Method for producing high-quality nickel-iron alloy by reducing laterite-nickel ore under control

A lateritic nickel ore, high-quality technology, applied in furnace types, furnaces, shaft furnaces, etc., can solve problems such as poor operation continuity, high S and P content, high energy consumption in process production, and a wide range of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

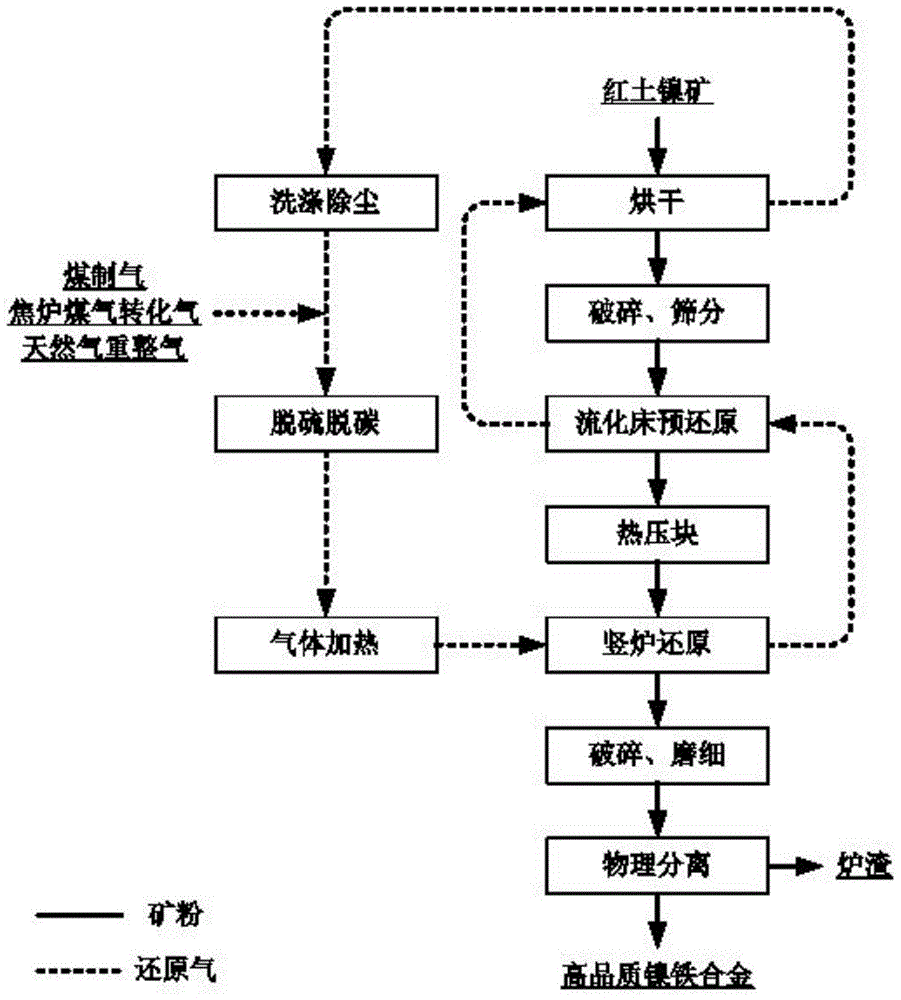

[0043] In order to better illustrate the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0044] As shown in the figure, a method for controlled reduction of laterite nickel ore to produce high-quality ferronickel comprises the following steps:

[0045] (1) carry out gas drying to laterite nickel ore raw material;

[0046] (2) The dried laterite nickel ore raw material is crushed and screened;

[0047] (3) The screened laterite nickel ore powder enters the fluidized bed for pre-reduction by reducing gas;

[0048] (4) Pre-reduced laterite nickel ore powder hot compact;

[0049] (5) The laterite nickel ore after briquetting enters the shaft furnace for reduction through reducing gas;

[0050] (6) The laterite nickel ore after the reduction treatment is crushed, ground and physically separated to obtain high-quality ferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com