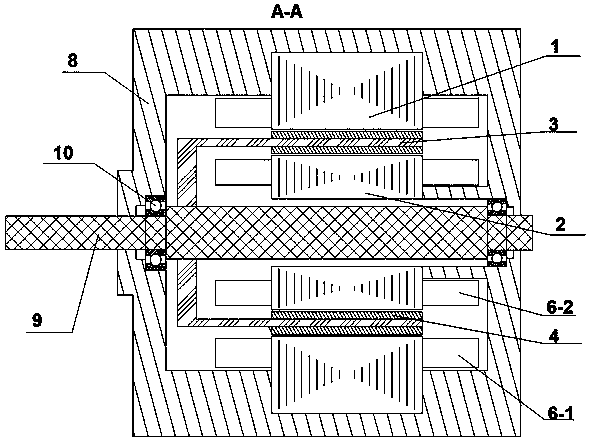

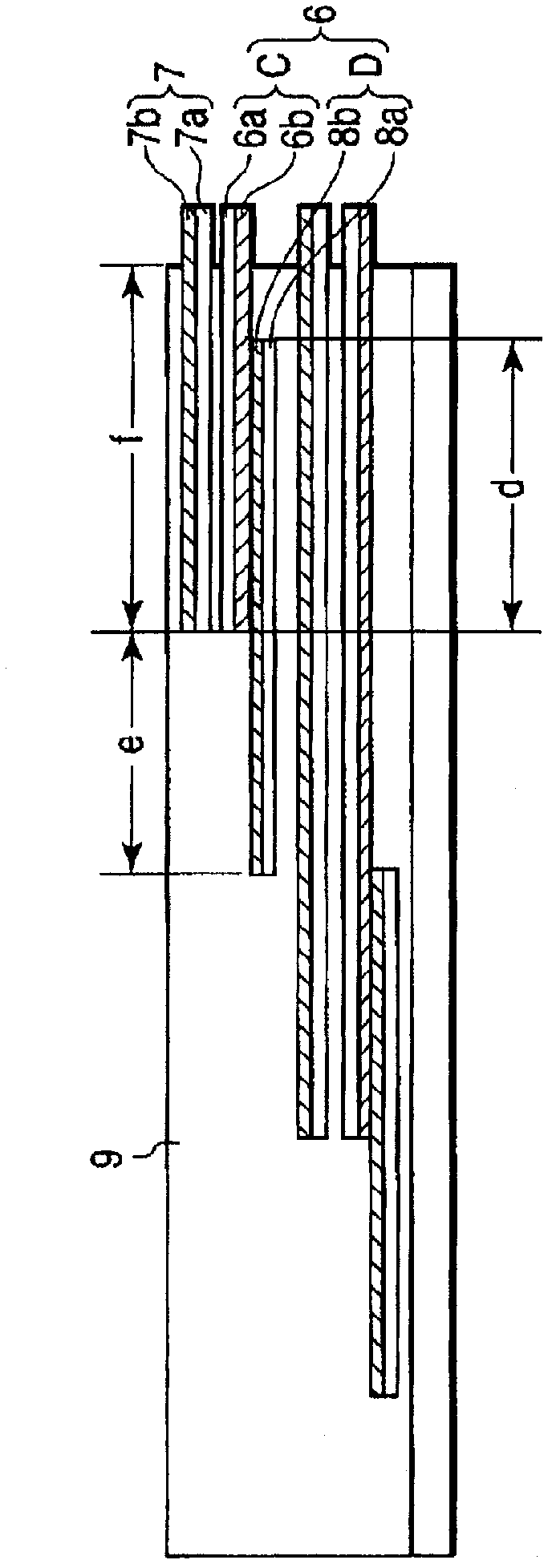

Small volume low loss superconductor CICC connector structure

InactiveCN1913231AReduce volumeReduce AC lossSuperconductor devicesClamped/spring connectionsEngineeringMechanical engineering

This invention discloses a small volume low-loss super-conduction CICC connector structure characterizing in including a layout shaft with a channel at the middle for cold flows, a sub-cable of the super-conduction line is fixed outside of the shaft, an inner shell is outside of the sub-cable, an outer shell is outside of the inner shell, both ends of the shaft form a taper, a taper cover covers the taper and the cover, the outer shell and the connector are connected in sealing.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

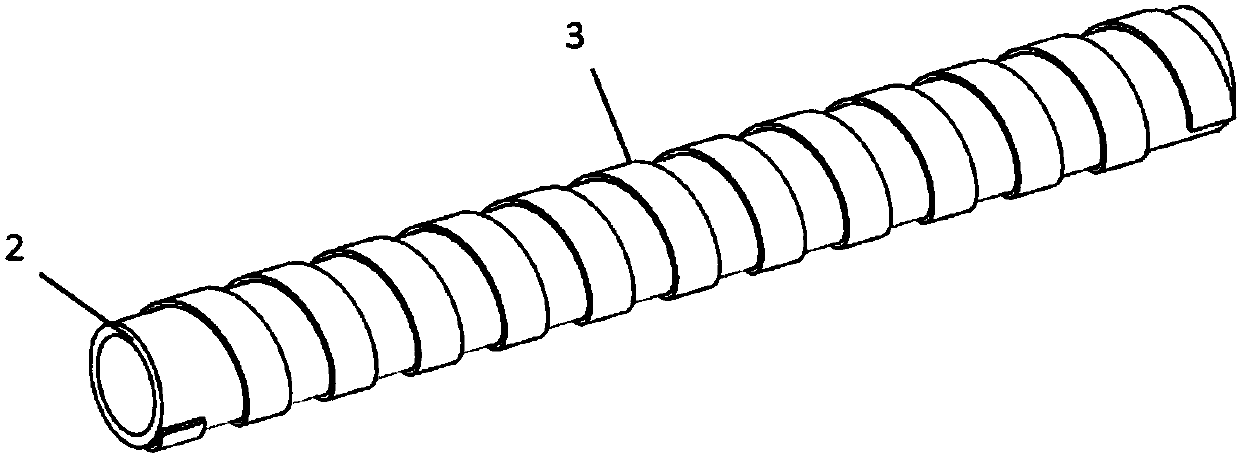

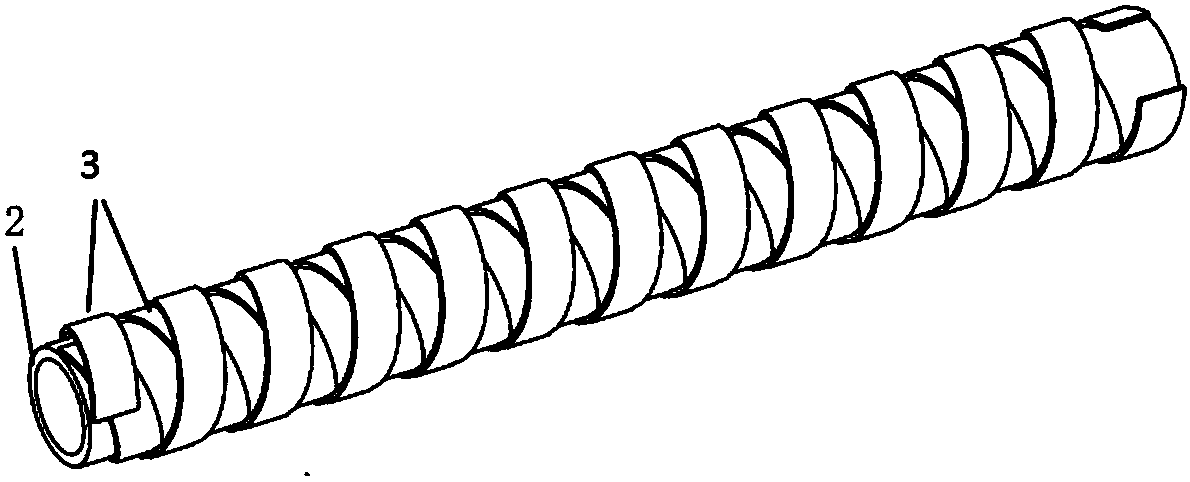

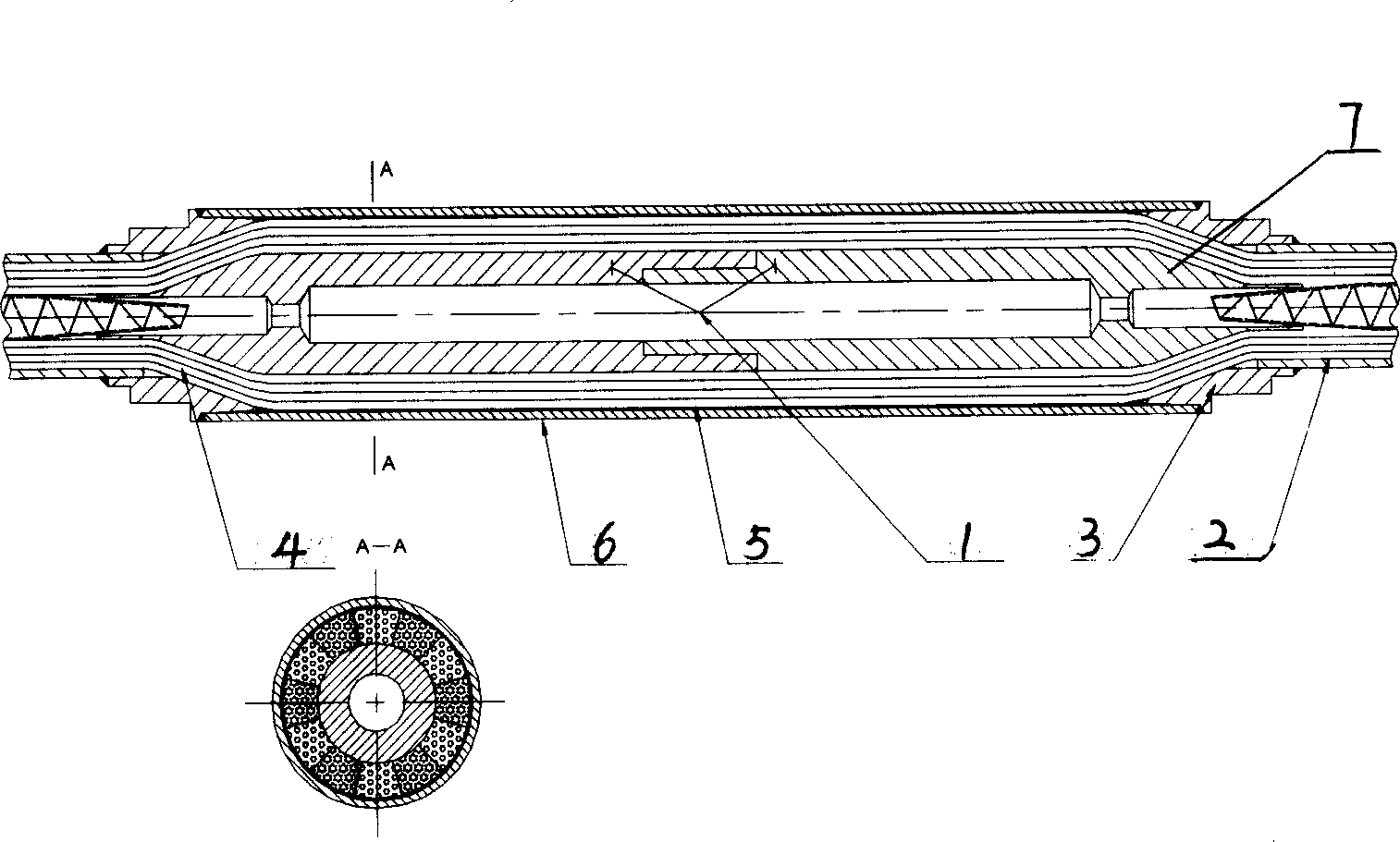

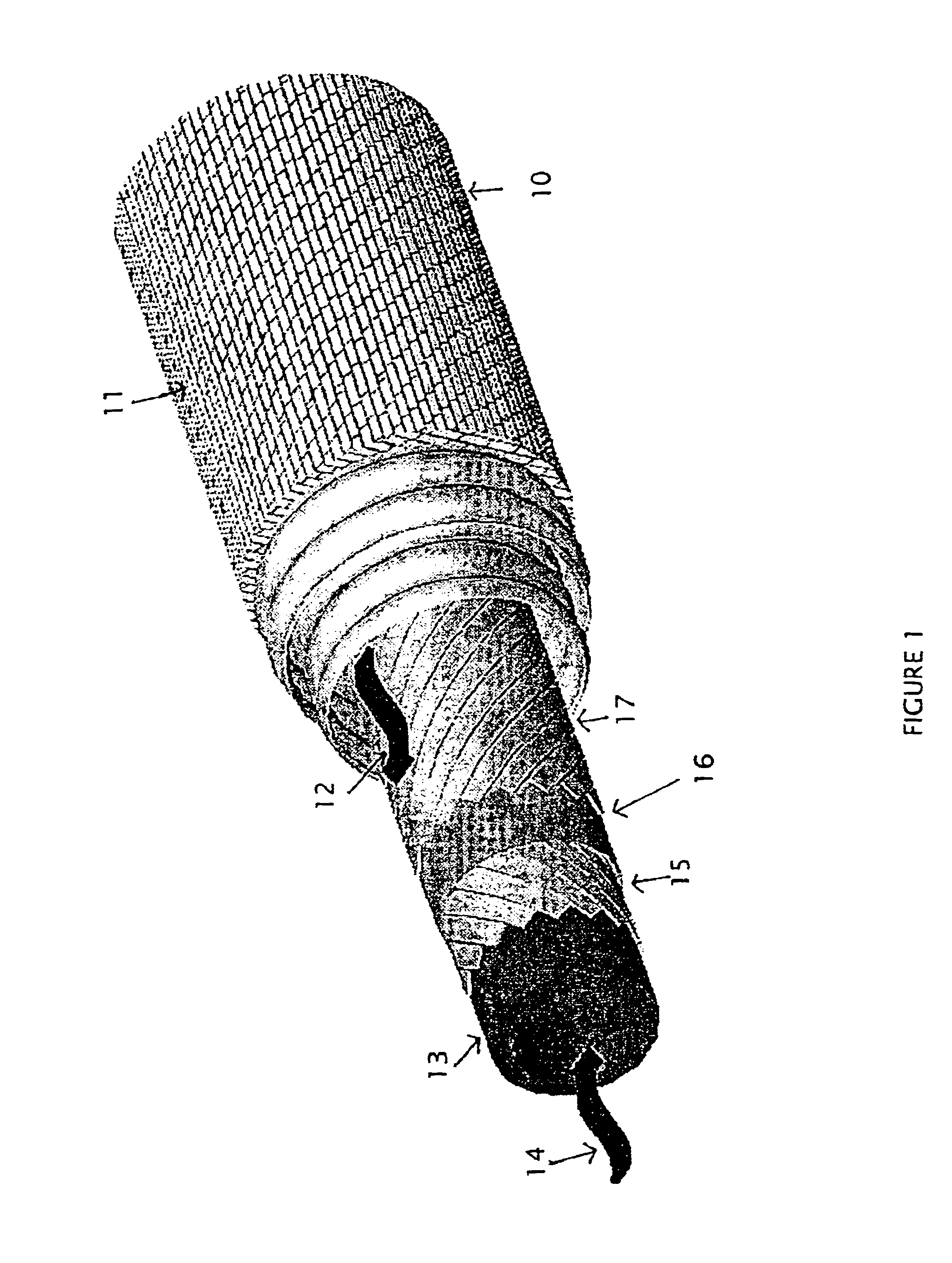

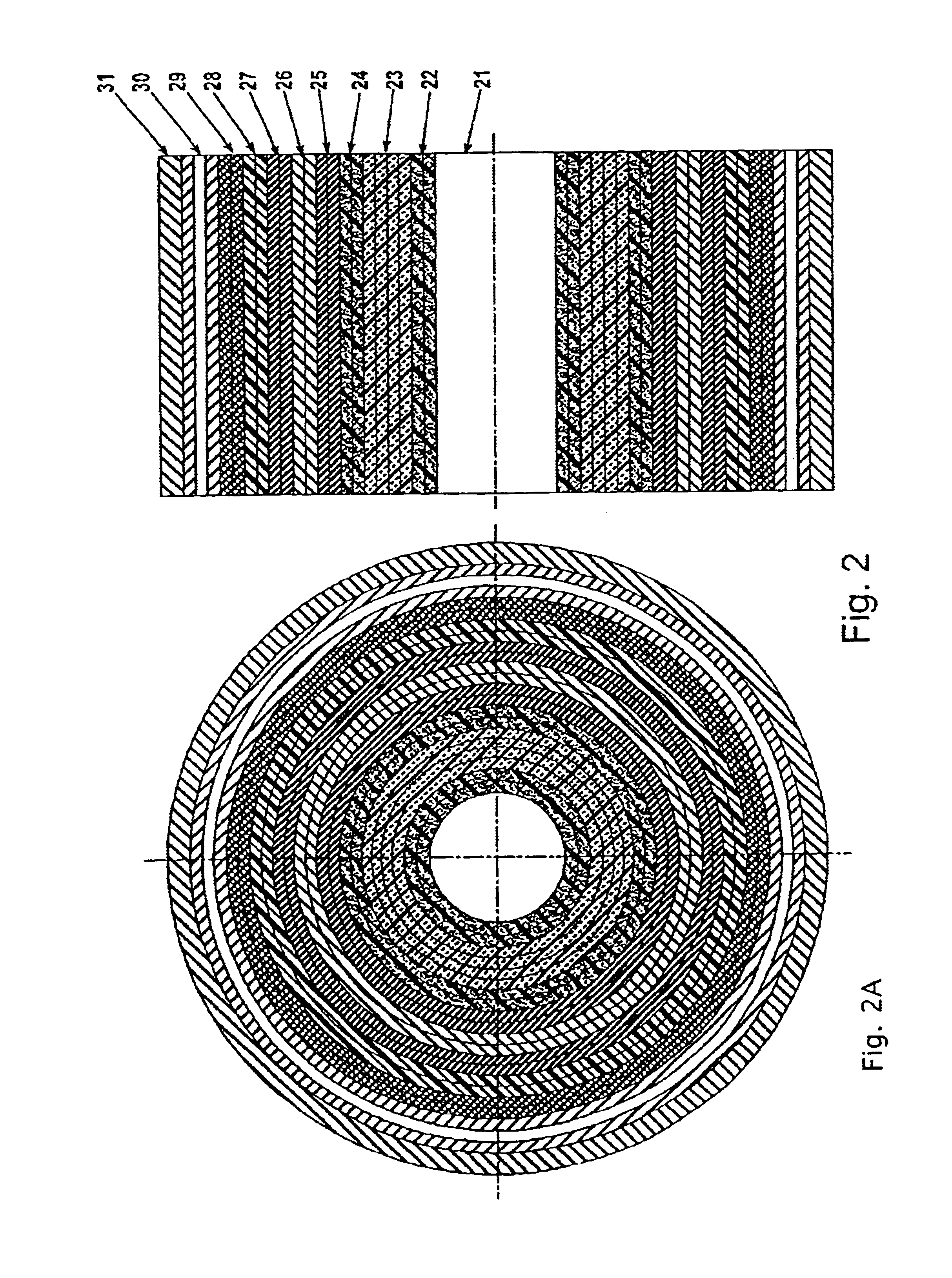

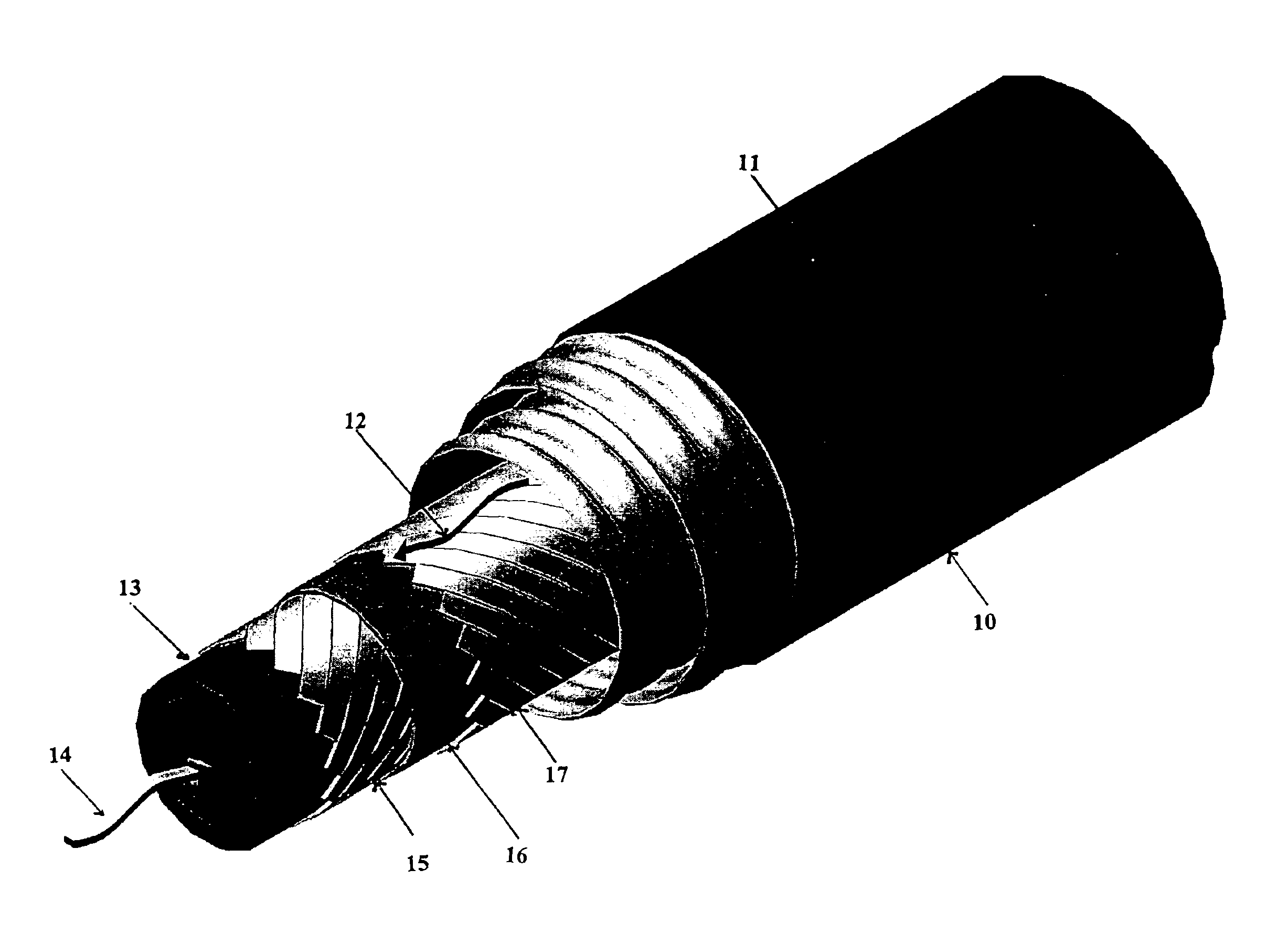

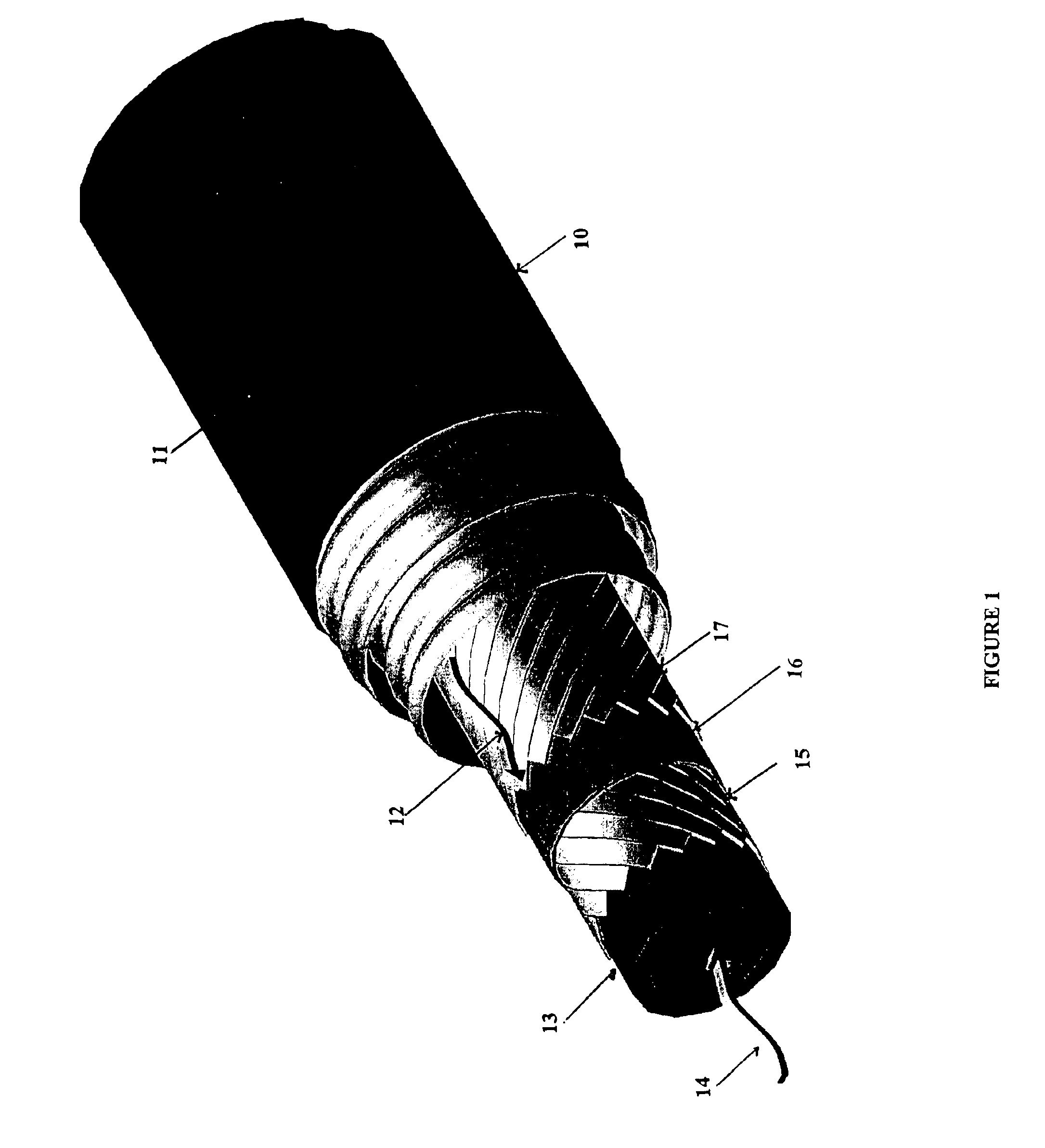

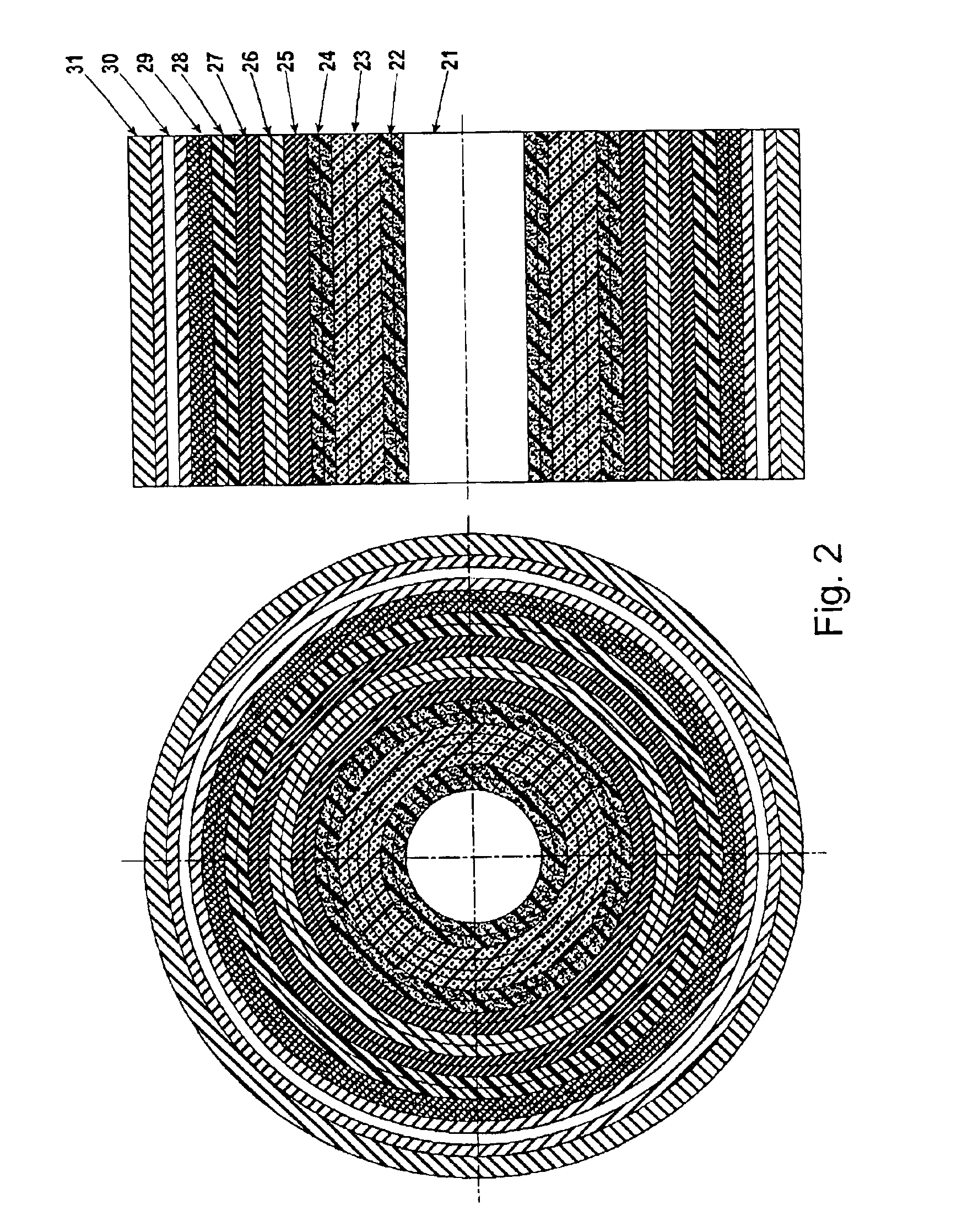

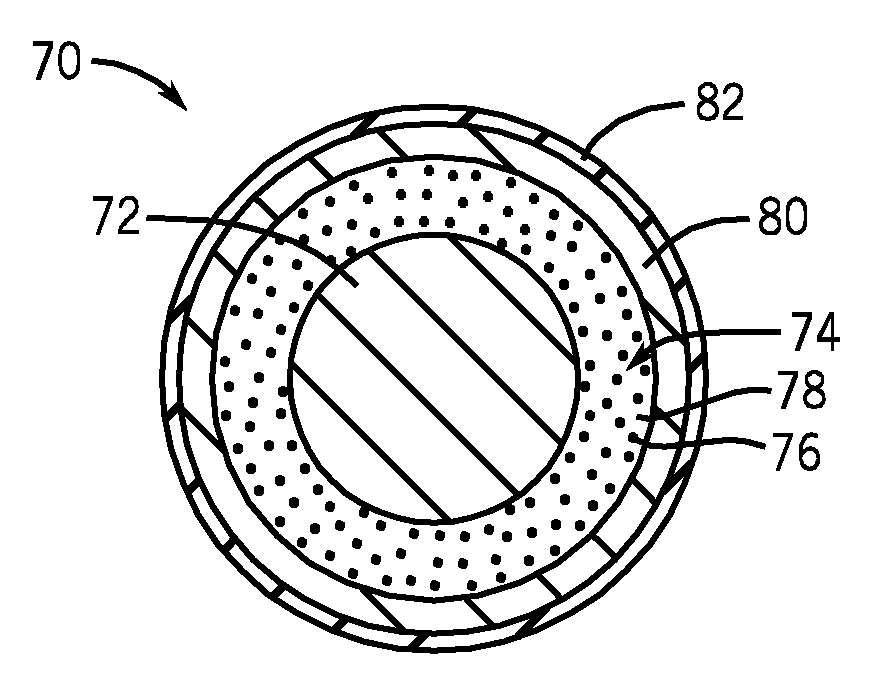

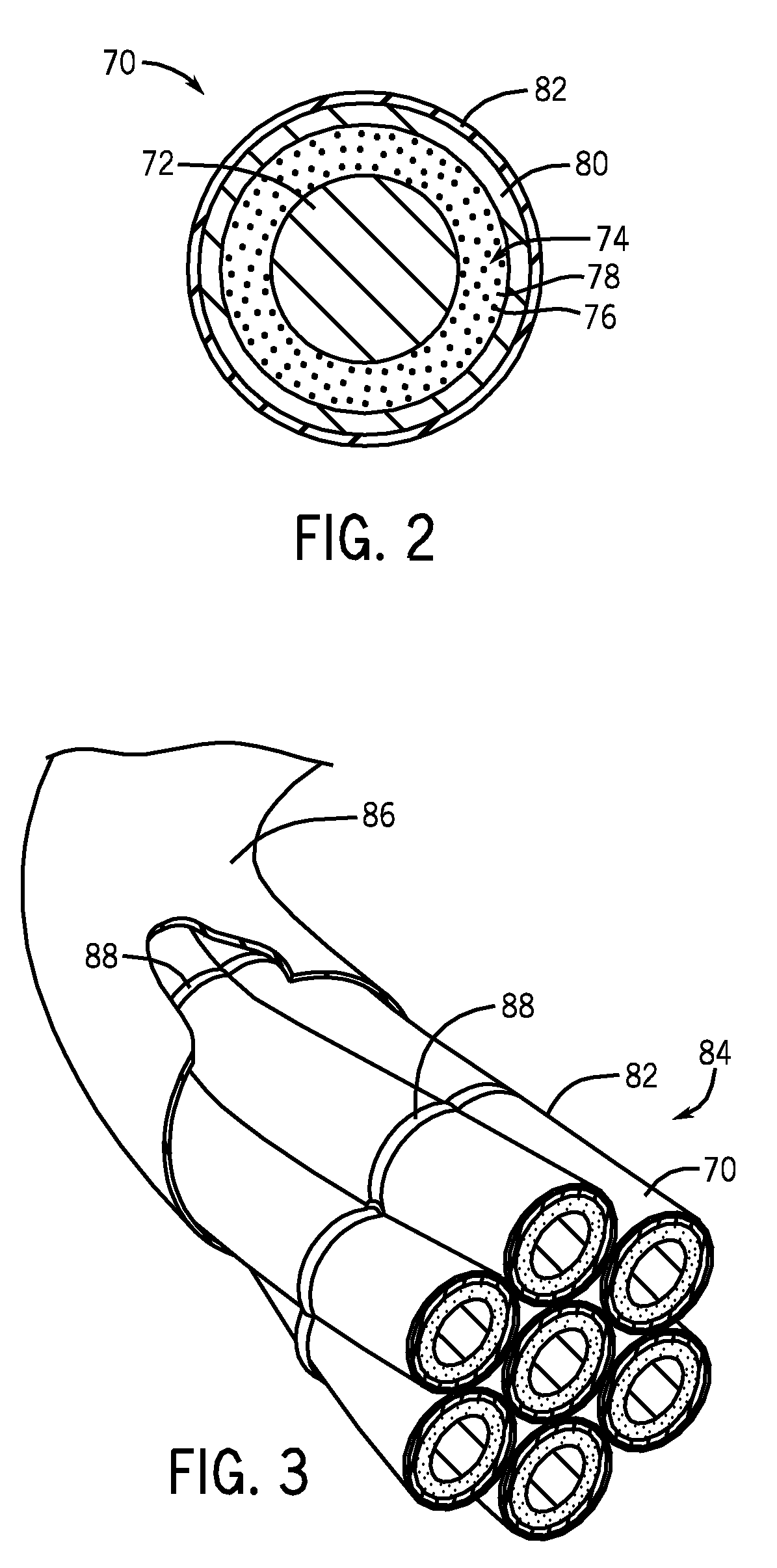

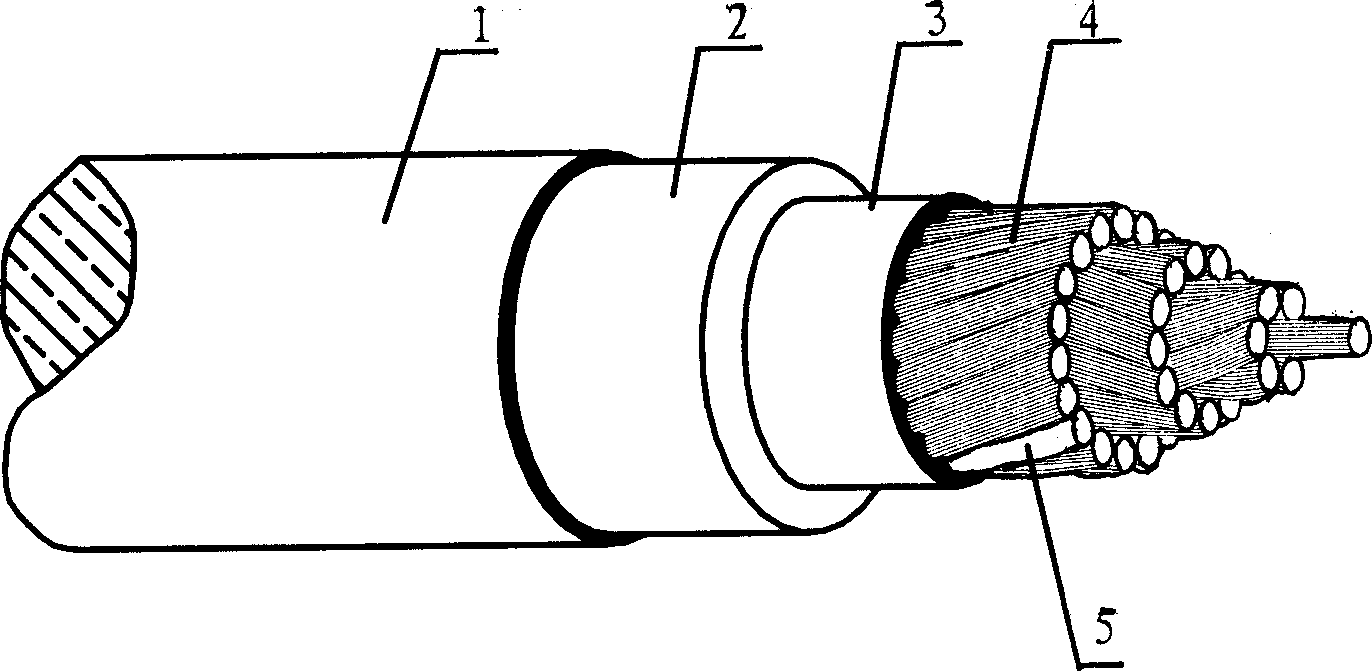

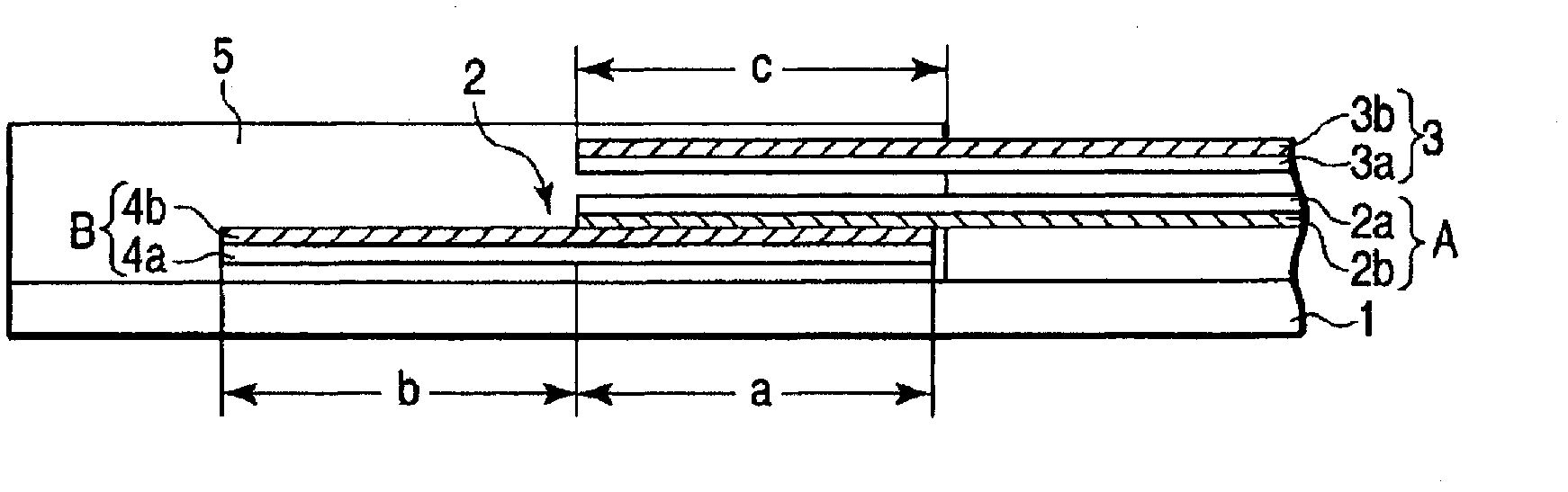

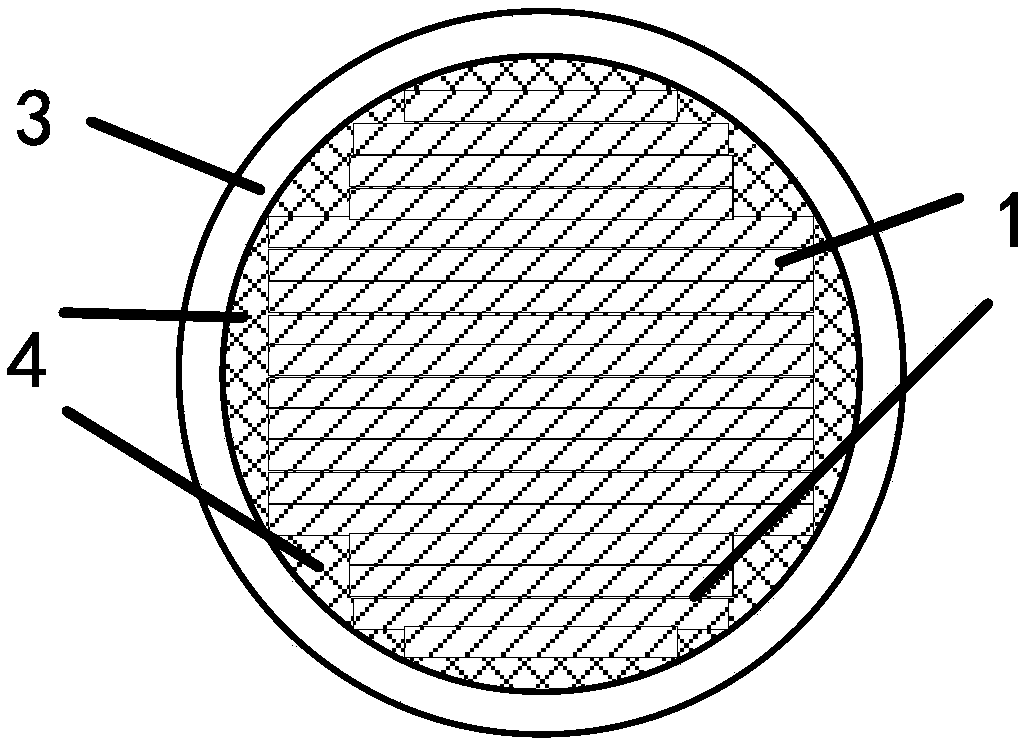

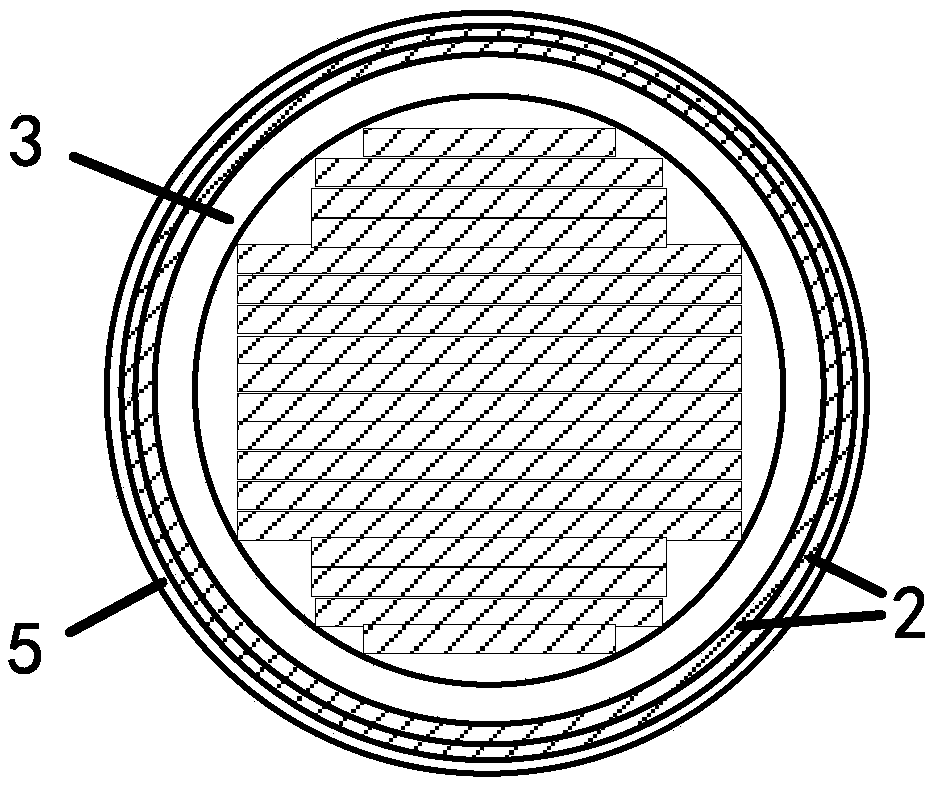

Superconducting cable having a flexible former

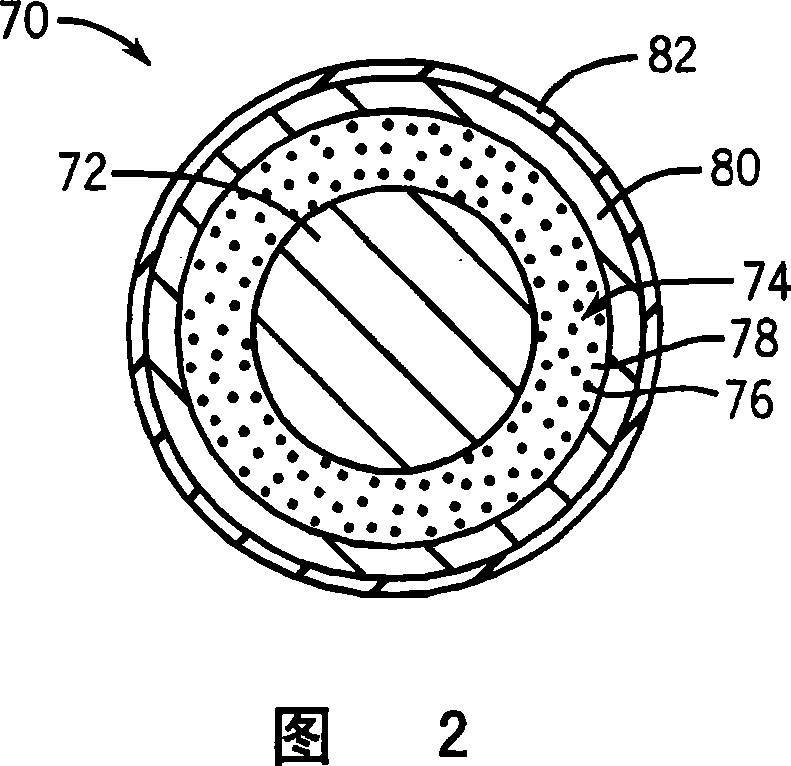

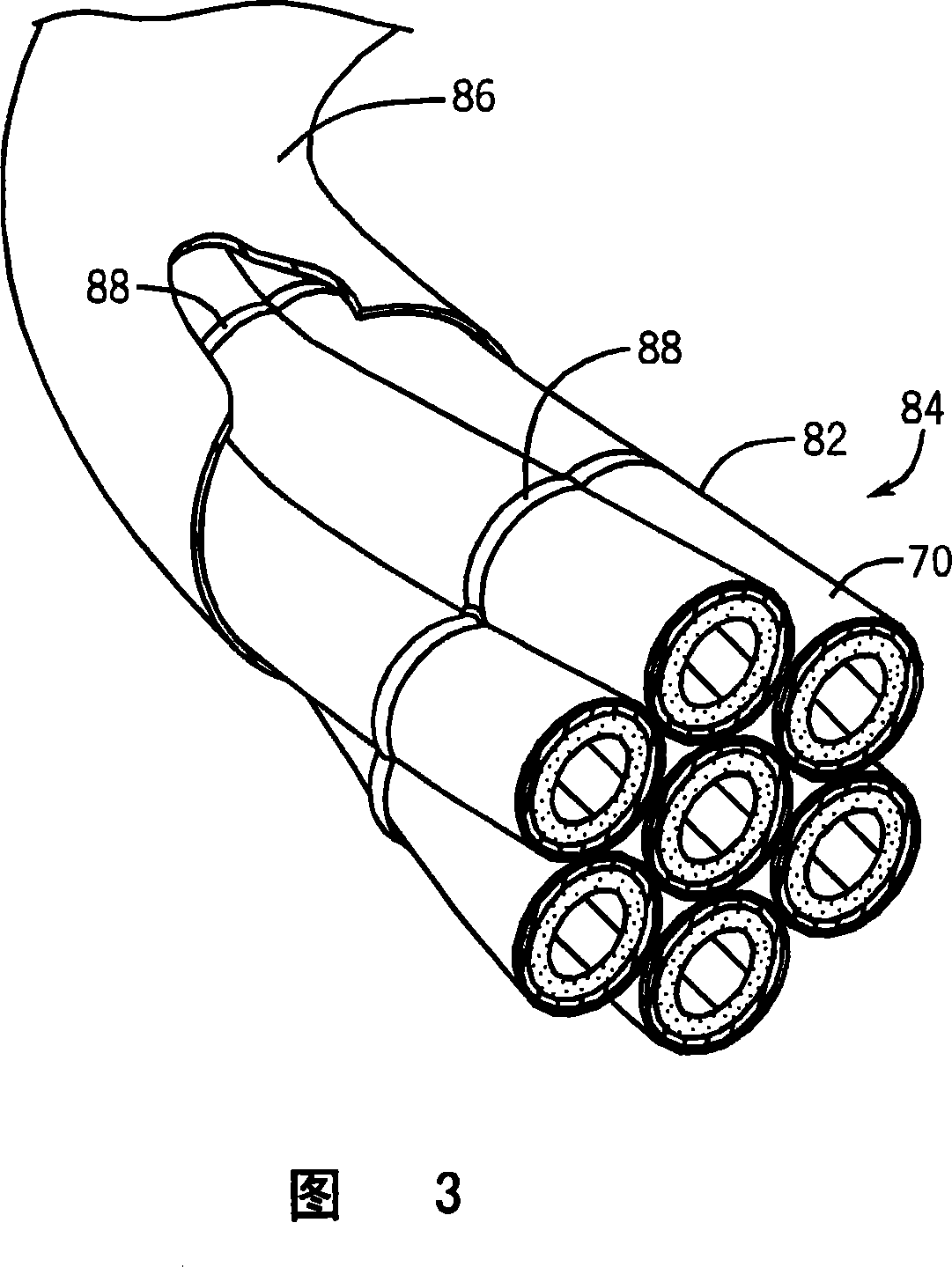

InactiveUS6864430B2Improve superconductivityIncrease the critical currentSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentBand shapeBending strain

In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0.2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

Owner:SOUTHWIRE CO LLC

Preparation method of ultrafine-core superconducting wire

ActiveCN102751048AGood current-carrying performance in high magnetic fieldReduce AC lossSuperconductors/hyperconductorsSuperconductor devicesExtrusionSuperconducting material

The invention relates to the field of superconducting materials, in particular to a preparation method of an ultrafine-core superconducting wire. The preparation method comprises the following steps of: assembling and sealing, hot extruding, manufacturing sub components, manufacturing and secondarily assembling a composite rod, drawing the composite rod, thermally treating the composite rod, etc. The quantity of total core wires of the superconducting wire reaches 106-107 through processes of double assembly of large quantities of core wires, hot extrusion, cold drawing, etc., Cu with good electrical / thermal conducting performance is used as a stable base body, and an Nb3Al superconducting wire with extremely low AC loss and extremely good stability is obtained.

Owner:西部超导材料科技股份有限公司

Superconducting cable having a flexible former

InactiveUS6867375B2Improve superconductivityIncrease the critical currentSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentBand shapeEngineering

In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0.2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

Owner:SOUTHWIRE CO LLC

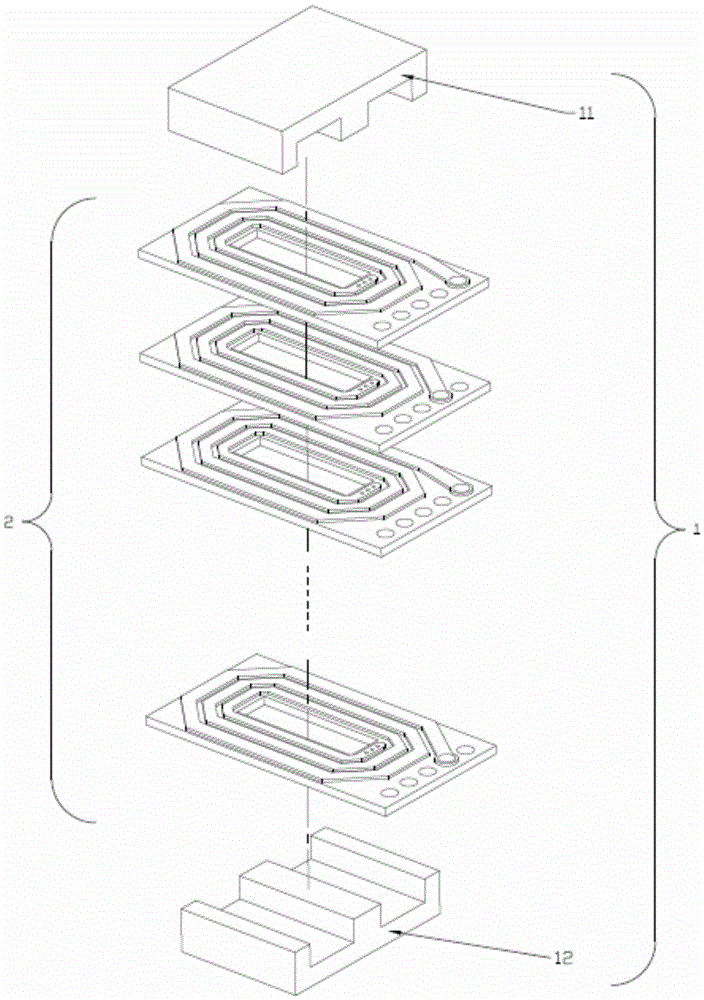

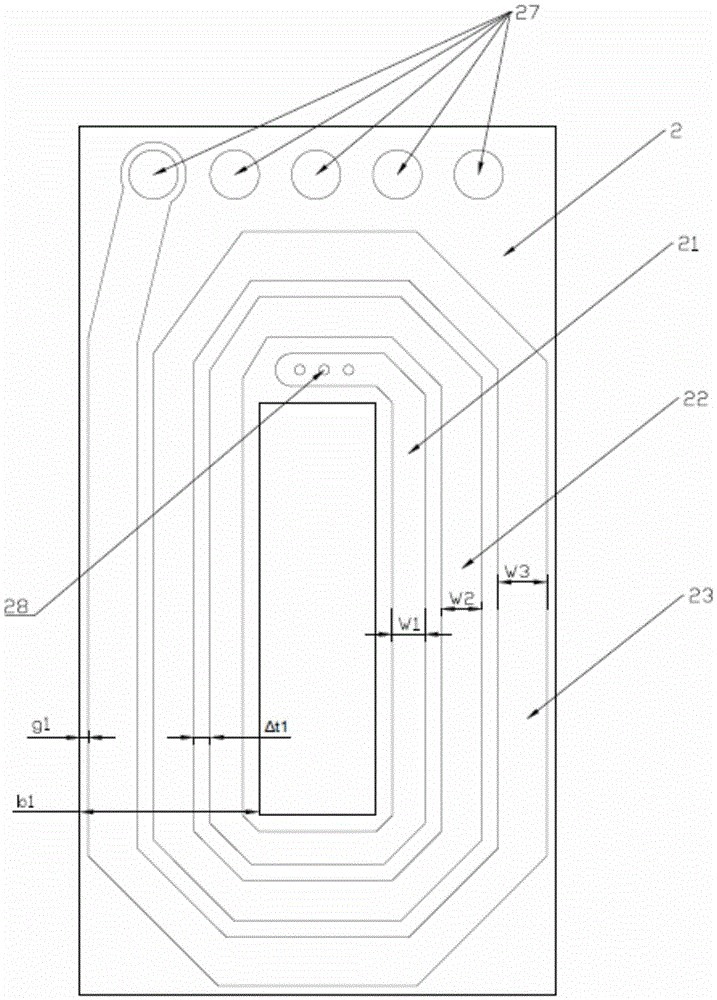

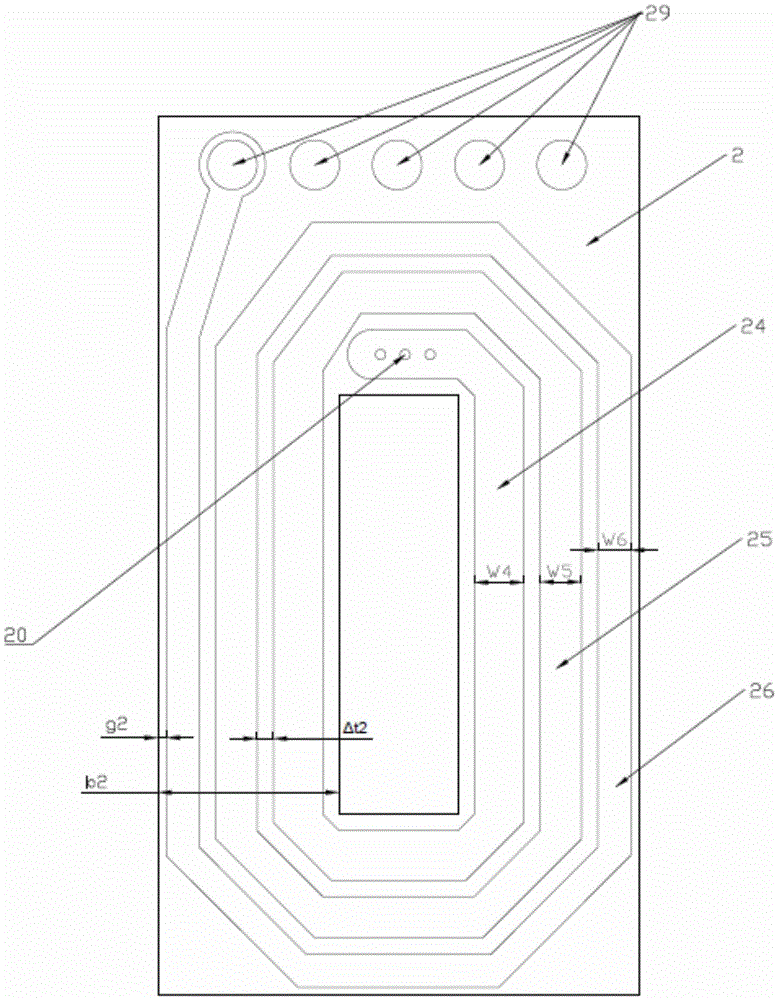

Planar transformer

ActiveCN105590735AImprove magnetic field couplingImprove flow capacityTransformers/inductances coils/windings/connectionsElectrical conductorLeakage inductance

The invention discloses a planar transformer. The planar transformer comprises an upper magnetic core, a lower magnetic core and multiple flat coils arranged between the upper magnetic core and the lower magnetic core. The adjacent flat coils are insulated. Each flat coil is formed by multiple turns of metal conductors coiled into a spiral shape. The flat coils are vertically projected in space and overlapped vertically. Some flat coils form primary windings of the planar transformer, and the other flat coils form secondary windings of the planar transformer. The planar transformer is characterized in that according to the direction from the center to the outer side of each flat coil, the widths of the turns of each flat coil change as the following form: W1:W2:...:Wn=1:a:...:a(n-1), W represents the widths of the coils, n represents the number of turns of the coils and is larger than or equal to 1, a is larger than or equal to 0.5 and smaller than 1 or a is larger than 1 and smaller than or equal to 1.5, and the widths of the turns of each flat coil change consistently. Magnetic field distribution of the transformer can be changed by changing the widths of the turns of each coil, so that coupling performance and the alternating current loss are changed. The planer transformer has the advantage that leakage inductance and alternating current resistance of the planer transformer can be adjusted according to the actual needs.

Owner:杭州博洲电器有限公司

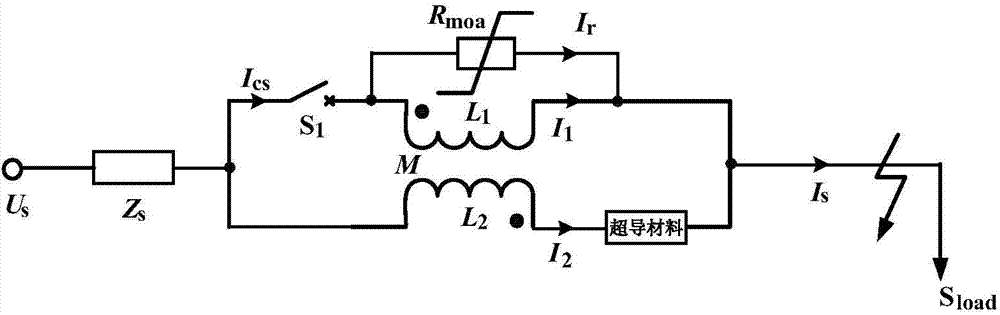

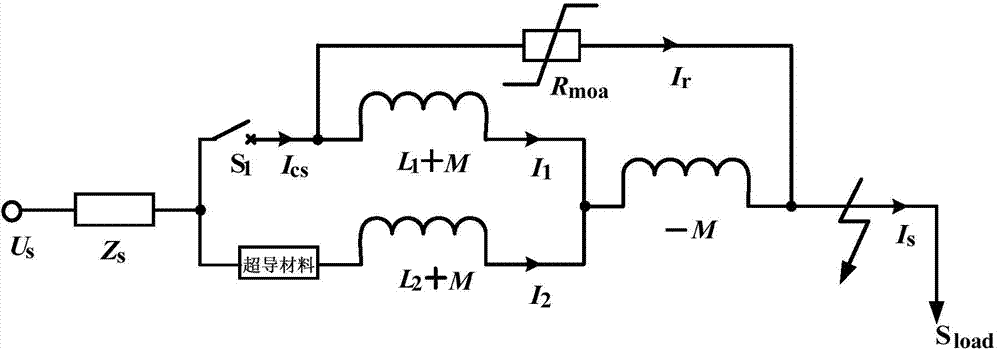

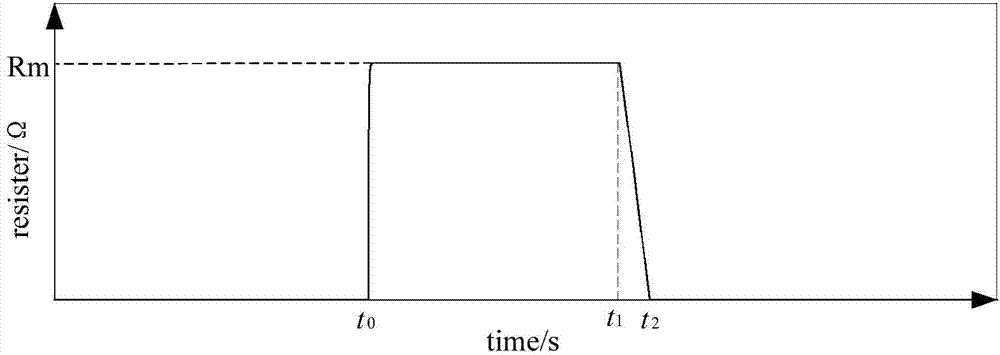

Hybrid type flux coupling superconduction fault current limiter and current limitation method

InactiveCN103887782AReduce AC lossImprove economyEmergency protective arrangements for limiting excess voltage/currentSuperconductor elements usageHybrid typeHigh resistance

The invention relates to a hybrid type flux coupling superconduction fault current limiter and current limitation method. According to the hybrid type flux coupling superconduction fault current limiter, a primary side winding coil of a coupling transformer and a high-speed switch are connected and are connected into an MOA zinc oxide resistor disc, a secondary side winding coil is connected with a superconduction current limiting material in series, and then the primary side winding coil and the secondary primary side winding coil are connected in an anti-parallel mode and then are connected into a main loop of a power system. When the power system operates normally, the high-speed switch is switched on; when the power system short-circuits, the high-speed switch is controlled to be triggered and switched off, the flux locking characteristic of the coupling transformer is relieved, the superconduction material is switched to be at the high resistance state as the through-flow of the superconduction material is larger than a set critical current, and at the moment, the current limiter carries out fault current limitation in an inductance-resistance hybrid mode. The hybrid type flux coupling superconduction fault current limiter is simple in structure and rapid in response, exchange losses generated when the superconduction current limiting material operates normally are reduced, and system economical efficiency of current limiting equipment is improved.

Owner:WUHAN UNIV

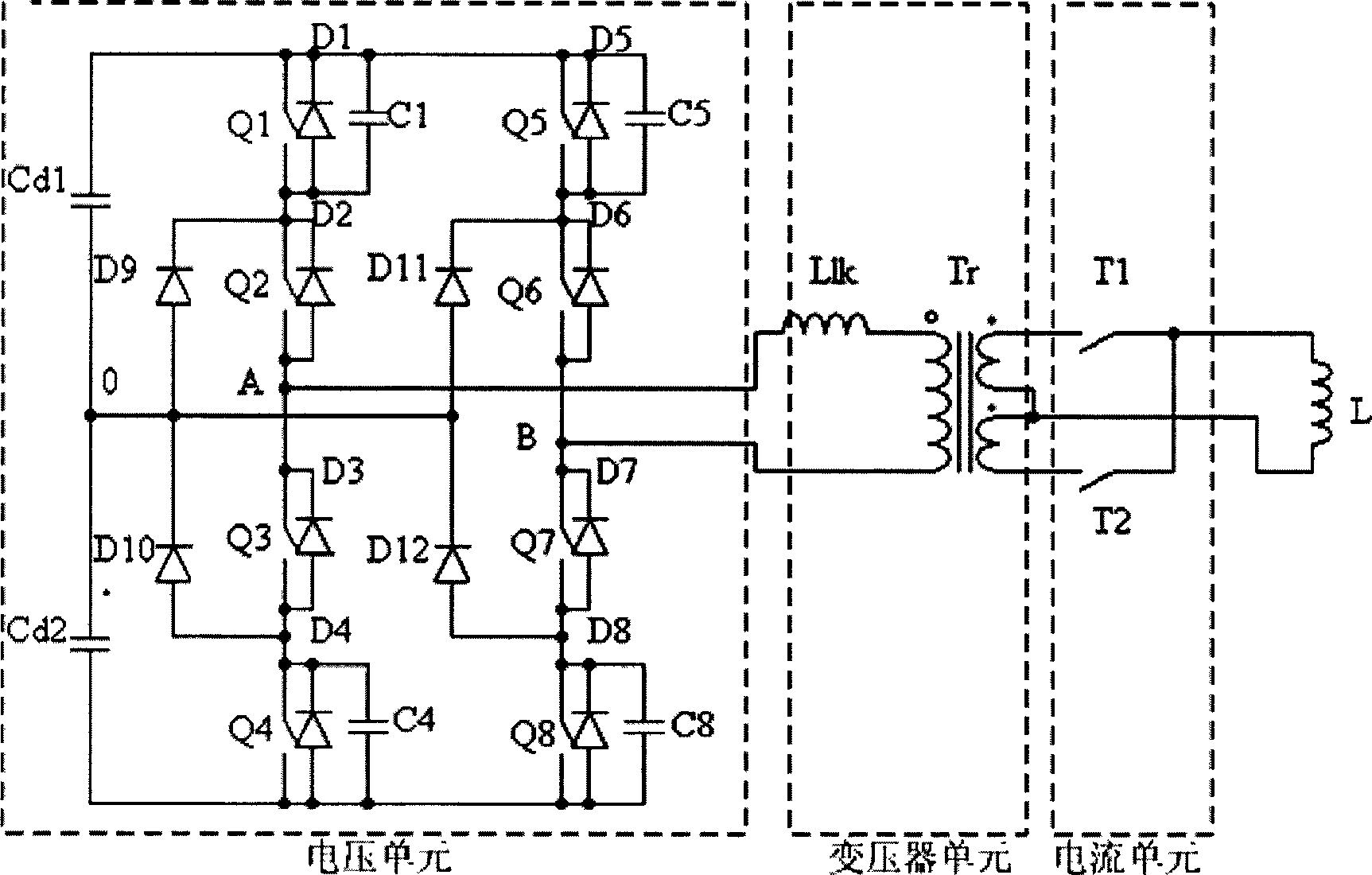

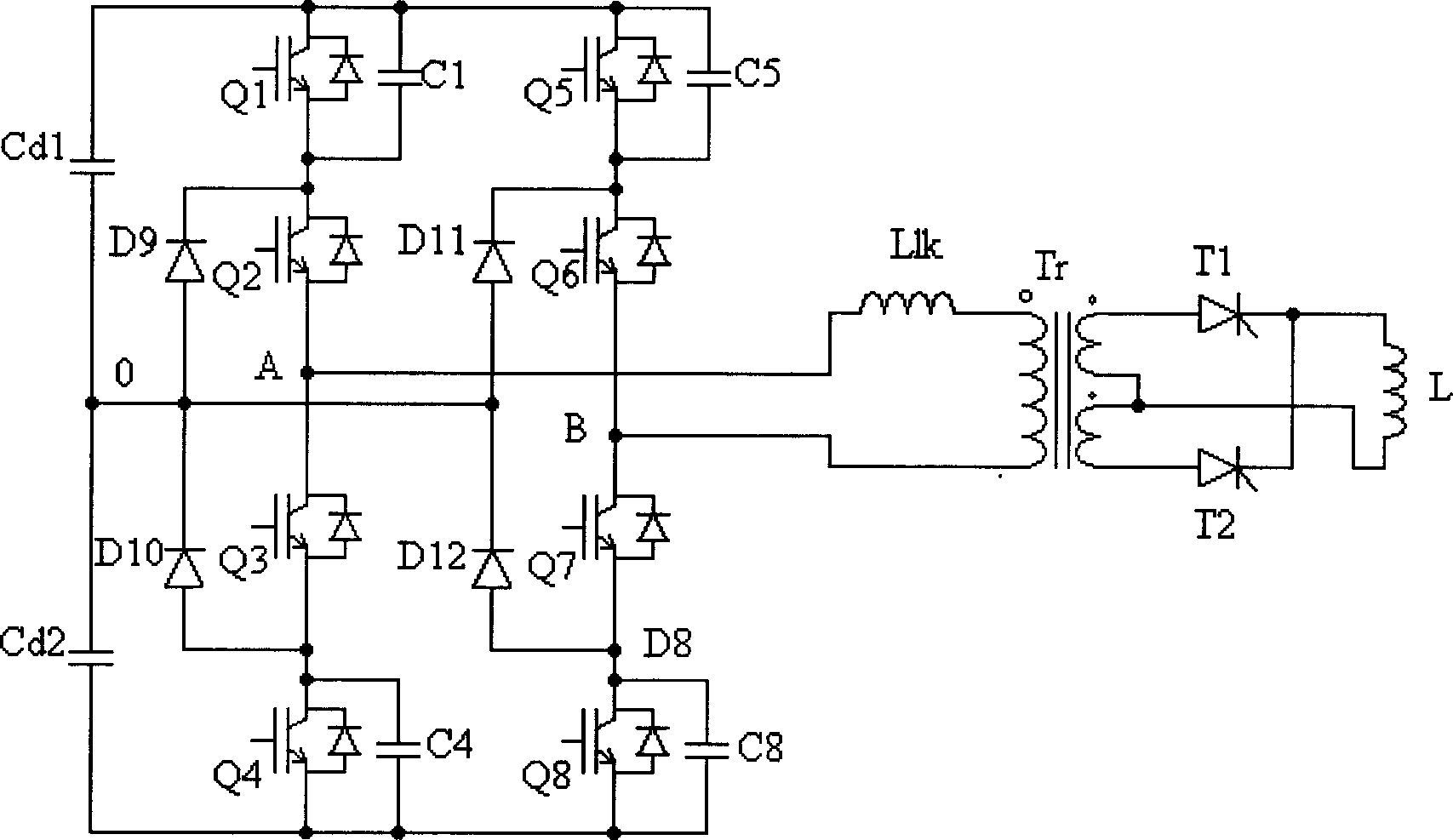

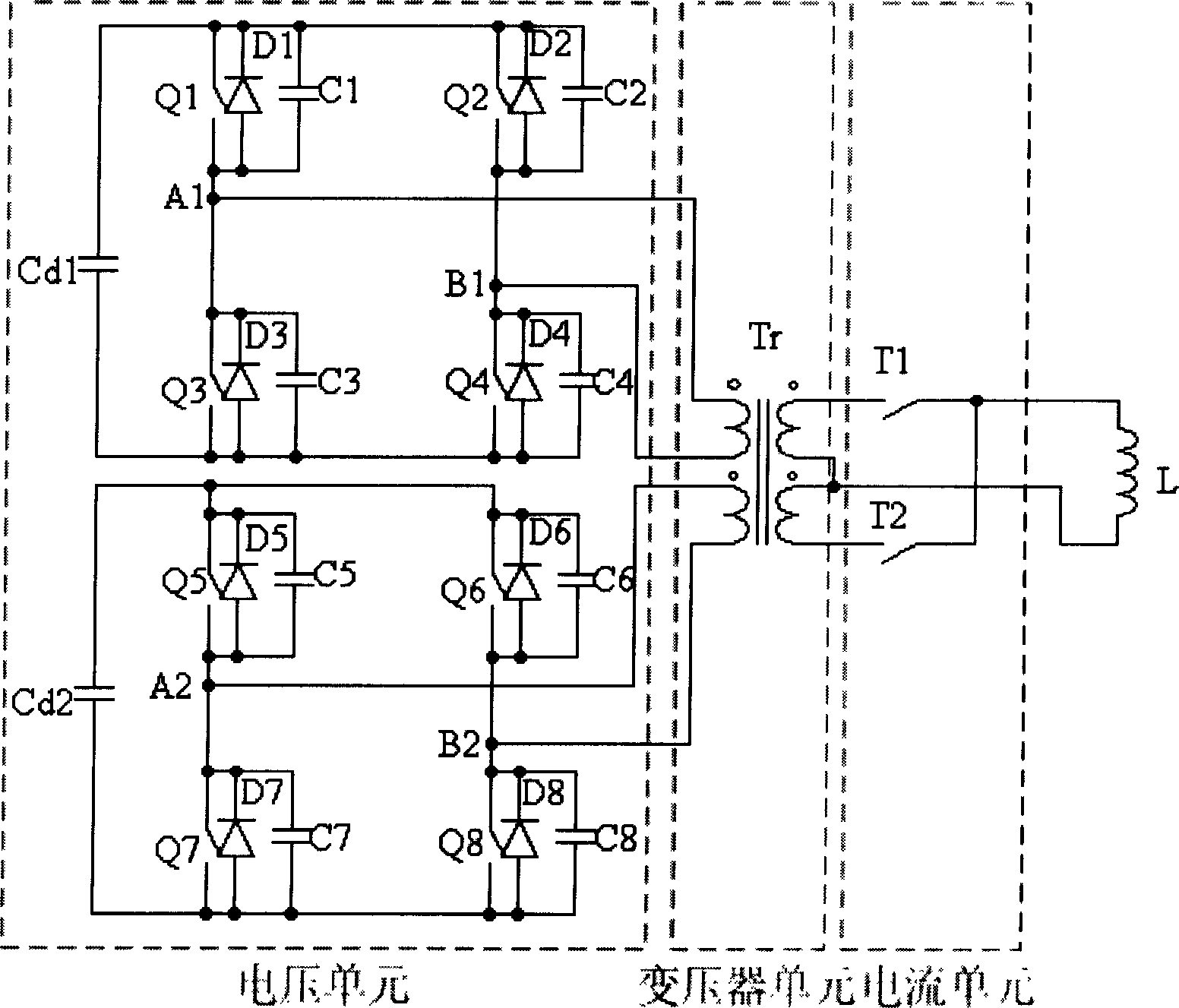

Bidirectional multi-level soft switch DC/DC for superconducting energy storage and its voltage side phase-shift controlling method

InactiveCN1845435ASmall rippleReduce AC lossEfficient power electronics conversionApparatus with intermediate ac conversionElectricityPhase shifted

The dual-way multi-level soft switch DC / DC for superconductance energy-storage comprises a voltage unit with voltage level being increased by adding primary winding and number of H-bridge inverter and current level being increased by paralleling with dc output end of H-bridge inverter, a transformer unit, and a current unit with current / voltage level being increased by paralleling / series connected with its dc output respectively. This invention reduces current ripple and requirement to circuit, and lets system work flexible within charge and discharge state.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

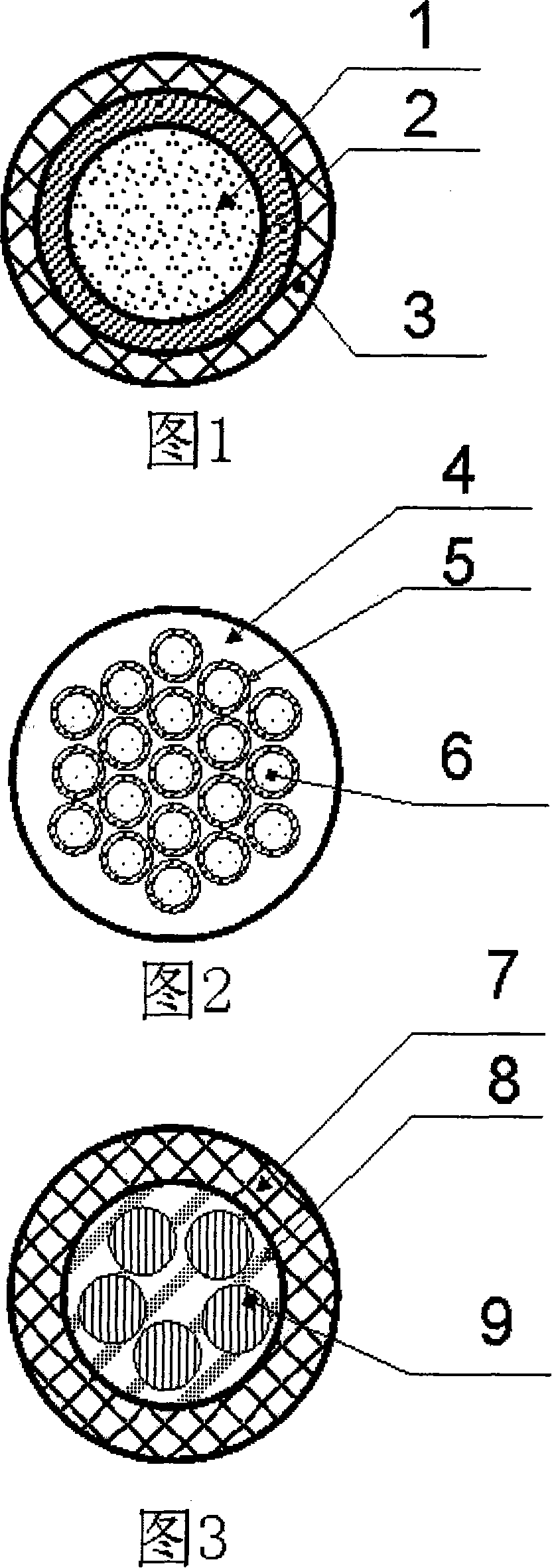

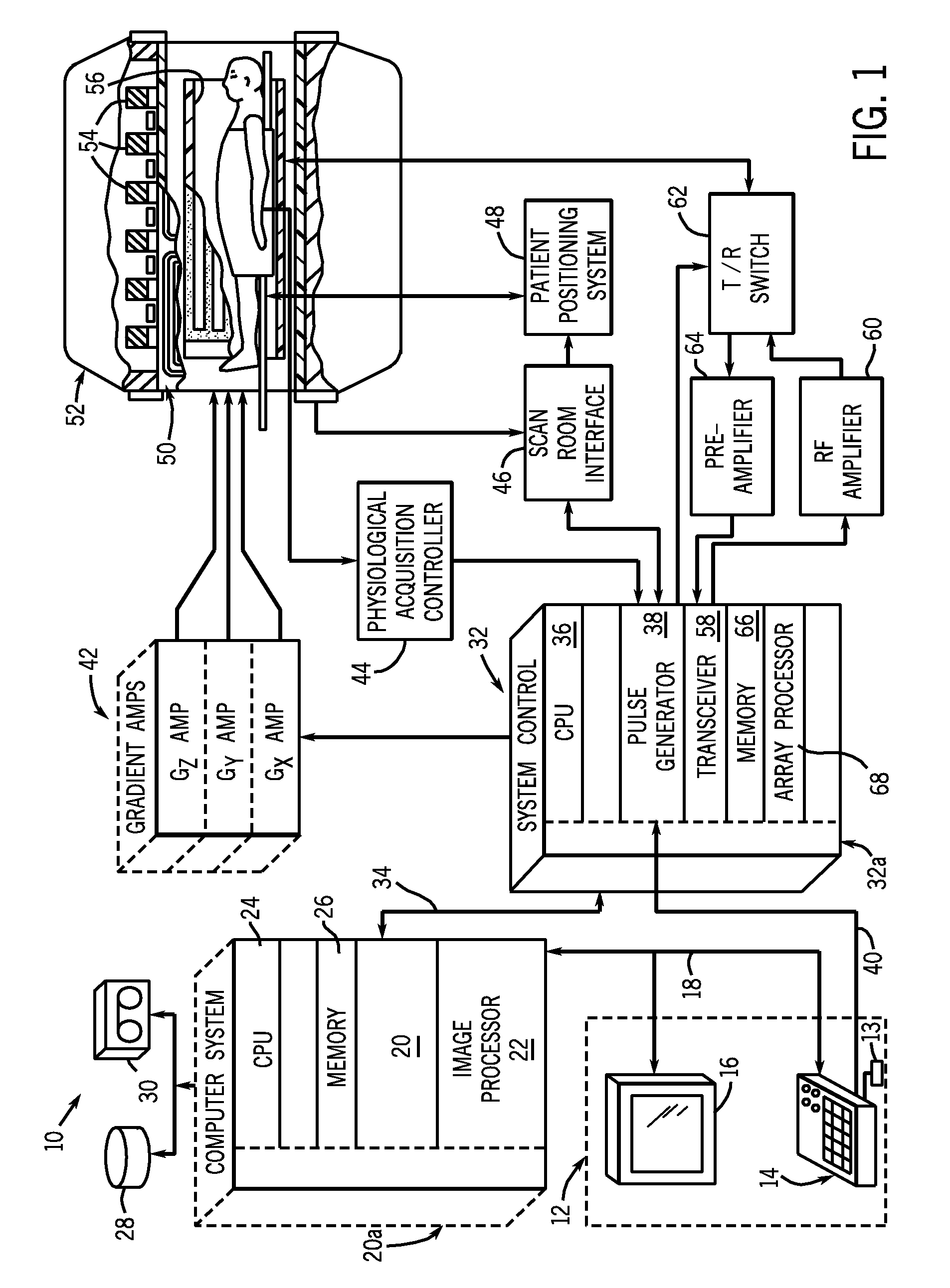

A low ac loss single-filament superconductor for a superconducting magnet and method of making same

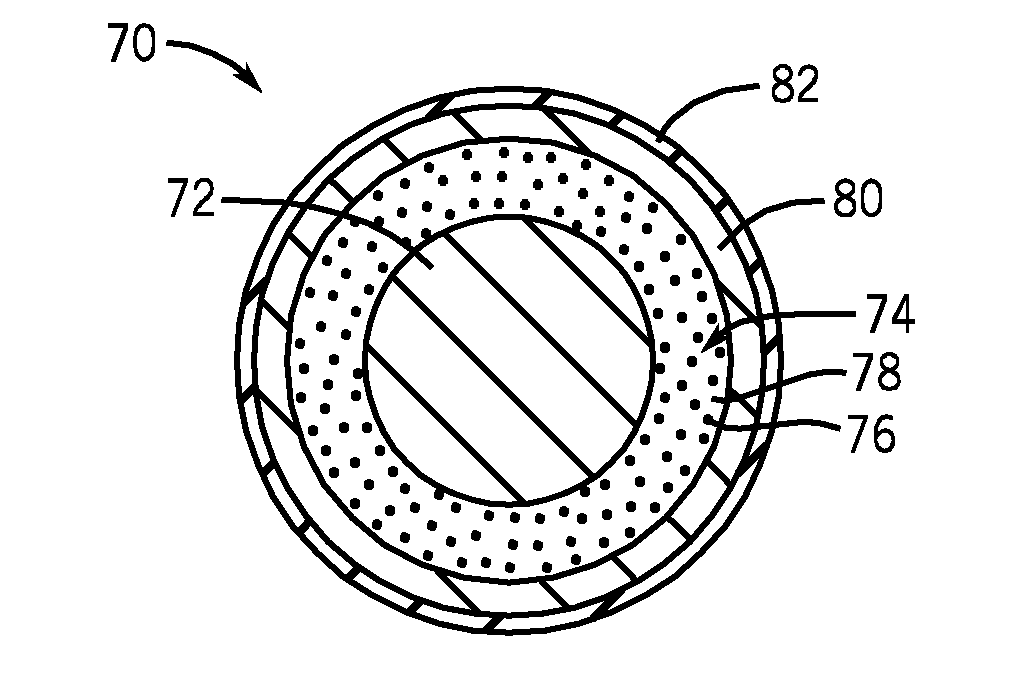

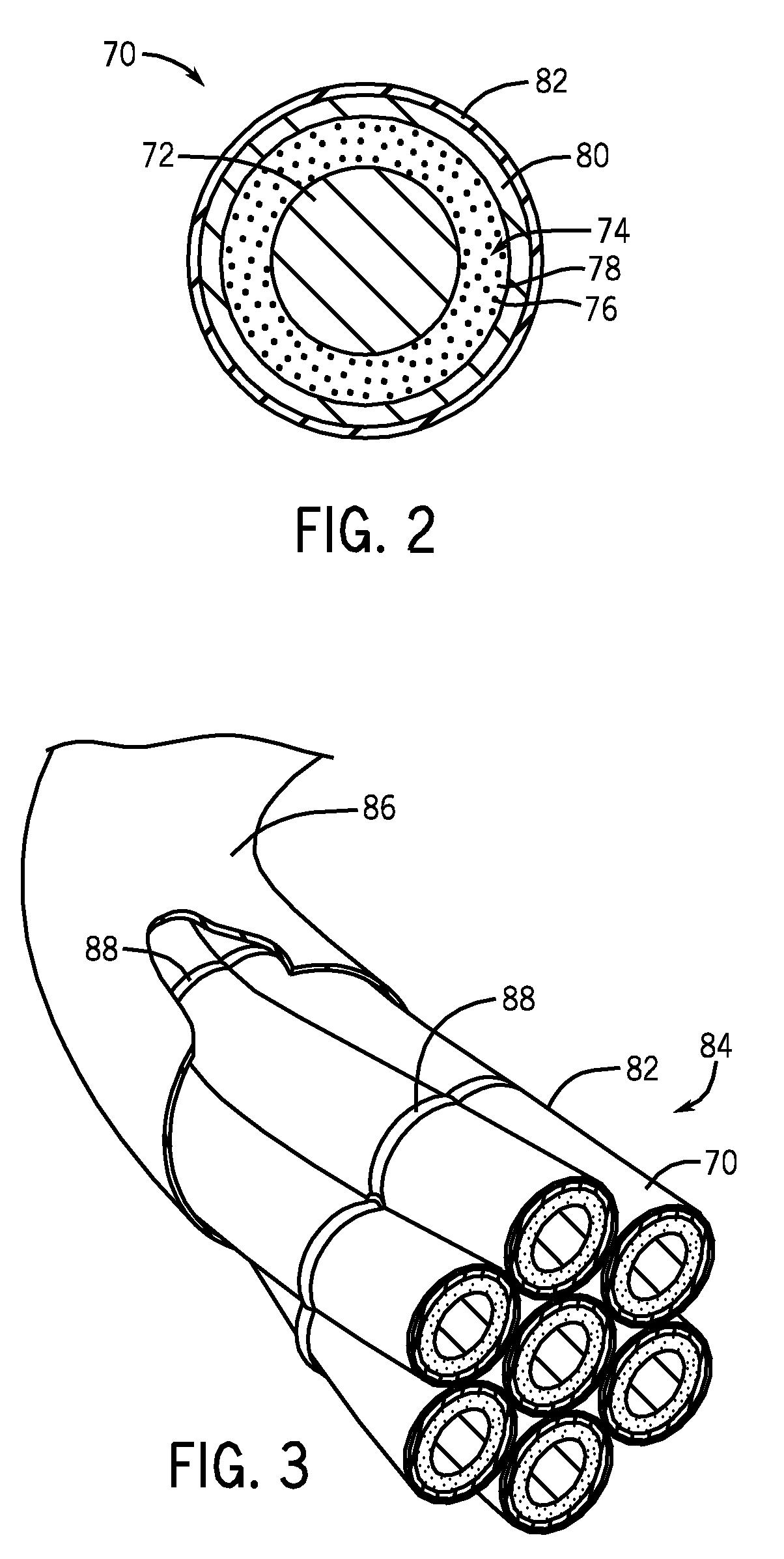

ActiveUS20070270314A1Reduce AC-lossSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentElectrical conductorSuperconducting Coils

A low AC loss electrical conductor includes a plurality of single-filament superconducting strands longitudinally wound about one another. An insulative housing surrounds the plurality of single-filament superconducting strands.

Owner:GENERAL ELECTRIC CO

A low ac loss superconductor for a superconducting magnet and method of making same

ActiveUS20070268101A1Reduce AC-lossSuperconductors/hyperconductorsMagnetsSuperconducting CoilsElectrically conductive

A low AC loss electrical conductor includes an electrically conductive core surrounded by a first layer of superconductor filaments. A resistive shell surrounds the first layer and an insulation coating radially encloses the resistive shell.

Owner:GENERAL ELECTRIC CO

Cable with processed conducting wire core specially for winding

InactiveCN1506981AReduce AC lossTo insulate each otherTransformers/inductances coils/windings/connectionsInsulated cablesHigh pressureElectrical conductor

The present invention relates to conductor for high voltage winding, and is especially one kind of cable with processed conducting wire core specially for winding. The twisted multi-core conductor is treated chemically, that is, the twisted multi-core conductor is soaked in low viscosity mixed solution containing sodium chlorite in 1-10 wt% and sodium hydroxide in 1-10 wt% to form thin insulating layer on the surface of each core conductor for mutual insulation. The formed copper oxide film will not be damaged in the subsequent twisting, pressing, drawing and other steps. The cable may be used in strong magnetic field and has the features of lowered AC loss, lowered eddy loss, saving in energy and high efficiency.

Owner:TEBIAN ELECTRIC APP CO LTD

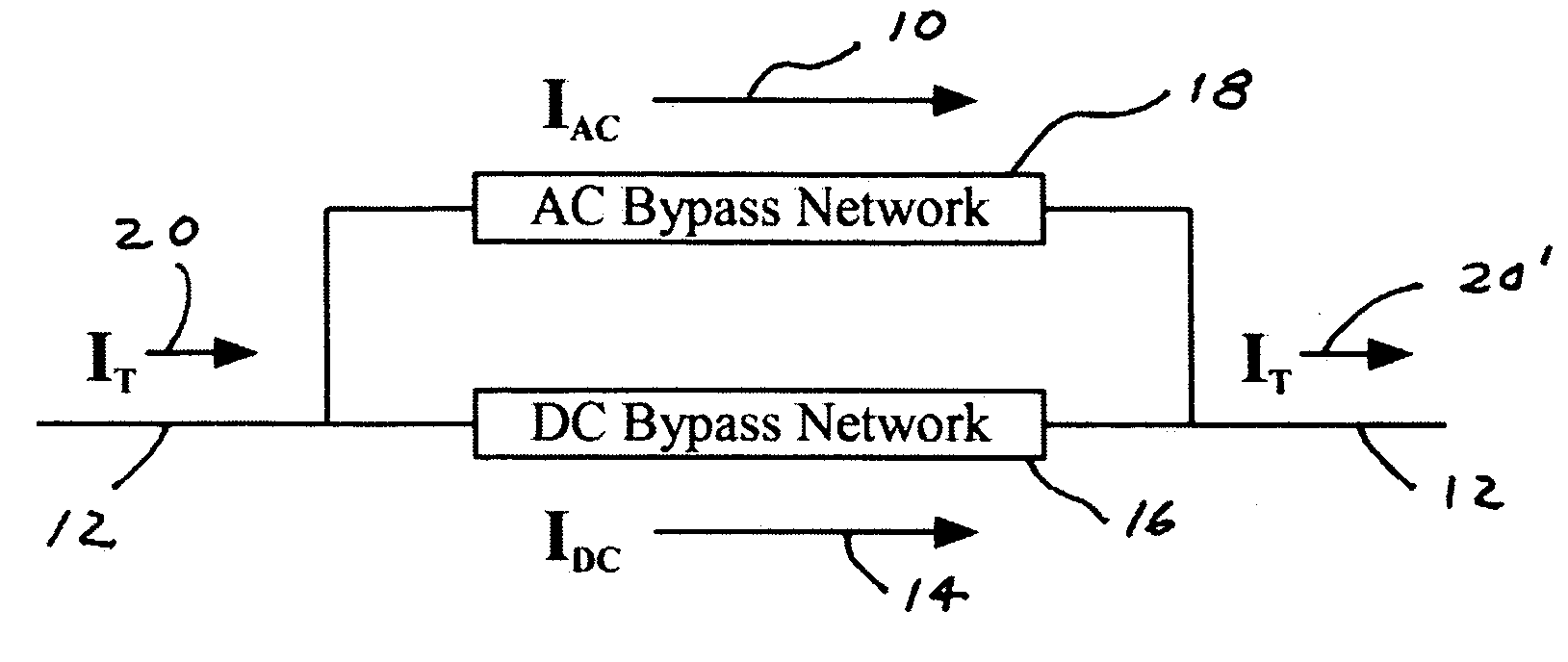

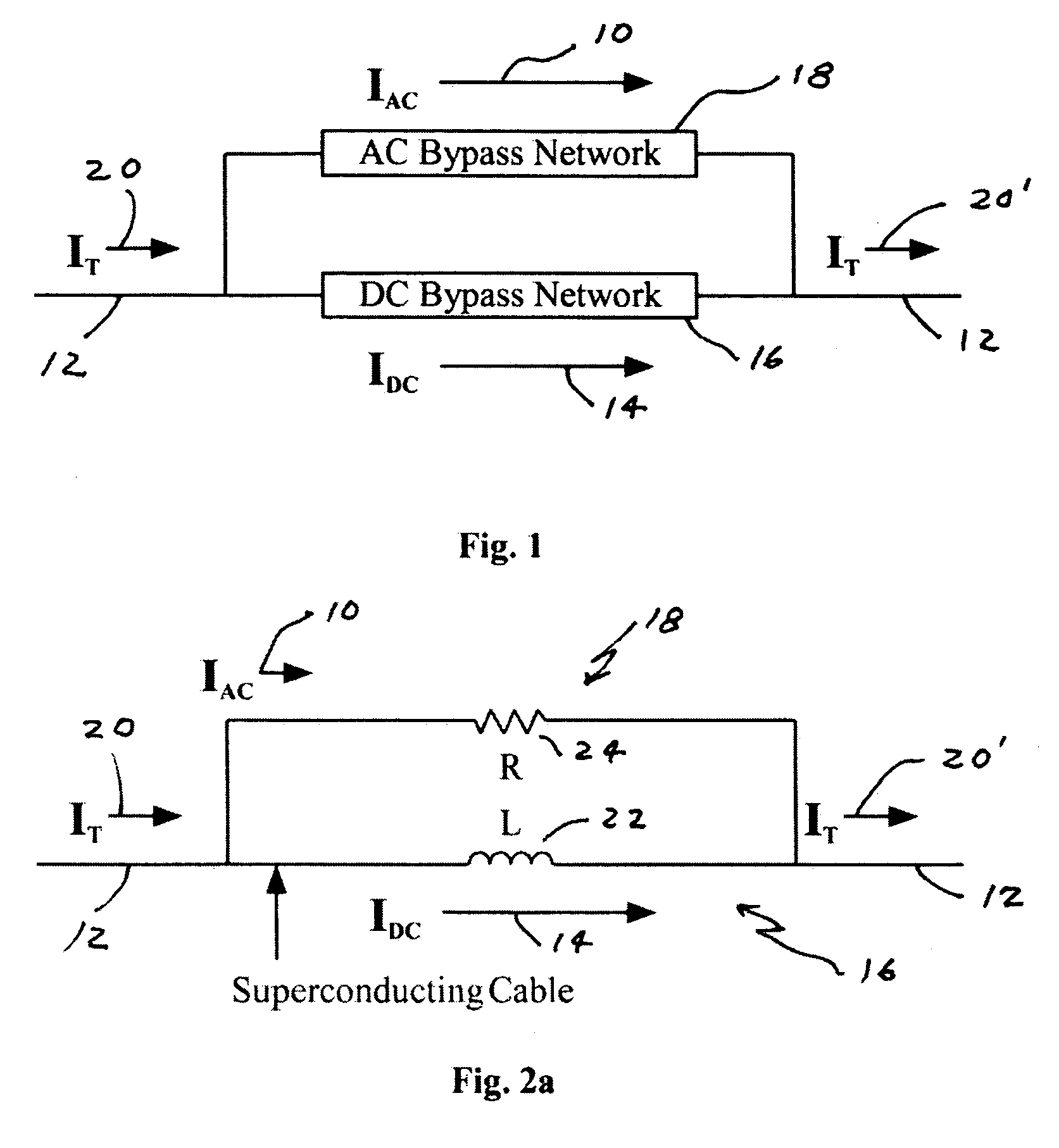

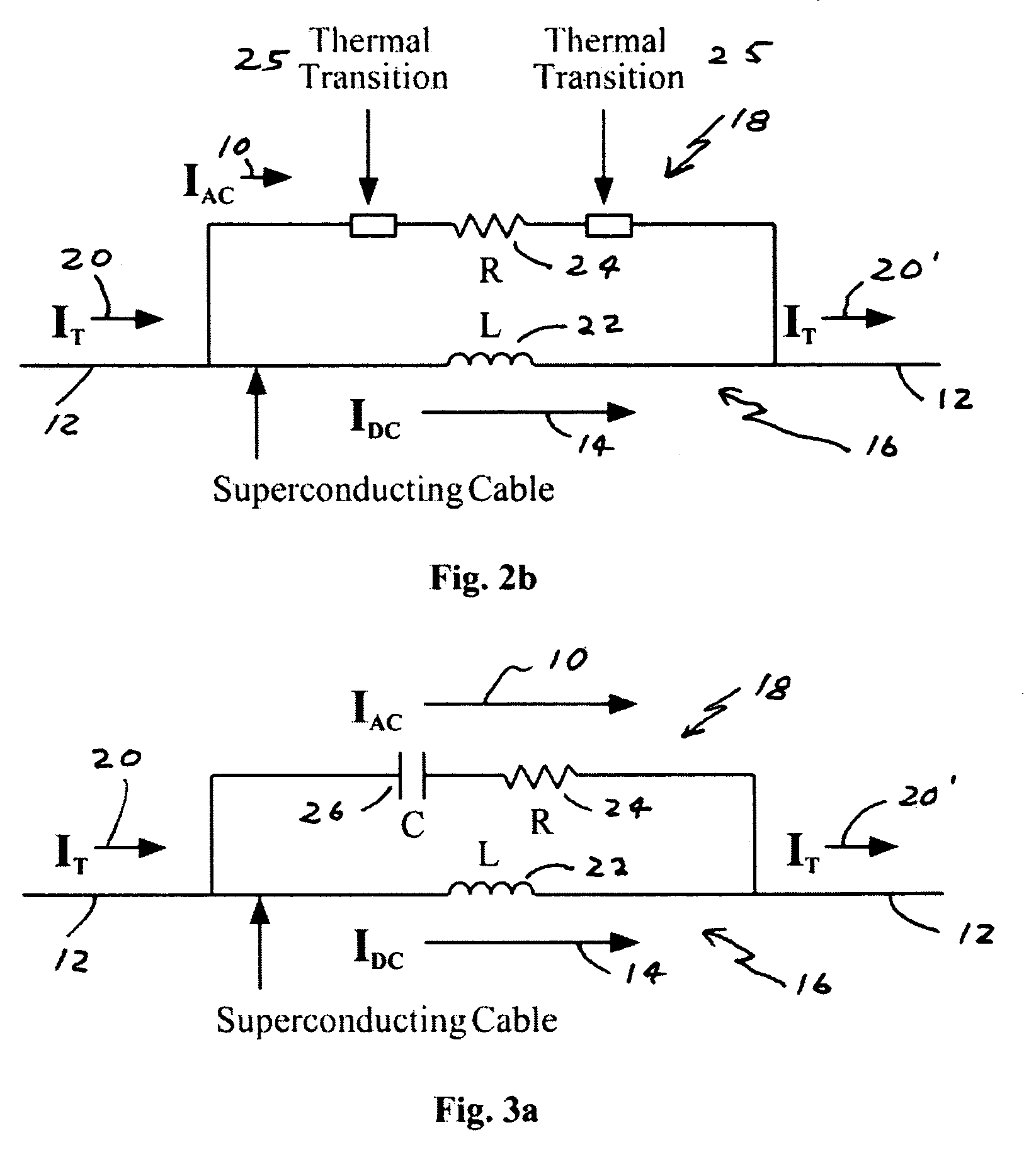

Hybrid bypass networks for low-loss cables and ripple filter chokes

InactiveUS7091799B1Minimizing AC lossZero lossSuperconductors/hyperconductorsCurrent interference reductionElectrical conductorDistribution system

Losses are reduced in electrical conductors and filters, especially those made with superconducting cables or inductors, which carry currents having both direct current (DC) and alternating current (AC) portions as in rectifier busses and power distribution systems. Superconducting cables and chokes are capable of passing direct current with practically zero losses, but they exhibit considerable AC losses. A low impedance AC bypass of the superconducting cables and chokes minimizes these losses.

Owner:MTECH LAB

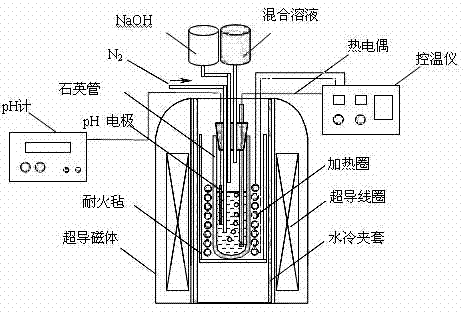

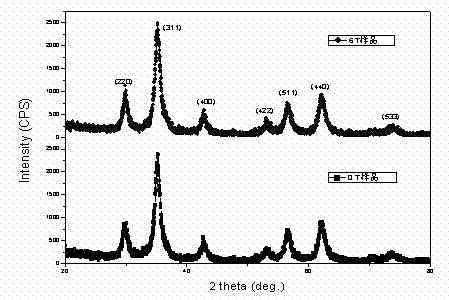

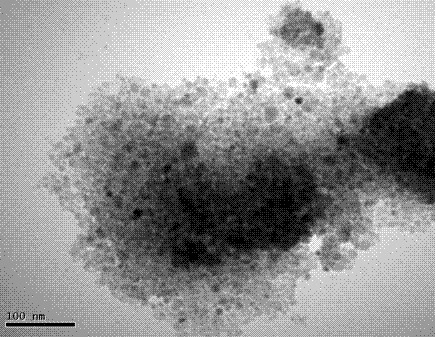

Preparation method of nano crystal MnZn ferrite with high saturation magnetization intensity

InactiveCN102211930AHigh saturation magnetizationLow blocking temperatureInorganic material magnetismParamagnetismSuperparamagnetism

The invention belongs to the technical field of magnetic materials, in particular relates to a preparation method of MnZn ferrite in a magnetic field. The method comprises the following steps: by using a phase conversion method, placing a certain amount of mixed solution of Fe, Mn and Zn metal ions in a 0-6T magnetic field; under the stirring of nitrogen at the speed of 160-260ml / min, controlling the pH value to 9-10, heating to 95 DEG C, and insulating for 3-5 hours; then filtering, washing, and drying at the temperature of 70-90 DGE C, so as to obtain nano crystal MnZn ferrite powder, wherein the obtained powder is a single-phase MnZn ferrite particle and is of a typical spinel structure, the grain size is about 7-11 nanometers, and super paramagnetism is shown within a 40-300K temperature range. The obtained MnZn ferrite material has the advantages that magnetic conductivity is large, frequency characteristic is good, saturation induction density is greatly improved on the original basis, and obstruction temperature is greatly reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Low AC loss superconductor used for superconducting magnet and manufacturing method thereof

InactiveCN101075488AReduce AC lossSuperconductors/hyperconductorsSuperconductor devicesElectrical conductorSuperconducting Coils

A low AC loss electrical conductor includes a plurality of single-filament superconducting strands longitudinally wound about one another. An insulative housing surrounds the plurality of single-filament superconducting strands.

Owner:GENERAL ELECTRIC CO

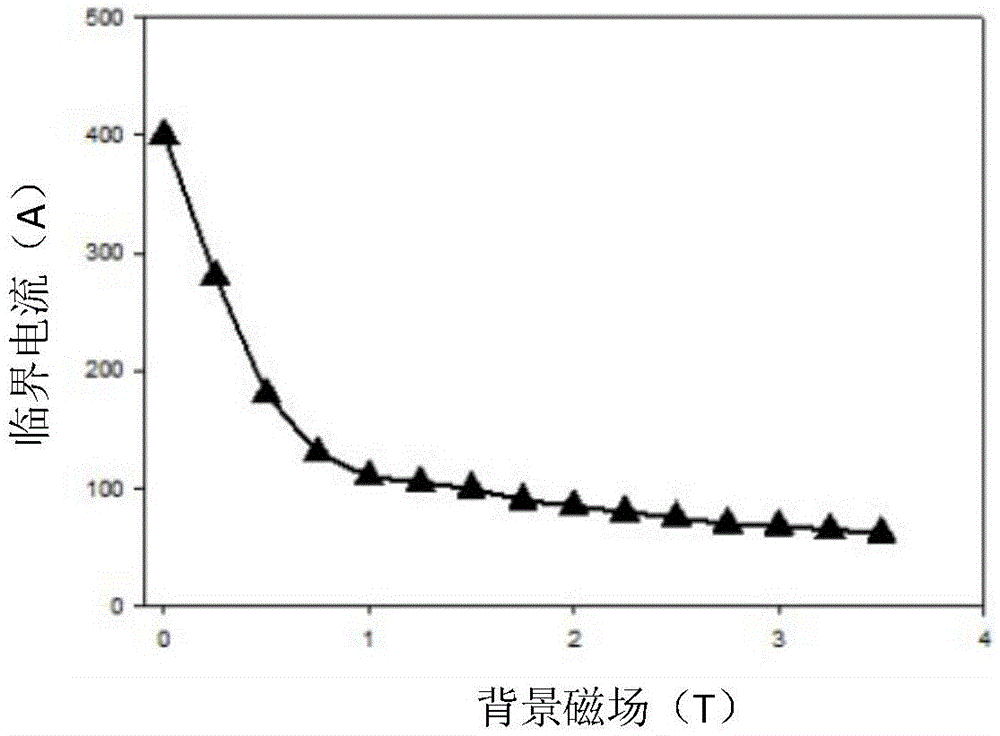

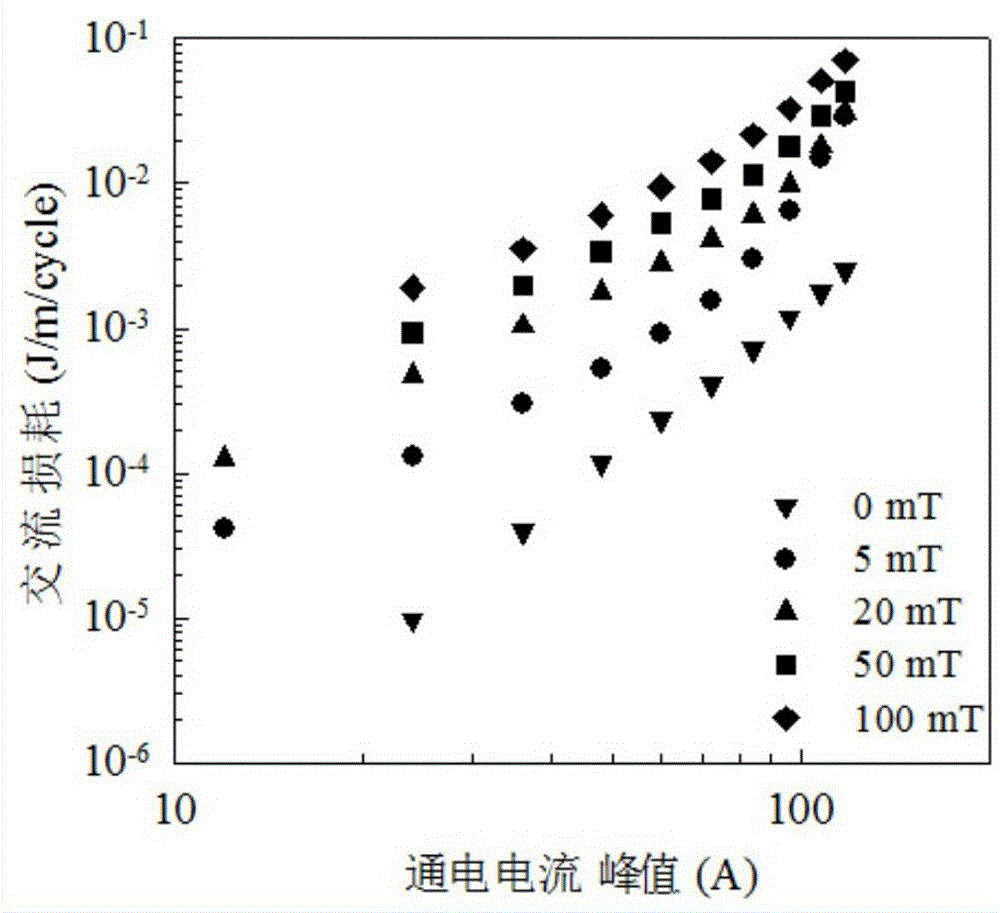

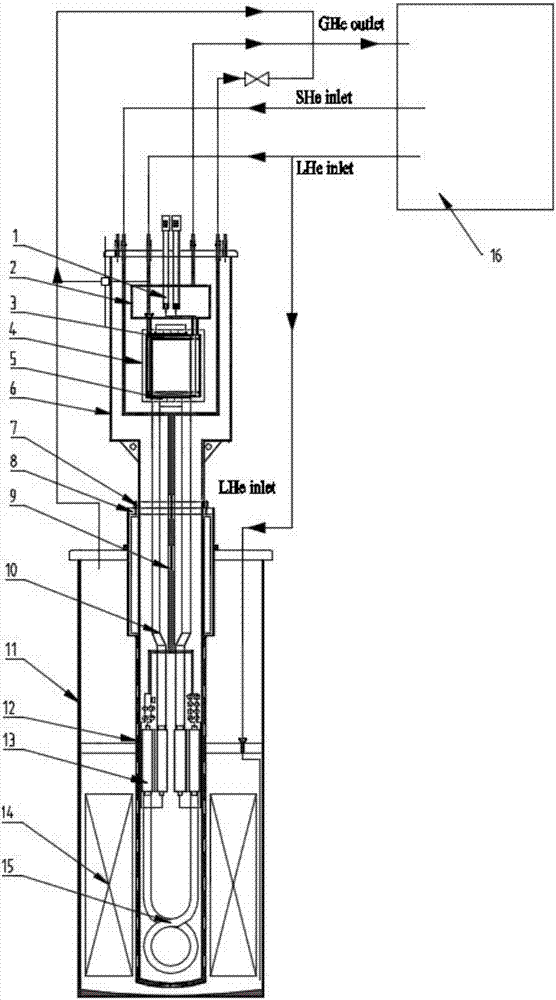

Superconductor critical current and shunt temperature test device

InactiveCN107064832AImprove the uniformity of the magnetic fieldHigh measurement accuracySuperconductive properties measurementsTransformerProtection system

The invention discloses a superconductor critical current and shunt temperature test device comprising a back field magnet, a temperature-variable sample dewar, a superconducting transformer, a cryogenic system, and a quenching detection and quenching protection system. The cryogenic system comprises a cryogenic refrigerator, a liquid helium storage tank, a superconducting transformer dewar, a back field magnet dewar, and a cryogenic transmission pipeline. The superconductor critical current and shunt temperature test device of the invention is applicable to superconductor critical current and shunt temperature test in a high back field. The maximum test back field is 10T, and the maximum test current is up to 50kA. The superconductor critical current and shunt temperature test device of the invention has the advantages of high test precision, low test cost, convenience of sample replacement, short test cycle, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

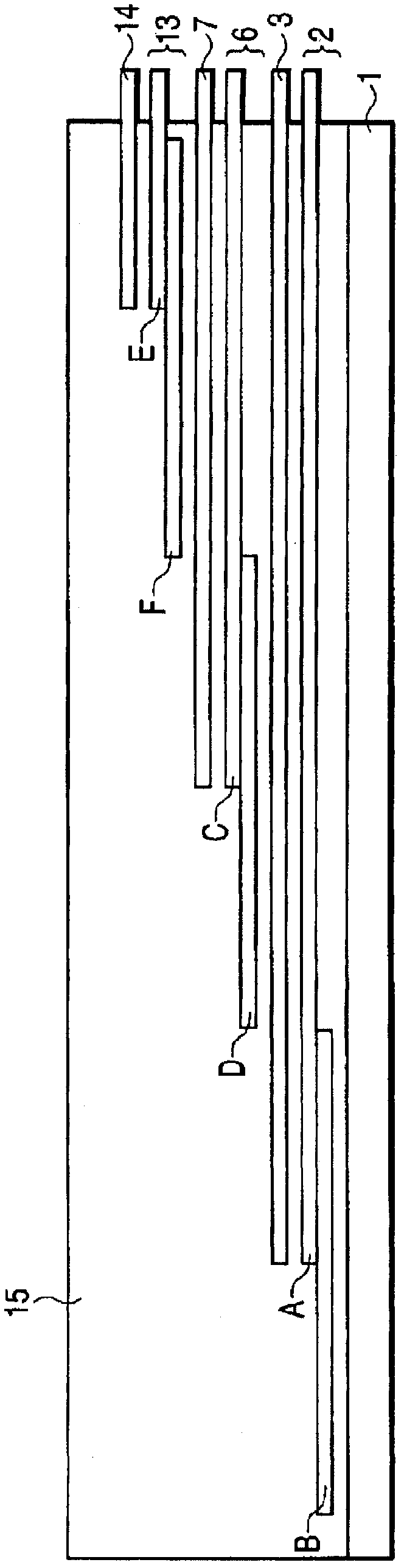

Current terminal structure of superconducting wire material and superconducting cable having this current terminal structure

ActiveCN102396112AReduce connection resistanceReduce AC lossSuperconductors/hyperconductorsCable fittings for cryogenic cablesCondensed matter physicsElectric current

A superconductor has one or more layers of a superconducting wire material including a superconducting layer formed on a substrate and wound around a former. In the superconductor, the first layer superconducting wire material wound immediately above the former is arranged so that the substrate side becomes outside and the superconducting layer side becomes inside. In a current terminal structure of the superconductor, a surface of the superconducting layer at an end of the first layer superconducting wire material, the surface being directed toward the inside, and part of a surface of the superconducting layer of a connection superconducting wire material, the surface being directed toward the outside, are faced and connected to each other.

Owner:FURUKAWA ELECTRIC CO LTD

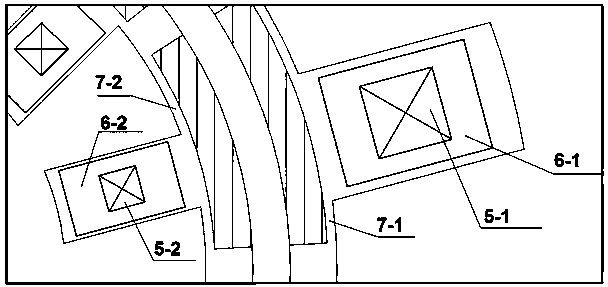

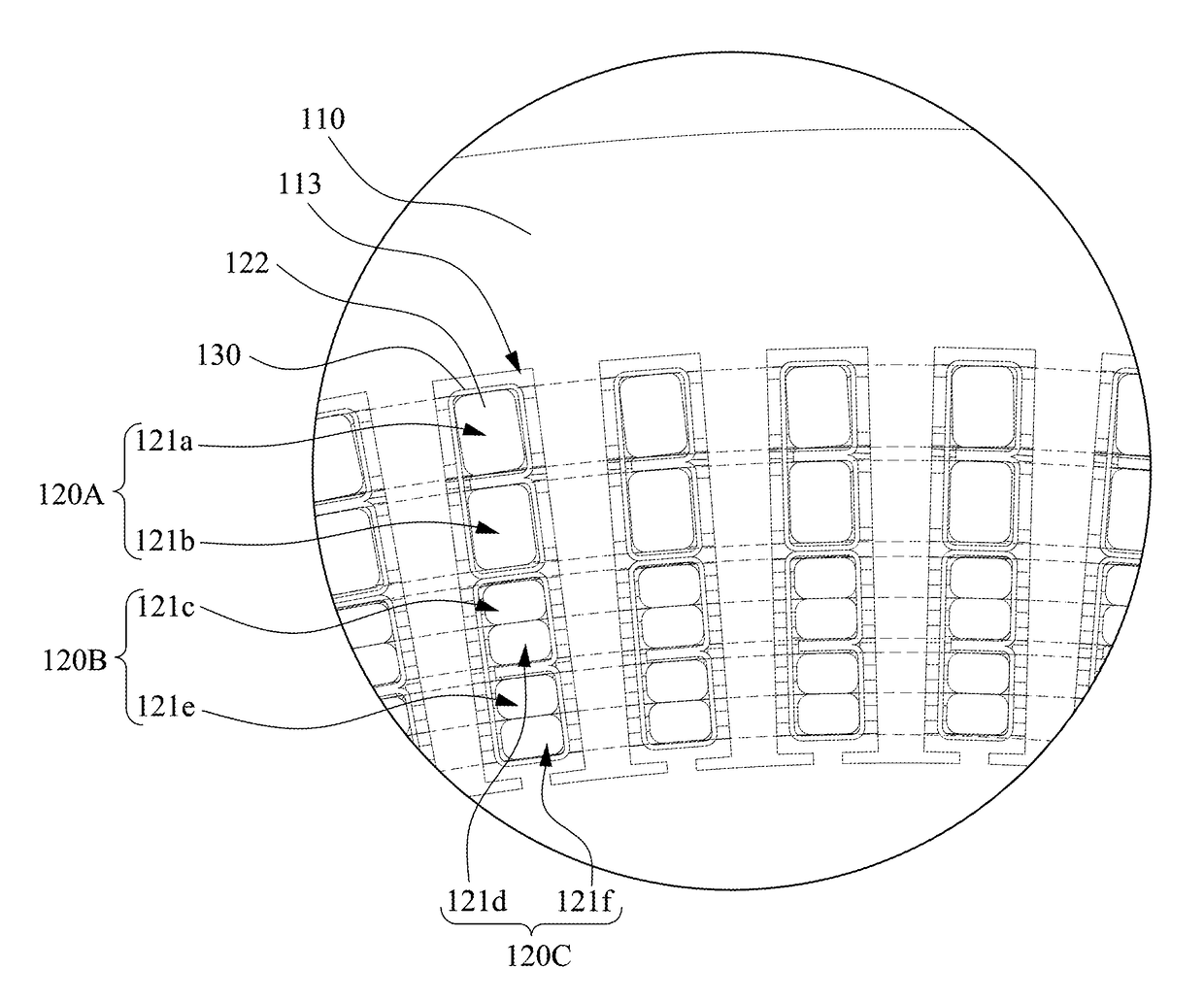

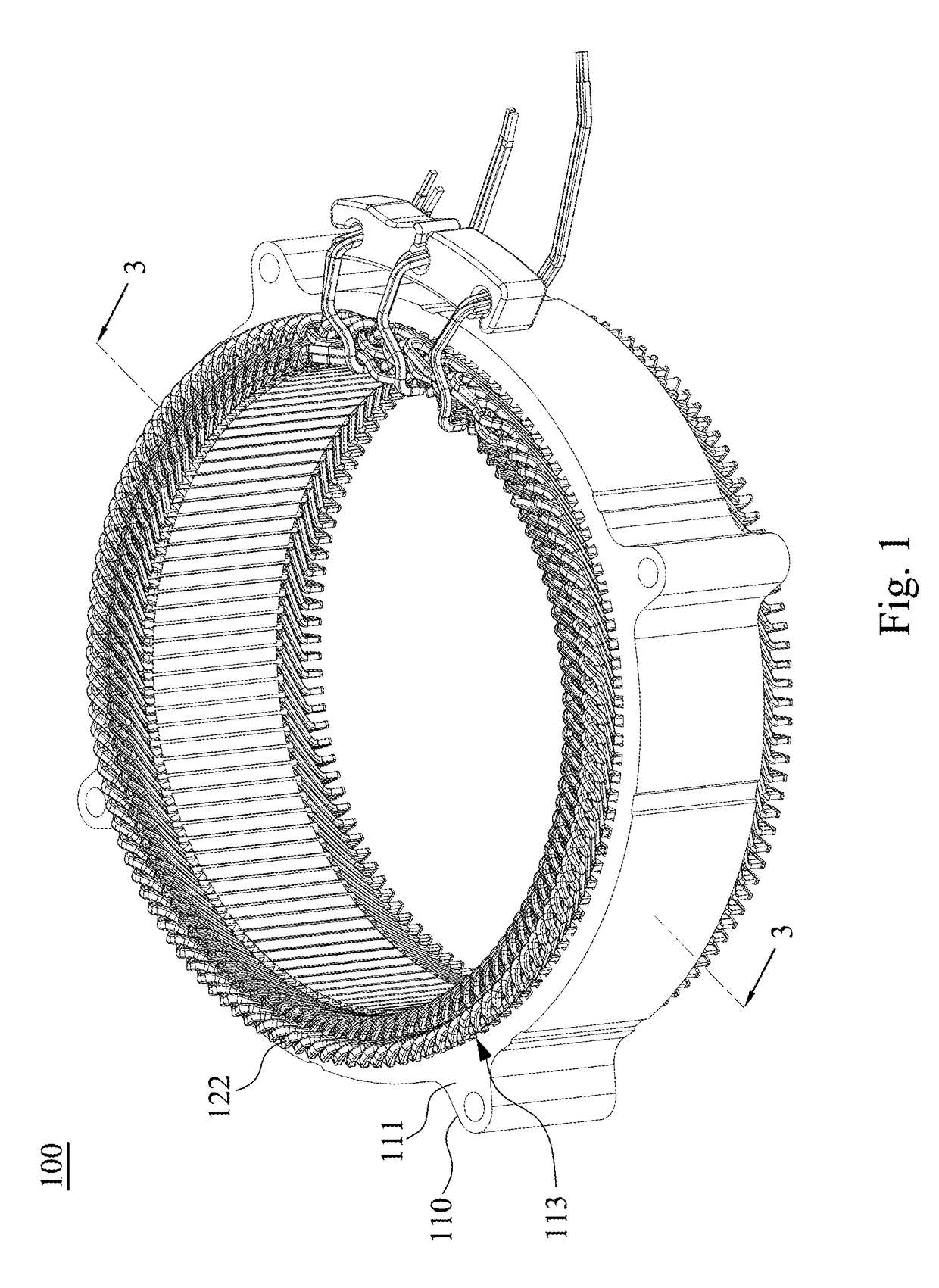

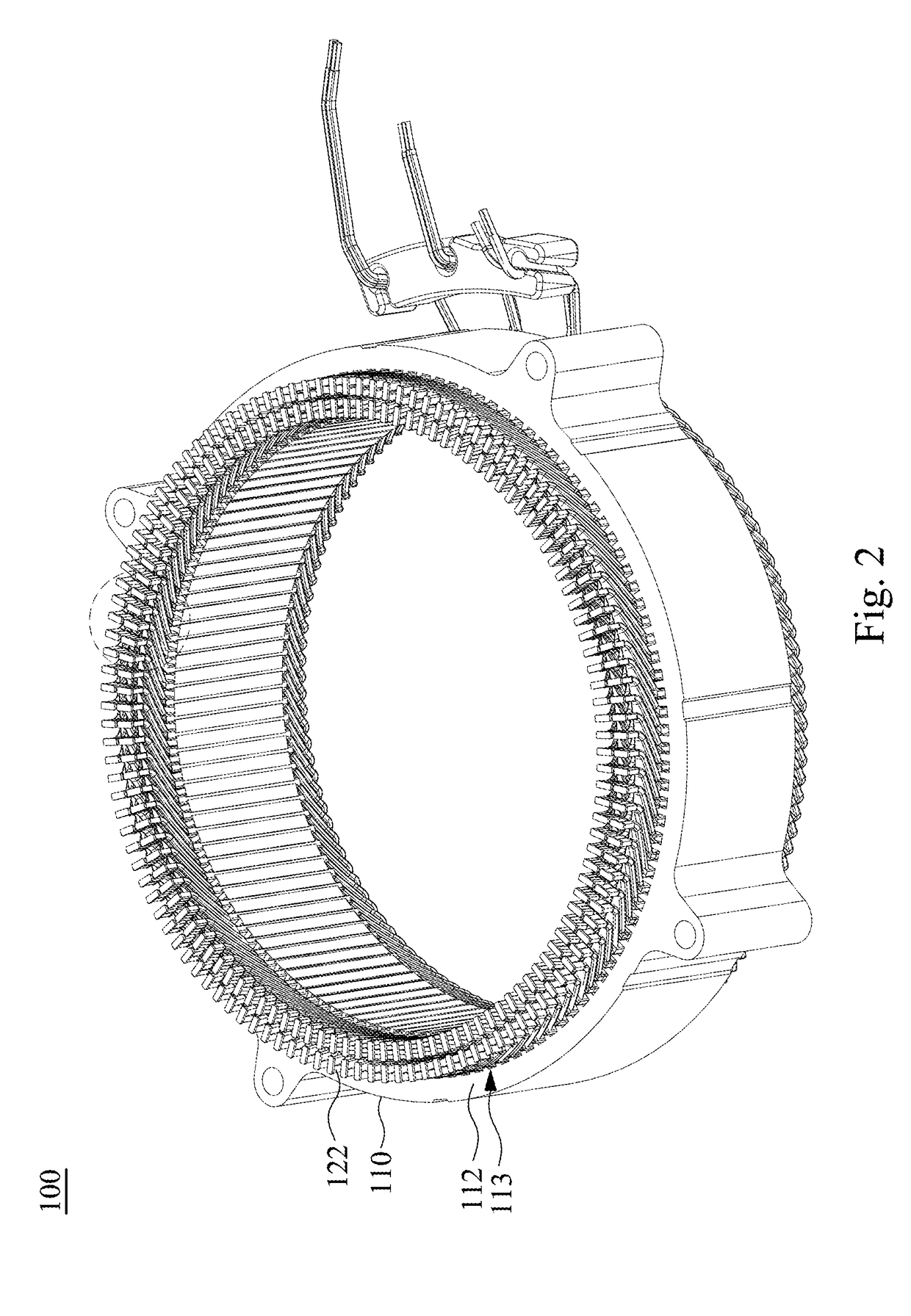

Stator

ActiveUS20180152070A1Reduce AC-lossLittle influenceWindings insulation shape/form/constructionMagnetic circuit stationary partsEngineeringConductor Coil

A stator is applied in an electrical motor. The stator includes a hollow iron core and a plurality of coil windings. The hollow iron core has two opposite surfaces and a plurality of accommodating spaces communicated with the surfaces. The accommodating spaces are arranged in an annular pattern. Each of the coil windings includes a plurality of wires winded via the accommodating spaces. Portions of the wires of the coil windings located in the accommodating spaces are radially concentrically arranged to form a plurality of winding layers. In at least one of the accommodating spaces, a wire cross-sectional area of the wire of the innermost one of the winding layers is smaller than a wire cross-sectional area of the wire of the outermost one of the winding layers.

Owner:DELTA ELECTRONICS INC

High-temperature superconducting composite conductor containing inner superconducting layer and outer superconducting layer

ActiveCN110752063ASimple structurePowerfulSuperconductors/hyperconductorsSuperconductor devicesHigh current densityElectrical conductor

The invention discloses a high-temperature superconducting composite conductor containing an inner superconducting layer and an outer superconducting layer. The superconducting composite conductor includes the inner superconducting layer and the outer superconducting layer. The inner superconducting layer includes inner superconducting layer units and filling factors which are arranged in a metalskeleton. The outer superconducting layer includes outer superconducting units winding the metal skeleton and an insulating layer outside the outer superconducting units. The superconducting compositeconductor has a simple structure and comprehensive functions, has high current-carrying performance and high current density due to the influence of a spatial magnetic field of the inner superconducting layer and the outer superconducting layer, and can further achieve good current-carrying performance in a low-temperature environment, and alternating-current loss is reduced.

Owner:CHINA ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com