Patents

Literature

794results about How to "Reduce movement distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

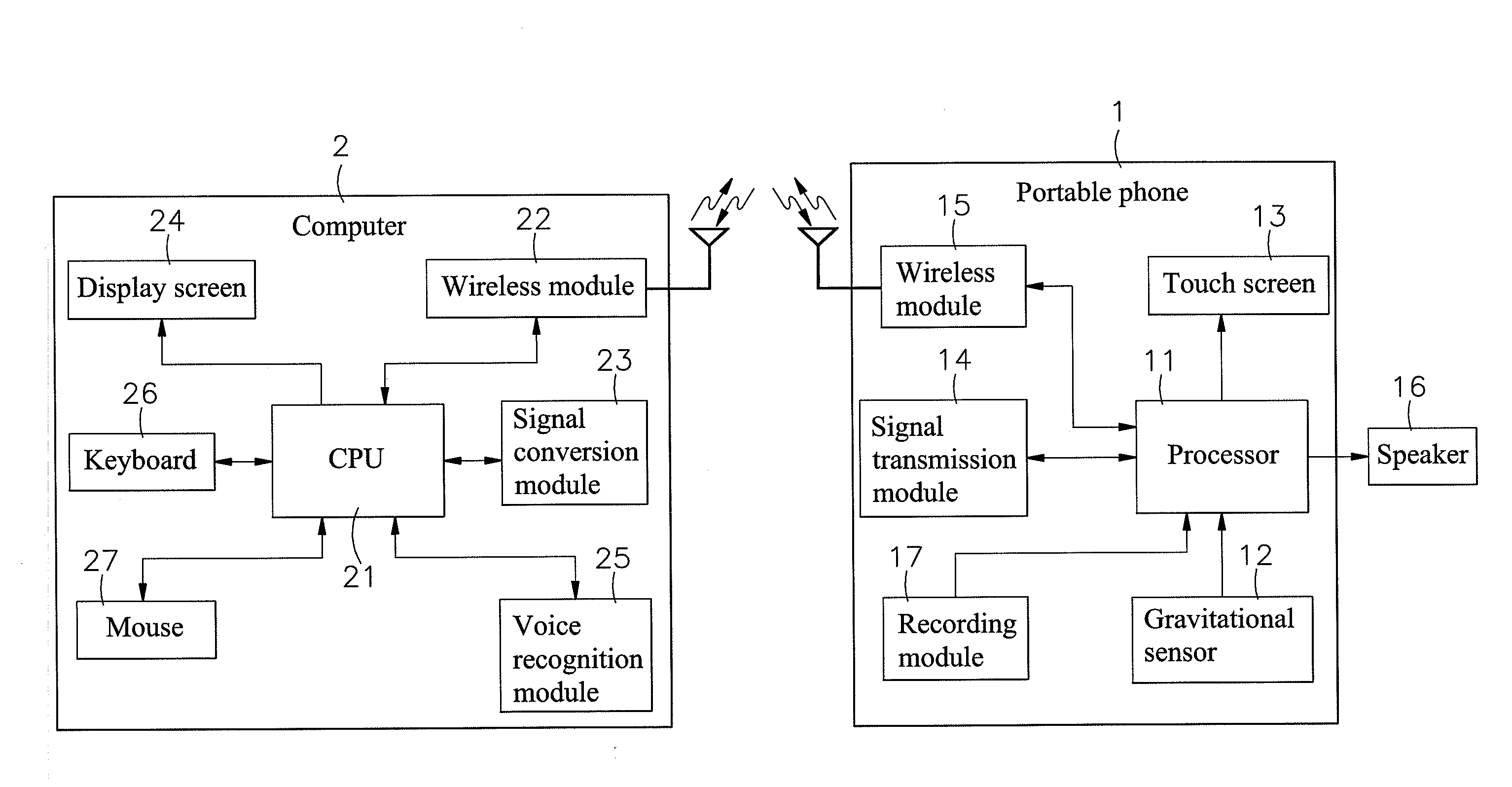

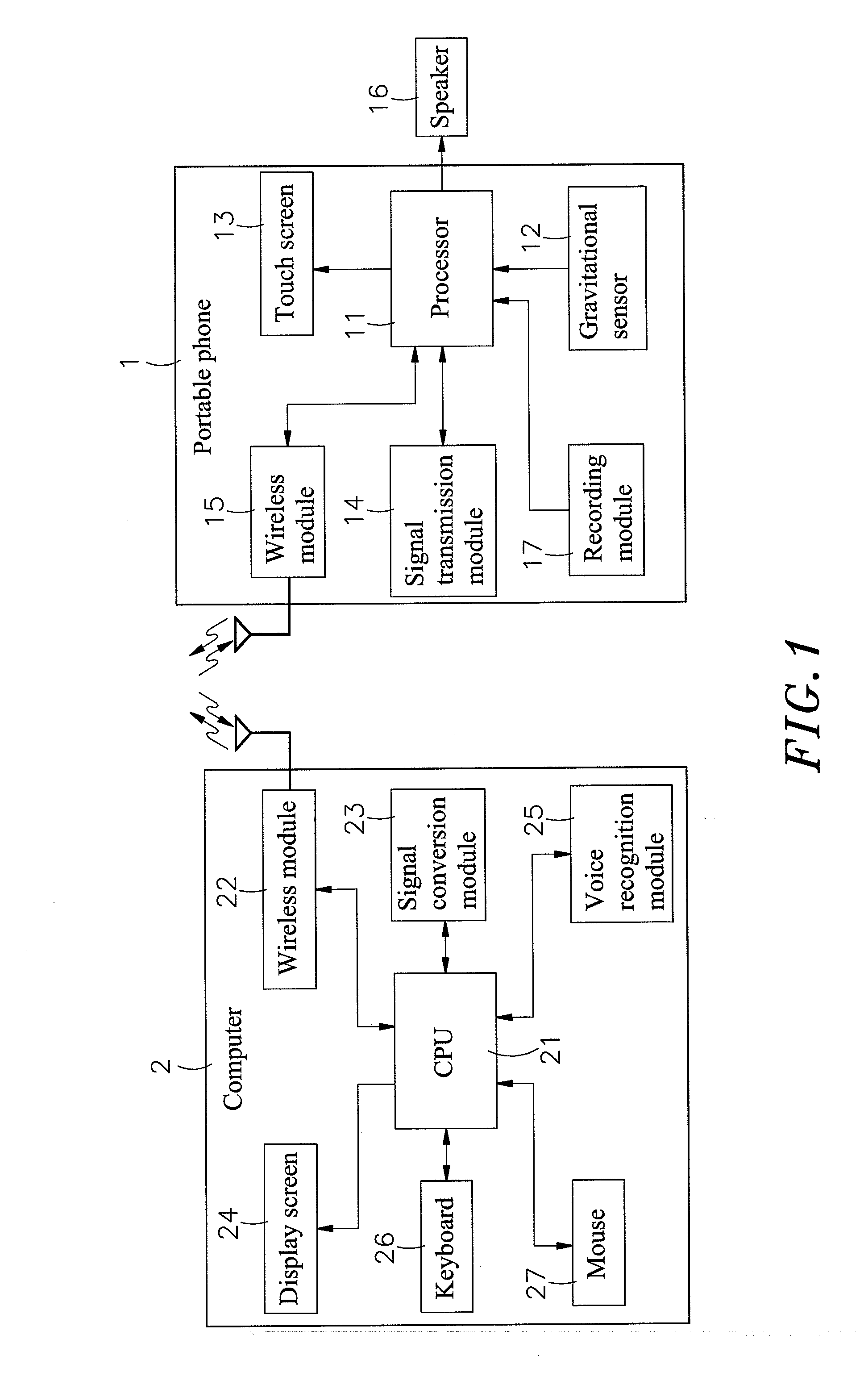

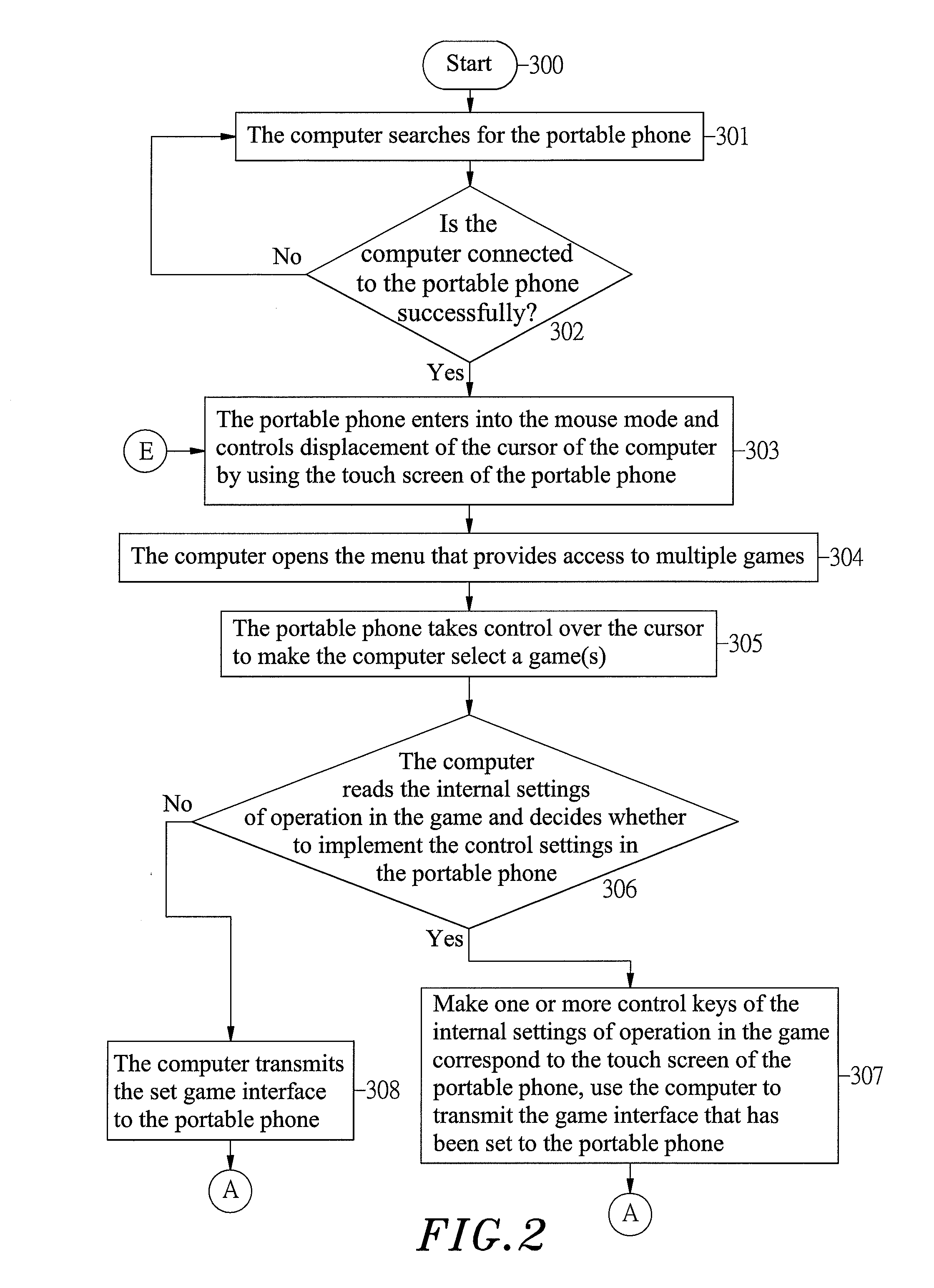

Method for portable phones to control computers

InactiveUS20110246902A1Low costEasy to operateTransmission systemsMultiple digital computer combinationsGame interfaceTouchscreen

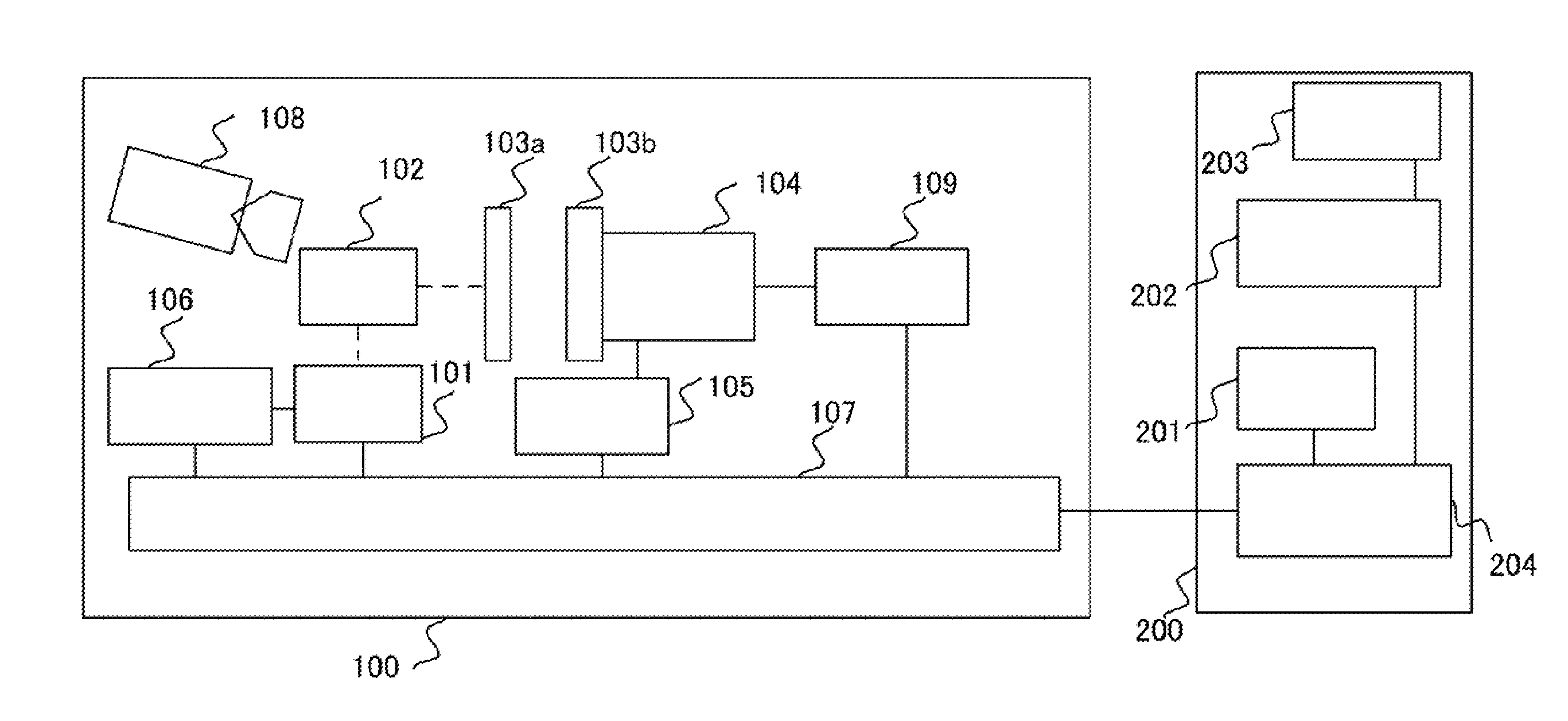

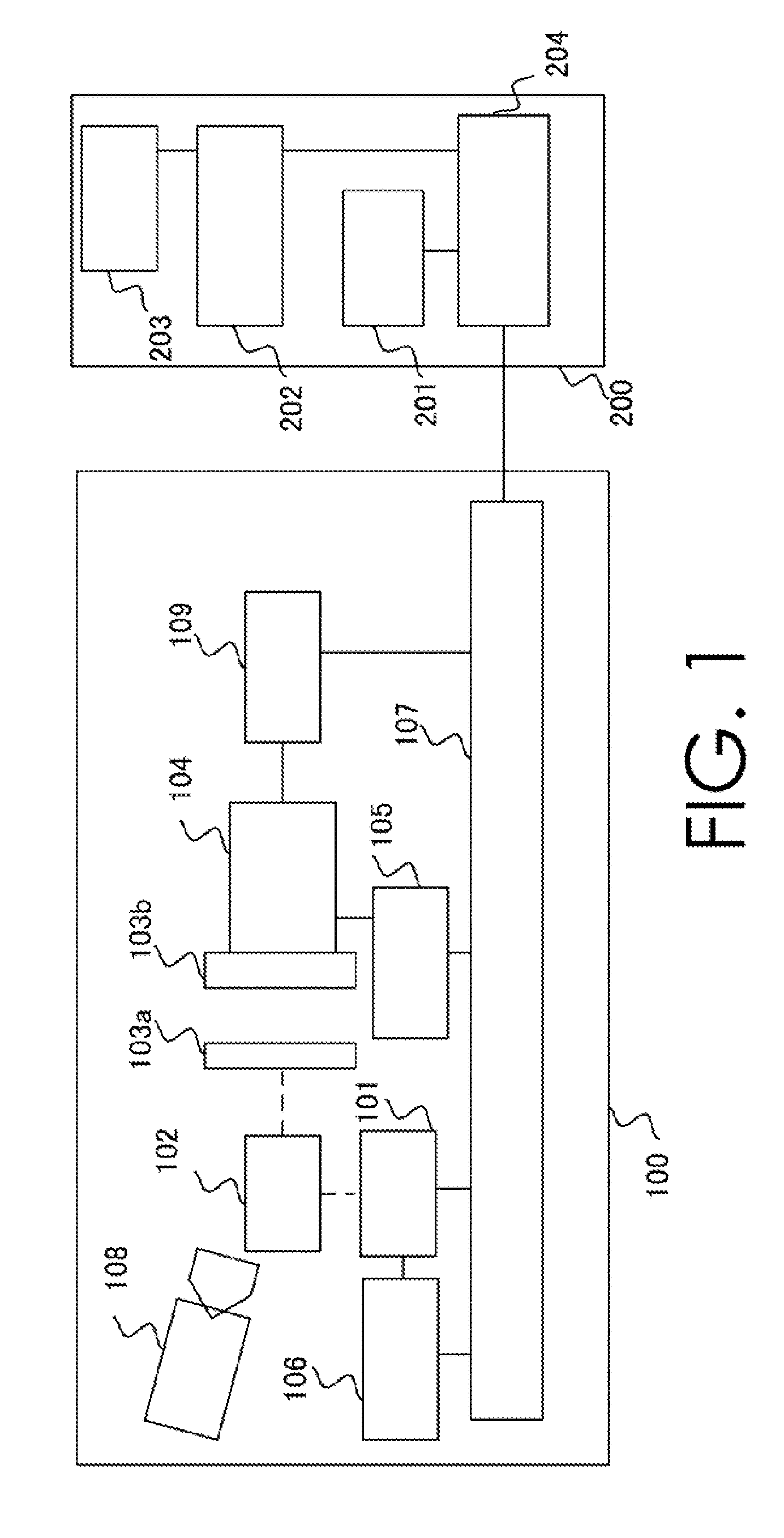

The present invention relates to a method for portable phones to control computers, comprising the steps of: the portable phone entering into the mouse mode after connecting with the computer; controlling the computer to open game menus and select a game through the touch screen of the portable phone; the computer transmitting the set game interface to the portable phone to allow keys to be displayed on the touch screen. Once the game is started, if there is any touch upon the keys on the touch screen, the portable phone will transmit the signals of control keys that correspond to the internal settings of operation in the game. When the portable phone is moved or picks up voices, the G sensor or recording module will transmit signals of the sensed or acquired data to the computer, which will compare these signals with the gesture database, angle-acceleration database or voice recognition database of the voice recognition module, and will transmit the signals of control keys resulting from comparison to the game to make it act accordingly. In this way, the portable phone will be able to exercise wireless and touch-based control over games, achieving the purposes of improved convenience and reduced cost.

Owner:AIBELIVE

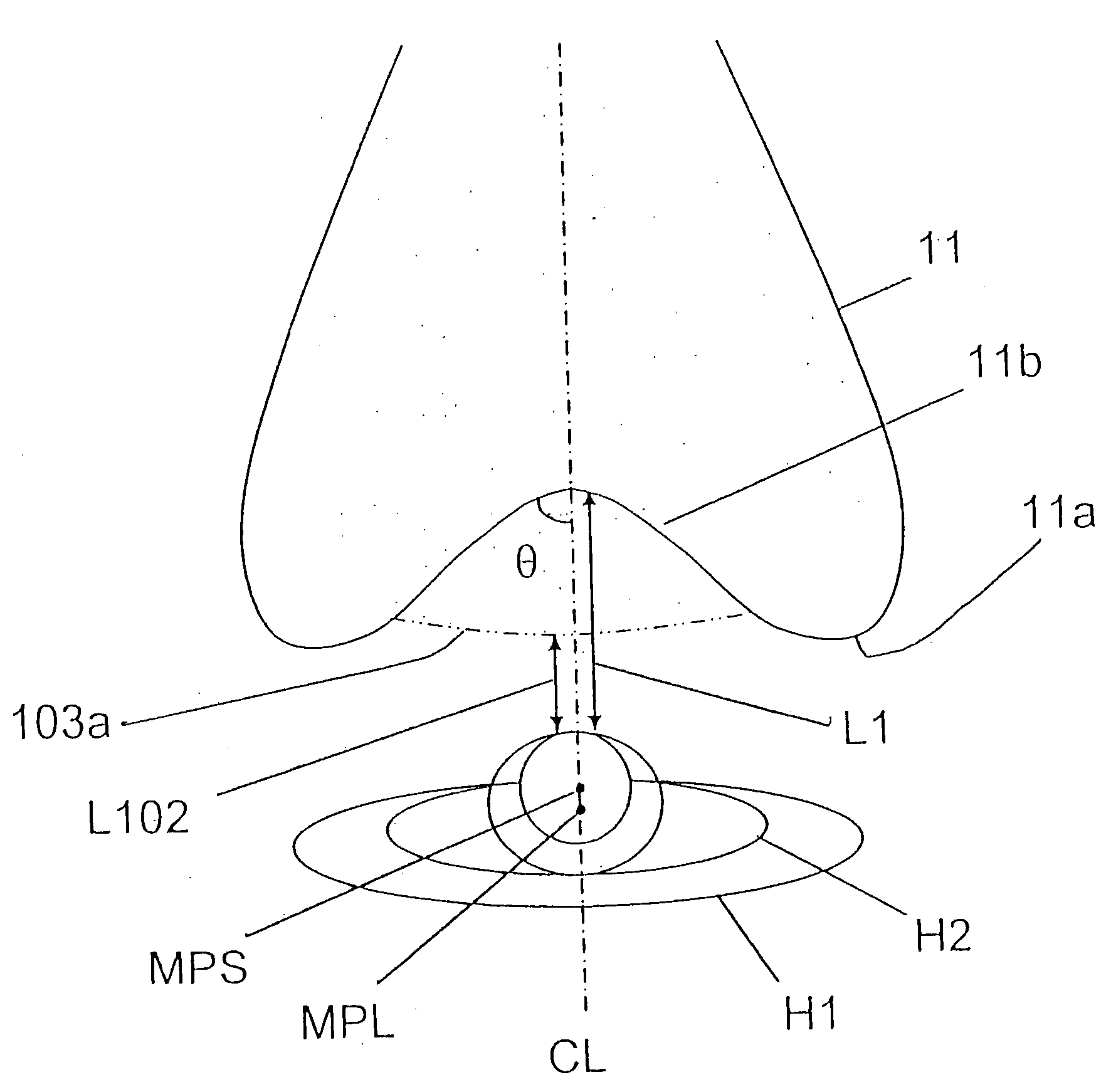

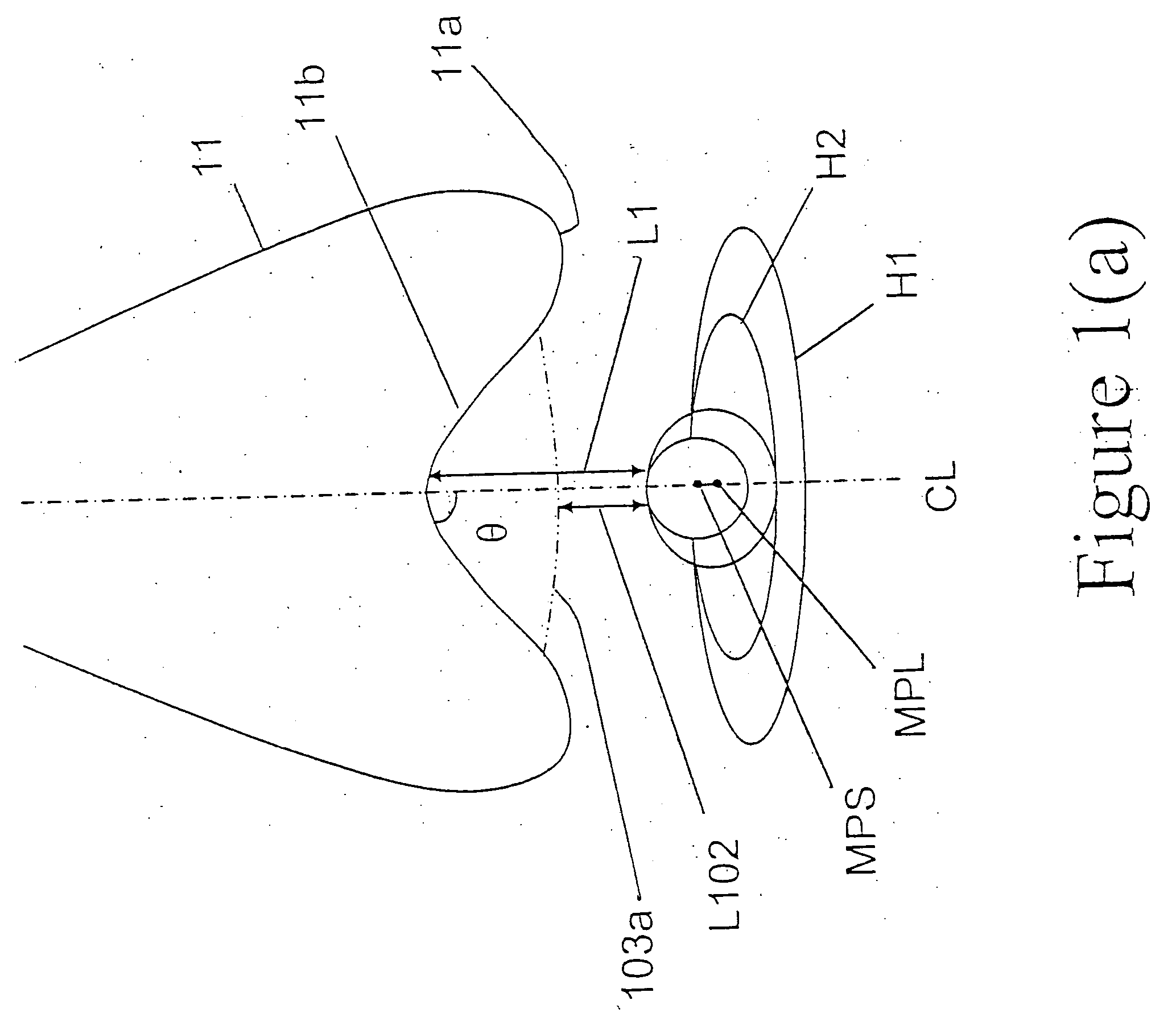

Airbag cushion with angled recess

InactiveUS20050098994A1OptimizationProtecting an occupant more efficientlyPedestrian/occupant safety arrangementAirbagCushion

An airbag device with an improved airbag configuration to protect a vehicle occupant more efficiently. The airbag device is stored in the upper portion of an instrument panel of a vehicle under normal situations. The airbag device has an airbag that is deployable into a space in front of a vehicle occupant in the event of a vehicle emergency, such as a collision. The airbag viewed from the top when fully deployed and inflated has a right side portion, a left side portion, and a recess between the right and left side portions. When pressure is applied to the right and left side portions, the recess maintains a recessed shape.

Owner:TAKATA CORPORATION

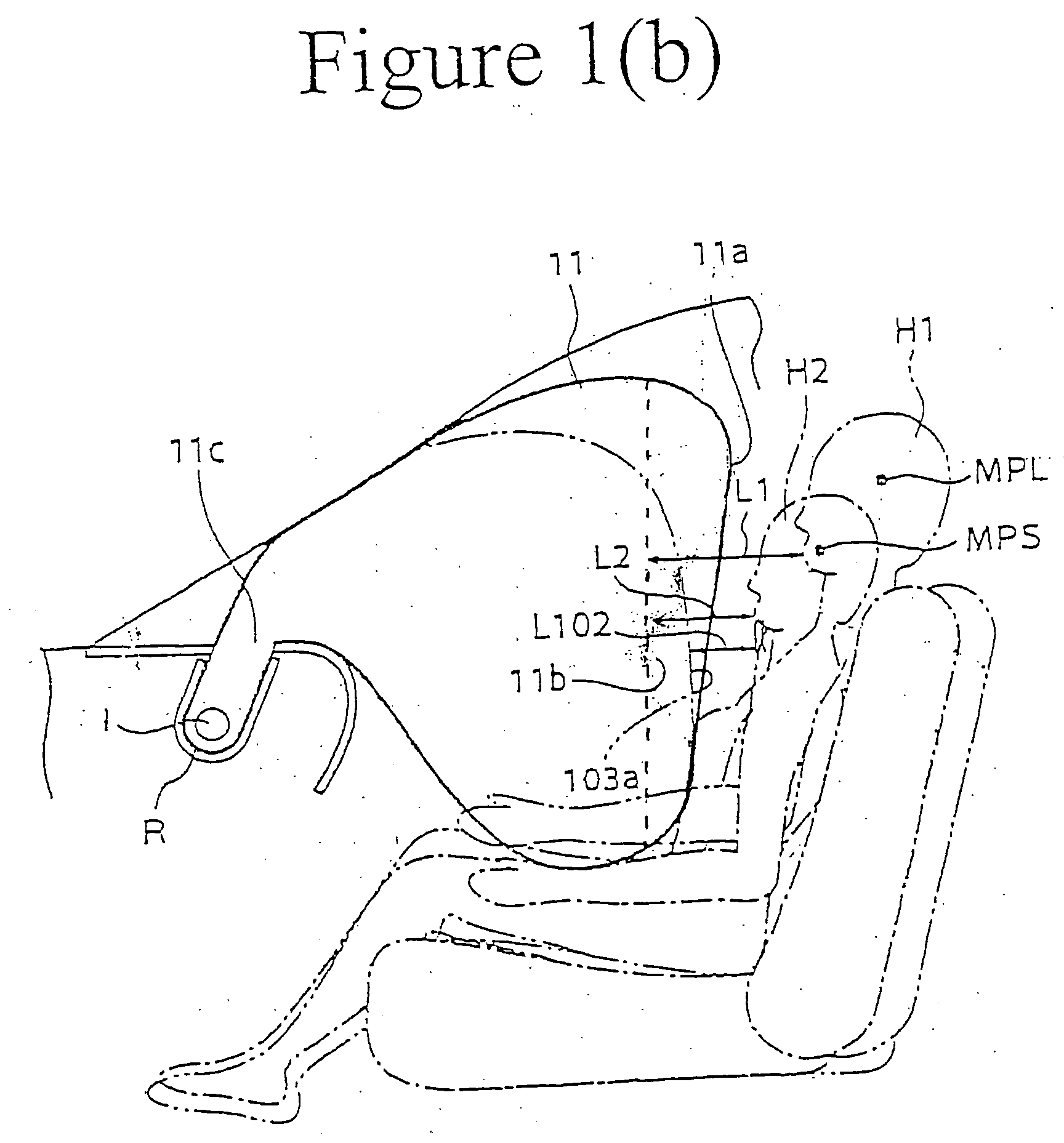

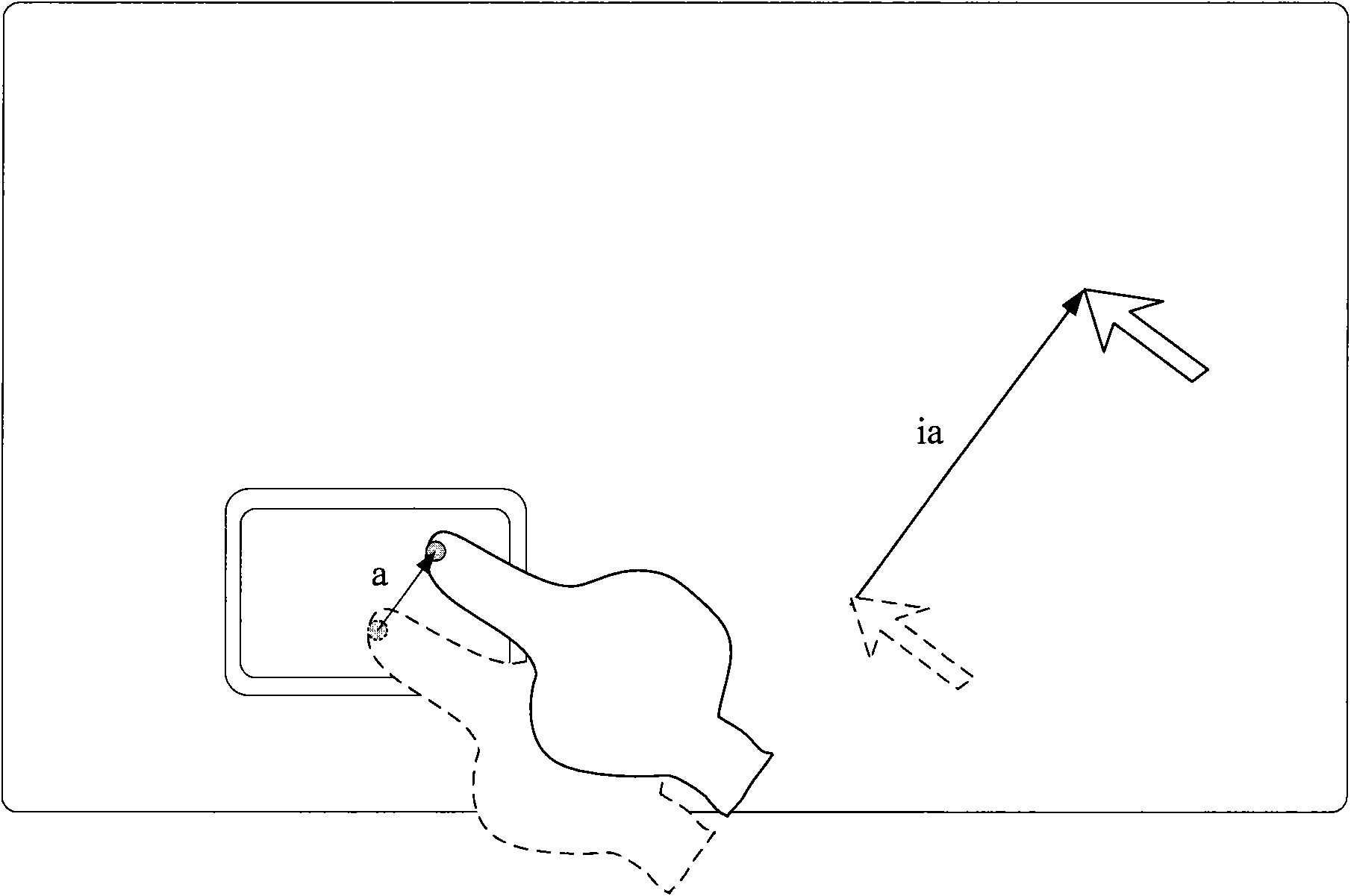

Processing method and apparatus for information input from touch screen

InactiveCN101676844AReduce user fatigueEasy to useInput/output processes for data processingTouchscreenProcess information

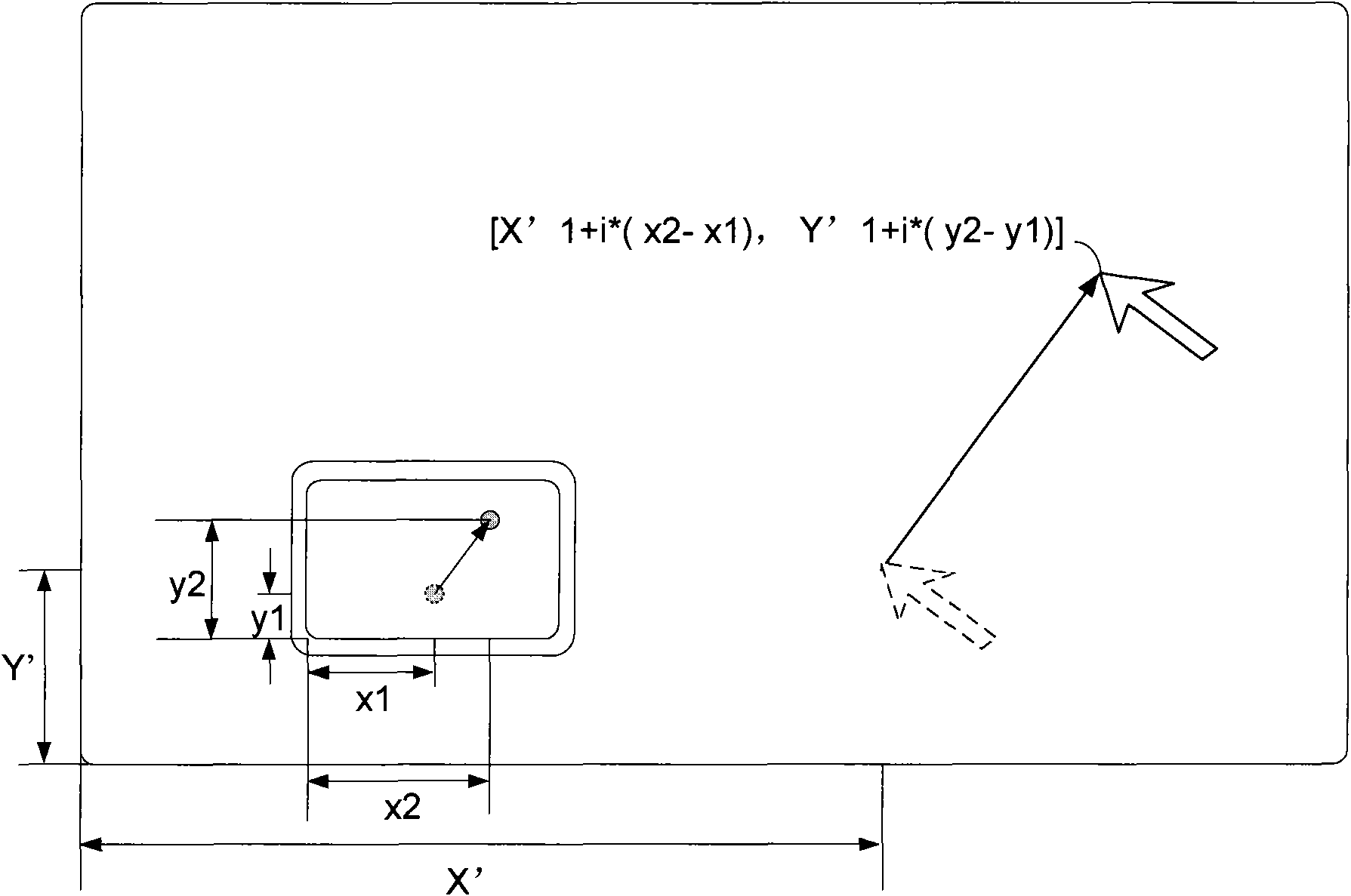

The embodiment of the invention discloses a method for processing information inputted from a touch screen, wherein a virtual touch screen window is provided in the touch screen. The method includes obtaining touch information, determining position of the touch point based on the touch information; displaying the position identification for indicating position on the predetermined position of thetouch screen when the position of the touch point is in the virtual touch board window; and performing the control operation corresponding to the touch information using the position identification. The embodiment of the invention further discloses an apparatus for implementing the method and equipment comprising the apparatus. A virtual touch board window is defined in the embodiment of the invention for processing the information inputted from the touch screen by the user. Screen touch operation can be performed by users through the virtual touch board window, so that selection and operationof widgets on the display interface are performed, the problem of the target widget is likely to be blocked and unable of being selected is avoided, and hand moving distance during user operation isshortened.

Owner:LENOVO (BEIJING) CO LTD

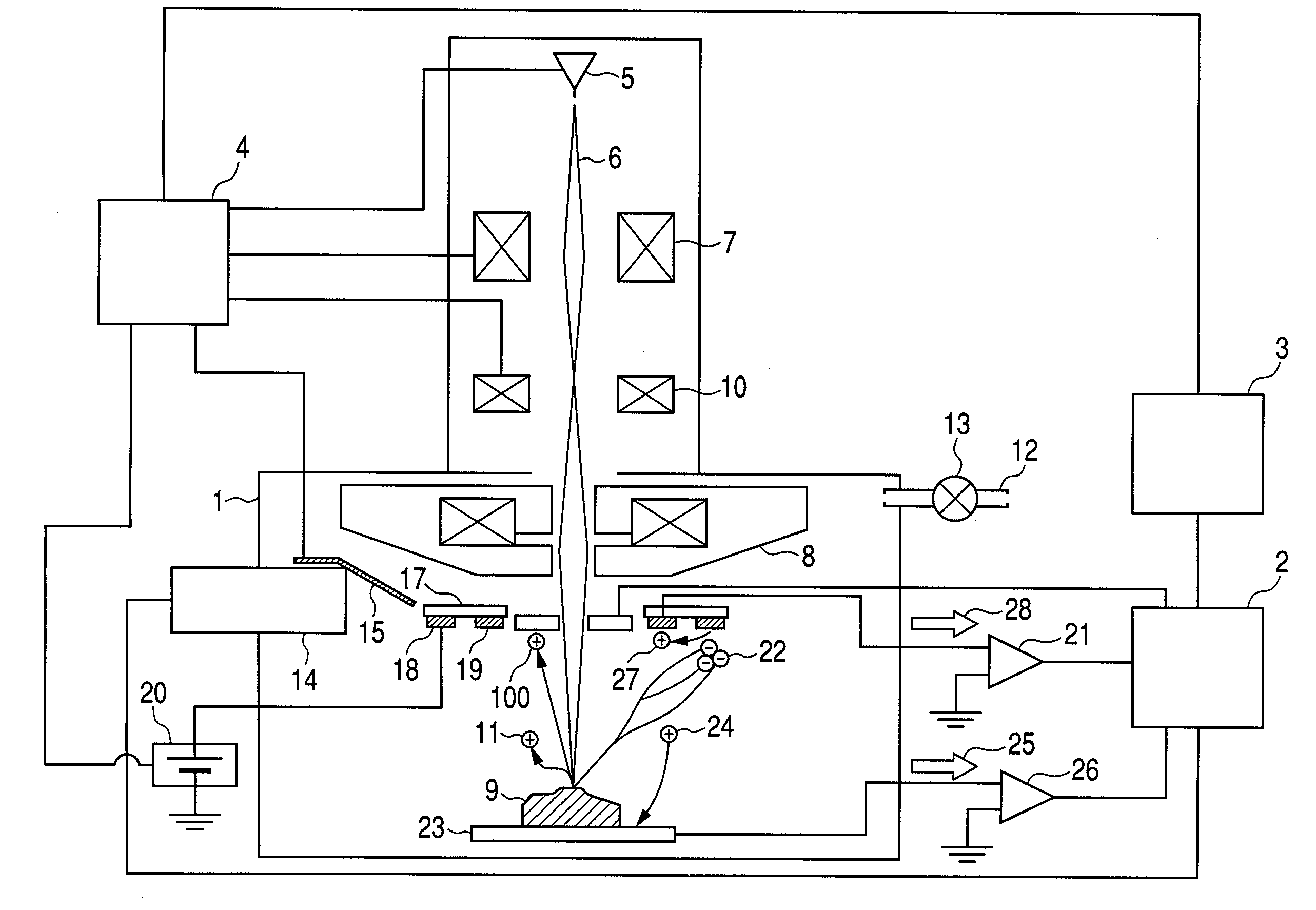

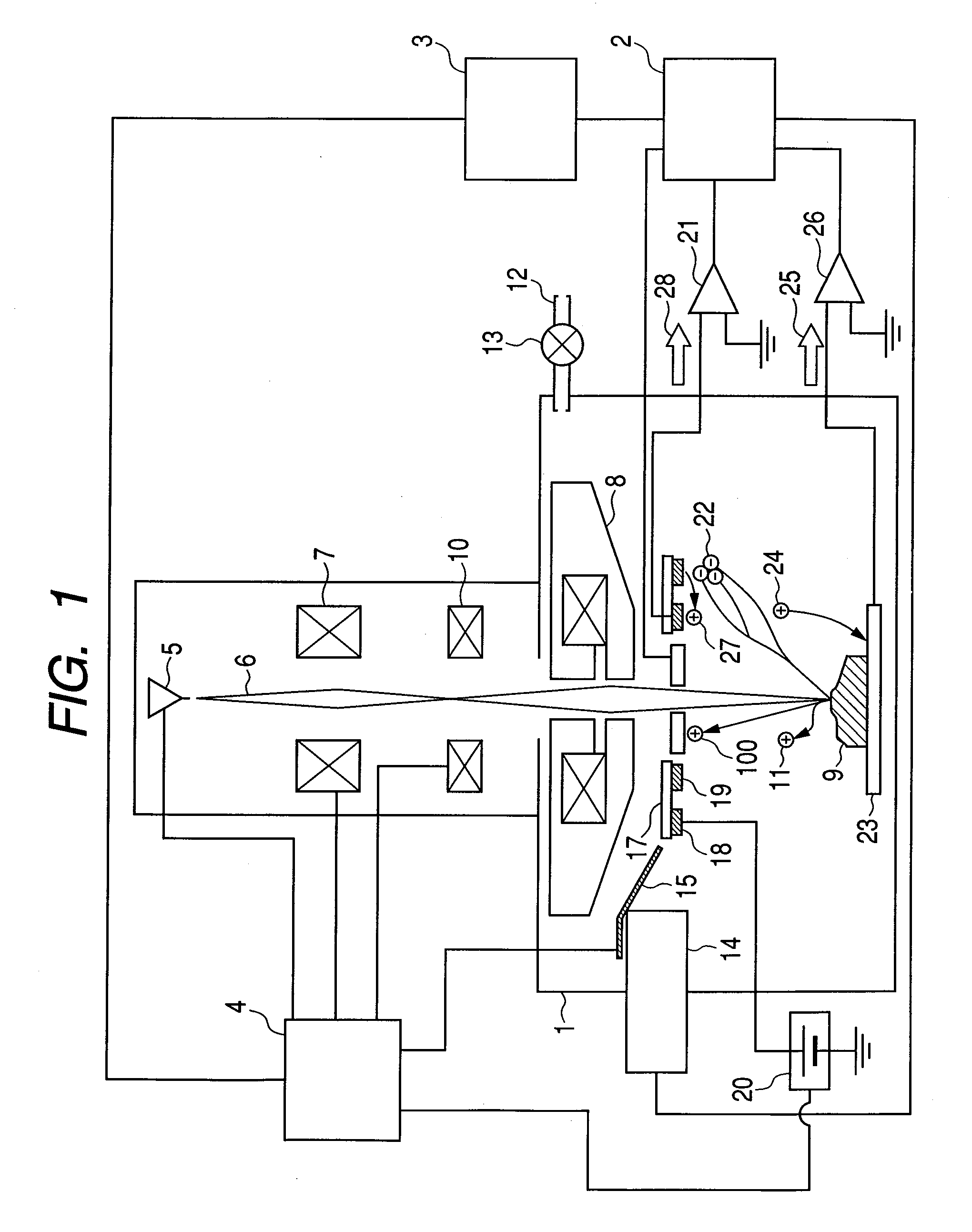

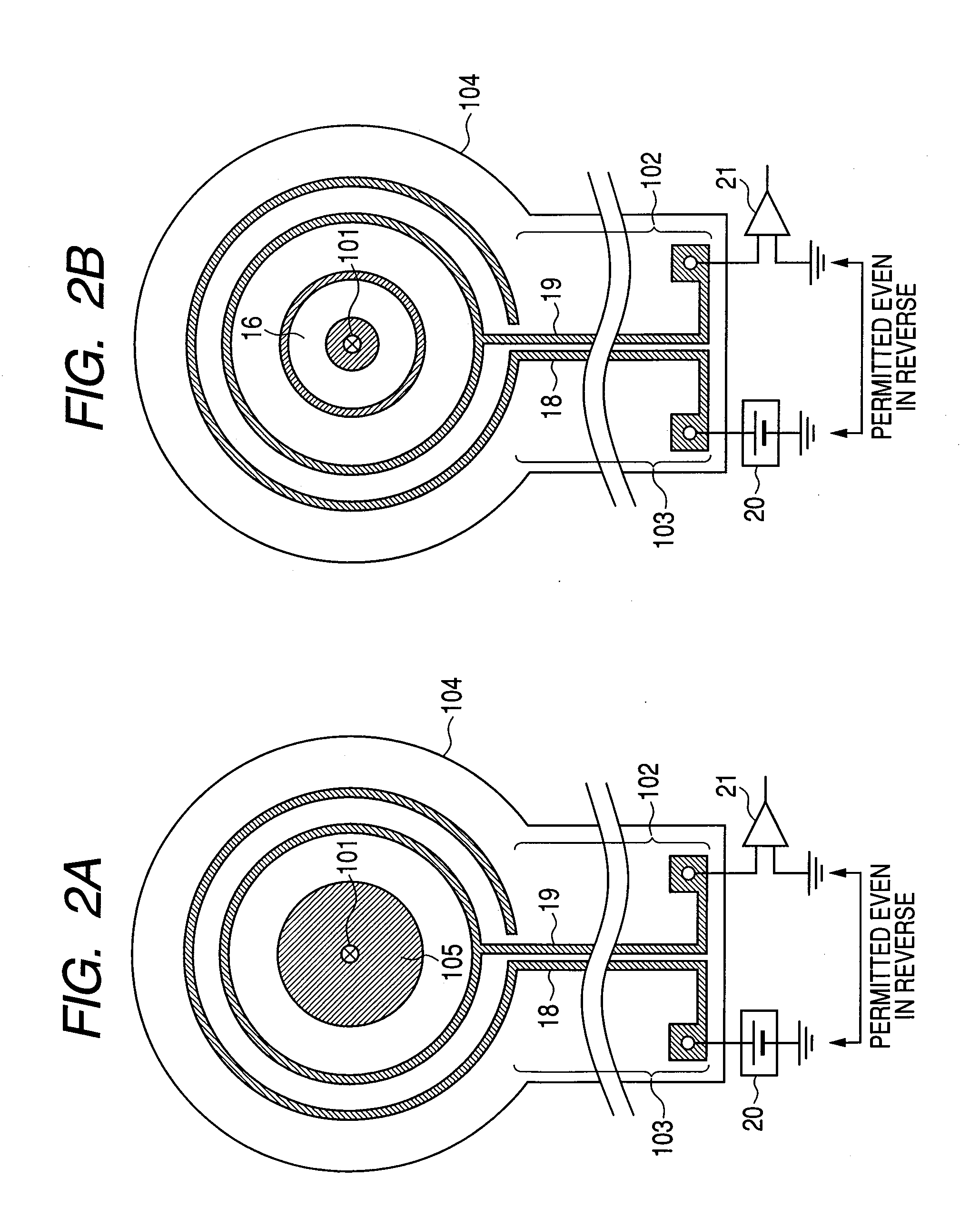

Scanning electron microscope

InactiveUS20090230304A1Low costSave spaceThermometer detailsMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

In a VP-SEM that uses gas multiplication induced within a low-vacuum sample chamber and uses a method of detecting a positive displacement current, a secondary electron detector for the VP-SEM that responds at high speed, which can acquire a TV-Scan rate image at a low cost while saving a space is provided. A secondary electron detector is formed by forming the electron supplying electrode and the detection electrode on the flexible thin film type substrate such as a polyimide film, etc., by an etching method. Thereby, the space can be saved while realizing low cost due to mass production. Further, the ion horizontally moving with respect to the surface of the secondary electron detector is detected and the ion moving in a vertical direction returned to the sample holder is not detected, making it possible to realize a high-speed response.

Owner:HITACHI HIGH-TECH CORP

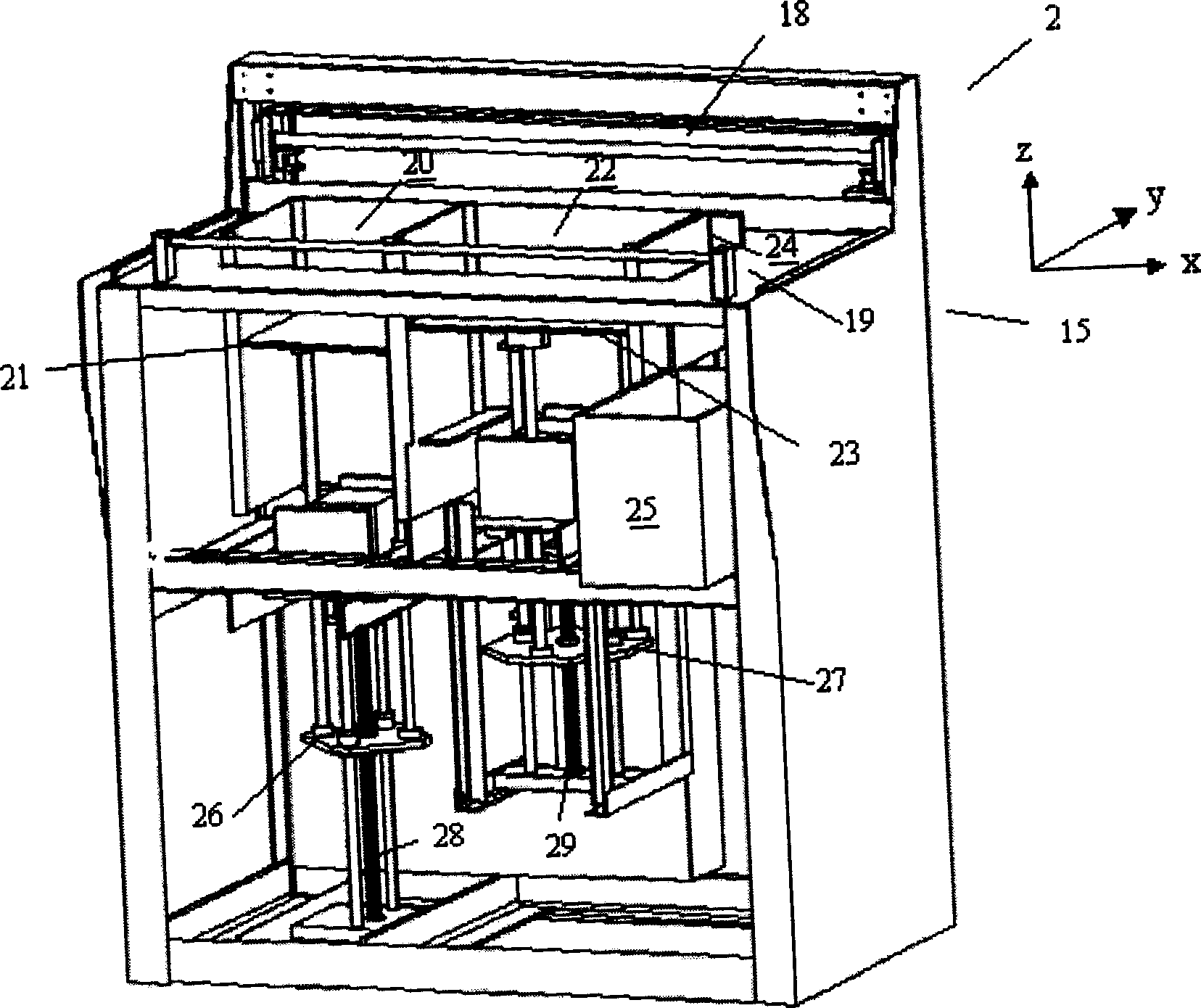

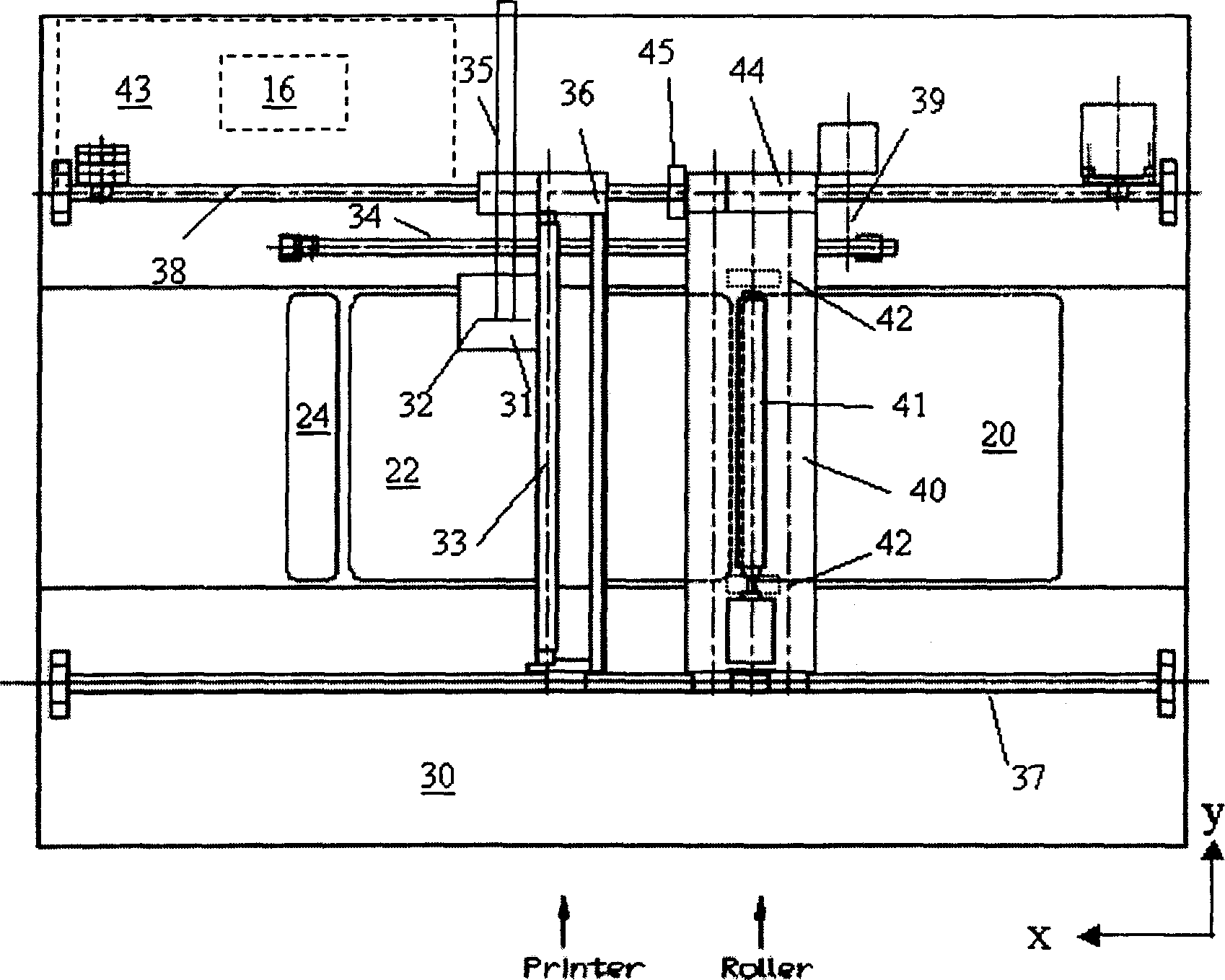

Fast shaping device for making body from image of computer and with printing machine

InactiveCN1911635AImprove stabilityImprove printing accuracyCoatingsPrintingEngineeringRapid prototyping

The present invention is one fast forming apparatus, in which the virtual image stored in the memory of computer is tomographically treated and the tomographical treatment obtained contours are jet printed one layer by one layer with fluid onto the powder in the constituting platform for combining with powder so as to form stereo real object. The fast forming apparatus includes the jet printing mechanism and firmware interfaces of a printer or a plotter, one work platform with tomographically operating software and jet printing control firmware, and one computer with memory with stored virtual image.

Owner:赖维祥 +1

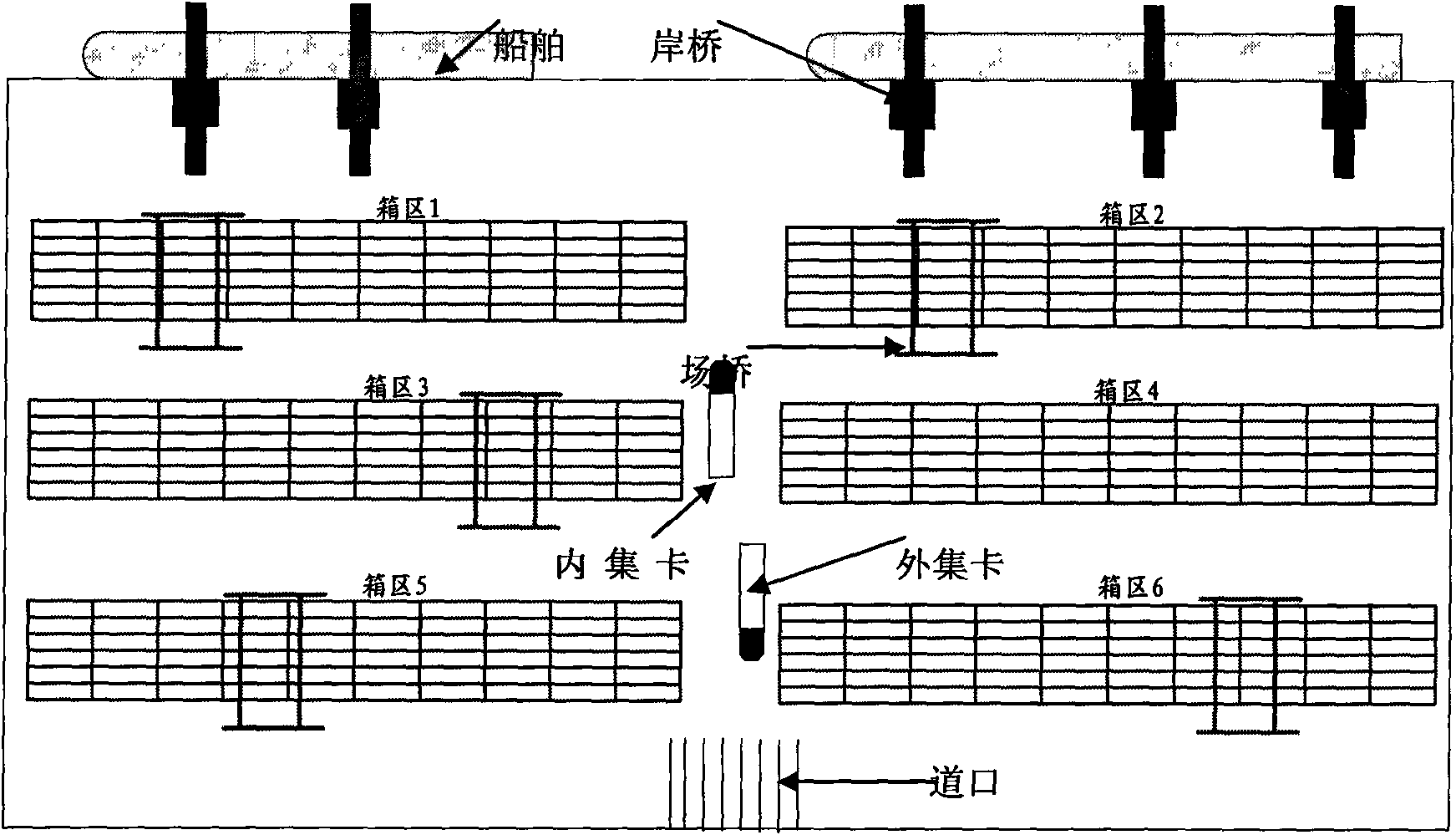

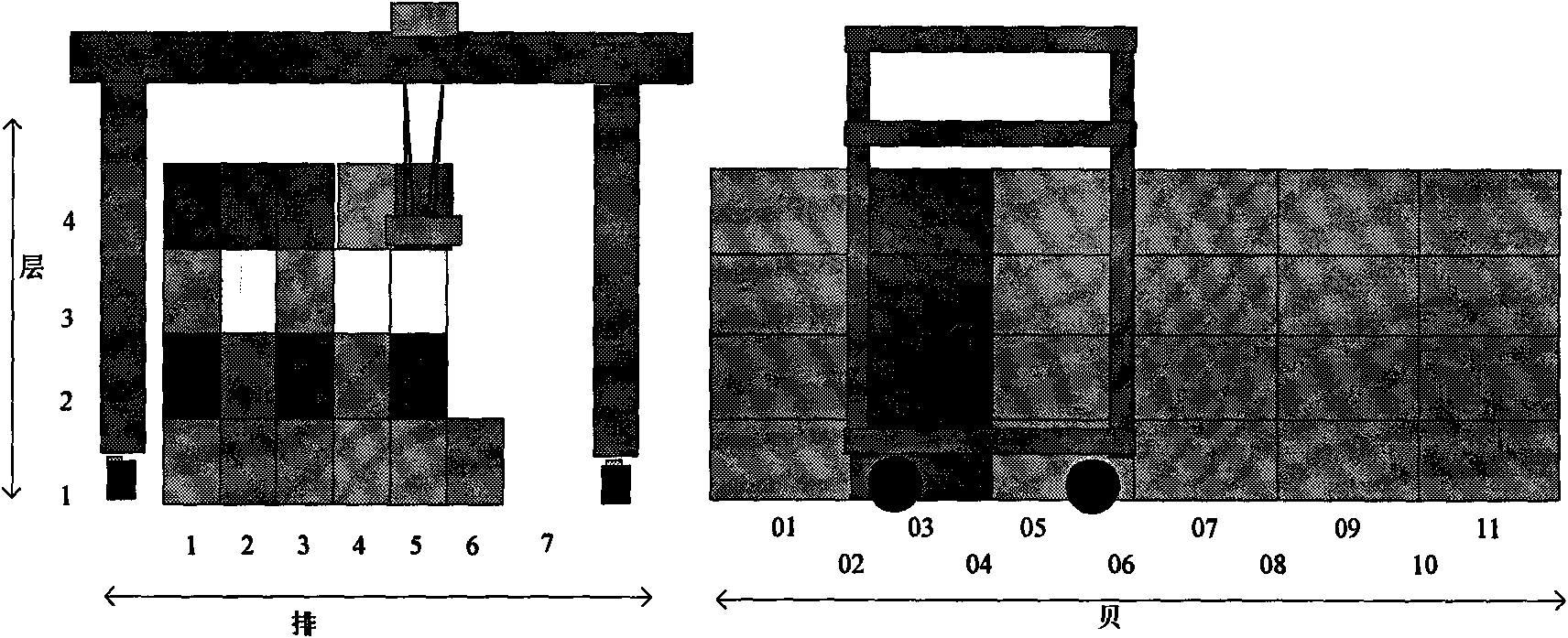

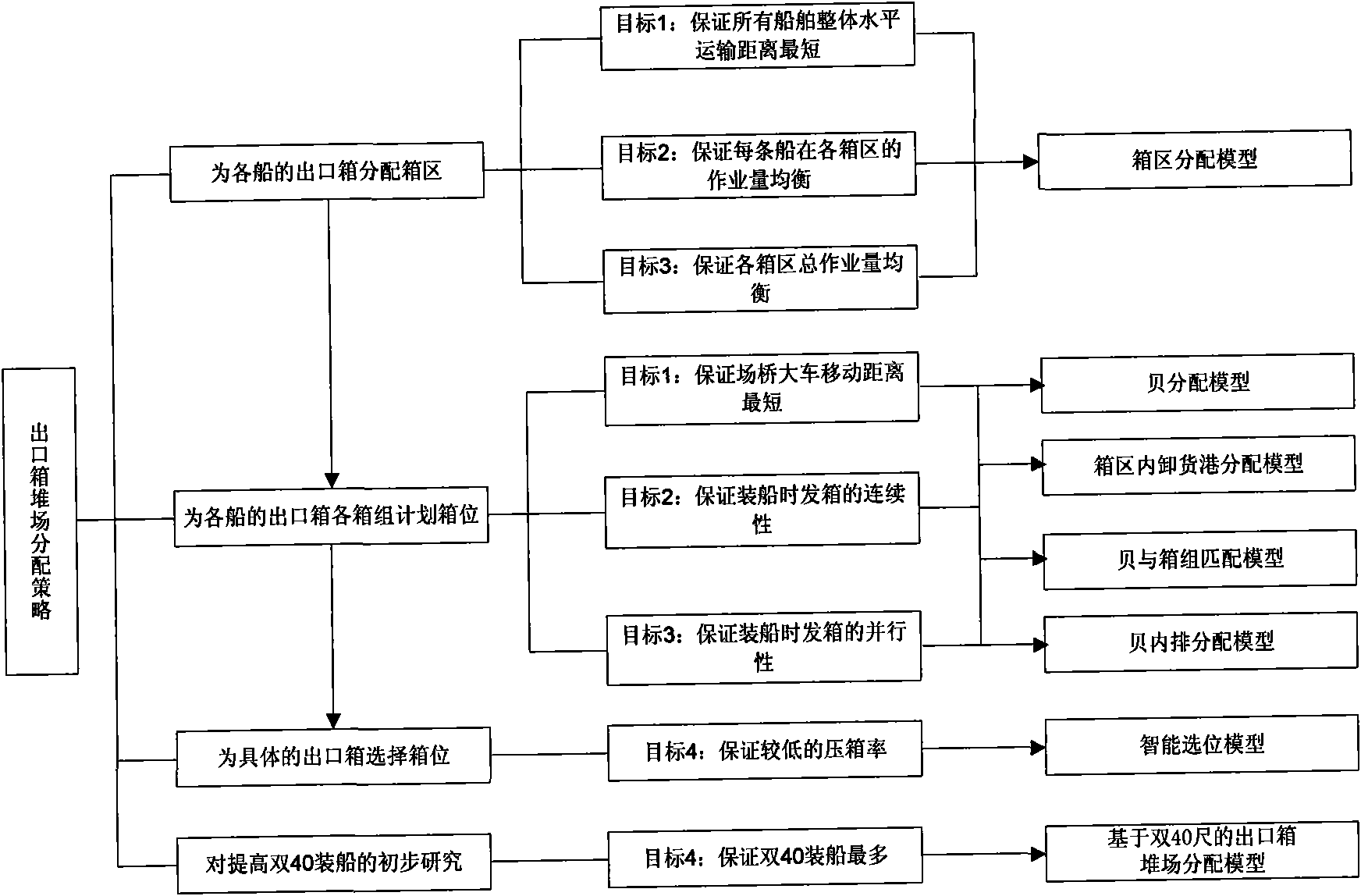

Distribution Method for export container yard of container wharf

InactiveCN101585453AReduce loading and unloading costsImprove service qualityData processing applicationsStorage devicesDistribution methodVolumetric Mass Density

The invention discloses a automatic distribution method for an export container yard of a container wharf, which comprises the following steps: firstly, distributing a container region for export containers of each ship; then, planning a container slot for each container set of the export containers of each ship; and finally, selecting the container slot for specific export containers. The method carries out deep research on the distribution of the export container regions, the planning of the container slots and the automatic slot selection of approach and preliminary consideration for improving the proportion of double 40 shipping, is favorable for improving the orderliness of the export container stacking under the predetermined yard density and has important significance in establishing good basis for the ordered organization of subsequent shipping operation.

Owner:SHANGHAI MARITIME UNIVERSITY

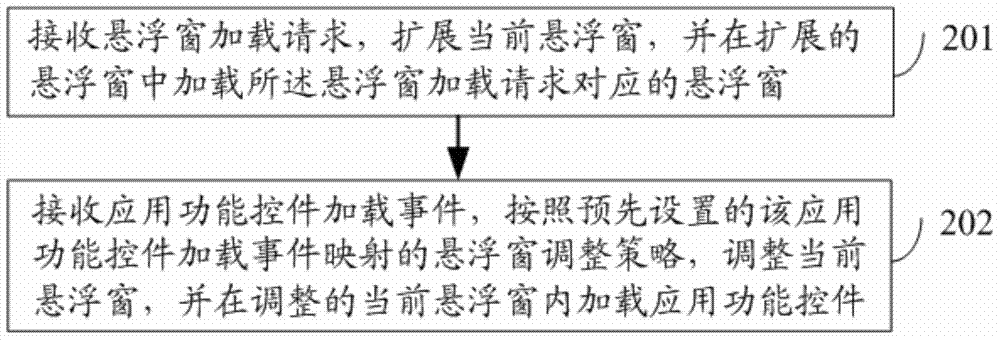

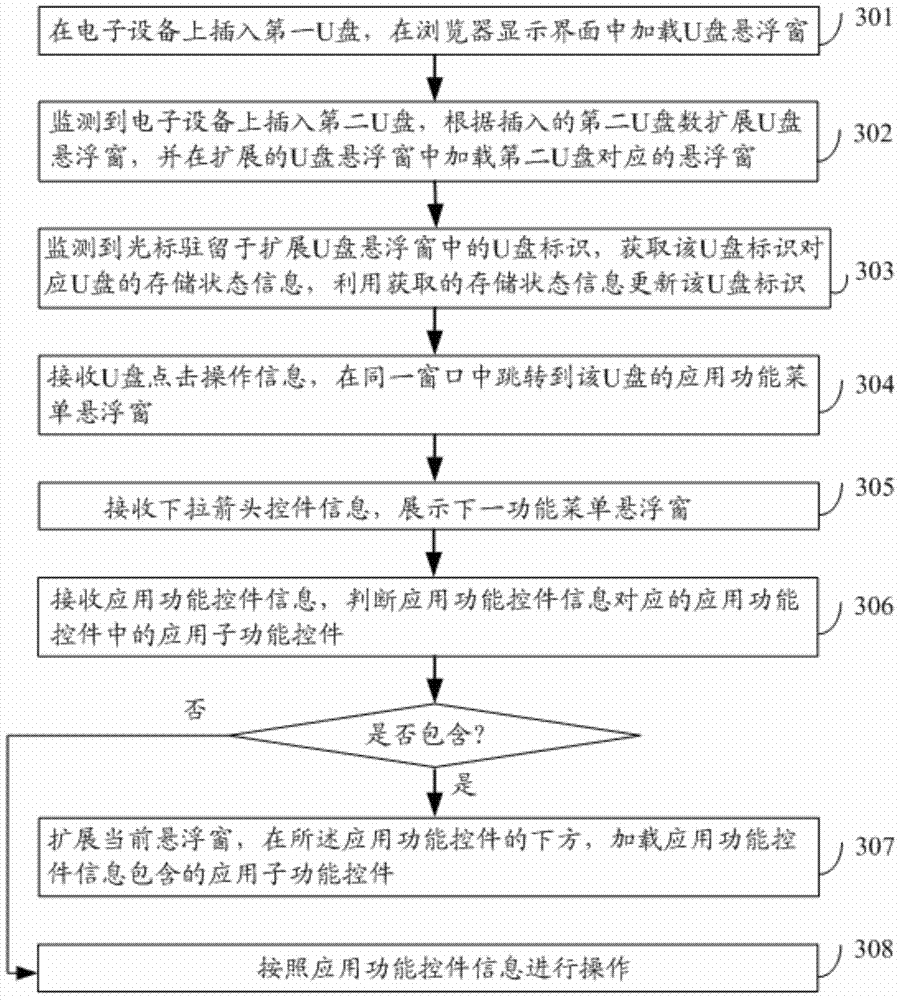

Window-based information loading method and device

ActiveCN104216752ACentralized operating areaFast operationProgram loading/initiatingStrategy mapComputer science

An embodiment of the invention discloses a window-based information loading method and device. The window-based information loading method includes the steps: receiving a suspended window loading request, extending a current suspended window and loading the suspended window corresponding to the suspended window loading request in the extended suspended window; receiving an application function control loading event, adjusting the current suspended window according to a preset suspended window adjustment strategy mapped by the application function control loading event, and loading an application function control in the adjusted current suspended window. By the method, operation time of users can be reduced.

Owner:ZHUHAI BAOQU TECH CO LTD

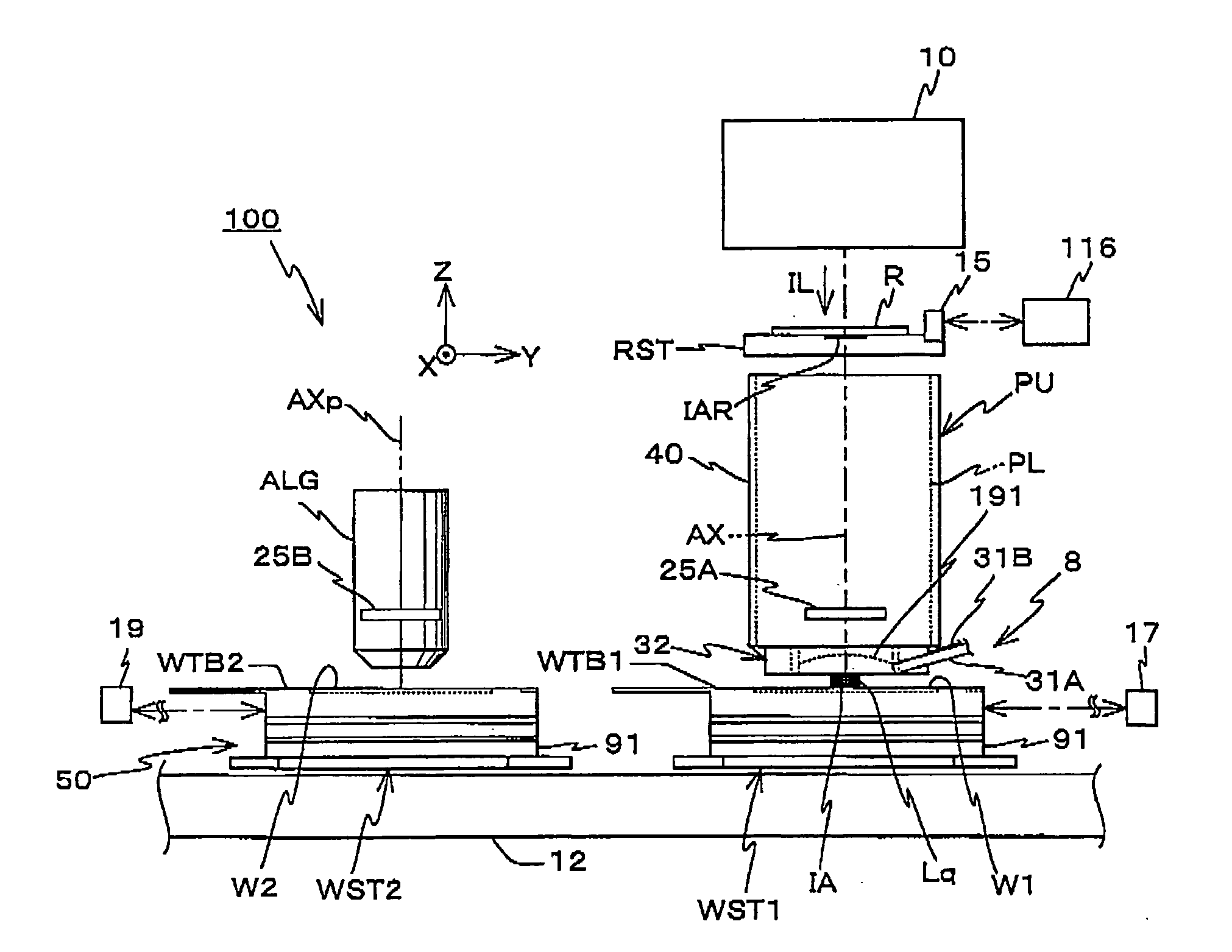

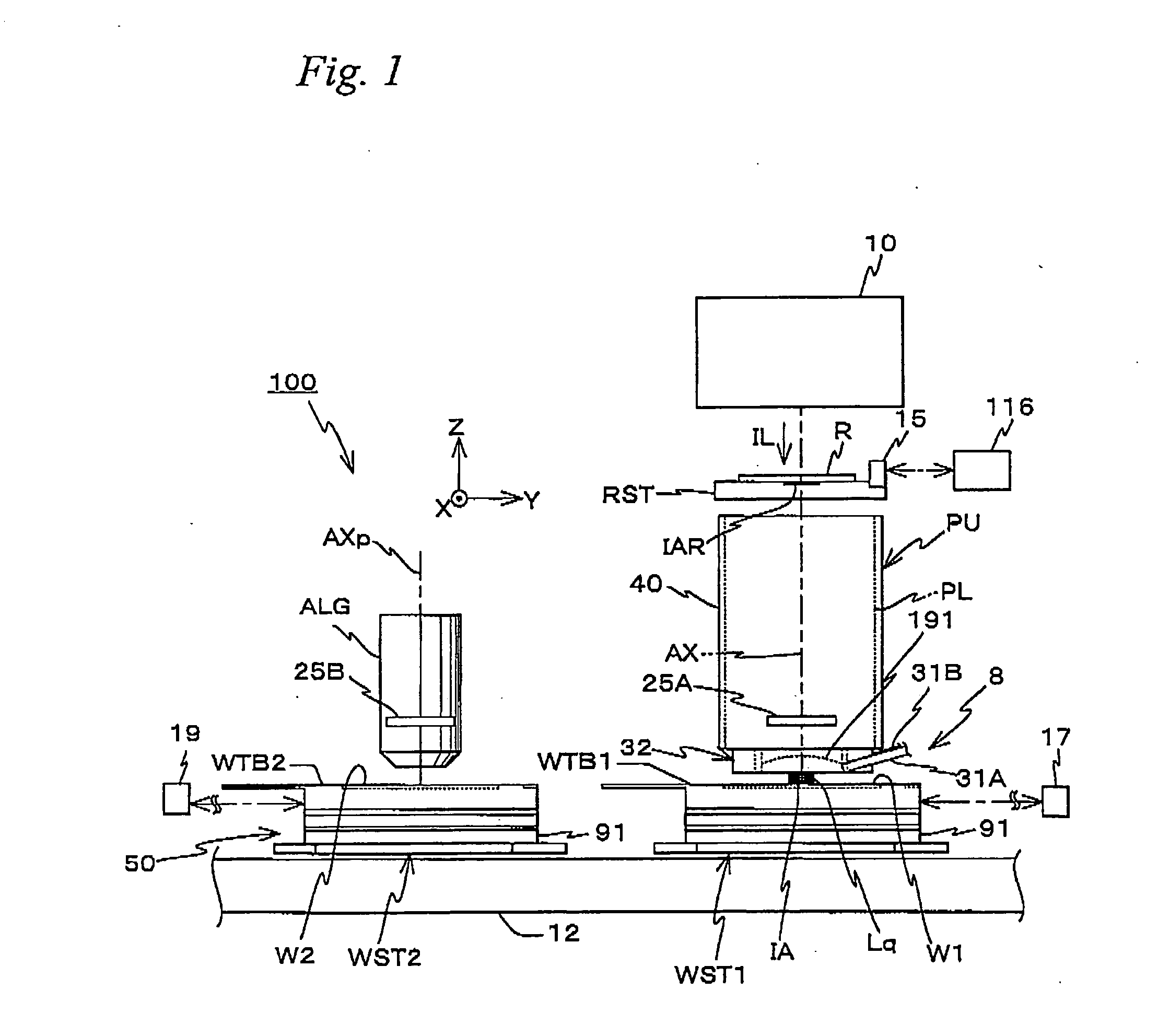

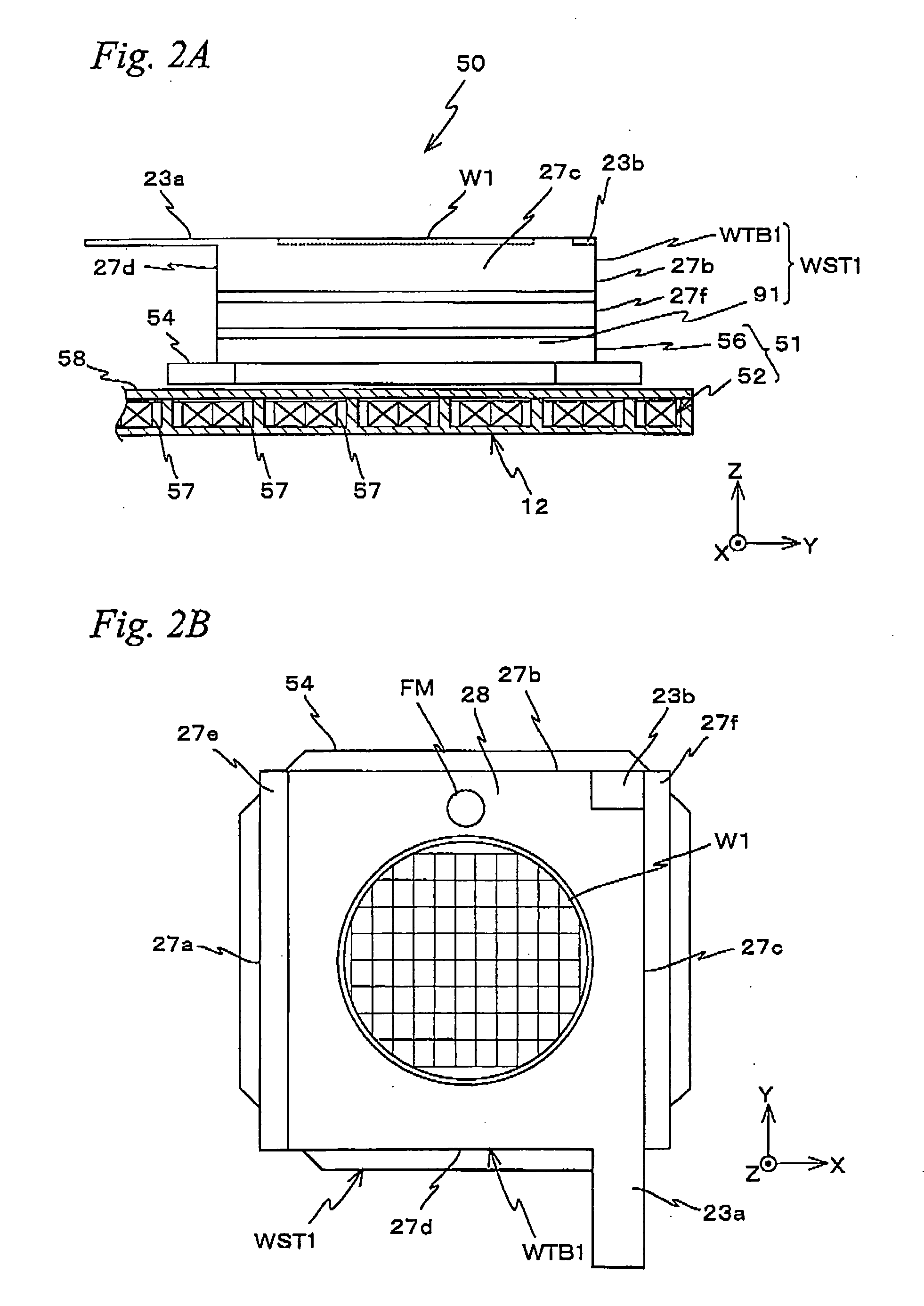

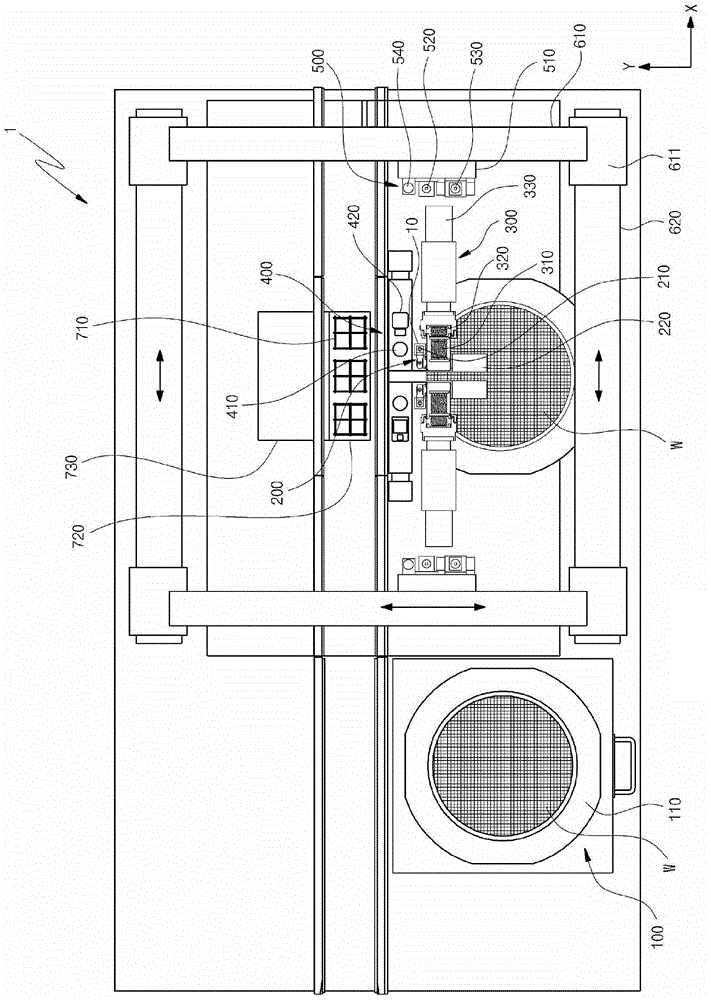

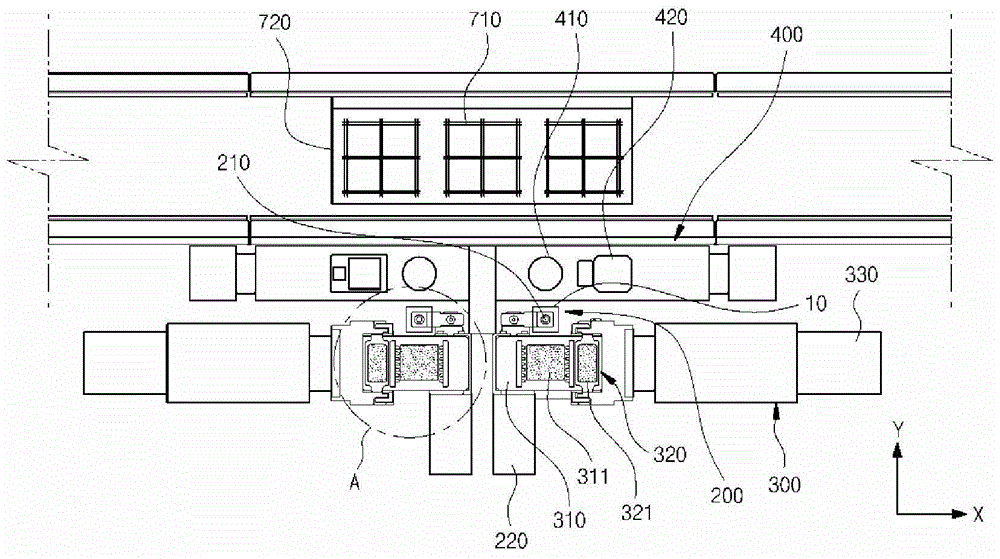

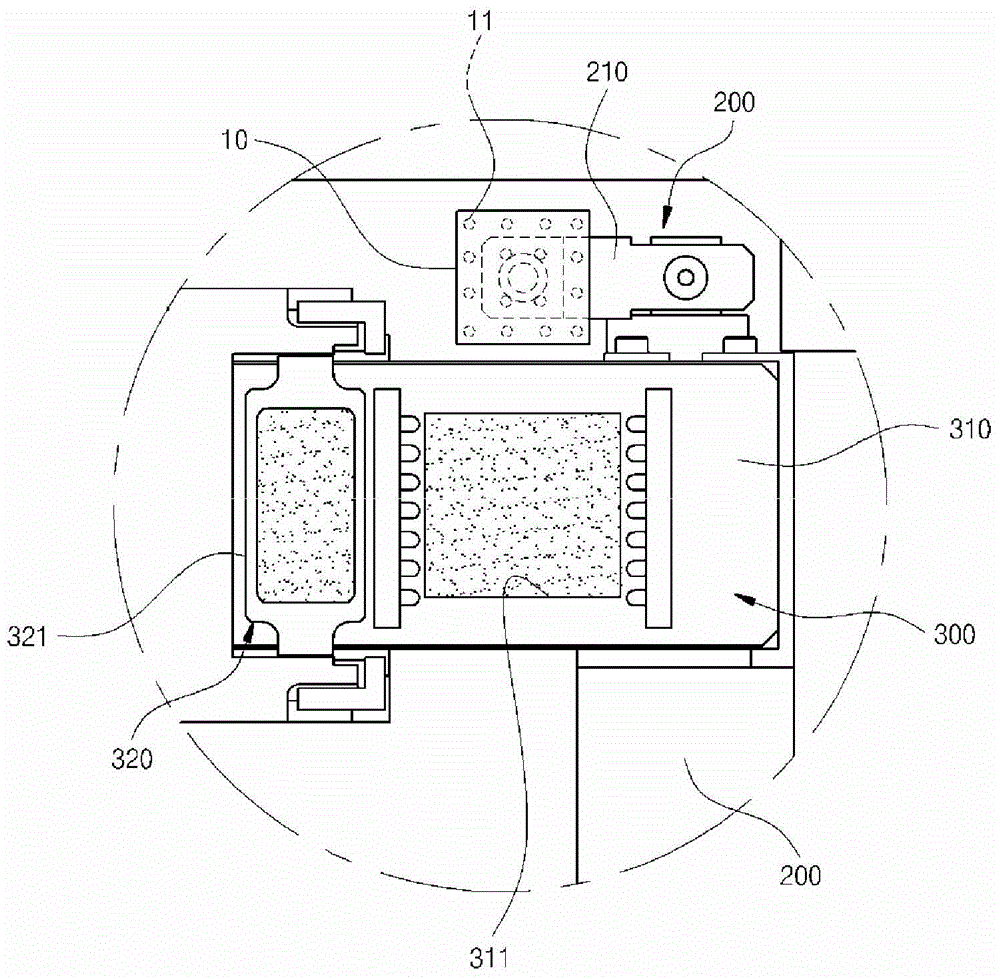

Exposure apparatus, exposure method, and device manufacturing method

InactiveUS20090225288A1Reduce movement distanceReduce movementPhotomechanical apparatusPhotographic printingEngineeringElectrical and Electronics engineering

During the transition from a state where one of wafer stages is located in an area below a projection optical system where a liquid immersion area is formed to a state where the other of the wafer stages is located in the area, both the wafer stages are made to be in proximity or in contact in a Y-axis direction in a state of being shifted in an X-axis direction, by making an overhang section and a stepped section that are arranged respectively on the wafer stages be engaged, and both the wafer stages are simultaneously driven in the Y-axis direction while maintaining this state. Accordingly, the liquid immersion area is delivered between the two wafer stages via the overhang section and leakage of a liquid that forms the liquid immersion area is restrained.

Owner:NIKON CORP

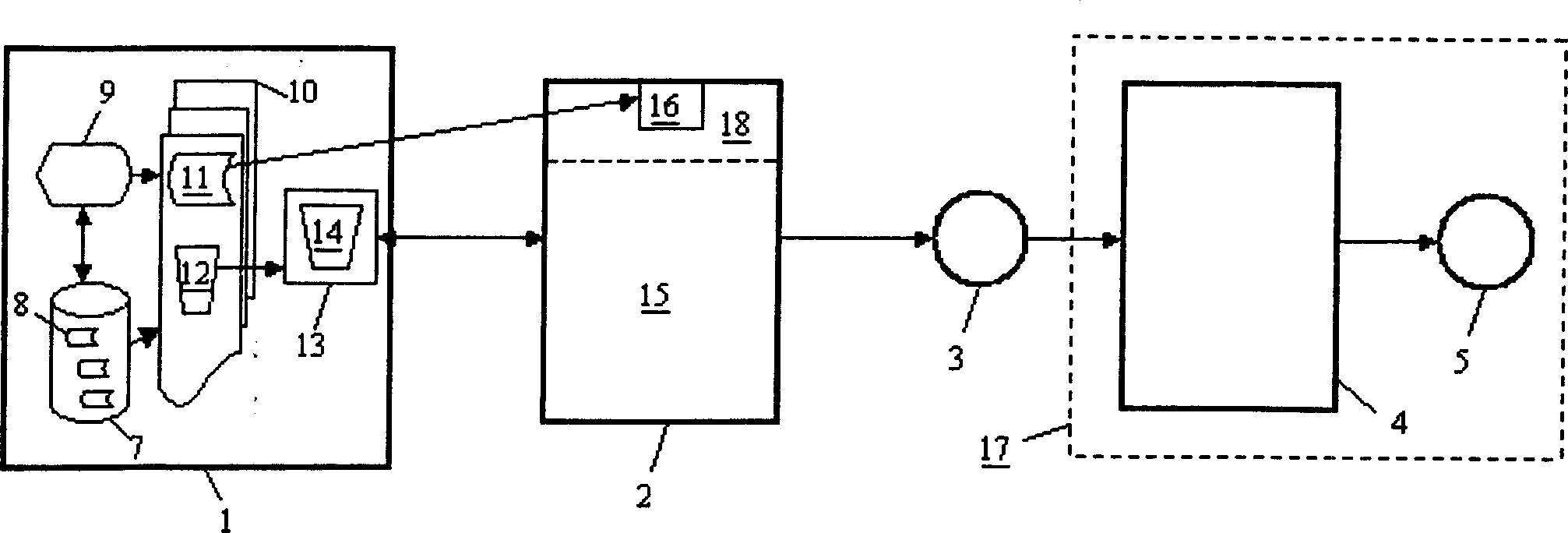

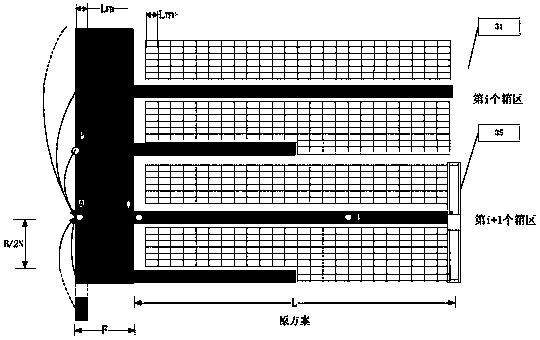

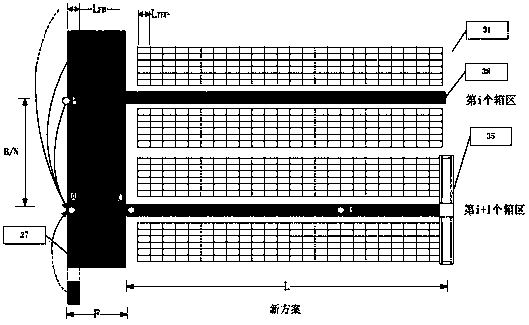

System and method for loading and unloading containers on multi-story frame type automated container yard

ActiveCN103723532AReduce movement distanceImprove loading and unloading efficiencyLoading/unloadingShoreElectricity

The invention discloses a system and method for loading and unloading containers on a multi-story frame type automated container yard. A frame bridge horizontal transportation system is adopted, the high level bridge and low level bridge matching form is adopted on bank sides, multiple stories of rail frames are also arranged inside the yard, and yard flat cars can freely move between the bank sides and the yard on the rail frames without interfering with one another. The scheme that the electric flat cars purely driven by electricity are matched with multi-storage frame type rail bridges is adopted, the containers can be rapidly conveyed between a shore bridge in front of a wharf and a yard bridge behind the wharf in a three-dimensional mode, intelligent scheduling and automation control are conveniently achieved, and the container conveying efficiency is improved. The yard flat cars which move at a high speed are used in the system, and therefore the moving distance of a transtainer is reduced, and efficiency of the ship loading and unloading, and container lifting and collecting in the yard is greatly improved. By means of the system and method for loading and unloading the containers on the multi-story frame type automated container yard, the area occupied by container areas on the wharf can be greatly reduced, and the construction cost for the wharf is reduced.

Owner:SHANGHAI MARITIME UNIVERSITY

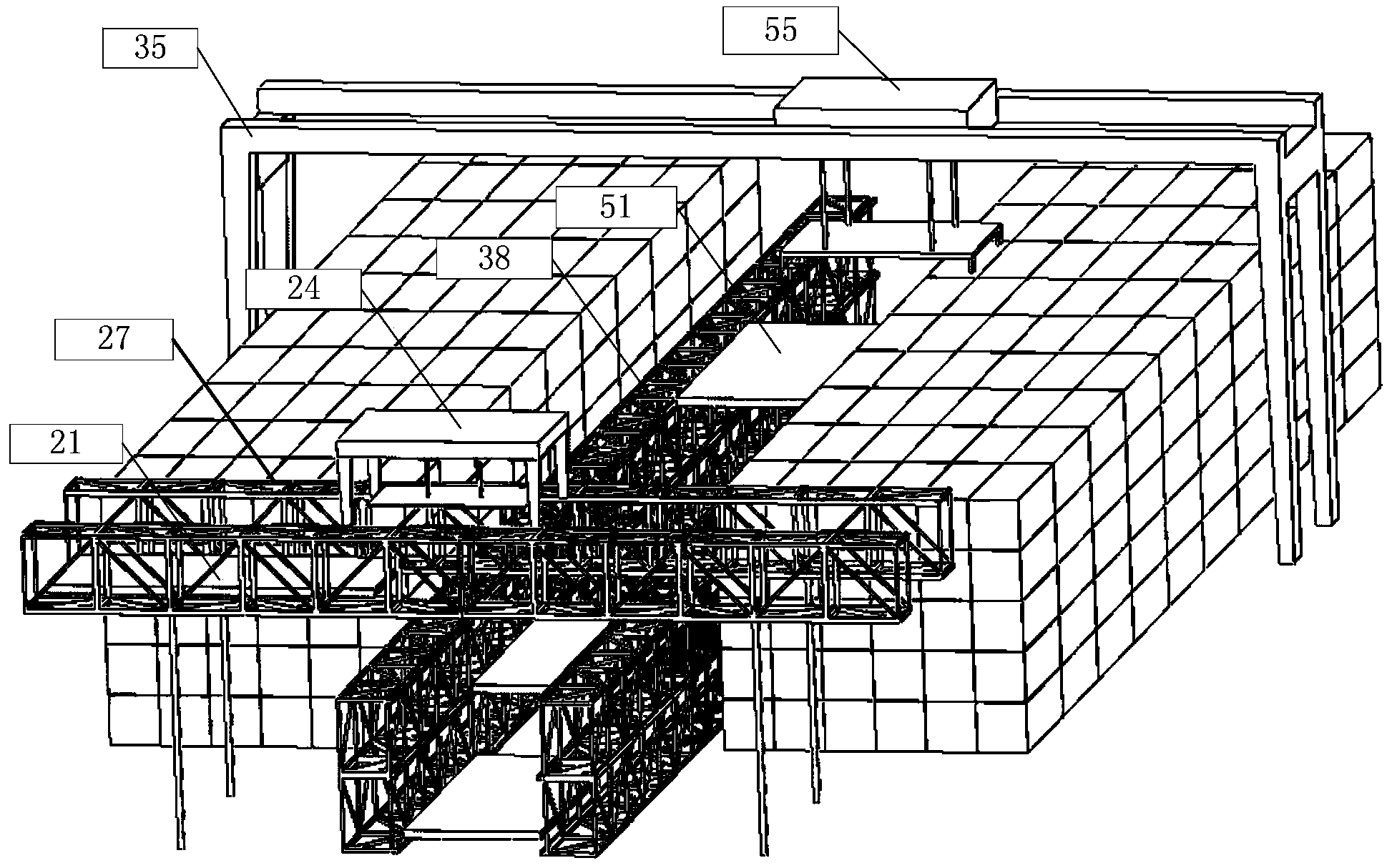

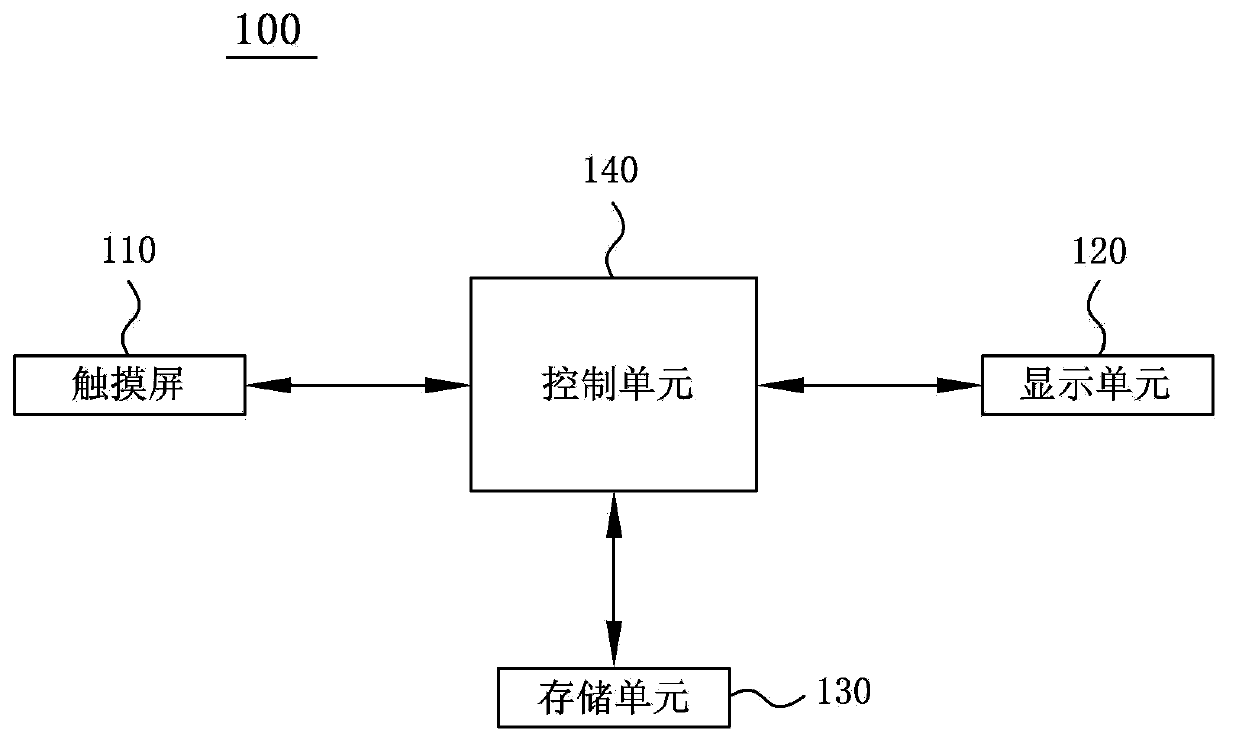

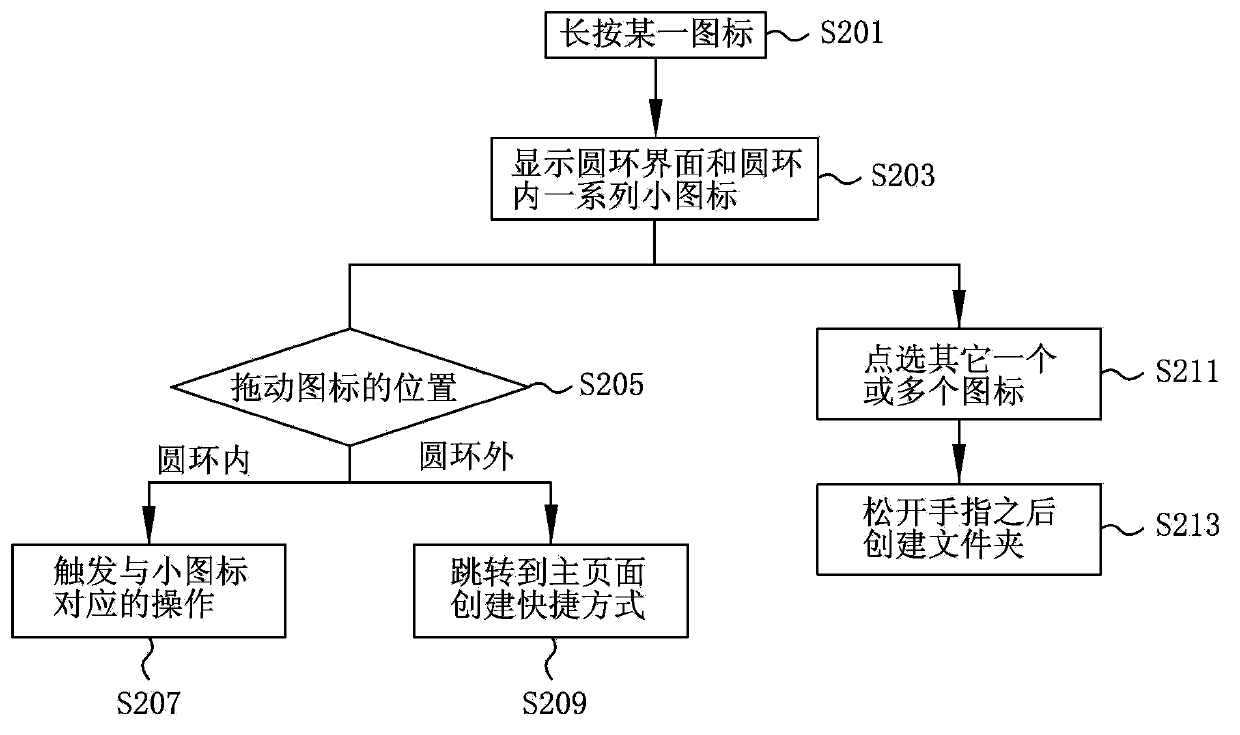

User interface operation method based on touch screen and terminal device using same

InactiveCN103870095AReduce movement distanceEasy to view informationInput/output processes for data processingTerminal equipmentUser interface

The invention provides a user interface operation method based on a touch screen and a terminal device using the same. The user interface operation method based on the touch screen comprises the steps of: determining whether a user long presses an icon in the user interface; if the user long presses the icon, displaying an auxiliary interface relating to the icon around the icon, wherein the auxiliary interface comprises at least one small icon and encircles the icon; implementing corresponding operation to the long pressed icon according to the operation of the user to the at least one small icon.

Owner:SAMSUNG GUANGZHOU MOBILE R&D CENT +1

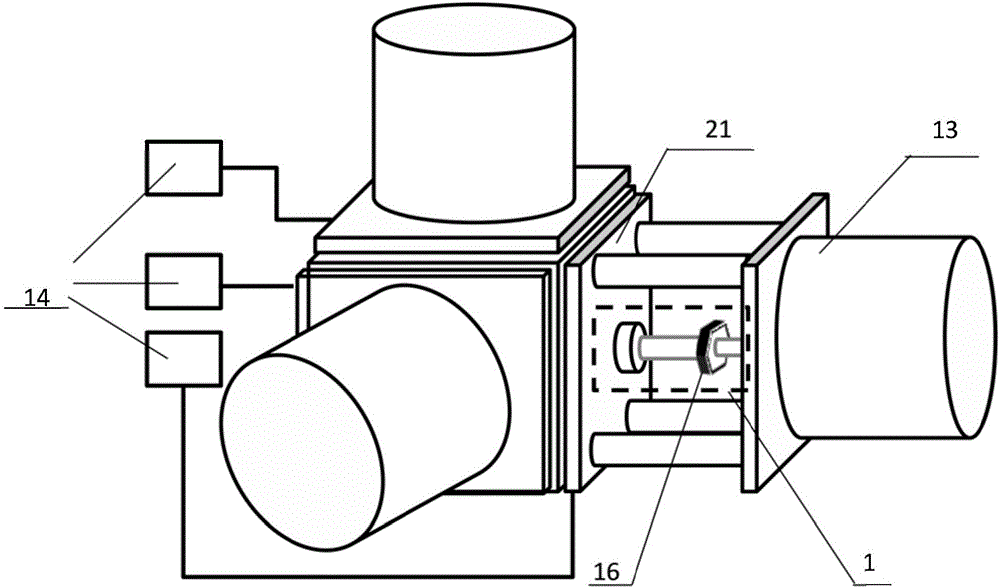

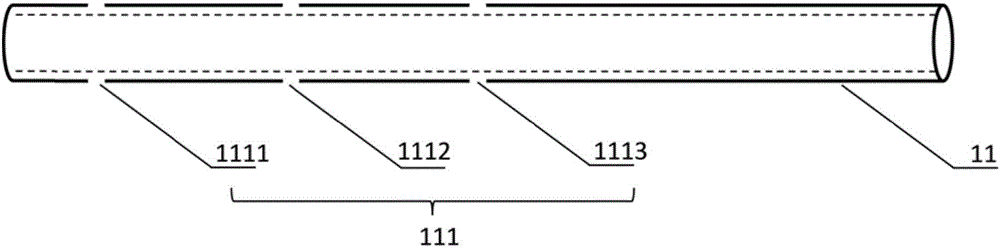

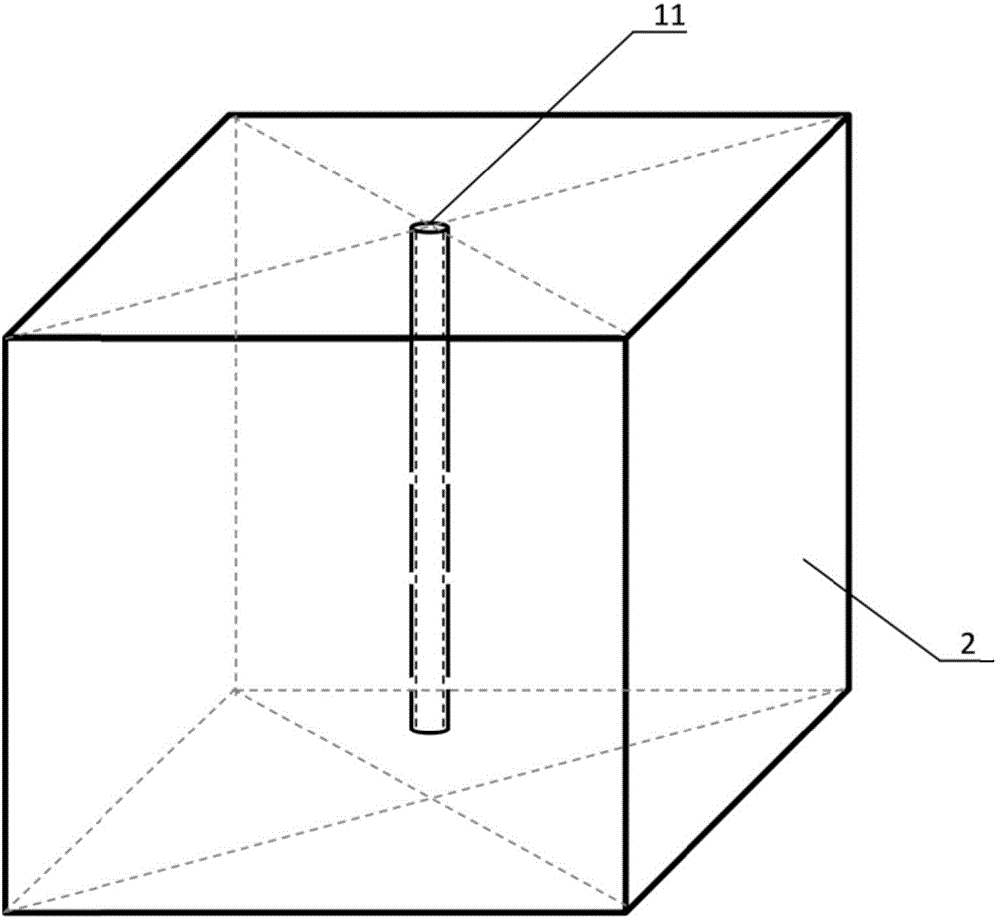

Simulation experiment system for staged fracturing or simultaneous fracturing of horizontal wells

InactiveCN106401551ASave spaceEffective guidanceFluid removalExperimental methodsInterference phenomenon

The invention provides a simulation experiment system for staged fracturing or simultaneous fracturing of horizontal wells. The system is used for performing fracturing simulation on a cubic artificial rock sample and comprises fracturing simulation assemblies, stress loading devices and fracture monitoring devices; each fracturing simulation assembly comprises a simulation wellbore, a liquid injection pipe and a position adjusting device; the simulation wellbores are located inside the artificial rock sample; the liquid injection pipes are located in the simulation wellbores; and at least two simulation perforations which are equal in number and different in position are formed in each simulation wellbore and each liquid injection pipe. Positions of the liquid injection pipes are controlled by the position adjusting devices, the communicating sequence of the simulation perforations in different fracturing sections is realized, and the different fracturing sections are fractured respectively. The simultaneous fracturing process of the two horizontal wells can be simulated by the two fracturing simulation assemblies. The simulation experiment system can simulate interference phenomena among fractures during staged fracturing of the horizontal wells or simultaneous fracturing of the two horizontal wells, and an experimental method is provided for understanding of hydraulic fracture propagation rules and fracture shapes.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

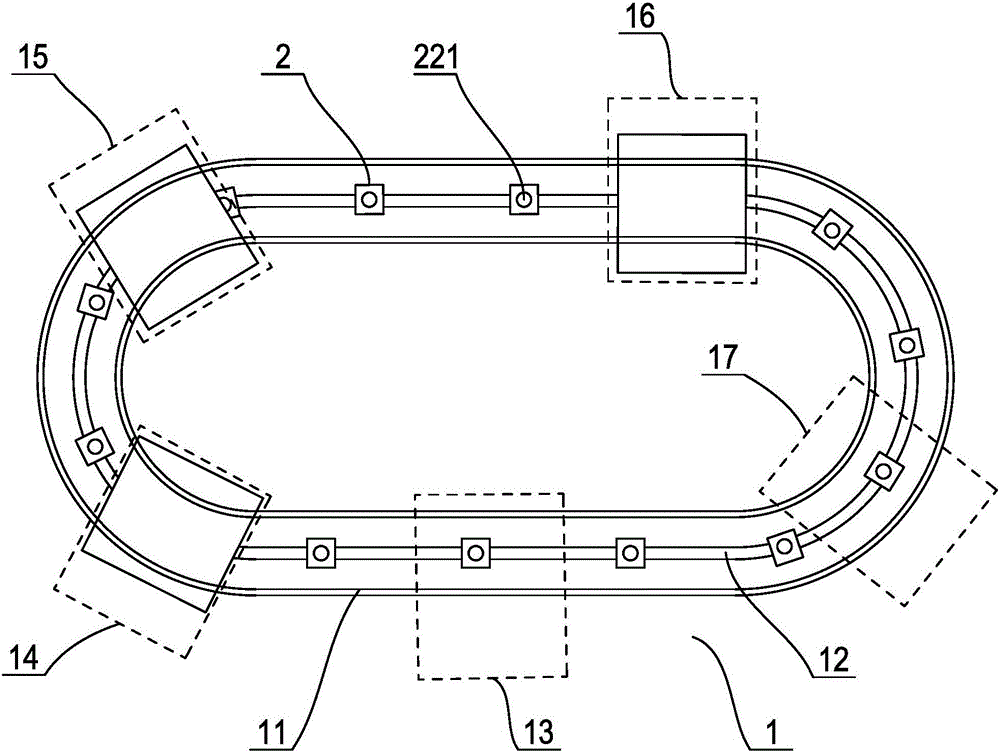

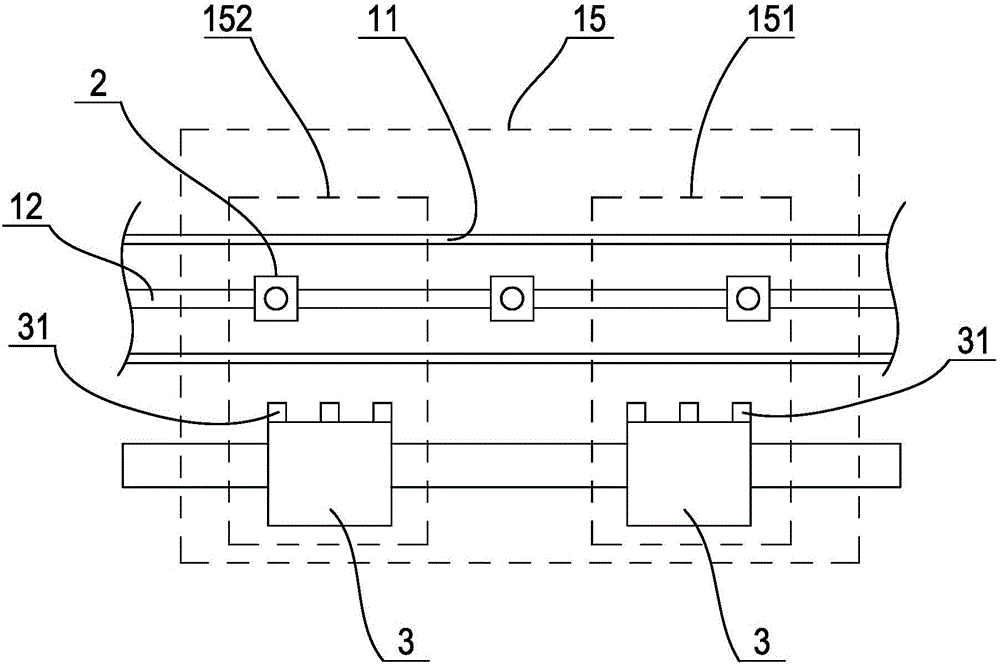

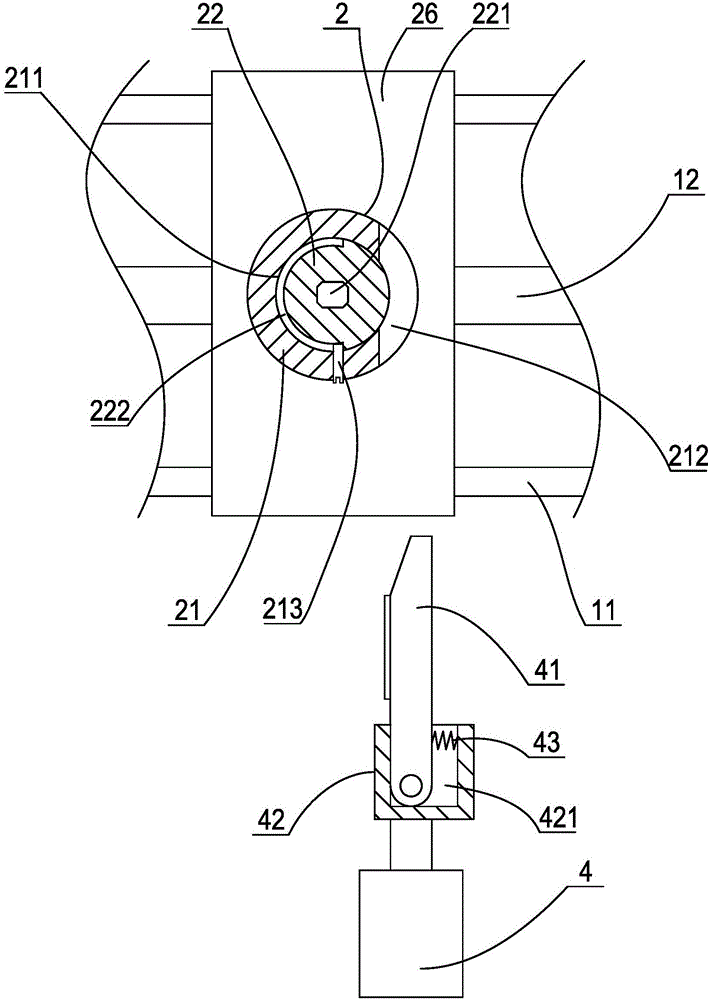

Racket automatic spraying system

ActiveCN106622771AAvoid mutual interferenceReduce movement distanceSpraying apparatusPretreated surfacesProduction lineControl signal

The invention discloses a racket automatic spraying system. The racket automatic spraying system comprises a loading station, a spraying station, a curing station and an unloading station arranged on a conveying production line in sequence; a driving chain of the conveying production line is provided with multiple racket fixed sleeves for inserting rackets; the spraying station is provided with a spraying manipulator; the spraying manipulator is provided with a combined spraying gun, a racket driving mechanism and a position detecting device; when the racket fixed sleeves move beside the spraying manipulator, the position detecting device sends a control signal; the spraying manipulator and the racket fixed sleeves keep synchronous movement; the combined spraying gun is controlled to automatically spray one surfaces of the rackets; after the combined spraying gun sprays one surfaces of the rackets, the racket driving mechanism acts to rotate the rackets on the racket fixed sleeves; and at this time, the combined spraying gun automatically sprays the other surfaces of the rackets by procedures. The racket automatic spraying system can realize full-automatic racket spraying to prominently improve the production efficiency, reduce the labor intensity of staff and effectively improve the spraying quality of the rackets.

Owner:杭州诚兴体育用品有限公司

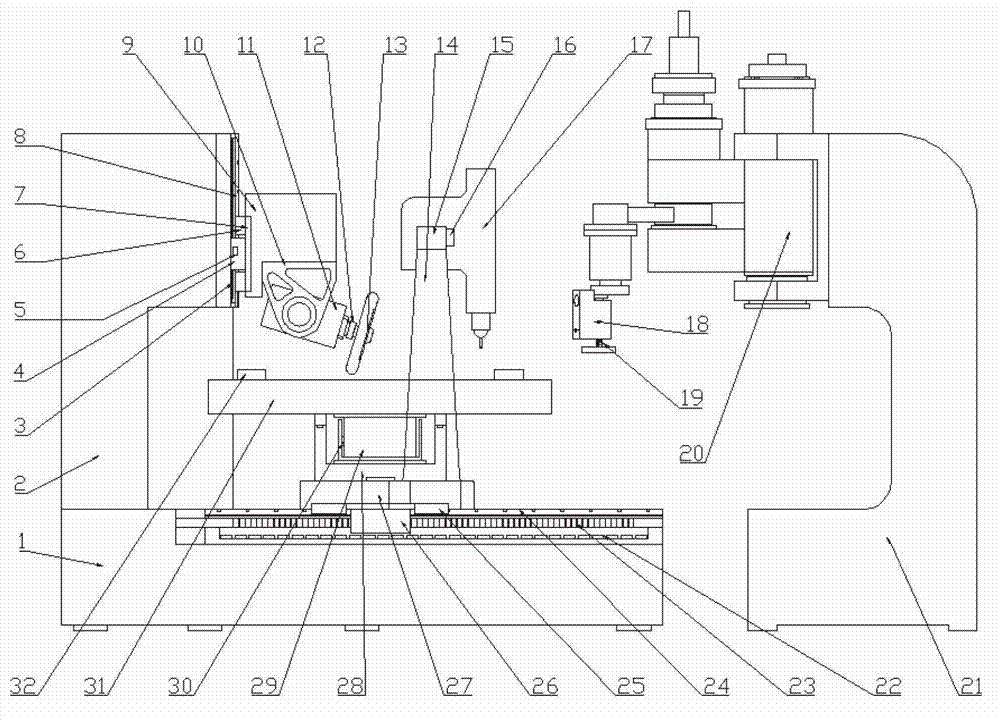

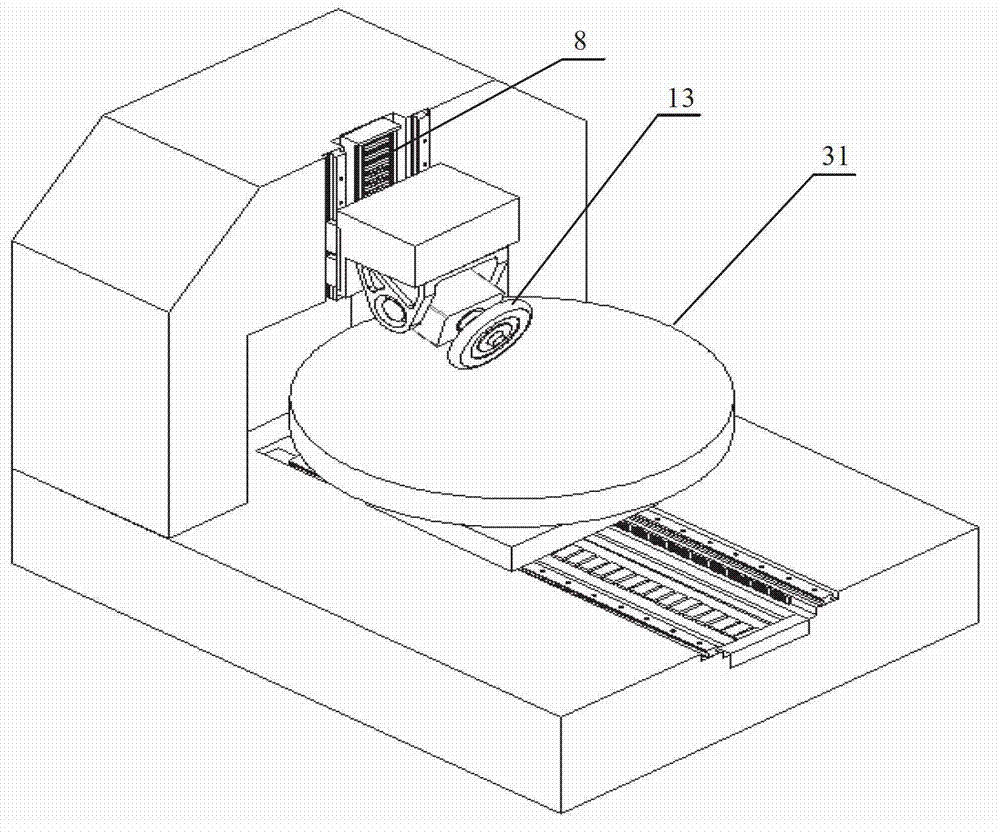

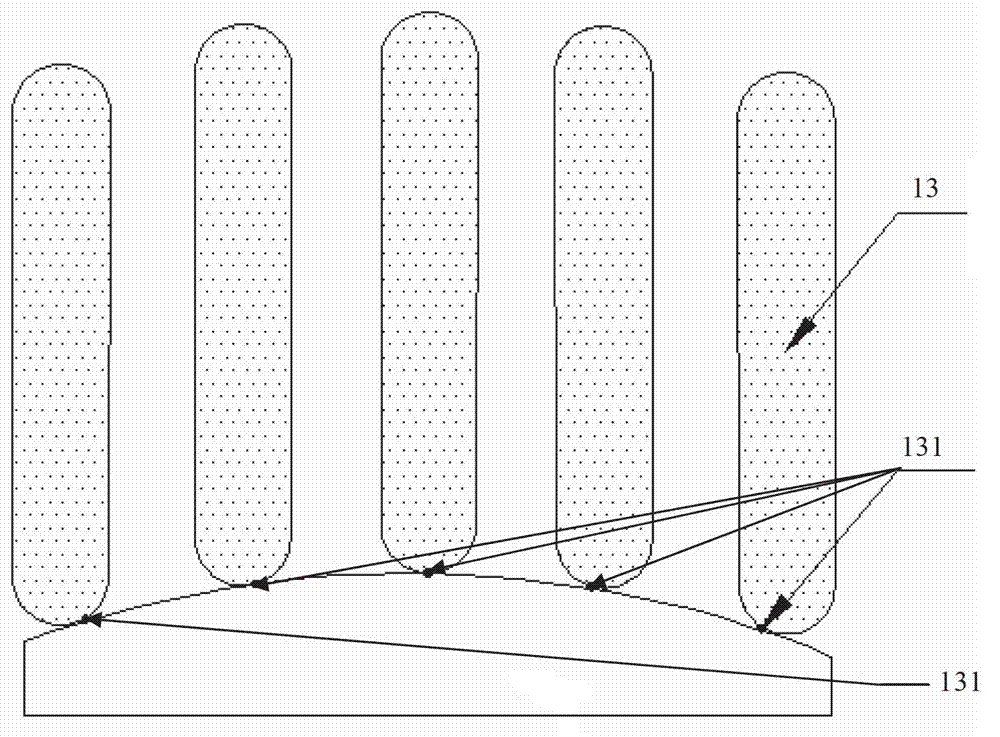

Ultra-precise processing integrated platform for large caliber optical mirror surface

ActiveCN102756316AEasy to moveAchieve multi-axis ultra-precision grindingOptical surface grinding machinesOptical processingSurface grinding

An ultra-precise processing integrated platform for a large caliber optical mirror surface solves the problem that processing and detection are not integrated while processing the large caliber optical mirror surface in the conventional optical processing technical field. The platform integrates grinding, detection and milling for processing the large caliber optical mirror surface, and comprises a base, a horizontal moving device, a rotation device, an ultra-precise grinding device, a mirror surface detection device and a milling device, wherein the horizontal moving device drives the rotation device to move to a workpiece mounting position, a grinding position, a surface shape detection position and a milling position in a horizontal direction; a vertical moving device drives a spindle system and a diamond grinding wheel to move up and down in a vertical direction; the spindle system can adjust the inclined angle of the diamond grinding wheel; the diamond grinding wheel has a cambered surface; when in the workpiece mounting position, the rotation device can conduct cambered surface grinding on a workpiece; when in the surface shape detection position, the rotation device can conduct surface shape detection on the workpiece; when in the surface shape detection position, the rotation device can mill the workpiece.

Owner:SHANGHAI JIAO TONG UNIV

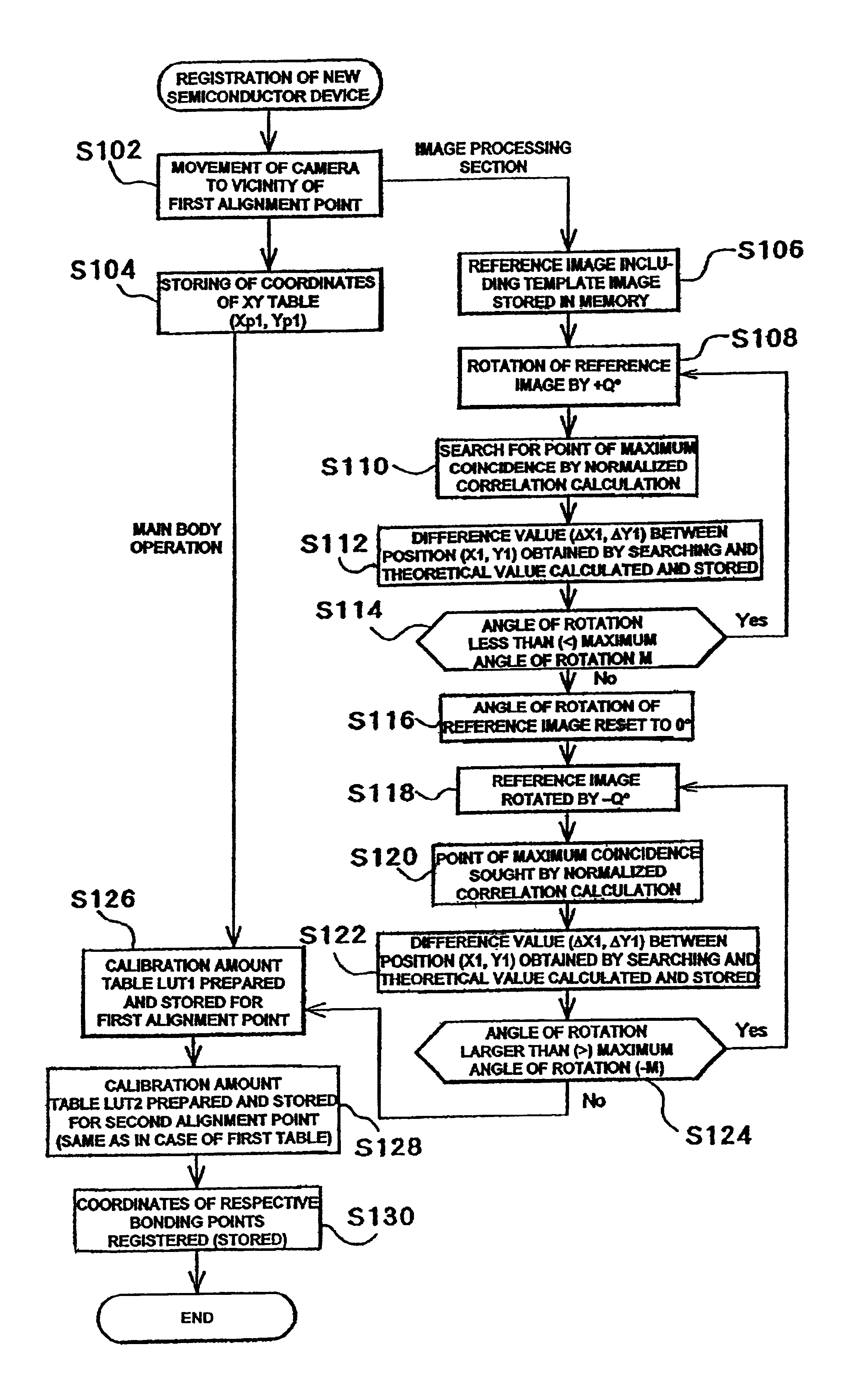

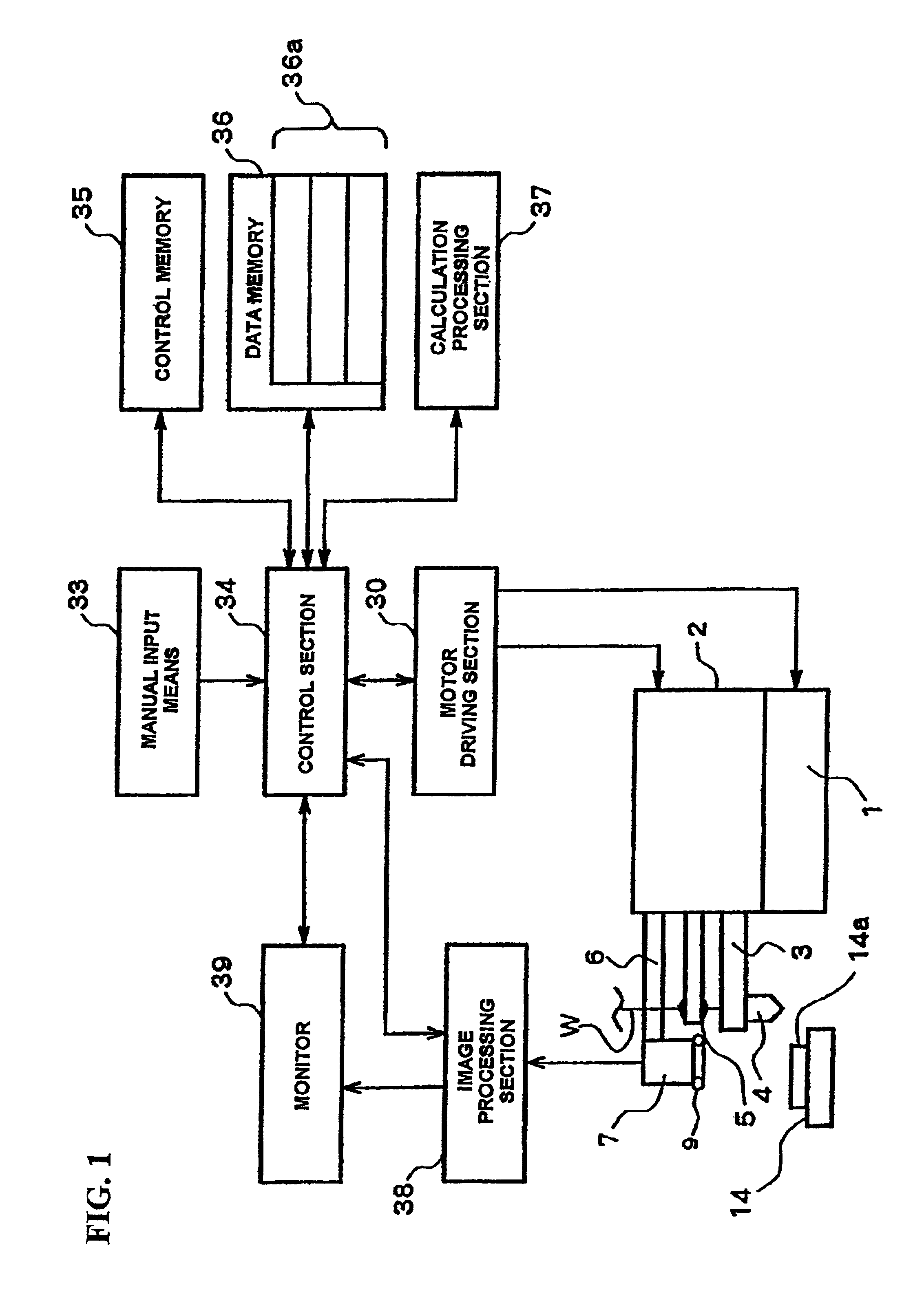

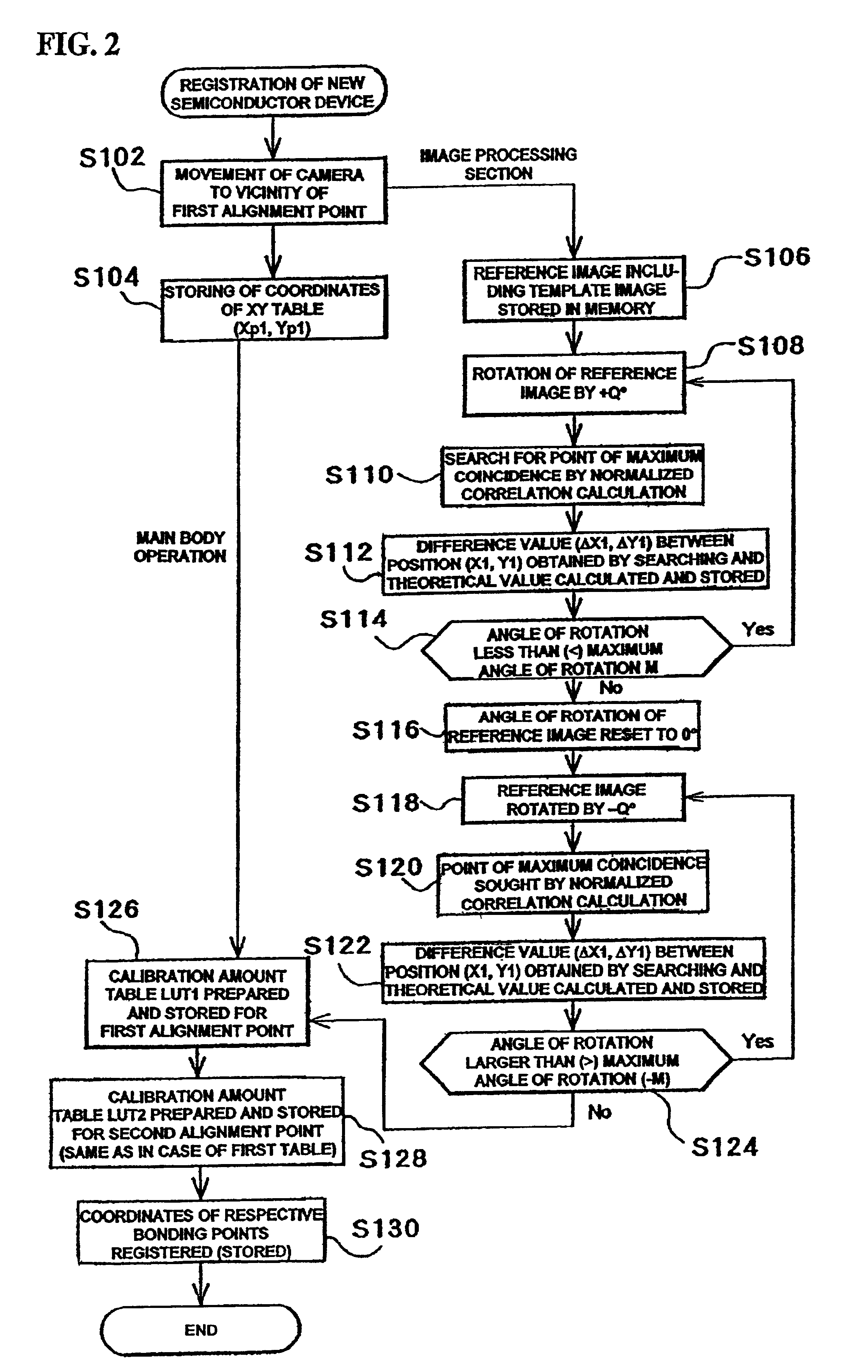

Image processing method, an image processing device and a bonding apparatus

InactiveUS6917699B2High-precision detectionPrecise positioningImage analysisSemiconductor/solid-state device testing/measurementImaging processingPattern matching

So as to perform high-precision position detection without performing pattern matching in the direction of rotation even when the object of detection involves a positional deviation in the direction of rotation, pattern matching between a reference image and a rotated image obtained by rotating this reference image is performed during registration, and then the difference between the measured value of the position obtained following rotation and the theoretical value of the position of the rotated image is retained as a calibration amount corresponding to the known angle of rotation. Upon detection, the measured value is detected by pattern matching between an image of the object of detection, which is detected by imaging the object of detection disposed in an attitude that includes a positional deviation in the direction of rotation, and a reference image; and this measured value is corrected by the calibration amount.

Owner:SHINKAWA CO LTD

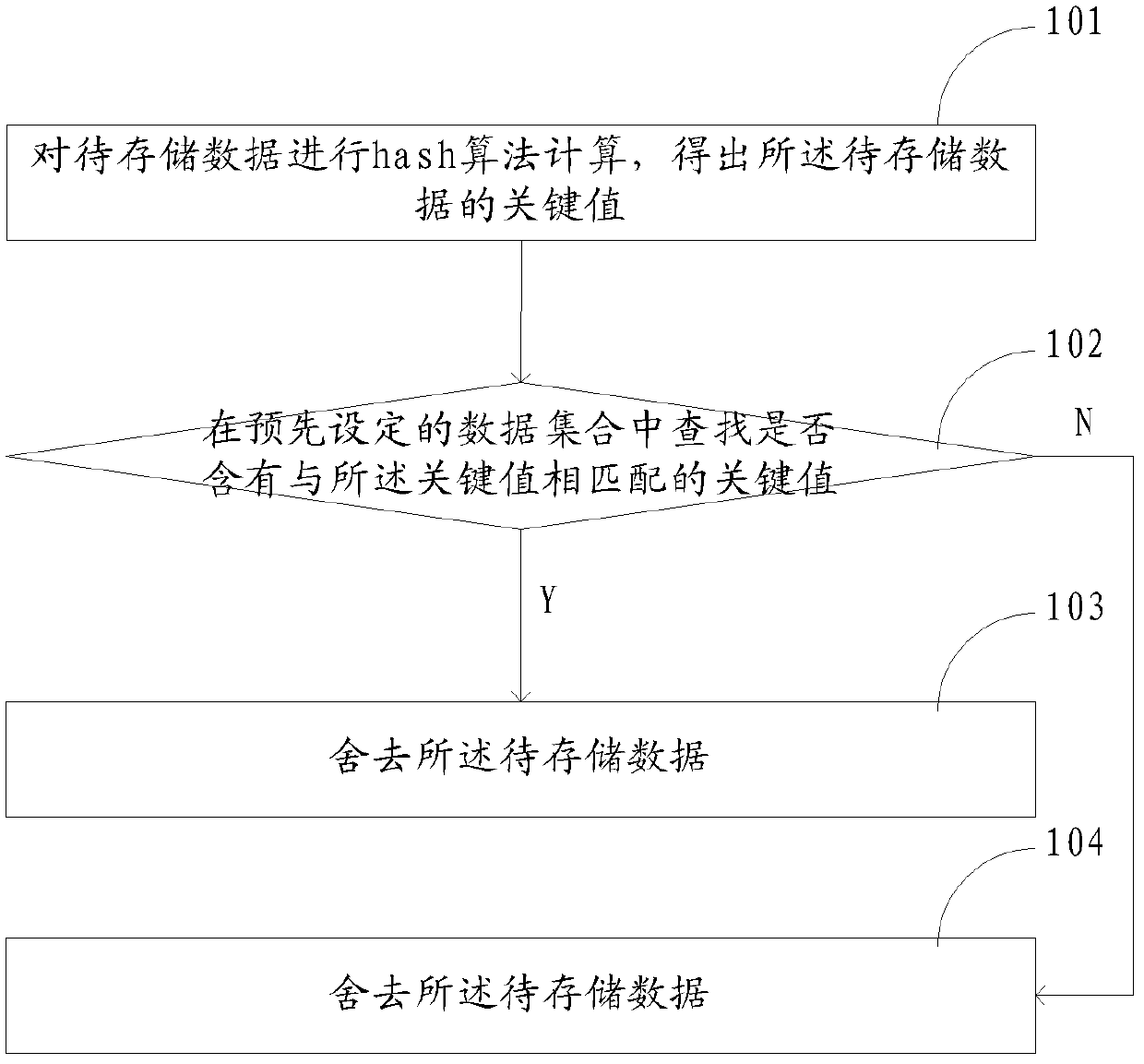

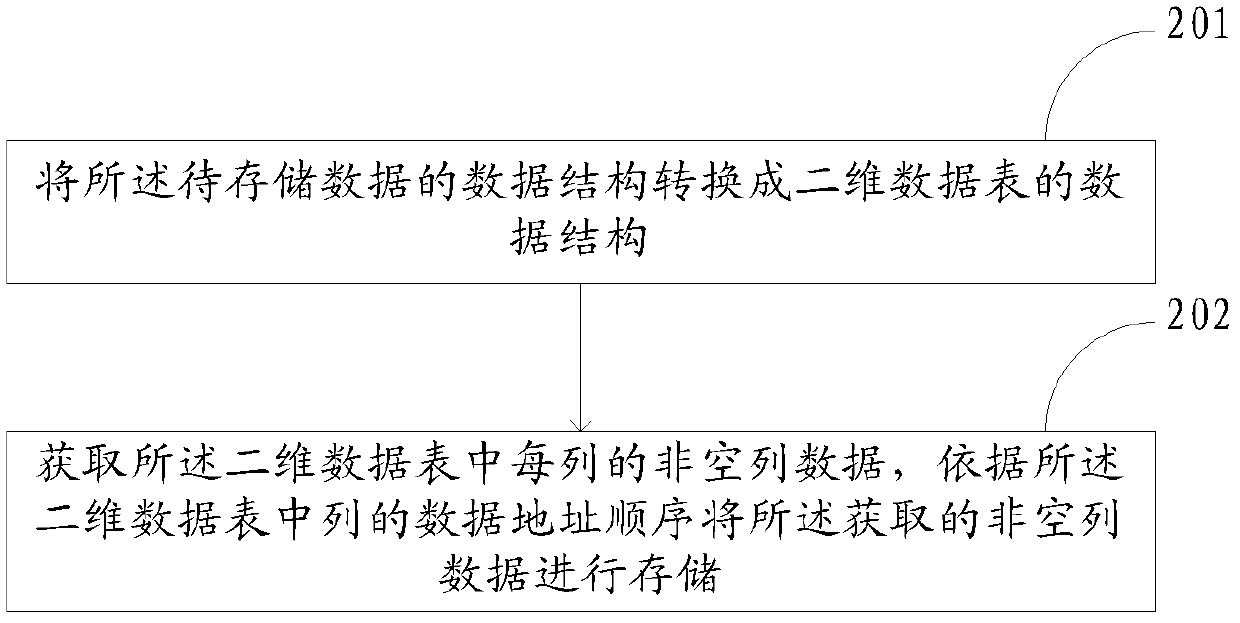

Data processing method, device and system

InactiveCN103294702AAvoid redundancyAvoid wastingSpecial data processing applicationsData processingTheoretical computer science

The invention provides a data processing method, device and system. The data processing method comprises the steps that to-be-stored data is subjected to hash algorithm calculation to obtain a key value of the to-be-stored data; and whether a key value matched with the key value is contained is searched in a preset data set, if yes, the to-be-stored data is rejected, otherwise, the to-be-stored data is stored in a column type storage method, and the key value of the to-be-stored data is stored in the data set. According to the data processing method, device and system provided by the embodiment of the invention, the hash calculation is performed before storage of the to-be-stored data in the column type storage method, duplication eliminating processing is performed on the to-be-stored data based on the obtained key value, so that data redundancy during mass data processing is avoided, and storage space waste is avoided.

Owner:上海淼云文化传播有限公司

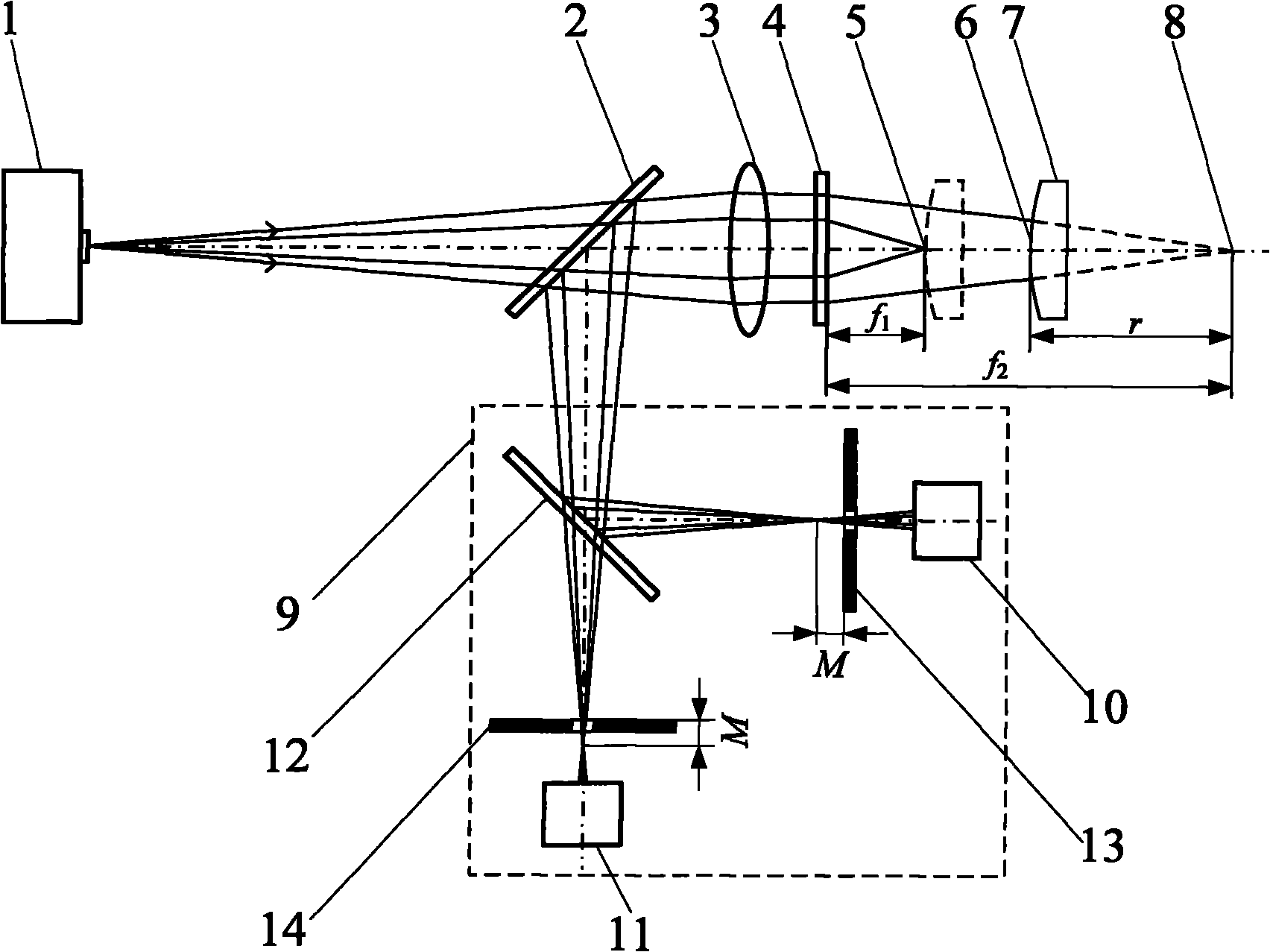

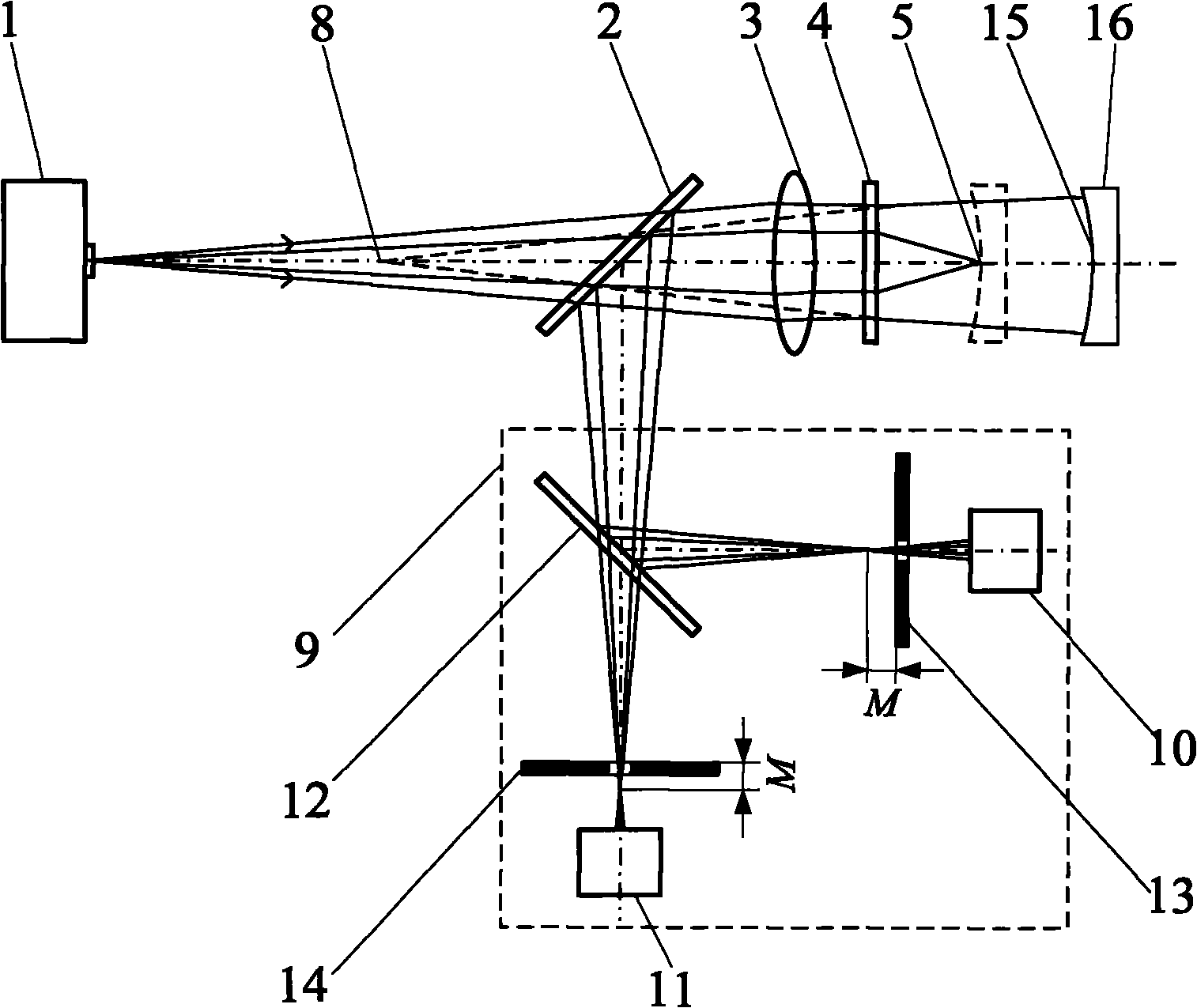

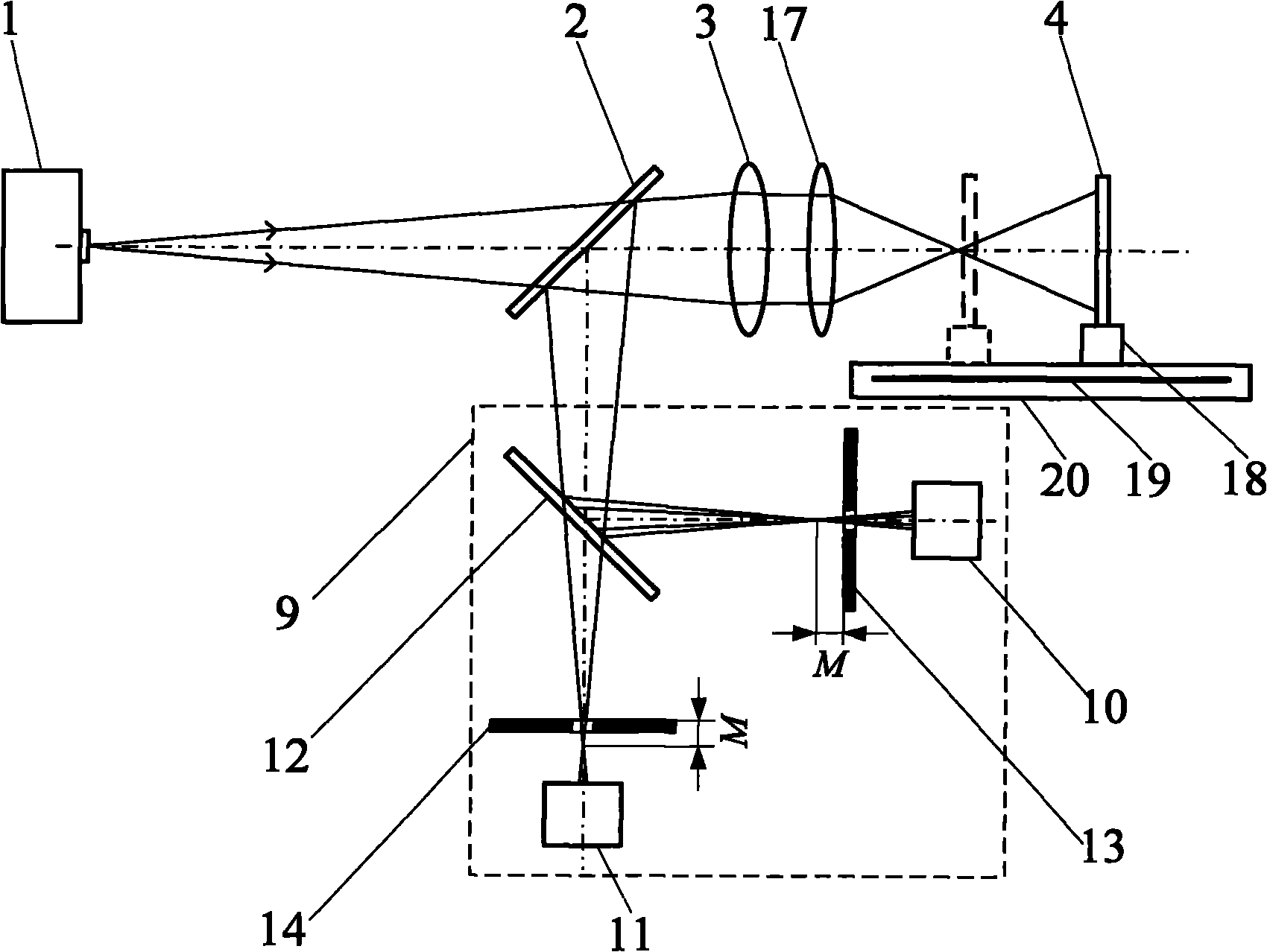

Multifocal holographic differential confocal super-large curvature radius measuring method and device

InactiveCN101858736AReduce mistakesReduce movement distanceUsing optical meansContact highInterference resistance

The invention relates to multifocal holographic differential confocal super-large curvature radius measuring method and device, belonging to the technical field of optical precision measurement. The method comprises the following steps of: firstly, calibrating the long-focus value of a multifocal holographic lens by utilizing a differential confocal system so as to reduce the system error of measurement; realizing non-contact high-precision positioning at the cat eye position and the cofocal position of a measured piece by utilizing a differential confocal fixed-focus principle; and subsequently, realizing the high-precision measurement of a super-large curvature radius by utilizing a geometrical optics principle. The device comprises a point light source, a first spectroscope, a collimator objective, the multifocal holographic lens, the differential confocal system, an adjusting frame, a length measuring system and a moving track. The invention integrates the differential confocal high-precision fixed-focus principle and a multifocal holographic lens compression optical path principle for the first time, has the advantages of small displacement distance of the measured piece, high measurement precision, high measurement speed, strong ambient interference resistance, no damage to the measured surface and the like and can be used for the high-precision non-contact measurement of the super-large curvature radius.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

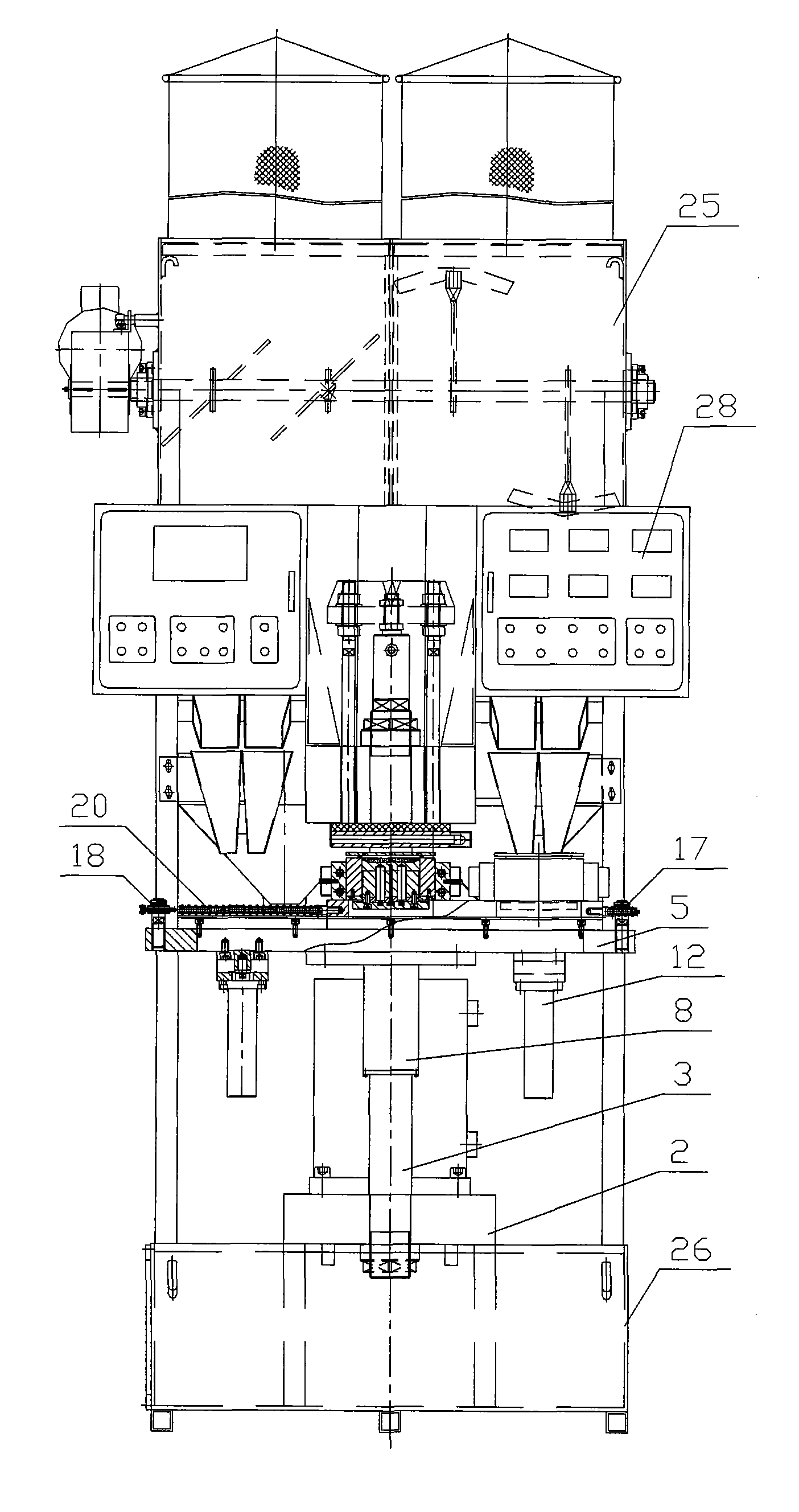

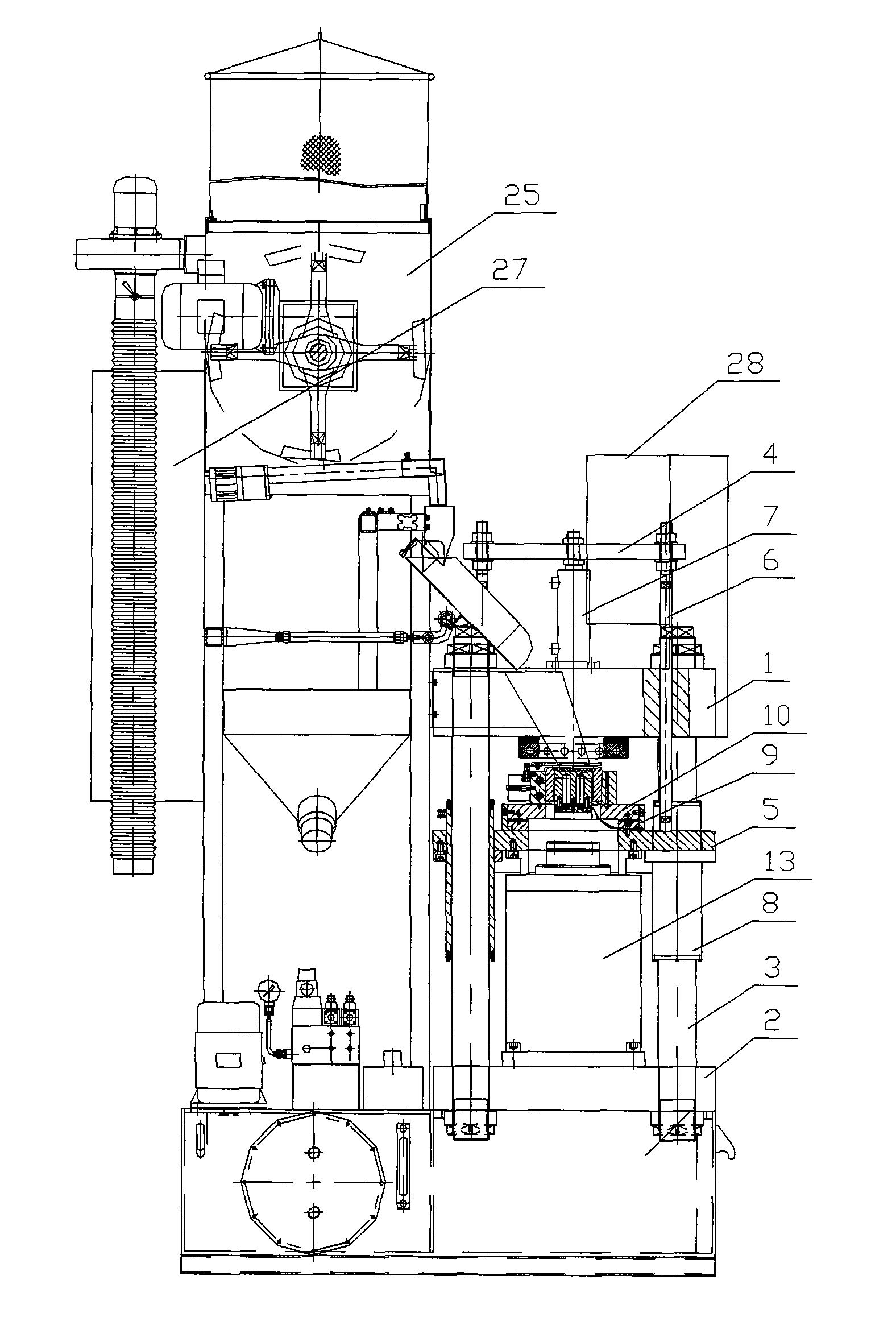

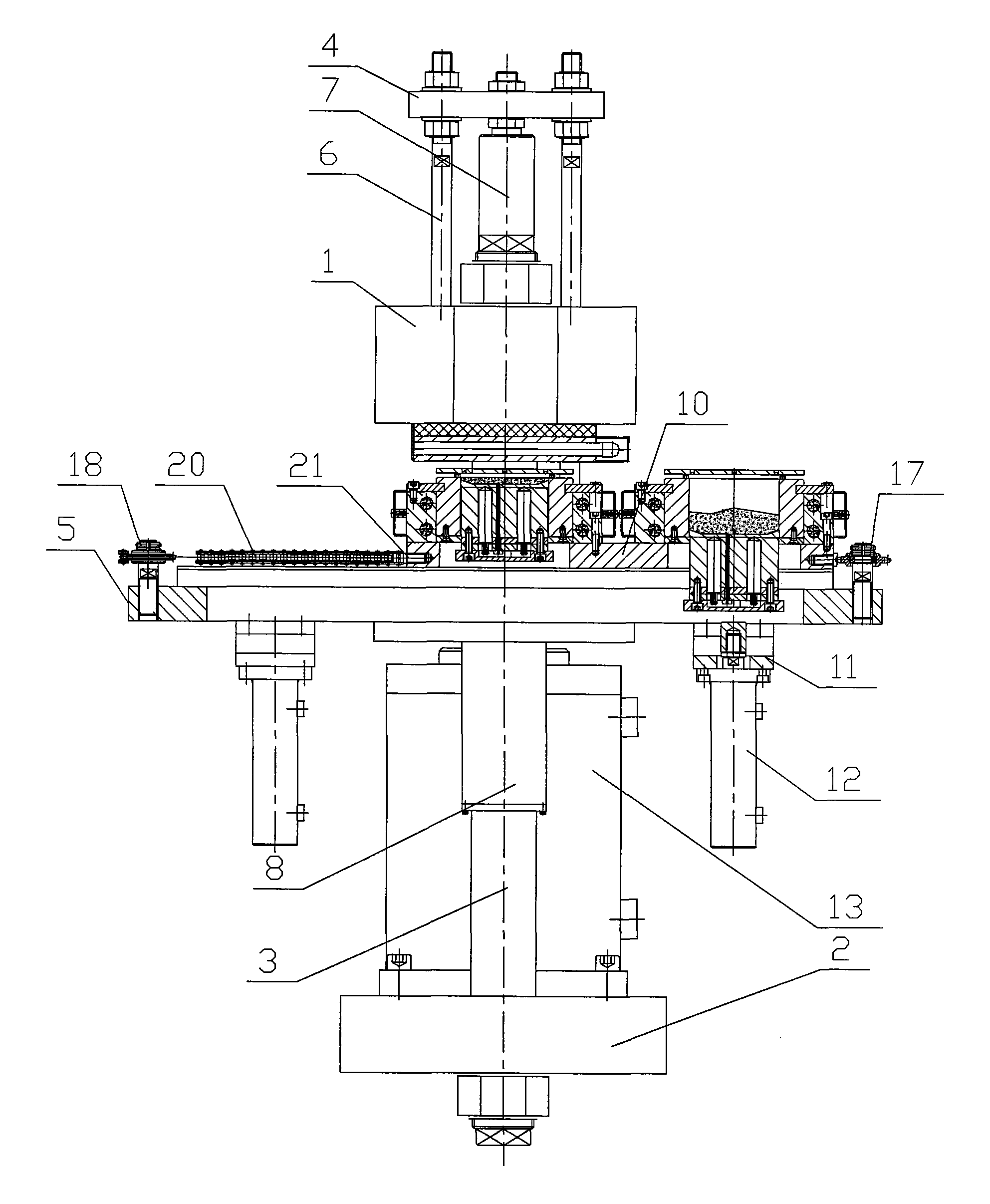

Hydraulic press with automatic weighing device and reciprocating work table

InactiveCN101602259AFunction increaseSmall logistics volumeWeighing apparatus with automatic feed/dischargeShaping pressCompression moldingMaster cylinder

The invention belongs to a hydraulic press and particularly relates to a press for powder compression molding forming. The press for powder compression molding forming consists of a hydraulic station taken as a power source, a control system and a main frame, wherein the main frame consists of a press and an automatic weighing device; and the press is formed according to the following mode: an upper beam (1), a lower beam (2) and a vertical column (3) are linked into a stress frame; an upper connecting plate (4), a movable cross-beam (5) and a pull rod (6) are linked into a closed frame which is fixedly connected with a piston rod of a potting oil cylinder (7) fixedly connected to an upper plane of the upper beam (1); the movable cross-beam (5) is guided through a guide sleeve (8) and can move up and down along the vertical column (3); an upper plane of the movable cross-beam (5) is fixedly provided with a guide rail (9); the guide rail (9) is provided with a reciprocating work table (10) which can move left and right along the guide rail; and a piston type master cylinder (13) fixedly connected with the lower beam (2) is arranged below the movable cross-beam (5). The press has the advantages of compact structure, automatic powder weighing, feeding and charging, and high automation degree of the whole machine.

Owner:吉林省吉大机电设备有限公司

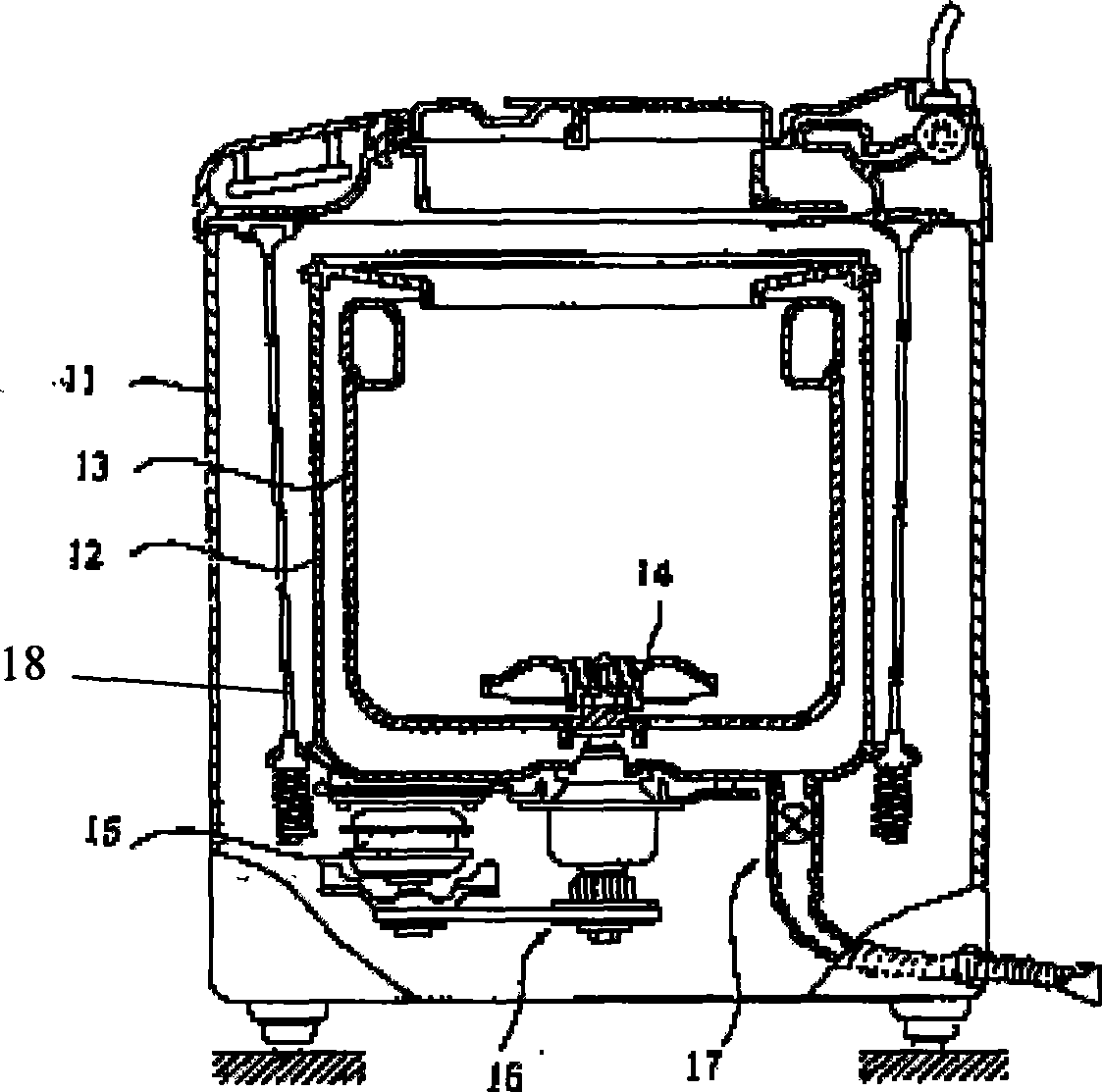

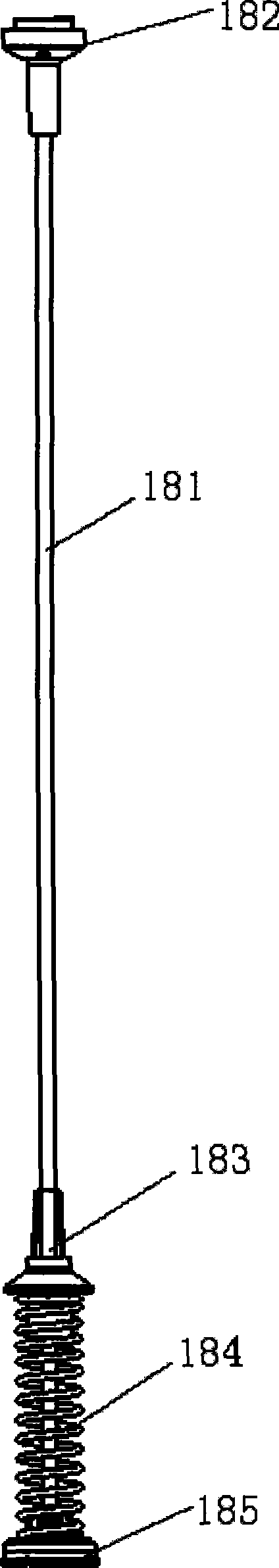

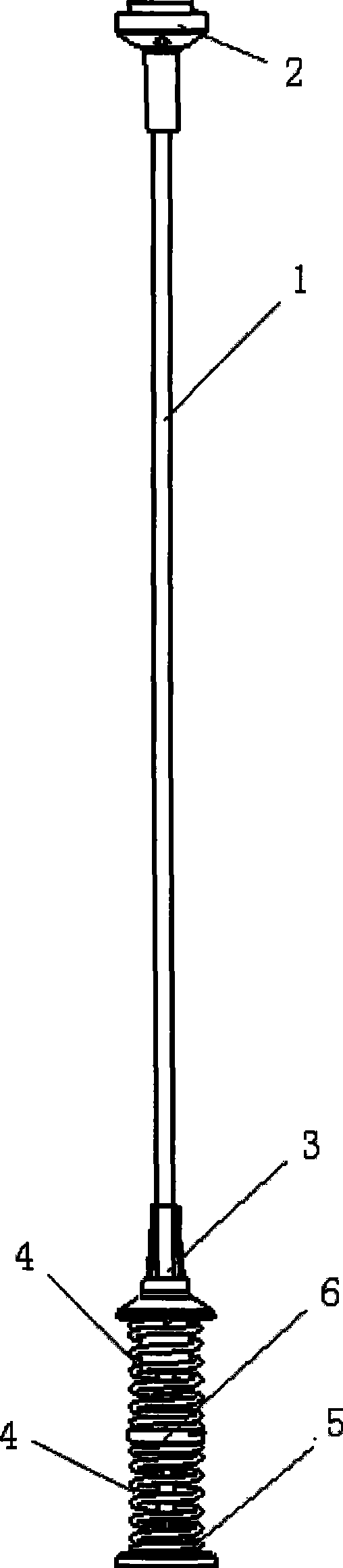

Shock-absorbing suspension rod of combined spring

InactiveCN101429718AReduce vibrationReduce movement distanceOther washing machinesTextiles and paperEngineering

The invention discloses a combined spring shock-absorbing suspension rod, which comprises a rod body, a connecting base, a mounting base, a group of springs and a fixing base, wherein the connecting base is positioned at the top end of the rod body, and the rod body is arranged on a shell of a washing machine through the connecting base; the mounting base is positioned at the lower part of the rod body for mounting an outer drum of the washing machine; and the fixing base is positioned at the bottom end of the rod body, and the group of the springs are sleeved on the rod body and positioned between the mounting base and the fixing base and connected together in series through a connecting sleeve. The combined spring shock-absorbing suspension rod adopts combined springs to change elastic coefficient of the suspension rod, improves shock-absorbing performance of the suspension rod, reduces shocking and moving distances of the washing machine, and reduces noise.

Owner:NANJING LG PANDA APPLIANCES

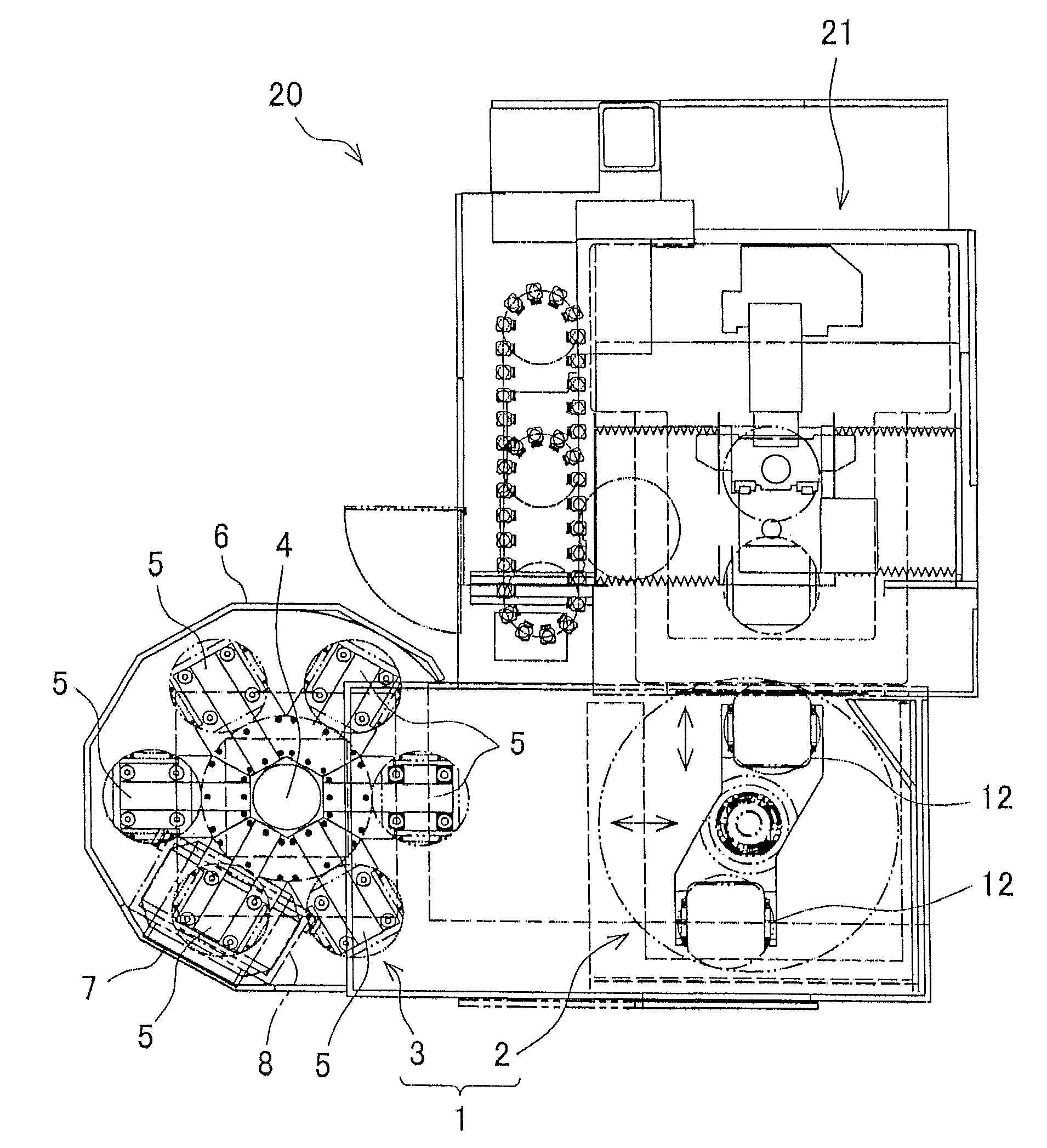

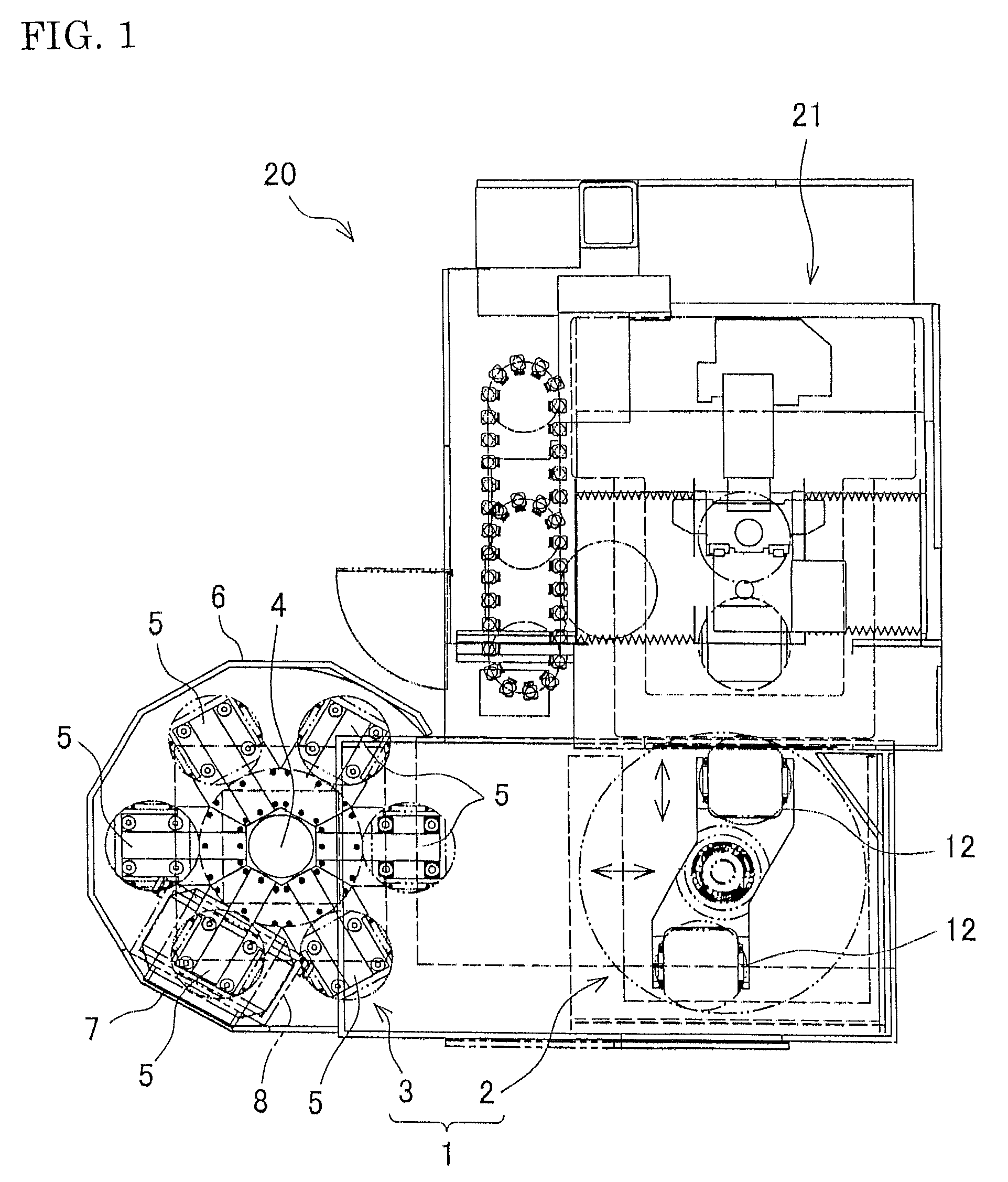

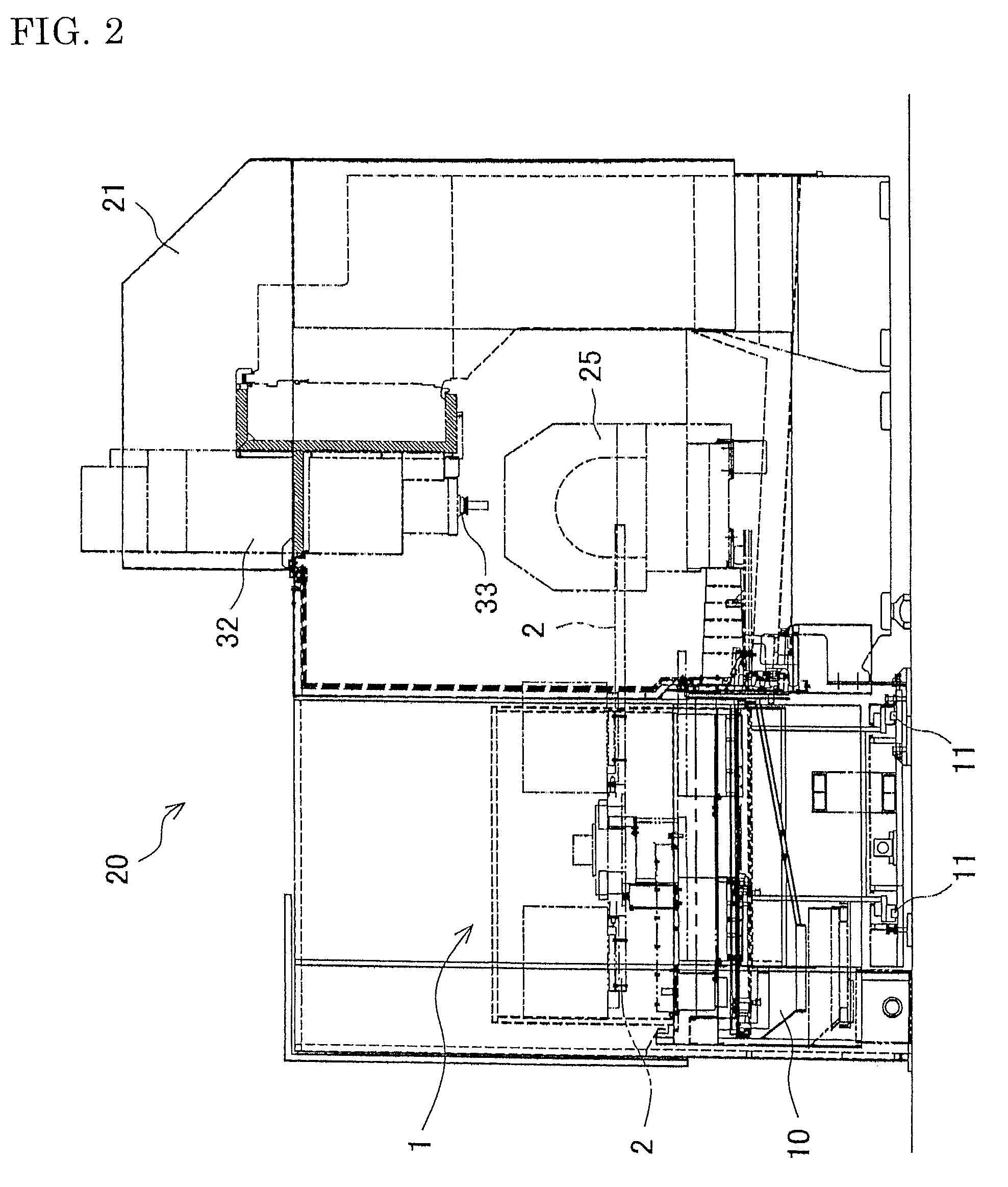

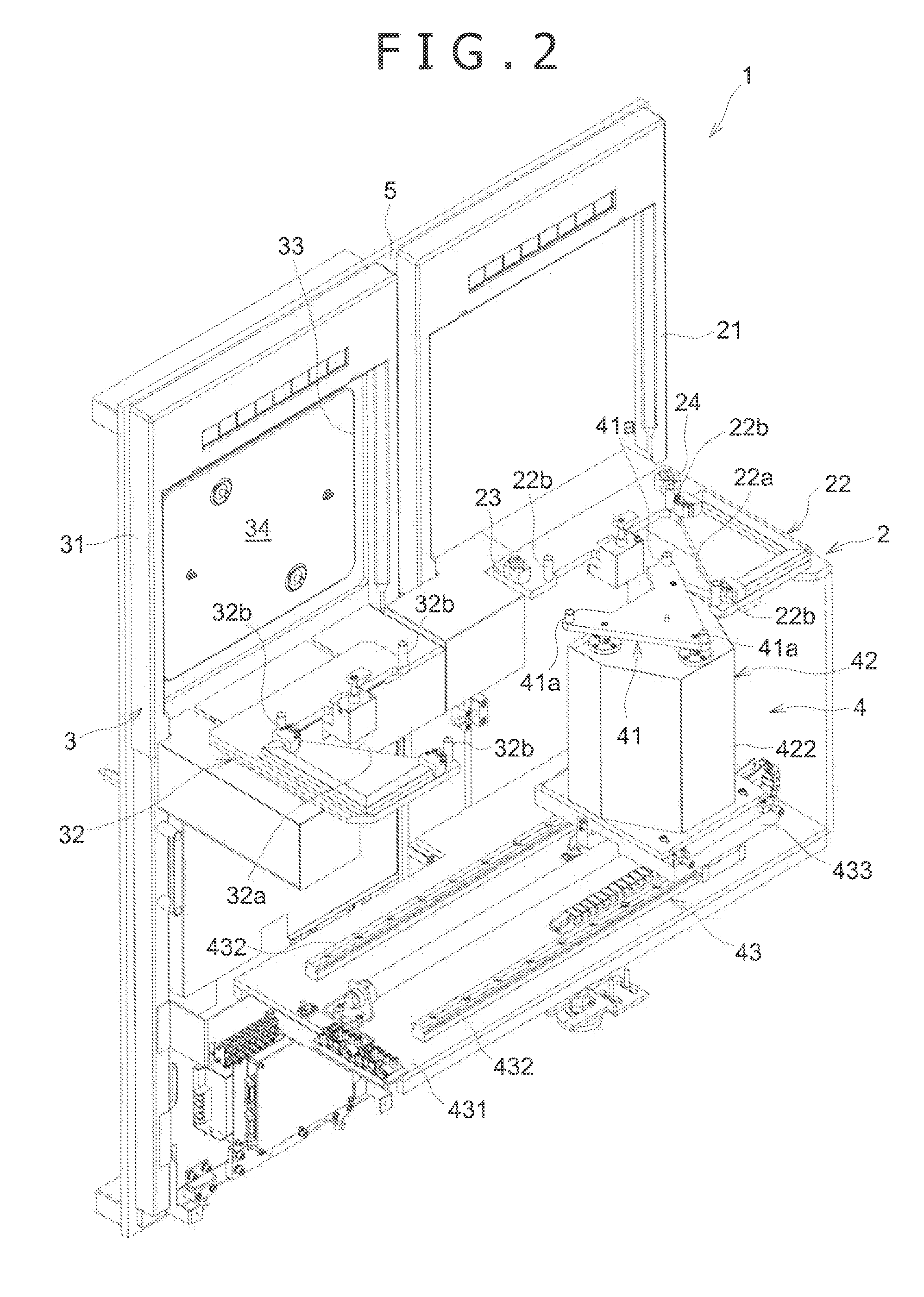

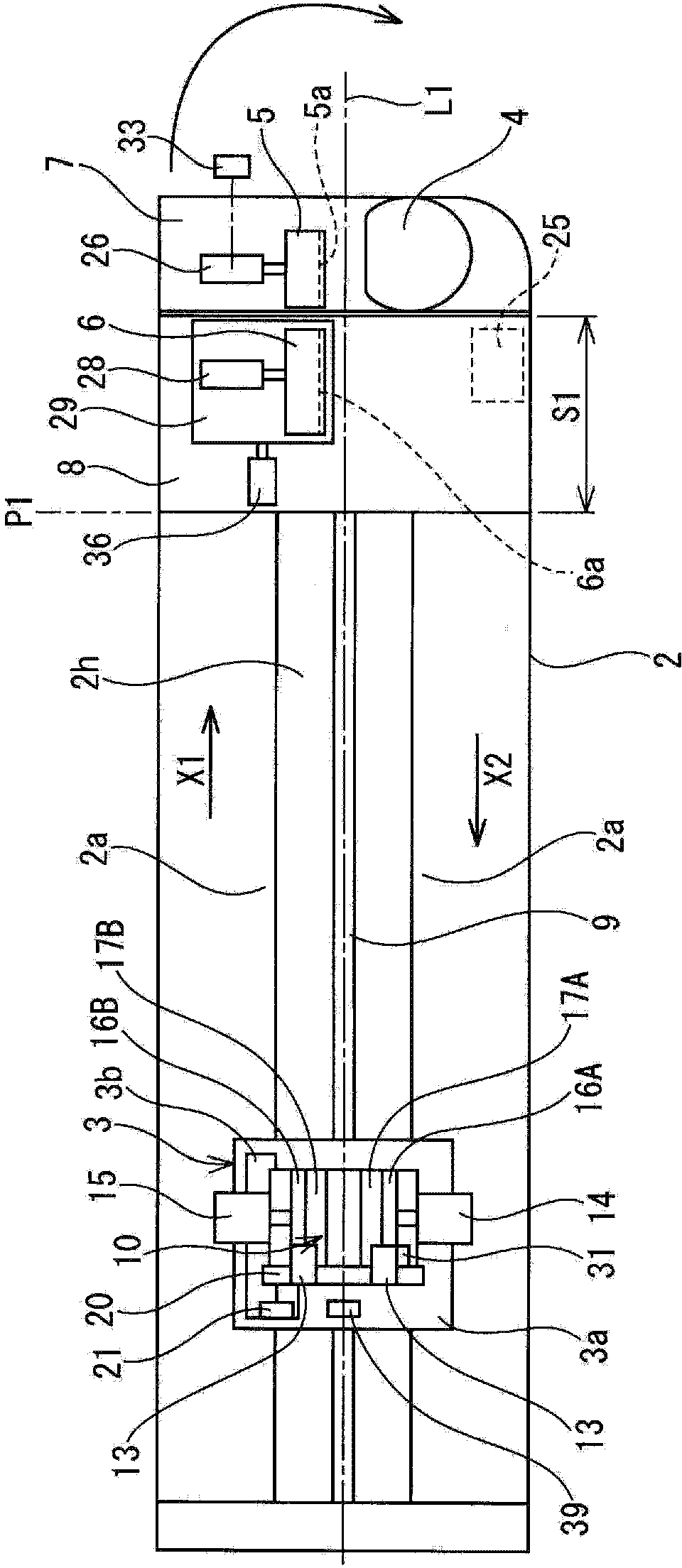

Pallet exchanging device

InactiveUS7621031B2Solve the lack of spaceImprove machine efficiencyControl devices for conveyorsCharge manipulationMulti phaseWorking space

Owner:OKUMA CORP

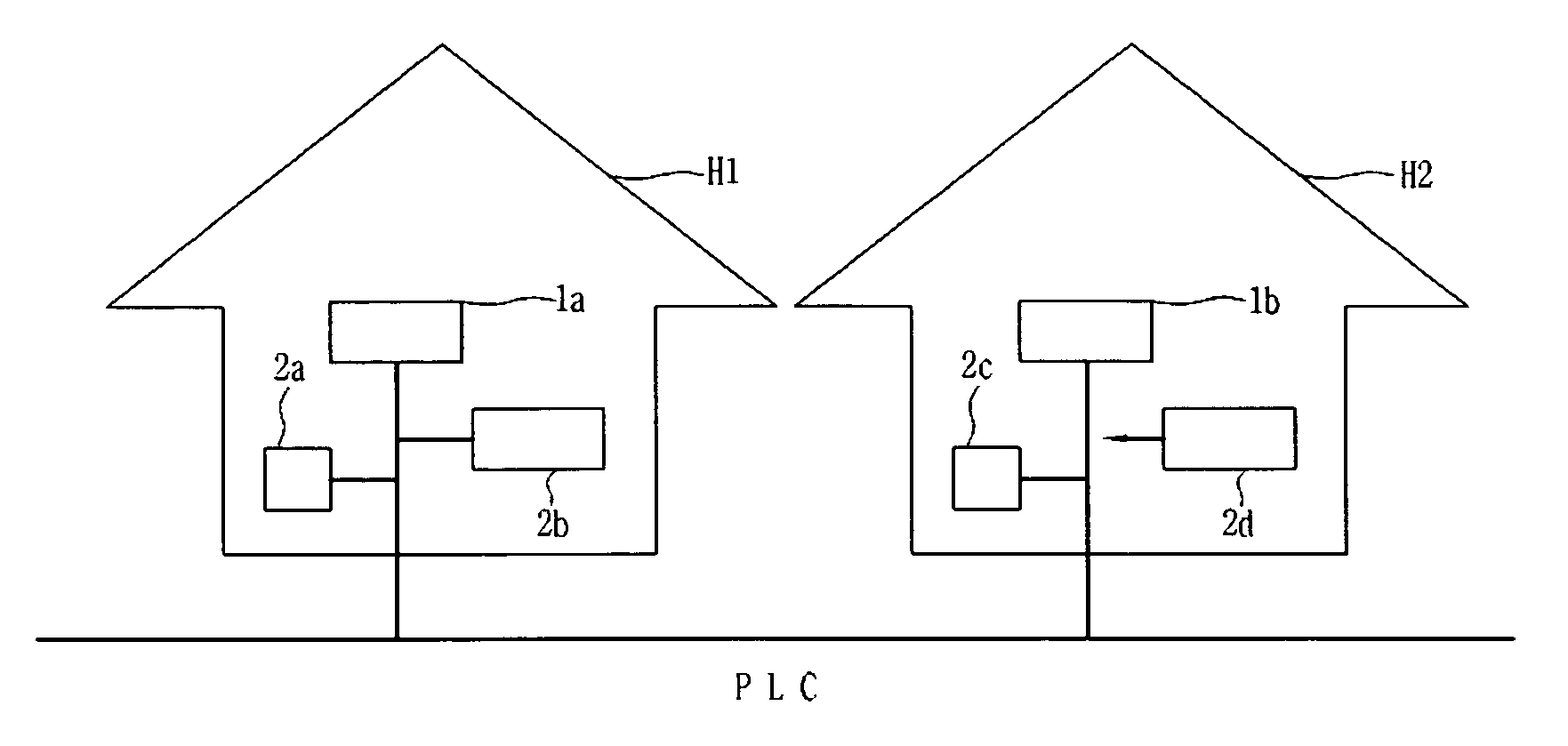

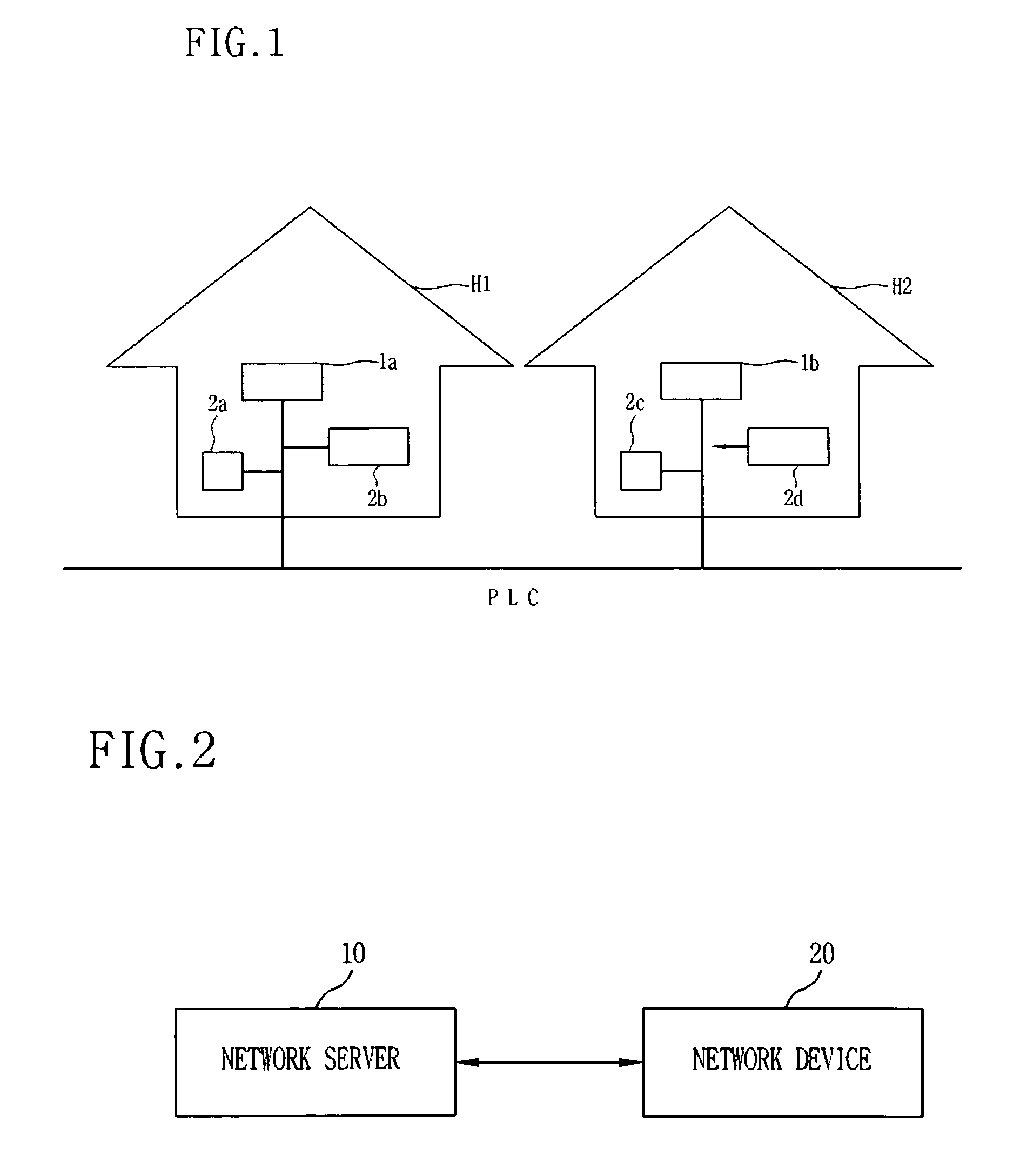

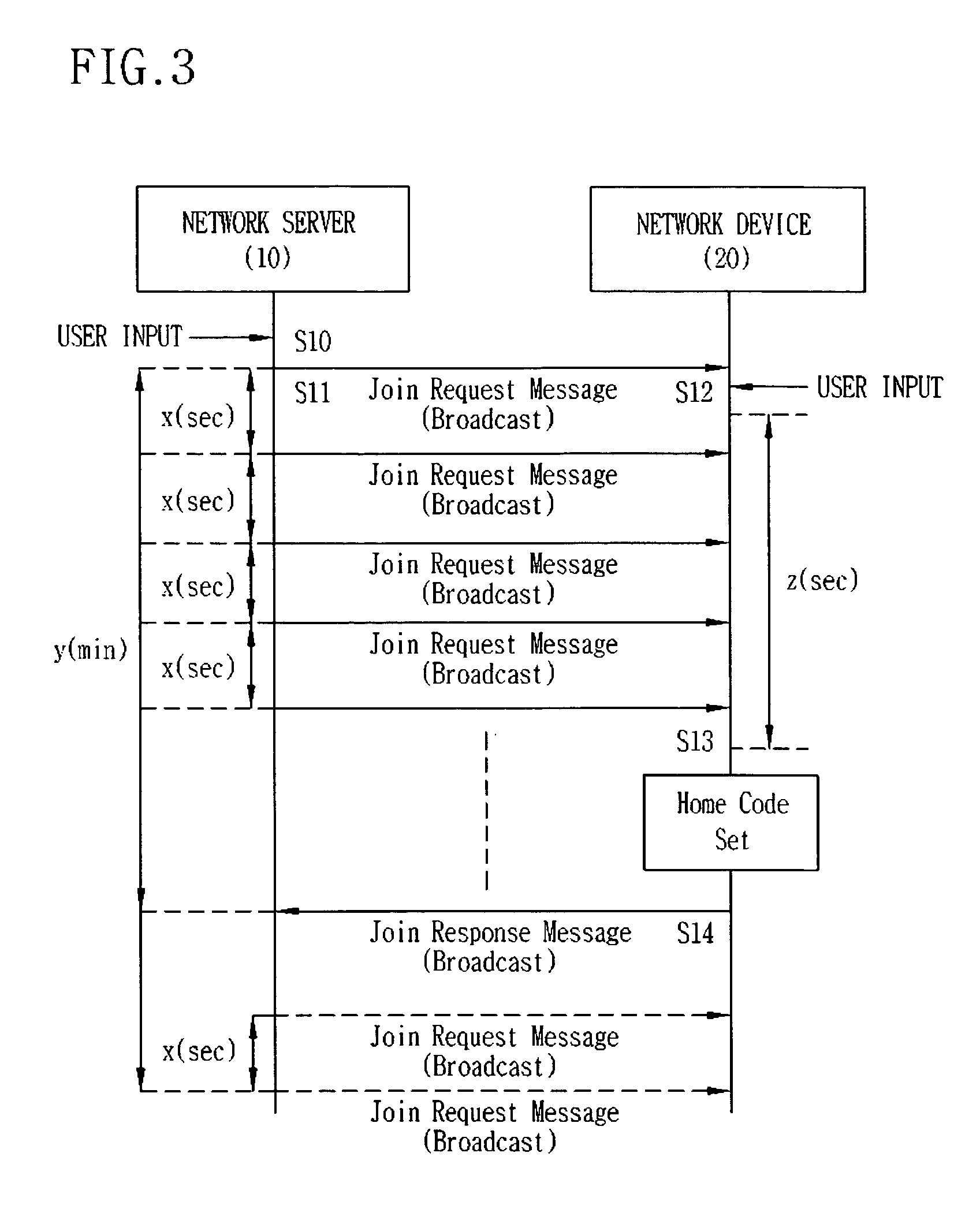

Home code setting method for home network system

ActiveUS8090807B2Highly reliable connection and registrationStably perform network connectionMultiple digital computer combinationsElectric digital data processingNetwork connectionNetwork service

The present invention discloses a home code setting method for a home network system which can overcome a spatial installation limit and improve reliability of network connection. The home code setting method for the home network system includes the steps of connecting a network server to one network, searching for a network at a network device, and when one network is searched for in the search step, performing, at the network device, connection or registration to the network server connected to the network.

Owner:LG ELECTRONICS INC

Apparatus for producing deionized water

InactiveUS6334941B1Improve the level ofReduce movement distanceSludge treatmentMachines/enginesIon-exchange membranesPolymer chemistry

An apparatus for producing deionized water, which has an ion exchanger accommodated in demineralizing compartments of an electrodialyzer having cation exchange membranes and anion exchange membranes alternately arranged between an anode and a cathode, wherein the ion exchanger is a composite ion exchanger comprising a first porous ion exchanger having a mixture of 60 to 95 wt % of cation exchange resin particles and 5 to 40 wt % of anion exchange resin particles bonded to each other and a second porous ion exchanger having a mixture of 60 to 95 wt % of anion exchange resin particles and 5 to 40 wt % of cation exchange resin particles bonded to each other.

Owner:ASAHI GLASS CO LTD

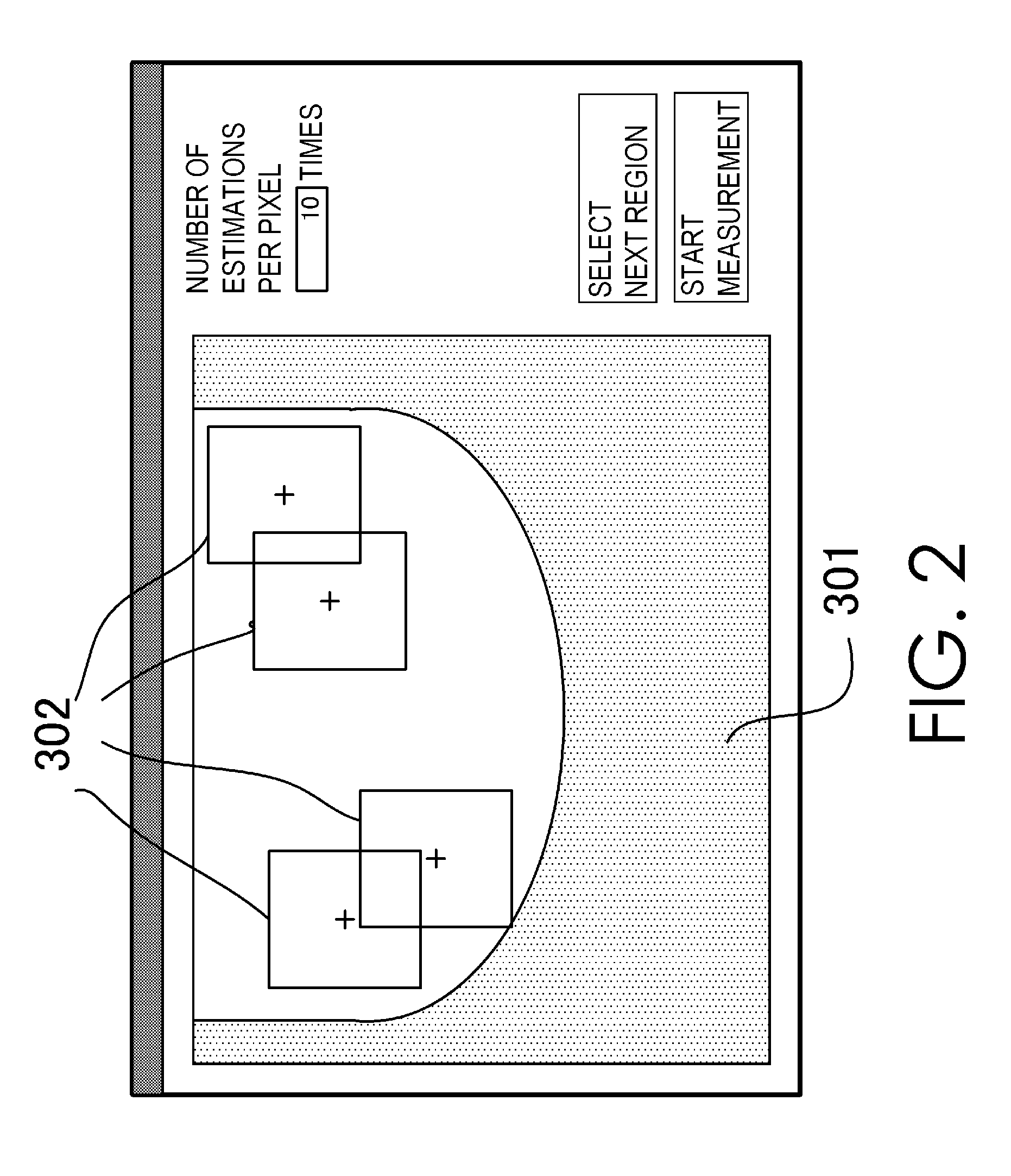

Acoustic wave measuring apparatus and control method of acoustic wave measuring apparatus

InactiveUS20130116537A1Simple processEasy to operateInfrasonic diagnosticsDiagnostic recording/measuringMeasurement devicePriority setting

Provided is an acoustic wave measuring apparatus including: an acoustic probe; region-of-interest setting unit for setting two or more regions of interest for an object; priority setting unit for setting priorities on the regions of interest; region calculating unit for determining, for each of the set priorities, an inclusion region including the regions of interest set with the priority; scanning method determining unit for assigning a scanning stripe to each of the inclusion regions so as to include all regions of interest included in the inclusion region; scanning path identifying unit for determining a scanning order of a plurality of scanning stripes having a same priority so as to shorten a movement distance of the acoustic probe; and scanning unit for scanning the scanning stripes according to the determined scanning order, based on the priority order, by moving the acoustic probe.

Owner:CANON KK

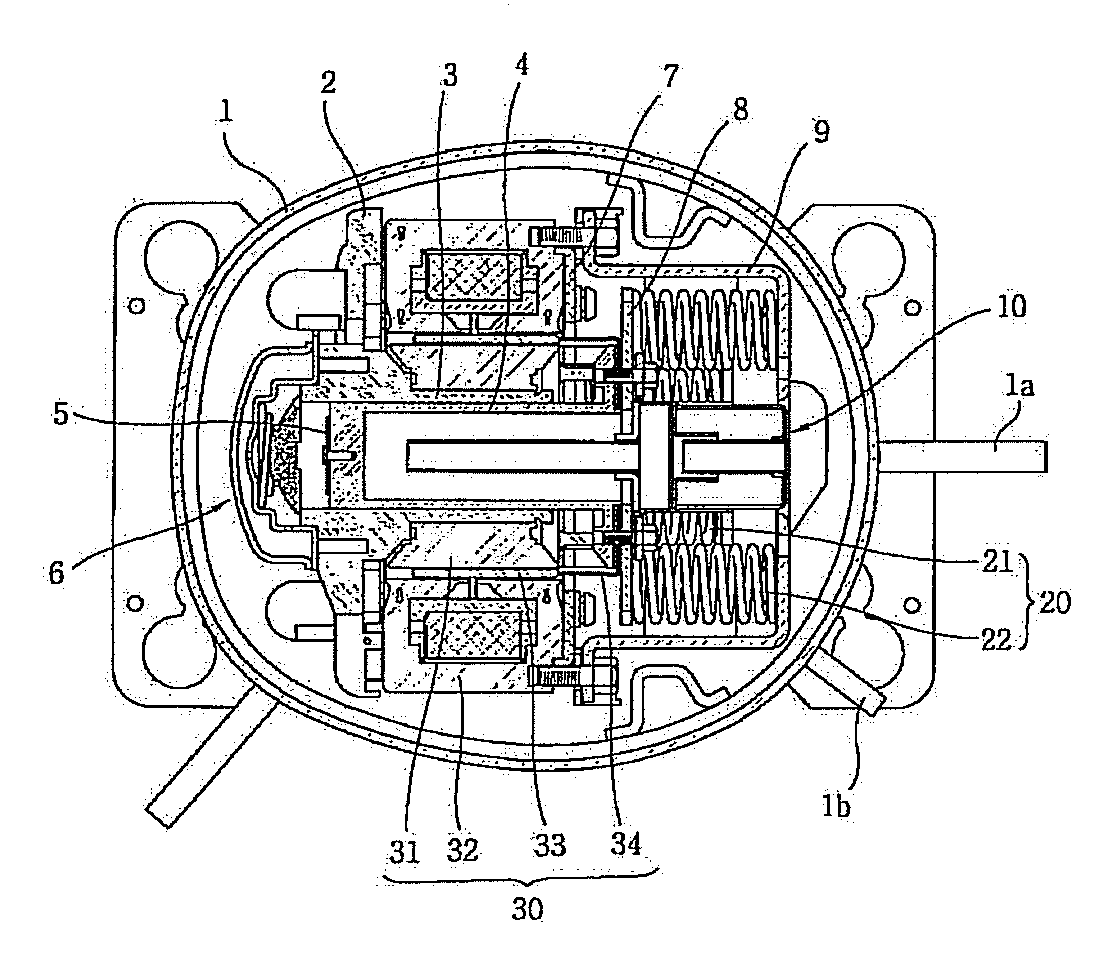

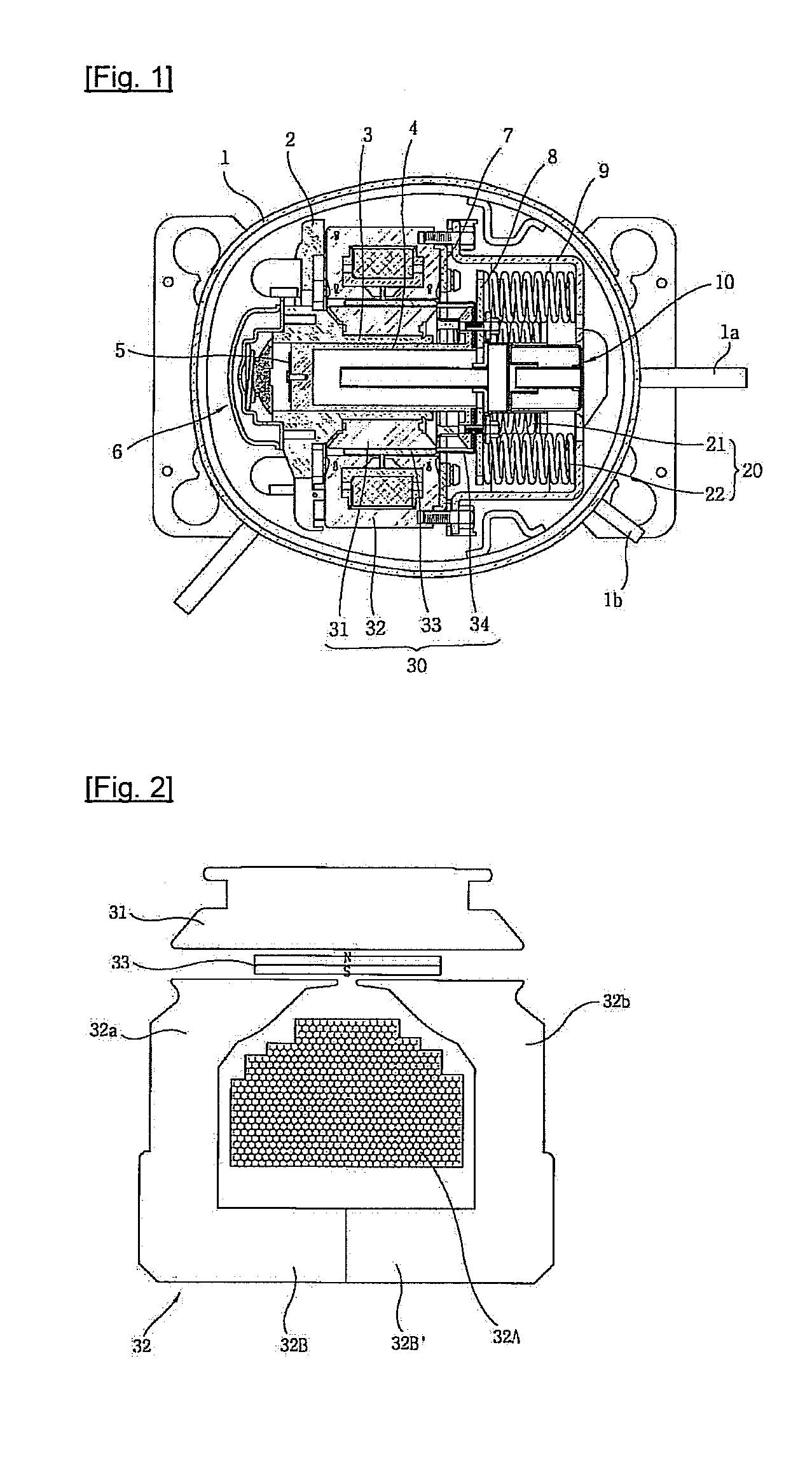

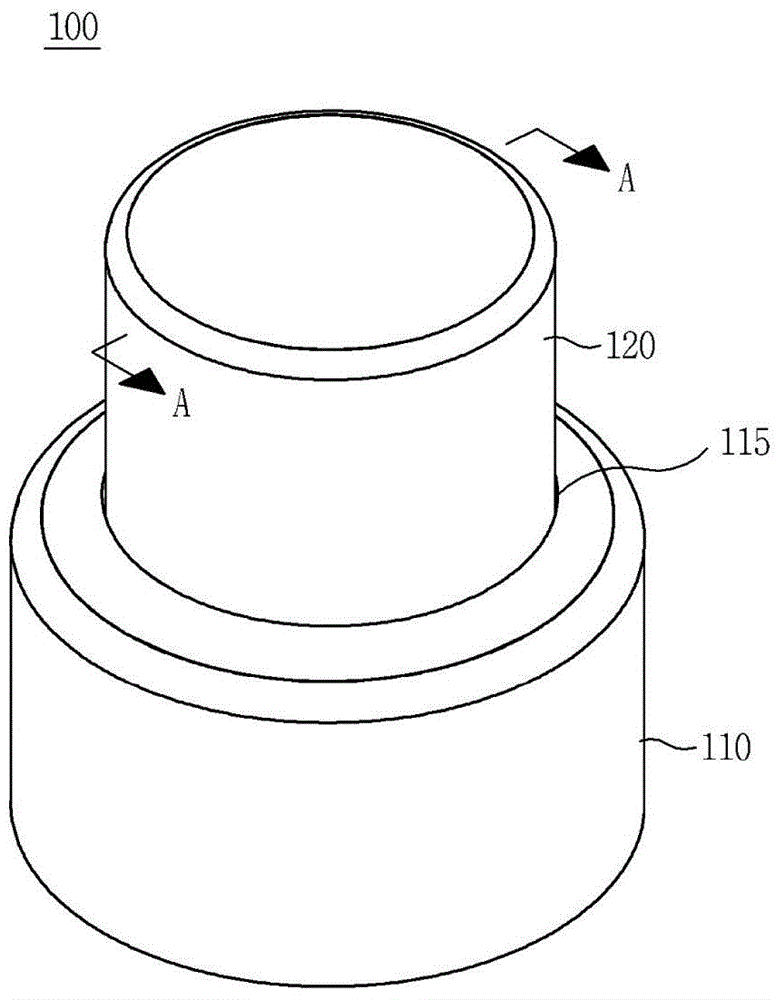

Linear compressor

ActiveUS20130129540A1Light weightSmall sizeReciprocating/oscillating/vibrating magnetic circuit partsPositive displacement pump componentsLinear motionLinear compressor

A linear compressor according to the present invention can prevent leakage of a magnetic force by changing the construction of a linear motor. As the construction of the linear motor is changed, a mechanical spring constant is set smaller in consideration of a magnetic spring constant, so that the size of springs supporting a piston in the reciprocal linear motion direction can be reduced and components supporting the springs can be removed. Therefore, the linear compressor achieves a small size / a light weight. With the characteristics of the linear motor construction, the linear compressor can suppress a stroke spreading influence and easily expand a compression capacity according to a load.

Owner:LG ELECTRONICS INC

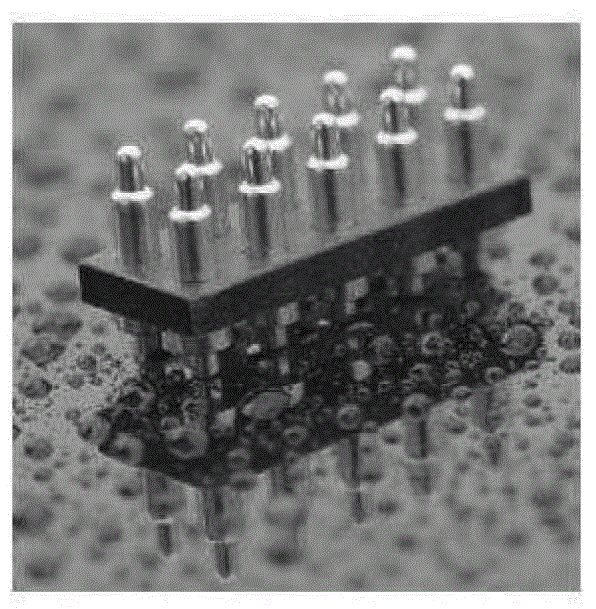

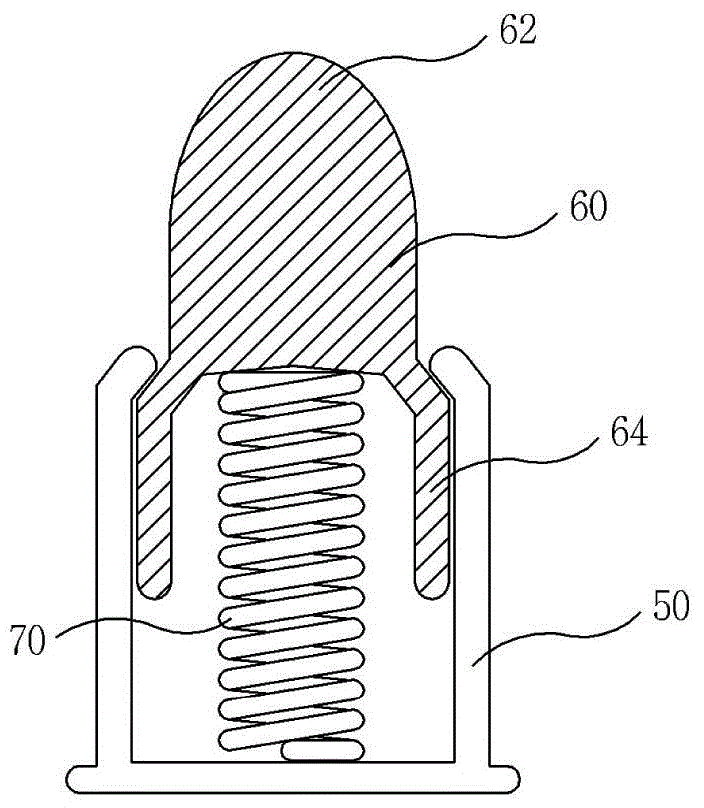

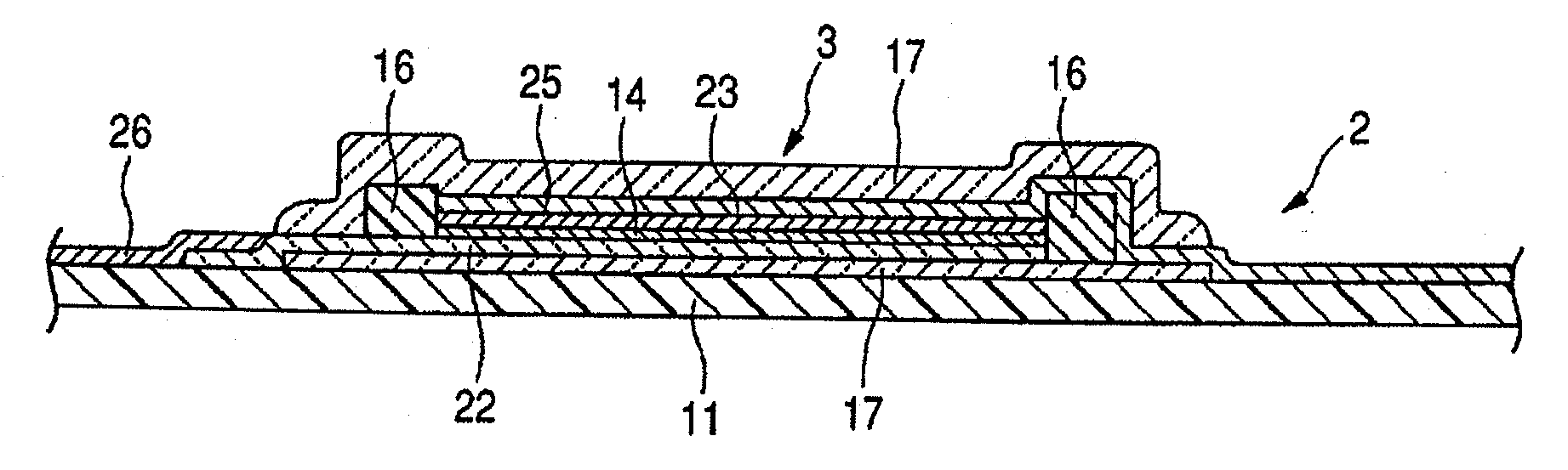

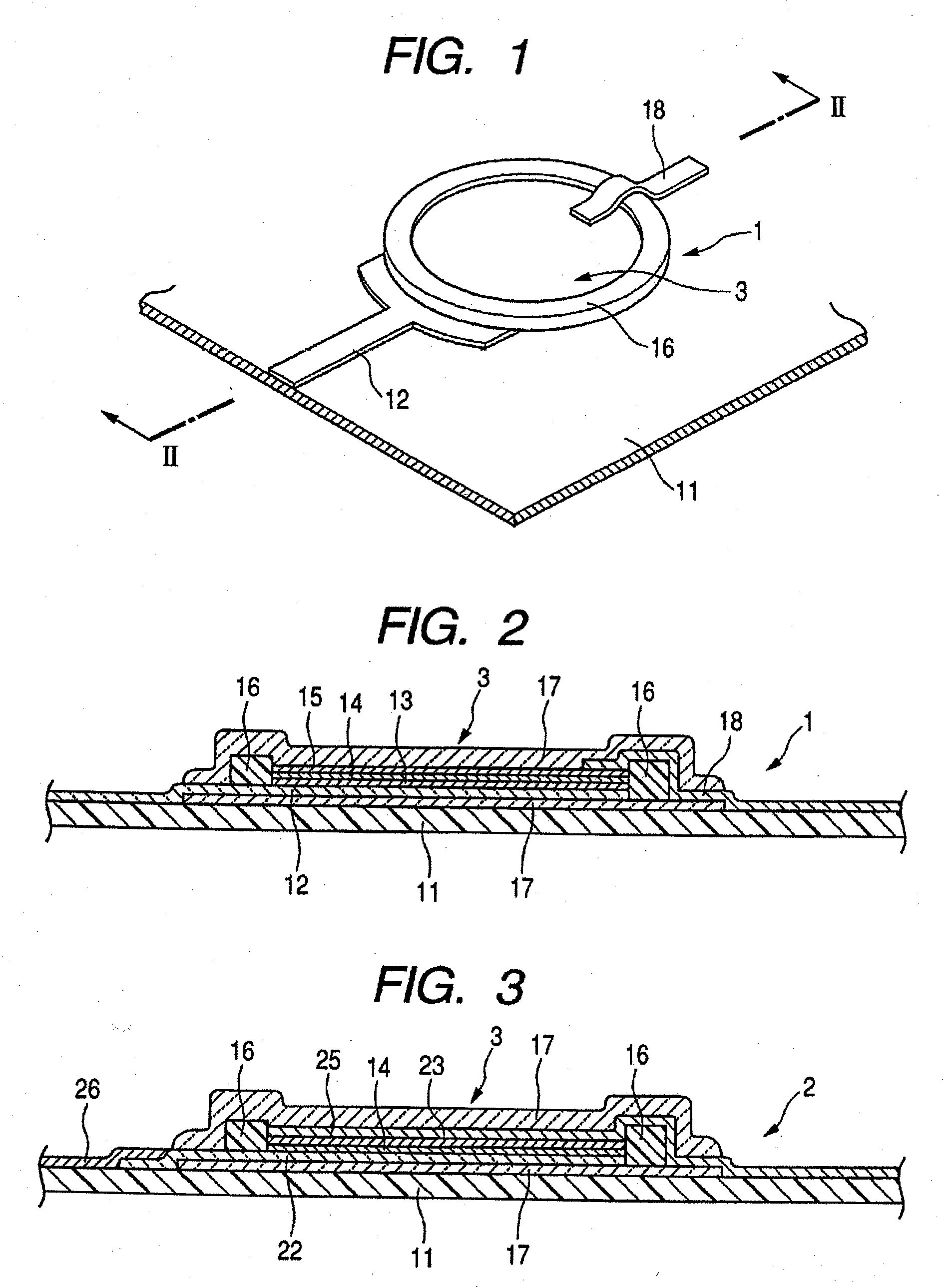

Surface-mount type electric connecting terminal, electronic module unit and circuit board using the same

ActiveCN104638413AIncrease travel distanceReduce the overall heightElectrically conductive connectionsFinal product manufactureSurface mountingMetallic materials

Provided is a surface-mount type electric connecting terminal which is disposed between opposing conductive objects (including for example a conductive pattern 12 on a PCB 10) and is configured to electrically connect the objects while easily adjusting pressing force and recovery force. The electric connecting terminal includes a cylindrical fixed member 410 which is made from a metallic material; a cylindrical movable member 420 which is slidably inserted in the fixed member and is made from a metallic material; and an electrical conductive spring 430 which is accommodated in the fixed member and whose one end contacts with the bottom of the fixed member and the other end contacts with the bottom of the movable member for thereby allowing the movable member to elastically slide against the fixed member. The fixed member comprises a hook portion to prevent the movable member from being disengaged from the fixed member when elastic recovery force is transferred from the spring. A flat surface is formed in an upper end surface of the movable member for the sake of vacuum pickup, and a lower end surface of the fixed member is configured to be reflow-soldered using solder cream 14.

Owner:JOINSET +1

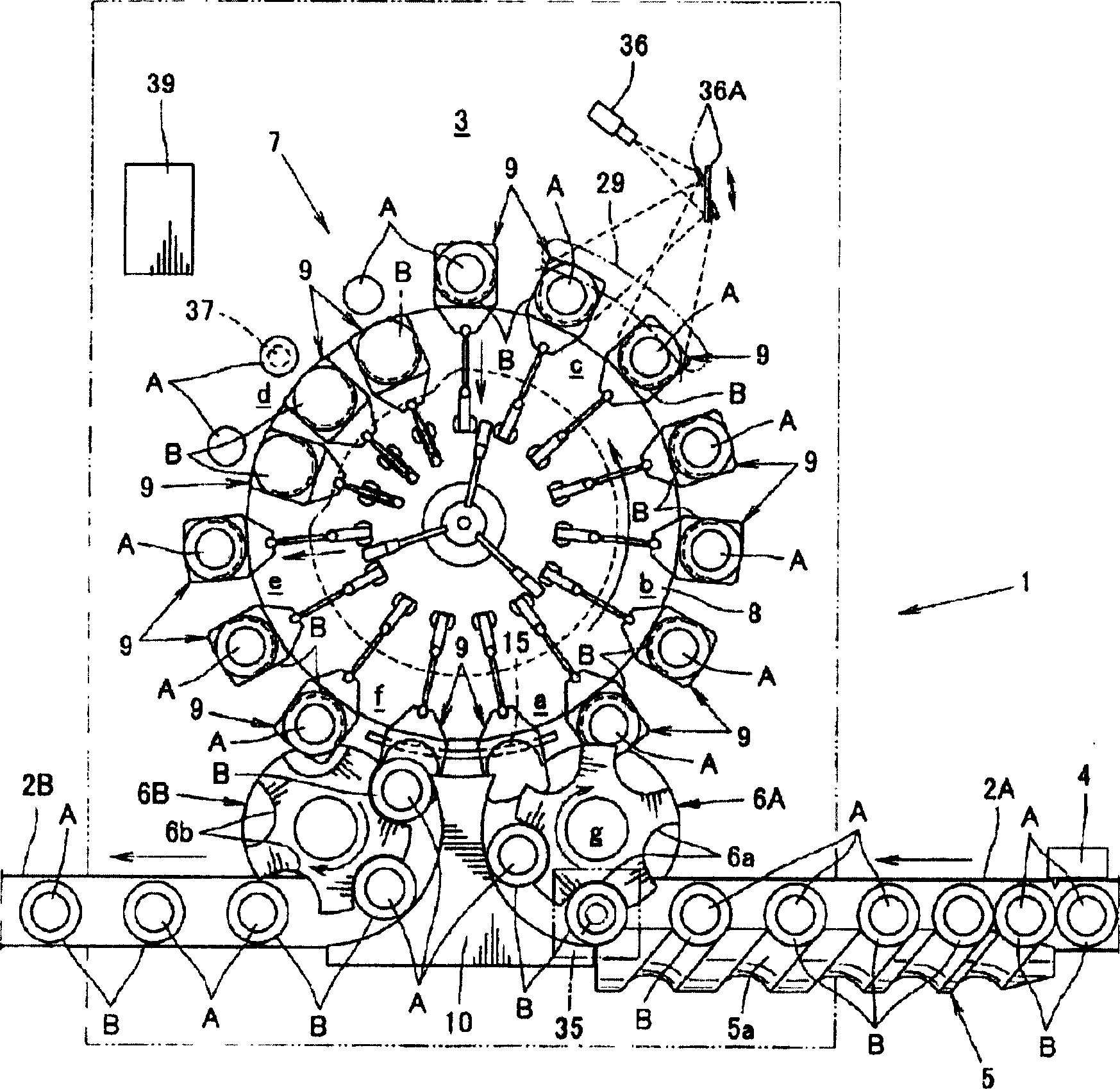

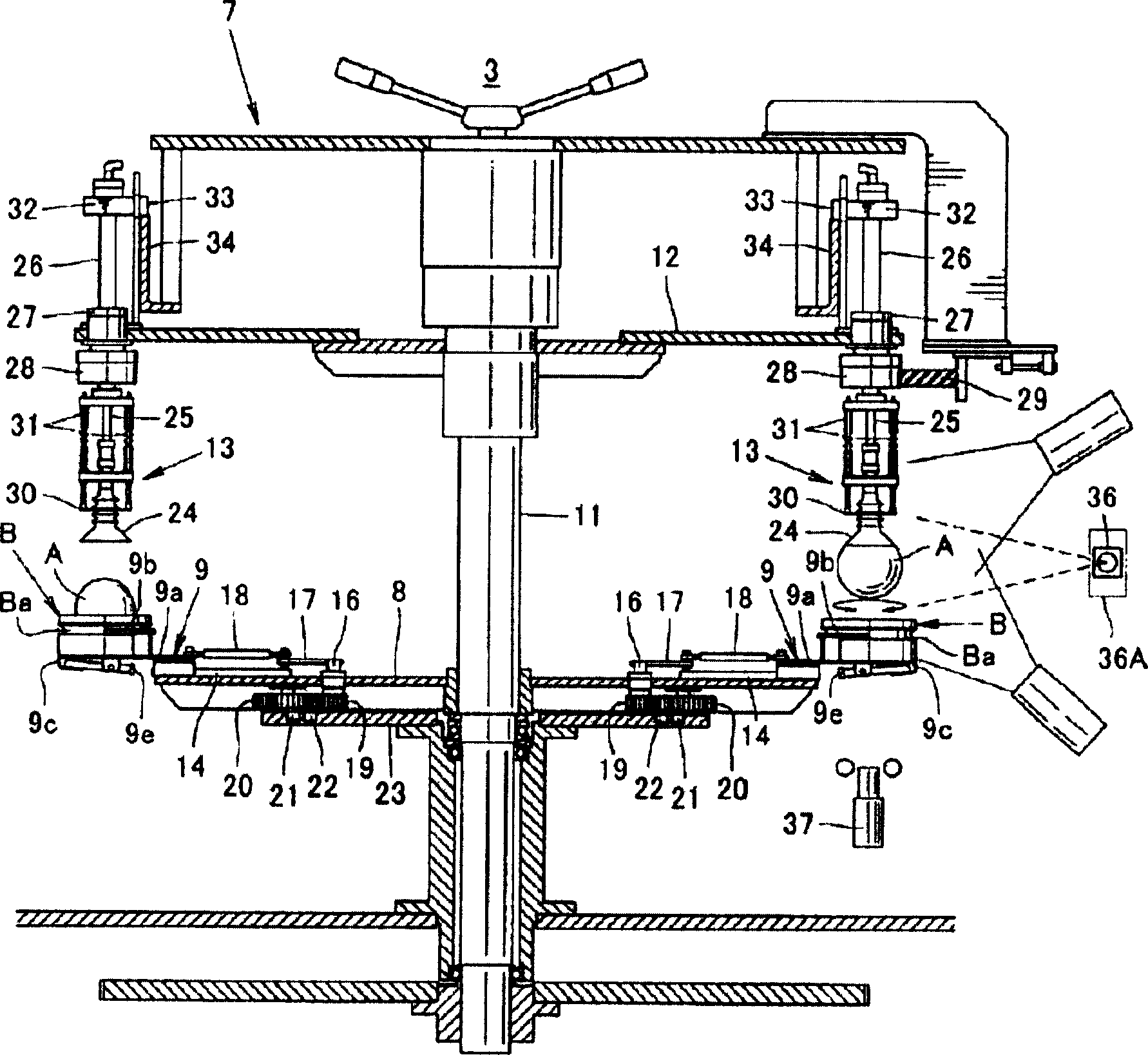

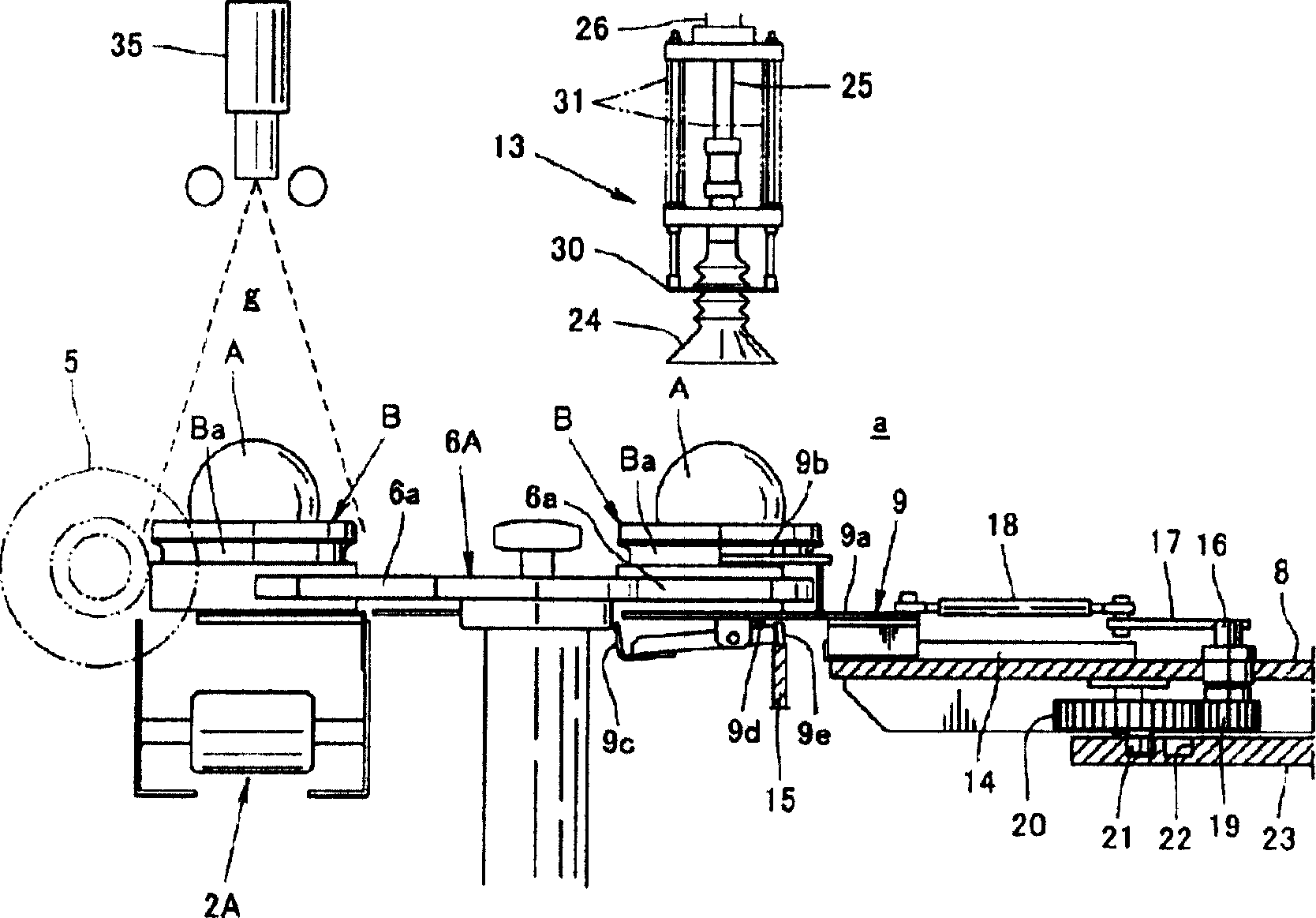

Agricultural product inspection device

ActiveCN1844898APrevent the situation that is easy to fly out to the outsideReduce movement distanceInvestigating moving fluids/granular solidsUsing optical meansProduct inspectionEngineering

There provides an inspection apparatus for agriculture product capable of performing an operation for inspecting whole surfaces of an agriculture product with a small space and facilitating layout of the apparatus. Each housing body (B) held on each holding stand 9 of a rotation table 8 constituting the inspection apparatus 1 for agriculture product is moved along a conveyance course in the circumferential direction and, at the same time, each agriculture product (A) housed in each housing body (B) is held and lifted by each holding head 13 and is revolved and moved into each region (a) to (f) on the conveyance course. In an inspection area (c) for lateral surface, the whole periphery of the lateral surface of each agriculture product (A) held by each holding head 13 is photographed by a lateral surface photographing camera 36 and, in an inspection area (d) for lower surface, the lower surface of each agriculture product (A) held by each holding head 13 is photographed by a lower surface photographing camera 37. Thereafter, each agriculture product (A) held by each holding head 13 is again housed by each housing body (B) and the housing body (B) in which the agriculture product (A) is housed is discharged from each holding stand 9.

Owner:SEGU SEIKO KK

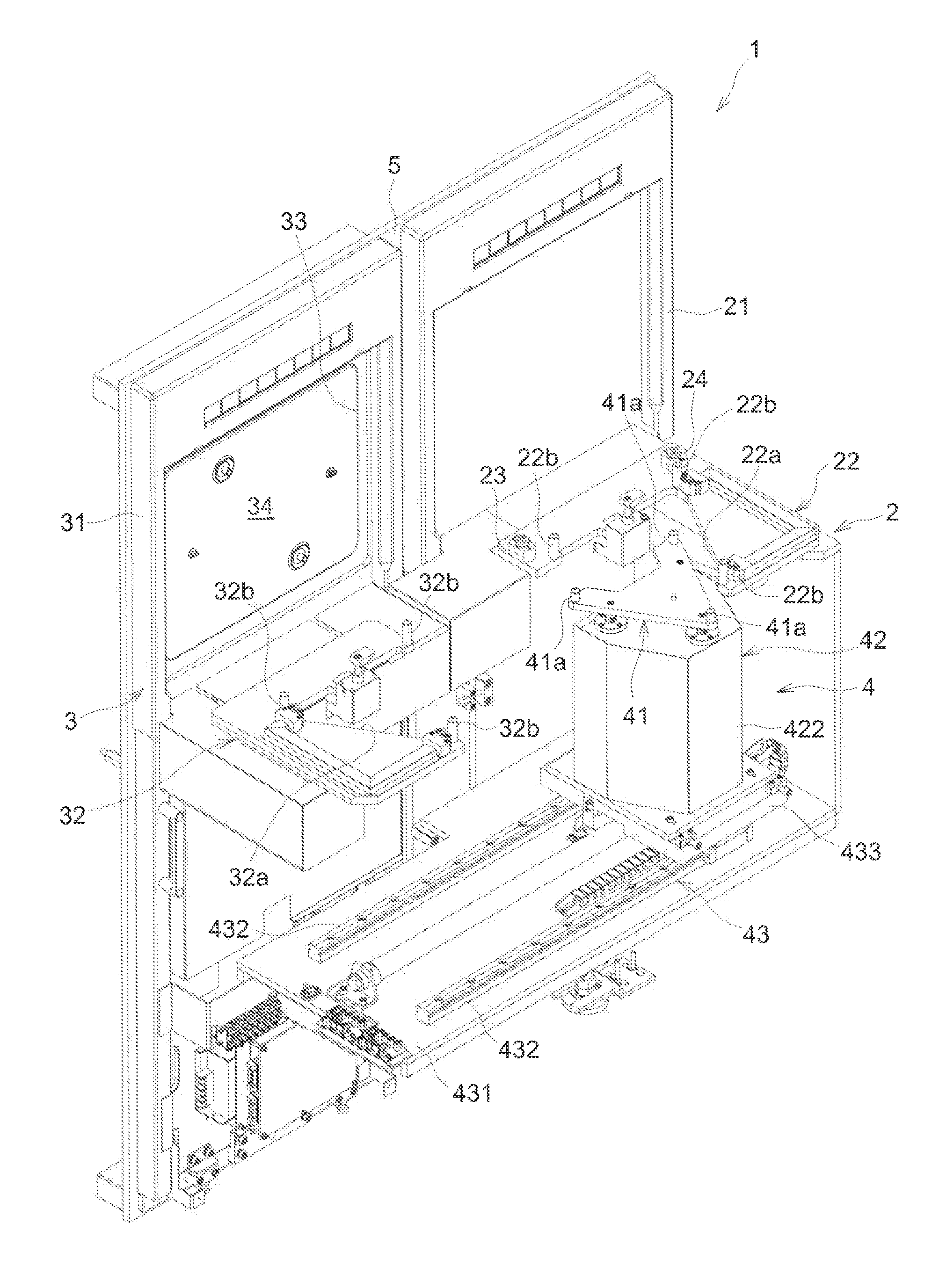

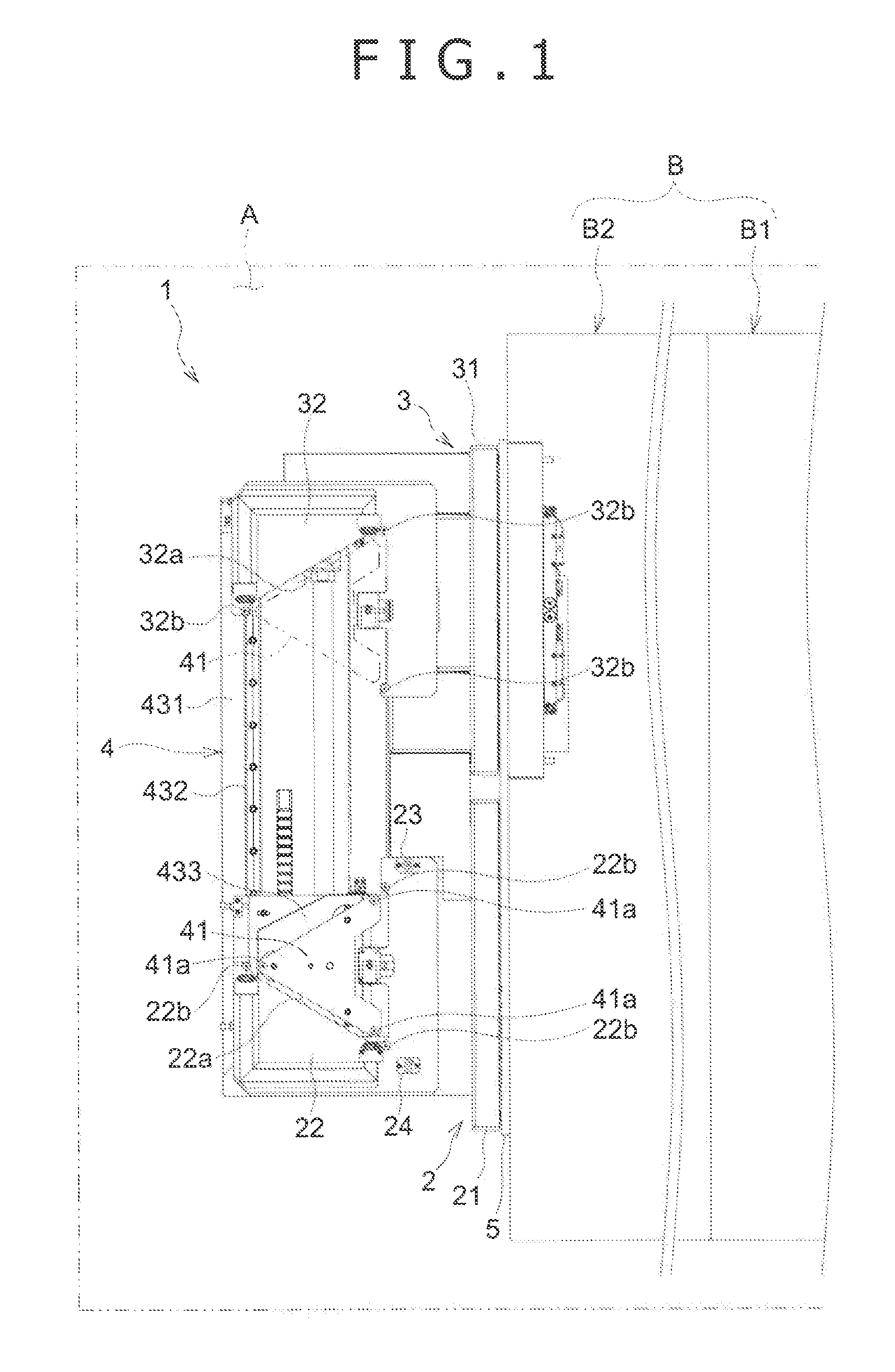

Load port

InactiveUS20100135753A1Easy to operateReduce movement distanceSemiconductor/solid-state device manufacturingStorage devicesNitrogen gasSemiconductor

A load port is disclosed which allows a wafer to be transferred between the inside of a FOUP and the inside of a semiconductor fabrication apparatus even during a purge operation. The load port is provided adjacent the semiconductor fabrication apparatus in a clean room and includes a purge stage having a purge port through which a gas atmosphere in the FOUP is replaced into nitrogen gas or dry air, an opener stage provided in a juxtaposed relationship with the purge stage and having an opening communicating with the inside of the semiconductor fabrication apparatus and a door section capable of opening and closing the opening, and a moving mechanism for moving the FOUP between the purge stage and the opener stage.

Owner:SINFONIA TECHNOLOGY CO LTD

Flip chip bonding apparatus and flip chip bonding method

ActiveCN104078373AReduce thermal expansion and vibrationImprove UPHSemiconductor/solid-state device testing/measurementSolid-state devicesSemiconductor chipFlip chip

Disclosed are a flip chip bonding device and a flip chip bonding method capable of delivering a flip chip from a flip over picker to a bonding picker. According to an embodiment of the present invention, the flip chip bonding device includes a wafer supply part supplying a wafer including multiple semiconductor chips, a picker unit picking up a semiconductor chip from the wafer, a bonding picker picking up the semiconductor chip from the picker unit to embed the chip in a substrate, a soaking unit soaking a lower bump of the semiconductor chip picked up by the bonding picker in a flux, an up-looking vision checking a lower surface of the semiconductor chip soaked in the flux of the soaking unit and picked by the bonding picker, a flux vision checking a flux state of the soaking unit, an operating part transferring at least one of the bonding picker and the flux vision to a x-y flat spot, and a bonding table in which the substrate is placed. The semiconductor chip picked by the bonding picker is checked after being soaked in the flux by the up-looking vision while at the same time flux vision checks the soaking unit.

Owner:HANMI SEMICON CO LTD

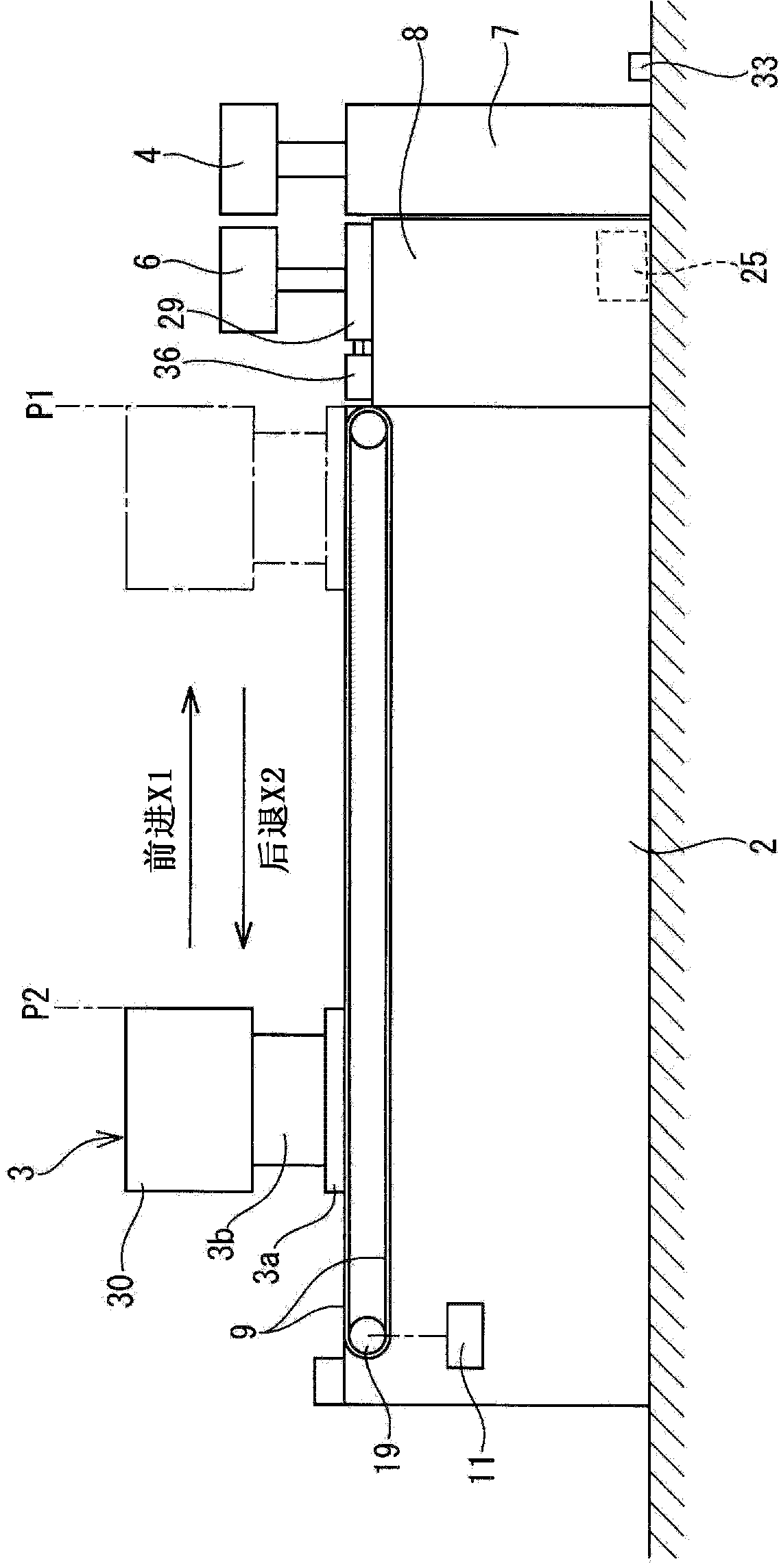

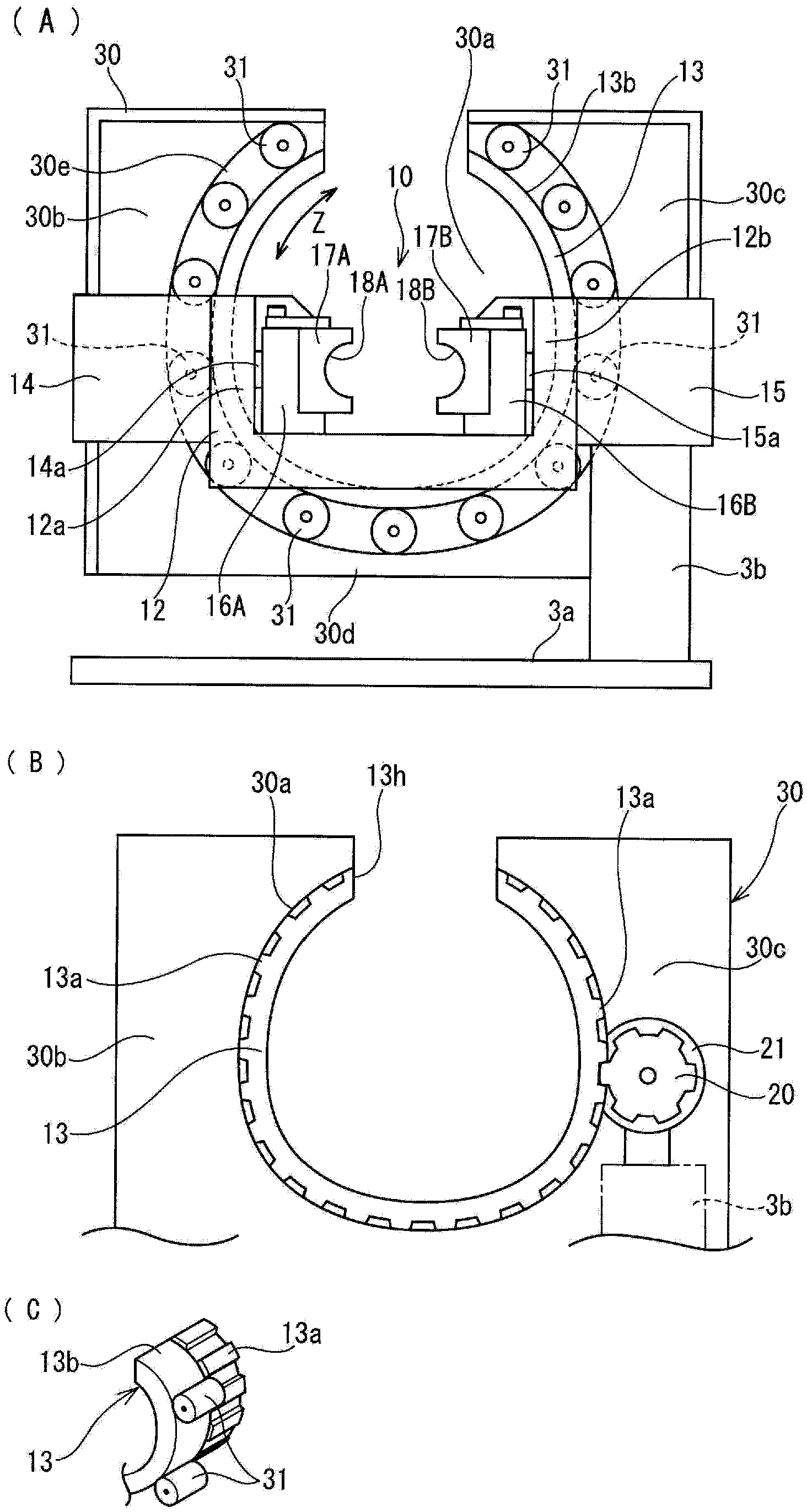

Pipe bending device and pipe bending method

The invention provides a pipe bending device, which is simplified and miniaturized, and a pipe bending method. A pipe chuck assembly is mounted on a movable cart which carries out reciprocation in a rectilinear direction on a base table. The pipe chuck assembly includes a chunk supporter which rotates under the driving of a chunk rotating unit on the movable cart; right and left chuck holders mounted on the chunk supporter; and a pair of chunk moulds which moves close to or away from each other by drive units fixed on the chunk supporter, and are provided with grooves fitting a semi-circumference part of the pipe on opposite faces of the chunk moulds. The bending device has a bending roller mould and a fastening mould which are positioned in front of a front stop position of the movable cart. When the pipe is inserted from above and clamped by the pair of chunk moulds on the movable cart, the pipe is rotated by the chunk rotating unit, the moving cart is moved to the front stop position, and the pipe is clamped by the bending roller mould and the fastening mould so as to be subjected to bending processing in three dimensional directions, wherein during the bending processing, the movable cart returns to a preset position.

Owner:SUMITOMO WIRING SYST LTD

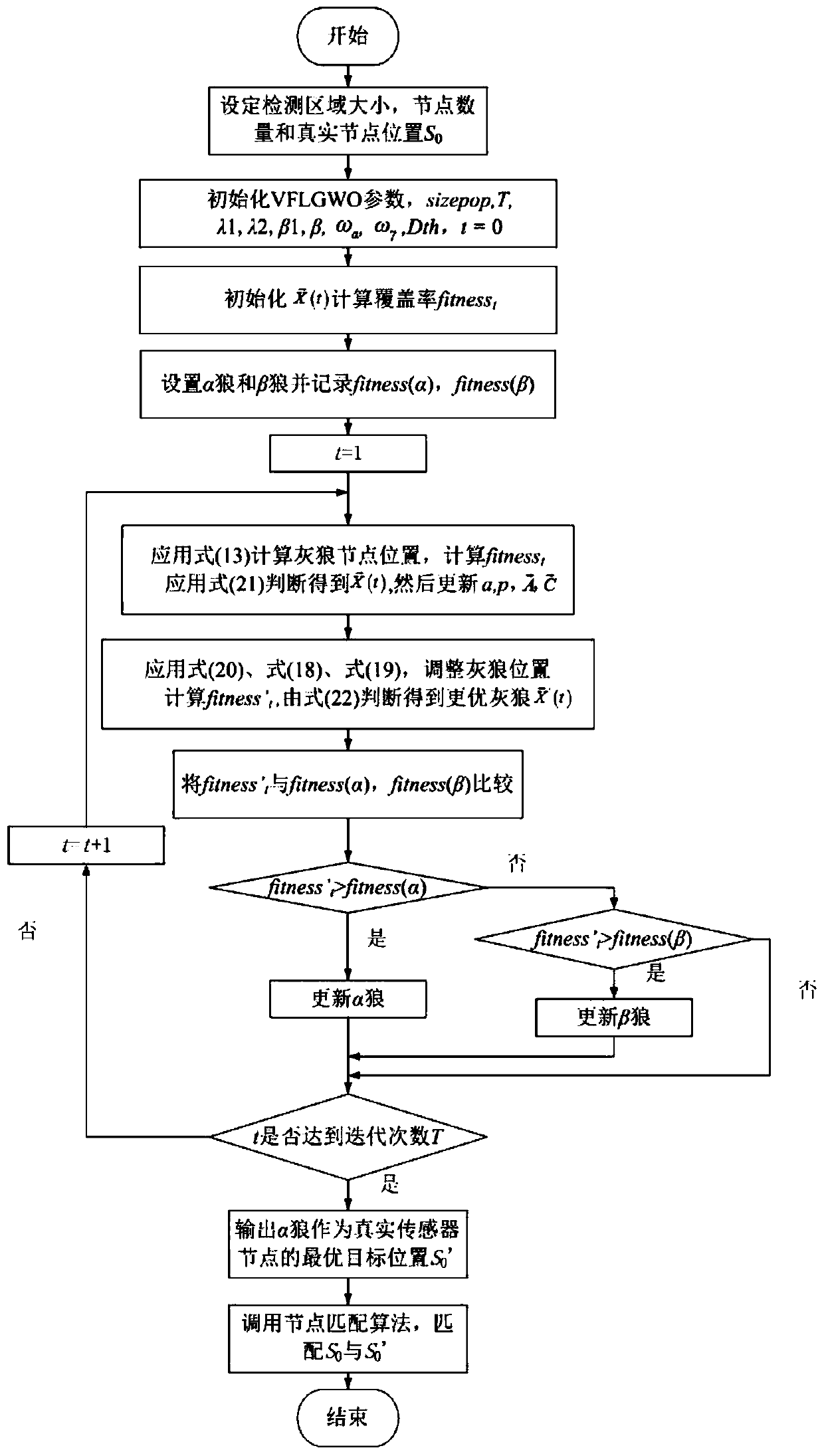

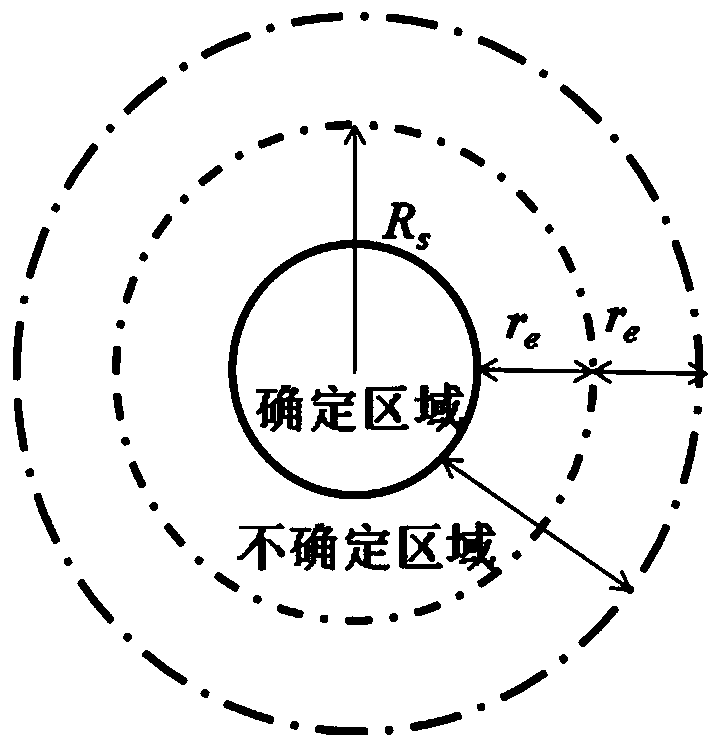

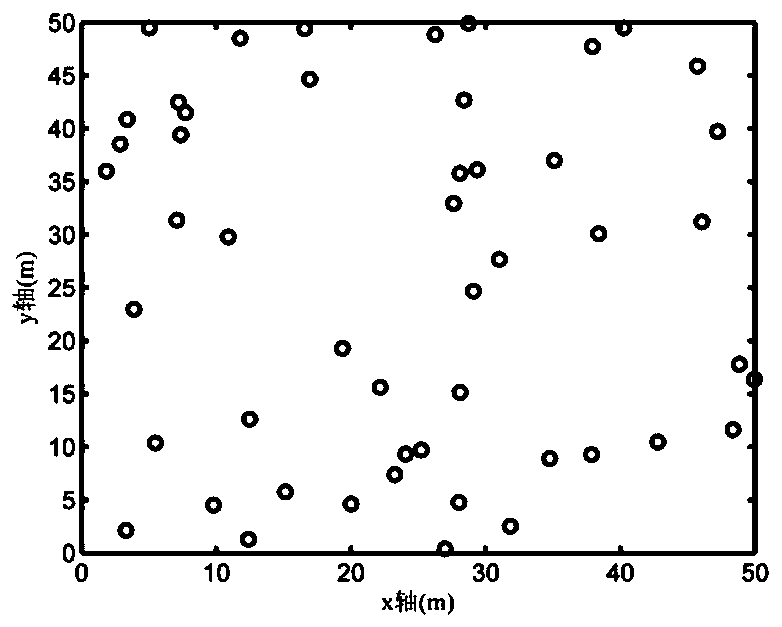

Wireless sensor network coverage optimization algorithm for gray wolf search of virtual force embedded Laivei flight and application

InactiveCN110087247ASolving Coverage Optimization ProblemsExcellent performance indexNetwork planningNODALWireless sensor networking

The invention discloses a wireless sensor network coverage optimization algorithm for gray wolf search of virtual force embedded Laivei flight. The method comprises the following steps: step 1, randomly determining N node positions in wireless sensor network coverage nodes as initial positions of real nodes; step 2, initializing a solution of an initial position into a virtual node position through a modified grey wolf search algorithm embedded in the Laivie flight; step 3, searching and updating the position through the modified grey wolf search algorithm embedded in the Laivie flight; 4, calculating a virtual force through an improved virtual force algorithm; the position of each group of solution nodes is adjusted through calculation; and step 5, through the superiority and disadvantageselection rule, reserving a better solution obtained by the improved virtual force algorithm, and judging whether to update the optimal solution wolf and the optimal solution wolf through the t-th generation of the better solution until the specified update frequency is reached. 6, outputting an optimal solution wolf as an optimal node position; and step 7, completing wireless sensor node deployment through a node matching algorithm.

Owner:JILIN UNIV

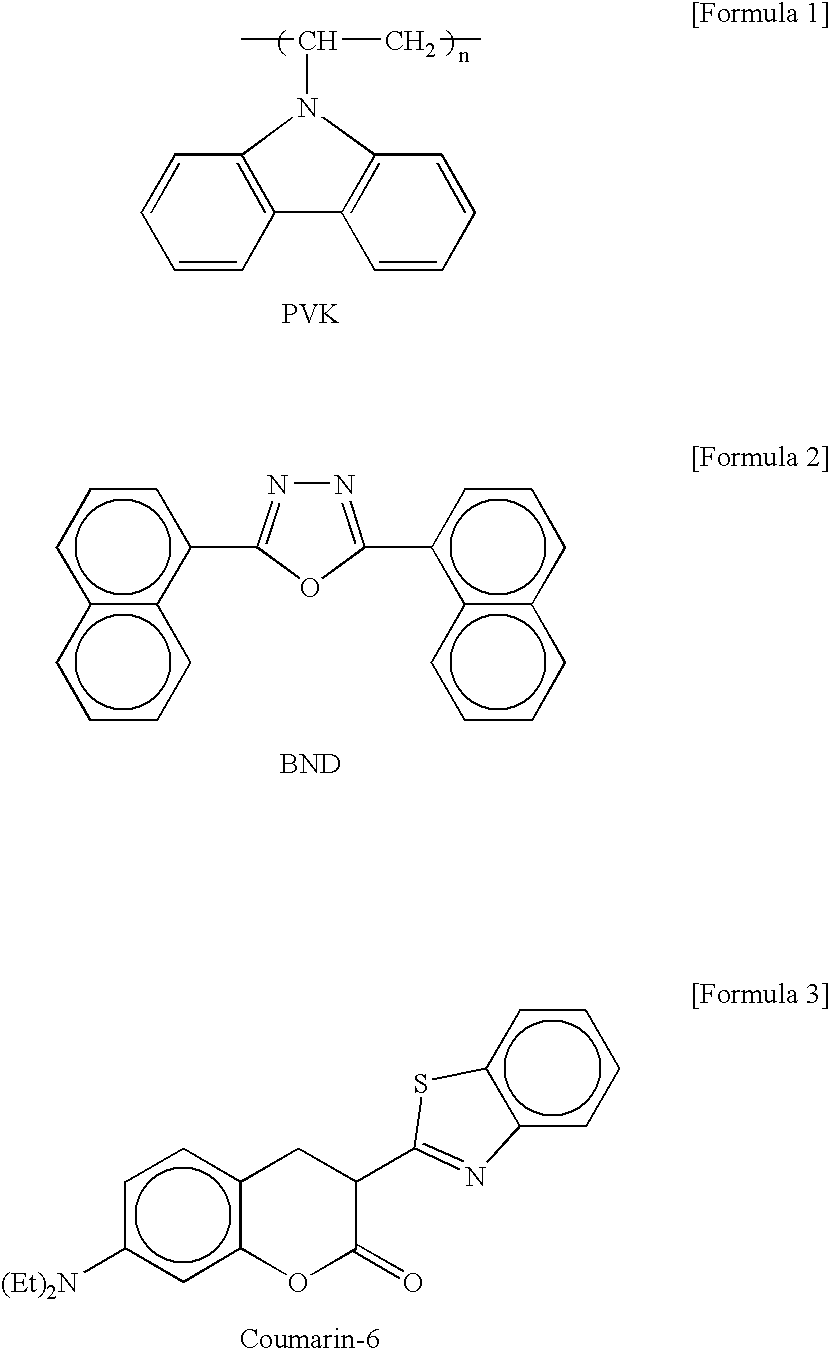

Light emitting device

InactiveUS20080213931A1Convenient lightingLower work functionSolid-state devicesSemiconductor/solid-state device manufacturingColloidAuxiliary electrode

A light emitting device includes a laminate of a lower electrode layer, an organic light-emitting layer, and an upper transparent electrode layer. In the light emitting device, an auxiliary electrode layer is formed of colloidal nano-sized particles of a conductive metal between the lower electrode layer and the organic light-emitting layer. The auxiliary electrode layer causes the lower electrode layer to be flat and the light emitting efficient to be improved. A light emitting device having a structure in which a transparent electrode layer is formed as the lower electrode layer, and an organic light-emitting layer, an auxiliary electrode layer, and an upper electrode layer are sequentially formed thereon has the same effects. When glass is produced by a sol-gel method using metal alkoxide and the light emitting device is sealed by the glass, it is possible to extend the light emitting period.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com