Self-alignment type clamping device for drilling

A clamping device and automatic centering technology, which is applied in the direction of drilling dies for workpieces, expanding mandrels, etc., can solve the problems that the machining accuracy cannot be effectively guaranteed, the labor intensity of laborers is increased, and the scribing work is complicated. To achieve the effect of easy promotion and use, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

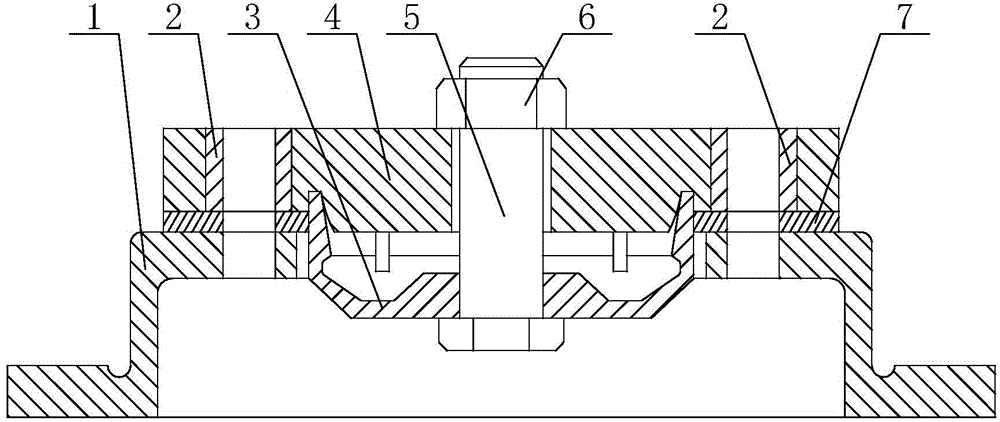

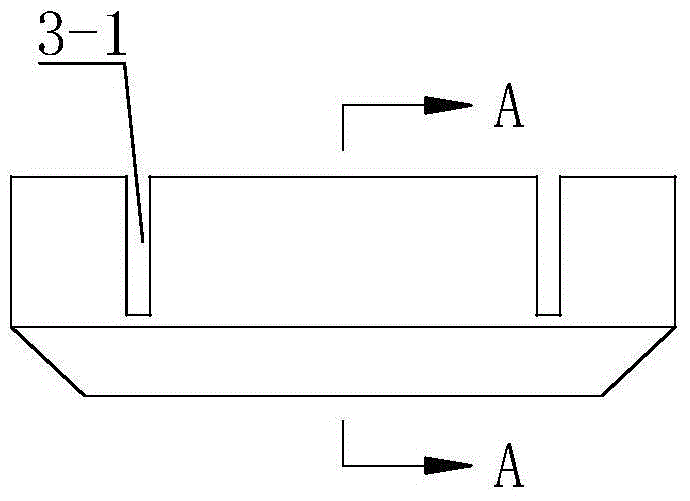

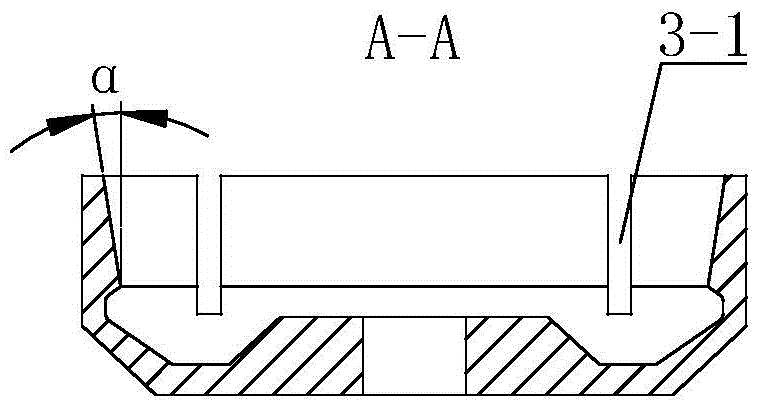

[0022] like Figure 1-Figure 4 The shown clamping device for self-centering drilling includes a chassis 1 that acts as a fixed support and a plurality of drill sleeves 2 for guiding the drill bit to drill holes on the annular workpiece 7 to be processed, and also includes The disc-shaped expansion sleeve 3 of the annular workpiece 7 to be processed and the drill template 4 with the boss 4-1 arranged on the lower end surface; the upper side of the chassis 1 is provided with the drill template 4, and the drill template 4 A plurality of drill sleeves 2 are fixedly arranged, a screw rod 5 is arranged in the middle of the drill template 4, a drive nut 6 is arranged on the upper end of the screw rod 5, and the disc-shaped expansion sleeve 3 is set on the lower end of the screw rod 5, and the The inside of the disk-shaped expansion sleeve 3 is provided with a taper angle matched with the boss 4-1, and the upper side of the disk-shaped expansion sleeve 3 is uniformly provided with at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com