Surface-mount type electric connecting terminal, electronic module unit and circuit board using the same

一种表面贴装、电连接的技术,应用在导电连接、连接装置的零部件、电路等方向,能够解决难以实现表面贴装真空拾取、柱塞60壁厚变薄、难以实现高度较等问题,达到移动顺畅、焊接强度良好、可靠焊接的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Hereinafter, a surface mount type electrical connection terminal according to an embodiment of the present invention will be specifically described with reference to the drawings.

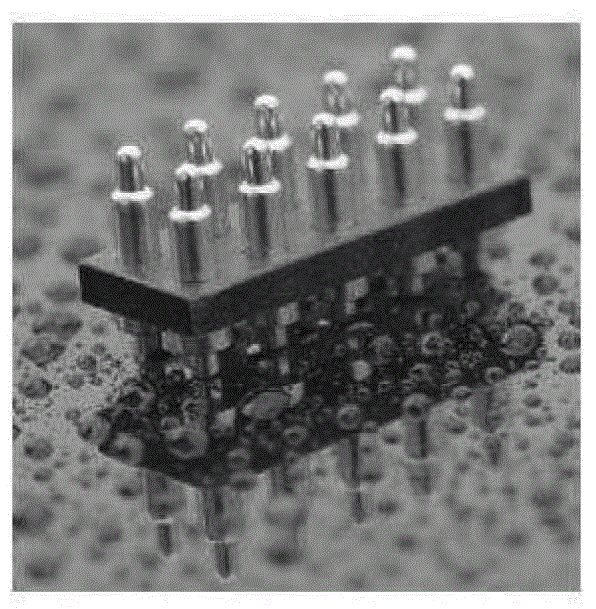

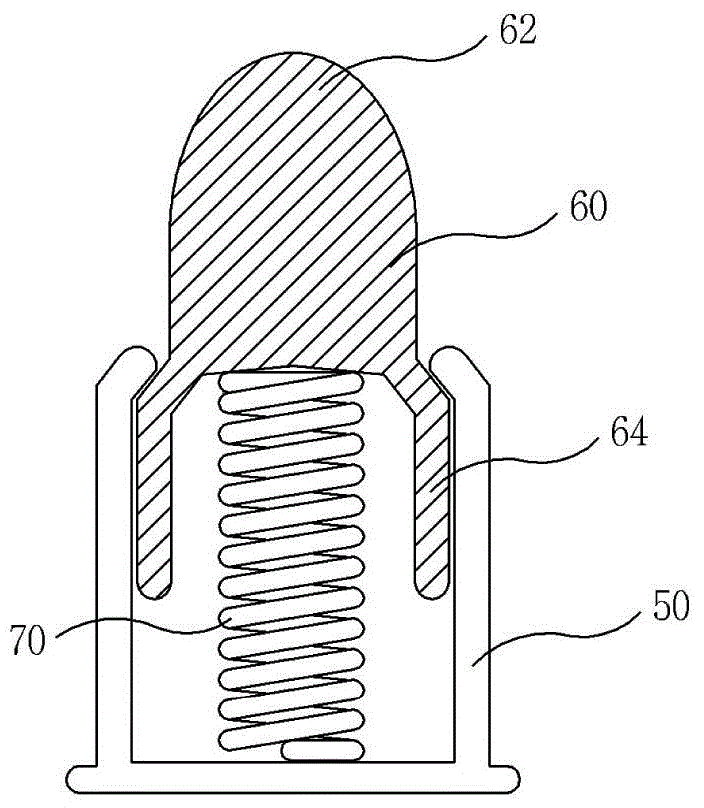

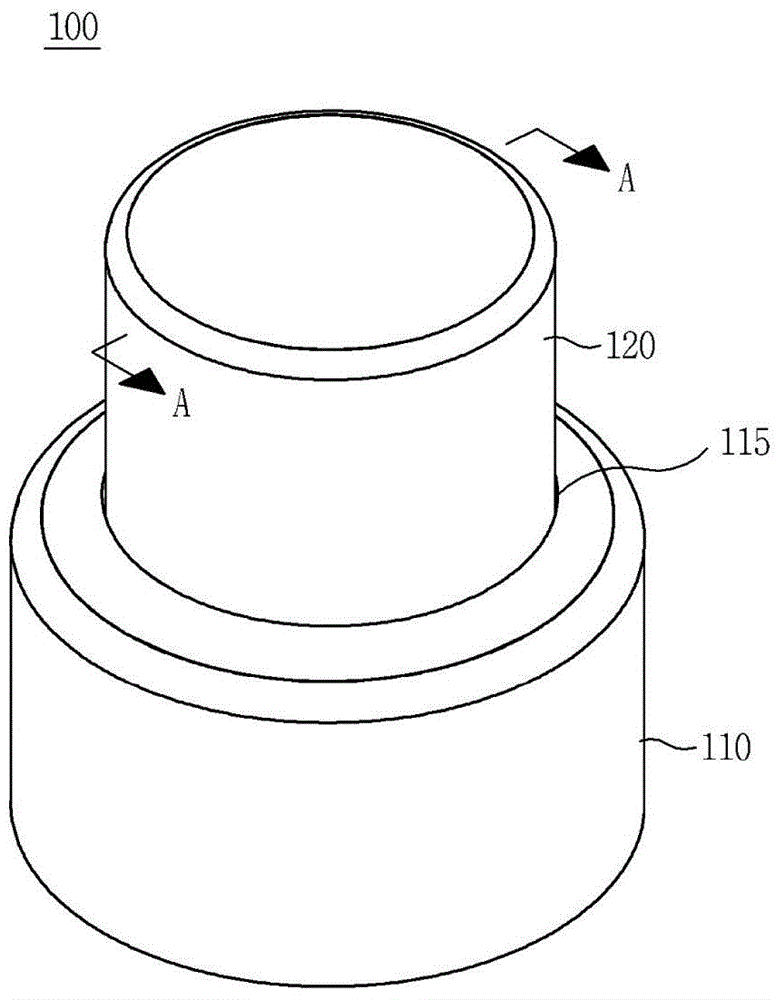

[0092] figure 2 To show a perspective view of a surface mount type electrical connection terminal according to an embodiment of the present invention, Figure 2A for along figure 2 A-A truncated cross-sectional view, image 3 (A) and (B) respectively represent the states before and after pressurizing the moving parts, Figure 4 (A) and (B) respectively represent actual product images of surface mount electrical connection terminals.

[0093] refer to figure 2 and Figure 2A , the surface mount type electrical connection terminal 100 consists of a fixed part 110 of metal material, a moving part 120 of metal material slidably combined with the fixed part 110, and provides elasticity and elastic restoring force so that the moving part 120 is inserted into the fixed part 110 And the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com