Purge system for a product container and table for use in the purge system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

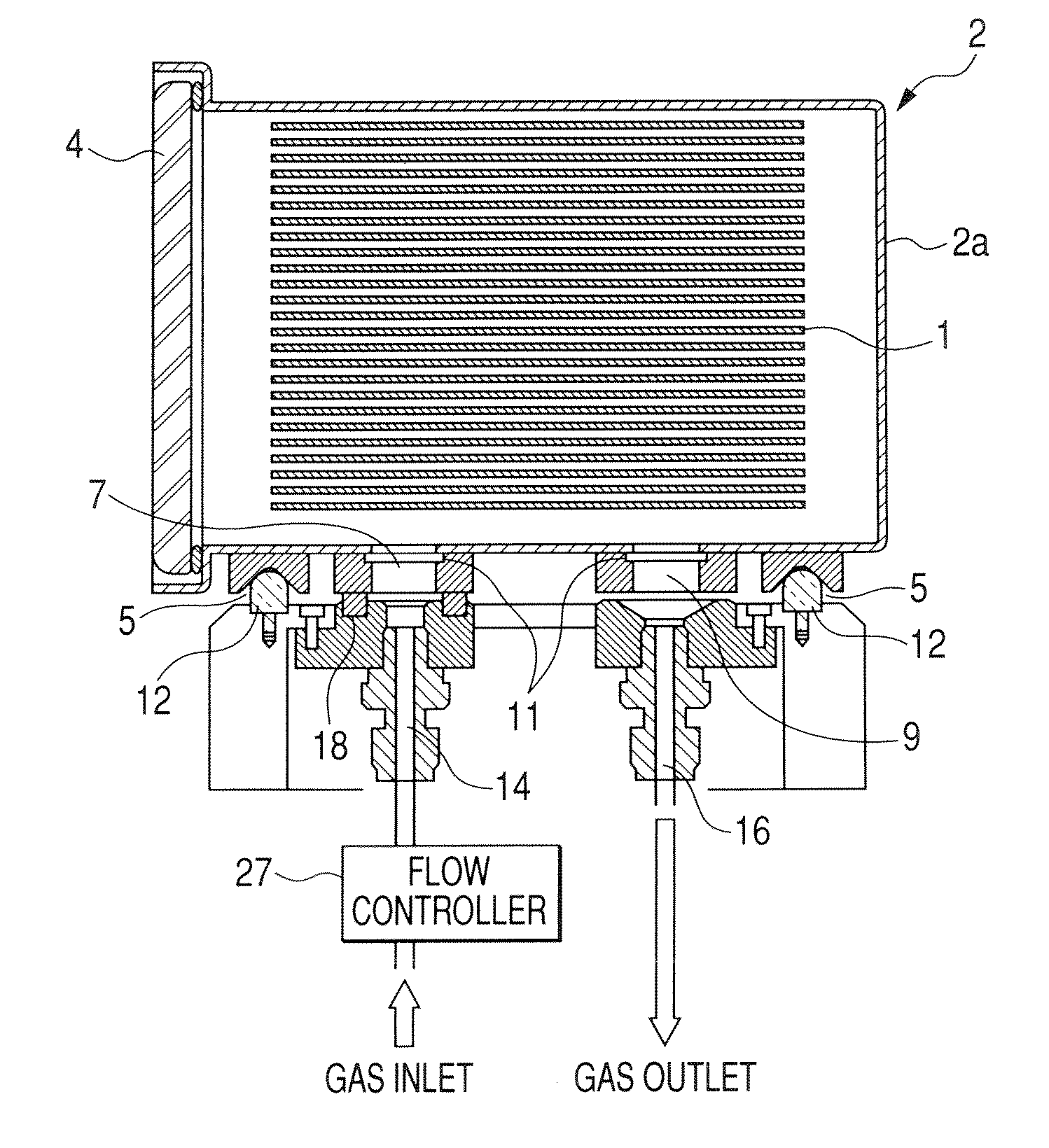

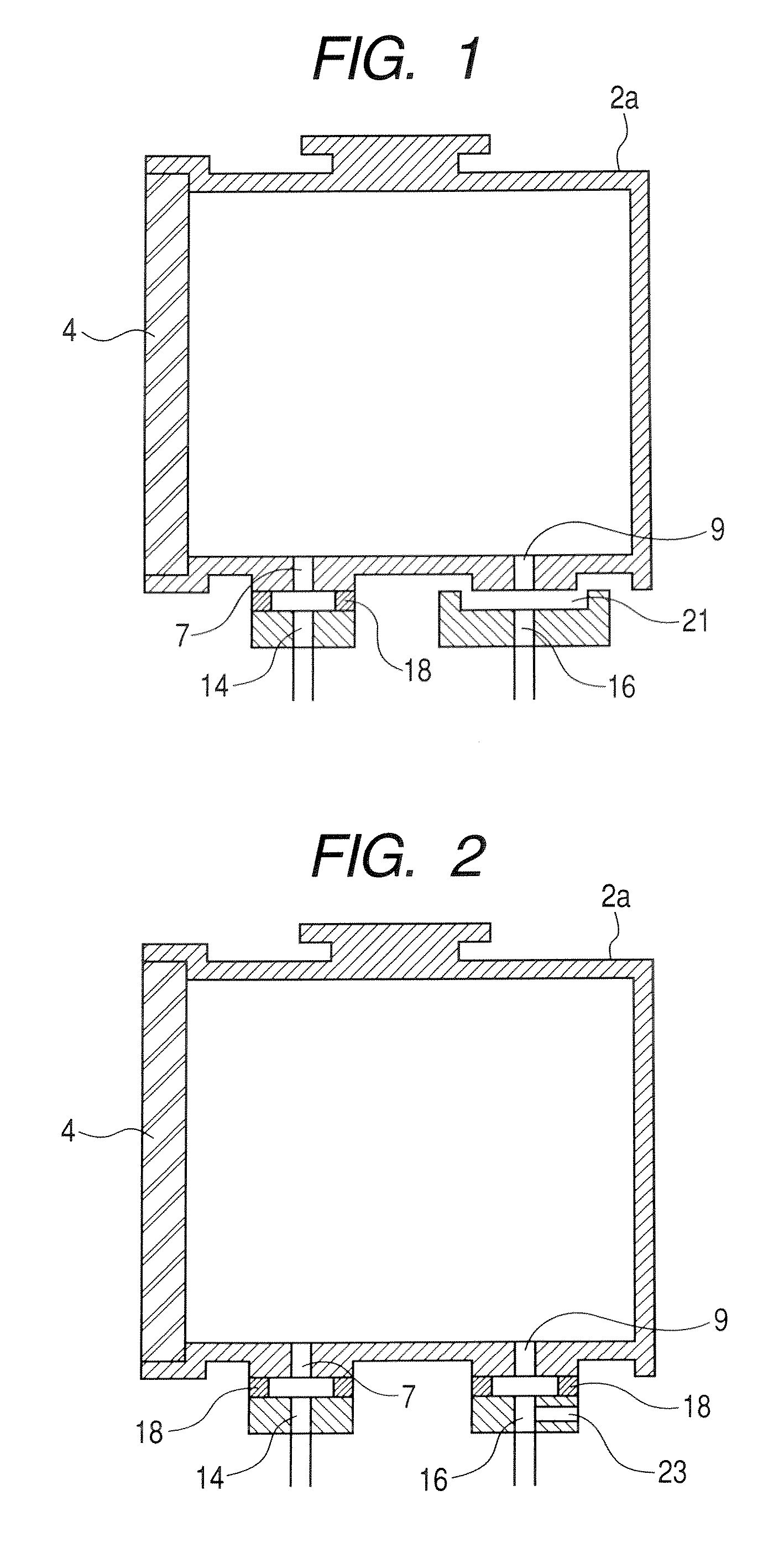

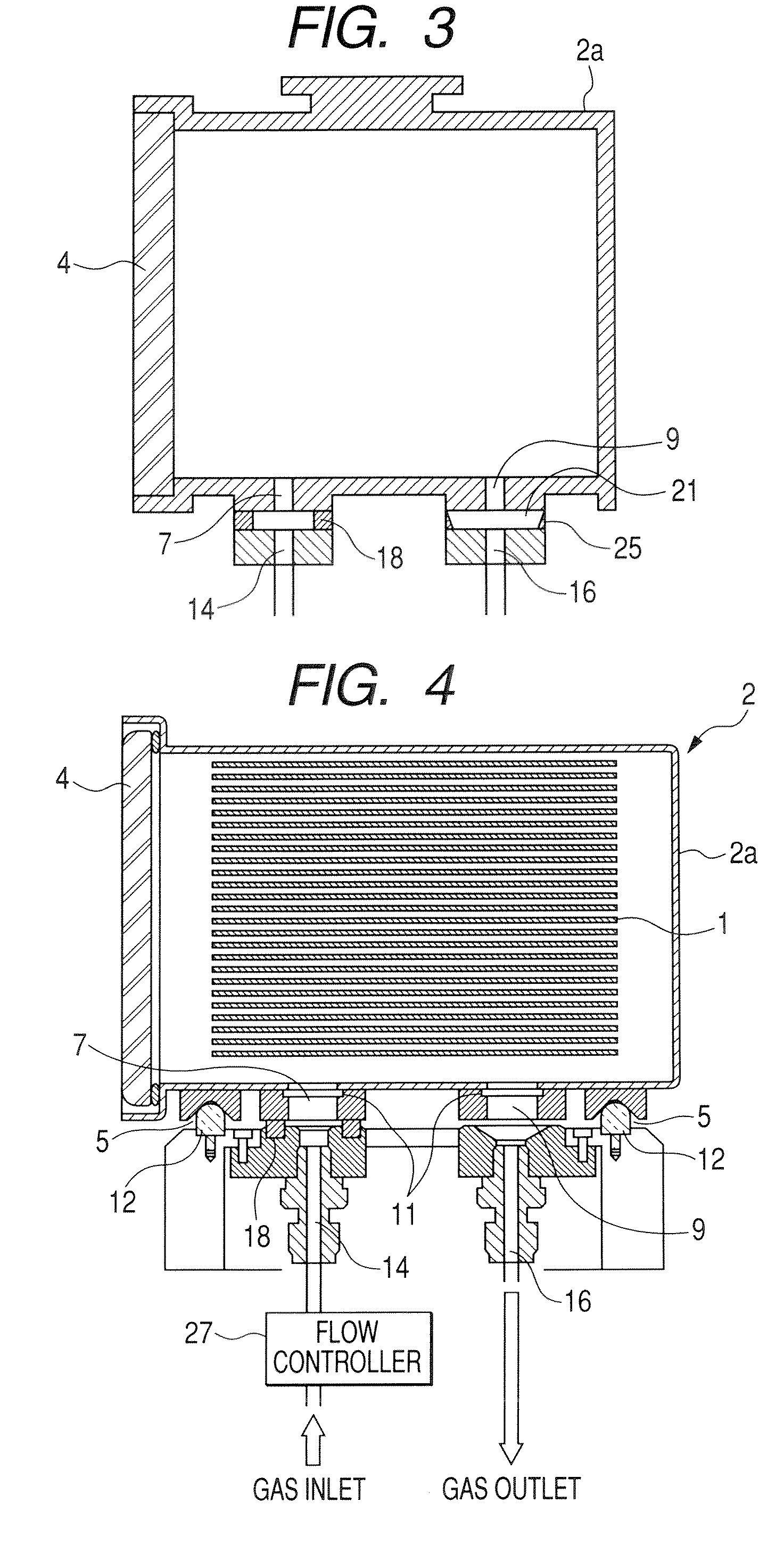

[0043] Now, a description will be given of embodiments of the present invention with reference to the accompanying drawings. FIG. 1 is a diagram schematically showing a purge system according to an embodiment of the present invention. To be more specific, FIG. 1 schematically shows a structure of a pod 2, and a table side inlet port 14 and a table side outlet port 16 which are disposed on a table 53 of FIG. 6, taken along a vertical section thereof. In the figure, the same structures as those of the respective structures shown in FIG. 5 as the conventional art are denoted by identical references for description.

[0044] Referring to FIG. 1, a sealing member 18 that is fixed to the table 53 side is interposed between an inlet port 7 of the pod 2 and a table side inlet port 14 that is connected to the inlet port 7. Therefore, a gas inlet system is completely sealed from an external space of the pod 2. On the contrary, no sealing member 18 is interposed between a outlet port 9 and a tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com