Five tungsten-based high-entropy alloys and preparation method thereof

A high-entropy alloy and alloy technology, which is applied in the field of high-entropy alloy and tungsten alloy material, can solve the problems of poor plasticity and unfavorable application, and achieve the effect of excellent compression resistance and high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

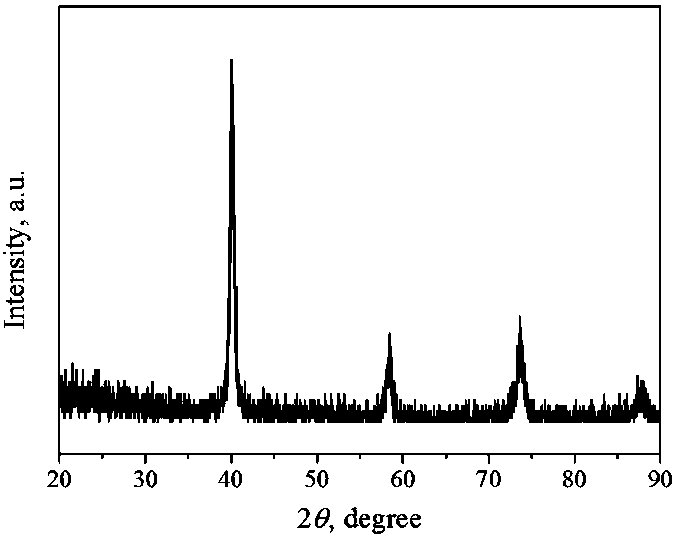

[0047] Embodiment 1 WVTi high entropy alloy

[0048] The preparation process of the tungsten-based high-entropy alloy of this embodiment is as follows.

[0049] (1) Powder pre-sintering

[0050] W, V and Ti are used as three kinds of powder raw materials, and they are configured according to the weight ratio of W:V:Ti=65.07:18.01:16.93, and the total mass is 100g. Seal the prepared powder raw material in a stainless steel drum with a diameter of 100 mm and a height of 150 mm, and fill it with high-purity argon gas with a purity of 99.999% by weight before sealing. Then, ball milling and dry mixing were carried out at a drum speed of 30 rpm for 10 hours to obtain a ball milling mixture. Afterwards, the ball-mill mixture was pressed for 15 min under a pressure of 180 MPa to make a powder compact. Then sinter the powder compact in a vacuum furnace at 1470-1500°C for 50 minutes to obtain a sintered sample of the alloy.

[0052] Cut the sintered sam...

Embodiment 2

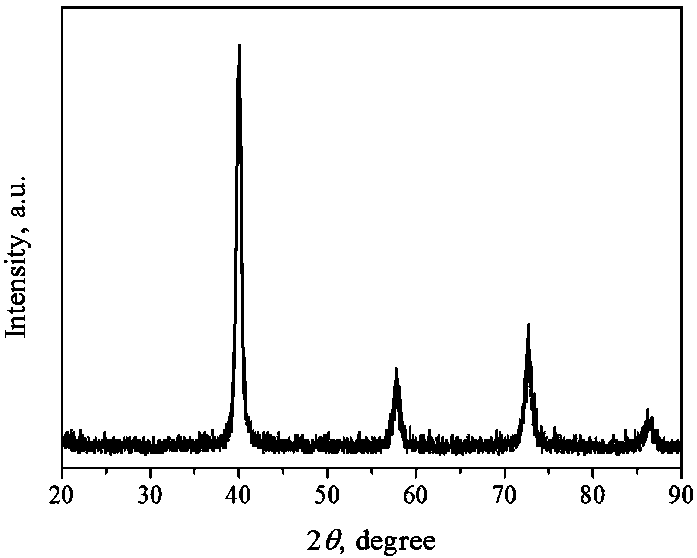

[0055] Embodiment 2 WVTiTa high entropy alloy

[0056] The preparation process of the tungsten-based high-entropy alloy of this embodiment is as follows.

[0057] (1) Powder pre-sintering

[0058] Using W, V, Ti, Ta four kinds of powder raw materials, according to the weight ratio of W: V: Ti: Ta = 39.66: 10.99: 10.33: 39.03 configuration, the total mass is 200g. Seal the prepared powder raw material in a stainless steel drum with a diameter of 100 mm and a height of 150 mm, and fill it with high-purity argon gas with a purity of 99.999% by weight before sealing. Then, ball milling and dry mixing were carried out at a drum speed of 30 rpm for 10 hours to obtain a ball milling mixture. Afterwards, under the pressure of 180 MPa, the obtained ball-milled mixture was pressed for 15 minutes to make a powder compact. Then sinter the powder compact in a vacuum furnace at 1470-1500°C for 50 minutes to obtain a sintered sample of the alloy.

[0060] Cut...

Embodiment 3

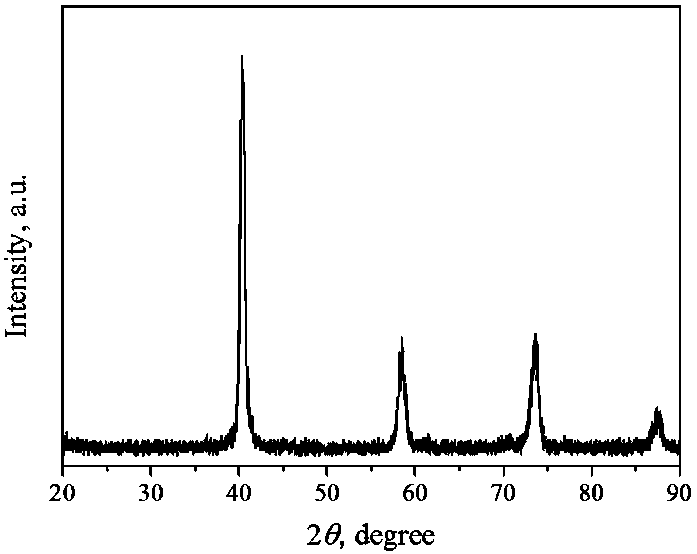

[0063] Embodiment 3 WVTiTaRe high entropy alloy

[0064] The preparation process of the tungsten-based high-entropy alloy of this embodiment is as follows.

[0065] (1) Powder pre-sintering

[0066] Five powder materials of W, V, Ti, Ta, and Re are used, and they are configured according to the weight ratio of W:V:Ti:Ta:Re=28.29:7.84:7.37:27.85:28.65, with a total mass of 300g. Seal the prepared powder raw material in a stainless steel drum with a diameter of 100 mm and a height of 150 mm, and fill it with high-purity argon gas with a purity of 99.999% by weight before sealing. Then, ball milling and dry mixing were carried out at a drum speed of 30 rpm for 10 hours to obtain a ball milling mixture. Afterwards, under the pressure of 180 MPa, the obtained ball-milled mixture was pressed for 15 minutes to make a powder compact. Then sinter the powder compact in a vacuum furnace at 1470-1500°C for 50 minutes to obtain a sintered sample of the alloy.

[0067] (2) Alloy smeltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice parameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com