Patents

Literature

129results about How to "Strong tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

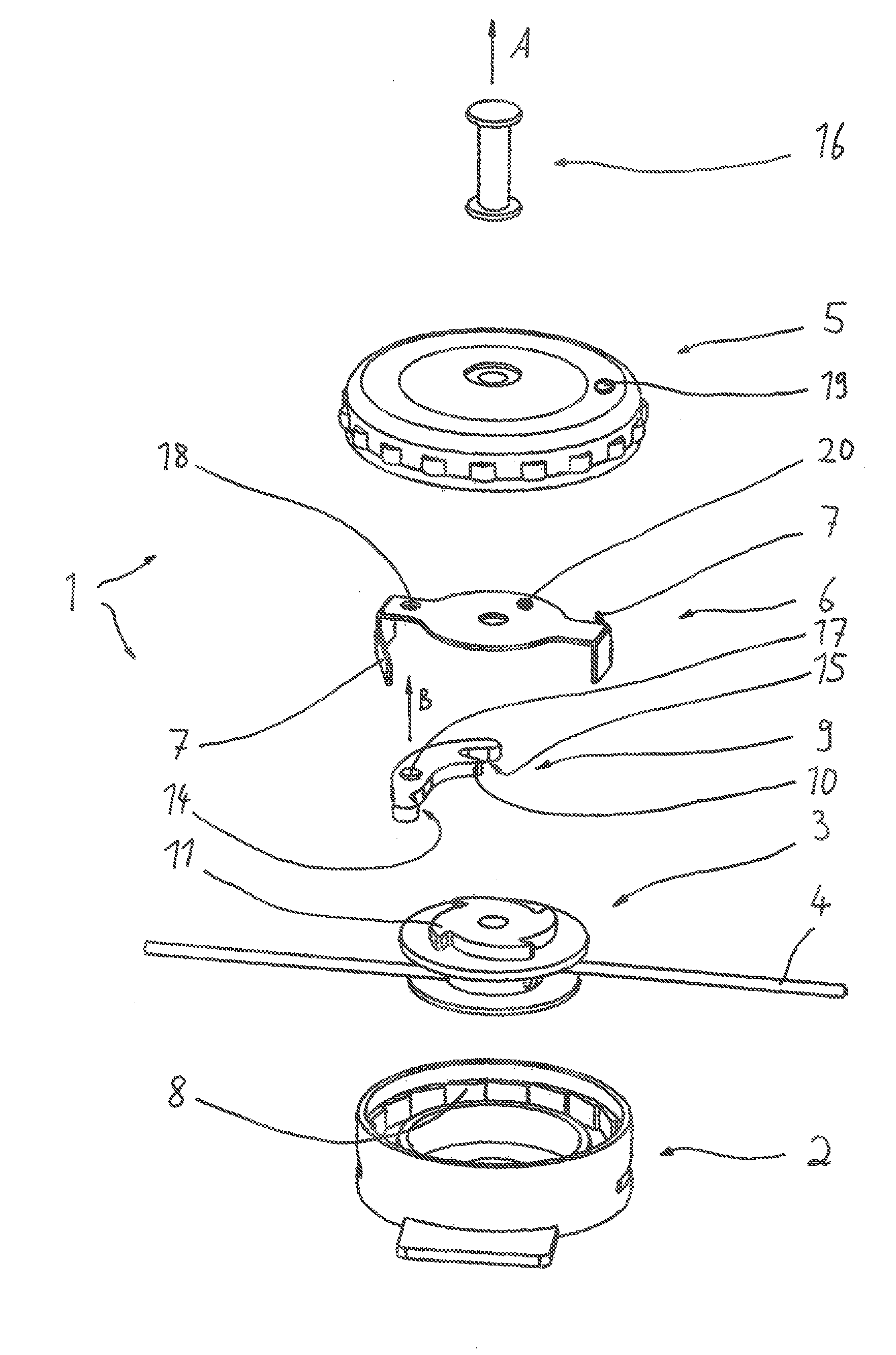

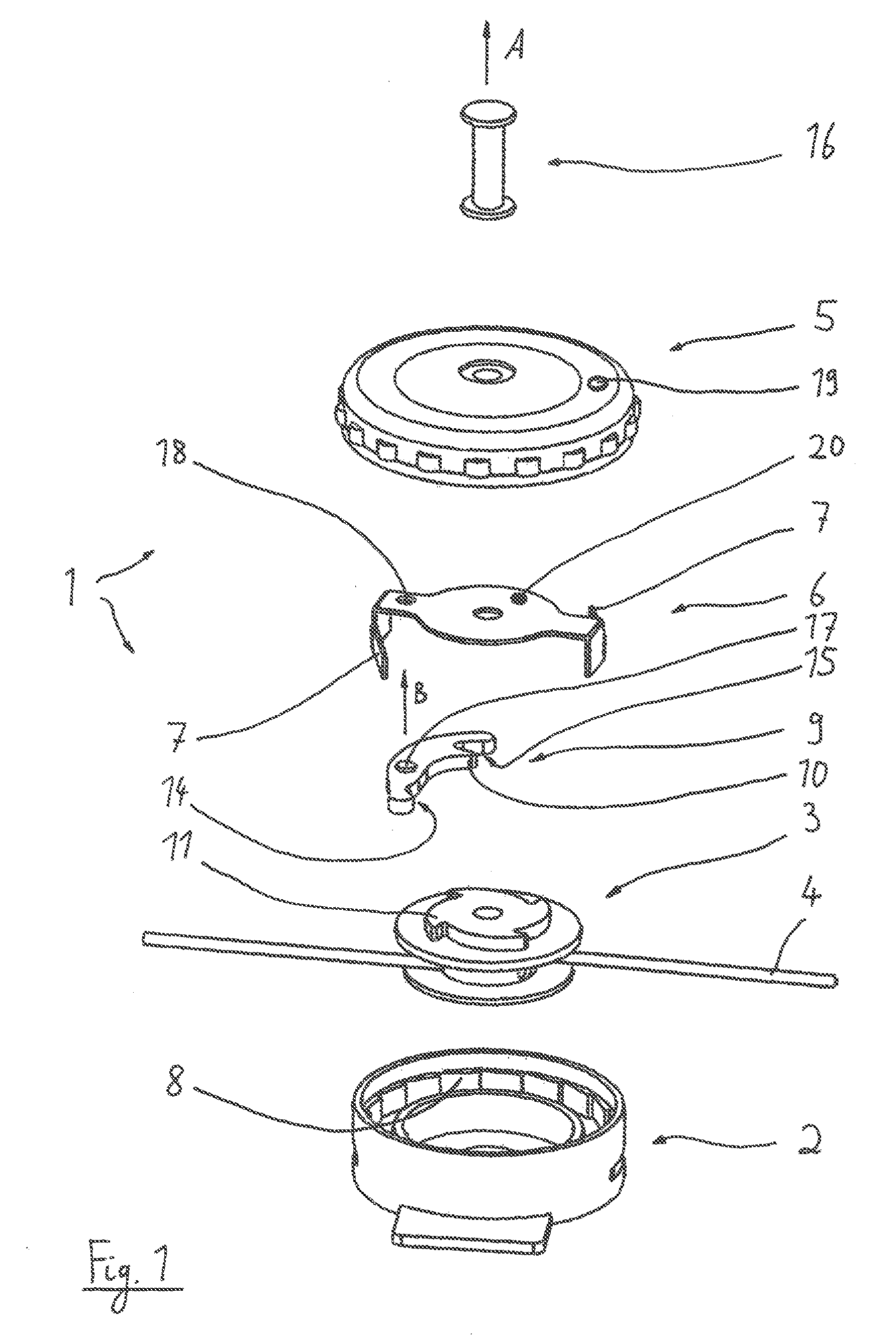

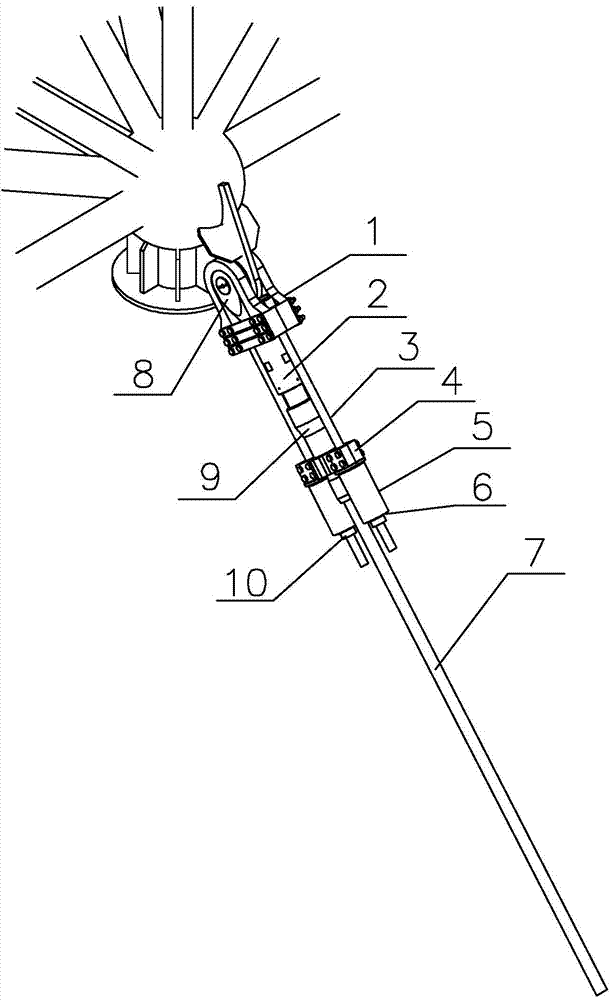

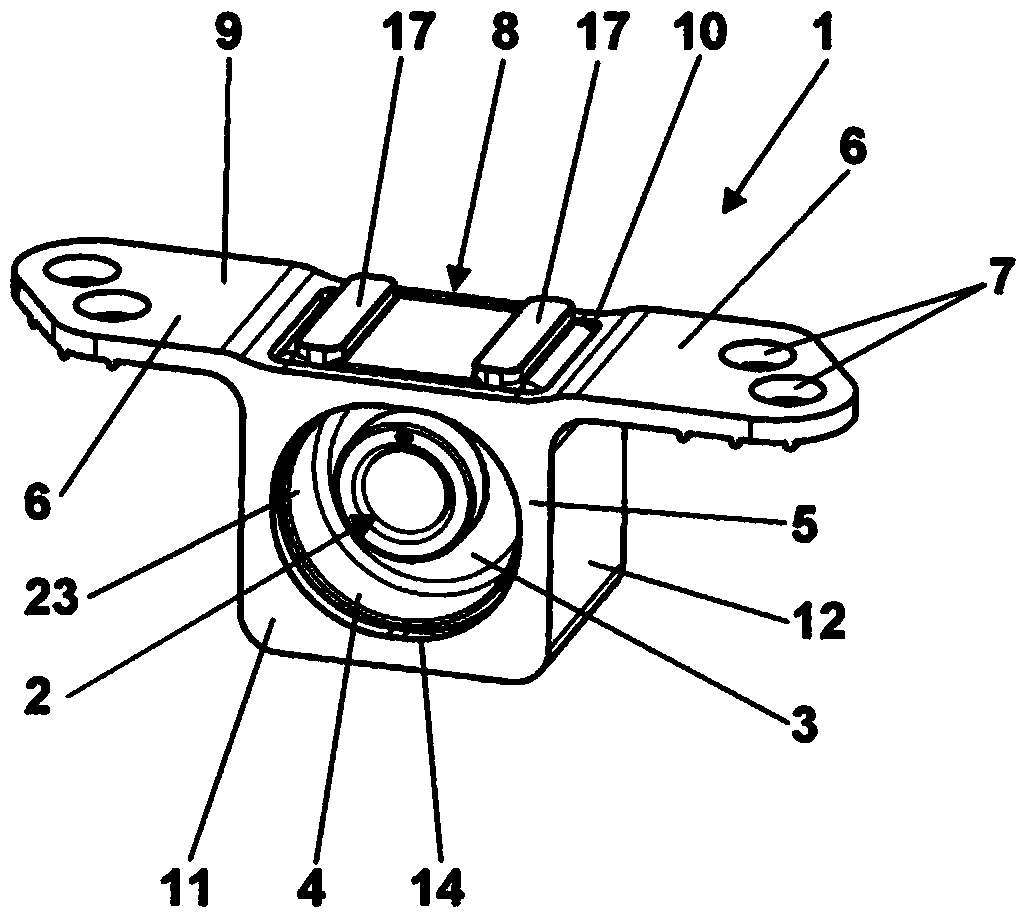

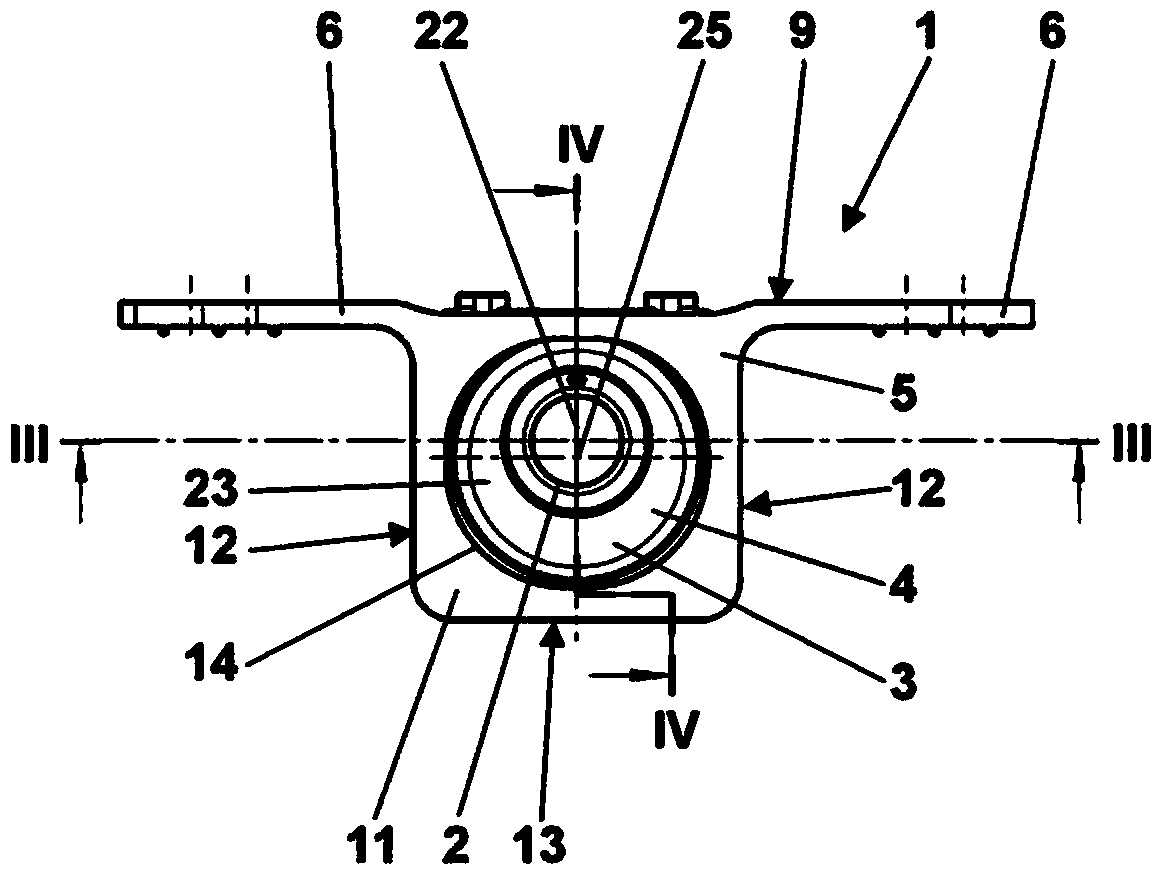

Rotary closure for a shoe

A rotary closure for a shoe, especially for a sports shoe, including a housing which can be attached to the shoe, a tensioning roller which is rotatably supported around an axis in the housing, wherein a tensioning element can be spooled during lacing of the shoe on the tensioning roller and a rotary knob which is arranged rotatable around the axis at the housing to turn the tensioning roller. The rotary closure furthermore includes an intermediate carrier, wherein the intermediate carrier has at least one pawl which engages in a first blocking gearing of the housing and at least one locking lever which is arranged in or at the intermediate carrier, wherein a first and a second control element which co-operate with first and second crank section of the locking lever, are disposed on the rotary knob.

Owner:PUMA SE

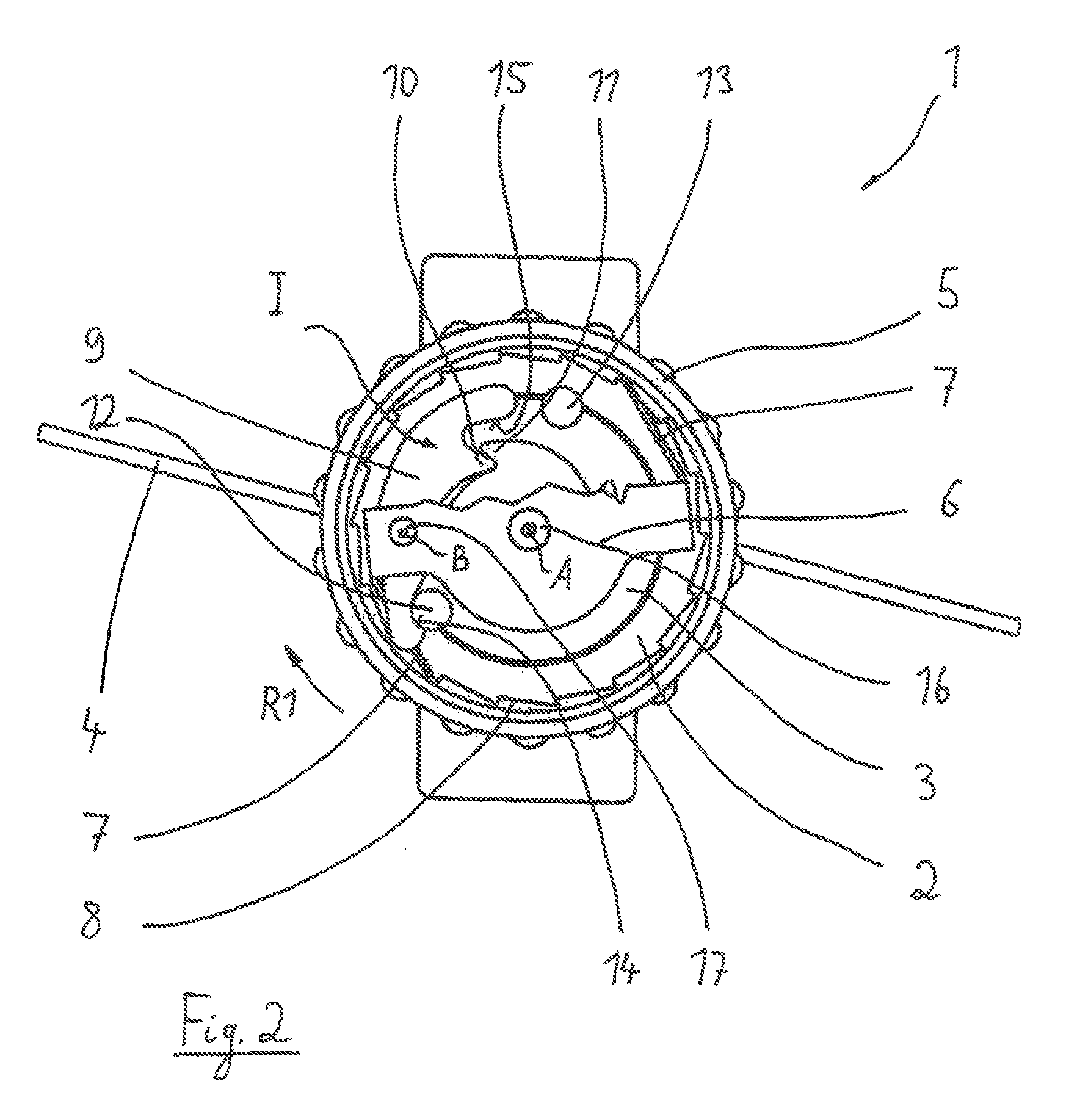

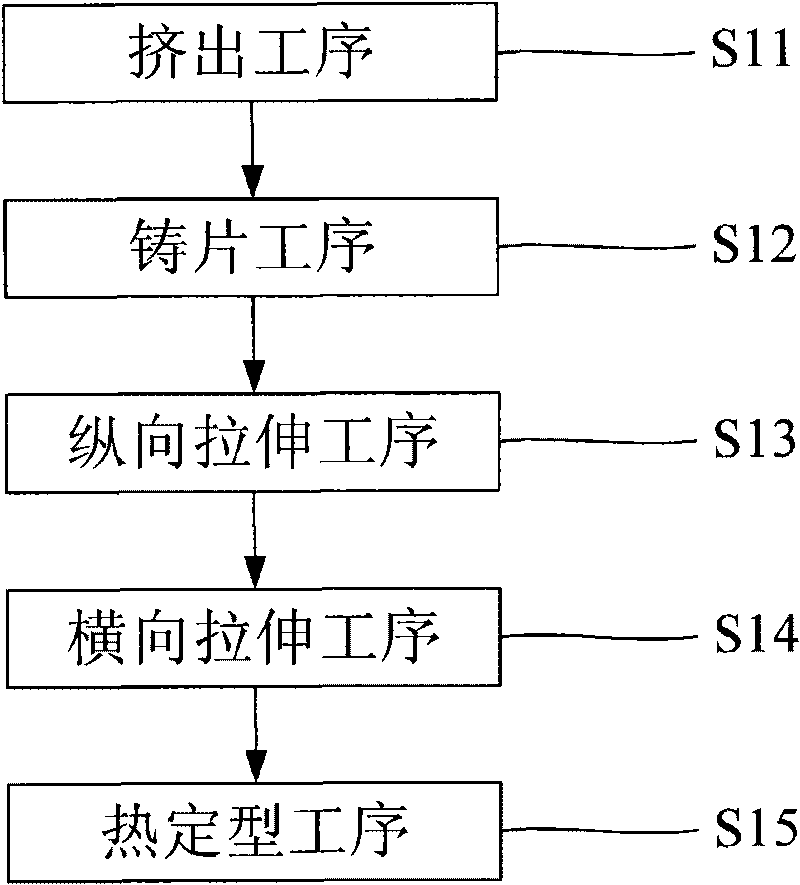

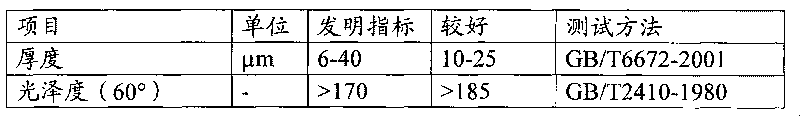

Low-haze multi-layer co-extrusion two-way stretching polyamide film and preparation method

InactiveCN101722700AReduce gapGood optical performanceSynthetic resin layered productsSurface layerPolyamide

The invention provides a low-haze multi-layer co-extrusion two-way stretching polyamide film and a preparation method. The two-way stretching polyamide film comprises at least three co-extrusion structures, namely a surface layer A, a surface layer C and a middle layer B, wherein the surface layer A and the surface layer C contain antiblocking agents. The invention also discloses a preparation method of the two-way stretching polyamide film, comprising the following steps of: preparing polyamide raw materials, extruding, casting pieces, thermoforming, slacking, drawing, winding, and the like. The two-way stretching polyamide film has the advantages of low haze, high gloss and high transparency and can be widely applied to the field of the packaging industry.

Owner:SHANGHAI ZIDONG CHEM MATERIALS

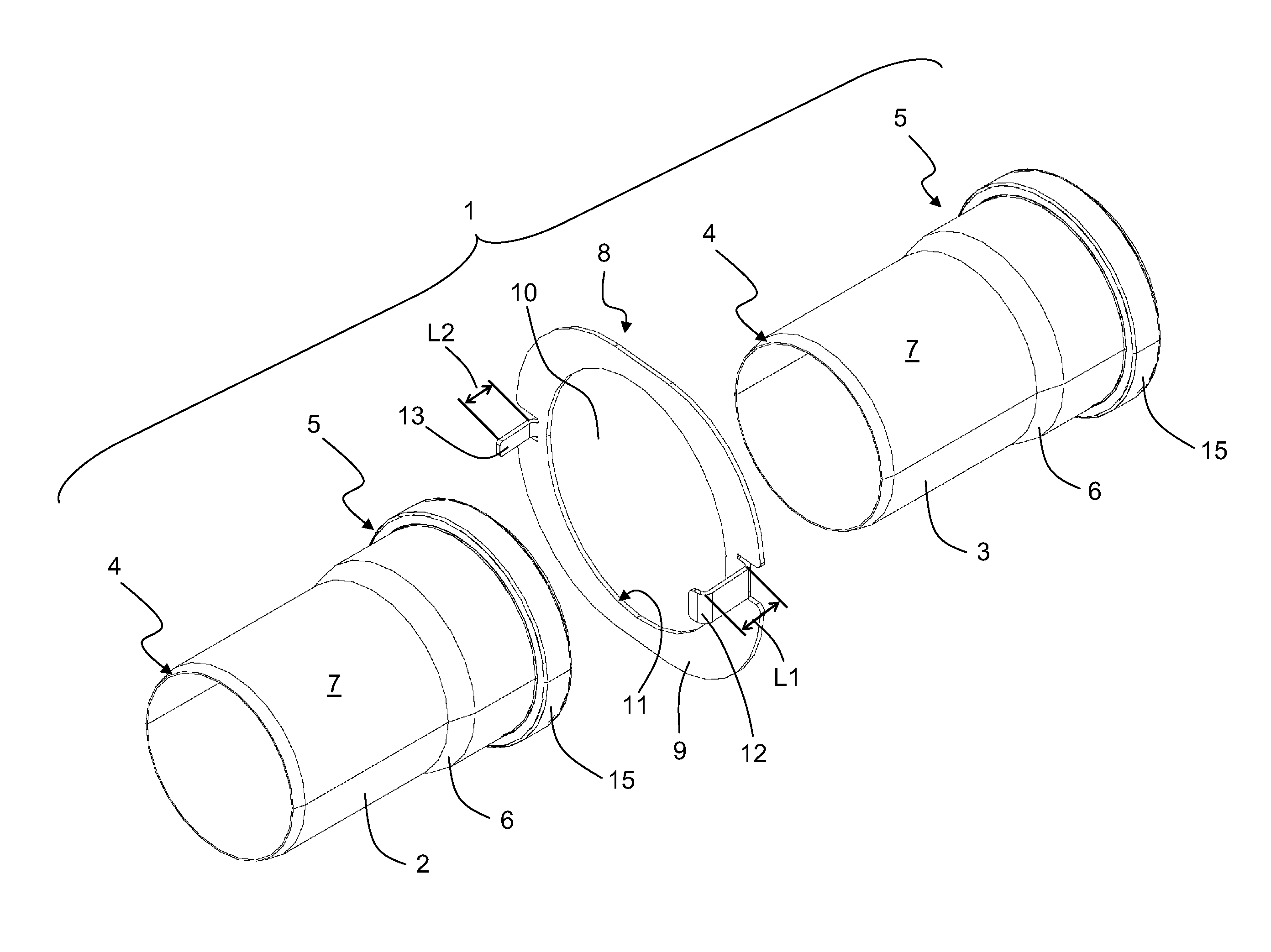

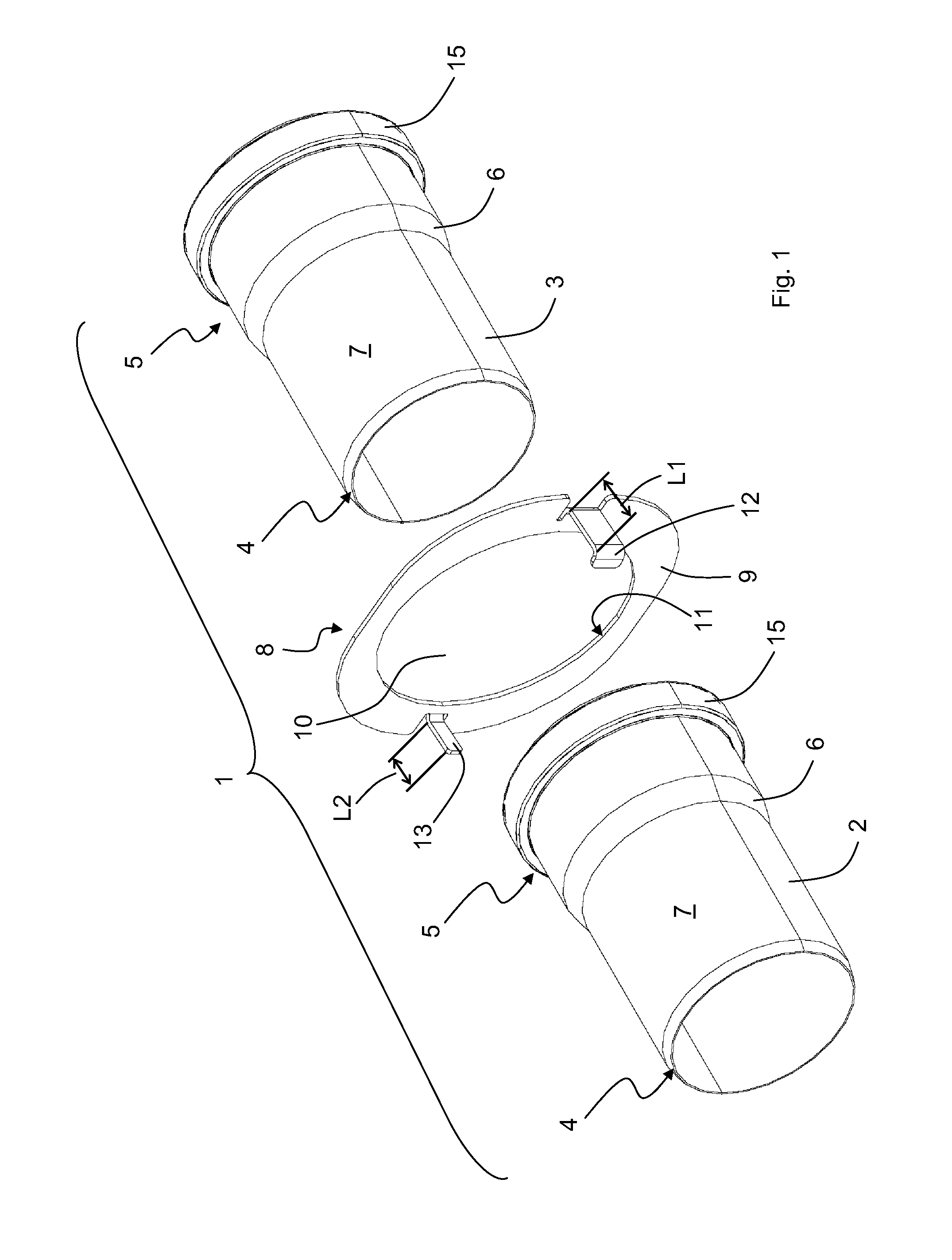

Securing device of a fluid line connection

ActiveUS8474878B2Improve fitEasy to removeSleeve/socket jointsPipe elementsShape designBiomedical engineering

A securing device for axially connecting a sleeve-shaped end section of a first fluid line part to an end section, which is designed as a pointed end, of a second fluid line part includes a clamping body which is of annular design and has a passage opening for insertion of the second fluid line part, at least one retaining element of a hook-shaped design, and at least one spacer of web-shaped design, wherein the at least one retaining element and the at least one spacer are both integrally formed with the clamping body and extend in the same axial direction.

Owner:CENTTHERM SYSTTECHN

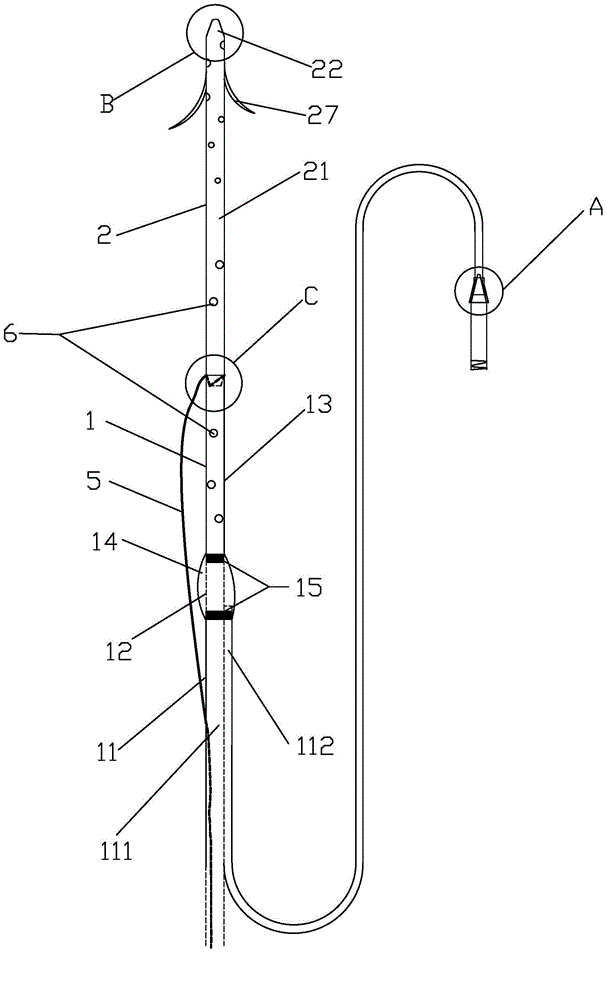

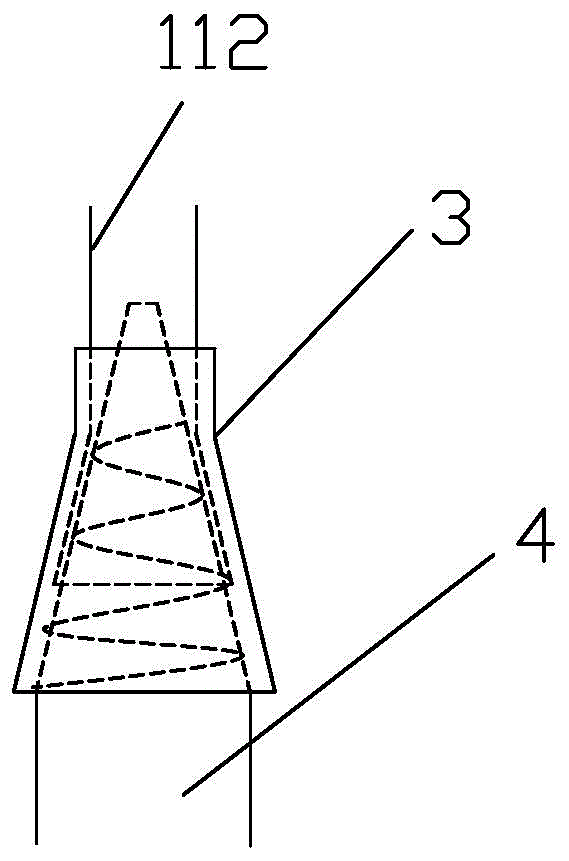

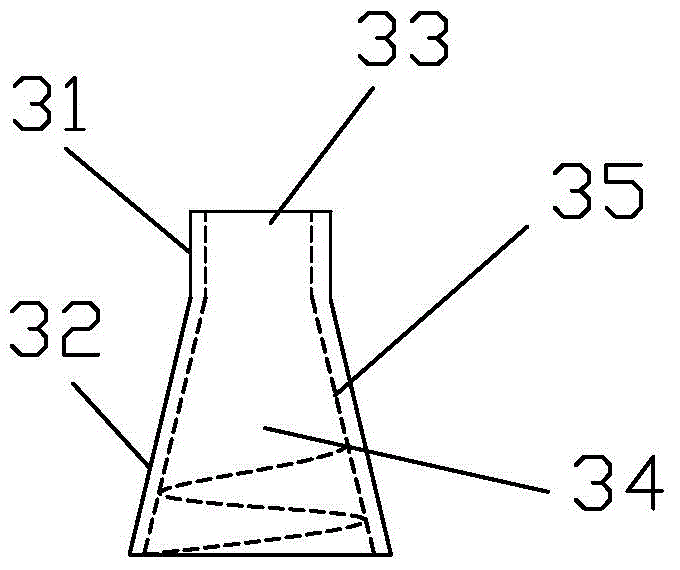

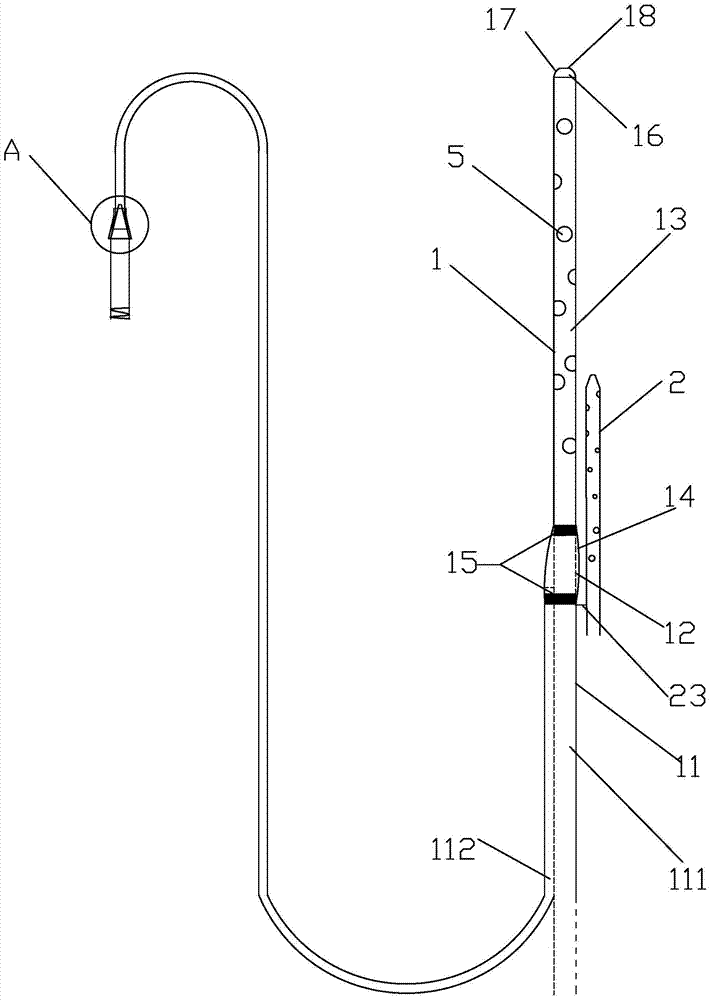

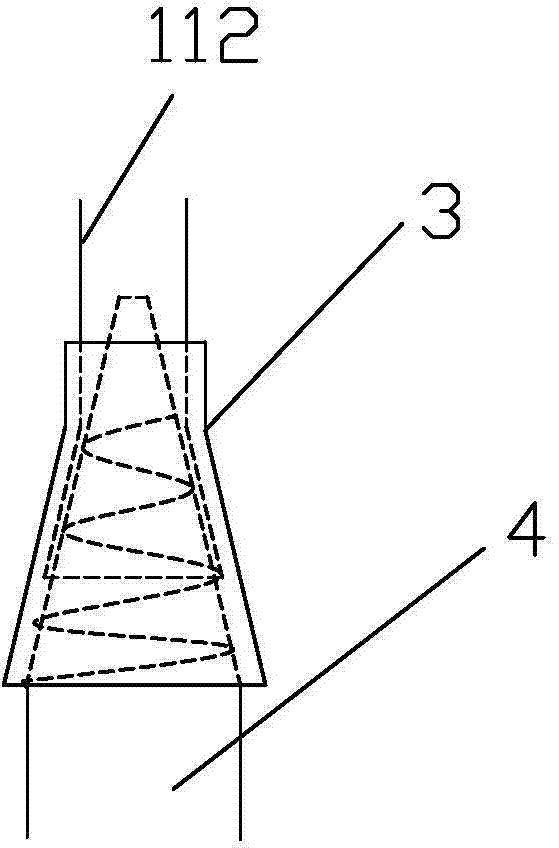

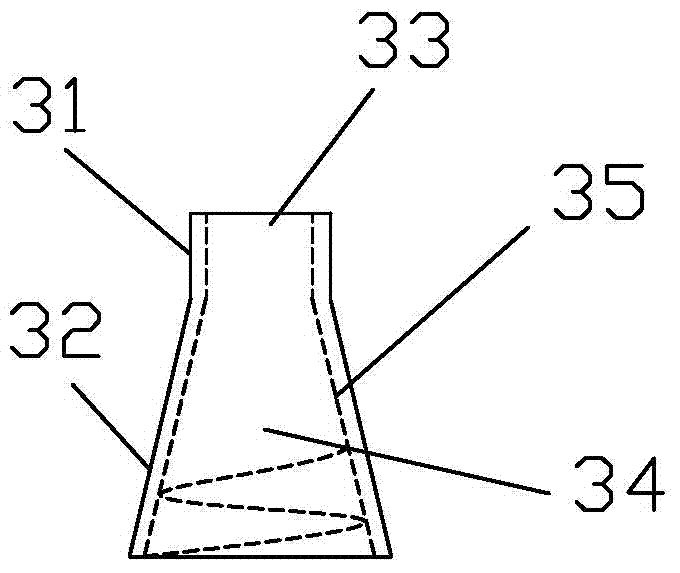

Integrated bile and pancreatic juice drainage pipe

The invention discloses an integrated bile and pancreatic juice drainage pipe which comprises a water sac type bile outer drainage pipe and a pancreatic juice inner drainage pipe. The water sac type bile outer drainage pipe comprises a drainage pipe section I, a drainage pipe section II and a drainage pipe section III which are communicated in sequence. The outer wall of the drainage pipe section II is sleeved with a balloon thin film. The pancreatic juice inner drainage pipe comprises a drainage pipe body, a pipe cap and a drainage pipe tail portion. The end, far away from the drainage pipe section II, of the drainage pipe section III is matched with the drainage pipe tail portion. The integrated bile and pancreatic juice drainage pipe has strong tension force, can have the function of avoiding disengagement of the water sac type bile outer drainage pipe, is suitable for bile ducts of various diameters, has no damage to bile duct mucosa, duodenal papillae and upper gastrointestinal tract mucosa, and cannot cause obstruction of biliary tracts while avoiding displacement of the water sac type bile outer drainage pipe. The pancreatic juice inner drainage pipe is connected with the water sac type bile outer drainage pipe through a line, and the function of avoiding displacement or disengagement of the pancreatic juice inner drainage pipe is achieved.

Owner:DALIAN UNIV

Y-type bile pancreatic juice drainage tube with water bag

The invention discloses a Y-type bile pancreatic juice drainage tube with a water bag. The Y-type bile pancreatic juice drainage tube comprises a water bag type bile outer drainage tube and a pancreatic juice inner drainage tube. The water bag type bile outer drainage tube comprises a drainage tube section I, a drainage tube section II and a drainage tube section III. The drainage tube section II is sleeved with a balloon film, and the pancreatic juice inner drainage tube comprises a drainage tube body and a tube cap I located at the upper end of the drainage tube body. The side wall of the drainage tube body is connected with the side wall of the drainage tube section I through a connecting part. The Y-type bile pancreatic juice drainage tube has the effects of preventing the water bag type bile outer drainage tube from disengaging and preventing the pancreatic juice inner drainage tube from shifting or disengaging, is suitable for bile ducts of various diameters and has no injury to the bile duct mucous membrane, the duodenal papilla and the upper digestive duct mucosa in the placing-in and taking-out processes, bile duct obstruction will not be caused while the water bag type bile outer drainage tube is prevented form shifting, and while the water bag type bile outer drainage tube is taken out, the pancreatic juice inner drainage tube can be taken out.

Owner:DALIAN UNIV

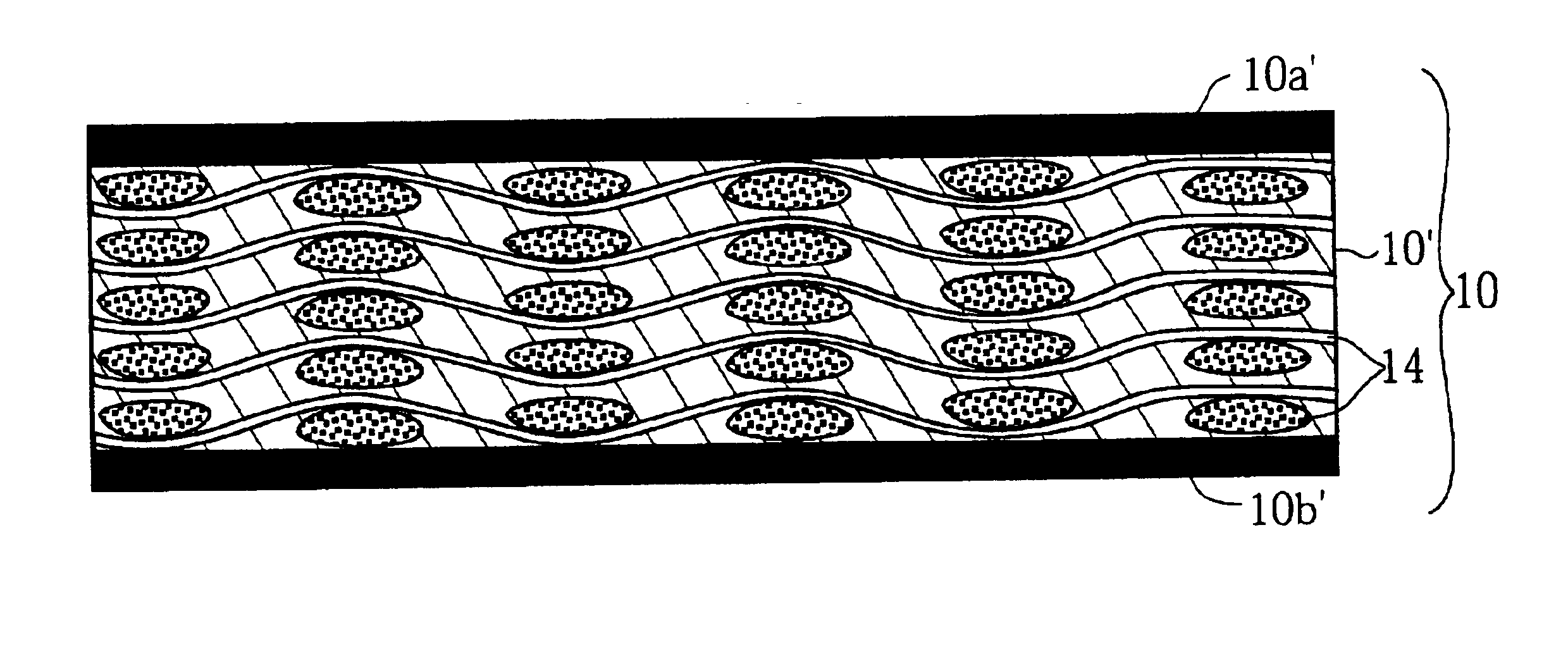

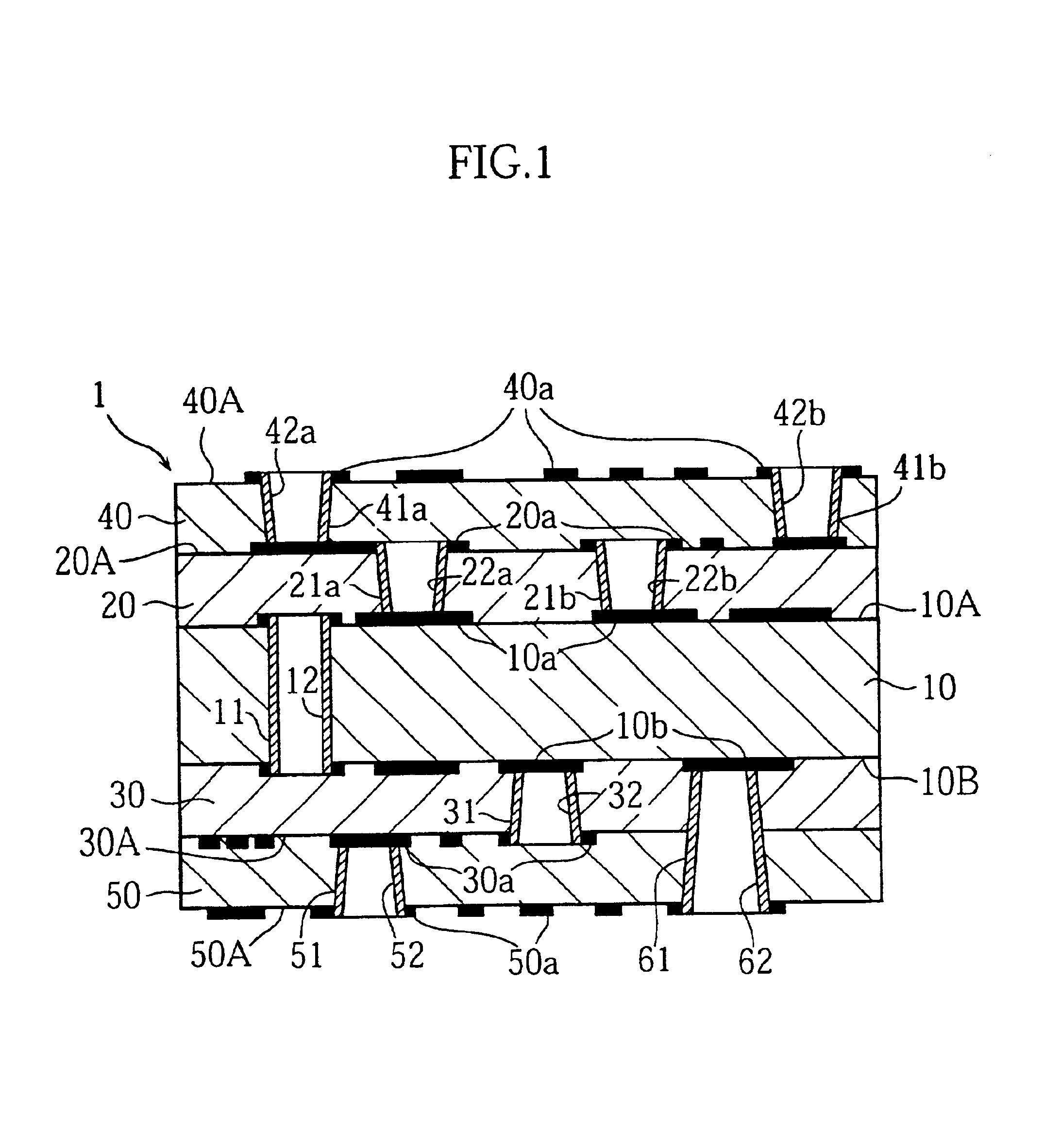

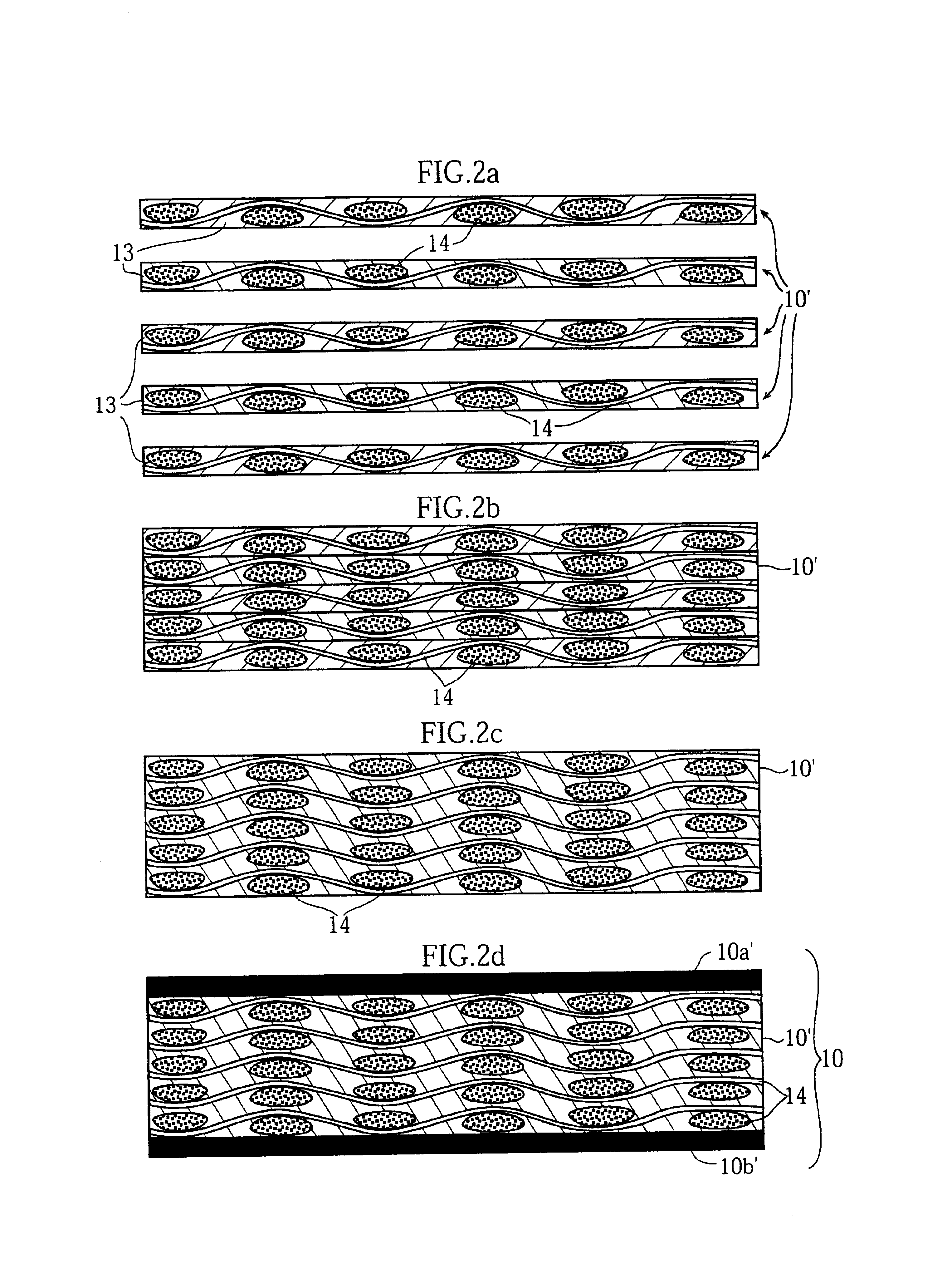

Multilayer printed wiring board

InactiveUS6846549B2High elastic modulusIncrease contact areaSynthetic resin layered productsPrinted circuit aspectsYarnEngineering

A multilayer printed wiring board includes a core member having a plurality of glass clothes impregnated with a resin. Each of the glass clothes is woven with glass yarns each of which includes a bundle of glass filaments. One or more buildup layers are laminated on one or each surface of the core member. The core member has an elastic modulus which is no less than 100 times that of the buildup layer at 240° C.

Owner:FUJITSU LTD

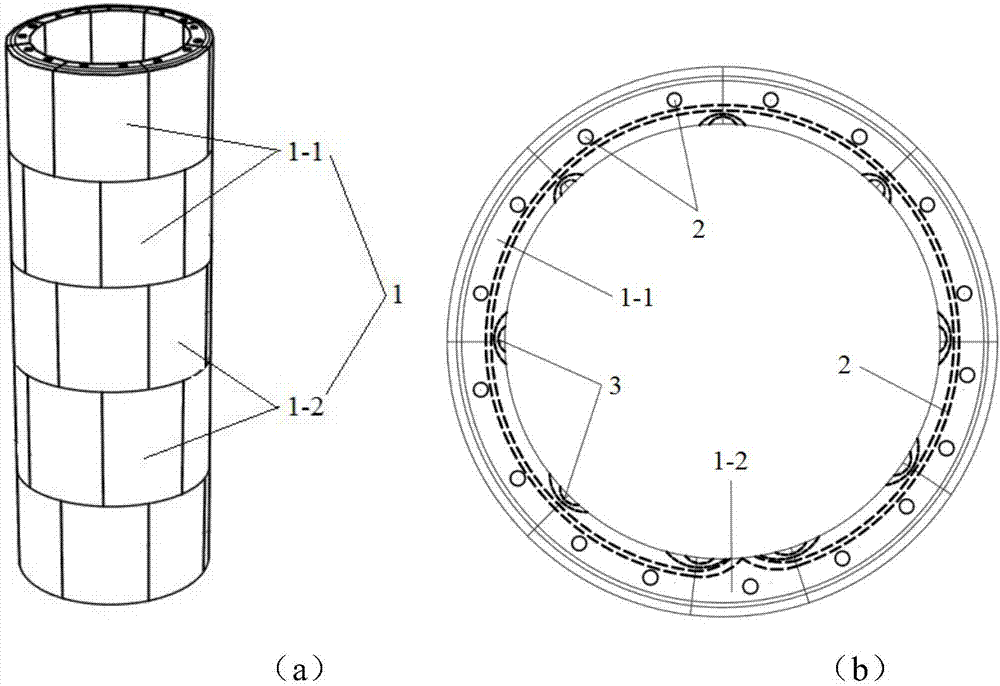

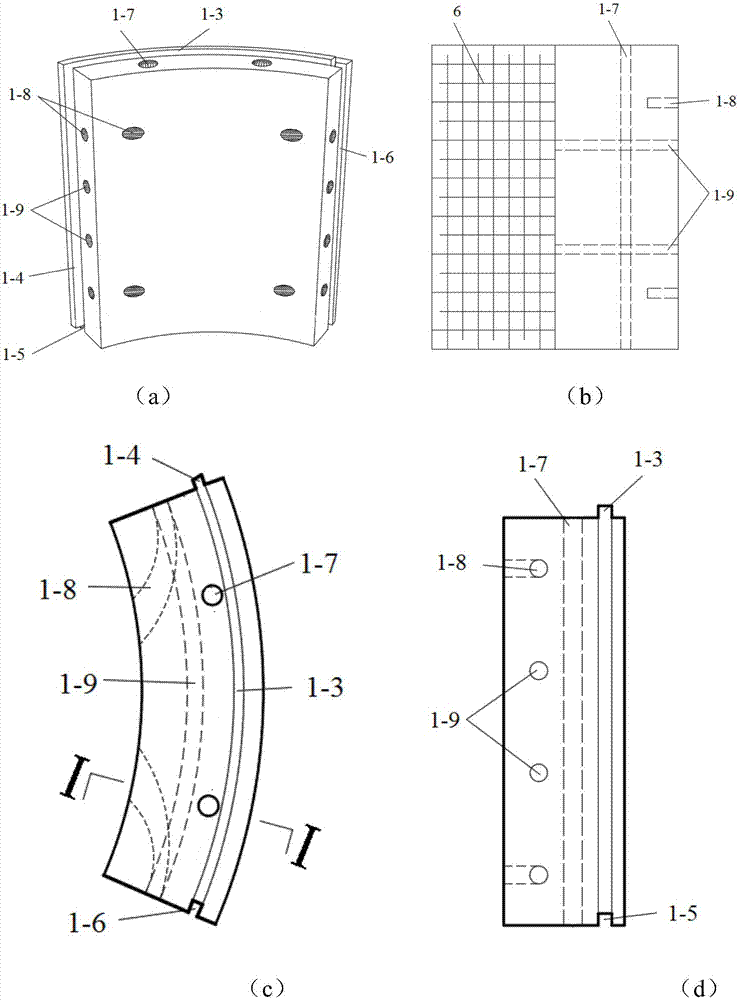

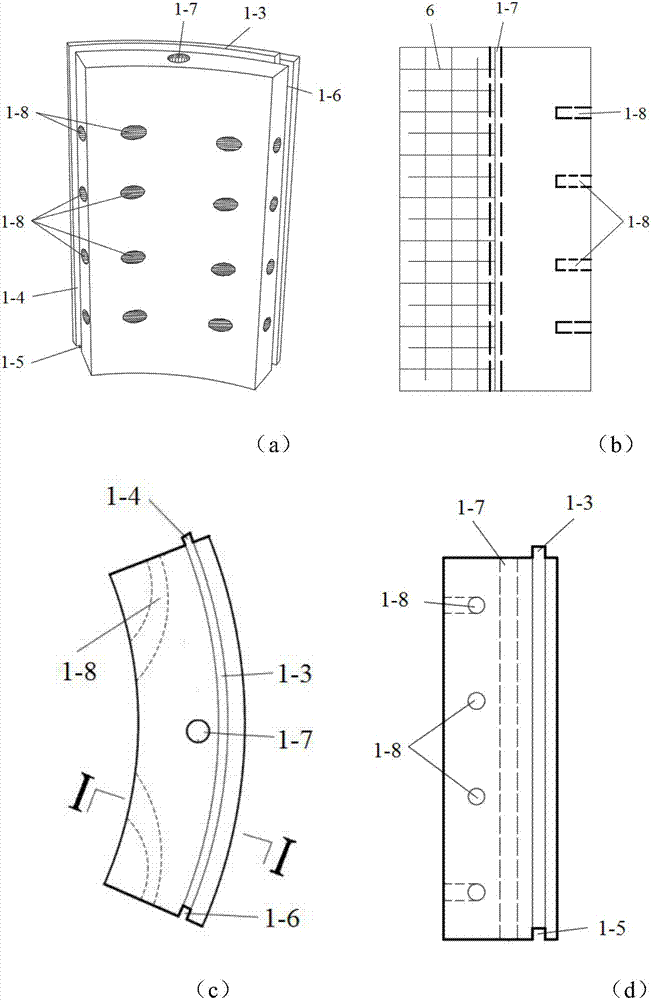

Super-large-diameter assembled hollow pile and assembling method thereof

ActiveCN107964948AIncrease flexibilityReduce tensionBulkheads/pilesArchitectural engineeringStructural engineering

The invention discloses a super-large-diameter assembled hollow pile and an assembling method thereof. The hollow pile comprises a plurality of arc pile pieces, the pile pieces are assembled in the annular direction to form sealed annular assembled pile sections, and the annular assembled pile sections are assembled in the axial direction of the pile sections to form the assembled hollow pile. Assembling seams in the adjacent annular assembled pile sections are staggered. The adjacent pile pieces are connected through cooperation of tenons and grooves and are further connected in an enhanced mode through high-strength bent bolts. The pile pieces are connected in series through prestressed anchor cables in the axial direction, and the pile pieces are also connected in series through prestressed anchor cables in the annular direction. The super-large-diameter assembled hollow pile is formed by assembling the pile pieces which can be prefabricated in a factory and are connected and assembled through the prestressed anchor cables on a construction site to form the whole pile body, and compared with traditional prefabricated pile sections which are laid down overall and cast is place informed holes, storage and transportation are convenient. Moreover, each pile piece can be prefabricated to have different heights and widths according to the pile diameters, so that flexibility is high.

Owner:CHANGAN UNIV

Anti-loosening alarm device for vibrating screen

The invention relates to an anti-loosening alarm device for screen cloth of a vibrating screen. The anti-loosening alarm device comprises a screen cloth fixing and supporting frame, a screen cloth tensioning device and a screen cloth compressing spring, wherein a micro-measuring sensor is arranged between the screen cloth fixing and supporting frame and the screen cloth tensioning device, and a detection alarm circuit is connected to the signal output of the micro-measuring sensor. Compared with the prior art, the anti-loosening alarm device can be used for monitoring the pull force looseningsituation of the screen cloth of the vibrating screen or the warp breakage situation of the screen cloth in real time by utilizing the micro-measuring sensor, outputting an alarm signal by virtue of the detection alarm circuit in real time, accurately judging whether the screen cloth of the vibrating screen is loosened or the warps of the screen cloth are broken under the condition of not openinga shell of the vibrating shell to inspect the screen cloth, and reminding an operator of increasing the tension force of the screen cloth in time, thereby prolonging the service life of the screen cloth and reducing the mixed screening rate by replacing the screen cloth in time.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

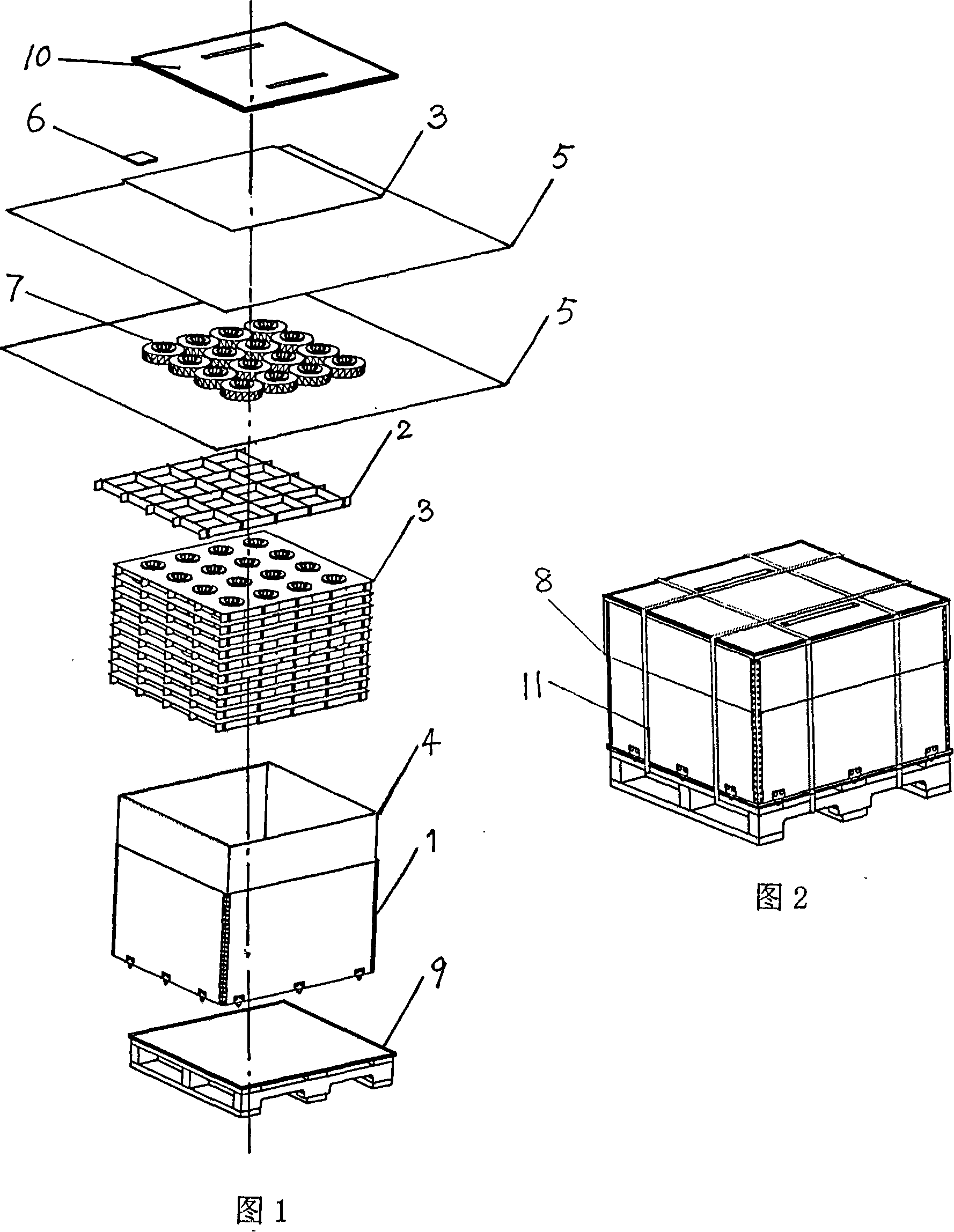

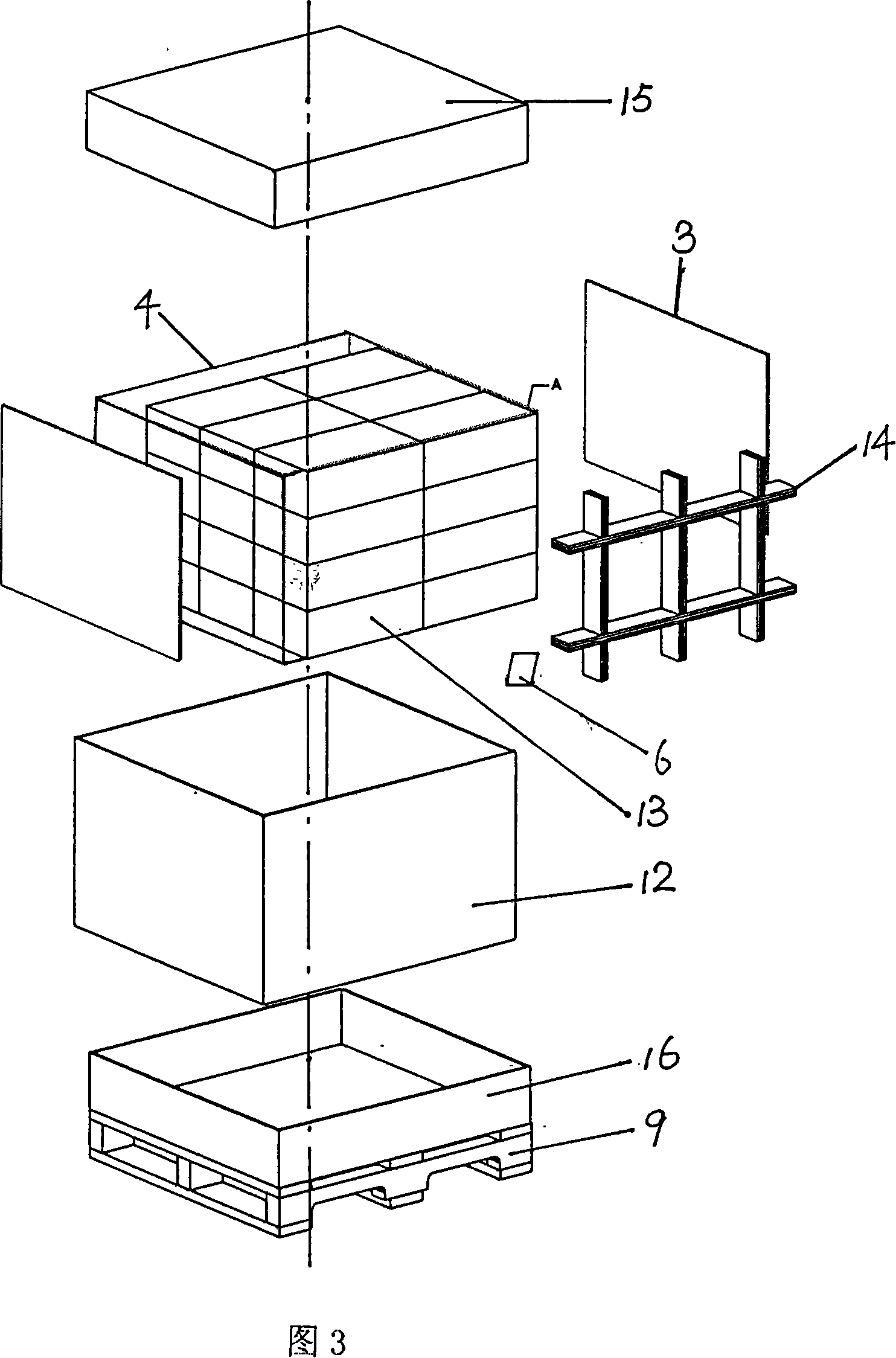

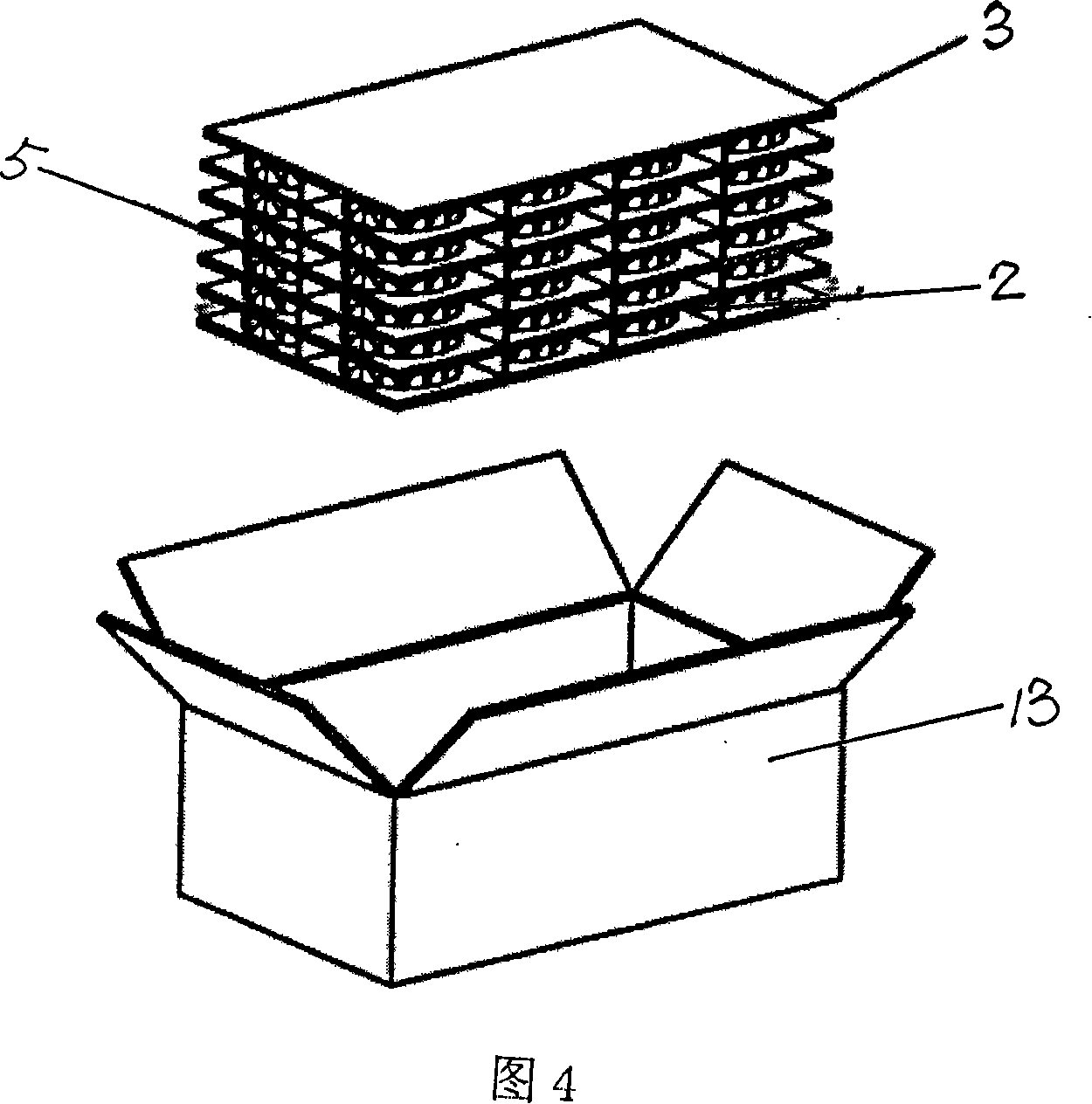

Rust prevention packaging method of metallic product

InactiveCN101108679AAvoid contactPrevent rust and corrosionRigid containersContainers with multiple articlesGas phaseEngineering

The invention belongs to the technology field of the metal product package, in particular to an anti-rust package method of the metal product. The invention solves the problems of poor anti-rust effect or high package cost existing in the anti-rust package of the current metal product. The procedure of the anti-rust package method of the metal product is as follows: an outer package is arranged with gas phase anti-rust bags inside, corrugated boards are rolled out; corrugated paper is added in to separate; gas phase anti-rust films are added; the metal product is filled; the gas phase anti-rust films are covered; the corrugated boards and dryers are added; gas phase anti-rust bags are arranged; the outer package is closed and is externally covered with PE rainproof films and PET is bound. The invention has the beneficial effects of oil-saving, environmental protection, anti rust, firm structure, simple technic, long anti-rust period and high reliability.

Owner:SHANXI DATONG GEAR GROUP

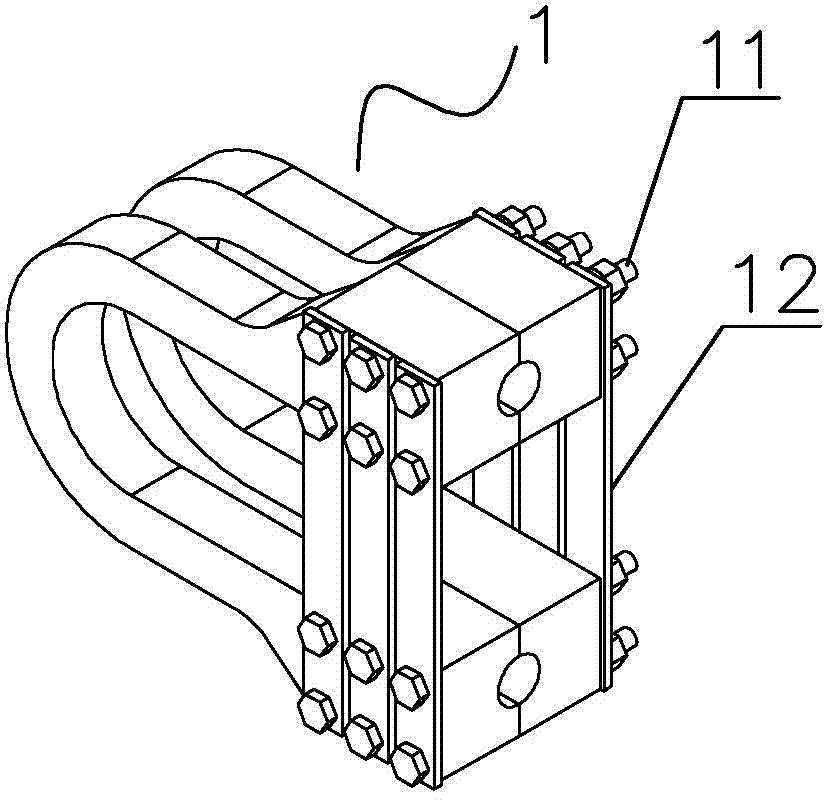

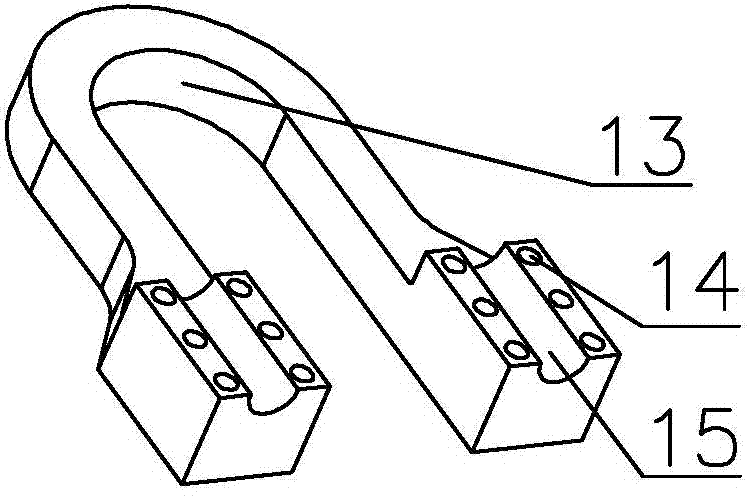

Device assembly for tensioning fork ear type stay rope or steel pull rod and tensioning construction method of device assembly

ActiveCN104847122ASimple designCompact structureBuilding material handlingClassical mechanicsStructural engineering

The invention provides a device assembly for tensioning a fork ear type stay rope or a steel pull rod. The device assembly comprises a counter-force rack, a tensioning rod, a carrying pole beam and a jack; the counter-force rack is of a similar U-shaped structure and divided into two pieces; the opening of the U-shaped structure is designed into a step shape, and a bolt holes and a tensioning rod semicircular groove I to allow the tensioning rod to pass through are formed in the step; the carrying pole beam is of a split two-half structure, and the stay rope or the steel pull rod is capable of passing through the middle of the split two-half structure, and tensioning rod semicircular grooves II for mounting the tensioning rod are formed on the two sides of the split two-half structure; when the device assembly is applied to tensioning construction, the two pieces of the counter-force rack are mounted on the two sides of the fork ear of the fork ear type stay rope or the steel pull rod and are integrated by use of a bolt and a connecting plate; the two-half carrying pole beam is mounted on the extension cylinder end of the fork ear type stay rope or the steel pull rod and fixed by use of a bolt; the tensioning rod is put through the carrying pole beam and the counter-force rack, and anchored by use of a fixing nut at one end of the counter-force rack; the jack and a base plate are mounted on the other end of the tensioning rod and the other end of the tensioning rod is anchored by use of a tensioning nut; the device assembly is good in safety and high in universality in tensioning construction.

Owner:LIUZHOU OVM ENG

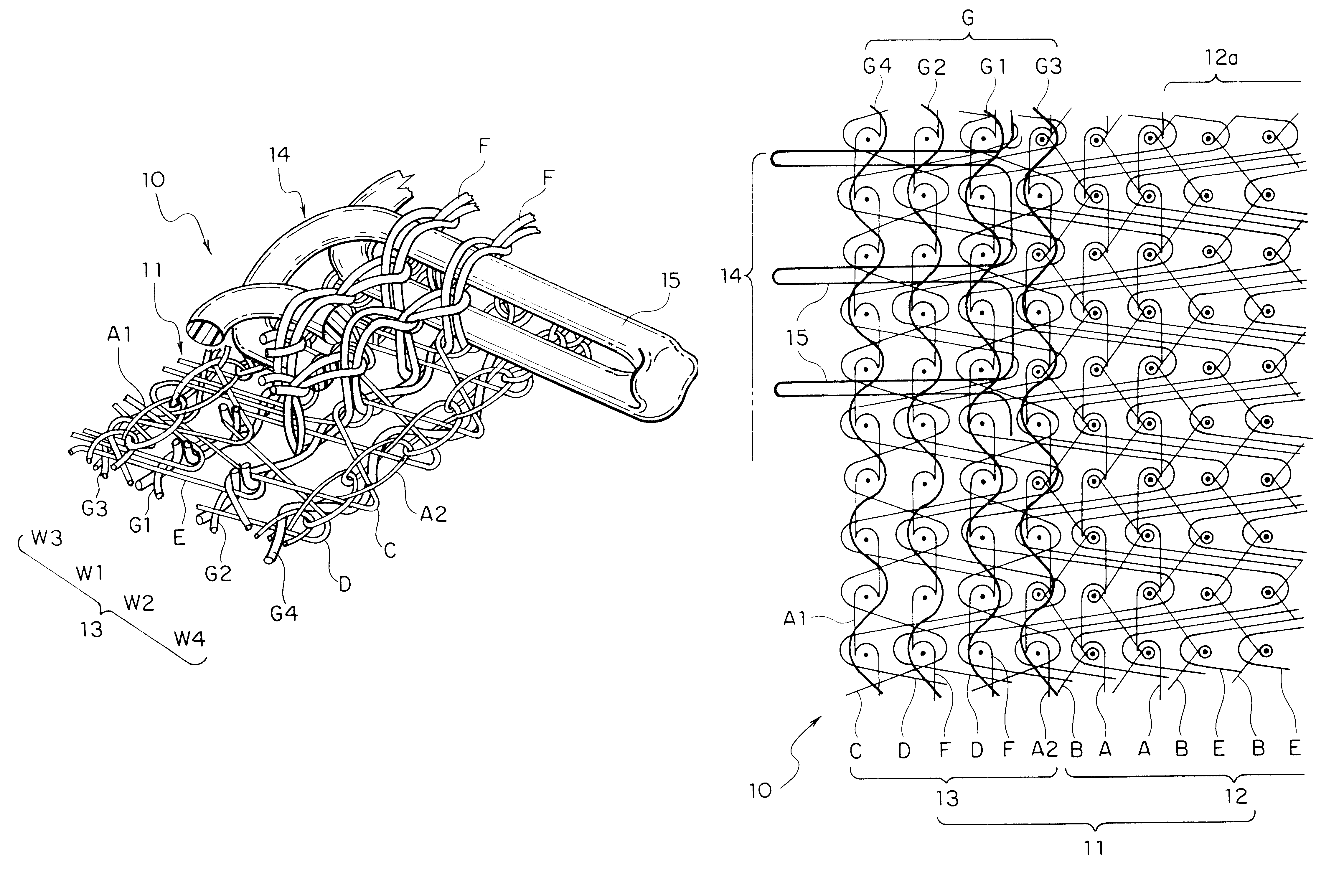

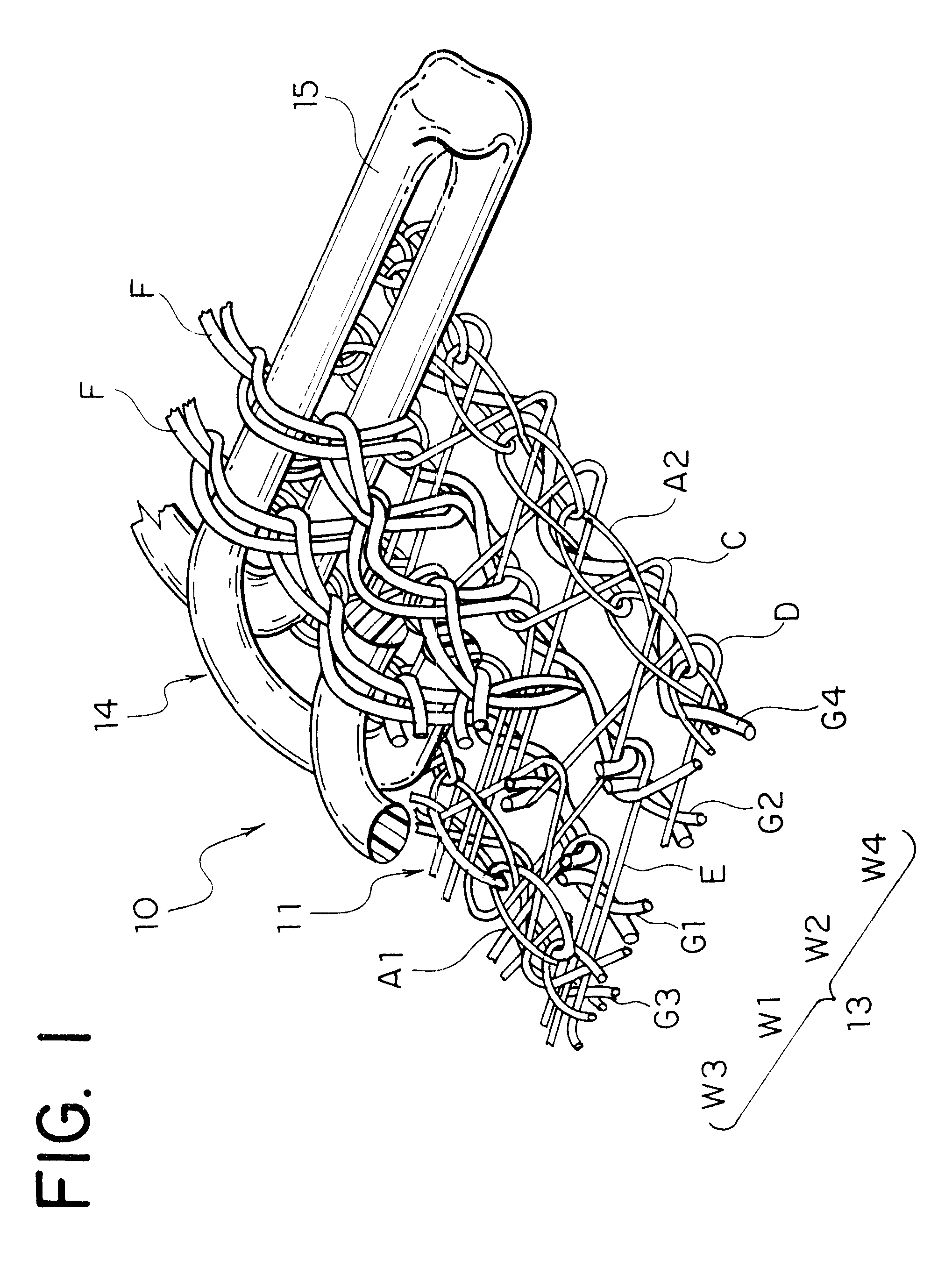

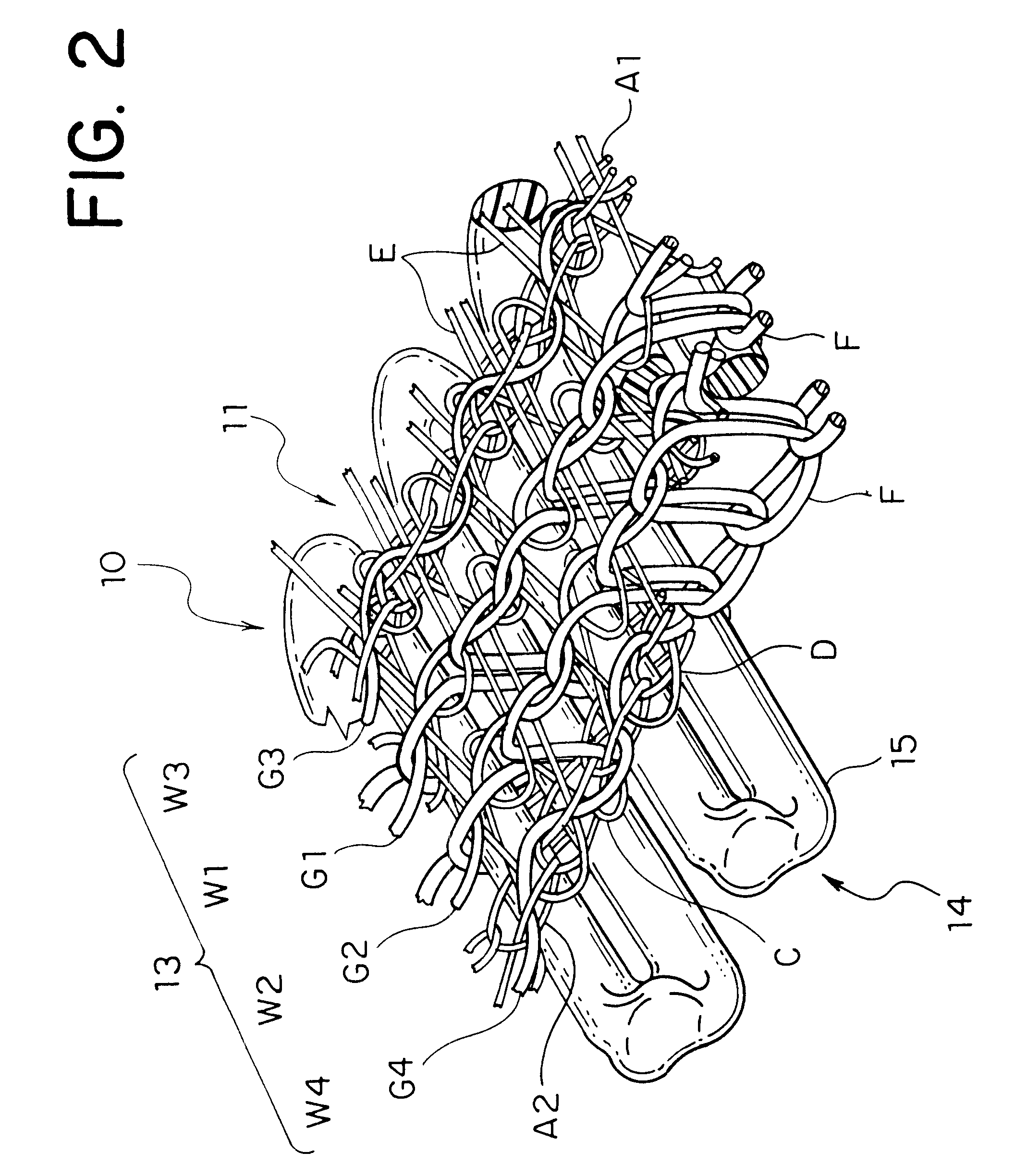

Knit-in slide fastener

There is provided a knit-in slide fastener in which a continuous fastener element row is knitted simultaneously with the knitting of a warp knitted fastener tape at a fastener element mounting portion on a longitudinal side edge portion of the fastener tape. Since a yarn composed of ordinary long fibers, or a textured yarn is employed as a fixing knitting yarn for the fastener element mounting portion, even if a sewing needle is pierced into the textured yarn, the fixing knitting yarn is never cut off because the sewing needle passes through a number of fibers which compose the textured yarn. Further, even when part of the fibers are cut off, no fraying occurs in the yarns, so that the fastener element row at the cut off portions does not separate from the fastener tape.

Owner:YKK CORP

Chinese medicine for curing neck protrusion of lumbar vertebral disc

ActiveCN101249187APromote blood circulationSmooth bloodSkeletal disorderMammal material medical ingredientsButtocksMyrrh

The invention discloses a traditional Chinese medicine for treating lumber or cervical intervertebral disc herniation, which is invented for solving the poor effect problem, etc., in the prior art. The traditional Chinese medicine comprises the raw ingredients as follows: panax notoginseng is 6g, eucommia bark is 6g, frankincense (through broiling) is 6g, myrrh (through broiling) is 6g, pangolin (through preparing) is 6g, Rhizoma Homalomenae is 6g, rhizoma drynariae is 6g, blood of dragon is 6g, trogopterus dung is 6g, bitter orange (through stir-frying) is 6g, Japanese teasel is 6g, safflower is 6g, and musk is 0.5 to 1g. The traditional Chinese medicine has very strong effect for activating the hemopoietic function of bone marrow at the fracture site, promotes the blood circulation of waist and buttocks to strengthen the tensility, and ensures that the frequency of blood exchange is accelerated, and the organism can generate benign reaction. The excrescence is expanded and softened to facilitate the excrescence to be absorbed gradually, so as to lead the blood circulation of nerve and other soft tissues to become unimpeded and lead the bone callus at the fracture site to grow and recover rapidly, so that the healing time is shortened, and the infection is avoided.

Owner:李秋

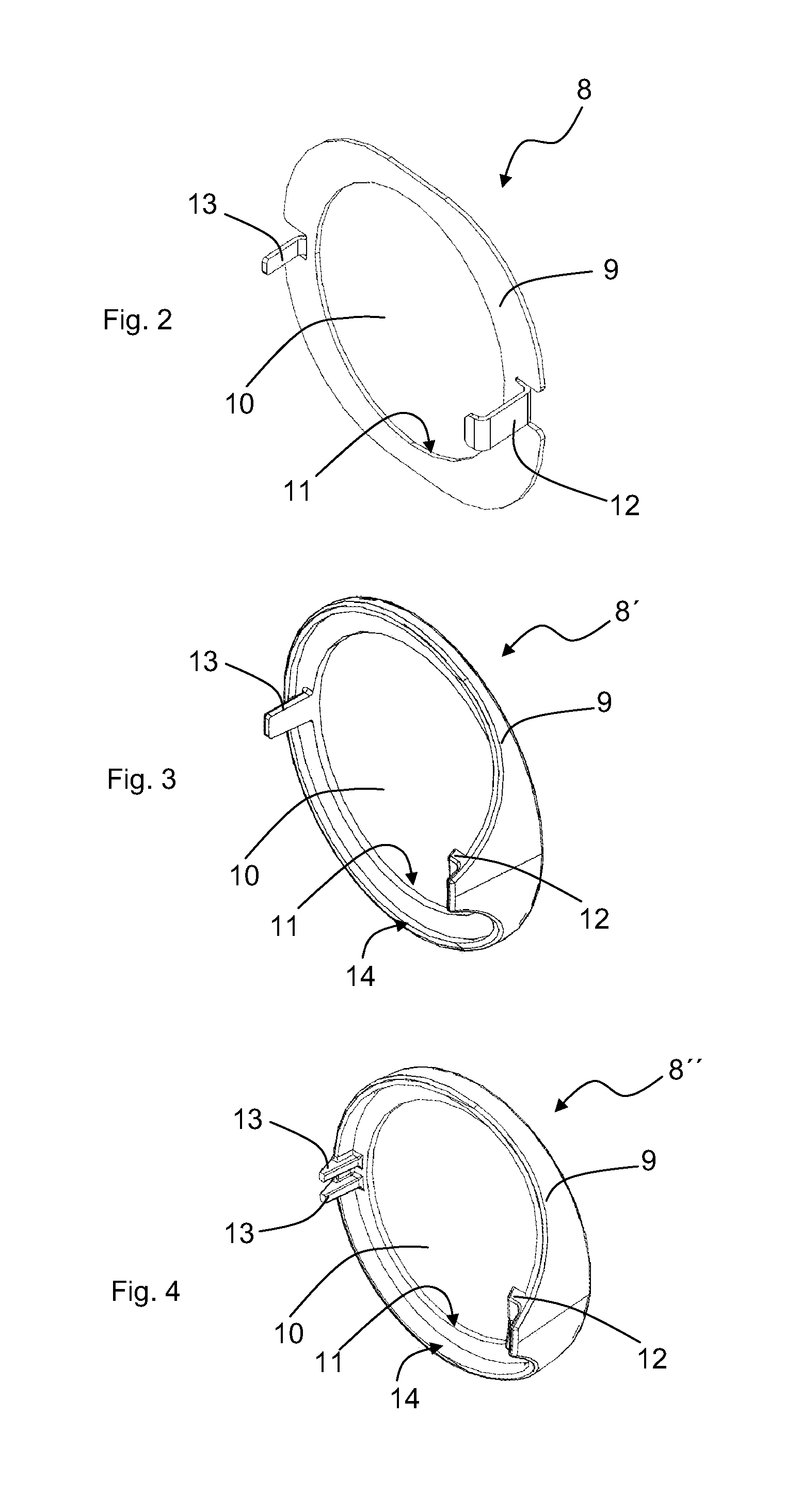

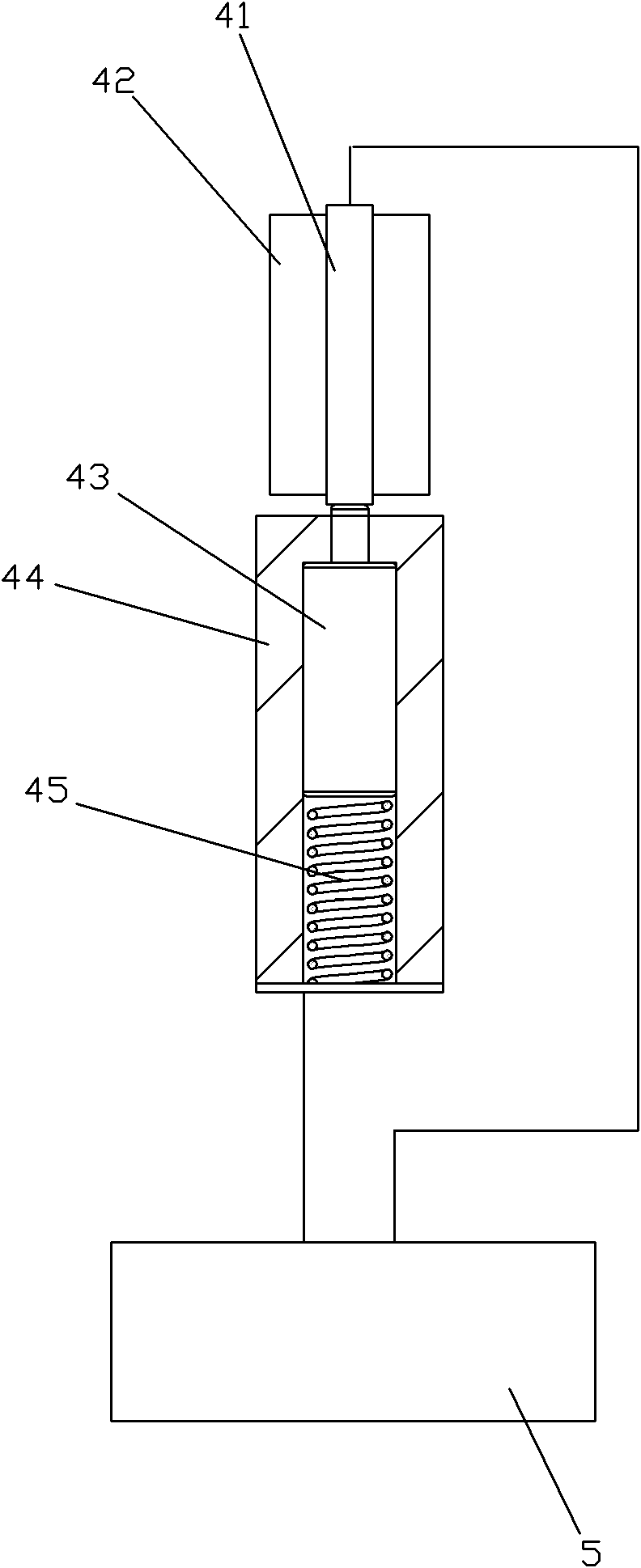

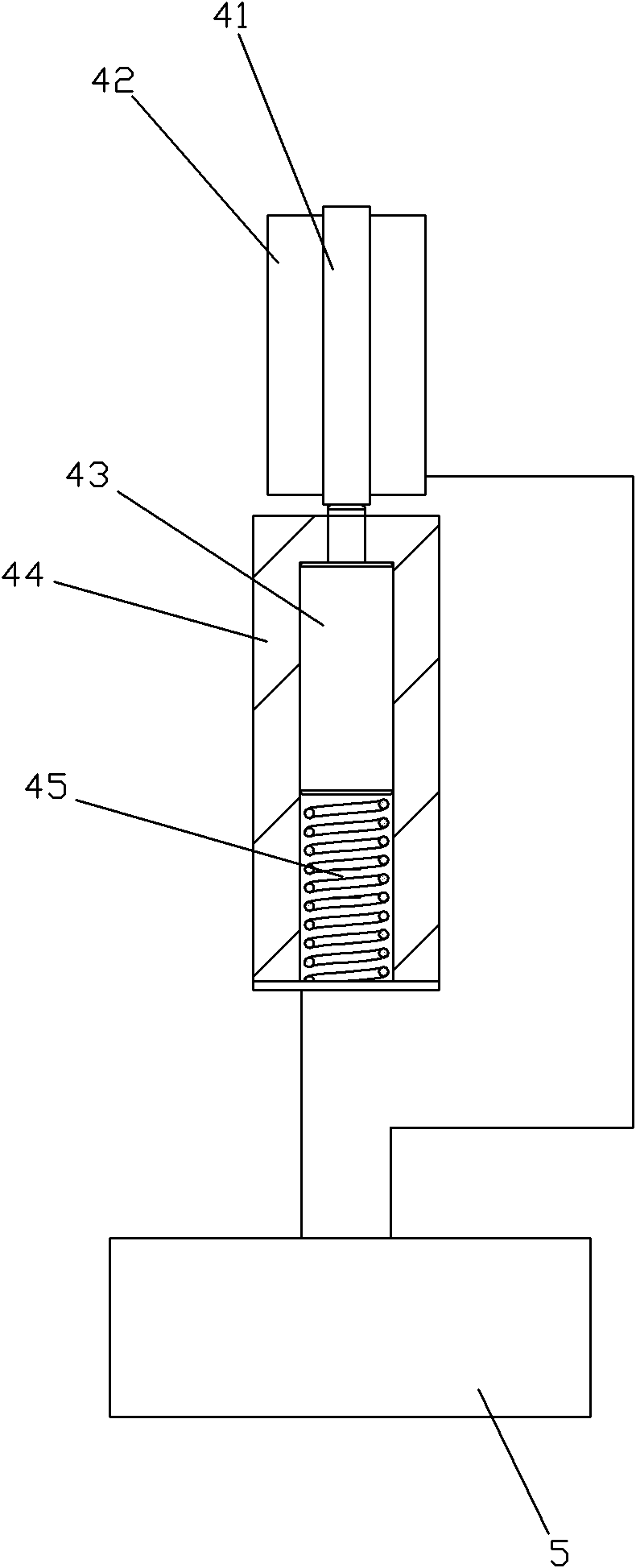

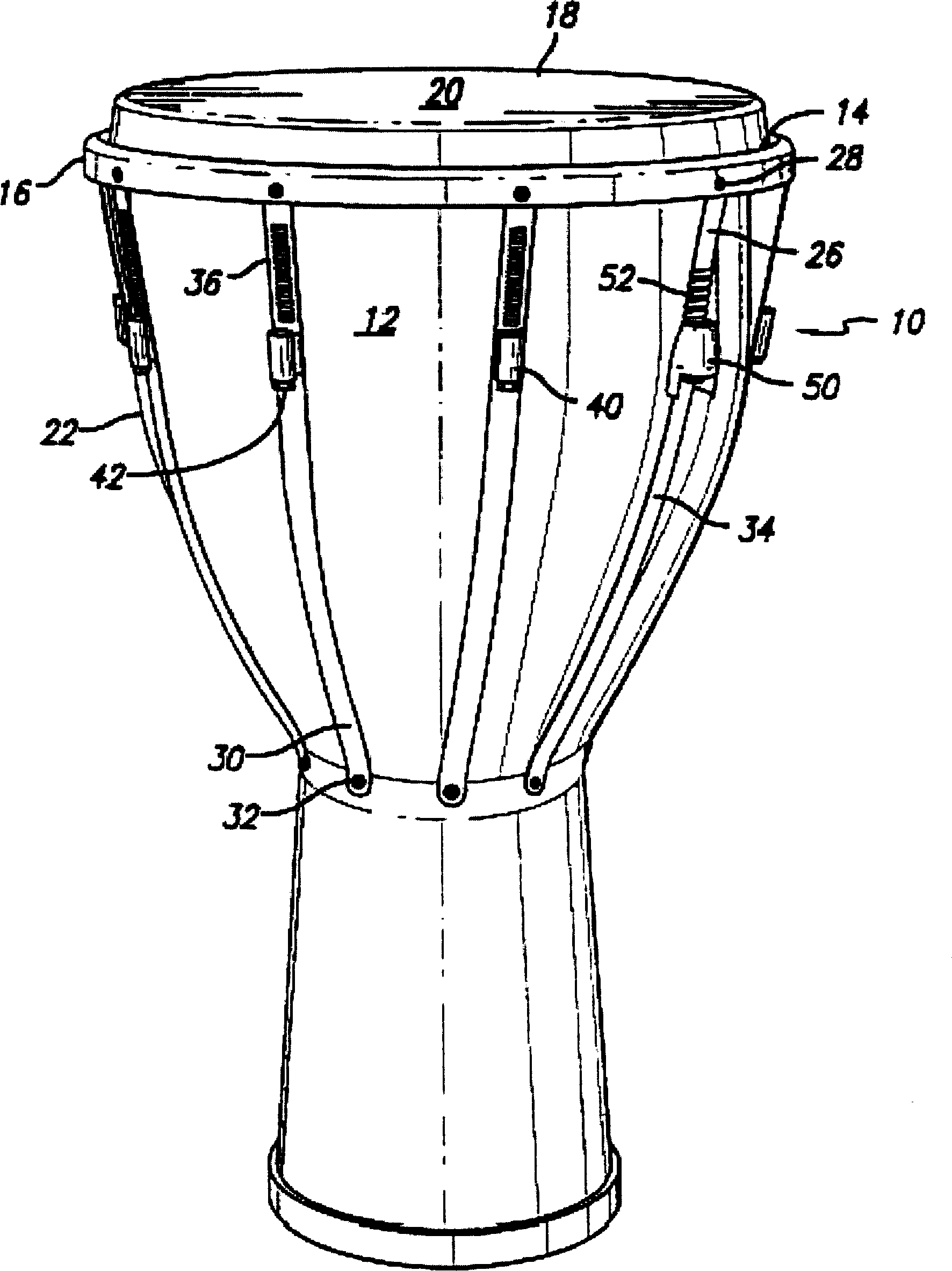

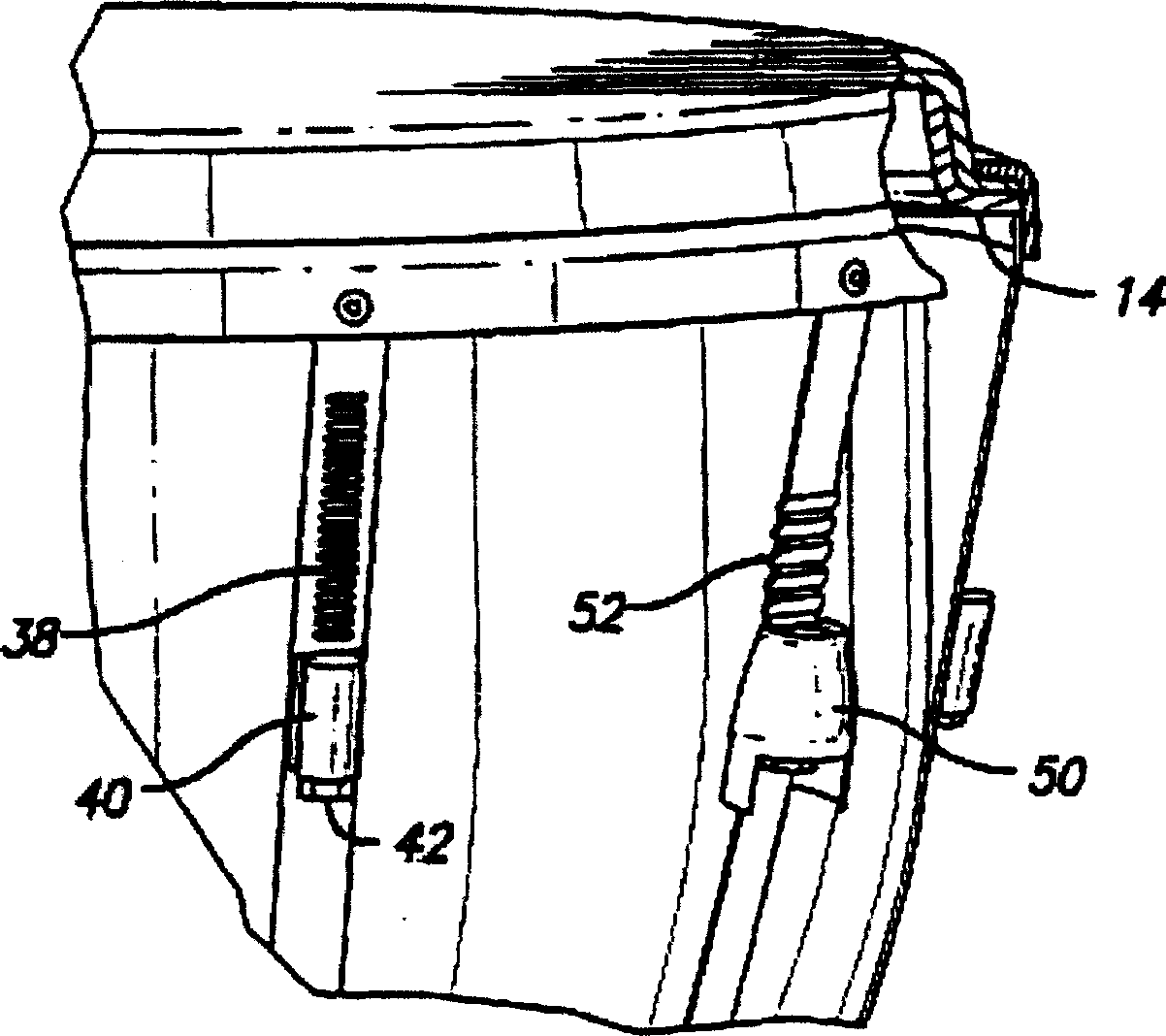

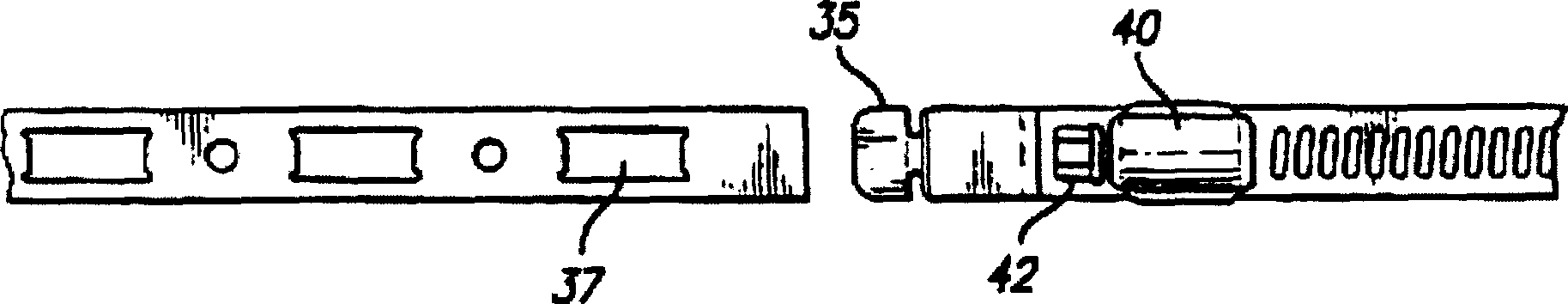

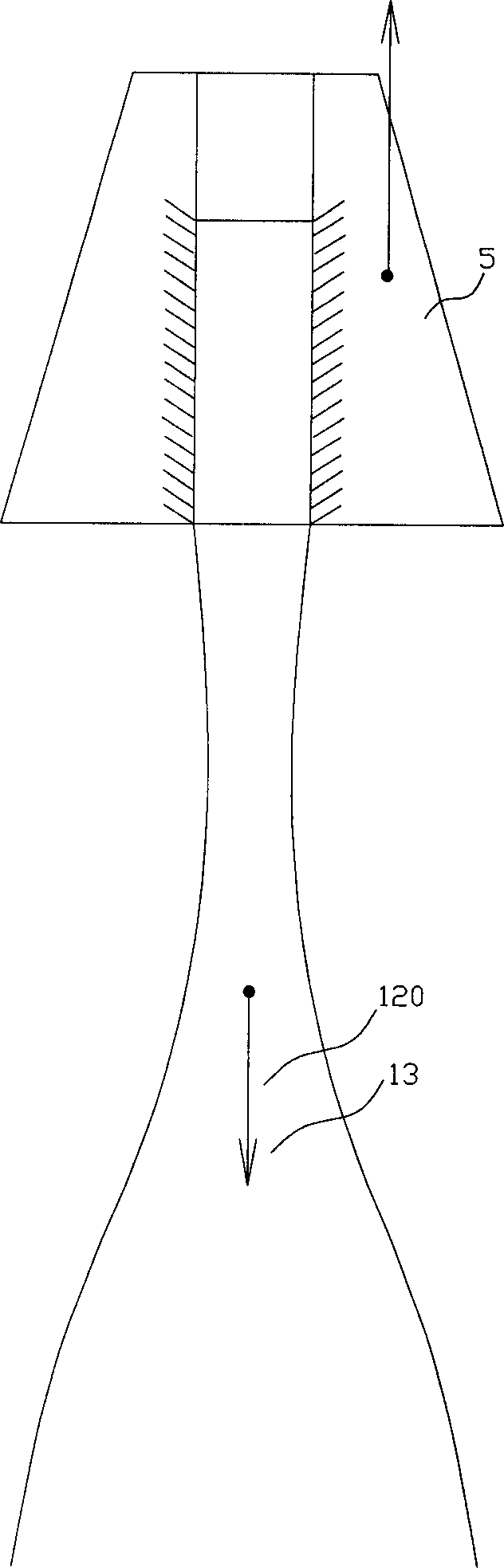

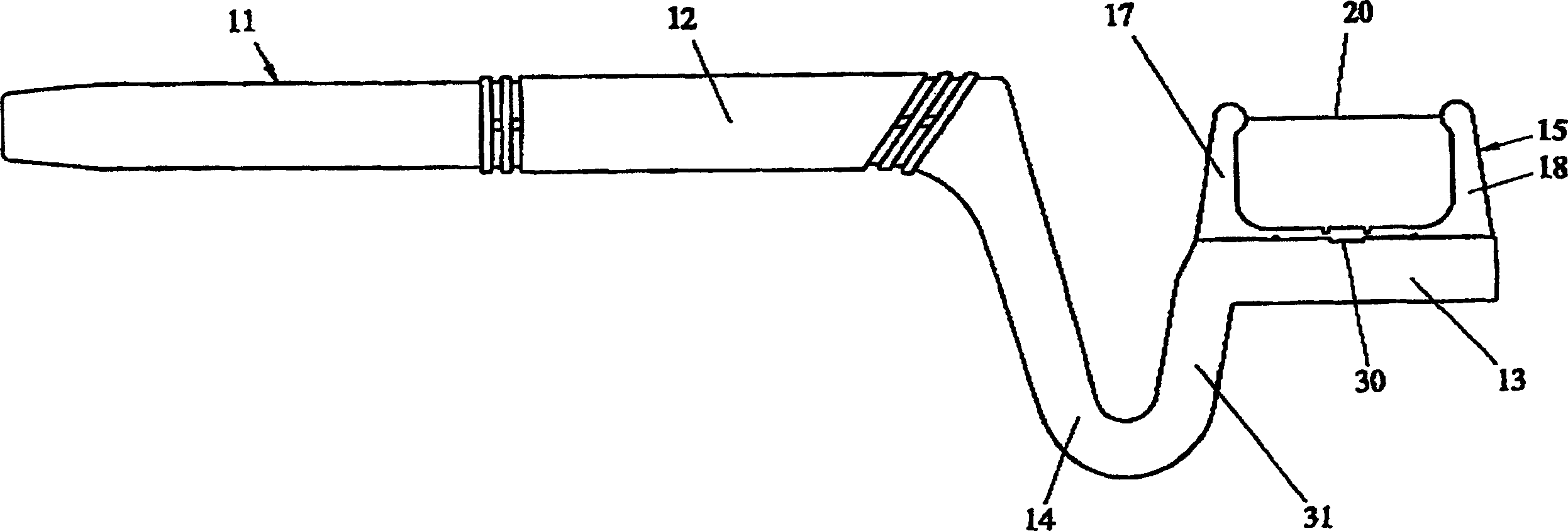

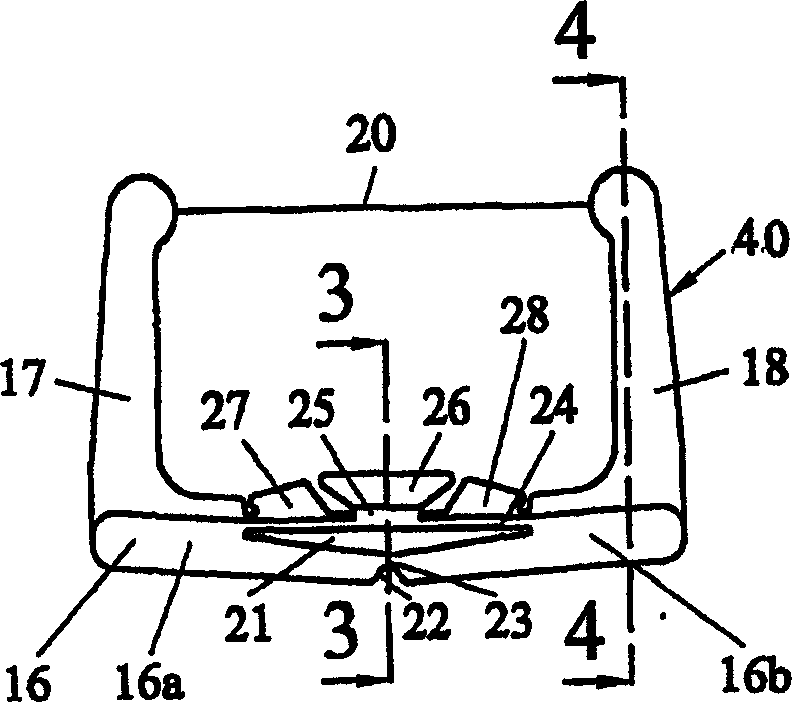

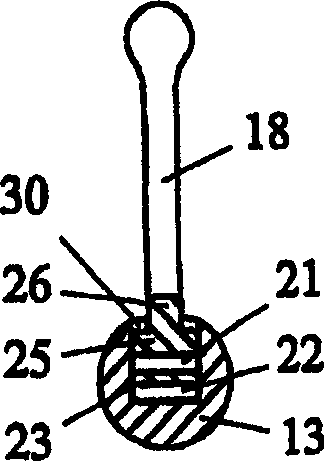

Drum tension adjusting device

In combination with a drum, which includes a drumshell, a flesh hoop, a counter-hoop and a drumhead with a drumming surface, a device for tensioning a drumhead that eliminates protruding and awkwardly designed components and protects against the associated physical discomfort to the musician which interferes with the enjoyment of playing the instrument and the musician's playing technique. The tensioning device includes a conventional mechanical worm-drive mechanism for applying a tensioning force substantially perpendicular to the drumming surface toward the flesh hoop to the counter-hoop to increase the tension of the drumming surface. One end of the tensioning device is affixed securely to the drumshell and the other end of the device is tightly attached to the counter-hoop. The tensioning device is also comprised of two or more generally flat, ribbon-like bands disposed in a low-profile fashion about the perimeter of the shell. A series of spaced apart parallel slots are disposed along sections of at least one of the bands to engage components in the worm-drive to enable the adjustment of the tension in the drumming surface.

Owner:REMO INC

Dropping pill with seaweed gel and agar as capsule wall material, and its production technology

InactiveCN104337779AExtensibleStrong tensionPill deliveryPharmaceutical non-active ingredientsBiotechnologyFormulary

The invention belongs to the technical field of medicine and health food products research and development, and relates to a formula and a production technology of a dropping pill based on seaweed gel. The technology comprises the following steps: 1, weighing 10.0-30.0wt% of seaweed gel, 3.0-10.0wt% of agar and 2.0-4.0wt% of a plasticizer, putting the above raw materials in 70.0-85.0wt% of deionized water, and maintaining at 85DEG C for 30min to realize seaweed gel and agar dissolving; 2, degassing at 85DEG C under 0.5atm for 10min, adding the obtained degassed solution into a pill dropping machine, and dropping; and 3, curing dropping pills by a composite curing agent, drying, sorting, and packaging to obtain the dropping pill. The dropping pill has the advantages of reasonable formula, safe eating, drug absorption benefiting, wide source and low price of the raw materials, simple production process, and suitableness for industrialized production.

Owner:SHANDONG UNIV

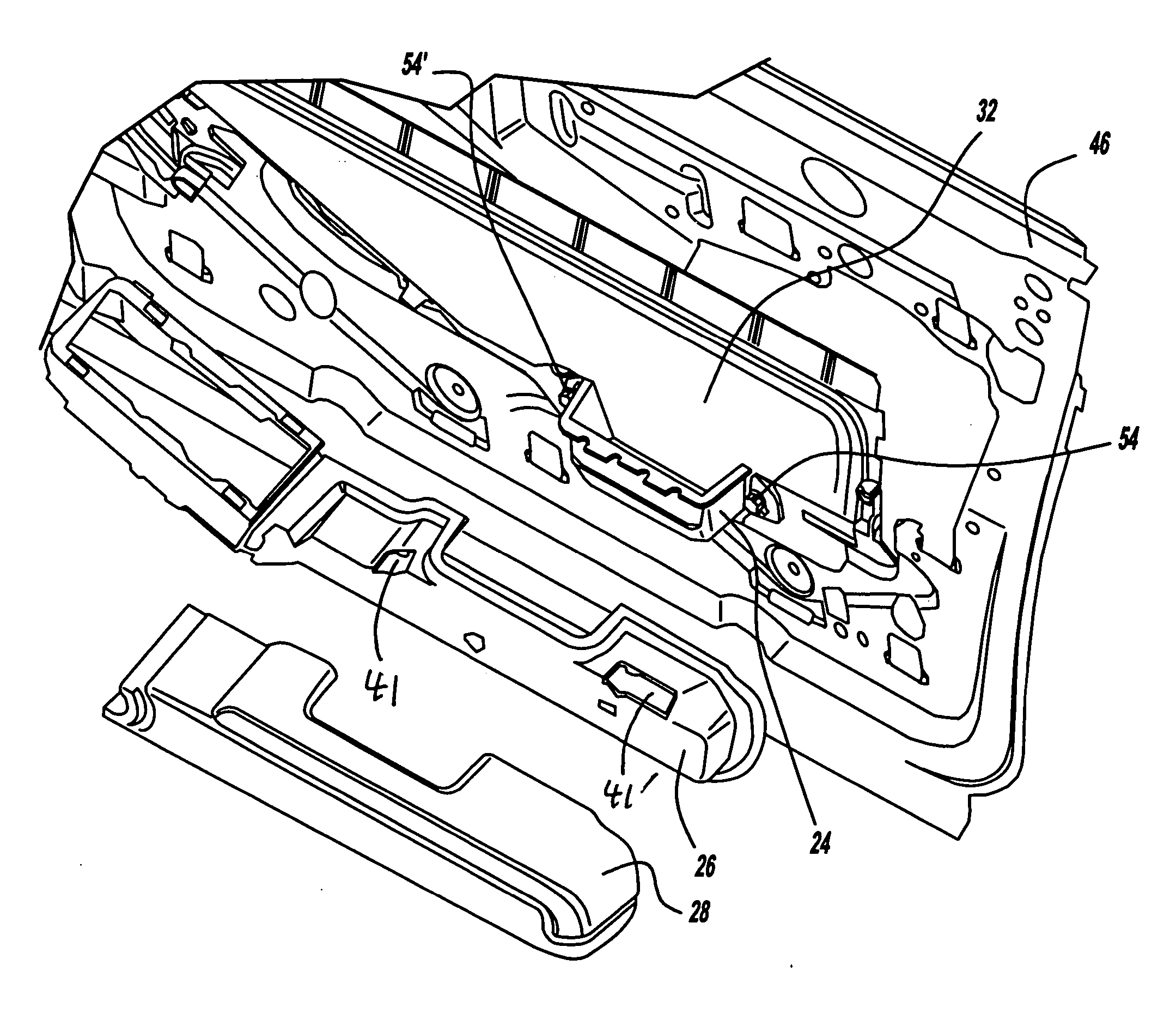

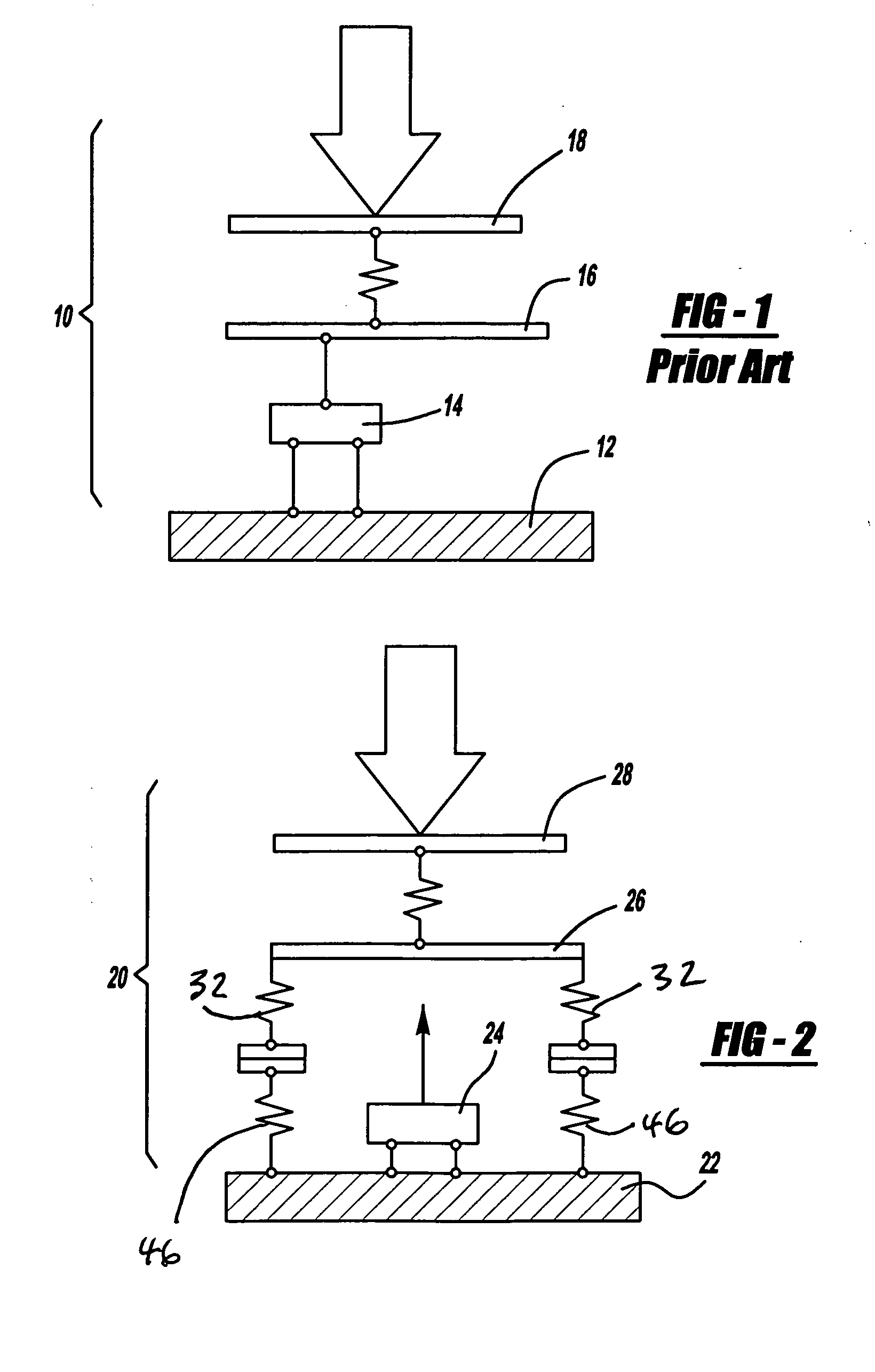

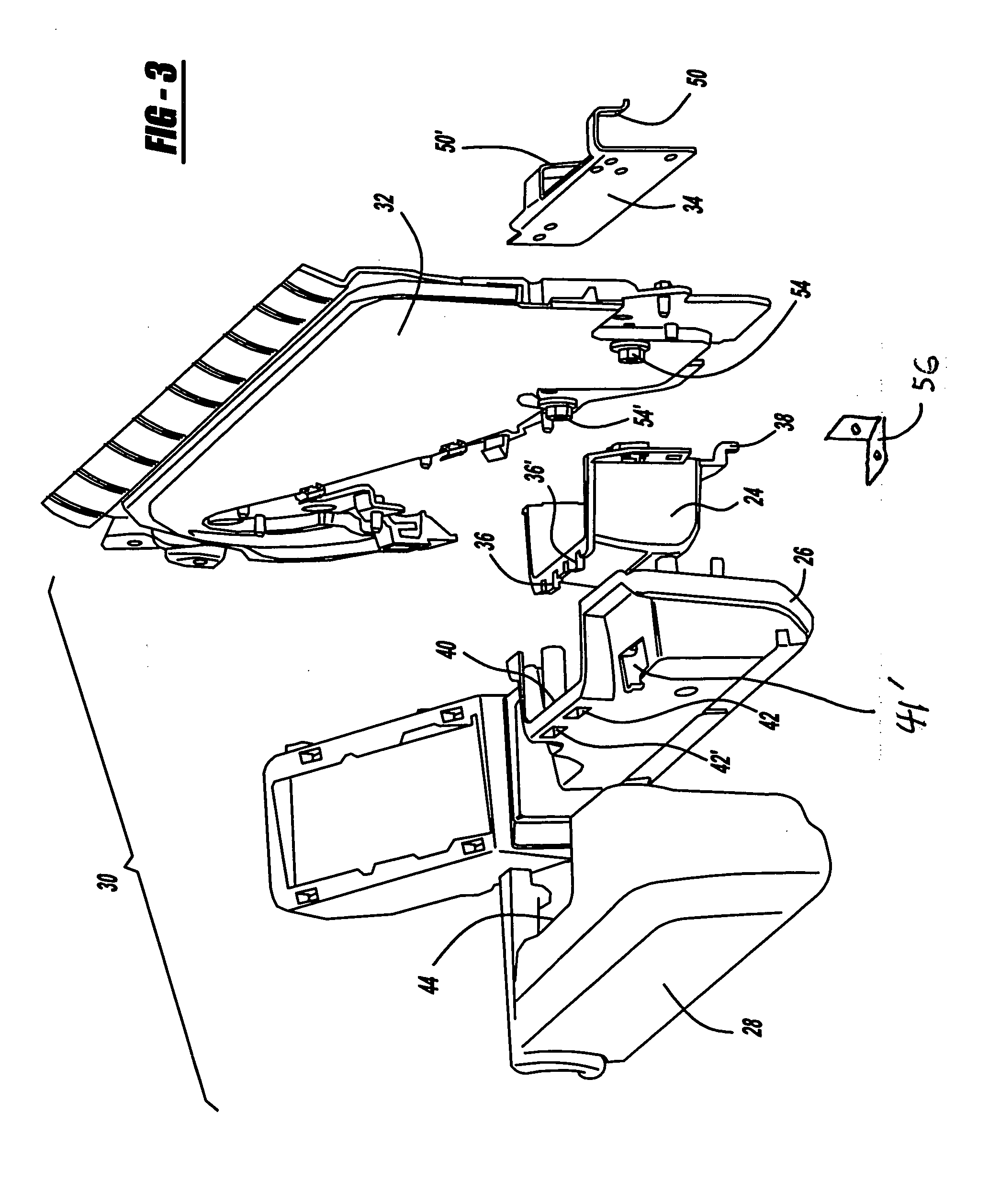

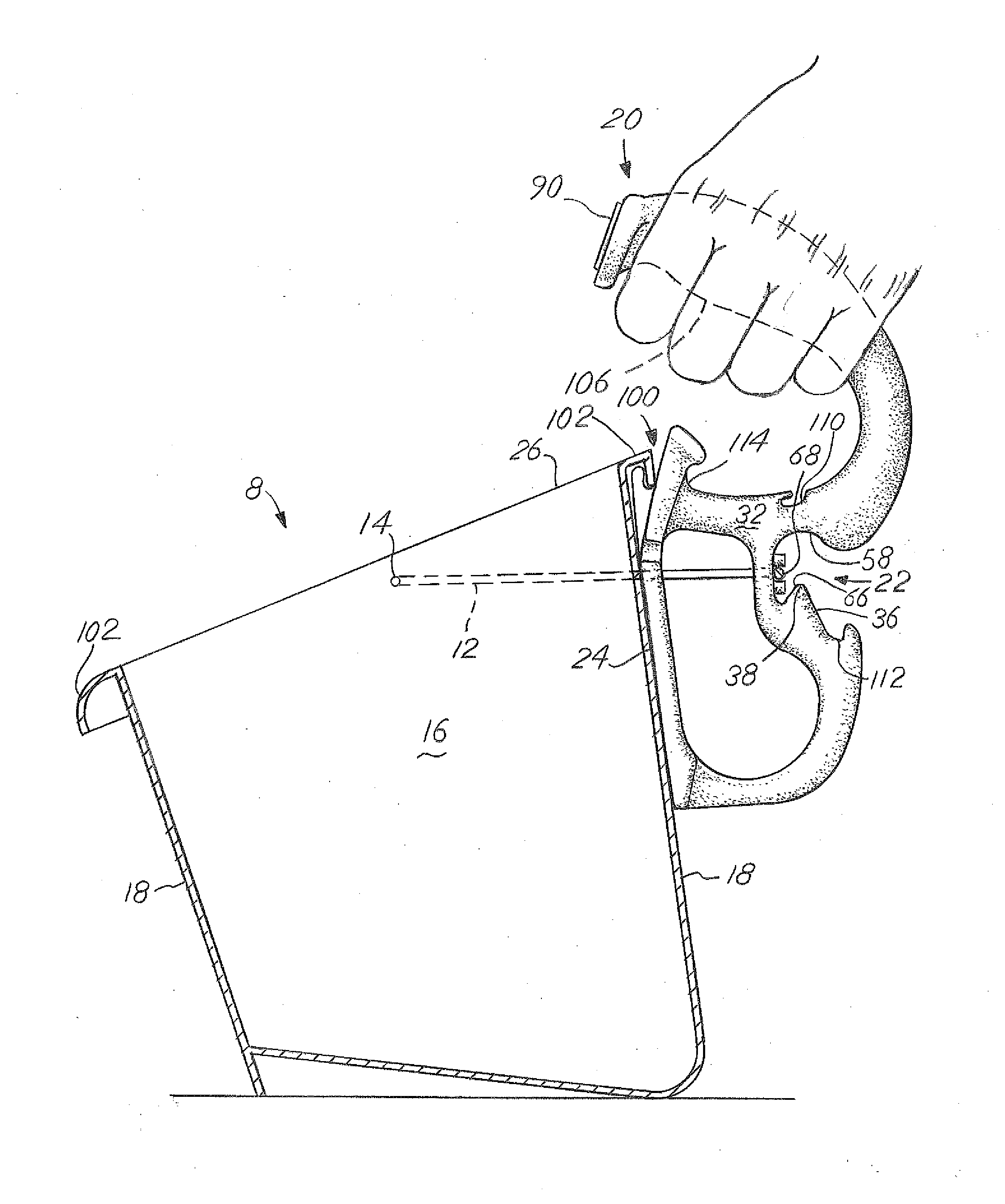

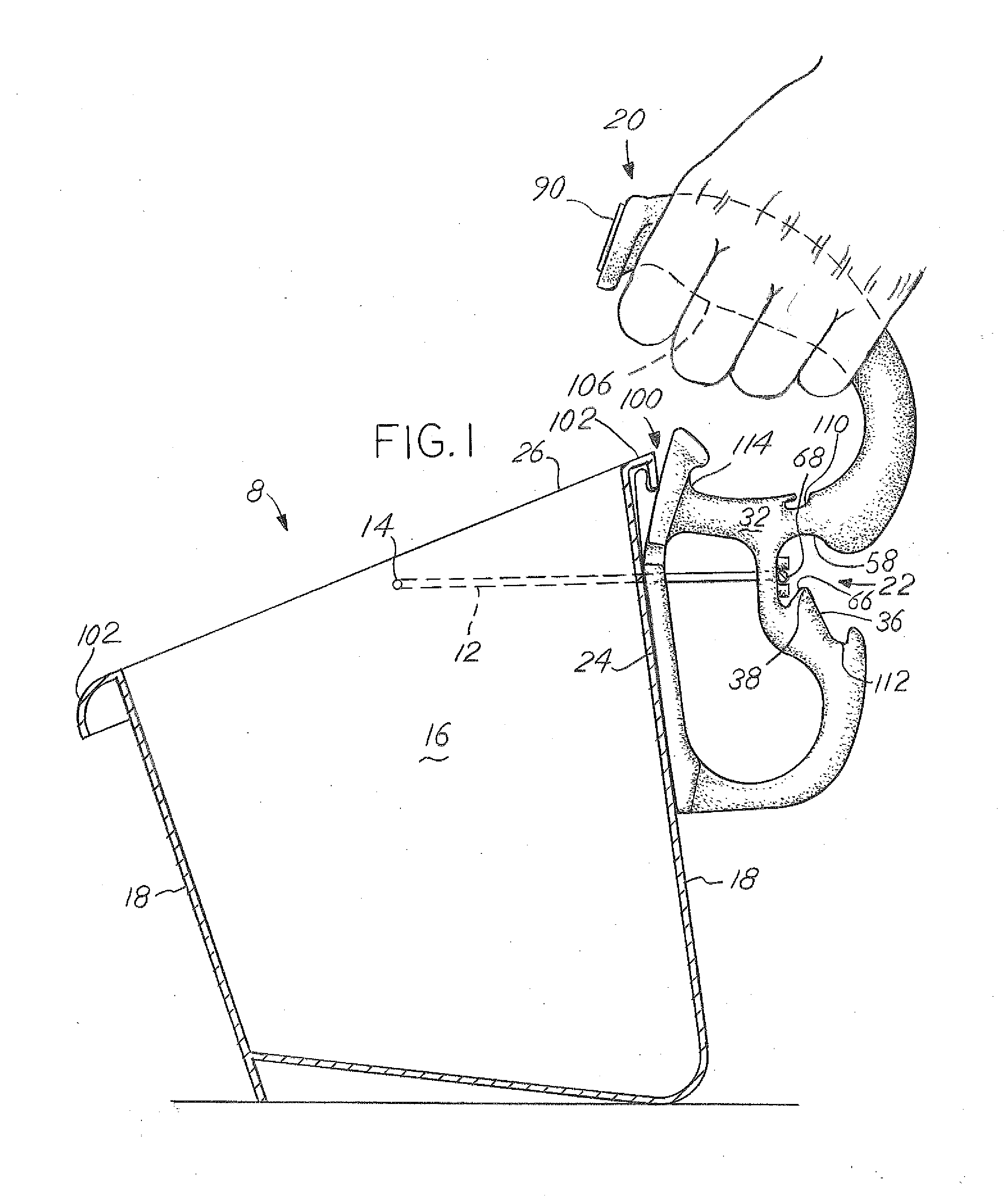

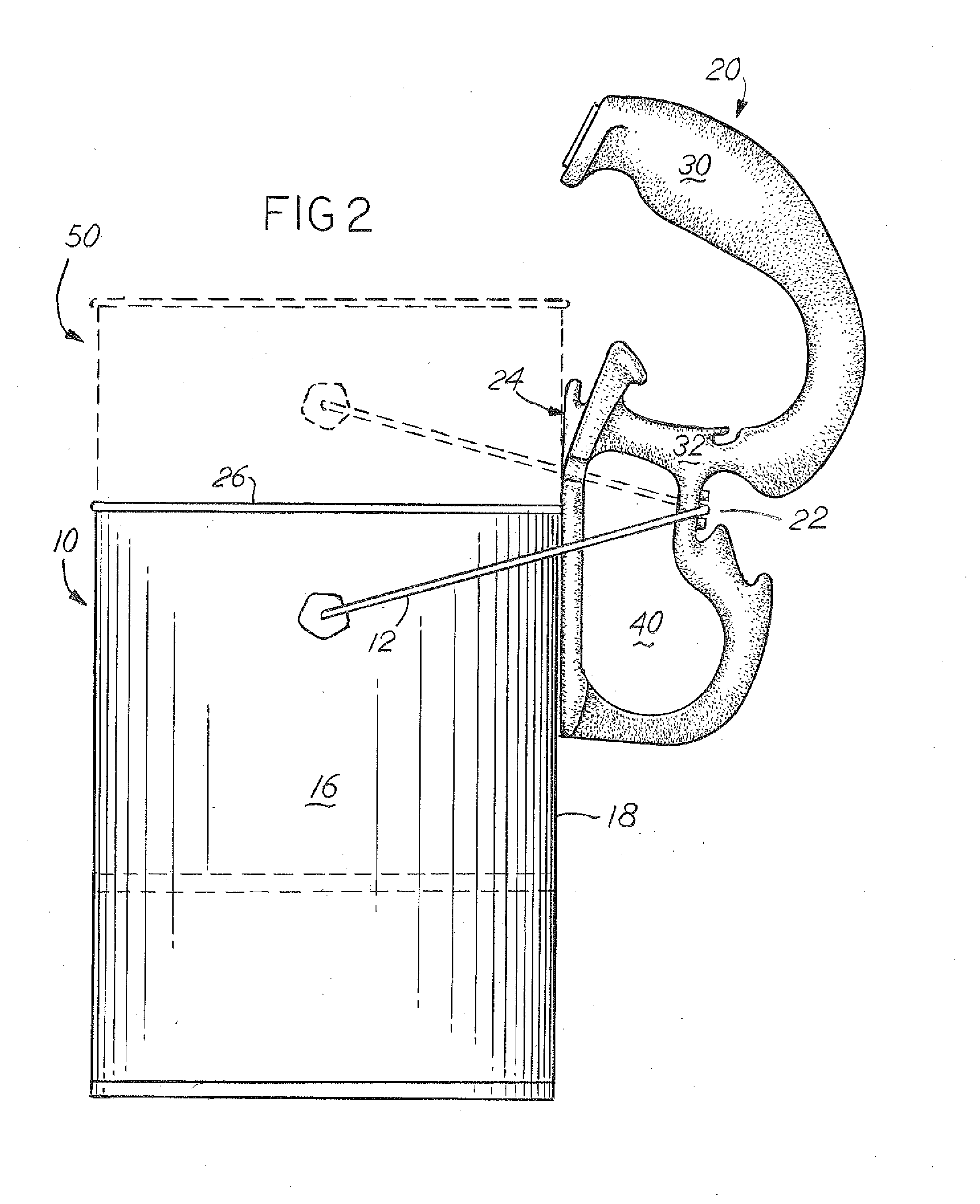

Collapsible armrest system with pull cup

InactiveUS20070246968A1Strong tensionWeak in compressionArm restsDashboardsClassical mechanicsCar door

Owner:FORD GLOBAL TECH LLC

Dropping pill with algal polysaccharide and flaxseed gum as capsule wall material, and its production technology

InactiveCN104338142AExtensibleStrong tensionPharmaceutical non-active ingredientsPill deliveryBiotechnologyFormulary

The invention belongs to the technical field of medicine and health food products research and development, and relates to a formula and a production technology of a dropping pill based on algal polysaccharide. The technology comprises the following steps: 1, weighing 10.0-30.0wt% of algal polysaccharide, 3.0-10.0wt% of flaxseed gum and 2.0-4.0wt% of a plasticizer, putting the above raw materials in 70.0-85.0wt% of deionized water, and maintaining at 85DEG C for 30min to realize algal polysaccharide and flaxseed gum dissolving; 2, degassing at 85DEG C under 0.5atm for 10min, adding the obtained degassed solution into a pill dropping machine, and dropping; and 3, curing dropping pills by a composite curing agent, drying, sorting, and packaging to obtain the dropping pill. The dropping pill has the advantages of reasonable formula, safe eating, drug absorption benefiting, wide source and low price of the raw materials, simple production process, and suitableness for industrialized production.

Owner:SHANDONG UNIV

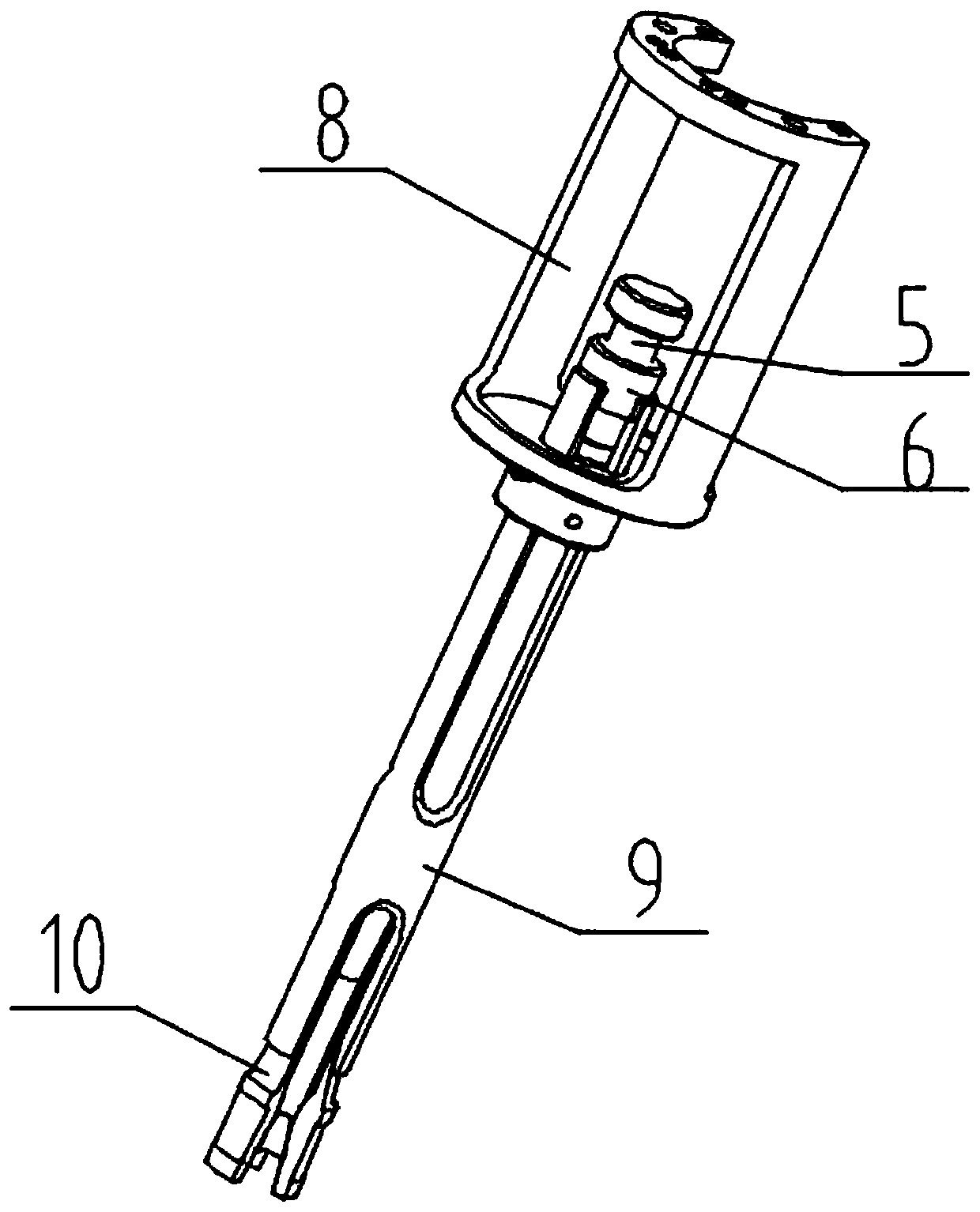

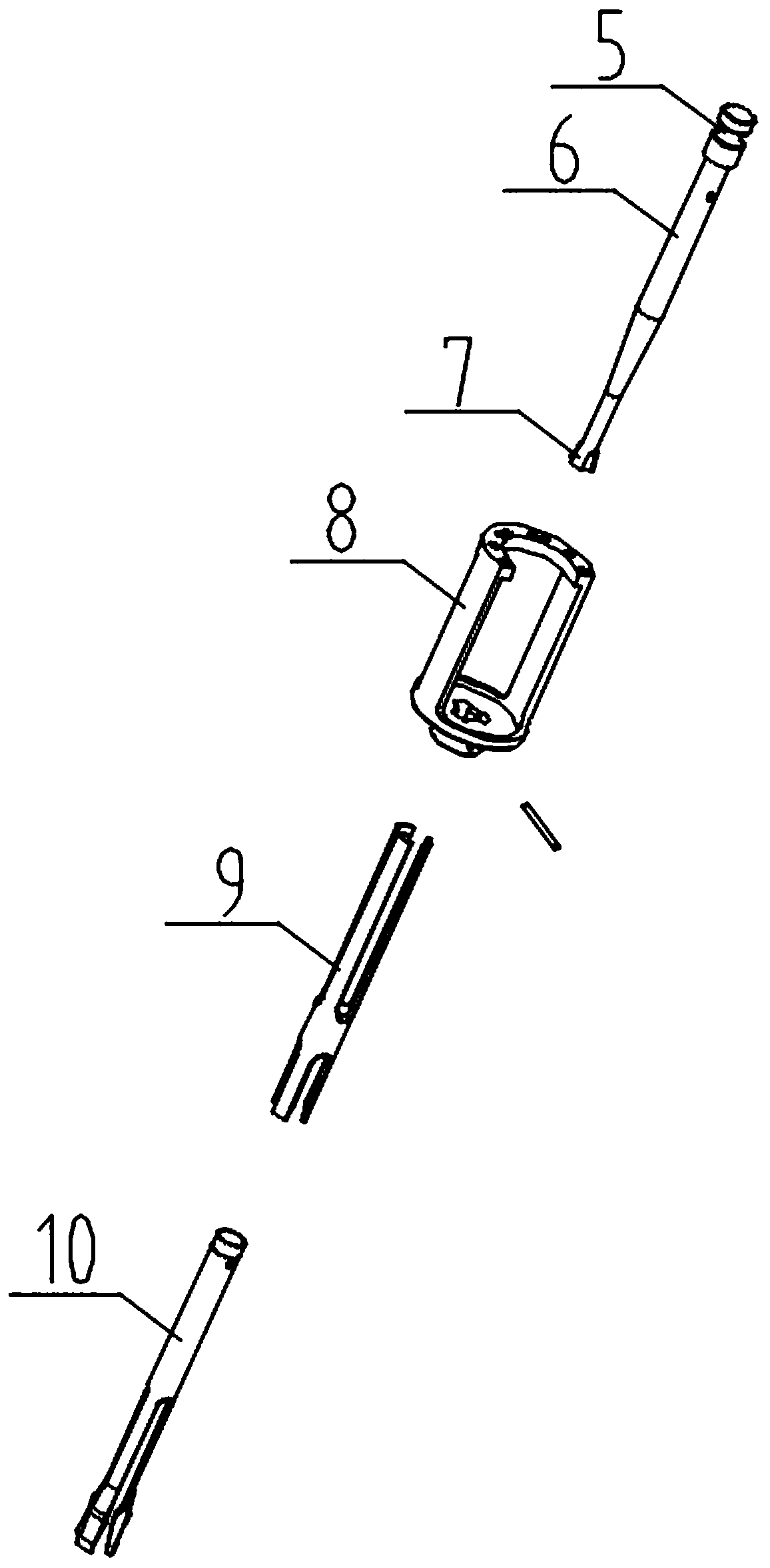

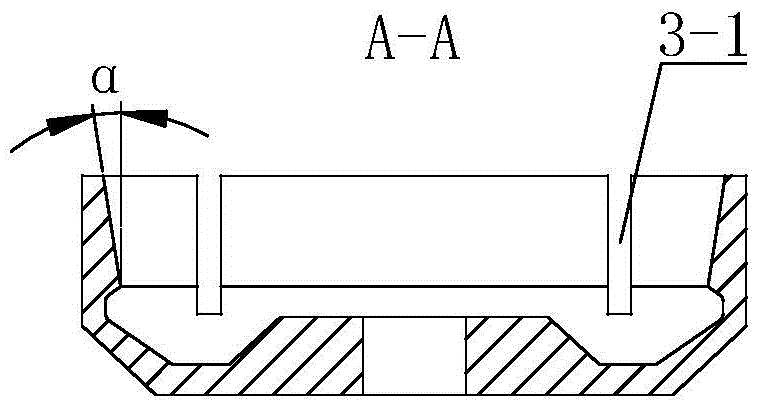

Inner hole expansion grabbing mechanism

PendingCN110103244AImprove rigidityImprove bearing capacityGripping headsCleaning processes and apparatusEngineeringBearing capacity

The invention discloses an inner hole expansion grabbing mechanism, which comprises a pull rod, an expansion sleeve, a tightening sleeve and a power part. The expansion sleeve sleeves the outer side of the pull rod, and the tightening sleeve sleeves the outer side of the expansion sleeve; a hole-series workpiece sleeves the outer side of the expansion sleeve, and the pull rod, the expansion sleeveand the tightening sleeve are coaxially arranged; the pull rod and the expansion sleeve are fixed and can relatively move, the tightening sleeve and the pull rod are fixed, and the power part and thepull rod are connected; and the pull rod moves in the central axis direction of the pull rod, in the vertical moving process of the pull rod, the expansion sleeve expands outwards and contracts inwards, and when contracting inwards, the expansion sleeve is extruded by the tightening sleeve. An inner core coaxial sleeve structure, a middle expansion coaxial sleeve structure and an outer tighteningcoaxial sleeve structure are arranged, the space is small and compact, the mechanism is high in rigidity, high in bearing capacity and high in tightening capacity, particularly through the tighteningsleeve with the outer tightening function, the contraction state and size of the mechanism are stable, and a robot is quickly and accurately inserted into an inner hole of the workpiece advantageously to grab the workpiece.

Owner:四川成焊宝玛焊接装备工程有限公司

Degradable and environmentally-friendly biomass plastic bag

The invention discloses a degradable and environmentally-friendly biomass plastic bag. The plastic bag is made from, by weight, 60-75 parts of LDPE, 15-22 parts of plant starch, 6-8 parts of calcium carbonate, 3-5 parts of butanetriol, 7-12 parts of glass fibers, 7-14 parts of wheat straw powder, 5-8 parts of polylactic acid, 12-13 parts of vinyltrimethoxy silane, 6-9 parts of potassium sorbate, 5-8 parts of biphenyl diphosphite, 3-6 parts of a photosensitizer, 1-3 parts of a bactericide and 6-8 parts of diethyl phthalate. The plastic bag has the advantages of non-toxicity, no pollution, good environmental protection property, strong degradation ability, strong tensile strength, good tension, and no harmful substances after decomposition.

Owner:QINGDAO DAFANG WISDOM NETWORK TECH CO LTD

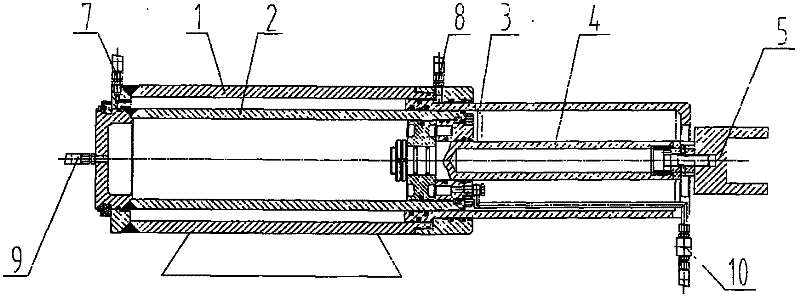

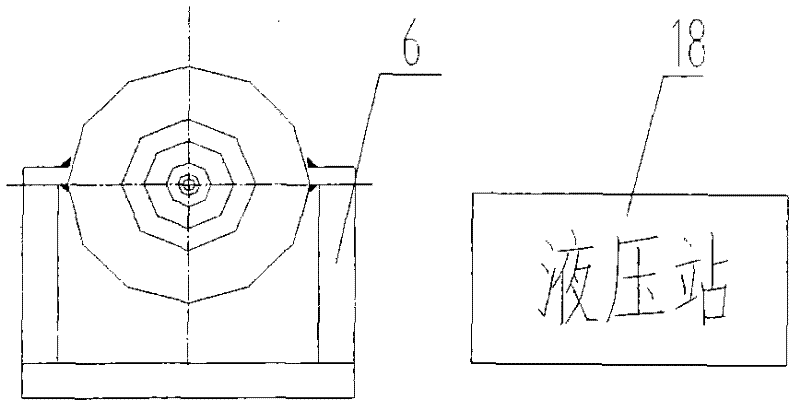

Hydraulic automatic pin pulling device

The invention discloses a hydraulic automatic pin pulling device. The hydraulic automatic pin pulling device comprises a support cylinder body, a pin pulling cylinder body, a support cylinder piston rod, a pin pulling cylinder piston rod and a bolt connector, wherein the pin pulling cylinder body is arranged inside the support cylinder body; the support cylinder body and the pin pulling cylinder body are in concentric nesting assembling; the support cylinder piston rod is of a closed type hollow shaft design; the pin pulling cylinder piston rod is arranged inside the support cylinder piston rod; the support cylinder piston rod and the pin pulling cylinder piston rod are in concentric nesting assembling; the top of the pin pulling cylinder piston rod is provided with the bolt connector which is linked with a pin shaft; the hydraulic automatic pin pulling device is arranged on a bearing support seat; the height of the bearing support seat is adjustable; and the hydraulic automatic pin pulling device is connected with a hydraulic station which is provided with a hydraulic control system. The hydraulic automatic pin pulling device has a reasonable structure and large tensioning force, is convenient to use, and is safe and reliable, thus the troublesome, time-consuming, labor-consuming and unsafe problems when a worker performs hammering by manual work originally are solved.

Owner:LIBO HEAVY MACHINE TECH

Container retaining device

InactiveUS20140265382A1Easy to holdEasy accessTravelling carriersHoldersEngineeringMechanical engineering

A bucket holder is provided with a handle portion for ergonomically carrying and holding a bucket during transportation and use. The body portion is comprised of a surface pressed up against the can, while a hook opposite from the surface holds the bail in tension, using gravity and distance between the surface and the hook to maintain tension. The holder has at least one surface that can be pressed up against the can, allowing more than one position for the handle to be located.

Owner:PIVOTAL PROD

Fastening apparatus and method

InactiveUS20060035041A1Reducing stiffness mismatchReduce pressure riseEnvelopes/bags making machineryNutsComposite plateMechanical engineering

The Invention is a fastening apparatus and method for transferring a load to a core of a composite structure, such as a composite panel used in ship construction. The apparatus comprises an insert. The insert is adapted to receive a tension load and adapted to transfer the tension load substantially to the core of the composite structure. The strain response characteristics of the insert in tension generally minimize the strain response of the core in shear.

Owner:MATERIAL SCIENCES CORPORATION

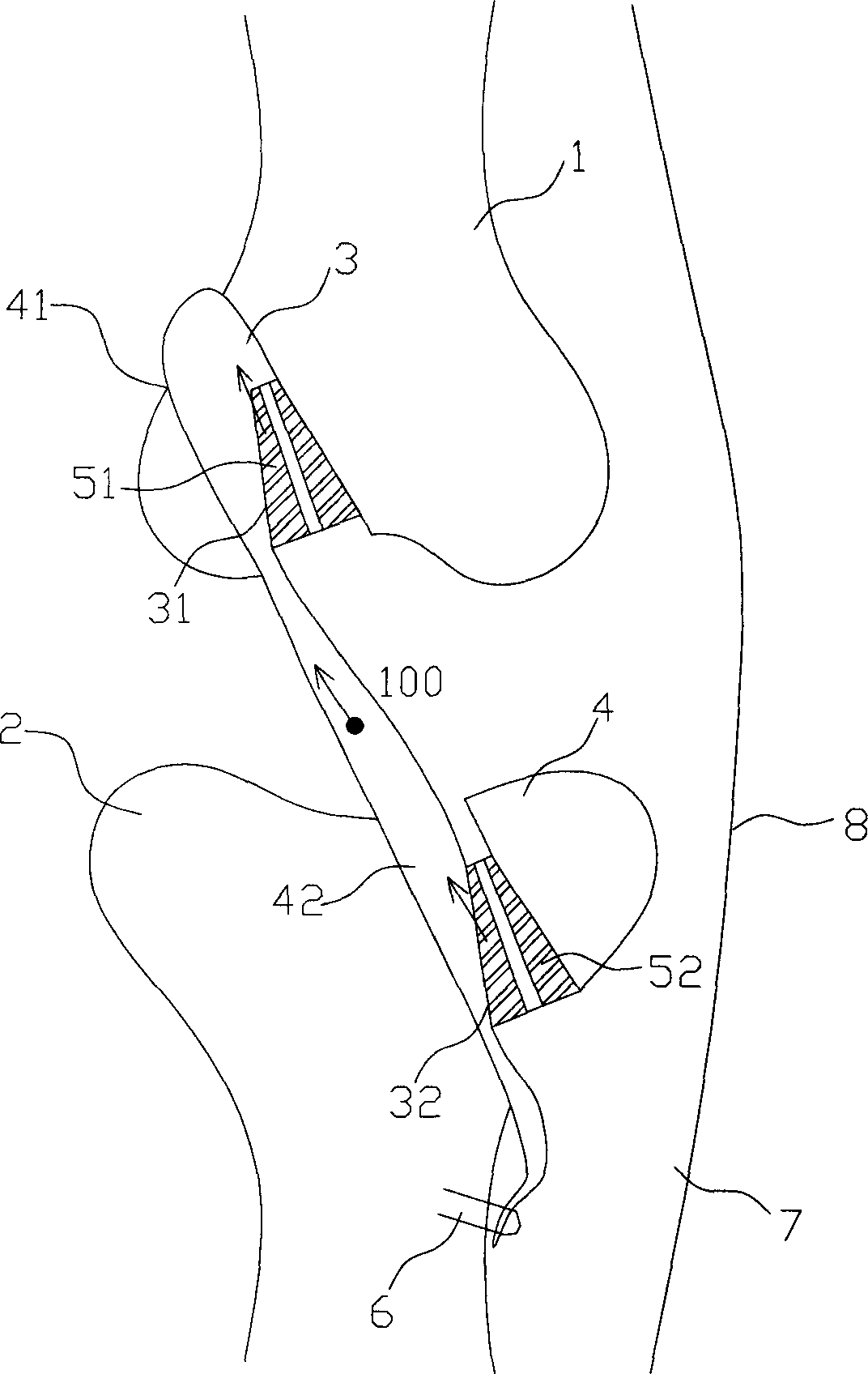

Reverse squeezing fixing method and device for ligament

The reverse ligament extruding and fixing process includes the following steps: forming one bone channel on skeleton with ligament to be repaired and setting one ligament substitute into the bone channel; penetrating steel wire into the bone channel and penetrating extruded matter onto the steel wire; fixing the upper fixing column to the tail of the extruded matter; tightening the steel wire inversely to force the extruded matter and the steel wire enter to the bone channel; penetrating the steel wire into the hole in the hollow screw driver, screwing the screw driver into the central hole in the extruded matter and inversely drawing or rotating to extrude the extruded matter into the bone channel and extrude the ligament substitute so as to fix one end of the ligament substitute; unloading the fixing column and the screw driver and withdrawing the steel wire. The said process can fasten the ligament effectively so as to make the repaired ligament possess high tension.

Owner:章亚东 +1

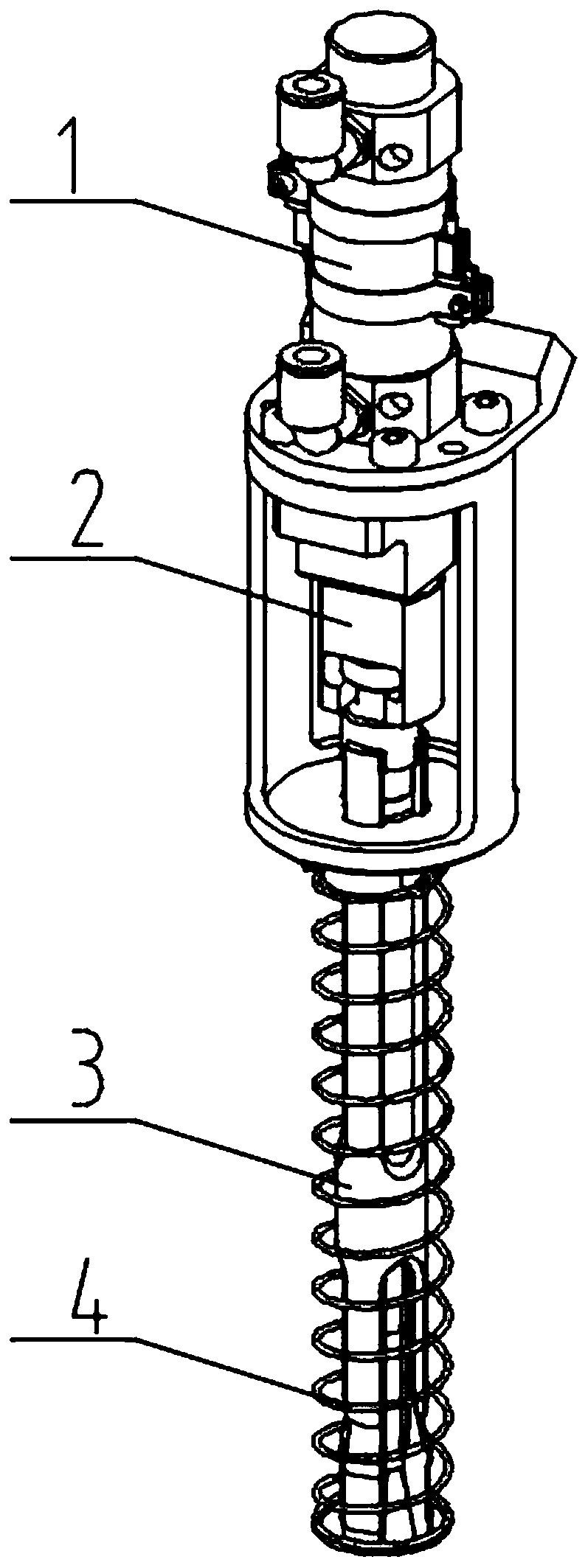

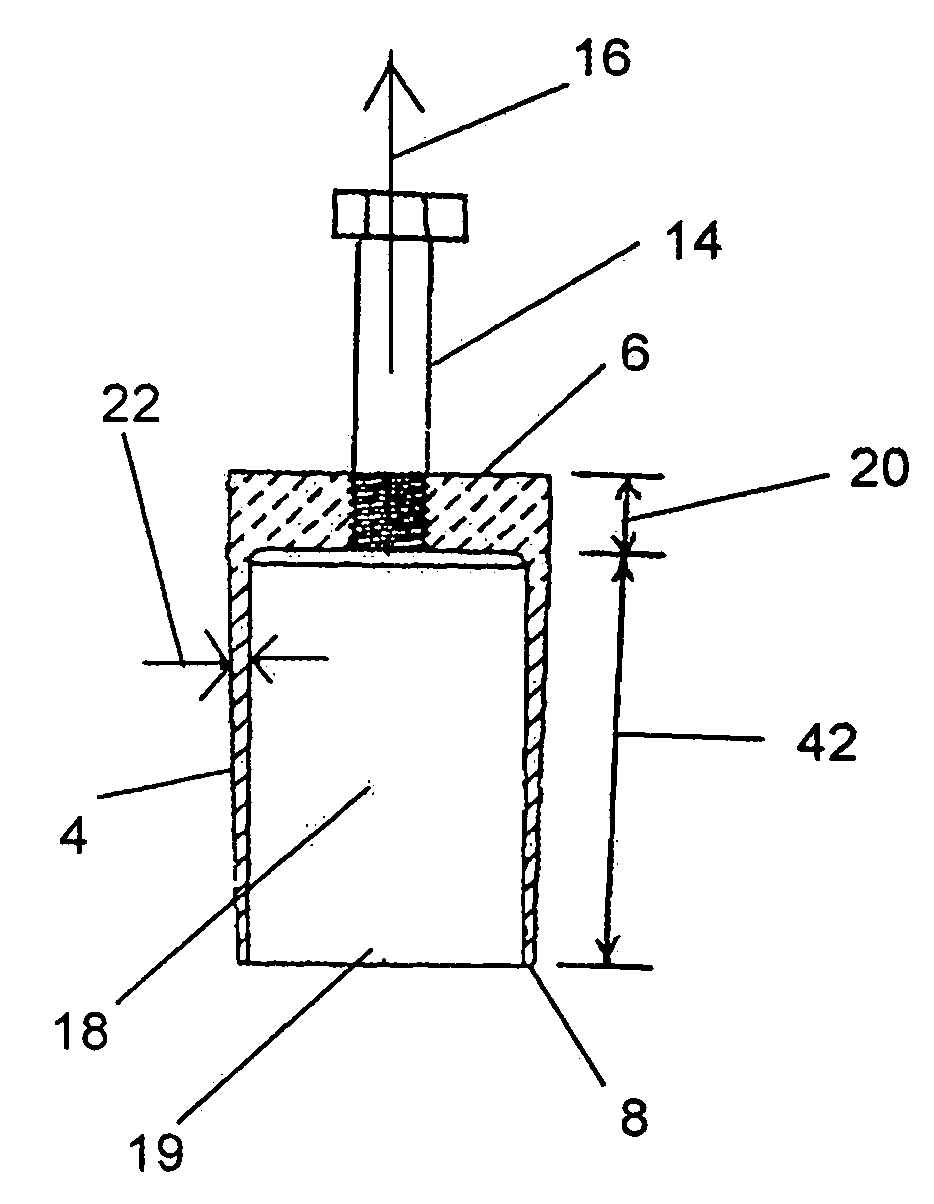

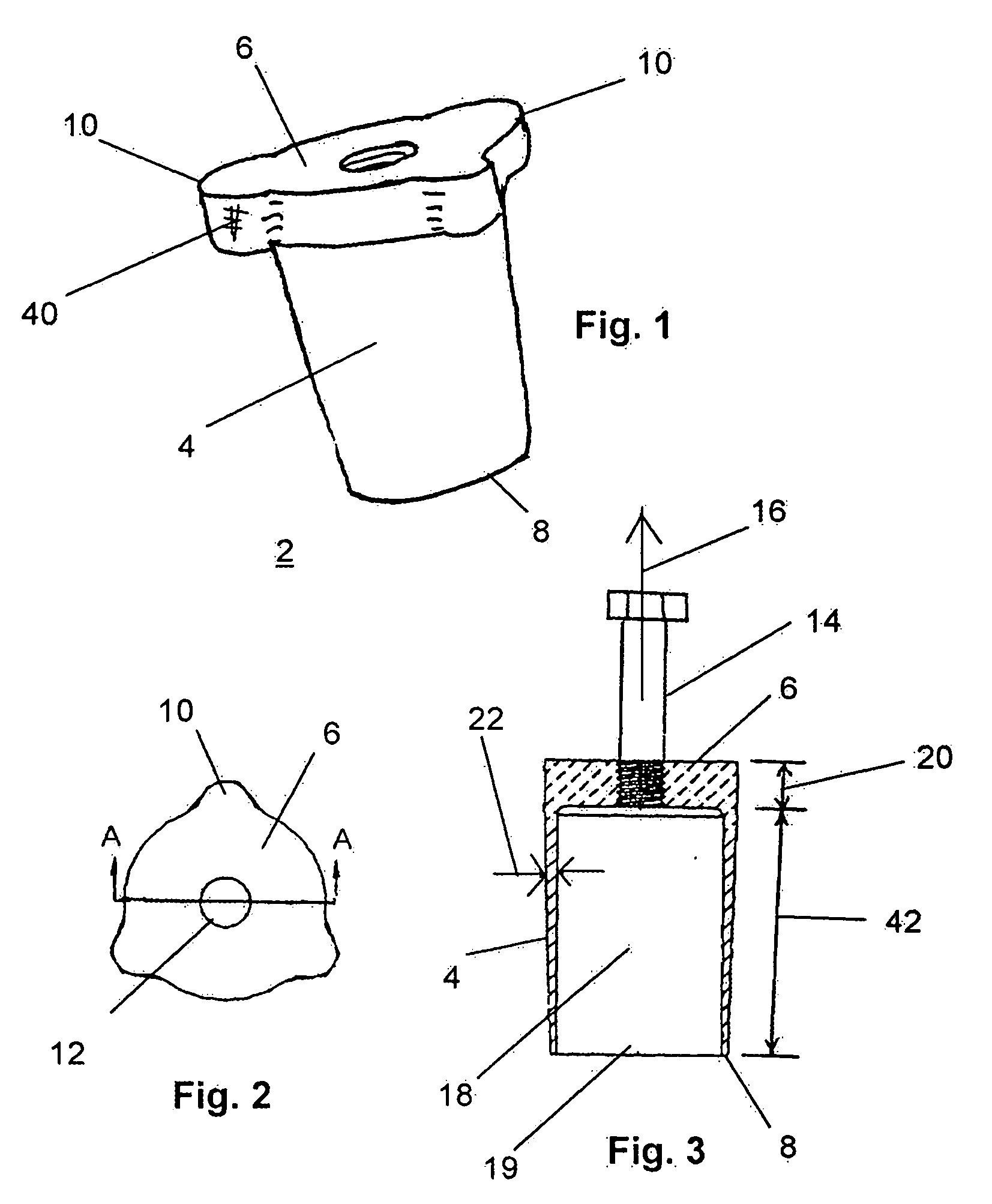

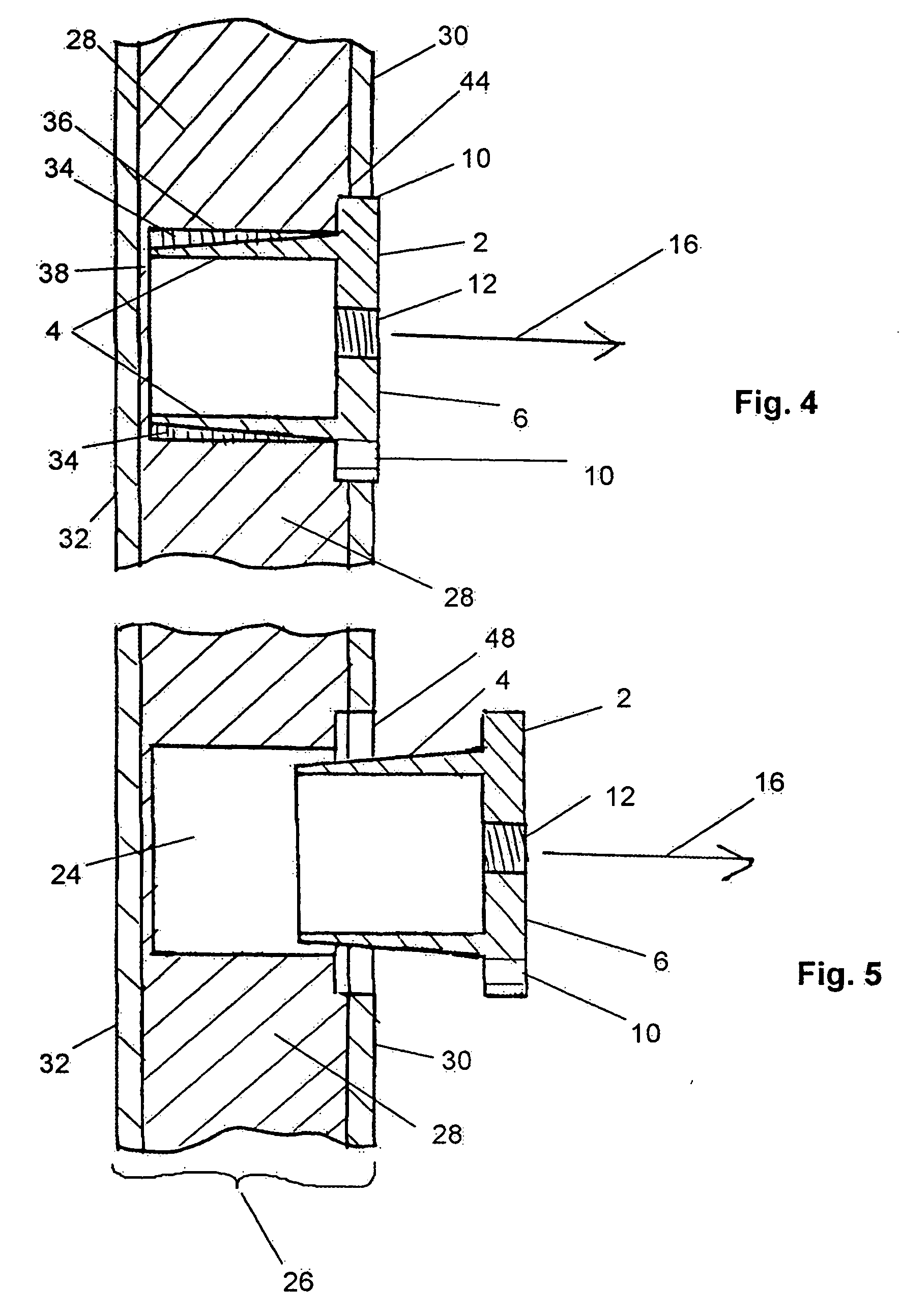

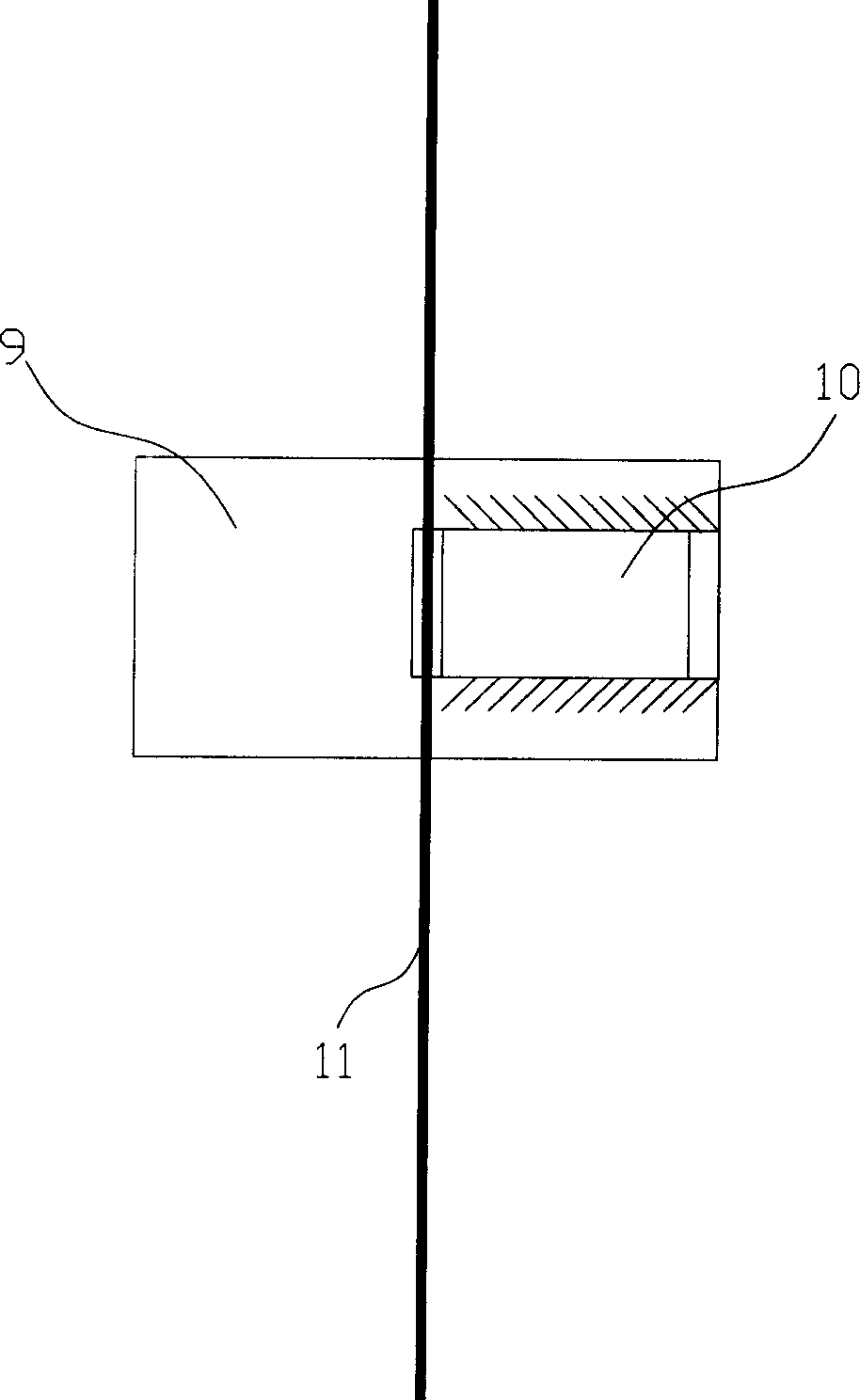

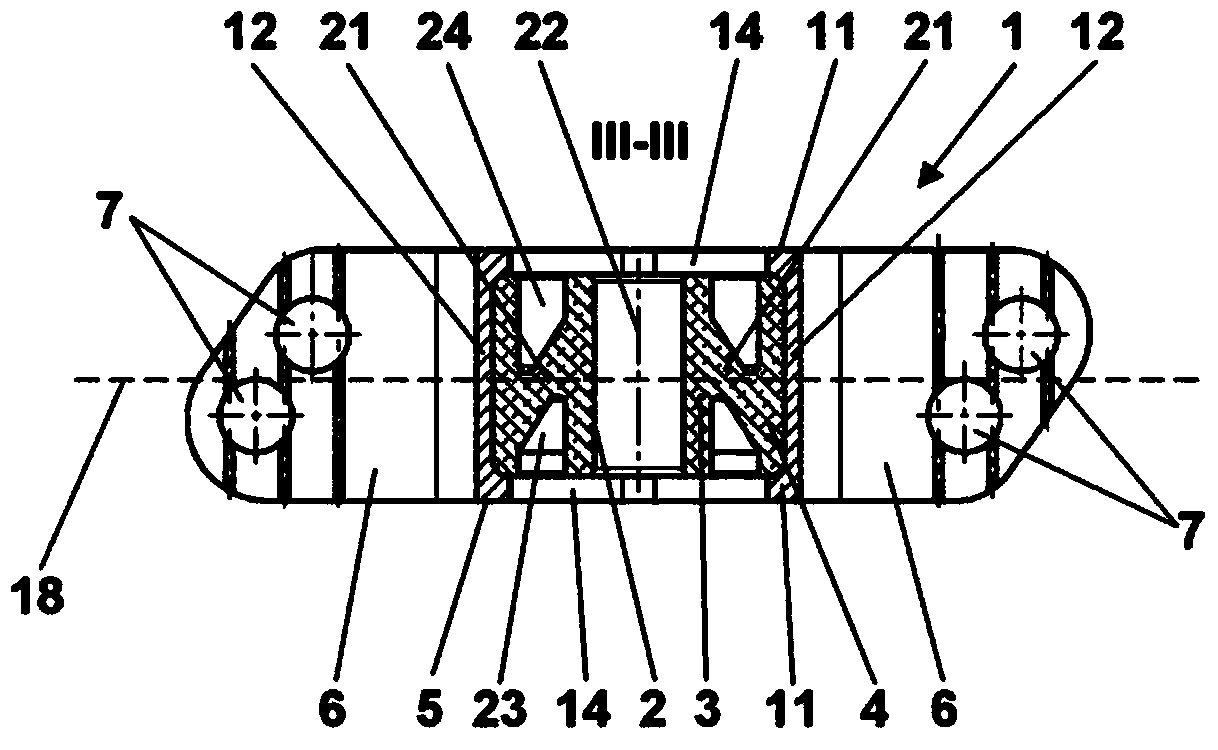

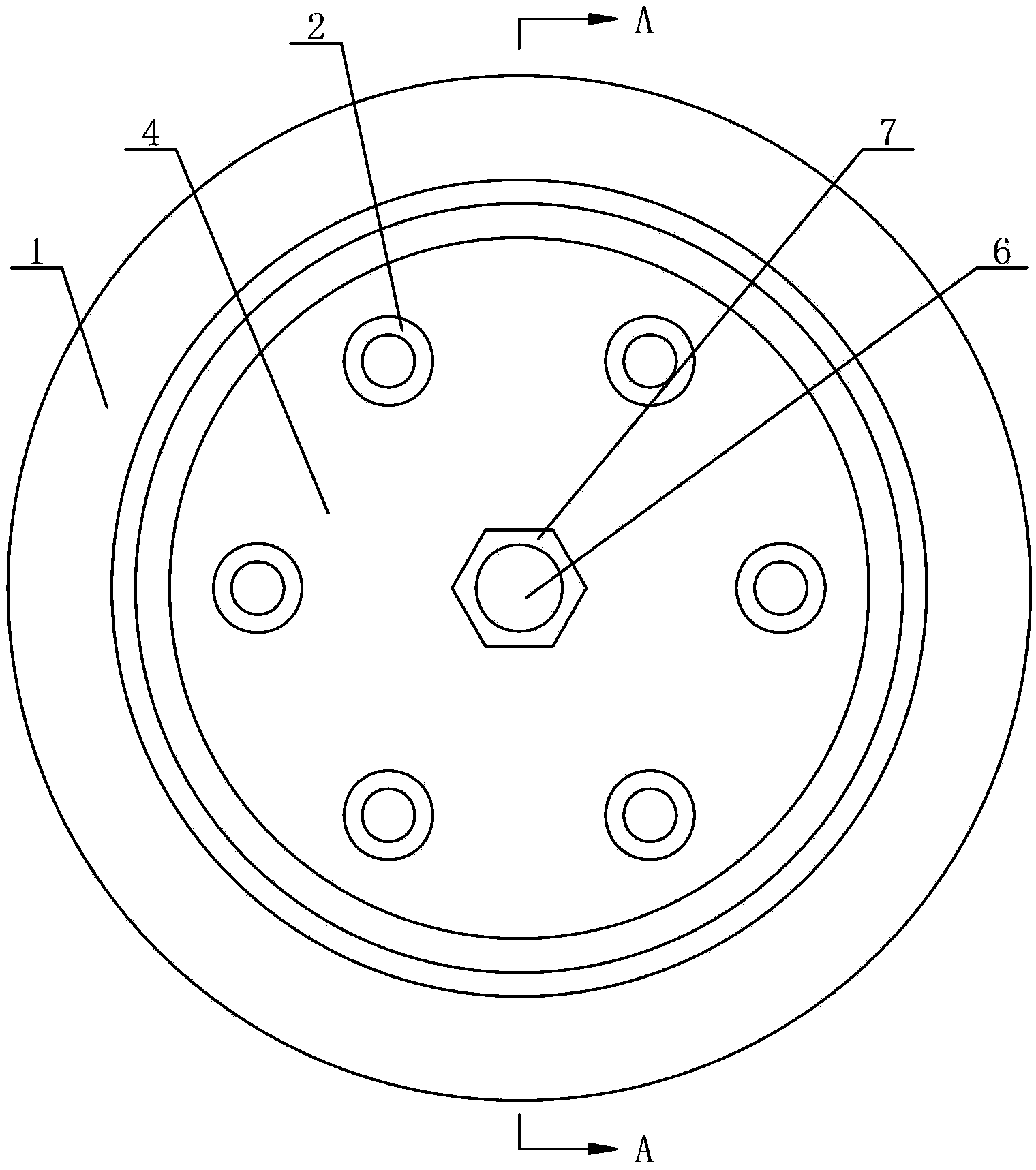

Compact elastic fixed bearing

ActiveCN103648821AIncreasing the thicknessStrong tensionSpringsPropulsion unit gas exhaustElastomerFixed bearing

An elastic fixed bearing (1) for mounting a dynamically loaded component to be supported on a supporting component has a dimensionally rigid frame (5), fastening devices (6, 7) for fastening the frame (5) rigidly to the supporting component, and a spring body (3) by means of which a bearing bush (2) for the component to be supported is elastically supported within the frame (5) in a main plane of the fixed bearing (1). The spring body (3), which is produced from an elastomer material (4), is inserted in a form-fitting manner into a cavity (10) of the frame (5), said cavity has a cuboidal basic shape, and those walls (11) of said cavity which run parallel to the main plane of the fixed bearing (1) have central openings (14) with a rounded periphery for the leadthrough of the component to be supported.

Owner:韦古减震有限公司

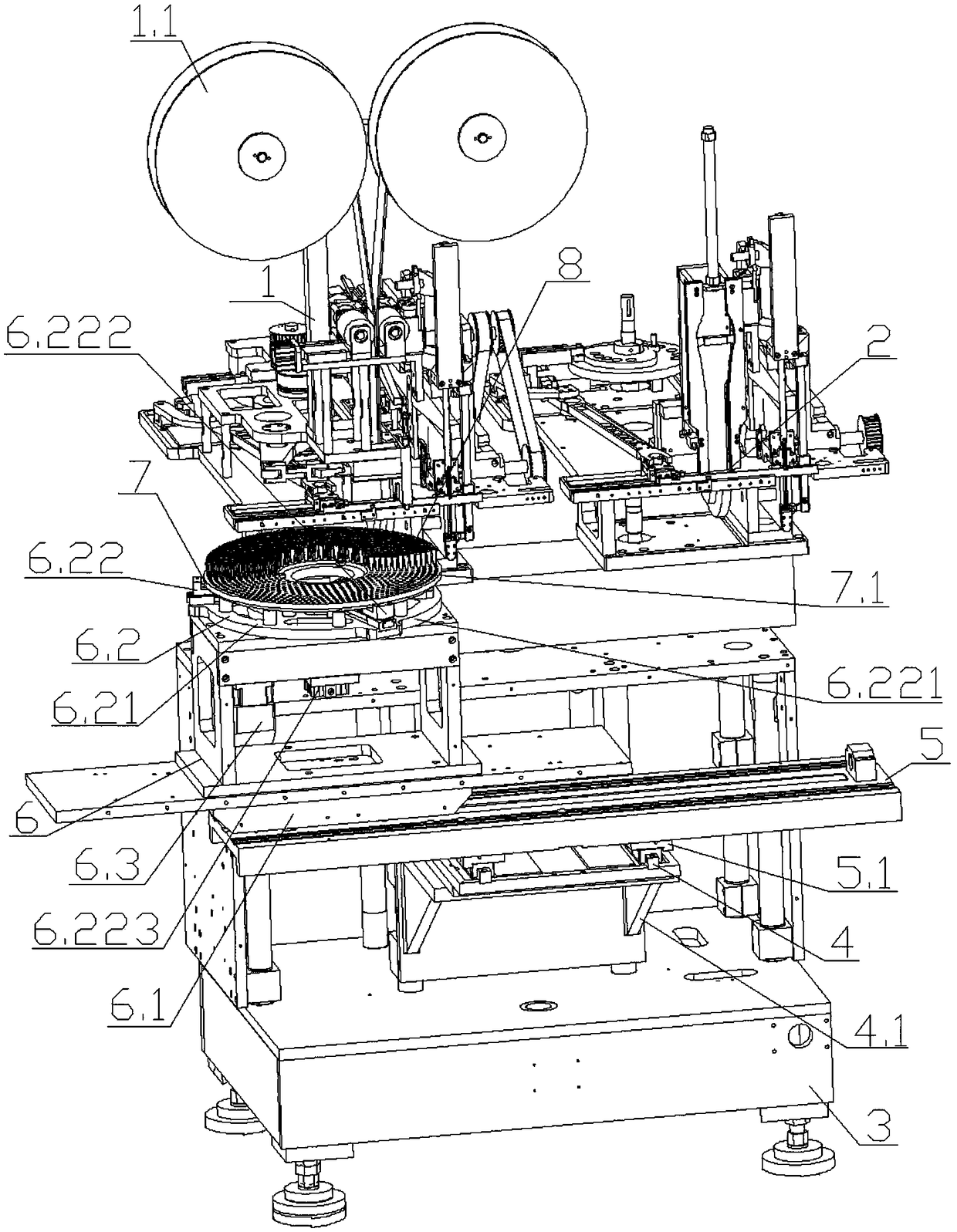

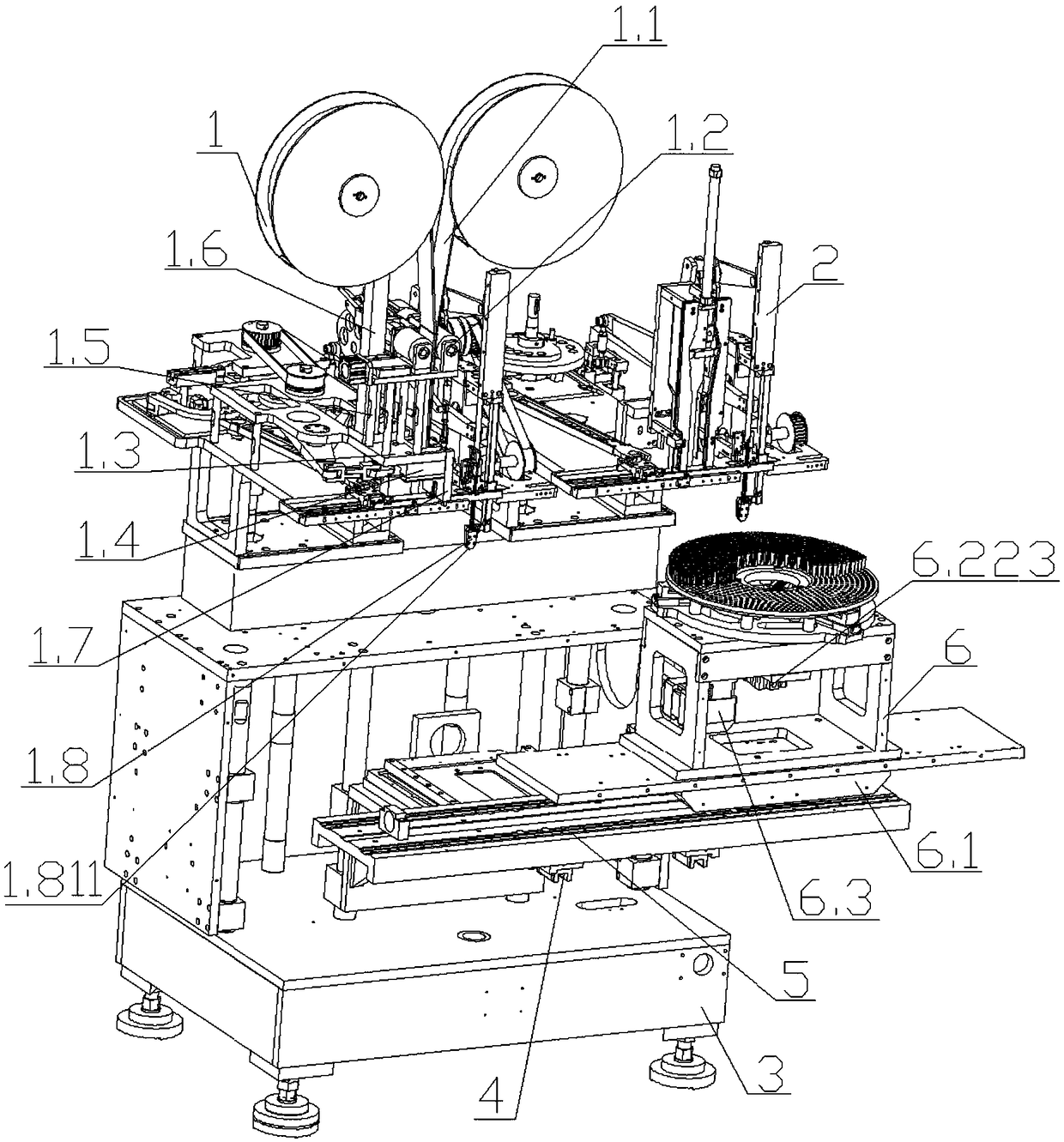

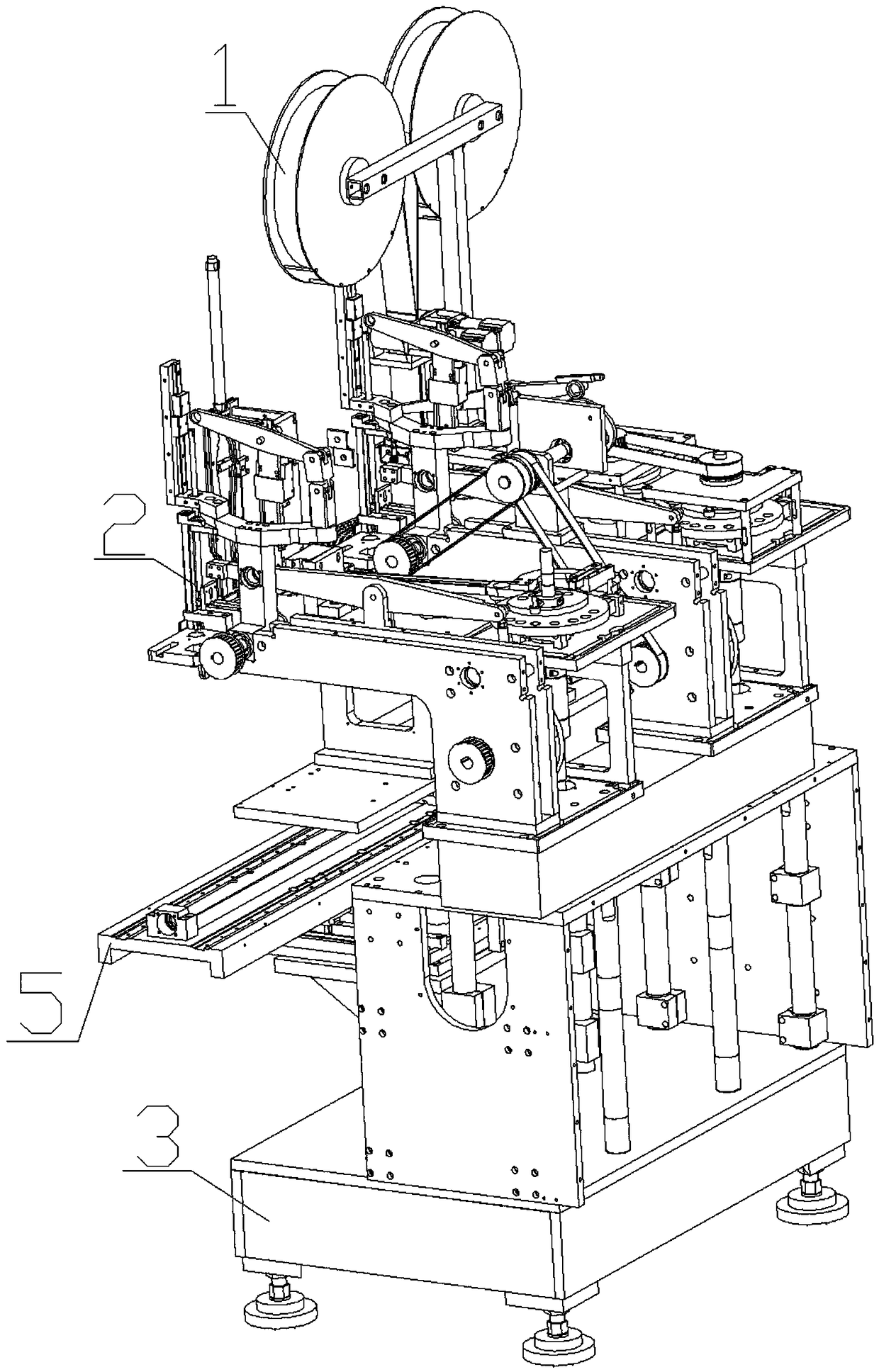

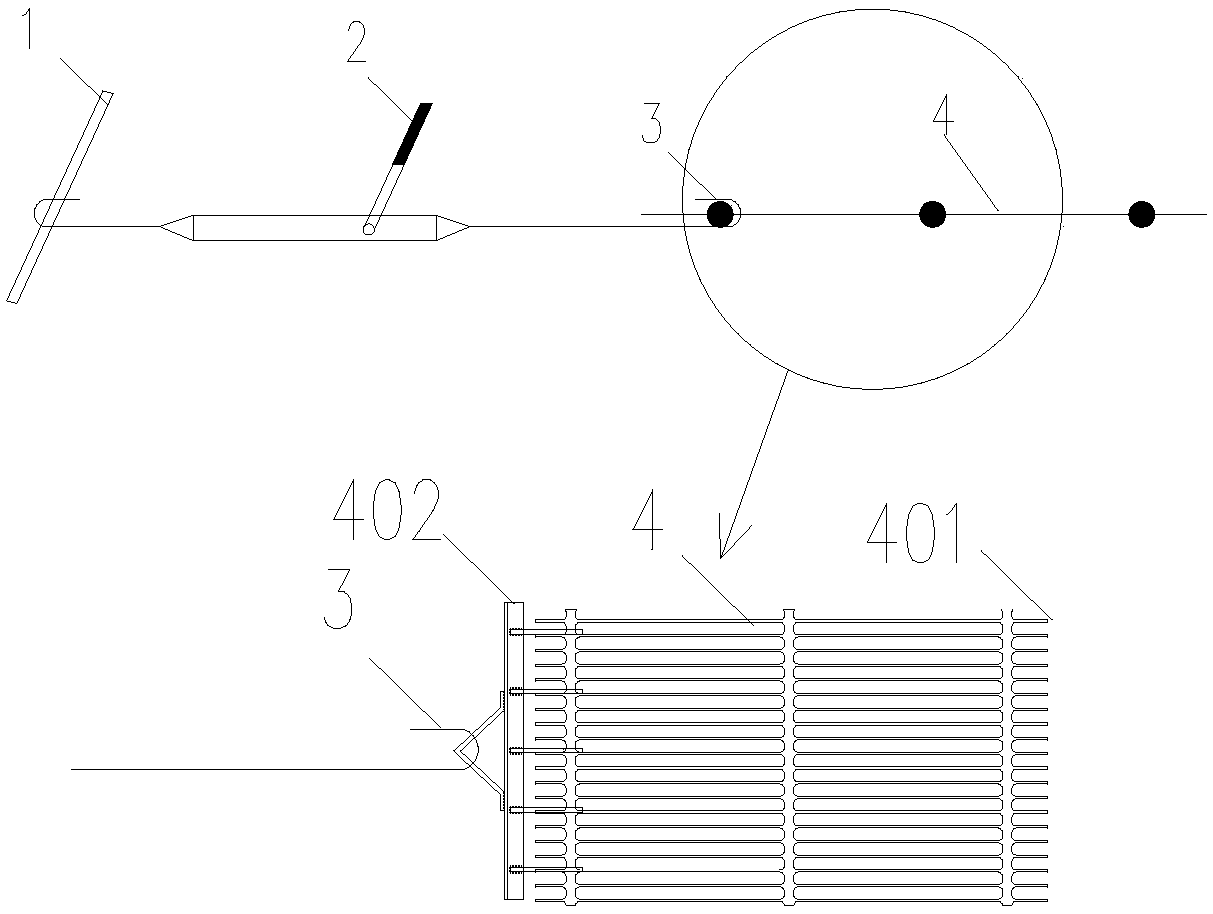

Automatic reciprocating hair planting machine for woolens of different materials and hair planting method thereof

ActiveCN109349789AStrong tensionReduce corrosionBrush bodiesAgricultural engineeringStructural engineering

The invention discloses an automatic reciprocating hair planting machine for woolens of different materials. The hair planting machine comprises a first hair planting mechanism and a second hair planting mechanism, a working platform and a base, a Y axis guiding rail is arranged on the base through a first supporting structure, an X axis sliding rail is slidably connected with the Y axis guiding rail through a first sliding block, and the lower end of the working platform is provided with a second sliding block which cooperates with the X axis guiding rail. The hair planting machine has the advantages that stagger hair planting can be conducted on a handle brush by adopting multiple woolens, hair does not easily fall, the working efficiency is high, labor force consumption is lesser, and the cost is lower. The invention further discloses a hair planting method of the automatic reciprocating hair planting machine for the woolens of different materials.

Owner:HUBEI C P NC MACHINERY

A dental floss holder

Owner:埃里克福塞尔

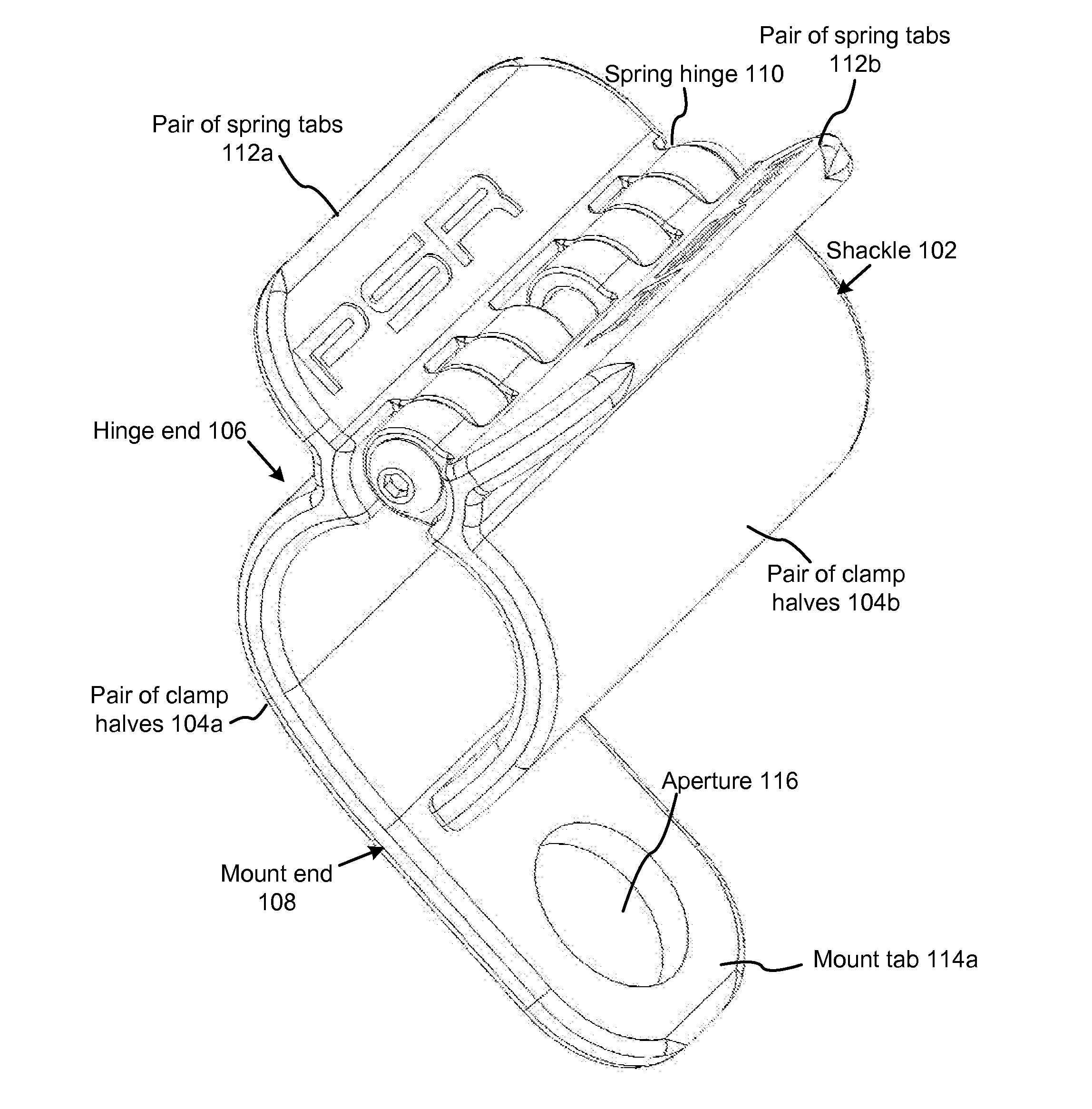

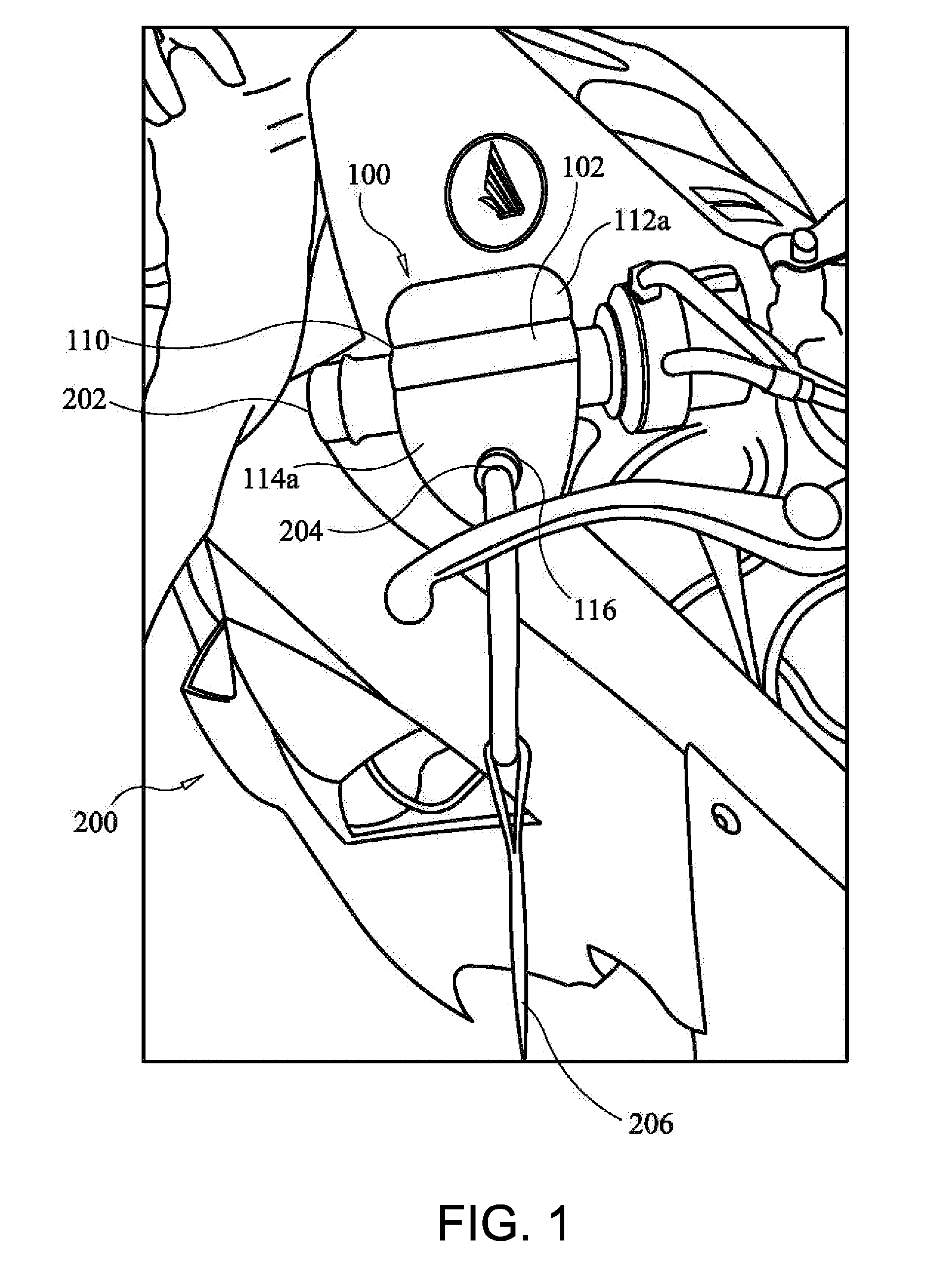

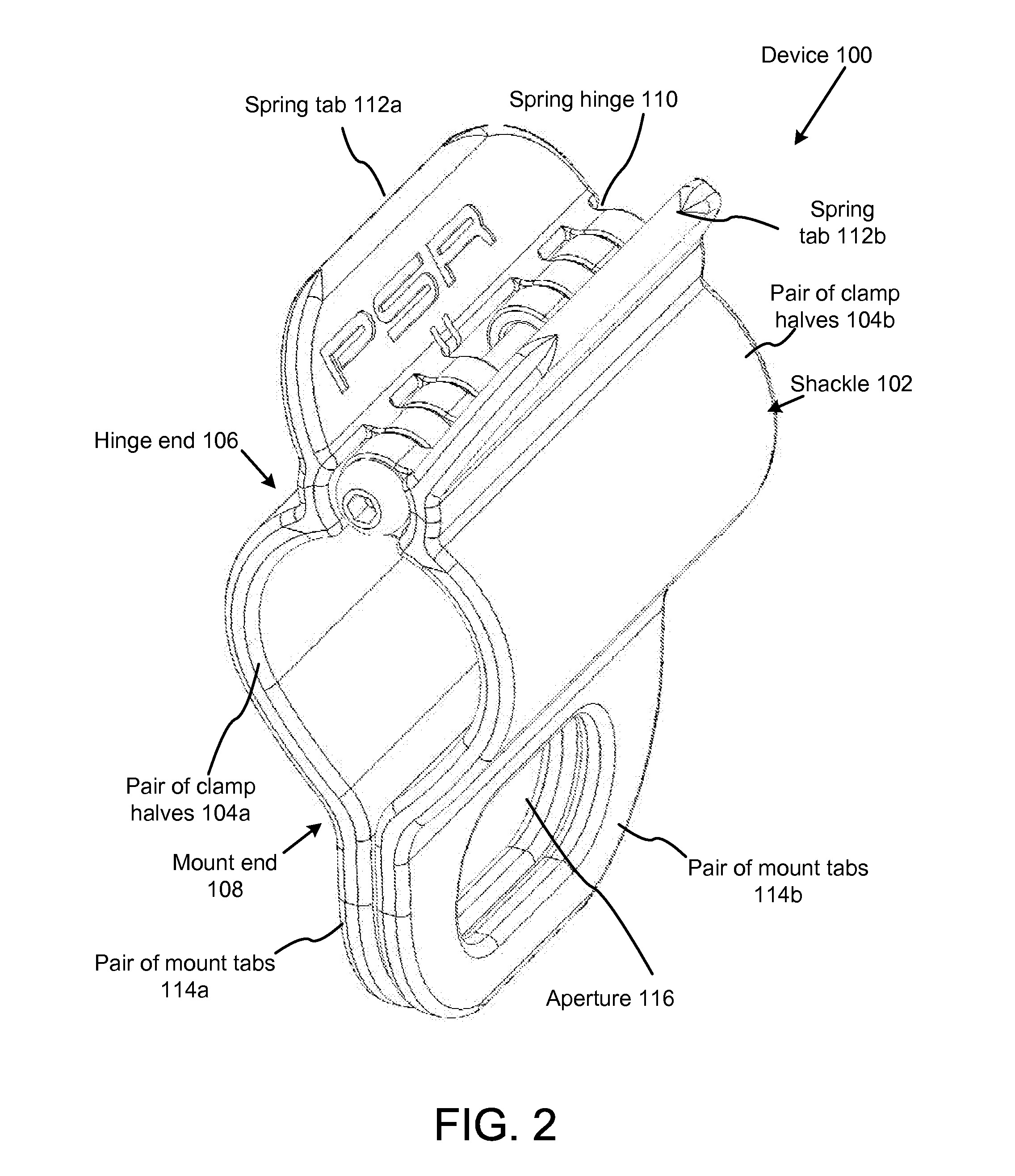

Shackle and method for stabilizing a vehicle during transport

ActiveUS20160311359A1Inexpensive to manufactureStabilize vehicleLoad securingItem transportation vehiclesAutomotive engineeringMultiple device

A device and method for stabilizing a vehicle during transport provides a detachably attached anchoring point on a vehicle for a tethered cable to securely fasten to from multiple directions and with strong tensions on the tethered cable. This creates a unique anchor on the vehicle that helps stabilize the vehicle during transport while minimizing damage to the vehicle. The device utilizes a biased, spring hinge to pivotally enclose a linear member, such as a grip, on the vehicle. A fastener at the terminus of the cable flexibly and detachably joins with the device at apertures. Tabs extend from the device to facilitate gripping for moving the device between an open and a closed position. The device may detachably attach to multiple areas of the vehicle, and multiple devices may be used throughout the vehicle. These flexible, multi-positional features of the device increase the effectiveness of the tethered cables.

Owner:HON CHARLIE R

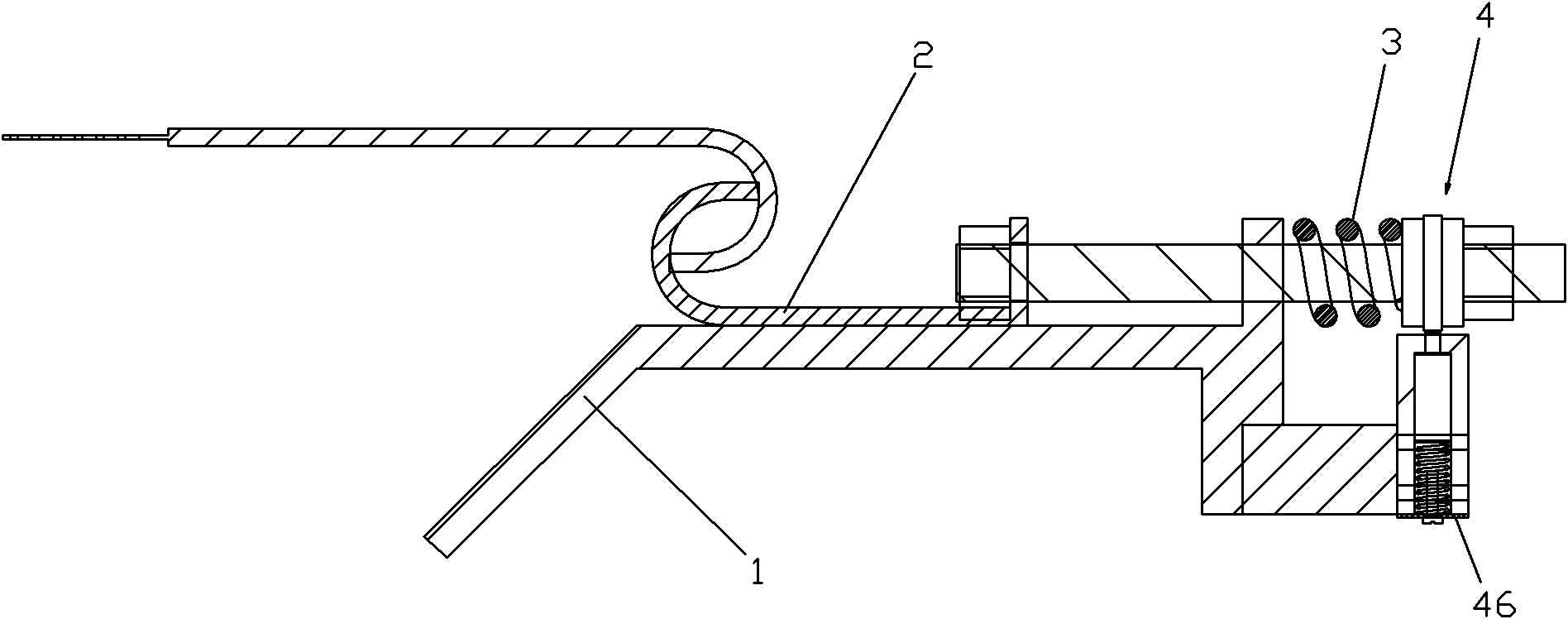

Geogrid construction structure and construction method

PendingCN108035364AImprove the stretching effectLabor savingArtificial islandsExcavationsEngineeringGeogrid

A geogrid construction structure is used for laying tensioning construction of geogrid and further comprises a take-up device, a connection piece and a fixing piece. The geogrid comprises a fixed endand a free end. The fixing piece is arranged on a laid ground on one side of the free end of the geogrid, and the fixing piece and the free end are arranged in a spaced manner. The connection piece isdetachably connected with the take-up device and the geogrid. The take-up device comprises two side connection parts, one side connection part is connected with the fixing piece, and the other side connection part is connected with the connection piece. The fixed end is fixed to the laid ground. According to a construction method for the geogrid carrying out pulling and tensioning through the take-up device, the construction method has the beneficial effects that the pulling strength is large, the pulling effect is good, labor is saved, the construction speed is high, the working efficiency is improved, and materials are saved and other beneficial effects, and the construction method is wide in application range.

Owner:青岛旭域土工材料股份有限公司 +1

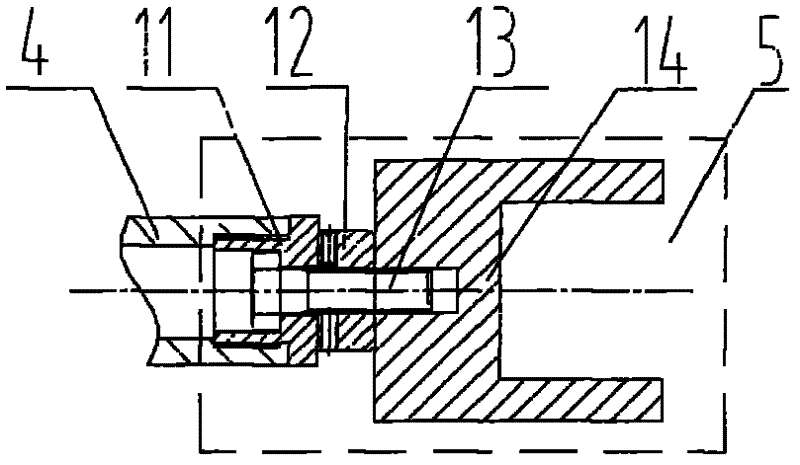

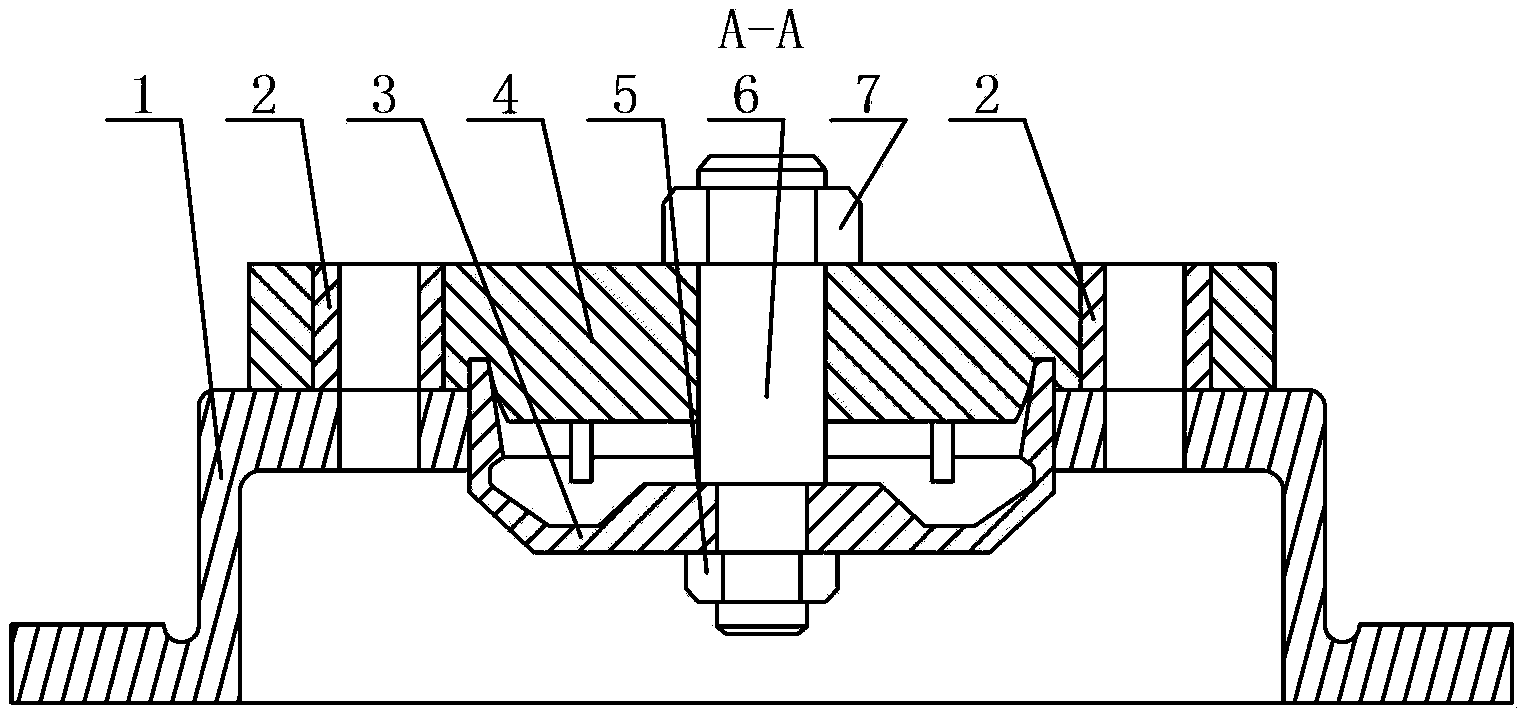

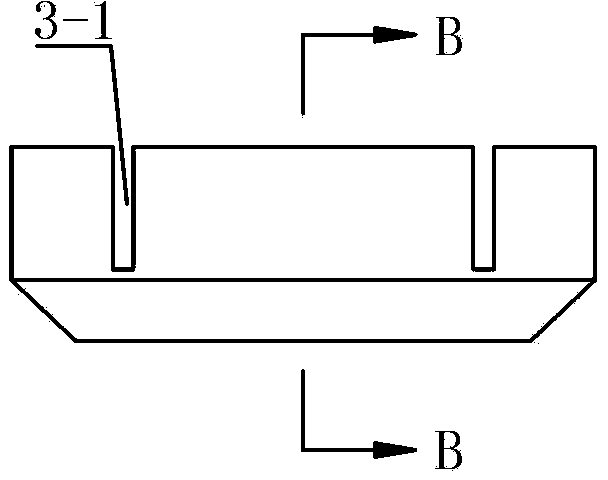

Taper-lock external expansion type centering drilling clamp

InactiveCN103769879AStrong tensionNo offsetDrilling/boring measurement devicesPositioning apparatusEngineeringMachining process

The invention discloses a taper-lock external expansion type centering drilling clamp which comprises a drill plate with a through hole formed in the middle. A boss is arranged at the lower end of the drill plate. Multiple drill bushes are evenly arranged on the drill plate in the axial direction of the drill plate. A step screw is arranged in the through hole in the middle of the drill plate. The lower end of the step screw penetrates through a disc-shaped taper-lock and is provided with a lower nut and an upper nut is installed at the upper end of the step screw. Multiple expansion grooves are evenly formed in the upper side of the disc-shaped taper-lock in the circumferential direction. An inner hole of the disc-shaped taper-lock has the taper so as to be matched with the boss in a sliding mode. The taper-lock external expansion type centering drilling clamp has the following advantages of being large in expansion force, free of deviation in the machining process, capable of being automatically centered, high in machining accuracy, reasonable in design, simple in structure, convenient to operate, small in size, low in weight, convenient to disassemble, assemble and transport, low in production cost and convenient to popularize and use.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

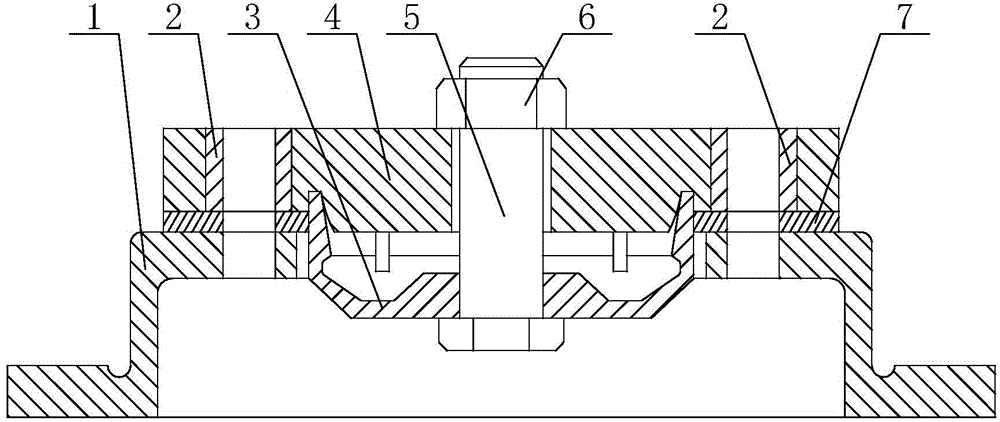

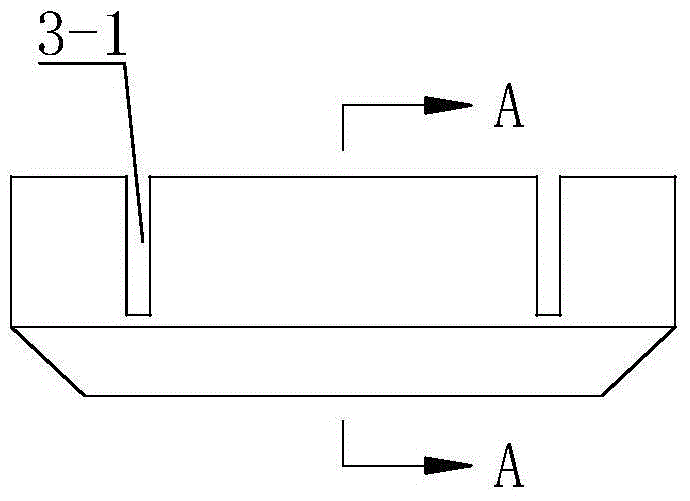

Self-alignment type clamping device for drilling

InactiveCN105665767AReasonable designSimple structureExpansion mandrelsDrill jigsEngineeringMachining process

The invention discloses a self-aligning type clamping device for drilling. The clamping device comprises a bottom plate, a plurality of drill bushings, a disc-shaped expansion bushing and a drill plate with the lower end face provided with a boss. The drill plate is arranged on the upper side of the bottom plate, the drill bushings are fixedly arranged on the drill plate, a screw rod is arranged in the middle of the drill plate, and a driving nut is arranged at the upper end of the screw rod. The lower end of the screw rod is sleeved with the disc-shaped expansion bushing, a taper angle matched with the boss is formed inside the disc-shaped expansion bushing, and at least two expansion grooves are evenly formed in the upper side of the disc-shaped expansion bushing in the circumferential direction of the disc-shaped expansion bushing. The self-aligning type clamping device for drilling has the following characteristics that self-alignment is achieved, drilling position precision is high, expansion force is large, and deviation is avoided in the machining process; the clamping device is reasonable in design, simple in structure, convenient to operate, small in size, low in weight, convenient to disassemble and assemble, long in service life and convenient to use and popularize.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com