Paper feeder cutter head and paper feeder having same and working method thereof

A paper-feeding knife and paper-feeding technology, applied in the directions of object supply, transportation and packaging, object separation, etc., can solve problems such as scratches, avoid scratches, improve market competitiveness, and facilitate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

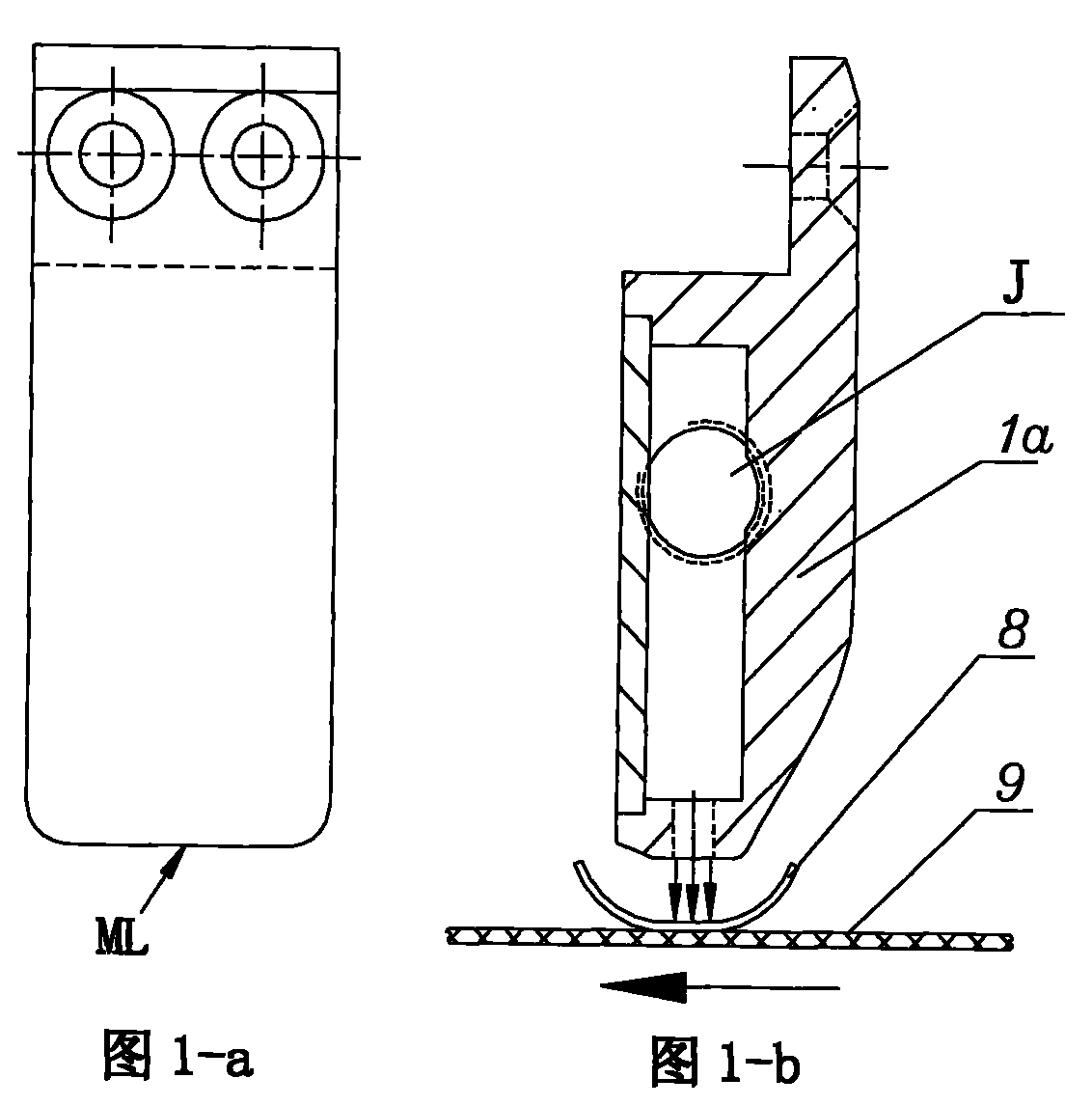

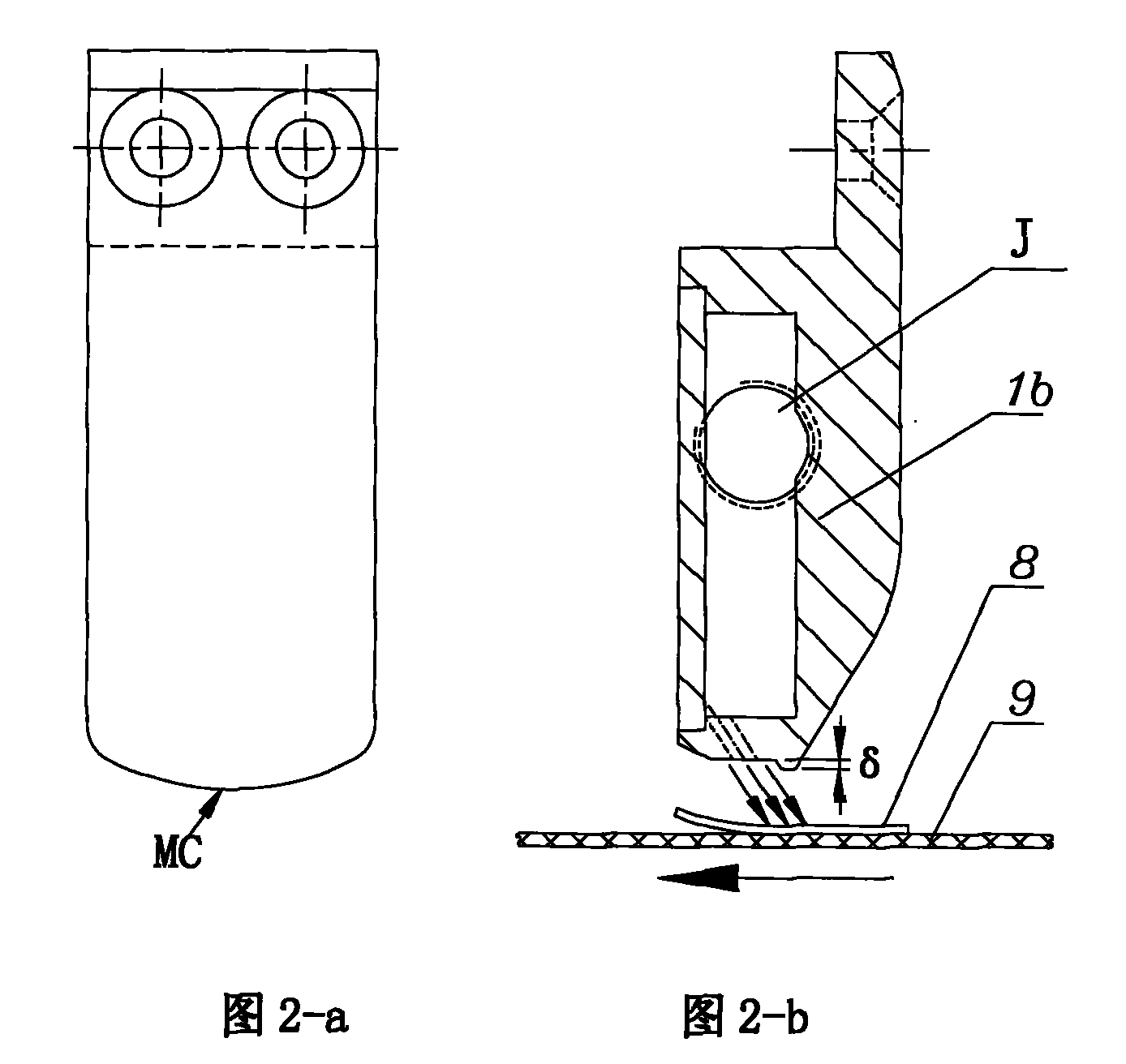

[0017] Embodiment: a kind of paper-feeding knife head (see figure 2 ), which is characterized in that the shape of its working end surface is arc-shaped, and the radius of the arc is 200mm; the lower end surface of the paper feeding cutter head has an air outlet, and the angle between the air outlet and the horizontal direction of the printed product 8 is less than 90 degrees; the arc working surface is the lowest is lower than the lower plane of the air outlet, and the distance δ is 0.5mm.

[0018] The air outlet mentioned above is connected with the air inlet J.

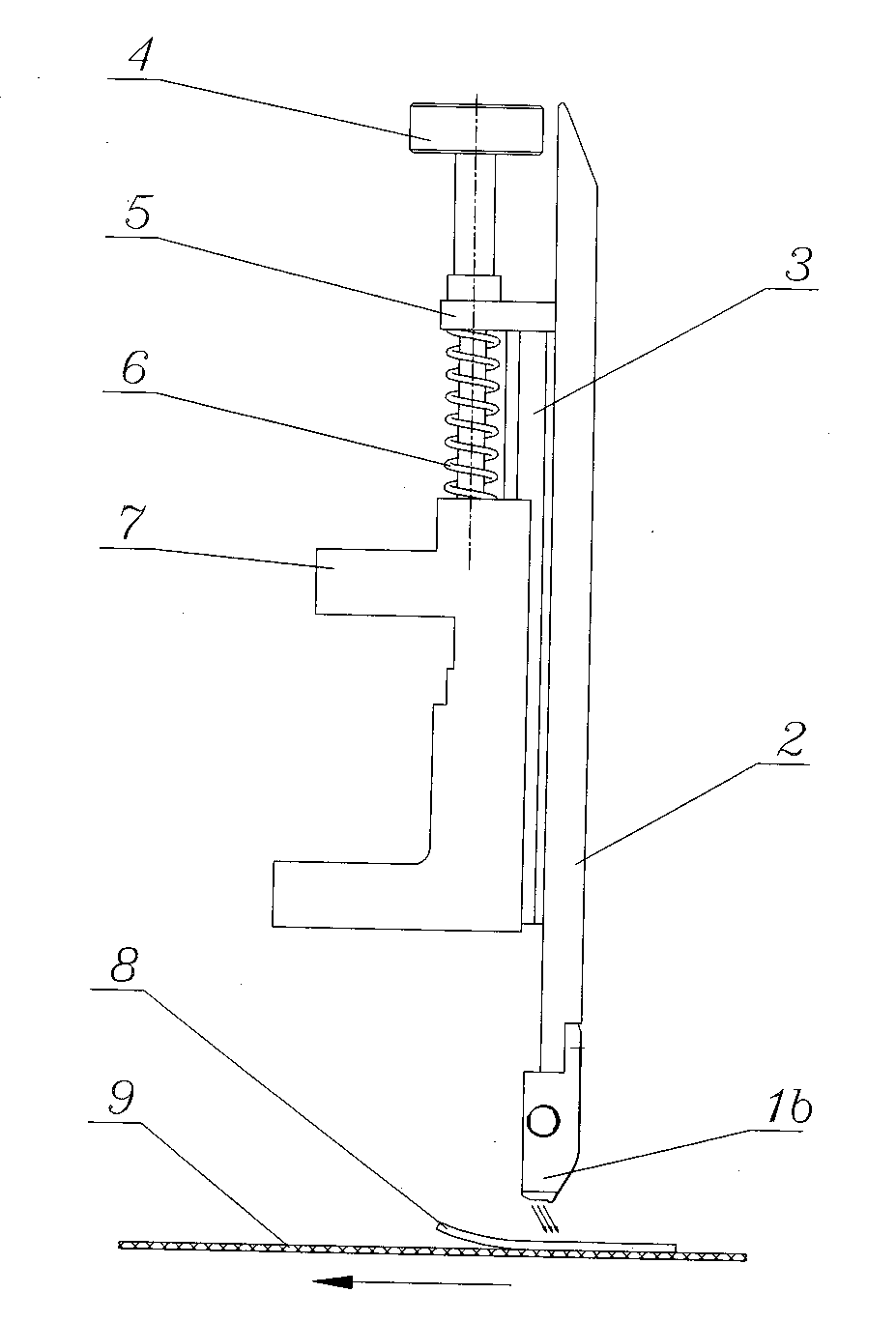

[0019] A paper feeding device equipped with a paper feeding cutter head (see image 3 ), which is characterized in that it includes a paper feed knife head 1b, a paper feed knife 2 and an adjustment device, said adjustment device is composed of a slide rail 3, an adjustment handle 4, a double-hole plate 5, a spring 6 and a slide block 7; said The paper-feeding knife head 1b is fixedly connected to the paper-feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com