Direction change device

A technology of direction conversion and conveying direction, which is applied in conveyor control device, transportation and packaging, turntable/car transfer platform, etc., which can solve the problems of inability to change direction, wasting time, and lengthening handling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

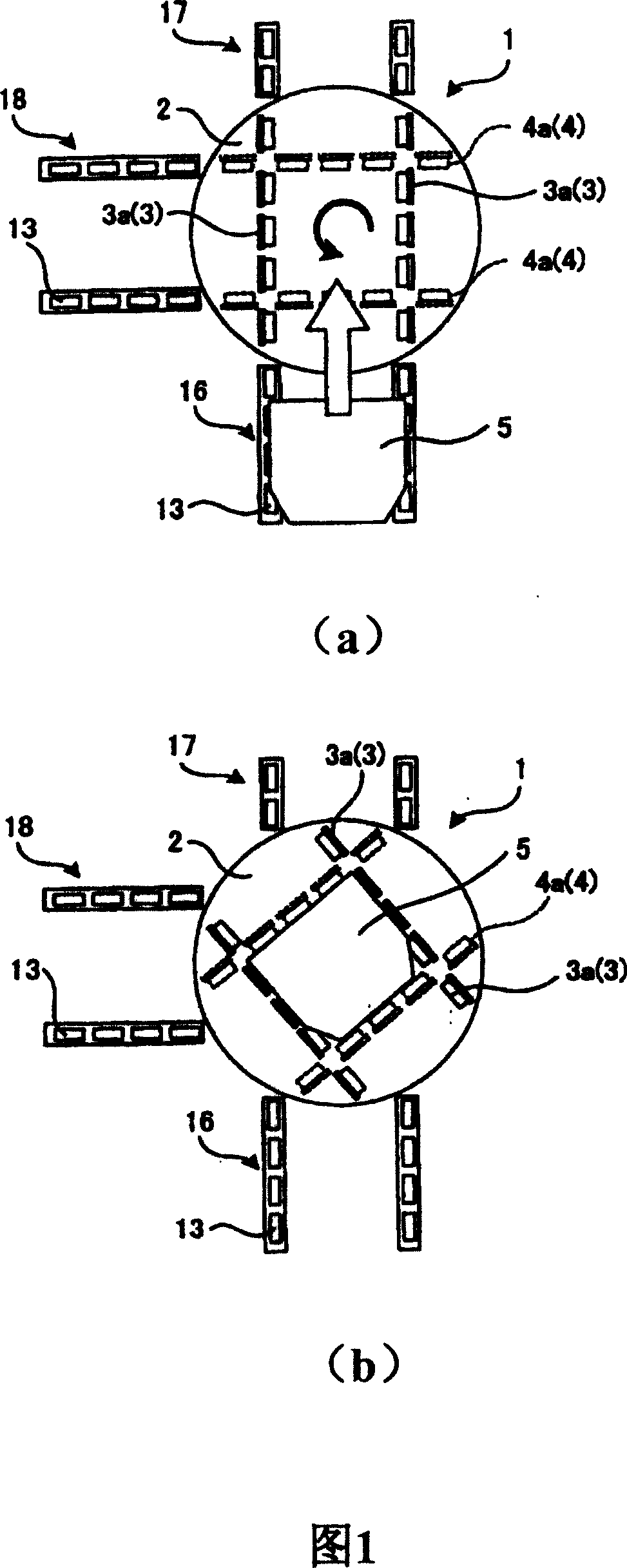

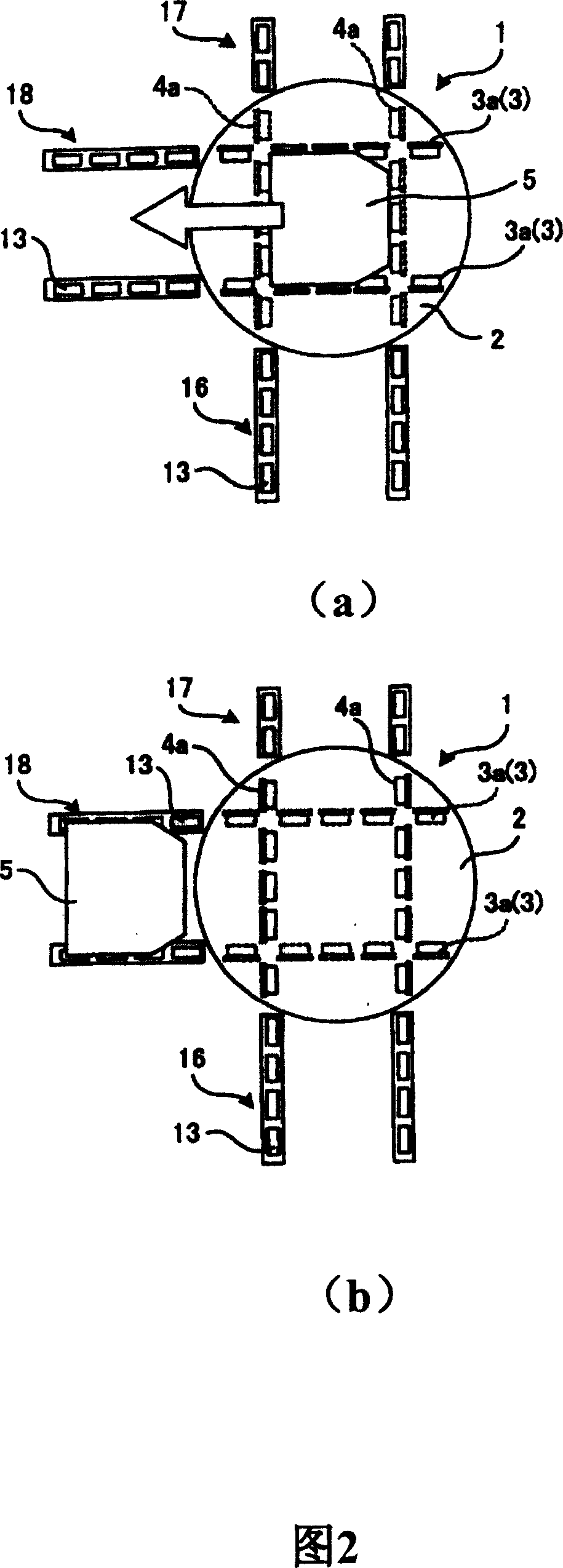

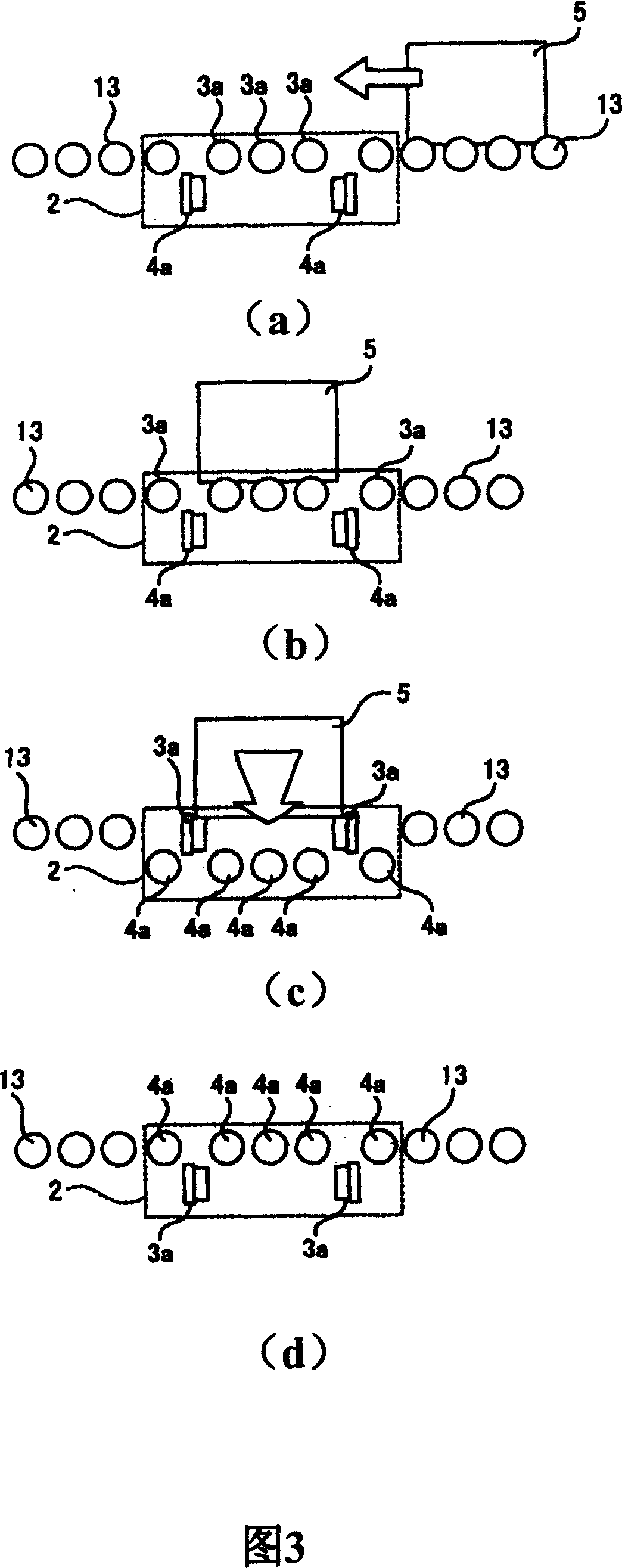

[0019] Next, preferred embodiments of the present invention will be described with reference to the drawings. The direction changing device in the present embodiment is particularly suitable for use in a transport system, such as a semiconductor product manufacturing facility, in which an object to be processed is transported by a transport rail within a process or between processes to form a final product. In addition, in the following description, although semiconductors are treated as objects to be processed, the conveyance system for conveying semiconductor substrates, glass substrates for liquid crystal display devices, glass substrates for photomasks, and substrates for optical discs is described. , but not limited to this, it can also be applied to various handling systems in all industries that carry electronic components, mechanical components, chemicals, food, books and other goods.

[0020] In addition, the term "semiconductor" refers to, for example, a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com