Technology for desalting and recycling salt-contained industrial wastewater containing calcium and magnesium and sulfate ions

A technology of sulfate ions, calcium and magnesium ions, applied in general water supply conservation, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of limited ion exchange resin capacity, calcium sulfate scaling, and high operating costs. Improve operation stability and water production rate, save operating costs, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

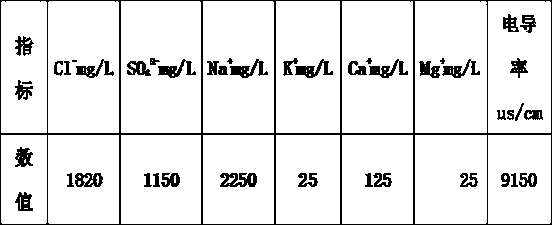

[0026] The main ion analysis of saline wastewater from a coking plant is shown in Table 1. The concentration of calcium, magnesium and sulfate ions is high. Conventional ultrafiltration and reverse osmosis are used for treatment. The water rate dropped severely, and the reverse osmosis membrane module was disassembled to find that the membrane was seriously scaled. It was difficult to remove the scale by cleaning with hydrochloric acid solution, which was analyzed as calcium sulfate scale.

Embodiment 2

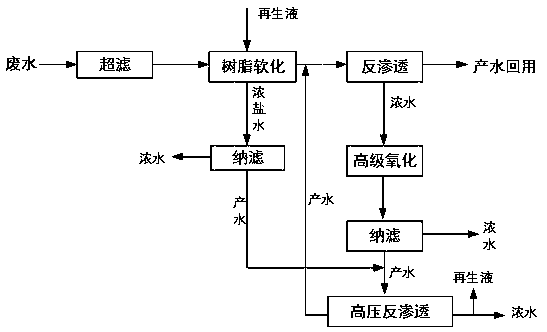

[0028] After transforming the desalination and recycling process of Example 1, the water quality analysis is the same as in Example 1. The waste water first enters the ultrafiltration unit to remove most of the colloids, suspended solids, and some macromolecular organic matter, and the ultrafiltration water enters the cation exchange resin to soften and soften. The calcium and magnesium ions in the effluent are controlled below 5 mg / L. When the calcium and magnesium ions in the effluent exceed the control indicators, high-pressure reverse osmosis is used to generate concentrated brine rich in sodium chloride for regeneration, and most of the calcium and magnesium ions in the wastewater are transferred to In the regeneration waste liquid; the resin softened effluent is mixed with high-pressure reverse osmosis water and then enters a reverse osmosis system. The reverse osmosis water production rate reaches more than 80%. Reuse. Due to the high content of concentrated organic mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com