Patents

Literature

79results about How to "Purify the melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

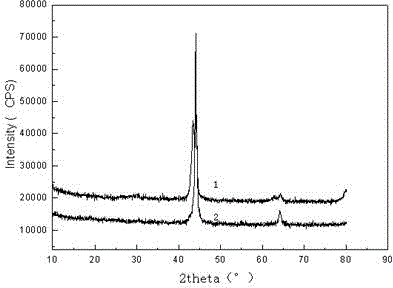

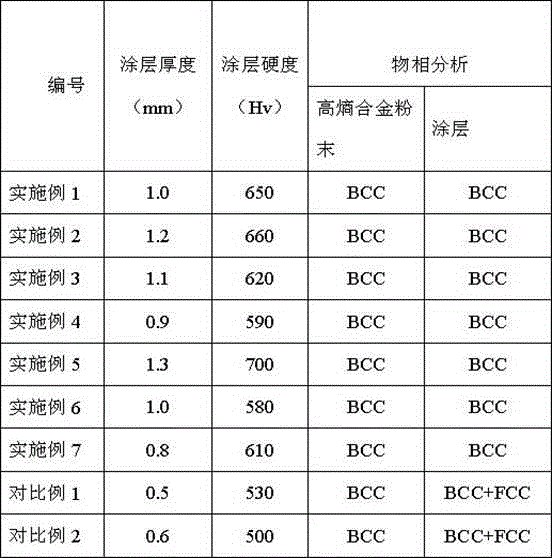

High-entropy alloy powder for spray coating and preparation method thereof, as well as composite material and preparation method thereof

InactiveCN104561878APurify the meltReduce oxygen contentMolten spray coatingRare-earth elementHigh entropy alloys

The invention provides high-entropy alloy powder for spray coating. The high-entropy alloy powder is composed of CraFebCocNidAleMfRg, wherein a, b, c, d, e, f, g are atomic percentages, a, b, c, d, e, f are nearly equal atomic percentages, g is larger than 0 and is smaller than 1, and a+b+c+d+e+f+g is equal to 100; M is at least one of Ti, HF, Mn and Cu; and R is at least one of rare earth elements. The invention further provides a preparation method of the high-entropy alloy powder, a composite material obtained by spray coating of the high-entropy alloy powder and a preparation method of the composite material. The high-entropy alloy coating provided by the invention has the advantages of high strength and low manufacturing cost, and has hardness and excellent adhesive force much better than those of traditional alloys, thereby being an excellent wear-resistant material and having a great application prospect.

Owner:BYD CO LTD

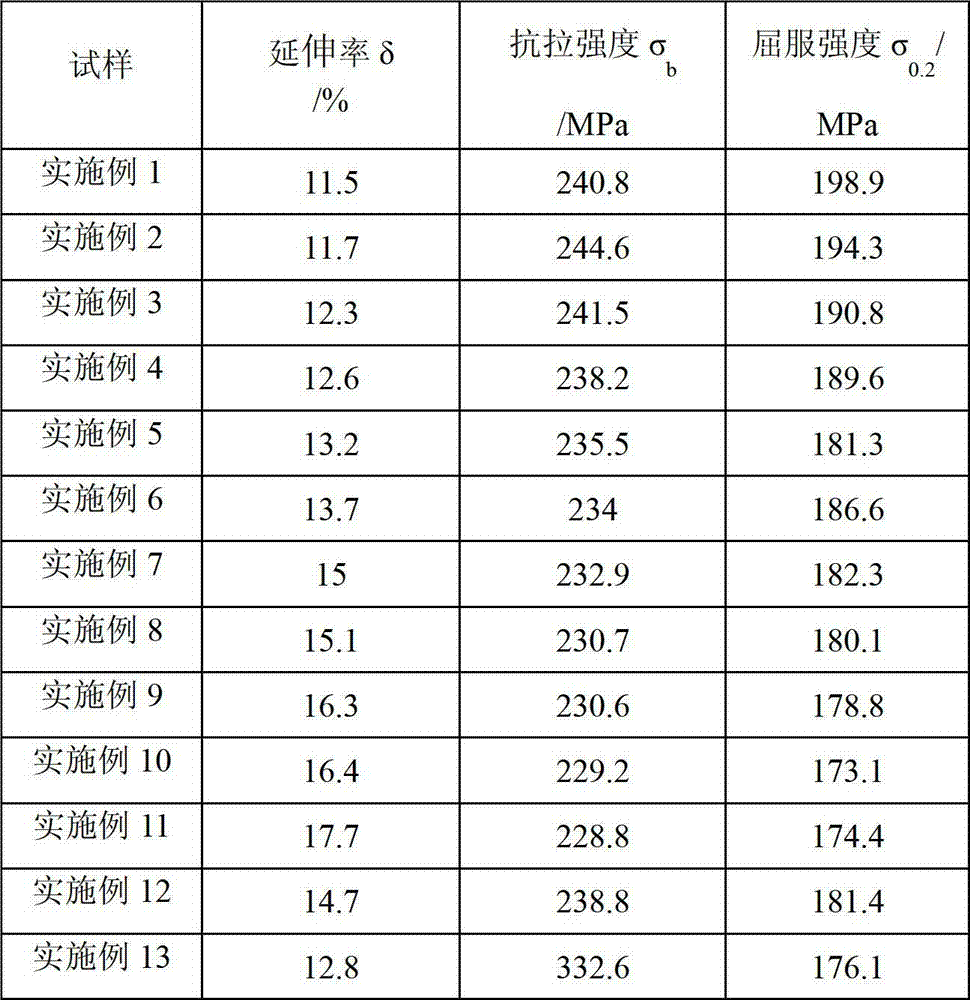

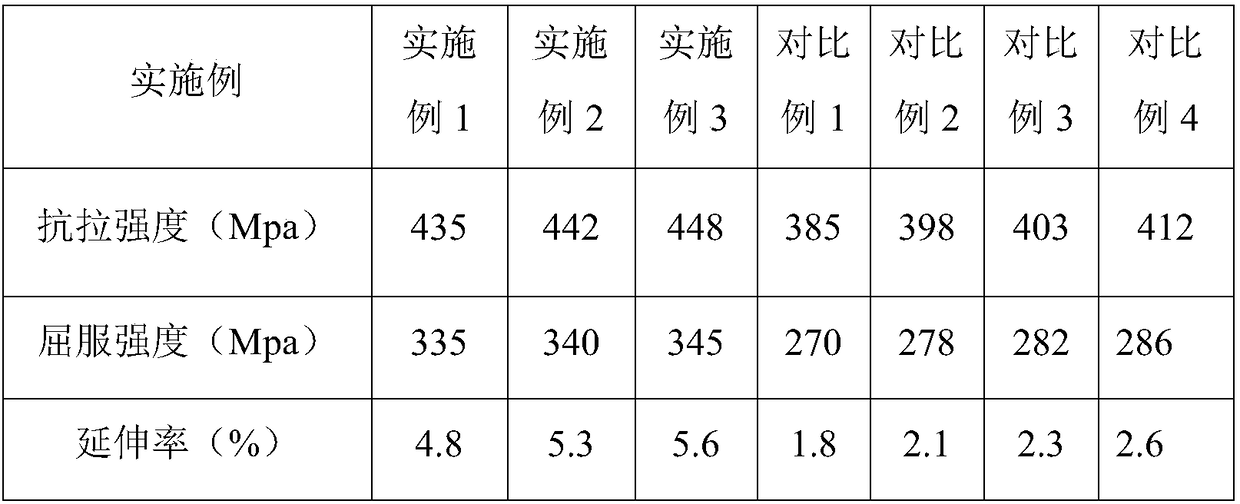

High-plasticity aluminum-silicon alloy for die casting and preparation method thereof

The invention provides high-plasticity aluminum-silicon alloy for die casting. The high-plasticity aluminum-silicon alloy comprises the following components in percentage by weight: 7.0 to 13.0 percent of silicon, 0.20 to 0.40 percent of magnesium, 0.20 to 0.50 percent of manganese, 0.01 to 0.15 percent of strontium, less than 0.15 percent of ferrum, less than 0.10 percent of copper, less than 0.10 percent of zinc and the balance of aluminum, wherein the sum of the mass percentage of each component is 100 percent. The aluminum-silicon alloy is light in weight, high in quality, strength and plasticity and high in flowing property, the elongation is more than 10 percent, and die casting pieces are easy to demold in the production process; and a preparation process is simple and low in cost.

Owner:南京宁铁有色合金科技开发有限公司

Heat resisting casting magnesium alloy and preparation method thereof

The invention provides a heat-resistant cast magnesium alloy, which belongs to the technical field of metal material and comprises the following compositions in percentage by weight: 1.5 to 4.5 percent of yttrium, 0.4 to 1.5 percent of zinc, 0.2 to 0.7 percent of zirconium, impurity elements: less than 0.005 percent of ferrite, less than 0.015 percent of copper and less than 0.002 percent of nickel and the balance of magnesium. The heat-resistant cast magnesium alloy is low in cost and high in efficiency, has good tensile strength, yield strength and elongation, and meanwhile has perfect creep resistance property and good casting property.

Owner:SHANGHAI JIAO TONG UNIV

Aluminum silicon alloy for air conditioner compressor cylinder body and preparation method thereof

ActiveCN105861886AReduce weightQuality improvementPositive displacement pump componentsPositive-displacement liquid enginesSilicon alloyDie casting

The invention provides an aluminum silicon alloy for an air conditioner compressor cylinder body; the aluminum silicon alloy includes the following components by the weight percentage: Si, Cu, Mg, Mn, Ti, Sr, Zr, Cr, Fe, B, V, Zn, Re, Sn, Pb, Be, Sc, Li, Ni, La, and the balance aluminum, wherein the sum of the mass percentages of the components is 100%. The aluminum silicon alloy has the advantages of light weight, good quality, high strength, high plasticity, high elongation rate, good flow performance, easy mold release in the production of die-casting parts, simple preparation process and relatively low cost.

Owner:江苏昊科汽车空调有限公司

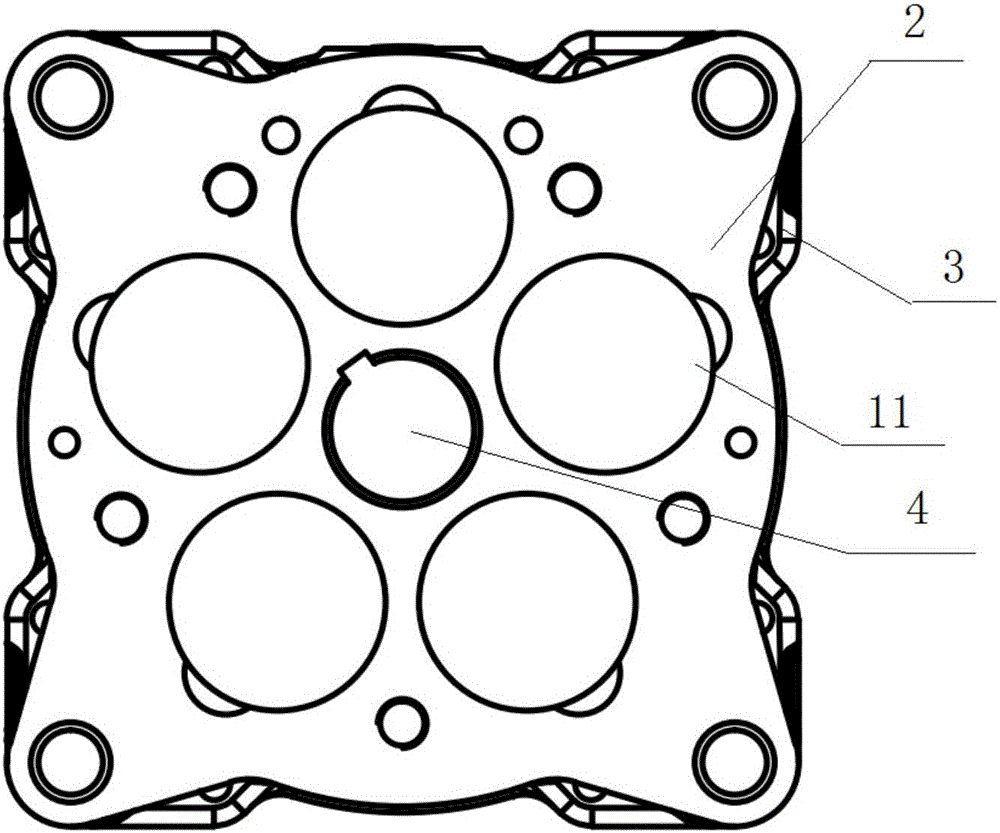

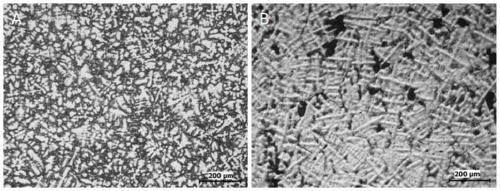

Composite metamorphic agent and composite metamorphic method of cast aluminum-silicon alloy

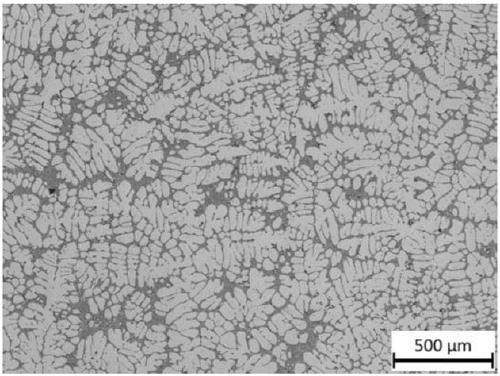

The invention discloses a composite metamorphic agent and a composite metamorphic method of a cast aluminum-silicon alloy, and relates to the technical field of metamorphism of cast aluminum alloys. The composite metamorphic method mainly uses the composite metamorphic agent for metamorphism. The composite metamorphic agent comprises an Al-Ti-B intermediate alloy, an Al-Sr intermediate alloy and an Al-RE intermediate alloy; the appending proportion of the Al-Ti-B intermediate alloy is 0.01%-0.04% of the melt mass of the cast aluminum-silicon alloy; the additive amount of Sr in the Al-Sr intermediate alloy is 0.01-0.05% of the melt mass; and the additive amount of RE in the Al-RE intermediate alloy is 0.01%-0.1% of the melt mass. According to the composite metamorphic method of the cast aluminum-silicon alloy, the cost is low, operation is easy, the purpose of synchronously refining alpha-Al crystalline grains and metamorphic eutectic silicon can be achieved through composite metamorphism, the additive amount of the Sr, and Al-Ti-B is decreased, thus the tensile strength and elongation of the alloy can be improved, and meanwhile, the strength and toughness of a cast aluminum alloy can be improved.

Owner:GUANGDONG INST OF NEW MATERIALS

High petential magnesium alloy sacrificial anode material and its manufacturing method

A high-potential Mg alloy used as consumable anode for the underground oil or gas pipeline, storage tank and water pipe is prepared through micro-alloying the Mg-Mn alloy by Mg-Ca and Mg-RE intermediate alloys, and refining by use of special refining agent to obtain Mg MnRECa alloy, which contains proportionally Mn, Ce, Ca, Si, Cu, Ni, Fe and Mg. Its advantages are high open-circuit potential 1.7-1.8 (-V) and high current efficiency (55-60%).

Owner:TAIYUAN UNIV OF TECH

Hot-dipping aluminum-zinc alloy containing rare earths and preparation method thereof

InactiveCN103045980AImprove corrosion resistanceExtended service lifeHot-dipping/immersion processesCeriumRare earth

The invention discloses a hot-dipping aluminum-zinc alloy containing rare earths and a preparation method thereof, belonging to the technical field of surface hot-dip coating of a steel plate and a steel plate component and solving the problems of poor forming property, poor corrosion resistance and poor surface appearance quality of the existing alloy hot-dipping board. The invention provides a hot-dipping aluminum-zinc alloy containing rare earths. The hot-dipping aluminum-zinc alloy comprises the following components in percentage by weight: 54%-59% of aluminum, 1.2%-1.8% of silicon, 0.05%-0.15% of rear earths, and the balance of zinc and inevitable impurities, wherein the rear earths refer to cerium or lanthanum or a rear earth mixture of cerium and lanthanum. The invention further provides the method for preparing the hot-dipping aluminum-zinc alloy, wherein the method comprises the following steps of: adding cerium or lanthanum or the rear earth mixture of cerium and lanthanum which is 0.07wt% or 0.12% to a Galvalume alloy melt to obtain the hot-dipping aluminum-zinc alloy containing rare earths. According to the hot-dipping aluminum-zinc alloy containing rare earths disclosed by the invention, the corrosion resistance, the formability and the spangles on the surface of the fine coating of the hot-dipping layer are improved; and the liquidity of the melt is improved.

Owner:YUNNAN KEENLY NEW MATERIAL +1

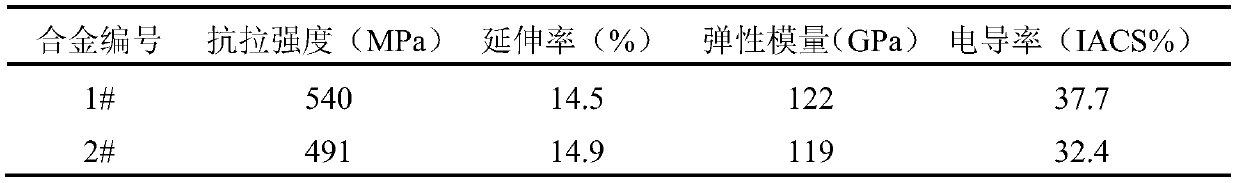

Environment-friendly high-conductivity elastic corrosion resistant copper alloy and production method of strip thereof

ActiveCN110284018APurify the meltGood melting and castingFurnace typesProcess efficiency improvementStress reliefMechanical property

The invention aims at disclosing an environment-friendly high-conductivity elastic corrosion resistant copper alloy and a production method of a strip thereof. The alloy comprises, by mass percent, 1.0 to 5.0% of Sn, 0.5 to 1.5% of Mg, 0.2 to 0.5% of Ni, 0.2 to 0.5% of Si, 0.2 to 0.5% of Zn, 0.05 to 0.2% of Al, 0.05 to 0.20% of Mn, 0.05 to 0.10% of Ce, 0.005 to 0.01% of Ca, and the balance Cu and inevitable impurities, wherein the content of the impurity Fe is smaller than or equal to 0.01%, and the total amount is 100%. In the alloying element, Sn / Mg is larger than or equal to 2.5 and smaller than or equal to 5.0, (Mg+Ni) / Si is larger than or equal to 2.5 and smaller than or equal to 4.0, and Ni / (Al+Mn) is larger than or equal to 2.5 and smaller than or equal to 4.0. In the copper ally, the content of Si, Mn, Ce, and Ca is reasonably controlled, the alloy melt can be effectively purified, the casting blank grains are refined, inverse segregation is reduced, the alloy smelting casting and machining performance is good, and electric conductivity is high. In the copper ally, the ratio of (Mg+Ni) / Si and the ratio of Ni / (Al+Mn) are reasonably controlled, through combined regulation of uniform annealing, cold rolling cogging, recrystallization annealing, intermediate rolling, aging, finish rolling and stress relief annealing, the strengthening phase in alloy can be sufficiently separated out, and the alloy board with the excellent mechanical property can be obtained.

Owner:CENT SOUTH UNIV

Overhead heat-resistance aluminum alloy conductor material and preparation method thereof

InactiveCN106893899ARaise the recrystallization temperatureAdd lessConductive materialMetal/alloy conductorsCeriumTemperature resistance

The invention discloses an overhead heat-resistance aluminum alloy conductor material and a preparation method thereof, and relates to the technical field of aluminum alloy conductor materials. The overhead heat-resistance aluminum alloy conductor material comprises the following elements in percentage by mass: 0.10-0.45% of zirconium, 0.01-0.10% of yttrium, 0.01-0.10% of scandium, 0.3-1.0% of lanthanum and cerium, 0.05-0.18% of iron, silicon not more than 0.05%, nickel not more than 0.05, magnesium not more than 0.02, zinc not more than 0.04, boron not more than 0.01, and the balance of aluminum and inevitable impurities. The preparation method comprises the following steps: foundry returns, aluminum ingots and Al-Fe intermediate alloy blanks are put in a smelting furnace, are heated for melting, and are transferred into an insulation furnace; then, Al-Zr, Al-Sc, Al-Y and Al-RE intermediate alloys are added for refining and deslagging to prepare fine alloy melts; a continuous casting and continuous rolling process is adopted to firstly pour the fine alloy melts as aluminum alloy castings; and the aluminum alloy castings are leaded into a rolling mill to roll aluminum alloy rods with needed specifications. The aluminum alloy conductor material is high in electric conductivity and excellent in high-temperature resistance; and the preparation method needs no heat treatment, saves the energy consumption, and reduces the production cost.

Owner:河北欣意电缆有限公司

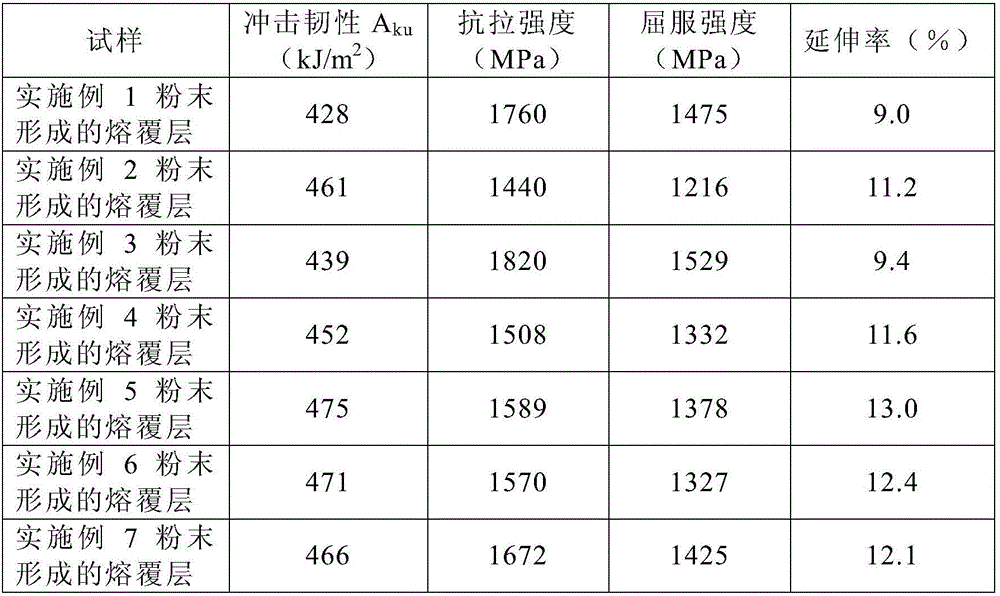

Laser cladding powder for 30CrMnSiNi2A steel and preparation method

ActiveCN106480363AHigh bonding strengthLess metallurgical defectsTransportation and packagingMetal-working apparatusRare earthUltimate tensile strength

The invention relates to laser cladding powder for 30CrMnSiNi2A steel and a preparation method. The laser cladding powder is prepared from the following components in weight percent: 0.8% to 1.0% of Cr, 0.75% to 1.10% of Mn, 0.65% to 1.10% of Si, 2.0% to 3.2% of Ni, 0.16% to 0.22% of C, 0.15% to 0.20% of Cu, 0.015% to 0.020% of P, 0.01% to 0.015% of S, 0.001% to 0.015% of rare earth and the balance of Fe. The invention further provides the preparation method of the laser cladding powder, the laser cladding powder is exclusively used in a laser cladding technique of the 30CrMnSiNi2A steel, excellent bonding strength and low metallurgical defects and dilution rate of a cladding interface are guaranteed, the toughness of a cladding layer is increased, the wettability of the cladding powder is improved, the cracking of the cladding layer is inhibited, and the crack growth rate is reduced.

Owner:国营芜湖机械厂

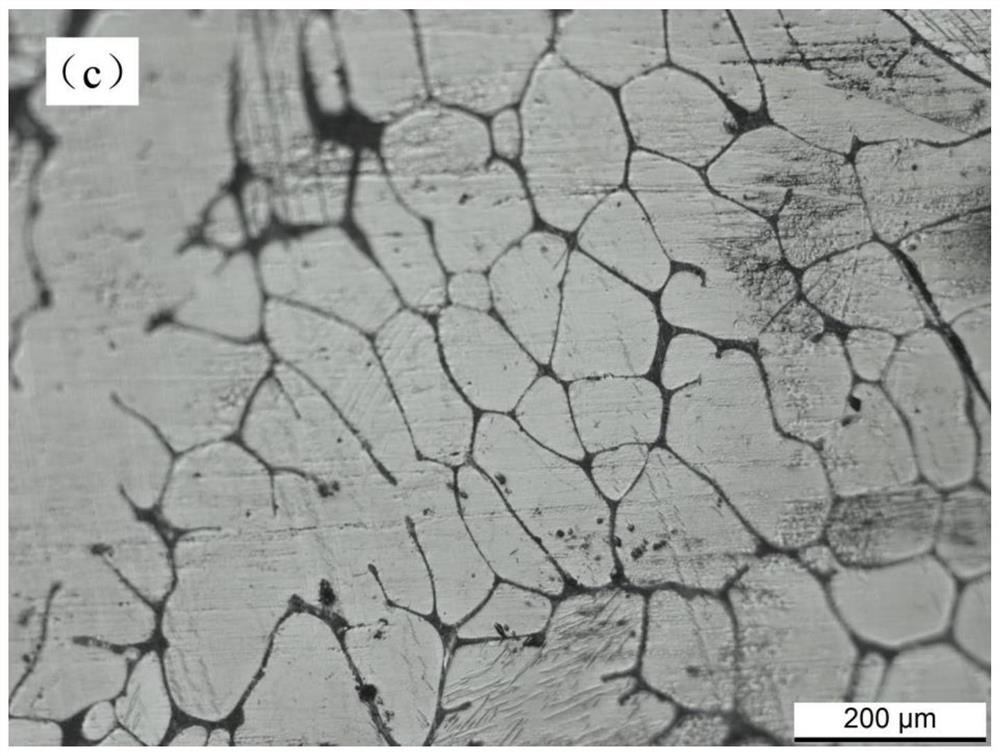

Method for preparing Zn-Cu-Ti alloy cast ingot, alloy cast ingot and alloy plate

The invention provides a method for preparing a Zn-Cu-Ti alloy cast ingot, the alloy cast ingot and an alloy plate. That is, in the smelting process of the Zn-Cu-Ti alloy, rare earth modification and high-energy ultrasonic synergistic treatment are utilized to promote an intermediate alloy containing Ti and Cu elements to be efficiently melted / dissolved at a low temperature, meanwhile, the high-quality Zn-Cu-Ti alloy is prepared by virtue of the effects of removing gas and impurities, improving the melt nucleation rate, inhibiting grain growth and the like, and a Zn-Cu-Ti alloy plate is produced by adopting multi-pass rolling. Compared with an existing Zn-Cu-Ti alloy casting process, according to the method, the low-temperature diffusion and dissolution speed of Ti and Cu atoms is increased, the smelting temperature is reduced, the burnout rate of Ti and Zn elements is reduced, and meanwhile Zn-Cu-Ti alloy solute homogenization, melt purification and structure refinement are promoted; and the high-quality plate which finally meets the European EN988 standard and is high in surface quality, high in mechanical performance and high in corrosion resistance is prepared, and the method is stable in process, high in controllability and good in application prospect.

Owner:CENT INT GROUP

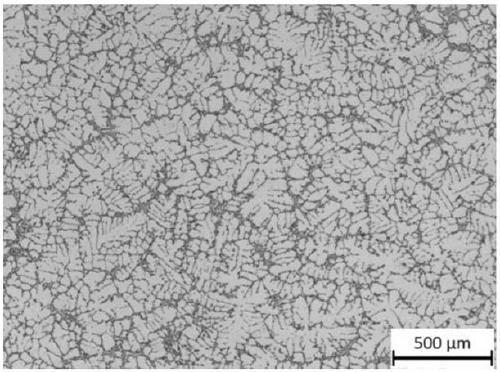

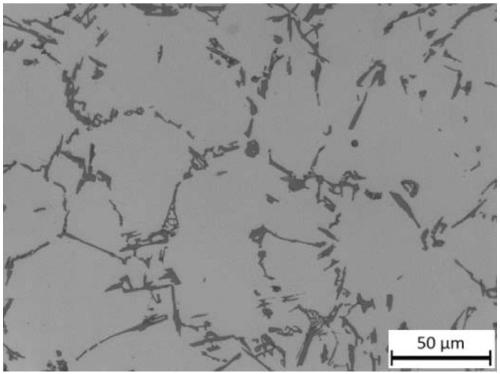

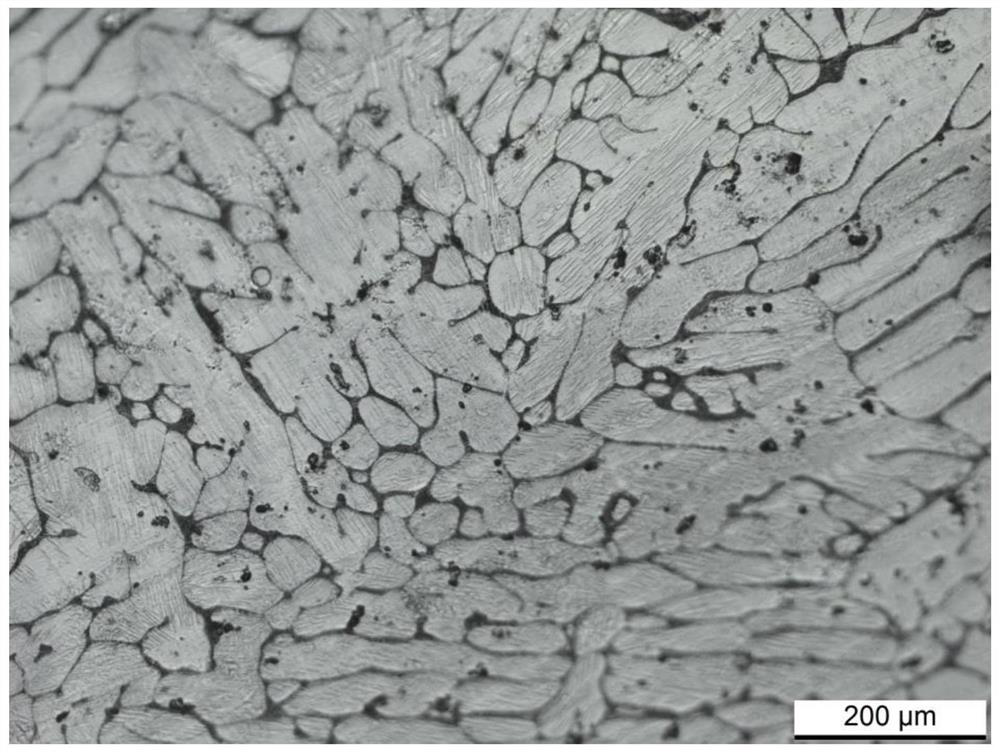

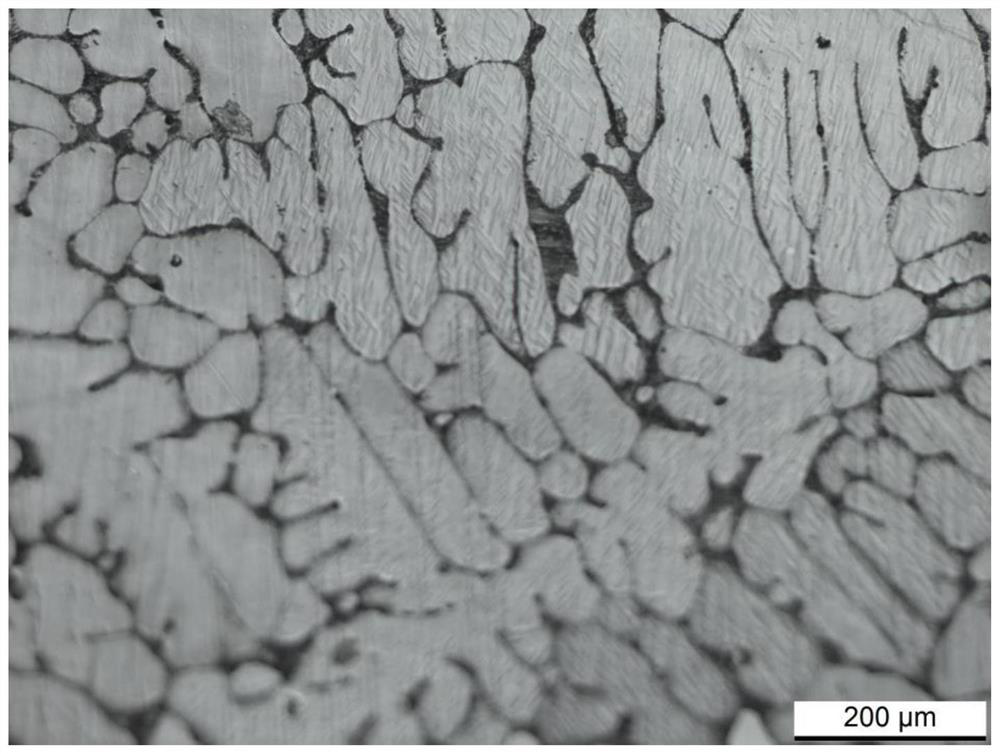

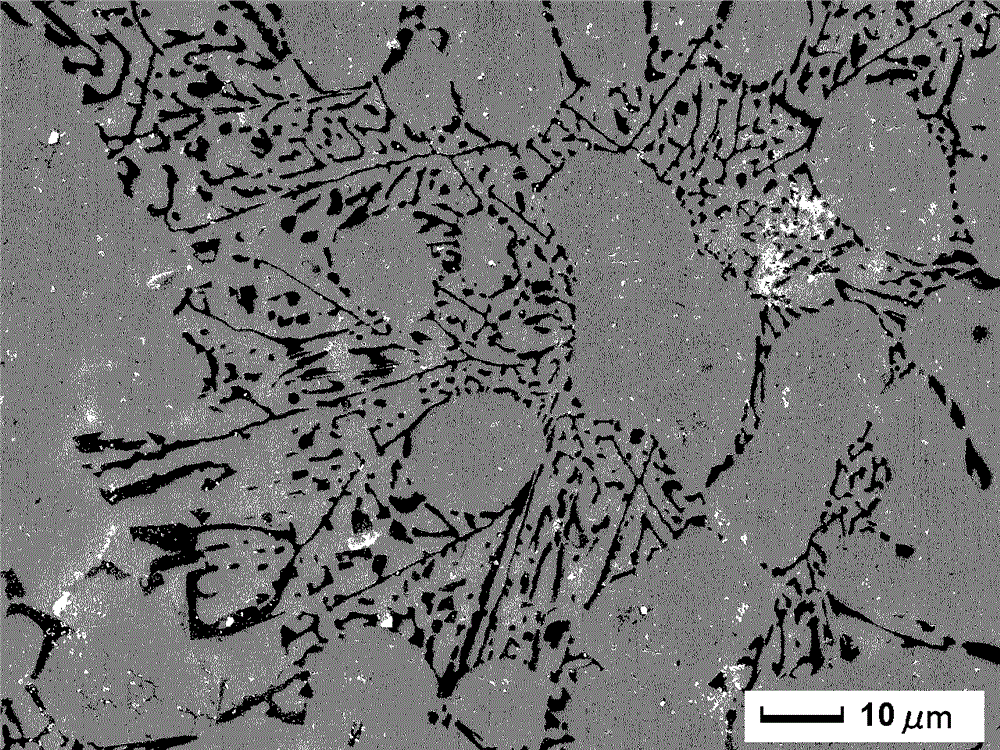

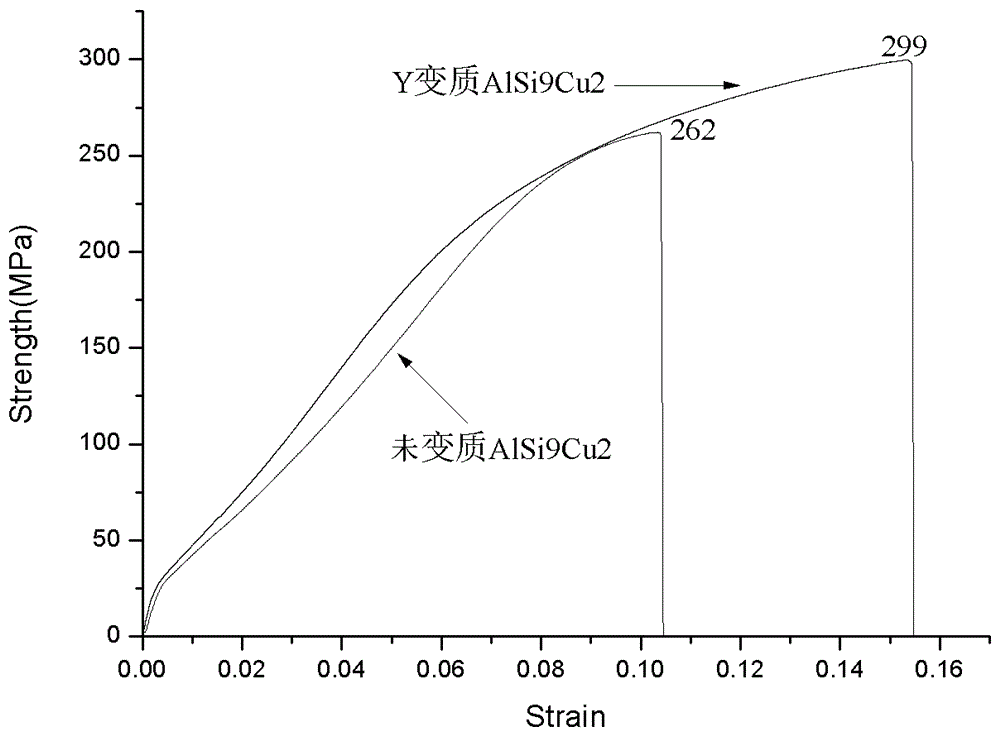

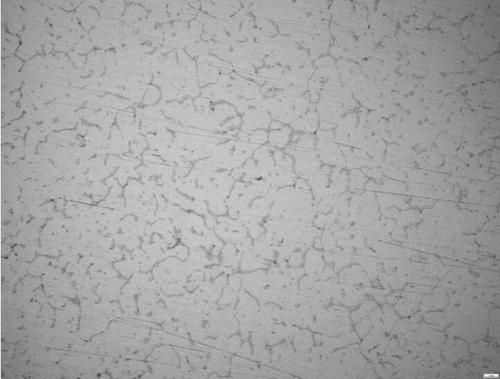

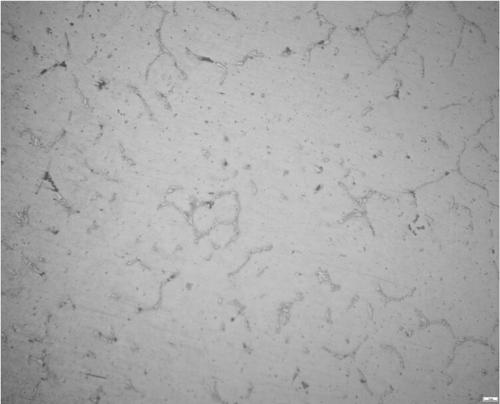

Method for modifying AlSi9Cu2 cast aluminum alloy by rare-earth Y

The invention discloses a method for modifying an AlSi9Cu2 alloy by rare-earth Y, and relates to a method for modifying a cast aluminum-silicon alloy. By using the method for modifying the AlSi9Cu2 alloy by the rare-earth Y, the problem that a gas-hole defect exists in an AlSi9Cu2 cast alloy obtained by adopting a modifier Sr is solved. The method provided by the invention comprises the following steps of weighing to take high-purity aluminum, an Al-2OSi intermediate alloy, high-purity copper and an Al-10Y intermediate alloy raw material, fusing the high-purity aluminum and the Al-2OSi intermediate alloy, then pressing the high-purity copper into an obtained first mixture, smelting an obtained second mixture to obtain a fused mass, then adding the Al-10Y intermediate alloy into the fused mass, smelting an obtained third mixture, and pouring the smelted third mixture, so that the AlSi9Cu2 alloy is obtained subsequently. The method provided by the invention is simple, and is suitable for mass production. No gas holes exist in the obtained Y-modified AlSi9Cu2 alloy; the cast structure of the alloy is obviously thinned; the obdurability of the AlSi9Cu2 alloy is improved; and the compactability of a casting is increased.

Owner:镇江创智特种合金科技发展有限公司

High-strength anodizing die-casting aluminium alloy and preparation method thereof

ActiveCN107447134ATo promote floatingImprove filtration efficiency5005 aluminium alloy6061 aluminium alloy

The invention belongs to the technical field of aluminium alloy and particularly relates to high-strength anodizing die-casting aluminium alloy and a preparation method thereof. Mg, Mn, Fe, Zn, Mo, Zr, Cr and Al constitute die-casting alloy elements, and the high-strength anodizing die-casting aluminium alloy is prepared by a smelting procedure and a die-casting procedure. The types, the contents and the adding modes of all the alloy elements are strictly controlled, so that lots of the elements mainly exist in a matrix in a solid solution format under the die-casting (fast cooling) condition; Zr and Mo ensure more uniform alloy tissue and refined crystal grains, so that the alloy has high strength and favorable die-casing performance and excellent anodizing performance; on a die-casting machine, die-casting molding can be performed by a die to directly obtain the required product without heat treatment or deformation, so that the production cost is greatly lowered; and the high-strength anodizing die-casting aluminium alloy is suitable for thin-walled shell members demanding much on the strength, the die-casting performance and the anodizing demand of the aluminium alloy.

Owner:苏州慧驰轻合金精密成型科技有限公司

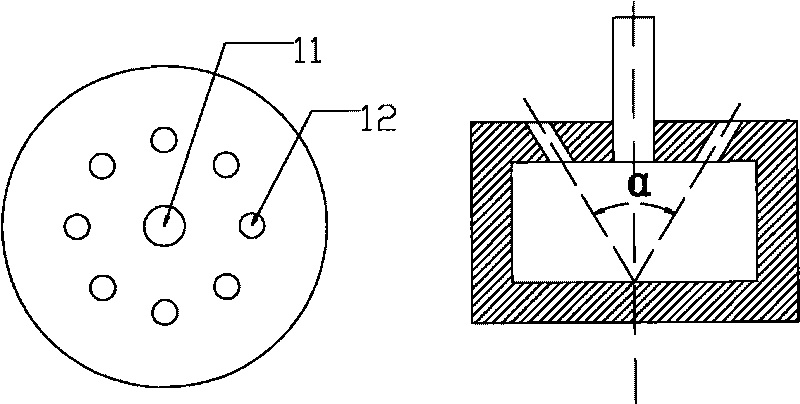

Method for preparing metal-based composite material

The invention relates to a method for preparing a metal-based composite material. The method comprises the following steps of: adding reinforcing particles into a molten metal in a ratio; and transferring impulsive high-pressure inert gas flow to the molten metal by a nozzle, wherein the high-pressure impulsive gas flow forms periodical bubbles in the molten metal and the bubbles are quickly expanded; and a strong vortex flow is formed due to the motion of the impulsive gas flow, so that the reinforcing particles are evenly dispersed in the molten metal. The particle reinforcing metal-based composite material has the advantages of wide material application range, no pollution against the composite materials, low cost, high efficiency and good application prospect.

Owner:有研金属复材技术有限公司

Low-carbon low-boron medium-chromium alloy steel, and preparation method thereof

The invention discloses a low-carbon low-boron medium-chromium alloy steel, and a preparation method thereof, and belongs to the technical field of alloy steel manufacturing. The low-carbon low-boronmedium-chromium alloy steel comprises 0.05 to 0.30% of carbon, 1.0 to 3.0% of silicon, 0.8 to 1.3% of manganese, phosphor of 0.04% or lower, sulfur of 0.04% or lower, 3.5 to 7.9% of chromium, 0 to 0.08% of titanium, 0.3 to 2.0% of nickel, 0.1 to 0.5% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.5 to 1.5% of cerium, 0.02 to 0.1% of tin, 0.3 to 1.0% of vanadium, 0.1 to 1% of tungsten, 0.05 to 0.3% of copper, 0.005 to 0.015% of tantalum, 0.05 to 0.15% of cobalt, 0.05 to 0.25% of niobium, and the balance iron and unavoidable impurities. The hardness of the low-carbon low-boron medium-chromium alloy steel is HRC45-55, the impact energy is 8 to 15J / mm<2>. The preparation method is capable of guaranteeing the high toughness and impact resistance, and improving the wear resistance and hardness, is convenient to control, and is suitable for civil applications and popularization.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

High-strength high-heat-resistant carbon nanometer aluminum-based composite material and preparation method

The invention provides a high-strength high-heat-resistant carbon nanometer aluminum-based composite material and a preparation method. Aluminum-zirconium alloy basic system design is adopted, graphene with nanometer aluminum oxide grown on the surface is taken as a reinforcing phase, powder is blown into aluminum melt by adopting inert gas, and a cast structure with the graphene evenly distributed is obtained. The graphene has the unique two-dimensional fold surface, aluminum oxide nanometer particles are grown on the surface to form graphene@aluminum oxide, the wettability of the graphene and the aluminum melt is improved, particle refined grains serving as heterogeneous nucleuses have the good chemical stability, and the heat stability of the aluminum-based composite material is improved through the particle refined grains and a Al3Zr phase jointly. According to the high-strength high-heat-resistant carbon nanometer aluminum-based composite material and the preparation method, the problem that in limited 1-series alloy tension joint splice application process, the strength and the heat resistance are insufficient is solved, and the aluminum-based composite material produced through a casting process has the characteristics that the compactness reaches 100%, the strength is improved by 30% or above, and the heat resistance is improved by 30%-50% or above.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV +2

Secondary aluminum modification treatment process and modification treatment agent

The invention discloses a secondary aluminum modification treatment process. The secondary aluminum modification treatment process comprises the steps that in the secondary aluminum production process, after alloying is finished, a waste aluminum material is added into molten aluminum and refined; after refining is completed, a waste aluminum material is added into the molten aluminum, the moltenaluminum is cooled to 740-760 DEG C, and a first-stage modificator is added into the molten aluminum; a waste aluminum material continues to be added into the molten aluminum, the molten aluminum is to cooled to 710-730 DEG C, and a second-stage modificator is added into the molten aluminum; and after stirring and melting, the obtained molten aluminum is adopted for cooling and casting; wherein the first-stage modificator comprises the following components in percentage by mass: 50-60% of AlTiB alloy, 20-30% of aluminum-antimony alloy, and 10-20% of aluminum-rare earth alloy, and the total percentage of the components is 100%; and the second-stage modificator comprises the following components in percentage by mass: 70-80% of AlSr alloy, and 20-30% of aluminum-zirconium alloy, and the total percentage of the components is 100%. According to the secondary aluminum modification treatment process, the modification effect is improved, crystal grains are refined, the product strength is enhanced, and the burning loss of the modificator is reduced.

Owner:顺博合金江苏有限公司

Preparation method of 650 MPa-grade ultrahigh-strength aluminum alloy thin strip

ActiveCN112538599AImprove plastic toughnessPurify the meltRare-earth elementUltimate tensile strength

The invention relates to the technical field of metal plate strip machining, in particular to a preparation method of a 650 MPa-grade ultrahigh-strength aluminum alloy thin strip. The preparation method comprises the steps that an Al-Zn-Mg-Cu alloy plate which is hot-rolled to 7.5 mm and contains a rare earth element Er is subjected to two-pass cold rolling and coiled, and a 3.5 mm alloy plate blank coil is obtained; primary annealing treatment is peformed on the alloy plate blank coil, and then four-pass cold rolling is performed to obtain an alloy strip coil with a thickness of 0.5 mm; and finally, solid solution heat treatment and spray quenching are performed, and then T6 aging treatment is performed to obtain the 650 MPa-grade ultrahigh-strength aluminum alloy thin strip. According tothe aluminum alloy thin strip obtained through the method, a cupping test value reaches 6.0 mm before solid solution state aging, when bent in a mold with a fillet of not less than 2 mm for 90 degrees, no cracks occur, and after T6 aging heat treatment, a tensile strength can reach 650-700 MPa, a yield strength can reach 550-620 MPa, and a percentage elongation after fracture can reach 10%-15%.

Owner:CENT SOUTH UNIV

Anti-corrosive anti-impact wearable steel ball and preparation method thereof

The invention discloses an anti-corrosive anti-impact wearable steel ball. The anti-corrosive anti-impact wearable steel ball comprises, by weight, 0.7-0.75% of C, 11-13% of Cr, 1-1.2% of Si, 1.5-1.6% of Mn, 0.05-0.06% of B, 1-2% of Ni, 2.1-2.15% of Y, 0.04-0.06% of Ti, 0.03-0.05% of Cu, 0.01-0.03% of Co, 0.3-0.4% of Zr, 0.03-0.04% of Nb, less than or equal to 0.012% of P, less than or equal to 0.002% of S, and the balance Fe. The invention further discloses a preparation method of the anti-corrosive anti-impact wearable steel ball. The anti-corrosive anti-impact wearable steel ball is good in corrosion resistance, high in impact resistance and good in wear resistance.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Method for preparing nano SiC and Yb reinforced A356.2 alloy

The invention discloses a method for preparing nano SiC and Yb reinforced A356.2 alloy. The method comprises the following steps of using nano SiC as particle reinforcements, performing ultra-high-temperature oxidation treatment, then uniformly wrapping high-purity metal Ti on the surfaces of SiC particles after oxidation treatment by adopting nano magnetron sputtering equipment, and adopting high-purity heavy rare earth modification and continuous ultrasound to assist to smelt, so that the casting quality is further increased. According to the method, an independent research and development resistance furnace bracket is used as auxiliary equipment, so that the SiC particles can be poured in a suspension state. The preparation method has the advantages of simplicity, low cost, short production cycle, greenness and no toxicity and has good industrialization prospects, and castings have high performance.

Owner:UNIV OF JINAN

Composite modifier for copper alloy of lead frame

ActiveCN101768680BImprove high temperature mechanical propertiesThe formula is scientific and reasonableSmelting processRare earth

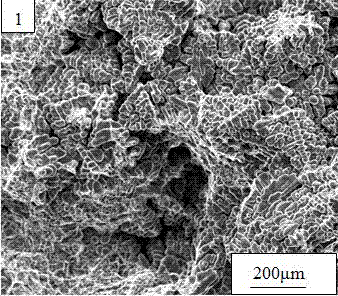

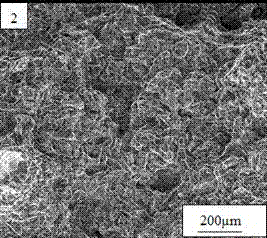

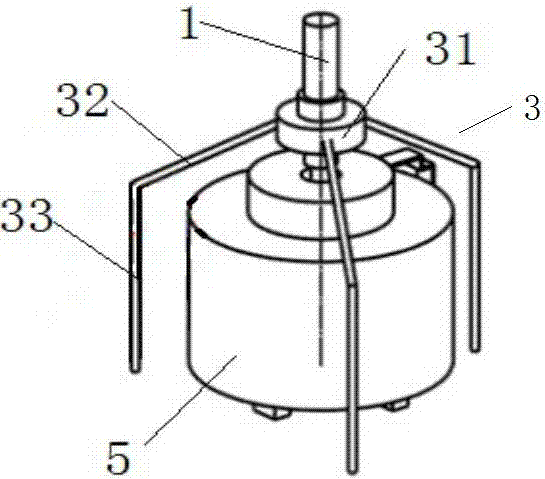

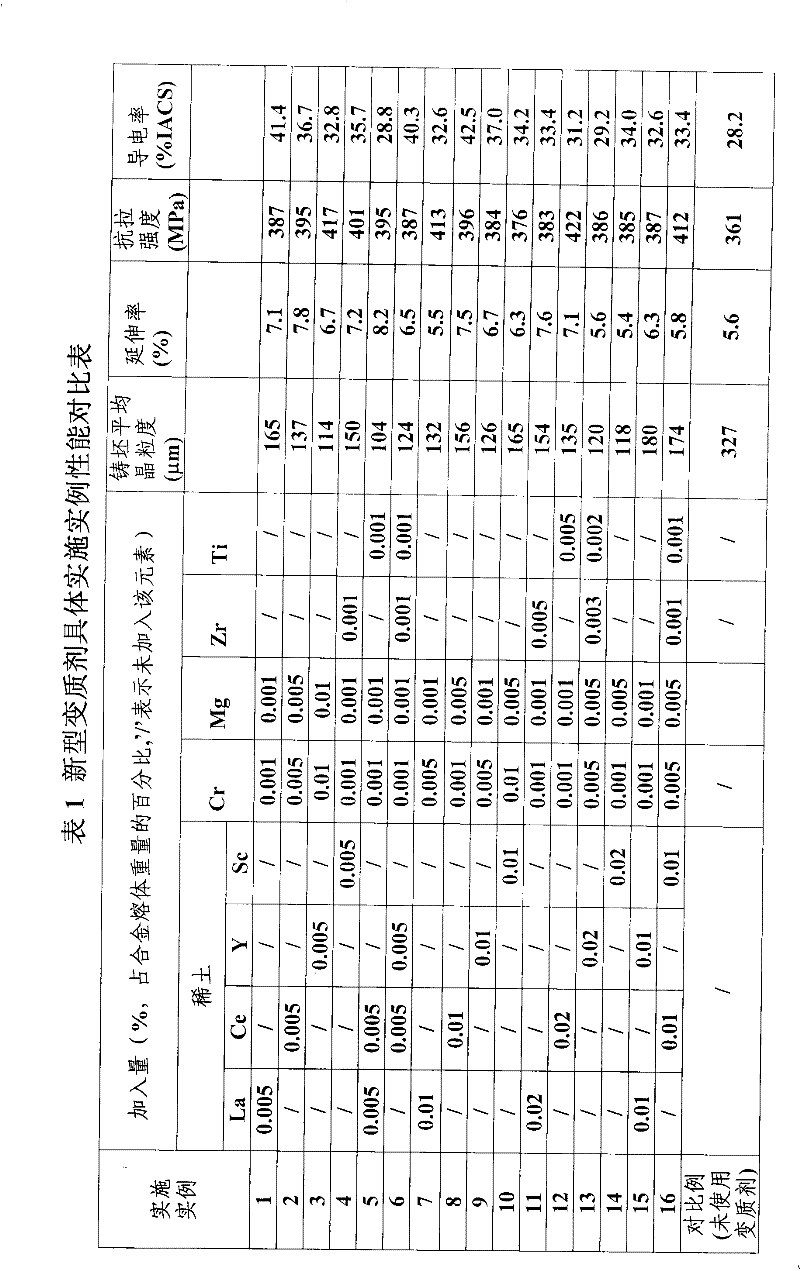

Composite modifier for copper alloy of a lead frame belongs to copper machining technical field and contains one or more than two of rare earth La, Ce, Y and Sc, also contains Cr and Mg, and one or both of Zr and Ti; all elements are prefabricated into copper master alloy. The content of the elements includes (by weight proportion of alloy melt): 0.005-0.02% of Rare Earth (RE), 0.001-0.01% of chromium (Cr), 0.001-0.01% of magnesium (Mg), wherein the total content of zirconium (Zr) and titanium (Ti) is no more than 0.005% of the total weight of the alloy melt. The composite modifier is used for the smelting process of copper alloy for lead frame, can purify melt, refines grain crystals, improves the casting blank quality and the machining performance, and finally improves the strength and electric conductivity of end products.

Owner:GRIMAT ENG INST CO LTD

Method for preparing Yb, La and SiC composite modified A356.2 alloy

The invention discloses a method for preparing a Yb, La and SiC composite modified A356.2 alloy. The method comprises the following steps of adopting nanoscale SiC as a particle reinforcement body, carrying out ultra-high temperature oxidation treatment, and coating the surfaces of the SiC particles subjected to oxidation treatment with high-purity metal Ti through a nano magnetron sputtering device; and carrying out high-purity composite heavy rare earth modification and continuous ultrasound-assisted smelting, so as to further improve casting quality. According to the method, an independently developed bracket is adopted as an auxiliary device, so that the SiC particles are casted in a suspension state; and the preparation method is simple in use, relatively low in cost and short in production cycle, and has good industrialization prospects.

Owner:冷金凤

High-strength magnesium alloy and die-casting method thereof

The invention provides a high-strength magnesium alloy. The high-strength magnesium alloy comprises Zn, Al, Cr, Mn, La, Ce, Nd, Yb, Y, VC, ZrC, WC, TiC, TiB2, ZrB2 and Mg. The invention further provides a die-pressing method of the high-strength magnesium alloy. According to the high-strength magnesium alloy, rare earth elements like La are added in the alloy and have high solubility in the magnesium alloy, the dispersion strengthening effect and the great solution strengthening can both be achieved, besides, the rare earth elements can also have a high bonding effect with impurities elements,such as oxygen, hydrogen, nitrogen, sulfur and iron in a raw material alloy, gas and inclusions in the alloy can be reduced, the form of the inclusions is improved, the inclusions tend to be spheroidized, the inclusions and gas can be removed advantageously, and a melt purifying effect is also achieved; and in addition, the added rare earth elements differ in content, and the synergistic effect of the different rare earth elements greatly improves the strength and corrosion resistance of the magnesium alloy.

Owner:仝仲盛

High-strength aluminum alloy metamorphosing through carbonyl W (CO) 6 and preparation method thereof

The invention discloses a high-strength aluminum alloy metamorphosing through carbonyl W (CO) 6 and a preparation method of the high-strength aluminum alloy metamorphosing through the carbonyl W (CO) 6. The high-strength aluminum alloy metamorphosing through the carbonyl W (CO) 6 comprises, by weight, 1.5%-2.0% of copper, 0.5%-0.7% of manganese, 0.8%-1.0% of magnesium, 0.3%-0.5% of nickel, <=1.0% of silicon, <=1.0% of ferrum, carbonyl W (CO) 6 accounting for 0.01%-0.03 of the total amount, and the balance aluminum and unavoidable trace impurities. In addition, a single trace impurity accounts for <=0.05% of the total amount and the total trace impurities account for <=0.15%. The aluminum material has better a performance and a higher impurity degree and the preparation method is simple.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

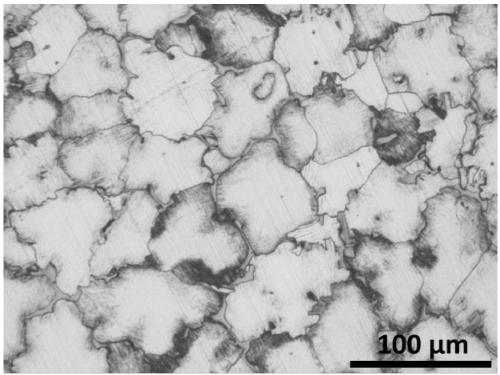

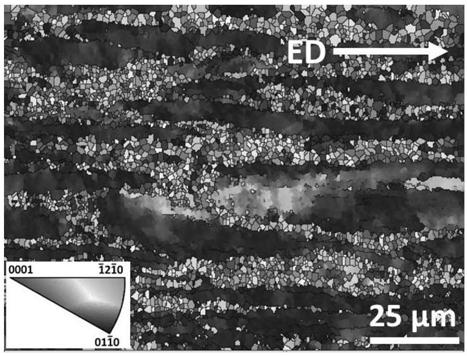

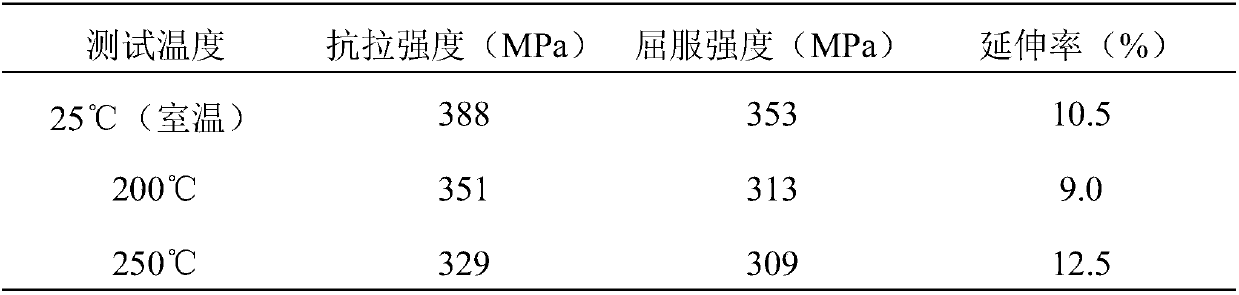

High-strength heat-resisting wrought magnesium alloy and preparation method thereof

The invention relates to a high-strength heat-resisting wrought magnesium alloy and a preparation method thereof, and belongs to the technical field of nonferrous materials and processing thereof. Thetechnical problem that the high-temperature mechanical property of magnesium alloys in the prior art is poor is solved, and the heat property, the mechanical property and stability of the rare-earthmagnesium alloy are improved. The magnesium alloy comprises 7.0-9.0wt% of Gd, Yb being larger than 0 and smaller than or equal to 4wt%, 1.0-1.5wt% of Zn, 0.4-0.6wt% of Zr and the balance Mg and inevitable impurity elements. The magnesium alloy has high strength and the excellent heat resistance; and through detecting, the property can achieve the conditions that the yield strength under room temperature is larger than 380 MPa and the yield strength under the temperature being 250 DEG C can keep being about 300 MPa. The high-strength heat-resisting wrought magnesium alloy is expected to be usedon force bearing structure components with the service temperature higher than 250 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

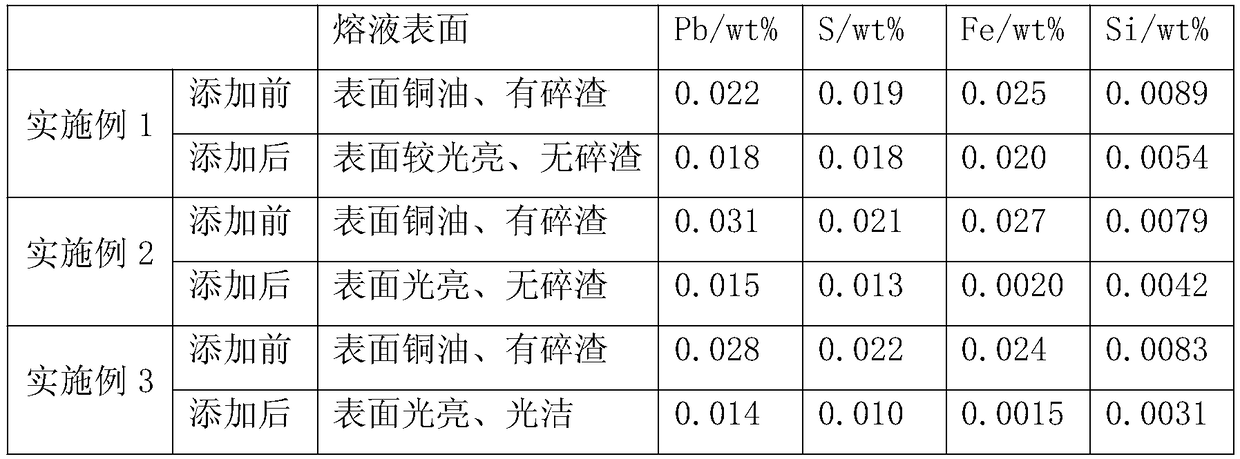

Impurity removing agent for smelting copper alloy and application method of impurity removing agent

The invention provides an impurity removing agent for smelting a copper alloy. The impurity removing agent is formed by mixing the following raw materials by weight: 10% to 30% of Eu2O3 powder, 5% to15% of Rb2O2 powder, 5% to 20% of SiO2 powder, 1% to 5% of TiO2 powder, 5% to 10% of Na2SiF6 powder, 15% to 20% of Na2CO3 powder and the balance Na2B4O7 powder. The invention further provides an application method of the impurity removing agent for smelting the copper alloy. According to the impurity removing agent provided by the invention, on the one hand, the formula of the impurity removing agent is optimized and improved; the raw materials in the formula are used for physically removing and chemically removing impurities; on the other hand, the application method of the impurity removingagent is optimized and improved to form a powerful combination situation; and due to the combination, the removal effect of trace impurity elements and nonmetal impurities existing in molten liquid ina smelting process of the copper alloy is finally improved.

Owner:CNMC ALBETTER ALBRONZE

Aluminum brass alloy and preparation method thereof

The invention discloses an aluminum brass alloy and a preparation method thereof. The alloy contains following elements: 76.0-79.0 percent of Cu, 1.8-2.5 percent of Al, 0.02-0.06 percent of As, 0.02-0.06 percent of Ti, 0.02-0.05 percent of Zr, 0.005-0.09 percent of B, 0.05-1.0 percent of Ni, 0.05-0.3 percent of rare earth, not more than 0.05 percent of impurities and the balance of Zn. The preparation method has the advantages that through using a means of trace element alloying, melt of the alloy is purified, an ingot structure of the alloy is thinned, the recrystallization temperature of the alloy is increased, the casting performance, the processing performance, the welding performance and the corrosion resisting performance of the alloy are improved, and the strength, the hardness and the wear resisting performance of the alloy are increased, so the aim of prolonging the service life of the alloy is achieved.

Owner:JINCHUAN GROUP LIMITED

Anti-corrosive steel ball and preparation method thereof

InactiveCN106191707APurify the meltImprove the mismatchAnti-corrosive paintsEpoxy resin coatingsSteel ballWear resistance

The invention discloses an anti-corrosive steel ball. The anti-corrosive steel ball comprises, by weight, 0.1-0.2% of C, 14-16% of Cr, 0.8-1.5% of Si, 1.5-2% of Mn, 0.02-0.03% of B, 0.5-1.5% of Ni, 0.05-0.07% of Cu, 1-2% of Y, 0-0.02% of P, 0-0.01% of S, and the balance Fe. The invention further discloses a preparation method of the anti-corrosive steel ball. The anti-corrosive steel ball is good in corrosion resistance, high in wear resistance and good in mechanical property.

Owner:ANHUI RUITAI NEW MATERIALS TECH

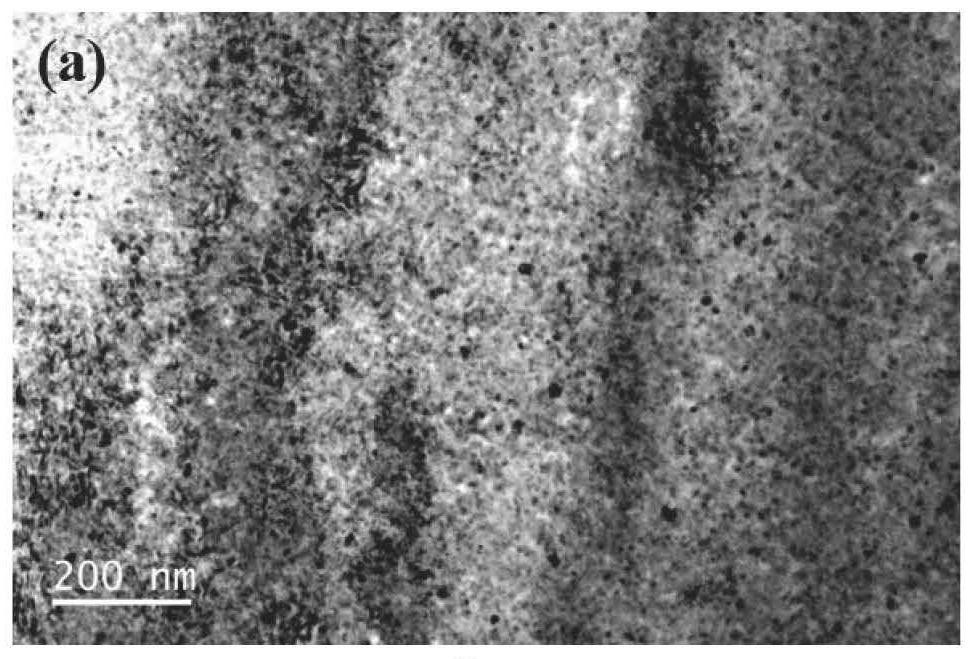

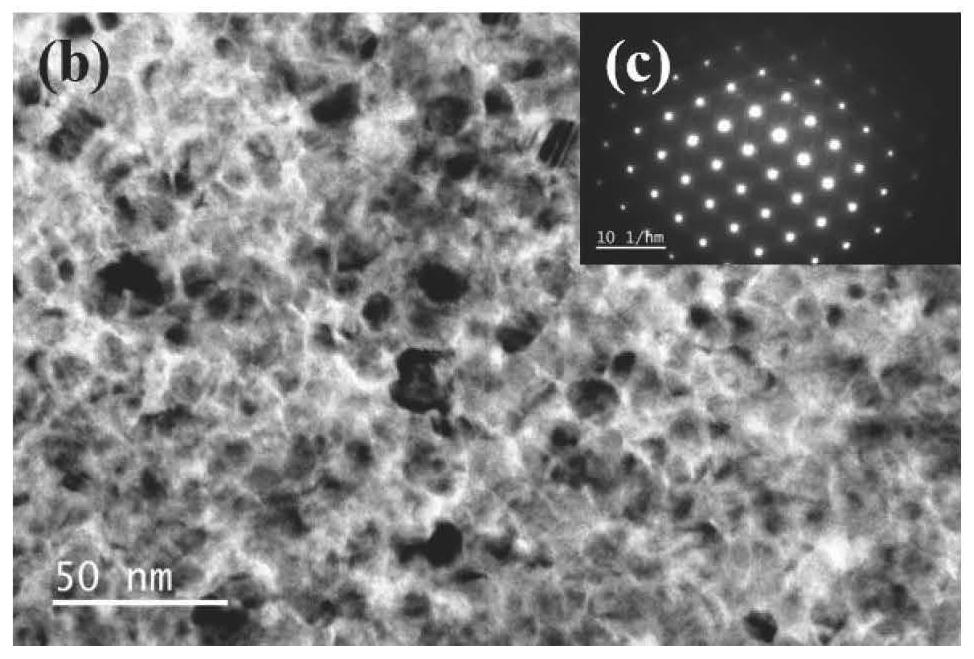

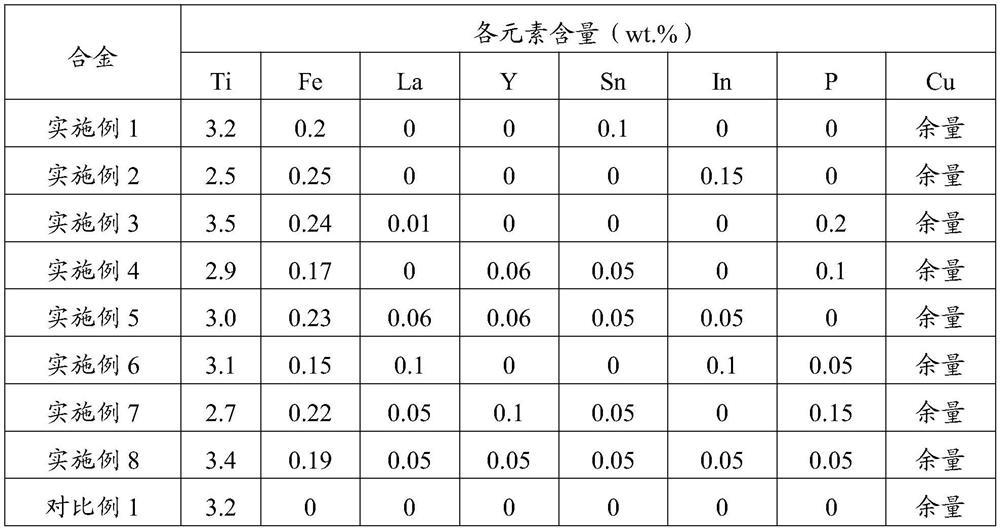

High-strength and high-elasticity titanium-copper alloy and preparation method thereof

The invention provides a high-strength and high-elasticity titanium-copper alloy and a preparation method thereof, and belongs to the field of non-ferrous metal processing. The high-strength and high-elasticity titanium-copper alloy provided by the invention comprises the following components in percentage by mass: 2.5 to 3.5 percent of Ti, 0.15 to 0.25 percent of Fe, 0 to 0.2 percent of rare earth element, 0.1 to 0.5 percent of microalloy element and the balance of Cu, the microalloy elements comprise one or more of Sn, In and P. The result of the embodiment shows that the volume fraction of discontinuous precipitated structures in the high-strength and high-elasticity titanium-copper alloy is smaller than 10%, nano precipitated phases distributed in a dispersed mode are contained in crystal grains, the size is smaller than 20 nm, the tensile strength is larger than or equal to 900 MPa, the hardness is larger than or equal to 285HV, the percentage elongation after fracture A11.3 is larger than or equal to 6%, and the tensile strength is larger than or equal to 900MPa. And meanwhile, the cable has good softening resistance, electromagnetic shielding performance and stress relaxation resistance.

Owner:浙江惟精新材料股份有限公司 +1

Special magnesium alloy for magnesium alloy wheel hub and preparation technology of special magnesium alloy

The invention discloses a special magnesium alloy for a magnesium alloy wheel hub. The special magnesium alloy is composed of the following components of, by mass, 0.8-1.53% of zinc, 7.8-8.5% of aluminum, 0.5-1.25% of cerium, 0.2-0.53% of yttrium, less than or equal to 0.10% of unavoidable impurities and the balance magnesium. The invention further discloses a preparation technology of the specialmagnesium alloy for the magnesium alloy wheel hub. The preparation technology prepares the magnesium alloy by adopting the following components of, by mass, 0.8-1.53% of the zinc, 7.8-8.5% of the aluminum, 0.5-1.25% of the cerium, 0.2-0.53% of the yttrium and the balance magnesium. According to the special magnesium alloy, light and heavy rare earth components are added, a melt is purified, the impurities are reduced, the second phase in the alloy is changed, so that the strength, the toughness and the anti-corrosion performance of the alloy are greatly improved, and the cracking tendency ofthe magnesium alloy wheel hub in the hot working process is reduced.

Owner:仝仲盛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com