Patents

Literature

507results about How to "Improve plastic toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

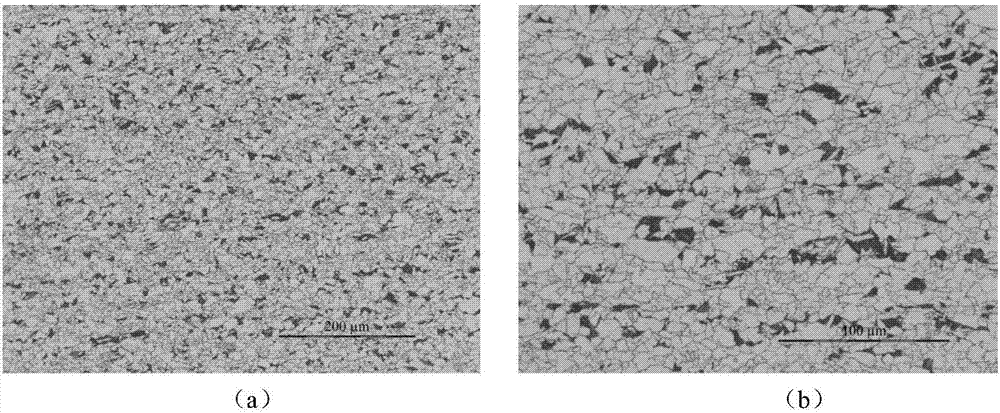

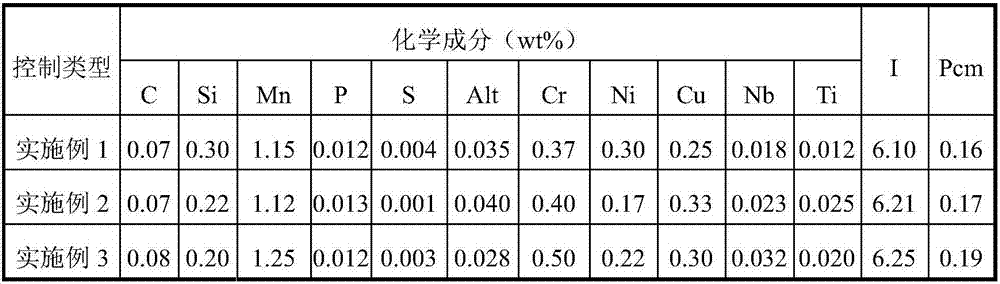

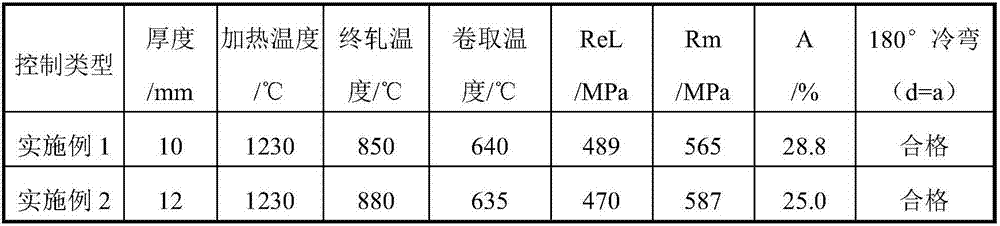

High-strength and high-toughness weather-proof hot-rolled steel plate and preparation method thereof

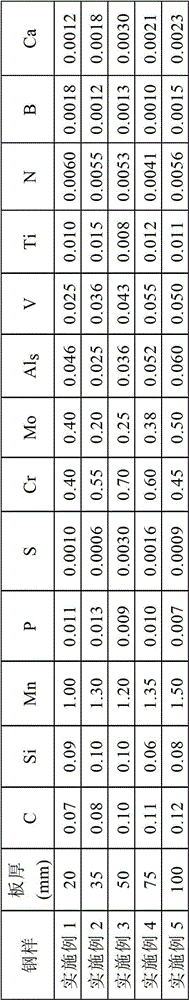

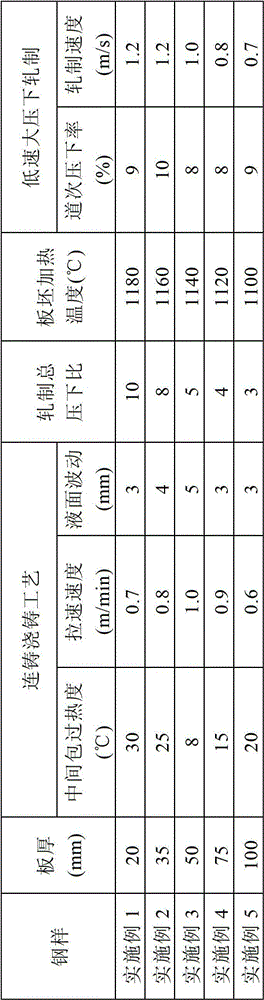

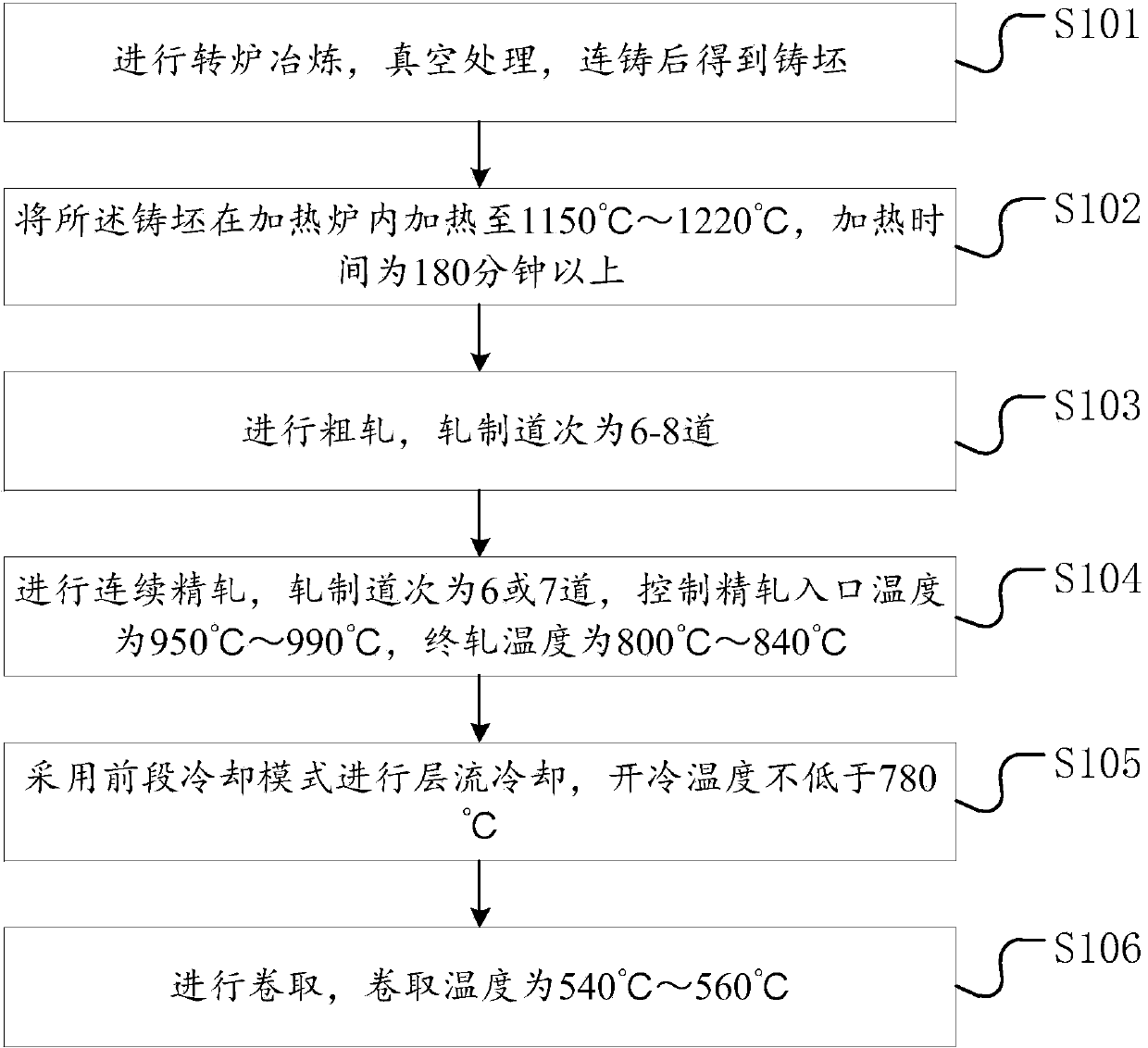

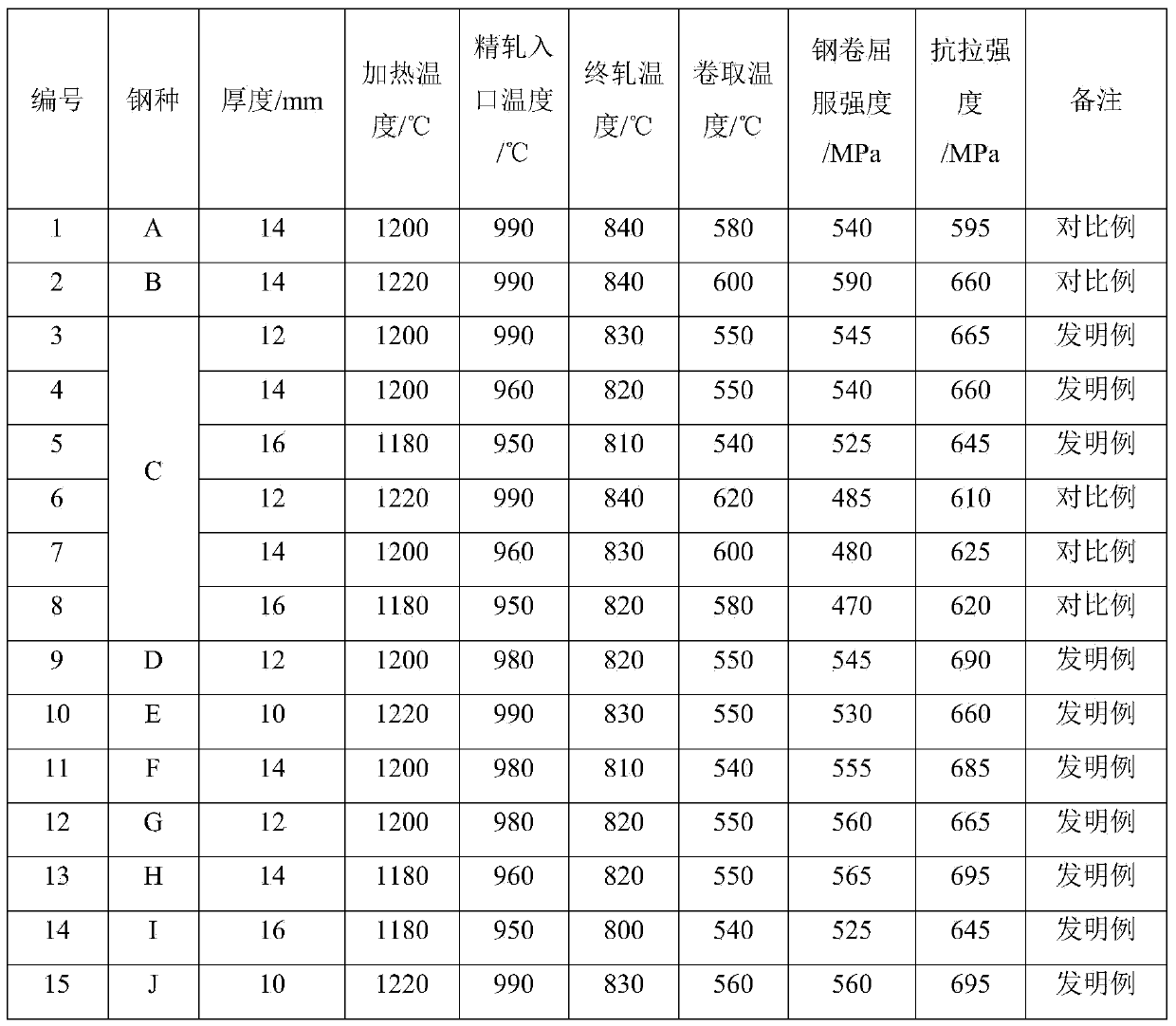

The invention relates to a high-strength and high-toughness weather-proof hot-rolled steel plate comprising the chemical components in percentage by weight: (wt,%): 0.05%-0.10% of C, 0.10%-0.50% of Si, 1.00%-1.30% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-0.70% of Cr, 0.10%-0.40% of Ni, 0.25%-0.50% of Cu, 0.020%-0.050% of Al, 0.010%-0.040% of Nb, 0.010%-0.030% of Ti and the balance Fe and unavoidable impurity elements. Meanwhile, the traditional hot strip rolling process is adopted, and a preparation method specifically comprises the steps: deep desulphurization of molten iron until S is less than or equal to 0.0050%, converter top and bottom combined blowing, alloy fine adjustment, LF secondary refining, slab continuous casting, heating, two-rack rough rolling and seven-rack finish rolling, laminar cooling and reeling. The steel plate disclosed by the invention has the mechanical properties that ReL is 450-500MPa, the Rm is greater than or equal to 550MPa, A is 25.0%-30.0%, the -60 DEG C longitudinal Charpy V-shaped gap impact power is greater than 300J, the high-strength and high-toughness weather-proof hot-rolled steel plate has good matching of strength and toughness, good cold bending forming and welding properties and favorable atmosphere corrosion resistance, and the corrosion resistance of the high-strength and high-toughness weather-proof hot-rolled steel plate is twice as high as that of Q345B steel.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

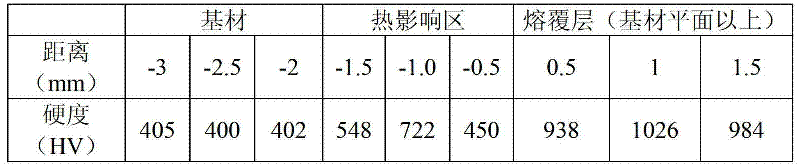

Special cobalt-based metal ceramic alloy powder for optical fiber laser cladding

ActiveCN102650012AHigh hardnessImprove plastic toughnessMetallic material coating processesHigh energyAlloy

The invention discloses special cobalt-based metal ceramic alloy powder for optical fiber laser cladding, which is matched with characteristics of optical fiber laser. The special cobalt-based metal ceramic alloy powder contains the following components by weight percent: 1-2% of carbon, 1-2% of silicon, 2-4% of iron, 1.5-2.5% of nickel, 3-4% of molybdenum, 8-12% of chromium, 3-4% of tungsten, 13-17% of tungsten carbonate, 2-3% of calcium fluoride, 1-2% of silicon nitrate and cobalt for the rest. The metal ceramic alloy powder is specially applied to a cladding process of a high-energy optical fiber laser device, a metal ceramic cladding layer with high hardness, high flexibility and high corrosion resistance can be formed on the surface of a work die of a steel and iron basis material, and the cladding layer is compact in structure, has no defects such as air holes, cracks, shrinkage cavities and the like, and has excellent metallographic performance such as high hardness, high plasticity, flexibility and corrosion resistance, and the like; moreover, the process is convenient and the thermal treatment does not need to be carried out in advance and afterwards. The special cobalt-based metal ceramic alloy powder is particularly suitable for the surface treatment of the die and can greatly prolong the service life of the die.

Owner:CHANGZHOU TIANZHENG IND DEV CO LTD

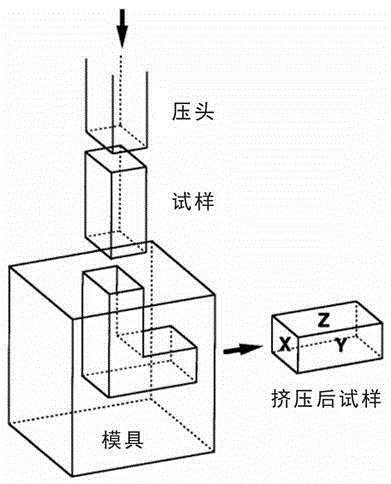

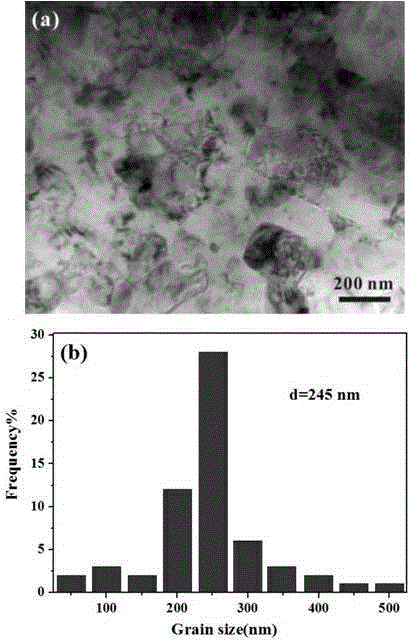

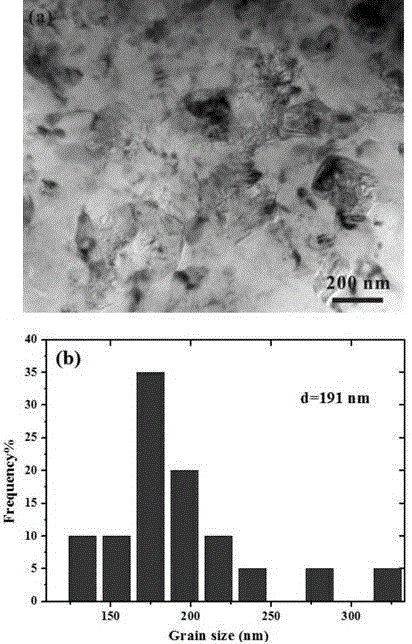

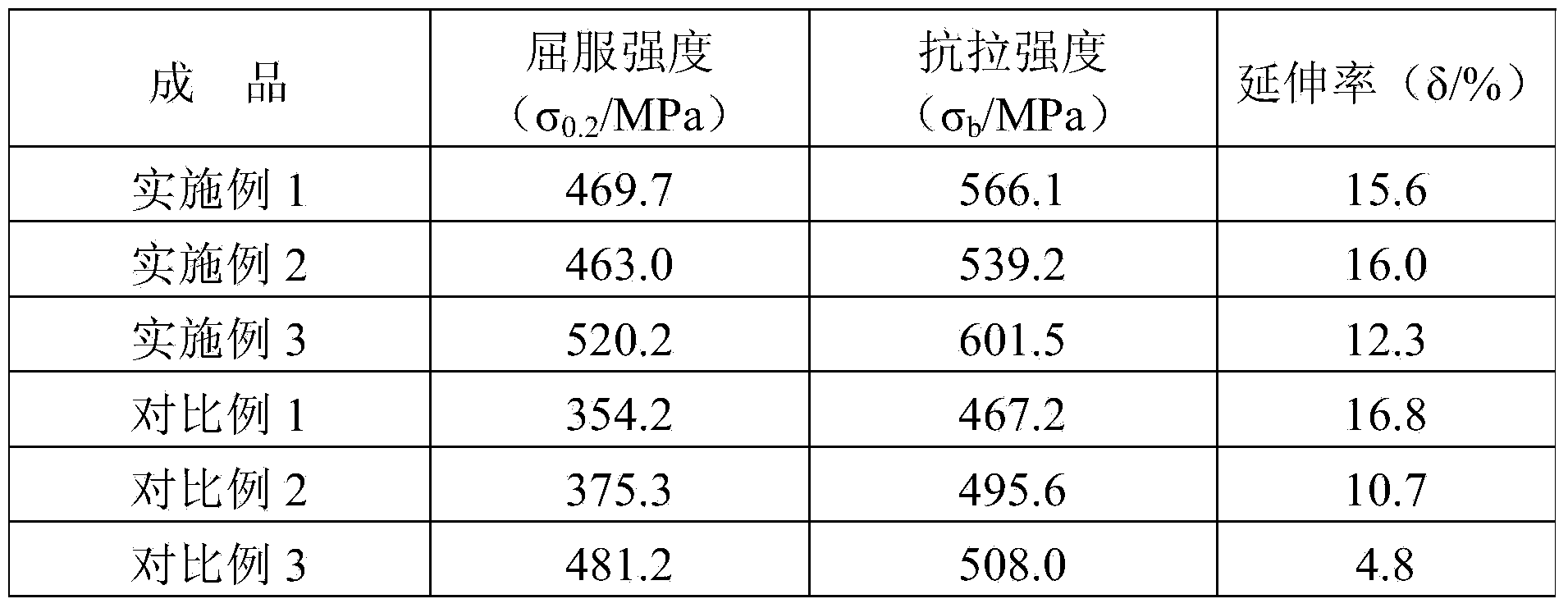

Preparation method for high-strength and high-toughness ultra-fine grain aluminium alloy

The invention belongs to the technical field of preparation of metal and alloy, and provides a preparation method for high-strength and high-toughness ultra-fine grain aluminium alloy. The preparation method comprises the steps that aluminium alloy is firstly cast to form a cast-state blank; then the cast-state blank is turned into an ECAP (Equal Channel Angular Pressing) blank, and then the ECAP blank is subjected to homogenization treatment and curing quenching treatment; and then the blank subjected to the curing quenching treatment is subjected to 1-8 passes of ECAP dynamic ageing treatment at temperatures ranging from the room temperature to 300 DEG C. According to the preparation method, through the ECAP dynamic ageing treatment at different temperatures, the grain size of the alloy is obviously refined; and the form and distribution of a nanometer ageing precipitated phase are more reasonable, so that the strength of the alloy is greatly improved, and meanwhile the alloy has excellent ductility and toughness.

Owner:JIANGSU UNIV

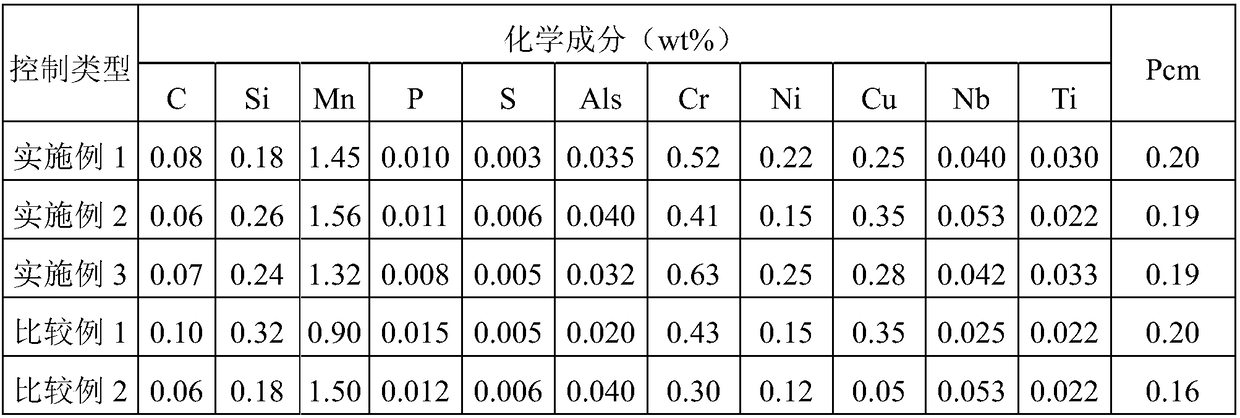

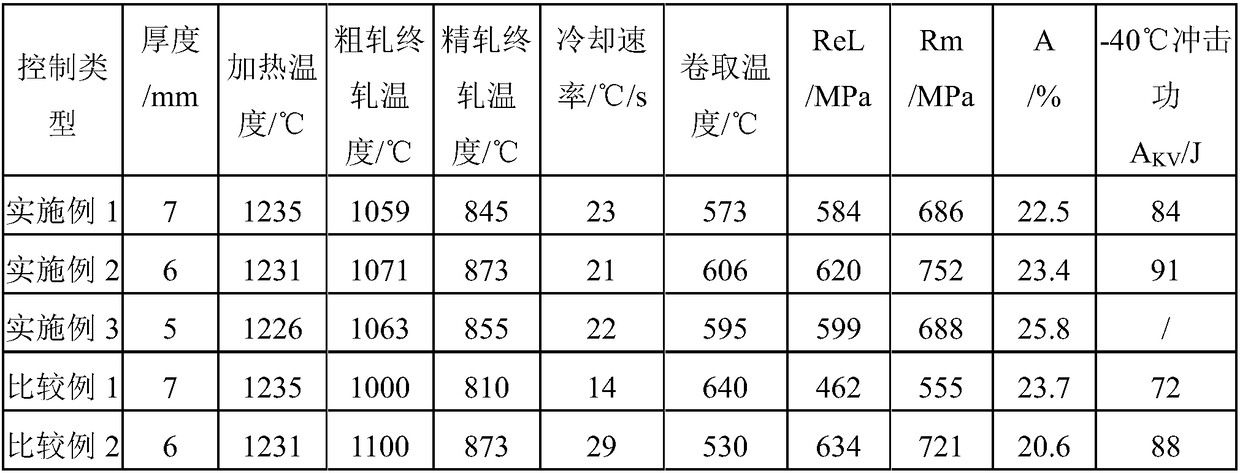

High-toughness weather-resistant steel plate with yield strength of 550MPa and preparation method of high-toughness weather-resistant steel plate

ActiveCN108486466AGood welding performanceExcellent cold forming performanceToughnessAtmospheric corrosion

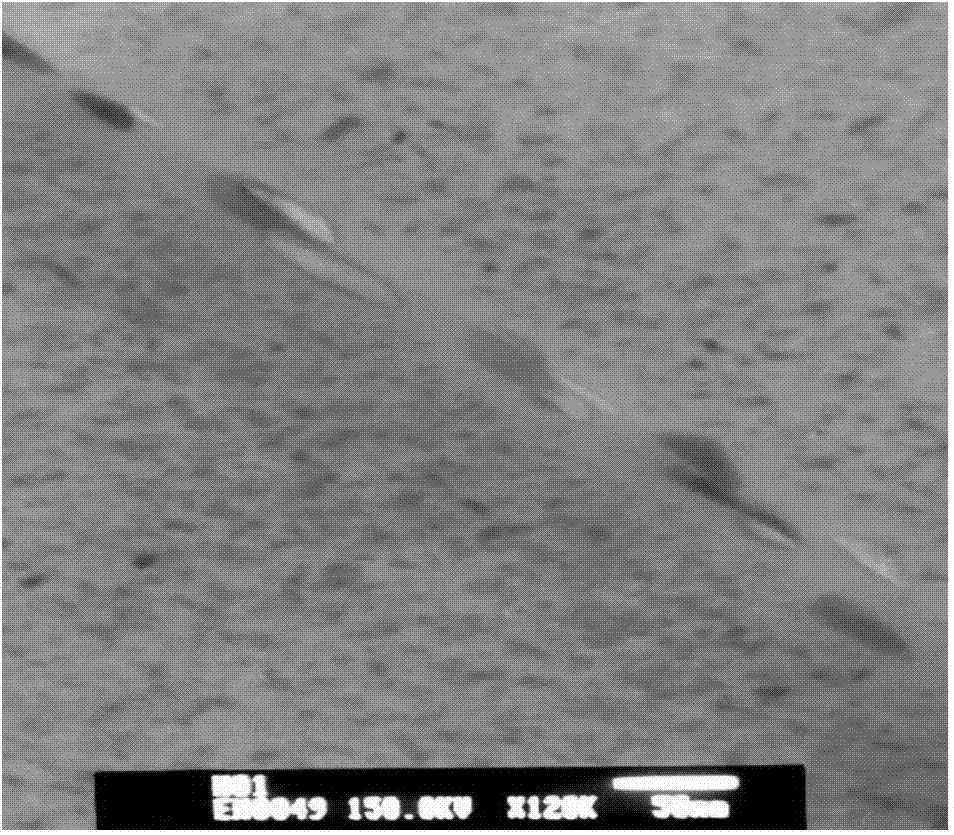

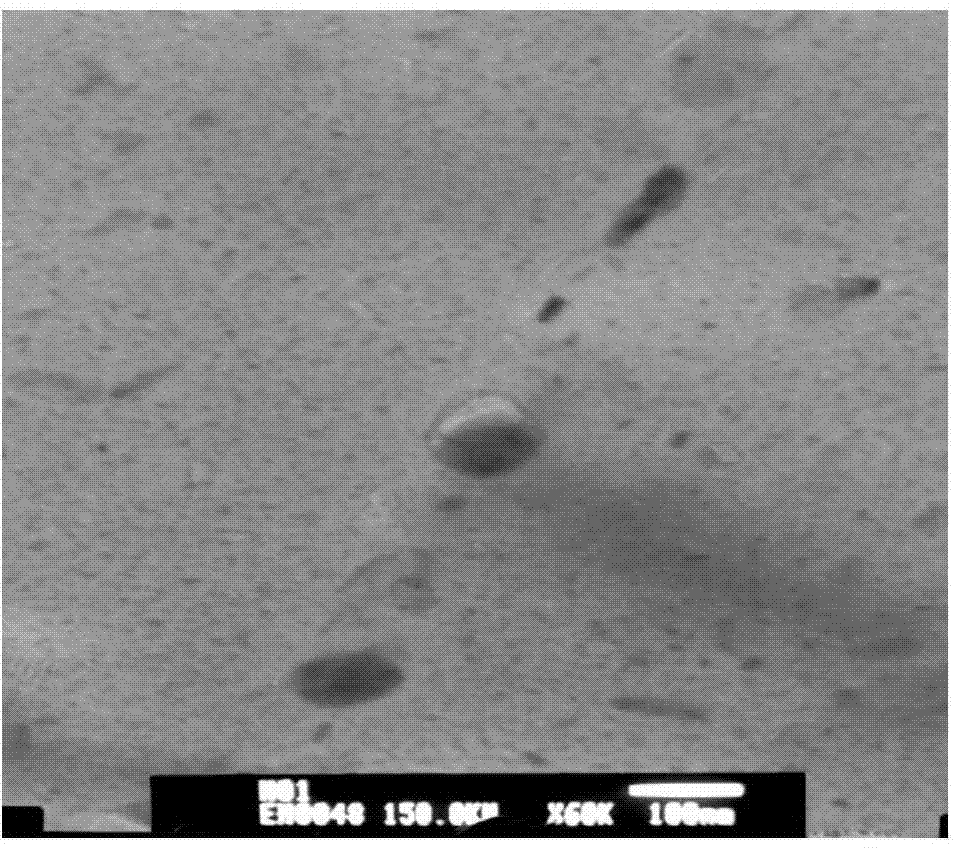

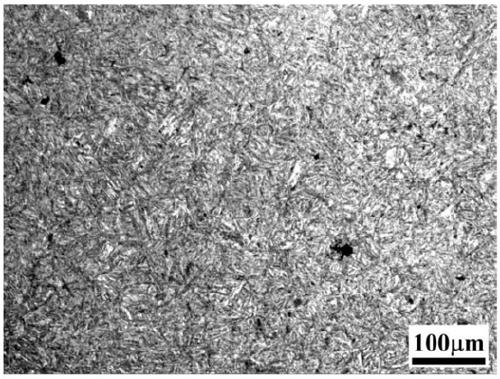

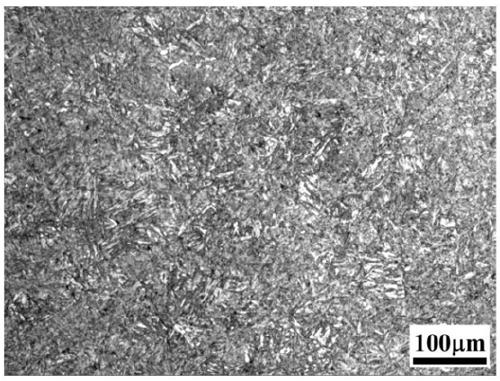

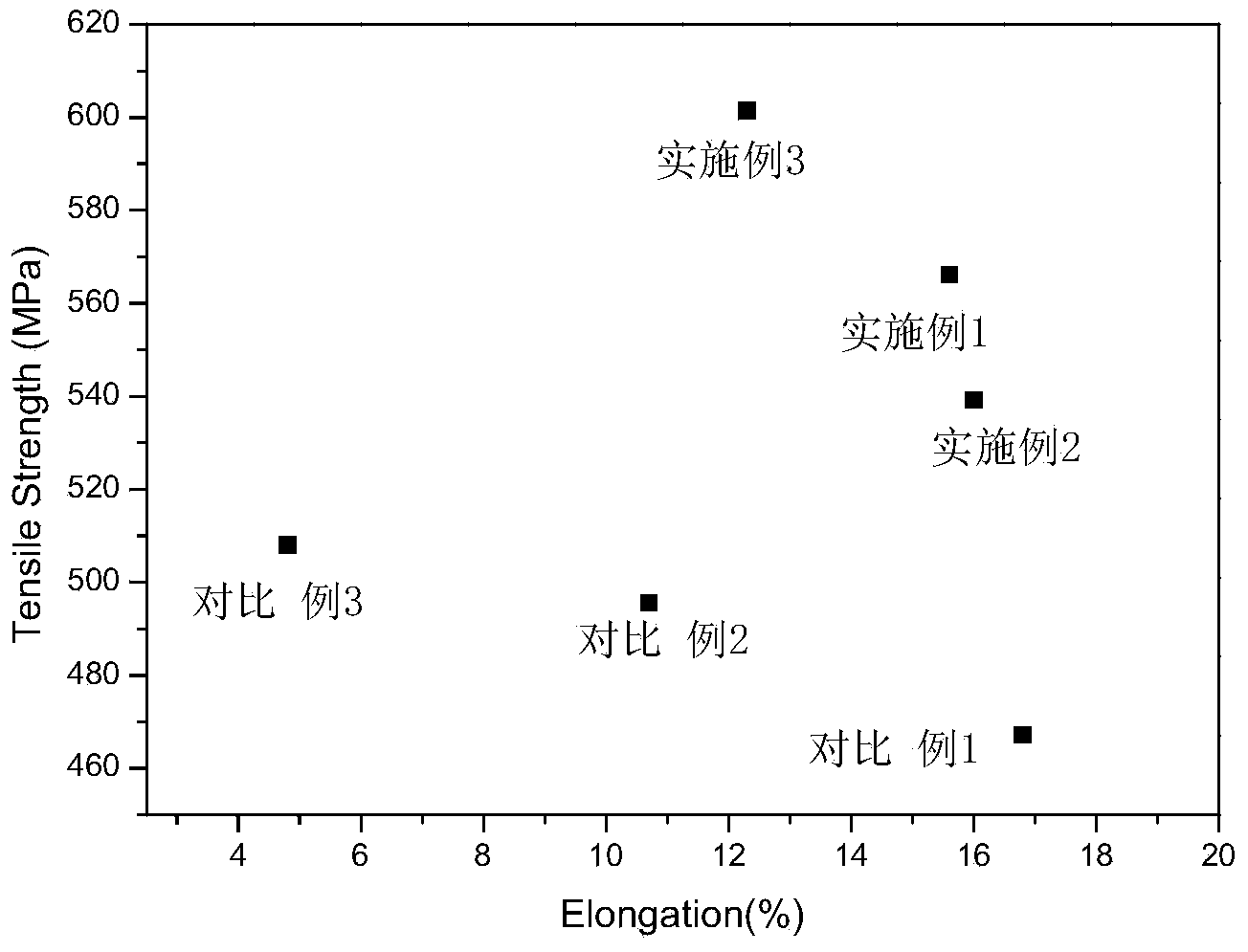

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

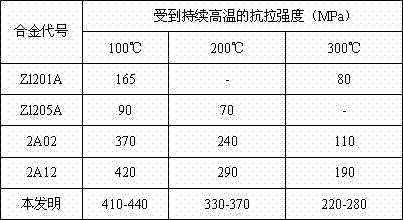

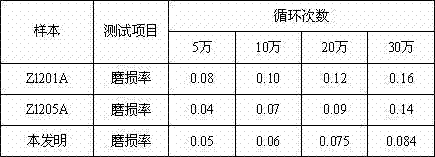

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

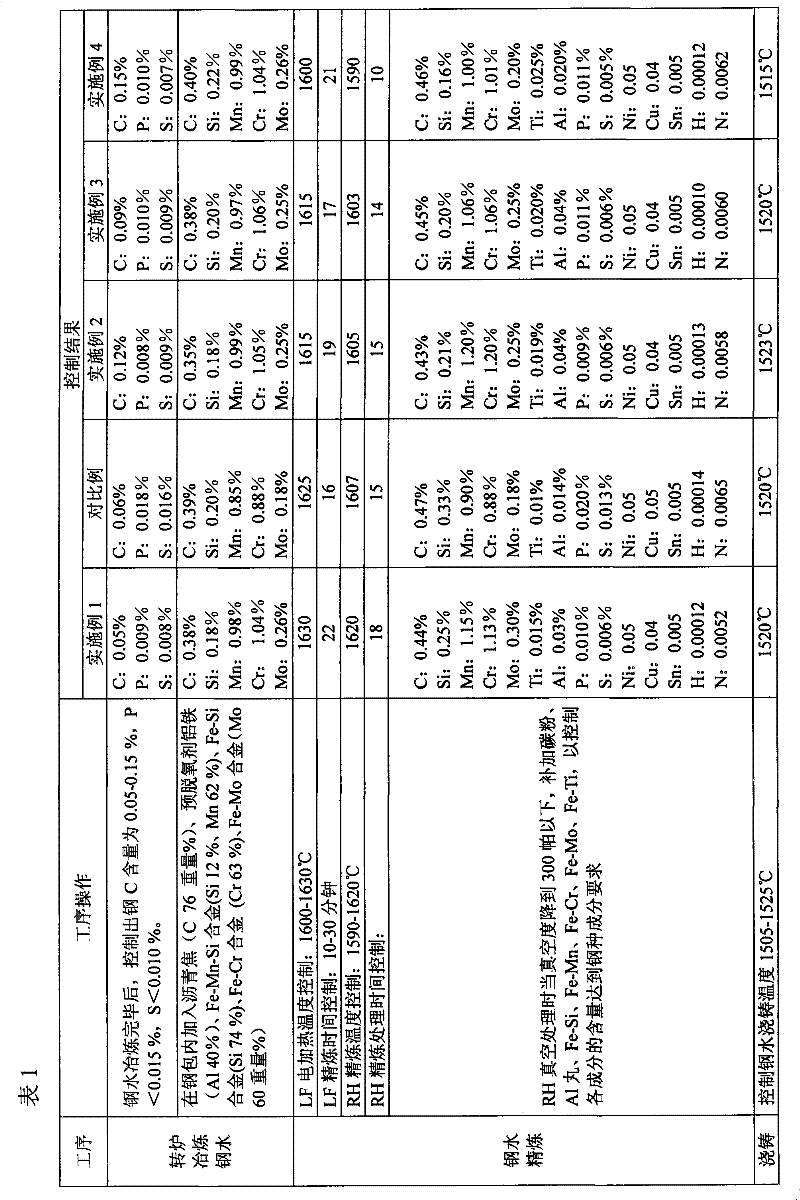

A kind of drill collar steel and its preparation method

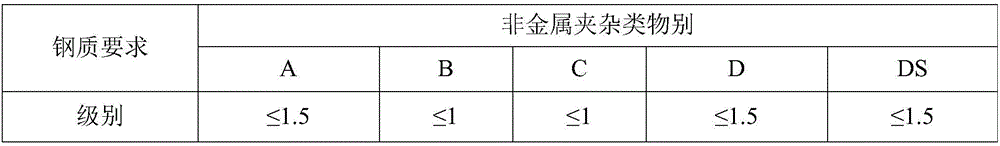

The invention relates to drill collar steel and a preparation method thereof. The drill collar steel comprises the following components based on the total weight of drill collar steel: 0.41-0.47wt% of C, 0.15-0.3wt% of Si, 0.95-1.2wt% of Mn, 0.95-1.2wt% of Cr, 0.15-0.3wt% of Mo, 0.02-0.04wt% of Al, 0.01-0.03wt% of Ti, less than or equal to 0.02wt% of P, less than or equal to 0.015wt% of S, less than or equal to 0.2wt% of Ni, less than or equal to 0.2wt% of Cu, less than or equal to 0.05wt% of Sn, less than or equal to 0.0002 wt% of H, less than or equal to 0.007wt% of N and the balance of Fe;and T[O] is less than or equal to 0.0020wt%, and the A,B,C and D impurities are less than or equal to 1.5 levels. By using the preparation method, the problem that the strength of the drill collar steel is not matched with plastic toughness is solved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Nickel-free high-toughness 80kg-grade high-strength steel and manufacturing method thereof

ActiveCN102719757ASimple welding processHigh strengthHeat treatment process controlNickel freeToughness

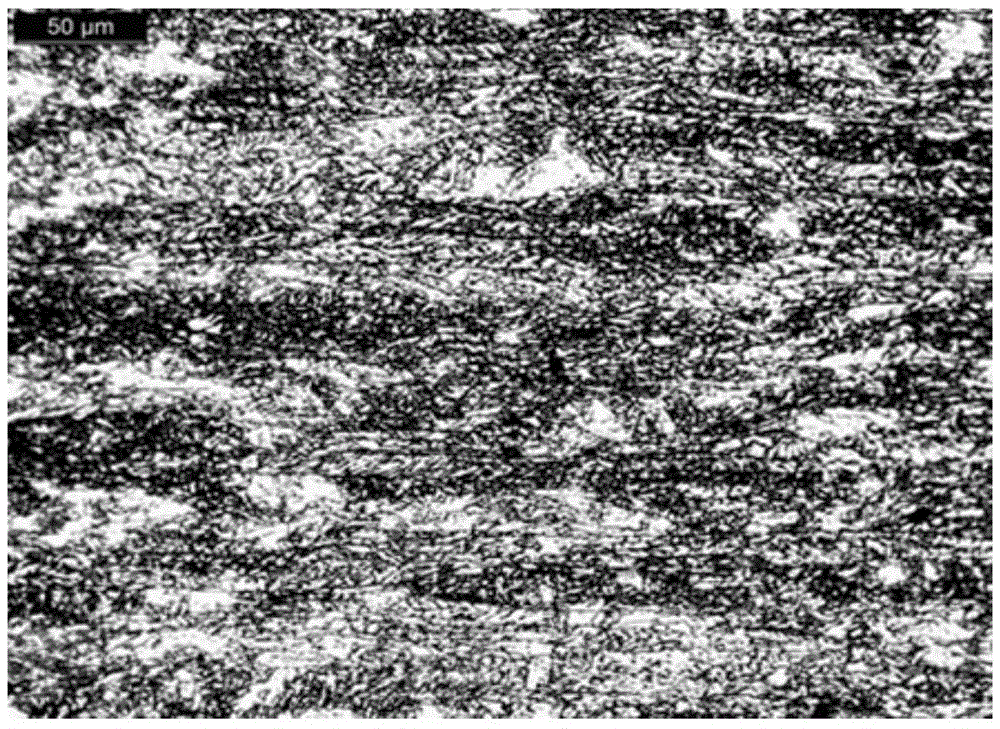

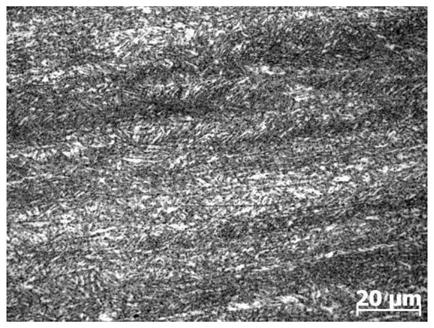

The invention relates to nickel-free high-toughness 80kg-grade high-strength steel and a manufacturing method thereof. A component system of ultralow C, ultralow Si, medium Mn and Ti, V and B microalloy steel is used as a basis; the acid-soluble Als content in steel is properly improved, the Als is not less than 10*[(%Ntotal)-0.292(%Ti)], Mn / C is not less than 12, (%C)*(%Si) is not more than 0.01, and [(%Cr)+1.3(%Mo)]*[(%V)+(%C)] is not less than 0.087; Ca treatment is carried out, the Ca / S ratio is 1.00-3.00, and (%Ca)*(%S)<0.18> is not more than 2.5*10<-3>; F*DI index number * zeta is not less than 2.0* finished steel plate thickness, wherein zeta is on-line DQ (direct quenching) hardenability contribution factor, and F is B element hardenability contribution factor; DQ (thermo mechanical control process: TMCP) and off-line tempering process (T) are optimized; the microscopic structure of the steel plate is fine low-carbon tempered martensite and tempered lower bainite; the steel has the average colony size below 20 mu m, has excellent strength and plasticity and strong toughness, and is particularly suitable for hydroelectric pressure water pipes, steel branch pipes, scrolls, ocean platforms, large-sized engineering machines and other large-sized steel structures and equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

600 MPa level automobile axle housing steel and production method thereof

The invention discloses 600 MPa level automobile axle housing steel and a production method of the 600 MPa level automobile axle housing steel. Compositions of the steel comprise, by weight, 0.21 percent to 0.26 percent of C, 0.51 percent to 0.6 percent of Si, 1.1 percent to 1.5 percent of Mn, 0.01 percent to 0.06 percent of Al, P smaller than or equal to 0.02 percent, S smaller than or equal to 0.01 percent, 0.05 percent to 0.06 percent of V, 0.012 percent to 0.016 percent of N, and the balance Fe and inevitable impurities. The ratio of V to N is smaller than or equal to 5:1. According to the method, the accurate V content, the accurate N content and the controlled rolling and controlled cooling process window are designed, hot rolling strip steel for a 600 MPa level automobile axle housing is produced, the strip steel has the good strength and toughness, and meanwhile various mechanical performance indexes of the axle housing after hot forming at the temperature more than 800 DEG C can be ensured. The method can be applied to automobile axle housing production, the thickness of materials can be effectively reduced, and on the premise that the safety of an automobile is ensured, the lightweight aim can be effectively achieved.

Owner:SHOUGANG CORPORATION

Manufacturing method of metal matrix nanocomposites with high toughness

The invention relates to the composite technical field, in particular to a manufacturing method of metal matrix nanocomposites with high toughness. According to the manufacturing method, the size, distribution, interface structure of reinforcement bodies and the metal matrix micro-structure are effectively controlled by the combined composite process of twice ball-milling, discharging plasma in situ reaction sintering and the large strain plastic deformation technology, so that ultra-fine grain metal matrix composites with evenly distributed in situ authigenic nanoparticles and good interface combination are manufactured, and good matching of intensity and toughness is obtained.

Owner:泰州赛龙电子有限公司

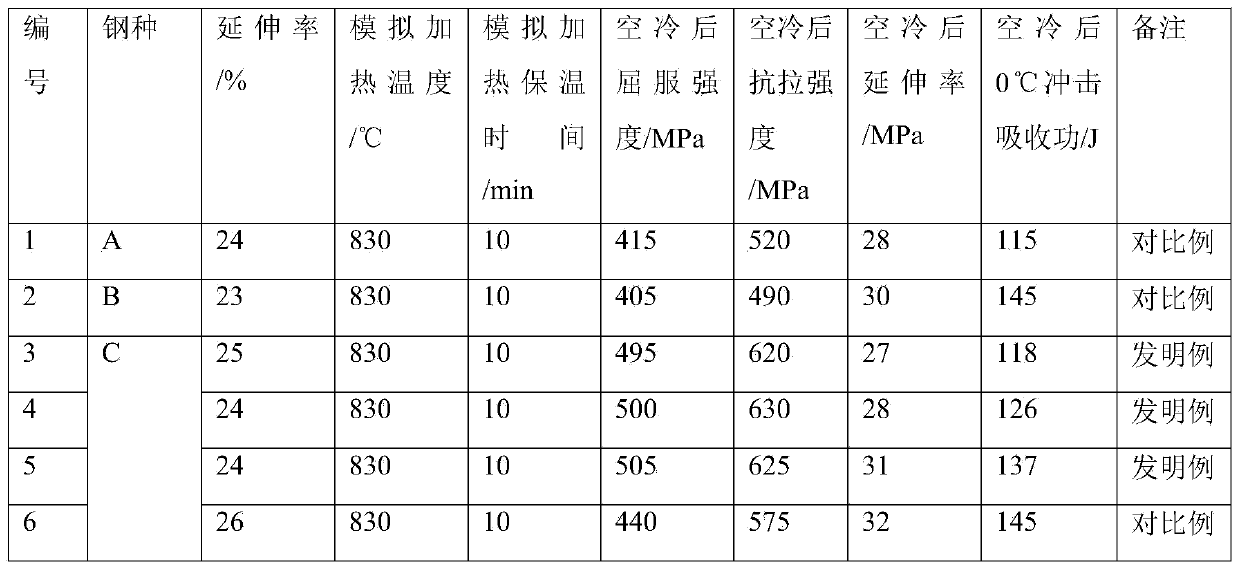

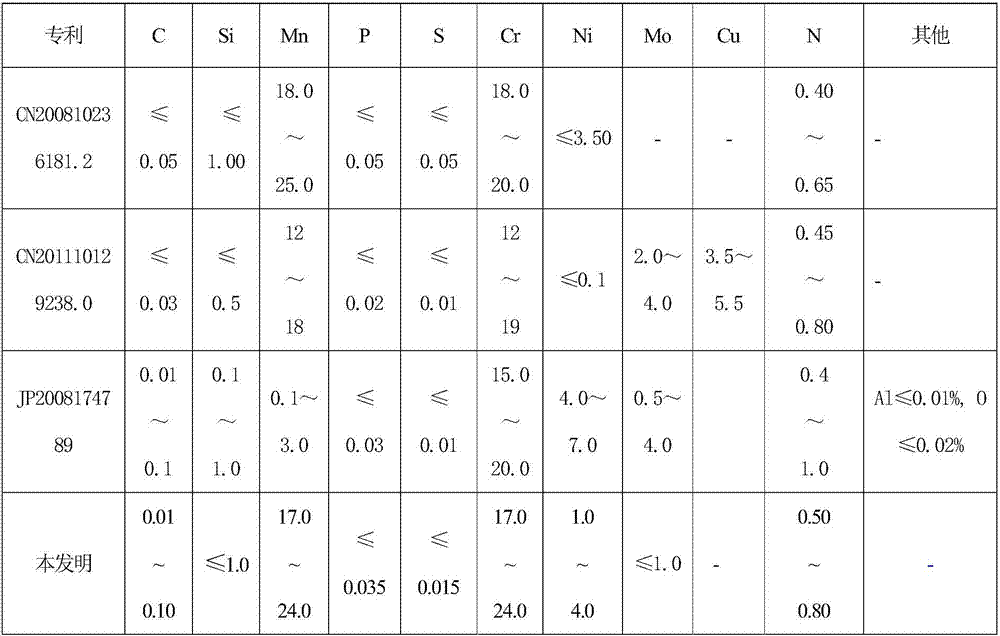

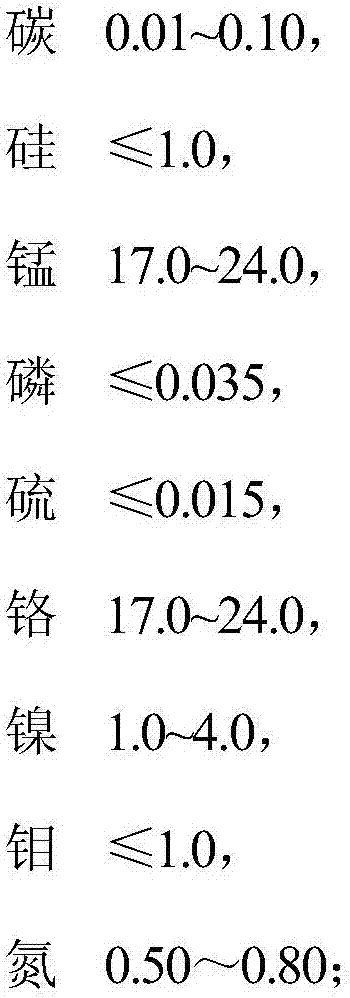

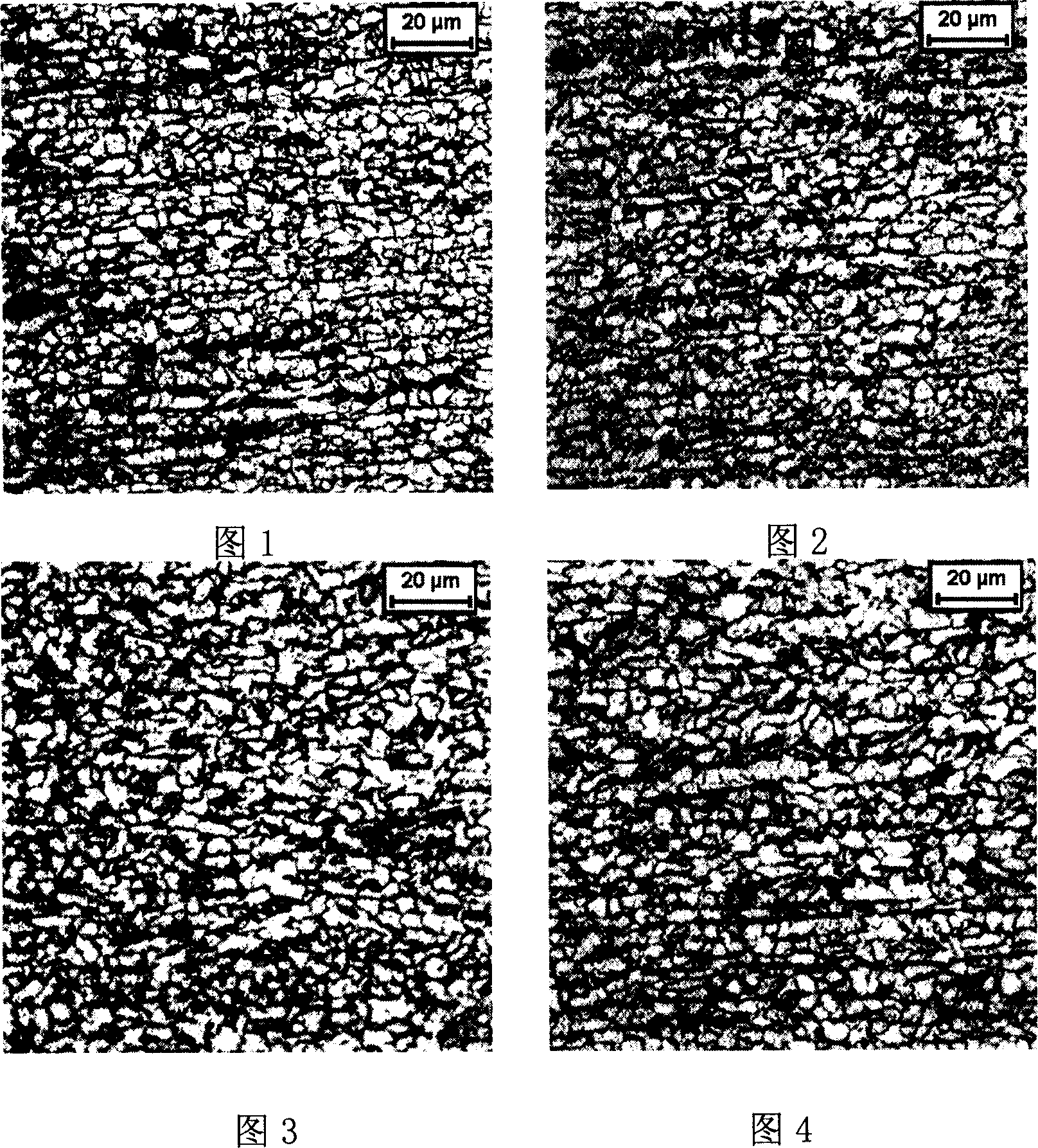

High-nitrogen non-magnetic austenitic stainless steel and manufacturing method thereof

The invention relates to high-nitrogen non-magnetic austenitic stainless steel. The high-nitrogen non-magnetic austenitic stainless steel comprises following chemical components including, by weight percent, 0.01% to 0.10% of C, not larger than 1.0% of Si, 17.0% to 24.0% of Mn, not larger than 0.035% of P, not larger than 0.015% of S, 1.0% to 4.0% of Ni, 17.0% to 24.0% of Cr, not larger than 1.0%of Mo, 0.50% to 0.80% of N and the balance Fe and inevitable impurities. The manufacturing method comprises the steps that the electric furnace+AOD+LF manner is adopted for smelting, continuous casting or die casting is adopted for making a slab ingot, and during continuous casting, the superheat degree is controlled to be smaller than 50 DEG C; a continuous casting blank or die casting slab ingotis put into a stepping type heating furnace to be heated, hot rolling on a rolling machine is carried out to form a board of the needed specification, the final rolling temperature ranges from 800 DEG to 950 DEG C, the hot-rolled board is subject to acid pickling, and the high-nitrogen non-magnetic austenitic stainless steel hot-rolled board finished product is obtained. The product has high yield strength, good ductility and toughness, corrosion resistance and wide application field and has no magnetism.

Owner:宝武特种冶金有限公司

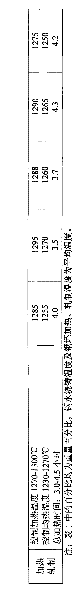

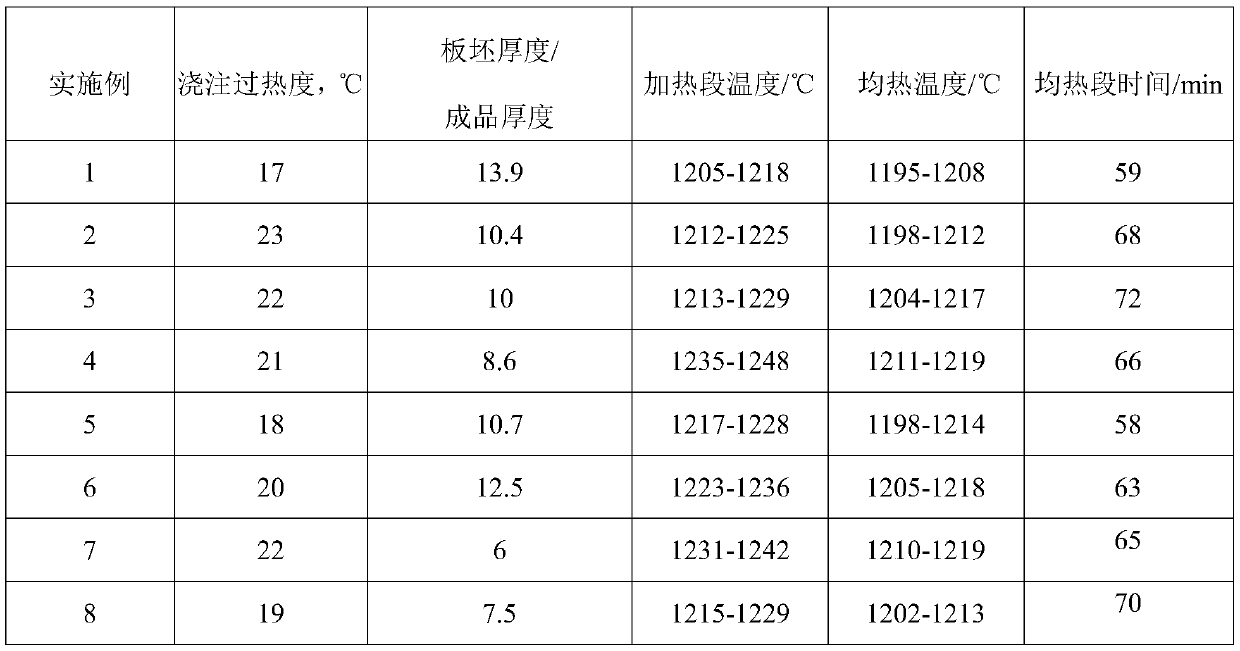

Method for medium sized or thin plate blank continuous casting and continuous rolling for producing superfine crystal grain steel plate and the steel plate

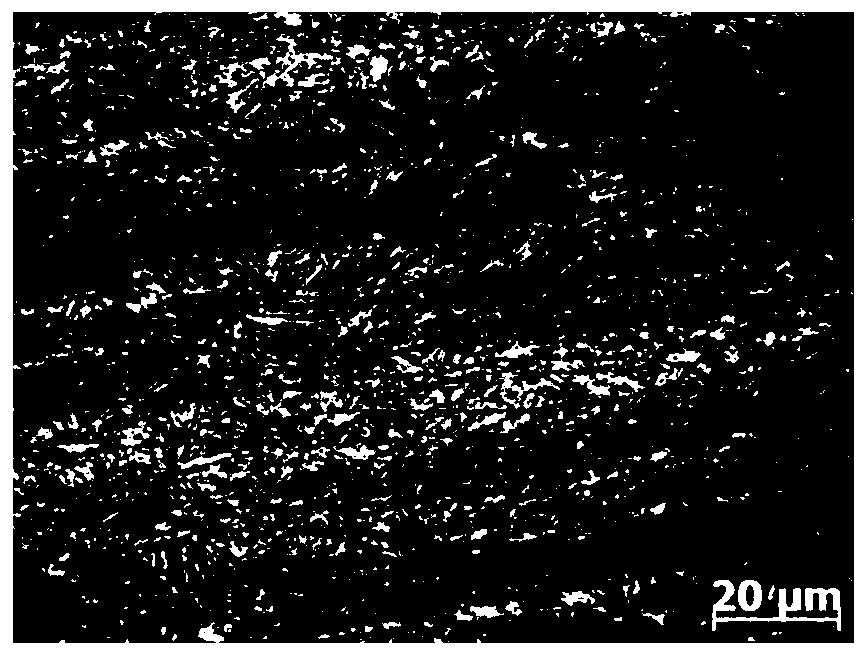

InactiveCN1995431ASimple chemical compositionImprove plastic toughnessTemperature control deviceFurnace typesSheet steelChemical composition

The invention discloses a manufacturing method of hyperfine crystal steel board through continuous rolling thin board, which comprises the following steps: allocating raw material with 0.12-0.18% C, 0.15- 0.35% Si, 0.65-1. 20% Mn, not more than 0.02% P, not more than 0.015% S and Fe; casting in the 100-200mm*1000-2000mm blank; setting the loading temperature over 800 deg. c; heating to 1100-1280 deg. c; reducing rough rolling of blank to 30-60 mm; setting refining rolling temperature between 920 and 1050 deg. c; exerting multi-channel and large-deforming strain accumulation with even deforming velocity at 1-10 / s; setting the refining rolling outlet temperature at 750-900 deg. c; setting cooling speed of laminar flow at 10-45 deg. c / s; coiling at 400-620 deg. c; setting the norm of continuous heat rolling steel at 2-18mm with even crystal size at 3-7um and yielding strength over 400Mpa; making the extending proof strength between 510 and 580 Mpa and extending rate over 26%.

Owner:ANGANG STEEL CO LTD

Magnesium-lithium alloy with enhanced long-period structure phase and preparation method thereof

ActiveCN103122431AMeet the requirements of various applicationsHigh strengthAlloy substrateMass content

The invention provides a magnesium-lithium alloy with an enhanced long-period structure phase and a preparation method thereof. The method adopts pure Mg, pure Li, pure Zn and Mg-Y intermediate alloy as raw materials and comprises the following steps of: proportionally putting the raw materials into a vacuum induction melting furnace, filling a protective gas, heating and smelting, and casting the smelted melt into a metal die to obtain an as-cast alloy; performing heat treatment at 490-510 DEG C for 5-10 hours to obtain a casting alloy with an LPSO structure phase through phase transformation; and performing extrusion deformation processing at 260-280 DEG C to obtain a magnesium-lithium alloy which comprises the following components in percentage by mass: 5.5-10% of Li, 4-10% of Y, 1-4% of Zn, less than 0.03% of inevitable impurities Fe, Cu, Ni and Si in total and the balance of Mg, wherein the mass content ratio of Y to Zn is 1-6. According to the invention, by reasonably selecting the alloy elements, the LPSO structure phase is introduced into a magnesium-lithium alloy substrate, and a magnesium-lithium alloy material with low density, high strength, high plasticity and good heat resistance is prepared.

Owner:HARBIN ENG UNIV

Production method of 150-400mm thick steel plate for plastic moulds

InactiveCN102896466AIncrease the compression ratioImprove mechanical propertiesAlloy elementSubmerged arc welding

The invention discloses a production method of a 150-400mm thick steel plate for plastic moulds and belongs to the field of metal materials. Continuous cast slab is used as raw material to produce the 150-400mm thick steel plate by the production method and comprises, by weight percent, 0.20-0.40% of C, 0.20-0.50% of Si, 1.00-1.60% of Mn, not more than 0.008% of S and P, 0.10-0.50% of Mo, 1.40-2.0% of Cr, 0.01-0.04% of V, and not more than 0.20% of other alloy elements (Nb, Ti and Ni). The high thickness slab can be produced by full-vacuum electron beam welding or by combined process of gas shielded welding, submerged-arc welding and vacuum electron beam welding and is then subjected to heating, rolling, slow cooling and heat treatment procedures, ultrasonic testing qualified rate of the produced steel plate for plastic moulds reaches more than 98%, the hardness is even, and the steel plate has excellent machinability, wear resistance and polishability and is suitable for production of various plastic moulds.

Owner:JIGANG GRP

Production method of copper-steel composite plate

ActiveCN102671943AGood direct connectionHigh strengthWork treatment devicesCleaning using liquidsSurface cleaningSpray coating

The invention relates to a production method of a copper-steel composite plate. The production method comprises the following steps of: performing surface cleaning, performing texturing treatment, spraying a binding layer, rolling and annealing, wherein before rolling, alloy plating layers are respectively plated on the surfaces of a steel plate and a copper plate, which need to be compounded through an immersion plating or spray coating way, the thickness of each plating layer is 4-8 mu m, and each alloy plating layer contains the following components: 6-8 parts by weight of Zr, 25-50 parts by weight of Zn, 5-30 parts by weight of Al, 10-40 parts by weight of Fe, 0.5-1 part by weight of Si and 0.4-0.6 part by weight of Mo. The production method disclosed by the invention has the beneficial effects that as the bonding layers with the mixture ratio are adopted, the direct bonding property between the steel plate and the copper plate is good; in addition, the compounding temperature is lower, the rolling reduction is smaller and the working cost is saved; and the composite copper-steel material prepared by the method disclosed by the invention has the advantages of high strength, high plasticity and toughness and excellent stress and corrosion resistance.

Owner:RUGAO OUTONG MACHINERY FITTINGS

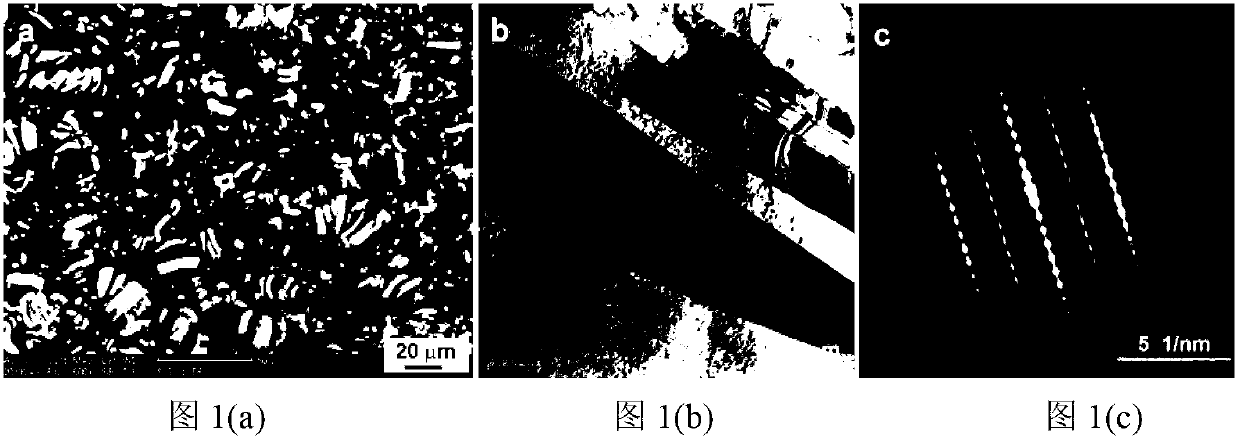

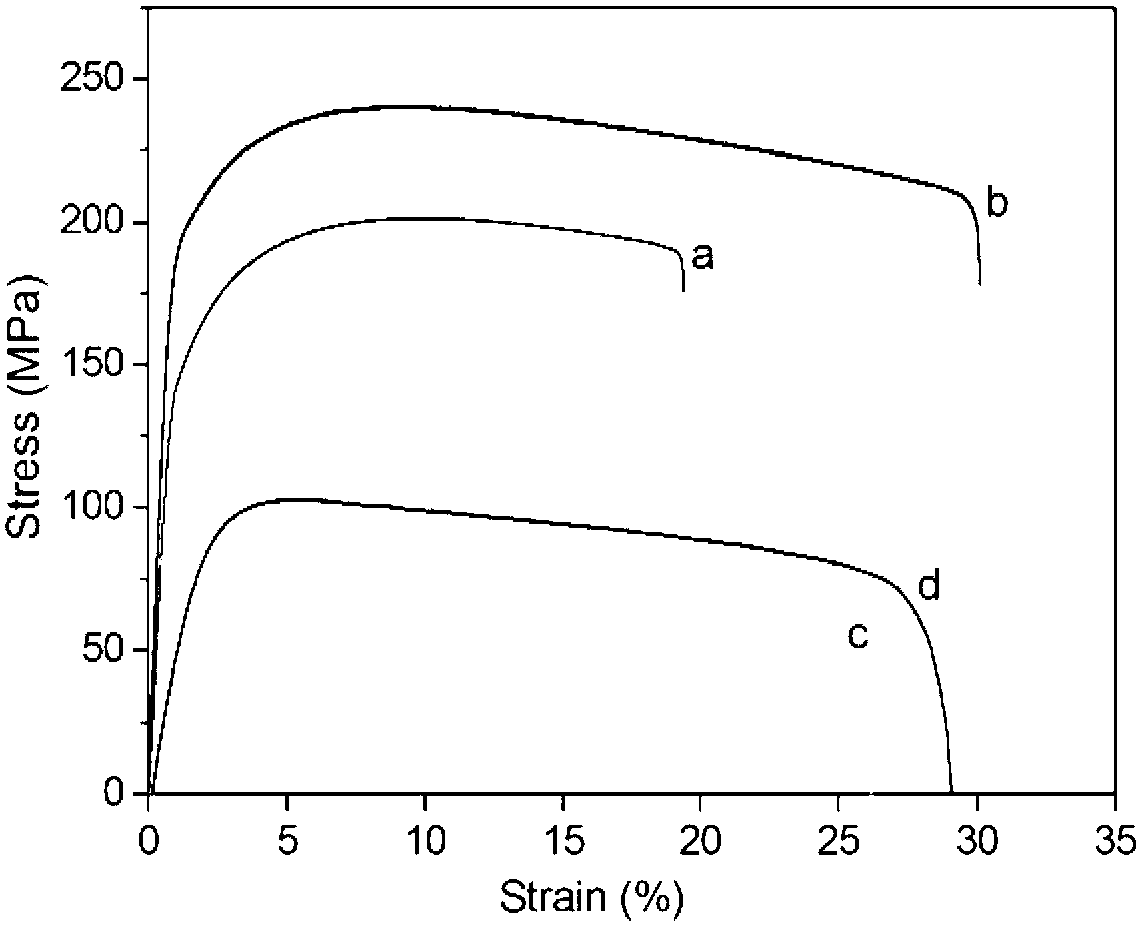

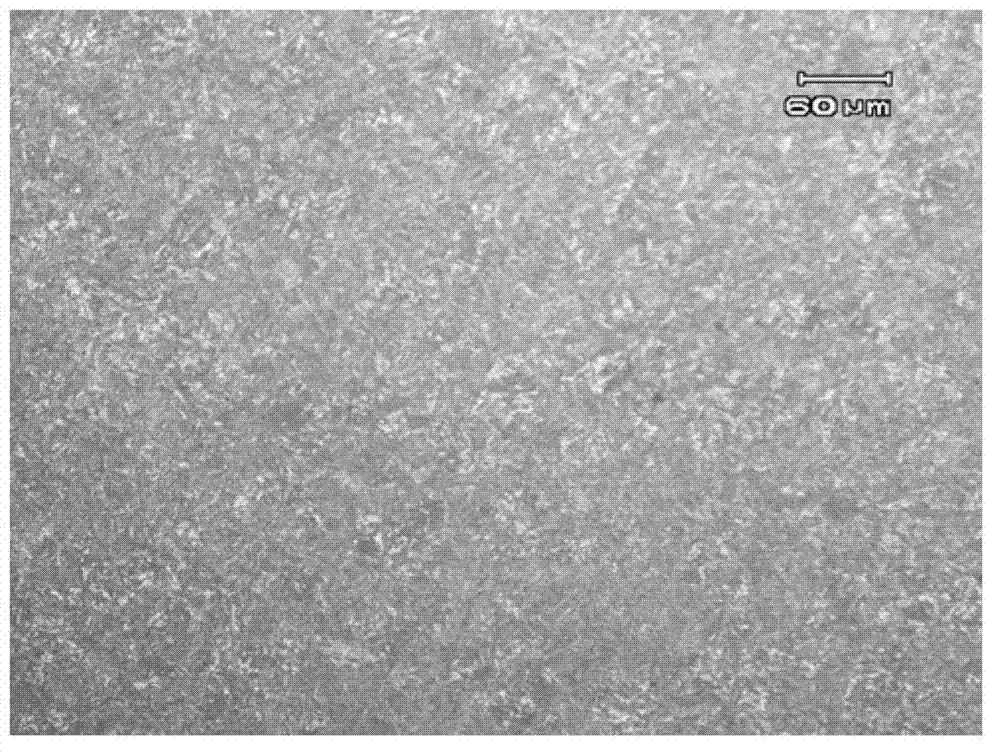

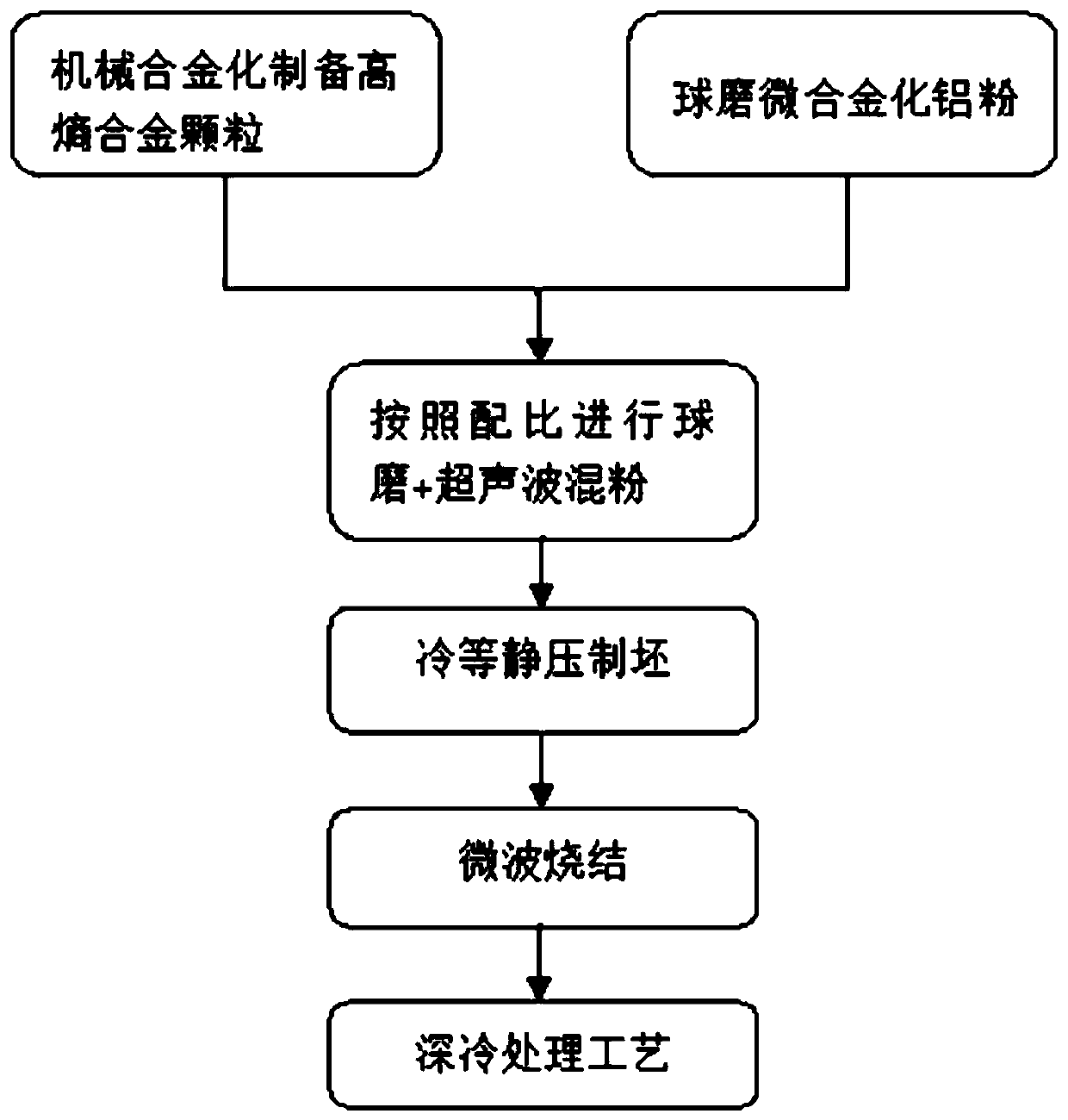

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

Method for rolling thick specification low-alloy structure steel plate by using middle and thin plate blank

InactiveCN101148735AIncreasing the thicknessIncrease reduction rateRoll mill control devicesMetal rolling arrangementsChemical compositionMaterials science

The present invention relates to production of structural low alloy steel plate, and is especially process of producing high strength hot rolled coiled sheet of 16-20 mm thickness with continuous cast billet of 150-170 mm thickness. The steel has chemical composition comprising C 0.15-0.20 wt%, Si 0.20-0.40 wt%, Mn 1.40-1.60 wt%, S not more than 0.030 wt%, P not more than 0.030 wt%, and Fe and impurity for the rest. The production process includes the steps of controlled heating, rough rolling, finish rolling, cooling, etc. and the produced hot rolled coiled sheet has simple composition, low cost, high tensile strength, high yield strength, high elongation, high impact toughness, high cold bending performance, good welding performance and other features.

Owner:LAIWU IRON & STEEL GRP

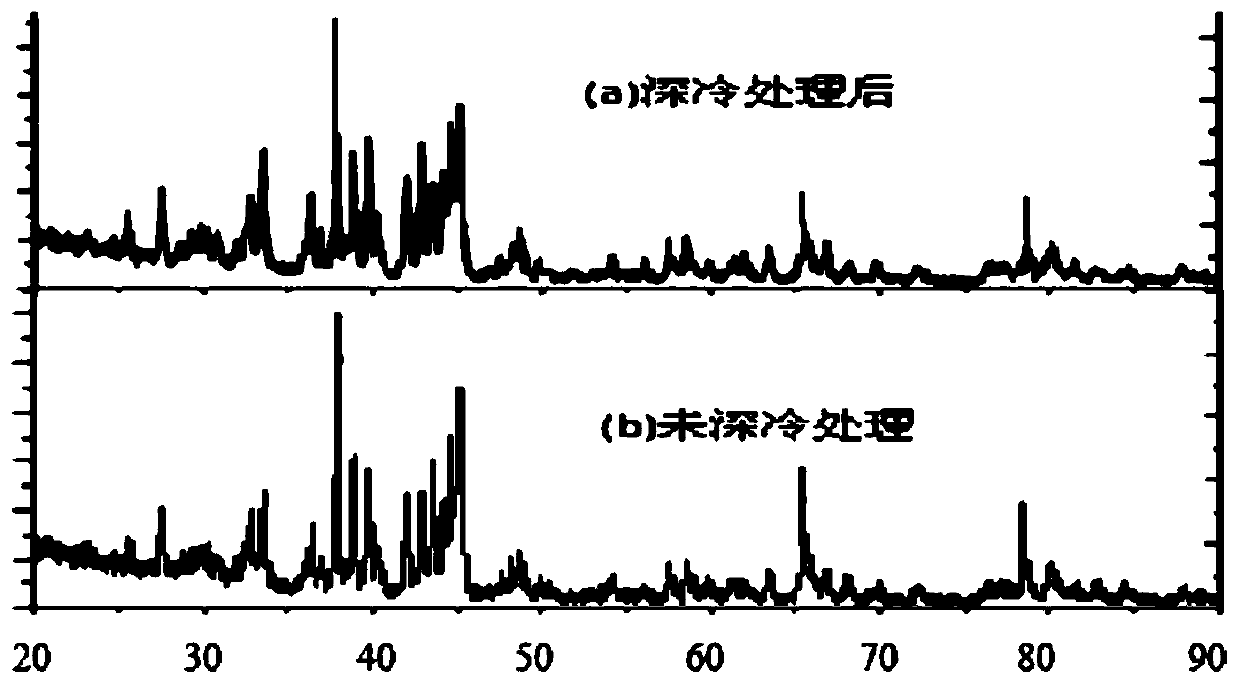

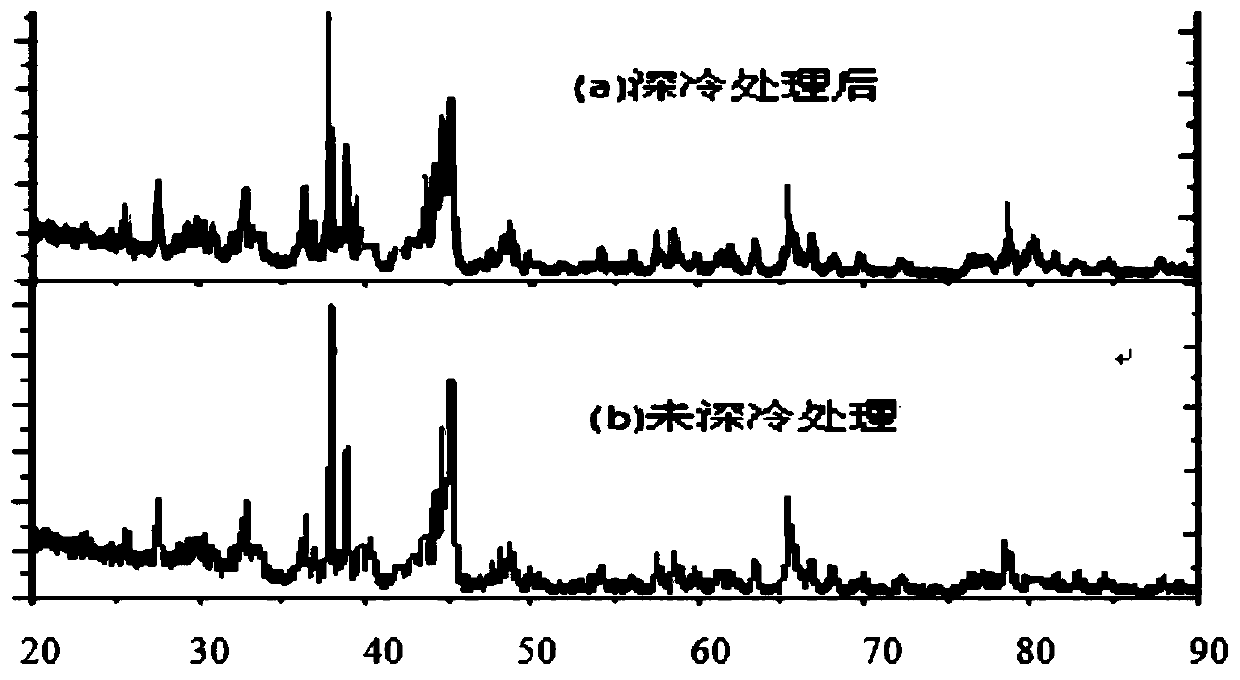

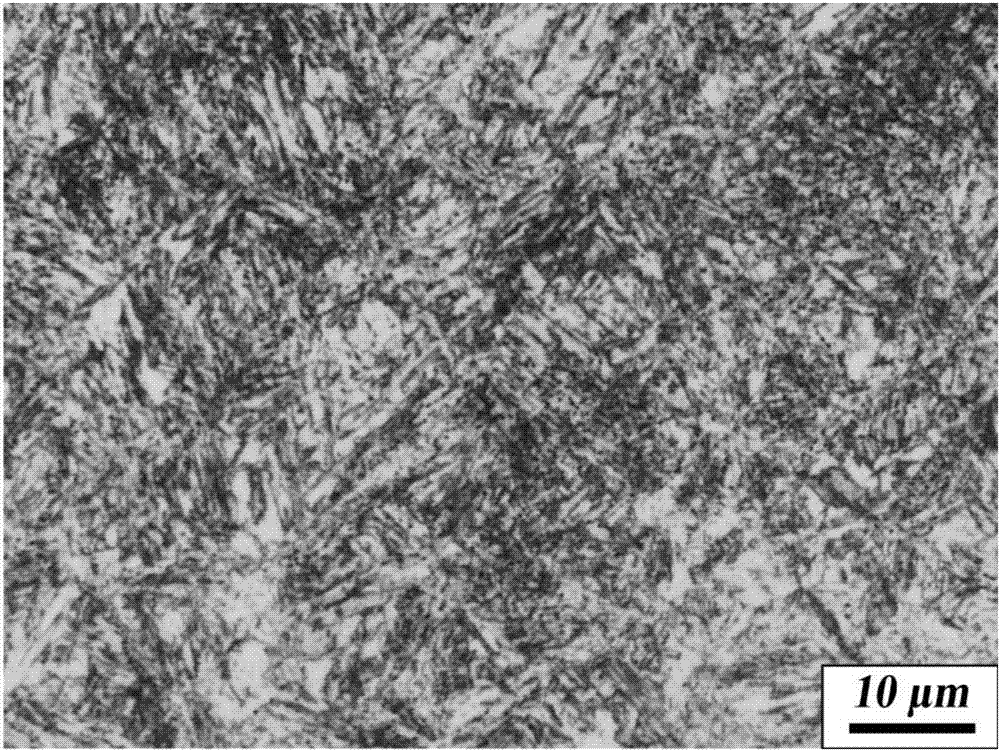

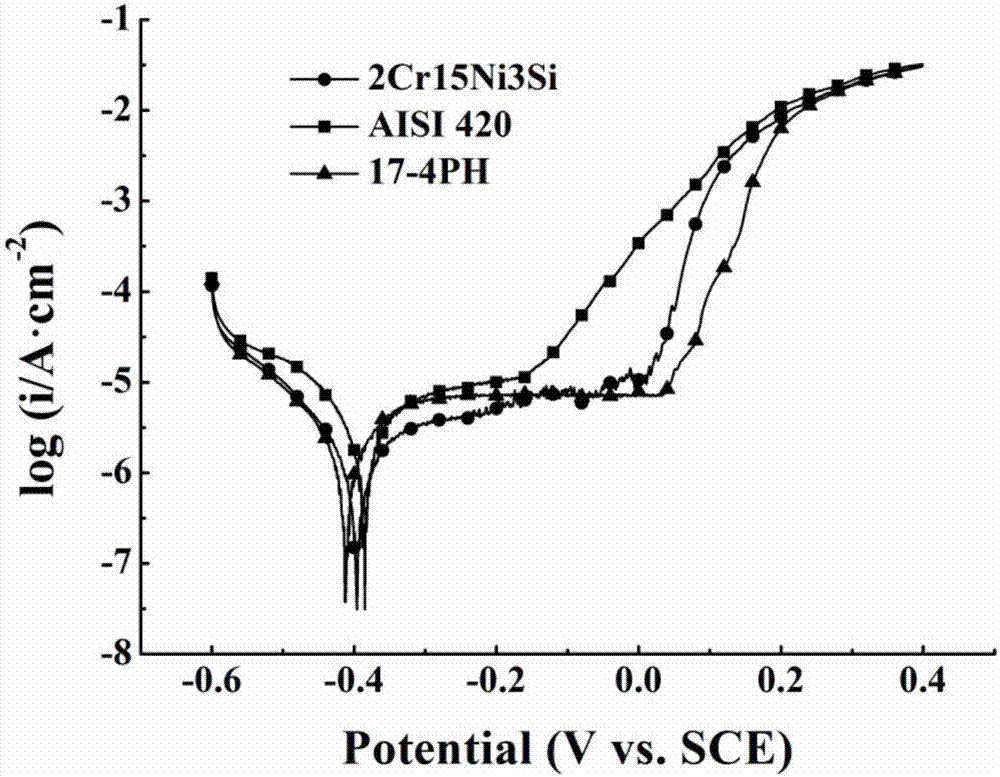

Ultrahigh-strength martensitic stainless steel and preparation method thereof

ActiveCN106906429AImprove mechanical propertiesImprove corrosion resistanceMartensitic stainless steelIngot

The invention discloses ultrahigh-strength martensitic stainless steel and a preparation method thereof. The ultrahigh-strength martensitic stainless steel is high in yield strength, high in tensile strength, good in ductility and good in impact toughness. The preparation method comprises the steps as follows: Step 1, a raw material is prepared from stainless steel components in percentage by weight according to the burnt value, is smelted in the vacuum environment and is poured to form a steel ingot; the steel ingot is prepared from components in percentage by weight as follows: 0.10%-0.25% of C, 11.0%-17.0% of Cr, 0.5%-2.0% of Mn, 1.1%-3.0% of Si, 0.1%-4.0% of Ni, 0.1%-0.3% of Cu, less than or equal to 0.02% of P, less than or equal to 0.02% of S and the balance of Fe and inevitable impurity elements; Step 2, forging of the steel ingot is started at 1,050-1,200 DEG C, the finish forging temperature ranges from 880 DEG C to 920 DEG C, the forging ratio is larger than or equal to 5, and air cooling is performed after forging; Step 3, a forging is subjected to heat preservation at 950-1,050 DEG C for 2-4 h, is subjected to water quenching and then is tempered at 200-300 DEG C for 2-4 h, and the ultrahigh-strength martensitic stainless steel is obtained after natural cooling.

Owner:XI AN JIAOTONG UNIV

Brake pad material for high-speed railway passenger train and preparing method thereof

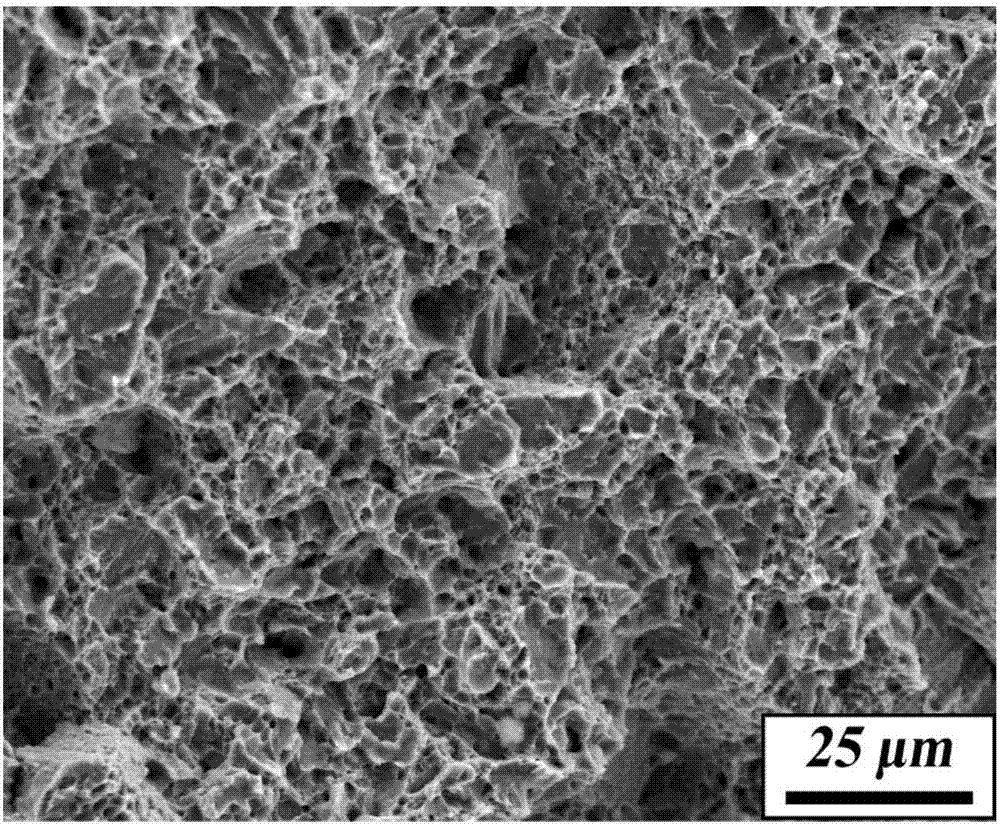

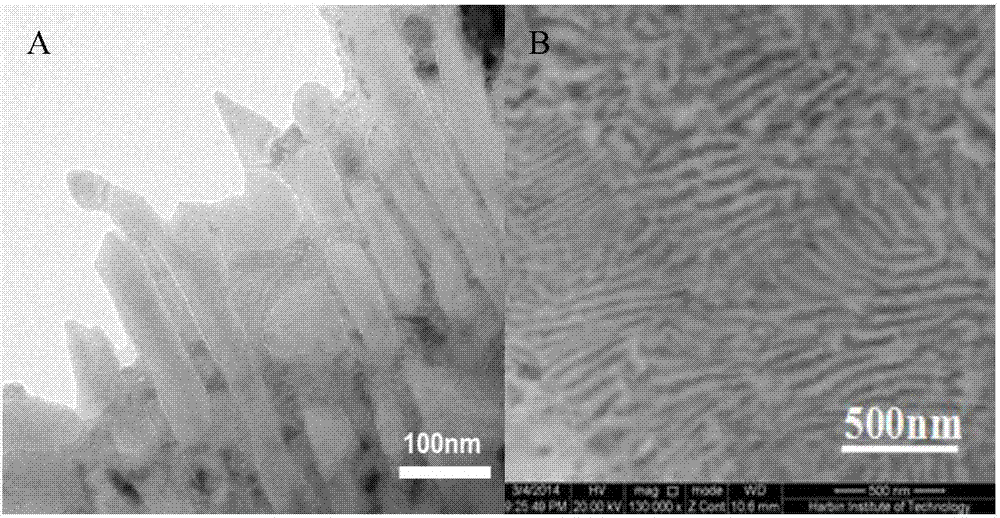

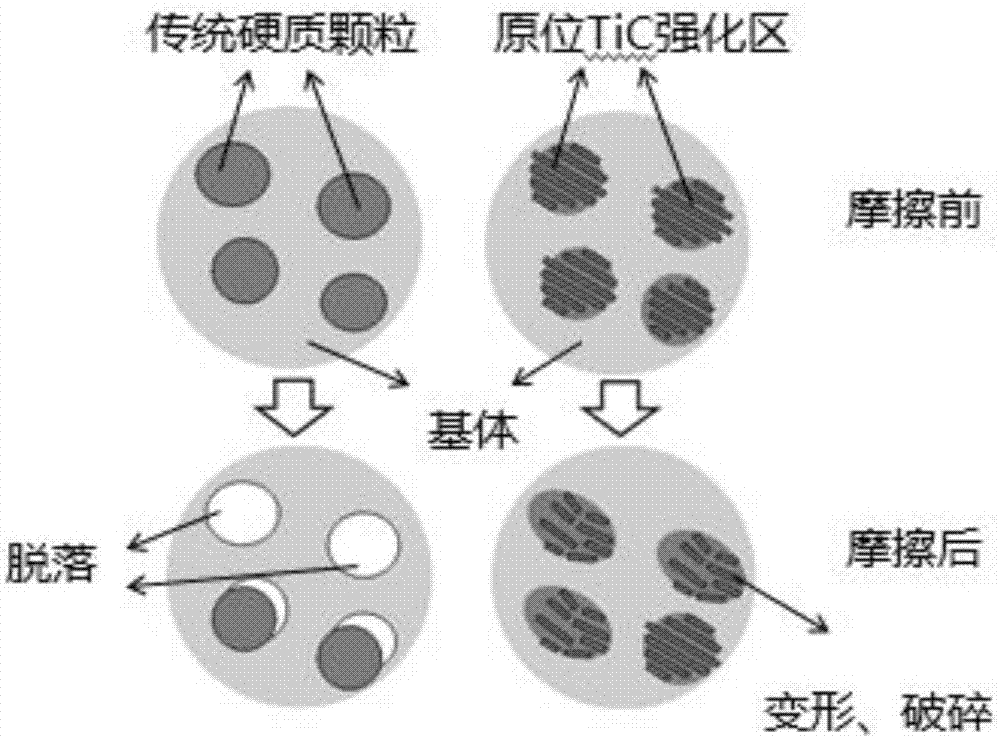

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

Preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming

The invention relates to a preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming, belongs to the technical field of preparation of acid-pickling steel strips, and aims at solving the technical problem of providing a low-cost preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming. According to the method, C and Mn serve as main elements, and the C content is increased; on the condition that alloy elements such as Nb, Ti, V, B, Mo, La and Cr are not added, on the premise of ensuring steel purity and chemical component uniformity of a cast blank by controlling the smelting procedure, and by means of reasonable rolling control and cooling control technological processes, hot-rolled steel plates which are moderate in strength and high in elongation rate are obtained, the hot-rolled steel plates are subjected to trimming, blanking and heating and then subjected to hot forming and hot treatment, and parts which are moderate in strength and high in ductility and toughness are obtained finally. The steel strips are widely applied to automotive structural parts and can replace part of hot-rolled and cold-rolled continuous annealing steel plates and steel strips which are high in alloy content and product cost and are used for high-strength automobile structures.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

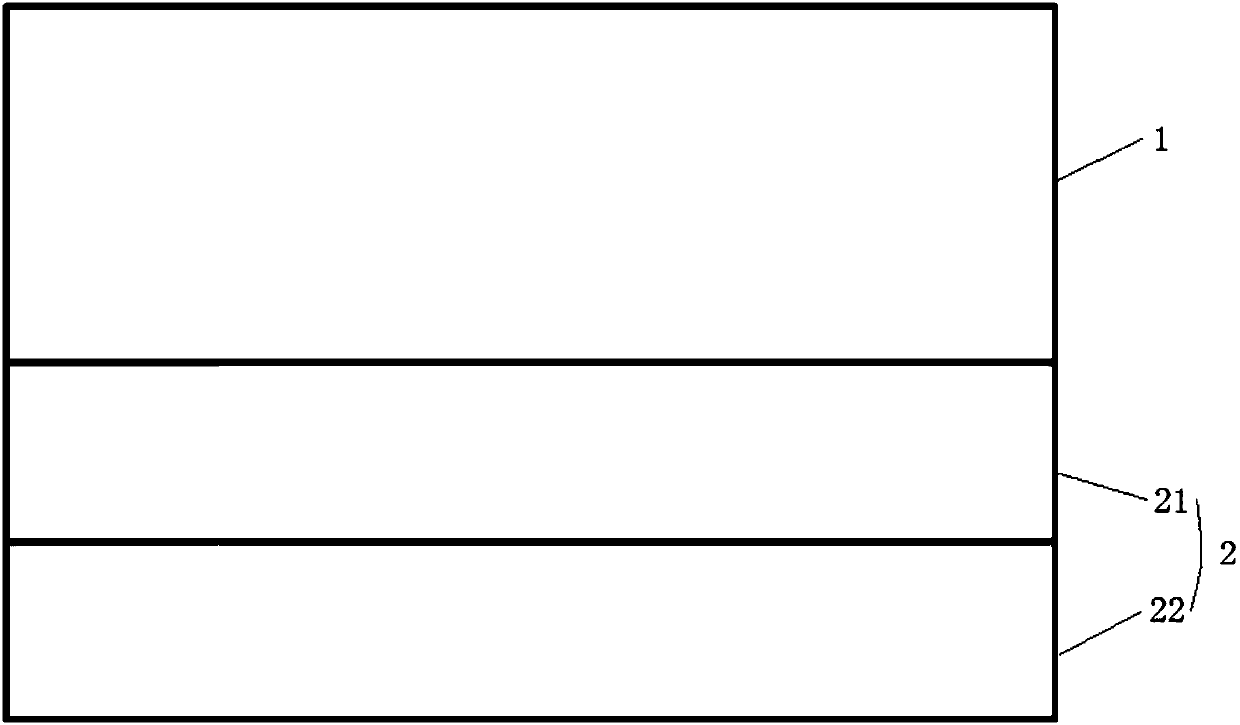

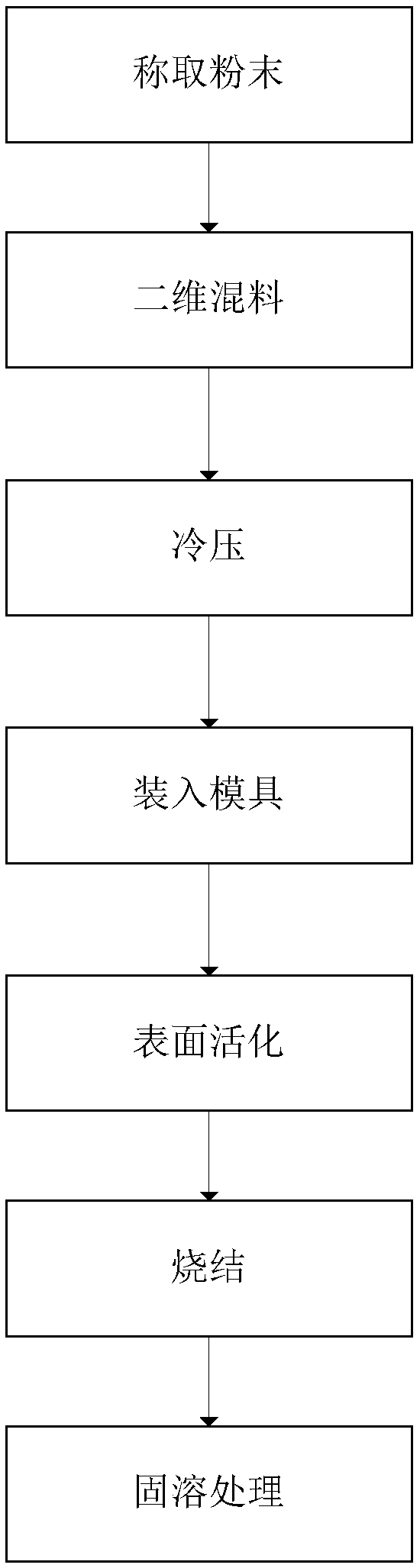

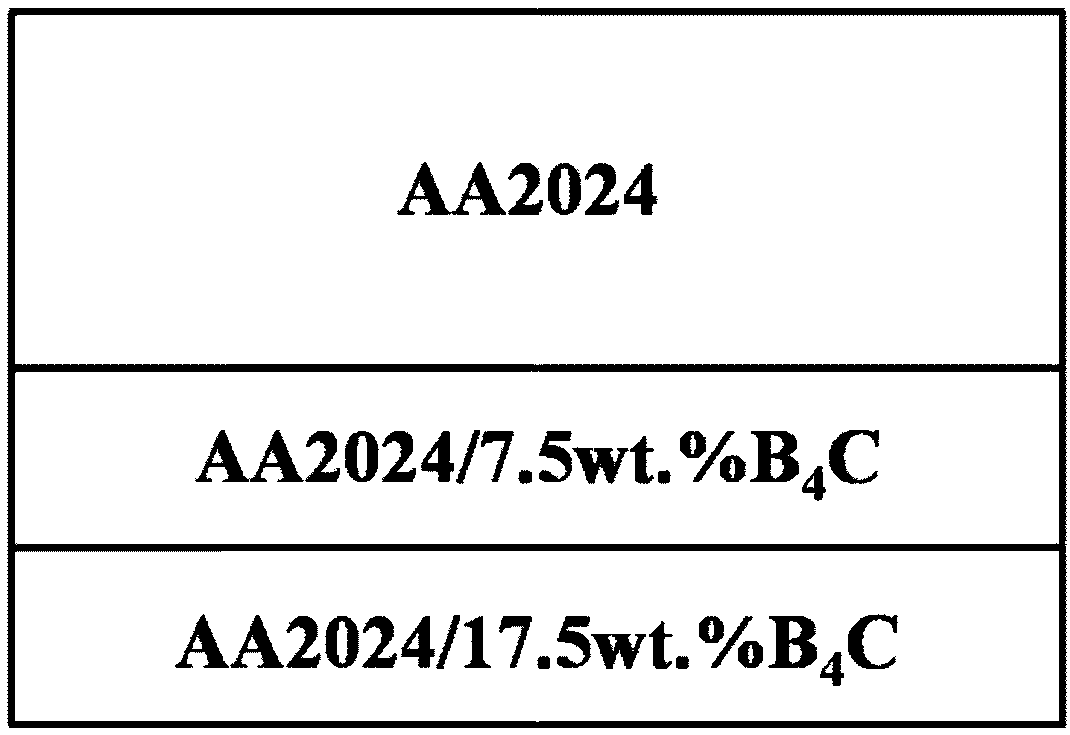

Functional gradient aluminum-based composite material with multilevel gradient structure and preparation method thereof

ActiveCN107805728AHigh strengthImprove plastic toughnessIncreasing energy efficiencyBoron carbideVolumetric Mass Density

The invention discloses a functional gradient aluminum-based composite material with a multilevel gradient structure. The functional gradient aluminum-based composite material comprises a wrought aluminum alloy layer and an aluminum-based composite material layer, wherein the aluminum-based composite material layer is used for separating out reinforced aluminum alloy as a matrix, and adopting boron carbide as an enhancement phase. The aluminum-based composite material layer is provided with a plurality of layers, the content of boron carbide in each layer of the aluminum-based composite material layer is different, the content gradient of the boron carbide is increased, and the content of each layer of the boron carbide is lower than 20% of the mass of the corresponding aluminum-based composite material layer. The invention further provides a preparation method of the functional gradient aluminum-based composite material with the multilevel gradient structure. According to the method,an electric field auxiliary sintering technology is adopted, and a voltage sintering method of direct current pulse current is utilized, so that the low-temperature rapid sintering can be realized, fine and uniform tissues can be obtained, the density of a sintered body is high, and the mechanical property is good.

Owner:武汉酷睿科技有限公司

Steel plate with super-low cost, 800MPa-grade high toughness and excellent weldability and manufacture method thereof

The invention provides a steel plate with super-low cost, 800MPa-grade high toughness and excellent weldability and a manufacture method thereof. According to the manufacture method, metallurgical technical control methods of selecting super-low C-super-low Si-high Mn-highAls-(low Mo+high Cr) alloying-(Ti+Nb+V+B)microalloying composition system as basis, properly increasing the content of acid solution Als in steel, performing Ca treatment and leading the value of [(%C)+(%Mn) / 6+(%Si) / 24+(%Ni) / 40+(%Cr) / 5+(%Mo) / 4+(%V) / 14+7.3(%B)]*V cooling speed / (T starting cooling temperature-T terminating cooling temperature)*t to be more than or equal to 0.60 and less than or equal to 1.00, and the like are adopted, a specific controlled-rolling and online tempering process is optimized, the tempered steel plate has excellent weldability while the strength, low-temperature toughness, obdurability and plasticity of the tempered steel plate are matched, the problem of the weldability of a nickel-free tempered steel plate can be successfully solved, the welding HAZ has high strength, high toughness and excellent plasticity. The steel plate is especially suitable for hydroelectric pressure pipelines / volute casings / steel bifurcated pipes, marine platforms, large maritime working machinery and other large steel structures and equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

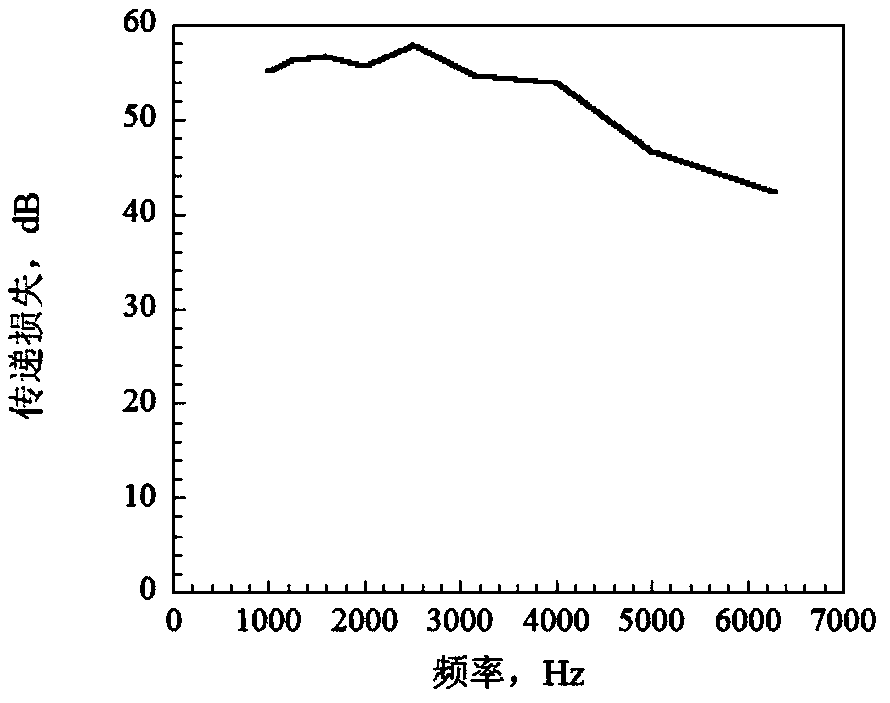

Preparation method of hollow sphere and aluminum alloy-based sound insulation material

The invention provides a preparation method of a hollow sphere and aluminum alloy-based sound insulation material, the method is a simple and convenient method for preparing the lightweight high-performance sound insulation material. The cleaned stainless steel hollow ball and the aluminum alloy base body are placed into a die, the stainless steel hollow spheres are randomly and uniformly distributed in the aluminum alloy matrix, so as to obtain a hollow sphere and an aluminum alloy prefabricated body, putting the prefabricated body and the mold into a vacuum hot-pressing sintering furnace for hot-pressing sintering, carrying out hot-pressing sintering, taking out and carrying out T7 heat treatment. The hollow sphere and the aluminum alloy sound insulation material obtained by the methodcan achieve uniform distribution of the hollow sphere in the matrix, and the porosity in the sound insulation material can be controlled.

Owner:HARBIN ENG UNIV

Novel high-strength corrosion-resistant rare earth aluminum alloy material and preparation method

The invention provides a novel high-strength corrosion-resistant rare earth aluminum alloy material and a preparation method. Based on a high-strength Al-Zn-Mg alloy, a proper amount of elements of Cu, rare earth Ce, rare earth Sc and rare earth Er are added, and the novel Al-Zn-Mg-Cu-Ce-Sc-Er aluminum alloy material is prepared. The material has the beneficial effects of being high in strength, good in plasticity and toughness, resistant to corrosion, good in fatigue resistance and the like. The material is a structural material which can be widely applied to aviation, spaceflight, ships and warships and means of conveyance. The production and preparation method of the material is simple and easy to practice, the processing technology of the material is easy to control, raw materials are sufficient and easy to obtain, the production cost is low, and the material has very wide production and application prospects.

Owner:HEFEI UNIV OF TECH

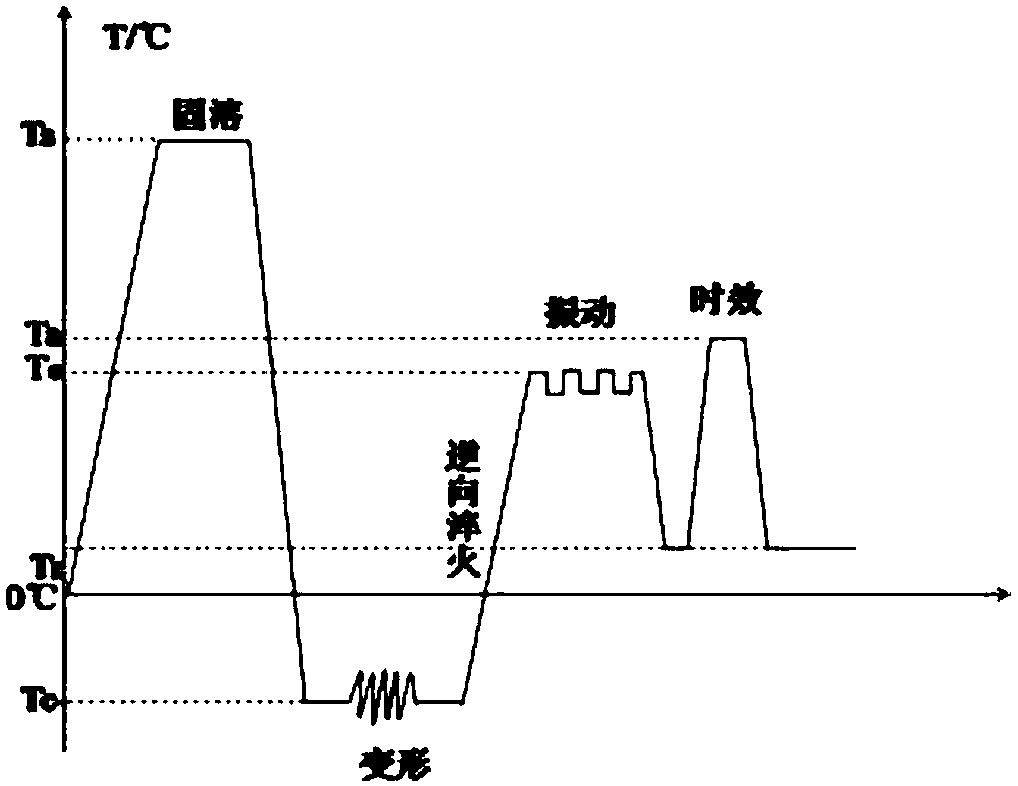

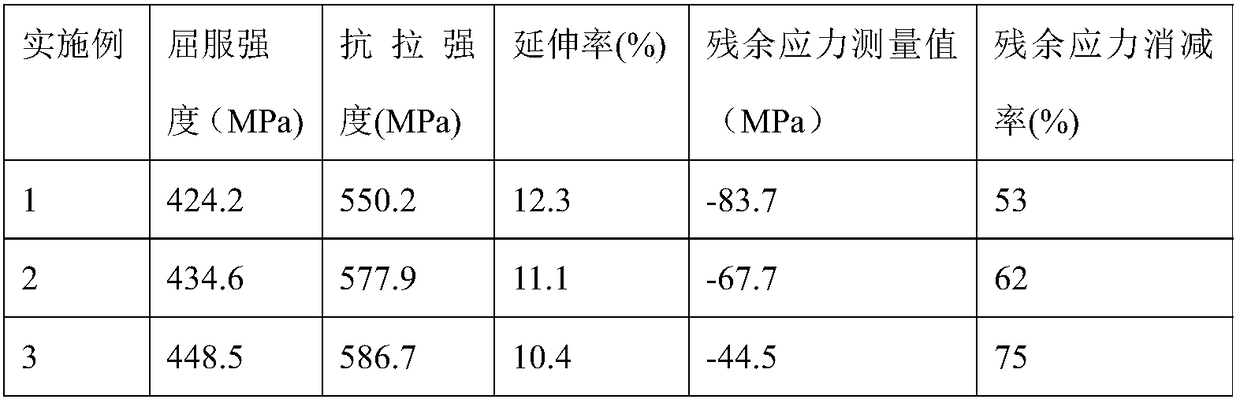

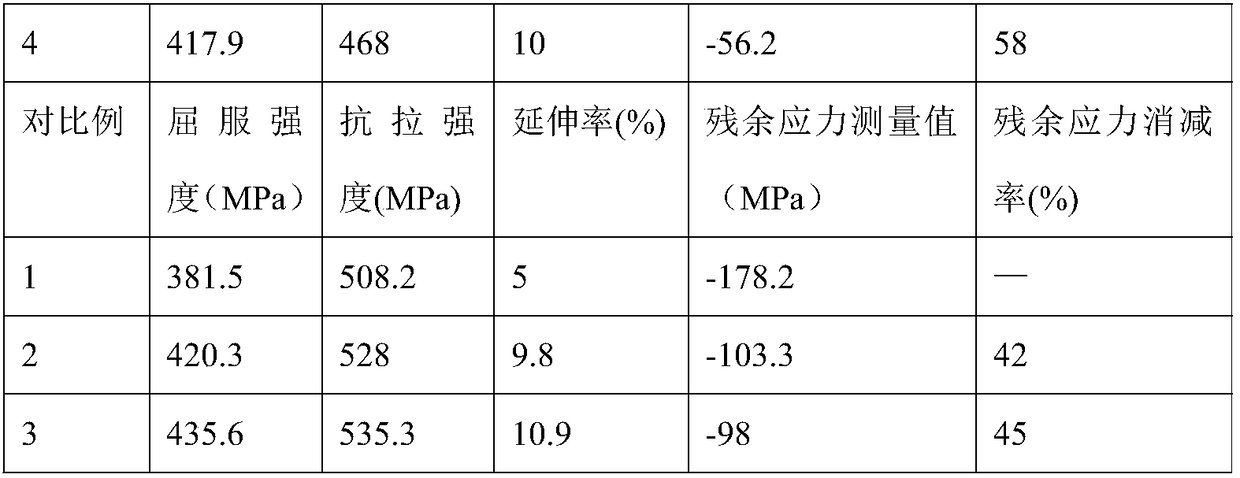

Heat treatment technology for preparing high-performance low-residual stress aluminum alloy

ActiveCN108531836AReduce residual stressHomogenization of dislocation distributionQuenchingSolution treatment

The invention relates to a heat treatment technology for preparing a high-performance low-residual stress aluminum alloy, and belongs to the technical field of aluminum alloy thermomechanical treatment. The method comprises the steps that 1, after an aluminum alloy sample is subjected to solution treatment and heat preservation, then is subjected to low-temperature quenching, and the transfer timedoes not exceed 10 seconds; 2, the sample obtained in the step 1 is subjected to cryogenic deformation to obtain a cryogenic deformation sample, the cryogenic deformation treatment temperature is lower than minus 120 DEG C, and the cryogenic deformation is equal or greater than 5%; 3, the cryogenic deformation sample obtained in the step 2 is put into a hot medium, the cryogenic deformation sample is vibrated by a vibration exciter, heat preservation and vibration maintaining are carried out, and the sample after the vibration reverse quenching treatment is obtained; and 4, the sample after the vibration reverse quenching treatment in the step 3 is subjected to aging treatment, and a finished product is obtained. The aluminum alloy prepared by the heat treatment technology has high comprehensive performance and low residual stress, and the stability of the material in service process is remarkably improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH +1

High-strength wear-resisting heat-resisting aluminium alloy material and preparation process thereof

ActiveCN102758109AImprove high temperature deformation resistanceImprove wear resistanceManganeseRare earth

The invention discloses a high-strength wear-resisting heat-resisting aluminium alloy material and a preparation process thereof. The material comprises, by weight, 4.0-6.5% of copper, 0.06-0.4% of titanium, 0.08-0.6% of manganese, 0.03-0.4% of antimony, 0.4-0.6% of nickel, 1.2-1.8% of cobalt, 0.2-0.3% of zirconium, 0.2-1.8% of rare earth and the balance aluminum. During preparation of the material, a special heat treatment process is used. The material has the advantages of being capable of improving the mechanical strength, the abrasive resistance and the high-temperature deformation resistance of an aluminium alloy simultaneously, the material can be used for cast members which are required to bear a certain high temperature and have high mechanical performance requirements, and a new field of application of the aluminium alloy material is developed.

Owner:贵阳华恒机械制造有限公司

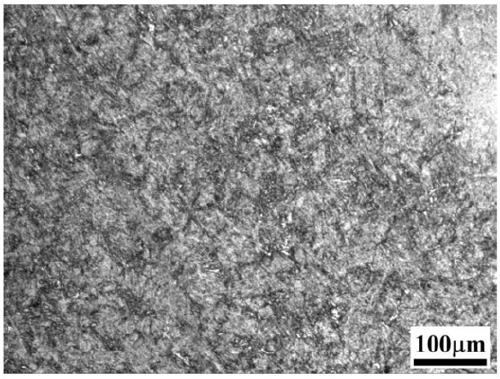

Mixed scale TiCN and TiB2 particle strengthened low alloy steel and preparation method thereof

InactiveCN109055860AGuaranteed StrengthImprove plastic toughnessUltimate tensile strengthMulti phase

The invention discloses a mixed scale TiCN and TiB2 particle strengthened low alloy steel. The mixed scale TiCN and TiB2 particle strengthened low alloy steel is prepared from, by mass, 0.38-0.50% ofC, 0.50-0.80% of Mn, 0.17-0.37% of Si, 0.035% or less of P, 0.035% or less of S, 0.8-1.1% of Cr, 0.25% or less of Ni, 0.25% or less of Cu, 0.018-0.28% of Al, 0.009-0.16% of TiCN and TiB2 and the balance Fe. The invention provides a preparation method of the mixed scale TiCN and TiB2 particle strengthened low alloy steel. Mixed scale TiCN and TiB2 particle intermediate alloy is added in low alloy steel melt, the percentage composition of components in the alloy steel is optimized, the mixed scale TiCN and TiB2 particle strengthened low alloy steel is obtained, and plasticity and toughness of the low alloy steel is improved on the premise that the strength of the low alloy steel is ensured by means of the synergistic effect of multi-phase mixed scale particles.

Owner:JILIN UNIV

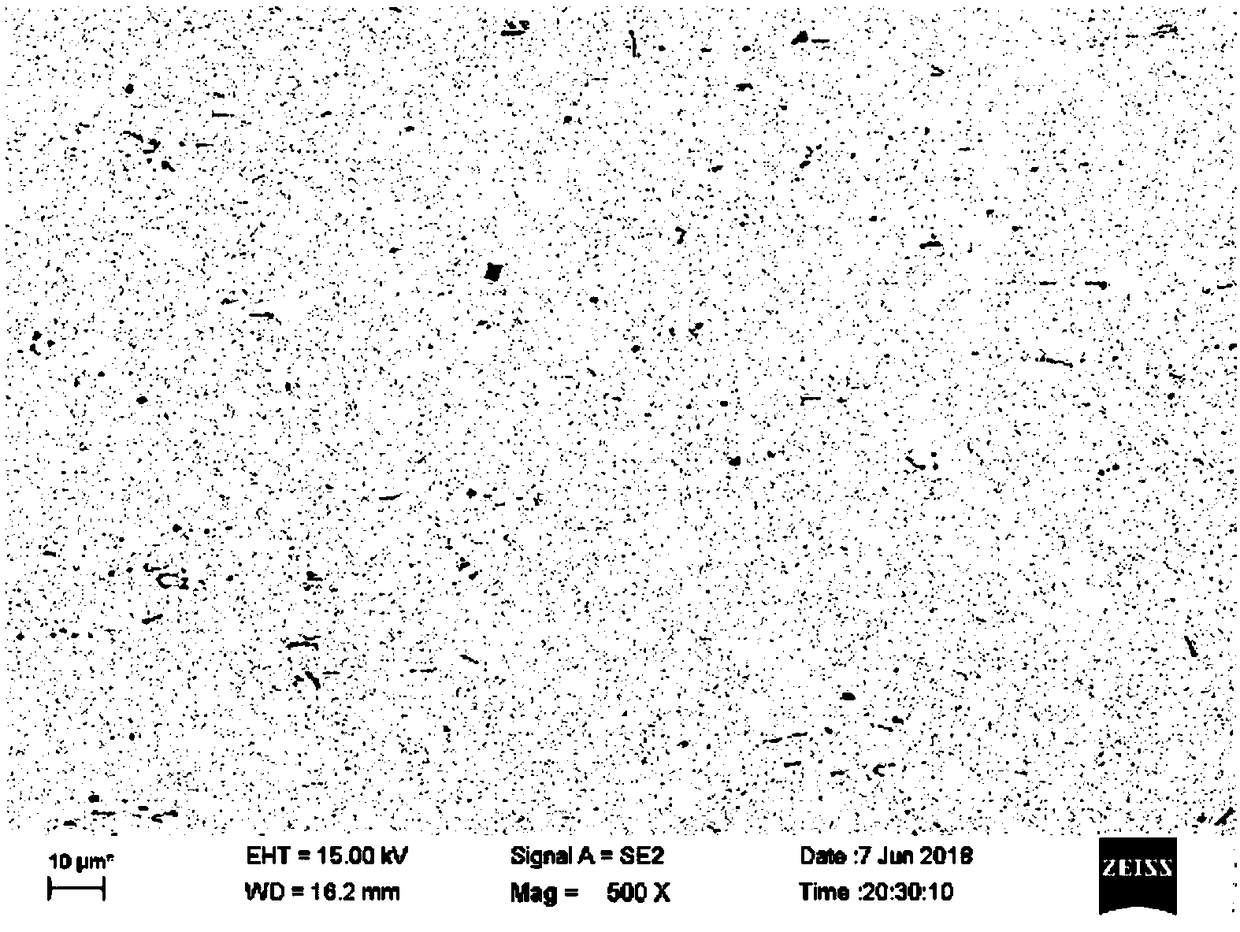

Martensitic wear-resistant steel plate with high wear resistance and manufacturing method thereof

ActiveCN109207853AImproved fine grain strengtheningFine grain strengtheningAustenite grainWear resistant

The invention discloses a martensite wear-resistant steel plate with high wear resistance, belonging to the technical field of steel manufacturing. According to a technical scheme in the invention, the martensite wear-resistant steel plate comprises the following chemical components by weight: 0.32 to 0.38 % of C, 0.02 to 0.30% of Si, 0.8 to 1.0% of Mn, 0.6 to 0.8% of Ti, 0.02 to 0.03% of Nb, 0.15-0.20% of Mo, 0.35-0.45% of Cr, 0.0010-0.0020% of B, no more than 0.003% of S and no more than 0.012% of P, with the balance being Fe and unavoidable impurity elements. In the process of hot continuous rolling in the invention, TiC particles precipitated through continuous casting are gradually fragmented and homogenized along a rolling direction; through rolling fragmentation and solid-state precipitation of nano-sized TiC, most of the micron-sized TiC particles precipitated through continuous casting disappear; and nano-sized TiC can refine original austenite grains and improve ductility andtoughness.

Owner:NORTHEASTERN UNIV +2

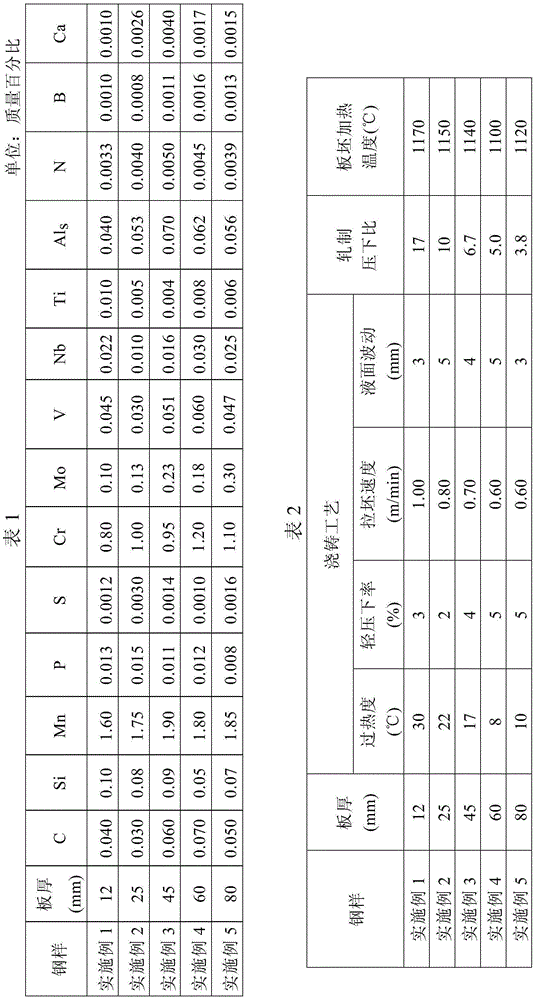

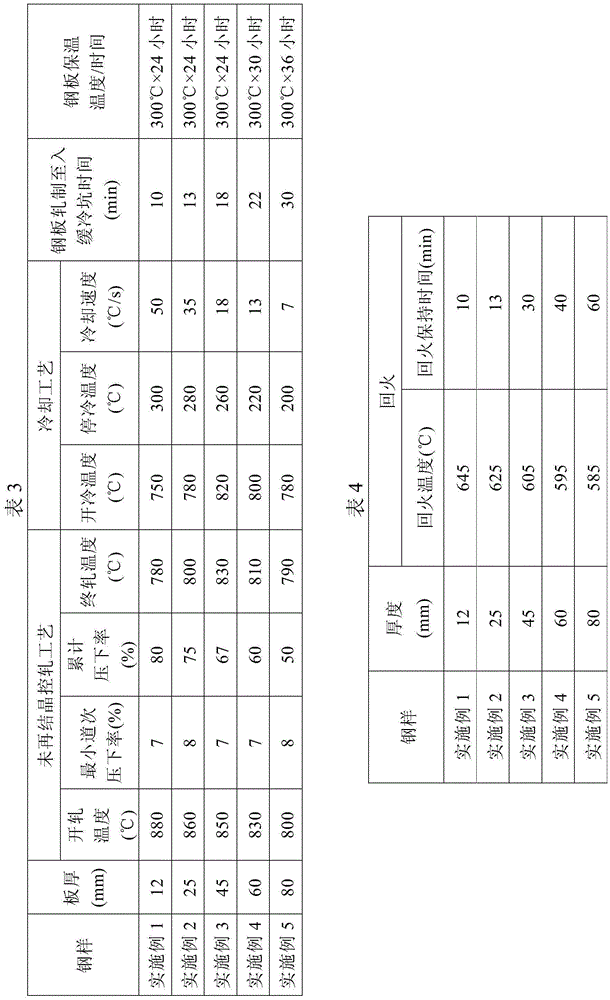

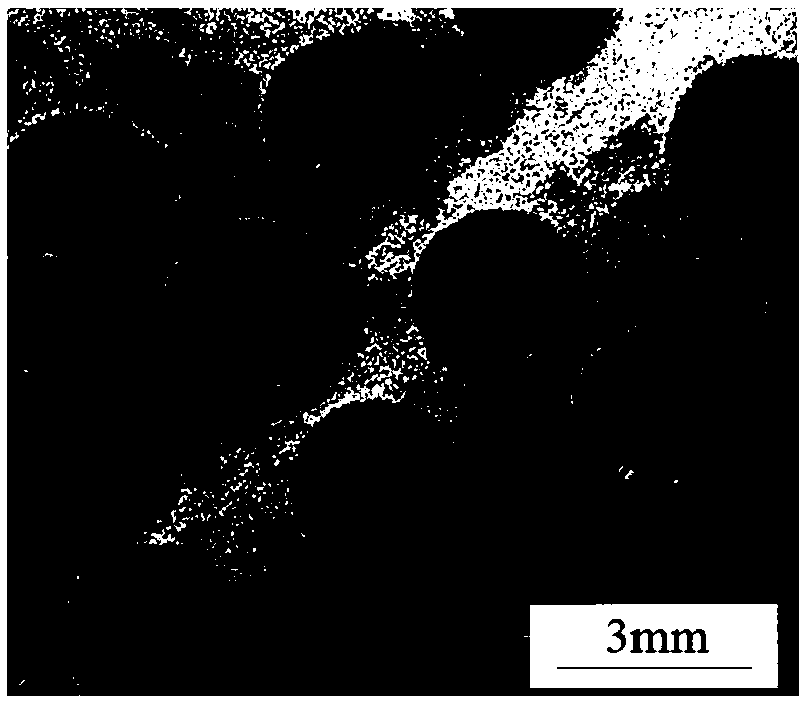

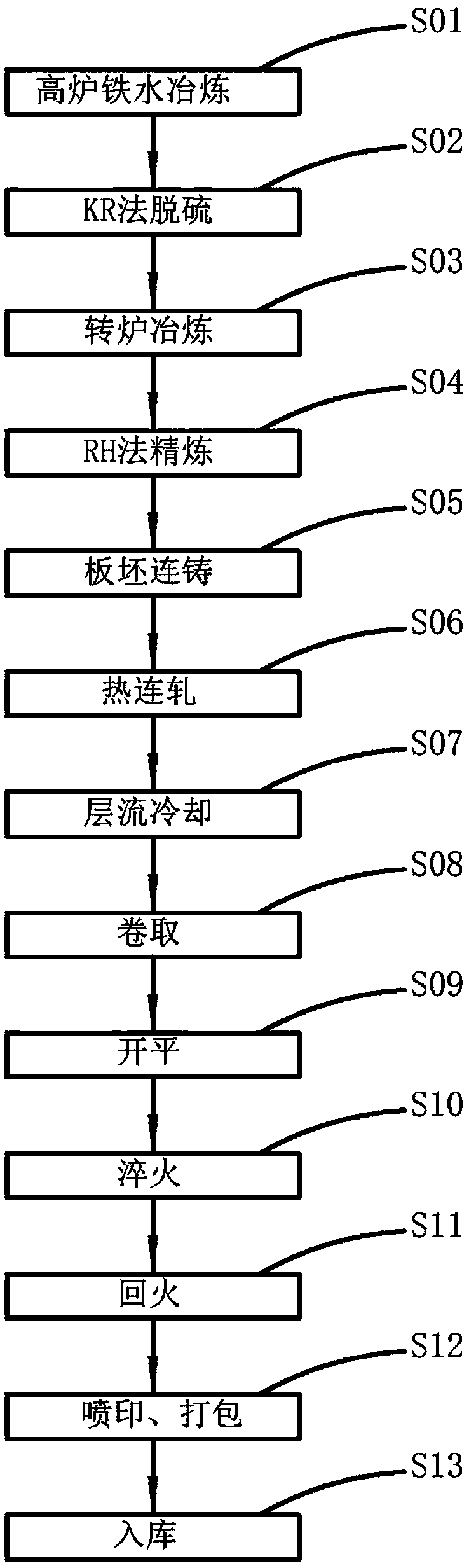

Fire-resistant weather-proof steel plate for 690MPa-grade building structure and manufacturing method thereof

The invention relates to the technical field of fire-resistant weather-proof steel plates for building structures, in particular to a fire-resistant weather-proof steel plate for 690MPa-grade buildingstructure and a manufacturing method thereof. The steel plate consists of the following chemical components in percentage by weight: 0.05%-0.10% of C, 0.10%-0.40% of Si, 1.20%-1.80% of Mn, less thanor equal to 0.010% of P, less than or equal to 0.003% of S, 0.7%-1.1% of Ni, 0.65%-1.10% of Cu, 0.20%-0.60% of Mo, 0.07%-0.12% of Nb, 0.05%-0.075% of V, 0.02%-0.035% of Ti, less than or equal to 0.0025% of B, 0.01%-0.04% of Al, and the balance of iron and inevitable impurities. The fire-resistant weather-proof steel plate adopts a two-phase region once thermal treatment process to obtain a reversetransformed austenite structure which is proper in proportion and stable, so that a multi-phase structure which consists of tempered-state martensite, a nano precipitated phase and retained austeniteis finally obtained. A smelting and continuous-casting process scheme realizes low-phosphor low-carbon control. The product has high strength and toughness, high plasticity, a low yield ratio, and excellent fire resistance, weather resistance and lamellar tearing resistance.

Owner:ANGANG STEEL CO LTD

Hot treatment process for remarkably improving comprehensive performance of aluminum alloy

ActiveCN103882354AMeet the requirements of large structural partsPractical application value of large industryAtomic clusterGrain structure

The invention relates to a hot treatment process for remarkably improving the comprehensive performance of aluminum alloy. According the hot treatment process, aluminum-copper-magnesium alloy in a solid solution state undergoes pre-aging treatment, asymmetric rolling deformation and secondary aging treatment; one part of atoms are segregated through pre-aging to form nanometer scale atomic clusters which block dislocation movement during subsequent deformation to form meshy dislocation cells or sub-boundary to refine grains; the other part of undecomposed solute atoms obtain vacancy / atomic cluster complex, G.P. zone, microtexture and special shearing texture under the strain action of subsequent deformation high shear stress; one part of fine grains grow with the aid of grain boundary migration due to the interaction of the compound textures during secondary aging to form a dual grain structure, so that the strength-plasticity coordination of the alloy is improved, and the toughness of the alloy is improved. The hot treatment process is simple, safely operated and conveniently, easily industrialized, and is a novel hot treatment technology with great application prospect; the comprehensive performance of the alloy is effectively improved through improving the microtexture of alloy according to the hot treatment process.

Owner:CENT SOUTH UNIV +1

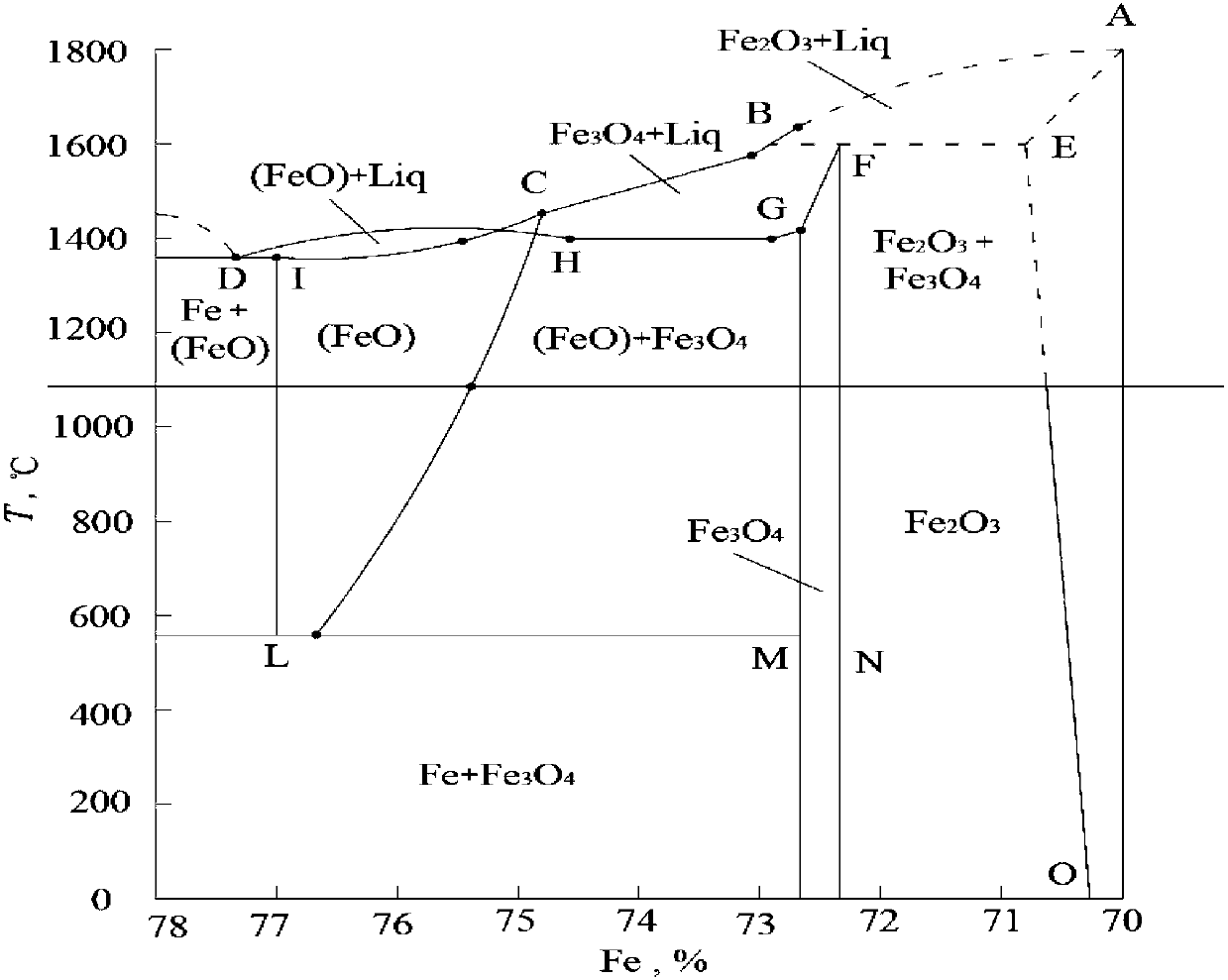

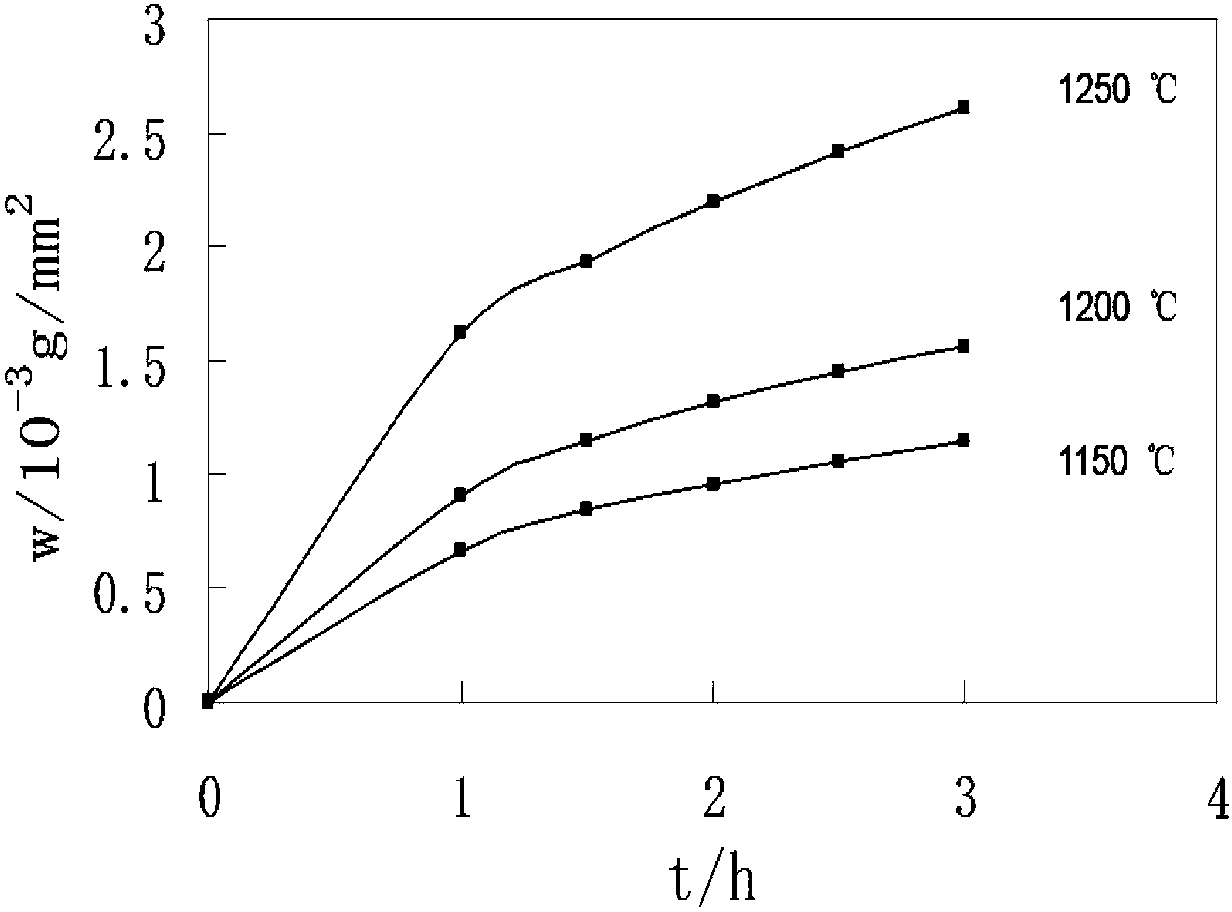

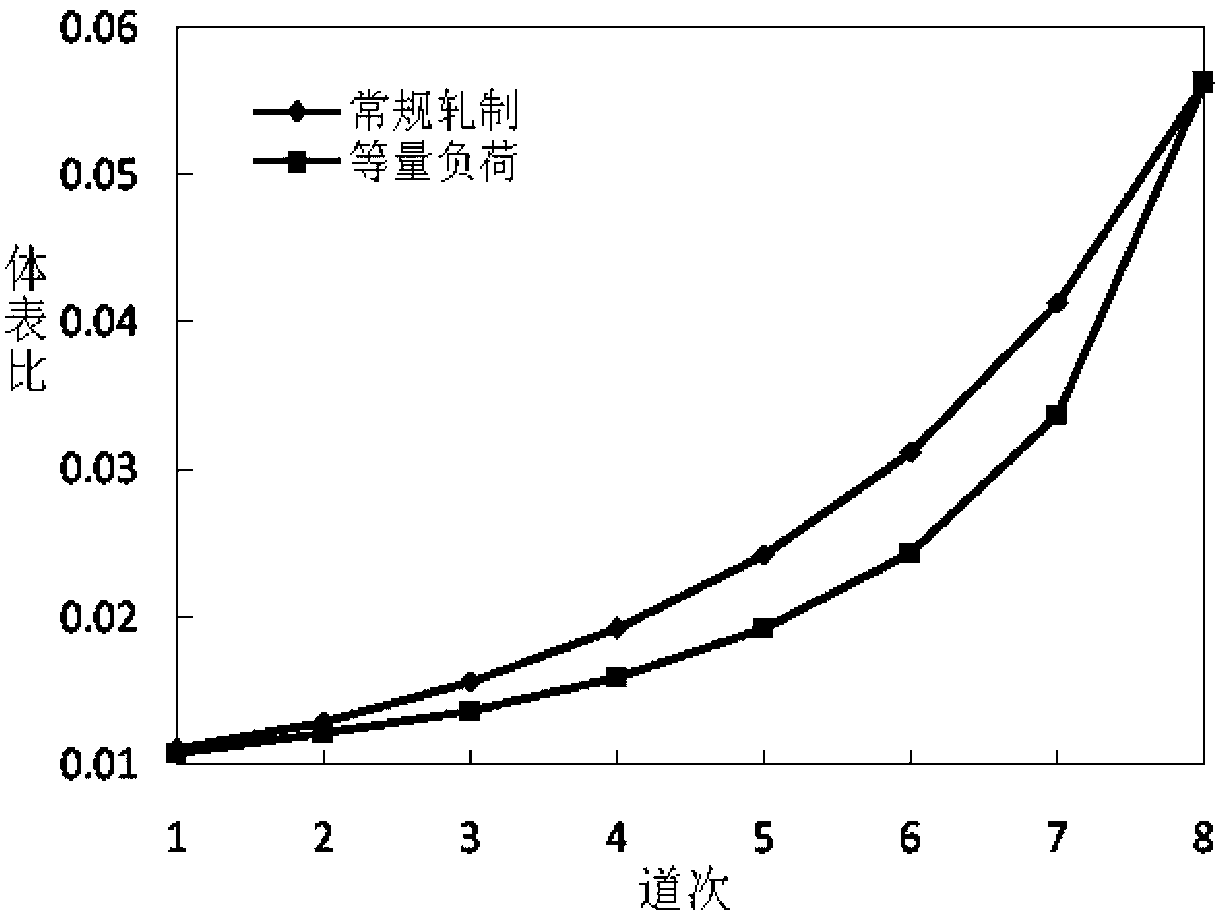

Method for reducing thickness of oxide scale on surface of hot-rolled steel sheet

InactiveCN103341498ALess weight gainReduce thicknessTemperature control deviceMetal rolling arrangementsAustenite grainSheet steel

The invention discloses a method for reducing the thickness of oxide scale on the surface of a hot-rolled steel sheet. The method for reducing the thickness of the oxide scale on the surface of the hot-rolled steel sheet comprises the steps of dephosphorization before rough rolling of a continuous casting billet, and control over rough rolling, wherein the total deformation of the rough rolling is 70%-85%, and the rolling reduction of passes of the rough rolling is controlled to be equal. The process of rough rolling is controlled, the pass load is distributed again, the rolling reduction of the passes can be equal, and the body surface of a slab is gradually increased along with reduction of the temperature. The body surface ratio of the slab in each pass is smaller than that of a slab in a corresponding pass in a rolling method that the rolling reduction decreases pass by pass under the premise that the total deformation of the rough rolling is the same, thus, the purpose of reducing the thickness of the oxide scale and the purpose of pressing the oxide scale are achieved, the surface quality of the hot-rolled steel sheet is improved, the acid amount and the time for acid pickling in the follow-up working procedure are reduced, and production efficiency and metal yield are improved. When the method for reducing the thickness of the oxide scale on the surface of the hot-rolled steel sheet is adopted, the size of a recrystallized austenite grain can be reduced, and the method for reducing the thickness of the oxide scale on the surface of the hot-rolled steel sheet is beneficial to obtaining even microstructures, and improves strength, ductility and toughness of the hot-rolled steel sheet.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com