Double-sided waxing device

A double-sided, waxed roller technology, applied in the direction of textiles and papermaking, can solve the problems of affecting weaving efficiency and fabric quality, poor wear resistance, color difference, etc., achieve advanced technology and equipment guarantee, reduce friction coefficient, friction The effect of drag reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

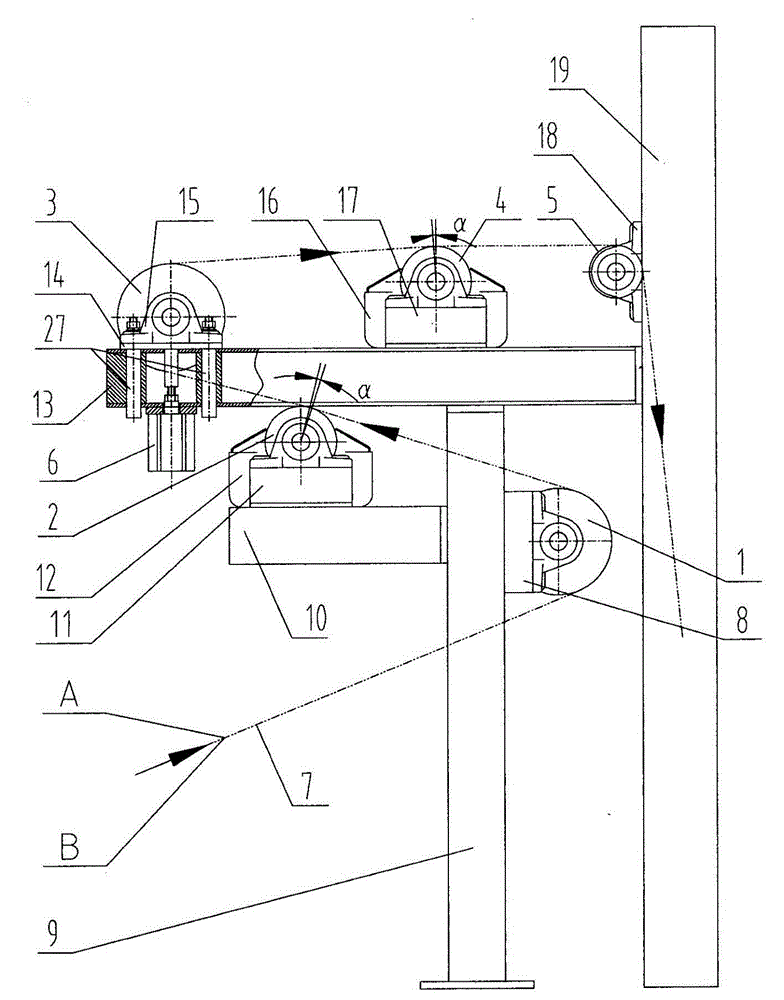

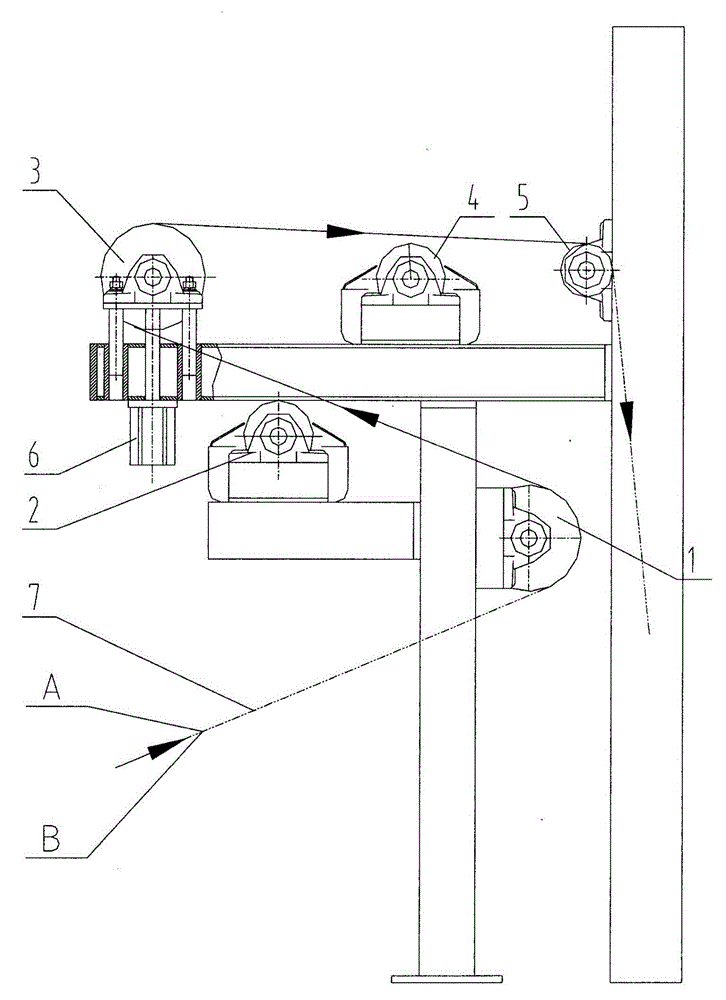

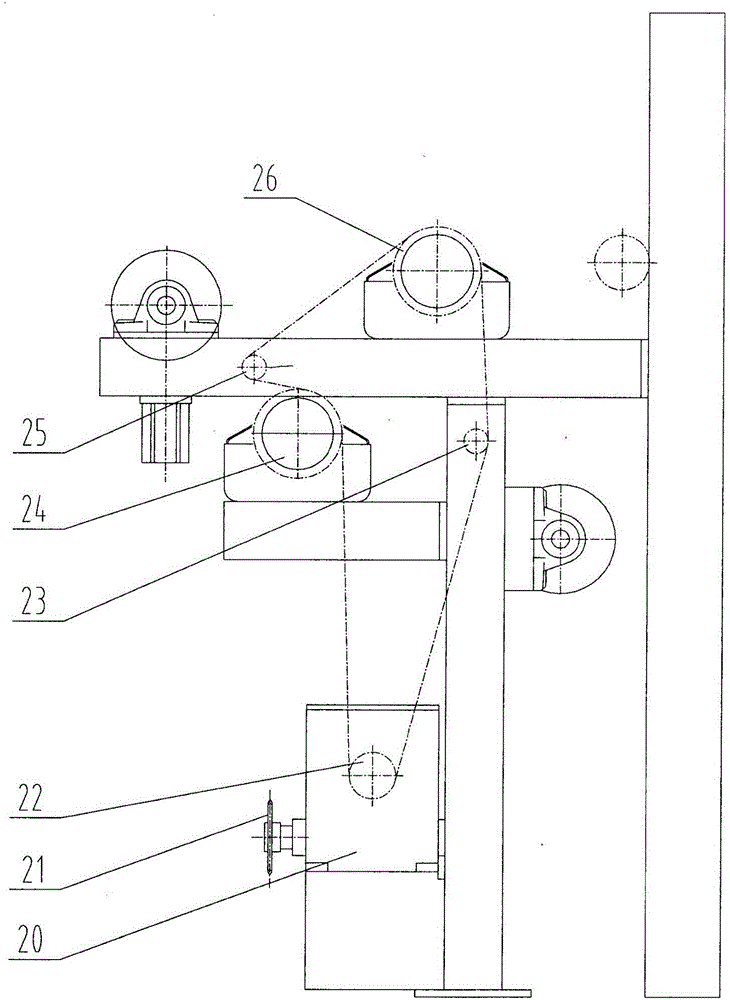

[0018] Such as figure 1 As shown, the double-face waxing device of the present invention comprises a column (19), a cross brace (13) arranged on the middle and upper part of the column (19) in a cantilever manner, and a pillar (9) supported below the cross brace (13) to form The rack, in the middle and upper part of the pillar (9) is provided with a cantilevered horizontal frame (10) parallel to the horizontal brace (13) and extending in the same direction, and installed with the cantilevered horizontal frame (10) The other side of the pillar (9) at the corresponding position on the side is equipped with the first fixed guide roller (1) through the bearing seat (8), and the first waxing roller (2) placed in the first wax tank (12) Installed on the cantilever cross frame (10) through the bearing seat (11), and installed on the cantilever end of the cross brace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com