A kind of production process of gauze

A production process and gauze technology, applied in the field of fabric weaving, can solve the problems of high noise of shuttle looms, short length of weft yarn, low wages, etc., achieve stable and reliable mechanism operation, reduce yarn hairiness, and heald frame movement smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

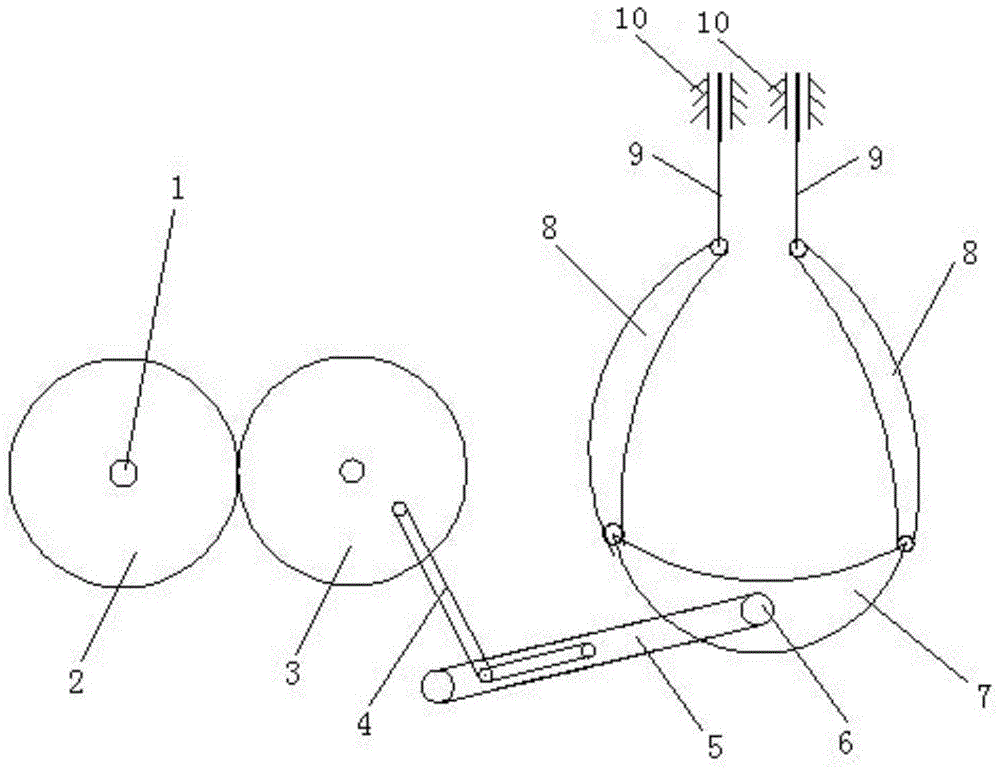

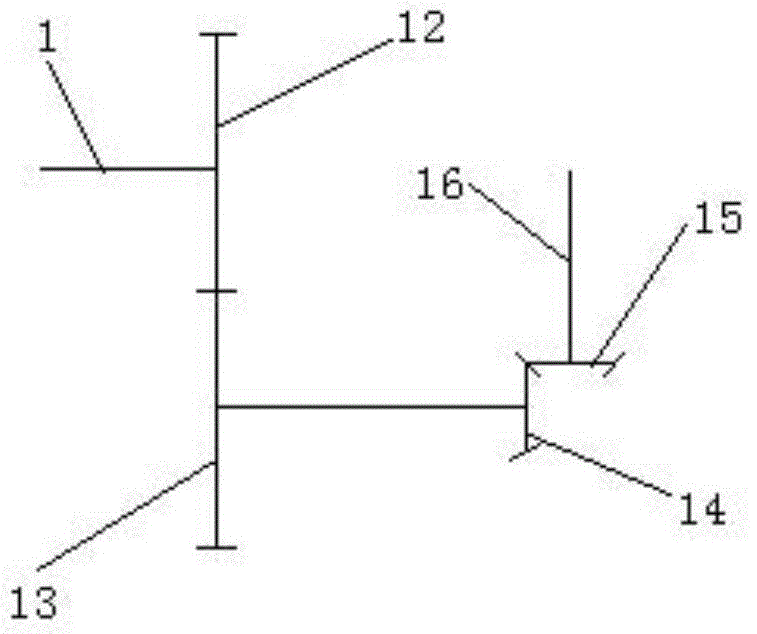

Method used

Image

Examples

Embodiment

[0044] 1. Generally, for gauze with a width of 98cm, the number of warp yarns is about 1080. According to the characteristics of small warp density and small number of warp yarns, we did not use section warping machines for warping, but modified batch warping machines. Expand the capacity of the creels from 800 to 1200, and directly replace the warp beams with weaving beams, which simplifies the technological process and eliminates the need for reversing beams. After the transformation, the warping speed is 30,000 meters per person per shift Increased to 100,000 meters per person per shift, the efficiency has increased by 330%, and the yarn tension is more uniform, the warping quality is higher, and the chance of yarn fluffing and pollution is reduced.

[0045] 2. Warp drawing, due to small warp yarn twist, low single yarn strength, no sizing, very wear-resistant, when drawing in healds, only wear heddles and reeds, not warp stoppers, and try weaving 1- 2 meters, the warp yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com