Patents

Literature

251results about How to "Guaranteed continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

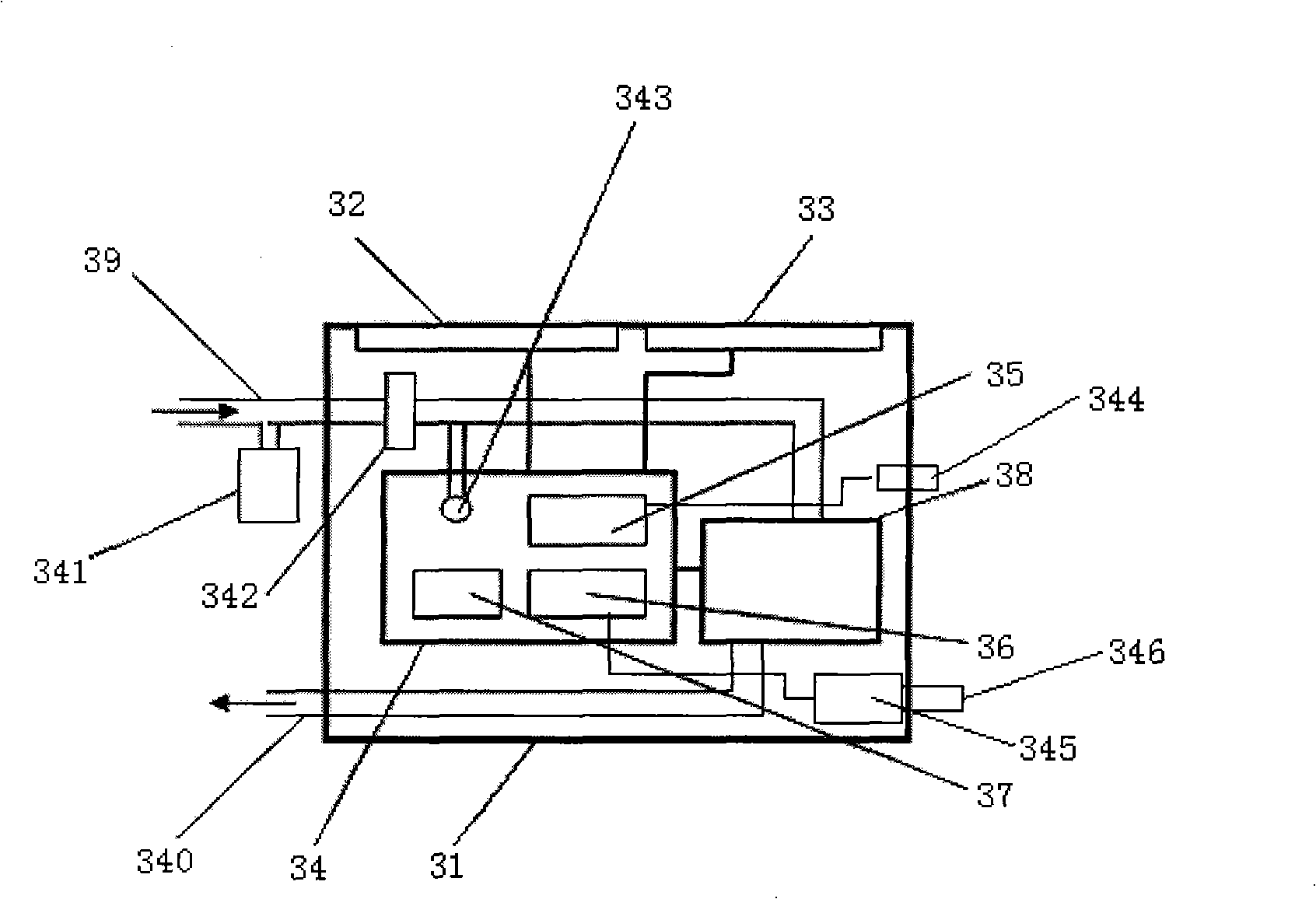

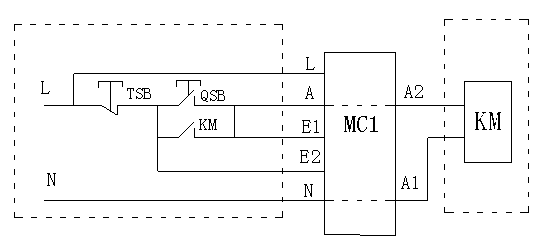

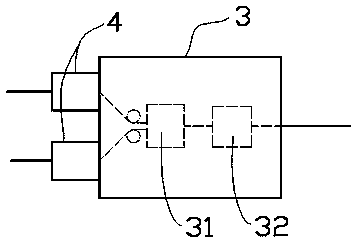

Intelligent control module for permanent magnet contactor

InactiveCN101477919AGuaranteed continuous operationEnsure safetyEmergency protective arrangements for automatic disconnectionRelaysContactorCapacitance

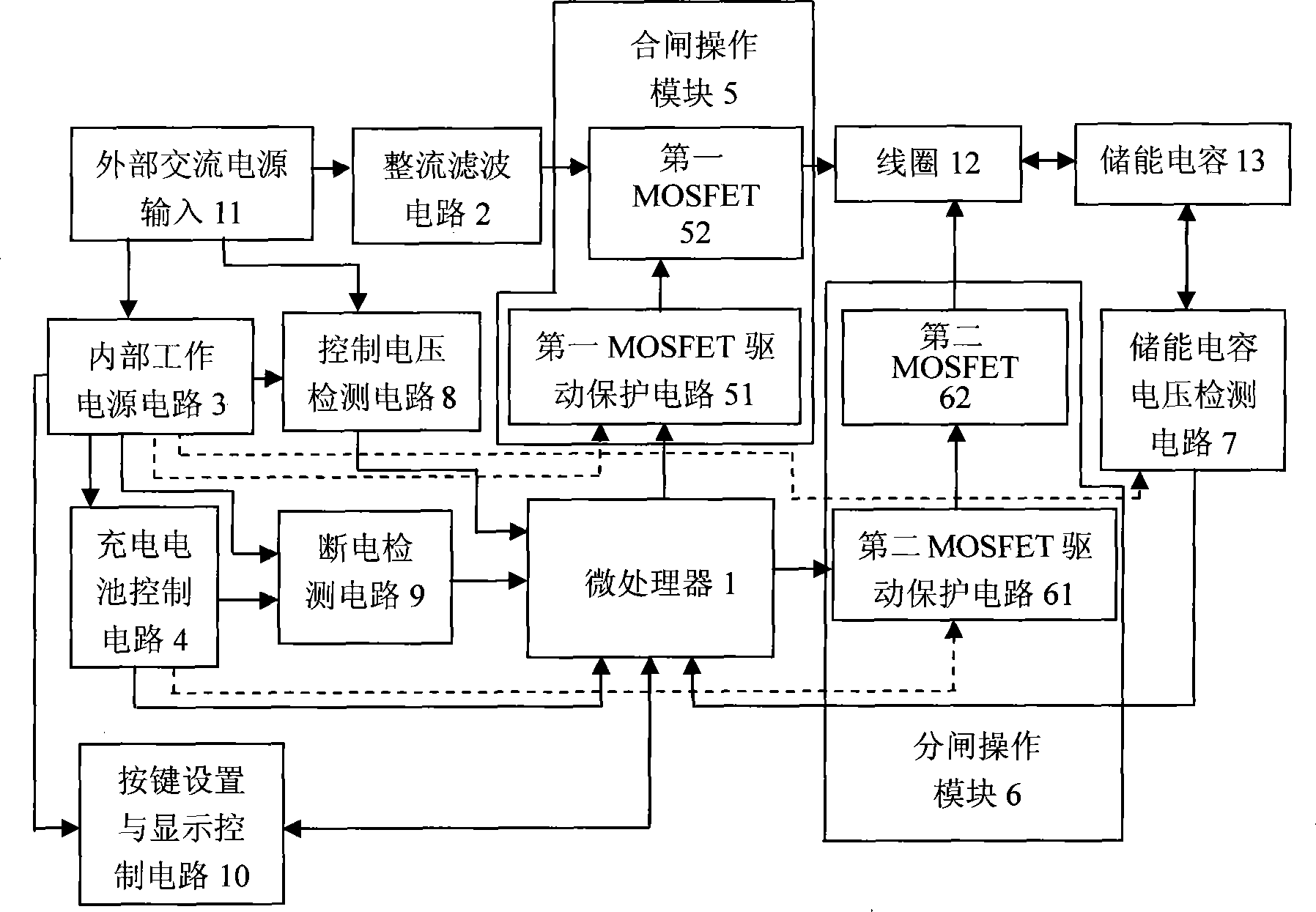

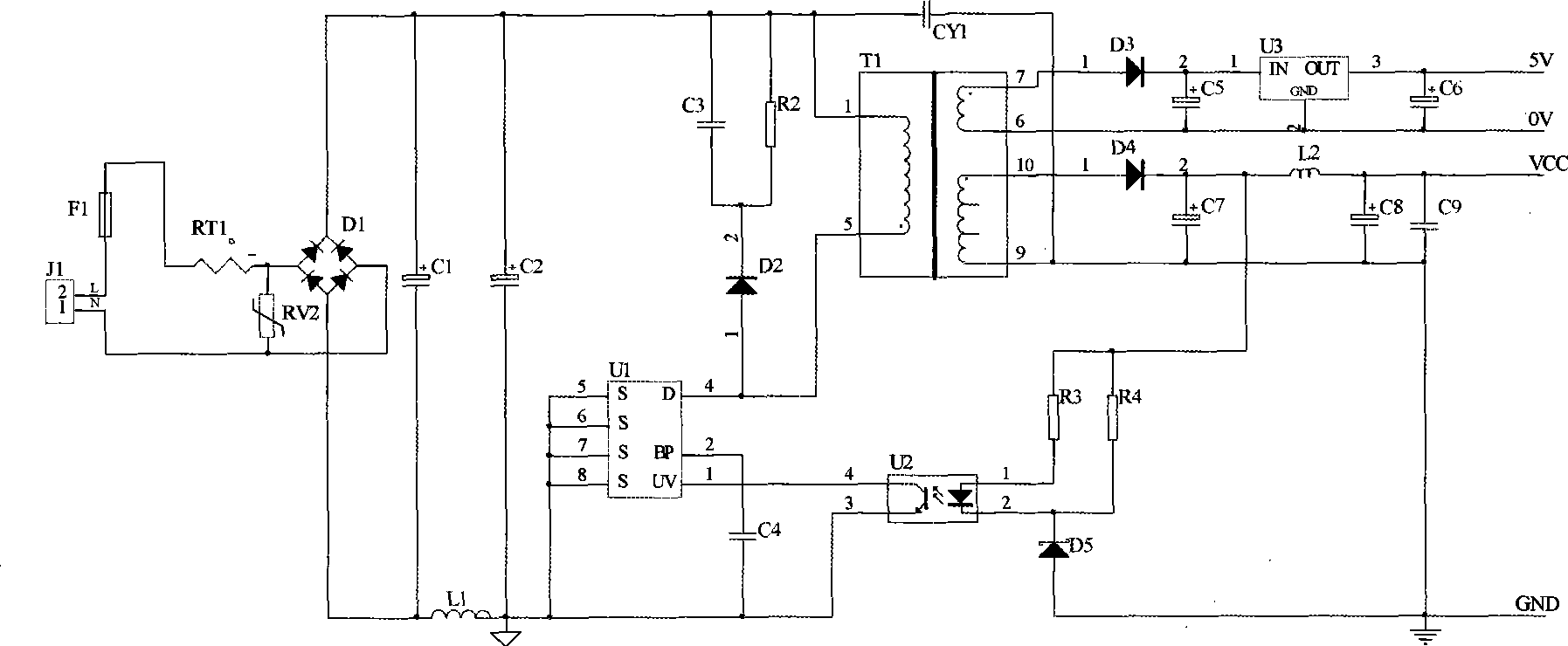

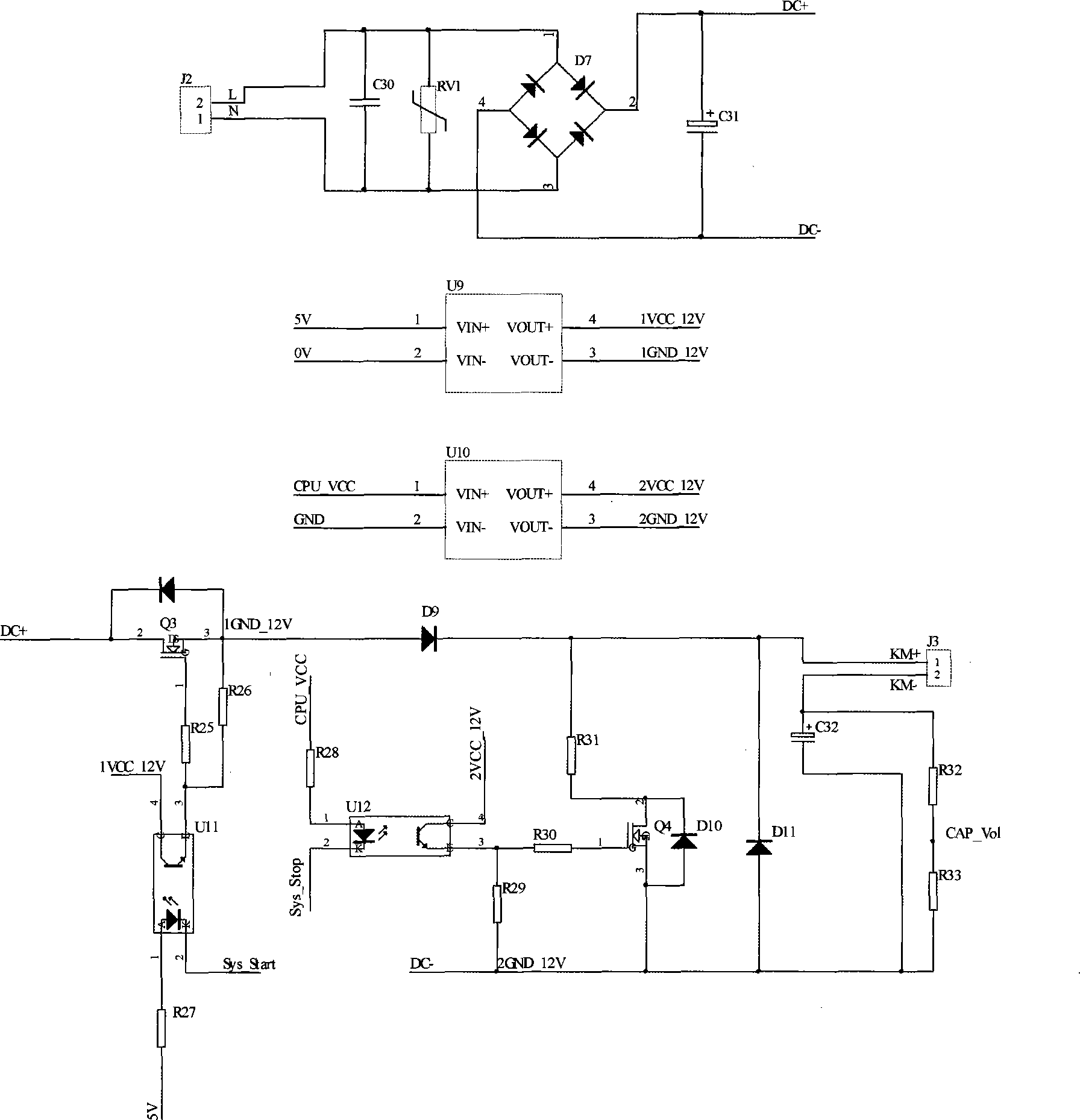

The invention discloses an intelligent control module of a permanent magnet contactor, which mainly comprises a microprocessor, a rectifier and filter, an internal working power circuit, a rechargeable battery control circuit, a closing operation module, an opening operation module, an energy-storage capacitor voltage detection circuit, a control voltage detection circuit, a power off detection circuit, and a key-press setting and display control circuit; wherein, the closing operation module consists of a first MOSFET driving protection circuit and a first MOSFET; and the opening operation module consists of a second MOSFET driving protection circuit and a second MOSFET. The intelligent control module can set delay time parameters of transient interference electricity through key-presses according to requirements of a customer, realizes delay disconnection of the permanent magnet contactor and can ensure the stable and continuous operation of equipment through staying away from influences of interference electricity; and as for conditions of requiring urgent opening operation, the intelligent control module can immediately cut off the contactor through key-press control, so as to ensure the safety of the operating equipment.

Owner:SOUTHEAST UNIV

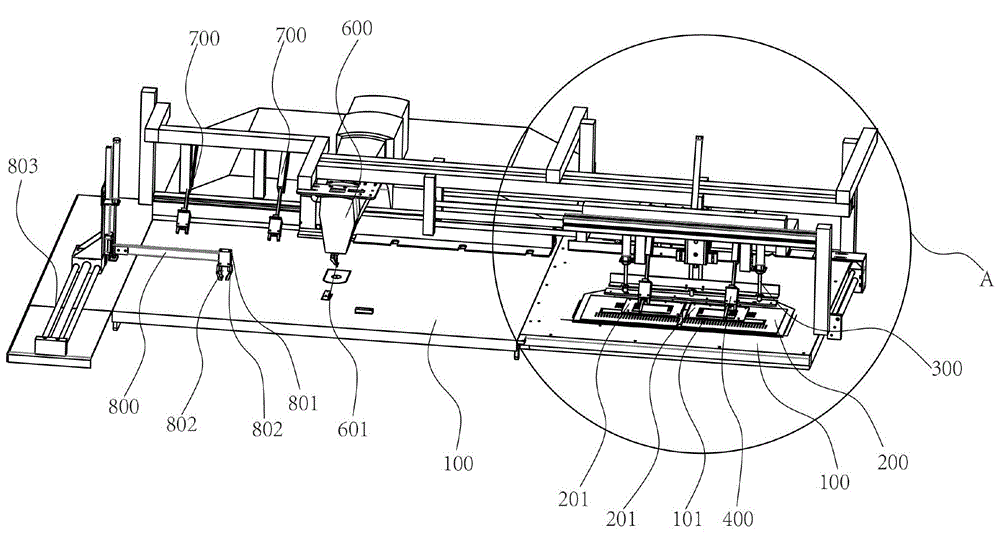

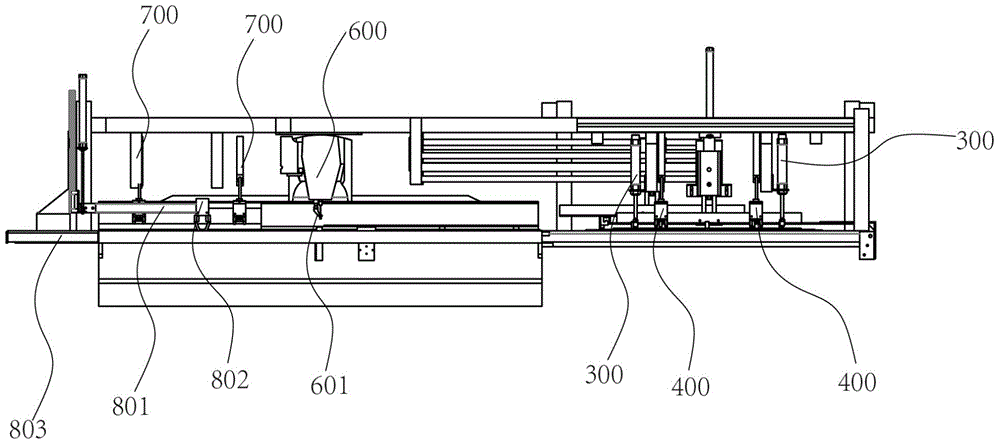

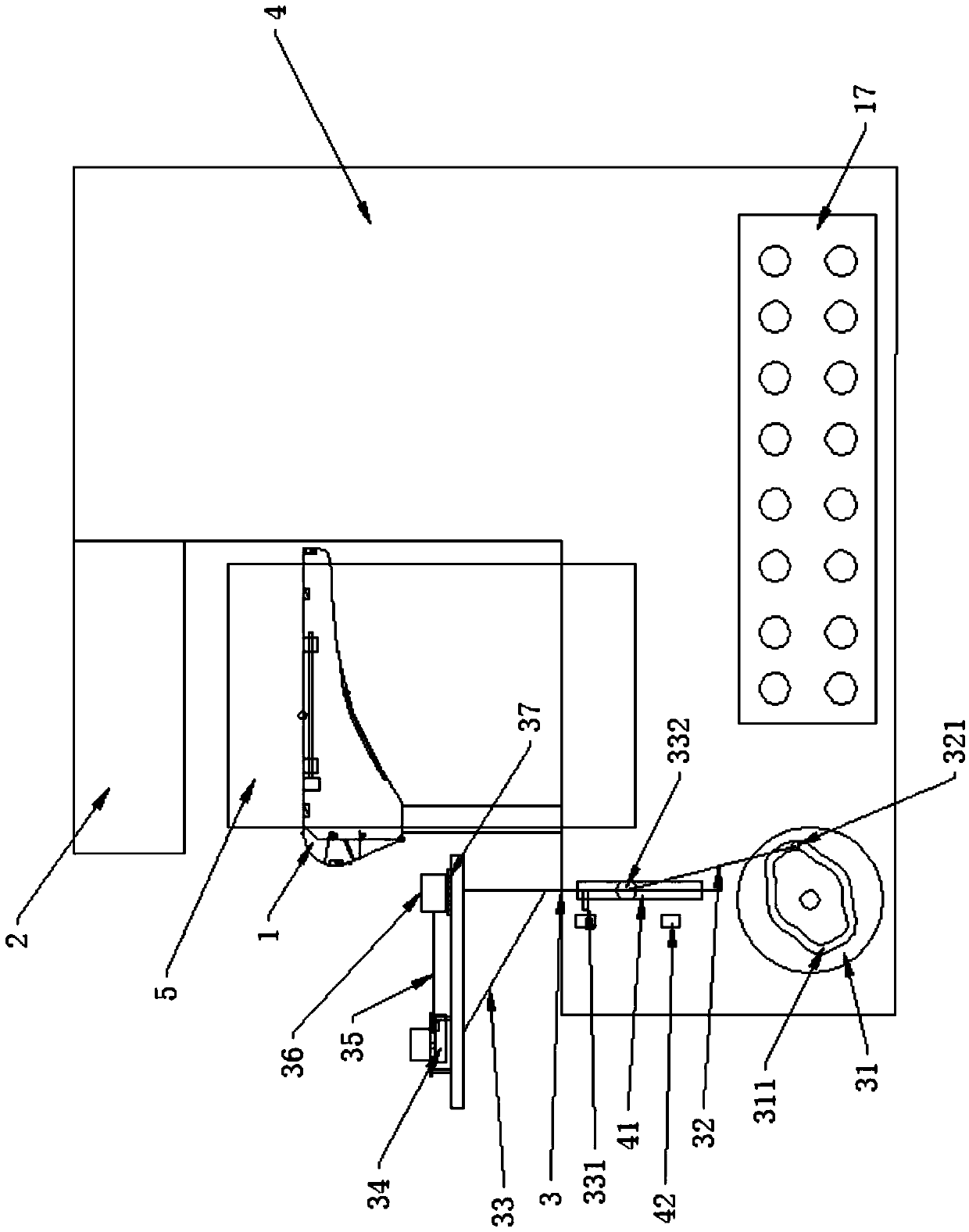

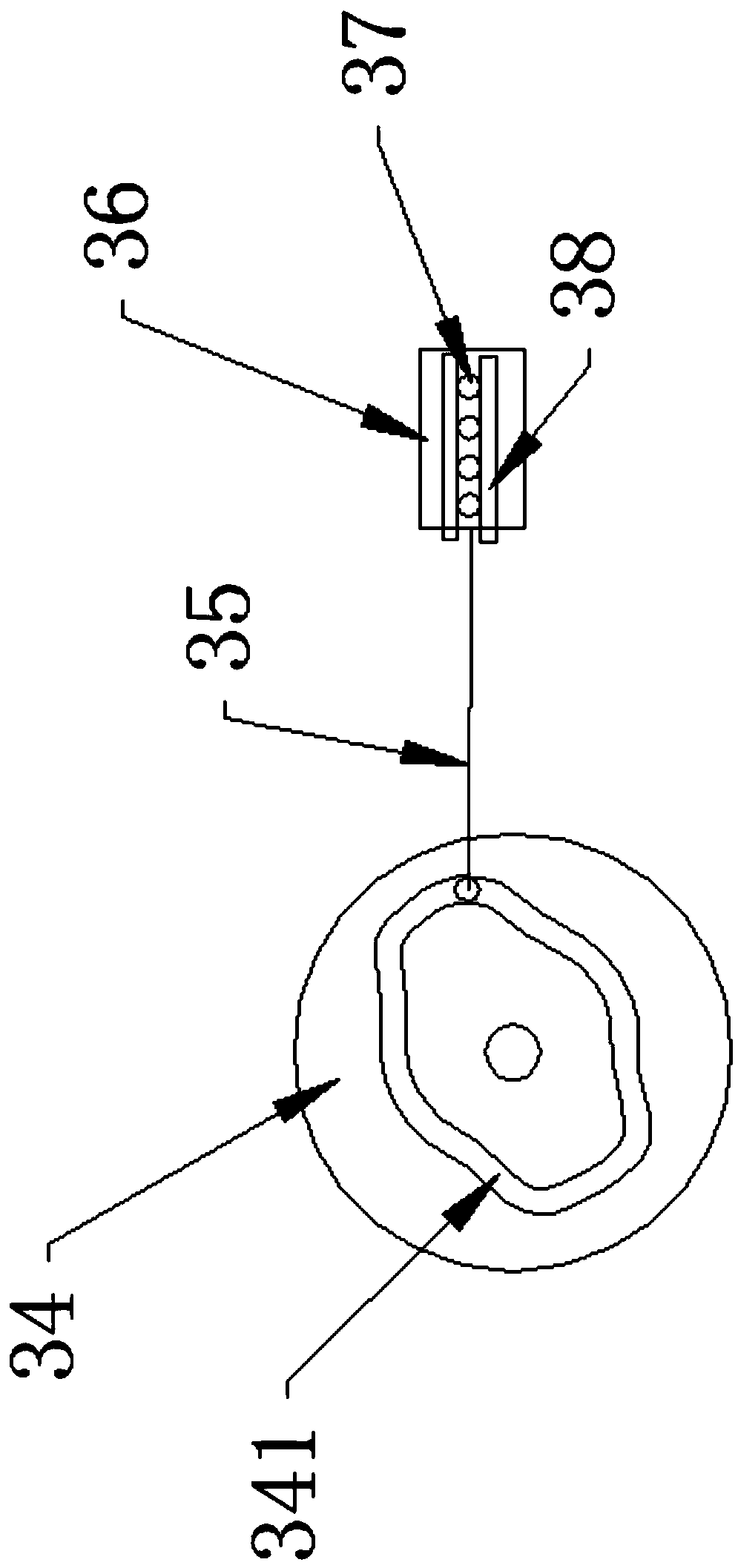

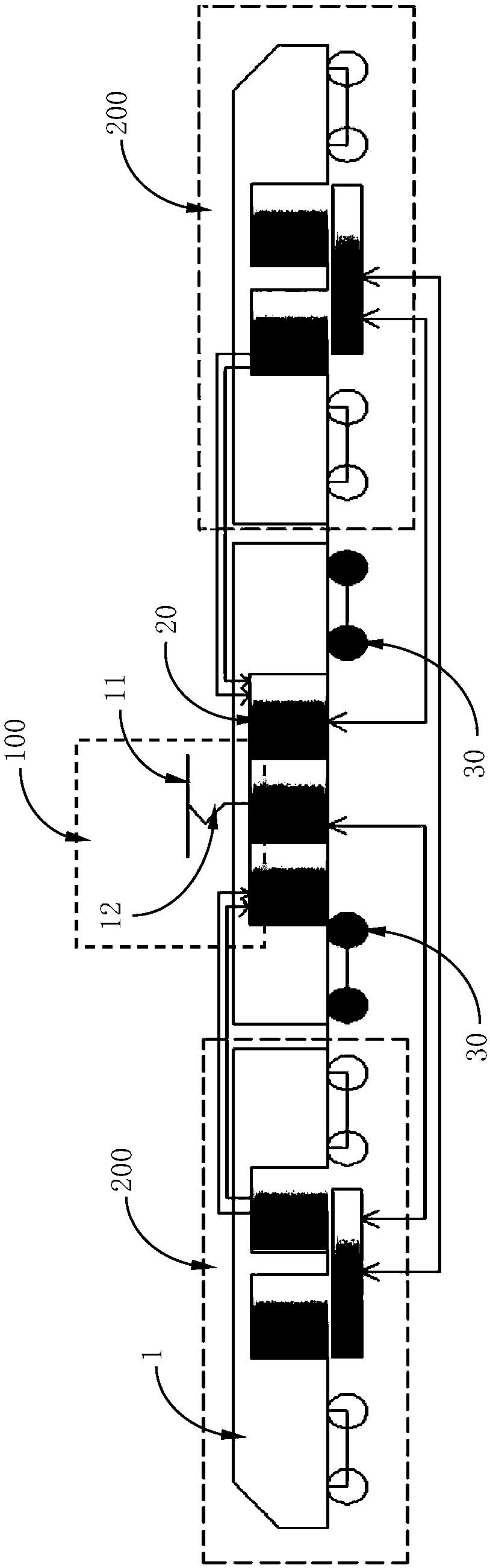

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

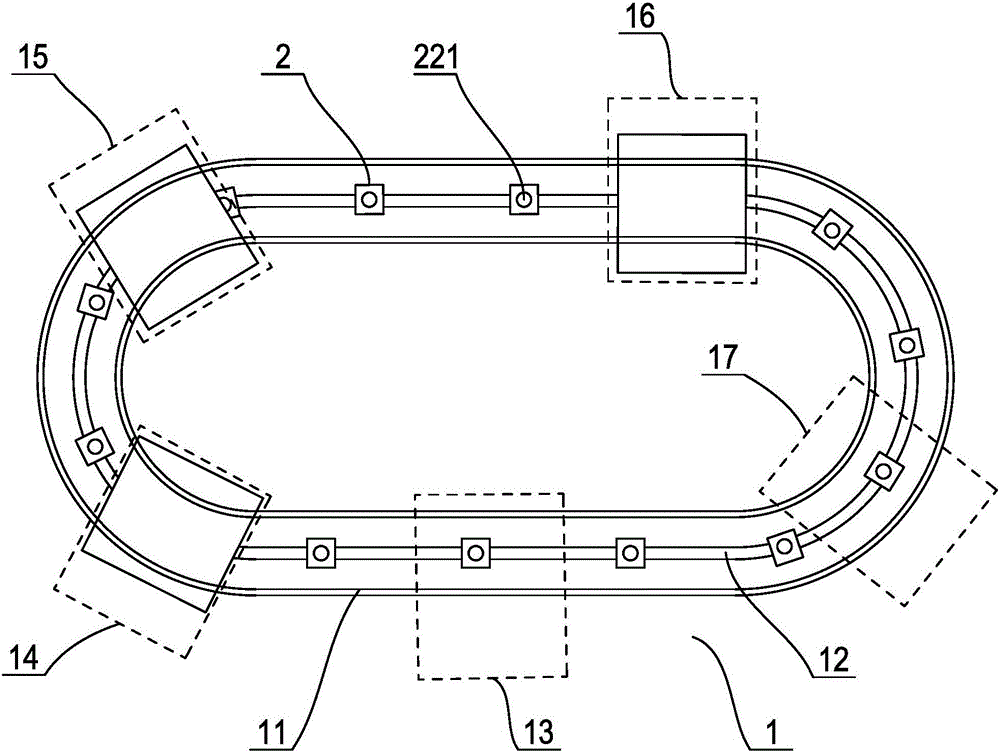

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

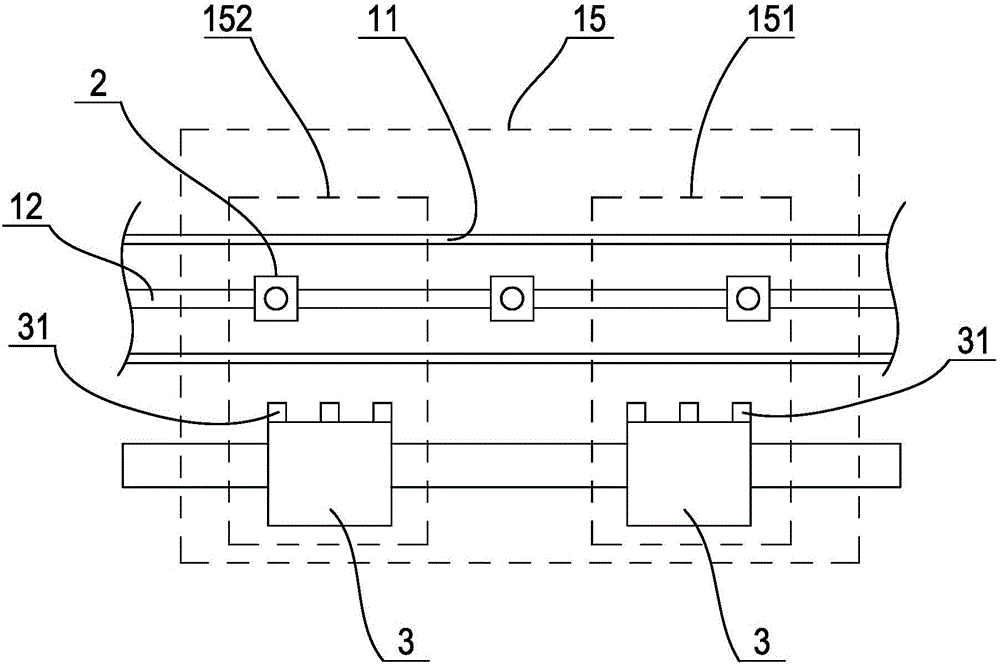

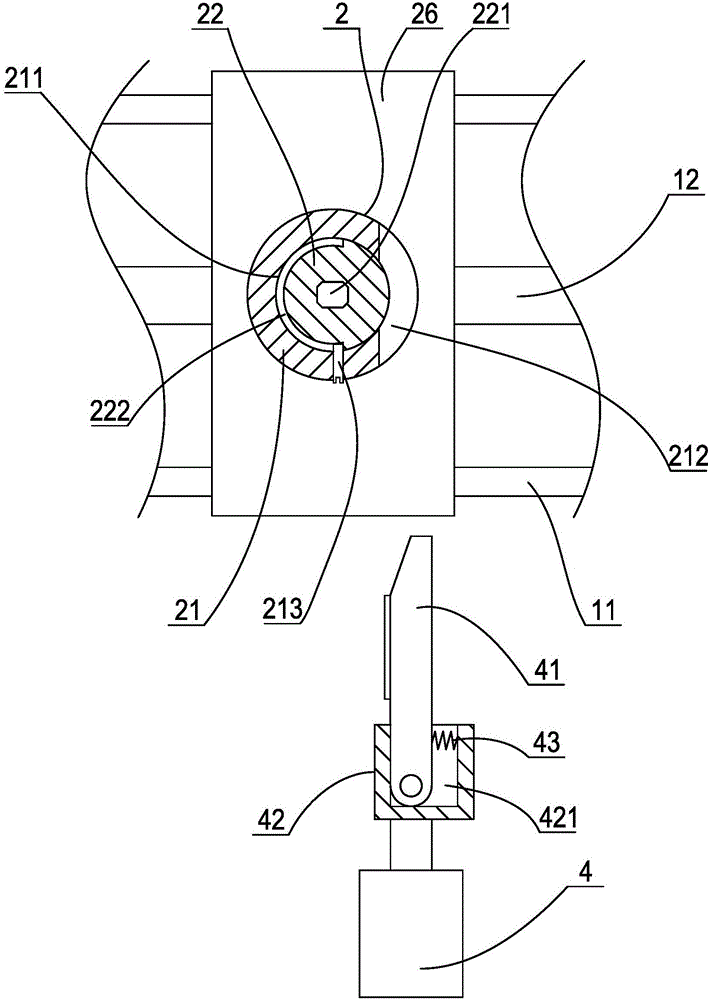

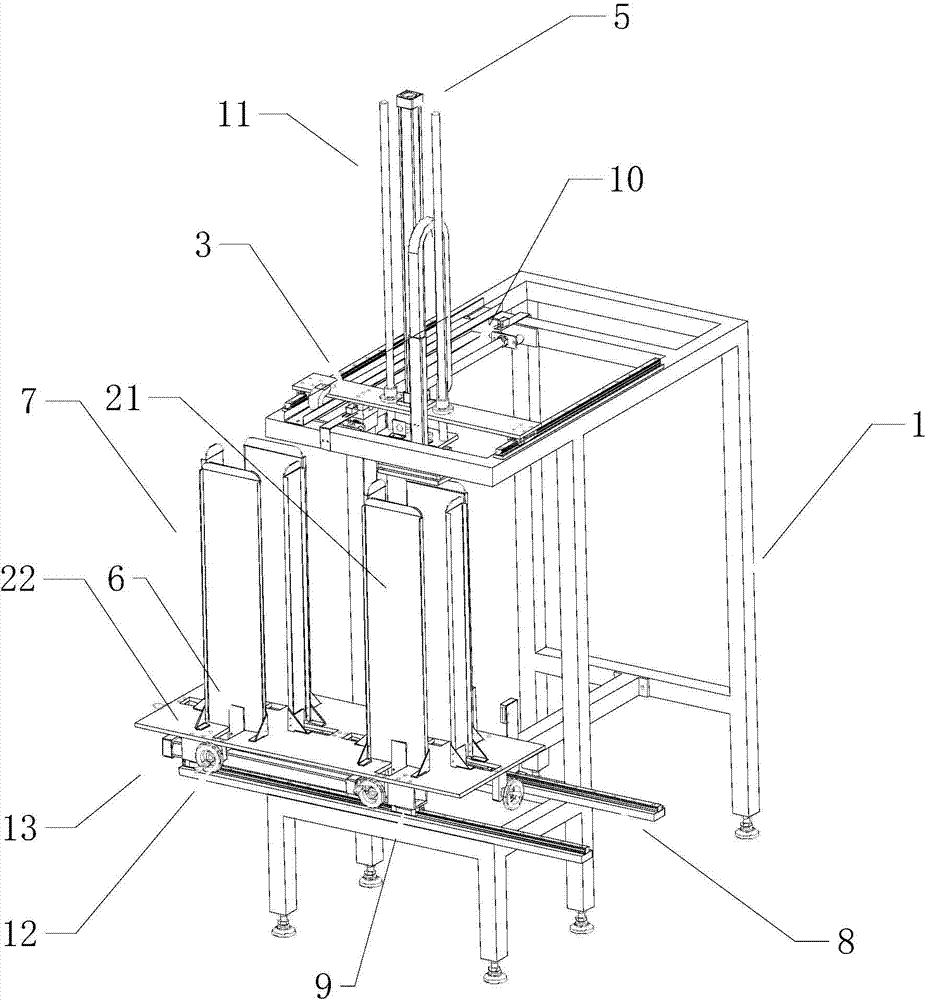

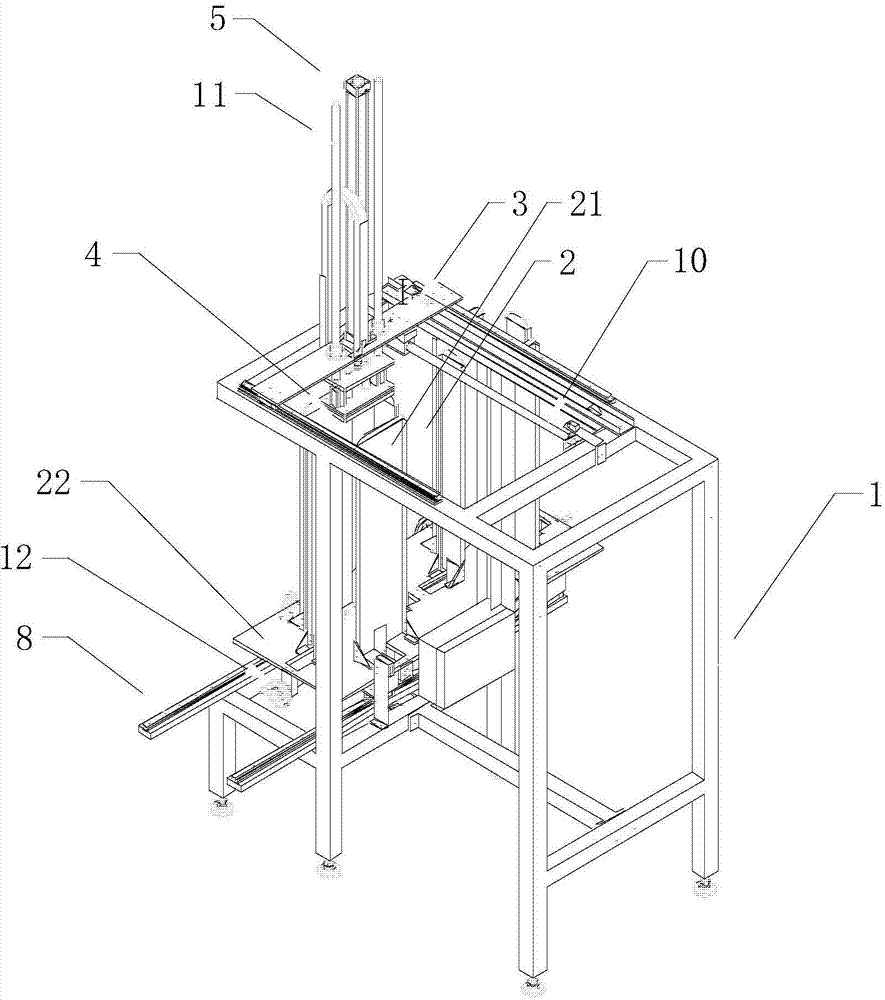

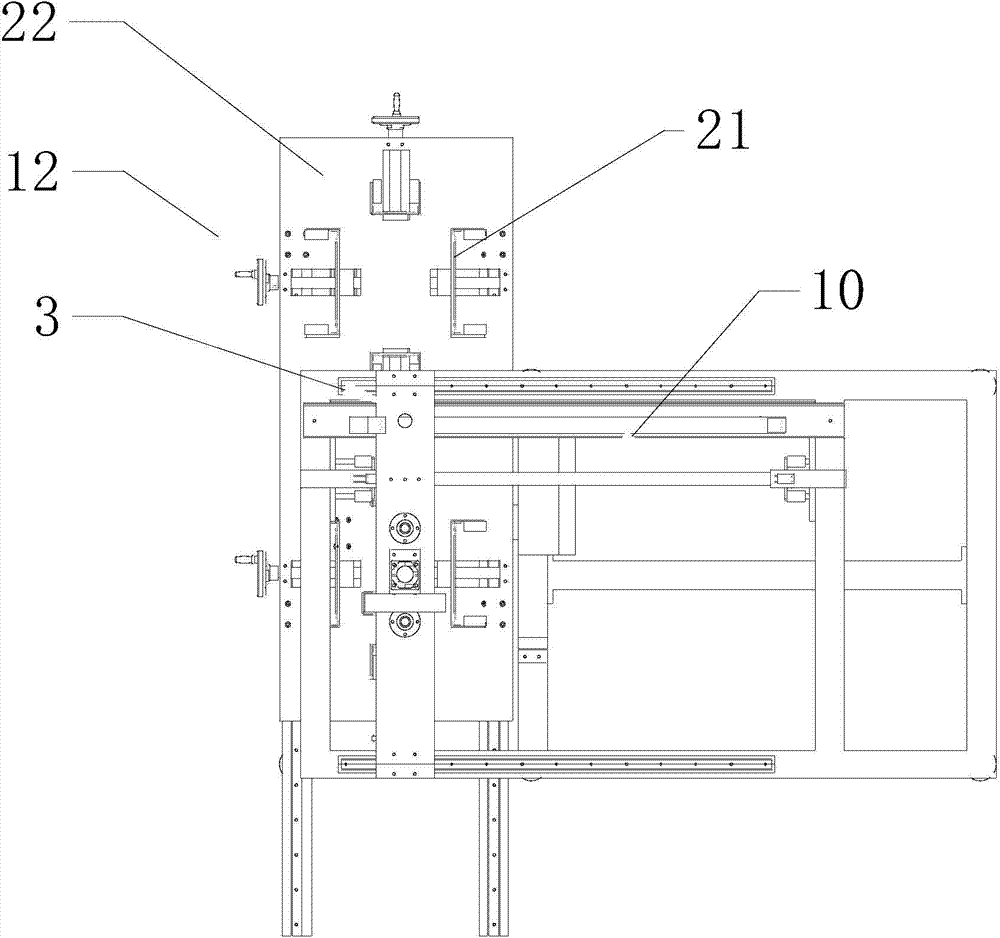

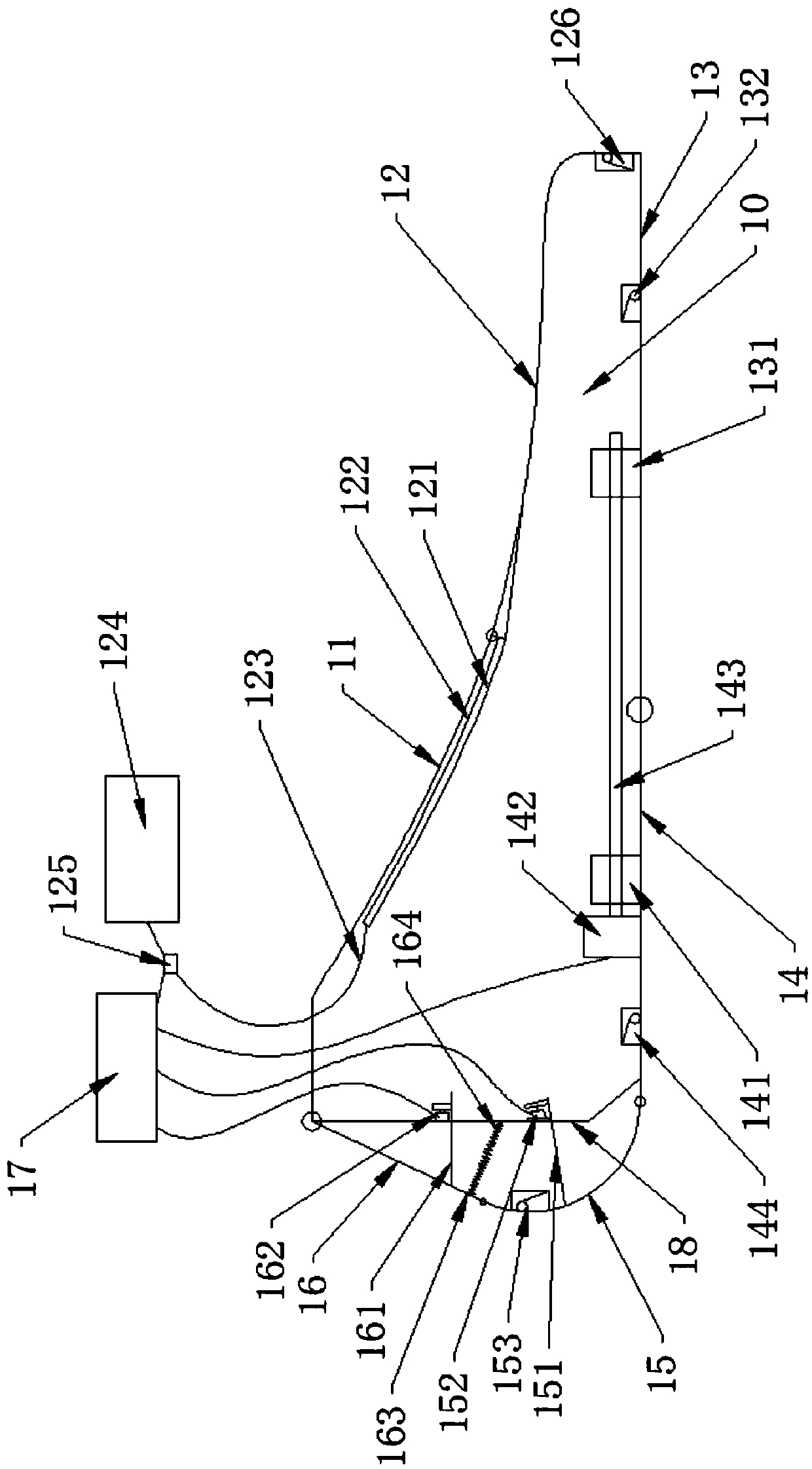

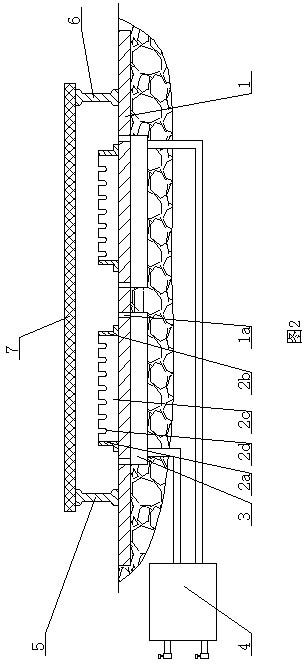

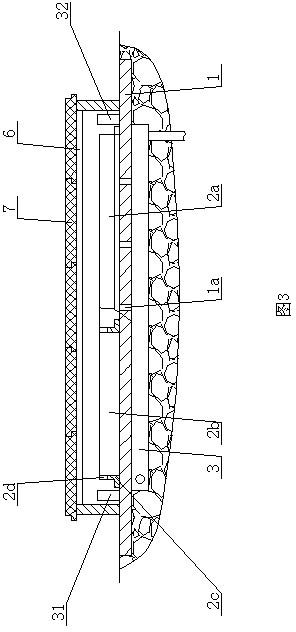

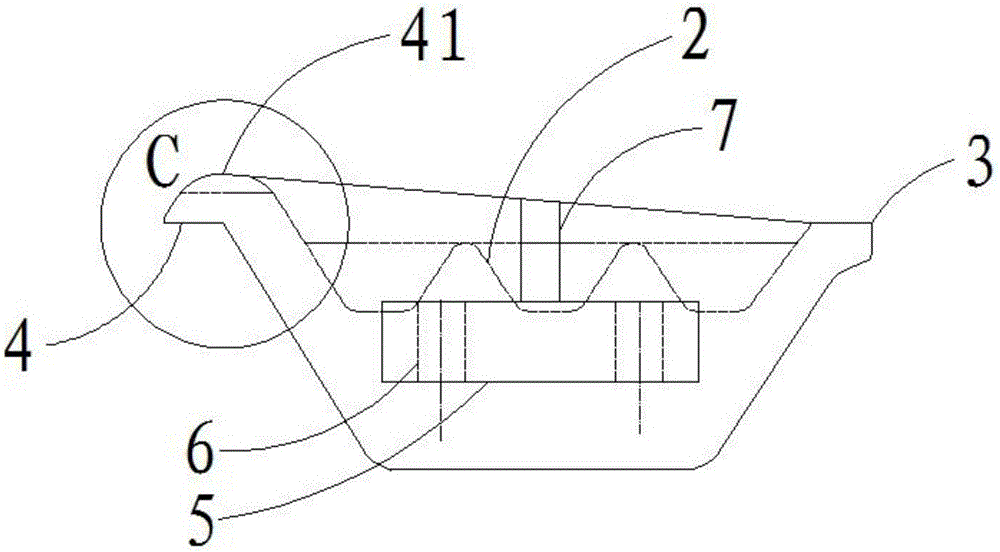

Automatic seam abutting device for cutting pieces and seam abutting method of automatic seam abutting device

ActiveCN104593956AGuaranteed continuous operationLower skill requirementsWork-feeding meansPressersEngineeringMechanical engineering

The invention discloses an automatic seam abutting device for cutting pieces and a seam abutting method of the automatic seam abutting device. The automatic seam abutting device comprises a machine table, a control device, an air sucking device, a stamper device, a positioning device, a feeding device and a sewing device, wherein the air sucking device is provided with a plurality of air sucking holes, and the air sucking holes are formed in a table surface of the machine table; the stamper device is provided with at least one pressing arm and a stamper driving device for driving the pressing arm to move; the positioning device is provided with at least one positioning arm and a positioning driving device for driving the positioning arm to move; the air sucking device, the stamper device, the positioning device, the feeding device and the sewing device are connected to the machine table, and the air sucking device, the stamper driving device, the positioning driving device, the feeding device and the sewing device are electrically connected to the control device. The automatic seam abutting device for the cutting pieces involved by the invention is suitable for the seam abutting technology of most collars, the requirements for the skills of workers are greatly lowered, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

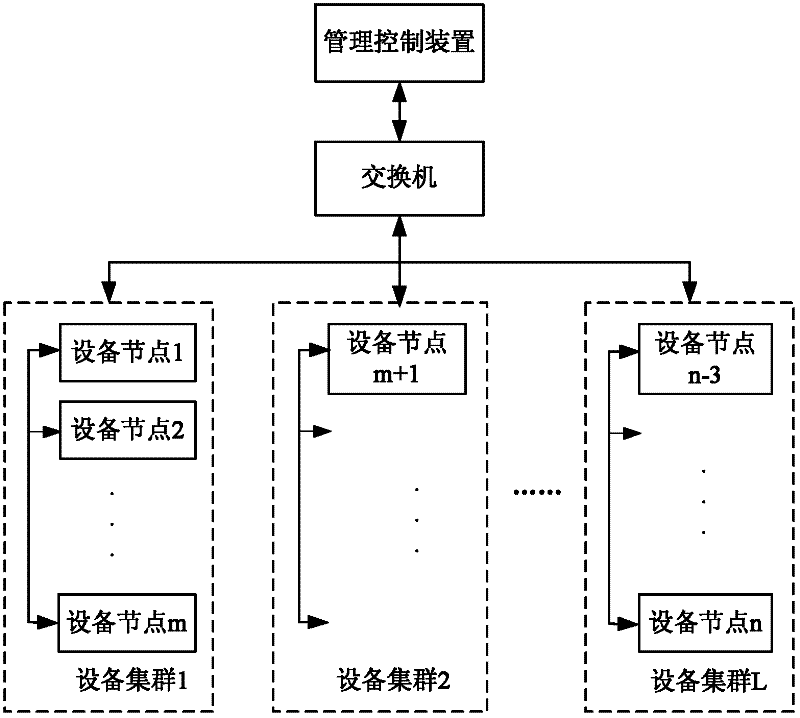

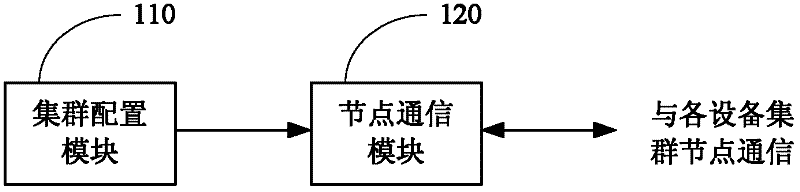

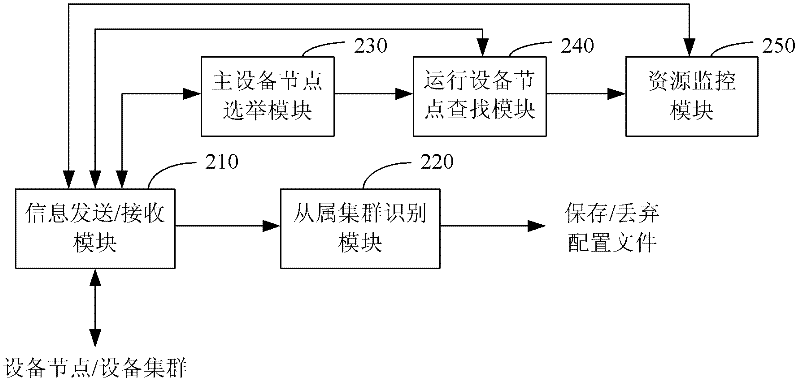

Service information system and method for realizing continuous operation by using same

InactiveCN102412988AGuaranteed continuous operationReduce complexityData switching networksService informationServer appliance

The invention discloses a service information system and a method for realizing continuous operation by using the same. In the system, a management control device configures a plurality of device nodes systemically operating same or different user services into one or a plurality of device clusters according to same or different service operation groups, and starts the device cluster(s); and the device cluster(s) selects / select one main device node from the plurality of device nodes of the local cluster(s). According to the invention, a plurality of originally existing server devices of user units of the traditional service information system are utilized to constitute a plurality of service clusters for the server equipment nodes, so that the user investment, the management complexity and the maintenance expense are reduced on the basis of ensuring the continuous operation of a user service.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

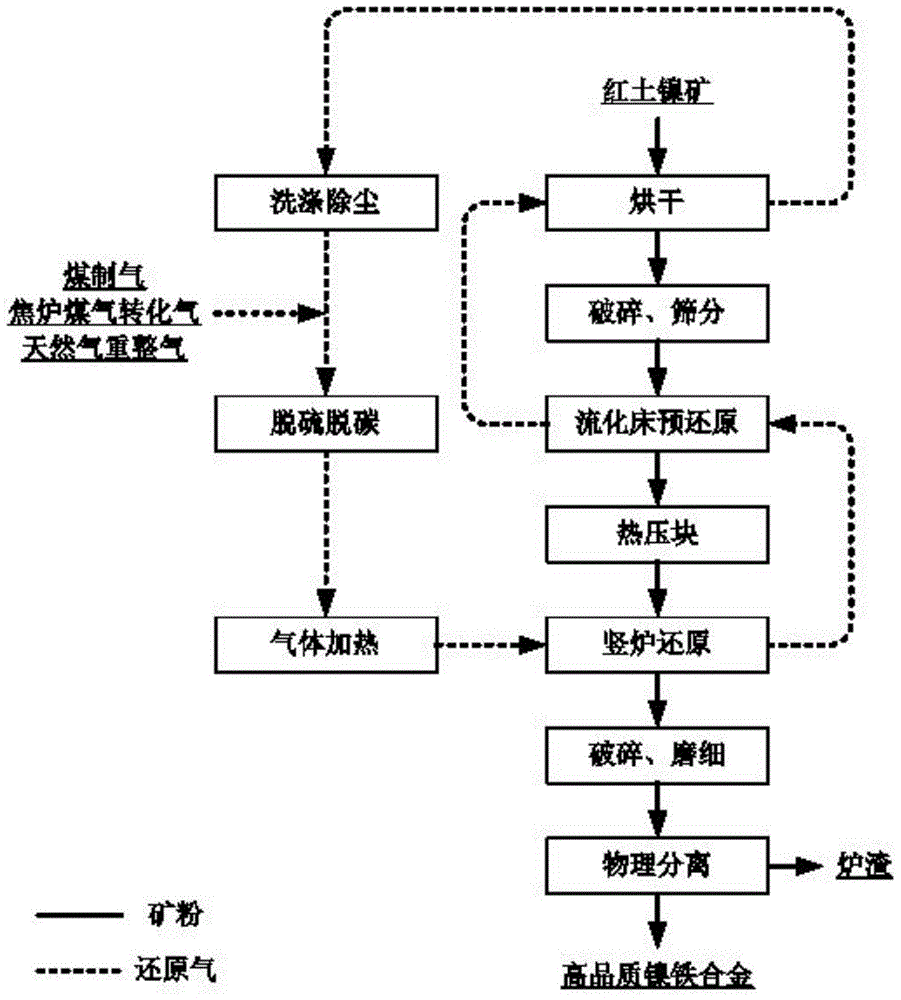

Method for producing high-quality nickel-iron alloy by reducing laterite-nickel ore under control

ActiveCN104531933ARealize the degree of regulation and restorationRealize regulatory contentShaft furnaceGas emission reductionReduction treatmentReaction temperature

The invention provides a method for producing high-quality nickel-iron alloy by reducing laterite-nickel ore under control. The method comprises the following steps: (1) drying ore raw material with gas; (2) pulverizing the dried ore raw material and screening; (3) feeding the screened ore powder into a fluidized bed and pre-reducing with a reducing gas; (4) hot-pressing the pre-reduced ore powder into blocks; (5) feeding the ore blocks into a shaft furnace and reducing with a reducing gas; and (6) pulverizing the reduced ore, fine-grinding, and separating physically to obtain the high-quality nickel-iron alloy. The method provided by the invention has the advantages of low reaction temperature, low consumption of energy, production of high-quality nickel-iron alloy and flexible adjustment of content of nickel in the nickel-iron alloy.

Owner:SHENWU TECH GRP CO LTD

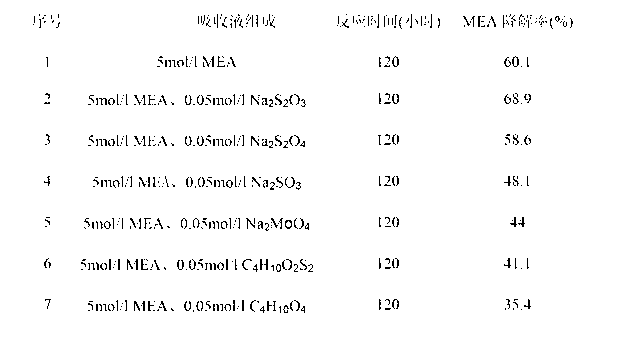

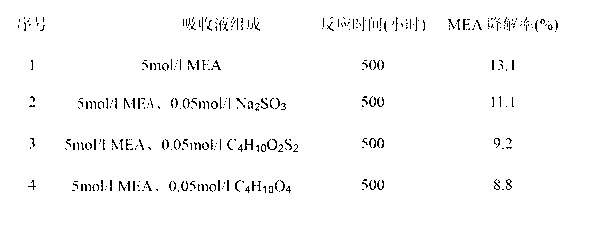

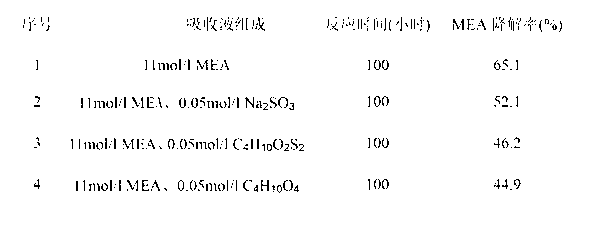

Method for inhibiting degradation of decarburization amine absorbent

ActiveCN103007687AAdd lessImprove antioxidant capacityProductsOrganic compound preparationAntioxidantOxidation resistant

The invention relates to a method for inhibiting degradation of a decarburization amine absorbent. Specifically, certain amount of antioxidant is added into the amine absorbent to inhibit degradation of the amine absorbent. The used antioxidant can be xylitol, threitol, dithiothreitol, erythritol, ethylene glycol, butanediol and other structurally similar alcohol compounds. By means of the principles of interrupting an oxidation reaction chain and decomposing an oxidative degradation product, the antioxidant can achieve significant antioxidant effects, and can be used under the circumstances of small adding amount, high temperature and wide oxygen content, thus greatly inhibiting degradation of amine water solution. Stability of a recovery solvent and continuous operation of separation equipment are ensured, the degree of corrosion caused by an absorption solvent on equipment can be reduced, and meanwhile the absorbent loss is also reduced. The method can be used for antioxidation of amine absorption solvents applied in capture and separation of carbon dioxide (CO2) from natural gas, shift gas, synthetic gas, flue gas and other industrial feed gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

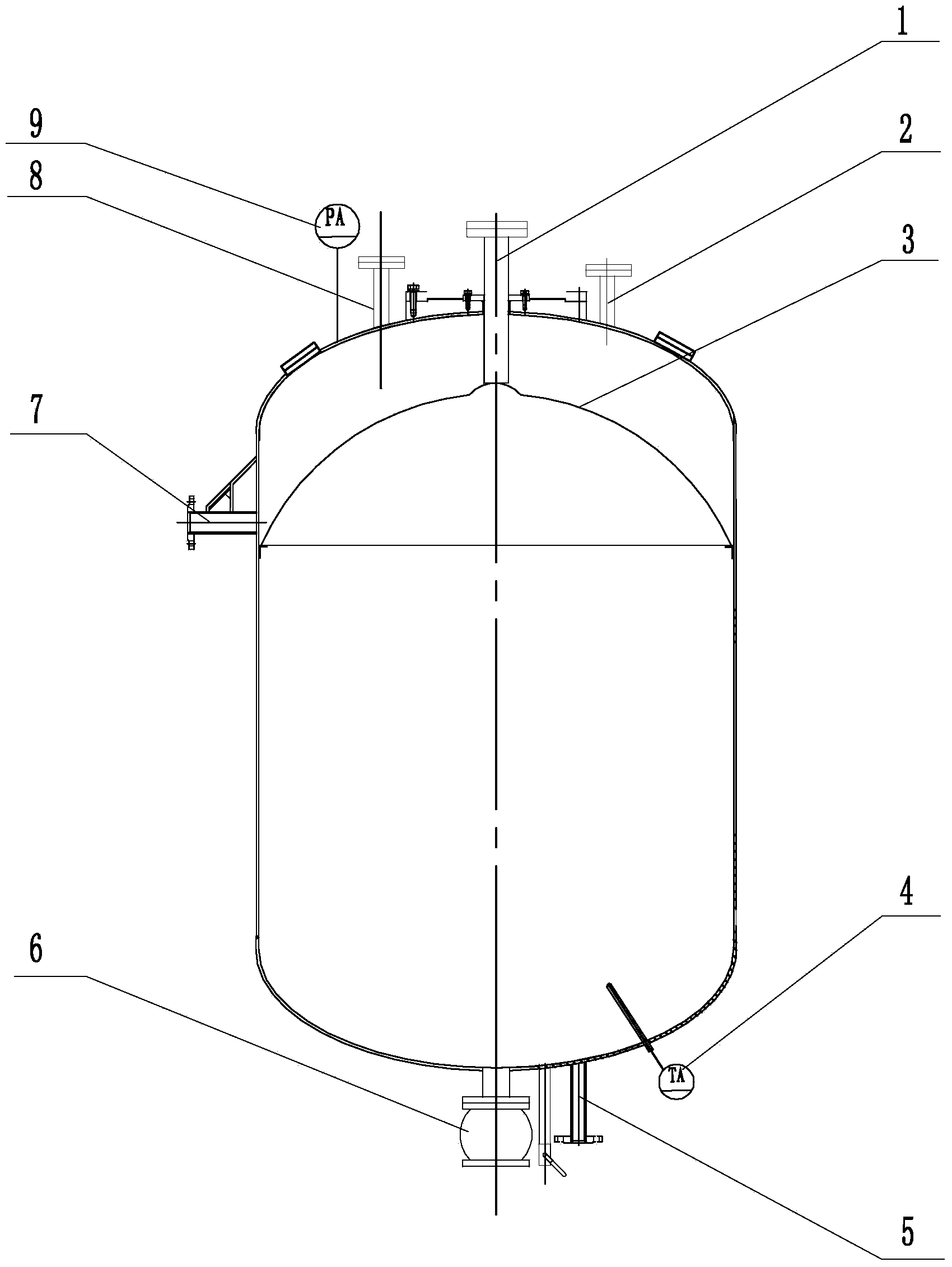

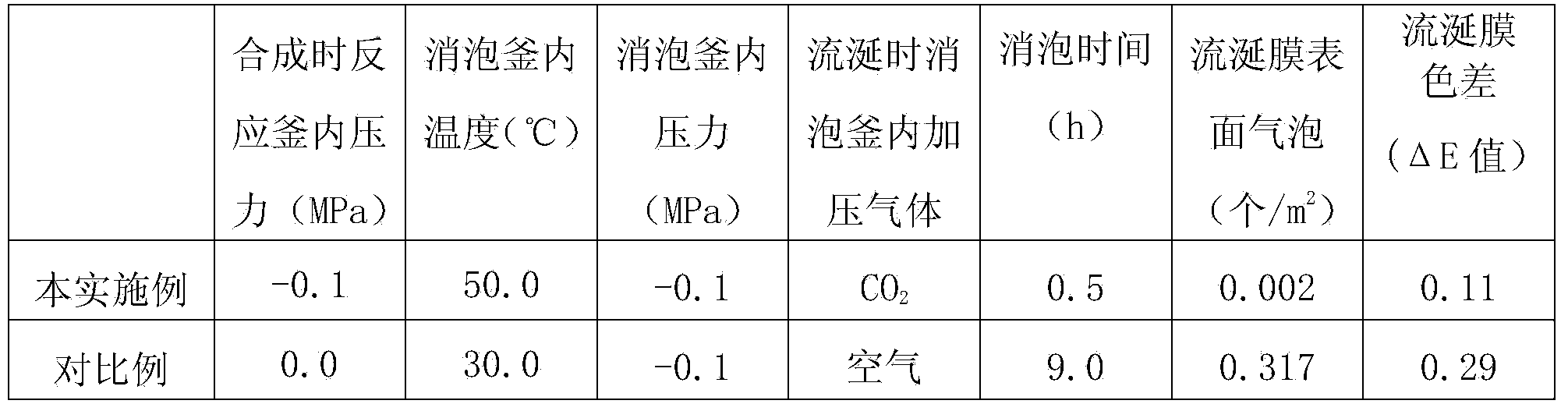

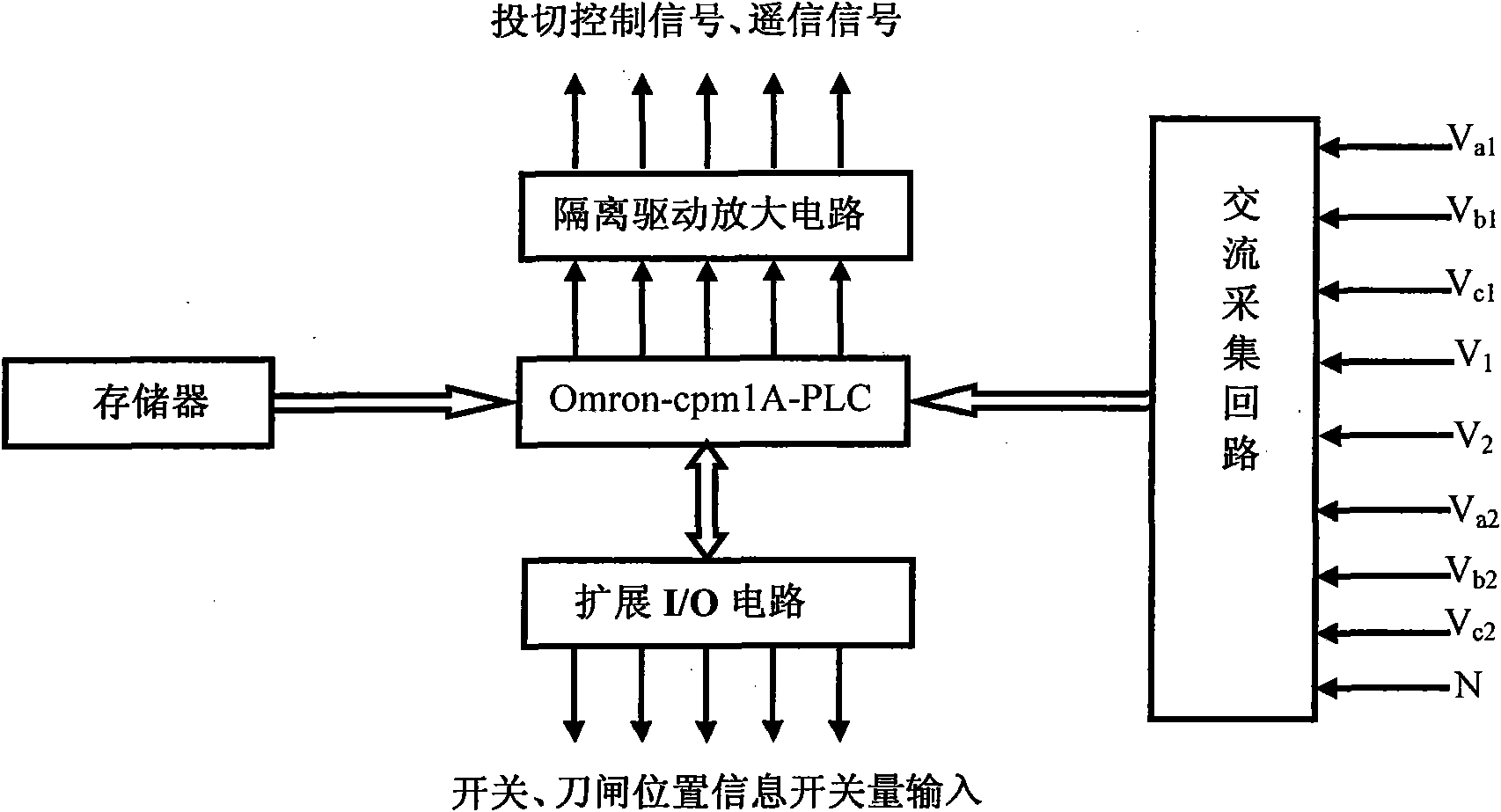

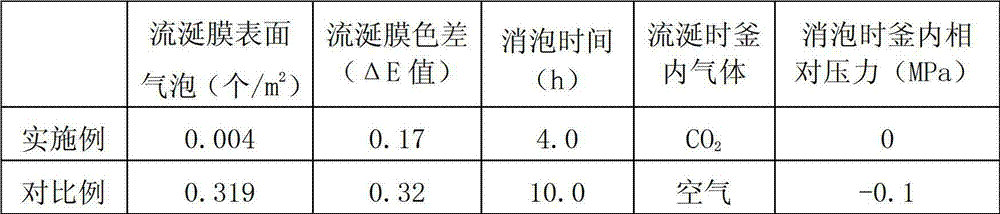

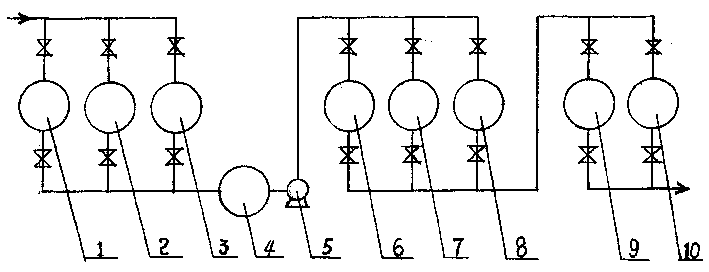

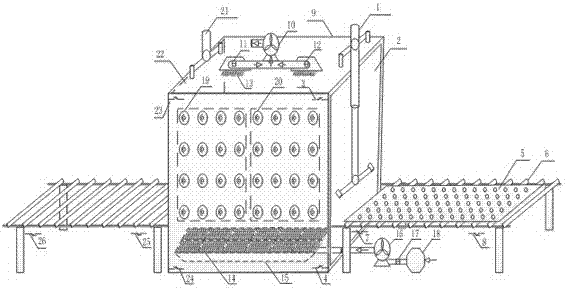

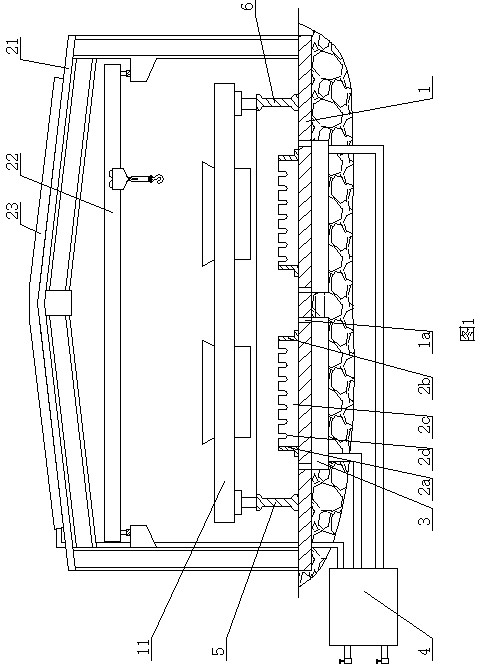

Defoaming kettle and defoaming method for preparing polyamide acid resin

ActiveCN104107565APrevent oxidationPrevent moisture absorptionFoam dispersion/preventionThin layerEngineering

The invention discloses a defoaming kettle and a defoaming method for preparing polyamide acid resin. A thin layer distributor with an arch rotary curve surface is fixedly installed in a defoaming kettle tank body; the distance from the curve surface arch top of the thin layer distributor to the lower end opening of a feeding pipe ranges from 0.01mm to 1 / 3 of the height of the tank body; the clearance between the lower edge of the curve surface of the thin layer distributor and the inner wall of the tank body is 0.01mm-10mm; the rotary curve surface of the thin layer distributor is a spherical surface; a resin conveying pipeline between a reaction kettle and the defoaming kettle is provided with a metering pump; the tank body is provided with a sandwiched sleeve, and an heat conduction medium inlet and outlet are formed at the top and bottom of the tank body. The defoaming method comprises the step that resin entering the defoaming kettle falls on the arch top of the curve surface of the thin layer distributor, and disperses and flows downward along the curve surface of the thin layer distributor to form a thin layer which results in bubble breakage. The metering pump is used for adjusting the flow rate of resin so as to keep that the thickness of the resin solution layer on the thin layer distributor is less than 5mm. Defoaming is completed immediately when resin is conveyed completely, and then pressurization is carried out for discharging. During defoaming, a heat conduction medium is introduced for warming, and negative pressure is kept in the tank body. According to the invention, defoaming is complete, and the defoaming time is shortened greatly so as to guarantee subsequent continuous film preparation. The defoaming kettle is simple in structure and convenient to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Method for cleaning container inner wall and cleaner thereof

InactiveCN101322972AGuaranteed continuous operationEasy to cleanHollow article cleaningWater flowImpurity

The invention relates to a method for cleaning the inner wall of a container and a cleaning device thereof. In the method, high-speed water flow carries spherical particles to flush and clean the inner wall of the container; during the operation, a container opening faces down and the spherical particles are used for cleaning again after leaving the container as the water falls back, so as to realize the recycling of the spherical particles; wherein, the high-speed water flow is supplied by a water pump and the spherical particles have a diameter ranging from 1.5 to 4.5mm. Driven by the high-speed water flow, the spherical particles flushes and rubs the inner wall of the container and absorbs impurities on the inner wall, so as to thoroughly clean the inner wall of the container with very ideal cleaning effect.

Owner:赵洪伟

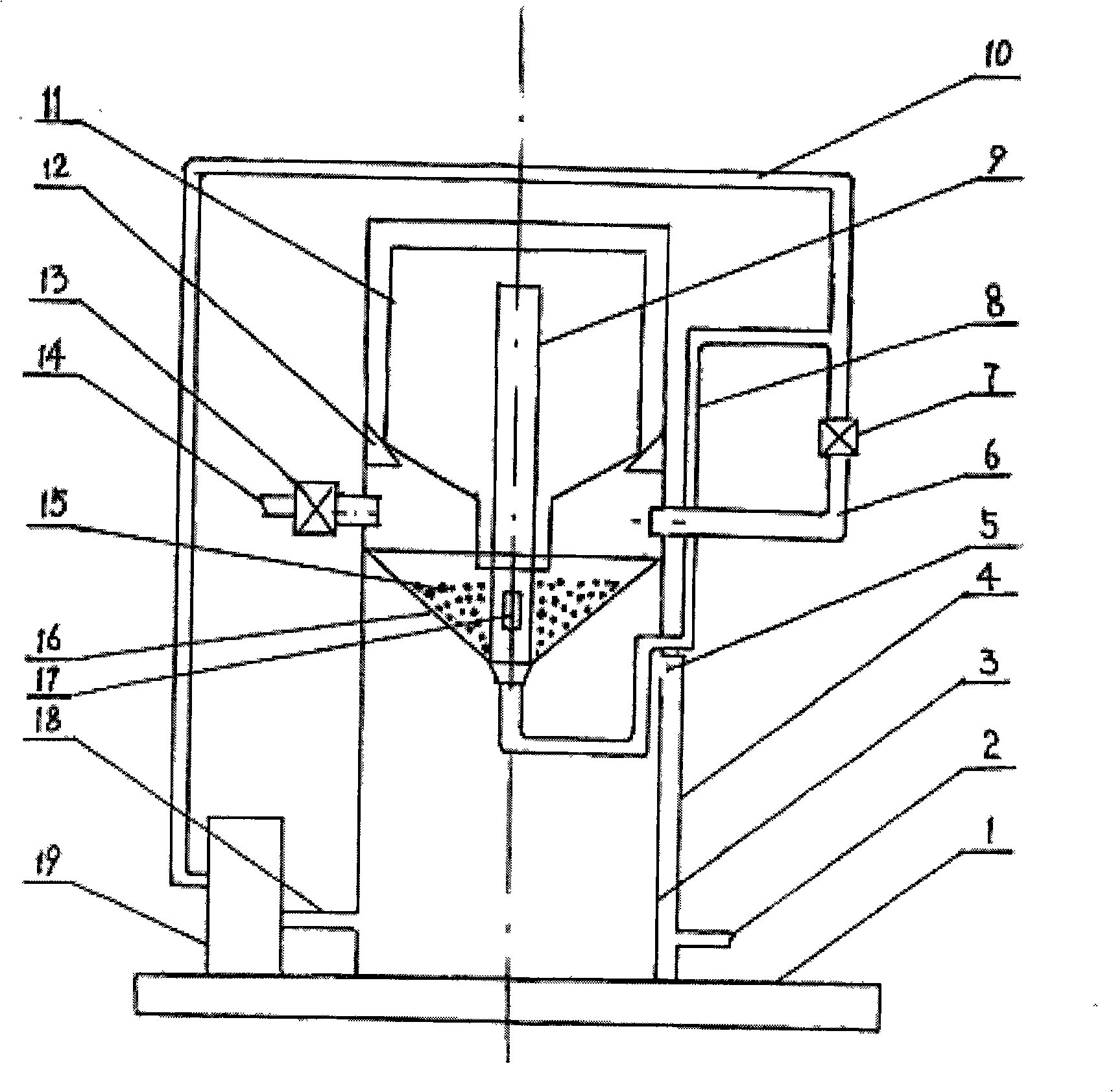

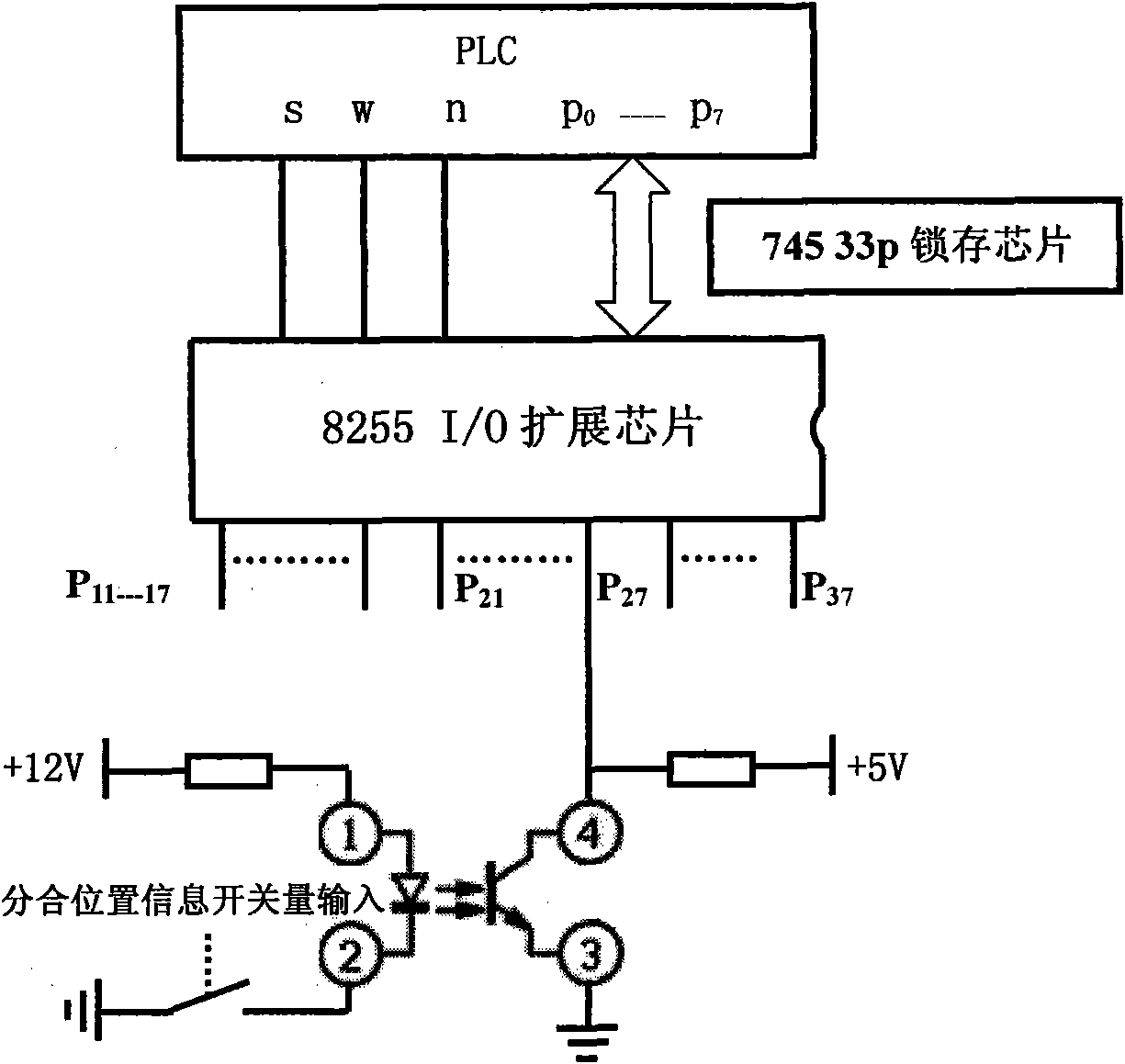

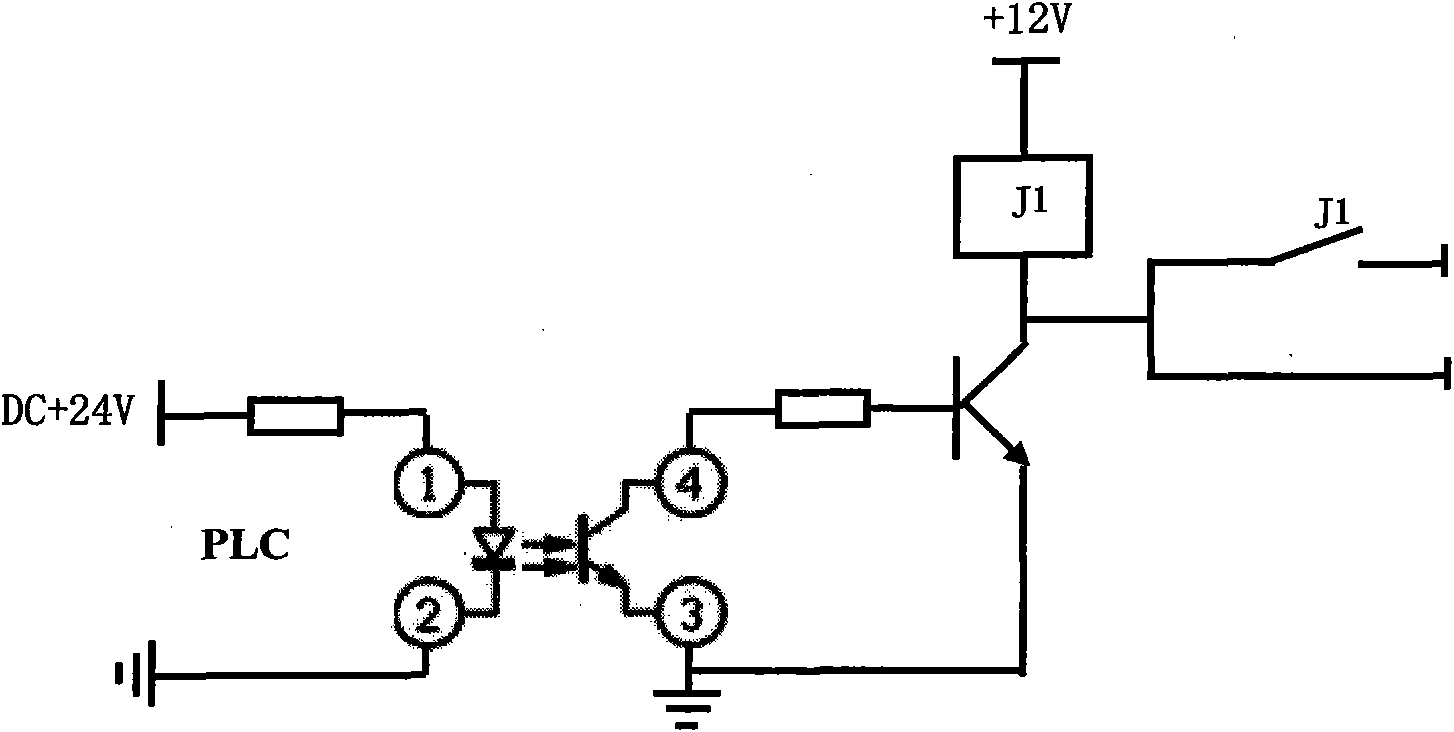

Low-voltage alternating current power supply programmable switching system of substation

InactiveCN101872999AGuaranteed continuous operationImprove adaptabilityEmergency power supply arrangementsInput/outputEngineering

The invention relates to an electric intelligent programmable logic control device of a substation, in particular to a low-voltage alternating current power supply programmable switching system of a substation. The system is characterized by comprising a programmable controller, wherein the programmable controller is connected with all power supply incoming wires and buses by an alternating current acquiring loop so as to obtain the three-phase voltage and the bus voltage at the wire incoming side; the programmable controller is connected with a corresponding switch by an expanded I / O (Input / Output) circuit so as to obtain the position information of the switch; and the programmable controller is also connected with a power supply switch by an isolation drive amplifying circuit so as to control the on-off of the corresponding power supply switch. The invention is particularly suitable for an occasion in which two sets or multiple sets of low-voltage power supplies for N+1 frequently work in turn; when an accident happens, at least one path of power supply works; and after the accident is eliminated, the system automatically restores and runs in an original way, can efficiently and reliably ensure the continuous running of a power supply system without manual intervention completely and is particularly suitable for an unattended substation of 35-750kV.

Owner:WUZHONG POWER SUPPLY COMPANY STATE GRID NINGXIA ELECTRIC POWER

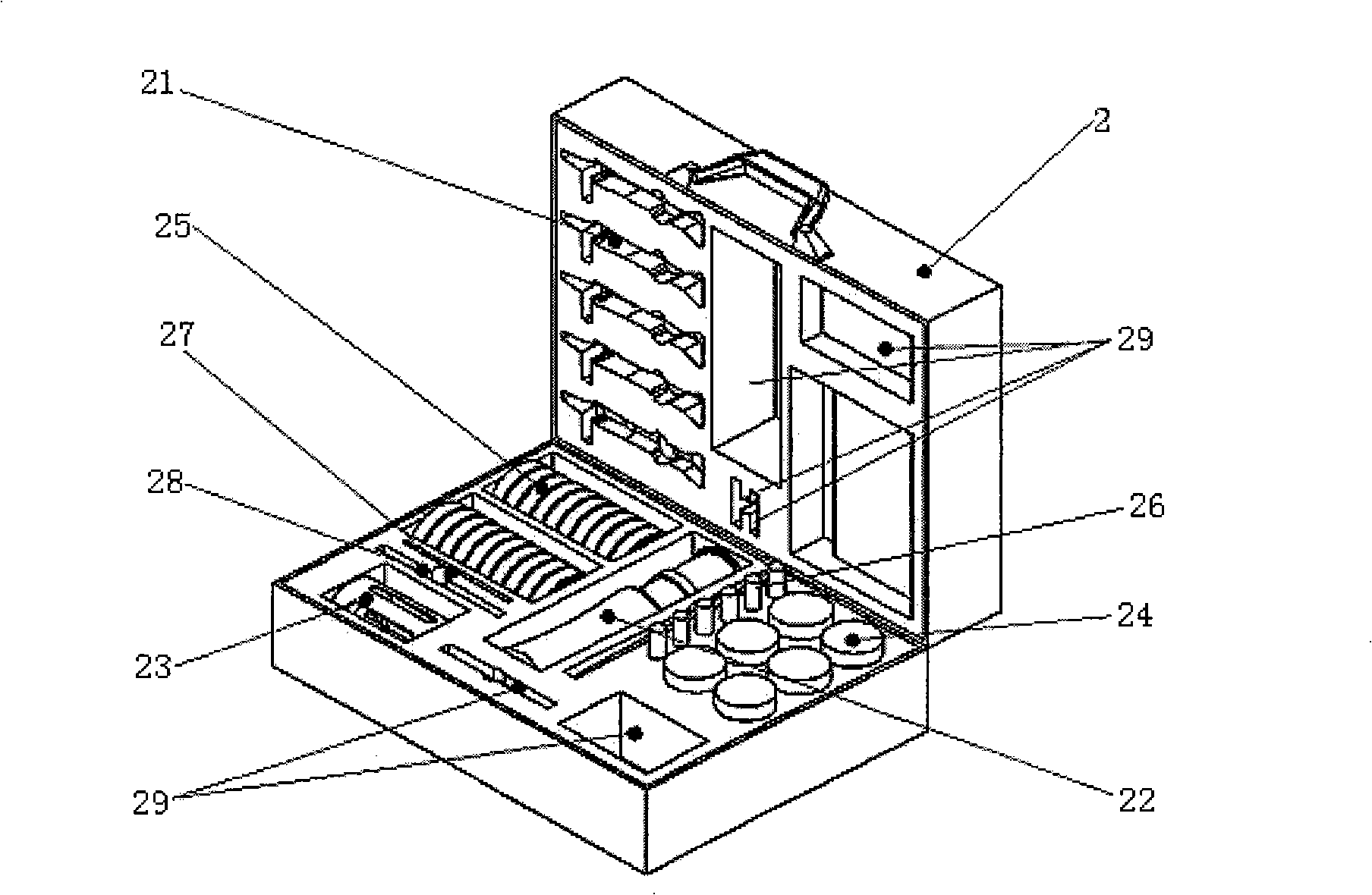

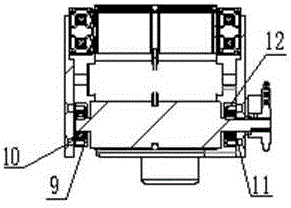

Foam board placement device for storage battery packaging line

The invention discloses a foam board placement device for a storage battery packaging line. The foam board placement device comprises a rack, a foam board superposing device and a board taking device, wherein the foam board superposing device comprises a foam board superposing frame and a standby foam board superposing frame which are slidably arranged on the rack, and the board taking device comprises a horizontal sliding seat which is horizontally and slidably arranged on the rack, a sliding seat driving device, a board taking assembly and a vertical board taking assembly driving device; the horizontal sliding seat is driven by the sliding seat driving device fixedly arranged on the rack to slide between a board taking station and a placement station, and the board taking assembly is vertically arranged on the horizontal sliding seat in a lifting way and is driven by the vertical board taking assembly driving device to vertically rise and fall; the foam board superposing frame and the standby foam board superposing frame can slide to the board taking station to be matched with the board taking assembly. The device has the advantages of realizing the automation and continuity of foam board placement, ensuring the continuous operation of the storage battery packaging line and improving production efficiency.

Owner:蚌埠航宇知识产权服务有限公司

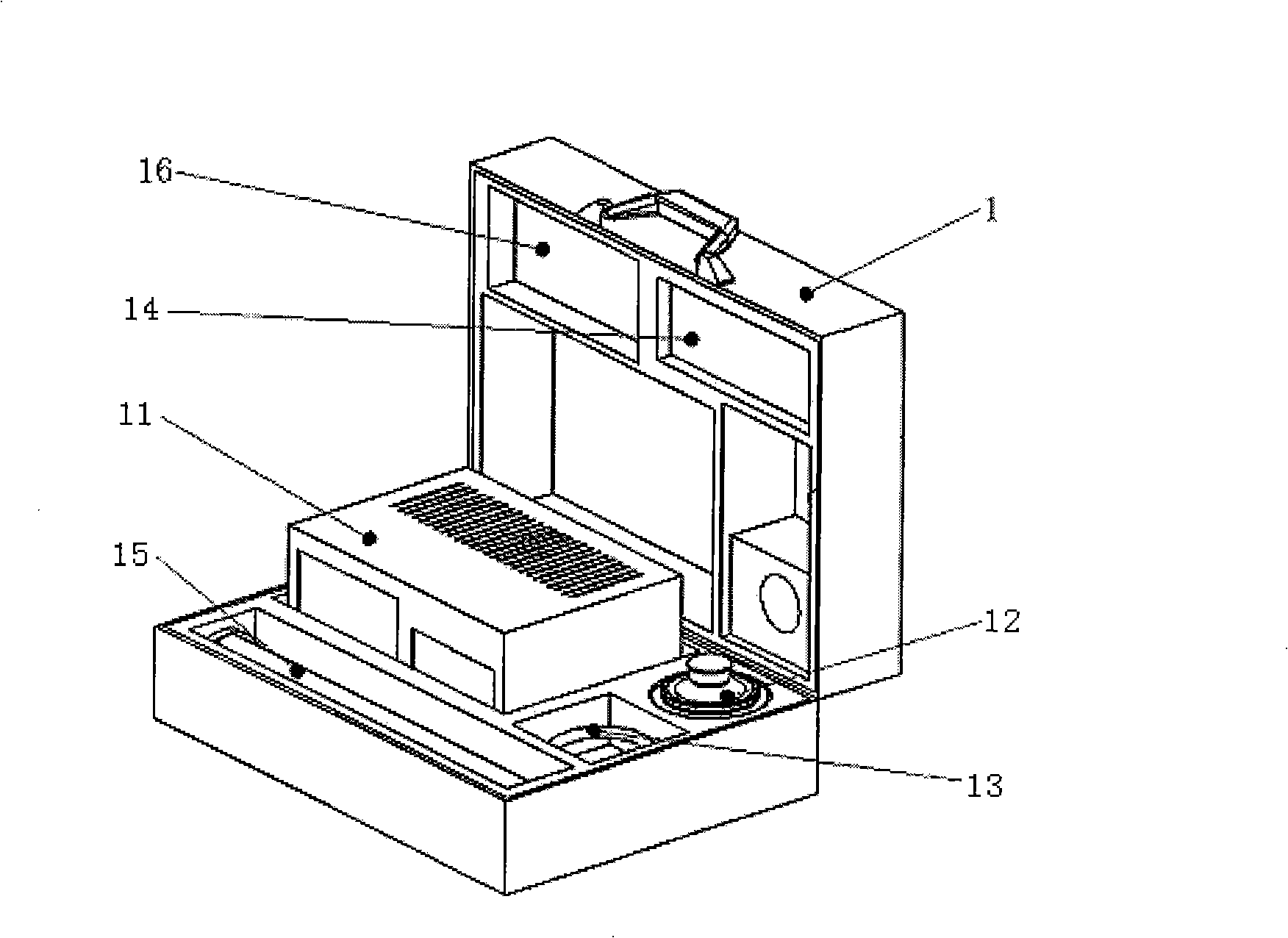

Multifunction air microbe sampling box

ActiveCN101338275AWith automatic constant current control functionReduce generationBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismFood industry

The invention relates to a multi-functional air microorganism sampling case, comprising two cases of I case and II case. The I case comprises a multi-functional air microorganism sampler, a second graded solid bumping sampler, a silicone tube, a charger and a multi-functional air microorganism sampler bracket. The II case comprises a plurality of all-glass liquid bumping samplers, a water filtering sampler, a liquid bumping sampler bracket, a plurality bottles of disinfection solution, a plurality of flat utensils, a plurality of plastic centrifuge tubes and auxiliary tools. The multi-functional air microorganism sampling case solidifies the three modes of the second graded bumping sampling, the liquid bumping sampling and water filtering sampling, which can collect the bacteria, fungi and viruses in the air, and also can collect and condense the microorganism in the polluted water. The multi-functional air microorganism sampling case has the characteristics of simple operation and portable carrying, which can be directly used for rapid inspecting on site, and also can be widely used in environmental protection, medical health, food industry, fermentation industry, medical preparation industry, agriculture and stockbreeding and the related research departments.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI

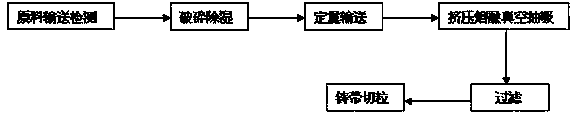

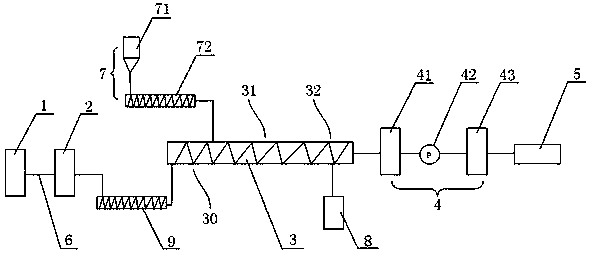

Recovery process and device for synthetic fiber waste

ActiveCN103509205AReduce processing stepsReduce cleaningPlastic recyclingVacuum pumpingBoiling point

The invention discloses a recovery process and a device for synthetic fiber waste. The recovery process is characterized by comprising the following steps: detecting waste: passing the synthetic fiber waste through a metal detector to remove metal impurities in the waste; crushing the waste and removing moisture: sending the detected waste in a crusher to crush, and heating to remove moisture; squeezing and fusing: squeezing and fusing the crushed and moisture-removed waste in an extruder, carrying out vacuum pumping to the fused melt, filtering with a first filter and a second filter, and then casting strips and granulating. The recovery process eliminates the forepart rinsing and drying step. The vacuum pumping step can remove low-boiling-point substances, impurities, oil solution and moisture in the waste fiber. The forepart pretreatment working procedure is eliminated; the waste fiber is directly recovered and recycled.

Owner:湖北绿宇环保有限公司

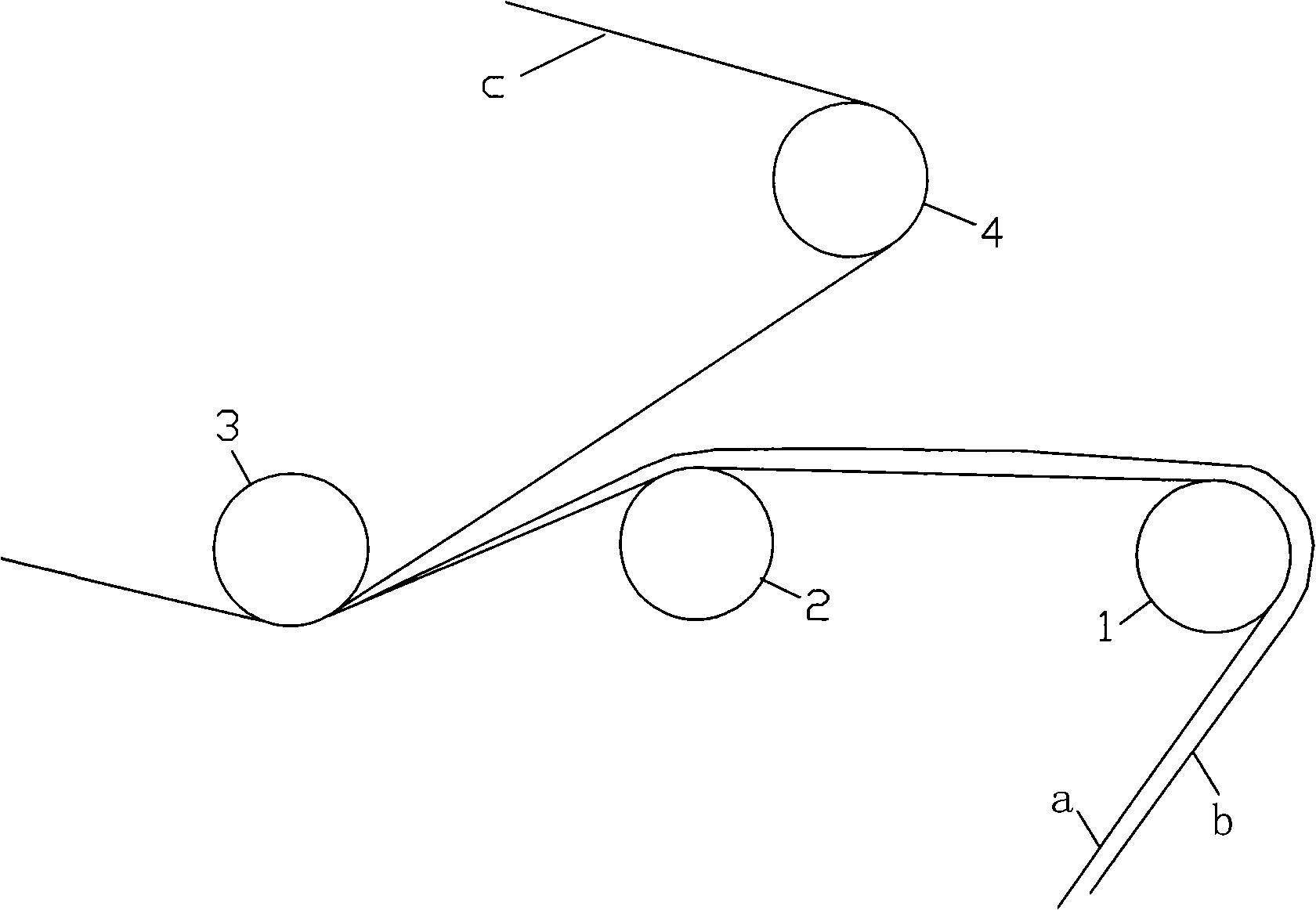

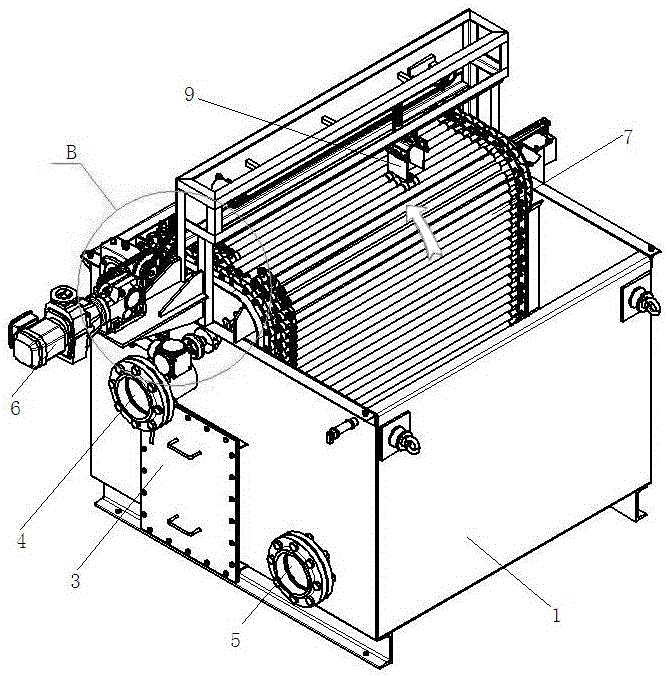

Band press filter with mud fixing belt

ActiveCN101279162AAvoid material runningGuaranteed continuous operationMoving filtering element filtersBand-pass filterEngineering

The invention discloses a solid-liquid separation device, in particular to a draper-type press filter with a mud fixing draper. The draper-type press filter with the mud fixing draper consists essentially of a chassis, a driving device, a feeding device, a pressing and filtering area and an auxiliary device. The pressing and filtering area comprises a press roll and filtering strips and is arranged on the chassis; the driving device is connected with the press roll; the filter strips are wrapped outside the press roll; the feeding device faces a feeding inlet of the pressing and filtering area and the auxiliary device is positioned at the corresponding position of the filter strips. The structure of the solid-liquid separation device is characterized in that: the solid-liquid separation device also comprises the mud fixing draper which is folded between an upper filter strip and a lower filter strip and wrapped outside the press roll together with the lower filter strip. The solid-liquid separation device effectively overcomes the defects of material escaping and unsmooth feeding of the draper-type press filter existing in the prior art, guarantees the normal operation of the press filter and greatly promotes the dehydration output of the draper-type press filter.

Owner:ZHEJIANG HUAZHANG TECH

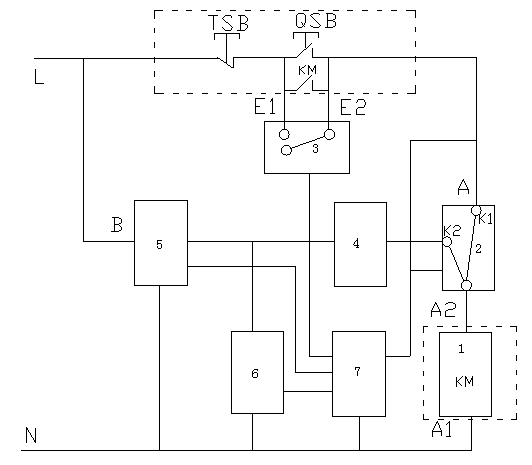

Alternating-current contactor in low-voltage alternating-current control circuit and control method of alternating-current contactor

ActiveCN102709116AAchieve the purpose of stoppingTo achieve the purpose of energy savingRelaysLoop controlLow voltage

The invention particularly relates to an alternating-current contactor in a low-voltage alternating-current control circuit and a control method of the alternating-current contactor. The alternating-current contactor comprises a circuit control switch, a starting run switch, a current output control unit, a direct-current power supply conversion unit, an energy storage unit, a central control unit and electric equipment, wherein a low-voltage alternating-current voltage end L is electrically connected with a K1 of the circuit control unit through an auxiliary switch circuit of the electric equipment; the auxiliary switch circuit is connected in parallel with the starting run switch; a one voltage detection end of the central control unit is electrically connected with the direct-current power supply conversion unit; another voltage detection end of the central control unit is electrically connected with an alternating-current output voltage end A; the voltage end A and a voltage end B are arranged at the two ends of the auxiliary switch circuit; and the central control unit is electrically connected with the circuit control switch, the starting run switch and the energy storage unit respectively. The working state of the electric equipment can be adjusted automatically, and the normal operation of the production process flow is ensured.

Owner:西安润辉科技发展有限公司

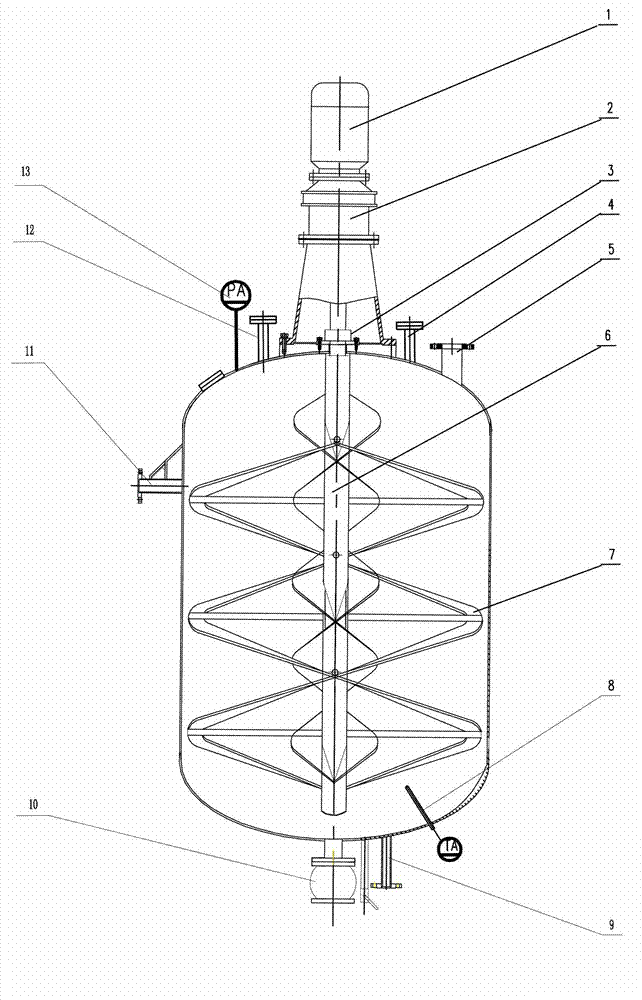

Defoaming kettle used in synthetic process of polyamic acid resin

InactiveCN103041620AUniform colorConvenient temperature and pressureFoam dispersion/preventionHeat conductingProduct gas

The invention discloses a defoaming kettle used in the synthetic process of polyamic acid resin. A pot body of the defoaming kettle is provided with a jacket; a stirring shaft of a multilayer spiral mixing blade is located in the defoaming kettle, and the top end of the stirring shaft is connected with a stirring electric motor and a reductor, which are located at the top of the pot body; the stirring shaft is a hollow shaft, and the mixing blade is a hollow blade, wherein a heat-conducting medium transmission pipeline is arranged in the mixing blade; a heat-conducting medium inlet on a rotary joint is connected with the upper end of the heat-conducting medium transmission pipeline of the mixing blade, and heat-conducting medium passes through the hollow shaft to a heat-conducting medium outlet at the upper end of the hollow shaft; a jacket medium inlet, a jacket medium outlet, the heat-conducting medium inlet and the heat-conducting medium outlet are connected with a heat-conducting medium heating device; and a gas inlet and a discharge pipe are arranged on the pot body in a sealed manner.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

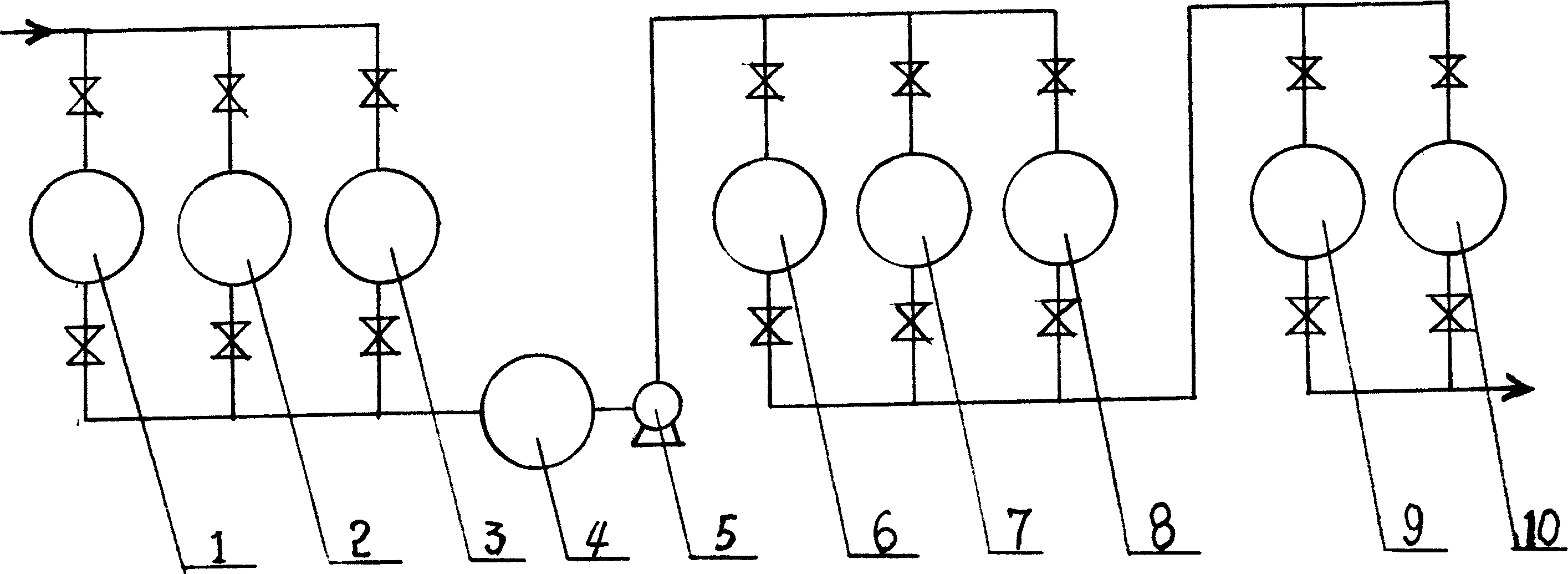

Ion exchange technology in preparing glucose

InactiveCN1390845ALow regeneration costExtended recovery periodMonosaccharidesGlucose productionIon exchangeIon

An ion exchange process for preparing glycose features that multiple cationic resin columns are parallelly connected into a group, multiple anionic resin columns are parallelly connected into a group, and both groups are connected via buffer tank and pump. Its advantages are regeneration of any resin column without stopping production, low cost for regeneration and saving resin by 30%.

Owner:XIWANG GROUP

Pass-type microwave drying system for sand mould

PendingCN107084608AAvoid damageImprove air flowDrying gas arrangementsDrying machines with progressive movementsTemperature controlMicrowave

The invention provides a pass-type microwave drying system for a sand mould. The pass-type microwave drying system for the sand mould comprises a roller way device, a microwave drying room and a humidity elimination blowing-in device. With humidity control as priority and temperature control as aiding, measuring temperature deviation of the sand mould is reduced, and a mode of top air drafting and bottom blowing-in is adopted so that the fact that air and water vapor in the microwave room circulate smoothly is ensured, quick, efficient and high-class drying of the sand mould is achieved; and multiple patterns such as local operation and remote operation are possessed, integration with other equipment or system is convenient and line production is achieved.

Owner:NINGXIA KOCEL MOLD

Smoke waste-heat utilization system based on selective catalytic reduction (SCR) denitration device

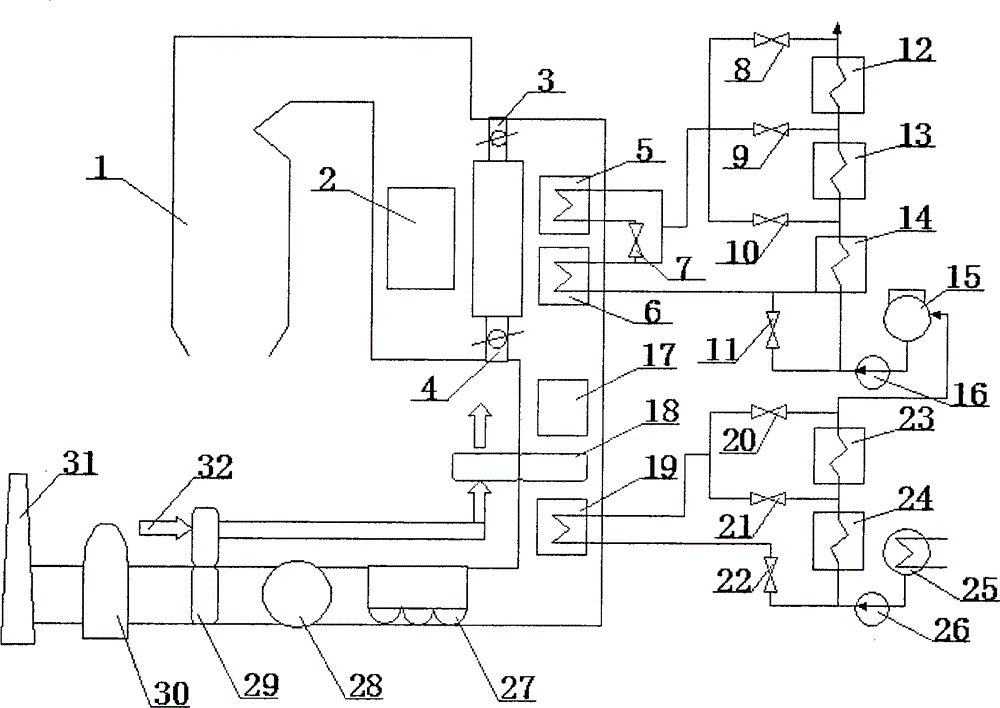

ActiveCN105318313AGuaranteed continuous operationReduce water consumptionLiquid degasificationCombustion processAir preheaterDeaerator

The invention discloses a smoke waste-heat utilization system based on a selective catalytic reduction (SCR) denitration device. The smoke waste-heat utilization system comprises a boiler (1), an economizer (2), the SCR denitration device (17), an air preheater (18), a front air preheater (29), a dust remover (27), an induced draft fan (28), a desulfurizer (30), a chimney (31), a smoke waste-heat recovery system and a water supply regenerative system. The smoke waste-heat recovery system comprises a first-grade heater (6), a second-grade heater (5) and a smoke cooler (19). The water supply regenerative system comprises a condenser (25), a water supply pump (16), a deaerator (15) and a condensate water pump (26). According to the smoke waste-heat utilization system, it can be ensured that the SCR denitration device is put into operation continuously, and emission of NOx is controlled; correspondingly, waste heat contained in temperature increasing of exhausted smoke needs to be recycled, so that the energy use efficiency is improved greatly, the efficiency of the dust remover is improved, and the water consumption of the desulfurizer is reduced.

Owner:TAIYUAN UNIV OF TECH

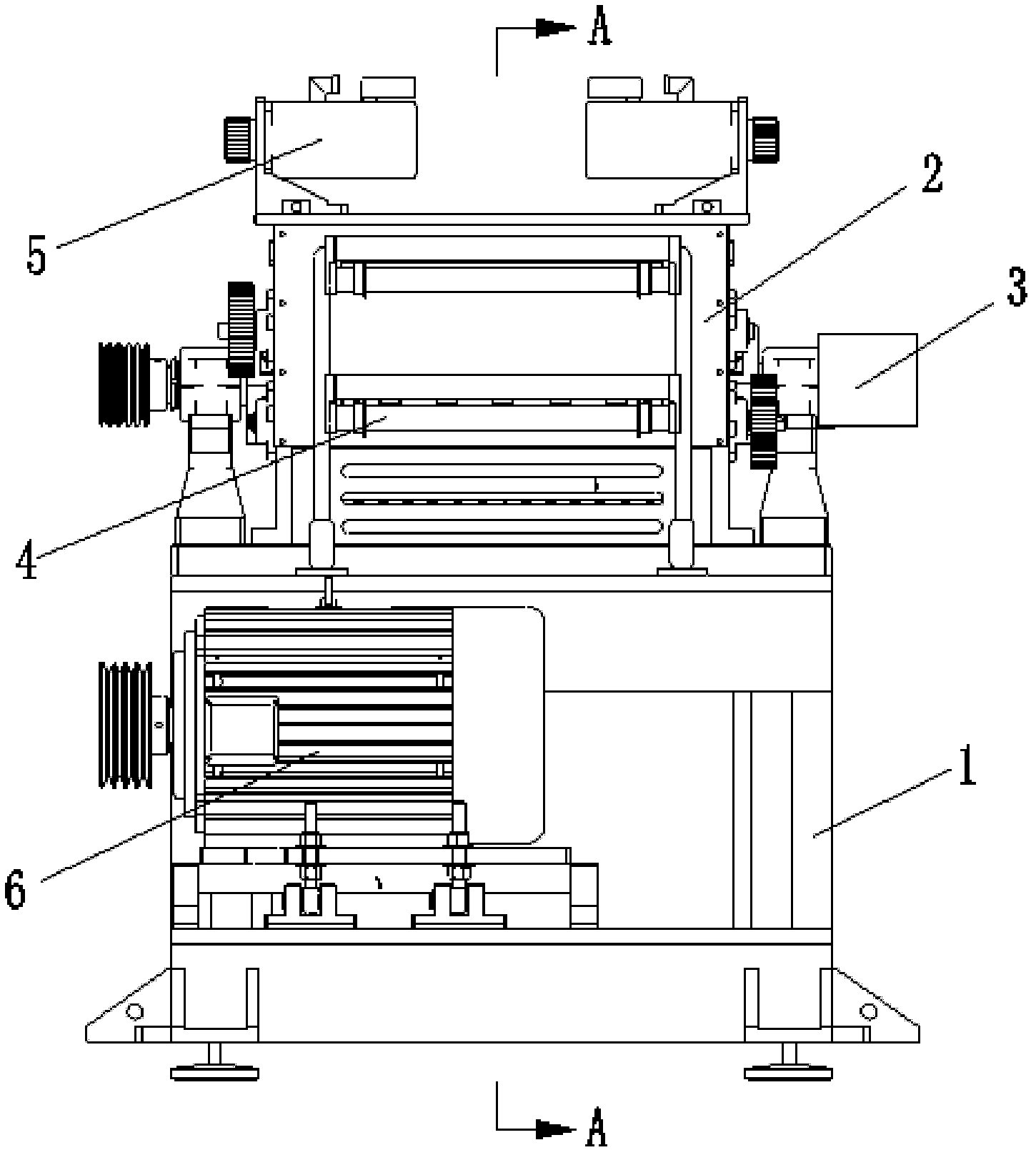

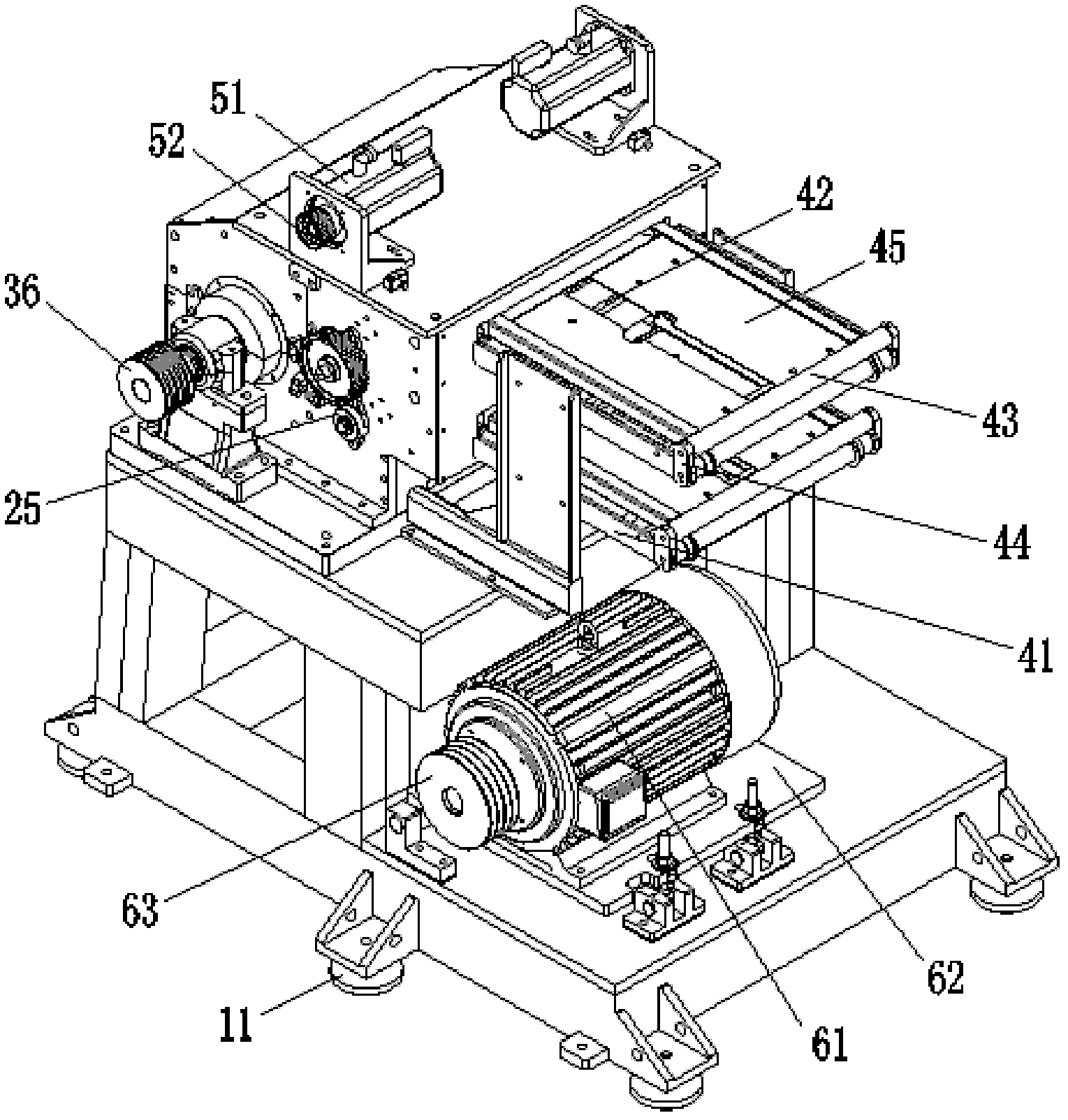

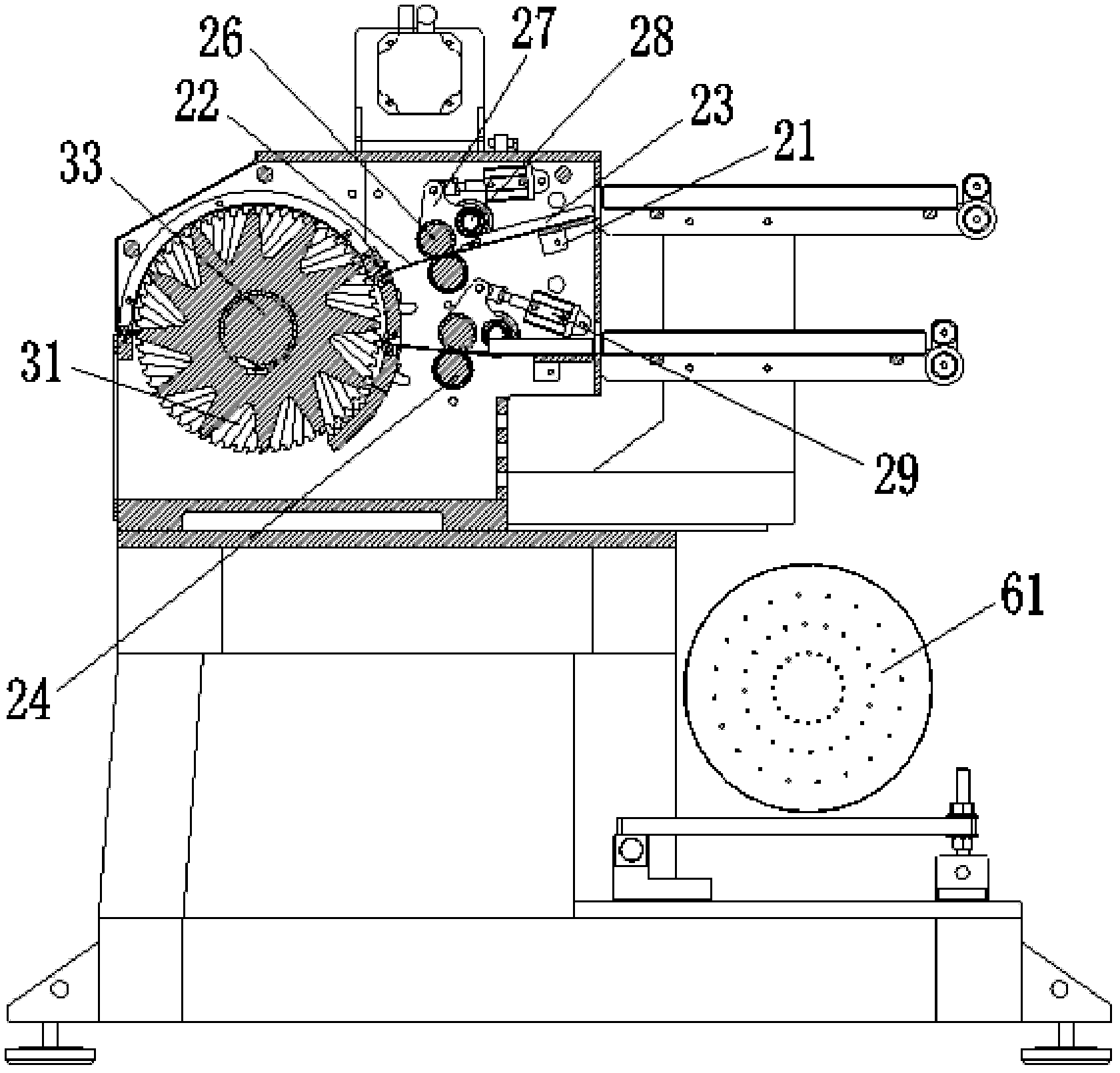

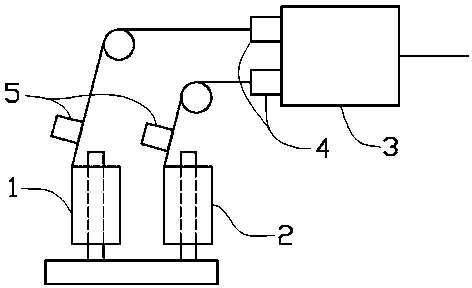

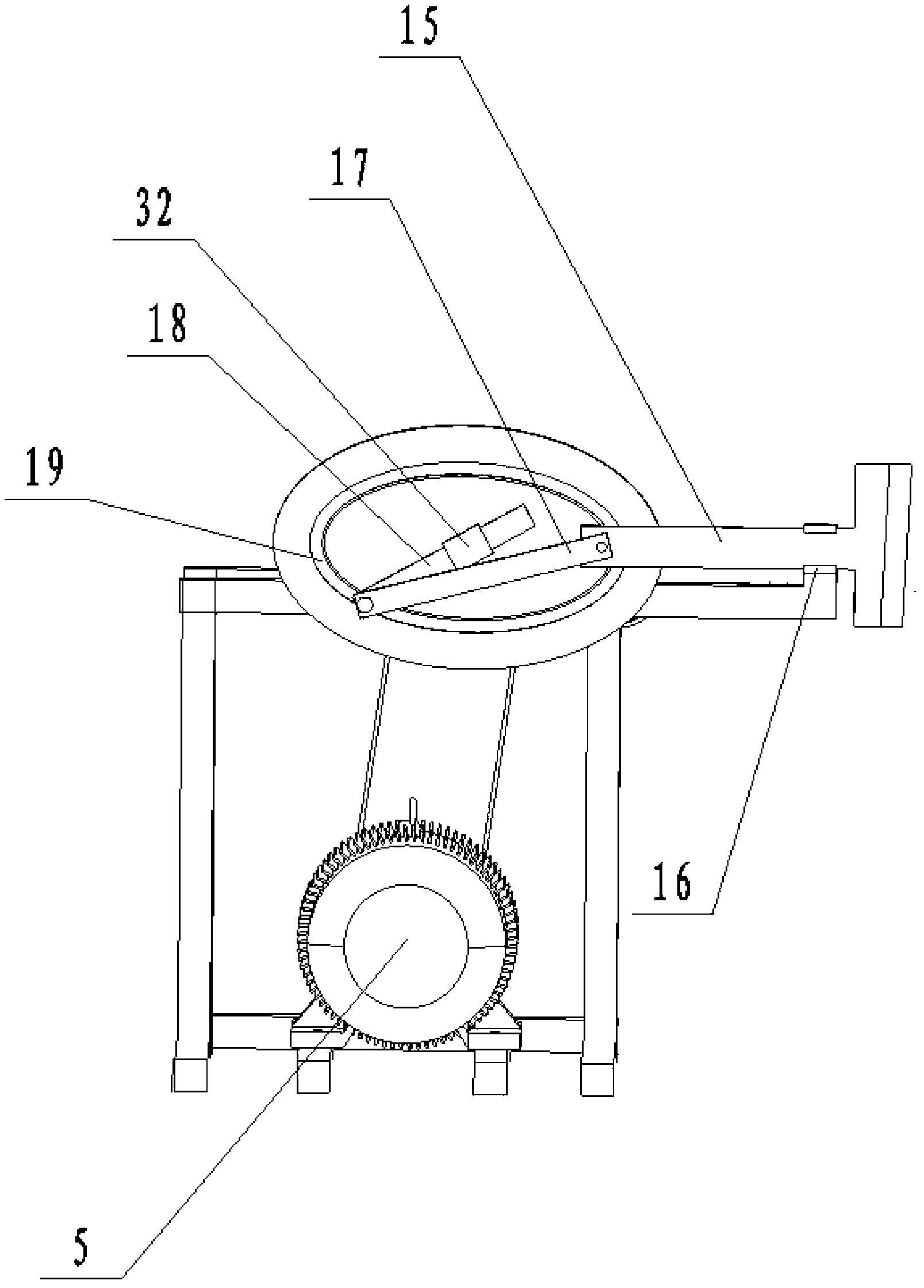

Cam-driven delasting-lasting integrated machine

The invention provides a cam-driven delasting-lasting integrated machine, belonging to the shoemaking equipment field. The integrated machine comprises a fixed frame, wherein an inverted shoe tree isfixedly arranged on the fixed frame, a flat pressing assembly is arranged above the shoe tree, clamping assemblies are arranged on the left and right sides of the shoe tree; and a delasting assembly is arranged at the rear end of the shoe tree and comprises a raising cam, a raising driving rod and a lifting frame, the raising cam is rotatably connected to the fixed frame, a first driving slot is formed in the raising cam and is used for driving the lifting frame to move up and down through the raising driving rod, a translation cam, a translation driving rod and a delasting block are arrangedat the upper end of the lifting frame, the translation cam is horizontally arranged and is rotatably connected with the lifting frame, a second driving slot is formed in the translation cam and is used for driving the block to move leftwards and rightwards through the translation driving rod. The integrated machine is driven by a power supply, so that the operation of the whole structure is relatively stable and reliable, the failure rate is greatly decreased, the energy consumption is reduced, the energy source is saved, and the integrated machine is relatively environment-friendly.

Owner:JIHUA LAB

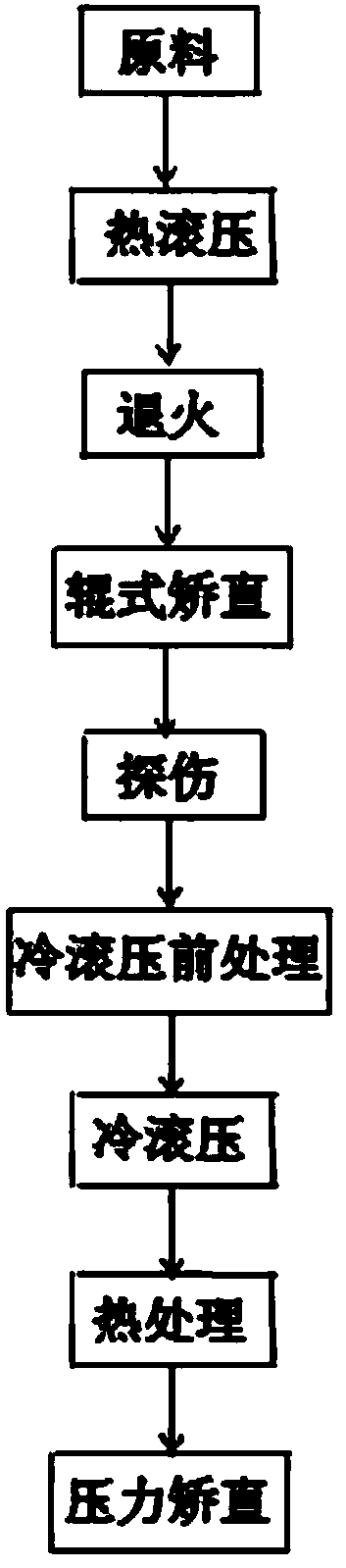

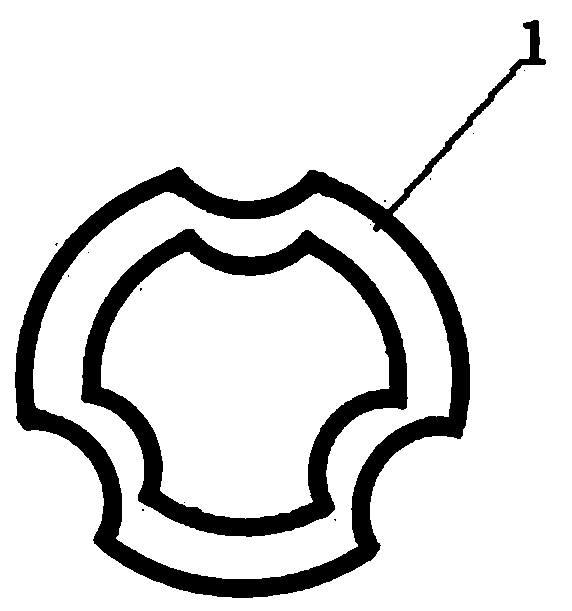

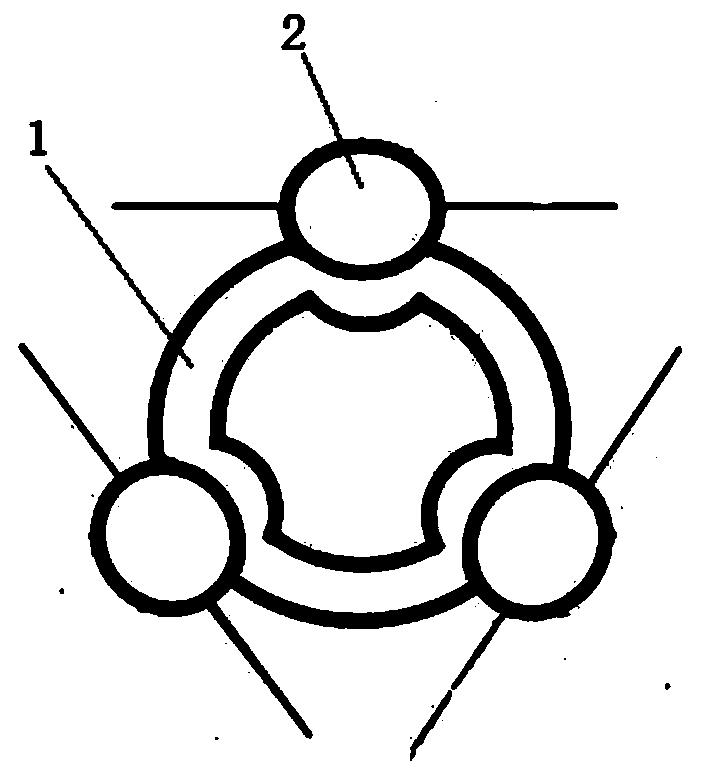

Special-shaped seamless steel pipe rolling manufacturing method

ActiveCN107626766AGuaranteed continuous operationReduce construction costsRoom temperatureHeat treated

The present invention relates to a special-shaped seamless steel pipe rolling manufacturing method, which directly uses cold rolling to manufacture a special-shaped seamless steel pipe, and specifically comprises: raw material preparing, roller type straightening, flaw detection, cold rolling pretreatment, cold rolling, heat treatment, straightening, marking and warehousing, wherein hot rolling isfirstly performed to obtain a special-shaped seamless steel pipe billet material for cold rolling at a room temperature, and the special-shaped seamless steel pipe is manufactured by using cold rolling, wherein the process steps specifically comprise raw material preparing, heating, hot rolling, annealing, roller type straightening, flaw detection, cold rolling pretreatment, cold rolling, heat treatment, straightening, marking and warehousing. According to the present invention, with the special-shaped seamless steel pipe rolling manufacturing method, the manufacture of the special-shaped seamless steel pipe is not limited by the raw material; the hot rolling and the cold rolling are combined by using the rolling tool and the core rod die or the cold rolling is separately performed, suchthat the advantages of easy performing and high yield are provided; and the flexible combination installation can be performed according to the requirement, and the installation precision can be controlled.

Owner:ANGANG STEEL CO LTD

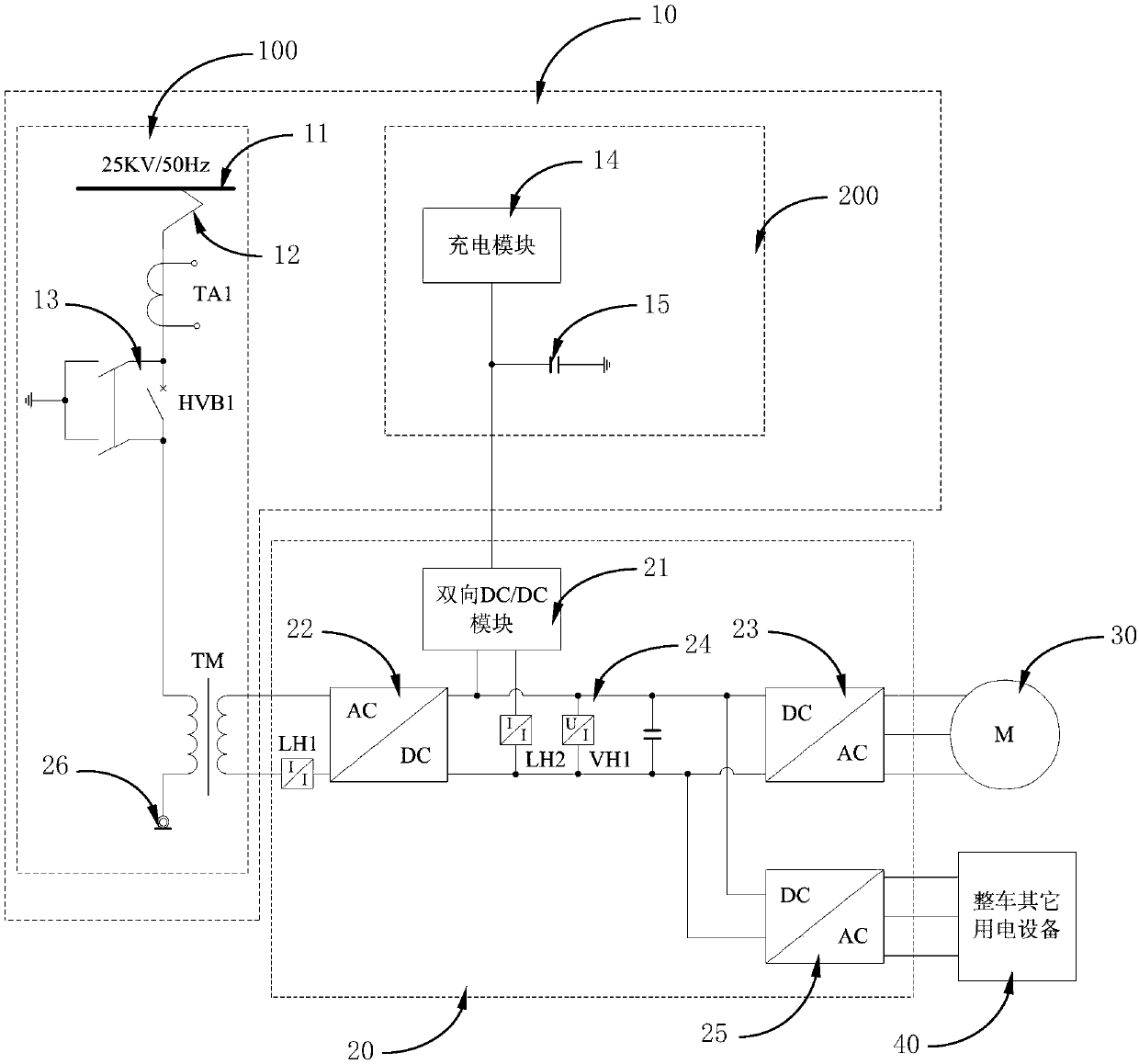

Railway engineering machine hybrid power source system

ActiveCN107554299AReduce points of failureReduce workloadPropulsion using ac induction motorsElectric powerElectric energyElectricity

The invention discloses a railway engineering machine hybrid power source system which comprises a hybrid power source and a converter connected with the hybrid power source. The hybrid power source comprises a main power source and an auxiliary power source, and electric energy from the main power source or the auxiliary power source is converted through the converter and treated to be electric energy needed by a whole vehicle electricity consumption device. When the system is electrically connected and communicated with an overhead line system and the overhead line system continues to be powered, the whole vehicle electricity consumption device is powered by the overhead line system power source; when the system is electrically disconnected with the overhead line system or the overhead line system cannot be continuously powered, the whole vehicle electricity consumption device is powered by the auxiliary power source; when the two power sources need to be switched, the whole vehicleelectricity consumption device is powered by both the main power source and the auxiliary power source in the switching process, and the replaced power source exits from power supply after switching is ended. The technical problems that according to an existing railway engineering machine internal combustion hydraulic power mode, maintenance is complex, the hydraulic oil leakage possibility exists, and environment pollution is serious can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

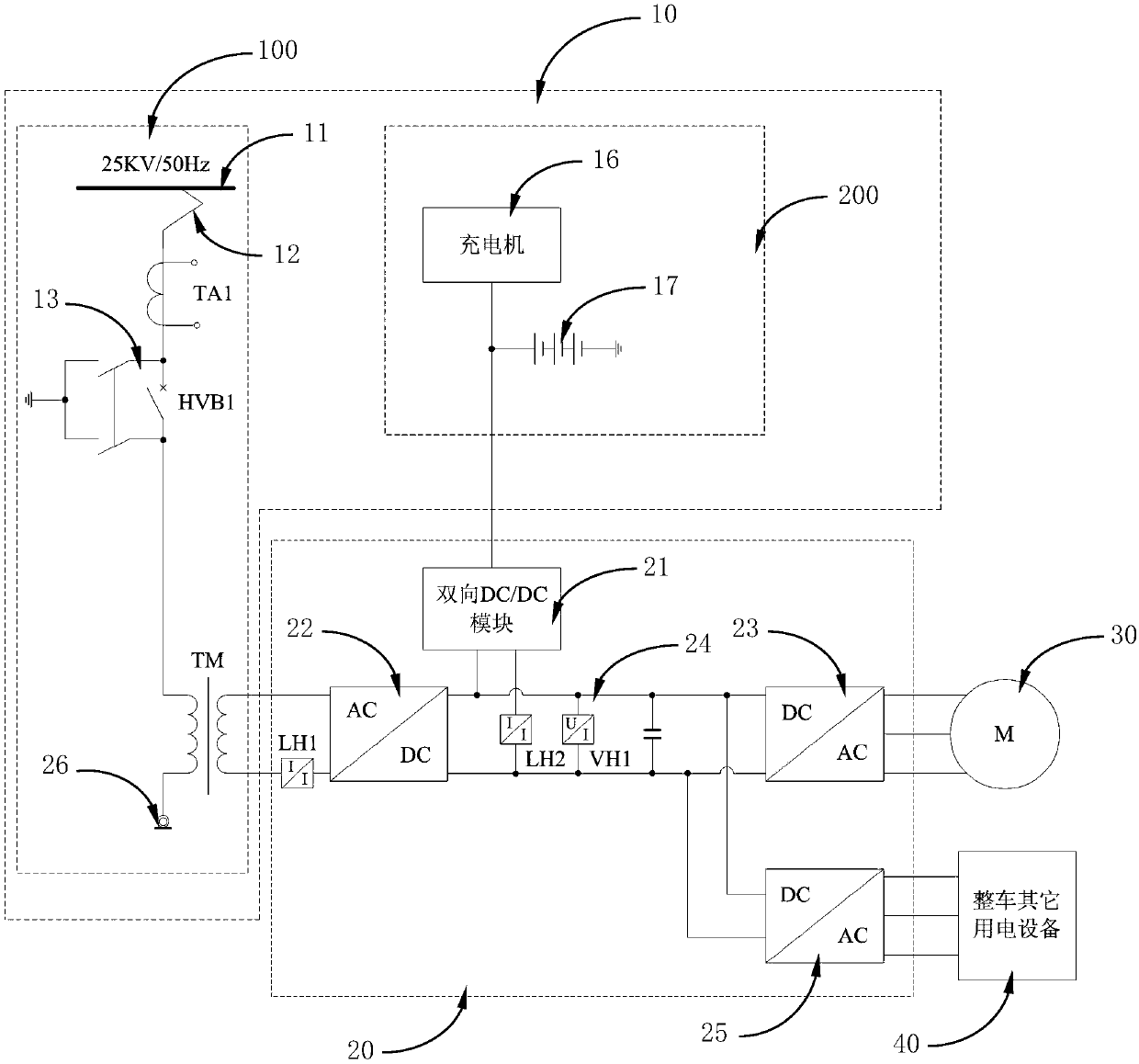

Kitchen waste treatment method and equipment

InactiveCN104858212AReduce storageGuaranteed continuous operationSolid waste disposalResource utilizationSlag

The invention relates to a kitchen waste treatment method and equipment. The method comprises the following steps of bag breaking separation, breaking pulping, sand removing, pyrolysis, three-phase separation. The steps are sequentially carried out, and normal-temperature anaerobic fermentation is carried out on water obtained through three-phase separation to generate marsh gas; and the marsh gas is used for fuel of a steam boiler in the pyrolysis process so as to generate heat to be supplied to a pyrolysis system. An efficient treatment method for treatment of kitchen waste separation, pulping, separation and resource utilization is provided. Treatment processes are combined, and through combination of technical advantages of kitchen waste separation, puling, oil and slag resource utilization, water up-to-standard releasing, and resource utilization, the aim of kitchen waste treatment is achieved.

Owner:BEIJING CENTURY GREEN ENVIRONMENTAL ENG &TECH

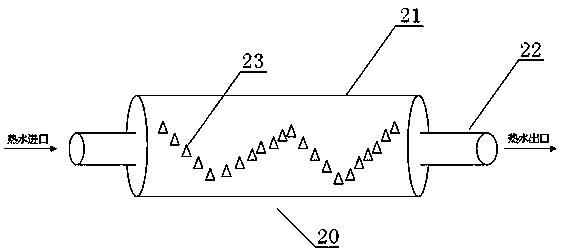

Concrete prefabricated part making method

ActiveCN102490246AEasy to operateMeet the needs of industrialized production of concrete prefabricated partsCeramic shaping apparatusOverhead craneRebar

The invention discloses a concrete prefabricated part making method. The concrete prefabricated part making method comprises the following steps of: (1) preparing concrete for future use; (2) making a water pool; (3) placing equipment; (4) making a mold; (5) placing a reinforcing steel bar treatment device; (6) preparing a curing water circulating device; (7) laying reinforcing steel bars betweentemplates; (8) starting a bridge crane to convey the concrete to a concrete spreader; (9) starting the concrete spreader to pour the concrete into the mold; (10) compacting the concrete and then temporarily stopping; (11) dipping a concrete prefabricated part in water; (12) preserving the heat of the hot water; (13) feeding the hot water on a platform back to a heating water tank after curing period; and (14) cutting off the reinforcing steel bars exposed on the external sides of the templates to obtain the concrete prefabricated part. According to the invention, the problems of lower production efficiency, higher operation cost and energy consumption, complicatedness in operation and maintenance and incapability of realizing industrial production in the prior art are solved.

Owner:SHANDONG ONE STAR CO NSTRUCTION TECH CO LTD

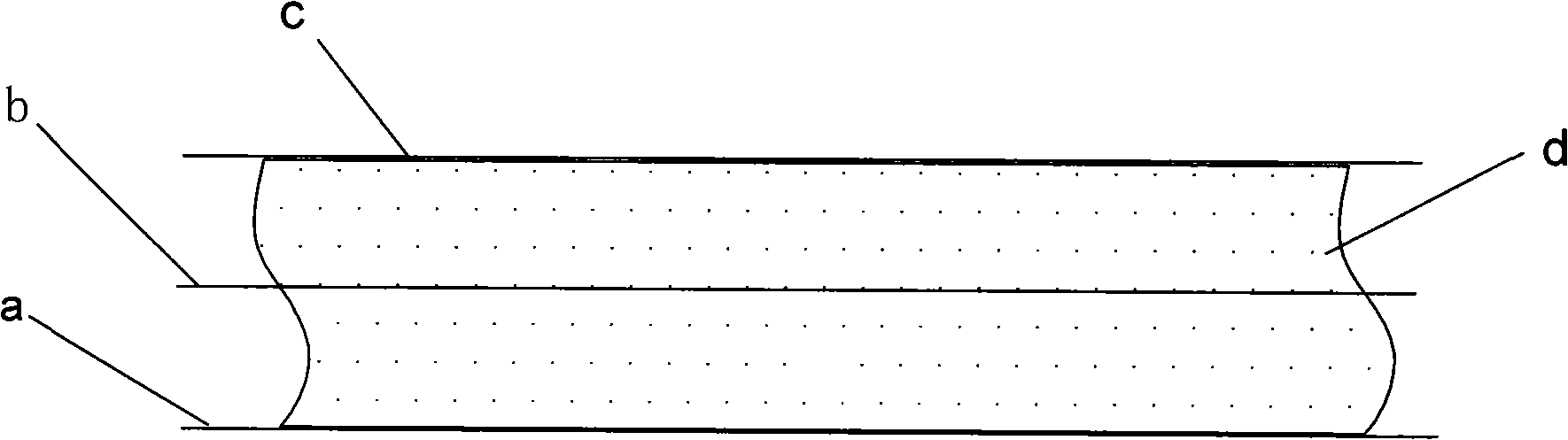

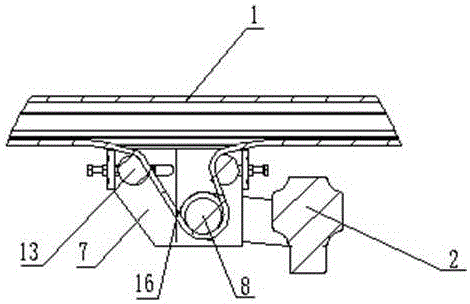

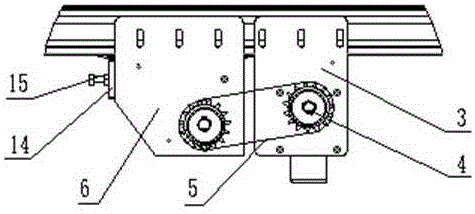

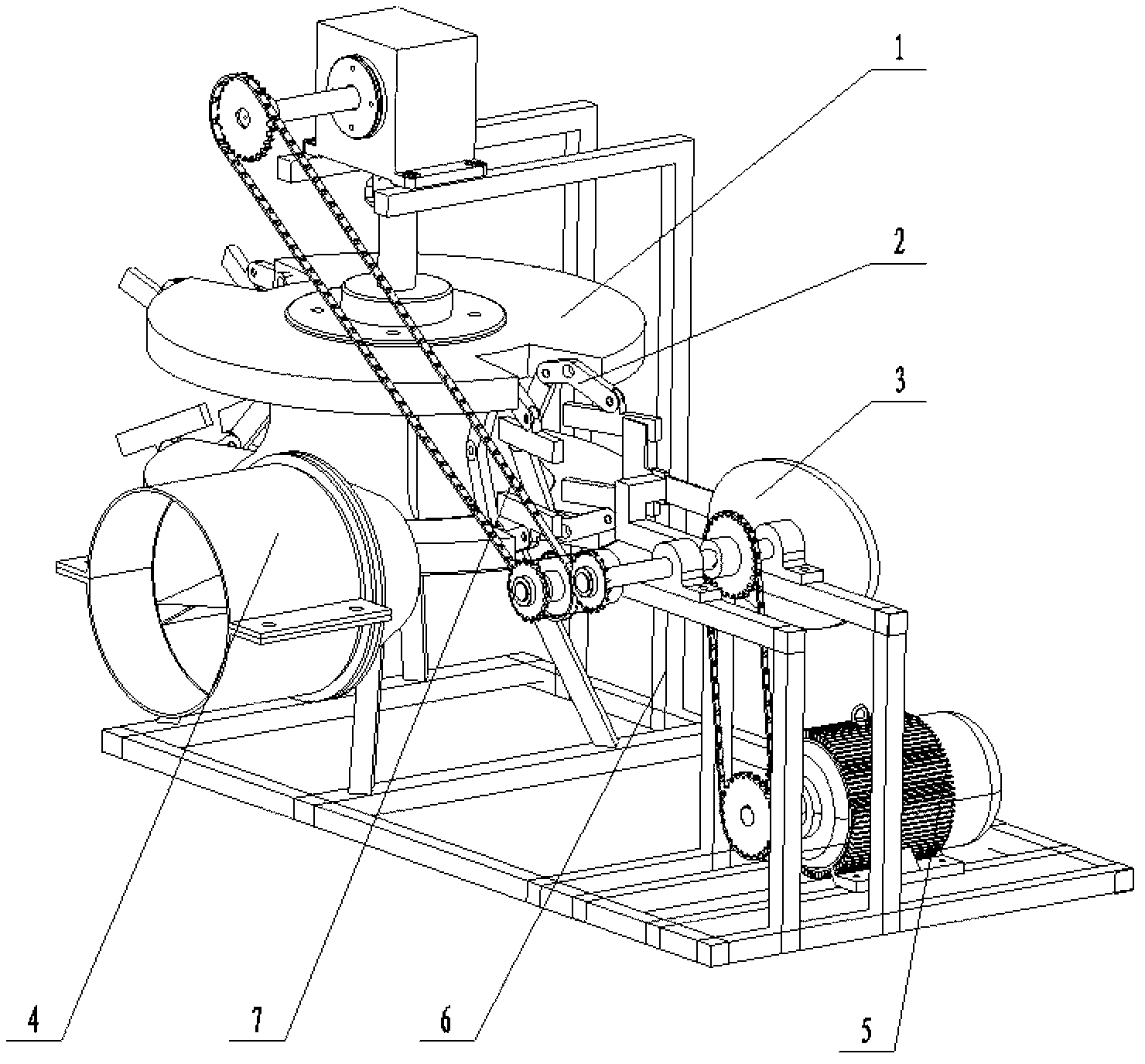

Driving and tensioning device for short-distance horizontal belt conveyor

The invention belongs to the field of design and manufacturing of transportation machinery, and in particular, relates to a driving and tensioning device for a short-distance horizontal belt conveyor. The device comprises a driving component and a tensioning component, and specifically comprises the following parts: a machine body 1, a motor 2, a motor mounting plate 3, a chain wheel 4, a chain 5, a right mounting panel 6, a left mounting panel 7, a driving roller 8, a mounting base 9, a deep groove ball bearing 10, a shaft retainer ring 11, a hole retainer ring 12, a tensioning wheel 13, an adjusting block 14, an adjusting screw rod 15, a conveying belt 16 and a driven roller 17. The device realizes integration of driving and tensioning, can realize any movement in the transverse position of a horizontal machine body according to space design requirements, is compact in structure, saves the space, is liable to modularize and exchange, can apply less space to realize relatively higher adjusting quantity, guarantees normal continuous operation of the belt conveyor, and is more reliable and stable.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

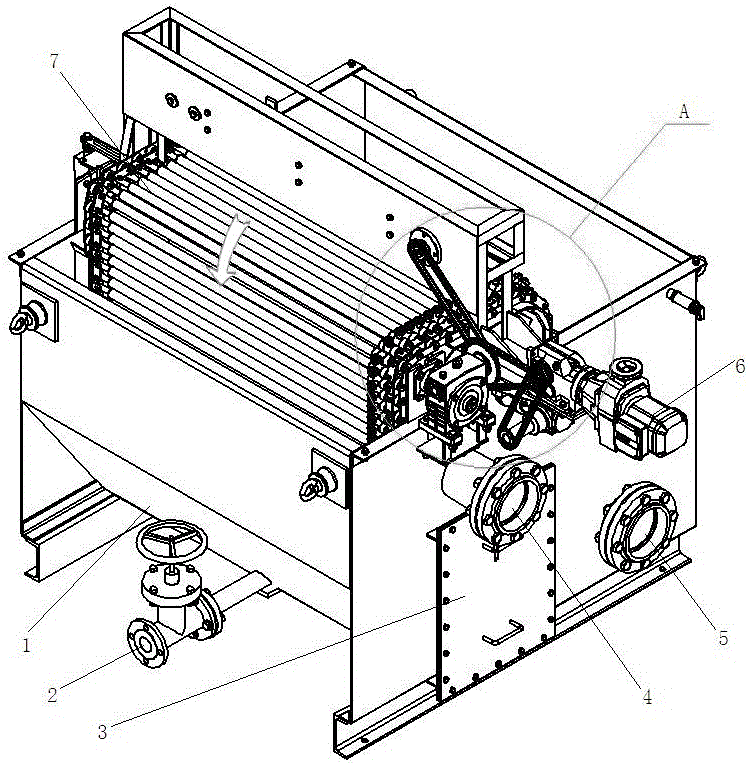

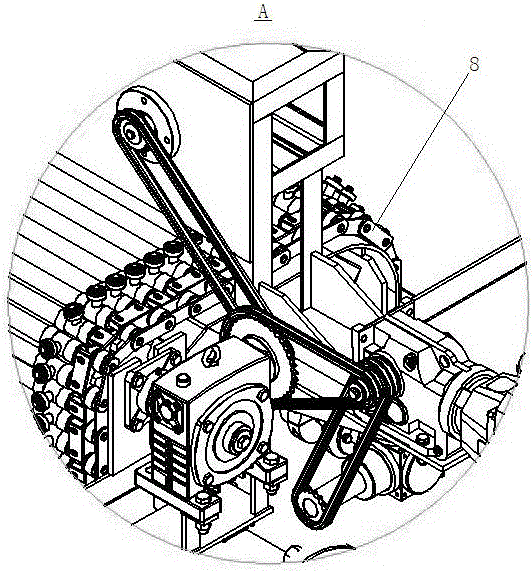

Chain bar type permanent magnet filter

The invention relates to a chain bar type permanent magnet filter. The chain bar type permanent magnet filter comprises a box, magnetic bar chains which are arranged in the box and can rotate around themselves, sludge scraping mechanisms arranged on the magnetic bar chains and sludge tanks which are arranged under the sludge scraping mechanisms and located in the magnetic bar chains; sludge conveying mechanisms are arranged in the sludge tanks, and each magnetic bar of the magnetic bar chains is sleeved with a scraping sleeve in a matched mode; each sludge scraping mechanism comprises a moving block capable of moving in the axial direction of the corresponding magnet bars in a reciprocating mode, two scrapers capable of only swinging in the axial direction of the corresponding magnetic bars are hinged to the lower portion of each moving block, can swing towards the side close to each other and reset and cannot swing to the side far away from each other, and the bottoms of the scrapers are lower than the tops of the scraping sleeves when the scrapers do not swing. The filter is simple in structure, low in cost, capable of ensuring continuous operation, good in scraping effect and convenient to maintain.

Owner:WISDRI ENG & RES INC LTD

Automatic material replacing and receiving crusher

ActiveCN103127979ACompact structureSmall footprintGrain treatmentsContinuous/uninterruptedMotor drive

The invention discloses an automatic material replacing and receiving crusher which comprises a machine frame, a machine head, a crushing roller, a material guide frame, a servo feeding mechanism and a motor driving mechanism. The machine frame is provided with two layers with the left heights and the right heights being different. The machine head is arranged on the upper layer of the machine frame, and the motor driving mechanism is arranged on the lower layer of the machine frame. Tooth sheets of the crushing roller are arranged in a material crushing cavity of the machine head. The material guide frame is arranged on a feeding port close to the machine head. The servo feeding mechanism is arranged on the top of the machine head and drives a feeding device inside the machine head. The motor driving mechanism drives the crushing roller to rotate. The automatic material replacing and receiving crusher is simple and compact in structure, small in occupied space and reasonable in design, achieves continuous feeding, and improves production capacity and production efficiency.

Owner:ANQING HENG CHANG MACHINERY

Automatic splicing device for broken yarn of weaving cotton cloth

InactiveCN103388227AGuaranteed continuous operationImprove work efficiencyAuxillary apparatusCotton clothYarn

The invention provides an automatic splicing device for a broken yarn of weaving cotton cloth, which is installed on a weaving machine. The automatic splicing device comprises a connection box, a main spindle and an auxiliary spindle, wherein two leading-in connectors which are respectively connected with the main spindle and the auxiliary spindle are installed on the front end of the connection box; a detector is respectively installed between the main spindle and the leading-in connector and between the auxiliary spindle and the leading-in connector; the detectors are respectively connected with a main control device, and only on of the main spindle and the auxiliary spindle is connected with a textile fabric; the detector can transmit a yarn breaking signal to the main control device, the connection box is controlled by the main control device to connect another yarn with the weaving machine, and the continuous running of the weaving machine can be guaranteed.

Owner:SUZHOU HAOJIAN TEXTILE

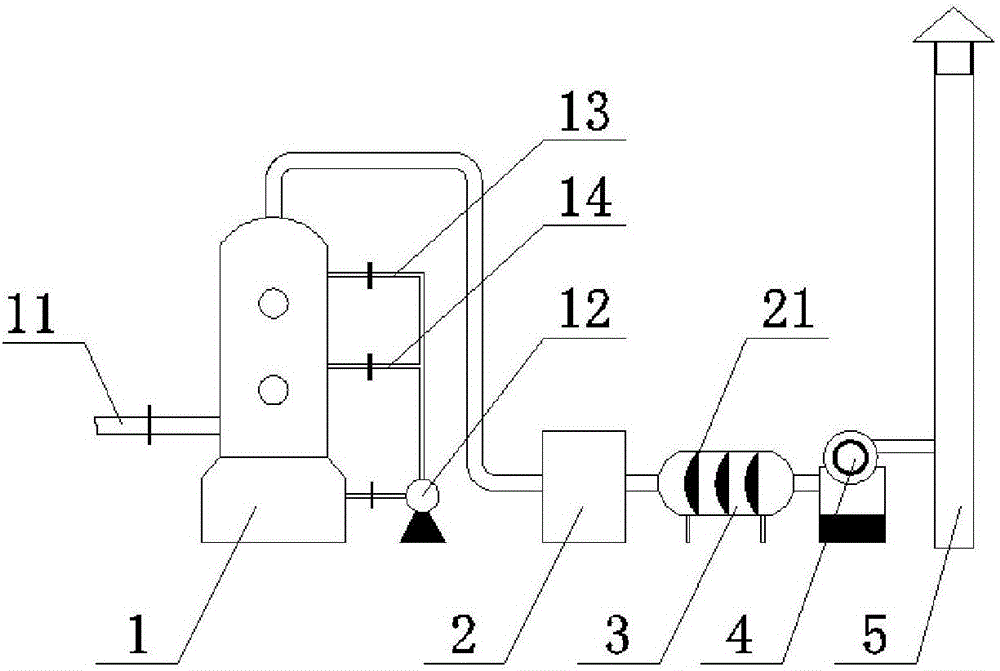

Paint spray room waste gas treating device

PendingCN106731395AAvoid clogging the linesGuaranteed continuous operationCombination devicesSpray towerActivated carbon

The invention relates to a paint spray room waste gas treating device, and belongs to the technical field of waste gas treating. The paint spray room waste gas treating device comprises a spray tower, a demisting device, an activated carbon adsorption device, a fan and a chimney which are connected in sequence by pipelines; paint spray room waste gas enters from a gas inlet of the spray tower, and passes through the spray tower, the demisting device, and the activated carbon adsorption device for purification treatment, and after meeting the standard, the waste gas is discharged from the chimney. The paint spray room waste gas treating device can be used for removing paint mist completely and has a good adsorption purifying effect on the waste gas.

Owner:安徽德玉环境工程装备有限公司

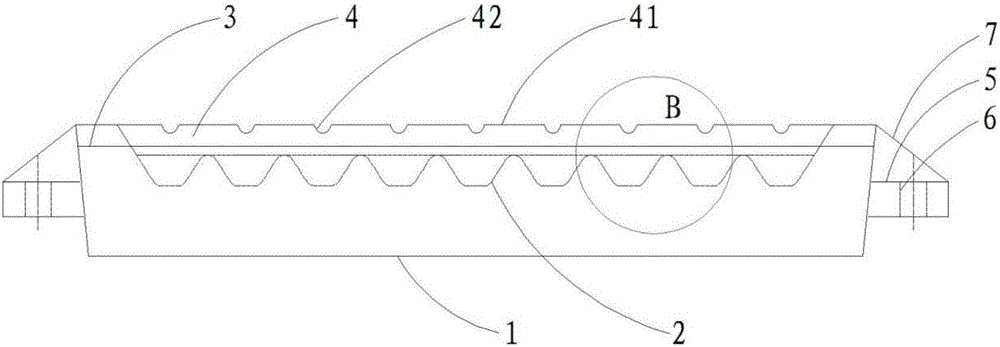

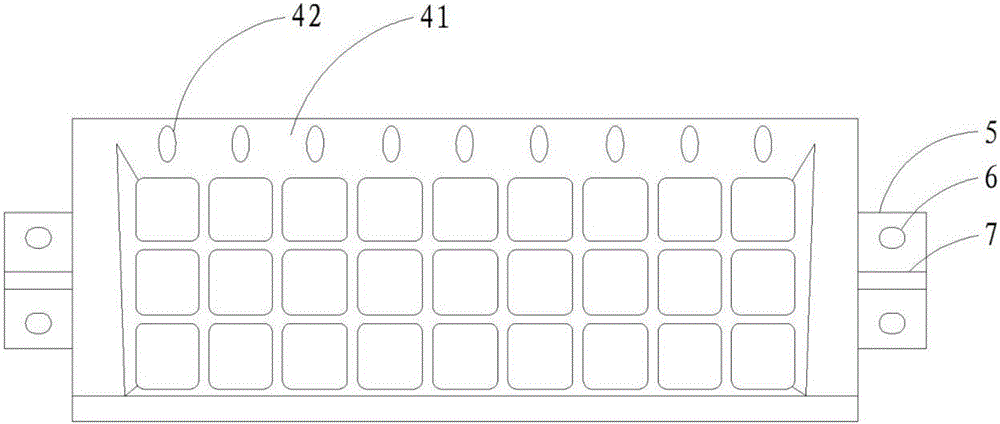

Receiving mould for continuous casting machine

InactiveCN105855471AResistance to impact erosionSimple structureFoundry mouldsFoundry coresLap jointAlloy

The invention belongs to a mould applied in an alloy smelting pouring process, and particularly relates to a molding receiving mould for an alloy continuous casting machine. The receiving mould comprises a mould main body and casting pit grooves uniformly distributed in the mould main body; the mould main body is of a rectangular structure, the upper plane of the front portion of the mould main body and the upper plane of the back portion of the mould main body are provided with a front lap-joint portion and a back lap-joint portion respectively, the middles of the two sides of the mould main body are provided with fixing lugs respectively, fixing bolt holes are formed in the fixing lugs, and diagonal reinforcing ribs are made at the joints of the fixing lugs and the mould main body. The receiving mould has the following advantages that the materials are low in cost and are easily obtained, the high temperature and molten steel impact and corrosion can be resisted, the structure is simple, demoulding can be perfectly achieved after detail treatment, the demoulding rate exceeds 99%, and it is guaranteed that the casting machine can continuously operate.

Owner:宁夏铸源机械制造有限公司

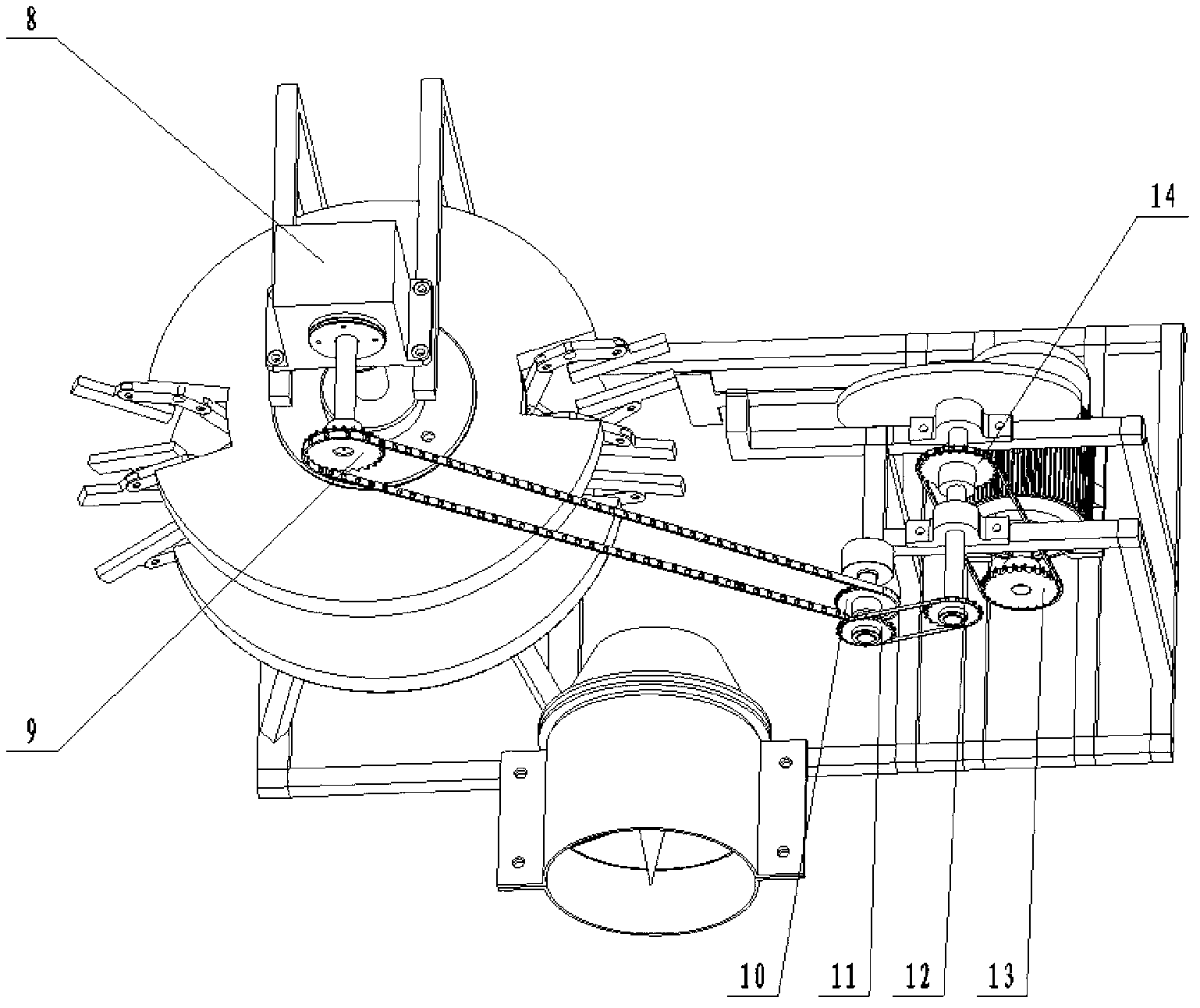

Grass braid fixed length traction cutoff device

InactiveCN103317536APrecise cuttingEasy to organizeMetal working apparatusEngineeringMechanical field

The invention belongs to the field of grass processing machinery and relates to a grass braid fixed length traction cutoff device. According to the grass braid fixed length traction cutoff device, a matched mode of a rotating disk mechanism, a clamping hand and a cutoff mechanism is adopted to finish fixed length traction cutoff work of grass braids in forming. The clamping hand is installed on a rotating disk, the rotating disk is oval, and the clamping hand can be powered intermittently along with rotation of the rotating disk, clamp the grass braids in a fixed length mode, rotate along with the rotating disk and clamp the grass braids to perform traction. A crank-link mechanism is adopted for the cutoff mechanism, and the grass braids are cut off in the fixed length mode along with rotation of the rotating disk. The grass braid fixed length traction cutoff device can accurately cut off the grass braids at proper lengths and guarantee continuity of operation. The standard and tidy grass braids facilitate follow-up tidying, transportation and storage.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com