Patents

Literature

72 results about "High shear stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

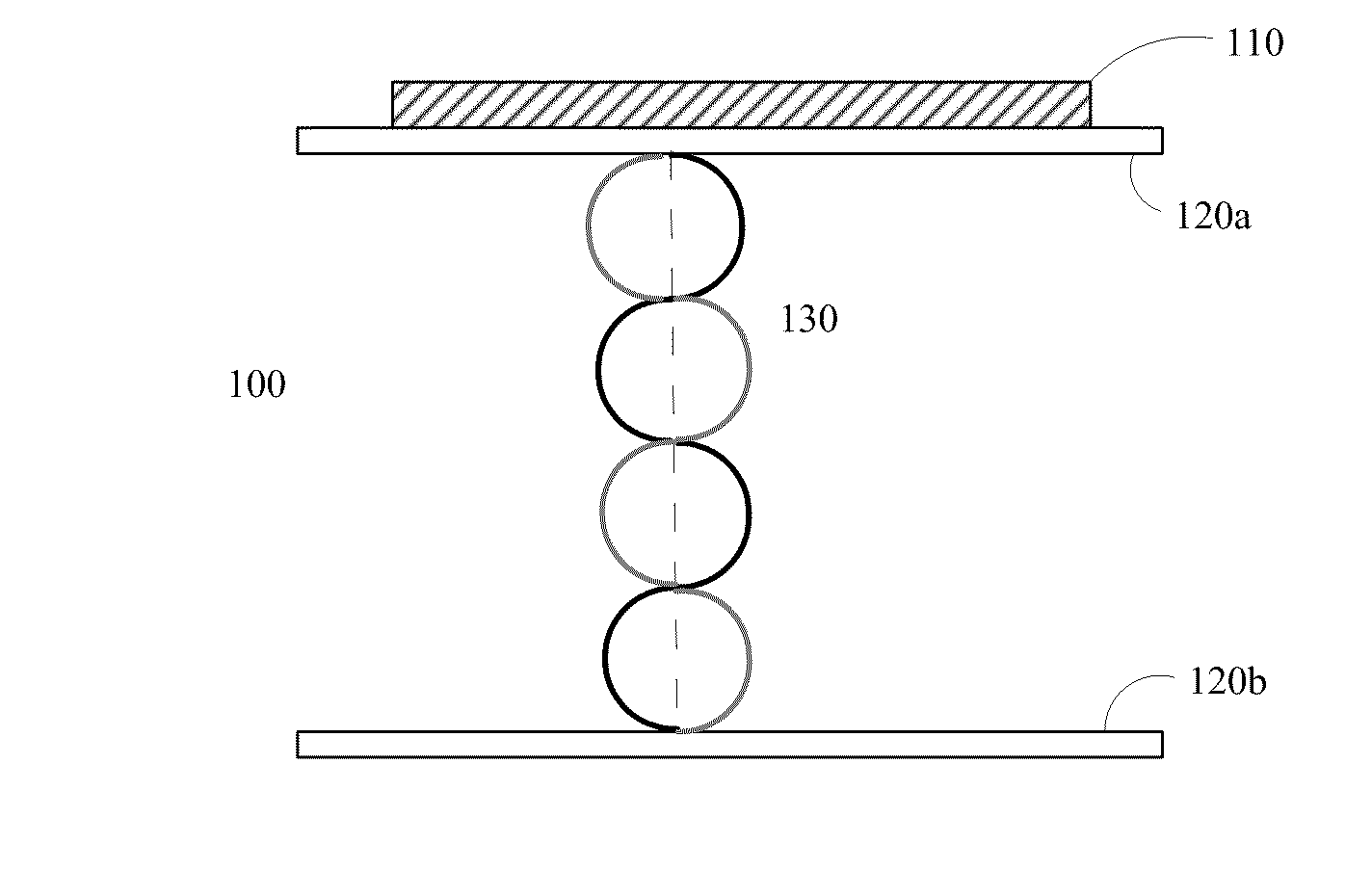

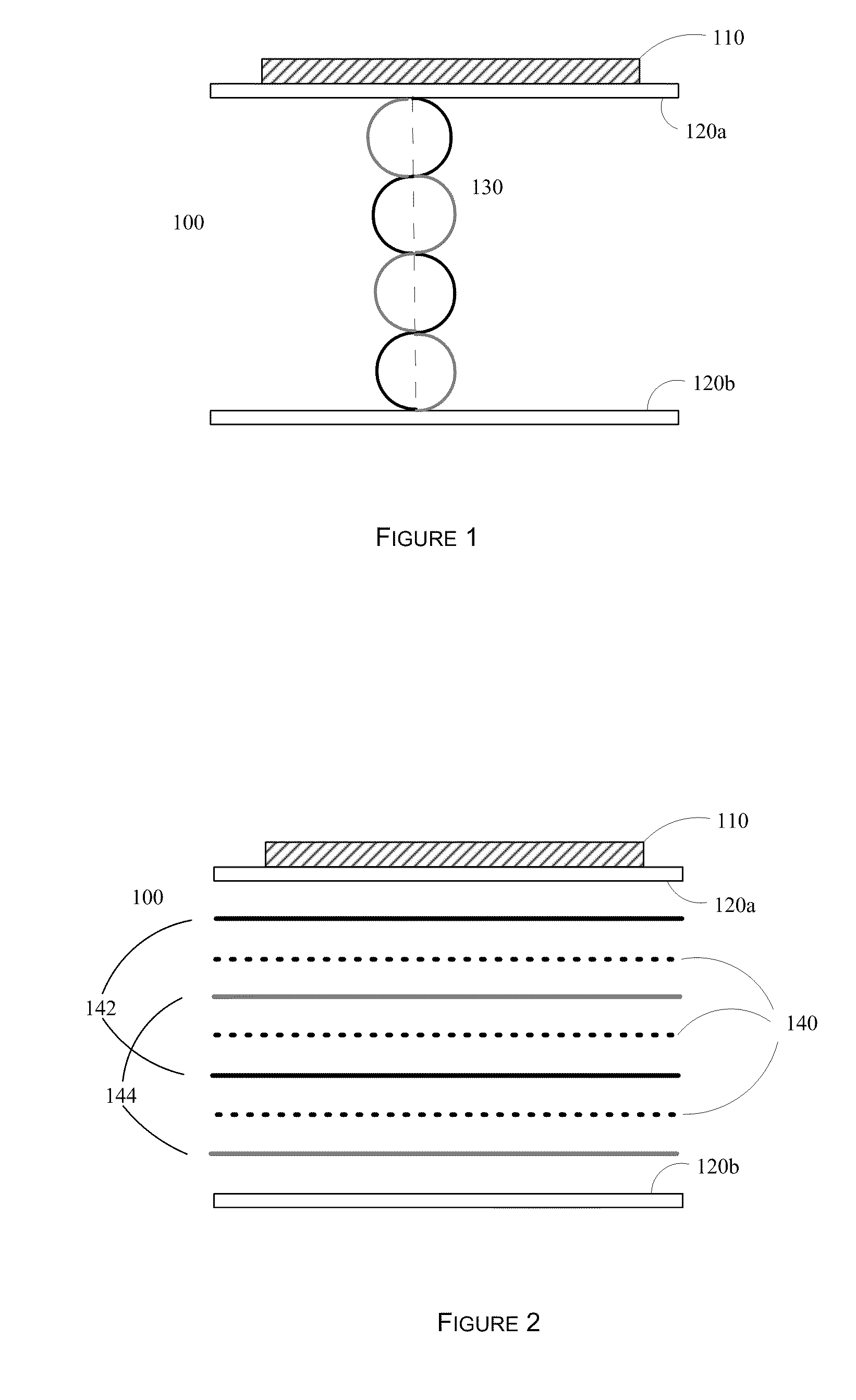

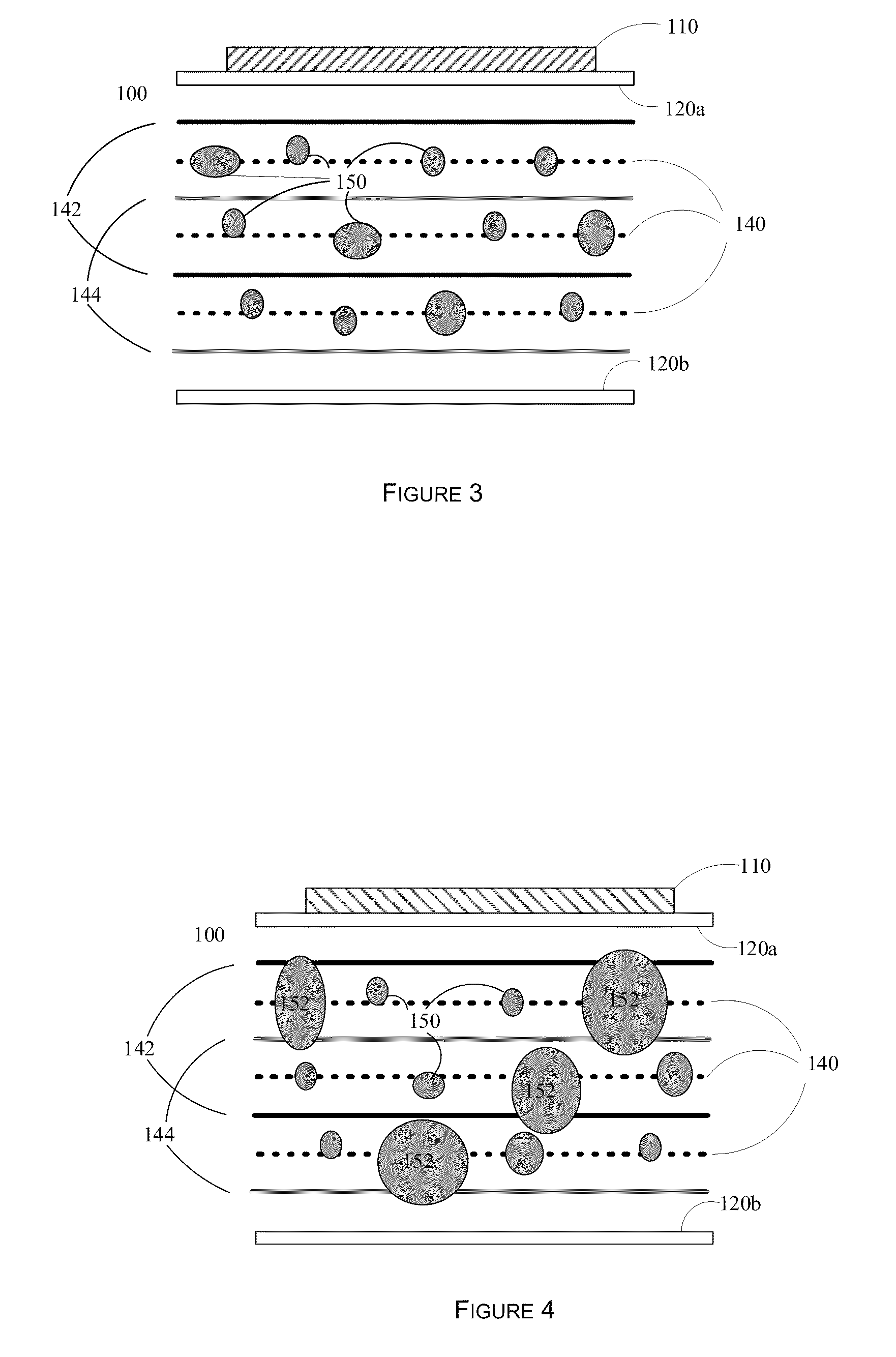

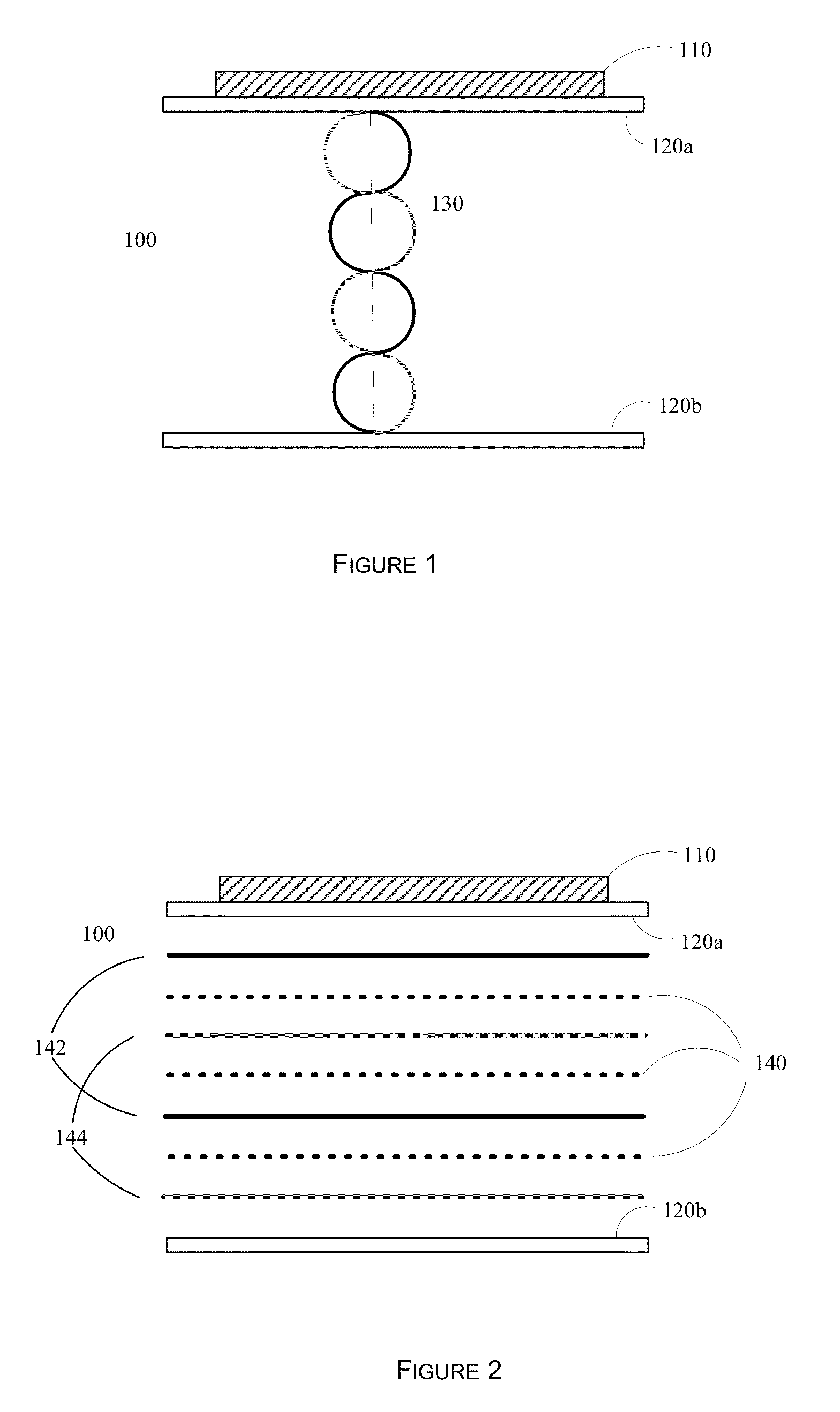

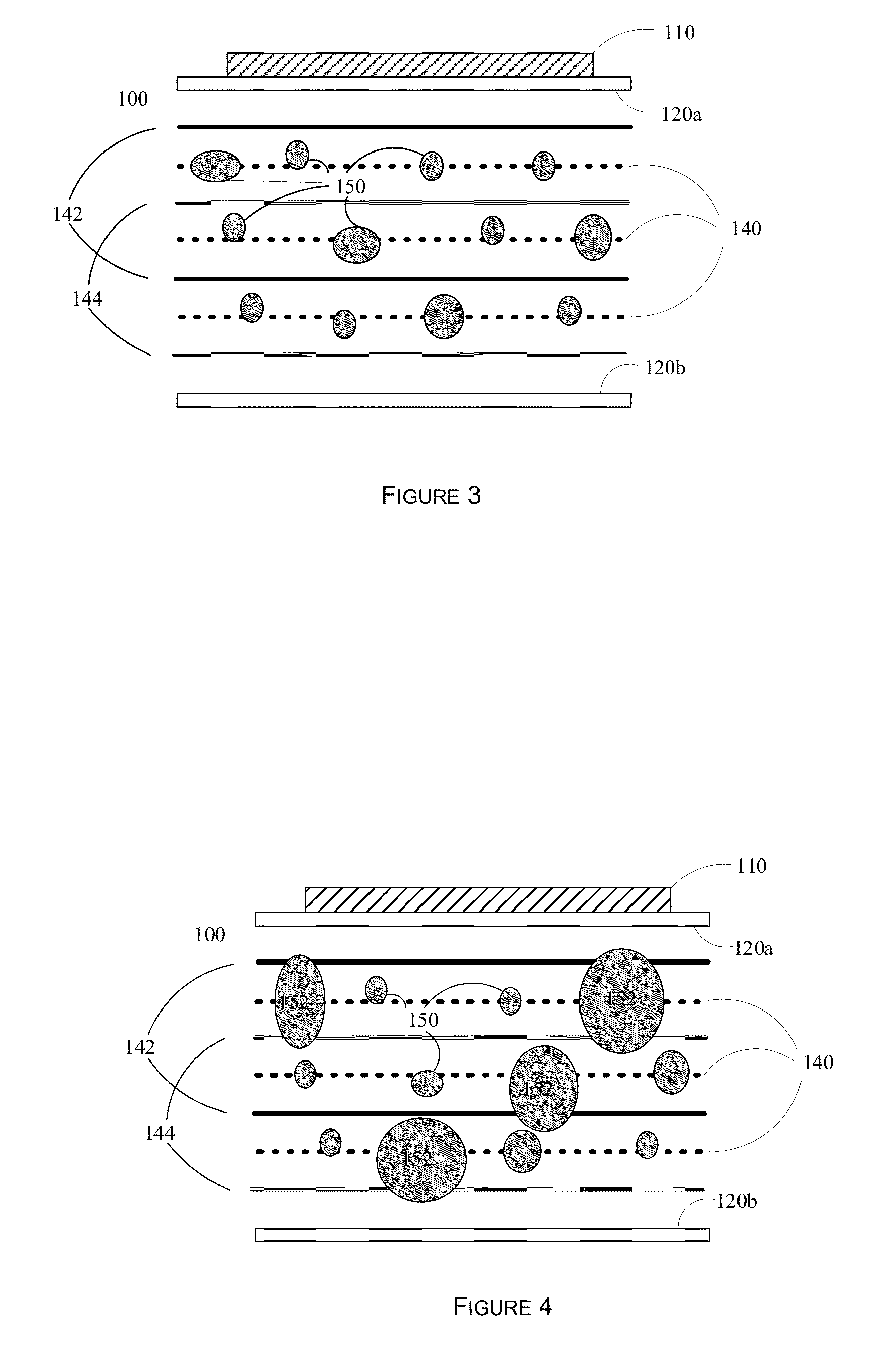

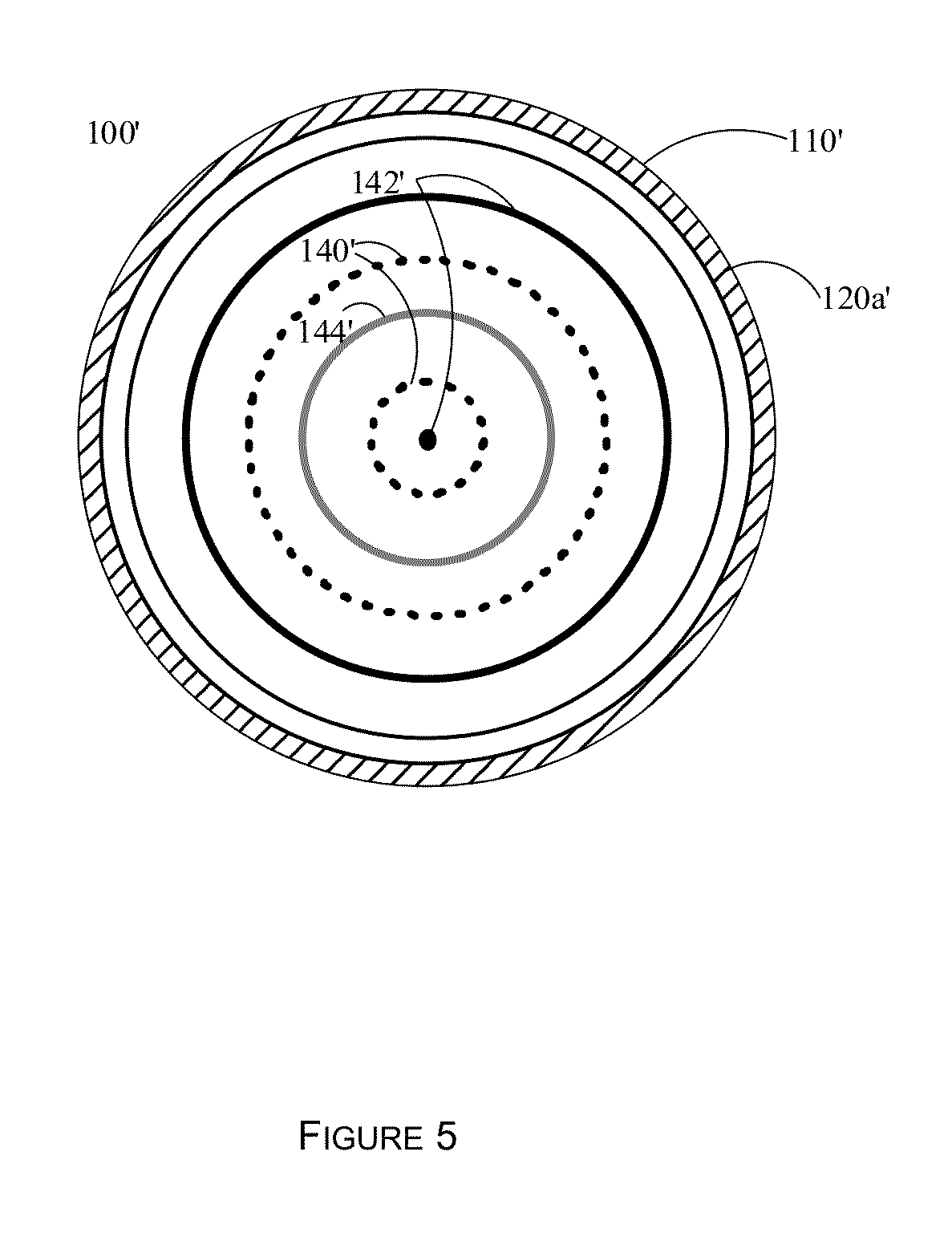

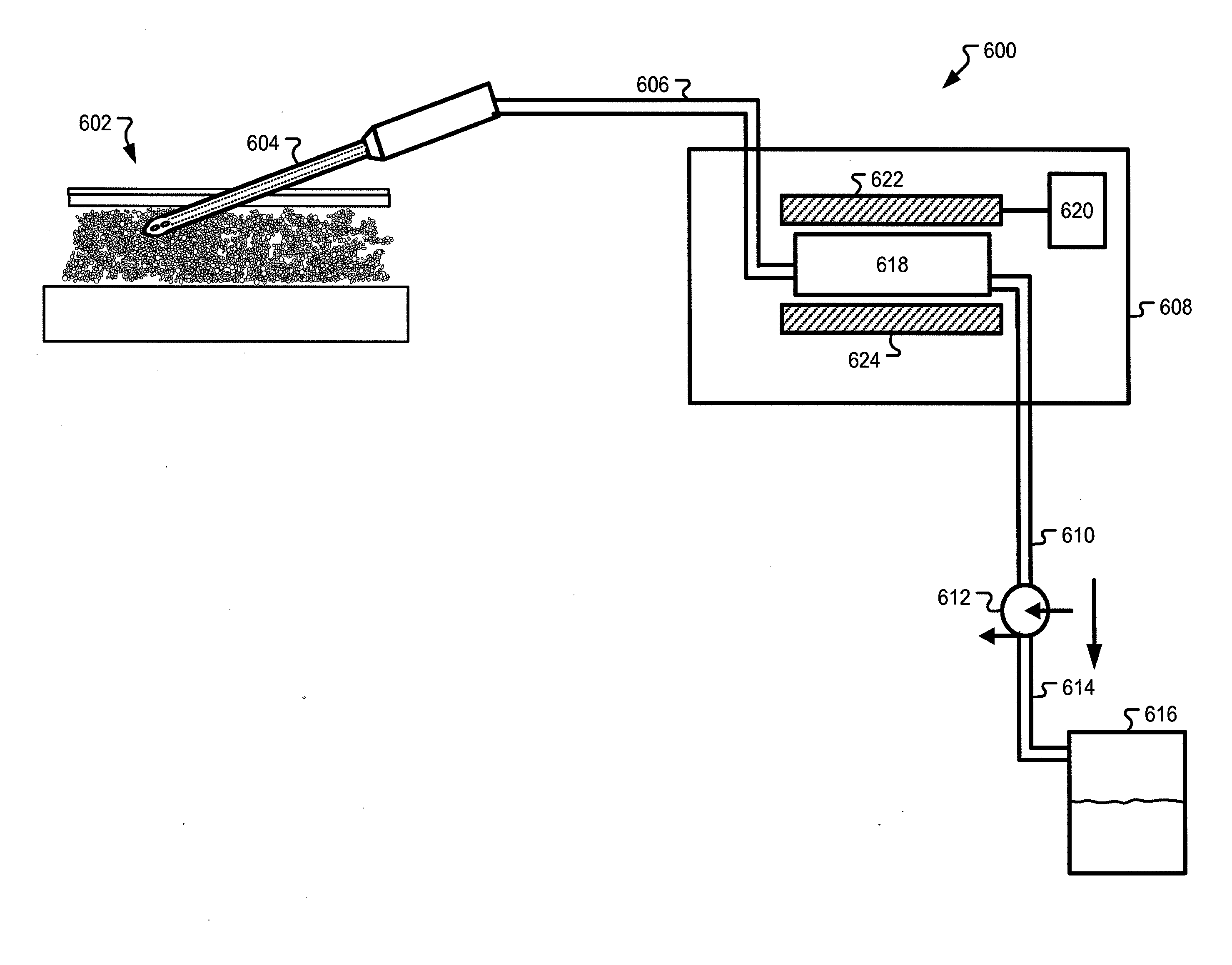

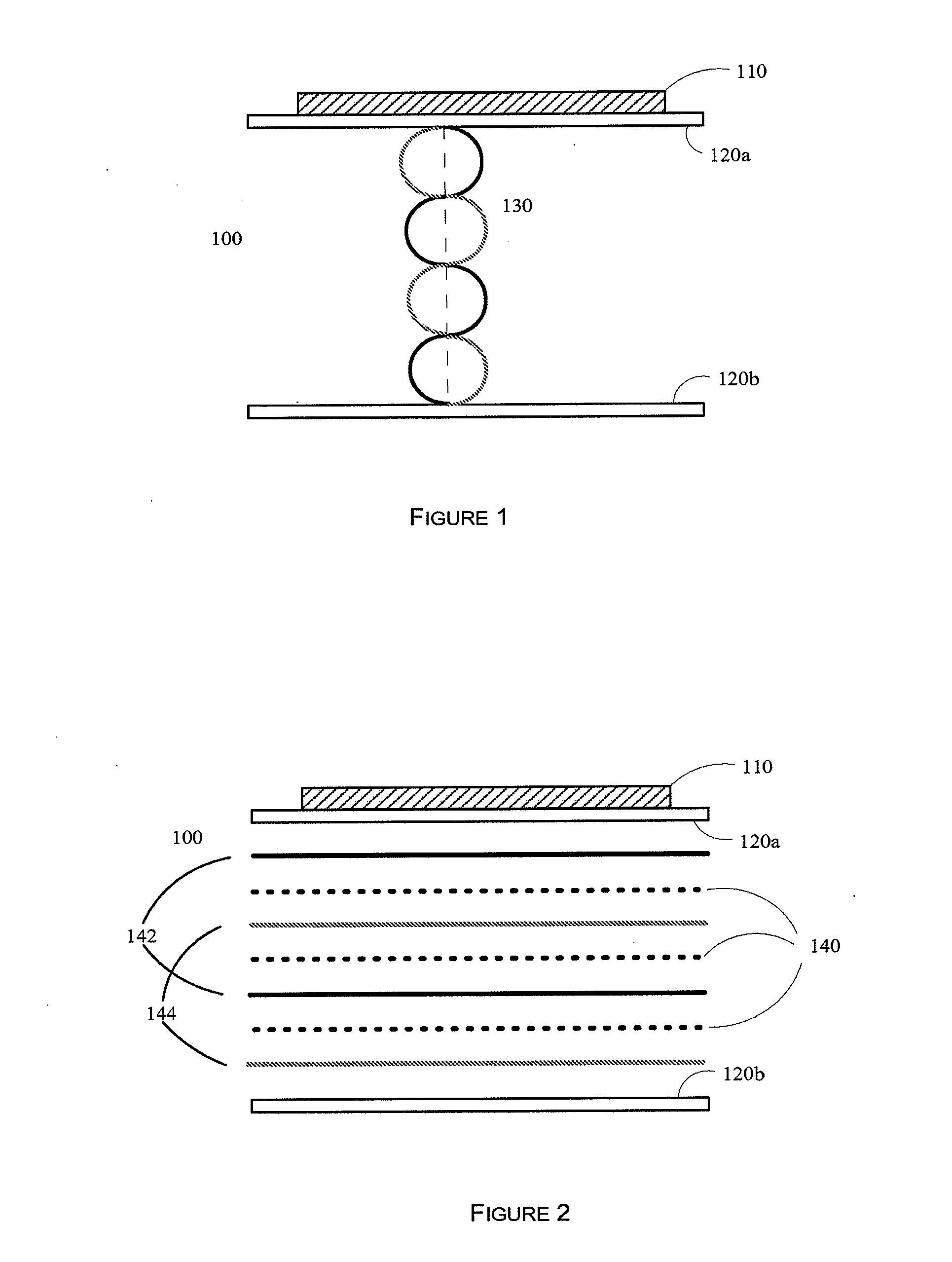

Selective lysing of cells using ultrasound

ActiveUS20110166551A1Easily maintaining sterilityReduce riskBioreactor/fermenter combinationsBiological substance pretreatmentsCell membraneUltimate tensile strength

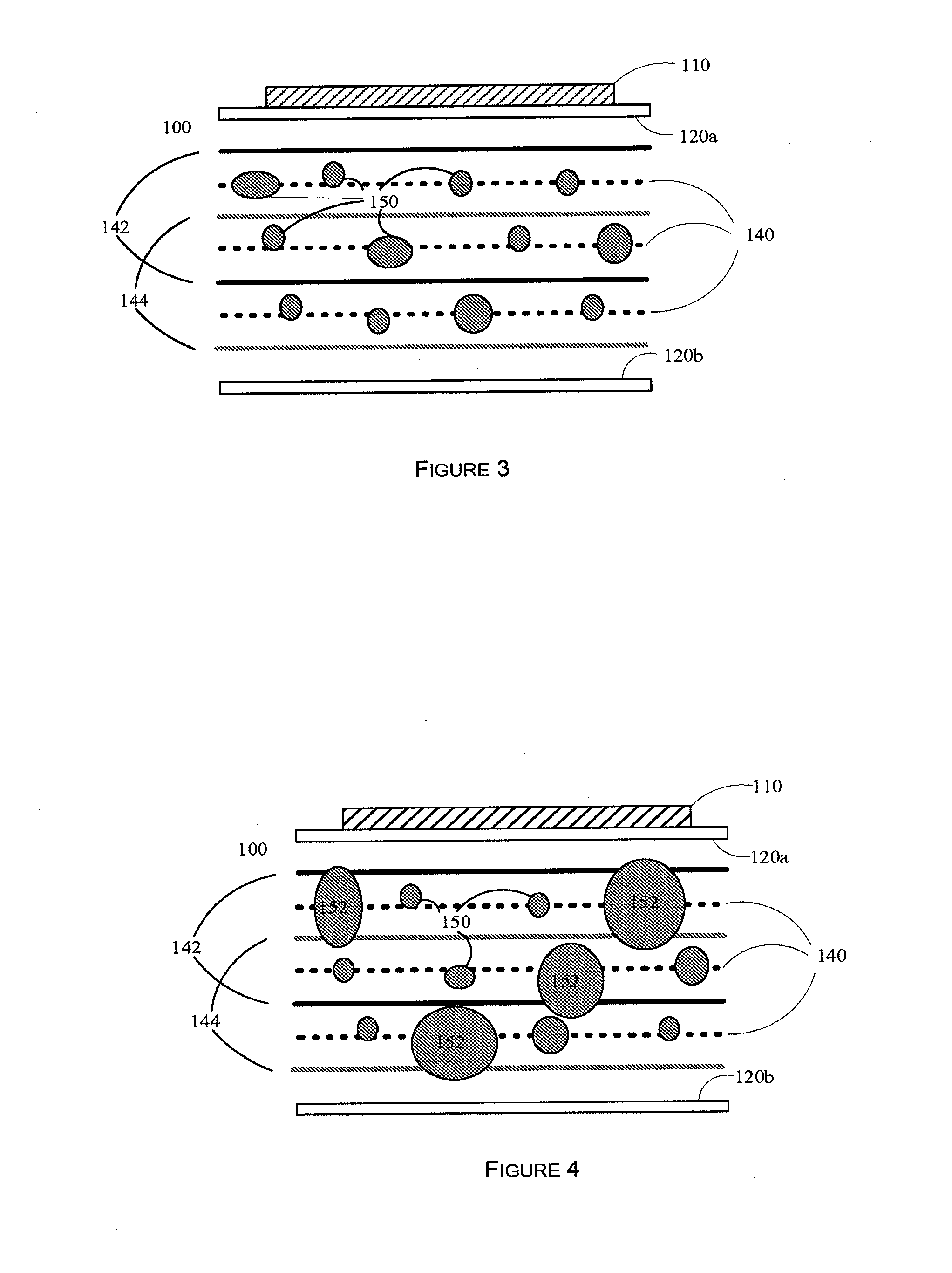

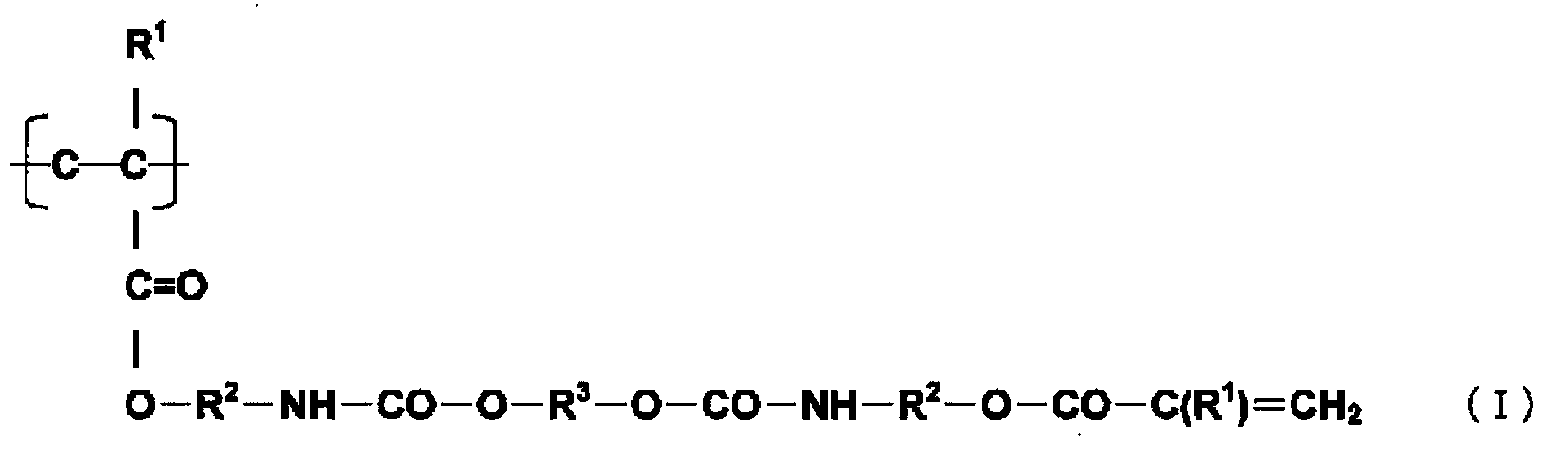

Described are embodiments that employ ultrasonic energy to selectively lyse larger adipose cells in a suspension containing adipose cells of different sizes resulting in a suspension in which the only viable cells are the small adipose cells and stem cells. Embodiments provide for generating an acoustic standing wave field of sufficient intensity and proper geometry, that high shear stress is induced on the cell membranes of cells larger than a predetermined size. The remaining small adipose cells can be physically separated from the suspension after the suspension is subjected to the acoustic standing wave field.

Owner:SOLTA MEDICAL

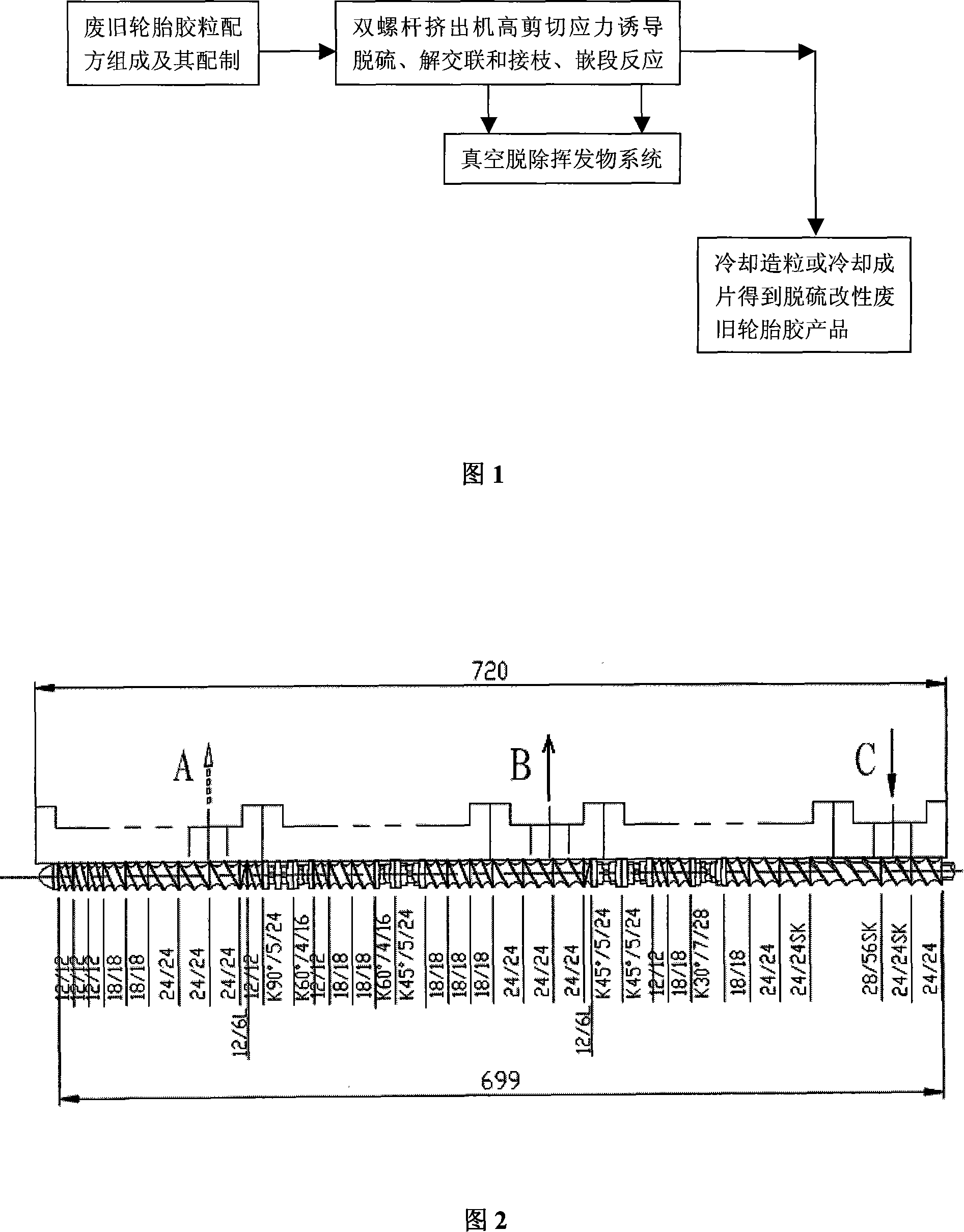

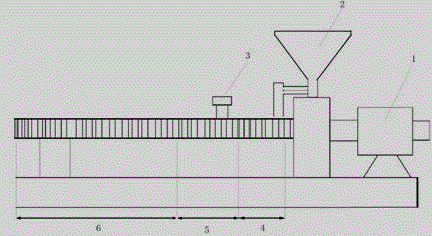

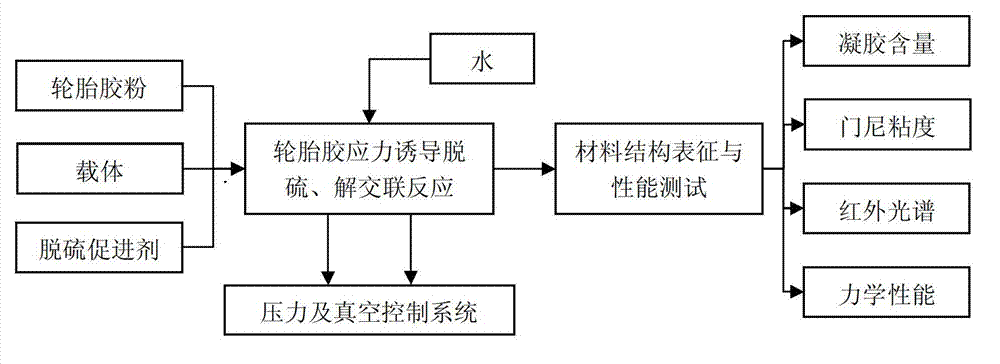

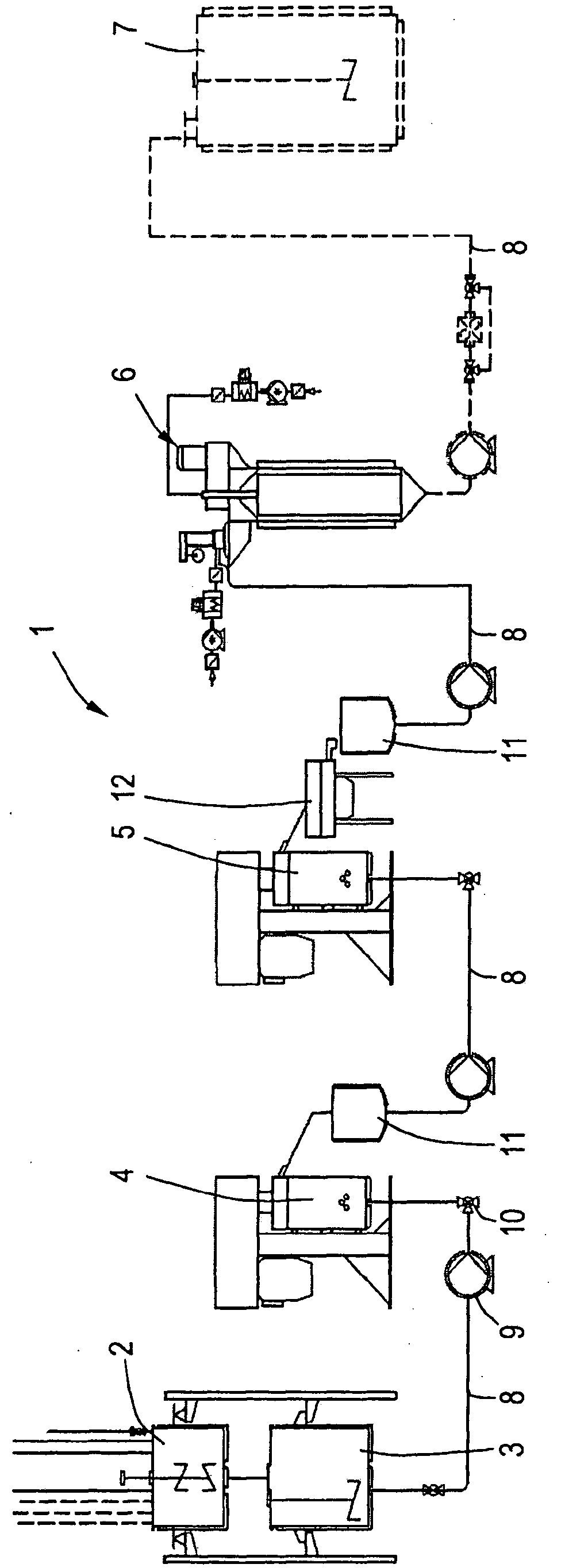

High shear stress induced desulfurization and modification method for waste and old tyre rubber

InactiveCN101168600AReduce pollutionImprove mechanical propertiesPlastic recyclingStress inducedEnergy expenditure

The invention relates to high shearing stress induced desulfurization of recycled tyre rubber, and a modified method. Linear high-molecular substances accounting for 5 to 50 percent of the percentage content of the reagent total weight, recycled tyre rubber powder accounting for 49 to 94 percent of the percentage content of the reagent total weight, and stabilization accessory ingredient accounting for 0.01 to 1.8 percent of the percentage content of the reagent total weight are mixed; the mixture is added into a high rotation speed and high shearing type co-rotating twin-screw extruder all together to be molten and extruded to operate the desulfurization reaction; through water cooling, pelleting, and drying or through roll calendering cooling and sheeting out, desulfurization modified regenerated rubber resultant is obtained. The invention integrates the desulfurization reaction, as well as the smelting process, the refining process, and the rubber filtering process into a whole, the efficiency of the desulfurization process is high, the production rate is high, the energy consumption is low, and the macro scale and the large scale are easy; the desulfurization reaction is easy to be controlled; the pollution of the reaction process to environment is small, and the mechanical property of the resulfurized material of the desulfurization resultant is good.

Owner:NANJING TECH UNIV +1

Magneto-rheological fluid with good settling agglomeration resistance

InactiveCN103215113AGood resistance to sedimentation and agglomerationImprove stabilityLubricant compositionWater basedAntioxidant

The invention relates to magneto-rheological fluid with good settling agglomeration resistance. The magneto-rheological fluid comprises the following ingredients in parts by weight according to 100 volume parts: 125-225 parts of ferromagnetic particles, 30-85 parts of carrier fluid, 0.2-5 parts of xanthan gum, and 0-12.5 parts of additives, wherein the additives are a thixotropic agent, a dispersing agent, an antioxidant and a lubricant when the carrier fluid is water-based; and when the carrier fluid is oil-based, the additives are a thixotropic agent, a dispersing agent, and a lubricant. The magneto-rheological fluid is good in stability within a larger temperature range (minus 18 DEG C-130 DEG C), difficult to settle, and also keeps the original performances, namely high shearing stress and good friction property.

Owner:CHONGQING MATERIALS RES INST

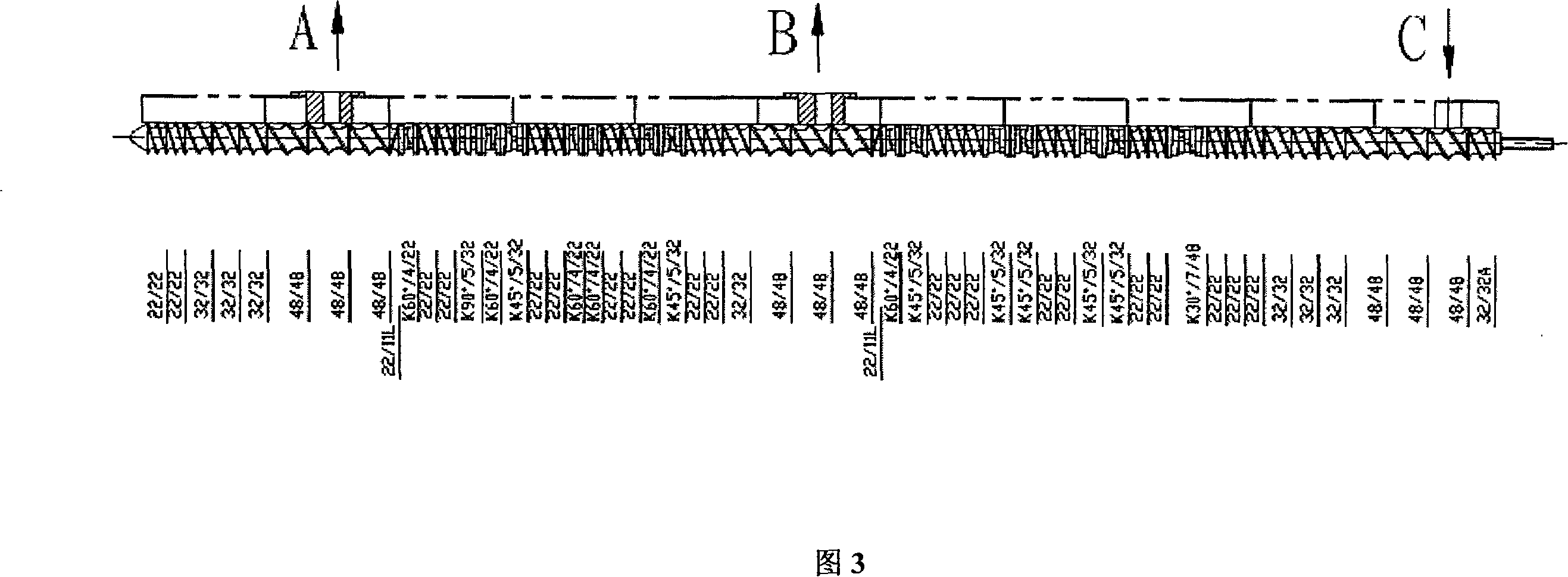

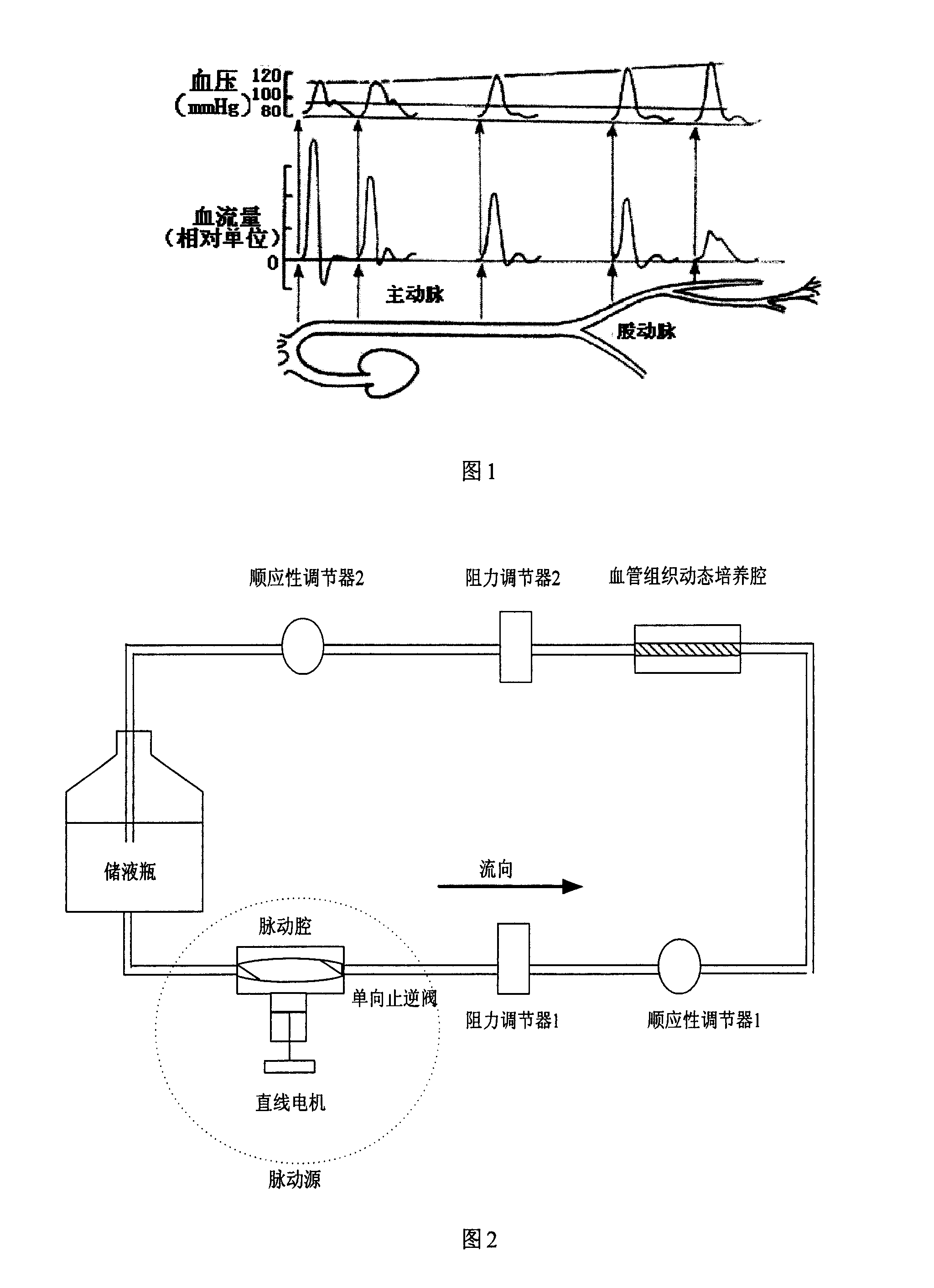

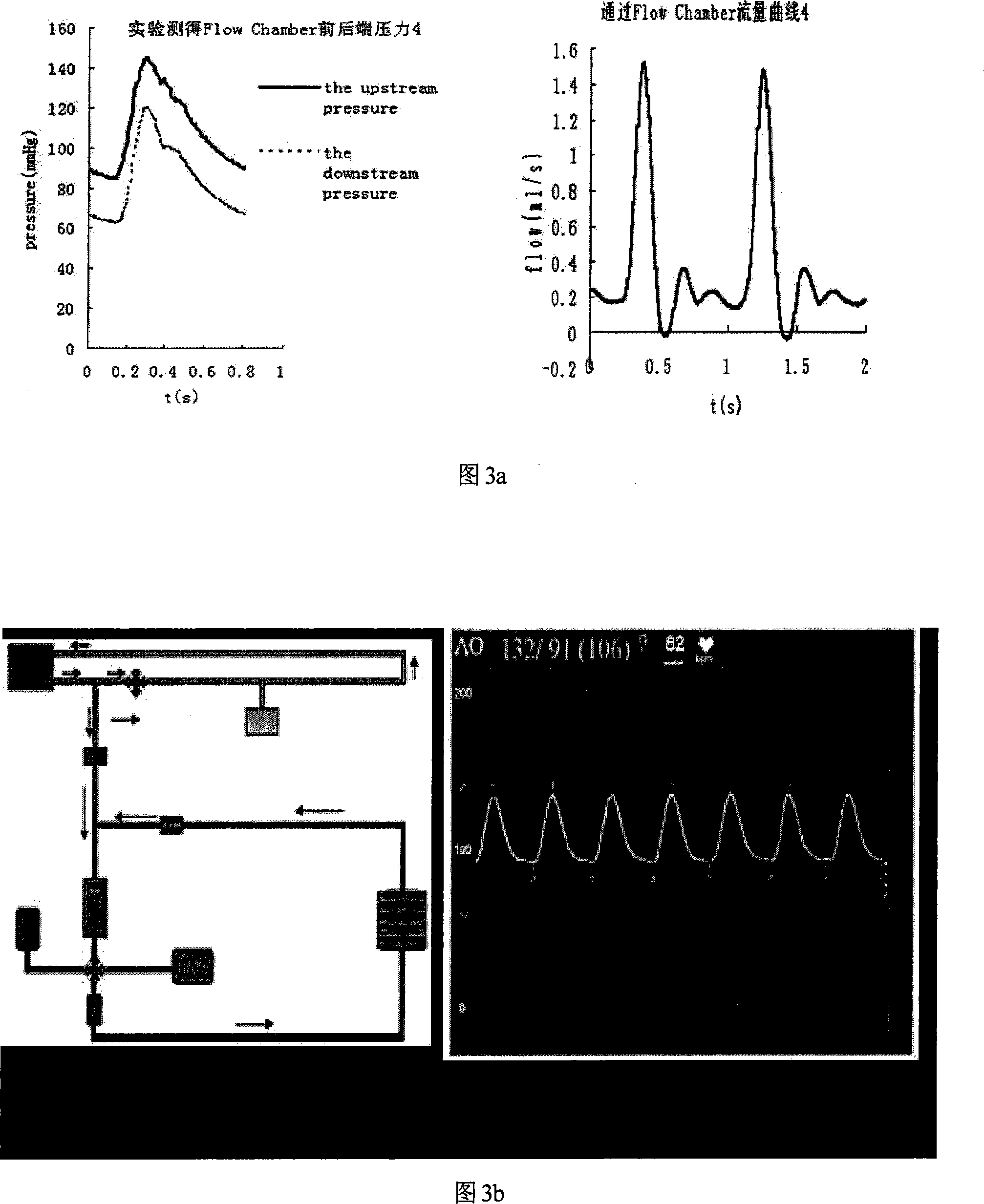

Arterial vessel tissue engineering reactor simulating physiological pulsating flow surrounding

ActiveCN101245314AEasy to replaceGood blood pressureTissue/virus culture apparatusStress based microorganism growth stimulationBlood Vessel TissueBottle

The invention discloses a quasi-physiological pulsatile flow environment arterial blood vessel tissue engineering reactor; the reactor includes a liquid storage bottle, a pulsation source, a resistance regulator, a compliance regulator and a blood vessel tissue dynamic culture cavity and is controlled by an industrial control computer; the reactor overcomes the shortcomings that the commonly used arterial blood vessel tissue engineering reactor in the tissue engineering filed can not simulate the blood flow compliance of the arterial blood vessel, flow inertia, flow resistance and other resistance characteristics and can not provide the quasi blood pulsatile flow environment in the artery; the reactor has the following functions that: a. the reactor is used for culturing the tissue engineering arterial blood vessel; b. the reactor is used for simulating the pulsating frequency, pulse waveform, secondary wave, amplitude and time phase of the pulsatile flow of the different arterial blood vessel under the physiological state, simulating the hemodynamics environment of high vessel inner pressure and high shear stress of the arterial blood vessel under the hypertension and other pathological states and simulating the hemodynamics status of the arterial blood vessel during the low shear stress.

Owner:BEIHANG UNIV +1

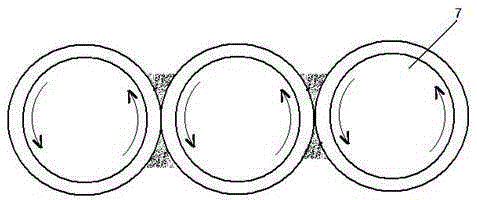

Method for continuously preparing graphene material in cut mode through screw machine

The invention provides a method for continuously preparing a graphene material in a cut mode through a screw machine. The method includes the steps that a graphite premixture is evenly dispersed in the screw rotating direction through the continuous-rotating same-direction engaging screw machine to form slice-shaped orientation, and cutting and stripping are carried out through the orientation direction of engaged screw elements, wherein stripping is carried out through a same-direction-engaging double-screw machine or a same-direction-engaging three-screw machine or a same-direction-engaging four-screw machine or a same-direction-engaging screw machine with more screws, high shearing stress is generated on interfaces between screws and the engaged screw elements in the same-direction rotating process of the screws, and therefore the large size area graphene is formed. The graphene is prepared in a stripped mode through the screw machine, the surge pressure on graphite layers is small, and cutting and striping are carried out in the direction parallel to the graphite layer faces. Further, continuous carbonizing, reduction, cutting and stripping of carbon raw materials can be achieved in the continuous screw machine, the layer face structure of the graphene is reserved to the maximum degree, the graphene can be continuously and stably prepared, the large-scale mass production of the graphene is further promoted, and remarkable market application value is achieved.

Owner:扬州九海新材料科技有限公司

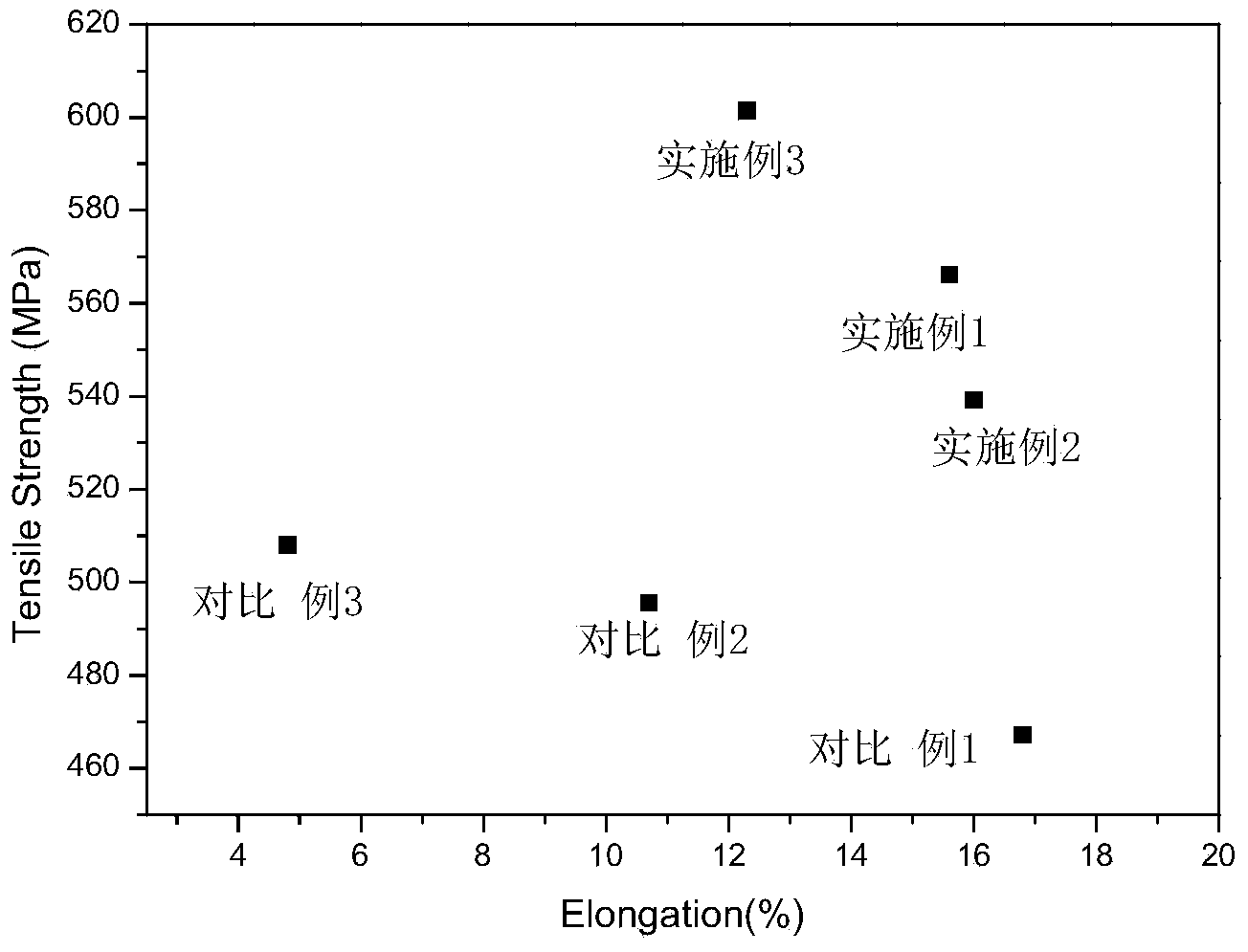

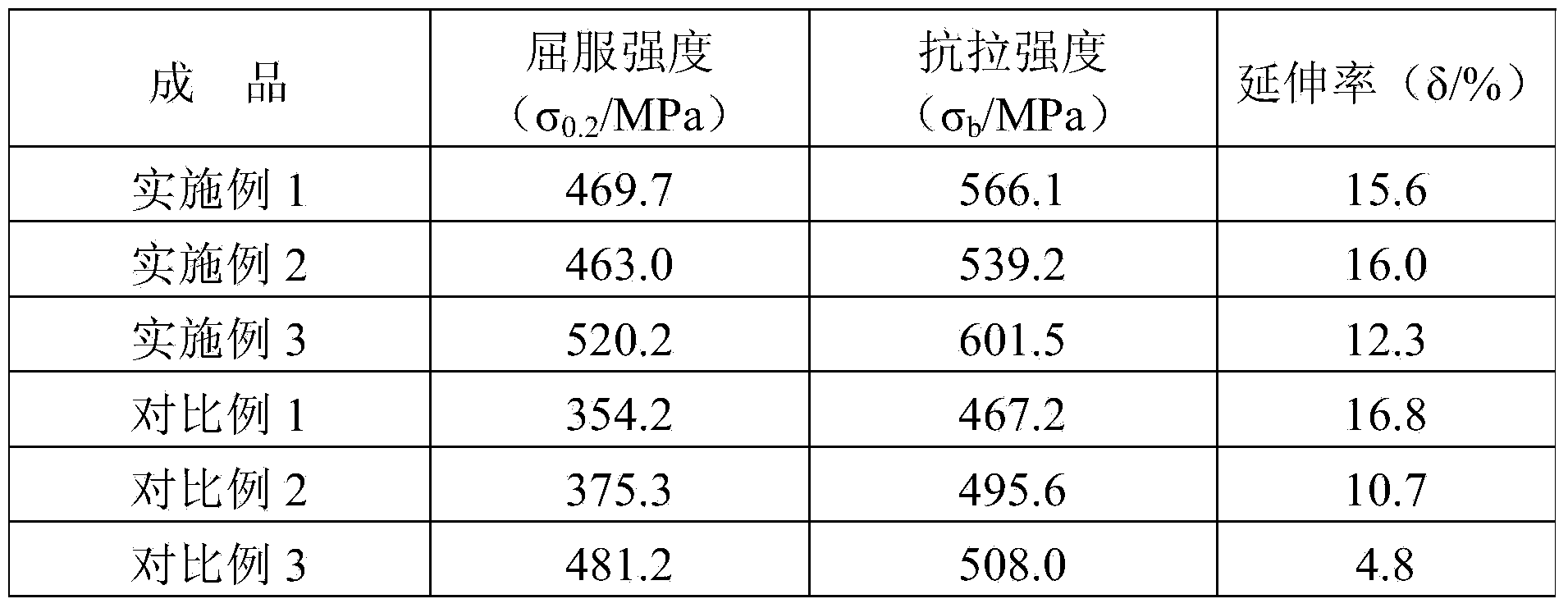

Hot treatment process for remarkably improving comprehensive performance of aluminum alloy

ActiveCN103882354AMeet the requirements of large structural partsPractical application value of large industryAtomic clusterGrain structure

The invention relates to a hot treatment process for remarkably improving the comprehensive performance of aluminum alloy. According the hot treatment process, aluminum-copper-magnesium alloy in a solid solution state undergoes pre-aging treatment, asymmetric rolling deformation and secondary aging treatment; one part of atoms are segregated through pre-aging to form nanometer scale atomic clusters which block dislocation movement during subsequent deformation to form meshy dislocation cells or sub-boundary to refine grains; the other part of undecomposed solute atoms obtain vacancy / atomic cluster complex, G.P. zone, microtexture and special shearing texture under the strain action of subsequent deformation high shear stress; one part of fine grains grow with the aid of grain boundary migration due to the interaction of the compound textures during secondary aging to form a dual grain structure, so that the strength-plasticity coordination of the alloy is improved, and the toughness of the alloy is improved. The hot treatment process is simple, safely operated and conveniently, easily industrialized, and is a novel hot treatment technology with great application prospect; the comprehensive performance of the alloy is effectively improved through improving the microtexture of alloy according to the hot treatment process.

Owner:CENT SOUTH UNIV +1

Rut resistant coating and method of applying rut resistant coating

ActiveUS7802941B2Increase resistanceHigh stressIn situ pavingsSingle unit pavingsMoisture barrierAsphalt

The present invention is directed to a rut resistant coating and a method for applying the rut resistant coating on an existing surface for increasing resistance to high vertical and horizontal strains and high shear stresses. The method includes applying a binding material layer of the rut resistant coating on the existing surface to provide a substantially impermeable moisture barrier to the existing surface, the binding material layer containing less than about 11% of the total binding material of the rut resistant coating. After applying the binding material layer, an aggregate mixture layer is applied on the binding material layer to provide the wear surface of the rut resistant coating and support and structure to the rut resistant coating to resist rutting, the aggregate mixture layer containing an asphalt solution.

Owner:ARRMAZ PROD INC

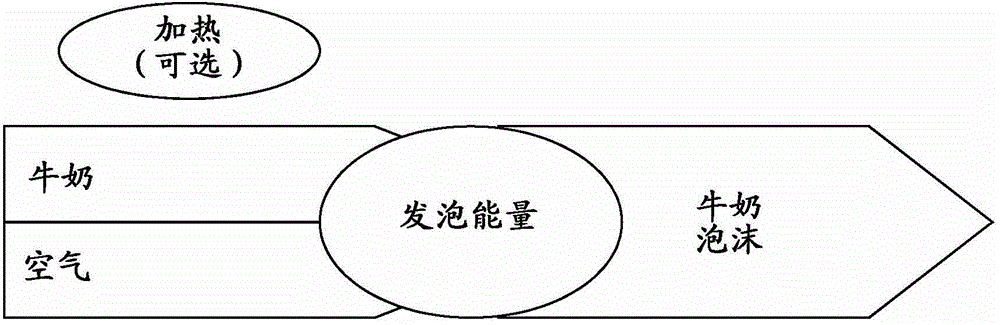

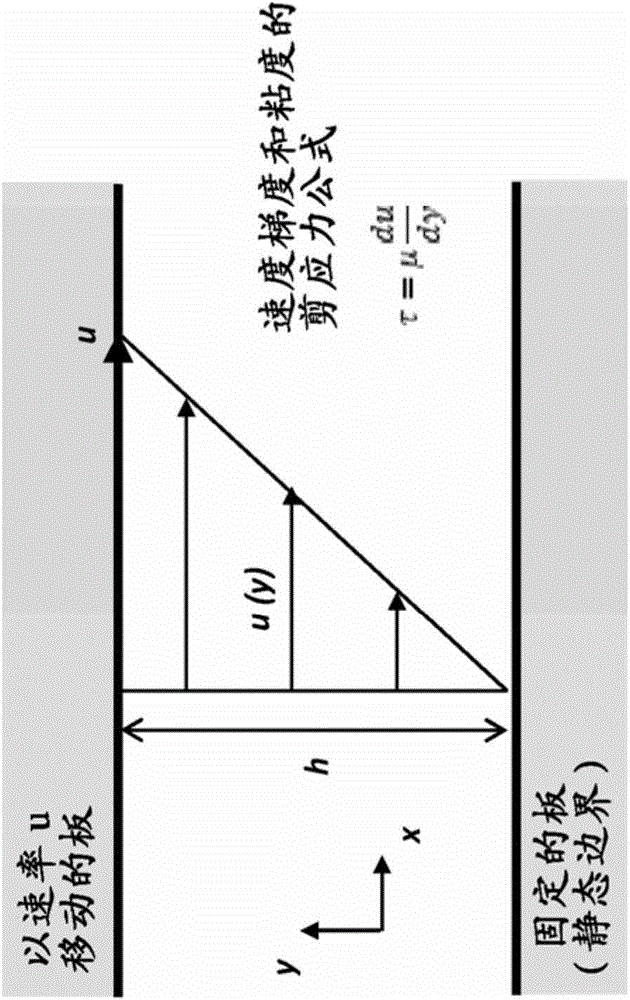

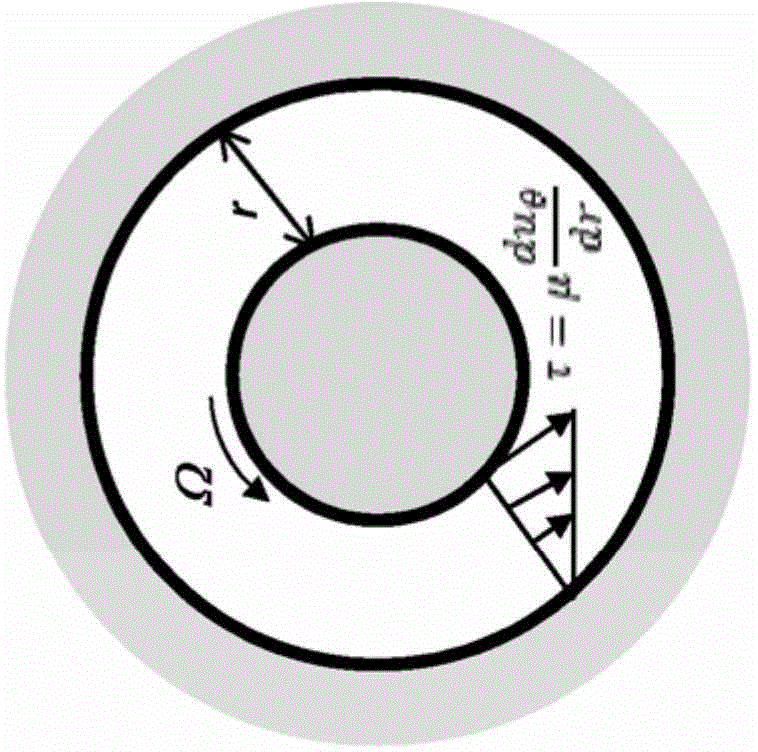

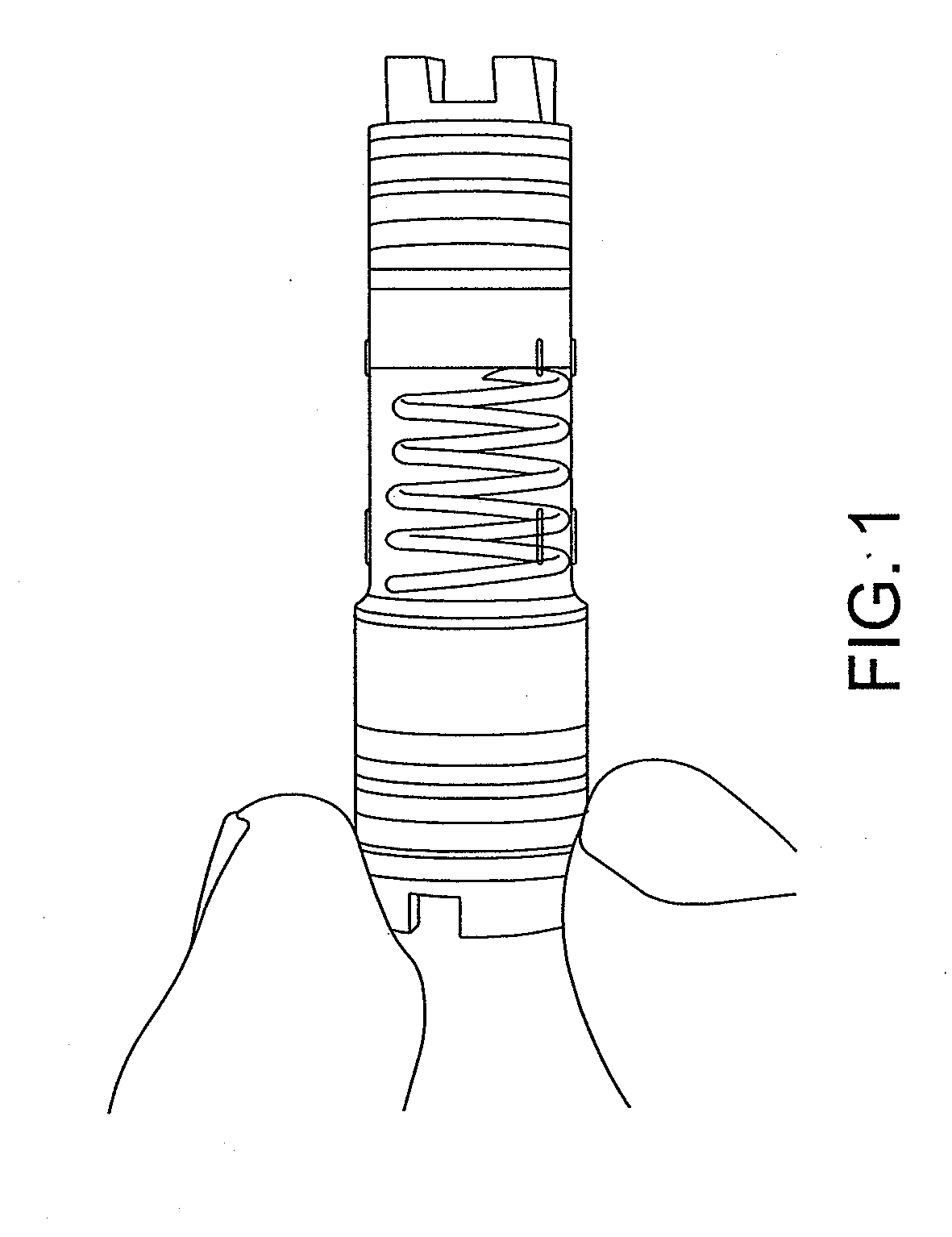

Device for producing milk foam

ActiveCN104869876AReduce frictionReduce energy consumptionTransportation and packagingMixingEngineeringHigh shear stress

The present invention provides a device 1 for producing milk foam, which makes use of Couette flow and a high shear stress that is accordingly applied to a milk-air mixture in a gap between a housing, in particular an outer cylinder, and a rotating element rotating arranged therein. The device further comprises a milk supply circuit supplying the fluid inlet with milk and an air supply circuit supplying the fluid inlet with air, both supply circuits being independent from each other.

Owner:SOC DES PROD NESTLE SA

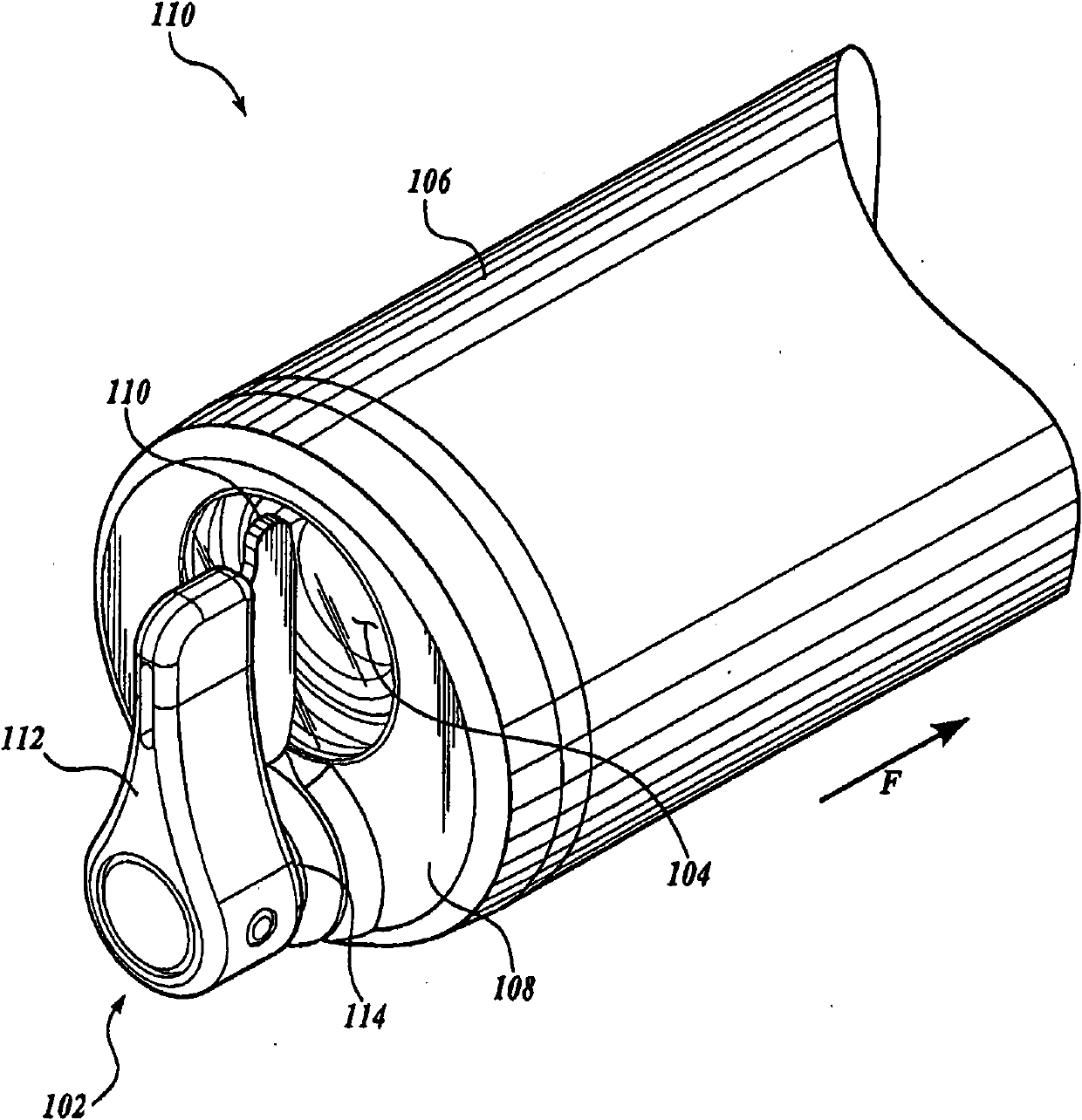

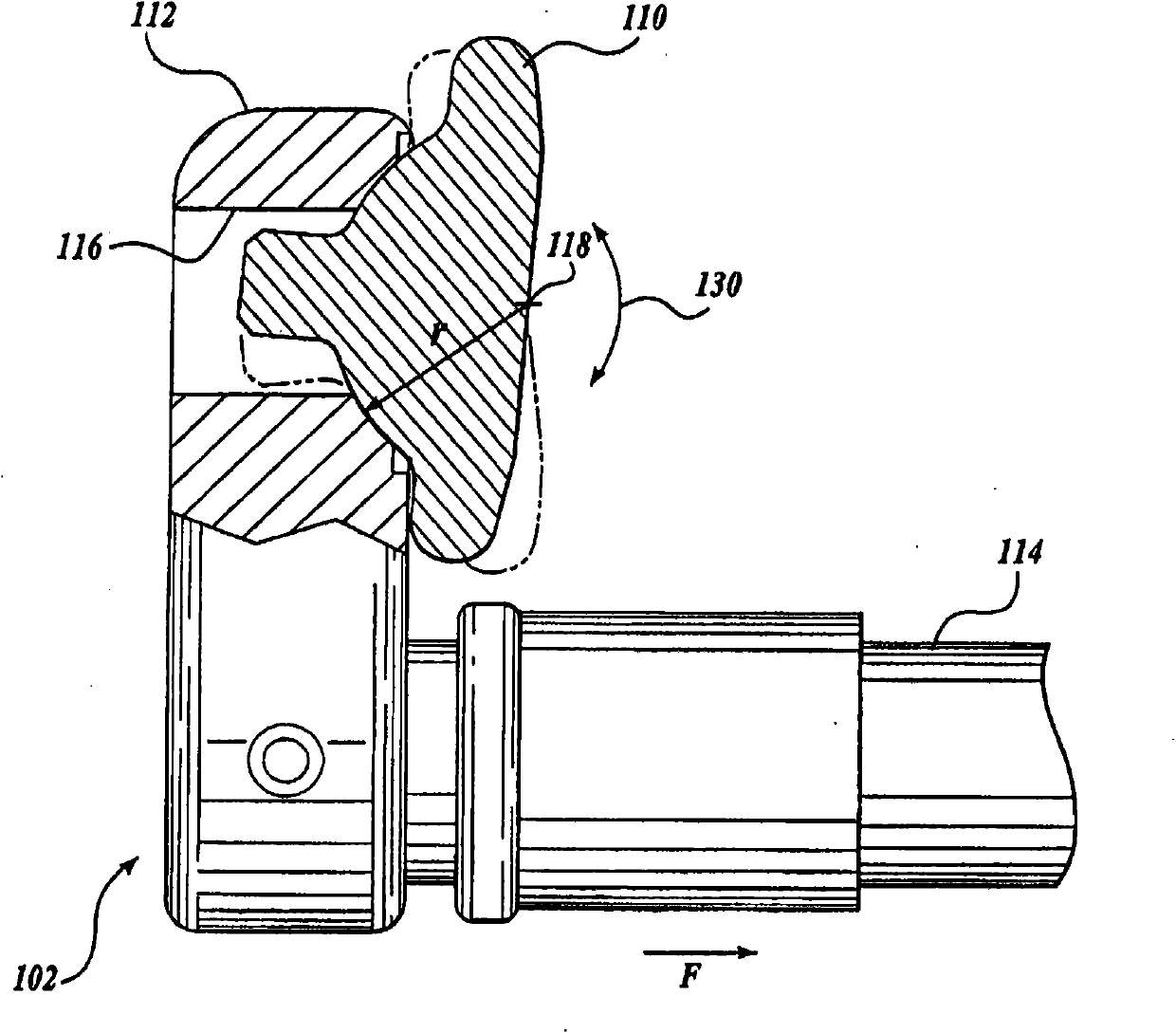

Shredder for mechanical disruption by gentle controlled compressive rotation

InactiveUS20100159507A1Flat surfaceUniform sizeBioreactor/fermenter combinationsBiological substance pretreatmentsPressure cyclingHydrostatic pressure

The systems and techniques of the present invention can also synergistically utilize mechanical disruption processes with the use of high hydrostatic pressure extraction, such as pressure cycling extraction techniques to achieve high yield of difficult to extract sample constituents without generating high shear stress or high temperatures.

Owner:TING EDMUND Y +6

Window scraper for an optical instrument

A scraper for an optical surface of a device is disclosed. The scraper includes a blade having an edge that is rigid and non-deforming to withstand high shear stresses. The blade is configured to rotate about a first axis parallel to the optical surface and also configured to move in a line with respect to a second axis perpendicular to the optical surface. This allows the rigid, non-deforming blade to maintain contact with the optical surface. Furthermore, the edge is configured to move across the optical surface to remove any materials adhered to the surface. The scraper can be used to clean the optical surface of an instrument, for example.

Owner:METTLER TOLEDO AUTOCHEM

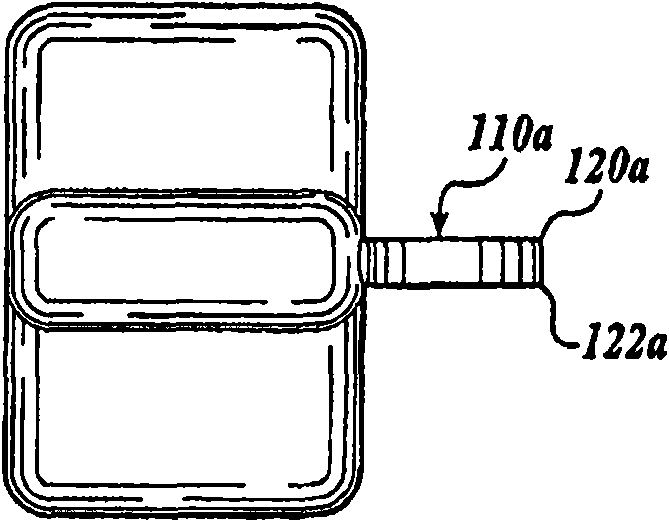

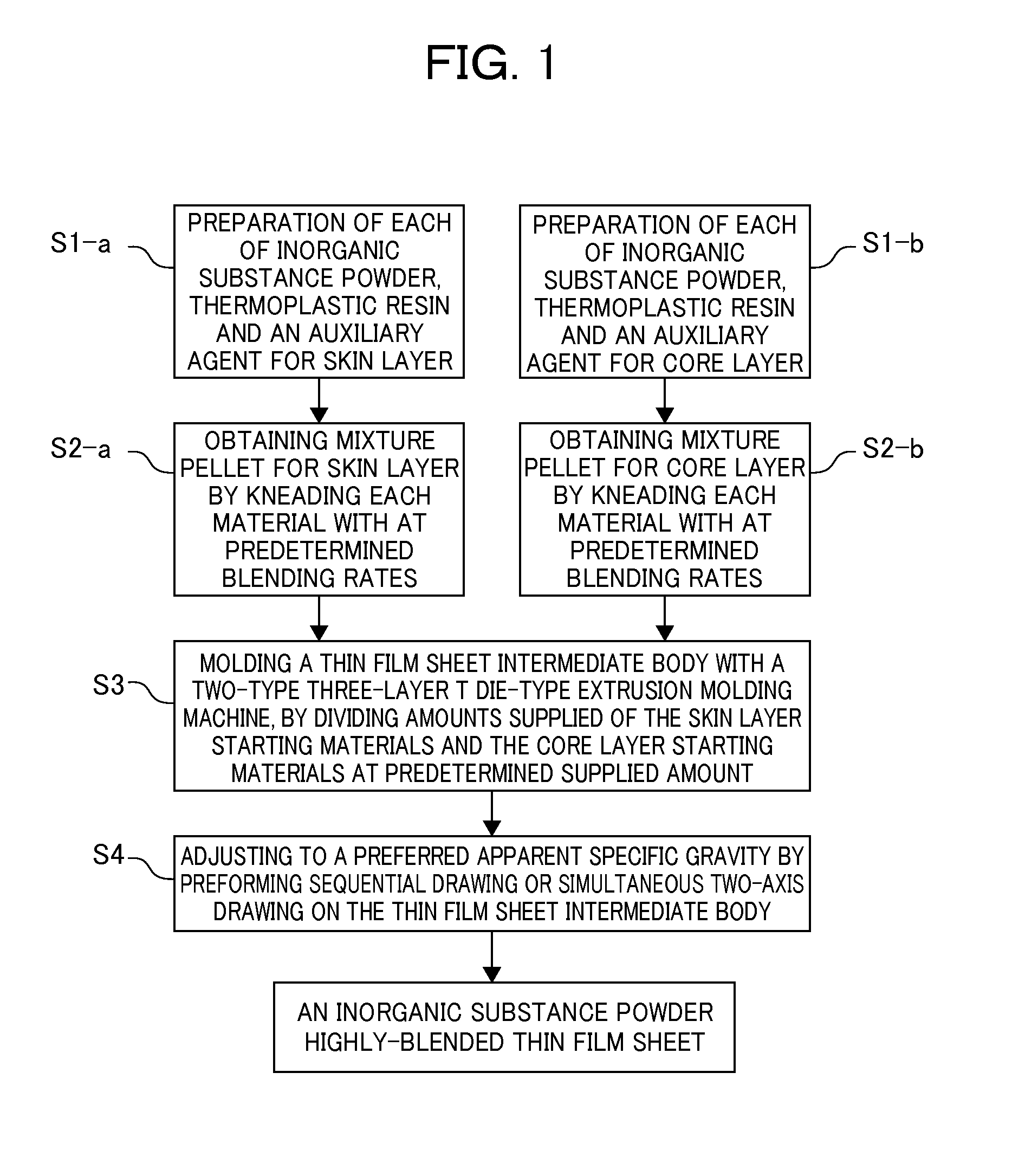

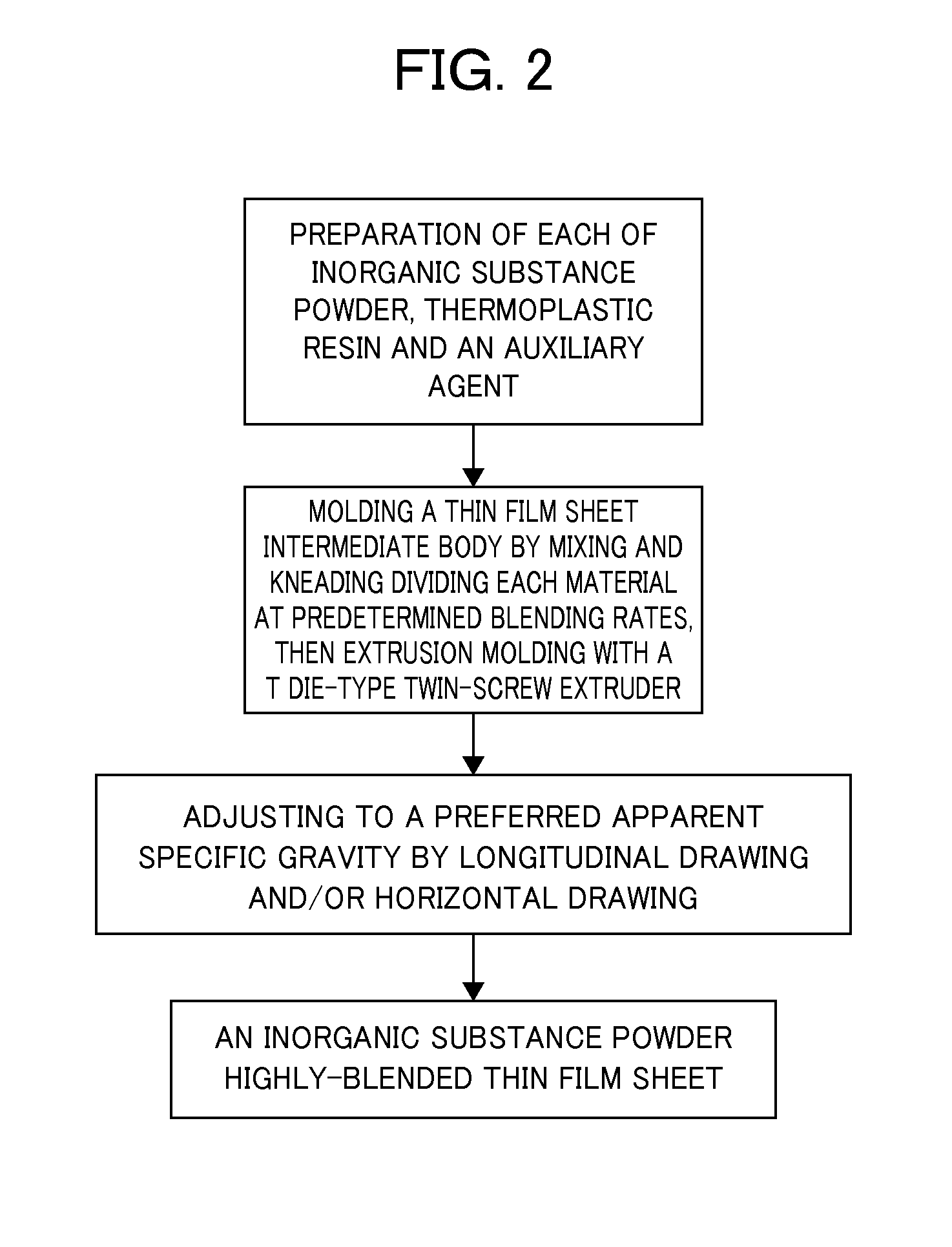

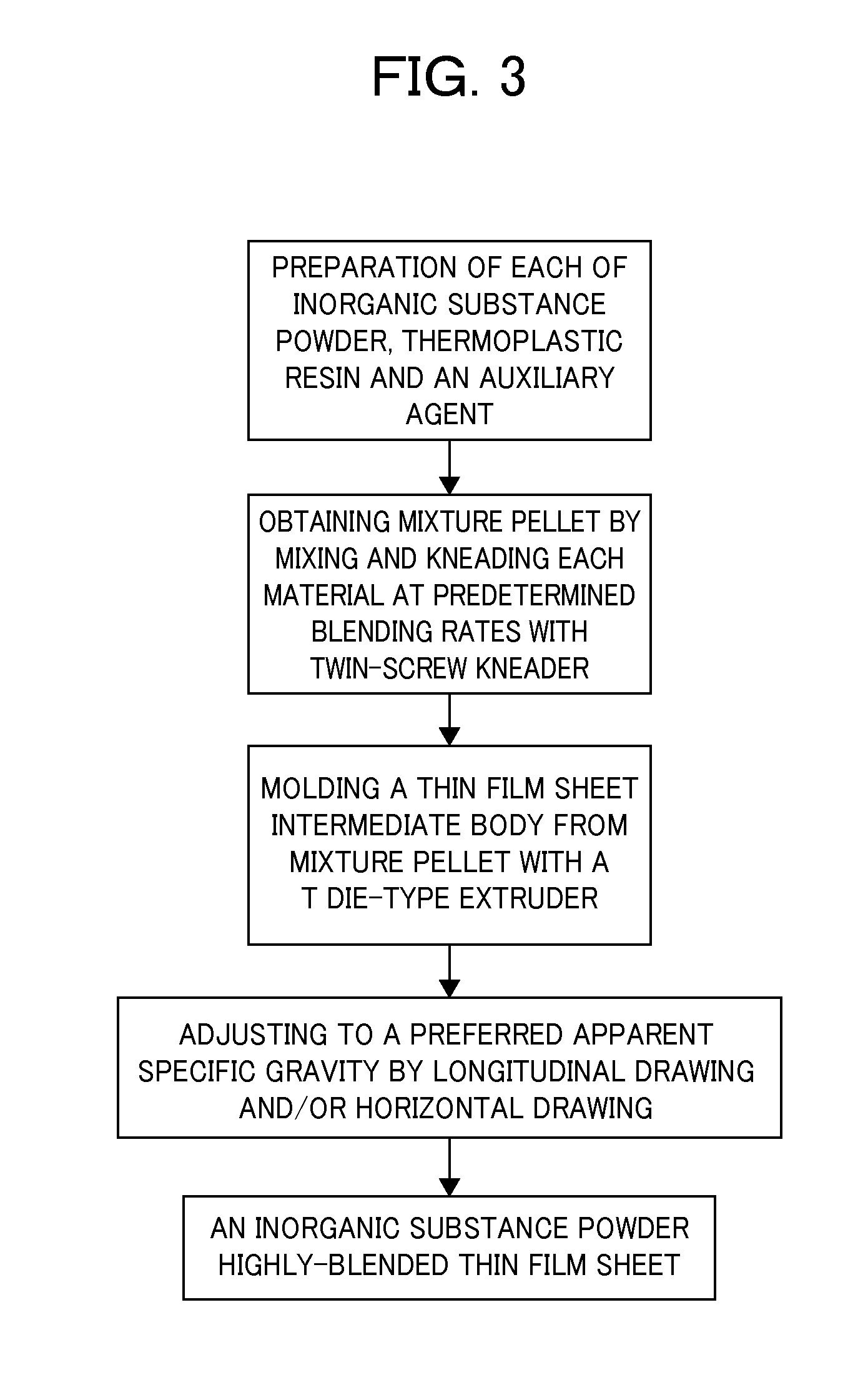

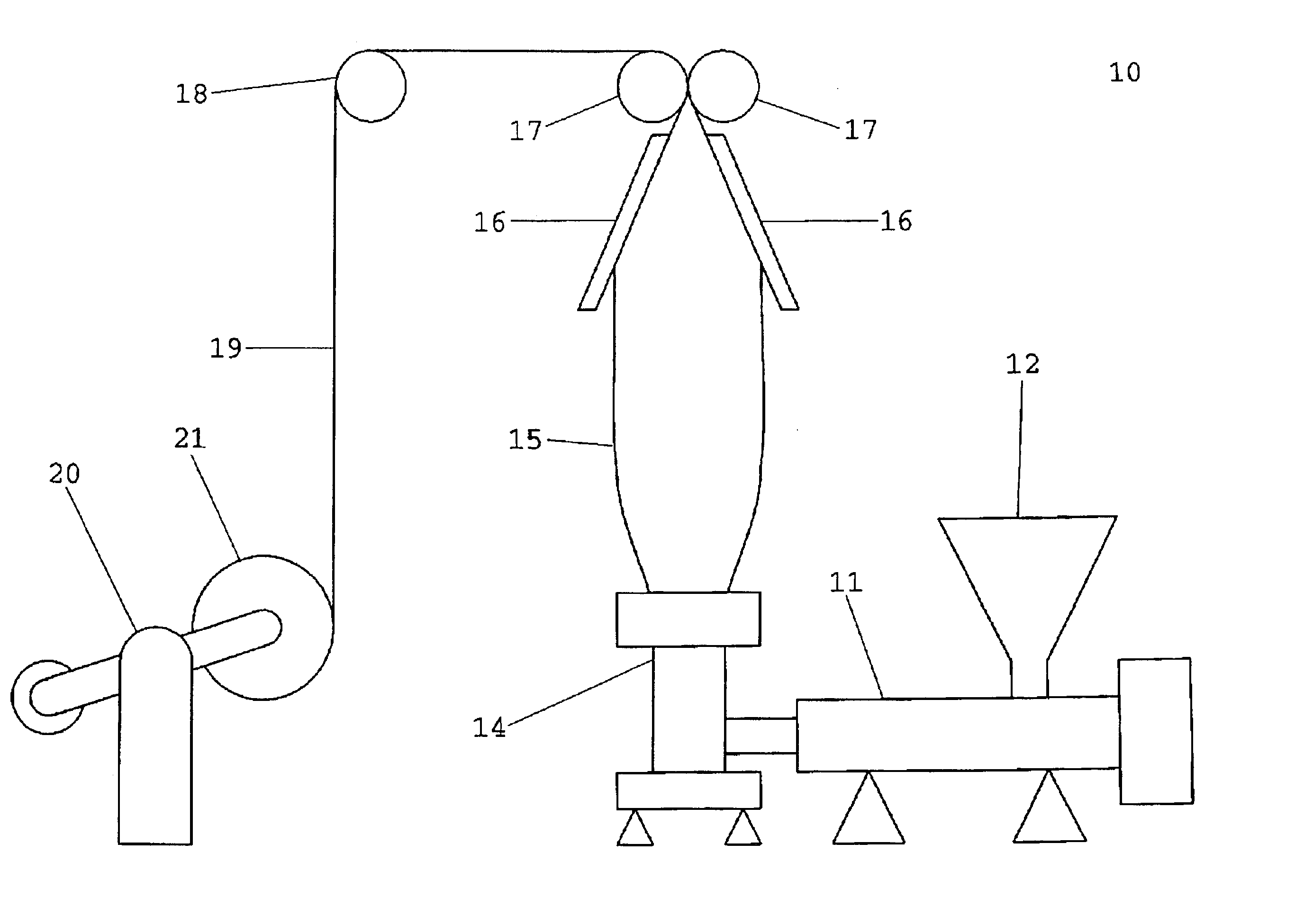

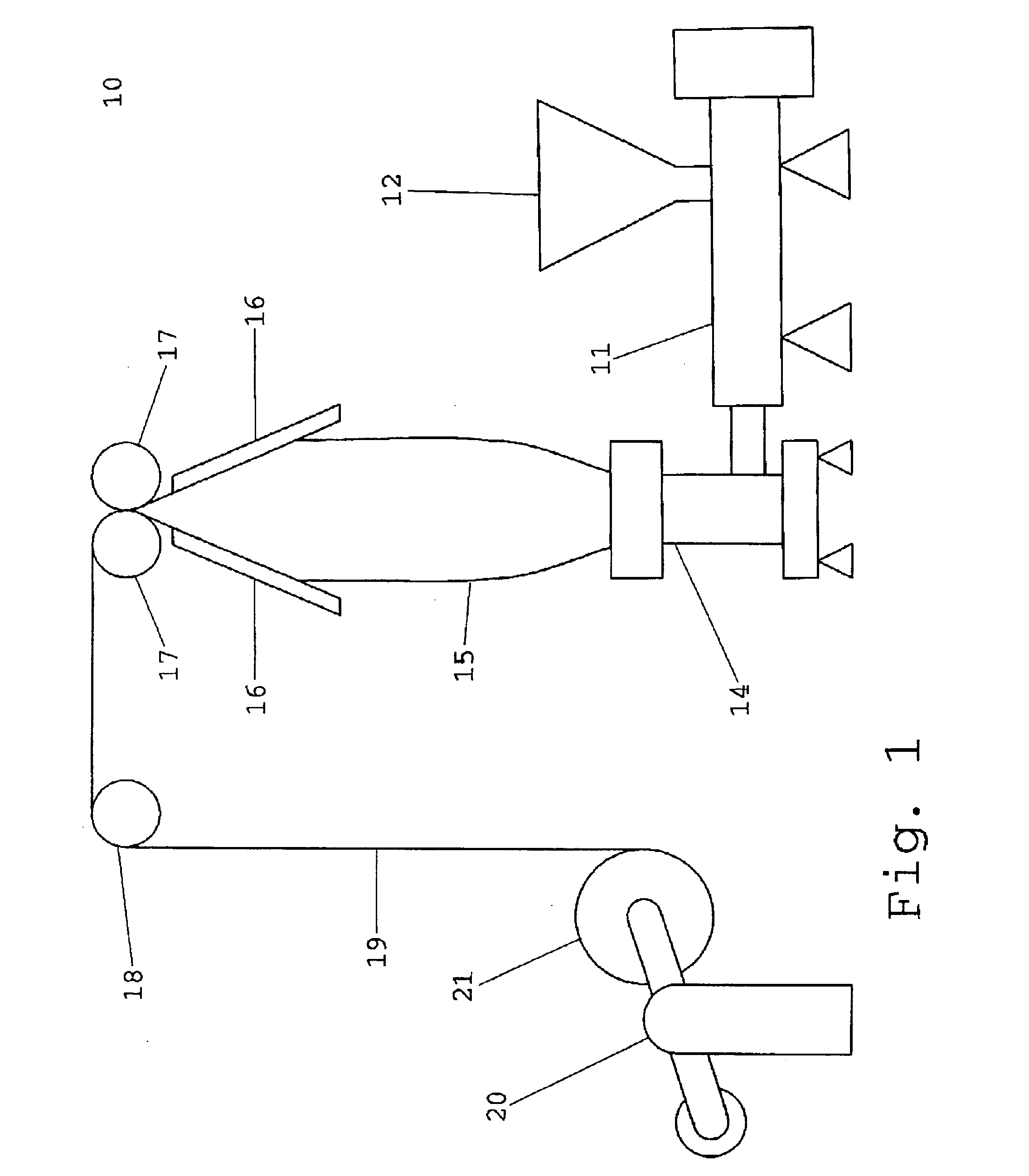

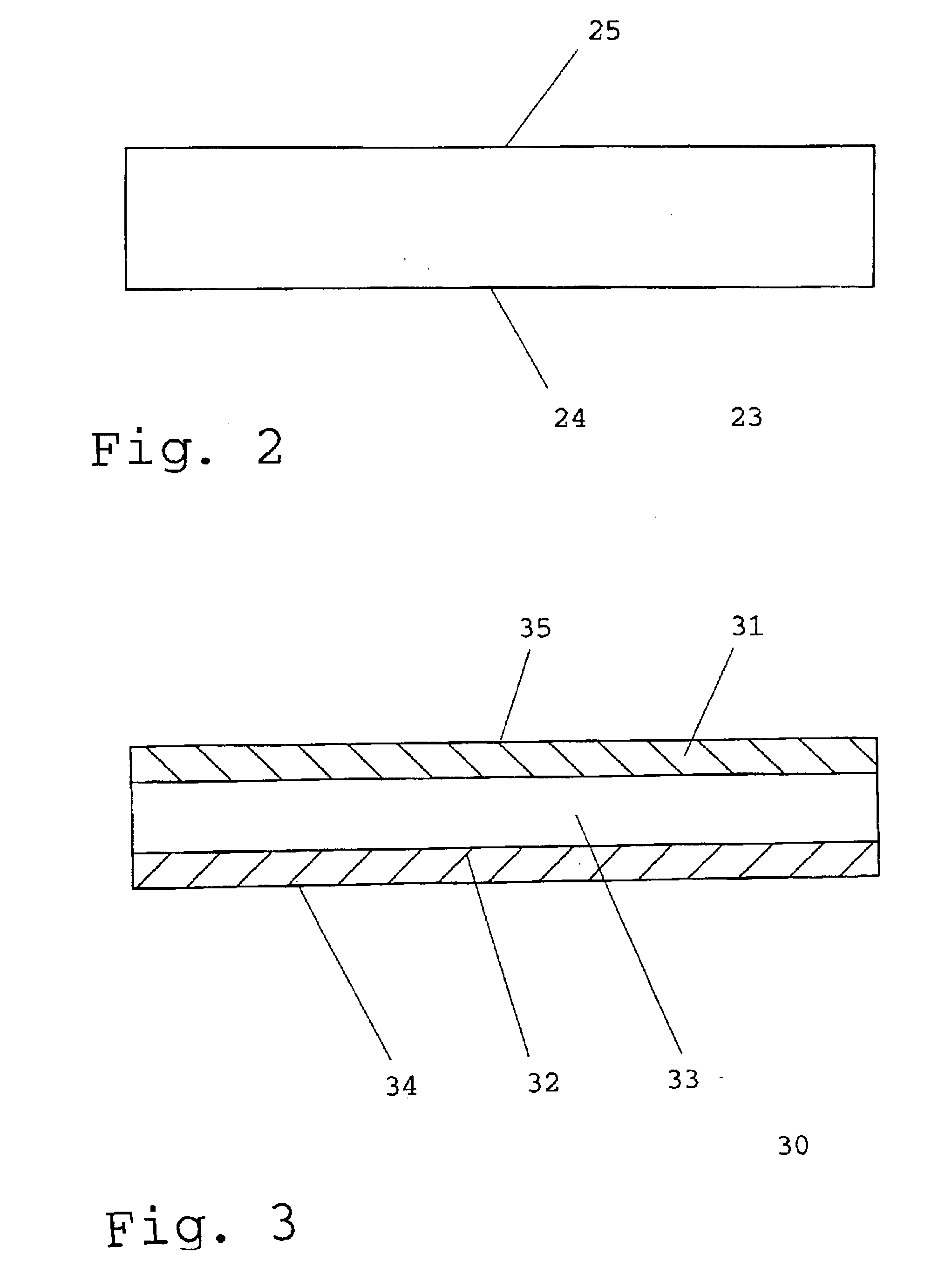

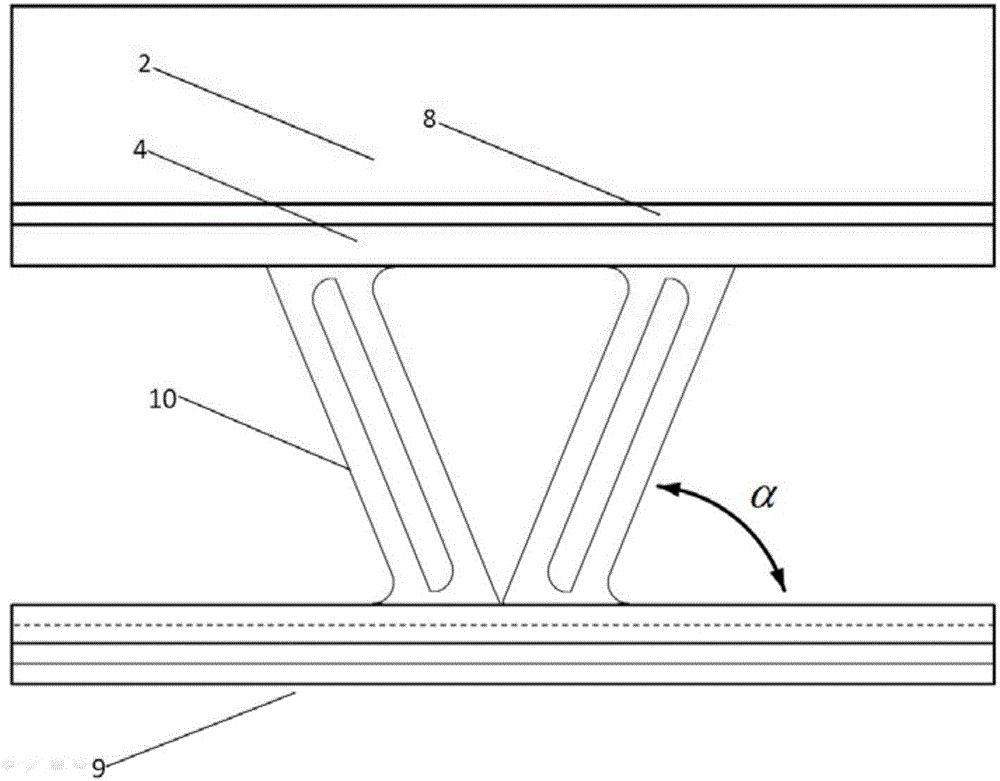

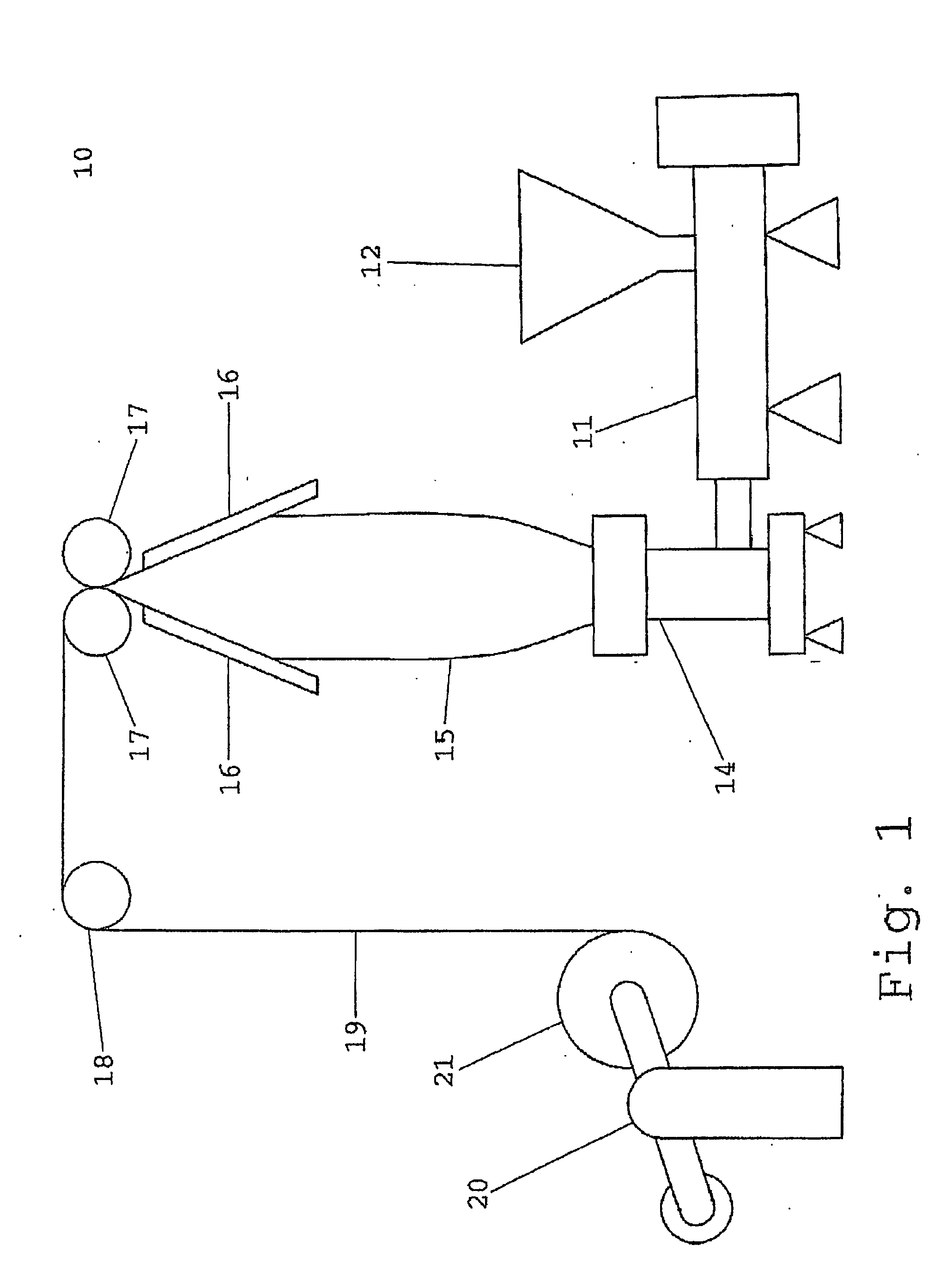

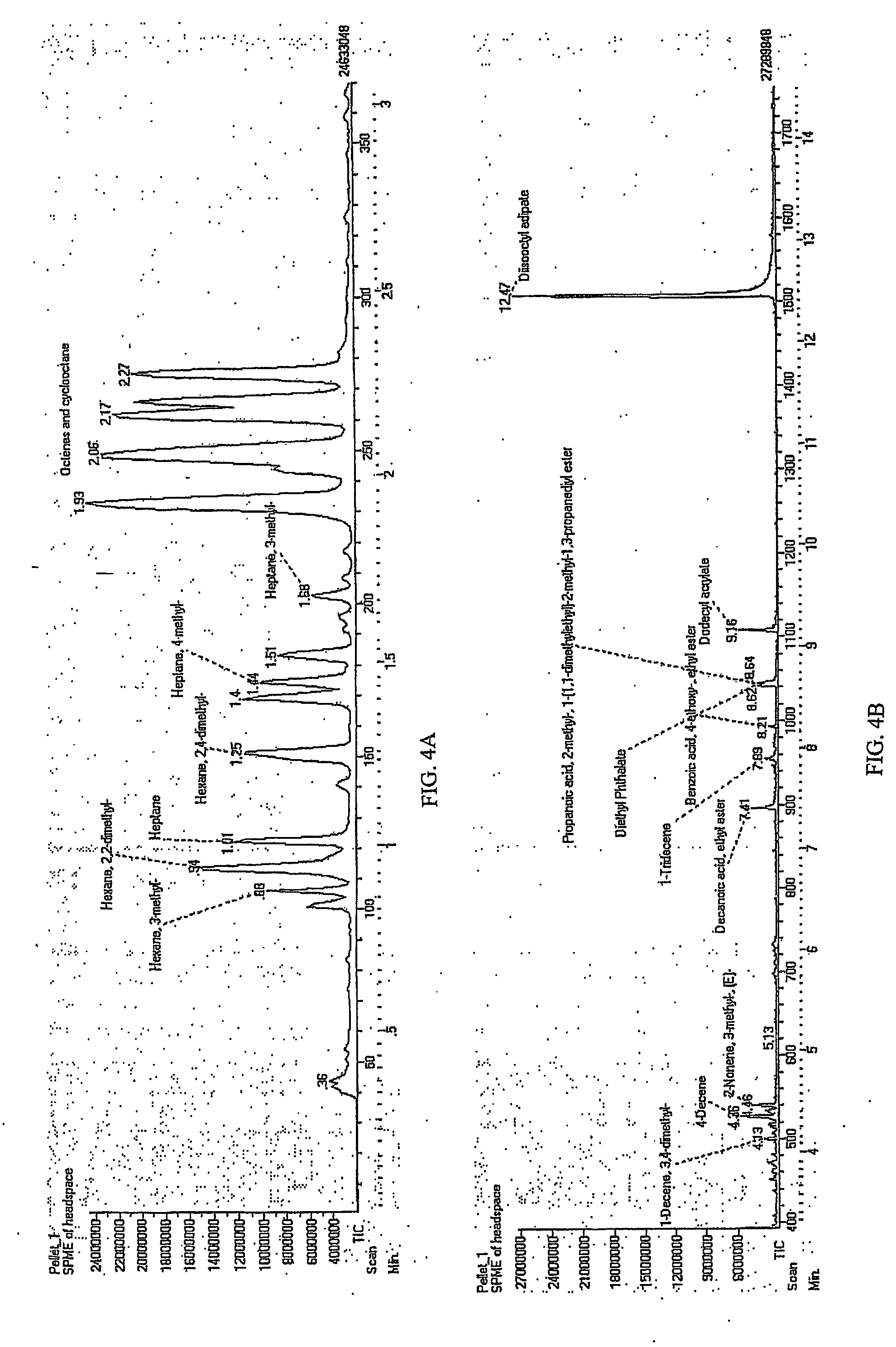

Method for producing inorganic substance powder highly-oriented thin film sheet

ActiveUS20140100328A1Little thickness unevennessImprove surface conditionArtificial filament physical treatmentDuplicating/marking methodsHigh shear stressImpurity

The problem addressed by the invention lies in providing a method for producing an inorganic substance powder highly-oriented thin film sheet with which it is possible to produce a sheet of uniform thickness while preventing the generation of impurities, improving sheet surface properties, adjusting apparent specific gravity, and the like. The method for producing a thin film sheet comprises a step for preparing a predetermined inorganic substance powder, thermoplastic resin, and auxiliary agent, a step for exposing the starting materials mixed at a predetermined mixture ratio to high shear stress while kneading, a step for feeding the kneaded starting materials to a T die-type extrusion molding device and molding a sheet, and a step for adjusting the apparent gravity as desired by stretching under predetermined conditions.

Owner:TBM

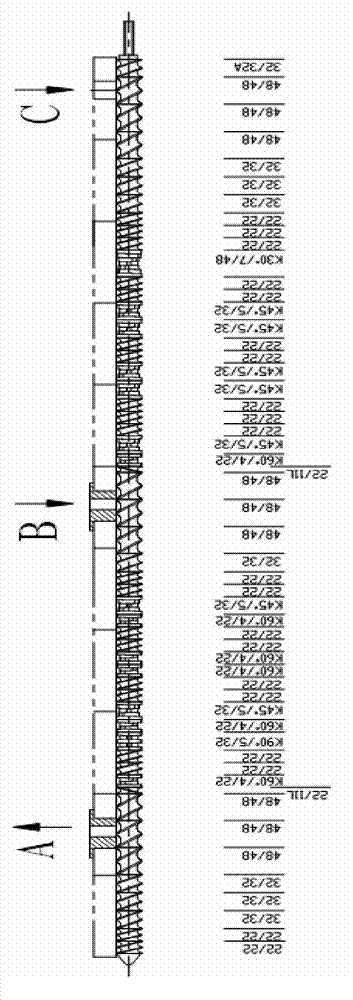

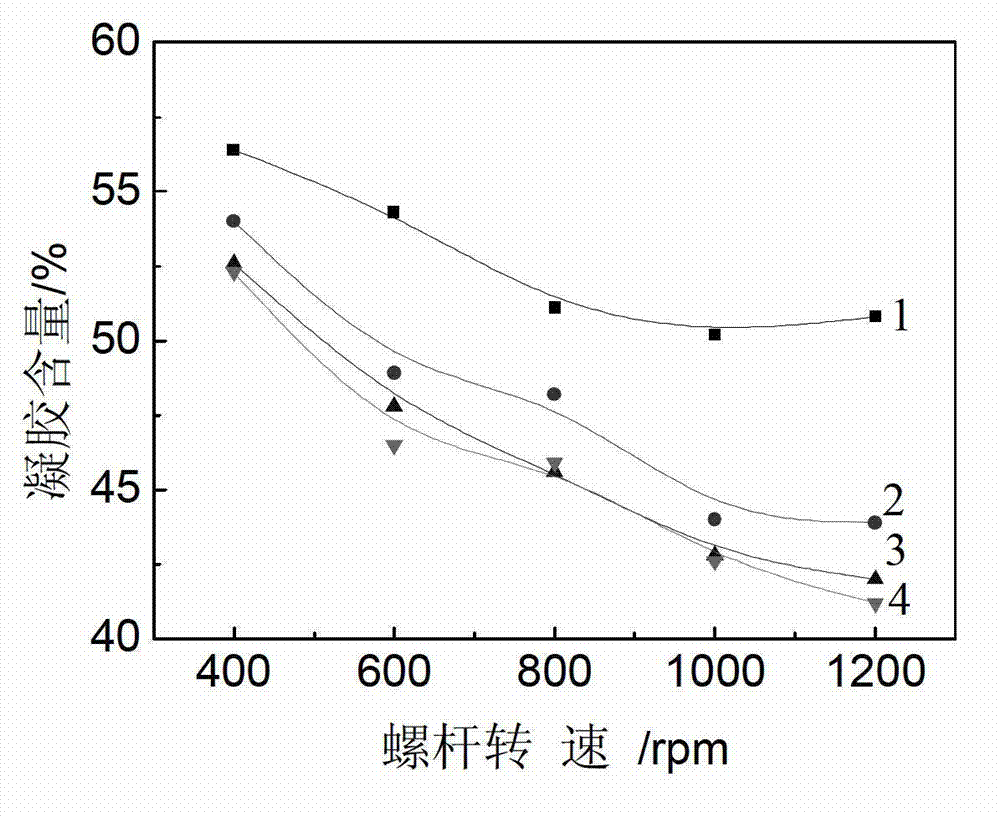

Method for inducing desulfurization reaction of vulcanized rubber powder through stress of subcritical water extrusion method

The invention relates to a technology for inducing a desulfurization reaction of vulcanized rubber powder through compounding subcritical water extrusion and high shearing stress, that is, according to the percentage content of the total mass of reaction materials, 0-30% of linear high molecular material, 65-97% of waste rubber powder and 0.2-5% of desulfurization auxiliary agent are mixed; the mixture is molten and extruded for desulfurizing in a double-screw extruder, wherein the double-screw extruder has subcritical water extraction reaction conditions and higher screw rotating speed; and the reaction product is cooled by water, extruded to strips and dried, or is calendered by a roller, cooled and extruded to sheets so as to obtain a regenerative rubber material after the desulfurization reaction. The method is a further improvement based on the original method for inducing desulfurization and modification through high shearing stress of waste tire rubber powder. The method further improves the efficiency of the desulfurization reaction, is easy to control the reaction process, generates no harmful gases, and has the advantages of high yield, low energy consumption, easiness in upsizing and scale production, low environmental pollution, and high mechanical performance of desulfurization products and resulfurization materials.

Owner:NANJING UNIV OF TECH +1

Dispersant For Reducing Viscosity

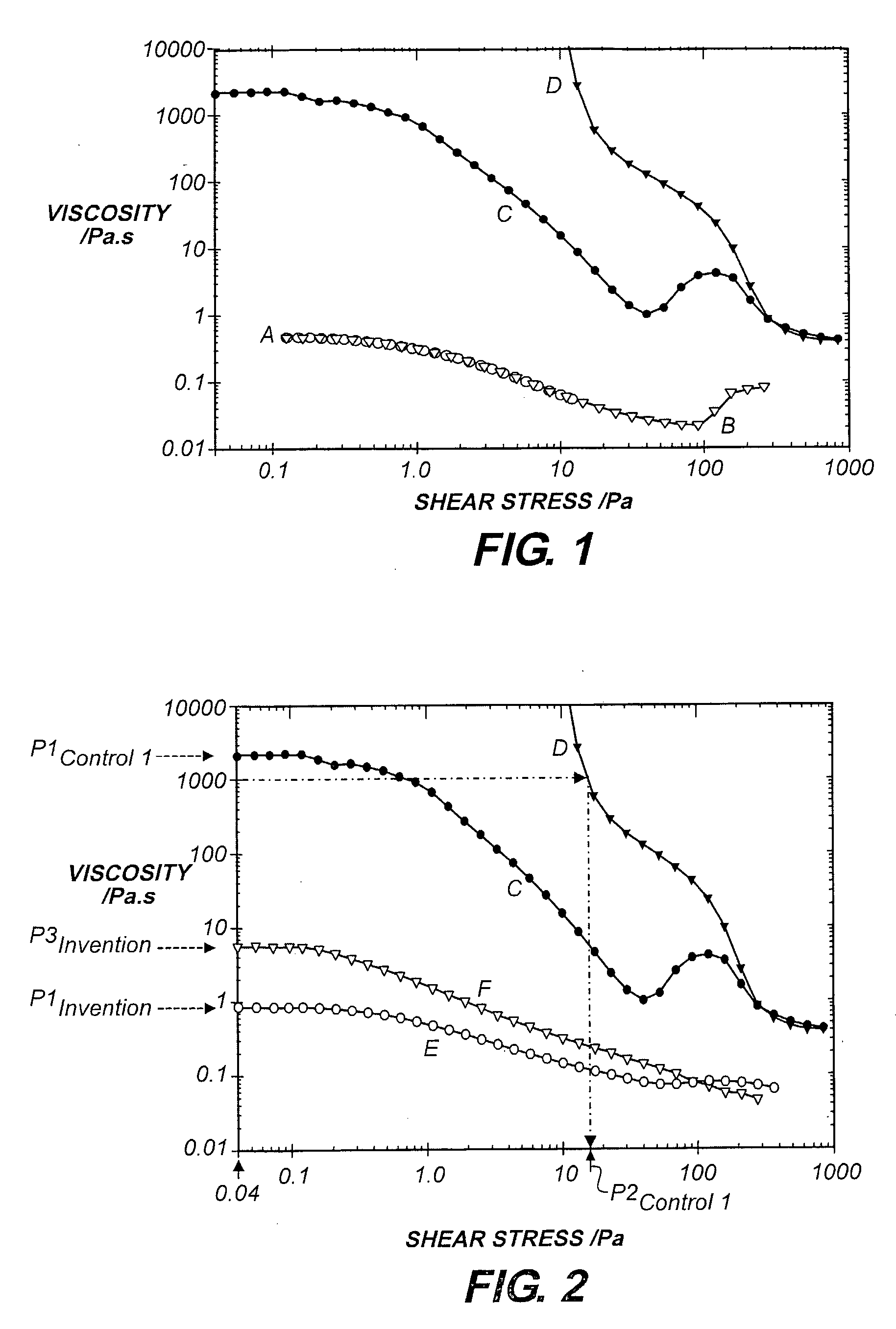

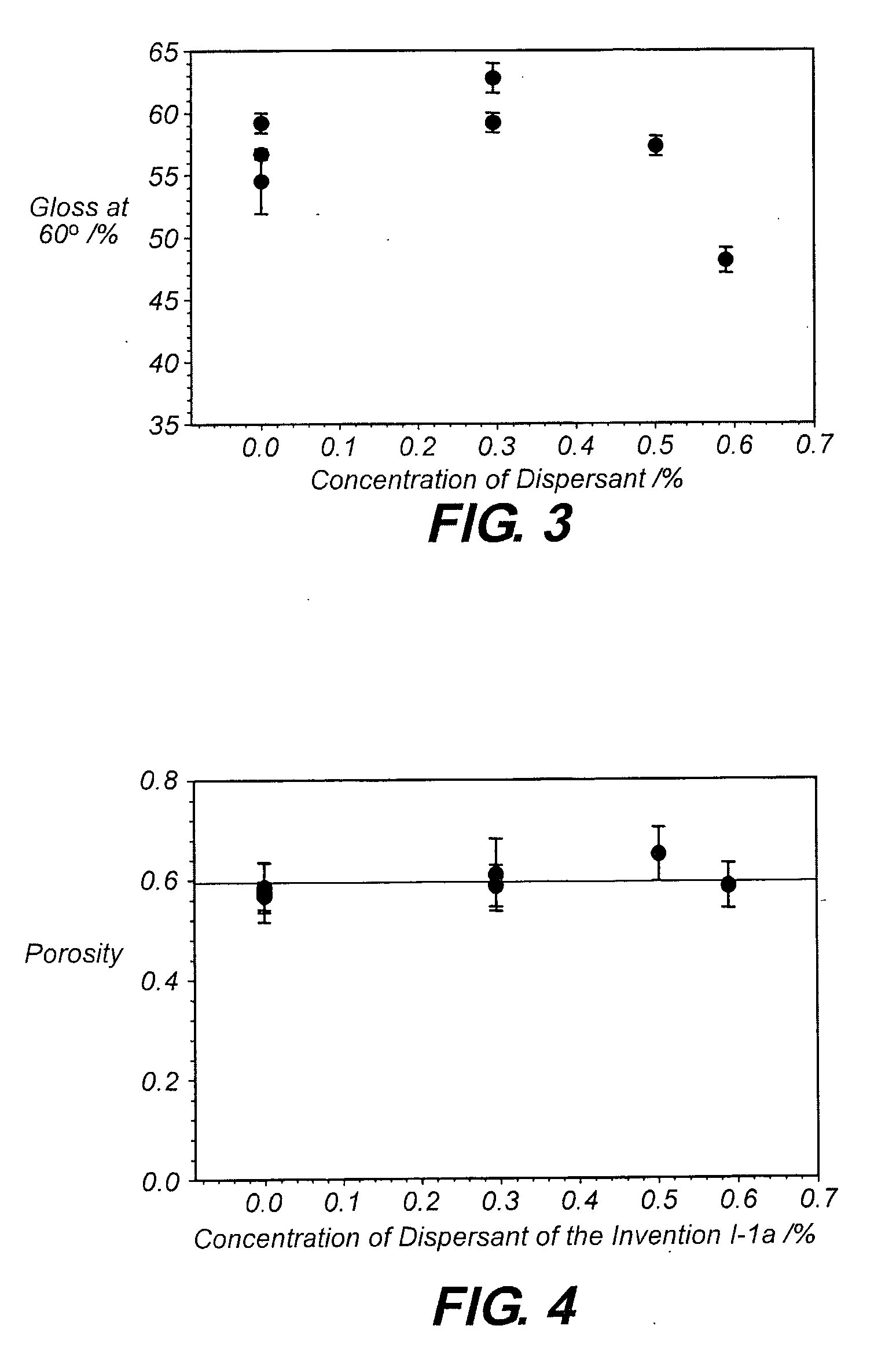

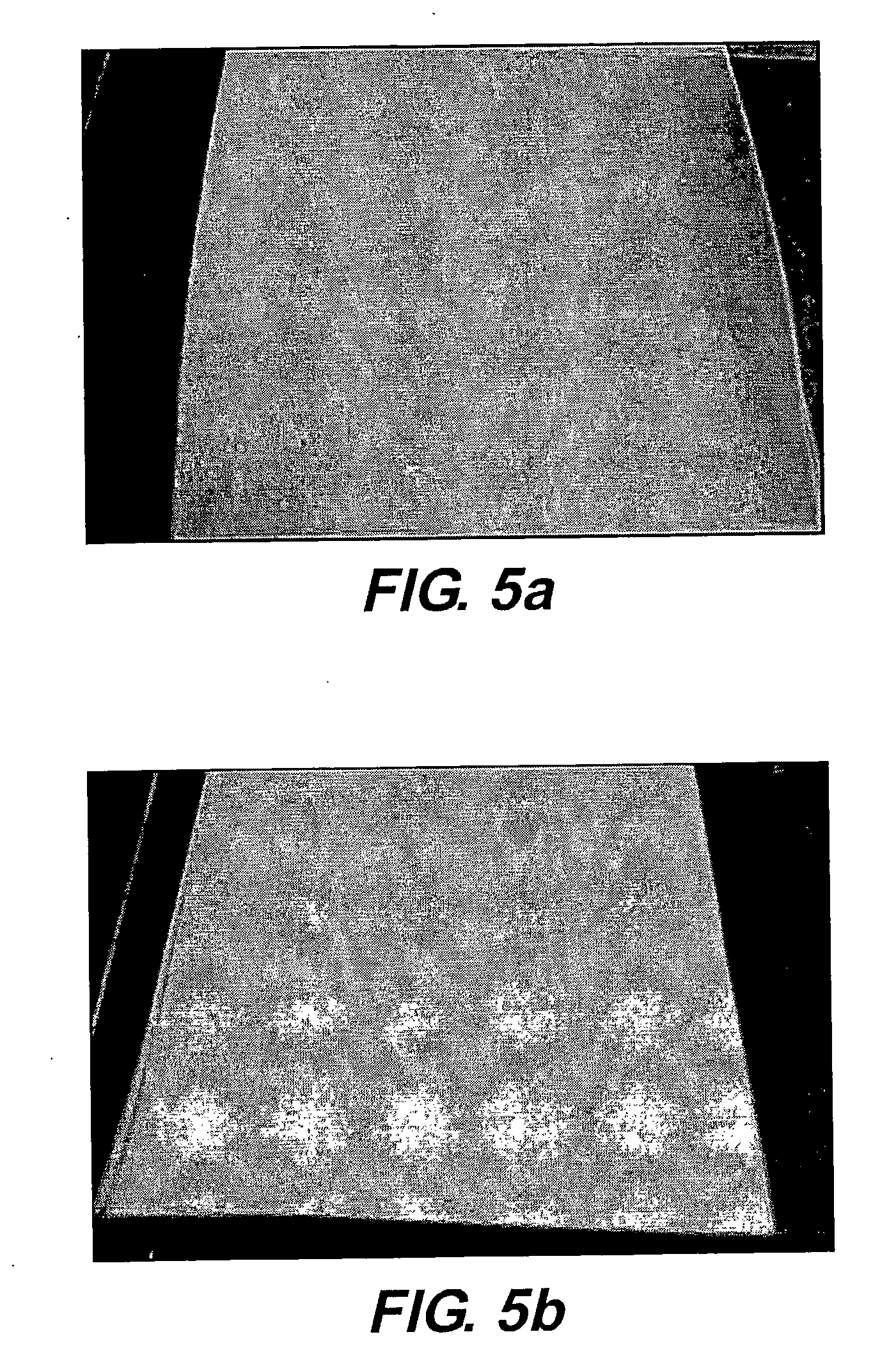

InactiveUS20080090012A1Low viscosityImproved dispersabilityPigmenting treatmentAluminium compoundsPorosityCarboxylic acid

The invention provides a dispersant for an aqueous dispersion of boehmite particles which comprises a compound having an anchoring moiety linked to a polymeric hydrophilic moiety, the anchoring moiety containing at least one acid and / or hydroxy group and having overall acidity or neutrality and the polymeric moiety having a lower affinity for a boehmite surface than the anchoring moiety. The anchoring moiety preferably contains at least two acid groups, preferably carboxylic acid groups, attached either in a [1,1], [1,2] or [1,3] relationship and is linked to the polymeric moiety, which is preferably derived from acrylamide or methacrylamide monomer units, preferably by a sulfur atom. The dispersant can reduce the viscosity of the boehmite dispersion and the tendency of the boehmite dispersion to increase in viscosity and / or form a gel or a yield stress material following periods of high shear stress. It may be used, for example, as a component of a coating material, a ceramic, paint, refractory material, filler, or in particular in an inkjet recording paper or film, wherein good porosity and gloss is maintained by the use thereof.

Owner:EASTMAN KODAK CO

Process for reducing surface aberrations

InactiveUS20050037220A1Reduce generationSynthetic resin layered productsCeramic shaping apparatusProduction rateProcedure Agents

The processes and resins of the present invention allow the extrusion of polymer products, such as polymer films, that have a reduced occurrence of surface aberrations, e.g., surface melt fracture and / or haze bands and / or haze. Preferably, the polymer products produced in accordance with the present invention are substantially free of surface aberrations even when manufactured under conditions of high sheer stress such as those conditions that occur at commercial production rates. In part, the present invention provides processes for polymer extrusion wherein the resins employed are treated using heat in an atmosphere sufficient to substantially eliminate the tendency to create surface aberrations. The resins can have reduced or substantially eliminated concentrations of low molecular weight components. In some embodiments, both the polymer resins and the extruded polymer products have reduced concentrations of processing aid(s), e.g., the polymer resins and the extruded polymer products are substantially free of processing aid(s).

Owner:BATTENFELD GLOUCESTER LLC

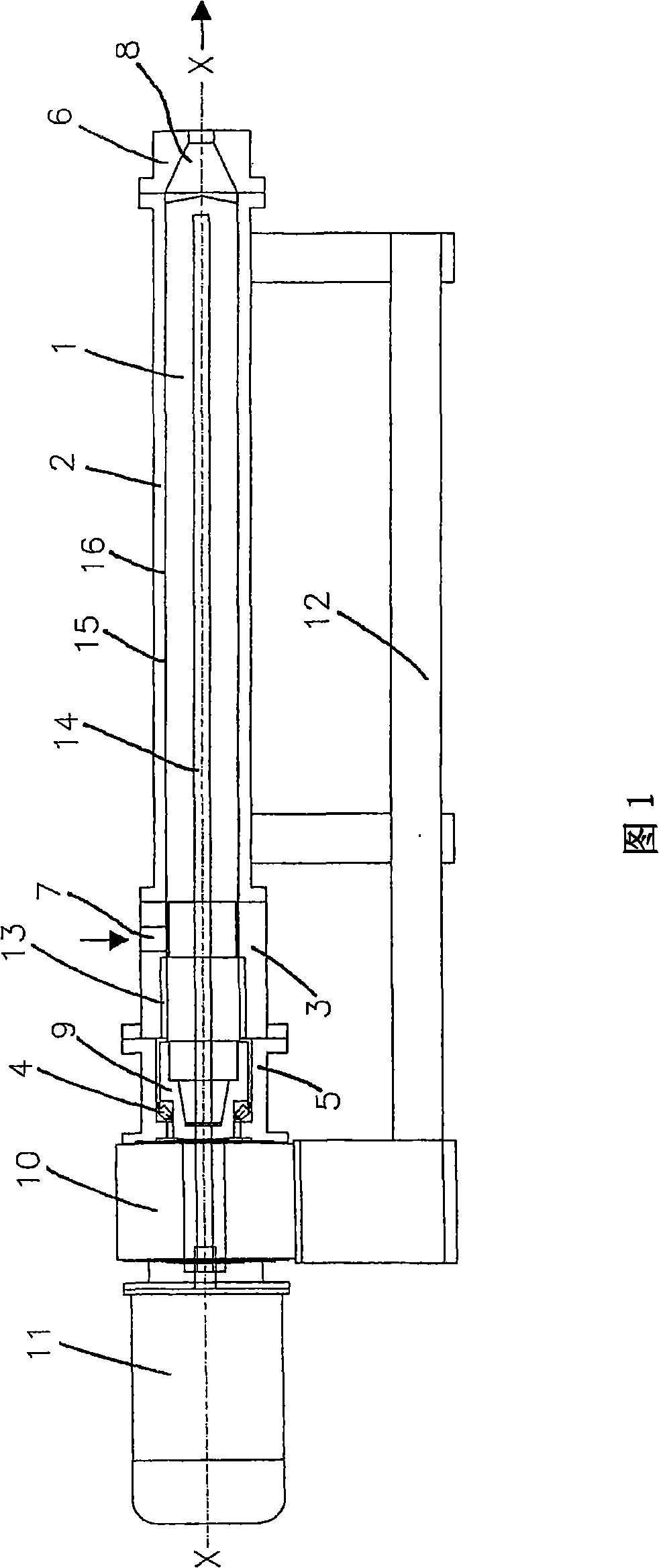

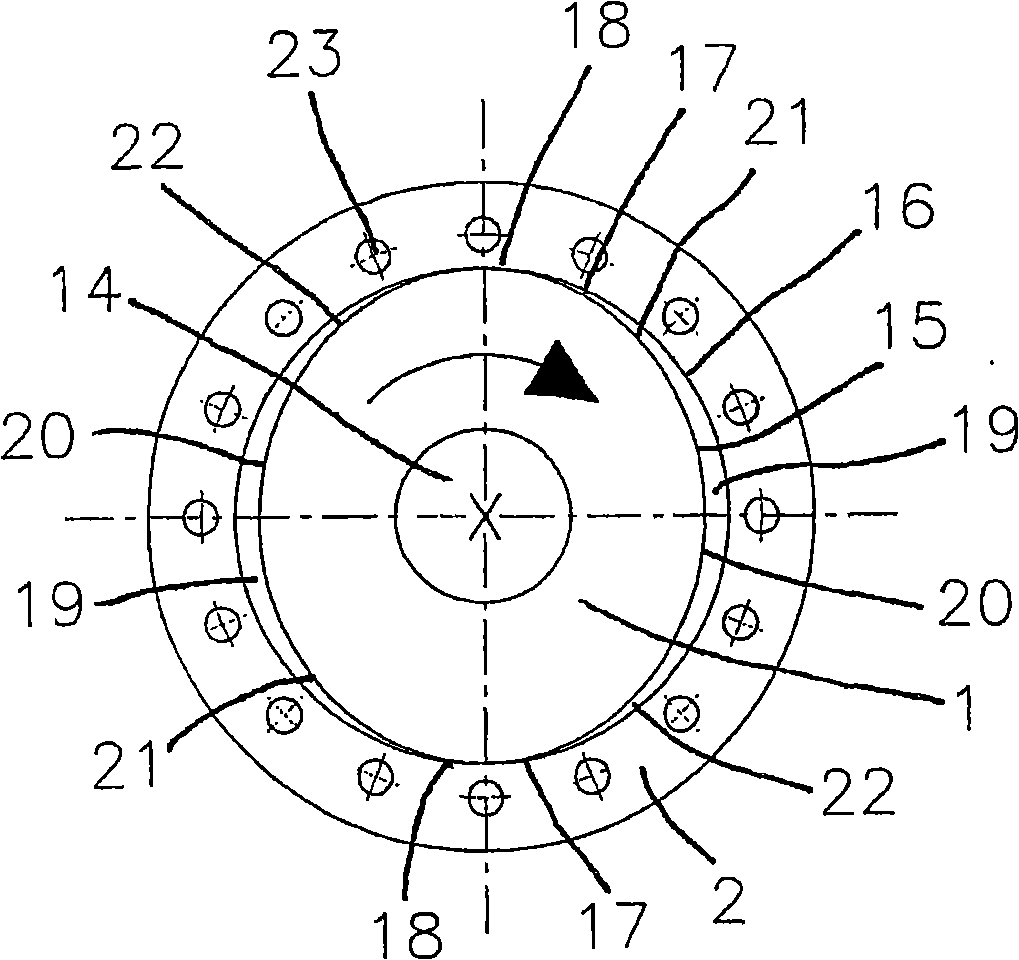

Mixer and method of mixing

InactiveCN101272847ASignificant pumping forceMaximize pumping efficiencyRotating receptacle mixersFlow mixersMixing effectMechanical engineering

A dynamic mixer in which two members (1,2) are rotated relative to each other about a predetermined axis (XX), the members having facing surfaces (15, 16) which extend axially and between which is defined a mixing chamber through which a flow path extends between an inlet (7) for material to be mixed and an outlet (8). An array of two or more mixing formations is defined on at least one of the facing surfaces (15, 16) which extend radially towards the facing surface of the other element (15, 16) and which act to mix material within the mixing chamber, and which extend axially generally parallel to the axis. A mixing formation thus defined is configured to provide a constricting flow passage followed by an expanding flow passage to material present in the mixing chamber as the first and second members are relatively rotated, with the mixing formations located around the axis on any plane perpendicular to the axis so as to provide a generally net balance of the radial loads imparted by material present in the space between the surfaces. The material within the mixing chamber is subjected to high extensional and or shear stresses arising from the circumferential drag flow induced between the closely separated facing surfaces, while being permitted to flow axially between the widely separated flowing surfaces. Dispersive mixing and distributive mixing effects are thereby obtained.

Owner:MAELSTROM ADVANCED PROCESS TECH

High shearing rate method for spinning poly-terephthaloyl p-phenylenediamine fibre

ActiveCN1752300AWell mixedStable mixFilament/thread formingMonocomponent polyamides artificial filamentFiberSlurry

The invented method includes the following steps: uniformly mixing PPTA and concentrated sulfuric acid whose concentration is greater than 99% in mixing cylinder, preparing mixed solution in which PPTA content is 14%-24%; making the prepared PPTA mixed solution pass through twin screw extruder, further dissolving to form liquid crystal spinning solution, defoaming, fully mixing and regulating temperature, applying high shear stress to the defoamed PPTA spinning slurry in extruder machine head, filtering and metering, adopting dry-jet wet-spinning process to obtain the invented PPTA fibre.

Owner:DONGHUA UNIV

High-stability magnetorheological fluid

ActiveCN107057810AImprove performanceEase of industrial applicationLubricant compositionAntioxidantMagnetorheological fluid

The invention discloses high-stability magnetorheological fluid, which is prepared from the following ingredients in percentage by weight: 75 to 85 percent of magnetic particles, 15 to 25 percent of carrier liquid, 0.3 to 1 percent of surface active agents, 0.3 to 1 percent of thixotropic agents, 0.3 to 1 percent of antioxidants and 0.3 to 1 percent of antiwear agents. The mineral oil or poly-alpha-alkene synthesis oil is used as the carrier liquid; the sensitivity on various beneficial additives is higher; agglomeration cannot easily occur; copolymers with acid groups are used as the surface active agents; the acid groups can take a reaction with -OH on the surfaces of the magnetic particles; the magnetic particles can be better dispersed into the carrying liquid through the surface active agents; the sedimentary stability of the magnetorheological fluid is improved; the half-month sedimentation rate is only 5 percent; the zero field viscosity of the magnetorheological fluid can also be reduced, and is only 0.38Pa.s; the dissolution capability of the magnetorheological fluid on the magnetic particles is improved; the shearing stress can improved in an occasion with high shearing requirement by improving the volume percentage of the magnetic particles; meanwhile, the good flowability is ensured.

Owner:NANJING UNIV OF SCI & TECH

Selective lysing of cells using ultrasound

ActiveUS8518681B2Easily maintaining sterilityReduce riskBioreactor/fermenter combinationsBiological substance pretreatmentsCell membraneUltimate tensile strength

Described are embodiments that employ ultrasonic energy to selectively lyse larger adipose cells in a suspension containing adipose cells of different sizes resulting in a suspension in which the only viable cells are the small adipose cells and stem cells. Embodiments provide for generating an acoustic standing wave field of sufficient intensity and proper geometry, that high shear stress is induced on the cell membranes of cells larger than a predetermined size. The remaining small adipose cells can be physically separated from the suspension after the suspension is subjected to the acoustic standing wave field.

Owner:SOLTA MEDICAL

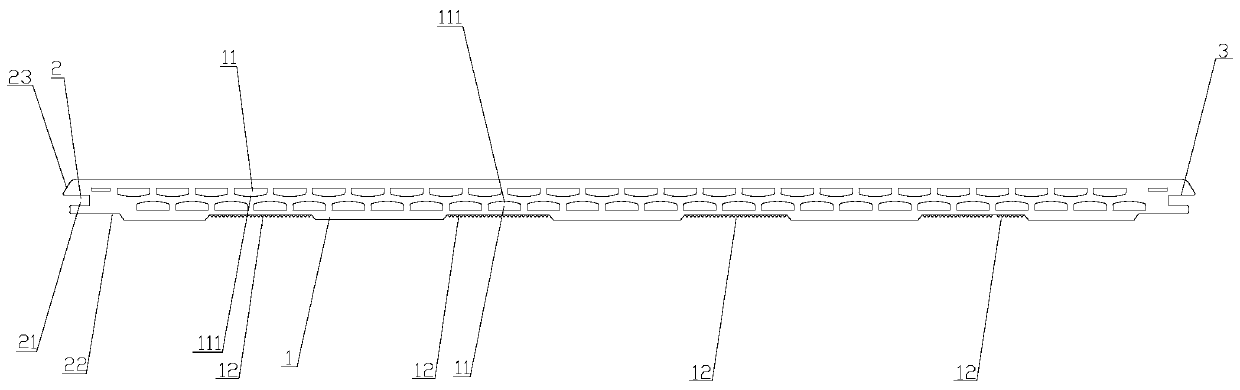

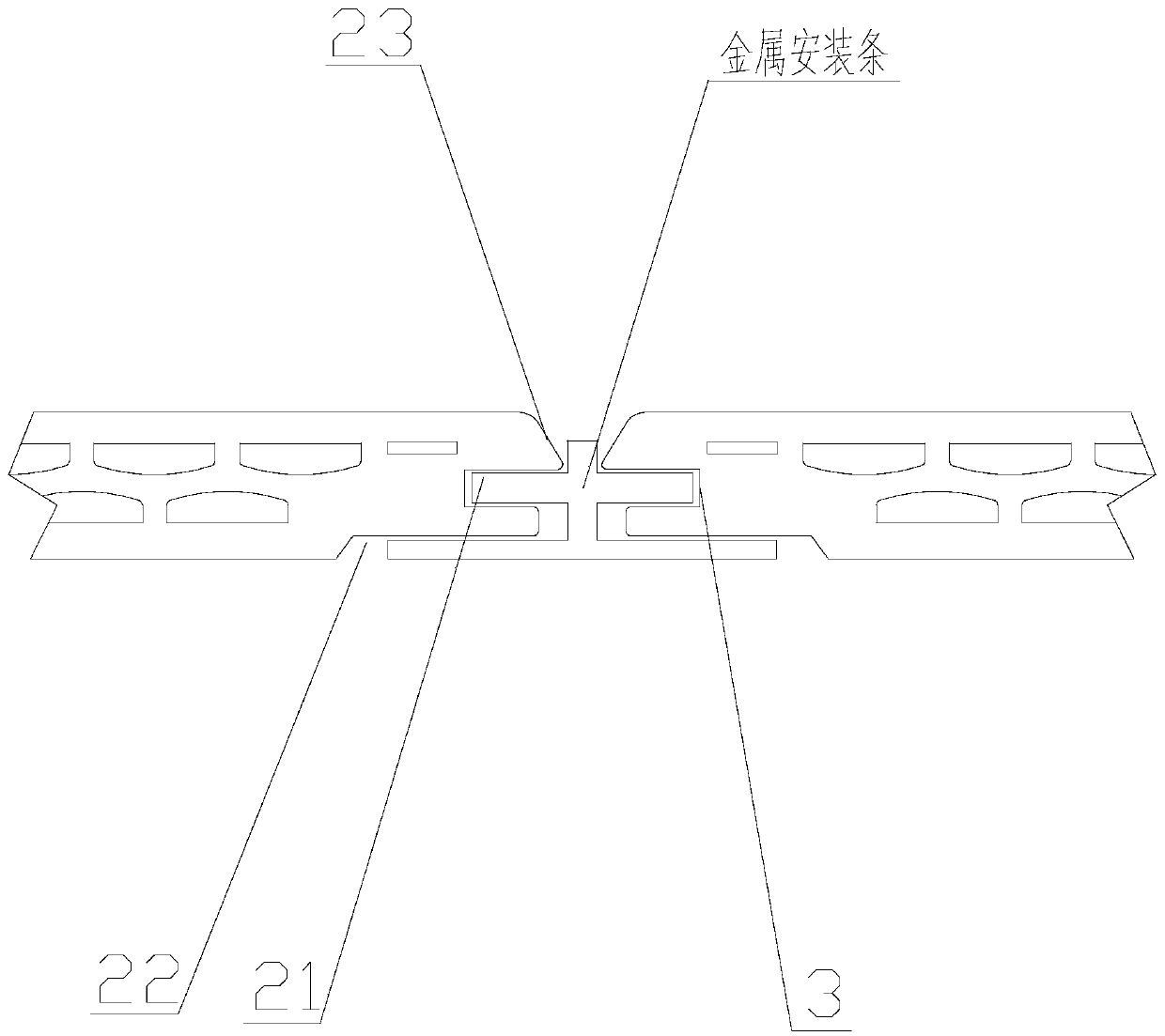

Two-row-hole fast-spliced lightweight integrated wall plate

PendingCN110230376AReduce weightImprove deformation resistanceCovering/liningsFlooringHigh shear stressFlexural rigidity

The invention discloses a two-row-hole fast-spliced lightweight integrated wall plate. The two-row-hole rapid-spliced lightweight integrated wall plate comprises a wall plate body, a wall plate firstconnecting part and a wall plate second connecting part, the cross section of the wall plate body is rectangular, the wall plate first connecting part is arranged at one end of the wall plate body, and the wall plate second connecting part capable of being matched with a wall plate first connecting part of a next wall plate body is arranged at the other end of the wall plate body. By forming two rows of hollow cavities in the wall plate body, the weight of the wall plate can be decreased, the hollow cavities are formed at intervals, curved surfaces are arranged on one sides of the hollow cavities, the mechanical principle is met, the anti-deformation ability of the wall plate can be improved, the weight of the wall plate can be decreased, the hollow cavities can bear higher shear stress, asandwich structure has high flexural rigidity, the hollow cavities further have the sound absorbing and sound insulation functions, sound can be absorbed by the hollow cavities, the influence of noise on the indoor space is reduced, the wall plate can be fast spliced and mounted through the connecting parts on the two sides, thus the mounting efficiency is improved, and the mounting quality is improved.

Owner:嘉兴市三一阳光家居科技股份有限公司

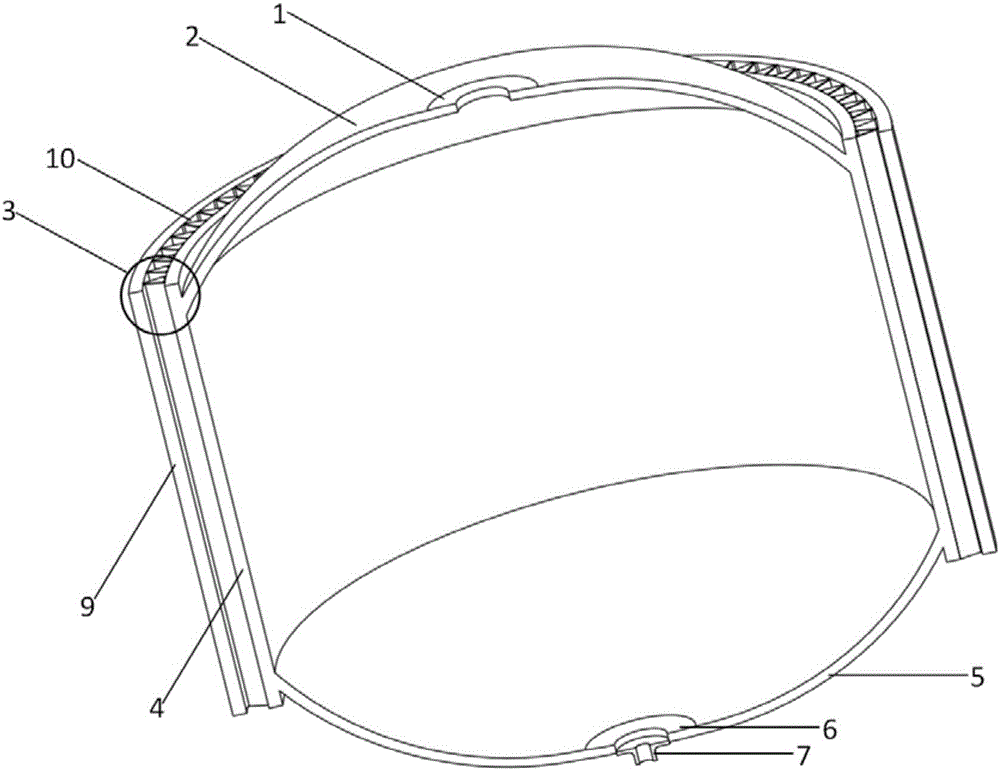

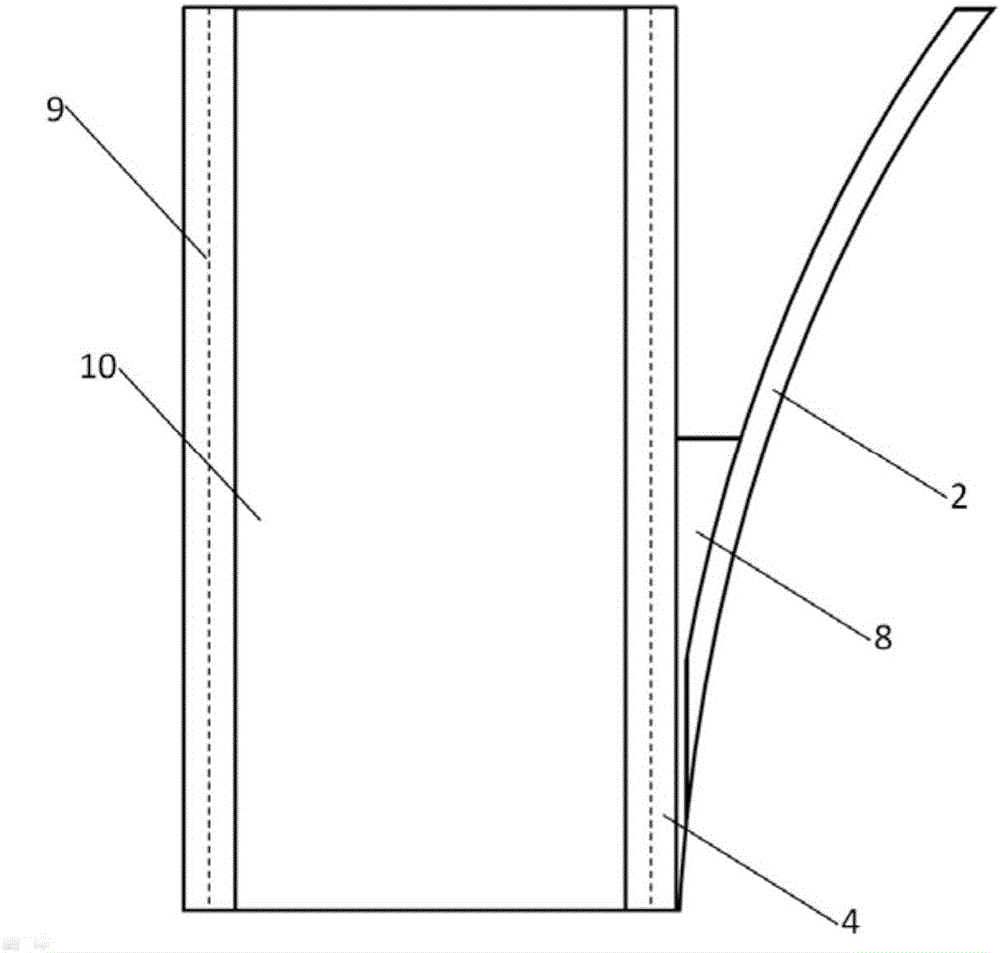

Launch vehicle low-temperature composite storage tank with triangular sandwich wall and processing method of tank

ActiveCN106586035AImprove axial load capacityIncreased shear strengthCosmonautic vehiclesCosmonautic propulsion system apparatusCarrying capacityEngineering

The invention provides a launch vehicle low-temperature composite storage tank with a triangular sandwich wall. The storage tank comprises a front bottom cover, a front sealing head, a tank cylinder section inner wall, a tank cylinder section outer wall, a rear sealing head, a rear bottom cover and a rear bottom tank housing and is characterized in that a triangular sandwich wall structure comprising reinforcing ribs is arranged between the tank cylinder section outer wall and the tank cylinder section inner wall; and Y ring triangular sandwich wall connecting structures are formed at connecting parts between the front sealing head and the tank cylinder section inner wall, between the front sealing head and the tank cylinder section outer wall, between the rear sealing head and the tank cylinder section inner wall and between the rear sealing head and the tank cylinder section outer wall. The invention further discloses a processing method of the storage tank, which employs an integral co-bonding forming technology of fiber winding forming combined with fiber laying forming. According to the storage tank, the triangular sandwich wall structures are arranged at the high shear stress connecting parts between the sealing heads and a tank cylinder section; the shear strength of the connecting parts is improved; and the storage tank has the effects that the axial carrying capacity of the storage tank is improved, the structure assembly complexity is reduced, and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

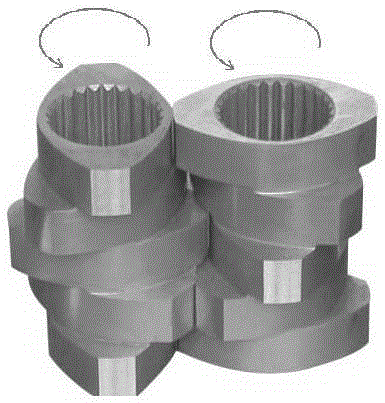

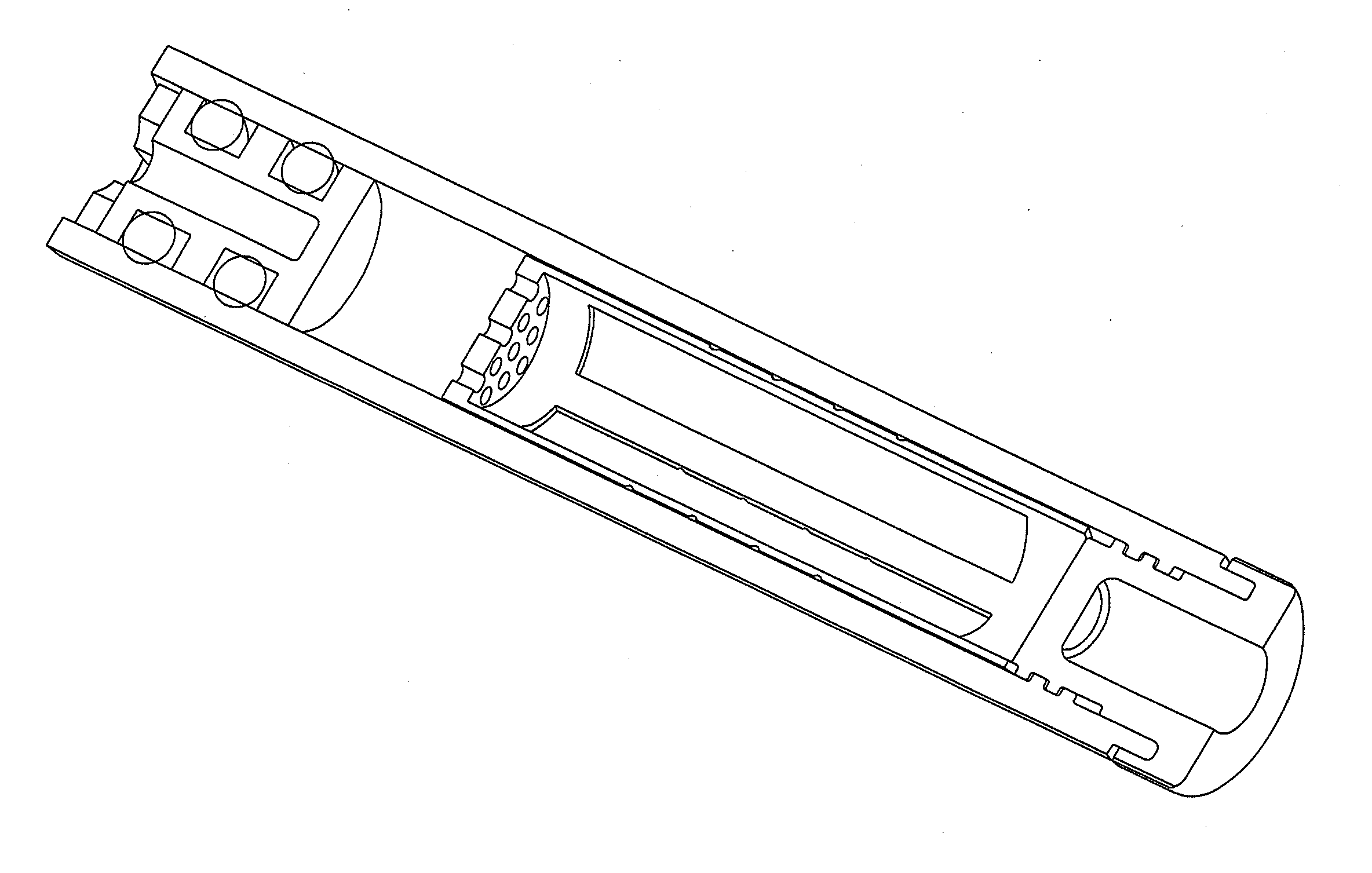

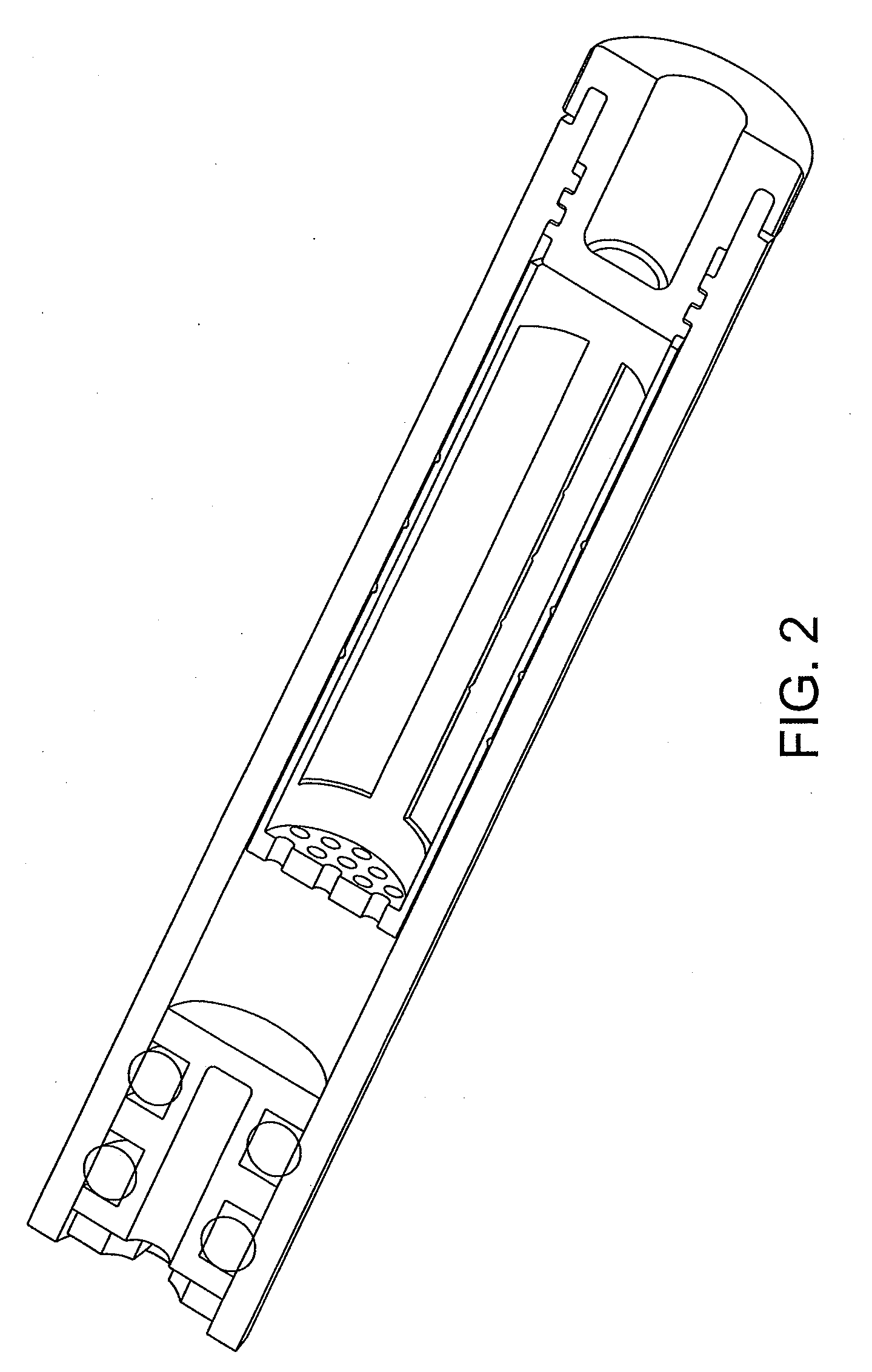

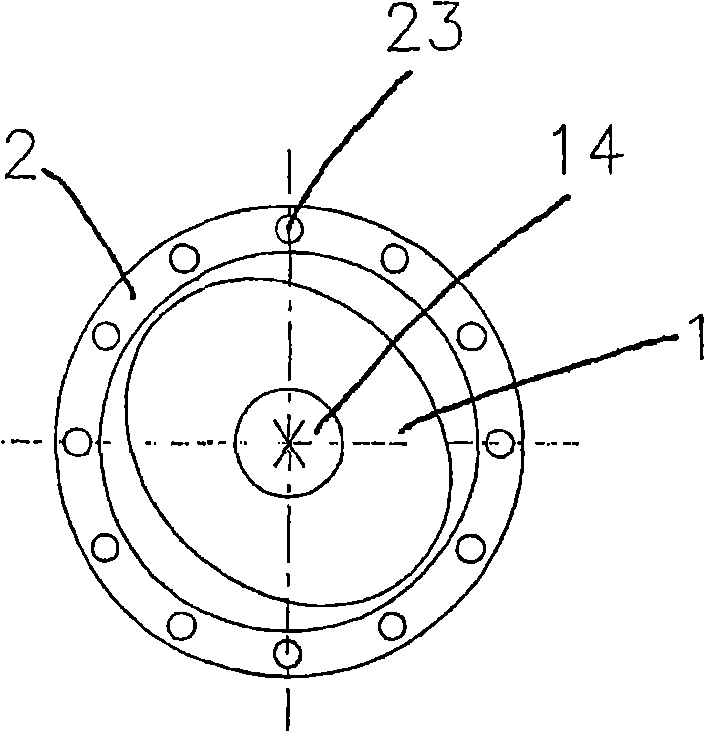

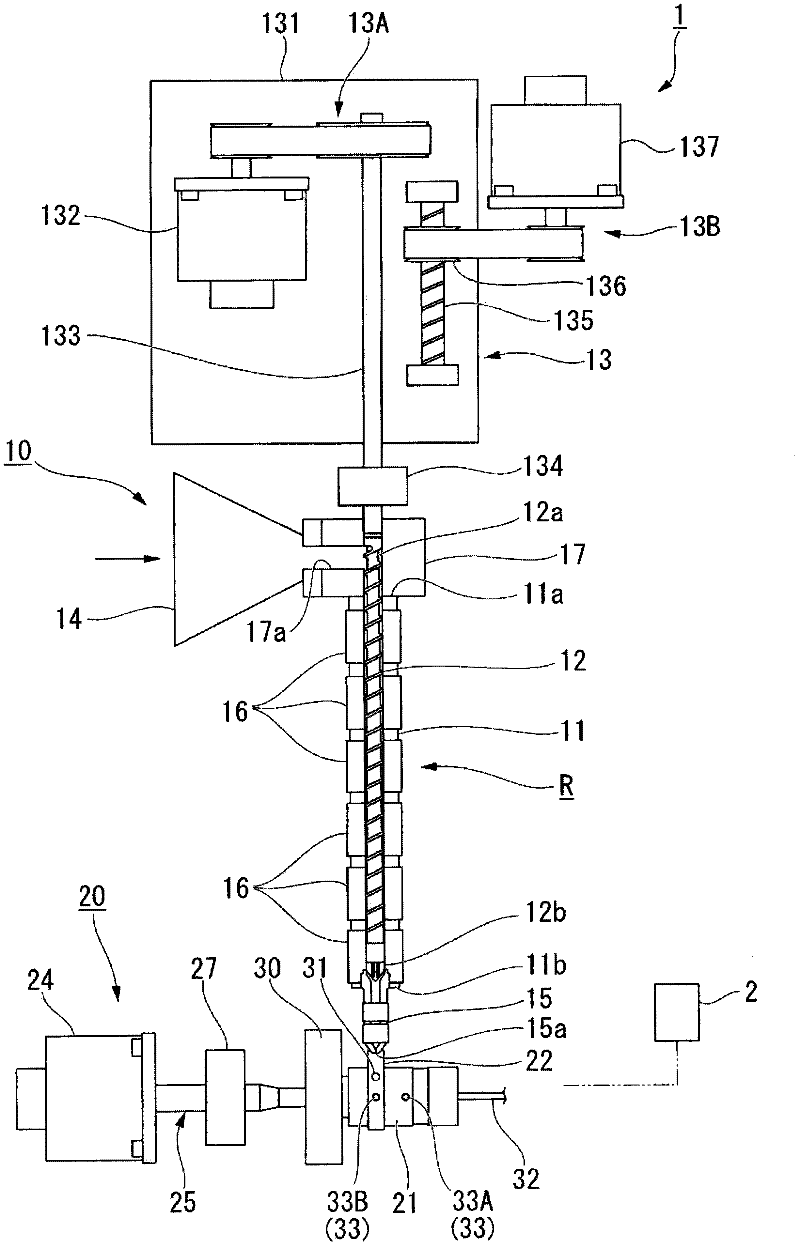

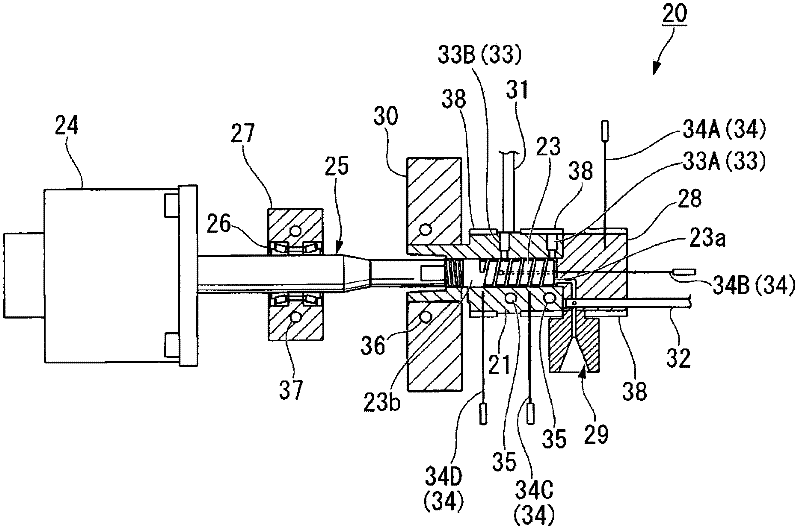

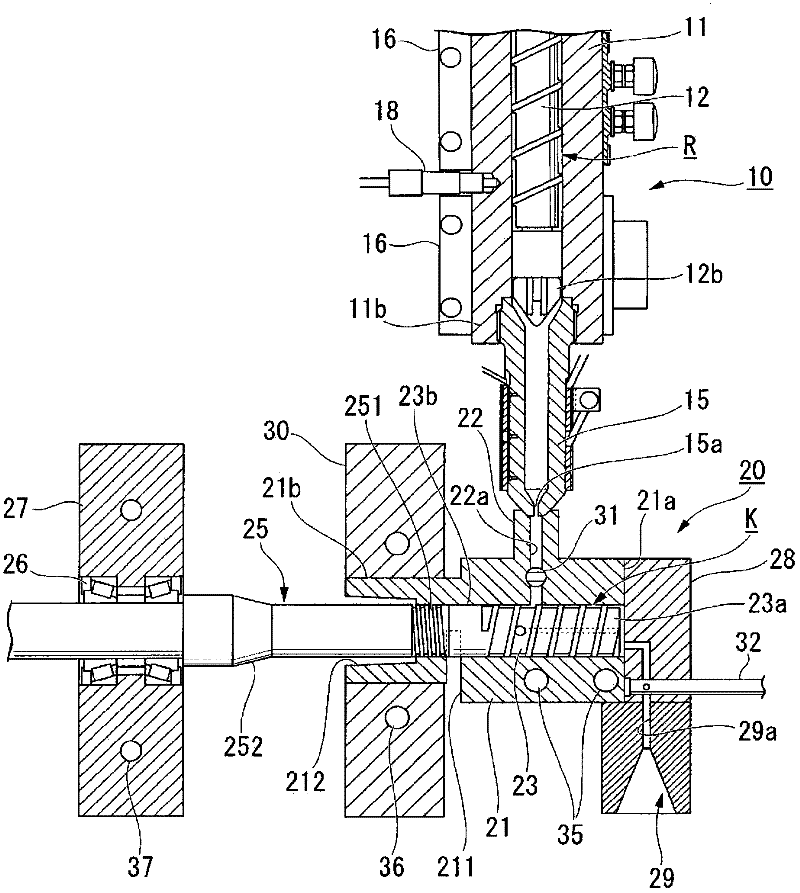

High-shear device and method of high shearing

A high-shear melt-kneader includes a high-shear unit (20) having an internal feedback-type screw (23) configured to apply high-shear stress to a melted resin, resin pressure sensors (33) for configured to detect a front portion resin pressure in the vicinity of an inlet of the internal feedback-type screw and a rear portion resin pressure in the vicinity of an outlet, and a control device configured to appropriately control a material supplying amount, a material temperature, a kneading time, and a screw rotation speed according to pressure values detected by the sensors. The control device controls the conditions such that waveforms with the lapse of time of the front and rear portion resin pressures are similar to each other and show variation to a steady state after formation of a predetermined peak value, and the front and rear portion resin pressures form a predetermined pressure difference with the lapse of time. According to the high-shear melt-kneader, it is possible to improve high-shear efficiency, increase precision of nano dispersion of a material, and stably and finely disperse / mix internal structures of immiscible polymer blend-based, polymer / filler-based and polymer blend / filler-based materials to a nano level.

Owner:NIIGATA MACHINE TECHNO CO LTD

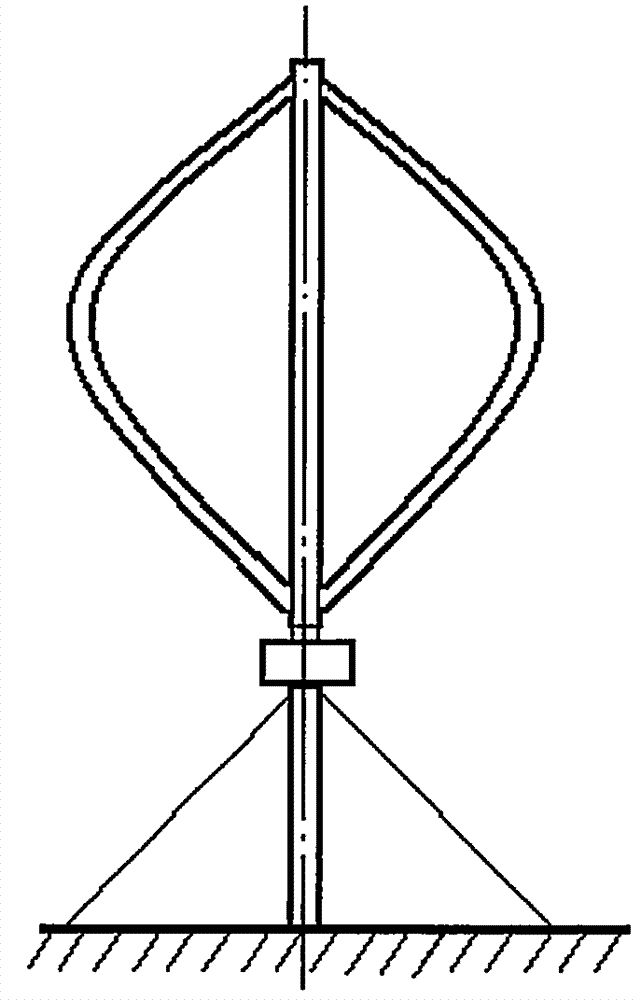

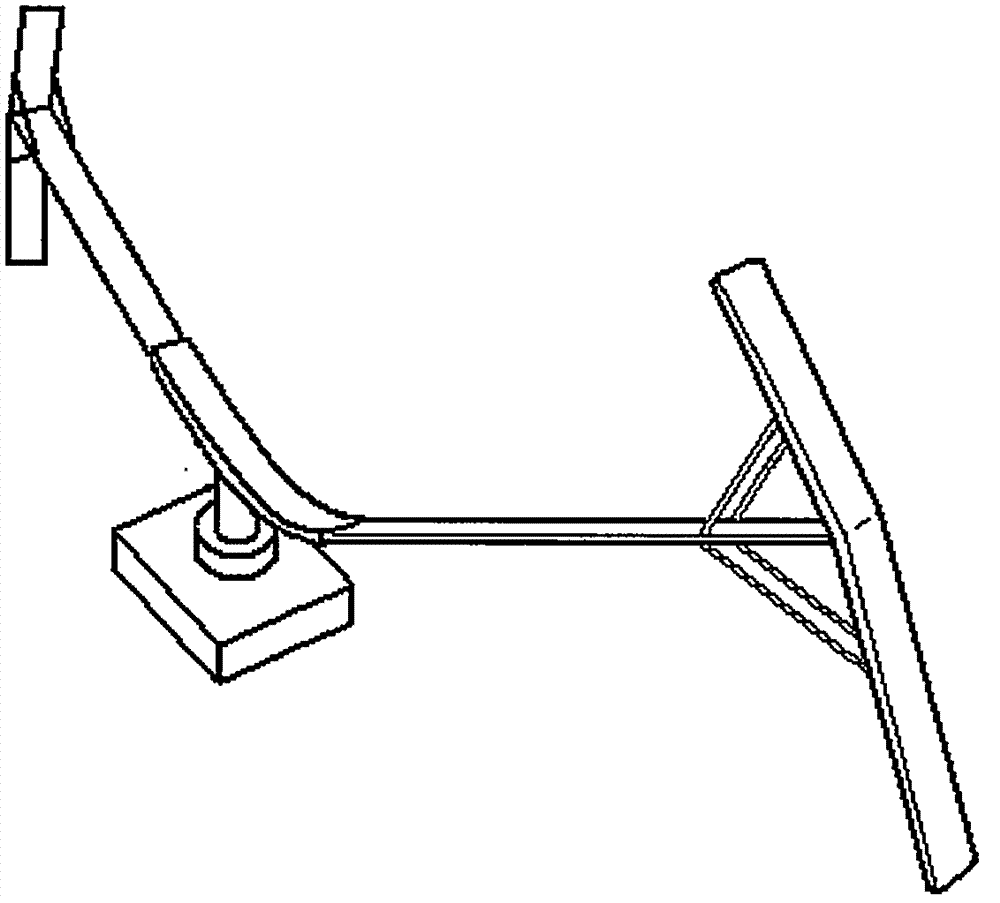

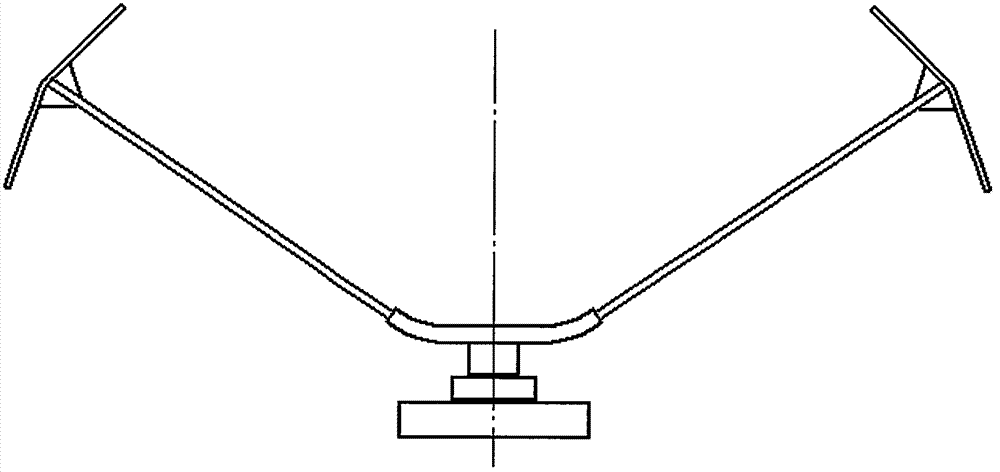

Improved extra-large vertical-axis wind-driven turbine power generator system

ActiveCN104747375ALarge starting torqueStarting torque balanceEnergy industryRenewable energy generationWind drivenForeign technology

The invention discloses a technology for an extra-large vertical-axis wind-driven turbine power generation unit. The technology for the extra-large vertical-axis wind-driven turbine power generation unit has the advantages that a turbine is an extra-large unit with the power level higher than or equal to 10MW, double-blade and single-arm AerogeneratorX designs of a British Arup company are improved to obtain double-blade and double-arm triangular designs from the perspective of structural mechanics, and accordingly the shortcoming of low structural strength due to high shear stress of cantilever beams can be overcome; starting torque can be increased by the aid of the additional Savonius turbine, driving torque is stable owing to the additional Savonius turbine, and output power of the unit can be increased; a novel power generator and a novel motor converter technology are matched with each other, so that a large wind power system can be formed and becomes the extra-large vertical-axis wind power generation unit with integrated novel domestic and foreign technologies and high industrial implementation degrees.

Owner:于岳亮 +8

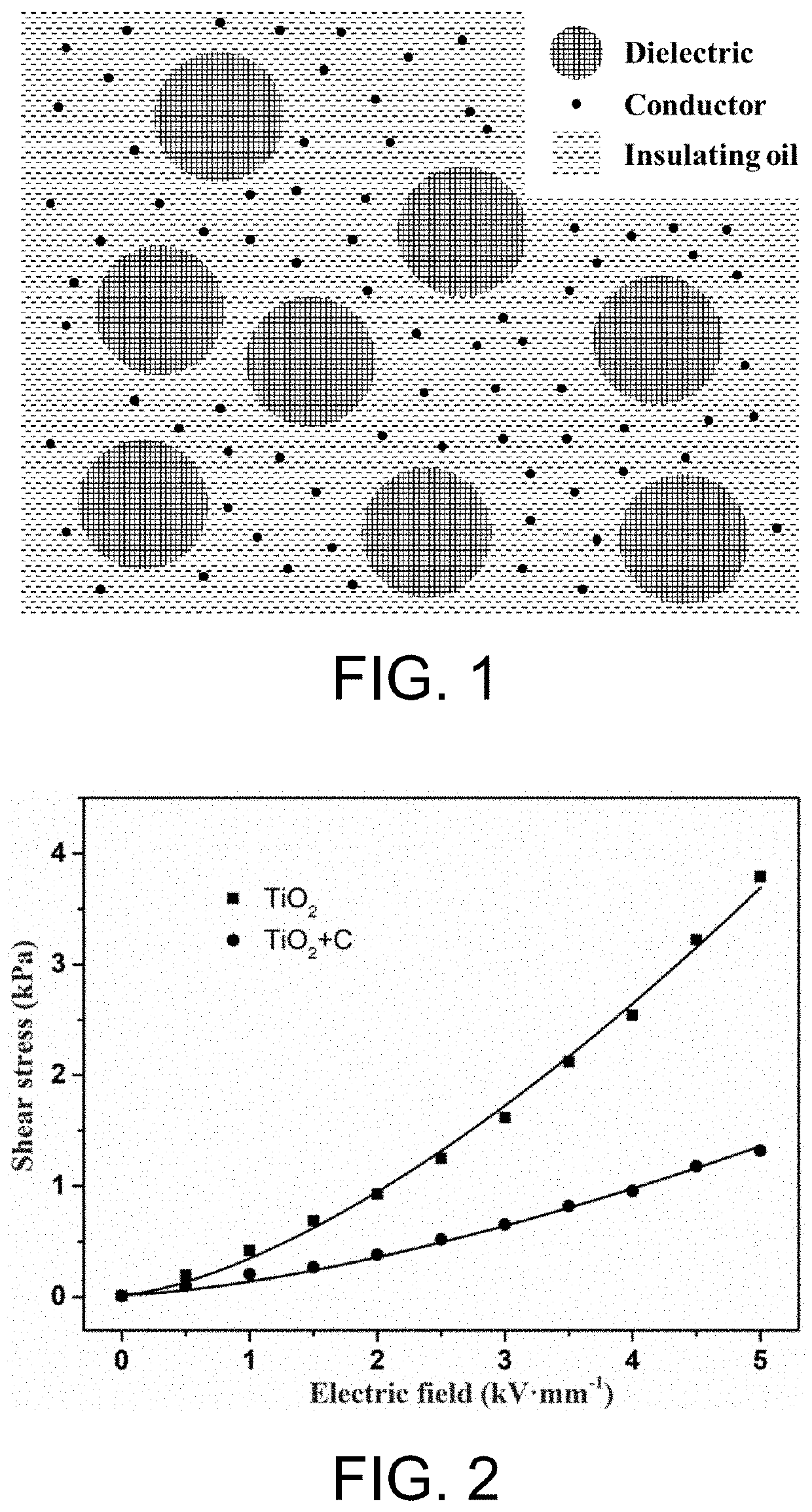

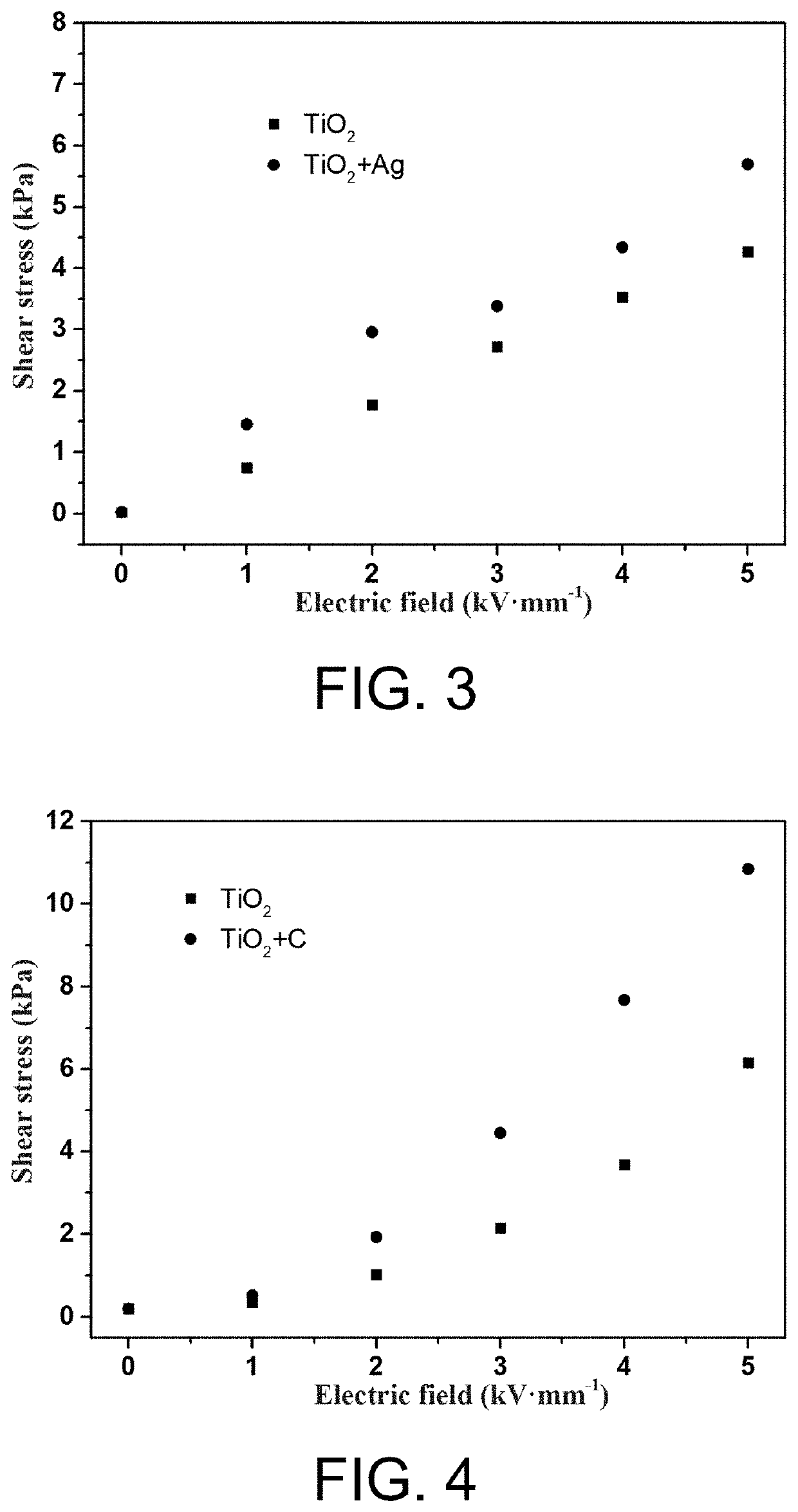

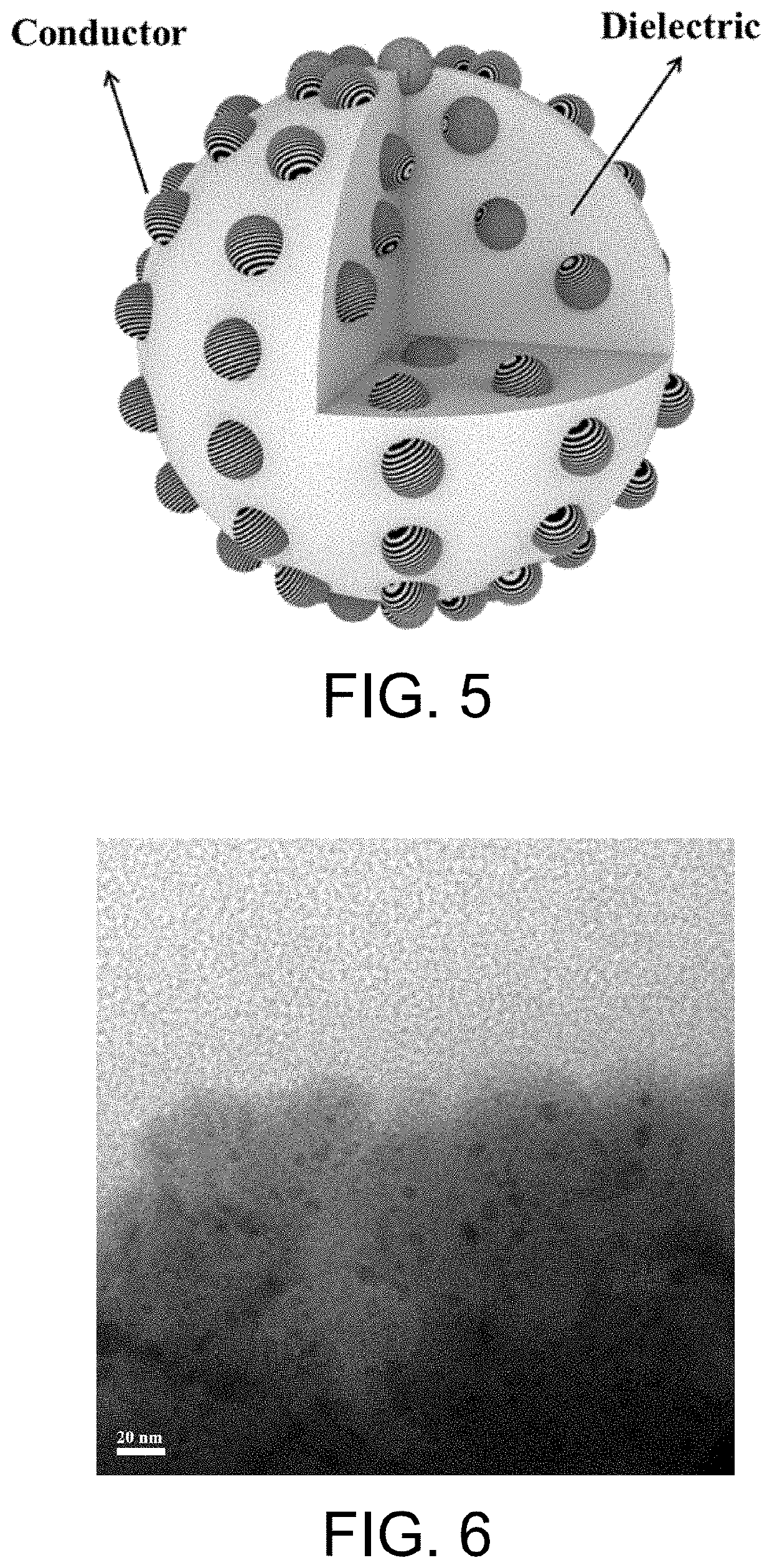

Electrorheological fluid

ActiveUS20200024543A1Increase shear stressSmall currentThickenersBase-materialsDielectricThermodynamics

The present invention provides an electrorheological fluid, which includes a dielectric particle, a conductor particle and insulating oil, and the dielectric particle is evenly dispersed in the insulating oil; wherein the conductor particle is evenly dispersed in the insulating oil or inlaid in an interior and on a surface of the dielectric particle. The electrorheological fluid has the advantages of high shear stress, long service life, good temperature stability and small leakage current.

Owner:SUN YAT SEN UNIV

High-strength lifting sling for building and manufacturing method thereof

InactiveCN104878312AHigh strengthIncrease shear stressFurnace typesHeat treatment furnacesConstruction engineeringStructural engineering

The invention relates to a high-strength lifting sling for a building. The lifting sling comprises a lifting sling head. By improving the contents of chemical components of the lifting sling head and a microstructure, and by improving a preparation method of the lifting sling head, a lifting sling product which has higher tensile strength and high shear stress resistance is obtained.

Owner:浙江汇力建设有限公司

Selective lysing of cells using ultrasound

InactiveUS20130012927A1Easily maintaining sterilityReduce riskCulture processMicroorganism lysisCell membraneViable cell

Described are embodiments that employ ultrasonic energy to selectively lyse larger adipose cells in a suspension containing adipose cells of different sizes resulting in a suspension in which the only viable cells are the small adipose cells and stem cells. Embodiments provide for generating an acoustic standing wave field of sufficient intensity and proper geometry, that high shear stress is induced on the cell membranes of cells larger than a predetermined size. The remaining small adipose cells can be physically separated from the suspension after the suspension is subjected to the acoustic standing wave field.

Owner:SOUND SURGICAL TECH

Silylene/graphene composite material, and preparation method and applications thereof

The invention provides a silylene / graphene composite material, and a preparation method and applications thereof. According to the preparation method, a silicon material and a graphene material are mixed, and are processed with high shear stress generated at the interfaces between screw rod engaged screw elements in extruder screw rotating process; the silicon material is taken as a grinding medium of the graphene material; and at the same time, relatively strong Van der Waals bonds are formed between the silicon material and graphene sheets, and rearrangement of silicon atoms on the graphene sheets is realized because of the sheet characteristics of graphene so as to form the silylene / graphene composite material. Mechanical exfoliation and physical shearing are adopted, exfoliation of graphene sheets and growth of silylene are completed via one step operation at the same time, complex high vacuum silylene growth technology is avoided, application of gas materials which are capable of inducing heavy pollution is avoided, cost is reduced, industrial application value is extremely high, and the silylene / graphene composite material is suitable to be taken as a lithium battery anode material.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

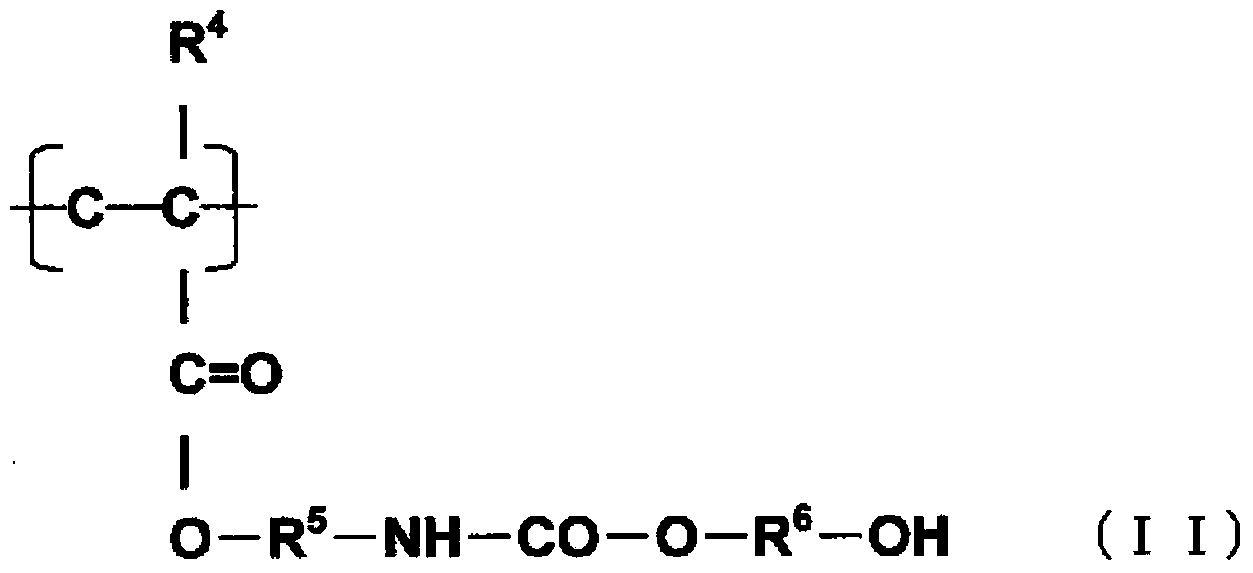

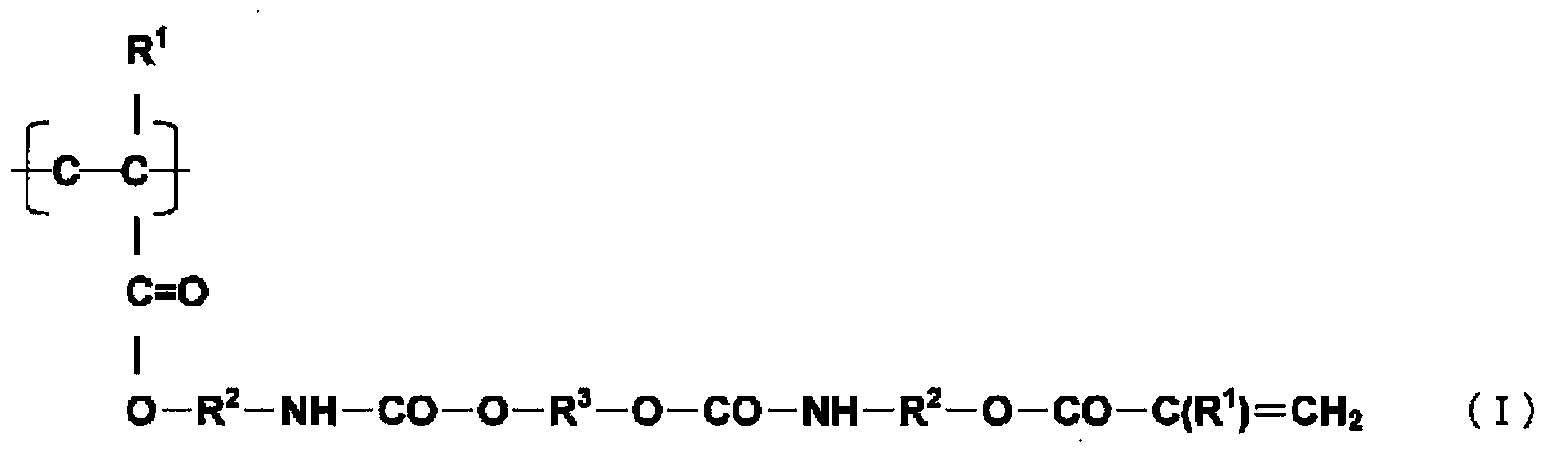

Composition for transparent adhesive/pressure-sensitive adhesive sheet, process for producing same, and transparent adhesive/pressure-sensitive adhesive sheet

InactiveCN104254582AImprove adhesionAltitude difference followabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolyolefinPolyol

Provided is a composition for transparent adhesive / pressure-sensitive adhesive sheets which are for use in sealing electronic components or protecting wiring, the composition showing moderate pressure-sensitive adhesive properties and conformability to level differences during initial adhesion to adherends and, upon photocuring after bonding, coming to show high peel resistance and high shear stress that are equal to those of adhesives. The composition for transparent adhesive / pressure-sensitive adhesive sheets comprises: (A) a (meth)acrylic copolymer having structural units represented by chemical formula (I) (wherein R1's each independently represent a hydrogen atom or a methyl group, R2's each independently represent a C1-6 alkylene group, and R3 represents a residue formed by removing hydroxy groups from a polyolefin polyol or hydrogenated polyolefin polyol) and chemical formula (II) (wherein R4 represents a hydrogen atom or a methyl group, R5 represents a C1-6 alkylene group, and R6 represents a residue formed by removing hydroxy groups from a polyolefin polyol or hydrogenated polyolefin polyol); (B) a crosslinking agent; and (C) a photopolymerization initiator.

Owner:SHOWA DENKO KK

Process for reducing surface aberrations

InactiveUS20070164467A1Reduce generationReduce occurrenceCeramic shaping apparatusFlat articlesProduction rateProcedure Agents

The processes and resins of the present invention allow the extrusion of polymer products, such as polymer films, that have a reduced occurrence of surface aberrations, e.g., surface melt fracture and / or haze bands and / or haze. Preferably, the polymer products produced in accordance with the present invention are substantially free of surface aberrations even when manufactured under conditions of high sheer stress such as those conditions that occur at commercial production rates. In part, the present invention provides processes for polymer extrusion wherein the resins employed are treated using heat in an atmosphere sufficient to substantially eliminate the tendency to create surface aberrations. The resins can have reduced or substantially eliminated concentrations of low molecular weight components. In some embodiments, both the polymer resins and the extruded polymer products have reduced concentrations of processing aid(s), e.g., the polymer resins and the extruded polymer products are substantially free of processing aid(s).

Owner:BATTENFELD GLOUCESTER LLC

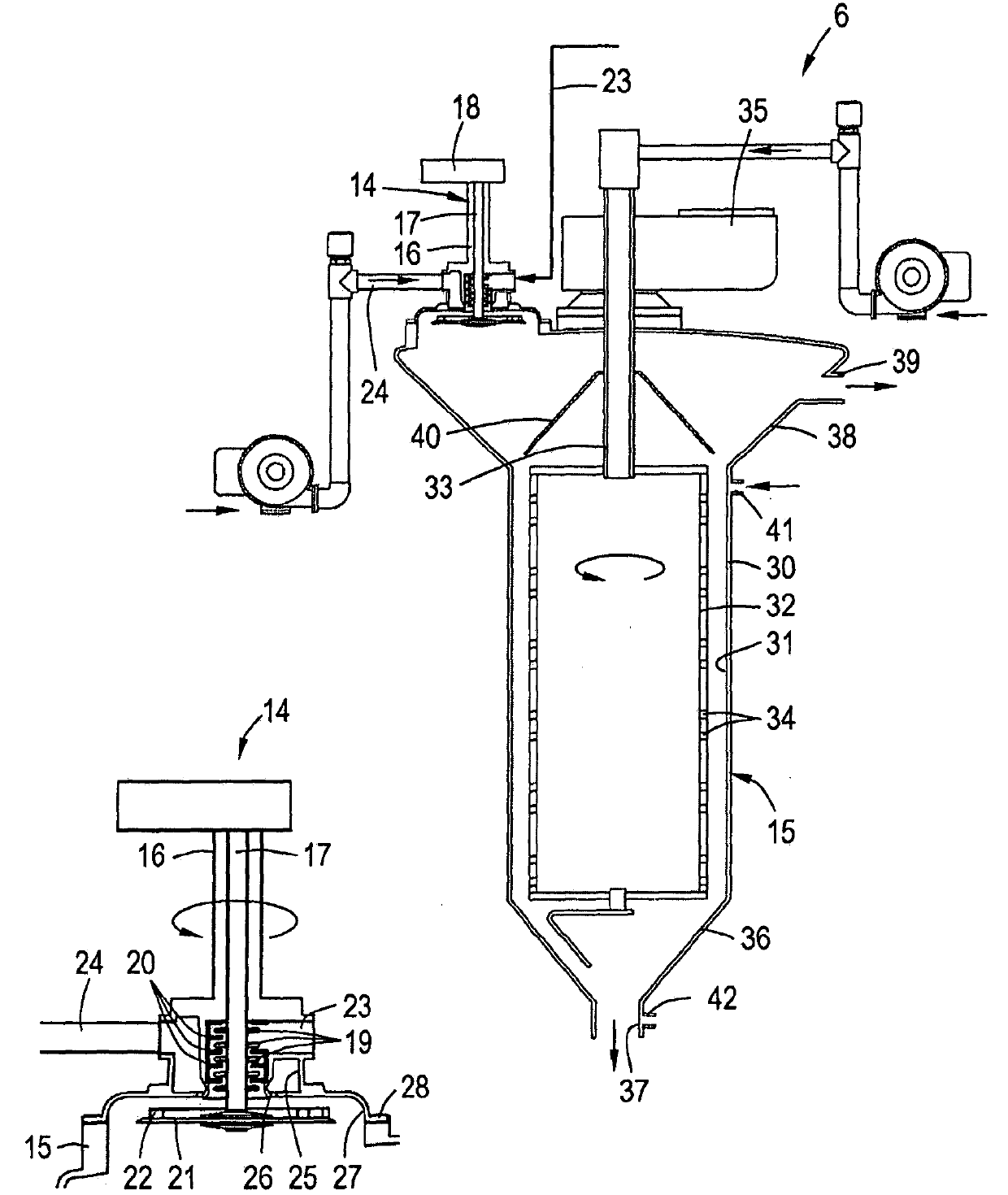

Device and process for conching edible mass

The invention relates to a system (1) for conching edible mass, in particular cocoa containing mass, such as chocolate, cocoa liquor or compound, comprising a shear device, in particular a so-called taste-changer (14), in turn comprising a housing (16), a shaft (17) rotatably mounted in the housing (16), means (19, 20) for subjecting the edible mass to high shear stresses, means (21, 22) for spreading the edible mass after it has been subjected to high shear, and an inlet (24, 25) for supplying a gas to the spread edible mass. The system further comprises a thin film evaporator (15) to treat the edible mass exiting the shear device (14).

Owner:ROYAL DUYVIS WIENER

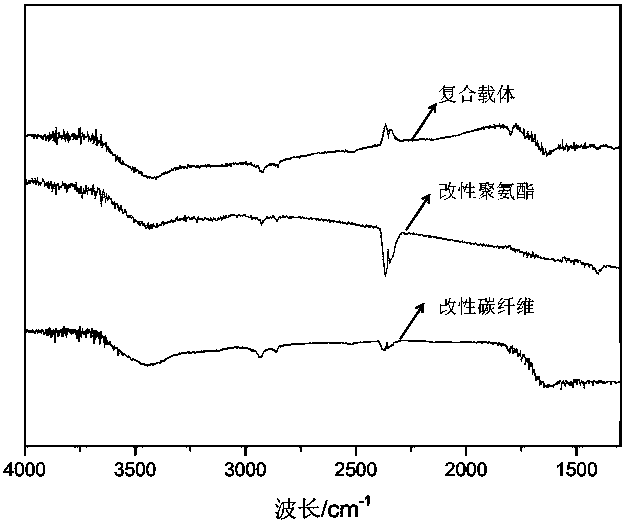

Method for preparing composite carrier by taking modified carbon fiber and polyurethane as raw materials

ActiveCN109266640AAvoid uneven mixingNo secondary pollutionOn/in organic carrierOn/in inorganic carrierFiberEpoxy

Carbon fiber was modified by coating and polyurethane was hydrophilically modified to prepare composite carrier for immobilized cells. The composite carrier of modified carbon fiber and polyurethane is obtained by weighing certain quality carbon fiber powder, coating in certain concentration solution, adding certain quality epoxy alcohol modified polyurethane, fully immersing, drying initially, and radiation oxidation in air. Carboxyl groups were introduced into the surface of coated carbon fibers, and hydroxyl groups were introduced into epoxy alcohol modified polyurethanes. The modificationof the two materials not only played an oxidative role, but also radiation oxidation treatment was helpful to improve the problem that the cells with larger pore size of polyurethane were easy to falloff and the cells were easy to fall off from carbon fibers under high shear stress. The modified carbon fiber and the polyurethane composite carrier prepared by the invention has the characteristicsof simple operation, strong stability, good biocompatibility, good immobilization effect and the like, and is a good cell immobilization carrier.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com