Patents

Literature

96 results about "Thermonuclear fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermonuclear fusion is a way to achieve nuclear fusion by using extremely high temperatures. There are two forms of thermonuclear fusion: uncontrolled, in which the resulting energy is released in an uncontrolled manner, as it is in thermonuclear weapons ("hydrogen bombs") and in most stars; and controlled, where the fusion reactions take place in an environment allowing some or all of the energy released to be harnessed for constructive purposes. This article focuses on the latter.

Manufacturing method of stainless steel large forging for thermonuclear fusion reactor

ActiveCN104174796AReduce surface cracksSmall crack depthMetal-working apparatusSS - Stainless steelIngot

The invention discloses a manufacturing method of a stainless steel large forging for a thermonuclear fusion reactor. The manufacturing method comprises the following steps: (1) preprocessing of a steel ingot; (2) heating of the steel ingot; (3) forging of the steel ingot; (4) twice upsetting forging and twice drawing out of the ingot; (5) shaping of the finished product; (6) heating processing of finished product forgings, wherein the finally obtained the stainless steel large forging is 300-1000 mm in thickness, 300-1800 mm in width and 500-2200 mm in length. The manufacturing method realizes that the grain size of the stainless steel large forging is greater than or equal to the second level, the depth of surface cracks of the stainless steel large forging is less than 1 mm, and the stainless steel large forging satisfies the quality requirement of the thermonuclear fusion reactor (the ITER Plan included).

Owner:NORTHEASTERN UNIV +1

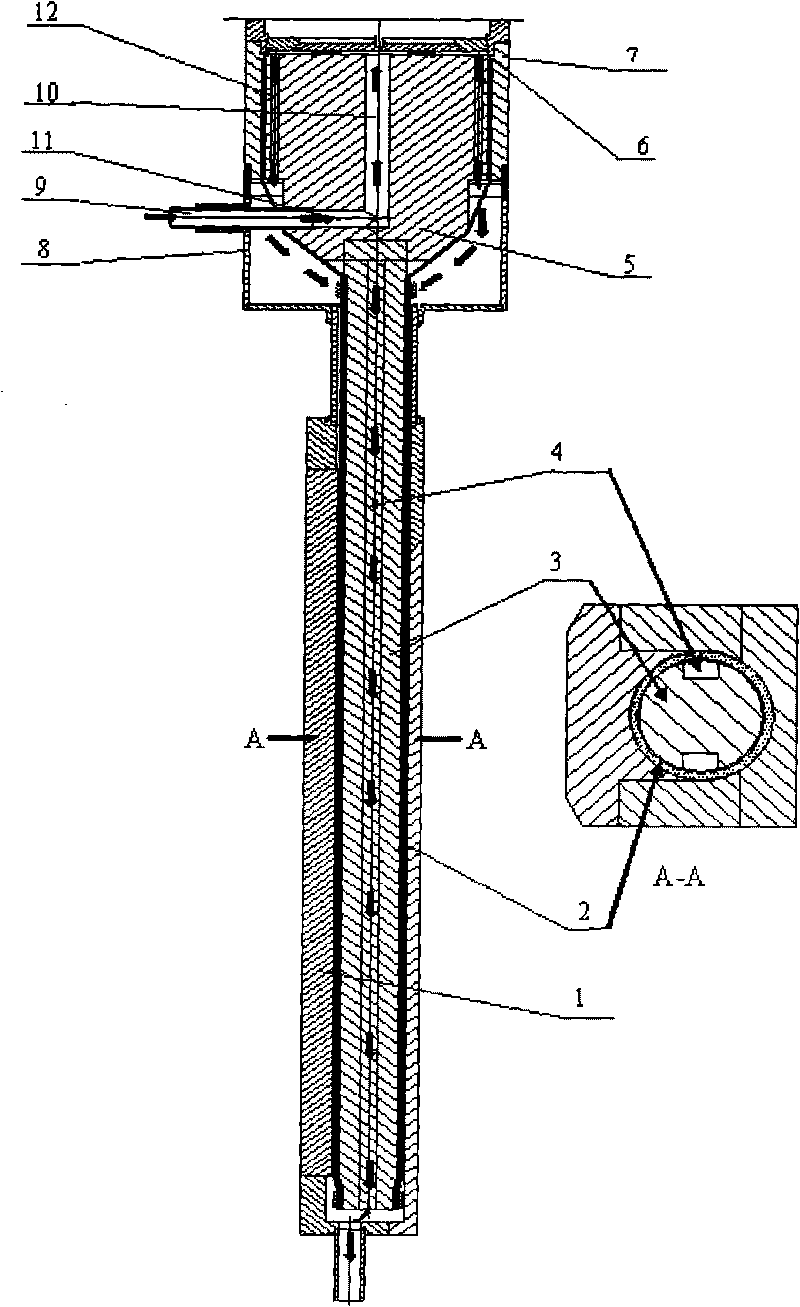

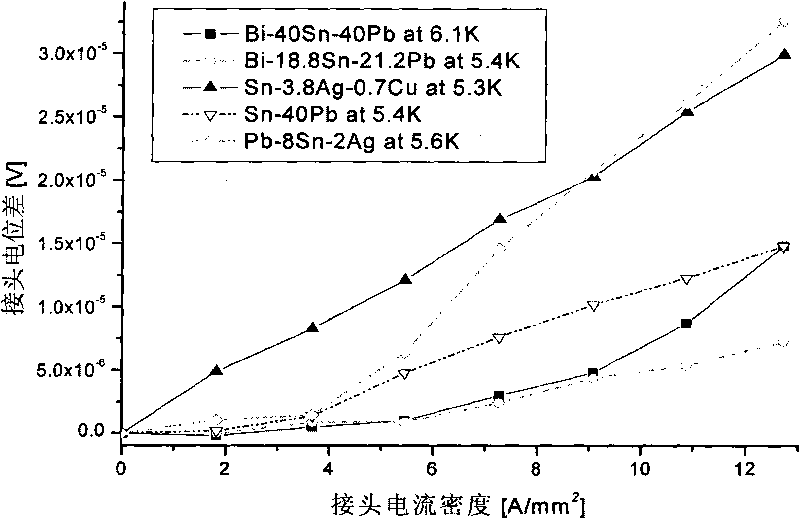

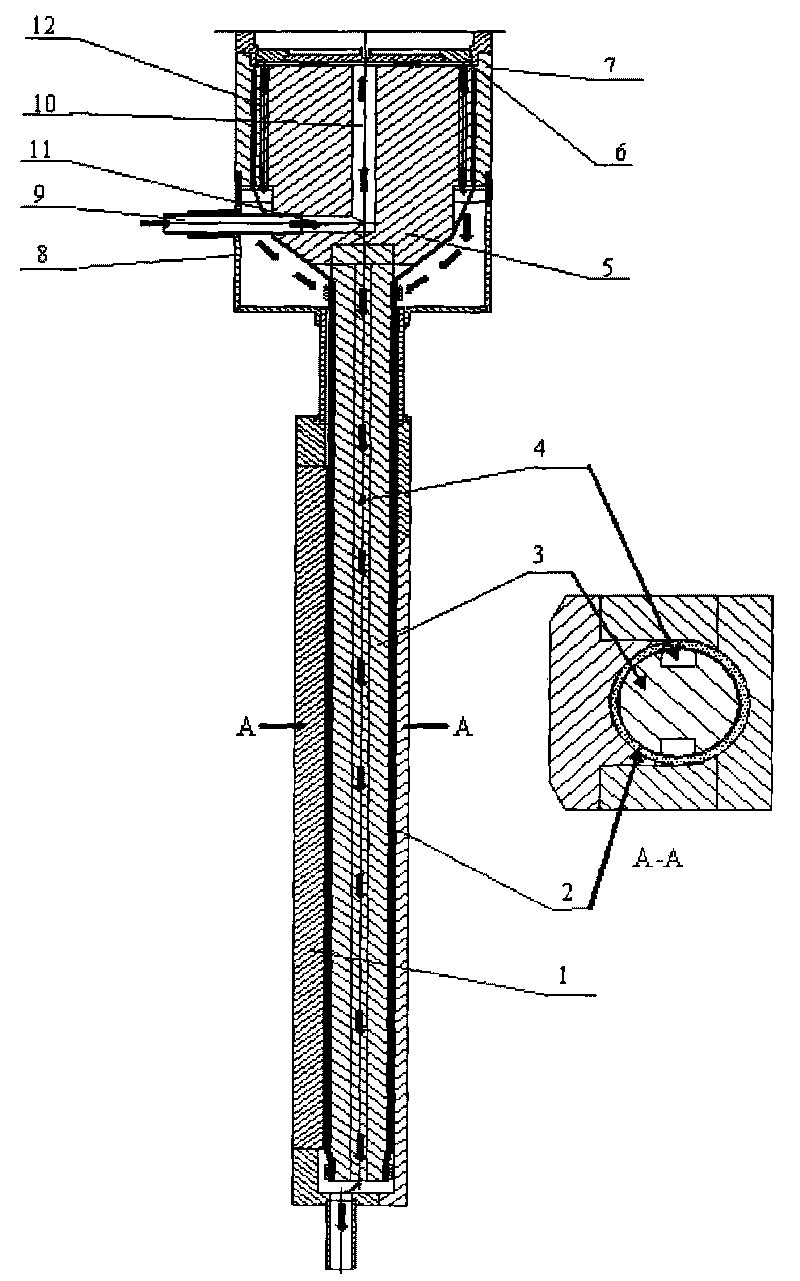

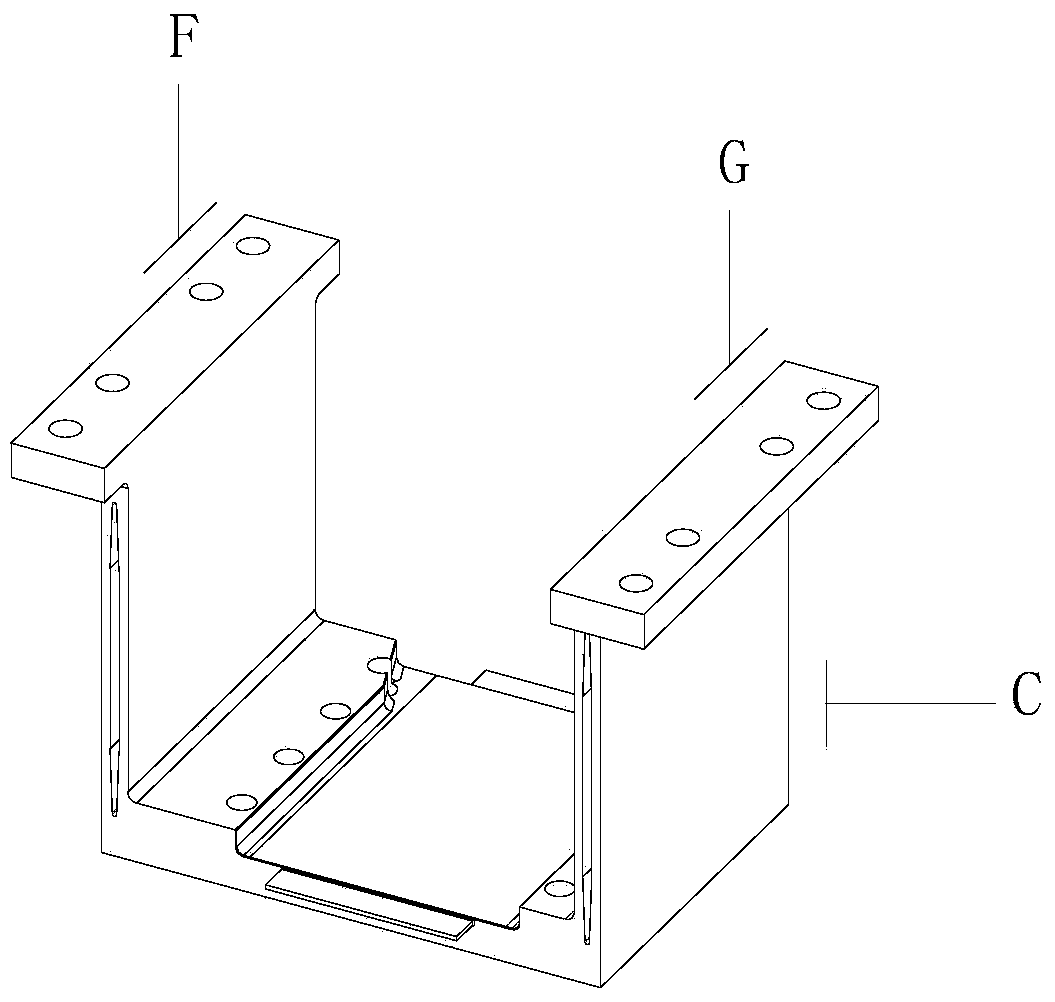

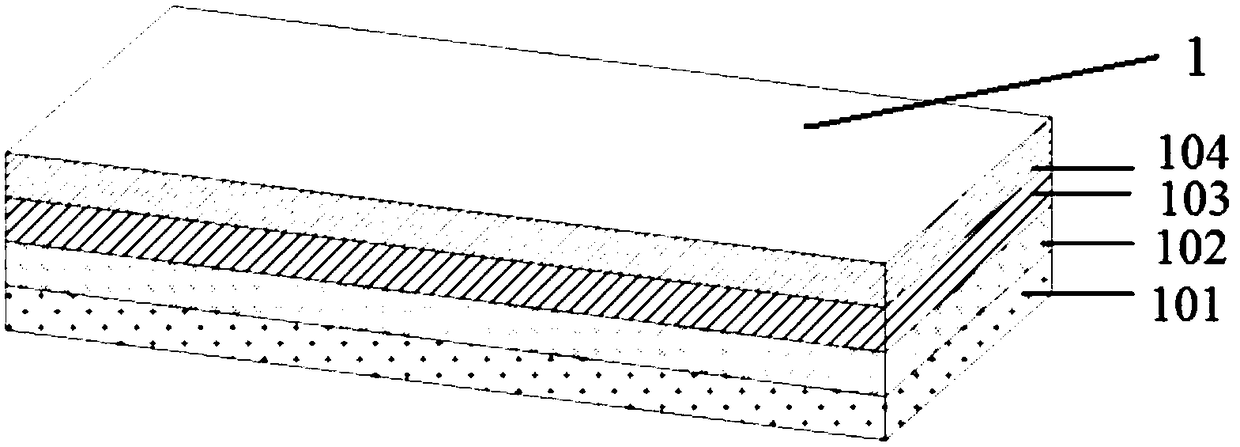

Low temperature superconducting assembly with low joint resistance for high temperature superconducting current lead cold end

InactiveCN101694908ASatisfy <1 nano-oh requirementSuperconducting magnets/coilsConnection contact member materialElectrical resistance and conductanceHigh-temperature superconductivity

The invention discloses a low temperature superconducting assembly with low joint resistance for a high temperature superconducting current lead cold end. The resistance of a 40-70kA high temperature superconducting super current lead of which the lower end is connected with a low temperature superconducting bus must be as low as 1 nano-ohm. A rectangular section niobium-titanium / copper superconducting wire or a high conductivity copper material and a paired box type joint structure connected with the superconducting bus are adopted in the low temperature superconducting assembly. Tests prove that the joint resistance of the low temperature superconducting assembly and a high temperature superconducting assembly can be as low as 0.5 nano-ohm, and the joint resistance of the superconducting bus is lower than 1 nano-ohm. The low temperature superconducting assembly is a middle result for developing super current leads of an international thermonuclear fusion test reactor and has the characteristics of novel conception and low manufacturing cost.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

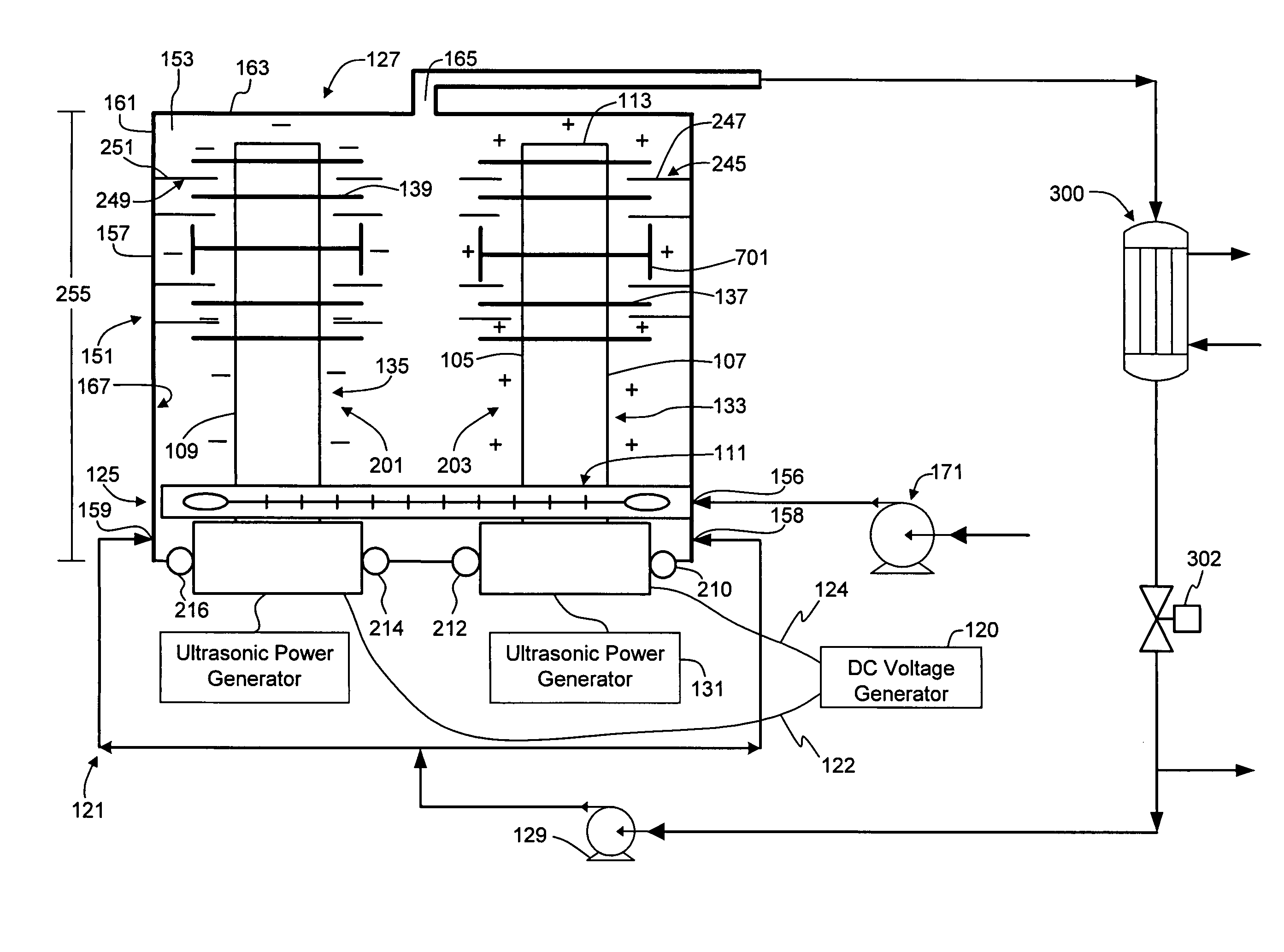

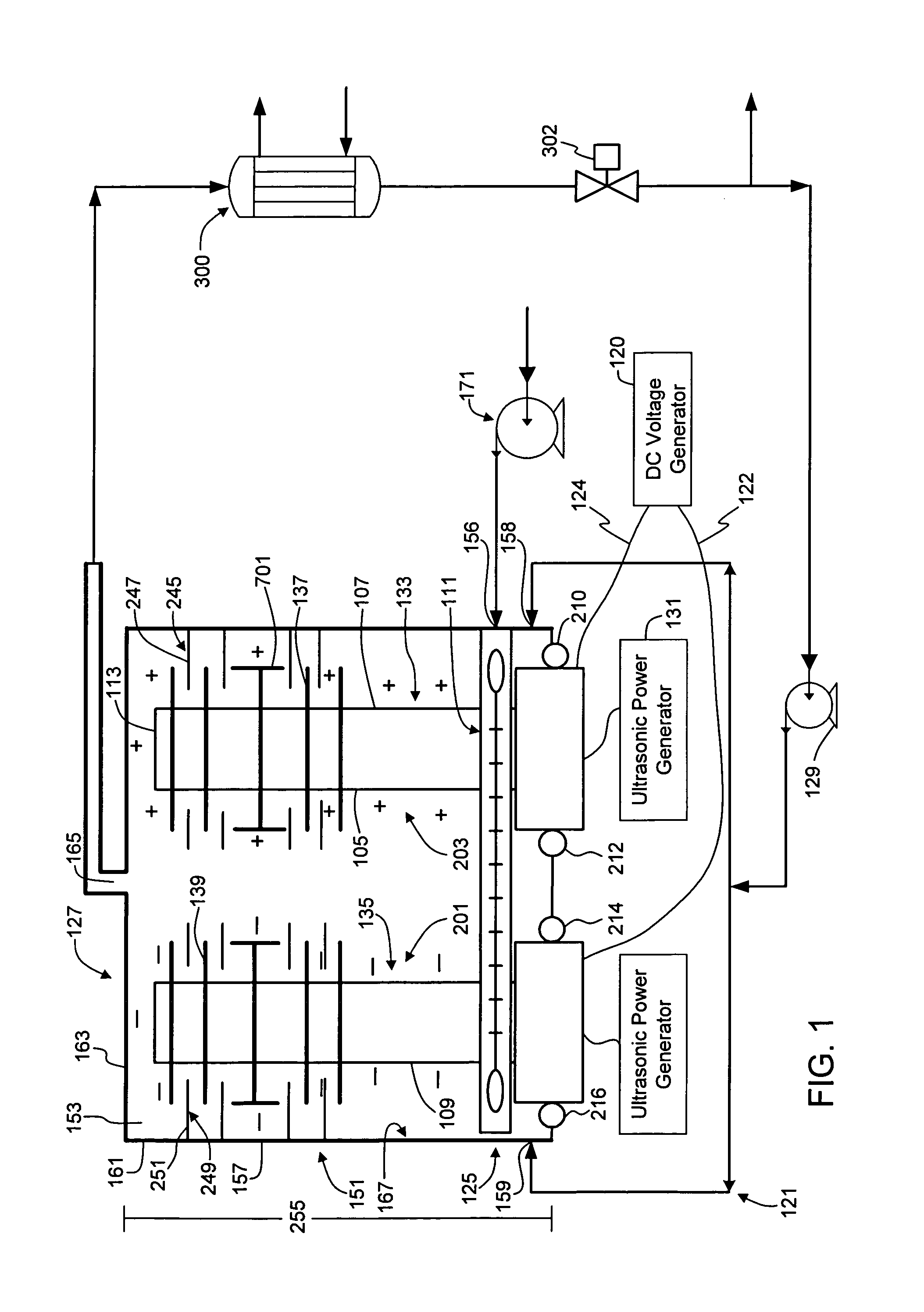

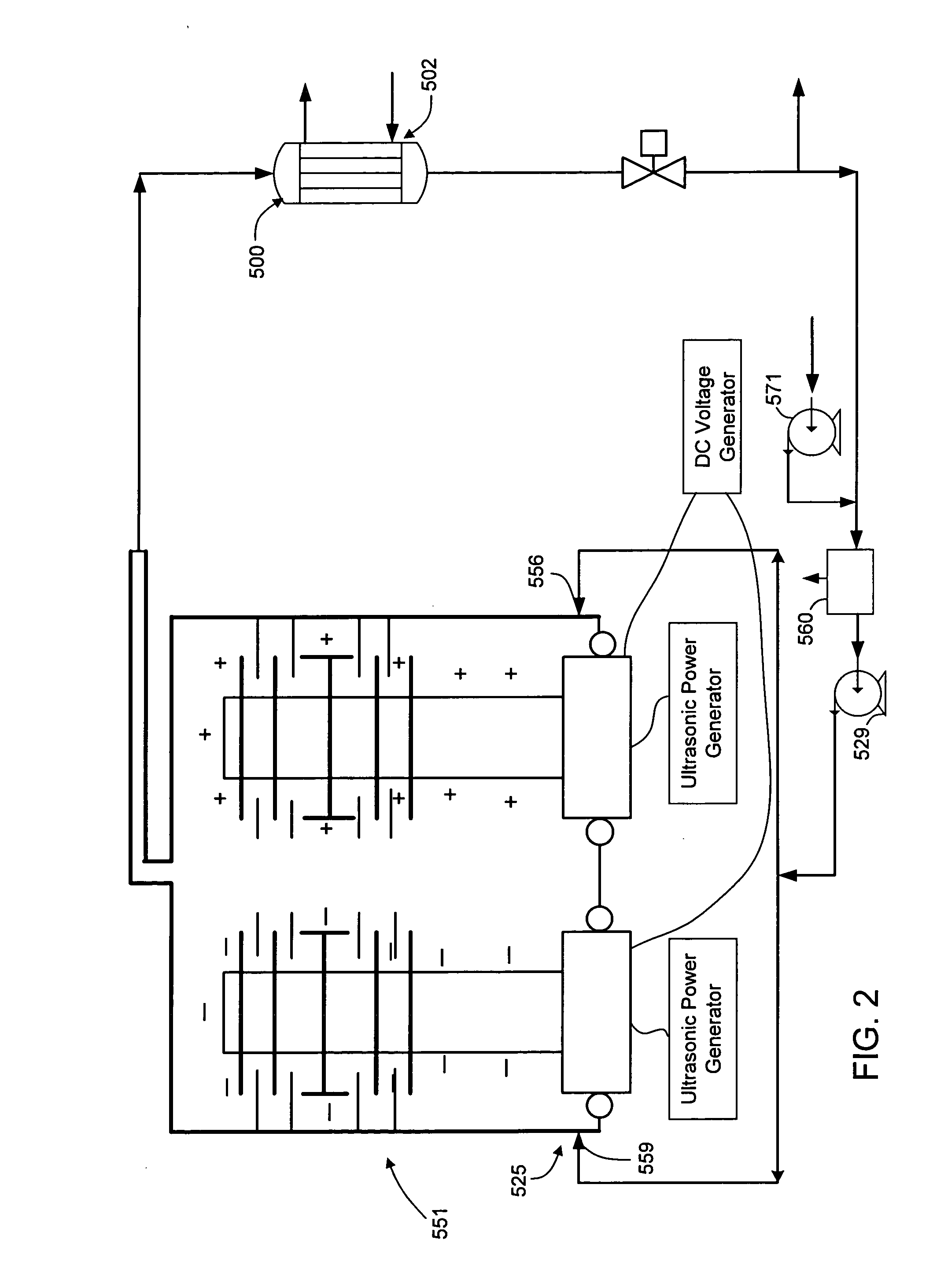

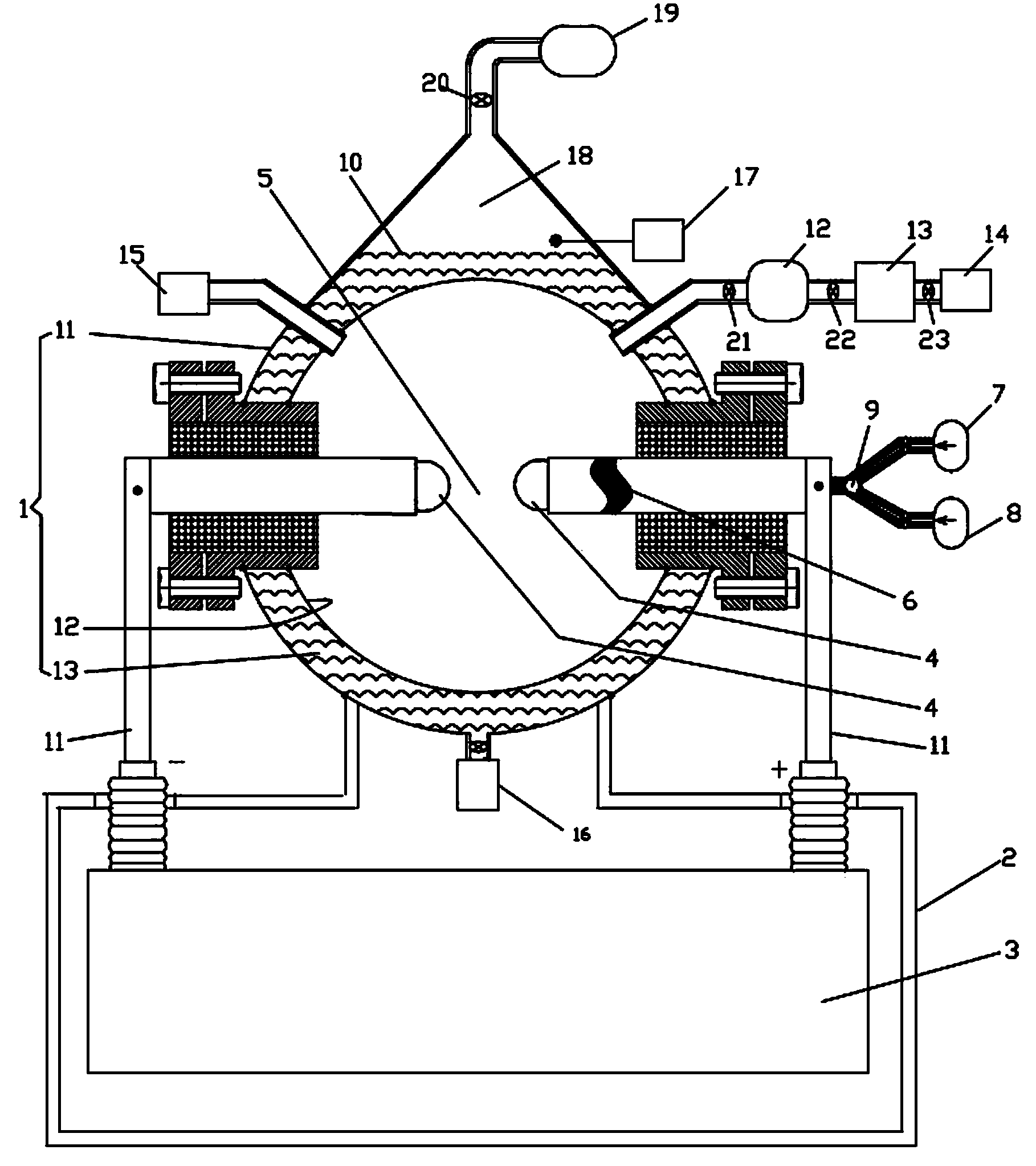

Ultrasonic treatment chamber for initiating thermonuclear fusion

InactiveUS20090147905A1Nuclear energy generationLow temperature fusion reactorElectrode potentialUltrasonic cavitation

A thermonuclear fusion system having a treatment chamber in which gas isotopes are fused to initiate a thermonuclear fusion reaction is disclosed. Specifically, the treatment chamber has an elongate housing through which liquid and gas isotopes flow longitudinally from an inlet port to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency and a predetermined electrode potential to ultrasonically enhance the concentration of dissolved hydrogen gas isotopes within the housing or energize and electrolyze the liquid and gas isotopes within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the liquid and gas isotopes being treated in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Explosive welding method for bimetal composite boards with special quality requirements

InactiveCN103056508AReliable weldingMeet welding quality requirementsNon-electric welding apparatusBond interfaceCharged body

The invention discloses an explosive welding method for bimetal composite boards with special quality requirements. The explosive welding method includes preprocessing blanks; charging powder; and performing explosive welding. In a powder charging procedure, 'basin'-shaped powder charge bodies are arranged on shroud plates and extension plates, upper and lower surfaces of the powder charge bodies are parallel to the shroud plates and the extension plates, and powder charging quantities are acquired by computing according to a formula. The welded rate of the composite boards welded by the explosive welding method reaches 100%, the bonding strength of welded surfaces of the bimetal composite boards meet a bimetal solid-phase metallurgical bonding strength law, bonding interfaces of the bimetal composite boards are finely wavy and are excellent in quality, and accordingly the quality requirements of critical equipment of thermonuclear fusion power generation test reactors on the composite boards are met.

Owner:中国人民解放军理工大学野战工程学院 +2

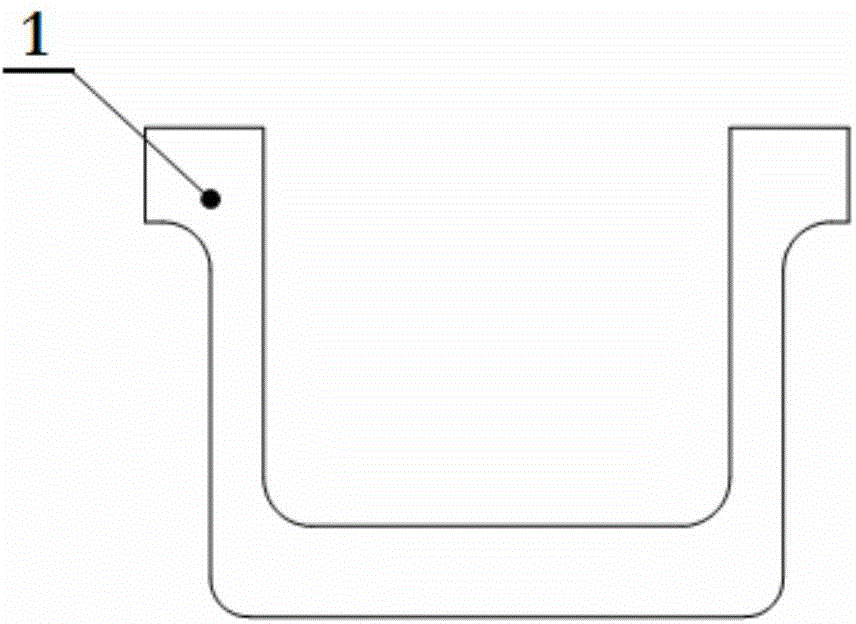

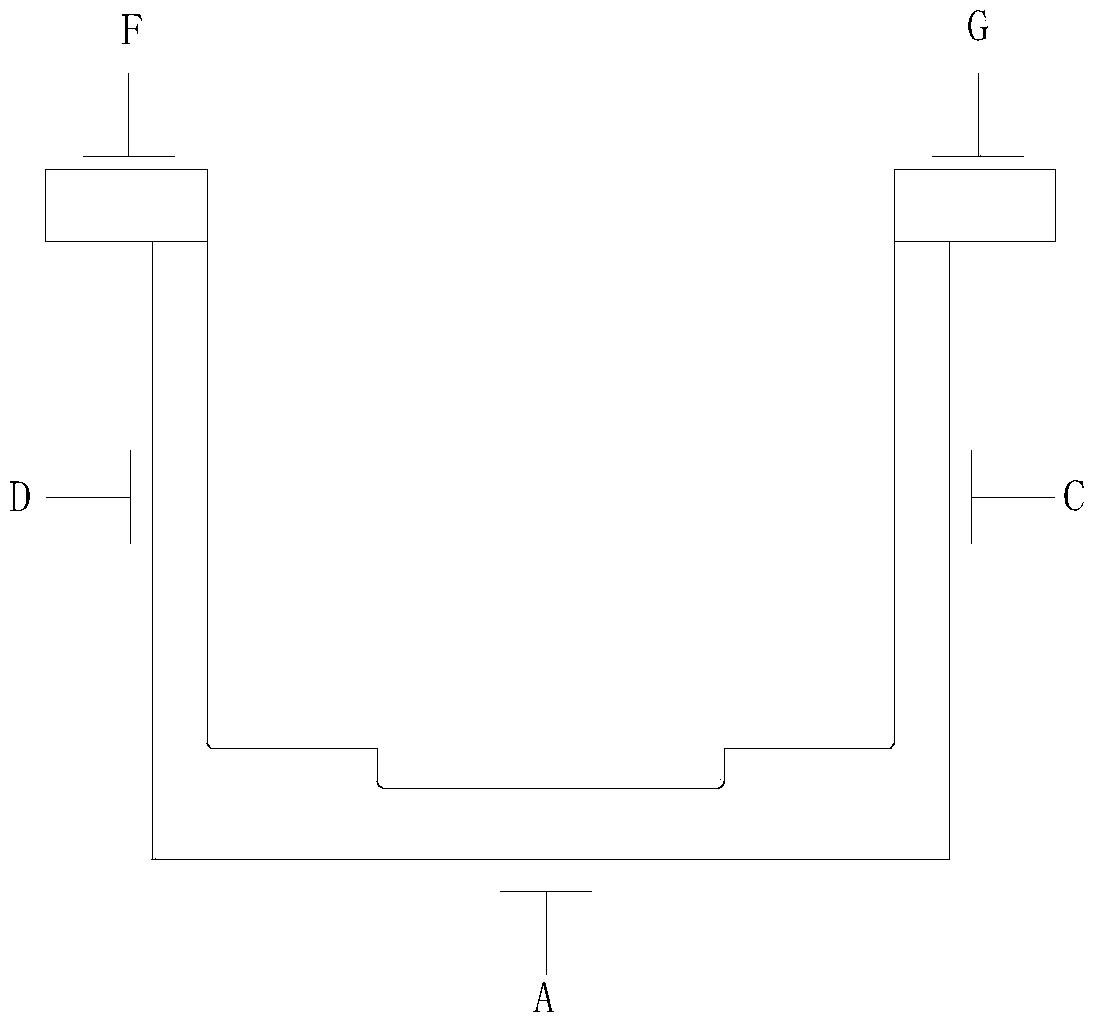

Method for forging double-lug U-shaped forged piece for thermonuclear fusion reactor

ActiveCN104162616AUniform deformationMeet the use requirementsMetal-working apparatusMetal fibersIngot

The invention discloses a method for forging a double-lug U-shaped forged piece for a thermonuclear fusion reactor. The method comprises the steps that firstly, a raw material ingot is heated to an initial forging temperature; secondly, a circular-ring-shaped blank is manufactured through the process of upsetting, punching, chambering and rounding, the circular-ring-shaped blank is forged into a rectangular-ring-shaped blank, the rectangular-ring-shaped blank is sawn off from the middle, and U-shaped blanks are obtained; thirdly, pressing is conducted through a hollow punch, so that the bottom of each U-shaped blank deforms to meet the size requirement; fourthly, the U-shaped blanks and the hollow punch are turned over together, each U-shaped blank is stretched, so that double-lug U-shaped blanks are obtained, and each double-lug U-shaped blank and the hollow punch are placed into a double-lug upsetting forming die together for overall upsetting; finally, the double-lug U-shaped forged piece is obtained. According to the method for forging the double-lug U-shaped forged piece for the thermonuclear fusion reactor, the metal fiber flow of the forged piece is distributed according to the shape of the product through integrated forging forming of complicated-structure parts, the structure is even, grain refinement is achieved, the shape is regular, and the special use demand of the thermonuclear fusion reactor can be met.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

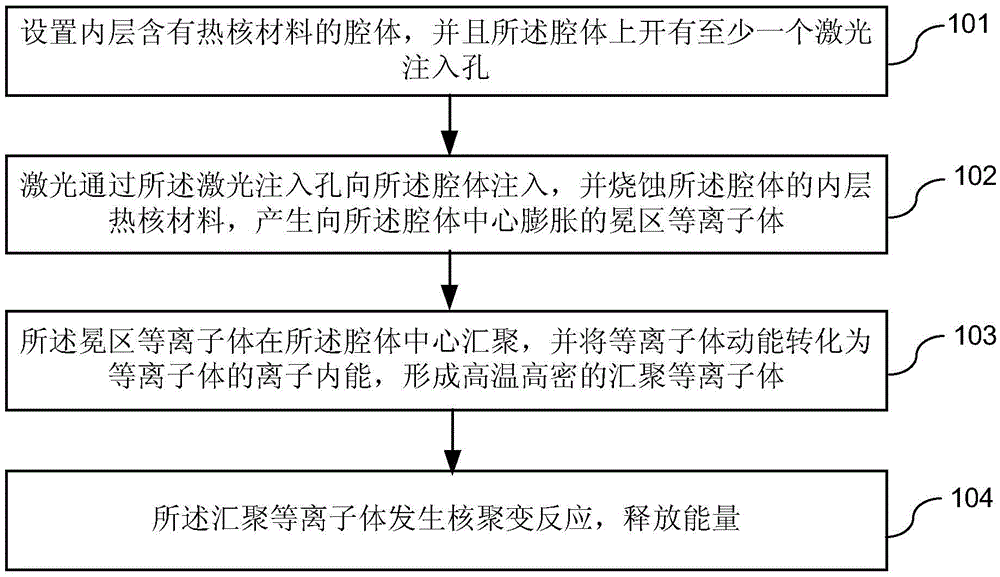

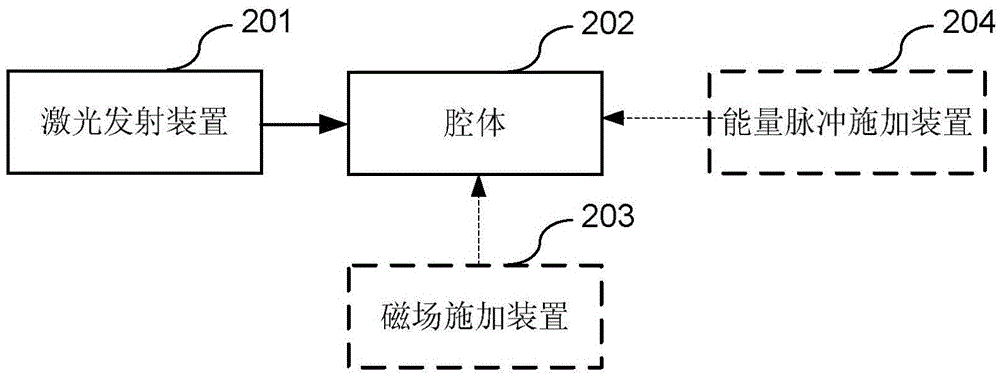

Thermonuclear fusion generating method and system

ActiveCN105575444AReduce the rate at which energy is lostImprove energy efficiencyNuclear energy generationThermonuclear fusion reactorHigh densityNuclear fusion

The invention discloses a thermonuclear fusion generating method and system. The method includes the following steps that: a cavity of which the inner layer contains a thermonuclear material is preset, and at least one laser injection hole is formed in the cavity; laser passes through the laser injection holes so as to be injected into the cavity and ablate the thermonuclear material of the inner layer of the cavity, so that coronal plasmas which are expanded towards the center of the cavity are generated; the coronal plasmas converge at the center of the cavity, and the kinetic energy of the plasmas is converted into the ion intrinsic energy of the plasmas, so that high-temperature and high-density converged plasmas can be formed; a nuclear fusion reaction occurs on the converged plasmas, and energy is released. With the thermonuclear fusion generating method and system provided by the technical scheme of the invention adopted, the temperature of an ignition hot spot can be increased, and stable high-fusion output can be realized.

Owner:INST OF APPLIED PHYSICS & COMPUTATIONAL MATHEMATICS

Method for adding nitrogen into stainless steel used for thermonuclear fusion reactor

The invention relates to a method for adding nitrogen into stainless steel used for a thermonuclear fusion reactor. The method comprises the following steps of: I, pouring molten steel meeting requirements of an AOD (argon oxygen decarburization) furnace into the AOD furnace to be smelted; II, carrying out a process for controlling nitrogen component of the AOD furnace, namely blowing argon and stirring before tapping, wherein argon blowing-in amount target value Y is calculated according to the following formula: Y=17.5e-0.002X, X (ppm) is the target nitrogen content of a product, and Y (cubic meter per ton of steel) is amount of argon blown into the molten steel; and III, carrying out an LF (ladle furnace) process, comprising the steps of pouring the molten steel into an LF, controlling LF bottom blowing nitrogen flow to be 0.2-1.0L / min per ton of steel when the nitrogen content of the molten steel is at the target range requirement, carrying out LF furnace nitrogen bottom blowing to increase nitrogen content when the nitrogen content of the molten steel is lower than target requirement, wherein the amount of nitrogen blown into the molten steel is calculated according to the following formula: W=K / (2.0*m), K is nitrogen content added value required by the product, m is time for blowing nitrogen, and W is flow rate of nitrogen blown into the molten steel; and tapping when composition requirement of the molten steel is met. By applying the method for adding nitrogen provided by the invention, the nitrogen content can be easily controlled to be within the target range.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

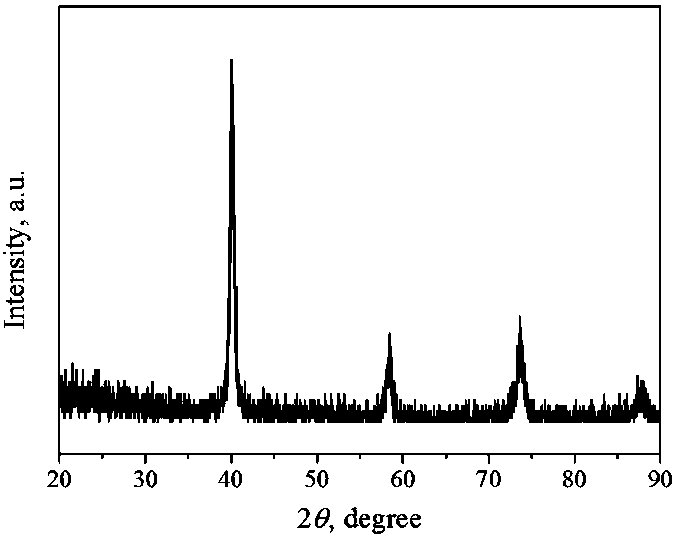

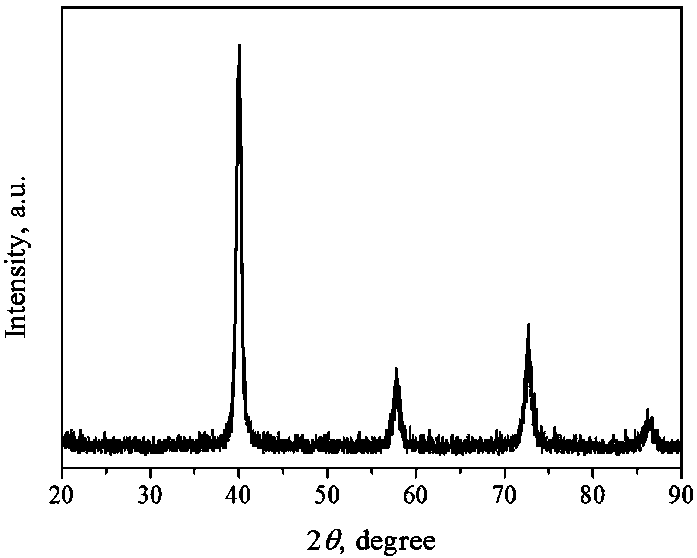

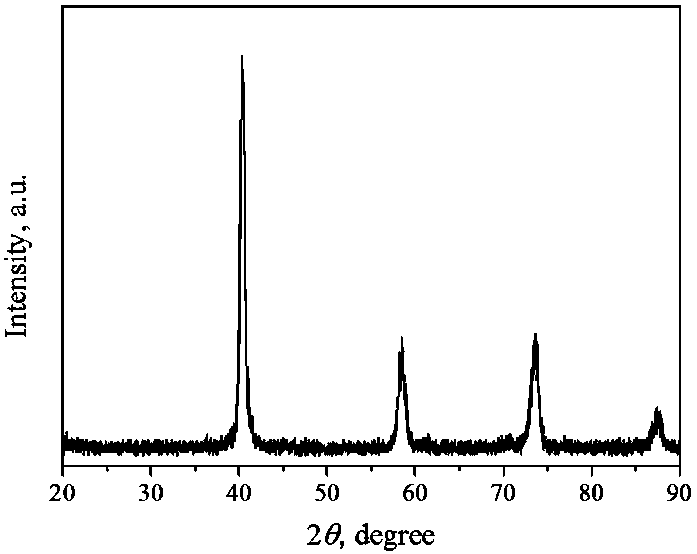

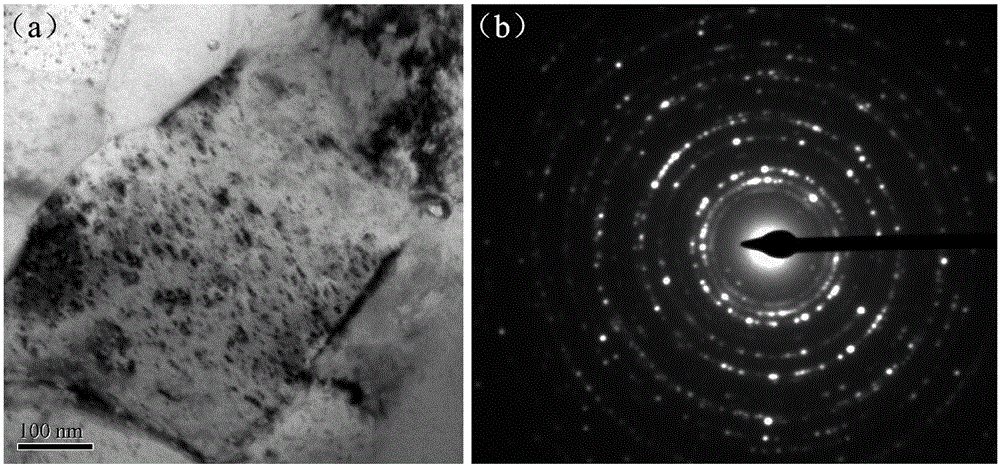

Five tungsten-based high-entropy alloys and preparation method thereof

InactiveCN111254339AAvoiding problems with elements with high neutron activation coefficientsLow neutron activation coefficientNuclear energy generationThermonuclear fusion reactorHigh entropy alloysTungsten alloy

The invention discloses tungsten-based high-entropy alloys and a preparation method thereof, belongs to the field of high-entropy alloys and tungsten alloy materials, in particular to the field of a first wall material facing plasma in a thermonuclear fusion reactor, and aims to solve the problems that existing tungsten-containing high-entropy alloys are poor in plasticity at normal temperature and almost contain high-neutron activation coefficient elements such as Nb and Mo, which are very unfavorable for future application in the international thermonuclear fusion reactor. The tungsten-basedhigh-entropy alloys are one or more of a W-V-Ti alloy, a W-V-Ta alloy, a W-Ti-Ta alloy, a W-Ti-V-Ta alloy and a W-Ti-V-Ta-Re alloy. Tests show that a single body-centered cubic structure is formed intypical alloys of five tungsten high-entropy alloy systems, and some alloys have excellent compression resistance. Meanwhile, the problem that the existing tungsten-containing high-entropy alloys almost contain the high-neutron activation coefficient elements is effectively solved, the contained elements of the tungsten-based high-entropy alloys have a low neutron activation coefficient, and thetungsten-based high-entropy alloys are beneficial to future application in the international thermonuclear fusion reactor and have high application value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

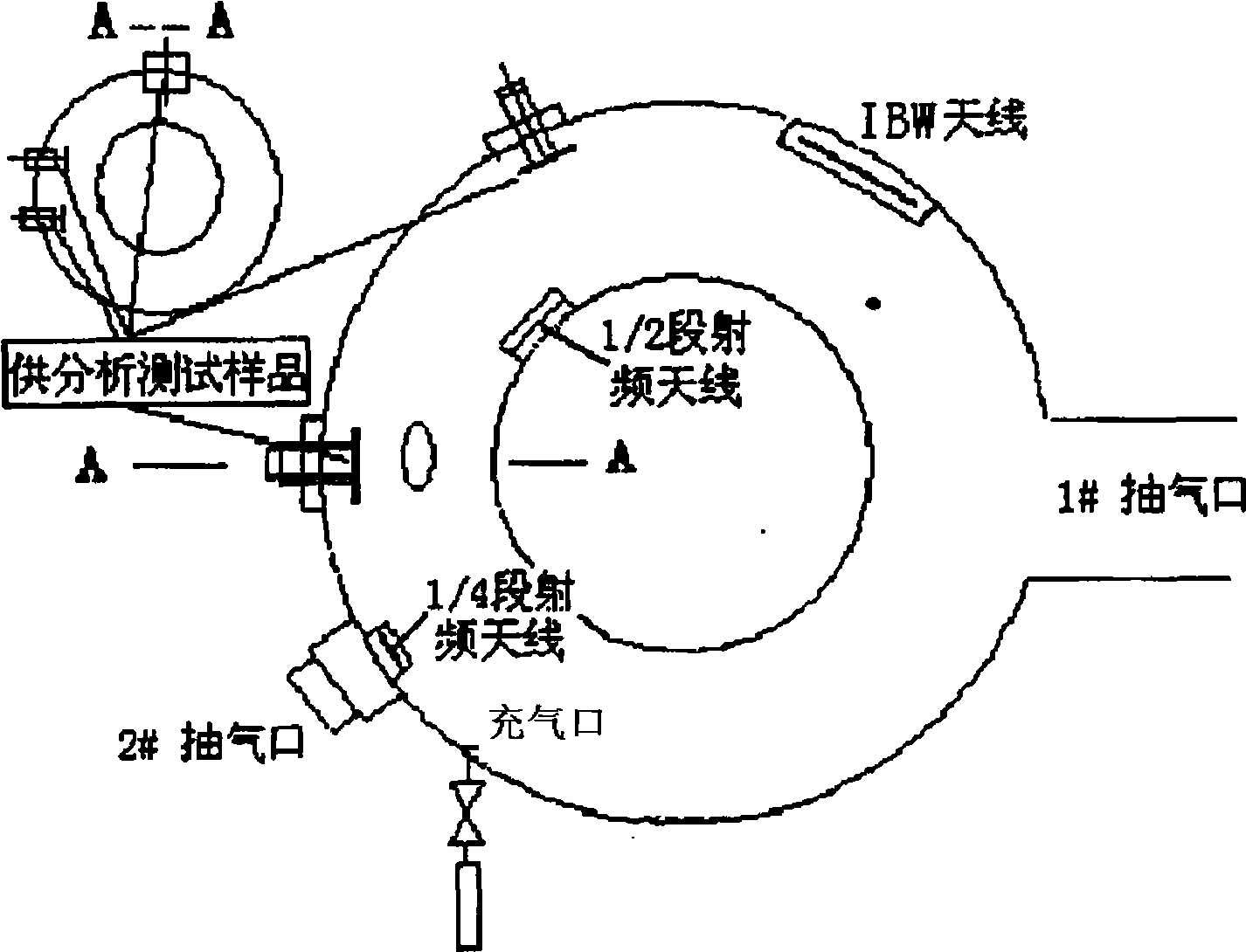

Method for removing hydrogen detained on first wall in magnetic constraint device by ion involution oxygen plasma

InactiveCN101533679AAchieve clearingEfficient removalNuclear energy generationPlasma techniqueChemical reactionPlasma technology

The invention discloses a method for removing hydrogen detained on a first wall in a magnetic constraint device by ion involution oxygen plasma. According to carbon and hydrogen codeposition characteristic in the magnetic constraint device, a plasma auxiliary chemical removing method is used, on a HT-7 superconducting tokmak and a EAST device having similar bit-type with ITER, under condition of keeping longitudinal magnetic fields of 1.5-2.0T and wall temperature of 400-470K, a ion involution plasma technology is employed, oxygen which is easy to react with carbon and hydrogen is employed to form ion involution oxygen plasma for removing carbon hydrogen re-deposition layer on the first wall, thereby effectively removing hydrogen detained on the first wall of a device. The technology is a unique and effective technology, creates excellent wall condition for re-deposition layer removal on the first wall, reduction of hydrogen detained in the device, particle recirculation lowering and nuclear fusion device high efficiency operation, and reduces safely and environment problems of future nuclear fusion device due to radioactive tritium detained on the first wall. Simultaneously, the treatment for the first wall can be carried out under condition that longitudinal field coil is not demagnetized, and is more suitable for future international thermonuclear fusion experiment reactor ITER and future fusion reactor.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

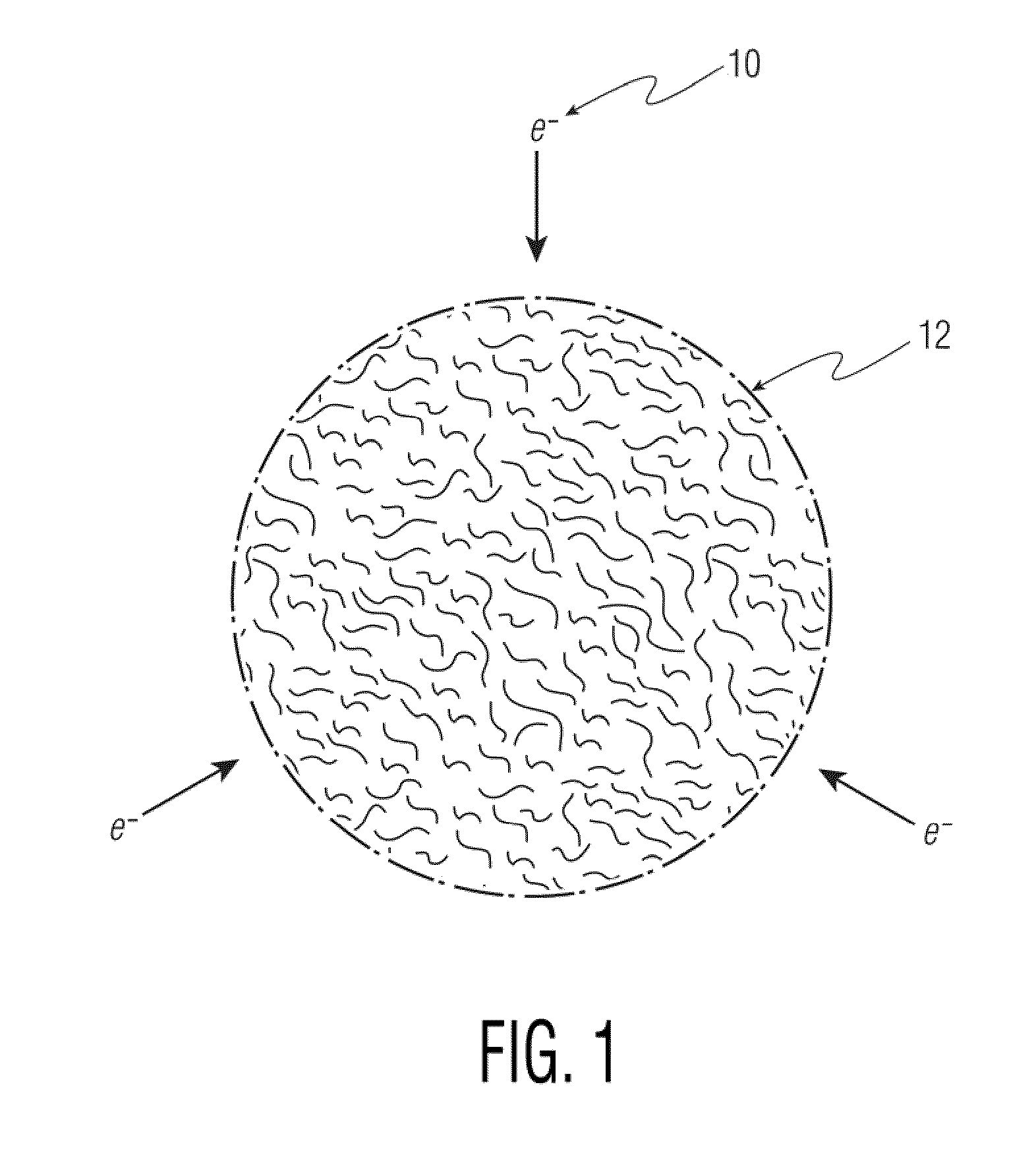

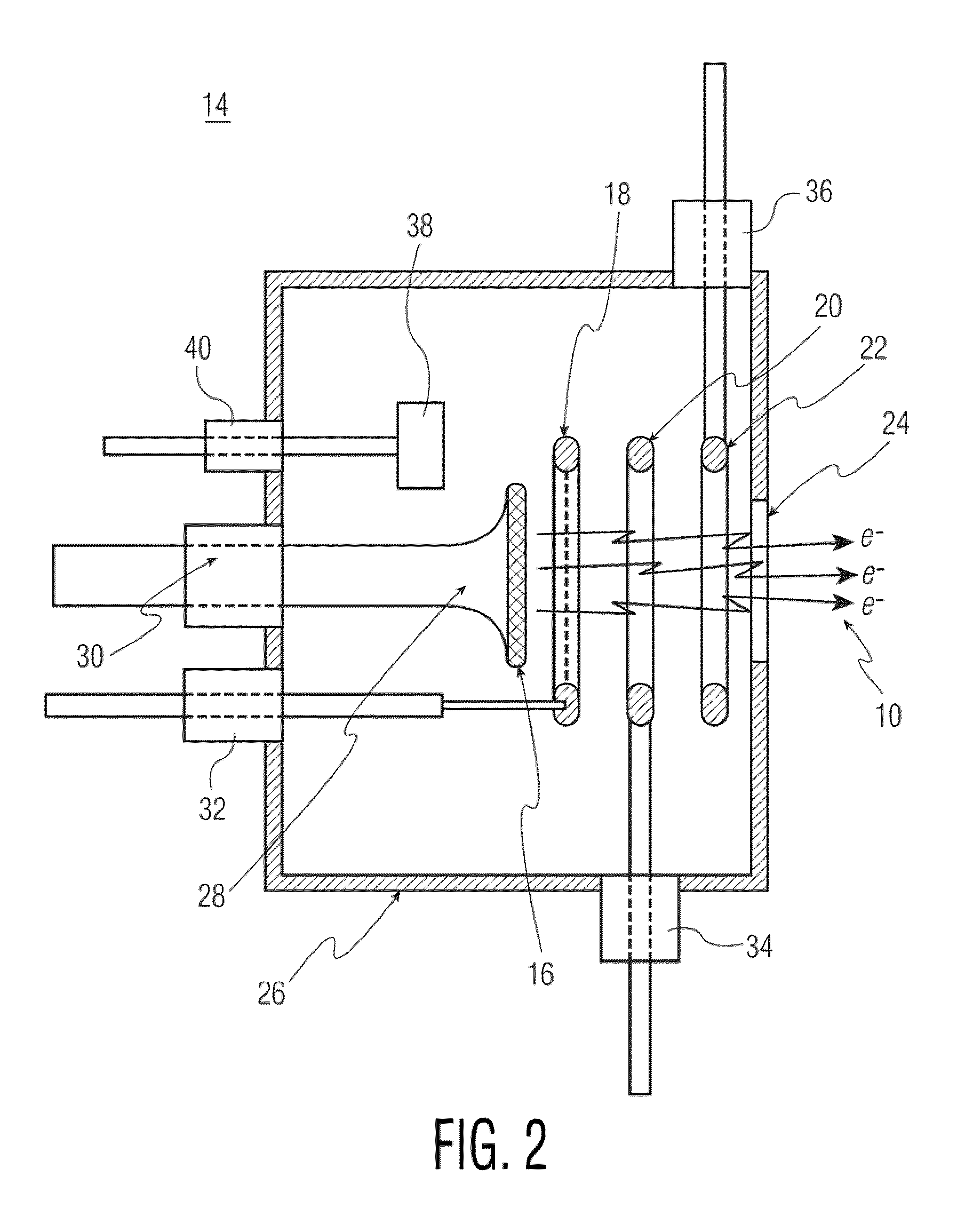

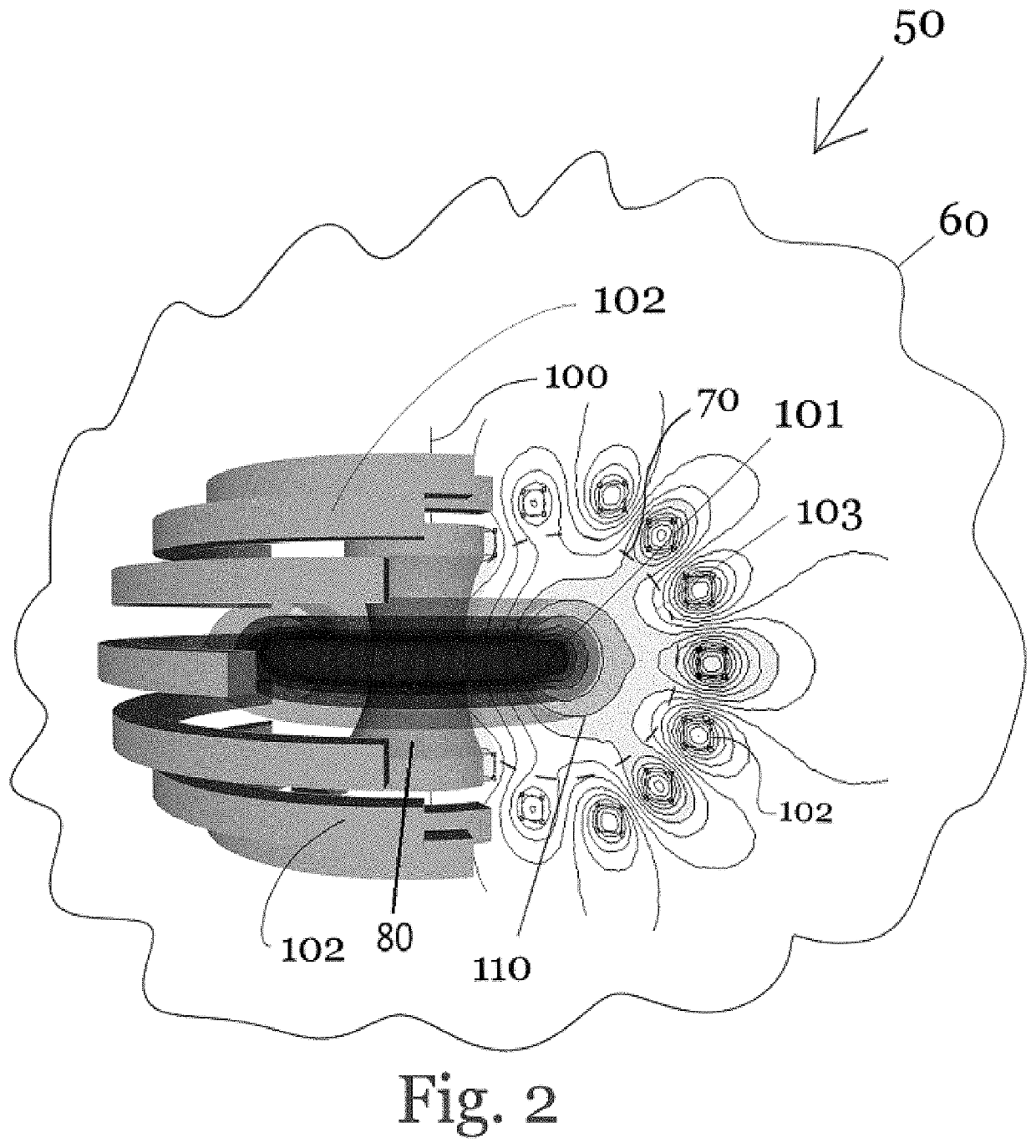

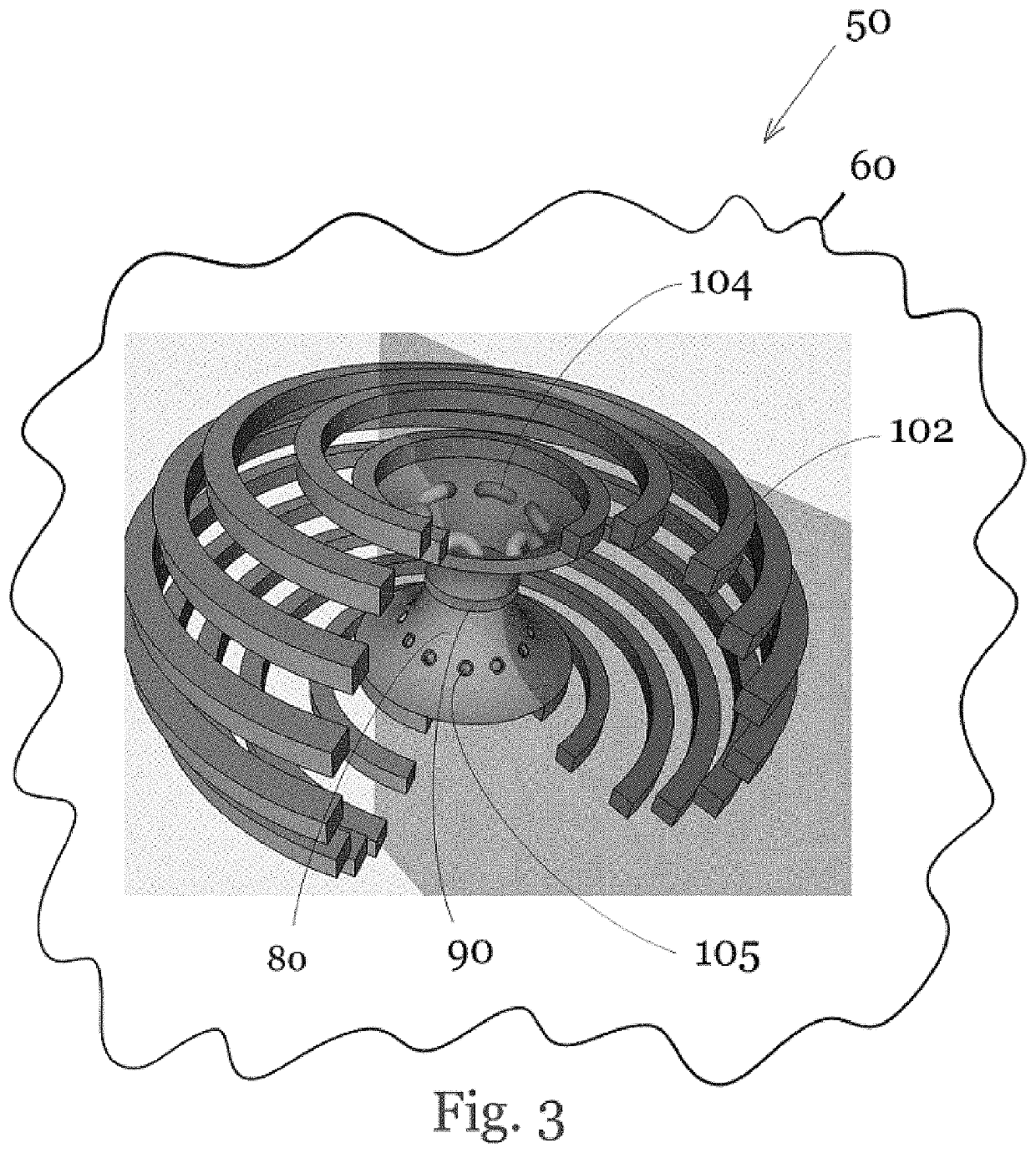

Systems for Enhancing Preignition Conditions of Thermonuclear Fusion Reactions

ActiveUS20100104058A1Reduce hydrodynamic instabilityEnhance preignition conditionNuclear energy generationThermonuclear fusion reactorElectron temperatureElectron source

Systems for enhancing preignition conditions of a fusion reaction are disclosed. A first system includes a target chamber for receiving a fusion fuel, and energy driving means oriented to direct plasma confinement structure onto to the fusion fuel to facilitate ignition of a controlled fusion reaction of said fusion fuel. A plurality of electron sources provides electron beams of a predetermined energy and one of fluence and quantity, directed onto and illuminating, a fusion fuel-derived plasma for controlling the ratio of ion temperature and electron temperature of the plasma. A second system comprises a central target chamber for receiving a spherical pellet of fusion target material and at least first and second pluralities of energy drivers oriented to supply temporally-staged X-ray pulses to the fusion target material in a 3-dimensionally symmetric manner about said pellet. A third system combines aspects of the first and second systems.

Owner:ADVANCED FUSION SYST LLC

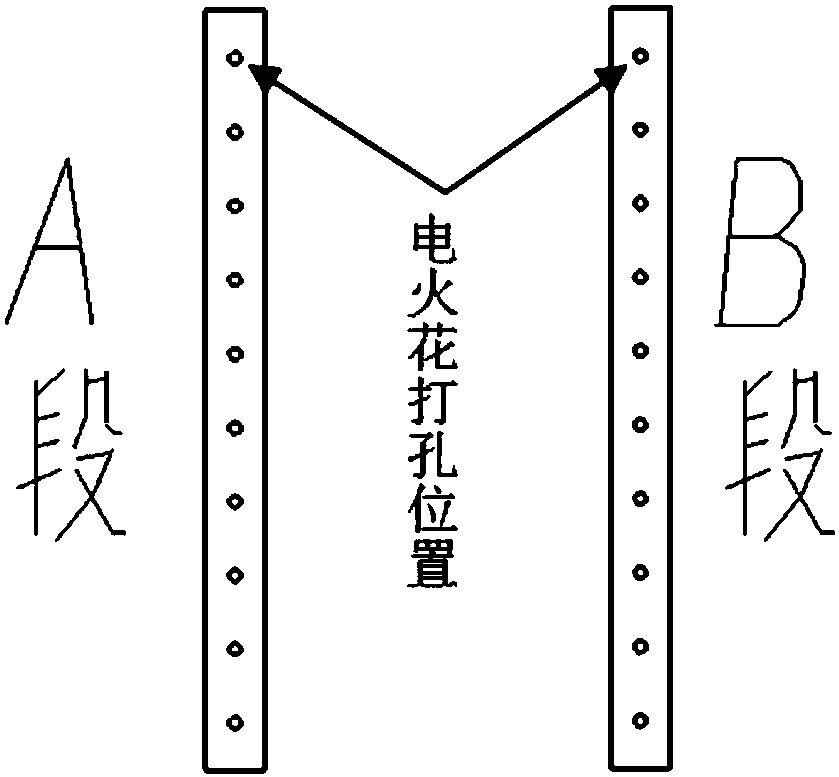

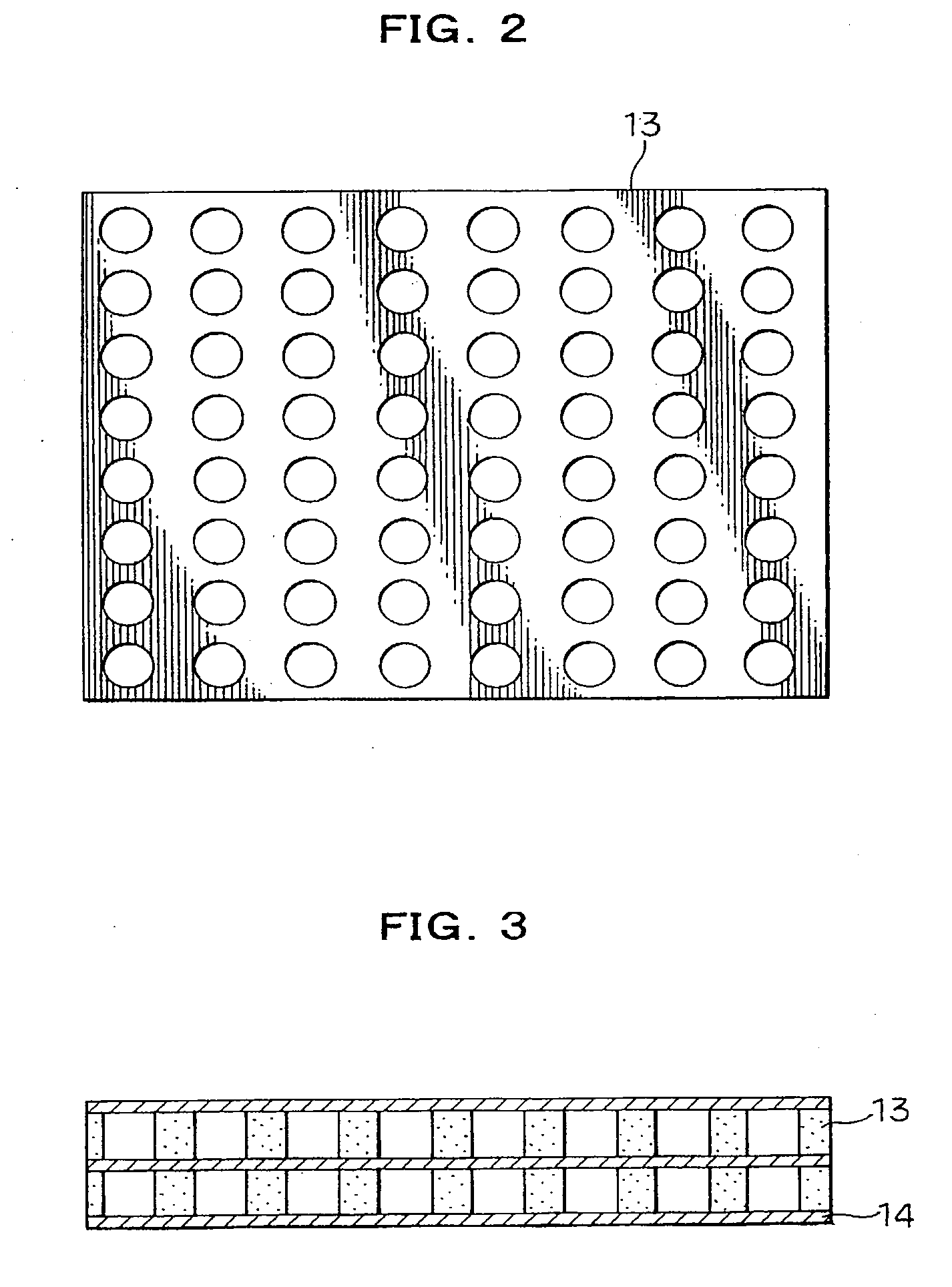

Processing and manufacturing method for ultra-long ultra-fine special-shaped multi-channel cooling plate

The invention relates to the design technology of an international thermonuclear fusion experimental reactor, and particularly discloses a processing and manufacturing method of an ultra-long ultra-fine special-shaped multi-channel cooling plate. After raw materials for cooling plate processing are prepared, holes are drilled by electric sparks. Then a special-shaped channel is cut, and a rectangular strip is welded. Each of the raw material plates processed blind holes are welded into a whole plate. And drilling again by the electric spark, a molybdenum wire is passed through the through holes, the centers of small holes are taken as dead centers, and the small holes are cut into square holes with flow channels of 2.5 mm in length and 4.5 mm in width. The welding method and nondestructivetesting adopted in the processing technology are simple, easy to operate, the processing quality of the ultra-long ultra-fine special-shaped multi-channel cooling plate is effectively ensured and theprocessing success rate is improved.

Owner:SOUTHWESTERN INST OF PHYSICS

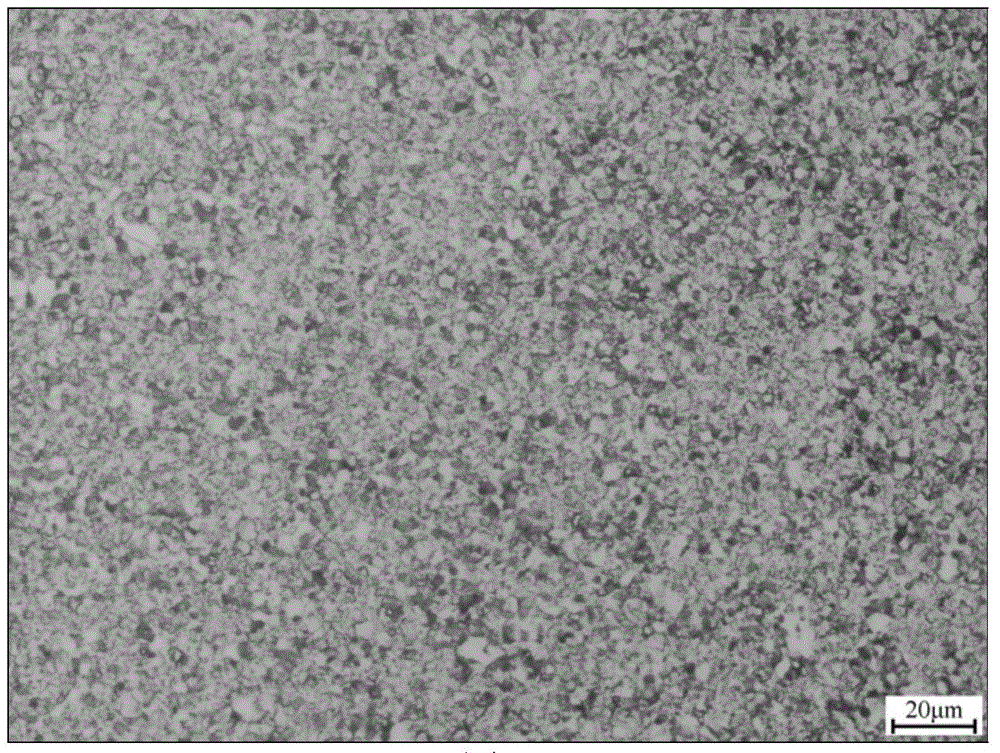

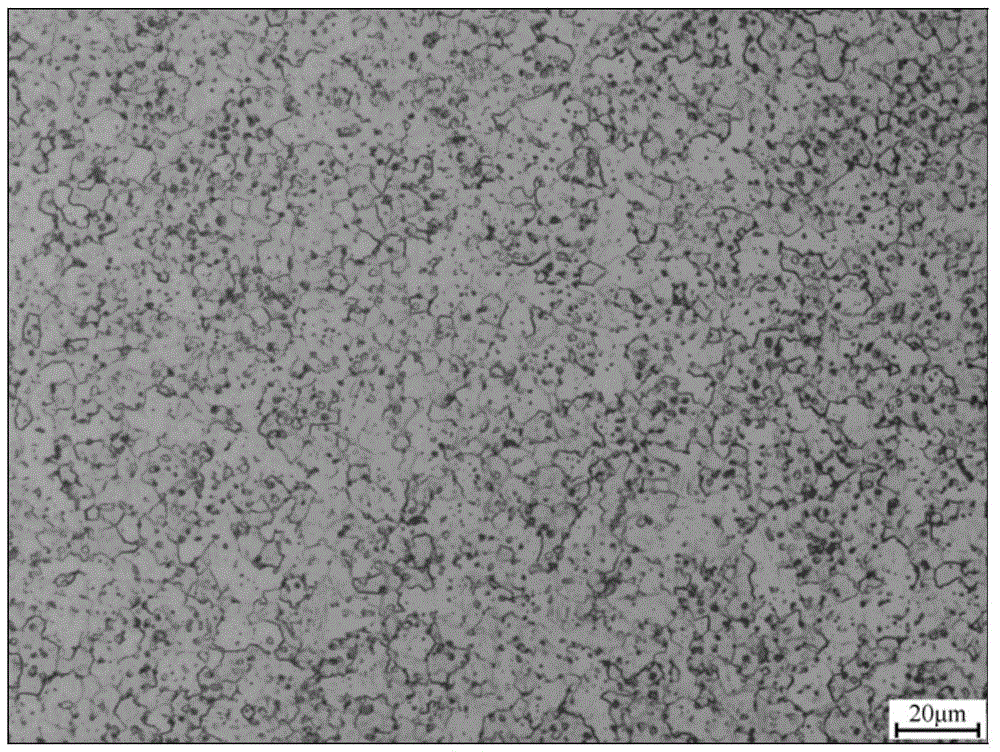

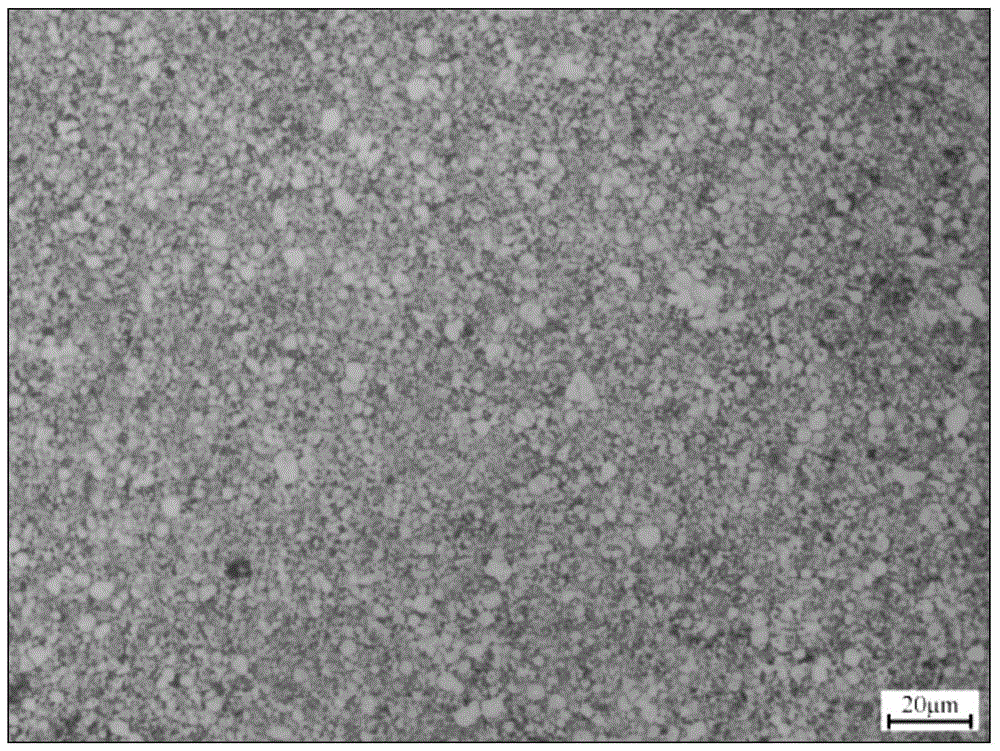

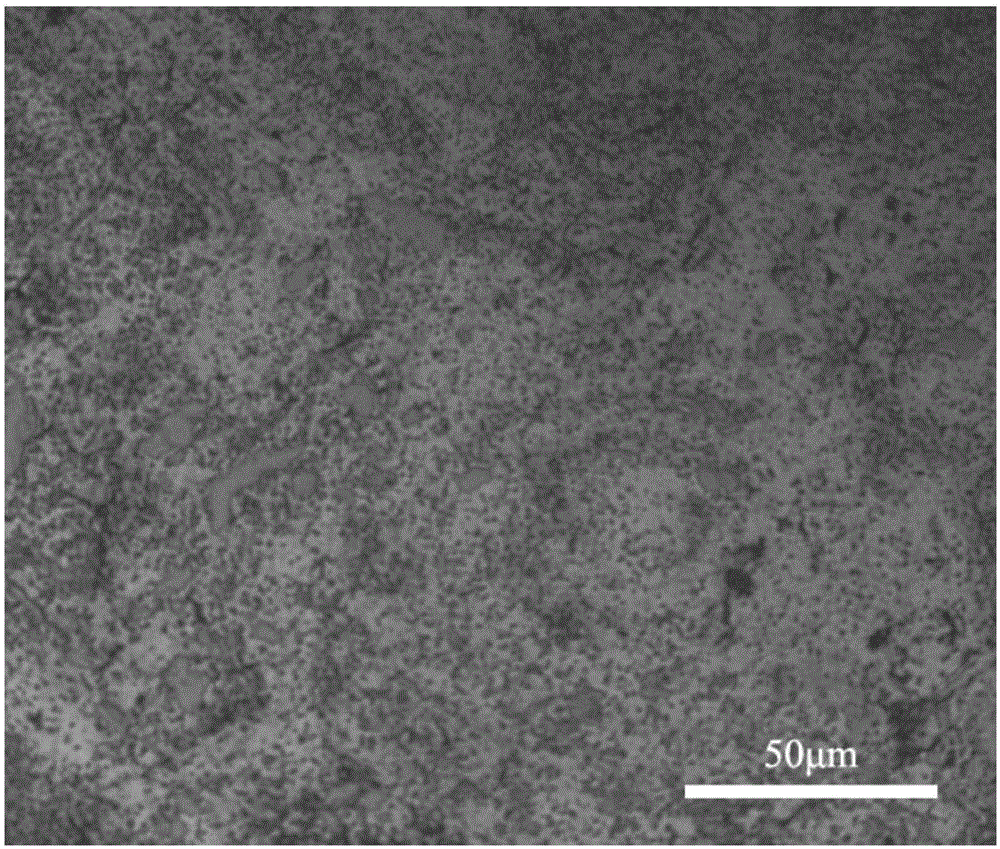

Preparation method of high-density fine-grain W-TiC alloy material

The invention provides a preparation method of a high-density fine-grain W-TiC alloy material, which comprises the following steps: 1. uniformly mixing TiC powder and W powder by a wet high-energy ball milling process, and carrying out vacuum drying to obtain mixed powder; 2. carrying out discharge plasma sintering on the mixed powder to obtain a sintered blank; and 3. carrying out multiple die forging on the sintered blank to obtain the high-density fine-grain W-TiC alloy material. The high-density fine-grain W-TiC alloy material comprises the following components in percentage by mass: 0.1-1% of TiC and the balance of W. The relative density of the W-TiC alloy material prepared by the method is not less than 99.5%, and the average grain size is not greater than 10 mu m; and thus, the W-TiC alloy material satisfies the requirements for PFM materials for thermonuclear fusion and the like in special aspects, and can be widely used as a plasma material faced with a diverter in a thermonuclear fusion reactor.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

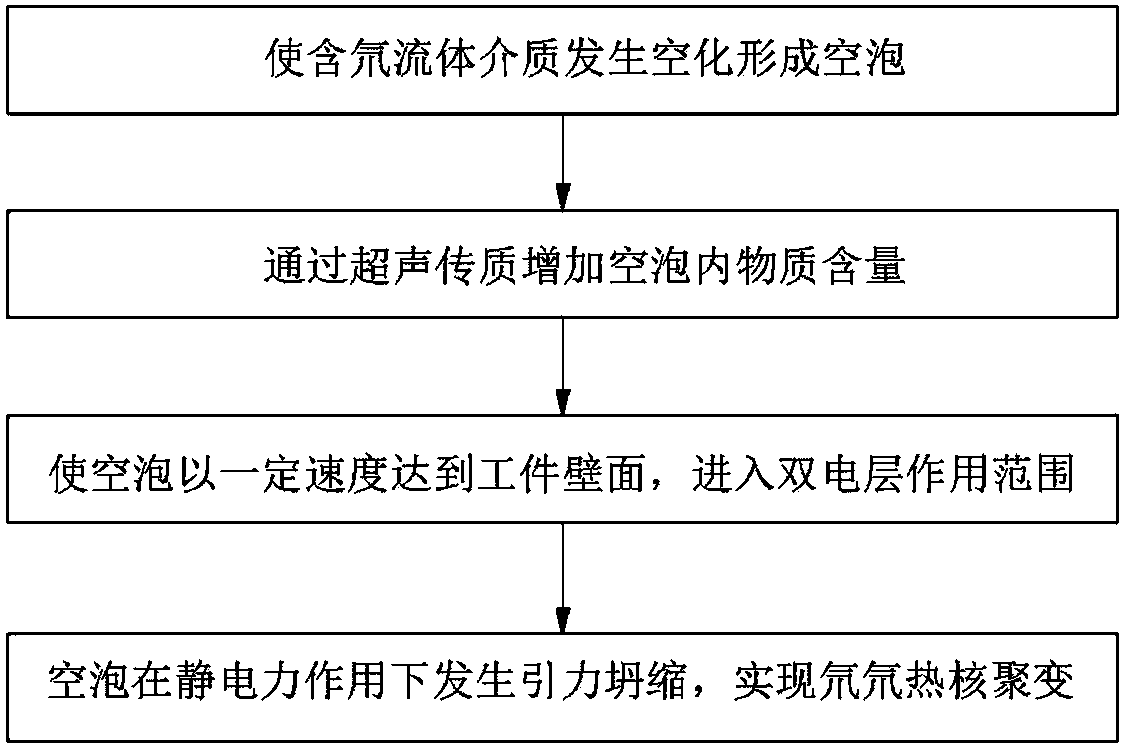

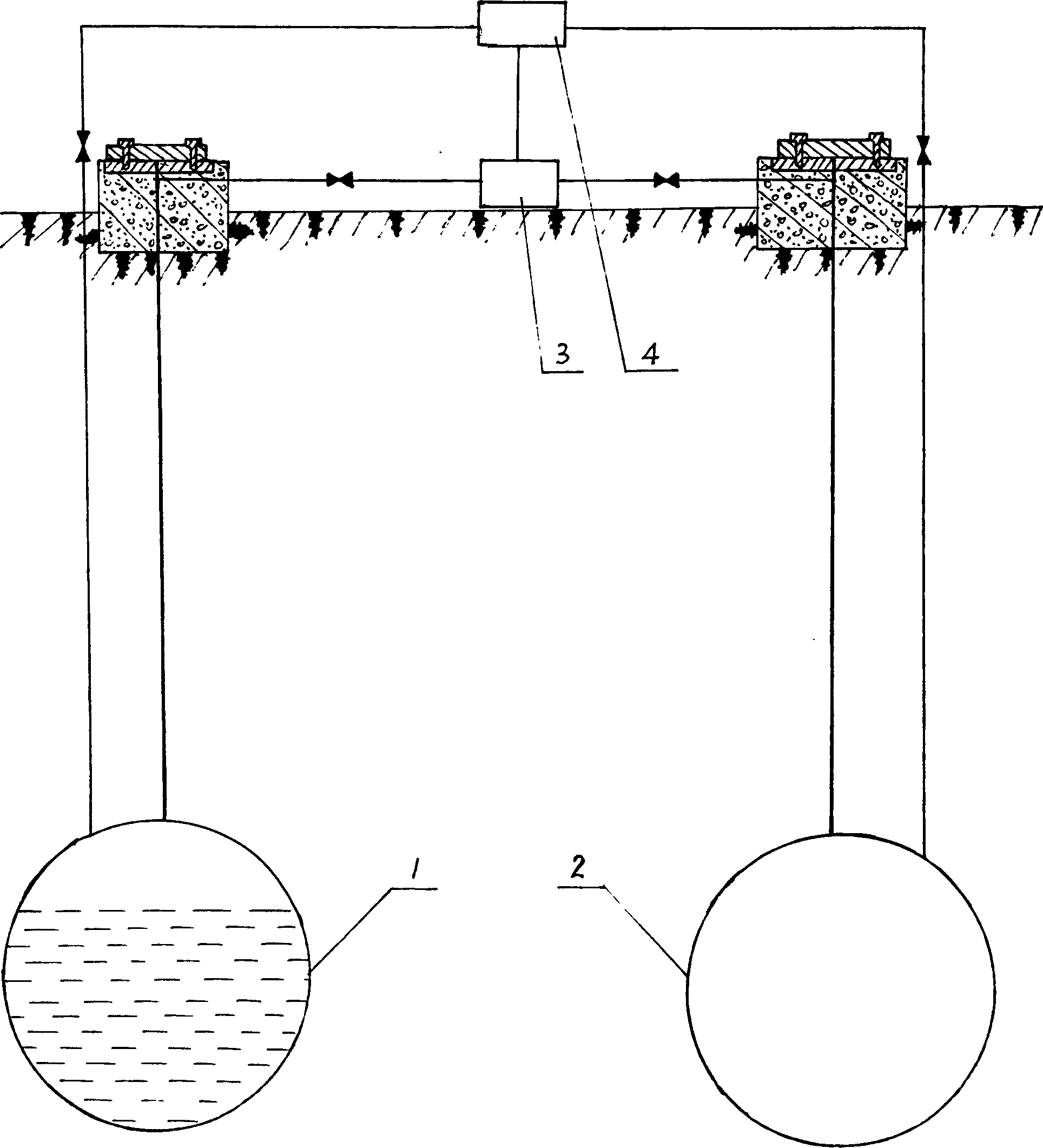

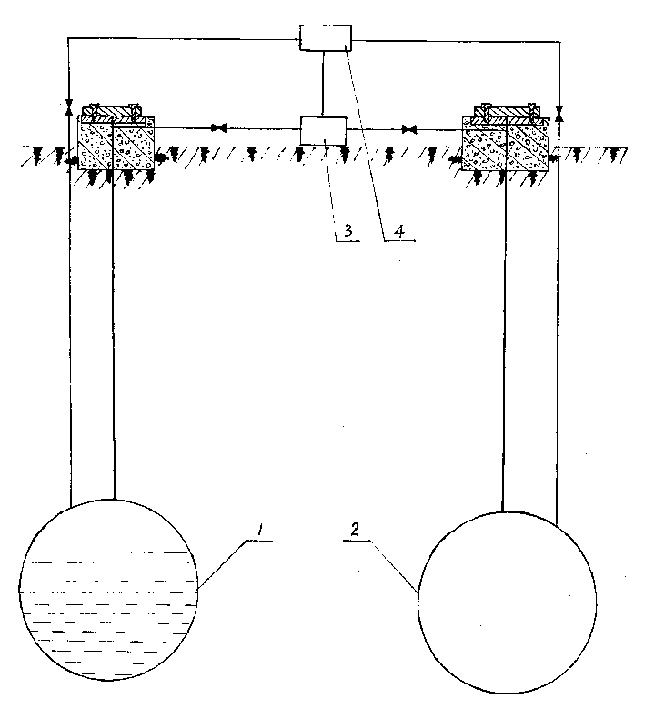

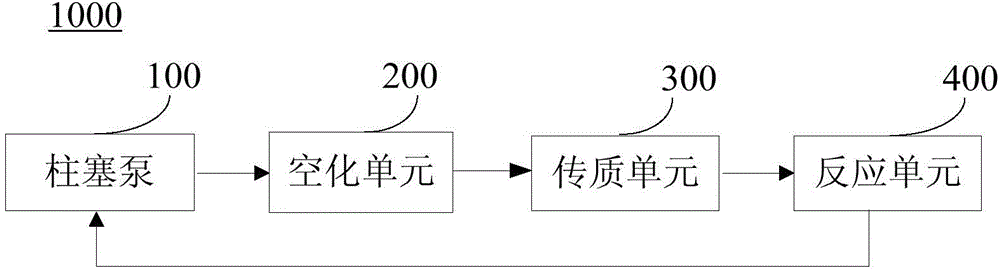

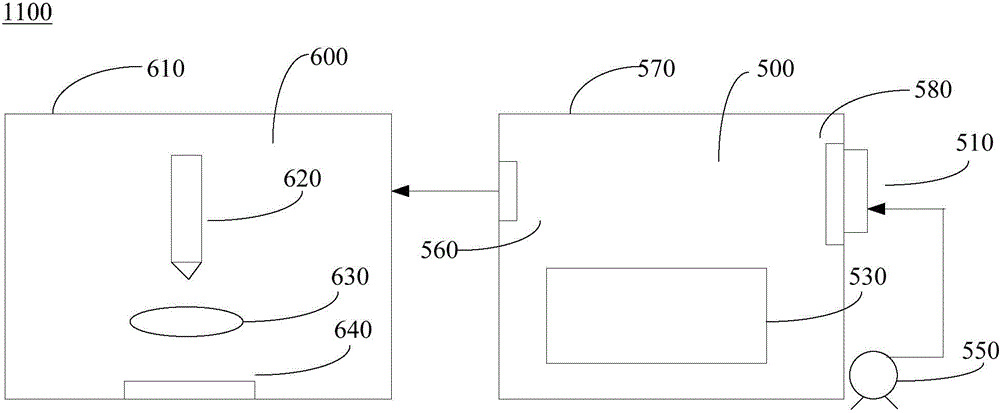

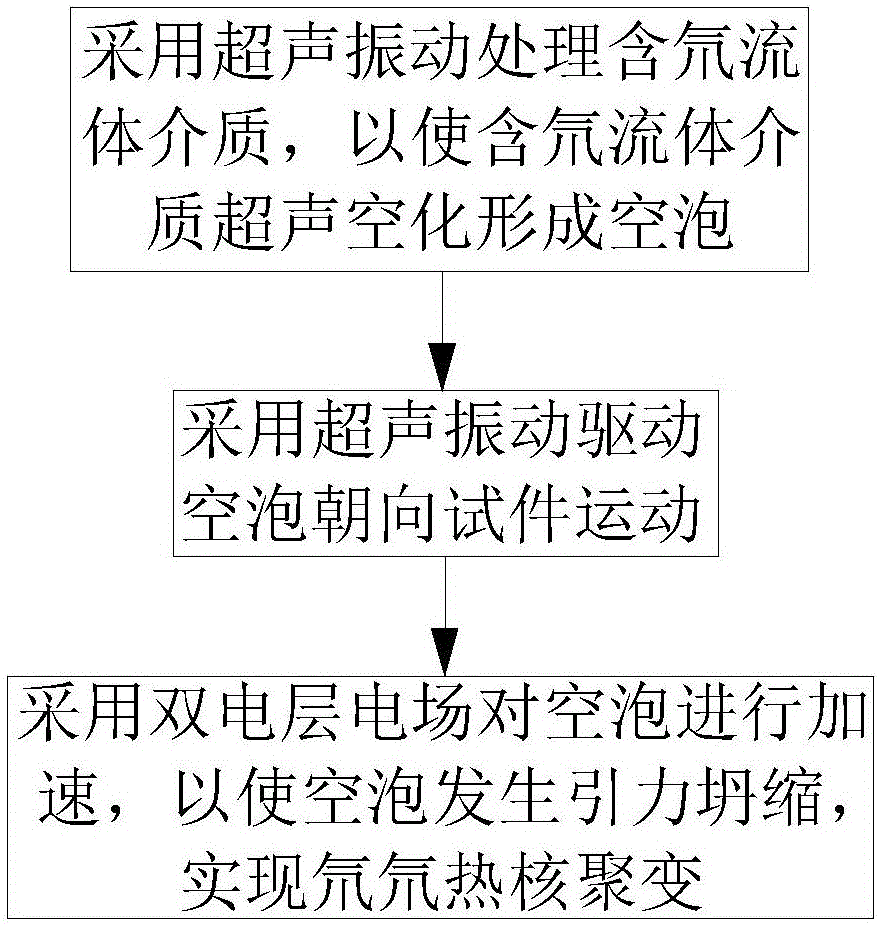

Method and device for achieving deuterium and deuterium thermonuclear fusion based on vacuole collapse

ActiveCN104200849AAchieve launchGuaranteed normal launchNuclear energy generationLow temperature fusion reactorEngineeringGravitational collapse

The invention relates to a method for achieving deuterium and deuterium thermonuclear fusion based on vacuole collapse. The method for achieving the deuterium and deuterium thermonuclear fusion based on the vacuole collapse includes following steps: forming vacuole by enabling fluid media which contain deuterium to cavitate; increasing the content of materials in the vacuole through ultrasonic mass transfer; enabling the vacuole to reach the wall surface of a work piece at a certain speed, and enabling the vacuole to enter a double electric layer action range; enabling gravitational collapse of the vacuole to occur under electrostatic force functions so as to achieve the deuterium and deuterium thermonuclear fusion. Additionally, the invention further relates to a device for achieving the deuterium and deuterium thermonuclear fusion based on the vacuole collapse.

Owner:TSINGHUA UNIV

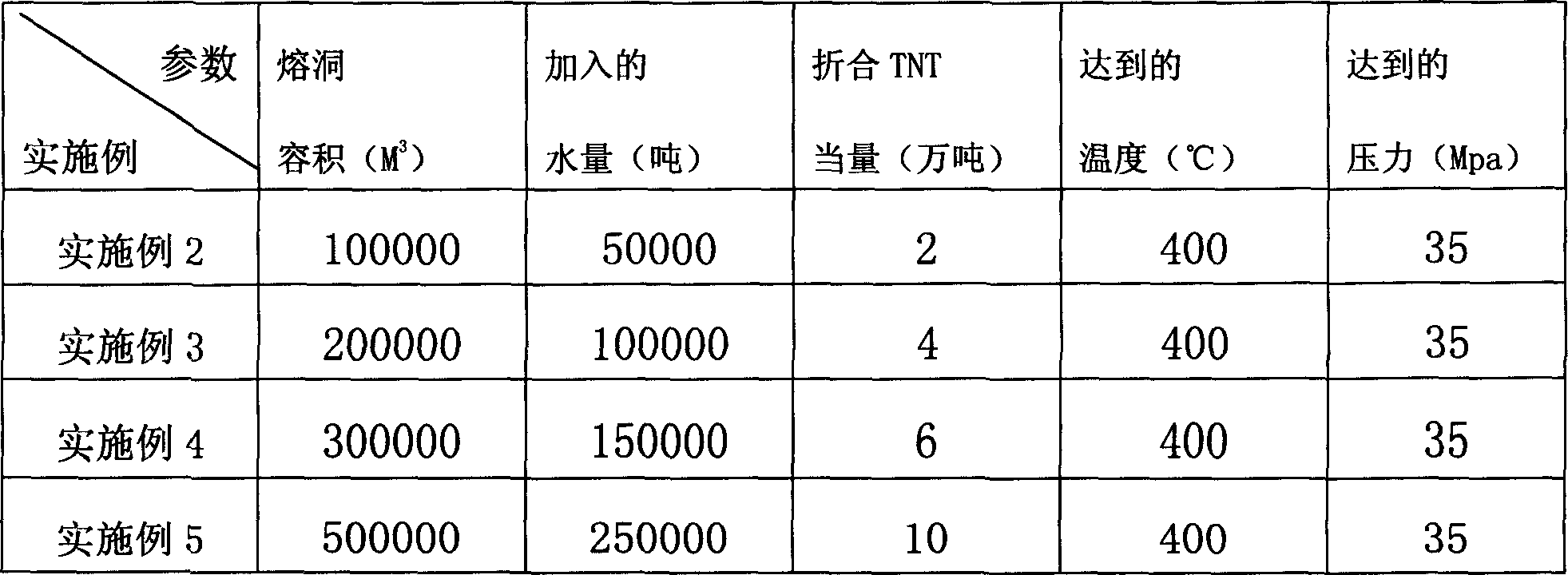

Method for electric power generation using thermonuclear fusion energy

InactiveCN1489157AEndless sourcesLow priceNuclear energy generationNuclear explosivesElectricityNuclear fusion

Water is filled into 1 / 3-2 / 3 of underground solution cave, and light type nuclear fusion body is put into the cave. Igniting the nuclear fusion body make water reach water vapour state in high temperature and high pressure 300-400 deg.C and 30-40Mpa, which drives rotation of turbo generator to generate electricity. With power being done, exhaust steam is condensed in condensator. Then, igniting the nuclear fusion body is carried out in another solution cave. Alternant igniting nuclear fusion bodies in two solution caves realizes cycling generating electricity. The method uses not exhausted very clean energy source of burning deuterium so as to have value for commerce development.

Owner:化建华

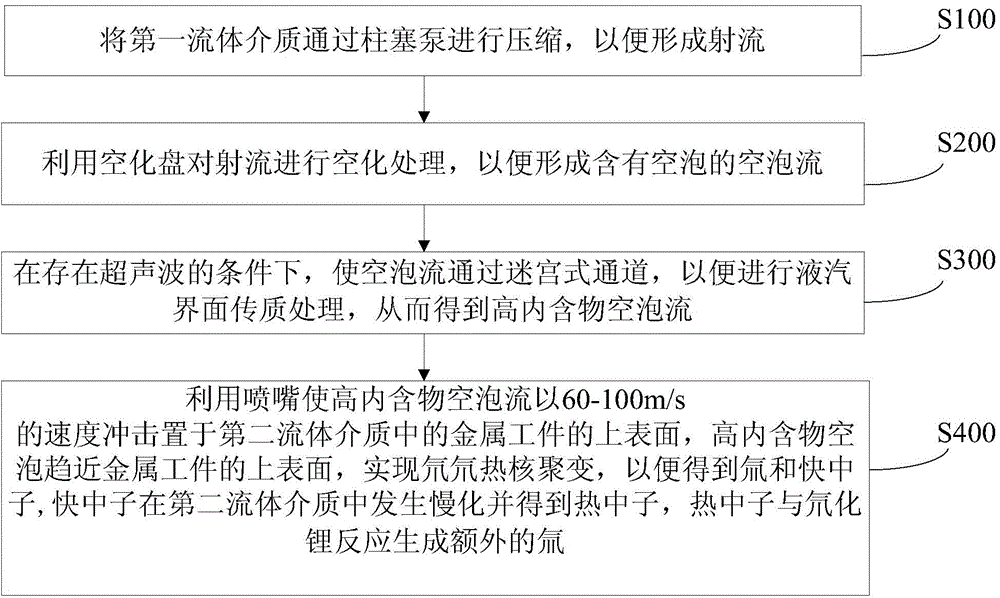

Method, device and system for preparing tritium

InactiveCN104900289ALow priceImprove securityConversion outside reactor/acceleratorsNuclear energy generationCavitationJet flow

The invention discloses a method, a device and a system for preparing tritium. The method for preparing tritium comprises the following steps: a first fluid medium is compressed through a plunger pump to form a jet flow, wherein the first fluid medium contains <6>LiD with concentration of at least 2mmol / L; the jet flow is cavitated with a cavitation plate to form a cavity flow containing cavities; the cavity flow passes through a labyrinth channel, and mass transfer is performed on a liquid-vapor interface under the effect of an ultrasonic field to obtain a high-content cavity flow; and a nozzle is used to make the high-content cavity flow to hit the upper surface of a metal work piece in a second fluid medium at the speed of 60-100m / s, and the high-content cavity flow approaches the upper surface of the metal work piece to realize deuterium-deuterium thermonuclear fusion and obtain tritium and fast neutrons, wherein the second fluid medium contains deuterium, the fast neutrons slow down in the second fluid medium to obtain thermal neutrons, and the thermal neutrons reacts with <6>LiD to generate additional tritium. By using the method, deuterium-deuterium thermonuclear fusion is realized, and tritium can be safely and simply prepared with low cost.

Owner:TSINGHUA UNIV

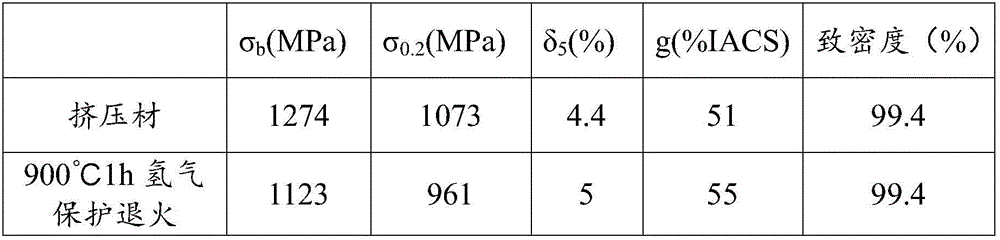

Cu-NbC nanometer dispersion strengthened copper alloy and preparation method thereof

The invention relates to the technical field of powder metallurgy materials, and discloses Cu-NbC nanometer dispersion strengthened copper alloy and a preparation method of the Cu-NbC nanometer dispersion strengthened copper alloy. The Cu-NbC nanometer dispersion strengthened copper alloy is prepared from, by volume, 3-10 vol% of NbC and the balance Cu. The preparation method of the alloy comprises the working procedures of in-situ synthesis of Cu-NbC alloy powder through a mechanical alloying method, hydrogen reduction, vacuum hot pressed sintering, canned hot extrusion and the like. The preparation process is simple, production equipment is common, and industrial production is promoted. The tensile strength sigma b of the prepared Cu-NbC alloy can reach 1000 MPa or more, the relative conductivity of the prepared Cu-NbC alloy is 50%-65% IACS, the annealing and softening resistance temperature reaches up to 900 DEG C or above, and the performance requirements of high-intensity magnetic field engineering fields of thermonuclear fusion, magnetically levitated trains, electromagnetic guns, microgravity devices and the like for conductive devices can be met.

Owner:CHINA JILIANG UNIV

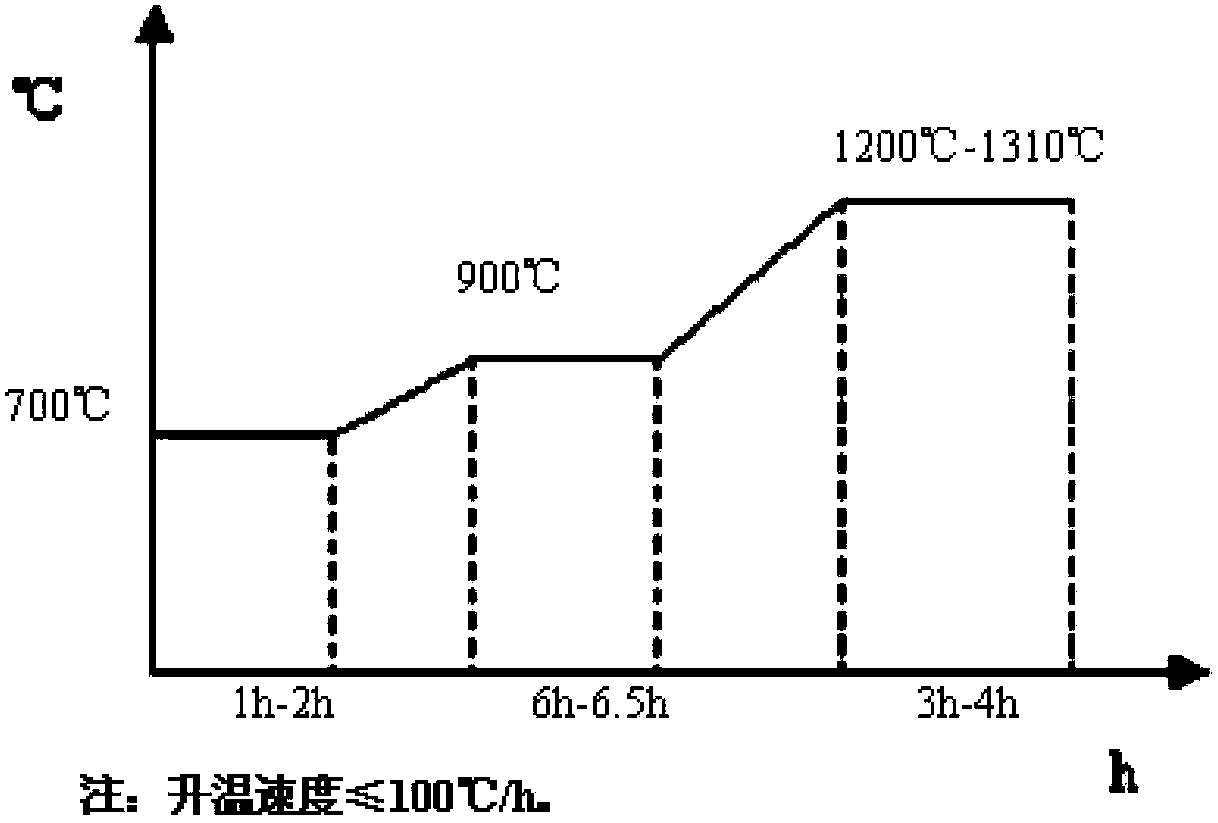

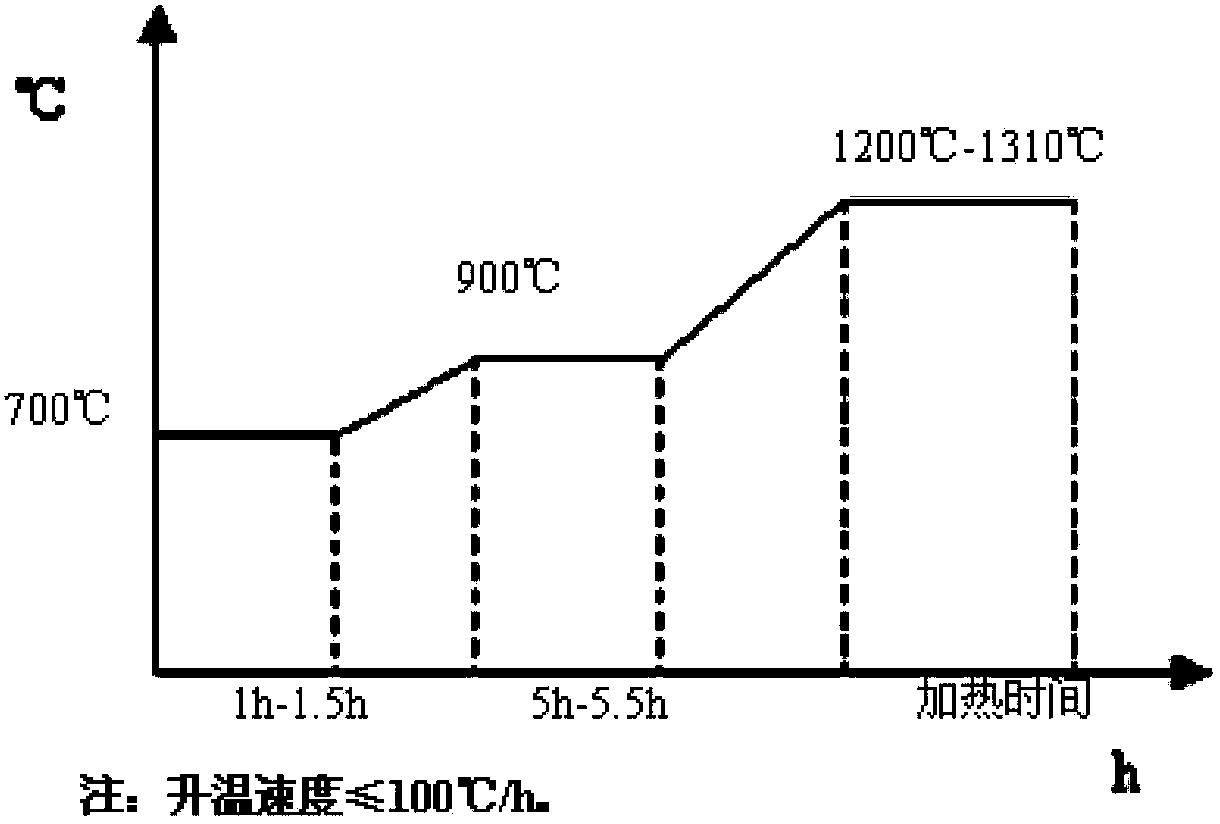

Rolling method of grain size of stainless steel plates used for controlling thermonuclear fusion reactors

ActiveCN103418614AGrain size stabilityTemperature control deviceMetal rolling arrangementsMetallurgyIngot

The invention belongs to a rolling method of steel plates, and particularly relates to a rolling method of the grain size of stainless steel plates used for controlling thermonuclear fusion reactors. The rolling method includes the steps of steel ingot heating, blooming, raw material plate heating, hot rolling and steel plate cooling. In the step of steel ingot heating, firstly, steel ingots are heated, the starting temperature of heating is 700 DEG C, the temperature is kept for 1-2 hours, and then the temperature is slowly raised to 900 DEG C; the 900 DEG C temperature is kept for 6-6.5 hours, then the temperature is continuously raised to be between 1200 DEG C and 1310 DEG C, and lastly, the temperature is kept between 1200 DEG C and 1310 DEG C for 3-4 hours. In the step of raw material plate heating, firstly, the starting temperature of heating is 700 DEG C, the temperature is kept for 1-1.5 hours, and then the temperature is raised to 900 DEG C; the 900 DEG C temperature is kept for 5-5.5 hours, then, the temperature is continuously raised to be between 1200 DEG C and 1310 DEG C, and lastly, the temperature is kept between 1200 DEG C and 1310 DEG C for a period of time. The rolling method has the advantages of enabling the grain size of the steel plates to be between grade 6 and grade 8 steadily though controlling the time duration of heat preservation in different stages and controlling the rolling process.

Owner:SOUTHWESTERN INST OF PHYSICS +1

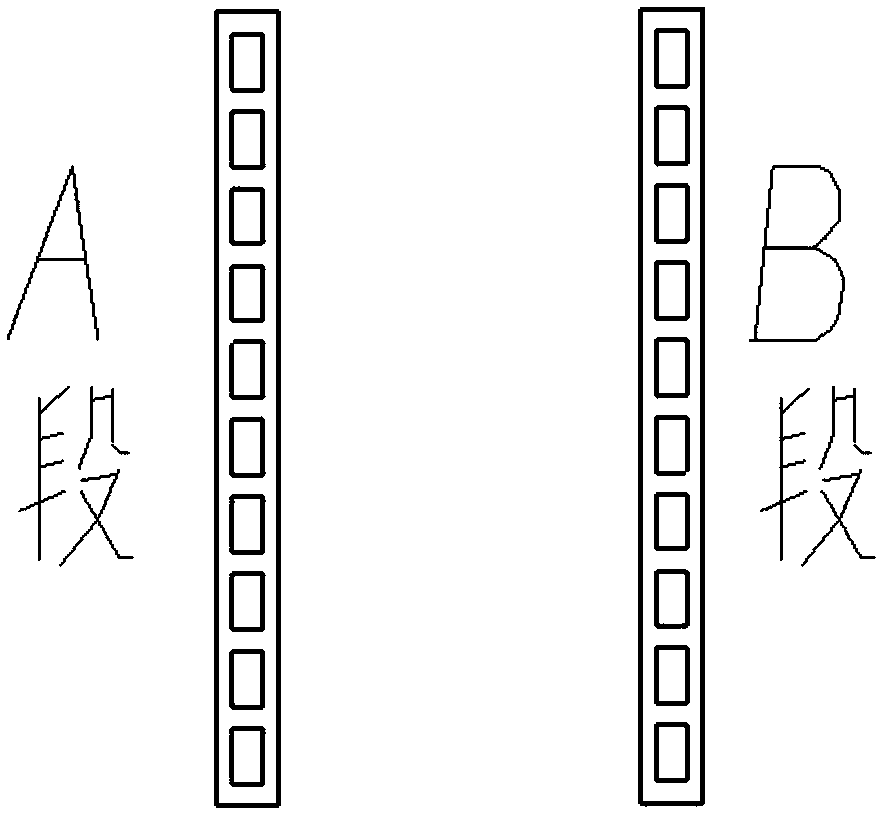

Binaural U-shaped piece welding-free integrated finish machining method for thermonuclear fusion reactor

The invention relates to a machining technology of U-shaped pieces, in particular to a binaural U-shaped piece welding-free integrated finish machining method for a thermonuclear fusion reactor. The binaural U-shaped piece welding-free integrated finish machining method comprises the steps of manufacturing U-shaped blank pieces by using a forming die; carrying out first ultrasonic flaw detection on the U-shaped blank pieces after rough machining is carried out on the U-shaped blank pieces; carrying out rough machining again after heat treatment is carried out, then carrying out second ultrasonic flaw detection, picking out qualified U-shaped pieces, and carrying out a performance test by extracting samples from bodies; machining the U-shaped pieces which are qualified in the performance test into U-shaped pieces with allowance, and then manufacturing the U-shaped pieces into primary semi-finish machining U-shaped pieces by carrying out first artificial aging treatment on the U-shaped pieces; machining the primary semi-finish machining U-shaped pieces into U-shaped pieces with allowance, and then manufacturing the U-shaped pieces into secondary semi-finish machining U-shaped pieces by carrying out second artificial aging treatment on the U-shaped pieces; machining the secondary semi-finish machining U-shaped pieces into finish machining U-shaped pieces, drilling through holes in the end surfaces of side plates of the finish machining U-shaped pieces, and obtaining finished U-shaped pieces through WEDM (Wire Electrical Discharge Machining) after a metal wire is enabled to penetrate through the through holes. The binaural U-shaped piece welding-free integrated finish machining method disclosed by the invention has the advantages that the machining efficiency is high, and the product quality is good.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

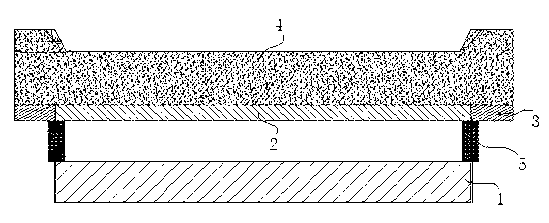

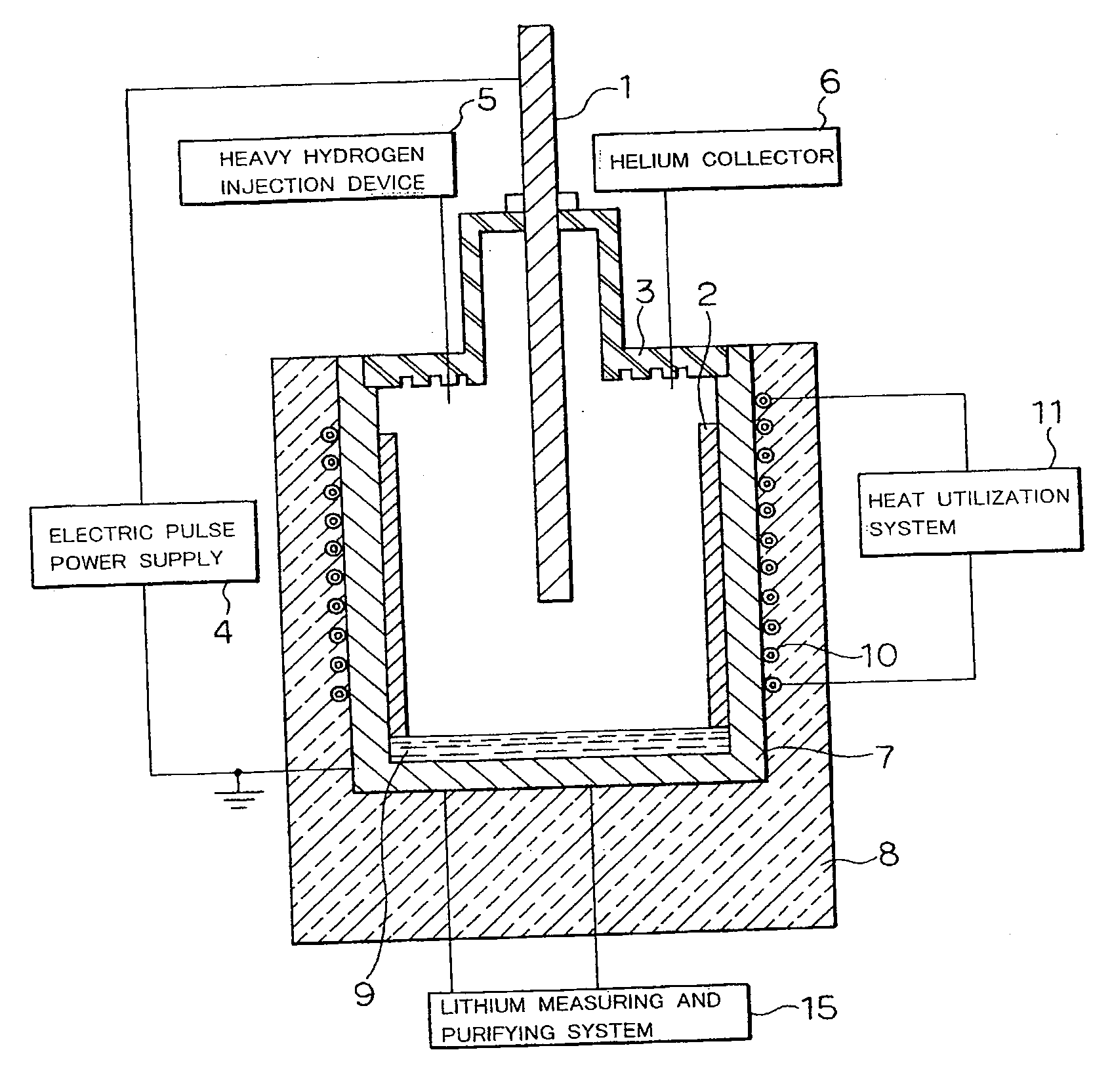

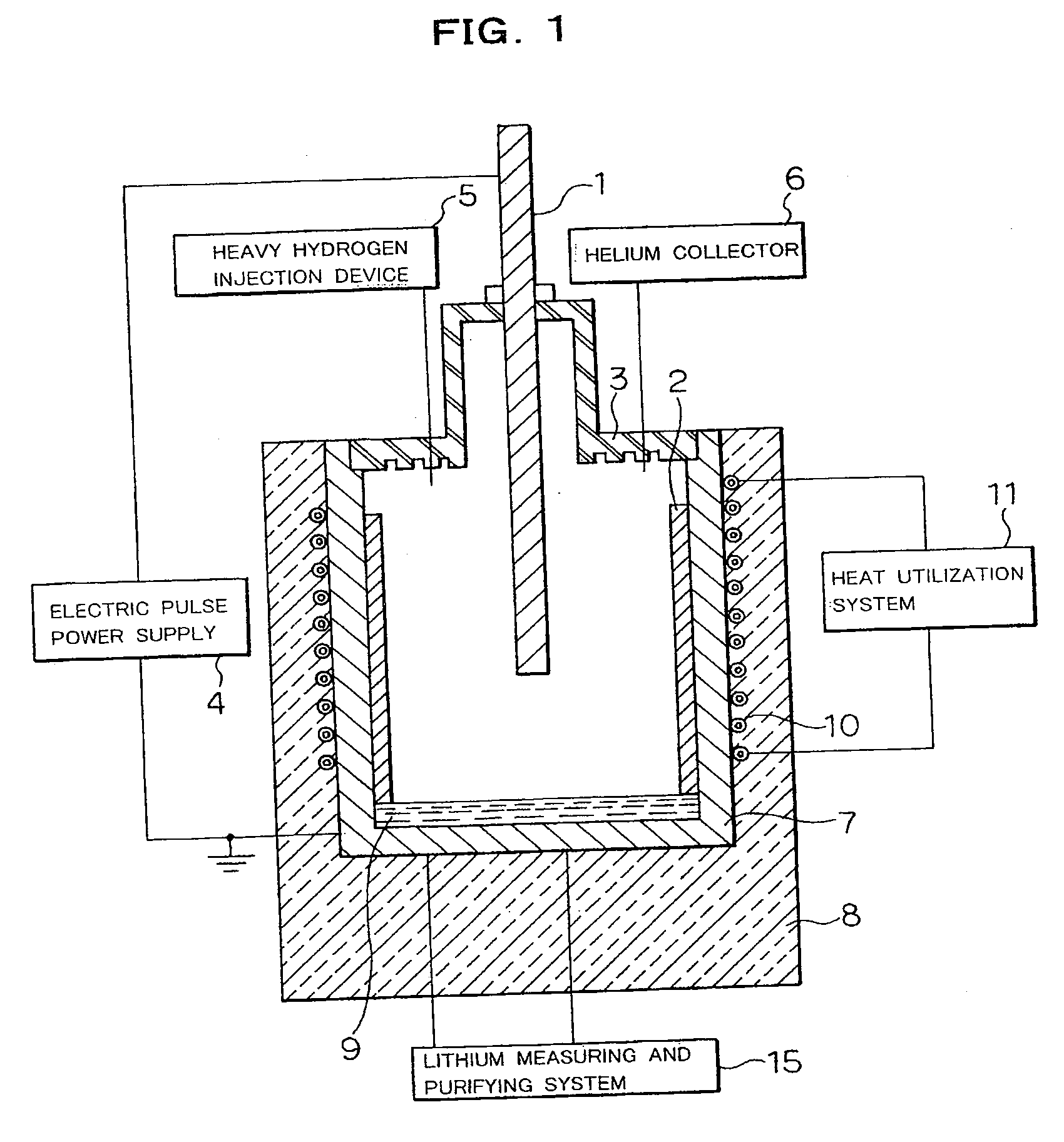

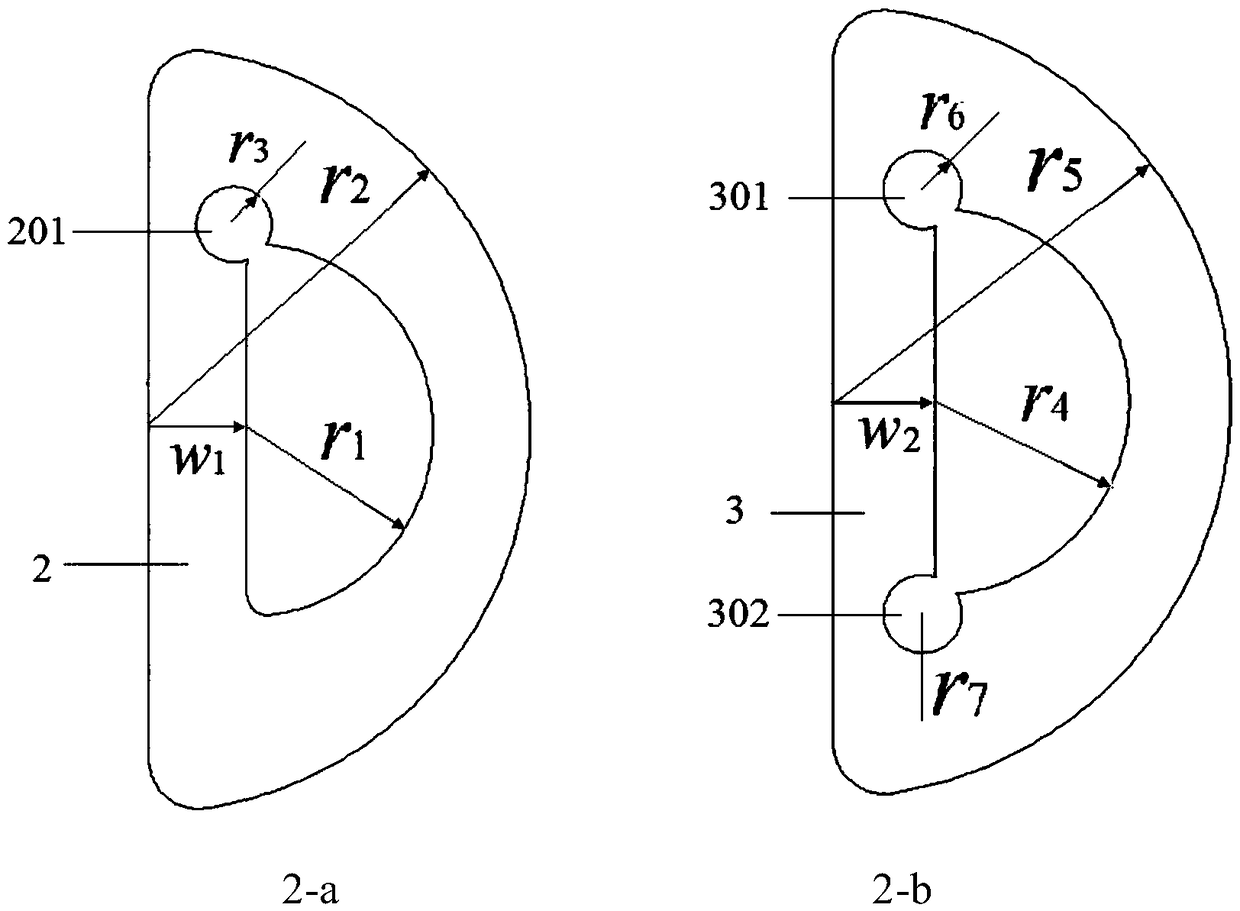

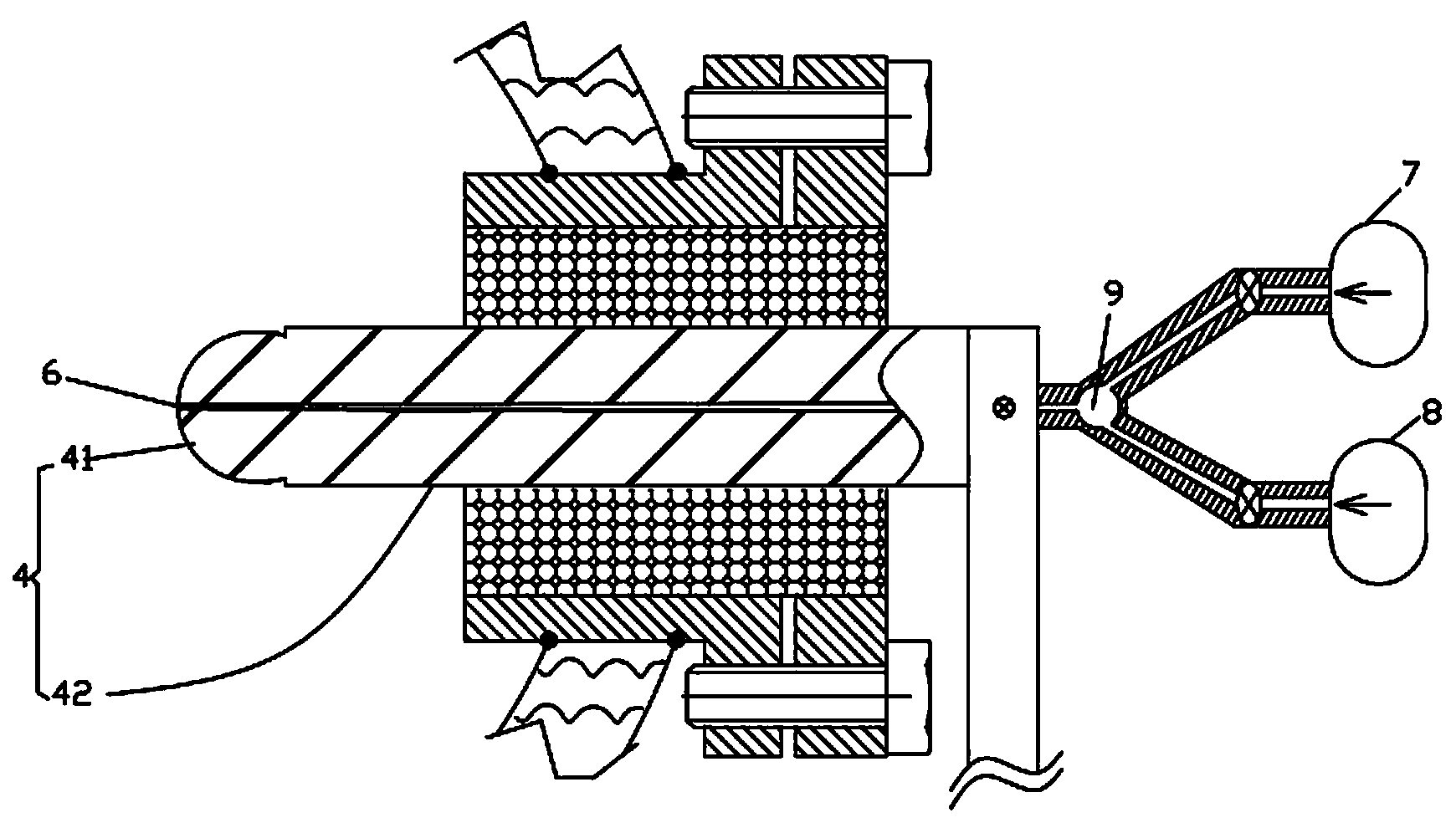

Method of and Apparatus for Generating Recoilless Nonthermal Nuclear Fusion

InactiveUS20090052603A1High densityImprove responseNuclear energy generationLow temperature fusion reactorMomentumNuclear fusion

A method of and apparatus for generating recoilless nonthermal nuclear fusion reaction, wherein deuterium ions accelerated by pulsed gas discharge plasma are implanted onto a surface of an electrode (2) formed of liquid lithium (9), and the momentum to be transferred to the lithium atoms coming into collision with the deuterium atoms is carried out by neutrons, so that the lithium atoms are prevented from being recoiled, and the recoilless nonthermal nuclear fusion reaction is enhanced without reducing a cohesion acting between atoms in the liquid lithium (9).

Owner:IKEGAMI HIDETSUGU

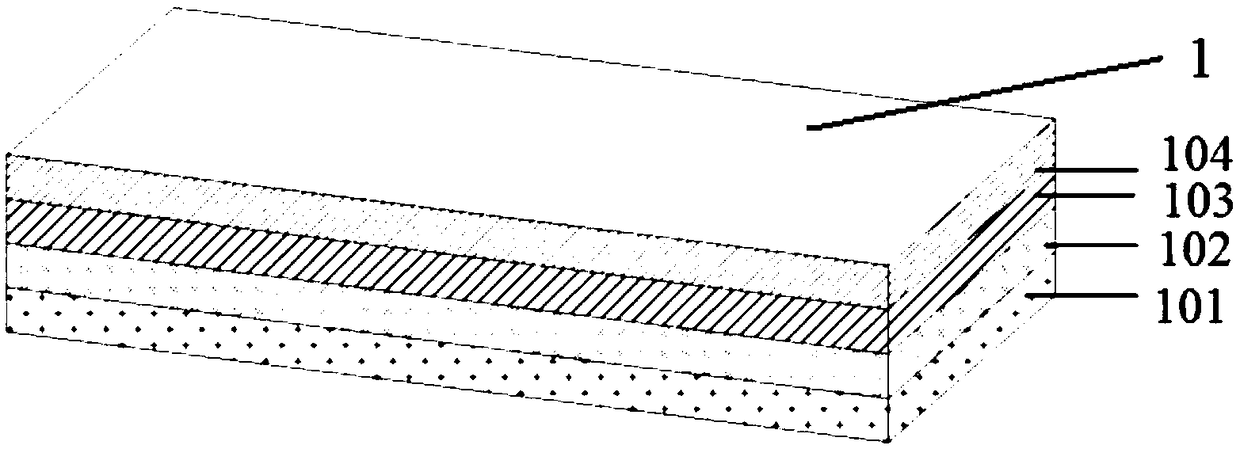

An annular magnet based on a ReBCO superconducting ring

InactiveCN109273188ABig spaceMagnetic field stabilizationSuperconducting magnets/coilsCarrying capacitySuperconducting Coils

The invention discloses an annular magnet based on a ReBCO superconducting ring piece belonging to the technical field of superconducting magnet application. The annular magnet is composed of a plurality of identical unit annular field magnets uniformly distributed along the annular direction, wherein, the unit annular field magnets are obtained by alternately stacking N ReBCO superconducting ringsheets and N+1 insulating sheets, wherein N is a positive integer; ReBCO superconducting rings are D-shaped, and N + 1 insulating rings are the same size as N ReBCO superconducting rings. A low-temperature Dewar immersion type cool magnet has that advantages of high magnet current carry capacity, low heat leakage, compact structure and disassembly, and can generate a stable large-space magnetic field, and is widely used in the fields of medium and large Tokamak magnet, thermonuclear fusion reaction and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

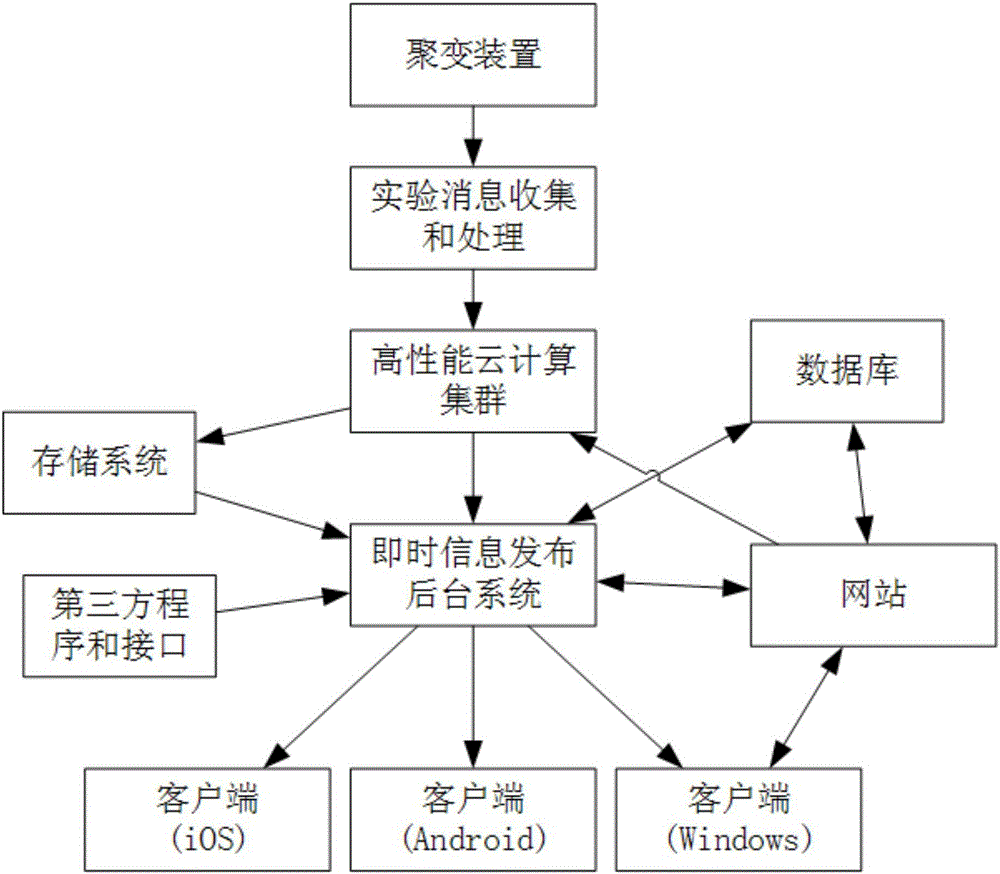

Instant message release system

The invention relates to the field of controlled thermonuclear fusion and instant message release, and specifically discloses an instant message release system, which can be applied to nuclear fusion tests. The instant message release system comprises a message collecting and processing system, a cloud computing platform, a storage system, an instant message release background system and at least one client. The instant message release system disclosed by the invention solves the problem that the existing system used for displaying nuclear fusion test results can only carry out the display on fixed display occasions, resulting in poor expandability, failure of meeting large-scale iterative code computation requirements, display content constraints and the like. The instant message release system disclosed by the invention is used in nuclear fusion tests, and all personnel interested in the tests can obtain all wanted information at the first time no matter at any place.

Owner:SOUTHWESTERN INST OF PHYSICS

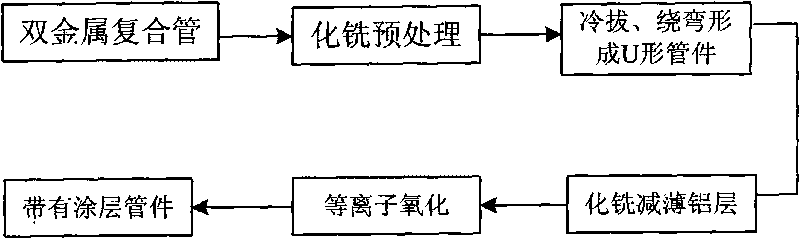

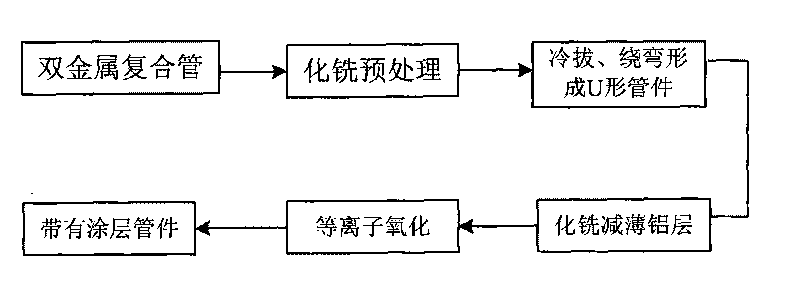

Preparation method of tritium-permeation resistant seamless U-shaped pipeline for thermonuclear fusion experimental reactor

The invention discloses a preparation method of a tritium-permeation resistant seamless U-shaped pipeline for a thermonuclear fusion experimental reactor. In the method, chemical milling pretreatment is first carried out on a duplex metal composite pipe with an aluminum coating; integral cold forming process is carried out on a treated composite pipe blank; and the seamless U-shaped pipeline is prepared by making full use of the excellent property that coating metal and metallurgical base materials are combined and cannot be easily cracked and layered in the deforming process and by reasonably controlling shapes and sizes of a forming mould and other forming parts. The U-shaped pipeline is chemically milled and the thickness of an aluminum layer is controlled according to actual engineering needs. An anti-corrosion tritium-permeation resistant alumina coating is formed in site on the surface of the U-shaped pipeline by a plasma oxidation method. Finally, the seamless composite U-shaped pipeline with the anti-corrosion tritium-permeation resistant alumina ceramic coating is prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

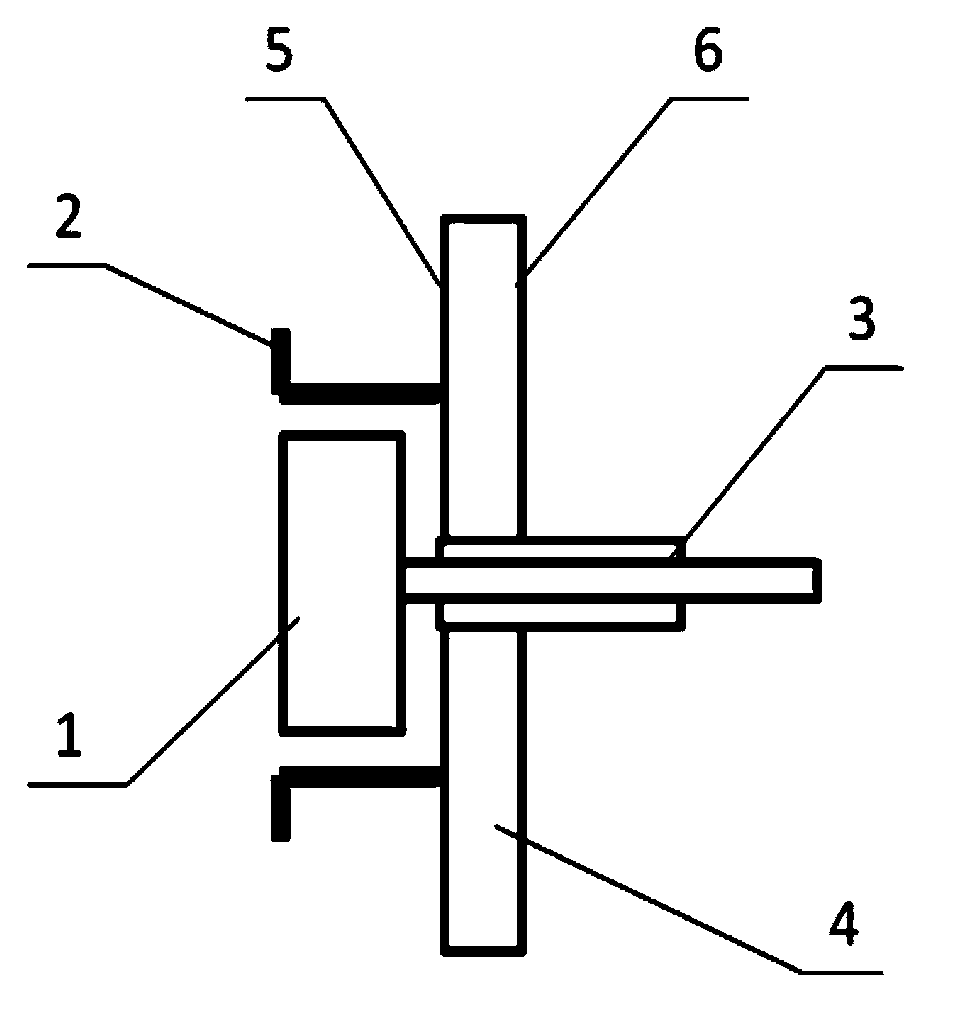

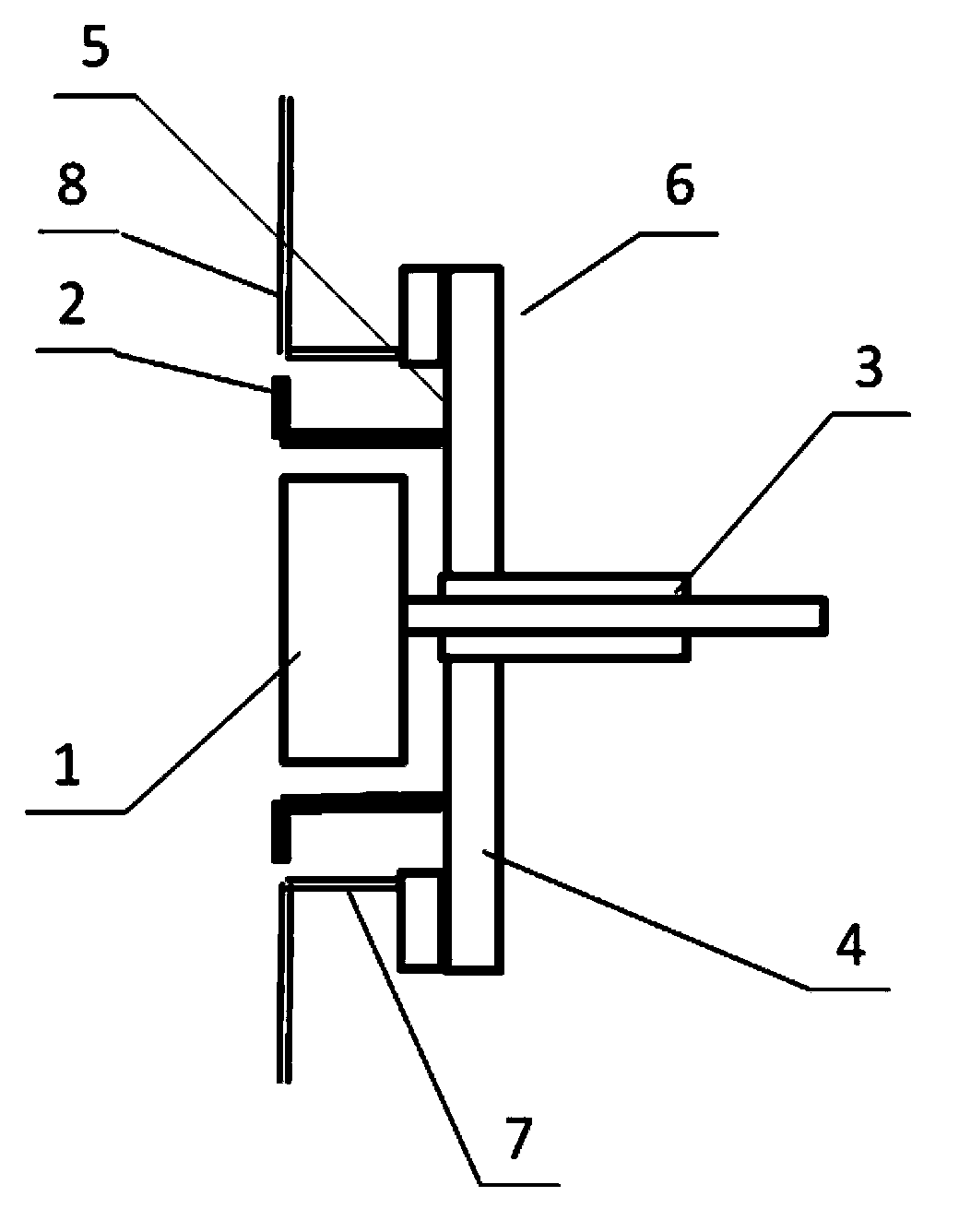

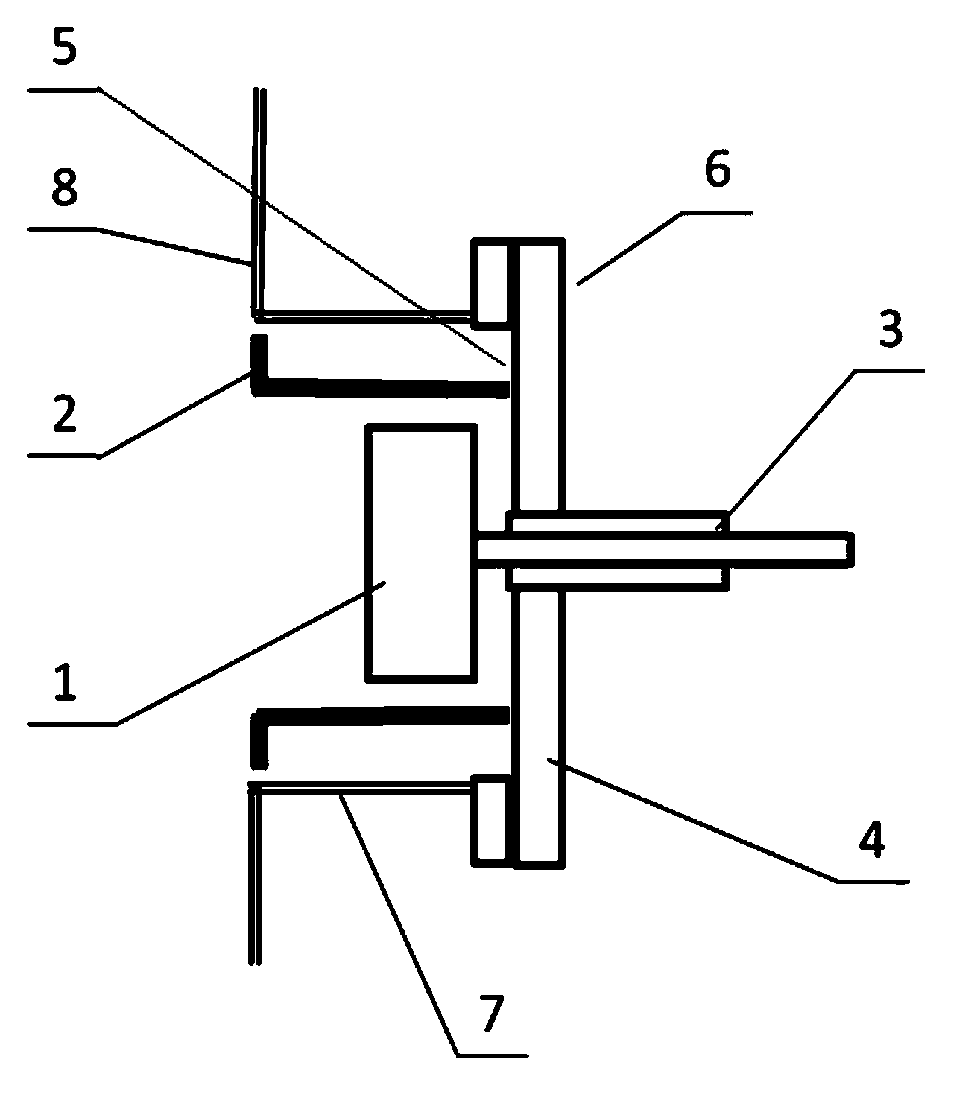

Embedded glow discharge electrode

ActiveCN103903931AReduce the risk of water leakageReduce design difficultyNuclear energy generationMounting/support/spacing/insulation of electrode assembliesWater leakageShielding gas

The invention belongs to a glow discharge electrode and particularly discloses an embedded glow discharge electrode. The embedded glow discharge electrode comprises a hollow flange, a vacuum electrical lead, an electrode tip and a shielding case; the electrode tip and the shielding case are positioned on one end of a vacuum side of the vacuum electrical lead; the electrode tip is arranged within the shielding case; one side of the shielding case sleeves the vacuum side of the vacuum electrical lead; and the other side of the shielding case is an opening. The embedded glow discharge electrode can avoid direct irradiation of plasma of deuterium and tritium, has a low water leakage risk, and guarantees the safety and reliability of a thermonuclear fusion experiment.

Owner:SOUTHWESTERN INST OF PHYSICS

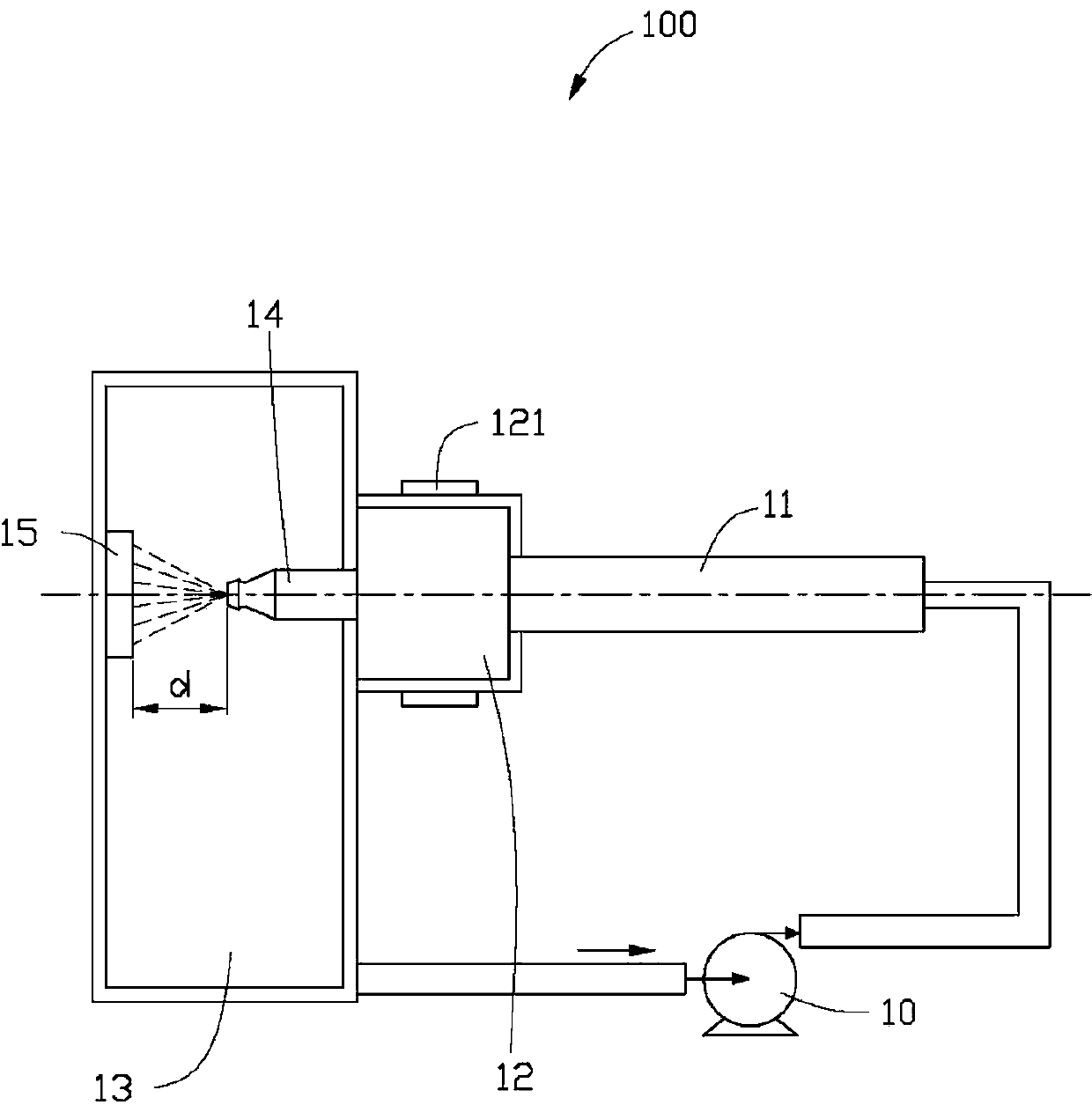

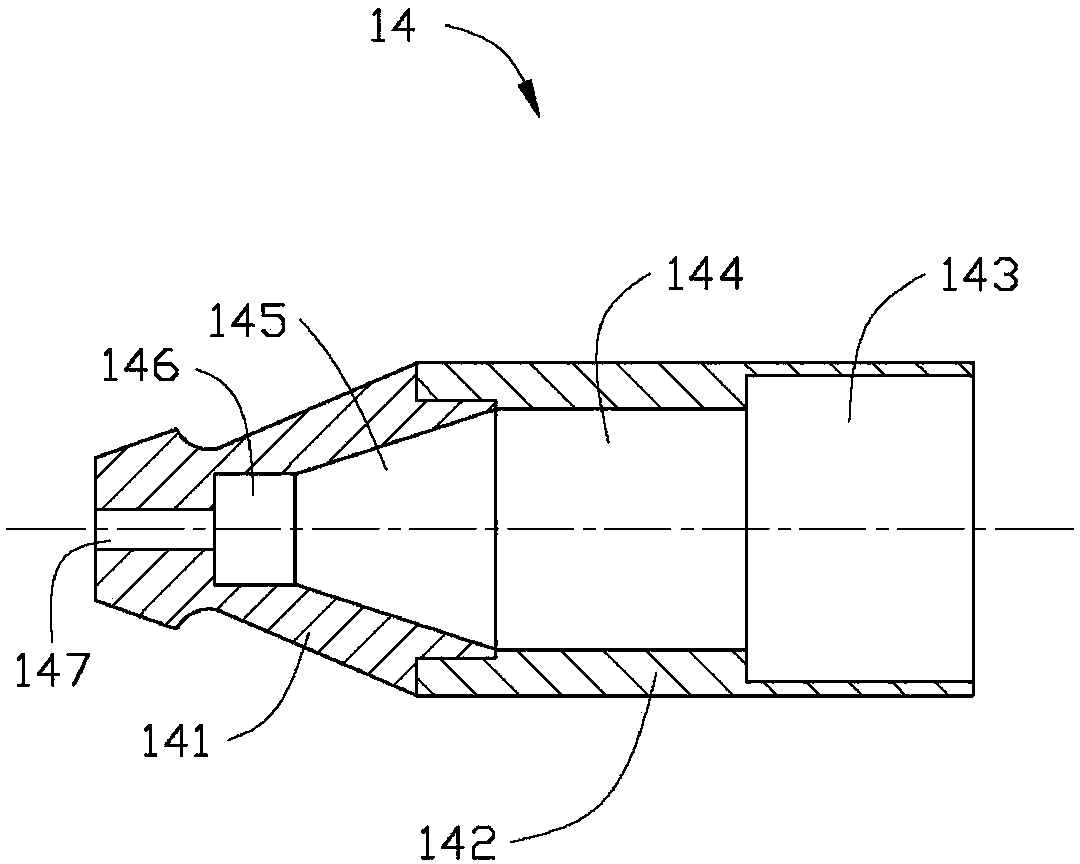

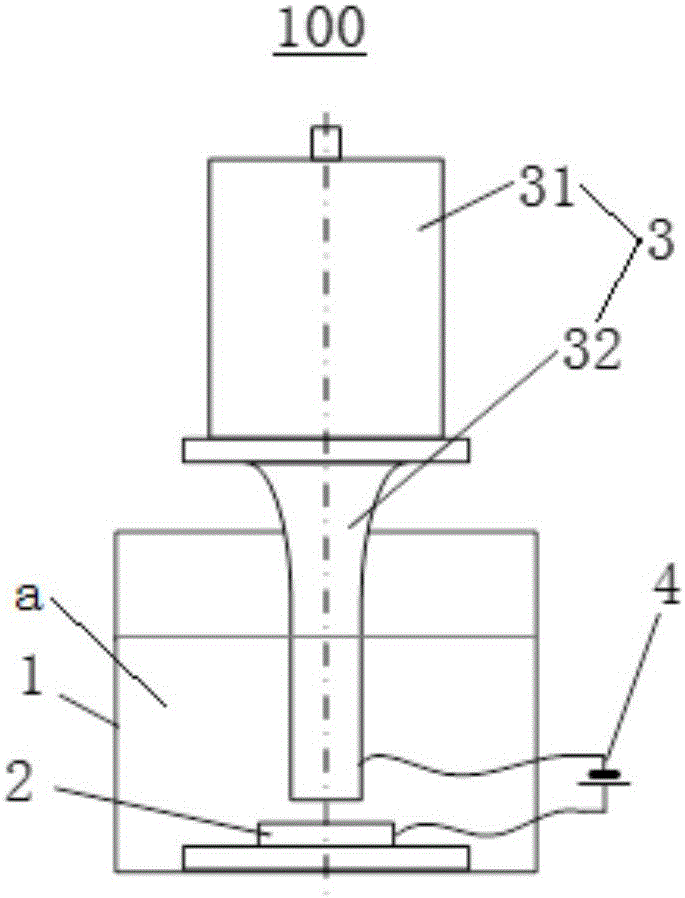

Device and method for realizing deuterium deuterium thermonuclear fusion through ultrasonic cavitation

InactiveCN106158051AAchieve fusionNuclear energy generationThermonuclear fusion reactorLiquid mediumUltrasonic cavitation

The invention discloses a device and method for realizing deuterium deuterium thermonuclear fusion through ultrasonic cavitation. The device comprises a liquid storage container, a test piece, an ultrasonic transducer and a double electric layer electric field, wherein a liquid storage chamber is defined in the liquid storage container; the test piece is arranged in the deuterium-containing liquid medium of the liquid storage container; the ultrasonic transducer comprises a transducer body and an amplitude transformer which are in connection; the amplitude transformer is suitable for extending into the deuterium-containing liquid medium of the liquid storage container and is separated from the test piece; the amplitude transformer can perform ultrasonic vibration under the driving of the transducer body so as to allow the deuterium-containing liquid medium to form vacuoles through ultrasonic cavitation and to drive the vacuoles to move towards the test piece; the double electric layer electric field is arranged between the ultrasonic transducer and the test piece, and is used for accelerating the vacuoles, allowing the vacuoles to generate gravitational collapse, and realizing deuterium deuterium thermonuclear fusion. The device for realizing deuterium deuterium thermonuclear fusion generates vacuoles through ultrasonic cavitation, constrains plasmas through a liquid-vapor interface, creates an increasingly enhanced pressure environment, and realizes deuterium deuterium thermonuclear fusion.

Owner:TSINGHUA UNIV +1

Nuclear reaction liquid for implementing sound-caused nuclear fusion

InactiveCN101303904AExtensive resourcesLow production costNuclear energy generationThermonuclear fusion reactorCavitationNuclear fusion

The invention relates to a nuclear reaction liquid which realizes nuclear fusion on the basis of acoustic cavitations and a preparation method thereof. The nuclear reaction liquid disclosed by the invention contains such nuclear reaction materials as tritium and a compound of tritium and lithium. The invention belongs to the technical field of the controlled thermal nuclear fusion. The nuclear reaction liquid of the invention mainly consists of the compound of tritium and lithium and heavy water with the mixed weight proportion mean value from 80 to 20. The three preparation methods of the nuclear reaction liquid of the invention are available as follows: 1. a neutron producer with proper energy is adopted for irradiating the lithium compound to have the nuclear reaction to generate the lithium compound containing the tritium and the lithium compound containing the tritium is dissolved into the heavy water to obtain the nuclear reaction liquid; 2. the lithium compound is dissolved into the heavy water in advance and a neutron producer with proper energy is adopted for irradiating the mixture to have nuclear reaction to generate the tritium and therefore to obtain the nuclear reaction liquid; 3. the tritide and the lithium compound are directly dissolved into the heavy water to obtain the nuclear reaction liquid.

Owner:SHANGHAI UNIV

Superconducting magnet based on ReBCO superconducting rings

InactiveCN109346262AThe magnetic field value is stableStable strong magnetic fieldSuperconducting magnets/coilsPower flowSuperconducting Coils

The invention discloses a superconducting magnet based on ReBCO superconducting rings, and belongs to the technical field of superconducting magnet application. The superconducting magnet is formed byalternately stacking and fixing one or more sets of N pieces of superconducting rings and N+1 pieces of insulating sheets which are stacked and then fixed through a fixing device; wherein N is a positive integer, the N pieces of superconducting rings are all square ring pieces or racetrack-shaped ring pieces, and the shapes and sizes of the N+1 pieces of insulating sheets are same as those of theN pieces of superconducting rings respectively. The superconducting magnet based on the ReBCO superconducting rings has the advantages that welding, a power source and a current lead are not needed among the ReBCO superconducting rings in the superconducting magnet, the structure is compact, the detachability is achieved, the stability is high, the preparation process is simple, a strong magneticfield can be stably output, the range of the ReBCO superconductors applied to strong magnetic fields is expanded, and the superconducting magnet can be widely applied to medium and large superconducting magnets and thermonuclear fusion reactions.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

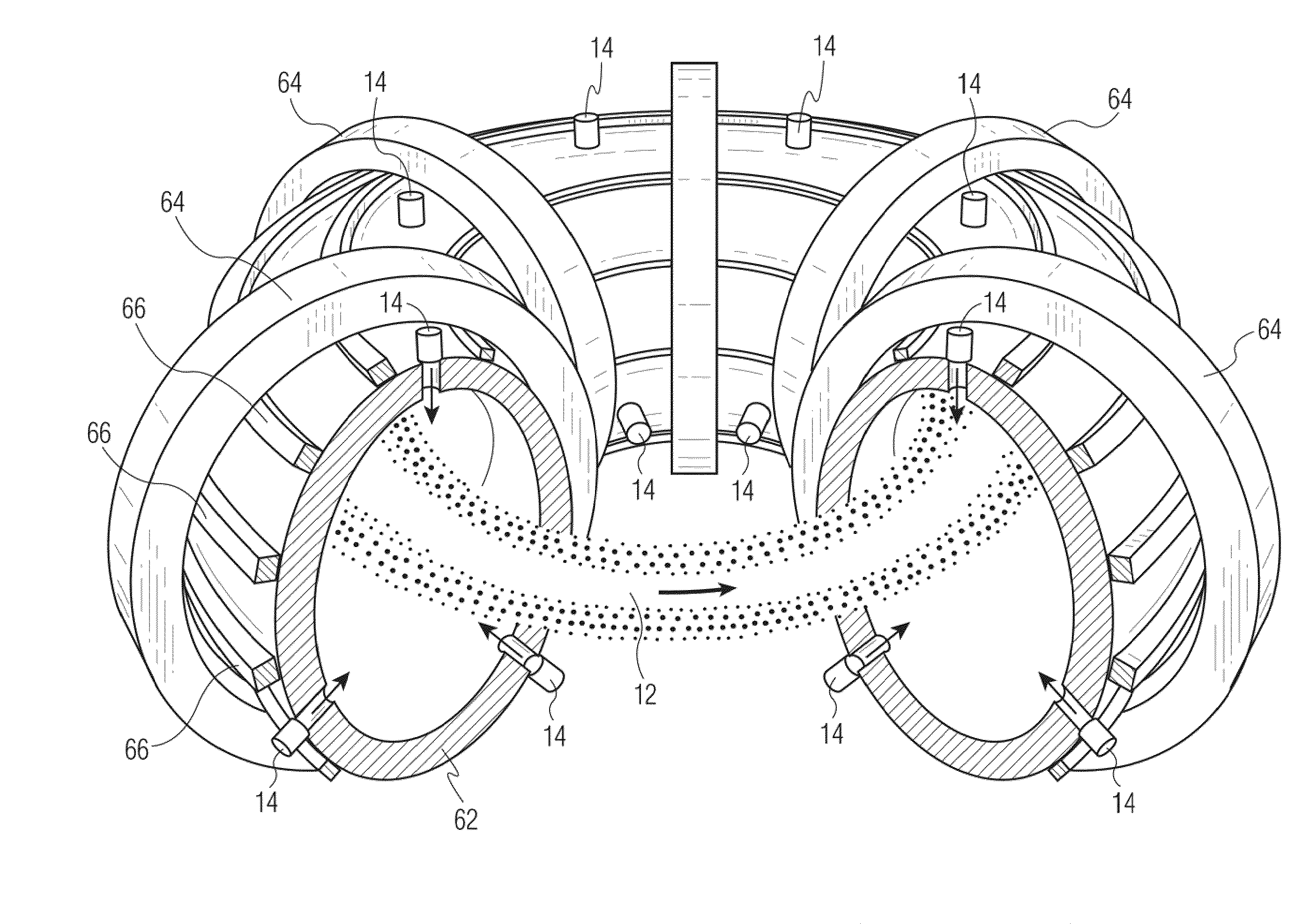

Plasma confinement device with helical current and fluid flow

ActiveUS11107592B2Reducing particle lossesNuclear energy generationPlasma techniqueNuclear engineeringCompact toroid

A device and method for generating plasma conditions for deuterium-tritium and advanced fuel thermonuclear fusion consisting of an inner helicity-containing plasma such as a spheromak compact toroid bounded by a plurality of outer cusped magnetic fields. Helicity driven by steady-inductive helicity injectors energizes the plasmoid with helicity. The device further includes means for driving fluid rotation about the device axis, about the device magnetic axis, and means for a hot electron sheath. Means are also provided for reducing particle losses out through the open cusp field lines through helicity injector rectification.

Owner:PRATER DANIEL

Pulse discharging operating nuclear fusion reaction method and reaction device of pulse discharging operating nuclear fusion reaction

InactiveCN103489487AEasy to controlEnsure safetyNuclear energy generationThermonuclear fusion reactorAutomatic controlUltra high voltage

Owner:曾泓瑞

Explosive welding method for bimetal composite boards with special quality requirements

InactiveCN103056508BReliable weldingMeet welding quality requirementsNon-electric welding apparatusBond interfaceCharged body

The invention discloses an explosive welding method for bimetal composite boards with special quality requirements. The explosive welding method includes preprocessing blanks; charging powder; and performing explosive welding. In a powder charging procedure, 'basin'-shaped powder charge bodies are arranged on shroud plates and extension plates, upper and lower surfaces of the powder charge bodies are parallel to the shroud plates and the extension plates, and powder charging quantities are acquired by computing according to a formula. The welded rate of the composite boards welded by the explosive welding method reaches 100%, the bonding strength of welded surfaces of the bimetal composite boards meet a bimetal solid-phase metallurgical bonding strength law, bonding interfaces of the bimetal composite boards are finely wavy and are excellent in quality, and accordingly the quality requirements of critical equipment of thermonuclear fusion power generation test reactors on the composite boards are met.

Owner:中国人民解放军理工大学野战工程学院 +2

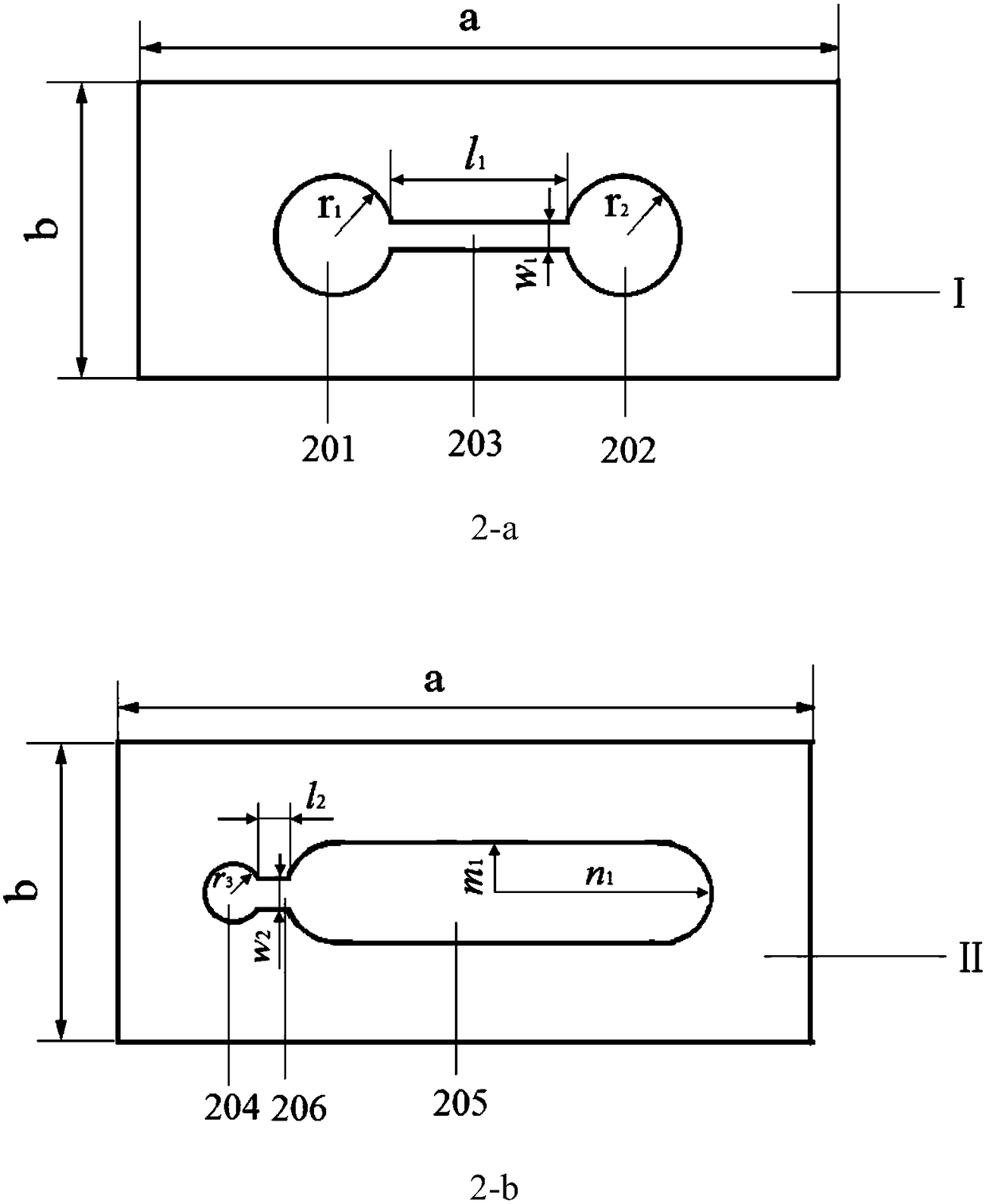

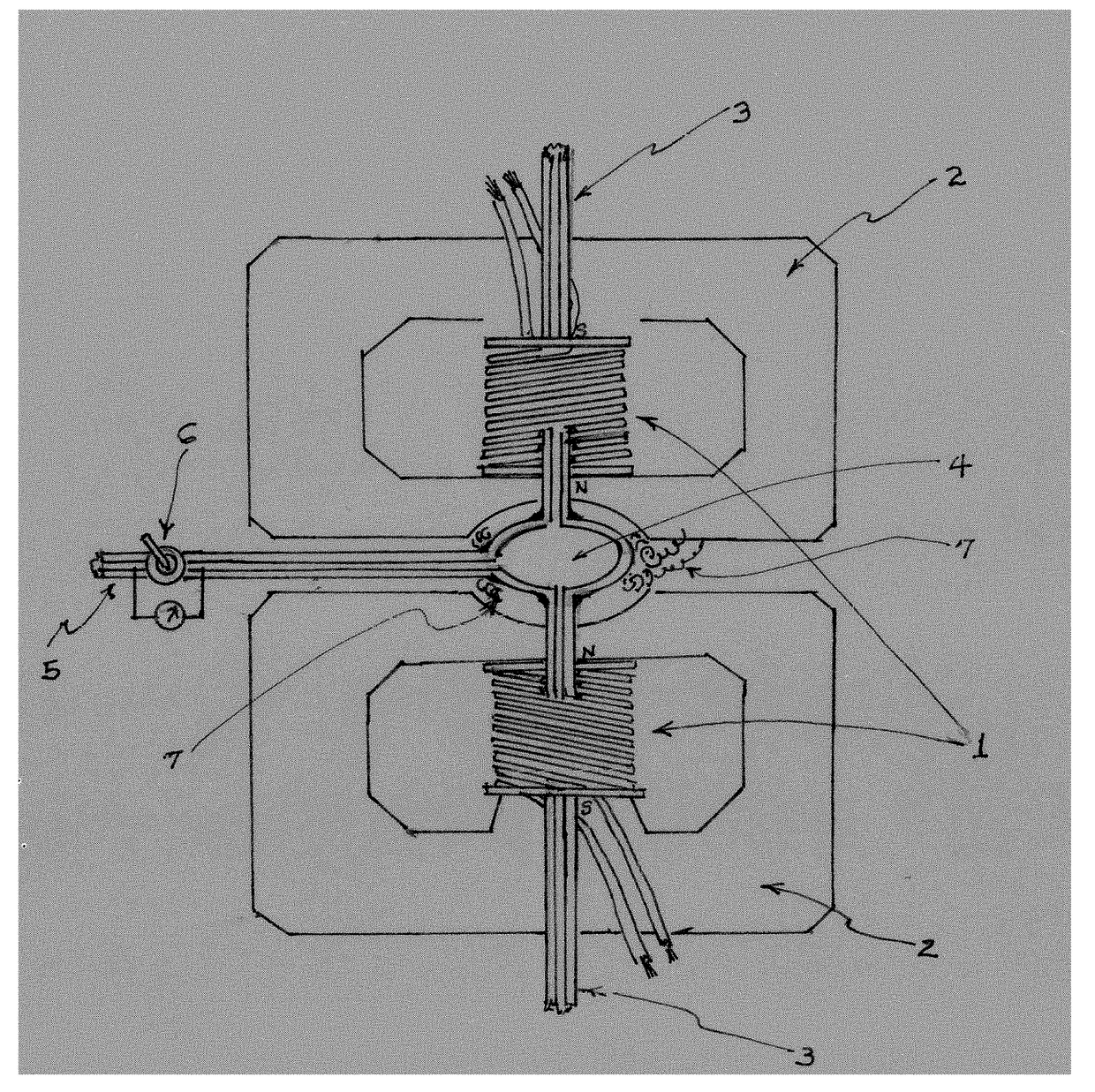

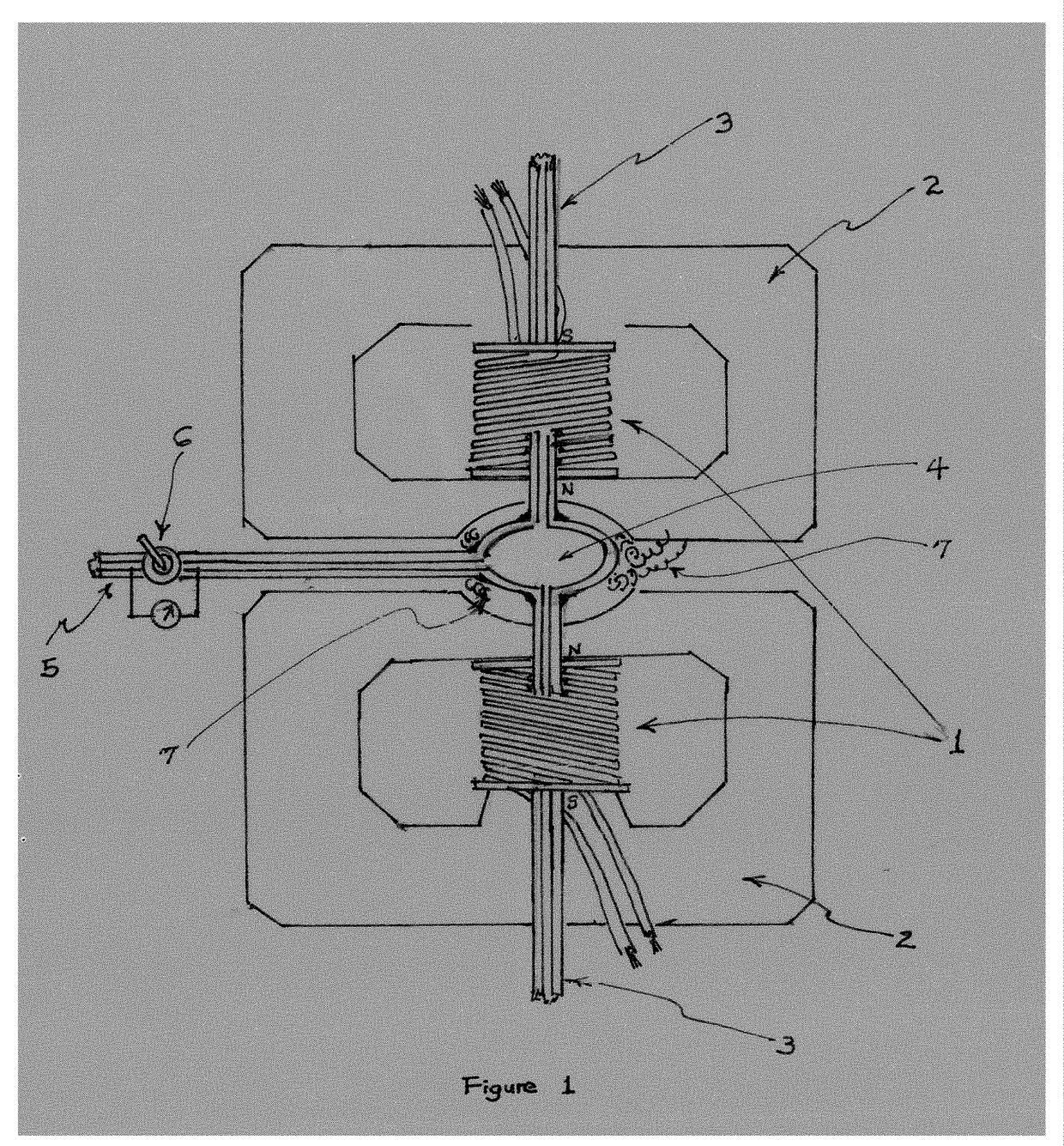

Apparatus for plasma confinement and for ion separation

InactiveUS20180254153A1Easily be produced in massEmission reductionContact surface shape/structureParticle separator tubesSource materialRapid rotation

Twin bar (electro)magnets with the North poles facing each other generate magnetic field lines converging into the middle, providing a space to place plasma cloud in magnetic confinement for thermonuclear fusion experiments. Source materials are injected through nozzles connected to axial pipes, and end products are taken out at the periphery of the reaction chamber. In ion separation, the source materials are injected at the periphery of the reaction chamber causing rapid rotation, and ions are attracted by electric potentials applied to the chamber walls. Naturally separated ions are expelled through the axial output pipes. The proposed apparatus for ion separation provides inexpensive means for producing massive volumes of hydrogen and oxygen gases. Use of hydrogen fuel can reduce consumption of carbon fuels, easing the global problem of rising temperature due to emission of CO2 gases.

Owner:MIZUKI MIKISO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com