Grass braid fixed length traction cutoff device

A cutting device and fixed-length technology, applied in metal processing and other directions, can solve the problems of low production efficiency, non-uniform cutting length, and inability to ensure uniformity in shape, and achieve the effect of solving low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

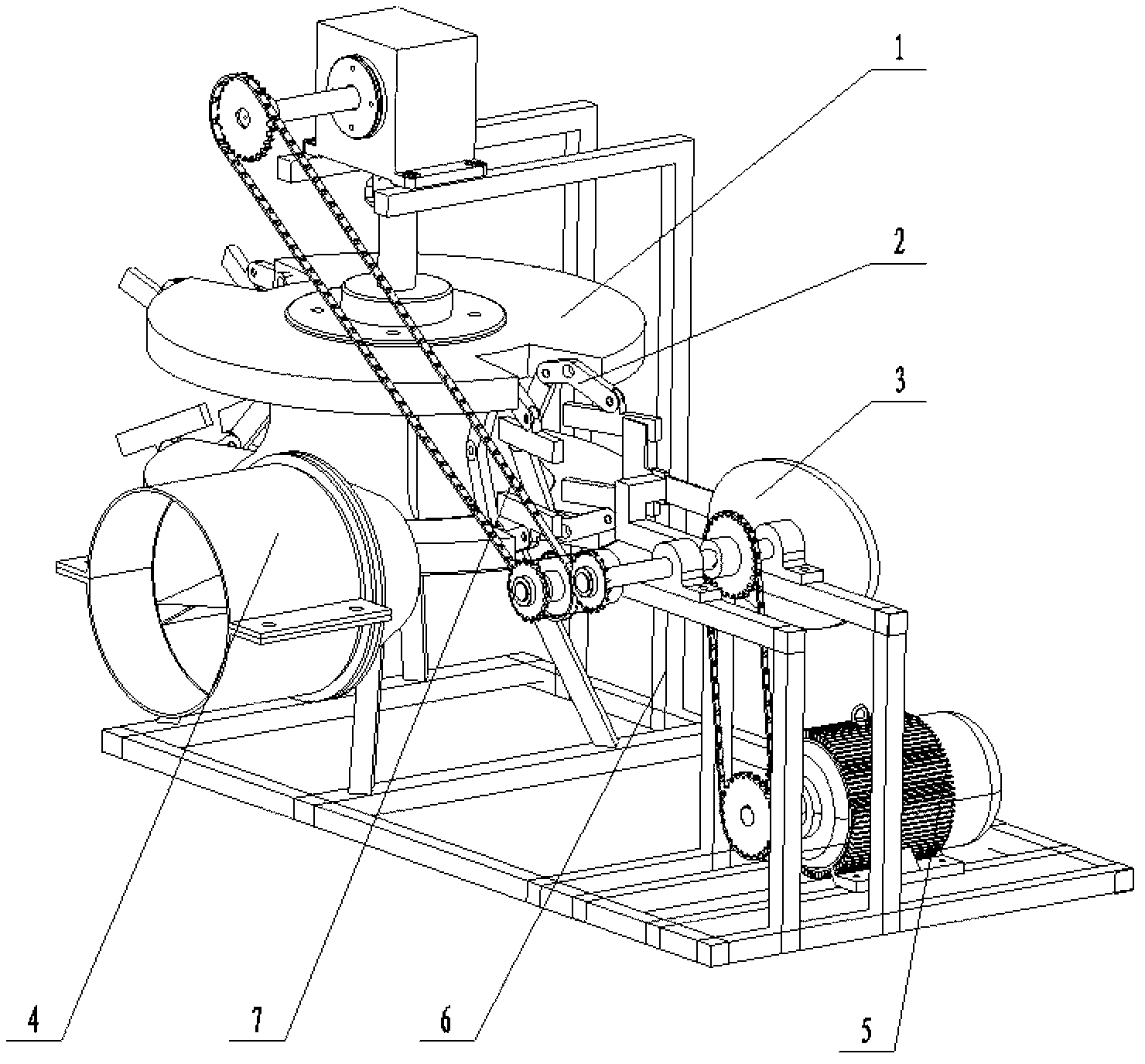

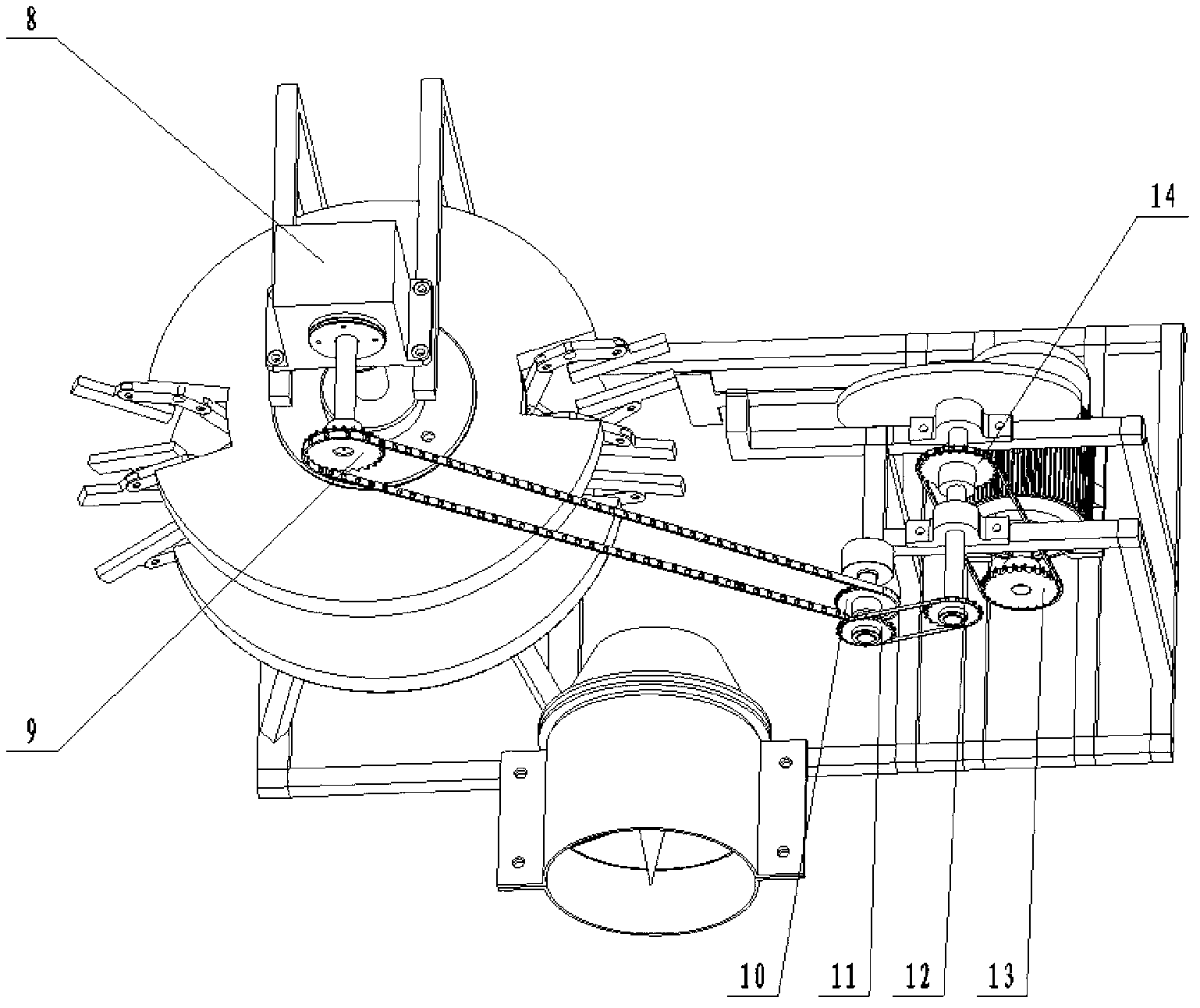

[0042] The fixed-length traction and cutting device for grass braids comprises a rotary disc mechanism 1, a clamping hand 2, a cutting mechanism 3, a transmission system 7, a motor 5, and a frame 6, and the clamping hand 2 is fixed on the upper rotary disc 22 and the lower rotary disc mechanism 1 of the rotary disc mechanism 1. On the rotating disk 23 , the irregular closed curve 21 of the fixed disk core 31 of the rotating disk mechanism 1 is in contact with the hinge point 30 of the two power clamps of the clamping hand 2 .

[0043] The irregular closed curve 21 of the fixed disk core 31 of the rotating disk mechanism 1 includes a large radius arc segment B and a small radius semicircle arc segment A.

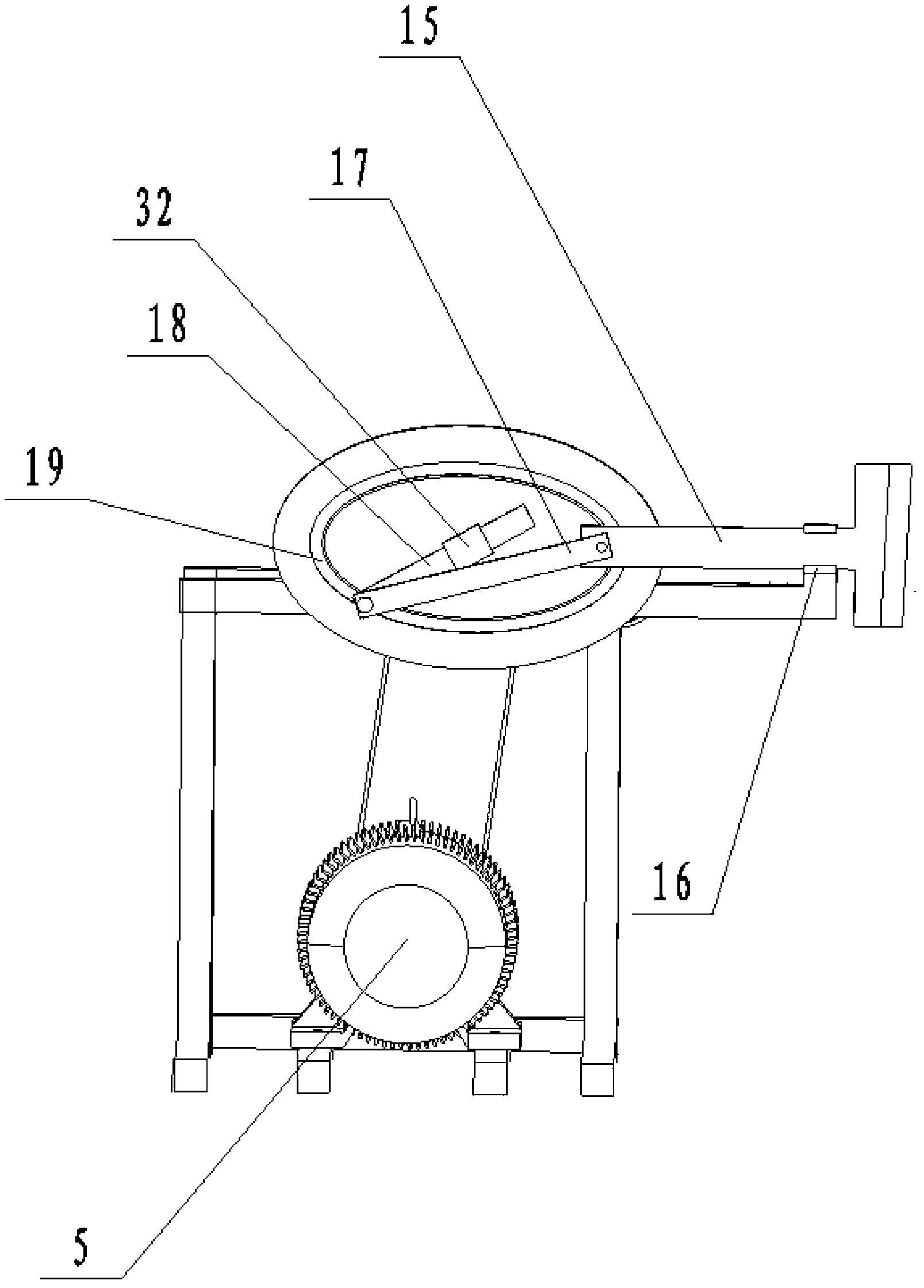

[0044] The cutting mechanism comprises a fixed elliptical disc 19, a cutter 15, a track arm 18, a movable arm 17, a cutter ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com