Clamping beam

A technology of clamping parts and tools, applied in the direction of forming tools, sleeve/socket connections, mechanical equipment, etc., can solve the problems of not being able to obtain directly frequently, increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

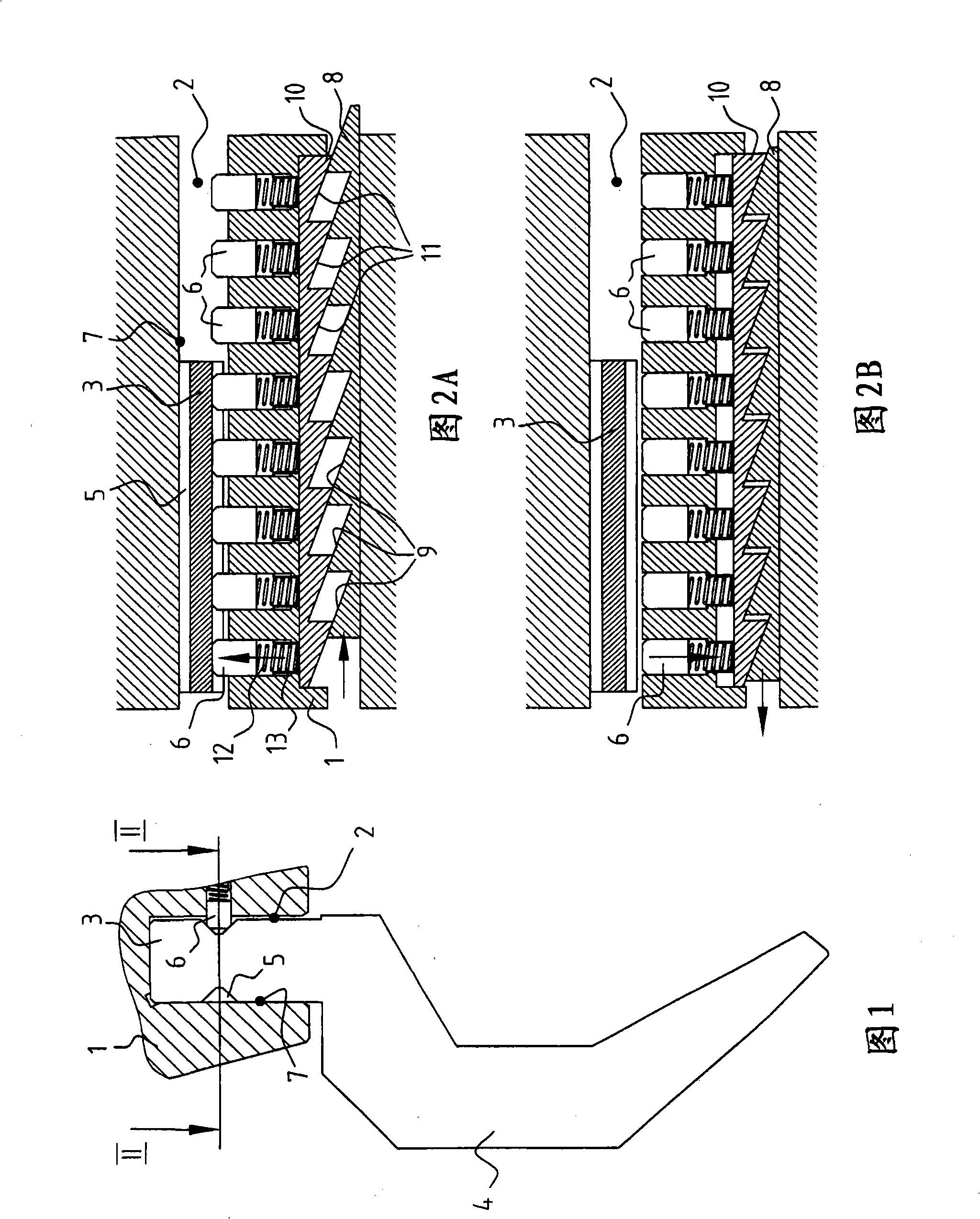

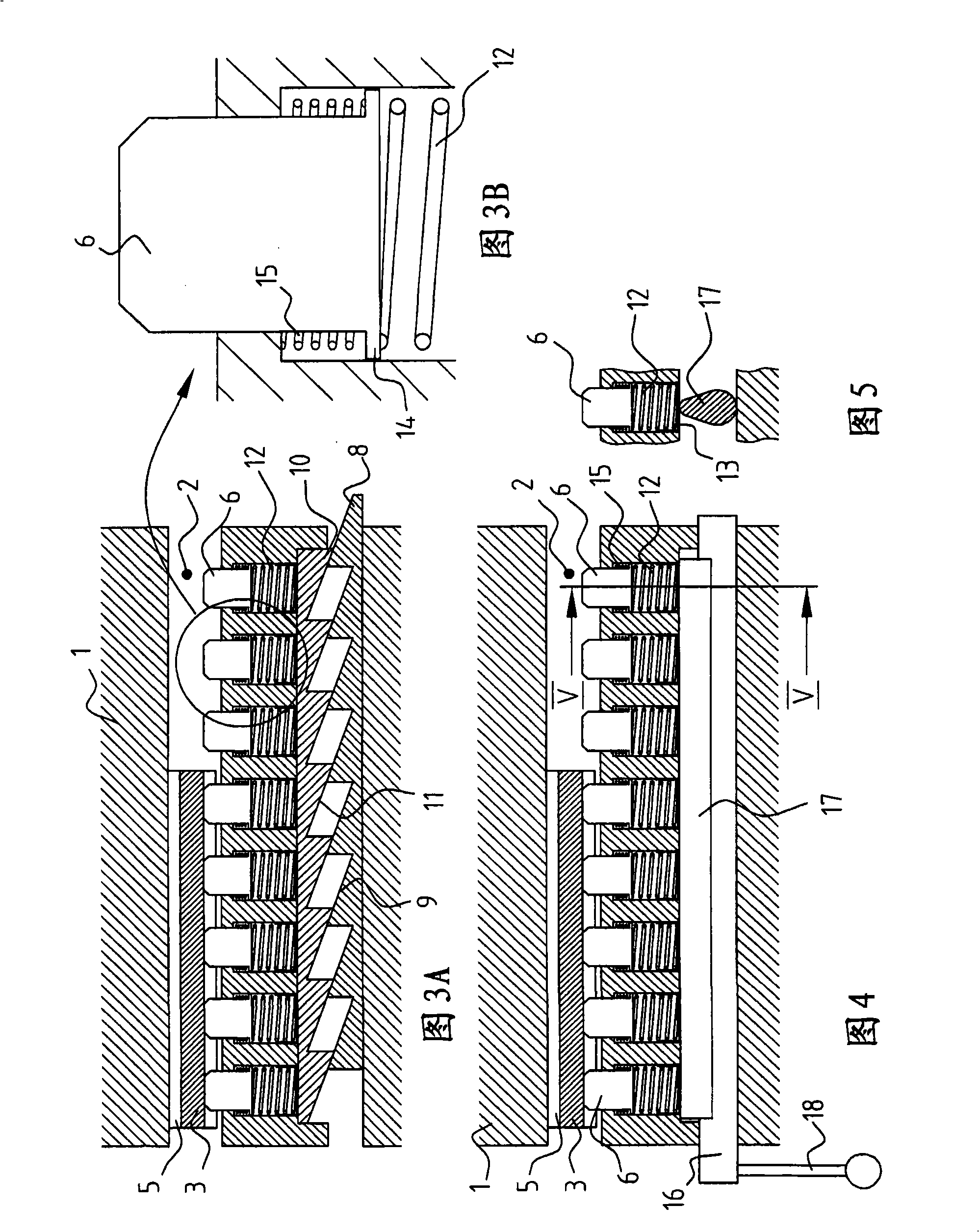

[0043] FIG. 1 shows a cross-sectional view of a clamping system 1 with a groove 2 in which a clamping part 3 of a tool 4 is arranged. The clamping part 3 of the tool has a V-shaped recess 5 into which a pin 6 is pushed to clamp the tool 4 . The pin 6 extends into the groove 2 , with the result that the clamping portion 3 is pushed against the wall 7 of the groove 2 .

[0044] FIG. 2A is a cross-sectional view along line II-II in FIG. 1 . The pin 6 is introduced into the body of the clamping system 1 . In the clamping system 1 , a first frame 8 with a slope 9 is slidably disposed in the clamping system 1 . A second frame 10 with a ramp 11 is adjacent to said frame 8 so that said ramps 9 and 11 work together. As shown in Figure 2A, by moving the frame 8 to the right, the frame 10 is laterally pushed away, resulting in the extension of the pin 6 into the groove 2, thereby clamping the tool 4 clamping part 3.

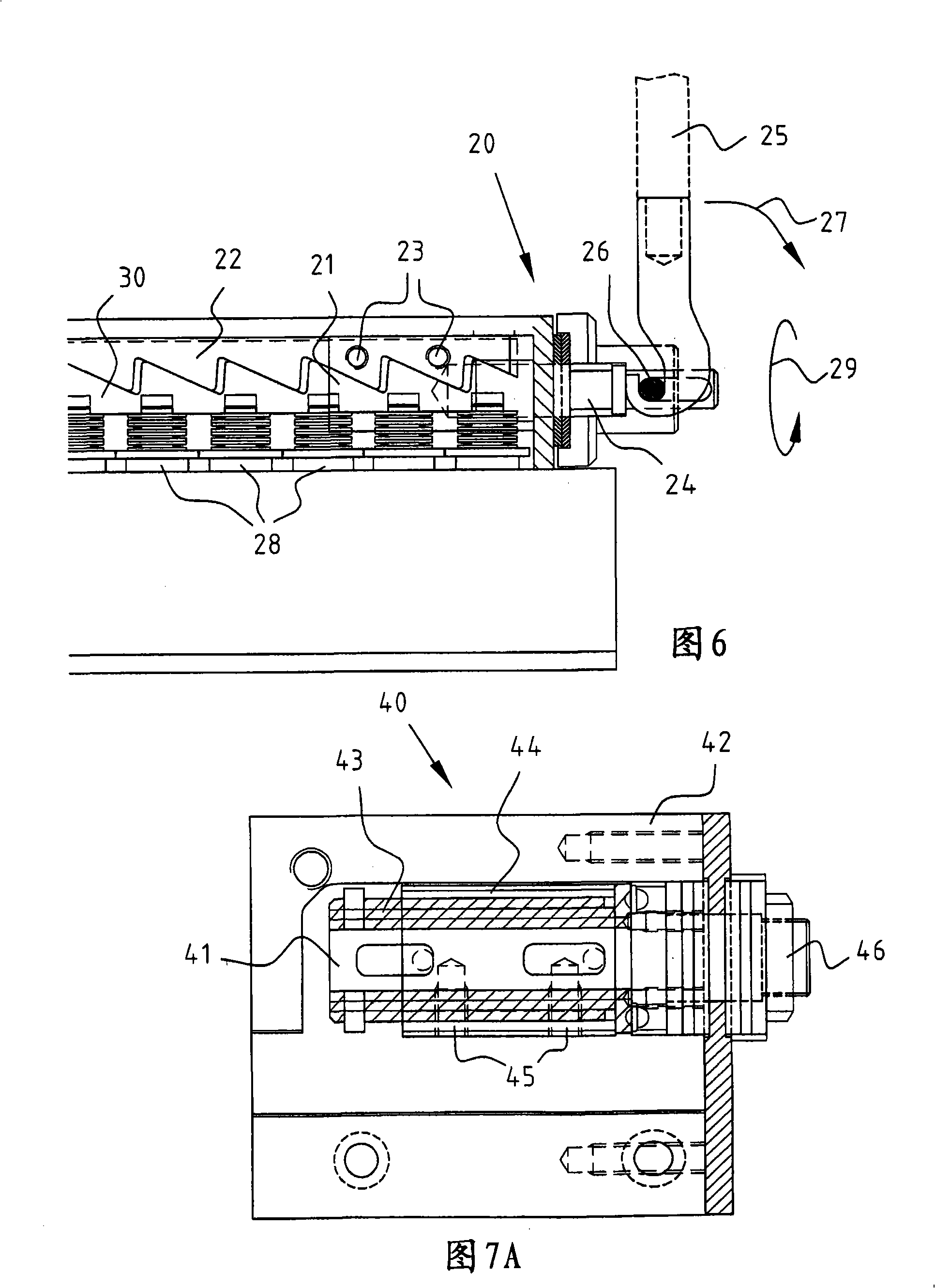

[0045] Each pin 6 is part of a pusher element. This pushing elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com