Bottom warp feeding tension balance regulating mechanism for towel rapier loom

A rapier loom and warp let-off tension technology, applied in looms, flannel looms, textiles, etc., can solve the problems of poor stability of warp tension, high breakage rate, difficulty in adjusting tension, etc. The effect of smooth tension and reduction of accidental tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

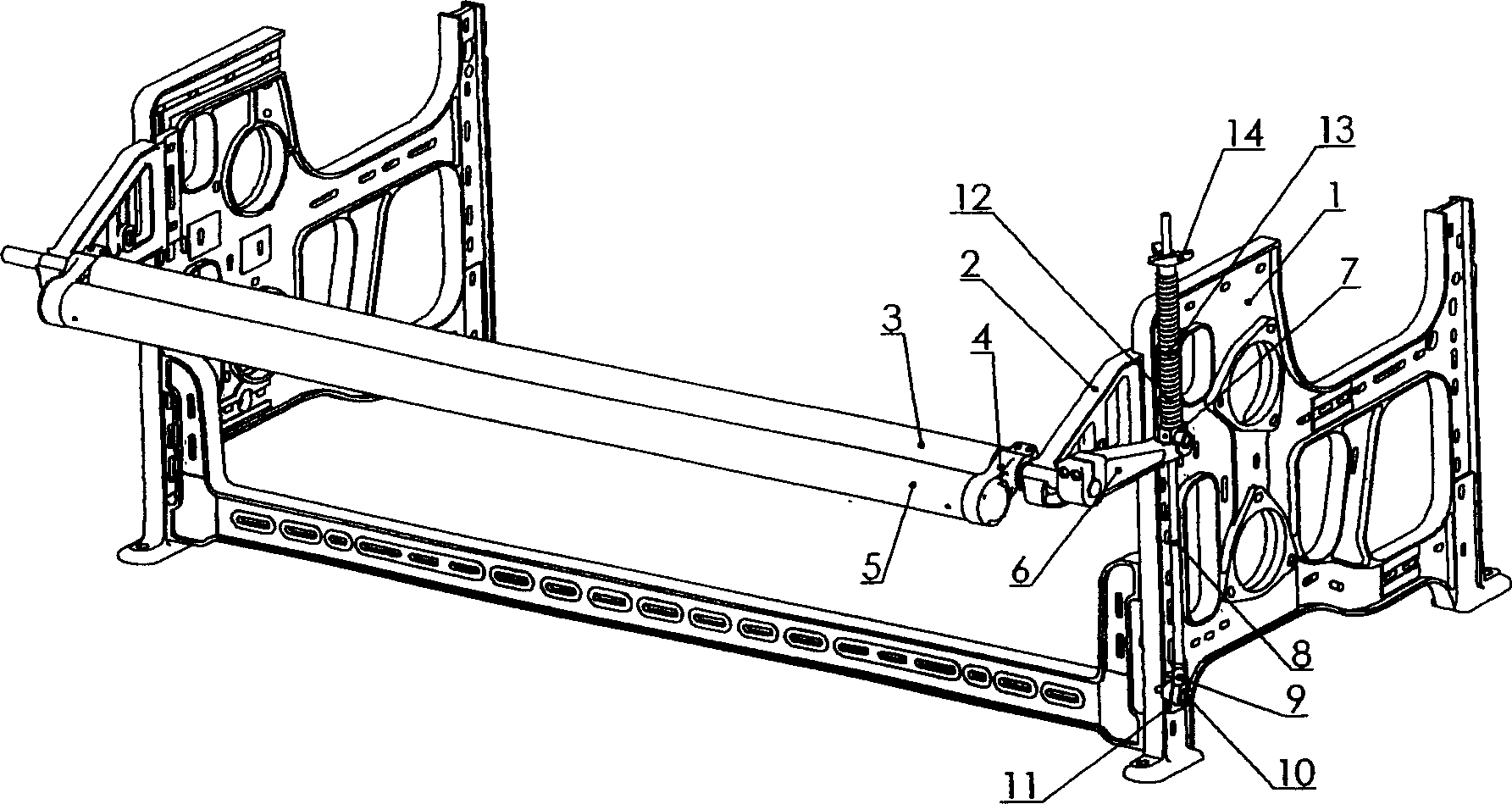

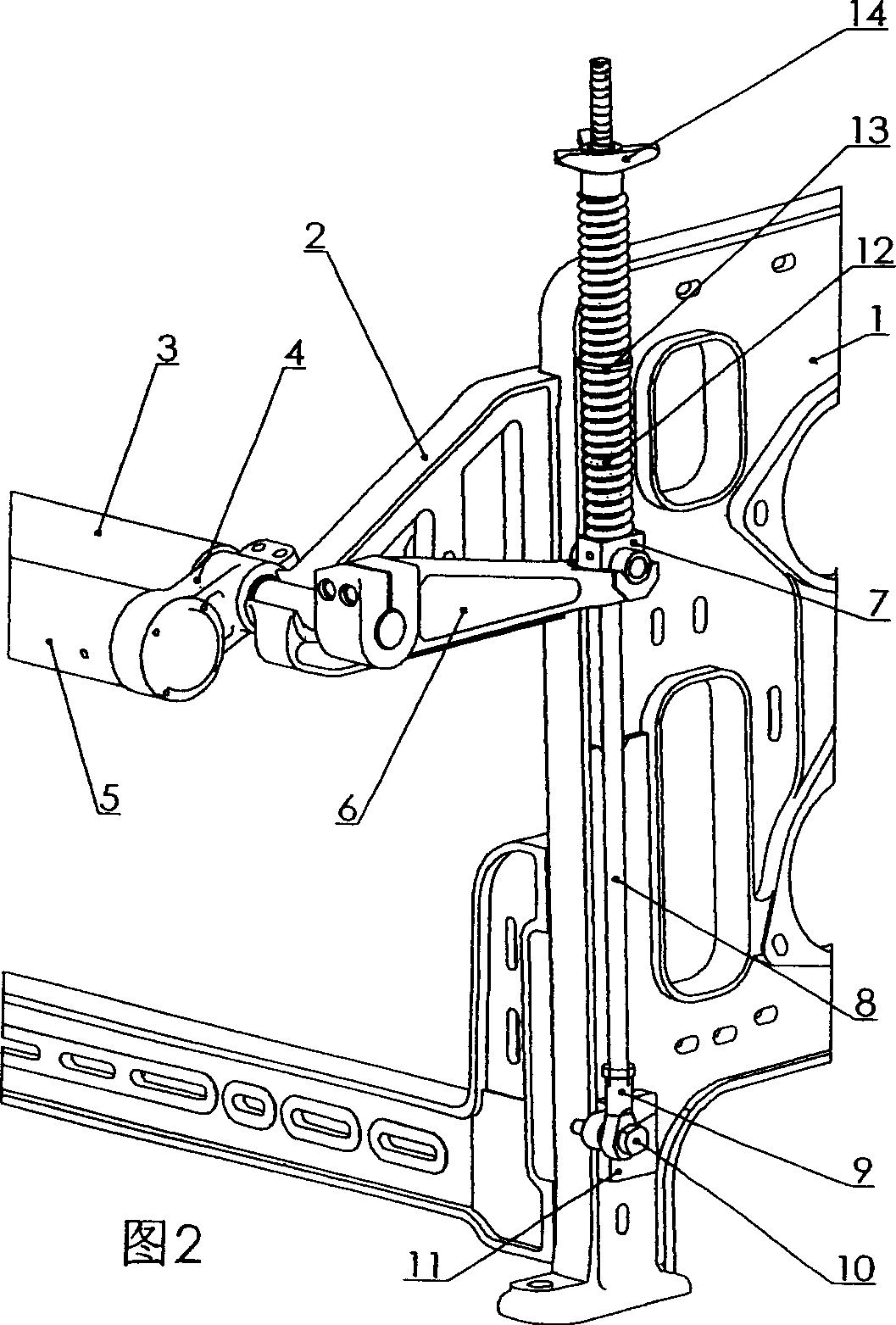

[0017] The tension balance adjustment mechanism of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] The bottom warp let-off tension balance adjustment mechanism of the towel rapier loom according to the present invention consists of a large wallboard 1, a rear beam support foot 2, a rear rod joint 3, a rocker arm joint 4, a tension roller joint 5, and a balance bar 6. Balance pressing block 7, tension balance connecting rod 8, joint bearing 9, mandrel 10, connecting rod support 11, pressure spring 12, spring guide plate 13, adjustment hand wheel 14, and the rear beam support 2 is fixed on the large wall On the plate 1, the rocker arm joint 4 is fixed on the rear rod joint 3, and the two ends of the rear pole joint 3 rest on the rear beam support 2, and the tension roller joint 5 is installed on the rocker joint 4 through rolling bearings. A balance bar 6 is fixedly mounted on the right end of the rear bar joint 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com