High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

A particle-reinforced aluminum and high-entropy alloy technology, which is applied in the field of metal-matrix composite material manufacturing, can solve the problems of preparing high-entropy alloy particle-reinforced aluminum-matrix composite materials, and achieve simple process, clean and smooth interface, and good high-temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

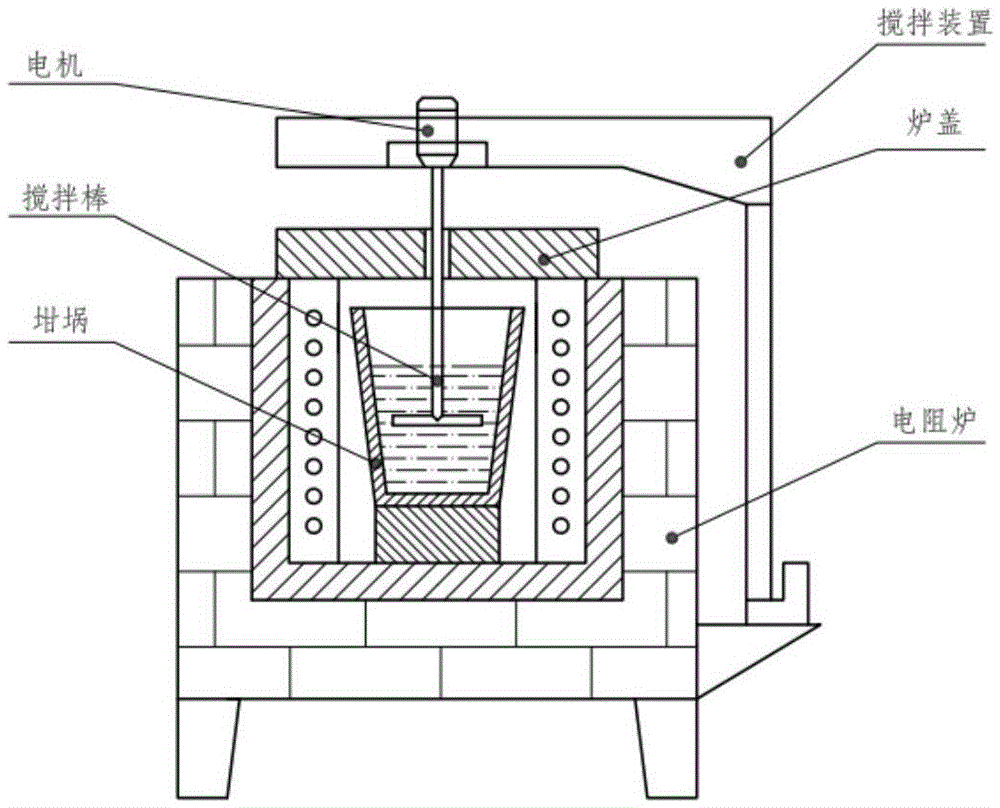

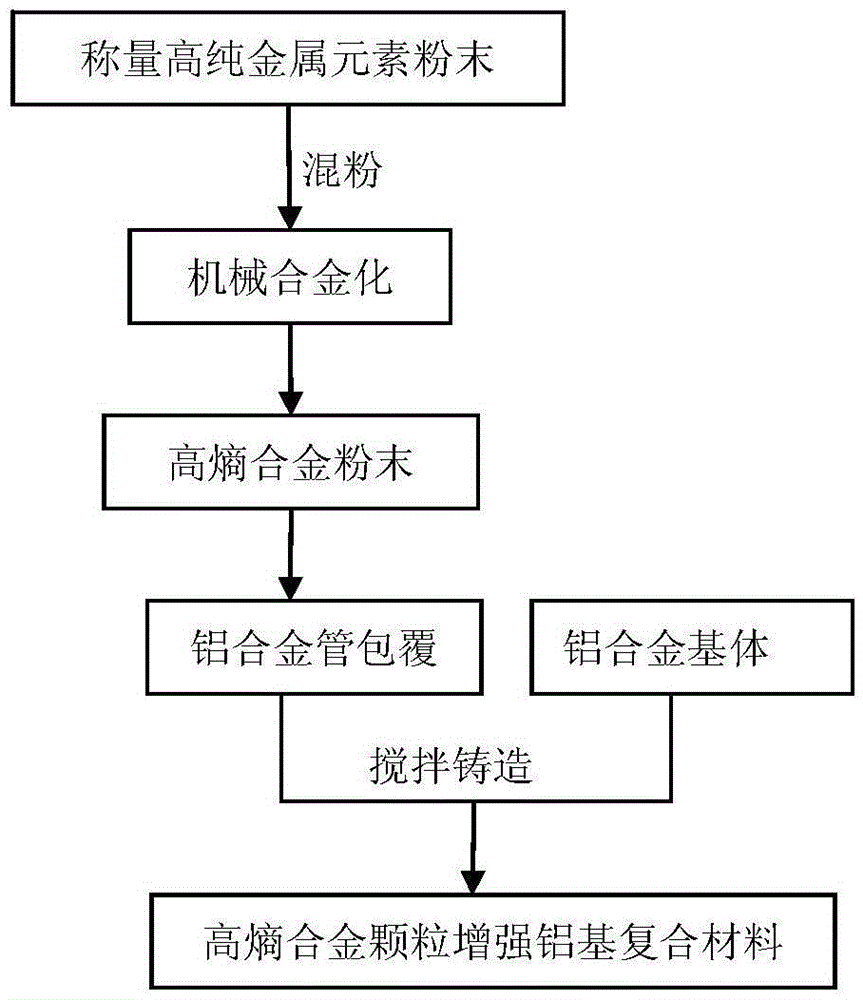

Method used

Image

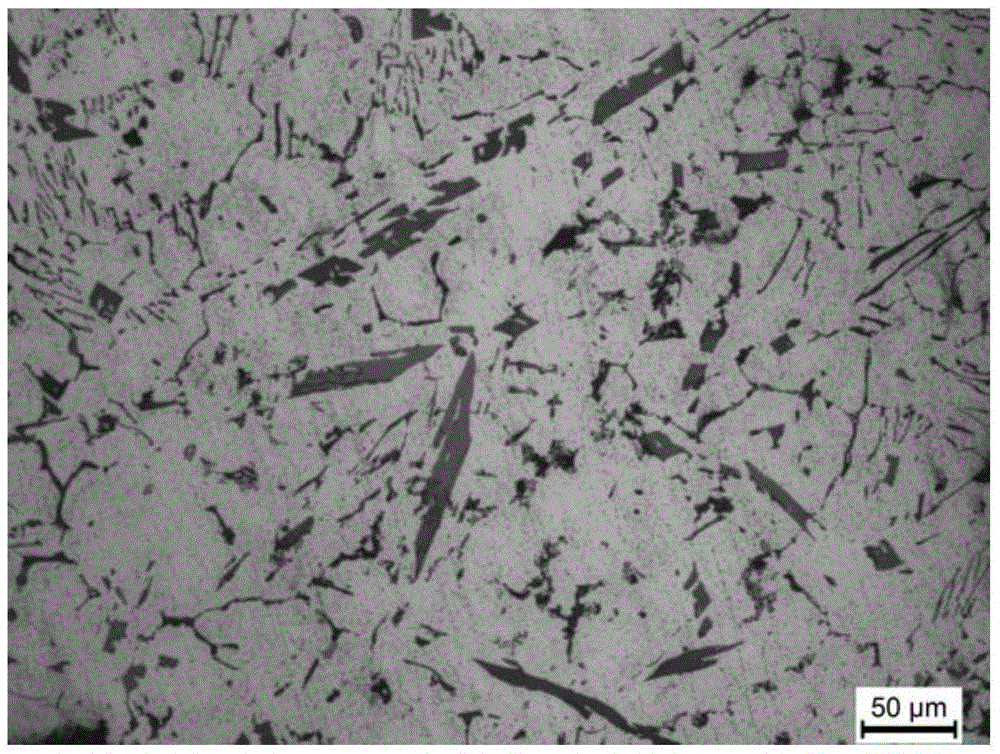

Examples

Embodiment 1

[0028] Step 1: Preparation of high-entropy alloy powder

[0029] First, AlCoCuFeNi high-entropy alloy particles are selected as the reinforcement phase, and the specific composition of the high-entropy alloy is Al 0.25 CoCu 0.75 FeNi, according to the high-entropy alloy Al 0.25 CoCu 0.75 The molar atomic ratio and mass fraction of each main element in FeNi, respectively calculate the mass of each component as pure Al powder 18.38g, pure Co powder 160.56g, pure Cu powder 133.94g, pure Fe powder 152.19g, pure Ni powder 159.94g , and use an electronic balance to weigh the corresponding mass, mix it on the powder mixer for 24 hours, mix it evenly, put it into a stainless steel ball mill tank, vacuumize it, fill it with argon, and then ball mill it on a planetary ball mill for 60 hours. The ball-to-material ratio is 8: 1. The rotation speed is 200r / min, the process control agent is absolute ethanol, and high-entropy alloy powder is prepared.

[0030] Step 2: Particle Sieving an...

Embodiment 2

[0035] Step 1: Preparation of high-entropy alloy powder

[0036] First, AlCoCrFeNi high-entropy alloy particles are selected as the reinforcing phase. The specific composition of the high-entropy alloy is AlCoCrFeNi. According to the molar atomic ratio and mass fraction of the main elements in the high-entropy alloy AlCoCrFeNi, the mass of each component is calculated as pure Al powder 66.80 g, 145.90g of pure Co powder, 128.73g of pure Cr powder, 138.27g of pure Fe powder, 145.30g of pure Ni powder, and weigh the corresponding mass with an electronic balance, mix it on the powder mixer for 20h, mix it evenly and put it into stainless steel In the ball mill tank, vacuumize, fill with argon, and then ball mill on a planetary ball mill for 56 hours, the ball-to-material ratio is 8:1, the speed is 150r / min, and the process control agent is absolute ethanol to prepare high-entropy alloy powder.

[0037] Step 2: Particle Sieving and Encapsulation

[0038] The high-entropy alloy po...

Embodiment 3

[0042] Step 1: Preparation of high-entropy alloy powder

[0043] First, AlCoCrCuFeNiTi high-entropy alloy particles are selected as the reinforcement phase, and the specific composition of the high-entropy alloy is Al 0.25 CoCrCu 0.25 FeNiTi 0.25 , according to the high-entropy alloy Al 0.25 CoCrCu 0.25 FeNiTi 0.25 The molar atomic ratio and mass fraction of each main element in the formula, the mass of each component is calculated as pure Al powder 16.18g, pure Co powder 141.35g, pure Cr powder 124.72g, pure Cu powder 39.31g, pure Fe powder 133.96g, Pure Ni powder 140.77g, pure Ti powder 28.71g, weigh the corresponding mass with an electronic balance, mix them on the powder mixer for 18 hours, mix them evenly, put them into a stainless steel ball mill tank, vacuumize, fill with argon, and then put them on the planetary Milled on a ball mill for 50 hours, the ball-to-material ratio was 8:1, the rotation speed was 220r / min, and the process control agent was absolute ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com