Patents

Literature

276 results about "FOUP" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

FOUP is an acronym for Front Opening Unified Pod or Front Opening Universal Pod. It is a specialised plastic enclosure designed to hold silicon wafers securely and safely in a controlled environment, and to allow the wafers to be transferred between machines for processing or measurement. FOUPs began to appear along with the first 300mm wafer processing tools in the mid 1990s. The size of the wafers and their comparative lack of rigidity meant that SMIF was not a viable technology. FOUPs were designed with the constraints of 300mm in mind, with the removable cassette being replaced by fins in the FOUP which hold the wafers in place, and the bottom opening door being replaced by a front opening door to allow robot handling mechanisms to access the wafers directly from the FOUP. The weight of a fully loaded 25 wafer FOUP at around 9 kilograms means that automated material handling systems are essential for all but the smallest of fabrication plants. To allow this, each FOUP has various coupling plates, pins and holes to allow the FOUP to be located on a load port, and to be manipulated by the AMHS (Automated Material Handling System). FOUPs may also contain RF tags that allow them to be identified by readers on tools, in the AMHS etc. FOUPs are available in several colors, depending on the customers wish. FOUPs and IC manufacturing equipment can have a nitrogen atmosphere, in an effort to increase device yield.

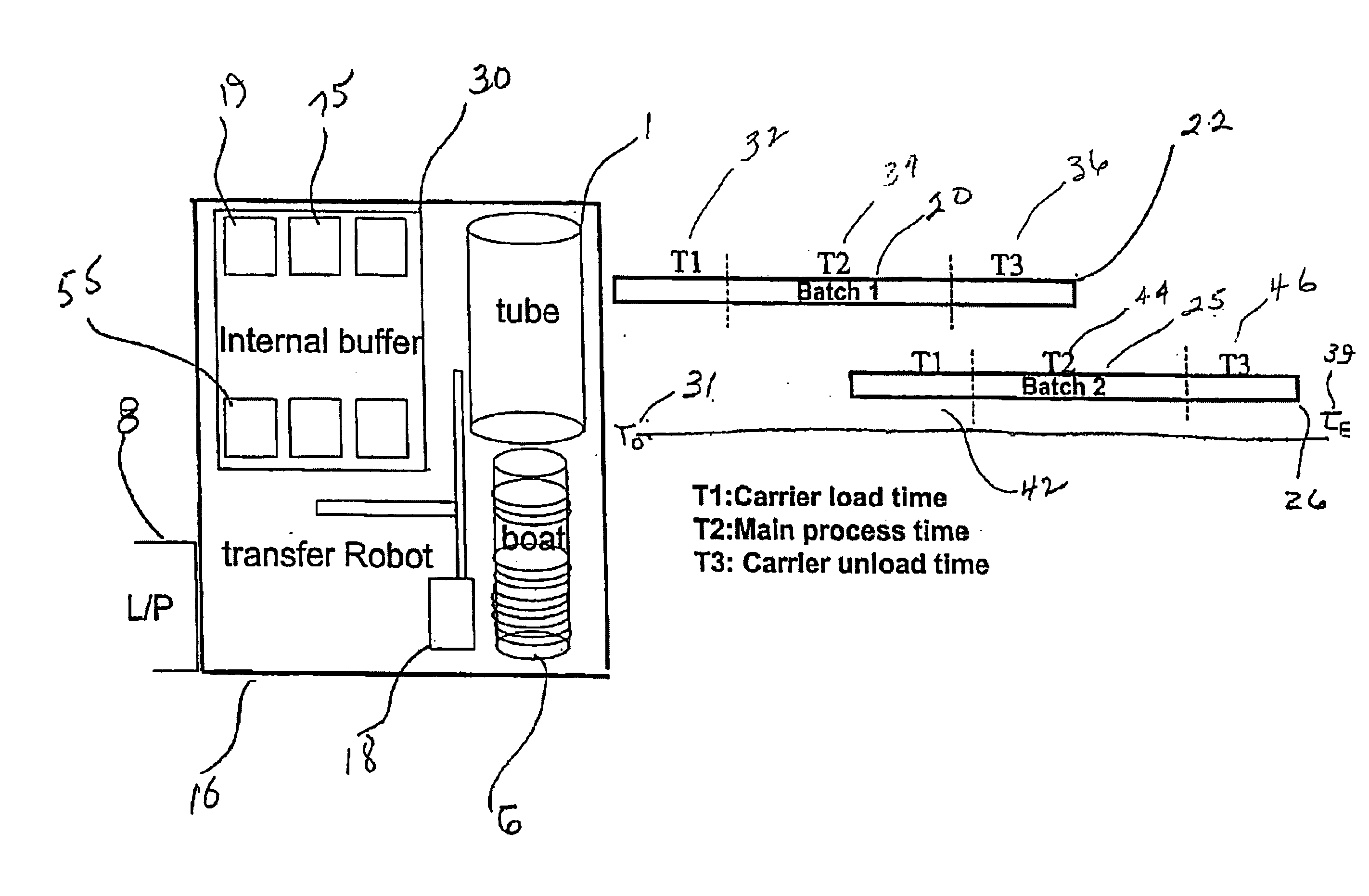

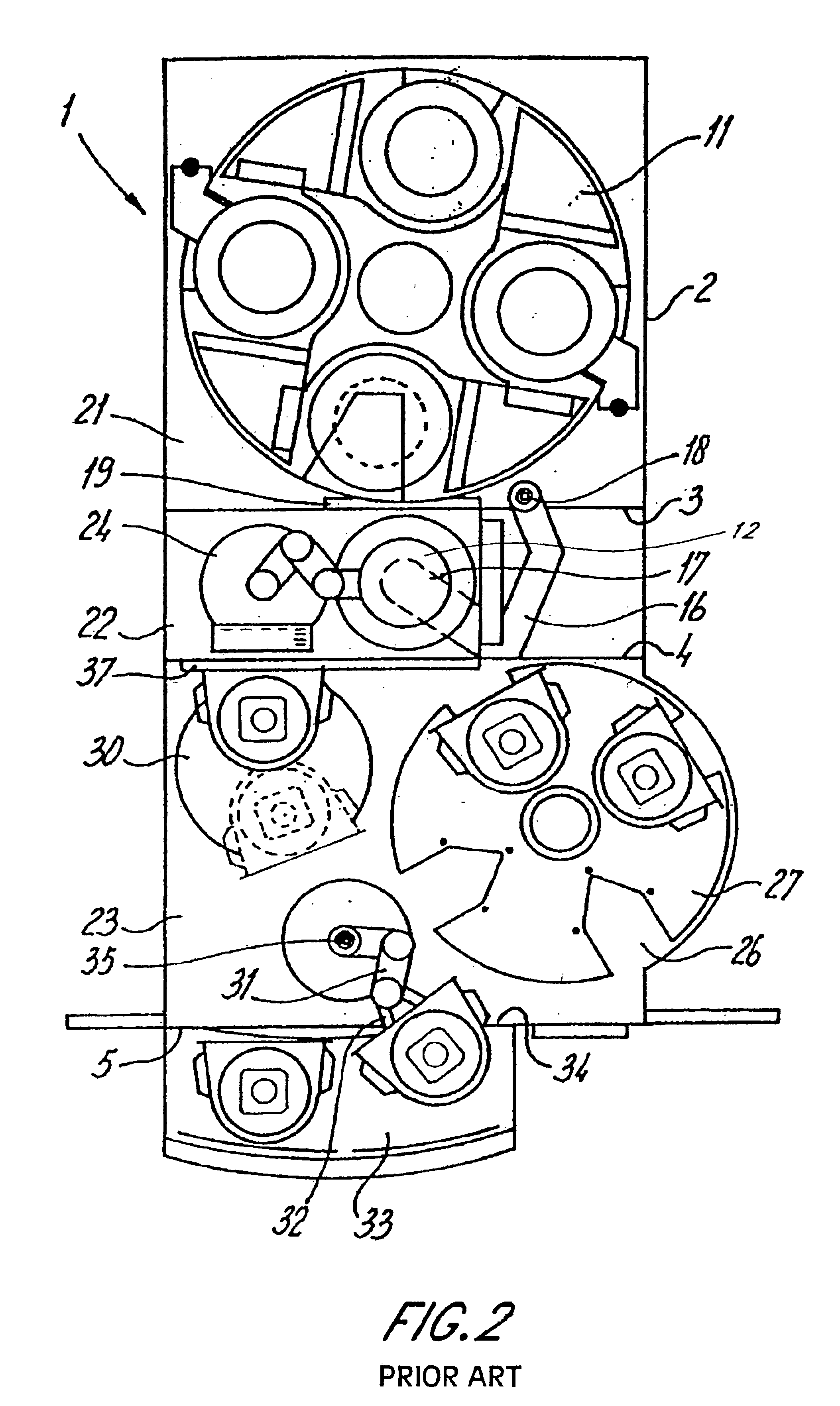

Intelligent full automation controlled flow for a semiconductor furnace tool

InactiveUS20050187647A1Reduce idle timeSemiconductor/solid-state device manufacturingSpecial data processing applicationsControl flowAutomatic control

The present invention relates to an apparatus and method for processing the flow of semiconductor wafers through a furnace tool having a front-opening unified pod (FOUP) material handling system. The invention provides for an automated control flow to realize greater efficiency and assure process quality. In one aspect of the invention the wafer batch completing its operation is discharged simultaneous with the charging of the next batch. Essentially the operation takes place by overlapping processing operations. An embodiment of the invention includes a process comprising the steps of: providing a first batch of semiconductor material, and loading the first batch into a carrier which transports the first batch into a semiconductor manufacturing process, and while the first batch undergoes the process, forming a second batch of semiconductor material, and pausing a second batch process operation until the first batch completes processing, to reduce the idle time of said process.

Owner:TAIWAN SEMICON MFG CO LTD

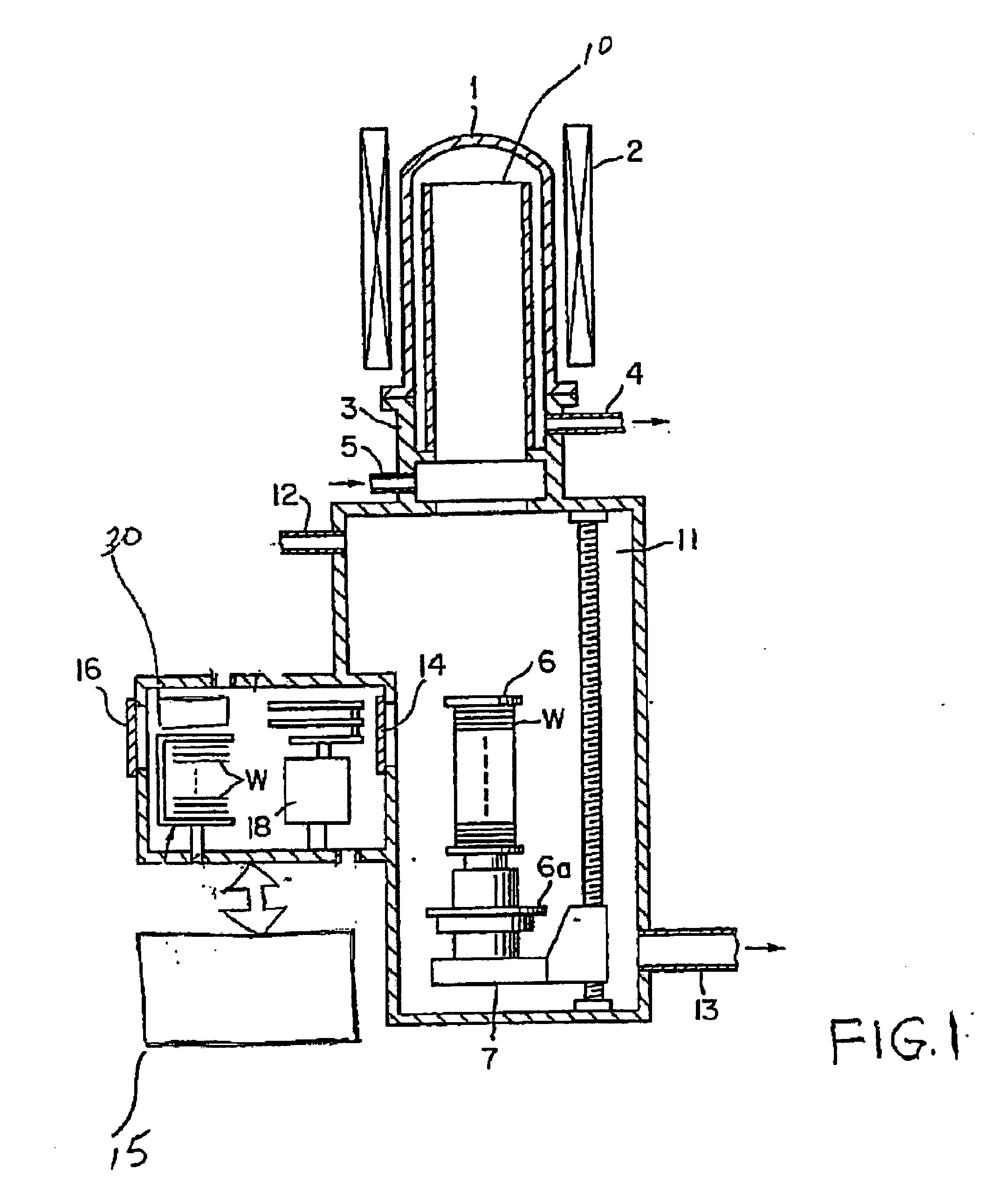

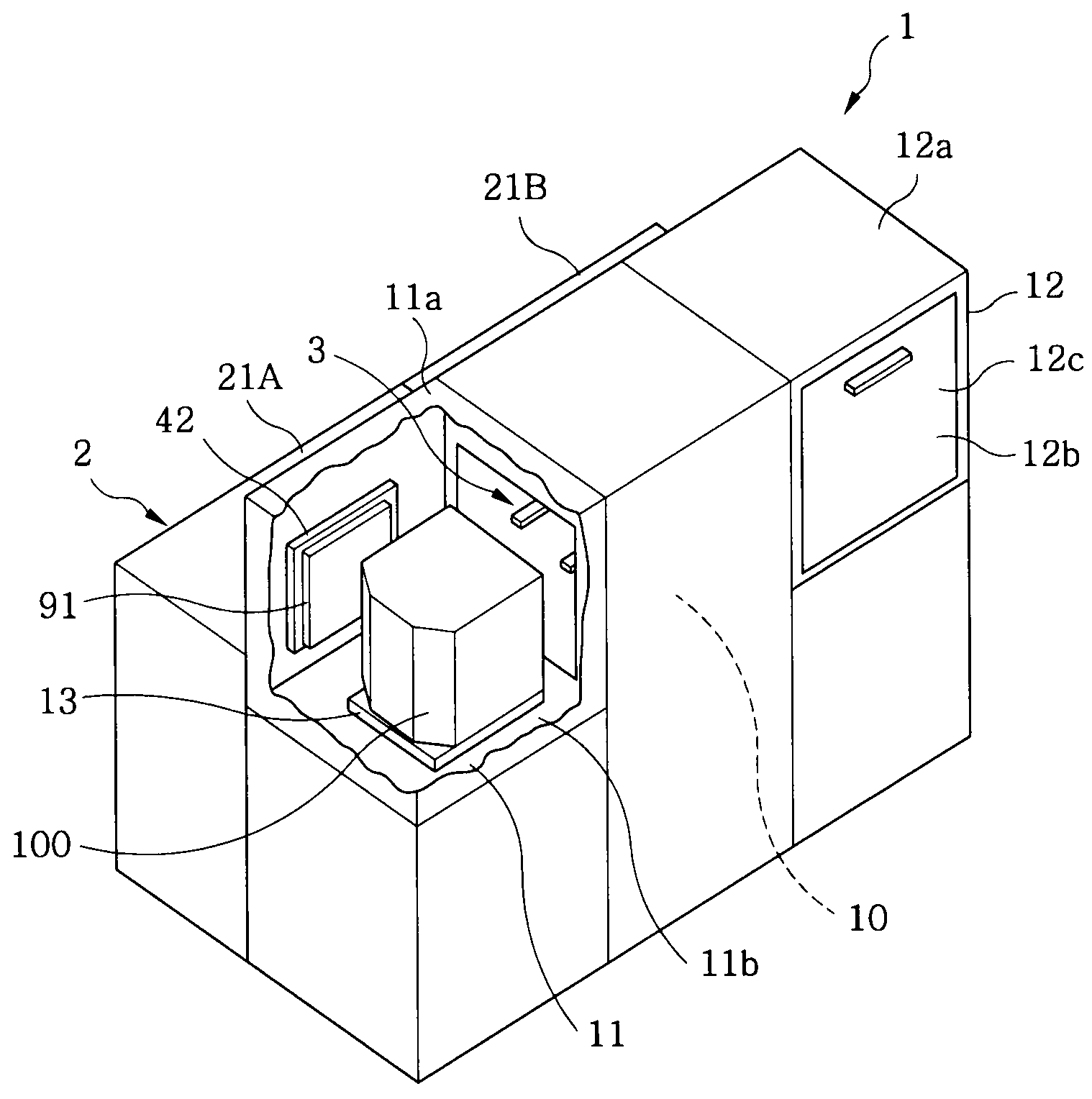

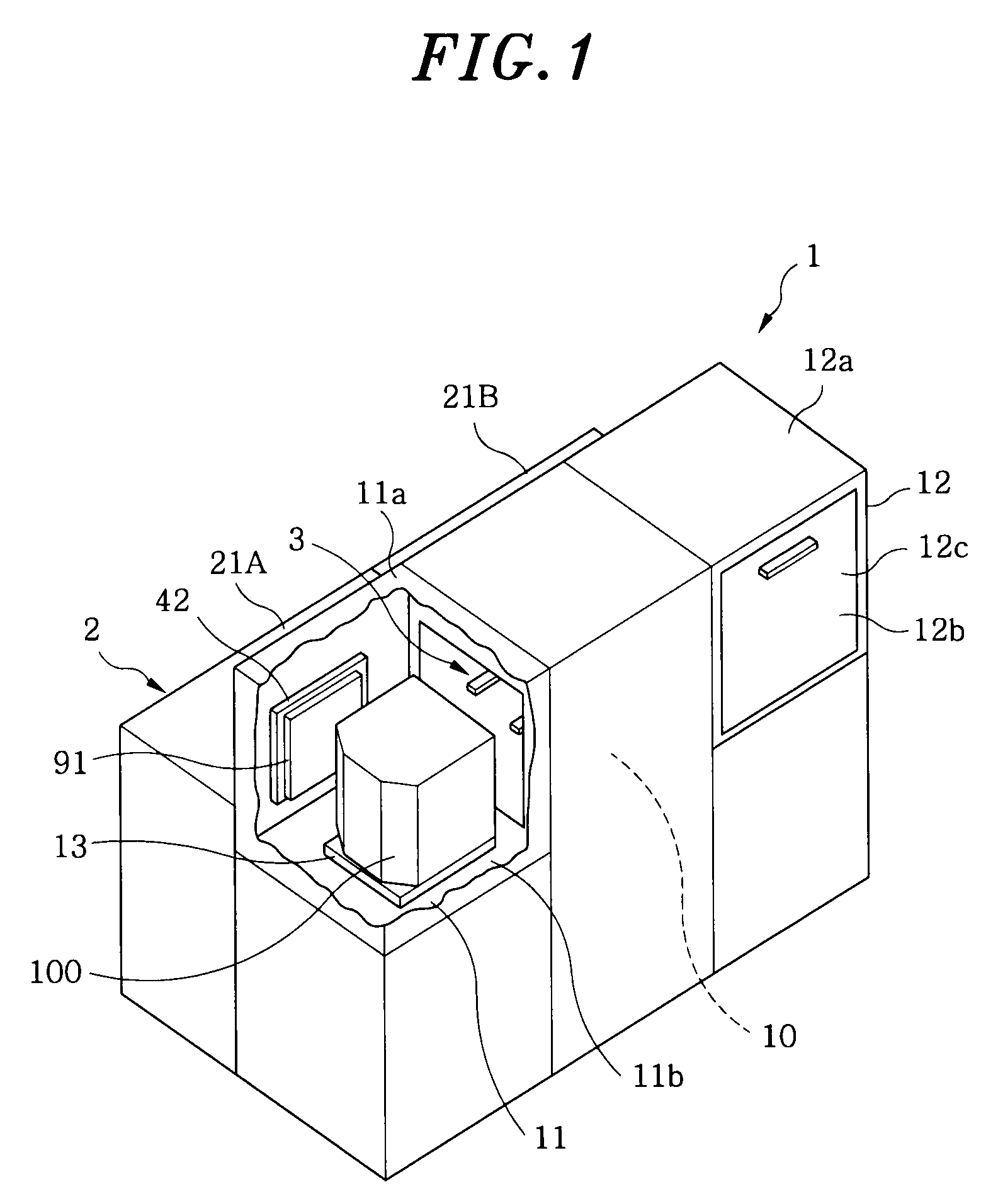

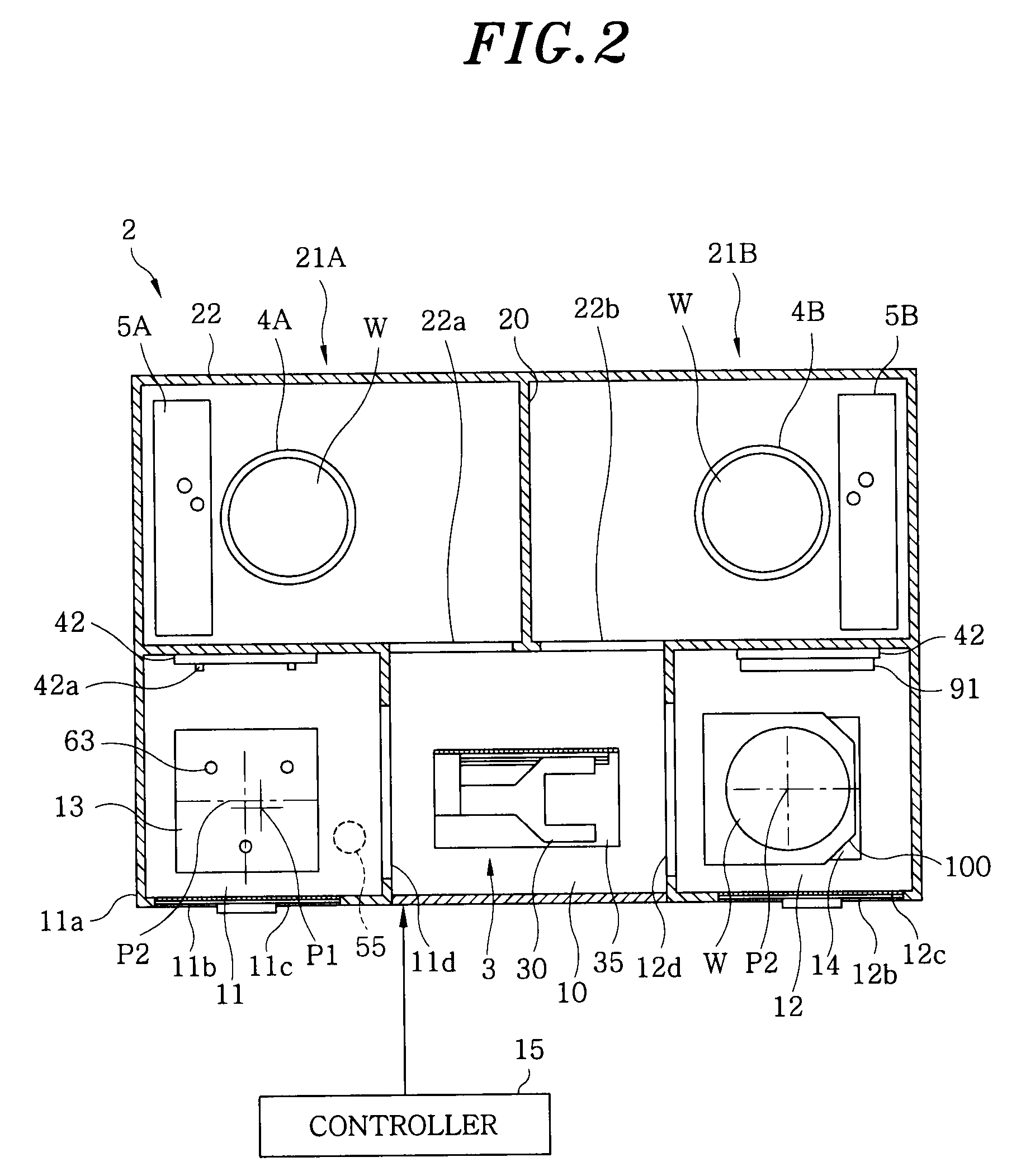

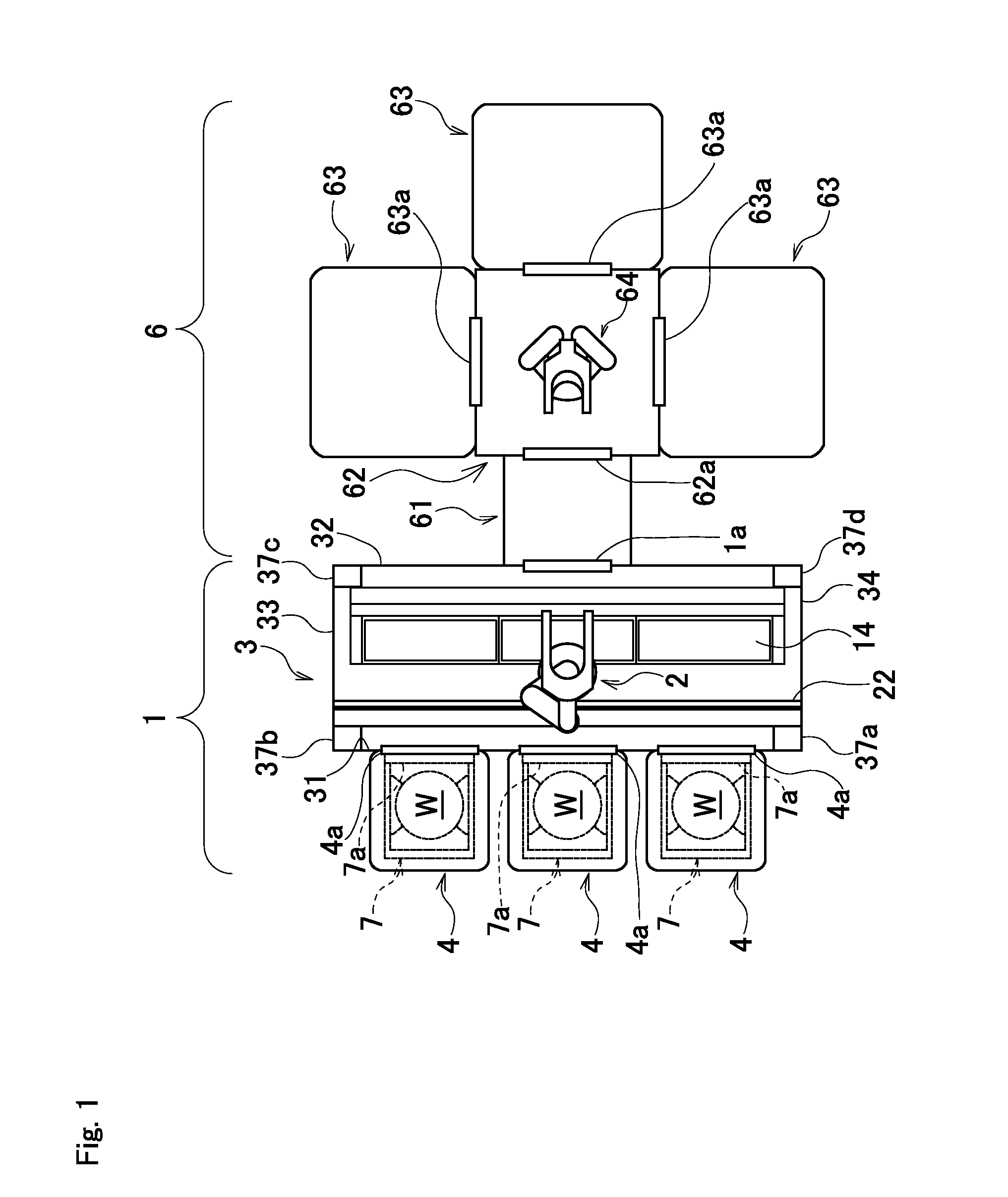

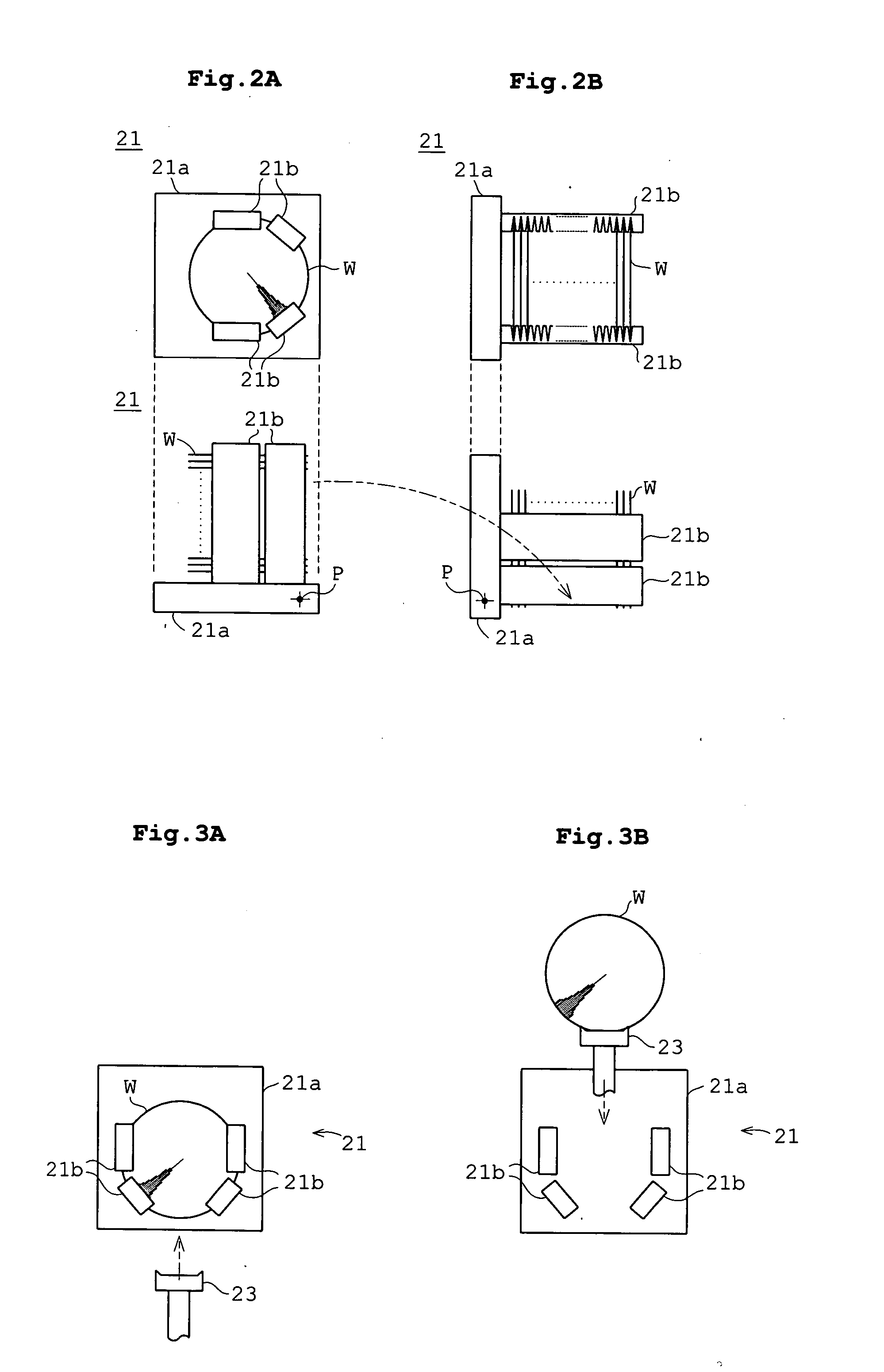

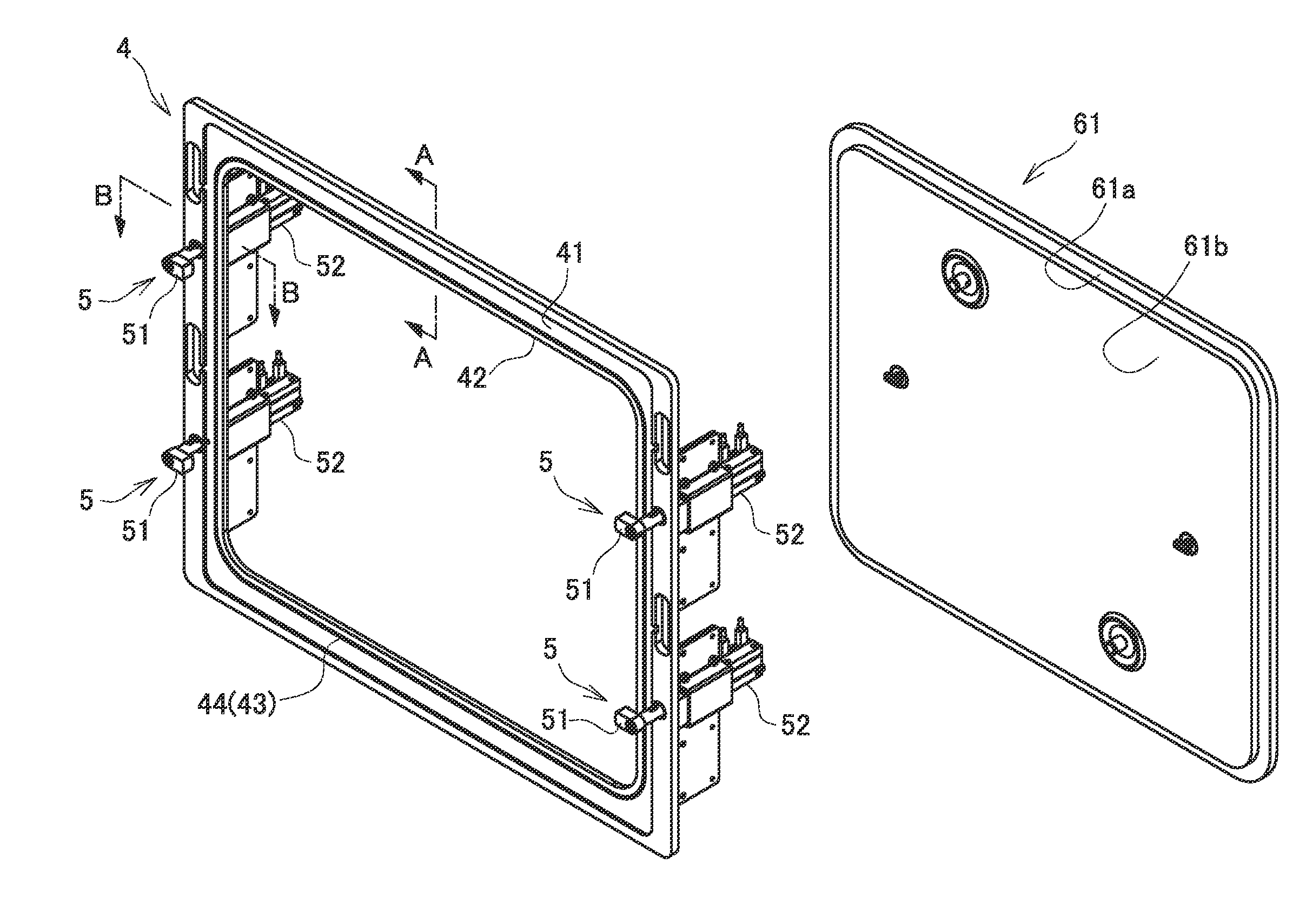

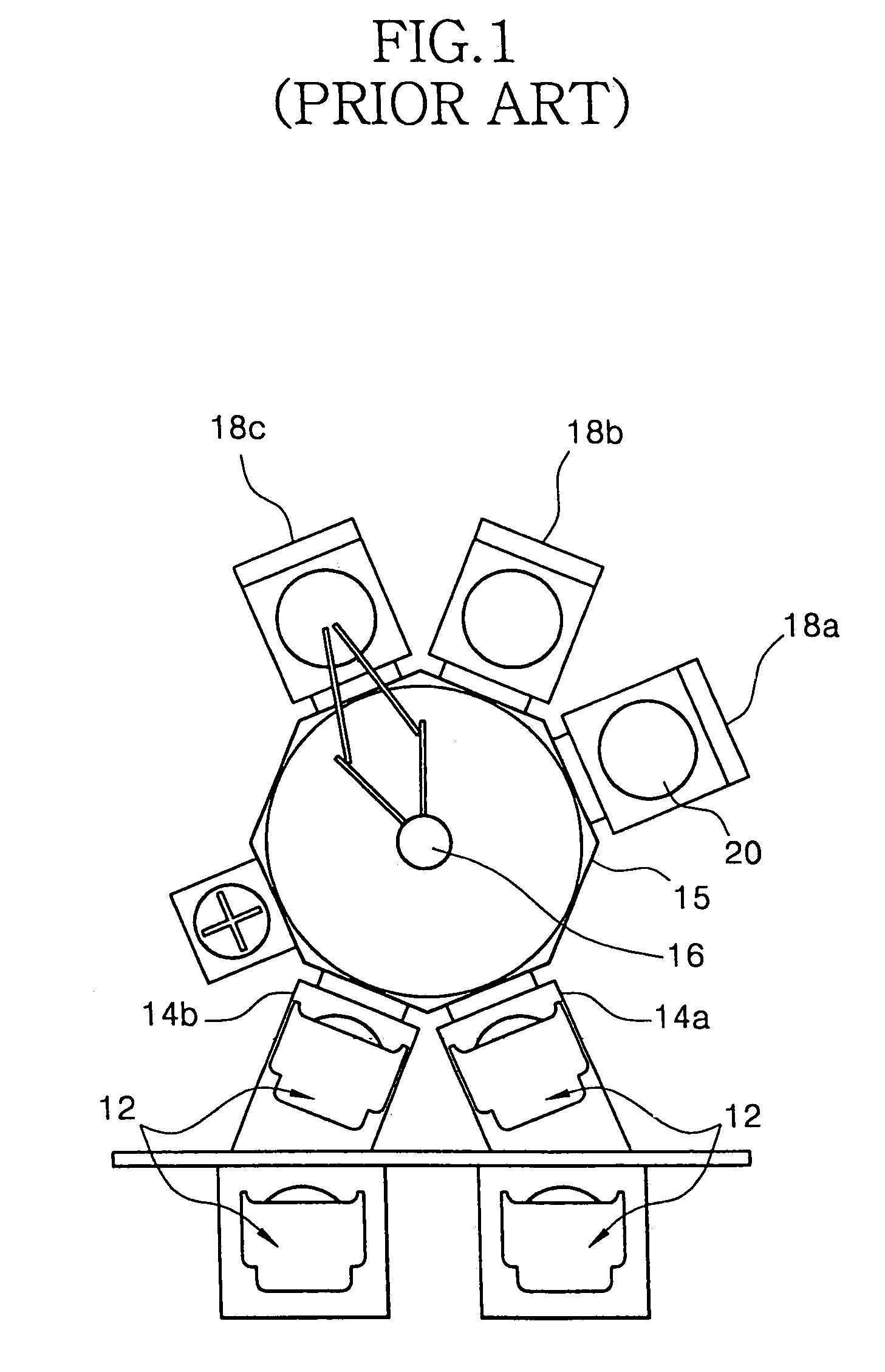

FOUP opening/closing device and probe apparatus

ActiveUS8267633B2Assure great degree of freedomEfficient comprehensive utilizationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalFOUP

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

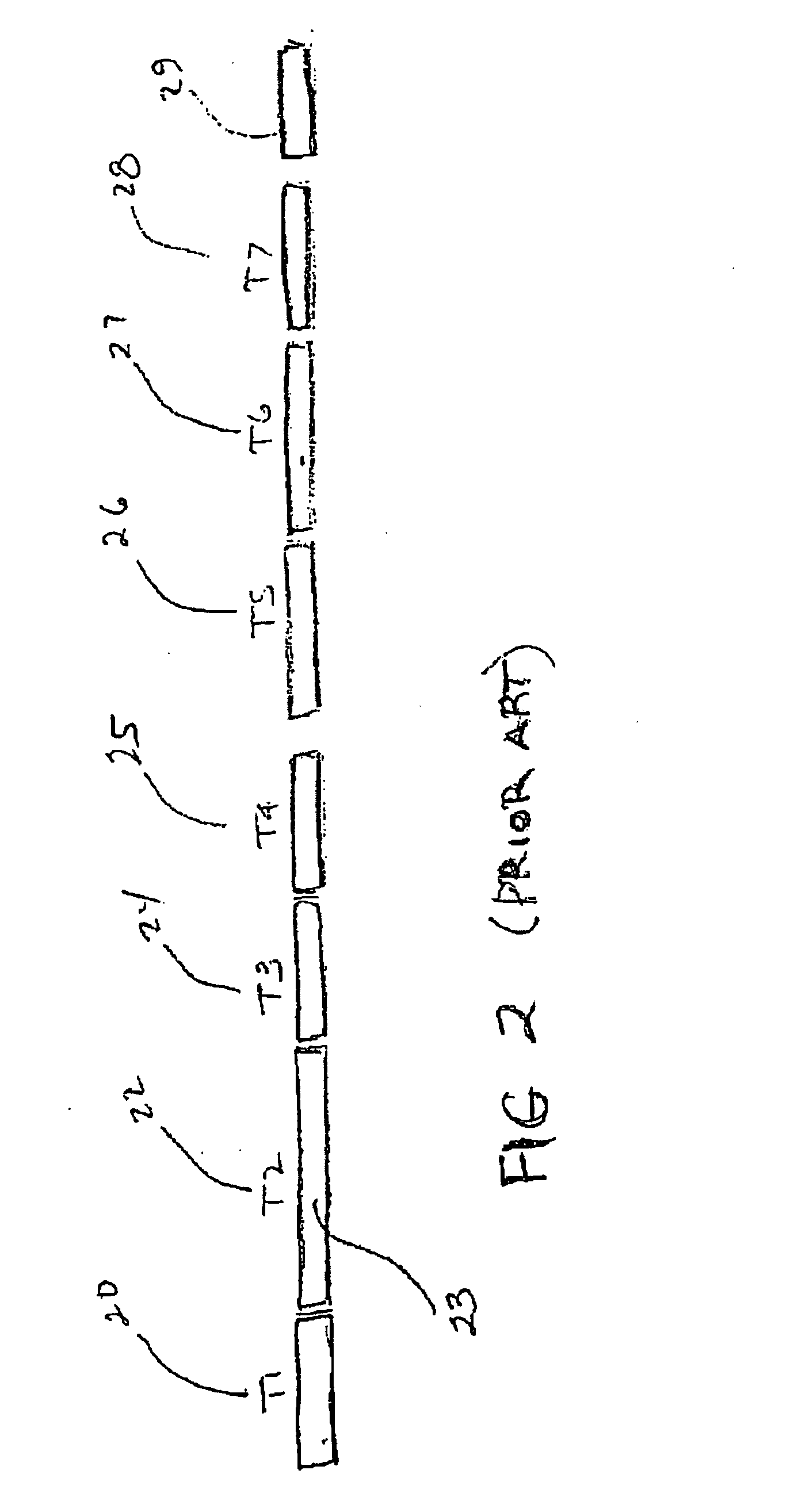

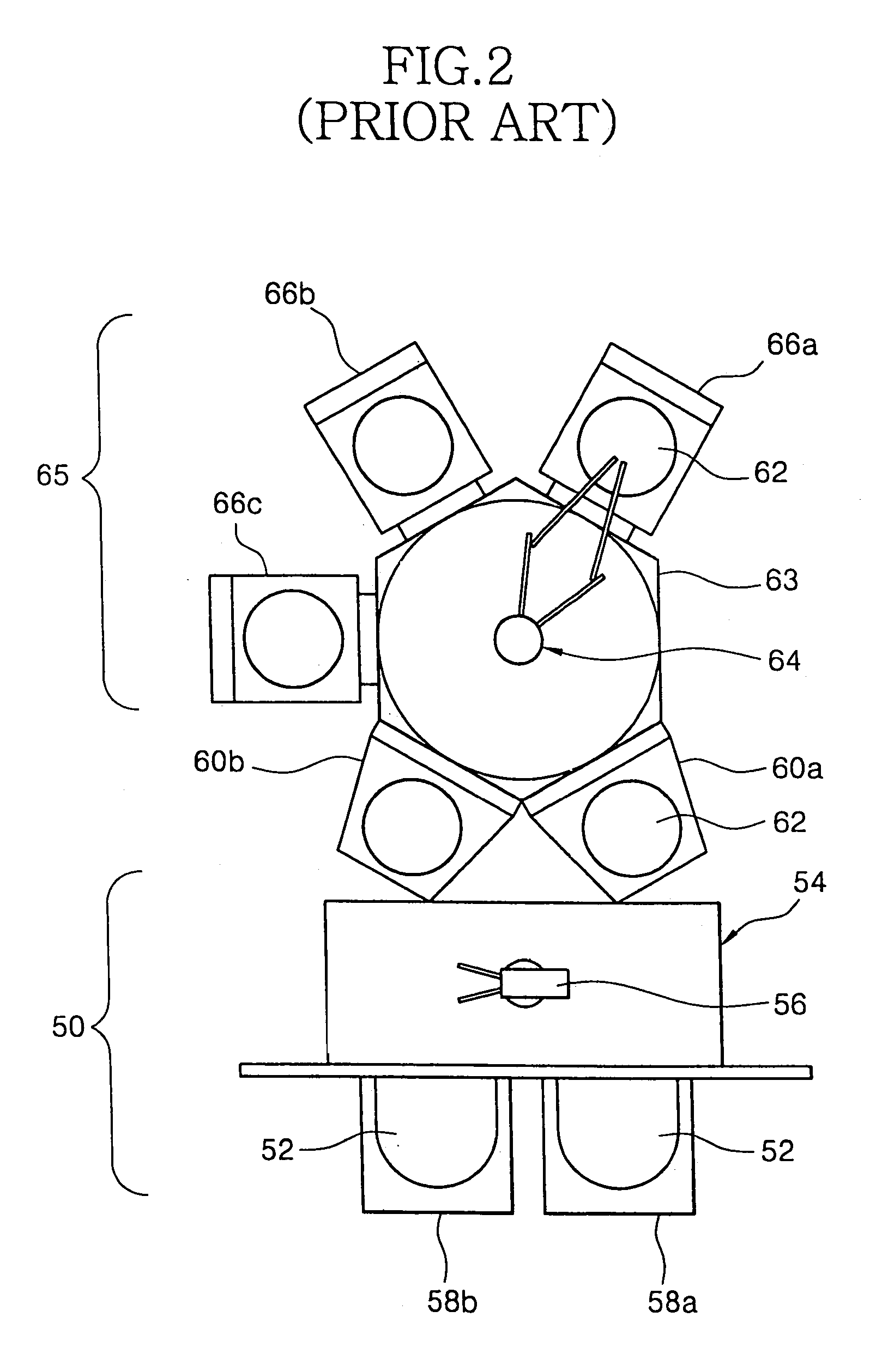

Wafer handling system

InactiveUS6981832B2Semiconductor/solid-state device manufacturingStorage devicesMagnetic tapeEngineering

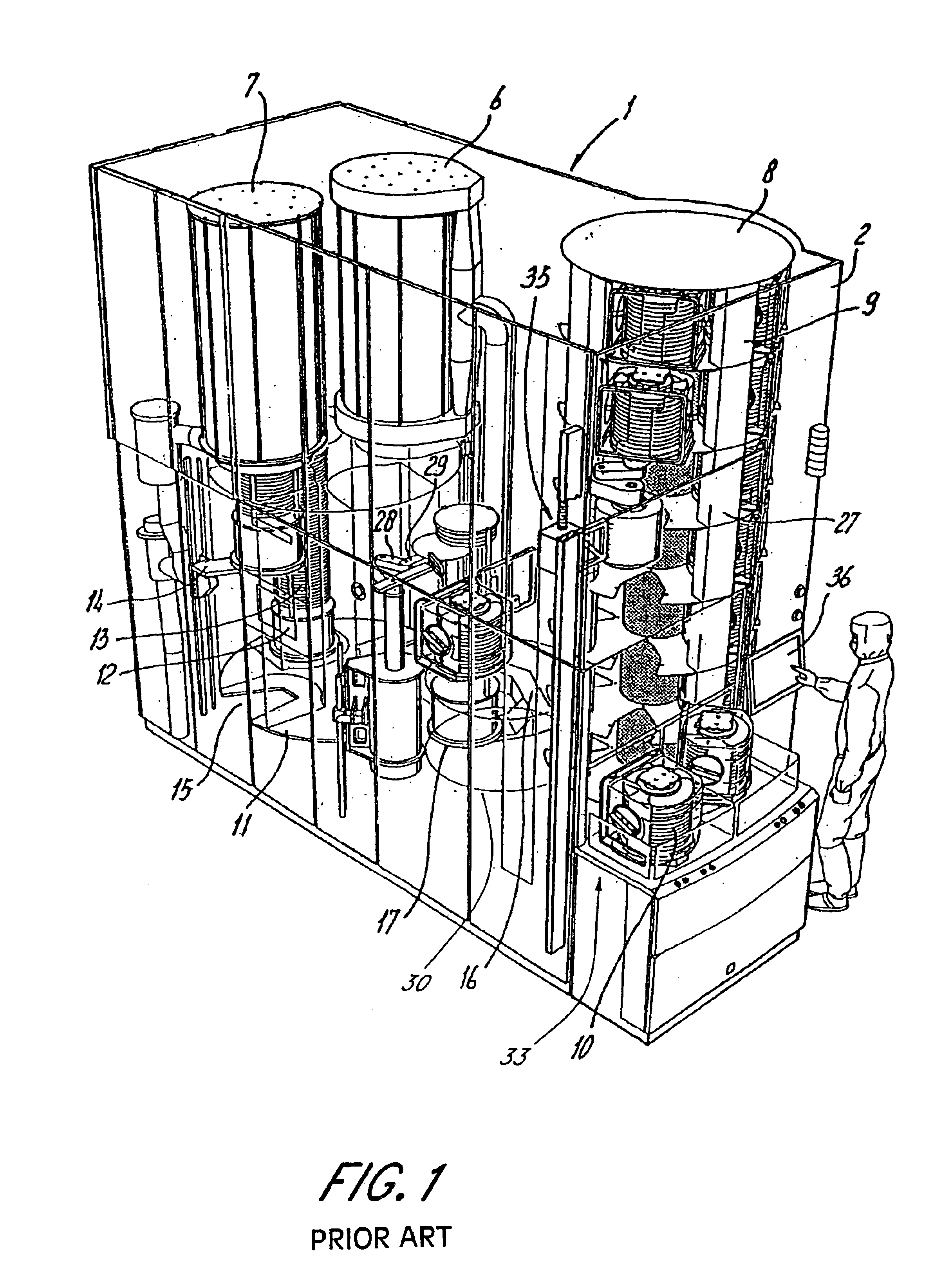

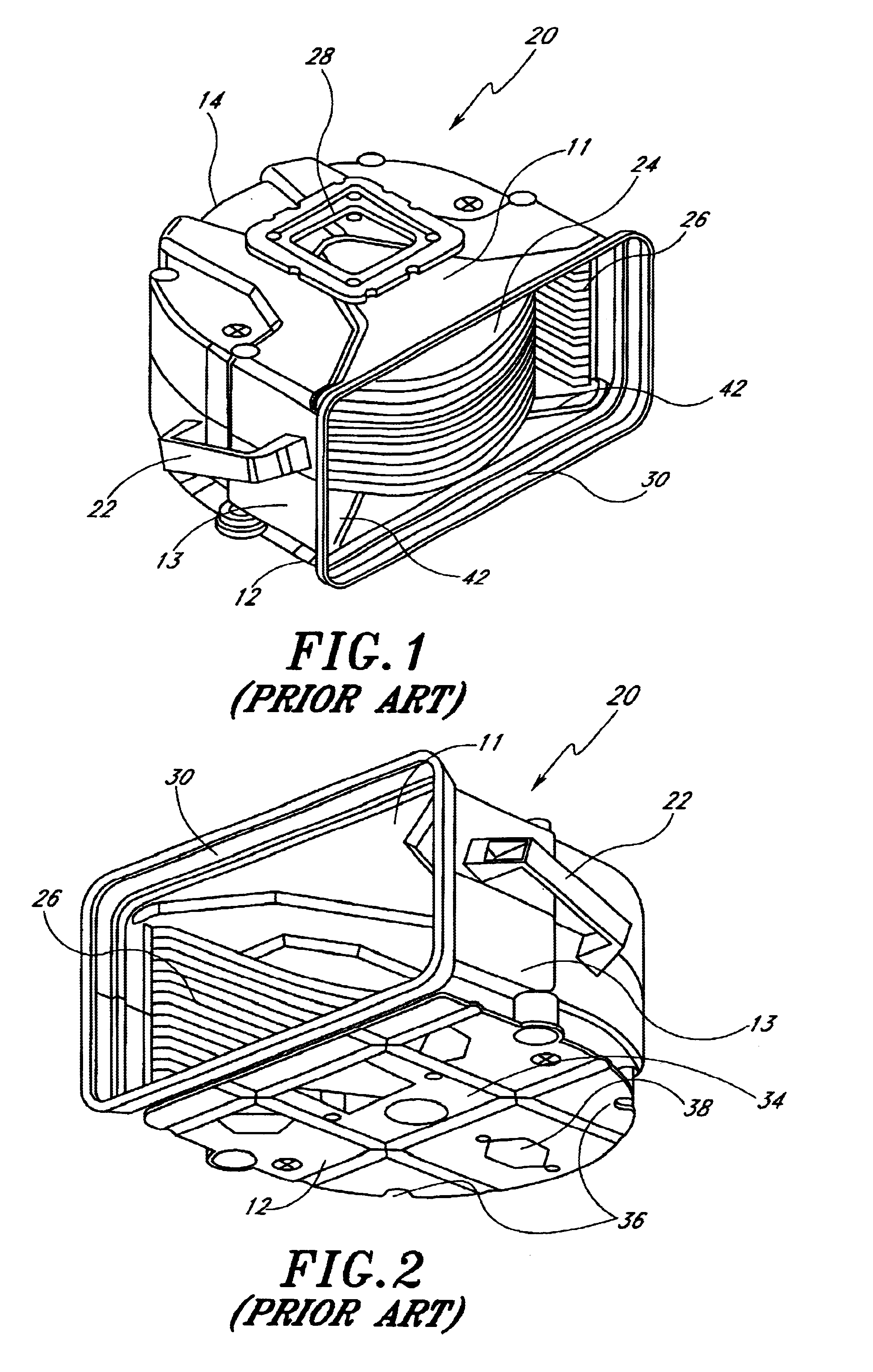

A system for processing semiconductor wafers includes adaptations allowing the selective handling of cassettes for both 200-mm wafers and 300-mm wafers. The system is configured initially for handling standard 300-mm FOUP cassettes. Adaptions for handling 200-mm wafer open cassettes include a load port adapter frame for receiving such cassettes on a input / output platform; a cassette handler adapter configured for reversibly mounting on a cassette handler end effector and for receiving 200-mm open cassettes; a store adapter frame for converting 300-mm FOUP storage compartments into compartments for storing 200-mm open cassettes; and a Transhipment FOUP for holding 200-mm open cassettes upon a cassette transfer platform and bringing such cassettes into an interface with a wafer handler. The Transhipment FOUP has outer surfaces resembling a standard 300-mm FOUP cassette, but is configured to receive a 200-mm open cassette therein.

Owner:ASM INTERNATIONAL

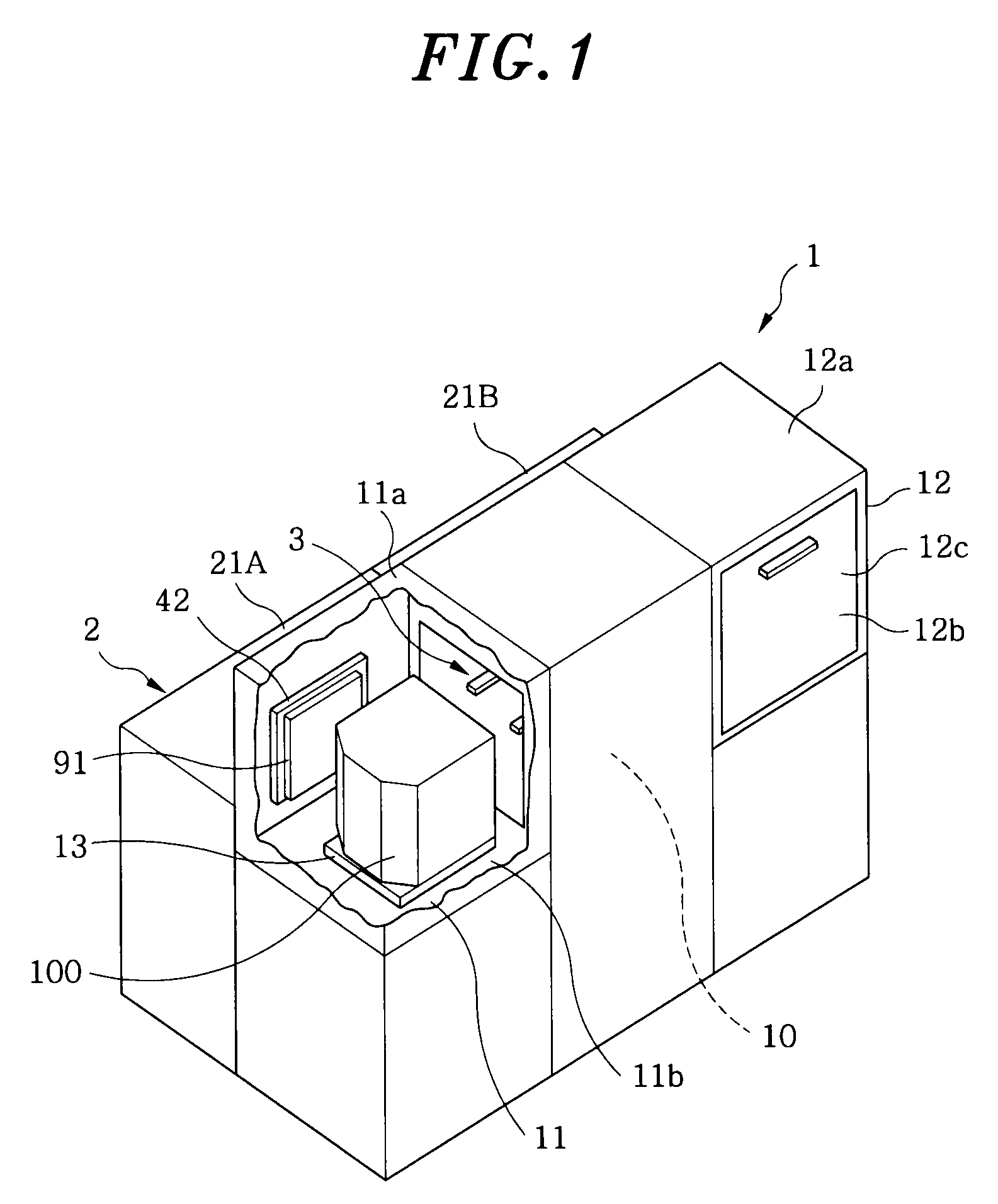

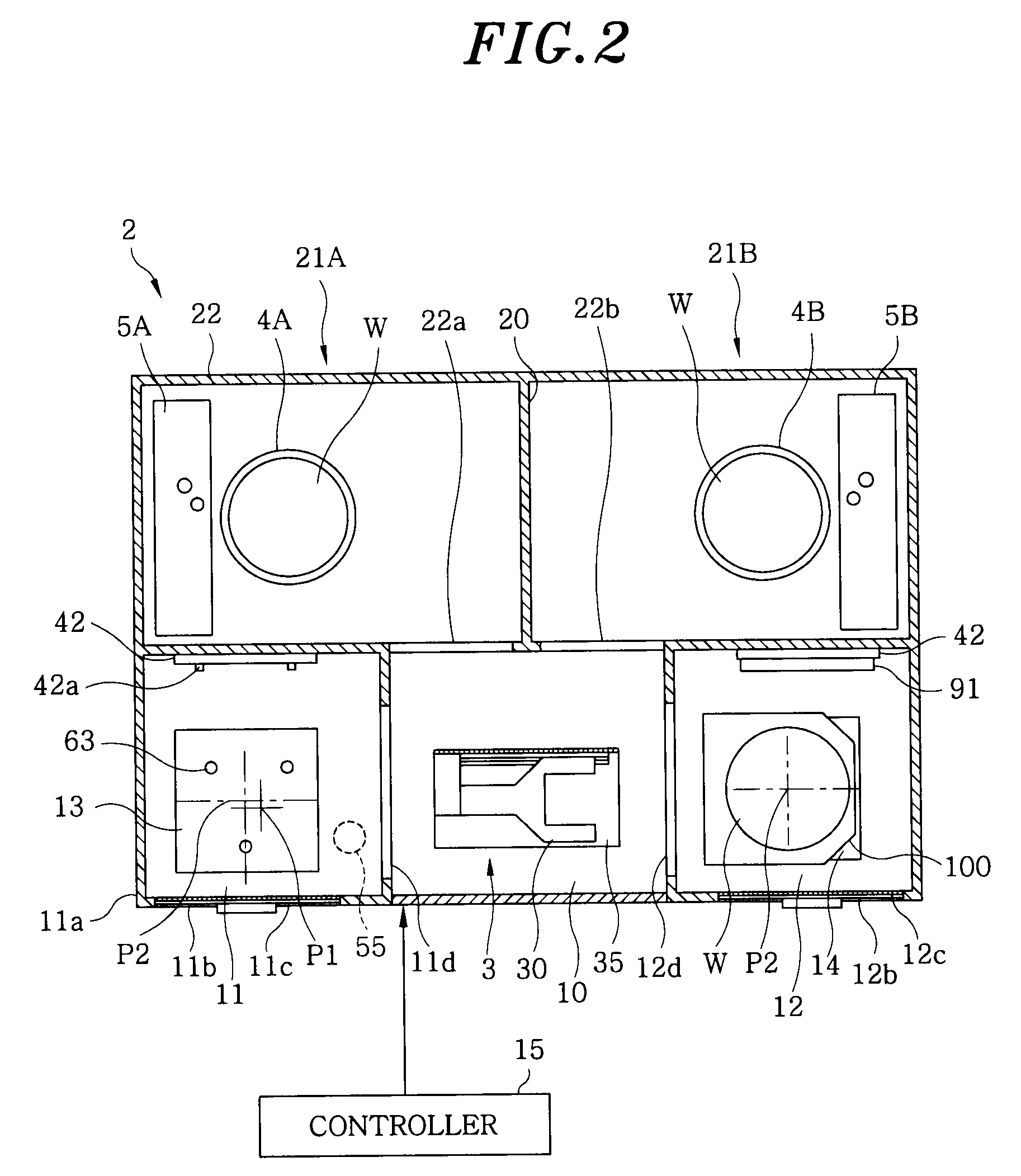

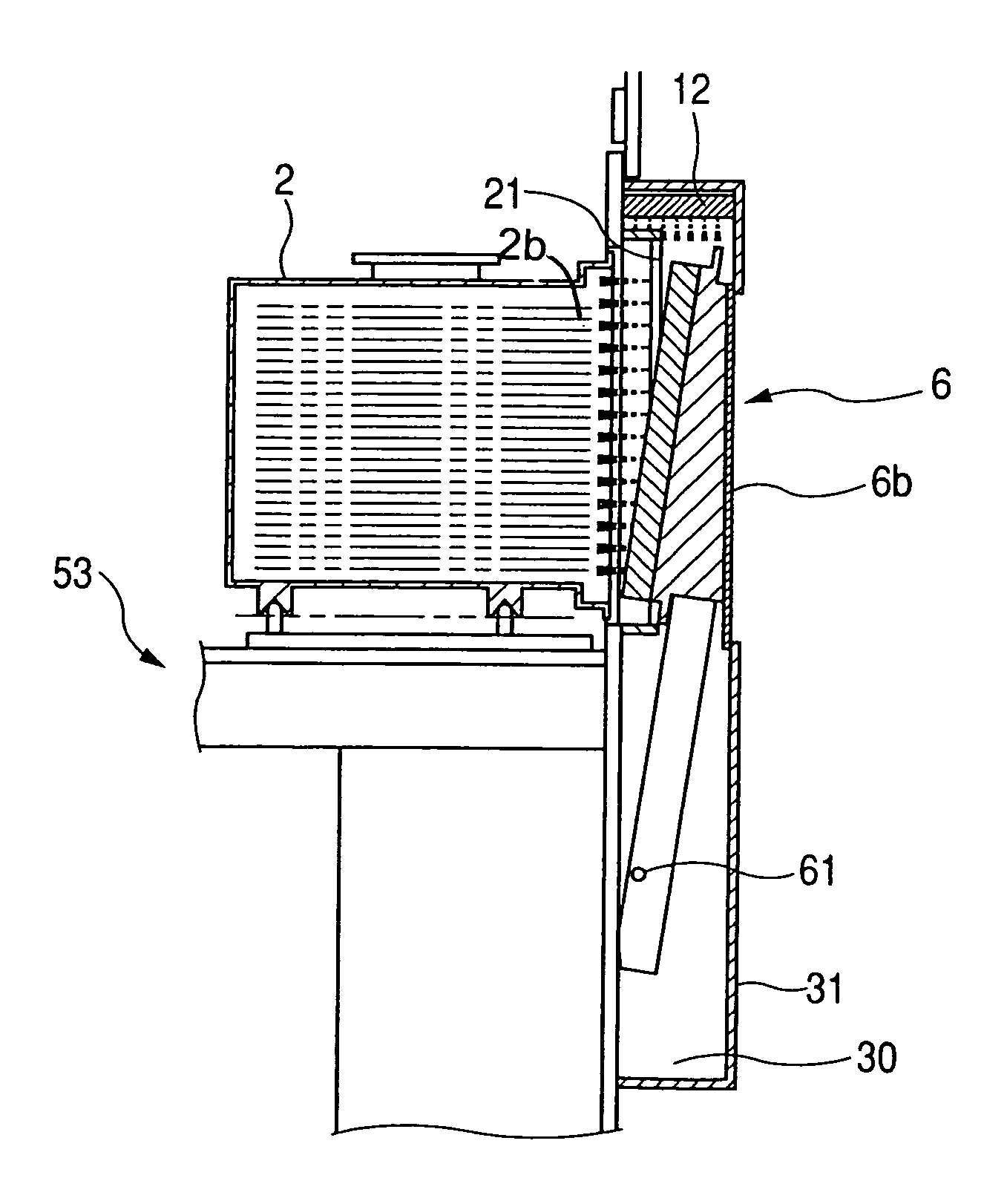

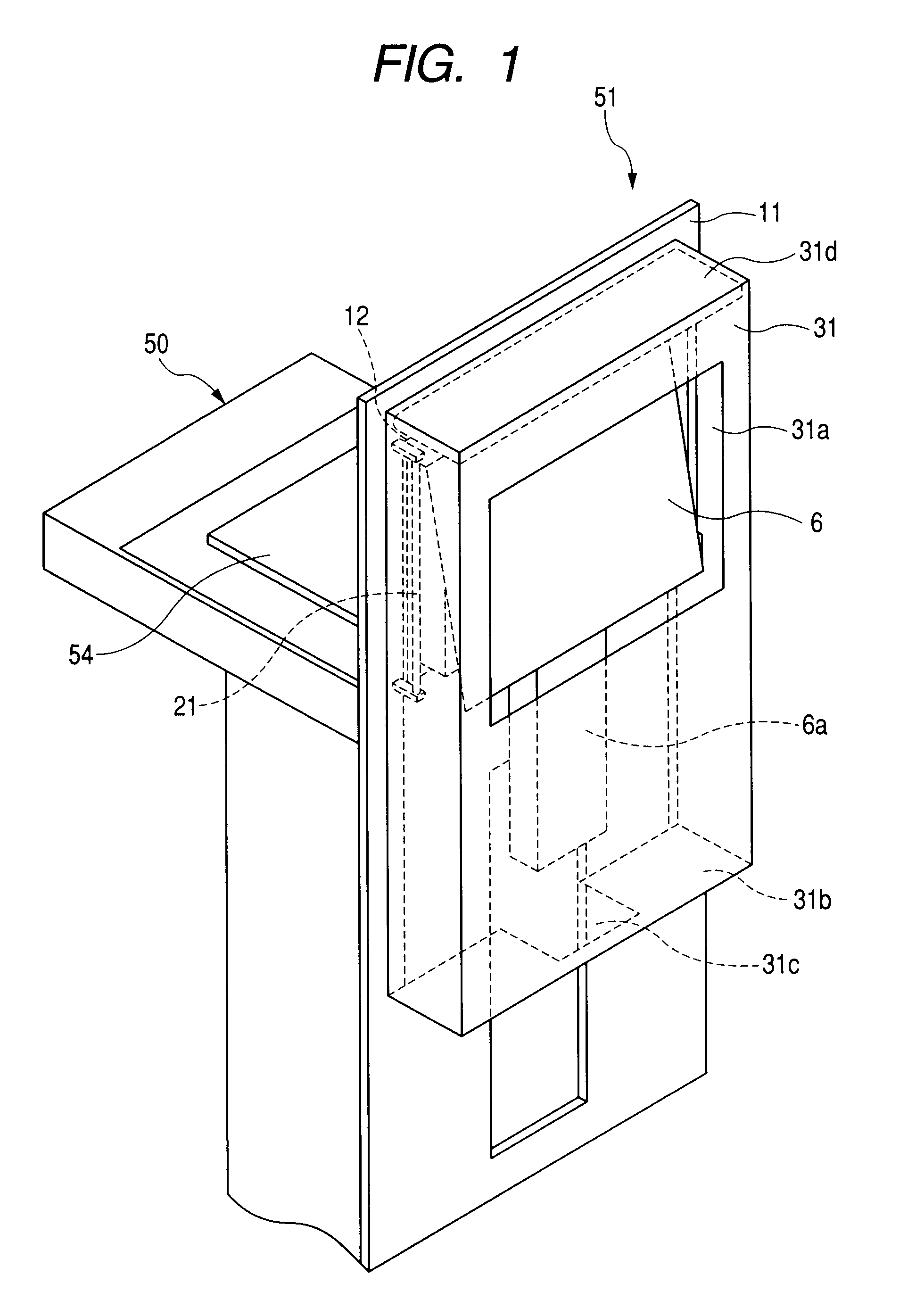

Foup opening/closing device and probe apparatus

ActiveUS20100040441A1Efficient space utilizationThe degree of freedom becomes largerSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl signalEngineering

A FOUP opening / closing device includes a housing containing a mounting table for mounting the FOUP thereon, an FOUP loading opening, and a delivery opening. The device further includes a rotator for rotating the mounting table, a door opening / closing unit to open or close the door of the FOUP and keep the door open, a mover for moving the FOUP and the door opening / closing unit in a reciprocating manner, to allow the FOUP and the door opening / closing unit to be connected to or separated from each other, and a controller to output control signals for moving the FOUP and the door opening / closing unit via operation of the mover to mount the door of the FOUP to the door opening / closing unit, separating the door from the FOUP, moving the FOUP and the door opening / closing unit away from each other, and rotating the mounting table to make the FOUP face the delivery opening.

Owner:TOKYO ELECTRON LTD

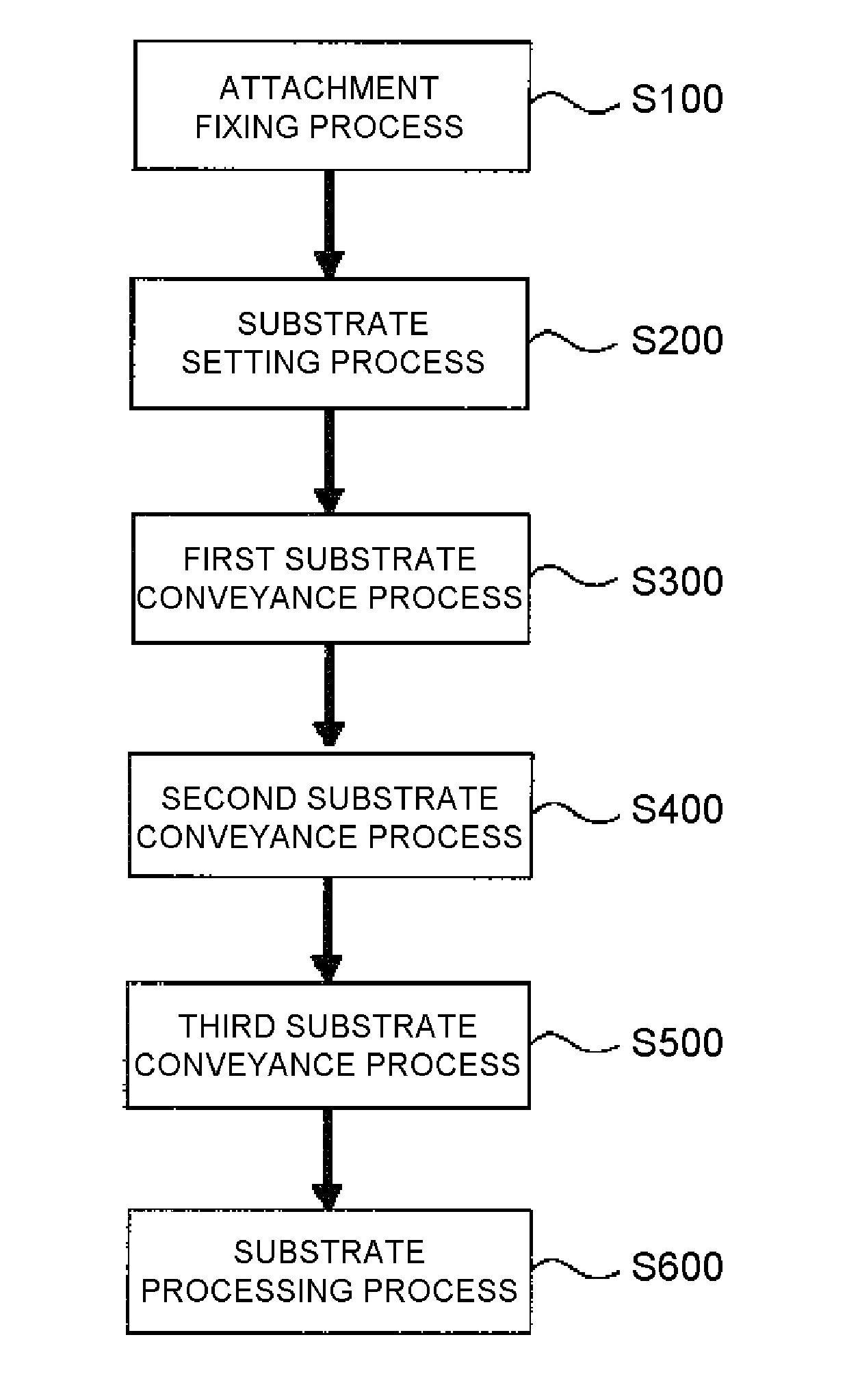

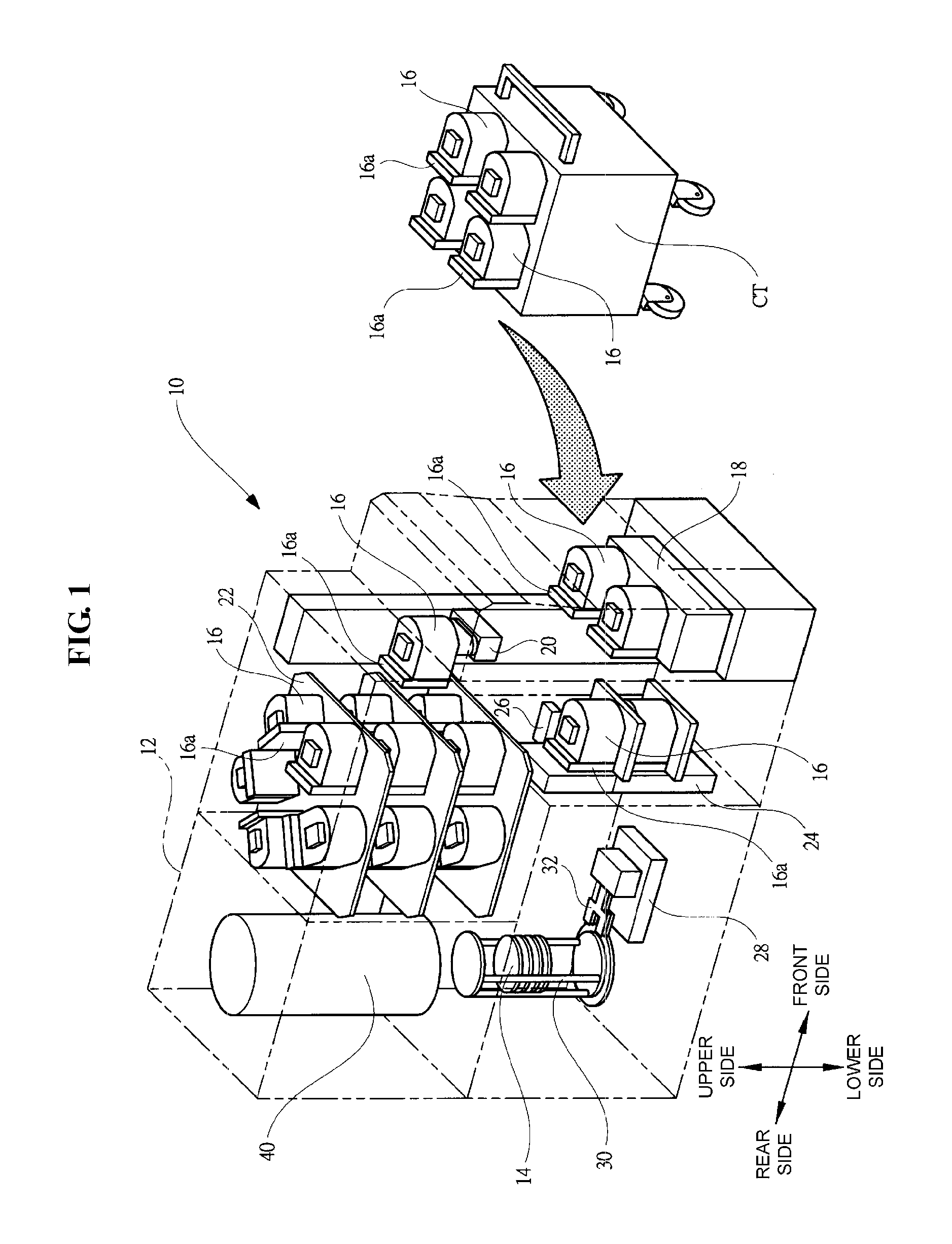

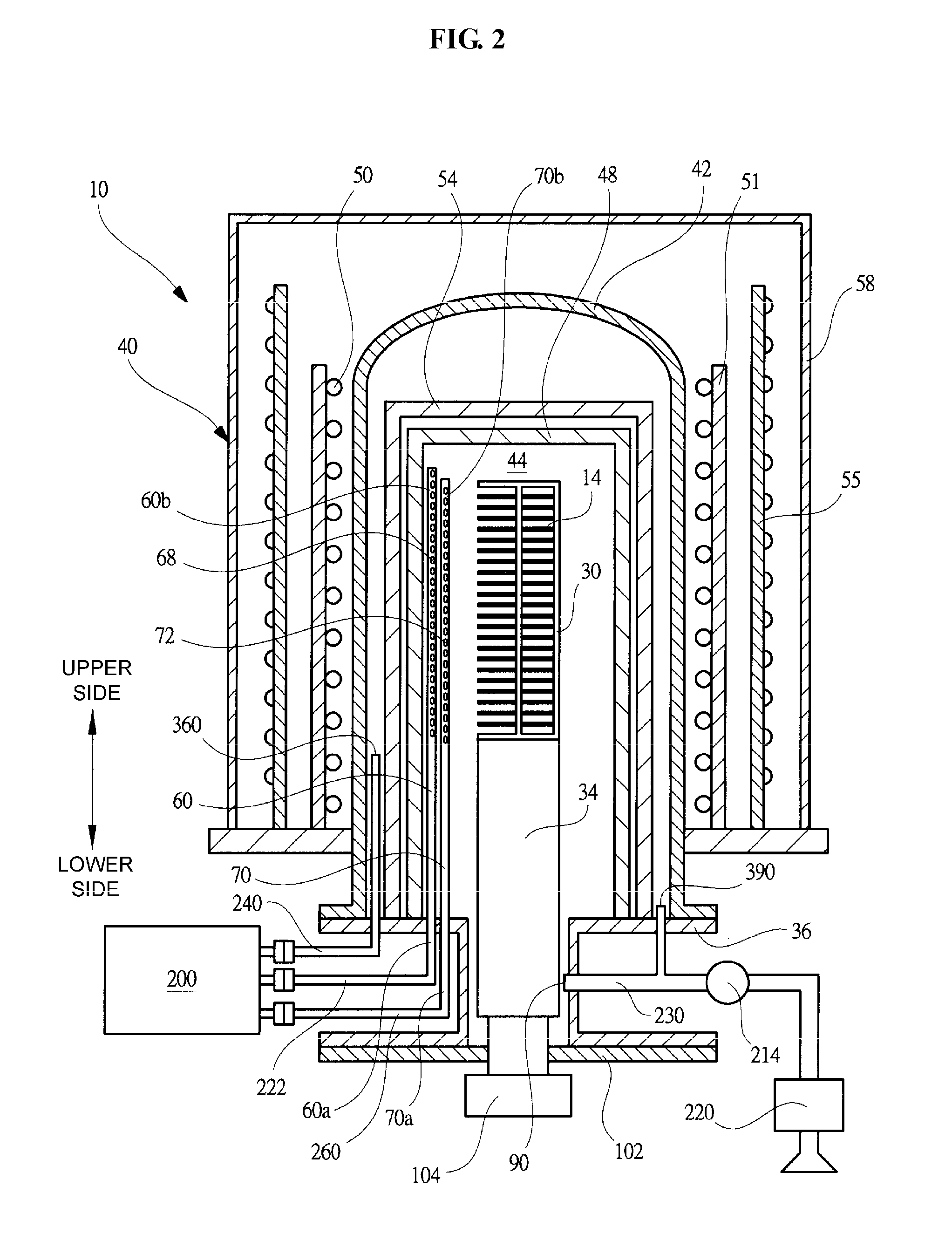

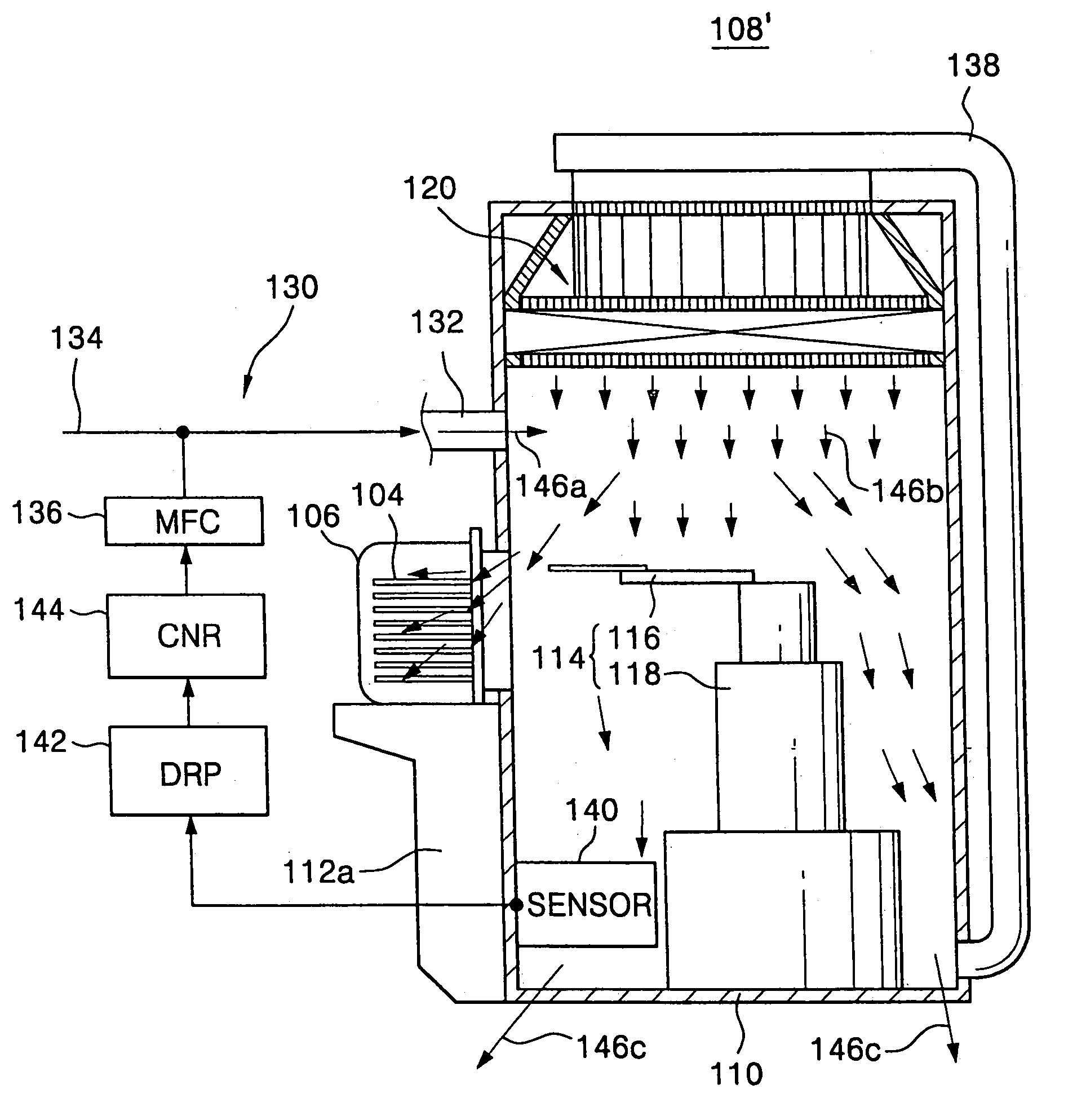

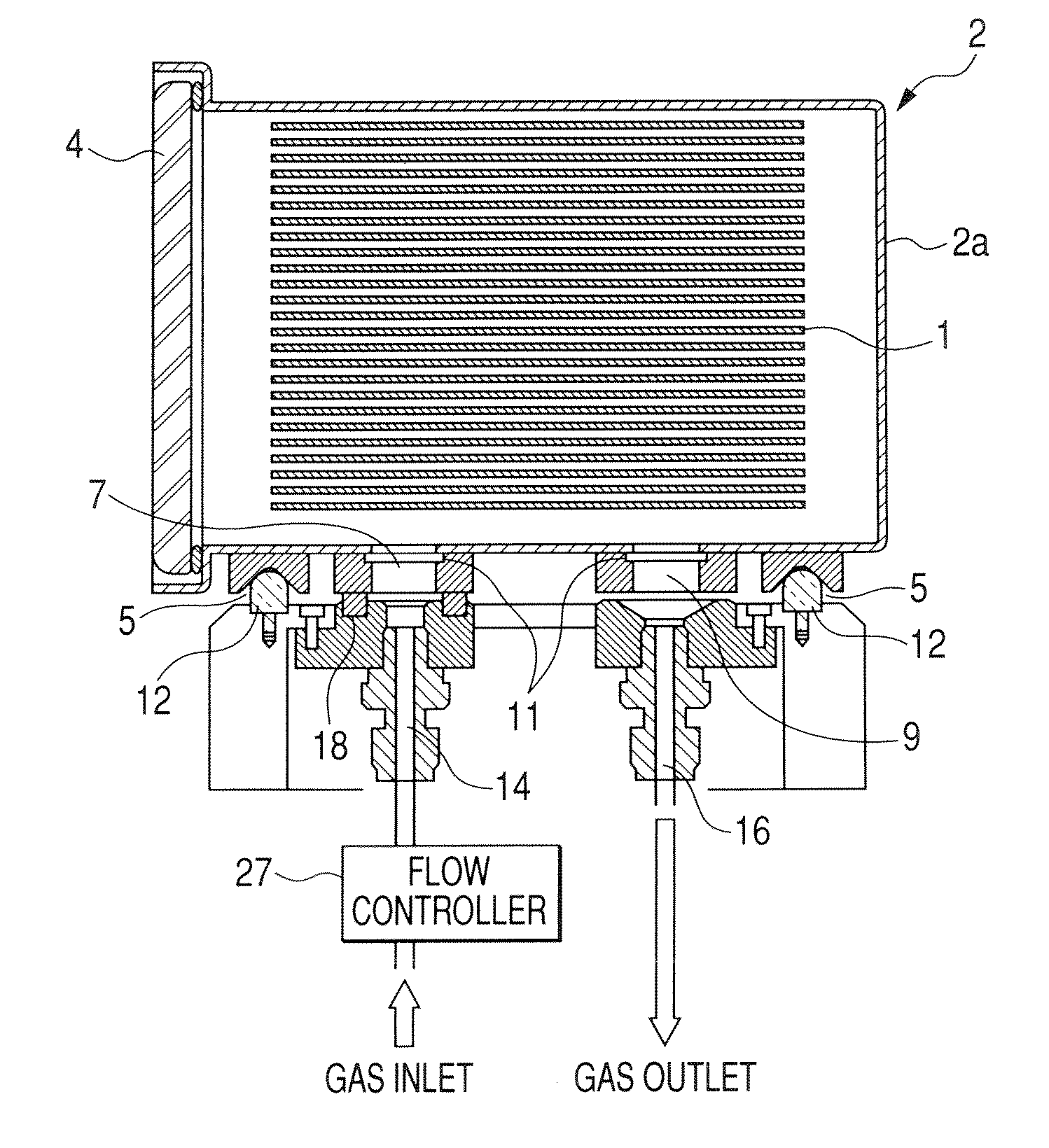

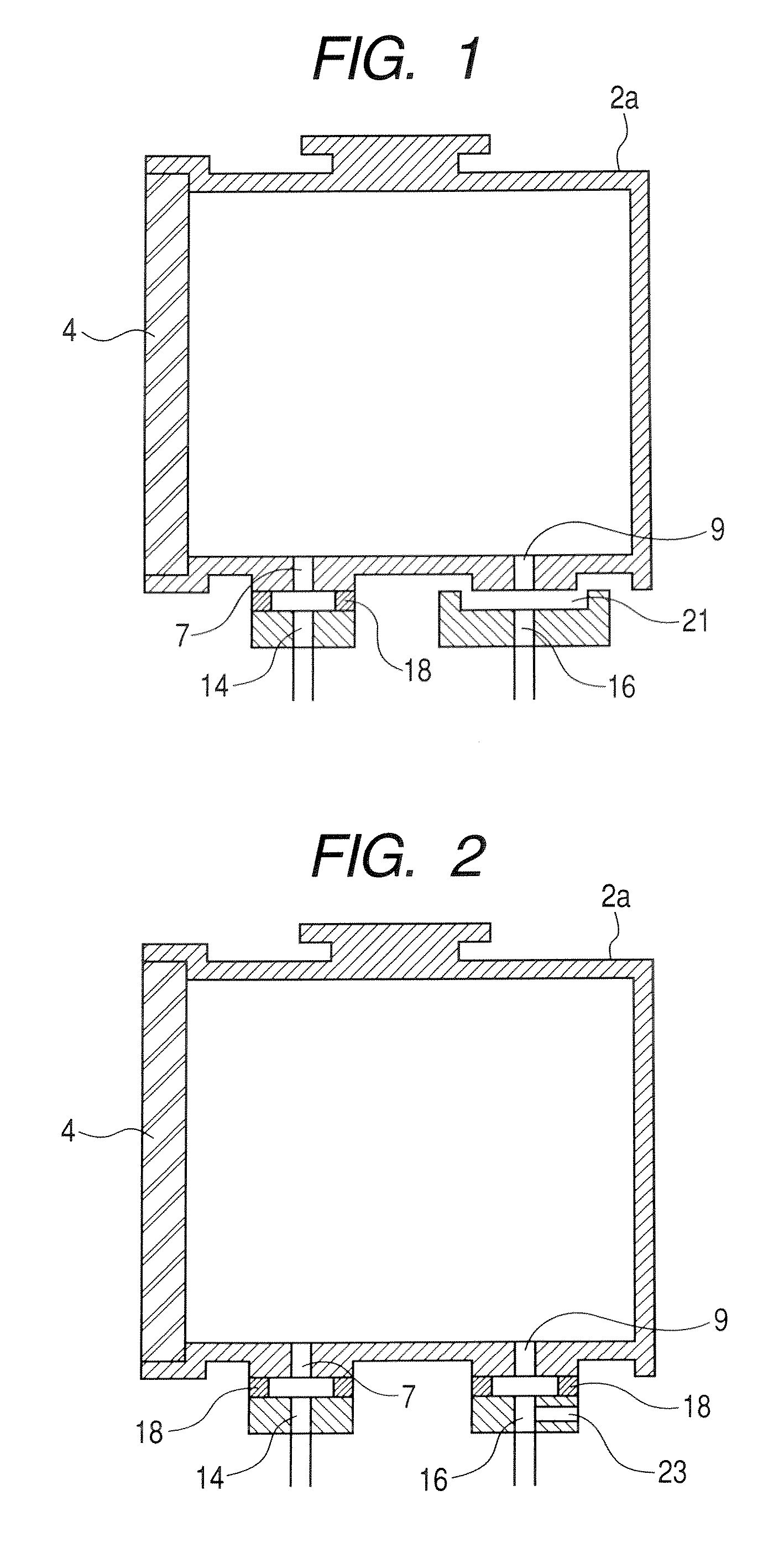

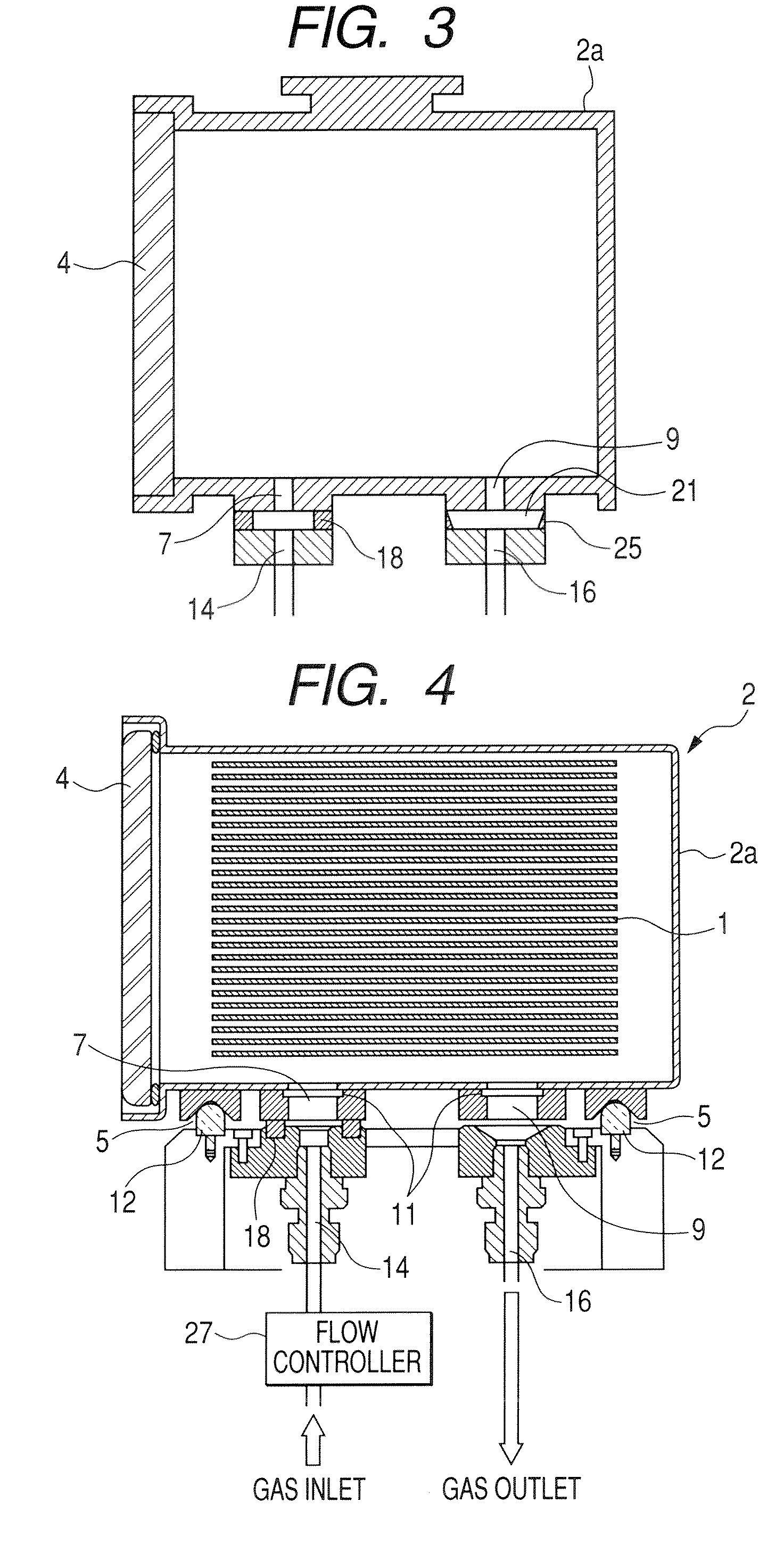

Attachment for substrates having different diameters, substrate processing apparatus, and method of manufacturing substrate or semiconductor device

InactiveUS20120216743A1Low costImprove film-forming precisionPolycrystalline material growthSemiconductor/solid-state device manufacturingReactive gasDevice material

A downsized substrate may be housed in a substrate accommodation vessel (FOUP) constituting a transfer system corresponding to a large diameter substrate. An attachment includes an upper plate and a lower plate supported by a first support groove that can support an 8-inch wafer, and holding columns installed at the upper plate and the lower plate and including a second support groove that can support a 2-inch wafer (if necessary, via a wafer holder and a holder member). Accordingly, the 2-inch wafer can be housed in a pod corresponding to the 8-inch wafer, and the pod, which is a transfer system, can be standardized to reduce cost of a semiconductor manufacturing apparatus. In addition, a distance from each gas supply nozzle to the wafer can be increased to sufficiently mix reactive gases before arrival at the wafer and improve film-forming precision to the wafer.

Owner:KOKUSA ELECTRIC CO LTD

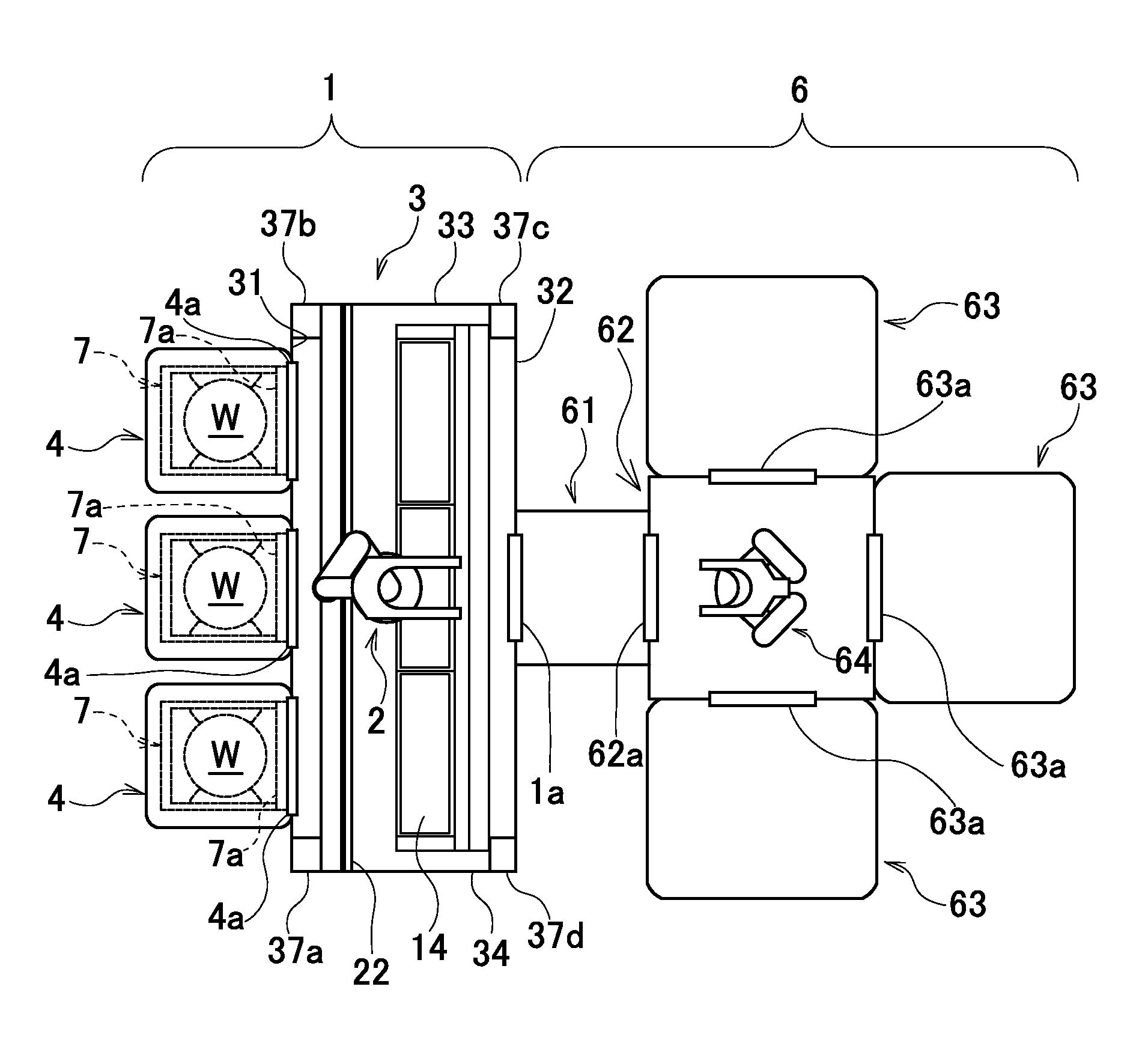

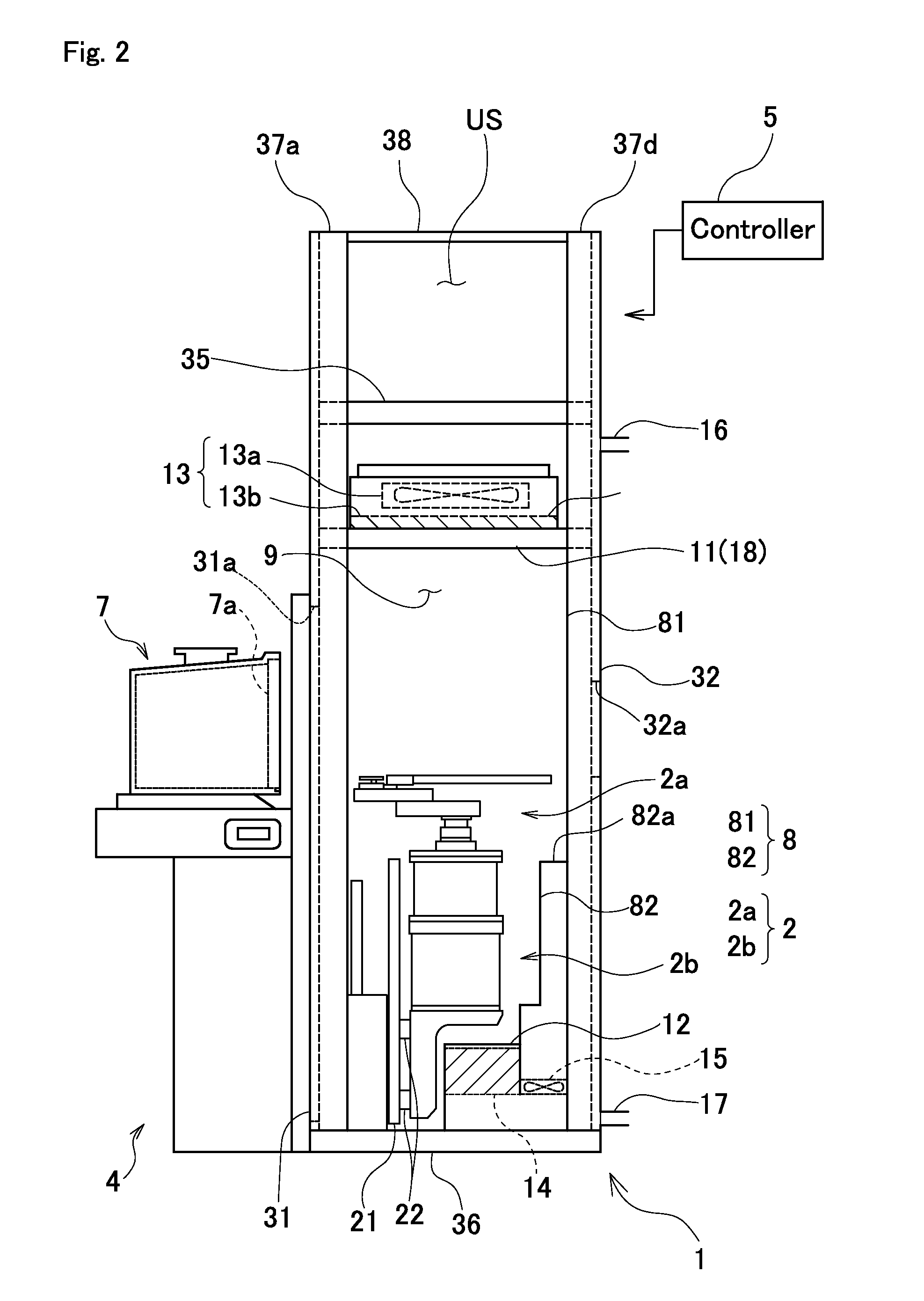

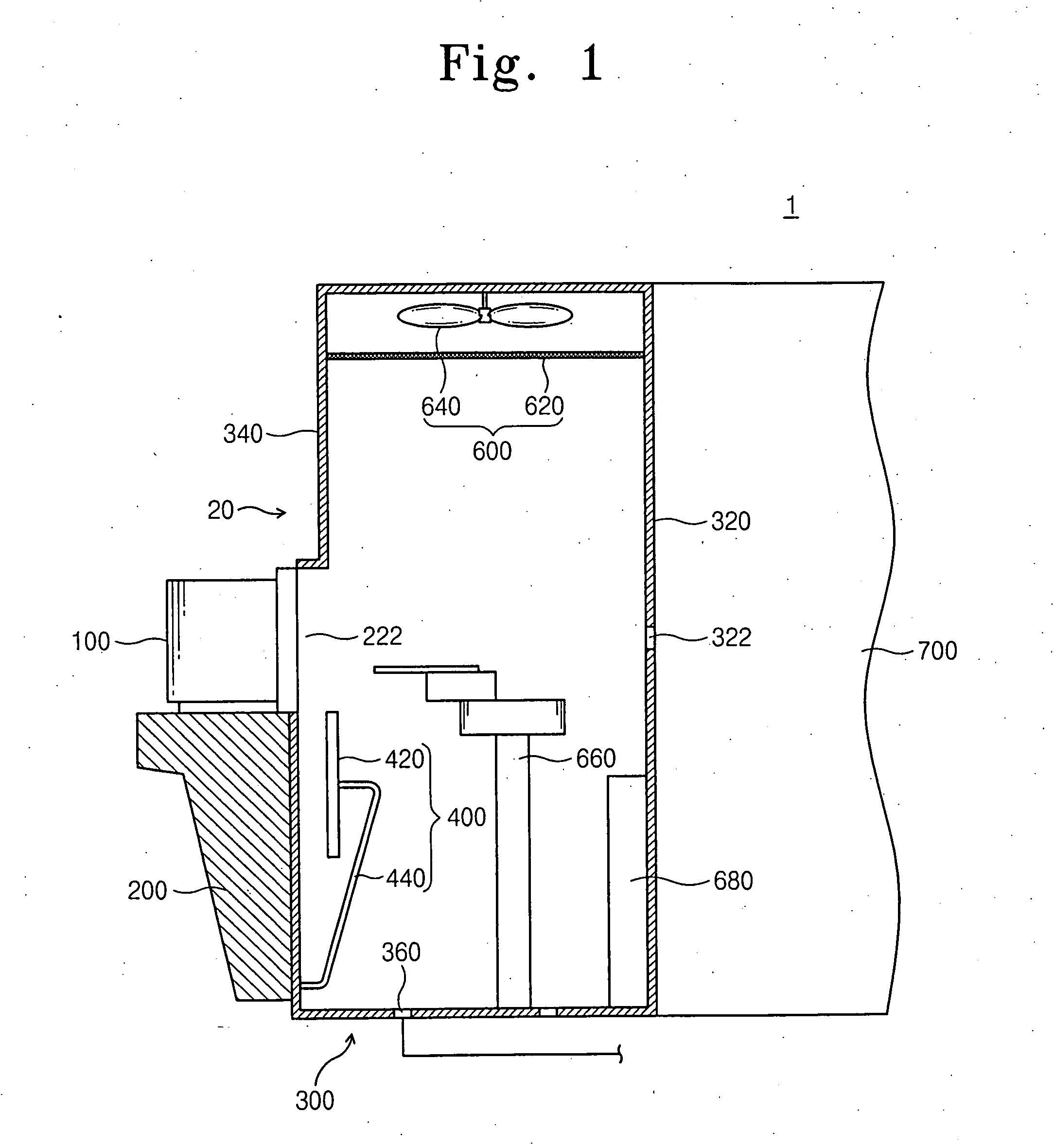

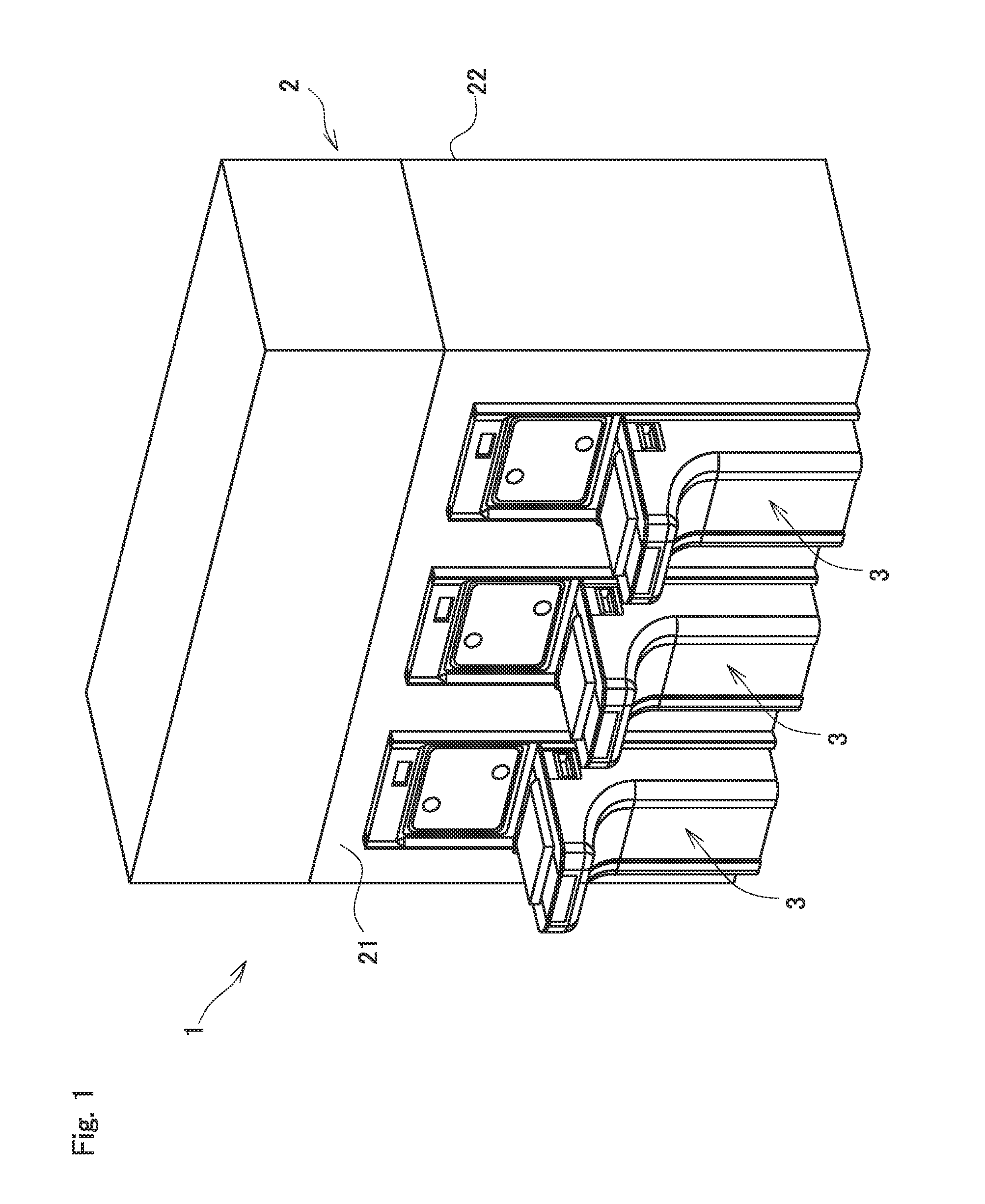

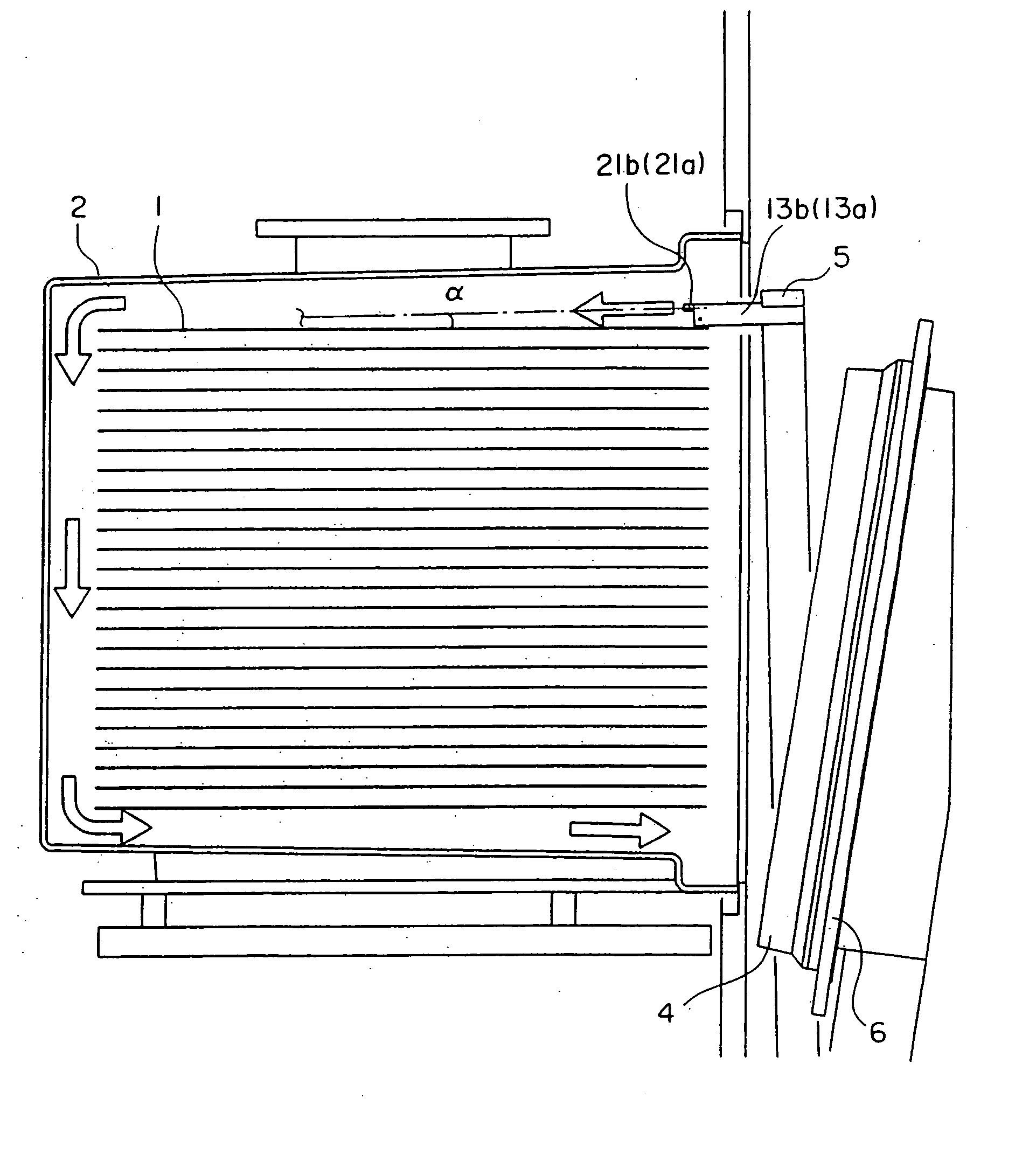

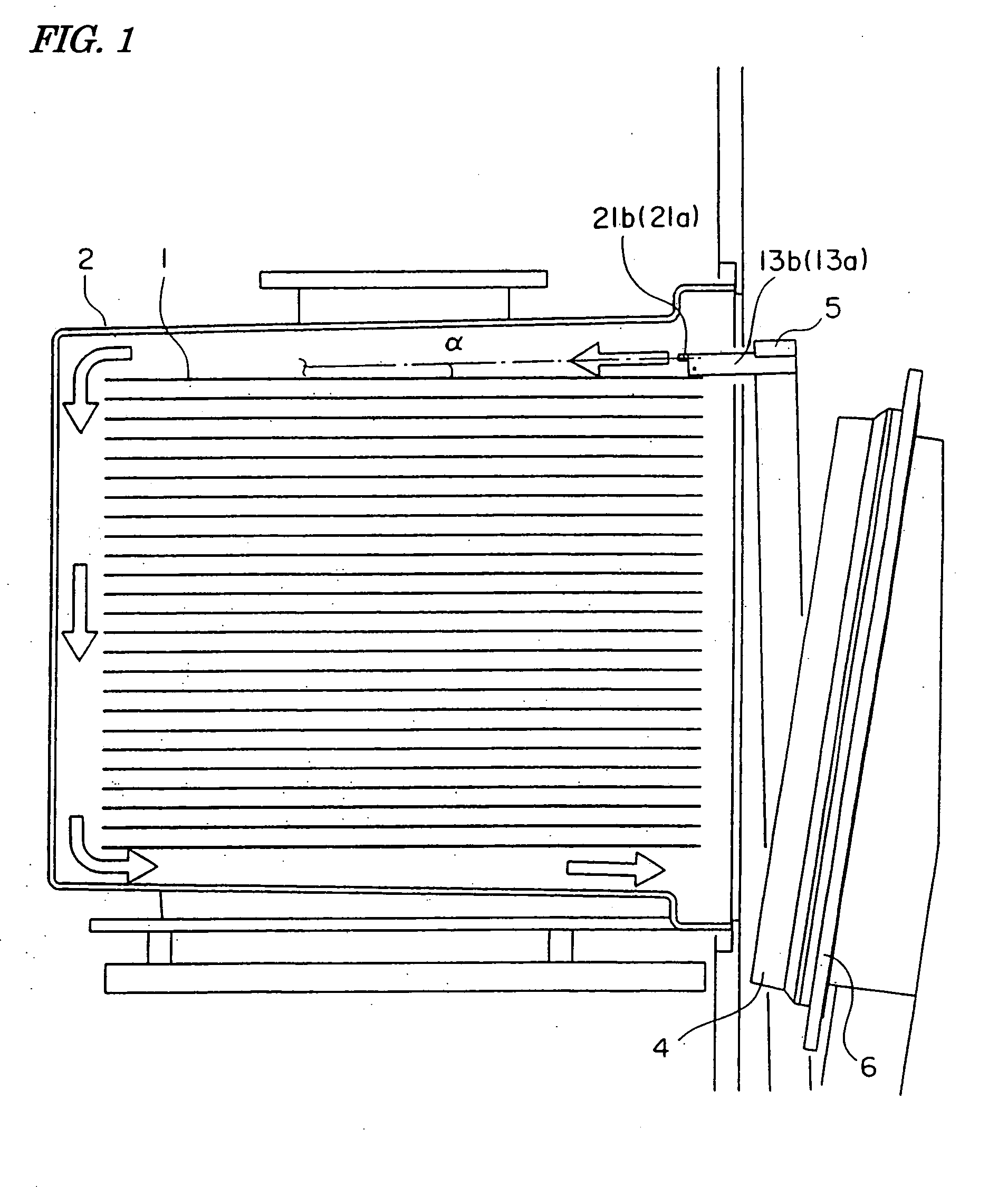

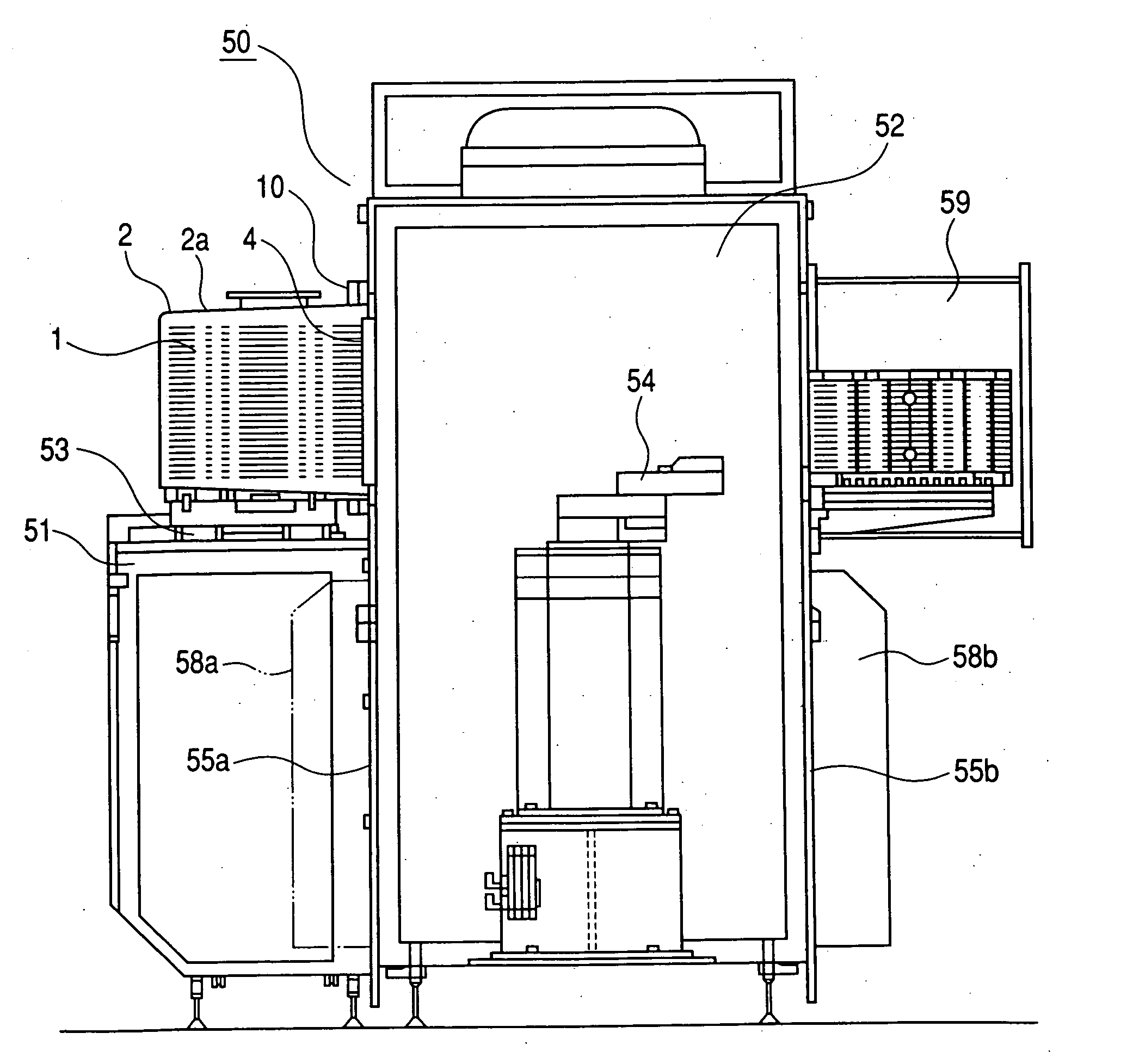

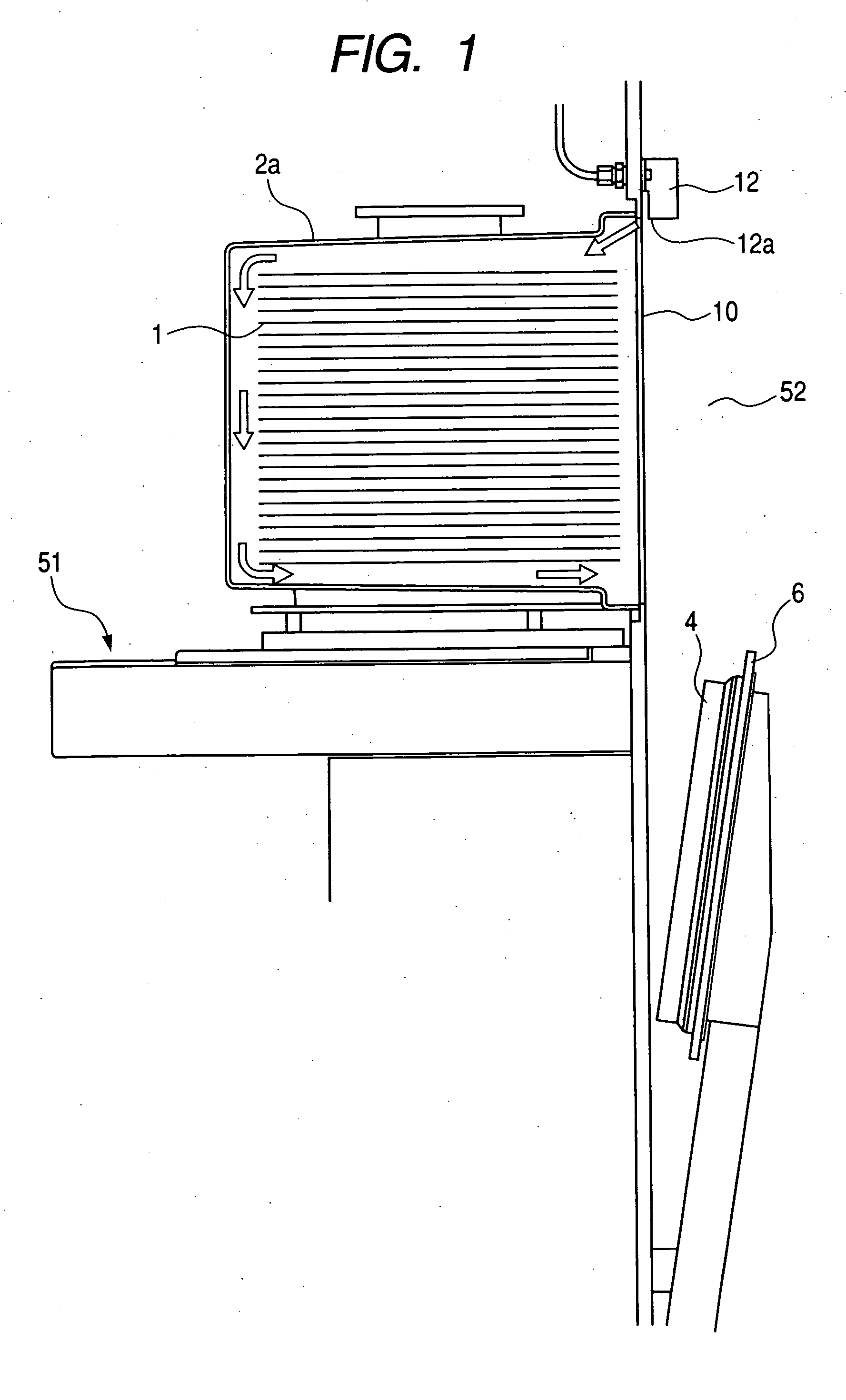

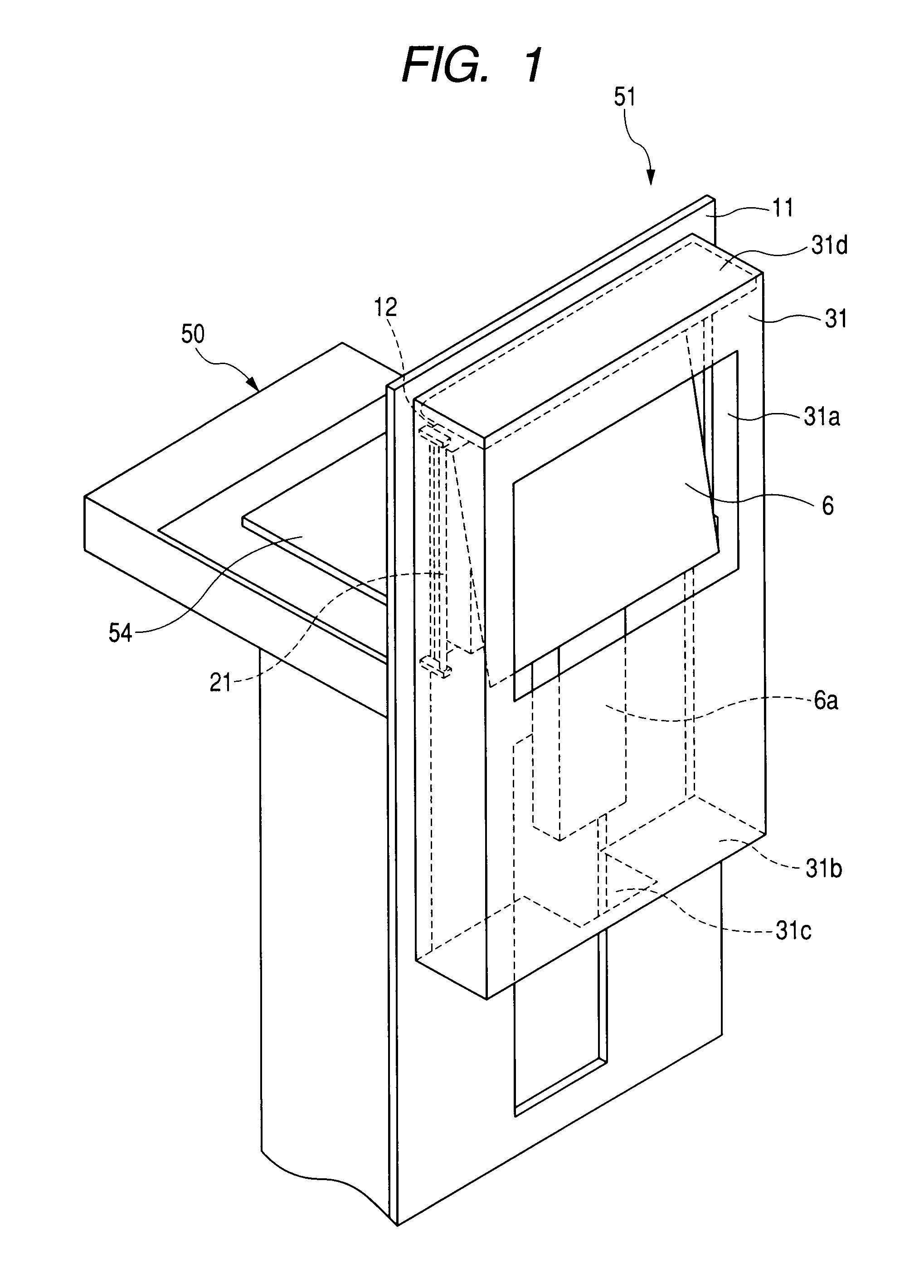

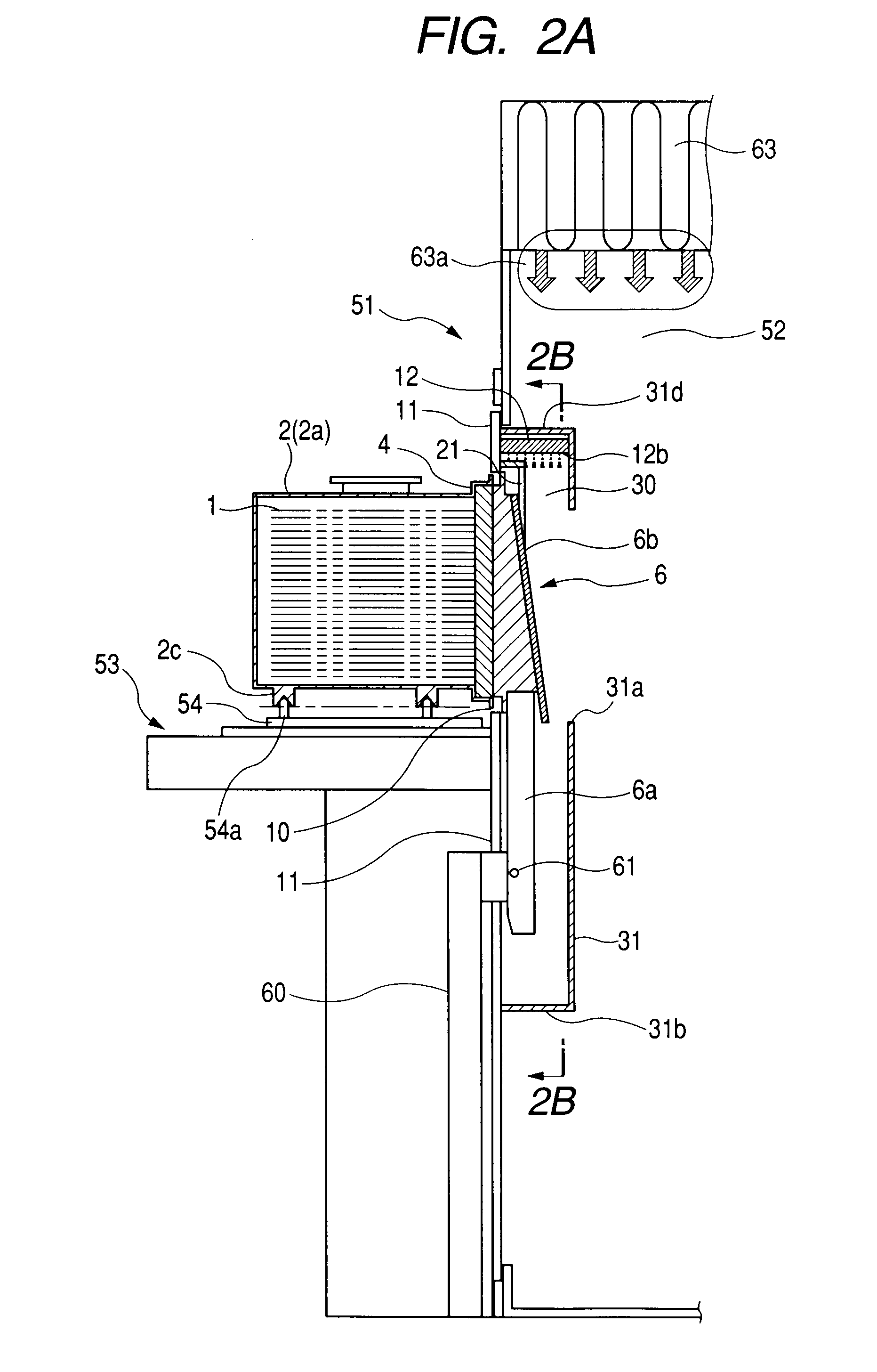

Efem

ActiveUS20150170945A1Avoid yield lossMaintain normal stateSemiconductor/solid-state device manufacturingConveyor partsWaste managementFOUP

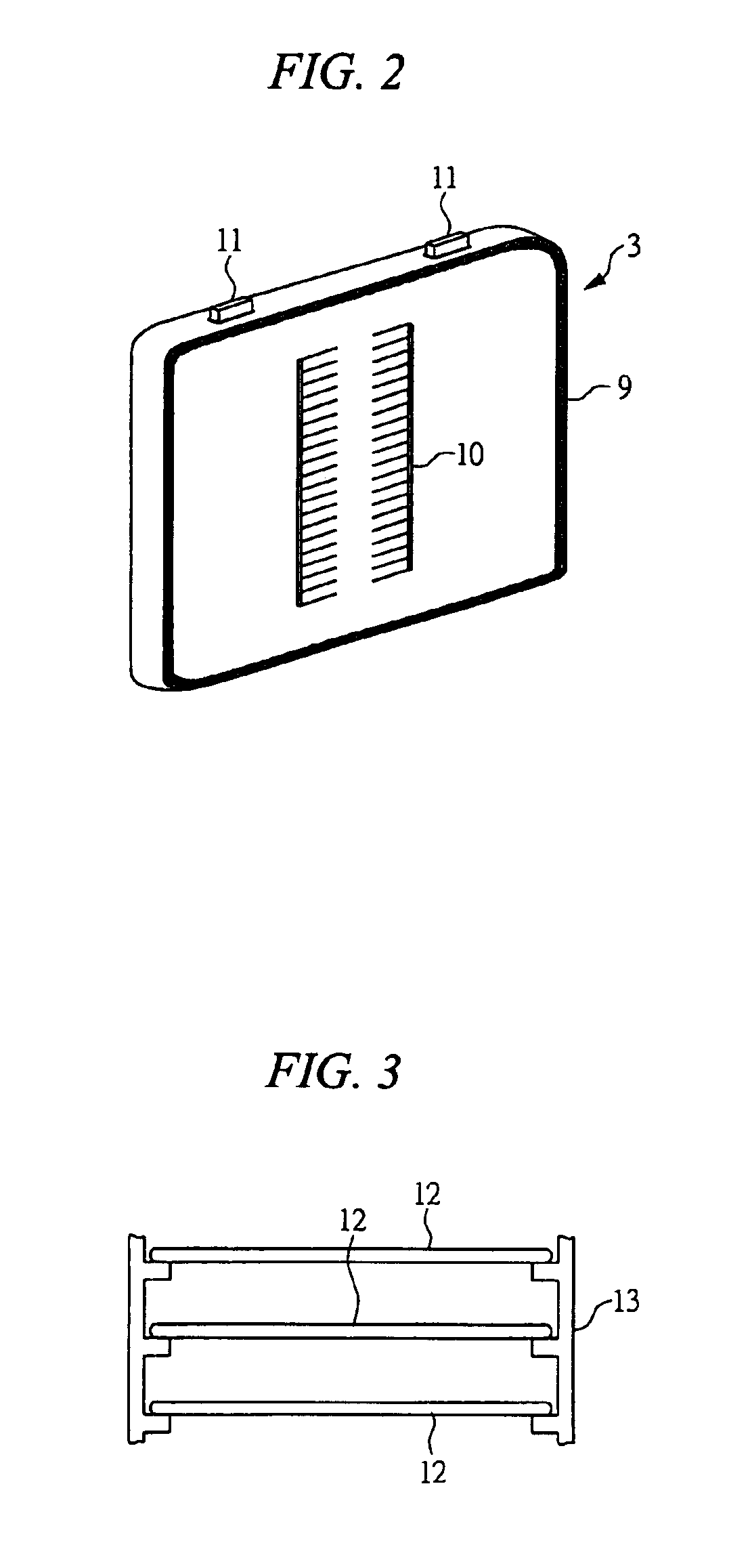

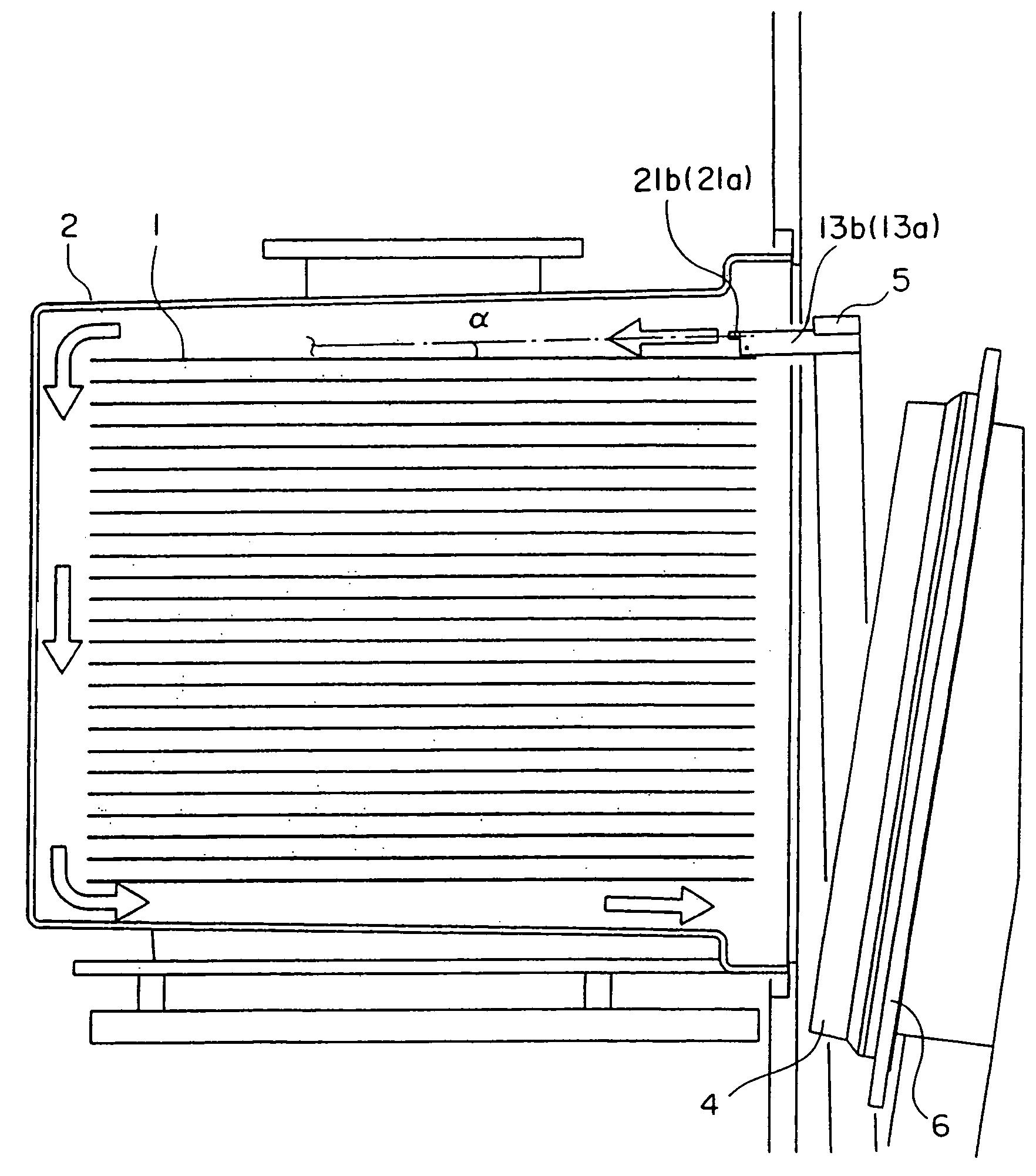

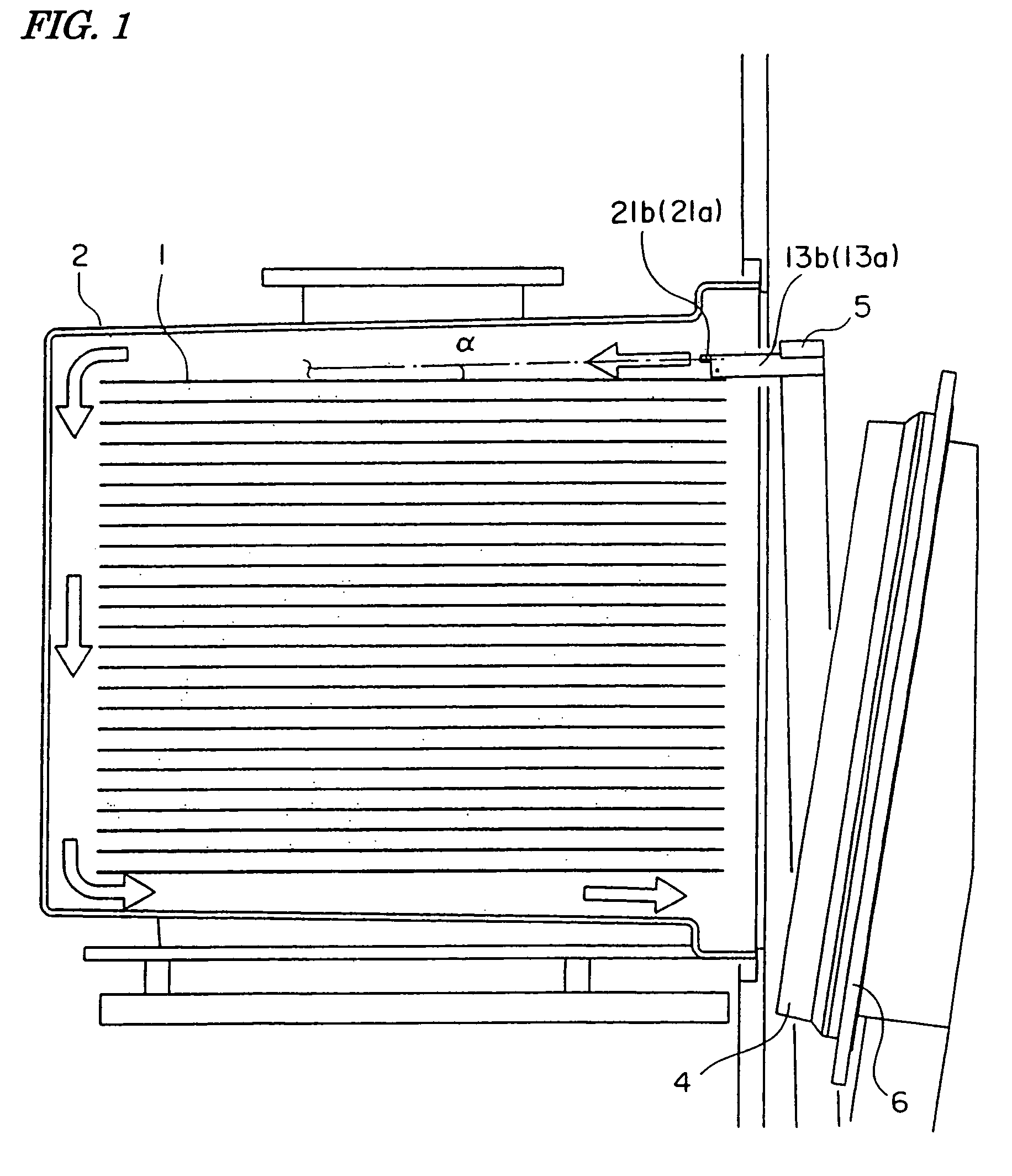

An EFEM includes a housing 3 that constitutes a wafer transport chamber 9 that is substantially closed by connecting load ports 4 to an opening 31a provided on a wall 31, and connecting a processing apparatus 6; a wafer transport apparatus 2, and transports a wafer between the processing apparatus 6 and the FOUPs 7 mounted on the load ports 4; a gas delivery port 11; a gas suction port 12; a gas feedback path 10; and a FFU 13 that includes a filter 13b that is provided in the gas delivery port 11, and eliminates particles contained in the delivered gas, wherein the gas in the wafer transport chamber 9 is circulated by generating a downward gasflow in the wafer transport chamber 9 and feeding back the gas through the gas feedback path 10.

Owner:SINFONIA TECHNOLOGY CO LTD

Method of purging wafer receiving jig, wafer transfer device, and method of manufacturing semiconductor device

InactiveUS6867153B2Drying gas arrangementsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A FOUP having semiconductor wafers received therein is transferred to a loading port and then the door of the FOUP is fixed and removed by a FIMS door and then the semiconductor wafers are taken out of the shell of the FOUP and then a predetermined manufacturing processing is performed to the semiconductor wafers. After performing the manufacturing processing, the semiconductor wafers are returned into the shell and the FIMS door is returned to a closed position and the shell is retracted about 50 mm to 65 mm to form a gap between the FIMS door and the shell. Then, purge gas is introduced from a gas introduction pipe arranged above the loading port on the left and right sides in a slanting forward direction of the FIMS door into the shell to replace the atmosphere in the shell with the purge gas.

Owner:TRECENTI TECHNOLOGIES INC

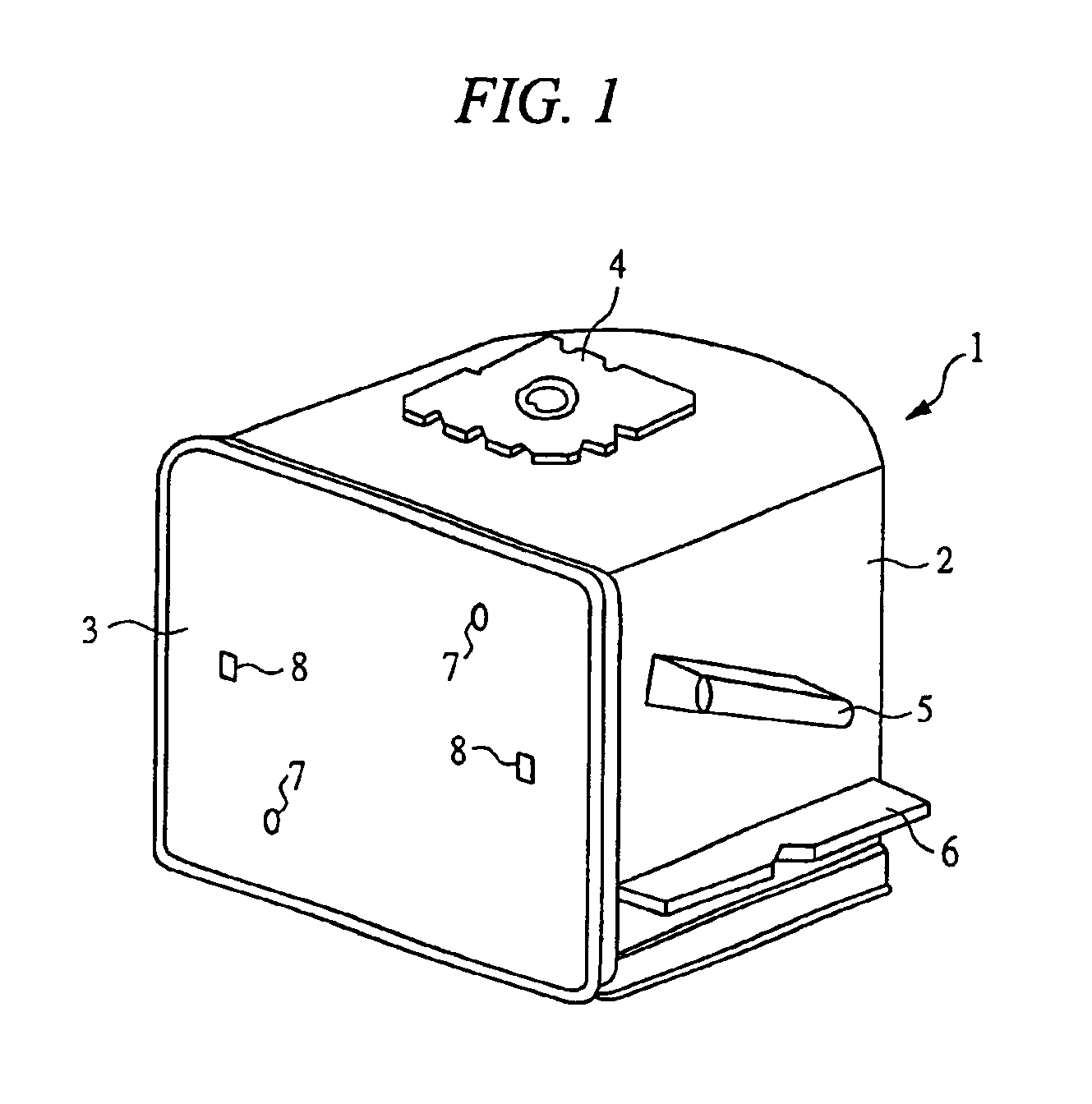

Front opening unified pod

InactiveUS6899145B2Reduce contentLiquid fillingSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

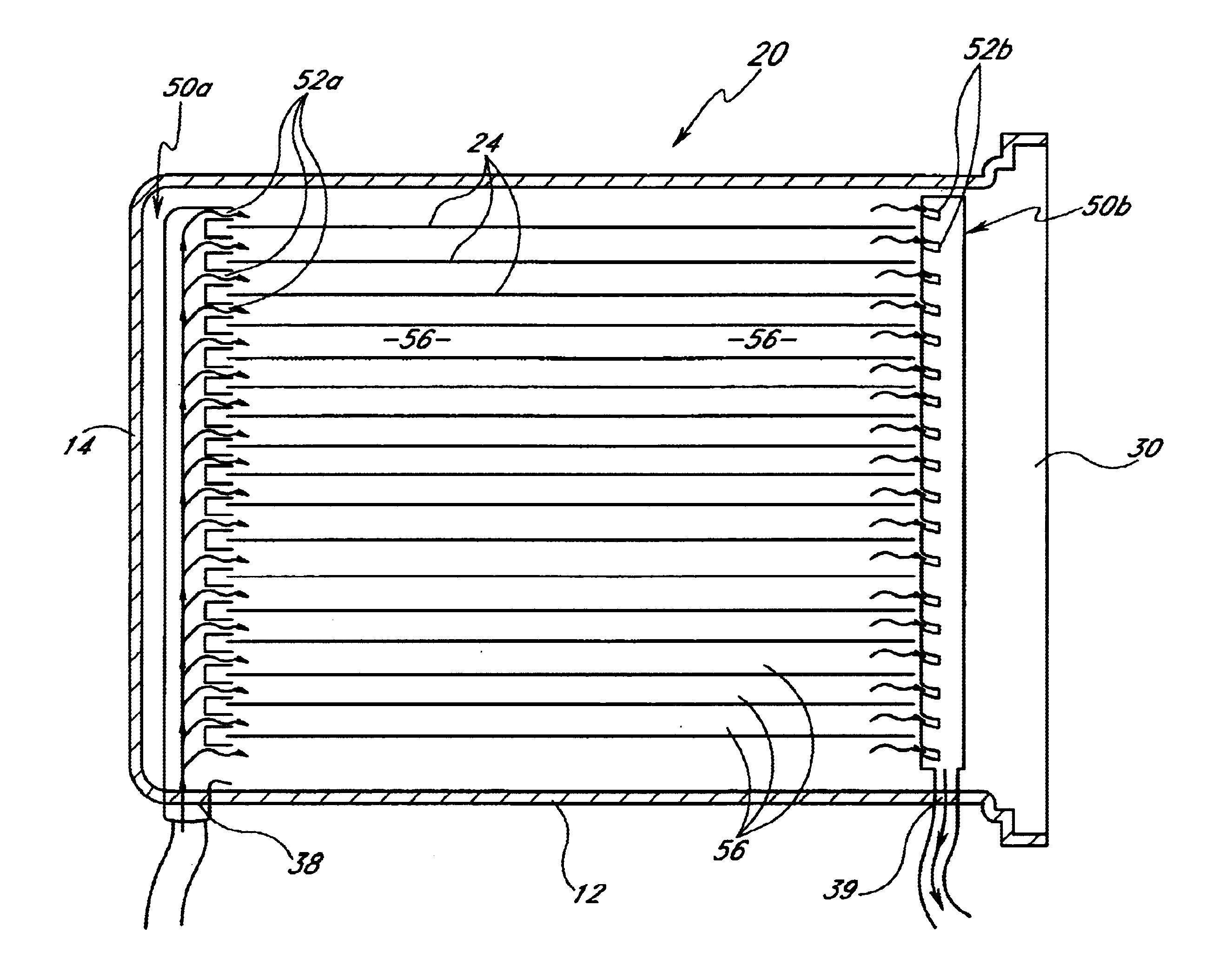

A front opening unified pod (FOUP) used for temporarily and portably storing semiconductor wafers between processing steps includes a manifold for uniformly distributing a purge gas in the FOUP during a purging process between wafer processing steps. The manifold can be a variety of shapes, and can be located in a number of appropriate locations within the FOUP. The manifold generally extends the full height of the FOUP and includes a plurality of openings configured to direct a flow of purge gas above and below each wafer held by the FOUP.

Owner:ASM IP HLDG BV

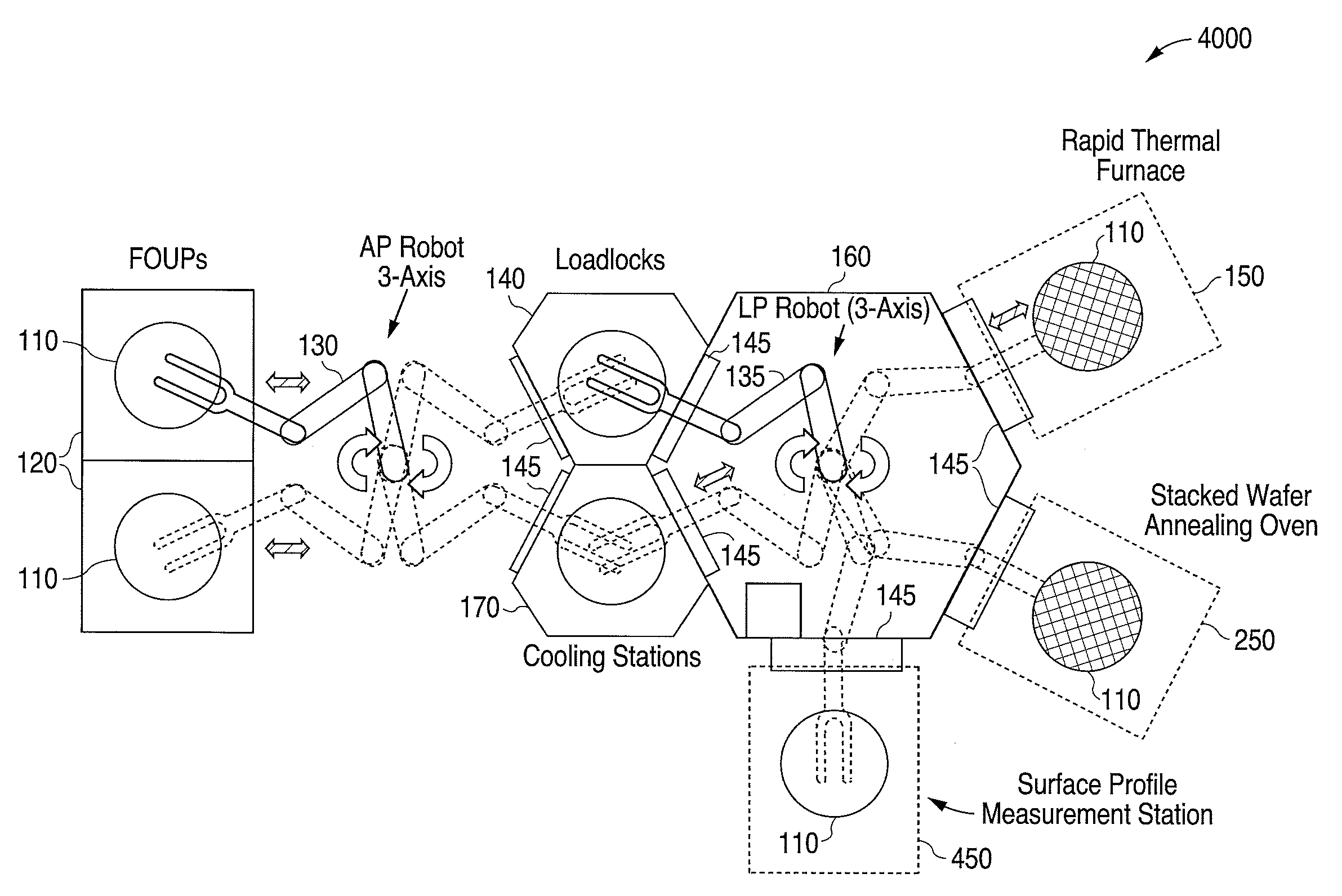

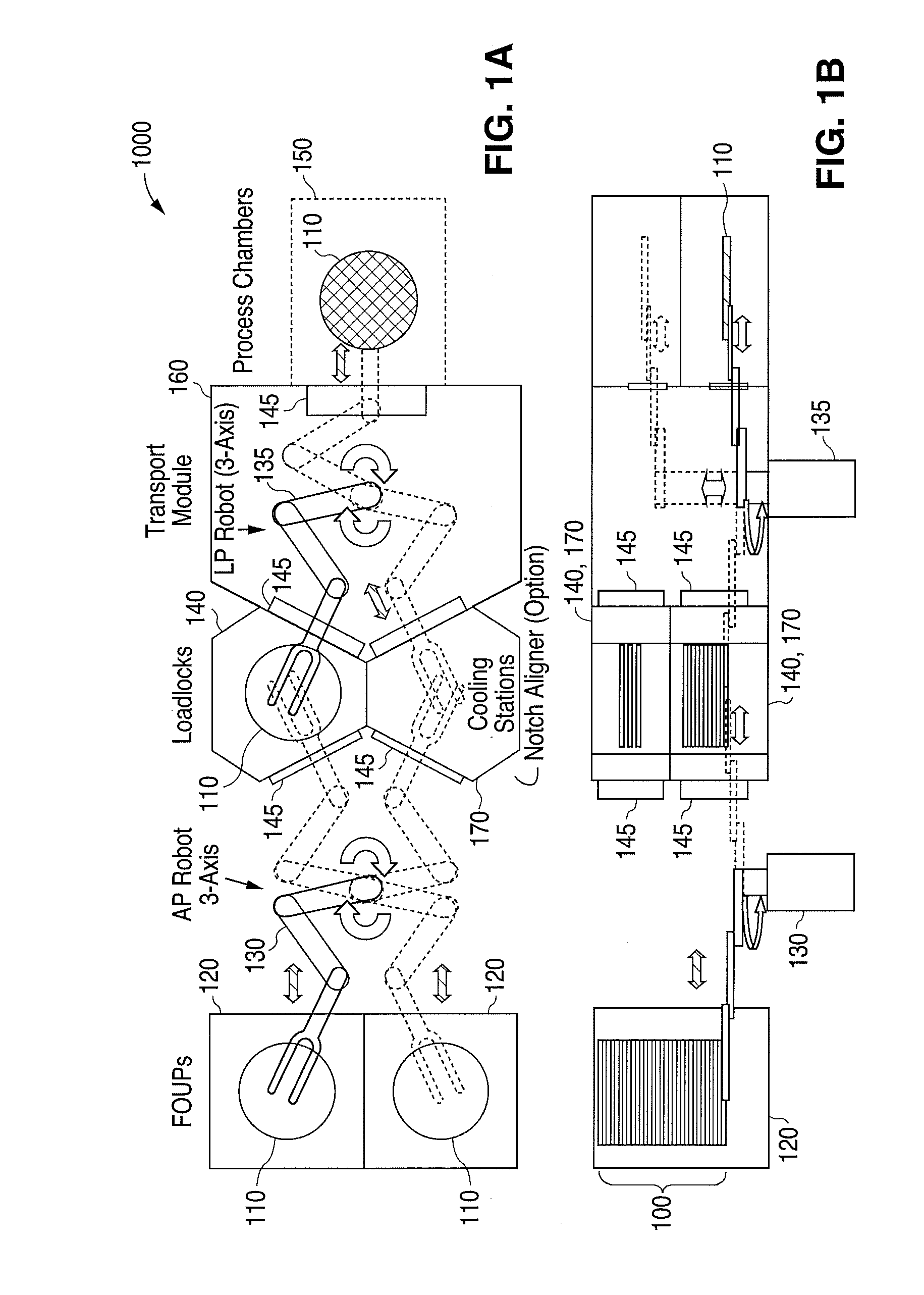

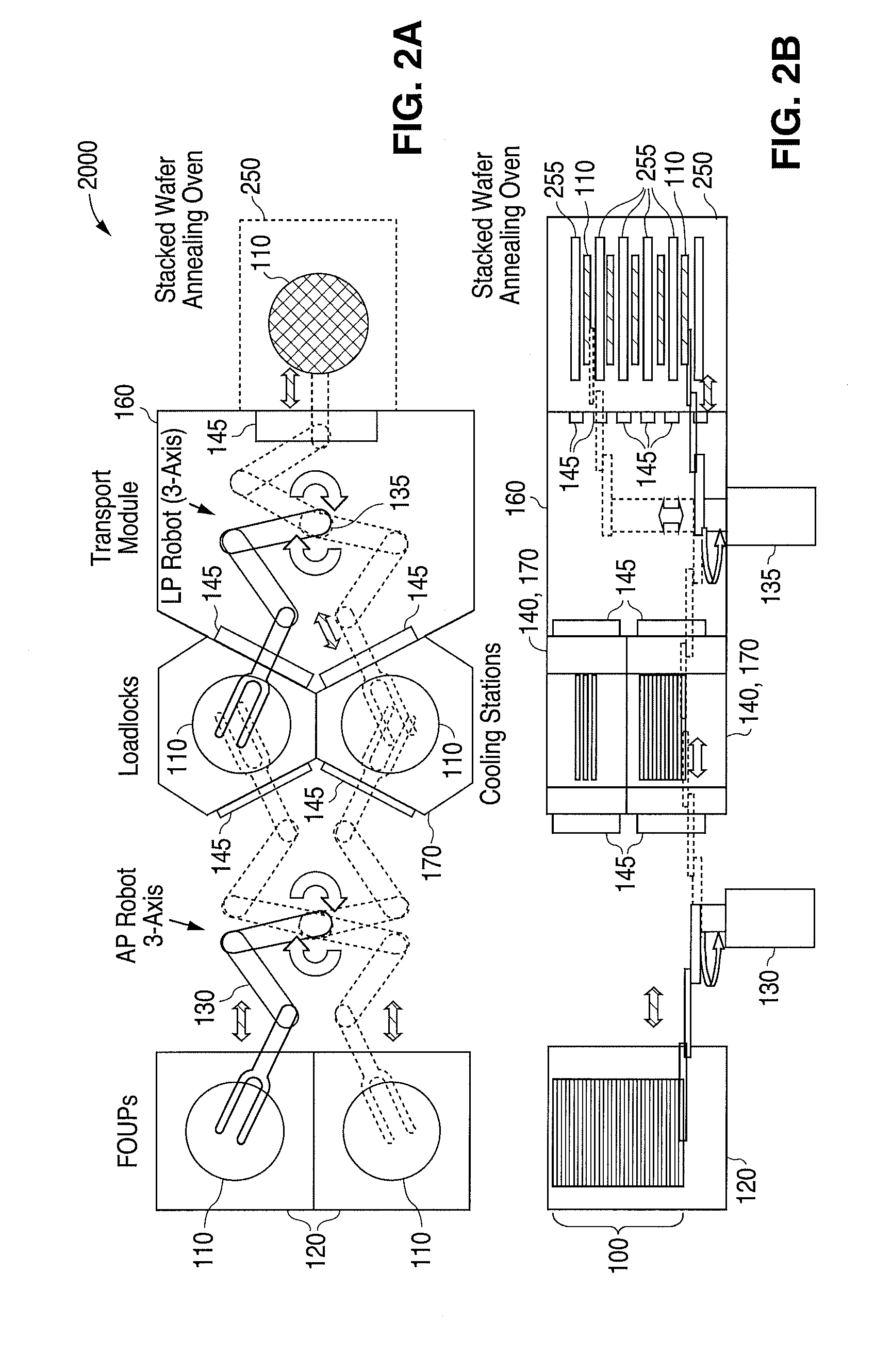

In-line wafer robotic processing system

InactiveUS20090016853A1ConveyorsSemiconductor/solid-state device manufacturingAmbient pressureCooling chamber

A system for processing semiconductor wafers, includes a plurality of front opening unified pods (FOUPs), loadlocks for receiving the plurality of wafers, a plurality of process chambers configured to perform processing steps and or measurement steps on the wafers, loadlock cooling stations for receiving the wafers from the processing chambers and a transport chamber interconnecting the loadlocks, cooling chambers and process chambers. A first multi-axis robot transfers wafers between the FOUPs, loadlocks and loadlock cooling stations, at an ambient pressure. A second multi-axis robot tranfers wafers between the loadlocks, process chambers and the loadlock cooling stations, and is adapted to operate in a transport chamber at a pressure that is different from the ambient pressure.

Owner:WAFERMASTERS

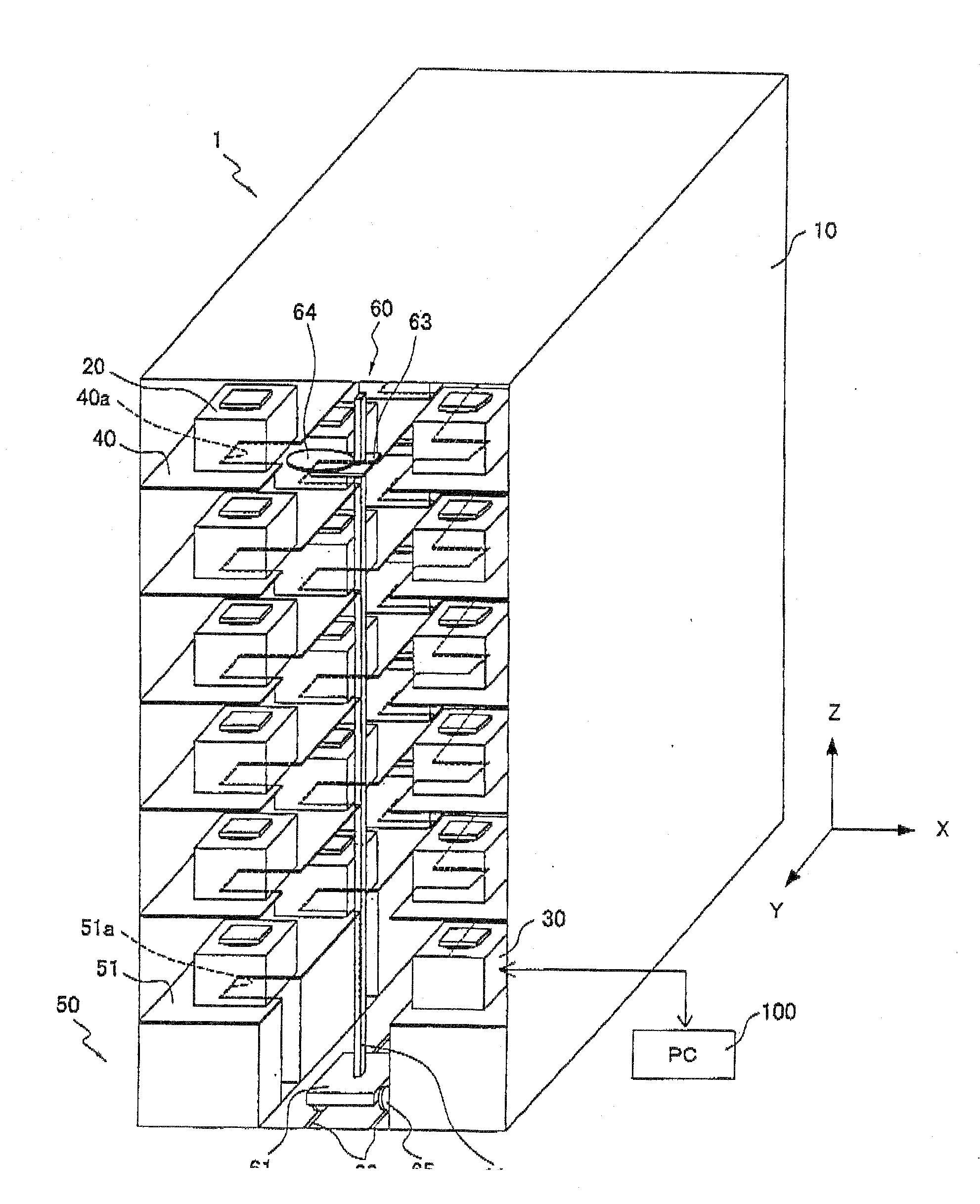

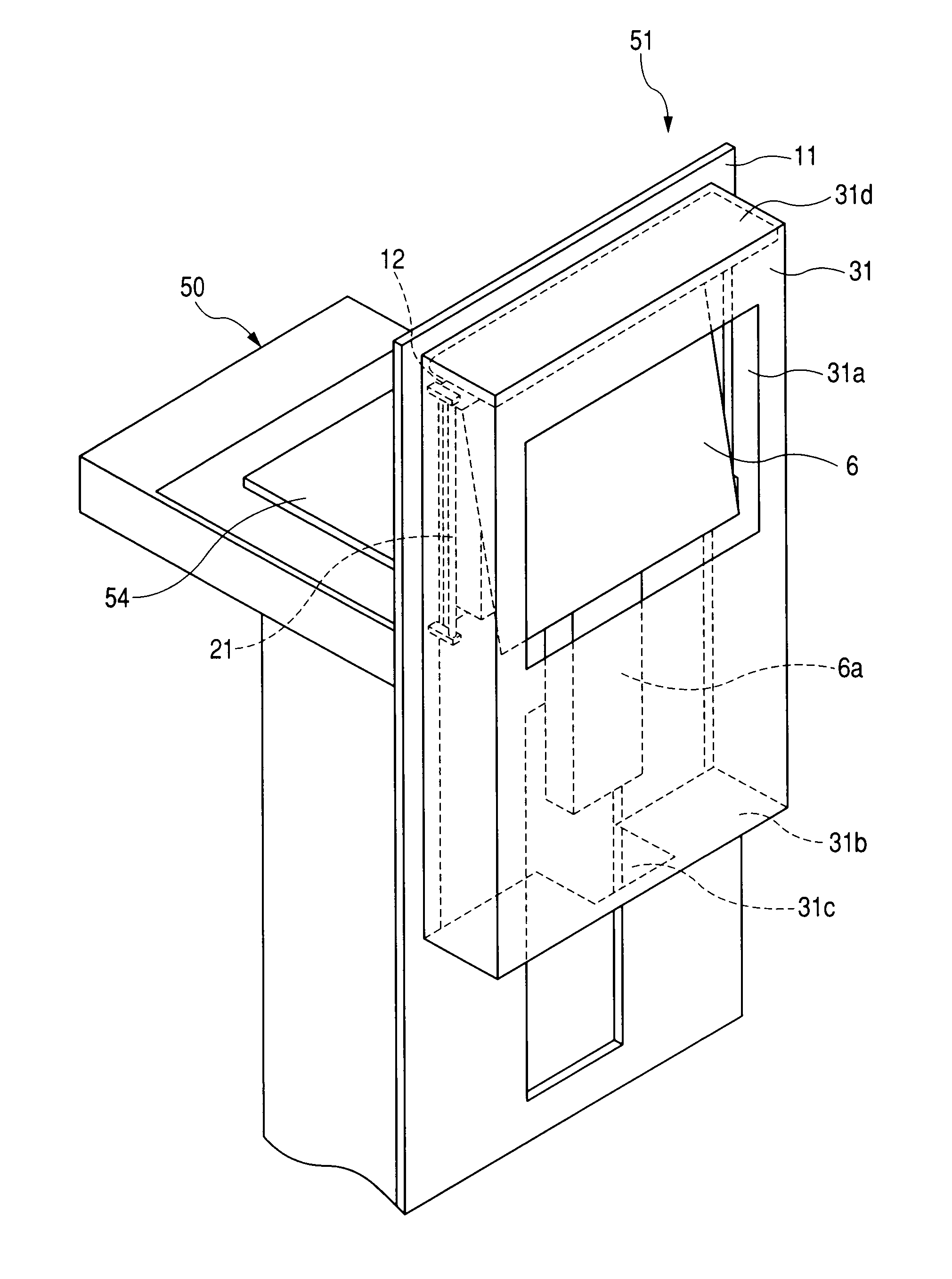

Container transport system and measurement container

ActiveUS20080156069A1Low costSave spaceDetection of fluid at leakage pointTesting/calibration apparatusTransport systemProcess engineering

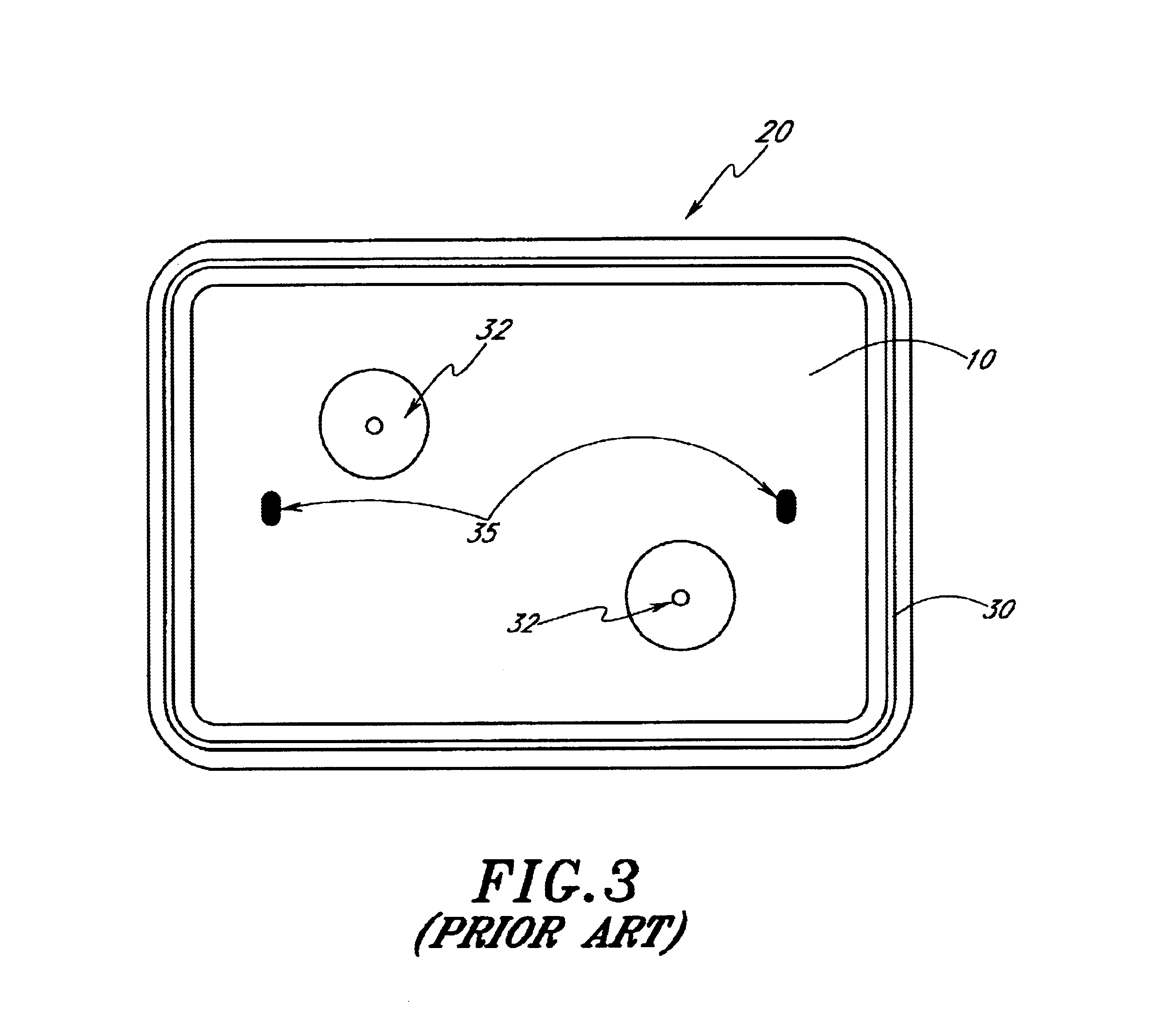

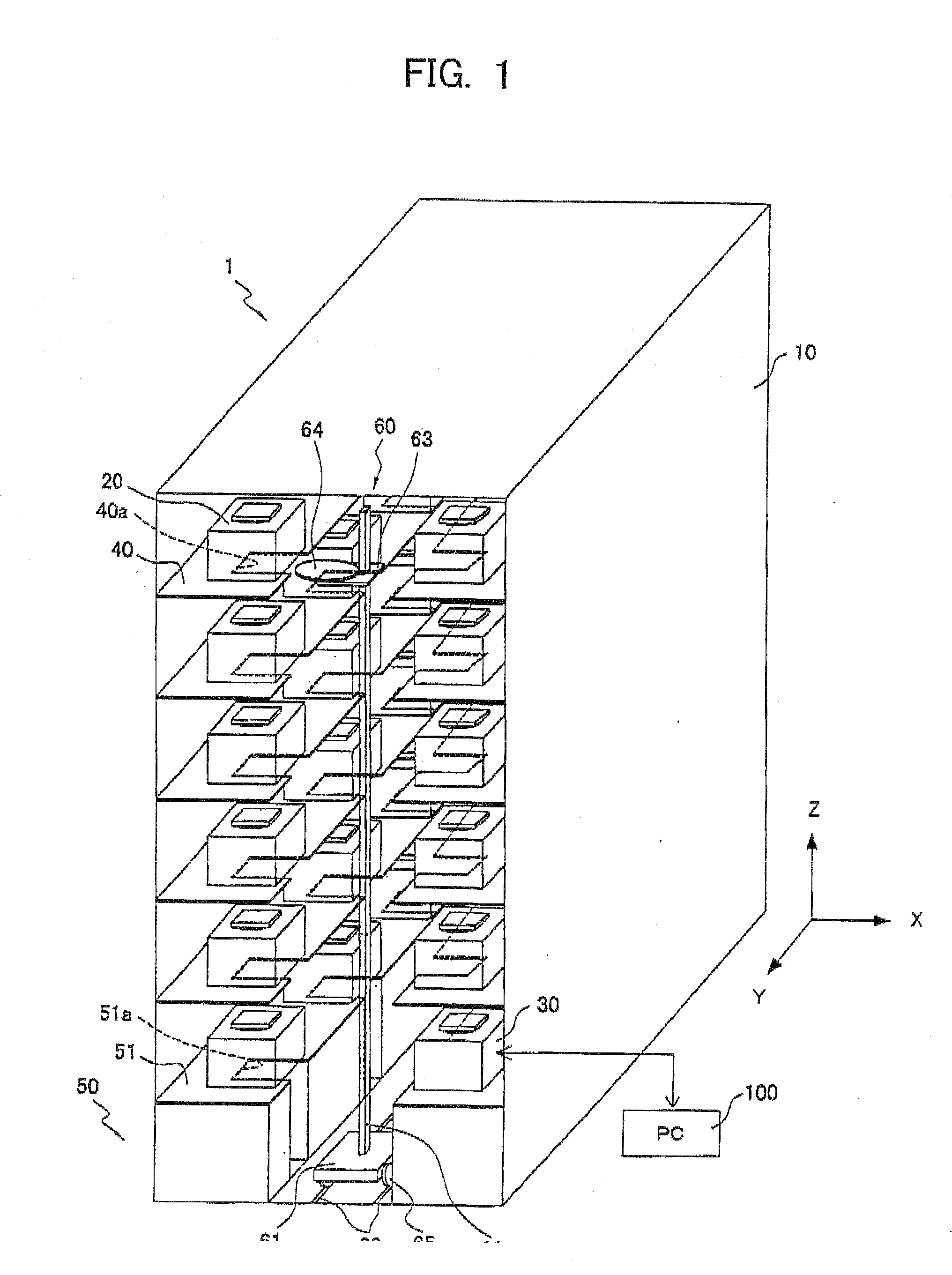

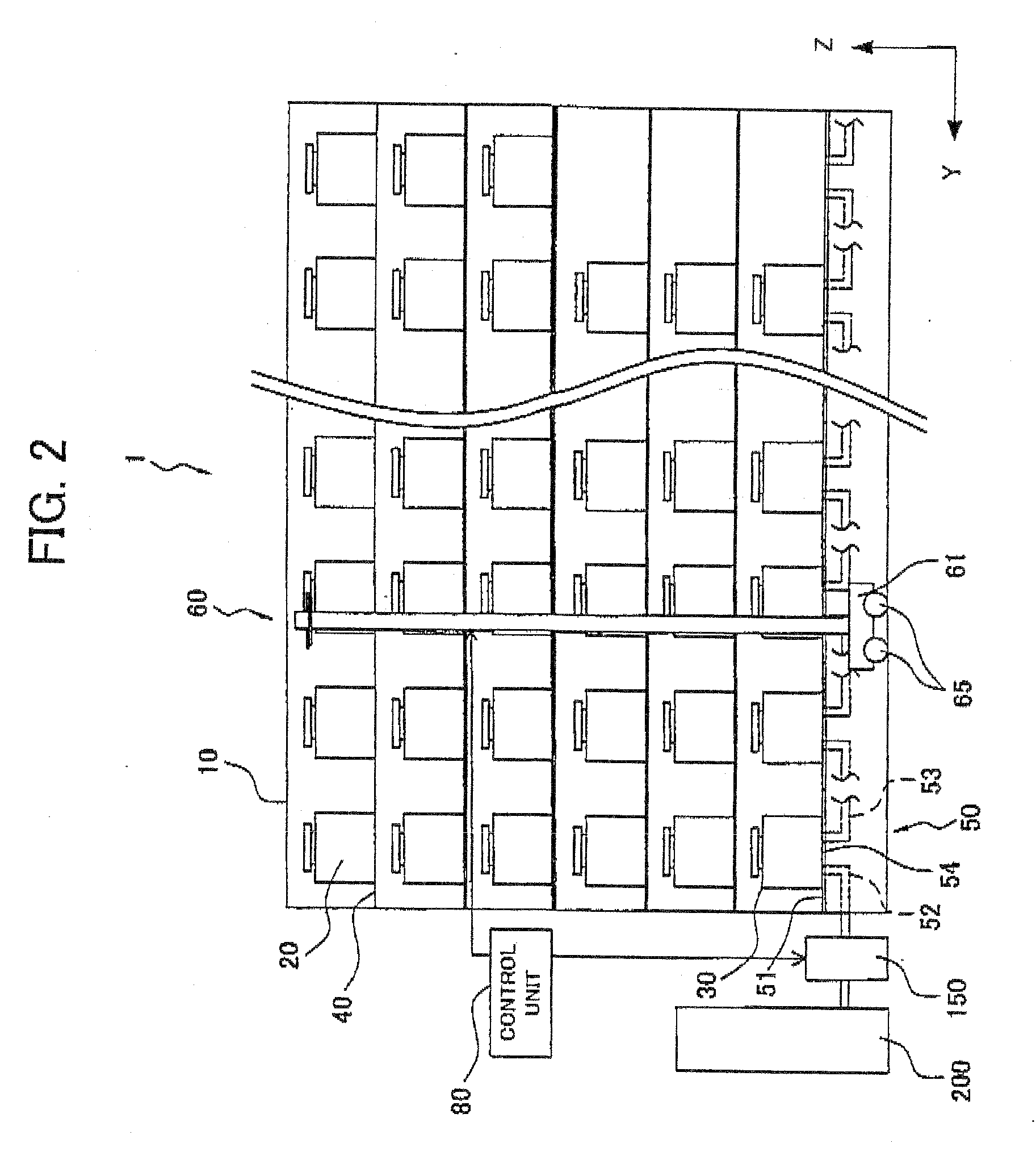

A stocker 1 includes a storage FOUP 20, plural purge units 50, a measurement FOUP 30 and a stacker crane 60. The storage FOUP 20 stores a semiconductor wafer inside. The measurement FOUP 30 includes a flow meter inside. The purge unit 50 includes a purge shelf 51 having plural purge tables 54 for placing the storage FOUP 20, and a nitrogen gas is supplied into the storage FOUP 20 placed on the purge table 54. The stacker crane 60 transports the storage container 20 onto the purge table 54, and the measurement FOUP 30 is transported between the plural purge tables 54.

Owner:MURATA MASCH LTD

Substrate treating apparatus

InactiveUS20060137726A1Reduced footprintIncrease the number ofLiquid surface applicatorsPhotomechanical apparatusMedicineFOUP

Owner:DAINIPPON SCREEN MTG CO LTD

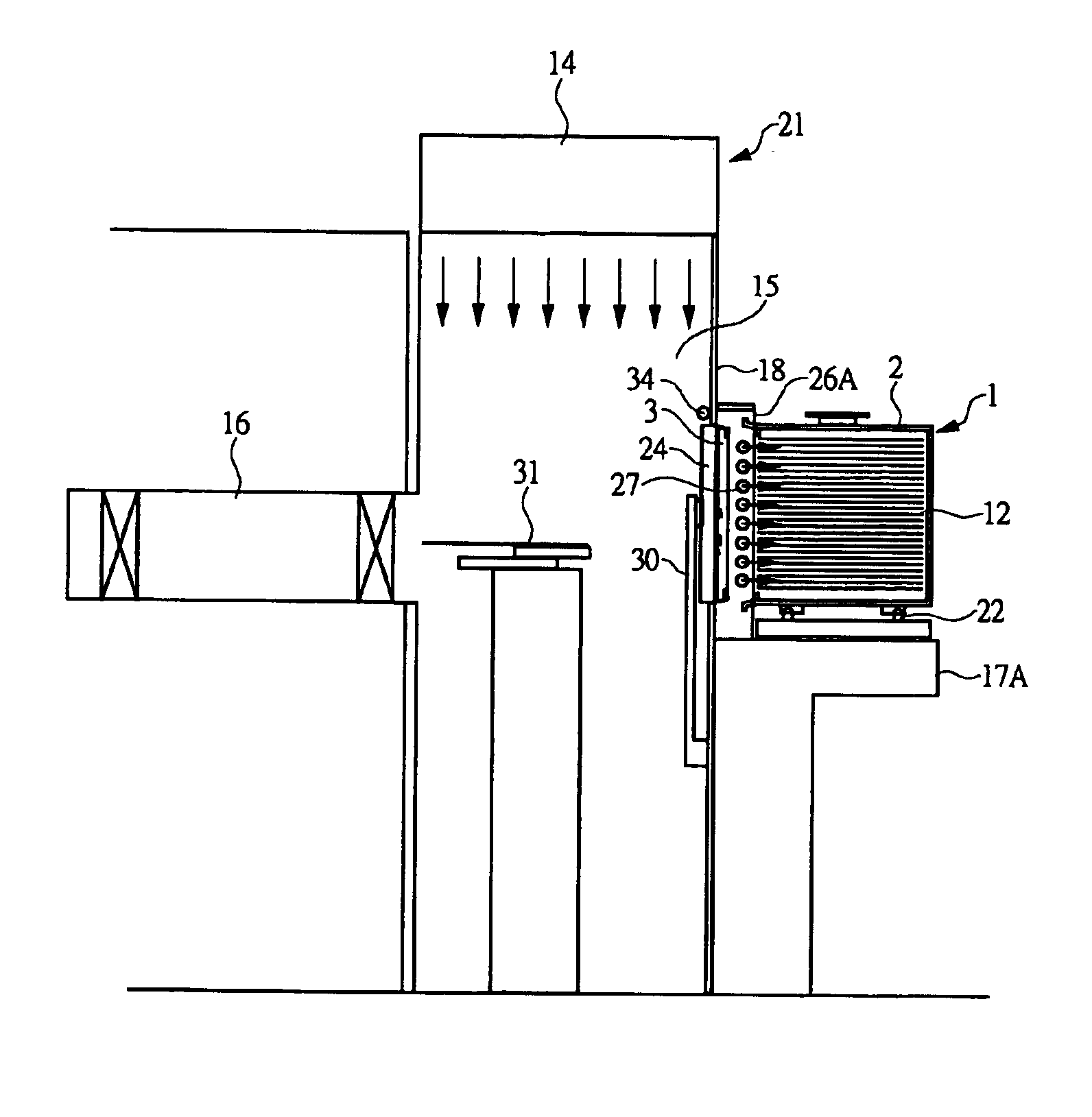

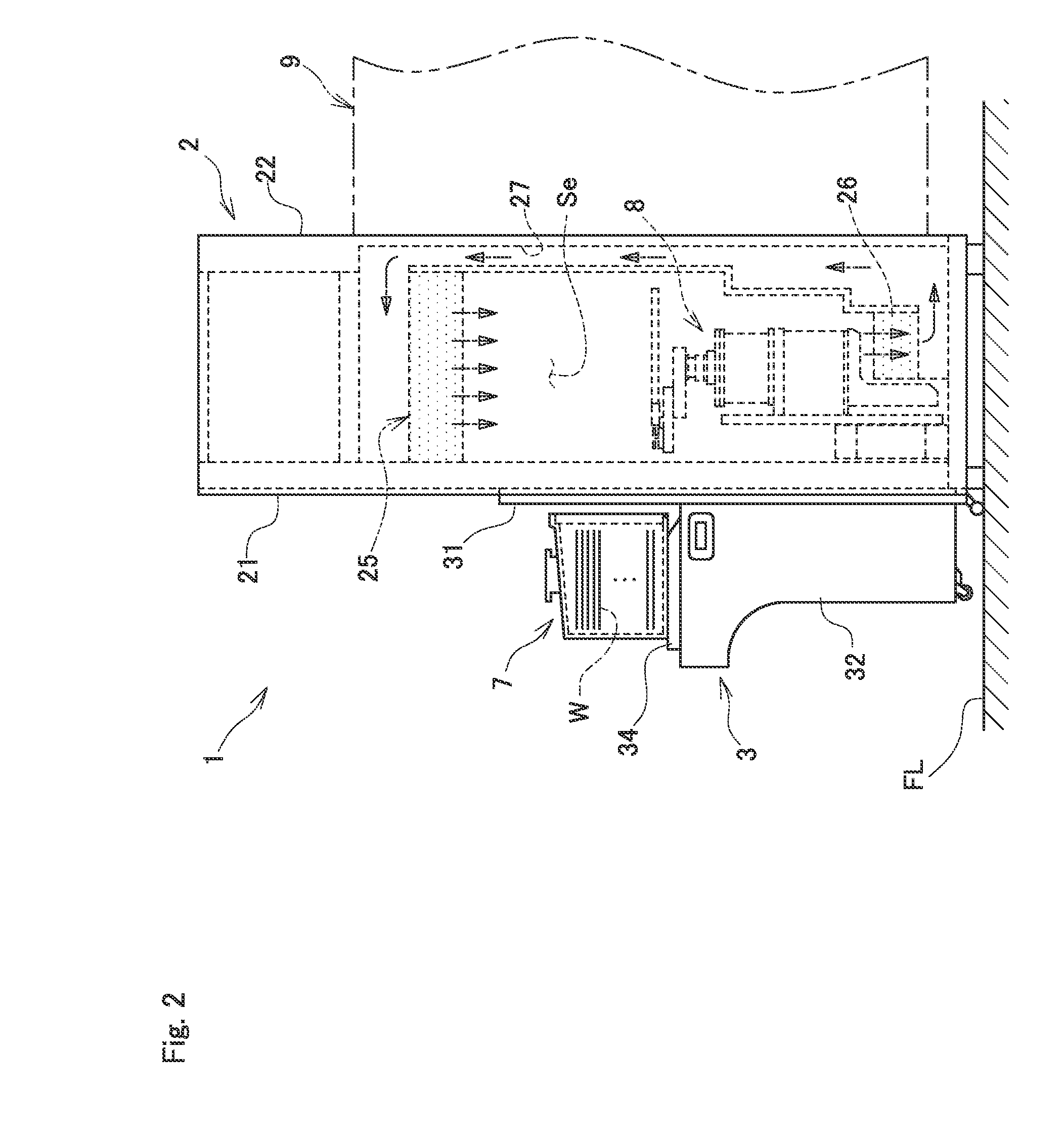

Apparatus and method for improved wafer transport ambient

InactiveUS20050111935A1Preventing and reducing introductionSemiconductor/solid-state device manufacturingCharge manipulationReactive gasEngineering

An improved wafer transfer apparatus is provided that allows the ambient atmosphere within a modified front open unified pod (“FOUP”) while the FOUP is positioned on a loading stage provided on an equipment front end module (“EFEM”). In particular, the wafer transfer apparatus includes both an injection assembly and an exhaust assembly that will be engaged when the door of the FOUP is docked to a door holder provided on the EFEM. The injection assembly may include a mass flow controller (“MFC”) for controlling the injection of purge gas(es) into the container. Similarly, the exhaust assembly may include a MFC for controlling the removal of fluid from the container. While the door is docked to the door holder, inert or less reactive gases may be introduced into the container, thereby reducing the likelihood of oxidation or contamination of the wafers therein.

Owner:SAMSUNG ELECTRONICS CO LTD

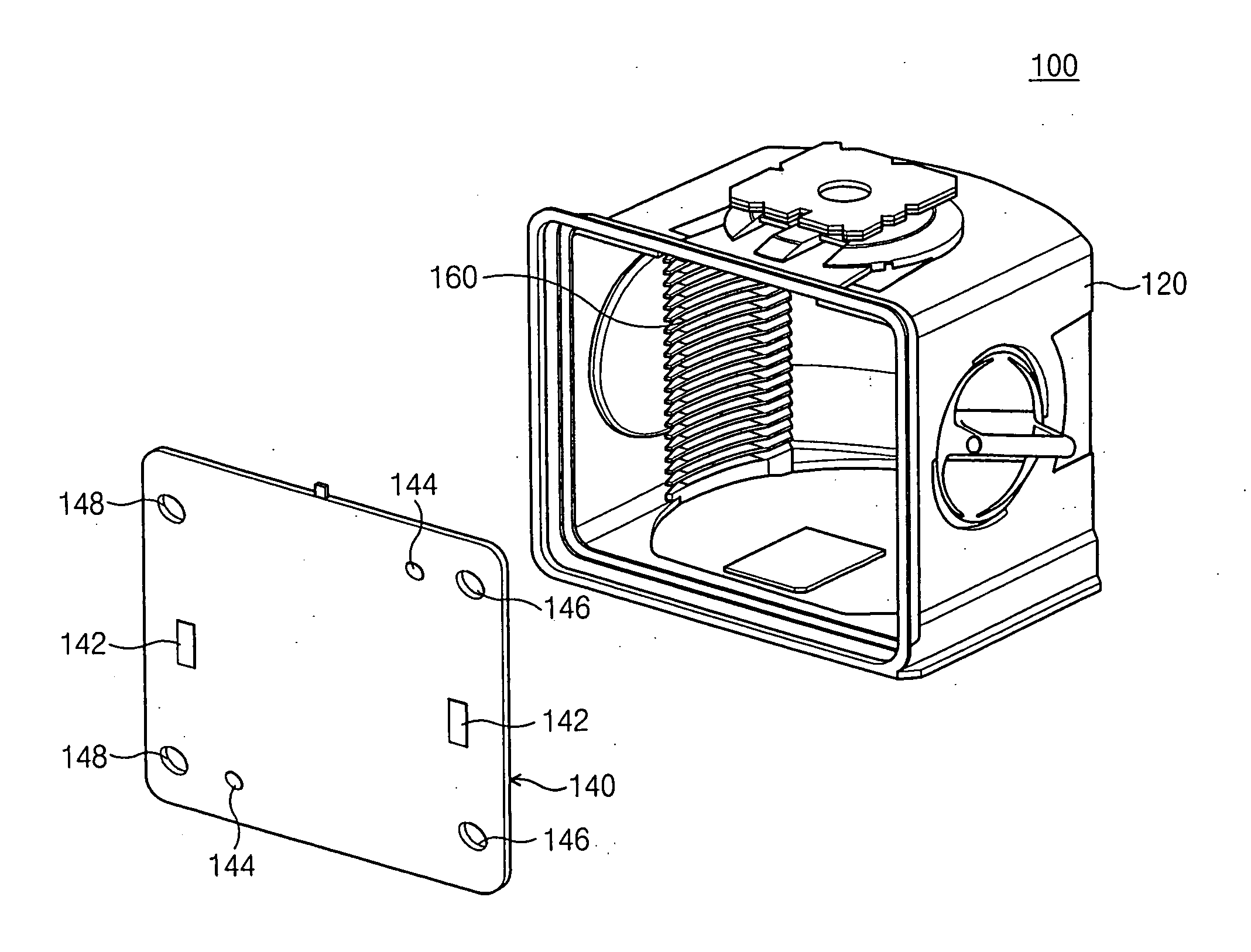

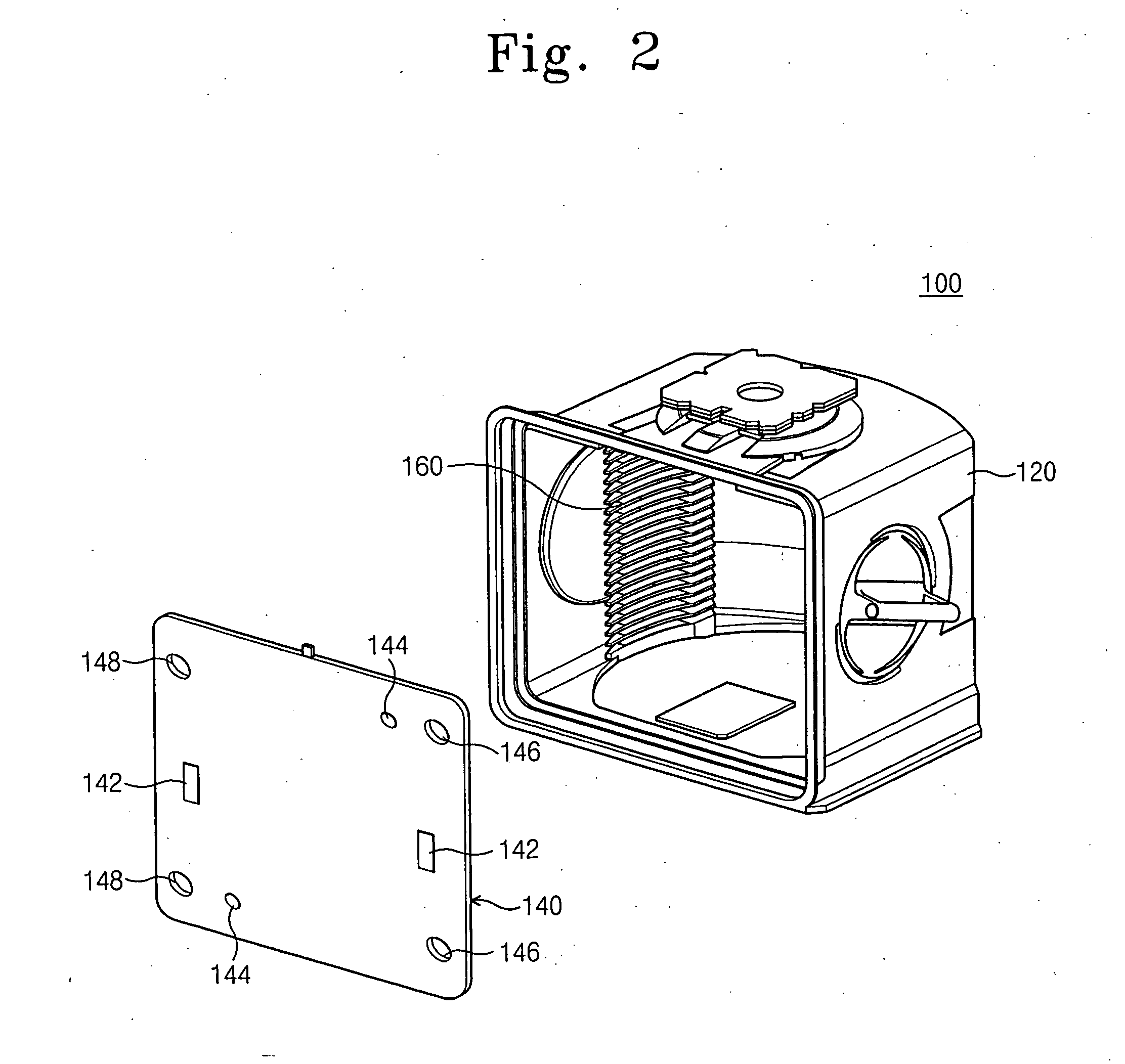

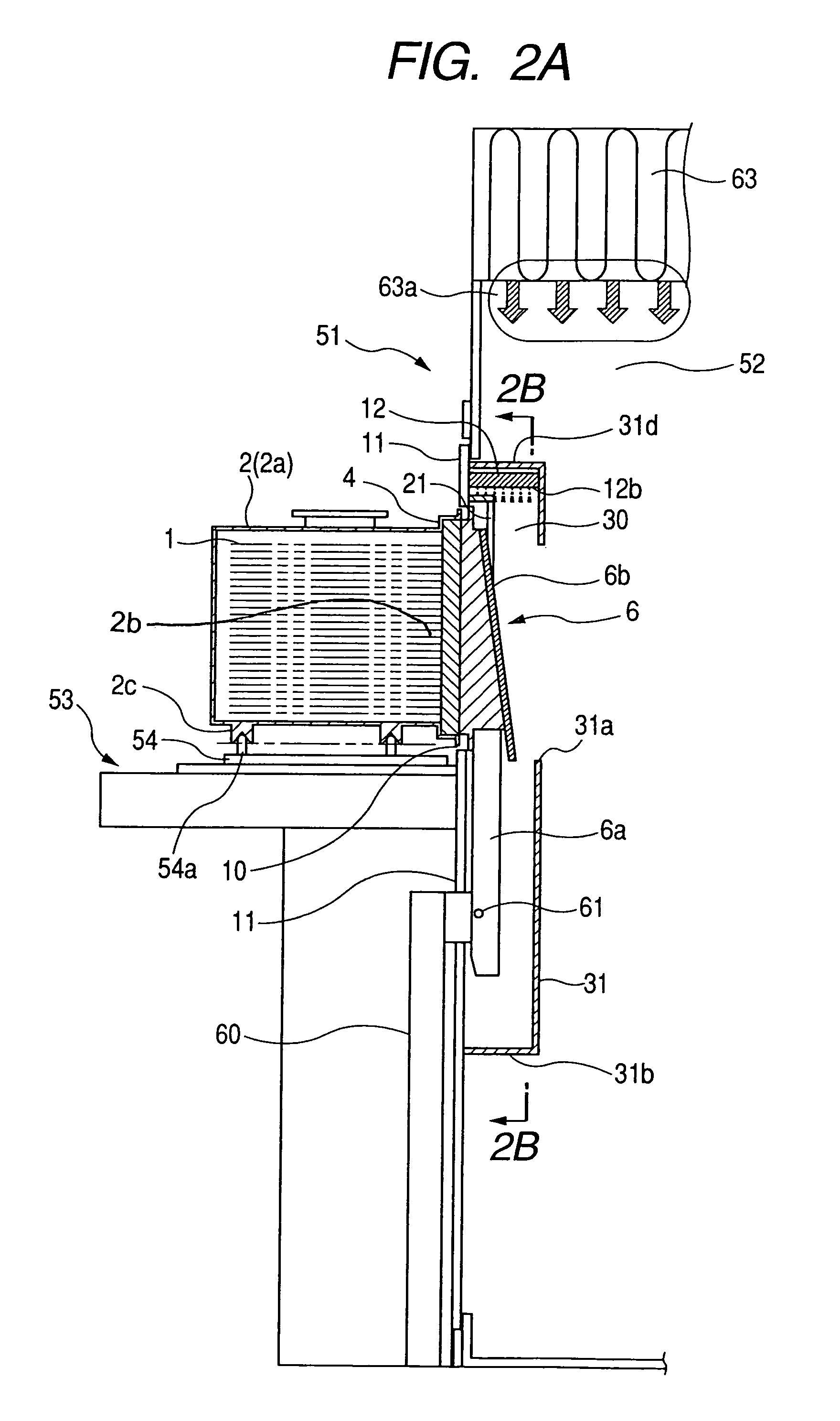

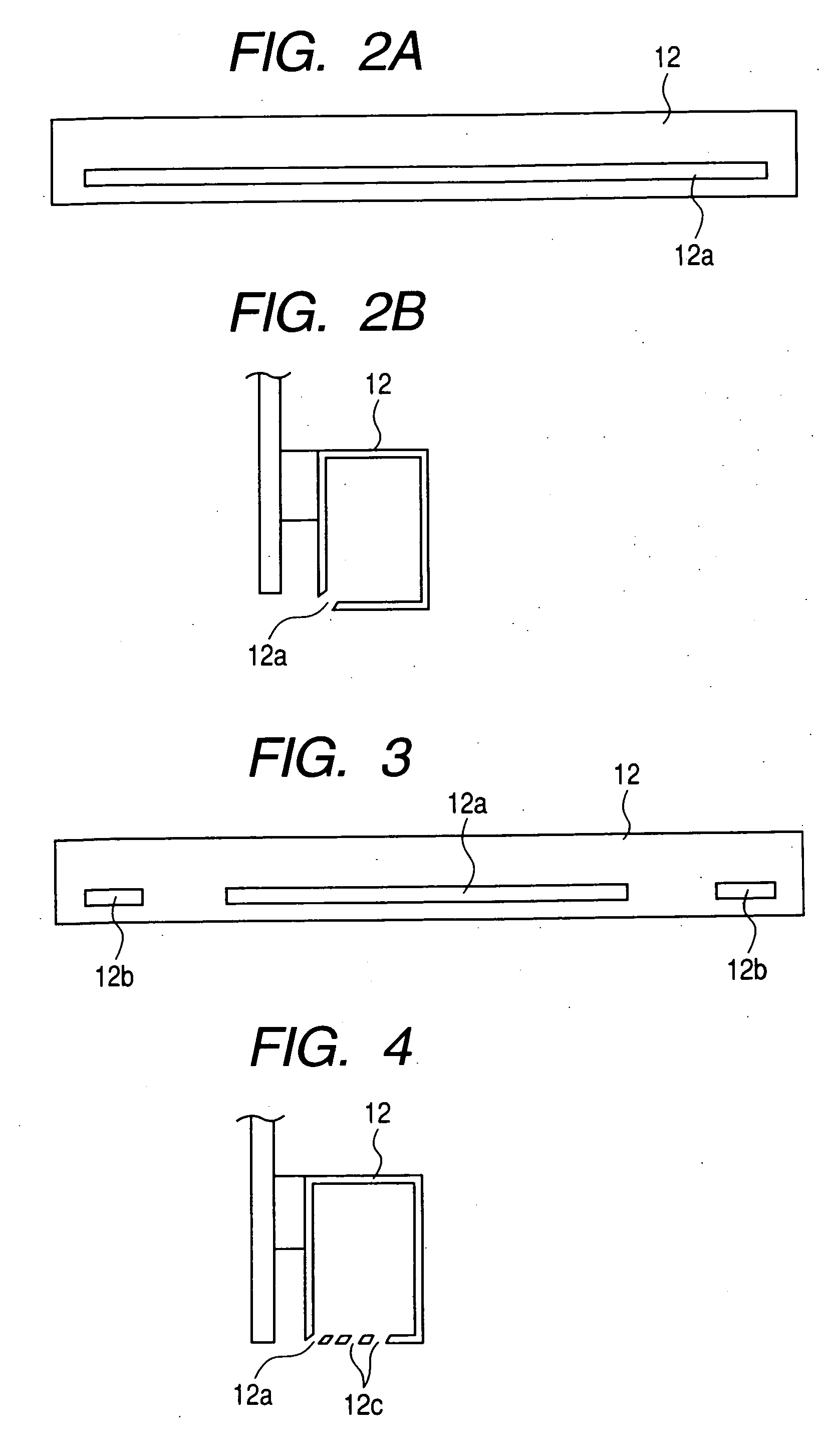

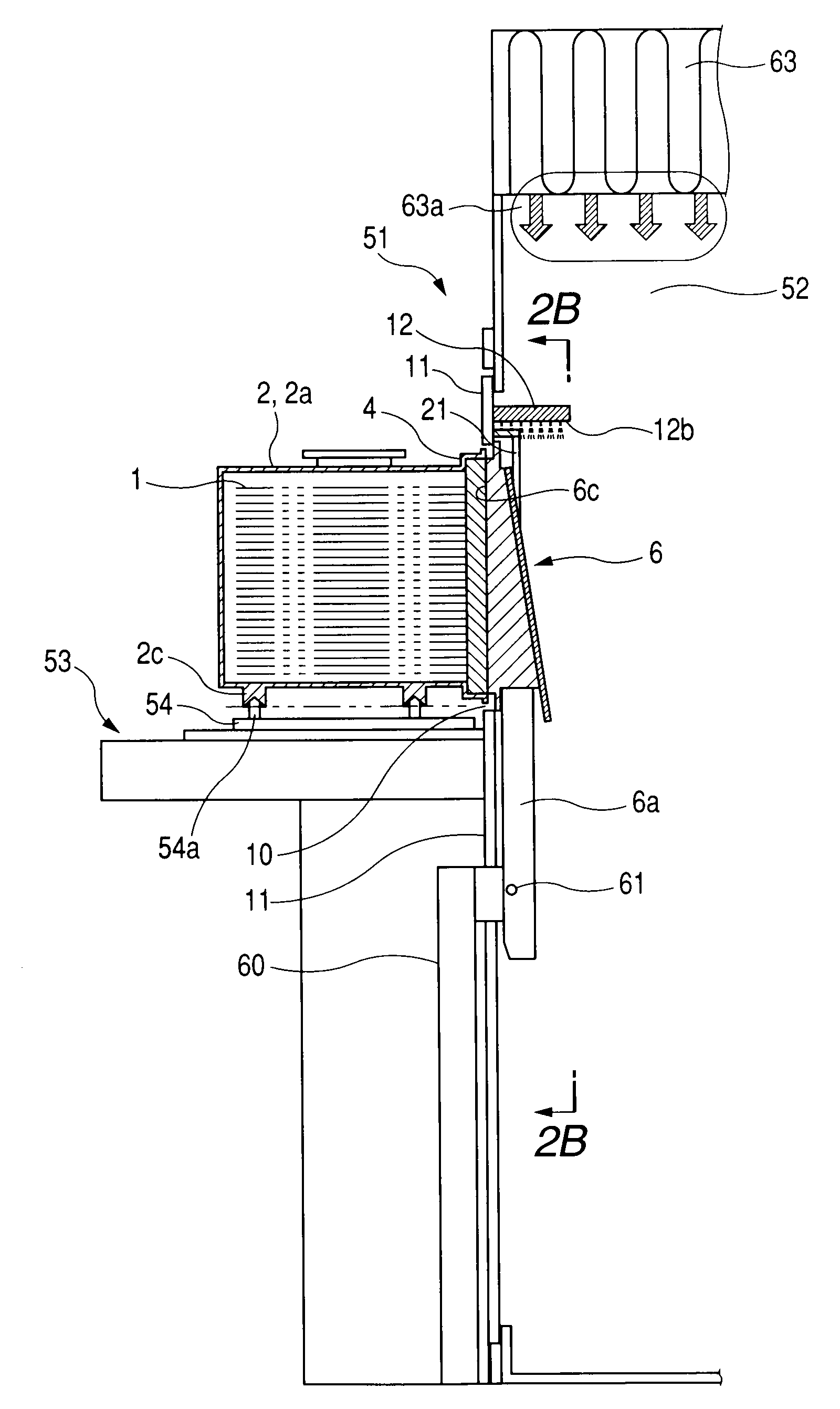

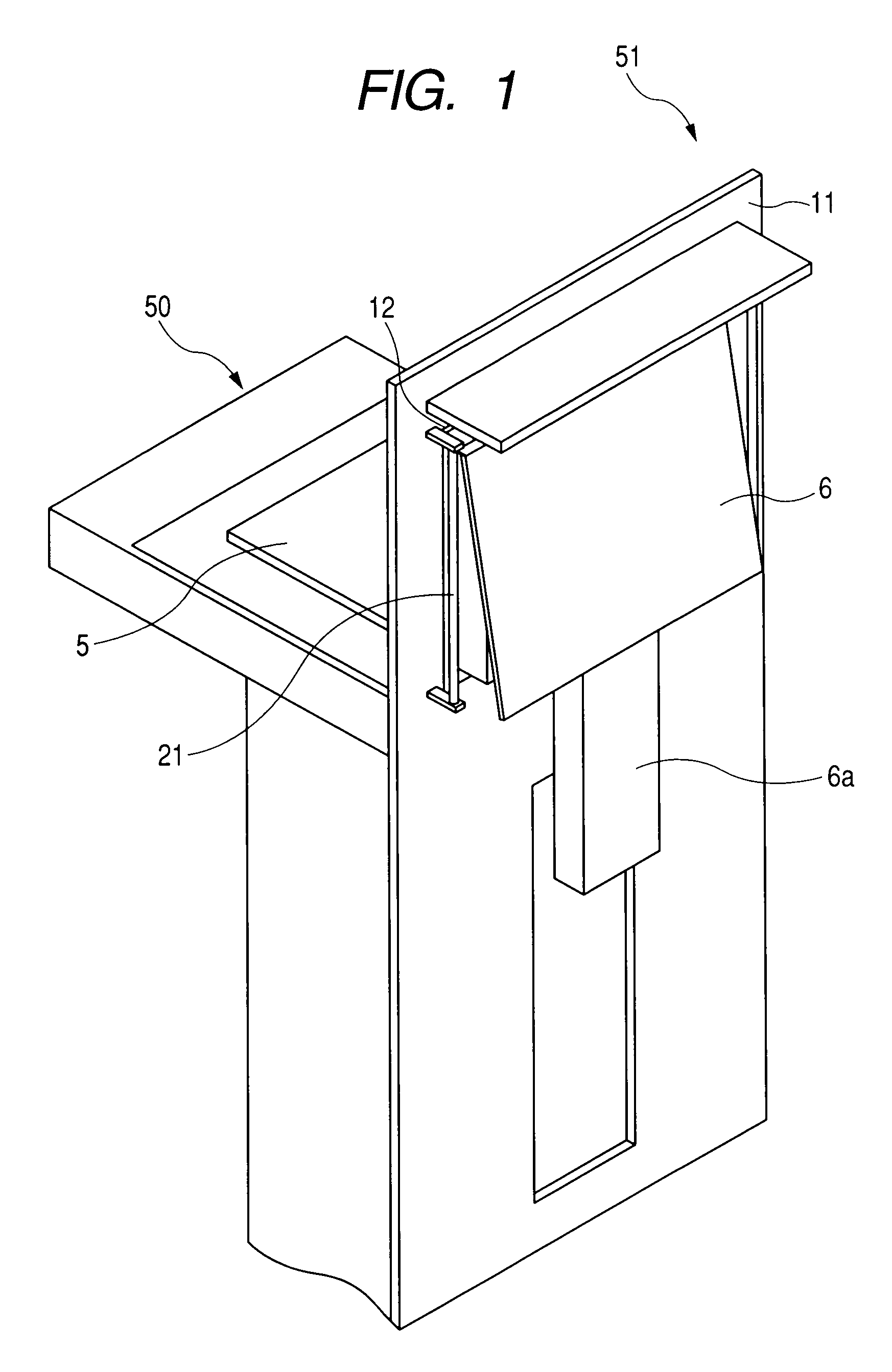

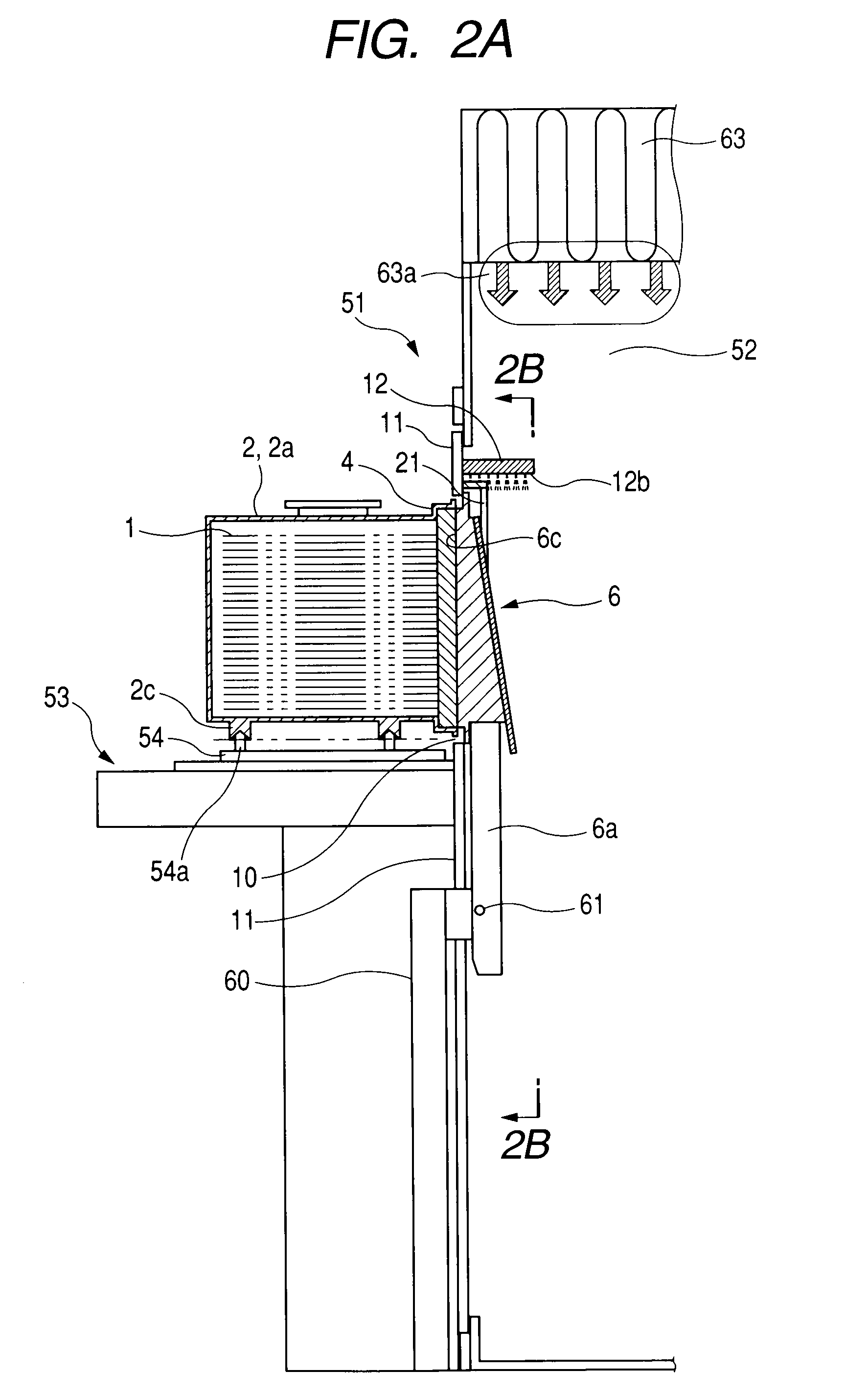

Load port and efem

ActiveUS20150221538A1Reduce supplyImprove Wafer QualitySemiconductor/solid-state device manufacturingConveyor partsInterior spaceEngineering

A load port provided adjacent to a wafer transport chamber for taking in and out a wafer W between the wafer transport chamber and a FOUP, includes a plate-shaped part that constitutes a part of a wall of the wafer transport chamber, and has an opening for opening the wafer transport chamber; a door part for opening and closing the opening; a mounting table that is configured to mount a wafer storage container so as to oppose a lid part for opening and closing an internal space to the door part, and to move to and from the plate-shaped part; and an elastic part that is provided on the mounting table side of the plate-shaped part along the peripheral edge of the opening, wherein the elastic part elastically contacts the periphery of the lid part in the wafer storage container by moving the mounting table toward the plate-shaped part.

Owner:SINFONIA TECHNOLOGY CO LTD

Substrate processing apparatus and method of processing substrate while controlling for contamination in substrate transfer module

InactiveUS6996453B2Avoid formingPrevent materialSpace heating and ventilation safety systemsSpace heating and ventilation control systemsControl systemComputer module

A substrate processing apparatus for processing substrates prevents the substrates from contaminating as they are transferred. The apparatus includes a container, like a FOUP, for containing substrates, at least one processing chamber where the substrates are processed, a substrate transferring module including a substrate transfer chamber and at least one load port for supporting a container, and a contamination controlling system for the substrate transfer chamber. The contamination controlling system includes a purge gas supply inlet connected to the substrate transfer chamber, and a gas circulating tube for recycling the purging gas to circulate through the chamber. The substrate transfer chamber is purged using the purging gas to remove moisture and contaminating materials from the substrate transfer chamber. The formation of particles on the substrate otherwise caused by a reaction between the moisture and contaminating materials while the substrate is standing by in the container can be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

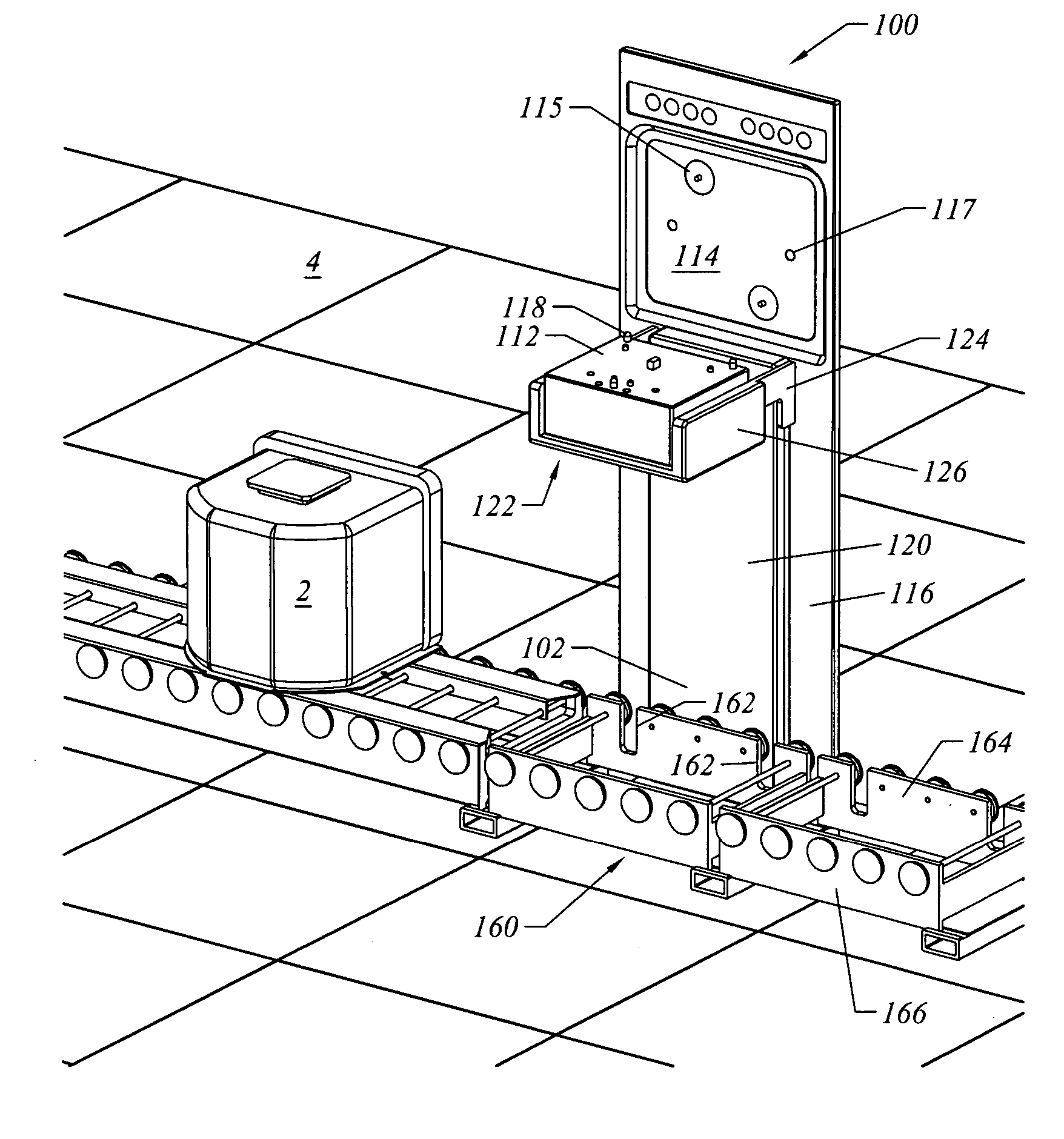

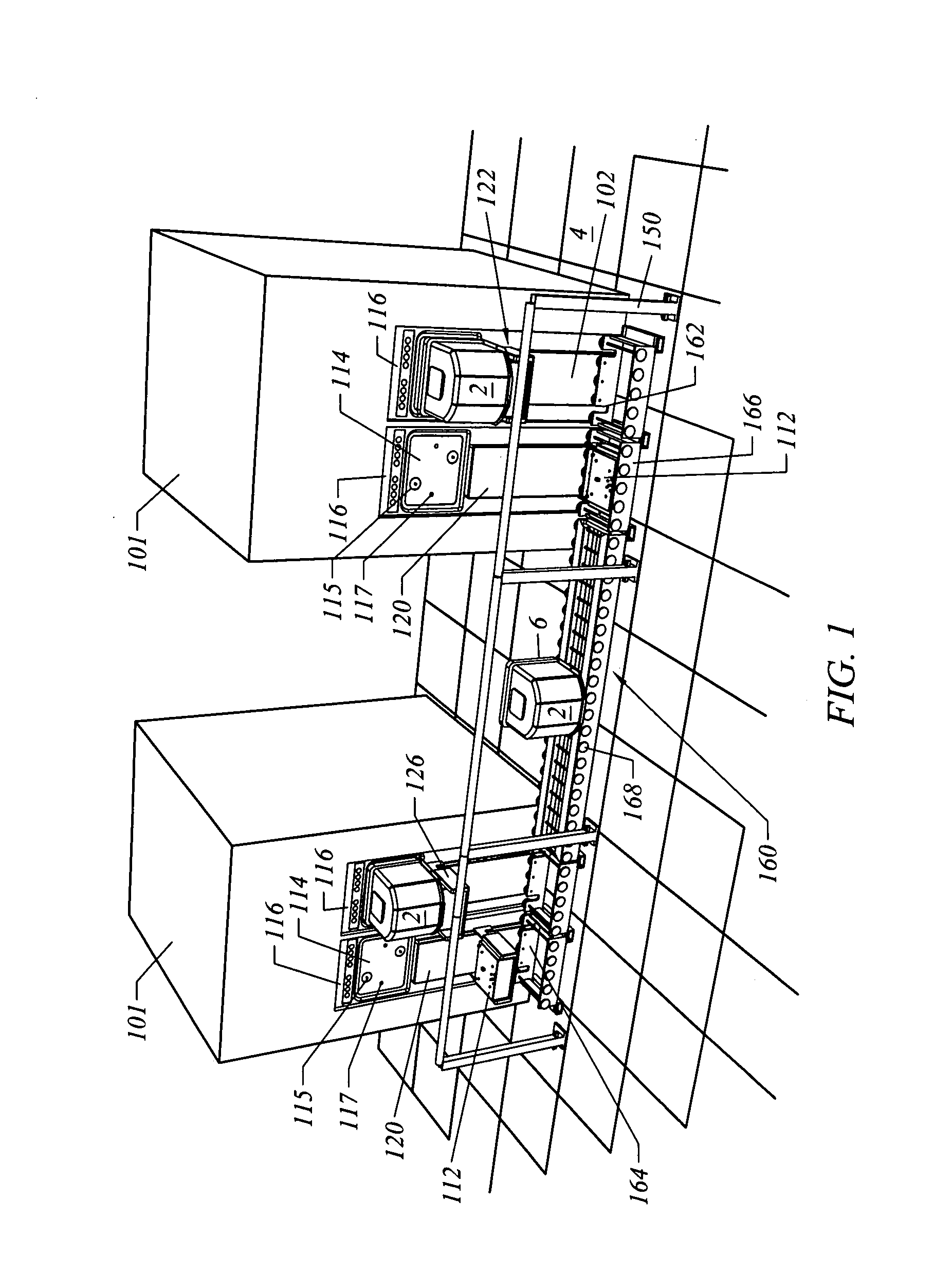

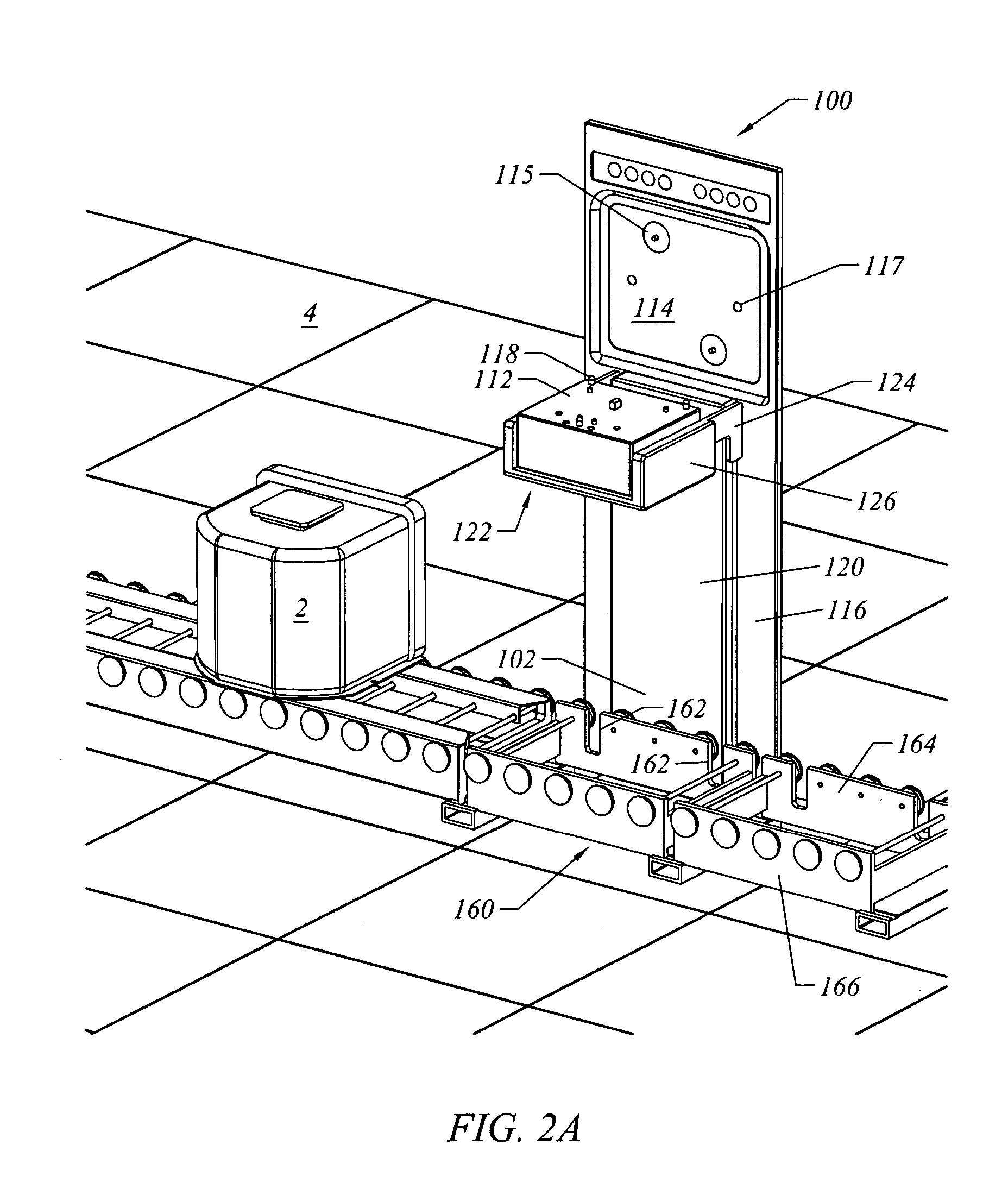

Direct tool loading

InactiveUS7410340B2Conveyor—reducing the number of times the container is handledMove containers efficientlySemiconductor/solid-state device manufacturingArticle unpackingTransport systemEngineering

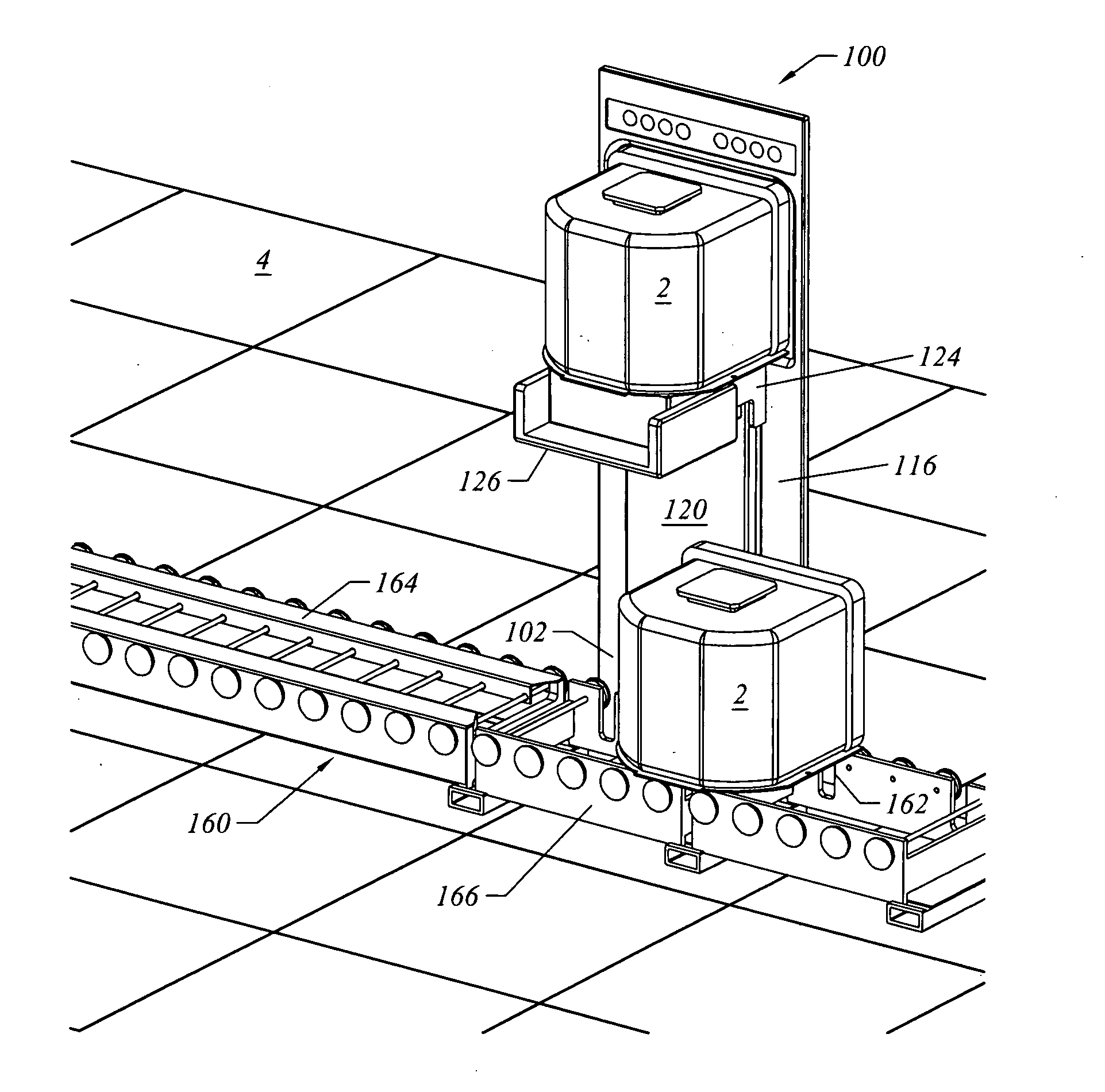

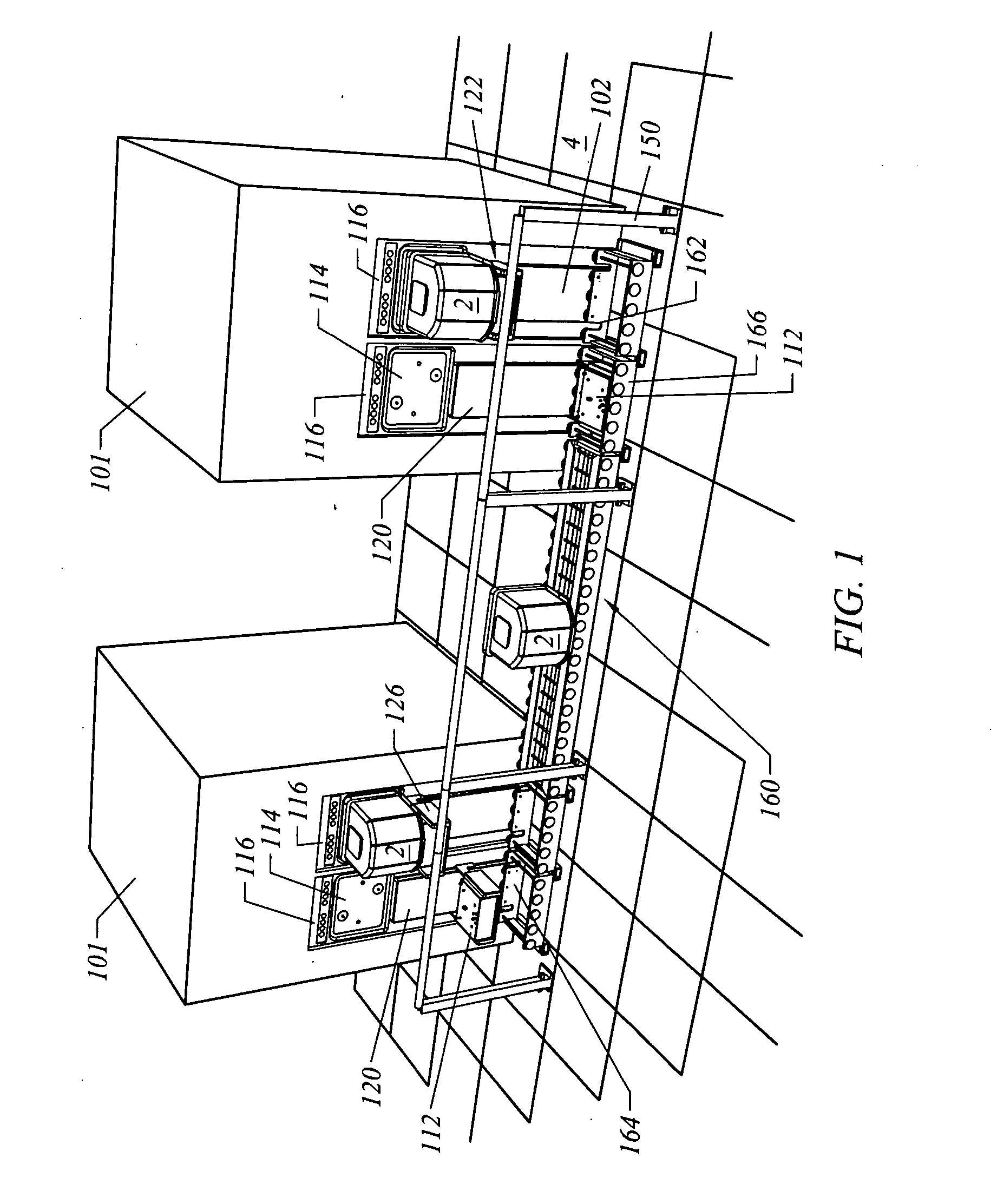

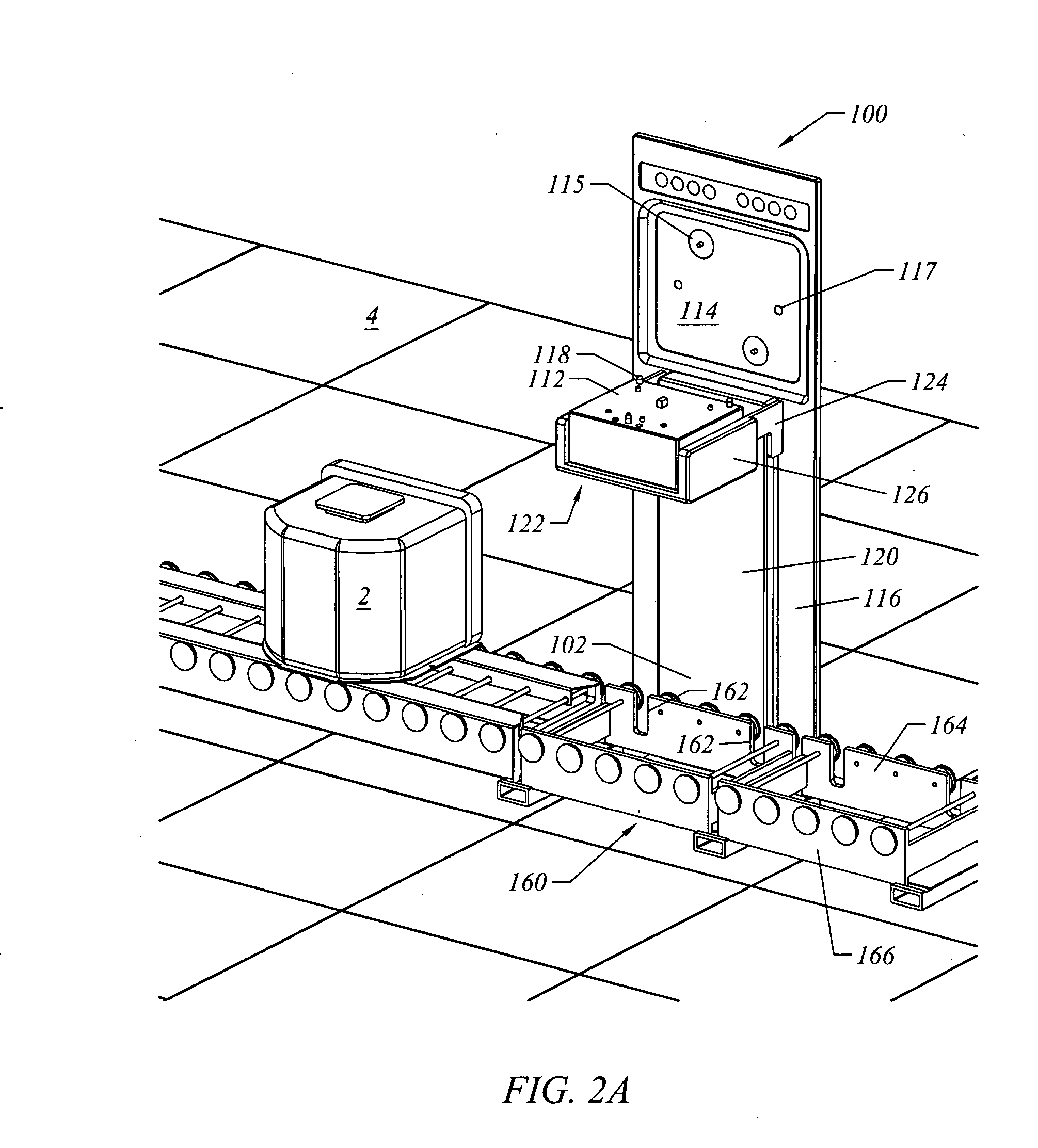

The present invention comprises a container transport and loading system. The system generally comprises a load port for presenting articles to a tool and a container transport system. In one embodiment, the load port includes a vertically movable FOUP advance plate assembly that is adapted to load and unload a FOUP from a conveyor that passes by the load port and move the FOUP horizontally. In another embodiment, the load port includes a vertically movable support structure that is adapted to load and unload a container from a shuttle that passes by the load port. The various embodiments of the load port and container transport system are improvements over conventional container transport systems. The present invention also includes a shuttle for simultaneously transporting multiple containers that a load port may load or unload a container from.

Owner:MURATA MASCH LTD

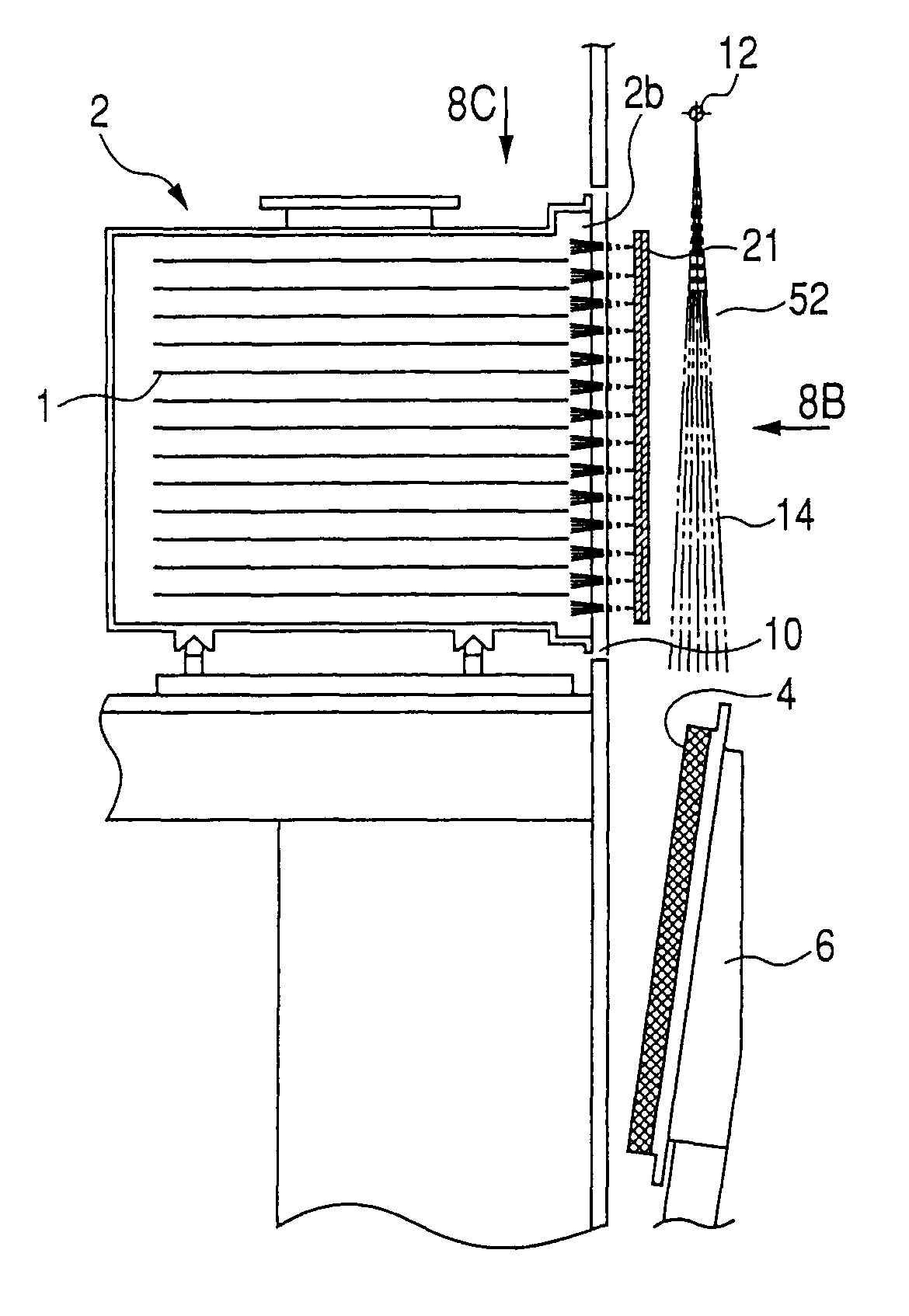

Purging apparatus and purging method

InactiveUS20060272169A1Efficient removalEffectively and securely removeLiquid fillingSemiconductor/solid-state device manufacturingEngineeringGas supply

It is an object of the present invention to easily and securely perform the removal operation of contaminant or the like from a wafer housed in a FOUP. To achieve the object, a purging apparatus of the present invention removes contaminant or the like from a wafer by moving a gas supply nozzle along a direction in which wafers are superimposed at the front of an opening while a lid of the FOUP is separated from a body and spraying clean gas on each wafer from the gas supply nozzle.

Owner:TDK CORPARATION

Purge system for a product container and table for use in the purge system

InactiveUS20060288664A1Avoid differential pressureSuppress pressure differenceSemiconductor/solid-state device manufacturingPackaging under special atmospheric conditionsPressure differenceAtmosphere

For the purpose of preventing a pressure difference from occurring between an interior of an FOUP and an exterior at the time of purging the interior of the FOUP, a communication path that communicates with the exterior of the FOUP and the interior of an outlet path is provided with respect to the outlet path that extends from a table side outlet port which is disposed on a table on which the FOUP is placed, and an external atmosphere is introduced to the outlet path through the communication path when a pressure difference starts occurring between the interior and the exterior of the FOUP.

Owner:TDK CORPARATION

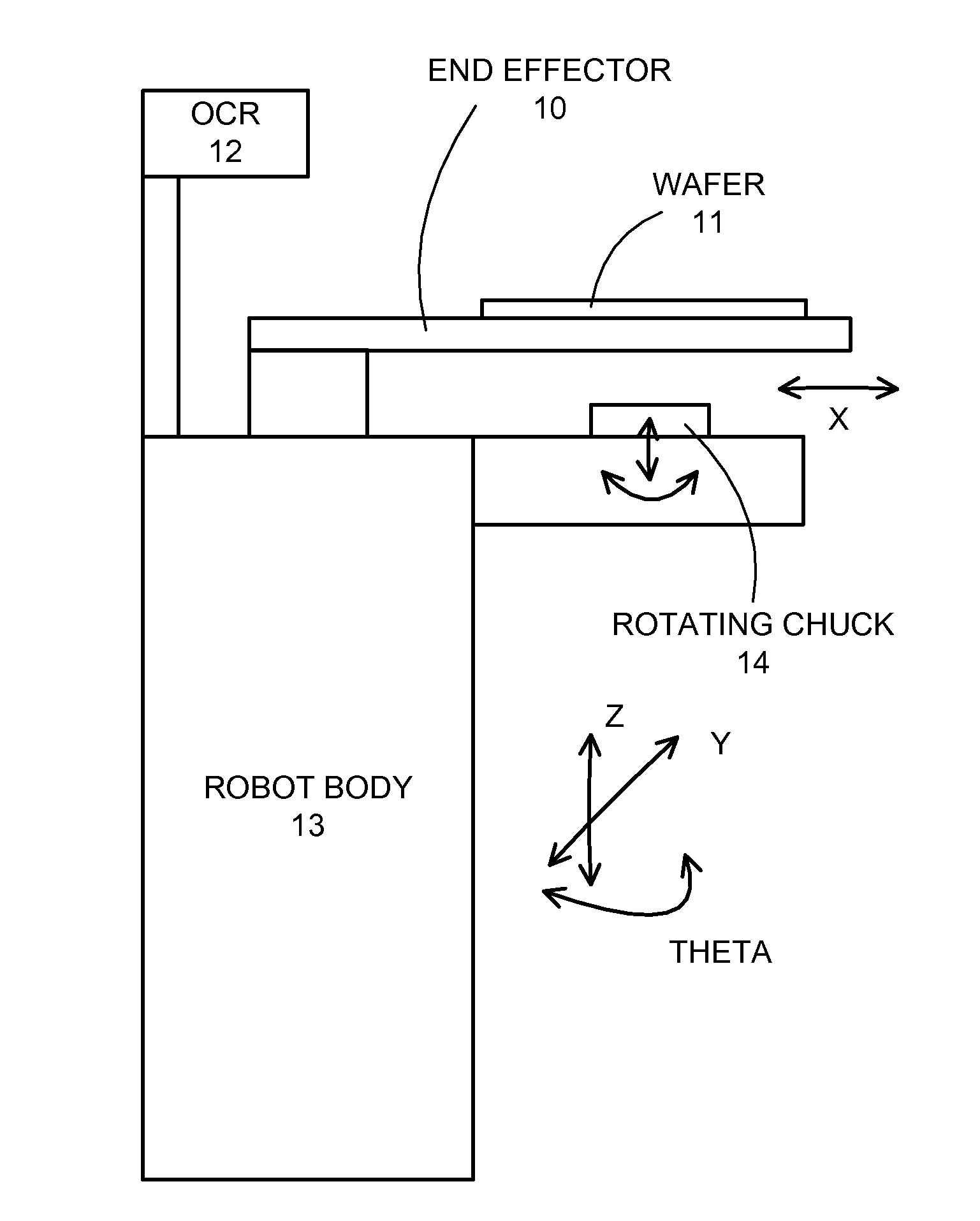

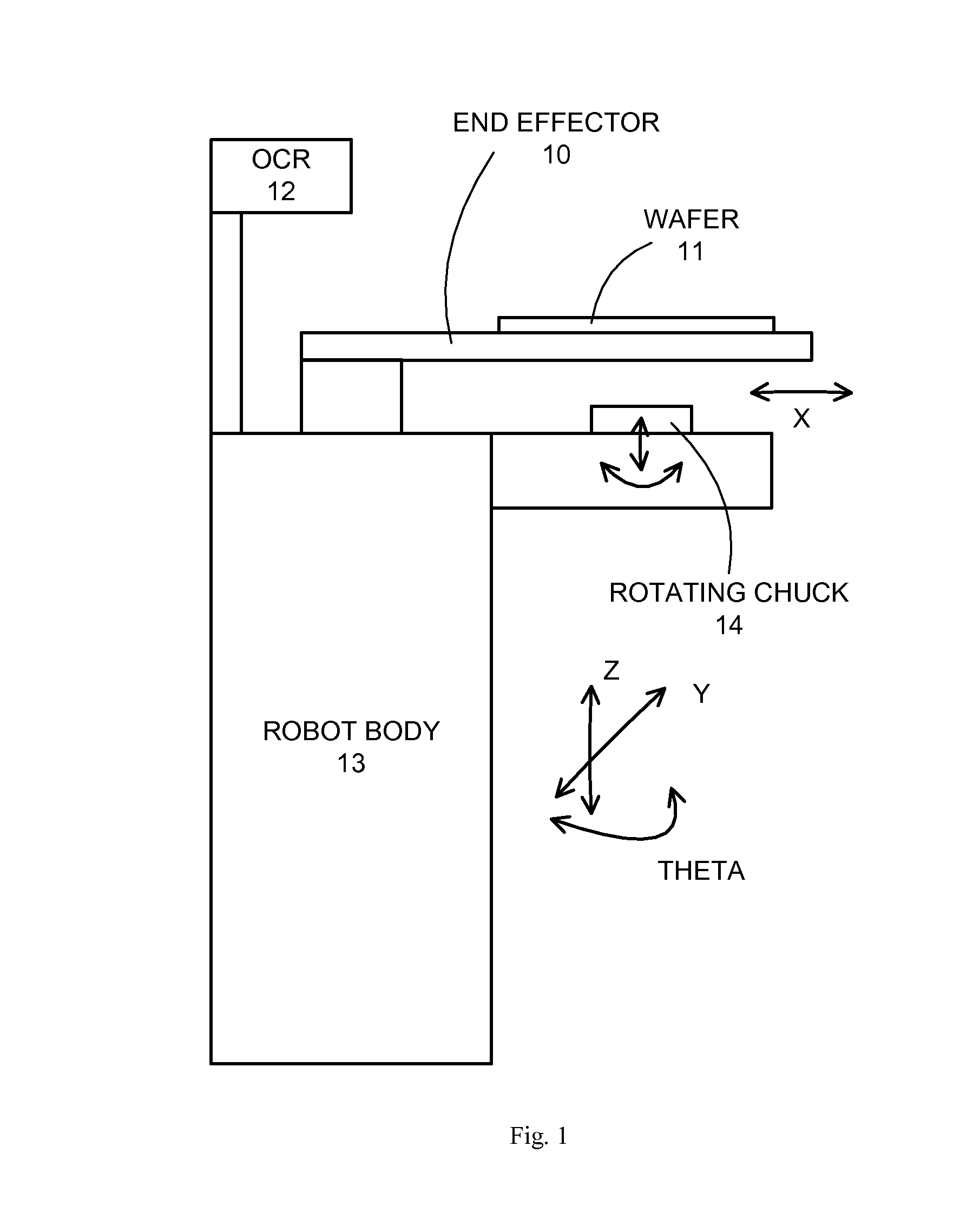

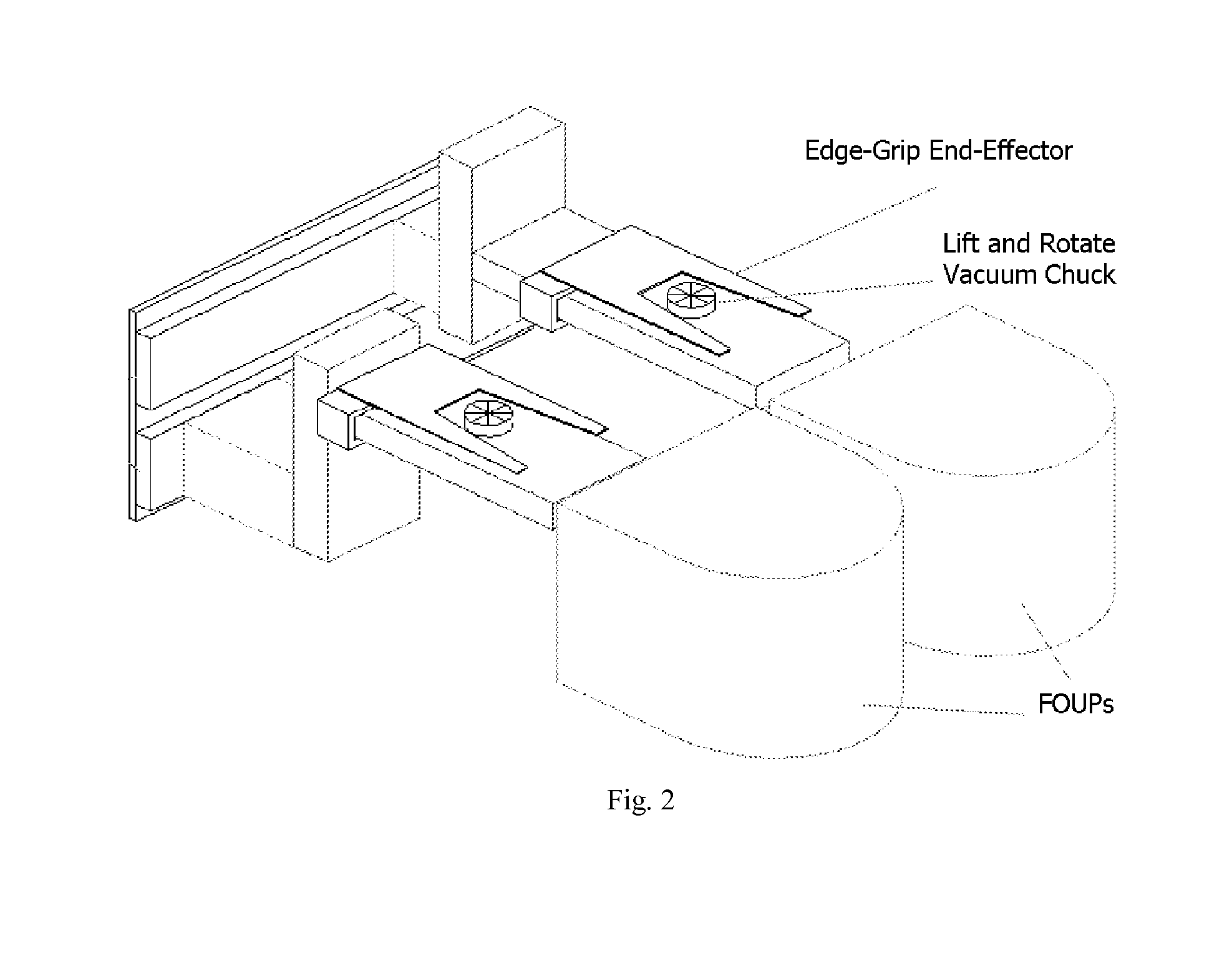

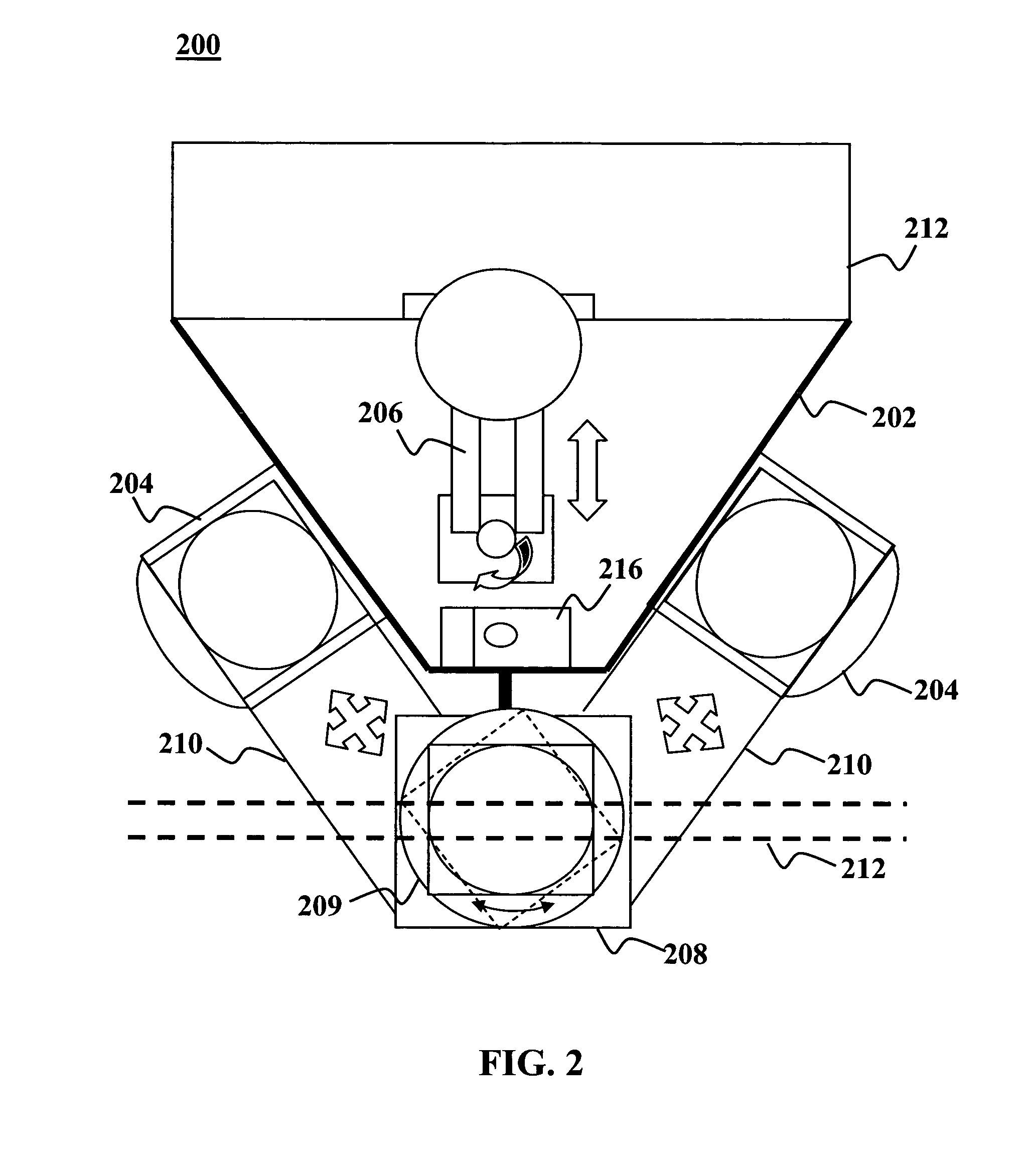

Integrated wafer transfer mechanism

An integrated high speed robotic mechanism is disclosed for improving transport equipment, integrating an object movement with other functionalities such as alignment or identification. The disclosed integrated robot assembly typically comprises an end effector for moving the object in and out of a chamber, a rotation chuck incorporated on the robot body to provide centering and theta alignment capability, and an optional identification subsystem for identifying the object during transport. The present invention also discloses a transfer robot system, employing a plurality of integrated robot assemblies; a transfer system where a transfer robot system can service a plurality of connected chambers such as FOUP or FOSB; a front end module (FEM); or a sorter system. Through the use of these incorporated capabilities into the moving robot, single object transfer operations can exceed 500 parts per hour.

Owner:BOOKS AUTOMATION US LLC +2

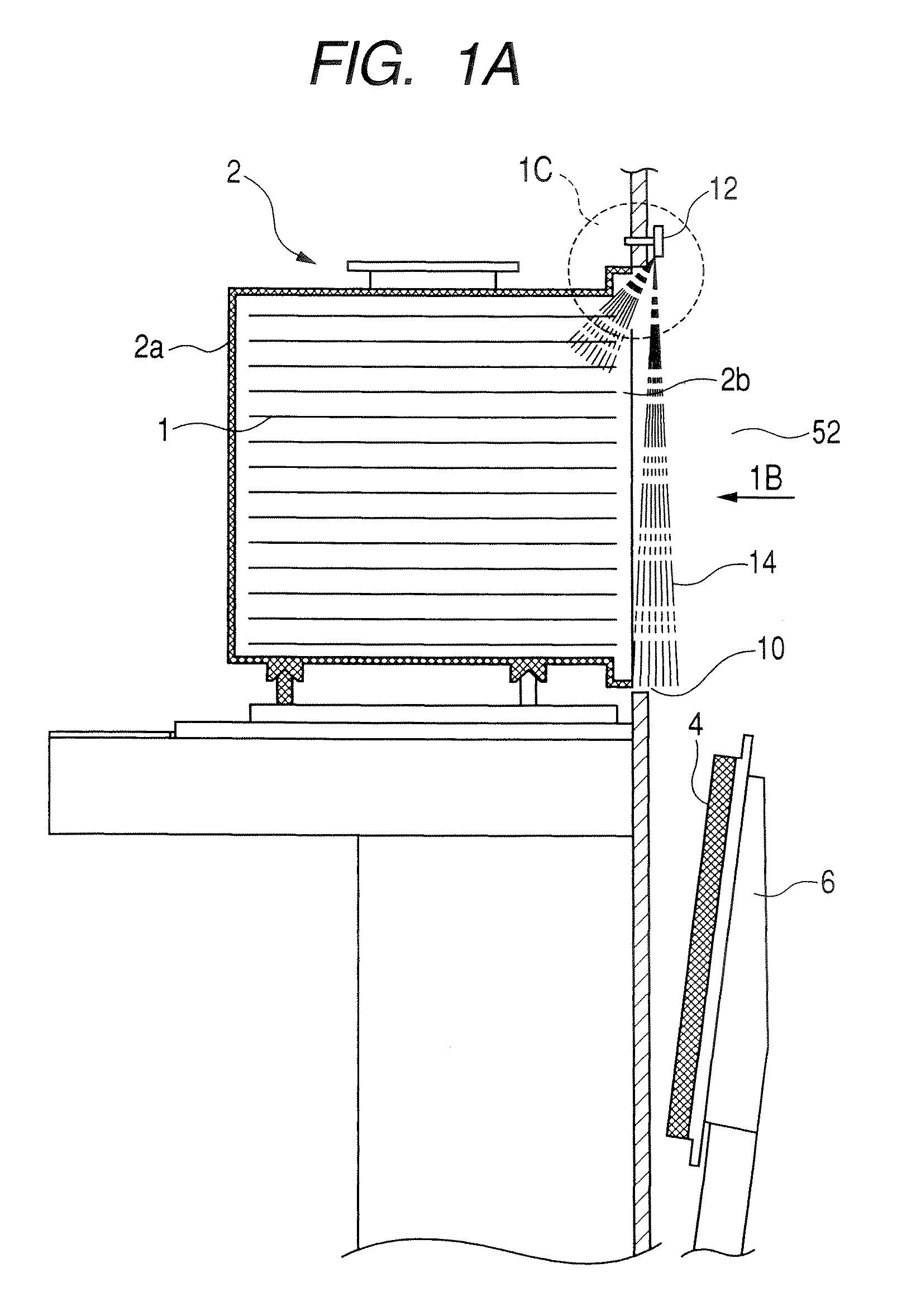

Lid opening/closing system for closed container and substrate processing method using same

ActiveUS7789609B2Improve closureReduce the amount requiredSemiconductor/solid-state device manufacturingArticle unpackingEngineeringPartial pressure

Owner:TDK CORPARATION

Enclosed container lid opening/closing system and enclosed container lid opening/closing method

ActiveUS20060088406A1Efficient removalLiquid fillingSemiconductor/solid-state device manufacturingEngineeringGas supply

In order to easily and surely remove contaminants or the like from wafers stored in a pod (FOUP), a gas supply pipe is located above an opening portion in a FIMS system. A clean gas is blown to the upper surfaces of the wafers stored in the inner portion of the pod through the gas supply pipe to remove the contaminants or the like from wafers.

Owner:TDK CORPARATION +1

Direct tool loading

InactiveUS20060188358A1Conveyor—reducing the number of times the container is handledMove containers efficientlySemiconductor/solid-state device manufacturingPackagingTransport systemMechanical engineering

The present invention comprises a container transport and loading system. The system generally comprises a load port for presenting articles to a tool and a container transport system. In one embodiment, the load port includes a vertically movable FOUP advance plate assembly that is adapted to load and unload a FOUP from a conveyor that passes by the load port and move the FOUP horizontally. In another embodiment, the load port includes a vertically movable support structure that is adapted to load and unload a container from a shuttle that passes by the load port. The various embodiments of the load port and container transport system are improvements over conventional container transport systems. The present invention also includes a shuttle for simultaneously transporting multiple containers that a load port may load or unload a container from.

Owner:MURATA MASCH LTD

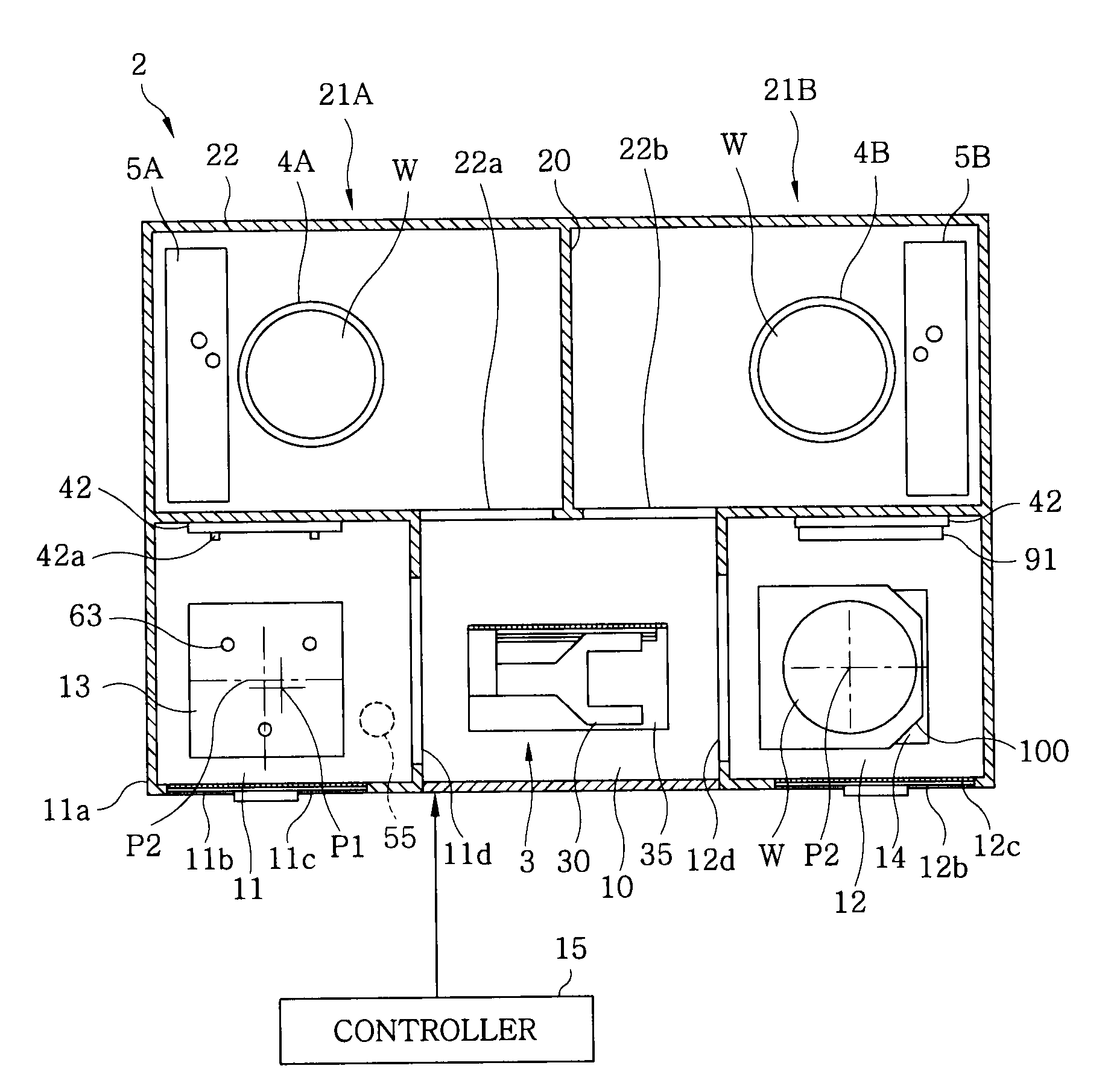

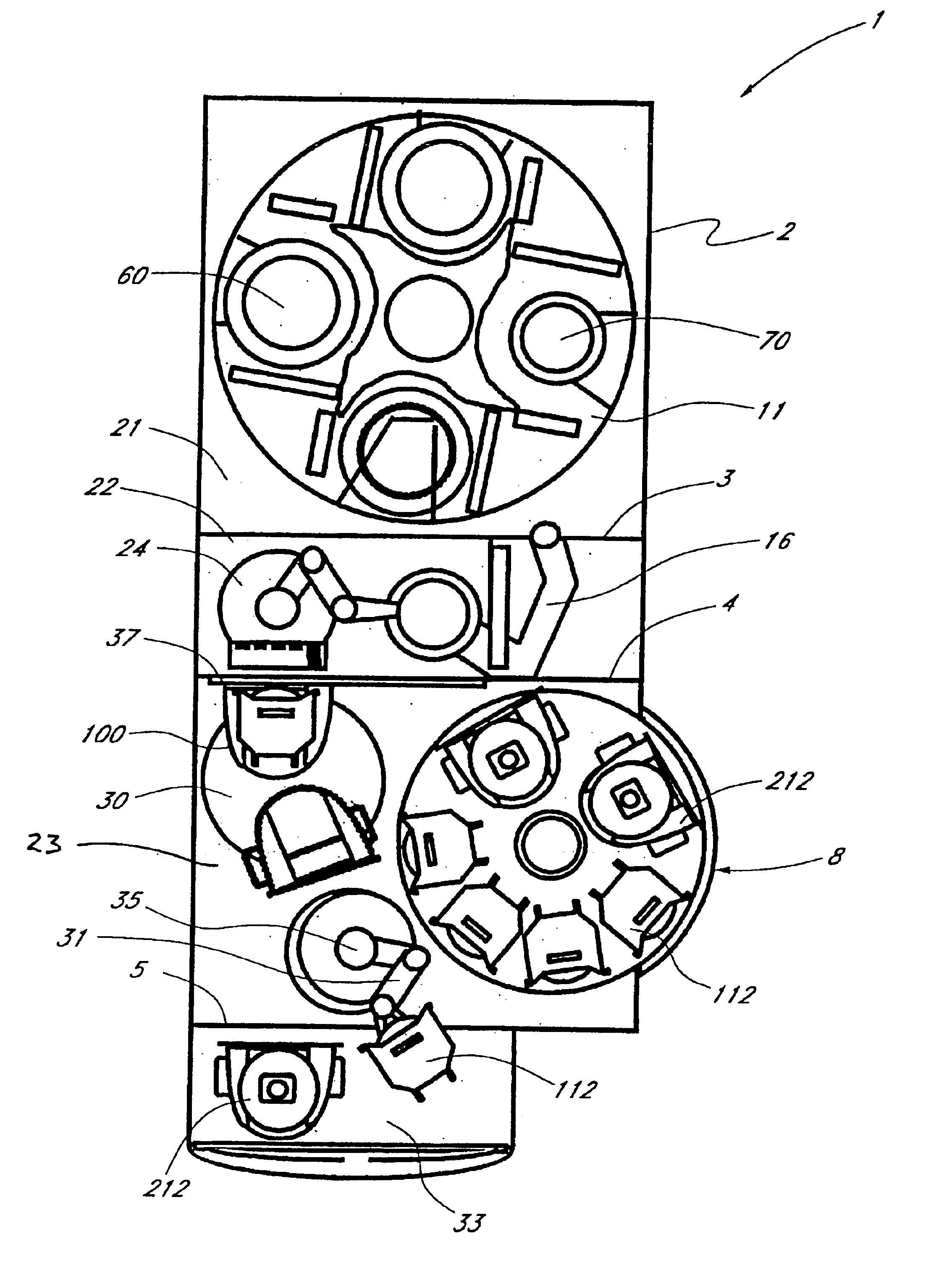

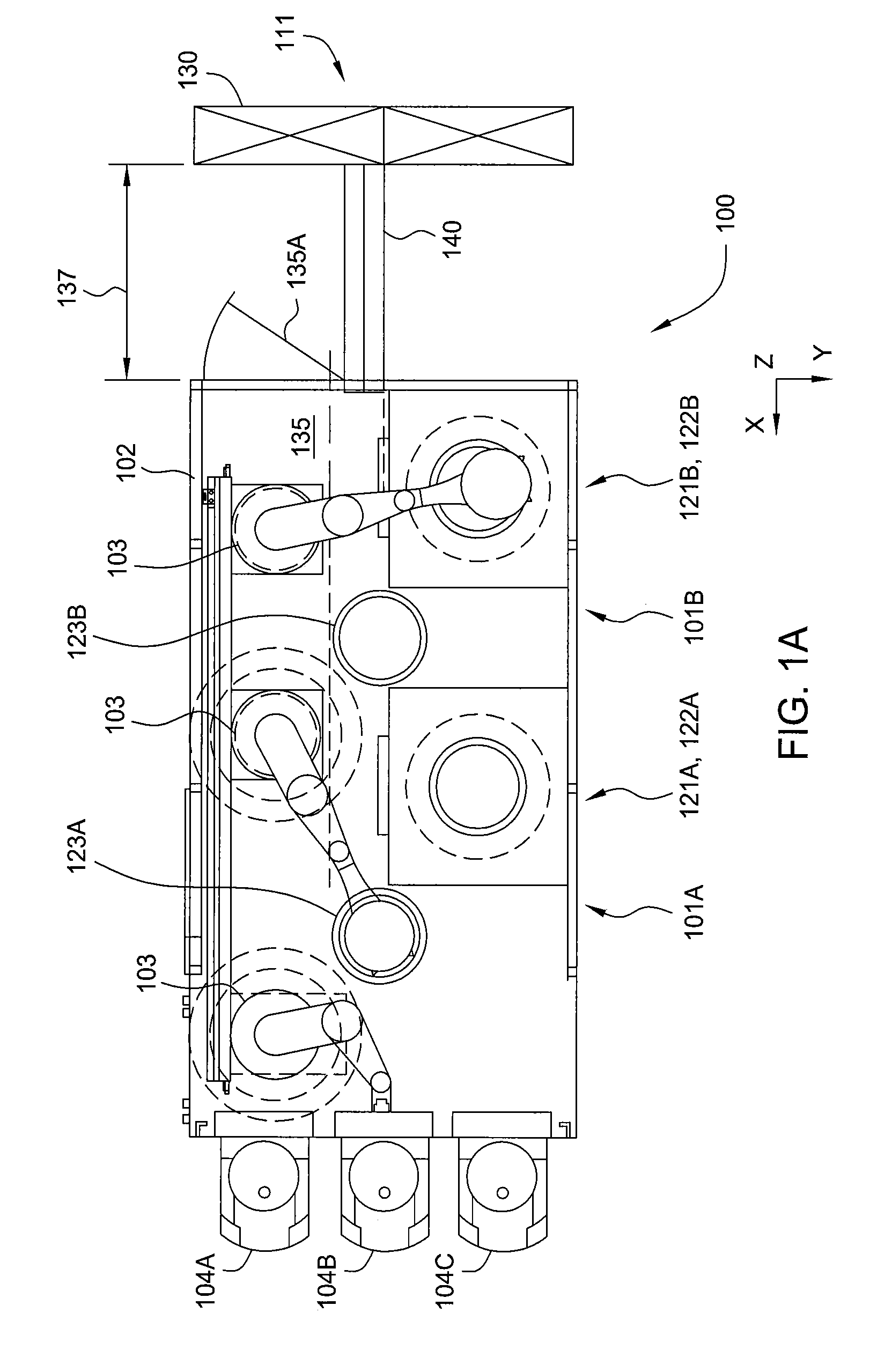

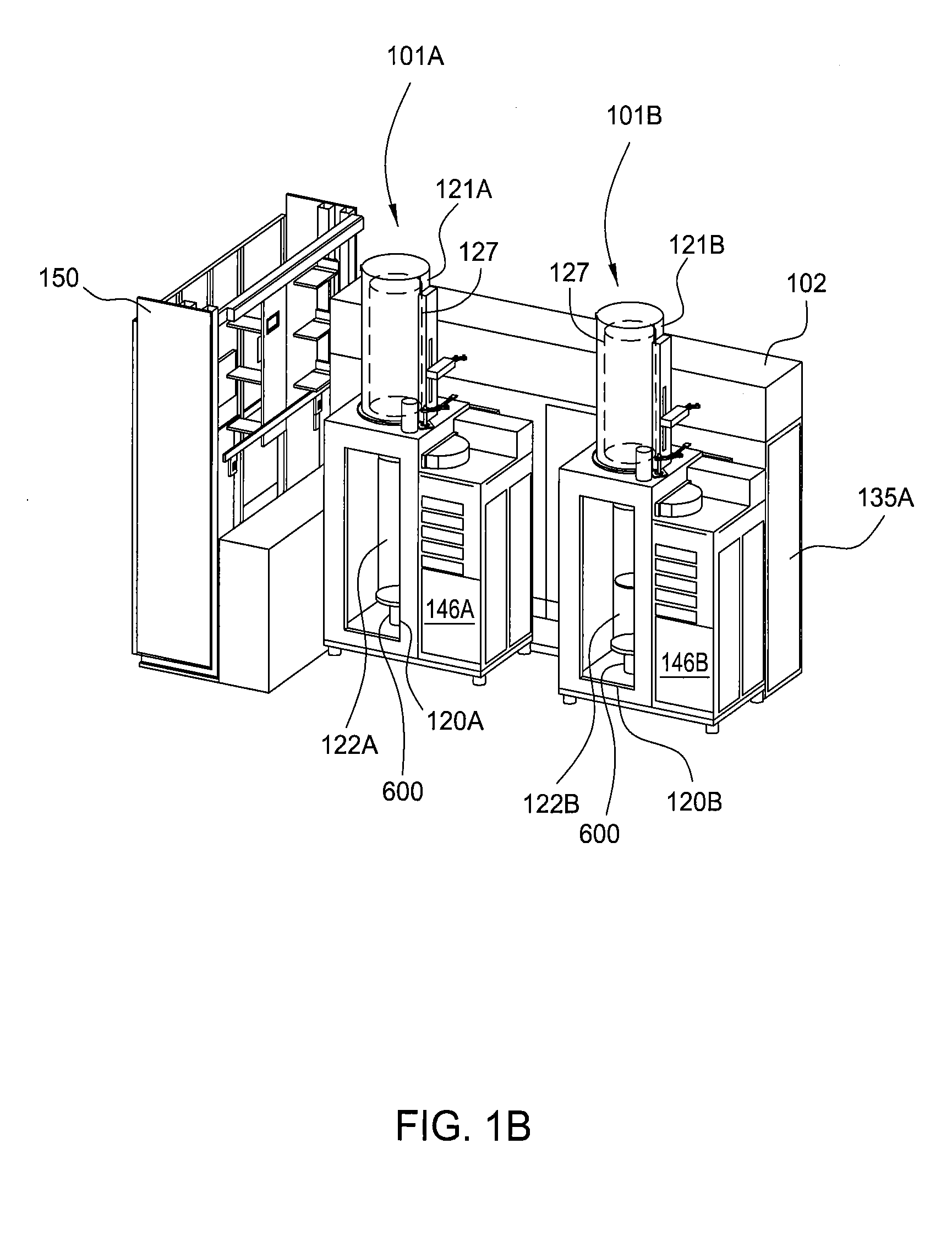

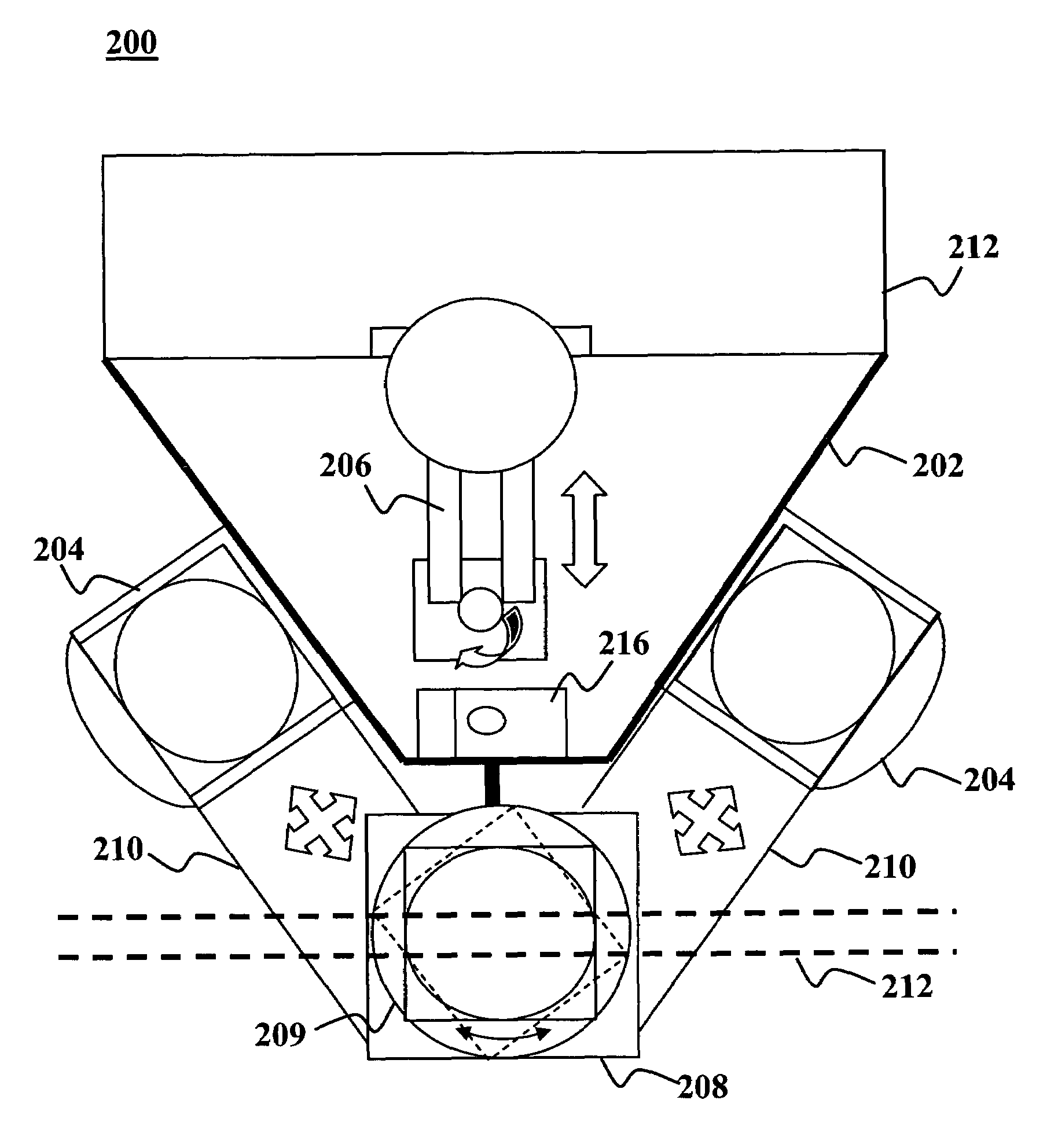

Batch Processing Platform For ALD and CVD

InactiveUS20070295274A1Minimized footprintImprove throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBatch processingEngineering

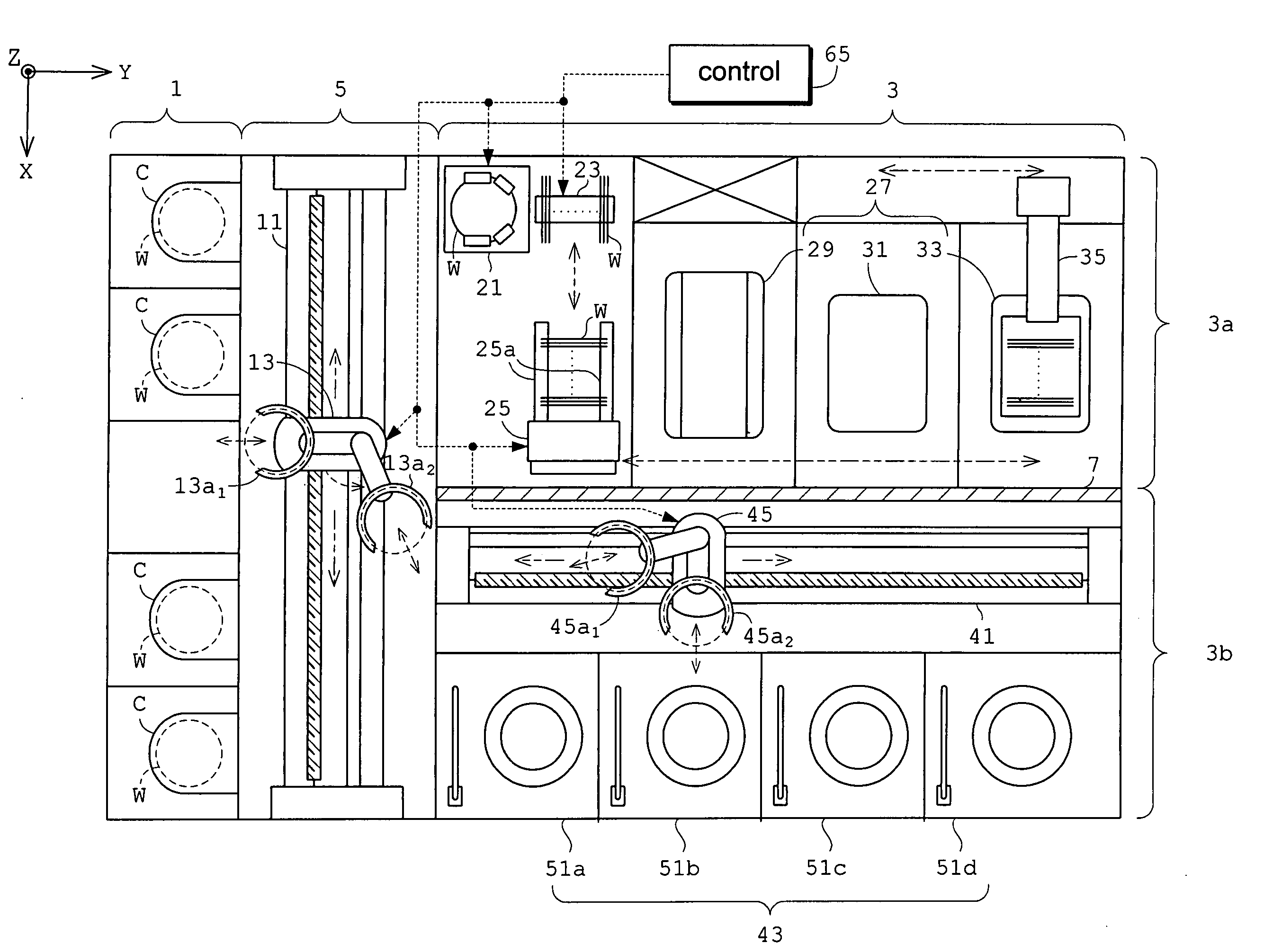

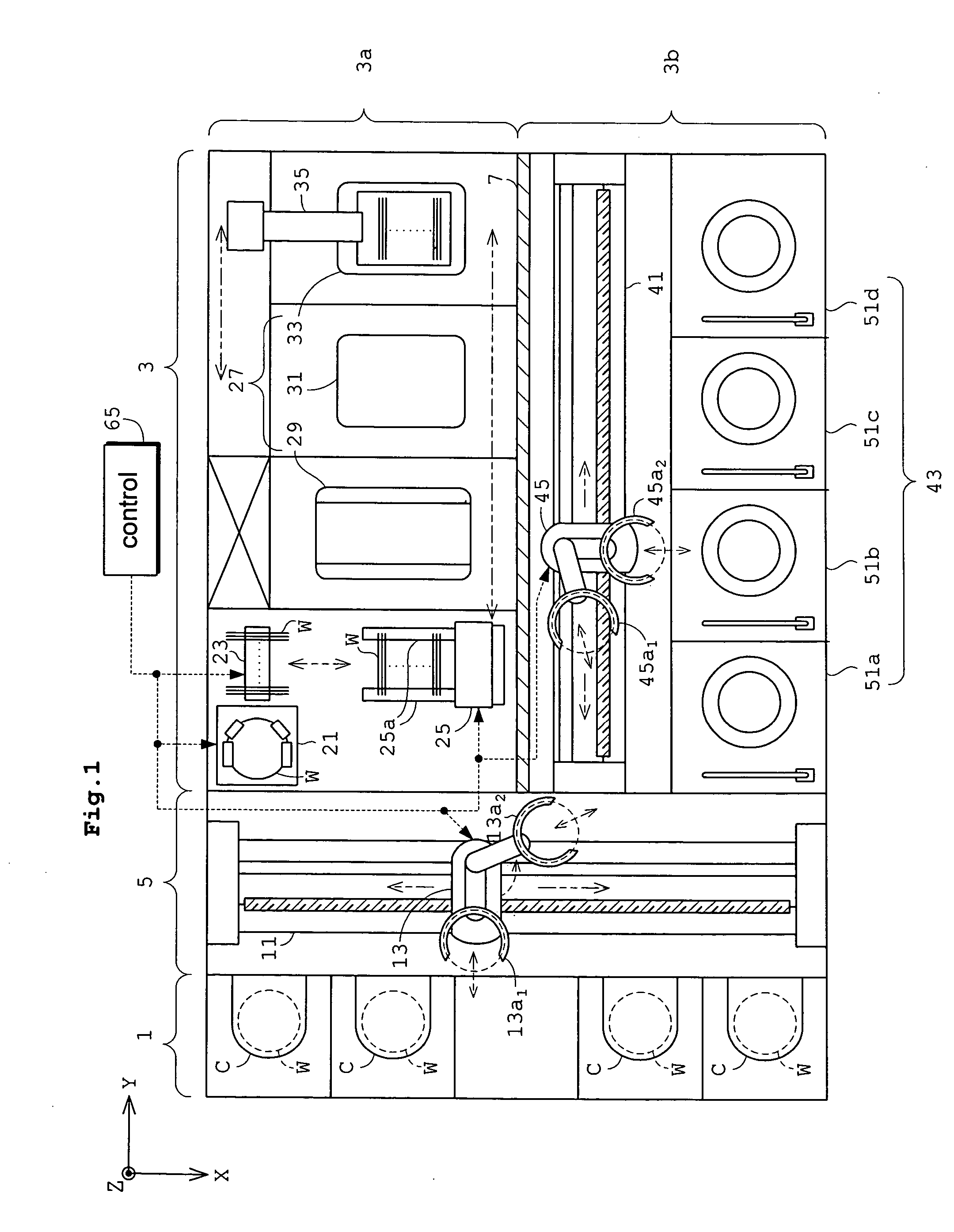

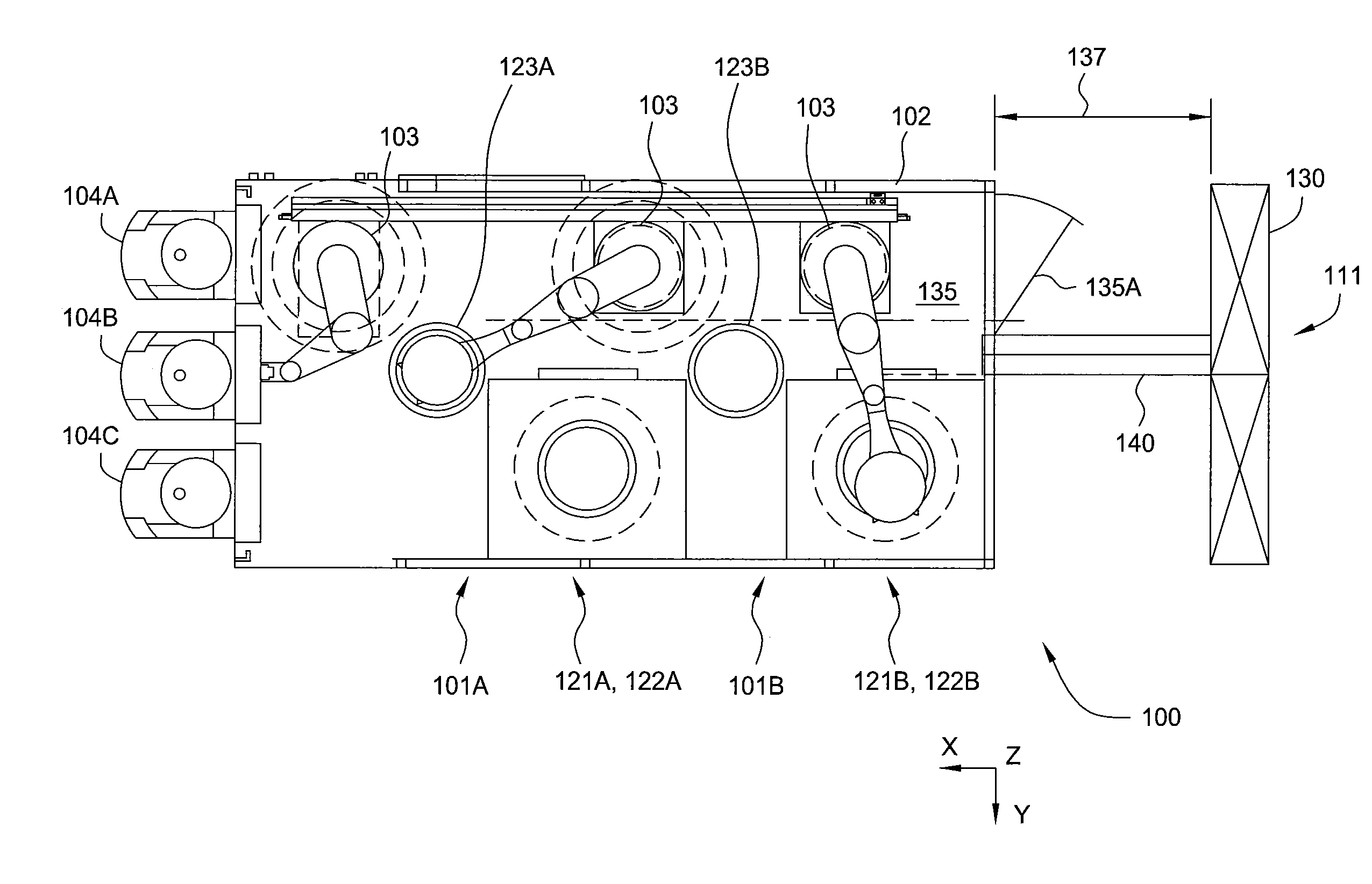

A batch processing platform used for ALD or CVD processing is configured for high throughput and minimal footprint. In one embodiment, the processing platform comprises an atmospheric transfer region, at least one batch processing chamber with a buffer chamber and staging platform, and a transfer robot disposed in the transfer region wherein the transfer robot has at least one substrate transfer arm that comprises multiple substrate handling blades. The platform may include two batch processing chambers configured with a service aisle disposed therebetween to provide necessary service access to the transfer robot and the deposition stations. In another embodiment, the processing platform comprises at least one batch processing chamber, a substrate transfer robot that is adapted to transfer substrates between a FOUP and a processing cassette, and a cassette transfer region containing a cassette handler robot. The cassette handler robot may be a linear actuator or a rotary table.

Owner:APPLIED MATERIALS INC

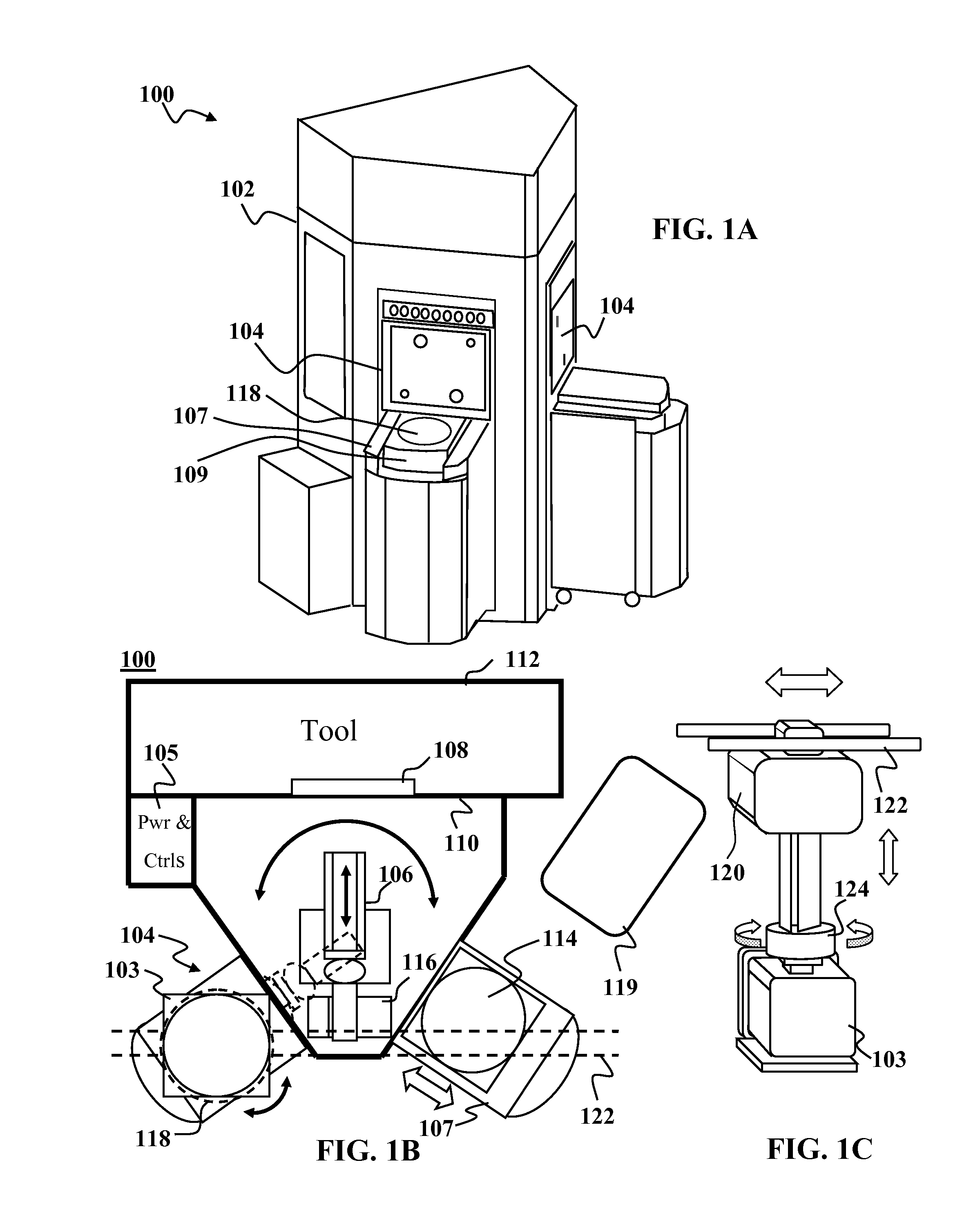

Equipment front end module

InactiveUS7604449B1Simpler and less-expensiveEasy programmingSemiconductor/solid-state device manufacturingArticle unpackingLinear motionSimulation

Equipment front end module (EFEM) systems and methods for handling workpieces at EFEMs are disclosed. An equipment front end module (EFEM) system has an enclosure and a robot within the enclosure. The enclosure has two or more load ports, each being adapted to receive a front opening unified pod (FOUP). The robot is configured to move work pieces between the FOUP(s) and one or more work piece processing tools proximate the enclosure. The load ports are positioned relative to said robot such that said robot can move the work pieces between the tool and a FOUP at each load port with a simple R-theta motion or pure linear motion with respect to two axes.

Owner:KLA TENCOR TECH CORP

Lid opening/closing system of an airtight container

ActiveUS7726353B2Increase pressureStay focusedLiquid fillingSemiconductor/solid-state device manufacturingProduct gasPartial pressure

A curtain nozzle is located above an opening portion (10) in a FIMS. A gas curtain formed of inert gas for closing the opening portion is formed, and at the same time, the inert gas is also supplied to an inside of a FOUP. Here, the direction of supply of the inert gas supplied to the inside of the FOUP is such that it does not have a flow component directing toward the gas flow forming the gas curtain. The above-mentioned structure prevents increase over time in a partial pressure of oxidizing gas in the FOUP fixed by a FIMS system in an open state.

Owner:TDK CORPARATION

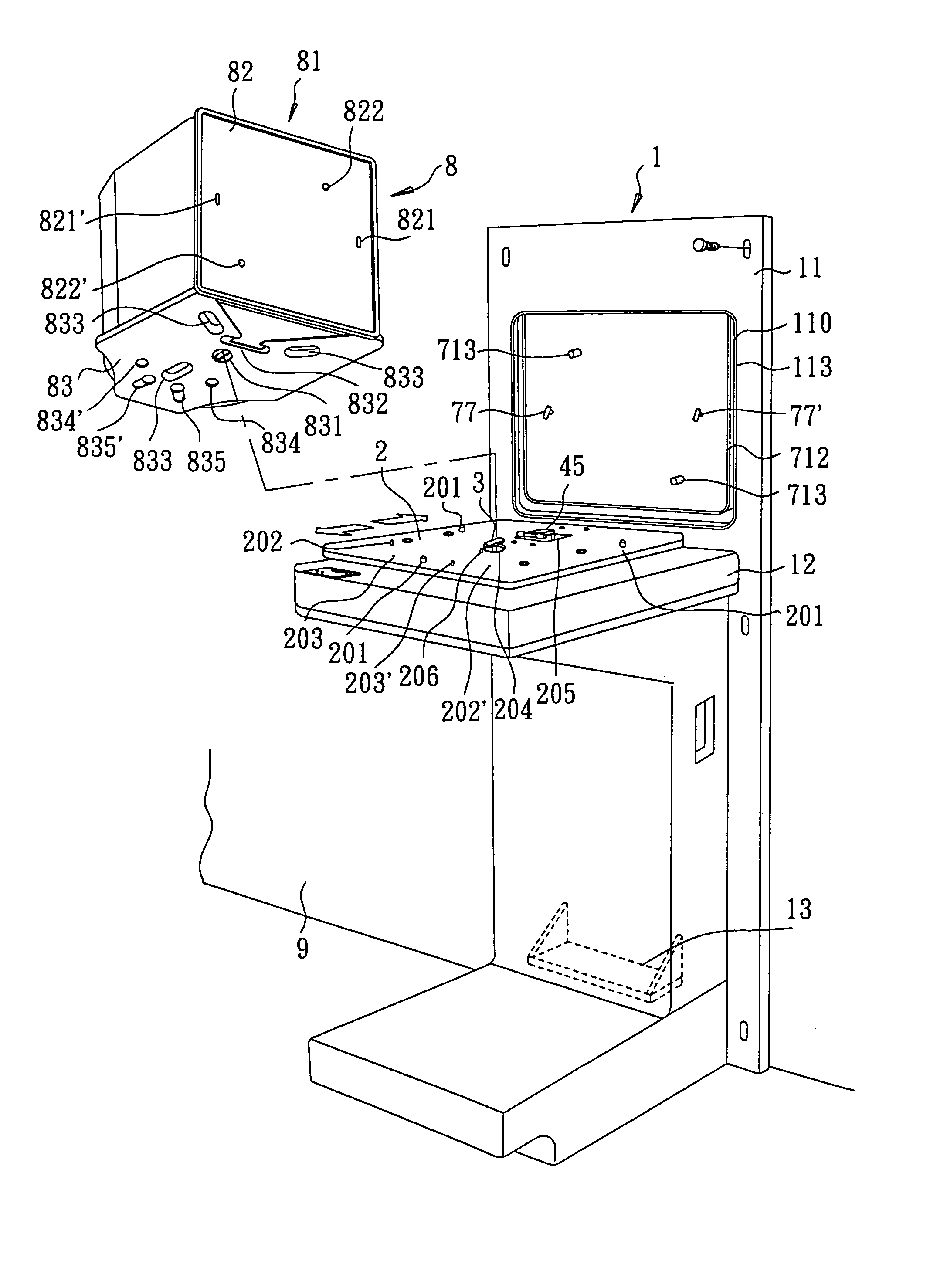

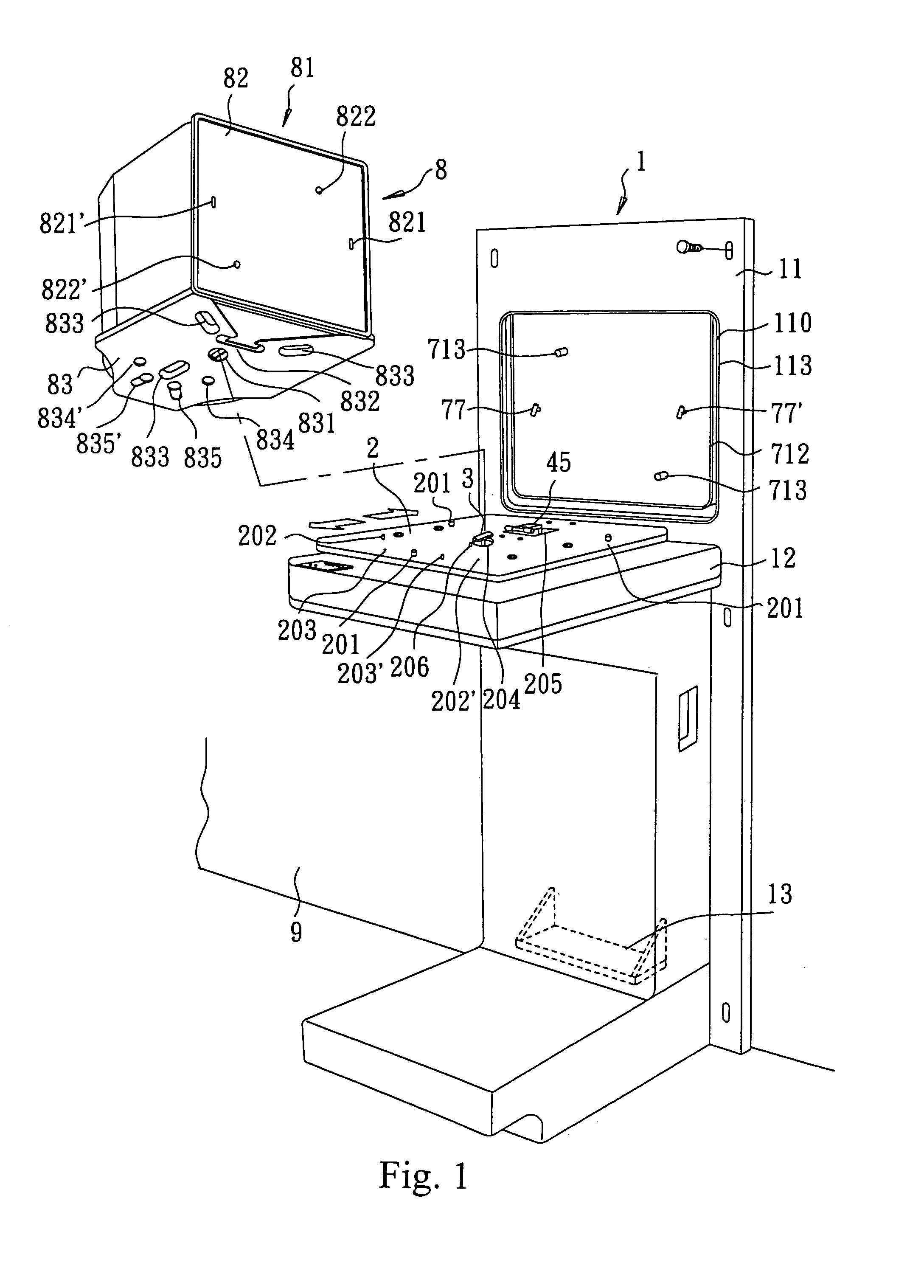

Front-opening unified pod auto-loading structure

InactiveUS6896470B1Avoid pollutionEliminate the problemSemiconductor/solid-state device manufacturingArticle unpackingHeadstockAutomation

The invention includes mainly a machine base, a carrier, a sliding control mechanism, a latch mechanism, a horizontal shifting mechanism, and a lifting mechanism. The FOUP (front-opening unified pod) is put on the carrier and latched by a locking plate of the latch at an accurate position. The carrier moves forwardly to tightly engage the FOUP to a gate on an access at a backboard of the machine base, and thus a cover of the FOUP is opened by a headstock gear at the back of the gate then carried backwardly away from the FOUP by the horizontal shifting mechanism and lowered by the lifting mechanism. Reversely, the cover is closed on the FOUP. As such, the cover is loaded and opened automatically, as well as in closed, which can be a part of automation and prevents wafers from contamination.

Owner:IND TECH RES INST

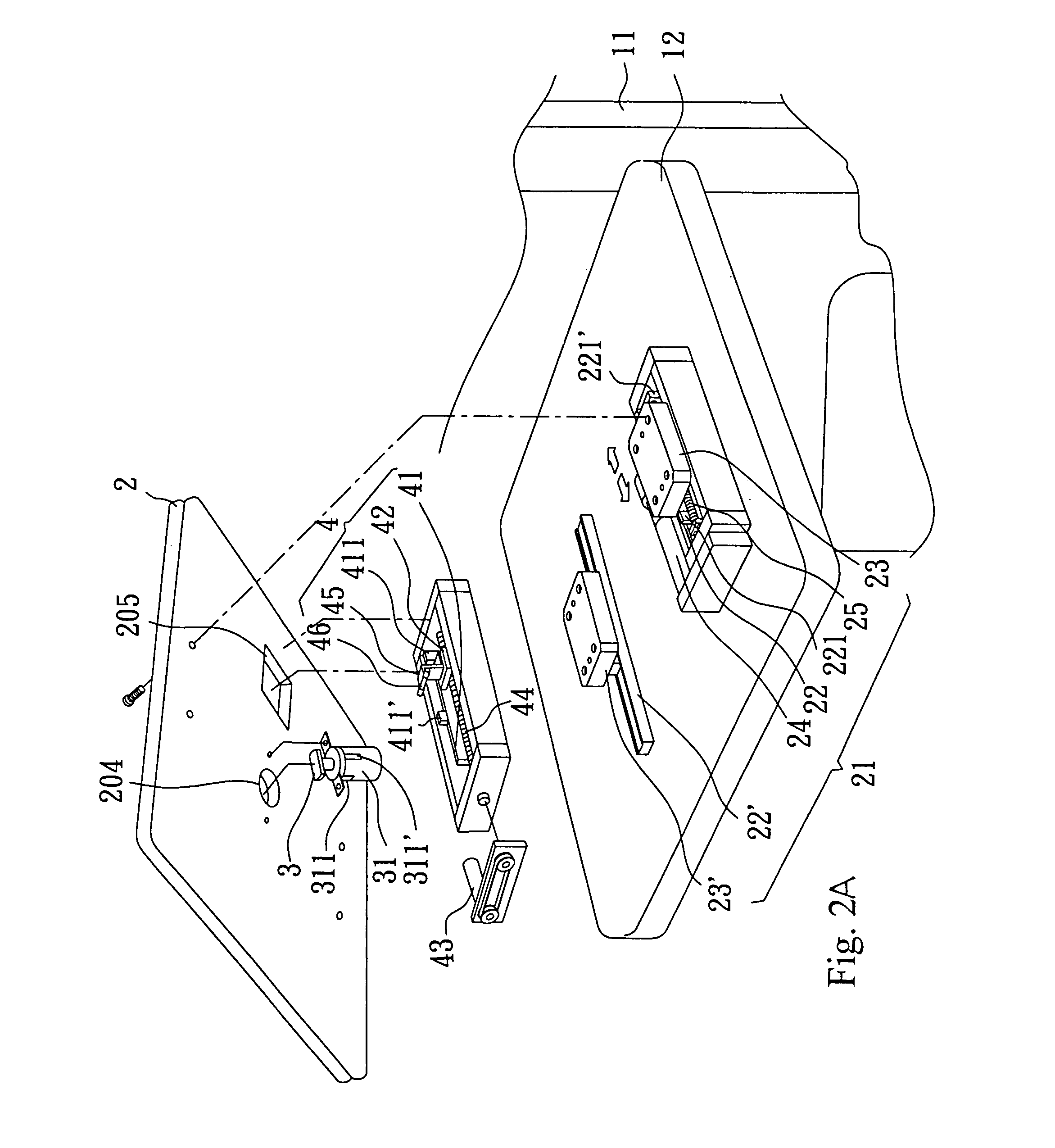

Lid opening/closing system for closed container and substrate processing method using same

ActiveUS20090035099A1Improve closureReduce the amount requiredSemiconductor/solid-state device manufacturingArticle unpackingEngineeringPartial pressure

Adjacent to an opening portion 10 in an FISM system is provided an enclosure that encloses the operation space of a door and has a second opening portion 31 opposed to the opening portion 10. A curtain nozzle is provided above the upper edge of the opening portion 10 in the upper portion in the enclosure. A purge gas is supplied from the curtain nozzle along a direction from the upper edge to the lower edge of the opening portion. In addition, a gas outlet through which the purge gas flows from the interior of the enclosure out into the exterior is provided on the wall of the enclosure to which the purge gas flowing in the above described direction is directed, whereby an increase in the partial pressure of oxidizing gases in the interior of the FOUP is prevented.

Owner:TDK CORPARATION

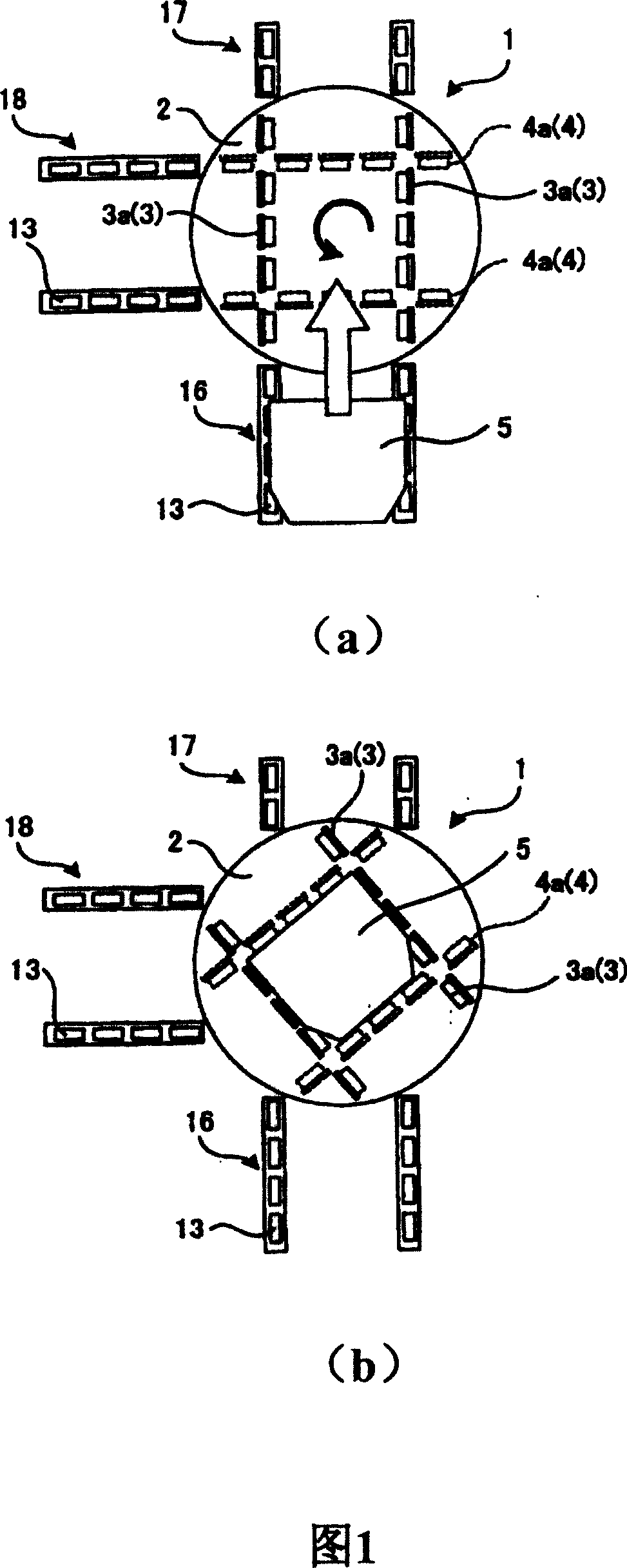

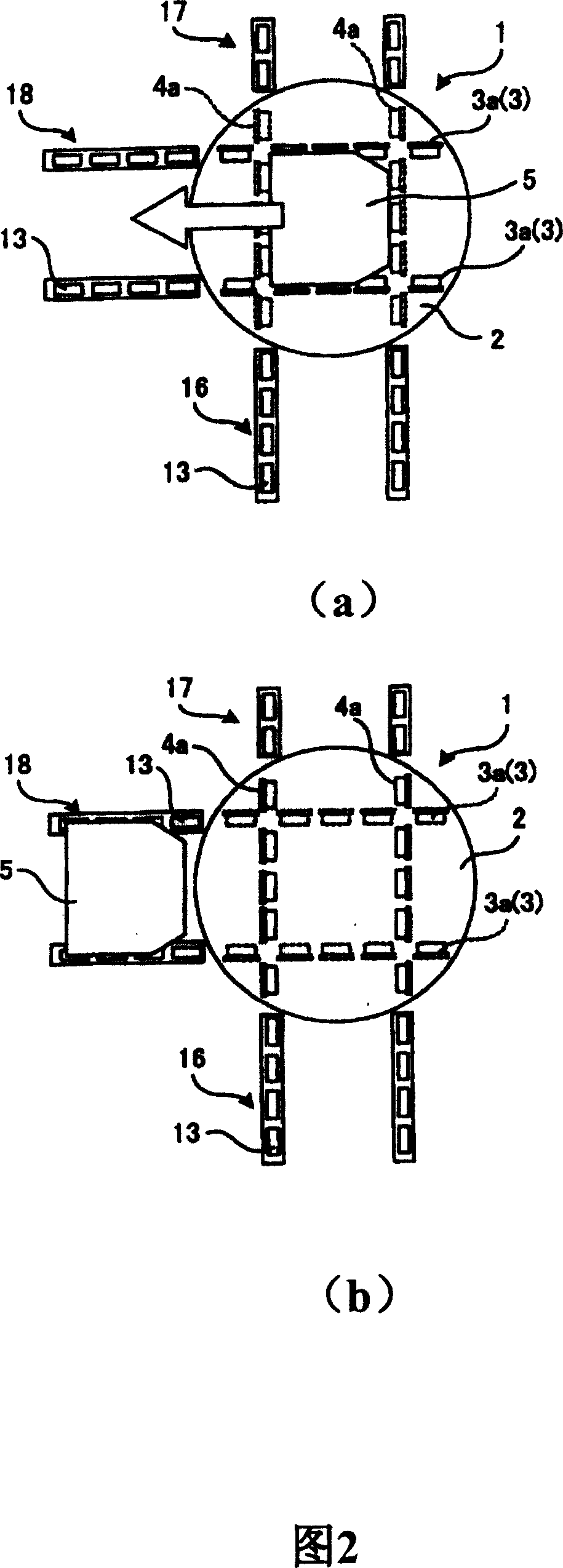

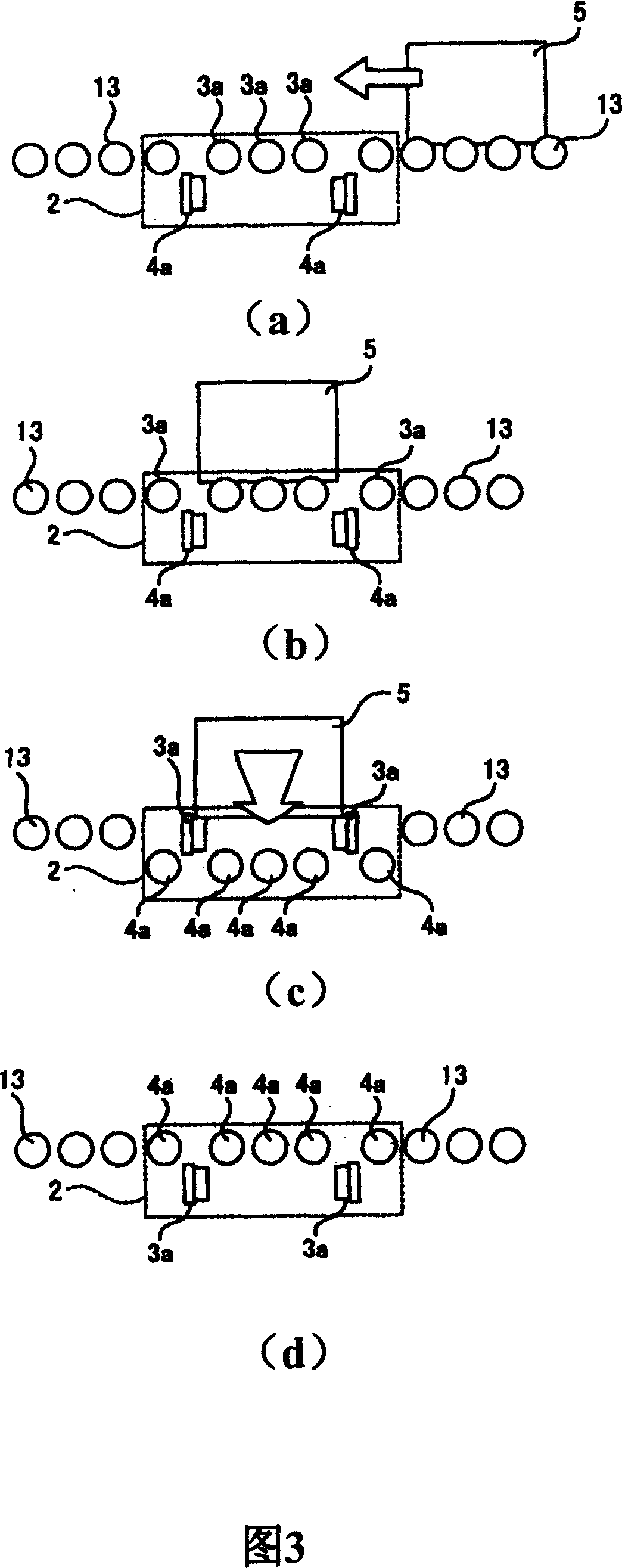

Direction change device

InactiveCN101020537ASave handling timeSemiconductor/solid-state device manufacturingControl devices for conveyorsTransport timeTransport engineering

The present invention provides a direction change device which can reduce the transport time, including first and second transport passage 3, 4, in which one of the transport passages is disposed at the same vertical position as that of the first transport rail 16, the other is disposed below the one, a rotating unit 22 rotating the transport passages 3, 4 about their central points, a lift unit 23 lifting the transport passages 3, 4 in a vertical direction and a control unit 21. The control unit 21 controls such that when the FOUP 5 is carried out from the transport rail 16 to the transport passage disposed at the same vertical position as that of the transport rail 16, rotating the transport passages 3, 4 by about 90 DEG, carrying out the FOUP 5 from one of the transport passages, and exchanging the respective vertical positions of the first and second transport passages 3, 4.

Owner:ASYST SHINKO INC

Method of processing an object in a container and lid opening/closing system used in the method

ActiveUS20090035100A1Control is possiblePurge operationLiquid fillingSemiconductor/solid-state device manufacturingGas supplyPartial pressure

A partial pressure of oxidizing gas in an opened state FOUP fixed in a FIMS system is reduced when the FOUP is closed. Purge gas supply nozzles are placed outside of two vertical sides of an opening portion (10) within the FIMS. A curtain nozzle is additionally installed which can form a gas curtain from purge gas above the top side of the opening portion (10). When a pod (2) is closed with a lid (4), a door opening / closing mechanism keeps the lid (4) at a given angle with respect to the flowing direction of curtain gas for a given period of time, and hence purge gas supplied to the gas curtain is additionally put into use for the purging of the interior of the pod by the lid 4.

Owner:TDK CORPARATION

Purging apparatus and purging method

InactiveUS7654291B2Efficient removalEffectively and securely removeLiquid fillingSemiconductor/solid-state device manufacturingEngineeringGas supply

It is an object of the present invention to easily and securely perform the removal operation of contaminant or the like from a wafer housed in a FOUP. To achieve the object, a purging apparatus of the present invention removes contaminant or the like from a wafer by moving a gas supply nozzle along a direction in which wafers are superimposed at the front of an opening while a lid of the FOUP is separated from a body and spraying clean gas on each wafer from the gas supply nozzle.

Owner:TDK CORPARATION

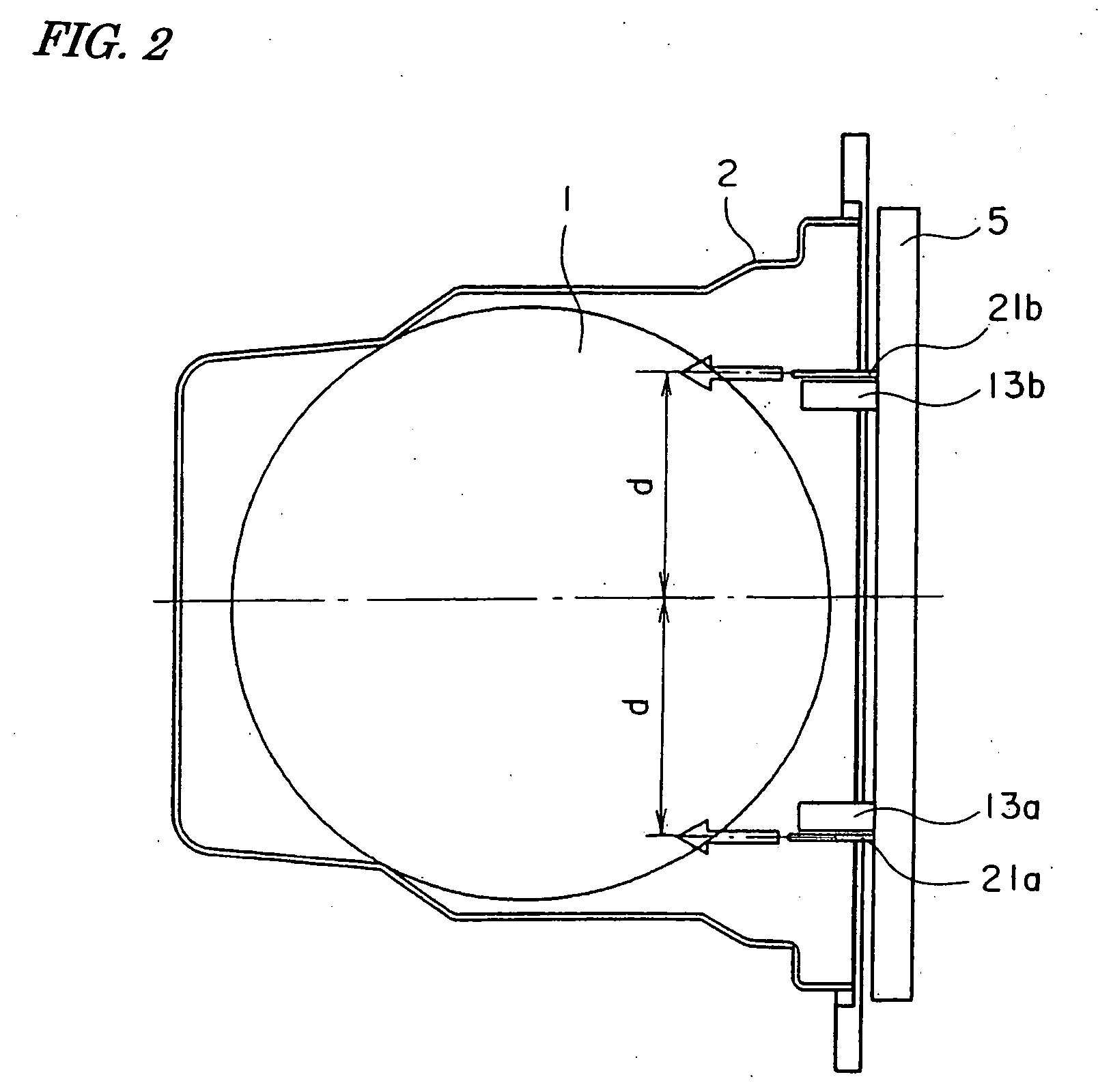

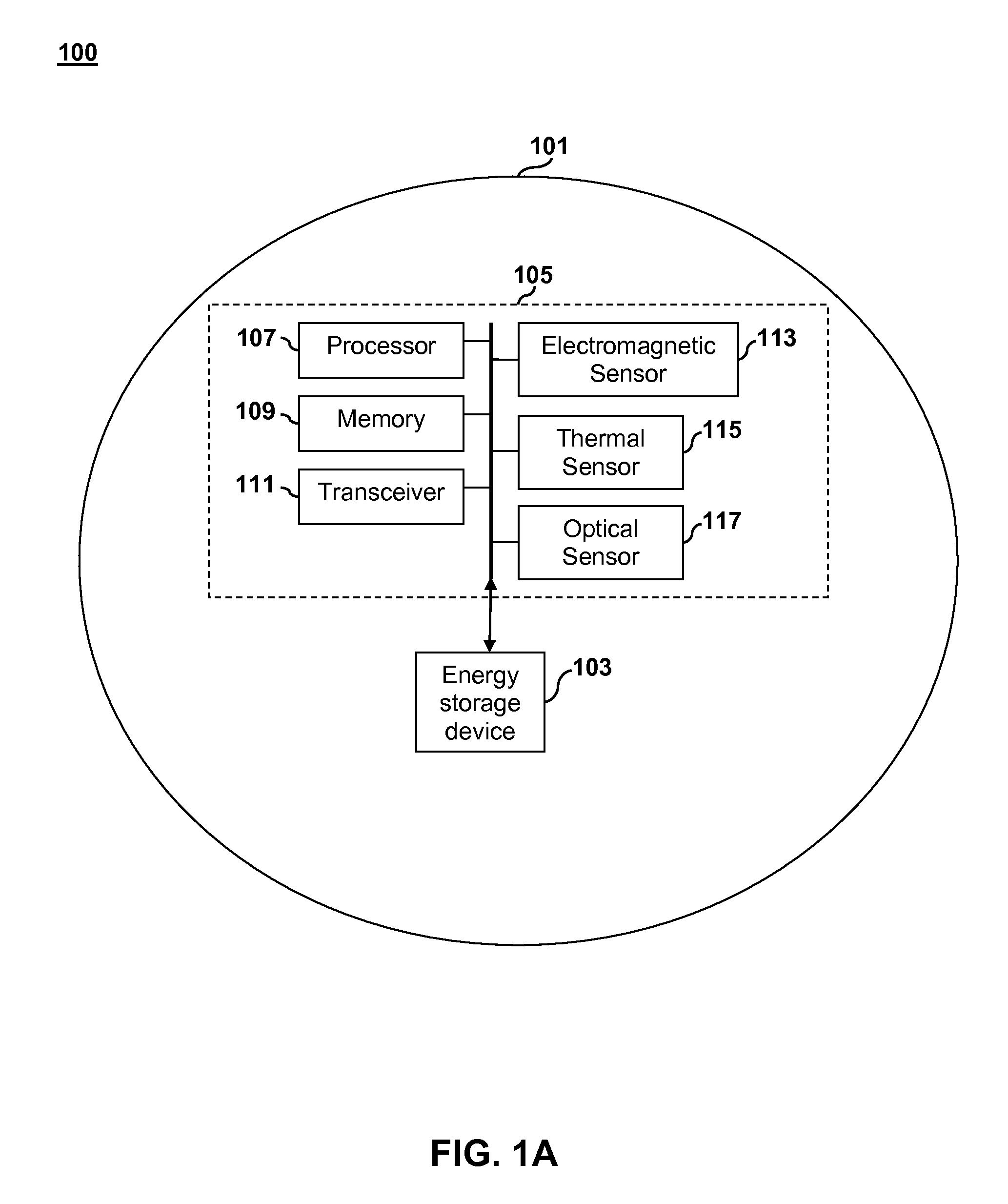

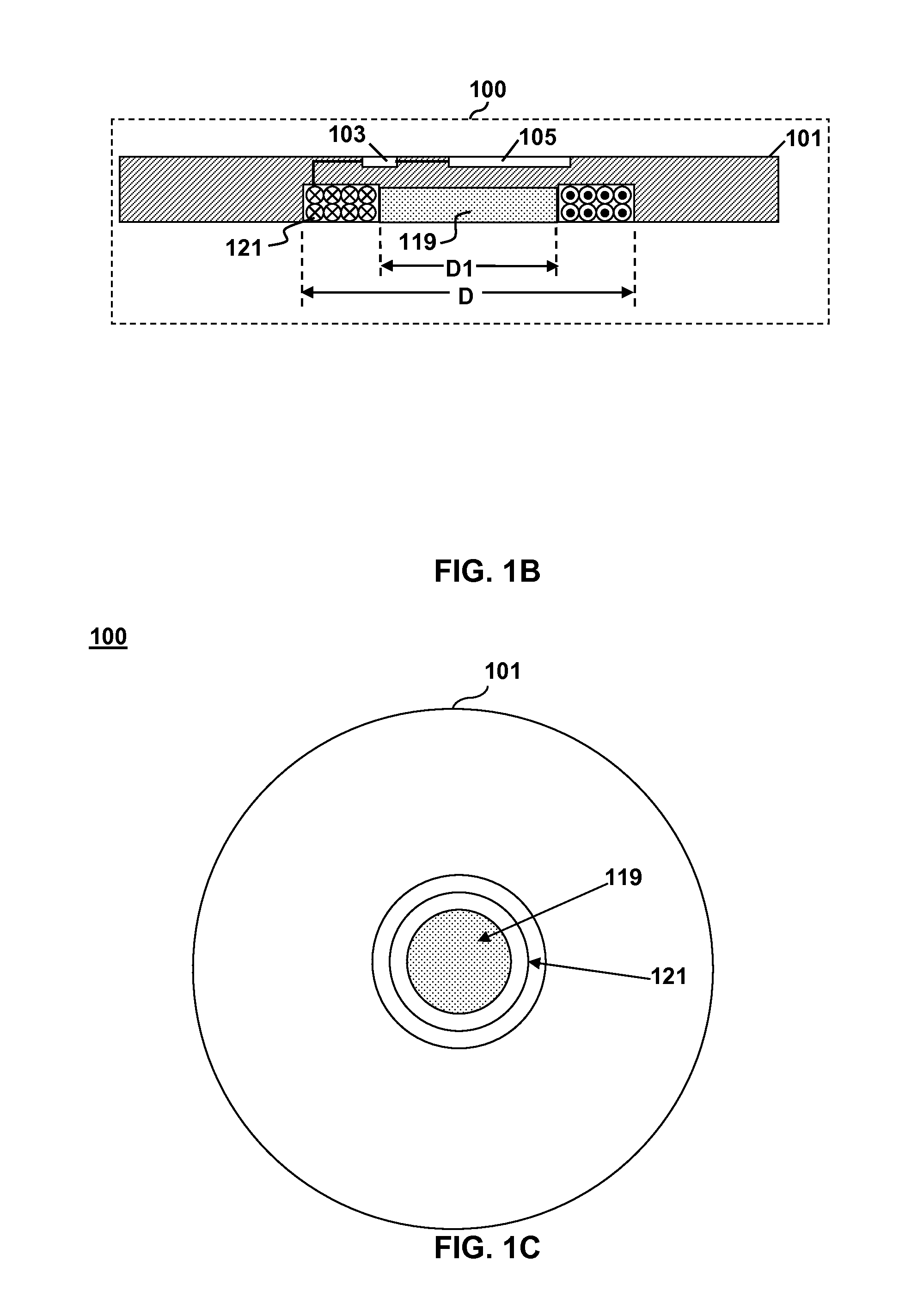

Non-contact interface system

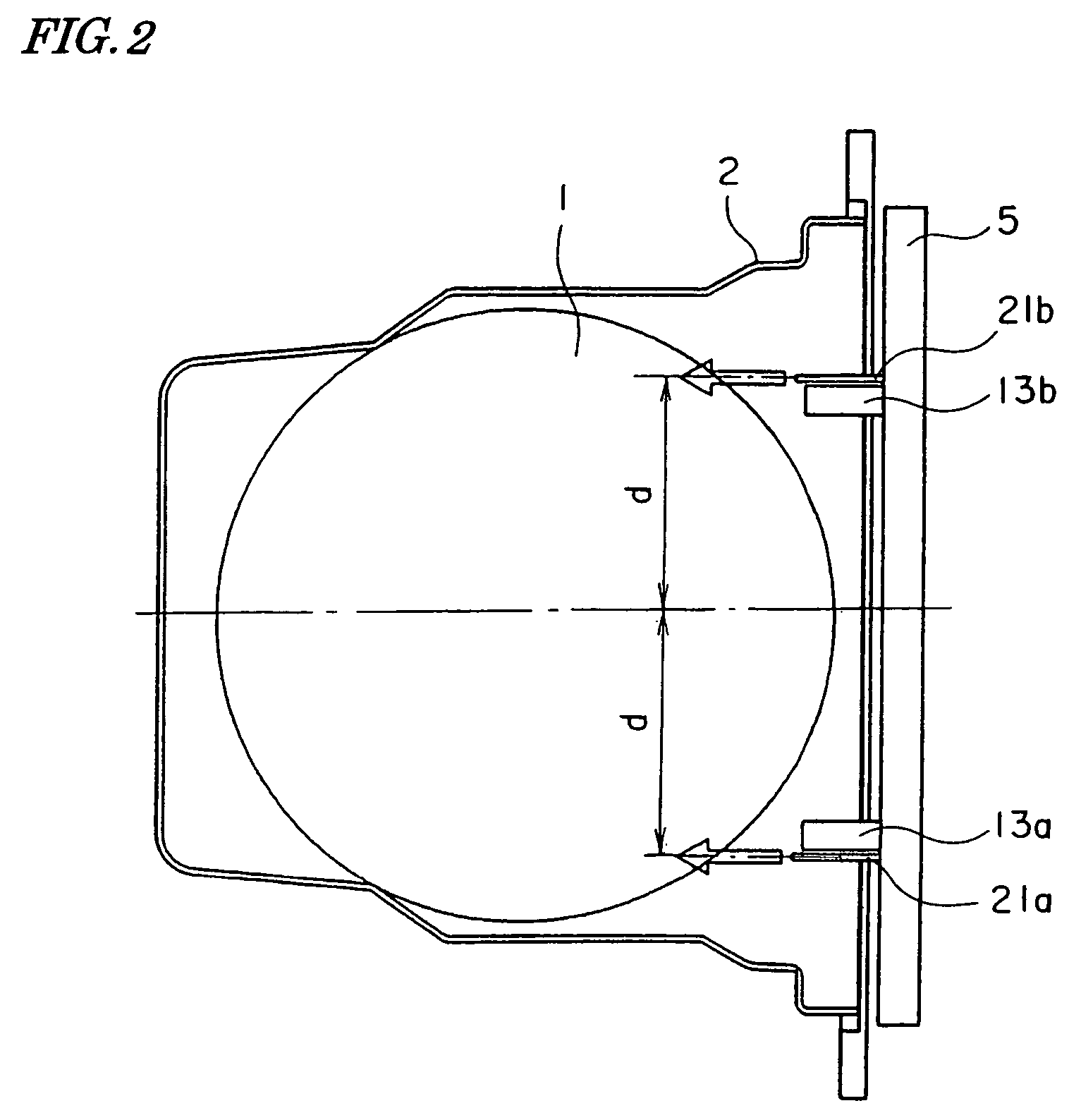

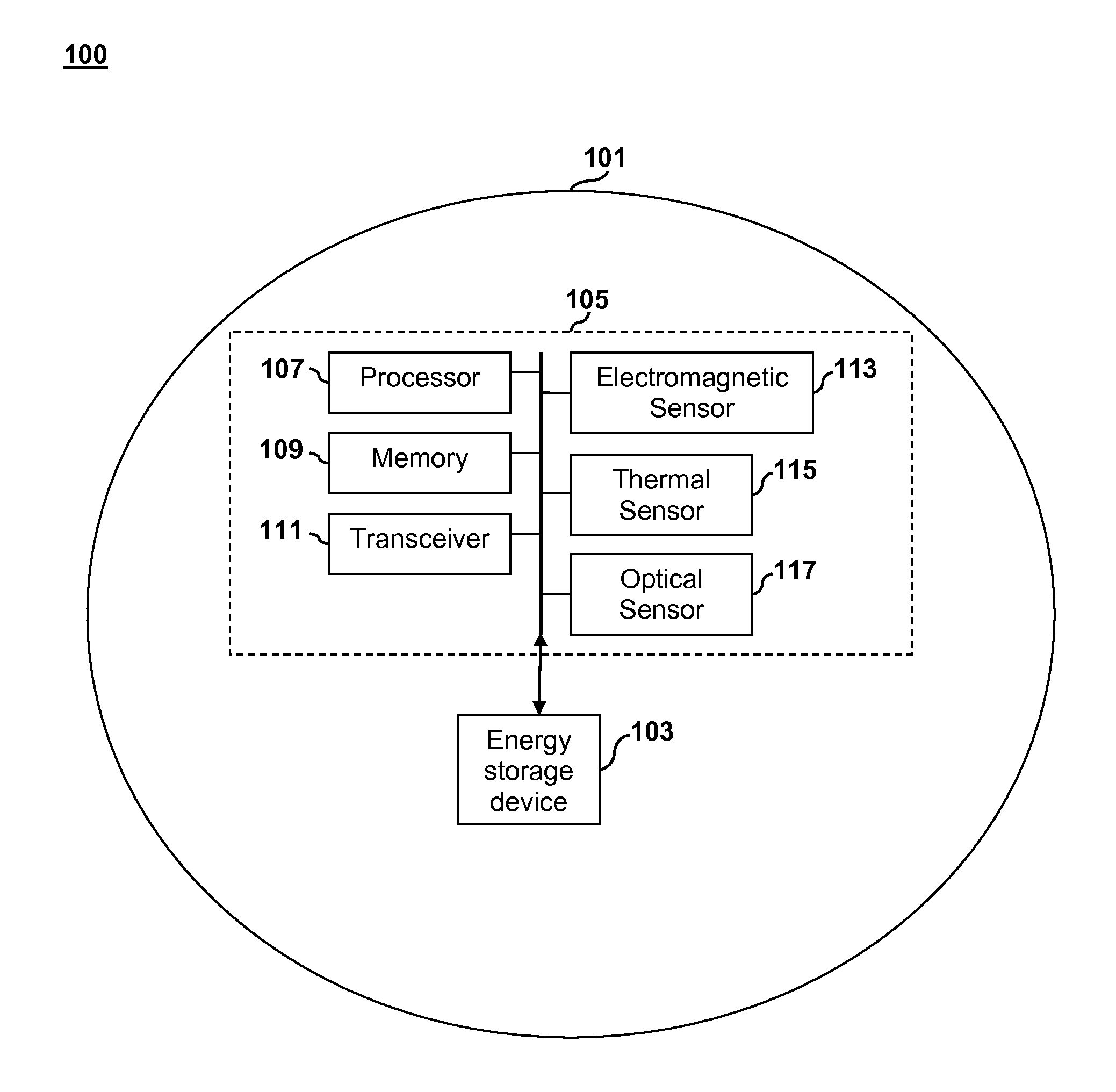

InactiveUS20110074341A1Near-field transmissionBatteries circuit arrangementsComputer moduleEnergy storage

An interface system for a sensor wafer may comprise a sensor wafer having a substrate. One or more sensors may be mounted to the substrate. An electronics module may be mounted to the substrate and coupled to the one or more sensors. An energy storage device may be mounted to the substrate and coupled to the electronics module. A secondary coil may be attached to a surface of the sensor wafer, and coupled to the electronics module of the sensor wafer, having a diameter of at least 50 millimeters. A primary coil may be attached to a front opening universal pod (FOUP). The primary coil, may situated and oriented in the FOUP such that the primary coil is concentric with the secondary coil and at least 8, but less than 12 millimeters from the sensor wafer when the sensor wafer is stored in a slot in the FOUP.

Owner:KLA TENCOR TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com