Patents

Literature

633 results about "Bill of materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bill of materials or product structure (sometimes bill of material, BOM or associated list) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. A BOM may be used for communication between manufacturing partners or confined to a single manufacturing plant. A bill of materials is often tied to a production order whose issuance may generate reservations for components in the bill of materials that are in stock and requisitions for components that are not in stock.

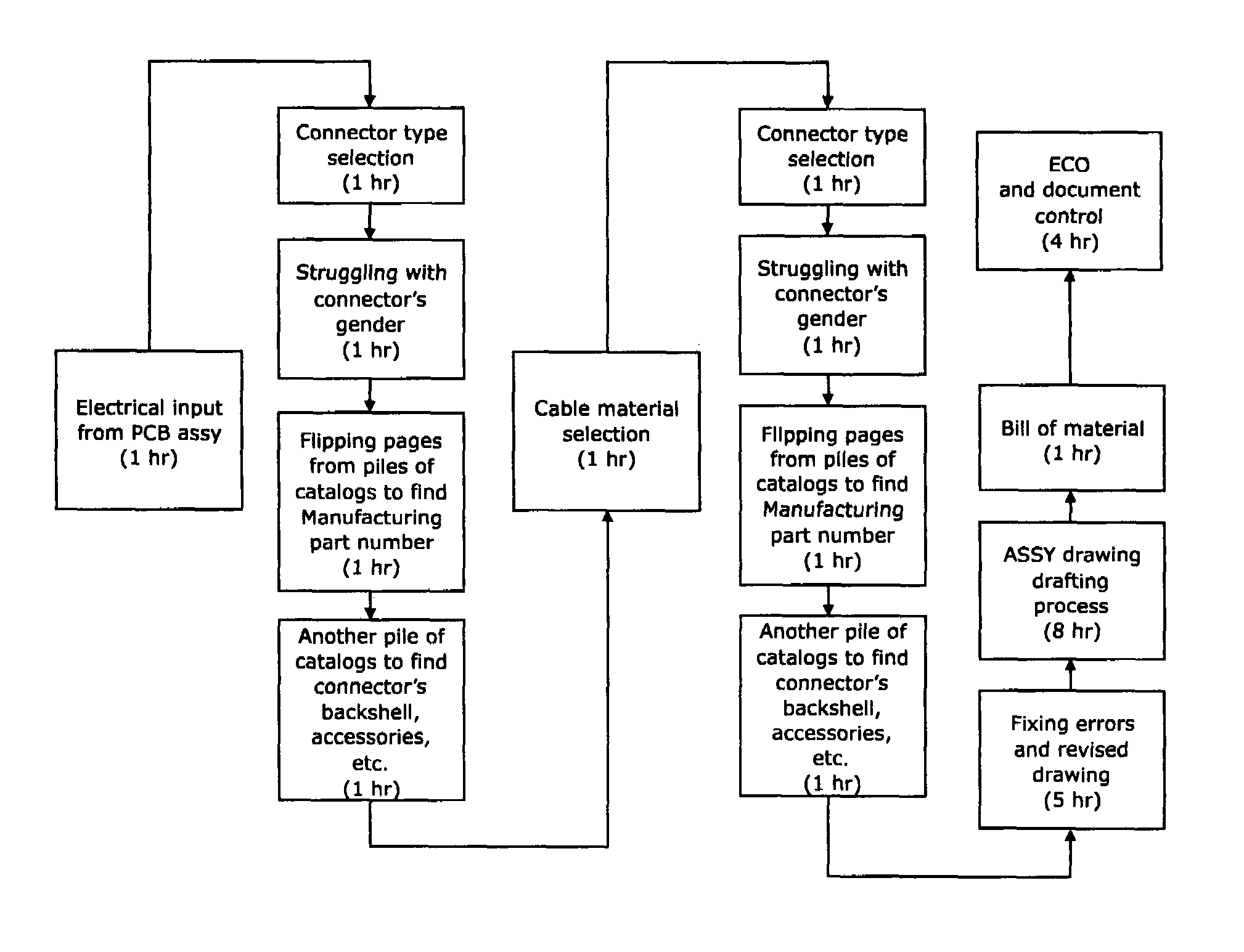

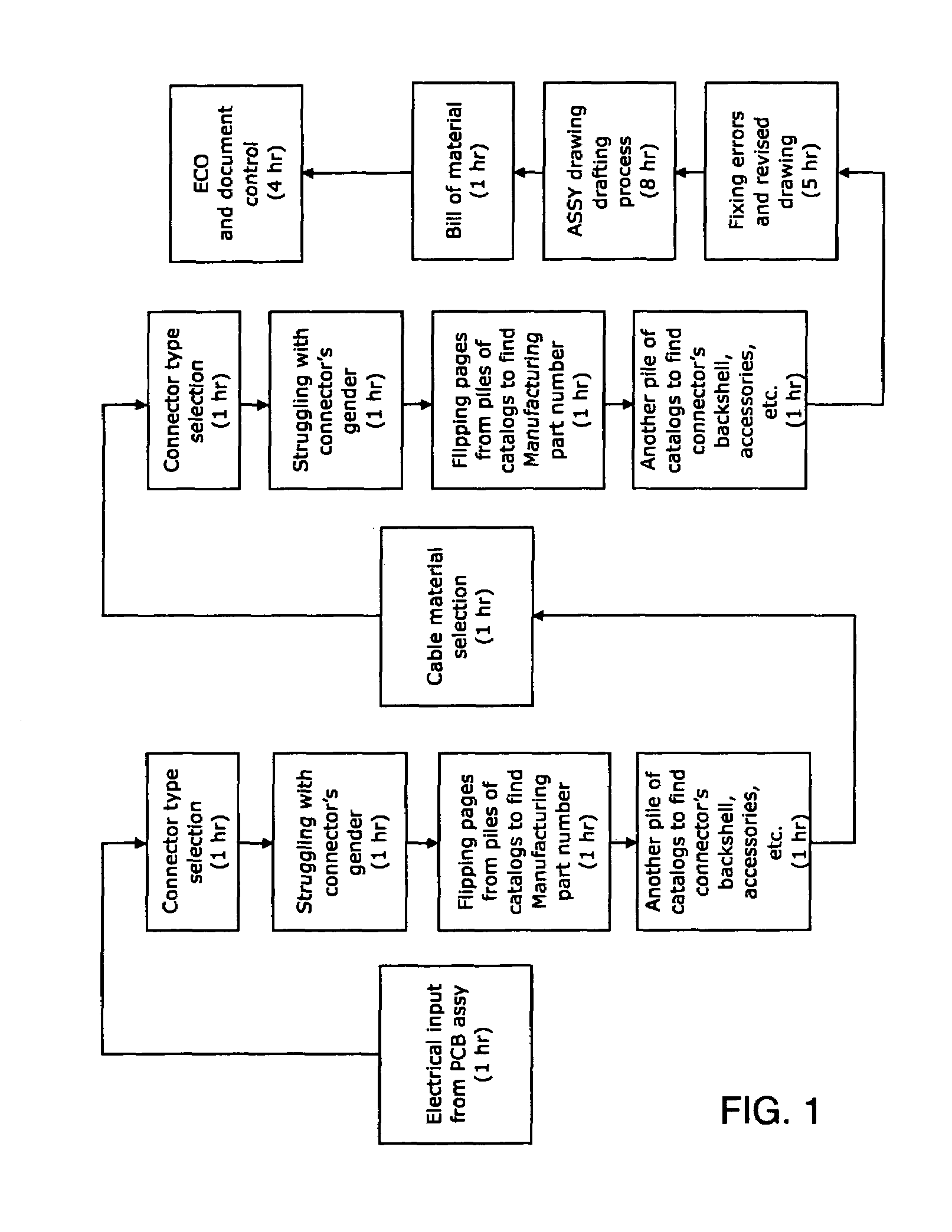

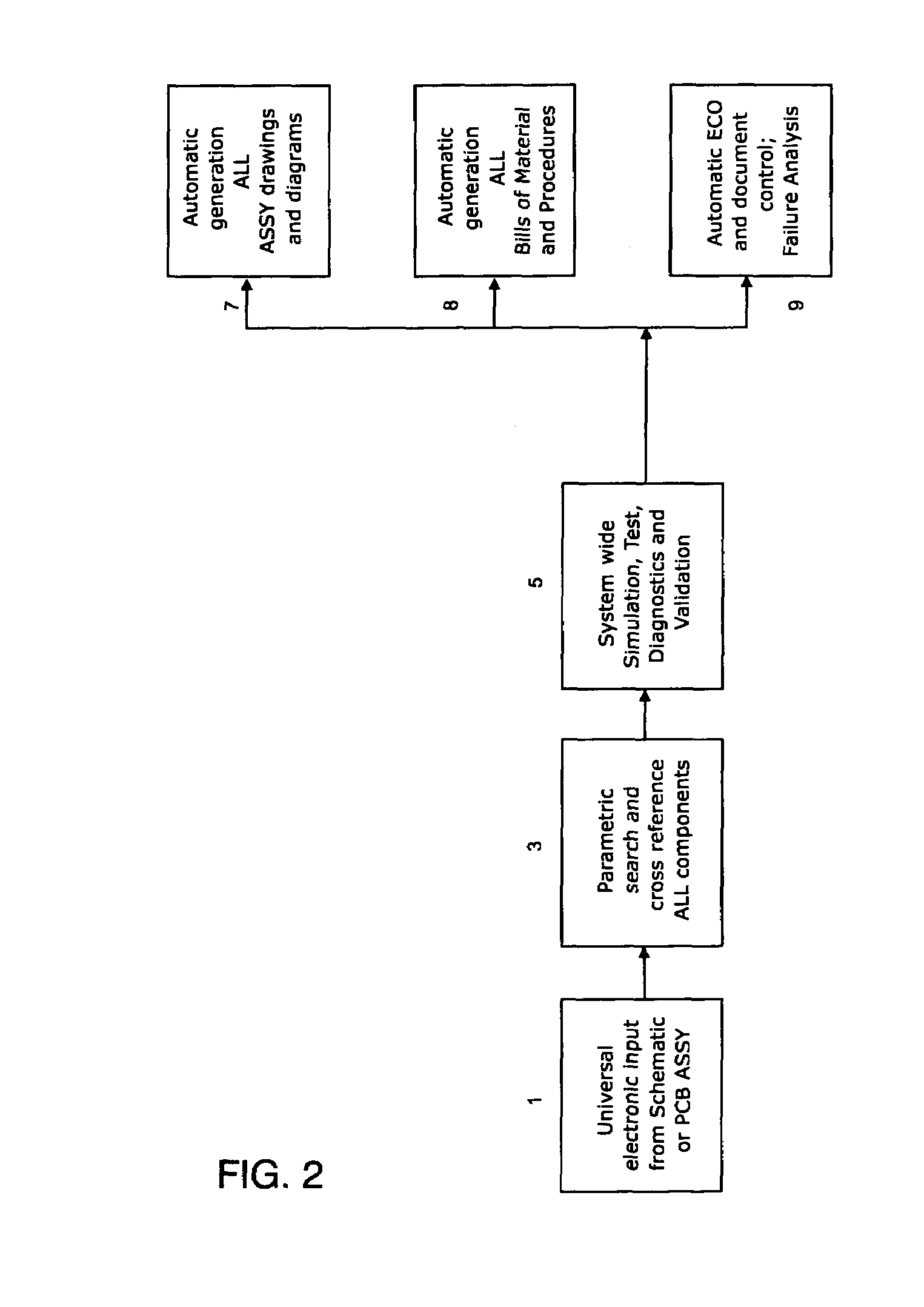

PLM-supportive CAD-CAM tool for interoperative electrical & mechanical design for hardware electrical systems

InactiveUS20050080502A1Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

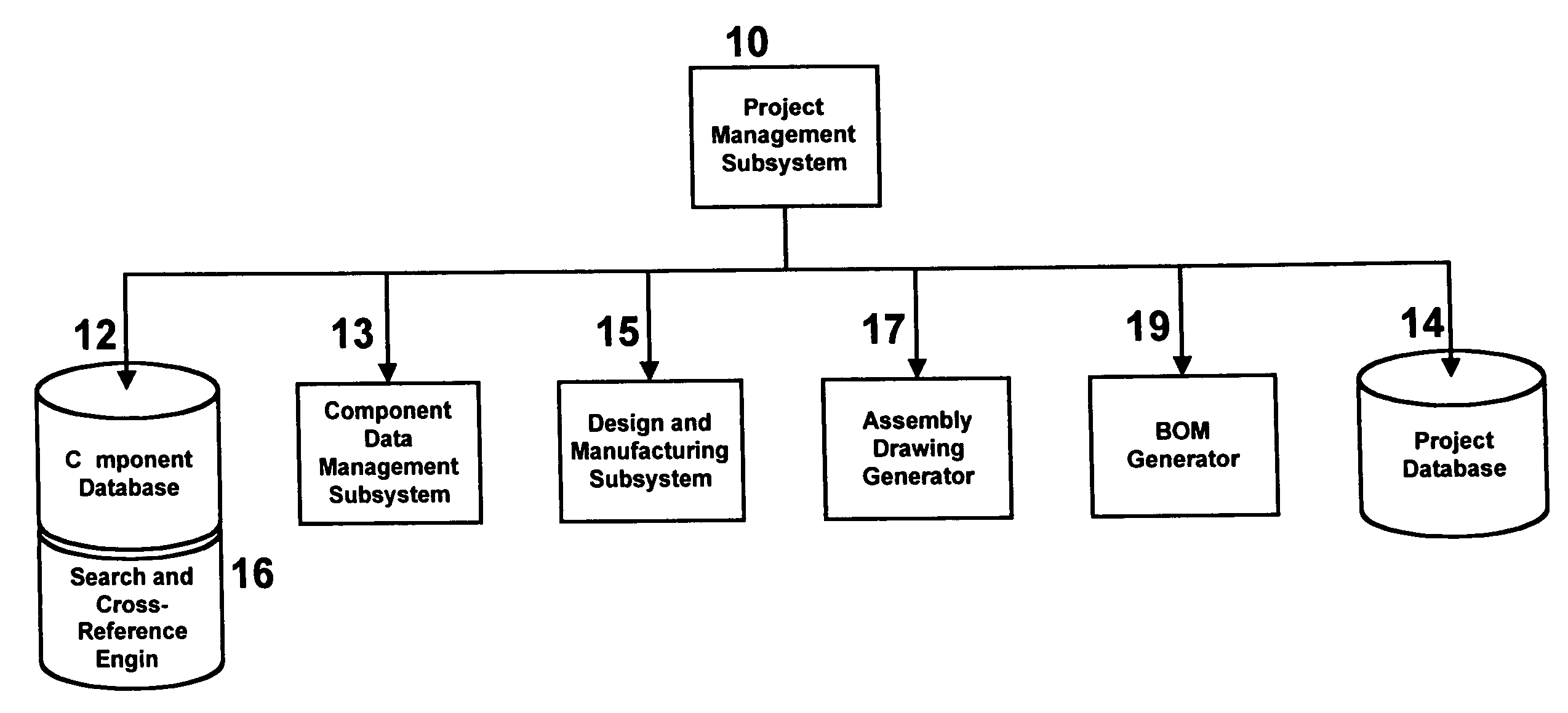

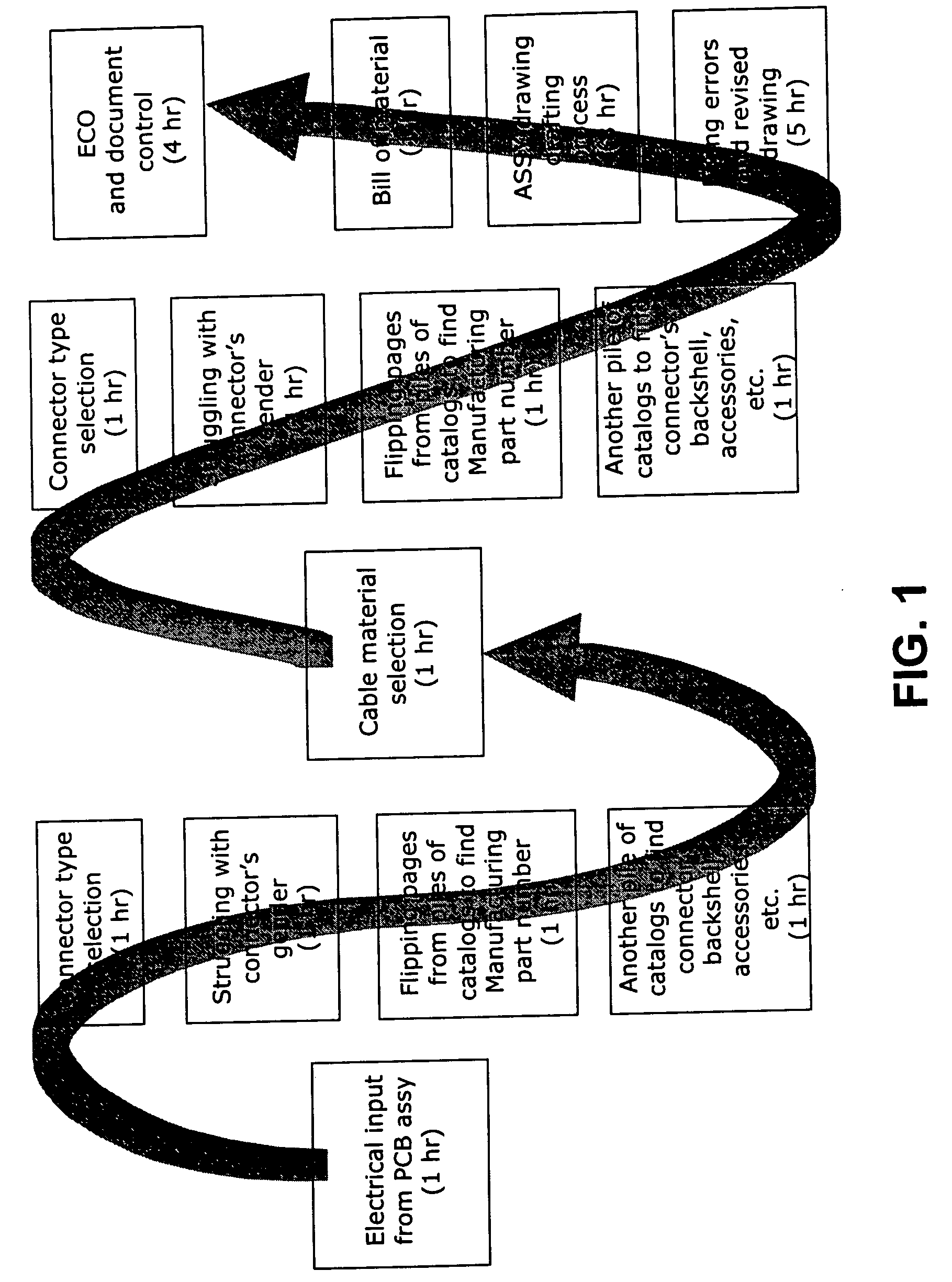

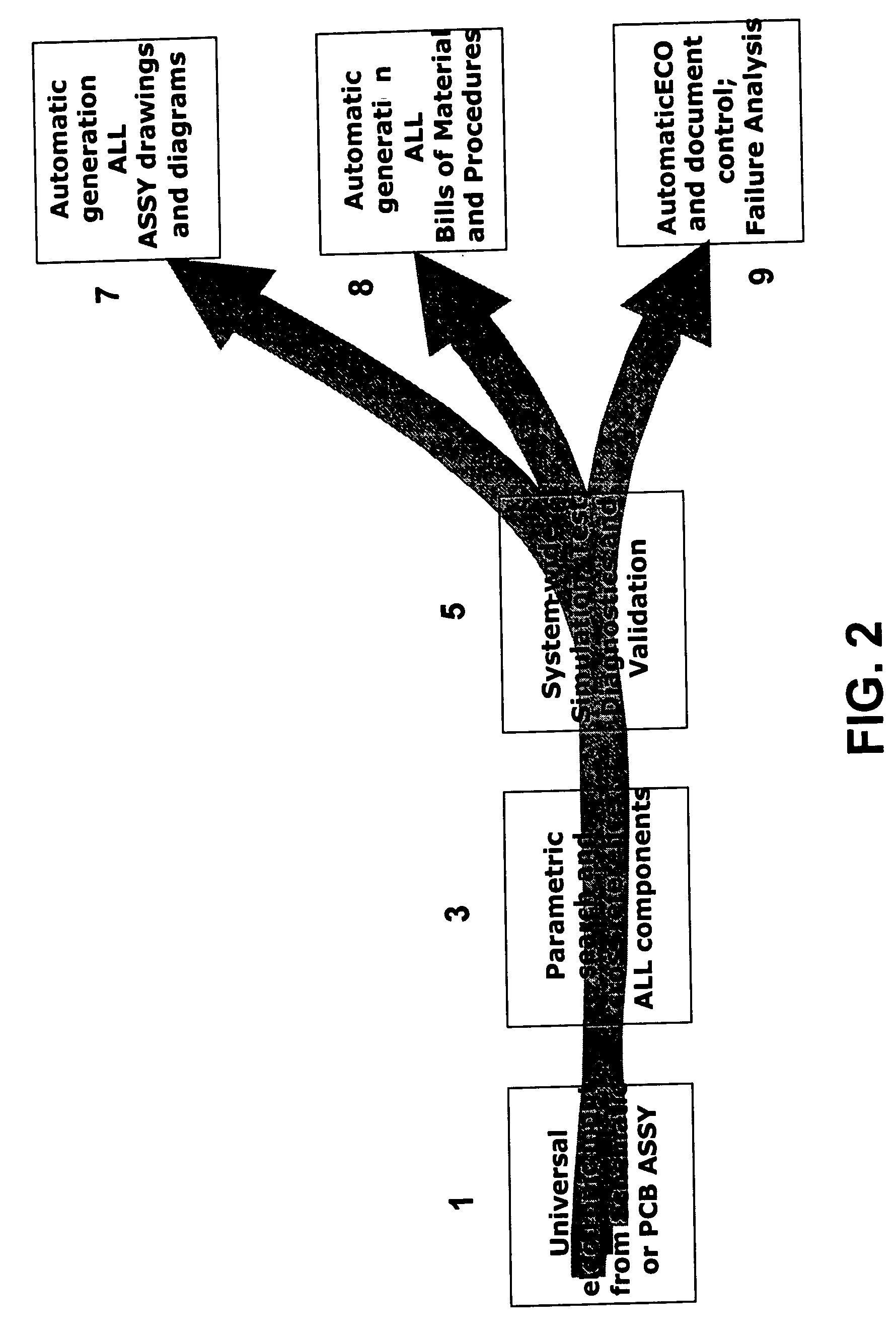

This invention is a tool for computer-aided design, computer-aided manufacturing forming a Project Management System, comprising: (1) a Component Database; (2) a Component Data Management System; (3) a Design and Manufacturing System; (4) an Assembly Drawing Generator; (5) a Bill of Materials Generator; and, (7) a Project Database. The Project Manager tracks the process and actions, recording and supervising version and change order compliance and task completion, from the start through verification of a production-ready finished version. Each project uses a master workbench. On it design specifications are entered for each subassembly element and connector. Then the user consults the Component Database using a Search and Cross Reference engine for components meeting those design specifications, until a constraint-satisfying design is completed. The tool generates a Bill of Materials, Assembly Drawings, and process records for the project in process.

Owner:CHERNYAK ALEX H +3

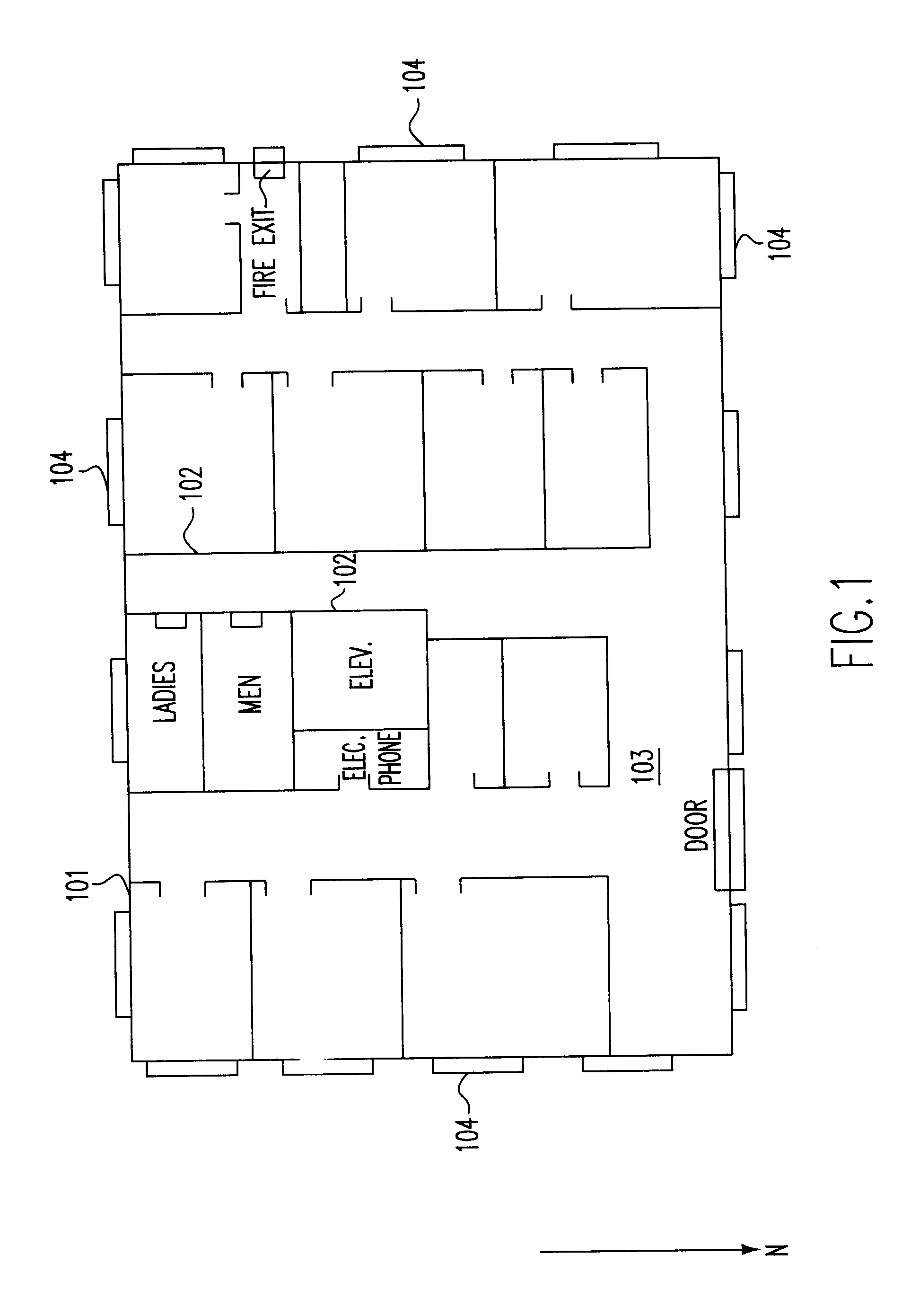

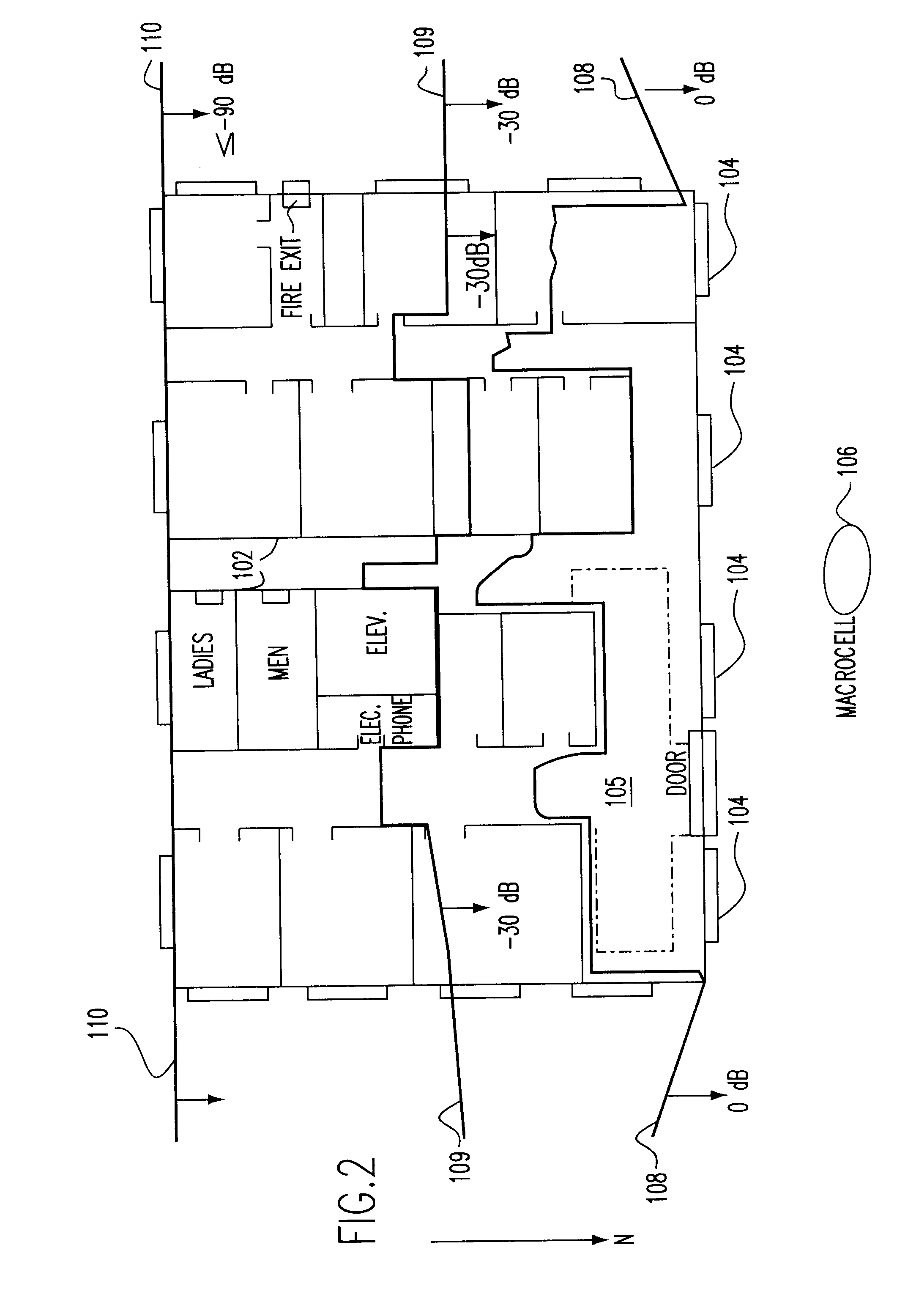

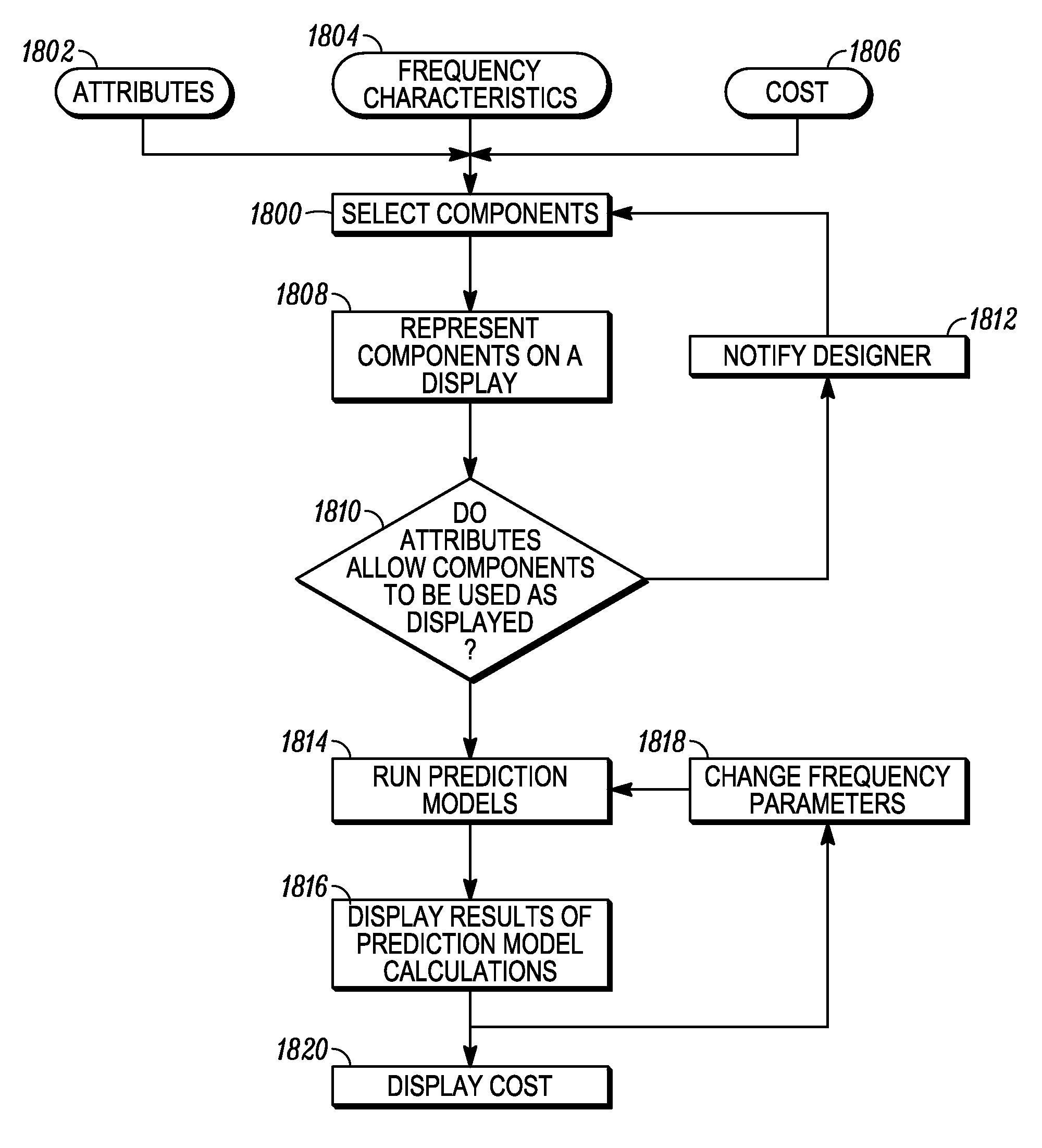

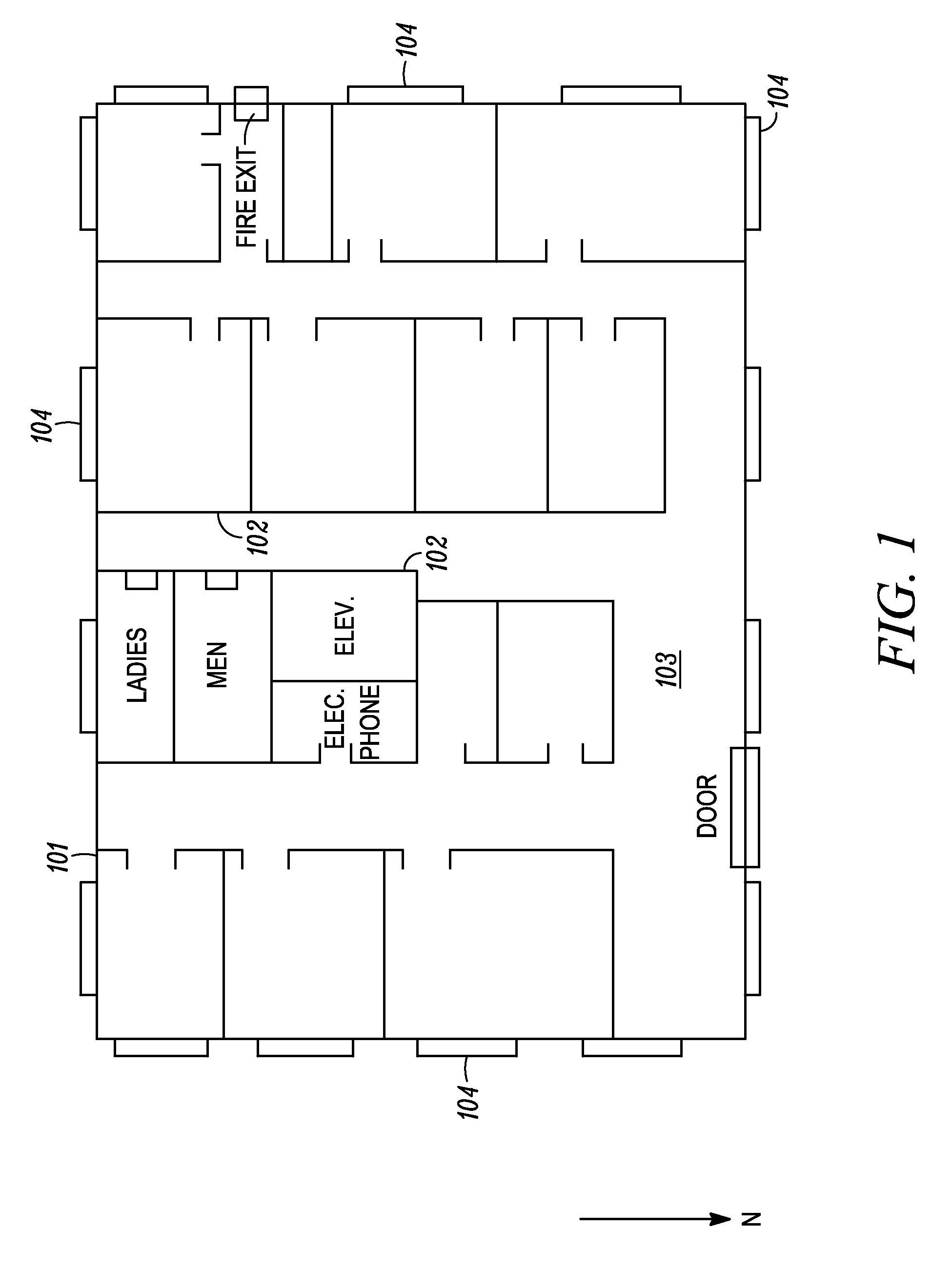

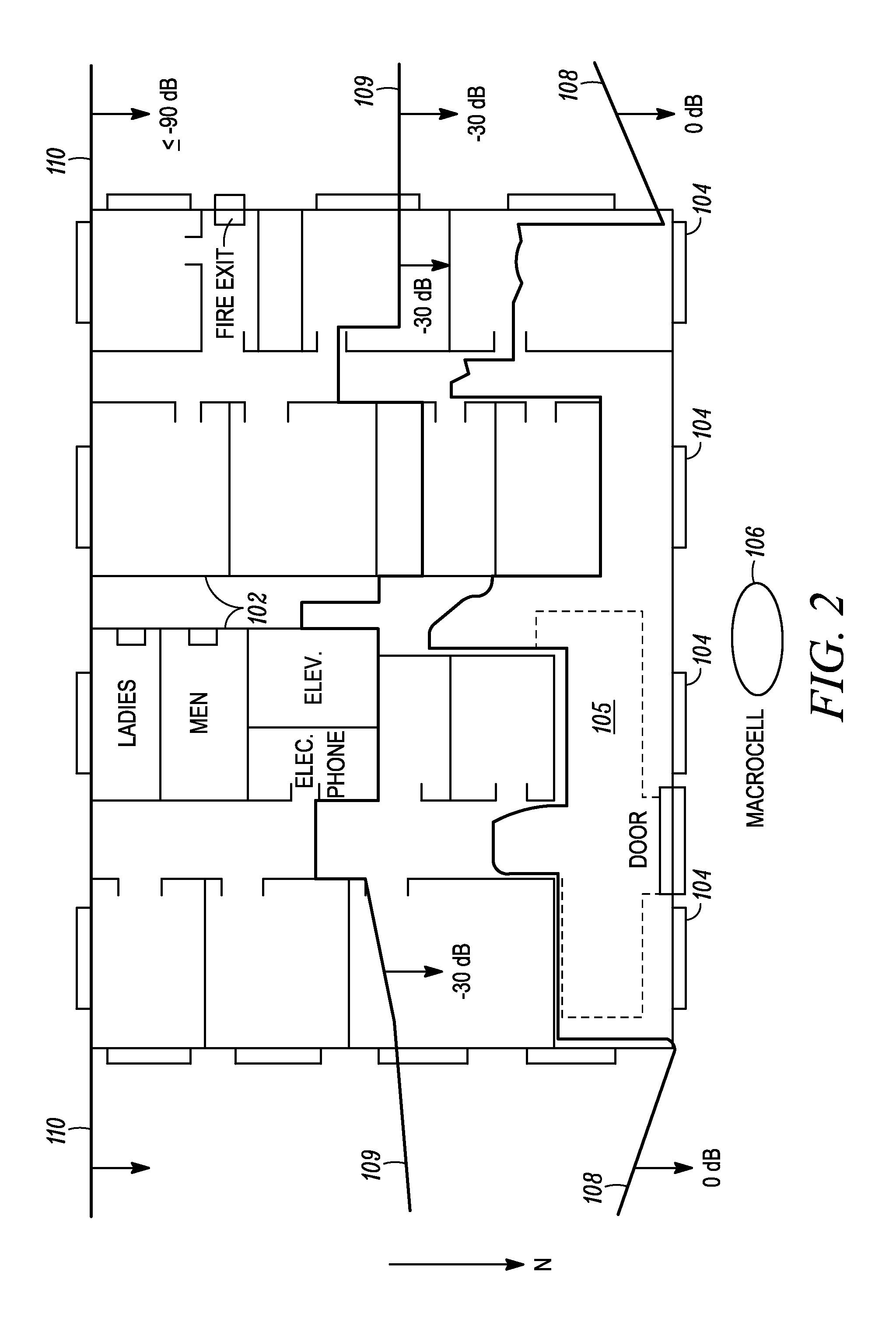

Method and system for designing or deploying a communications network which considers frequency dependent effects

InactiveUS6625454B1Simply and quickly prepareOptimize timingReceivers monitoringRadio/inductive link selection arrangementsBill of materialsDesign engineer

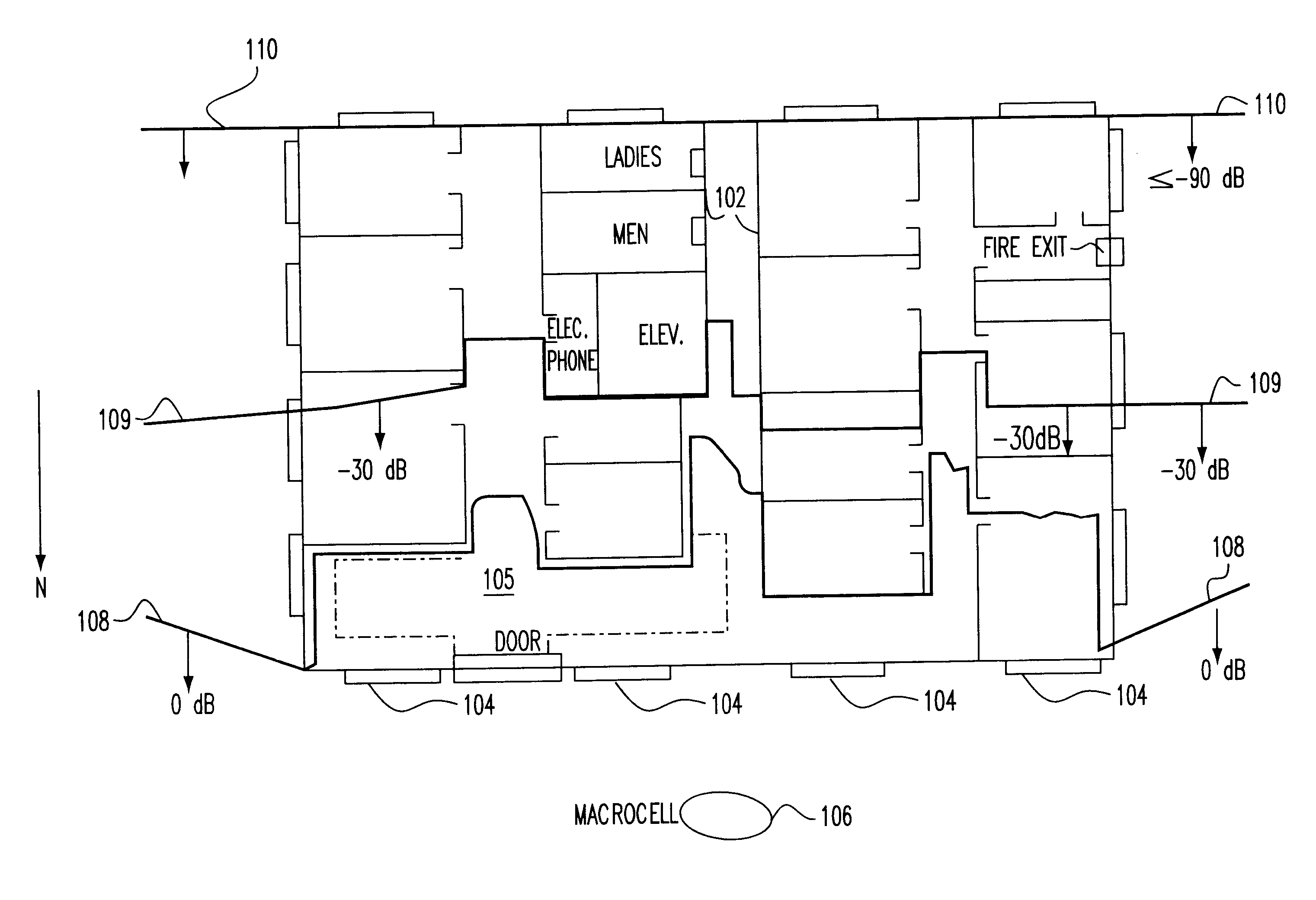

A computerized model provides a display of a physical environment in which a communications network is or will be installed. The communications network is comprised of several components, each of which are selected by the design engineer and which are represented in the display. Errors in the selection of certain selected components for the communications network are identified by their attributes or frequency characteristics as well as by their interconnection compatibility for a particular design. The effects of changes in frequency on component performance are modeled and the results are displayed to the design engineer. A bill of materials is automatically checked for faults and generated for the design system and provided to the design engineer. For ease of design, the design engineer can cluster several different preferred components into component kits, and then select these component kits for use in the design or deployment process.

Owner:EXTREME NETWORKS INC

PLM-supportive CAD-CAM tool for interoperative electrical and mechanical design for hardware electrical systems

InactiveUS7103434B2Reduce frictionCAD network environmentComputer programmed simultaneously with data introductionTask completionBill of materials

Owner:CHERNYAK ALEX H +3

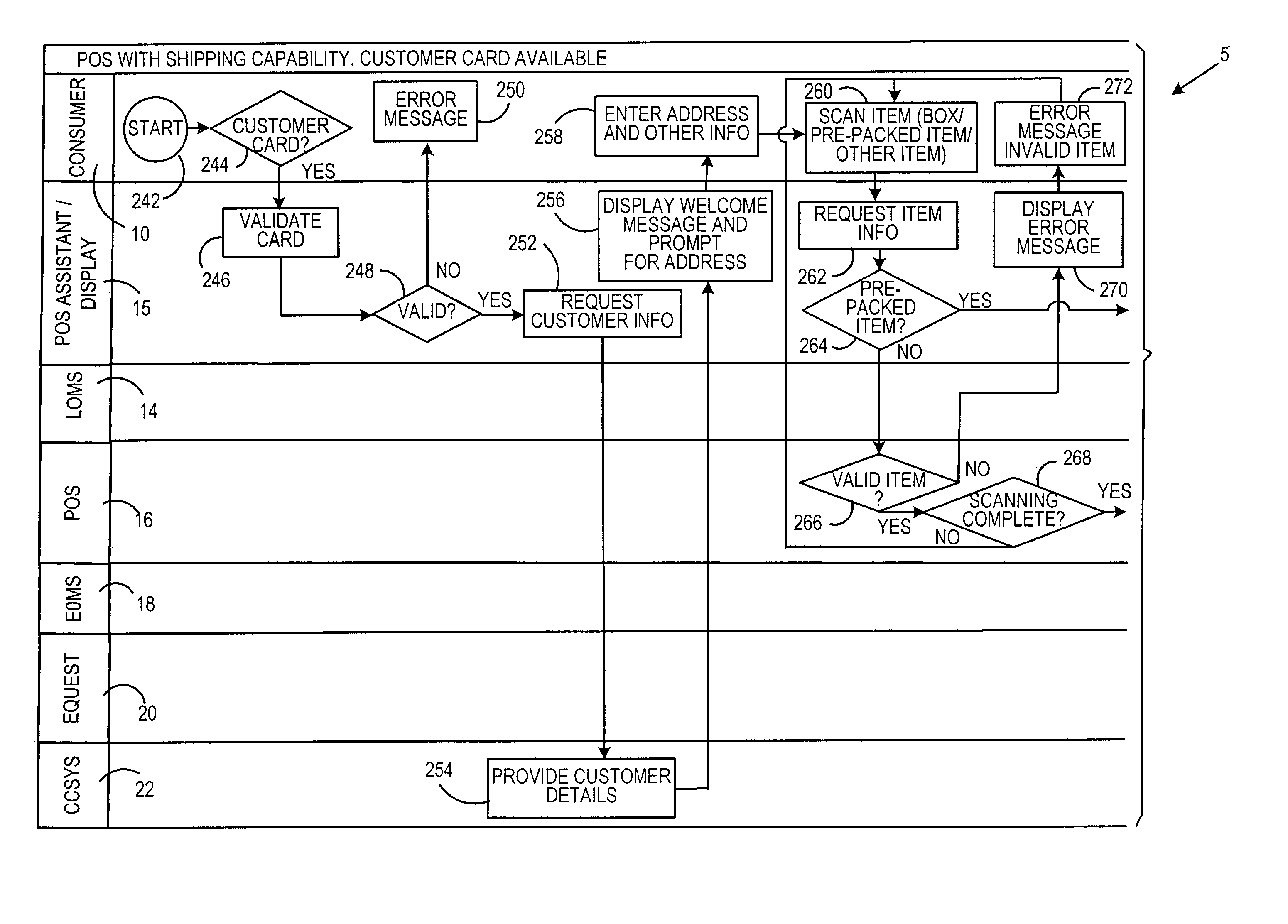

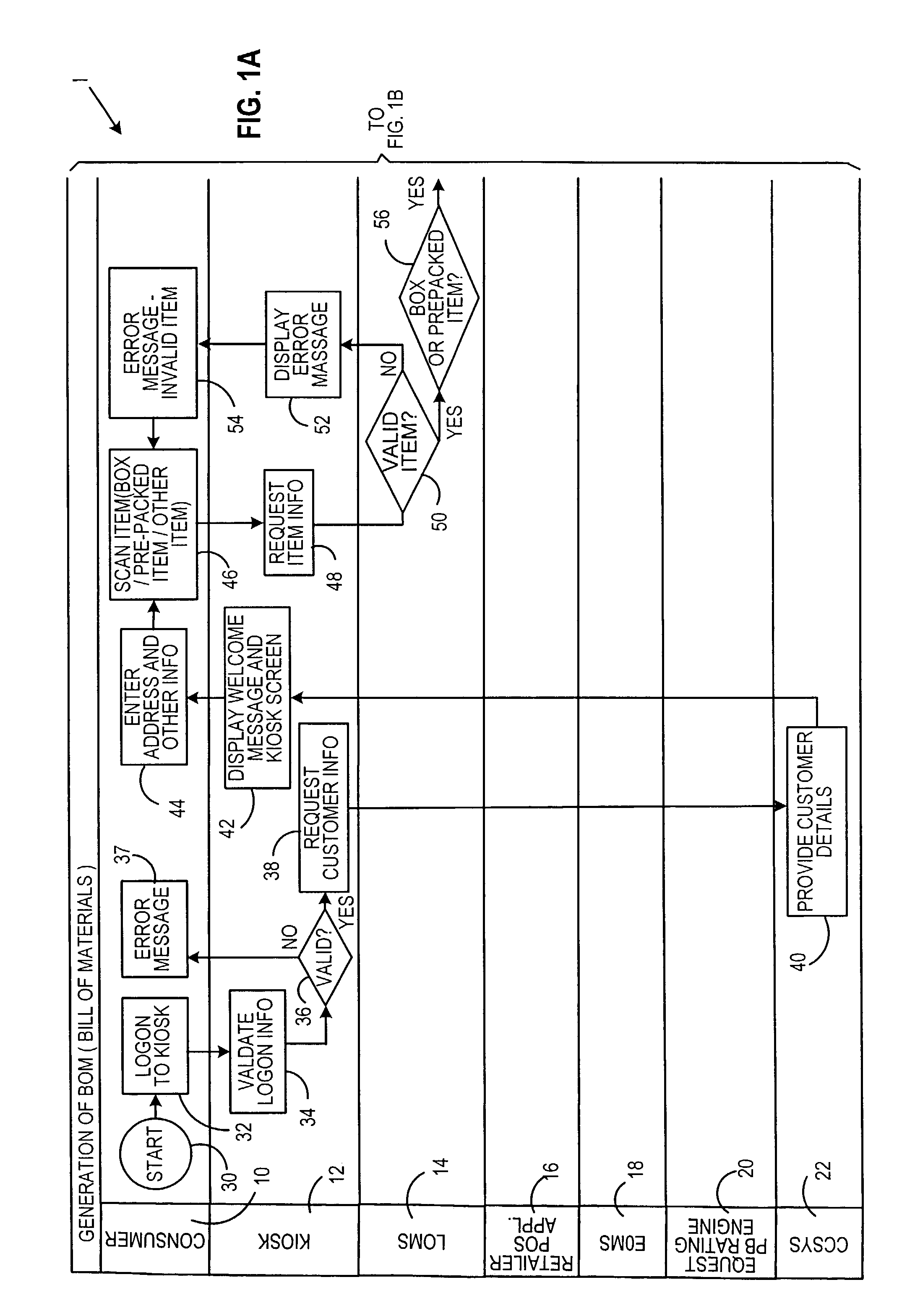

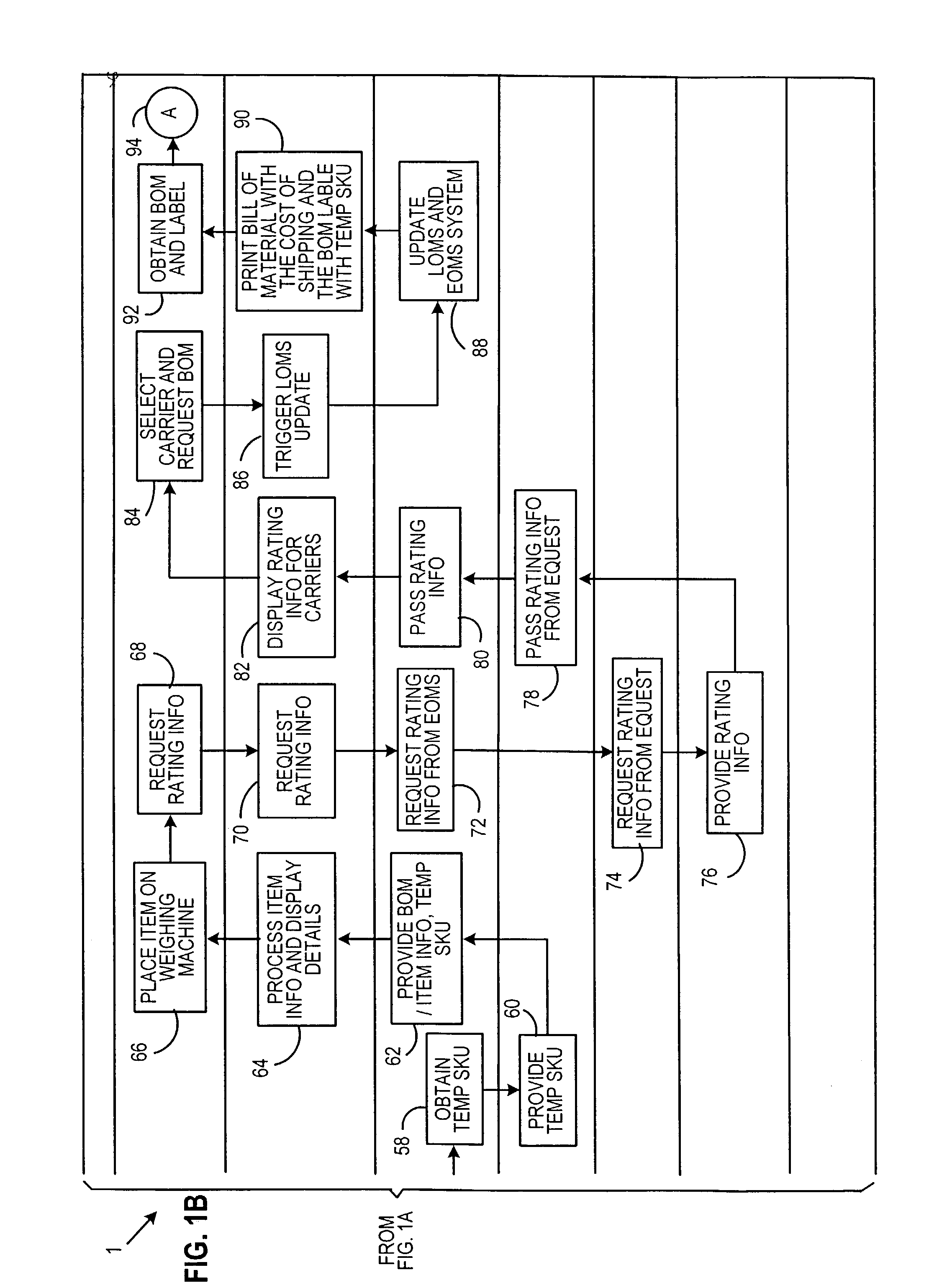

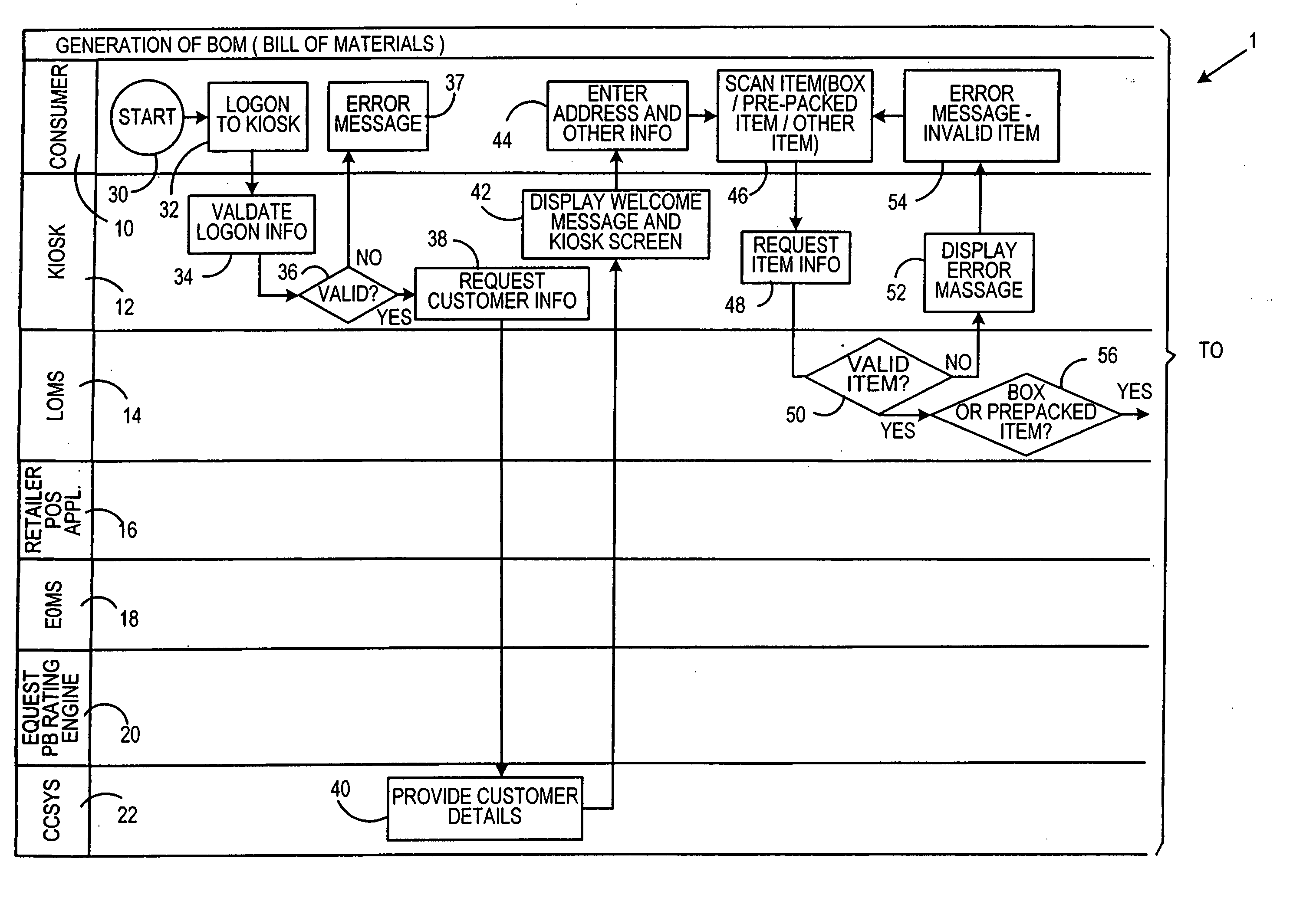

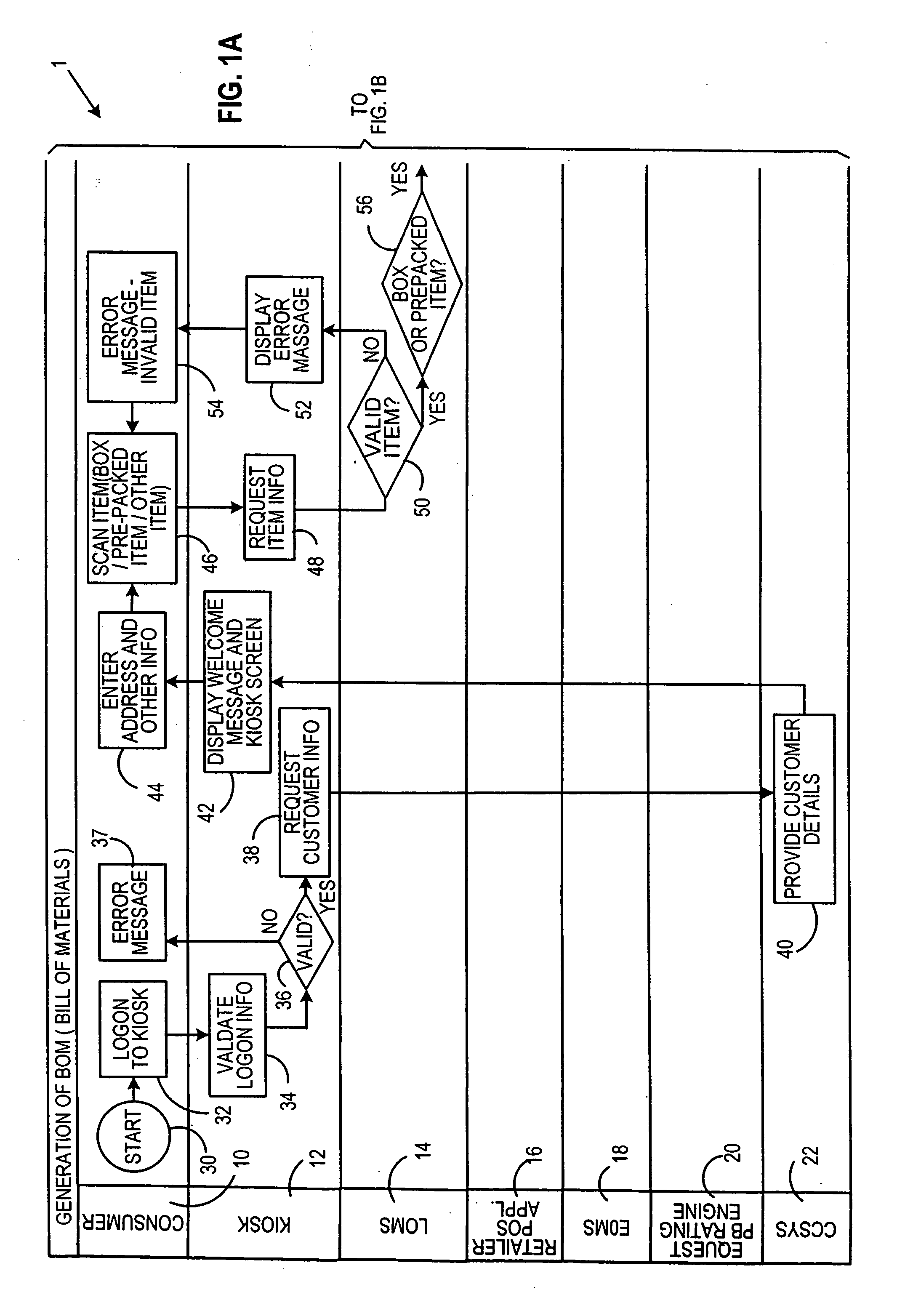

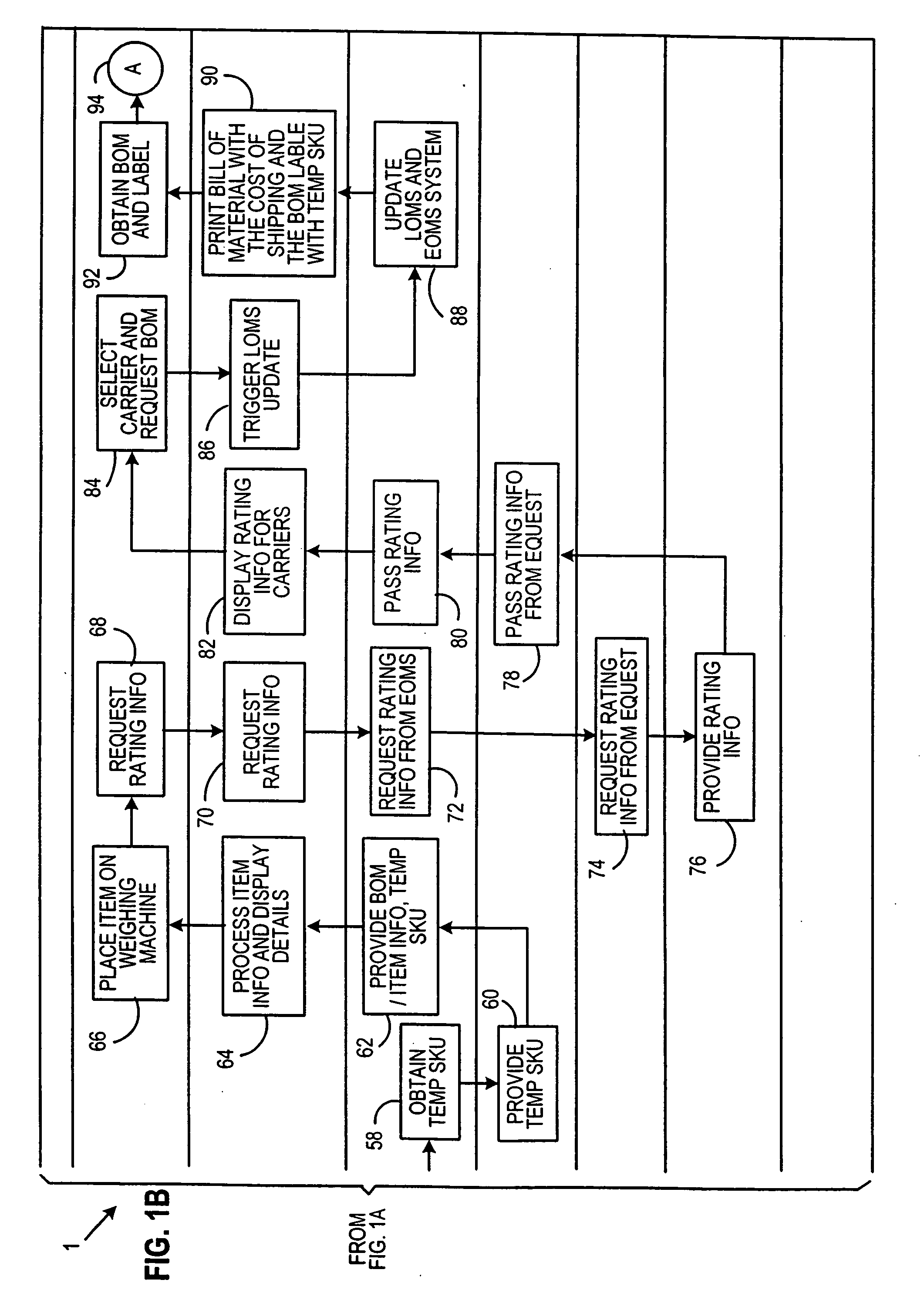

Method and system for enterprise-level unassisted customer shipping

InactiveUS6970855B2Enhancing customer convenienceImprove integrityFranking apparatusLogisticsPaymentBill of materials

A system and method for unassisted enterprise-level unassisted customer shipping is described providing for payment of shipping and item costs in a single transaction. In one configuration, a customer utilizes a kiosk to process a shipping bill of materials for presentment at a point of sale terminal.

Owner:DMT SOLUTIONS GLOBAL CORP

Method and system for designing or deploying a communications network which considers component attributes

InactiveUS7085697B1Simply and quickly prepareOptimize timingAnalogue computers for electric apparatusRadio/inductive link selection arrangementsBill of materialsDisplay device

A computerized model provides a display of a physical environment in which a communications network is or will be installed. The communications network is comprised of several components, each of which are selected by the design engineer and which are represented in the display. Errors in the selection of certain selected components for the communications network are identified by their attributes or frequency characteristics as well as by their interconnection compatability for a particular design. The effects of changes in frequency on component performance are modeled and the results are displayed to the design engineer. A bill of materials is automatically checked for faults and generated for the design system and provided to the design engineer. For ease of design, the design engineer can cluster several different preferred components into component kits, and then select these component kits for use in the design or deployment process.

Owner:EXTREME NETWORKS INC

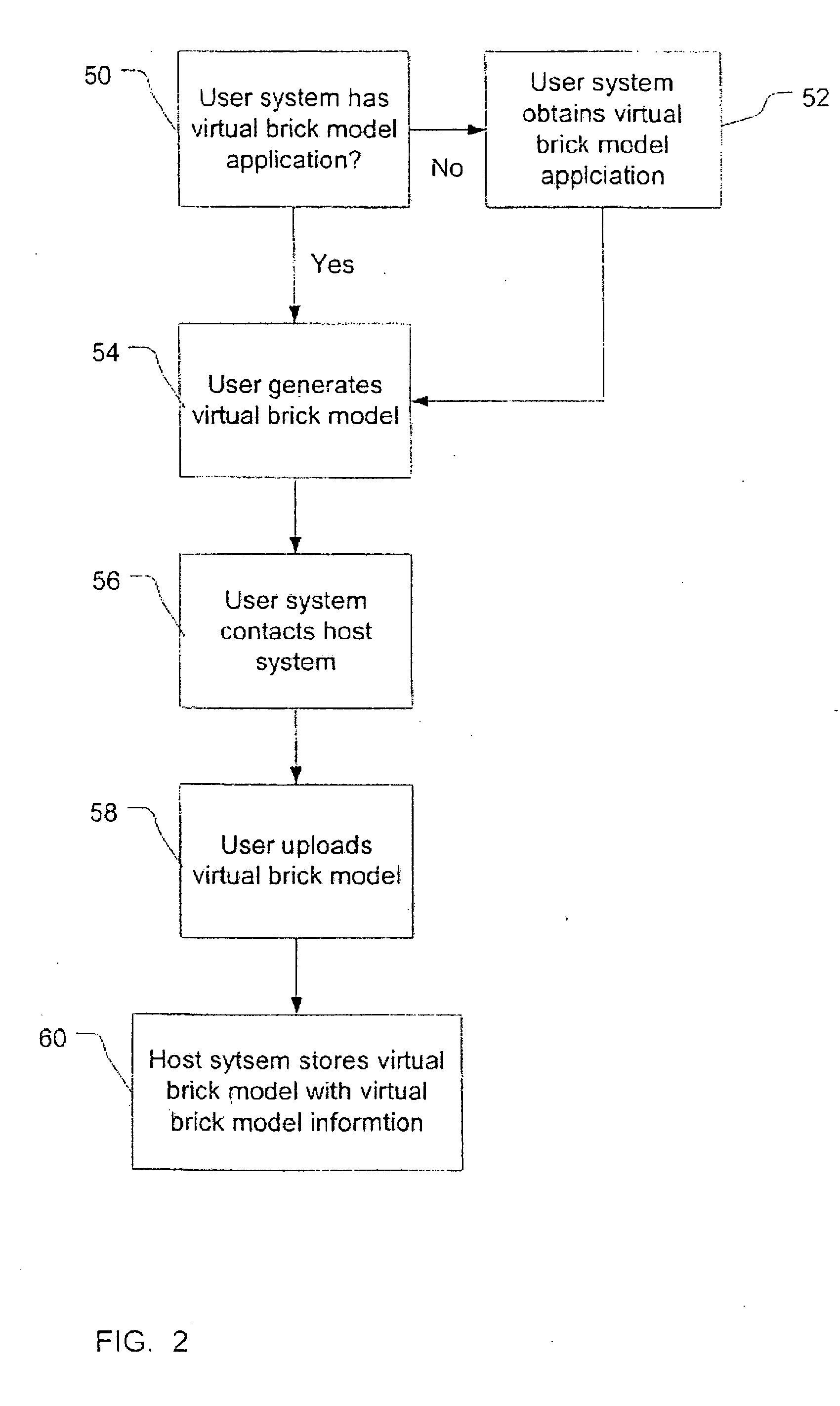

Selecting virtual brick models

A method of selecting a virtual toy construction model, the method comprising: receiving by a host computer system a digital representation of an input toy construction model, the input toy construction model including a plurality of construction elements; generating a bill-of-materials that includes at least all construction elements of the received input construction model; performing a search in a repository of respective digital representations of a plurality of virtual toy construction models for one or more construction models that can be constructed from the set of construction elements included in the bill of materials; presenting on a client computer system at least one of the construction models identified in the search.

Owner:LEGO AS

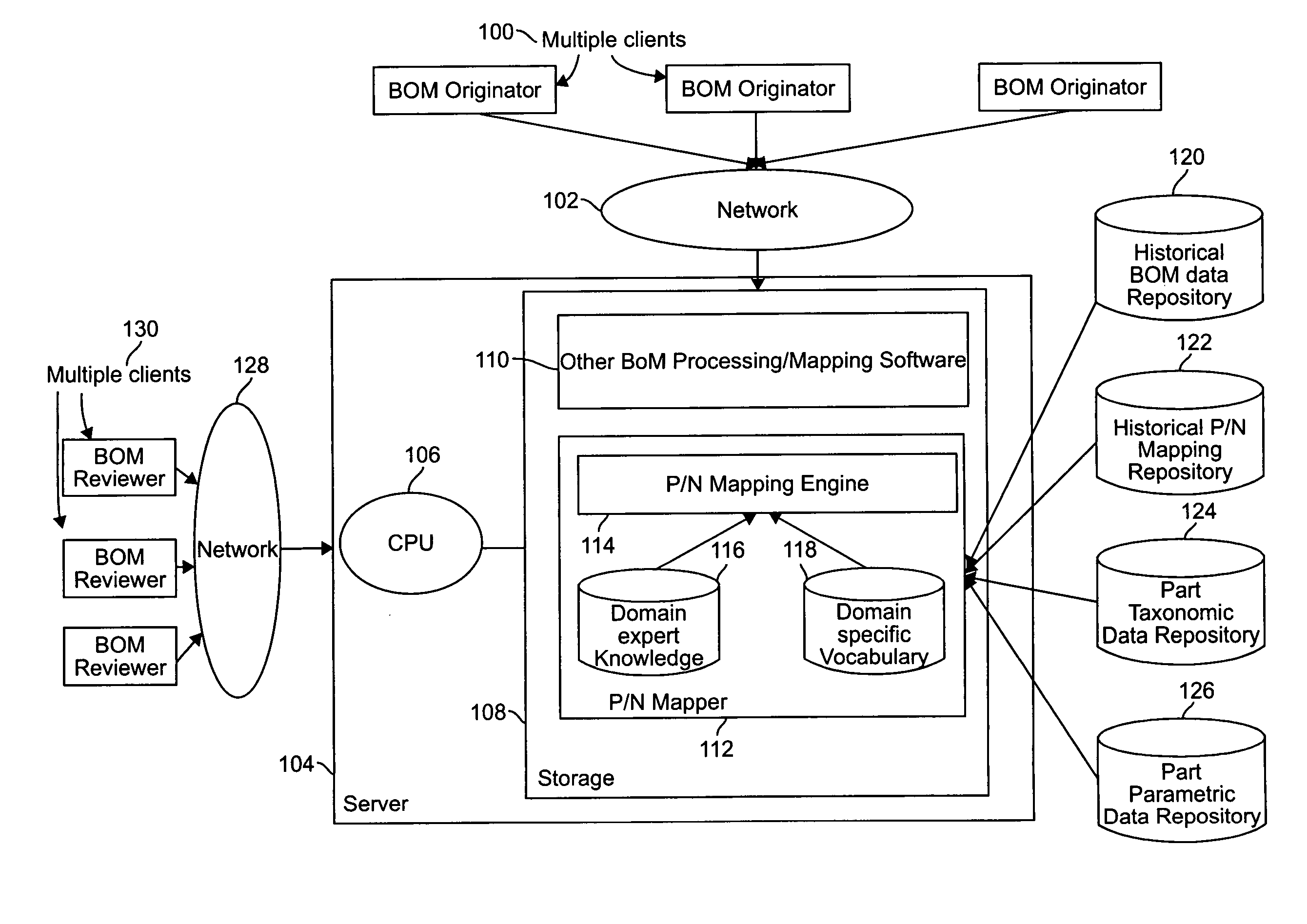

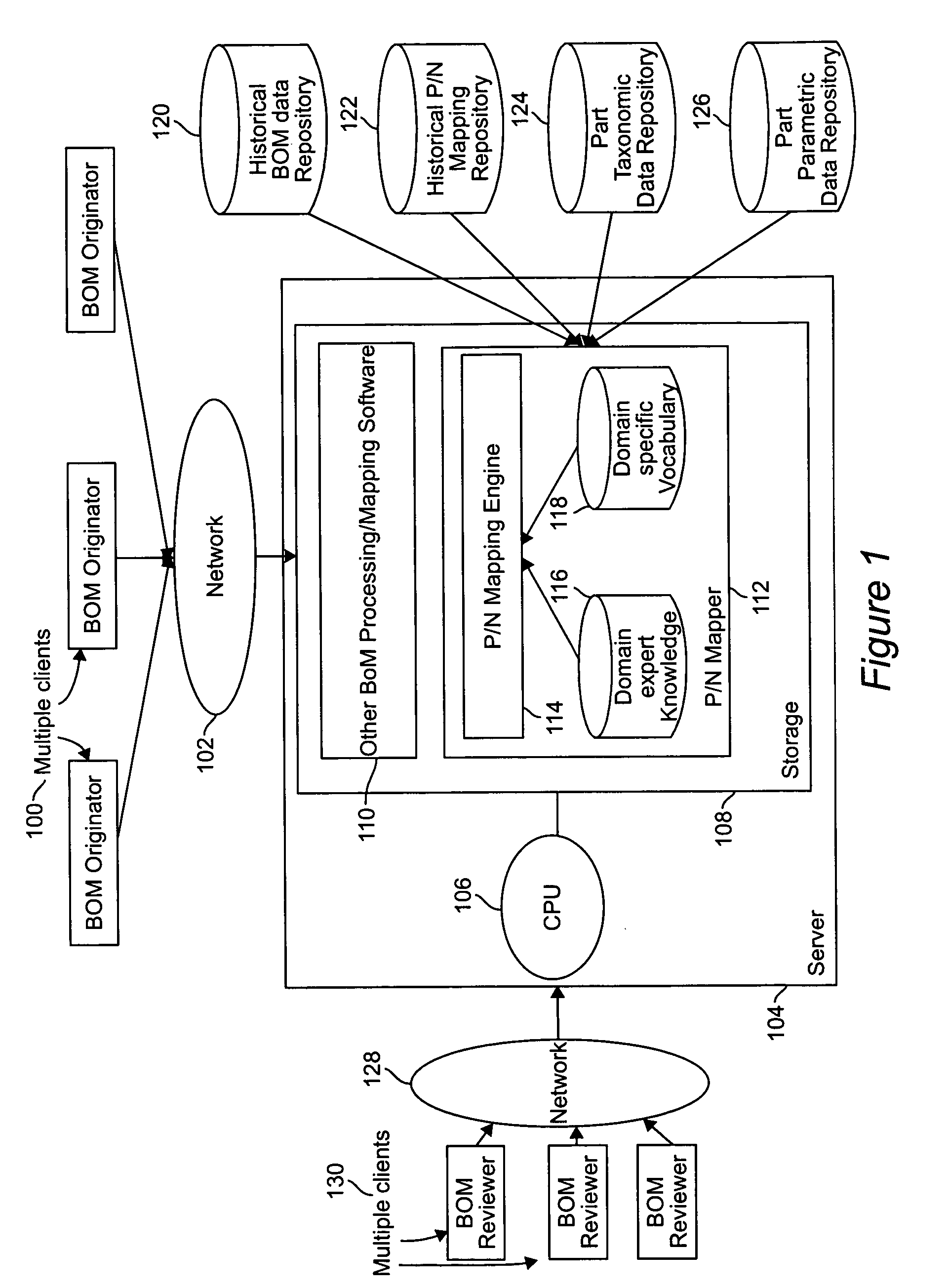

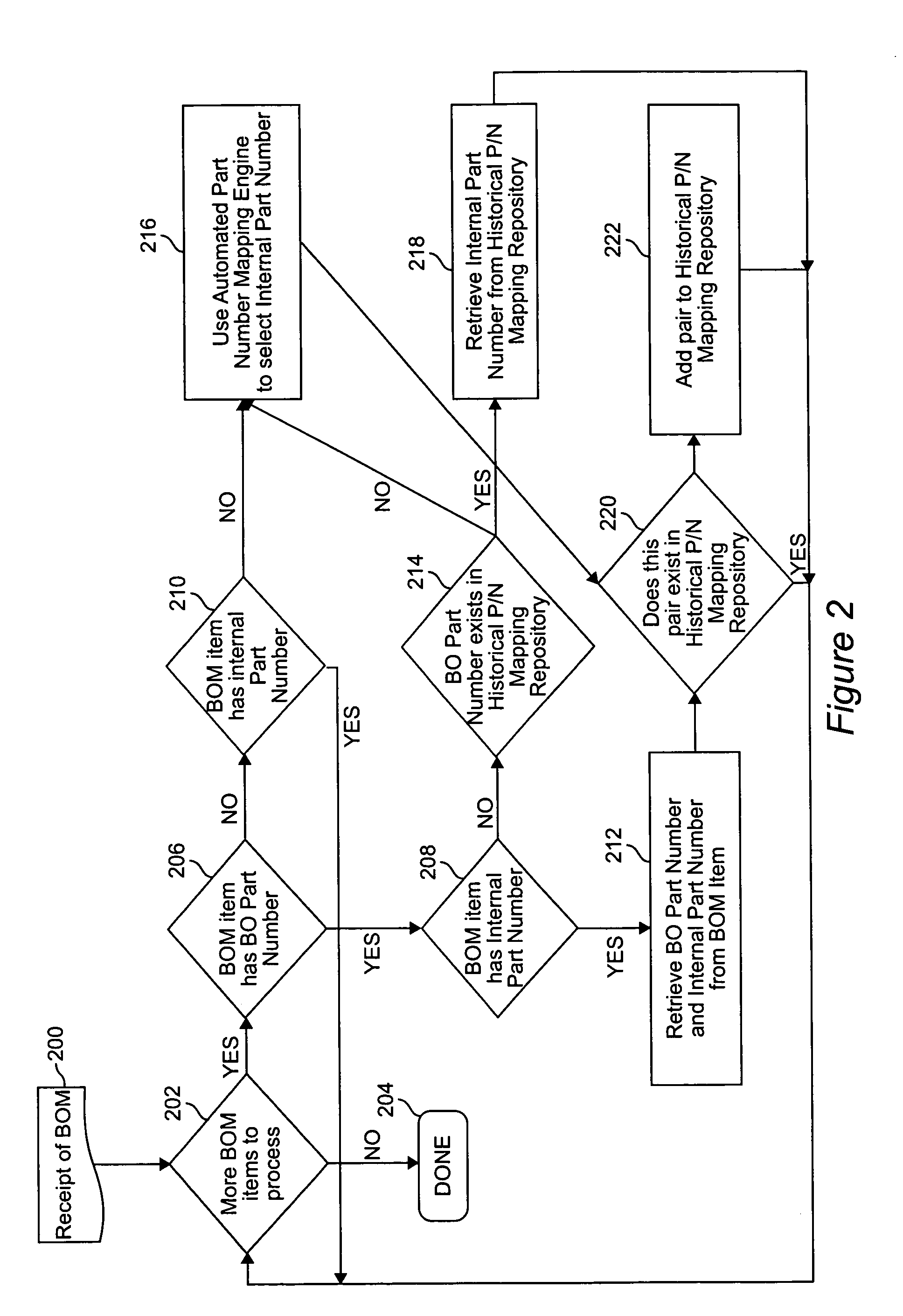

System and method for automated part-number mapping

InactiveUS20050125311A1Improve classification resultsEasy to drawHand manipulated computer devicesAnimal feeding devicesData setBill of materials

Automated mapping of part numbers associated with parts in a bill of materials (BOM) submitted by a BOM originator to internal part numbers assigned to those parts by a BOM receiver is performed by one or more computers connected to one or more networks through one or more network interfaces. A first receive component receives one or more data sets containing historical data on bills of materials received in the past by the BOM receiver. A second receive component receives one or more data sets containing known mappings between internal part numbers used by the BOM receiver, and part numbers used by various BOM originators. A third receive component receives one or more data sets containing information of various parameters and their values describing the parts to which the BOM receiver has assigned internal part numbers. A fourth receive component receives one or more methods of automatically learning models for predicting internal part numbers from the above mentioned historical BOM data, mapping data and part parametric data. A learning component learns the models from the data. A fifth receive component receives a BOM from a requesting process. The BOM has one or more parts with a missing internal part number. A mapping component applies the learned models to the received BOM to automatically determine internal part numbers for all unmapped BOM originator part numbers. A release process assigns internal part numbers to all unmapped parts in the BOM and releases the BOM to the requesting process.

Owner:IBM CORP

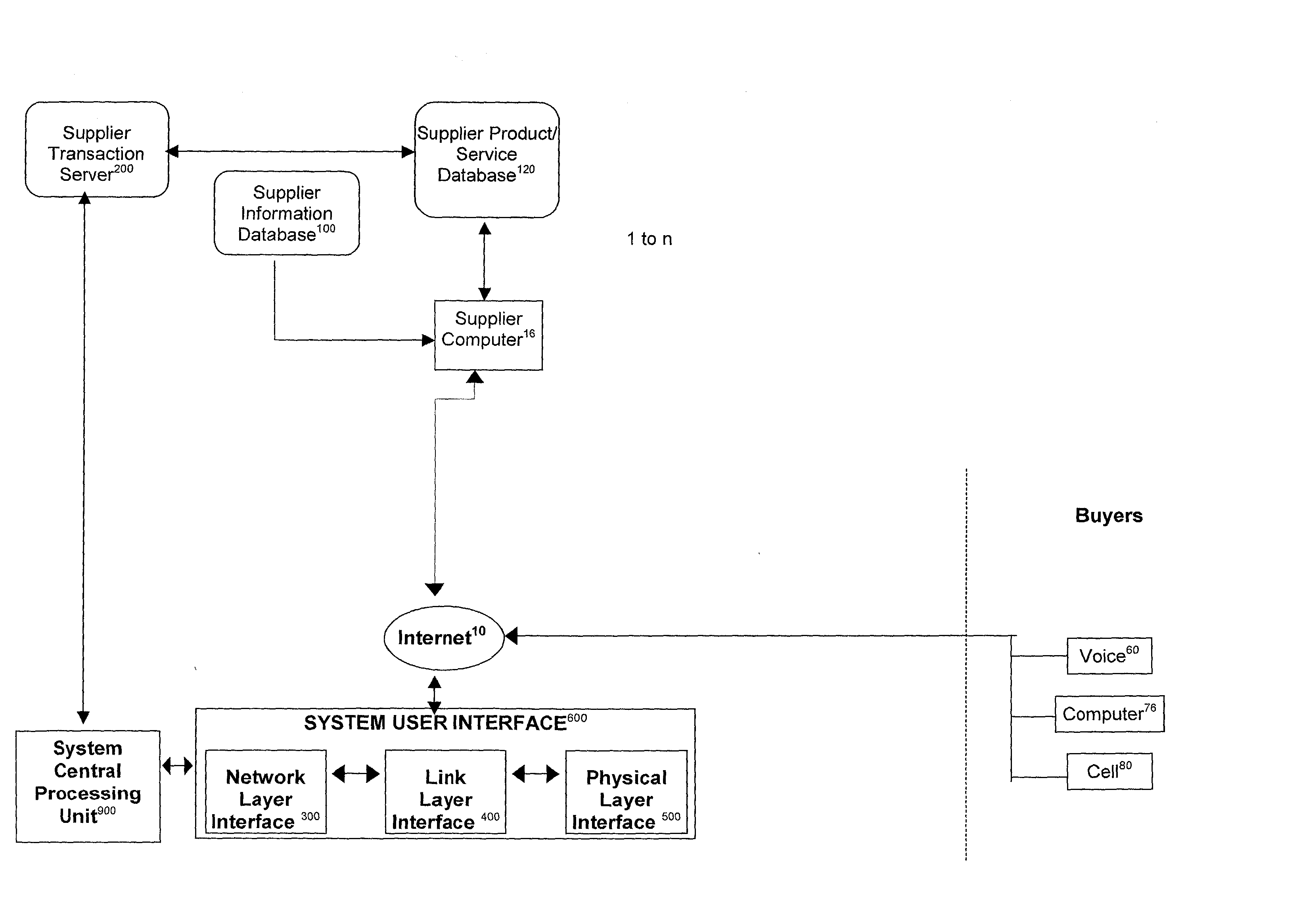

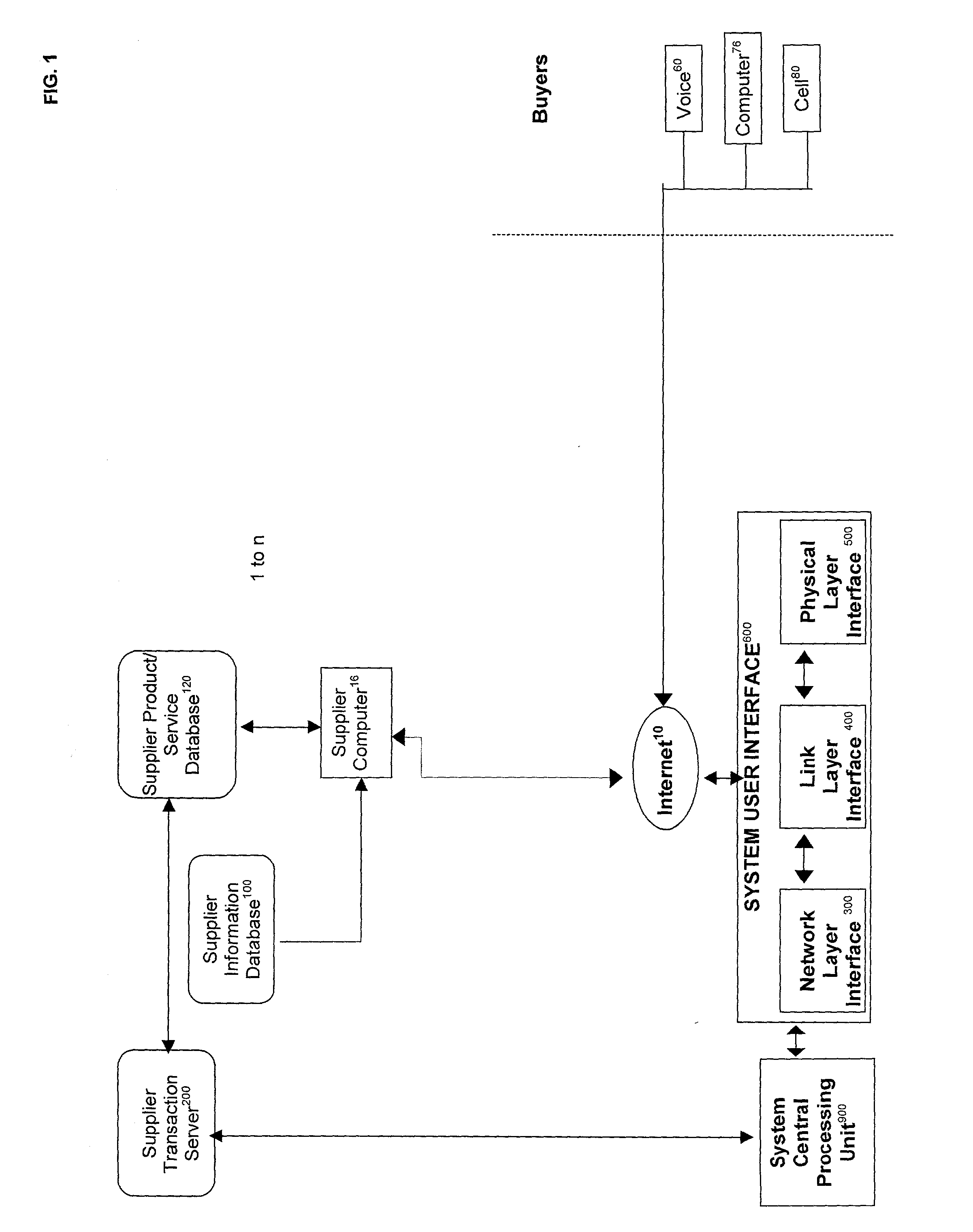

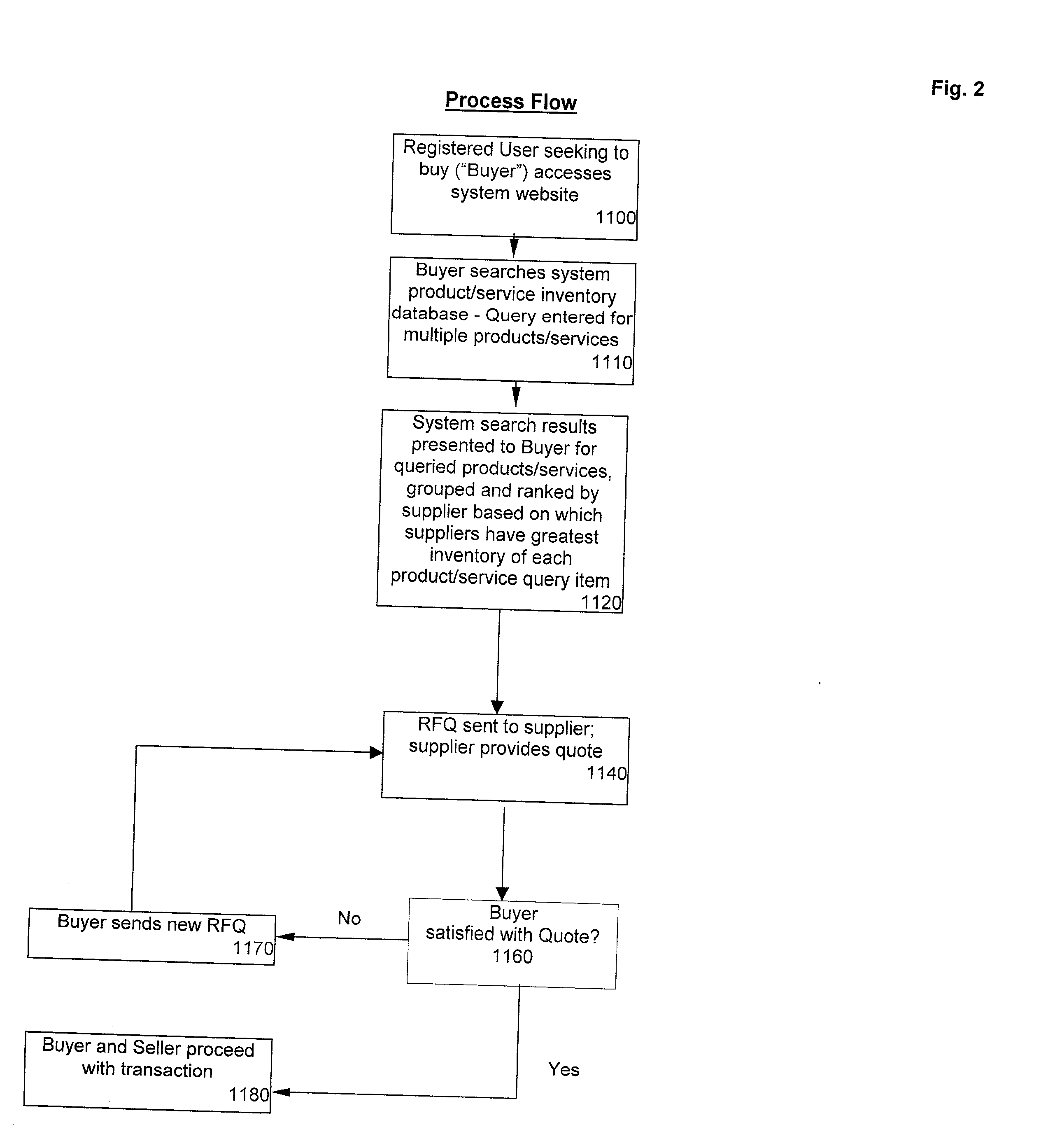

Smart multi-search method and system

InactiveUS20030144924A1Buying/selling/leasing transactionsSpecial data processing applicationsInternet communicationWeb site

The present invention is a searchable product / service database software system enabling complex multiple-product / service item query searching of databases, providing, in response to a single search query, search results for multiple products / services that are grouped and ranked by supplier based on which supplier(s) have inventory with respect to the greatest number of the queried products / services. The user can identify which vendor can best fill the entire order, simplifying the buying process. A single query can be entered by a user covering their entire required bill of materials list. The system is preferably implemented via a website server using known methods of Internet communication. The search results can be customized further to categorize suppliers by geographic location, supplier type, pricing or other criteria. Also disclosed and claimed is a method for providing complex multiple product / service item query searching with search results grouped and ranked by supplier based on which suppliers have inventory with respect to the greatest number of queried products / services.

Owner:NETCOMPONENTS

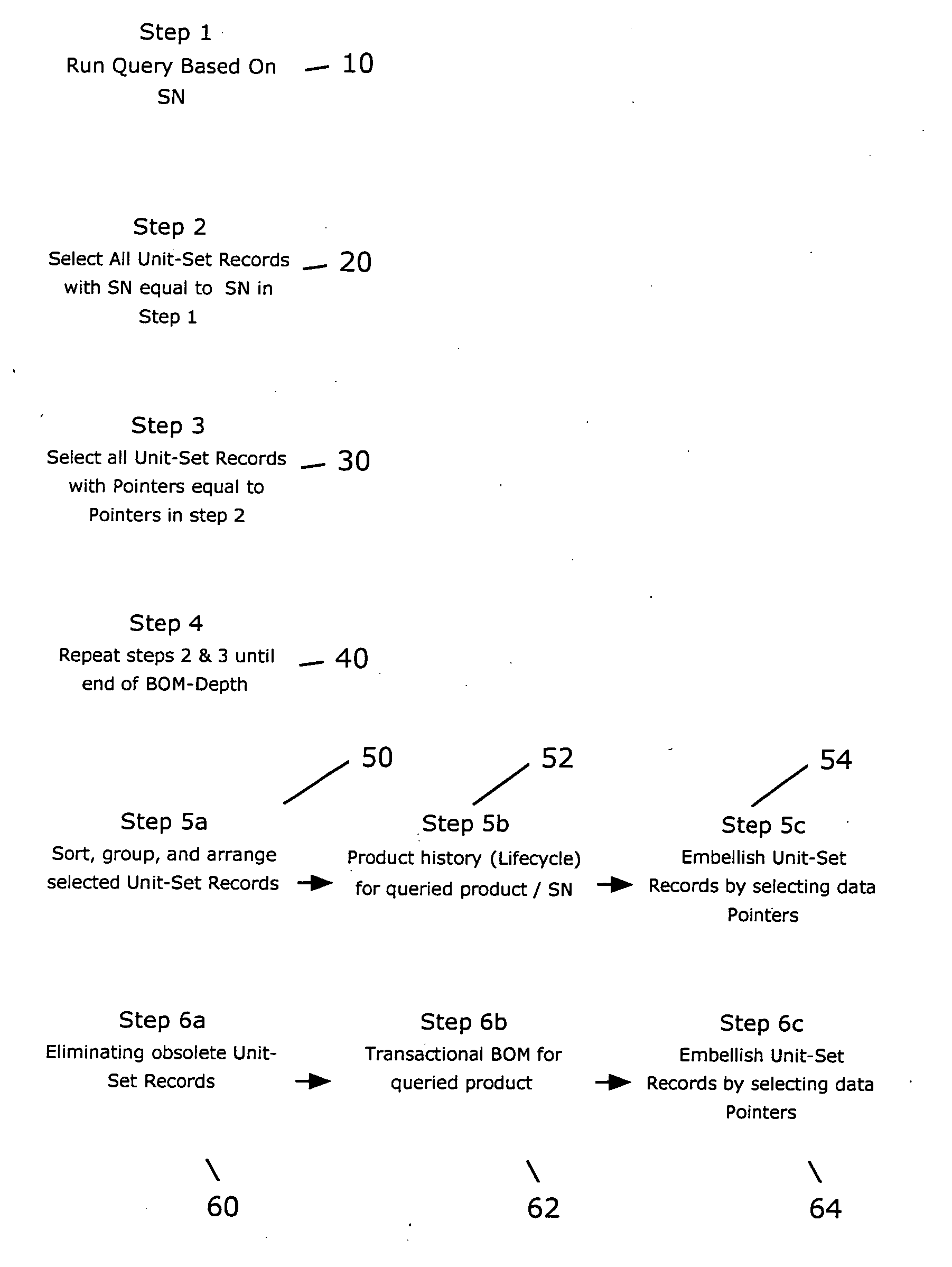

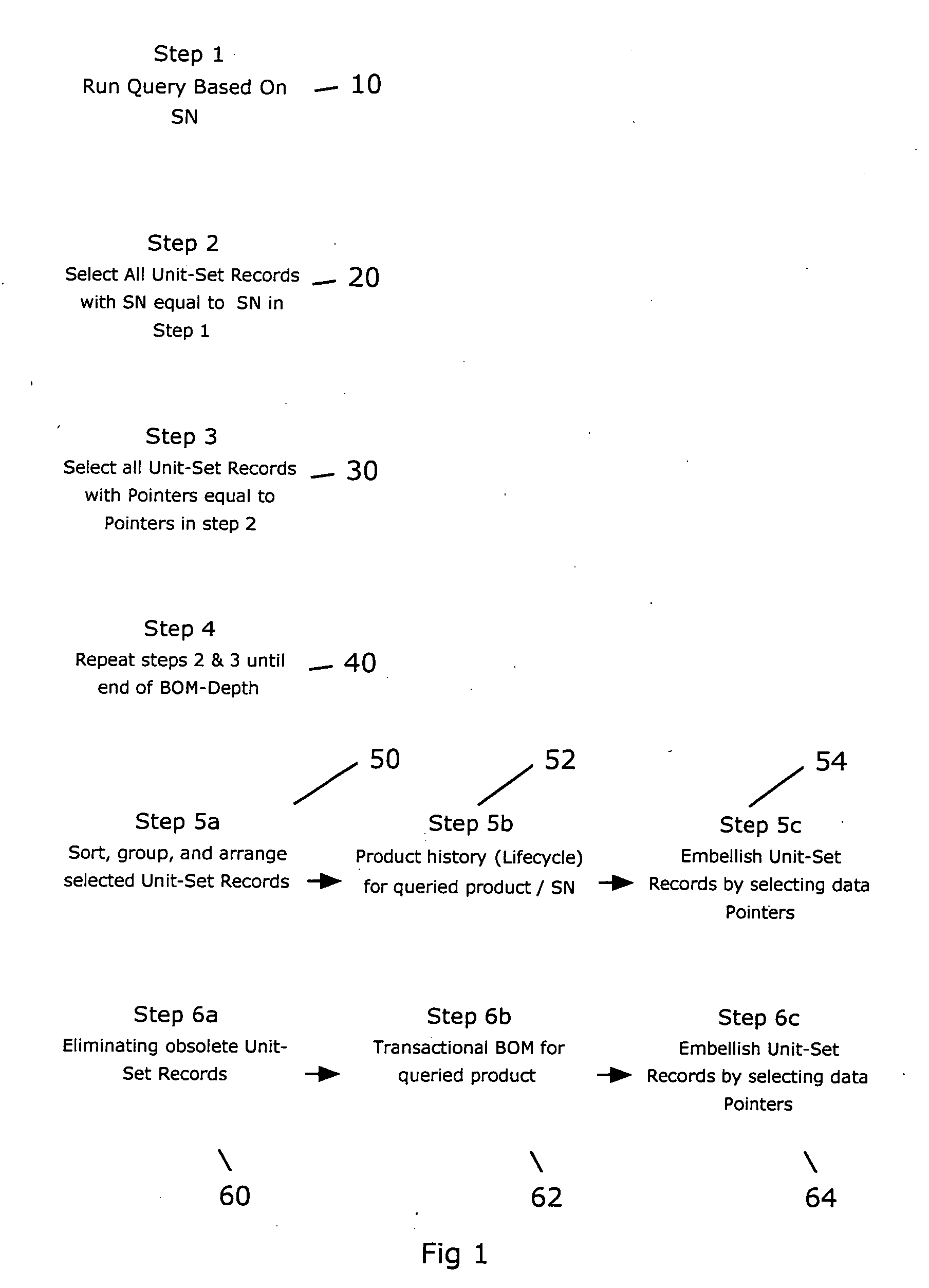

Method and system for creating, sustaining and using a transactional bill of materials (T-BOM (TM))

InactiveUS20050278296A1Quick useLow costDigital data processing detailsLogisticsBill of materialsTransaction data

The inventive approach provides a dynamic data system and computationally efficient method to uniquely identify a product of interest and by means of querying any number of databases for pertinent transaction data, create a complete product history (lifecycle) as well as the current product state. The inventive method provides a means for rapidly assigning a unique identifier to specific instances of a product or component. The invention also provides for the elimination of duplicative or obsolete lifecycle data, generating a current picture of product data (denominated, by reason of the method of creation, a “transactional bill of materials” (T-BOM™) for every product component or composite product. The invention provides a method supportive of improved product uptime as well as other advantages including improved customer service, reduced costs to provide customer service, and profitability management.

Owner:BOSTWICK PETER

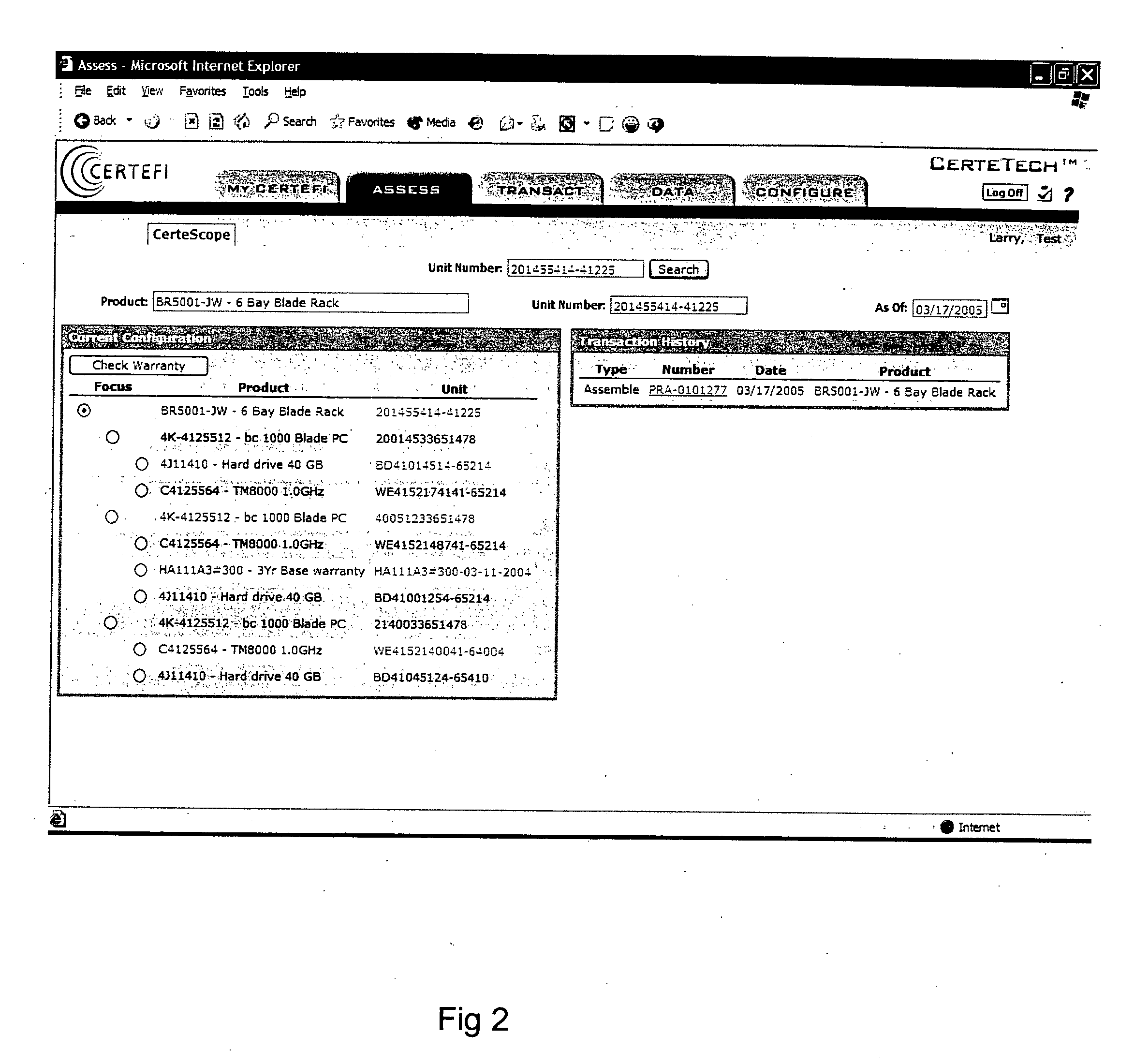

Mass customization configurator

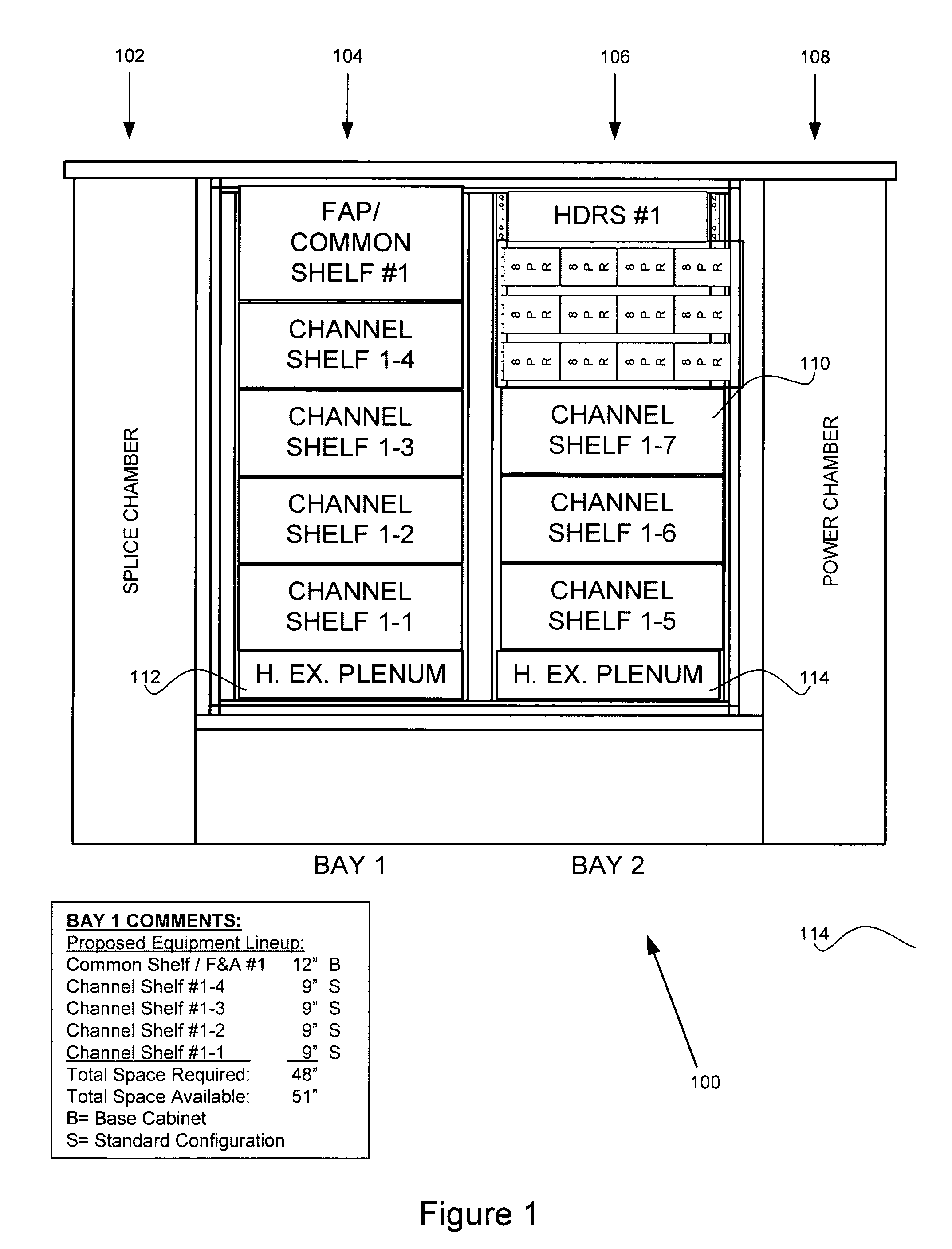

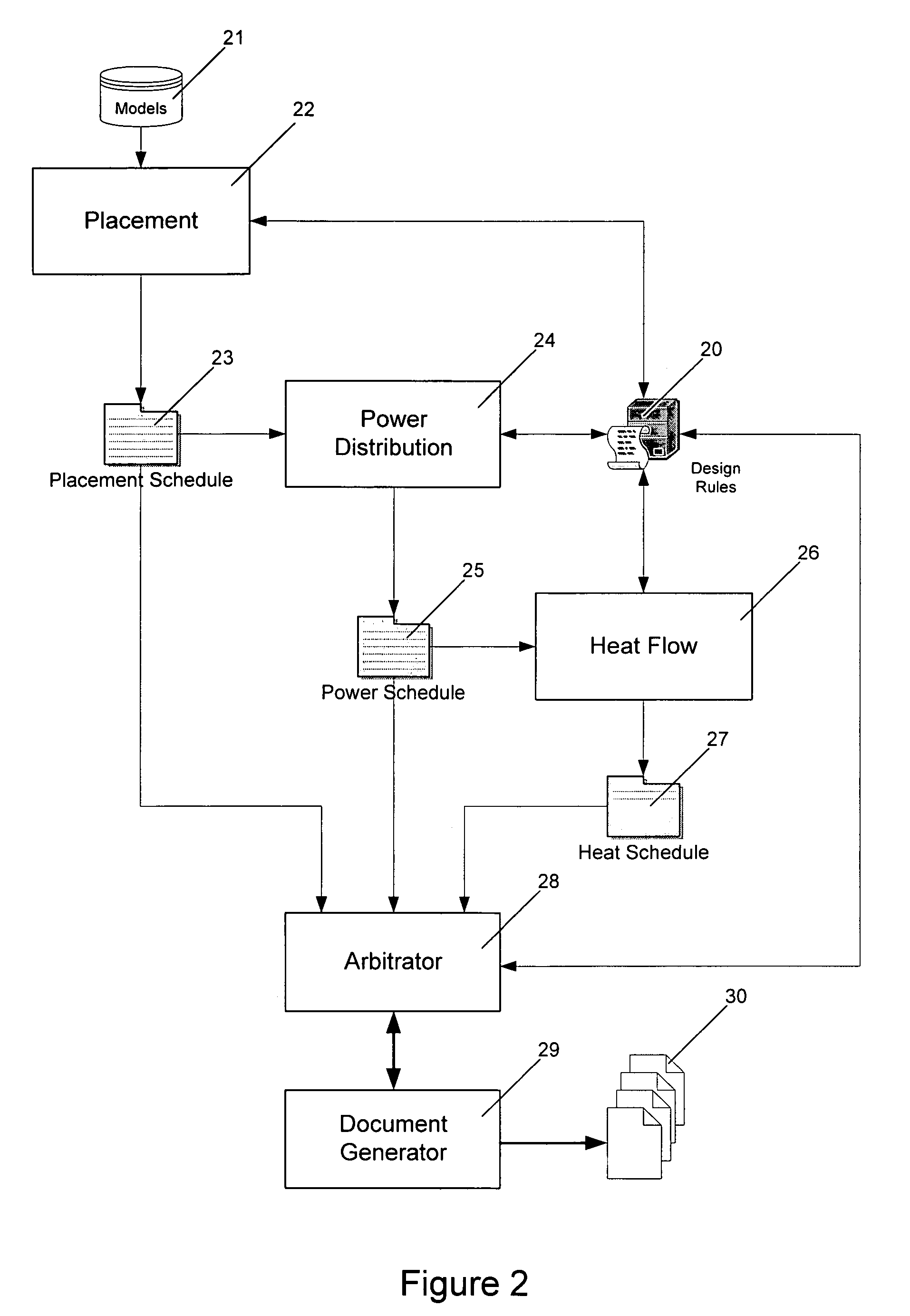

InactiveUS7472043B1Accelerate time to marketReducing the engineering life cycleThermometer detailsDigital computer detailsAuto-configurationBill of materials

The present invention provides an automated configuration system and method for electronics enclosures. The system receives user requirements generates a configuration including placement schedule, power usage schedules and heat flow schedules. Included as output of the system is a bill of materials, an equipment layout drawing and pricing based on predetermined material and labor pricing. Methods for generating a configuration are described that include iteratively repeating combinations of the steps of generating design rules, deriving a placement schedule, mapping the distribution of power usage within the enclosure and producing a heat flow analysis. Processes used to generate the configuration can be controlled by design rules derived from user requirements.

Owner:TELLABS BEDFORD

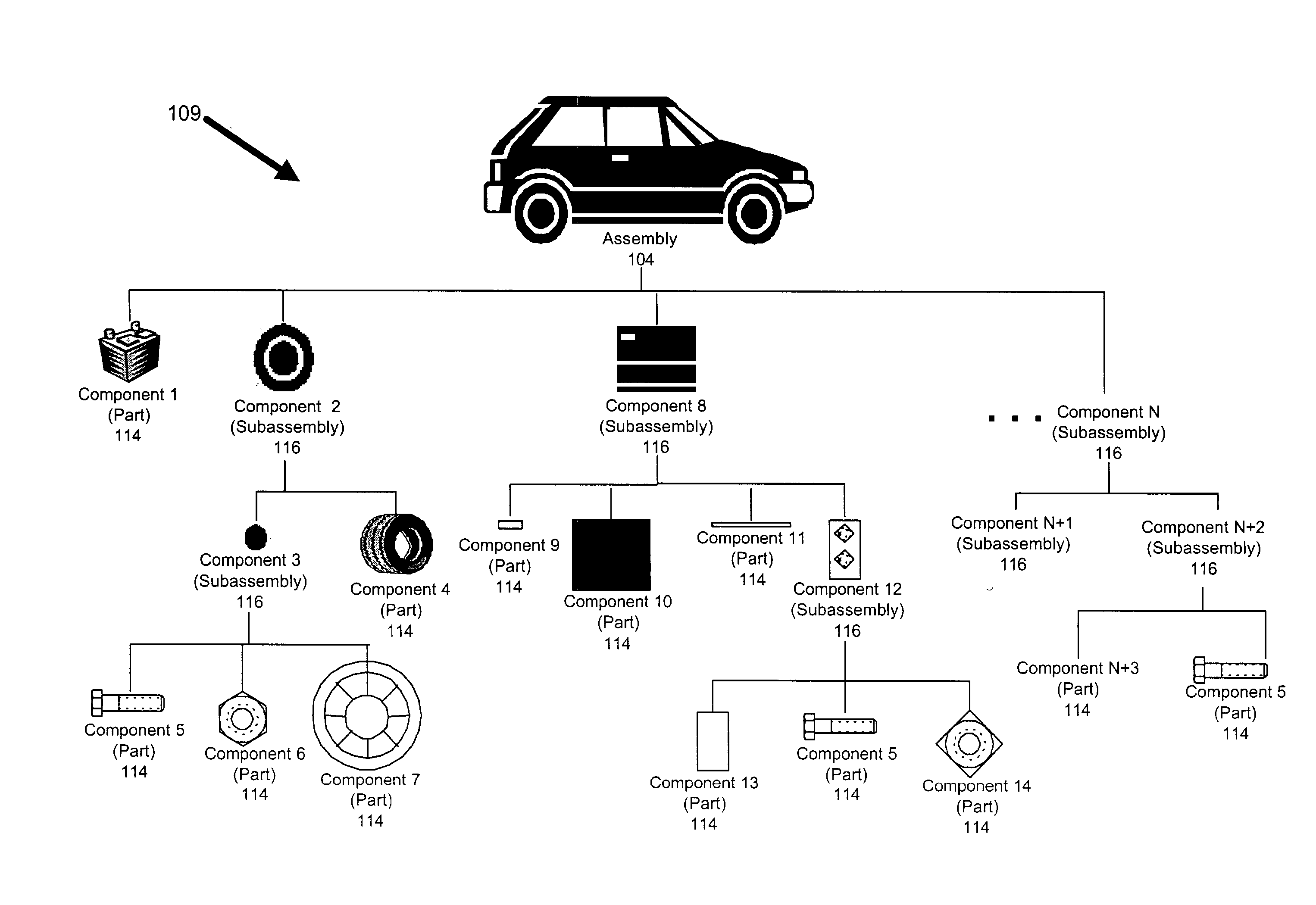

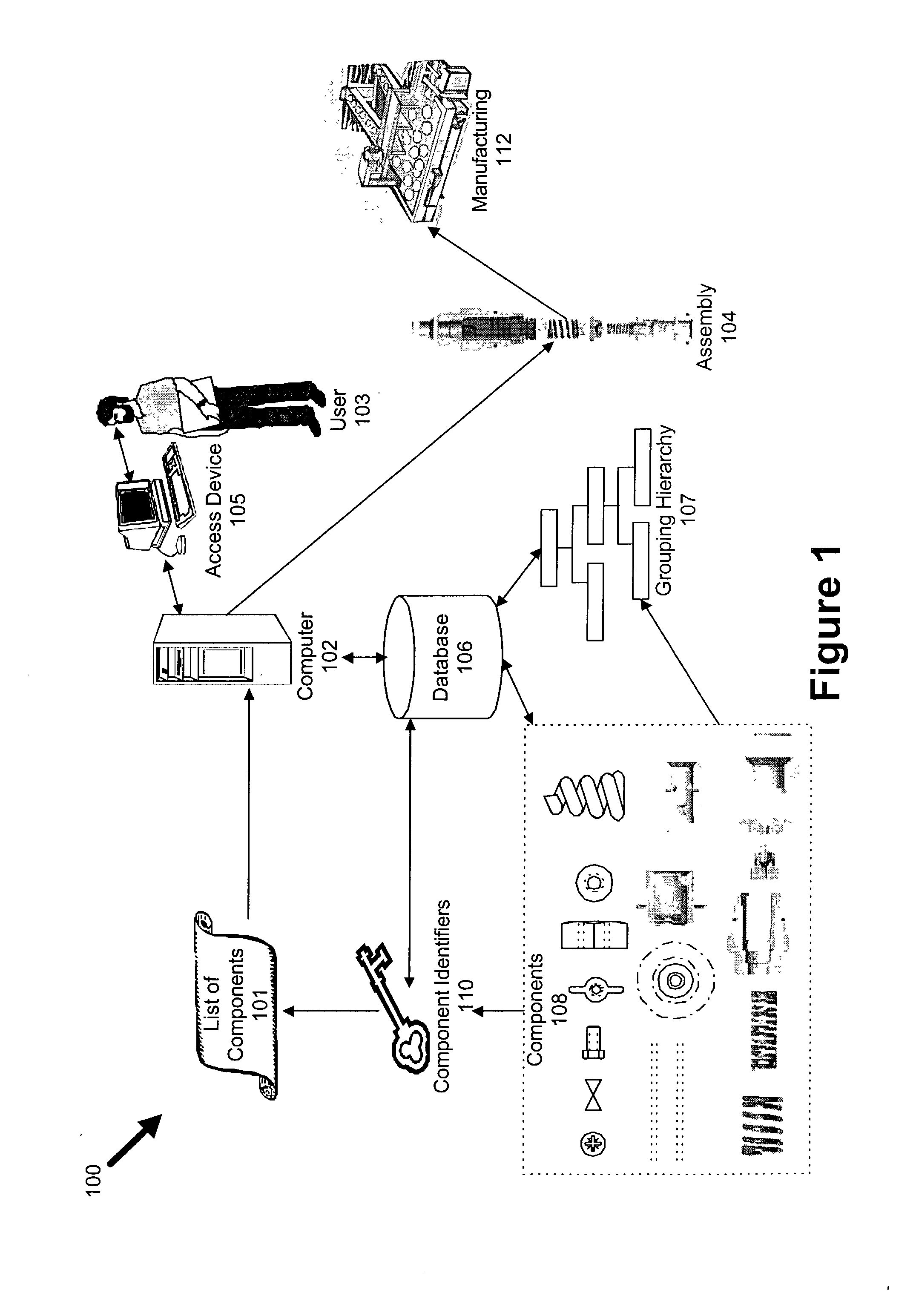

System and method for creating a representation of an assembly

InactiveUS20040098151A1Configuration CADSpecial data processing applicationsGraphicsBill of materials

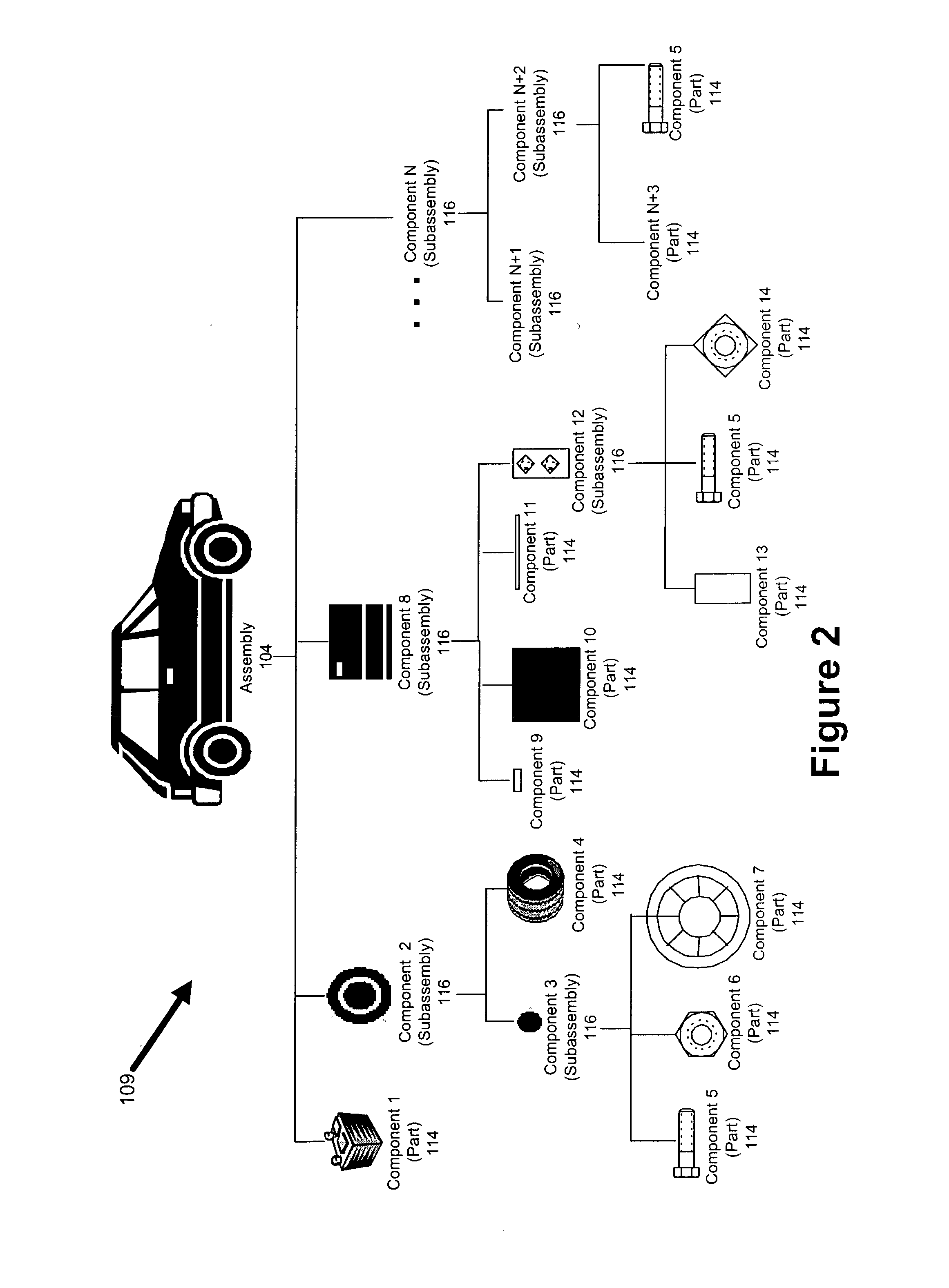

The invention is a system or method (collectively the "drawing system" or simply "system") for automatically creating a drawing, model, or other type of representation (collectively a "drawing") of an assembly from a list of component parts. The system can use a list of components, a hierarchy of assembly components, and a hierarchy of component groups, to automatically create a drawing of an assembly. The system can also be configured to automatically create a drawing of an assembly from a bill of materials and a database of components. The system can be implemented through various combinations of subsystems.

Owner:QSSOLUTIONS +1

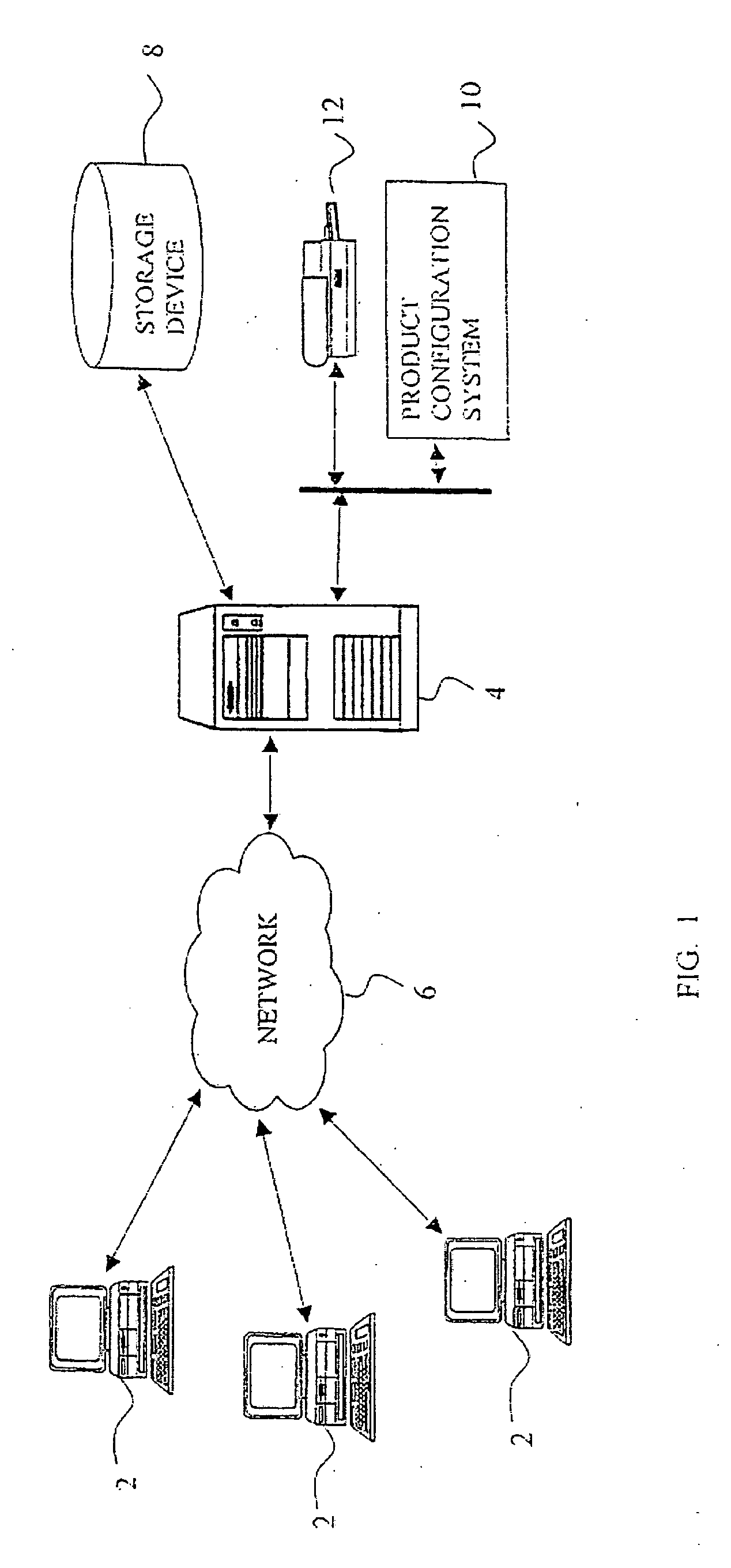

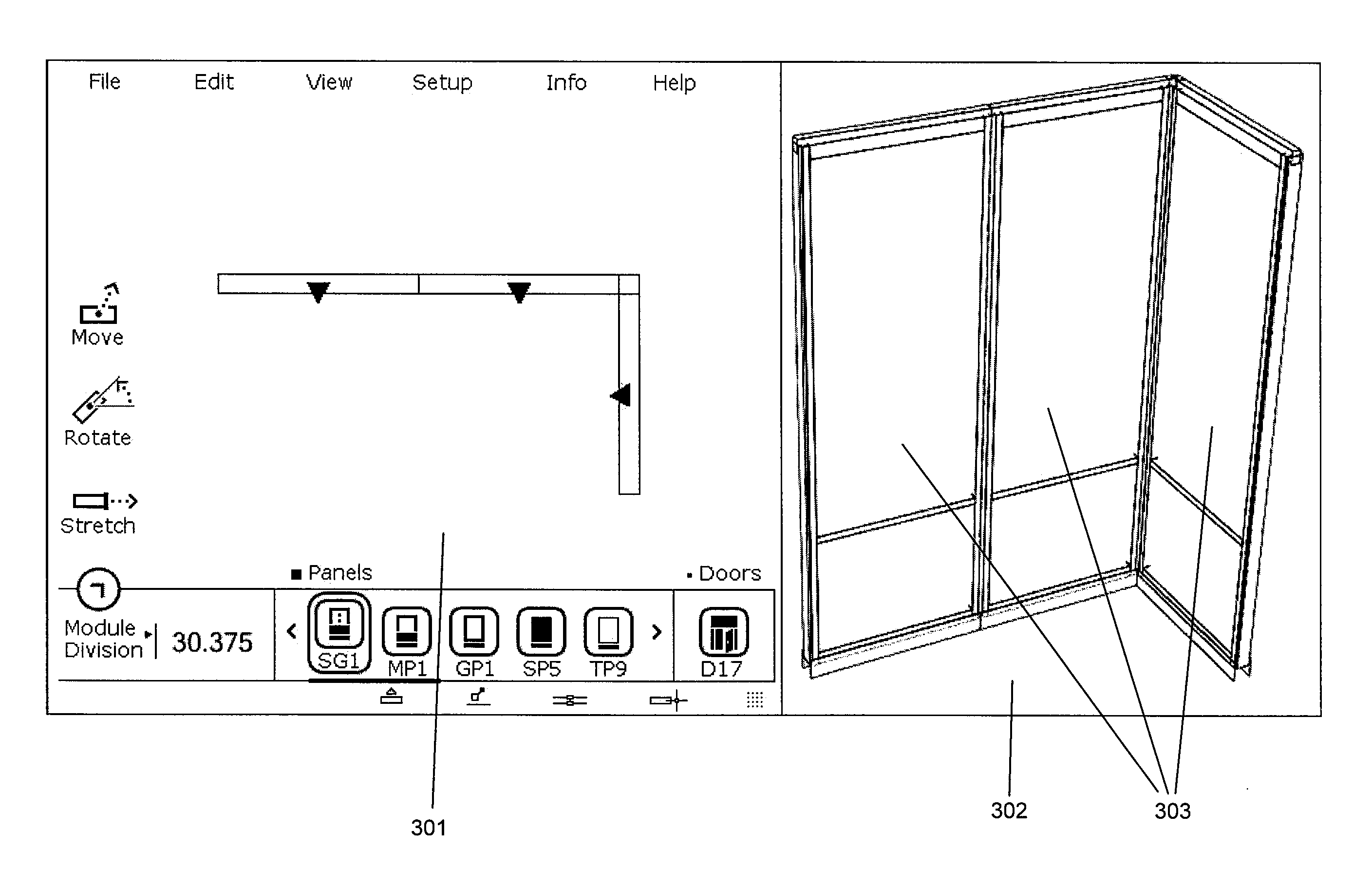

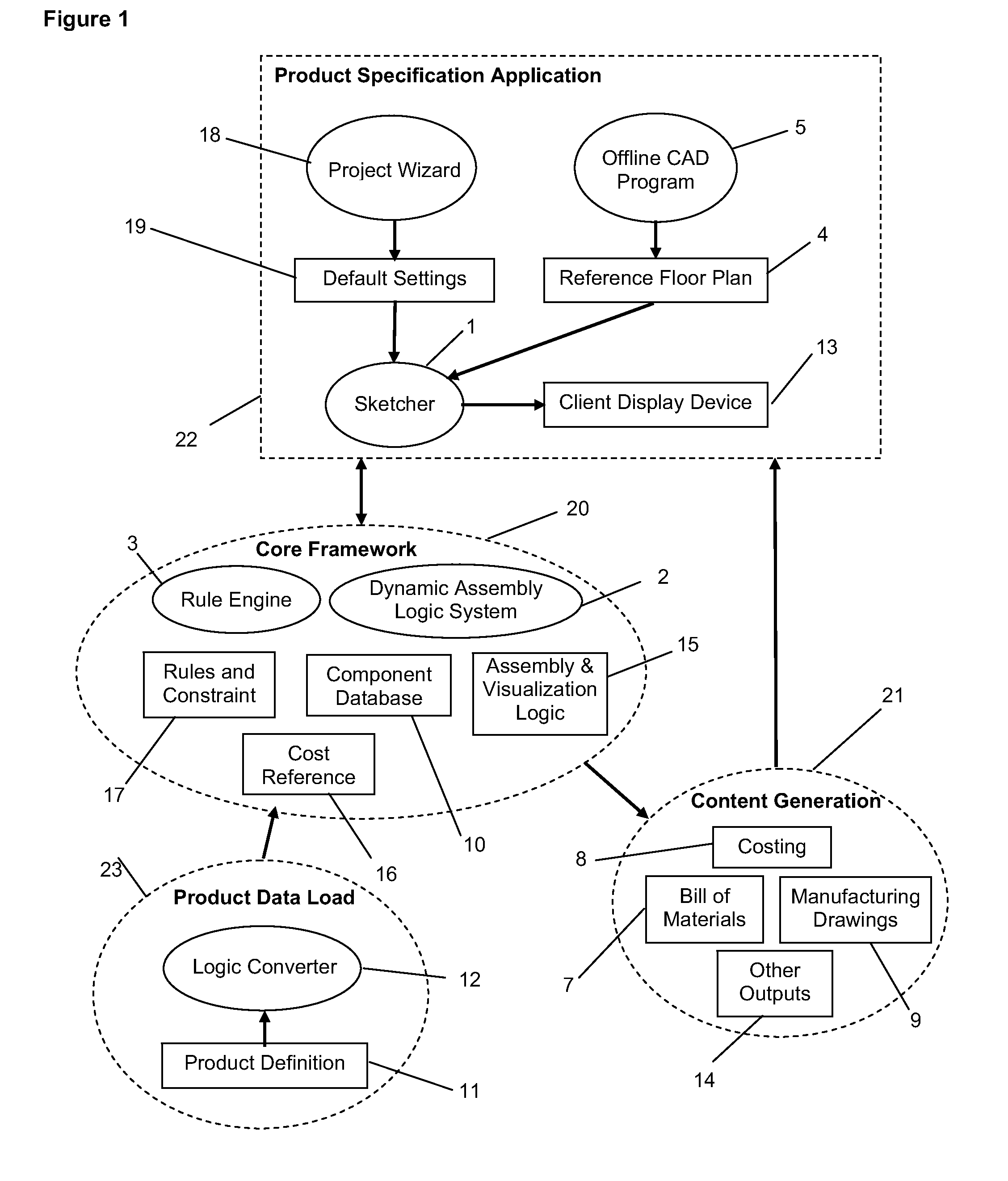

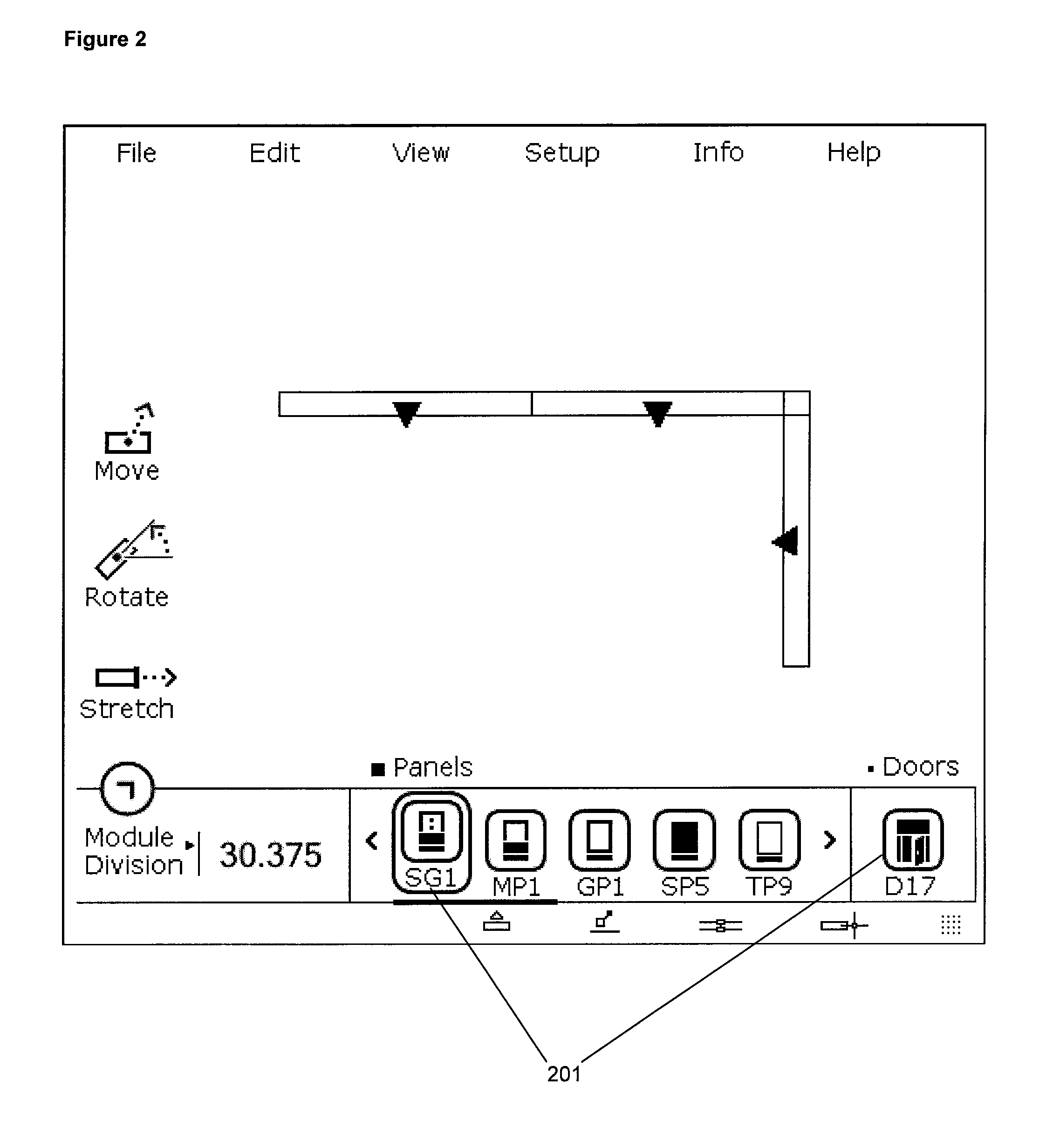

Parametric product configuration system

A generic, integrated, parametric, automated product configuration system for parametric configuration of products such as offices on a building space plan. The system can produce bills of materials, costings and manufacturing drawings in real-time at the request of a user as the user specifies and configures the product components and parameters values. The system provides for real time three-dimensional visualization and editing of the product as it is configured. It also includes a rule engine for validating the product and automatically incorporating missing necessary components in a configuration in real-time as the user configures a product.

Owner:GENEXIS DESIGN

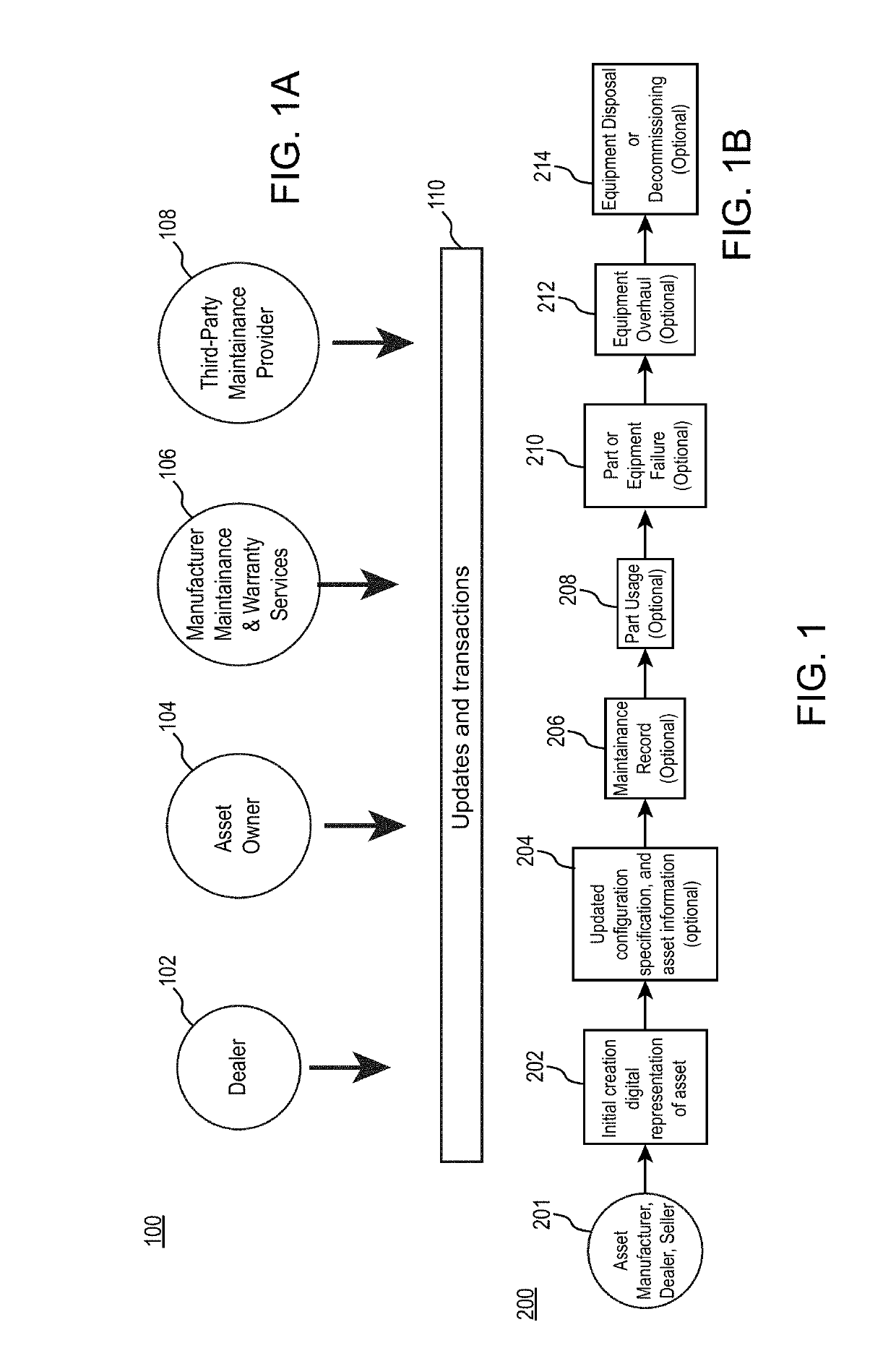

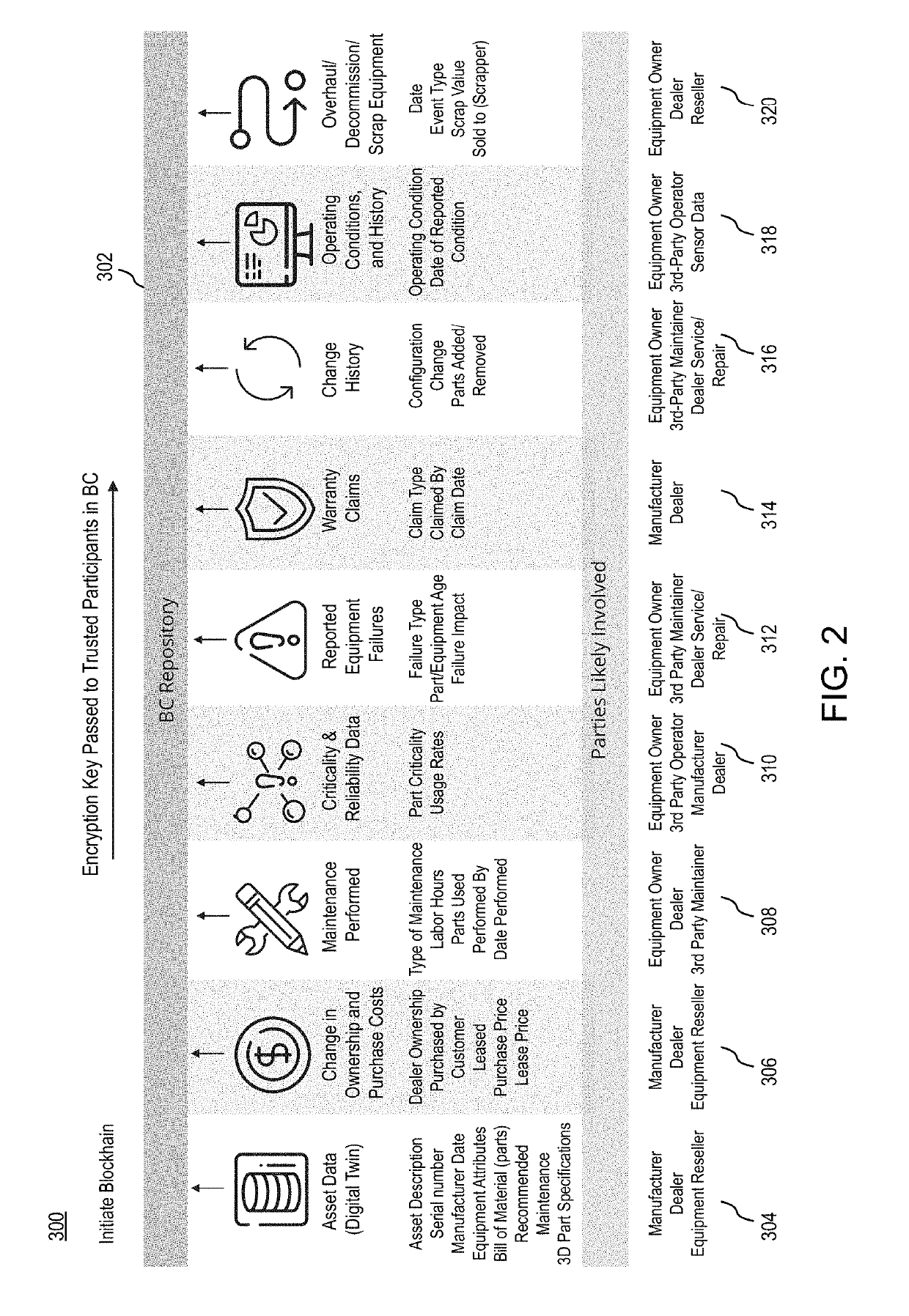

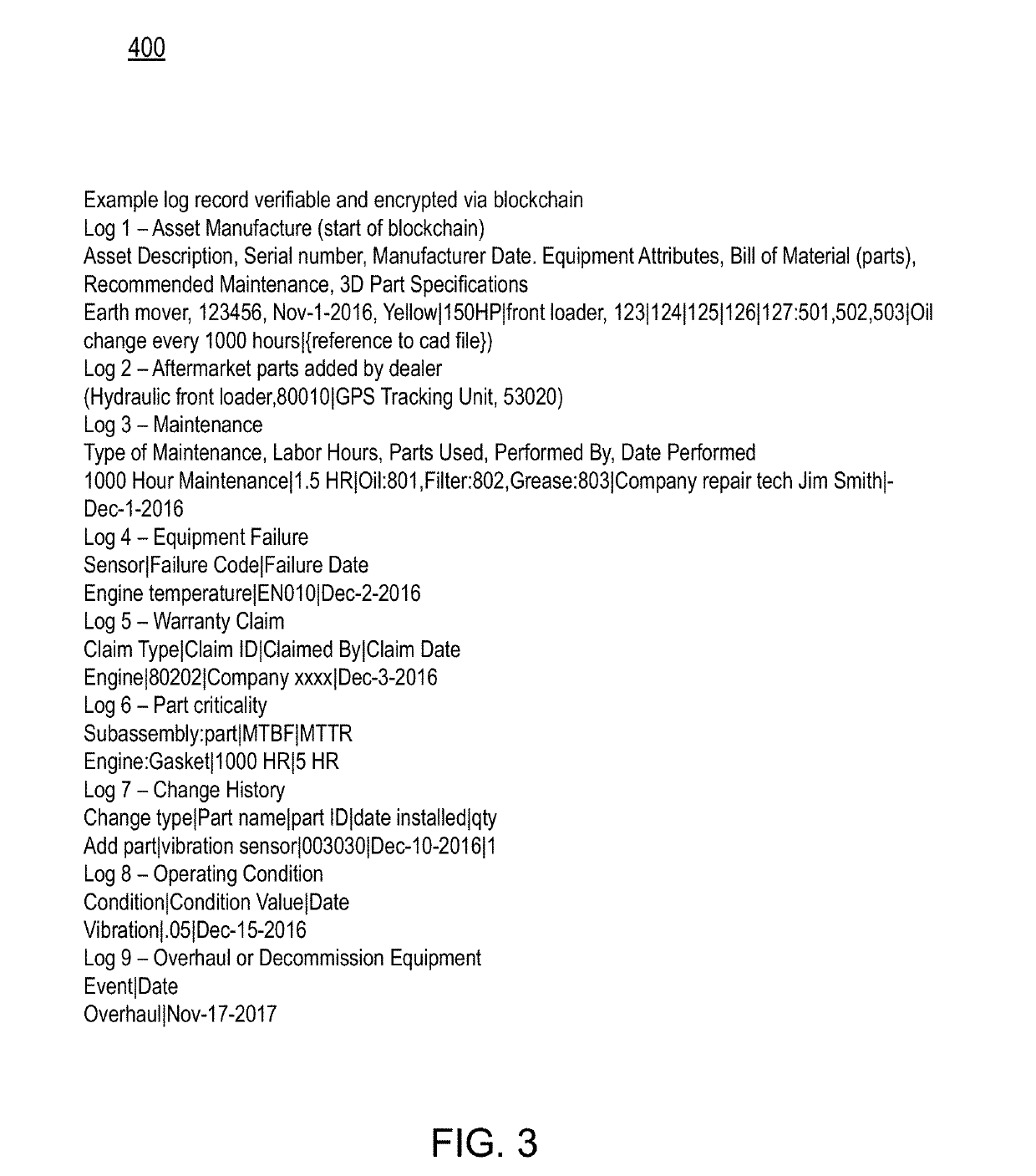

Exchanging Asset, Maintenance, And Spares Parts Information Via Blockchain

InactiveUS20190158270A1Encryption apparatus with shift registers/memoriesPublic key for secure communicationElectronic documentDocumentation procedure

A system for generating, tracking, and recording a digital representation of an asset including an electronic log of the attributes, specifications, bill of material, information to replicate parts on a 3D printer or other part duplication device, the assets warranty and claims, recommended maintenance, actual maintenance and parts (a digital footprint or digital twin) for an asset from initial creation, to its sale, during its usage and through decommissioning. The system uses block chain and encryption technology to register information about an asset that is manufactured and for which the digital footprint is to be tracked and recorded. Through use of encryption key pairs and blockchain encryption technology, an electronic document is created in an encrypted transaction log updated at each change to the equipment including the parts and its maintenance records. From the manufacturer or distributor, the asset is shipped with an encryption key that provides access to the equipment information and allows further updates on parts that are added or removed, maintenance performed, warranty work completed and operating metrics are to be provided as available.

Owner:ONIQUA PTY LTD +1

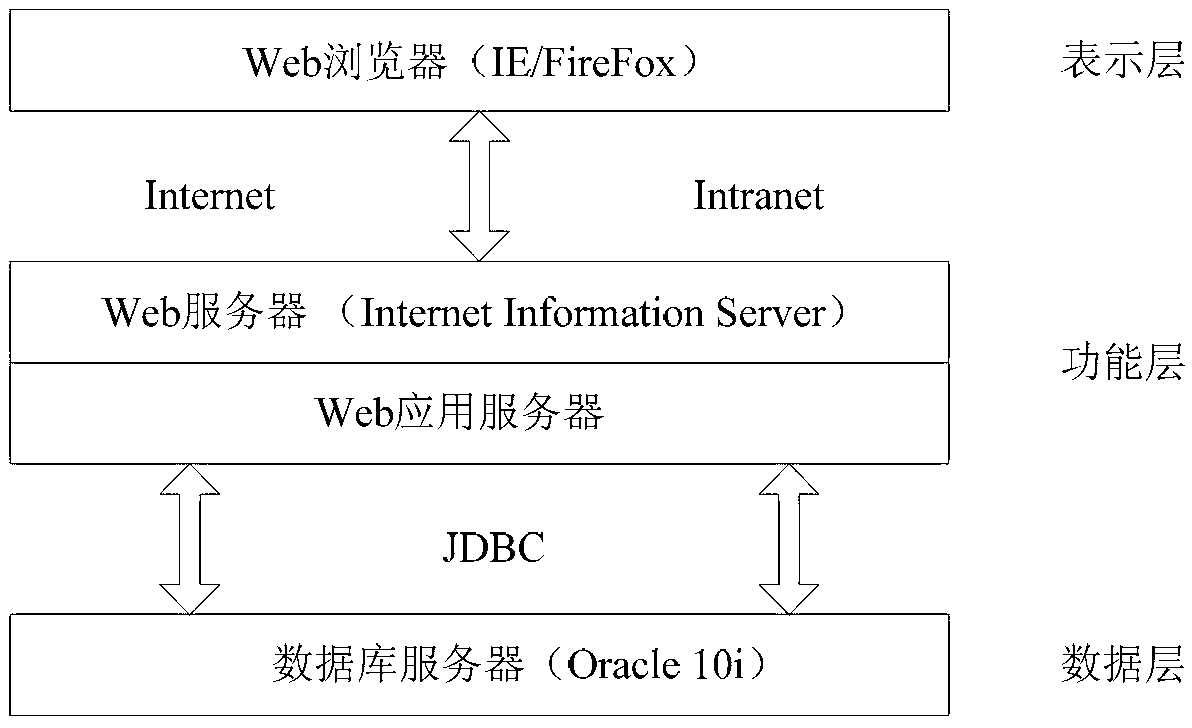

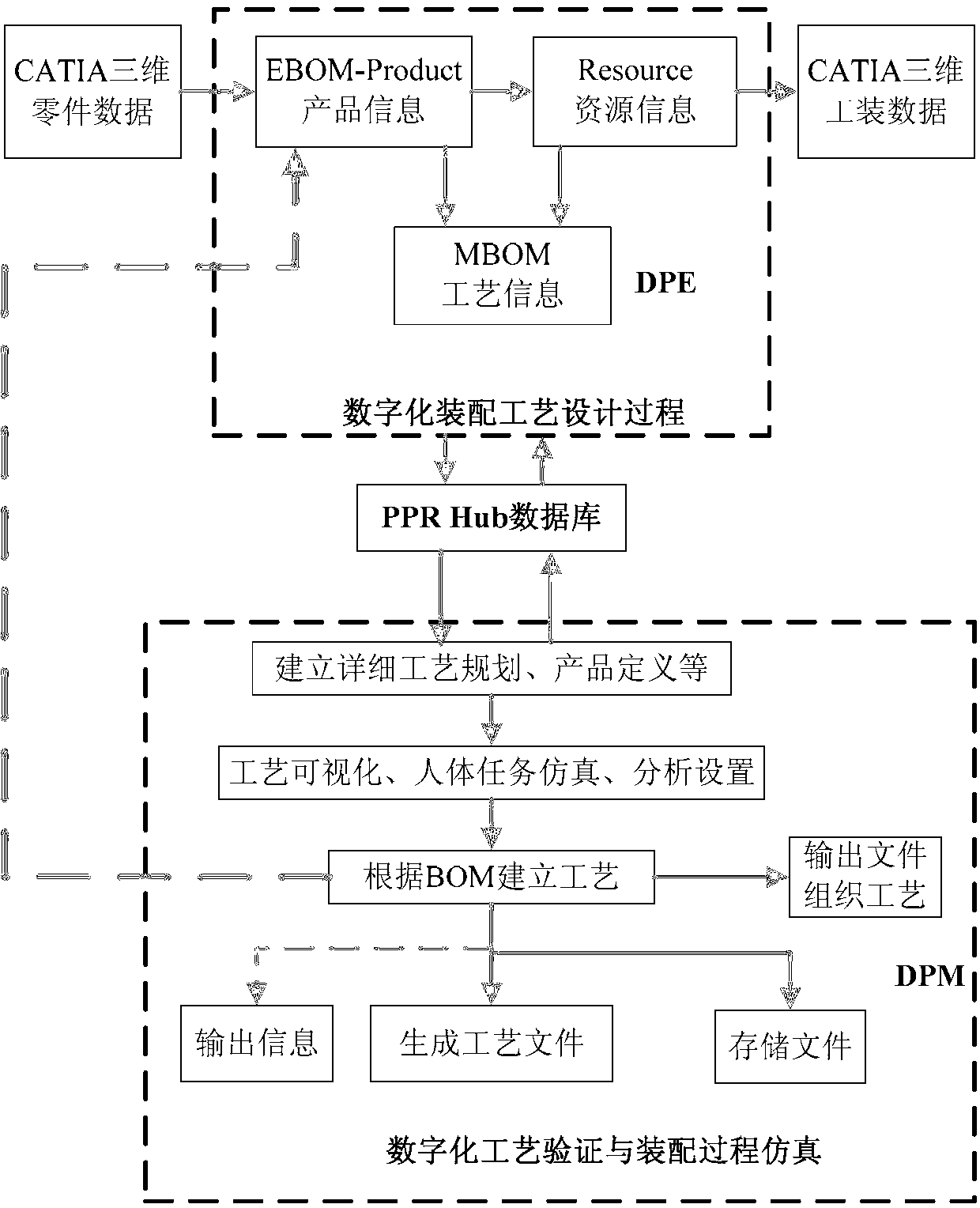

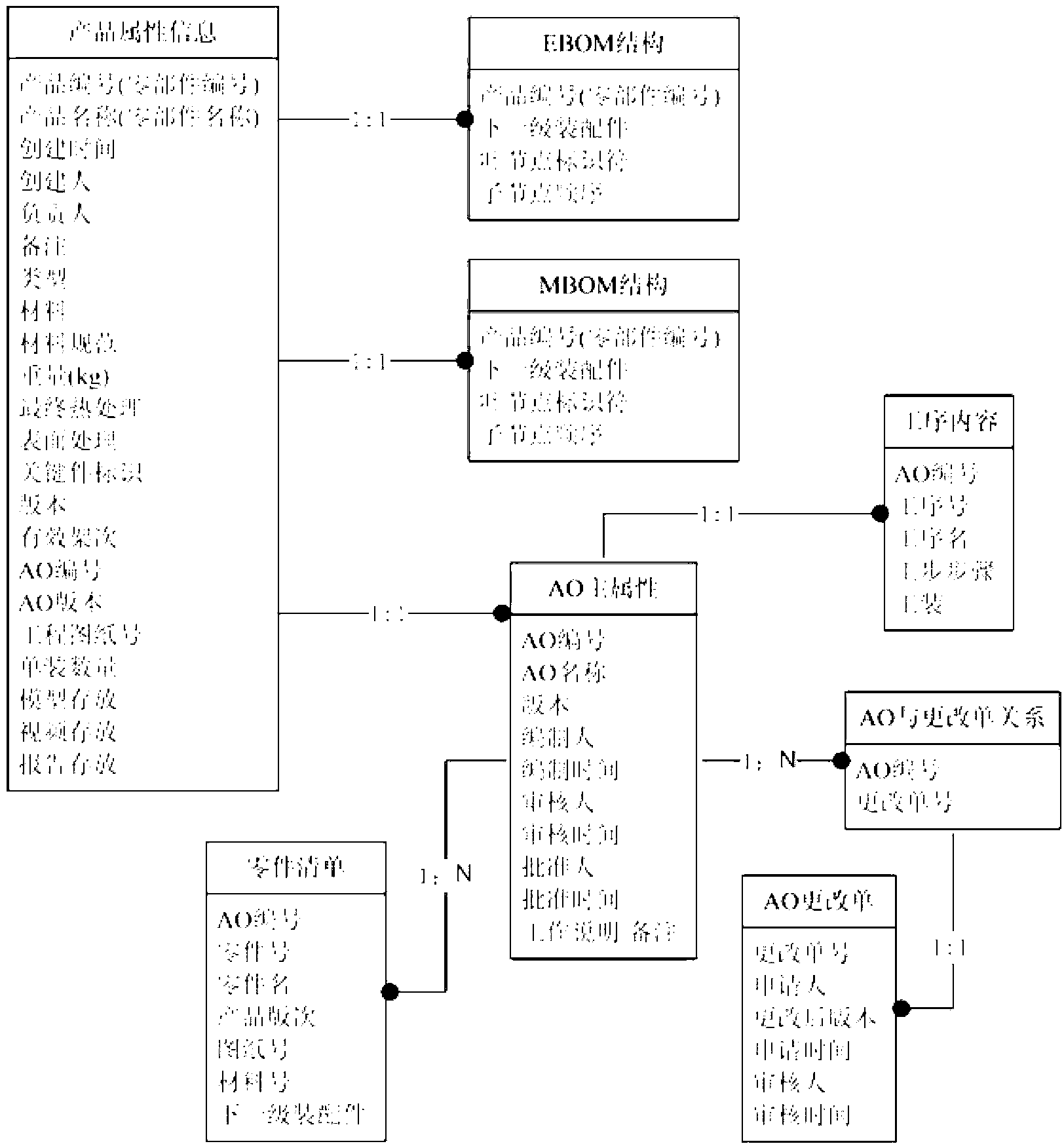

Aircraft assembly data visualization method based on Web

ActiveCN103020393ARealize online browsingReduce redundancySpecial data processing applicationsBill of materialsSimulation

The invention relates to an aircraft assembly data visualization method based on Web. The method comprises four steps as follows: step 1, setting up system architecture and development environment; step 2, visualization AO (Assembly Order) designing; step 3, assembling process simulation; and step 4, using in an assembly site. The method is used for realizing visual online browse of data such as BOM (Bill of Material), AO, product information and the like, and the assembly quality and the working efficiency of aircrafts are increased. The method has a better practical value and a wide application prospect in the aircraft industry.

Owner:BEIHANG UNIV

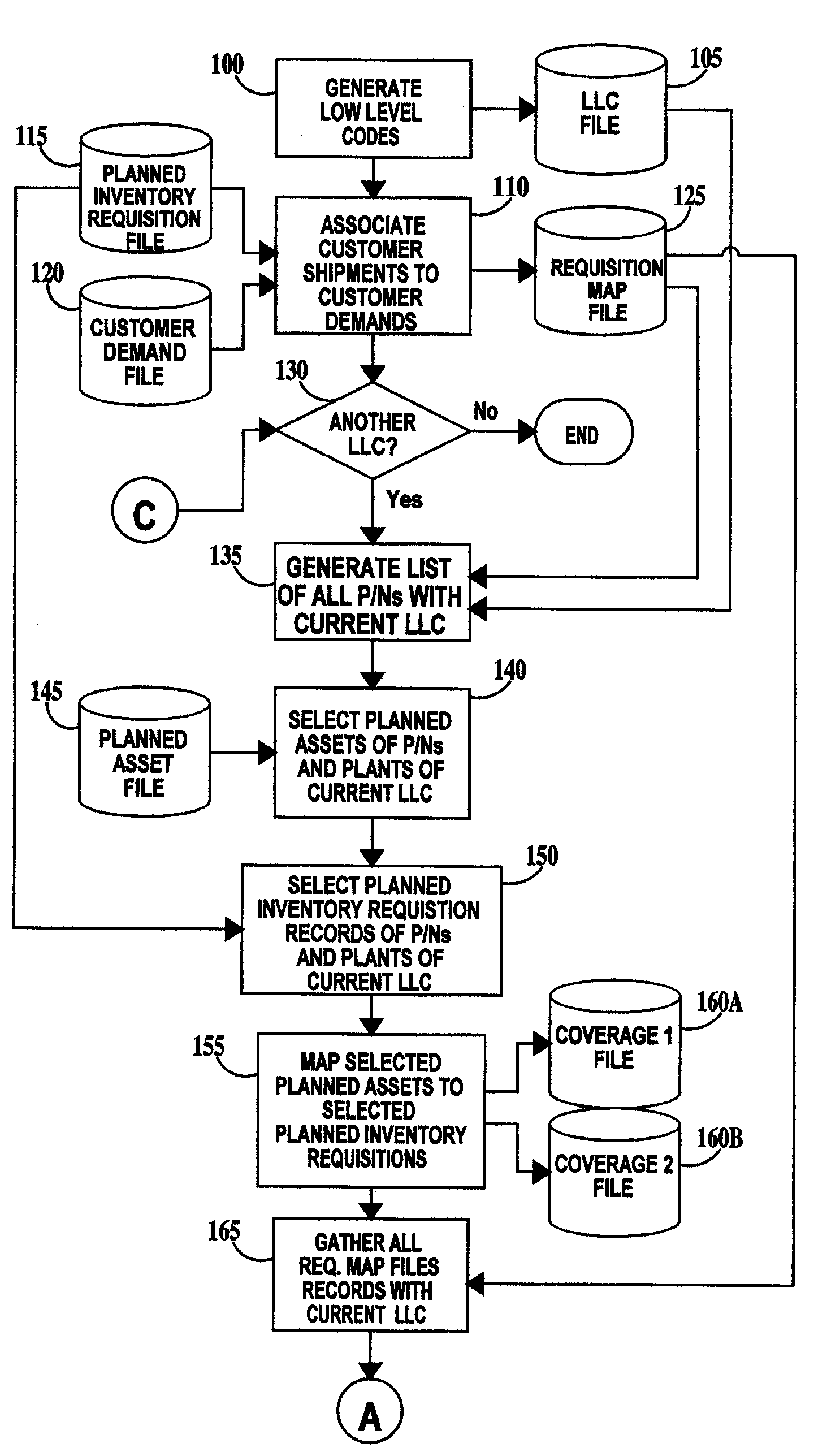

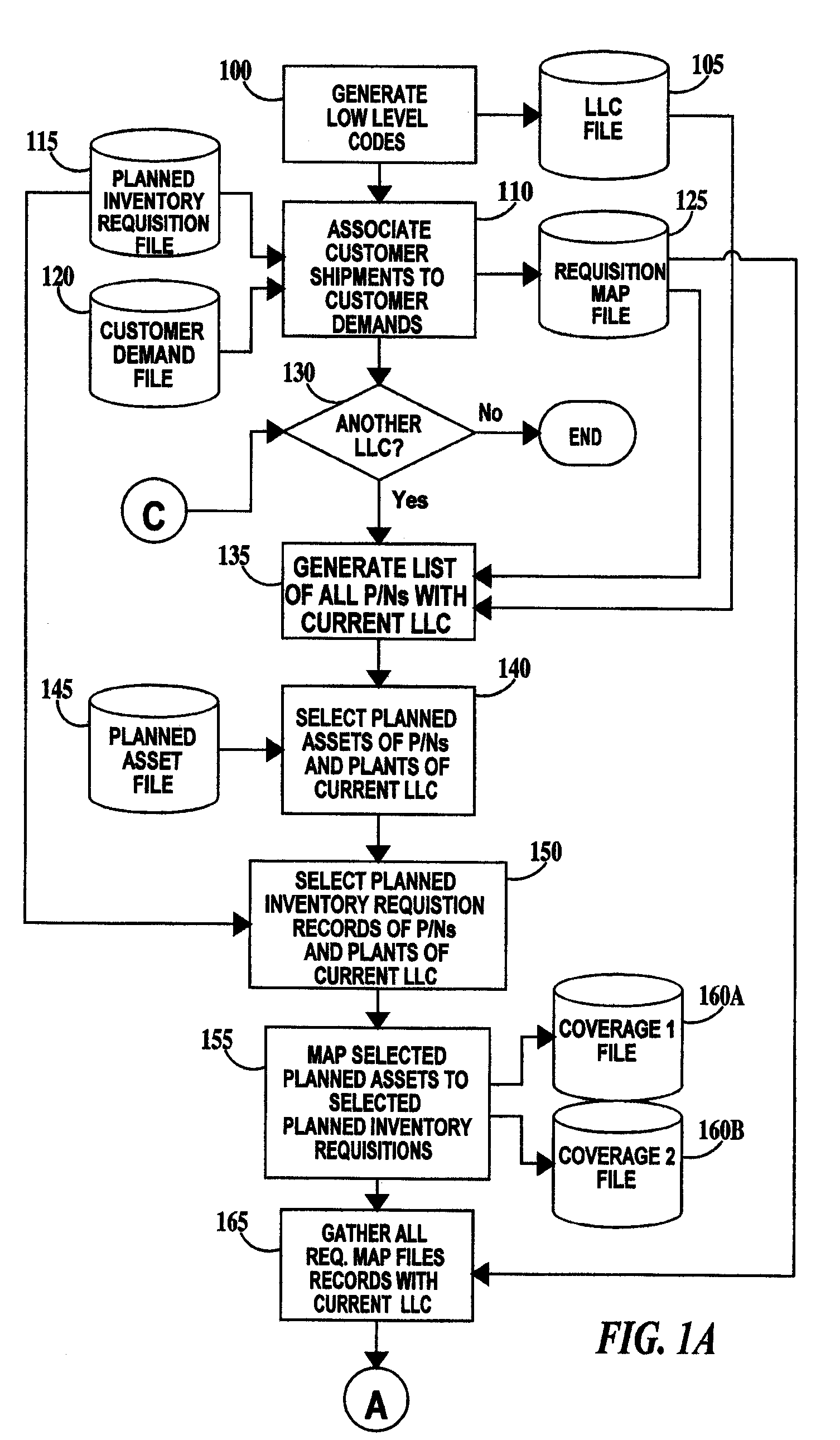

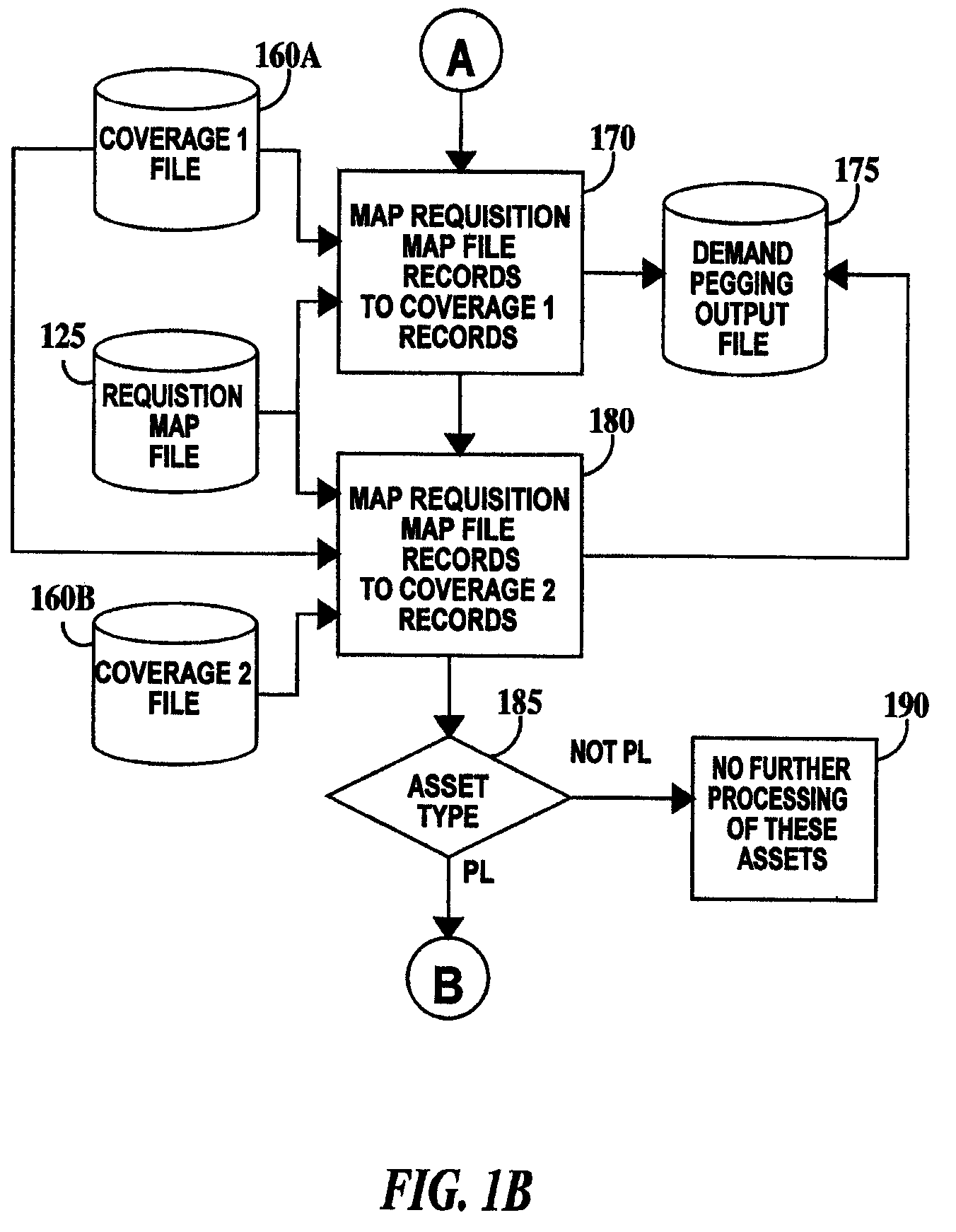

Method for identifying product assets in a supply chain used to satisfy multiple customer demands

InactiveUS7606743B2Hand manipulated computer devicesPayment architectureTime scheduleBill of materials

A method, a system for practicing the method and a storage device storing the method for identifying product assets in a supply chain used to satisfy customer demands. The method including: receiving a feasible schedule of all components to be assembled into products; receiving customer schedules for delivery of the products; and generating from the feasible schedule, from the customer schedules and from bills of materials listing all components required for a particular product, a set of demand pegging records, the demand pegging records associating a quantity and an availability date of each component of each product with a required quantity of each of the products, each demand pegging record consistent with the feasible schedule.

Owner:INT BUSINESS MASCH CORP +1

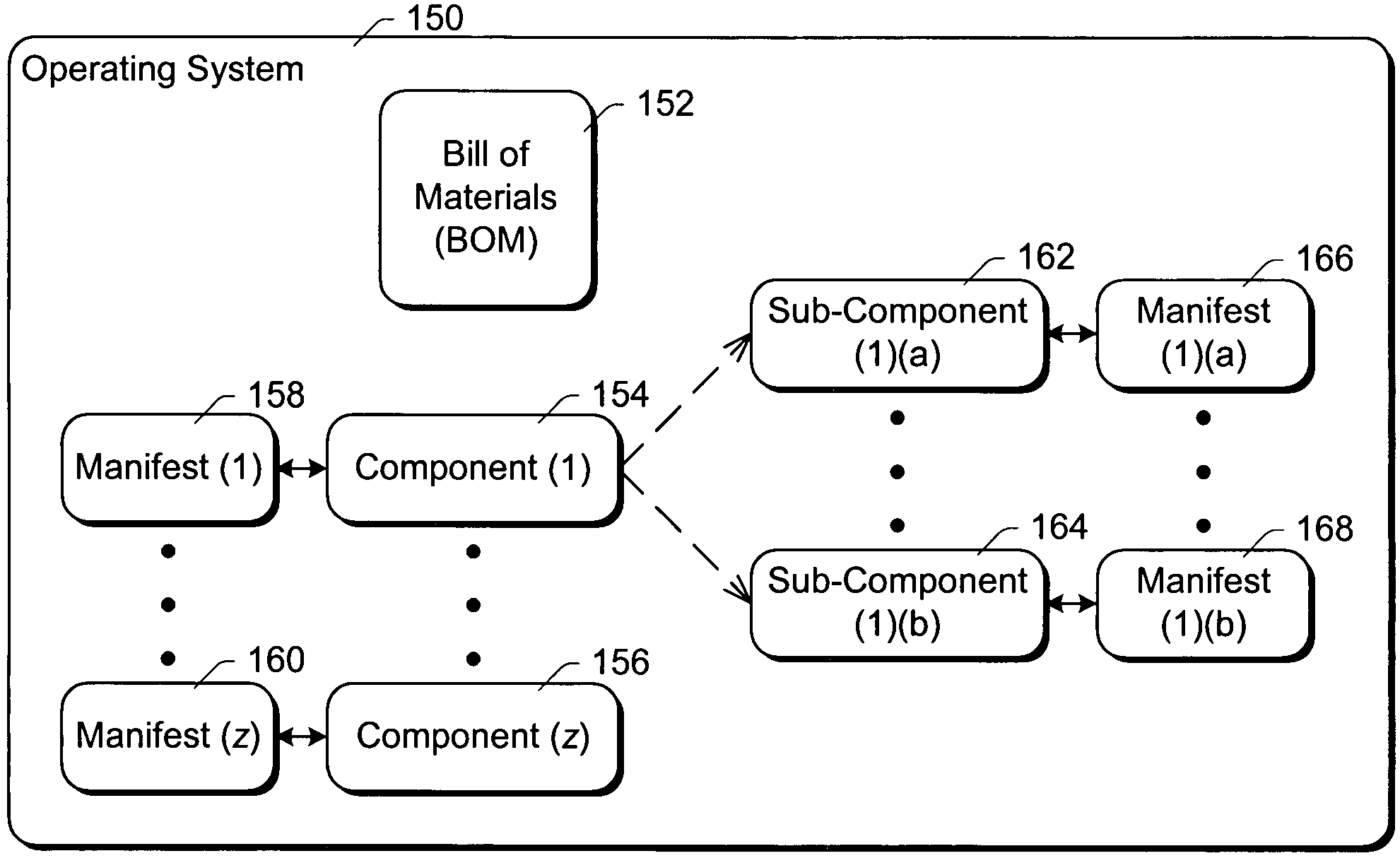

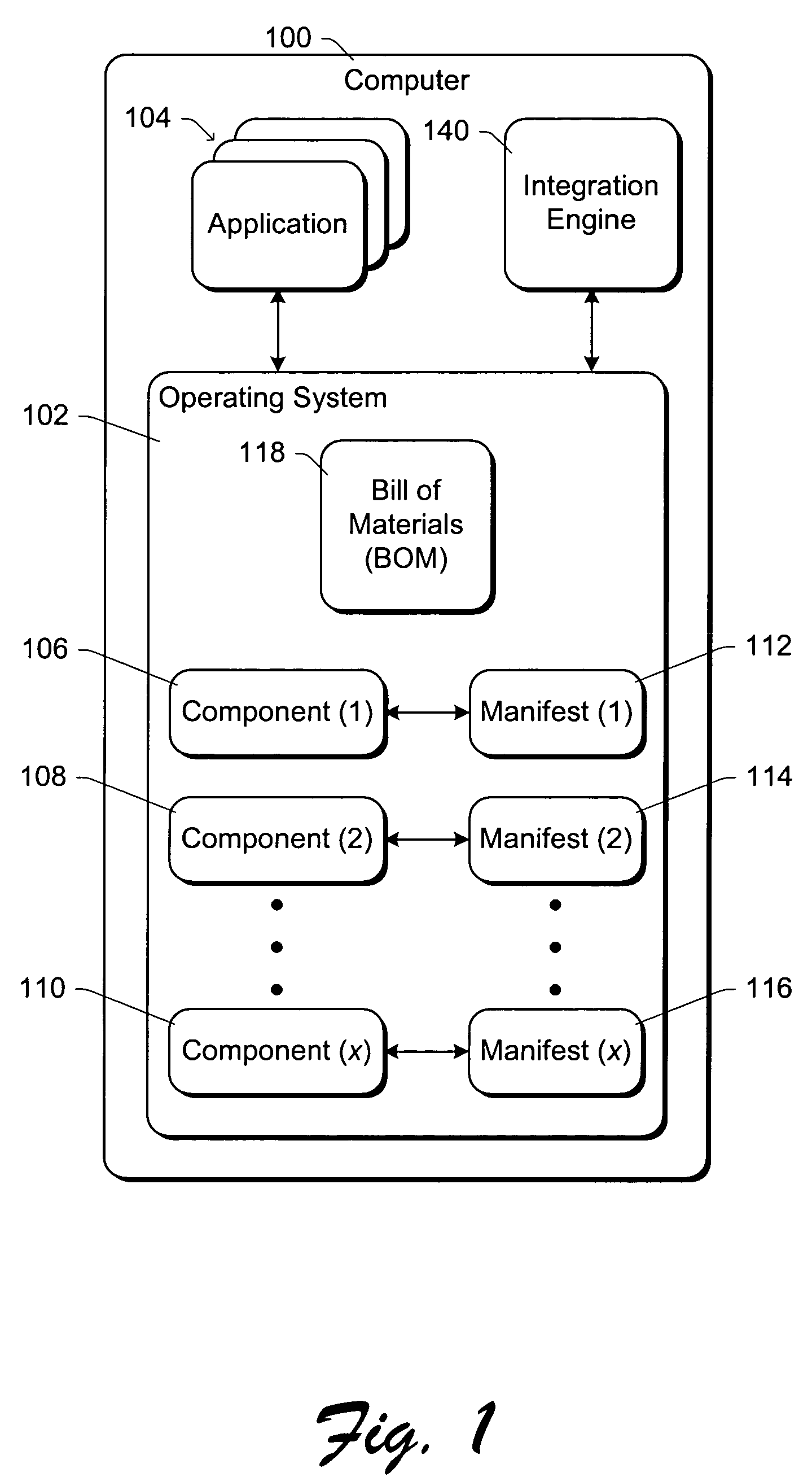

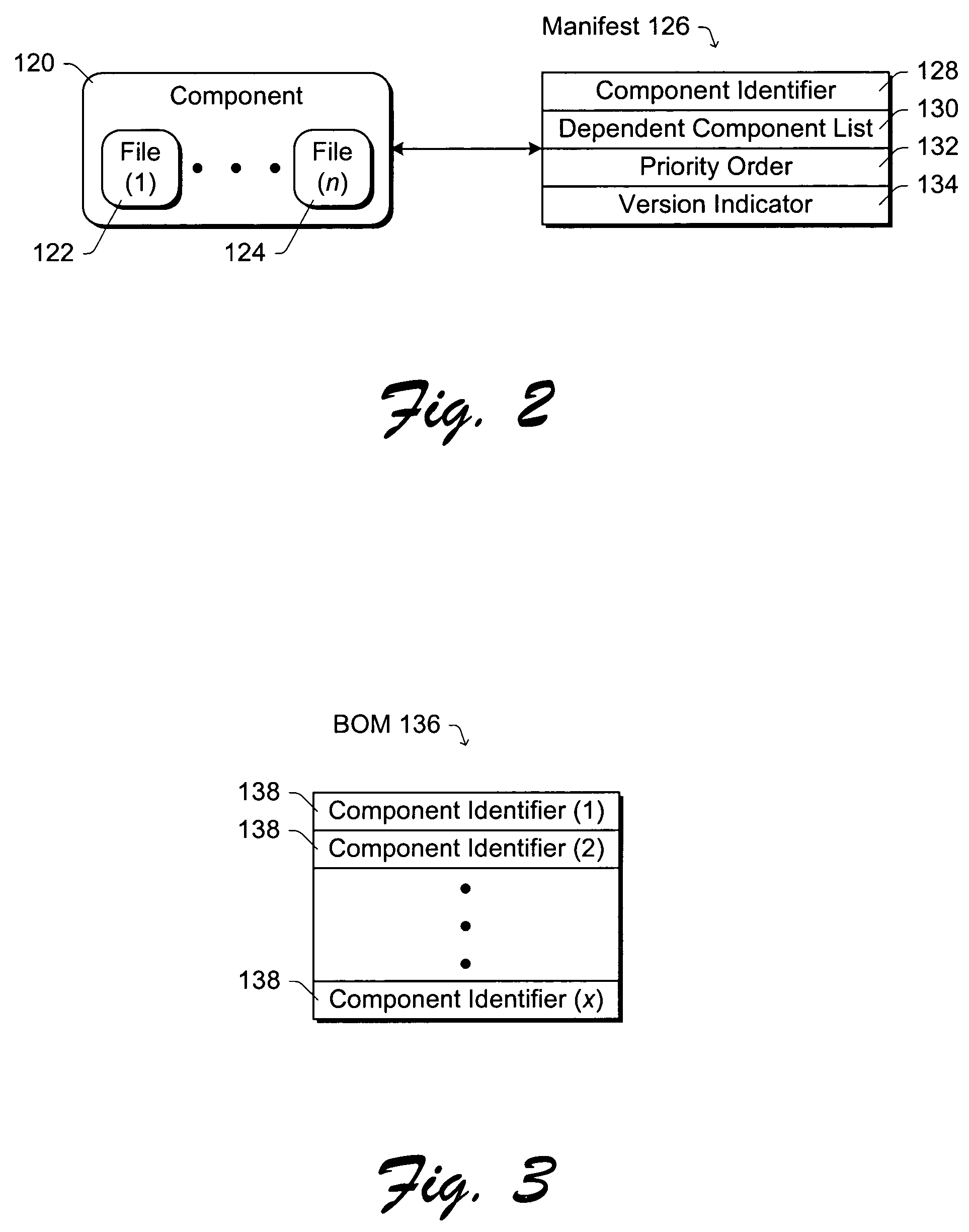

Componentized operating system

InactiveUS7155713B1Readily availableProgram loading/initiatingMemory systemsOperational systemBill of materials

A componentized operating system is separated into multiple different components. In certain embodiments, a bill of materials (BOM) identifies at least one component that is installed (or is to be installed) for an operating system image on a computer. Each component includes one or more files and has a corresponding manifest that identifies which other components (if any) the component is dependent on. During an installation or upgrading process, the manifest for a component can be accessed to determine which additional components (if any) are to be installed even if they are not explicitly identified in the BOM.

Owner:MICROSOFT TECH LICENSING LLC

Method and system for resource requirement planning and generating a production schedule using a uniform data model

InactiveUS7209869B1Avoid exponential growthEasy to understandAnimal feeding devicesResourcesDocumentation procedureBill of materials

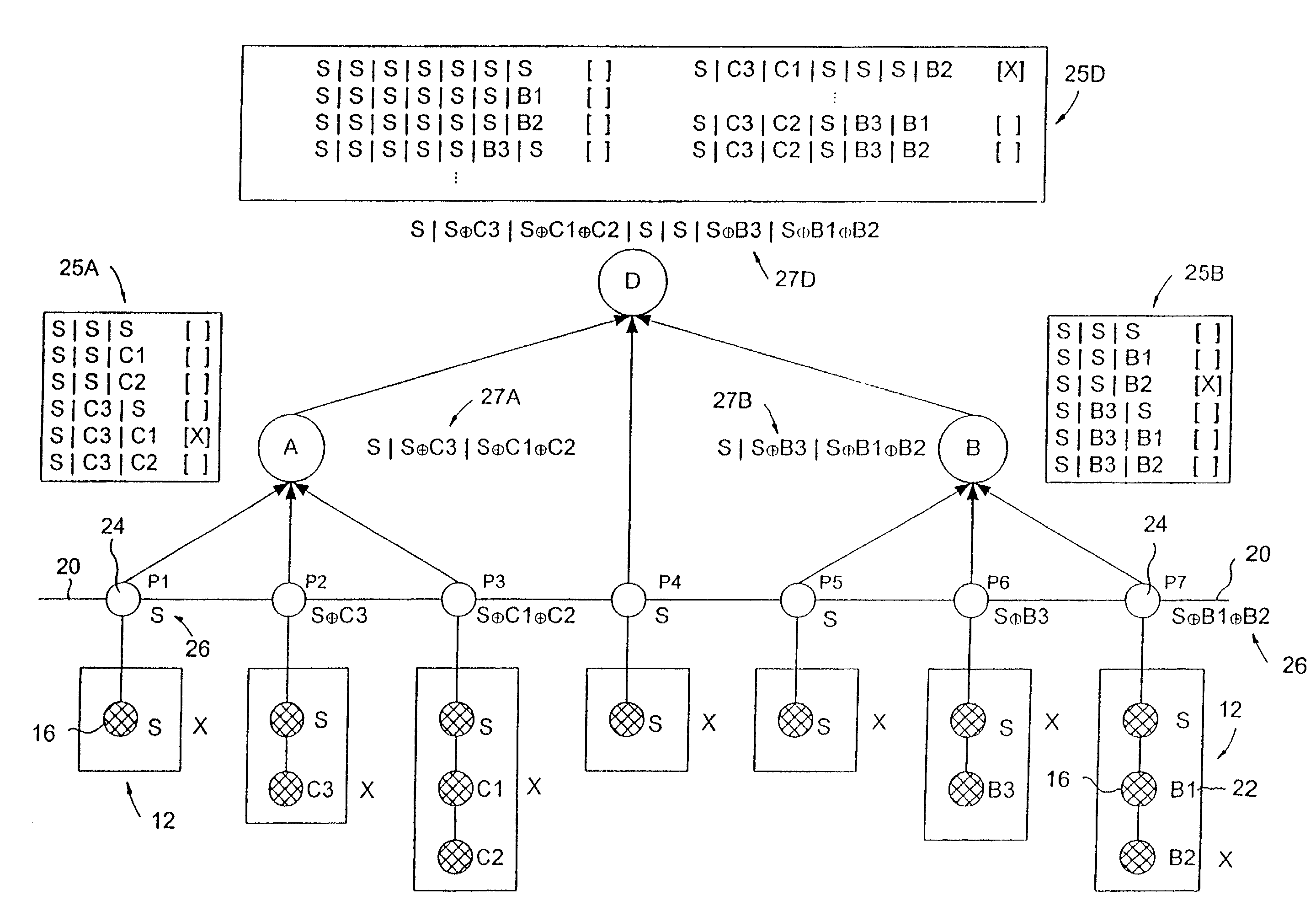

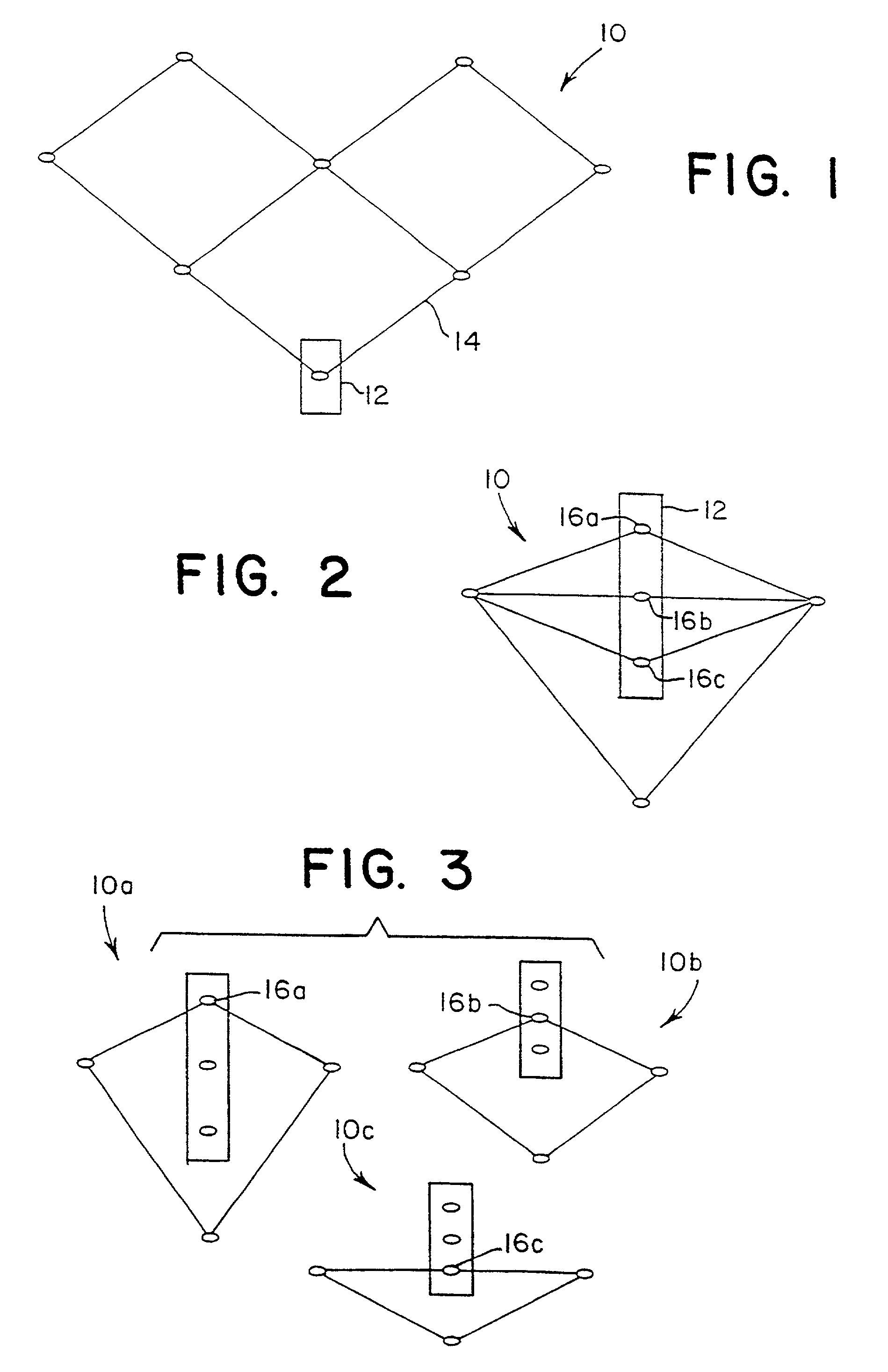

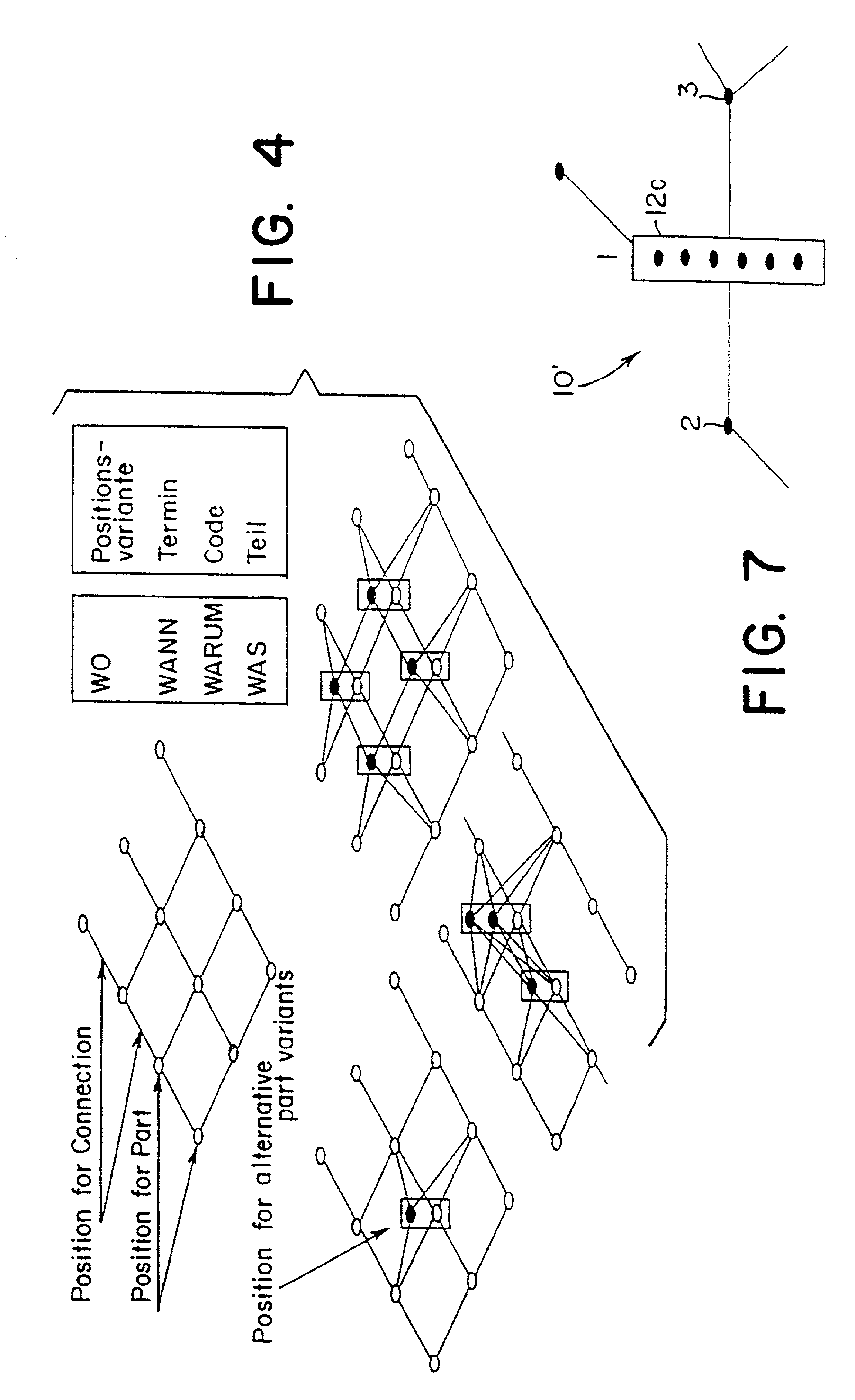

A method for representing the structure of an article of manufacture having a plurality of design variants includes defining a plurality of positions corresponding to different predefined locations on the article of manufacture and assigning at least one variant to each position. Each variant identifies a specific part that may be used in the respective position or a specific type of connection between a pair of parts. In any given position, at most one part or connection variant can be selected. Code rules are defined for each variant which indicate when a particular variant should be used in accordance with specified design options. The position and variant representation can be implemented as part of a bill of materials used for manufacturing resource planning. Improved methods for defining the code rules, for evaluating the code rules in the bill of materials to determine manufacturing parts requirements for a plurality of orders, and for generating documentation for manufactured variants of the article are also disclosed.

Owner:MONKE ECKHARD +1

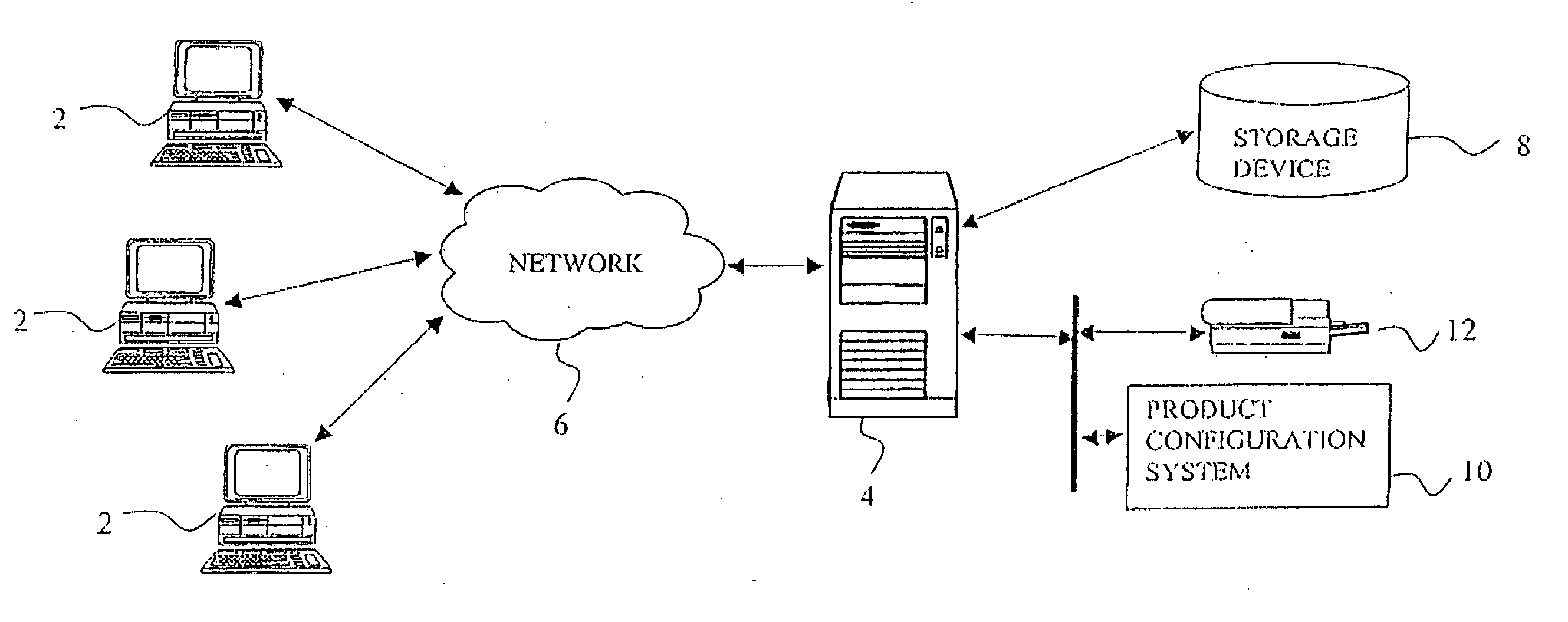

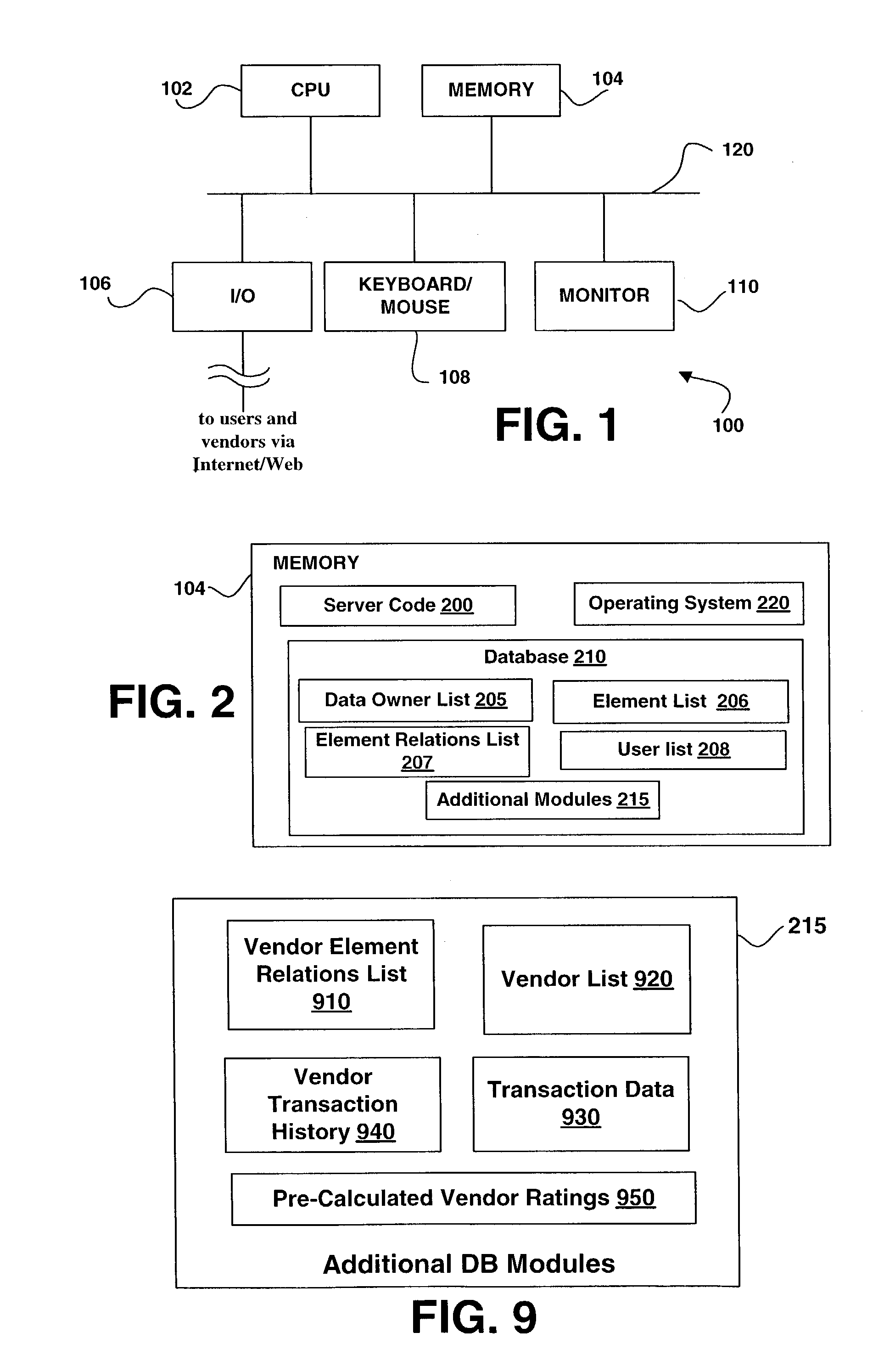

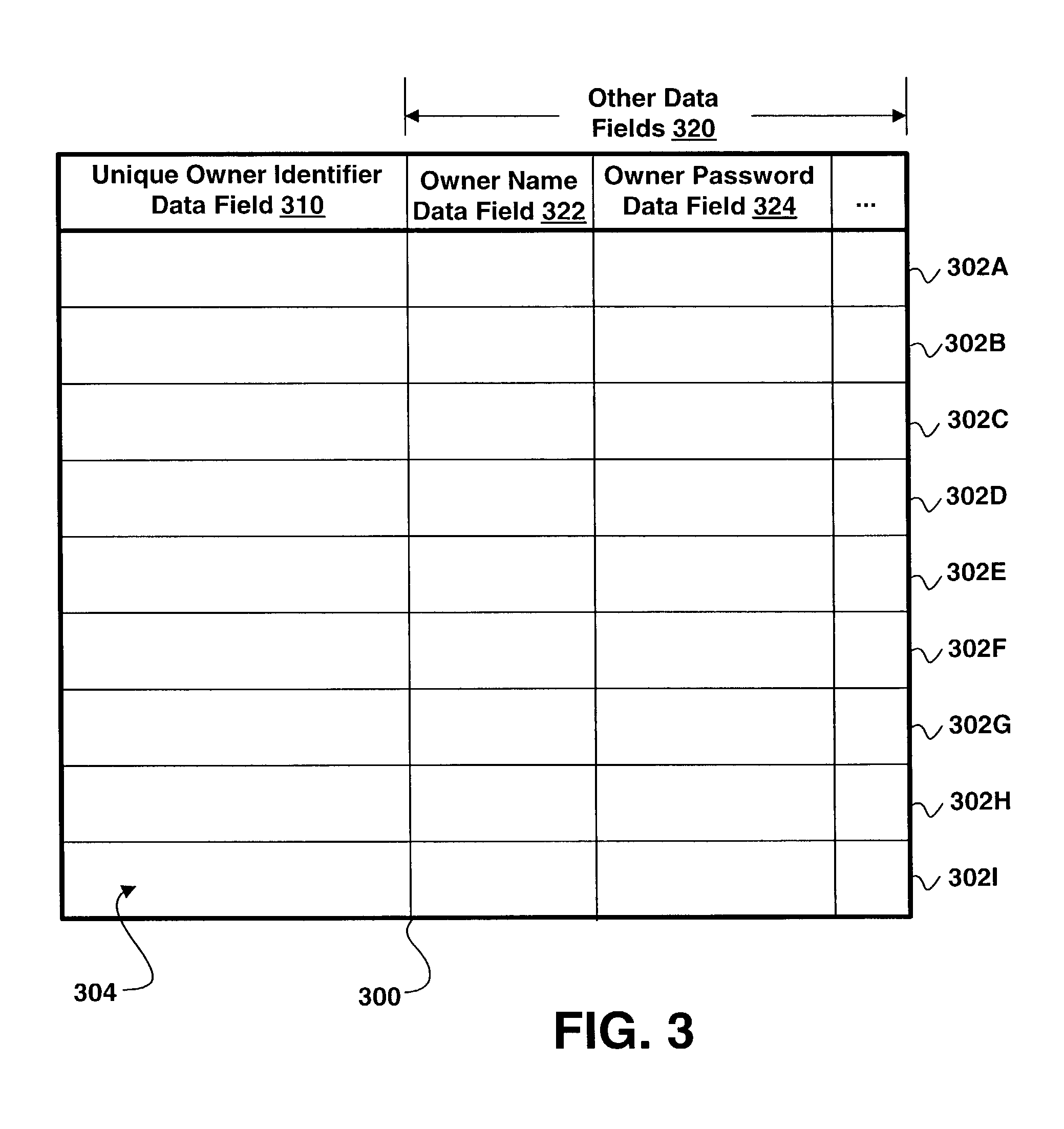

System and method for managing data in multiple bills of material over a network

ActiveUS7558793B1Reduce dataReduce duplicationAnimal feeding devicesSpecial data processing applicationsInternet privacyBill of materials

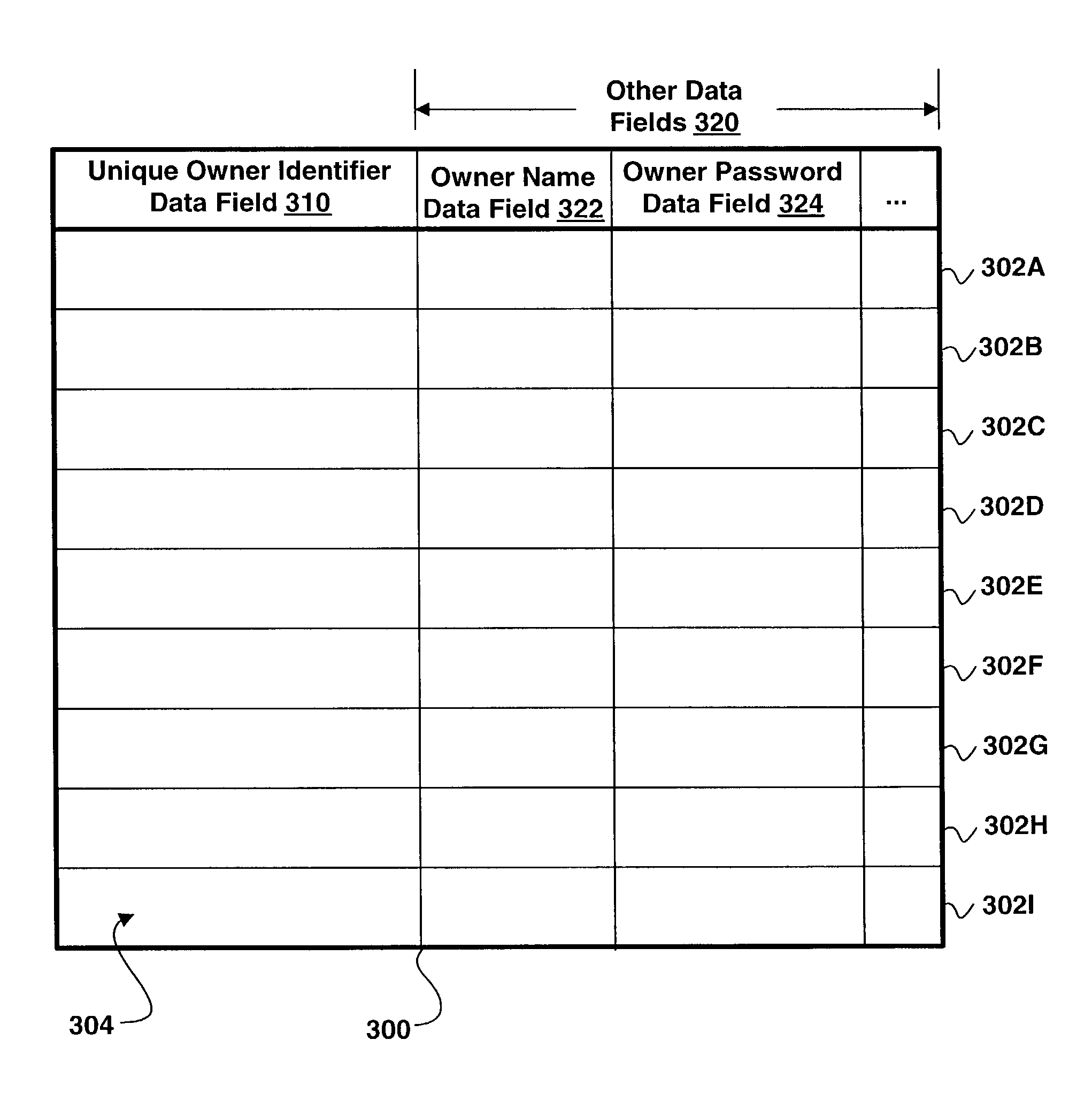

A method of storing and managing BOMs of different owners in the same environment. One or more BOMs have an owner. An owner's BOM includes may include confidential information such that unrestricted access to the confidential information is limited to the owner and any designates of the owner. In particular, one embodiment of the invention and maintains a list of items that include the items in the BOMs of the different owners. A unique identifier is used for each item of the list. The item identifiers thus form one namespace. BOMs of different owners share data including confidential data within the same namespace.

Owner:ARENA SOLUTIONS

Method and system for enterprise-level unassisted customer shipping

A system and method for unassisted enterprise-level unassisted customer shipping is described providing for payment of shipping and item costs in a single transaction. In one configuration, a customer utilizes a kiosk to process a shipping bill of materials for presentment at a point of sale terminal.

Owner:DMT SOLUTIONS GLOBAL CORP

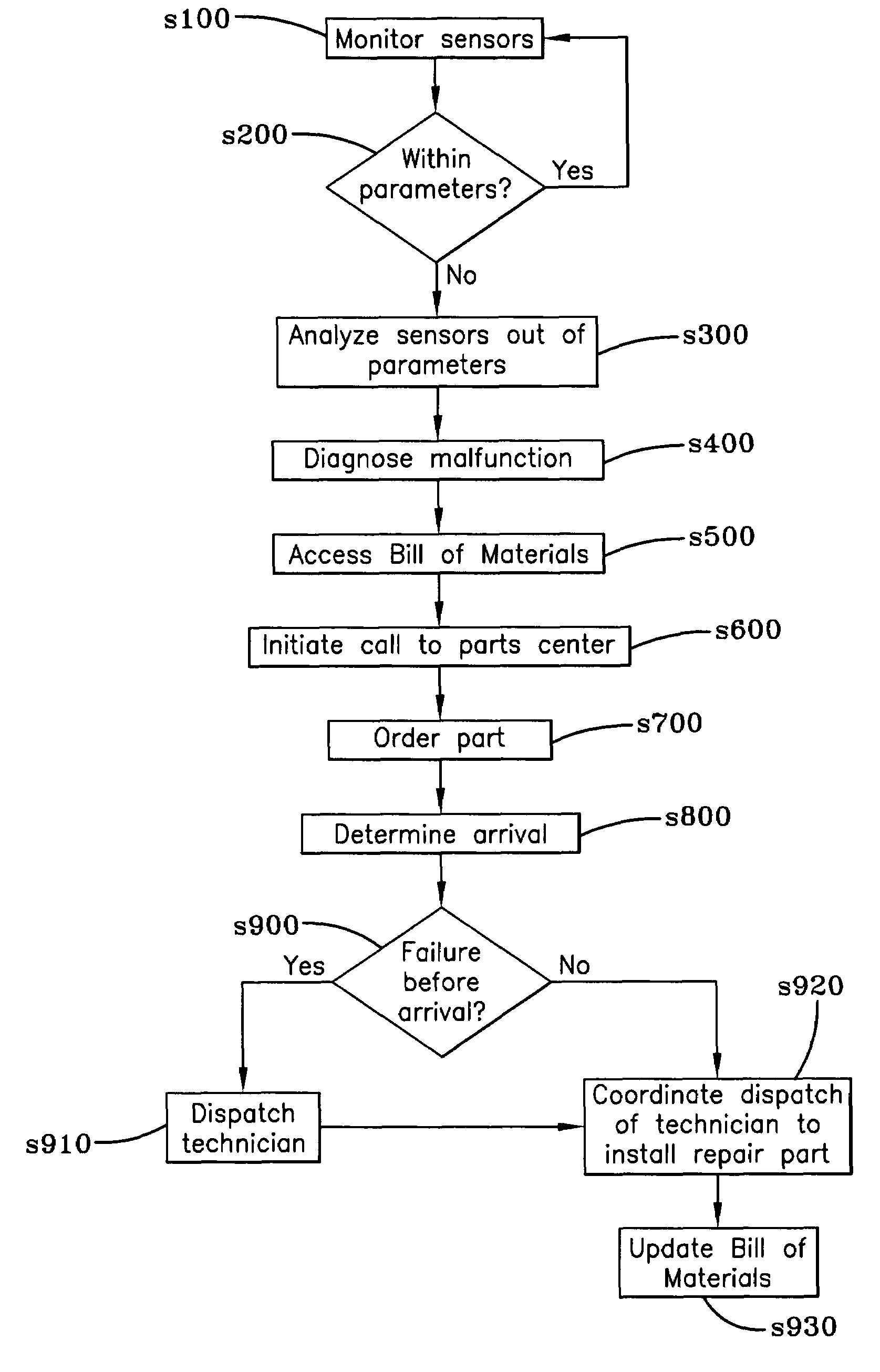

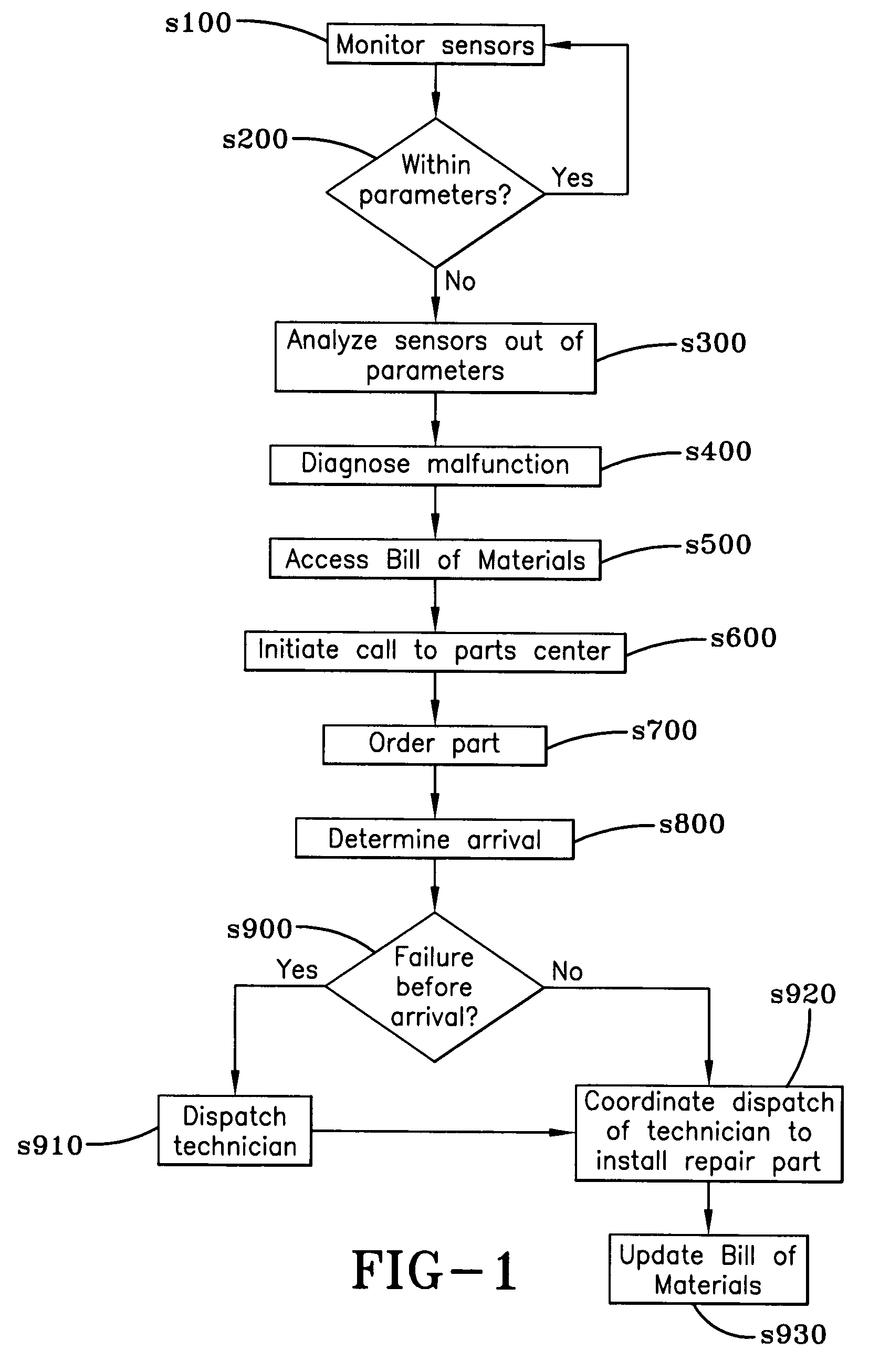

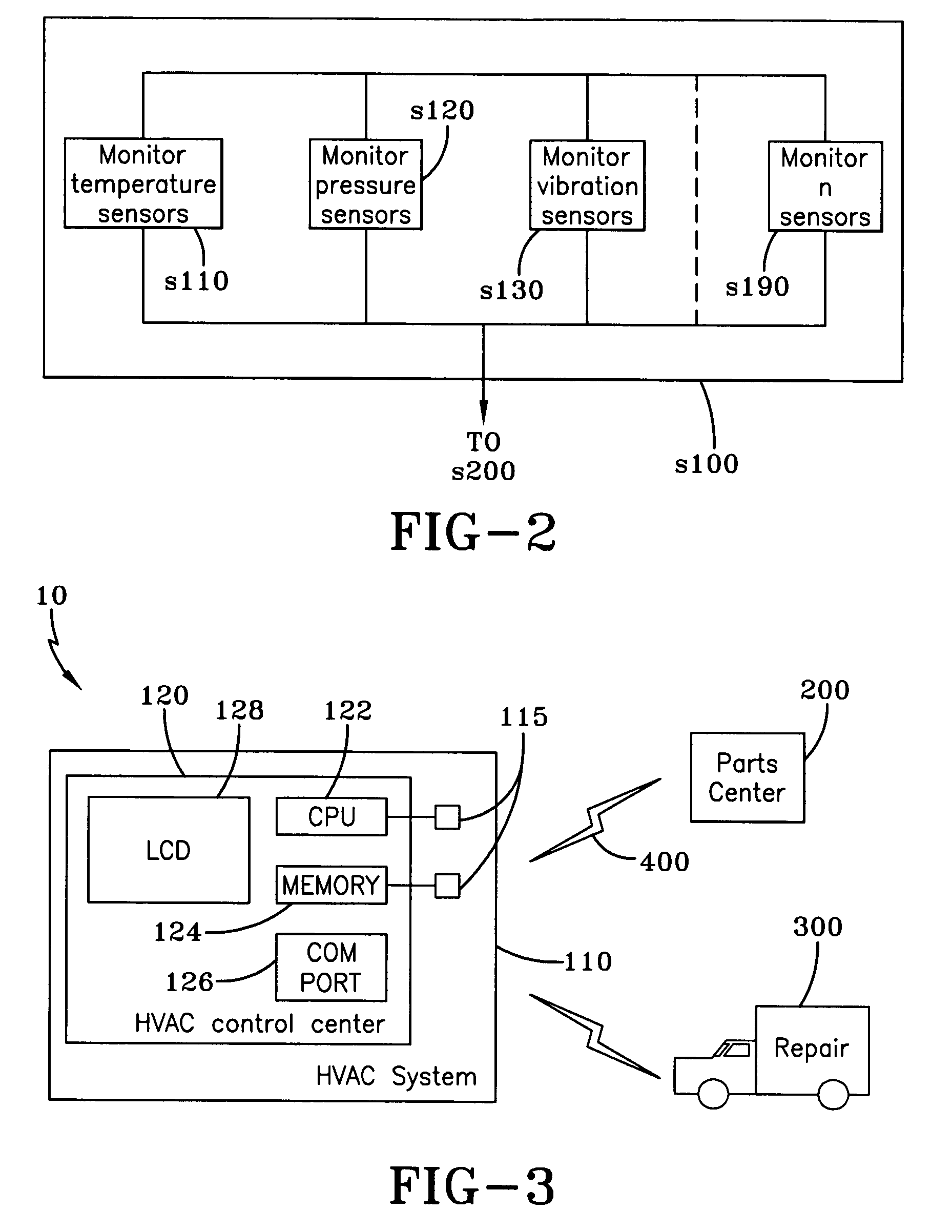

Automated part procurement and service dispatch

A method for repairing an HVAC system is disclosed. The method includes monitoring a plurality of sensors positioned throughout the HVAC system and receiving data associated therewith, determining whether the data received from the plurality of sensors is within corresponding predetermined operational parameters, analyzing data determined to be outside the corresponding predetermined operational parameters to diagnose a malfunction of the HVAC system, accessing an on-board bill of materials to determine a proper replacement part to correct the malfunction, automatically ordering the replacement part, and automatically dispatching a service technician to install the replacement part.

Owner:YORK INT CORP

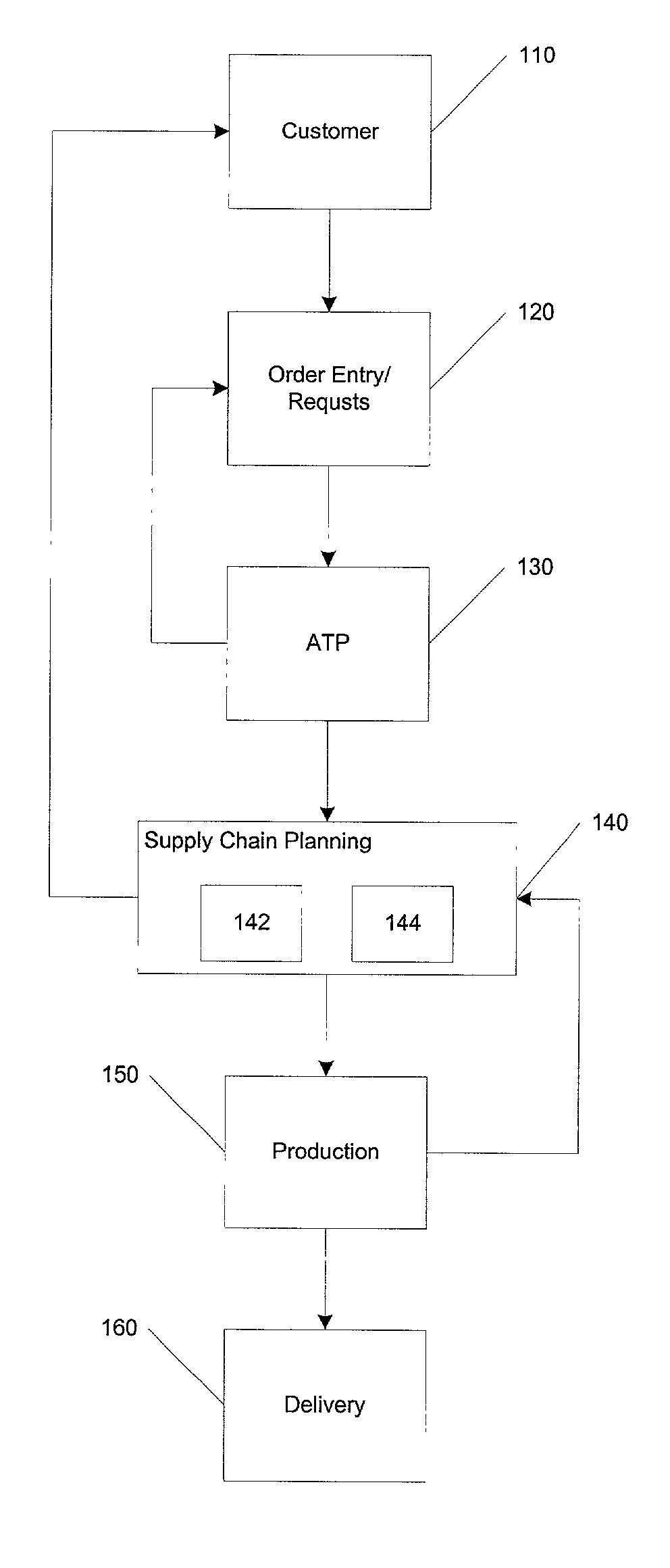

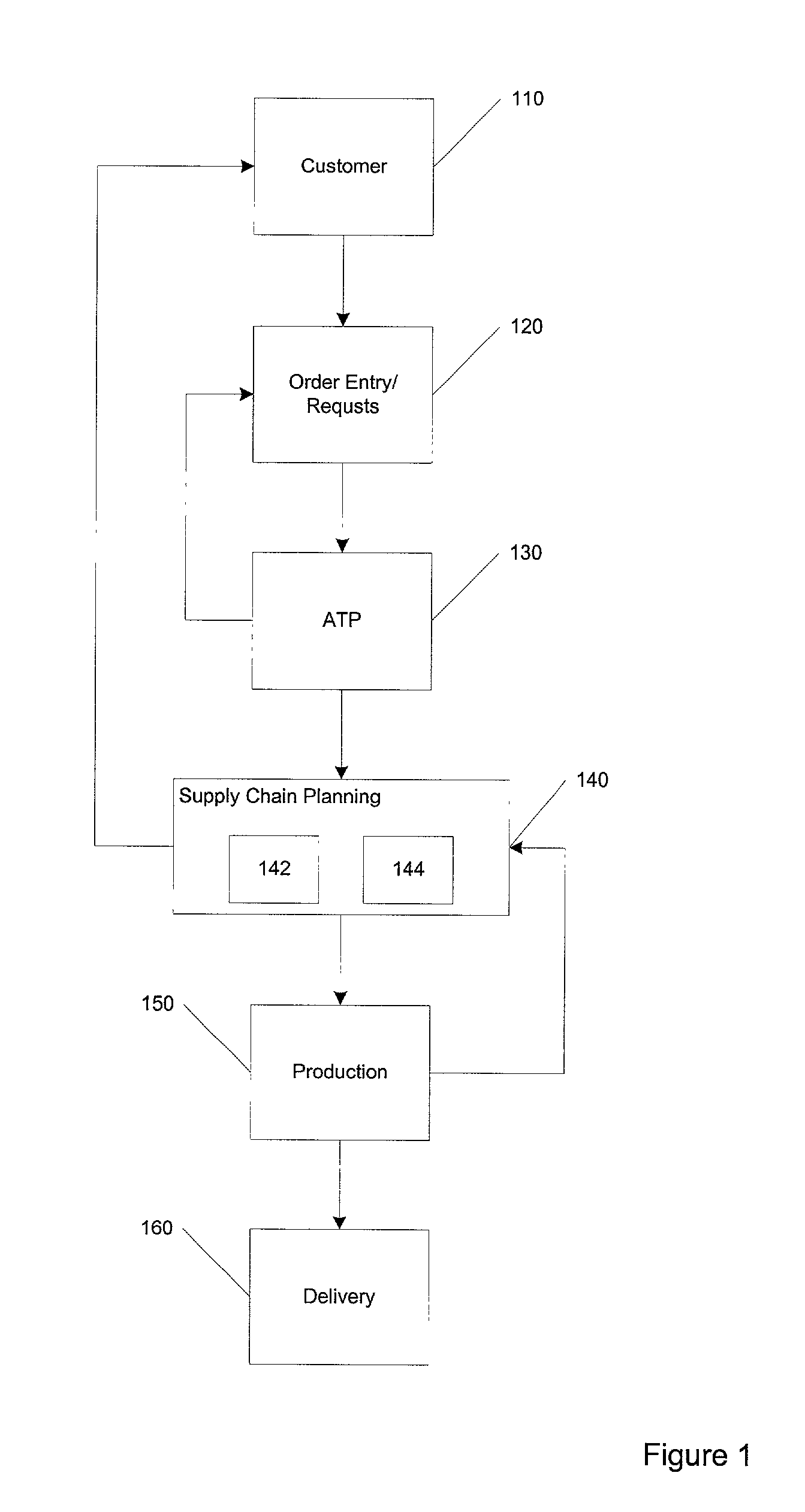

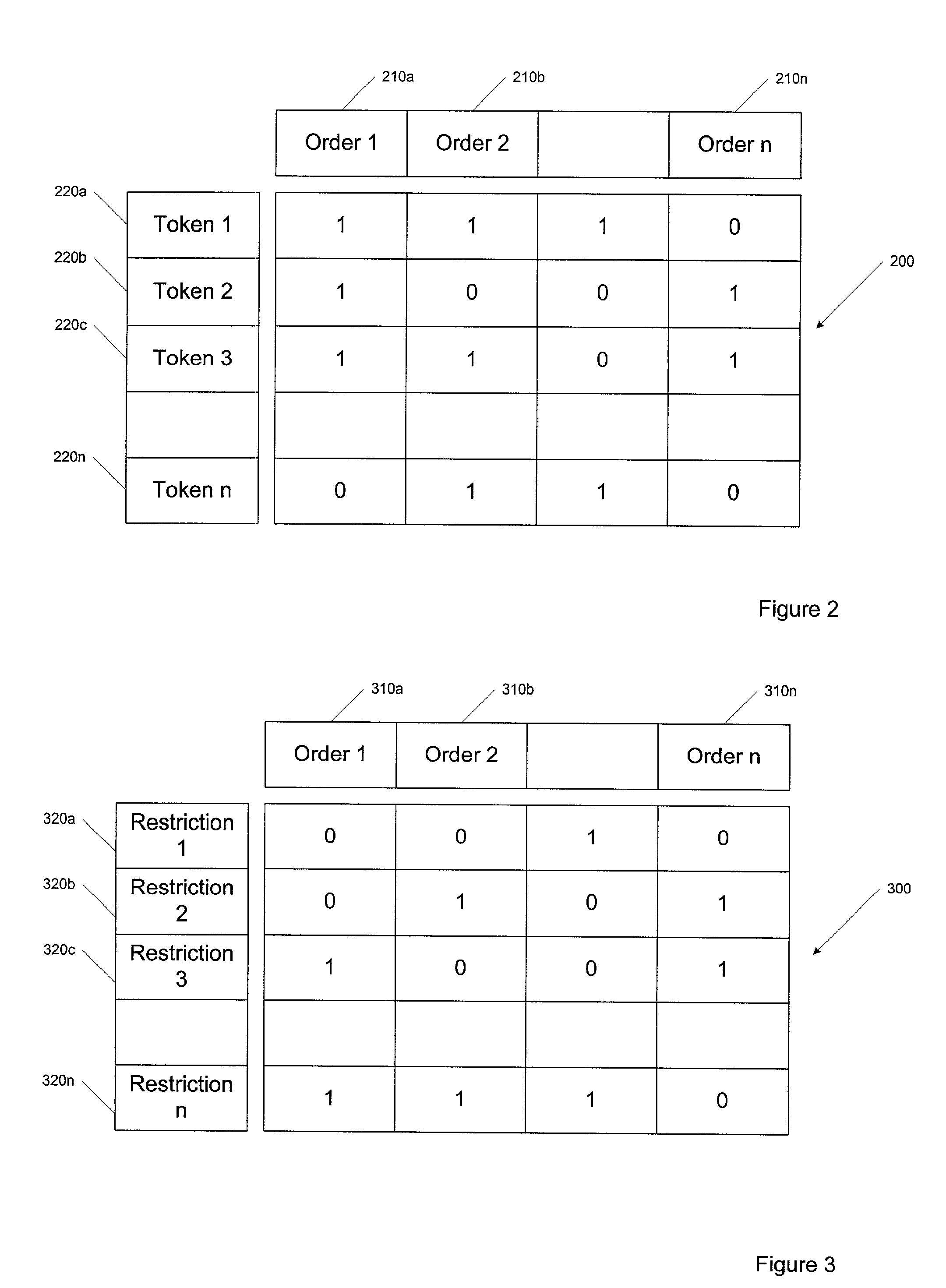

Matrix methods and systems for supply chain management

InactiveUS20020007293A1Fast executionFacilitates compact storageAnimal feeding devicesResourcesSupply managementMatrix method

A system and method of receiving orders, placing orders in an order matrix, determining potential production periods for an order, rescheduling orders, and generating a bill of materials. The method receives an order having one or more tokens out of a set of possible tokens. Each token is a combination of a characteristic and a value of the characteristic. The orders are placed in an order matrix. An order restriction matrix for the orders is generated based on certain selection conditions. The method then examines the restrictions that apply to the order and derives an order derived production restriction matrix for the order, which is evaluated to determine possible production periods for the order. The order matrix may also be used to generate a bill of materials.

Owner:SAP AG

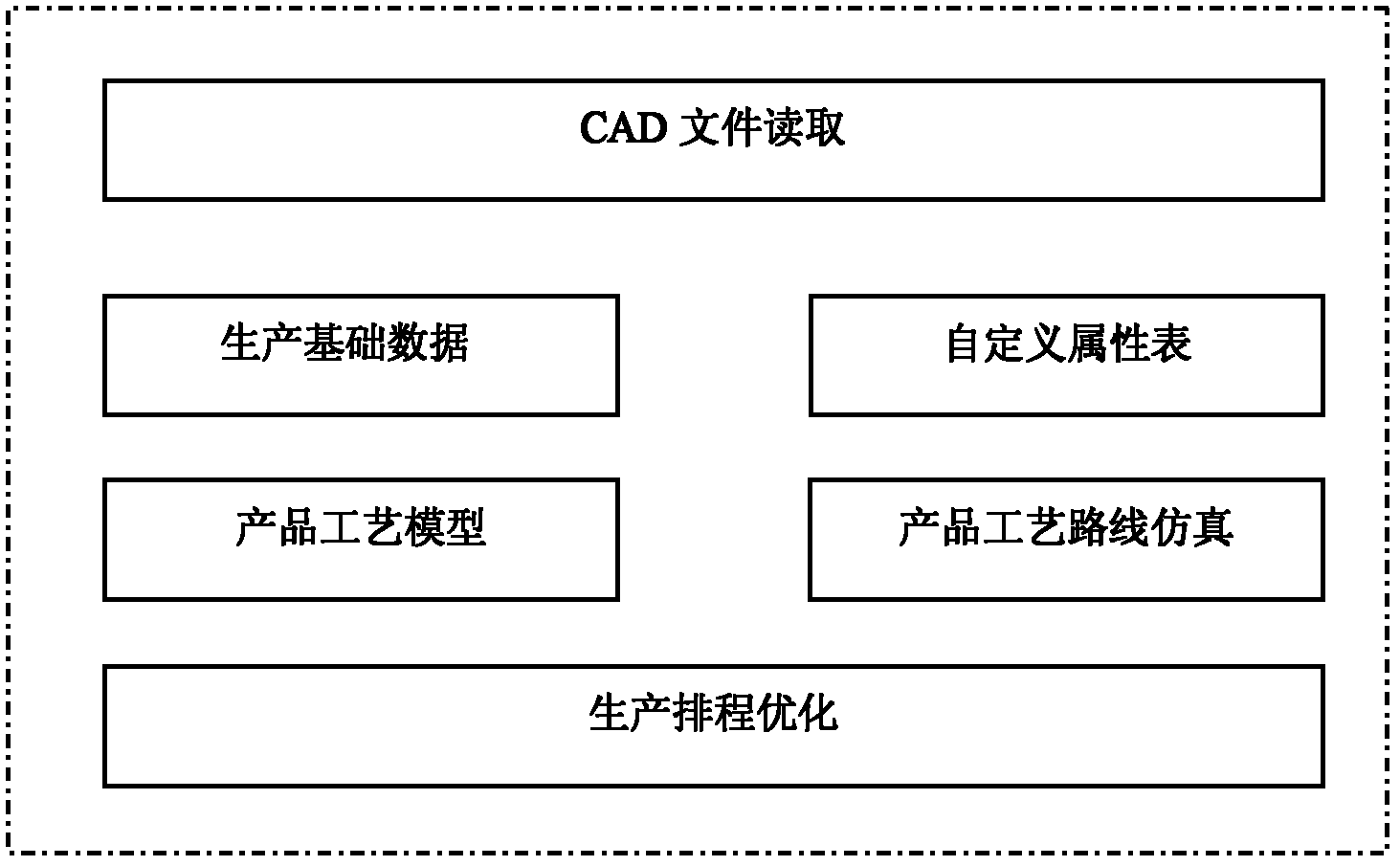

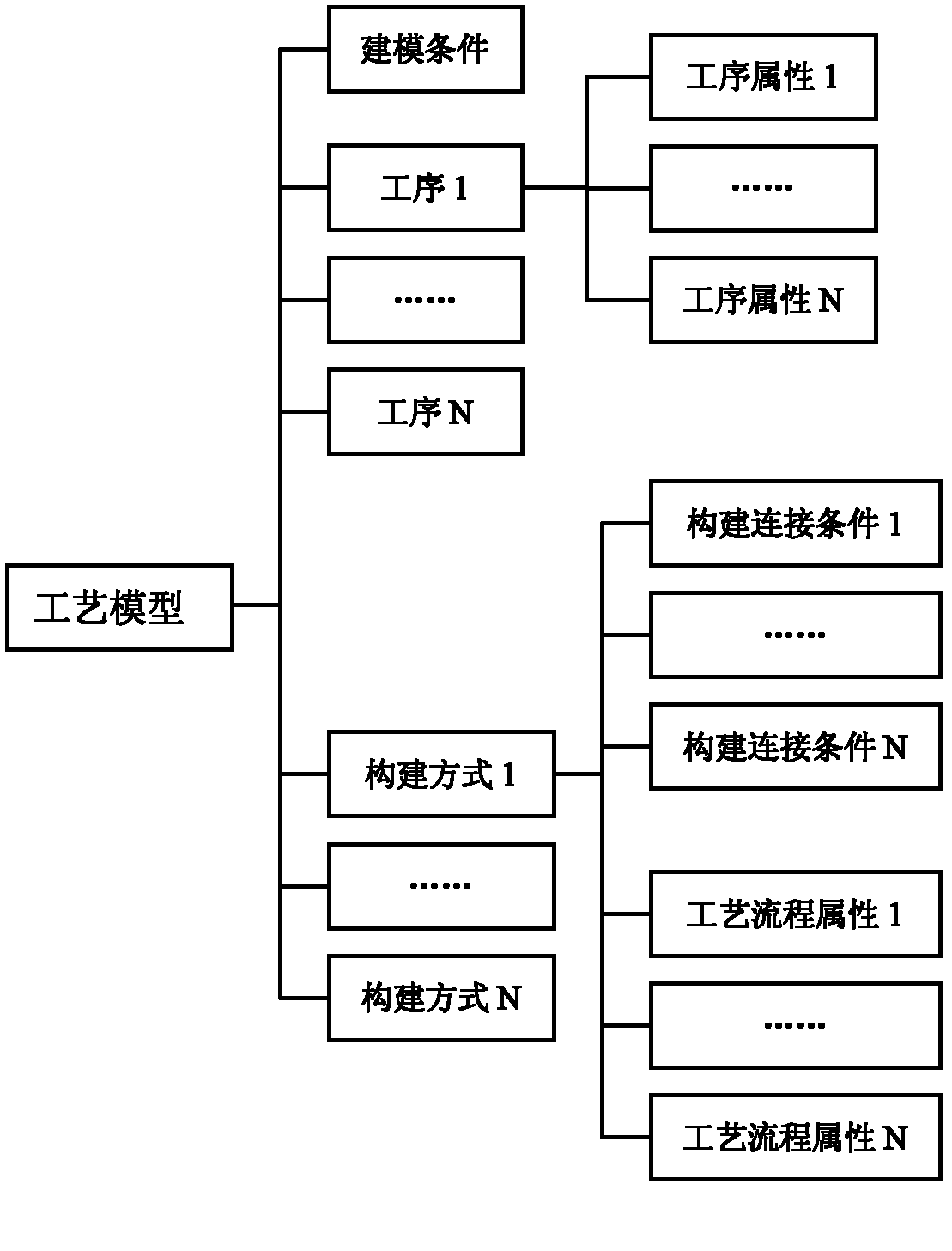

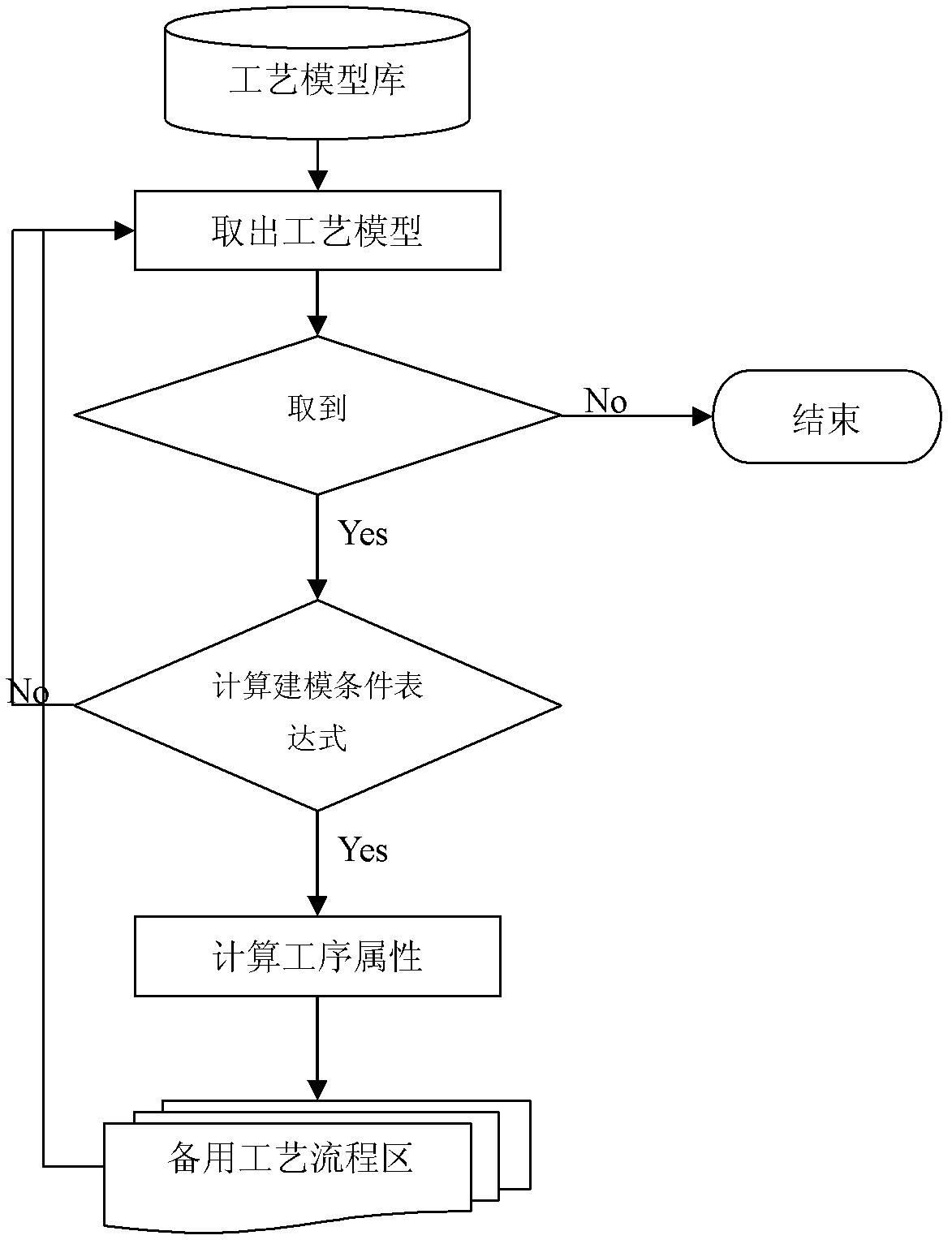

Product production process computer simulation system and method

InactiveCN102289743ARealize the automatic transfer of the listOptimize the process routeData processing applicationsBill of materialsProcess engineering

The present invention relates to a system and method for a product process route, which is a computer simulation system and method for a product production process, including a file reading module, a basic data module, a custom attribute module, a product process model module, a route simulation module and The production scheduling optimization module, among them, the file reading module is used to read the data of the product design system and put it into the product process model module; the basic data module is used to set the status data of the production site; the custom attribute module is used to It is used to maintain the attributes of the calculation parameters that constitute the product bill of materials and product process; the product process model module is used to manage the product process model for establishing product process routes; the route simulation module is used to calculate the process route according to the product process model, and to process Routes are managed; the production scheduling optimization module is used to change the process route replacement conditions of the route simulation module to obtain the optimal scheduling result. The system simulates or optimizes the product process route, saving cost, time and effort.

Owner:YIDAKANG NANJING INFORMATION SYST

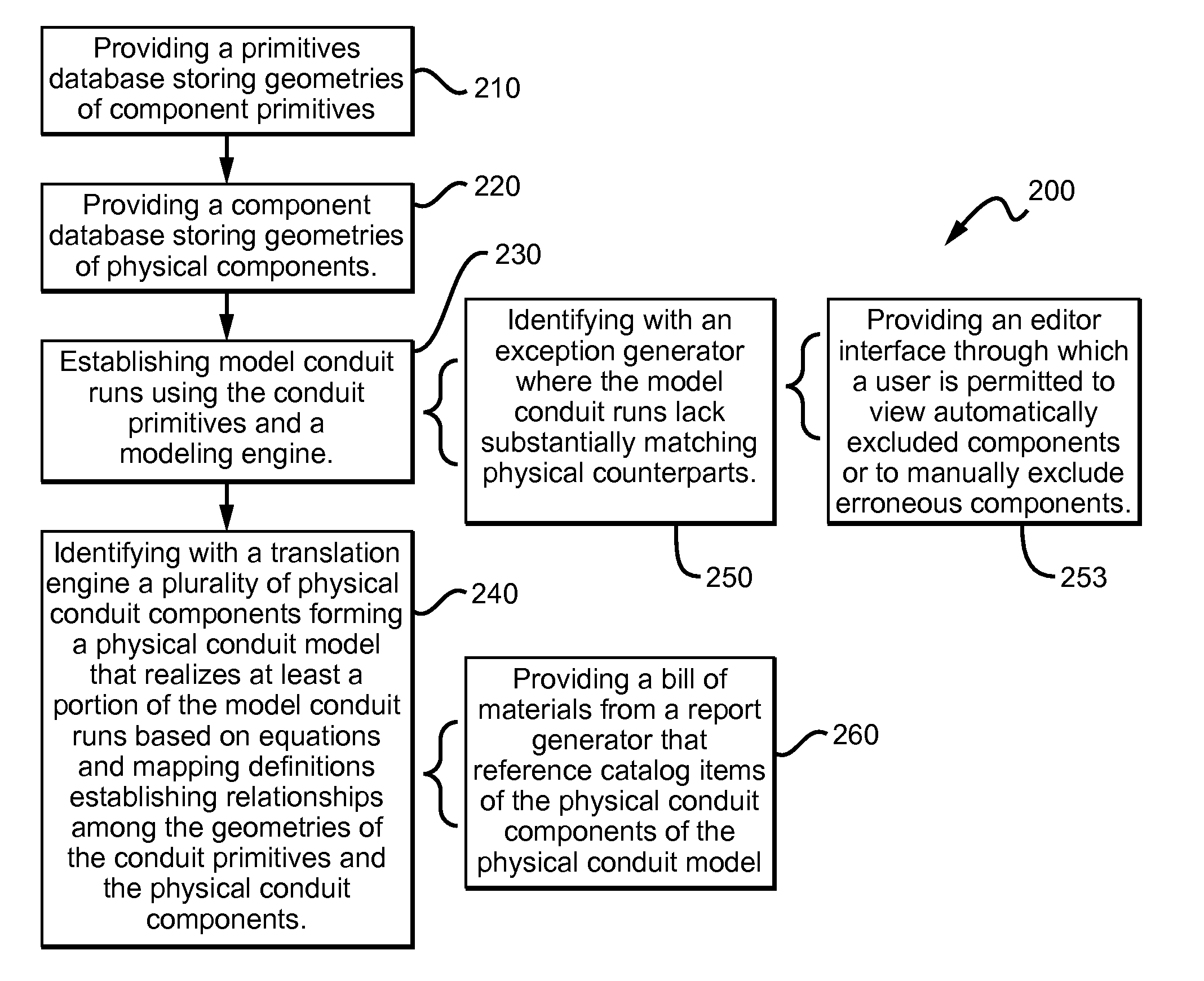

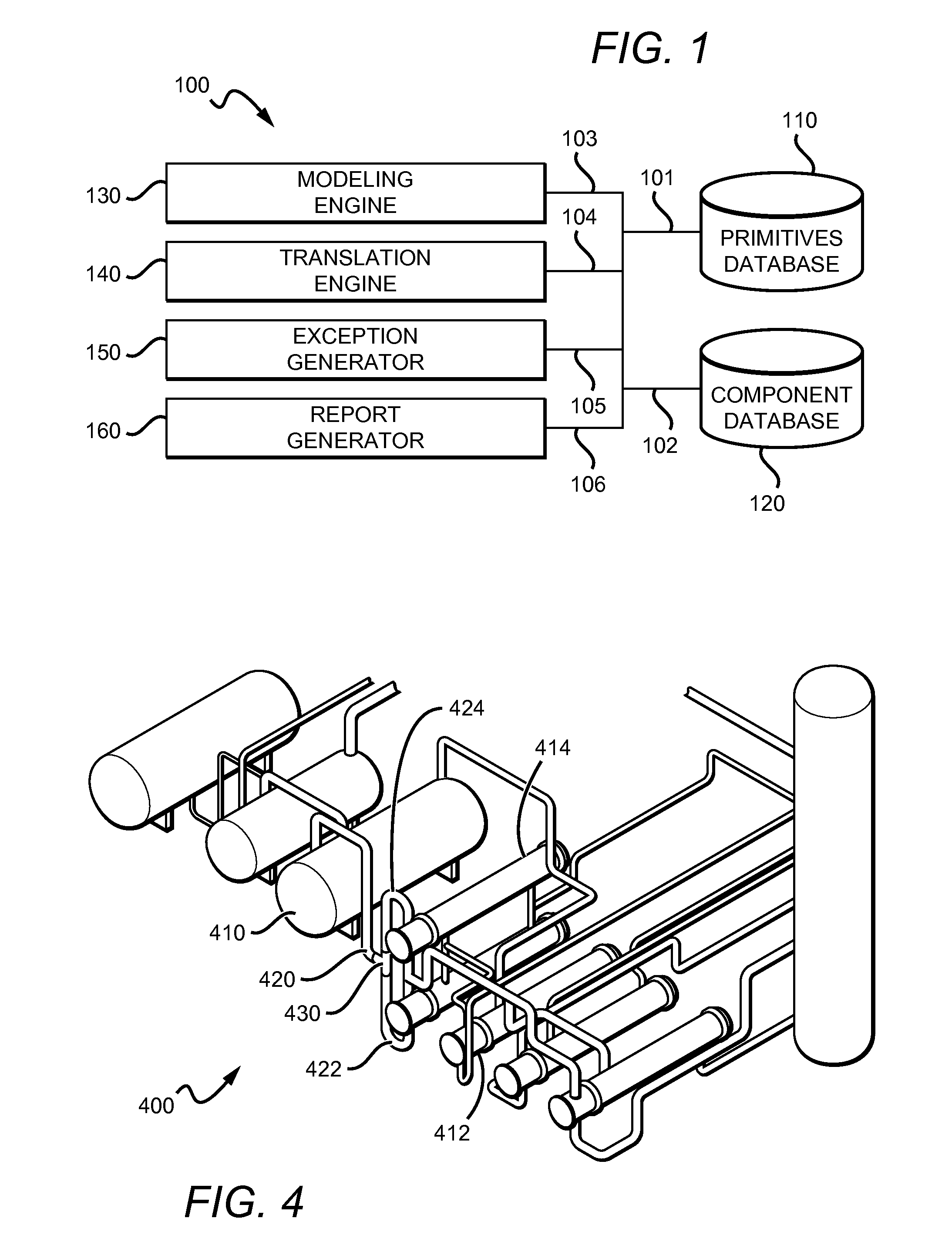

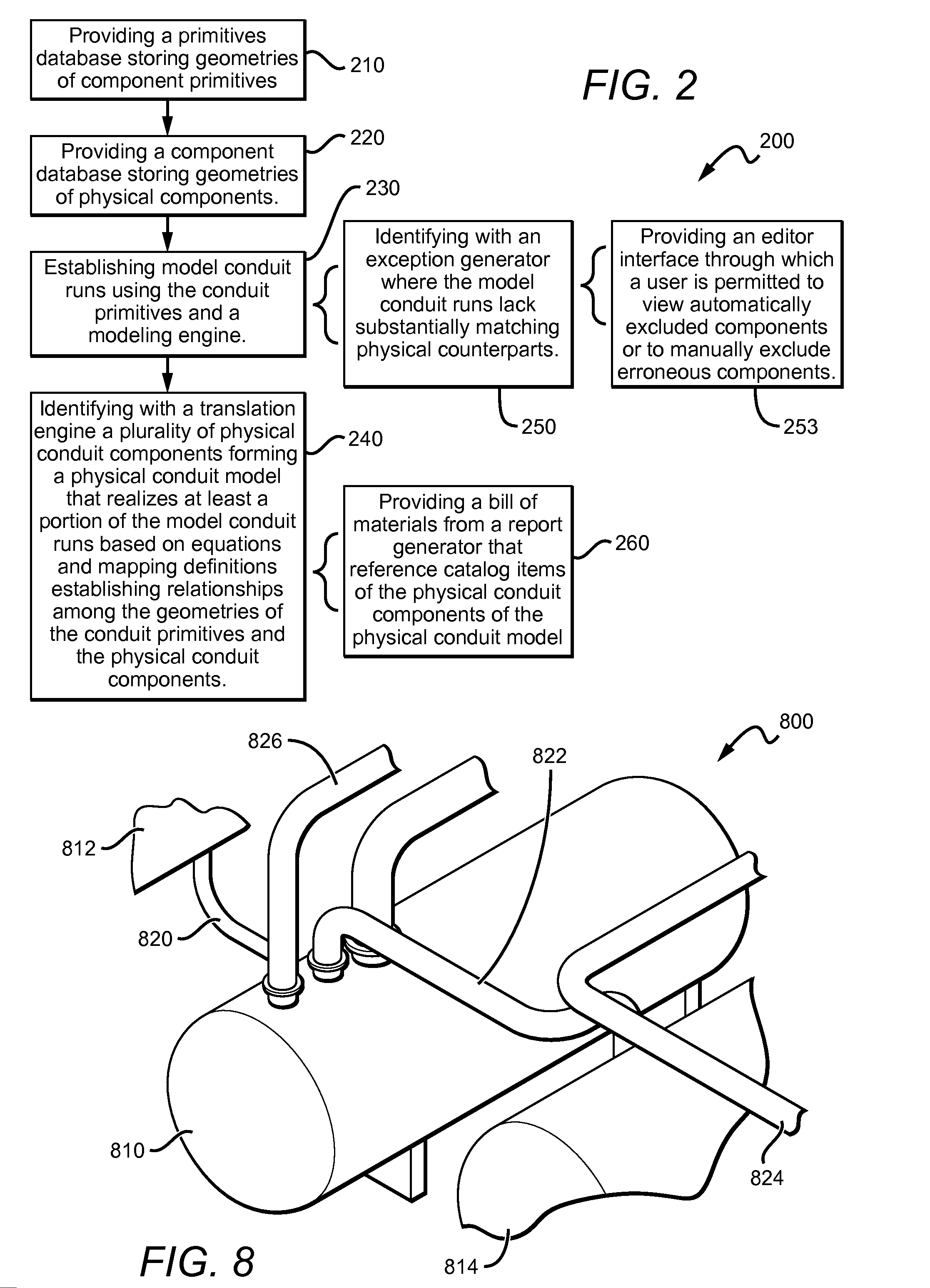

3D plant modeling systems and methods

InactiveUS20130035904A1Function can be ensuredGeometric CADConfiguration CADBill of materialsPlant models

Systems and methods for leveraging a preliminary plant model to create a detailed physical plant model are presented. The system stores instances of component primitives, and can utilize stored geometries of the component primitives to identify a plurality of physical components to form a physical plant model. The physical plant model can realize at least a portion of the component runs based on equations and mapping definitions that establish relationships among the geometries of the equipment and piping. The components of the physical plant model can be mapped to catalog items based on the geometries of the components. After translation, a bill of materials listing the physical plant model components can be produced.

Owner:FLUOR TECH CORP

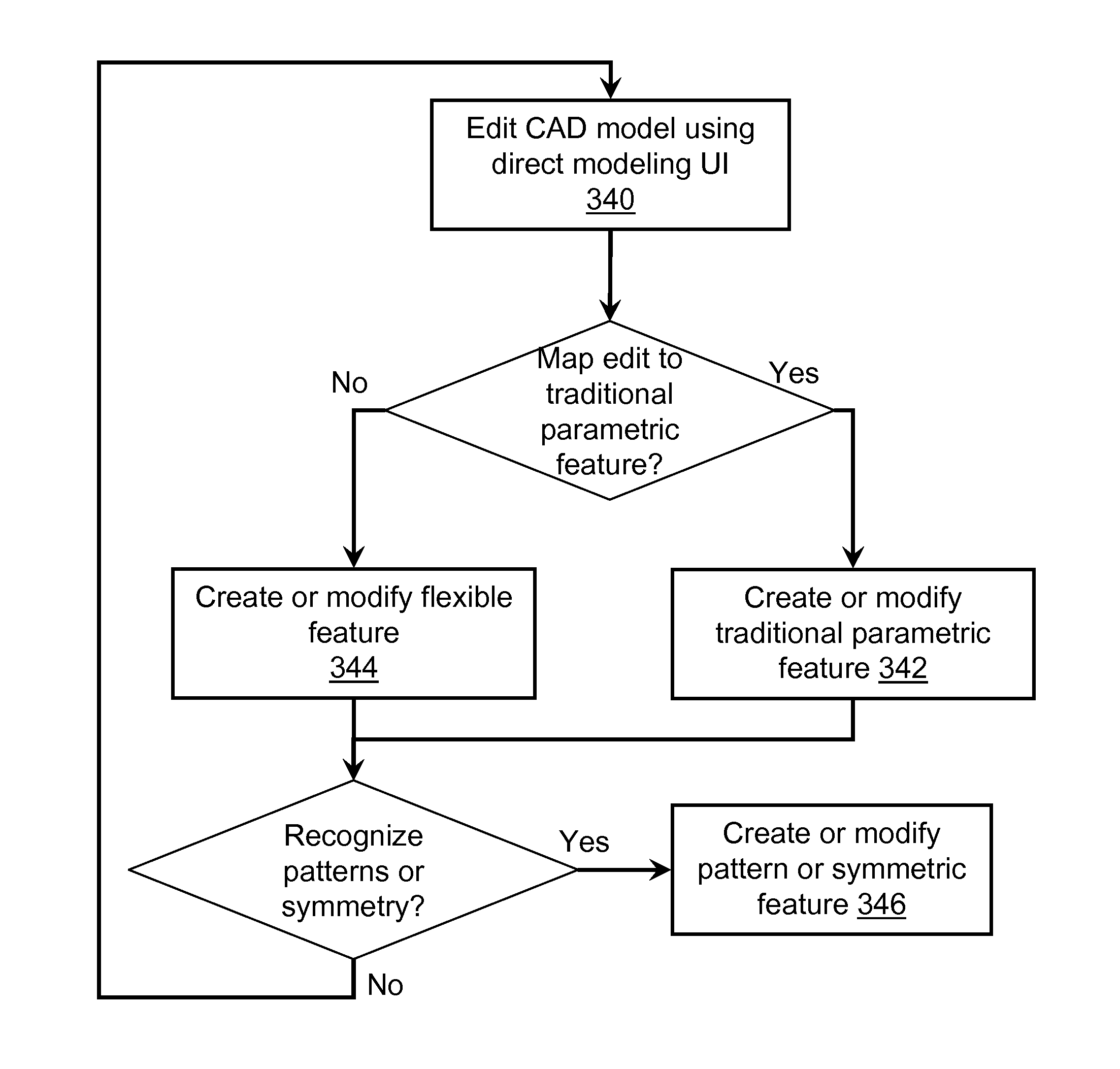

Methods and systems for creation of a dynamically configurable product design

ActiveUS20120109350A1Computation using non-denominational number representationComputer aided designBill of materialsProgram planning

The present disclosure features methods and systems for creation of a dynamically configurable product design, sometimes referred to as business driven assemblies. Such product designs may be referred to as driven by a bill-of-materials (BOM) or selection of options by a customer, sales representative, or vendor, and may be performed responsive to a product lifecycle management (PLM) plan. The system allows a customer to define specifications of a product, and then dynamically generates a CAD model responsive to the defined specifications or selected options.

Owner:PARAMETRIC TECH CORP

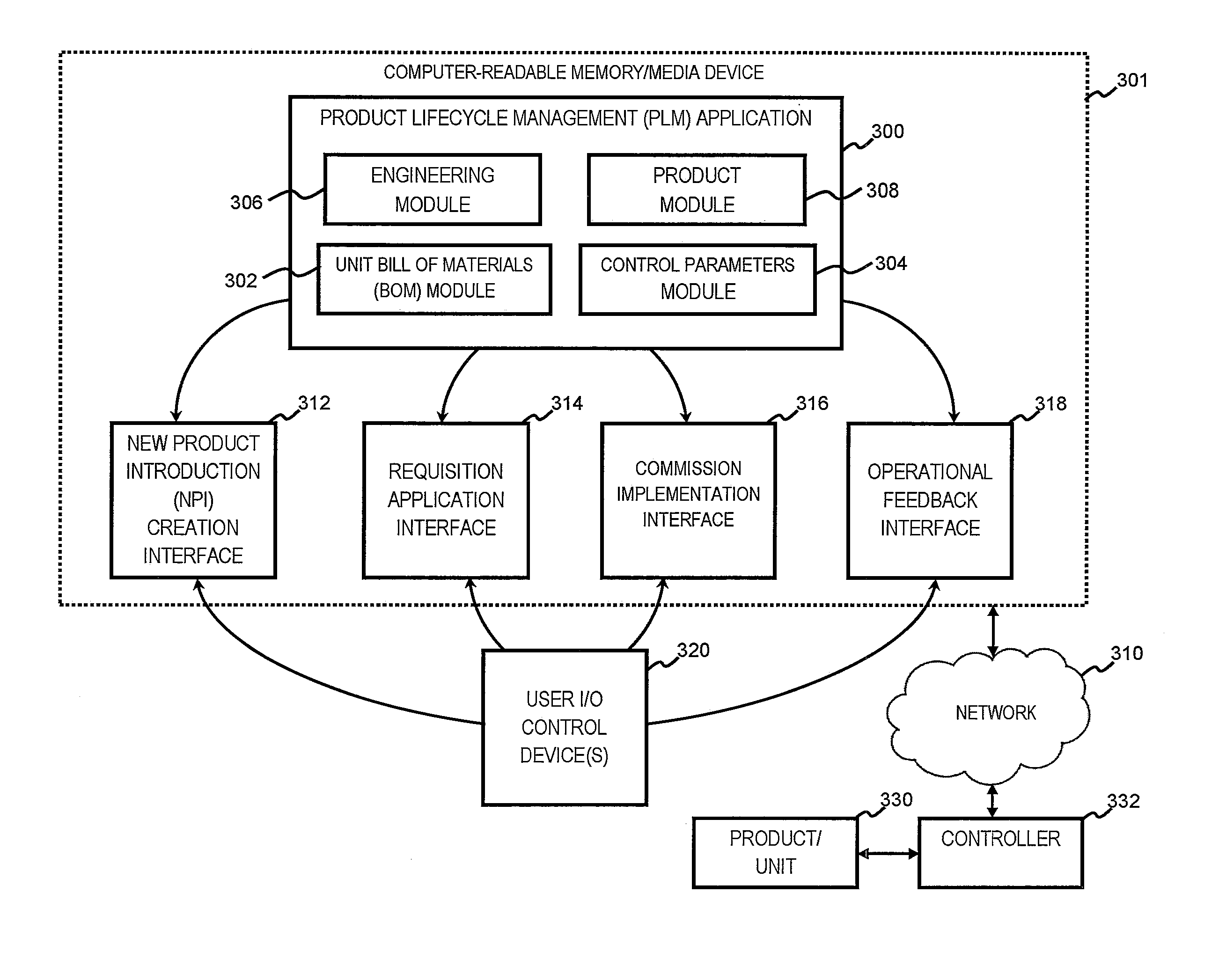

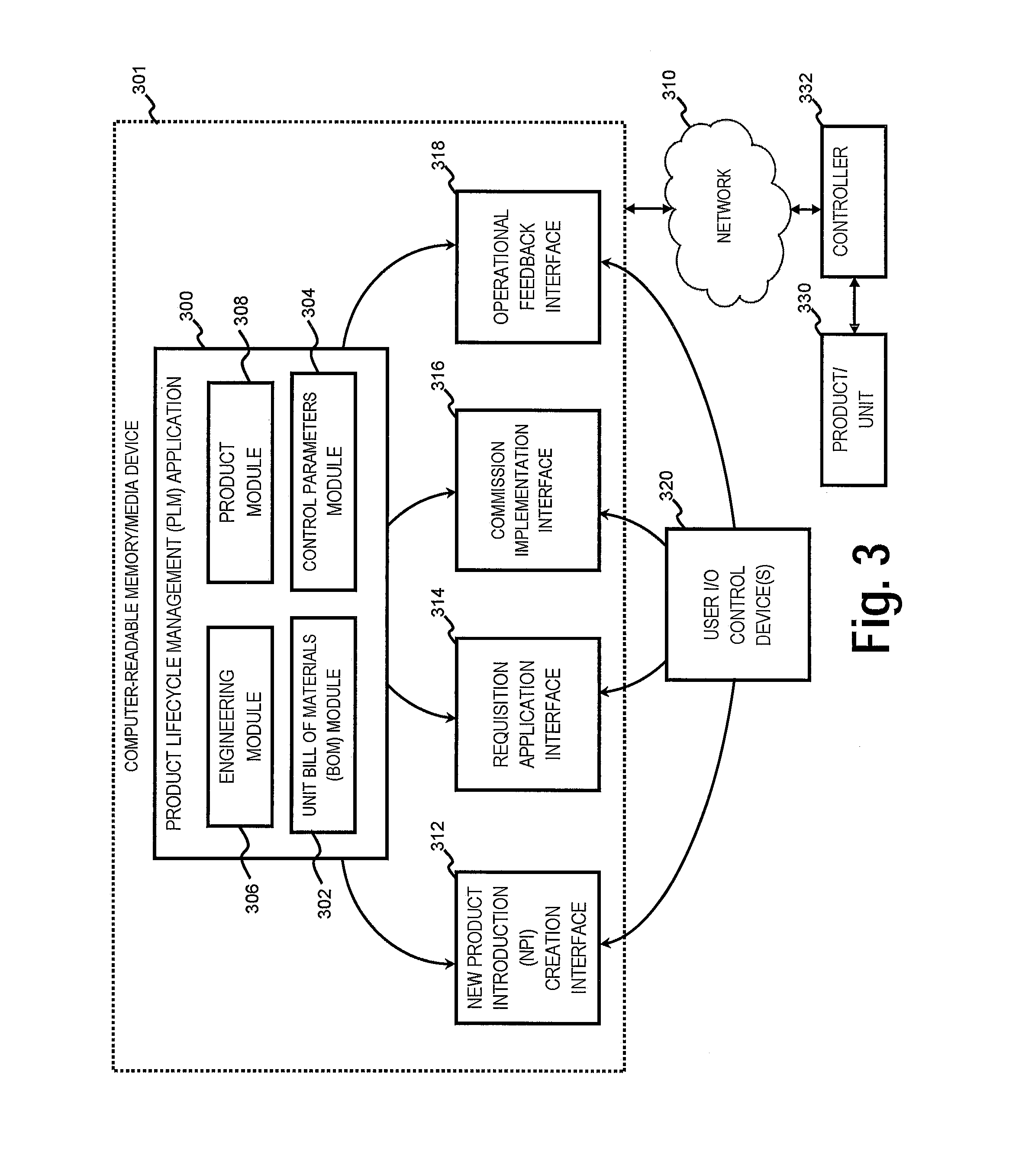

Automated system for digitized product management

Systems and methods associated with digitized and automated product management provide for a holistic representation of a product throughout its lifecycle, including physical and non-physical components thereof. More particular features include generation of unit bills of material and application of non-physical components, eg., control parameters, to product units. Features for managing bills of material involve providing a pre-established mapping of technical feature rules that relate commercial feature options for a product to different combinations of technical functions and parts for potential use in a product. Pre-established manufacturing templates are also provided and combined with the mapping to generate an order-specific bill-of-materials, after which point a unit bill-of-materials can be created. Features for digitizing and applying non-physical components, e.g. control parameters, involve establishing a plurality of non-physical components, e.g. control parameter definitions, and database relationships between control parameters and products within a network accessible database. Interfaces may be provided for changing selected aspects of the control parameters, and the parameters are ultimately provided as direct input to a product.

Owner:GENERAL ELECTRIC CO

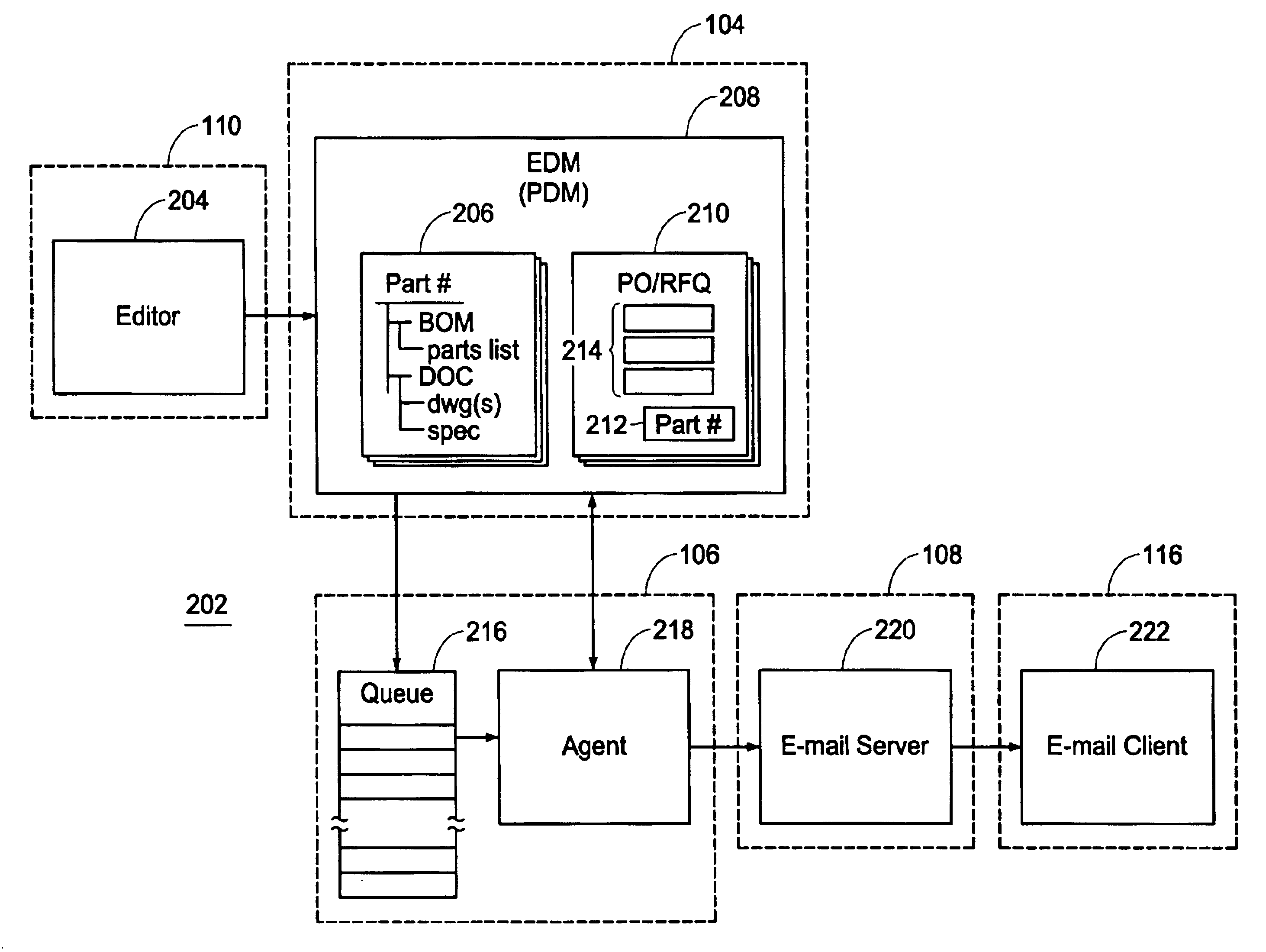

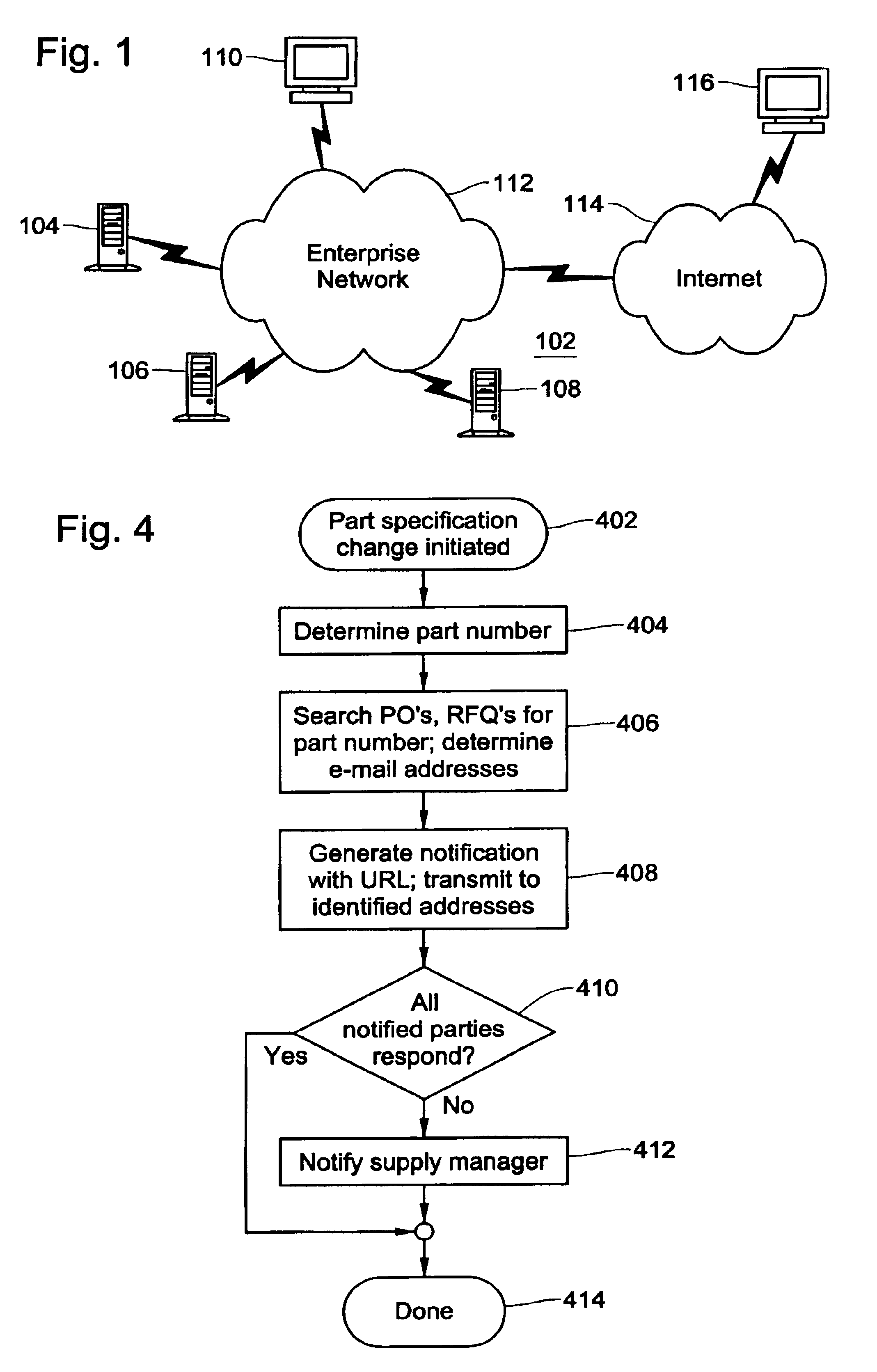

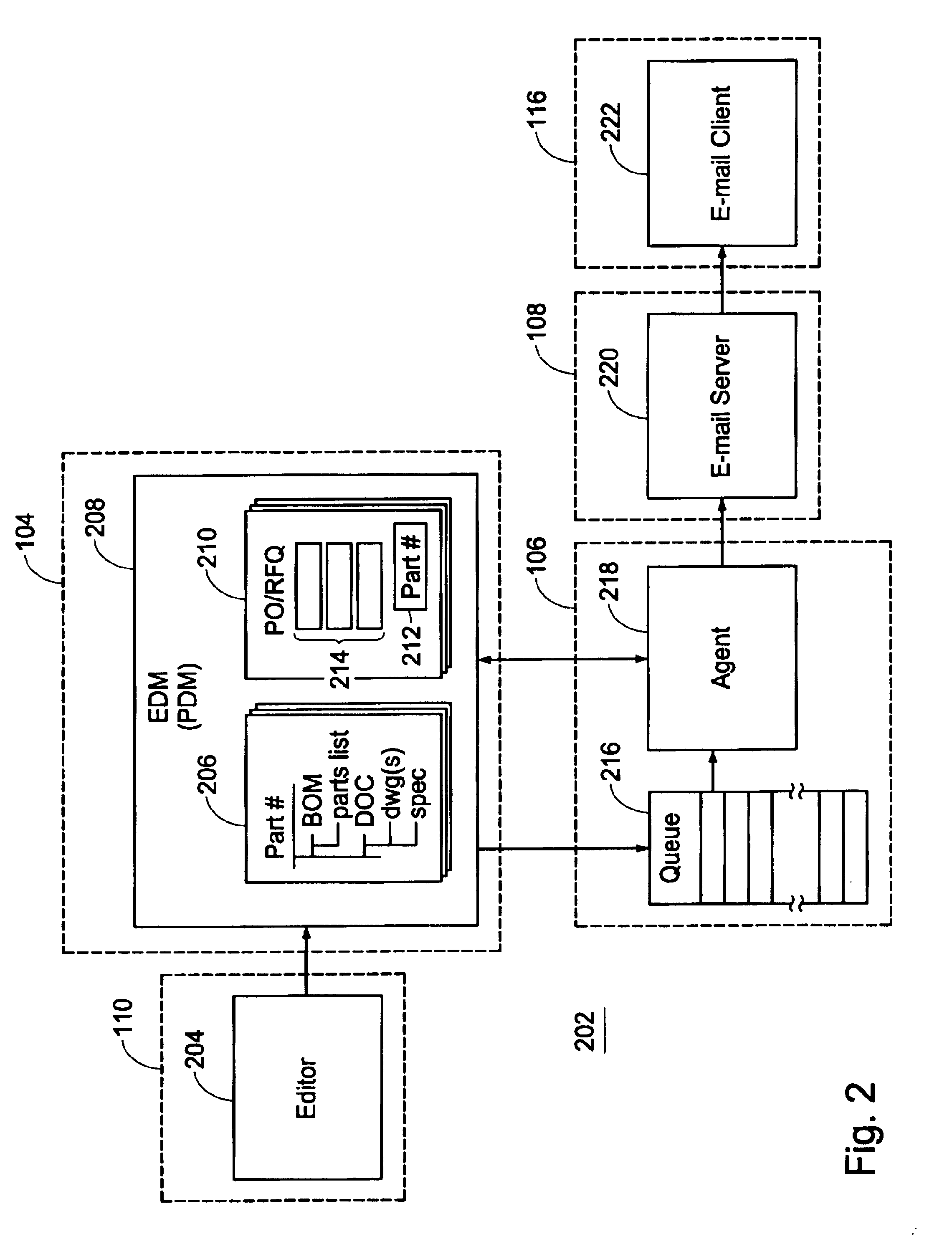

Automated notification of part revisions for outside suppliers

Revision of a part specification document, such as a drawing, a part specification, or a bill of materials, prompts execution of an automated notification process. A unique part number associated with the revised part specification document is employed in searching open purchasing documents for purchase orders or request for quotes containing the part number. Electronic mail addresses for outside supplier contacts are kept in the database and linked to the supplier master of the open purchasing documents containing the part number. An electronic mail notification of the part specification document revision is generated and transmitted to each electronic mail address identified as being associated with an open purchasing document containing the subject part number.

Owner:VETCO GRAY

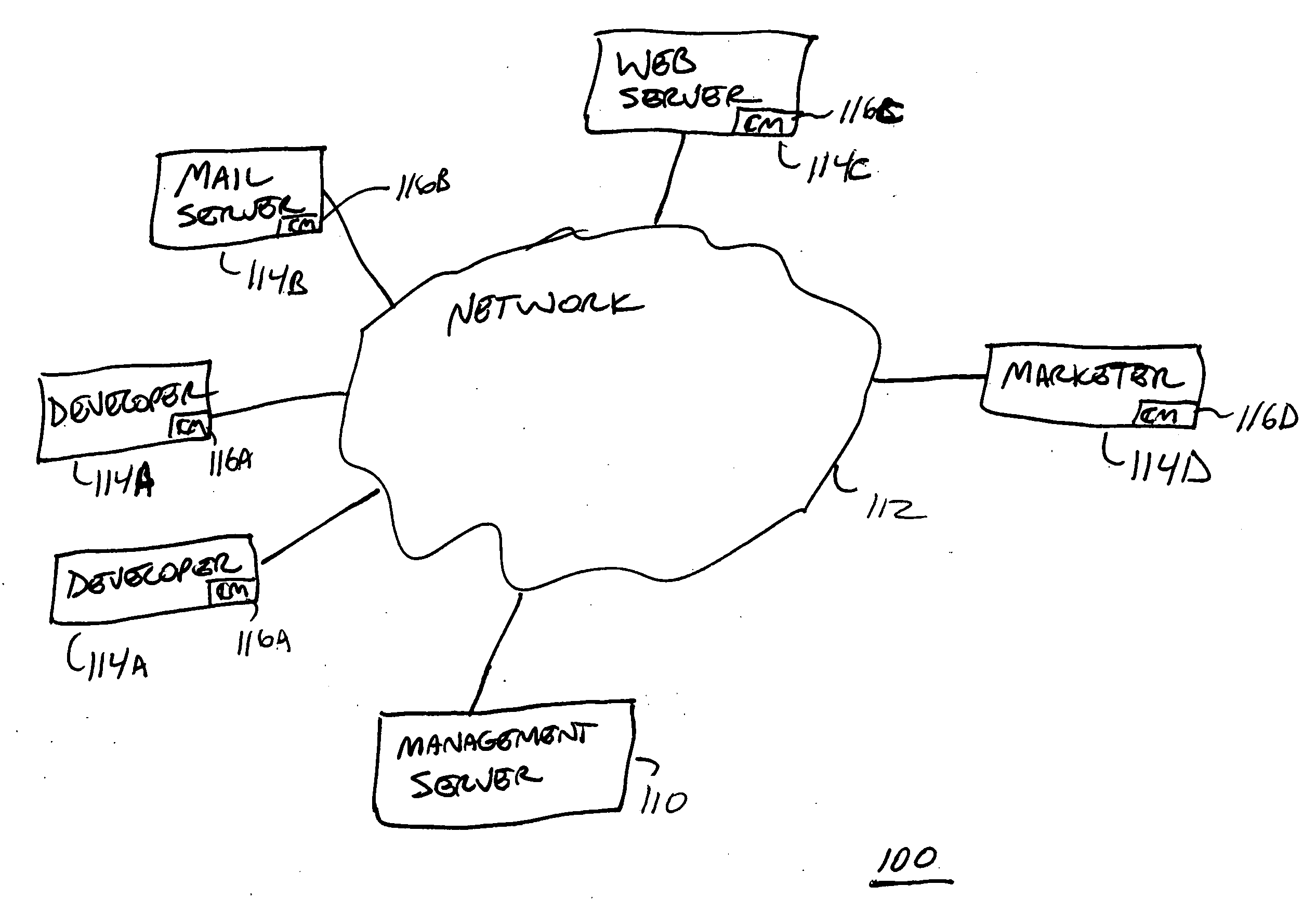

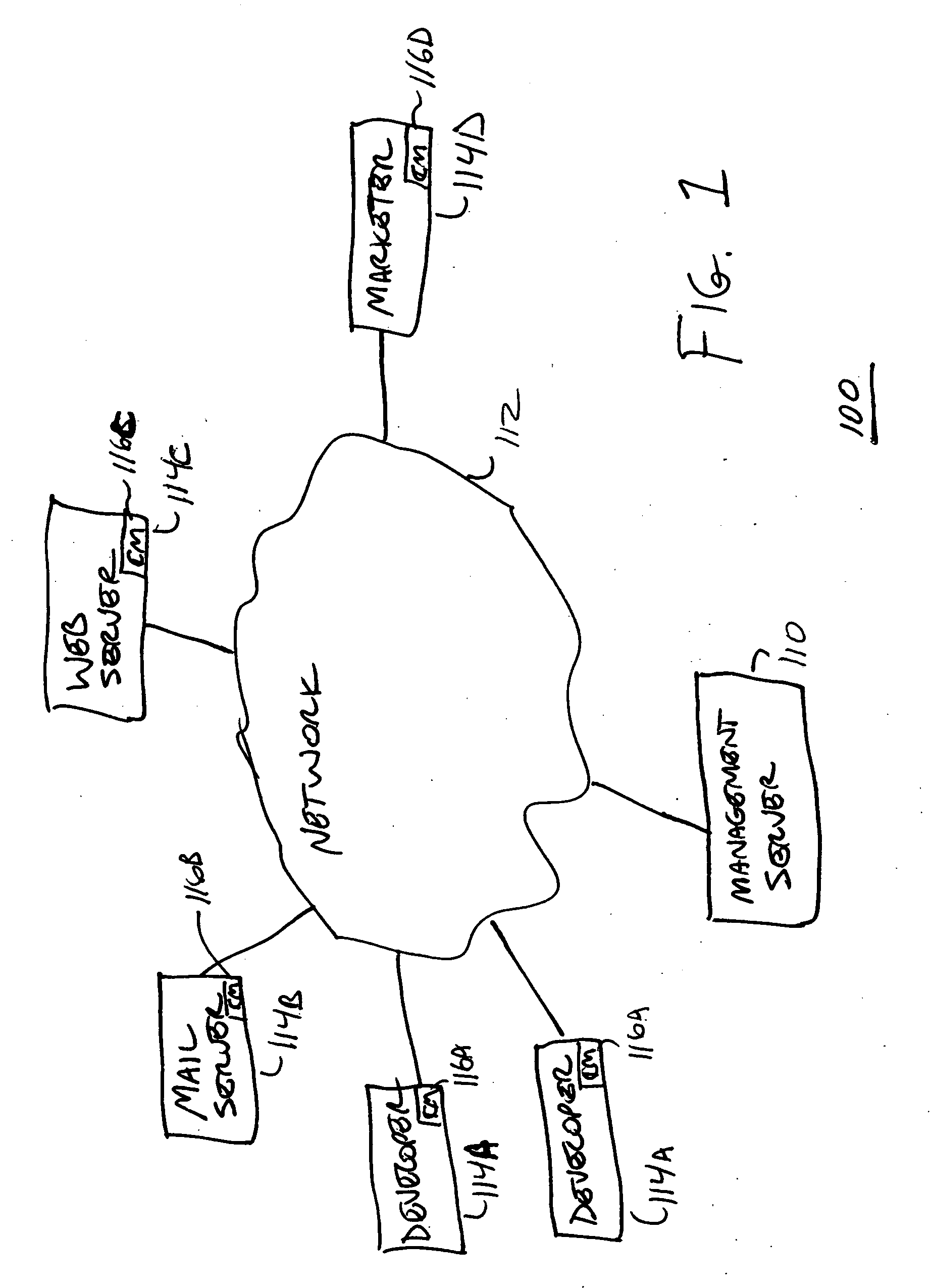

Enterprise computer management

InactiveUS20060235863A1TransmissionSpecial data processing applicationsOperational systemBill of materials

A management server has a file server containing operating systems and software packages utilized by typical computers in an enterprise. The management server also includes a bills of material module having bills of material that identify the roles of computers used by typical enterprises,, and one or more templates specifying the operating systems, software packages, and configuration files utilized by the computers in different roles. The management server can instantiate managed computers of a particular bill of materials using the templates, thereby creating computers functioning in the specified roles. The managed computers share the set of files on the file server. When a managed computer attempts to modify a shared file, the file server creates a new copy of the file, maps all requests from the managed computer to the new copy, and allows the modification to proceed. The management server tracks the changes.

Owner:LEVANTA

Sourcing of bills of materials

InactiveUS7050874B1Disadvantages and of reduced eliminatedProblems of reduced eliminatedLogisticsSpecial data processing applicationsBill of materialsFinancial transaction

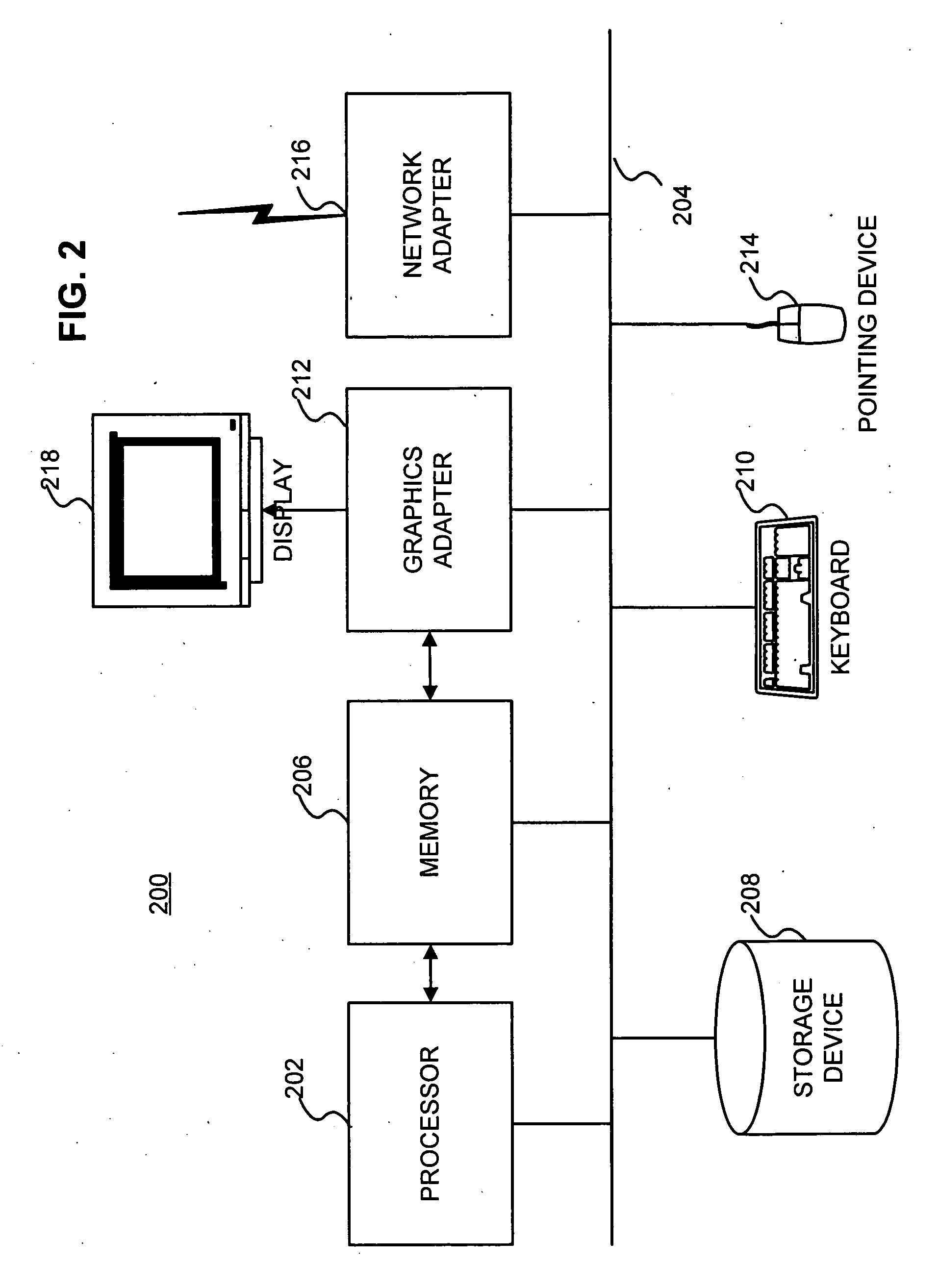

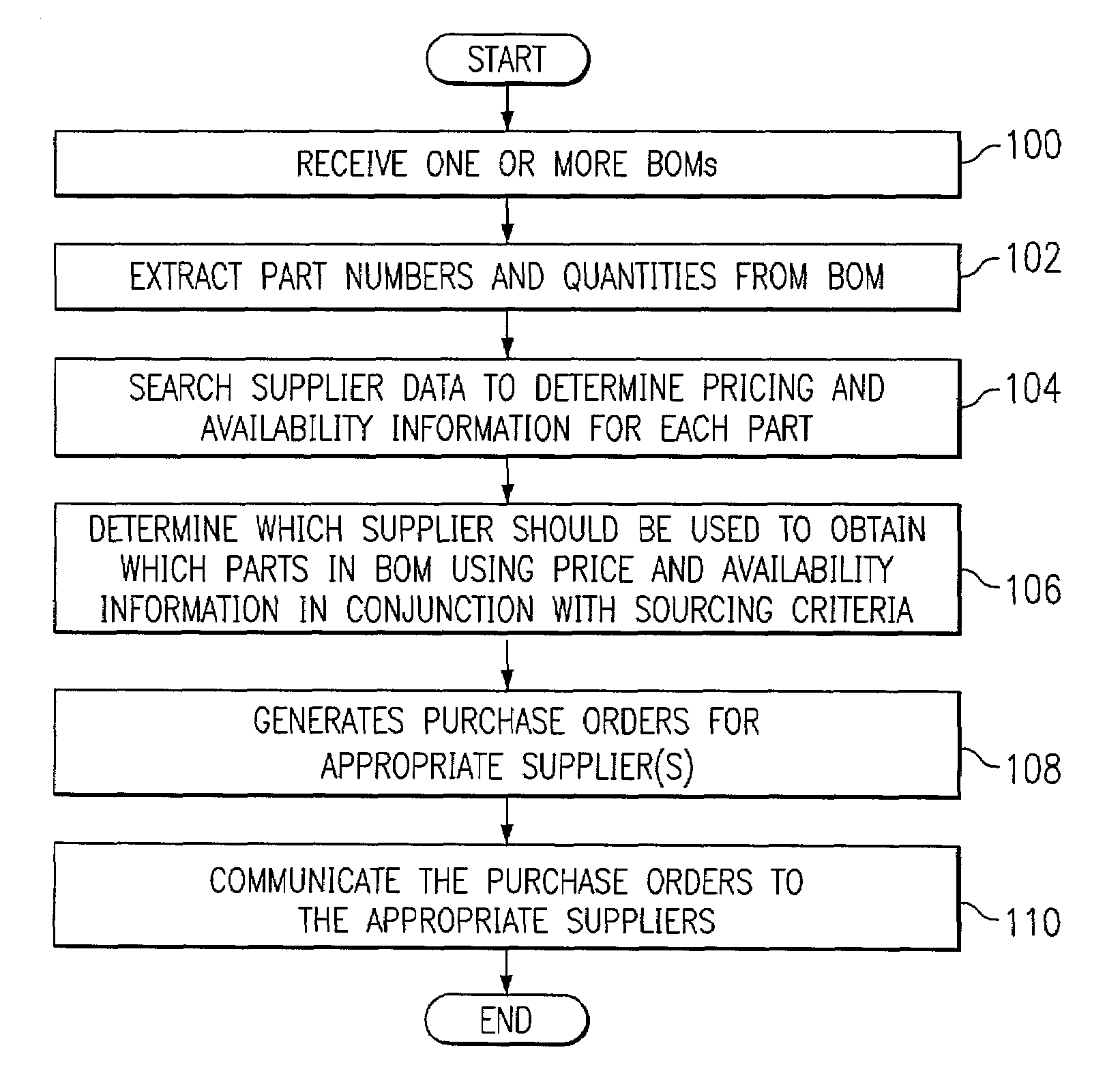

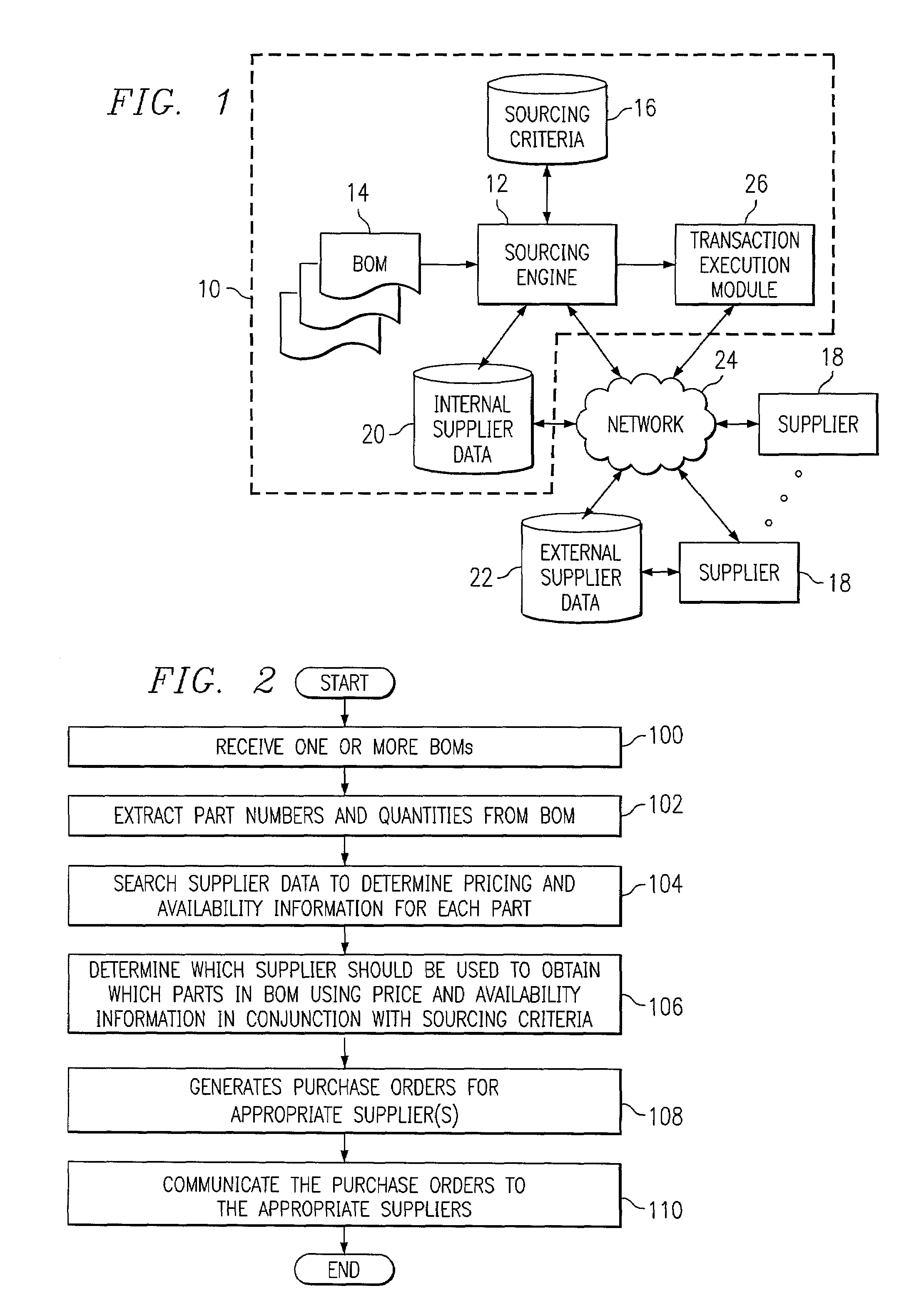

A bill of materials (BOM) sourcing system includes one or more data storage locations that store BOM sourcing criteria. The system also includes a sourcing engine that receives a BOM that includes a plurality of part identifiers. The sourcing engine identifies one or more part identifiers included in the BOM and searches supplier data to obtain pricing information associated with the identified parts. Furthermore, the sourcing engine receives sourcing criteria and determines which supplier should be used to supply each identified part based on the pricing information and the sourcing criteria. In addition, the system includes a transaction execution module that receives from the sourcing engine a part identifier for each identified part and the identity of the supplier to be used to supply each identified part. The transaction execution module generates one or more transaction documents based on this information and communicates the one or more transaction documents to the associated suppliers.

Owner:BLUE YONDER GRP INC

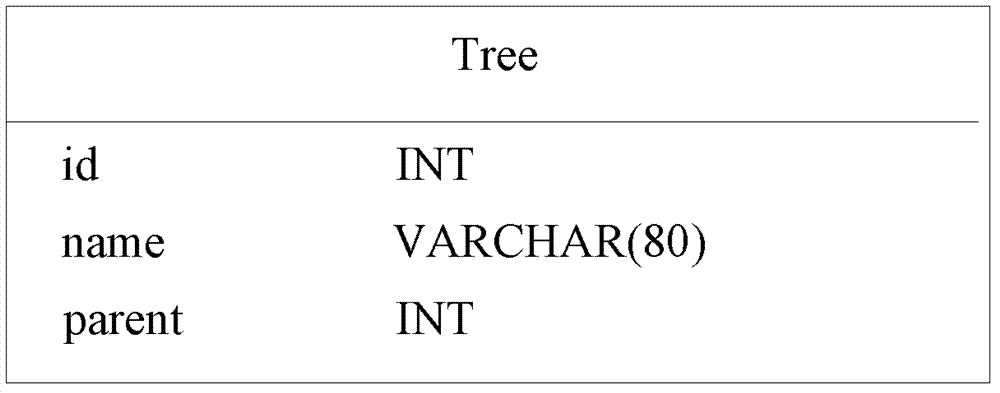

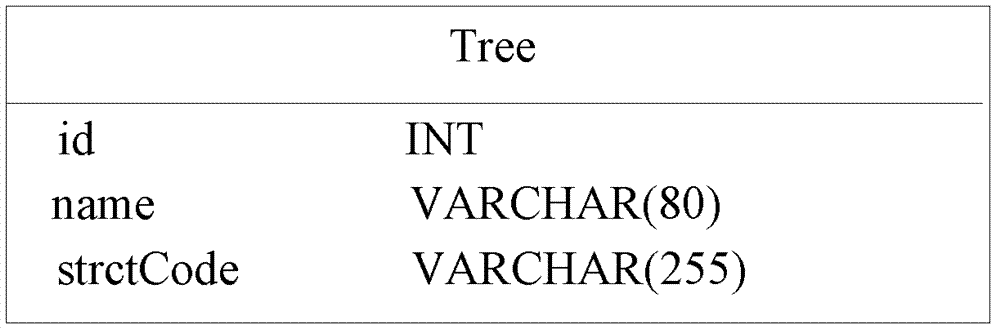

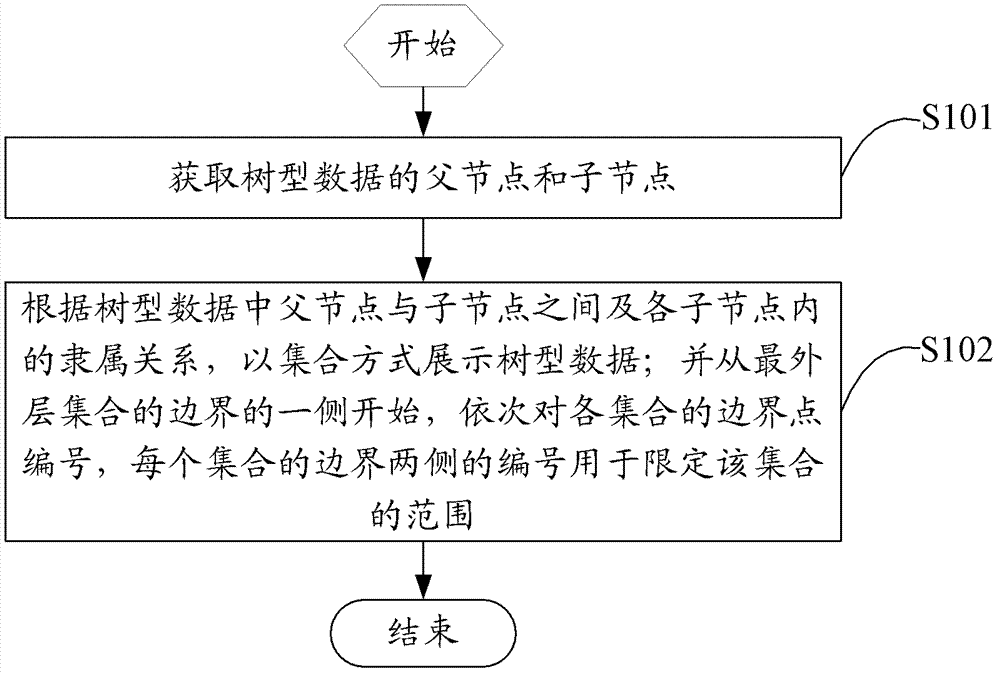

Processing method and device of tree type data

ActiveCN102819536AEasy to handleImprove query performanceSpecial data processing applicationsRelationship - FatherBill of materials

The invention relates to a processing method and a device of tree type data. The method includes obtaining a father node and child nodes of the tree type data; displaying the structure of the tree type data in a set mode according to the subjection relations between the father node and the child nodes and between the child nodes; and starting from one side of the boundary of the set at the outermost layer to number boundary points of each set sequentially, wherein the numbers at two sides of the boundary of each set are used for limiting the range of the set. According to the method and the device, the problem of insufficient structural management of the tree type data in the prior art is solved, the management of the tree type data is more efficient, the query performance is higher, simultaneously, limit of the tree type data hierarchy is eliminated, and the method and the device are particularly suitable for the management of mass tree type data such as a family tree, a gene spectrum and a bill of material (BOM).

Owner:北京金蝶云基科技有限公司

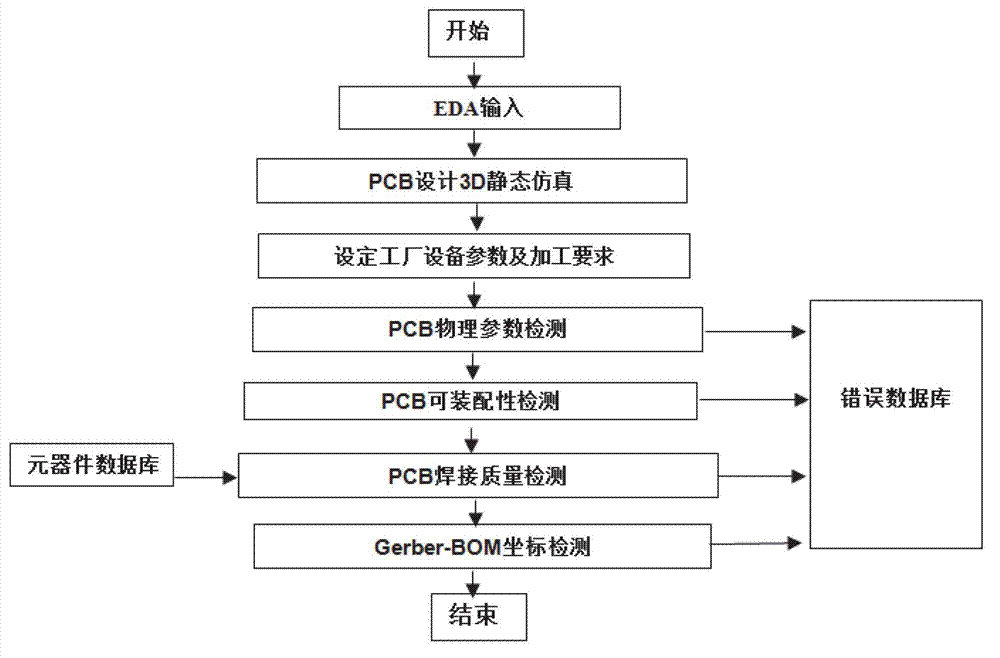

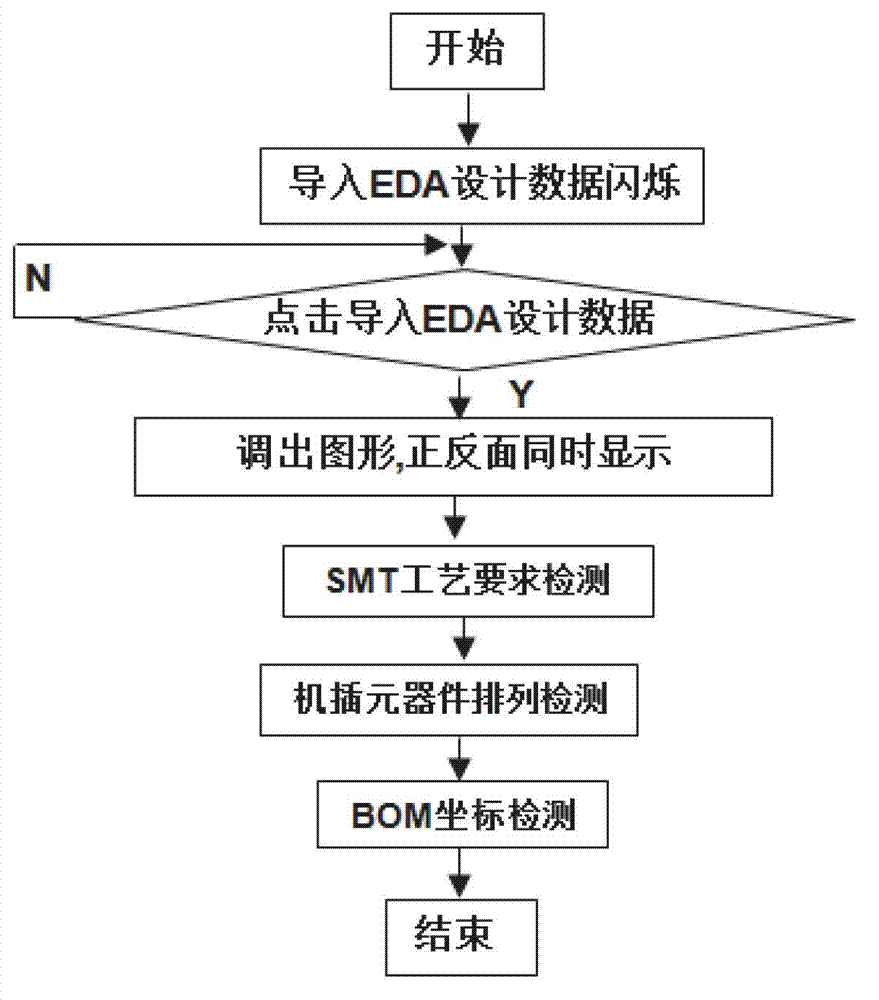

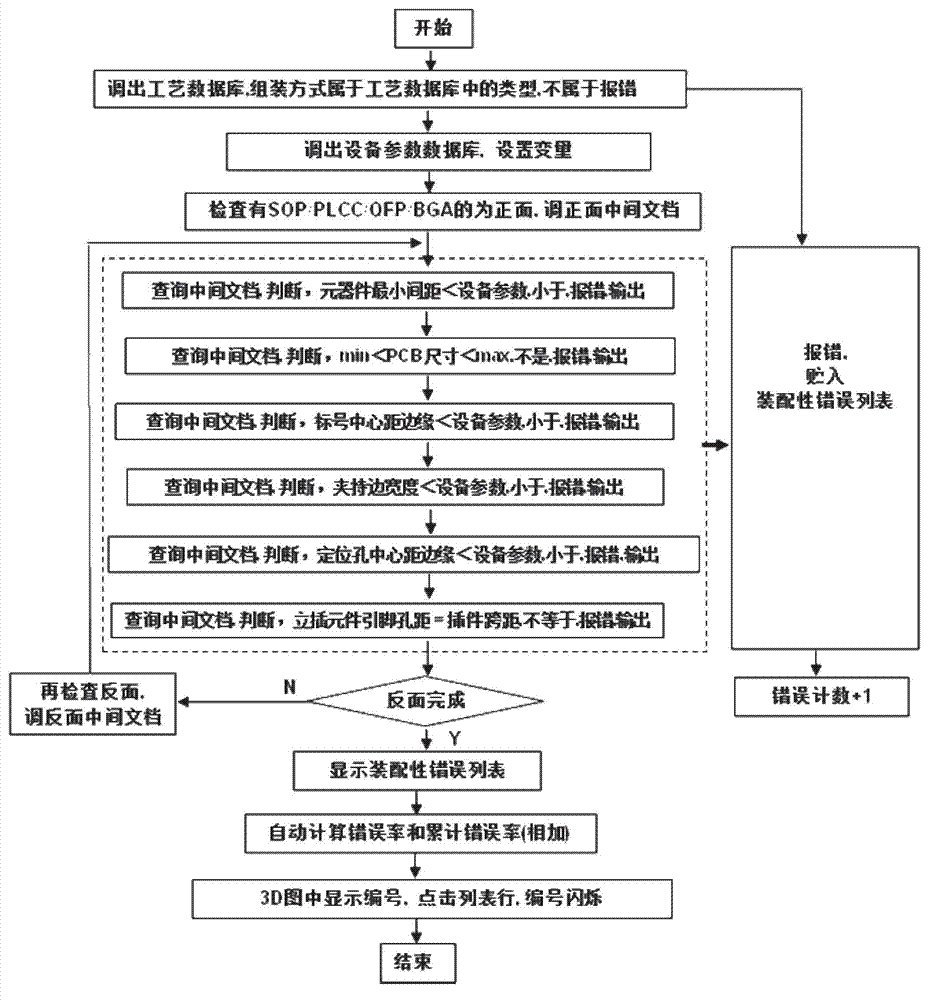

Visualization detection method of electronic product electronic design automation (EAD) design manufacturability

ActiveCN102930114AImprove efficiencyQuality improvementSpecial data processing applicationsInformation processingGraphics

The invention discloses a visualization detection method of electronic product electronic design automation (EDA) design manufacturability. Printed circuit board (PCB) three dimensional (3D) simulation of an EDA design document is conducted, PCBphysical parameter detection, PCB assembling ability, PCB welding quality detection and Gerber bill of material (BOM) coordinate detection are conducted in sequence, and specific error positions and types of former four steps of detection are displayed in visualization mode on a PCB 3D figure. On the basic of complete actual production experiences, the visualization detection method and a system of the EAD design manufacturability are developed according to international standard of information processing center (IPC), the PCB physical parameter detection, the PCB assembling ability, the PCB welding quality detection and the gerber BOM coordinate detection which are all designed by EDA are integrated, the various actual problems which are the contradictions of manufacture and design of PCB and are faced by enterprises are resolved, and efficiency and quality of electronic manufacture in particular to an original equipment manufacturer (OEM) are improved.

Owner:CHANGZHOU AUTOSMT INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com