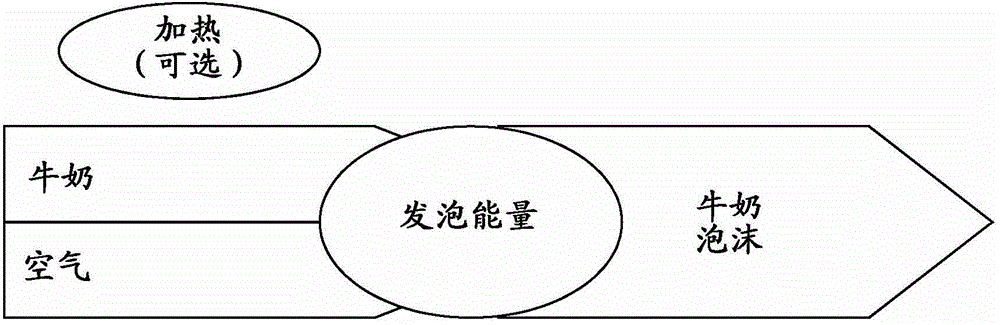

Device for producing milk foam

A milk foam and milk technology, which is applied in beverage preparation devices, applications, kitchen utensils, etc., can solve the problems of unreliable milk foam and difficult to accurately control, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

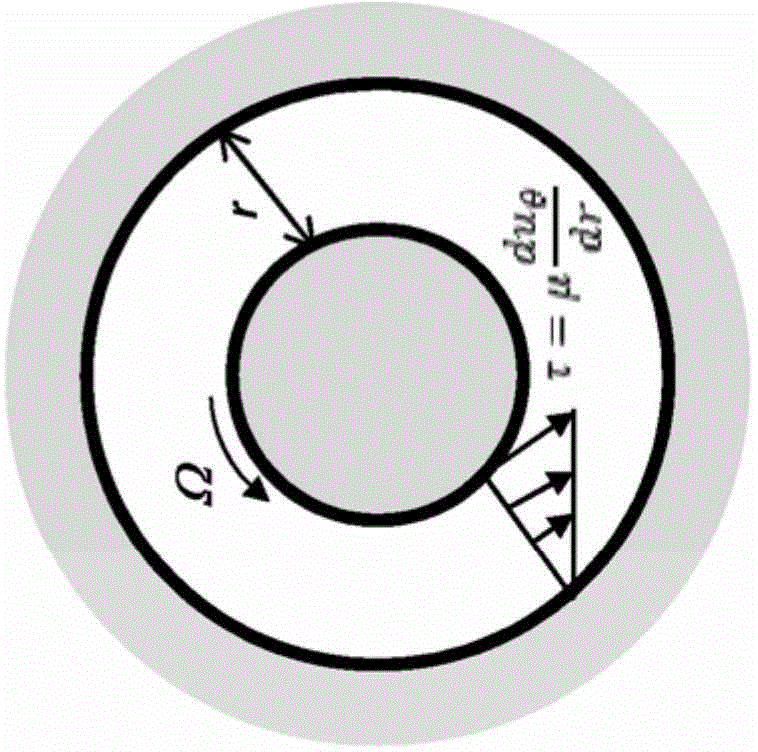

[0052] Although the milk and air supply circuits are part of the device according to the invention, for simplicity, the Figures 3 to 7 They are not shown in .

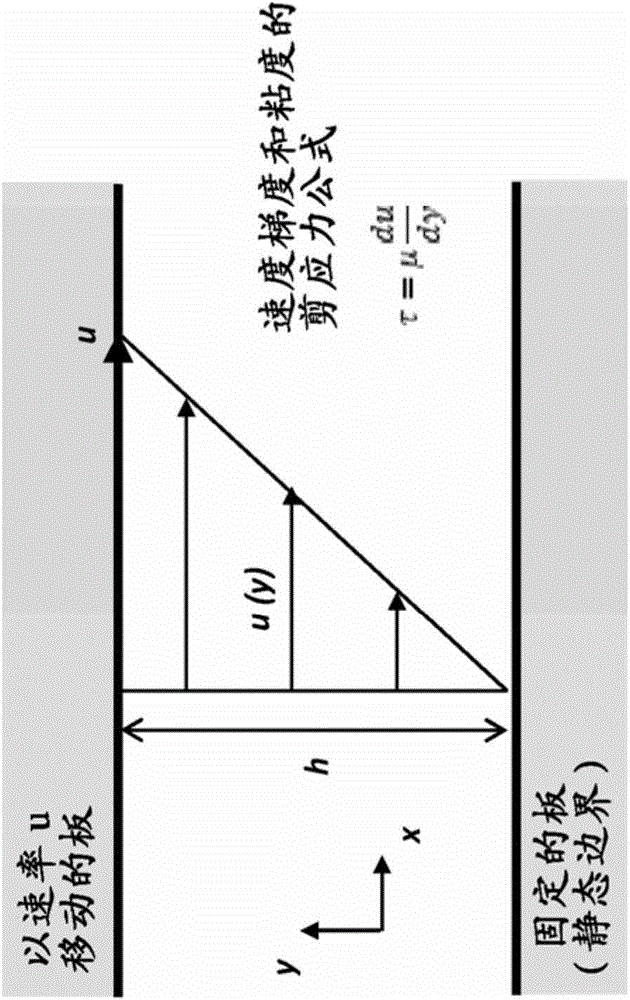

[0053] image 3 A device 1 for generating milk froth according to a first embodiment of the invention is schematically shown. The device 1 comprises an at least partially hollow outer cylinder 2, wherein the hollow defines an inner diameter o of the outer cylinder. Inside the outer cylinder 2 , that is, in the hollow portion, an inner cylinder 3 concentric with the outer cylinder 2 is provided. The inner cylinder 3 has an outer diameter i. The outer cylinder 2 and the inner cylinder 3 are rotatable relative to each other about a common axis of rotation. To this end, preferably, the inner cylinder 3 can surround image 3 The axis of rotation indicated by the dotted line in the middle rotates, that is, the inner cylinder 3 is the rotor. The outer cylinder 2 is preferably fixed, ie the outer cylinder 2 is preferabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com