Patents

Literature

134results about How to "Optimize the process route" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of carbon nanotubes/nano ATO (antimony tin oxide)/polypropylene electroconductive fibers

InactiveCN102409421AImprove fill factorImprove electrical performanceElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentPolypropylene compositesOrganic solvent

The invention discloses a preparation method of carbon nanotubes / nano ATO (antimony tin oxide) / polypropylene electroconductive fibers. The preparation method comprises the following steps of: (1) mixing nano ATO and carbon nanotubes, placing in an organic solvent together with a dispersant, and carrying out surface treatment to obtain a double-component nano electroconductive agent; (2) mixing the double-component nano electroconductive agent with polypropylene slices, and carrying out melt blending and strip preparation and granulation with a screw extruder to obtain double-component nano electroconductive agent / polypropylene composite electroconductive slices; (3) carrying out melt spinning on the composite electroconductive slices to obtain carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers; and (4) stretching and shaping the carbon nanotubes / nano ATO / polypropylene nascent electroconductive fibers to obtain the carbon nanotubes / nano ATO / polypropylene electroconductive fibers. By using the preparation method, the filling factor of a filler is increased, the content of an electroconductive filler in the material is reduced, the electric conductivity of the material is improved, and the electric performance stability of the material is simultaneously improved; and the preparation method has low price and no special requirement on equipment, has a economicand simple process route, and is suitable for industrial production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

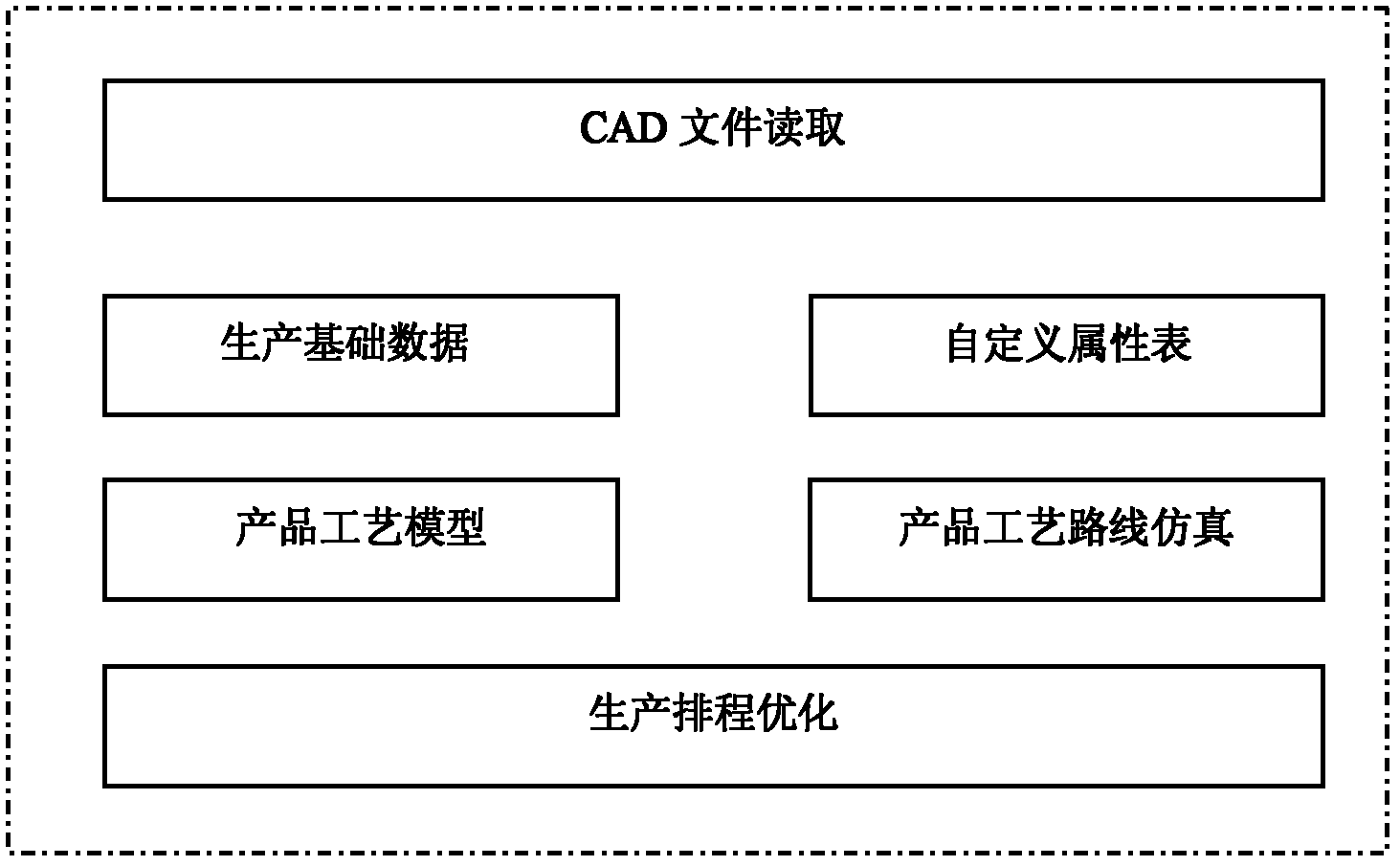

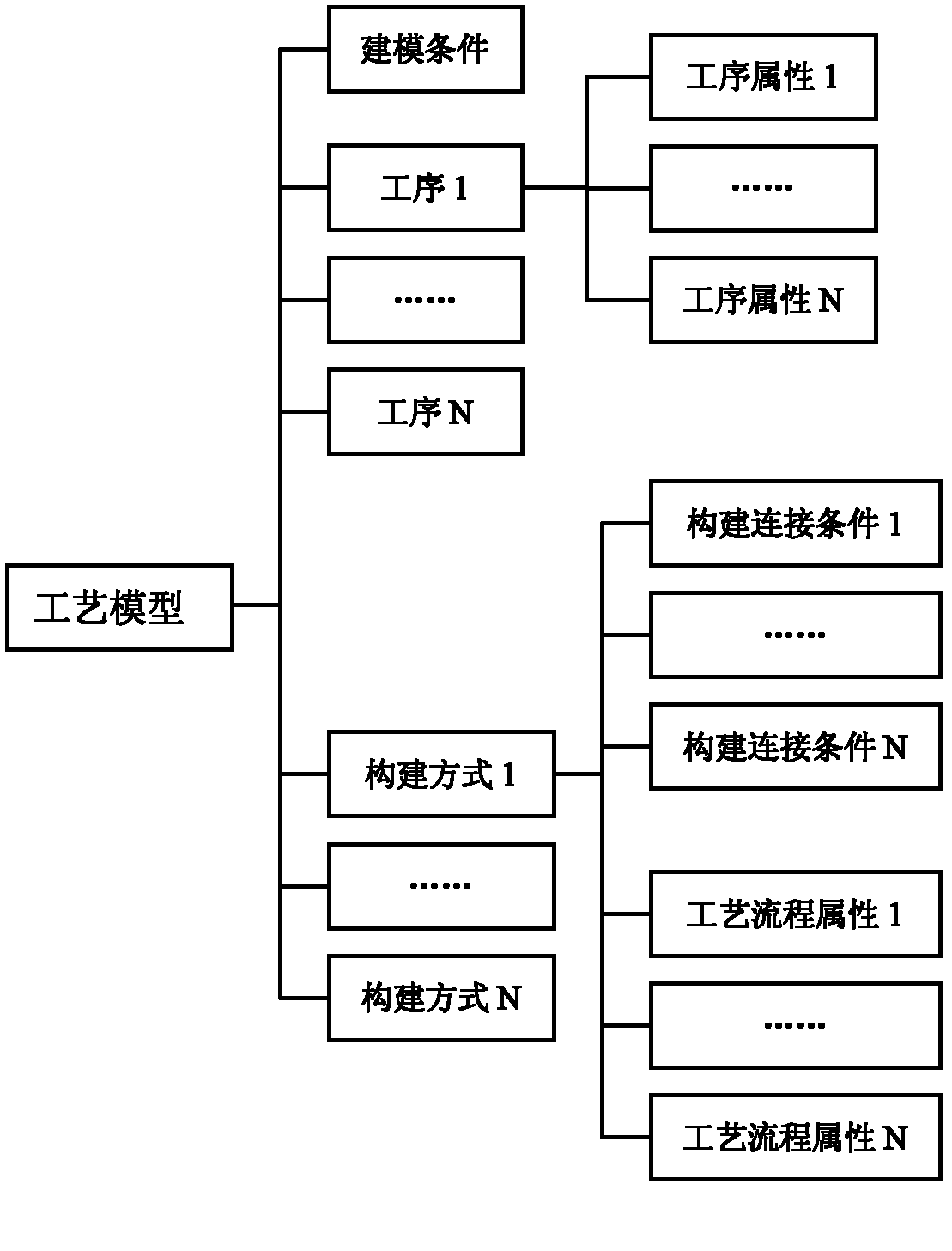

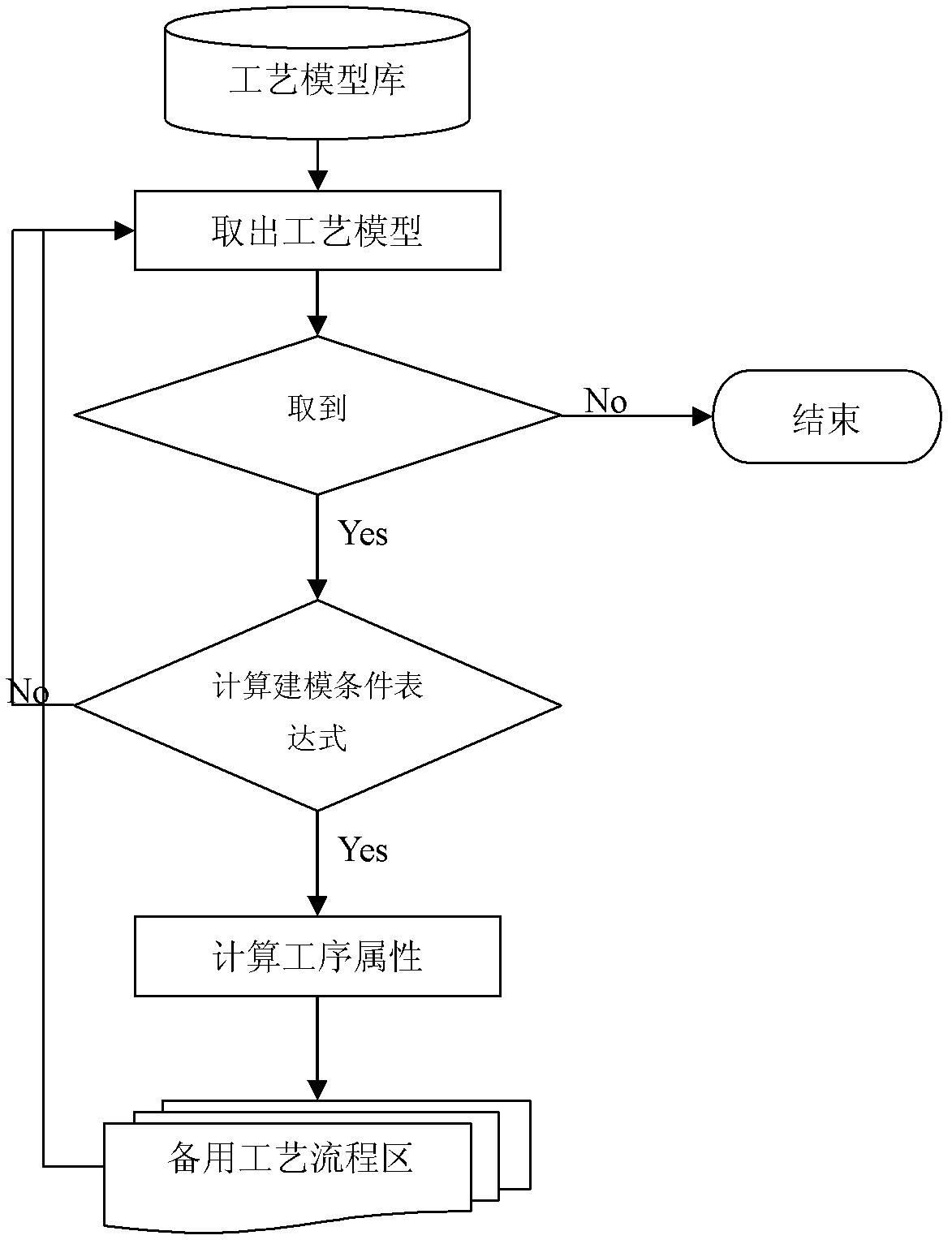

Product production process computer simulation system and method

InactiveCN102289743ARealize the automatic transfer of the listOptimize the process routeData processing applicationsBill of materialsProcess engineering

The present invention relates to a system and method for a product process route, which is a computer simulation system and method for a product production process, including a file reading module, a basic data module, a custom attribute module, a product process model module, a route simulation module and The production scheduling optimization module, among them, the file reading module is used to read the data of the product design system and put it into the product process model module; the basic data module is used to set the status data of the production site; the custom attribute module is used to It is used to maintain the attributes of the calculation parameters that constitute the product bill of materials and product process; the product process model module is used to manage the product process model for establishing product process routes; the route simulation module is used to calculate the process route according to the product process model, and to process Routes are managed; the production scheduling optimization module is used to change the process route replacement conditions of the route simulation module to obtain the optimal scheduling result. The system simulates or optimizes the product process route, saving cost, time and effort.

Owner:YIDAKANG NANJING INFORMATION SYST

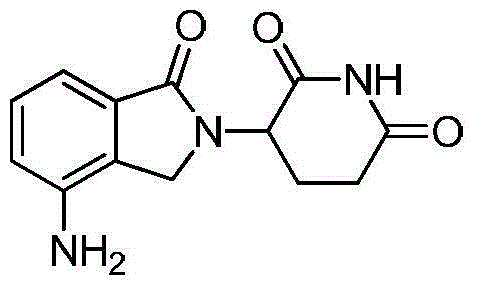

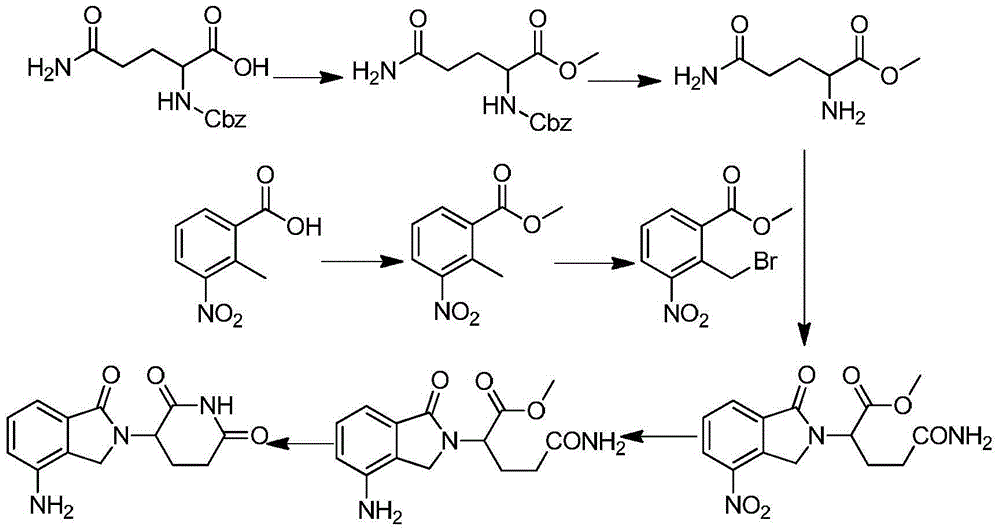

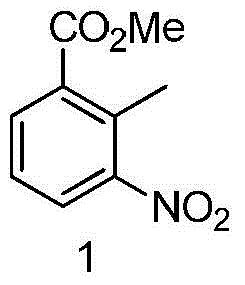

Method for preparing lenalidomide

InactiveCN104311536ASignificant technological progressOptimize the process routeCarbamic acid derivatives preparationOrganic compound preparationDicarbonateL-Glutamin

The invention discloses a method for preparing lenalidomide. The method comprises the following steps: firstly, etherifying 2-methyl-3-nitrobenzoic acid to obtain 2-methyl-3-nitrobenzoic acid methyl ester, brominating to obtain 2-brooethyl-3-nitrobenzoic acid methyl ester, reacting L-glutamine and tert-butyl dicarbonate to obtain N-Boc glutamic acid, acquiring 3-amino-2,6-piperidine diketone protected by Boc from N-Boc-glutamic acid in the presence of a condensing agent and a catalyst, further reacting with acid to prepare 3-amino-2,6-piperidine diketone hydrochloride, reacting 3-amino-2,6-piperidine diketone with 2-brooethyl-3-nitrobenzoic acid methyl ester so as to obtain 3-(4-nitryl-1,3 dihydro-1-oxo-2 hydrogen-isobenzazole-2-yl) piperidine-2,6-diketone, and finally reducing, thereby obtaining lenalidomide. The method disclosed by the invention is high in product yield.

Owner:SHANGHAI INST OF TECH

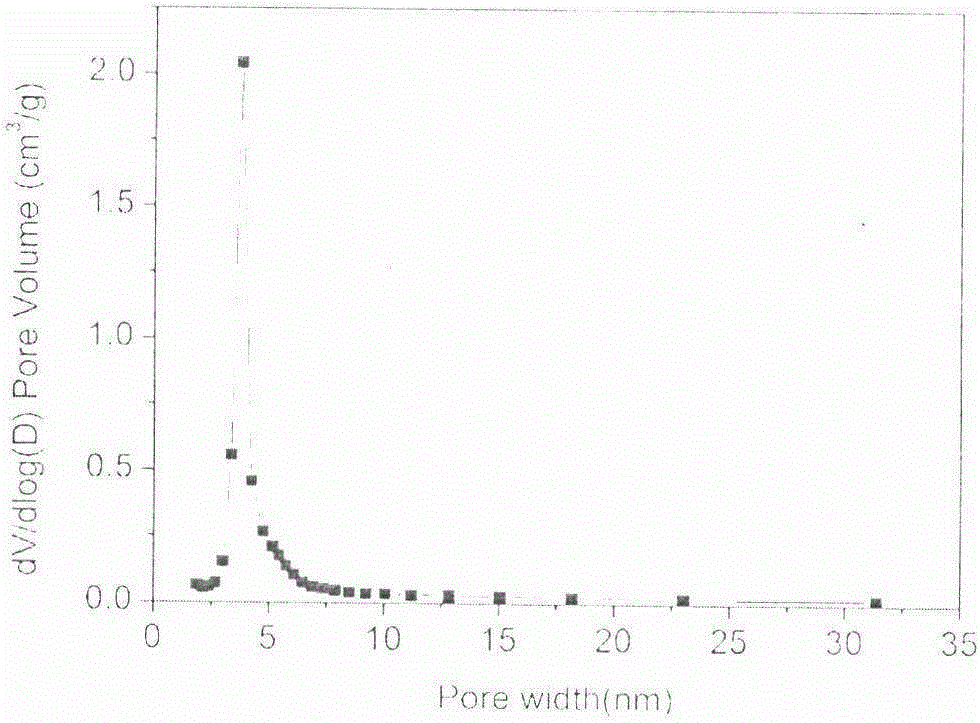

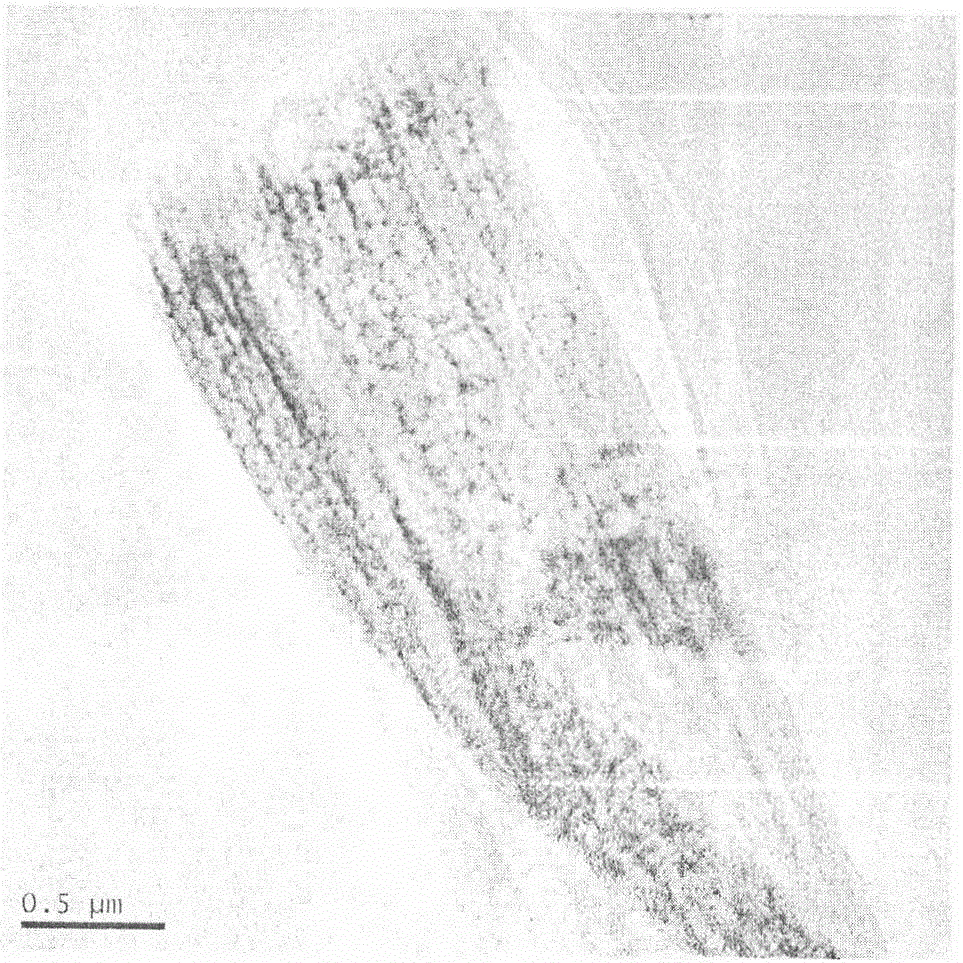

Preparation method of ordered mesoporous carbon nanofibers

The invention relates to a preparation method of carbon nanofibers with ordered mesoporous structures and a product prepared from the carbon nanofibers. The preparation method of the carbon nanofibers comprises the following steps of firstly, preparing phenolic resin, polyvinylpyrrolidone, an amphiphilic copolymer, inorganic salts and ethanol into a solution according to a certain proportion; secondly, preparing carbon nanofiber precursors by electrostatic spinning; thirdly, curing the carbon nanofiber precursors; fourthly, performing carbonizing and acid pickling to obtain the carbon nanofibers. The method is simple in process, low in cost and suitable for large-scale continuous production. The prepared carbon fibers contain abundant ordered mesopores; pore canals are parallel to the direction of a fiber axis, the diameters of the fibers are 300 to 900nm, pore sizes can be adjustable between 3nm and 20nm, the porosity is 80 to 97 percent, and the specific surface area is 100 to 1000m<2> / g; the carbon nanofibers have potential application in aspects of capacitors, lithium batteries, catalyst carriers, drug carriers, adsorbents and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Method for gathering/recovering VE (Vitamins E), squalene and polyunsaturated fatty acids from deodorized distillate of plant oil

ActiveCN103483305AShort crystallization timeReduce lossesFatty acids production/refiningCrystallisation purification/separationSolventSterol

The invention discloses a method for gathering / recovering VE (Vitamins E), squalene and polyunsaturated fatty acids from the deodorized distillate of plant oil. Specifically, the method comprises the following steps: adopting urea and a solvent as addition agents; mixing the addition agents with the distillate so as to dissolve the addition agents in the distillate; carrying out flexible packaging, vacuum degassing and sealing; applying a super high pressure for quickly crystallizing and agglomerating saturated fatty acids, monounsaturated fatty acids, fatty hydrocarbons, sterols and the like in the distillate; adsorbing a large quantity of impurities with an inclusion compound; carrying out pressure filtering and separating to obtain filter residue and filtrate; removing the solvent from the filtrate to obtain the VE, squalene and polyunsaturated fatty acids with high concentration. According to the method, the recovery rates of the VE, squalene and polyunsaturated fatty acids are all more than 80%, and neutral oil can be reserved.

Owner:潘见

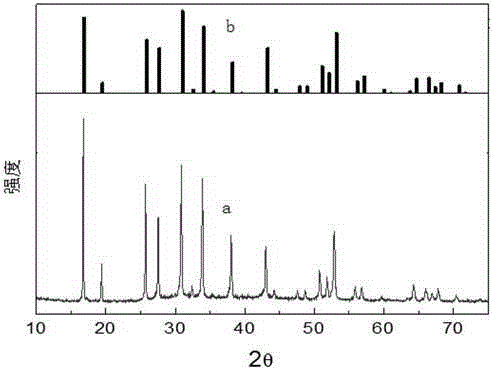

Tantalum-doped cubic garnet structure Li7La3Zr2-xTaxO12 material and preparation method thereof

ActiveCN105244536AReduce high temperature lossLow content requirementSolid electrolytesSecondary cellsLithiumPhysical chemistry

The invention discloses a tantalum-doped cubic garnet structure Li7La3Zr2-xTaxO12 material and a preparation method thereof. The preparation method comprises the steps that 1, lanthanum zirconate, a lanthanum source, a lithium source and a doped element being a tantalum source are weighed; the materials are placed in a container successively, a complexing agent is added into the container, and then stirring is performed for 4-6 h; 2, the temperature is gradually increased to 80 DEG C and kept till excessive moisture is removed, and a precursor processed in a high-temperature solid-phase mode is obtained; 3, the precursor is preheated for 3-5 h at the temperature of 400 DEG C, and a product is taken out, sufficiently and evenly ground and roasted for 1.5-5 h at the temperature of 900 DEG C to obtain a primary roasted product, wherein the value of x is 0.25-0.6. The method is simple in process, the requirement for the content of the doped materials is lowered, energy consumption and lithium high-temperature losses are reduced in the preparation process due to the fact that the roasting time is shortened, energy is saved, the cost is greatly reduced, and the preparation method is quite suitable for large-scale production.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH +1

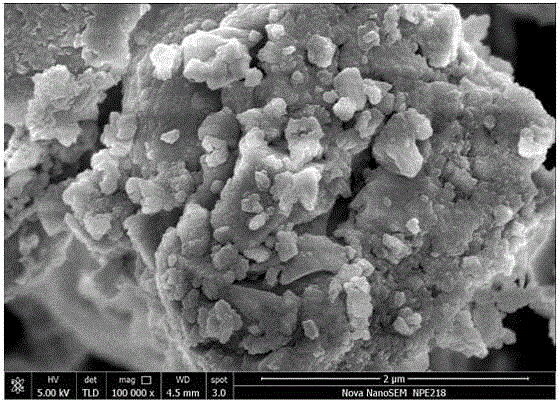

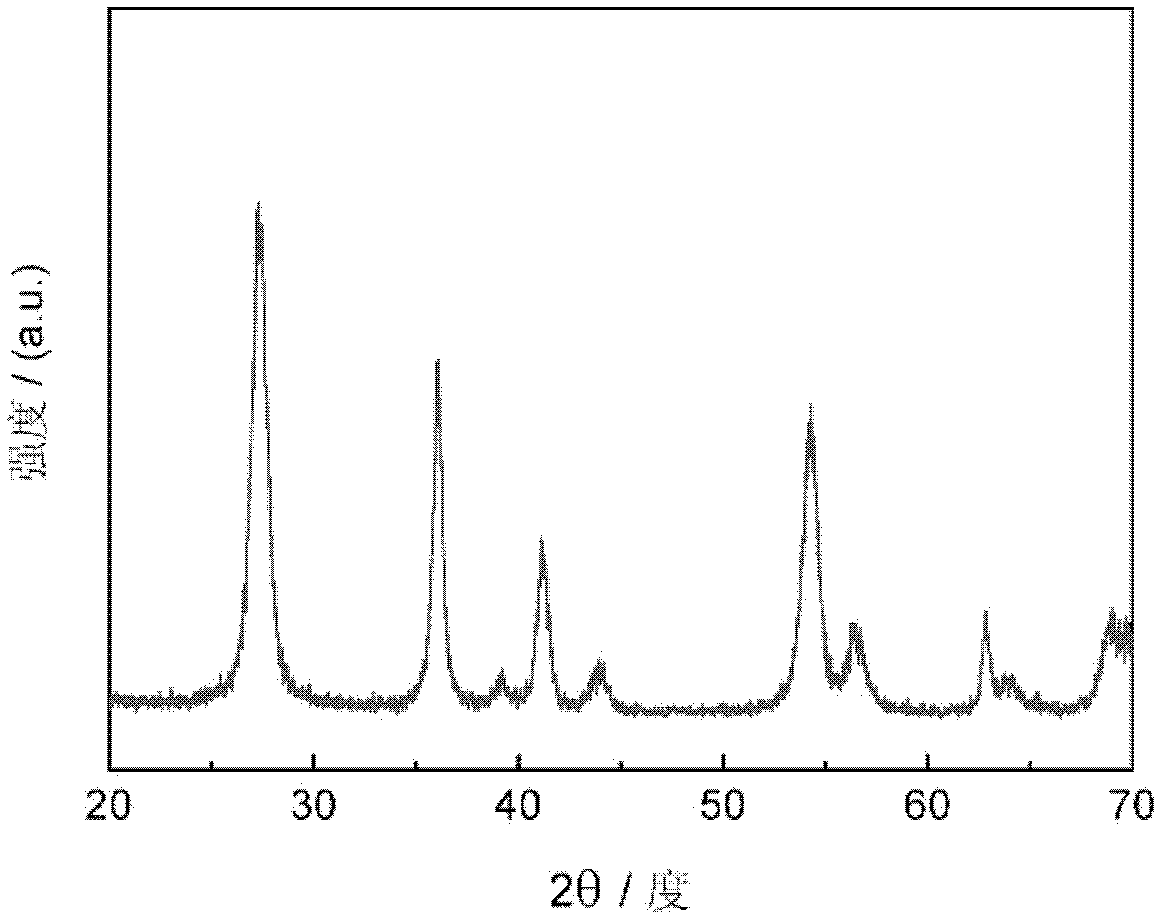

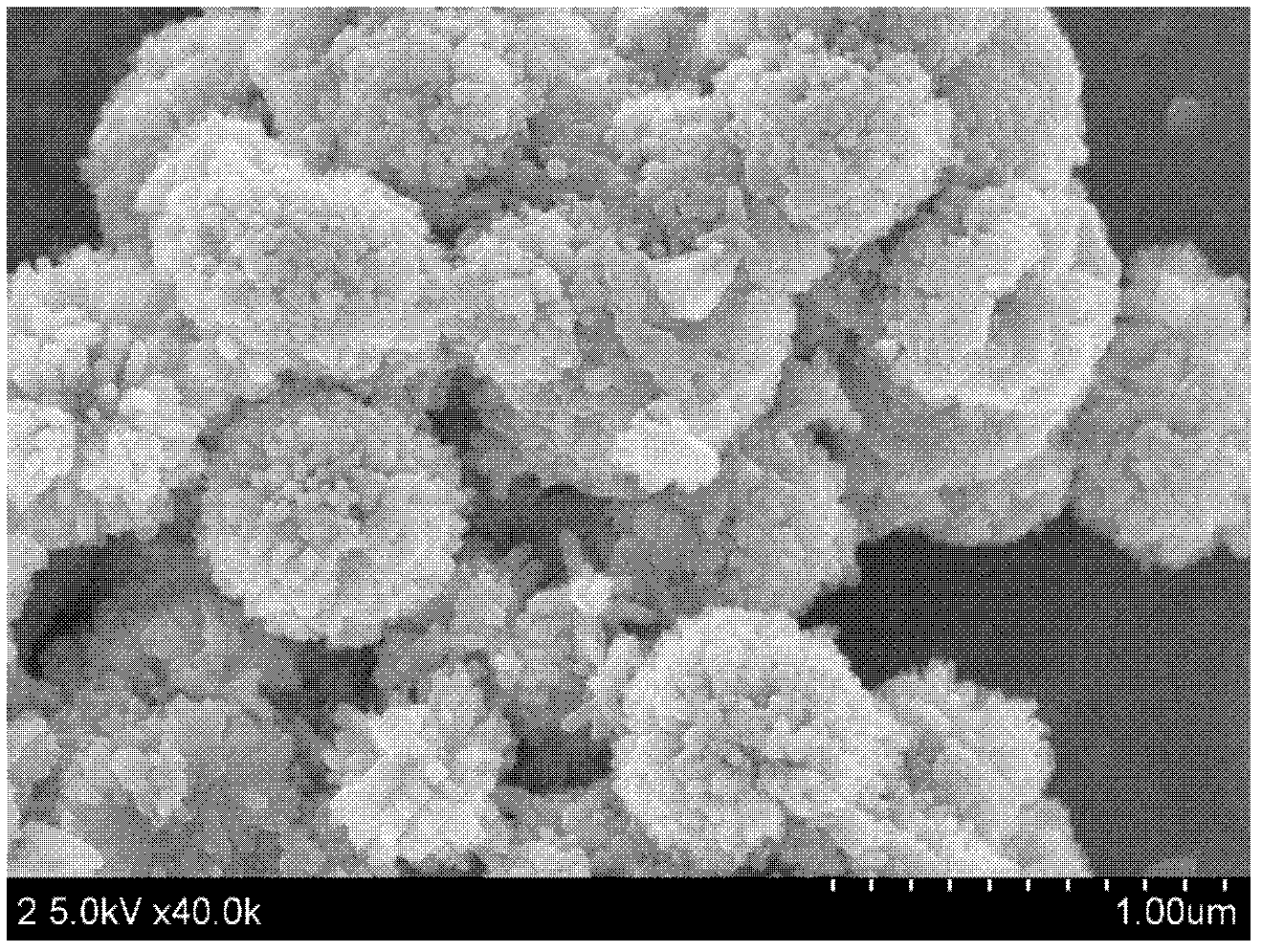

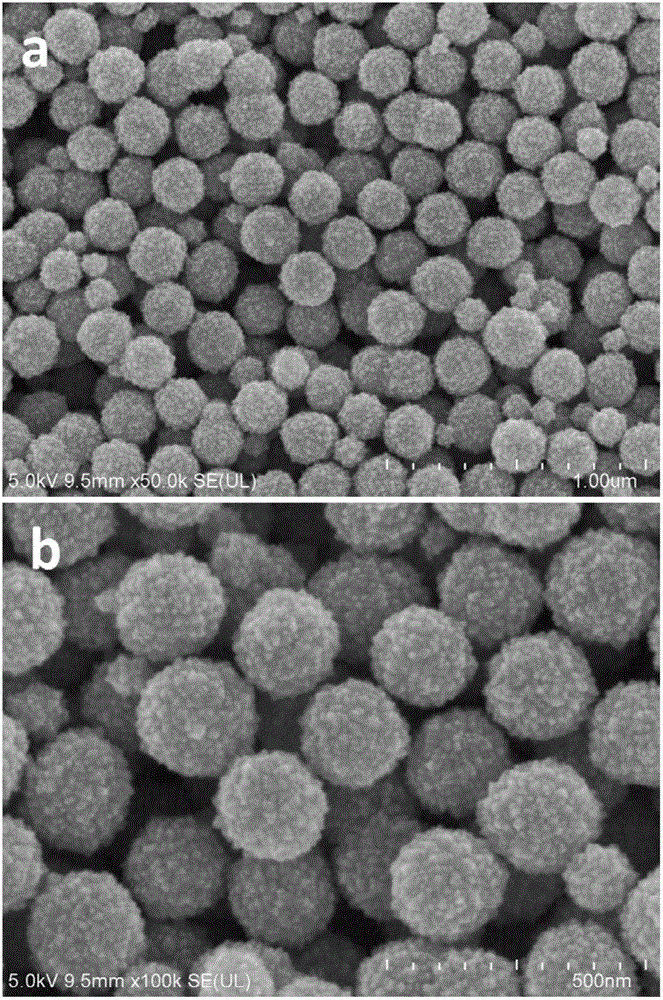

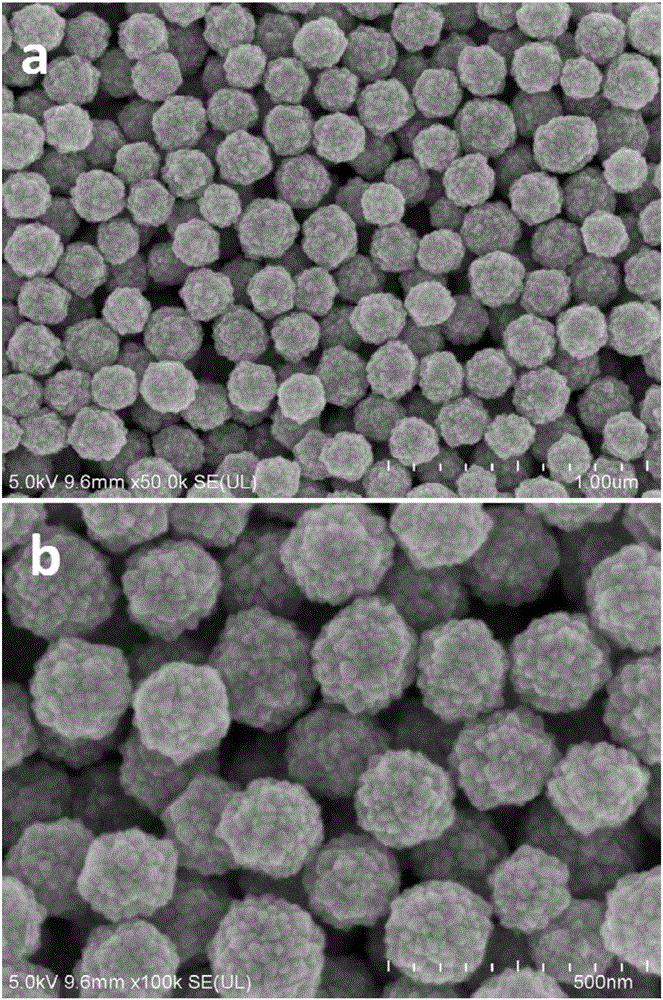

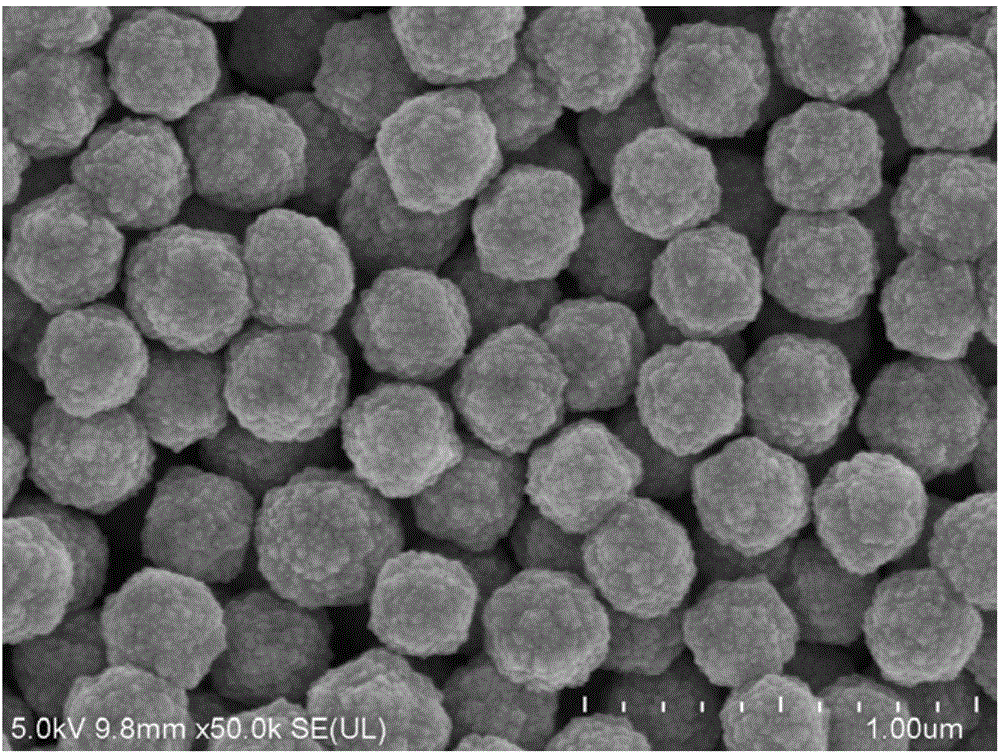

Method for preparing rutile type titanium dioxide nanorod microsphere

InactiveCN102786085AReduce energy consumptionShort cycleNanotechnologyTitanium dioxideNew energyMicrosphere

The invention relates to a method for preparing a rutile type titanium dioxide nanorod microsphere. The method comprises the following steps of (1) mixing concentrated hydrochloric acid, deionized water and non-polar solvent, adding titanium alkoxide in the mixed solvent drop by drop under a magnetic stirring condition, after the titanium alkoxide is added, continuously stirring the mixture for 30-60 minutes, so that the titanium alkoxide can be fully hydrolyzed to form layered mixed solution; and (2) transferring the mixed solution to a high pressure reaction kettle to perform solvothermal reaction, after the reaction is finished, naturally cooling the high pressure kettle by placing the reaction kettle at a room temperature, and repeatedly washing and centrifugally separating the obtained precipitate to obtain the titanium dioxide nanorod microsphere. According to the method provided by the invention, the solvothermal reaction is carried out in the interface of polar / non-polar solution by adopting the titanium alkoxide, the process route is simple and convenient, no surfactant is required; the prepared titanium dioxide nanorod microsphere is good in dispersion, high in degree of crystallinity, large in specific area, and can be used in various fields of photochemical catalyst, paints, cosmetics, new energy and the like.

Owner:DONGHUA UNIV

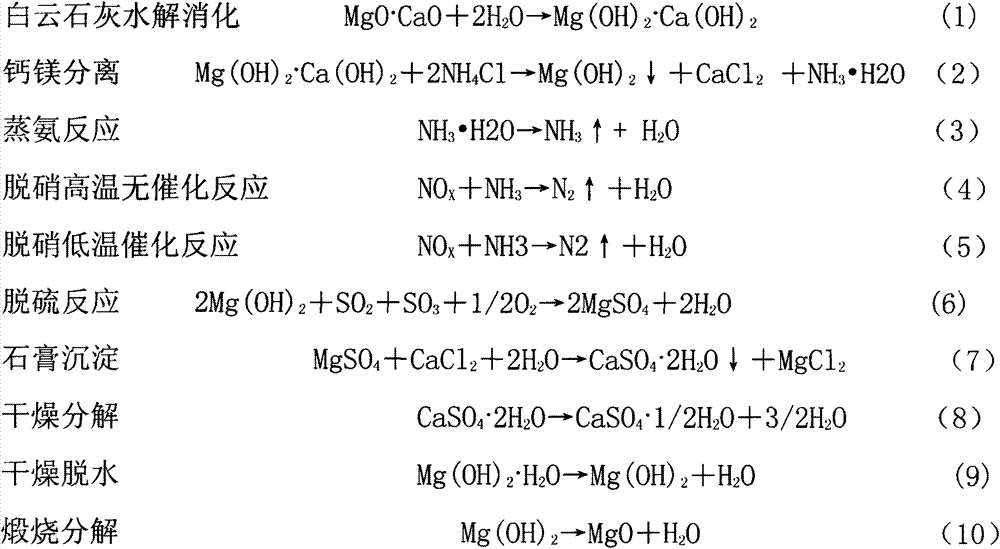

Method for preparing magnesium hydroxide, magnesium oxide and gypsum from dolomite lime denitration and desulfurization of flue gas

ActiveCN103566726ASolve the separation problemRealize comprehensive utilizationCalcium/strontium/barium sulfatesDispersed particle separationDistillationDolomite

The invention relates to a method for simultaneously preparing magnesium hydroxide, magnesium oxide and gypsum from dolomite lime denitration and desulfurization of flue gas, and belongs to the technical field of flue gas pollution control. The problems of separation of dolomite lime calcium-magnesium separation are ingeniously solved by a low-cost solution of NH4Cl. Ammonia gas (NH3) obtained by ammonia distillation in a calcium-magnesium separation process is heated for denitration. Mg(OH)2 precipitates formed in the calcium-magnesium separation process are used for the desulfurization of the flue gas. A solution of CaCl2 subjected to solid-liquid separation after calcium-magnesium separation is used for precipitating a solution of MgSO4 generated by desulfurization to produce byproducts CaSO4.1 / 2H2O building gypsum and a solution of MgCl2. Residual Mg(OH)2 is dried or calcinated to form a finished product Mg(OH)2 or MgO. According to the method, the denitration and desulfurization cost is greatly lowered; in addition, a novel production process for magnesium hydroxide and magnesium oxide products are created, and waste is comprehensively utilized.

Owner:彭振超 +1

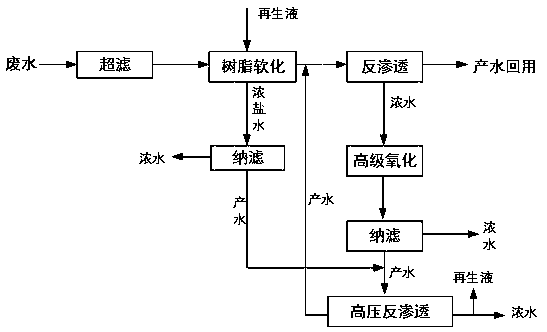

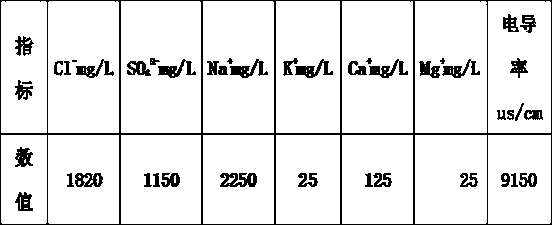

Technology for desalting and recycling salt-contained industrial wastewater containing calcium and magnesium and sulfate ions

InactiveCN107640860AReduce pollutionImprove running stability and water production rateGeneral water supply conservationWater contaminantsSaline waterChemistry

The invention discloses a technology for desalting and recycling salt-contained industrial wastewater containing calcium and magnesium and sulfate ions. The technology is characterized in that impurities are removed by pretreating; calcium and magnesium can be removed by resin softening; the obtained wastewater is further treated by reverse osmose, and the produced water is recycled; concentratedwater is treated by advanced oxidation to remove organic matters and then treated through a nanofiltration system to remove sulfate ions so as to obtain strong brine rich in monovalent cation salt; the strong brine is further concentrated by high-pressure reverse osmosis to obtain a regenerated liquid; the regenerated liquid is treated by resin softening again in order to be used for resin generating; the obtained strong brine is treated by nanofiltration and then is further concentrated by high-pressure reverse osmosis; the water produced by high-pressure reverse osmosis and the water produced by resin softening are mixed and then treated by reverse osmosis; calcium and magnesium in the wastewater can be removed by the resin softening, so that the pollution of a reverse osmosis membrane can be obviously reduced, and the running stability of a high reverse osmosis system can be greatly improved; the water production rate is beyond 95%; moreover, calcium and magnesium in the strong brine used for regenerating resin and sulfate ions in the concentrated water obtained in first-stage reverse osmosis are separated by nanofiltration, the recycling of the waste liquid in resin regenerating and the concentrated water obtained in reverse osmosis is achieved, as a result, the operation cost is decreased, and the drained strong brine of the whole system is less than 3%.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL TECH RES INST CO LTD

Can type sparkling grape wine and brewing method thereof

ActiveCN106047548ALow costGuaranteed costMicroorganism based processesWine preparationYeastTemperature control

The present invention relates to a can type sparkling grape wine and a brewing method thereof. The can type sparkling grape wine is characterized in that the brewing process comprises: 1) raw material sorting, 2) stalk removing and breaking, 3) air bag pressing, 4) low temperature clarification, 5) clear juice separating, 6) first glue adding treatment, 7) first low temperature filtration, 8) first freezing treatment, 9) second low temperature filtration, 10) low temperature storage for spare, 11) temperature returning treatment, 12) wild yeast inoculation, 13) temperature control fermentation, 14) temperature control pressure maintaining fermentation, 15) fermentation terminating, 16) second glue adding treatment, 17) second freezing treatment, 18) third low temperature filtration, 19) low temperature isopiestic pressure filling, and 20) finished product warehousing. According to the present invention, the process has advantages of simple and scientific process, convenient operation, short production period and effective production cost reducing, and can achieve the large-scale and continuous production of the sparkling grape wine.

Owner:COFCO GREAT WALL WINE YANTAI

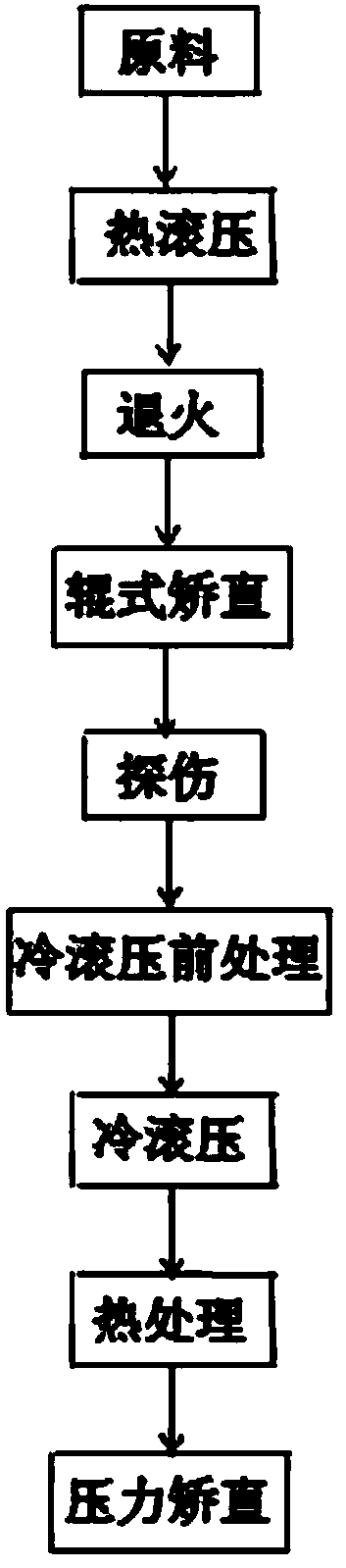

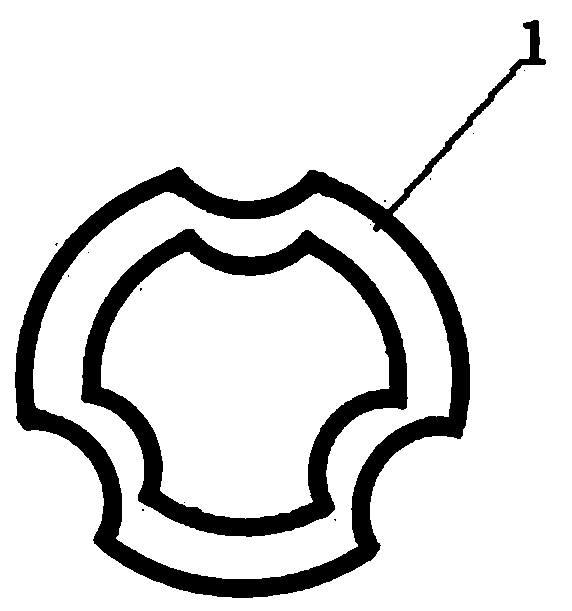

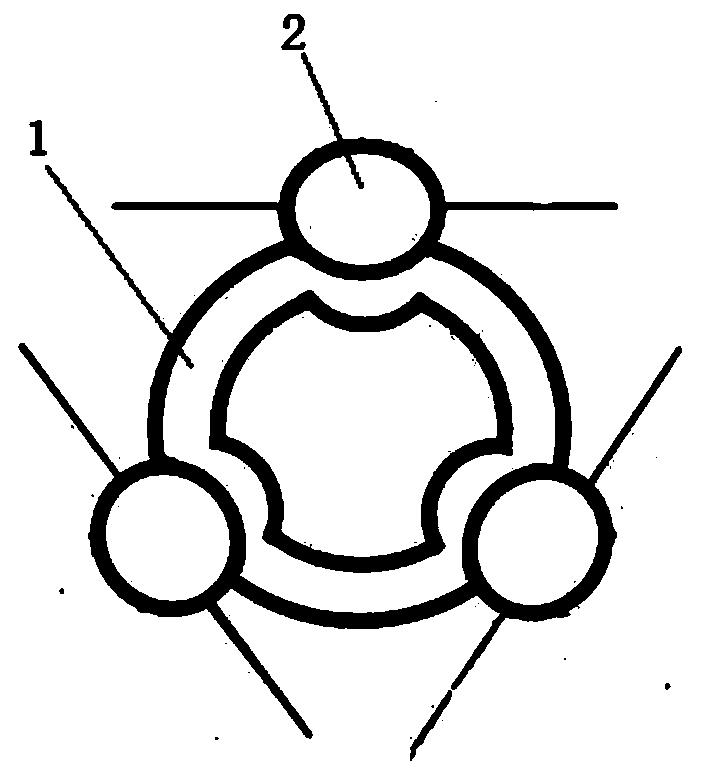

Special-shaped seamless steel pipe rolling manufacturing method

ActiveCN107626766AGuaranteed continuous operationReduce construction costsRoom temperatureHeat treated

The present invention relates to a special-shaped seamless steel pipe rolling manufacturing method, which directly uses cold rolling to manufacture a special-shaped seamless steel pipe, and specifically comprises: raw material preparing, roller type straightening, flaw detection, cold rolling pretreatment, cold rolling, heat treatment, straightening, marking and warehousing, wherein hot rolling isfirstly performed to obtain a special-shaped seamless steel pipe billet material for cold rolling at a room temperature, and the special-shaped seamless steel pipe is manufactured by using cold rolling, wherein the process steps specifically comprise raw material preparing, heating, hot rolling, annealing, roller type straightening, flaw detection, cold rolling pretreatment, cold rolling, heat treatment, straightening, marking and warehousing. According to the present invention, with the special-shaped seamless steel pipe rolling manufacturing method, the manufacture of the special-shaped seamless steel pipe is not limited by the raw material; the hot rolling and the cold rolling are combined by using the rolling tool and the core rod die or the cold rolling is separately performed, suchthat the advantages of easy performing and high yield are provided; and the flexible combination installation can be performed according to the requirement, and the installation precision can be controlled.

Owner:ANGANG STEEL CO LTD

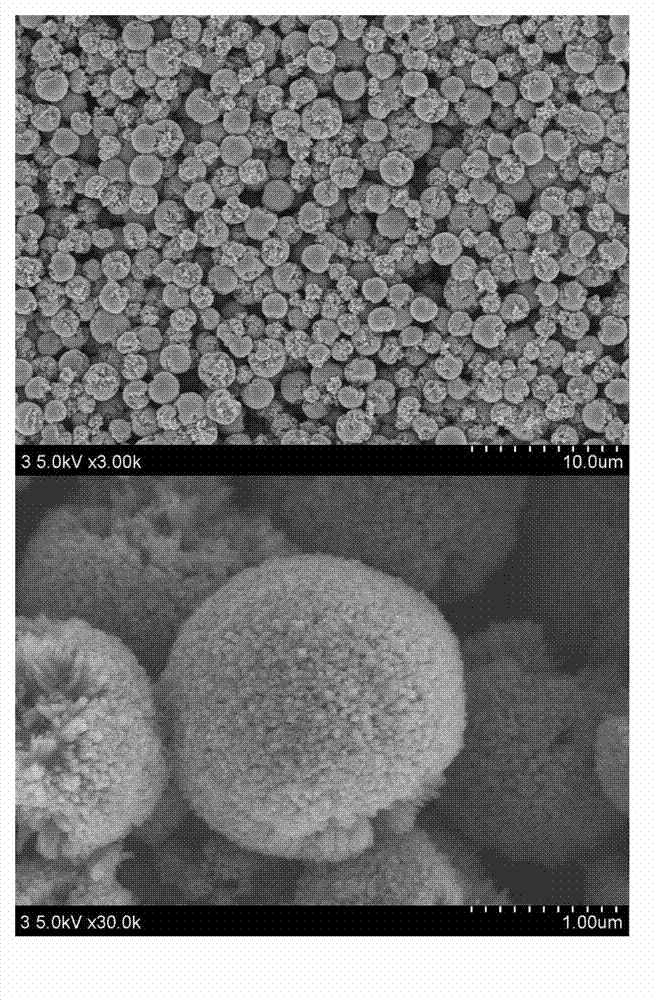

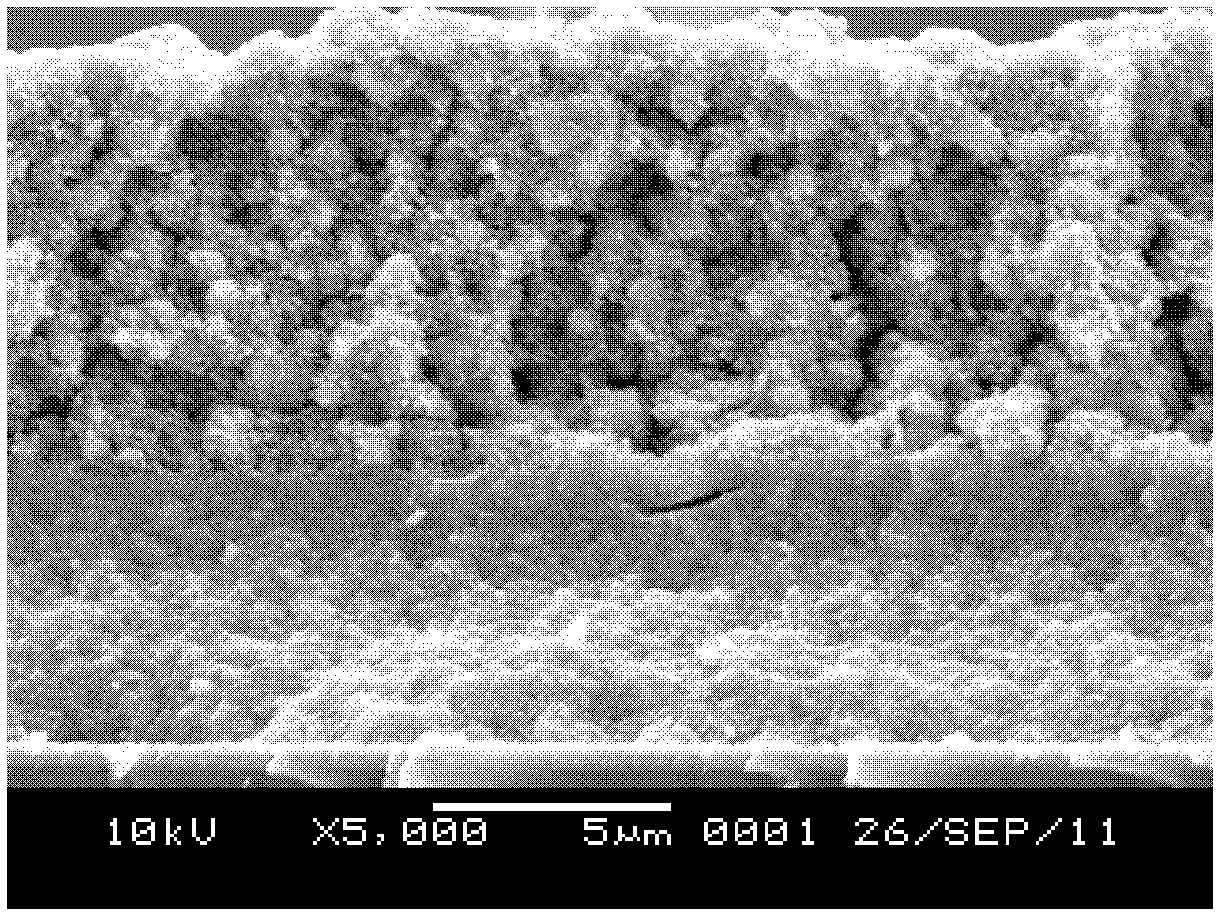

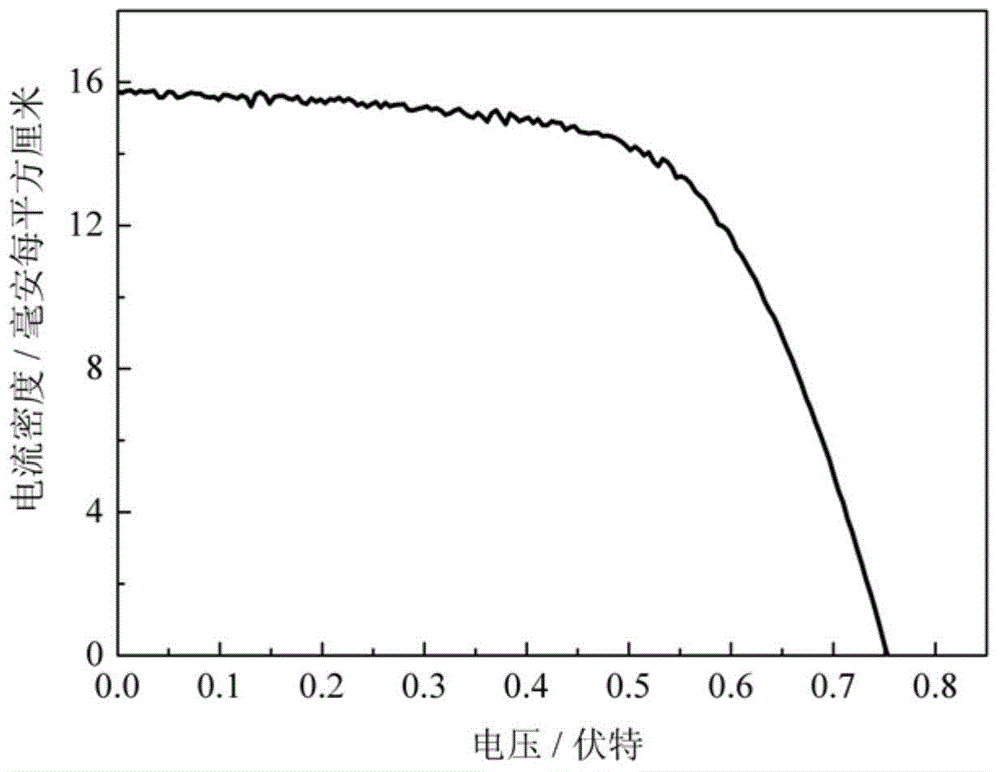

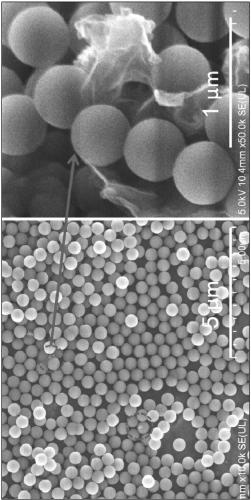

Preparation method for scattering layer of dye-sensitized solar battery

InactiveCN102522207AIncrease ionic strengthEnhanced light absorptionLight-sensitive devicesSolid-state devicesMicrosphereSlurry

The invention relates to a preparation method for a scattering layer of a dye-sensitized solar battery. The preparation method comprises the following steps of: (1) mixing titanium tetrachloride and a salt solution, and then conducting the hydro-thermal reaction on the titanium tetrachloride and the salt solution in a reaction kettle, thus obtaining titanium oxide scattering microspheres; (2) transferring the titanium oxide microspheres into a mortar, adding a pore-forming agent and a solvent in the mortar in sequence, and grinding the mixture for 0.5-3h to obtain uniform slurry; and (3) coating a layer of scattering layer slurry on a small particle base layer of the dye-sensitized solar battery by adopting a screen printing method or a blade coating method, sintering at the temperature of 400 DEG C-500 DEG C, and finally obtaining the scattering layer of the dye-sensitized solar battery. According to the method, the provided process is simple and convenient, the used raw materials are wide in source, a surface active agent does not need to be used, and the cost is low; and due to the provided large-particle scattering layer, the light absorbing capability of the photoanode of the battery is improved, simultaneously, the dye absorbing amount is increased, and the scattering layer has an industrial application prospect.

Owner:DONGHUA UNIV

Danhong freeze dried powder injection agent and its preparation method

A freeze-dried powder injection for treating coronary heart disese, angina pectoris and cerebrovascular disease is prepared from red sage root and safflower through extracting in organic solvent, ultrafiltration for purifying, etc.

Owner:邹巧根

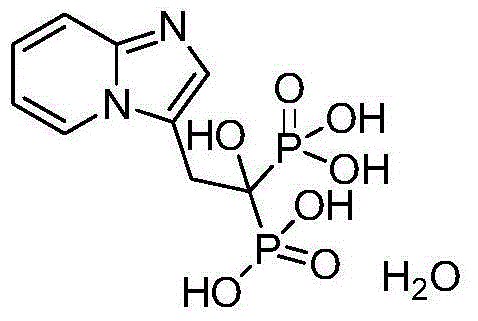

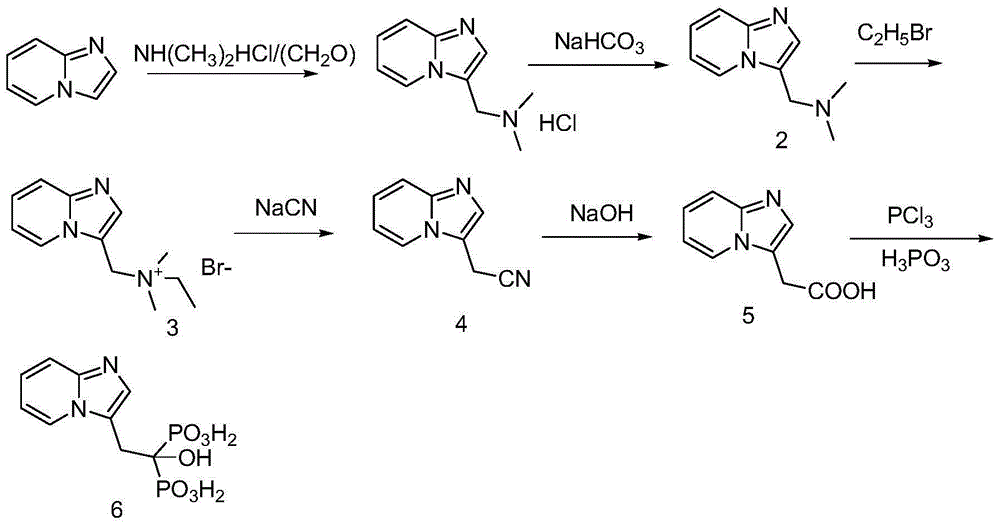

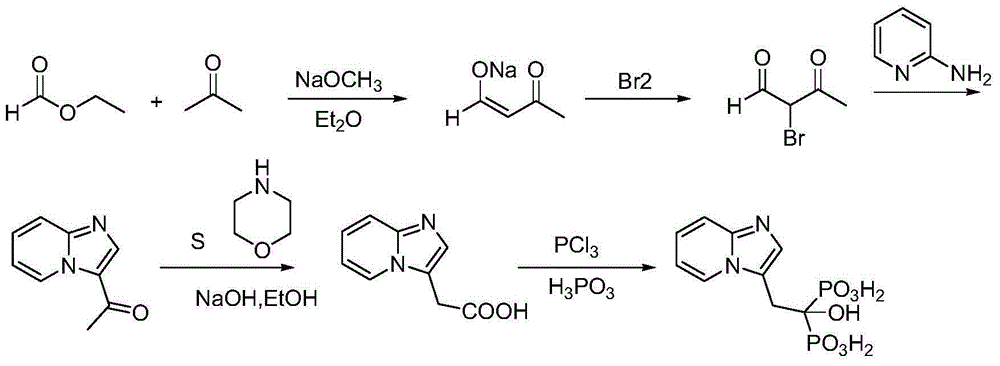

Method for producing minodronic acid monohydrate by using water as solvent

InactiveCN105111238ALow costEnvironmentally friendlyGroup 5/15 element organic compoundsSolventBromine

The present invention discloses a method for producing a minodronic acid monohydrate by using water as a solvent. According to the method, ethyl 4-bromoacetoacetate or methyl 4-bromoacetoacetate is adopted as a raw material and reacts with 2-aminopyridine by adopting water as a solvent under the effect of a catalytic amount of an organic alkali so as to highly-selectively obtain 2-(imidazo[1,2-a]pyridine-3-yl)ethyl acetate, the 2-(imidazo[1,2-a]pyridine-3-yl)ethyl acetate (methyl acetate) is hydrolyzed with an alkali solution to obtain 2-(imidazo[1,2-a]pyridine-3-yl)acetic acid, the 2-(imidazo[1,2-a]pyridine-3-yl)acetic acid, phosphorous acid and phosphorus trichloride react to obtain minodronic acid, and refining is performed to obtain the minodronic acid monohydrate. According to the present invention, the process has characteristics of simple reaction operation, easily available raw materials, easy post-treatment, high yield, application of the water as the solvent, and environmental protection, and is suitable for mass production.

Owner:ZHONGSHAN HAIHONG MEDICINE CO LTD

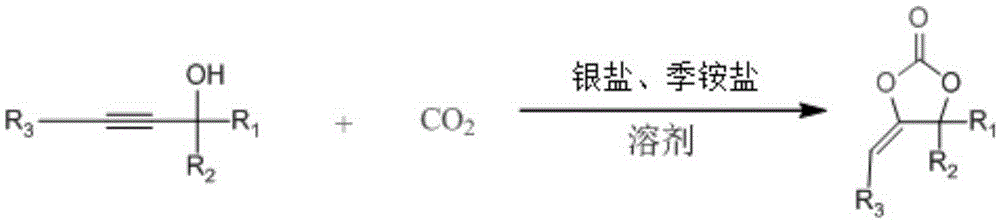

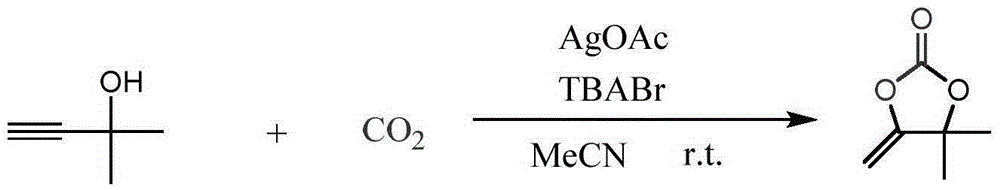

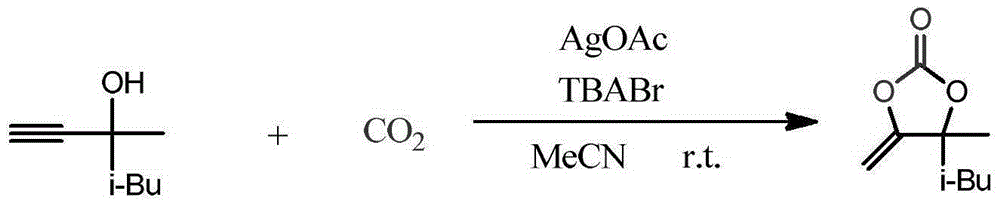

Method for synthesizing cyclic carbonate through CO<2> and propargyl alcohol

The invention discloses a method for synthesizing cyclic carbonate through CO<2> and propargyl alcohol. The method is characterized in that propargyl alcohol, silver salt and quaternary ammonium salt are mixed into acetonitrile or methylbenzene or DMF solvent, CO<2> is introduced at the normal temperature and normal pressure for conducting a synthetic reaction, after reaction liquid is extracted, a product, namely the cyclic carbonate, is obtained, and the mole ratio of the propargyl alcohol to the silver salt, the quaternary ammonium salt to the acetonitrile and the methylbenzene to the DMF solvent is 100:5-45:30-150:5-10000. Compared with the prior art, the method is simple in process and high in yield, raw materials are cheap and easy to obtain, the green house gases such as carbon dioxide are effectively utilized, air pollution is greatly reduced, addition of propargyl alcohol and the carbon dioxide and effective synthesis of the cyclic carbonate are achieved at the same time, and the method is a quite convenient process route with great industrial value.

Owner:EAST CHINA NORMAL UNIV

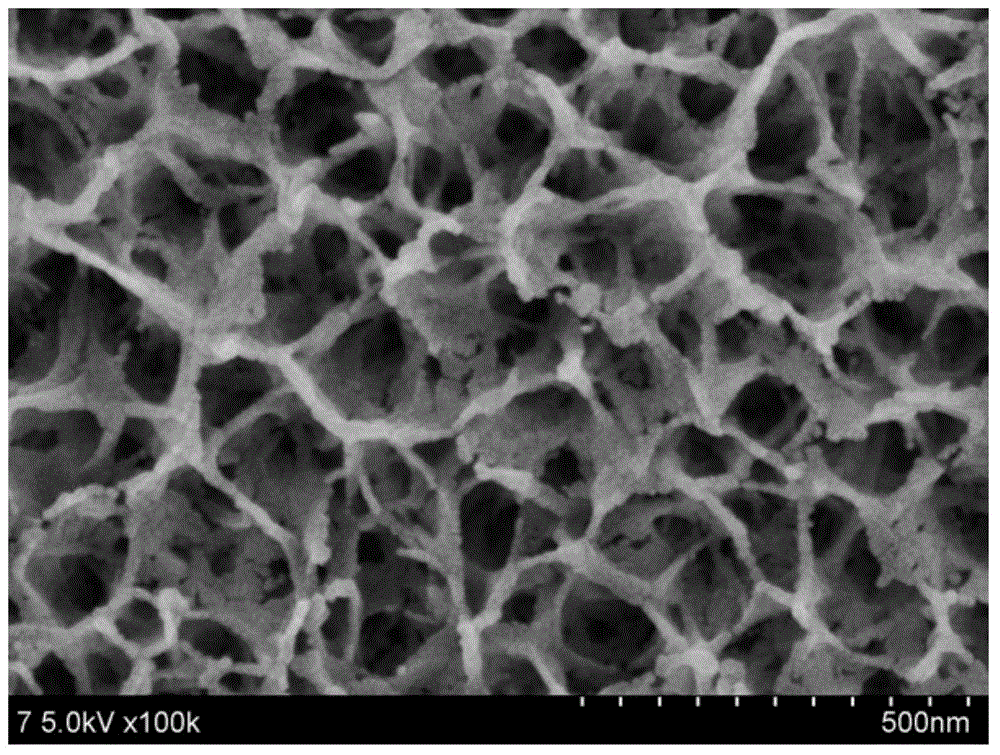

Self-supported titanium nitride/graphene combined electrode and preparation method thereof

The invention relates to a self-supported titanium nitride / graphene combined electrode and a preparation method of the self-supported titanium nitride / graphene combined electrode. The preparation method comprises the steps that (1) titanium foil is soaked with acid liquid, ultrasonic processing is conducted on the titanium foil, the titanium foil is taken out, washed by deionized water, and soaked with a hydrogen peroxide solution, the temperature of the solution is increased to 60DEG C-95DEG C from the room temperature under the normal pressure through heating, the temperature is kept for 10-60 minutes, and the titanium foil is taken out and dried after an reaction ends; (2) the titanium foil is placed into a tubular atmosphere furnace, ammonia is fed into the tubular atmosphere furnace to conduct nitrogen treatment on the titanium foil, and titanium nitride is formed on the surface of the titanium foil; (3) a layer of graphene is formed on the surface of the titanium nitride in a deposition mode through a dipping-pull method or a drop casting method, and the graphene and the titanium nitride are placed into a drying oven at the temperature ranging from 60DEG C to 100DEG C to be dried, so that the self-supported titanium nitride / graphene combined electrode is obtained. Compared with the prior art, a graphene / titanium nitride three-dimensional network is directly formed on the surface of flexible metal foil so that the self-supported electrode can be formed. The combined electrode is low in cost, high in porosity ratio and good in catalytic activity and electrical conductivity, and has the broad application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

High-temperature-resistance and unimpressed pressure sensitive adhesive (PSA) for polyethylene protective film, preparation method thereof and prepared polyethylene protective film

InactiveCN104710951ABroaden the field of applicationImprove prospectsNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membraneFunctional monomer

The invention discloses a high-temperature-resistance and unimpressed pressure sensitive adhesive (PSA) for a polyethylene protective film, a preparation method thereof and a prepared polyethylene protective film. The high-temperature-resistance and unimpressed PSA for the polyethylene protective film is prepared from the following raw materials by a seeded emulsion polymerization method: a monomer group, an emulsifier, an initiator, a chain transfer agent, a PH regulator and deionized water, wherein the monomer group comprises the following components by weight percent: 80-90% of a soft monomer, 5-10% of hard monomer, and 5-10% of functional monomer. When the polyethylene protective film prepared from a PSA emulsion coated on a high-light metal sheet is removed at a high temperature, no imprint generates, so that the appearance of products is not influenced; compared with the existing production process, the preparation method provided by the invention has the advantages that the process route is optimized, the production is easy to control, the production cost is low, and the market prospect is wide.

Owner:潍坊胜达科技股份有限公司

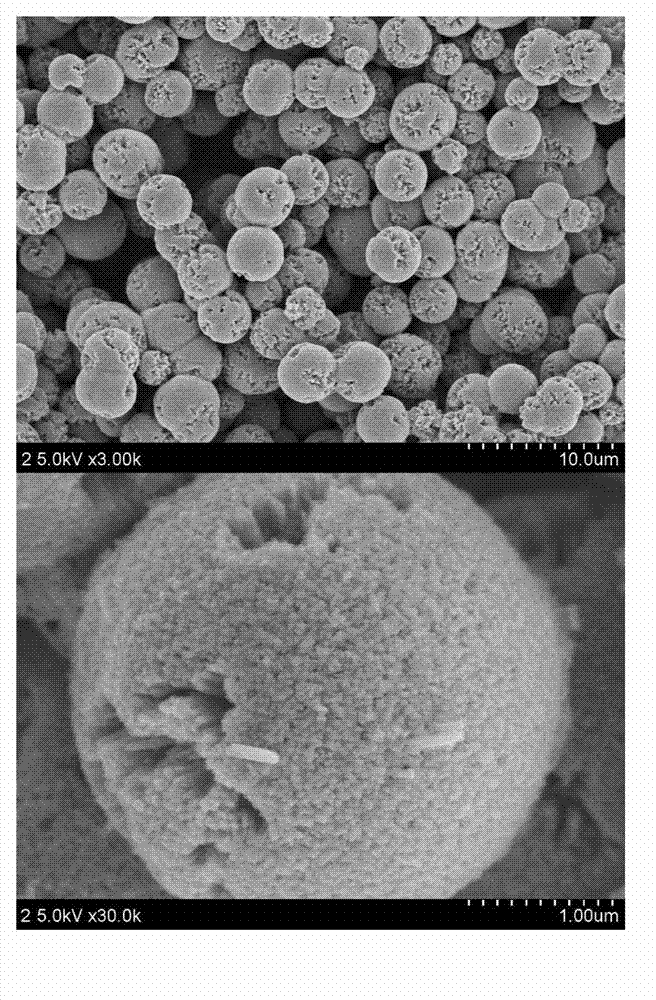

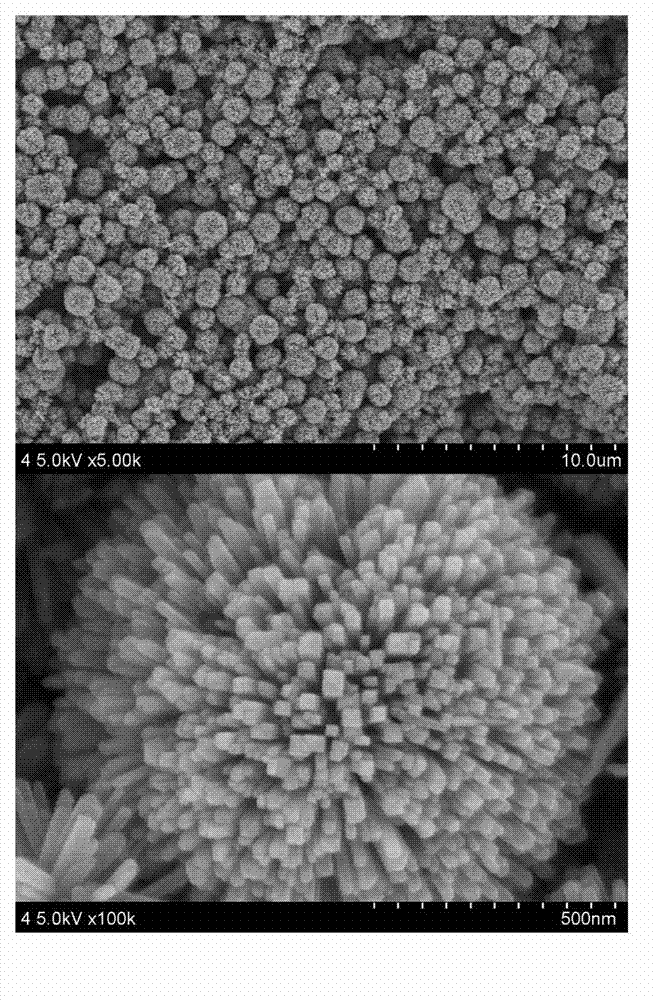

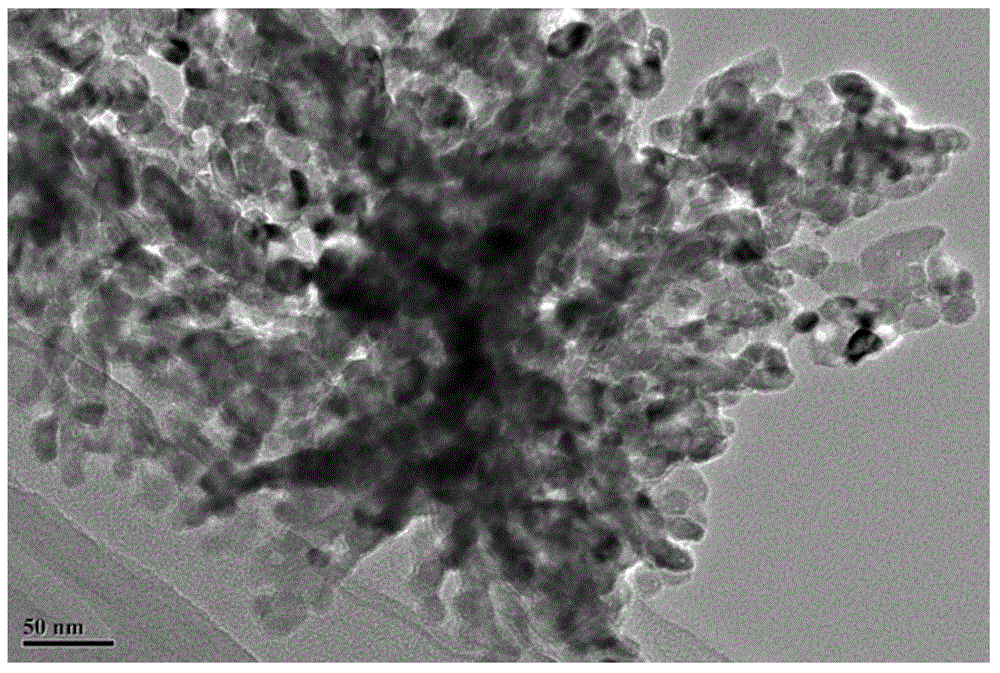

A Stannic Oxide Microballoon with Controllable Crystallite Dimension and its Preparation Method and Application

ActiveCN106277040AInhibit hydrolysisPromote nucleation growthLight-sensitive devicesSecondary cellsChemistryPhotocatalysis

This invention involves a kind of stannic oxide microballoon with controllable crystallite dimension and its preparation method and application. This stannic oxide microballoon is composed of stannic oxide microcrystal with fine crystallinity through self-assembly. The grain size of stannic oxide microcrystal is adjustable within range of 5-30nm. The diameter of stannic oxide microballoon is 200-400nm and its specific surface area >40m2 / g; During preparation, add concentrated hydrochloric acid and tin source into the mixed solution of normal propyl alcohol and water in order, forming the transparent homogeneous solution; Conduct solvothermal reaction; After the reaction ends, take out the sediment, wash and separate it. Being compared with the current technology, this invention has simple and easy process route, which does not need surface active agent. And the multilevel structure Sno2 microballoon with equally distributed dimension can be gotten through one-step method, which is composed of stannic oxide microcrystal through self-assembly. Also, the dimension of Sno2 microcrystal can be adjusted and controlled through adjusting the alcohol / water proportion in the reaction system. The microballoon has features of high specific area and submicron level dimension, which has wide application prospect in areas of solar cell, lithium ion battery and photocatalysis.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of sodium butyrate

InactiveCN102070435AConvenient sourceLow priceCarboxylic acid salt preparationSide reactionButyric acid

The invention provides a preparation method of sodium butyrate, and the method comprises the following steps: dropwisely adding butyric acid into an NaOH water solution to react; and after the reaction finishes, evaporating out water in the system, and drying to obtain the sodium butyrate. By using the preparation method provided by the invention, after the reaction finishes, all the water is evaporated out, and drying is carried out so as to obtain the target product. The process route is optimally selected, and special drying equipment capable of ensuring fewer side reaction impurities and large-scale production is directly used for drying, thereby reducing the labor intensity, saving the production time and greatly increasing the yield which can be higher than 98%.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

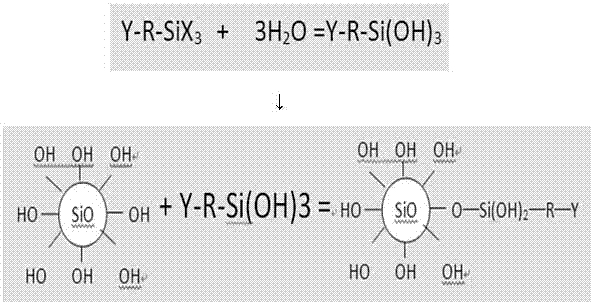

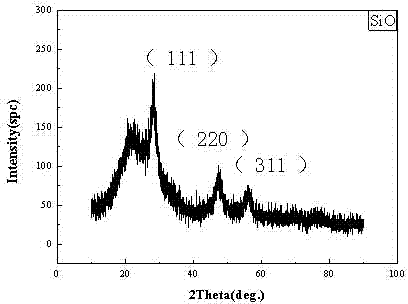

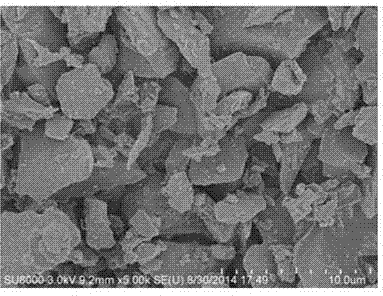

Silane compound modified SiO anode material as well as preparation method and application thereof

ActiveCN104852050AInhibition of differentiationImprove cycle stabilityCell electrodesSilanesHydrolysis

The invention discloses a silane compound modified SiO anode material as well as a preparation method and the application thereof, wherein the material takes SiO as a substrate, and the substrate is modified by a layer of silane compound. The preparation method comprises the steps of 1, hydrolyzing the silane compound to enable the chemical bonds of a coupling agent connected with silicon atoms to be hydrolyzed and generate siloxane with low degree of polymerization, and carrying out ultrasonic treatment on SiO powder in water-alcohol mixed liquid; 2, mixing the hydrolyzed silane compound with the SiO, and carrying out reflux heating reaction in the atmosphere of inert gas; and 3, centrifuging the mixed solution, and then carrying out vacuum drying. The SiO anode material with the silane compound modification layer can be mixed with graphite so as to be used as the anode material for a lithium-ion battery. The surface of the material is modified by the silane compound, so that the problem of rapid capacity fading caused by powdering of the silicon material in the charge and discharge processes can be solved. The process route adopted by the invention is convenient, simple and easy to operate; furthermore, the needed material is low in cost, so that the silane compound modified SiO anode material is favorably produced in a factory on a large scale.

Owner:HARBIN INST OF TECH

Preparation method for isoalkylalkenyloxysilane

InactiveCN107936052AOptimize the process routeImprove securitySilicon organic compoundsParaffin waxDistillation

The invention discloses a preparation method for isoalkylalkenyloxysilane. The preparation method comprises the following steps: adding alkyl ketone, an acid binding agent and a catalyst in a mass ratio of 1000: 1090: (1-5) into a reaction vessel, and carrying out heating under stirring until the temperature of the reaction vessel is 40 DEG C; maintaining the temperature of the reaction vessel tobe 20 to 60 DEG C, adding chlorosilane into the reaction vessel drop by drop within 20 to 40 min, carrying out heat-preserved reflux after completion of addition of chlorosilane until the content of isoalkylalkenyloxysilane in the reaction vessel is greater than 30%, and hermetically filtering out a tertiary amine hydrochloride solid so as to obtain a first filtrate; subjecting the first filtrateto distillation at normal pressure so as to first mother liquor; adding solid paraffin and a chloride ion neutralizer into the first mother liquor, maintaining the temperature of the reaction vessel to be 40 to 60 DEG C, carrying out a reaction for 1 to 3 h, and then carrying out filtering under the condition that vessel temperature is 35 to 40 DEG C so as to obtain a second filtrate; and subjecting the second filtrate to vacuum rectification at a temperature of 124 to 126 DEG C and a pressure of 0.0130 to 0.0140 MPa so as to obtain isoalkylalkenyloxysilane. The isoalkylalkenyloxysilane prepared in the invention has a purity of 94% or above and yield of more than 63%.

Owner:湖北新蓝天新材料股份有限公司

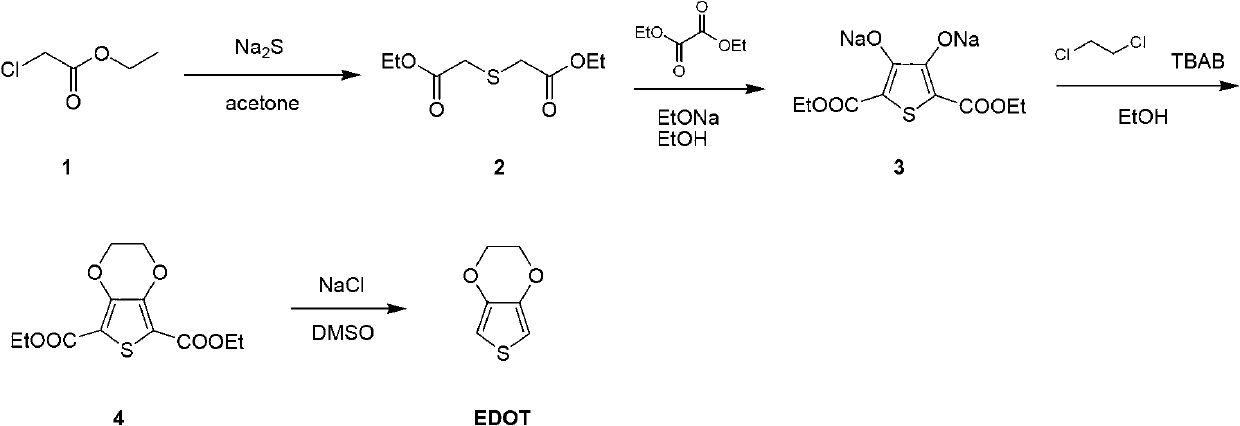

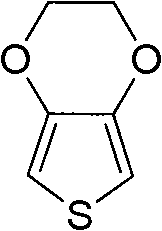

Method for preparing polymer monomer 3,4-ethylenedioxythiophene

ActiveCN102775423AShort routeShorten the production cycleOrganic chemistryPolymer scienceEthylenedioxy

The invention relates to a method for preparing polymer monomer 3,4-ethylenedioxythiophene. The method includes firstly dissolving ethyl chloroacetate and sodium sulphide in acetone to react to obtain diethyl thioglycolate; secondly, dissolving the diethyl thioglycolate to ethanol, adding sodium ethoxide and diethyl oxalate into the ethanol, heating and reflowing to obtain ethanol solution of 2,5-dioctyl phthalate ethyl ester-3,4-thiophene glycol sodium; thirdly, adding dichloroethane and tetrabutylammonium bromide into the ethanol solution of the 2,5-dioctyl phthalate ethyl ester-3,4-thiophene glycol sodium, heating and reflowing to obtain 3,4-ethylenedioxy-2,5-dioctyl phthalate ethyl ester thiophene; fourthly, dissolving the 3,4-ethylenedioxy-2,5-dioctyl phthalate ethyl ester thiophene in mixed solvent, adding sodium chloride, heating and reacting, and finally reducing pressure and rectifying. The method for preparing polymer monomer 3,4-ethylenedioxythiophene is few in procedures, low in cost, safe and reliable in technique, simple and fast in post-treatment method, and products are high in yield and purity.

Owner:TAISHAN MEDICAL UNIV

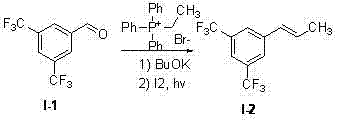

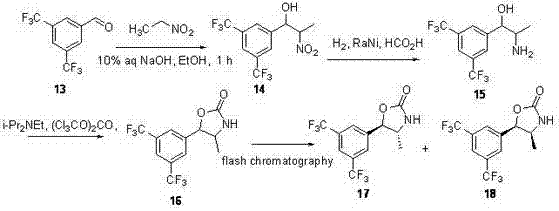

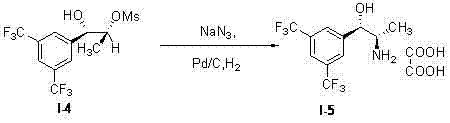

Synthesis method of key intermediate of anacetrapib

The invention discloses a synthesis method of a key intermediate of anacetrapib. The synthesis method comprises the steps: making 3,5-bi(trifluoromethyl) benzaldehyde as a raw material perform a witting reaction with ethyltriphenylphosphonium bromide to obtain a mixture, performing inversion of configuration on the mixture under the illumination in the presence of an iodine elementary substance of a catalytic amount to obtain a transform product (I-2); performing Shi-dissymmetry epoxidation on the transform product (I-2) to obtain a compound (I-3); performing hydrolysis and ring opening on the compound (I-3) under an acidic condition, and then reacting under an alkaline condition to obtain a transform product (I-4); substituting the compound (I-4) by sodium azide, and performing inversion of configuration, performing hydrogenation reduction in the presence of Pd / C into an amino group, salifying with a feasible acid to obtain a compound (I-5); and performing ring closing on the compound (I-5) and triphosgene to obtain the key intermediate of anacetrapib. The synthesis method has the advantages of simplicity in operation, availability in raw materials, no need of purification of the intermediate, high yield, and environmental friendliness, and is easy to post-process, and suitable for large-scale production.

Owner:汕头经济特区鮀滨制药厂

Preparation method of dispersed graphene with bifunctional ligands for coatings

ActiveCN109294317AThe process route is simpleReduce energy consumptionAnti-corrosive paintsEpoxy resin coatingsCvd grapheneGraphene coating

The invention relates to the field of dispersed graphene preparation, and particularly relates to a preparation method of dispersed graphene with bifunctional ligands for coatings. The preparation method includes the following steps: (1) mixing oxides and bifunctional ligands in pigments or fillers for coatings in solvents, and adding graphene into the mixture while stirring the mixture with a magnetic stirring device, thereby obtaining a mixed solution; (2) continuously stirring the mixed solution obtained in step (1) for 1-3 hours, and carrying out centrifuging and drying to obtain oxide-graphene; and (3) adding the oxide-graphene prepared in step (2) into liquid for further use, carrying out dispersing with a high-speed stirring device, and then adding resins, thereby obtaining a highly-dispersed graphene coating application system. The preparation method is simple and convenient in whole process route and low in energy consumption, and the obtained graphene is good in dispersion performance, and is of great benefit in the application of anti-corrosion coatings, solar cells and other fields.

Owner:XINHE NEW MATERIALS CO LTD

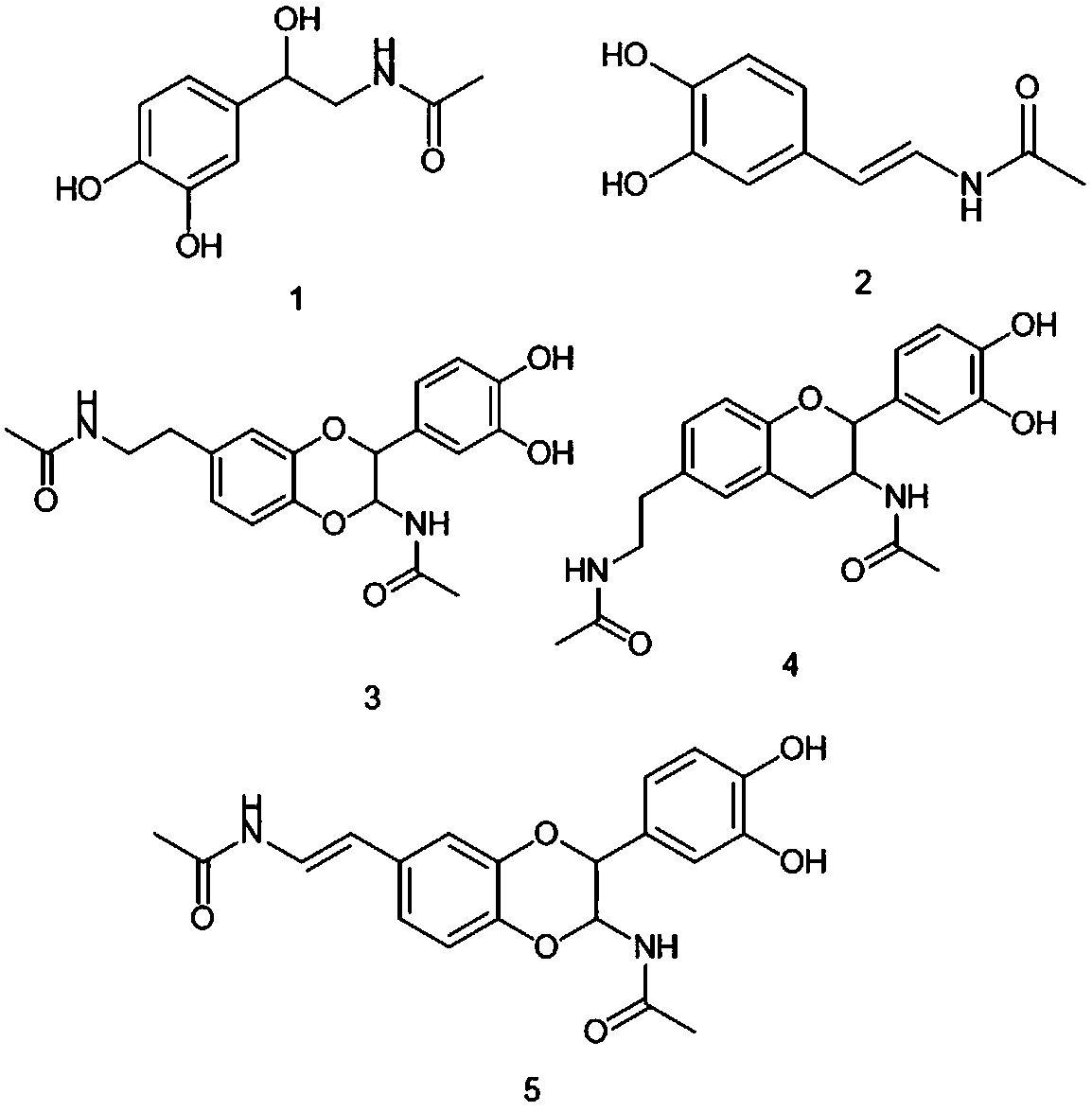

Separation method for simultaneously preparing five dopamine compounds from aspongopus

ActiveCN110818585AA large amountFully exploreCarboxylic acid amide separation/purificationAgainst vector-borne diseasesMedicinal herbsChromatographic separation

The invention discloses a separation method for simultaneously preparing five dopamine compounds from aspongopus, and belongs to the technical field of separation and purification of compound monomers. According to the method, dried aspongopus is used as a raw material, and the five dopamine compound monomers are obtained at the same time through the steps of ethanol extraction, vacuum concentration, step-by-step extraction, silica gel column enrichment and elution, efficient preparative liquid chromatography separation and product recovery; a foundation is laid for deeply researching the medicinal value of the aspongopus medicinal material and the synthesis and development of a new drug, and meanwhile, the development and utilization of traditional aspongopus resources are also facilitated.

Owner:ZUNYI MEDICAL UNIVERSITY

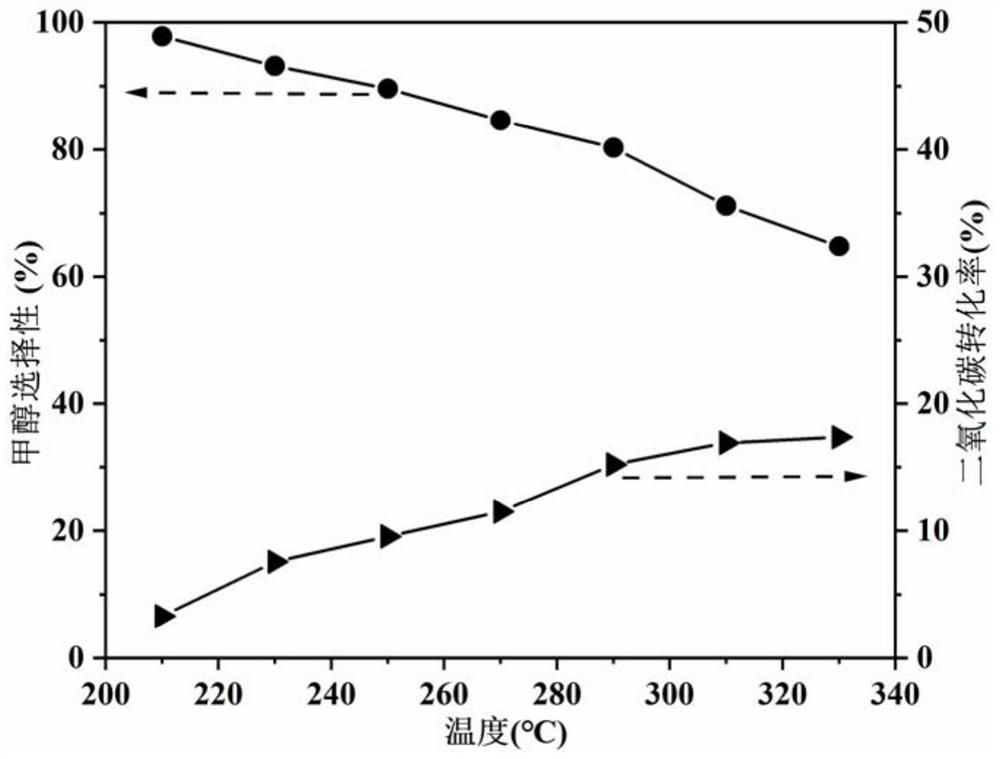

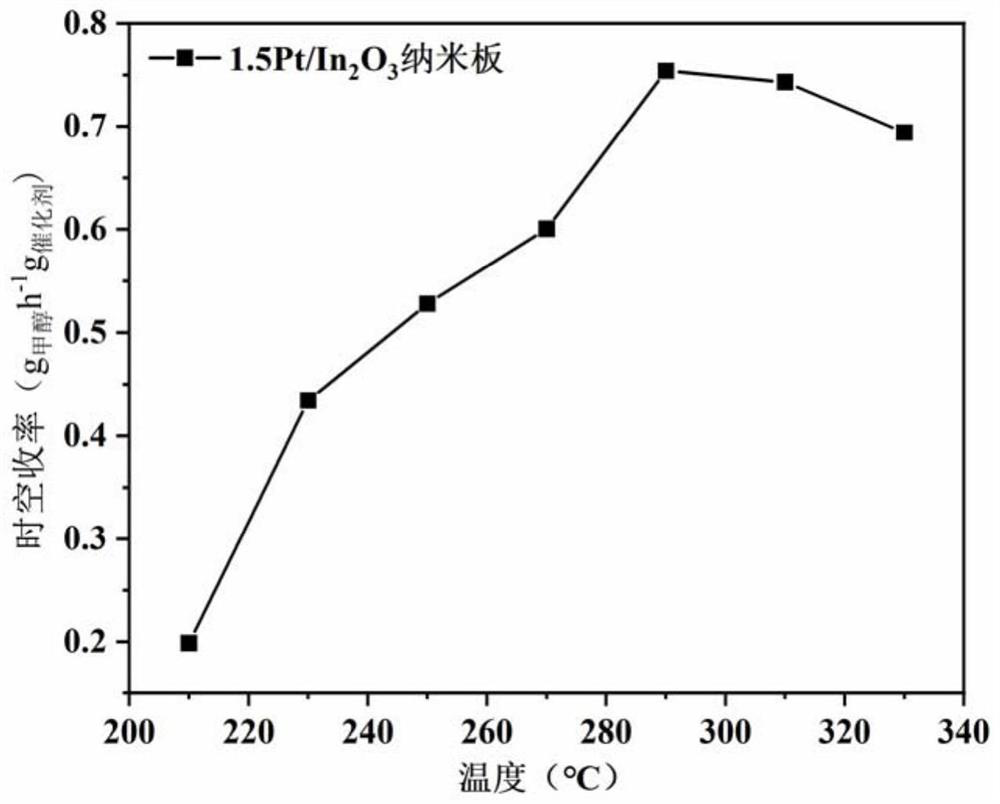

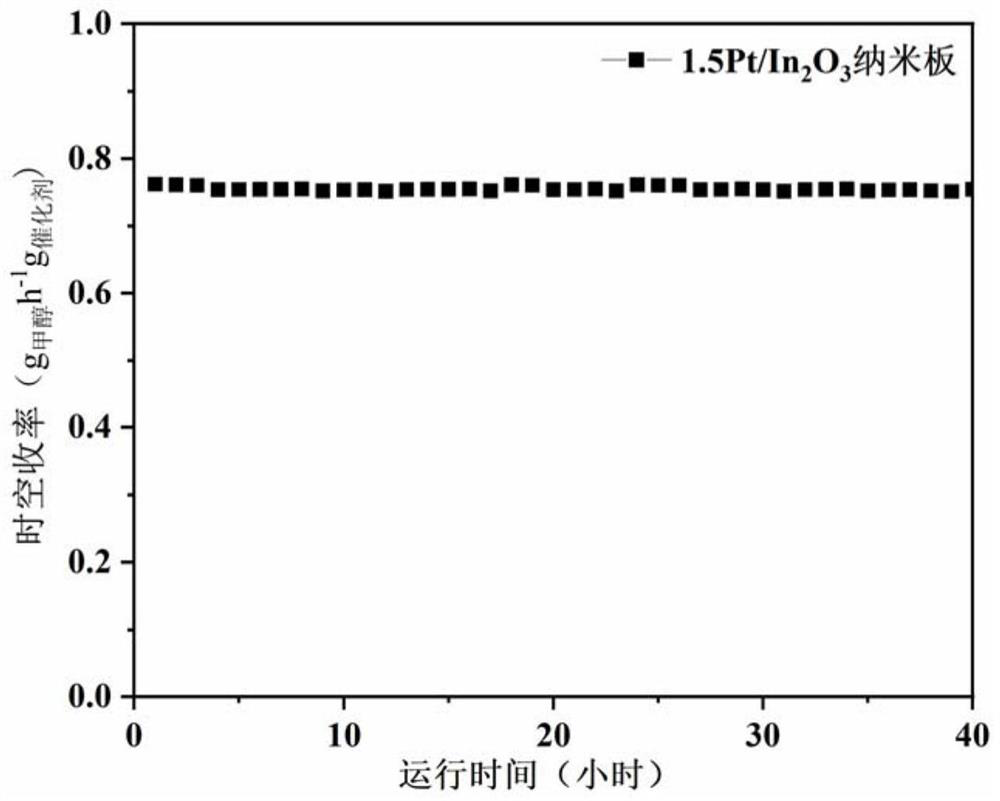

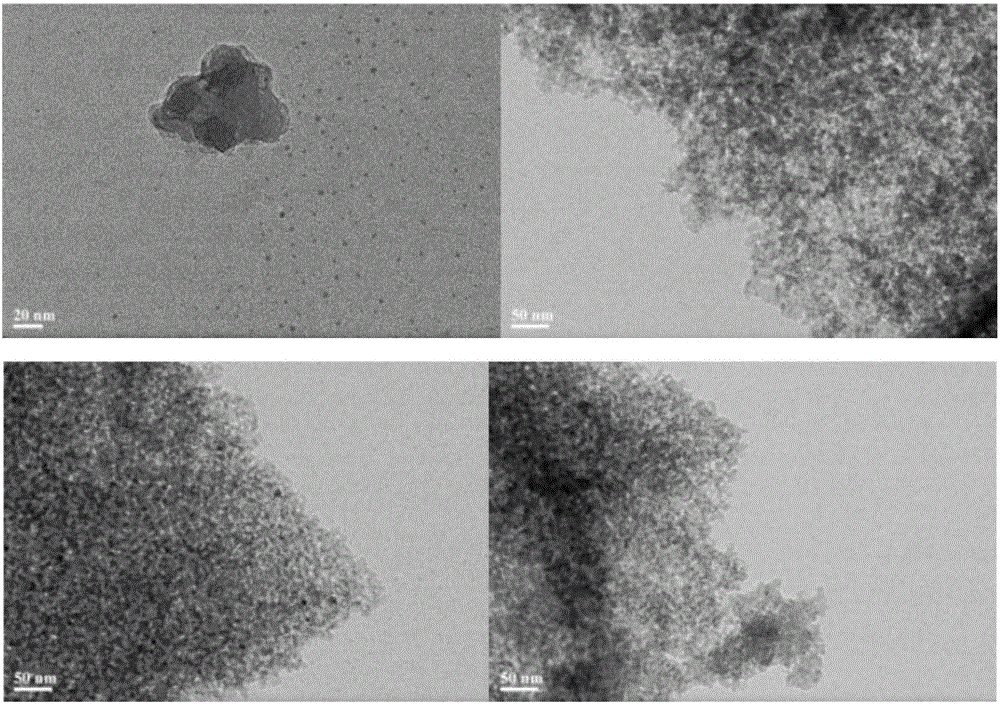

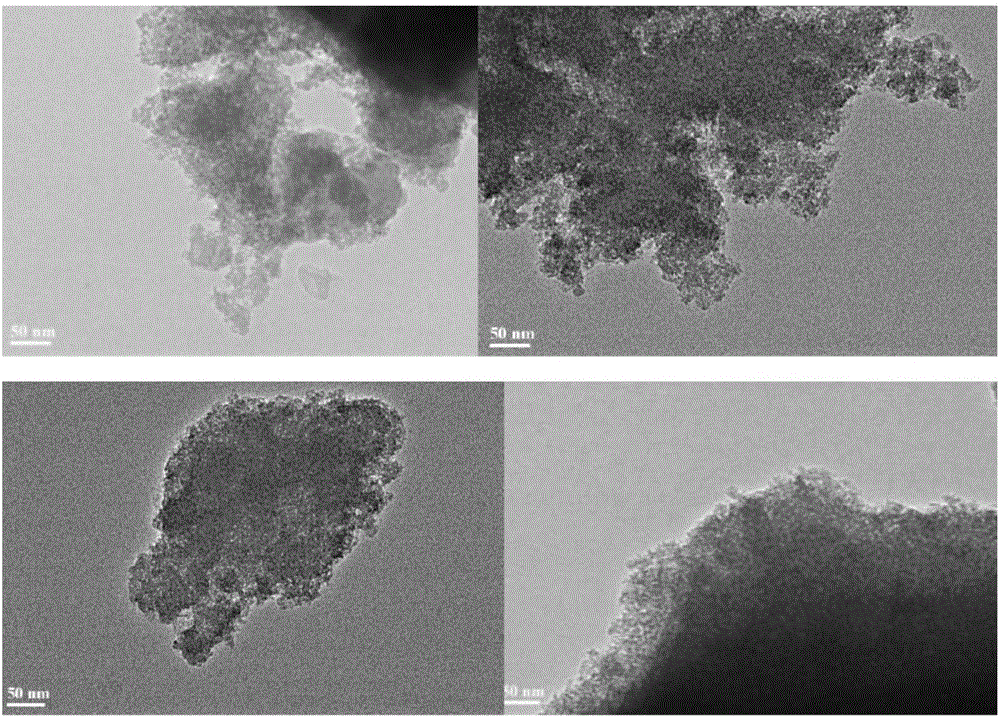

Platinum-modified indium-based oxide catalyst as well as preparation method and application thereof

ActiveCN114405505AImprove stabilityHigh catalytic activityOrganic compound preparationHydroxy compound preparationPlatinumPtru catalyst

The invention relates to a platinum-modified indium-based oxide catalyst as well as a preparation method and application thereof. The catalyst mainly comprises a noble metal active component Pt and an oxide carrier In2O3. The Pt / In2O3 composite catalyst is adopted, the activity of the carbon dioxide hydrogenation reaction is improved, and the carbon dioxide conversion rate larger than 15% and the methanol selectivity larger than 80% can be achieved when the catalyst is applied to the reaction for synthesizing methanol through carbon dioxide hydrogenation under high pressure. The method has the characteristics of simple process route, high selectivity, high conversion rate and high yield, the reaction conditions are mild, the raw materials are easy to obtain, and the method has a good application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

Efficient preparation method of mesoporous silica particles with efficient blood coagulation function

The invention discloses an efficient preparation method of mesoporous silica particles with an efficient blood coagulation function. The method comprises the following steps of (1) dissolving tetraethylortho silicate into a hydrochloric acid water solution or an ammonia-water solution and carrying out solating and gelation on the solution to form wet gel; (b) adding the wet gel and a forming agent to a granulator to obtain blank particles; and (c) drying the blank particles to obtain the mesoporous silica particles. According to the method, the raw material cost is greatly reduced, the polluting dust is eliminated, a gel drying stage is not needed, the preparation cycle of a product is obviously shortened, and the time cost is reduced while the utilization rate of equipment is improved.

Owner:苏州佰济生物科技有限公司

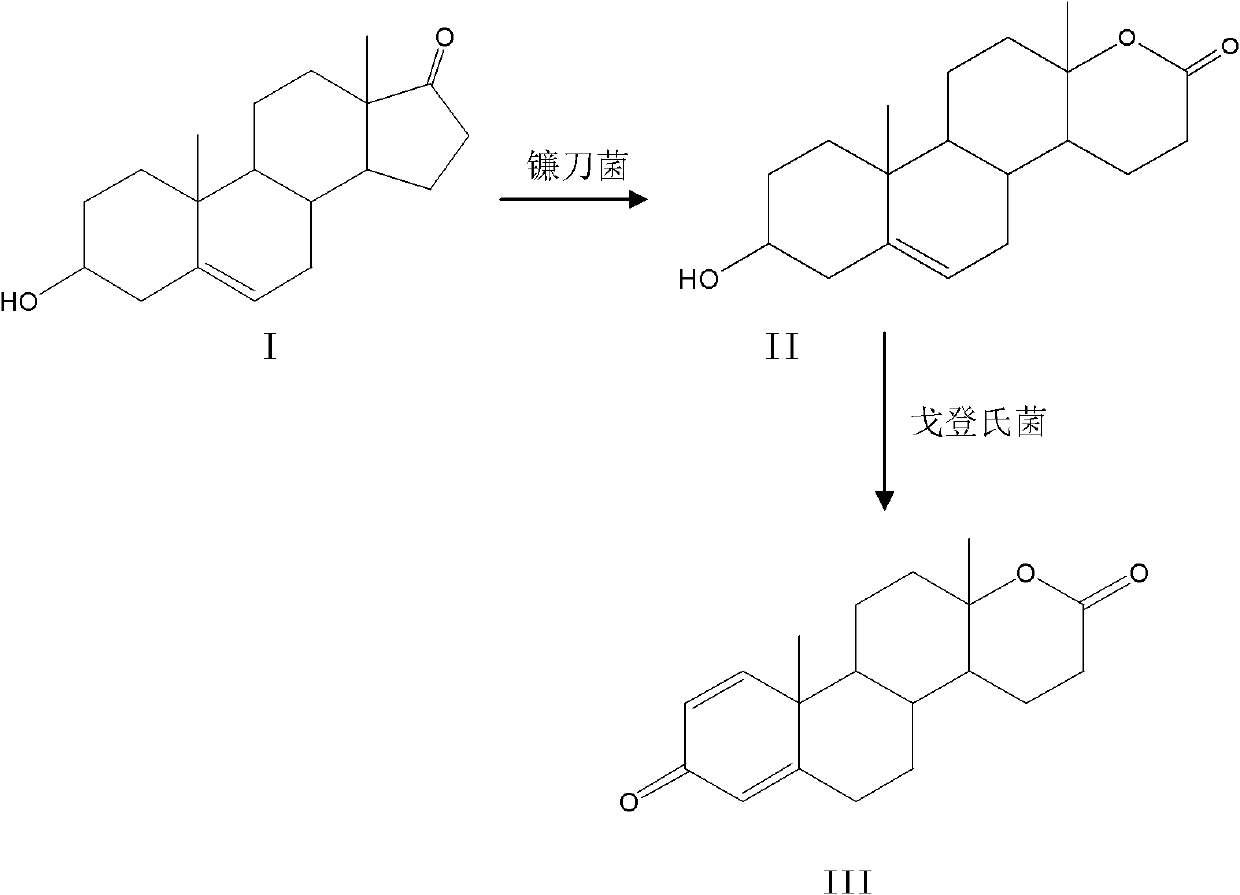

Method for preparing testolactone by microbial transformation

InactiveCN102703560ALow priceOptimize the process routeMicroorganism based processesFermentationMicroorganismBaeyer–Villiger oxidation

The invention discloses a method for preparing testolactone by microbial transformation, which mainly comprises the following steps: dissolving dehydroepiandrosterone in a solubilizer, adding the mixture in a transformation solution to prepare a transformation substrate solution; adding the transformation substrate solution into a transformation reaction device, adding fusarium oxysporum, transforming to obtain an intermediate of 3beta-hydroxy-17alpha-oxo-D-hexocyclo-androst-5-ene-17-ketone under the fusarium oxysporum resting cell transformation action through a Baeyer-Villiger oxidation reaction, adding gordonia after the transformation reaction is completed, performing a transformation reaction of the intermediate under the gordonia resting cell action to obtain testolactone. The method for preparing testolactone of the invention has the advantages of simple process route, easily available raw materials, cheap auxiliary materials, high substrate transformation rate, few by products, low production cost, and the like, overcomes the deficiencies of original production technology, and is suitable for industrial production.

Owner:SICHUAN NORMAL UNIVERSITY

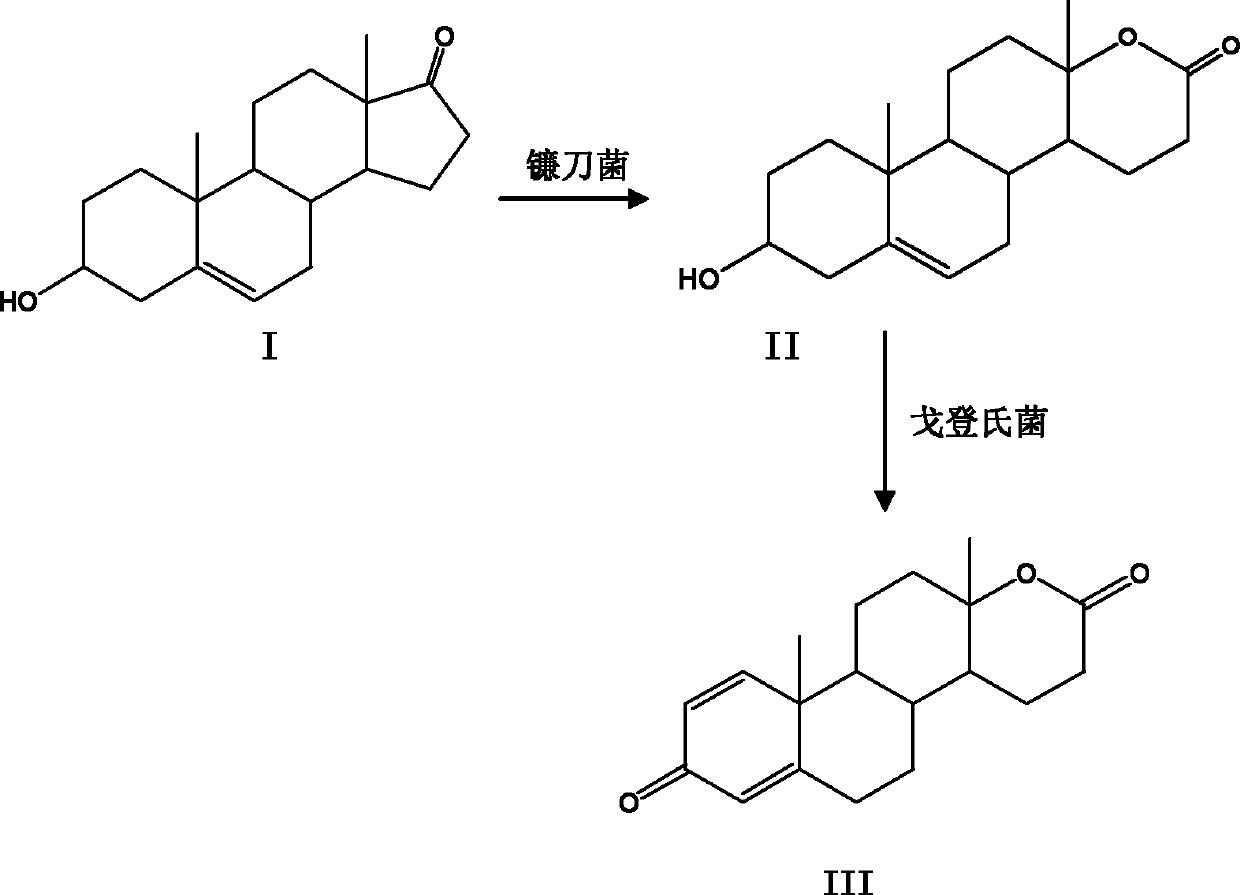

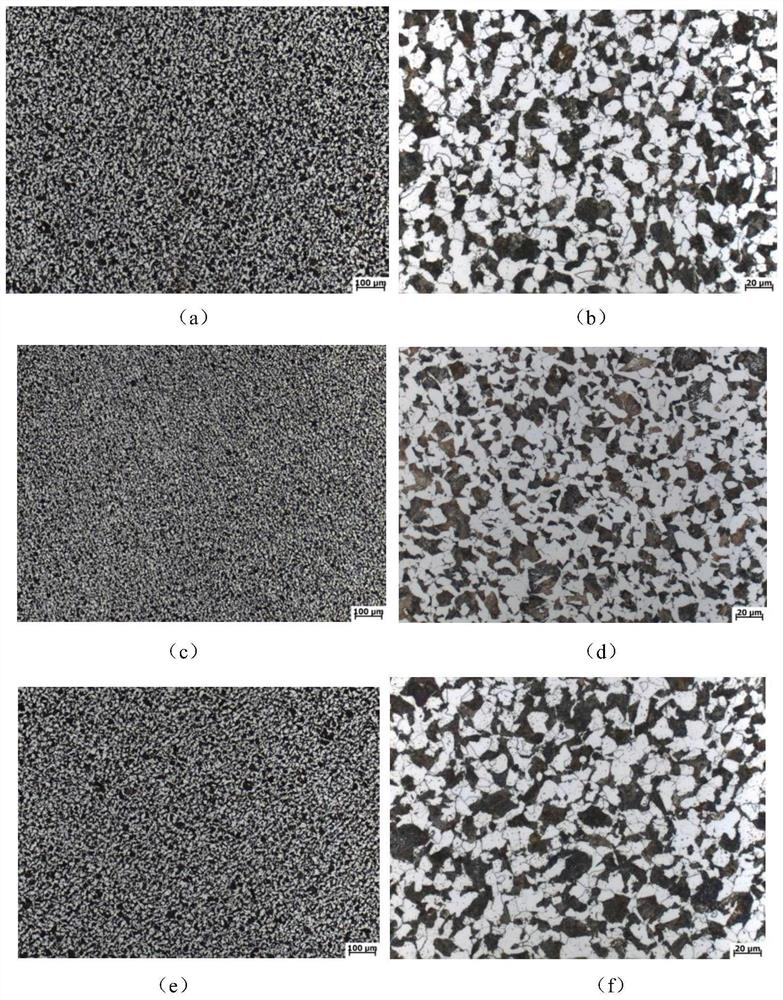

Application process of Ti microalloying in 400MPa-grade steel bar production

Owner:JIANGSU YONGGANG GROUP CO LTD

Soybean-source anti-oxidative peptide nano-liposome and preparation method thereof

ActiveCN104940139ALow costOptimize the process routePeptide/protein ingredientsAntinoxious agentsFreeze-dryingLiposome

The invention belongs to the technical field of agricultural product processing, in particular to a soybean-source anti-oxidative peptide nano-liposome and a preparation method thereof. The preparation method comprises the steps of mixing, ultrasonic processing, low-pressure evaporation, vacuum evaporation, re-ultrasonic processing, adding of a freeze-drying protective additive, and freeze drying under the conditions that 3-10 kDa soybean anti-oxidative peptide is taken as a raw material, and the encapsulation efficiency, grain size and electric potential are taken as quality test indicators. The preparation method integrates a reverse evaporating method, an ultrasonic method and a freeze-drying method, and has the advantage that liposome, of which the encapsulation efficiency is 45.43% or higher, the grain size reaches 531.2 mm or lower, and the electric potential reaches -19.8 mV or lower, is obtained finally. The soybean-source anti-oxidative peptide nano-liposome and the preparation method have the advantages that the raw material cost is lower; the designed process route is simple and convenient; the method is creative; a novel way is provided for comprehensive utilization of soybean-source anti-oxidative peptide.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com