Patents

Literature

46results about How to "Realize heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

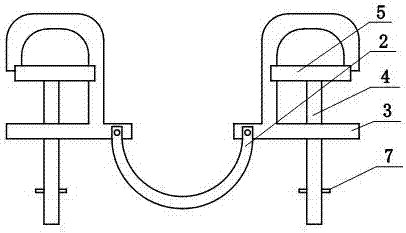

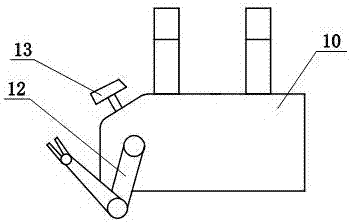

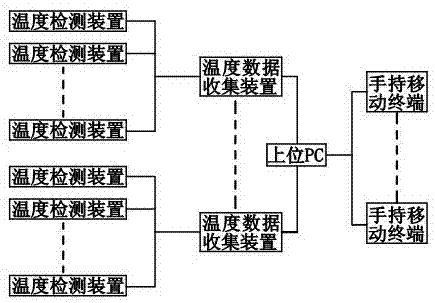

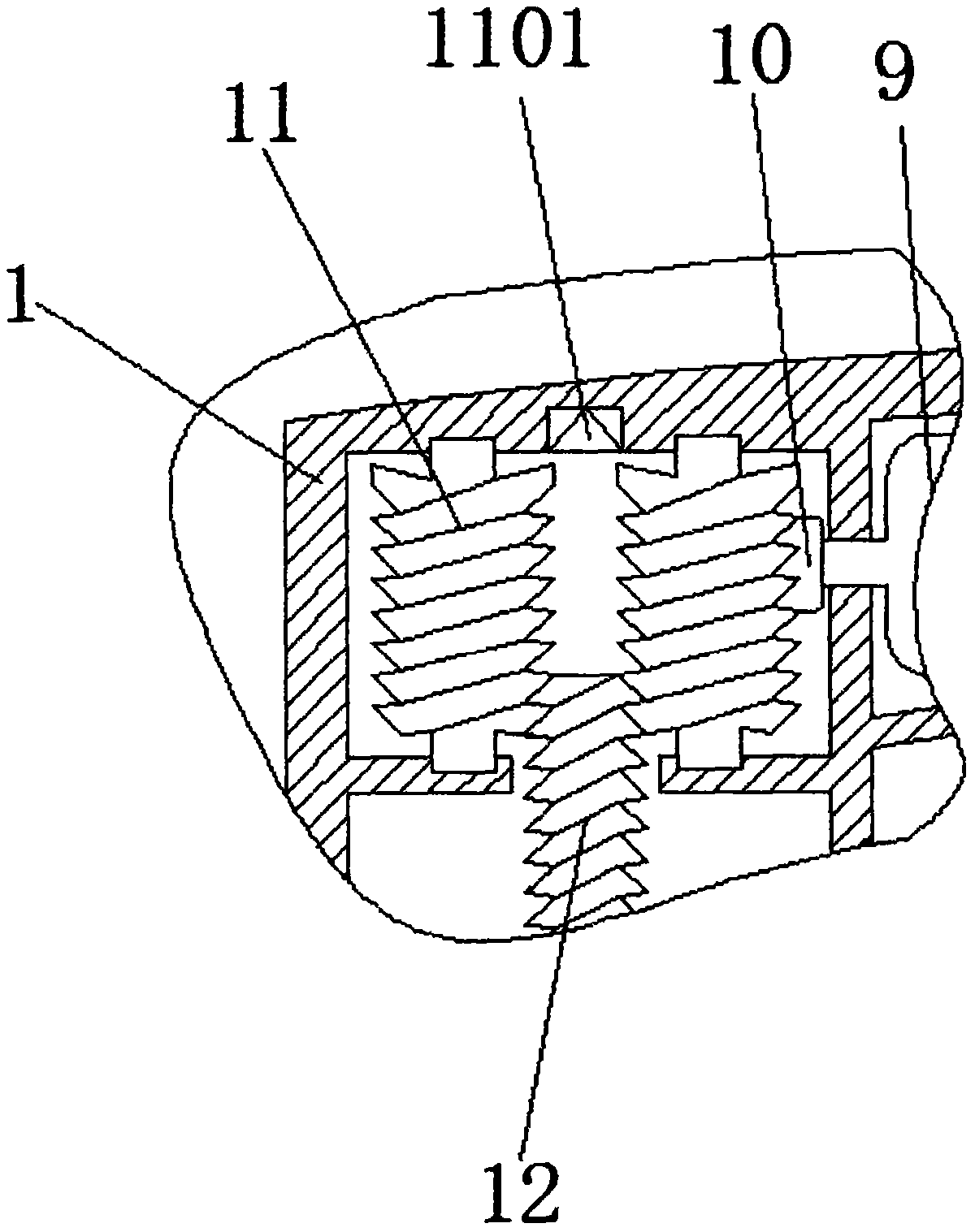

Electric processing apparatus of heating tape of transmission line connector

PendingCN107257104ARealize heat treatmentWith temperature monitoring functionCoupling contact membersCleaning using toolsWireless transmissionTemperature monitoring

The invention discloses an electric processing apparatus of a heating tape of a transmission line connector. The electric processing apparatus comprises a hot-line work tool, a shunt fastening device, and temperature detection devices that cooperate with each other. The hot-line work tool consists of an insulating rod and a walking robot capable of walking back and forth on a wire. The shunt fastening device includes two wire clamps connected by a shunt wire. At least two temperature detection devices are arranged at wires of transmission line contact points and include infrared sensors for detecting temperatures of the wire contact points; and the infrared sensors are connected with a temperature data collection unit with power supply based on the solar energy by a wireless transmission device. On the basis of combination of the hot-line work tool, the shunt fastening device, and the temperature detection devices, heating processing is carried out on the transmission line connector and cutting processing is carried out on foreign matters at the transmission line; the temperature monitoring function of the transmission line connector is realized; and the fusion operation of the different devices is realized.

Owner:ZHUMADIAN POWER SUPPLY ELECTRIC POWER OFHENAN +1

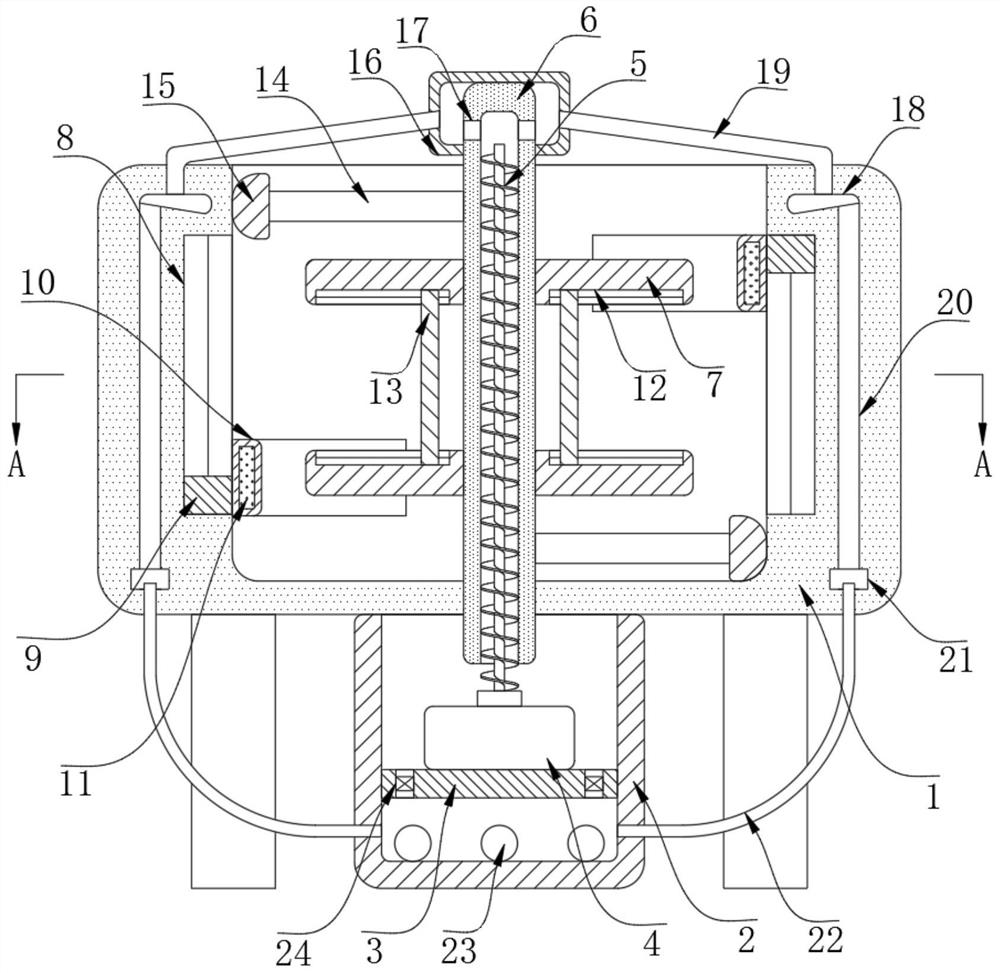

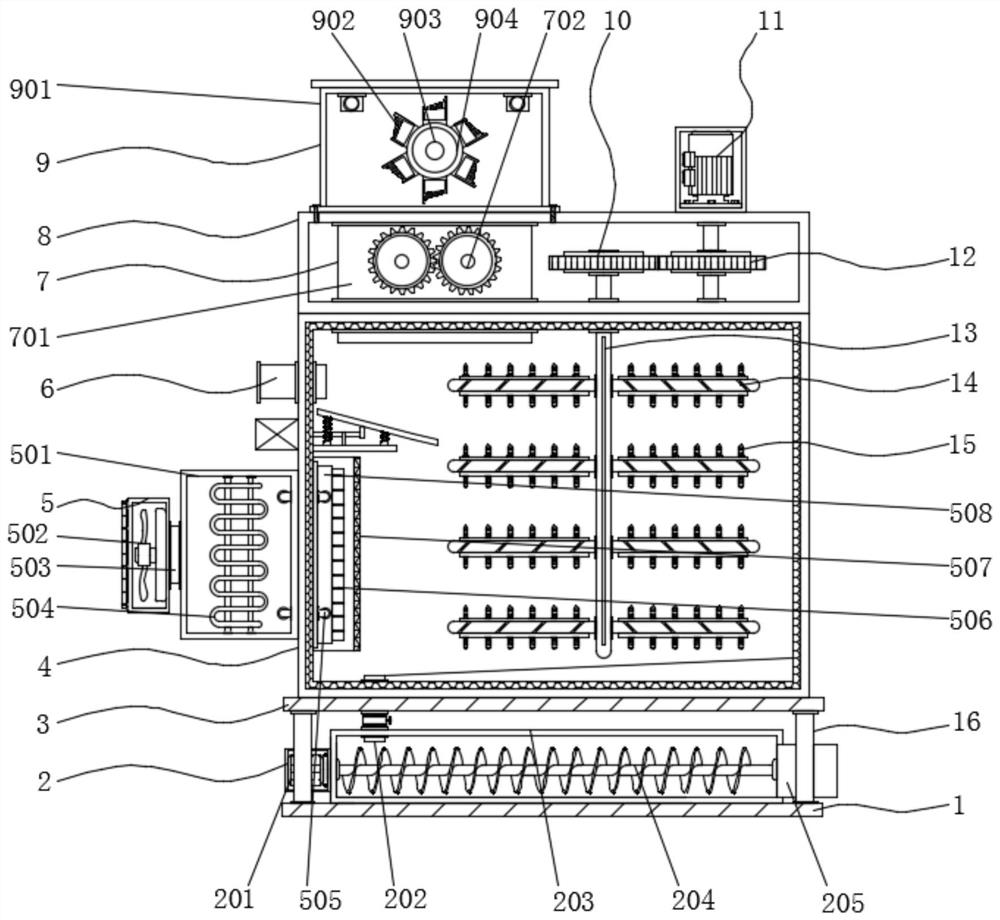

Production process of concrete tubular pile

ActiveCN111958821AFast heating stateRealize heat treatmentCement mixing apparatusElectric machineStructural engineering

The invention discloses a production process of a concrete tubular pile. The production process mainly comprises the following processing steps: charging; liquid injection and heating; and stirring. Processing equipment used in a processing course of the production process of the concrete tubular pipe comprises a stirring cylinder. A water tank is fixed to the outer bottom of the stirring cylinder, a partition plate is fixed to the inner wall of the water tank, a motor is fixed to the upper end of the partition plate, and an auger rotating shaft is fixed to an output shaft of the motor. The production process has the advantages that by arranging a magnetic block in a scraper blade, when the stirring rod drives electromagnets to rotate, the magnetic block subjected to an magnetic forces ofthe electromagnets drives the scraper blade to slide along the inner wall of the stirring cylinder, so that raw materials are not attached to the inner wall of the stirring cylinder for a long time, and therefore, the raw materials are mixed and stirred uniformly; meanwhile, two electromagnets which are high and low are arranged, so that the scraper blade moves circularly in a reciprocating mannereffectively in the rotating process of the electromagnets, the inner wall of the stirring cylinder is scraped and cleaned effectively all the time, and the mixing and stirring process is more thorough .

Owner:台州伟兴科技有限公司

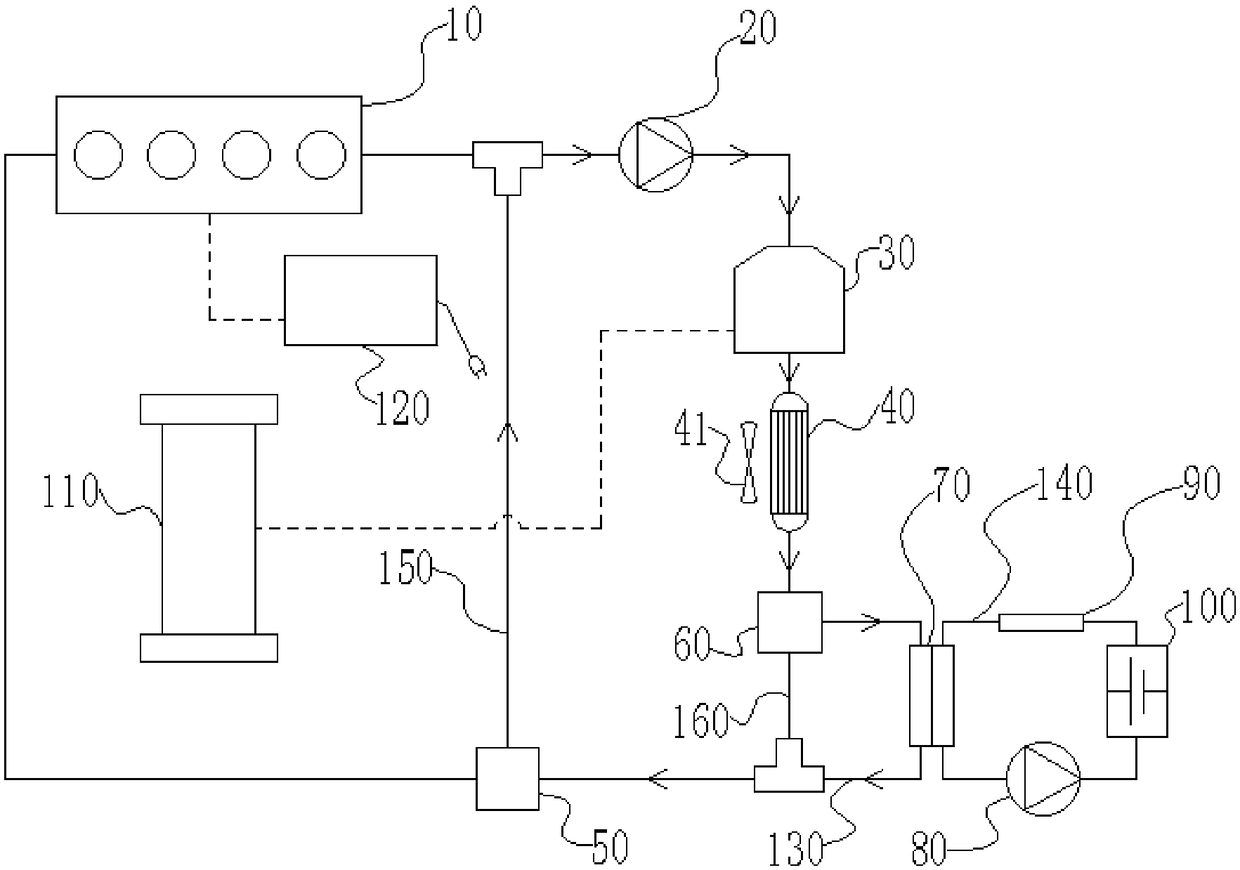

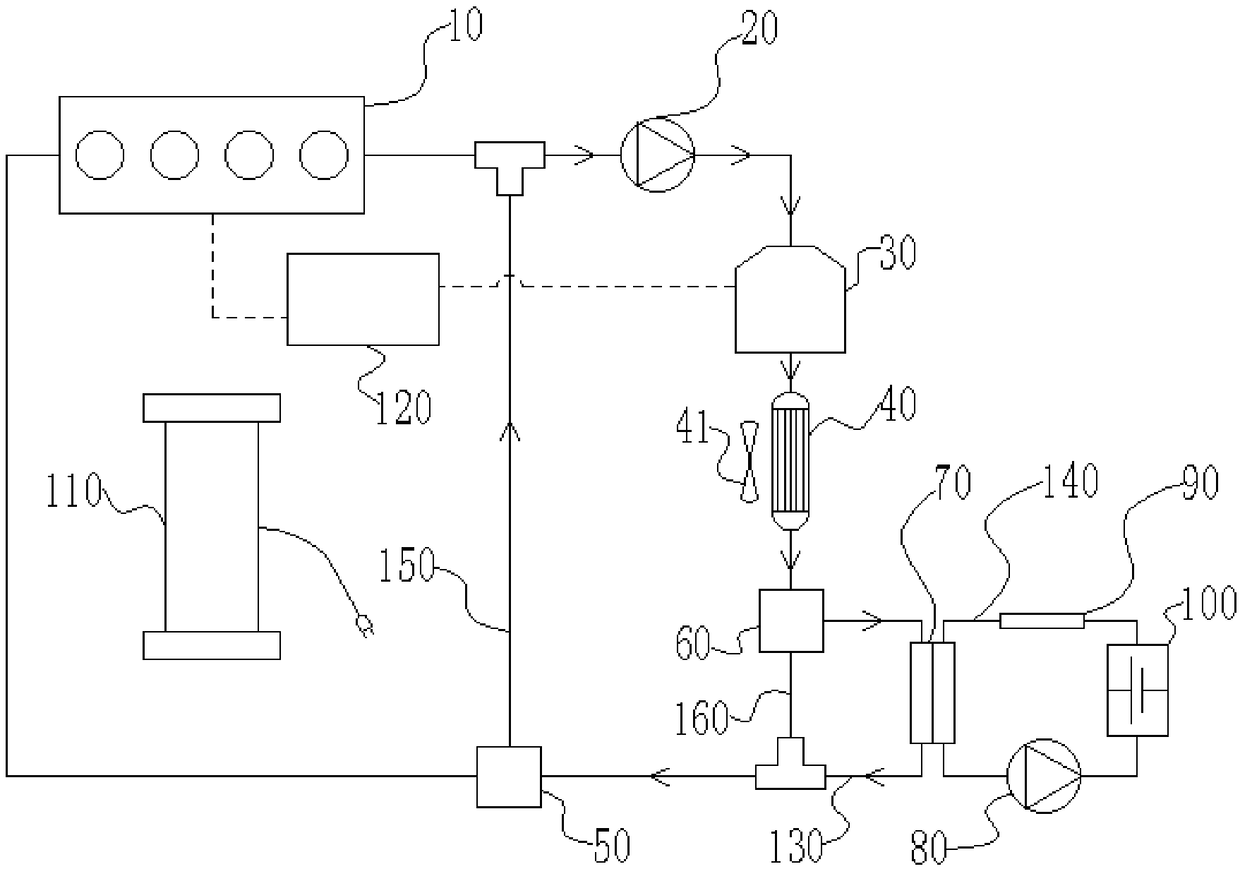

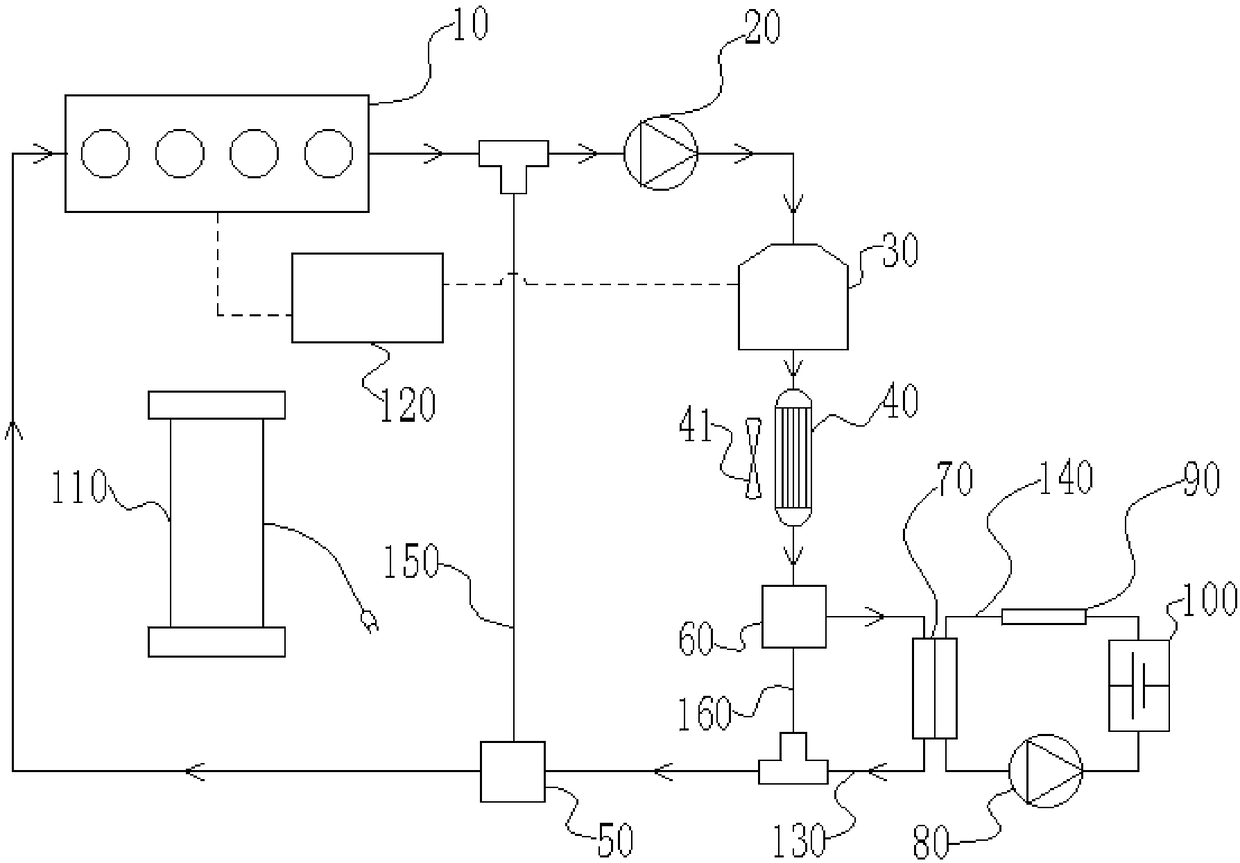

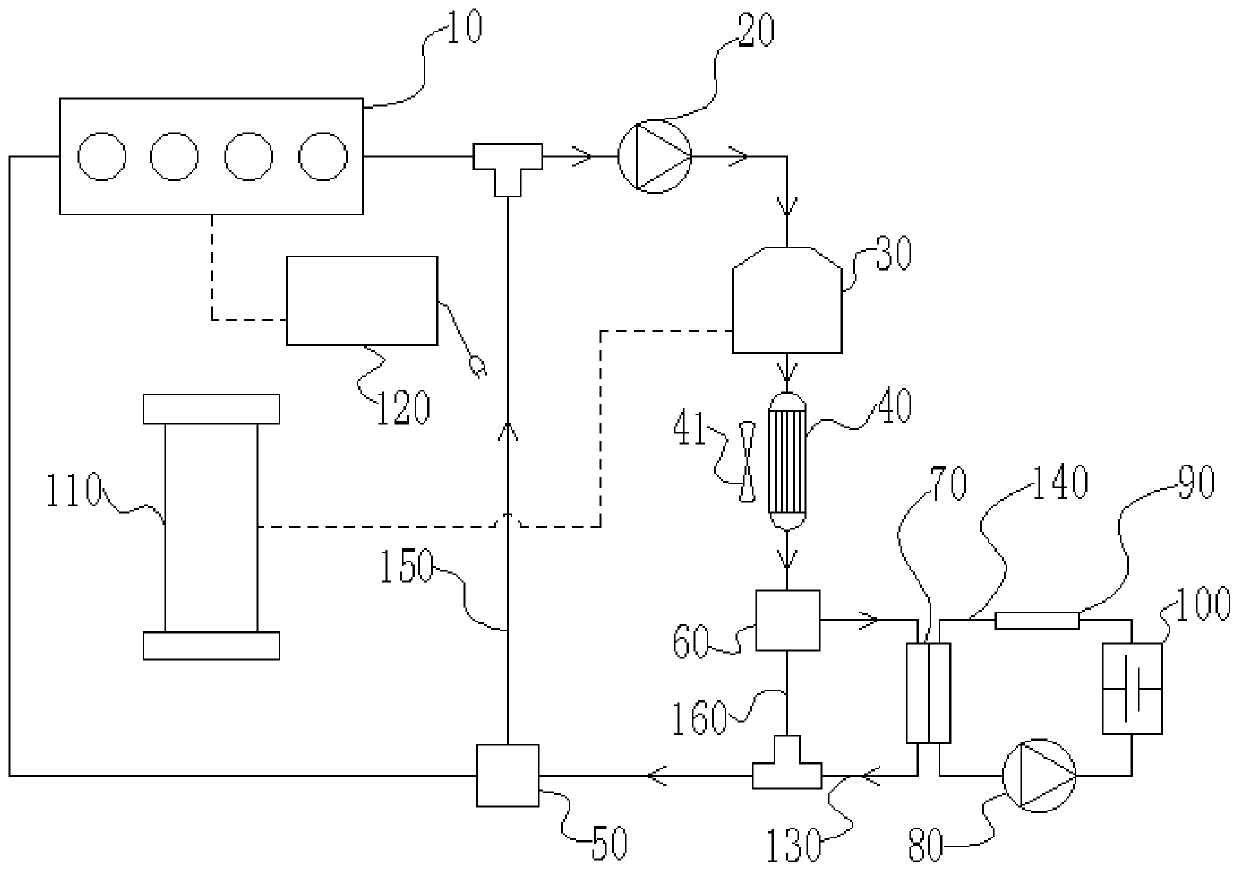

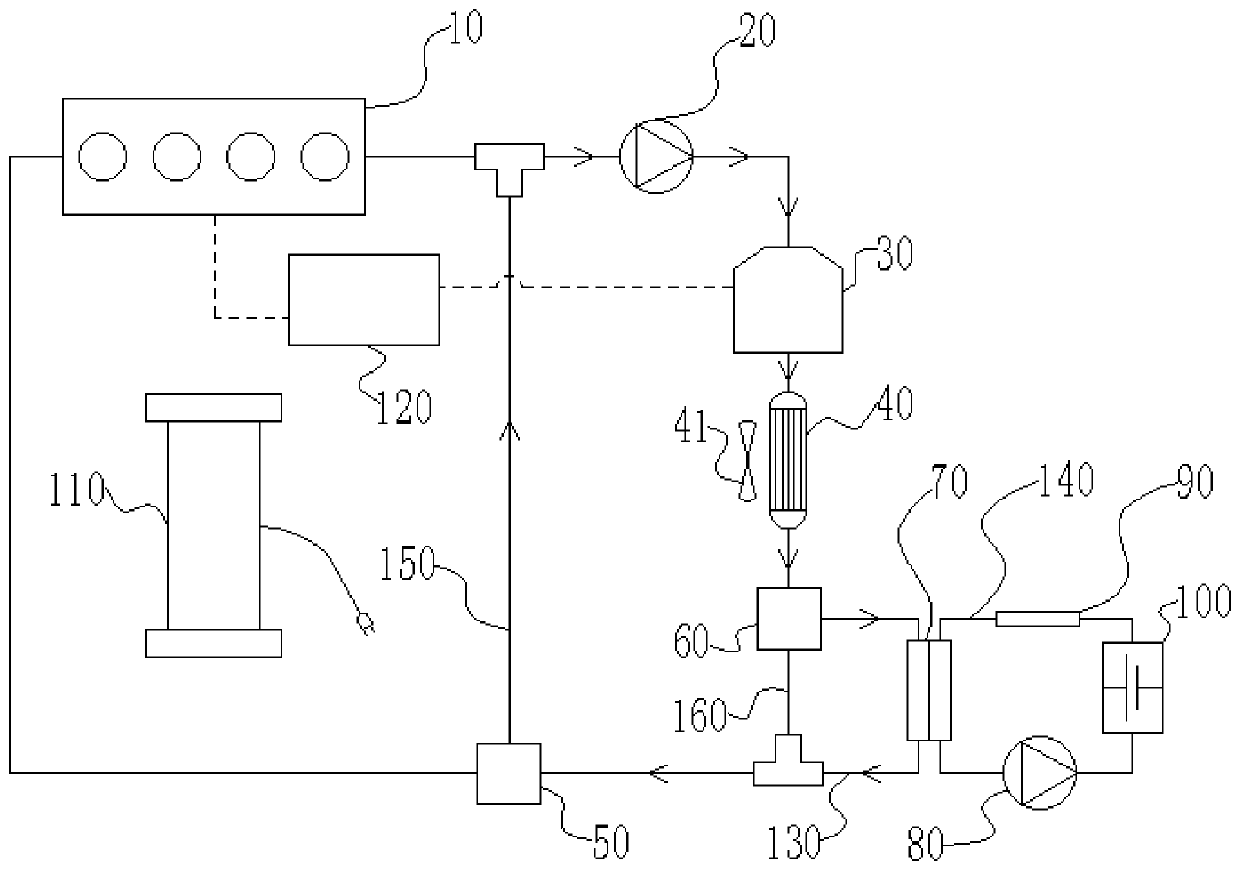

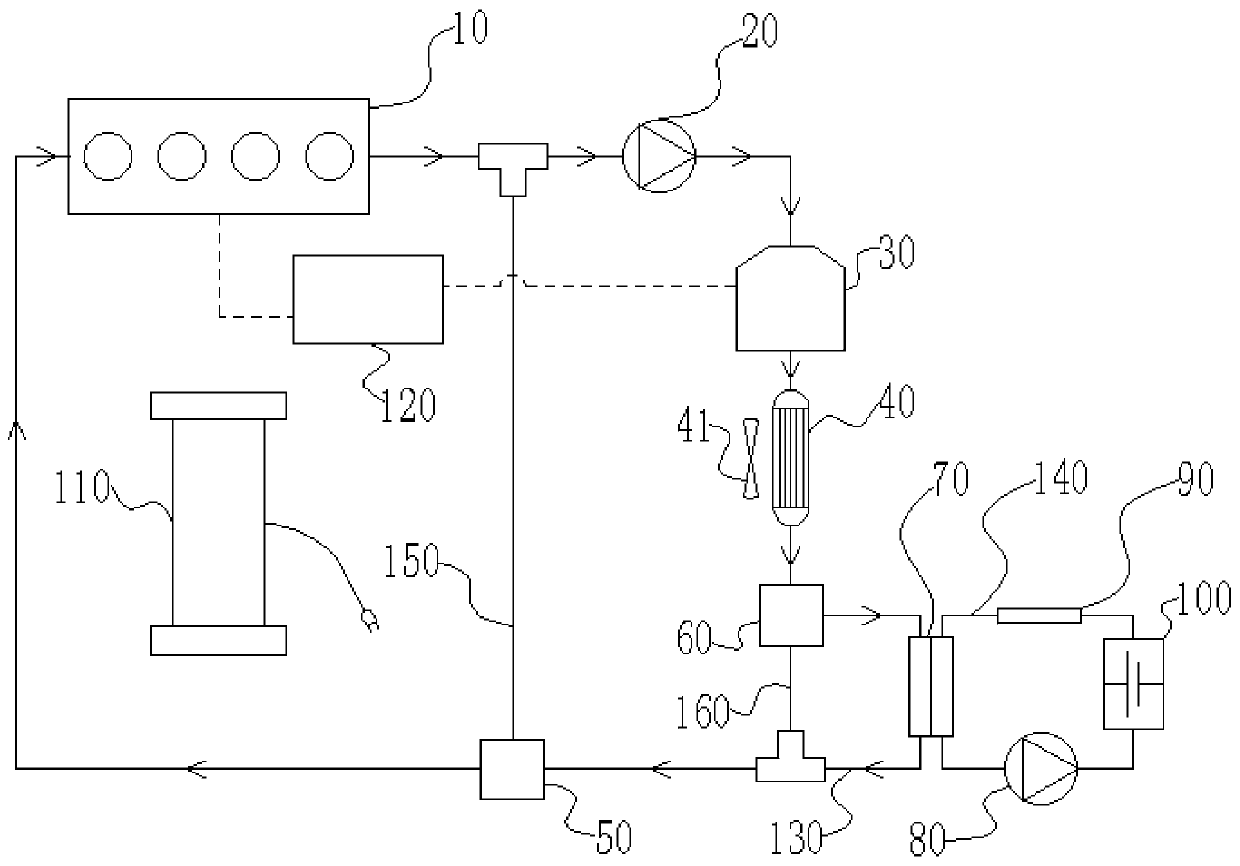

Automobile-mounted battery pack thermal management system and method and automobile

ActiveCN108177534ARealize heat treatmentHybrid vehiclesPropulsion using engine-driven generatorsElectrical batteryThermal management system

The invention provides an automobile-mounted battery pack thermal management system and method and an automobile and relates to the technical field of automobiles. The system and method and the automobile are designed in order to solve the problems that an existing battery pack is large in occupied space and single in thermal management use working condition. The automobile-mounted battery pack thermal management system comprises a battery pack heating loop. The battery pack heating loop comprises a heating device and a heat exchanger which are arranged in a warm air loop, and the heat exchanger transmits heat generated by the heating device to a battery pack; and power is supplied to the heating device through a charging pile or an electric generator. The automobile-mounted battery pack thermal management method uses the above automobile-mounted battery pack thermal management system for conducting thermal management on the battery pack. The automobile comprises the above automobile-mounted battery pack thermal management system. The automobile-mounted battery pack thermal management system and method and the automobile are used for meeting the thermal management requirement of the battery pack.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +1

Plastic film raw material mixing device

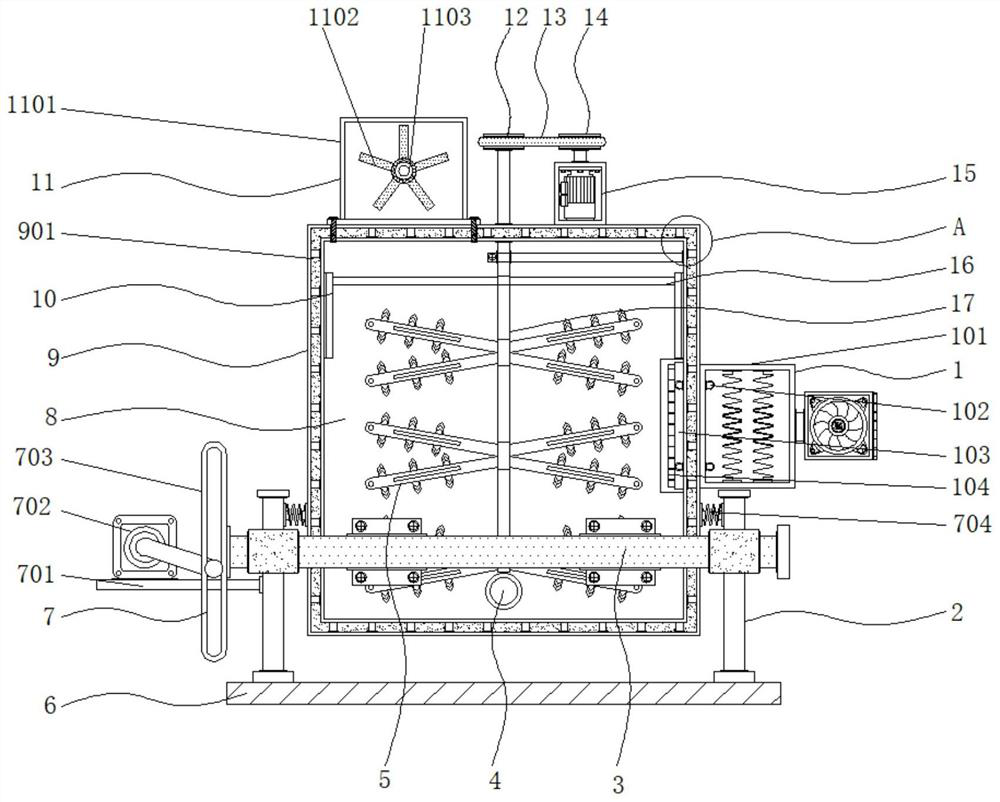

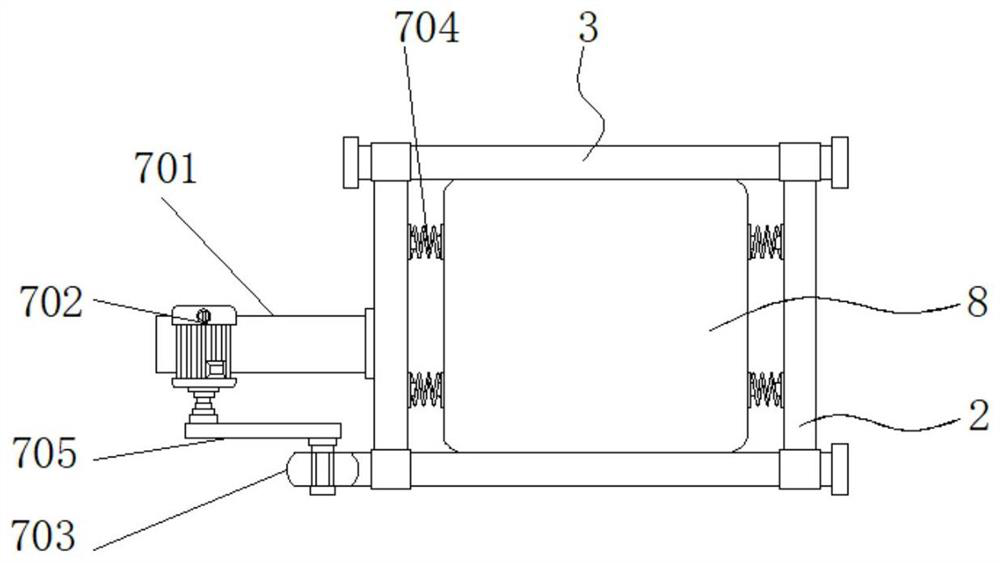

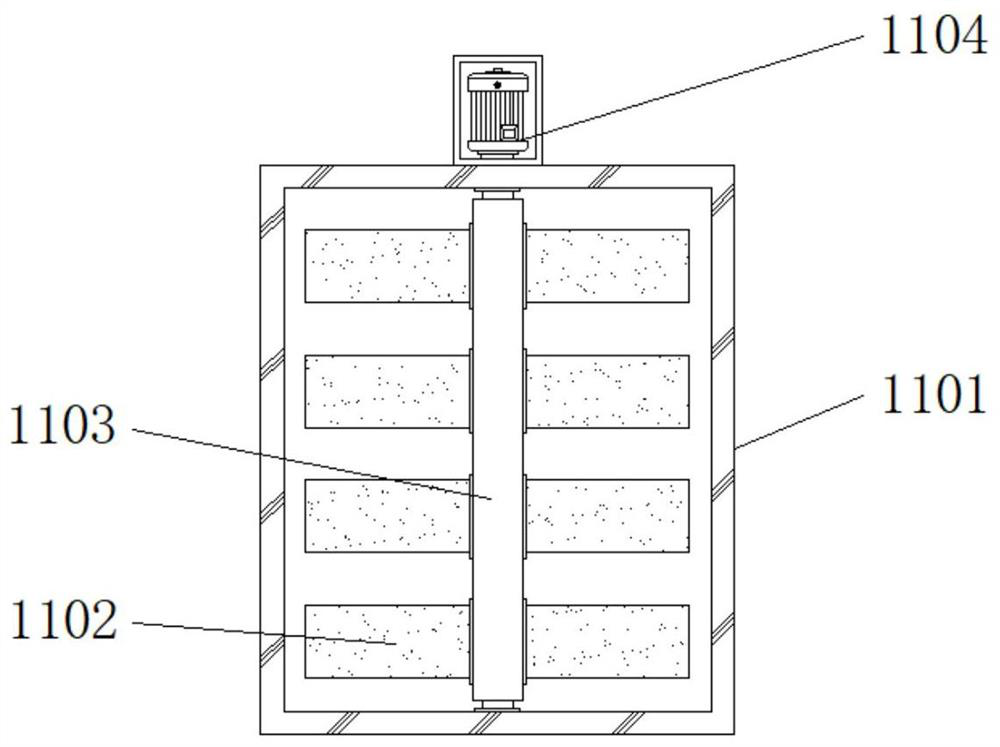

InactiveCN113211668AImprove the mixing effectWell mixedHollow article cleaningVibration suppression adjustmentsElectric machineEngineering

The invention discloses a plastic film raw material mixing device, and particularly relates to the technical field of plastic film processing. The plastic film raw material mixing device comprises a device body, wherein the two ends of the bottom of the device body are fixedly connected with a fixed bracket; the two sides of the fixed bracket are fixedly connected with supporting plates through connecting sleeve blocks; the bottom ends of the supporting plates are fixedly connected with a bottom plate; and one side of the fixed bracket is equipped with a vibrating mixing mechanism. According to the plastic film raw material mixing device disclosed by the invention, a charge base, a connecting plate, a connecting rotary shaft and a drive motor are arranged, so that raw materials are poured in through an opening in the top of the charge base in use; the drive motor is started, and drives the connecting rotary shaft to rotate through a coupler, so that the connecting rotary shaft drives the connecting plate to rotate while rotating; and the connecting plate consists of five groups of rectangular plates to form a windmill shape, so that the raw materials are uniformly charged, and therefore, blockage caused by excessive raw materials poured in once is prevented, working efficiency of the device is improved, a raw material blockage condition is reduced, and raw material processing efficiency is guaranteed.

Owner:刘和斌

Activated sludge biofilm composite integrated treatment device

ActiveCN111875042AEasy to handleEasy to cleanBiological treatment apparatusCleaning using toolsActivated sludgeBiofilm

The invention discloses an activated sludge biofilm composite integrated treatment device which comprises a working plate and treatment covers which are symmetrically and detachably connected to the upper surface of the working plate; a discharging hole is formed in one end of the treatment cover, a baffle is detachably connected to the end of the discharging hole, a first arc-shaped plate is fixedly connected to the inner side wall of the treatment cover, a connecting plate with a communicating hole is fixedly connected to the inner side wall of the first arc-shaped plate, and a containing groove is formed in the connecting plate. A mounting plate is detachably connected to the interior of the accommodating groove, and a biological membrane tape is connected to the side wall of the mounting plate; a movable plate is movably connected above the working plate located between the treatment covers, a rotary disc is rotatably connected above the movable plate, a connecting plate is telescopically connected to the rotary disc, and a treatment box is fixedly connected to one end of the connecting plate. The sludge treatment device is convenient to treat sludge, and meanwhile, the workingplate is convenient to clean.

Owner:广东清境世嘉环境技术有限公司

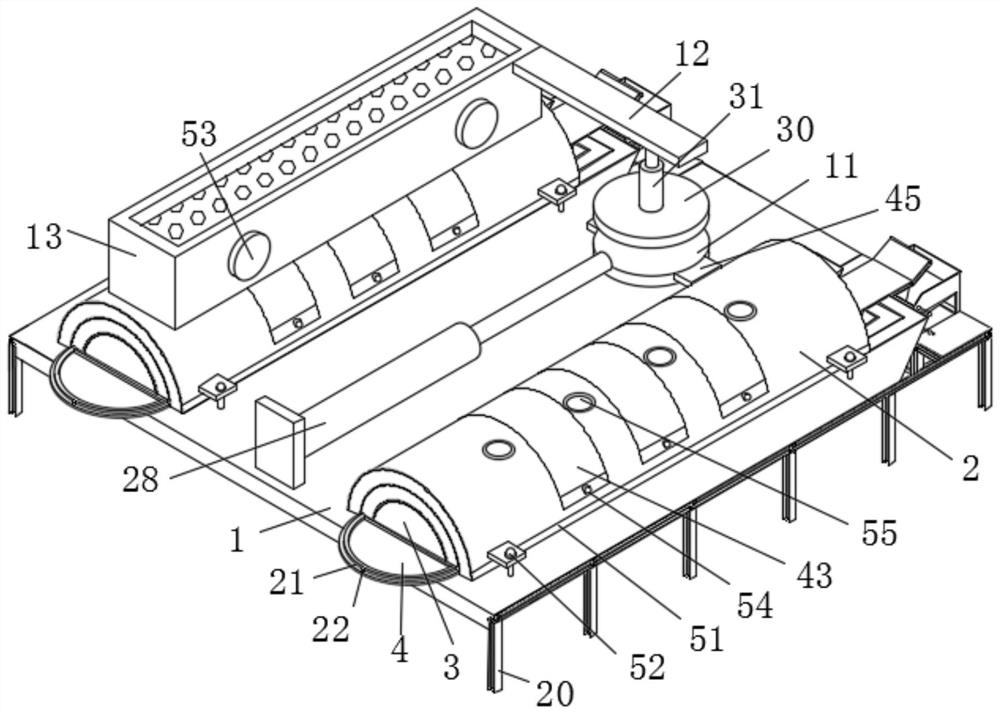

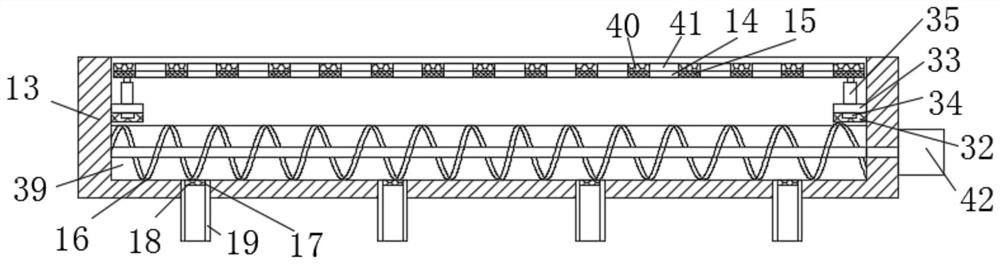

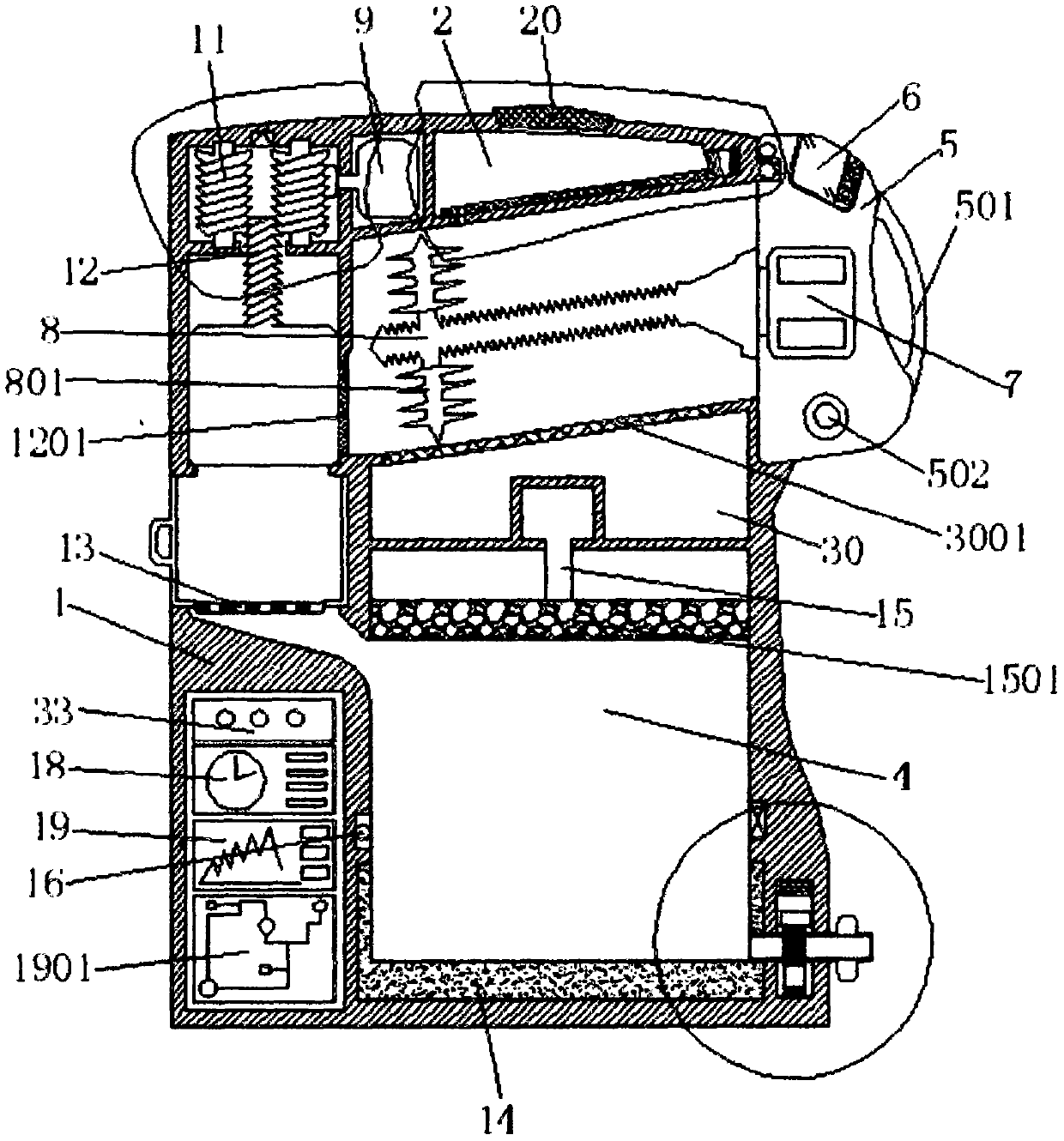

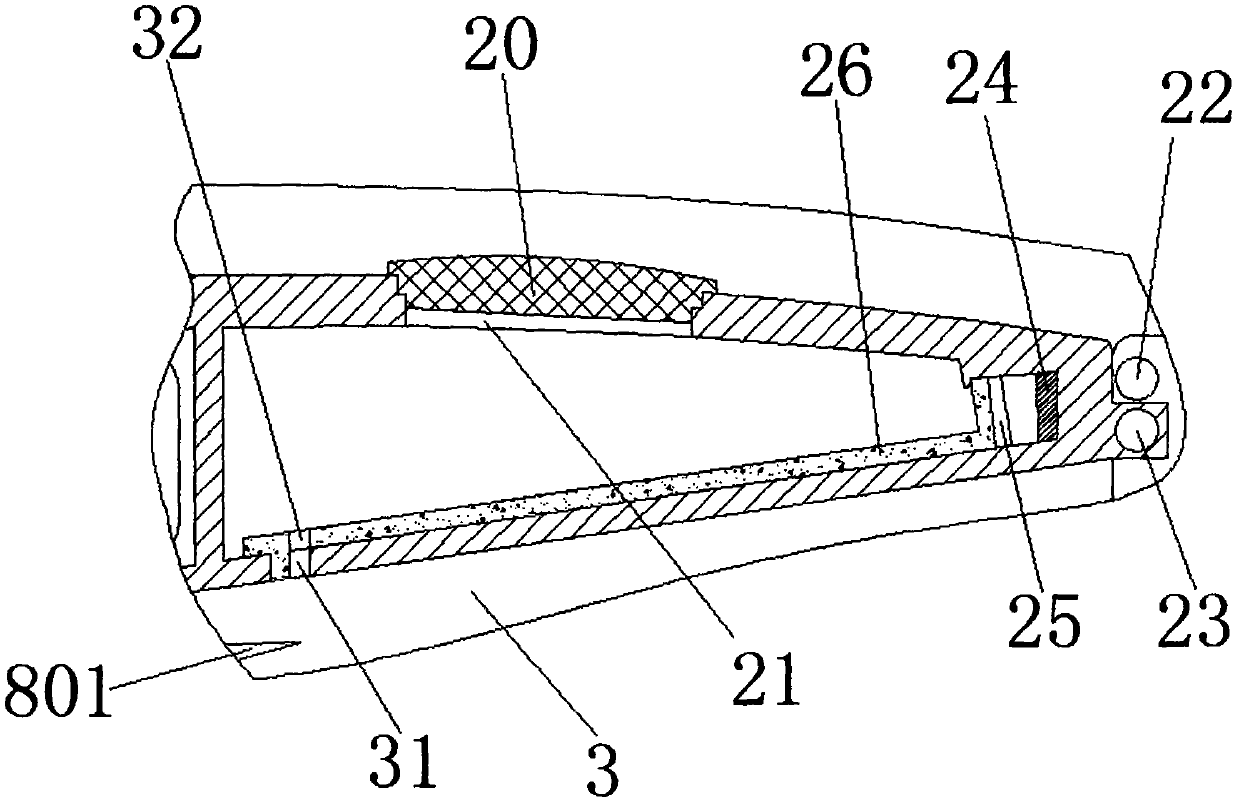

Continuous green killing and tea strip tidying machine

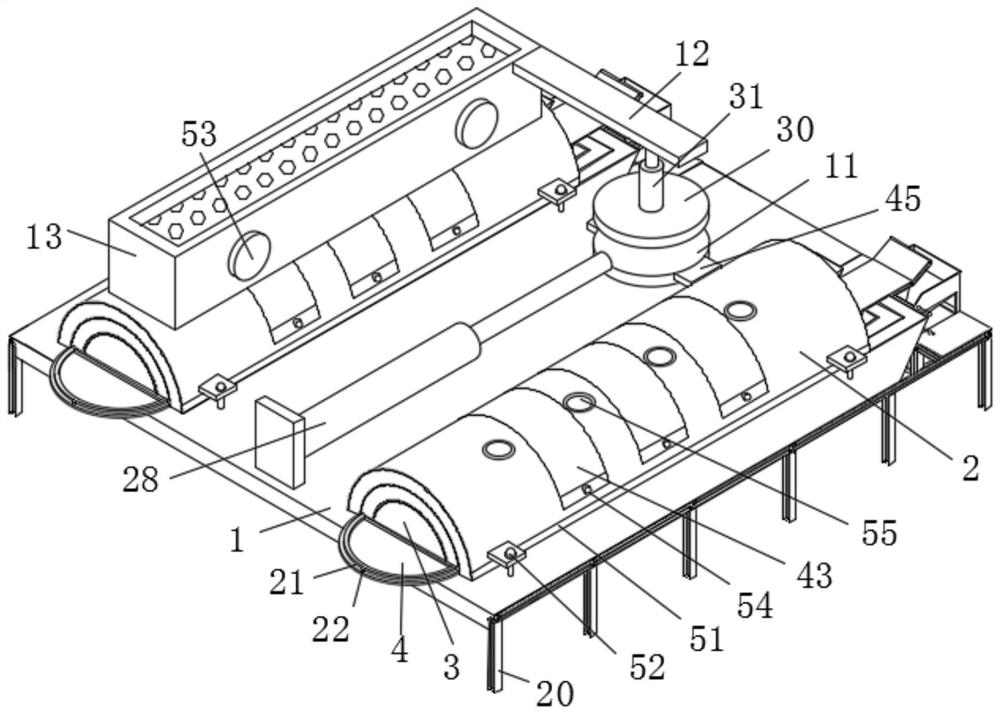

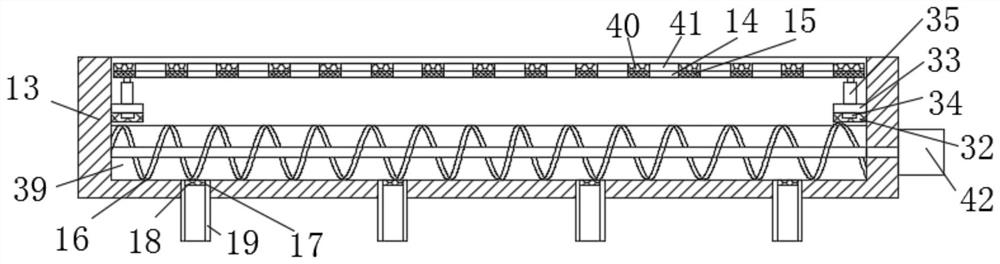

ActiveCN110574799AAchieve recyclingPrevent heat lossPre-extraction tea treatmentAgricultural engineeringTemperature control

The invention discloses a continuous green killing and tea strip tidying machine. The continuous green killing and tea strip tidying machine includes a tea strip tidying machine body, and further includes a heat preservation cover and a material distributing assembly; the heat preservation cover is arranged above the tea strip tidying machine body, a plurality of infrared heating plates are fixedly connected to the side wall of the heat preservation cover relative to the tea strip tidying machine body, the outer side wall of the tea strip tidying machine body is fixedly connected with a temperature-controlled switch electrically connected with the infrared heating plates, the heat preservation cover is internally provided with a waste heat cavity, the top end surface of the heat preservation cover is fixedly connected with a draught fan, the air outlet end of the draught fan communicates with the interior of the waste heat cavity, an air outlet is formed in the bottom of the waste heatcavity, and the air outlet is located at the feeding end of the tea strip tidying machine body; and the material distributing assembly includes an discharging plate, the discharging plate obliquely communicates with a groove pot in the discharging end of the tea strip tidying machine body, and a material collection barrel is arranged on the lower part of the discharging end of the discharging plate. According to the continuous green killing and tea strip tidying machine, heating treatment of tea above the tea strip tidying machine is realized, and collection of the processed tea is facilitated.

Owner:安徽宣城华阳茶叶机械股份有限公司

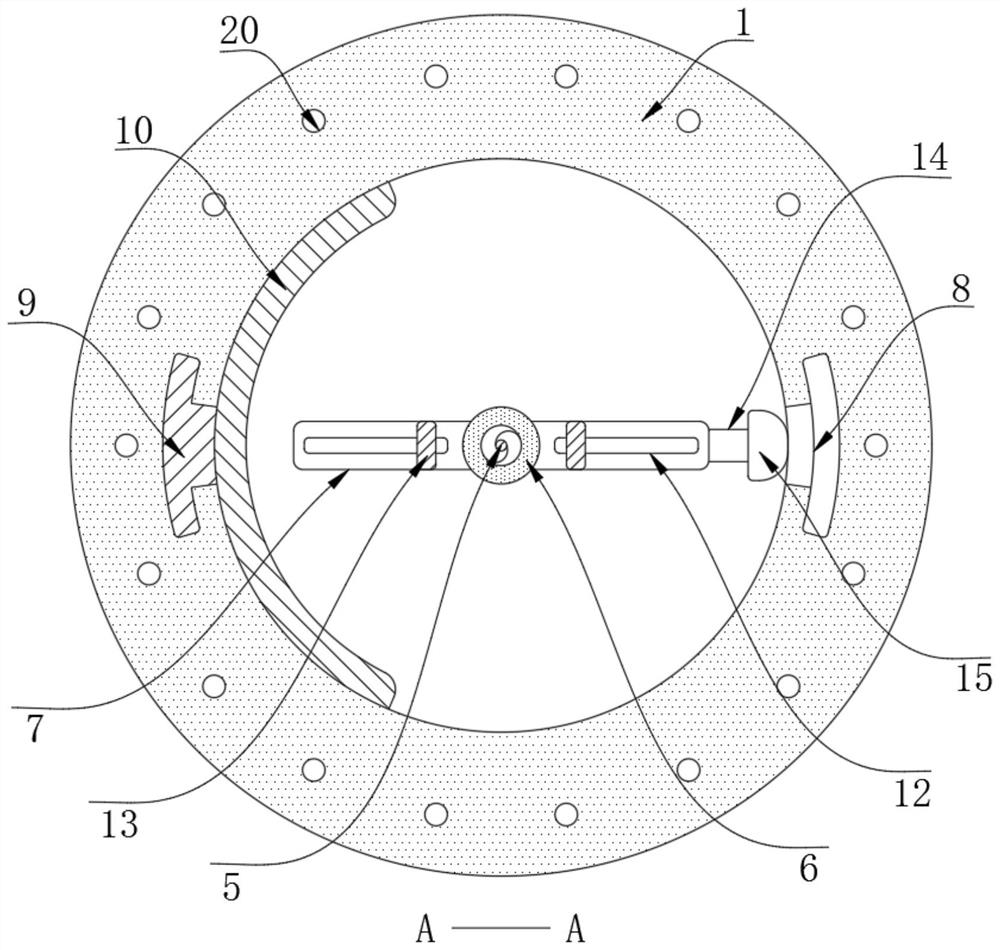

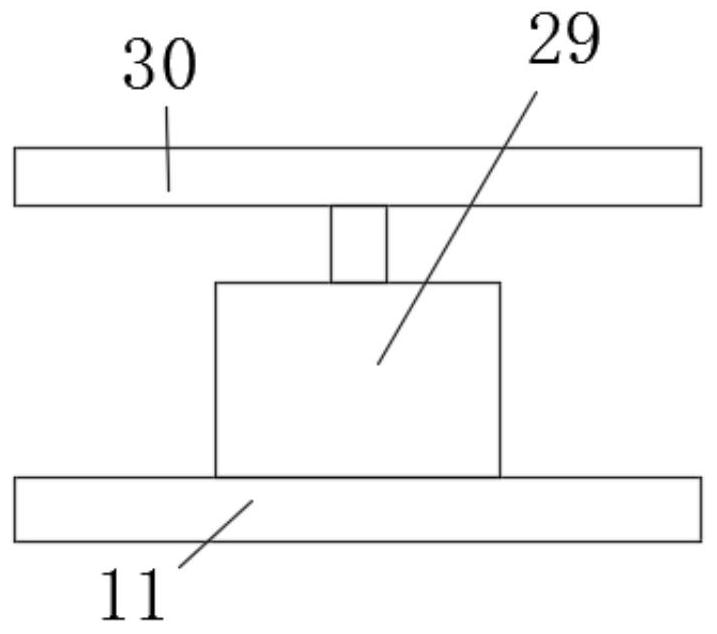

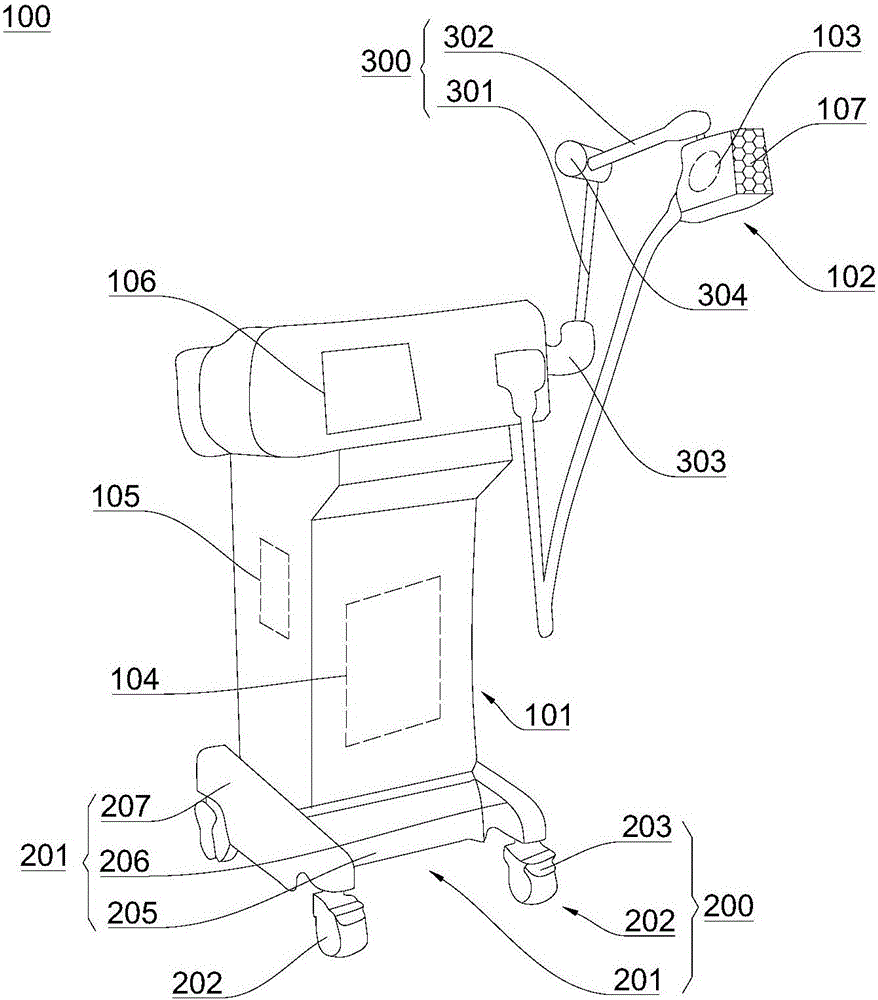

Physiotherapy instrument

InactiveCN106237549AReduce hindranceAvoid damageUltrasound therapyVibration massageElectricityTreatment effect

Disclosed is a physiotherapy instrument. The physiotherapy instrument comprises a power supply, an ultrasonic generator, a treatment head and a body provided with an accommodation cavity, wherein the power supply is arranged in the accommodation cavity of the body, the ultrasonic generator is electrically connected with the anode and the cathode of the power supply, the treatment head is provided with an accommodation hole for accommodating the ultrasonic generator, the accommodation hole is internally provided with a sound bearing medium, and the treatment head is provided with a contact surface which is in contact with a human body and is made of a metal material. The physiotherapy instrument provided by the invention has a treatment effect on man's genital diseases such as premature ejaculation and the like by use of ultrasonic waves and is convenient to use. Compared to medicament treatment, the physiotherapy instrument can greatly reduce drug resistance of the human body and the side effect of medicaments.

Owner:徐斌

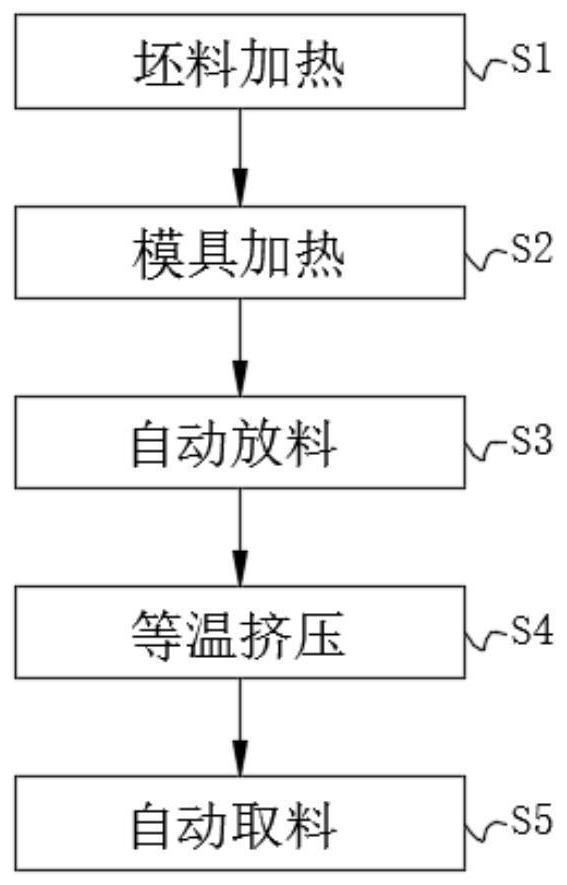

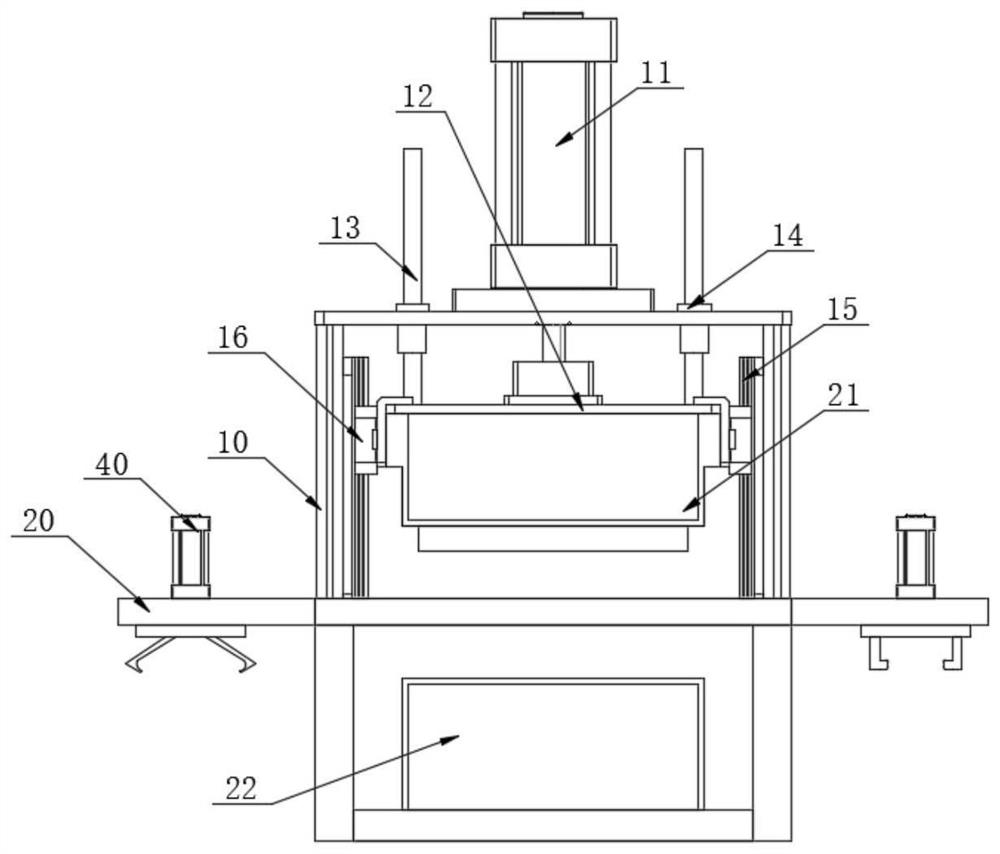

Isothermal extrusion process for titanium alloy profiled bar

InactiveCN113878013ASolve uneven deformationImprove enduranceShaping toolsMetal-working feeding devicesMetallic materialsBar pressing

The invention relates to an isothermal extrusion process for a titanium alloy profiled bar, which belongs to the technical field of metal material forming, and comprises the steps of titanium alloy blank heating, mold heating, automatic discharging, isothermal extrusion and automatic material taking. By preheating a titanium alloy blank and a forming die respectively, then the constant temperature of the titanium alloy blank in the extrusion forming process is kept through an isothermal mechanism, and the problem that in the prior art, when the titanium alloy blank is subjected to extrusion forming, due to the fact that the temperature difference between the surface and the core is large, deformation is uneven is solved; after preheating the titanium alloy blank, extrusion treatment is carried out, the tolerance of the titanium alloy blank is improved; the defects that the titanium alloy blank is prone to cracking and uneven in forming under the action of a pressing rod are effectively overcome; and in addition, the hollow pipe titanium alloy blank is adopted, the titanium alloy blank is not prone to stacking in the machining process, and the utilization rate of the titanium alloy blank is increased.

Owner:索罗曼(常州)合金新材料有限公司

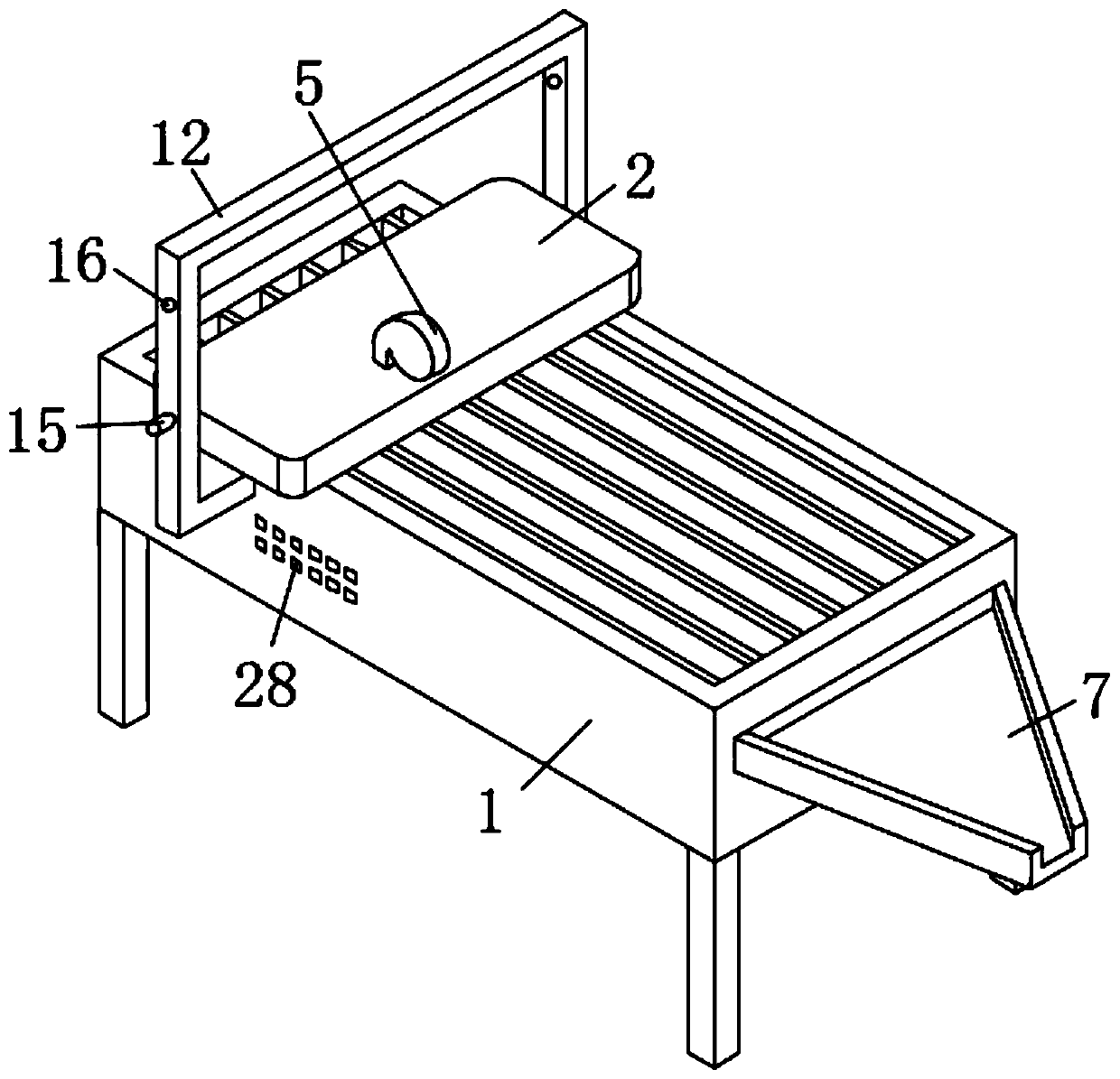

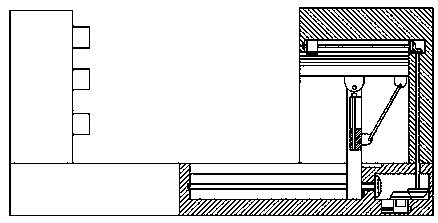

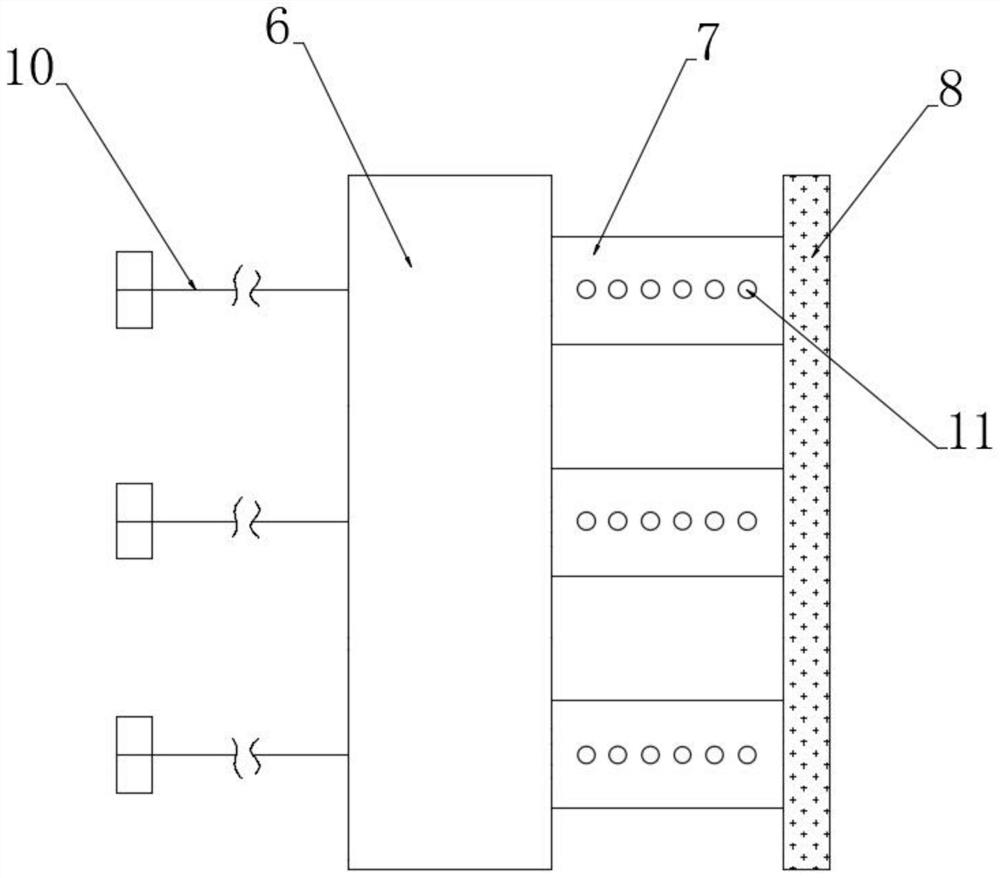

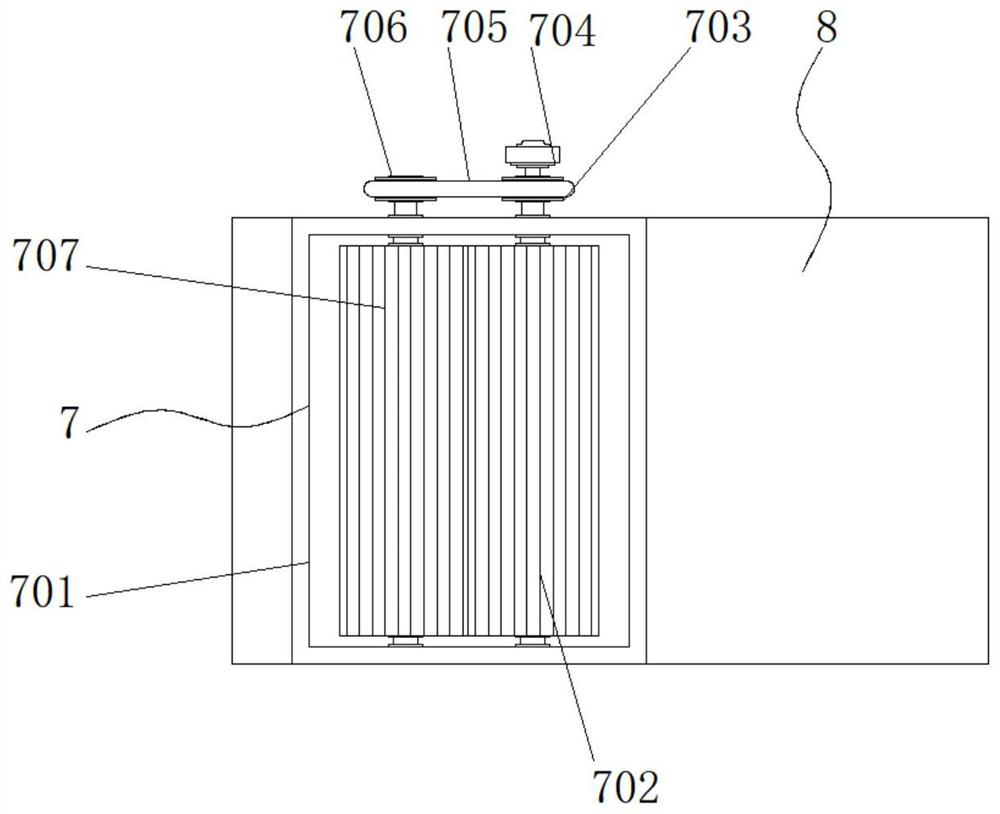

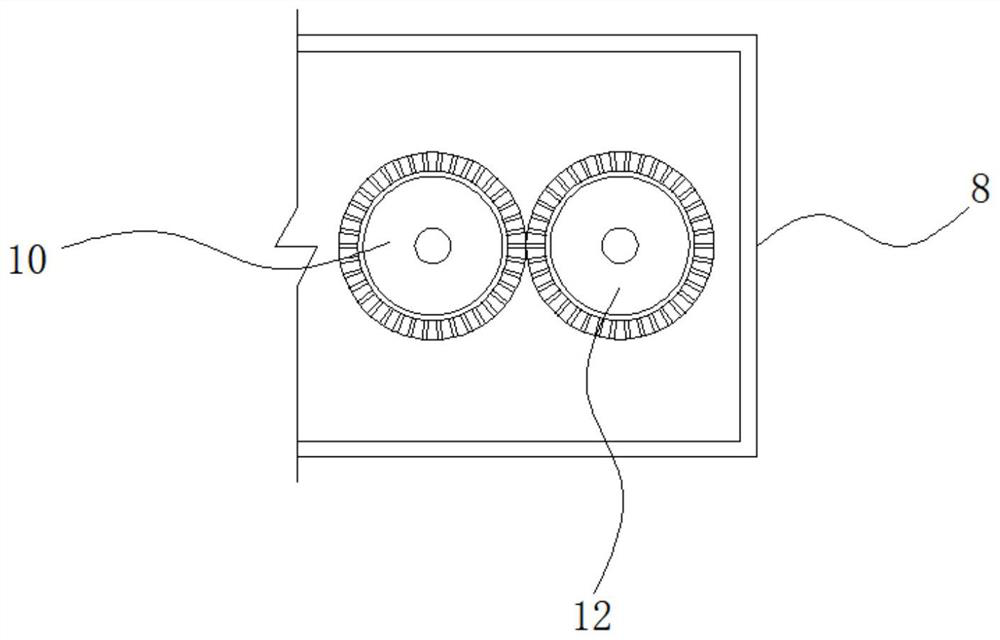

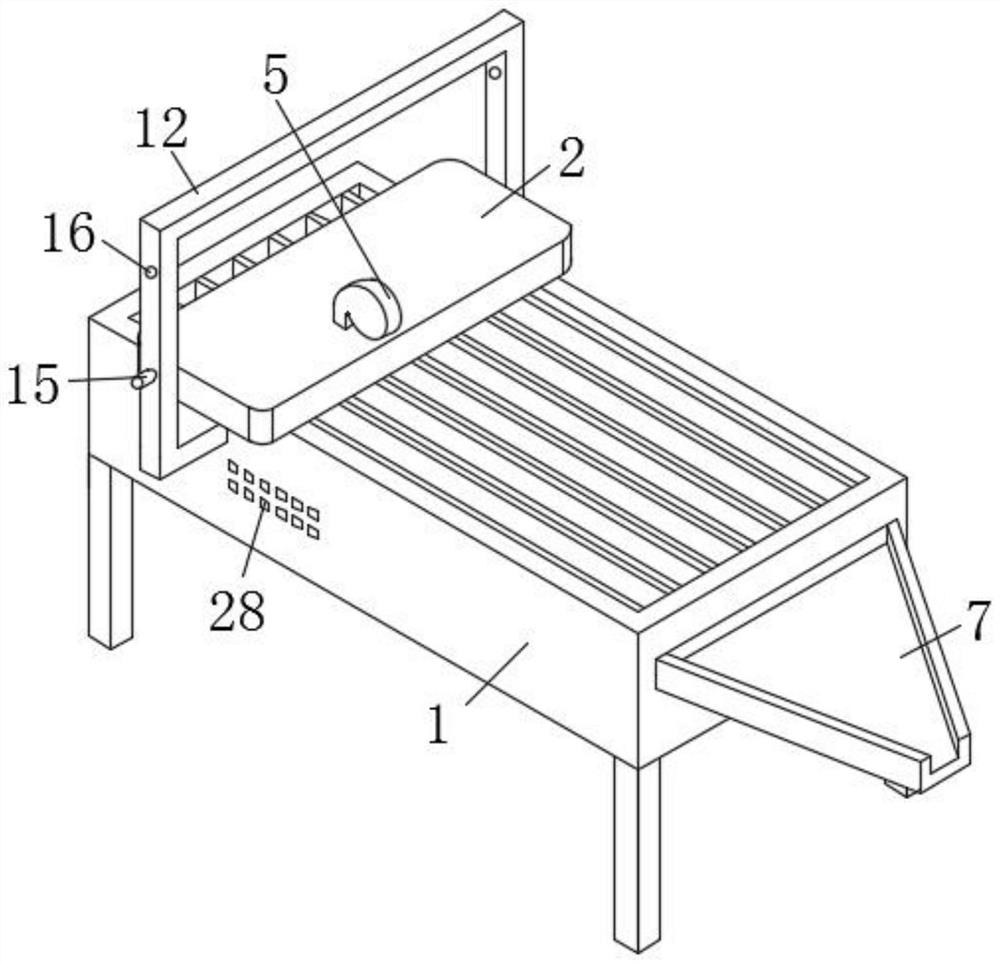

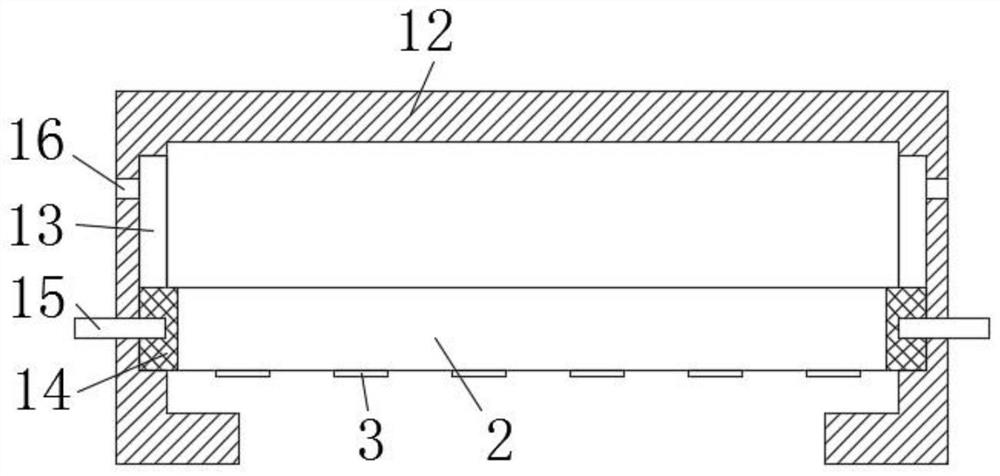

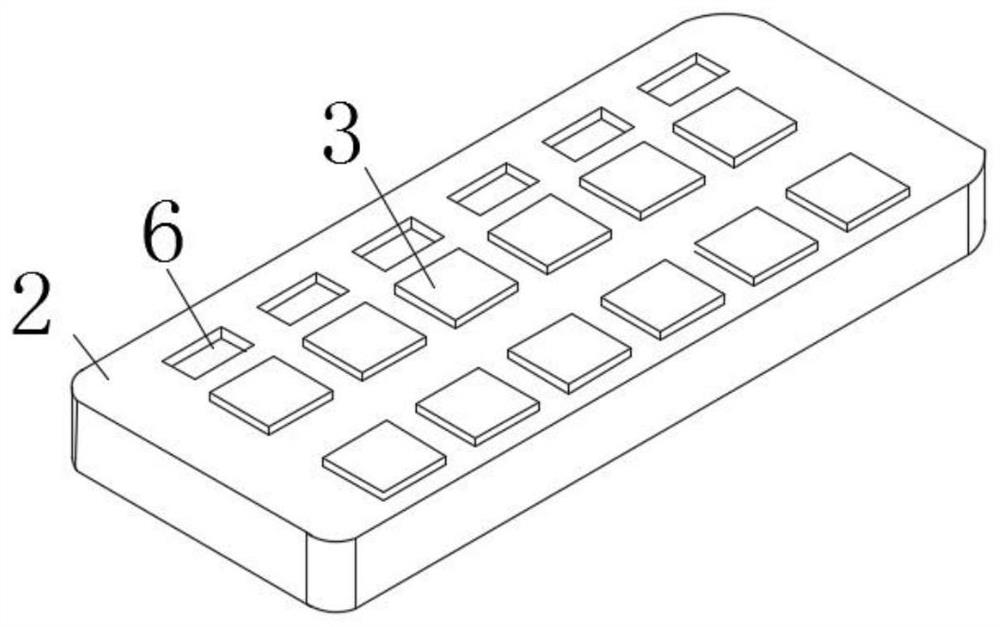

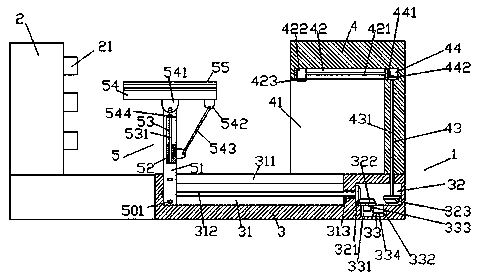

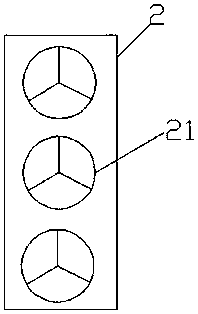

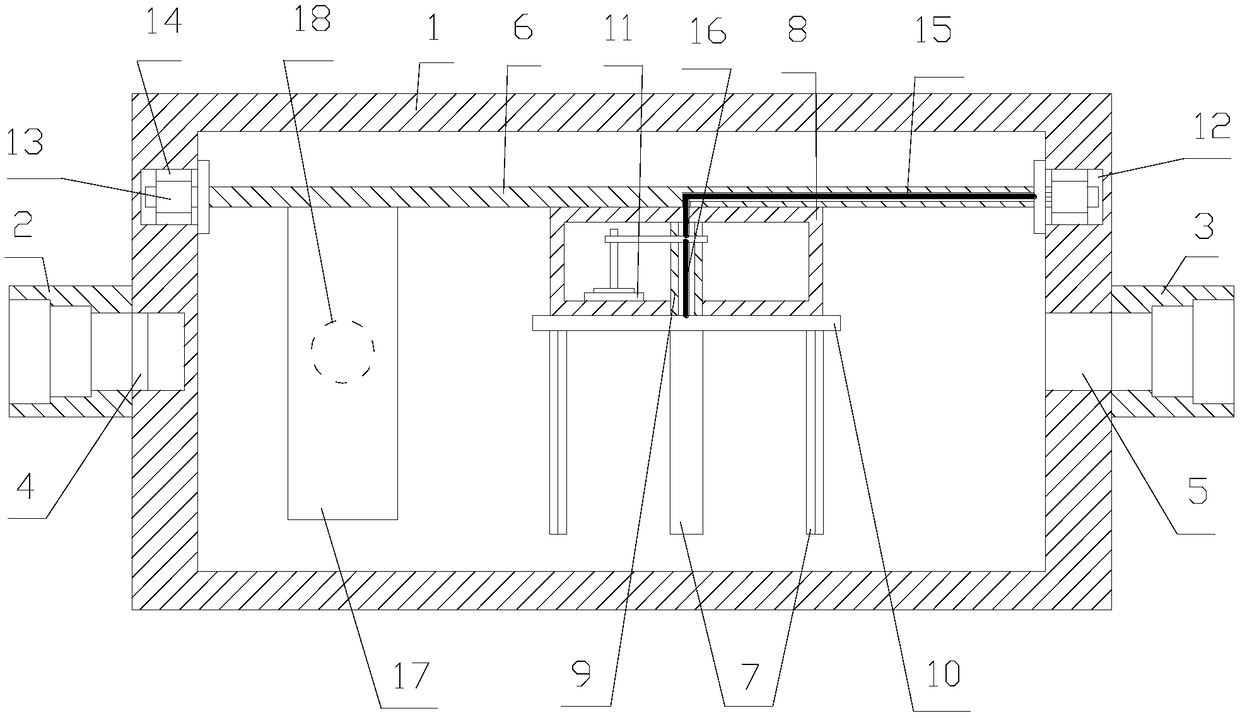

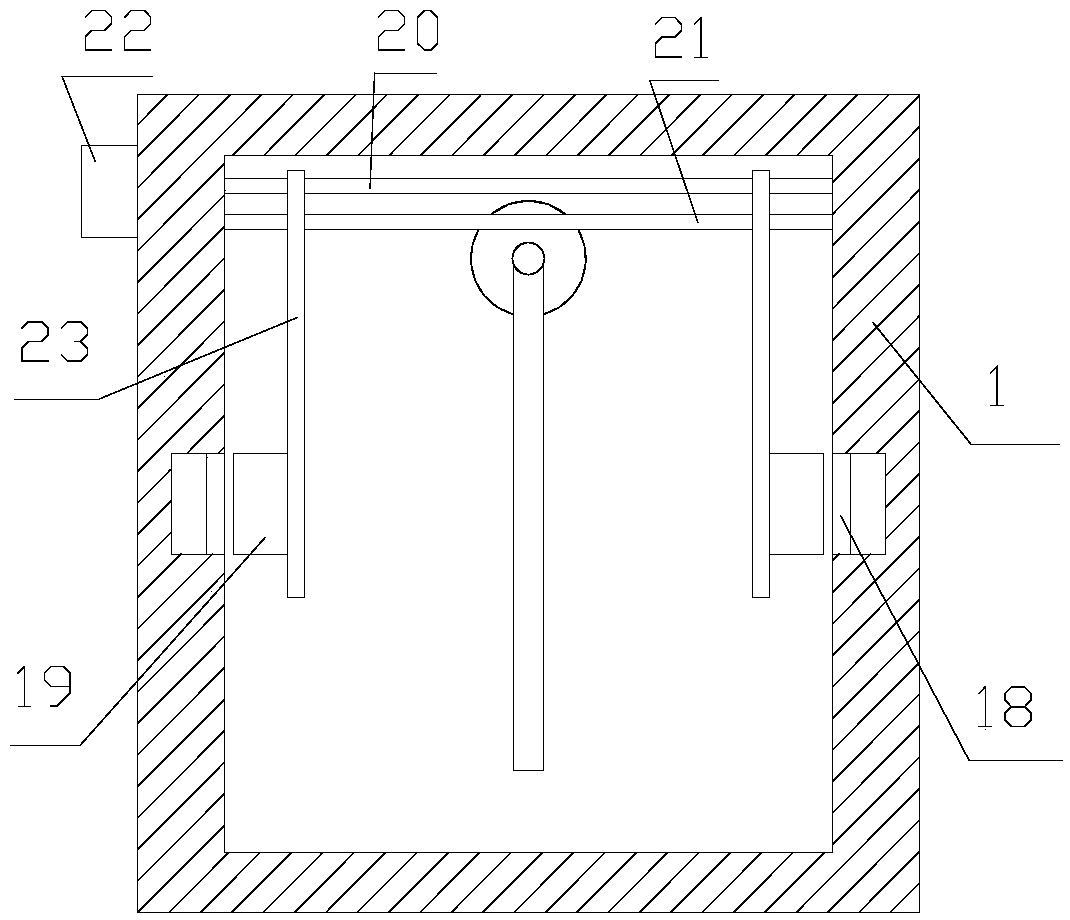

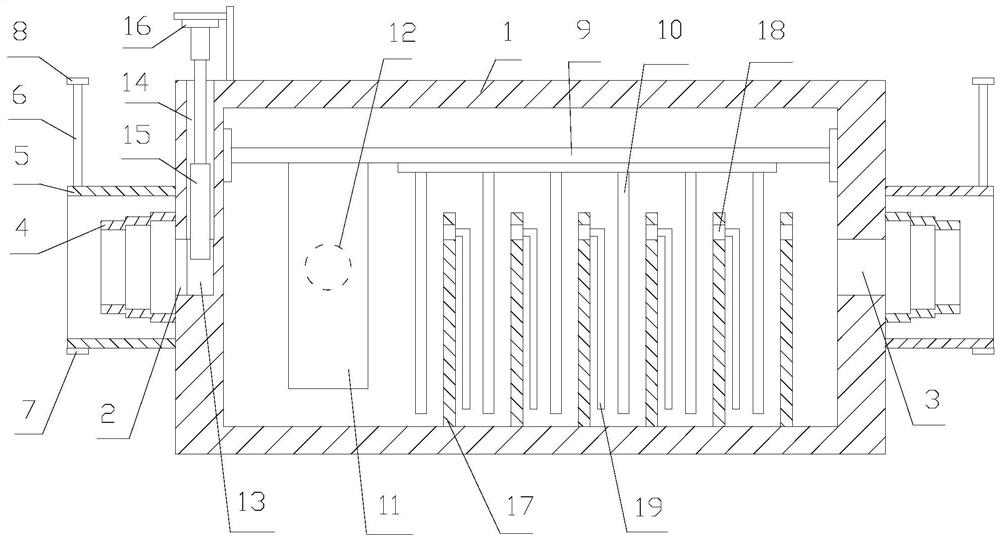

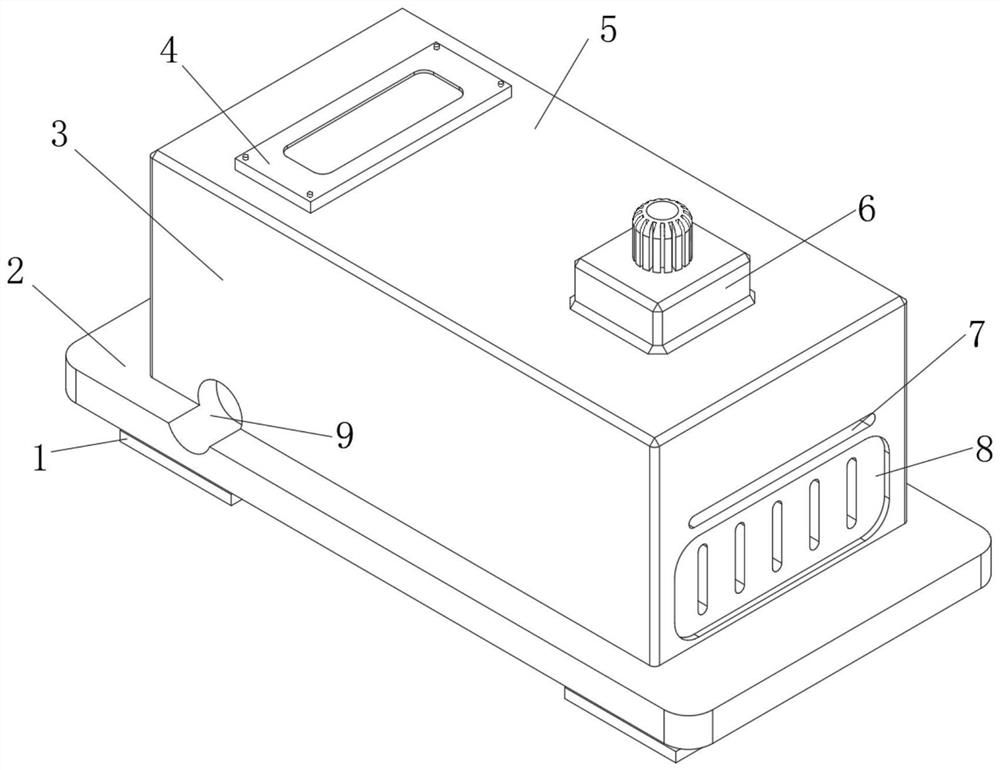

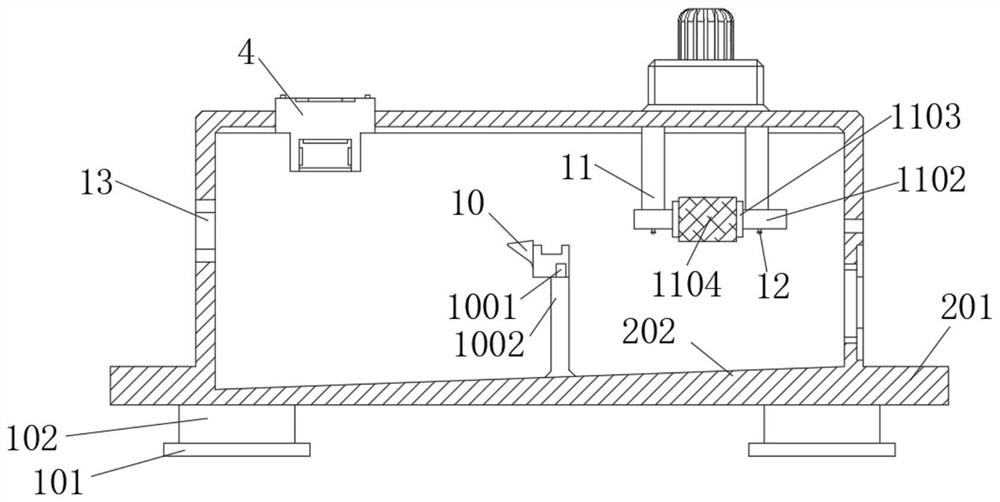

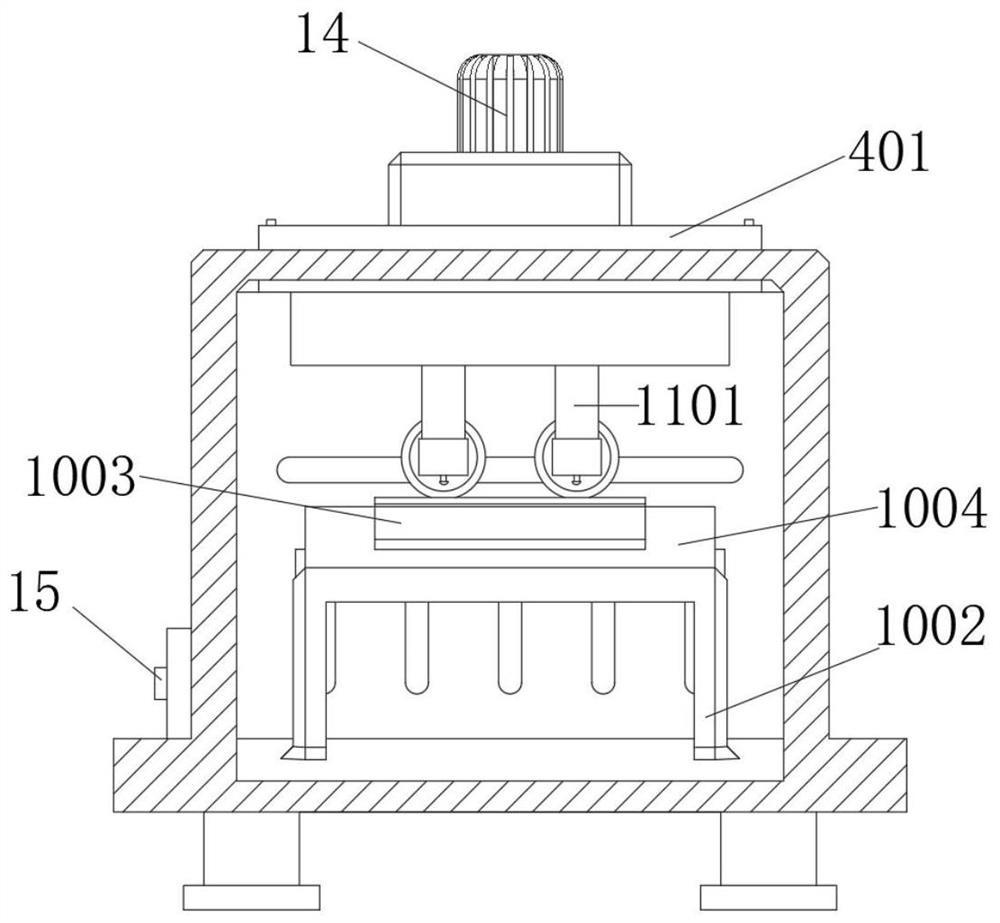

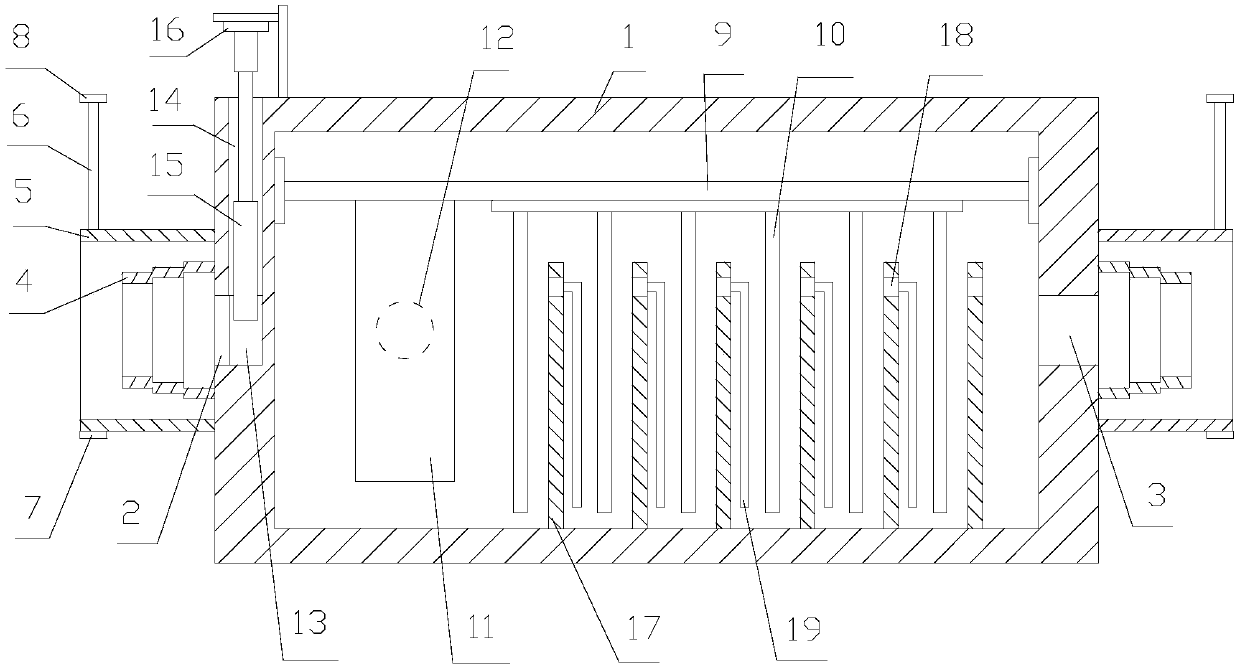

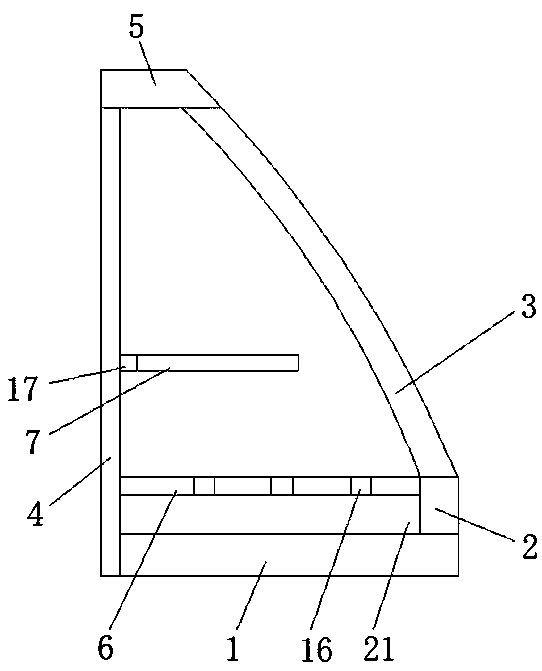

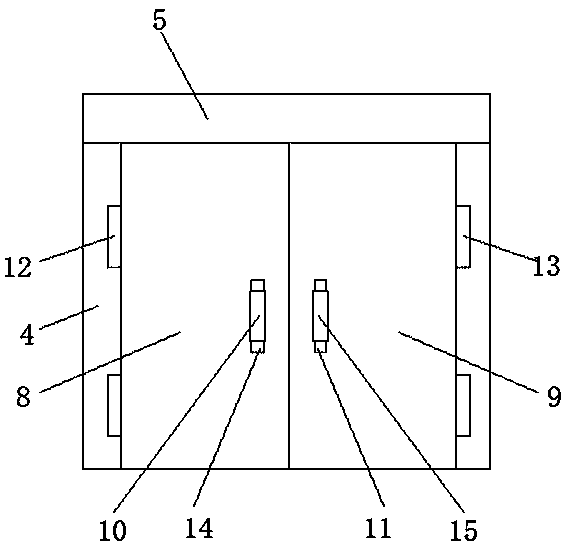

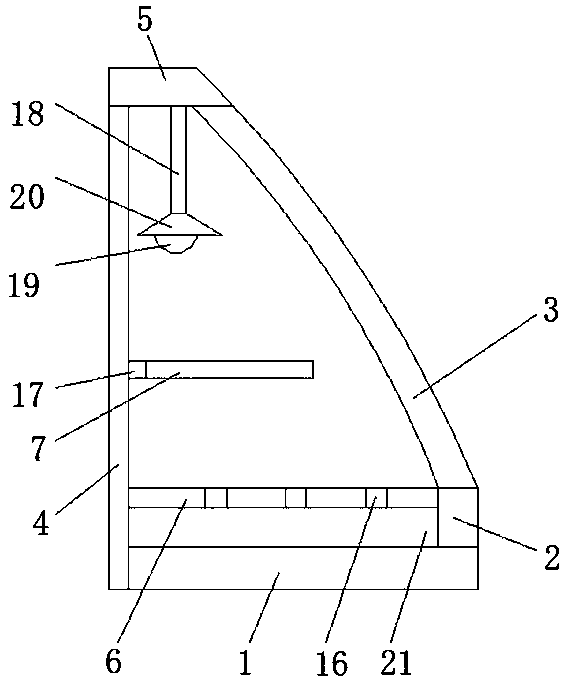

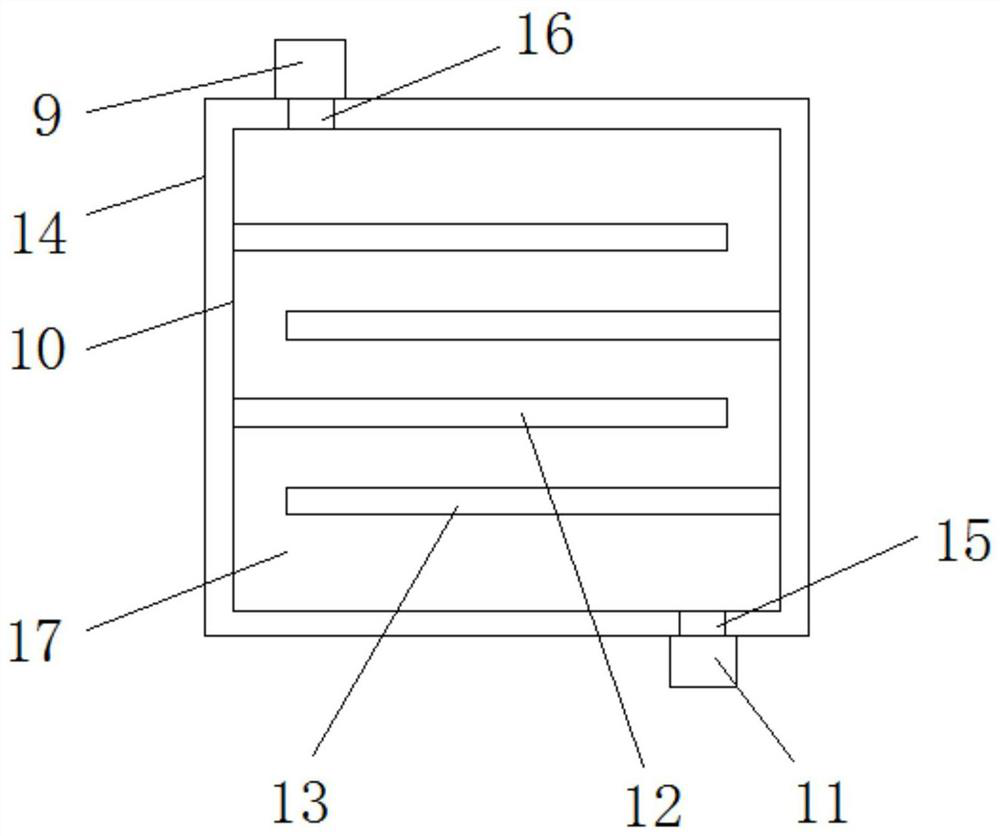

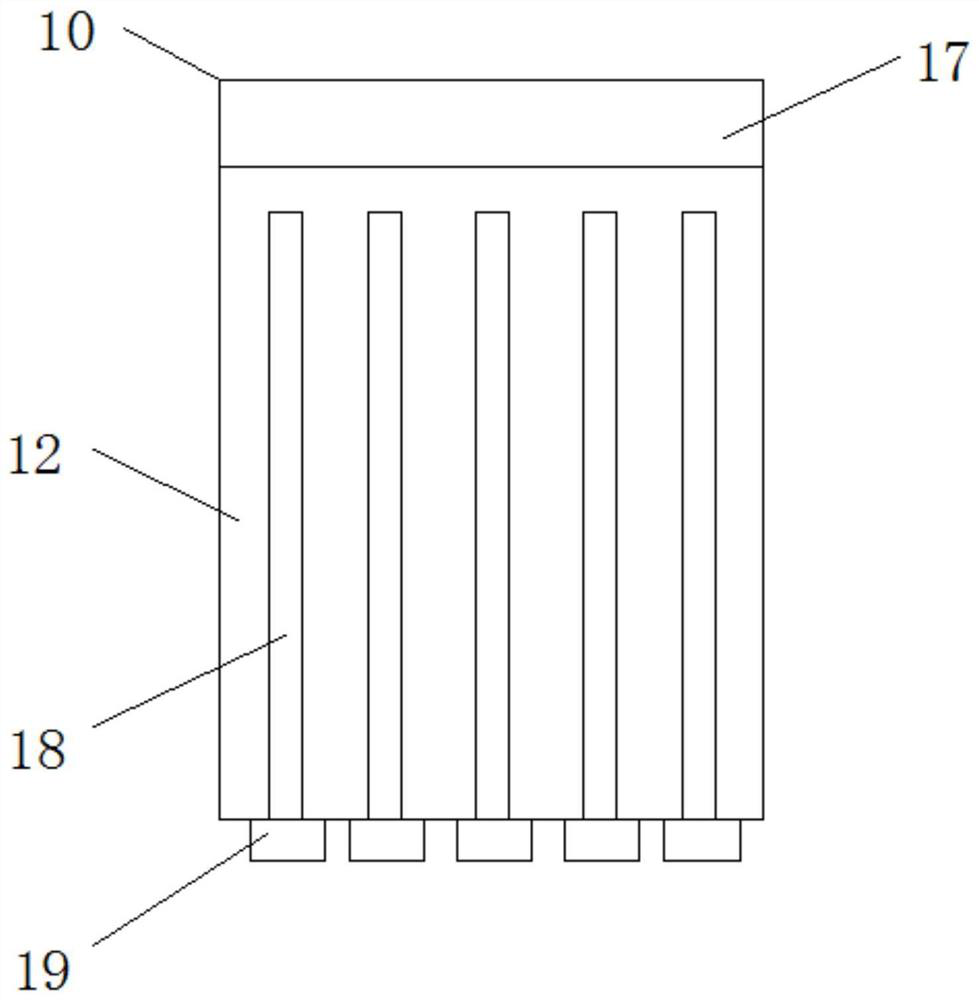

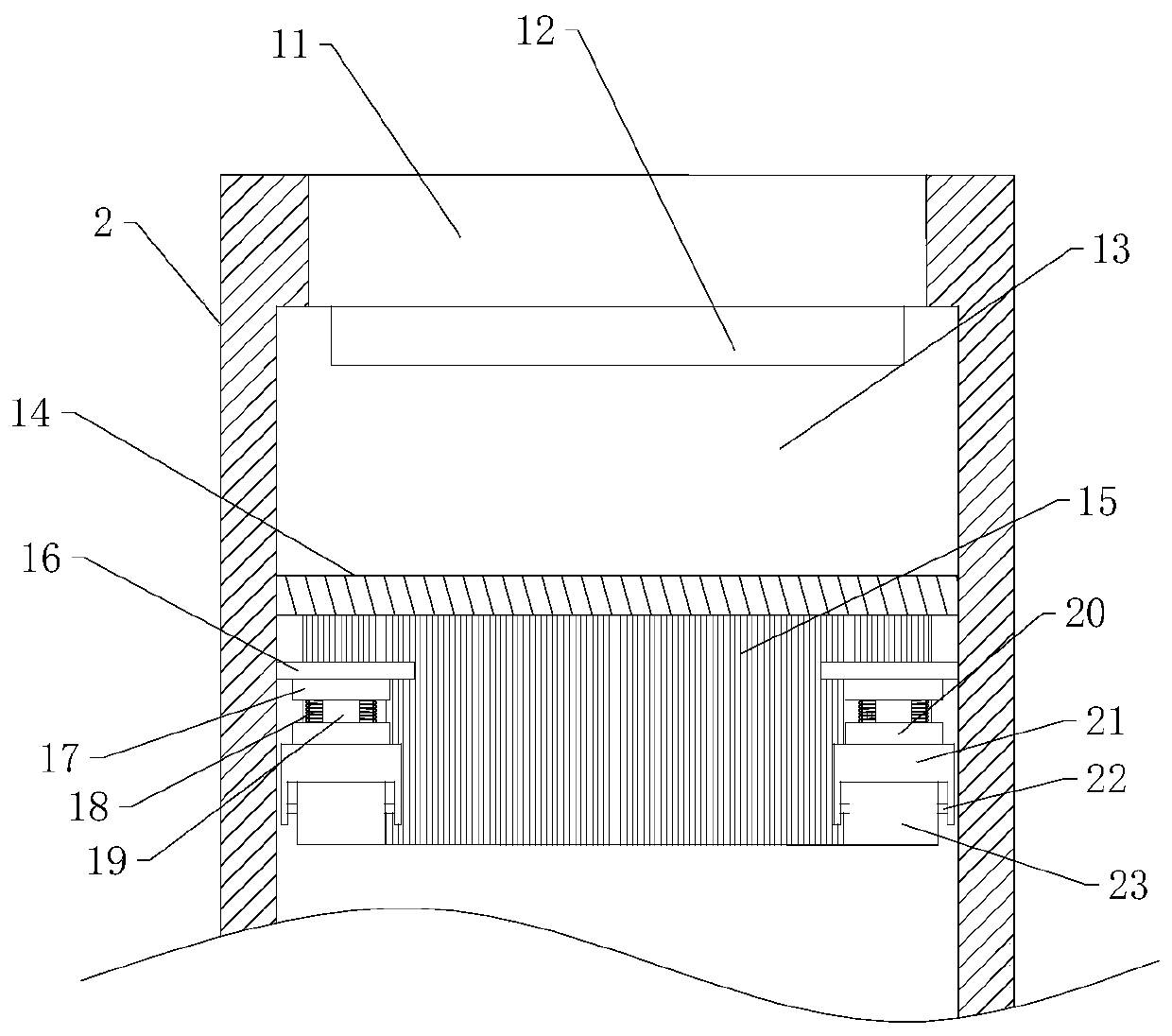

Plywood hot-pressing sizing device

The invention discloses a plywood hot-pressing sizing device. The plywood hot-pressing sizing device comprises a frame body, a heating part is arranged on the upper portion of the left side of the frame body, multiple heaters are arranged on the end face of the right side of the heating part in an up-and-down manner, a pressure exerting part is arranged on the upper portion of the right side of the frame body, and an adjusting and control part is arranged on the portion, between the pressure exerting part and the heating part, of the frame body; a first sliding groove is formed inside the right side of the frame body, the top of the first sliding groove is provided with an empty groove which is formed in an extending manner along the first sliding groove, and a first transmission groove is formed in the portion, at the right side of the first sliding groove, in the frame body; a first spiral rod which extends towards the left side and the right side is arranged in the first sliding groove, the right side extending section of the first spiral rod penetrates through the inner wall of the frame body and is rotationally connected with the inner wall of the frame body in a matched manner, and the tail of the right side of the first spiral rod penetrates into the first transmission groove and is provided with a first toothed connection wheel; the bottom of the first transmission groove is provided with a second sliding groove, a second spiral rod is arranged in the second sliding groove, the tail of the right side of the second spiral rod is connected with a first electric motor, and a first sliding block is connected to the second spiral rod in a threaded and matched manner; and a second electric motor is arranged in the top of the first sliding block, and the top of the second electric motor is provided with a main tooth connection wheel which penetrates into the first transmission groove and is rotationally connected with the first transmission groove in a matched manner.

Owner:徐州春艺阳木业有限公司

Vehicle-mounted battery pack thermal management system, vehicle-mounted battery pack thermal management method, and vehicle

ActiveCN108177534BRealize heat treatmentHybrid vehiclesPropulsion using engine-driven generatorsElectrical batteryThermal management system

The invention provides an automobile-mounted battery pack thermal management system and method and an automobile and relates to the technical field of automobiles. The system and method and the automobile are designed in order to solve the problems that an existing battery pack is large in occupied space and single in thermal management use working condition. The automobile-mounted battery pack thermal management system comprises a battery pack heating loop. The battery pack heating loop comprises a heating device and a heat exchanger which are arranged in a warm air loop, and the heat exchanger transmits heat generated by the heating device to a battery pack; and power is supplied to the heating device through a charging pile or an electric generator. The automobile-mounted battery pack thermal management method uses the above automobile-mounted battery pack thermal management system for conducting thermal management on the battery pack. The automobile comprises the above automobile-mounted battery pack thermal management system. The automobile-mounted battery pack thermal management system and method and the automobile are used for meeting the thermal management requirement of the battery pack.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +1

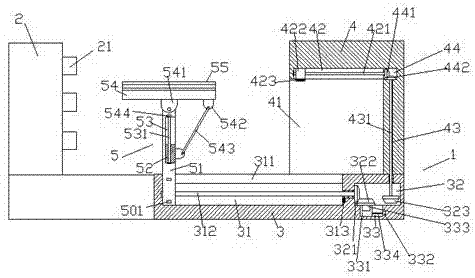

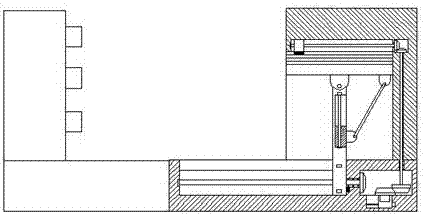

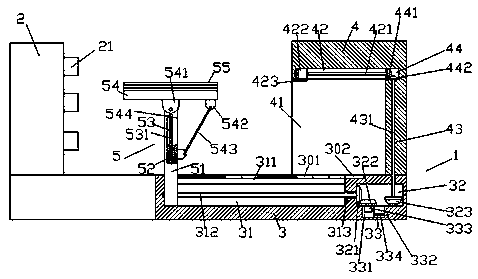

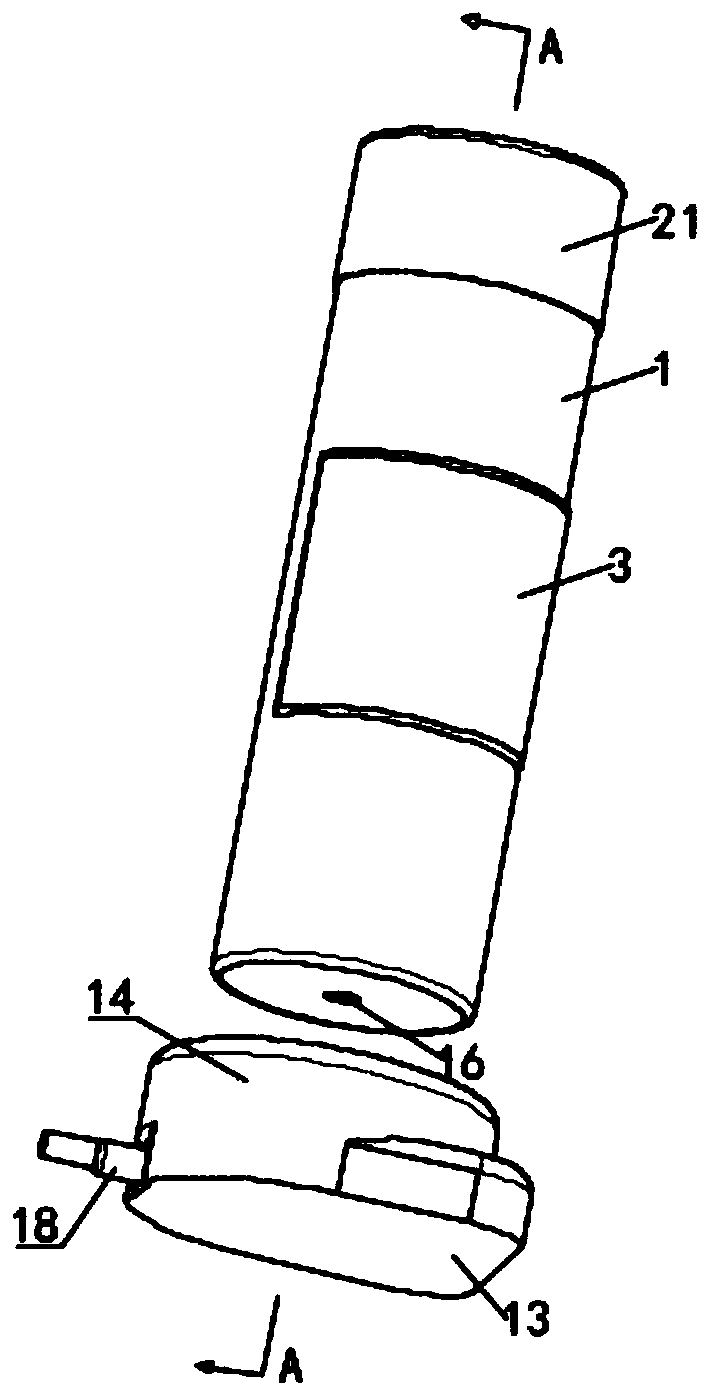

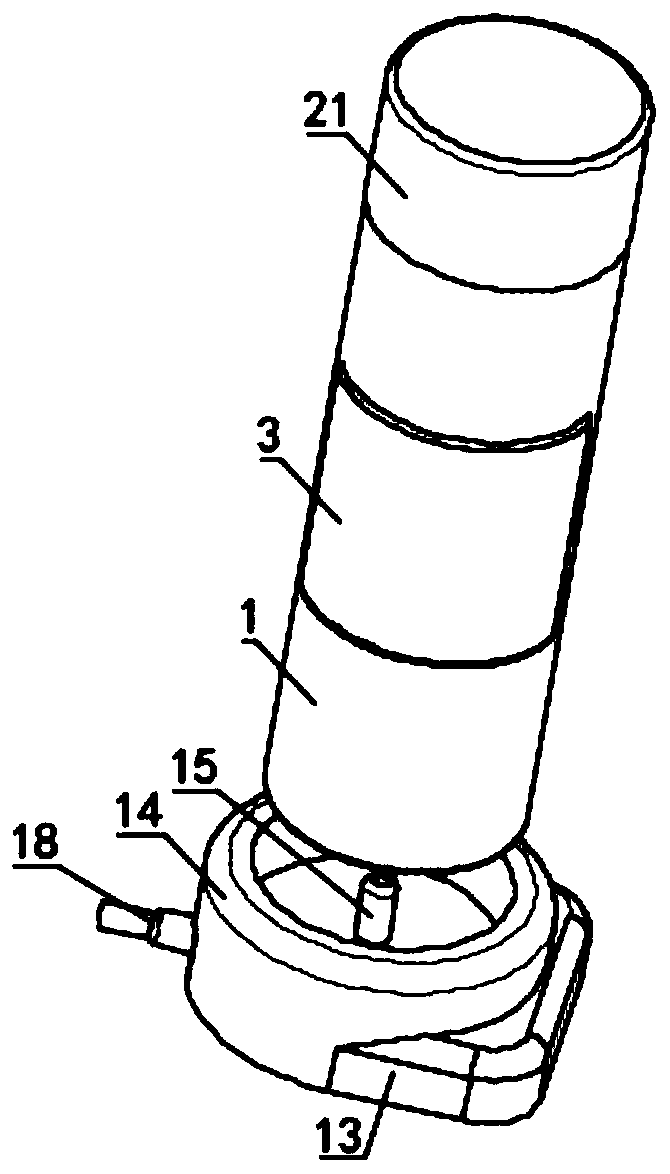

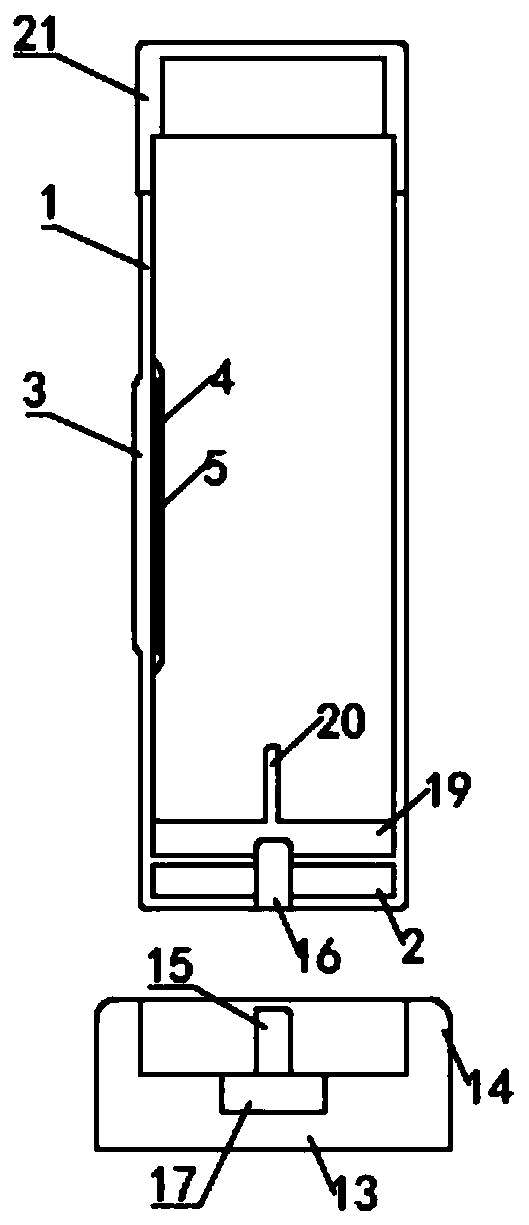

A plywood heating and shaping device

ActiveCN107309981BRealize automatic switching controlReduce stepsWood veneer joiningMating connectionEngineering

The invention discloses a plywood heating sizing device. The plywood heating sizing device comprises a frame body, a heating part is arranged on the upper portion of the left side of the frame body, multiple heaters are arranged on the end face of the right side of the heating part in an up-and-down manner, a pressure exerting part is arranged on the upper portion of the right side of the frame body, and an adjusting and control part is arranged on the portion, between the pressure exerting part and the heating part, of the frame body; a first sliding groove is formed inside the right side of the frame body, the top of the first sliding groove is provided with an empty groove which is formed in an extending manner along the first sliding groove, and a first transmission groove is formed in the portion, at the right side of the first sliding groove, in the frame body; a first spiral rod which extends towards the left side and the right side is arranged in the first sliding groove, the right side extending section of the first spiral rod penetrates through the inner wall of the frame body and is rotationally connected with the inner wall of the frame body in a matched manner, and the tail of the right side of the first spiral rod penetrates into the first transmission groove and is provided with a first toothed connection wheel; the bottom of the first transmission groove is provided with a second sliding groove, a second spiral rod is arranged in the second sliding groove, the tail of the right side of the second spiral rod is connected with a first electric motor, and a first sliding block is connected to the second spiral rod in a threaded and matched manner; and a second electric motor is arranged in the top of the first sliding block, and the top of the second electric motor is provided with a main tooth connection wheel which penetrates into the first transmission groove and is rotationally connected with the first transmission groove in a matched manner.

Owner:宁夏丰通新材料科技有限公司

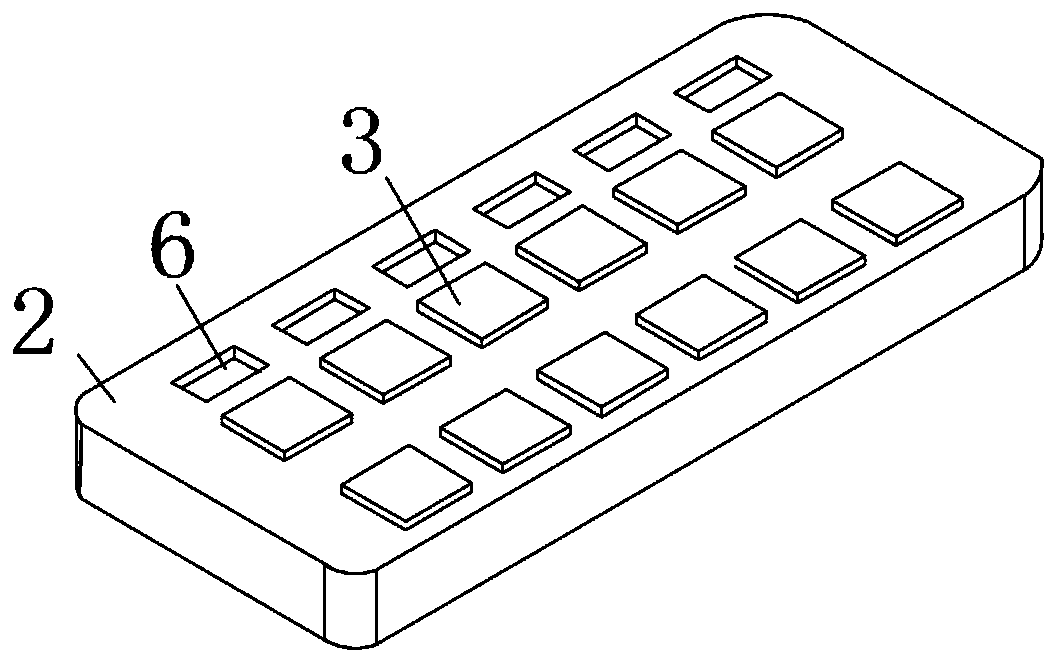

High-precision mold equipment with informatization and digitization functions

PendingCN112917852AAvoid affecting the molding effectUniform heat conductionInformatizationThermodynamics

The invention discloses high-precision mold equipment with informatization and digitization functions, and belongs to the technical field of molds. A plurality of heating plates are distributed in a heating cavity of a lower mold at intervals, the heating plates, a temperature sensing section layer and a heat conduction pad are matched to conduct heat for a female mold cavity, and temperature sensing memory deformation bodies are arranged in the temperature sensing section layer; a plurality of temperature sensing memory deformation bodies are used for sensing the temperature of each position in the heating cavity, when the temperature of a certain position does not reach a preset heating temperature, a heating wire at the position is in a heating state, so that the temperature of each position of the heating cavity is increased and is consistent; and when the temperature sensing memory deformation bodies sense that the temperature of the certain position exceeds the preset temperature, the temperature sensing memory deformation bodies stretch due to high-temperature deformation, contact pieces are pushed to be disconnected after stretching, a heating wire at the position is closed at the moment, the situation that the local temperature is too high due to continuous heating is avoided, the temperature is precisely regulated and controlled in real time through one-to-one cooperation between the plurality of temperature sensing memory deformation bodies and heating triggering bodies, and the product forming effect is effectively prevented from being influenced.

Owner:吉云

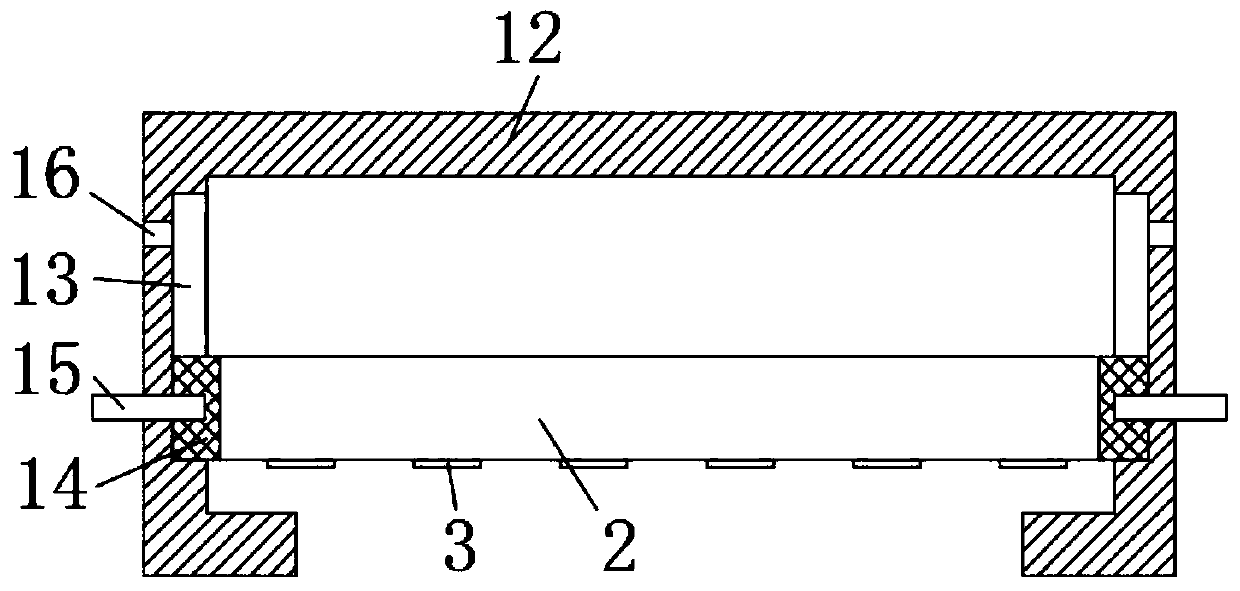

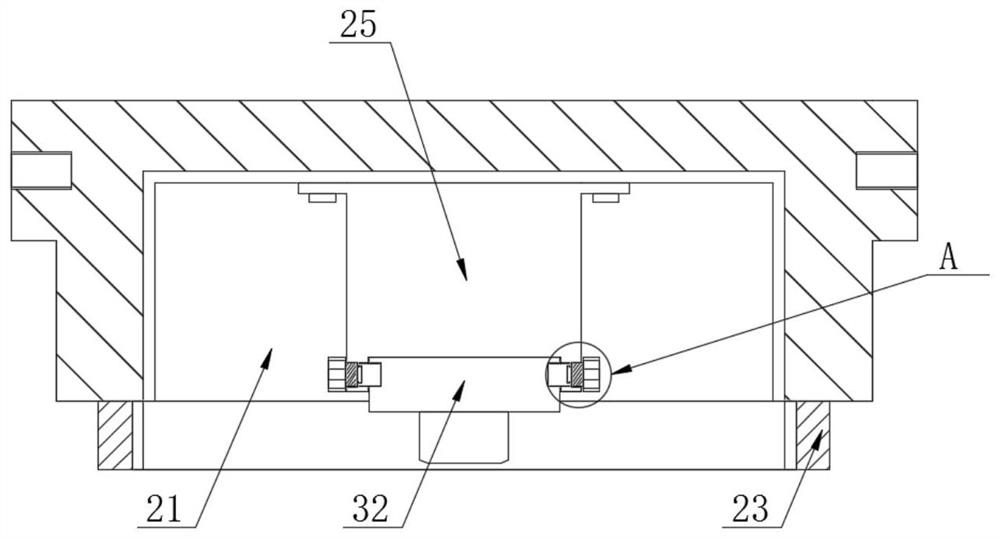

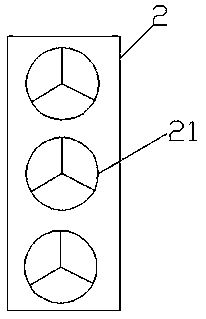

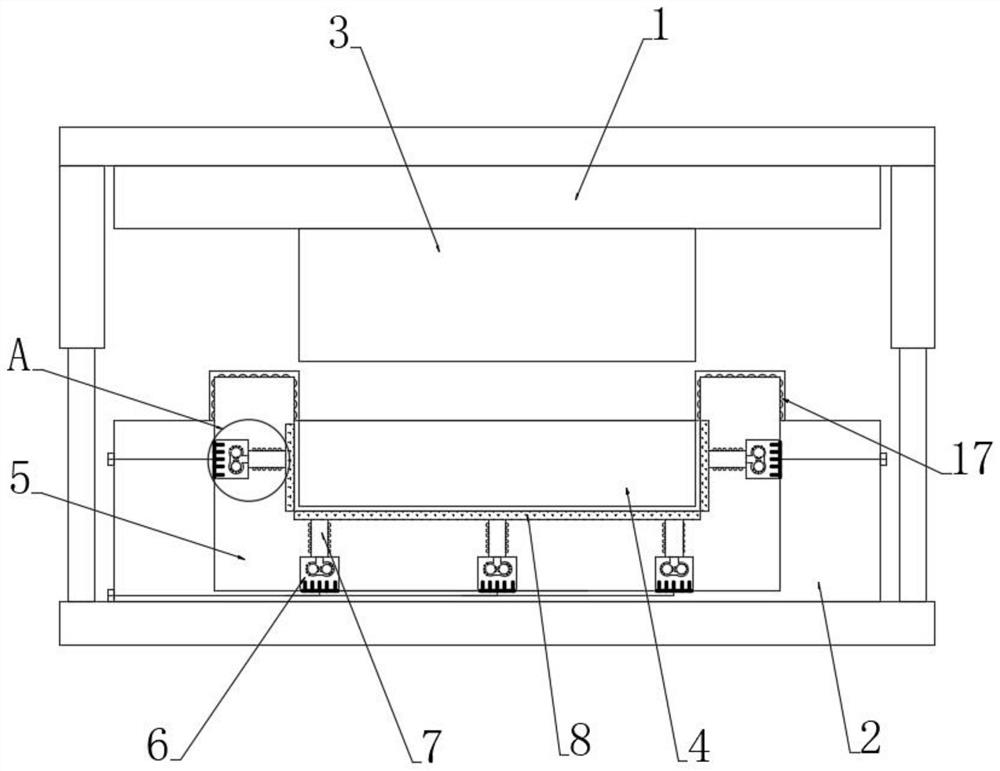

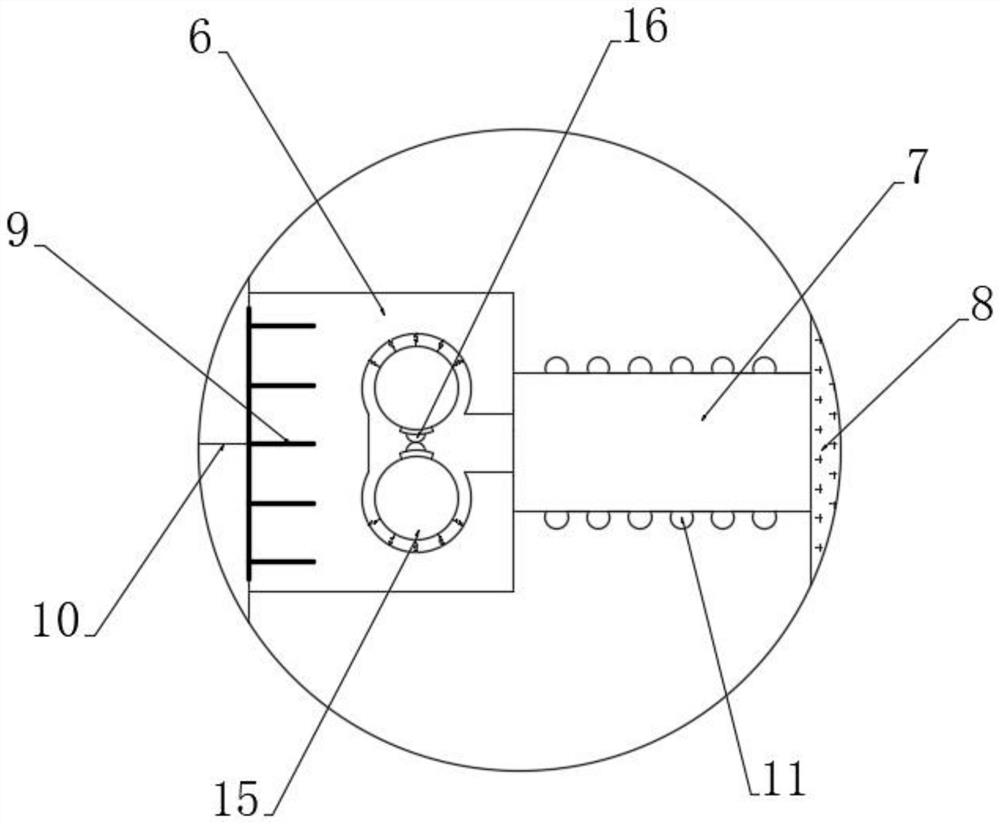

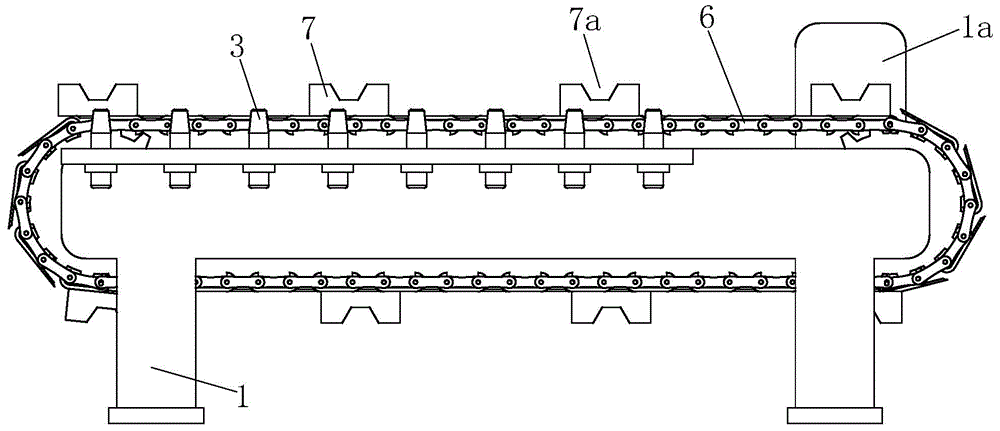

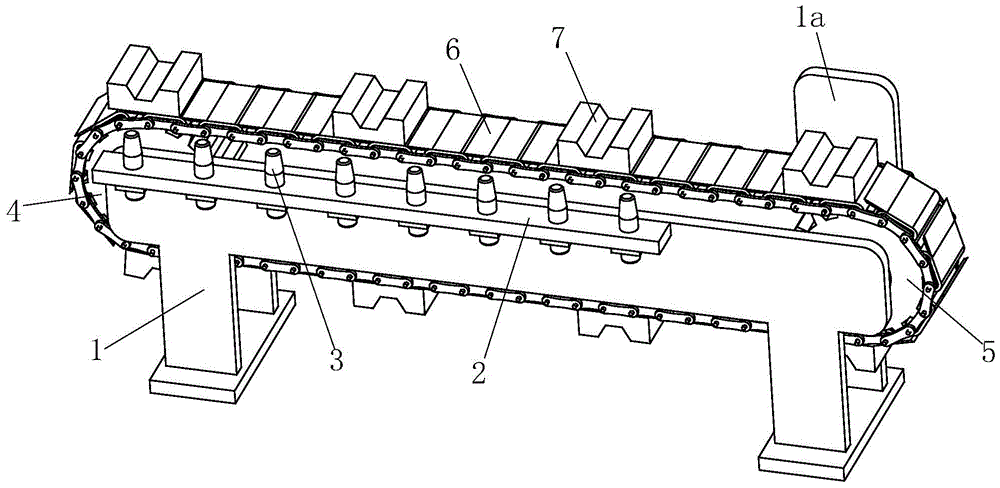

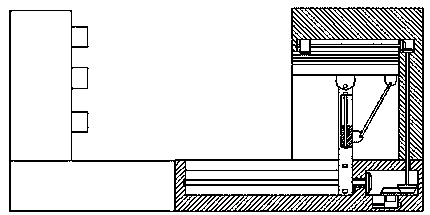

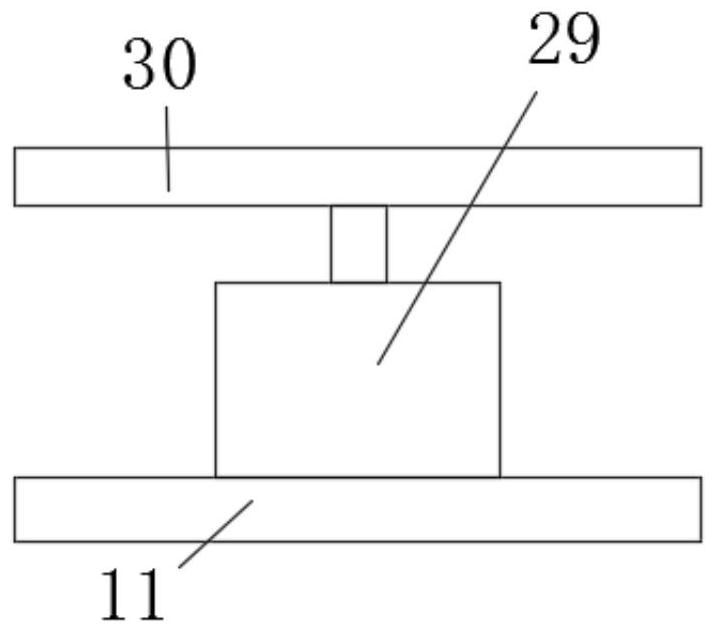

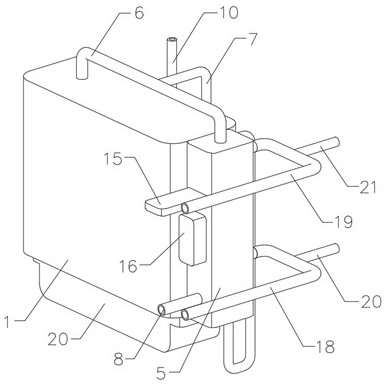

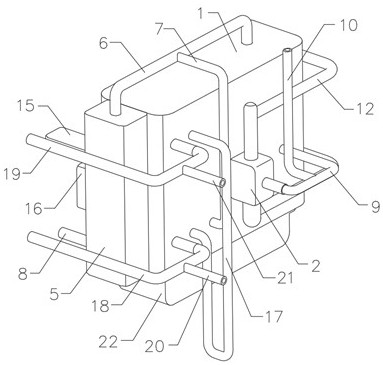

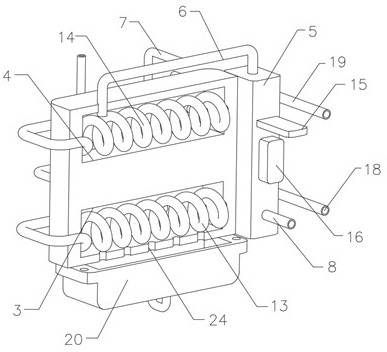

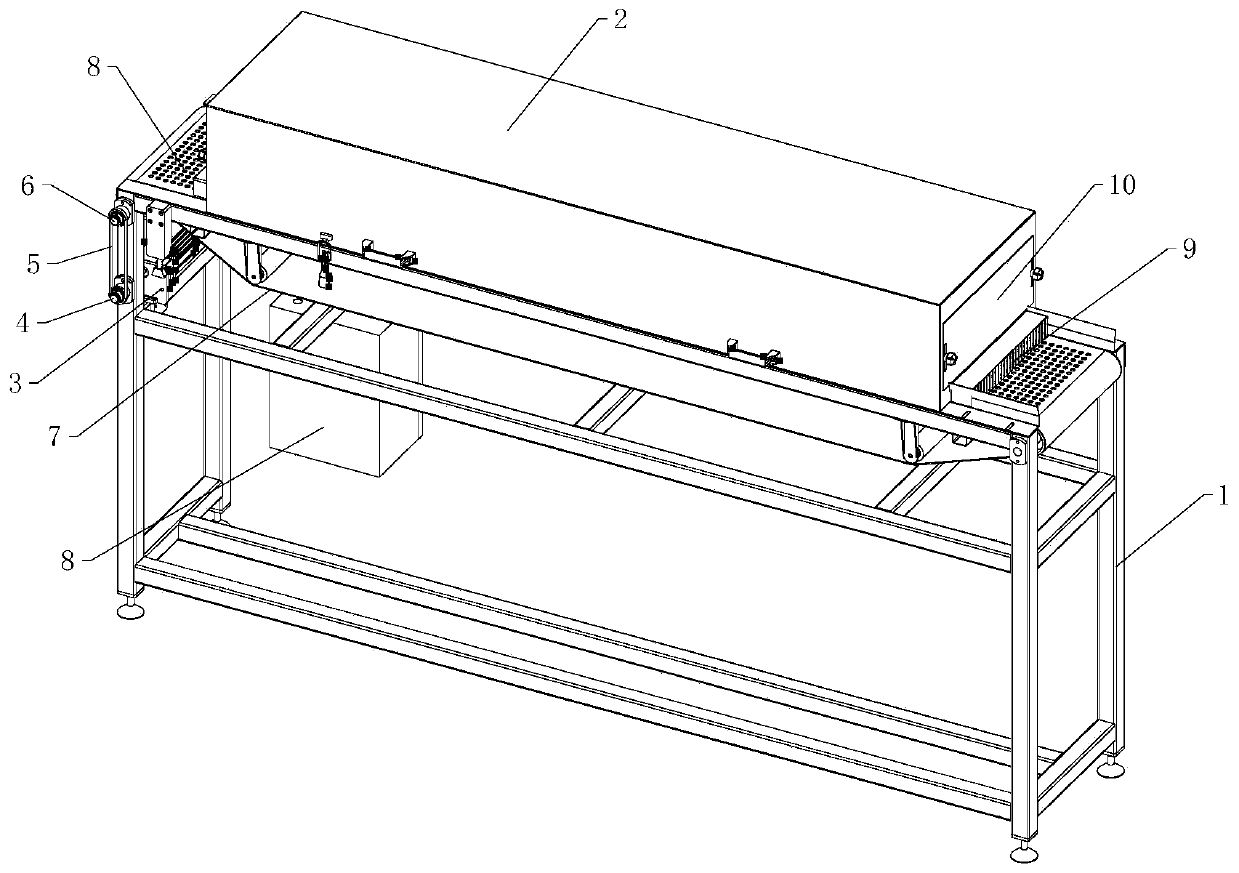

A conveying heating device of a red punch processing and forming system

ActiveCN104493063BRealize heat treatmentImprove processing efficiencyBoltsHandling devicesEngineeringAutomation

The invention relates to a conveying and heating device for a hot-forging processing forming system. The conveying and heating device comprises a conveying frame, a driving conveying belt wheel, a driven conveying belt wheel, a transport chain plate, transport V-shaped blocks, a fixed heating frame and heating spray heads, wherein the driving conveying belt wheel and the driven conveying belt wheel are respectively and correspondingly mounted at the left part and the right part of the conveying frame; the transport chain plate wraps the driving conveying belt wheel and the driven conveying belt wheel; the transport V-shaped blocks are fixed on the outer side surface of the transport chain plate in the wrapping direction of the transport chain plate at equal intervals; an upward limiting baffle is arranged at the upper end of the right part on the rear side wall of the convening frame; the fixed heating frame is positioned on the front side of the transport chain plate and is horizontally fixed at the upper end of the left part on the front side wall of the conveying frame; the heating spray heads are mounted on the fixed heating frame. The conveying and heating device has the advantages of reasonable structural design, high degree of automation, low production and manufacturing cost and the like and can realize heating treatment on a rod material in the process of conveying the rod material so as to improve the bolt processing efficiency.

Owner:WUHU YINXING AUTO PARTS

Mixing equipment for flame-retardant thermoplastic polyurethane elastomer

InactiveCN113601744ARealize heat treatmentRealize shreddingElectric machineThermoplastic polyurethane

The invention discloses mixing equipment for a flame-retardant thermoplastic polyurethane elastomer. The mixing equipment comprises an equipment main body, the bottom end of the equipment main body is fixedly connected with a top plate, the two sides of the bottom end of the top plate are fixedly connected with supporting rods, the bottom ends of the supporting rods are fixedly connected with a bottom plate, and a uniform discharging mechanism is arranged between the top plate and the bottom plate. A material guiding mechanism is arranged below a water inlet and comprises a third driving motor arranged on the outer wall of the equipment main body, the third driving motor is transversely arranged, a rotating shaft is arranged at the output end of the third driving motor, and the third driving motor, a cam, a spring and a discharging plate are connected in a matched mode. Materials crushed by a crushing mechanism and materials entering from the water inlet can fall on the surface of the discharging plate and fall near a mixing and crushing mechanism through the discharging plate, the material guiding effect is achieved, and the materials can be prevented from being concentrated at the corner of the equipment main body.

Owner:李宁

A multifunctional automatic replenishment device for neurology

InactiveCN105919817BAchieve sealingAvoid flowing intoTransportation and packagingRotary stirring mixersDual actionFiltration

The invention discloses a neurology multifunctional automatic replenishment device. When in use, the medical staff can firstly operate the operation panel according to the eating time of the patient, set the corresponding starting time for the timer, and open the water tank through the timer to make the clear water Enter the mixing tank, and then turn on the first motor through the timer, so that the stirring rod can stir and break the food, and filter the food under the double function of the filter screen and the filter box. At the same time, the medical staff can also use the temperature controller to The heating tube is heated, and the temperature is evenly transmitted to the food in the storage tank to realize the heating treatment of the food. Finally, under the action of the extrusion force of the electric push rod, the food in the storage tank is sent to the patient's stomach. The multi-functional automatic feeding device, on the basis of stirring and crushing food, also adds functions such as stirring and filtering, food heating, etc., which can not only automatically send liquid food into the patient's stomach, but also increase the comfort of the patient during eating.

Owner:THE SECOND AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

Meteorological early warning cup for student

InactiveCN110772102ARealize heat treatmentReal-time displayWater-boiling vesselsWarming devicesInsulation layerAtmospheric sciences

The invention discloses a meteorological early warning cup for a student in the technical field of meteorological data processing. The meteorological early warning cup for the student comprises a cupbody, wherein a rechargeable battery panel is arranged at the bottom of the cup body; an electronic display screen is arranged at the side surface of the cup body; the rechargeable battery panel is electrically connected with the electronic display screen; a heat insulation layer is arranged at the inner side of the cup body positioned at one side of the electronic display screen; a meteorologicaldata loading module used for obtaining meteorological information is arranged on the heat insulation layer; and a meteorological information display module corresponding to the meteorological data loading module is arranged on the electronic display screen. The meteorological early warning cup has the advantages that by using the electronic display screen, the real-time display of meteorologicalinformation and water temperature information can be realized when a water cup is used; through the connection of an installing seat and the cup body, the heating treatment on the water temperature can be conveniently realized; and the use practicability of the cup is improved.

Owner:JIANGSU METEOROLOGICAL OBSERVATORY

A continuous finishing machine

ActiveCN110574799BAchieve recyclingSolve uneven temperaturePre-extraction tea treatmentDrying solid materials with heatTemperature controlHeat conservation

The invention discloses a continuous stripping machine, which comprises a stripping body, and also includes a heat preservation cover and a material distribution assembly; the heat preservation cover is arranged above the stripping body, and the heat preservation cover is on the side wall of the stripping body A plurality of infrared heating plates are fixedly connected, and a temperature control switch electrically connected with the infrared heating plates is fixedly connected to the outer wall of the strip body, and a waste heat cavity is opened in the heat preservation cover, and the top surface of the heat preservation cover A fan is fixedly connected, and the air outlet end of the fan communicates with the waste heat cavity, and an air outlet is provided at the bottom of the waste heat cavity, and the air outlet is located at the feeding end of the sliver machine body; the material distribution component includes an outlet The material plate, the discharge plate is connected to the tank at the discharge end of the slitting machine body obliquely, and a collecting bucket is arranged below the discharge end of the slitting plate. The present invention realizes the heat treatment of the tea leaves above the slitting machine, and simultaneously It is convenient for the collection of processed tea leaves.

Owner:安徽宣城华阳茶叶机械股份有限公司

A plywood hot-press setting device

ActiveCN107309984BRealize automatic switching controlReduce stepsPlywood pressesVeneer pressesEngineeringSizing

Owner:徐州春艺阳木业有限公司

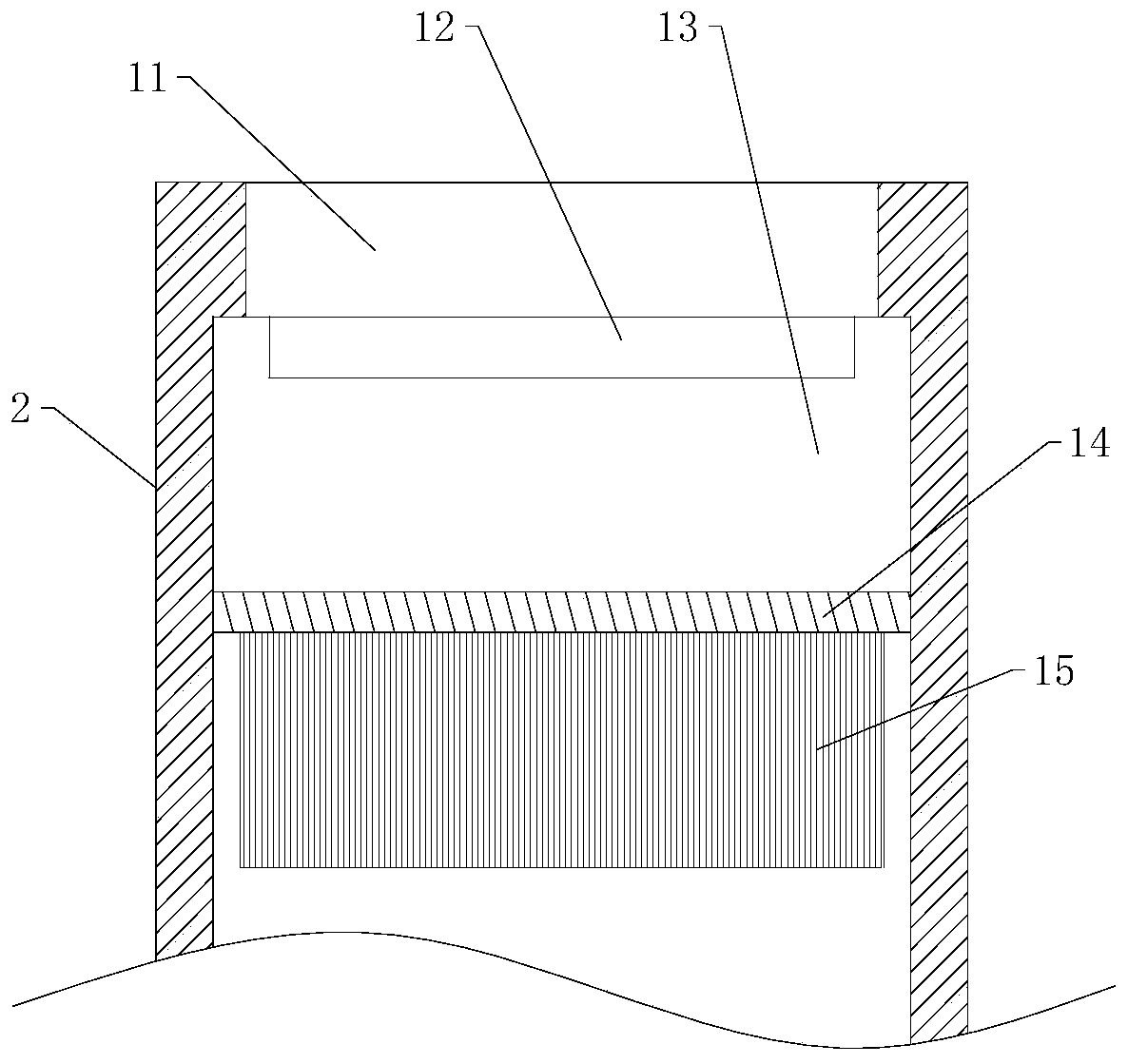

Heating tube assembly convenient to detach

The invention discloses a heating tube assembly convenient to detach. The heating tube assembly comprises a shell, a heating part, a first connecting pipe and a second connecting pipe, wherein a waterinlet, a water outlet, a heating part are formed in the shell, and the heating part are located in the shell; one end of the first connecting pipe is rotationally connected with the water inlet, a first internal thread is arranged on the inner wall of the first connecting pipe, and the inner diameter of the first connecting pipe is gradually reduced from one end, far away from the water inlet, ofthe first connecting pipe towards one end, close to the water inlet, of the first connecting pipe; and one end of the second connecting pipe is rotationally connected with the water outlet, a secondinternal thread is arranged on the inner wall of the second connecting pipe, and the inner diameter of the second connecting pipe is gradually reduced from one end, far away from the water outlet, ofthe second connecting pipe to one end, close to the water outlet, of the second connecting pipe.

Owner:安徽华铝铝业有限公司

A heating tube assembly for a water heater

ActiveCN108679847BRealize heat treatmentImprove adaptabilityFluid heatersMechanical engineeringHeat pipe

The invention discloses a heating tube assembly for a water heater. The heating tube assembly for the water heater comprises a housing, a heating part, a first connecting unit and a second connectingunit. A water inlet and a water outlet are arranged on the housing, and the heating part is located in the housing. The first connecting unit comprises a first connecting tube, a first sealing sleeve,and a first connecting ring. One end of the first connecting tube is connected with the water inlet. A first external thread is arranged on the outer wall of the first connecting tube. The outer diameter of the first connecting tube gradually decreases as the distance from the water inlet increases. The first sealing sleeve is disposed outside of the first connecting tube. The first sealing sleeve is made of a deformable material. A first clamping block is arranged on the first sealing sleeve. The first connecting ring is made of a flexible material. One end of the first connecting ring is hinged with the first sealing sleeve. A first card slot that cooperates with the first clamping block is arranged on the first connecting ring.

Owner:ANHUI ANZE ELECTRIC GRP +1

An activated sludge biofilm composite integrated treatment equipment

ActiveCN111875042BEasy dischargeAchieve fixationBiological treatment apparatusCleaning using toolsActivated sludgeMechanical engineering

The invention discloses an activated sludge biofilm composite integrated treatment equipment, which comprises a working plate and a treatment cover symmetrically detachable on the surface of the working plate; one end of the treatment cover is provided with a discharge hole, and the discharge hole A baffle plate is detachably connected to the end of the processing cover, a first arc-shaped plate is fixedly connected to the inner side wall of the first arc-shaped plate, and a connecting plate with a communication hole is fixedly connected to the inner side wall of the first arc-shaped plate. An accommodation groove is opened on the connection plate, and a mounting plate is detachably connected to the accommodation groove, and a biofilm belt is connected to the side wall of the mounting plate; a moving plate is connected to the moving plate above the working plate between the processing covers , the top of the moving plate is rotatably connected with a turntable, and the connecting plate is telescopically connected with a connecting plate, and one end of the connecting plate is fixedly connected with a processing box. to clean up.

Owner:广东清境世嘉环境技术有限公司

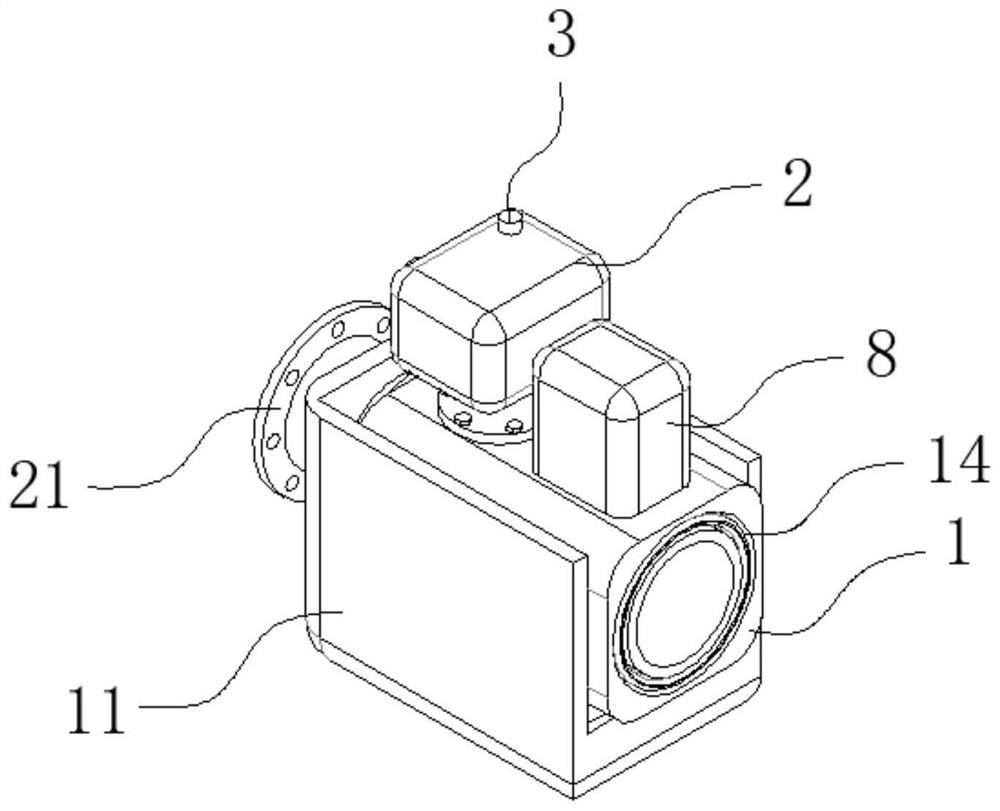

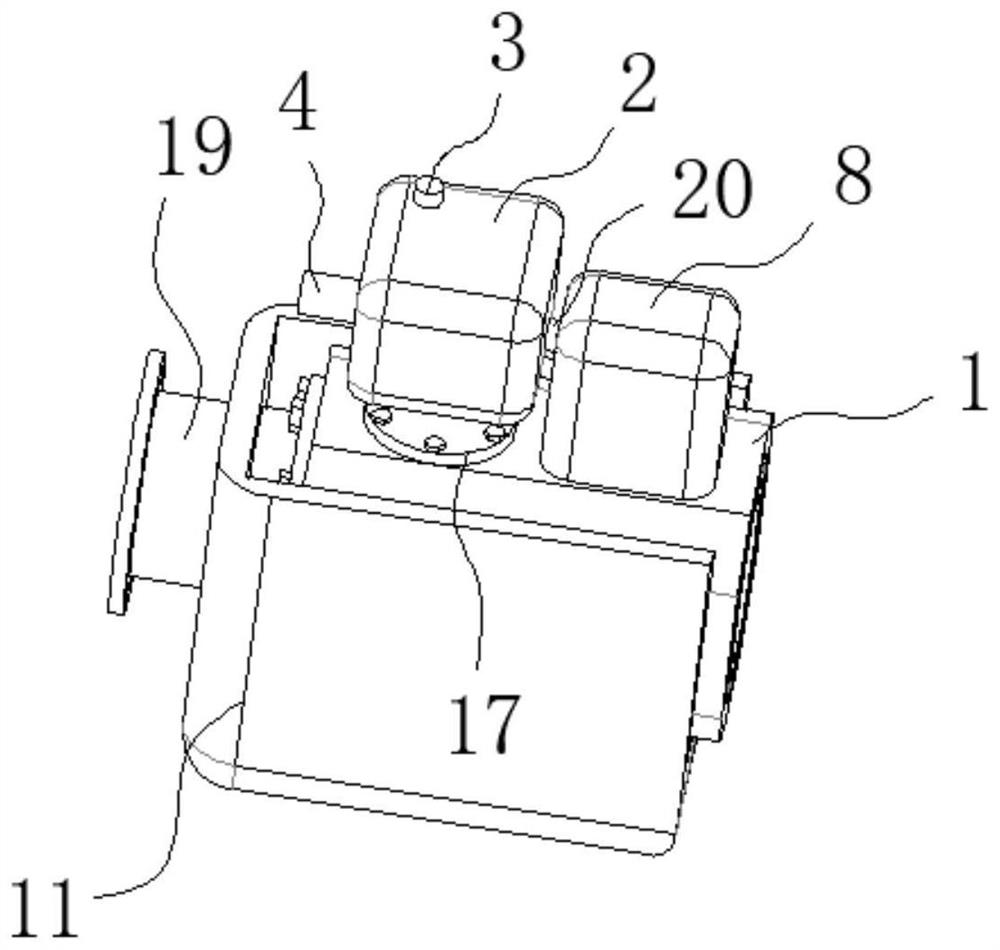

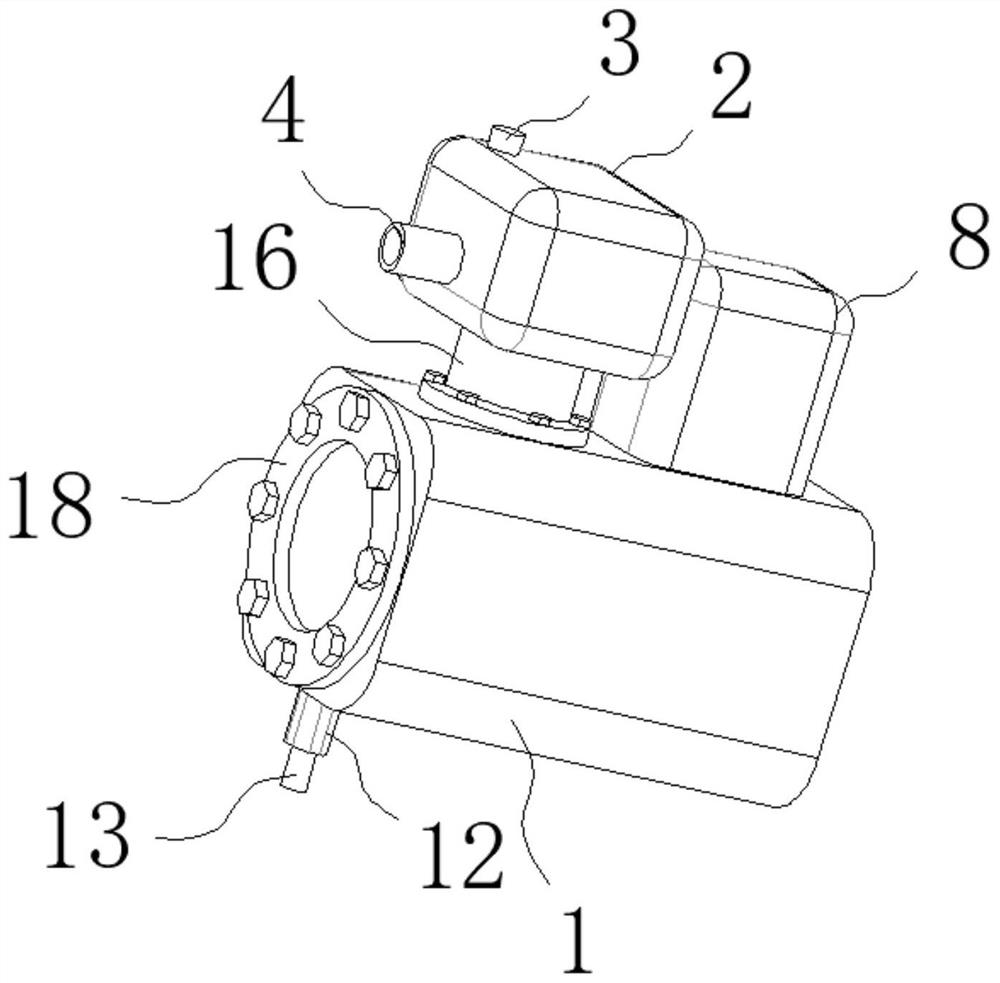

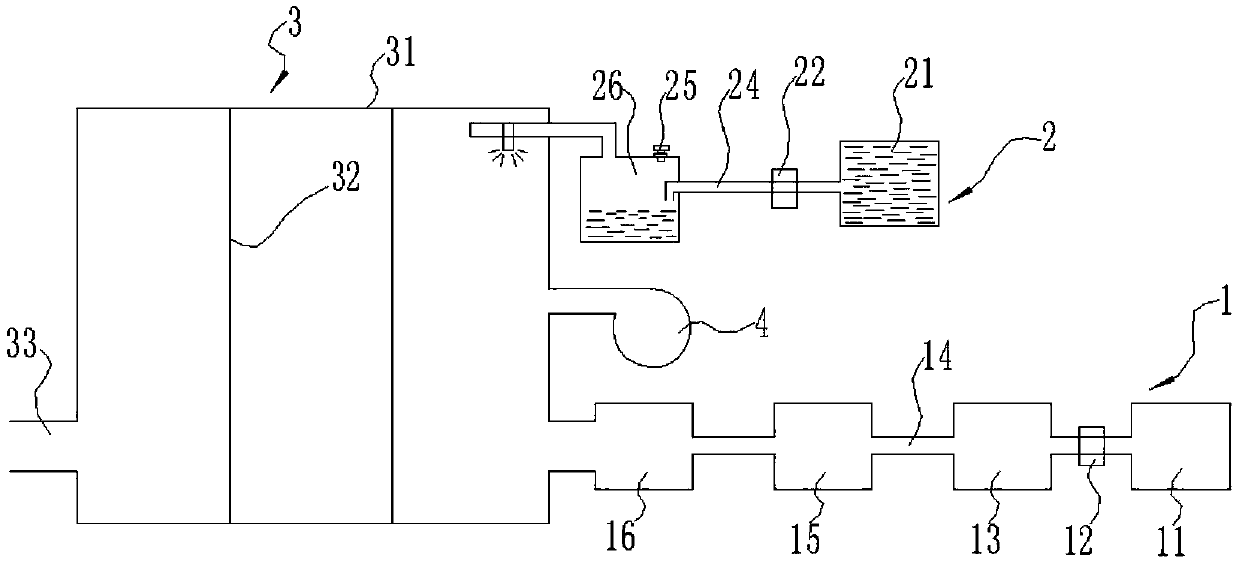

Flowmeter pipe section anti-freezing structure and method

PendingCN113175969ARealize heat treatmentPrevent freezingVolumetric apparatus damage preventionPipeline systemsThermodynamicsCarrier fluid

The invention discloses a flowmeter pipe section anti-freezing structure which comprises a flowmeter pipeline. A control box is installed on the flowmeter pipeline, an electromagnetic valve controller is installed on one side of the flowmeter pipeline, a liquid carrying box is arranged at the bottom of the flowmeter pipeline, a heating cavity is formed in the outer wall of the flowmeter pipeline, and a plurality of groups of heating rings are mounted in the heating cavity. The using method of the anti-freezing structure of the flowmeter pipe section comprises the following steps of S1, controlling a detection flow and an environment condition in a pipeline; S2, detecting the environment temperature through an external environment temperature detection head at the upper part of the control box; S3, enabling the control box to control the heating ring to heat the flowmeter pipeline; and S4, judging whether leakage occurs or not through the liquid carrying box. According to the invention, icing detection and heating unfreezing can be realized, and leakage detection can also be realized too.

Owner:MAXTOR INSTR CO LTD

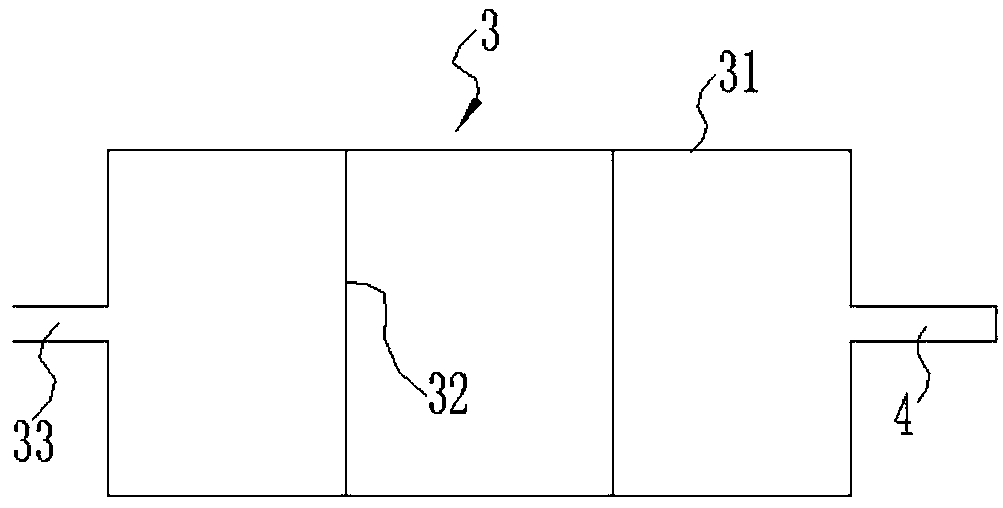

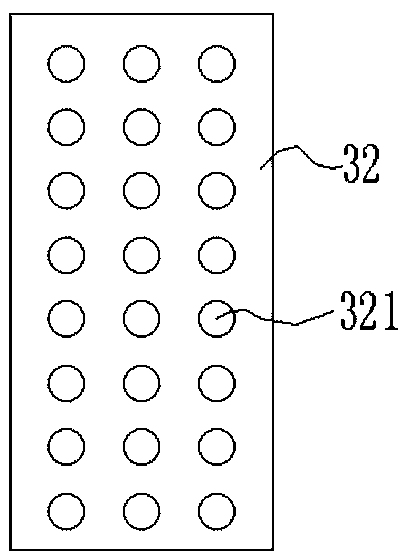

Boiler burners and boilers

InactiveCN106524139BRealize heat treatmentIncrease speedNon-combustible gases/liquids supplyCombustorEngineering

The invention discloses a burner of a boiler and the boiler, relates to the technical field of boiler equipment, and is designed to solve the problem of serious pollution caused by burners of boilers. The burner comprises a fuel supply system, a steam supply system and a gasification device communicating with the fuel supply system and the steam supply system; the gasification device comprises a gasification cavity, at least one sieve plate arranged in a cavity body of the gasification cavity and a nozzle arranged on the cavity wall of the gasification cavity; and a plurality of sieve holes are formed in each sieve plate. The burner of the boiler and the boiler are used for realizing sufficient burning of fuel.

Owner:冯军 +1

Ventilation device for ship navigation

ActiveCN113562151BImprove ventilationIncrease humidityAuxillariesVessel ventillation/heating/coolingCold airEngineering

The invention discloses a ventilation device for ship navigation, which comprises an integrated box, a vortex tube is fixed on the side wall of the integrated box, a dehumidification chamber is opened inside the integrated box, and the air inlet of the vortex tube is connected with a The inner wall of the dehumidification chamber is fixed with a cooling pipe, and the two ends of the cooling pipe are respectively connected with a cold flow pipe and a cold air pipe. The other end passes through the side wall of the dehumidification chamber and communicates with the interior of the dehumidification chamber, the side wall of the distribution pipe is inserted with an air inlet pipe, the side wall of the dehumidification chamber is inserted with a direct pipe, and the integrated box A heating chamber is opened inside, and a heating constant temperature mechanism is arranged inside the heating chamber. The advantage is that the airflow can effectively cool down and dehumidify through the dehumidification chamber, so that the airflow entering the room is low-temperature and effectively dehumidified, which can ensure good indoor ventilation without excessive humidity, and ensure a good indoor living environment.

Owner:南通沪通海洋科技有限公司

Surface ice piton cleaning device for outdoor cable

PendingCN113451971AReduce adhesionEliminates sharp surfacesOverhead installationApparatus for overhead lines/cablesThermodynamicsEngineering

The invention discloses a surface ice piton cleaning device for an outdoor cable, and relates to the technical field of cable cleaning. The surface ice piton cleaning device for the outdoor cable comprises a bottom plate and a box body, supporting bottom feet are welded to the bottom of the bottom plate, the box body is welded to the upper portion of the center of the bottom plate, a top plate is riveted to the top of the box body, a feeding port is machined in the outer side of the box body, a discharging port is machined in one side of the box body, and a power supply device is machined at the bottom of the outer surface of the box body. A heating device is installed outside the top plate through screws, a cutting device is installed on the top of the bottom plate, a rolling device is welded to the bottom of the top plate, and water outlets are machined in the box body and the bottom plate. Through the arrangement of the heating device, heating treatment of the ice piton is achieved, the surface of the ice piton is partially melted, attachment of the ice piton to a cable is reduced, the ice piton is easy to separate, meanwhile, the sharp surface of the ice piton is eliminated, protection of the interior of the device is achieved, and the service life of the device is prolonged.

Owner:江苏润华电缆股份有限公司

Heating tube assembly for water heater

The invention discloses a heating tube assembly for a water heater. The heating tube assembly for the water heater comprises a housing, a heating part, a first connecting unit and a second connectingunit. A water inlet and a water outlet are arranged on the housing, and the heating part is located in the housing. The first connecting unit comprises a first connecting tube, a first sealing sleeve,and a first connecting ring. One end of the first connecting tube is connected with the water inlet. A first external thread is arranged on the outer wall of the first connecting tube. The outer diameter of the first connecting tube gradually decreases as the distance from the water inlet increases. The first sealing sleeve is disposed outside of the first connecting tube. The first sealing sleeve is made of a deformable material. A first clamping block is arranged on the first sealing sleeve. The first connecting ring is made of a flexible material. One end of the first connecting ring is hinged with the first sealing sleeve. A first card slot that cooperates with the first clamping block is arranged on the first connecting ring.

Owner:ANHUI ANZE ELECTRIC GRP +1

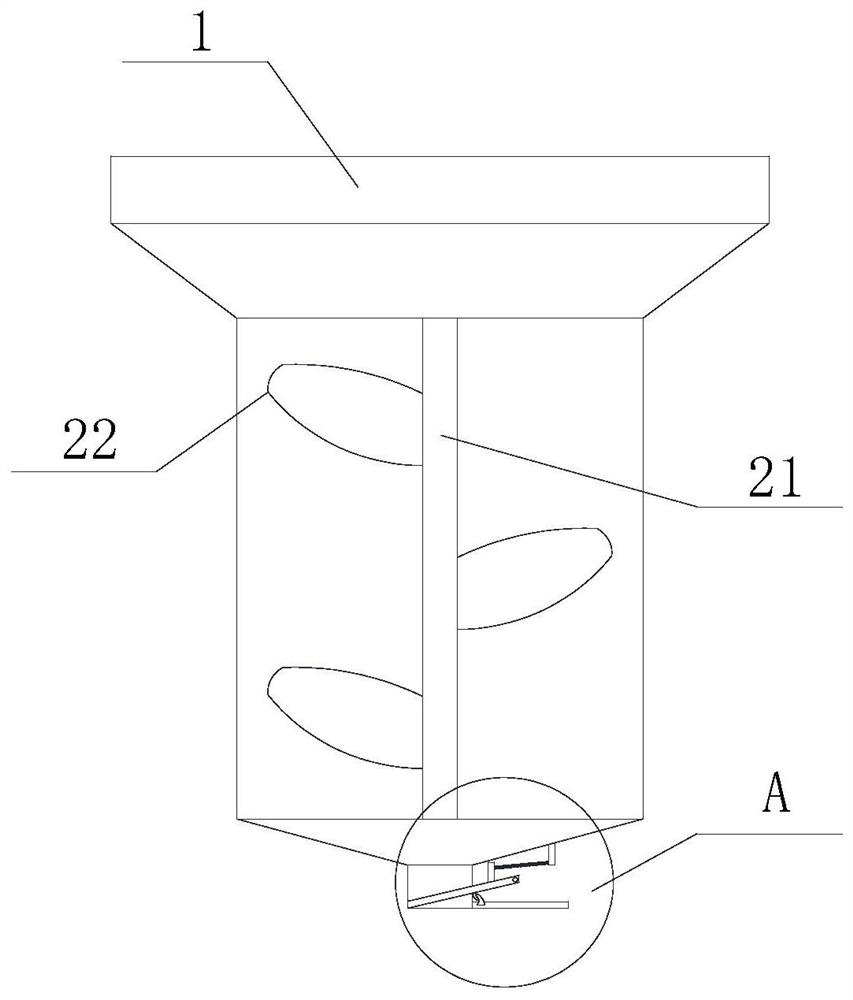

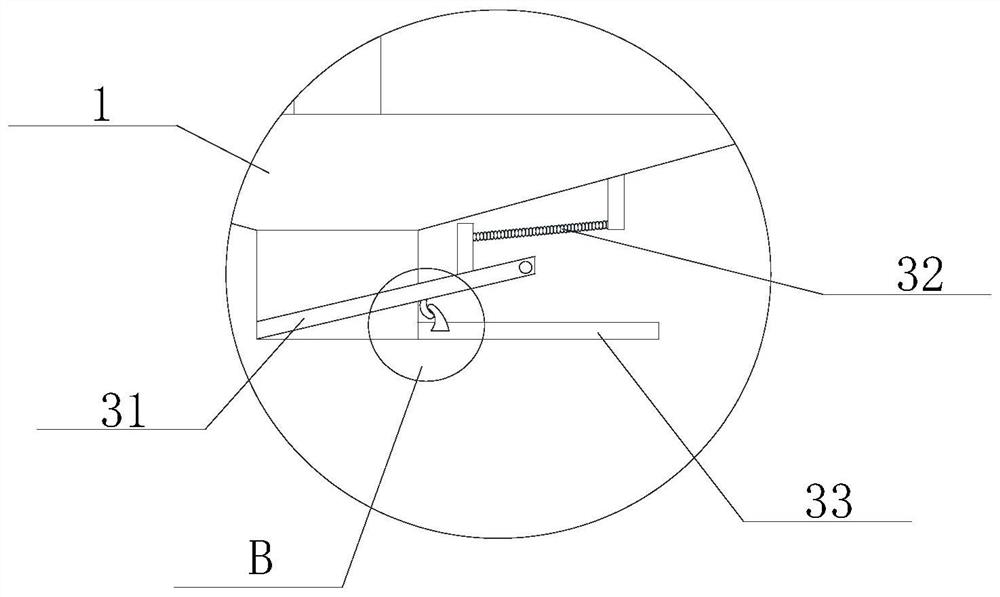

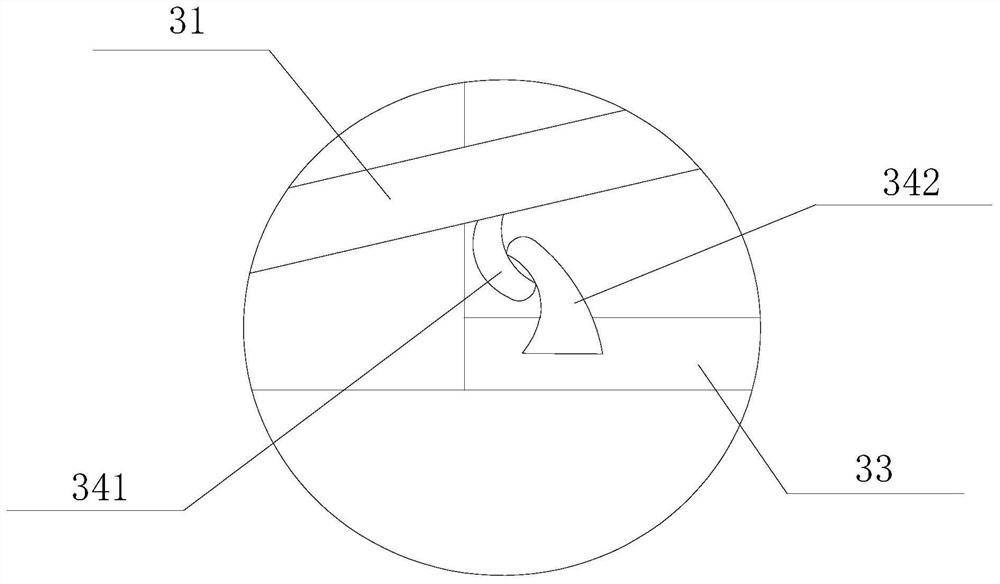

Crude spirits production aging storage tank

InactiveCN112457943ARealize up and down exchangeRealize heat treatmentLarge containersAlcoholic beverage preparationRotational axisStorage tank

The invention is suitable for the technical field of spirits liquid processing, and provides a crude spirits production aging storage tank. The tank comprises a tank body, a stirring device and a discharging device; the stirring device comprises a rotating shaft and stirring blades connected with the rotating shaft, the stirring blades have an inclination angle, the inclination angle faces the upper part of the tank body, and uniformly distributed heating elements are arranged on the upper surfaces of the stirring blades; and the discharging device comprises a movable plate, a return piece anda baffle, the movable plate is inserted below the tank body, the inclination angle of the movable plate is larger than 40 degrees, a fixed plate is arranged on one side of the lower end of the tank body, an upper stop block and a lower stop block which are matched with each other are arranged on the movable plate and the fixed plate, balls are arranged on the contact surfaces of the upper stop block and the lower stop block, the upper stop block is fixedly connected with the movable plate, the lower stop block is inserted into the fixed plate, and the return piece is connected with the movable plate and the tank body through a vertical plate. According to the tank, the stirring treatment on spirits liquid can be effectively realized, and the processing quality of the spirits liquid is improved.

Owner:山东景芝白酒有限公司

Cooked food heating device for catering industry

The invention discloses a cooked food heating device for catering industry. A heating plate is included, a supporting plate is fixedly connected to the upper surface of one side of the heating plate,the upper end of the supporting plate is fixedly connected with an observation window, the other end of the heating plate is fixedly connected with a door frame, the upper end of the door frame is fixedly connected with a top plate, a first cooked food tray is fixedly connected between the door frame and the supporting plate, a second cooked food tray is arranged above the first cooked food tray,the second cooked food tray is fixedly connected with the door frame, a first blocking door and a second blocking door are movably installed on the inner surface of the door frame, and a first door handle is fixedly connected to the outer surface of the first blocking door. According to the cooked food heating device in the invention, multiple heating structures are added to the heating device, people can heat different types of cooked food conveniently, the device is enabled to be filled with heat, the heating effect is improved, the structure is simple, the manufacturing cost is low, convenience is brought to use, and the heating effect is good.

Owner:湖南面面嗦餐饮管理有限公司

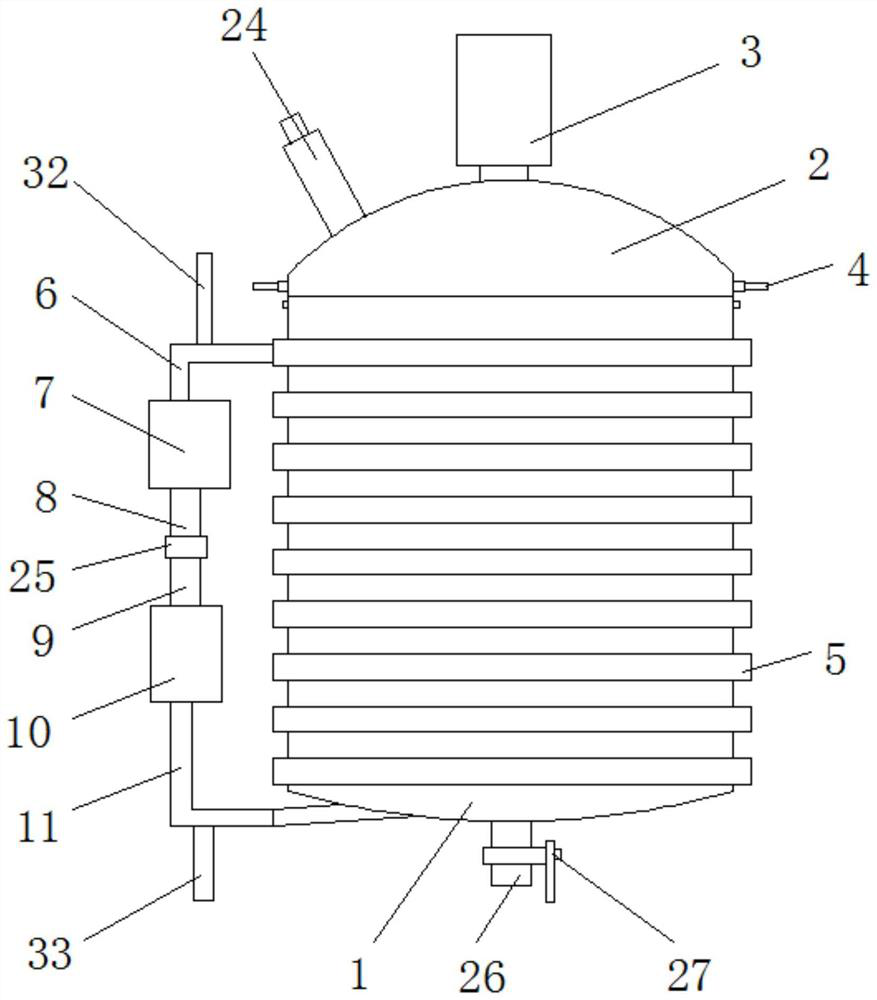

Water-saving heating reaction kettle for laboratory

InactiveCN111686671ARealize heat treatmentHeating evenlyChemical/physical/physico-chemical stationary reactorsWater savingThermodynamics

The invention discloses a water-saving heating reaction kettle for a laboratory. The reaction kettle comprises a reaction kettle body, a sealing cover is arranged on the upper surface of the reactionkettle body; a stirring motor and a feeding pipe are fixedly mounted on the upper surface of the sealing cover; lock catches are movably hinged to the two ends of the sealing cover. The outer surfaceof the reaction kettle body is fixedly sleeved with a heating sleeve; one end of the top of the heating sleeve is fixedly connected with a water inlet pipe; a circulating water pump is fixedly connected to the lower end of the water inlet pipe, a first connecting pipe is fixedly connected to the lower end of the circulating water pump, a second connecting pipe is fixedly connected to the lower endof the first connecting pipe, a constant-temperature heating box is fixedly connected to the lower end of the second connecting pipe, and a water outlet pipe is arranged at the lower end of the constant-temperature heating box. The reaction kettle is uniform in heating, capable of recycling heated water, capable of avoiding waste of water resources, good in water saving effect, good in heat preservation performance, convenient to move, stable in stopping and capable of meeting different requirements of people under different conditions.

Owner:何庆

Sterilization and dust collection device for luggage production

PendingCN110882960AImprove efficiencyQuality improvementMechanical cleaningPressure cleaningDrive wheelDust control

The invention relates to the technical field of luggage production and manufacturing and discloses a sterilization and dust collection device for luggage production in order to solve the problems thatthe dust collection and sterilization efficiency is low and the quality is poor during luggage fabric production in the prior art. The sterilization and dust collection device specifically comprisesa main frame. A treatment box is mounted on the main frame. A motor is mounted on the main frame. A driving wheel is mounted on the motor. A driving belt is mounted on the driving wheel. A driven wheel is mounted on the driving belt. The driven wheel is sleeved with the driving belt. The driving belt penetrates through the treatment box. The main frame is further provided with an electric controlcabinet electrically connected with the motor. A storage battery is mounting at the inner top end of the treatment box. A UV lamp tube is mounted on the storage battery. A treatment passage is arranged in the treatment box. A brush mounting plate is mounted in the treatment passage. A brush is mounted on the brush mounting plate. The sterilization and dust collection device for luggage productioncan effectively improve the sterilization and dust collection efficiency and quality of luggage fabrics.

Owner:耒阳市康意电子箱包科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com