Connector assembly of two low-temperature superconduction cable terminals and fabrication method of connector assembly

一种电缆终端、低温超导的技术,应用在低温电缆的电缆配件、导电连接、连接触头材料等方向,能够解决最大运行电流低、接头组件尺寸大、接头电阻波动较大等问题,达到减少交流损耗、降低接头电阻和交流损耗、结构紧凑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

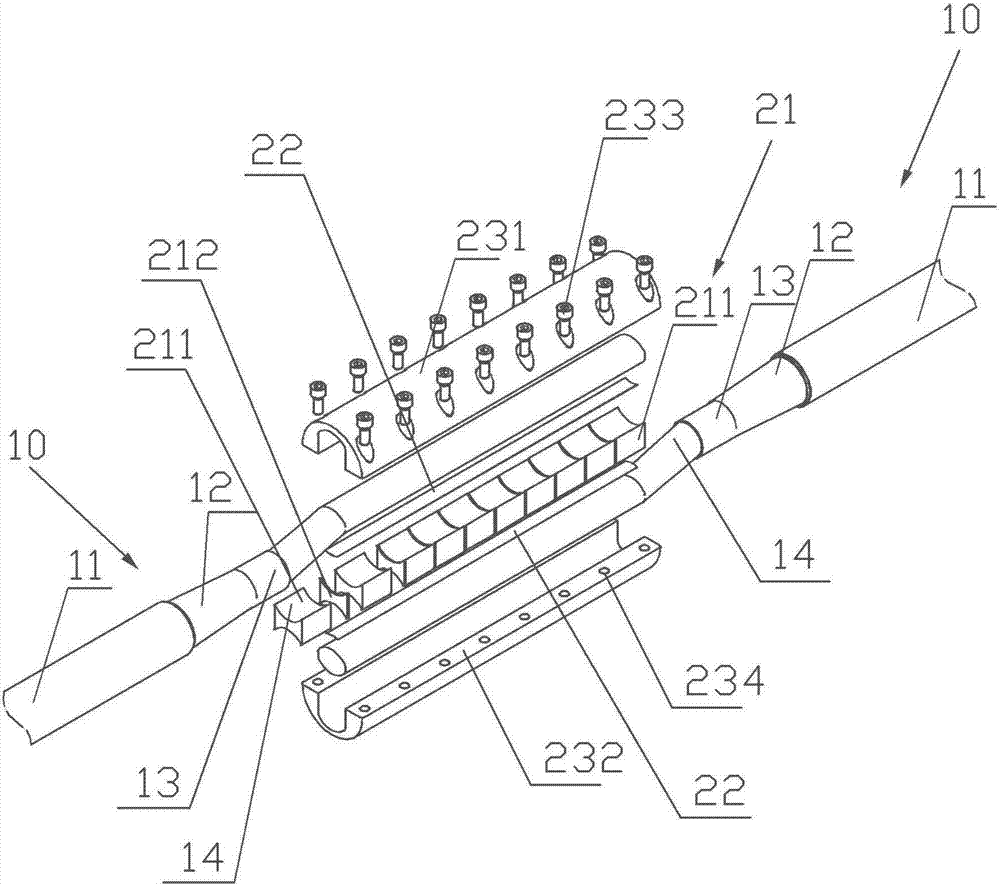

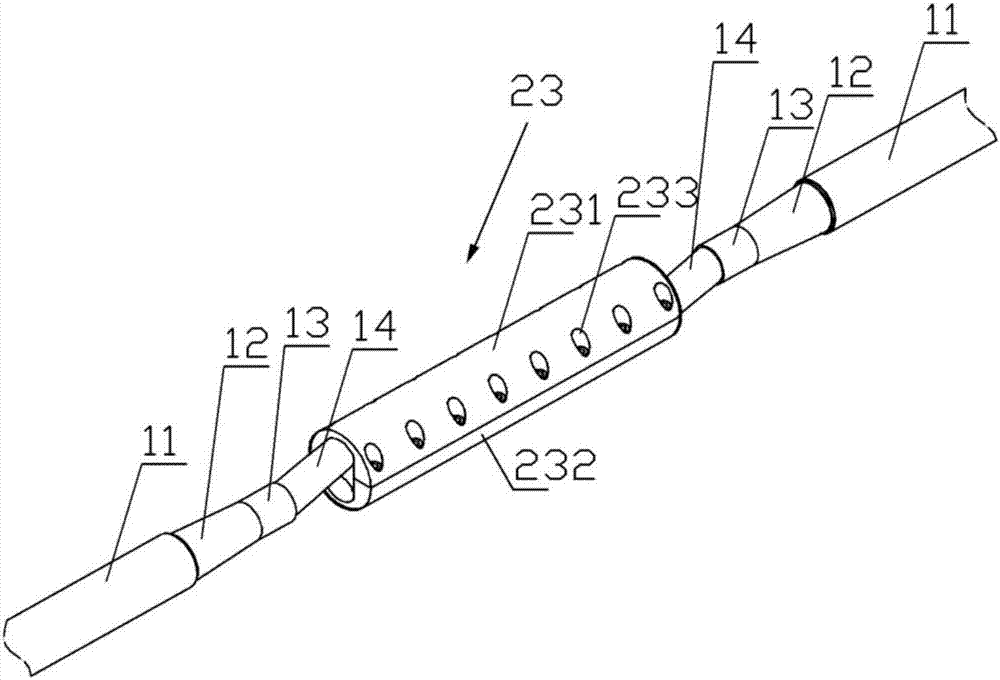

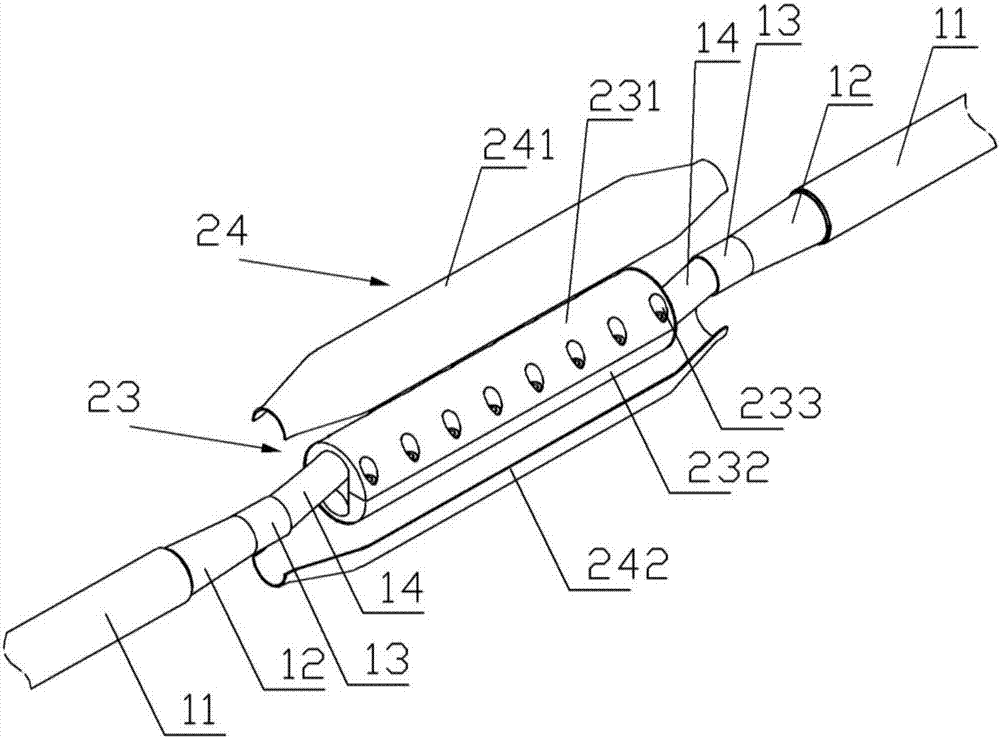

[0034] Combine below Figure 1 to Figure 7 , the two low-temperature superconducting cable terminal connection joint assembly and the manufacturing method thereof of the present invention are described in detail.

[0035] like figure 1 and Figure 5 As shown, the two low-temperature superconducting cable terminal connection joint assemblies of the present embodiment have copper pads 21 respectively provided with two low-temperature superconducting cable terminals 10 in parallel on both sides, and are sandwiched between the two low-temperature superconducting cable terminals 10 and the copper pads. The second solder layer 22 between the layers 21, the clamp mechanism 23 wrapped on the outer surface of the two low-temperature superconducting cable terminals 10, the stainless steel inner shell 24 arranged on the outer surface of the clamp mechanism 23, and the outer surface of the inner shell 24 The stainless steel outer shell 25. Wherein, the low temperature superconducting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com