Stranding machine traction stepped wheel device

A technology of twisting machine and tower wheel, which is applied to auxiliary devices for rope making, textiles, papermaking, textile cables, etc., can solve the problems of insufficient guarantee of product quality, large fluctuation of traction tension, affecting equipment performance, etc. Achieve the effect of improving equipment efficiency, stable tension and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

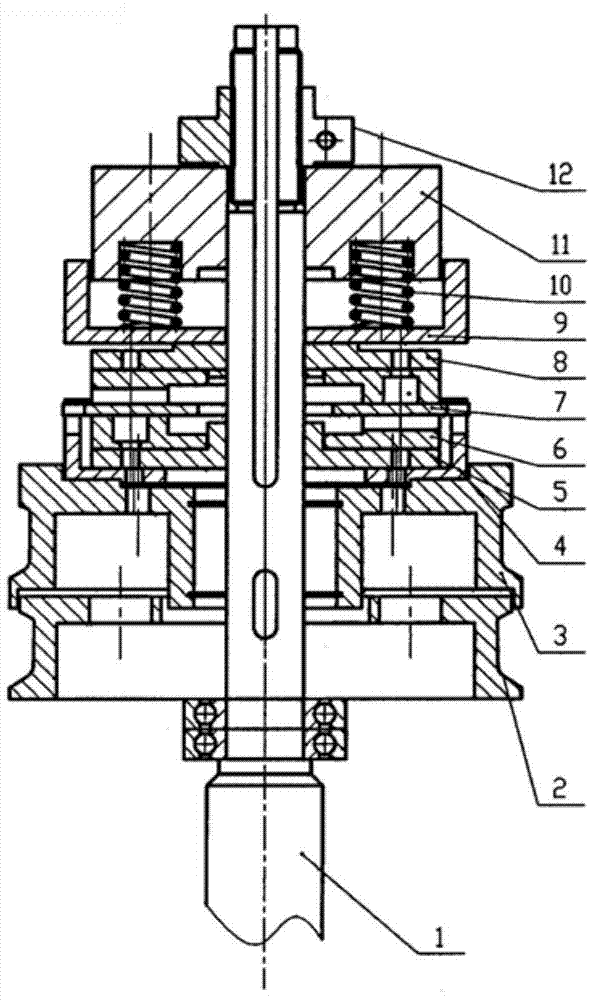

[0010] Traction tower pulley 1, traction tower pulley 2, 3 are fixed on the traction tower wheel shaft 1 through bearings, traction tower pulley 1, 2, are attached to traction tower pulley 2, 3, traction tower pulley tension friction support plate 4 is fastened on the traction tower pulley by screws On the tower wheel two 3, the traction tower wheel tension friction fixing plate one 5 is fixed on the traction tower wheel tension friction support plate 4 by screws, and is connected with the traction tower wheel shaft 1 as a whole, and the traction tower wheel friction damping plate 6 is fixed on the traction tower wheel shaft by screws. On the traction sheave tension friction fixing plate one 5, the traction sheave friction mirror surface 7 is fixed in the keyway of the traction sheave tension friction support plate 4 through key clips, and the traction sheave tension friction sheet pressing the traction sheave friction mirror surface 7 is fixed The plate 2 8 is fixed on the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com