Pass-type microwave drying system for sand mould

A microwave drying and sand molding technology, which is applied in drying, drying machines, progressive drying machines, etc., can solve the problems of inaccurate control of drying quality, inability to dry completely, poor drying uniformity, etc., and achieve smooth in and out, Improved service life and synchronous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

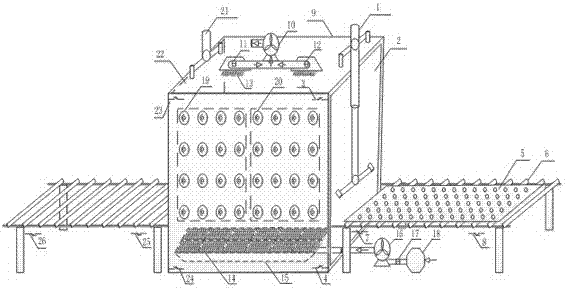

[0036] According to one aspect of the present invention, the present invention provides a pass-through microwave drying system for sand molds, figure 1 It is a structural diagram of a pass-through microwave drying system for sand molds of the present invention, as figure 1 As shown, it includes a roller table device, a microwave drying chamber and a moisture exhausting air supply device, wherein the roller table device includes: a roller table and a limit mechanism, and the microwave drying chamber is arranged on the roller table of the roller table system, The inlet and outlet of the microwave drying chamber (9) are provided with a limit mechanism, which is used to limit the sand mold bearing tooling (5); the front and rear walls of the microwave drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com