Patents

Literature

71 results about "Belt friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Belt friction is a term describing the friction forces between a belt and a surface, such as a belt wrapped around a bollard. When one end of the belt is being pulled only part of this force is transmitted to the other end wrapped about a surface. The friction force increases with the amount of wrap about a surface and makes it so the tension in the belt can be different at both ends of the belt. Belt friction can be modeled by the Belt friction equation.

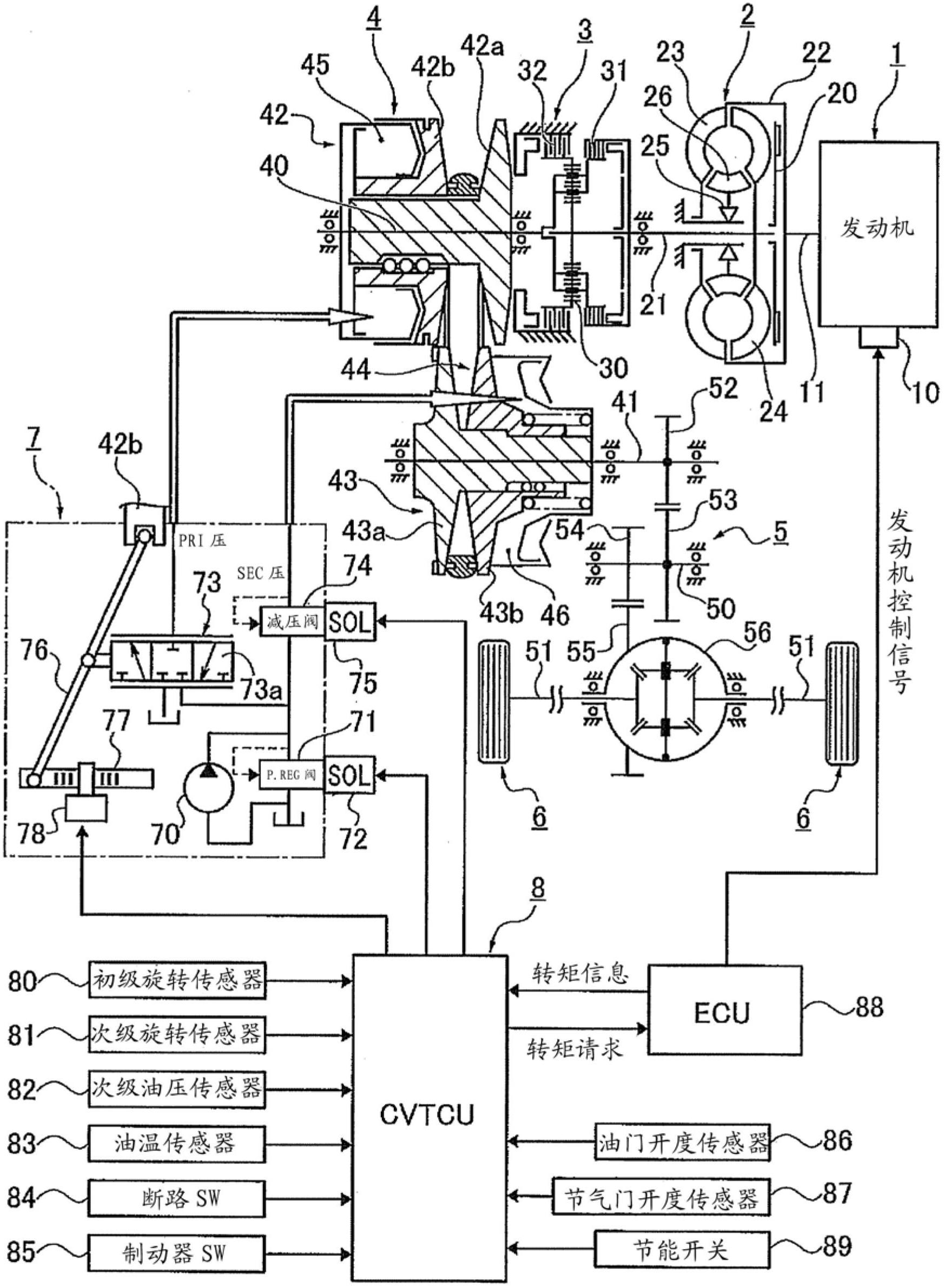

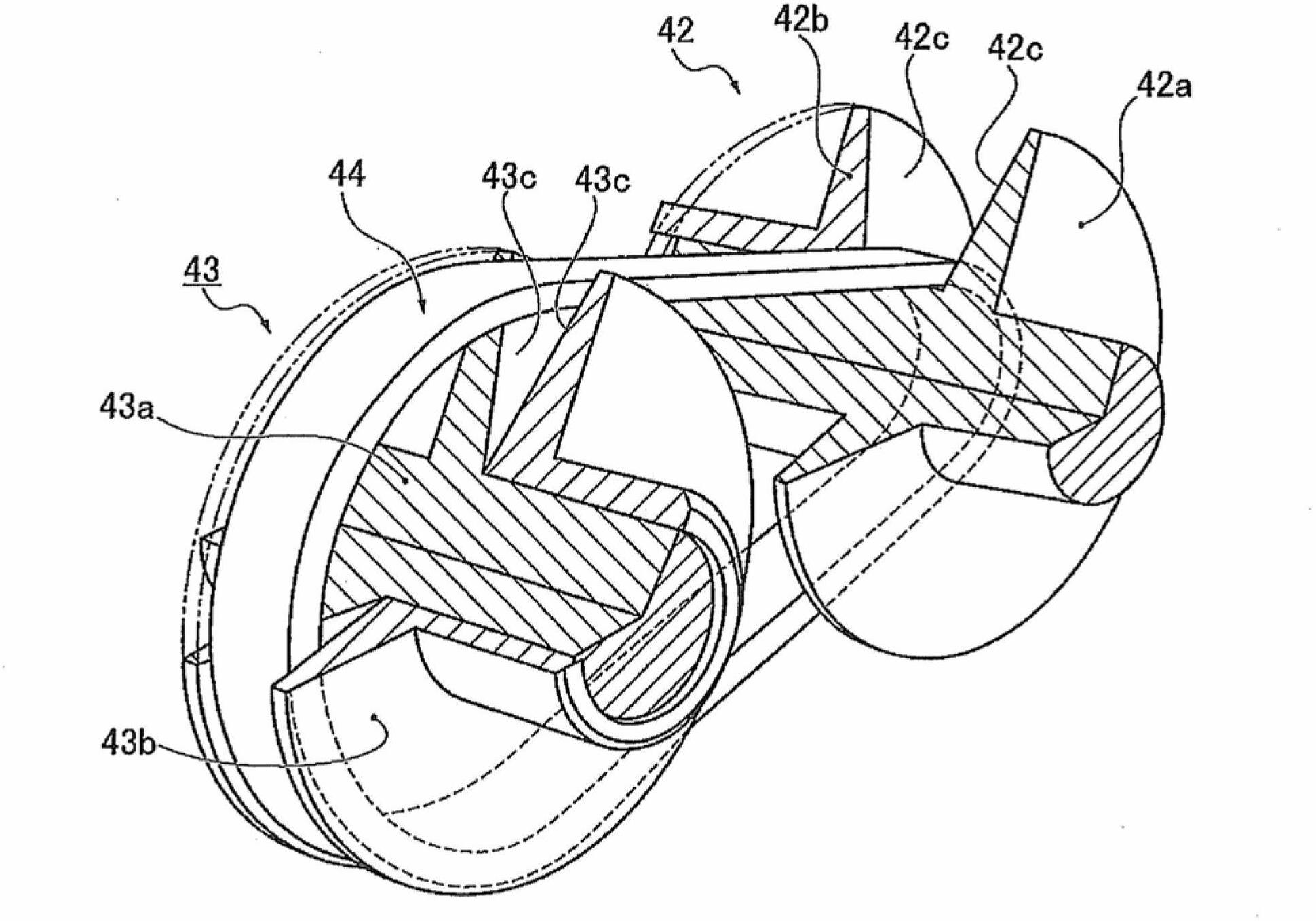

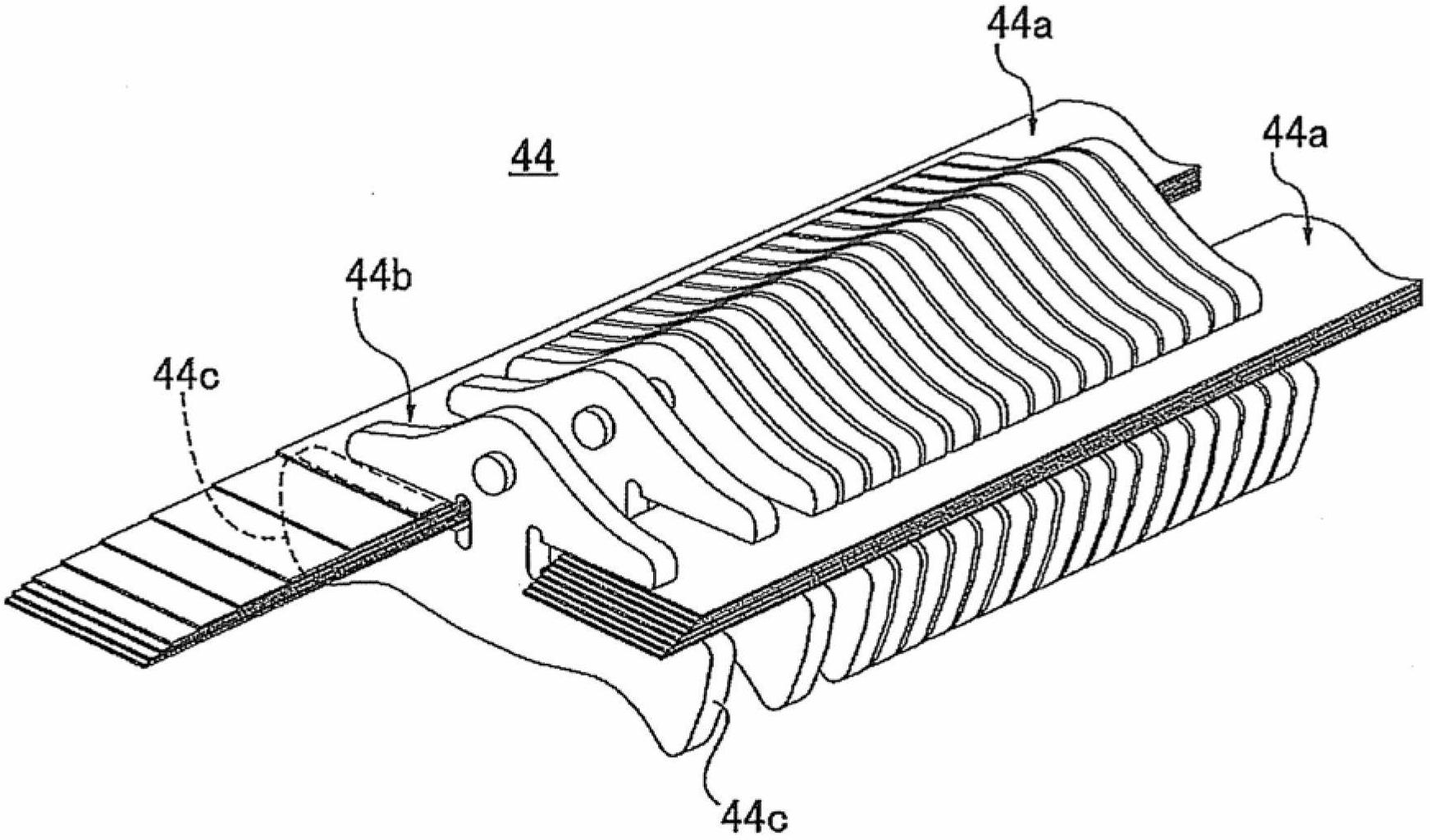

Device and method for controlling a belt-type continuously variable transmission for a vehicle

Disclosed is a continuously variable transmission that expands the operating range over which belt-slip control is allowed, while maintaining the estimated precision of the belt-slip state. This reduces belt friction, thereby reducing the drive energy used. A belt (44) is wrapped around a primary pulley (42) and a secondary pulley (43), and the gear ratio is controlled by controlling a primary hydraulic pressure and a secondary hydraulic pressure. The disclosed belt-type continuously variable transmission for a vehicle is provided with a belt-slip control means (fig. 8) and a gear-ratio change-rate limitation means (step S23 in fig. 12). When a gear-ratio change rate is less than a given value, said gear-ratio change rate being the rate at which the gear ratio changes, the belt-slip control means controls the secondary hydraulic pressure on the basis of a phase difference ( ) between a vibration component due to oscillation in the actual gear ratio and a vibration component due to oscillation in the actual secondary hydraulic pressure. The gear-ratio change-rate limitation means uses prescribed acceleration limitation allowance conditions to determine whether or not the acceleration of the vehicle may be limited (steps S21, S22, and S26 in fig. 12), and if so, limits the gear-ratio change rate to less than the aforementioned given value.

Owner:NISSAN MOTOR CO LTD +1

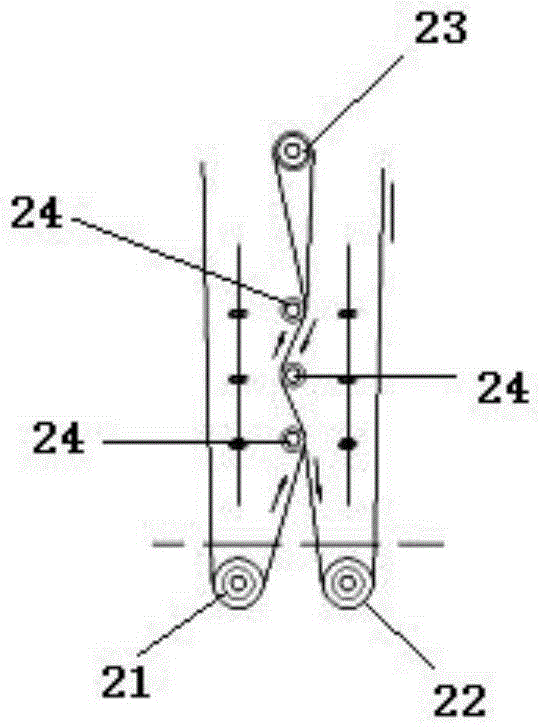

Cage twisting machine wire barrow paying out tension controlling method and apparatus

InactiveCN1933038ASmall initial pay-off tensionGood radial positioningFilament handlingCable/conductor manufactureInstabilityMagnetic poles

Strain of payoff control method and device uses for cage stranger payoff tray of electrical wire and cable equipment. Existing technology adopts strap friction to control the strain of payoff, while the strain of payoff is instability and is disaccord of some cradle payoff tray. It adopts permanent damp technology to adjust magnetic pole air-gap of damp tray and to control strain of payoff. It relates to passive damp tray, active damp tray, accommodate handle, active tray slide cover, transmission shaft, graduation direction mark, fix seat of passive damp tray, bearing, bearing cover and cradle body. Turn accommodate handle to adjust strain of payoff. Accommodate moment is extended constant and dose not change with temperature, time and opposite slide difference speed for non-friction. The whole operation keeps steady strain of payoff and realizes the coherence of strain of payoff to all cradle payoff trays by clearance graduation direction mark.

Owner:百通赫思曼工业(苏州)有限公司

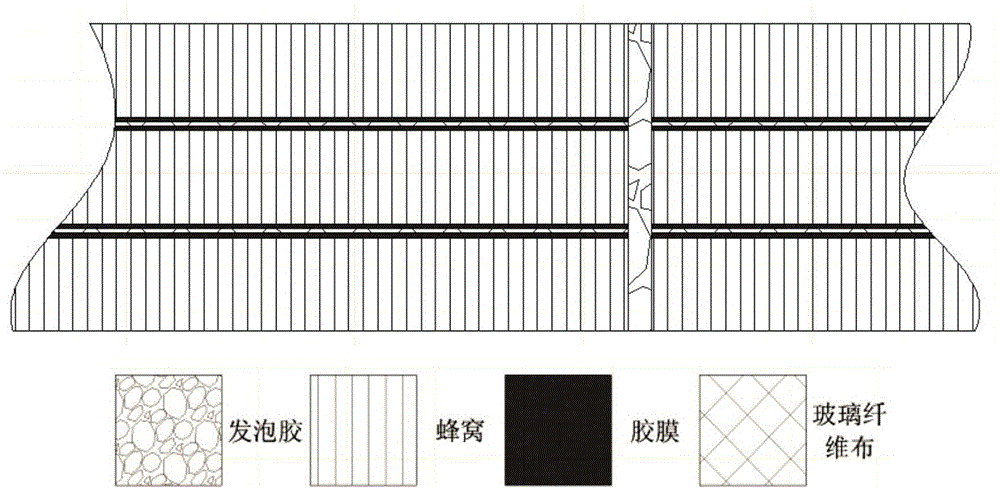

Multi-layer splicing forming method for honeycomb

The invention belongs to the field of aerospace honeycomb processing and particularly relates to a multi-layer splicing forming method for a honeycomb. The defects of the retraction, sliding and collapse and the like of the honeycomb still cannot be overcome by adjusting the curing parameter and an anti-sliding belt friction bolt system for a large-thickness large-chamfering honeycomb interlayer structural component with the high design rigidity and weight requirements. According to the multi-layer splicing forming method for the honeycomb, the thickness of the honeycomb interlayer structural component is laminated, each layer of the honeycomb is spliced in a partitioned manner, and through the splicing and performing of the honeycomb multiple layers, the lateral pressure resistance of the honeycomb is improved; and the purpose of forming and manufacturing the large-thickness large-angle honeycomb interlayer structural component without changing the weight and rigidity conditions is achieved, and the appearance quality of the formed part is good.

Owner:哈尔滨哈飞航空工业有限责任公司

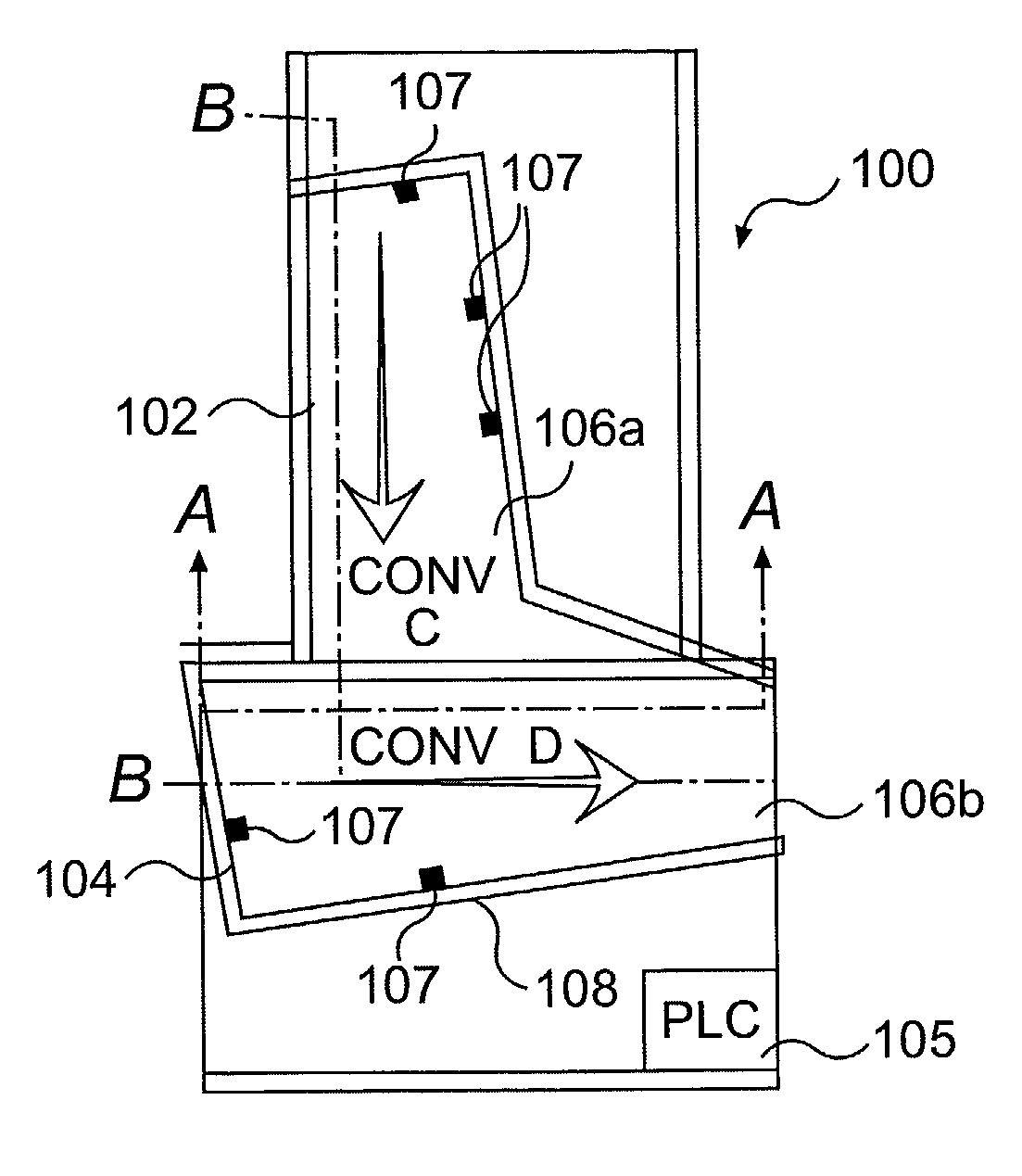

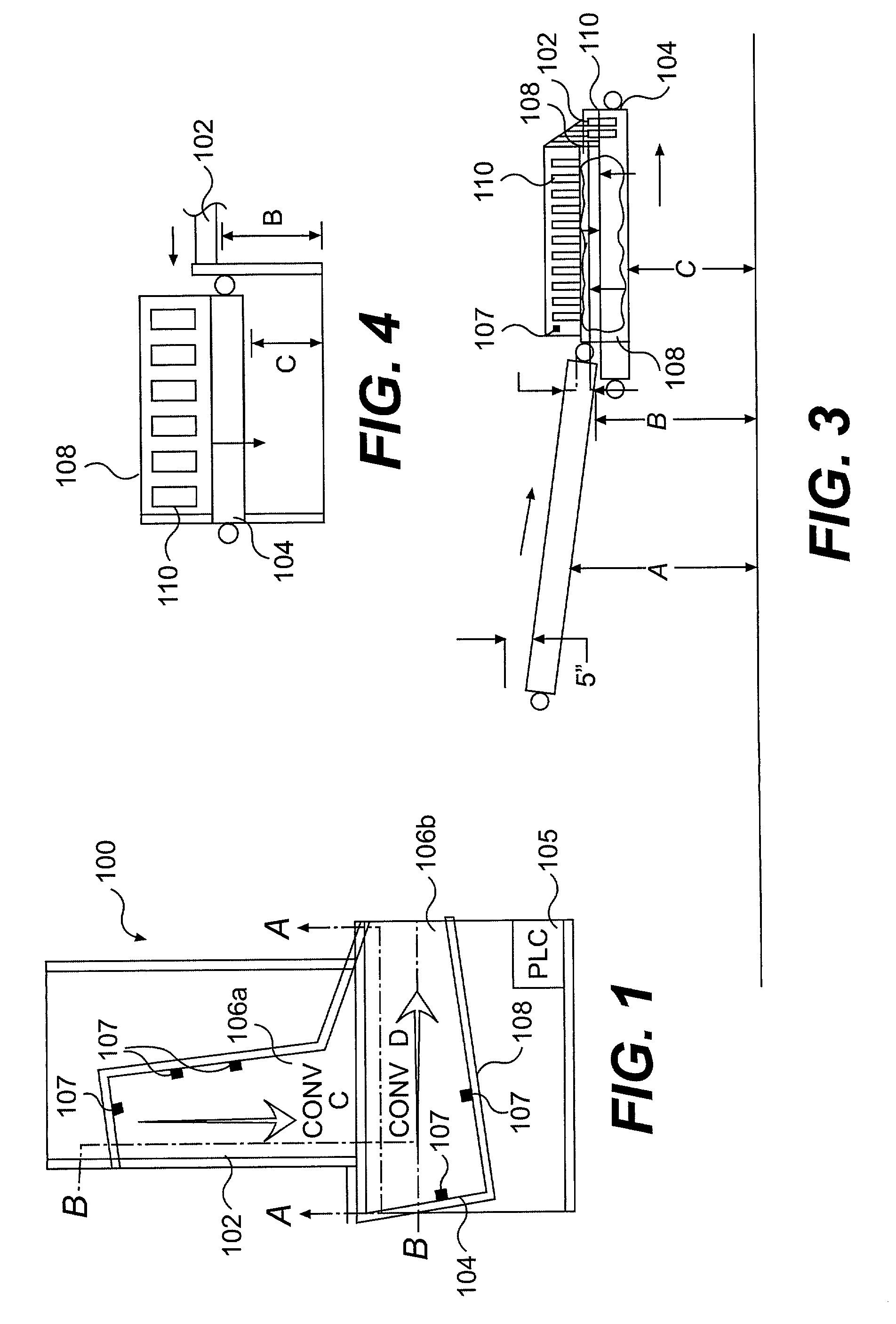

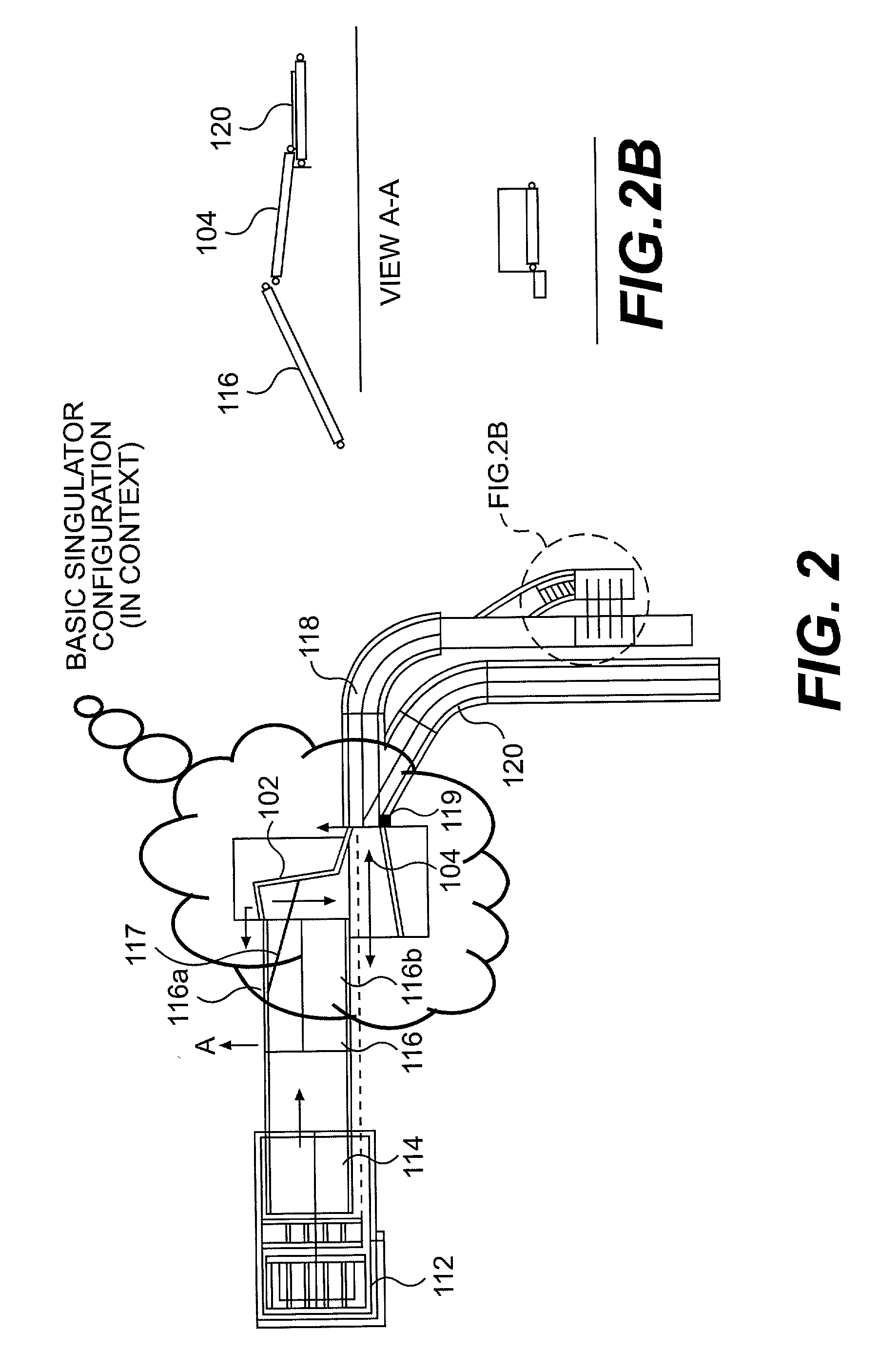

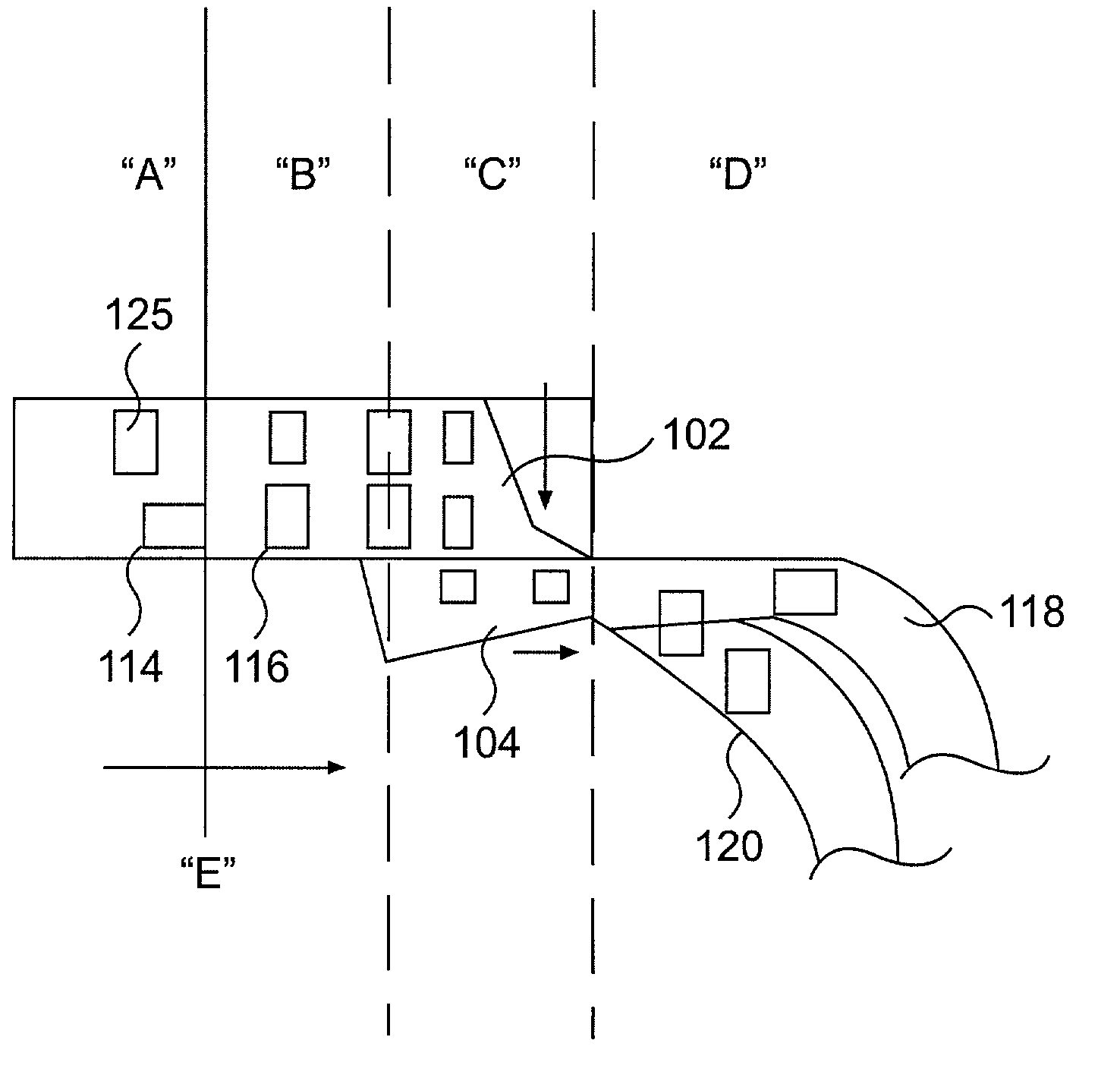

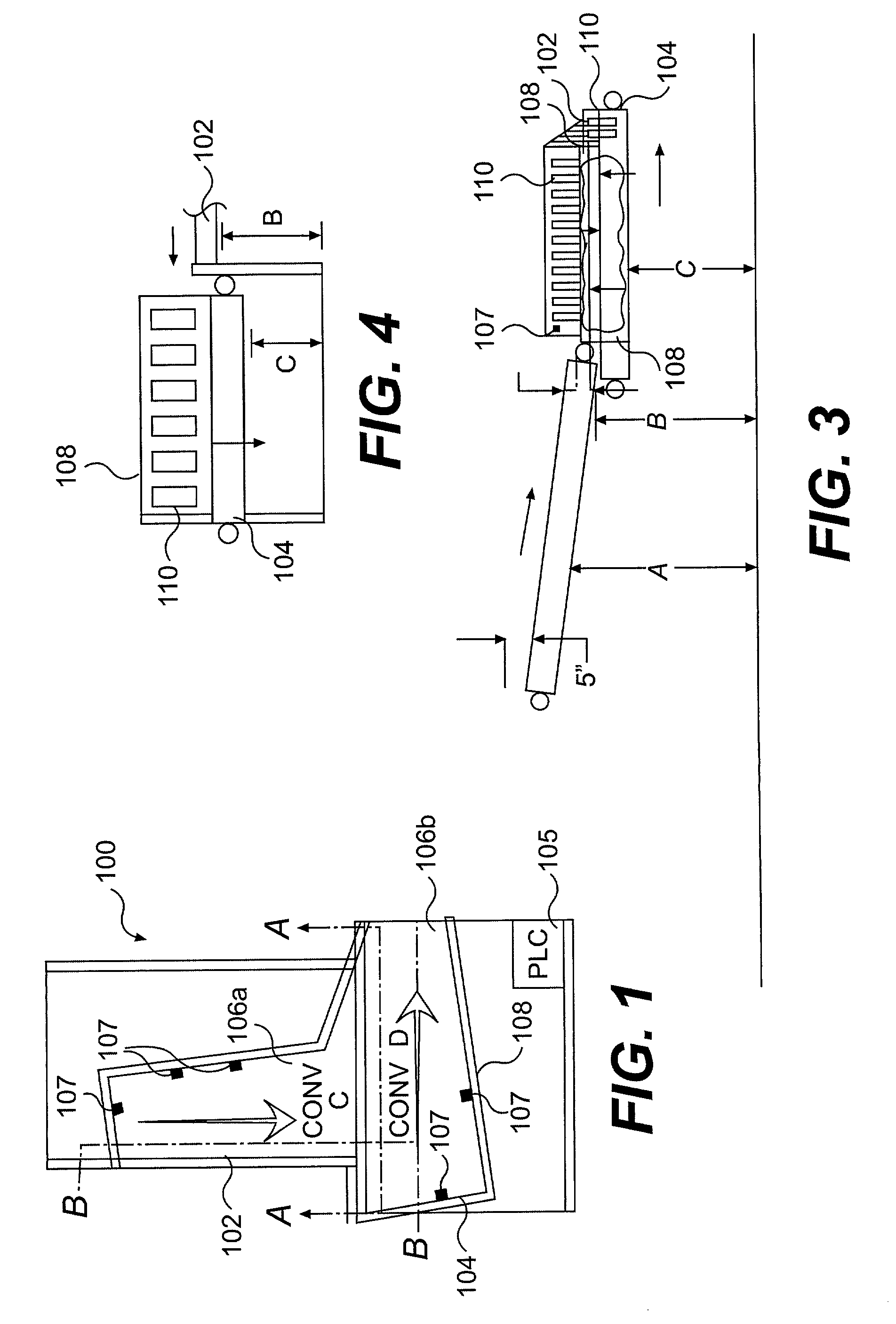

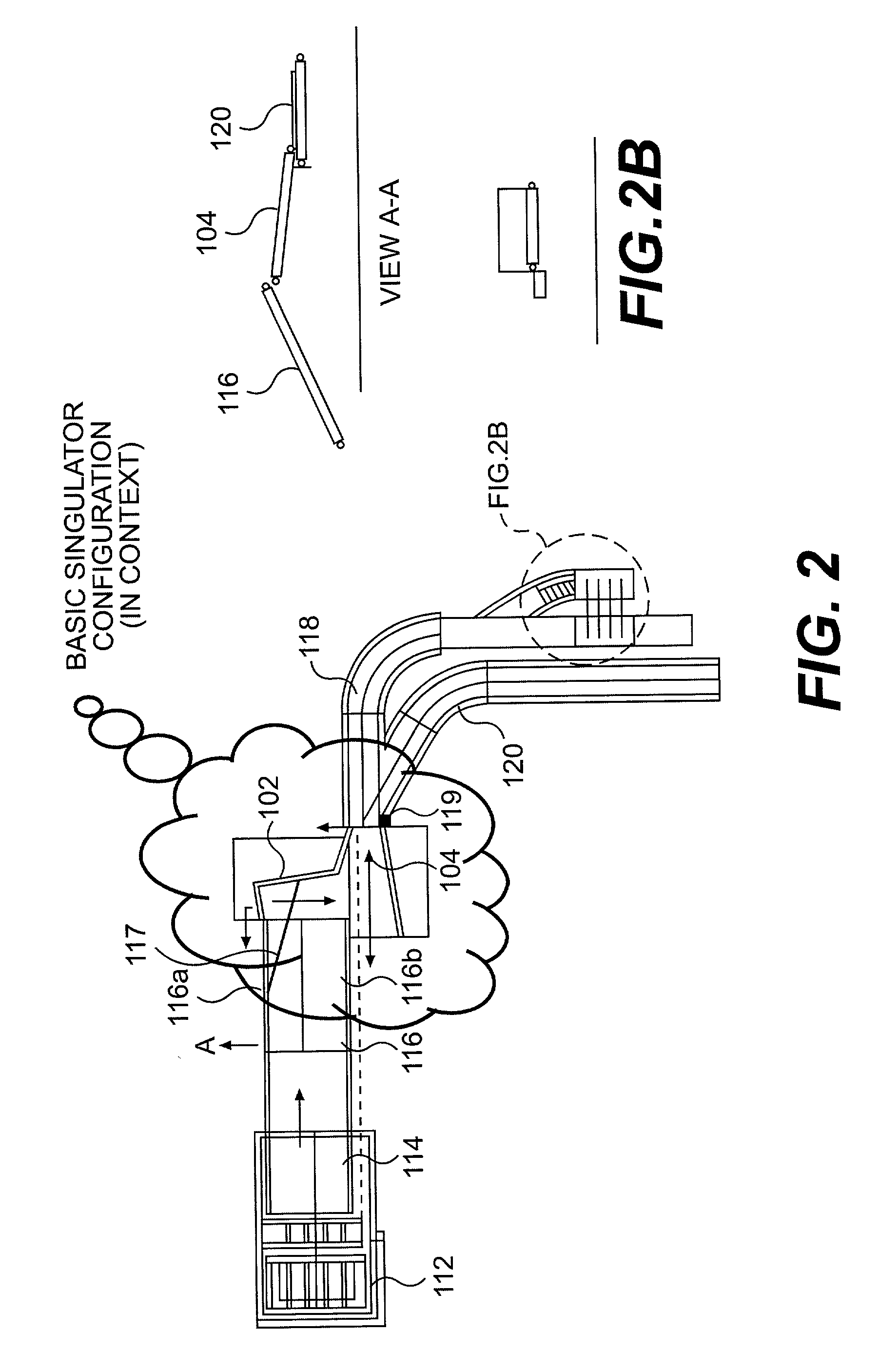

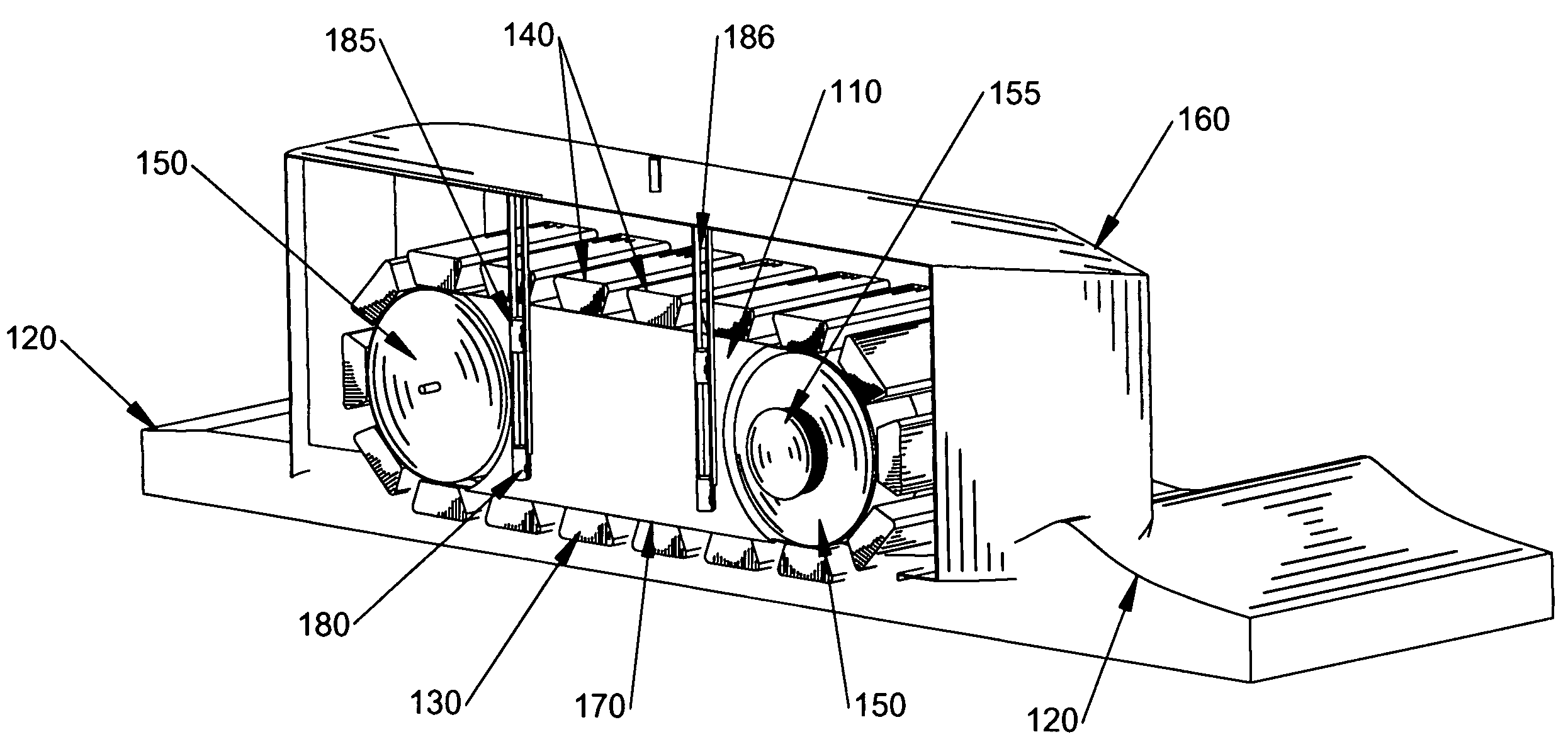

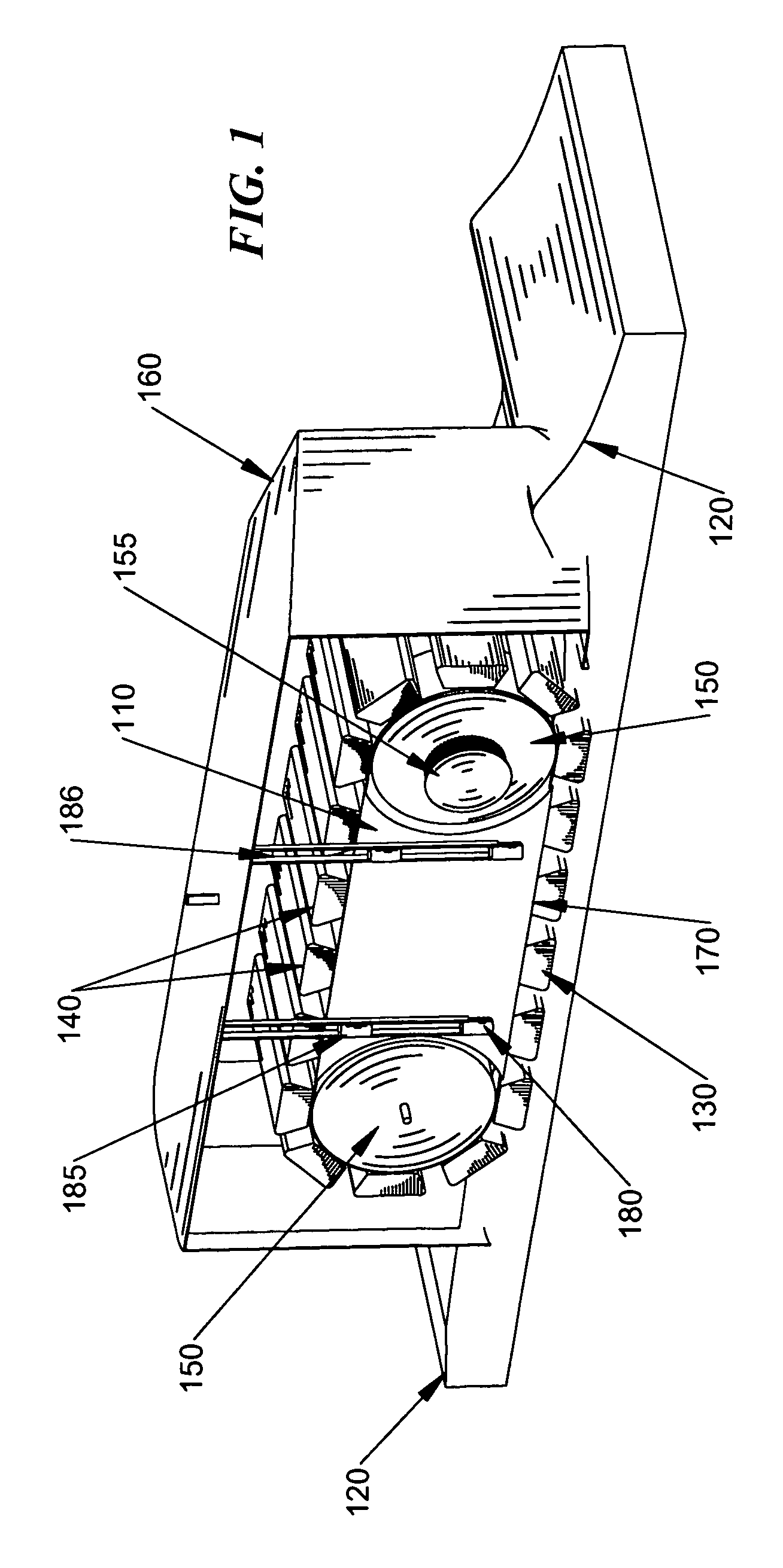

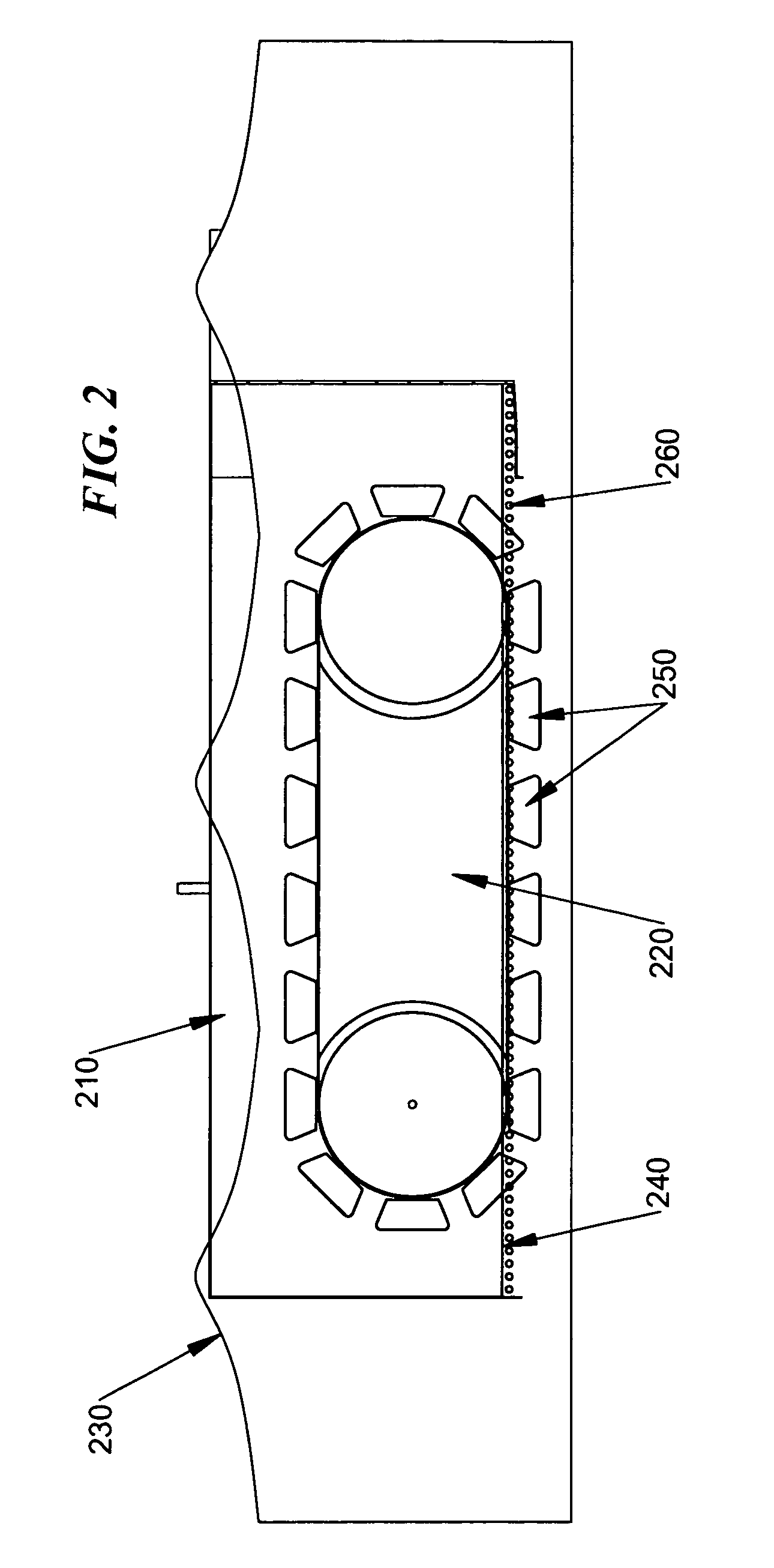

Mail tray singulator and method of use

InactiveUS7137502B2Unified directionControl devices for conveyorsDownstream processingProgrammable logic controller

A mail tray singulator for controlling the handling, movement and sensing of mail trays or other mail items into a single file arrangement on a conveyor system for downstream processing. The mail tray singulator includes conveyor modules configured at preferably right angles with respect to one another. The modules are configured so that they can be readily adapted to preexisting conveyor systems with minimal reconfiguration. The system may use differing speed, height and belt friction conveyor belts between adjacent modules to achieve separation and enhance the effect of the right angle configuration between adjacent conveyor modules. Guard rails and side rail rollers may also be employed. Photoeyes, in conjunction with a programmable logic controller, allow the conveyors to be started / stopped based on pre-programmed scenarios.

Owner:LOCKHEED MARTIN CORP

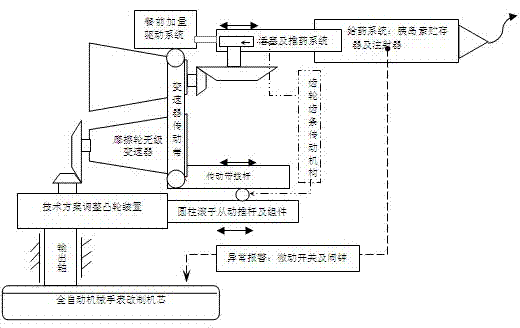

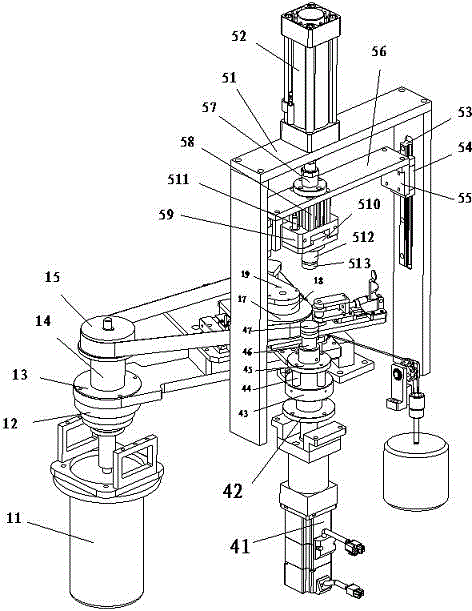

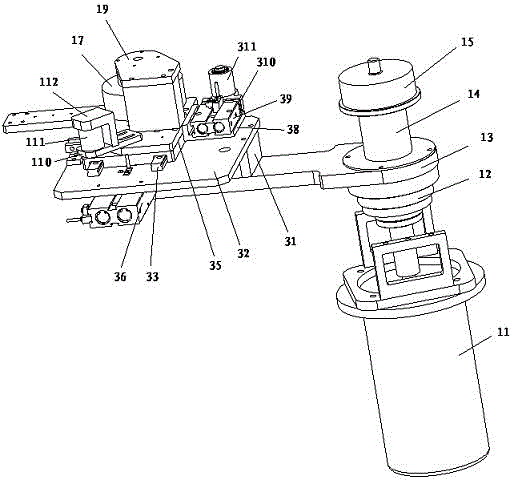

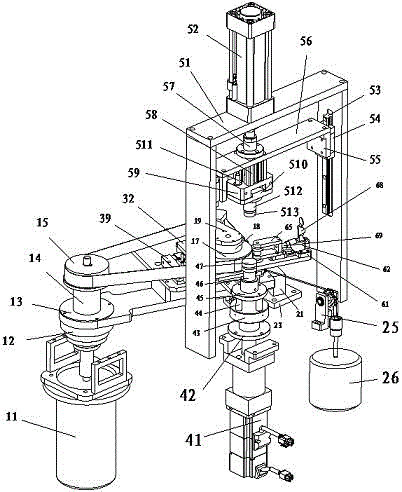

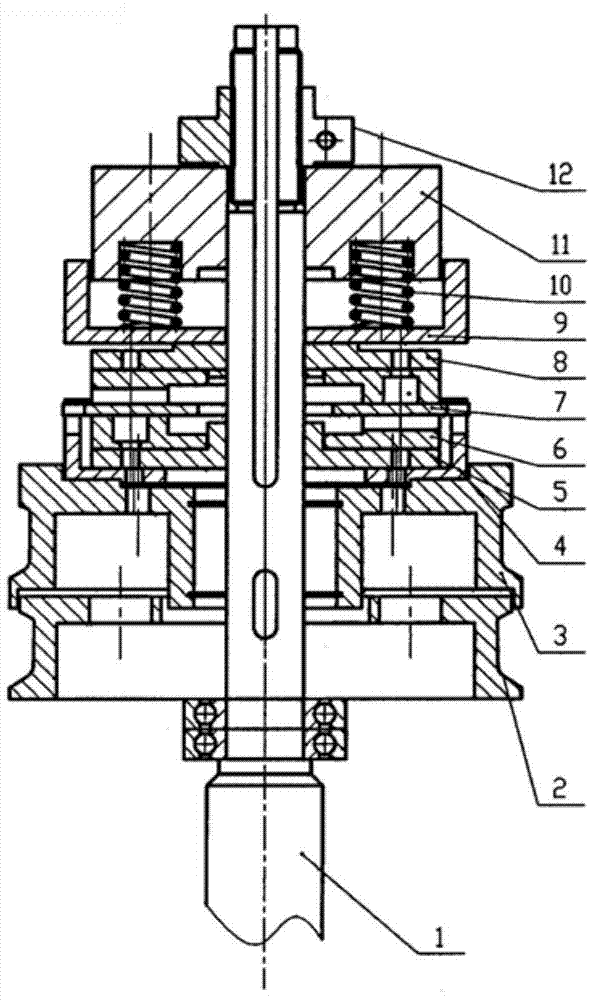

Fully-automatic mechanical insulin injection pump

InactiveCN102526840ASmooth transmissionNo pollution in the processAutomatic syringesLife qualityTreatment effect

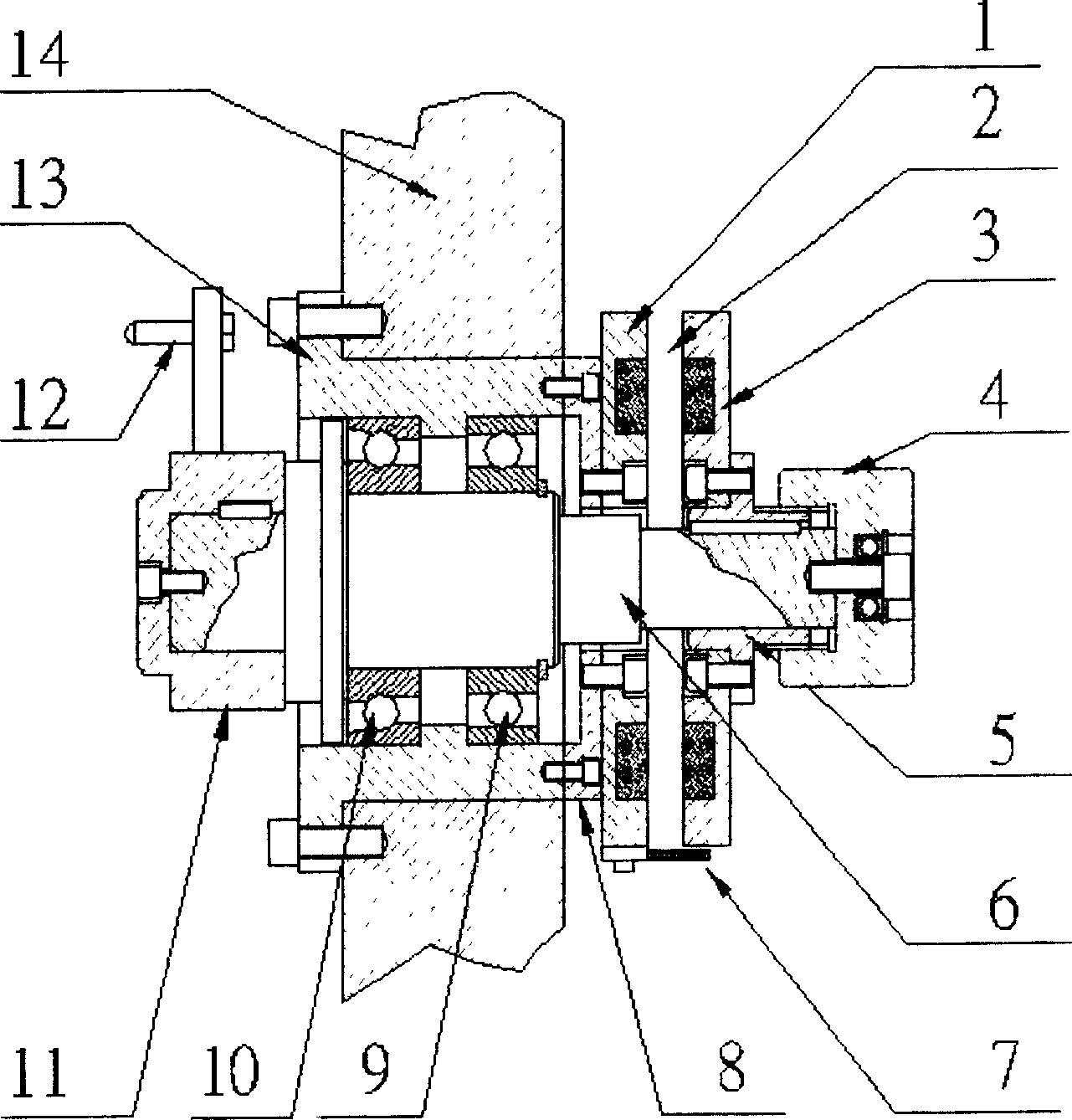

The invention discloses a fully-automatic mechanical insulin injection pump, which comprises a reformed mechanism of a mechanical watch, a continuously variable transmission of a belt friction wheel, an adjusting cam device of technical scheme, a gear rack precise injection and transmission mechanism, a dosage injection mechanism before meal, a medicine feeding system and the like. On the one hand, the output shaft of the mechanism drives the adjusting cam device of the technical scheme to further drive the continuously variable transmission of the belt friction wheel and the gear rack precise injection and transmission mechanism and finally drives the medicine feeding system to perform micro-injection of basic amount. On the other hand, a driven push rod on the cam device pushes a transmission belt on the continuously variable transmission of the belt friction wheel to change the axial position of the friction wheel so as to adjust the transmission ratio of the continuously variable transmission of the belt friction wheel. The fully-automatic mechanical insulin injection pump driven by fully-automatic mechanical way is environmentally friendly, safe and reliable, and can reduce the use cost. Therefore, the invention can vigorously accelerate the treatment effect of diabetes patients, alleviate the economic and spiritual pressure, improve the life quality and obtain good economic and social benefits.

Owner:HUAIHAI INST OF TECH

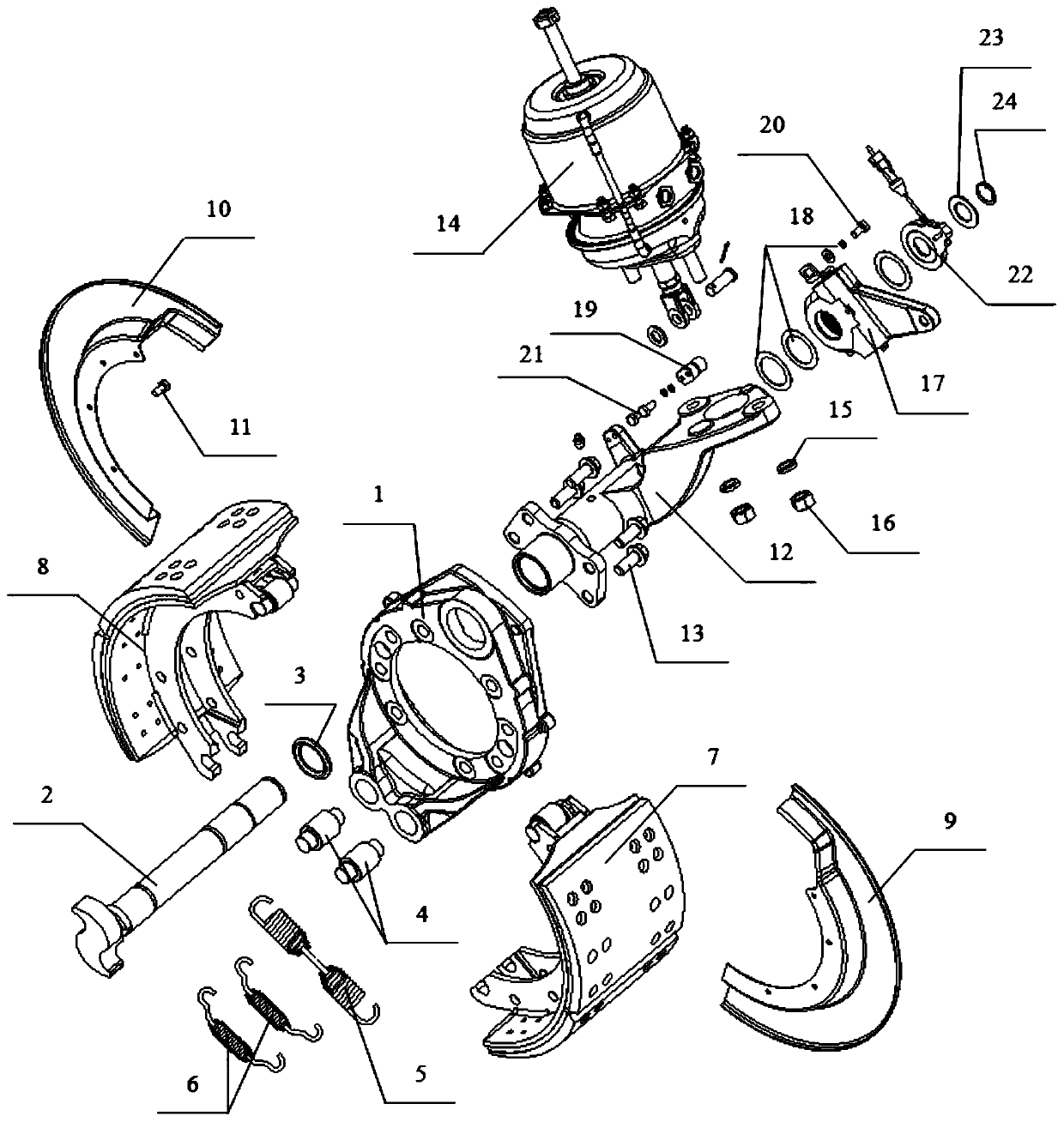

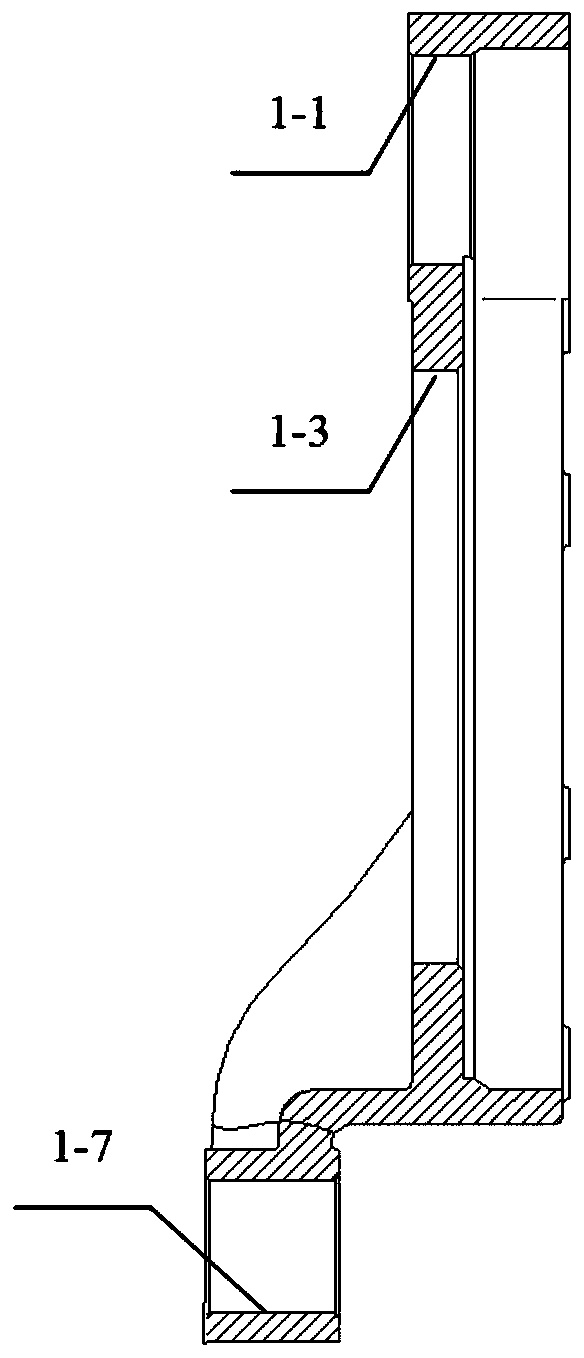

Brake assembly with corner type brake shoe friction plate abrasion alarm device

The invention provides a brake assembly with a corner type brake shoe friction plate abrasion alarm device. The brake assembly comprises a brake bottom plate, a cam shaft, an active brake shoe iron belt friction plate assembly, a driven brake shoe iron belt friction plate assembly, a cam support, a spring brake cylinder, an automatic adjusting arm, a brake friction plate abrasion alarm sensor andother parts. According to the brake assembly, the brake friction plate abrasion alarm sensor is used for detecting the adjustment angle difference value between the automatic adjusting arm and the camshaft to judge whether the brake shoe friction plate reaches the abrasion limit, a corner displacement signal is converted into an electric signal, and then the electric signal is converted into a sound, light and other signals to give an alarm to a driver in the driving room. According to the brake assembly, the brake assembly body does not need to be changed, only the cam shaft needs to be correspondingly changed, the abrasion limit of the brake shoe friction plate can be monitored, the brake friction plate abrasion alarm sensor can be repeatedly used, and the service life is long.

Owner:FAW JIEFANG AUTOMOTIVE CO

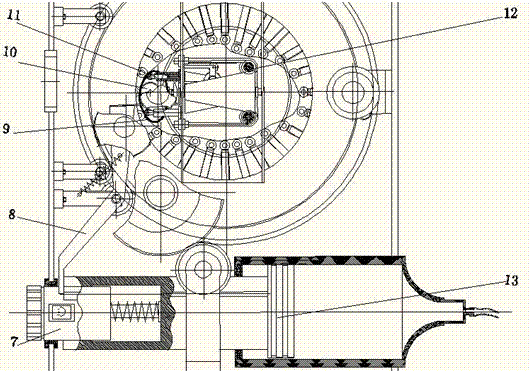

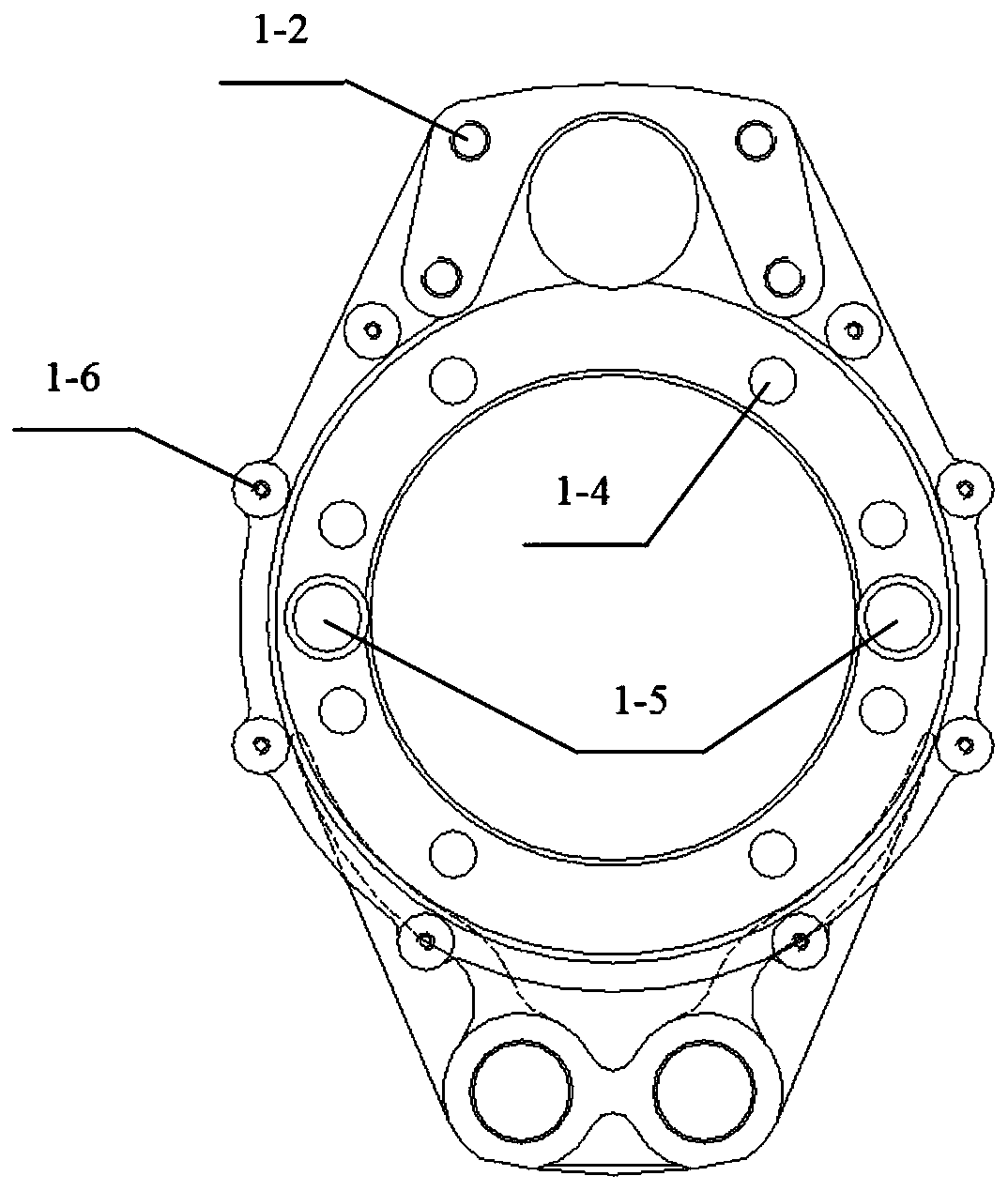

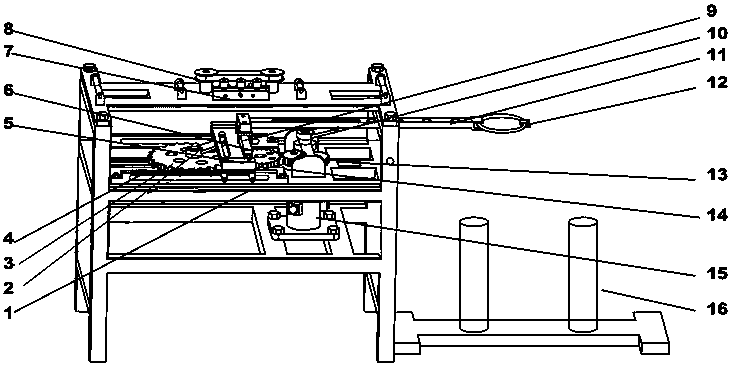

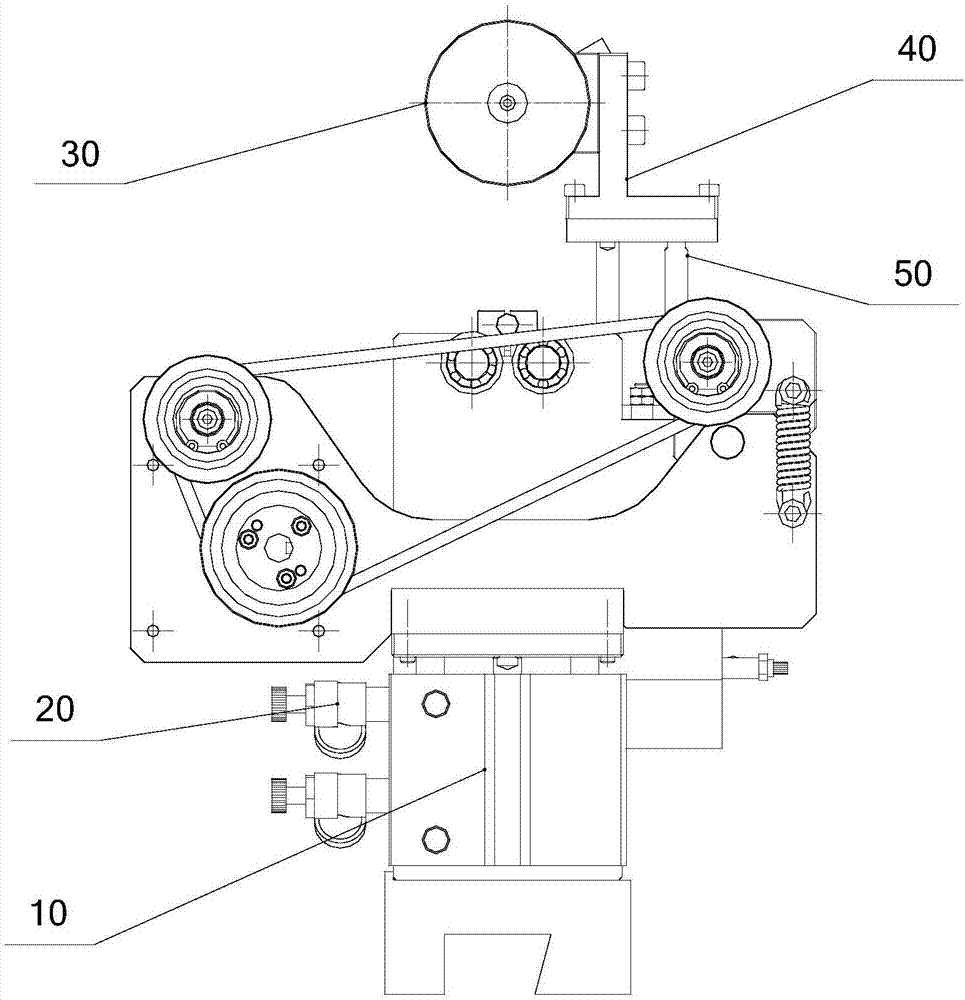

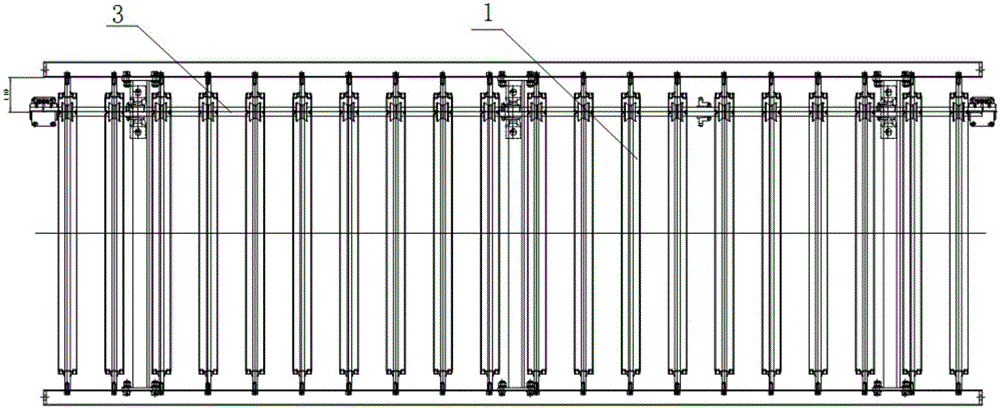

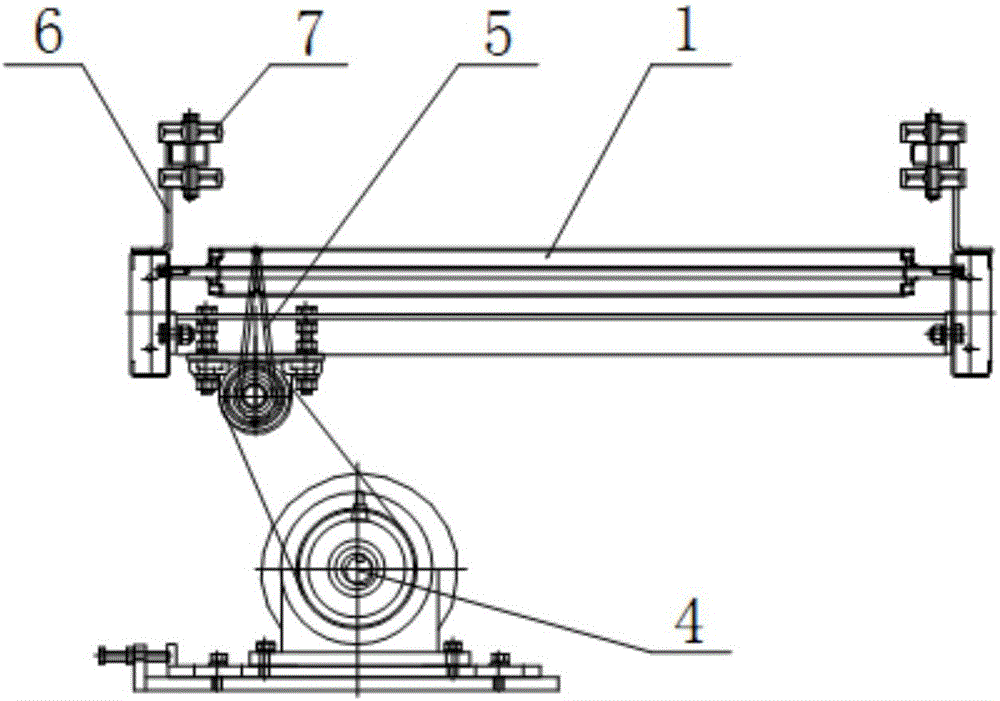

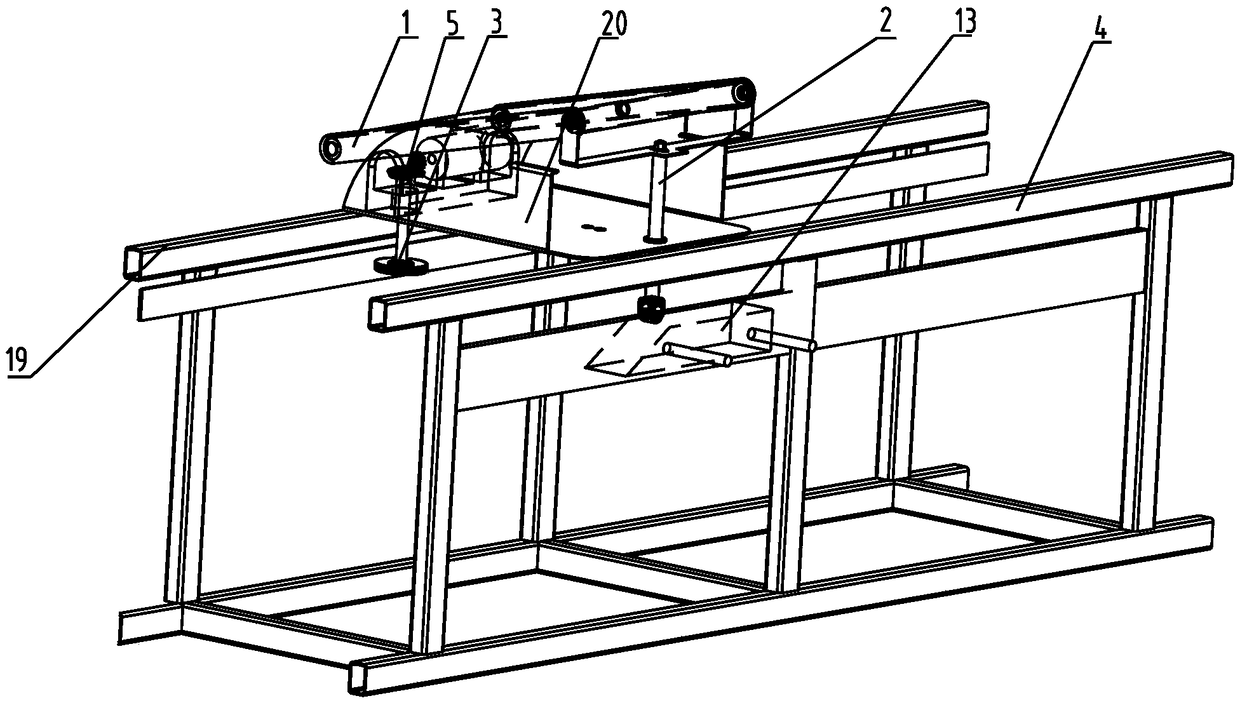

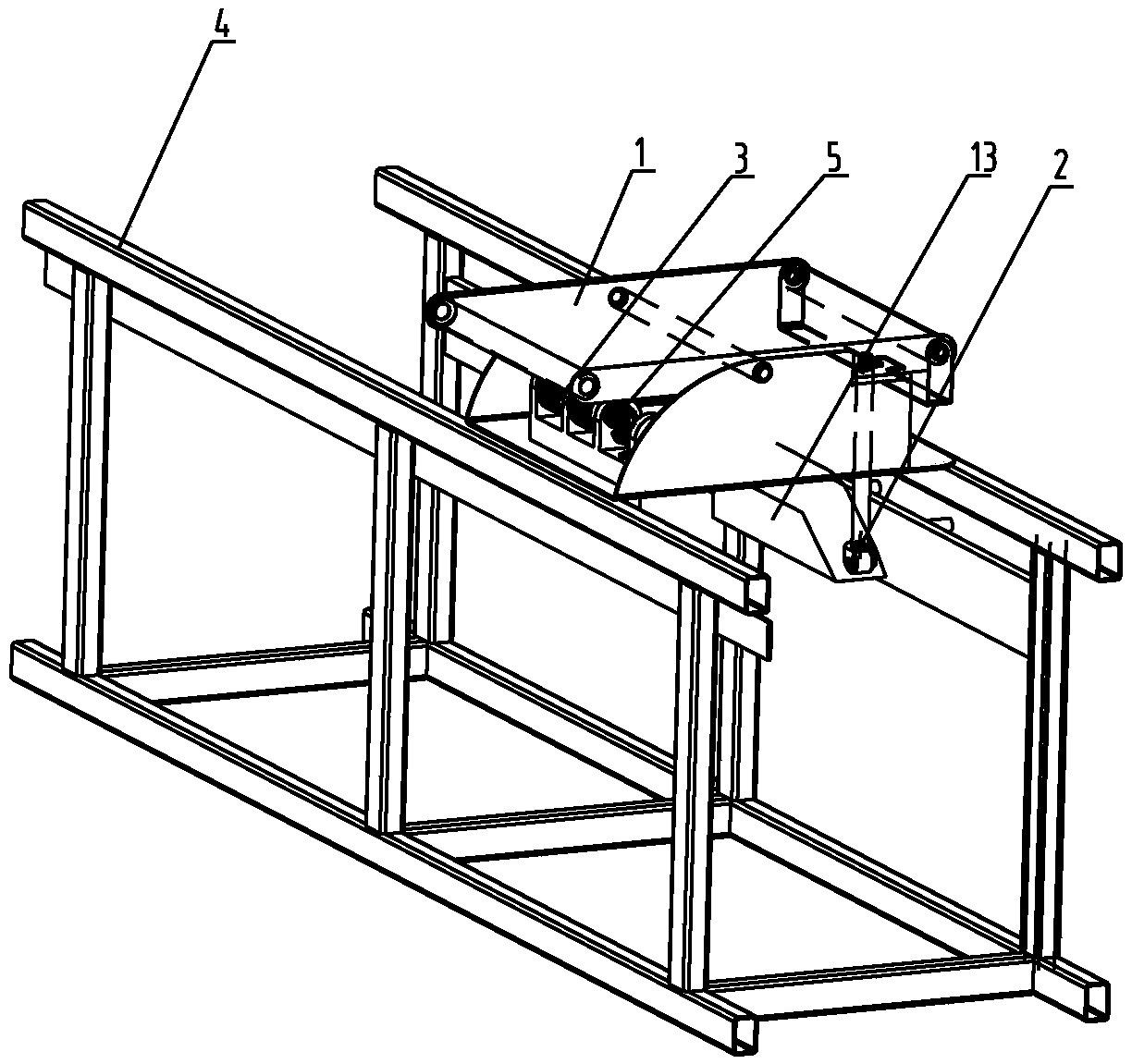

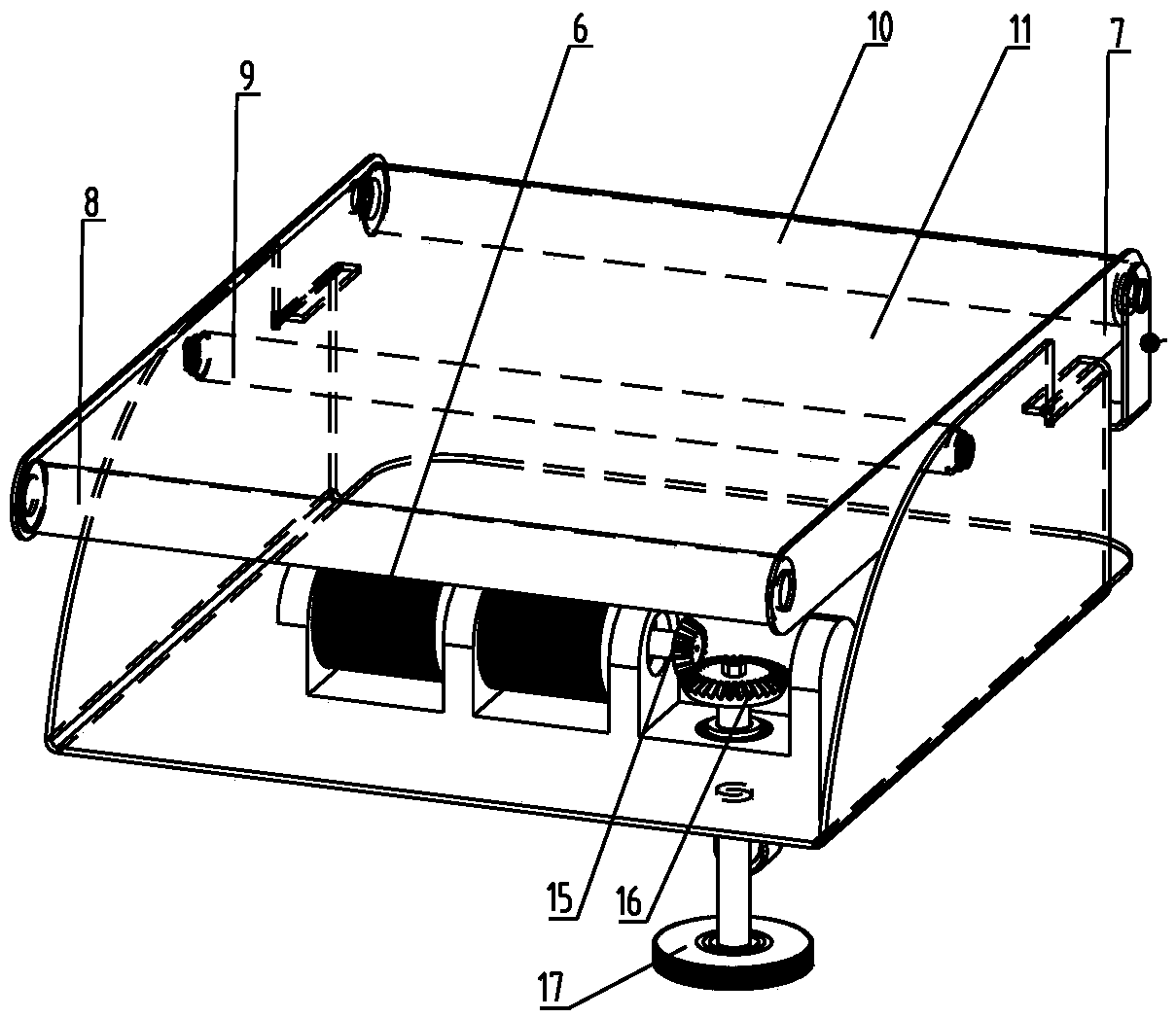

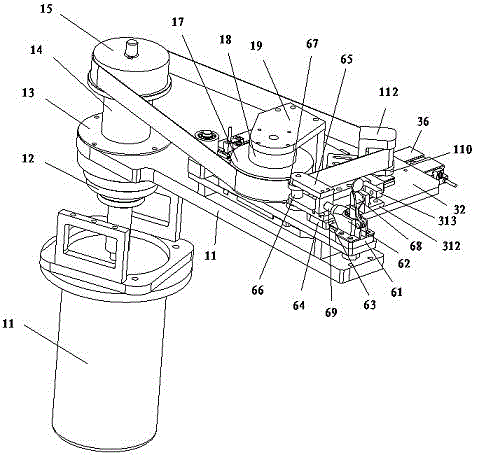

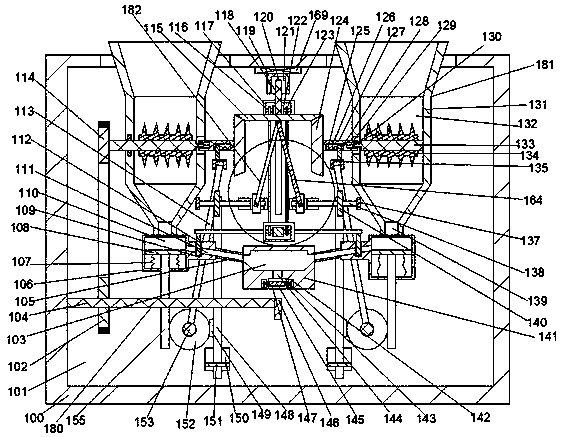

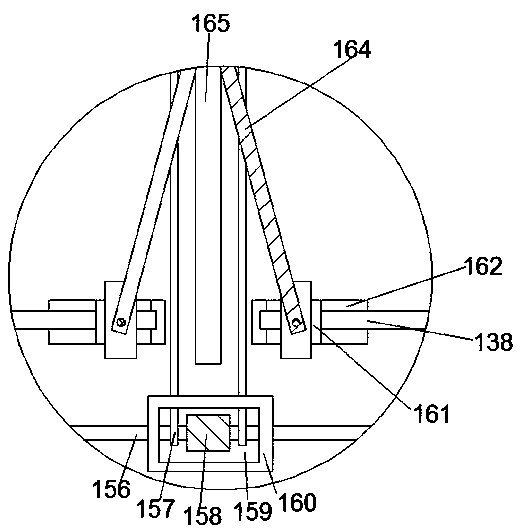

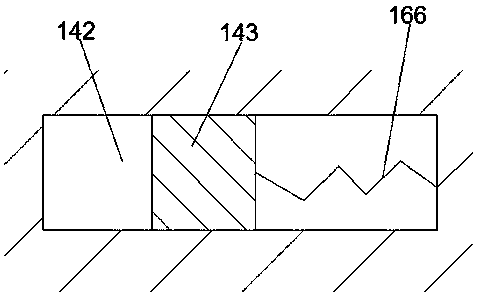

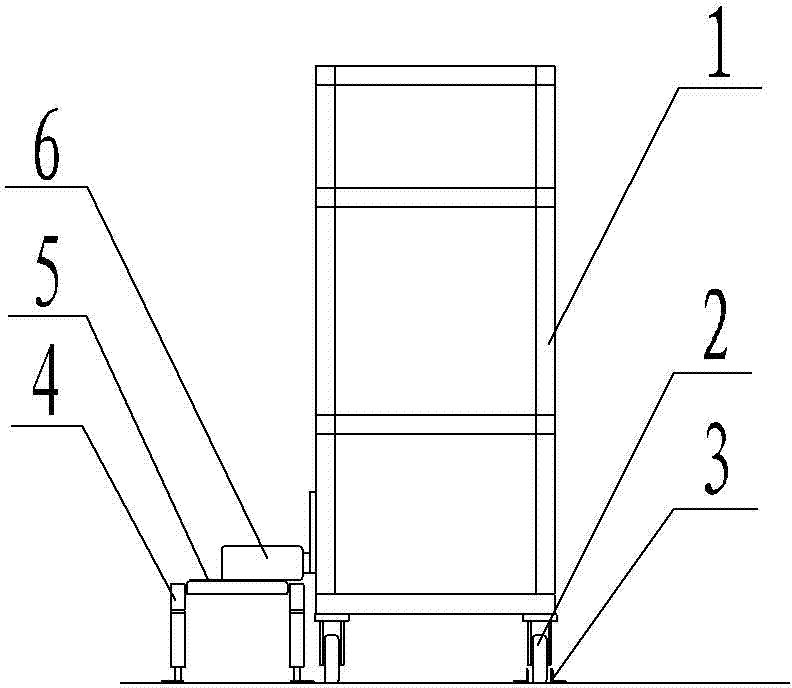

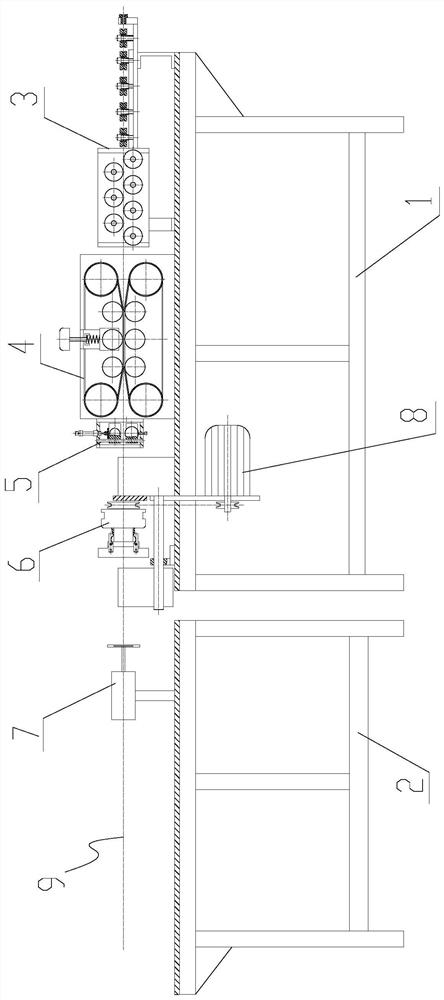

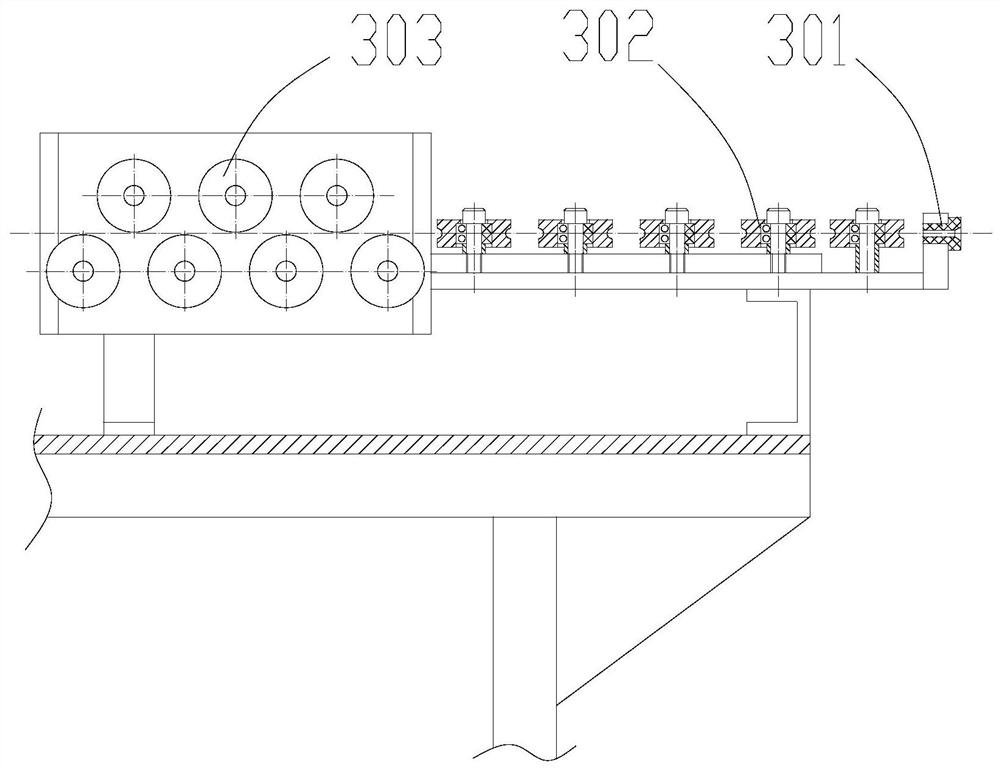

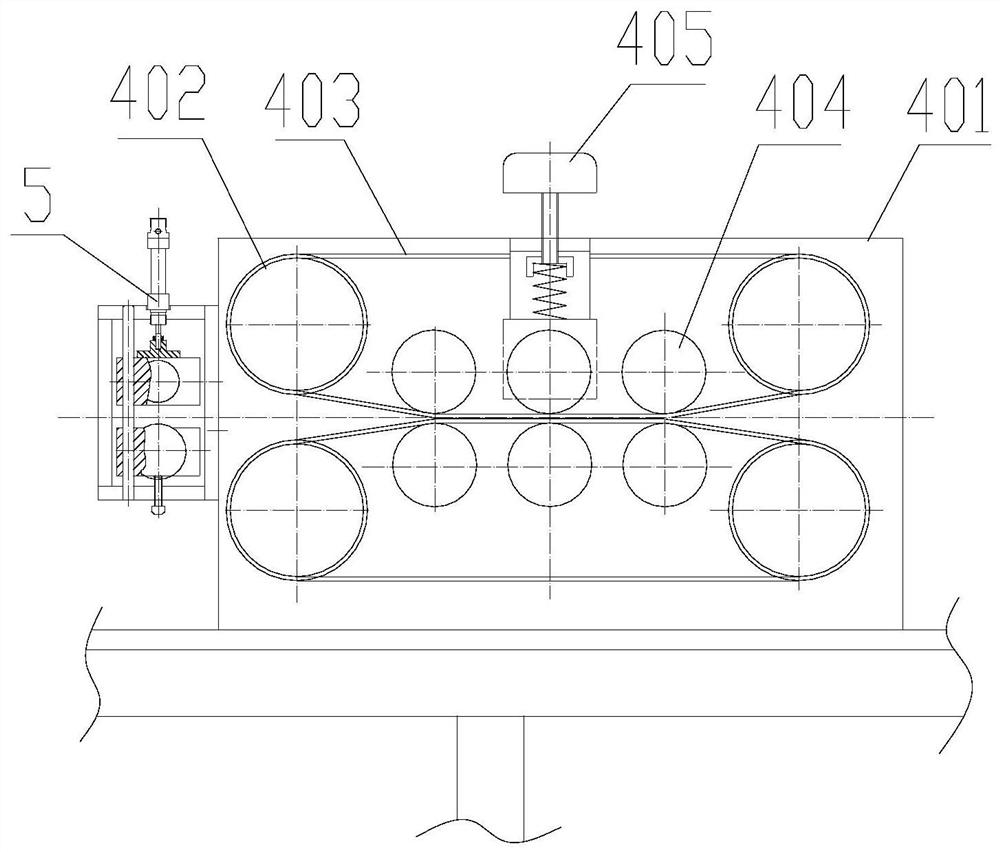

Underground coal mine fully mechanized coal mining face high-voltage cable no-twisting rolling device

The invention discloses an underground coal mine fully mechanized coal mining face high-voltage cable no-twisting rolling device, and belongs to the field of mine machinery. The underground coal minefully mechanized coal mining face high-voltage cable no-twisting rolling device comprises a low-speed hydraulic motor driving device, a cable conveying device, a 8-shaped device, a frame and the like;and the low-speed hydraulic motor driving device is positioned below the frame, and provides power to the 8-shaped device. The cable conveying device is positioned above the frame, and comprises a cable pressing mechanism, a flat belt friction conveying mechanism and a support roller; and the cable conveying device drags redundant cables on a working surface to convey the cables for the rolling operation of the 8-shaped device. The 8-shaped device is positioned at the middle part of the frame, and comprises a transmission gear set, a longitudinal moving crank slide block mechanism, a transverse moving crank slide block mechanism and a guide sliding mechanism; large and small gears in the transmission gear set provide power to the two sets of crank slide block mechanisms; and when relativeinitial mounting positions of two crankshafts are determined, a rotating speed ratio of the two crankshafts is 1: 2, a cable rolling rod synchronously moves in the longitudinal and transverse directions, and the tail end of the wire rolling rod moves in a similarly 8-shaped trajectory. Through use of the 8-shaped cable winding method, the torsion of the cables in the rolling process can be reduced, and the torsion margin in the cable rolling process after rolling can be effectively counteracted. The device is convenient to operate, and can solve the problems of time and labor wastes in traditional manual cable rolling operation, cable damage and difficult guarantee of the rolling quality in an underground coal mine fully mechanized coal mining face.

Owner:HENAN POLYTECHNIC UNIV

Mail tray singulator and method of use

InactiveUS20030209408A1Control devices for conveyorsDownstream processingProgrammable logic controller

A mail tray singulator for controlling the handling, movement and sensing of mail trays or other mail items into a single file arrangement on a conveyor system for downstream processing. The mail tray singulator includes conveyor modules configured at preferably right angles with respect to one another. The modules are configured so that they can be readily adapted to preexisting conveyor systems with minimal reconfiguration. The system may use differing speed, height and belt friction conveyor belts between adjacent modules to achieve separation and enhance the effect of the right angle configuration between adjacent conveyor modules. Guard rails and side rail rollers may also be employed. Photoeyes, in conjunction with a programmable logic controller, allow the conveyors to be started / stopped based on pre-programmed scenarios.

Owner:LOCKHEED MARTIN CORP

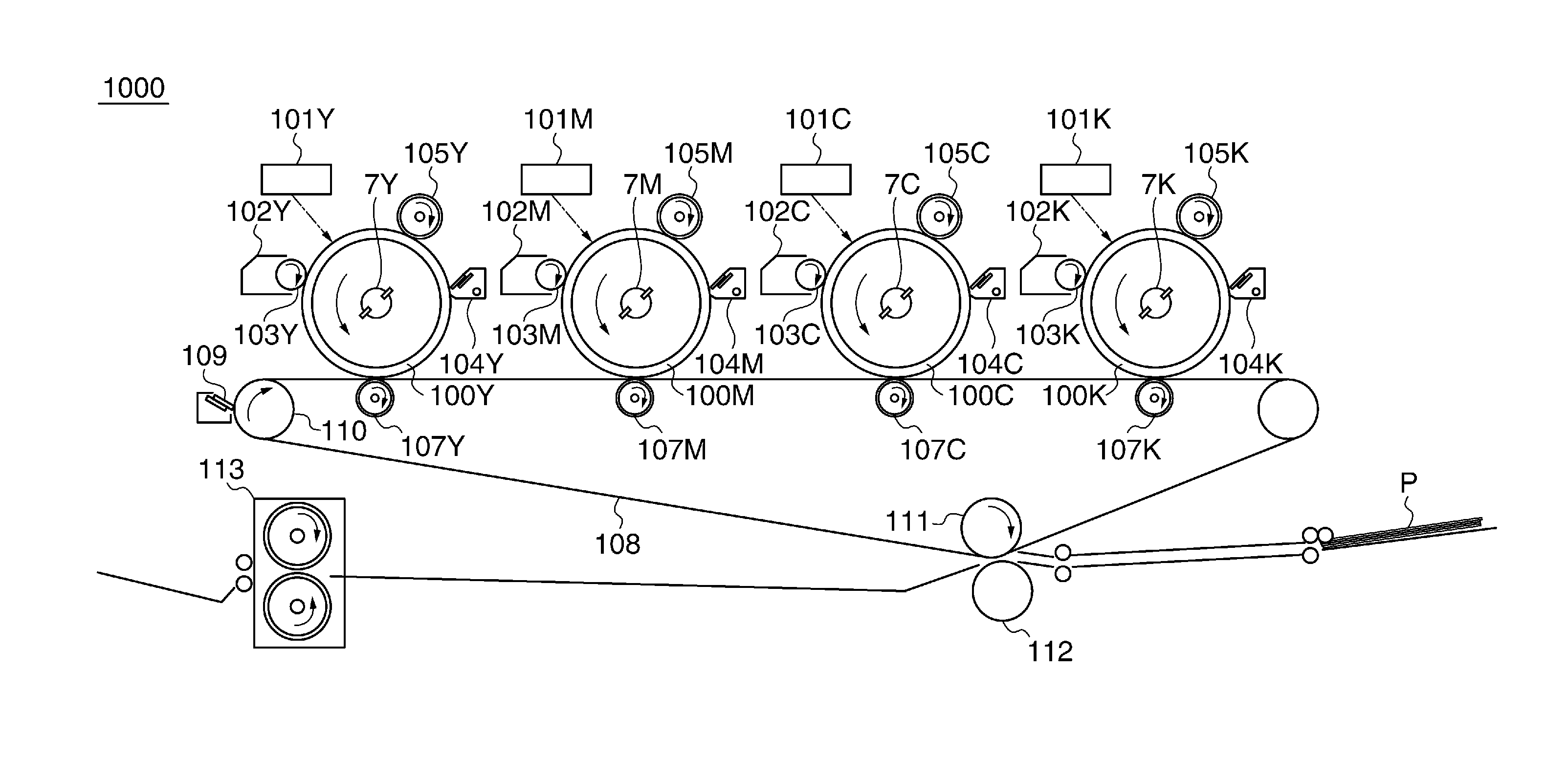

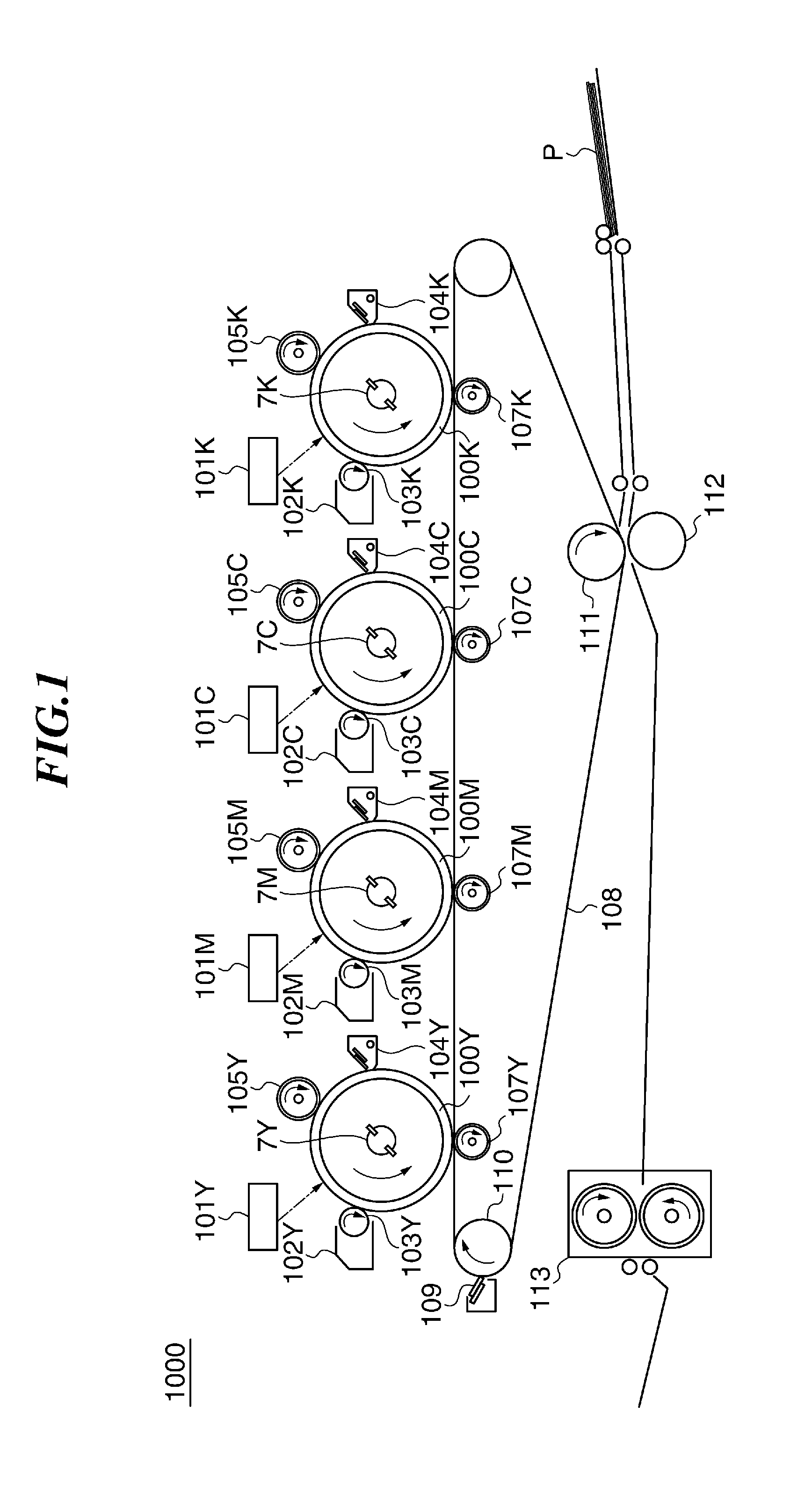

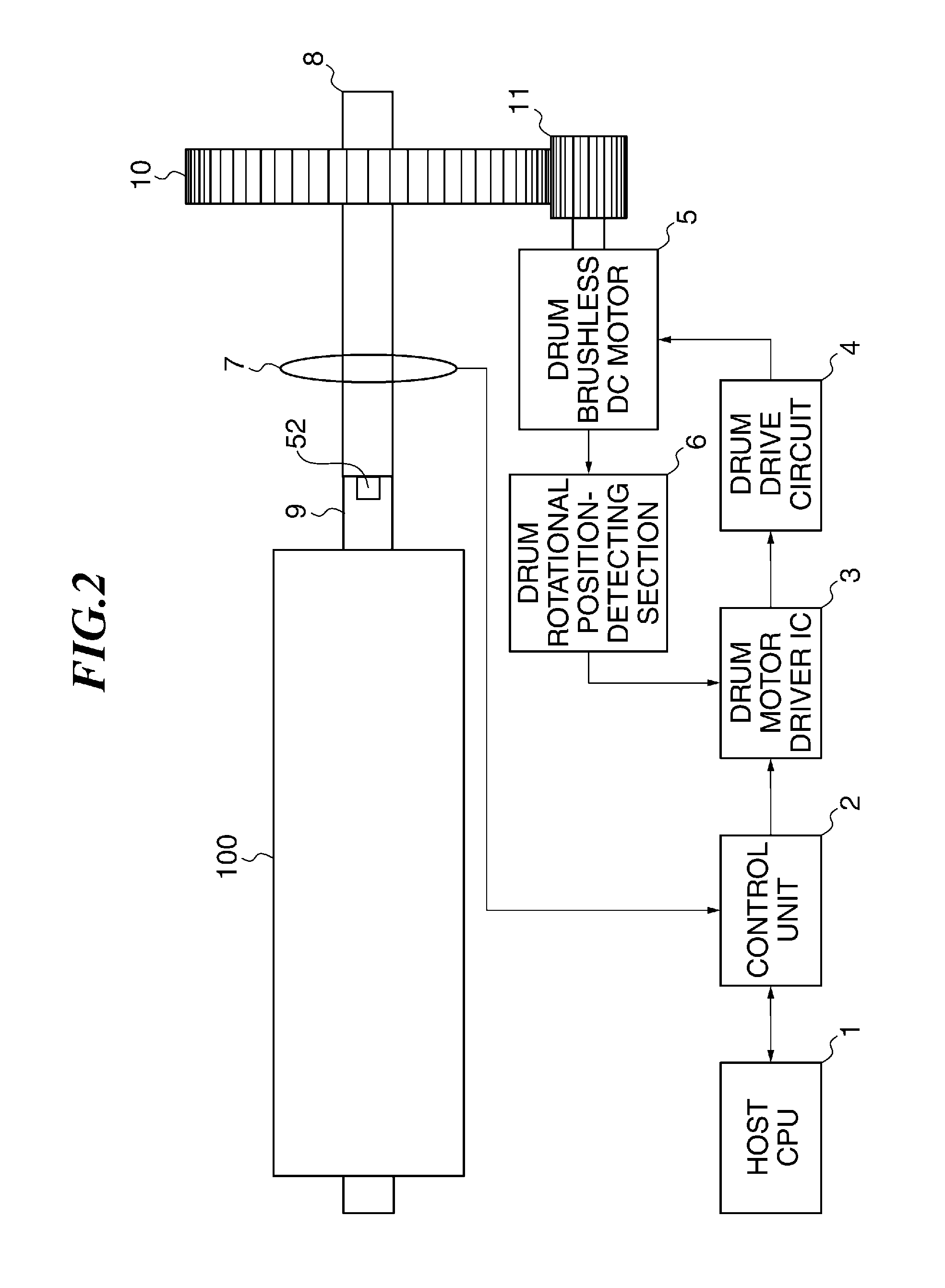

Image forming apparatus that suppresses occurrence of color shift in images and method of controlling the same

ActiveUS20140168338A1InhibitionColor shiftRecording apparatusElectrographic process apparatusColor shiftLatent image

An image forming apparatus that suppresses occurrence of color shift in images transferred from image bearing members onto an intermediate transfer member. A surface of each of a first photosensitive drum and second photosensitive drums is charged. An exposure device, provided for each photosensitive drum, forms an electrostatic latent image by exposing an associated one of the charged photosensitive drums. A developing device, provided for each photosensitive drum, develops the electrostatic latent image with toner. An intermediate transfer belt friction-drives the photosensitive drums for rotation and has the developed images transferred thereon. Timing for exposing the second photosensitive drums is controlled based on a first surface distance from an exposure light irradiated position to a primary transfer position of the first photosensitive drum, and a second surface distance from an exposure light irradiated position of each second photosensitive drum to a primary transfer position thereof.

Owner:CANON KK

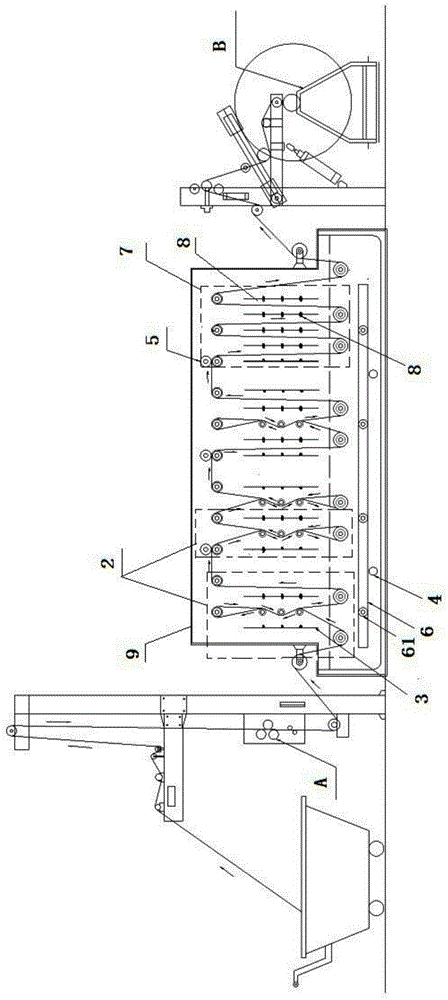

Open width sand washing machine

ActiveCN105297311AImprove operational efficiencyImprove efficiencyTextile treatment machine arrangementsTextile treatment by spraying/projectingPulp and paper industryAssembly line

The invention relates to an open width sand washing machine. The open width sand washing machine comprises a sand washing addition agent container. A plurality of rows of conveying roller sets with belt friction rollers which are sequentially arrayed to the textile fabric output direction from the textile fabric input direction are arranged above the sand washing addition agent container. High-pressure spray pipes with nozzles are arranged on one side or the two sides of the conveying roller sets with the belt friction rollers, and the input ends of the high-pressure spray pipes are connected with the sand washing addition agent container or a sand washing addition agent storage mechanism through a pump. Each conveying roller set with the belt friction rollers comprises an input roller allowing textile fabric to be input, an output roller allowing the textile fabric to be output, a revolution roller allowing the textile fabric to be turned to the output direction from the input direction and at least one friction roller. Each fiction roller is provided with a friction part which allows the textile fabric to pass through in the input direction and the output direction at the same time and generates friction. The open width sand washing machine has the advantages of being large in sand washing quantity, good in sand washing effect, capable of saving energy, environmentally friendly, low in labor cost, beneficial to achieving large-scale assembly line production of the textile fabric, and the like.

Owner:王佳茹

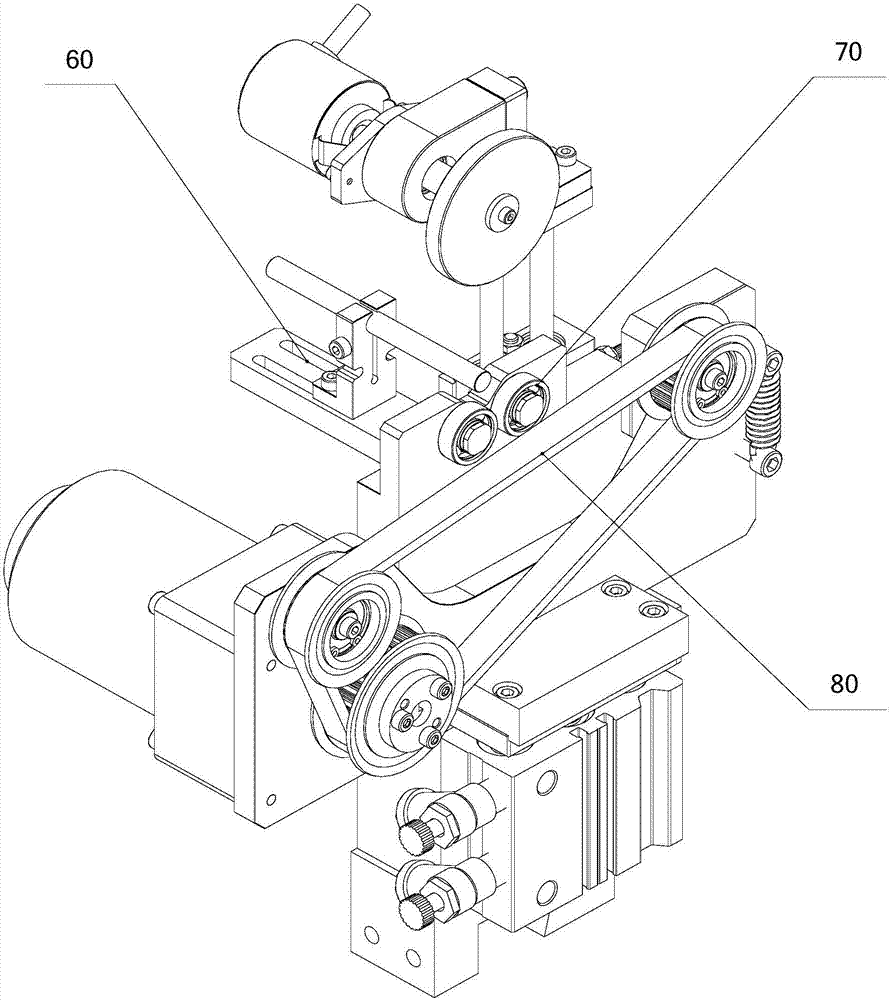

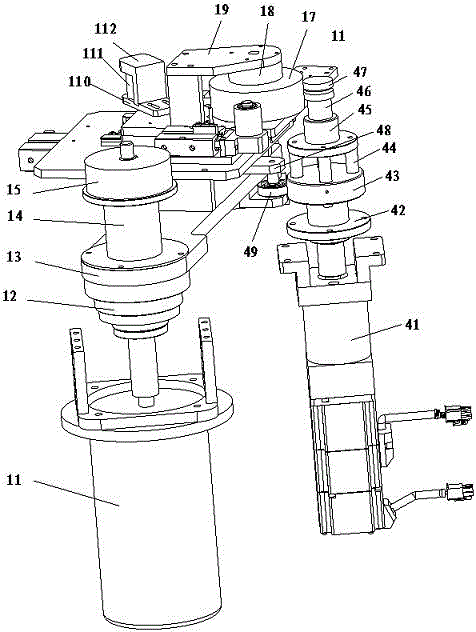

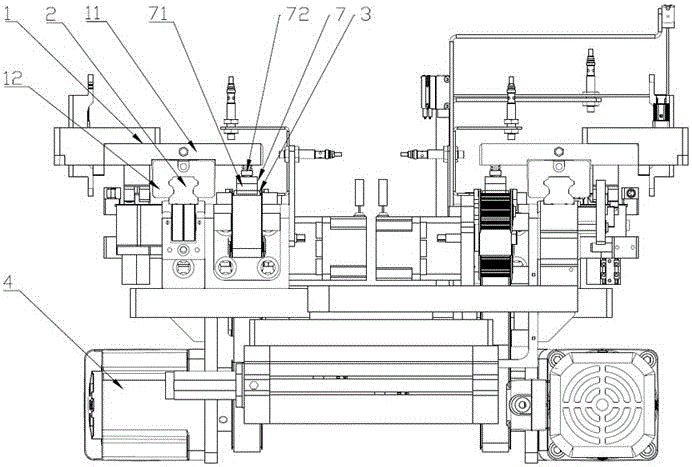

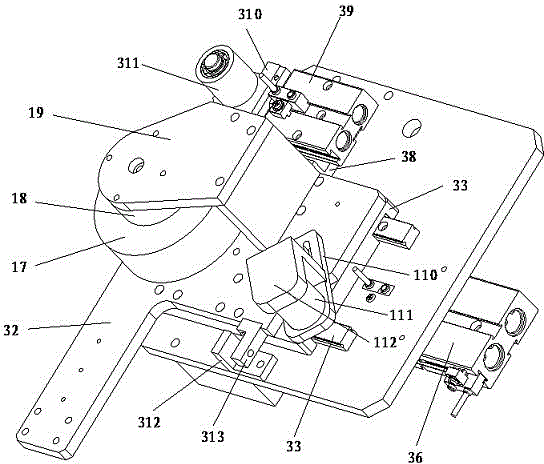

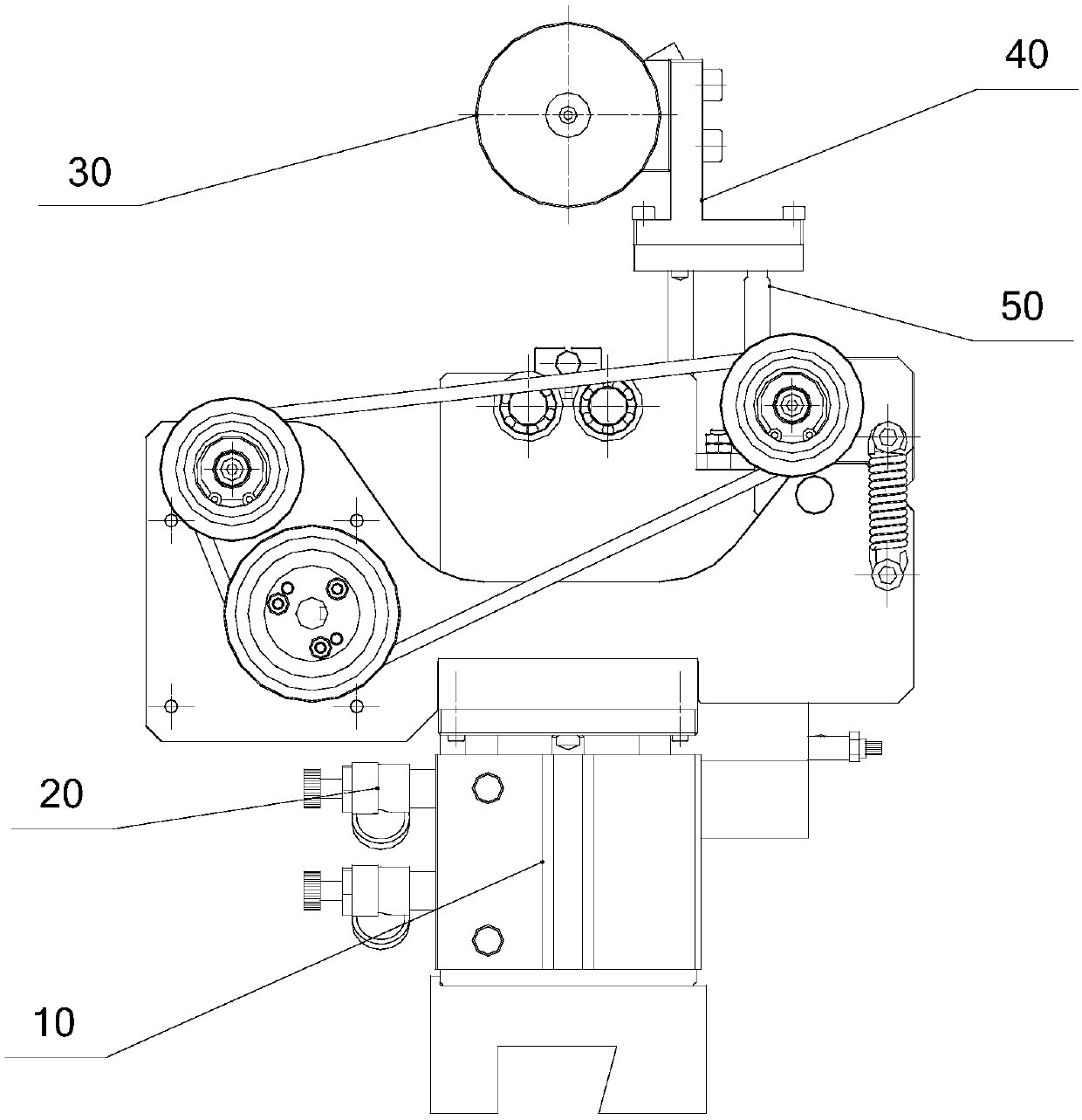

Straightening machine and belt friction driving device thereof

ActiveCN107377678APrevent slidingAvoid Feedback Angle ErrorsMetal working apparatusEngineeringFriction force

Owner:CHANGCHUN HUIKAI TECH +1

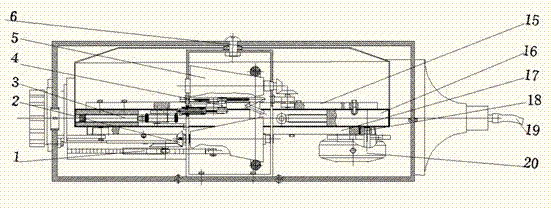

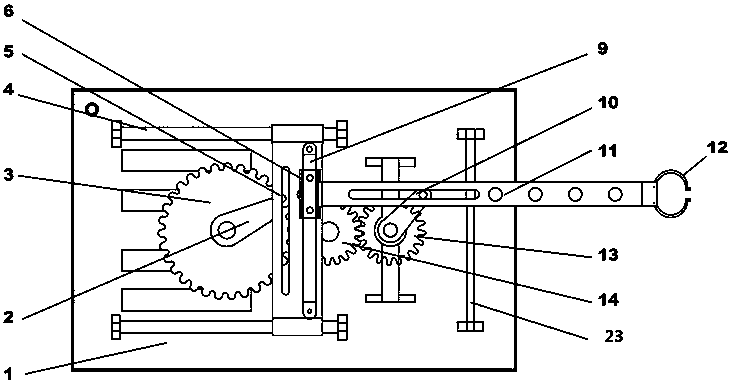

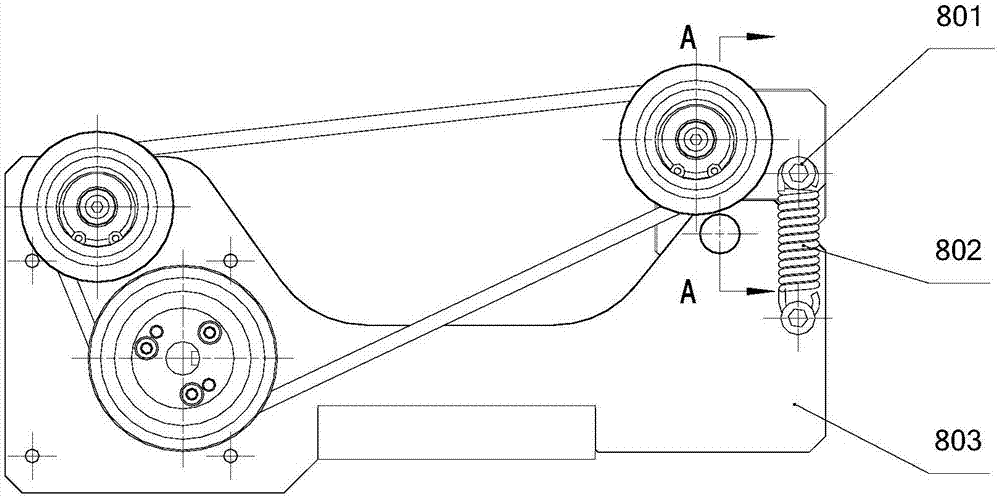

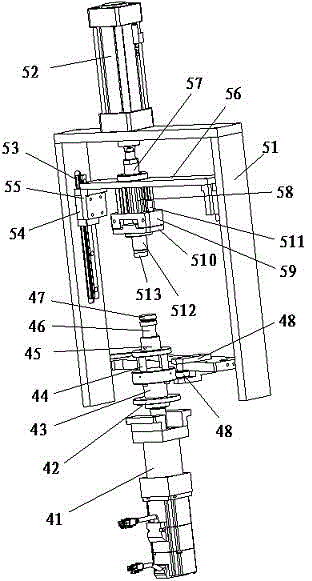

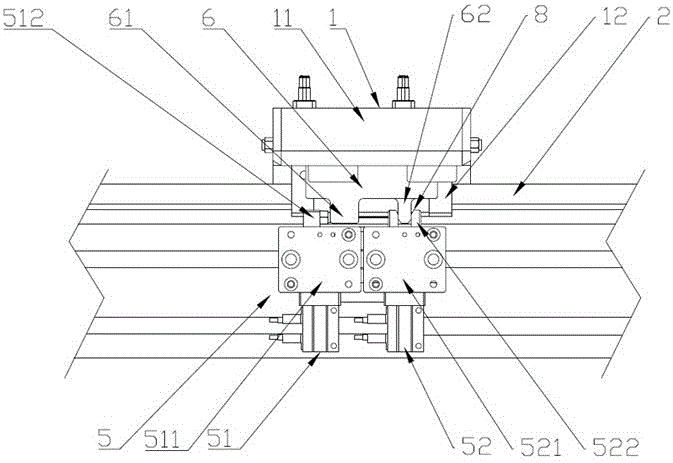

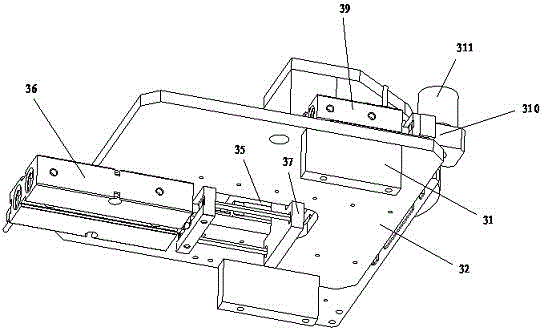

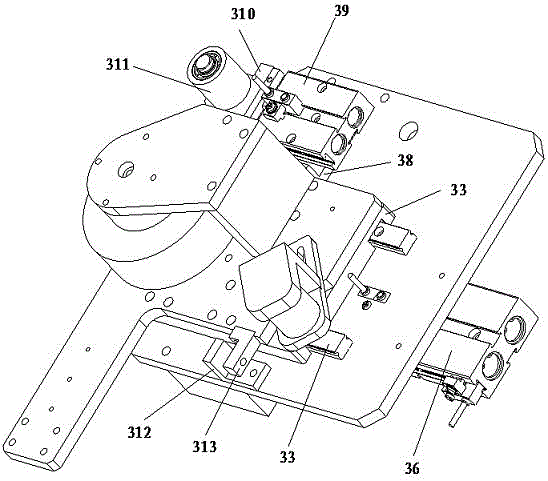

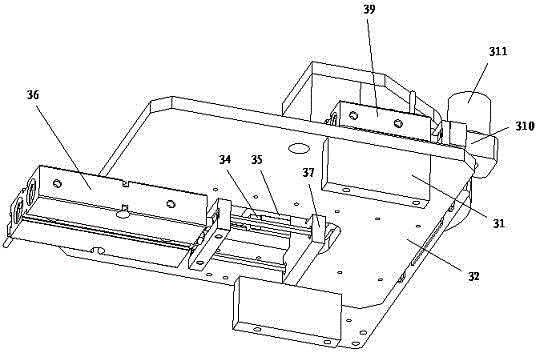

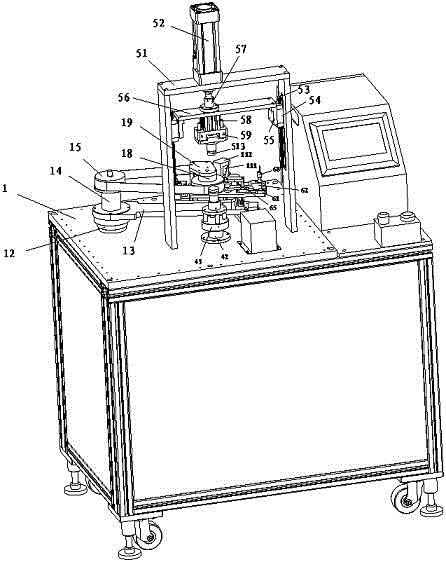

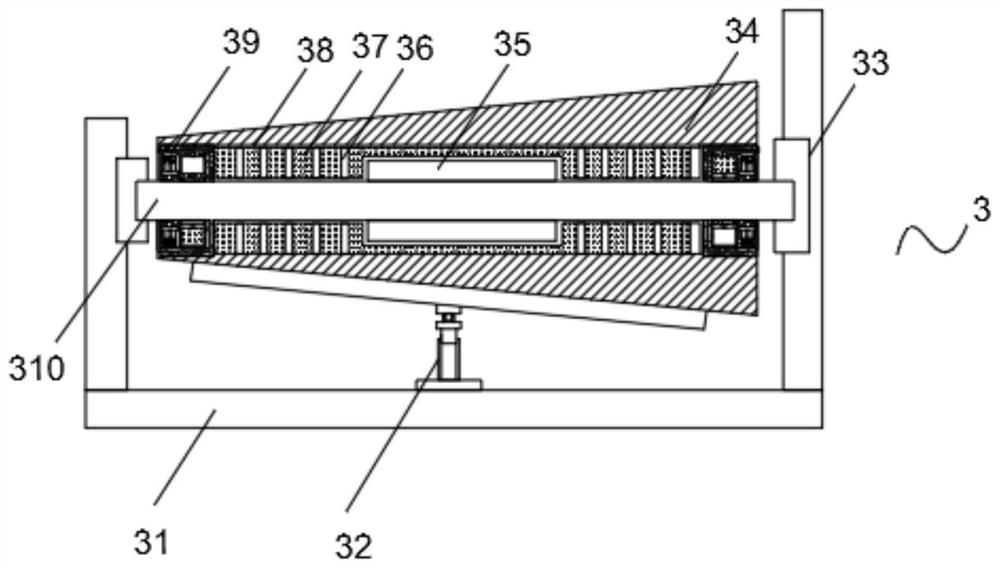

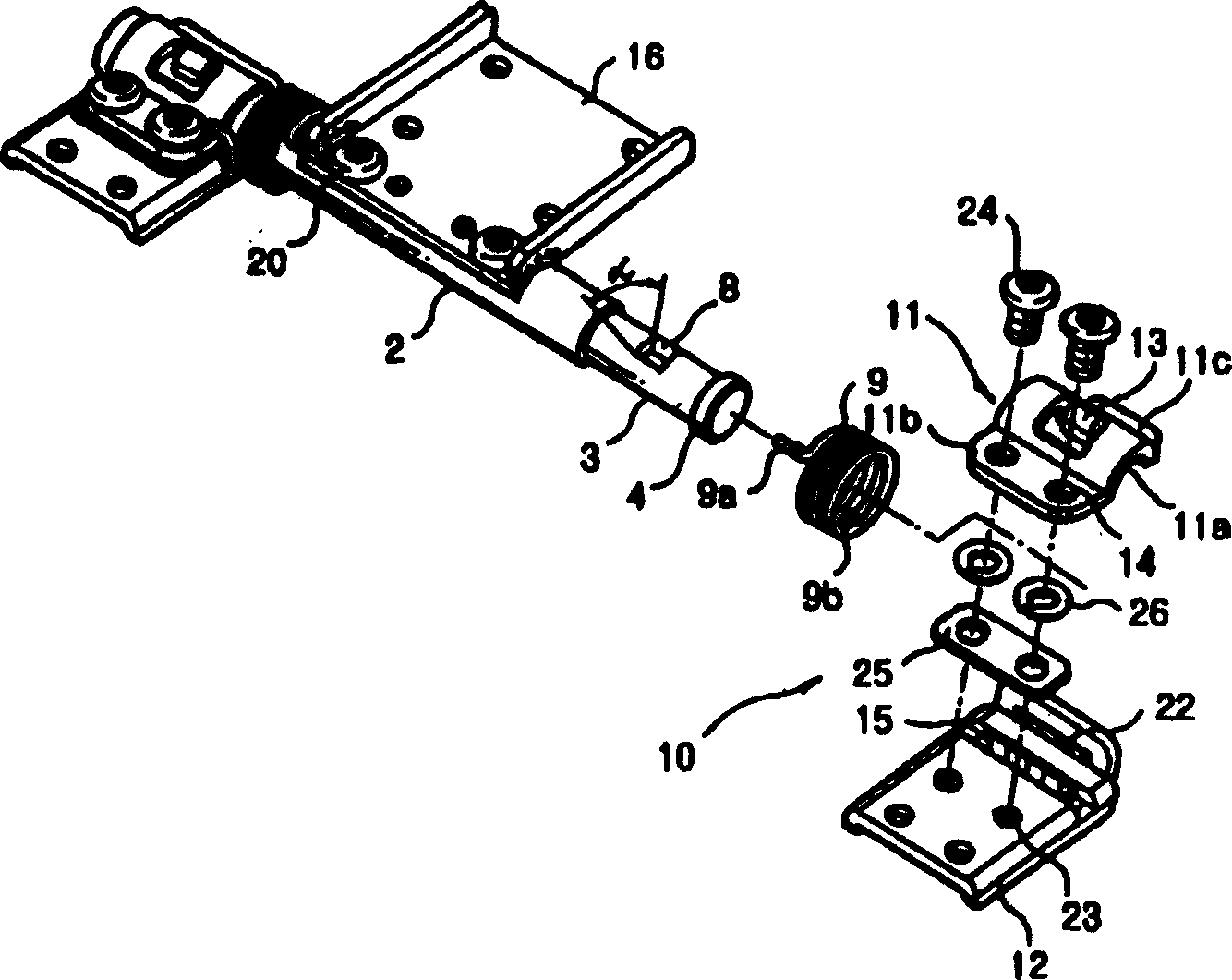

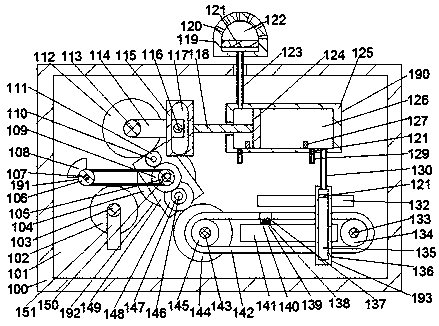

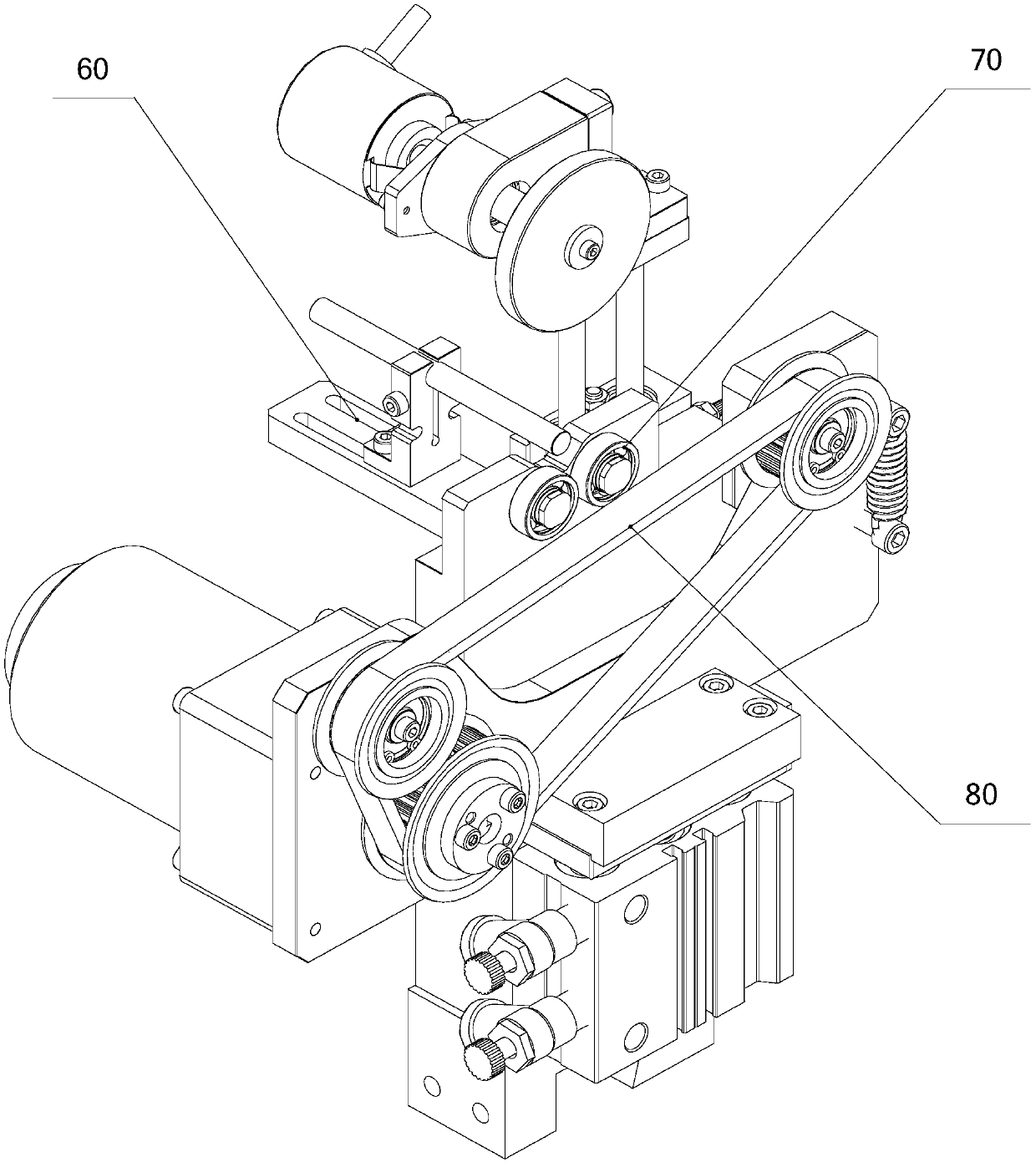

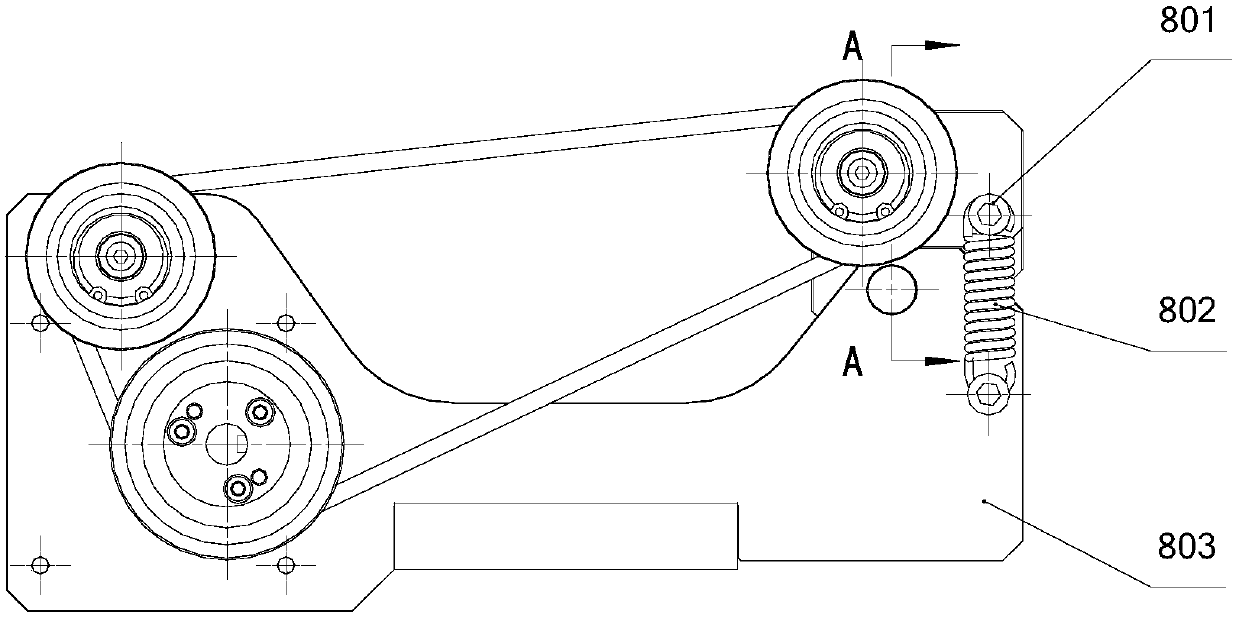

Belt driving device, friction testing and aligning device of belt friction test machine

InactiveCN104949784AAutomatic tension adjustmentGuaranteed stabilityApparatus for force/torque/work measurementEngineeringMechanical engineering

The invention discloses a belt driving, friction testing and aligning device of a belt friction testing machine. The belt driving, friction testing and aligning device comprises a belt driving device, a belt friction testing device and a belt friction test aligning device which are fixedly mounted with a working table, wherein the belt driving device comprises a movable belt driving device and a fixed belt driving device, the fixed belt driving device is fixed with the working table and is provided with a fixed belt driving swing rod, and the movable belt driving device is arranged at a movable end of the fixed belt driving swing rod; the belt friction testing device and the belt friction test aligning device are fixedly mounted with the working table, a friction testing head of the belt friction testing device is propped against a belt, and an aligning head of the belt friction test aligning device is vertically arranged above the belt friction testing device. The belt driving, friction testing and aligning device can perform different tests according to different belts, adjust the tension of the belt automatically, test the friction of the belt automatically and guarantee the stability of a belt friction test result; the mechanism structure is reasonable, the operation is convenient, the working efficiency is improved greatly, and manpower and cost are saved.

Owner:SUZHOU CHANG FEI AUTOMATION EQUIP FACTORY

O-shaped rubber belt friction roller tyre conveying device

InactiveCN106144393APrevent cascading congestionPrevent slippingConveyorsPackagingDrive shaftConveyor belt

The invention discloses an O-shaped rubber belt friction roller tyre conveying device, which comprises a plurality of conveying roller arranged in parallel and a drive device. Each conveying roller is connected with the drive device through an O-shaped rubber belt and is driven by the drive device to rotate. The drive device comprises a motor and a transmission shaft; the motor drives the transmission shaft to rotate through belt drive; a plurality of O-shaped belt wheels are arranged on the transmission shaft; and each conveying roller is connected with the corresponding O-shaped belt wheel through the corresponding O-shaped rubber belt. Tyre retaining devices are arranged on two sides above each conveying roller. The O-shaped rubber belt friction roller tyre conveying device provided by the invention adopts an O-shaped rubber belt drive manner, so that when a tyre is impeded, the O-shaped rubber belt slips when being stressed by impeding force, the conveying rollers stop rotating without stopping rotating the motor, and thus the stack-up crowding of tyres is prevented. With the tyre retaining devices on two sides above the conveying rollers, the tyres can be prevented from slipping off from a conveyor belt after being impeded.

Owner:无锡益联机械有限公司

Conveying device

The invention discloses a conveying device. The conveying device comprises a carrier, a guide rail, a belt, a power mechanism and a positioning mechanism. The carrier is composed of a carrying table, a sliding block, a limiting assembly and a pressing plate assembly and arranged on the guide rail in a sliding mode through the sliding block. The pressing plate assembly abuts against the belt, and friction force between the pressing plate assembly and the belt is larger than that between the sliding block and the guide rail. The carrier is in a suspended state or a moving state under the action of the positioning mechanism. The conveying device has the advantages that the guide rail plays a role in supporting, so that loads on the belt are reduced; meanwhile, the friction force between a pressing block and the belt is larger than that between the sliding block and the guide rail, so that conveying is convenient and flexible, and the structure is ingenious; the positioning mechanism is provided with a stopping part and a positioning part, the stopping part performs stopping, and then the positioning part performs accurate positioning, so that the suspending position of the carrier is more accurate through secondary positioning; the guide rail and the belt are in a cyclic ring shape, so that cyclic conveying is achieved; just one guide rail and one belt are needed, so that the conveying device is simple in structure, small in occupied space and low in cost.

Owner:IXMATION SUZHOU CO LTD

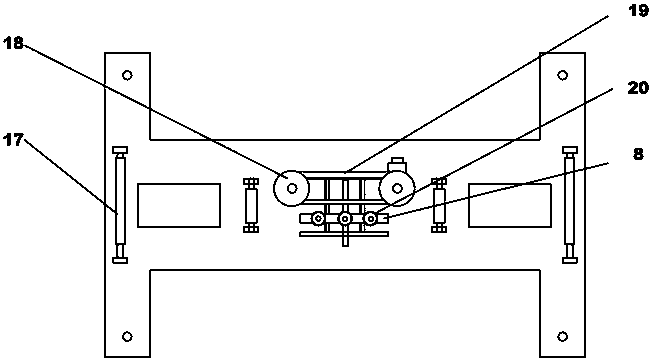

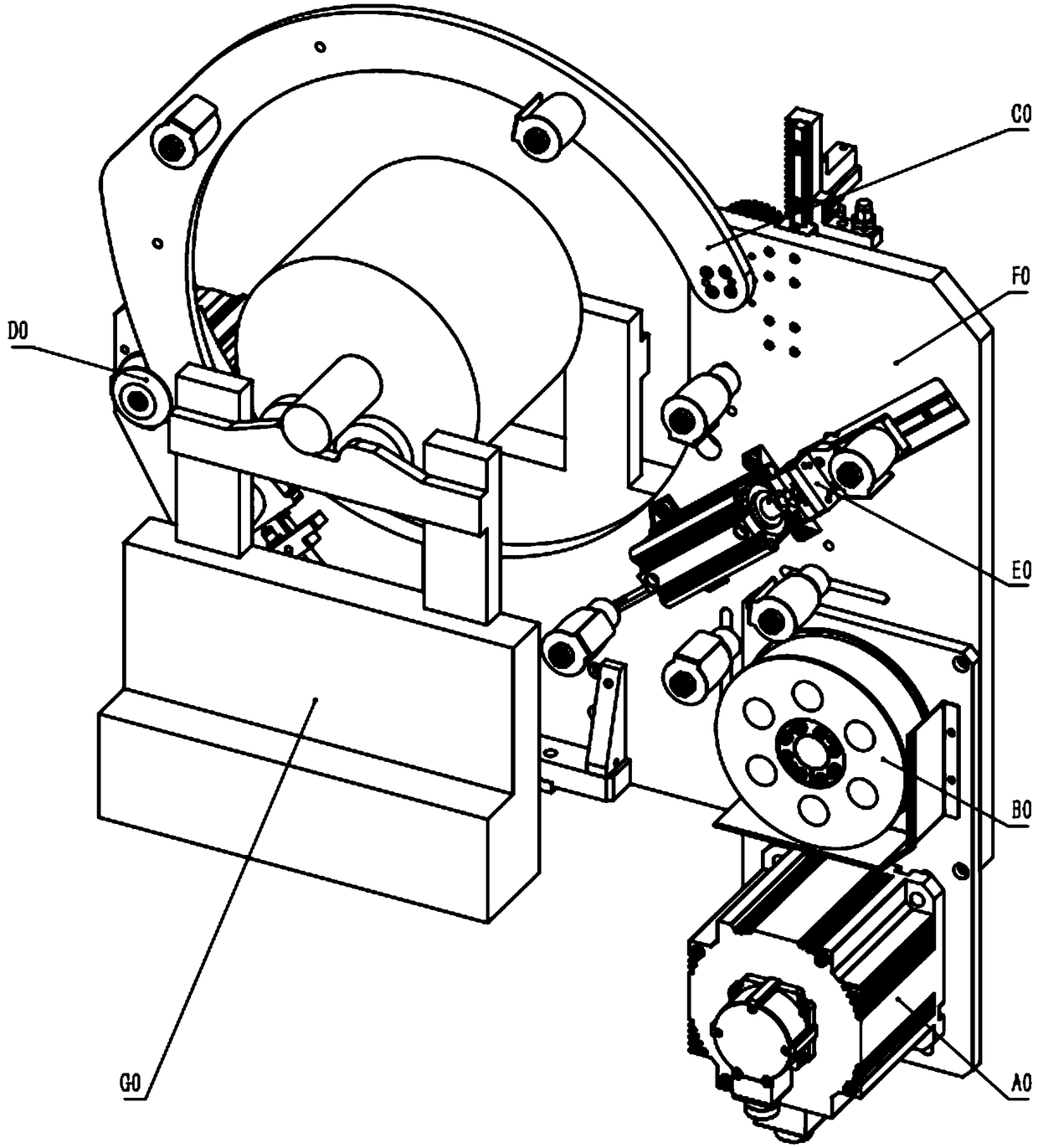

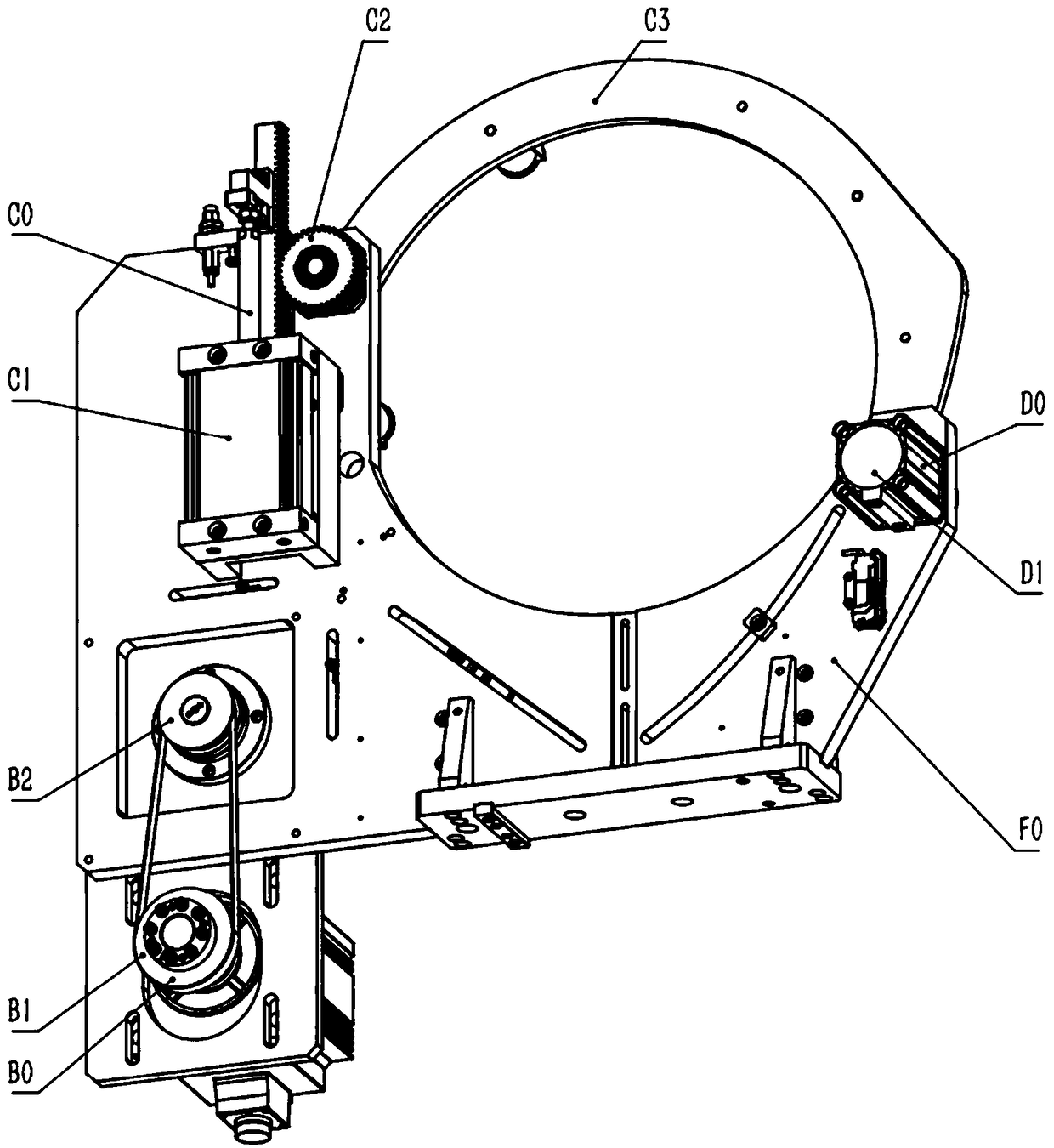

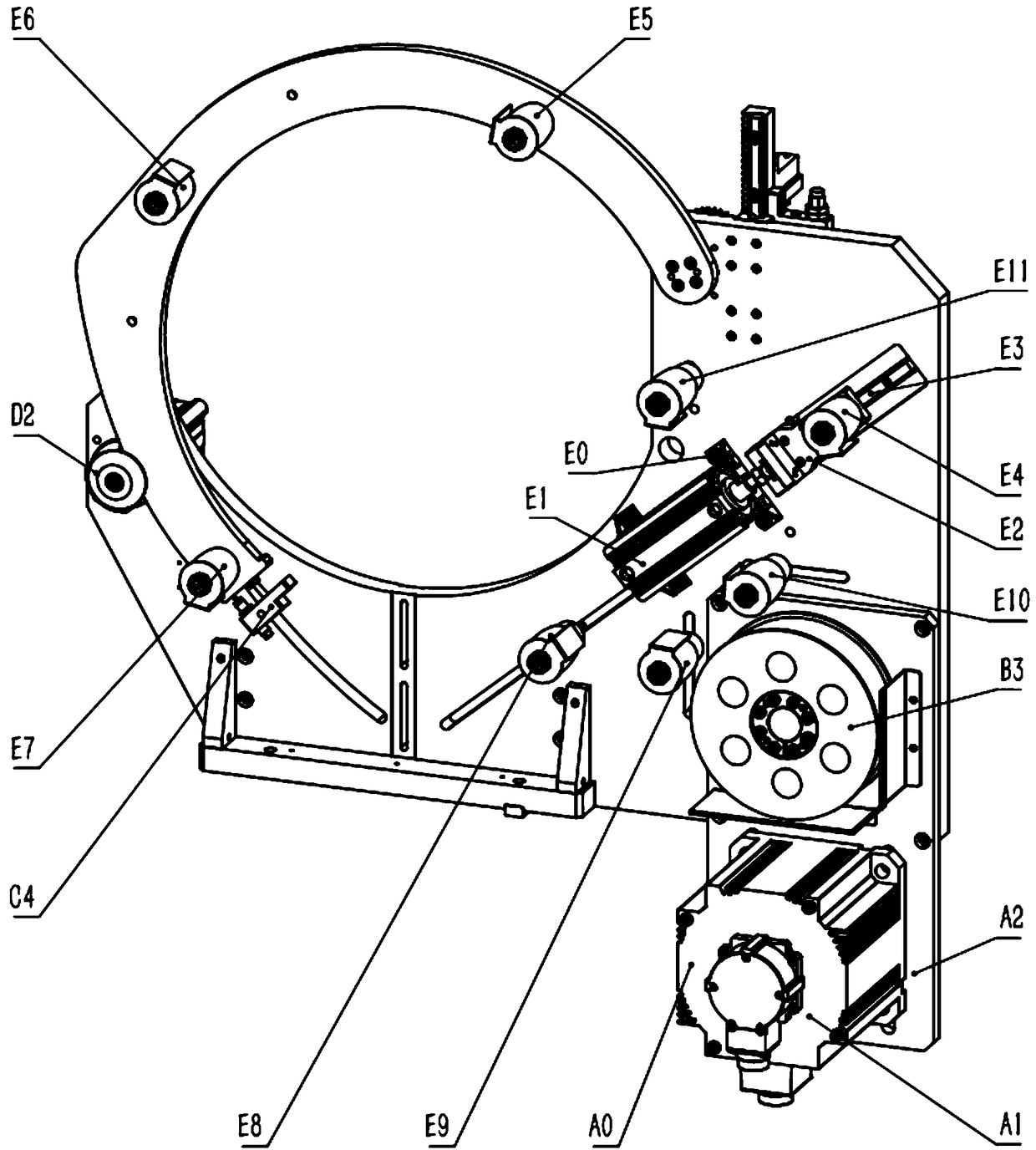

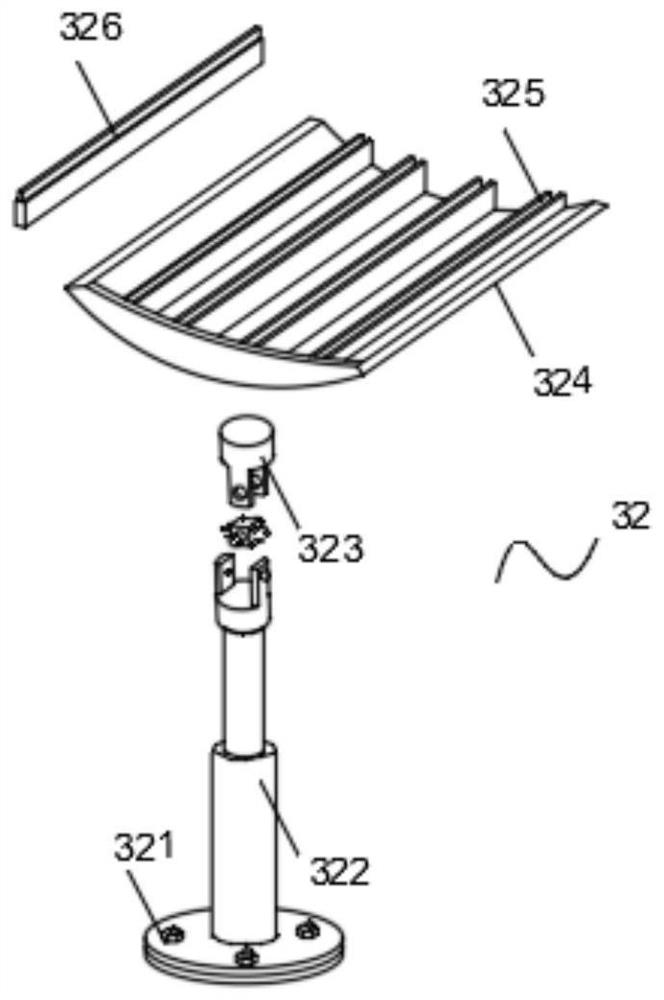

Driving device used for new energy car motor rotor balancing machine

PendingCN109505934ARealize self-adaptive rotation drive adjustmentIncrease frictionGearingStatic/dynamic balance measurementBalancing machineNew energy

The invention discloses a driving device used for a new energy car motor rotor balancing machine. A driving mechanism base is a vertical plate, an arc gap is formed in the upper portion of the drivingmechanism base, the position, on the arc gap, of the motor rotor balancing machine is horizontally supported and mounted through a supporting frame, a belt pressing-down assembly is movably connectedwith and mounted on the position between two sides of the upper portion of the driving mechanism base and crosses over the arc gap, a power assembly and a transmission assembly are arranged on the bottom of the driving mechanism base, the power assembly is connected with the transmission assembly, a driving arm clamping assembly and a belt tensioning assembly are arranged on the periphery of thearc gap, the transmission assembly, the belt pressing-down assembly and the belt tensioning assembly are connected through a belt, and the belt is pressed on a rotor. A wrap angle is increased, when arotor rotates, the large belt friction force can be obtained, slippage is avoided, the air inlet pressure of an air cylinder can be adjusted, the tensioning force of the belt can be adjusted, the belt can be compatible with a rotor with the large outer diameter range, and belts with different lengths do not need to be replaced.

Owner:杭州集智机电股份有限公司

Belt driving device and belt tension adjusting device of belt friction test machine

ActiveCN104960849AAutomatic friction adjustmentAutomatic tension adjustmentConveyorsMachine gearing/transmission testingEngineeringHuman power

The invention discloses a belt driving device and a belt tension adjusting device of a belt friction test machine. The belt driving device comprises a belt moving driving device and a belt fixed driving device. The belt fixed driving device is fixed with the working table facet. The belt fixed driving device is provided with a belt fixed driving oscillating rod. A belt tension adjusting device is arranged on the upper end face of the belt fixed driving oscillating rod. The belt moving driving device is installed on the belt tension adjusting device. According to the belt driving device and the belt tension adjusting device of the belt friction test machine, different tests can be conducted according to different belts, the tension of the belt can be adjusted automatically, the friction of the belt is tested automatically, the stability of the result of the belt friction test is guaranteed, the mechanism is reasonable in structure and convenient to operate, the working efficiency is improved greatly, and human power and labor are saved.

Owner:SUZHOU CHANG FEI AUTOMATION EQUIP FACTORY

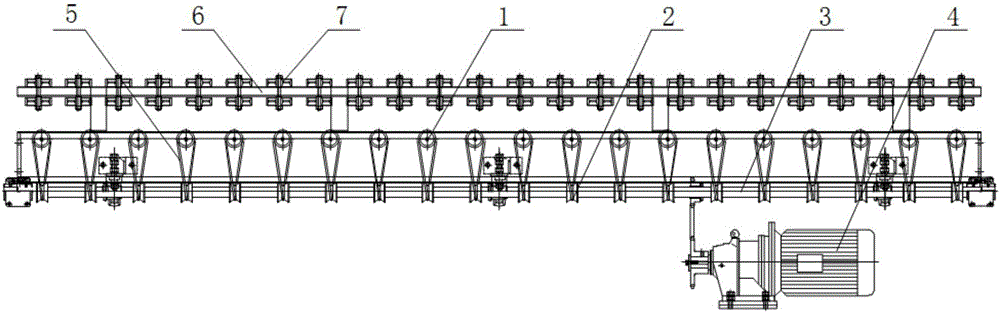

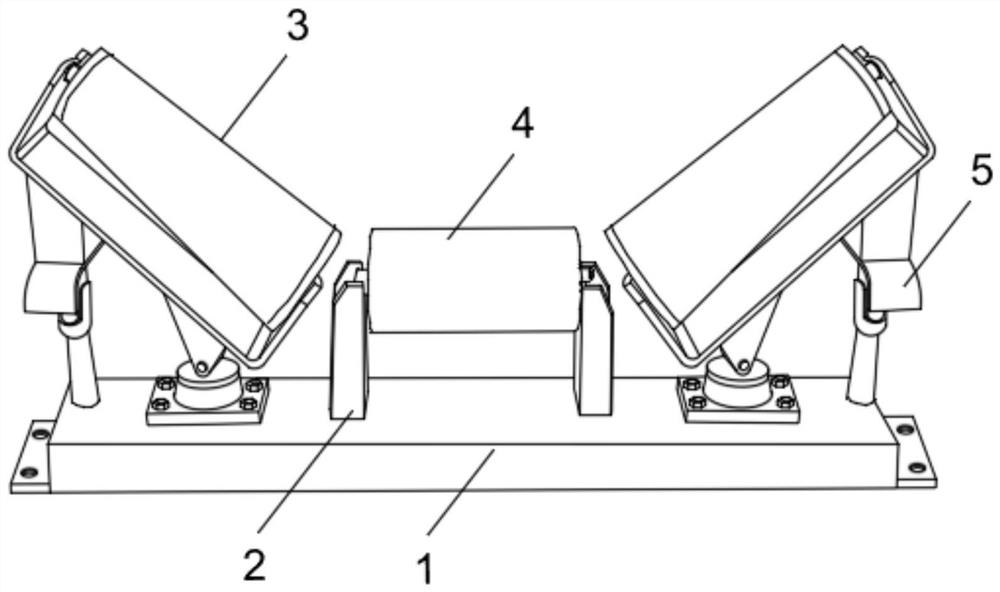

Sorting devices for logistics sorting machine

PendingCN108928611AReduce consumptionReduce manufacturing costConveyorsSupporting framesEngineeringMechanical engineering

The invention relates to logistics sorting equipment, in particular to sorting devices for a logistics sorting machine. Each of the sorting device comprises a tiltable belt transmission mechanism, anoblique wedge mechanism, a box body, a friction wheel power mechanism and a main frame, wherein the corresponding friction wheel power mechanism is mounted on the box body and comprises a power mechanism and belt friction wheels; the belt friction wheels are driven by the power mechanism so as to be rotated; the power mechanism is driven by a driving device, a plurality of sorting devices are driven by one driving device; the corresponding box body is mounted on the corresponding main frame, and is driven by the corresponding power mechanism to be moved along the main frame; the correspondingtiltable belt transmission mechanism is hinged with the corresponding box body; the corresponding oblique wedge mechanism is fixedly connected with one end of the corresponding tiltable belt transmission mechanism; the corresponding tiltable belt transmission mechanism is driven by the corresponding oblique wedge mechanism to be inclined at 1 degree to 60 degrees; after inclination is carried out,the other end of the corresponding tiltable belt transmission mechanism is in contact with the belt friction wheels; and belts are driven by the belt friction wheels to be rotated. The sorting devices for the logistics sorting machine has the advantages of energy conservation and cost reduction, and can sort over-thin and excessive small objects and can effectively prevent easily damaged parts.

Owner:辽宁黑北健科技有限公司

Belt tension adjusting device of belt friction force testing machine

InactiveCN104973465AAutomatic friction adjustmentAutomatic tension adjustmentApparatus for force/torque/work measurementEngineeringFriction force

The invention discloses a belt tension adjusting device of a belt friction force testing machine. The belt tension adjusting device comprises two belt tension adjusting supporting plates fixed to a belt driving fixing swing rod, a belt tension adjusting fixing plate is installed on the two belt tension adjusting supporting plates, parallel belt tension adjusting sliding rails are arranged on the belt tension adjusting fixing plate and provided with belt tension adjusting sliding blocks, the belt tension adjusting sliding blocks are provided with a belt tension adjusting transferring plate, a belt tension adjusting motor is fixedly installed on the lower end face of the belt tension adjusting fixing plate, the output shaft of the belt tension adjusting motor is connected with a belt tension adjusting moving plate, and the upper end face of the belt tension adjusting moving plate is fixedly connected with the lower end face of the belt tension adjusting transferring plate. By means of the belt tension adjusting device, different tests can be carried out according to different belts, the tension of the belts is automatically adjusted, the friction force of the belts is automatically adjusted, the stability of the friction testing result of the belts is ensured, the mechanism structure is reasonable, operation is convenient, the working efficiency is greatly improved, and manpower and cost are saved.

Owner:SUZHOU CHANG FEI AUTOMATION EQUIP FACTORY

Belt driving device and belt running deflecting proof device of belt friction test machine

InactiveCN104964010AAutomatic Friction TestAutomatic tension adjustmentGearingUsing mechanical meansEngineeringHuman power

The invention discloses a belt driving device and a belt running deflecting proof device of a belt friction test machine. The belt driving device fixedly installed with a working table facet is included. The belt driving device comprises a belt moving driving device and a belt fixed driving device. The belt fixed driving device is fixed with the working table facet. The belt fixed driving device is provided with a belt fixed driving oscillating rod. A belt running deflecting proof device is arranged on the moving end of the belt fixed driving oscillating rod. According to the belt driving device and the belt running deflecting proof device of the belt friction test machine, different tests can be conducted according to different belts, the tension of the belt can be adjusted automatically, the friction of the belt is tested automatically, the stability of the result of the belt friction test is guaranteed, the mechanism is reasonable in structure and convenient to operate, the working efficiency is improved greatly, and human power and labor are saved.

Owner:SUZHOU CHANG FEI AUTOMATION EQUIP FACTORY

Belt drive propulsion system

ActiveUS7322865B1Reduces parasitic frictionImprove efficiencyAmphibious vehiclesPropulsive elements of non-rotary typeBelt frictionAir bearing surface

An apparatus and method for providing propulsion to naval vehicles by using one or more suspended belt drives to consistently engage the water proximate to the surface using a variety of belts with multiple attachments, tires, or variable lugs. The drive belt system incorporates the use of a linear air bearing surface to minimize the belt friction of the drives. This invention also involves the use of open-bottomed enclosures to insulate the propulsion system from adverse water conditions that might otherwise prevent the belt drives from consistently and efficiently engaging the water.

Owner:FOI GRP

Belt friction force testing machine

InactiveCN104990662AAutomatic tension adjustmentGuaranteed stabilityApparatus for force/torque/work measurementEngineeringFriction force

The invention provides a belt friction force testing machine comprising a case and a controller installed on the case. A working table top is installed on the case. The testing machine also comprises a belt driving device, a belt driving deflection-preventing device, a belt tension adjusting device, a belt friction testing device, a belt deflection-preventing device, and a belt friction testing positioning device. The belt driving device comprises a belt moving driving device and a belt fixed driving device, wherein the belt fixed driving device is fixed to the working table top and is provided with a belt fixed driving swing rod; the moving end of the belt fixed driving swing rod is provided with the belt driving deflection-preventing device; the upper end surface of the belt fixed driving swing rod is provided with the belt tension adjusting device. The belt friction force testing machine can be used for conducting different tests for different belts, can automatically adjust the tension of belts and testing the friction force of the belts, and can guarantee the stability of the results of the belt friction tests. The belt friction force testing machine is reasonable in structure and convenient to operate, increases the working efficiency greatly and saves the manpower and cost.

Owner:SUZHOU CHANG FEI AUTOMATION EQUIP FACTORY

A roller belt conveyor

ActiveCN112374029BImprove structural strengthAvoid loss of structural strengthConveyorsCleaningStructural engineeringConveyor belt

The invention discloses an idler belt conveyor, which comprises an installation base, on which a working mechanism and a heating idler are arranged; wherein, the working mechanism includes middle legs, straight rollers, and side legs; the The middle outrigger is fixedly installed in the middle of the upper surface of the installation base; the two side outriggers are symmetrically installed in the edge position of the upper surface of the installation base; the side outriggers are rotatably connected with heating rollers through bearings. The present invention can dissolve the ice layer by arranging heating rollers, avoiding the problem that water falls on the surface of the belt and easily forms an ice layer, thereby reducing the friction coefficient of the belt, which is not conducive to the stable transportation of materials. The mechanism can scrape off the dirt on the surface of the heating roller, and can avoid the abnormal deformation of the outer circumference of the roller. In severe cases, it will cause the deviation of the conveyor belt and cause the change of the material conveying line, ensuring the normal use of the belt conveyor. .

Owner:淮北合众机械设备有限公司

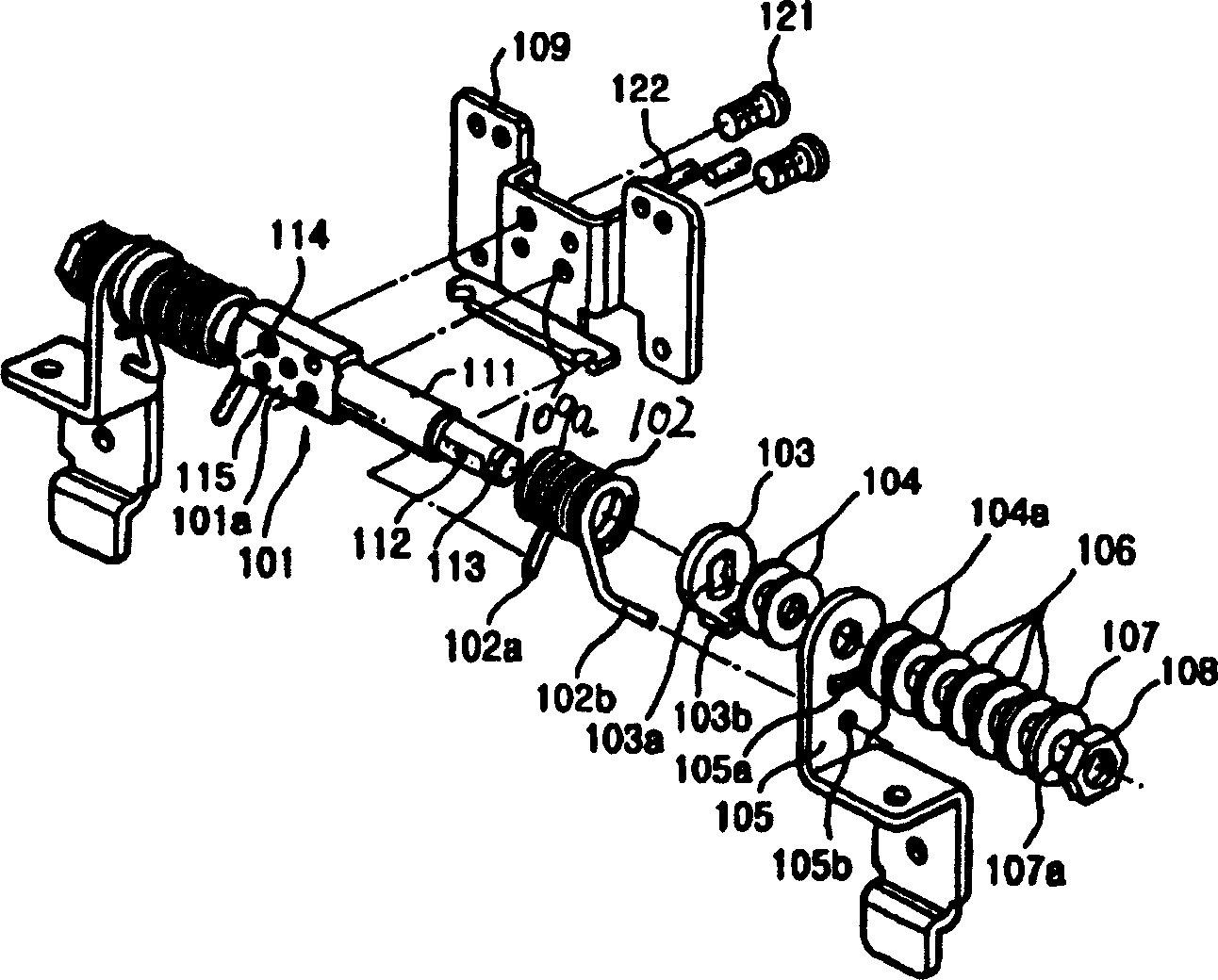

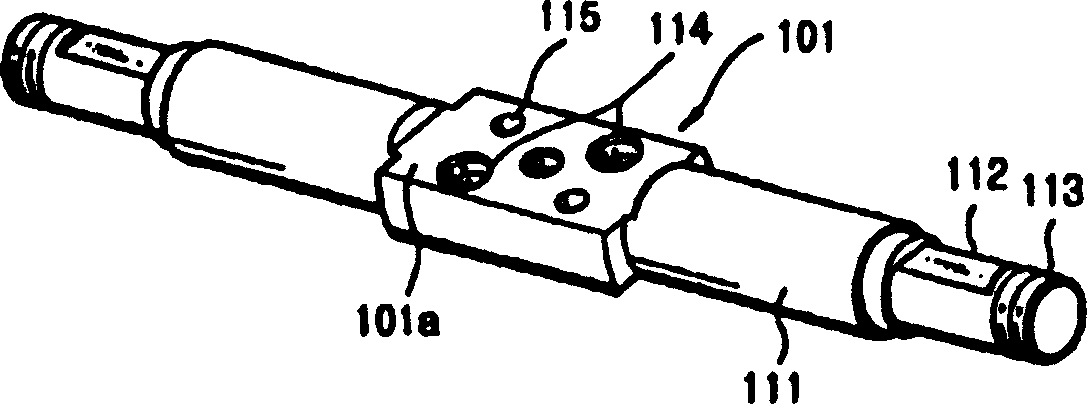

Articulated mounting using draper type friction part

InactiveCN1567420AAvoid flowEasy to processCathode-ray tube indicatorsNon-linear opticsDisplay deviceEngineering

This invention published a kind of hinged apparatus that utilizing the belt friction part. The hinged apparatus is cylindrical, and comprises the following parts: large diameter part in center; on two sides of the large diameter part is the small diameter part that with arc section groove, and hinged rotation axis that has the display supporting bracket that can form a plane part on large diameter part; protruding plate that combines the joining plate and the groove of small diameter part; belt friction part that on small diameter part and combined frictionally in the form of belt. One side of the belt friction part integrates with the multiple holes of supporting bracket that arranged in arc form; the other side includes the spring that setting on the hinged rotation axis for supporting the belt friction part. The process and structure of the hinged rotation axis are simple and cheap.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

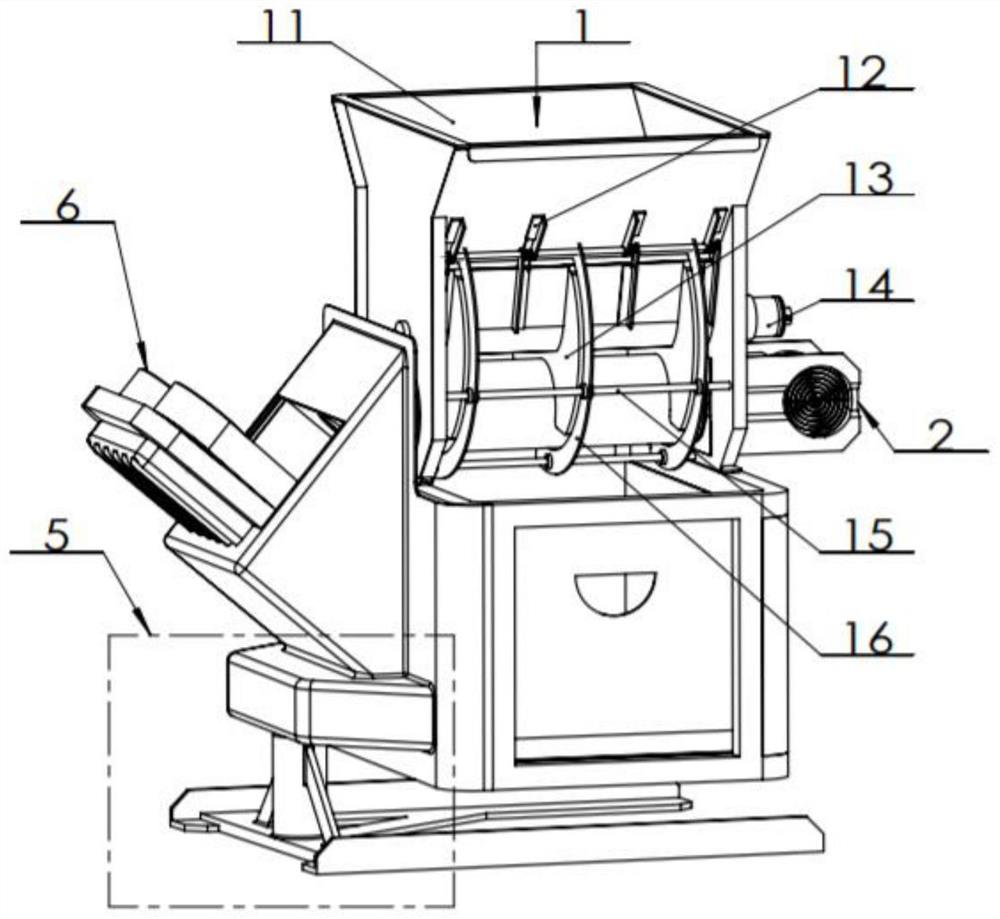

Manufacturing method of water-base resin synthesizing equipment

ActiveCN110171071AGuarantee product qualityGuaranteed stabilityGrain treatmentsWater basedBelt friction

The invention discloses a manufacturing method of water-base resin synthesizing equipment. The water-base resin synthesizing equipment comprises a resin mixer. A working space is arranged in the resinmixer. A feeding mechanism is arranged in the working space. A discharging mechanism is arranged on the lower side of the feeding mechanism. The feeding mechanism is in belt friction transmission with the discharging mechanism. By means of the equipment, blocky resin additives can be crushed into required powder, the powder is prepared and mixed evenly according to resin preparing proportion, inaddition, after a product is finished, the product can be discharged automatically, the next product can be manufactured immediately, and uninterrupted manufacturing at a quite high speed can be achieved while the resin manufacturing quality is guaranteed. According to the equipment, the automation degree is quite high, operators only need to add raw materials and collect the products, the other steps are completed by the equipment, the stability of resin in the manufacturing process is guaranteed, risks which may happen to the operators in the manufacturing process are also reduced, and the production efficiency is quite high.

Owner:广东睿鹏材料科学有限公司

Stranding machine traction stepped wheel device

The invention relates to a stranding machine traction stepped wheel device. A first traction stepped wheel, a second traction stepped wheel, a traction stepped wheel tension friction supporting plate, a traction stepped wheel friction mirror surface, a second traction stepped wheel tension friction plate fixing plate, a traction stepped wheel tension pressing plate, a traction stepped wheel spring weight and a traction stepped wheel tension nut are sequentially installed on a traction stepped wheel shaft. A first traction stepped wheel tension friction plate fixing plate is arranged on the traction stepped wheel tension friction supporting plate. A traction stepped wheel friction damping fin is fixed to the first traction stepped wheel tension friction plate fixing plate. The traction stepped wheel friction mirror surface is arranged in a traction stepped wheel tension friction supporting plate key groove. On the stepped wheel friction mirror surface, compression springs sequentially arranged on the traction stepped wheel spring weight are pressed on the traction stepped wheel tension pressing plate. During operation, the traction stepped wheel shaft is driven by a speed reducer to rotate; when a steel wire generates tension when wound around the first traction stepped wheel and the second traction stepped wheel, the stretching and retracting space of the compression springs is decreased by the traction stepped wheel spring weight by adjusting the tightness degree of the traction stepped wheel tension nut so that tension can be adjusted.

Owner:HUBEI FUXING NEW MATERIAL TECH +6

Efficient heat dissipation system of large lithium battery

InactiveCN110212266AHas the function of flushing and coolingImprove transmission efficiencySecondary cellsMaterial resourcesTime control

The invention discloses an efficient heat dissipation system of a large lithium battery. The efficient heat dissipation system comprises a heat dissipation box, wherein a work space is formed in the heat dissipation box; a linkage mechanism is arranged in the work space; the linkage mechanism is in transmission connection through belt friction; the linkage mechanism comprises a swing rod, a clamping block and a belt wheel shaft, and a time control mechanism is arranged on the rear side of the linkage mechanism; the device is arranged in the large lithium battery, and has the function of washing and radiating the large lithium battery; water spraying can be carried out on the large lithium battery automatically in a proper time for a certain time continuously, and watering and heat dissipation to the large lithium battery are performed; the large lithium battery can be circularly cleaned automatically at night, so that manpower and material resources can be reduced; and only one motor is used in the whole device, so that the transmission efficiency is relatively high.

Owner:杭州虹妍服饰有限公司

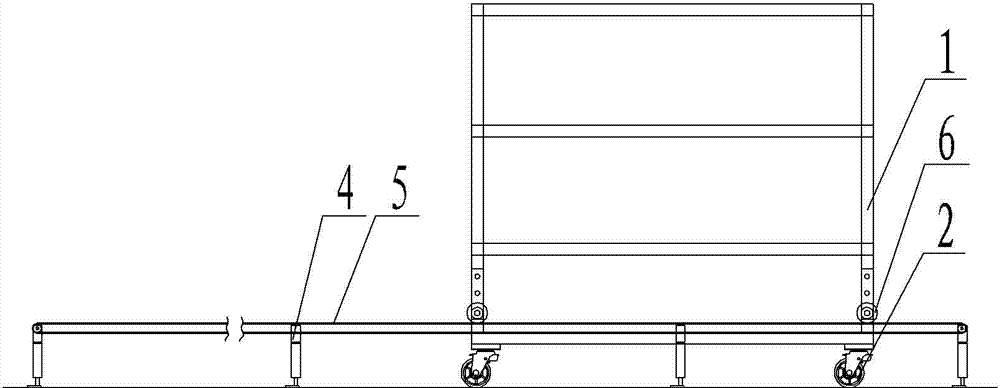

Belt friction type conveying machine

The invention relates to the field of belt conveying machines, in particular to a belt friction type conveying machine. The belt friction type conveying machine has a simple structure, can realize long-distance quick transportation of a trolley conveniently and improves the conveying efficiency. The belt friction type conveying machine comprises a trolley, wherein the trolley comprises trolley castors; the trolley castor on at least one side is positioned in a guide rail; a belt conveying machine is arranged on one side of the trolley; the belt of the belt conveying machine has a rough surface; and a friction roller with a rough surface is arranged on the trolley and corresponds to the belt conveying machine.

Owner:WUXI FORMEN TECHN

Straightening machine and its drive device with friction

ActiveCN107377678BPrevent slidingAvoid Feedback Angle ErrorsMetal working apparatusElectric machineryEngineering

The invention discloses a belt friction driving device used for a shaft straightening machine. Friction force generated through contact of a belt and a workpiece drives the workpiece to rotate. Compared with a traditional rolling wheel driving device, the belt friction driving device overcomes shortages of traditional driving. According to the belt friction driving device, all functions of the traditional rolling wheel driving device can be achieved, and meanwhile, the shortages of the traditional rolling wheel driving device are overcome fully. The belt friction driving device has the advantages that belt friction driving is adopted, the friction contact area and the friction coefficient are increased, relative sliding between the driving belt and the workpiece is avoided, meanwhile, a feedback angle error of an angle sensor caused by relative sliding between the driving belt and the workpiece is avoided, and the straightening efficiency is improved. The belt friction driving device mainly applied to workpiece rotating driving with an outer circle as benchmark and widely applied to straightening driving of a motor torsion bar, and a robot drive straightening driving of a motor transmission screw bar. The invention further discloses a straightening machine which applies the belt friction driving device.

Owner:CHANGCHUN HUIKAI TECH +1

Continuous discharging mechanism for micro-diameter pipes

PendingCN111843511AAccurate length quantificationSolve the problem of not being able to pull away completelyOther manufacturing equipments/toolsStructural engineeringPipe

The invention discloses a continuous discharging mechanism for micro-diameter pipes. The mechanism comprises a main rack and a falling frame arranged at the tail end of the main rack along a conveyingpipe center line, and is characterized in that a straightening device is erected on the main rack, a belt conveying device is arranged behind the straightening device, and a cutting device is arranged behind the belt conveying device; and a clapping device is arranged on the falling frame and corresponds to the cutting device. In the whole discharging process, the micro-diameter pipes are pushedand conveyed through the friction force of a belt, so that the defects that the surfaces of the micro-diameter pipes are abraded and indentations are generated are avoided; and meanwhile, the micro-diameter pipes are further straightened, it is ensured that length determination of the micro-diameter pipes is more accurate, the problem that cutting points of pipe bodies cannot be completely pulledaway due to residual burrs caused by annular cutting is effectively solved, and the mechanism automatically works and is safe and reliable.

Owner:浙江康盛科工贸有限公司

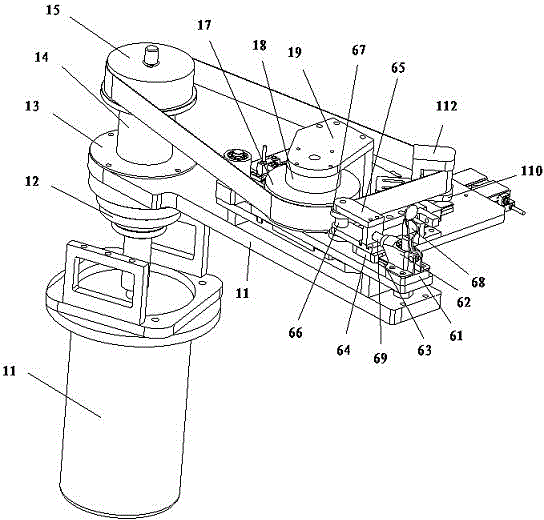

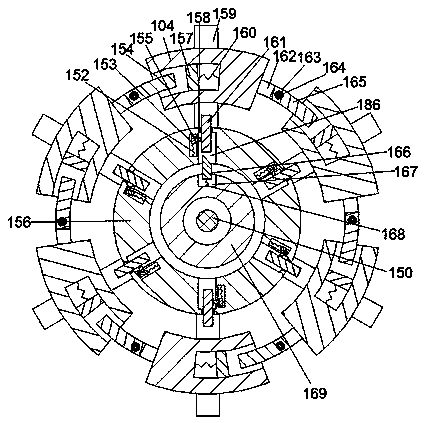

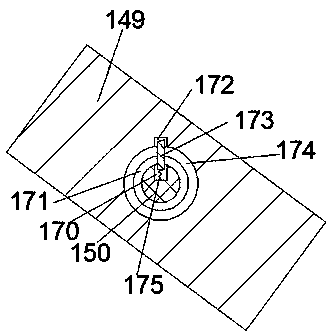

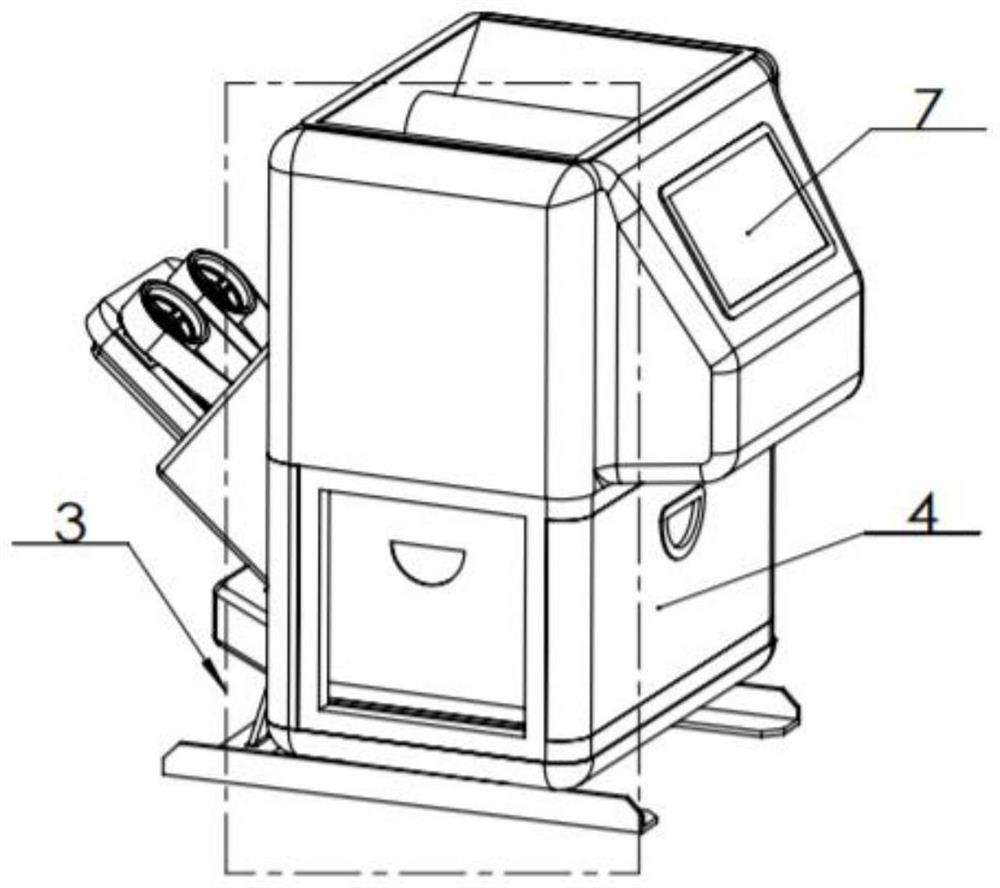

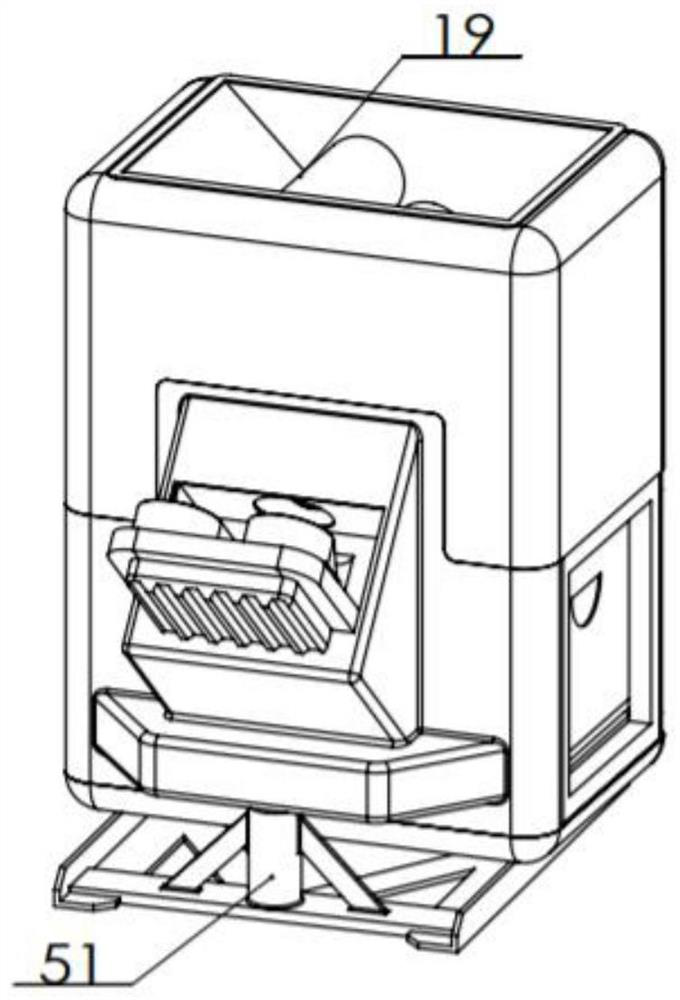

Badminton serving machine and method for belt friction serving

ActiveCN113181618BLower the altitudeImprove stabilityRacket sportsEngineeringIntelligent control system

The invention relates to a badminton serving machine and method using belt friction to serve the ball, which comprises a box body, a ball barrel replacement device, an intelligent control system, a ball pushing device, a ball serving device, an empty ball barrel storage box and an angle changing device. The box body includes an upper box body and a lower box body. The ball barrel replacement device is located in the middle of the upper box body. The ball pushing device is fixed on the lower side of the ball barrel replacement device and above the lower box body; the empty ball barrel storage box is placed in the lower box body. In the body, it forms a moving pair with the lower box; the ball-serving device is located in front of the lower box and is on the lower side of the pushing device; the angle changing device is fixed under the lower box; the intelligent control system is fixed on the upper box and is in the replacement The rear side of the bucket device. The invention adopts belt friction to serve the ball, utilizes the control system to control the change of the angle and strength so that the sent shuttlecock meets the training requirements, and can be used in various modes of badminton training.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com