Patents

Literature

71results about How to "Realize the clamping operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

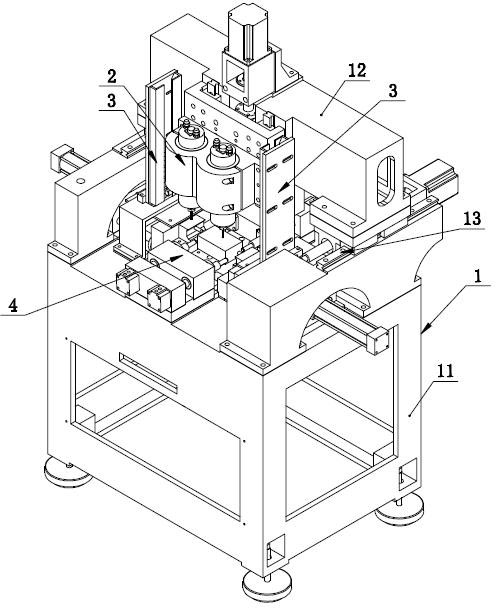

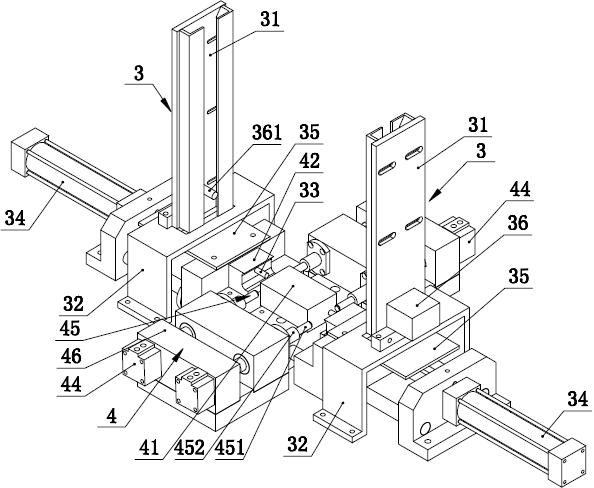

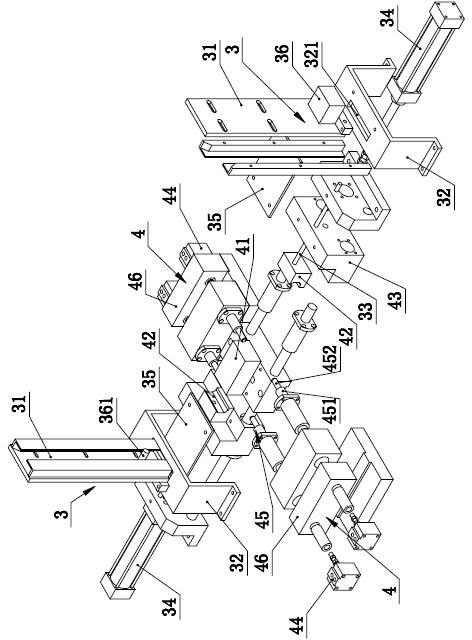

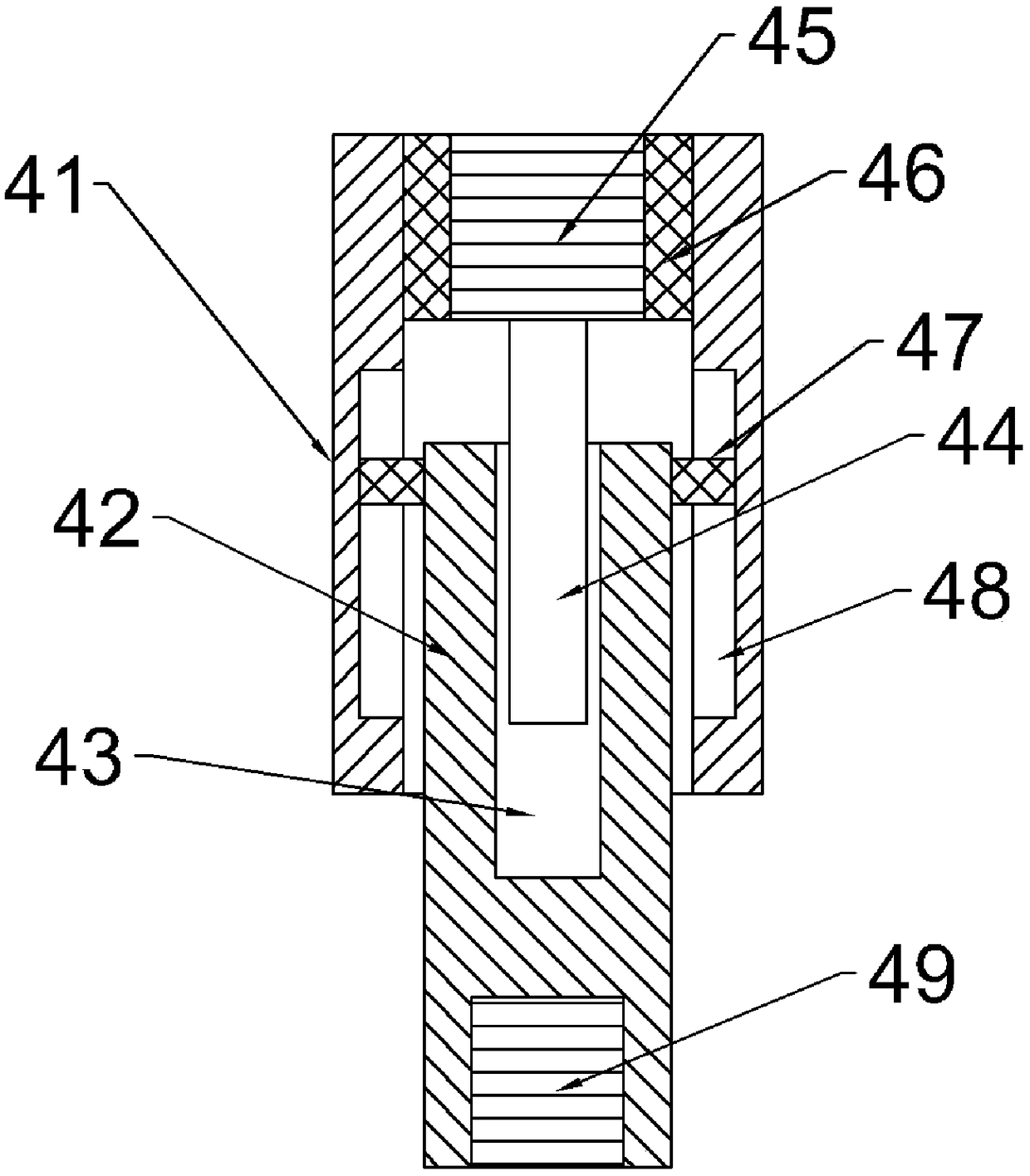

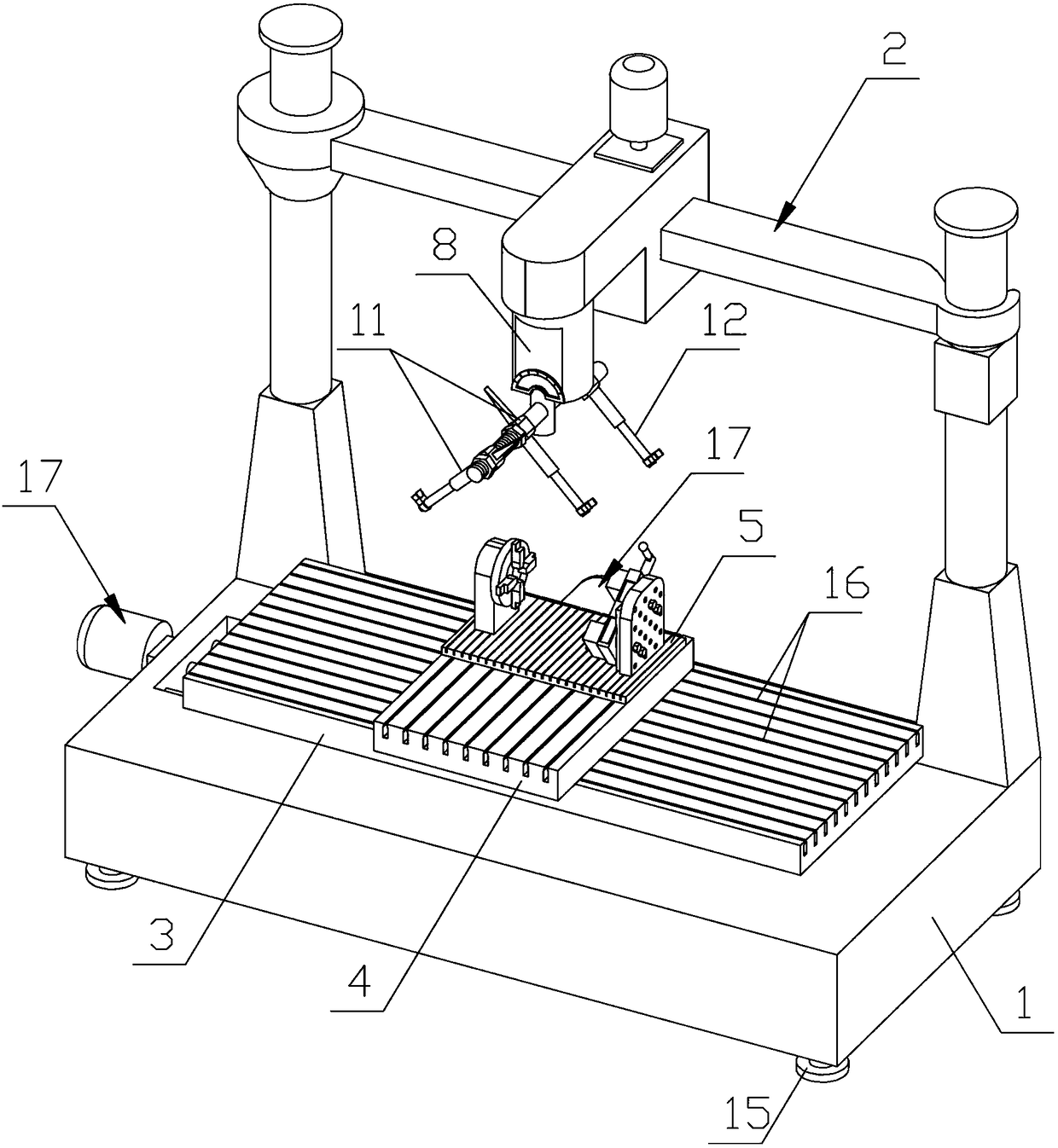

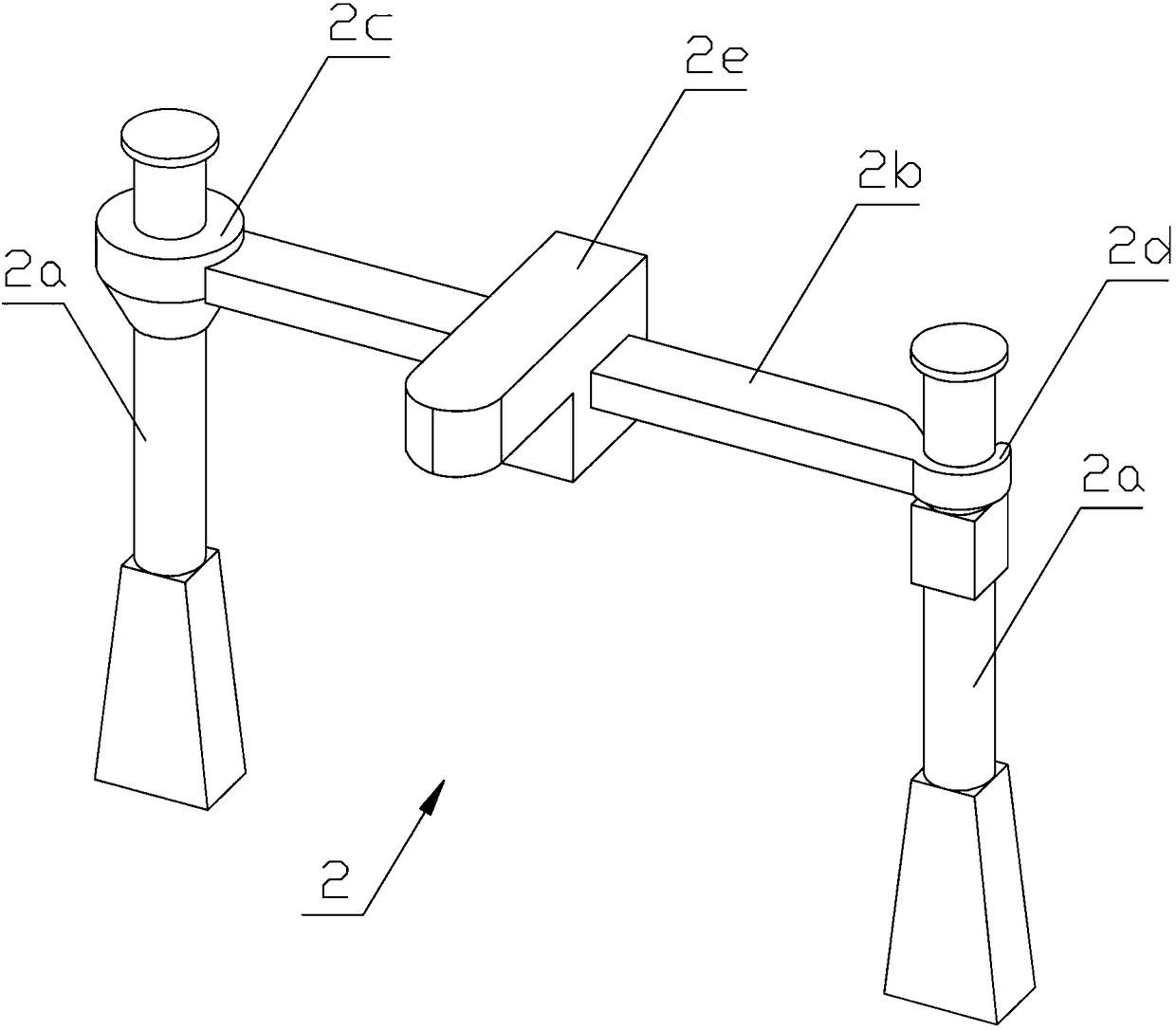

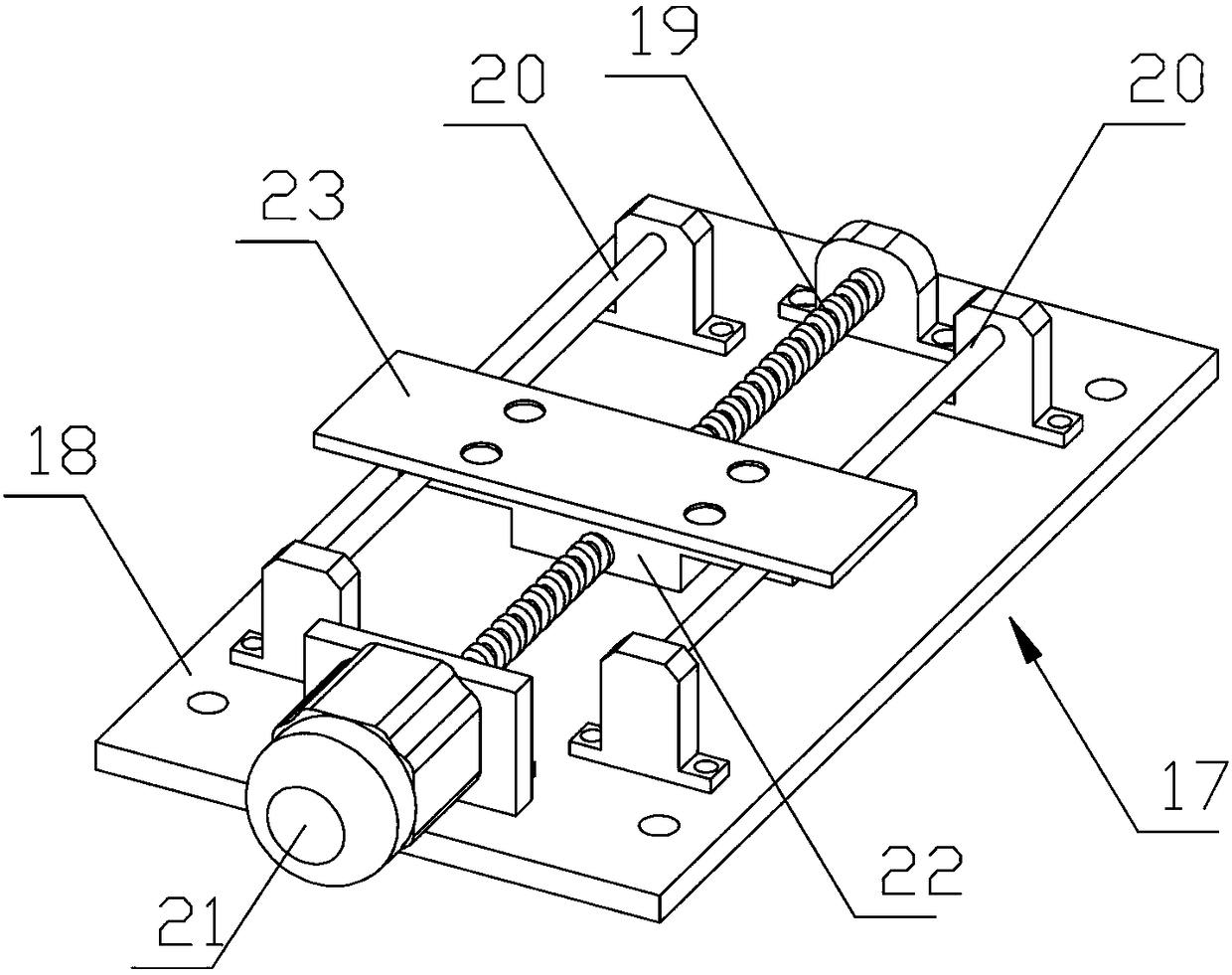

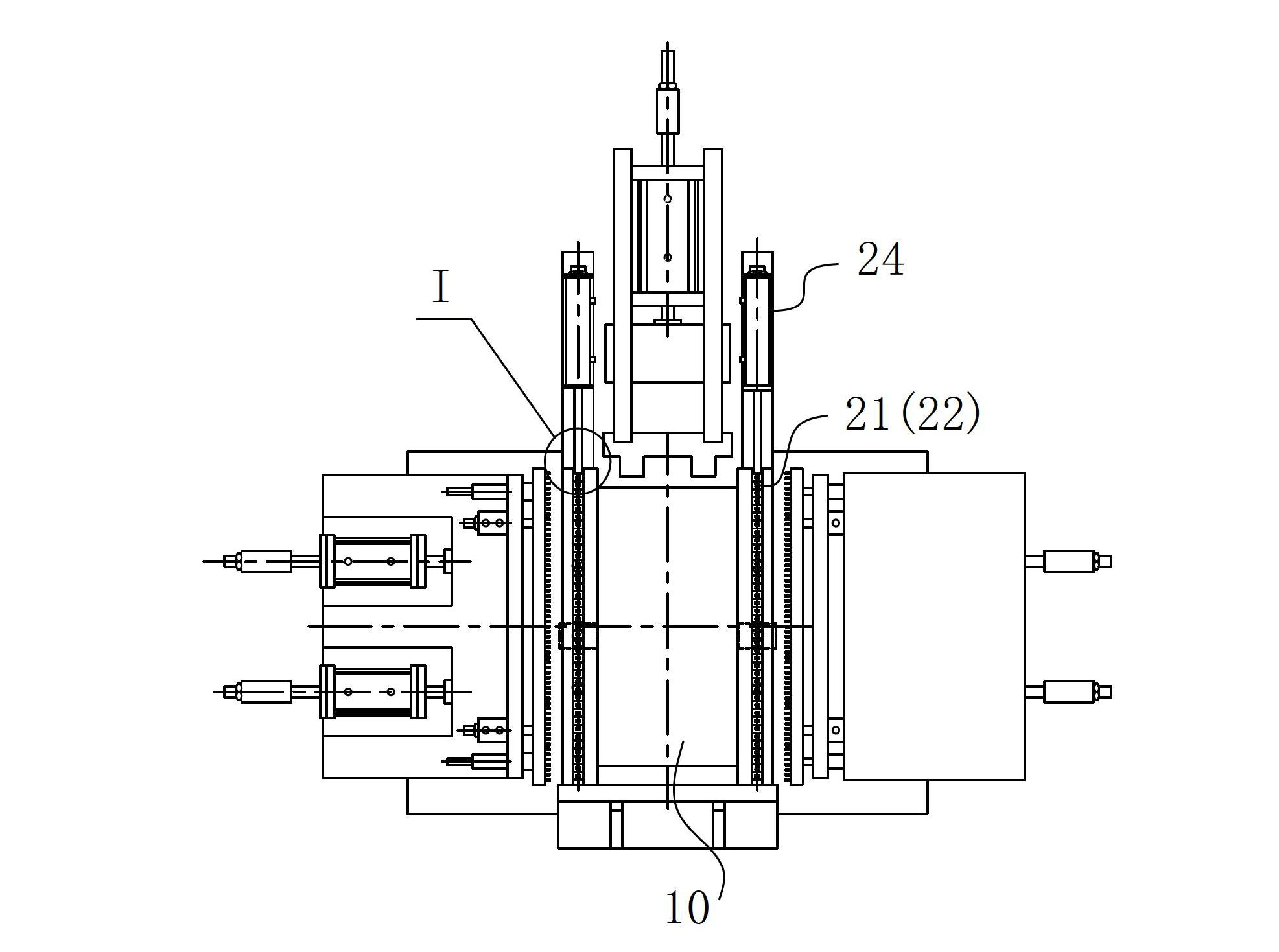

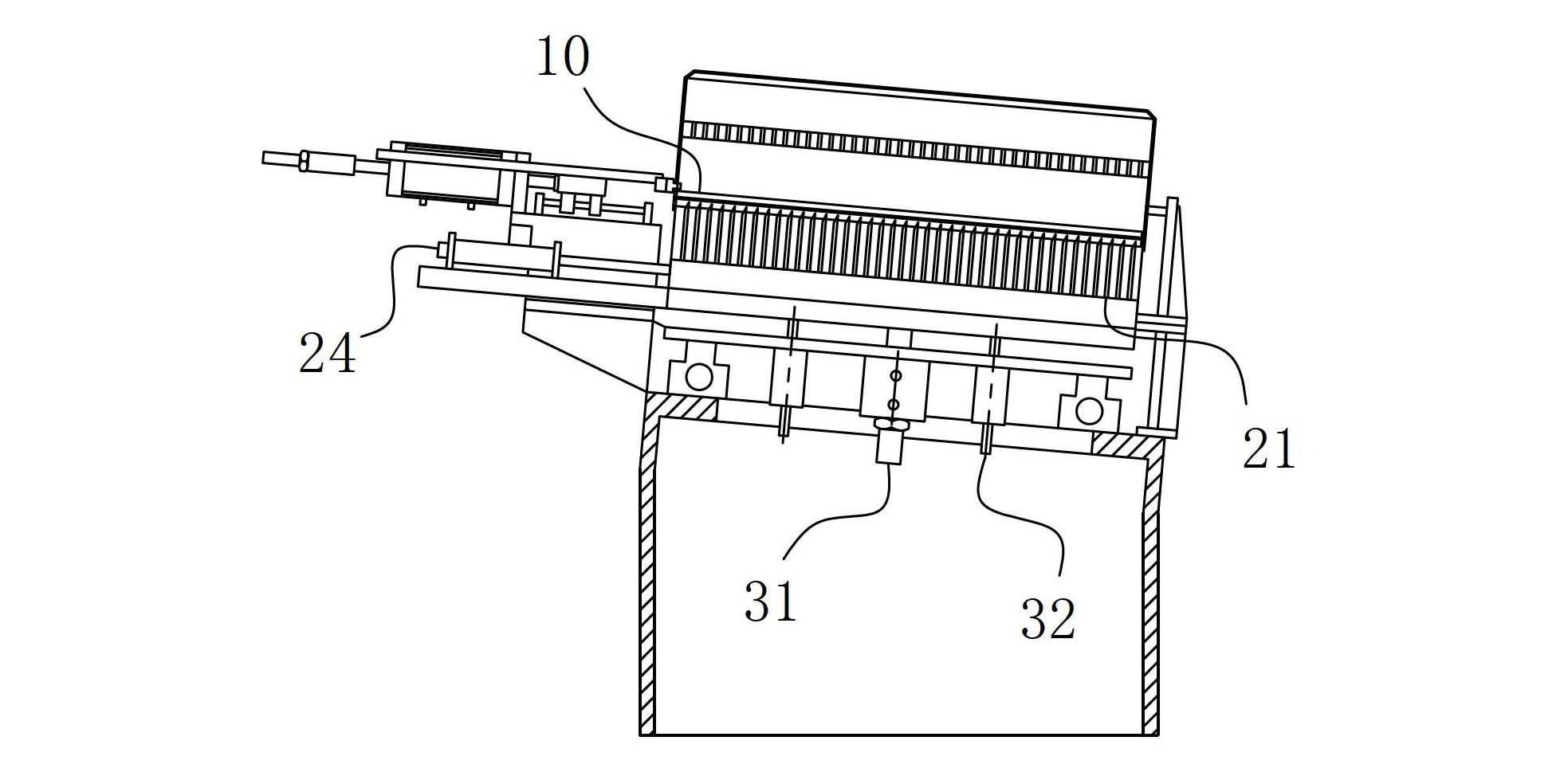

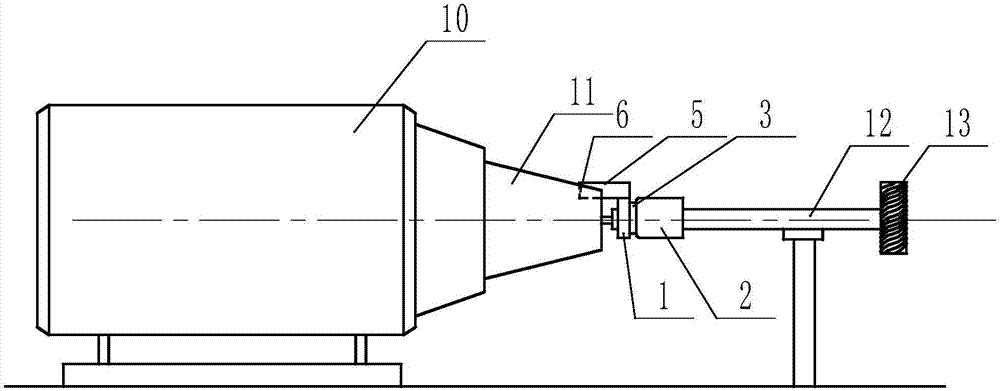

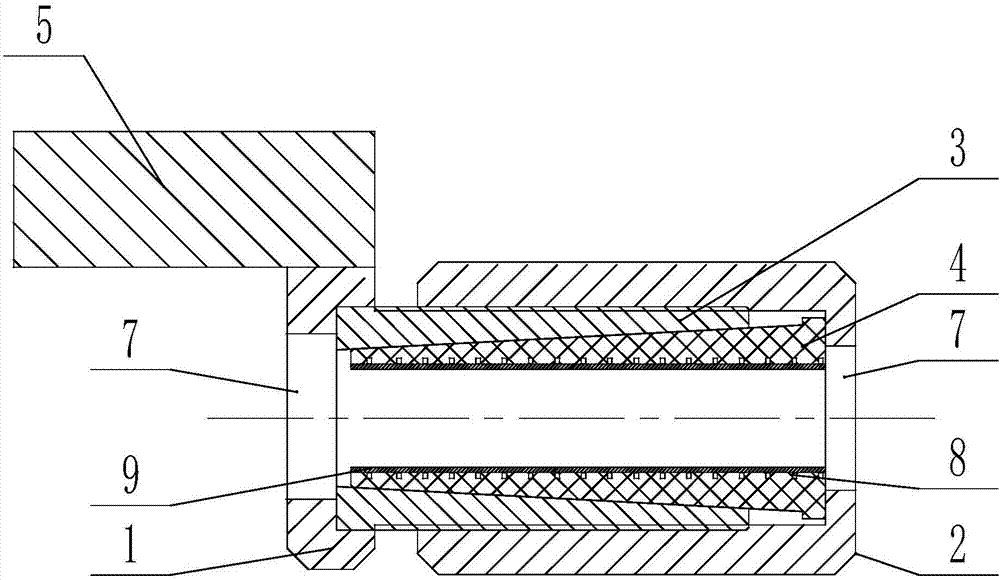

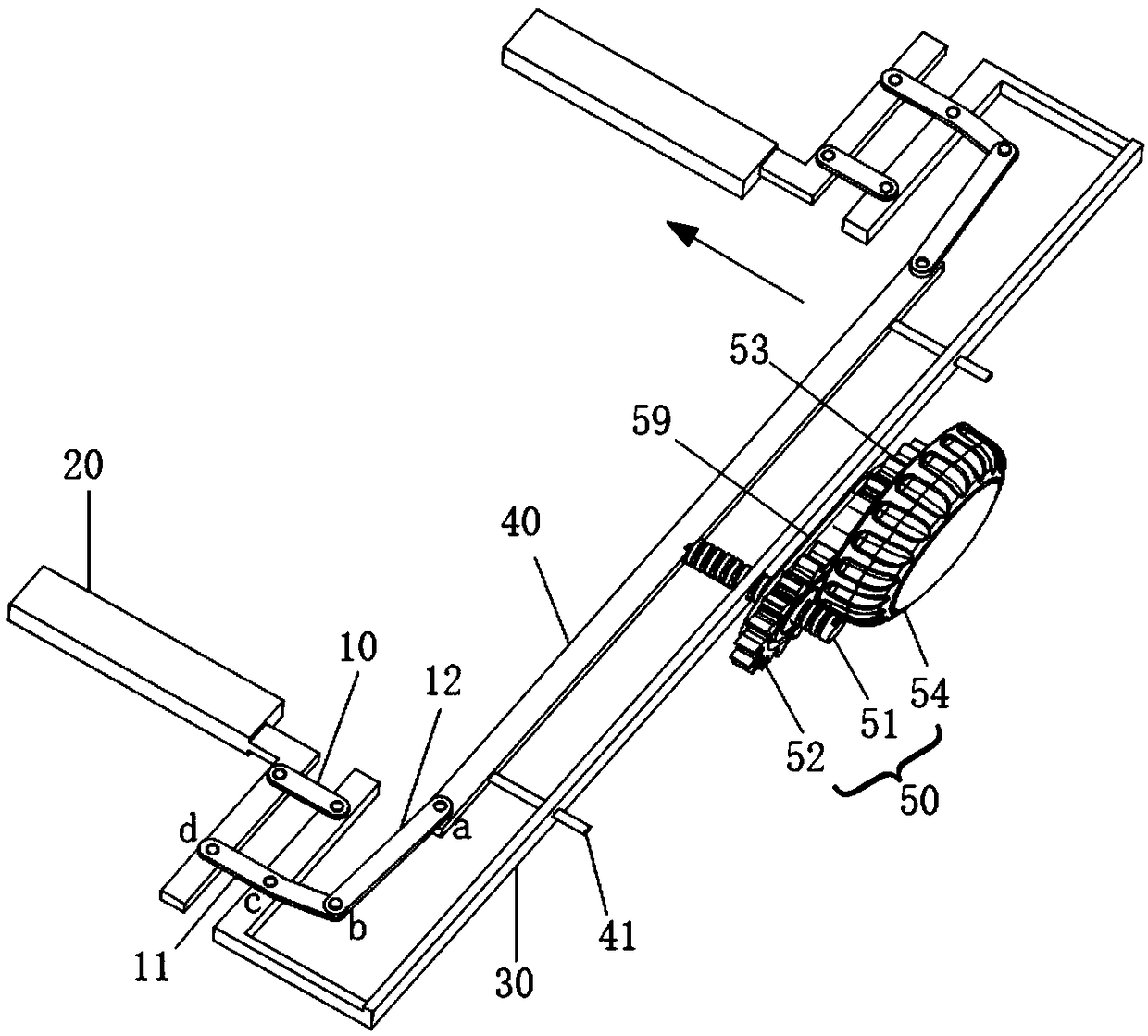

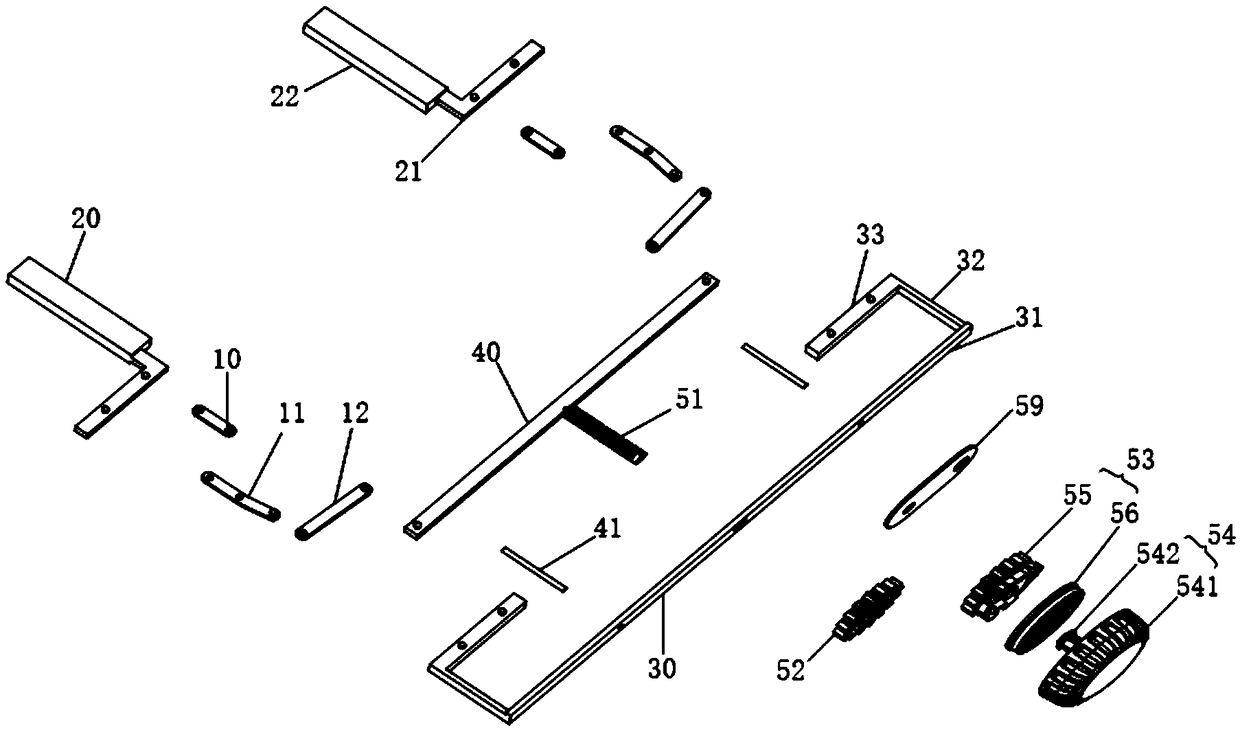

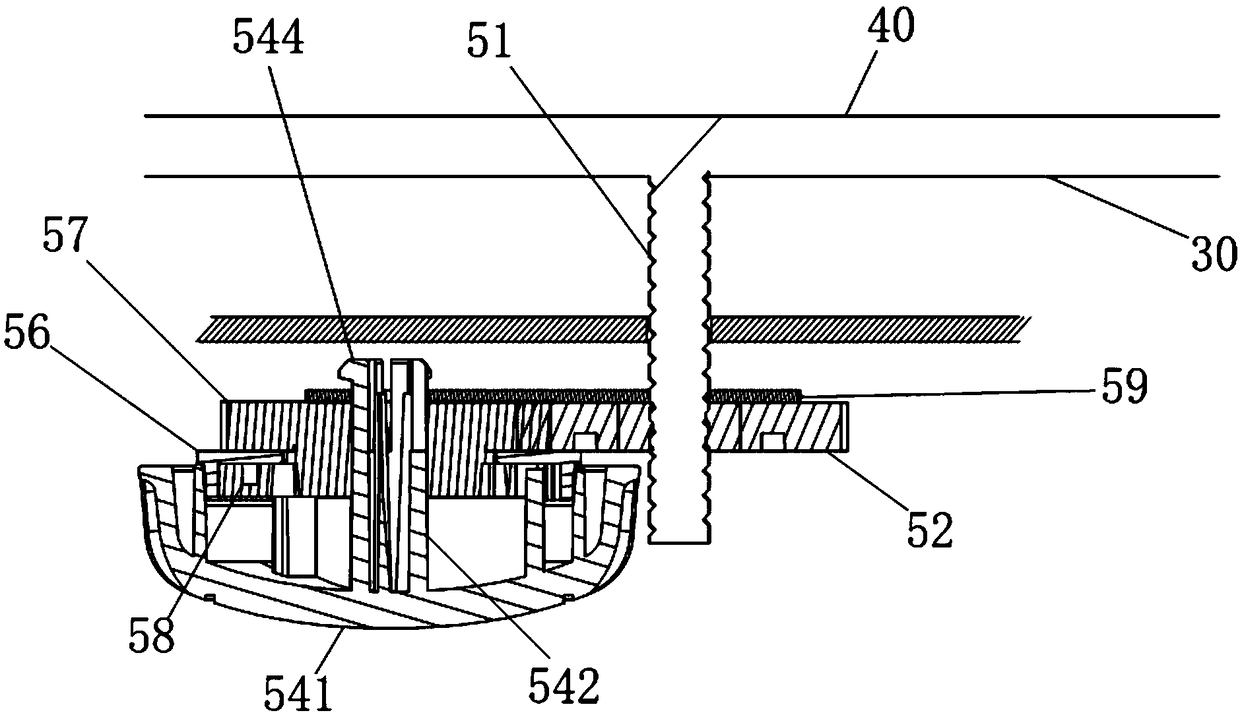

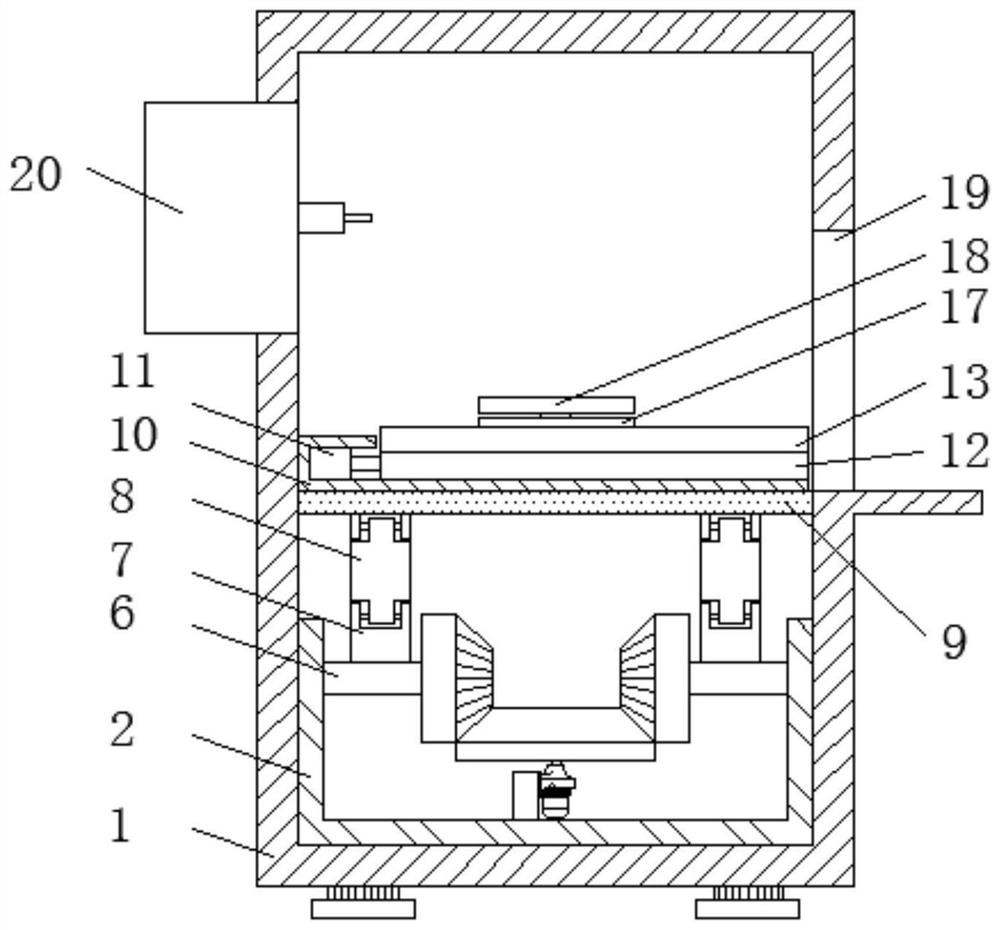

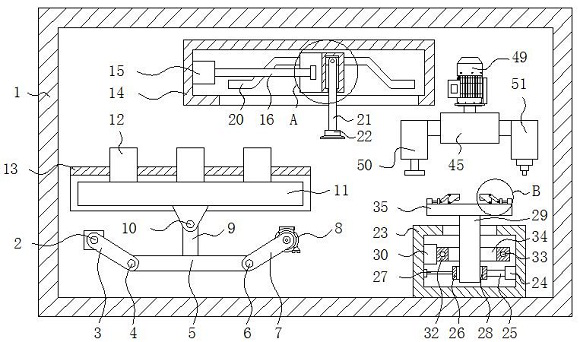

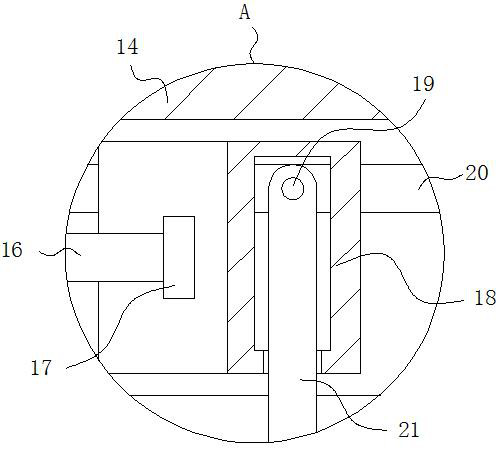

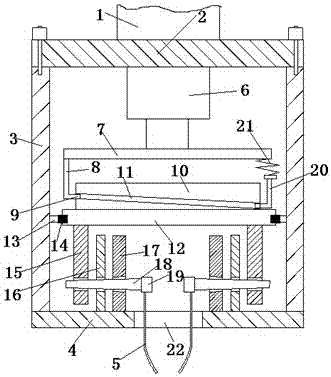

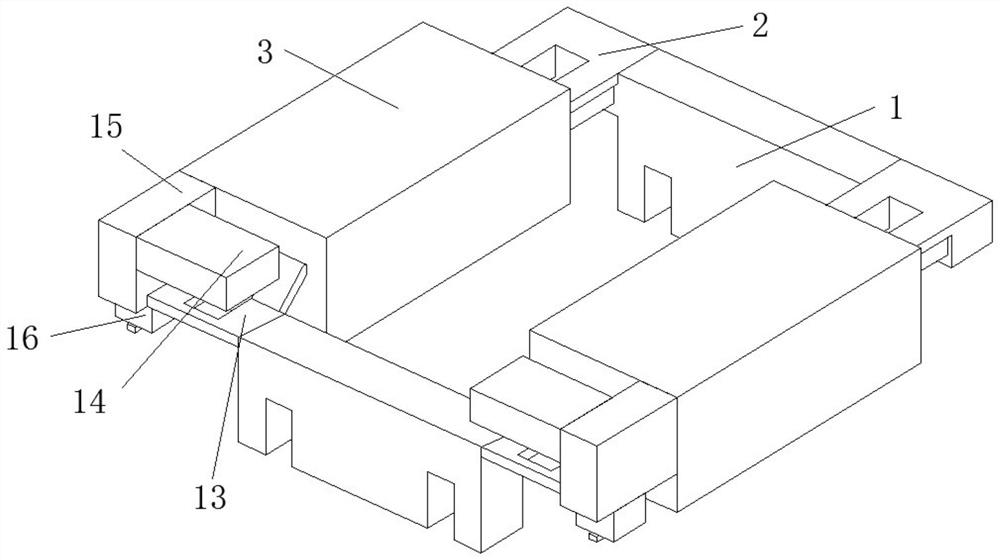

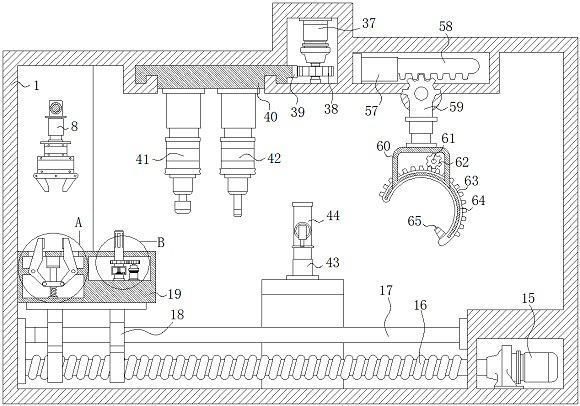

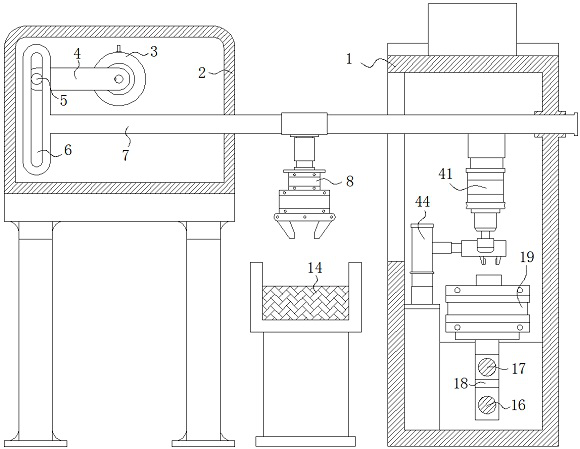

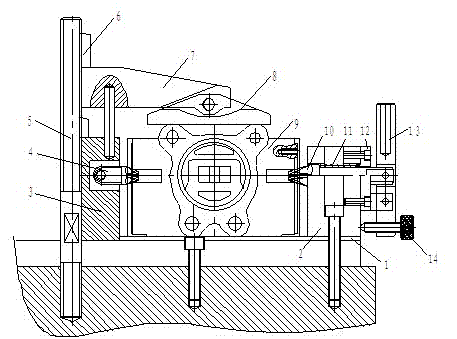

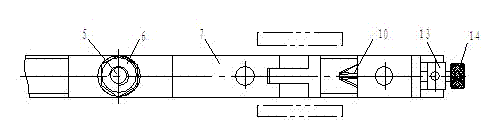

Lock core shell billiard hole drilling machine of numerical control mortise lock

ActiveCN102009203ASimplify the manual operation processImprove efficiencyBoring/drilling componentsBoring/drilling machinesNumerical controlControl system

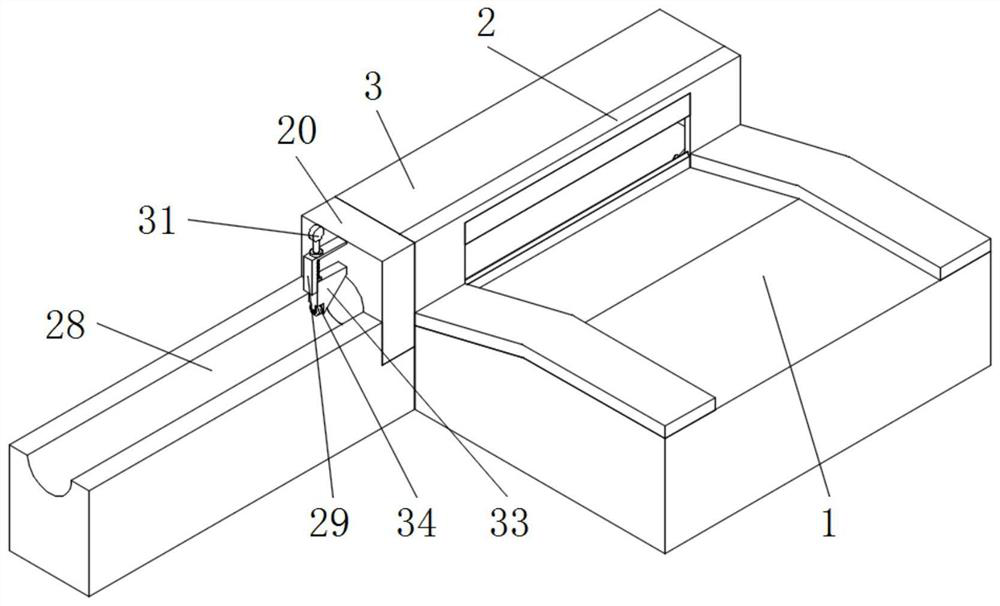

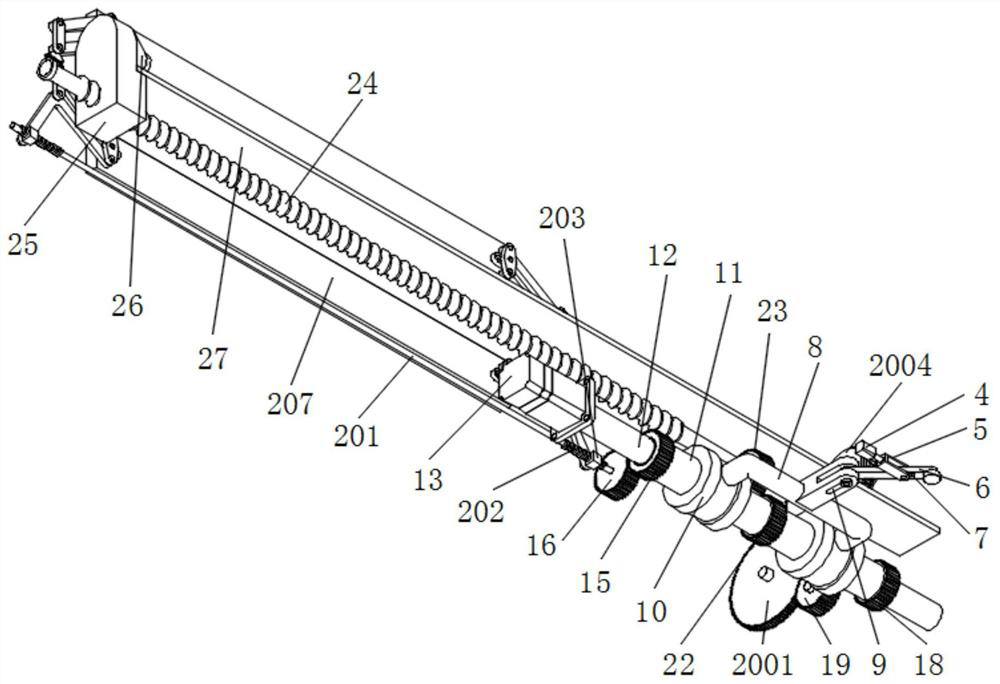

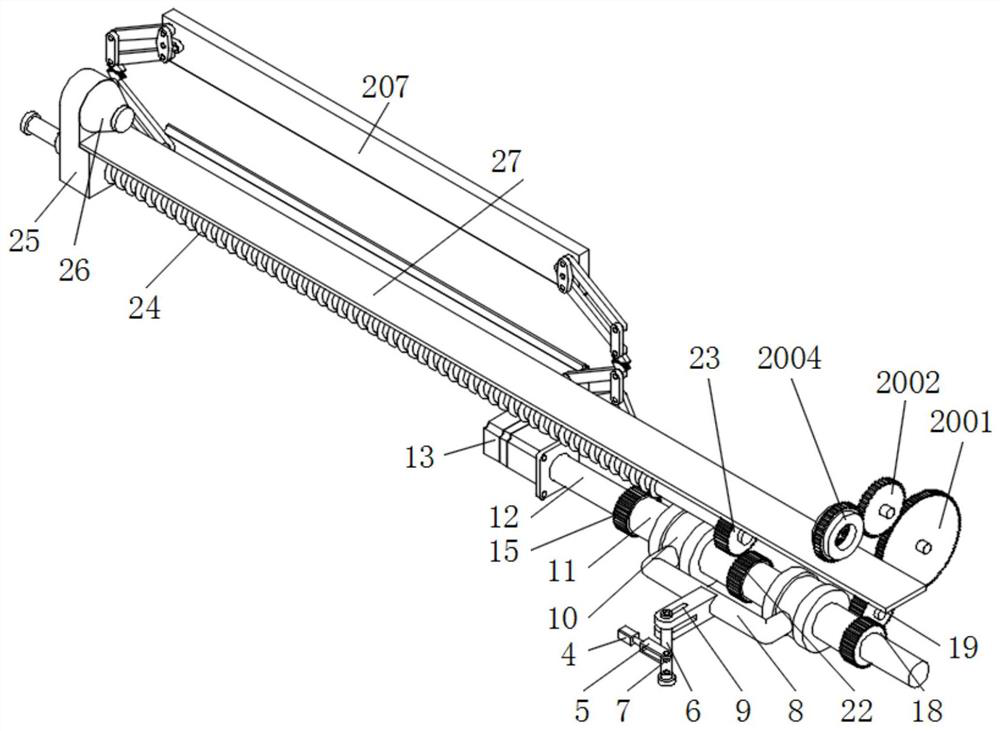

The invention discloses a lock core shell billiard hole drilling machine of a numerical control mortise lock. The machine comprises a machine body, a drilling mechanism, a feeding mechanism, a positioning and clamping mechanism and a control system, wherein the machine body consists of a pedestal and a gantry frame; a guide rail and a guide post which are matched with each other in a sliding way are arranged between the gantry frame and the pedestal; the drilling mechanism is fixed on the gantry frame; the feeding mechanism and the positioning and clamping mechanism are fixed on the pedestal; the output end of the feeding mechanism is connected with the positioning and clamping mechanism; a machined lock core shell conveyed out by the feeding mechanism is clamped and positioned by the positioning and clamping mechanism; and drilling operation of the machined lock core shell is finished by the drilling mechanism. By using the structure, only a lock core shell to be machined needs to be placed in a feeding groove frame, and the subsequent processes such as feeding, clamping and positioning, drilling, discharging and the like can be fully automatically operated; and compared with the conventional manual operation type lock core shell billiard hole drilling machine of the mortise lock, the machine simplifies the manual operation process, improves the efficiency and ensures that one person can simultaneously operate a plurality of machines.

Owner:温州杰拓数控设备有限公司

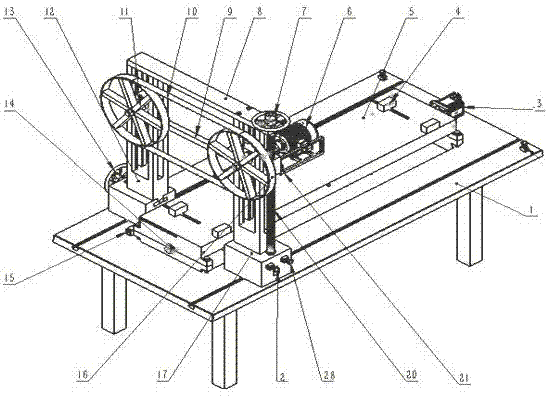

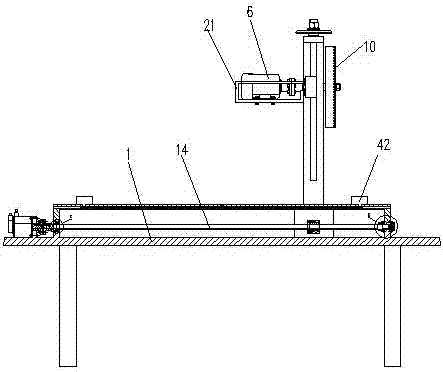

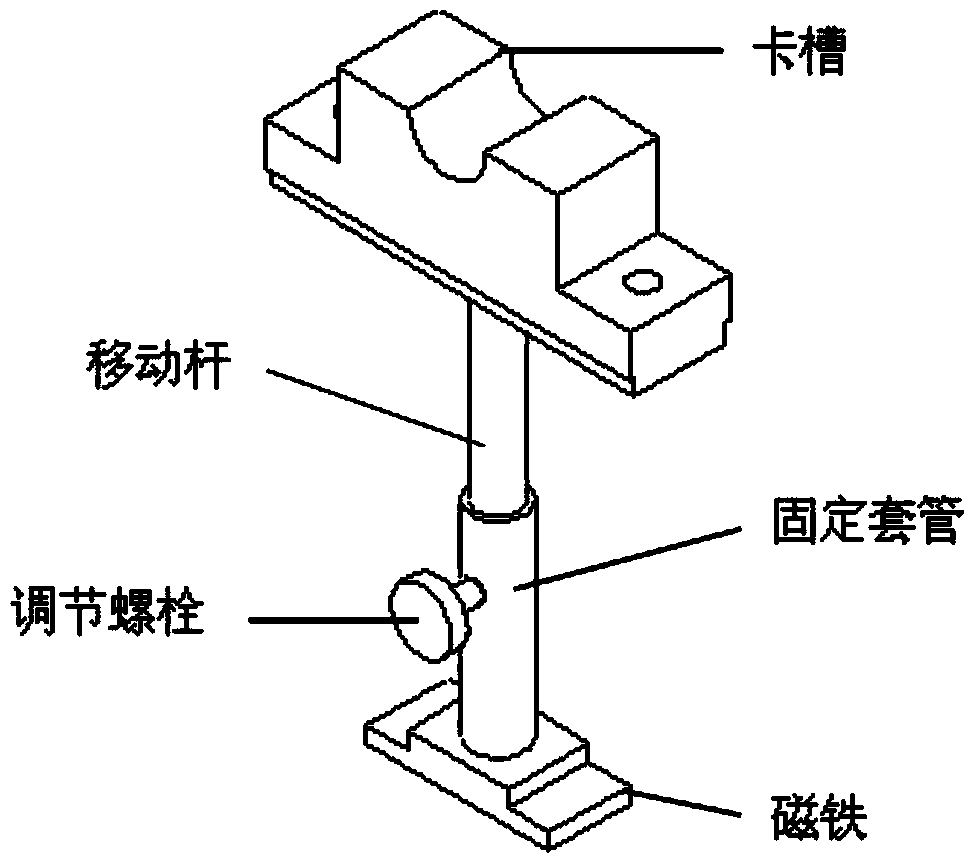

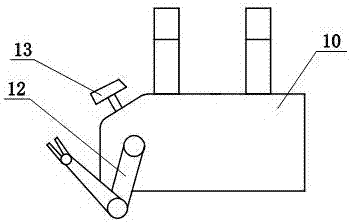

Improved log sawing machine

PendingCN107336286AOptimize the installation structureHigh precisionGripping devicesClamping devicesReciprocating motionSmall footprint

The invention discloses an improved log sawing machine, which comprises an operating desk, a saw bench and a saw blade device. The saw bench is arranged on the operating desk. The saw blade device is connected with the operating desk in a sliding mode. The saw blade device is arranged on the saw bench. The saw bench is provided with at least one clamping device of magnetic type. The operating desk is provided with at least two adjustable clamping devices. The log sawing machine has the advantages of being compact in structure, small in occupied area, achievable in adopting an ordinary feed screw nut pair for driving the reciprocating motion of the saw blade device, achievable in adopting a travel switch for simple control, high in cutting efficiency, low in labor intensity and convenient to operate. Furthermore, the improved log sawing machine is a practical woodworking machinery product of mechanical and electrical integration, and has a certain promotion value; the clamping device has a good improved effect, thereby being suitable for clamping logs of different sizes.

Owner:TAIZHOU POLYTECHNIC COLLEGE

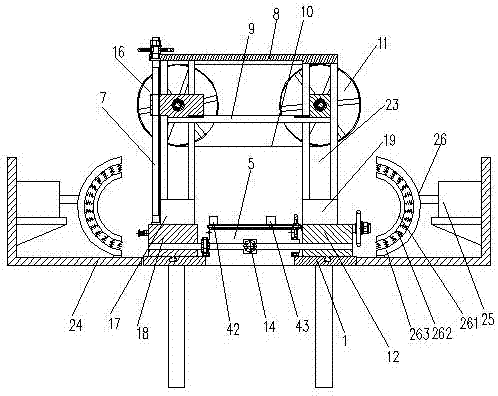

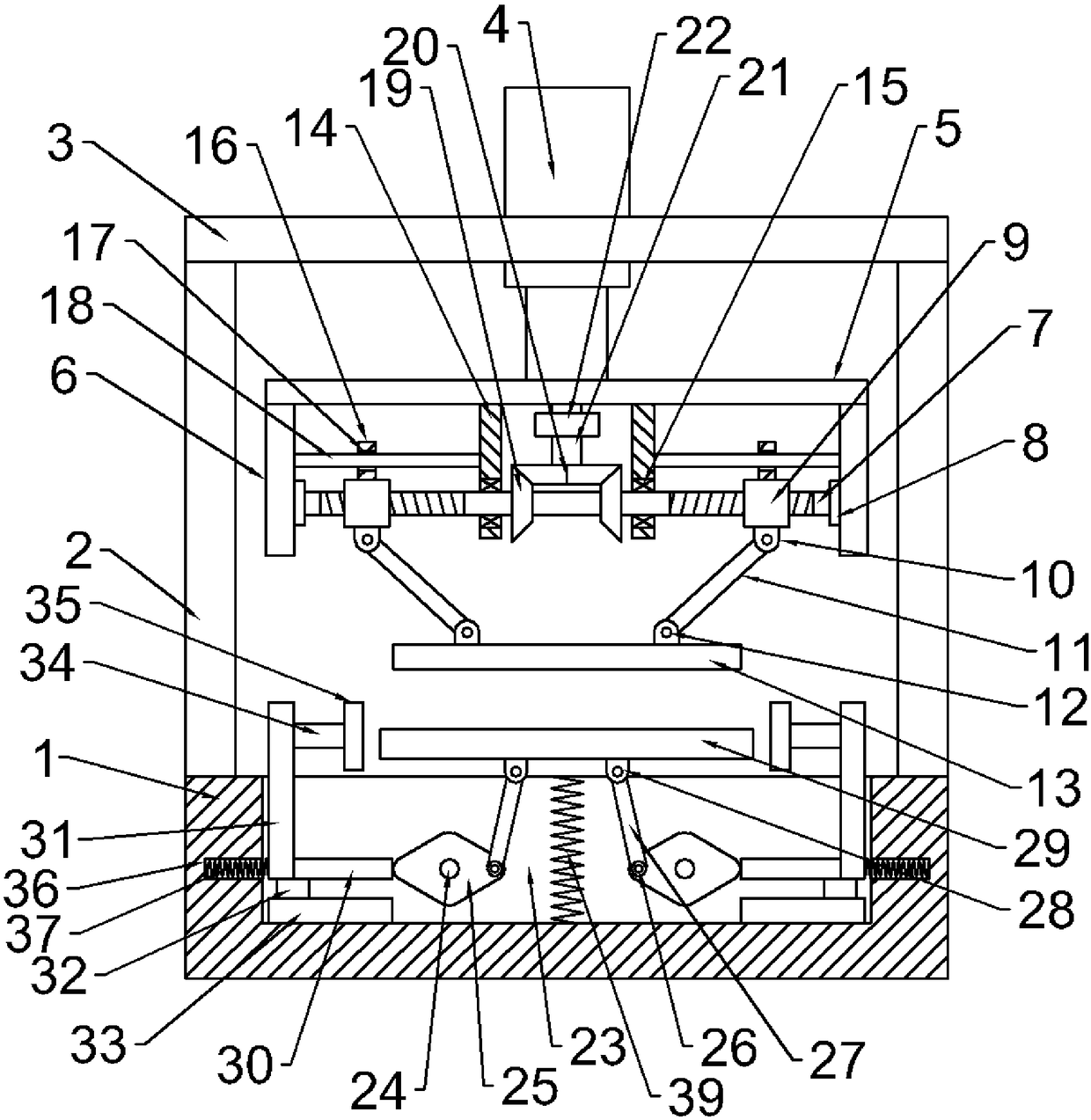

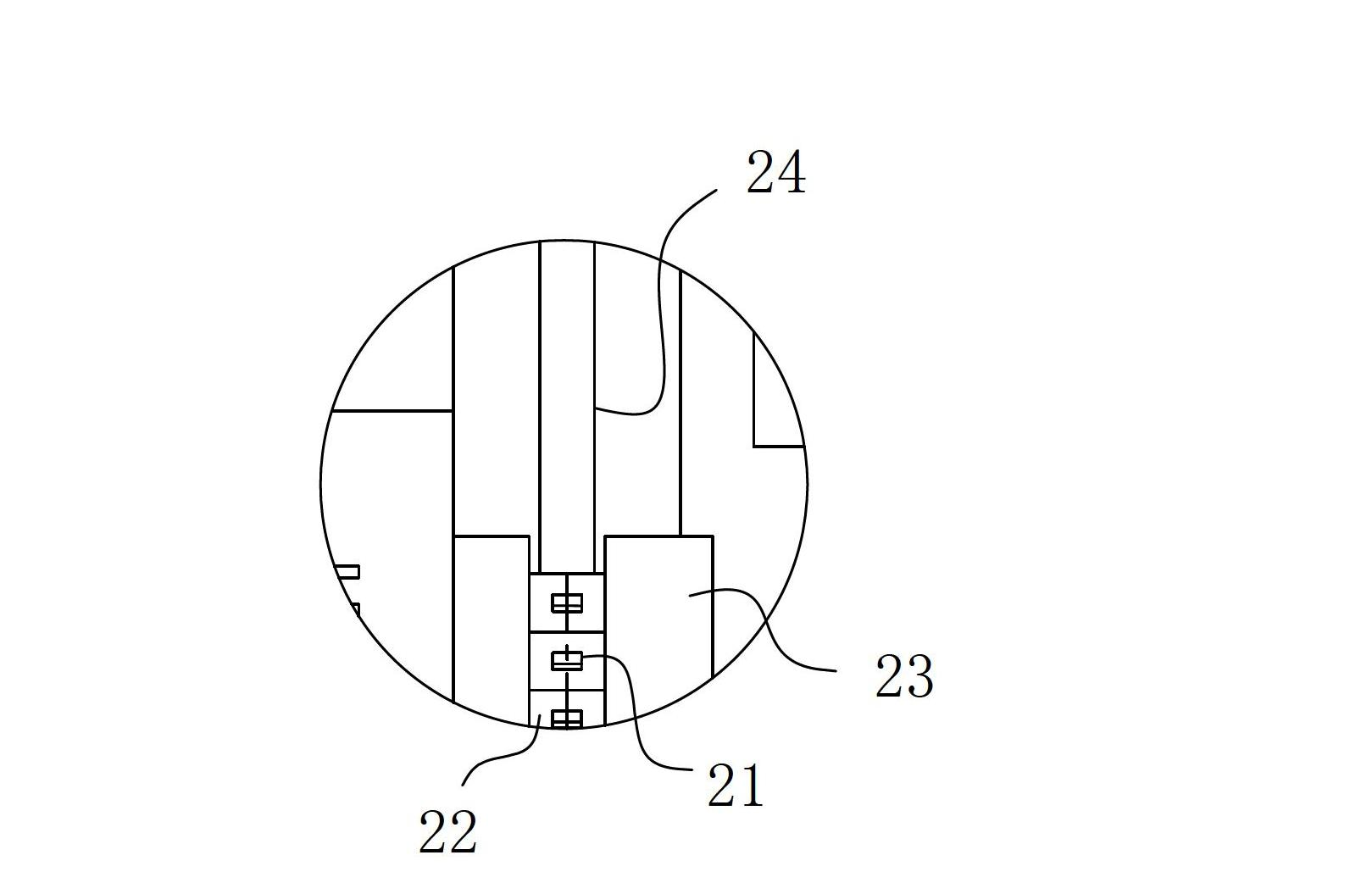

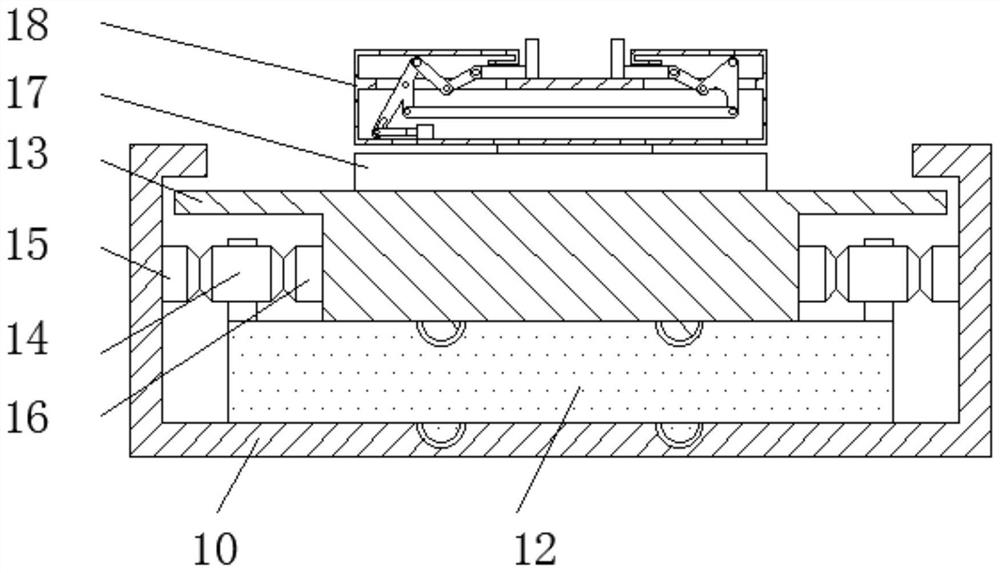

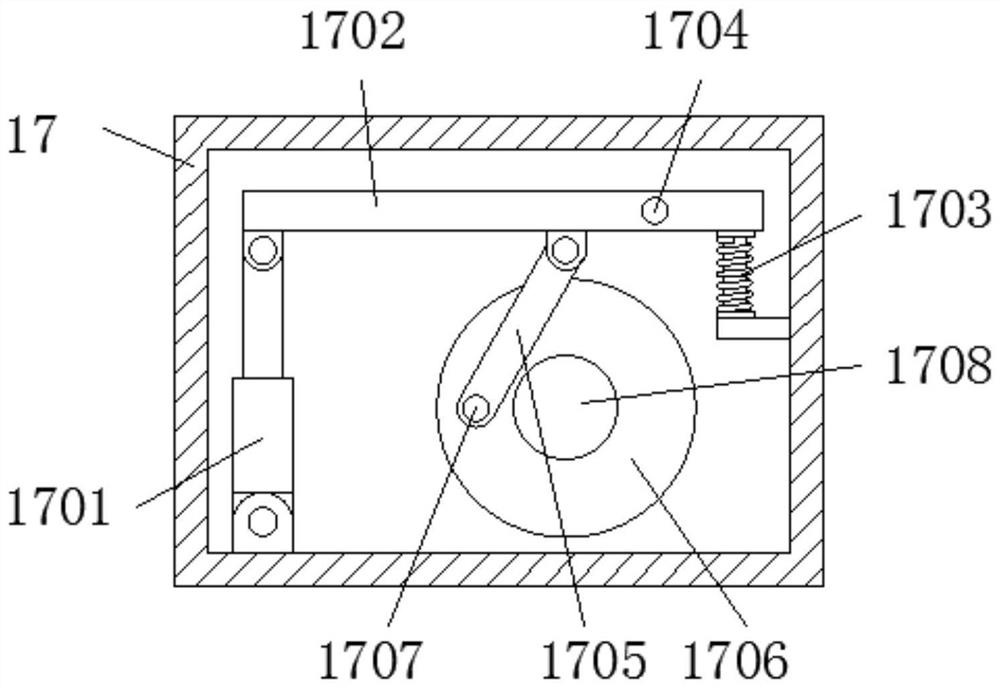

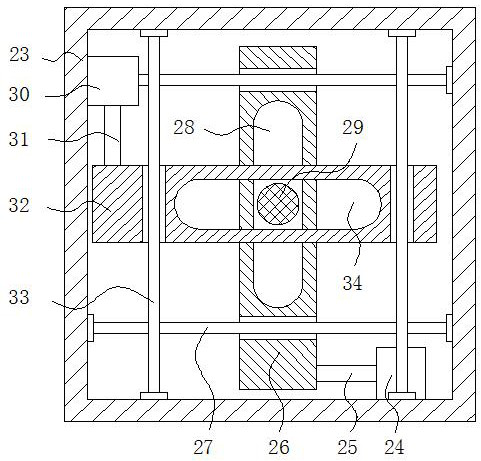

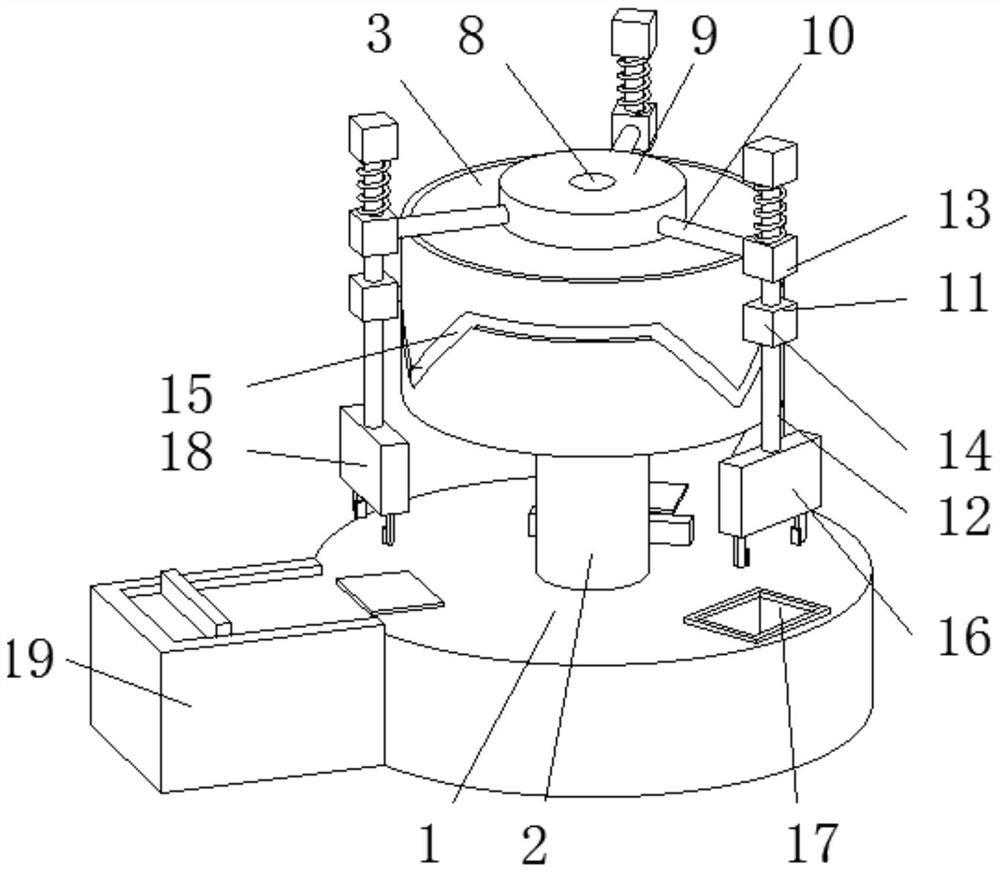

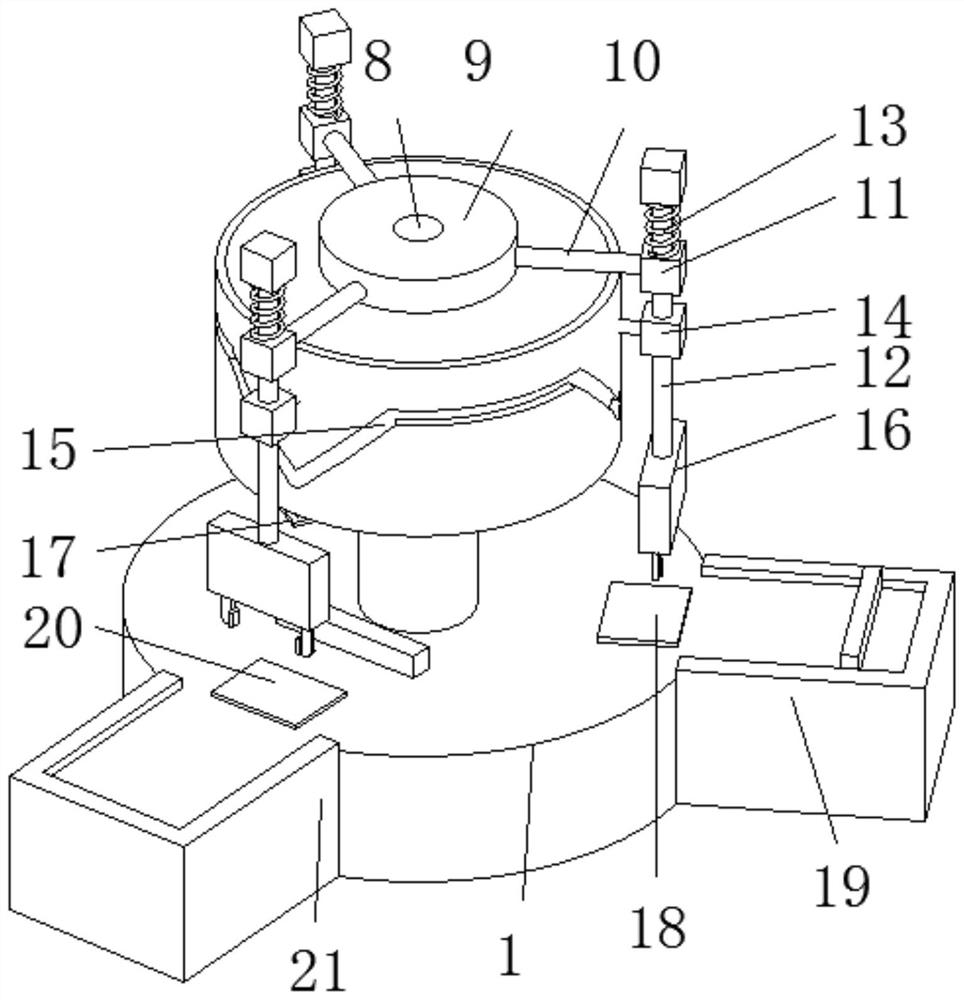

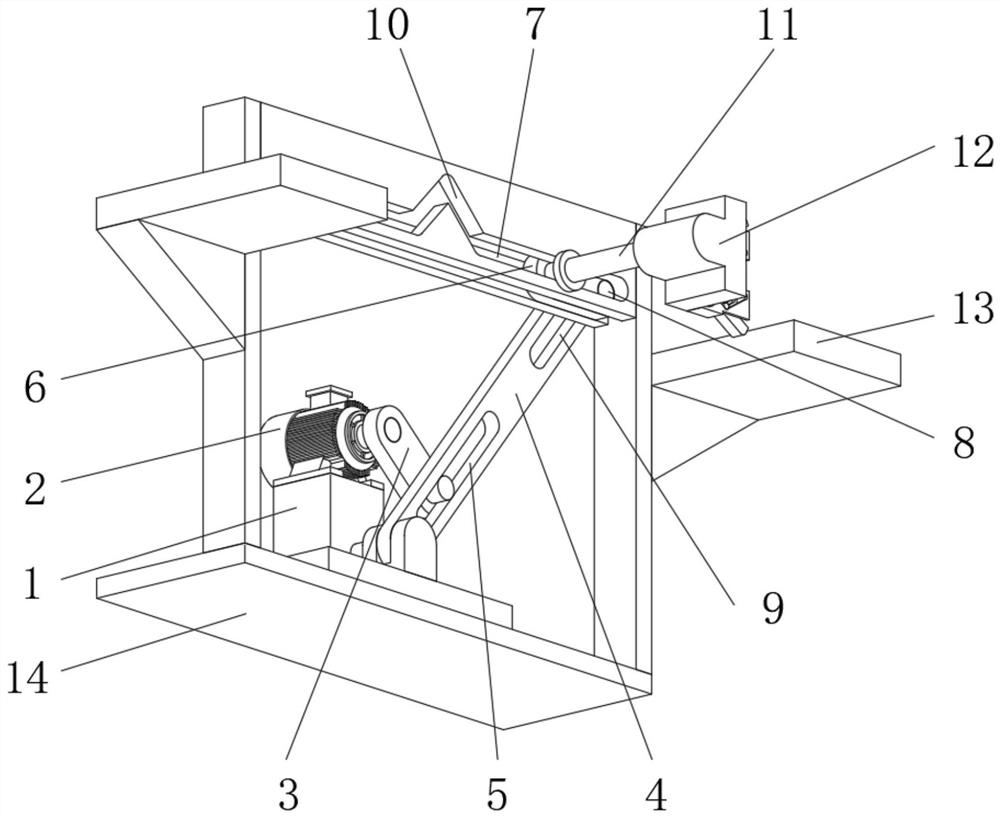

Material compaction device for food packaging

InactiveCN108190061AAchieve back and forth rotationRealize the clamping operationSolid materialTransverse planeEngineering

The invention discloses a material compaction device for food packaging. The material compaction device comprises a base, a support column, a transverse plate, a lifting device, a mounting plate, a vertical plate, a rotating shaft, a threaded part, a threaded sleeve, a first hinged seat, a first connecting rod, a second hinged seat, a pressing plate, support blocks, a guide block, a guide hole anda guide rod, wherein two driven bevel gears are symmetrically installed on the rotating shaft and are located between the two support blocks along the center, the two driven bevel gears are oppositely arranged, and a semicircular bevel gear is engaged with the upper ends of the two driven bevel gears. According to the material compaction device, the directions are opposite when the two driven bevel gears are respectively engaged with the semicircular bevel gear to move, so that the back-and-forth rotation of the rotating shaft can be realized, the up-and-down reciprocating movement of the pressing plate is realized, and continuous reciprocating downward pressing is realized; when pressure is applied to a bearing plate, a clamping plate is close to the center of the upper end of the bearing plate so as to clamp a material tank body on the bearing plate, when the pressure applied to the bearing plate disappears, the bearing plate and the clamping plate are automatically reset, and manual adjustment is not needed.

Owner:顾志裕

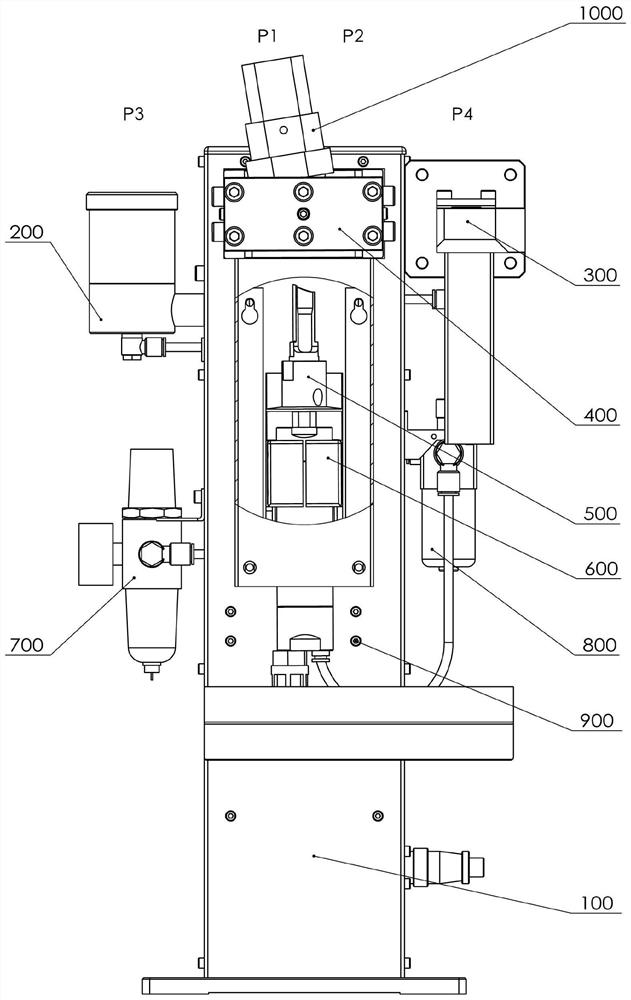

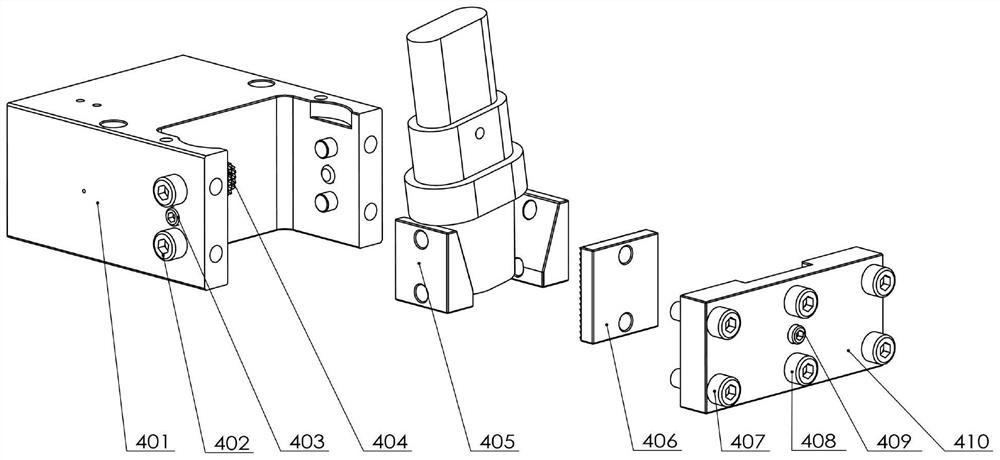

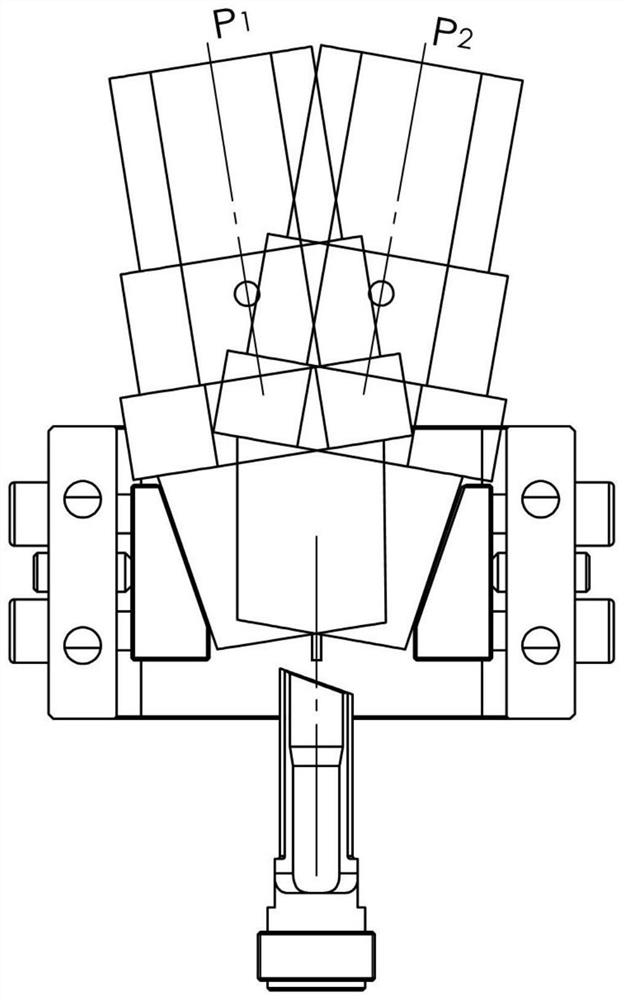

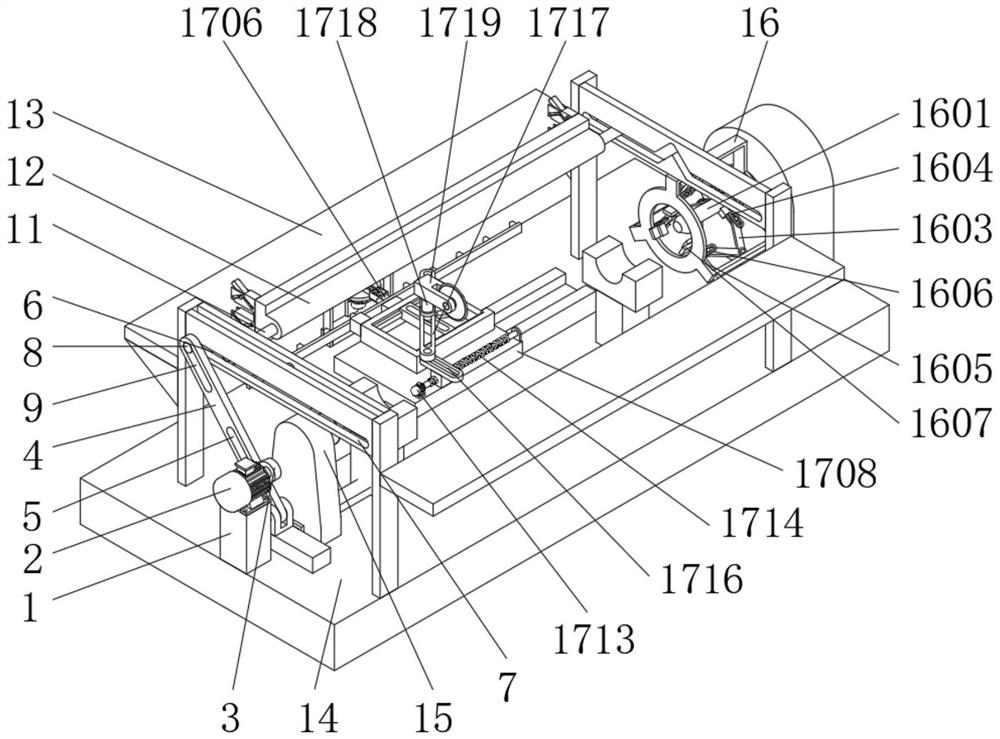

Full-automatic welding tool capable of achieving flat welding and vertical welding simultaneously

PendingCN108526782AVersatileReduce difficultyWelding/cutting auxillary devicesAuxillary welding devicesTransverse axisEngineering

The invention relates to a full-automatic welding tool capable of achieving flat welding and vertical welding simultaneously. The tool comprises a rack comprising a base and a hoisting bracket, wherein an X direction sliding table is mounted on the base; a Y direction sliding table is mounted on the X direction sliding table; a horizontal workbench is mounted on the Y direction sliding table; a left fixing seat and a right fixing seat are arranged on horizontal workbench; a clamping device is mounted between the left fixing seat and the right fixing seat; a mechanism case is fixed on the hoisting bracket and internally equipped with a main shaft extending in a Z direction; a cross shaft is mounted at the extension end of the main shaft; at least one welding connecting rod and a defect detection connecting rod are mounted on rod bodies on the two sides of the cross shaft; welding guns and a defect probe are correspondingly mounted at fastening ends of the welding connecting rods and thedefect detection connecting rod; pointers are mounted at non-fastening ends of the welding connecting rods and the defect detection connecting rod; and an angle scale is arranged on a front / rear sidewall of the mechanism case. The tool achieves welding and defect detection of a spatial complicated piece in the X, Y and Z directions, effectively improves welding efficiency, guarantees welding quality and has broad space and prospects.

Owner:HUBEI POLYTECHNIC UNIV

Automatic power construction robot

ActiveCN108381587ARealize the clamping operationImprove stabilityGripping headsMechanical energy handlingInterference fitElectric power

The invention discloses an automatic power construction robot which structurally comprises a mechanical arm, a power connection wire, a connection arm, a rotary connection seat and a fixed base; a through hole is formed in the upper side of the connection arm; the mechanical arm is connected to the interior of the through hole in an embedding manner; the connection arm is connected with the mechanical arm in an interference fitting manner; one end of the power connection wire is connected to the interior of the mechanical arm in the embedding manner and is closely connected with the interior of the mechanical arm; one end of the bottom of the connection arm is connected with the rotary connection seat through a bearing; the cross section of the rotary connection seat is of a circular structure; and the rotary connection seat is arranged on the fixed base. The automatic power construction robot provided by the invention realizes clamping operation on an object during construction and can effectively improve the clamping stability to the object, avoids the conditions of loosening, falling and the like, is beneficial to maintaining the construction order and improves the working efficiency in the construction process.

Owner:QINGYUAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID CO LTD +1

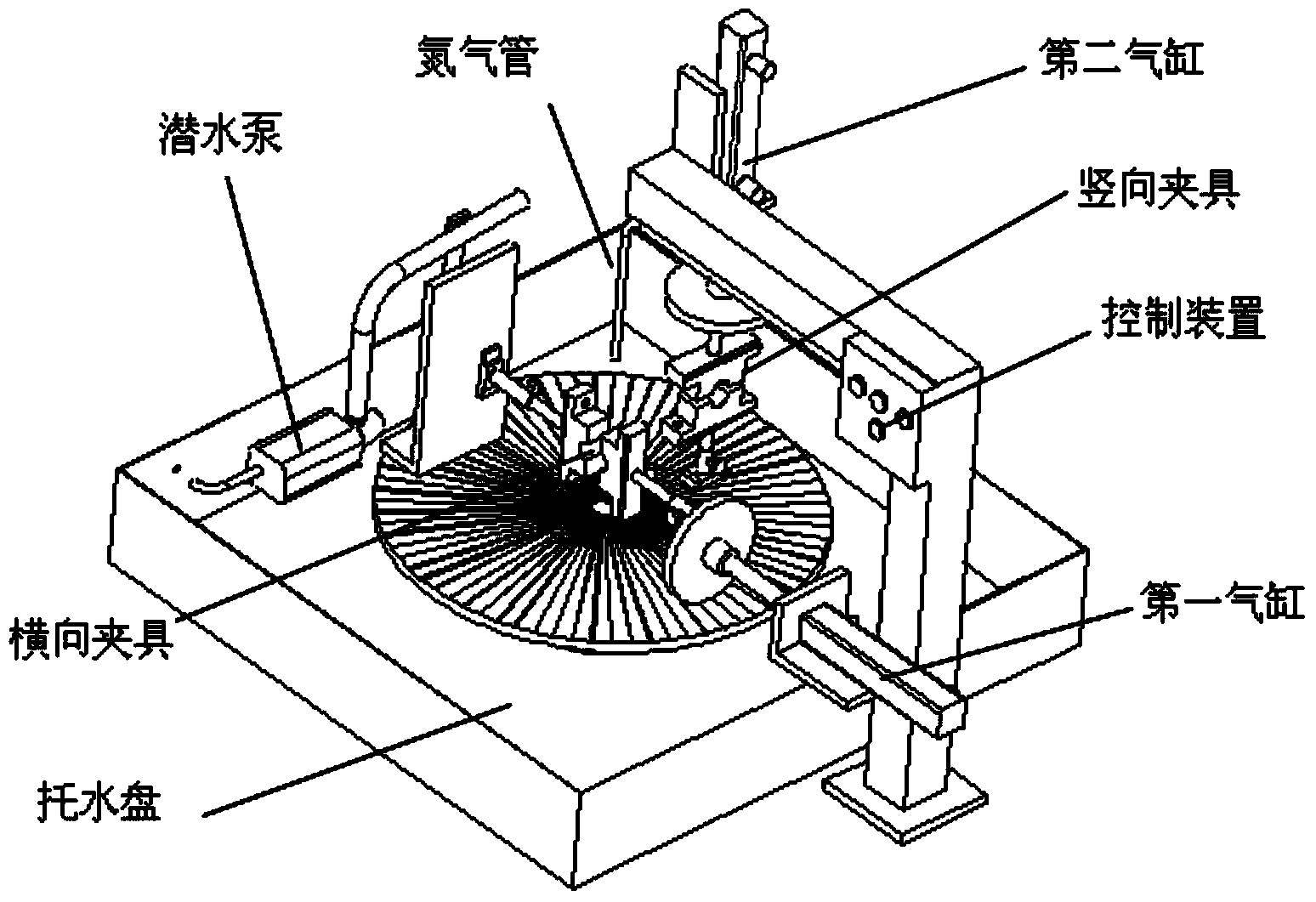

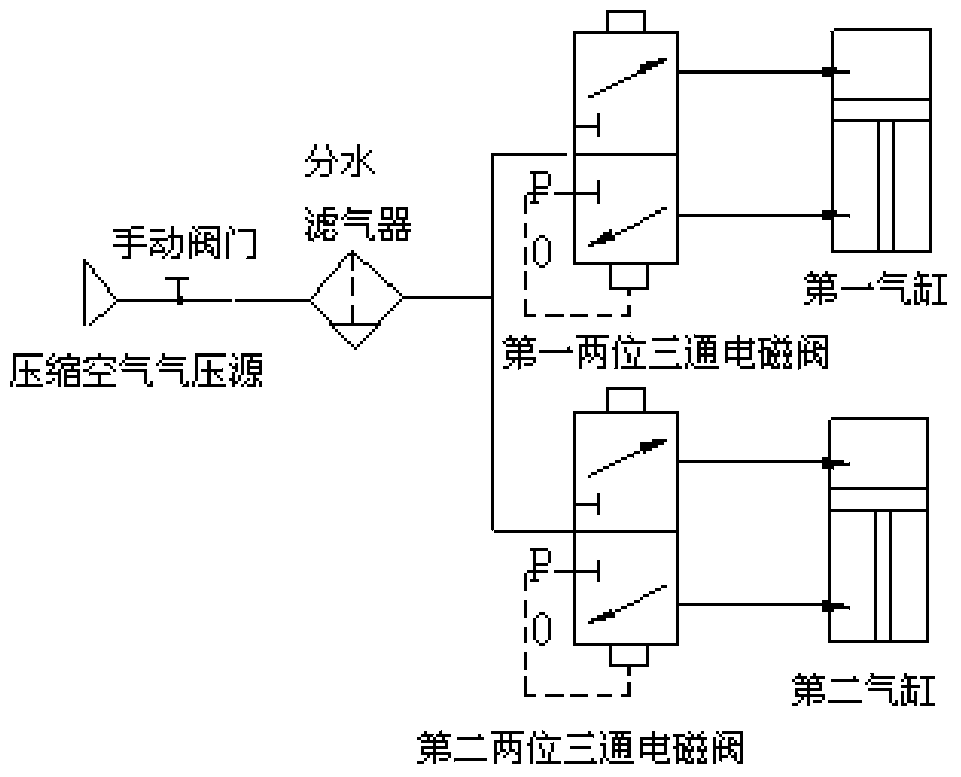

Pre-welding tool for refrigerating system valve assembly

ActiveCN103521975ARealize the clamping operationNo manual effort requiredWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPiston rod

The invention relates to a pre-welding tool for a refrigerating system valve assembly. The pre-welding tool comprises a water tray and a clamp for clamping an object to be welded. The clamp is composed of a first clamp and a second clamp. The first clamp and the second clamp are respectively composed of a supporting rod which is of a retractable structure and a clamping groove in the top of the supporting rod. The clamping groove of the first clamp and the clamping groove of the second clamp are arranged oppositely. The pre-welding tool further comprises an air cylinder and a control device, wherein the air cylinder is used for pushing the clamp to enable the first clamp and the second clamp to be clamped mutually and tightly, and the control device is used for controlling the motion of the air cylinder. The bottom of the supporting rod of the second clamp is fixed, and the bottom of the supporting rod of the second clamp is connected with a piston rod of the air cylinder. The pre-welding tool solves the problems that when an existing valve assembly welding tool is used for clamping and welding a valve body or a pipeline, the valve body or the pipeline may be damaged, the welding quality is poor and working efficiency is low.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

Positioning mechanism based on heat radiating tubes

InactiveCN102642130ARealize the clamping operationQuick and easy piping operationAssembly machinesWork benchesClamp connectionEngineering

The invention belongs to the field of heat radiator assembly and particularly relates to a positioning mechanism based on heat radiating tubes. The positioning mechanism comprises a work table surface and a clamp connection unit, wherein the clamp connection unit comprises a plurality of guide strips in mutually parallel arrangement, gaps among the guide strips form a clamp connection opening arranged on the clamp connection unit, the guide strips are in arrangement in a mode that the arrangement direction of the guide strips is parallel to or intersected with the arrangement direction of the heat radiating tubes. When each guide strip arranged on the clamp connection unit is respectively in an external expansion state in the arrangement direction of the guide strips, the minimum gap of the clamp connection opening is greater than the heat radiating strip width in the flat straight state. When each guide strip arranged on the clamp connection unit is respectively in the gathering state, the minimum gap of the clamp connection opening is equal to the heat radiating strip width in the flat straight state. The positioning mechanism also comprises a motive power unit, when the motive power unit is positioned in an initial position, the clamp connection unit is positioned at a work platform part, and after the gathering action of the clamp connection unit is completed, the motive power unit acts and drives the clamp connection unit to move away from the work platform. The positioning mechanism has the advantages that the assembly positioning force is balanced, and the work efficiency is high.

Owner:HUANGSHAN KENENG AUTO RADIATOR

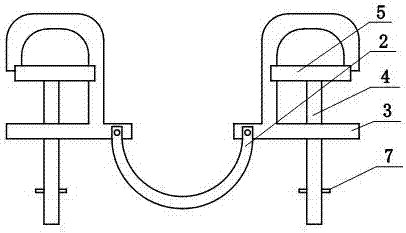

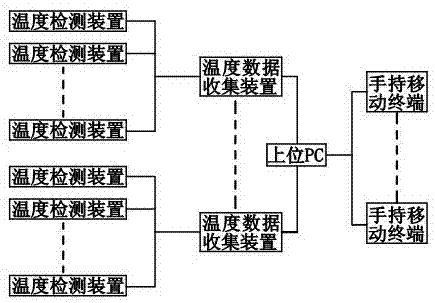

Electric processing apparatus of heating tape of transmission line connector

PendingCN107257104ARealize heat treatmentWith temperature monitoring functionCoupling contact membersCleaning using toolsWireless transmissionTemperature monitoring

The invention discloses an electric processing apparatus of a heating tape of a transmission line connector. The electric processing apparatus comprises a hot-line work tool, a shunt fastening device, and temperature detection devices that cooperate with each other. The hot-line work tool consists of an insulating rod and a walking robot capable of walking back and forth on a wire. The shunt fastening device includes two wire clamps connected by a shunt wire. At least two temperature detection devices are arranged at wires of transmission line contact points and include infrared sensors for detecting temperatures of the wire contact points; and the infrared sensors are connected with a temperature data collection unit with power supply based on the solar energy by a wireless transmission device. On the basis of combination of the hot-line work tool, the shunt fastening device, and the temperature detection devices, heating processing is carried out on the transmission line connector and cutting processing is carried out on foreign matters at the transmission line; the temperature monitoring function of the transmission line connector is realized; and the fusion operation of the different devices is realized.

Owner:ZHUMADIAN POWER SUPPLY ELECTRIC POWER OFHENAN +1

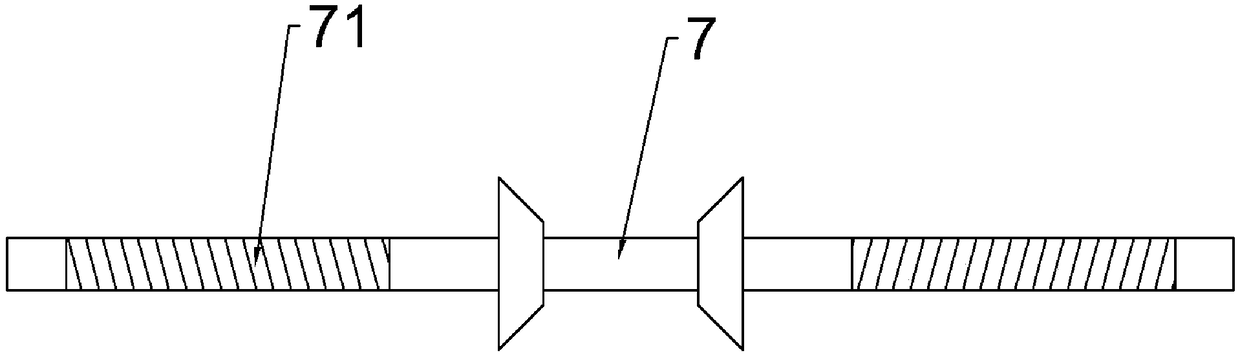

Shaft coupling used between motor rotating shaft and spline connecting shaft

InactiveCN107202074ASo as not to damageAvoid corrosionCouplings for rigid shaftsMechanical energy handlingMaximum diameterCoupling

The invention provides a shaft coupling used between a motor rotating shaft and a spline connecting shaft. The shaft coupling used between the motor rotating shaft and the spline connecting shaft comprises a left sleeve chuck, a right sleeve chuck, a shaft sleeve and a conical sleeve; a positioning key which is fixed in the axis direction is welded on the outer surface of the left sleeve chuck; the positioning key is clamped in a positioning groove in the motor rotating shaft; the shaft sleeve is connected with the left sleeve chuck; internal threads are formed on the inner side of the right sleeve chuck and are matched with external threads on the shaft sleeve; the two ends of the shaft sleeve are open; the inside diameter of the opening in one end, which is in contact with the left sleeve chuck, of the shaft sleeve is smaller than that of the opening in the other end of the shaft sleeve, so that a conical through hole is formed; the conical sleeve which is matched with the conical through hole of the shaft sleeve is arranged in the shaft sleeve; a shaft hole is formed in the conical sleeve; tightening openings are formed in the end surfaces of the left sleeve chuck and the right sleeve chuck; the inside diameters of the tightening openings are greater than the inside diameter of the shaft hole and smaller than the maximum diameter of the conical sleeve; and the conical sleeve is extruded to the shaft sleeve through the tightening openings by rotating the right sleeve chuck. The shaft coupling provided by the invention is simple in structure; force is applied to the spline connecting shaft uniformly; a fixing effect is good.

Owner:HUBEI WEINENGDA TRANSMISSION CO LTD

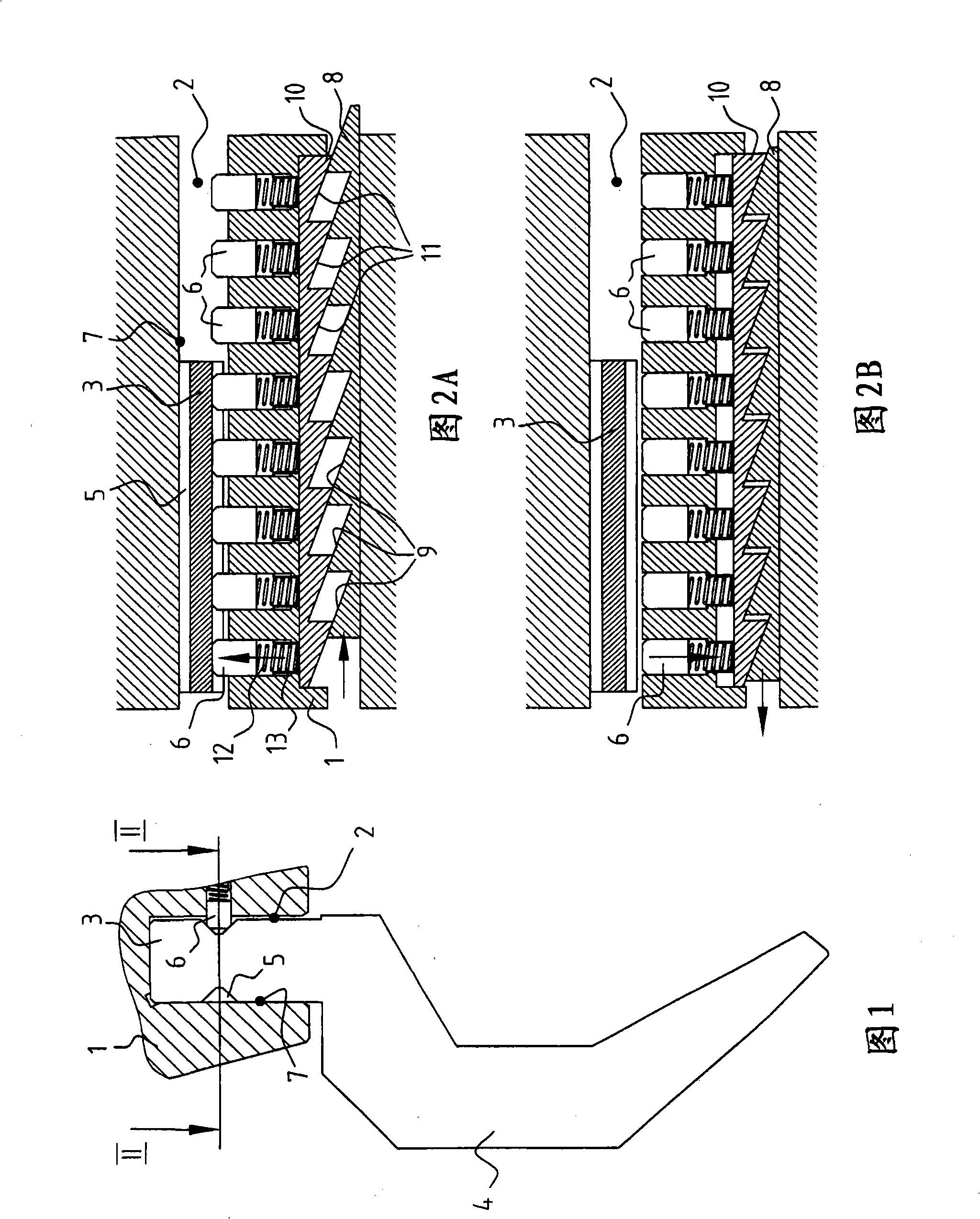

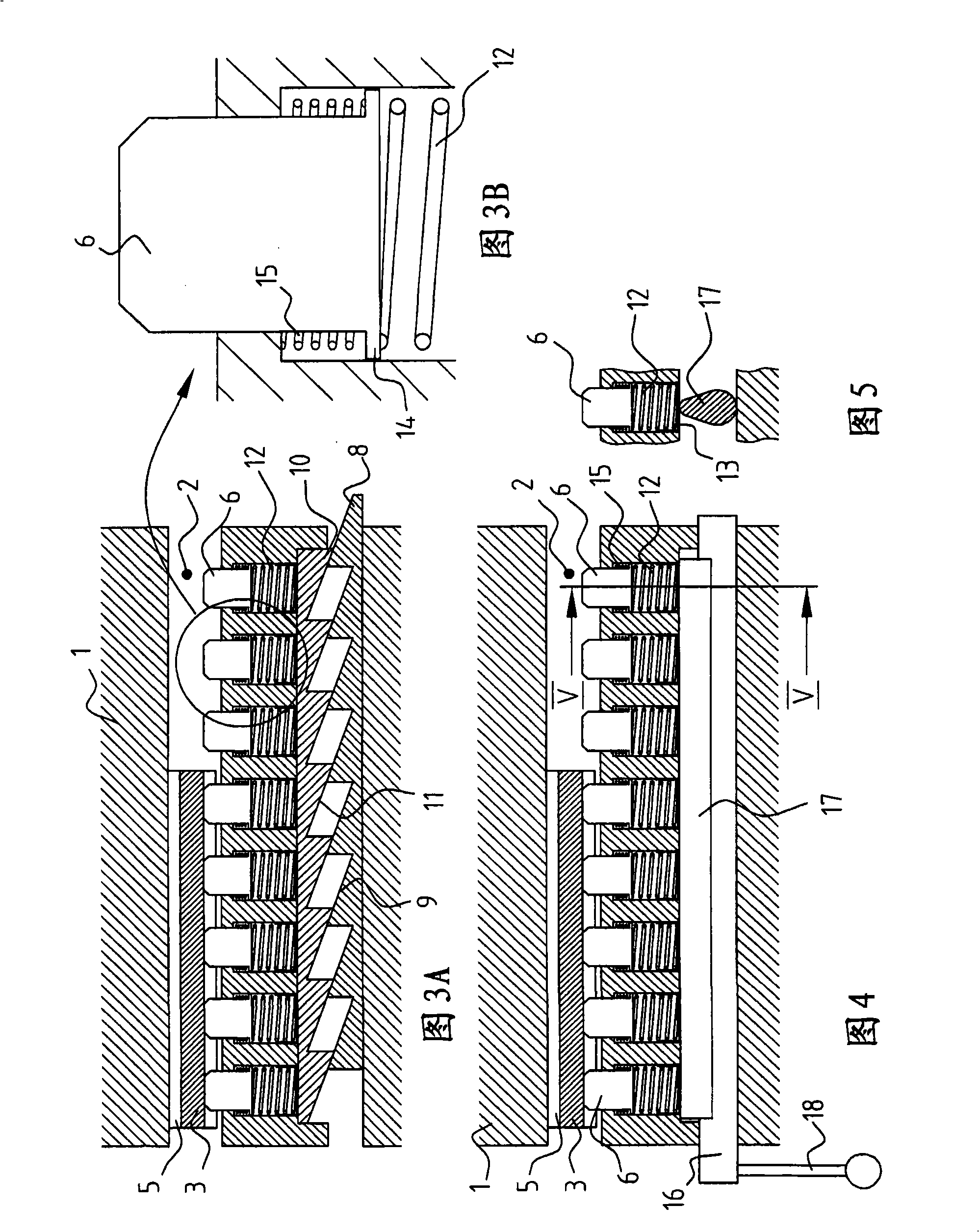

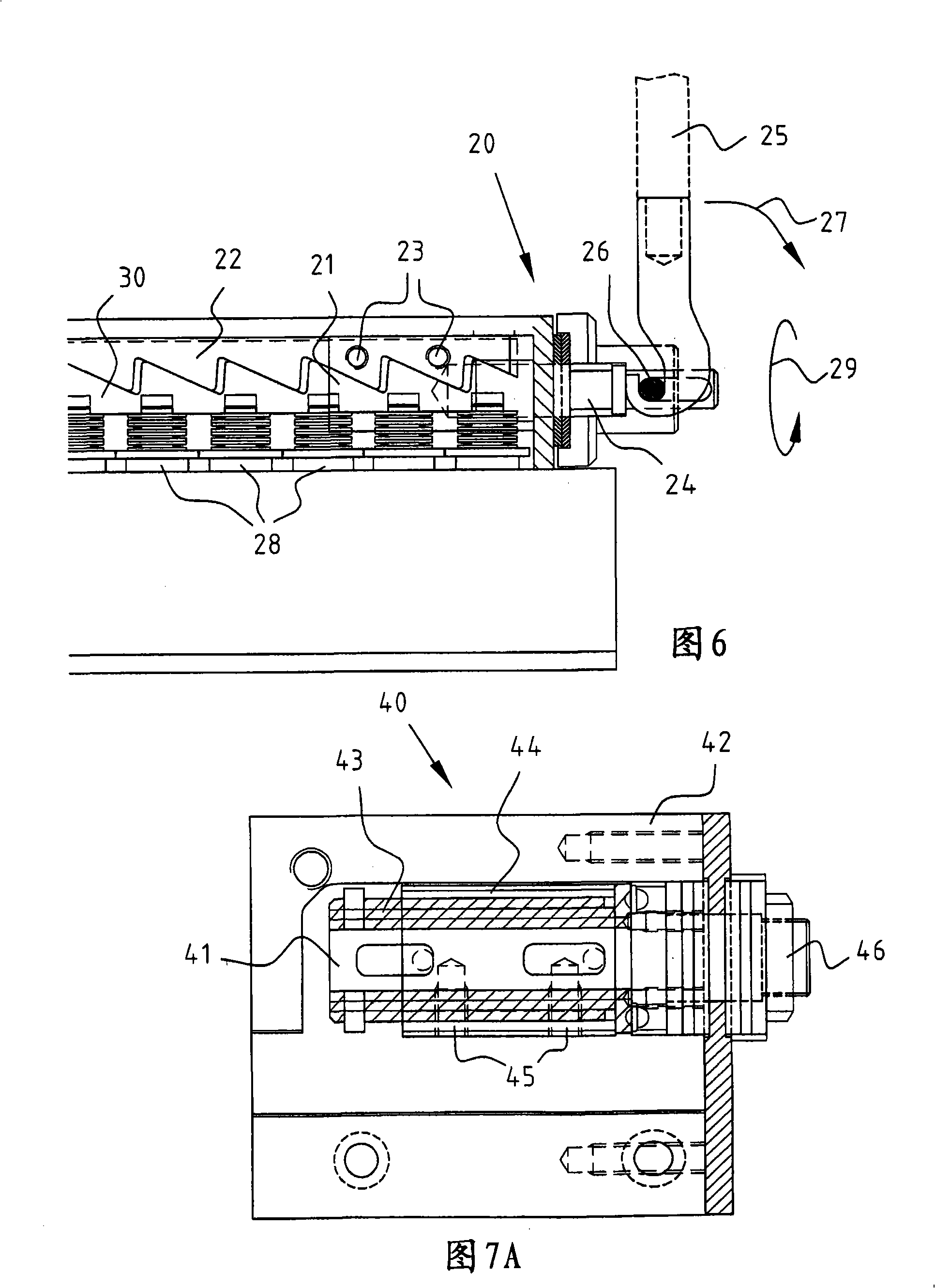

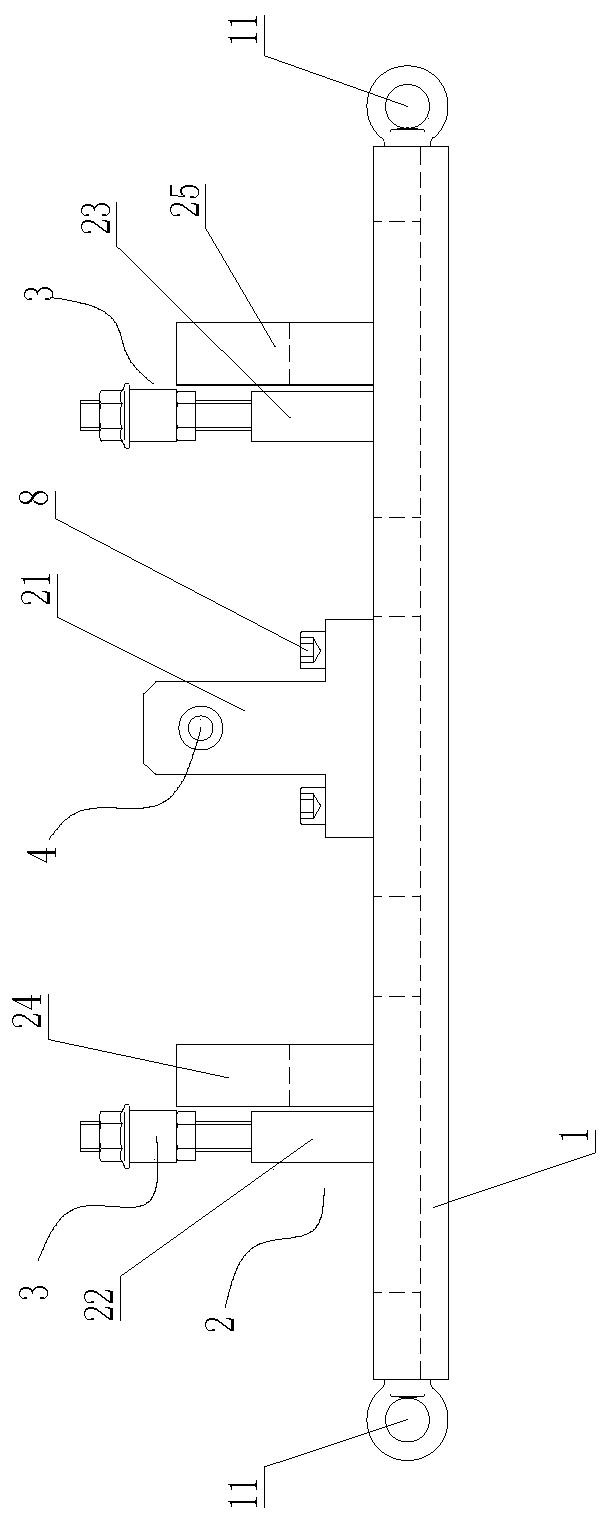

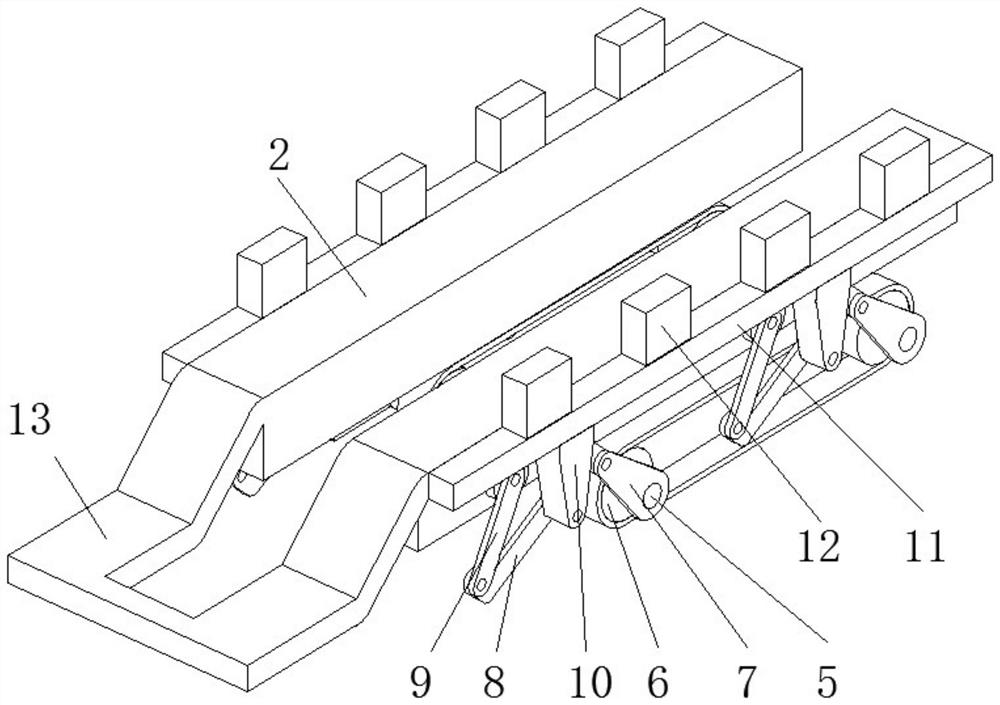

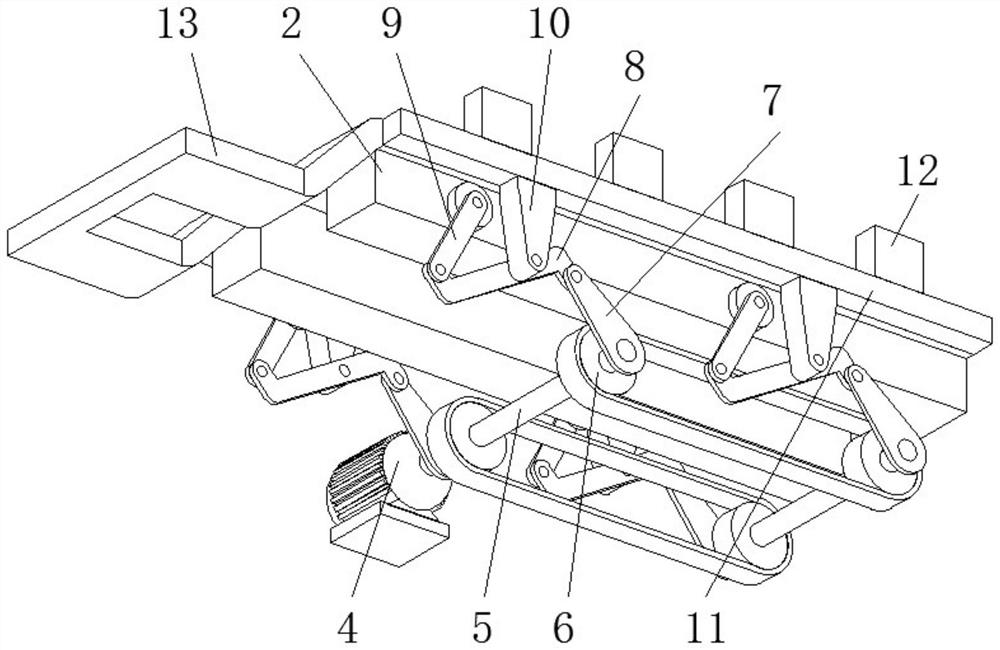

Clamping beam

ActiveCN101322994ARealize the clamping operationSleeve/socket jointsShaping toolsMechanical engineering

The invention relates to a clamping system for clamping a plurality of tools, wherein the system comprises: a body; an elongated groove (2) arranged in the body for reception of a clamping part of at least one tool; at least one pusher element extendable into the groove for pushing the clamping part of a tool against a wall of the groove; wherein, shape imposed displacement means for displacing the at least one pusher element from a first position substantially freeing the groove, enabling insertion of the clamping part of the tool into the groove, towards a second position, in which the at least one pusher element extends into the groove.

Owner:WILA

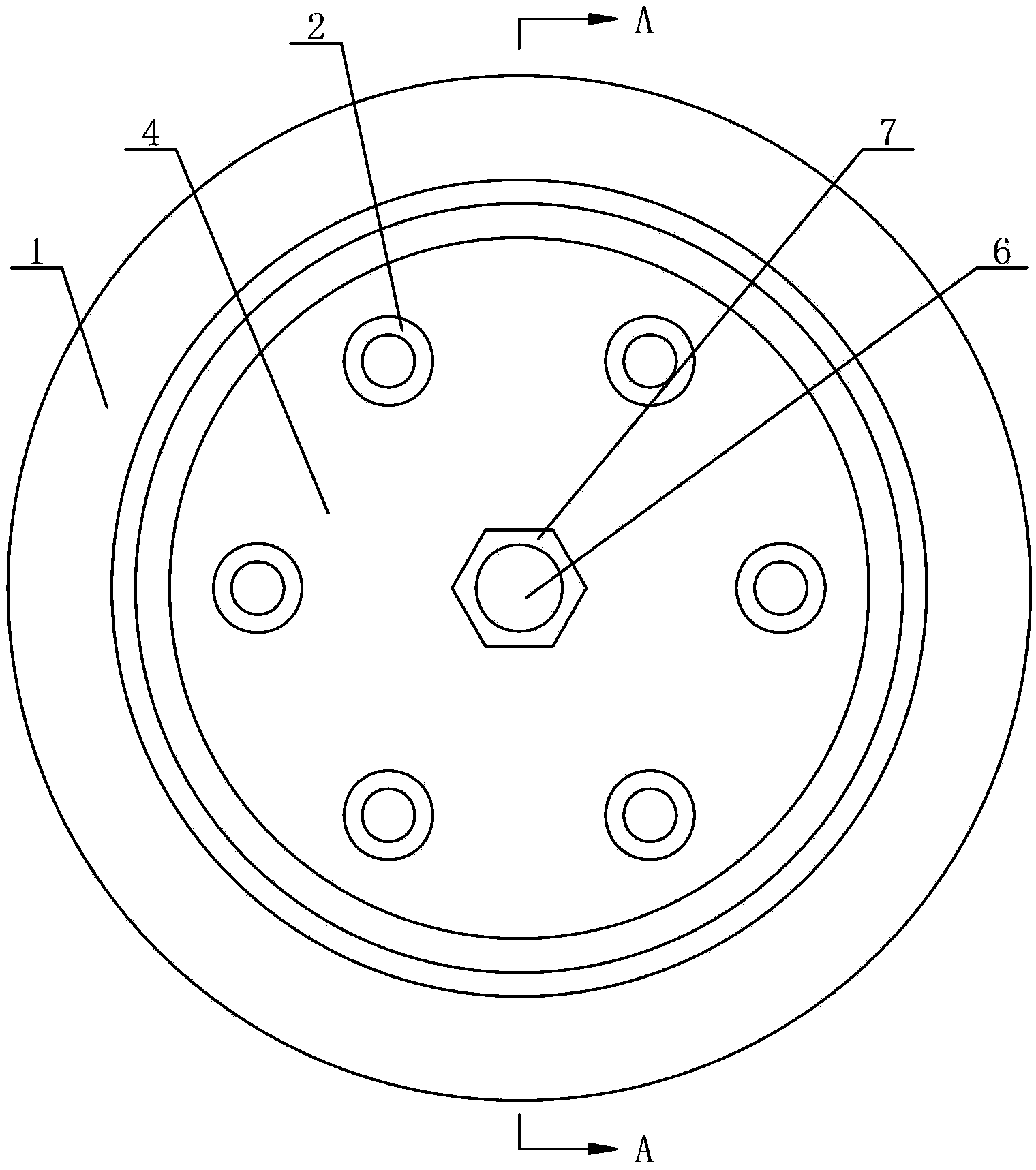

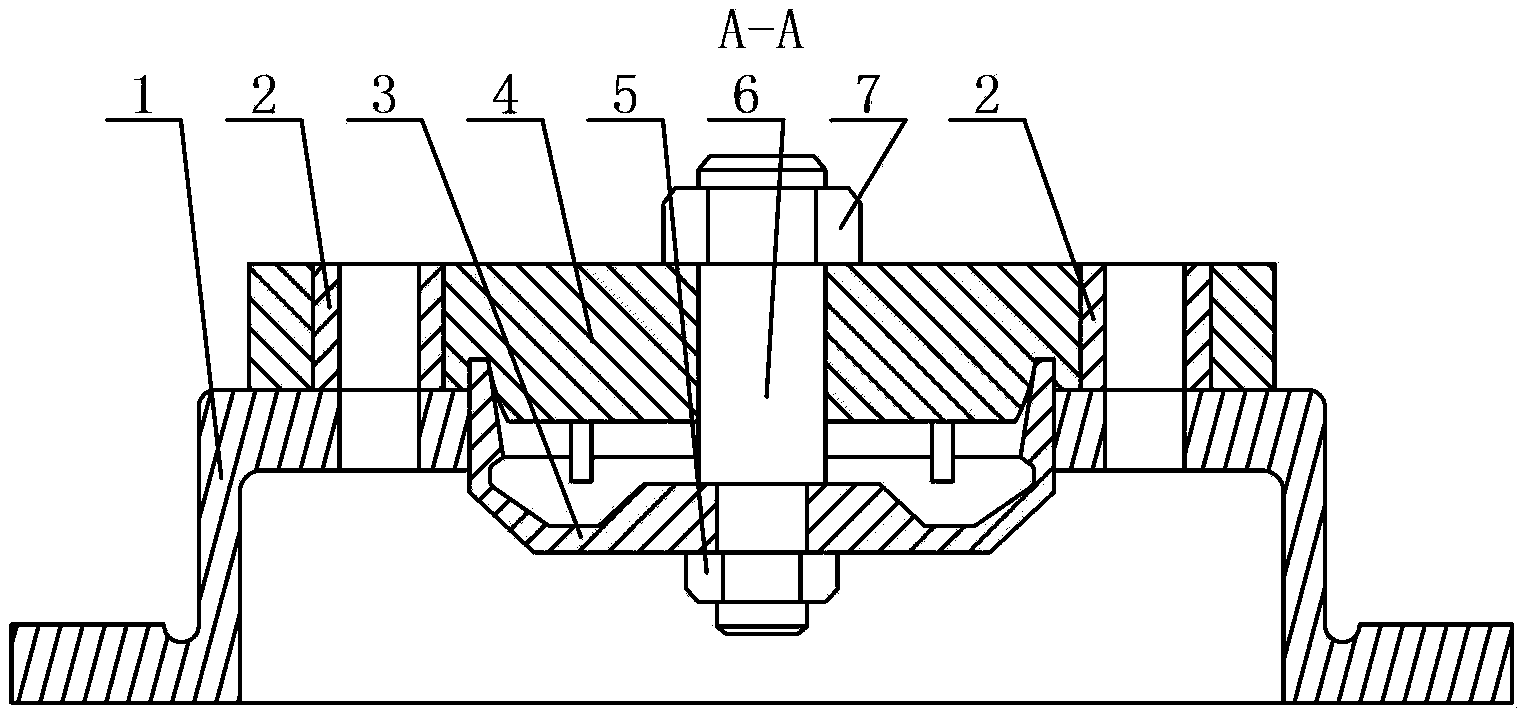

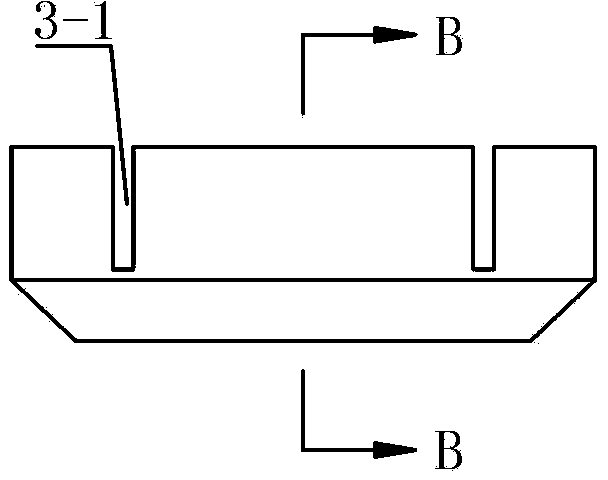

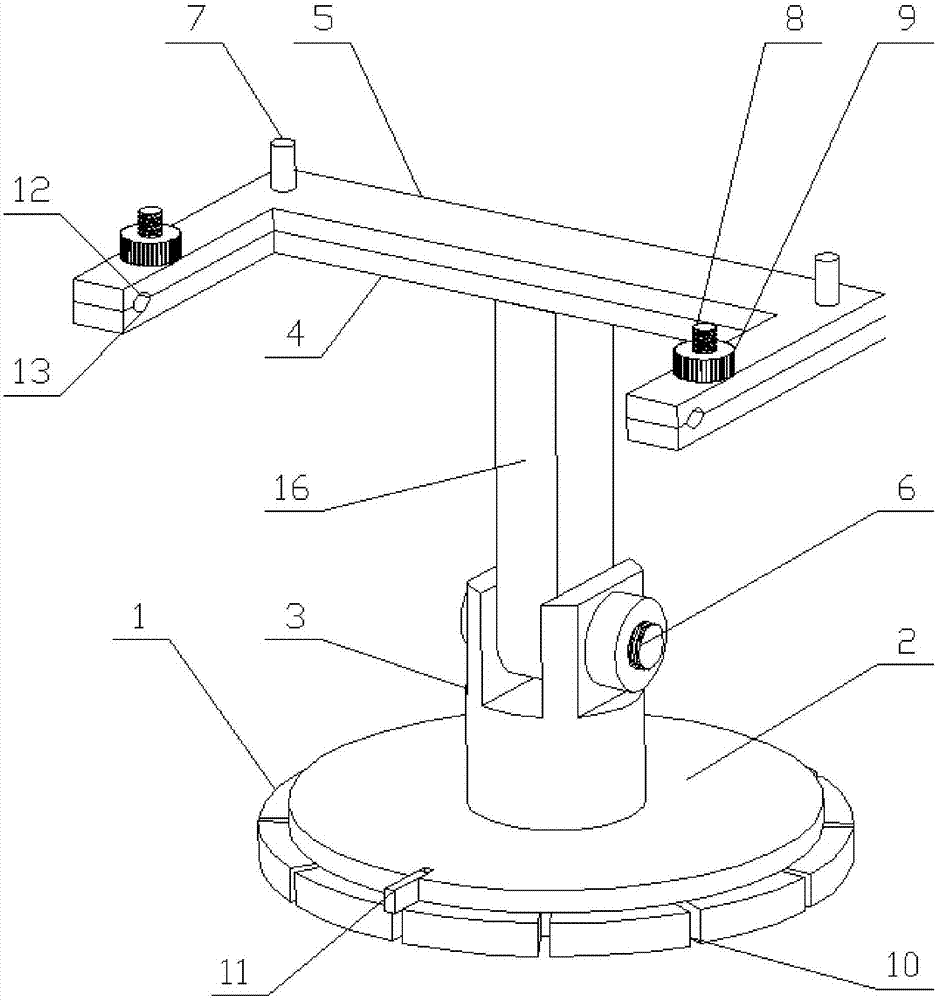

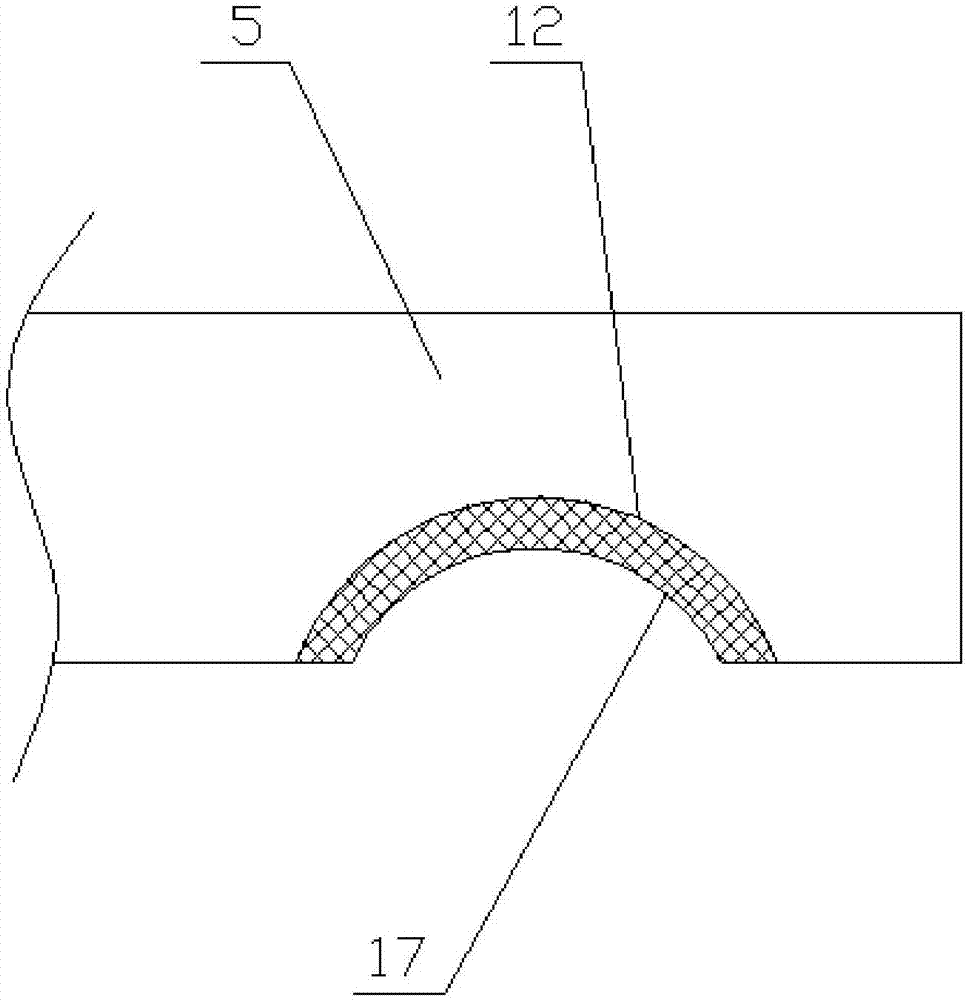

Taper-lock external expansion type centering drilling clamp

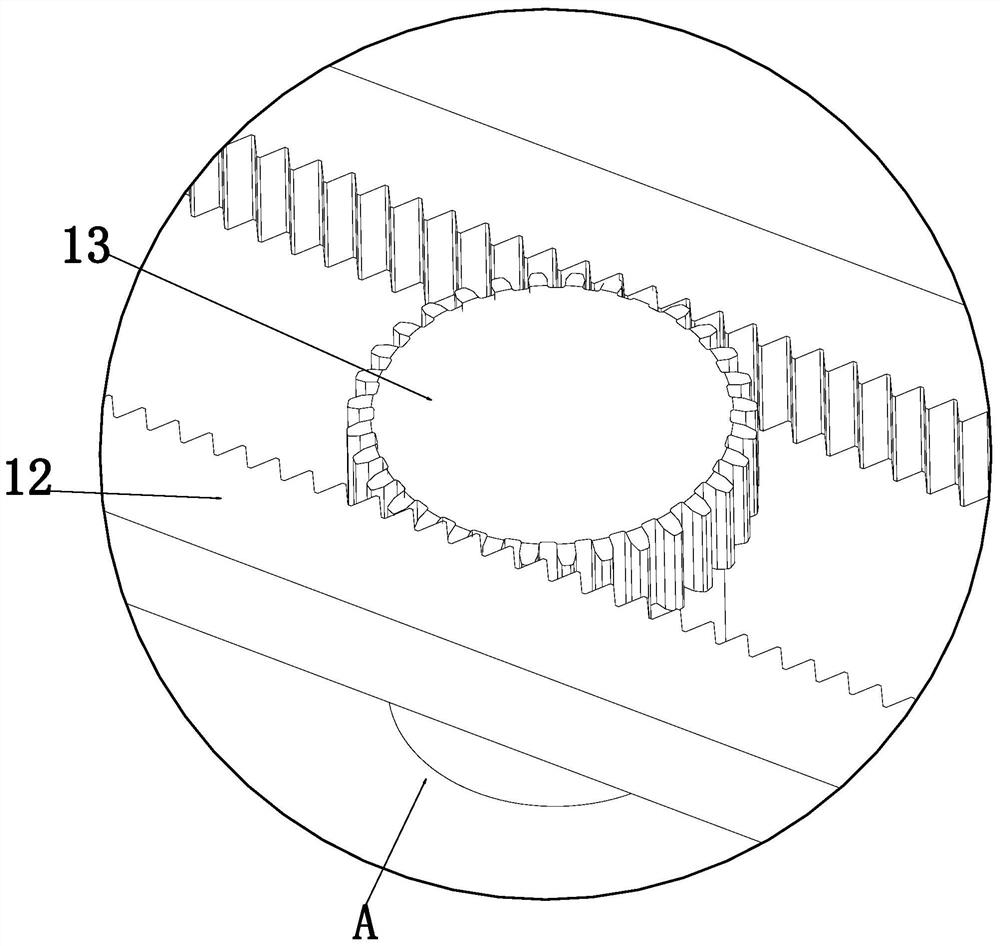

InactiveCN103769879AStrong tensionNo offsetDrilling/boring measurement devicesPositioning apparatusEngineeringMachining process

The invention discloses a taper-lock external expansion type centering drilling clamp which comprises a drill plate with a through hole formed in the middle. A boss is arranged at the lower end of the drill plate. Multiple drill bushes are evenly arranged on the drill plate in the axial direction of the drill plate. A step screw is arranged in the through hole in the middle of the drill plate. The lower end of the step screw penetrates through a disc-shaped taper-lock and is provided with a lower nut and an upper nut is installed at the upper end of the step screw. Multiple expansion grooves are evenly formed in the upper side of the disc-shaped taper-lock in the circumferential direction. An inner hole of the disc-shaped taper-lock has the taper so as to be matched with the boss in a sliding mode. The taper-lock external expansion type centering drilling clamp has the following advantages of being large in expansion force, free of deviation in the machining process, capable of being automatically centered, high in machining accuracy, reasonable in design, simple in structure, convenient to operate, small in size, low in weight, convenient to disassemble, assemble and transport, low in production cost and convenient to popularize and use.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

Clamp for static blade milling total length machining

PendingCN110370045AAchieve horizontal fixationRealize the clamping operationPositioning apparatusMetal-working holdersTip positionPulp and paper industry

The invention discloses a clamp for static blade milling total length machining. By means of the clamp, manpower, equipment, materials and other resources can be saved, the equipment input cost can bereduced, the manufacturing and machining period is shortened, and resource waste can be effectively avoided. The clamp comprises a bottom plate, and the bottom plate is provided with a blade profilepositioning assembly, a tip positioning device and a blade pressing device. The blade profile positioning assembly comprises three supporting blocks which are arranged in a triangle manner and includethe first supporting block, the second supporting block and the third supporting block, and two parallel profile positioning blocks including the first profile positioning block and the second profile positioning block. The first profile positioning block and the second profile positioning block correspond to the two side end faces of a blade correspondingly. The bottom plate is provided with atleast two sets of parallel kidney-shaped holes arranged in the strip length direction of the bottom plate, and the first profile positioning block and the second profile positioning block are fixed inthe kidney-shaped holes in the two sides correspondingly.

Owner:WUXI AIERFU BLADE

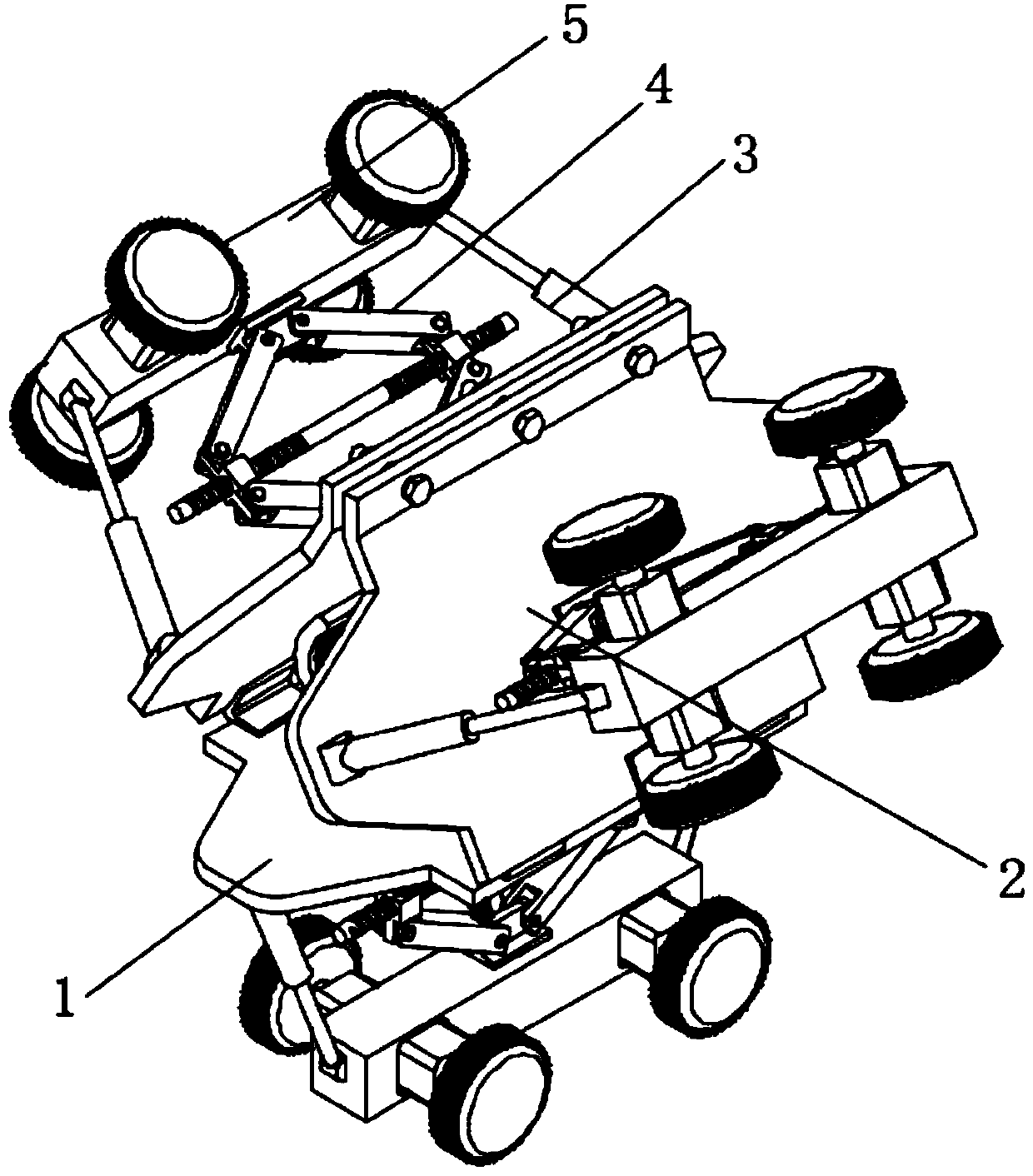

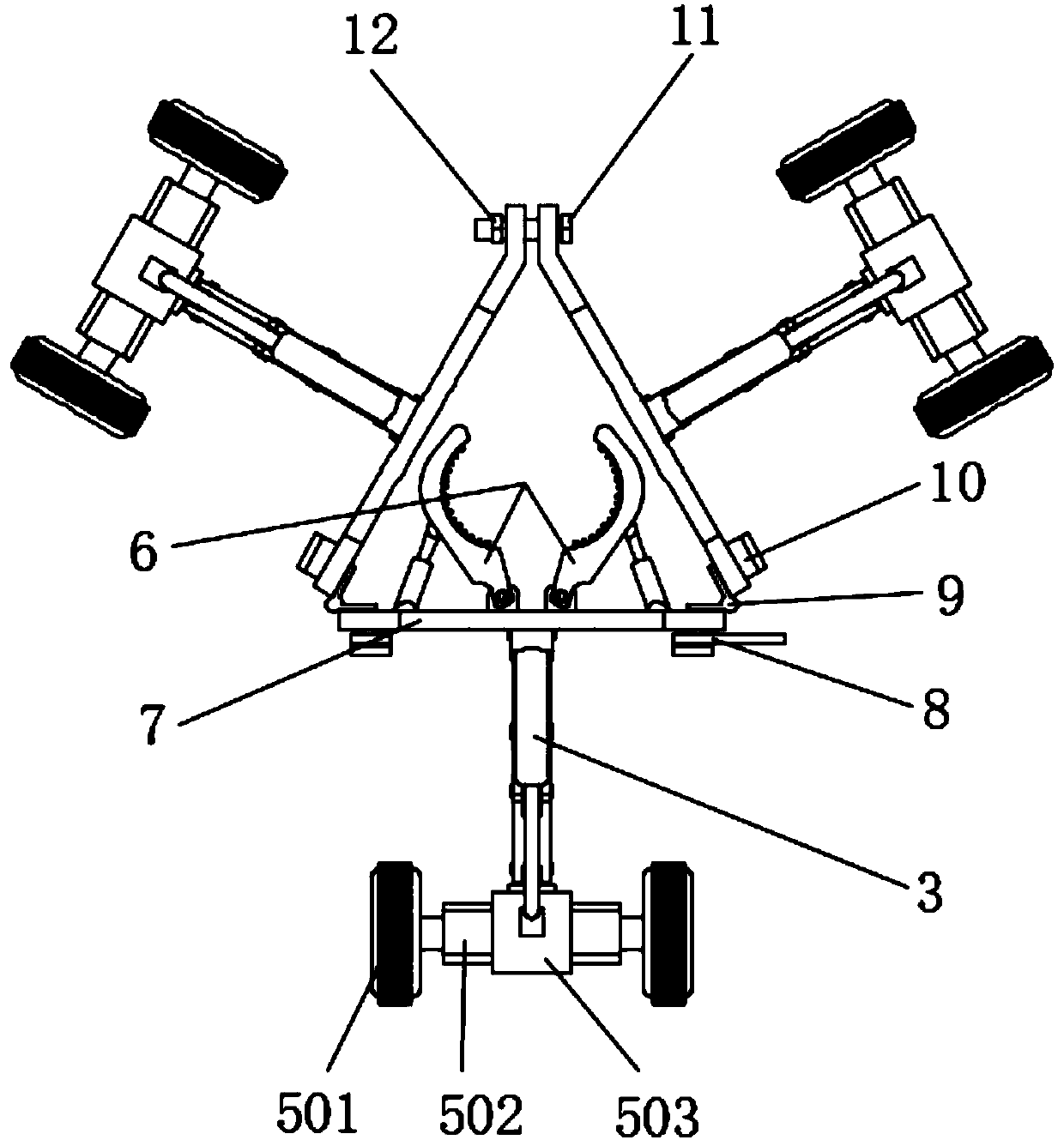

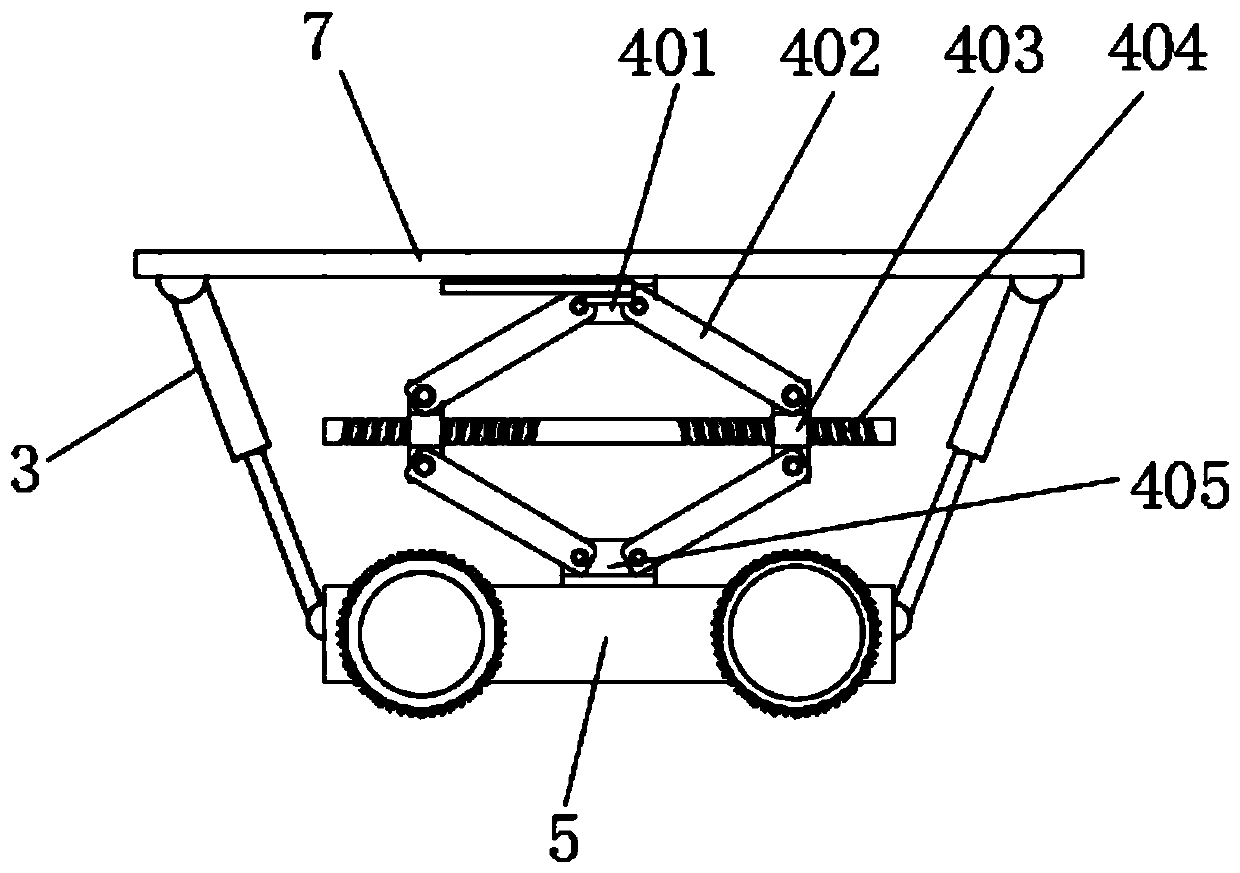

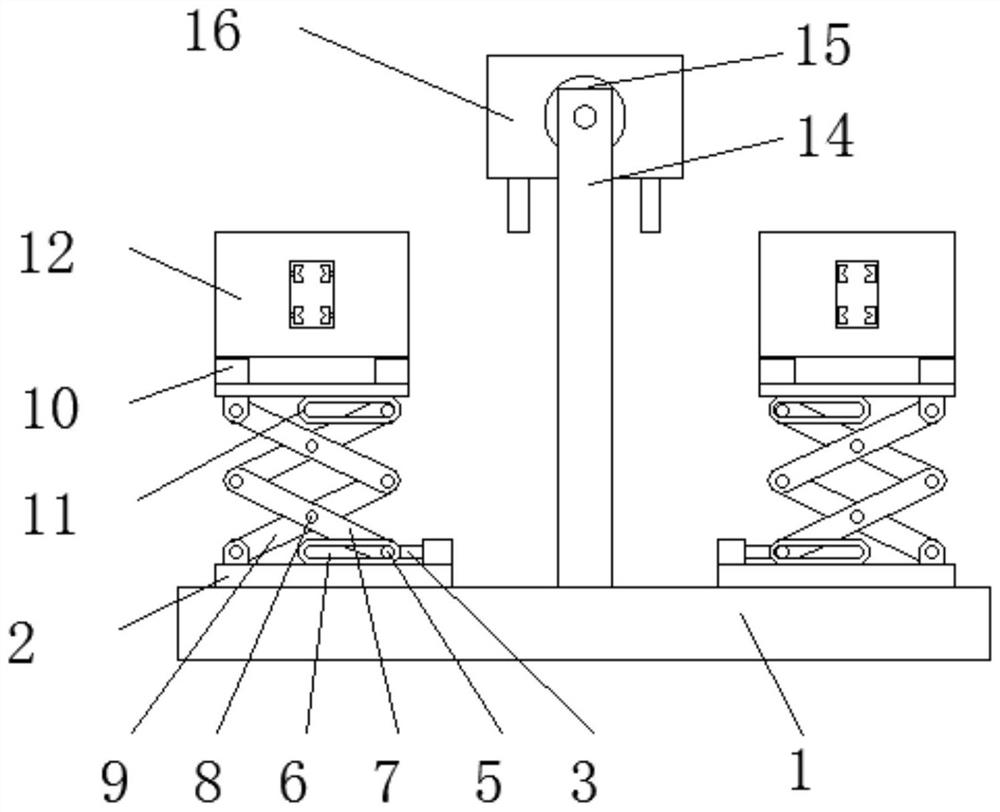

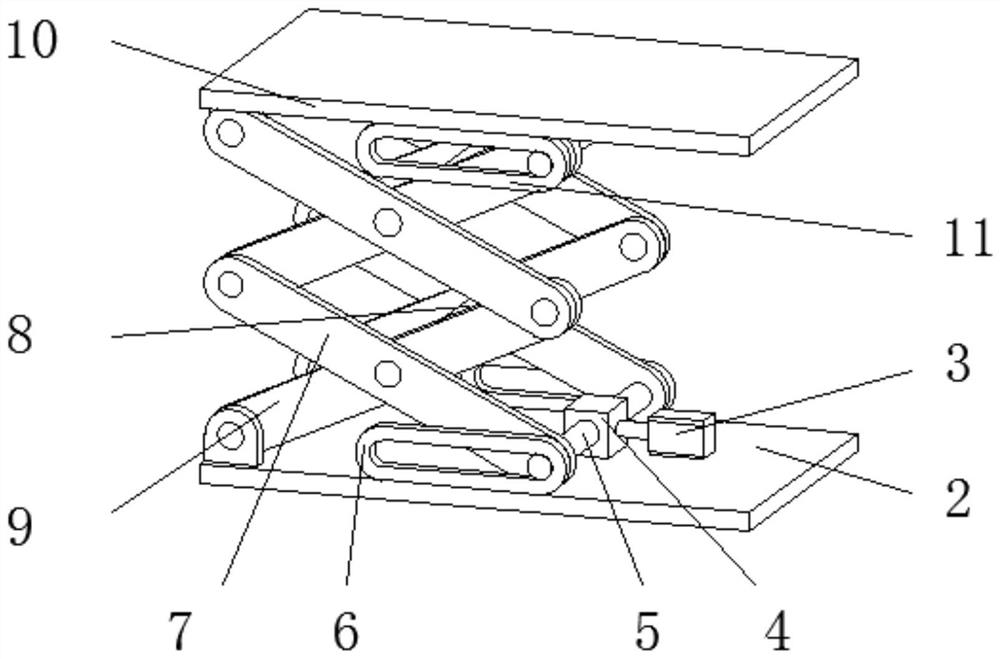

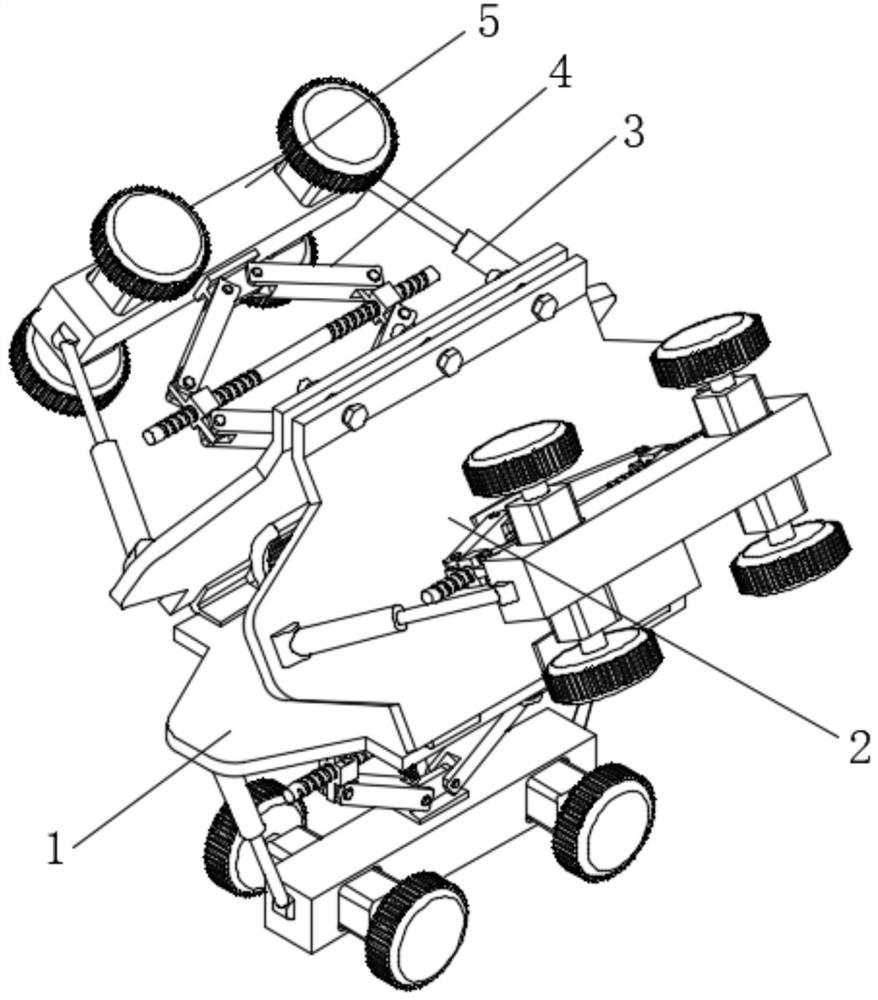

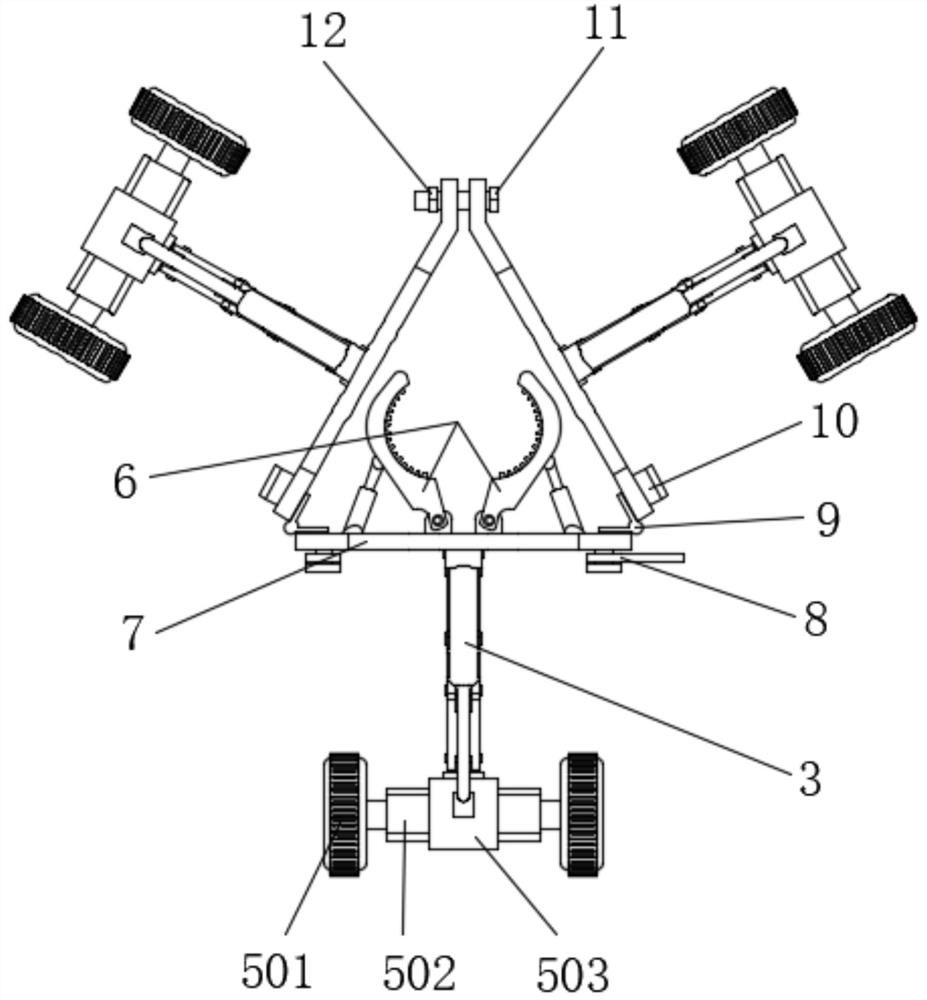

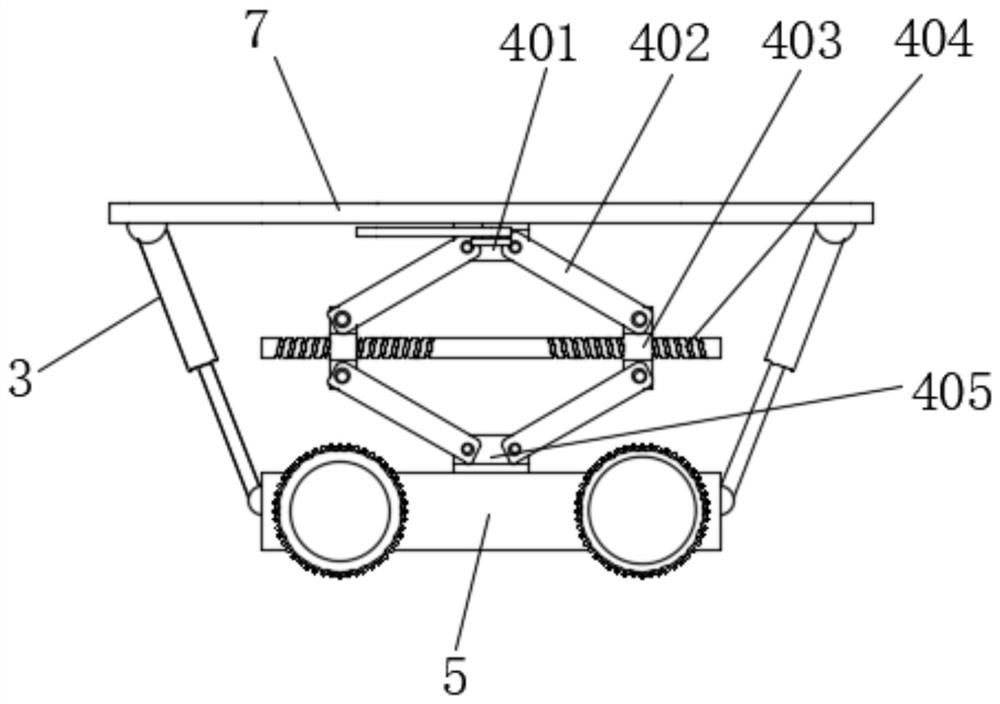

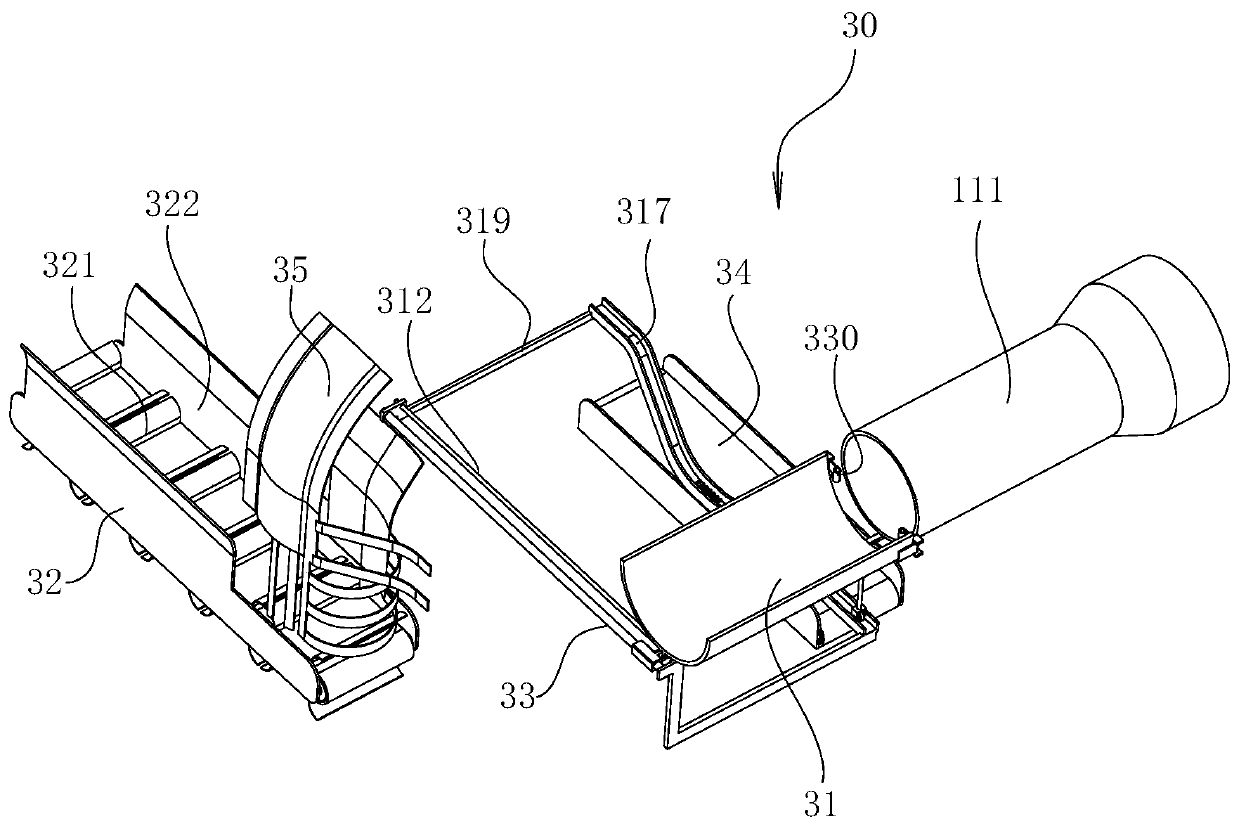

Traction device for cable laying of power supply company

ActiveCN111029971ARealize the clamping operationSave human effortApparatus for laying cablesStructural engineeringElectric cables

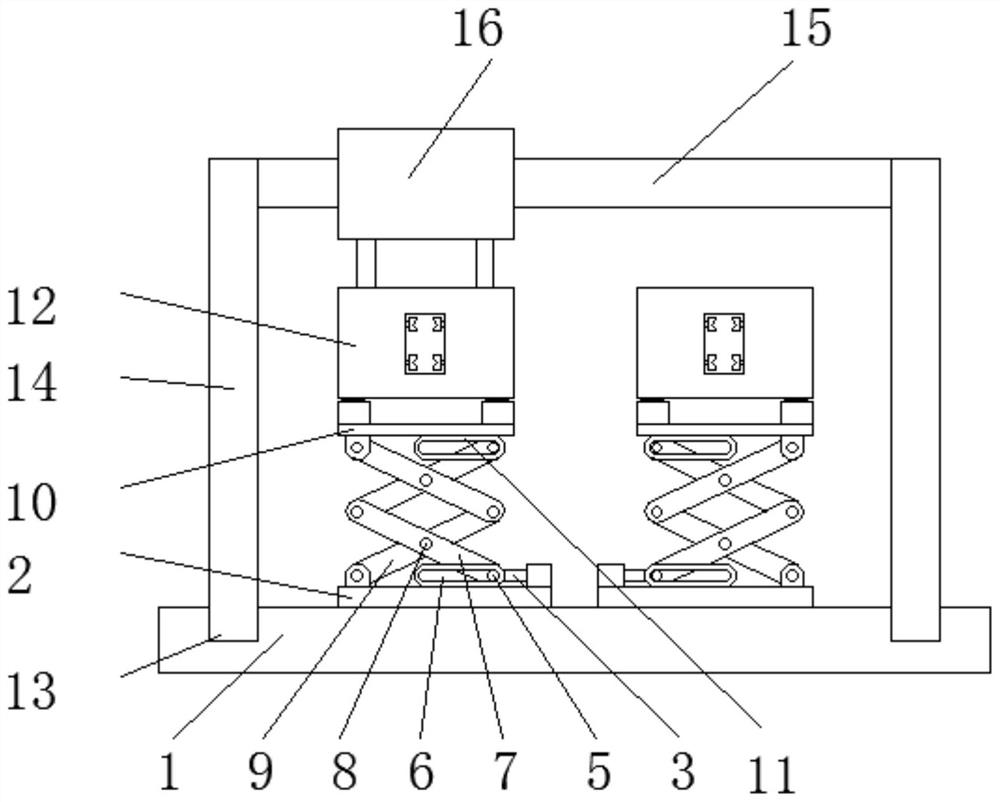

The invention discloses a traction device for cable laying of a power supply company. The device comprises a main walking unit and two sets of auxiliary walking units hinged to the main walking unit.The two sets of auxiliary walking units are hinged to the corresponding side ends of the main walking unit through hinges respectively, the corresponding side ends of the two sets of auxiliary walkingunits are connected through bolts and nuts, and the main walking unit and the two sets of auxiliary walking units form a triangular mechanism used for crawling in a pipeline. Each of the main walkingunit and the two sets of auxiliary walking units comprises a base plate. The middle of the side face, away from the center of the triangular mechanism, of the base plate is hinged to one end of a shear fork telescopic mechanism. The device saves manpower, is convenient to use, is combined into a triangular structure, realizes crawling traction operation of cables of different specifications in pipelines of different sizes, can adapt to pipeline turning, can also be combined into a horizontal linear mechanism, can pull the cables on the ground, is wide in application range and adapts to different working conditions.

Owner:STATE GRID CORP OF CHINA +1

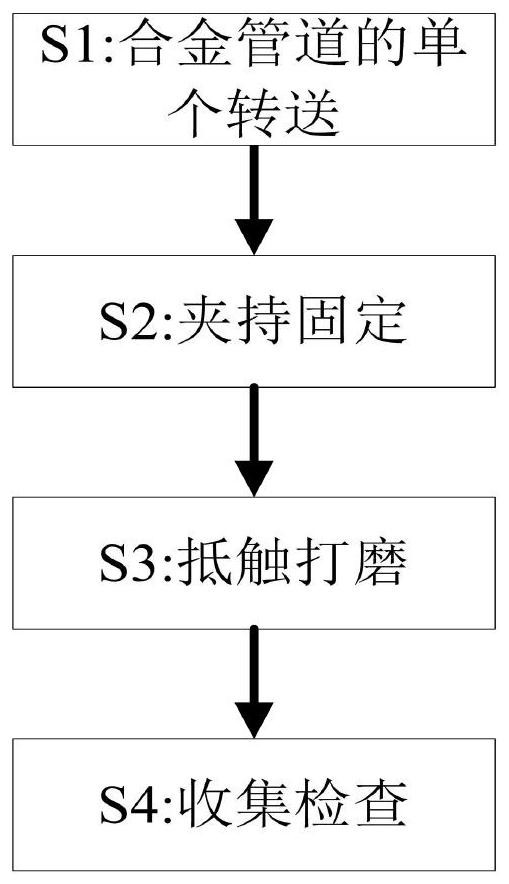

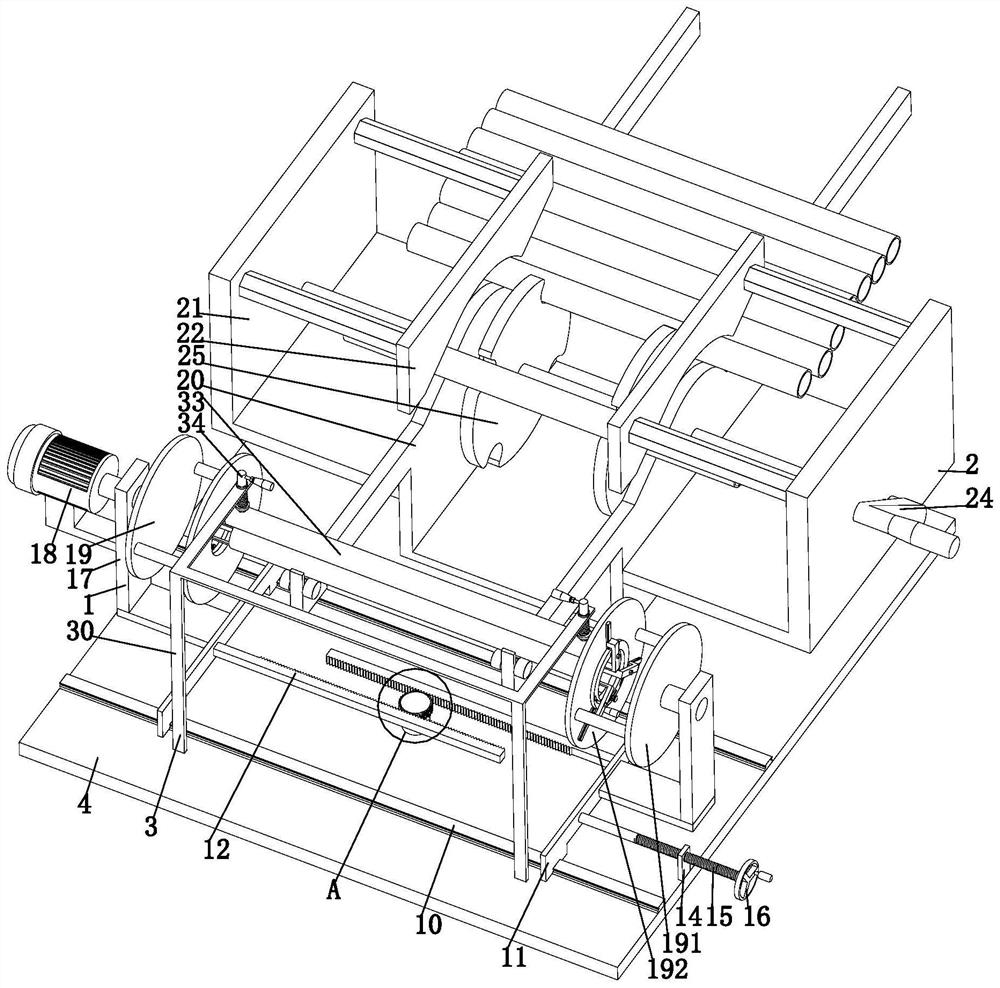

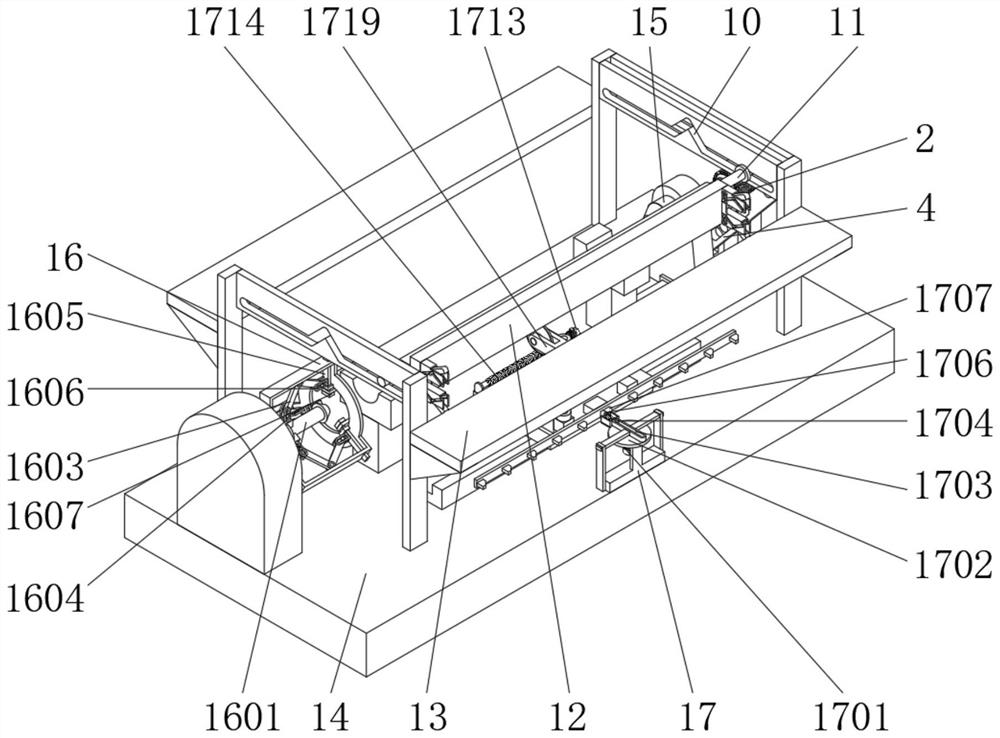

Alloy pipeline anti-corrosion treatment process

InactiveCN112548698AAvoid the bottomReduce frictional resistanceRevolution surface grinding machinesGrinding drivesPolishingAlloy

The invention provides an alloy pipeline anti-corrosion treatment process which comprises a clamping mechanism, a transferring mechanism, a polishing mechanism and a bottom plate, the transferring mechanism is installed on the bottom plate, the clamping mechanism is arranged right ahead the transferring mechanism, the clamping mechanism is installed on the bottom plate, the polishing mechanism isarranged right ahead the clamping mechanism, and the polishing mechanism is mounted on the bottom plate. According to the alloy pipeline anti-corrosion treatment process, the problems that at present,an alloy pipeline is polished manually by an operator, a large amount of dust is generated when a polishing block and the alloy pipeline are polished, the dust is inhaled into the body of the operator, certain harm is caused to the operator, air is polluted, and the alloy pipeline is difficult to stably clamp and fix due to the fact that the alloy pipeline is in an arc shape, and the effect and the quality of the surface of the polished alloy pipeline cannot meet the requirements are solved.

Owner:谢祥松

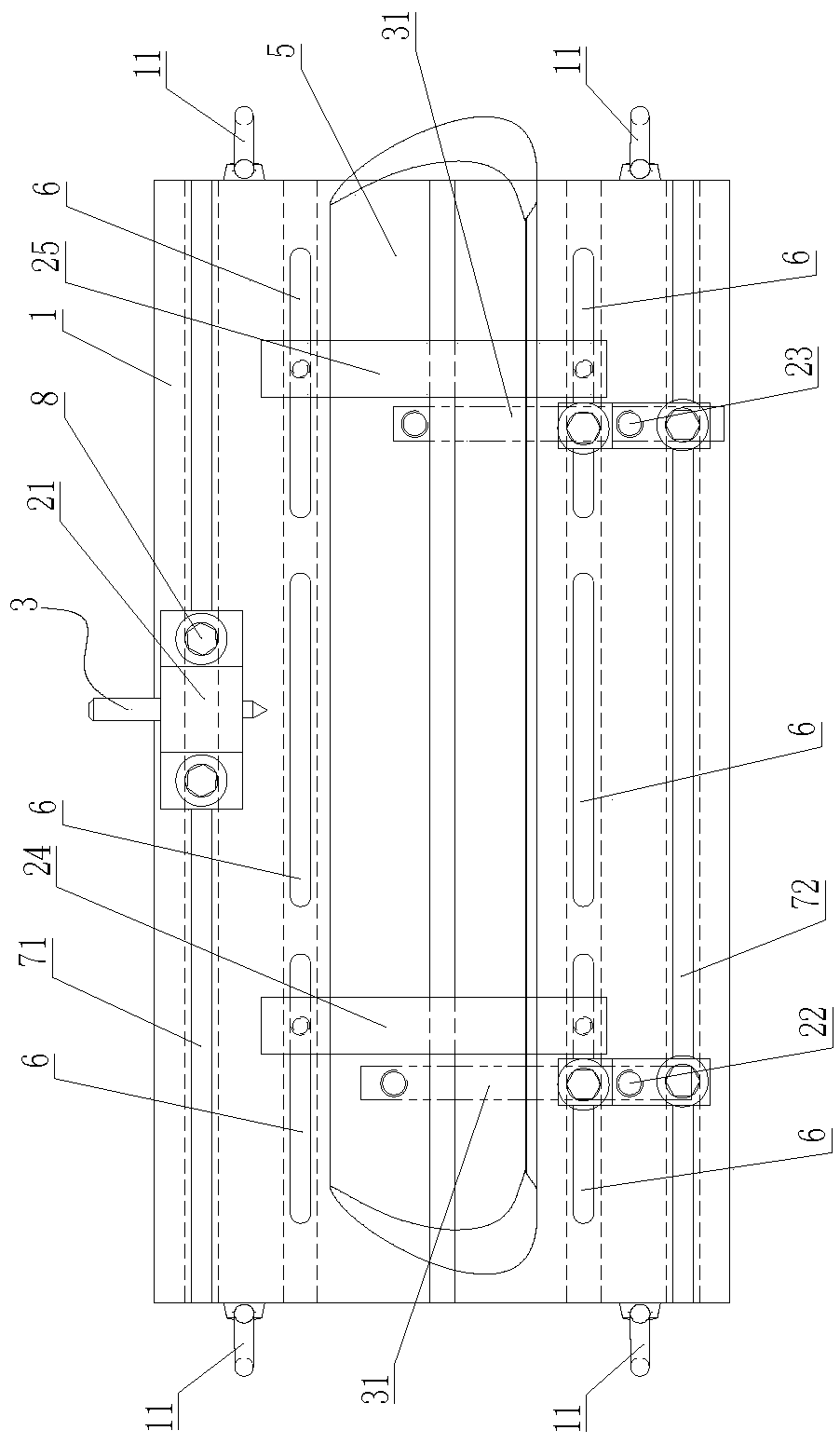

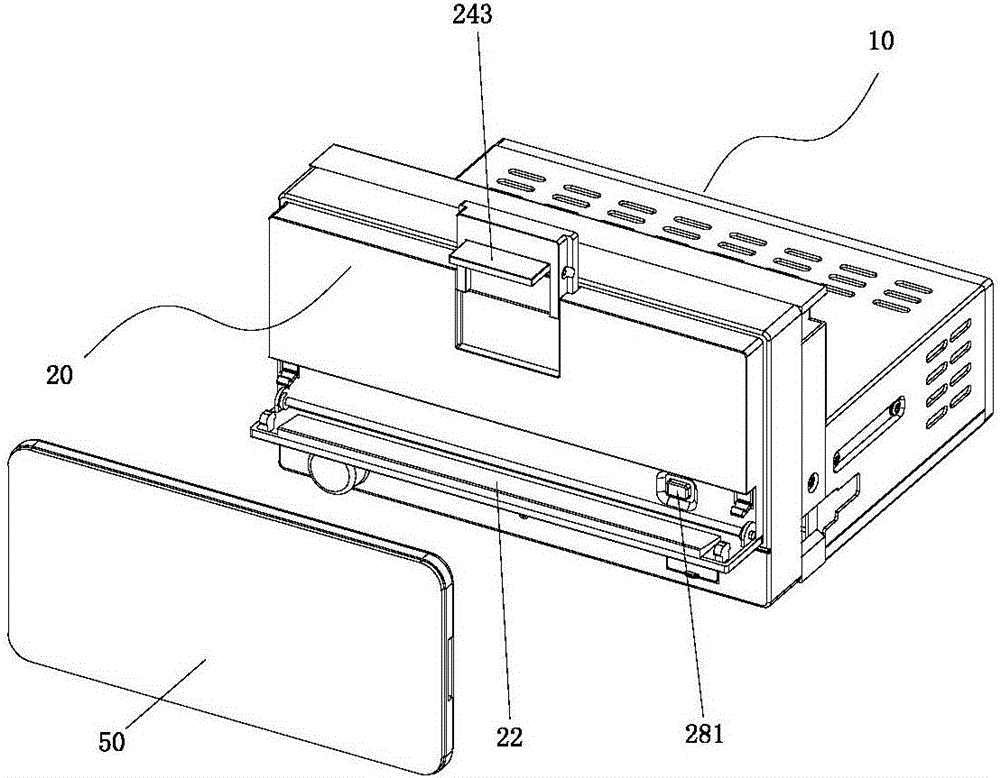

Clamping device and head mounted equipment

PendingCN109413250AEasy to operateImprove user experienceTelephone set constructionsReciprocating motionEngineering

The embodiment of the invention discloses a clamping device and head mounted equipment. The clamping device comprises at least one pair of clamping plates respectively provided with a transmission component as well as a fixed support, a drive rod and a regulating mechanism, wherein the paired clamping plates are oppositely arranged and form a clamping space; each transmission component comprises an oriented rod, a first transmission rod and a second transmission rod; one end of each oriented rod is rotatably connected with the corresponding clamping plate, and the other end of each oriented rod is rotatably connected with the fixed support; each first transmission rod is rotatably connected on the fixed support, one end of each first transmission rod is rotatably connected with the corresponding clamping plate, and the other end of each first transmission rod is rotatably connected with one end of a corresponding second transmission rod; the other end of each second transmission gear is rotatably connected with the drive rod; the drive rod is connected with the regulating mechanism; and the regulating mechanism can drive the drive rod to do a straight reciprocating motion, and thedrive rod drives the paired clamping plates to be close to each other or far away from each other by virtue of the transmission components, so that the paired clamping plates clamp or release a clamped element contained in the clamping space.

Owner:GEER TECH CO LTD

Detection system and detection method for surface quality of stainless steel pipe

ActiveCN113029057ARealize orderly loading operationImplement the switching operationMaterial analysis by optical meansConveyor partsGear wheelSS - Stainless steel

The invention discloses a detection system and a detection method for the surface quality of a stainless steel pipe, and belongs to the technical field of the surface quality of stainless steel pipes. According to the detection system and the detection method for the surface quality of a stainless steel pipe, the system comprises a feeding table, a separation mechanism, a detection mechanism and a clamping mechanism, and one side of the feeding table is fixedly connected with the separation mechanism. A detection roller is arranged, a working gear is pushed to rotate to drive a screw rod to rotate, the screw rod rotates to drive a pushing jacking column to move through a pushing sliding block, a stainless steel pipe drives a lifting inclined block to slide along a detection support through a clamping mechanism, the inclination angle of the lifting inclined block is 45 degrees, lifting operation of the lifting inclined block is facilitated, and damage of the stainless steel pipe to the lifting inclined block is reduced. The detection roller rolls along the outer wall of the stainless steel pipe to drive a depth gauge connected with a lifting column to move, the bottom end of the detection roller is as high as the central axis of the clamping mechanism, and accurate detection operation of the surface quality of the stainless steel pipe is achieved.

Owner:佛山绿水清源管业科技有限公司

Bridge arch rib hoisting and supporting bracket integrated construction device

InactiveCN112609579ARealize lifting operationImplement fine-tuning operationsLifting framesTrolley cranesStructural engineeringRelative motion

Owner:嘉兴纯柔贸易有限公司

Surface rust-proof treatment device for metal part production

ActiveCN112474121AEasy to rust-proof operationRealize lifting movementSpraying apparatusElectric machineryBevel gear

The invention discloses a surface rust-proof treatment device for metal part production. The surface rust-proof treatment device comprises a main body frame, wherein a lifting frame is fixedly mountedat the bottom end of the inner wall of the main body frame; a motor is mounted at the bottom end of the inner wall of the lifting frame; a first bevel gear is arranged at the output end of the motor;the top end of the first bevel gear is meshed with second bevel gears; a swinging rotating shaft is fixedly mounted at one end, far away from the first bevel gear, of each second bevel gear; a firstconnecting rod is welded on the outer wall of each swinging rotating shaft; and a second connecting rod is rotationally connected to the top end of each first connecting rod. According to the surfacerust-proof treatment device for metal part production, the second bevel gears are arranged, the motor rotates to drive the first bevel gear to rotate, the first bevel gear drives the first connectingrods to rotate through the second bevel gears, the rotating angle is 90 degrees, the three groups of second bevel gears are arranged, and the lifting motion of a lifting table is realized through therotation of the first connecting rods, so that rust-proof operation can be conveniently carried out on metal parts at different heights.

Owner:深圳市虹喜科技发展有限公司

Robot double-wire welding gun cleaning station

PendingCN112548289AImprove welding quality and efficiencyGood versatilityWelding accessoriesManufacturing engineeringAir filtration

The invention discloses a robot double-wire welding gun cleaning station which comprises a machine body, an oil mist spraying device and a wire shearing device. The machine body is of a box structure,the oil mist spraying device is fixedly installed above one side wall of the machine body, and an air filtering device is arranged below the oil mist spraying device; and the air filtering device isconnected with the machine body through bolts, and the wire shearing device is arranged above the side wall, opposite to the oil mist spraying device, of the machine body. According to a gun cleaningdevice, through cooperation of a side face positioning block, a tooth block and a clamping air cylinder, the gun cleaning device can adapt to angle changes of different double-wire welding gun nozzles, so that splashing is removed in the two directions between two welding wires in the double-wire welding gun nozzles, the subsequent welding quality and efficiency of a double-wire welding gun are improved, meanwhile, through cooperation of the side face positioning block, the tooth block and the clamping air cylinder, clamping operation on the double-wire welding gun nozzles of different sizes is achieved so as to adapt to the different double-wire welding guns, and the universality of the whole device is good.

Owner:北京德尔机电设备有限公司

Processing equipment with automatic stamping and perforating functions and for circuit protection cover production

InactiveCN112091627AImprove stabilityOrderly automatic feeding operationMetal-working feeding devicesOther manufacturing equipments/toolsStampingKinematic pair

The invention discloses processing equipment with automatic stamping and perforating functions and for circuit protection cover production. The processing equipment comprises a main frame; and a firstkinematic pair is mounted on the left side of the lower part in the main frame, a second kinematic pair is connected to the right side of a first connecting rod in a screwed mode, and a third kinematic pair is connected to the right side of a second connecting rod in a screwed mode. Compared with existing common circuit protection cover production equipment, through an arranged moving rod, a first servo motor rotates to drive a third connecting rod to rotate, the third rotating rod drives the second connecting rod to rotate through the third kinematic pair and by taking the second kinematic pair as the circle center, the first connecting rod and the third connecting rod are equal in length, the rotating stability of the second connecting rod is improved, the second connecting rod and a fourth connecting rod are in solid connection, the second connecting rod drives the fourth connecting rod to rotate, the fourth connecting rod drives the moving rod to rotate through a fourth kinematicpair, and circuit protection covers are orderly and automatically fed.

Owner:东莞市夯牛机电科技有限公司

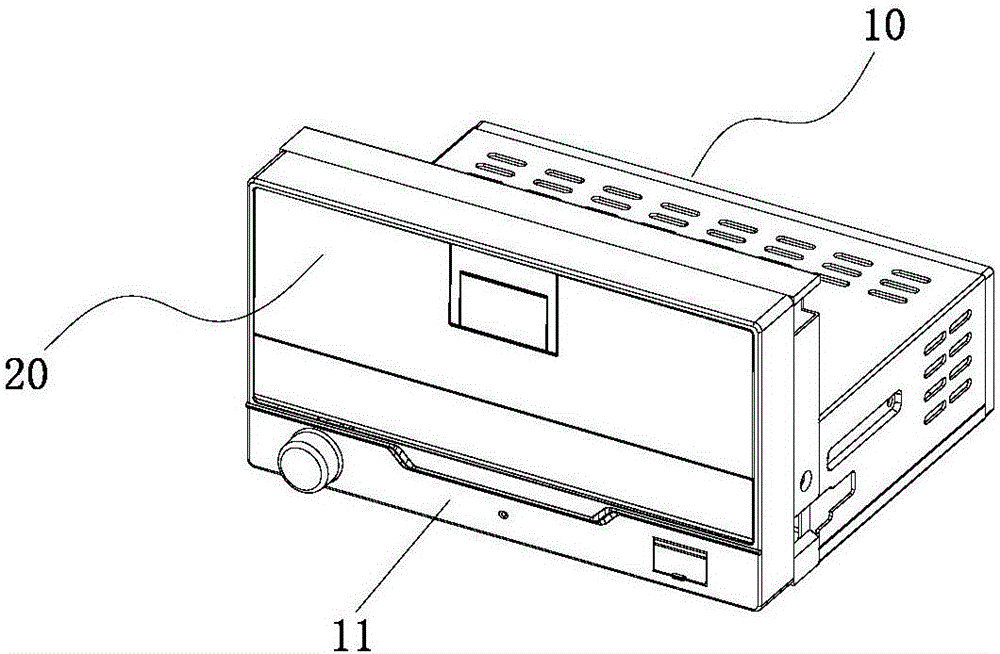

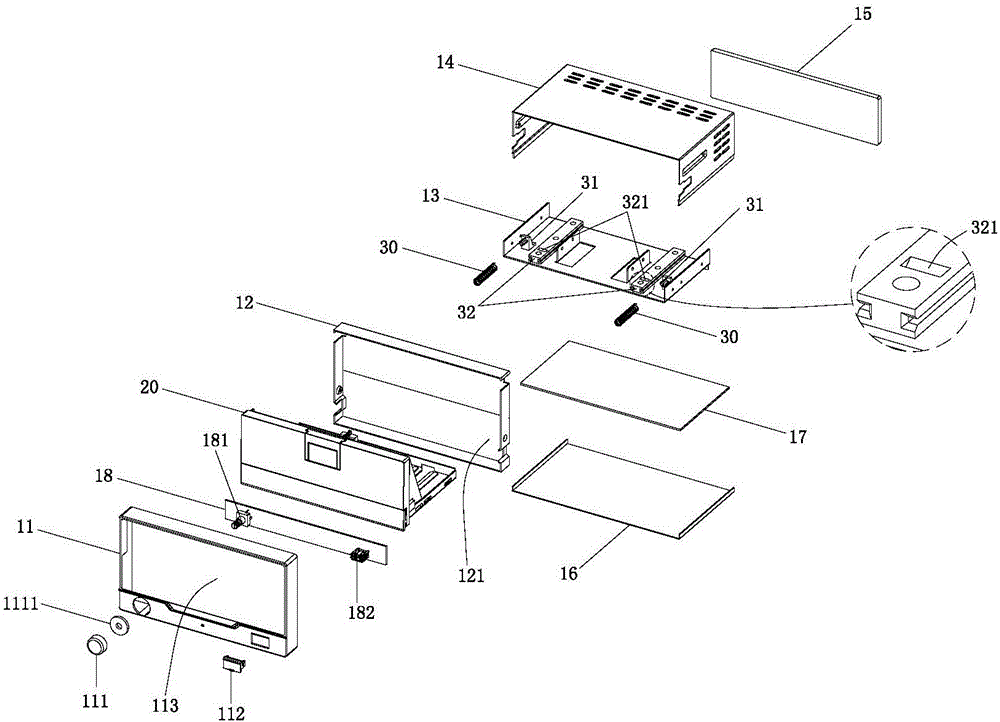

Automobile loudspeaker box with intelligent mobile phone control

ActiveCN106686189ARealize the clamping operationImprove aestheticsSubstation speech amplifiersTelephone set constructionsEngineeringIngot

The invention relates to an automobile loudspeaker box with intelligent mobile phone control. The automobile loudspeaker box comprises a main machine and a clamping mechanism, wherein the clamping mechanism is embedded in the main machine, moves along a horizontal direction and extends out of the exterior of the front of the main machine; a lock catch and a supporting cover which are arranged on the clamping mechanism can reverse outwards; and an intelligent mobile phone can be clamped between the lock catch and the supporting cover. The automobile loudspeaker box with intelligent mobile phone control has the beneficial effects that the clamping mechanism and the main machine are matched and connected into a whole, so that the whole automobile loudspeaker box looks nice, the clamping mechanism can be ejected when required, thereby causing the automobile loudspeaker box to be matched with intelligent mobile phones of different sizes; the clamping of various mobile phones under standard double-ingot sizes is realized; and the automobile loudspeaker box can be operated with one hand and is simple and convenient.

Owner:FORYOU GENERAL ELECTRONICS

A traction device for cable laying in a power supply company

ActiveCN111029971BRealize the clamping operationSave human effortApparatus for laying cablesEngineeringStructural engineering

The invention discloses a traction device for cable laying of a power supply company. The device comprises a main walking unit and two sets of auxiliary walking units hinged to the main walking unit.The two sets of auxiliary walking units are hinged to the corresponding side ends of the main walking unit through hinges respectively, the corresponding side ends of the two sets of auxiliary walkingunits are connected through bolts and nuts, and the main walking unit and the two sets of auxiliary walking units form a triangular mechanism used for crawling in a pipeline. Each of the main walkingunit and the two sets of auxiliary walking units comprises a base plate. The middle of the side face, away from the center of the triangular mechanism, of the base plate is hinged to one end of a shear fork telescopic mechanism. The device saves manpower, is convenient to use, is combined into a triangular structure, realizes crawling traction operation of cables of different specifications in pipelines of different sizes, can adapt to pipeline turning, can also be combined into a horizontal linear mechanism, can pull the cables on the ground, is wide in application range and adapts to different working conditions.

Owner:STATE GRID CORP OF CHINA +1

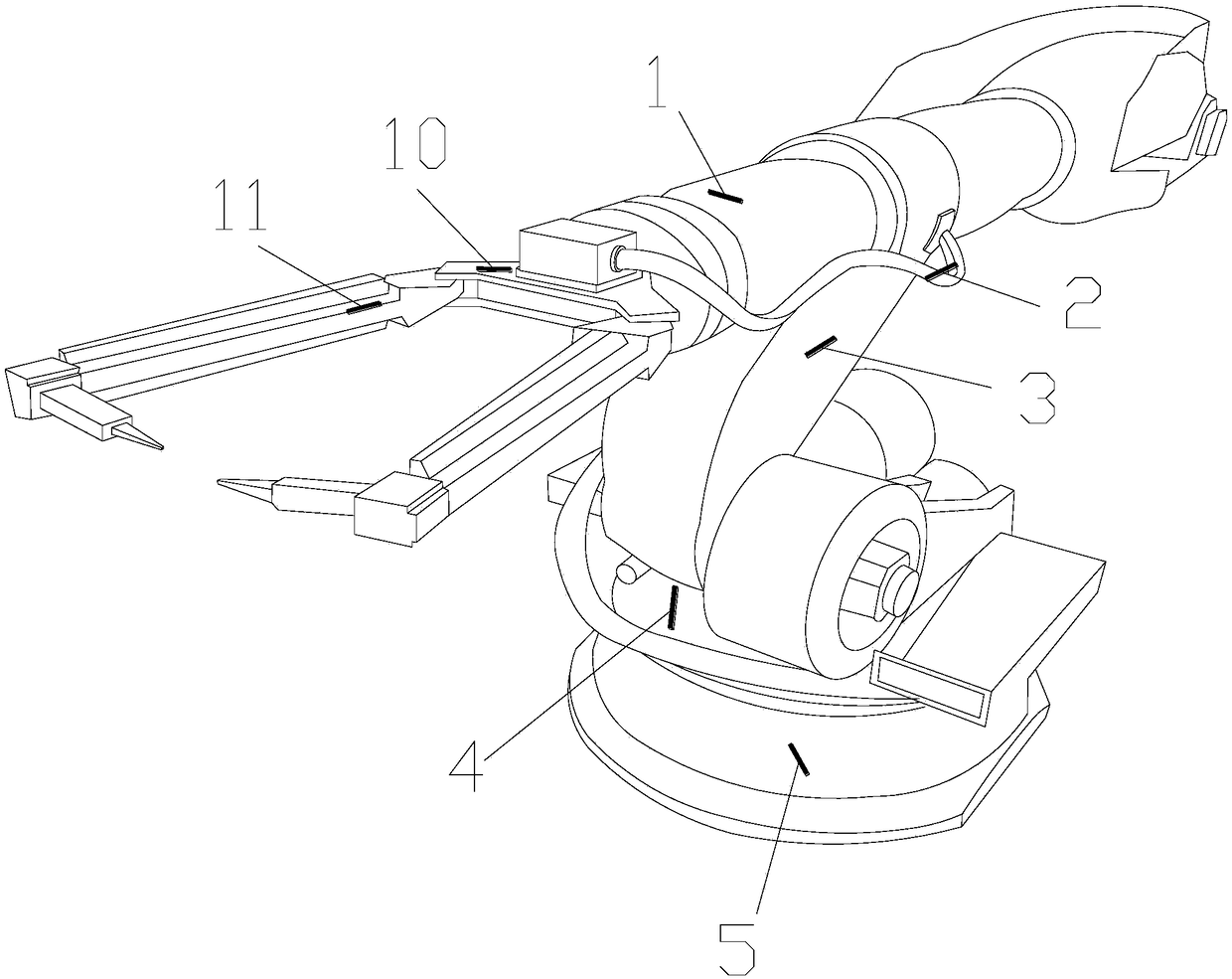

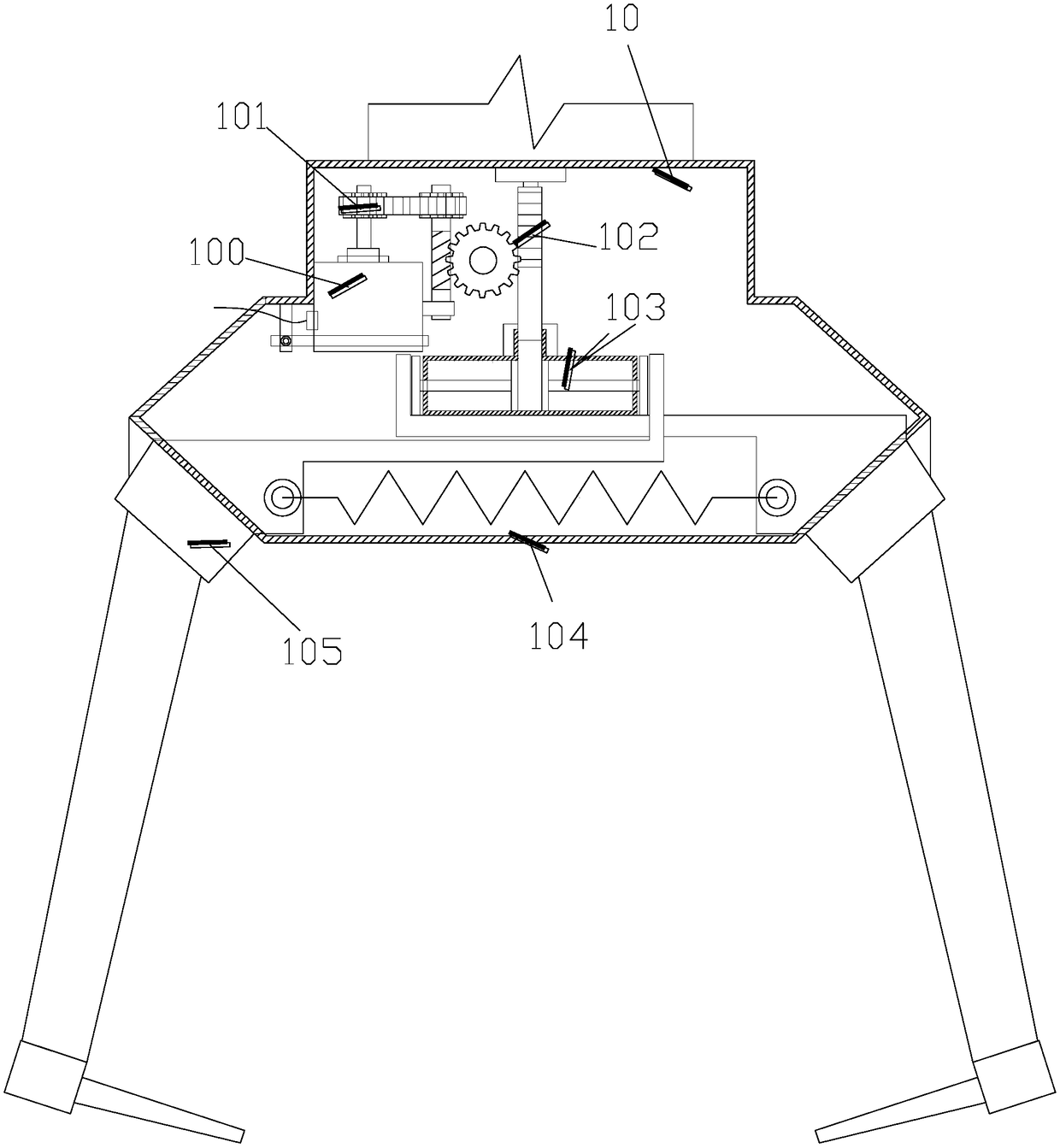

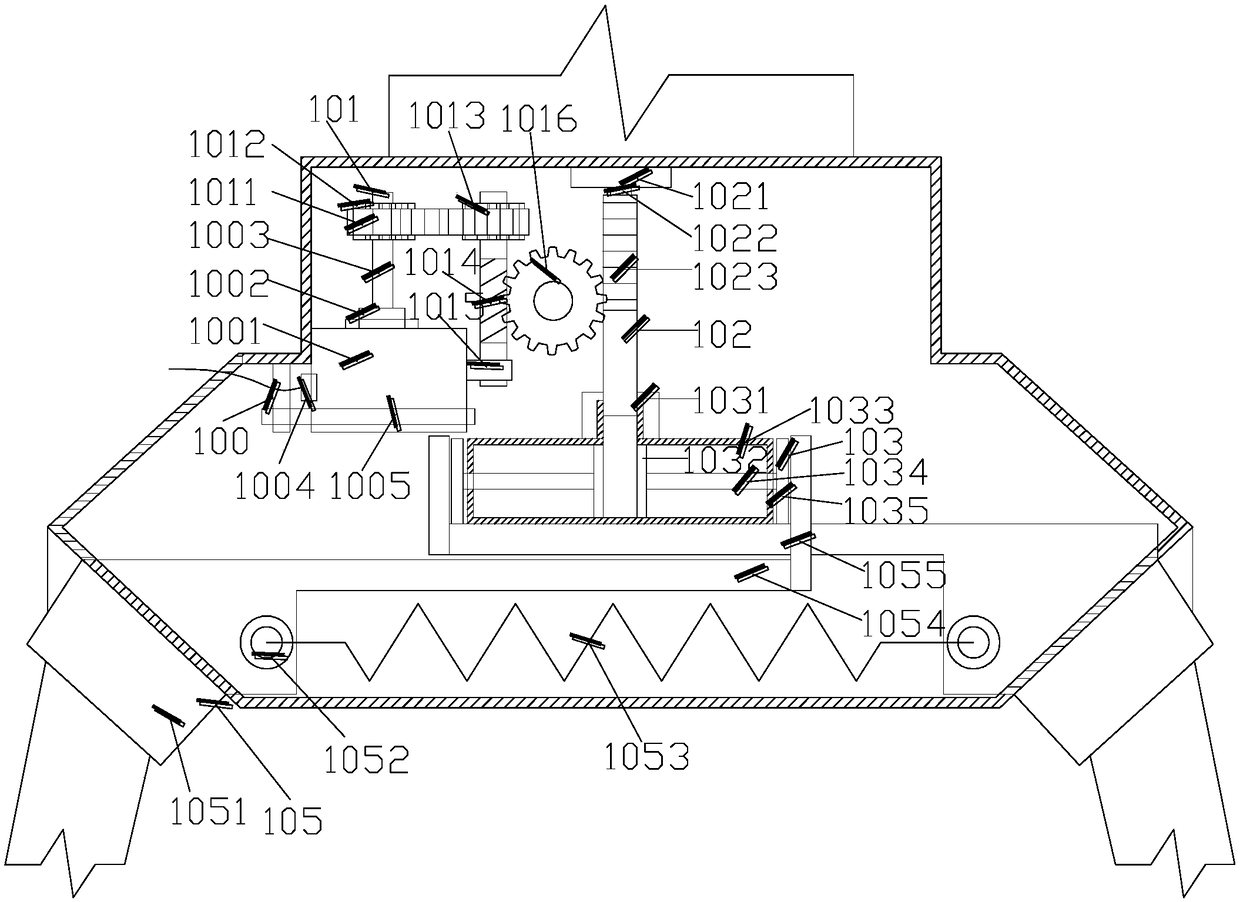

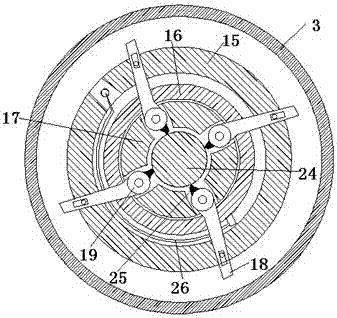

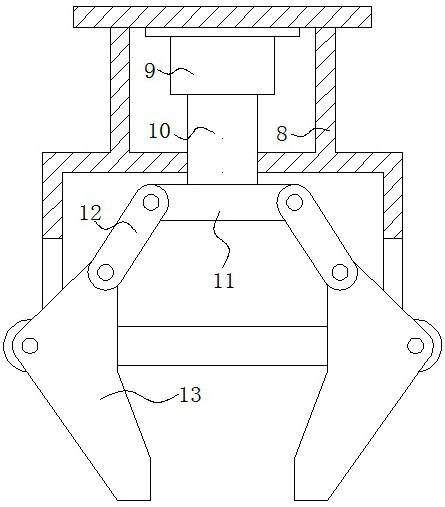

Full-automatic clamping mechanical arm

InactiveCN107351110ARealize the clamping operationImprove applicabilityGripping headsMetal working apparatusCamManipulator

The invention discloses a full-automatic clamping mechanical arm. The lower end of the connecting base is fixedly arranged on a fixed base, the fixed base is provided with an air cylinder, a piston rod of the air cylinder is connected with the cam component, the lower end of the cam component is connected with a rotary component, the rotary assembly is provided with a clamping assembly, the clamping assembly achieves clamping of a workpiece under driving of the air cylinder, the clamping assembly is provided with a clamping head and a clamping arm, the clamping arm is detachably arranged at the lower side face of the clamping head, the clamping arm extends downwards in the central axis direction of the clamping assembly, and the clamping head moves in the axial direction of the clamping assembly to conveniently clamp the workpiece in the circumferential direction of the workpiece. Self-centering clamping operation on a cylindrical workpiece can be conducted through the adoption of the clamping head, a detachable clamping arm can further be utilized to clamp workpieces in other shapes, the application effect of the full-automatic clamping mechanical arm is improved, the full-automatic clamping mechanical arm is high in clamping and positioning precision, positioning is fast and conveniently conducted, and self-centering operation can be quickly achieved.

Owner:JINGGANGSHAN UNIVERSITY

Rail fastening device for rail transit equipment

InactiveCN112982035AFor precise adjustmentRealize adjustment operationRail fastenersElectric machineryWorm drive

The invention discloses a rail fastening device for rail transit equipment. A belt pulley is mounted on the outer wall of a rotating shaft, a rotating plate is fixedly connected to one side of the belt pulley and located on the outer wall of the rotating shaft, and a rotating bent rod is rotationally connected to the end, away from the rotating shaft, of the rotating plate; a swing plate rotationally connected with the outer wall of the feeding guide rail is rotationally connected to the end, away from the rotating plate, of the rotating bent rod, a feeding moving plate is rotationally connected to the outer wall of the middle of the rotating bent rod, and a feeding plate slidably connected with the outer wall of the feeding guide rail is welded to the top end of the feeding moving plate. According to the rail fastening device for rail transit equipment, through arranging the rotating plate, in the adjusting frame, a second motor works to drive a worm to rotate, the worm drives a rotating shaft to rotate through a worm gear, the rotating shaft rotates to drive a rotating plate to rotate, the rotating plate drives a sliding plate to slide along the inner wall of the adjusting frame through a movable hole plate, the sliding length of the sliding plate is two times that of the rotating plate, and the sliding plate drives a clamping frame to slide through a connecting column. Adjustment operation of the clamping frame is achieved.

Owner:杭州皓辰机械设备有限公司

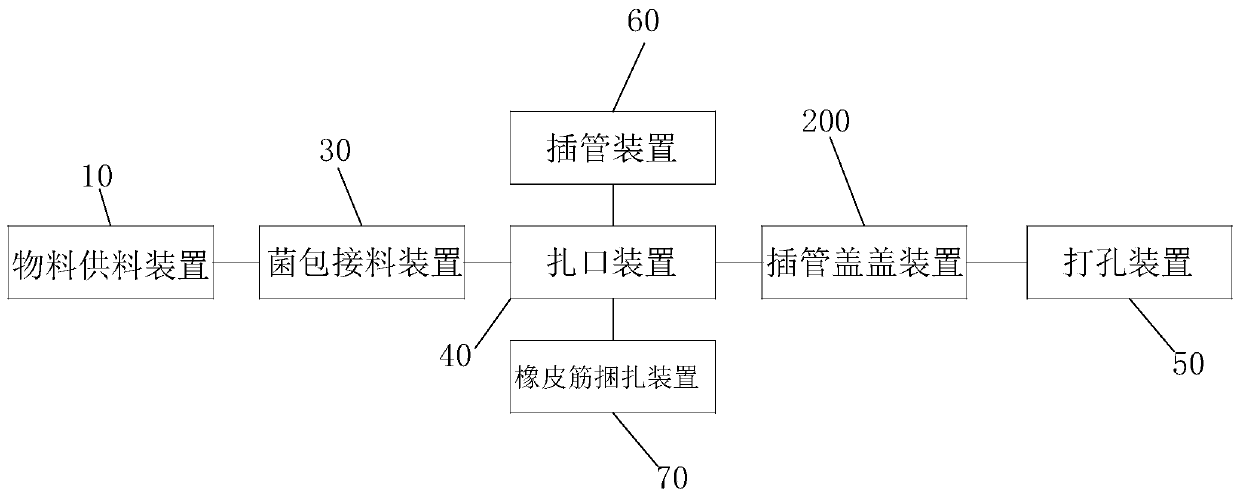

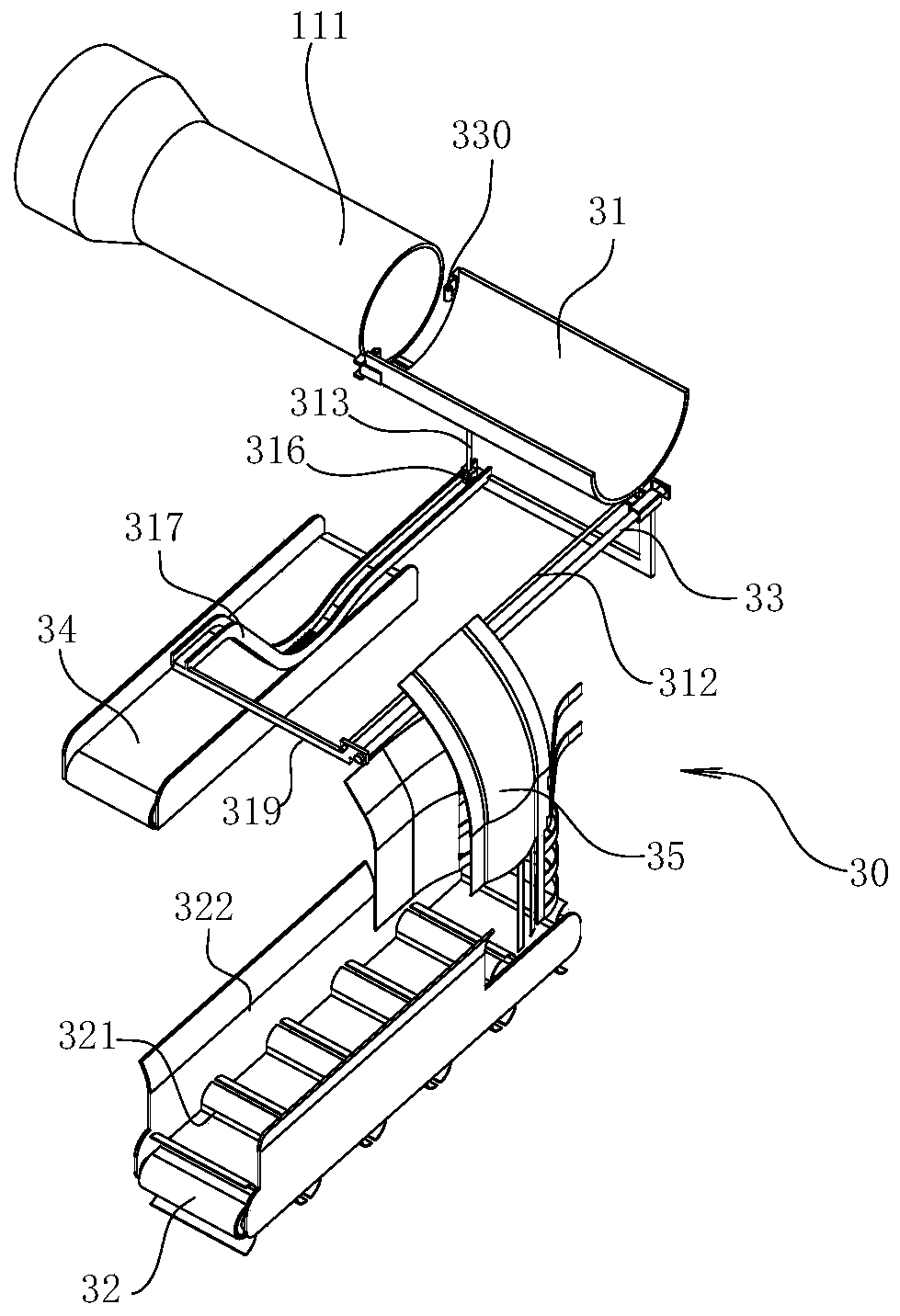

Fastening device

InactiveCN109729923ARealize the clamping operationHigh sealing efficiency and reliabilityCultivating equipmentsMushroom cultivationEngineeringMechanical engineering

The invention relates to an edible fungus bag fastening device. The device comprises a rotary drum, wherein the mouth of rotary drum is vertically upward; a clamping mechanism for clamping a fungus bag is arranged in the rotary drum; a fastening mechanism for fastening the mouth of the fungus bag is arranged at the mouth of the rotary drum; and the rotary drum is driven by a power mechanism to rotate. The device has the beneficial effects that the fungus bag is clamped by utilizing the clamping mechanism in the rotary drum, the power mechanism is started to rotate the rotary drum and a film atthe mouth of the fungus bag is clamped by utilizing the fastening mechanism, so that the fastening operation on the fungus bag is realized, the sealing efficiency is high and the sealing is firm.

Owner:岳西神农氏农业科技有限公司

Special-shaped nut machining equipment with multi-angle paint spraying function

ActiveCN112827730ARealize the operation of automatic feedingQuick releaseGrinding drivesGrinding machinesElectric machineryMachining

The invention discloses special-shaped nut machining equipment with a multi-angle paint spraying function. The special-shaped nut machining equipment comprises a main body frame, a feeding frame is arranged behind the left side of the interior of the main body frame, a feeding motor is fixed above the center of the interior of the feeding frame, a rotating plate is arranged at the front end of the feeding motor, and a feeding sliding block is fixed at the left end of the rotating plate. Compared with existing special-shaped nut machining equipment, the special-shaped nut machining equipment with the multi-angle paint spraying function is provided with the feeding frame, the feeding motor in the feeding frame drives the rotating plate to rotate, so that a feeding rod moves in the horizontal direction, then a clamping hand air rod moves downwards through a clamping hand air cylinder in a feeding clamping hand frame, clamping hand movable plates at the left end and the right end of a clamping hand fixing plate drive a feeding clamping plate to clamp materials, then the materials are moved to the position above the clamping plate through the feeding rod, and operation of automatic feeding of special-shaped nuts is realized.

Owner:东台市新杰科机械有限公司

Cone locating and milling clamp for valve body

InactiveCN102848224APrecise positioningGuarantee processing qualityPositioning apparatusMetal-working holdersSet screwEngineering

Owner:HUAIAN SHENGJIE HYDRAULIC MACHINERY

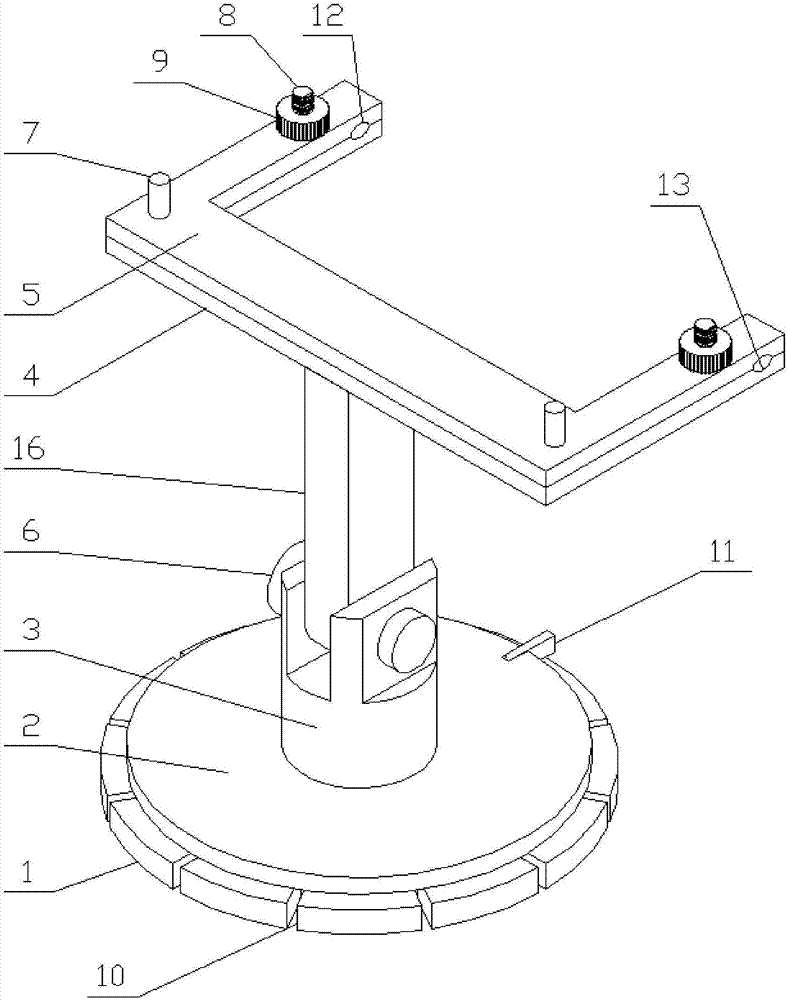

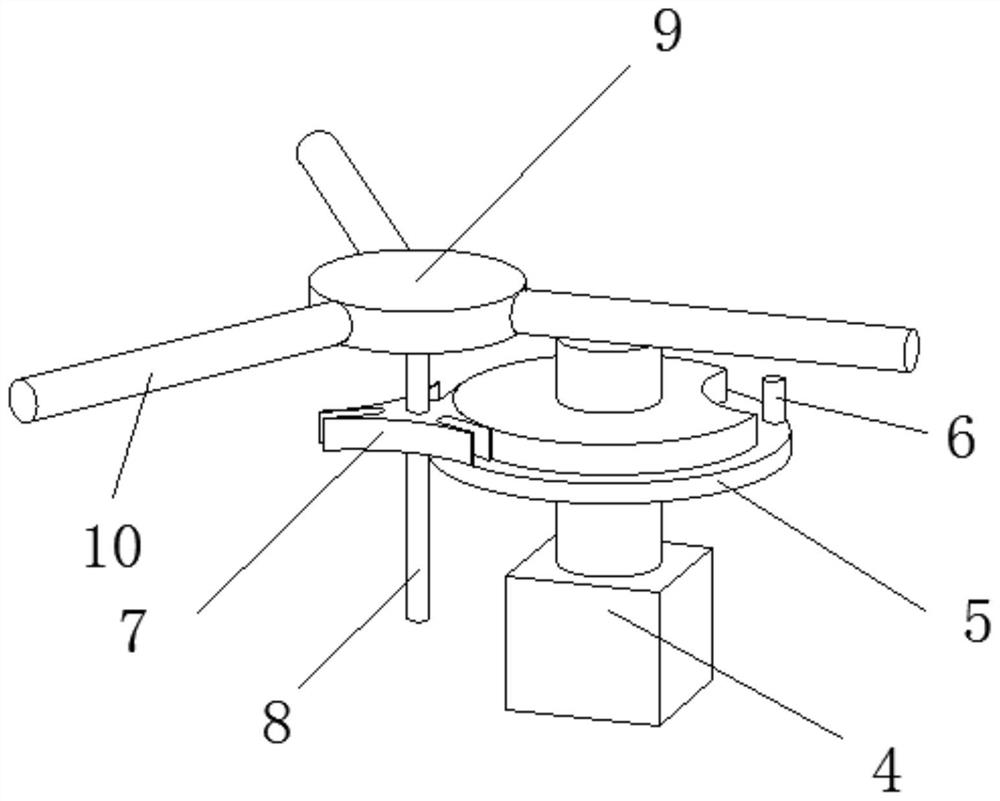

Clamping mechanism for fixing wiring harness

InactiveCN107332098ARealize the clamping operationSimple structureVehicle connectorsLine/current collector detailsMechanical engineeringCable harness

The invention discloses a clamping mechanism for fixing a wire harness, which relates to the technical field of automobile wire harness processing, and comprises a circular base, a disk, a hinged seat and a clamping mechanism, and the disk is rotatably connected to the circular base through a bearing , the hinge seat is fixed at the center of the disc top, the clamping mechanism includes a fixed splint and a movable splint, the bottom of the fixed splint is connected with a support seat, and the support seat and the hinge seat are connected by locking bolts, the The movable splint is installed on the fixed splint through the guide mechanism, and the fixed splint is U-shaped. The fixed splint is provided with bolts, and the movable splint passes through the bolts and is fastened by nuts. The present invention has simple structure and convenient operation. The rotating disk can realize the adjustment of the angle of the clamping mechanism in the horizontal direction, and at the same time, the adjustment of its inclination angle can also be realized by using the hinged seat, so as to meet the individual needs of people.

Owner:WUHU BOKANG ELECTRICAL

Environment-friendly treatment equipment of copper material polishing liquid

ActiveCN112538631AAutomate polishing operationsRealize the clamping operationElectric machineEngineering

The invention discloses environment-friendly treatment equipment of copper material polishing liquid. The environment-friendly treatment equipment of the copper material polishing liquid comprises a base, wherein a supporting column is welded to the top end of the base, a rotating frame is welded to the top end of the supporting column, a motor is fixedly connected with an inner wall of the rotating frame, a turntable is installed at an output end of the motor, a guiding block is welded to the edge of the top end of the turntable, a runner is arranged at the portion, located at the top end ofthe turntable, of one side of the guiding block, a rotating shaft penetrates through the runner, and the top end of the rotating shaft extends to the top end of the rotating frame, and is in screw joint with a rotating disk. According to the environment-friendly treatment equipment of the copper material polishing liquid, by arranging the runner, the motor rotates to drive the turntable to rotate,through the guiding block, the turntable drives the runner to rotate, the guiding block drives the runner to rotate 120 degrees when making a round, through the rotating shaft, the runner drives therotating disk to rotate, through rotating rods, the rotating disk drives rotating blocks to rotate, and through lifting rods, the rotating blocks drive clamping frames to move along a path where sliding blocks move along guiding grooves, so that automatic polishing operation is conducted on a copper material.

Owner:贵溪市正鑫铜业有限公司

Binding tape cutting machine capable of achieving automatic feeding and discharging

InactiveCN113967936ARealize automatic loading and unloading operationRealize the clamping operationMetal working apparatusElectric machineryStructural engineering

The invention provides a binding tape cutting machine capable of achieving automatic feeding and discharging, and belongs to the technical field of binding tape cutting machines. The binding tape cutting machine comprises a feeding frame, a swing hole plate, an overturning plate, a horizontal limiting groove and an overturning hole groove, wherein the top end of the feeding frame is fixedly connected with a feeding motor, a rotary plate used for driving the swing hole plate to vertically swing is installed at the output end of the feeding motor, and a driving hole groove is formed in the connecting portion of the rotary plate and the swing hole plate. When the binding tape cutting machine is used, a horizontal limiting groove and an overturning hole groove are arranged, in the feeding frame, the rotary plate rotates to drive the swing hole plate to swing through the driving hole groove, the swing hole plate swings to drive a driving guide column to horizontally slide along the horizontal limiting groove through the driven hole groove, so that the driving guide column moves to drive the driven guide column to slide along an inverted-V-shaped overturning hole groove through the overturning plate, the driven guide column drives the overturning plate to overturn, and automatic feeding and discharging operation of raw materials is achieved.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com