Patents

Literature

141results about How to "Small elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

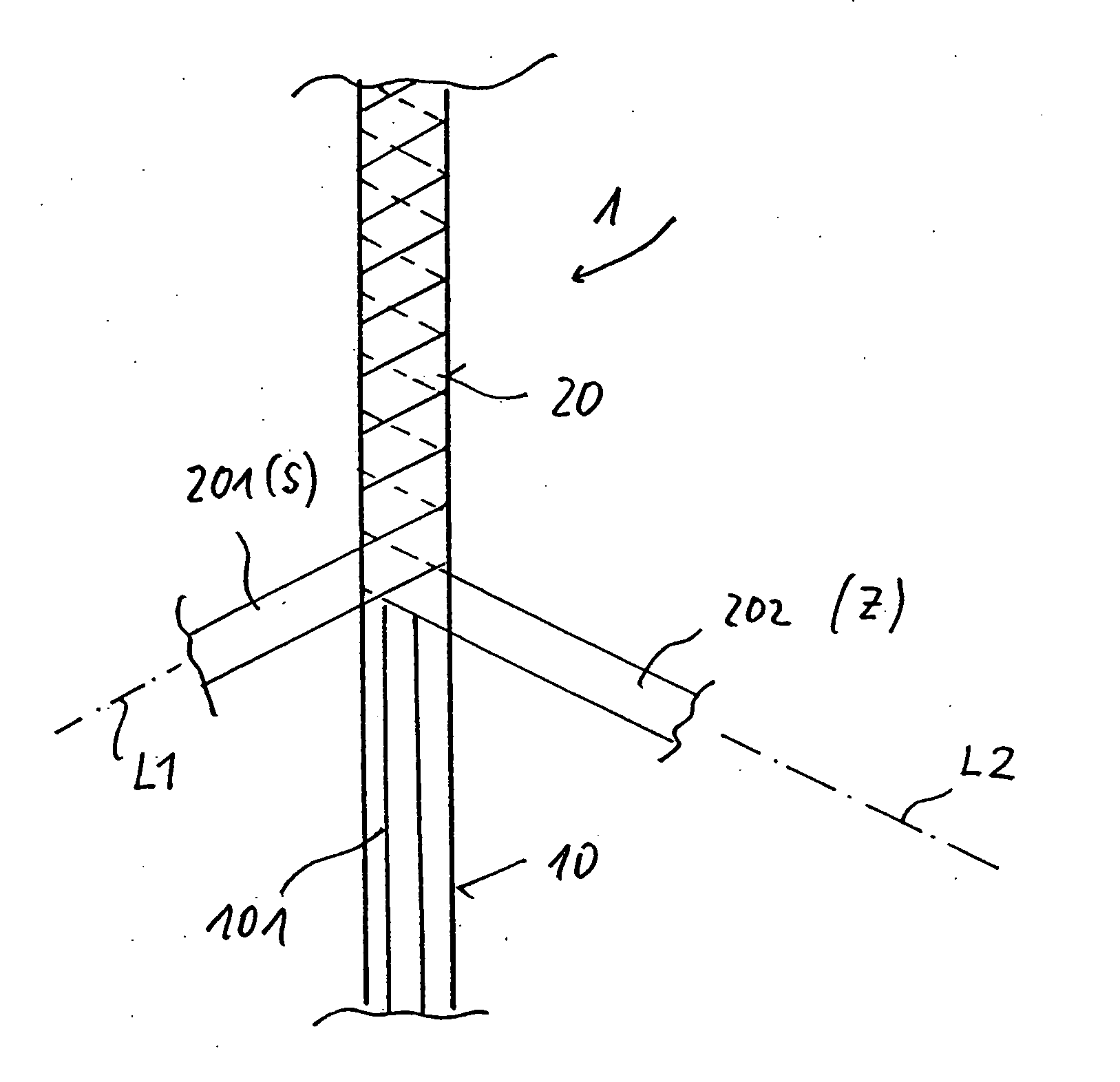

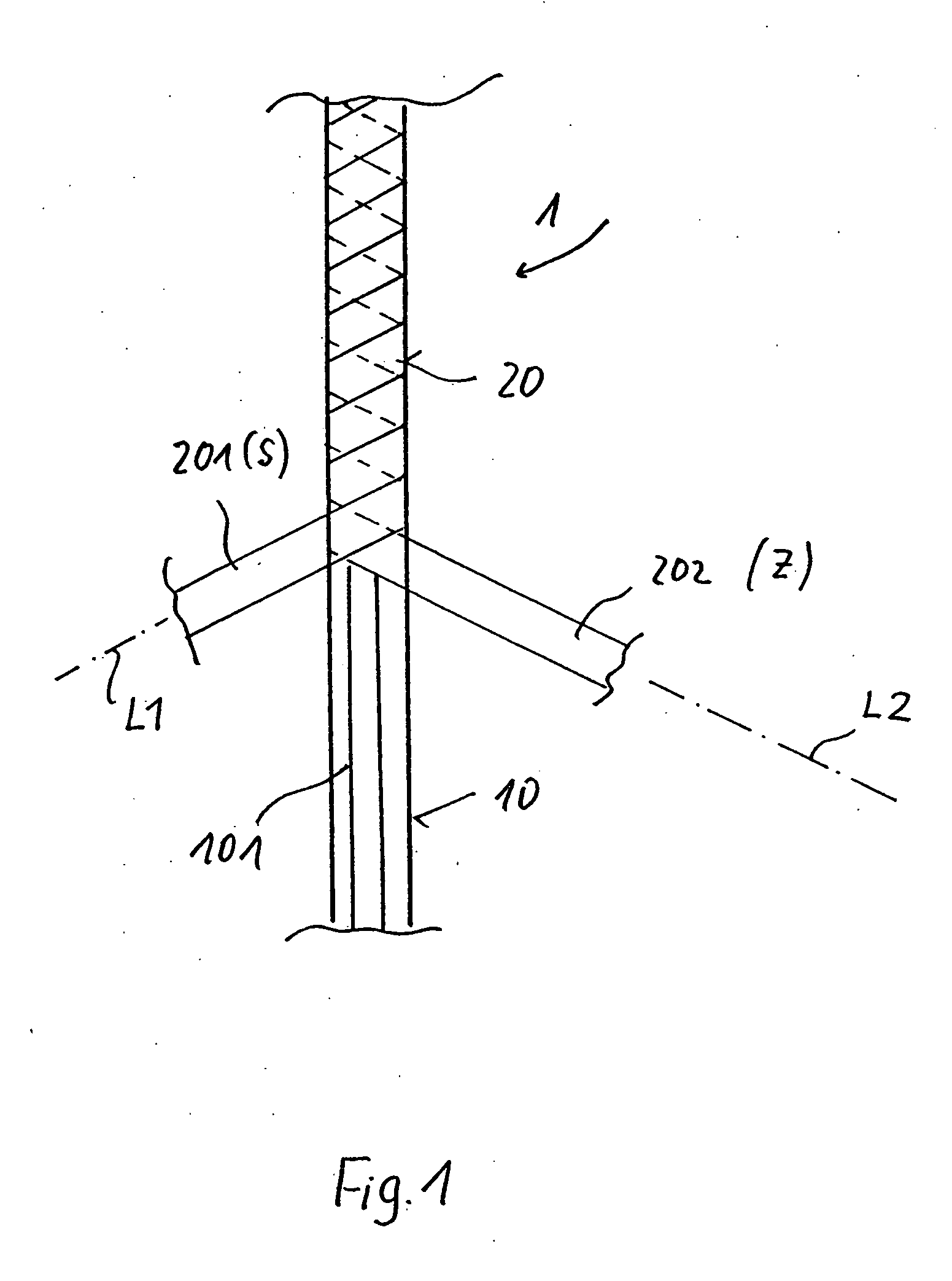

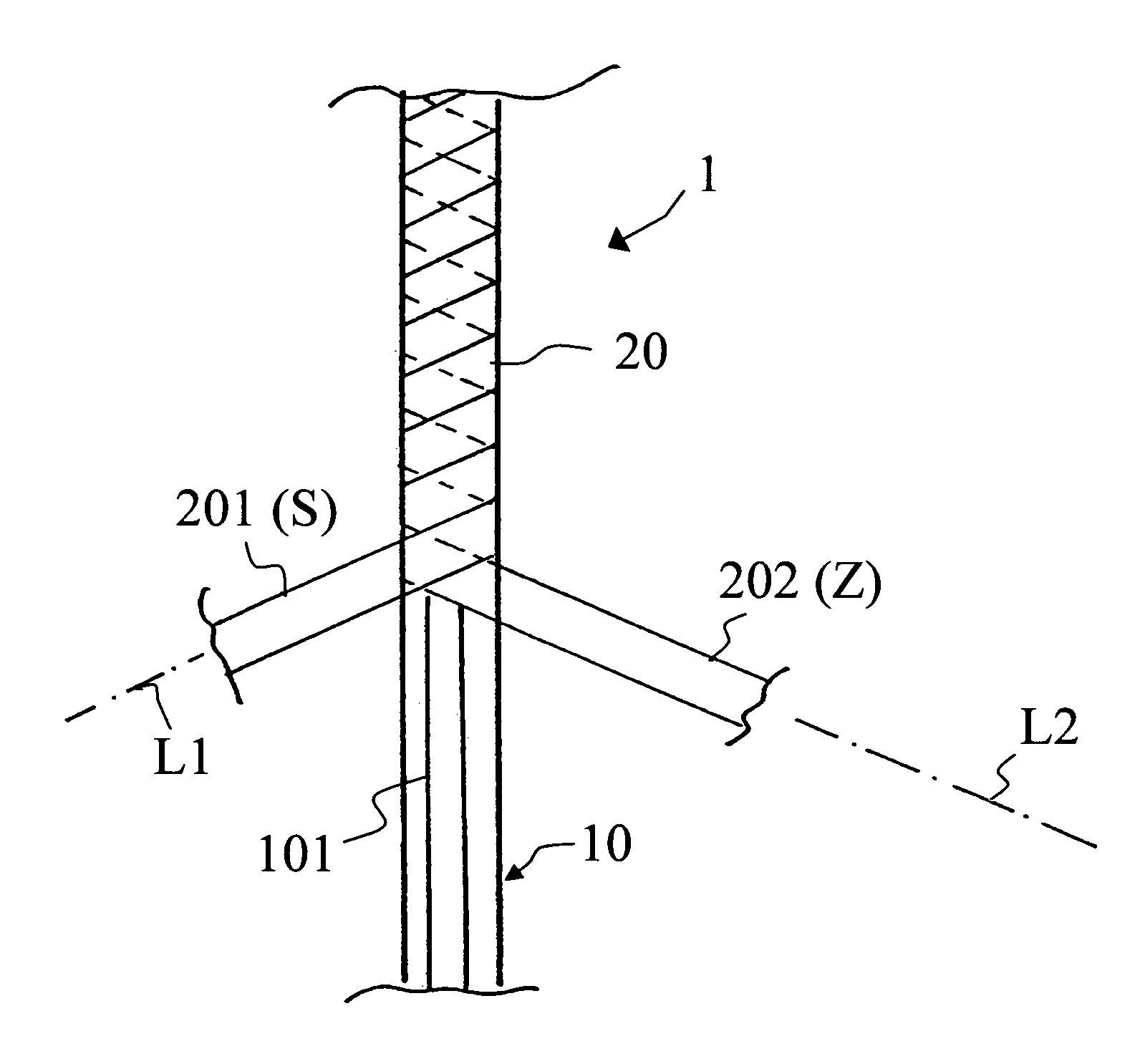

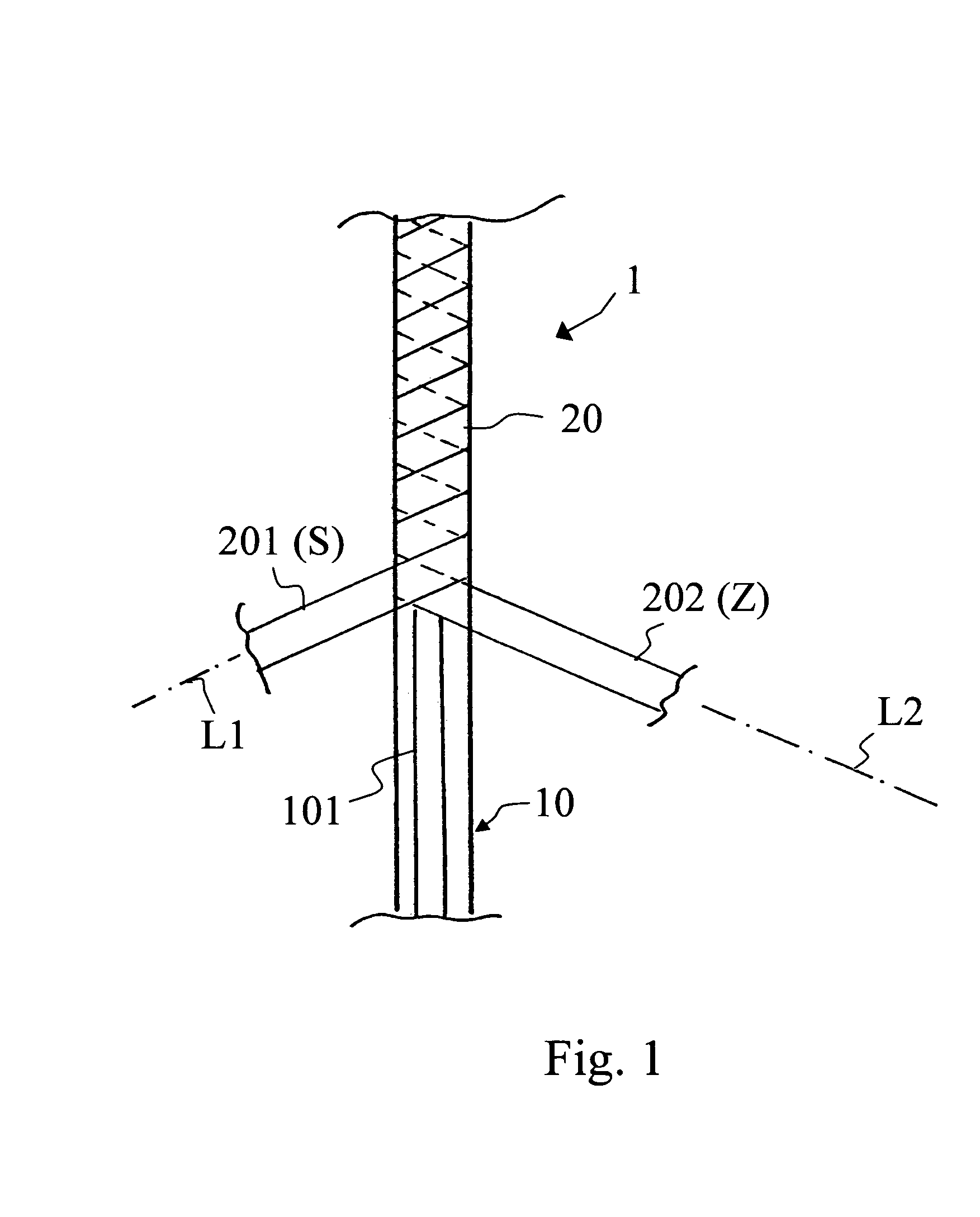

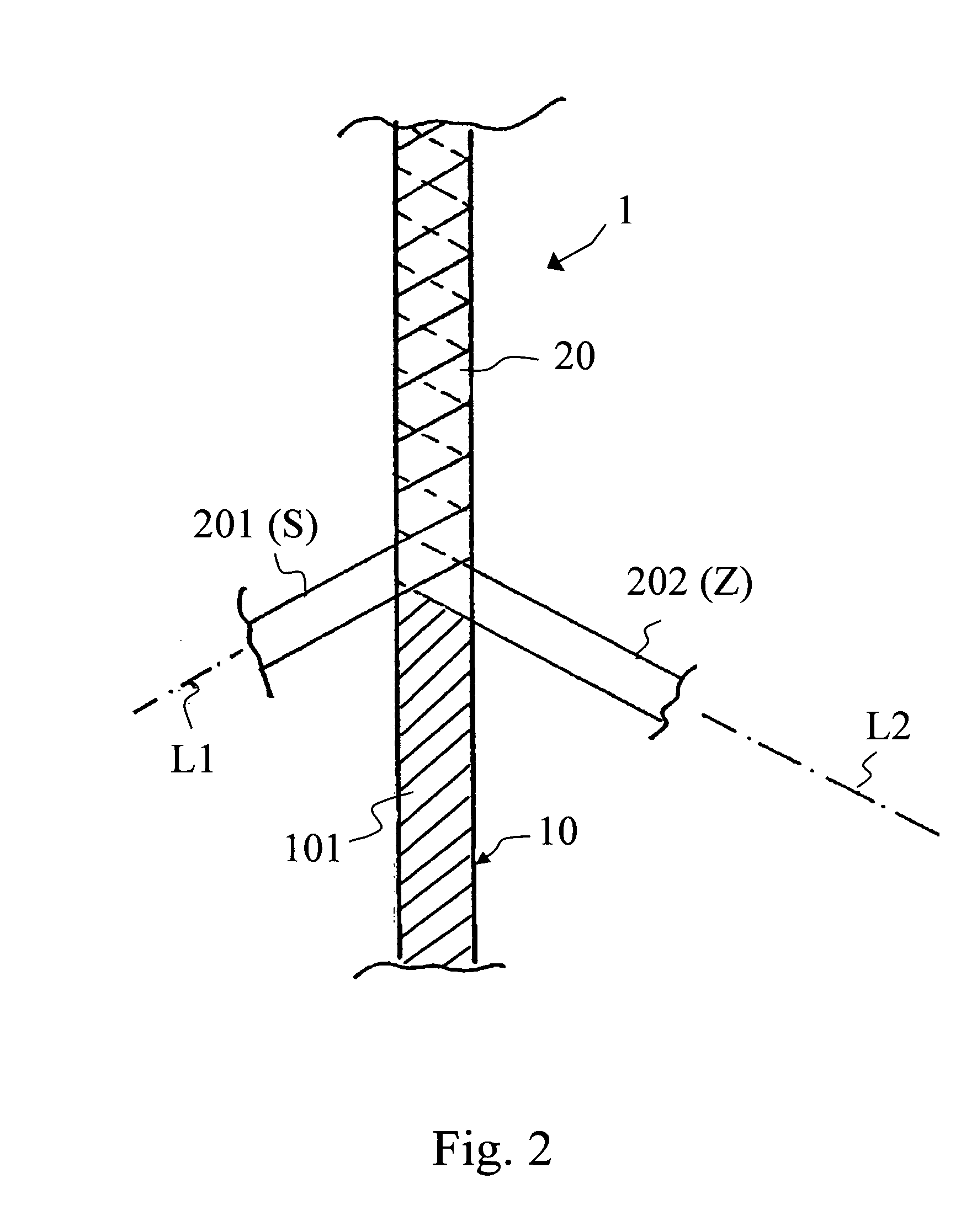

Textile thread

A textile thread having a core and a sheath surrounding the core. The core, formed of high-tenacity synthetic organic endless fibers, is tightly wound by slit film tapes made of polytetrafluoroethylene (PTFE) in the S-direction and the Z-direction, or vice versa, and the slit film tapes forms a sheath.

Owner:BLOCH KLAUS

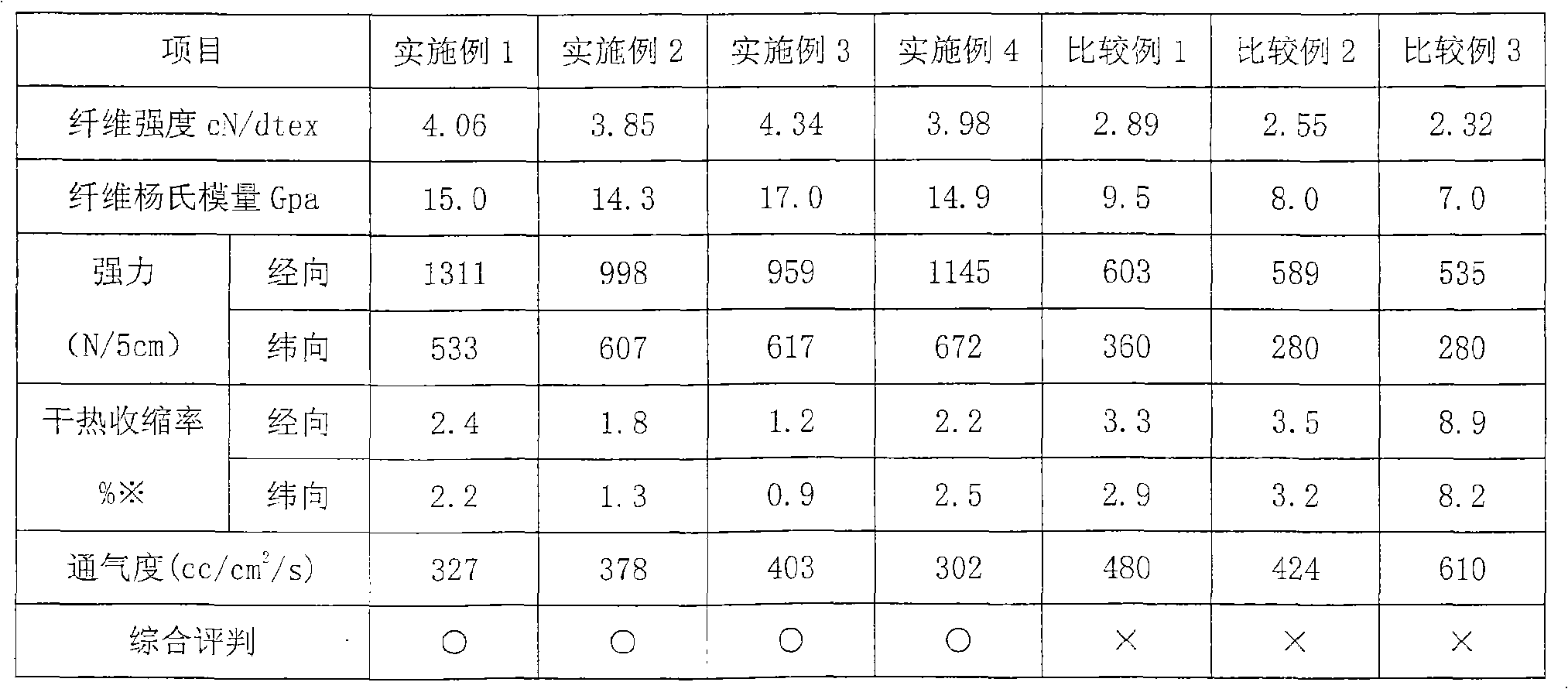

Reinforcing fabric for non-woven fabric heat-resisting filter material and application thereof

The invention discloses reinforcing fabric for a non-woven fabric heat-resisting filter material. Fibers for forming the reinforcing fabric at least contain meta-aromatic polyamide fibers. The reinforcing fabric has high strength and good size stability. The invention provides the reinforcing fabric used for the high-strength non-woven fabric heat-resisting filter material so as to prolong the service life of the filter material.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

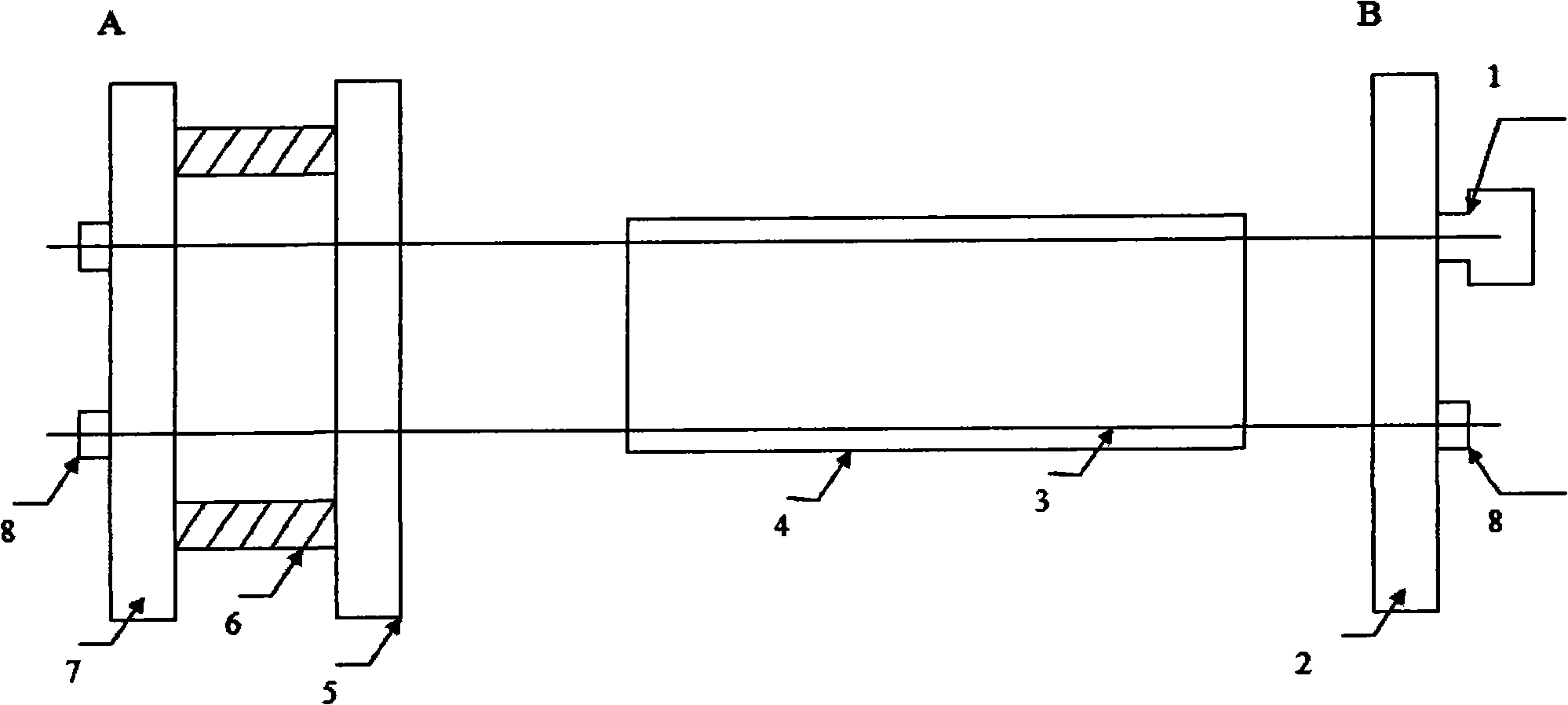

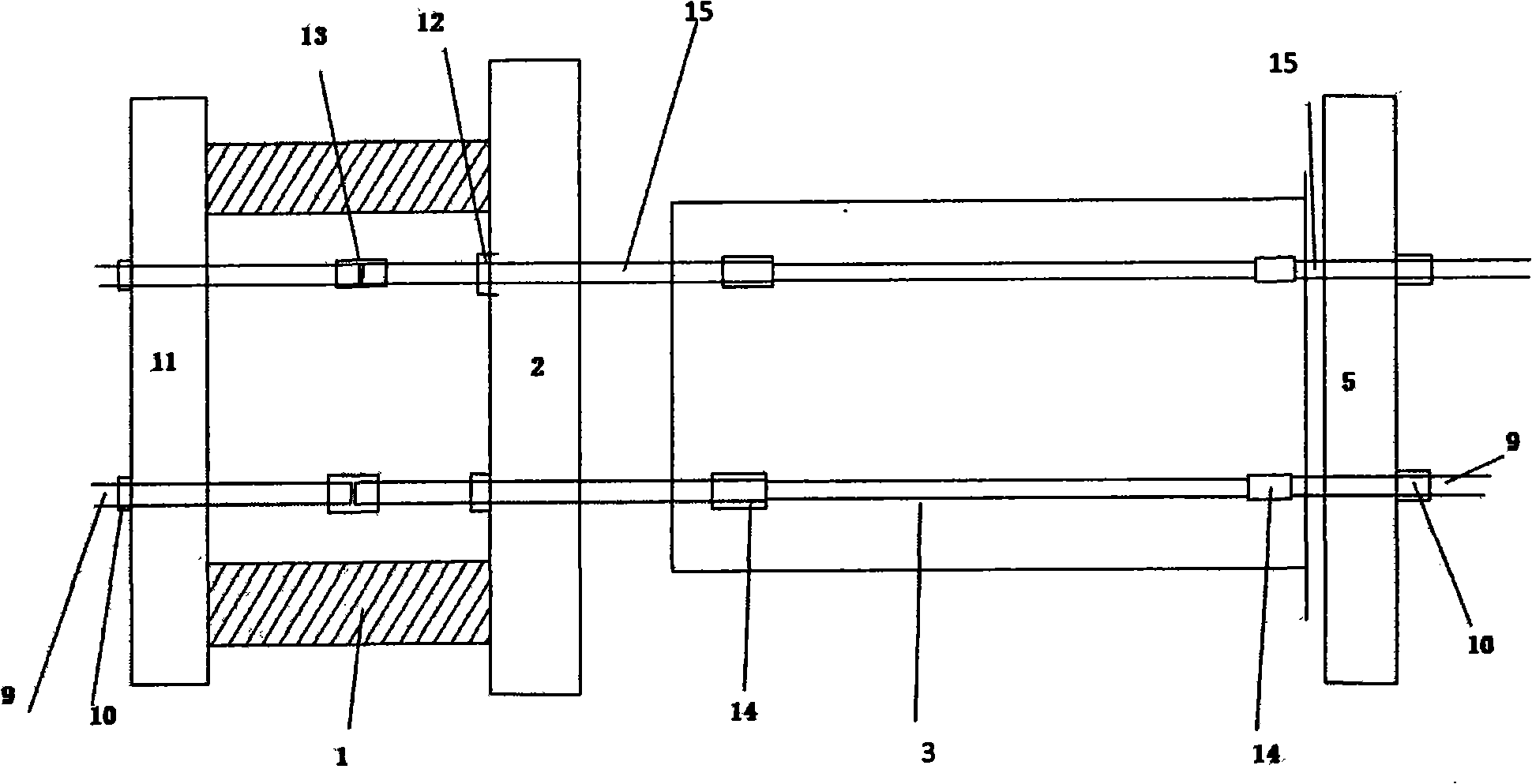

Integral tension, relaxation system and technique for pre-tensioned prestressing tension technique

InactiveCN101279483AImprove prefab speedShorten the timeCeramic shaping apparatusPre stressJackscrew

The invention discloses an integral tensioning and relaxation system for pre-tensioning method prestressing technology and a process, which have the advantages of simple construction, material saving, and an accurate exertion of prestressing force value. The integral tensioning and relaxation system comprises a fixed cross beam at a passive end, a prefabricated pedestal, a fixed cross beam at a tensioning end, a movable cross beam, and a pair of jacks arranged between the fixed cross beam at the tensioning end and the movable cross beam. The invention is characterized in that the invention at least comprises one fine bundle spiral steel tool pull rod, and the fine bundle spiral steel tool pull rod is connected with a corresponding working pull rod through a connector for the corresponding working pull rod and a tool pull rod; the working pull rod is connected with a corresponding steel strand through a corresponding steel strand-fine bundle deformed steel bar connector; the other end of the steel strand is then connected with another corresponding working pull rod through the corresponding steel strand-fine bundle deformed steel bar connector; the working pull rod is fixed on the fixed cross beam at the passive end.

Owner:CHINA NAT CHEM COMM CONSTR GRP CO LTD

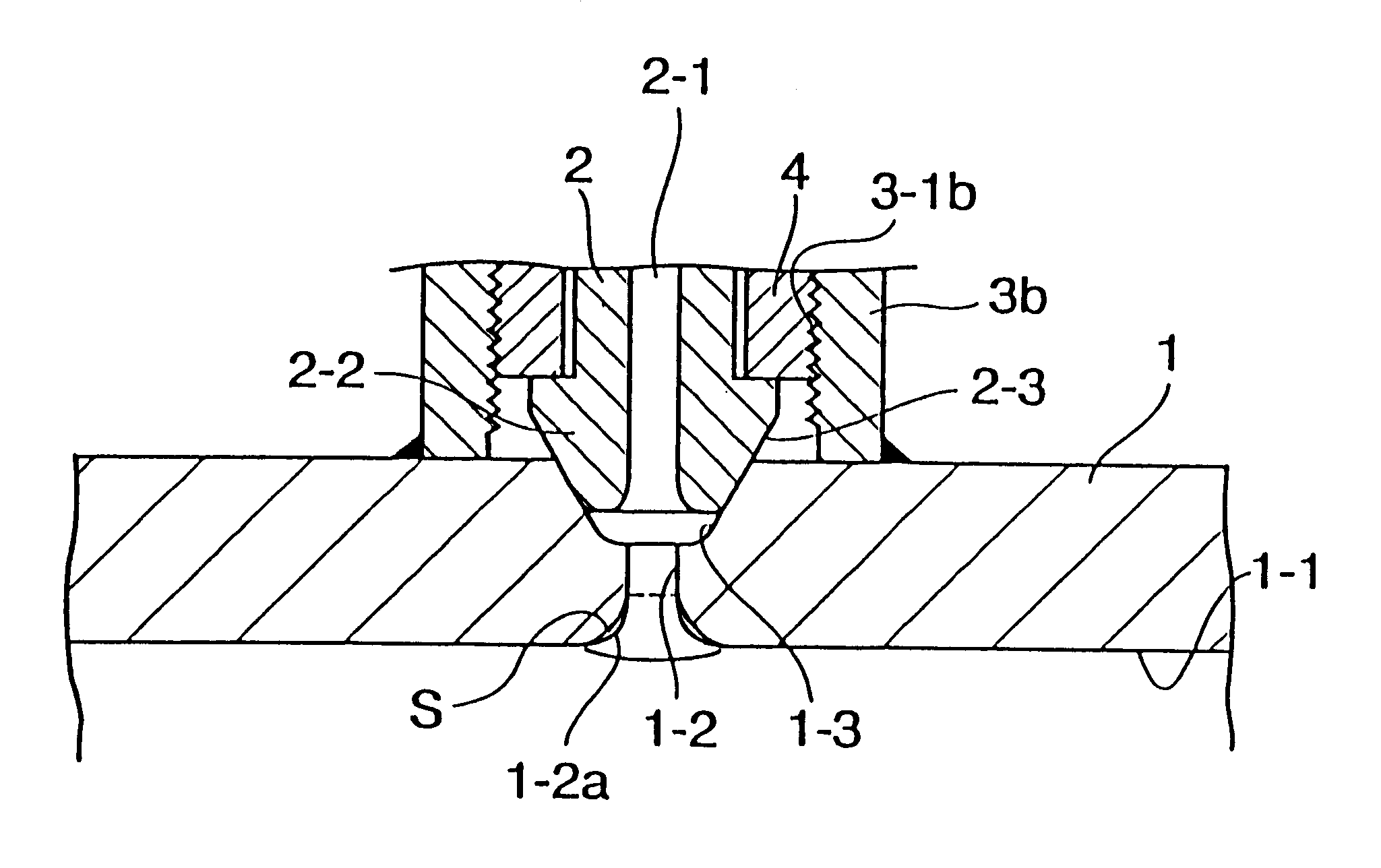

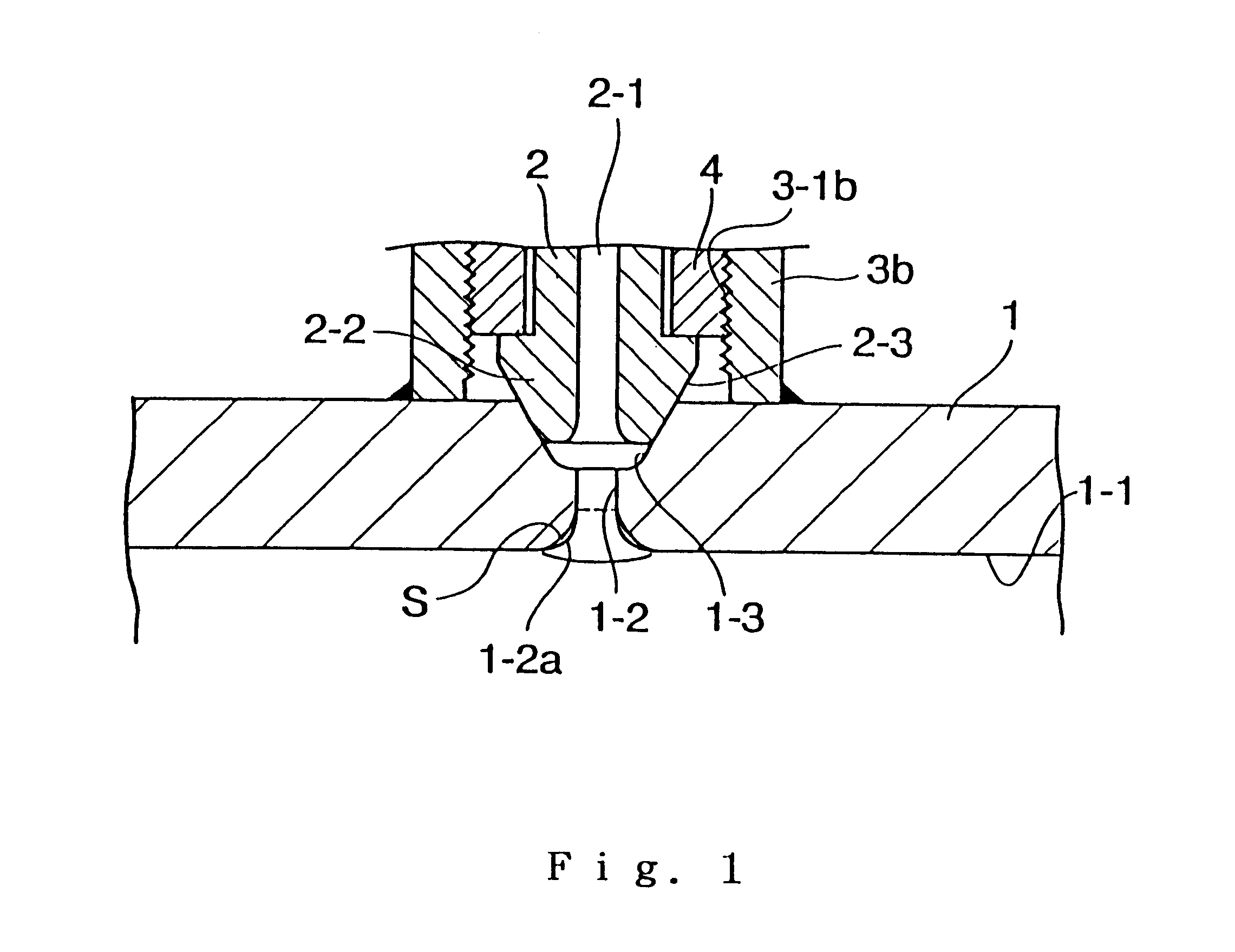

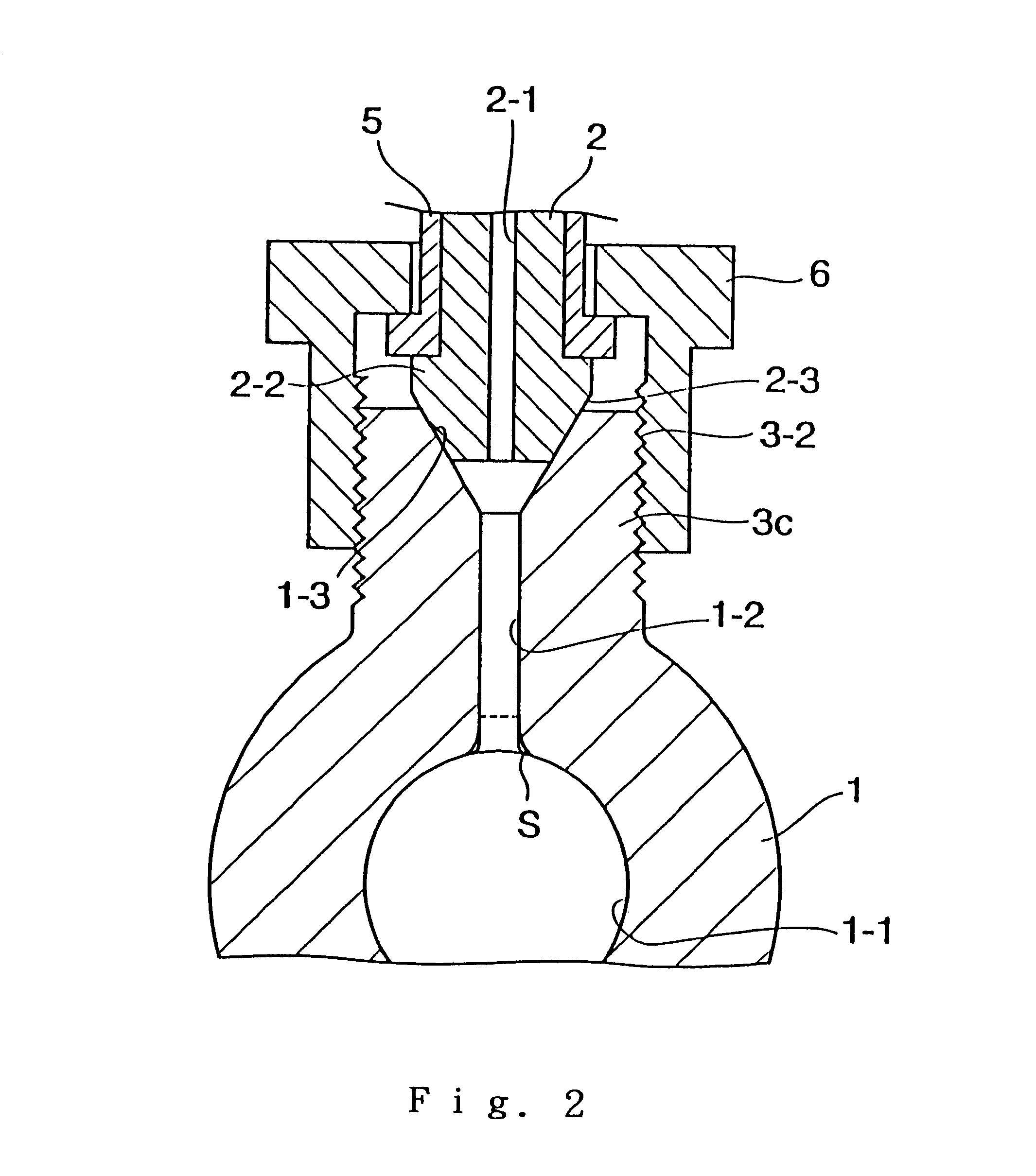

Common rail for diesel engine

InactiveUS6494183B2High strengthReduce stress concentrationLow pressure fuel injectionMachines/enginesInternal pressureCommon rail

A common rail includes a main pipe rail having a circulating passage extending in its inside in the axial direction thereof, branch holes formed in an axial peripheral wall portion of the main pipe rail, and branch connectors connected to the respective branch holes integrally or via separate connecting members. A Ni-diffused fatigue strength reinforcing layer is formed by heating a Ni layer plated in advance on at least a portion of an inner circumferential surface of the common rail. The increased strength and the action of the fatigue strength reinforcing layer lowers the degree of fatigue concentration to increase fatigue strength against inner pressure.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Preparation technology of ultralow contraction terylene industry long filament

ActiveCN1904153AAvoid RelaysGuaranteed viscosity uniformityMelt spinning methodsMonocomponent polyesters artificial filamentTextile fiberPolyester

This invention relates to the process of a kind of ultra-low contraction polyester fiber industry filament, which introduces the spinning and stretch one-stage process, including: solid phase increases sticks, melting spinning, high temperature stretches, heat setting, coiling formation. This invention adopts the innovative 5 pairs of hot rollers stretch heat setting technique, in comparison with the tradition 4 pairs, which adopts the 2-step heat stretch and 2-step heat setting. The new level heat setting processing method can reduce the textile fiber stretch speed effectively, lengthen the textile fiber heat setting time, and enables the textile fiber possessing evenly stable orientation structure, which guarantees product physics performance, optimizes the spinning condition. This ultra-low contraction polyester fiber industry filament preparation method provided with polyester fiber industry having high density, big module, small elongate, good heat-resisting performance, resisting impingement, and bearing the fagged performance.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

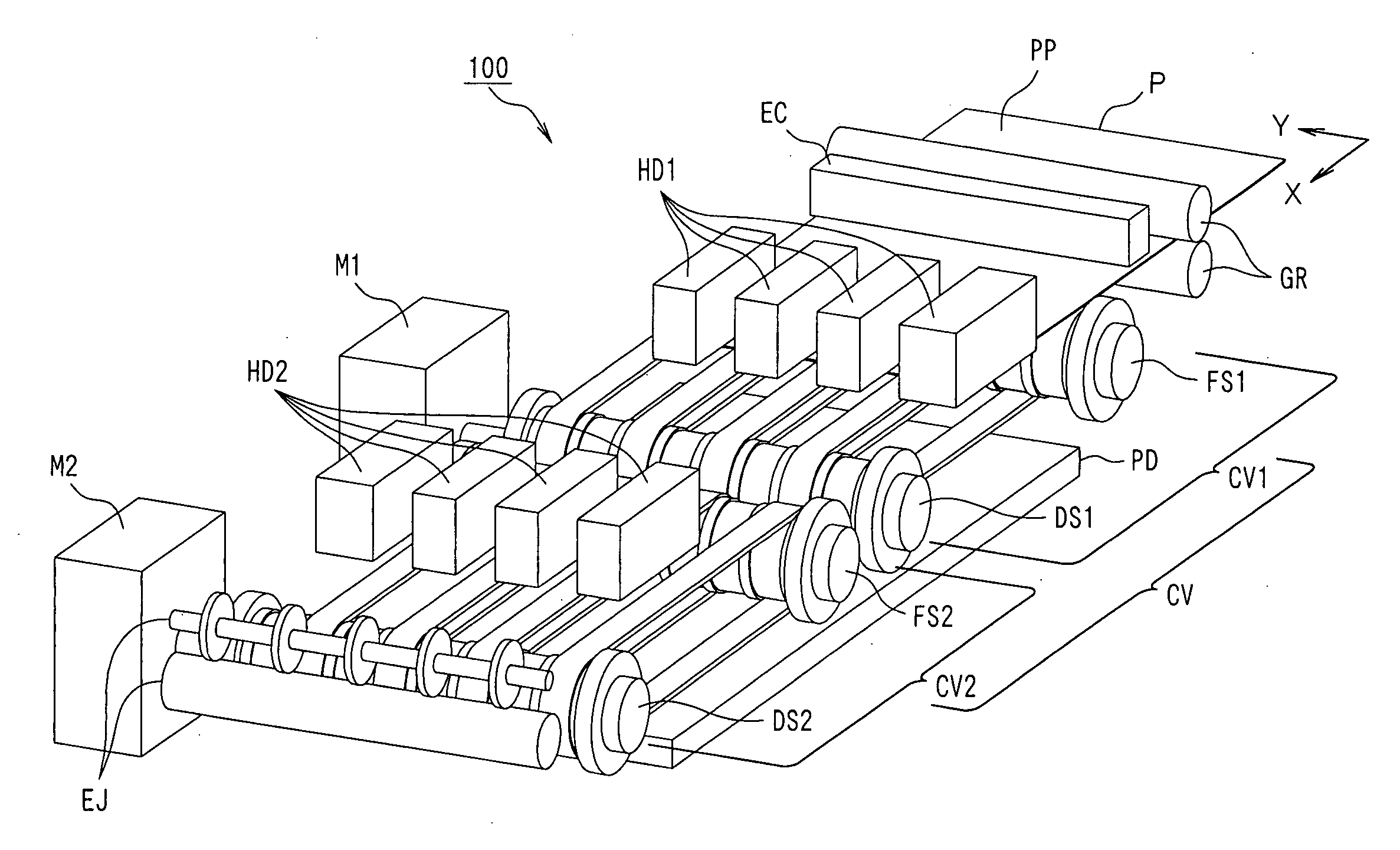

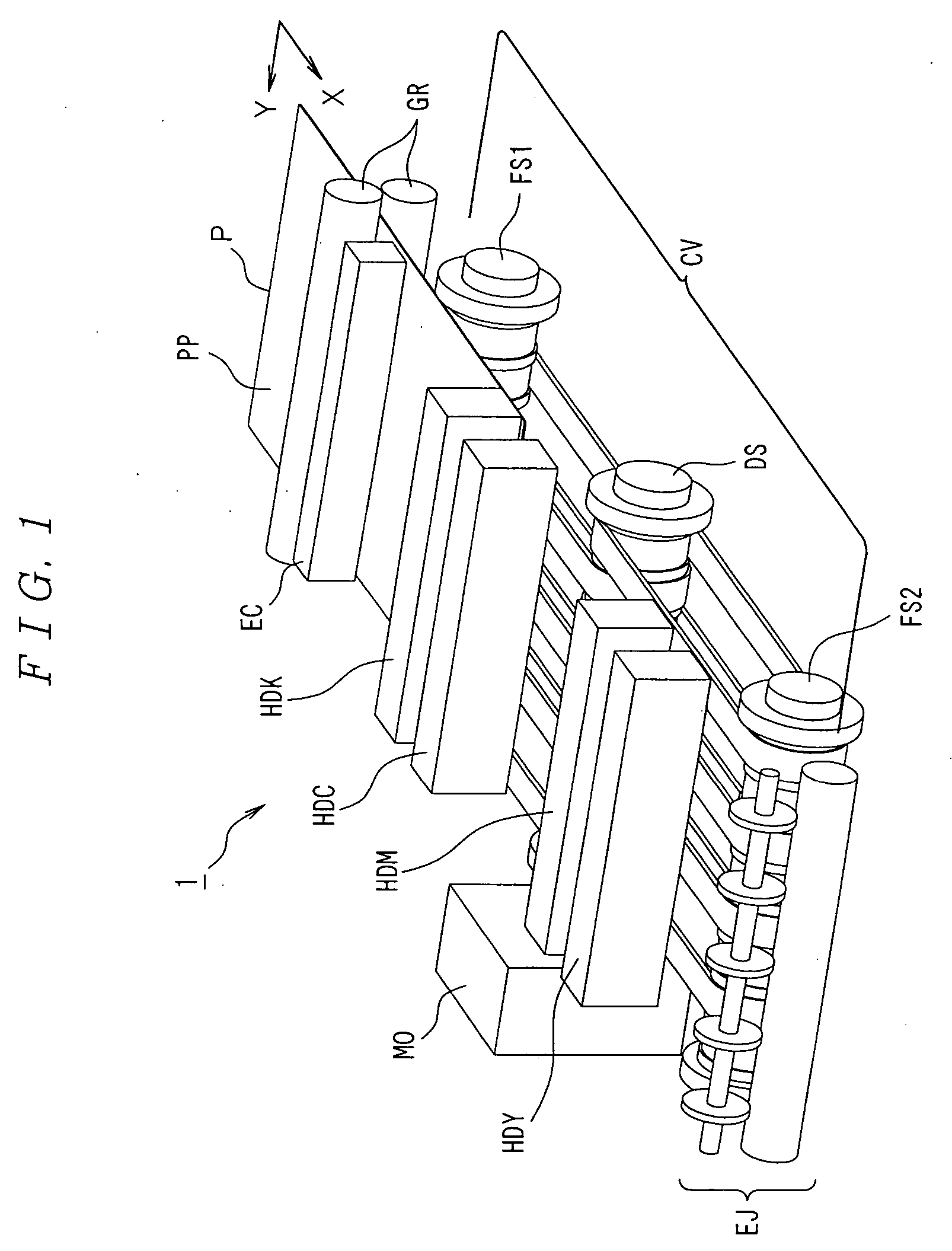

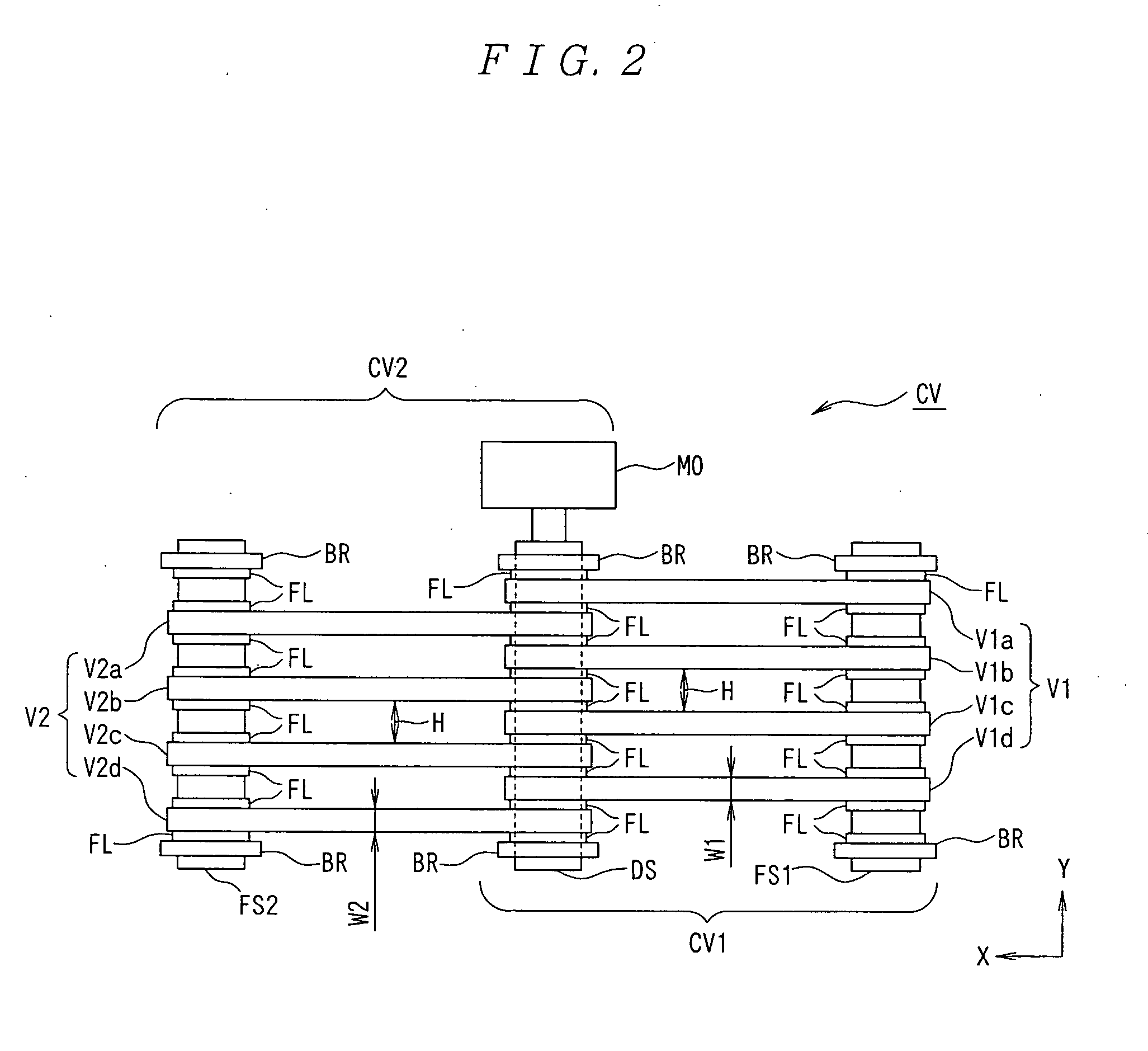

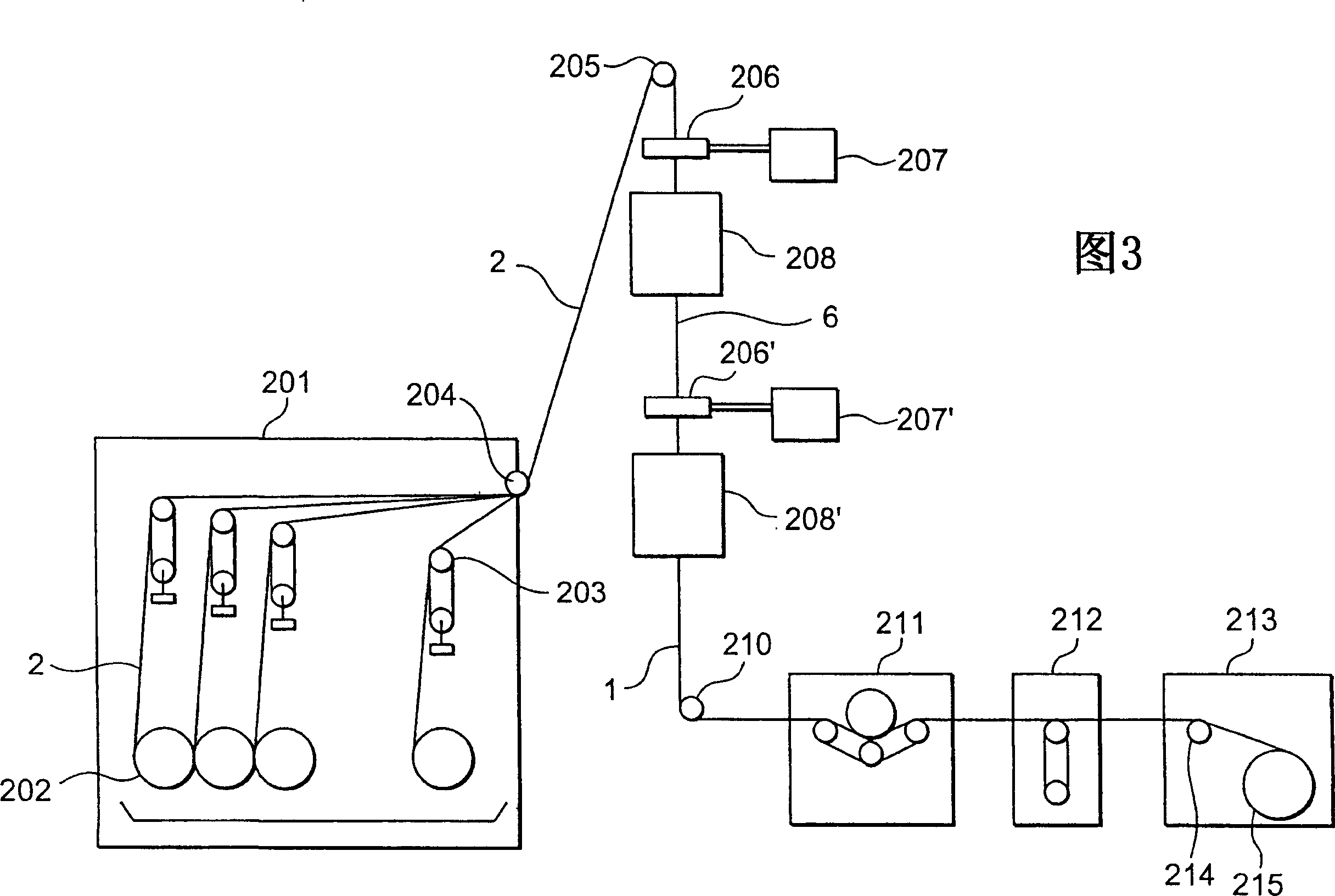

Ink jet printer

InactiveUS20050206708A1Improve discharge performanceLow elongationOther printing apparatusArticle feedersComputer printingInk printer

Owner:SEIKO EPSON CORP

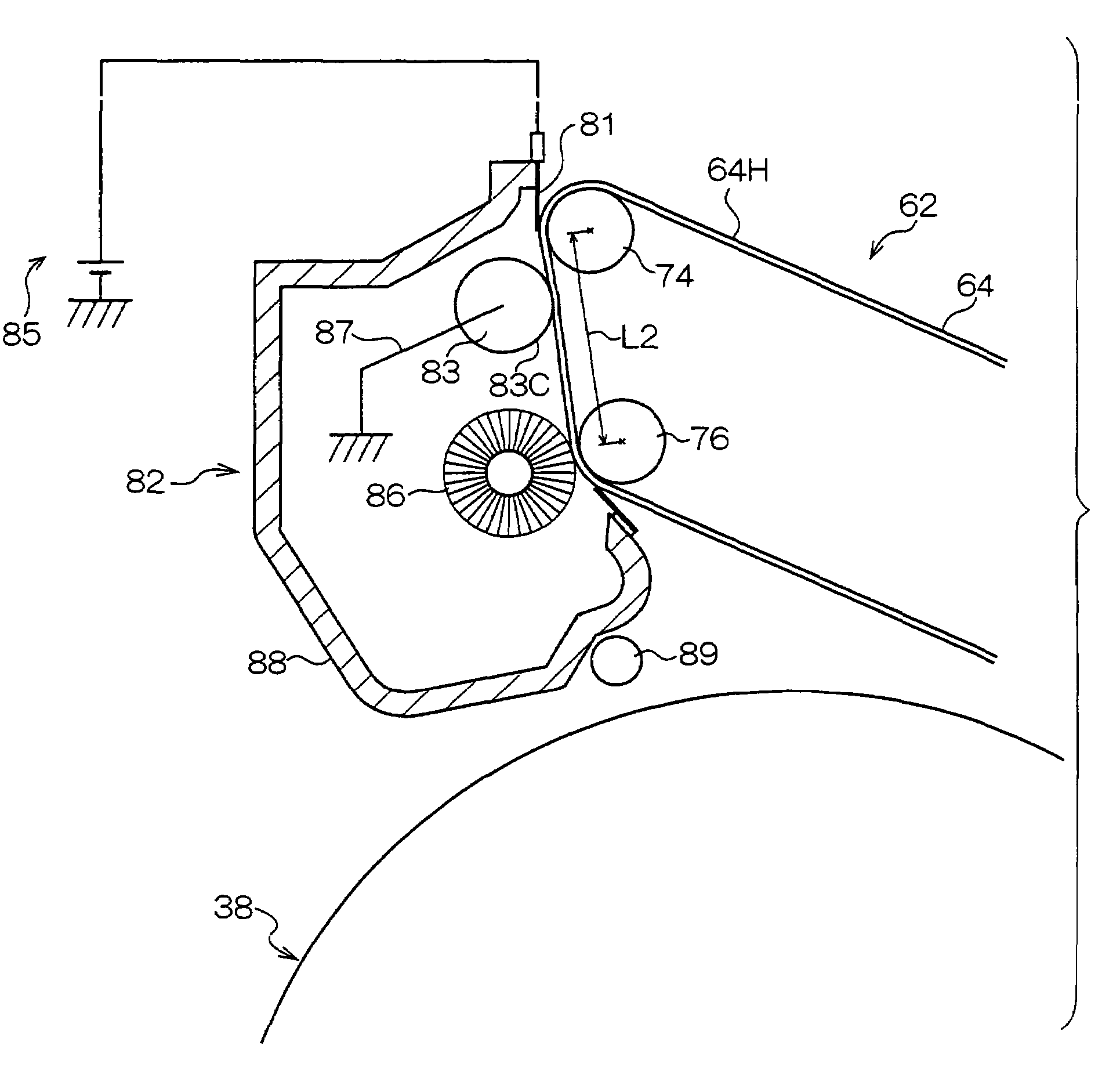

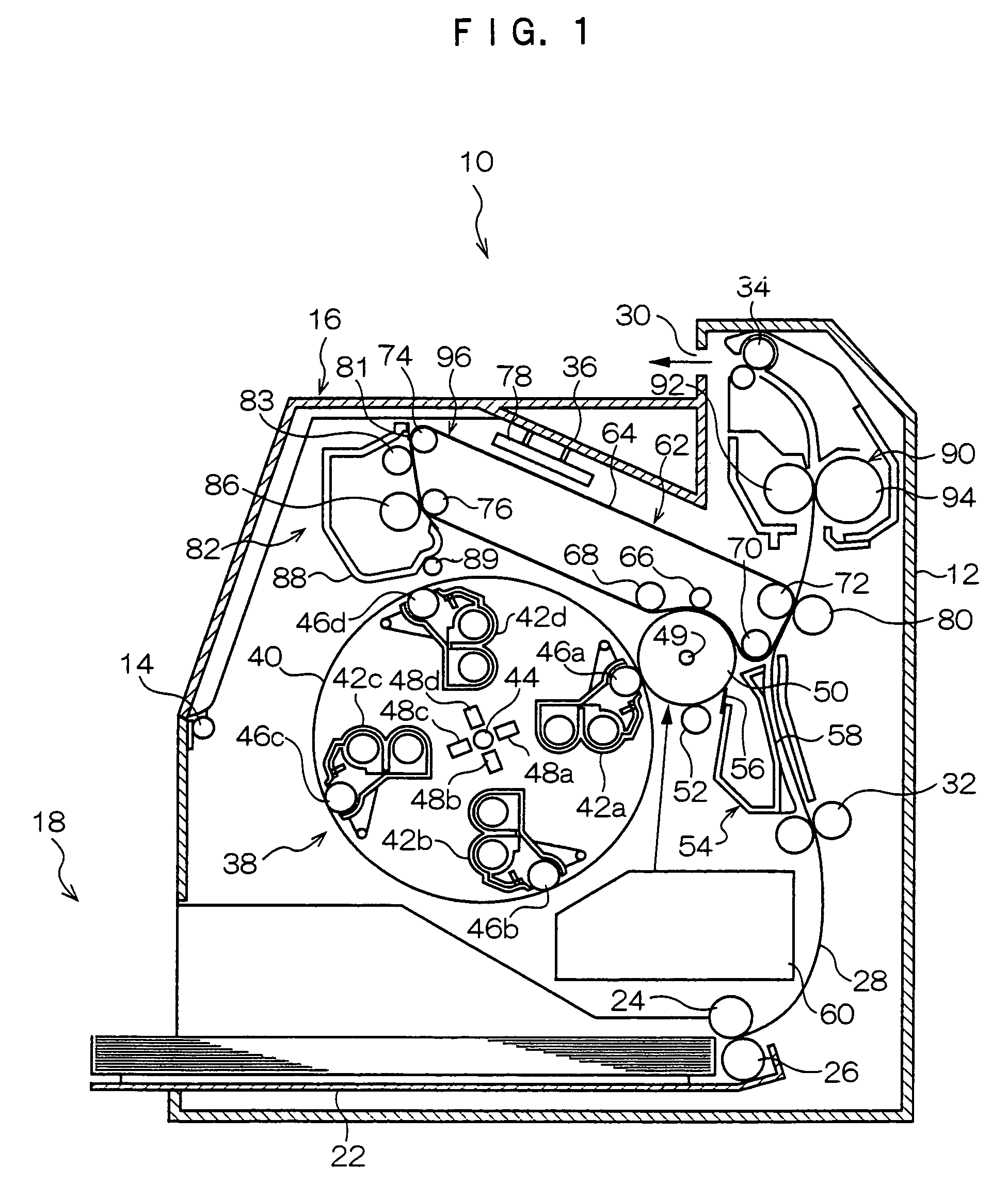

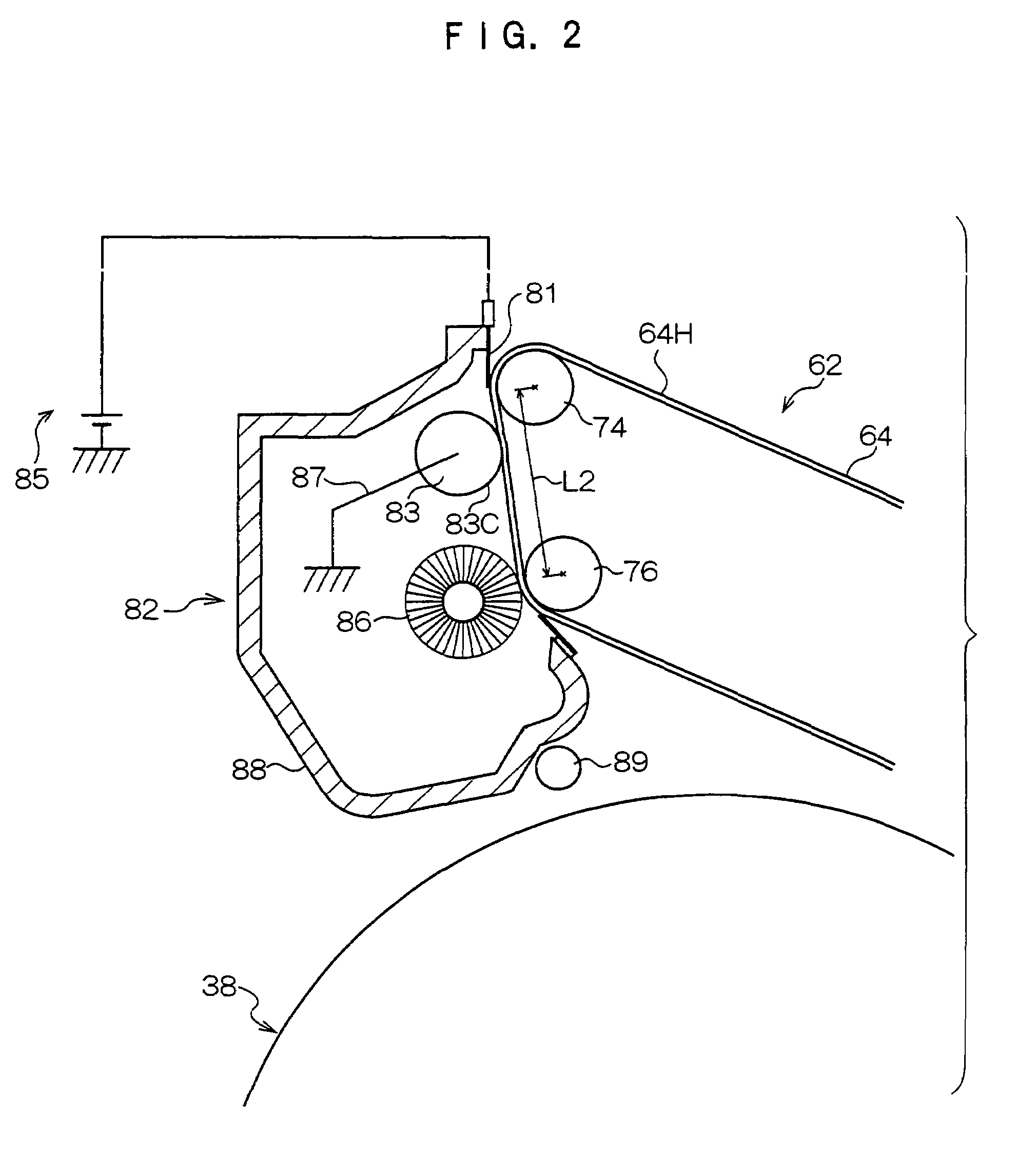

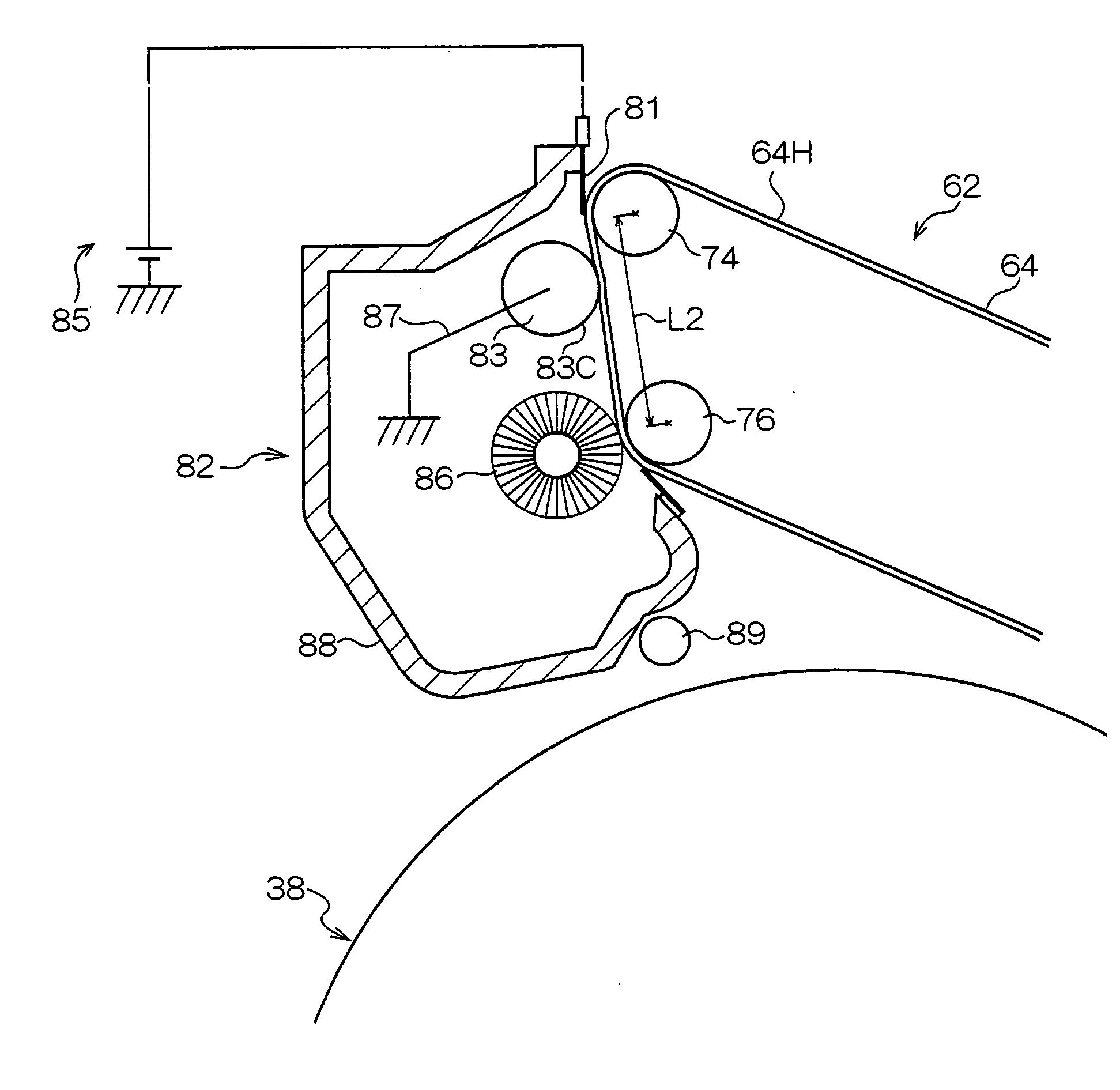

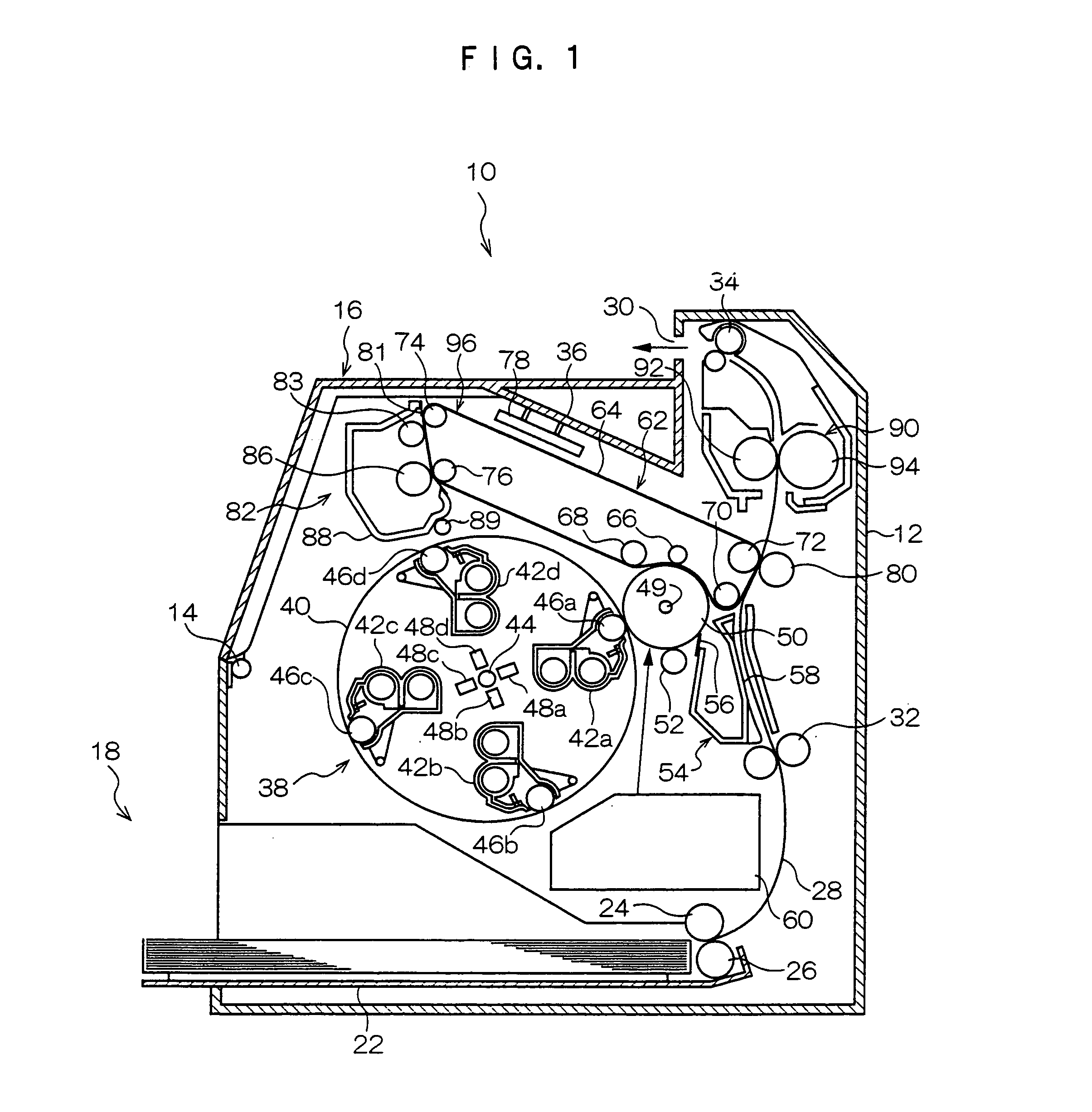

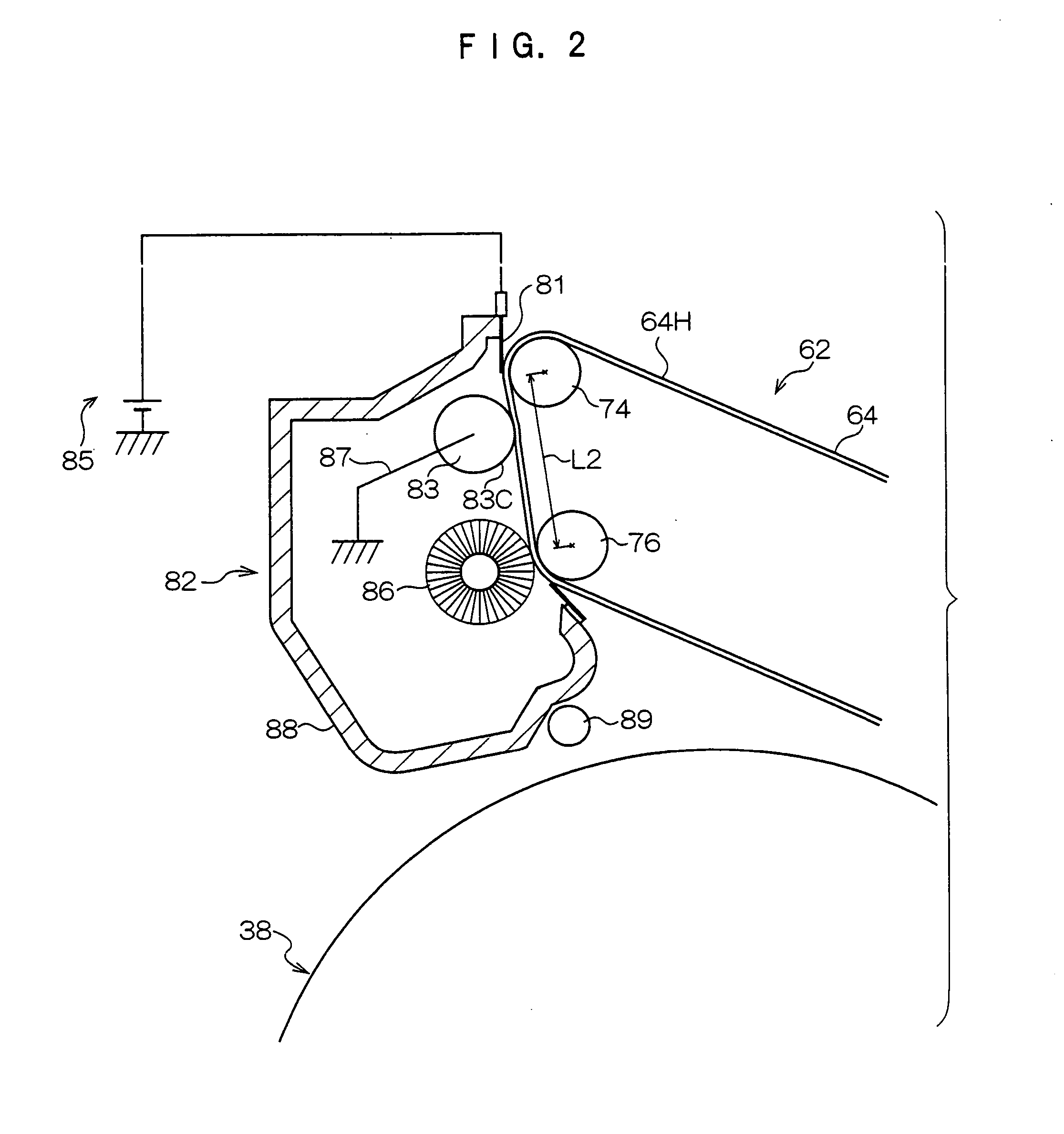

Intermediate transfer device and image forming device

InactiveUS7190919B2Reliably removedReduce mechanical stressElectrographic process apparatusEngineeringVoltage

An intermediate transfer device has: an intermediate transfer belt supported by a plurality of belt supporting mechanisms so as to be able to circulate, and having elasticity at least in a direction of circulating; a first bias applying mechanism applying a first bias voltage to toner on a toner carrier surface of the intermediate transfer belt; a layer thinning mechanism contacting the toner carrier surface and electrostatically attracting the toner which is on the toner carrier surface so as to thin a layer of the toner; a second bias applying mechanism applying a second bias voltage to the toner whose layer has been thinned; an image carrier carrying a visible image to be transferred onto the toner carrier surface, the toner on the toner carrier surface, to which the second bias voltage has been applied, being transferred onto the image carrier; and a toner removing mechanism removing the toner on the image carrier.

Owner:FUJIFILM BUSINESS INNOVATION CORP

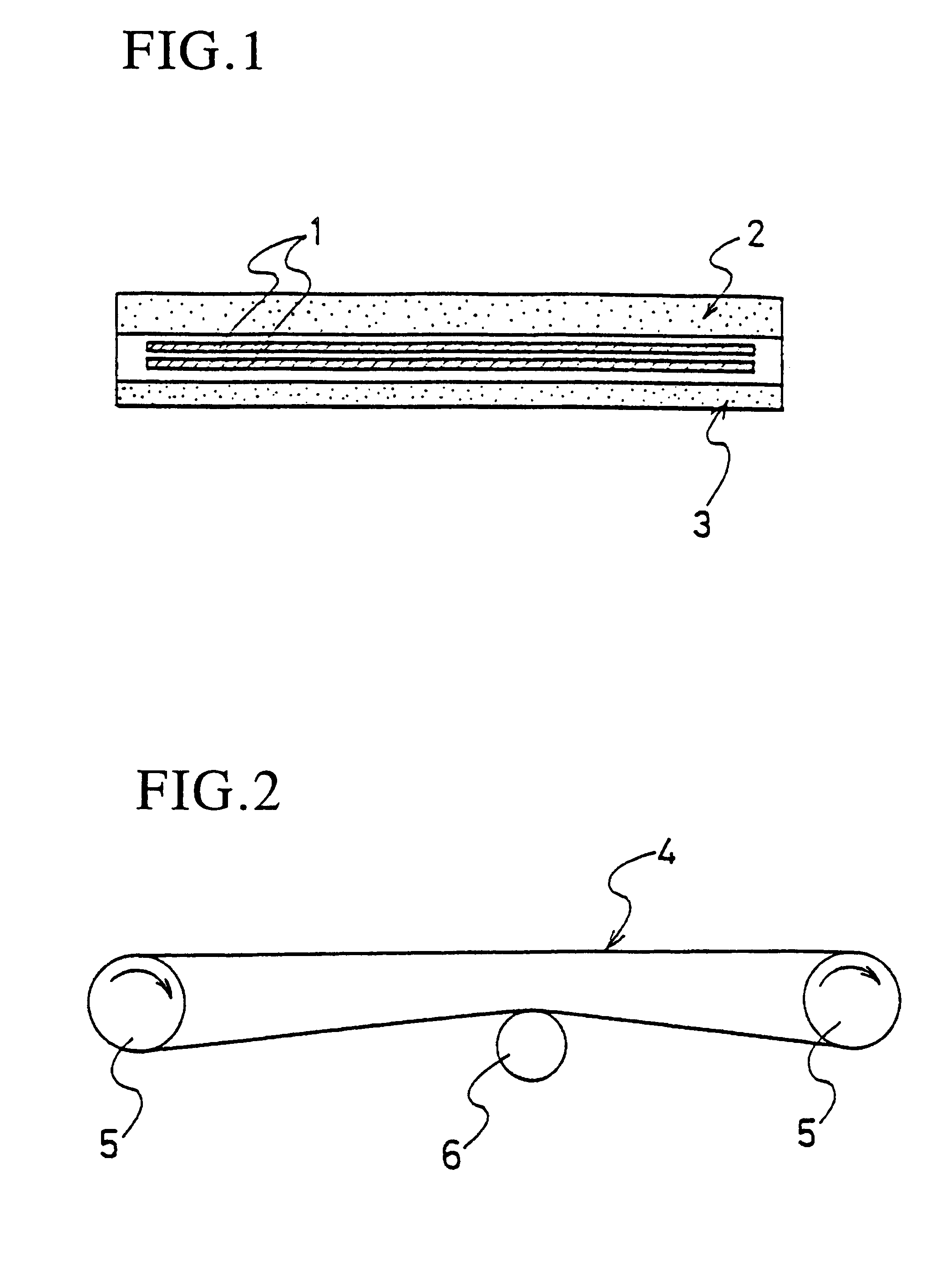

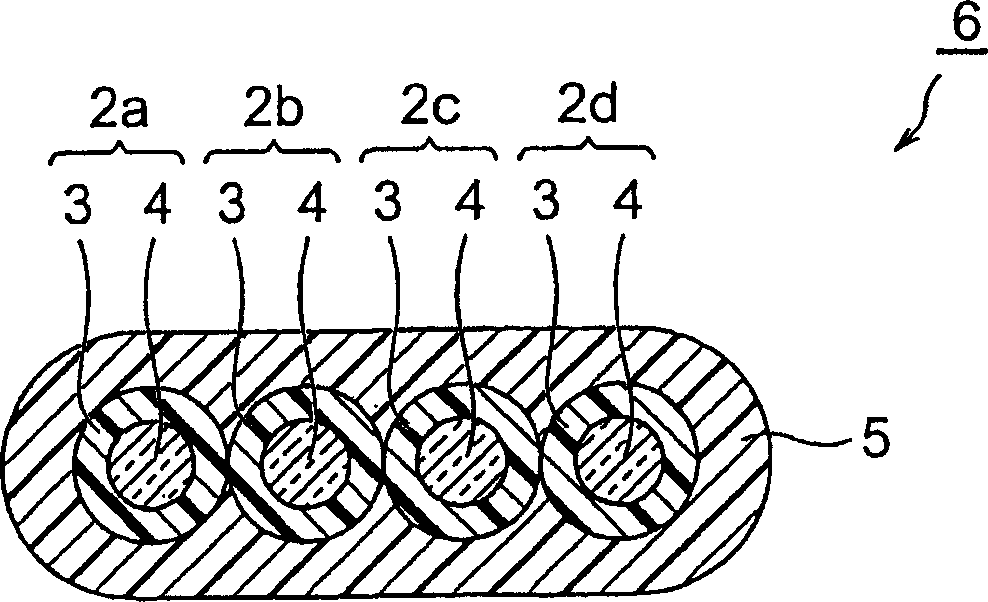

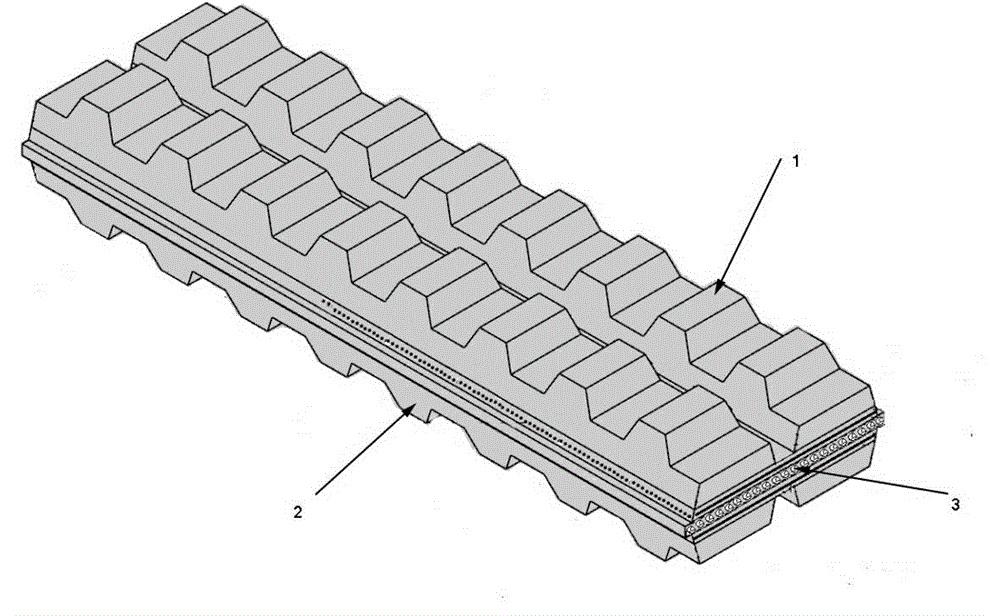

Conveyor belt

InactiveUS6260692B1Not easy to damageSmall elongationConveyorsSynthetic resin layered productsWoven fabricSynthetic fiber

Owner:YOKOHAMA RUBBER CO LTD

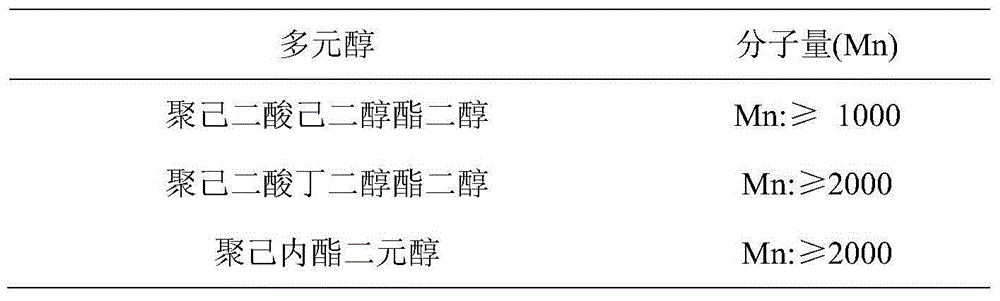

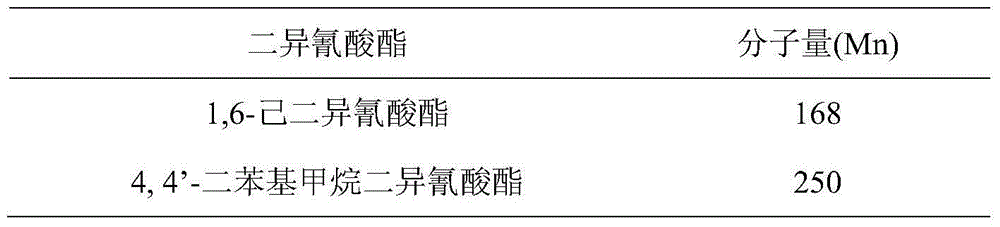

Shape memory fiber, manufacturing method thereof and textile product manufactured by shape memory fiber

ActiveCN104695041AEasy to stretchSmall elongationMonocomponent polyurethanes artificial filamentMelt spinning methodsPolyolLinear density

The present invention relates to a shape memory fiber, a method for manufacture thereof, and a textile made therefrom. The shape memory fiber is prepared from shape memory polyurethane that is prepared from a diisocyanate forming hard segments, a chain extender, and a long-chain polyol forming soft segments. The preparation process of the shape memory fiber is: preparing the shape memory polyurethane made of hard segments and soft segments; melt spinning the shape memory polyurethane by melting and extruding the polyurethane through a fiber spinneret to form filature, then cooling and solidifying the filature to obtain the shape memory fiber. The shape memory fiber of the invention has lower resilience than spandex under the same linear density, lower shape fixity than traditional shape memory materials, and increasing shape fixity with increasing elongation. The textiles made with it have good comfort characteristic, and can adapt to different shapes of body with single size.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

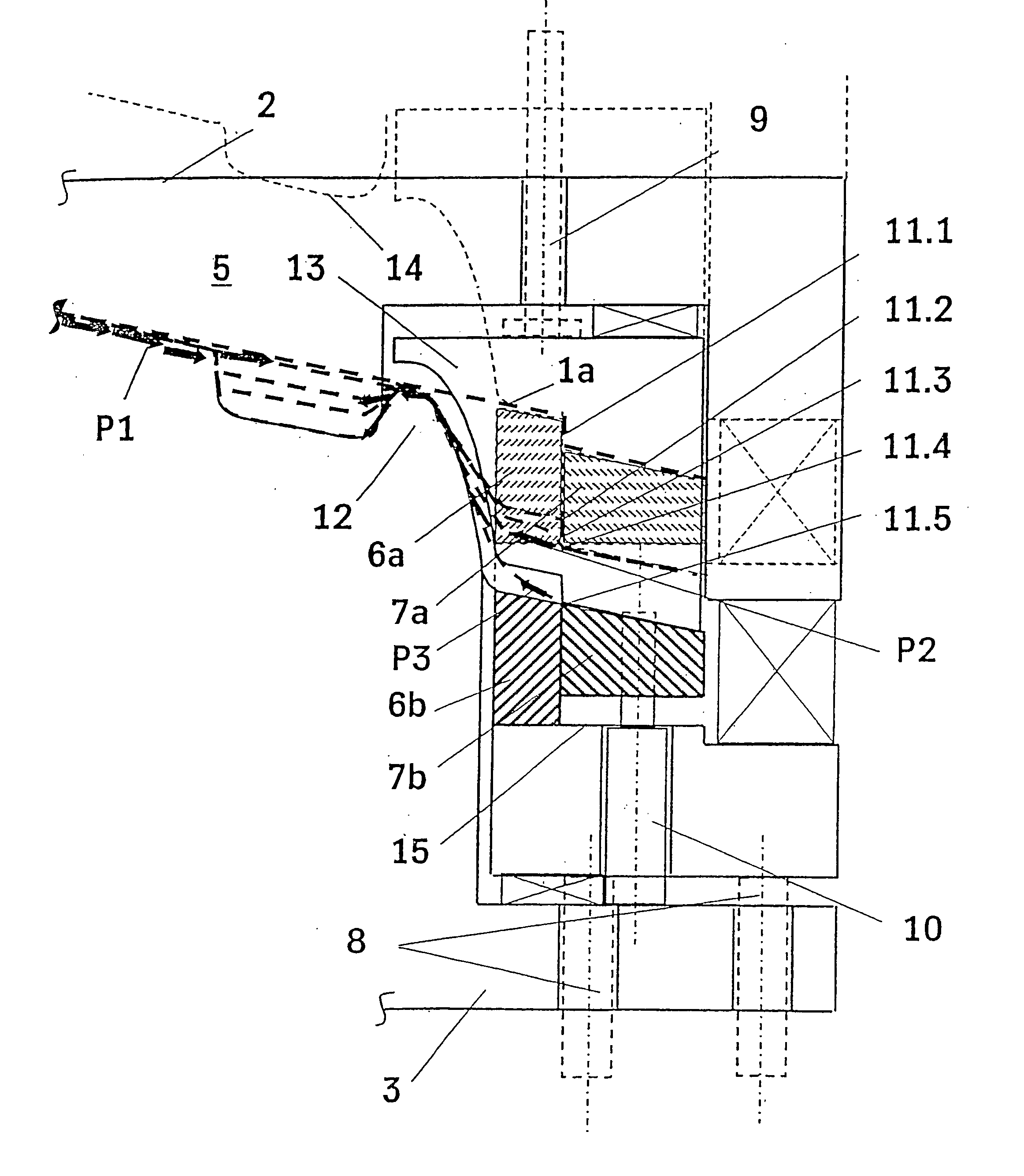

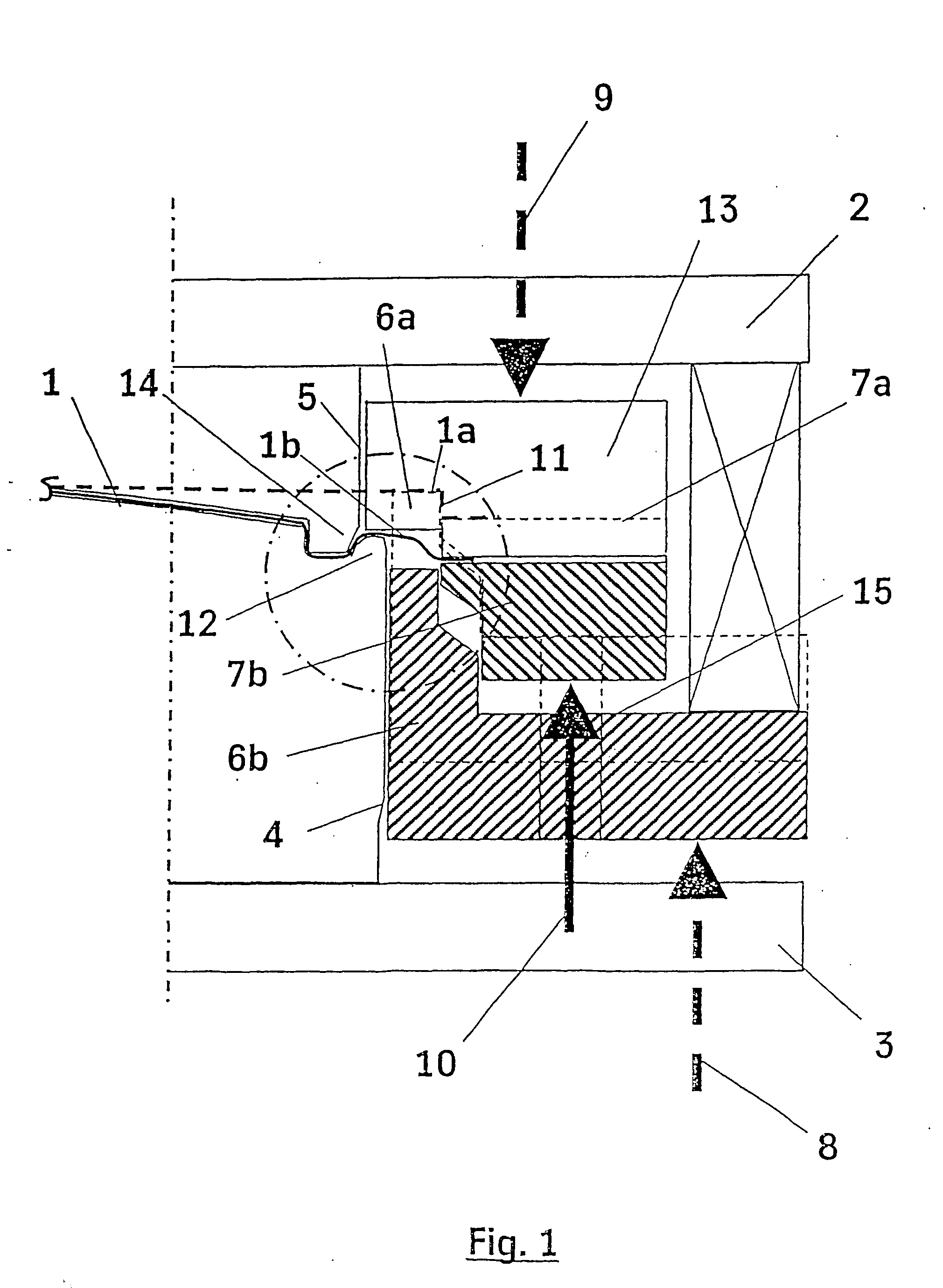

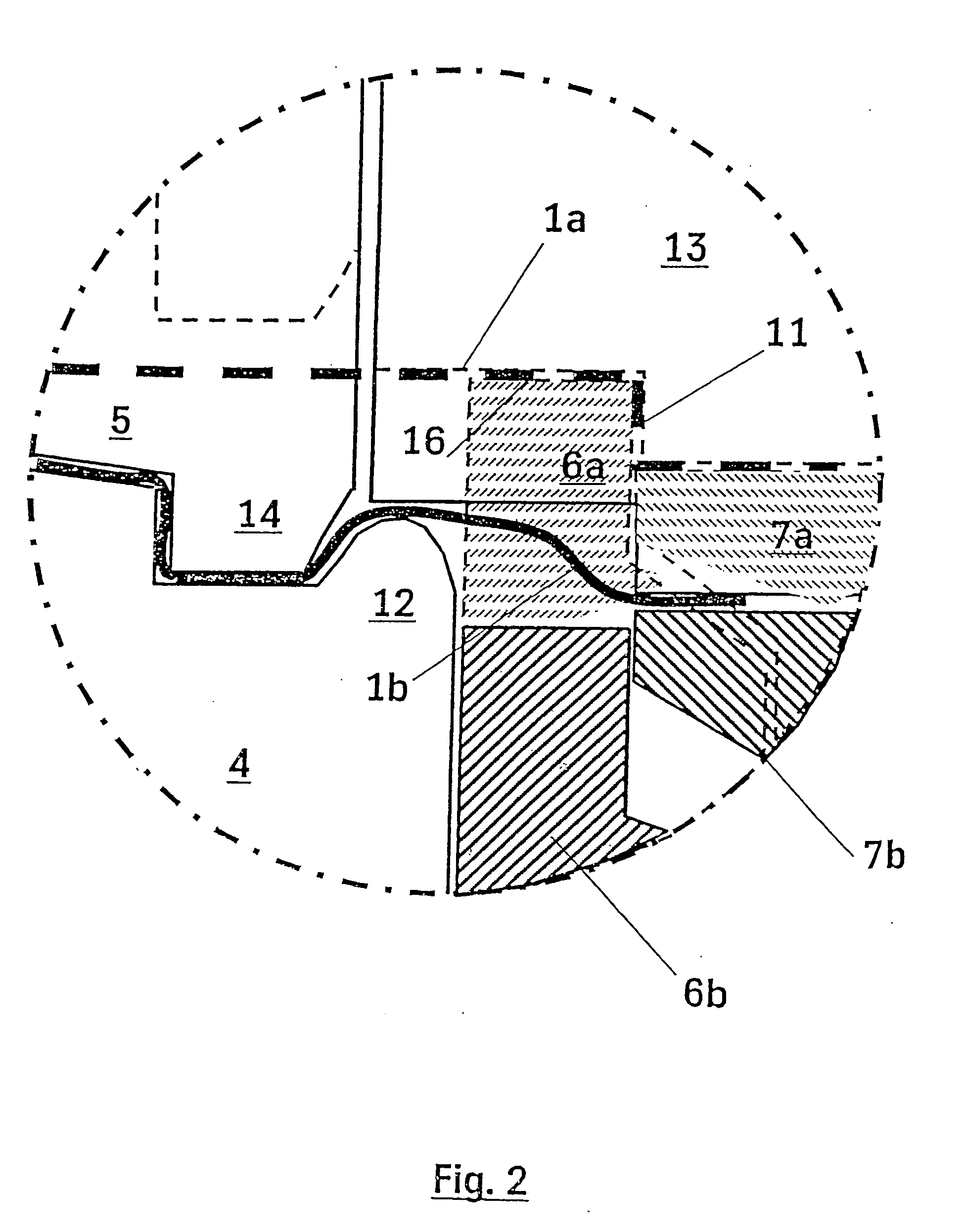

Method for controlling the material flow during the deep-drawings of sheet metal, and deep-drawing tool

A method for controlling the material flow during the deep-drawing of sheet metal involves compressing the edges of the sheet metal (1) between at least one upper stopper (13) and at least one lower stopper (6, 7) during the deep-drawing process, with a controllable elastic force (8, 9). A corresponding deep-drawing tool is also provided. A Z-shaped blocking step (11) is stamped into the edge (1a) of the sheet metal when the upper and lower stoppers (13, 6, 7) are closed, the basic shape is then produced by deep-drawing, maintaining the blocking step (11) and completely blocking the sheet metal between the stoppers. The sheet metal (1) is outwardly stretched, and the blocking step (11) is then reduced in terms of height, facilitating the outward displacement of the sheet metal towards the outside. The deep-drawing tool has a lower stopper including an inner stopper (6) and an outer stopper (7). The stoppers are arranged in an annular manner on the edge of the sheet metal (1) and can be displaced in relation to each other in the holding direction.

Owner:THYSSENKRUPP DRAUZ NOTHELFER GMBH

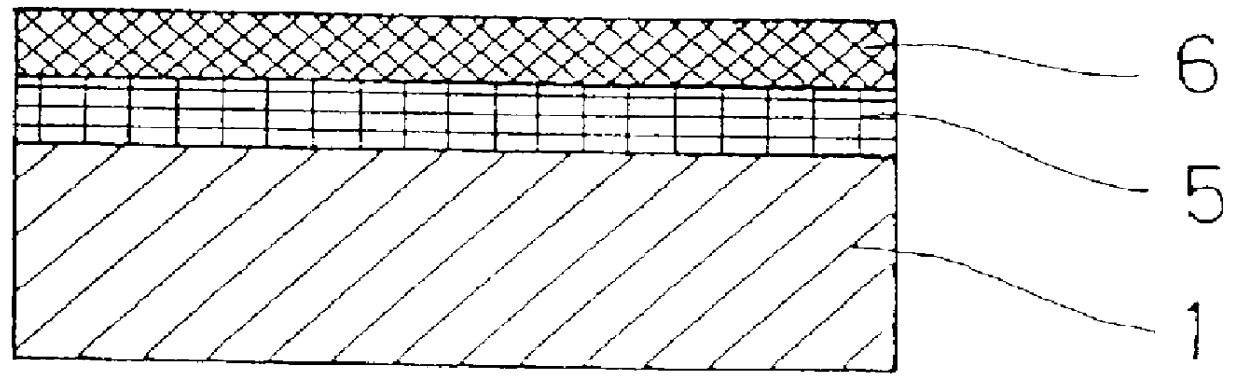

Method for preparing aramid fiber fibre composite sheet material

InactiveCN101165271AAvoid the needAvoid the need to useMechanical working/deformationSpecial paperPolyesterAdhesive

The present invention discloses composite aramid fiber sheet making process, and is especially process of making sheet with aramid fiber / polyester paper or aramid fiber / polyphenyl thioether paper as material. Aramid fiber / polyester paper or aramid fiber / polyphenyl thioether paper is produced into different types of sheet through superposing, heating in hot roller and pressurizing. During the production, PET film or polyphenyl thioether film to act as adhesive is added between two sheets of paper, and this simplifies the production process, raises the product performance and lowers the production cost.

Owner:四川华通特种工程塑料研究中心有限公司

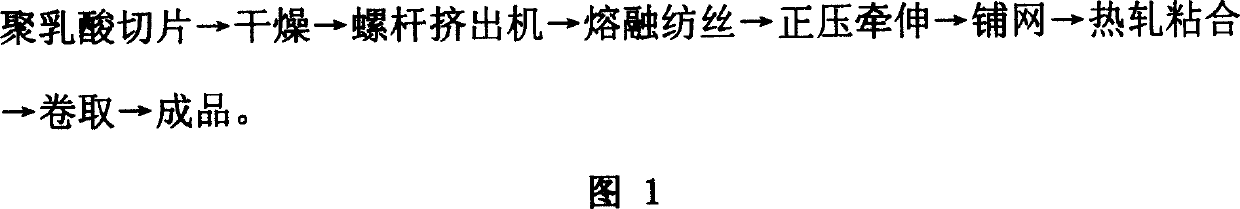

Spinning and conglutinating method polylactic acid nonwovens preparation method

InactiveCN1730763AHigh strengthSmall elongationNon-woven fabricsMonocomponent polyesters artificial filamentPolymer sciencePositive pressure

The present invention relates to spinning and adhering process of preparing non-woven polylactic acid fabric. The present invention prepares non-woven polylactic acid fabric with polylactic acid L-isomer material with high purity, medium molecular weight and high melt index and through low temperature drying, high speed spinning, positive pressure drafting, spreading net, hot rolling to adhere and other technological steps. The present invention has short production process and high production efficiency, and the prepared non-woven polylactic acid fabric has high strength, less elongation, excellent mechanical performance and biodegradability, and may be used in disposable medical articles.

Owner:DONGHUA UNIV +1

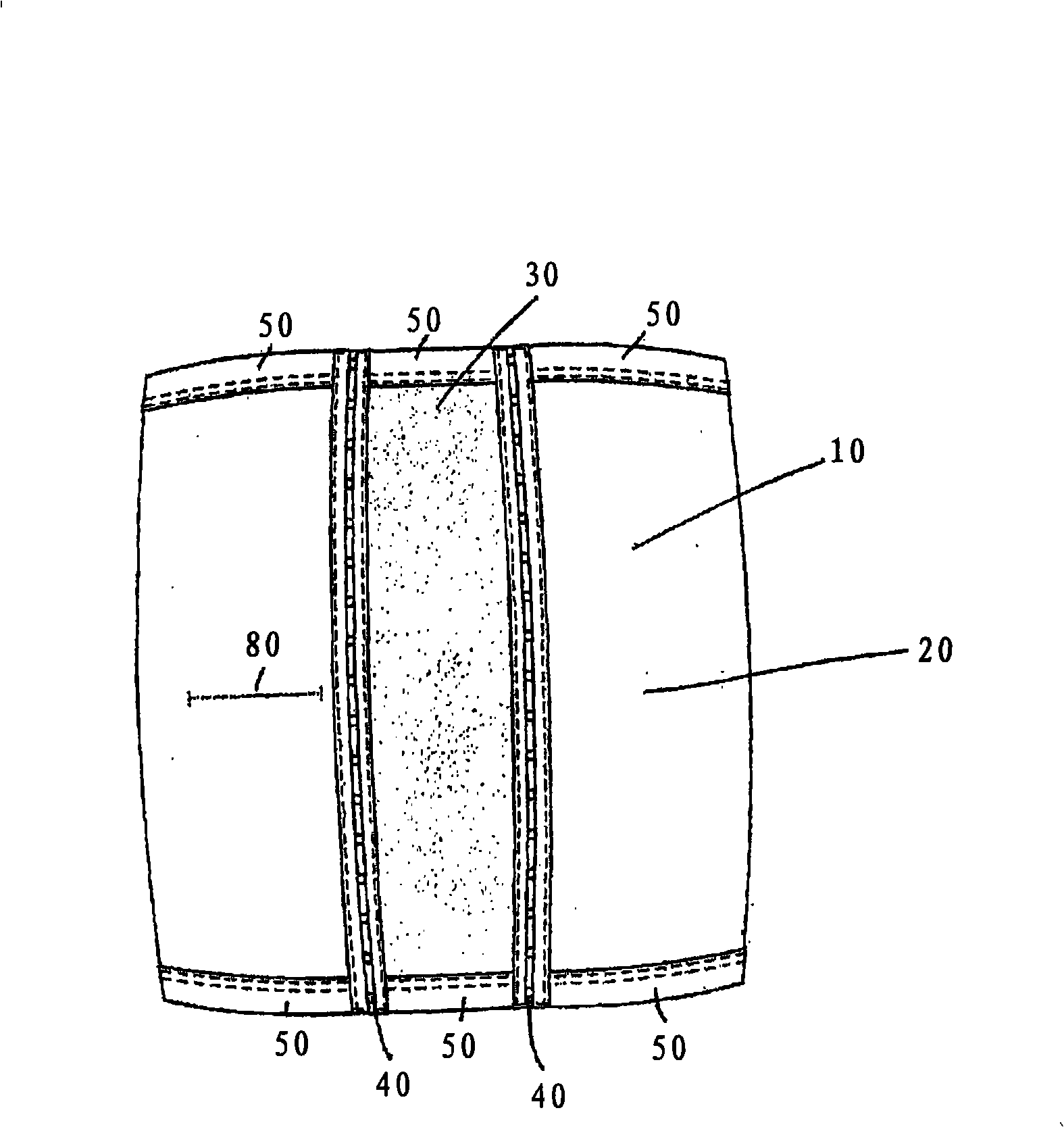

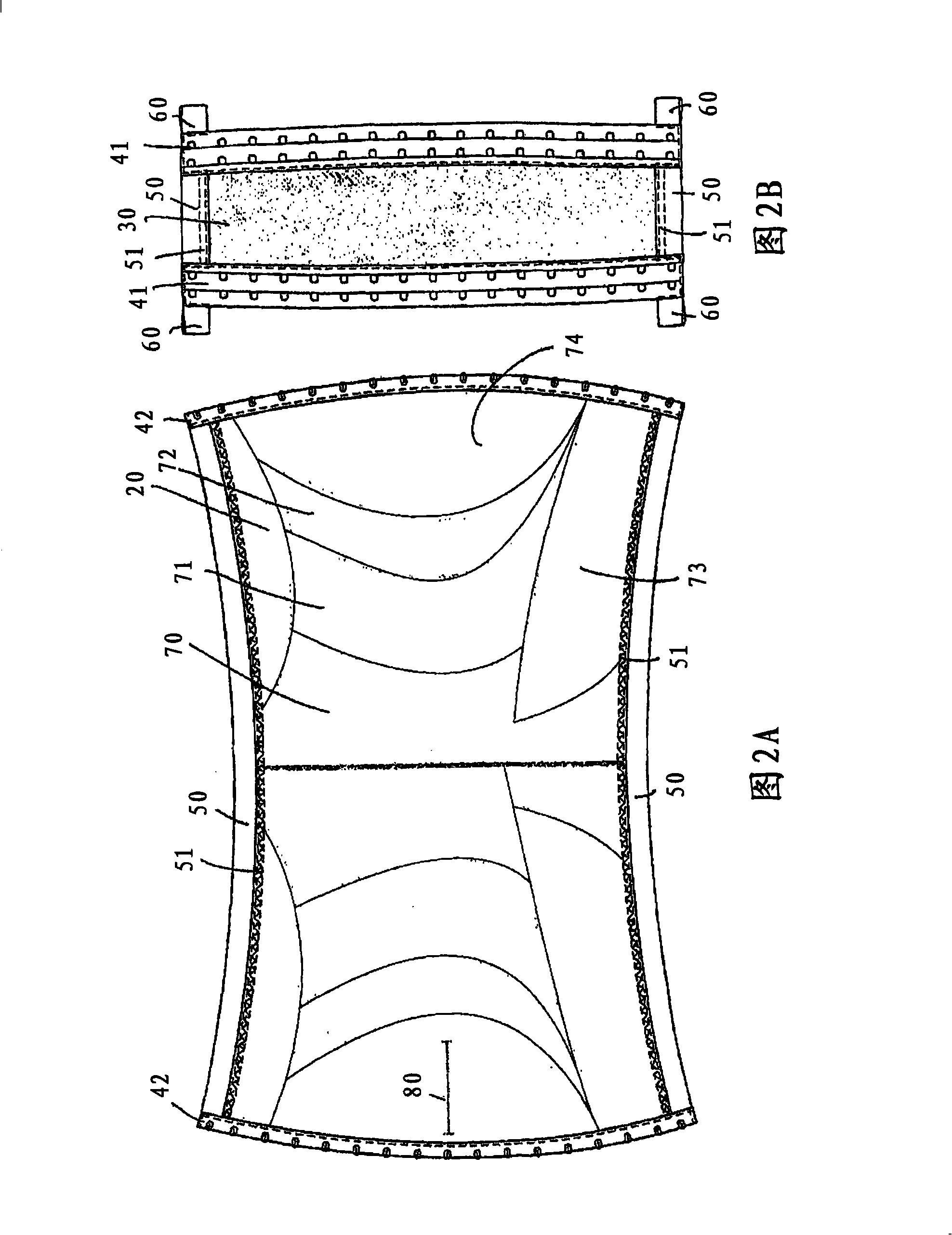

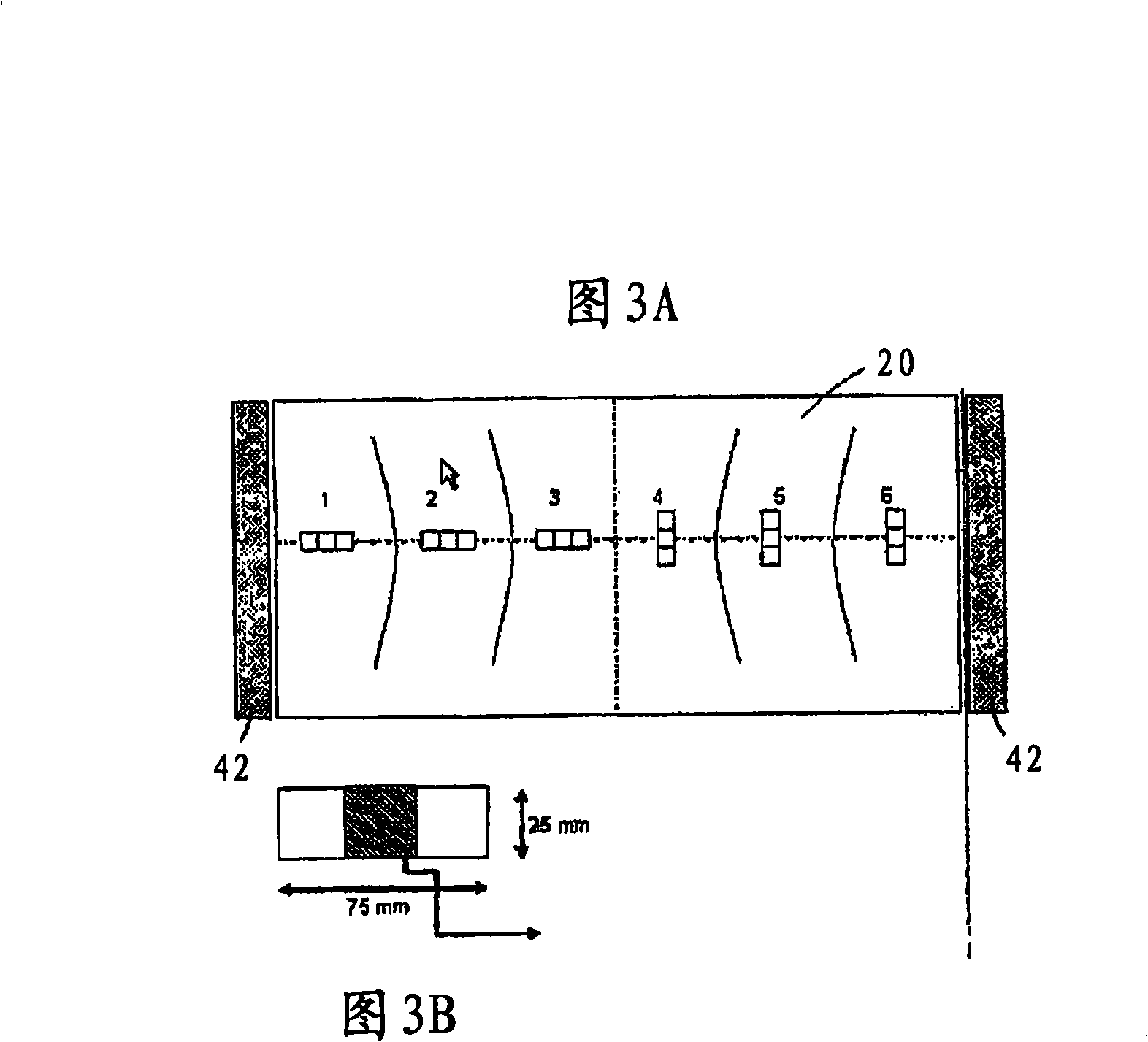

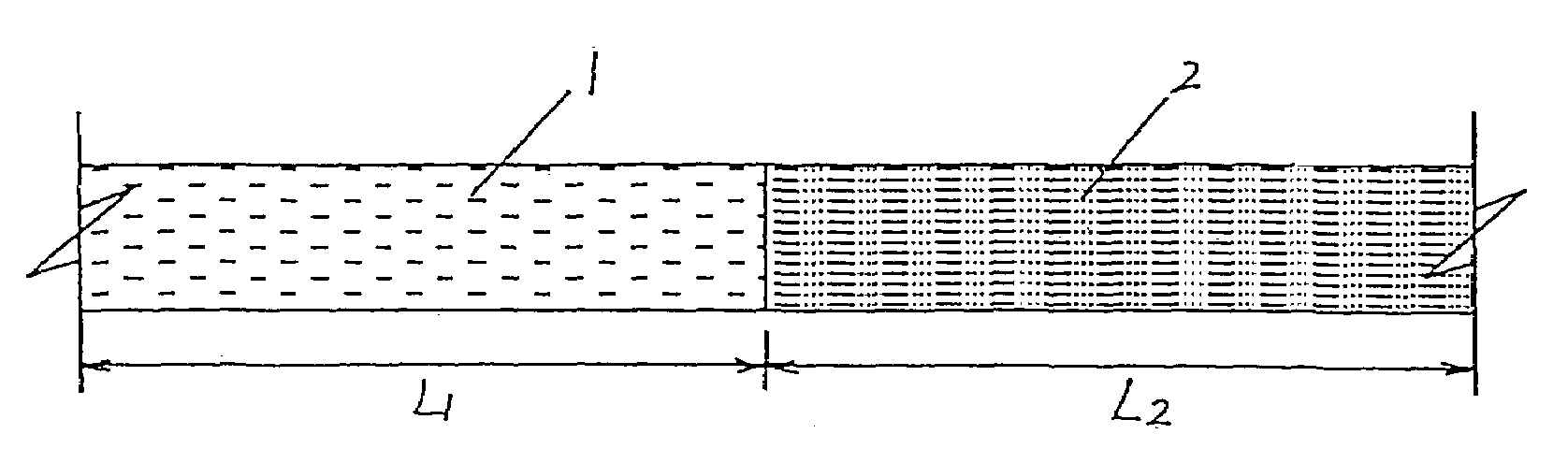

Abdominal compression

InactiveCN101325930AReduce incisional hernia formationSmall elongationBandagesAbdominal compressionEngineering

A post-operative compression garment (10) having a linear elastic section (20) and a supportive section (30) is provided. The supportive section has a controlled stretch-profile with progressive elastic material properties with linear elastic material properties below an extension of 20%. The supportive section may be constructed of a layered material where the two layers have different material properties and where one of the layers is slightly oversized compared to the other layer. The garment can be constructed to fit various parts of the wearer' s body and can be worn immediately after surgery to prevent hernia and / or wound rupture .

Owner:TYTEX AS

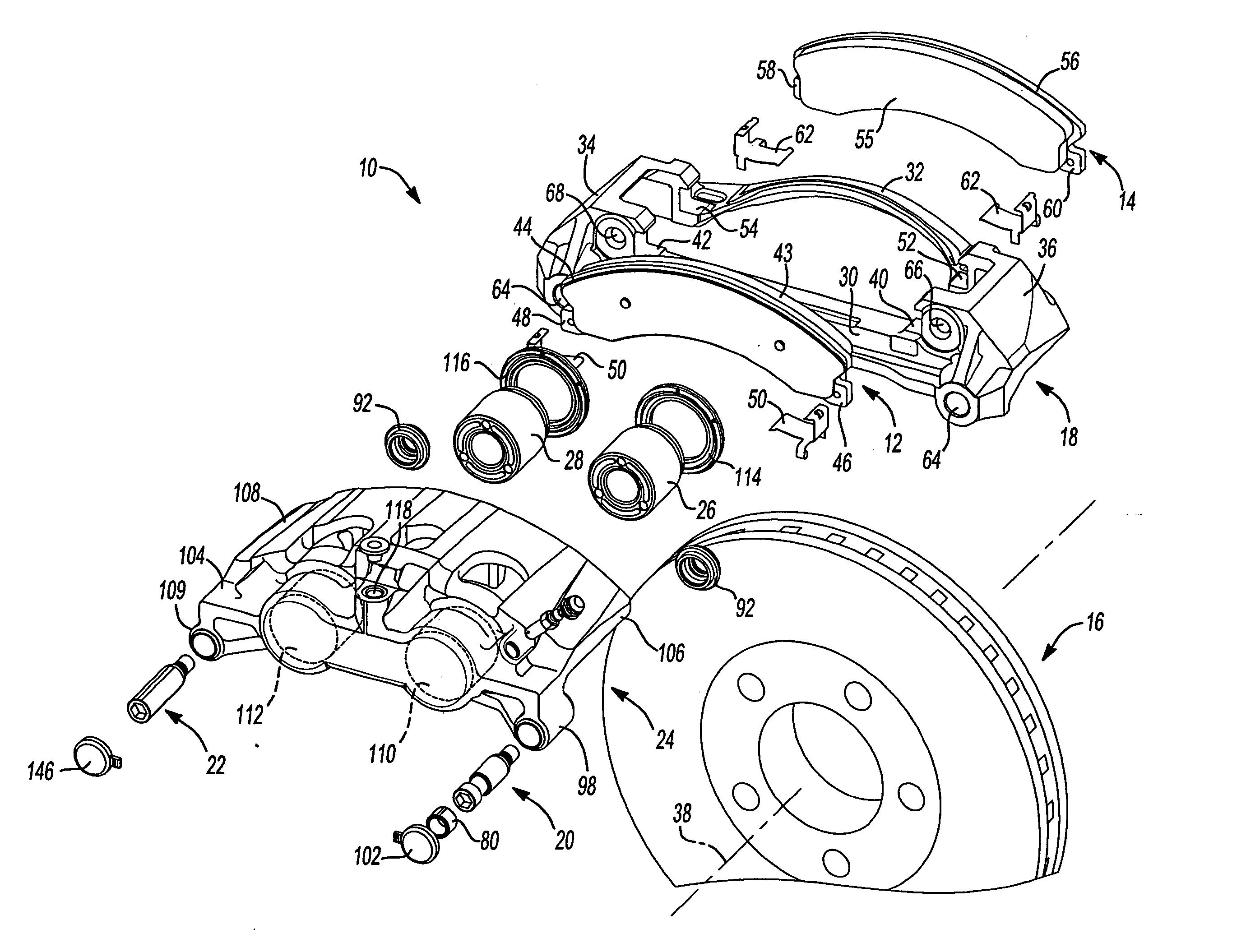

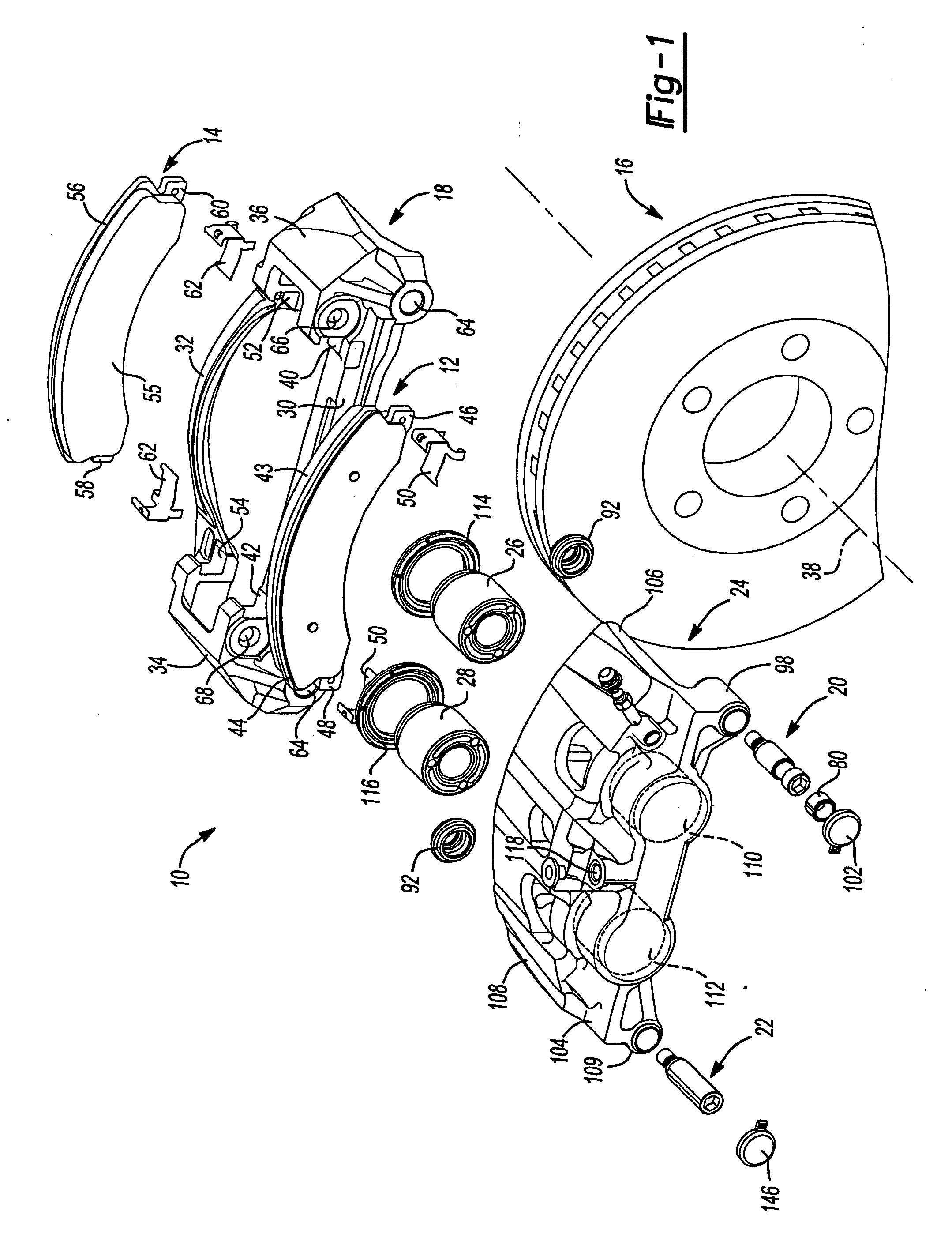

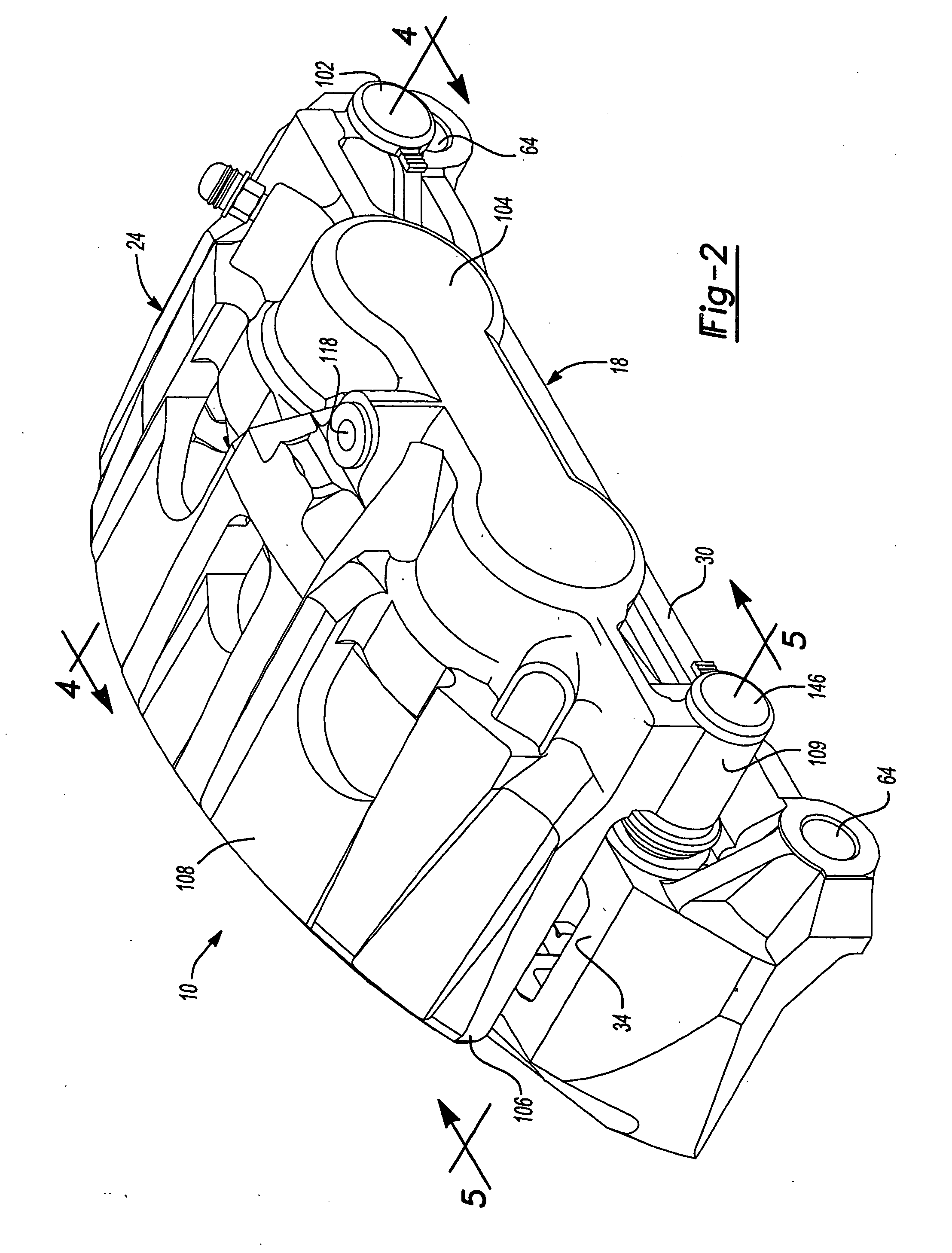

Tapered pin design

InactiveUS20070051568A1Decrease clamp loadSmall elongationAxially engaging brakesBrake actuating mechanismsEngineeringCalipers

The present invention relates to a disc brake operable to apply a clamping force to a rotatable disc. The disc brake includes a support bracket, slide pins coupled to the support bracket, inner and outer brake shoes and a caliper supported by the slide pins. The support bracket is a substantially rectangular frame defining a window. The window is adapted to accept a portion of a disc protruding therethrough. The support bracket includes a pair of spaced apart apertures extending through the frame where each aperture includes a threaded portion and a conical seat extending along an axis aligned to intersect the disc. The slide pins are threadingly engaged with a threaded portion. The slide pins do not extend through the window but protrude outwardly away from the window. Each slide pin has a tapered portion in engagement with one of the conical seats.

Owner:AKEBONO CORP (NORTH AMERICA)

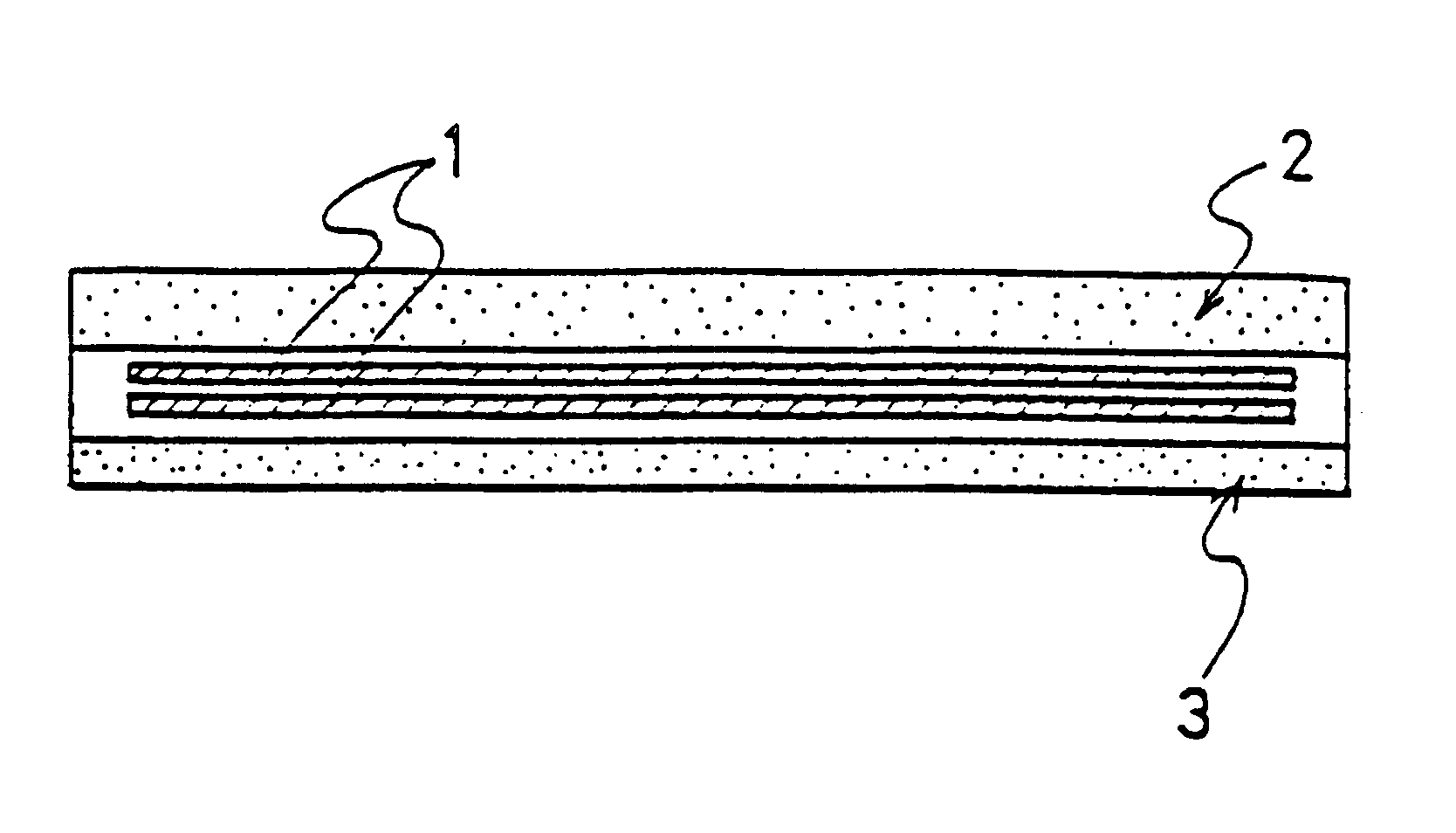

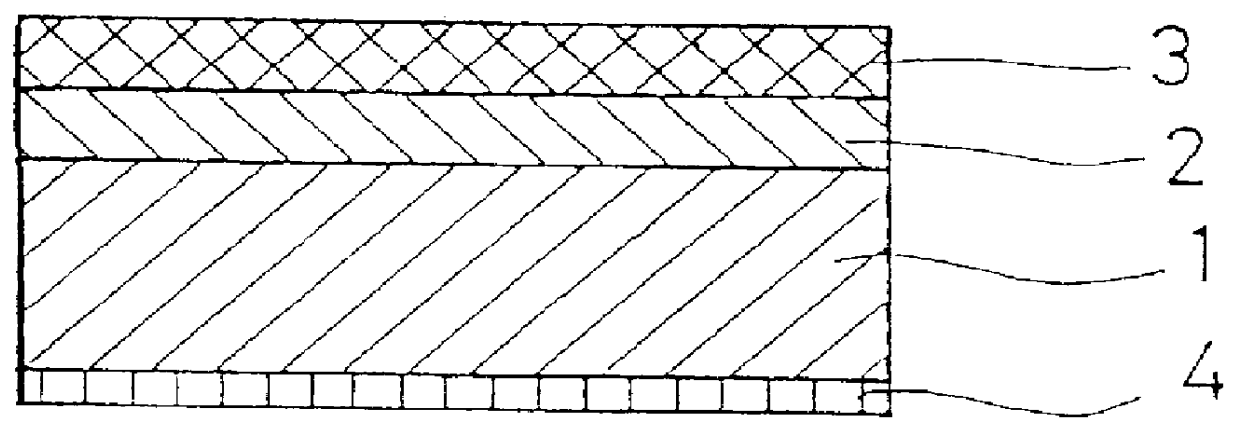

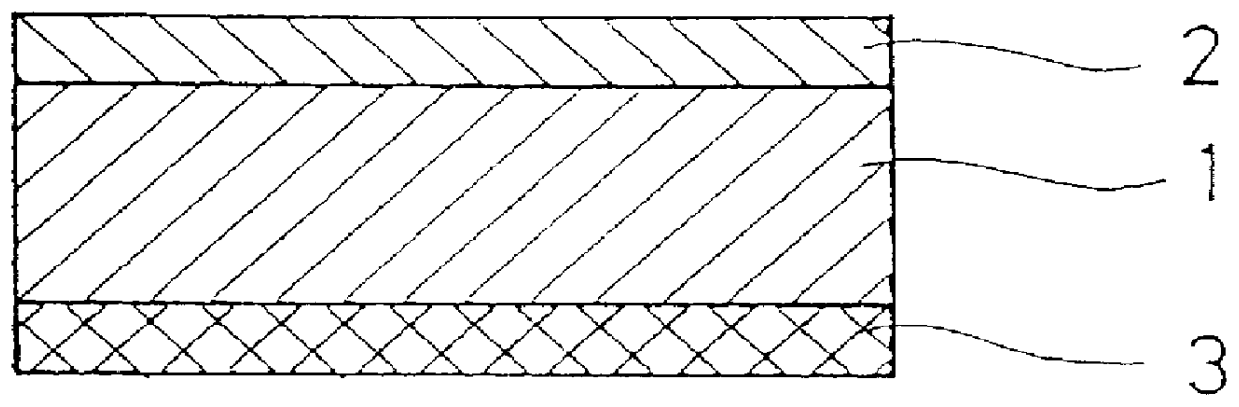

Moistureproof paper having shading property and recyclability

InactiveUS6117563AGood shading effectPromote productionCoatings with pigmentsSynthetic resin layered productsPulp and paper industryHue

PCT No. PCT / JP96 / 02911 Sec. 371 Date Feb. 9, 1998 Sec. 102(e) Date Feb. 9, 1998 PCT Filed Oct. 7, 1996 PCT Pub. No. WO97 / 14848 PCT Pub. Date Apr. 24, 1997The object is to provide a moistureproof paper which is excellent in light-screening, moisture-proof, waterproof and heat-sealing properties and regeneration property at the time of reuse as a used paper, and in order to attain the object, a moisture-proof layer (3) of maceration, regeneration and heat-sealing properties is provided on the surface of a coated base (1) having a light-screening layer (2) of a hue of from 25 to 70 in terms of the luminosity index L* to obtain a moisture-proof paper having a light-screening and regeneration properties.

Owner:NIPPON PAPER IND CO LTD +2

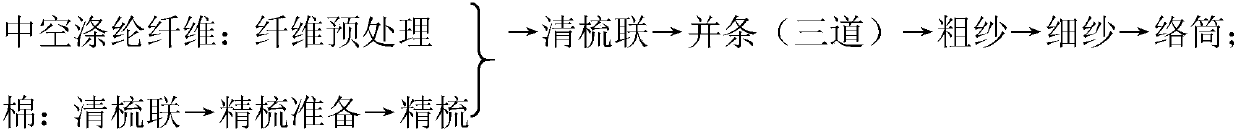

Design method and production technology of multi-layer heat preserving shell fabric

ActiveCN109537126AStrong three-dimensional structureAvoid breakingMulti-ply fabricsPolyesterSurface layer

The invention discloses a design method and a production technology of a multi-layer heat preserving shell fabric. The design method is characterized in that a woven fabric on the surface layer is prepared by blending polyimide fiber and hollow polyester fiber with compact sirospun yarn; the shell fabric is high in strength, high in friction resistance and high in heat preserving performance; warpyarn of the woven fabric on the intermediate layer is cotton and hollow polyester fiber blended yarn; weft yarn is OUTLAS phase-changed fiber and coffee carbon polyester fiber blended yarn; a relatively long floating line of the weft yarn is positioned between the woven fabrics on the surface layer and the inner layer, so that the yarn is in a loose state and supports the woven fabrics on the surface layer and the inner layer, and as a result, a heat preserving layer is formed; the yarn in the intermediate layer is relatively thick, the twisting coefficient is small, and heat absorbing and preserving fibers are adopted, so that the heat preserving performance of the woven fabrics can be ensured. The inner layer is the cotton and hollow polyester fiber blended yarn, so that the heat preserving effect is good; the shell fabric is skin friendly, can absorb moisture and is breathable, so that the problem of discomfort caused by that a woven fabric with too high moisture regain absorbs moisture and adheres to the body can be avoided.

Owner:泰州虹纬纺织有限公司

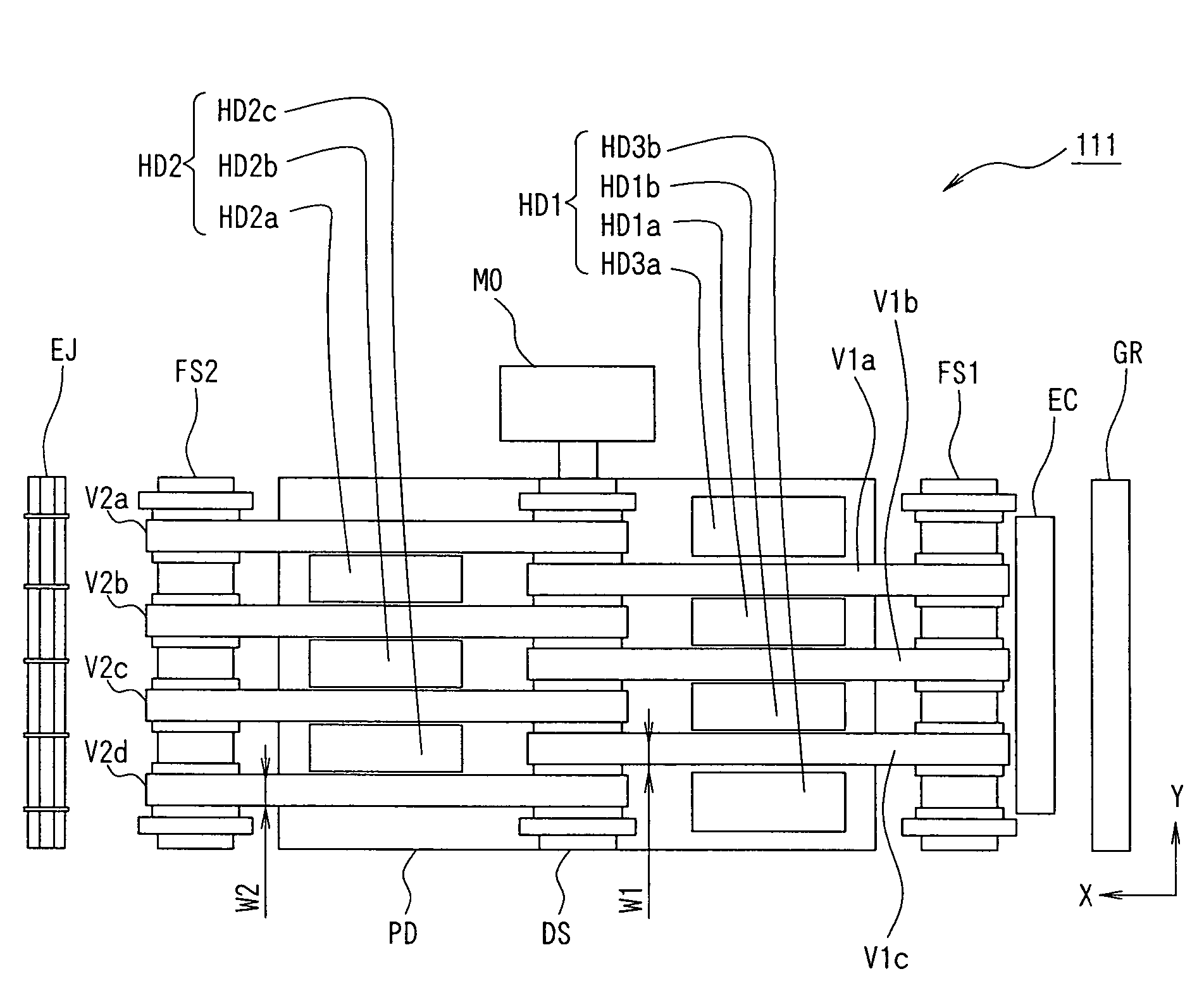

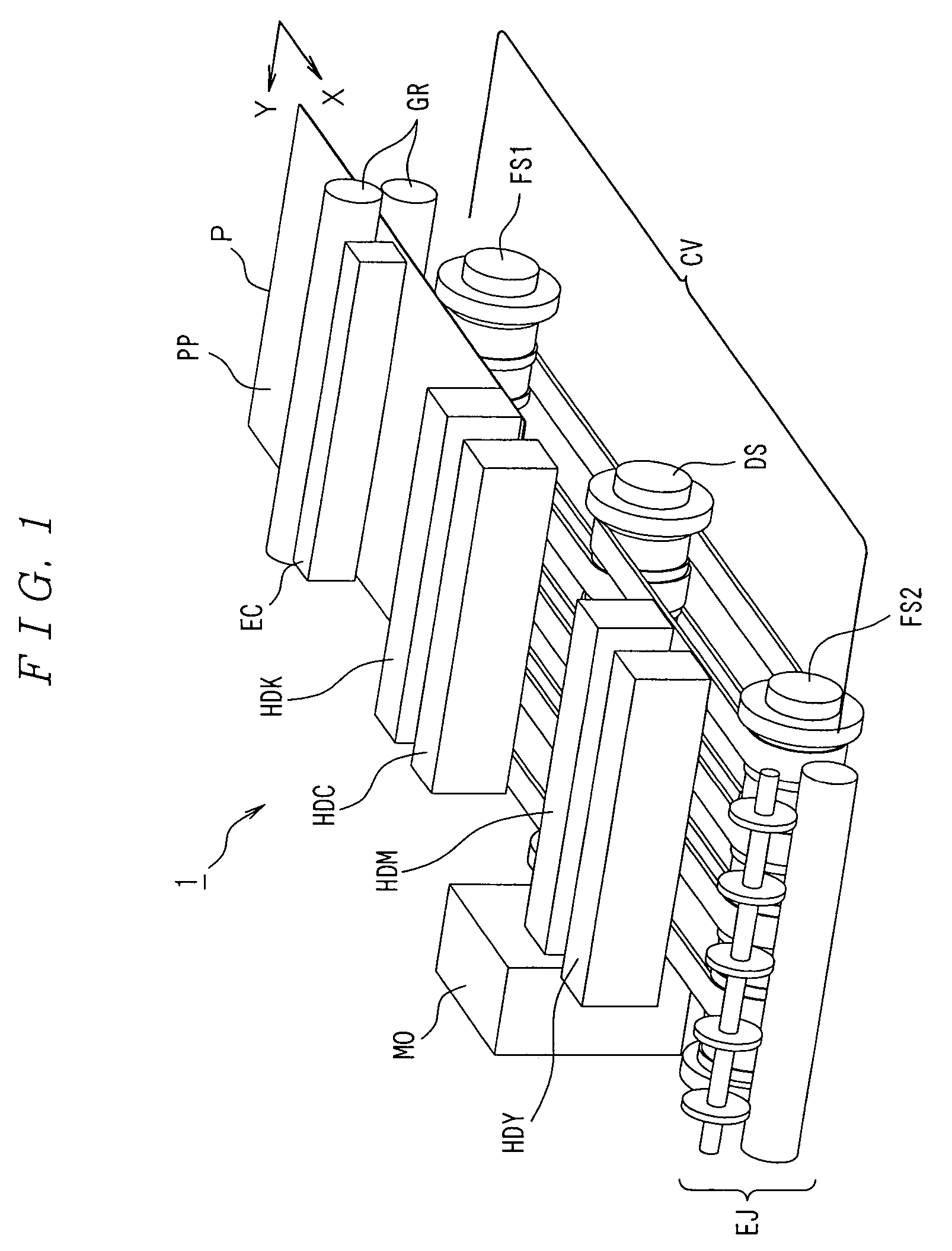

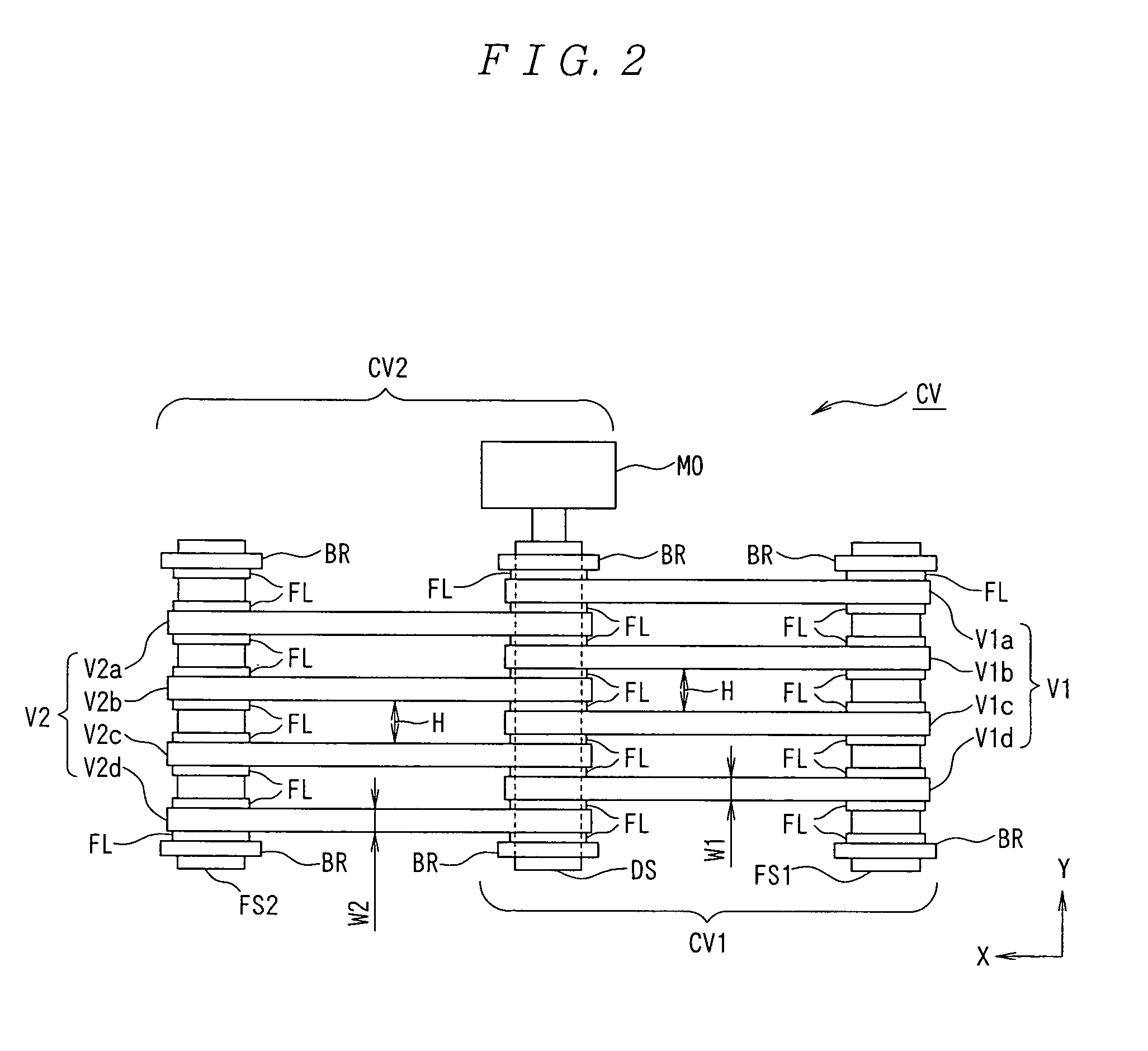

Ink jet printer

InactiveUS7316477B2Low elongationDecrease the fluctuation of the conveying speed of a printing mediumOther printing apparatusArticle feedersEngineeringNozzle

Owner:SEIKO EPSON CORP

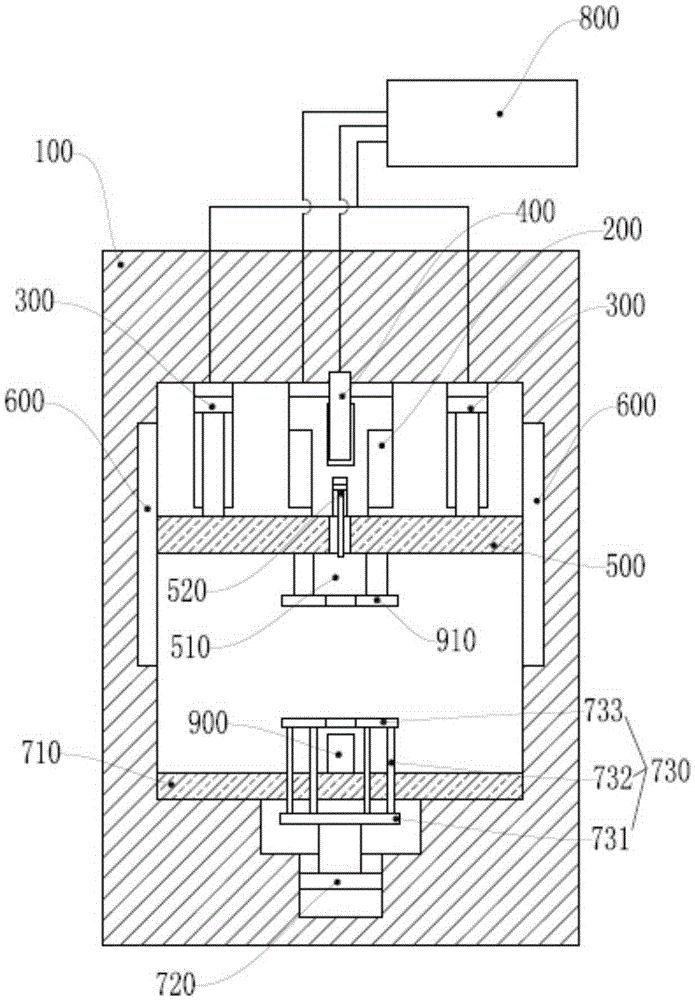

Multifunctional combined hydraulic machine

InactiveCN105312384AIncrease the area of actionSmall area of actionPress ramEngineeringMultiple function

The invention relates to the field of metallurgy pressing machines, in particular to a multifunctional combined hydraulic machine. The multifunctional combined hydraulic machine comprises a rack, a main driving cylinder, a built-in rapid driving cylinder, an auxiliary driving cylinder, a movable cross beam, a guide mechanism, a workbench, a control system, a male die and a female die, wherein the workbench is arranged at the lower end of the rack in a sliding way; the movable cross beam is arranged on the upper end of the rack and located right above the workbench; and the main driving cylinder and the auxiliary driving cylinder are connected with the movable cross beam. The action areas of piston rods of the main driving cylinder, the auxiliary driving cylinder and the built-in rapid driving cylinder are unequal, the action area of the piston rod of the main driving cylinder is maximum, and the action area of the piston rod of the built-in driving cylinder is minimum, so that when hydraulic liquid flow amounts are equal, the extension extent of the piston rod of the built-in rapid driving cylinder is maximum, and the extension extent of the piston rod of the main driving cylinder is minimum. According to the multifunctional combined hydraulic machine, under the control of a control system, the hydraulic machine is provided with different feeding speeds and can adapt to the production technology of different materials.

Owner:FOSHAN CONSTANT HYDRAULIC MACHINERY

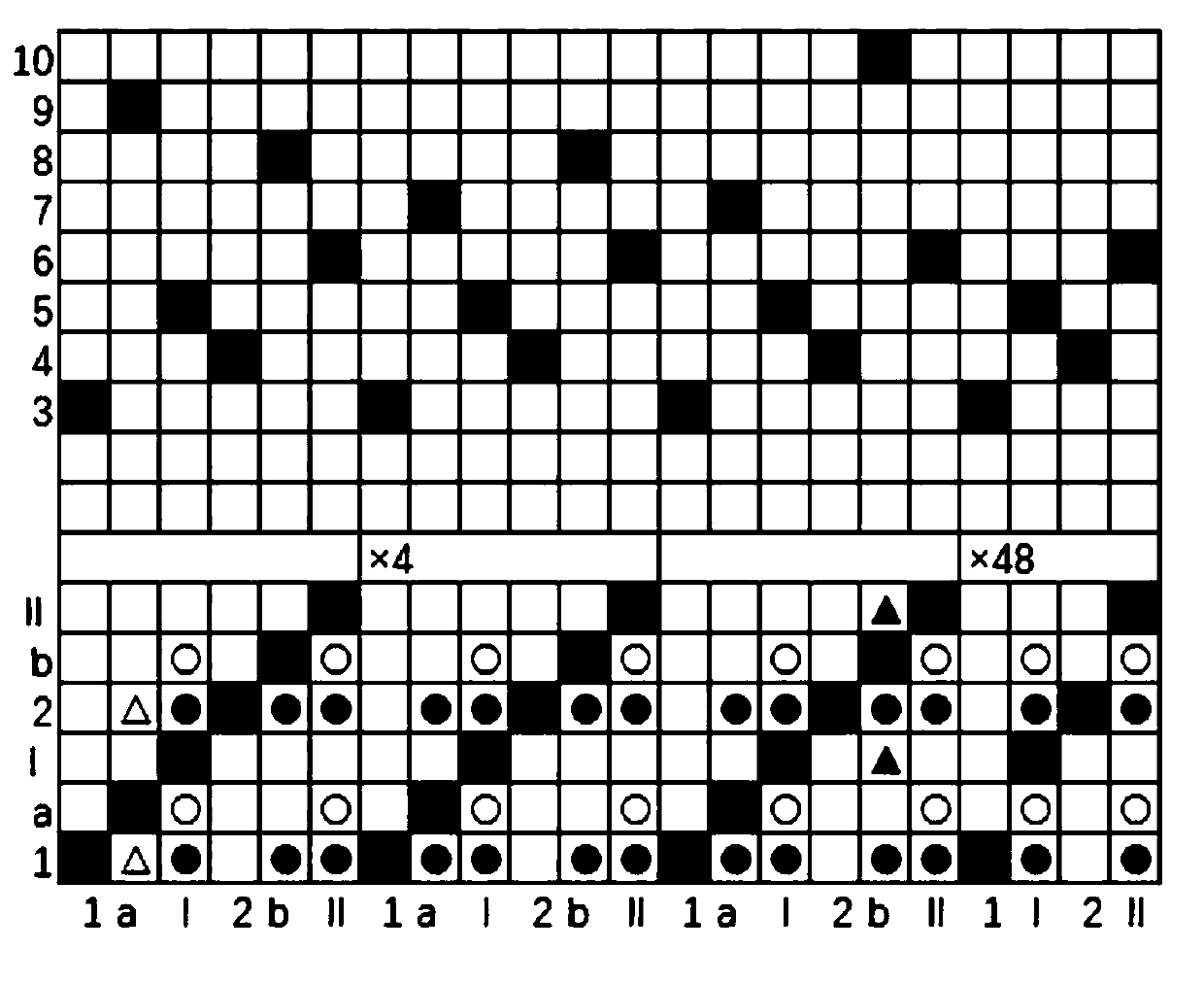

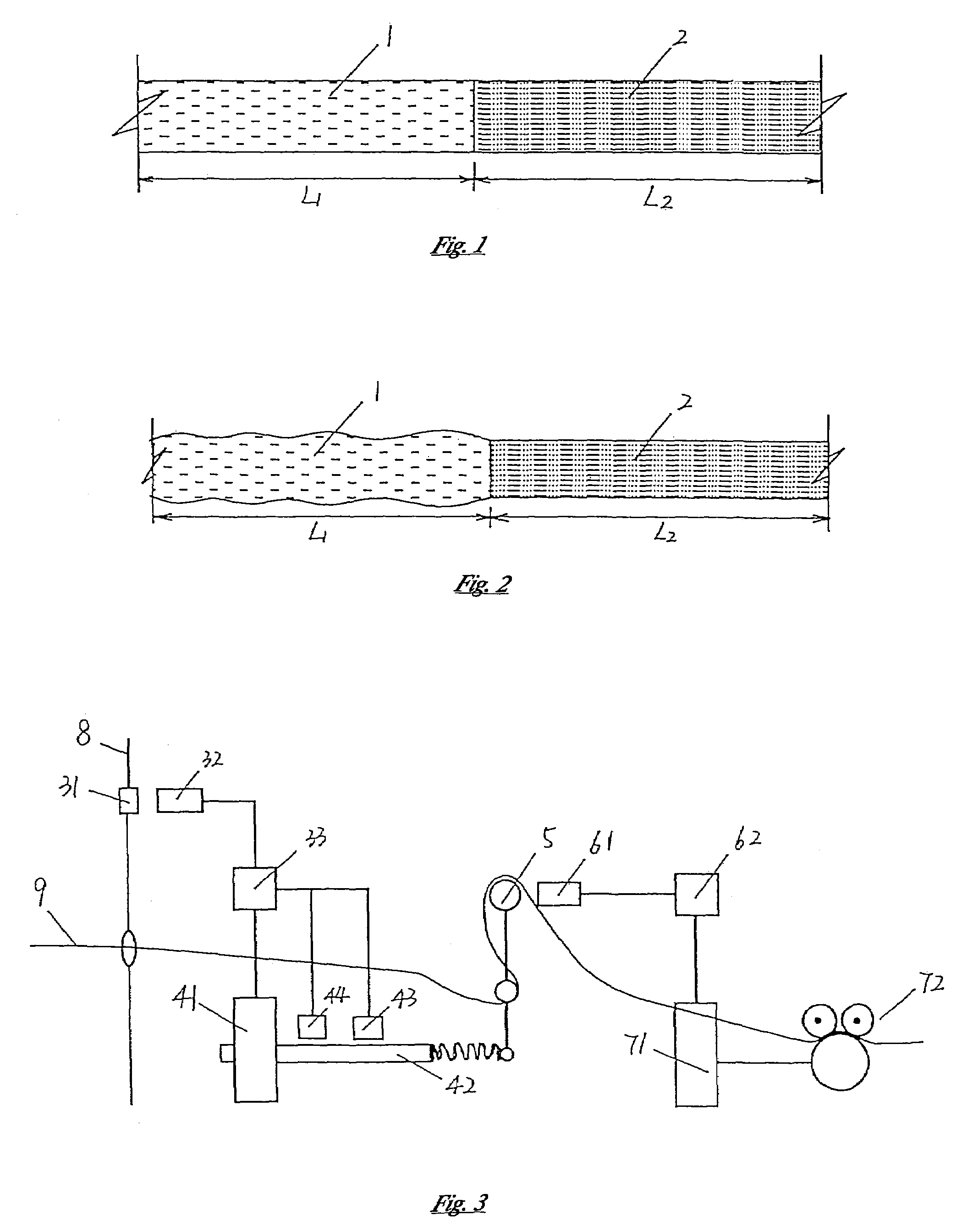

Elastic woven tape and a method of forming same

ActiveUS7117900B2Guaranteed aestheticsLarge elongationLayered productsShoulder strapContinuous integrationEngineering

An elastic woven tape is disclosed as being composed of at least two kinds of tape sections, each of which having a respectively different elongation and / or modulus, and formed by alternating and continuous integration of these two kinds of tape sections by weaving. The weaving method of the said elastic woven tape includes controlling the changes in the degrees of elasticity provided by elastic threads for the woven tape in mechanized weaving through the control of the feeding speeds of the elastic threads. The advantageous effects of this invention lie in the production of a woven tape composed of tape sections respectively with larger elongation but smaller modulus and with smaller elongation but larger modulus by means of their alternating and continuous integration by weaving, which simplifies the post-weaving operation and improves production efficiency. The resultant woven tape has no connections or joints, which assures the overall beauty of the apparel with the woven tape and the comfort of the apparel in wearing.

Owner:PIONEER ELASTIC FABRIC

Sand-proof anchor cable with three layers of parallel ultra-high molecular weight polyethylene fiber braided rope cores

InactiveCN102619115AHigh breaking strengthSmall elongationTextile cablesPolyurethane adhesiveDouble stranded

The invention discloses a sand-proof anchor cable with three layers of parallel ultra-high molecular weight polyethylene fiber braided rope cores and relates to textile cables. A rope formed by braiding polyester fiber single-stranded and double-stranded rope strands and ultra-high molecular weight polyethylene (UHMWP) 8 to 12-strand braided ropes is adopted. The sand-proof anchor cable is characterized in that: as an outer layer, the polyester fiber single-stranded and double-stranded rope strand is braided on the three layers of parallel inner cores which are formed by braiding the UHMWP 8 to 12-strand braided ropes; the rope strands of the inner cores do not have joints; the outer layer and the inner cores are impregnated in a polyurethane adhesive; and a polyester non-woven fabric wraps on the three layers of parallel inner cores to form a middle sand-proof layer. The sand-proof anchor cable is used for anchoring ocean engineering super-long towropes, is applied to framework steel cables of deep sea fishery, such as high-opening and middle-layer dragnets, large seines and the like, is applied to special ocean engineering, such as deep sea salvage, sea exploration and the like, and is applied to projects, such as aerospace military, traffic shipping, industry, agriculture, mines and the like.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Novel ultra-high molecular weight polyethylene woven fire-fighting hose and manufacturing method thereof

The invention discloses a novel ultra-high molecular weight polyethylene woven fire-fighting hose and a manufacturing method thereof. The novel ultra-high molecular weight polyethylene woven fire-fighting hose comprises a hose woven layer and a liner coating, wherein a fluorine-containing organic silicon modified polyethylene coating is arranged in the hose woven layer. The manufacturing method of the novel ultra-high molecular weight polyethylene woven fire-fighting hose comprises the steps that warp threads made from ultra-high molecular weight polyethylene filaments and weft threads made from ultra-high molecular weight polyethylene purely-spun staple fiber yarns are first woven into the cylindrical hose through a circular weaving machine, the outer surface of the obtained product is coated with the fluorine-containing organic silicon modified polyethylene coating by using a cylindrical woven bag plastic coating machine, heating is performed for curing after forming, and then the outer surface of the hose is turned inwards to serve as an inner surface by using a hose turning device. The novel ultra-high molecular weight polyethylene woven fire-fighting hose is ultra-light and explosion-proof, is resistant to abrasion, bending, ultrahigh pressure and corrosion and is easy to coil and long in service life.

Owner:浙江民安消防设备有限公司

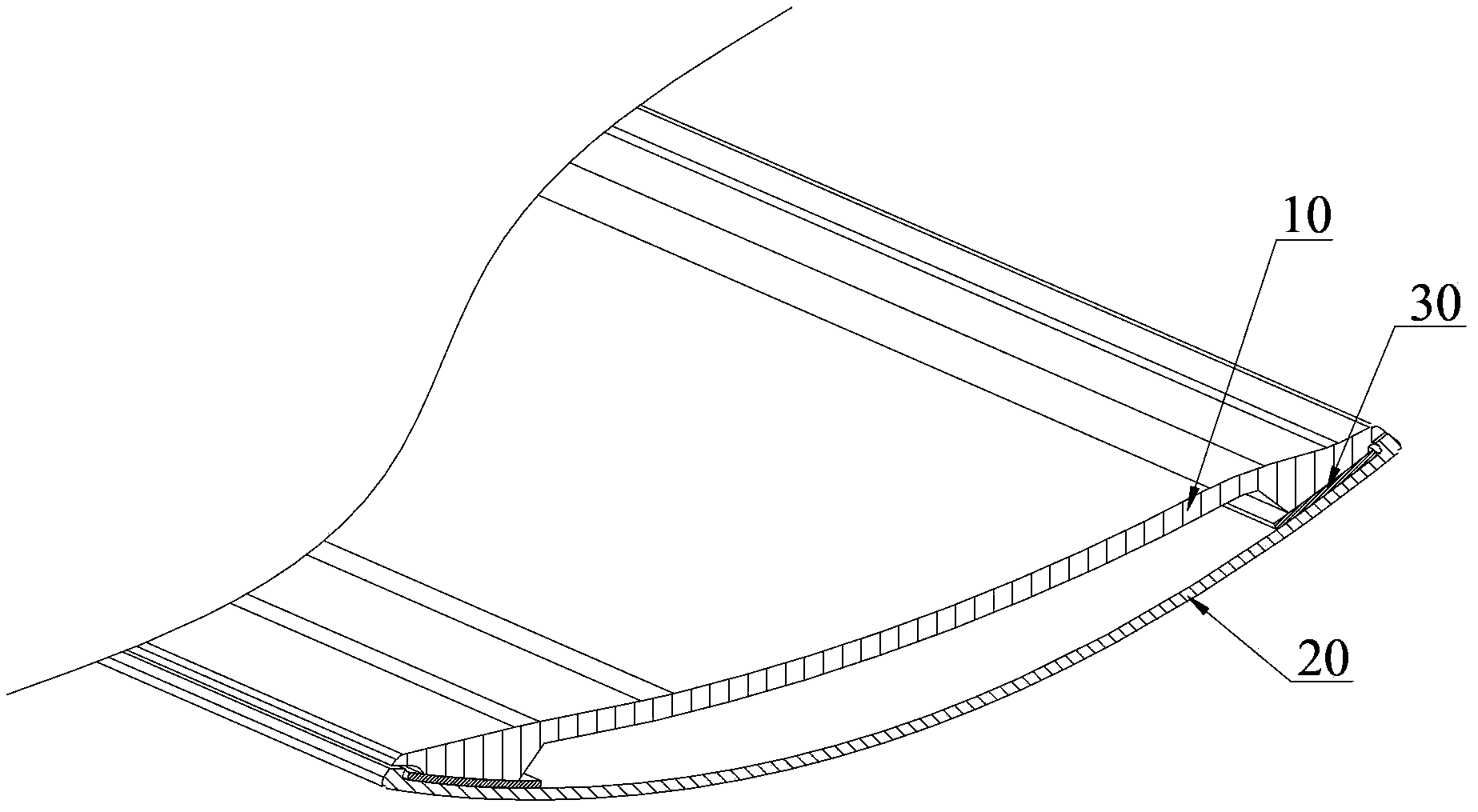

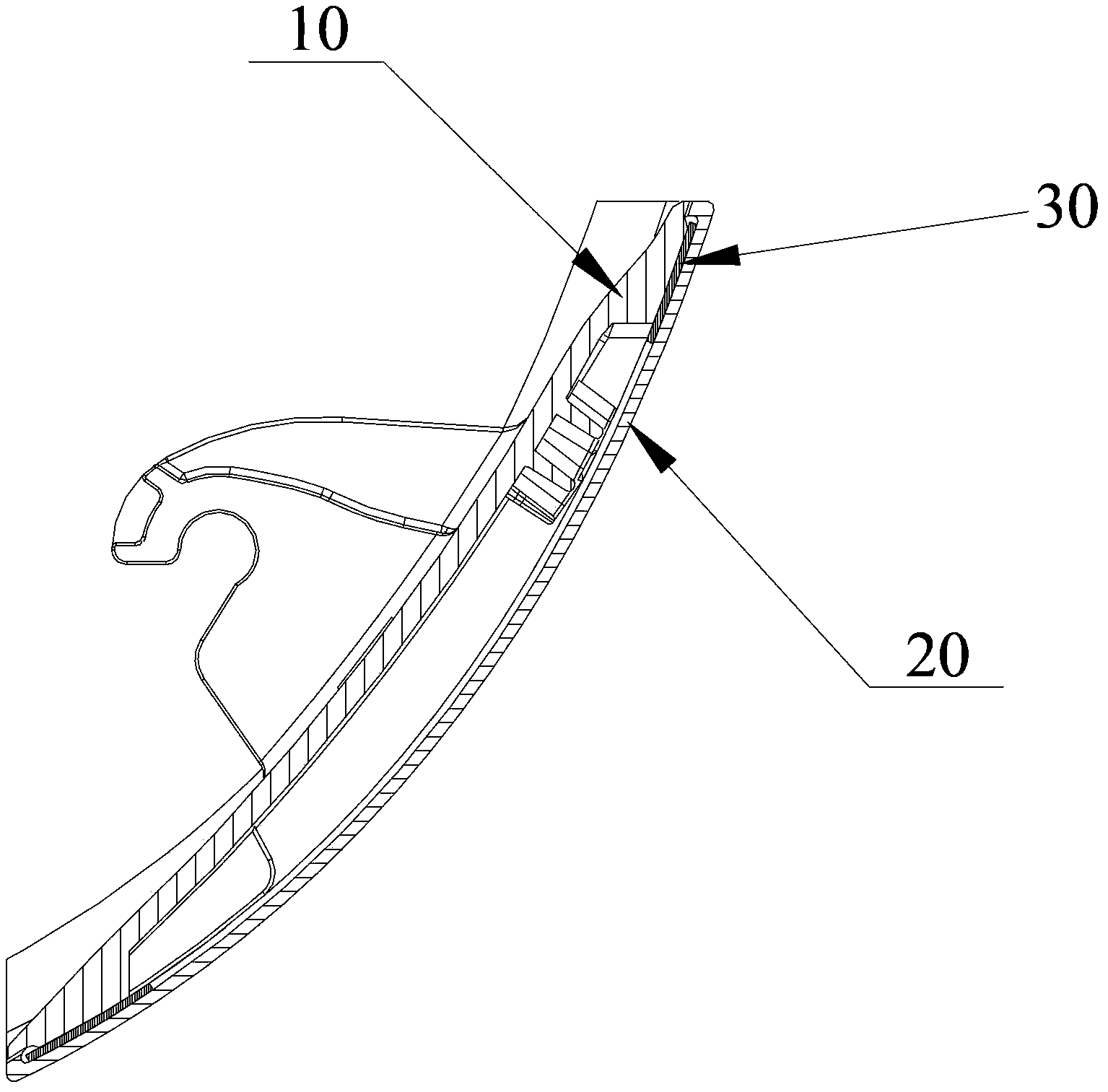

Air guide plate assembly and air conditioner with same

The invention provides an air guide plate assembly and an air conditioner with the air guide plate assembly. The air guide plate assembly comprises a first air guide plate (10) and a second air guide plate (20), wherein the first air guide plate (10) and the second air guide plate (20) are oppositely arranged, the air guide plate assembly further comprises buffer parts (30) arranged between the first air guide plate (10) and the second air guide plate (20), the first air guide plate (10) and the second air guide plate (20) are connected through the buffer parts (30), and the buffer parts (30) are made of elastic materials. According to the air guide plate assembly and the air conditioner with the air guide plate assembly, the problem that operation of an air conditioner in the prior art is unreliable because of deformation of an air guide plate assembly of the air conditioner is solved.

Owner:GREE ELECTRIC APPLIANCES INC

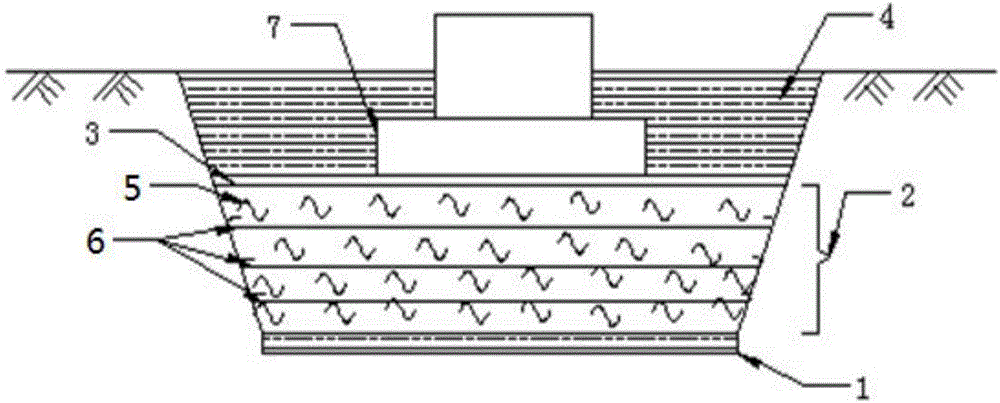

Composite reinforced loess foundation and construction method thereof

The invention discloses a composite reinforced loess foundation and a construction method thereof, and relates to the technical field of foundation treatment. By the adoption of the composite reinforced loess foundation and the construction method thereof, the problem that in the prior art, dynamic settlement of a loess foundation is caused by loess collapse and vibration of locomotives is solved. The composite reinforced loess foundation is sequentially composed of a lime soil under layer, a composite reinforced loess replacing and filling layer, a composite geo-membrane and a lime soil backfilling layer from bottom to top. Glass fibers are evenly mixed into the composite reinforced loess replacing and filling layer, and a plurality of layers of bidirectional geogrids are evenly laid in the composite reinforced loess replacing and filling layer in the horizontal direction. According to the composite reinforced loess foundation and the construction method thereof, the glass fibers and the bidirectional geogrids are combined to serve as reinforcing materials of the composite reinforced loess replacing and filling layer so that the overall compressive strength, tensile strength and shearing strength of the foundation can be improved, loess collapse is eliminated to the maximum extent, and the shock resistance of the foundation is enhanced to the maximum extent.

Owner:NORTHWEST UNIV(CN)

Composition for stretchable film

ActiveUS20120088423A1Small permanent elongationImprove adhesionLamination ancillary operationsPersonal carePolyolefinCopolymer composition

The present invention provides a composition for a stretchable film, which achieves a high-level balance between a high elastic modulus and a small permanent elongation, which is excellent in adhesive force when laminated with a non-woven fabric or the like, and also has good formability. The present invention also provides a composition for a stretchable film comprising a block copolymer composition containing a block copolymer A represented by the following general formula (A) and a block copolymer B represented by the following general formula (B), and a polyolefin-based thermoplastic resin:Ar1a-Da-Ar2a (A)(Arb-Db)n-X (B),in these formulas, Ar1a and Arb each represent an aromatic vinyl polymer block having a weight average molecular weight of 6,000 to 20,000; Ar2a represents an aromatic vinyl polymer block having a weight average molecular weight of 40,000 to 400,000; Da and Db each represent a conjugated diene polymer block having a vinyl bond content of 1 mol % to 20 mol %; X represents a single bond or a residue of a coupling agent; and n represents an integer of 2 or greater.

Owner:ZEON CORP

Non-woven cambric and production thereof

A non-woven bast cloth for the inner surface of car top and the liner of artificial leather used for car, or as polishing material for steel, copper, or aluminium is prepared from bast fibres through airflow netting, immersing and adhering. Its advantages are high tension strength and temp stability, good moisture and air permeability, and high heat insulation.

Owner:张进建

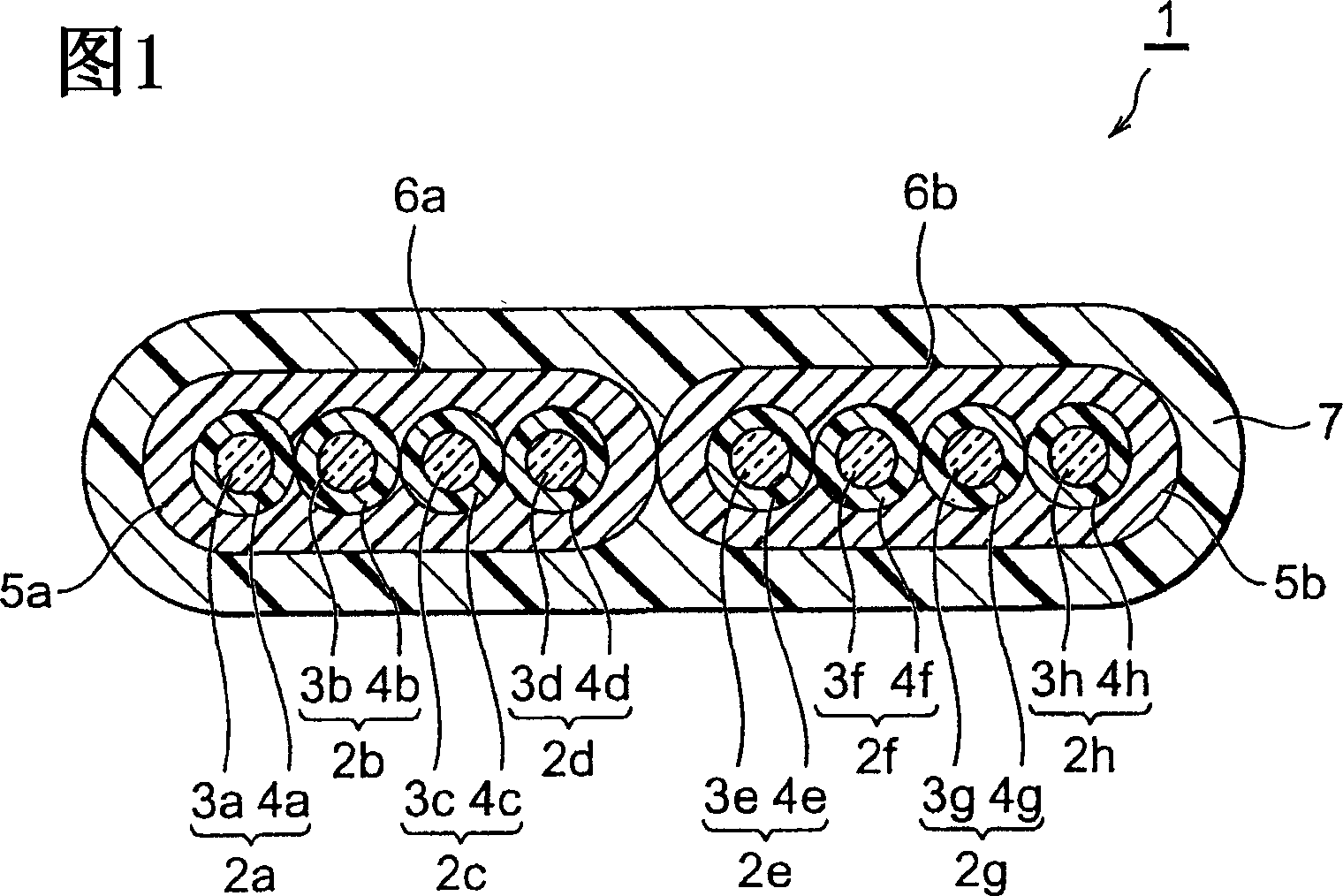

Split type optical fiber core

InactiveCN1459040AImprove segmentation performanceSmall elongationFibre mechanical structuresUV curingUltraviolet

Owner:SUMITOMO ELECTRIC IND LTD

Intermediate transfer device and image forming device

InactiveUS20050254852A1Reliable removalLow elongationElectrographic process apparatusImage formationEngineering

An intermediate transfer device has: an intermediate transfer belt supported by a plurality of belt supporting mechanisms so as to be able to circulate, and having elasticity at least in a direction of circulating; a first bias applying mechanism applying a first bias voltage to toner on a toner carrier surface of the intermediate transfer belt; a layer thinning mechanism contacting the toner carrier surface and electrostatically attracting the toner which is on the toner carrier surface so as to thin a layer of the toner; a second bias applying mechanism applying a second bias voltage to the toner whose layer has been thinned; an image carrier carrying a visible image to be transferred onto the toner carrier surface, the toner on the toner carrier surface, to which the second bias voltage has been applied, being transferred onto the image carrier; and a toner removing mechanism removing the toner on the image carrier.

Owner:FUJIFILM BUSINESS INNOVATION CORP

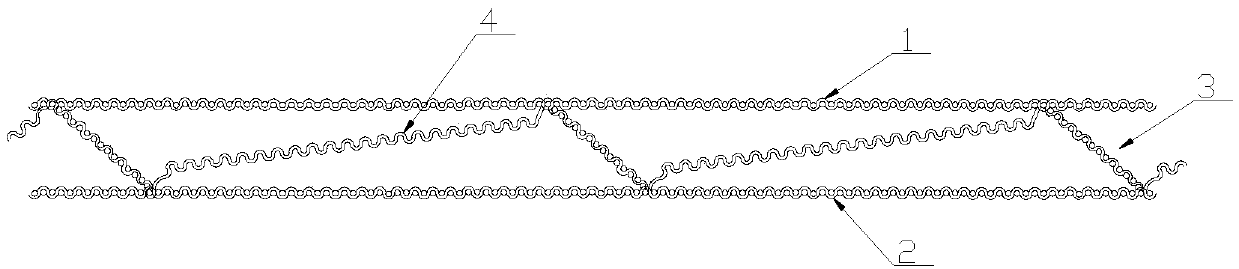

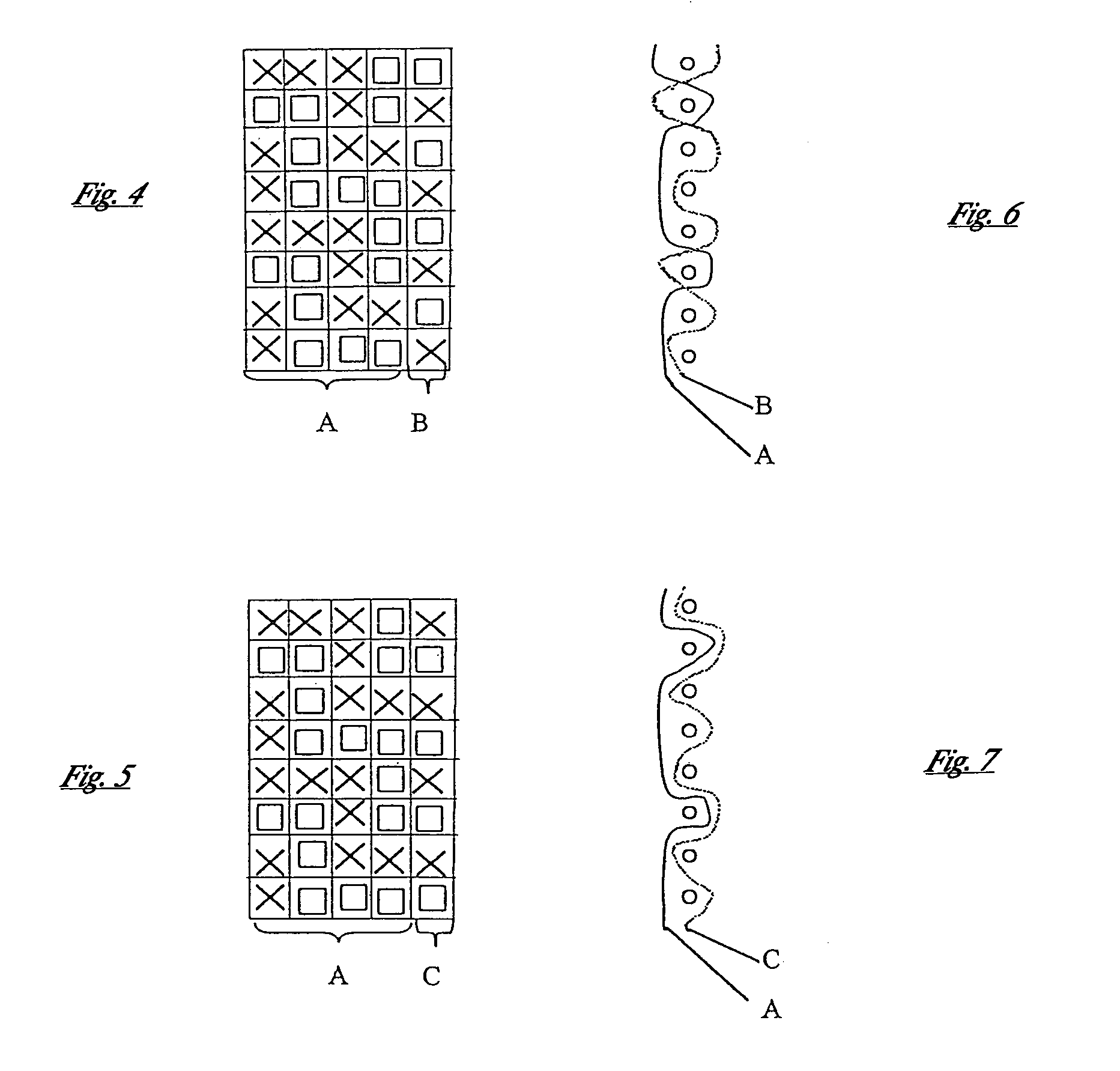

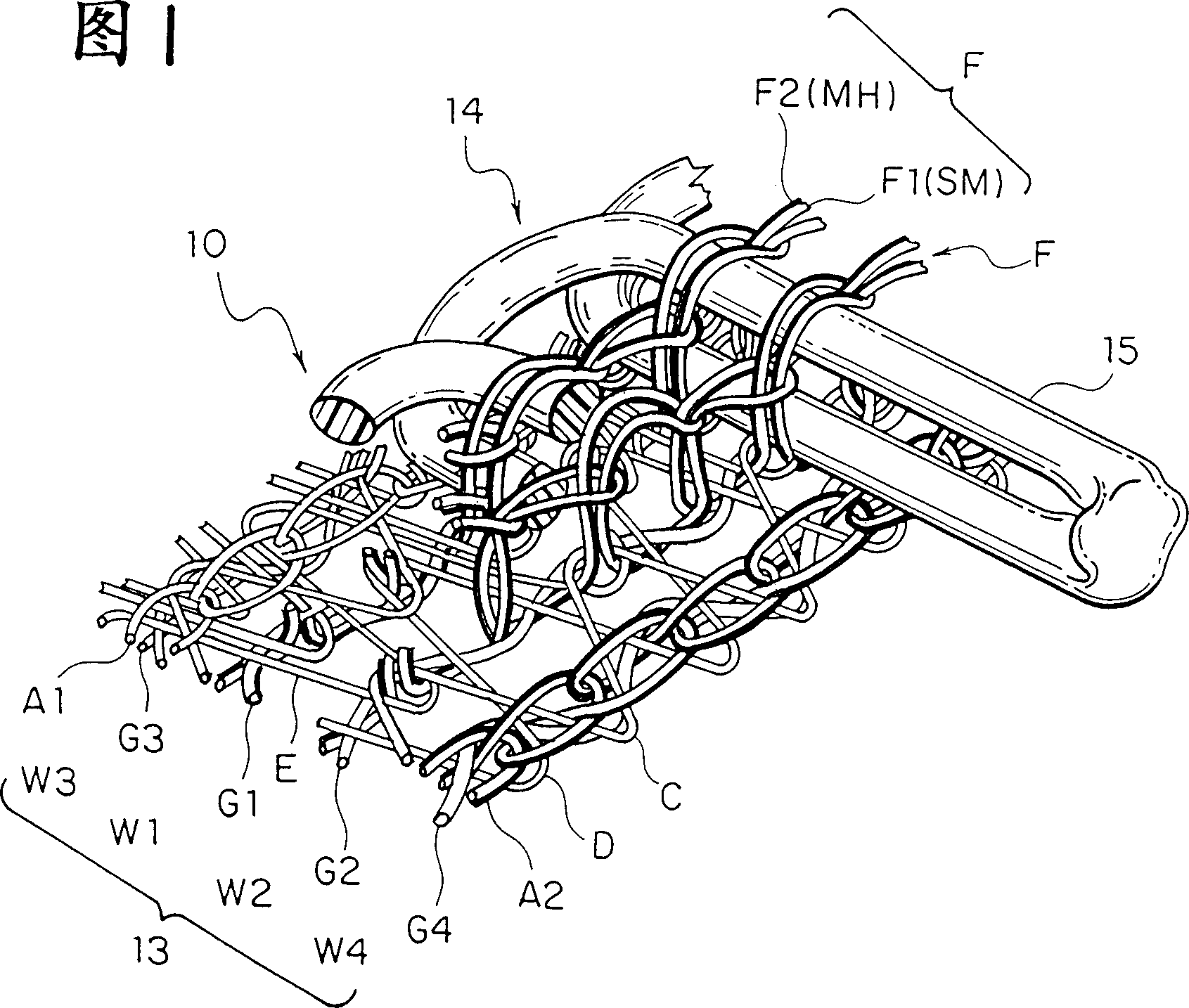

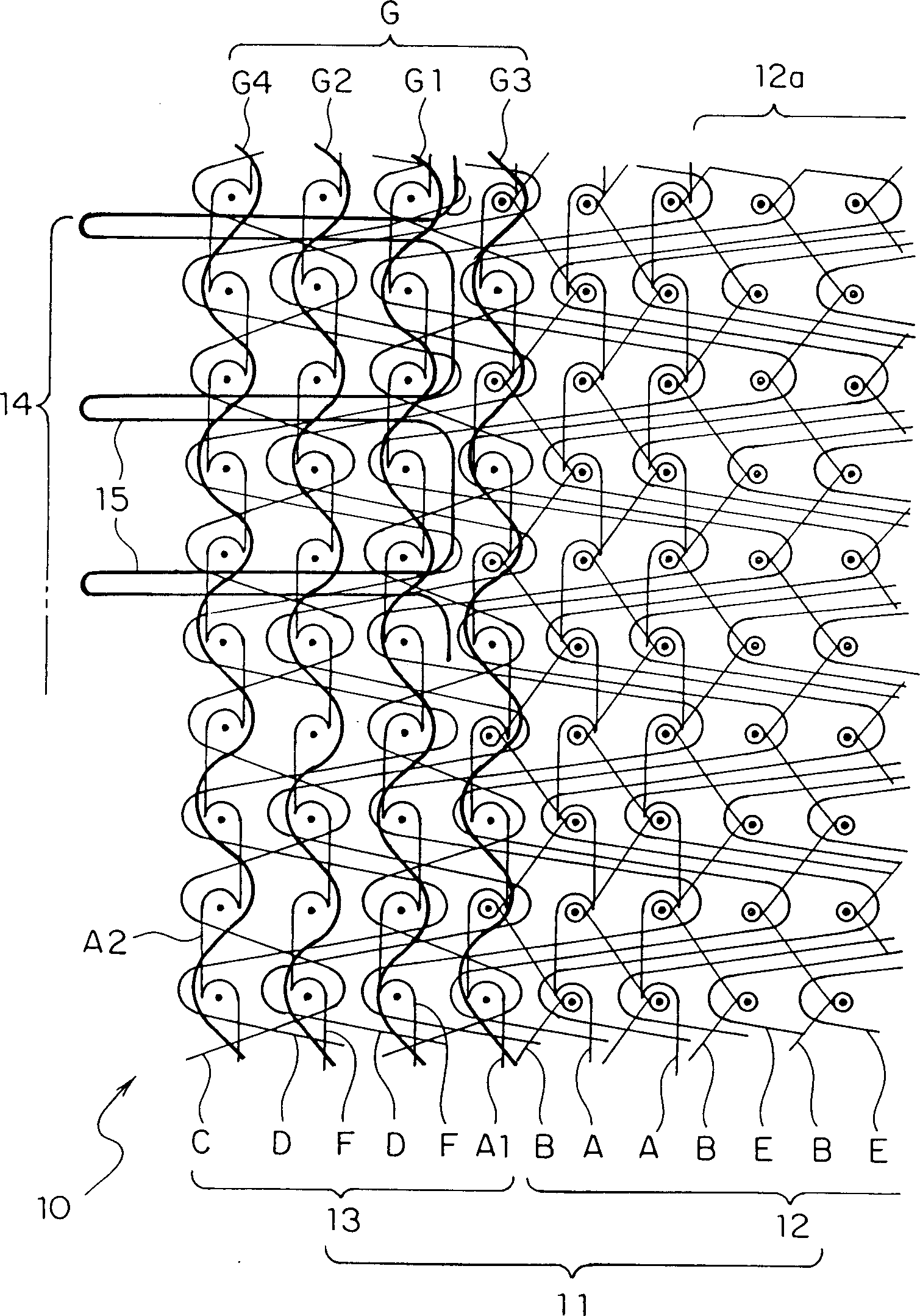

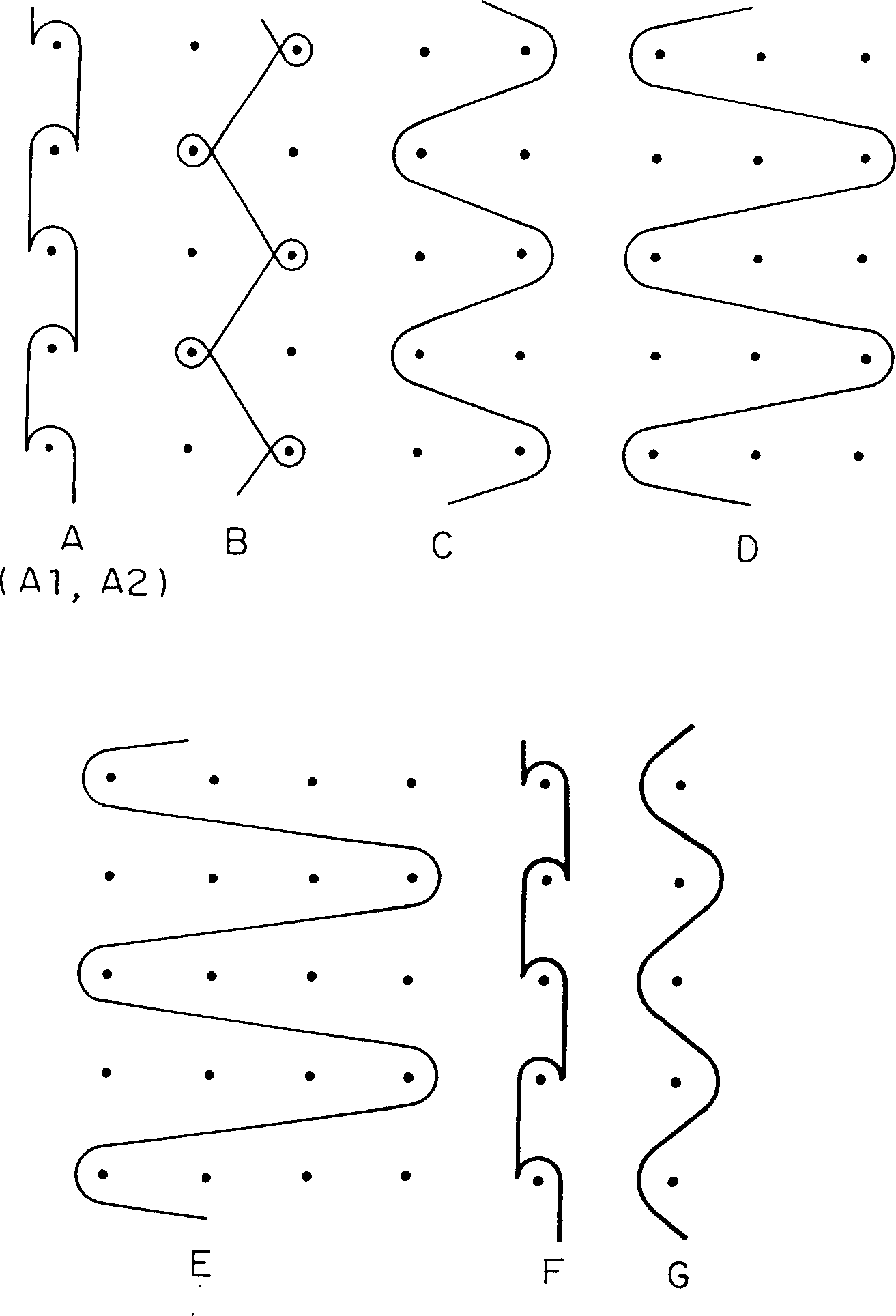

Knit zippers

A knitted-in slide fastener comprising a continuous fastener element row (14) which is knitted in at the same time as knitting of a fastener tape (11), wherein a fastener element mounting portion (13) on a side edge portion in the longitudinal direction of the warp knitted fastener tape (11) is knitted with a fixing knitting yarn (F) for sandwiching and fixing upper and lower leg portions of each fastener element (15) in a direction of front and rear of the fastener tape and other knitting yarns (C, D, G1 to G4). Part of these composition yarns is composed of composite fiber yarns formed of heat shrinkage fiber material (SM) and heat fusion fiber material (MM), and the heat shrinkage fiber material (SM) is shrunk by heat treatment and at the same time, the heat fusion fiber material (MM) is fused with other the composition yarns (F, C, D, G1 to G4) in the vicinity thereof. Consequently, no fraying occurs in yarns even if a knitting yarn, which forms the fastener element mounting portion, is cut out so that the fastener element row of that portion is not separated from the fastener tape.

Owner:YKK CORP

Textile thread having a polytetrafluoroethylene wrapped core

Owner:BLOCH KLAUS

Edge-cutting double-sided transmission tooth-shaped tight-up belt

ActiveCN104151657AImprove performanceImprove transmission efficiencyFibre treatmentDriving beltsFiberActive agent

The invention belongs to the technical field of transmission belt production and particularly relates to an edge-cutting double-sided transmission tooth-shaped tight-up belt product. The tight-up belt structurally comprises top fabric, a primer and transverse connection core ropes, wherein the primer comprises the following raw materials in parts by mass: 100 parts of rubber / plastic alloy hydrogenated nitrile butadiene rubber, 15-25 parts of poly-p-phenylene terephthamide pulp fiber, 8-10 parts of liquid carboxyl nitrile butadiene rubber, 13-20 parts of fumed silica, 45-55 parts of high-wear-resistant carbon black, 15-25 parts of semi-reinforcing carbon black, 1.5-3.0 parts of vulcanizing agent, 1.5-3.0 parts of accelerator, 5-9 parts of active agent, 1-5 parts of anti-aging agent and 2.5-6 parts of binder. The tight-up belt disclosed by the invention has the characteristics of high transmission efficiency, low elongation rate, tension-free maintenance and the like; the service life of the tight-up belt used on supporting equipment is more than 3 years; and the tight-up belt has relatively good promotion adaptability.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com