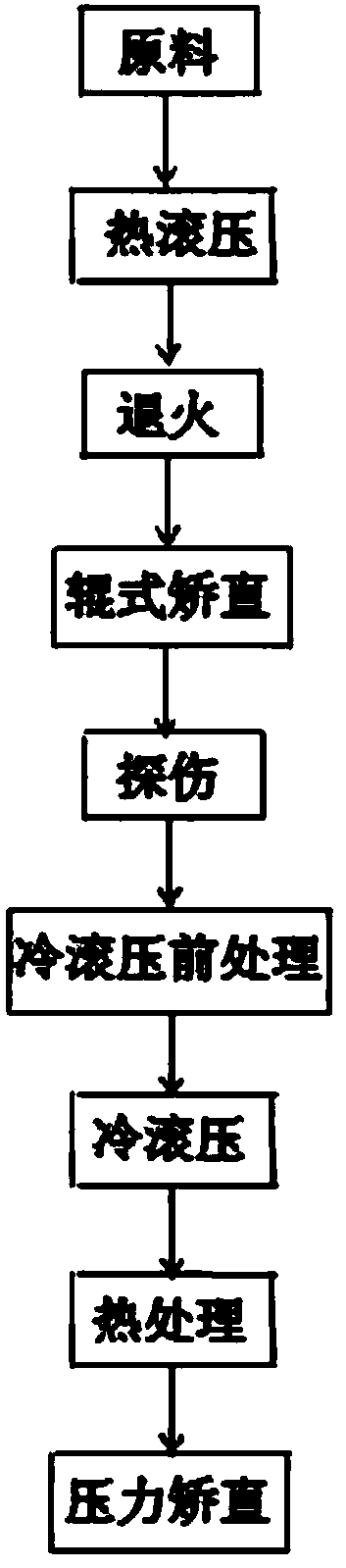

Special-shaped seamless steel pipe rolling manufacturing method

A technology of seamless steel pipe and manufacturing method, which is applied in the field of manufacturing seamless steel pipe products, can solve the problems of increased production cost, waste of resources such as manpower and material resources, and large development investment, and achieves a reduction in construction cost, high yield and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

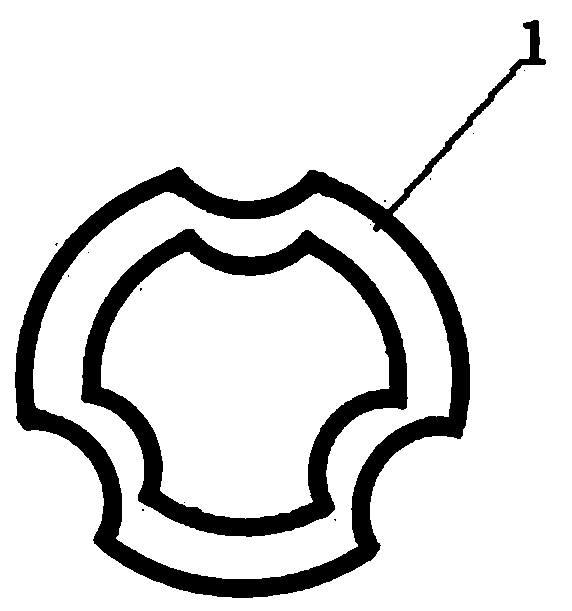

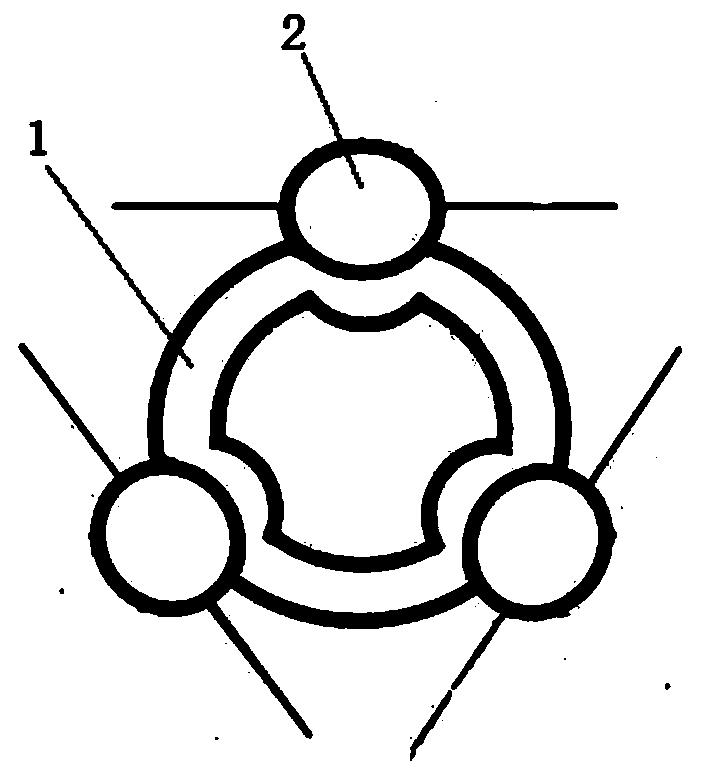

[0049] The present invention will be further elaborated below in conjunction with a specific embodiment of a three-lobed seamless steel pipe, but the present invention is not limited thereto. Other special-shaped seamless steel pipes 1: such as outer square inner circle, hexagonal, square, octagonal Shaped, semicircular, unequal hexagonal, melon-shaped special-shaped steel pipes, etc., only need to change the shape of the corresponding hot rolling die and cold rolling die.

[0050] Using the above manufacturing method, the production figure 1 The special-shaped seamless steel pipe 1 shown is specifically manufactured by the following steps:

[0051] In addition to the above-mentioned raw materials, the source of raw materials can also be special-shaped seamless pipes formed by welding and forming plate-shaped raw materials after rolling.

[0052] Hot rolling, the mandrel mold used has a margin for cold rolling, that is, the raw material tube is heated to 1200°C, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com